Page 1

HP Designjet

T1100/T1100ps/T610/

T1120/T1120ps/T620

printer series

Version 9.1

August 22, 2009

Page 2

For HP internal use only

© Copyright Hewlett-Packard

Company 2009

This document contains

proprietary information that is

protected by copyright. All

rights are reserved. No part of

this document may be

photocopied, reproduced, or

translated to another language

without the prior written

consent of Hewlett-Packard

Company.

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes

no warranty of any kind

with regard to this

material, including, but

not limited to, the implied

warranties of

merchantability and

fitness for a particular

purpose.

Hewlett-Packard shall not be

liable for errors contained

herein or for incidental or

consequential damages in

connection with the furnishing,

performance, or use of this

material.

Warning

The procedures described in

this manual are to be

performed by HP-qualified

service personnel only.

Electrical shock hazard

Serious shock hazard leading

to death or injury may result if

you do not take the following

precautions:

• Ensure that the AC power

outlet (mains) has a protective

earth (ground) terminal.

• Disconnect the Printer from

the power source prior to

performing any maintenance.

• Prevent water or any other

liquids from running onto

electrical components or

circuits, or through openings in

the enclosure.

Electrostatic discharge

Refer to the beginning of

Chapter 4 of this manual, for

precautions you should take to

prevent damage to the Printer

circuits from electrostatic

discharge.

WARNI NG

The Warning symbol calls

attention to a procedure,

practice, or the like, which, if

not correctly performed or

adhered to, could result in

personal injury. Do not

proceed beyond a Warning

symbol until the indicated

conditions are fully understood

and met.

CAUTION

The Caution symbol calls

attention to an operating

procedure, practice, or the like,

which, if not correctly

performed or adhered to, could

result in damage to or

destruction of part or all of the

product. Do not proceed

beyond a Caution symbol until

the indicated conditions are

fully understood and met.

Content Management Department,

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Vallès

Spain

Safety symbols

General definitions of safety

symbols are given immediately

after the table of contents.

Page 3

Table of Contents 1

1 Troubleshooting

2 System Error Codes

3 Service Tests and Utilities

4 Service Calibrations

5 Parts and Diagrams

6 Removal and Installation

7 Preventive Maintenance

For information about Using this Manual, please refer to the next page.

Page 4

Table of Contents

Using this manual

Purpose

This Service Manual contains information necessary to test, calibrate and

service:

HP Designjet T1100 Printer 24 inch (Model Q6683A)

HP Designjet T1100 Printer 44 inch (Model Q6687A)

HP Designjet T1100ps Printer 24 inch (Model Q6684A)

HP Designjet T1100ps Printer 44 inch (Model Q6688A)

HP Designjet T610 Printer 24 inch (Model Q6711A)

HP Designjet T610 Printer 44 inch (Model Q6712A)

HP Designjet T620 Printer 24 inch (Model CK835A)

HP Designjet T1120 Printer 24 inch (Model CK837A)

HP Designjet T1120 Printer 44 inch (Model CK839A)

HP Designjet T1120ps Printer 24 inch (Model CK838A)

HP Designjet T1120ps Printer 44 inch (Model CK840A)

For information about using these printers, refer to the corresponding User’s

ide.

Gu

Readership

The procedures described in this Service Manual are to be performed by HP

Certified service personnel only.

Part numbers

Part numbers for printer options, accessories and service parts are located in

Chapter 5 Parts and Diagrams on page 5-1.

Conventions

Any text that uses the blue underlined format (except this one) is a link that

directs you to the page number of the reference. If you are viewing the

document as a PDF file, you can click on that link to be taken there directly.

2 HP Designjet T Series — Service Manual

Page 5

Troubleshooting 1

Using the Front Panel 1-3

General Troubleshooting 1-4

Introduction 1-4

Troubleshooting System Error Codes 1-4

Performing a Service Test on a failed Assembly 1-4

Performing the Necessary Service Calibrations 1-4

The Front Panel is blank 1-5

Solving Print Quality Problems 1-5

The Printer does not Power ON 1-5

The Printer Continuously Rejects Printheads 1-5

Cover Sensors are not Working 1-5

The Line Sensor has Problems Detecting Media 1-5

Banding at variable extreme environmental conditions 1-6

Worm marks on HP Coated media with light area fills 1-6

Solving Media-Handling Problems 1-7

Print quality troubleshooting 1-9

Print Quality Troubleshooting Actions 1-9

The Service Image Quality Diagnostic Print 1-9

Reading the Diagnostic Print Results 1-11

Diagnostic Part 1: Printhead Reliability 1-11

Diagnostic Part 2: Printhead Alignment 1-12

Diagnostic Part 3: Printheads & Paper Advance 1-13

The Advanced Diagnostic Prints 1-15

Reading the Advanced Diagnostic Print Results 1-16

Troubleshooting Print Quality Problems 1-24

Print Quality General Advice 1-24

Horizontal Lines Across the Image (Banding) 1-24

Lines are Missing, Too Thin, or Too Thick 1-25

Problems with Stepped Lines 1-26

Lines are Printed Double or in Wrong Colors 1-27

Lines are discontinuous 1-27

Lines are Blurred (Ink Bleeds from Lines) 1-28

Problems with Graininess 1-28

Paper is not Flat 1-29

Ink marks on the paper 1-30

Horizontal smears on the front of coated paper 1-30

Ink marks on the back of the paper 1-30

Problems with the Edges of objects 1-31

Stepped or not sharp 1-31

Darker than expected 1-31

Black and white prints do not look neutral 1-31

Horizontal lines at the end of a cut sheet print 1-31

Vertical lines of different colors 1-31

White spots on the print 1-32

1

HP Designjet T Series — Service Manual 1-1

Page 6

Problems with Color Accuracy 1-32

Output Only Contains a Partial Print 1-33

Problems with Image Clipping 1-33

Some objects are missing from the printed image 1-34

A PDF file is clipped or objects are missing 1-34

Print Quality Troubleshooting Wizard 1-34

Ink Supplies Troubleshooting 1-38

Introduction to ink supplies 1-38

What are Ink Supplies? 1-38

Ink Cartridges 1-38

Available Ink Cartridges 1-39

Printheads 1-39

Available Printheads 1-40

General Information About the Ink Supplies 1-40

General Precautions When Handl

When Should You Replace the Ink Supplies? 1-41

Ink Cartridge Levels, Information, and Replacement 1-41

Ink Cartridge Levels 1-41

“View Ink Levels” Direct Access Key 1-41

“View Ink Levels” from the ink menu 1-41

Obtaining Ink Cartridge Information 1-41

The printer consumes more gray ink ink than M, C, or Y 1-43

Changing an Ink Cartridge 1-43

Printhead Information, Replacement and Alignment 1-45

Obtaining Printhead Information 1-45

Changing a Printhead 1-46

Aligning Printheads 1-48

Reinsert Printheads Procedure 1-48

Image Quality Maintenance Procedure 1-48

Scanning errors during alignment 1-49

Ink Cartridge and Printhead Status Messages 1-49

Ink Cartridge Status Messages 1-49

Printhead status messages 1-50

Printhead Error Codes 1-50

Solving Ink Supplies Problems 1-52

You Cannot Insert the Ink Cartridge Into the Printer 1-52

You Cannot Insert the Printhead Into the Printer 1-52

The front panel says to reset or replace a printhead 1-52

Maintaining and Cleaning the Printheads 1-53

Clean the printheads 1-53

Flex Contacts Cleaning Tool 1-54

ing Ink Supplies 1-40

HP Designjet T Series — Service Manual 1-2

Page 7

Using the Front Panel

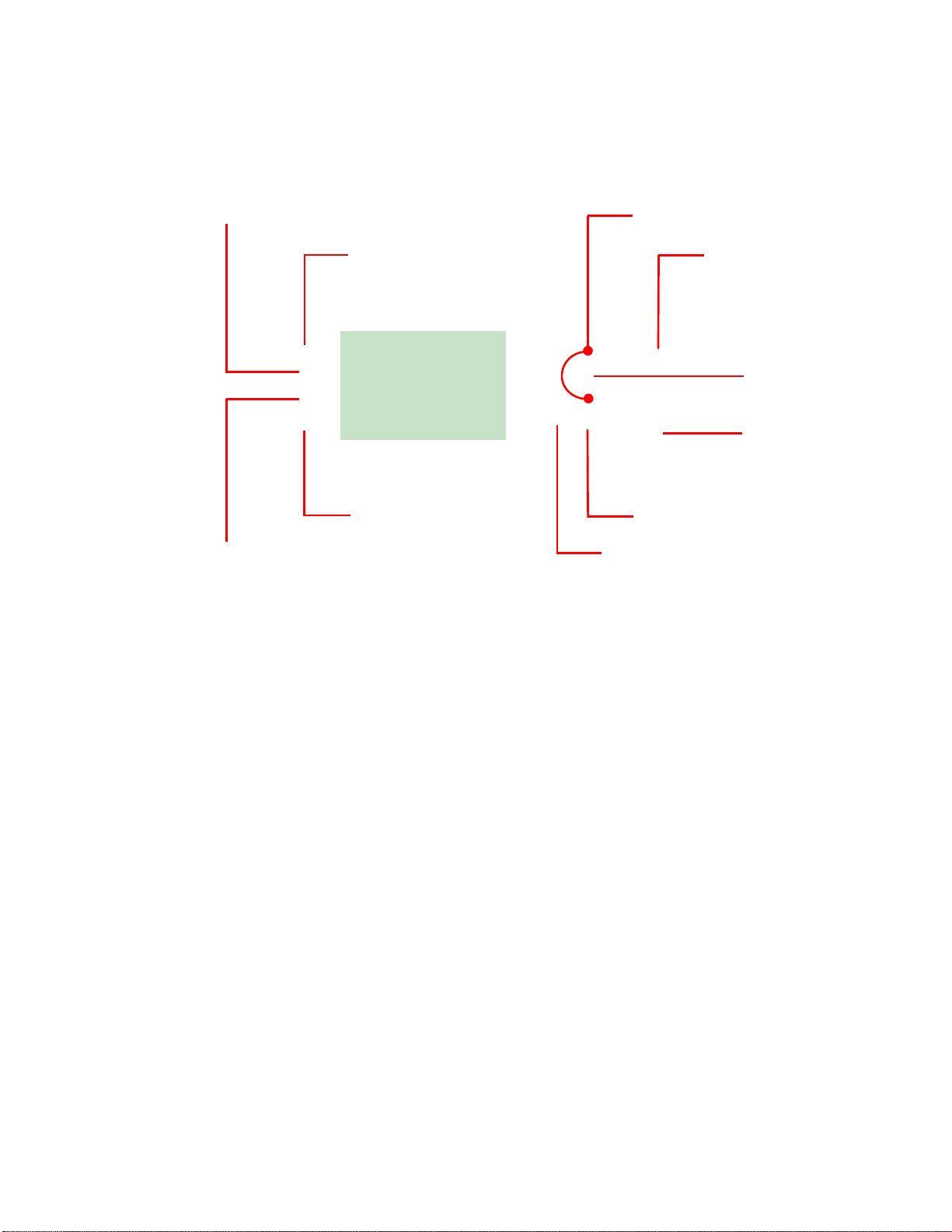

Below is a diagram of the front panel.

