HP AA988A, StorageWorks 2012sa User Manual

HP StorageWorks

2012sa Modular Smart Array

user guide

Part number: 488320-002

Second edition: July 2008

Legal and notice information

© Copyright 2008 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be photocopied,

reproduced, or translated into another language without the prior written consent of Hewlett-Packard. The information is provided “as is”

without warranty of any kind and is subject to change without notice. The only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft and Windows are U.S. registered trademarks of Microsoft Corporation.

3

Contents

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rack Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

HP Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Customer Self Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Warranties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Subscription Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

HP Websites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1. System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Management Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HP StorageWorks MSA2000 Family Storage Management Utility (SMU) . . . . 12

Command-Line Interface (CLI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hardware Components and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controller Enclosure Components and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Drive Enclosure Components and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2. Installing and Cabling Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Site Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing Enclosures Into a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Preparing the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Assembling and Installing the Rackmount Bracket Kit . . . . . . . . . . . . . . . . . . . 28

Attaching the Ear Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connecting Controller and Drive Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Testing the Enclosure Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

General Practice for Powering the System Off and On . . . . . . . . . . . . . . . . . . . 37

Obtaining IP Values for Your Storage System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Correcting Enclosure IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3. Connecting Hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Host System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installing the MSA2000 Family SES Driver for Microsoft Windows Hosts . . . 40

Connecting the Enclosure to Data Hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connecting Remote Management Hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4. Configuring a System for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting Management Port IP Addresses Using the CLI . . . . . . . . . . . . . . . . . . . . . . 42

Configuring Your Web Browser for SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Logging in to SMU from a Local Management Host . . . . . . . . . . . . . . . . . . . . . . . . 46

Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Selecting an Appropriate Time to Perform the Online Upgrade . . . . . . . . . . . . 47

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Creating Virtual Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Mapping a Volume to a Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Testing the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Logging Out of SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Contents 5

5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Fault Isolation Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Gather Fault Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Determine Where the Fault Is Occurring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Review the Event Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Isolate the Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Correcting Enclosure IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Using System LEDs to Diagnose Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Is the front panel Fault ID amber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Is the controller back panel OK LED off? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Is the controller back panel Fault/Service Required LED amber? . . . . . . . . . . . 57

Are both drive module LEDs, Online/Activity, and Fault/UID LEDs off? . . . . 57

Is the drive module Fault/UID led blinking amber? . . . . . . . . . . . . . . . . . . . . . 58

Is a connected port’s Host Link Status LED off? . . . . . . . . . . . . . . . . . . . . . . . . 59

Is a connected port’s Expansion Port status LED off? . . . . . . . . . . . . . . . . . . . . 59

Is a connected port’s Ethernet link status LED off? . . . . . . . . . . . . . . . . . . . . . . 60

Is the power-and-cooling module AC Power Good LED off? . . . . . . . . . . . . . . 60

Is the power-and-cooling module DC Voltage/Fan Fault/Service Required LED

amber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Is the drive enclosure back panel OK LED off? . . . . . . . . . . . . . . . . . . . . . . . . 61

Is the drive enclosure Fault/Service Required LED amber? . . . . . . . . . . . . . . . 62

Isolating a Host-Side Connection Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Isolating a Controller Module Expansion Port Connection Fault . . . . . . . . . . . . . . . 64

Resolving Voltage and Temperature Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Sensor Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Power Supply Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cooling Fan Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Power-and-Cooling Module Voltage Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

A. Environmental Requirements and Specifications . . . . . . . . . . . . . . . . . . . . . . . . 71

B. Regulatory Compliance and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7

About This Guide

Intended Audience

This guide is intended for use by system administrators and information

professionals who are experienced with the following:

■ Direct attach storage (DAS) or storage area network (SAN) management

■ Network administration

■ Network installation

■ Storage system installation and configuration, including installing an HP rack

Prerequisites

Prerequisites for installing and configuring this product include familiarity with:

■ Servers and computer networks

■ Host communications protocols, such as serial-attached SCSI (SAS) and Ethernet

8 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Document Conventions

Rack Stability

Caution – To reduce the risk of personal injury or damage to the equipment:

■ Extend leveling jacks to the floor.

■ Ensure that the full weight of the rack rests on the leveling jacks.

■ Install stabilizing feet on the rack.

■ In multiple-rack installations, secure racks together.

■ Extend only one rack component at a time. Racks may become unstable if more

than one component is extended.

Typeface Meaning Examples

AaBbCc123 Book title, new term, or

emphasized word

See the user guide.

