Page 1

HP StorageWorks

Disk System 2100 / 2110

User’s Guide

Edition E0304

Order No. A7381-96013

Printed in U.S.A.

Page 2

Notice

© Hewlett-Packard Company, 2004. All rights

reserved.

Hewlett-Packard Company makes no warranty of

any kind with regard to this document, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose. HewlettPackard shall not be liable for errors contained

herein or for incidental or consequential damages in

connection with the furnishing, performance, or use

of this material.

This document contains proprietary information,

which is protected by copyright. No part of this

document may be photocopied, reproduced, or

translated into another language without the prior

written consent of Hewlett-Packard. The information contained in this document is subject to change

without notice.

Warranty

If you have any questions about the warranty for

this product, contact your dealer or local HewlettPackard sales representative.

Components bearing this symbol may

be hot to touch.

Components bearing this symbol are

fragile. Handle with care.

Components bearing this symbol are

susceptible to damage by static

electricity. ESD precautions are

required.

Operation

The front door should be closed and locked at all

times during the operation of this product except

when replacing disks.

This product is intended to be operated in a

restricted access area.

Service

Maintenance or repair of the backplane and

mezzanine boards must be performed by authorized

service-trained personnel.

Format Conventions

Safety Notices

Warning

Weight exceeds 50 lbs. (22.5 kg.)

Do NOT lift unassisted. Use

a lift device or two people.

To protect against personal injury and product

damage, do not attempt to lift the product without

the assistance of another person or lift device.

2

Denotes

WARNING A hazard that can cause

personal injury

CAUTION

Note Significant concepts or operating

this font Text to be typed verbatim: all

this font Text displayed on the screen

A hazard that can cause hardware

or software damage

instructions

commands, path names, and file

names. Also menu and button

selections in GUI contexts

Page 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Components of the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Disk Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Power LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SCSI ID Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AC Site Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the SCSI IDs for the Disk Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect the SCSI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting the Power Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Powering On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power On the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Off the Disk System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adding Disk Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Add a Disk Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure the new Disk Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Remove and Replace A Disk Module . . . . . . . . . . . . . . . . . . . . . . . . . 19

Remove a Disk Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replace a Disk Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Remove the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting Up the Hardware Event Monitor (HP-UX Only) . . . . . . . . . . . 22

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Event Notification (HP-UX Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

View Disk Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

STM Disk Information: HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

STM Disk Information: MPE/iX 6.5 or Later . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Isolating Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Product Numbers and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Upgrade Disk Products Available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operating Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3Tab le of Co nt en t s

Page 4

Table of Contents4

Regulatory Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Safety Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

A. FCC Notice for United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

B. Canadian Notice (Avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

C. Notice for European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

D. Notice for France . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

E. Notice for Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

F. Harmonics Conformance (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

G. BSMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

H. Notice for Germany . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

I. Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Product Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Page 5

Figure 1 Disk Module LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2 System Power LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3 Rear View of the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4 Power Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5 SCSI ID Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6 AC Power Connector Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7 SCSI Switch Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8 SCSI Port Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9 AC Power Connector Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10 Power Button Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 11 Installing a Disk Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 12 Removing the Disk System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13 Sample Hardware Event Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14 LED Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 15 Sample STM Information Log (HP-UX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 16 Sample STM Expert Tool Disk Error Log (MPE/iX 6.5 or Later). . . . . . . . . . . . . . . . . . . . . . 29

5List of Figures

Page 6

List of Tables6

Table 1 Disk LED Activity Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2 System Power LED Activity Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3 AC Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4 SCSI Switch Setting Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5 SCSI Address Priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 6 LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 7 Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 8 Product Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9 Available Upgrade Disk Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 10 Upgrade Products for Hewlett-Packard Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 11 Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 12 Supported HP Cables and Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 13 Physical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 14 AC Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 15 Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 7

Overview

HP StorageWorks Disk System 2100 / 2110

7

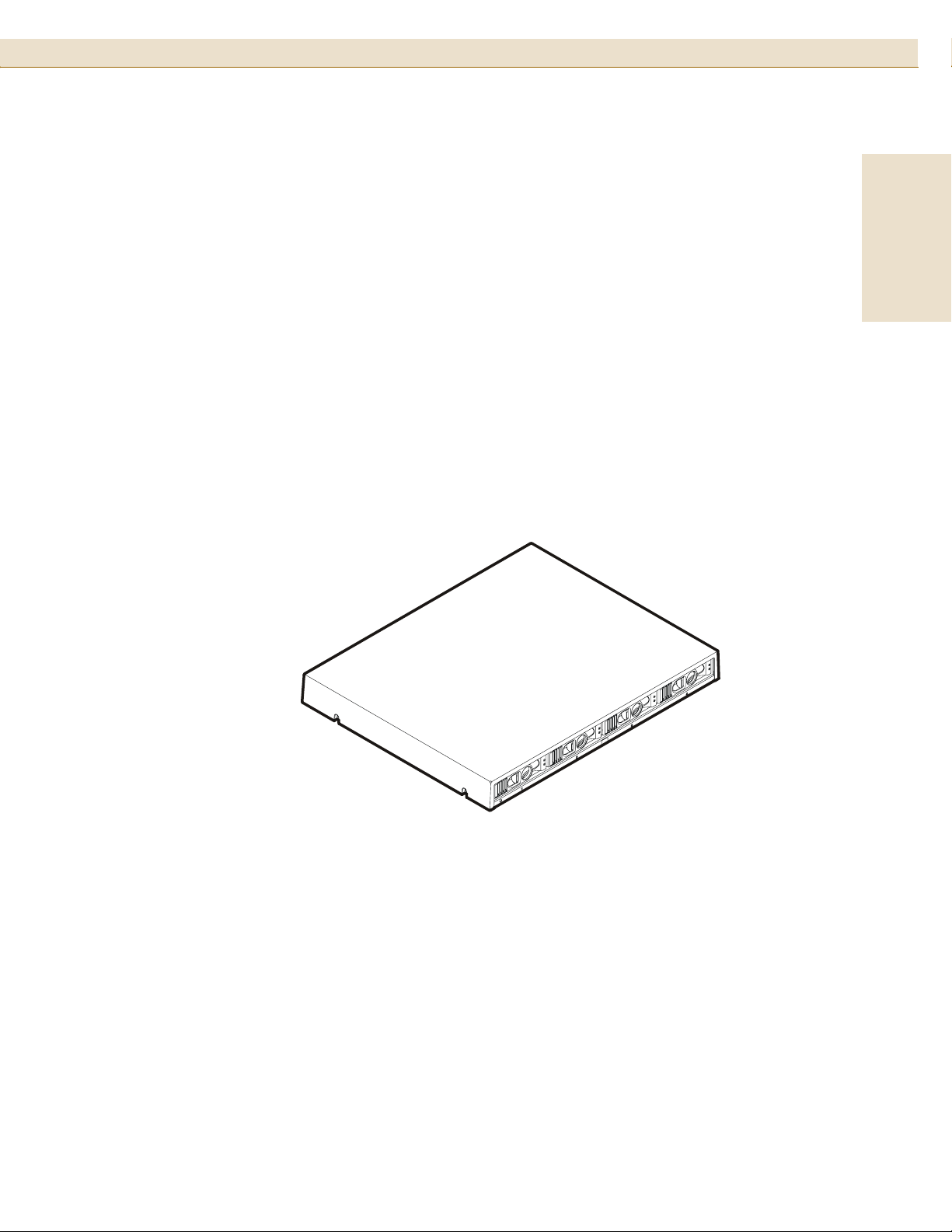

The HP StorageWorks Disk System 2100 and Disk System 2110 are 1-EIA unit disk

systems capable of accommodating up to four disk modules. They are designed to

provide inexpensive, high performance rack-optimized online mass storage for entrylevel configurations in three distinct markets: (1) HP servers/workstations, (2) open

systems JBODs, and (3) open systems IDACs (Internal Disk Array Controller).