Using the Front Panel

View Loaded Paper

Unload Paper

Key Function

Arrow Keys

Use the Arrow keys to scroll through a menu or toggle between YES or

NO

Cancel

Use the Cancel key to abort or stop a procedure or reject test results.

OK

Use the OK key to select a menu option.

Power

Use the Power key to turn the printer ON and OFF.

Menu

Use the Menu key to enter the main menu.

Back

Use the Back key to go back to the previous menu or reject test results.

View Ink Levels

Form Feed and Cut

when prompted.

Up and Down

Cancel

OK

Power

Menu

Back

Service Key Combinations

Diagnostic mode

With the printer OFF, press and hold the UP and OK keys. While holding

the Up and OK k

printer. Hold all three keys until the Power key stops flashing, usually

about 5 seconds.

eys down, press and hold the Power key to turn on the

Service Menu (Service Engineers Only)

From the main menu, press and hold the Up and Cancel keys.

Service Menu (For users)

From the main menu, press and hold the Down and Cancel keys.

HP Designjet T Series — Service Manual 1-3

Page 8

Troubleshooting

General Troubleshooting

Introduction

This chapter will guide you through the relevant steps to take when

troubleshooting the printer.

Troubleshooting System Error Codes

Chapter 2 Introduction on page 2-2 contains a list of system error codes and

their respective descriptions and recommended corrective actions. Only try

ecommended action at a time and check if the error code has

one r

disappeared.

If you have an error code which is not documented in this Service Manual or

yo

u have an error which you cannot resolve, then report the error to the HP

Response Center or the nearest HP Support Office. When reporting the

error, have the following information ready:

Model and Serial Number of the printer.

Which firmware revision the printer is using (See Note below). Check

firmware in Utilities / Statistics / Code rev.

The complete error number (See Note below).

The Service Configuration Print.

The Current configuration sheet.

Which software application the customer is using (name, version, etc.).

When reporting the System Error Code, make sure that you supply the full

Er

ror Code and the firmware version. Without this information, HP Support

Personnel cannot help you.

Performing a Service Test on a failed Assembly

If possible, always perform a Service Test on the component/assembly that

you are about to replace, just to make sure that is the component/assembly

that has failed.

If the test on that component/assembly passes, you should NOT replace it.

For information on the Service Tests and how to use them see

Service Tests and Utilities on page 3-1.

Performing the Necessary Service Calibrations

Is the printer calibrated correctly after replacing a component? For

information on the Service Calibrations and how to use them see

Service Calibrations on page 4-1.

Remember that certain Calibrations are required even if an Assembly has

been disas

sembled to gain access to another Assembly or Component.

Chapter 3

Chapter 4

1-4 HP Designjet T Series — Service Manual

Page 9

Solving Print Quality Problems

Whenever a Print Quality problem appears, it is advisable to print the

Diagnostic Print to help diagnose the problem. The Diagnostic Print will help

you differentiate between possible printhead errors and other problems such

as incorrect front-panel selection, driver or RIP configuration or mechanical

problems.

The Front Panel is blank

1 See What to do if the Front Panel is blank on page 2-5.

The Printer does not Power ON

1 Check that the power cord is connected correctly to the Printer and to the

Power Socket.

heck that the Power Switch on the BACK of the Printer is in the ON

2 C

position.

heck to see the LED on the Front Panel Power Switch are On.

3 C

heck that the Front-Panel Cable is correctly connected to the Electronics

4 C

Module. Also make sure that the Front-Panel cable is not damaged.

General Troubleshooting

eplace the Power Supply Unit. See Starwheel Assembly on page 6-214.

5 R

The Printer Continuously Rejects Printheads

1 Clean the flex contacts on the Printhead and in the Carriage Assembly using

the Carriage Interconnect Wiper and try again. See

Tool on page 1-54.

2 If A

LL the Printheads are rejected (the status message on the Front Panel does

NOT show "OK" for ALL the Printheads) then perform the Electronic Module

Test. See

3. Electronics Module on page 3-21.

Cover Sensors are not Working

1 Perform the Sensors Test. See 5. Sensors on page 3-31.

heck if the cable for the faulty sensor is not damaged and is connected

2 C

correctly.

eplace the faulty Sensor.

3 R

The Line Sensor has Problems Detecting Media

1 Check the type of media that is being used since the Line sensor may have

problems detecting transparent media or some types of Non-HP media. Try

loading white HP media into the Printer and check if the Line sensor detects

it.

he Line Sensor is not calibrated correctly. Perform the Line Sensor

2 T

Calibration. See

Line Sensor Calibration on page 4-14.

Flex Contacts Cleaning

he Line Sensor is damaged or faulty. Replace the Line Sensor. See Line

3 T

Sensor (T1120/T1120ps/T620) on page 6-161.

HP Designjet T Series — Service Manual 1-5

Page 10

Troubleshooting

Troubleshooting Media Jams/Printhead Crashes

The failure modes "media jam" and "head crash" are grouped together

because in many cases a media jam causes the media to lift up into the

Carriage path and cause a Printhead crash, thus causing many media jam

failures to be reported as head crashes.

d the media jam occur when loading media?

4 Di

If the client has had media jams, it is common for pieces of media to get

stuck in the media path. Clear the media path.

When clearing a media jam, sometimes media is stuck in the paper path. To

c

lear this, you must lift the Media Lever and insert thicker media into the

paper path to push out the media that is still stuck there.

5 Is the c

ustomer using non-HP media?

The use of non-HP media can easily be the cause of media jams and

head crashes (especially head crashes because HP media is specially

formulated to avoid cockle, one of the primary causes of head crashes). If

the media is not HP approved, advise the customer to use HP media and

check to see if the problem is now solved.

Banding at variable extreme environmental conditions

Since the Accuracy Calibration has been done at normal environmental

conditions, printing in extreme environmental conditions will cause banding

because the advance of the Media Advance Roller does not correspond to

the same conditions that the calibration was done in. To solve the problem,

try the following:

Perform the Accuracy Calibration in the new environmental conditions (Refer

the User’s Guide).

to

Worm marks on HP Coated media with light area fills

Light bands (S-shaped) in Paper axis direction where light area fills are

printed, causing unacceptable Image Quality defect.

Print the Service Configuration Print and check if the level of Humidity is

very low (below 30%). Increasing humidity may help in reducing the

severity of the problem.

The media is causing the problem and NOT the Printer. Do not attempt to try

and r

eplace Printer parts to solve this problem.

1-6 HP Designjet T Series — Service Manual

Page 11

The Media Basket was damaged during printer setup

The Media Basket was damaged during printer setup

1 There are three plastic parts that could break during printer installation and

need replacing.

heck the parts table and graphics in Parts and Diagrams to identify what

2 C

service parts you must order. See

eplace the component. See Bin Assembly on page 6-10.

3 R

Solving Media-Handling Problems

The Front Panel indicates that media is misaligned or incorrectly positioned

Printer Support on page 5-2.

Roll media

Sheet media

The roll may be loaded the wrong way. The paper should load over the

roll toward you.

Check that the paper is correctly loaded onto the spindle.

The paper may be loaded at an angle. The right-hand edge must be

aligned with the blue line on the Print Platen.

With 24 inch printers, ensure that the paper is wrapped tightly on the roll.

T

his is a very important step to remember because if this is not done, the

media may be loaded at an angle, causing the media to be rejected.

Check that the Right Spindle Holder (rewinder included) is properly

attached and screwed to the printer.

For 44 inch printers, the Rewinder, located on the Right Spindle Holder

ewinder included), should maintain proper back tension. If the Right

(r

Spindle Holder (rewinder included) is misaligned or not properly

attached to the printer, the Rewinder will not function properly.

For a graphic of a properly installed Rewinder, see

and Rewinder (T1120/T1120ps/T620) on page 6-87. To further diagnose

problems with the Rewinder, see

6. Rewinder on page 3-34.

Right Spindle Holder

Always load sheet media using the Rear Input Tray. Do NOT load the

media as you would load roll media.

It must be loaded with the right-hand edge against the blue line on the

Print Platen.

The media may be crumpled or warped or may have irregular edges.

If hand-cut media is used, the edges may not form a right-angle or they

may be rough. If possible, hand-cut media should not be used. Only

purchased sheet media should be used in the Printer.

If you have problems with paper jams, check that the Overdrive is not

obstructed by bits of paper or using the Turn Drive Roller Service Utility.

1. Turn Drive Roller on page 3-57.

See

Check that the Right Spindle Holder (rewinder included) is properly attached

and screwed to the printer.

For 44 inch printers, the Rewinder, locate

(rewinder included), should maintain proper back tension. If the Right

Spindle Holder (rewinder included) is misaligned or not properly attached to

d on the Right Spindle Holder

HP Designjet T Series — Service Manual 1-7

Page 12

The Media Basket was damaged during printer setup

the printer, the Rewinder will not function properly.