A virtual disk (vdisk) can ....

You must ...

AaBbCc123 Directory or file name,

value, command, or

on-screen output

The default file name is store.logs.

.The default user name is manage

Type exit

AaBbCc123 Text you type, contrasted

with on-screen output

# set password

Enter new password:

AaBbCc123 Variable text you replace

with an actual value

Use the format user@domain.

About This Guide 9

HP Technical Support

Telephone numbers for worldwide technical support are listed on the HP support

website:

http://www.hp.com/support/.

Collect the following information before calling:

■ Technical support registration number (if applicable)

■ Product serial numbers

■ Product model names and numbers

■ Applicable error messages

■ Operating system type and revision level

■ Detailed, specific questions

For continuous quality improvement, calls may be recorded or monitored.

Customer Self Repair

HP customer self repair (CSR) programs allow you to repair your HP StorageWorks

product. If a CSR part needs replacing, HP ships the part directly to you so that you

can install it at your convenience. Some parts do not qualify for CSR. Your HPauthorized service provider will determine whether a repair can be accomplished by

CSR.

For more information about CSR, contact your local service provider. For North

America, see the CSR website:

http://www.hp.com/go/selfrepair

Product Warranties

For information about HP StorageWorks product warranties, see the warranty

information website:

http://www.hp.com/go/storagewarranty

10 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Subscription Service

HP strongly recommends that customers sign up online using the Subscriber's

choice website:

http://www.hp.com/go/e-updates.

Subscribing to this service provides you with e-mail updates on the latest product

enhancements, newest versions of drivers, and firmware documentation updates as

well as instant access to numerous other product resources.

HP Websites

For other product information, see the following HP websites:

■ http://www.hp.com

■ http://www.hp.com/go/storage

■ http://www.hp.com/service_locator

■ http://www.hp.com/support/manuals

■ http://www.hp.com/support/downloads

Documentation Feedback

HP welcomes your feedback.

To make comments and suggestions about product documentation, please send a

message to

storagedocs.feedback@hp.com. All submissions become the

property of HP.

11

CHAPTER

1

System Components

The MSA2000 Family 2012sa Modular Smart Array and MSA2000 Drive Enclosure

are high-performance storage solutions that combine outstanding performance with

high reliability, availability, flexibility, and manageability.

Supported configurations include a controller enclosure with or without attached

drive enclosures. A controller enclosure can contain two controllers that interact and

provide failover capability for the data path. The controller enclosure can use SATA

or SAS disk drive modules.

This chapter provides information about the system components, and includes the

following topics:

■ “System Management Software” on page 12

■ “Hardware Components and LEDs” on page 13

12 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

System Management Software

Embedded management software includes a web-browser interface and the

command-line interface described below.

HP StorageWorks MSA2000 Family Storage

Management Utility (SMU)

SMU is the primary interface for configuring and managing the system. A web

server resides in each controller module. SMU enables you to manage the system

from a web browser that is properly configured and that can access a controller

module through an Ethernet connection.

Information about using SMU is in its online help and in the reference guide.

Command-Line Interface (CLI)

The embedded CLI enables you to configure and manage the system using

individual commands or command scripts through an out-of-band RS-232 or

Ethernet connection.

Information about using the CLI is in the CLI reference guide.

Chapter 1 System Components 13

Hardware Components and LEDs

This section describes the main hardware components of your storage system

enclosures.

Controller Enclosure Components and LEDs

Table 1-1 describes the controller enclosure components.

Table 1-1 Controller Enclosure Components

Description Quantity

Controller (I/O) module 1 or 2

1

1 Air-management system drive blanks or I/O blanks must fill empty slots to maintain optimum airflow through the chassis.

SAS or SATA drive module 2–12 per enclosure

AC power-and-cooling module 2 per enclosure

3-Gbps, 4-lane SAS host ports (SFF-8088

standard interface)

2 per controller module

3-Gbps, 4-lane SAS expansion port (SFF8470 standard interface)