Both units support Ultra3 (U160) drives and the new U320 drives. However, the U320

drives are supported at a maximum of 160 MB/s speeds. The Disk System 2100 does

not support the U320 73-GB drive (part number A7286A) or the U320 146-GB drive

(part number A7287A).

For both the DS2100 and DS2110, connectivity to U320 initiators is supported if the

speed of the U320 initiator is set to limit negotiations to U160 speed. The U320 drives

do not operate reliably at U320 speeds and are not supported at those speeds. This is

due to limitations within the controller and not the U320 drive mechanisms.

English

Page 8

HP StorageWorks Disk System 2100 / 21108

Components of the Disk System

Front Panel

The disk modules can be accessed from the front of the disk system. It can accept up

to 4 low profile disk drives. If your storage system contains less than 4 disk modules,

the remaining empty slots contain filler panels. These filler panels (part number

A6198-60002) ensure that the proper cooling is maintained within the storage system.

Remove filler panels only when a disk module is added to the system.

Disk Module LEDs

Each disk module has two LEDs: an amber LED on the top (see Figure 1) and a green

LED on the bottom. The amber LED is not operational. The green LED provides disk

module status information as listed in Table 6.

FIGURE 1

TABLE 1 Disk LED Activity Definitions

Disk Module LEDs

LED Activity Indication

Blinking Disk activity

On solid for

approximately 1 second

Off Disk is idle or off

Bus reset

System Power LED

Amber LED (not used)

Green LED

Disk Module

LEDs

The System Power LED (see Figure 2) gives diagnostic information about the disk

system operation. Refer to Table 2 on page 9 for more information.

Page 9

HP StorageWorks Disk System 2100 / 2110

9

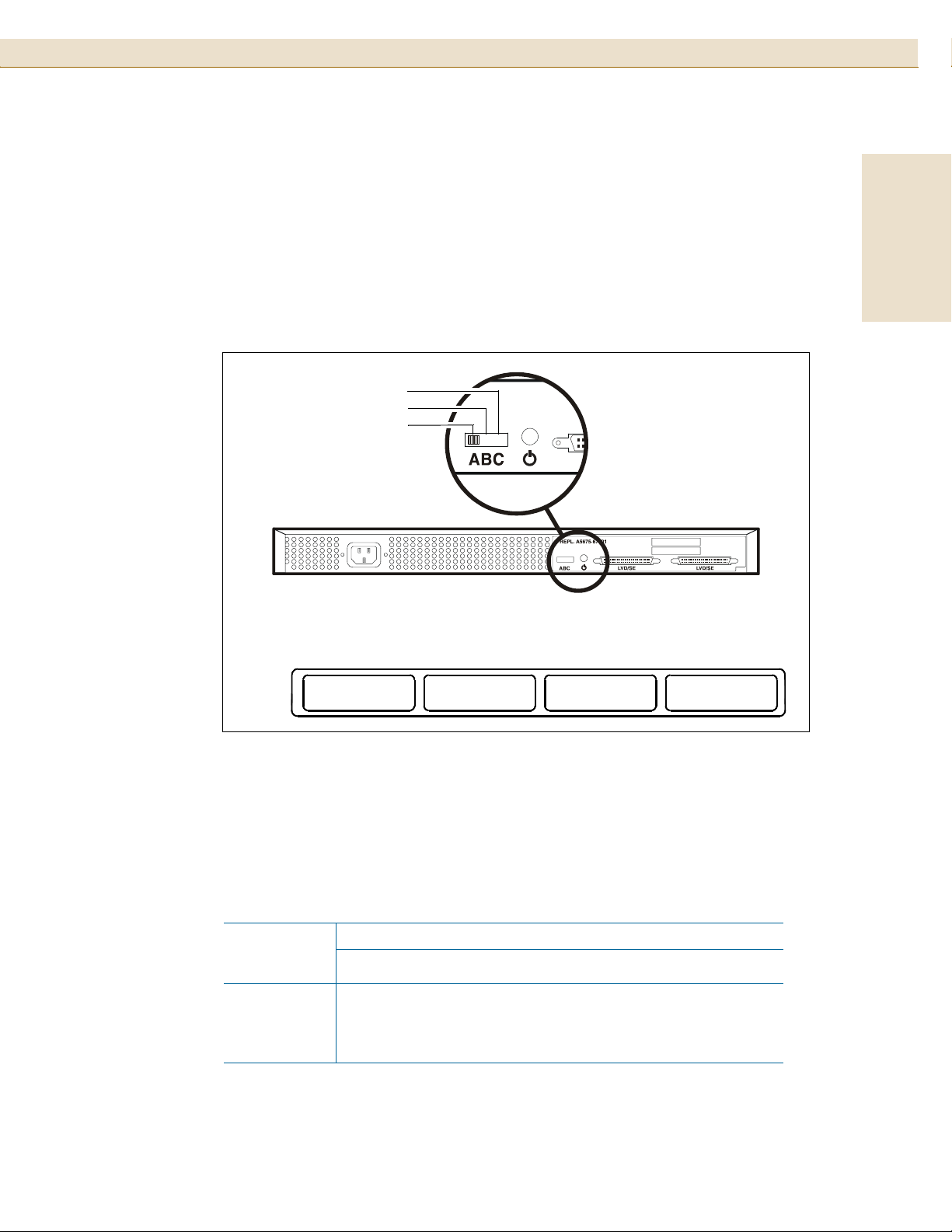

FIGURE 2

TABLE 2 System Power LED Activity Definitions

System Power LED

System

Power LED

LED Activity Indication

Blinking Malfunction - either a fan is not operating

properly or internal voltage is too low.

On solid Disk system is operating properly.

Off Disk system is off.