To further diagnose problems with the Rewinder, See

3-34.

6. Rewinder on page

HP Designjet T Series — Service Manual 1-8

Page 13

Print quality troubleshooting

Print Quality Troubleshooting Actions

For some Print Quality problems, a Call Agent can try and troubleshoot the

Printer by requesting the Customer to perform certain actions. Using this

process, most problems can resolved without the need of an on-site visit.

Use the Print Quality Troubleshooting Wizard to help customers with their

pr

int quality or color problems. For information about how to use the Print

Quality Troubleshooting Wizard, see

on page 1-34.

When faced with a Print Quality problem, perform the following actions in

or

der to resolve the problem:

inter Configuration:

1 Pr

Check that the paper type loaded corresponds to the paper type selected

in the front panel and in the software. You can verify the paper type

selected through the Front Panel (Main Menu/Paper menu/View loaded

paper).

Make sure that the correct Print Quality settings are used for different

types of print content. See

1- 9 for further information.

Dry time should be set to “Optimal”.

Print Quality Troubleshooting Actions on page

Print quality troubleshooting

Print Quality Troubleshooting Wizard

erform Printhead recovery (Main Menu/Image Quality Maintenance/

2 P

Clean Printheads).

3 Medi

a:

Select the correct media type through the front panel when loading it.

Make sure that HP or HP-approved media is being used.

erform the Printhead Alignment (Main Menu/Image Quality Maintenance/

4 P

Align Printheads), using the same paper type with which you were

experiencing unacceptable image quality, if feasible (some paper types are

not suitable for Printhead Alignment).

heck if the latest version of the firmware is installed. If not, install the latest

5 C

firmware revision.

The Service Image Quality Diagnostic Print

What is the Service Image Quality Diagnostic Print?

The Printer contains an internal Image Quality Test which helps you to

di

agnose the possible source of any image quality defects. The Service IQ

Diagnostic Print is available in the following options:

1 Image Q

detail the possible source of any image quality defects. It is accessible

through the Service Utility Menu.

The Image Q

in to three parts as follows:

Diagnostic Part 1: Printhead Reliability Test. The purpose of this test is to

uality Service Best Plot. This plot helps you to diagnose in more

uality Service Best Plot uses the Best Print Mode and is divided

identify which Printhead is faulty.

HP Designjet T Series — Service Manual 1-9

Page 14

Print quality troubleshooting

Diagnostic Part 2: Printhead Alignment Test. This test is designed to check

any color-to-color and bi-directional misalignment the printer may have.

Diagnostic Part 3: Printheads and Paper Advance test. This test is

designed to check whether the Printheads and the Media Advance

Mechanism are working correctly.

2 Image Q

Quality Service Best Plot but uses the Normal Print Mode.

dvanced Diagnostic Plot. These tests provide more information of the IQ

3 A

defects that we could find in the Image Quality Service plot. For more

information, see

Considerations for Printing the Diagnostic Print

he IQ Diagnostic Print prints in A3 and B sizes so you must have media

1 T

loaded (roll or sheet) that is this size or larger.

se the same type of media that the customer was using when they found

2 U

the image quality problem.

the customer is using non-HP media and after the Image Quality Test you

3 If

still have the same image quality problems, change to genuine HP media

and repeat the Image Quality Test.

If you do see problems with the Image Quality Test, continue with the

A

dvanced Diagnostic procedures which will help you diagnose the problem.

uality Service Normal Plot. This plot is the same as the Image

The Advanced Diagnostic Prints on page 1-15.

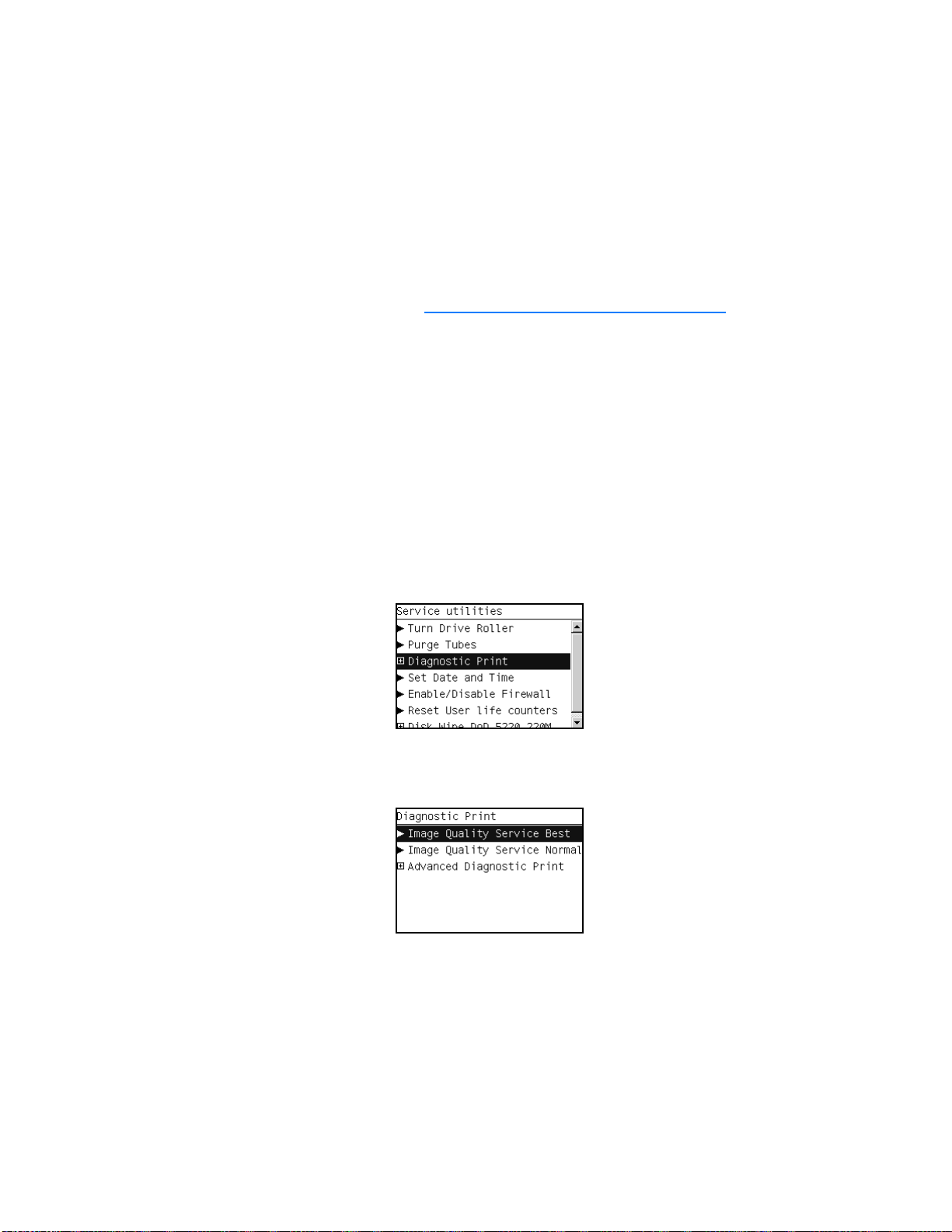

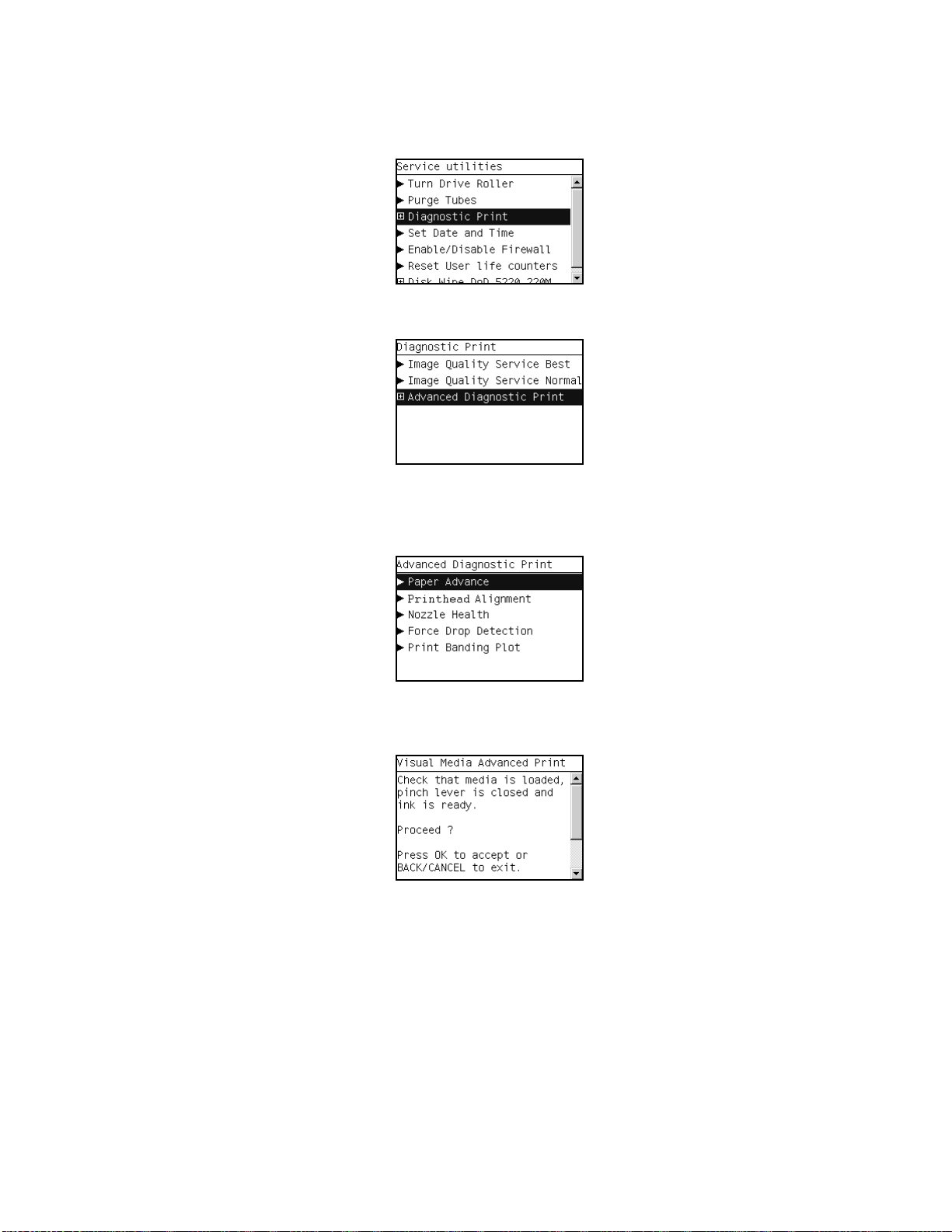

Printing the Diagnostic Print

1 In the

2 Y

3 If

Service Utilities submenu, scroll to “Diagnostic Print” and press OK.

ou will be given three options. Use the Arrow keys to make the selection

and press the OK key to start printing the required Diagnostic Print or to

enter the Advanced Diagnostics menu.

you selected the Advanced Diagnostics Prints in the previous step, use the

Arrow keys to make the required selection Paper Advance, Printhead

HP Designjet T Series — Service Manual 1-10

Page 15

Print quality troubleshooting

Alignment Diagnostic, Nozzle Health, Force Drop Detection or Print Banding

P

lot, and press the Enter key to start printing.

