Page 1

Installation

Guide

HP StorageWorks

SAN Switch 2/8V

2/16V and 2/16N

Product Version: 4.2.x

Second Edition (April 2004)

Part Number: AA–RVULB–TE

This user guide provides procedures for setting up, configuring, and managing the SAN Switch

2/8V, SAN Switch 2/16V, and 2/16N models.

Page 2

© Copyright 2004 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another language without the prior written consent of Hewlett-Packard.

The information contained in this document is subject to change without notice.

Microsoft®, Windows®, and Windows NT® are U.S. registered trademarks of Microsoft Corporation.

UNIX® is a registered trademark of The Open Group.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein. The

information is provided “as is” without warranty of any kind and is subject to change without notice. The warranties

for Hewlett-Packard Company products are set forth in the express limited warranty statements for such products.

Nothing herein should be construed as constituting an additional warranty.

Printed in the U.S.A.

SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Second Edition (April 2004)

Part Number: AA–RVULB–TE

Page 3

contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Text Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rack Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Storage Web site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Authorized Reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SAN Switch 2/8V, 2/16V and 2/16N Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SAN Switch 2/8V and 2/16 Switches Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SAN Switch Licensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Switch Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Port Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Nonport Side of SAN Switch 2/8V, 2/16V and 2/16N . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ISL Trunking Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Supported (Optional) Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional Hardware Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Contents

2 Installing the SAN Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

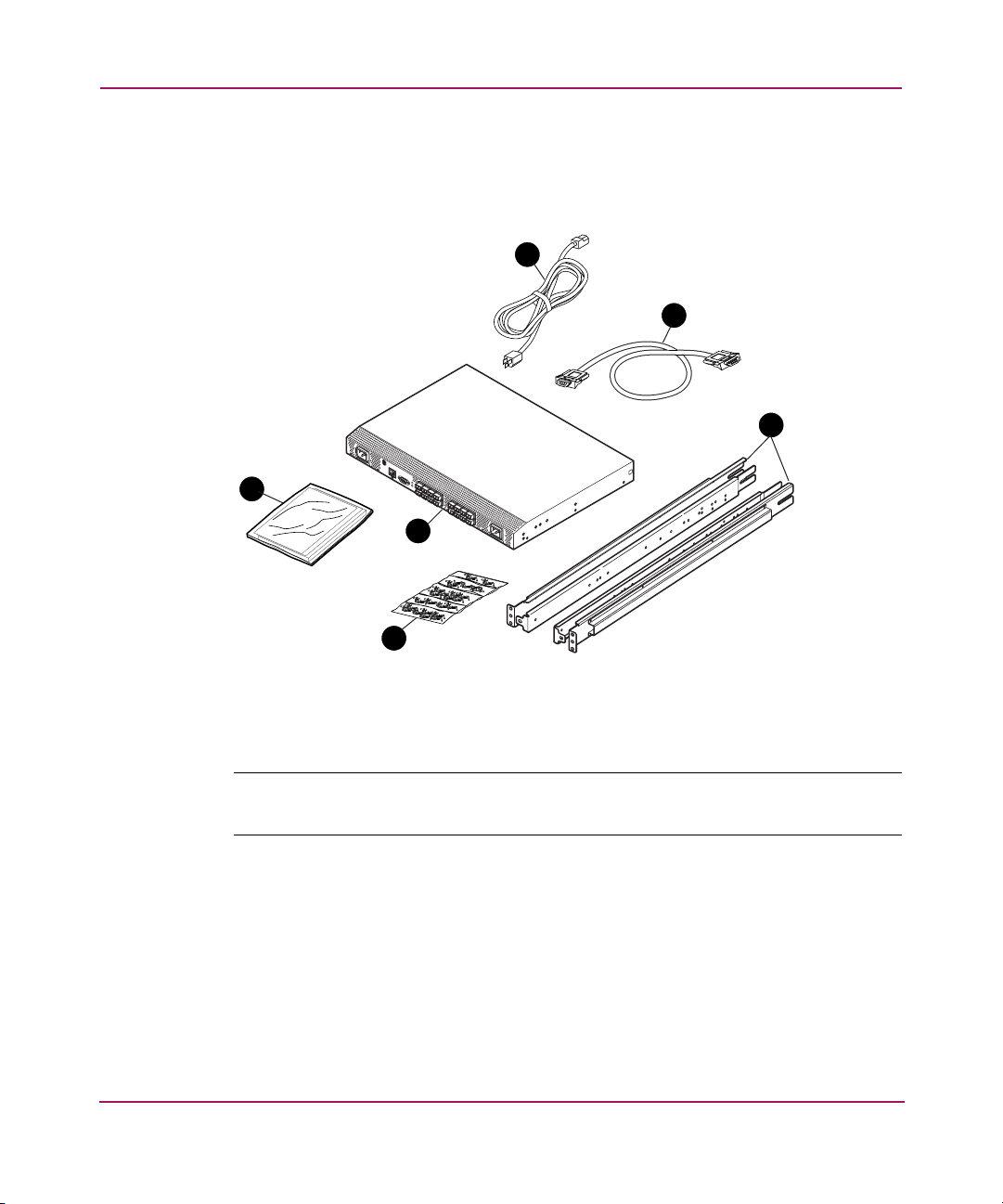

Items Included with the SAN Switch 2/8V, 2/16V and 2/16N. . . . . . . . . . . . . . . . . . . . . . . . 26

Shipping Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 4

Contents

Installation and Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing a Stand-Alone SAN Switch 2/8V, 2/16V and 2/16N . . . . . . . . . . . . . . . . . . . . . . . 31

Installing a SAN Switch 2/8V, 2/16V or 2/16N Into an EIA Cabinet . . . . . . . . . . . . . . . . . . 32

Selecting an Operating Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing the Switch in a Rack Using the SAN Switch Rack Mount Kit . . . . . . . . . . . . 34

Cabling and Configuring the SAN Switch 2/8V, 2/16V or 2/16N. . . . . . . . . . . . . . . . . . . . . 47

Recommendations for Cable Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Items Required for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Configuring the SAN Switch 2/8V, 2/16V and 2/16N . . . . . . . . . . . . . . . . . . . . . . . 48

Create a Serial Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Power Up the Switch and Log In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Create an Ethernet Connection and Log In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Modify the Fibre Channel Domain ID (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Install the SFP Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connect the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Verifying Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Backing Up Your Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3 Managing the SAN Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Powering the Switch On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Interpreting LED Activity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

LED Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

LED Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

System and Power LED Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Port LED Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Ethernet LED Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

POST and Boot Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Interpreting POST Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 5

Contents

4 Backing Up the Configuration and Upgrade Firmware . . . . . . . . . . . . . . . . . . . . . . .67

SAN Switch 2/8V, 2/16V and 2/16N Management Features . . . . . . . . . . . . . . . . . . . . . . . . 68

Maintaining the SAN Switch 2/8V, SAN Switch 2/16V and SAN Switch 2/16N. . . . . . . . . 70

Installing an SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Removing an SFP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Diagnostic Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

A Regulatory Compliance Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

FCC EMC Statement (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

EMC Statement (Canada). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

EMC Statement (European Union). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

European Union Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Germany Noise Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

VCCI EMC Statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

RRL EMC Statement (Korea) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Battery Replacement Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

B Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Grounding Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

C Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Data Transmission Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Fibre Channel Port Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Serial Port Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Weight and Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Memory Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Supported SFPs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Facility Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Supported HBAs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

System Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 6

Contents

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Figures

1 Port Side of SAN Switch 2/8V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Port Side of the SAN Switch 2/16V and 2/16N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Trunking groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Shipping carton contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 Installing the rear mounting brackets (HP 10000 series or comparable EIA cabinet). . . 35

6 Installing the rear mounting brackets (HP System/e rack-left rear upright) . . . . . . . . . . 36

7 Installing the outer rails (HP 10000 series or comparable EIA cabinet) . . . . . . . . . . . . . 37

8 Assembling the outer rails (HP 10000 series or comparable EIA cabinet) . . . . . . . . . . . 38

9 Assembling the outer rails (HP System/e cabinet). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10 Assembling the inner rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11 Assembling the inner rails on a SAN Switch with plenum . . . . . . . . . . . . . . . . . . . . . . . 42

12 Installing the switch into a rack (HP 10000 series or comparable EIA cabinet) . . . . . . . 43

13 Installing the switch into a rack (HP System/e cabinet) . . . . . . . . . . . . . . . . . . . . . . . . . 44

14 Connecting the serial cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

15 Connecting the power cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

16 Connecting the Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

17 SAN Switch 2/8V LED locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

18 SAN Switch 2/16V LED locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

19 Installing or removing an SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Tables

1 Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 SAN Switch 2/8V port side components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 SAN Switch 2/16V and 2/16N port side components . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Orderable Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Shipping Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Rack Mount Kit rails and rail mounting hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Number of screws required to assemble the inner rails . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 SAN Switch 2/8V LED Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9 SAN Switch 2/16V LED Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10 System LED Patterns During Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11 Port LED Patterns During Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

12 Ethernet LED Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 7

Contents

13 Management Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

14 Laser Data Transmission Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

15 Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

16 Switch specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

17 Memory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

18 Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

19 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

20 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 8

Contents

8 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 9

about this

guide

This installation guide provides information to help you configure the HP

StorageWorks SAN Switch 2/8V, SAN Switch 2/16V, and SAN Switch 2/16N.

Note: Throughout this guide, information about the SAN Switch 2/16V is applicable

to the SAN Switch 2/16N, unless otherwise noted.

“About this Guide” topics include:

■ Overview, page 10

■ Conventions, page 11

■ Rack Stability, page 14

About this Guide

About this Guide

9SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 10

About this Guide

Overview

This section covers the following topics:

■ Intended Audience

■ Related Documentation

Intended Audience

This book is intended for use by system administrators and technicians who are

experienced with the following:

■ Configuration aspects of customer Storage Area Network (SAN) fabric

■ Customer host environment, such as Microsoft Windows or IBM AIX

■ Web Tools graphical user interface (GUI) for confinguring the switches

through a supported web browser

Related Documentation

Documentation, including white papers and best practices documents, is available

via the HP website. Please go to:

http://www.hp.com/country/us/eng/prodserv/storage.html

To access SAN Switch related documents:

.