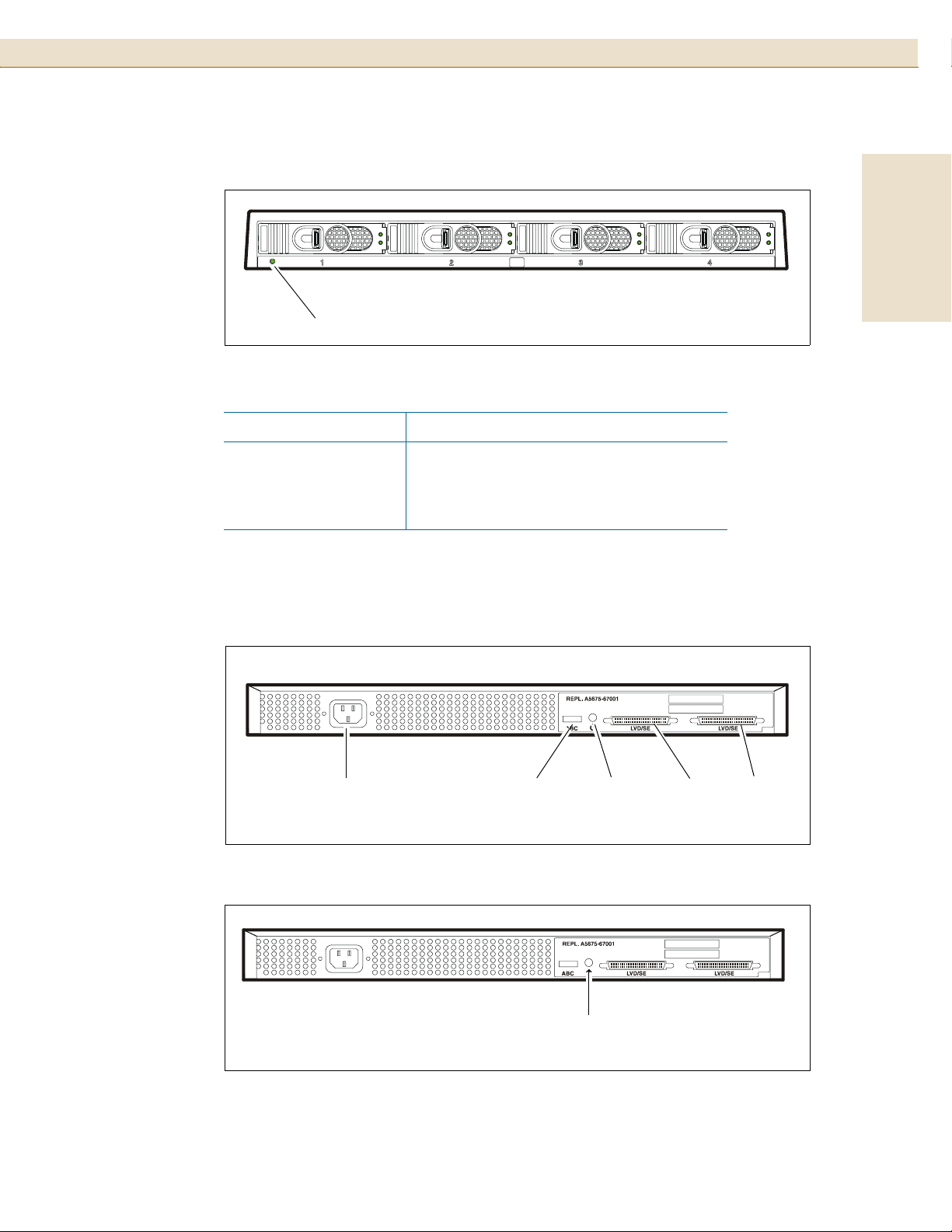

Rear Panel

English

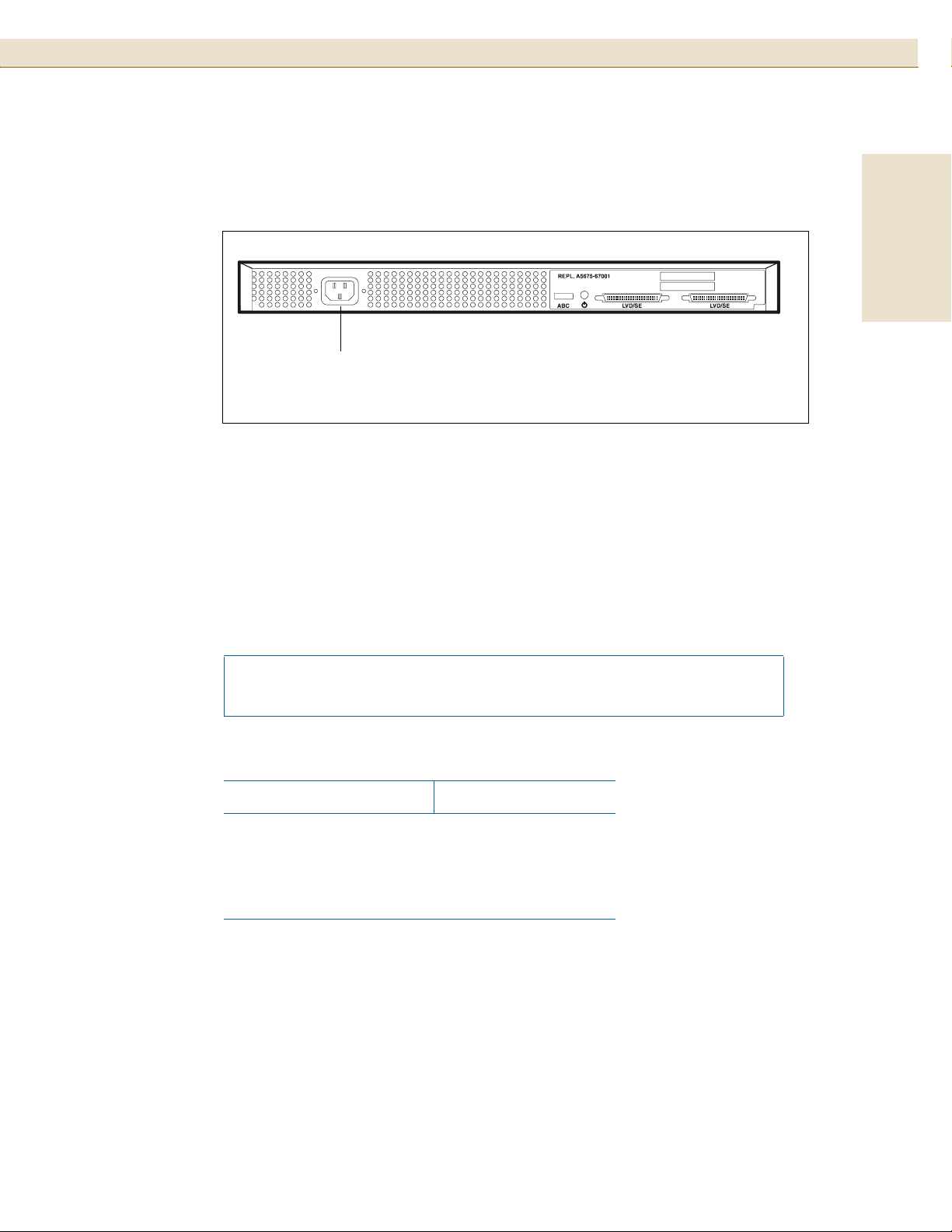

FIGURE 3

FIGURE 4

Rear View of the Disk System

AC

Power

Connector

Power Button

SCSI

Address

Switch

Power

Button

Power

Button

LVD/SE

SCSI

Port

LVD/SE

SCSI

Port

With the power button in the “ON” position, power is supplied to the disk system.

Page 10

HP StorageWorks Disk System 2100 / 211010

SCSI ID Switch

The SCSI ID switch sets the address for the disk drives.

There are three possible settings for the SCSI address switch: A, B, and C. Each

setting assigns a different set of addresses to the disk modules installed in the disk

system. For SCSI address switch setting A, the addresses for the installed disk

modules are (from left to right, looking at the disk system from the front) 0, 2, 4, and

6. For SCSI address switch setting B, the addresses for the installed disk modules are

8, 10, 12, and 14. For SCSI address switch setting C, the addresses for the installed

disk modules are 9, 11, 13, and 15. See Figure 5, below.

SCSI address 7 is reserved for use by the host bus adapter.

FIGURE 5

SCSI ID Switch Settings

C

B

A

SCSI

Address

Switch

Setting

A

B

C

Disk Module SCSI Addresses (Viewed from front of storage enclosure)

0

8

9

2

10

11

4

12

13

6

14

15

Note The disk system requires a terminator when it is installed at the end

of the SCSI bus.

Page 11

Power Connector

HP StorageWorks Disk System 2100 / 2110

11

FIGURE 6

AC Power Connector Location

AC

Power

Connector

Electrical Requirements

AC Site Requirements

Overcurrent protection devices are required for each cabinet where the disk system is

installed. They must be positioned between the power source and the disk system.