1 per controller module

Ethernet port (RJ-45) 1 per controller module

CLI port (RS-232 micro-DB9) 1 per controller module

14 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

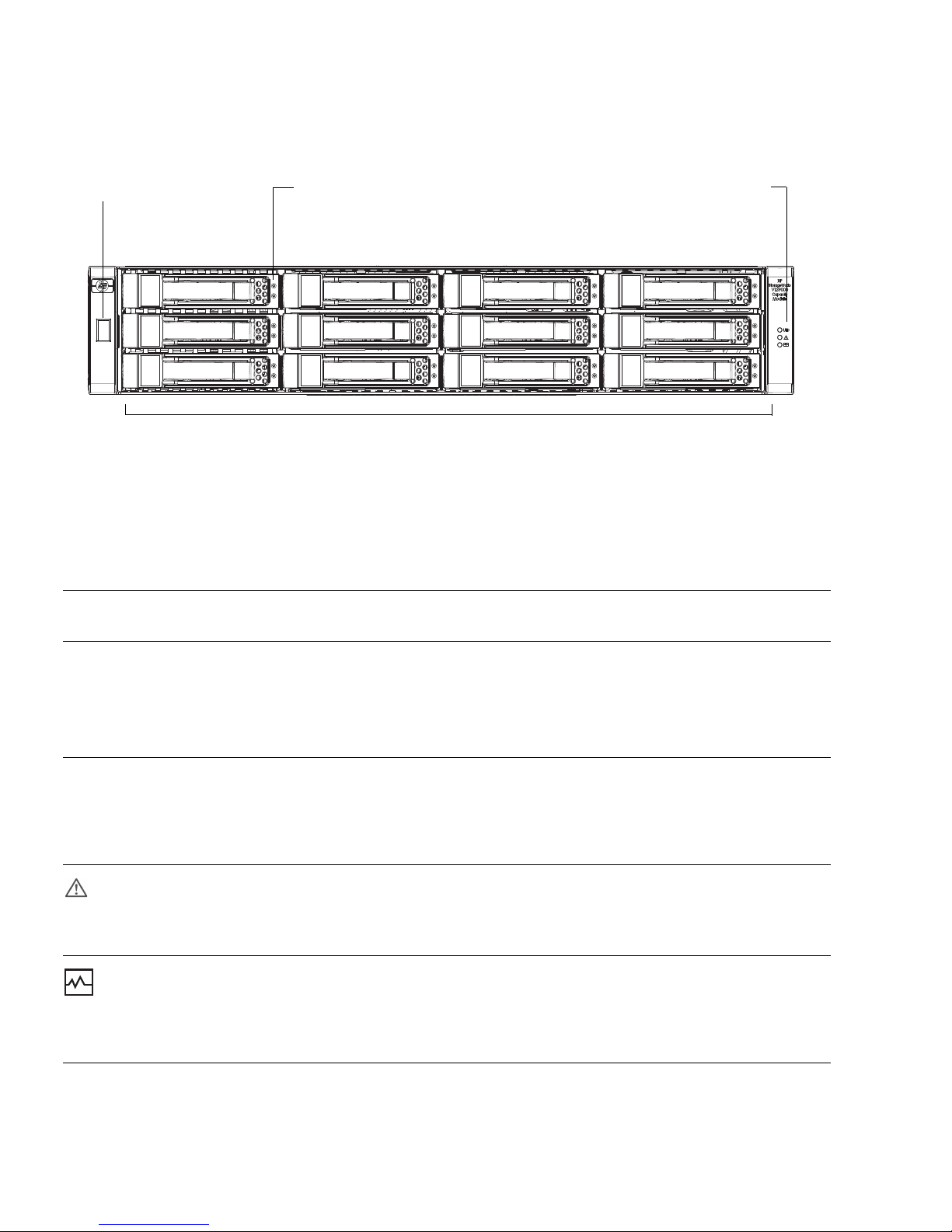

Figure 1-1 shows the LEDs on the front of a controller enclosure.

Figure 1-1 Controller Enclosure LEDs (Front View)

Table 1-2 describes the LEDs on the front of a controller. For information about

troubleshooting the system using LEDs, see “Troubleshooting” on page 53.

Table 1-2 Controller LEDs (Front)

LED Color

Operating

State Description

Enclosure ID Green On Shows the enclosure ID, which enables you to correlate an

enclosure with logical views presented by management

software. The enclosure ID for a controller enclosure is zero

(0); the enclosure ID for an attached drive enclosure is

nonzero.

UID

(Unit

Identification)

Blue On Identified.

Off Not identified.

Fault ID Amber Off No fault condition exists.

On Fault condition exists. The event has been acknowledged

but the problem needs attention. Service action is required.

Heartbeat Green On The enclosure is powered on with at least one power and

cooling module operating normally.

Off Both power and cooling modules are off; the system is

powered off.