1. Locate the Networked storage section of the web page.

2. Under Networked storage, go to the By type subsection.

3. Click SAN infrastructure. The SAN infrastructure page displays.

4. Locate the Fibre Channel Switches section.

5. Locate the B-Series Fabric subsection, then go to the Entry-level subsection.

6. Select SAN Switch 2/8V, SAN Switch 2/16V or SAN Switch 2/16N. The

switch overview page displays.

7. Go to the product information section, located on the far right side of the

web page.

8. Click technical documents.

9. Follow the onscreen instructions to download the applicable documents.

10 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 11

Conventions

Conventions consist of the following:

■ Document Conventions

■ Text Symbols

■ Equipment Symbols

Document Conventions

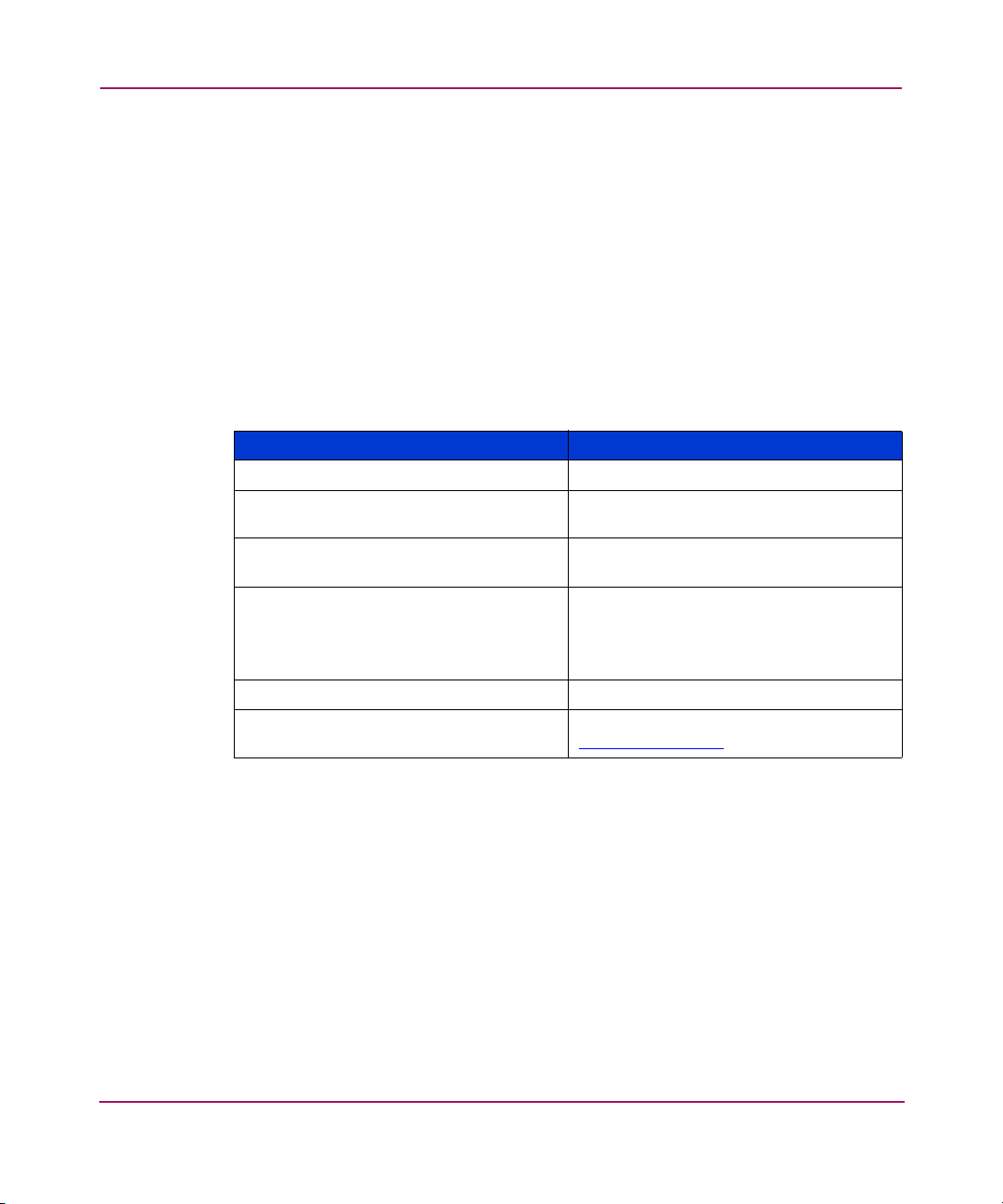

The document conventions included in Tabl e 1 apply in most cases.

Table 1: Document Conventions

Cross-reference links Blue text: Figure 1

Key and field names, menu items,

buttons, and dialog box titles

File names, application names, and text

emphasis

User input, command and directory

names, and system responses (output

and messages)

Variables <monospace, italic font>

Web site addresses Blue, underlined sans serif font text:

About this Guide

Element Convention

Bold

Italics

Monospace font

COMMAND NAMES are uppercase

monospace font unless they are case

sensitive

http://www.hp.com

SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

11

Page 12

About this Guide

Text Symbols

The following symbols may be found in the text of this guide. They have the

following meanings.

WARNING: Text set off in this manner indicates that failure to follow

directions in the warning could result in bodily harm or death.

Caution: Text set off in this manner indicates that failure to follow directions

could result in damage to equipment or data.

Note: Text set off in this manner presents commentary, sidelights, or interesting points

of information.

Equipment Symbols

The following equipment symbols may be found on hardware for which this guide

pertains. They have the following meanings.

Any enclosed surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards. Enclosed

area contains no operator serviceable parts.

WARNING: To reduce the risk of personal injury from electrical shock

hazards, do not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network

interface connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors

into this receptacle.

12 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 13

About this Guide

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. Contact with

this surface could result in injury.

WARNING: To reduce the risk of personal injury from a hot component,

allow the surface to cool before touching.

Power supplies or systems marked with these symbols indicate the

presence of multiple sources of power.

WARNING: To reduce the risk of personal injury from electrical

shock, remove all power cords to completely disconnect power

from the power supplies and systems.

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to

handle safely.

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manually handling material.

SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

13

Page 14

About this Guide

Rack Stability

Rack stability protects personnel and equipment.

WARNING: To reduce the risk of personal injury or damage to the

equipment, be sure that:

■ The leveling jacks are extended to the floor.

■ The full weight of the rack rests on the leveling jacks.

■ In single rack installations, the stabilizing feet are attached to the rack.

■ In multiple rack installations, the racks are coupled.

■ Only one rack component is extended at any time. A rack may become

unstable if more than one rack component is extended for any reason.

14 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 15

Getting Help

If you still have a question after reading this guide, contact an HP authorized

service provider or access our web site:

HP Technical Support

Telephone numbers for worldwide technical support are listed on the following

HP web site:

of origin.

Note: For continuous quality improvement, calls may be recorded or monitored.

Be sure to have the following information available before calling:

■ Technical support registration number (if applicable)

■ Product serial numbers

■ Product model names and numbers

■ Applicable error messages

http://www.hp.com

http://www .hp.com/support/

About this Guide

.

. From this web site, select the country

■ Operating system type and revision level

■ Detailed, specific questions

HP Storage Web site

The HP web site has the latest information on this product, as well as the latest

drivers. Access storage at:

http://www.hp.com/country/us/eng/prodserv/storage.html

select the appropriate product or solution.

HP Authorized Reseller

For the name of your nearest HP authorized reseller:

■ In the United States, call 1-800-345-1518.

■ In Canada, call 1-800-263-5868.

■ Elsewhere, see the HP web site for locations and telephone numbers:

http://www .hp .com

SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

.

. From this web site,

15

Page 16

About this Guide

16 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 17

Overview

The SAN Switch 2/8V, SAN Switch 2/16V and SAN Switch 2/16N are Fibre

Channel Gigabit switches that support link speeds up to 2 Gb/sec. They can

operate in a fabric containing multiple switches or as the only switch in a fabric.

The SAN Switch 2/16N is identical to the 2/16V; however, the SAN Switch 2/16N

includes a full-fabric license.

Note: Unless otherwise noted, functionality and features for the 2/16V are applicable

to the 2/16N throughout this guide.

This chapter provides the following information:

■ SAN Switch 2/8V, 2/16V and 2/16N Features, page 18

■ Switch Characteristics, page 20

■ ISL Trunking Groups, page 22

■ Supported (Optional) Features, page 23

1

17SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 18

Overview

SAN Switch 2/8V, 2/16V and 2/16N Features

The SAN Switch 2/8V, 2/16V and 2/16N provide the following features:

■ Air-cooled 1U chassis. The chassis can be installed as a stand-alone unit or

mounted in a standard Electronic Industries Association (EIA) 19 in.

(48.26 cm) cabinet.

■ 8 or 16 Fibre Channel ports, with the following characteristics:

— Automatic negotiation to the highest common speed of all devices

connected to port.

— Port interfaces compatible with small form factor pluggable (SFP)

transceivers, both short wavelength (SWL) and long wavelength (LWL).

— Universal and self-configuring ports: capable of becoming an F_Port

(fabric enabled), FL_Port (fabric loop enabled), or E_Port (expansion

port).

■ 8 or 16 short wavelength SFP transceivers (optional).

■ One RS-232 serial port, designed to connect to a DTE port.

■ One 10/100 Mb/sec Ethernet port with an RJ-45 connector.

■ One (SAN Switch 2/8V) or two (SAN Switch 2/16V) built-in power supplies.