These protective devices must not trip when exposed to an inrush current of 30 amps

lasting 5 ms.

English

Note These protection devices must meet all applicable electrical safety

requirements and be approved for the intended purpose.

I

TABLE 3 AC Power Requirements

Electrical Element Requirements

Voltage 100-240 VAC

Frequency 50-60 Hz

Input Current < 1 amp

Maximum Surge Current 30 amps peak

Page 12

HP StorageWorks Disk System 2100 / 211012

Installing the Disk System

Hardware Requirements

The following hardware is included with the disk system:

One power cord comes with each disk system.

Your host computer must have one of the following:

■ An on board UltraSCSI port

■ An UltraSCSI host bus adapter board installed in the host system:

– A6828A Single Port Ultra160 SCSI Host Bus Adapter (HP Series 9000 only)

– A6829A Dual Port Ultra160 SCSI Host Bus Adapter (HP Series 9000 only)

– A7059A Windows and Linux Ultra160 SCSI Host Bus Adapter

– A7060A Windows and Linux Dual Port Ultra160 SCSI Host Bus Adapter

– P3413A Single Port Ultra3 SCSI Host Bus Adapter for HP Netservers

The following accessories are available for your storage disk system:

■ A6828A Single Port Ultra160 SCSI Host Bus Adapter

■ A6829A Dual Port Ultra160 SCSI Host Bus Adapter

■ C2364A High Density 68-pin Terminator for LVD or Single-Ended

The DS2100 and DS2110 support a maximum SCSI speed of U160. Connectivity to

U320 initiators is supported if the speed of the U320 initiator is set to limit

negotiations to U160 speed. U320 drives do not operate reliably at U320 speeds and

are not supported at those speeds. This is due to limitations within the controller and

not the U320 disk mechanisms. Contact your HP support representative for assistance

with the configuration.

Preparing for Installation

Before the disk system is ready for installation, its SCSI IDs must be set and the host

system must be prepared to recognize the newly installed disk system. See your

operating system administration manual for configuration procedures for the host bus

adapter.

Page 13

HP StorageWorks Disk System 2100 / 2110

Setting the SCSI IDs for the Disk Modules

13

FIGURE 7

1 Determine which SCSI addresses are not being used on the host system.

Refer to your system administration manual for information on determining

which SCSI addresses are available on the host system.

2 Locate the SCSI switch on the back of the disk system.

SCSI Switch Location

C

B

A

SCSI

Address

Switch

Setting

A

B

C

Disk Module SCSI Addresses (Viewed from front of storage enclosure)

0

8

9

10

11

2

12

13

4

14

15

English

6

Set the SCSI IDs.

3

Verify that the SCSI IDs you have chosen are available. If you are daisy-chaining

these disk systems together, each SCSI ID switch must be set for a unique

available set of SCSI IDs.

TABLE 4 SCSI Switch Setting Definitions

SCSI

Switch

Setting

A0246

B 8 10 12 14

C 9 11 13 15

1234

Disk Slot

Page 14

HP StorageWorks Disk System 2100 / 211014

Keep in mind that the host bus adapter should have the highest SCSI address priority.

See Table 5 below.

TABLE 5 SCSI Address Priority

SCSI ID7654321015141312111098

Priority Highest Lowest

Installing the Disk System

See the installation instructions enclosed with your rackmount kit.

Connect the SCSI Cables

1 Make sure that the host system has been powered down.

FIGURE 8

2 Connect one end of an Ultra SCSI cable (included in the shipping box) to the host

system. For the SCSI port location on your host system, refer to your host system’s

documentation.

3 Connect the other end of the SCSI cable to one of the LVD/SE ports on the rear of

the disk system.

SCSI Port Locations

LVD/SE

SCSI

Port

LVD/SE

SCSI

Port

Page 15

HP StorageWorks Disk System 2100 / 2110

4 Determine if this disk system is at the beginning or end of the SCSI bus.

15

– If the disk system is at the end of the SCSI bus (you are not going to daisy-chain

another device off this one), install the appropriate terminator (part number

5183-2657) on the available SCSI port and go to “Connecting the Power Cable”

(see Figure 9 on page 16).

– If the disk system is at the beginning or middle of the SCSI bus (you are going

to daisy-chain another device off this one), consider the following:

• Due to SCSI ID restrictions, no more than three of these disk systems can be

daisy-chained together.

• For the DS2110, use only 0.5-meter cable between enclosures in daisy-chain

configurations. Longer cable lengths between enclosures are not supported.

• Ensure that the SCSI IDs assigned for the disk drives in the second disk

system or other peripheral are not already assigned to another device on the

SCSI bus. Refer to “Setting the SCSI IDs for the Disk Modules” (see Figure 7

on page 13 for the SCSI IDs assigned for each SCSI switch setting).

• If you connected the SCSI cable to the on-board UltraSCSI port on the host

system, verify that the SCSI IDs assigned to the disk drives in the second disk

system or additional peripherals are not already assigned to any other

peripherals installed in the host system.

• For the DS2100, the overall SCSI bus length cannot exceed

12 meters. For the DS2110, the overall SCSI bus length cannot exceed 9

meters.

English

The SCSI bus length for the disk system internal cables is 1.1 meters. If

another type of peripheral is being connected on this SCSI bus, refer to that

peripheral’s documentation for its internal SCSI cable length.

5 Connect one end of an Ultra SCSI cable (get it from the shipping box) to the

available SCSI port on the rear of the first disk system on the SCSI bus.

6 Connect the other end of the Ultra SCSI cable to the SCSI IN port on the rear of

the second disk system on the SCSI bus.

7 Repeat Steps 3, 5, and 6 for the last disk system on the SCSI bus if three disk

systems are being installed. Keep in mind the maximum bus length (12 meters).

8 Install a terminator if the device is the last one on the bus. For supported

terminators, see Table 10 on page 33 or Table 12 on page 34.

Note The disk system, when connected at the end of a SCSI bus, requires

a terminator. Refer to the documentation that came with your wide

SCSI device to determine if it needs a terminator or not. Narrow

SCSI devices at the end of a daisy-chain always require a terminator.

Page 16

HP StorageWorks Disk System 2100 / 211016

Connecting the Power Cable

Ensure that the connection of multiple units to the supply circuit does not

CAUTION

overload the supply overcurrent protection or the supply wiring. Refer to

the storage electrical ratings when determining the correct branch circuit

rating for your installation. See Table 3 on page 11.