Drive modules are numbered by column top to bottom: 0–2, 3–5, 6–8, 9–11

Drive module LEDs (top to bottom)Enclosure ID Status LEDs (top to bottom):

UID

Fault ID

Heartbeat

Fault/UID

Online/activity

Chapter 1 System Components 15

Table 1-3 describes the LEDs on the drive module.

Table 1-3 Drive Module LED Combinations (Front)

Online/Activity

(green)

Fault/UID

(amber/blue) Description

On Off The drive is online, but it is not currently active.

Blinking

irregularly

Off The drive is active and operating normally.

Off Amber, blinking

regularly (1 Hz)

Offline; the drive is not being accessed. A predictive

failure alert may have been received for this device.

Further investigation is required.

On Amber, blinking

regularly (1 Hz)

Online; no activity. A predictive failure alert may have

been received for this device. Further investigation is

required.

Blinking

irregularly

Amber, blinking

regularly (1 Hz)

The drive is active, but a predictive failure alert may

have been received for this drive. Further investigation

is required.

Off Amber, solid Offline; no activity. A critical fault condition has been

identified for this drive.

Off Blue; solid Offline. The drive has been selected by a management

application.

On or blinking Blue; solid The drive is operating normally, and it has been selected

by a management application.

Blinking regularly

(1 Hz)

Off Do not remove the drive. Removing a drive may

terminate the current operation and cause data loss.

The drive is rebuilding.

Off Off Either there is no power, the drive is offline, or the drive

is not configured.