■ The following light-emitting diodes (LEDs):

— Power status

—System status

— Ethernet status

— Port status and port speed for each port

SAN Switch 2/8V and 2/16 Switches Comparison

The basic difference between the SAN Switch 2/8V and the SAN Switch 2/16V is

the number of ports: the SAN Switch 2/8V contains 8 ports, while the SAN

Switch 2/16V contains 16. The SAN Switch 2/8V contains only 1 power supply

while the SAN Switch 2/16V has built-in redundancy and contains 2 power

supplies; thus, the SAN Switch 2/16V also weighs more.

The SAN Switch 2/16V can operate indefinitely on either one of its power

supplies.

18 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 19

SAN Switch Licensing

The SAN Switch 2/8V, 2/16V and 2/16N are switches based on existing HP product lines

but with limits placed on the number of domains that can be used.

■ The SAN Switch 2/8V comes configured from the factory with a 2-domain

fabric license. Customers can purchase a full-fabric license.

■ The SAN Switch 2/16V comes configured from the factory with a 2-domain

fabric license. Customers can purchase a 4-domain fabric license or a

full-fabric license.

■ The SAN Switch 2/16N comes configured from the factory with a full-fabric

license.

The SAN Switch 2/8V and 2/16V products can be upgraded by purchasing an

optional license; refer to the HP StorageWorks Fabric OS Procedures 4.2x User

Guide to learn how to upgrade a license.

To determine the type of licensing your SAN Switch 2/8V or SAN Switch 2/16V

run, use use the licenseshow command.

switch:root> licenseshow

XXXnnXXnXnnXXX:

Fabric Watch license

Release v4.2 license

XXXnnXXnXnnXXX:

Zoning license

XXXnnXXnXnnXXX:

Web license

XXXnnXXnXnnXXX:

2 Domain Fabric license

Overview

19SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 20

Overview

Switch Characteristics

The next few sections describe the physical characteristics of the SAN Switch

2/8V, 2/16V and 2/16N and some important requirements for proper operation.

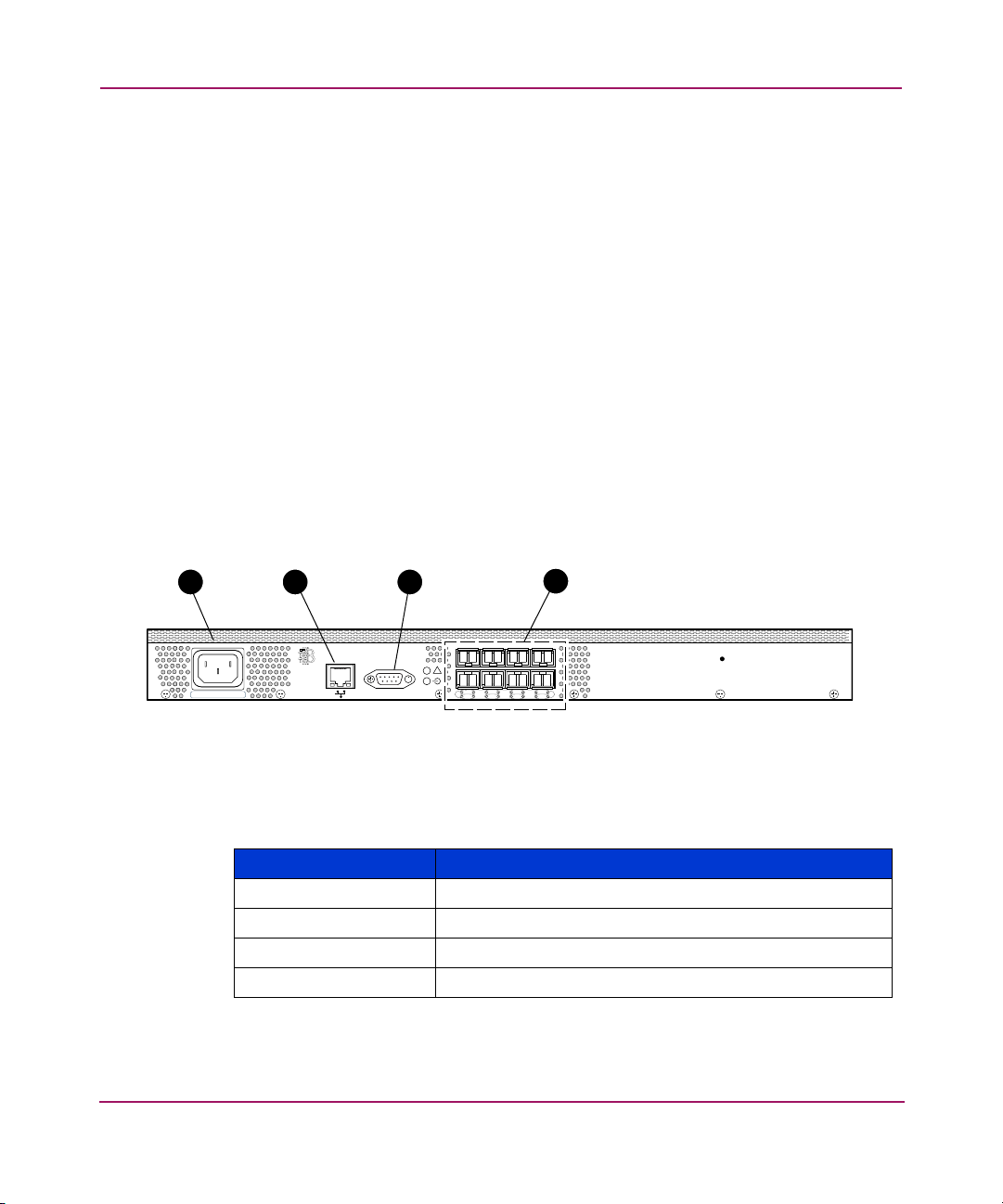

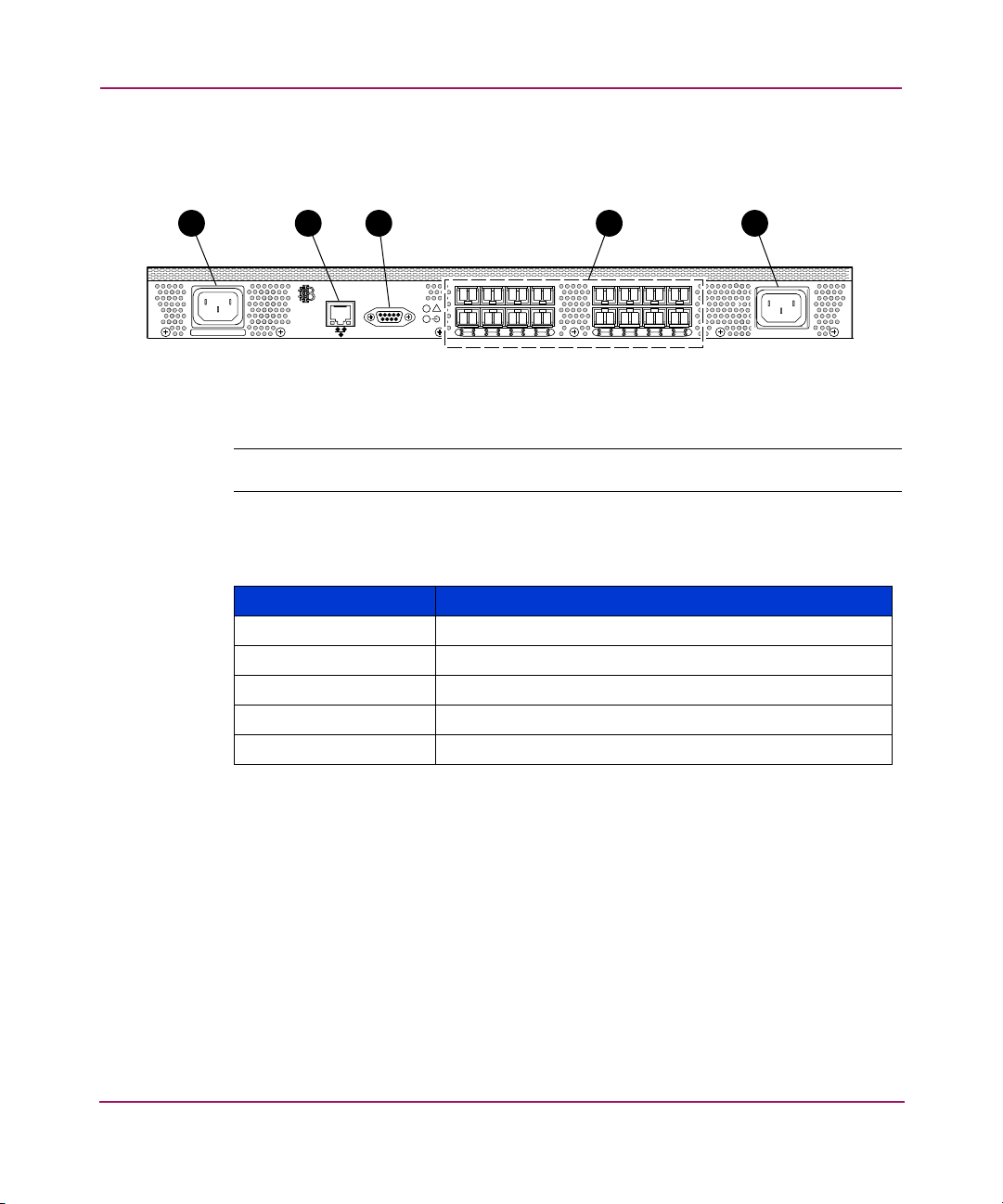

Port Side

You can see the physical differences between the SAN Switch 2/8V and the SAN

Switch 2/16V switches in the following figures. The most noticeable difference is

the number of ports. Figure 1 shows the port side of the SAN Switch 2/8V, and

Figure 2 shows the port side of the SAN Switch 2/16V.

All LEDs are on the port side of the switch: the nonport side is used for serial

number labeling and to allow the free flow of air. The SAN Switch enclosures

have forced-air cooling, with the fans pushing the air from the nonport side of the

chassis through the enclosure, and exhausting to the port side.

A complete description of the locations and interpretations of these LEDs can be

found at “Interpreting LED Activity” on page 59.