4 Mak

5 T

e sure media is loaded, the Media Lever is lowered and that the Ink

System is correctly installed. Press the OK key to print the Diagnostic Print or

press Back/Cancel to exit without printing the Diagnostic Print.

he selected Diagnostic Print will now be printed.

Reading the Diagnostic Print Results

Diagnostic Part 1: Printhead Reliability

The Nozzle Print Test test is designed to check if the Printhead nozzles print

cor

rectly.

The nozzles check (top of the plot) is printed in a one-pass full swath mode.

T

he diagnostics test prints out every single nozzle of each Printhead without

applying an error hiding or alignment algorithm.

For each Printhead, you can see both the adjacent and the consecutive

no

zzles.

If any nozzles are not printing correctly

each Printhead Nozzle test. There is a series of numbered stepped diagonal

lines. If one or more of the nozzles are clogged, malfunctioning or mispositioned, you will see that the stepped lines are broken or misdirected in

one or more places.

HP Designjet T Series — Service Manual 1-11

they will be shown on the right of

Page 16

Print quality troubleshooting

Below, the stepped lines highlighted in yellow are broken. When the line is

c

ompletely broken, this means the nozzle is out.

Below, the stepped lines highlighted in yellow are misdirected. When the

ne is misdirected, this means the nozzle is malfunctioning or out of

li

position.

On the left of each Printhead Nozzle test, there is a series of horizontal

traight lines. If one or more nozzles are misdirected there will be unequal

s

spaces between the corresponding lines.

Corrective Action

If the printer has nozzle defects, you can s

The printer can automatically compensate for nozzle defects, so there is no

need to replace the Printhead.

The method of improving Nozzle Defects is to:

ecover the Printheads, using the Front Panel Main Menu/Image Quality

1 R

Maintenance/Clean Printheads option.

eprint the Printhead Nozzles Test Plot to verify that the defective nozzles

2 R

have been corrected.

3 If the

problem continues, replace the defective Printhead.

Diagnostic Part 2: Printhead Alignment

This test is designed to check any color-to-color and bi-directional

mi

salignment the printer may have.

till get perfect print quality results.

HP Designjet T Series — Service Manual 1-12

Page 17

Print quality troubleshooting

1 If

the Printer is experiencing horizontal misalignment problems, the

Alignment Test will show something like this:

f the Printer is experiencing vertical misalignment problems, the Alignment

2 I

Test will show something like this:

the Printer is experiencing bi-directional misalignment problems, the

3 If

Alignment Test will show something like this:

Corrective Action

Perform the Printhead Alignment (Main Menu/Image Quality Maintenance/

lign Printheads), using the same paper type with which you were

A

experiencing unacceptable image quality, if feasible (some paper types are

not suitable for Printhead Alignment).

Diagnostic Part 3: Printheads & Paper Advance

This test is designed to check whether the Printheads and the Paper Advance

hanism are working correctly. This part of the Image Quality Test should

Mec

NOT be used to check for color consistency or accuracy.

HP Designjet T Series — Service Manual 1-13

Page 18

Print quality troubleshooting

Banding

If the Printer is experiencing a banding problem, you will see repetitive

hor

izontal bands within the printed image.

Darker horizontal bands or lines repeated along the vertical band (from

top to bottom at the same distance).

Whiter horizontal bands or lines along the vertical band (from top to

bottom at the same distance).

The plot is printed in Best or Normal mode (according to the menu option

s

elected) with Error Hiding ON. The top band has 100% ink density patches

while the bottom band has 50% ink density patches.

Troubleshooting Banding Problems

If banding doe

Printhead problem. In this case, try the following:

heck that the appropriate print quality settings are being used (refer to the

1 C

User’s Guide for more information).

ecover the printheads using the option through the Front Panel (Main

2 R

Menu/Image Quality Maintenance/Clean Printheads). Reprint the

Diagnostic Print or the print file and if the problem persists, replace the faulty

Printhead.

If banding doe

Advance problem:

s NOT occur in ALL the colors, then it is more than likely a

s occur in ALL the colors, then it is more than likely a Paper

If the bands are light, it means that the paper has advanced too much.

If the bands are dark, it means that the paper hasn’t advanced enough.

HP Designjet T Series — Service Manual 1-14

Page 19

Print quality troubleshooting

In high quality modes, graininess in ALL colors can indicate problems

either with alignment or Paper Advance.

Corrective Action

In order to solve problems that result in banding, try the following:

heck that the appropriate print quality settings are being used (refer to the

1 C

User’s Guide for more information).

heck that the loaded media is the same type as selected in the printer. You

2 C

can verify the media type selected through the Front Panel (Main Menu/

Paper menu/View loaded paper).

the customer is using low quality paper, try recommending better quality

3 If

paper (preferably HP paper). Printer performance can only be guaranteed

by using recommended papers.

erform the Paper Advance Calibration using the same type of paper that

4 P

will be used for the final print (Main Menu/Image Quality Maintenance/

Paper Advance Calibration/Calibrate Paper Advance).

If there is white point banding in only one color band and the problem

cannot be f

a drop detection option can fix this issue. See

1-2 4.

ixed using the Printhead recoveries, in some cases using the force

Force Drop Detection on page

No Printing Defects Found in the Diagnostic Print

If all the test patterns from the Diagnostic Print are correct and you still

e

xperience Image Quality problems, you can use the following procedures

to resolve the problem.

Reading the Advanced Diagnostic Print Results

Printhead Alignment

Nozzle Health

Force Drop Detection

The Advanced Diagnostic Prints

What are the Advanced Diagnostic Prints?

Advanced Diagnostic Plot.

defects found in the Image Quality Service plot.

The Adva

Visual Media Advanced Diagnostic. Used to check advance reliability.

Printhead Alignment Diagnostic. Used to check pen alignment reliability.

Visual Nozzle health Diagnostic. Used to check nozzle health reliability.

Force Drop Detection. Used to reset the nozzle health historic data base

nced Diagnostic Plot is divided into the following parts:

and force new drop detection.

These tests provide more information of the IQ

HP Designjet T Series — Service Manual 1-15

Page 20

Print quality troubleshooting

Printing the Advanced Diagnostics Print

1 In the

2 Y

3 F

Service Utilities submenu, scroll to “Diagnostic Print” and press OK.

ou will be given three options. Use the Arrow keys to select the Advanced

Diagnostics menu.

rom the displayed options, use the Arrow keys to make the required

selection Paper Advance, Printhead Alignment Diagnostic, Nozzle Health,

Force Drop Detection or Print Banding Plot, and press the OK key to start

printing.

4 Mak

5 T

e sure media is loaded, the Media Lever is lowered and that the Ink

System is correctly installed. Press the OK key to print the Diagnostic Print or

press Back/Cancel to exit without printing the Diagnostic Print.

he selected Advanced Diagnostic Print will now be printed and, if

necessary, automatically scanned.