16 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

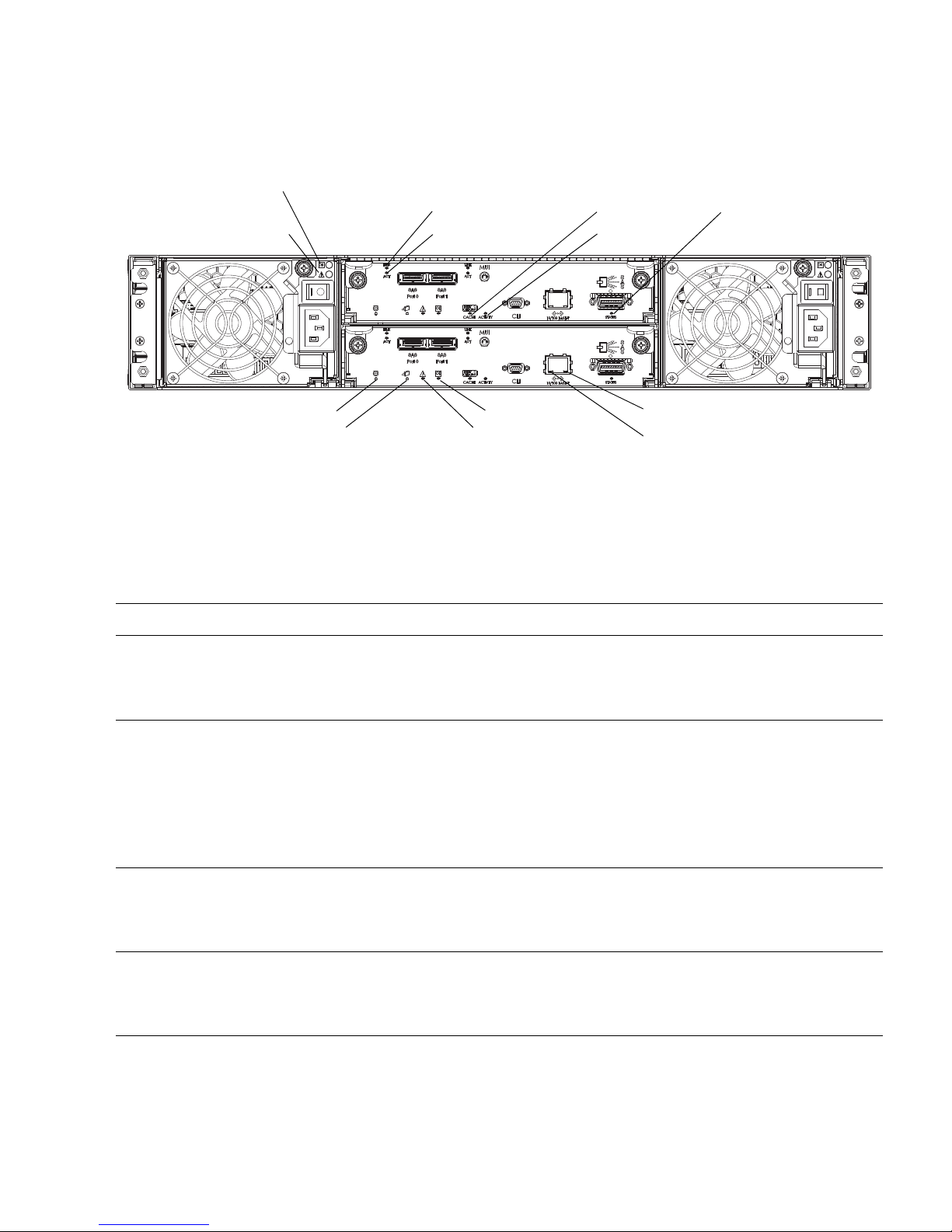

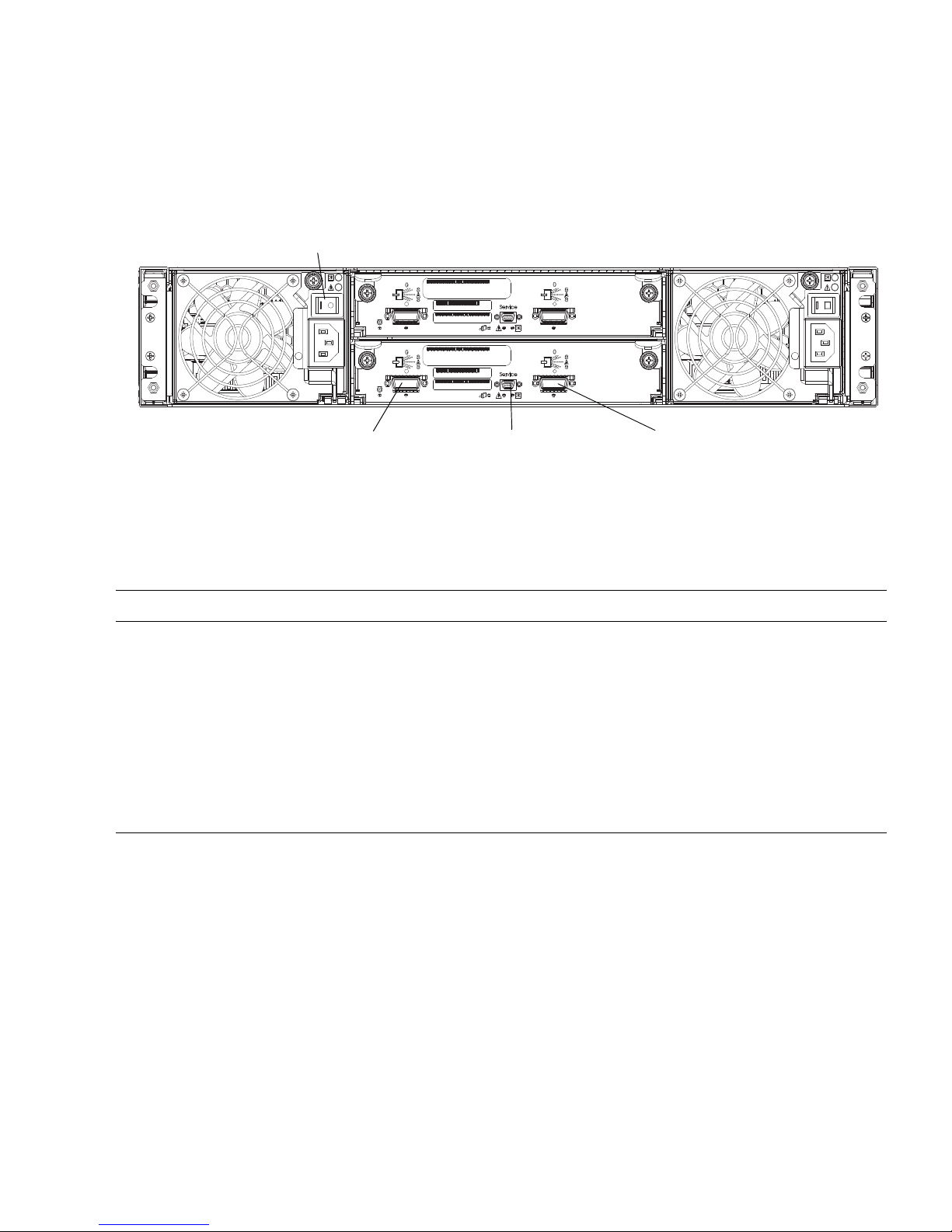

Figure 1-2 shows the ports and switches at the back of the controller enclosure.