4

3

7

6

0018a

100-240 VAC 1.0A 47-63Hz

IOIOI

321

!

0

152

4

Figure 1: Port Side of SAN Switch 2/8V

Tabl e 2 lists the SAN Switch 2/8V port side components.

Table 2: SAN Switch 2/8V port side components

Number Description

1 AC power receptacle

2 Ethernet port

3 Serial port

4 FC ports (8)

20 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 21

Overview

As shown in Figure 2, the SAN Switch 2/16V and SAN Switch 2/16N has twice

the number of ports and a second AC power receptacle.

4321

!

100-240 VAC 1.0A 47-63Hz 100-240 VAC 1.0A 47-63Hz

IOIOI

0

4

152

3

7

6

8

12

91310

11

15

14

5

Figure 2: Port Side of the SAN Switch 2/16V and 2/16N

Note: The SAN Switch 2/16N has the same characteristics as the 2/16V.

Tabl e 3 lists the SAN Switch 2/16V port side components.

Table 3: SAN Switch 2/16V and 2/16N port side components

Number Description

1 AC power receptacle

2 Ethernet port

3 Serial port

4 FC Ports (16)

5 Second AC power receptacle

0020a

Nonport Side of SAN Switch 2/8V, 2/16V and 2/16N

The nonport side of the SAN Switch 2/8V, 2/16V and 2/16N is used solely for air

flow and for serial number labels. There are two labels on the rear of the chassis;

both contain a serial number label for the switch; the left label also contains the

2/8V and 2/16V MAC address and WWN.

21SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 22

Overview

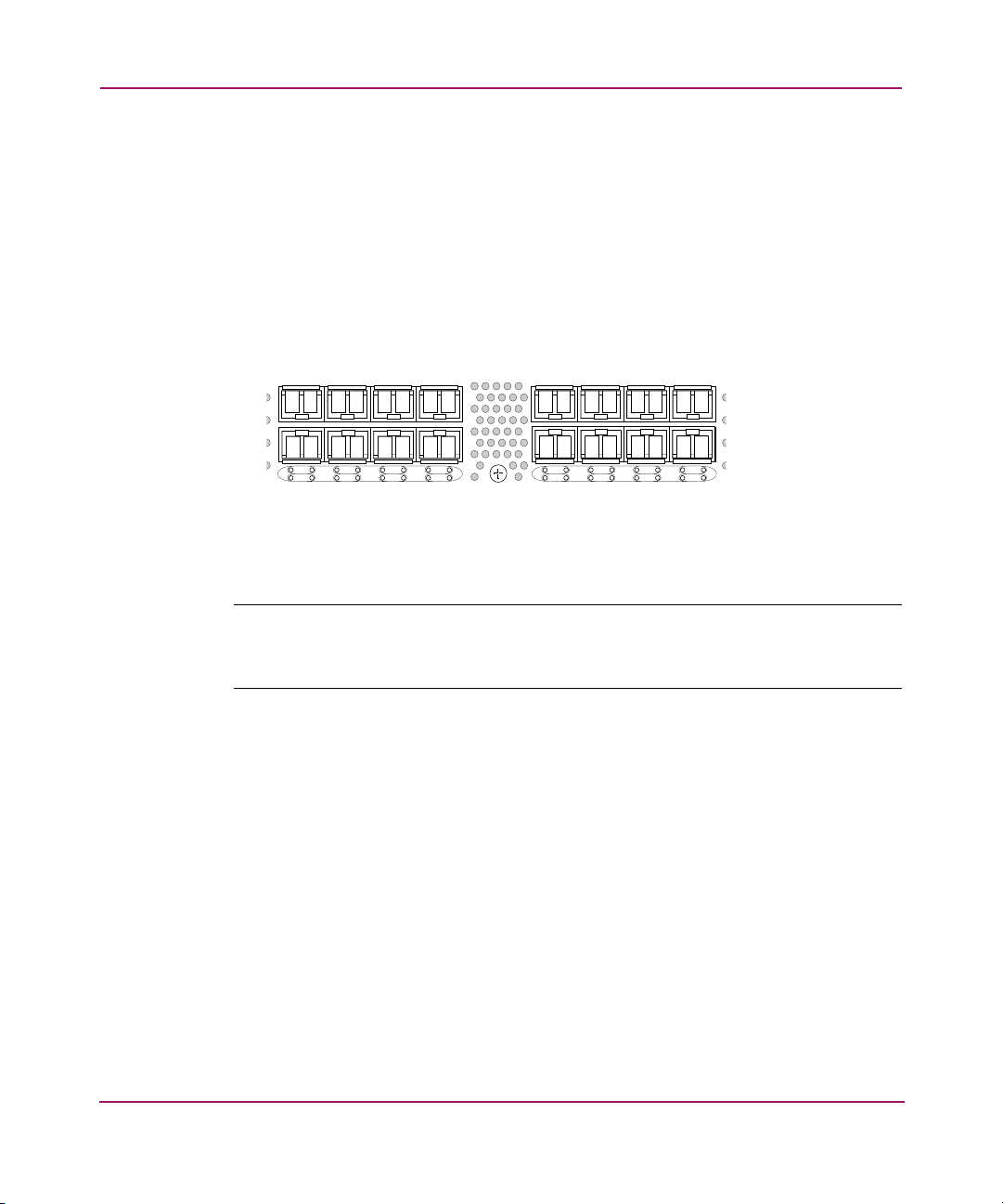

ISL Trunking Groups

If your SAN Switch 2/8V, 2/16V and 2/16N switch is licensed for ISL trunking,

use the trunking groups available on the switch.

The Fibre Channel ports are numbered from left to right, color-coded into groups

of four to indicate the groups of ports that can be used in the same interswitch link

(ISL) trunking group. The trunking groups are the two or four sets of four ports at

the top or at the bottom of the group, as shown in Figure 3.

0

1

4

5

3

2

7

6

8

9

12

13

11

10

15

14

Figure 3: Trunking groups

Note: ISL Trunking is optional software that allows you to create trunking groups of ISLs

between adjacent switches. For more information about trunking, refer to the

StorageWorks Features 4.2x User Guide

.

HP

22 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 23

Supported (Optional) Features

The SAN Switch 2/8V, 2/16V and 2/16N support the following optional software

that can be activated with the purchase of the corresponding license key.

Note: The SAN Switch 2/16N comes configured from the factory with a full-fabric

license, Advanced Zoning and Web Tools features. If you purchased a SAN Switch

2/16N power pack, it also includes the following optional software.

■ ISL Trunking

■ Fabric Watch

■ Advanced Performance Monitoring

■ Extended Fabrics

■ Remote Switch

For information on any of these features, refer to the HP StorageWorks Features

4.2x User Guide.

Overview

23SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 24

Overview

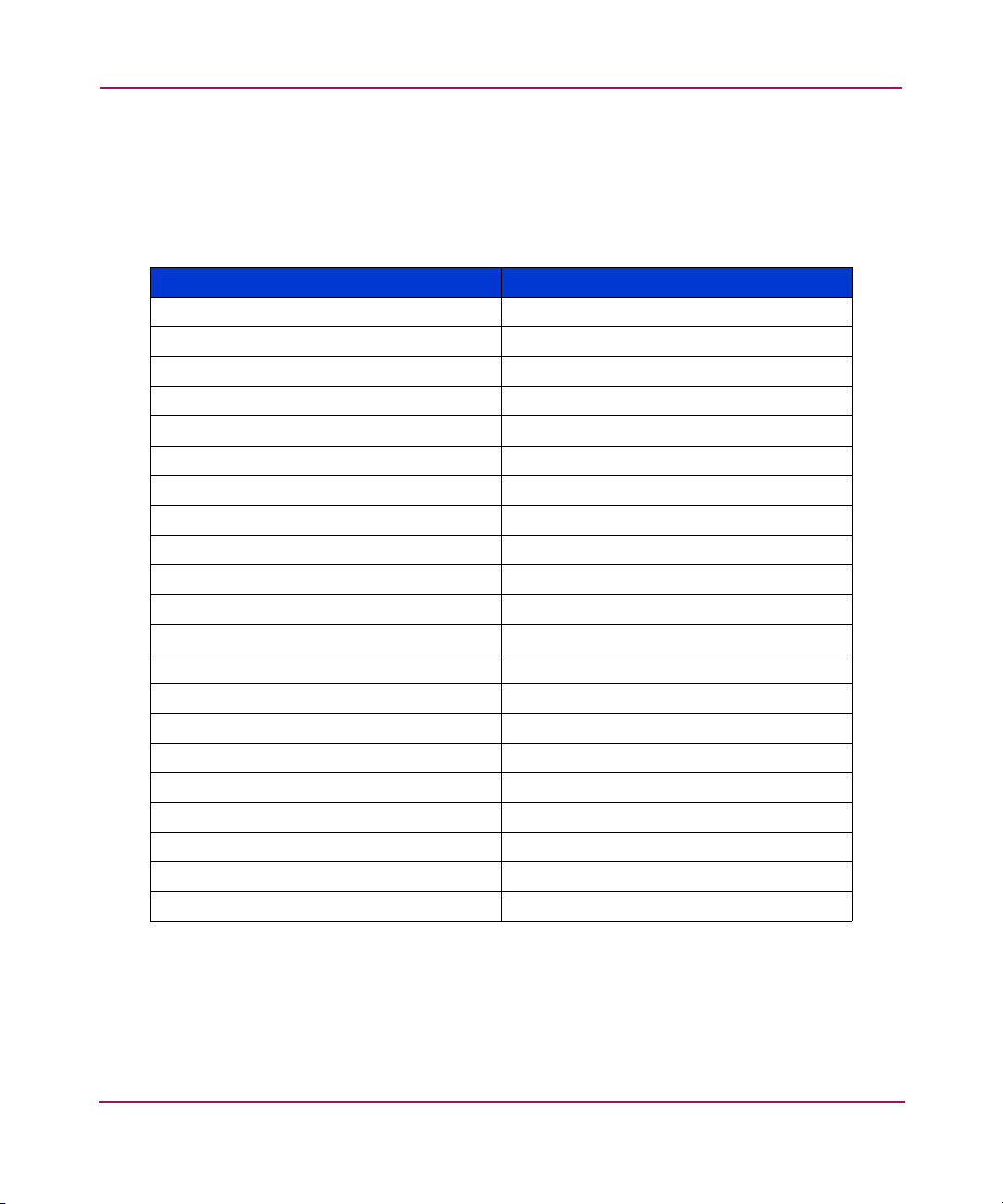

Optional Hardware Kits

Tabl e 4 lists optional hardware kits that support of the SAN Switch 2/8V, 2/16V and

2/16N

.