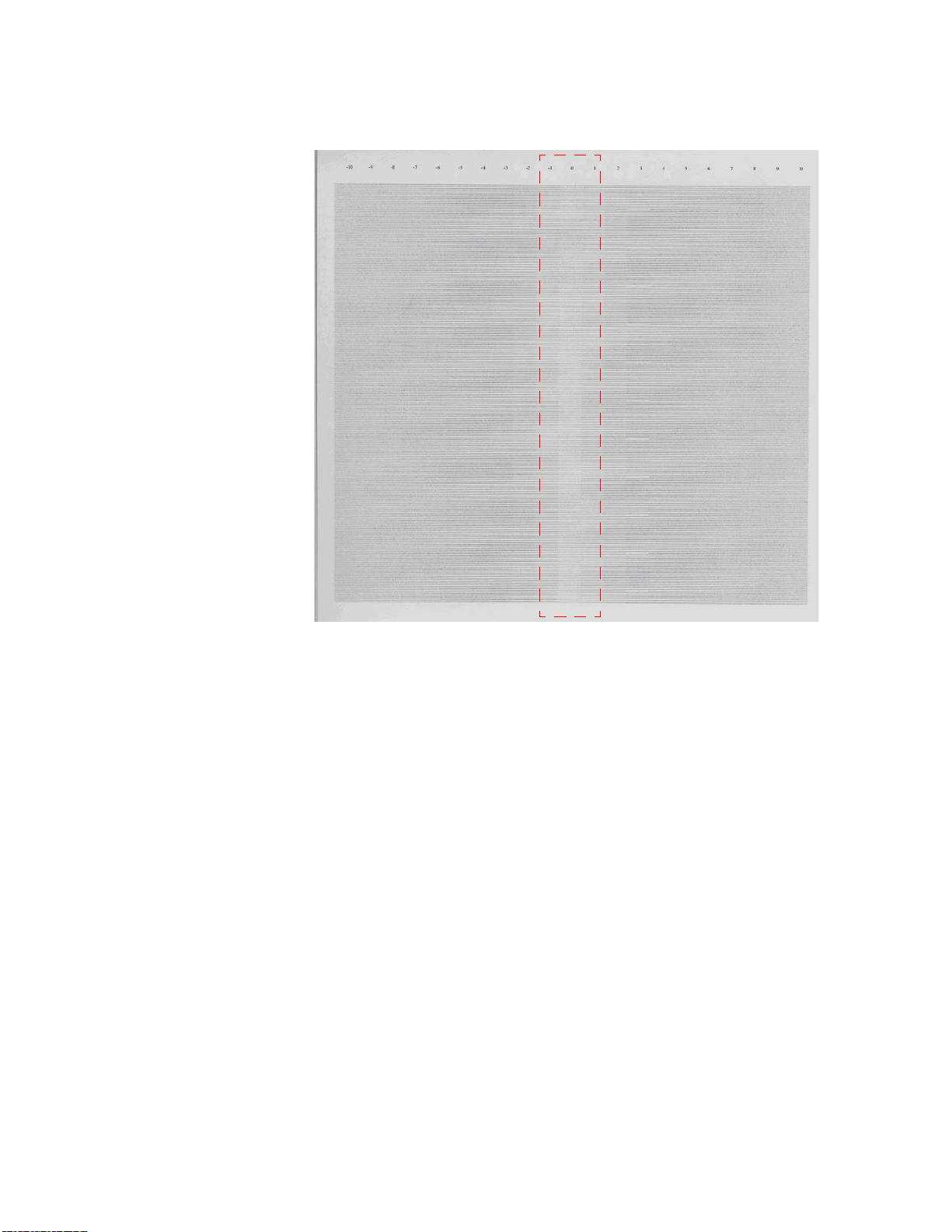

Reading the Advanced Diagnostic Print Results

Paper Advance

This plot helps you to visually check any alignment problems of the printer.

Y

ou use it to precisely measure the media advance error with a one dot row

accuracy, and to verify the stability of the media advance.

HP Designjet T Series — Service Manual 1-16

Page 21

Print quality troubleshooting

The whitest vertical line should be positioned in the 0 offset column with

mino

r variations between +2 and -2 columns. If the offset is not positioned

on the 0 column or between +2 and -2 columns and the whitest vertical

varies greatly, the printer requires Paper Advance Calibration

Image Quality Maintenance/Paper Advance Calibration/Calibrate Paper

Adva

nce).

It is very important to verify that the loaded media is the same media type

as sel

ected in the front panel. You can verify the media type selected

through the Front Panel (Main Menu/Paper menu/View loaded paper). The

wrong type of paper selected will produce an offset error in the Paper

Advance.

(Main Menu/

HP Designjet T Series — Service Manual 1-17

Page 22

Print quality troubleshooting

The following plot shows correct media advance, there is a straight white

line po

sitioned close to the 0 column for the majority of the points.

HP Designjet T Series — Service Manual 1-18

Page 23

Print quality troubleshooting

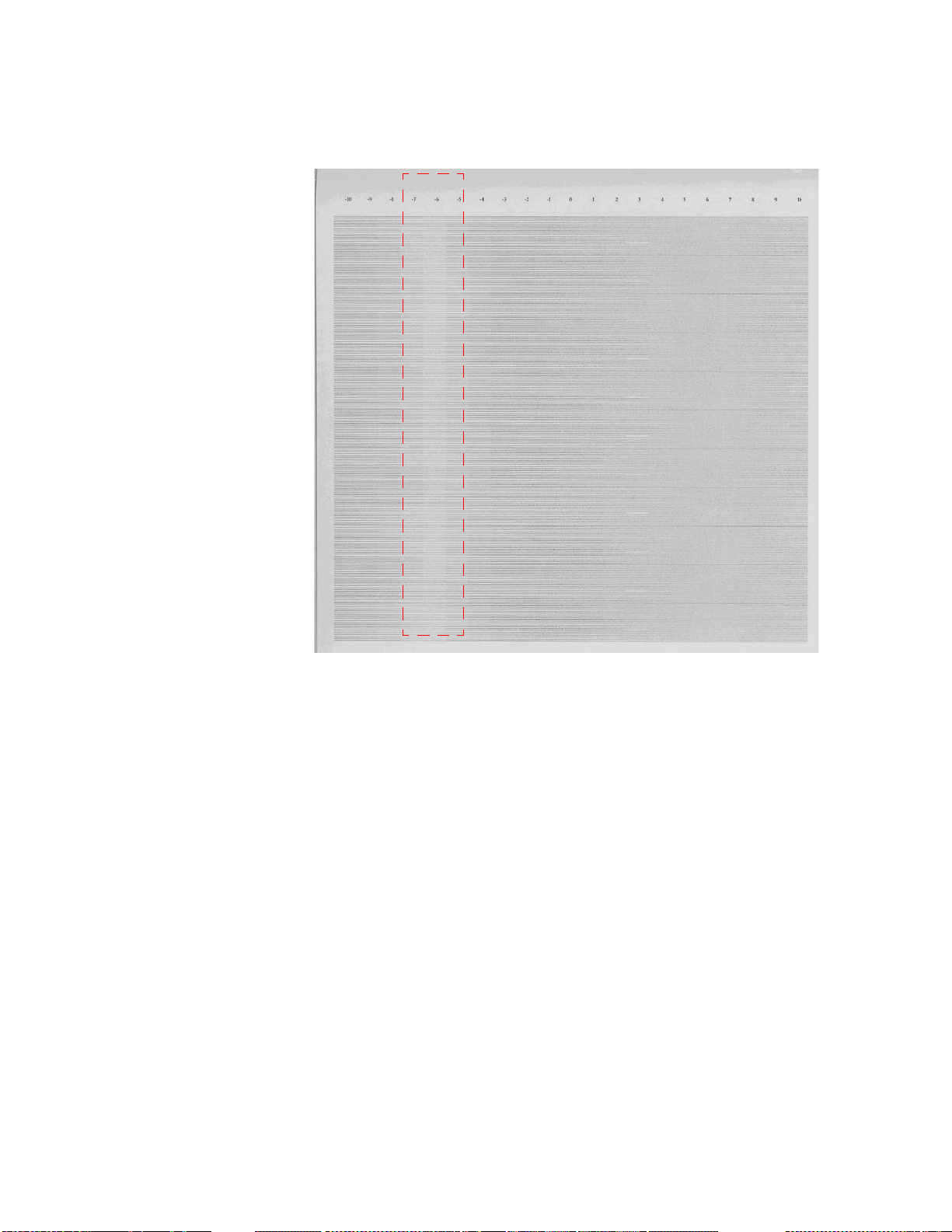

The following plot shows a bad media advance, there is a straight white line

po

sitioned close to the -6 column, instead of the 0 column for the majority of

the points.

Corrective Action

To fix Paper Advance problems, try the following:

1 C

heck the Paper Advance Calibration Status. This can be done by going to

Main Menu/Paper/View Loaded Paper. At the bottom, the Front Panel

displays the Paper Advance Calibration status. There are three status

messages:

DEFAULT. The paper loaded is recognized as HP paper, which is

already optimized and calibrated for the printer. Do Not calibrate the

Paper Advance for this paper.

RECOMMENDED. The paper loaded is NOT recognized as HP paper,

and Paper Advance values have NOT been customized for this paper

type. In this case, calibrate the Paper Advance from the user menu.

OK. This indicates that the paper loaded has been calibrated before. If

the printer continues to have banding and graininess problems, calibrate

the Paper Advance from the user menu.

Whenever the printer's firmware is upgraded, the paper advance

calibr

ation values will be reset to factory default.

o calibrate the Paper Advance from the user menu, go to Main Menu/

2 T

Image Quality Maintenance/Paper Advance Calibration/Calibrate

Paper Advance.

HP Designjet T Series — Service Manual 1-19

Page 24

Print quality troubleshooting

It is very important to verify that the loaded media is the same media type

as sel

ected in the front panel. You can verify the media type selected

through the Front Panel (Main Menu/Paper menu/View loaded paper). The

wrong type of paper selected will produce an offset error in the Paper

Advance.

Some paper types are not suitable for Paper Advance Calibration. Do NOT

use color

film, matte film, tracing paper, or vellum.

aper Advance calibration from the user menu will only calibrate the Paper

3 P

Advance for the paper type loaded in the printer at that moment.

Calibrate Paper Advance has mostly solved the problem, try Adjust Paper

4 If

Advance to fine tune the Paper Advance (Main Menu/Image Quality

Maintenance/Paper Advance Calibration/Adjust Paper Advance).

Select the percentage of change from -100% to 100%. To correct light

banding

percentage.

he Paper Advance calibration from the service menu will calibrate the

5 T

Paper Advance for ALL paper types. This action is recommended when:

ed papers or transparent materials such as translucent bond, clear

, decrease the percentage. To correct dark banding, increase the

The Paper Advance calibration from the user menu does NOT solve the

problem.

The Paper Advance problems affect ALL paper types.

The procedure for Paper Advance Calibration from the service menu is

umented in Chapter 5, Service Calibrations. See

doc

Calibration on page 4-6.

Paper Advance

Printhead Alignment

To ensure you obtain meaningful results, use the same type of media that

t

he customer was using when they encountered the image quality problem.

This plot helps you to visually check any alignment problems of the printer.

Y

ou use it to precisely measure the alignment error with a 3 dot row

accuracy. For the printer to be considered correctly aligned, the results must

be within ±3 dot row.

HP Designjet T Series — Service Manual 1-20

Page 25

Print quality troubleshooting

The illustration shows the complete Printhead Alignment that identifies each

f the specific alignment test results covered.

o

a

b

c

d

e

The Printhead Alignment Diagnostic print sh

results:

ine Sensor Calibration

a L

en to Pen Align

b P

rriage thetaZ

c Ca

directional align (high)

d Bi

directional align (Low)

e Bi

For tests a, b, and c, the order of the color band is:

For tests e and

Once the printer has correctly printed and scanned the Printhead Alignment

Di

agnostic print, the Front Panel displays the results. The top row displays the

printhead, and the left column displays the test.

f, the order of the color band is:

ows the following diagnostic test

HP Designjet T Series — Service Manual 1-21

Page 26

Print quality troubleshooting

The results are seperated onto two screens. Use the A

the second results screen.