FIGURE 9

AC Power Connector Location

AC

Power

Connector

Powering On and Off

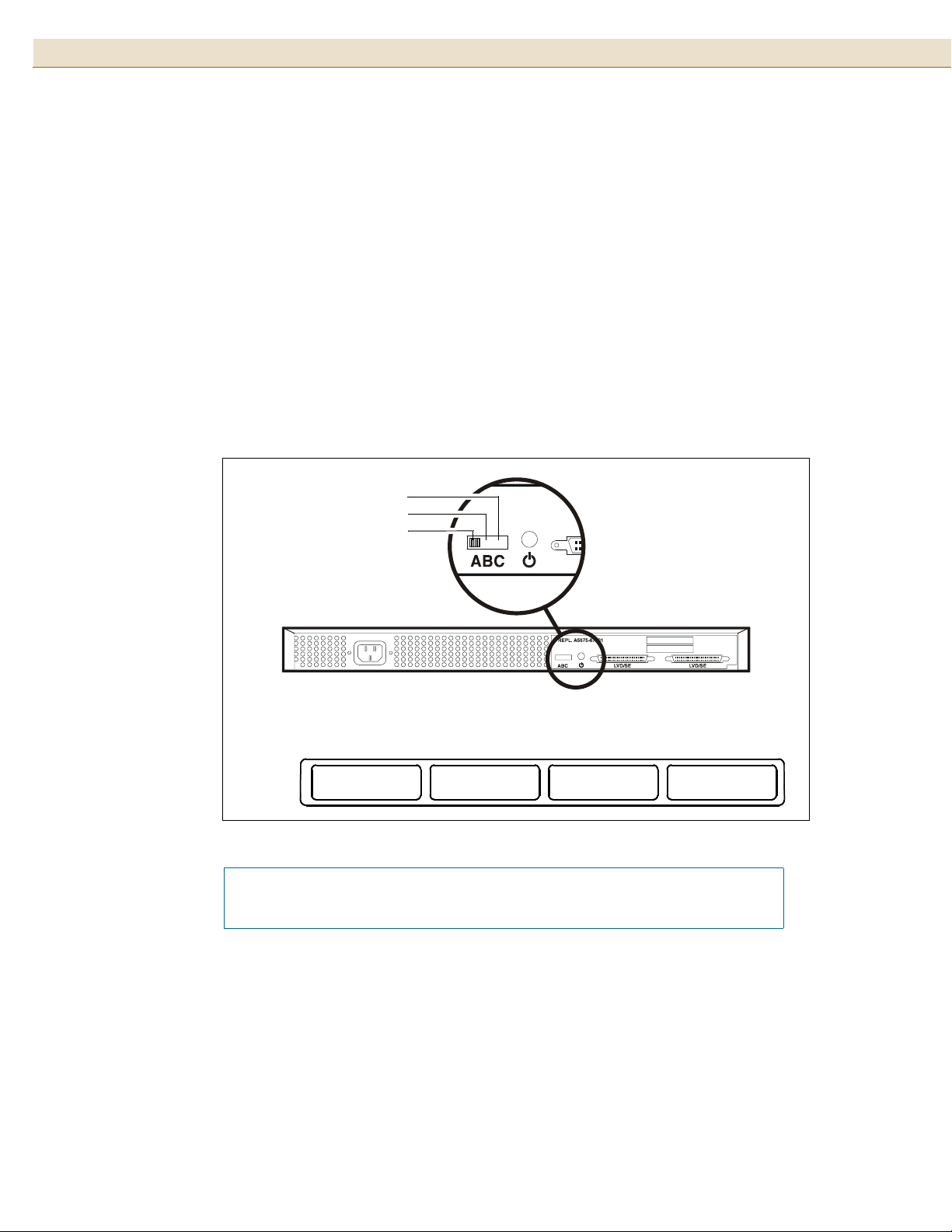

Power On the Disk System

1 Press the power button and release it. The power button will stay in a depressed

position, indicating that the power is on.

See Figure 10 on page 17 for the location of the power button.

2 Confirm that the disk system is running properly by checking the system power

LED and the disk module LEDs at the front of your disk system. A system reboot

may be necessary to assure that the host system recognizes the disk drives within

the disk system.

Refer to “Front Panel” on page 3 for explanations of the LED functions and their

meanings.

Page 17

Power Off the Disk System

HP StorageWorks Disk System 2100 / 2110

17

1 Back up all data if the disk system is still operational.

English

2 Ensure that no data on disk modules within the disk system is being accessed.

3 Unmount any file systems associated with the disk system that is going to be

powered off. Refer to the system administration manual for your host system’s

operating system for the correct procedure for unmounting a file system or

stopping access to the disk modules within the disk system.

Note

If your host system’s boot or root disk drive resides in the disk

system, the host system must be brought down before the power

to the disk system can be turned off. See your host system’s

system administrator’s manual for the correct procedures.

4 Turn the disk system off by pressing the power button. See Figure 10 (below) for

the power button location.

5 Confirm that the storage disk system System Power LED is off. See Figure 2 on

page 9.

6 Disconnect the power cable from the power connector at the rear of the disk

system.

FIGURE 10

Power Button Location

Power

Button

Page 18

HP StorageWorks Disk System 2100 / 211018

Adding Disk Modules

Disk modules can be added, removed, and replaced while the disk system is running.

Because the disk modules can be handled in this way, they are called

hot-pluggable.

The SCSI addresses for the disks are set using the addressing switches on the back of

the disk system. You can determine the assigned SCSI addresses by looking at the

SCSI address switch settings at the rear of the disk system.

If your storage system contains less than 4 disk modules, the remaining empty slots

require filler panels. These filler panels ensure that the proper cooling is maintained

within the storage system.

The system administration procedure for adding a disk module is operating system

specific. You must decide where the disk module is to be installed and install it. Once

the disk module is installed, the operating system must be configured to recognize it.

Add a Disk Module

1 Select an available slot for the new disk module. Note the slot chosen for

application configuration.

2 Remove the disk module filler panel. Store the filler panel for future use.

3 Hold the locking handle open on the disk drive. Push the locking lever to the left

to release the latch.

4 Slide the disk into the appropriate slot.

5 Gently push the drive until the locking mechanism engages. When the disk

module is completely installed, an audible click can be heard.

6 Close the locking handle completely, using gentle downward pressure.

Page 19

HP StorageWorks Disk System 2100 / 2110

19

FIGURE 11

Installing a Disk Module

Configure the new Disk Module

Configure a new disk module within your application.

These procedures should be performed only by qualified system

CAUTION

administrator. Performing hot-plug operations on an active disk drive can

result in data loss or corruption.

English

Remove and Replace A Disk Module

Remove a Disk Module

If the disk system is running and a disk module slot does not contain a disk

CAUTION

drive or filler panel, the disk system will not cool properly and may

overheat. If you are not replacing the disk module immediately, a filler

panel must be installed to maintain proper cooling.

Ensure that you have a replacement disk or filler panel before removing the

disk module from the disk system unless you are returning a defective disk

system.

1 Ensure there is no activity on the drives.

If the Disk Drive LED for that disk module is flashing green, the disk drive is

active. When the Disk Drive LED off, the disk module is either idle or

completely off (see Table 1 on page 8). In this state, it is safe to remove the disk

module.

Page 20

HP StorageWorks Disk System 2100 / 211020

2 Prepare the software environment to remove the drive.

See your operating system documentation for instructions and procedures

required to remove a disk module. It may be necessary to unmount file systems

associated with the disk drives installed in the disk system.

3 Unlatch the disk module handle and remove the disk module.

Squeeze the latch to unlock the disk module. Put a finger behind the latch and

pull the disk module out until it disengages from the backplane. Leave it in its

slot for two to three minutes to allow the disk drive to spin down before removing

the disk module from the enclosure.

If you are going to replace the disk module immediately, refer to “Replace a Disk

Module” below.

If you are not going to replace the disk module immediately insert a filler panel

into the open slot to assure the required cooling.

Replace a Disk Module

1 Refer to your operating system documentation for requirements and procedures

for replacing disk modules.

2 Align the replacement disk module with the disk module slot.

3 Slide the disk module into the slot until it engages with the backplane.

4 Press on the locking handle until it locks. You will hear an audible click when the

locking mechanism is fully engaged.

Page 21

Remove the Disk System

Some data paths may be slot-dependent. Be sure to note the slot from which

CAUTION

the disk module is removed so it can be installed in the same slot in the

replacement disk system.

Reverse the installation instructions enclosed with the rackmount kit for your cabinet:

■ A5679A - Hewlett-Packard Rack Systems/E for Enterprise Systems

■ A5680A - all other Hewlett-Packard rack systems for Enterprise Systems

purchased before November 1998.