Table 4: Orderable Hardware

Accessory Part Number

Short wavelength SFP A6515A* or 300834-B21**

Long wavelength SFP, 10 km A6516A* or 300835-B21**

Long wavelength SFP, 35 km 300836-B21**

2m LC-to-LC Fibre Channel (fc) cable C7524A*

2m LC-to-LC multi-mode fc cable 221692-B21**

16m LC-to-LC fc cable C7525A*

5m LC-to-LC multi-mode fc cable 221692-B22**

50m LC-to-LC fc cable C7526A*

15m LC-to-LC multi-mode fc cable 221692-B23**

200m LC-to-LC fc cable C7527A*

30m LC-to-LC multi-mode fc cable 221692-B26**

50m LC-to-LC multi-mode fc cable 221692-B27**

2m LC-to-SC fc cable C7529A*

2m LC-to-SC multi-mode fc cable 221691-B21**

16m LC-to-SC fc cable C7530A*

5m LC-to-SC multi-mode fc cable 221691-B21**

15m LC-to-SC multi-mode fc cable 221691-B23**

30m LC-to-SC multi-mode fc cable 221691-B26**

50m LC-to-SC multi-mode fc cable 221691-B27**

SC female to SC female adapter C7534A*

2m LC male to SC male adapter kit C7534A*

* premerger HP part number

** premerger Compaq part number

24 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 25

Installing the SAN Switch

This chapter provides the following information:

■ Items Included with the SAN Switch 2/8V, 2/16V and 2/16N, page 26

■ Installation and Safety Considerations, page 29

■ Installing a Stand-Alone SAN Switch 2/8V, 2/16V and 2/16N, page 31

■ Installing a SAN Switch 2/8V, 2/16V or 2/16N Into an EIA Cabinet, page 32

■ Cabling and Configuring the SAN Switch 2/8V, 2/16V or 2/16N, page 47

■ Items Required for Installation, page 48

2

25SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 26

Installing the SAN Switch

Items Included with the SAN Switch 2/8V, 2/16V and 2/16N

The following items are included with the standard shipment of the SAN Switch

2/8V, 2/16V and SAN Switch 2/16N. When you open the product packaging,

verify that these items are included in the package and that no damage has

occurred during shipping:

■ One SAN Switch 2/8V, SAN Switch 2/16V or SAN Switch 2/16N includes:

— One cabinet-mountable 1U chassis designed to be mounted in a 19 inch

cabinet space, with forced-air cooling that flows from the non-port side of

the switch to the port side.

— 8 or 16 Fibre Channel ports, compatible with SFP transceivers, SWL and

LWL.

— One RS-232 serial port (DB-9 connector).

— One IEEE-compliant RJ-45 connector for use with 10/100 Mbps Ethernet

or in-band.

— LEDs as described in “LED Location” on page 60.

— The SAN Switch 2/8V comes with one fixed power supply and built-in

fans. The SAN Switch 2/16V comes with two fixed power supplies and

built-in fans.

— A real-time clock (RTC) with a 10-year battery.

— Plenum, part number 5697-4919

■ An accessory kit containing:

— One or two grounded 6 ft. (1.8 m.) country-specific power cords,

depending on the number of power supplies installed in the switch.

— One or two grounded 10 ft. (3.0 m.) PDU power cords depending on the

number of power supplies installed in the switch.

— One 10 ft. (3.0 m.) RS-232 serial cable; if necessary, convert this RS-232

cable to an RJ-45 connector by removing the adapter on the end of the

cable.

— One HP StorageWorks SAN Switch Rack Mount Kit, with instructions.

—The HP StorageWorks SAN Switch 2/8V and 2/16V Installation Guide

(this document).

26 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 27

Shipping Carton Contents

Figure 4 shows the shipping carton contents.

1

Installing the SAN Switch

3

4

5

2

6

0011a

Figure 4: Shipping carton contents

Note: Throughout the rest of this guide, examples in figures show the SAN Switch

2/16V, unless otherwise noted.

27SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 28

Installing the SAN Switch

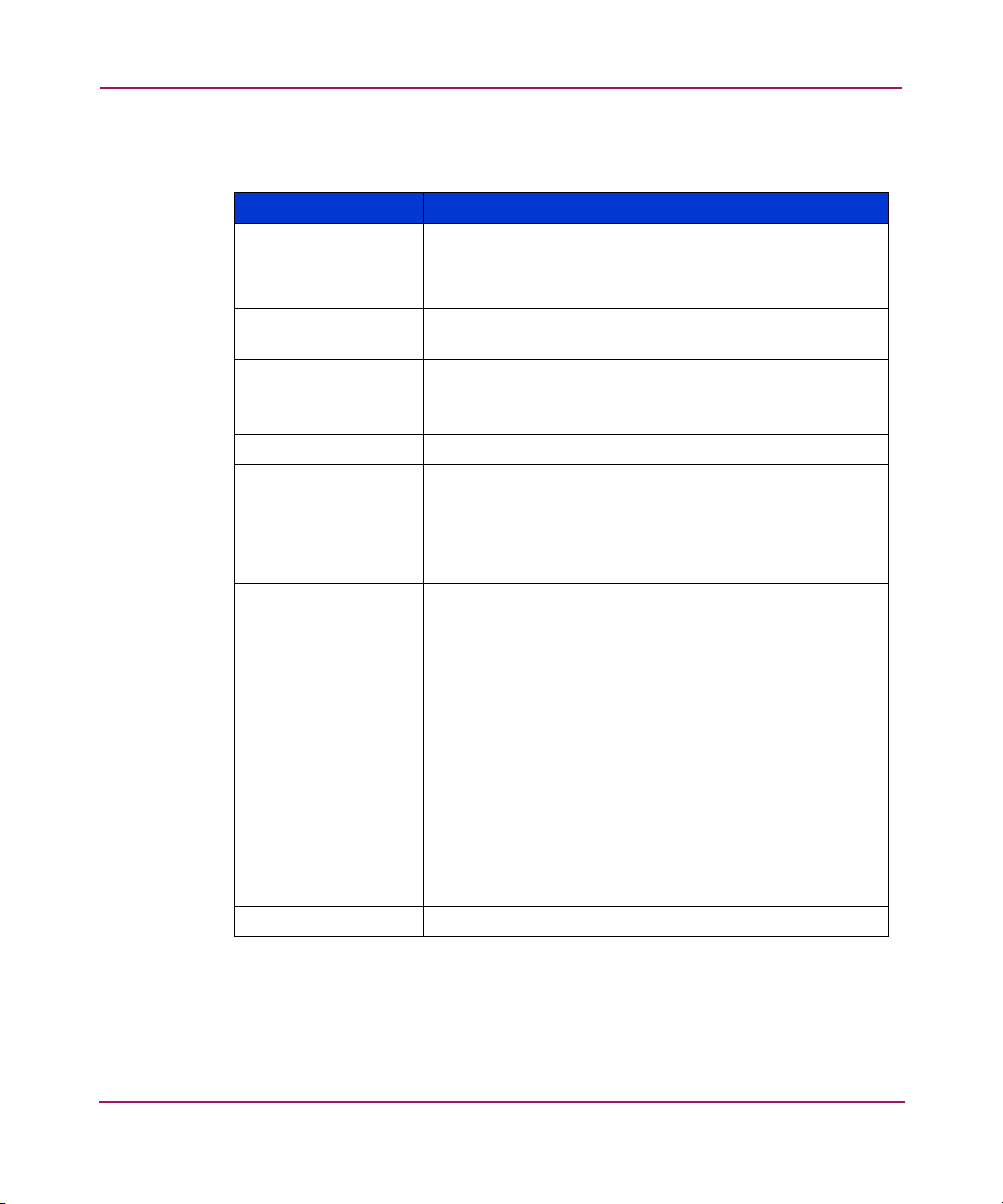

Tabl e 5 lists the contents included with your SAN Switch 2/8V, 2/16V or 2/16N.

Table 5: Shipping Carton Contents

Item Number Description

1 One set of HP StorageWorks SAN Switch product

documentation including Read Me First document,

Installation Guide, Safety Guides, User License and

Warranty

2 One HP StorageWorks SAN Switch 2/8V, SAN Switch

2/16V, or SAN Switch 2/16N.

3 One standard AC power cord, and one PDU cord for the

SAN Switch 2/8V. The SAN Switch 2/16V includes two

AC power cords and two PDU cords (not shown).

4 One RS-232 Serial cable

5 Rail assemblies and hardware:

■ (2) rear mounting brackets

■ A right inner rail and a right outer rail

■ A left inner rail and a left outer rail

6 Rack Mount hardware pouch:

■ (14) #8-32 x 3/16-inch Phillips pan-head screws

with thread lock for the SAN Switch 2/32 only

■ (14) #8-32 x 5/16-inch pan-head SEMS screws for

use with the SAN Switch 2/8, SAN Switch 2/8V,

SAN Switch 2/16, SAN Switch 2/16V and SAN

Switch 2/16N.

■ (10) #10-32 x 1/2-inch Phillips pan-head screw

with captive star lock washer

■ (8) #10 alignment washer

■ 8) #10 adapter washer

■ (2) 1/4-20 hex nut with captive star lock washer

■ (2) 1/4-inch flat washer

Plenum (Not shown) Part number 5697-4919

28 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 29

Installation and Safety Considerations

You can install the SAN Switch 2/8V or 2/16V using one of the following

methods:

1. As a stand-alone unit on a flat surface.

2. In an Electronic Industries Association (EIA) cabinet using a sliding rail rack

mount kit, which is provided with the switch.