Any printhead with a test result containing

dot row range is misaligned.

The mK printhead is used as a reference to test the other printheads. If all

t

he printheads fail the Pen to Pen tests, it is the mK printhead that is

misaligned.

a number that is not within the ±3

rrow keys to display

Reading the Printhead Alignment Diagnostic Print

The following plot shows correct printhead alignment for all patterns. The

lear band is in the center of the pattern.

c

The following plot shows bad printhead alignment. The clear band is not in

center of the pattern.

the

Corrective Action

If any of the printheads are misaligned beyond the ±3 dot row range,

perform a Printhead Alignment. See

Aligning Printheads on page 1-48.

If a Printhead Alignment does not correct the problem, replace the bad

printhead.

If the customer is using non-HP media and af

still have the same image quality problems, change to genuine HP media

and repeat the Image Quality Test. The best alignment calibration is

obtained using HP Photo Paper.

ter the Image Quality Test you

HP Designjet T Series — Service Manual 1-22

Page 27

Print quality troubleshooting

Nozzle Health

The print contains three separate parts.

a

b c

a T

he Variable Frequency Nozzle health plot with odd/even nozzles

separation. This is used to detect misdirected nozzles, weak nozzles, or

nozzles not working correctly at all frequencies.

spector measuring tool test plot.

b In

Test b should NOT be used by Service Engineers.

c Nozzle Print Test

which is also part of the Image Quality Service Plot.

This test is designed to check that the Printhead nozzles print correctly.

The test prints out every single nozzle of each Printhead. No error hiding

or Printhead Alignment algorithm is applied. For each Printhead, you can

see both the adjacent and the consecutive nozzles.

This is what you would see in the N

ozzle Print Test part if there are

nozzles not printing correctly:

n the right of each Printhead Nozzle test, there is a series of numbered

1 O

stepped diagonal lines. If one or more of the nozzles are malfunctioning or

mis-positioned, you will see that the stepped lines are broken or misdirected

in one or more places.

2 On

the left of each Printhead Nozzle test, there is a series of horizontal

straight lines. If one or more nozzles are misdirected there will be unequal

spaces between the corresponding lines.

Corrective Action for Nozzle Defects

If the printer has nozzle defects, it

does not mean that you will not get

perfect print quality results. The printer has automatic procedures to hide

many nozzle defects.

ecover the Printheads using the option through the Front Panel (Main

1 R

menu/Image quality maintenance/clean printheads).

eprint the Nozzle Print test to check that the defective nozzles have been

2 R

corrected.

3 If the

problem continues, replace the defective Printhead.

HP Designjet T Series — Service Manual 1-23

Page 28

Force Drop Detection

If the N

one color that cannot be fixed with a printhead recovery, you can use this

option to resolve the problem by resetting the nozzle health data base so

that all nozzles are assumed to be correct.

Once the nozzle health data base has b

The normal cause of this white point banding in

incorrect detection of failed nozzles by the drop detector.

ozzle Print Test plot has persistent white point banding in only

Troubleshooting Print Quality Problems

Print Quality General Advice

o achieve the best performance from the printer, only genuine HP

1 T

accessories and supplies should be used.

2 Mak

e sure that the paper type selected in the Front Panel is the same as

the paper type loaded into the Printer.

Print quality troubleshooting

een reset drop detection is forced.

a single color is the

3 Mak

4 C

5 C

e sure to use the most appropriate print quality settings for your

purposes. A lower print quality is likely to be seen if the print quality slider

has been moved to the Speed end of the scale, or the custom quality level

set to Fast.

heck that the environmental conditions (temperature, humidity) are within

the temperature/humidity range as specified for the Printer (refer to the

User’s Guide for more information).

heck that the ink cartridges and printheads have not exceeded their

expiration dates.

Horizontal Lines Across the Image (Banding)

Description of problem

When you look at the image you have printed, there are horizontal lines

ross the image. Shown below is an example of what you might see if you

ac

have this problem:

HP Designjet T Series — Service Manual 1-24

Page 29

Print quality troubleshooting

Corrective Action

heck that the paper type loaded corresponds to the paper type selected in

1 C

the front panel and in the software. You can verify the paper type selected

through the Front Panel (Main Menu/Paper menu/View loaded paper).

heck that the appropriate print quality settings are being used (refer to the

2 C

User’s Guide for more information) and reprint the image. In some cases

print quality problems can be resolved by selecting a higher print quality

level.

int the Service Image Diagnostics Print, and clean any printheads that

3 Pr

need cleaning. Reprint the job in case the problem has been solved

4 Check the paper advance calibration status. If the status is PENDING,

perform the Paper Advance Calibration (Main Menu/Image Quality

Maintenance/Paper Advance Calibration/Calibrate Paper Advance).

fter calibration reprint the job.

5 A

atch the printer carriage when it reaches the end of its swath. If there is an

6 W

unexpected delay, this may cause the banding.

This delay is possibly the result of the following:

.

The user is performing tasks with other applications while printing

(particularly image processing applications). These applications are

using too many computer resources, and the computer cannot effectively

process the print job.

The file to be printed is complex, and the computer does not have the

capacity to print such complex files.

If printing over a LAN, it is possible that the LAN is too slow to meet the

requirements of the print job.

If this is the case, the following corrective measures can be taken:

1 Do

not use the computer while printing. Close applications that use a large

amount of computer resources.

onvert the file PDF. Formats like PDF require less resources to print, which

2 C

may solve your banding problem.

Lines are Missing, Too Thin, or Too Thick

Description of problem

Shown below is an example of what you

Corrective Action

heck that the paper type loaded corresponds to the paper type selected in

1 C

the front panel and in the software. You can verify the paper type selected

HP Designjet T Series — Service Manual 1-25

might see if you have this problem:

Page 30

Print quality troubleshooting

through the Front Panel (Main Menu/Paper menu/View loaded paper).

heck that the appropriate print quality settings are being used (refer to the

2 C

User’s Guide for more information). Select the custom print quality options in

the Print dialog, and if you are using best quality and glossy paper, try

turning on the Maximum detail option. Reprint the job in case the problem

has been solved.

3 If the

4 C

5 C

6 U

resolution of the image is greater than the printing resolution, a loss of

line quality may be seen. You can find the Max. Application Resolution

option in the Windows driver dialog's Advanced tab, under Document

Options > Printer Features. Reprint the job in case the problem has been

solved.

heck the Printhead alignment status. If the status is PENDING, perform the

Printhead Alignment (Main Menu/Image Quality Maintenance/Align

Printheads). After alignment reprint the job.

heck the paper advance calibration status. If the status is PENDING,

perform the paper advance calibration (Main Menu/Image Quality

Maintenance/Paper Advance Calibration/Calibrate Paper Advance). After

calibration reprint the job.

se Part 3 of the Image Quality Diagnostic Print, check if there are a

significant amount of nozzles out in the color that is actually causing the

problem (if see you a problem with the Black color in the customer print, then

only check the Black printhead in the Image Quality Diagnostic Print). If

there is a significant amount of nozzles out then replace the defective

Printhead.

Problems with Stepped Lines

Description of problem

When you look at the image you have printed there are ‘

the borders of arrows and diagonal lines. The lines should be straight with

no stepping.

Shown below is an example of what y

with Stepped Lines:

ou might see if you have problems

stepped lines’ in

Corrective Action

he problems may be inherent in the image that you are trying to print. Try

1 T

to improve the image with the application that generated the file.

heck that the appropriate print quality settings are being used (refer to the

2 C

User’s Guide for more information).

elect the custom print quality options in your Print dialog, and if you are

3 S

using Glossy media and BEST quality, turn on the Maximum Detail

option.

HP Designjet T Series — Service Manual 1-26

Page 31

Print quality troubleshooting

4 C

hange the image rendering resolution to 300 dpi (only in EconoMode

Printmode) or 600 dpi depending on the printing needs. You can find the

Max. Application Resolution option in the Windows driver dialog's

Advanced tab, under Document Options > Printer Features.

Lines are Printed Double or in Wrong Colors

Description of problem

This problem can have various visible symptoms, as shown below:

Colored lines are

printed double, in

different colors

Corrective Action

eseat the Printheads by removing them and then reinserting them.

1 R

As you reseat the printheads, the printer will automatically align the

pr

intheads. It is important that the alignment is completed properly. See

Aligning Printheads on page 1-48.

Lines are discontinuous

If the lines are broken in the following way:

1 C

heck that the appropriate print quality settings are being used (refer to the

User’s Guide for more information).

eseat the Printheads by removing them and then reinserting them.

2 R

As you reseat the printheads, the printer will automatically align the

pr

intheads. It is important that the alignment is completed properly. See

Aligning Printheads on page 1-48.

Borders of colored

blocks are wrongly

colored

HP Designjet T Series — Service Manual 1-27

Page 32

Print quality troubleshooting

Lines are Blurred (Ink Bleeds from Lines)

Description of problem

This problem is often caused by the ink soaking into the paper, making the

line

s blurred and fuzzy. This could be because of the humidity in the air.

Corrective Action

heck that the environmental conditions (temperature, humidity) are suitable

1 C

for high-quality printing.

2 Mak

3 T

e sure that the paper type selected in the Front Panel is the same as

the paper type loaded into the Printer.

ry using a heavier paper type. When printing dense colors, it is

recommended to use HP Heavyweight Coated Paper or HP Super

Heavyweight Coated Paper.

glossy paper is being used, try changing to a different type of glossy

4 If

paper.

lign the printheads. See Image Quality Maintenance Procedure on page 1-

5 A

48.