■ A6532A - Hewlett-Packard Rack Systems/E for Commercial Systems

■ A6533A - all other Hewlett-Packard rack systems for Commercial Systems

purchased before November 1998.

HP StorageWorks Disk System 2100 / 2110

21

English

FIGURE 12

If your disk system is a factory-integrated unit, see the figure below for removal

instructions.

Removing the Disk System

If you are exchanging a desktop disk system, be sure to remove and store the plastic

Desktop Disk System Cover for use on the replacement disk system.

Page 22

HP StorageWorks Disk System 2100 / 211022

Setting Up the Hardware Event Monitor (HP-UX Only)

Hardware event monitors run on HP-UX hosts, versions 10.20 and later. The Disk

Monitor (disk_em) monitors all disks bound to sdisk drivers. Consequently, if the

Disk Monitor is active on your host, it is already set up to monitor the disks of a new

disk system. If you need to install or activate the Disk Monitor, refer to the EMS

Hardware Monitors User’s Guide in the latest IPR Support Media or on the Web

(http://www.docs.hp.com/hpux/diag/).

Note This Disk Monitor should not be confused with the EMS disk

monitor that is used to monitor LVM resources.

The way you configure the monitor determines, among other things, where event

messages will be sent and what level of severity will be reported.

Configuration Overview

The following steps will help you identify and resolve disk system failures:

1 Gather information from all sources:

– Hardware event notifications (page 25)

– Disk system LED status (page 25)

– Online information tools (page 26)

2 Isolate the cause of the problem (Table 7 on page 30).

3 Correct the problem. (See page 19 for disk module removal and replacement.)

4 Verify operational status with ioscan or other host utilities.

Page 23

Event Notification (HP-UX Only)

HP StorageWorks Disk System 2100 / 2110

23

The Disk Monitor, an EMS hardware event monitor, reports changes in disk status.

Depending on how the monitor is set up, it sends messages to the console, an e-mail

address, a log file, or a third-party application. These messages give early notice of a

disk problem. Events include media errors, failed read and write attempts, invalid

commands, changed operating parameters, failed diagnostics, and many others.

Event severity ranges from critical to informational:

Critical An event that causes data loss, host system downtime, or

other loss of service. Host system operation will be affected if

the disk system continues to be used without correction.

Immediate action is required. For example, read data could

not be recovered.

Serious An event that may cause data loss, host system downtime, or

other loss of service if left uncorrected. Host system and

hardware operation may be adversely affected. The problem

needs repair as soon as possible. For example, the request

queue is full.

Warning An event that could escalate to a serious condition if not

corrected. Host system operation should not be affected and

normal use of the disk system can continue. Repair is needed

but at a convenient time. For example, the bus failed to reset.

Information An event that is expected as part of the normal operation of

the hardware. No action is required. For example, write

protection was switched on or off.

English

Event messages (see Figure 13) contain the following types of information:

■ Message Data – Date and time the message was sent, the source and destination

of the message, and the severity level.

■ Event Data – Date and time of the event, the host, event ID, name of the monitor,

event number, event class, severity level, hardware path, associated OS error log

entry ID.

■ Error Description – Narrative information indicating the component that

experienced the event and the nature of the event.

■ Probable Cause/Recommended Action – The cause of the event and suggested

steps toward a solution. This information should be the first step in

troubleshooting.

Page 24

HP StorageWorks Disk System 2100 / 211024

FIGURE 13

Sample Hardware Event Notification

Notification Time: Wed Feb 3 11:27:15 1999

yourserver sent Event Monitor notification information:

/storage/events/disks/default/10_4_4_0.0 is >=1.

Its current value is CRITICAL(5)

Event data from monitor:

Event Time: Wed Feb 3 11:27:15 1999

Hostname: yourserver.rose.hp.com IP Address : 15.43.213.13

Event ID: 0x0036b8a313000000002 Monitor : disk_em

Event # : 100037 Event Class: I/O

Severity : CRITICAL

Disk at hardware path 10/4/4/0.0 : Media failure

Associated OS error log entry id(s) : 000000000000000000

Description of Error:

The device was unsuccessful in reading data for the current I/

O request due to an error on the medium. The data could not be

recovered. The request was likely processed in a way which

could cause damage to or loss of data.

Probable Cause / Recommended Action:

The medium in the device is flawed. If the medium is removable,

replace the medium with a fresh one. Alternatively, if the

medium is not removable, the device has experienced a hardware

failure. Repair or replace the device, as necessary.

Page 25

Status LEDs

HP StorageWorks Disk System 2100 / 2110

25

LEDs indicate the status of the disk system itself and each of the disk modules. A

green system LED is visible on the front of the disk system. It shows that a fault has

occurred or that power is on. Disk activity LEDs are on the front of the disk modules

(see Figure 14 and Table 6 below).

FIGURE 14

TABLE 6 LED Status Indicators

LED Status Indicators

System Power

LED

LED State Indication

System Power Green Power is on

Blinking Malfunction - either a fan is not operating

OFF Power is off

Disk Module Green Installed and spinning up. If the LED is still on

Flashing I/O activity on the disk. The LED flashes at

OFF Not installed, not operating, or no I/O activity

English

Amber LED (not used)

Green LED

Disk Module

LEDs

properly or internal voltage is too low.

3 minutes after term power is engaged and

there is no I/O activity occurring, the disk may

be faulty.

variable speeds, depending on the I/O activity.

The LED may appear to be on solid during

periods of high I/O activity.

Page 26

HP StorageWorks Disk System 2100 / 211026

View Disk Status

HP-UX and MPE/iX utilities provide descriptive and diagnostic information about

disks, including disk type, firmware revision, and errors. On HP-UX and MPE/iX 6.5

or later, the disk utility is Support Tools Manager (STM). For all other operating

systems, consult the appropriate system administration manual for disk module status

checking procedures.

STM Disk Information: HP-UX

STM displays the last-generated Information Log for a selected disk. Start STM and

run the Information tool as follows.

1 Log on the system.

2 At the system prompt, type xstm&. STM starts and displays a graphic of the

devices on the system.

3 Select the desired disk.

4 Select Information from the Tools menu.

5 To generate a current log, select Run. The log will be displayed as soon as it is

generated

6 To view a log without updating the contents, select Information Log.

7 Select Done when you have finished viewing the information.

8 To quit STM, type exit.

Figure 15 shows a sample Information Log.

Page 27

HP StorageWorks Disk System 2100 / 2110

27

FIGURE 15

Sample STM Information Log (HP-UX)

English

Page 28

HP StorageWorks Disk System 2100 / 211028

STM Disk Information: MPE/iX 6.5 or Later

STM displays the last-generated Information Log for a selected disk. Start STM and

run the Information tool as follows.

1 Log on the system.

2 At the system prompt (:), type vsclose <physical volume number>. This removes

the disk from use.

3 At the system prompt (:), type cstm. STM starts.

4 At the cstm prompt, type map. STM displays a list of all the disks installed on the

system.

5 Select the desired disk by typing select device <number>; for example, select

device 15.

6 Type information. STM updates the system map.

7 To display the information log, type infolog. A sample information log is shown

in Figure 16.