Electrical Considerations

For successful installation and operation of the switch, ensure that the following

electrical requirements are met. For power supply information, refer to “Technical

Specifications” on page 87.

■ Primary AC input 100-240 VAC (switch auto-senses input voltage),

47-63 Hz.

■ Correctly wired primary outlet, with circuit protected by a circuit breaker and

grounded in accordance with local electrical codes.

■ Adequate supply circuit, line fusing, and wire size, as specified by the

electrical rating on the switch nameplate.

Installing the SAN Switch

Environmental Considerations

■ At a minimum, adequate cooling requires that you install the switch with the

non-port side, which contains the air intake vents, facing the cool-air aisle.

■ Verify that a minimum of 24 cubic ft./minute of air flow is available to the air

intake vents on the nonport side of the switch.

■ Verify that the ambient air temperature does not exceed 40° C (104° F) while

the switch is operating.

■ If installing the switch in a cabinet:

— The cabinet must be a standard EIA cabinet.

— Plan a cabinet space that is 1 rack unit (1.75 inches; 4.45 cm) high, 19

inches (48.3 cm) wide, and at least 30 inches (76.2 cm) deep.

— Ground all equipment in cabinet through a reliable branch circuit

connection and maintain ground at all times. Do not rely on a secondary

connection to a branch circuit, such as a power strip.

29SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 30

Installing the SAN Switch

— Ensure that airflow and temperature requirements are met on an ongoing

basis, particularly if the switch is installed in a closed or multicabinet

assembly.

— Verify that the additional weight of the switch does not exceed the

cabinet’s weight limits or unbalance the cabinet in any way.

— Secure the cabinet to ensure stability in case of unexpected movement,

such as an earthquake.

30 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 31

Installing the SAN Switch

Installing a Stand-Alone SAN Switch 2/8V, 2/16V and 2/16N

To install the SAN Switch as a stand-alone unit, follow the procedure described

here:

1. Unpack the switch and verify that all items listed on “Shipping Carton

Contents” on page 27 are present and undamaged.

2. Apply the adhesive rubber feet. Applying the rubber feet in the switch helps

prevent the switch from sliding off the supporting surface.

a. Clean the indentations at each corner of the bottom of the switch to ensure

that they are free of dust or other debris that might lessen the adhesion of

the feet.

b. With the adhesive side against the chassis, place one rubber foot in each

indentation and press into place.

3. Place the switch on a flat, sturdy surface.

4. Provide power to the switch as described in “Powering the Switch On and

Off” on page 58.

Caution: Do not connect the switch to the network until the IP address is

correctly set. For instructions on how to set the IP address, see “Cabling and

Configuring the SAN Switch 2/8V, 2/16V or 2/16N” on page 47.

31SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 32

Installing the SAN Switch

Installing a SAN Switch 2/8V, 2/16V or 2/16N Into an EIA Cabinet

The rack mount kit can be installed in two ways:

■ To allow the port side of the switch to slide out of the exhaust-air side of the

cabinet.

In this installation, the port side of the switch is flush with the edge of the

cabinet.

■ To allow the nonport side of the switch to slide out the cool-air side of the

cabinet.

In this installation, the port side of the switch is set 3 in. (7.62 cm.) back from

the edge of the cabinet, allowing a more gradual bend in the fiber optic cables.

Follow the installation instructions in the following sections.

Selecting an Operating Location

To ensure correct operation of the switch, the location must meet the following

requirements:

■ Adequate supply circuit, line fusing, and wire size, as specified by the

electrical rating on the switch nameplate.

■ An air flow of at least 300 cubic feet per minute, available in the immediate

vicinity of the switch.

■ If installing the switch in the HP 10000 Series, or comparable EIA cabinet:

— All equipment installed in the cabinet should have a reliable branch

circuit ground connection, and should not rely on a connection to a branch

circuit, such as a power strip.

— The cabinet should be balanced and the installed equipment should be

within the cabinet’s weight limits. Ensure the cabinet is mechanically

secured to insure stability in the event of an earthquake.

Cooling Requirements

Cooling air is drawn into the switch chassis by the fans mounted on the rear of the

chassis. The air is expelled through vents in the front (port side) of the chassis,

next to the HP logo. HP recommends installing the switch so that air intake and

exhaust for all components in the rack are flowing in the same front-to-back

direction.

32 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 33

Note: HP highly recommends mounting the switch in a cabinet or rack so that the fans

reside in the front of the cabinet, and the ports (cables) reside in the rear of the cabinet.

Follow these guidelines to ensure proper air flow, and prevent component

overheating:

■ To ensure adequate cooling, install the switch with the non-port side,

■ Verify a minimum of 47 cubic feet/minute (79.8 cubic meters/hour) of air

■ Verify that the ambient air temperature does not exceed 40° Celsius

Power Requirements

The AC power source must meet these requirements:

■ Primary AC Input 100–240 VAC (switch auto-senses input voltage) 47–63 Hz

■ Correctly wired primary outlet, with circuit protected by a circuit breaker and

grounded in accordance with local electrical codes

Installing the SAN Switch

which contains the air intake vents, facing the cool-air aisle.

flow is available to the air intake vents on the non-port side of the switch.

(104° Fahrenheit) while the switch is operating.

Caution: Do not block air vents. The switch uses ambient air for cooling.

■ Adequate supply circuit, line fusing, and wire size, as specified by the

electrical rating on the switch nameplate

■ Voltage capability of 85–264 VAC

■ Input voltage frequency of 47–63 Hz

■ Power capability of 75 W minimum

33SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 34

Installing the SAN Switch

Installing the Switch in a Rack Using the SAN Switch Rack Mount Kit

This section provides instructions for installing the switch in an HP System/e

cabinet, or in an HP 10000 series cabinet using the HP StorageWorks SAN Switch

Rack Mount Kit supplied with your switch. The Rack Mount Kit installation

requires one technician to install a SAN Switch.

Note: The Rack Mount Kit installation requires one technician.

The following items are required to install the switch in a cabinet:

■ SAN Switch 2/8V, SAN Switch 2/16V or SAN Switch 2/16N

■ Power cables

■ #2 Phillips screwdriver

■ 7/16-inch wrench or socket

The SAN Switch Rack Mount Kit rails and rail mounting hardware listed in

Tabl e 6:

Table 6: Rack Mount Kit rails and rail mounting hardware

Item Description

(2) rear mounting brackets

A right inner rail and a right outer rail

A left inner rail and a left outer rail

34 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 35

Installing the SAN Switch

Table 6: Rack Mount Kit rails and rail mounting hardware (Continued)

Item Description

(14) #8-32 x 3/16-inch Phillips

pan-head screw with thread lock for

the SAN Switch 2/32 only

(14) 8-32 x 5/16-inch Phillips pan-head

SEMS screw for use with the SAN

Switch 2/8, SAN Switch 2/8V, SAN

Switch 2/16, SAN Switch 2/16V and

SAN Switch 2/16N (screw not shown

here).

(10) #10-32 x 1/2-inch Phillips pan-head

screw with captive star lock washer

(8) #10 alignment washer

(8) #10 adapter washer

(2) 1/4-20 hex nut with captive star lock

washer

(2) 1/4-inch flat washer

35SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 36

Installing the SAN Switch

Caution: For proper air flow, the SFP media side of the SAN Switch 2/8V or

SAN Switch 2/16V must face the rear of the rack. This mounting allows air to

enter from the front of the rack and to exhaust at the rear of the rack, similar to

other rack-mounted equipment. This prevents switch overheating, which may

cause it to fail.

36 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 37

Installing the SAN Switch

To install the switch in a rack:

1. Check contents of the shipping carton to verify all the required parts and

hardware are available.

2. Choose a mounting location in the rack for the switch.

3. Attach the rear mounting brackets to the rear rack uprights by completing one

of the following steps:

— For an HP 10000 series or comparable EIA cabinet, assemble each of the

two brackets with (2) #10-32 x 1/2-inch Phillips pan-head screws with

captive star lock washers and (2) #10 adapter washers as shown in

Figure 5.

Figure 5: Installing the rear mounting brackets (HP 10000 series or comparable EIA cabinet)

— For an HP System/e rack, install each of the two rear mounting brackets

with (2) #10-32 x 1/2-inch Phillips pan-head screws and (2) #10

alignment washers as shown in Figure 6.

37SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 38

Installing the SAN Switch

Figure 6: Installing the rear mounting brackets (HP System/e rack-left rear upright)

Note: This kit contains both left rails and right rails. The rails are marked with

and

Left

.

Right

4. Assemble the outer rails by completing the following steps:

38 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 39

Installing the SAN Switch

a. Attach the left outer rail and the right outer rails to the rear mounting

brackets using (2) 1/4-20 hex nuts with captive star lock washers attached

loosely as shown in Figure 7. Don’t tighten them. The nuts will be

tightened later in step 8 on page 46.

Figure 7: Installing the outer rails (HP 10000 series or comparable EIA cabinet)

39SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 40

Installing the SAN Switch

b. Depending on the rack you are using, complete one of the following tasks:

— For an HP 10000 series or comparable EIA cabinet, install two #10-32 x

1/2-inch Phillips pan-head screws with captive star lock washers and two

#10 adapter washers in the upper and lower hole locations of the right rail.

Then install two #10-32 x 1/2-inch Phillips pan-head screws with captive

star lock washers and two #10 adapter washers in the upper and lower

hole locations of the left rail. See Figure 8.

Figure 8: Assembling the outer rails (HP 10000 series or comparable EIA cabinet)

40 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 41

Installing the SAN Switch

— For an HP System/e cabinet, install two #10-32 x 1/2-inch Phillips

pan-head screws with captive star lock washers and two #10 alignment

washers in the upper and lower hole locations of the right rail. Then install

two #10-32 x 1/2-inch Phillips pan-head screws with captive star lock

washers and two #10 alignment washers in the upper and lower hole

locations of the left rail. See Figure 9.