Figure 1-2 Controller Ports and Switches (Back View)

Table 1-4 describes the ports and switches on the back of the controller.

Table 1-4 Controller Ports and Switches (Back)

Location Port/Switch Description

Power-andcooling module

Power switch On/Off toggle

Controller

module

Host ports 3-Gbps, 4-lane SAS ports (12 Gbps total) used to connect to data

hosts. Host port 0 and 1 correspond to host channel 0 and 1,

respectively.

Controller

module

Expansion

port

3-Gbps, 4-lane (12 Gbps total) table-routed SAS Out port used to

connect drive enclosures.

Controller

module

Ethernet port 10/100BASE-T Ethernet port used for TCP/IP-based out-of-band

management of the RAID controller. An internal Ethernet device

provides standard 10 Mbit/second and 100 Mbit/second full-duplex

connectivity.

Controller

module

CLI port Micro-DB9 port used to connect the controller enclosure to a local

management host using RS-232 communication for out-of-band

configuration and management.

Controller

module

MUI

(Service) port

3.5-mm jack port used by service personnel only.

Power switch

Host ports Expansion portCLI port Ethernet portMUI (Service) port

Chapter 1 System Components 17

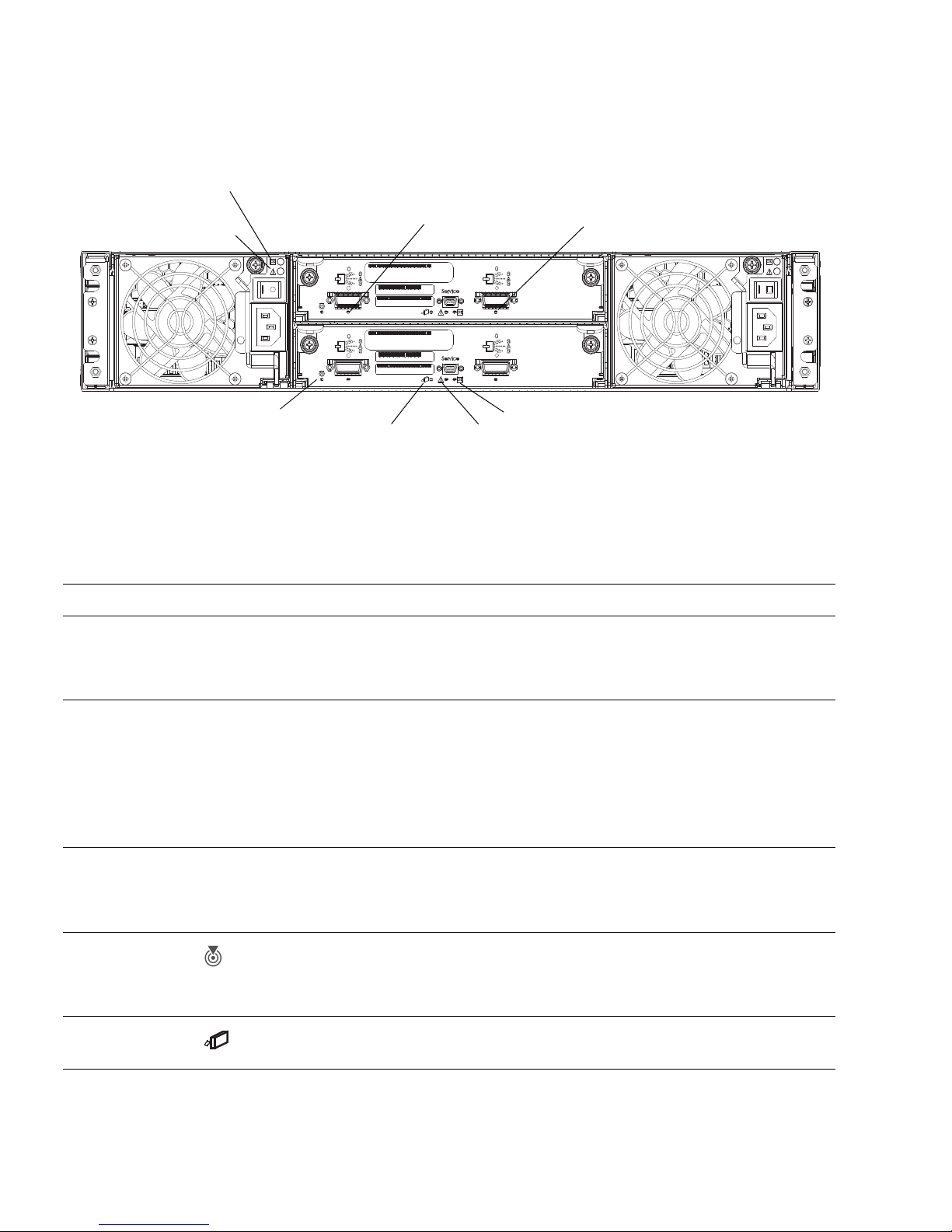

Figure 1-3 shows the LEDs at the back of the controller.

Figure 1-3 Controller LEDs (Back View)

Table 1-5 describes the LEDs on the back of the controller. For information about

troubleshooting the system using LEDs, see “Troubleshooting” on page 53.

Table 1-5 Controller LEDs (Back)

Location LED Color State Description

Power-andcooling module

AC Power Good Green Off AC power is off or input voltage is below

the minimum threshold.

On AC power is on and input voltage is normal.

Power-and

cooling module

DC Voltage/

Fan Fault/

Service Required

Amber Off DC output voltage is normal.

On DC output voltage is out of range or a fan is

operating below the minimum required

RPM.

Controller

module

Host link status Green Off The port is empty or the link is down.

On The port link is up and connected.

Controller

module

Host link activity Green Off The host port is not connected or the link is

down.

On The host link is up and active.

AC Power Good

Service Required

DC Voltage/Fan Fault/

Host link status

Host link activity

Unit Locator

OK to Remove Fault/Service Required

OK

Cache status

Host activity

Expansion port status

Ethernet activity

Ethernet link status

18 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Controller

module

Unit Locator White Off Normal operation.

Blink Physically identifies the controller module.

Controller

module

OK to

Remove

Blue Off The controller module is not prepared for

removal.

On The controller module can be removed.

Controller

module

Fault/Service

Required