Page 29

HP StorageWorks Disk System 2100 / 2110

29

FIGURE 16

Sample STM Expert Tool Disk Error Log (MPE/iX 6.5 or Later)

Write Error Statistics

Errors Corrected Without Delay: N/A

Errors Corrected With Delay: 0

Total Retries: 0

Total Errors Corrected: 0

Correction Algorithm Executions: 0

Total Bytes Processed: 6.3253e+10

Total Uncorrected Errors: 0

Read Error Statistics

Errors Corrected Without Delay: 23781

Errors Corrected With Delay: 0

Total Retries: 0

Total Errors Corrected: 23781

Correction Algorithm Executions: 23781

Total Bytes Processed: 9.6191e+10

Total Uncorrected Errors: 0

Read Reverse Error Statistics

Errors Corrected Without Delay: N/A

Errors Corrected With Delay: N/A

Total Retries: N/A

Total Errors Corrected: N/A

Correction Algorithm Executions: N/A

Total Bytes Processed: N/A

Total Uncorrected Errors: N/A

English

Verify Error Statistics

Errors Corrected Without Delay: 0

Errors Corrected With Delay: 0

Total Retries: 0

Total Errors Corrected: 0

Correction Algorithm Executions: 0

Total Bytes Processed: 36864

Total Uncorrected Errors: 0

Non-Medium Error Counts: 0

Page 30

HP StorageWorks Disk System 2100 / 211030

Isolating Faults

Table 7 lists the probable causes and solutions for problems you may detect on the

disk system. When more than one problem describes your situation, investigate the

first solution that applies. The table lists the most basic problems first and excludes

them from subsequent problem descriptions.

Erratic LED behavior on the disk system could be observed in the following

situations:

■ When a server that is connected to a Disk System 2110 is powered down or loses

power (and the disk system remains powered on)

■ When the disk system is powered up when connected to a downed server

■ When an unconnected disk system is powered up

An example of this LED behavior is the LEDs staying lit solidly. This condition is

caused by the disk system being deprived of term power when the server loses power

or is powered down. The disk system does not provide its own term power. It relies on

the host bus adapter to which it is connected for term power.

TABLE 7 Troubleshooting Table

Problem

Description

Disk system

fails to power

on when

installed

Operating

system

reports

errors on a

device

LED

State Probable Cause Solution

System

power LED

is off

System

power LED

is blinking

Disk

module

LED is on

solid or off

Power cord is not plugged in. Plug in the power

cord.

The power button is not

pressed.

AC breaker is tripped or AC

power source has failed.

The PDU/PDRU is defective. Replace the PDU/

Enclosure chassis is faulty. Replace the enclosure

Power supply is defective. Replace the enclosure

Cooling fans are not spinning

at the correct speed.

Use diagnostic utilities to

determine disk status.

Press the power

button.

Confirm AC power

availability.

PDRU.

chassis.

chassis.

Replace the enclosure

chassis.

Depending on the

results, monitor or

replace disk module.

Page 31

HP StorageWorks Disk System 2100 / 2110

31

Problem

Description

ioscan (HPUX) lists disk

as NO_HW,

or Mapper or

dstat all

(MPE/iX) lists

no device

type

Unable to

configure

device for

use by

operating

system

LED

State Probable Cause Solution

Disk

module

LED is on

solid or off

Disk

module

LED is on

solid or off

Disk module is faulty. Replace the disk

module.

Enclosure is faulty. Replace the enclosure

chassis.

If the all disks on the bus have

this problem, the cable is

faulty.

Disk module possibly not

correctly seated.

If troubleshooting an existing

installation, run diagnostics to

determine drive status.

Replace the cable.

Remove and reinstall

the disk module.

If the problem cannot

be resolved, replace

the disk module.

English

Page 32

HP StorageWorks Disk System 2100 / 211032

Reference Information

Product Numbers and Options

TABLE 8 Product Numbers

Disk System 2100

Product

Number UPC Code Description

A5675A (None) Field-racked disk system with at least one drive

A5675AD (None) Desktop disk system with at least one drive

A5675AZ (None) Factory-racked disk system with at least one drive

A5675AE 0 88698-48848 5 Field-racked disk system, empty enclosure only

A5675ED 0 88698-48849 2 Desktop disk system, empty enclosure only

Disk System 2110

Product

Number UPC Code Description

A7381A 8 08736-55999 7 Field-racked disk system with at least one drive

A7381AD 8 08736-56000 9 Desktop disk system with at least one drive

A7381AZ 8 08736-56002 3 Factory-racked disk system with at least one drive

A7381AE 8 08736-56001 6 Field-racked disk system, empty enclosure only

A7381ED 8 08736-56003 0 Desktop disk system, empty enclosure only

When ordering disk modules for a product, specify Option OD1 to install the module

in the product before it ships from the factory. For example, to order a desktop Disk

System 2110 with one 18-GB, 15,000 rpm disk module, request the following:

Product

Number Quantity Description

A7381AD 1 Desktop Disk System 2110

A7328A 1 18-GB 15,000 rpm LVD U320 disk module

A7328A (OD1) 1 Factory integration of the disk module

Page 33

Upgrade Disk Products Available

HP StorageWorks Disk System 2100 / 2110

33

TABLE 9 Available Upgrade Disk Modules

Product

Number UPC Code Description

1

A6571A 8 08736-45416 2 36-GB 10,000 rpm LVD U320 disk module

A7285A 8 08736-45417 9 73-GB 10,000 rpm LVD U320 disk module

2

A7286A28 08736-45418 6

2

A7287A

8 08736-45419 3

73-GB 15,000 rpm LVD U320 disk module

2

146-GB 10,000 rpm LVD U320 disk module

A7328A 8 08736-33052 7 18-GB 15,000 rpm LVD U320 disk module

A7329A 8 08736-33053 4 36-GB 15,000 rpm LVD U320 disk module

1

The U320 drives are supported at 160 MB/s speeds only. U320 drives do not operate

reliably 320 MB/s speeds and are not supported at those speeds. This is due to

limitations within the controller and not the disk mechanisms.

2

May only be used in Disk System 2110.

TABLE 10 Upgrade Products for Hewlett-Packard Systems

Product

Number Description

English

A4999A Single Port Ultra2 SCSI Host Bus Adapter for Hewlett-Packard

Workstations

A5675A HP StorageWorks Disk System 2100

A5679A Rail kit for the Rittal Style Rack Systems and HP Rack Systems/E

A5680A Rail kit for HP Rack Systems

A5856A Internal Disk Array Controller for HP-UX Systems

A6828A Single Port Ultra160 SCSI Host Bus Adapter for HP-UX Systems

A6829A Dual Port Ultra160 SCSI Host Bus Adapter for HP-UX Systems

A7059A Windows and Linux Ultra160 SCSI Host Bus Adapter

A7060A Windows and Linux Dual Port Ultra160 SCSI Host Bus Adapter

A7381A HP StorageWorks Disk System 2110

C2364A LVD/SE SCSI Terminator (HDTS68)

P3413A Single Port Ultra3 SCSI Host Bus Adapter for HP Netservers

Page 34

HP StorageWorks Disk System 2100 / 211034

TABLE 11 Replaceable Parts

Product

Number Description

Replaceable

Part Numbers

Customer

Replaceable

Unit (CRU)

Field

Replaceable

Unit (FRU)

A5675A DS2100 Base Disk System Assembly A5675-69003 Yes Yes

A6198A Disk Filler Panel A6198-67002 Yes Yes

A6571A* 36-GB 10,000 rpm LVD U320 disk mod. A6571-69001 Yes Yes

A7285A* 73-GB 10,000 rpm LVD U320 disk mod. A7285-69001 Yes Yes

A7286A* 73-GB 15,000 rpm LVD U320 disk mod. A7286-69001 Yes Yes

A7287A* 146-GB 10,000 rpm LVD U320 disk mod. A7287-69001 Yes Yes

A7328A* 18-GB 15,000 rpm LVD U320 disk mod. A7328-69001 Yes Yes

A7329A* 36-GB 15,000 rpm LVD U320 disk mod. A7329-69001 Yes Yes

A7381A DS2110 Base Disk System Assembly A7381-69001 Yes Yes

Desktop Disk System Cover 5065-5217 No Yes

Desktop Disk System Feet 0403-0285 No Yes

* The U320 drives are supported at 160 MB/s speeds only. U320 drives do not operate reliably 320 MB/s

speeds and are not supported at those speeds. This is due to limitations within the controller and not the

disk mechanisms.