Problems with Graininess

Description of problem

Shown below is an example of what y

with graininess:

Corrective Action

heck that the paper type loaded corresponds to the paper type selected in

1 C

the front panel and in the software. You can verify the paper type selected

through the Front Panel (Main Menu/Paper menu/View loaded paper).

heck that printing is on the correct side of the paper.

2 C

ou might see if you have problems

HP Designjet T Series — Service Manual 1-28

Page 33

Print quality troubleshooting

3 C

heck that the appropriate print quality settings are being used (refer to the

User’s Guide for more information). In many cases, you can correct grainy

printing by raising the print quality settings. Reprint the job in case the

problem has been solved.

heck the Printhead alignment status. If the status is PENDING, perform the

4 C

Printhead Alignment (Main Menu/Image Quality Maintenance/Align

Printheads). After alignment reprint the job.

heck the paper advance calibration status. If the status is PENDING,

5 C

perform the paper advance calibration (Main Menu/Image Quality

Maintenance/Paper Advance Calibration/Calibrate Paper Advance).

fter Paper Advance Calibration, reprint the job.

6 A

Paper is not Flat

Description of problem

If the paper does not lie flat when it comes out of the Printer, but has shallow

aves in it, you are likely to see visible defects in the printed image, such as

w

vertical stripes. This can happen when you use thin paper that becomes

saturated with ink.

Shown below is an example of what y

with the paper not being flat:

ou might see if you have problems

Corrective Action

heck that the paper type loaded corresponds to the paper type selected in

1 C

the front panel and in the software. You can verify the paper type selected

through the Front Panel (Main Menu/Paper menu/View loaded paper).

HP Designjet T Series — Service Manual 1-29

Page 34

Print quality troubleshooting

2 T

ry using a heavier paper type. When printing dense colors, it is

recommended to use HP Heavyweight Coated Paper or HP Super

Heavyweight Coated Paper.

Ink marks on the paper

This problem may occur for several different reasons.

Horizontal smears on the front of coated paper

If a lot of ink is used on plain or coated paper, the paper absorbs the ink

uickly and expands. As the printheads move over the paper, the printheads

q

may come into contact with the paper and smear the printed image. This

problem is normally seen only on cut sheets of paper (not on roll paper).

Corrective Action

heck that the paper type loaded corresponds to the paper type selected in

1 C

the front panel and in the software. You can verify the paper type selected

through the Front Panel (Main Menu/Paper menu/View loaded paper).

se a recommended paper type and the correct print settings.

2 U

using sheet paper, try rotating the sheet 90 degrees. The orientation of the

3 If

paper fibers may affect performance.

ry using a heavier paper type. When printing dense colors, it is

4 T

recommended to use HP Heavyweight Coated Paper or HP Super

Heavyweight Coated Paper.

ry to increase the margins by relocating the image to the center of the page

5 T

with the software application being used.

Ink marks on the back of the paper

This can happen after a lot of border less printing, especially with non-

tandard paper sizes. Ink residues on the platen are likely to mark the back

s

of the paper.

Corrective Action

Clean the platen with a soft cloth. Clean each rib separately without

touching the foam between the ribs.

HP Designjet T Series — Service Manual 1-30

Page 35

Print quality troubleshooting

Problems with the Edges of objects

Stepped or not sharp

The edges of objects or lines appear to be poorly defined or lighter in

densit

y than expected.

Corrective Action

If the print quality slider has already been set to Quality in the Print

dialog, select the custom print quality options, and try setting the quality

level to Normal (refer to the User’s Guide for more information).

Darker than expected

The edges of objects seem darker than expected.

Corrective Action

If the print quality slider has already been set to Quality in the Print

dialog, select the custom print quality options, and try setting the quality

level to Normal.

Black and white prints do not look neutral

Consider printing in grayscale (color opti

preference menu). See the User´s Guide for more information.

Horizontal lines at the end of a cut sheet print

There is a type of defect that only affects the end of a print, within

pproximately 30 mm of the trailing edge of the paper. Some very thin

a

horizontal lines may be seen across the print.

Corrective Action

int the Service Image Diagnostics Print, and clean any printheads that

1 Pr

need cleaning. Reprint the job in case the problem has been solved

2 Try printing with roll paper.

ry using larger margins around the image.

3 T

Vertical lines of different colors

The print has vertical bands of different colors along it.

ons submenu inside the printing

.

HP Designjet T Series — Service Manual 1-31

Page 36

Print quality troubleshooting

Corrective Action

ry using a heavier paper type. When printing dense colors, it is

1 T

recommended to use HP Heavyweight Coated Paper or HP Super

Heavyweight Coated Paper.

se higher print quality settings (refer to the User’s Guide for more

2 U

information).

White spots on the print

White spots are seen on the print. This is probably due to paper fibers, dust,

se coating material.

or loo

Corrective Action

lean the paper manually with a brush before printing, to remove any loose

1 C

fibers or particles.

lways keep the cover of the printer closed.

2 A

otect paper rolls and sheets by storing them in bags or boxes.

3 Pr

Problems with Color Accuracy

Corrective Action

1 Ensur

e that the paper type being used has been color calibrated, which will

give color consistency

from print to print, and from Printer to Printer.

2 Check that printing is on the correct side of the paper.

heck that the appropriate print quality settings are being used (refer to the

3 C

User’s Guide for more information). Reprint the job in case the problem has

been solved.

the problem consists of color differences between your print and your

4 If

monitor, please follow the instructions in the "How to calibrate your monitor"

section of the HP Color Center. At this point, you may wish to reprint your

job in case the problem has been solved.

elect suitable options in the application (refer to the User’s Guide for more

5 S

information).

HP Designjet T Series — Service Manual 1-32

Page 37

Print quality troubleshooting

6 Pr

int the Service Image Diagnostics Print, and clean any printheads that

need cleaning. Reprint the job in case the problem has been solved

Color accuracy using EPS or PDF images in page layout

applications

Page layout applications such as Adobe InDesign and QuarkXPress do not

su

pport color management of EPS, PDF, or grayscale files.

If these types of files have to be used, try to ensure that the EPS, PDF, or

gr

ayscale images are already in the same color space that is intended to be

used later on in Adobe InDesign or QuarkXPress. For instance, if the final

objective is to print the job in a press that follows the SWOP standard, at the

time of creating the EPS, PDF or grayscale the image should be converted

into SWOP.

Output Only Contains a Partial Print

If the output that was expected only cont

following to resolve the problem:

ains a partial image, then try the

.

1 Wa

2 Th

3 T

4 Mak

5 If

s the Cancel key pressed before all the data was received by the

Printer? If so, send the file again and make sure that the Cancel key is not

pressed.

e I/O Timeout setting may be too short. Increase the I/O timeout setting

(Setup Menu/I/O Setup/IO Timeout) and then send the file again.

here might be a communications problem between the Printer and

Computer. Check the USB or network cable between the computer and the

Printer to make sure it is not damaged and is connected correctly.

e sure that the software settings are correct for the current page size

(e.g. long-axis prints).

network software is being used, make sure it has not timed out.

Problems with Image Clipping

This normally indicates a discrepancy between the actual printable area on

the load

kind of problem can often be identified before printing by previewing the

print.

ed paper and the printable area as understood by the software. This

Check the actual printable area for the paper size that is loaded.

printable area = paper size – margins

Check what the software understands to be the printable area (which it

may call “printing area” or “imageable area”). For example, some

software applications assume standard printable areas that are larger

than those used in this Printer.

If a custom page size with very narrow margins has been defined, the

printer may impose its own minimal margins, clipping the image slightly.

Consider using a larger paper size, or border less printing.

If the image contains its own margins, it may be possible to print it

successfully by using the Clip Contents by Margins option.

If a very long image needs to be printed on a roll, check that the software

is capable of printing an image of that size.

The page may have been rotated from portrait to landscape on a paper

size that is not wide enough.

HP Designjet T Series — Service Manual 1-33

Page 38

Print quality troubleshooting

If necessary, change the printable area in the software.

If necessary, reduce the size of the image or document in your software

application, so it fits between the margins

Another Possible Explanation

Some applications, such as Adobe Photoshop, Adobe Illustrator, and

orelDRAW, use an internal 16–bit coordinate system which means that they

C

cannot handle an image of more than 32,768 pixels. If you try to print an

image larger than this from these applications, the bottom of the image will

be clipped. In this case, the only way to print the whole image is to reduce

the resolution so that the whole image requires fewer than 32,768 pixels. The

HP-GL/2 printer driver contains an option called Compatibility with 16–

bit applications, which can be used to reduce the resolution of such

images automatically. This option can be found option in the Advanced tab,

under Document Options > Printer Features.

Some objects are missing from the printed image

Large quantities of data may be necessary to print a high-quality large-

ormat print job, and in some specific workflow there may be issues that can

f

lead to some objects missing from the output.

Corrective Action

In the Advanced tab, select Document options, Printer features, and set

Send job as bitmap to Enabled (HP-GL/2 driver only).

In the Advanced tab, select Document options, Printer features, and set

16-bit App. Compatibility to Enabled.

In the Advanced tab, select Document options, Printer features, and set

Max. Application resolution to 300.

The above settings are mentioned for troubleshooting purposes and may

ad

versely affect the final output quality or the time necessary to generate the

print job. Therefore, they should be restored to their default values if they do

not help to solve the problem.

When working under Mac OS, the above settings are not available. Instead,

y reducing the resolution of bitmap images in the application software

tr

being used.

A PDF file is clipped or objects are missing

In older versions of Adobe Acrobat or Adobe Reader, large PDF files could

clipped or lose some objects when printing with the HP-GL/2 driver at

be

high resolution. Upgrade the Adobe Acrobat or Adobe Reader software to

the latest version. From version 7 onwards, these problems should be solved.

Print Quality Troubleshooting Wizard

Here we describe the main guidelines that a customer can follow to

troubleshoot print quality and/or color issues, whenever a customer calls HP

Support complaining about having any kind of printing quality problems or

artifacts.

The Print Quality (PQ) troubleshooting Wizard is a set of processes and

rective actions that the customer can trigger in the printer whenever the

cor

print quality of the printer does not meet their expectations.