Amber On A fault has been detected or a service action

is required.

Blink Indicates a hardware-controlled power up or

a cache flush or restore error.

Controller

module

OK Green Off Controller module is not OK.

On Controller module is operating normally.

Blink System is booting.

Controller

module

Cache status Green Off Cache is clean (contains no unwritten data).

On Cache is dirty (contains unwritten data) and

operation is normal.

Table 1-5 Controller LEDs (Back) (Continued)

Location LED Color State Description

Chapter 1 System Components 19

Controller

module

Cache status Green Blink A Compact Flash flush or cache self-refresh

is in progress. Indicates cache activity.

• If the LED is blinking evenly, a cache

flush is in progress. When a controller

module loses power and write cache is

dirty (contains data that has not been

written to disk), the super-capacitor pack

provides backup power to flush (copy)

data from write cache to Compact Flash

memory. When cache flush is complete,

the cache transitions into self-refresh

mode.

• If the LED is blinking slowly, a cache

flush is in progress. In self-refresh mode,

if primary power is restored before the

backup power is depleted (3

–30 minutes,

depending on various factors), the system

boots, finds data preserved in cache, and

writes it to disk. This means the system

can be operational within 30 seconds, and

before the typical host I/O timeout of 60

seconds at which point system failure

would cause host-application failure. If

primary power is restored after the backup

power is depleted, the system boots and

restores data to cache from Compact

Flash, which can take about 90 seconds.

Note: The cache flush and self-refresh

mechanism is an important data protection

feature; essentially four copies of user data

are preserved: one in each controller’s cache

and one in each controller’s Compact Flash.

Controller

module

Host activity Green Off The host ports have no I/O activity.

Blink At least one host port has I/O activity.

Controller

module

Ethernet link status Green Off The Ethernet port is not connected or the

link is down.

On The Ethernet link is up.

Table 1-5 Controller LEDs (Back) (Continued)

Location LED Color State Description

20 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Drive Enclosure Components and LEDs

A drive enclosure can be connected to a controller enclosure or to another drive

enclosure to provide additional disk storage capacity. Table 1-6 describes the drive

enclosure components.

Controller

module

Ethernet activity Green Off The Ethernet link has no I/O activity.

Blink The Ethernet link has I/O activity.

Controller

module

Expansion port

status

Green Off The port is empty or the link is down.

On The port link is up and connected.