TABLE 12 Supported HP Cables and Terminators

Order

Number Description

Part

Number

C2978B 0.5-meter HDT S68 SCSI multimode cable 5183-2670

C2911C 1.0-meter HDT S68 SCSI multimode cable 5183-2671

C2979B 1.5-meter HDT S68 SCSI multimode cable 5183-2672

C2924C 2.5-meter HDT S68 SCSI multimode cable 5183-2673

C7521A 5.0-meter HDT S68 SCSI multimode cable 5183-2678

C2361B 1.0-meter VHDT S68/HDT S68 SCSI multimode cable 5183-2674

C2362B 2.5-meter VHDT S68/HDT S68 SCSI multimode cable 5183-2675

C2365B 5.0-meter VHDT S68/HDT S68 SCSI multimode cable 5183-2676

C2364A SCSI Terminator LVD/SE HDTS68 5183-2657

Page 35

Specifications

HP StorageWorks Disk System 2100 / 2110

35

TABLE 13 Physical Dimensions

Measure Metric English

Width 45.08 cm 17.75 in

Depth 38.10 cm 15.0 in

Height 4.32 cm 1.7 in

Weight without disk modules 4.94 kg 10.90 lbs

Weight fully loaded 8.11 kg 17.89 lbs

Electrical Specifications

TABLE 14 AC Power Requirements

Electrical Element Requirement

Product Voltage Range 100 - 240 VAC RMS

Product Frequency Range 50 - 60 Hz

English

TABLE 15 Environmental Specifications

Climate Control

Disk System 2100

Tem p e r at u r e (d ry b u l b)

Disk System 2110

Tem p e r at u r e (d ry b u l b)

Relative Humidity

(non-condensing)

Altitude (based on disks) Operating -1000 ft to +10,000 ft (3048 M)

Heat Dissipation (maximum) Operating < 100 watts

Operating

Storage

Operating

Storage

Operating

Storage

Storage 40,000 ft (12,092 M)

°C - +40°C

0

-40

°C - +70°C

°C - +35°C

0

°C - +70°C

-40

5% - 95% Relative Humidity at 40

90% Relative Humidity at 65

°C

°C

Page 36

HP StorageWorks Disk System 2100 / 211036

Operating Temperatures

If the storage system is installed in a multi-unit rack assembly, the operating ambient

temperature of the rack environment may exceed room ambient temperature. For the

Disk System 2100 the rack environment ambient temperature cannot exceed 40°

Celsius (104° Fahrenheit). For the Disk System 2110 the rack environment ambient

temperature cannot exceed 35° Celsius (95° Fahrenheit).

If your storage system contains less than 4 disk modules, the remaining empty slots

require filler panels. These filler panels (part number A6198-60002) ensure that the

proper cooling is maintained within the storage system.

Regulatory Statements

Safety Certifications

UL listed, UL 1950:1995 – 3rd Edition

CSA certified, C22.2 No. 950:1995

TUV certified with GS mark, EN 60950:1992 + A1:1993, A2:1993, A3:1995,

A4:1997, A11:1997

CE mark (see I. Declaration of Conformity on page 39)

EMC Compliance

Australia: AS/NZS 3548, Class A

Canada: ICES-003, Class A

China: GB9254-88

European Union: EN55022 Class A, EN55024

Japan: VCCI Class A

Taiwan: CNS 13438, Class A

US: 47 CFR Parts 2 & 15, Class A

A. FCC Notice for United States

The Federal Communications Commission (in 47 CFR 15.105) has specified that the

following notice be brought to the attention of the users of this product.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

Page 37

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Hewlett-Packard’s certification tests were conducted with a Hewlett-Packard

supported computer system and Hewlett-Packard shielded cables, such as those you

received with your storage product. Changes or modifications not expressly approved

by Hewlett-Packard could void the user’s authority to operate the equipment. Cables

used with this device must be properly shielded to comply with the requirements of

the FCC.

B. Canadian Notice (Avis Canadien)

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur

le matériel brouilleur du Canada.

HP StorageWorks Disk System 2100 / 2110

37

English

C. Notice for European Union

This is a Class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

D. Notice for France

DECLARATION D'INSTALLATION ET DE MISE EN EXPLOITATION d'un

matériel de traitement de l'information (ATI), classé A en fonction des niveaux de

perturbations radioélectriques émis, définis dans la norme européenne EN 55022

concernant la Compatibilité Electromagnétique.

E. Notice for Japan

F. Harmonics Conformance (Japan)

Page 38

HP StorageWorks Disk System 2100 / 211038

G. BSMI

H. Notice for Germany

Schalldruckpegel Lp = 55.0 dB(A)

Am Arbeitsplatz (operator position)

Normaler Betrieb (normal operation)

Nach ISO 7779:1999 (Typprüfung)

Page 39

I. Declaration of Conformity

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and EN 45014

Manufacturer's Name: Hewlett-Packard Company

Manufacturer's Address: 11311 Chinden Blvd.

Boise, ID 83714

USA

Declares, that the product

Product Name: hp StorageWorks disk system 2100 and 2110

Product Number: A5675A/AD/AZ/ED, A5676A/AD, and

A7381A/AD/AE/AZ/ED

Regulatory Model Number: BOISA-0301

Product Options: All

HP StorageWorks Disk System 2100 / 2110

39

English

Conforms to the following Product Specifications:

Safety: IEC 60950:1991+A1+A2+A3+A4 / EN 60950:1992+A1+A2+A3+A4+A11

GB 4943:1995

IEC 60825-1:1993 / EN 60825-1:1994 +A11, Class 1 (Laser/LED)

EMC: CISPR 22:1997+A1 / EN 55022:1998 +A1 Class A

GB 9254:1988

CISPR 24:1997 / EN 55024:1998

IEC 61000-3-2:1995 / EN 61000-3-2:1995 + A14

IEC 61000-3-3:1994 / EN 61000-3-3:1995

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

1) The Product was tested in a worst-case configuration which maximizes RFI

emissions.

Boise, ID USA

March 7, 2003

1

European contact for regulatory topics only: Hewlett-Packard GmbH, HQ-TRE, Herrenberger Strasse 140, and D-71034

Böblingen (FAX: + 49-7031-14-3143)

Page 40

HP StorageWorks Disk System 2100 / 211040

Product Web Site

For the most current information about the HP StorageWorks Disk System 2100, visit

the support Web site located at http://www.hp.com/support/ds2100

For the most current information about the HP StorageWorks Disk System 2110, visit

the support Web site located at http://www.hp.com/support/ds2110.

Related Documents

The following resources contain information on using the system software interfaces

to the HP StorageWorks Disk System 2100 / 2110:

■ Online Diagnostics (for HP 9000): Support Tools Manager Overview, available at

http://docs.hp.com/hpux/diag/

■ HP-UX documentation, available at http://docs.hp.com

Page 41

HP StorageWorks Disk System 2100 / 2110

41

English

Page 42

HP StorageWorks Disk System 2100 / 211042

Loading...

Loading...