Figure 9: Assembling the outer rails (HP System/e cabinet)

41SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 42

Installing the SAN Switch

5. Determine the number of #8-32 x 5/16-inch Phillips pan-head SEMS screws

Table 7: Number of screws required to assemble the inner rails

SAN Switch 2/16V,

SAN Switch 2/16N

SAN Switch 2/8V 10

6. For the SAN Switch 2/16V, complete step a on page 43. For the SAN Switch

Note: The mounting holes in the inner rails are marked with 32, 16, and 8. When

mounting the SAN Switch 2/8V or SAN Switch 2/16V, use the mounting holes labelled

8 when installing the inner rails on the switch.

required to assemble the inner rails by referring to Tab le 7.

Switch Number of #8-32 x 5/16-inch Screws

10

2/8V, complete step b on page 44.

Caution: Do not use any screws other than the fourteen that are provided. Use

of any longer lengths can cause damage to internal components.

When viewing a rack from the front, the left rails are used in the left side of the rack and

the right rails are used in the right side of the rack. The rails must match up—right inner

with right outer and left inner with left outer. Note that the SAN Switch mounts in the

rack with its front, the port side, facing the back of the rack. The rear of the switch, the

AC side, faces the front of the rack.

42 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 43

Installing the SAN Switch

a. Assemble the two inner rails (one on each side) to the switch using the

appropriate number (from step 5 on page 42) of #8-32 x 5/16-inch

Phillips pan-head SEMS screws as shown in Figure 10.

Note: The rail kit provides fourteen #8-32 x 5/16-inch screws for assembling the inner

rails. Each switch requires a different number of these screws. For example, Figure 10

shows the an inner rail being attached to the SAN Switch 2/16V with five screws.

Attaching both inner rails requires ten screws.

0012a

Figure 10: Assembling the inner rails

Note: For factory integration only, tighten the #8-32 x 5/16-inch Phillips pan-head

SEMS screws

and torque between 6 to 8 inch-pounds.

43SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 44

Installing the SAN Switch

Note: The plenum is a required part of this installation when the SAN switch 2/8V,

SAN switch 2/16V or 2/16N are installed in an HP 9000 or 10000 serires, System/e

or comparable EIA cabinet.

The plenum allows air to dissipate at the rear of the rack, preventing overheating. If the

Plenum is not pre-installed, refer to step b on page 44 for instructions.

b. For the SAN Switch 2/8V, assemble the two inner rails (one on each side)

to the switch and plenum using the appropriate number (from step 5 on

page 42) of #8-32 x 5/16-inch Phillips pan-head SEMS screws as shown

in Figure 11.

1

2

0013a

Figure 11: Assembling the inner rails on a SAN Switch with plenum

The components in Figure 11 include:

1

2

Plenum

Switch

7. Insert the switch with the attached inner rails into the outer rails.

44 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 45

Installing the SAN Switch

Note: This step applies to both the HP 10000 series, System/e cabinet or comparable

EIA cabinets.

Figure 12: Installing the switch into a rack (HP 10000 series or comparable EIA cabinet)

Insert the switch into the rack and install (2) #10-32 x 1/2-inch Phillips

pan-head screws with captive star lock washers with one on each side. See

Figure 12 and Figure 13.

45SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 46

Installing the SAN Switch

Figure 13: Installing the switch into a rack (HP System/e cabinet)

8. Tighten the nuts installed in step a on page 39 of step 4 on page 39. See

Figure 7 on page 39.

Note: To uninstall a switch, remove the middle #10-32 x 1/2-inch Phillips pan head

screw with captive star lock washer from either side of the rack uprights.

46 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 47

Installing the SAN Switch

Cabling and Configuring the SAN Switch 2/8V, 2/16V or 2/16N

The SAN Switch 2/8V or 2/16V must be configured to ensure correct operation

within a network and fabric. For instructions about configuring the switch to

operate in a fabric containing switches from other vendors, refer to the HP

StorageWorks Fabric OS Procedures 4.2x User Guide.

For more information about the commands used in this procedure, refer to the HP

StorageWorks Fabric OS 4.2.x Command Reference Guide.

Recommendations for Cable Management

The minimum bend radius for a 50 micron cable is 2 inches under full tensile load

and 1.2 inches with no tensile load.

Cables can be organized and managed in a variety of ways: for example, using

cable channels on the sides of the cabinet or patch panels to minimize cable

management. Following is a list of recommendations:

■ Plan for rack space required for cable management before installing the

switch.

■ Leave at least 3.28 ft. (1 m.) of slack for each port cable. This provides room

to remove and replace the switch, allows for inadvertent movement of the

rack, and helps prevent the cables from being bent to less than the minimum

bend radius.

■ If you are using ISL Trunking, consider grouping cables by trunking groups.

The cables used in trunking groups must meet specific requirements, as

described in the HP StorageWorks Fabric OS Features 4.2.x User Guide.

■ For easier maintenance, label the fiber optic cables and record the devices to

which they are connected.

■ Keep LEDs visible by routing port cables and other cables away from the

LEDs.

■ Do not use tie wraps on fiber optic cables, because the wraps are easily

overtightened and can damage the optic fibers. HP recommends using Filcrow

wraps.

47SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 48

Installing the SAN Switch

Items Required for Installation

The following items are required for configuring and connecting the SAN Switch

2/8V and SAN Switch 2/16V for use in a network and fabric:

■ SAN Switch 2/8V and SAN Switch 2/16V installed and connected to a power

source

■ Workstation with an installed terminal emulator, such as HyperTerminal

■ Unused IP address and corresponding subnet mask and gateway address

■ Serial cable (provided)

■ Ethernet cable

■ SFP transceivers and compatible cables, as required

■ Access to an FTP server for backing up the switch configuration (optional)

Configuring the SAN Switch 2/8V, 2/16V and 2/16N

Follow the steps described in the next sections to configure your SAN Switch

2/8V, 2/16V or 2/16N for use:

1. Create a Serial Connection, page 49

2. Power Up the Switch and Log In, page 50

3. Set the IP Address, page 51

4. Create an Ethernet Connection and Log In, page 52

5. Modify the Fibre Channel Domain ID (Optional), page 53

6. Install the SFP Transceivers, page 54

7. Connect the Cables, page 54

48 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 49

Create a Serial Connection

IOIOI

100-240

C 1.0A 47-63Hz

100-240

C 1.0A 47-63Hz

Before you can begin configuring the switch, you must create a connection via the

serial port. To create a serial connection:

1. Insert the provided serial cable into the serial port on the switch.

2. Connect the serial cable to an RS-232 serial port on the workstation

(Figure 14).

1

0

0

2

4

0

VAC

1

.0

A

4

7

6

3

H

z

Figure 14: Connecting the serial cable

Installing the SAN Switch

IOIOI

!

1

0

0

2

4

0

VAC

1

.0

A

4

7

6

3

H

z

0014a

If the serial port on the workstation uses an RJ-45 connector instead of an

RS-232, remove the adapter on the end of the serial cable and insert the

exposed RJ-45 connector into the RJ-45 serial port on the workstation.

3. Disable any serial communication programs running on the workstation.

49SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 50

Installing the SAN Switch

IOIOI

100-240

C 1.0A 47-63Hz

100-240

C 1.0A 47-63Hz

4. Open a terminal emulator application (such as HyperTerminal on a PC or

TERM in a UNIX environment) and configure the application as follows:

■ In a Windows 95, 98, 2000, or NT environment:

Bits per second 9600

Databits 8

Parity None

Stop bits 1

Flow control None

■ In a UNIX environment, type the following string at the prompt:

tip /dev/ttyb -9600

Power Up the Switch and Log In

Once a serial connection is established, provide power to the switch; power is

supplied to the switch as soon as the first power supply is connected and powered

on:

1. Connect the power cords to both power supplies and power sources

(Figure 15).

1

0

0

2

4

0

VAC

1

.0

A

4

7

6

3

H

z

IOIOI

!

1

0

0

2

4

0

VAC

1

.0

A

4

7

6

3

H

z

0015a

Figure 15: Connecting the power cords

50 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 51

2. After POST is complete, verify that the System Status and Power Status LEDs

3. Using a serial connection, when the terminal emulator application stops

4. Log in using the administrative account; the logon is “admin” and the default

Set the IP Address

Replace the default IP address and related information with the information

provided by your network administrator:. By default, the IP address is set to

10.77.77.77.

Installing the SAN Switch

To protect against AC failure, connect the power cords to outlets on separate

circuits. Ensure that the cords have a minimum service loop of six inches

available at the connection to the switch and are routed to avoid stress.

The power supply LED lights up green, and the switch begins running Power

On Post Test (POST). POST should complete and the switch will complete

the boot process in about three minutes.

are green.

reporting information, press Enter to display the login prompt.

password is “password”. Up to two simultaneous admin sessions and four

user sessions can be created. For details, refer to the

HP StorageWorks Fab ric

OS Procedures 4.2x User Guide and the Fabric OS 4.2.x Command Reference

Guide.

1. Type ipaddrset at the terminal emulator application prompt.

2. Type the requested information as prompted.

Example:

switch:admin> ipaddrset

Ethernet IP Address [192.168.1.1]:10.32.53.47

Ethernet Subnetmask [255.255.255.0]:255.255.240.0

Fibre Channel IP Address [0.0.0.0]:

Fibre Channel Subnetmask [0.0.0.0]:

Gateway IP Address [0.0.0.0]:10.32.48.1

Set IP address now? [y = set now, n = next reboot]:y

IP address being changed...

Committing configuration...Done.

switch:admin>

3. Optionally, verify that the address was correctly set by entering the

ipaddrshow command at the prompt.

4. Record the IP address on the label clearly displayed on the port side of the

chassis.

51SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 52

Installing the SAN Switch

IOIOI

100-240

C 1.0A 47-63Hz

100-240

C 1.0A 47-63Hz

5. If the serial port is no longer required, log out of the serial console, remove the

serial cable, and replace the safety plug in the serial port.

Note: Any time the port is not in use, the safety plug should be installed to protect it

from foreign material.

Create an Ethernet Connection and Log In

Use these steps to create an Ethernet connection.

1. Connect an Ethernet cable to the Ethernet port and to the workstation or to an

Ethernet network containing the workstation (Figure 16).

1

0

0

2

4

0

VAC

1

.0

A

4

7

-6

3

H

z

IOIOI

!

1

0

0

2

4

0

VAC

1

.0

A

4

7

-6

3

H

z

0016a

Figure 16: Connecting the Ethernet cable

After this connection is made, the switch can be accessed remotely, by

command line or by Advanced Web Tools. Ensure that the switch is not being

modified from any other connections during the remaining steps.

2. Log in to the switch by telnet, using the admin account.

52 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 53

Modify the Fibre Channel Domain ID (Optional)

If desired, you can modify the Fibre Channel domain ID. The default Fibre

channel domain ID is domain 1. If the switch is not powered on until after it is

connected to the fabric and the default Fibre channel domain ID is already in use,

the domain ID for the new switch is automatically reset to a unique value. If the

switch is connected to the fabric after is has been powered on and the default

domain ID is already in use, the fabric segments.

The domain IDs that are currently in use can be determined using the fabricshow

command. The number of domains is determined by your domain fabric licensing.

To modify the domain ID:

1. Disable the switch by typing switchdisable.

2. Type configure. This prompts display sequentially; type a new value or press

Enter to accept each default value.

3. At the Fabric Parameters prompt, type Y and press Enter:

Fabric parameters (yes, y, no, n): [no] y

4. Enter a unique domain ID, such as the domain ID used by the previous switch,

if still available:

Installing the SAN Switch

Domain: (1..239) [1] 3

5. Complete the remaining prompts or press Ctrl+D to accept the remaining

default settings.

6. Re-enable the switch by entering the switchenable command.

7. Optionally, specify any custom status policies:

a. Enter the switchstatuspolicyset command at the prompt. This command

sets the policy parameters that determine the overall switch status.

b. Customize the status policies as desired.

To deactivate the alarm for a particular condition, enter 0 at the prompt for that

condition.

53SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 54

Installing the SAN Switch

Install the SFP Transceivers

The SAN Switch 2/8V, 2/16V and 2/16N do not ship with SFP transceivers, these

are a saleable option.

Use the following procedure to install the SFP transceivers into the Fibre Channel

ports. A list of supported SFPs can be found in “Technical Specifications” on

page 87.

The ports selected for use in trunking groups must meet specific requirements. For

a list of these requirements, refer to the HP StorageWorks Fabric OS Features

4.2.x User Guide.

To install SFP transceivers:

1. Position a transceiver so that it is oriented correctly and insert it into a port

until the latching mechanism clicks. The transceivers are keyed to ensure

correct orientation. If a transceiver does not install easily, ensure that it is

correctly oriented.

For instructions specific to the type of transceiver, refer to the transceiver

manufacturer’s documentation.

2. Repeat for the remaining ports, as required.

Connect the Cables

Caution: The minimum bend radius for a 50-micron cable is 2 inches under

full tensile load, and 1.2 inches with no tensile load.

Because they are easily overtightened, tie wraps are not recommended for

optical cables.

Connect the cables to the transceivers:

1. The cable connectors are keyed to ensure correct orientation. Orient a cable

connector so that the key (ridge on one side of connector) aligns with the slot

in the transceiver and insert cable into transceiver until latching mechanism

clicks. If a cable does not install easily, ensure it is correctly oriented. For

instructions specific to cable type, refer to the cable manufacturer’s

documentation.

2. Repeat for the remaining transceivers, as required.

54 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 55

The cables used in trunking groups must meet specific requirements. For a list of

these requirements, refer to the HP StorageWorks Fabric OS Features 4.2.x User

Guide.

Verifying Configuration

After completing the configuration, use the LEDs and commands to verify that the

configuration has been accepted:

1. Check the LEDs to verify that all components are functional. For information

about LED patterns, refer to “Interpreting LED Activity” on page 59.

2. Verify the correct operation of the SAN Switch 2/8V and SAN Switch 2/16V

by entering the switchshow command from the workstation. This command

provides information about the switch and port status.

3. Verify the correct operation of the SAN Switch 2/8V and SAN Switch 2/16V

in the fabric by entering the fabricshow command from the workstation. This

command provides general information about the fabric.

Backing Up Your Configuration

HP recommends regular backups to ensure that a recent configuration is available

for downloading to a replacement switch, if required. For specific instructions

about how to back up the configuration, refer to the HP StorageWorks Fabric OS

Procedures 4.2x User Guide.

Back up the switch configuration to an FTP server by entering the configupload

command and following the prompts. This command uploads the switch

configuration to the server, making it available for downloading to a replacement

switch, if necessary.

Installing the SAN Switch

55SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 56

Installing the SAN Switch

56 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 57

Managing the SAN Switches

This chapter provides the following information:

■ Powering the Switch On and Off, page 58

■ Interpreting LED Activity, page 59

■ LED Location, page 60

■ LED Patterns, page 62

■ POST and Boot Specifications, page 65

■ Interpreting POST Results, page 66

3

57SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 58

Managing the SAN Switches

Powering the Switch On and Off

To apply power to the SAN Switch 2/8V or SAN Switch 2/16V, connect at least

one power cable to an AC receptacle on the switch and to a power source. The

switch runs POST (power-on self-test) by default each time it is powered on, reset,

or rebooted, and requires as long as 3 minutes.

To end the flow of power to the SAN Switch 2/8V or SAN Switch 2/16V, remove

the power cord from the power source.

Note: Removing all power from the switch triggers a system reset. All devices are

returned to their initial state the next time the switch is powered on.

58 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 59

Interpreting LED Activity

System activity and status can be determined through the activity of the LEDs on

the switch.

There are three possible LED states: no light, a steady light, and a flashing light.

The steady lights and flashing lights can be green or amber.

The LEDs flash any of these colors during boot, POST, or other diagnostic tests.

This is normal and does not indicate a problem unless the LEDs do not indicate a

healthy state after all boot processes and diagnostic tests are complete. A healthy

state is indicated by a steady green light. See Ta ble 10 on page 62 for details about

LED activity.

Managing the SAN Switches

59SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 60

Managing the SAN Switches

LED Location

All 2/8V and 2/16V LEDs are located on the port side. They include:

■ Switch Status

■ Power

■ Port Status

■ Port Speed

■ Ethernet

Figure 17 shows the port side of the SAN Switch 2/8V, paying special attention to

the LEDs. Figure 17 shows the port side of the SAN Switch 2/16V.

100-240 VAC 1.5A 47-63Hz

IOIOI

!

0

4

152

3

7

6

0017a

1 2

3

Figure 17: SAN Switch 2/8V LED locations

Tabl e 8 lists the LEDs locations.

Table 8: SAN Switch 2/8V LED Locations

Component Description

1

2

3

Ethernet LEDs

System and Power LEDs

Port LEDs

The 2/8V and 2/16V switches are physically similar except for the number of

ports—and related port LEDs—and the second AC power receptacle.

60 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 61

Managing the SAN Switches

All LEDs are on the port side of the switch. Figure 18 shows the location of these

LEDs. See “LED Patterns” on page 62 for details about interpreting LEDs.

!

100-240 VAC 2.0A 47-63Hz 100-240 VAC 2.0A 47-63Hz

IOIOI

0

4

152

3

7

6

8

12

91310

11

15

14

00

21

Figure 18: SAN Switch 2/16V LED locations

Tabl e 9 lists the LEDs locations.

Table 9: SAN Switch 2/16V LED Locations

Component Description

1

2

3

Ethernet LEDs

System and Power LEDs

Port LEDs

3

61SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

Page 62

Managing the SAN Switches

LED Patterns

Tabl e 10 and Ta ble 11 summarize LED location, color, and meaning of the 2/8V

and 2/16V LEDs, as well as any recommended user response.

System and Power LED Patterns

The system and power LED patterns are shown in Table 10 .

Table 10: System LED Patterns During Normal Operation

LED Name,

Location

System

Status and

Power

Status

At right of

serial port

on bottom

LED Color Status of Hardware Recommended Action

No light Switch is off, boot is not

complete, or boot failed.

Steady green Switch is on and power

supplies are functioning

properly.

Slow-flashing

green

(on 1 second,

off 1 second)

One or both of the following

are true:

One or more environmental

ranges are exceeded.

Error log contains one or

more port diagnostic error

messages.

Verify that switch is on and

has completed booting.

No action required.

Check environmental

conditions, error log, Port

Status LEDs, transceivers,

cables, and loopback

plugs.

Correct error condition.

Clear error log.

Rerun diagnostics to verify

fix.

Amber One failed power supply in

the SAN Switch 2/16V

62 SAN Switch 2/8V, 2/16V and 2/16N Installation Guide

No action required, but

failure of the remaining

power supply will cause the

switch to fail.

Page 63

Port LED Patterns

Each port has two LEDs: a port speed and a port status indicator. Table 11 shows

the LED location, color, and meaning for these port LEDs.

Table 11: Port LED Patterns During Normal Operation

LED Name,

Location

Port Status

Below ports

on left

LED Color Status of Hardware Recommended Action

No light No light or signal carrier

(transceiver or cable)

detected.

Steady green Port is online (connected

to external device) but has

no traffic.

Slow-flashing

green

(on 1

second, off 1

second)

Fast-flashing

green

Port is online but

segmented, indicating a

loopback cable or

incompatible switch.

Port is in internal loopback

(diagnostic).

Managing the SAN Switches

Check transceiver and cable.

No action required.

Verify that the correct device

is connected to port and that

the switch and port settings

are correct.

No action required.

Port Status

Below ports

on left

(on 1/4

second, off

1/4 second)

Flickering

green

Steady

amber