HP Designjet T Series — Service Manual 1-34

Page 39

Print quality troubleshooting

Some of these corrective actions that the customer can perform to enhance

the

print and/or color quality are: printhead cleaning, media advance

calibration, printhead alignment, and color calibration.

The main benefits of this Print Quality Troubleshooting Wizard tool are that it

c

reates a better customer experience, solving customer PQ issues fast,

efficiently, and with a minimum cost for them and also for HP Support.

Customers can perform PQ/color trouble

(PU), the Embedded Web Server (EWS) or by following the steps described

in the User’s Manual or the HP Knowledge Center.

shooting through the Printer Utility

Print Quality Troubleshooting Wizard main window

When to use the Print Quality troubleshooting tool:

The Print Quality Troubleshooting Wizard can help customers solve their

/color problems without the need to call to HP Support. Some of the

PQ

problems for which it can help are the following:

Troubleshooting area fill uniformity issues such as:

– Horizontal lines across the image (banding)

– The entire image is blurry or grainy (graininess)

Troubleshooting line and text quality issues such as:

– Lines are too thick, too thin, or missing

– Lines appear stepped or jagged

– Lines print double or in the wrong colors

– Lines are discontinuous

– Lines are blurred

HP Designjet T Series — Service Manual 1-35

Page 40

Print quality troubleshooting

Troubleshooting color issues such as:

– Colors are inaccurate

Troubleshooting printhead reliability issues

Corrective actions a customer can perform:

The corrective actions on the printer’s systems that the customer can perform

t

o enhanced the print and/or color quality are:

Clean Printheads is recommended only if the customer is

experiencing problems with print quality where we know that printhead

cleaning will help.

Calibrate Paper Advance is used to adjust the printer’s parameters

for use with different types of print media. This only affects the physical

movement of paper and does not affect the color calibration profiles.

Align Printheads is recommended only if the customer is experiencing

problems with print quality where we know that proper printhead

alignment will help (i.e. graininess).

Calibrate Color is recommended only if the customer is experiencing

problems with color print quality where we know that proper color

calibration with help (i.e. color accuracy).

Troubleshooting for banding issues

How to start the Print Quality Troubleshooting Wizard

rom the HP Printer Utility under Windows: go to the Support tab, and

1 F

HP Designjet T Series — Service Manual 1-36

Page 41

Print quality troubleshooting

select P

2 F

quality troubleshooting.

rint quality troubleshooting.

rom the Embedded Web Server: go to the Support tab, then select Print

For Mac OS

rom the HP Printer Utility under Mac OS: select Support, and then Print

1 F

quality troubleshooting.

rom the Mac OS Print dialog: go to the Services panel, select Device

2 F

Maintenance, then select Print quality troubleshooting from the list of

maintenance tasks.

HP Designjet T Series — Service Manual 1-37

Page 42

Ink Supplies Troubleshooting

Introduction to ink supplies

What are Ink Supplies?

For each of the ink colors used in the printer, there are two components, the

Pr

inthead and Ink Cartridge. These components are called Ink Supplies.

Ink Supplies Troubleshooting

Ink Cartridges

Ink Cartridges

The printer's six Ink Cartridges provide matte black, magenta, yellow, cyan,

gr

ay and photo black ink to the Printheads. The color Ink Cartridges

supplied with the printer have a capacity of 69 ml but optional 130 ml are

also available

All these ink cartridges are physically the same size. Only the internal

capacity varies.

.

Printheads

HP Designjet T Series — Service Manual 1-38

Page 43

Ink Supplies Troubleshooting

The Ink Cartridges for the T printer series require no maintenance or

c

leaning. As long as each Ink Cartridge is inserted correctly into its slot, the

ink will flow to the Printheads. Because the Printheads control the amount of

ink transferred to the page, you will continue to see high-quality printing

results even when the ink levels are getting low.

The front panel displays the status of the Ink Cartridge. Using the front panel,

ailed information can be checked on the Ink Cartridges.

det

Available Ink Cartridges

T Printer Series Cartridges Part

number

HP 72 69 ml Photo Black Ink

Cartridge

Ink Cartridge C9397A

HP 72 69 ml Cyan Ink Cartridge Ink Cartridge C9398A

HP 72 69 ml Magenta Ink

Ca

rtridge

HP 72 69 ml Yellow Ink

Ca

rtridge

Ink Cartridge C9399A

Ink Cartridge C9400A

HP 72 69 ml Gray Ink Cartridge Ink Cartridge C9401A

HP 72 130 ml Matte Black Ink

Ca

rtridge

HP 72 130 ml Photo Black Ink

Ca

rtridge

HP 72 130 ml Cyan Ink

Ca

rtridge

HP 72 130 ml Magenta Ink

Ca

rtridge

HP 72 130 ml Yellow Ink

Ca

rtridge

Ink Cartridge C9403A

Ink Cartridge C9370A

Ink Cartridge C9371A

Ink Cartridge C9372A

Ink Cartridge C9373A

HP 72 130 ml Gray Ink Cartridge Ink Cartridge C9374A

theads

Prin

The Printheads are extremely durable and

do not need to be replaced every

time an Ink Cartridge is replaced. They are independent of the Ink

Cartridges and will continue giving excellent image quality results even if the

Ink Cartridges are low on ink.

HP Designjet T Series — Service Manual 1-39

Page 44

Ink Supplies Troubleshooting

If you notice a decline in print quality such as lines or dots missing from text/

gr

aphics, see

Available Printheads

Troubleshooting Print Quality Problems on page 1-24.

Printhead Type Printer Model Part

number

HP 72 Gray & Photo Black

inthead

Pr

HP 72 Magenta & Cyan Printhead C9383A

HP 72 Matte Black & Yellow

inthead

Pr

General Information About the Ink Supplies

For optimum results from the printer and modular ink delivery system always

f

ollow these guidelines when handling the ink supplies:

All

C9380A

C9384A

Always install the Ink Cartridges and Printheads before the expiration

date, which is on the packaging.

Install Ink Cartridges and Printheads in their color-coded slots.

Follow the instructions on the front panel of the Printer during installation.

Avoid unnecessary removal of the Ink Cartridges and Printheads.

When turning off the Printer always use the power Off button on the front

panel. The Printheads are then stored correctly which prevents them from

drying out.

The Ink Cartridges should never be removed while the printer is printing.

They should only be removed when the printer is ready for you to replace

them. The front panel will guide you through the removal and installation

procedure.

General Precautions When Handling Ink Supplies

Use the following precautions when handling Ink Supplies:

Do not touch, wipe or attempt to clean the printhead nozzles. This can

damag

e the printhead.

Handle the ink supplies with care. In particular the Printhead, which is a

high precision device and must be handled carefully.

Do not touch the Printhead nozzles.

Do not put the Printhead down on the nozzles.

Do not be rough when handling the Printheads. Always set them down

gently.

Do not drop the Printheads.

Proper handling will assure optimum performance throughout the

Printhead life.

Do not touch the end of the Ink Cartridge which is inserted into the printer

as there may be a small amount of ink on the connection.

Avoid storing partially used Ink Cartridges on their ends.

HP Designjet T Series — Service Manual 1-40

Page 45

Ink Supplies Troubleshooting

When Should You Replace the Ink Supplies?

When to change the ink supplies is mostly determined by you with guidance

f

rom the front panel. In conjunction with the messages displayed in the front

panel and the message explanations in this chapter, you will be able to

choose for yourself when is the right time to change the ink supplies.

The Printer will also display the ink level and will tell you when the ink supply

w on ink. This means you have constantly updated information about the

is lo

ink supplies.

Ink Cartridge Levels, Information, and Replacement

Ink Cartridge Levels

The front panel displays Ink Levels shown as level bars. These bars represent

w much ink is remaining in the Ink Cartridges: as ink is used up the bars

ho

get shorter in length.

There are two methods for checking the ink levels of your Ink Cartridges.

“View Ink Levels” Direct Access Key

Pressing the “View ink levels” direct access key on the Front Panel will

immediately show you the ink levels. For more information about direct

access keys, see

Using the Front Panel on page 1-3

“View Ink Levels” from the ink menu

Choosing the View ink levels option from the Ink menu will

immediately show you the ink levels:

Obtaining Ink Cartridge Information

1 S

croll to the Ink Menu icon and press OK.

HP Designjet T Series — Service Manual 1-41

Page 46

Ink Supplies Troubleshooting

2 In the Ink Men

OK.

3 In the Ink C

want information on and press OK.

he front panel displays information on the selected Ink Cartridge. Use the

4 T

Arrow keys to scroll through the information.

u submenu, scroll to Ink cartridge information and press

artridge Information submenu, scroll to the Ink Cartridge that you

The information supplied is:

The color of the Ink Cartridge

The make of the Ink Cartridge (hp no.72 is recommended).

The product number of the Ink Cartridge.

The serial number of the Ink Cartridge.

The current status of the Ink Cartridge.

The current ink level of the ink cartridge in milliliters.

Original capacity of the ink cartridge in milliliters.

The Expiration Date of the ink cartridge.

The manufacturer of the Ink Cartridge (hp is recommended).

The current warranty status of the Ink Cartridge.

HP Designjet T Series — Service Manual 1-42

Page 47

Ink Supplies Troubleshooting

The printer consumes more gray ink ink than M, C, or Y

This is not a problem, and no action should be taken to “correct” this

at

tribute of the printer.

In general the higher frequency of change is because Matte Black ink is the

one that

coated, HW coated, natural tracing paper, etc.), which are the types of

contents that are more commonly printed with this type of printer.

About gray ink

The T Series Printers are the first HP Designjet technical products to include

Gr

quantities than Cyan, Magenta and Yellow inks. This happens because of

the following reasons:

1) Gray areas (which are very typical in technical drawings) can now be

pr

combining Cyan, Magenta and Yellow inks. This means that Gray ink is

used more frequently than the rest of the inks (C, M, Y) which are now used

less frequently, so the difference in consumption is noticeable. However

overall the T Series Printers will actually need to use in total less ink to print

gray areas than previous Designjet products.

2) Soft colors can now be printed by combining C, M and Y inks with Gray.