Table 1-6 Drive Enclosure Components

Description Quantity

Expansion (I/O) module 1 or 2

1

1 Air-management system drive blanks or I/O blanks must fill empty slots to maintain optimum airflow through the chassis.

SAS or SATA drive module 2–12 per enclosure

AC power-and-cooling module 2 per enclosure

3-Gbps, 4-lane SAS In port 1 per expansion module

3-Gbps, 4-lane SAS Out port 1 per expansion module

Service port (RS-232 micro-DB9) 1 per expansion module

Table 1-5 Controller LEDs (Back) (Continued)

Location LED Color State Description

Chapter 1 System Components 21

The components and LEDs on the front of a drive enclosure are the same as on a

controller enclosure; see Figure 1-1 and Table 1-2.

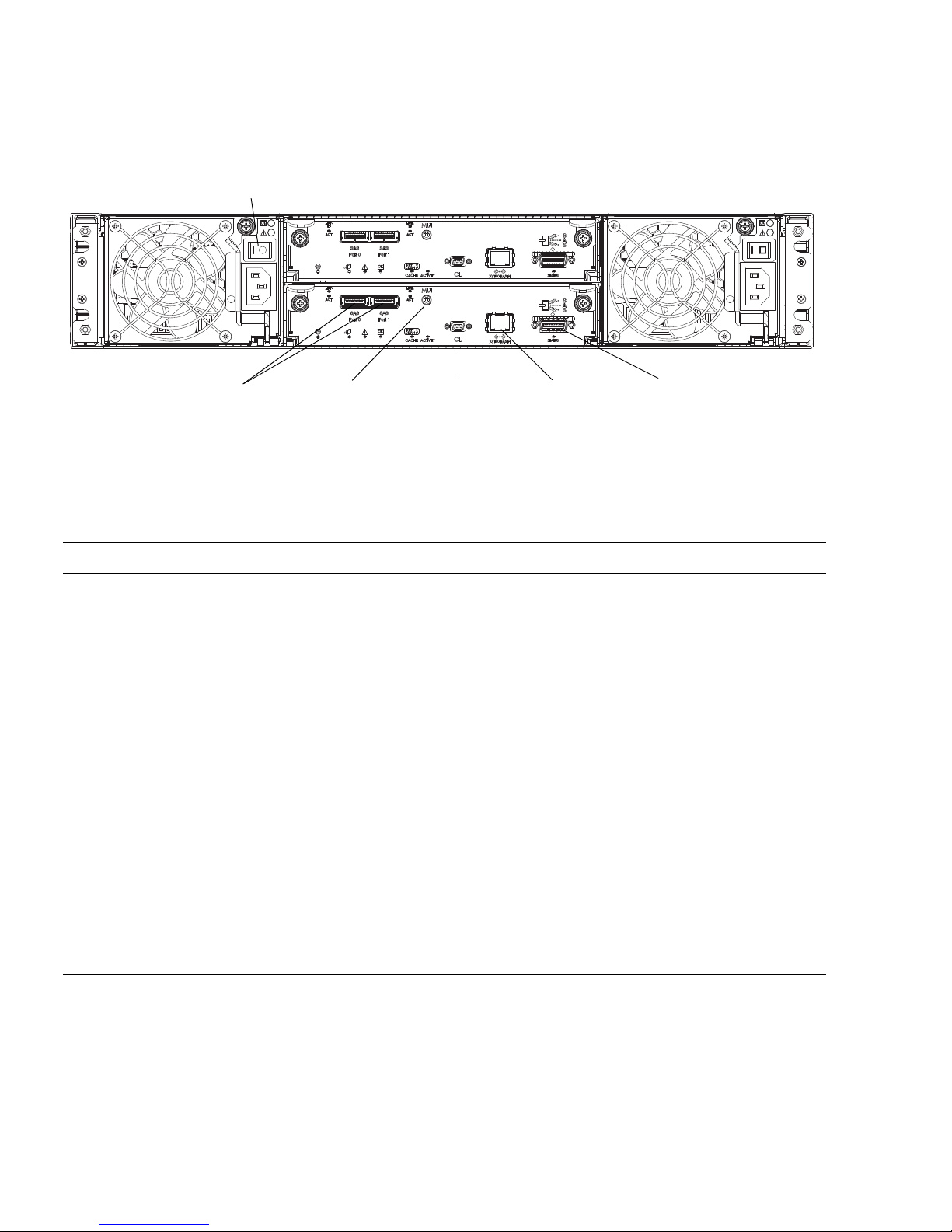

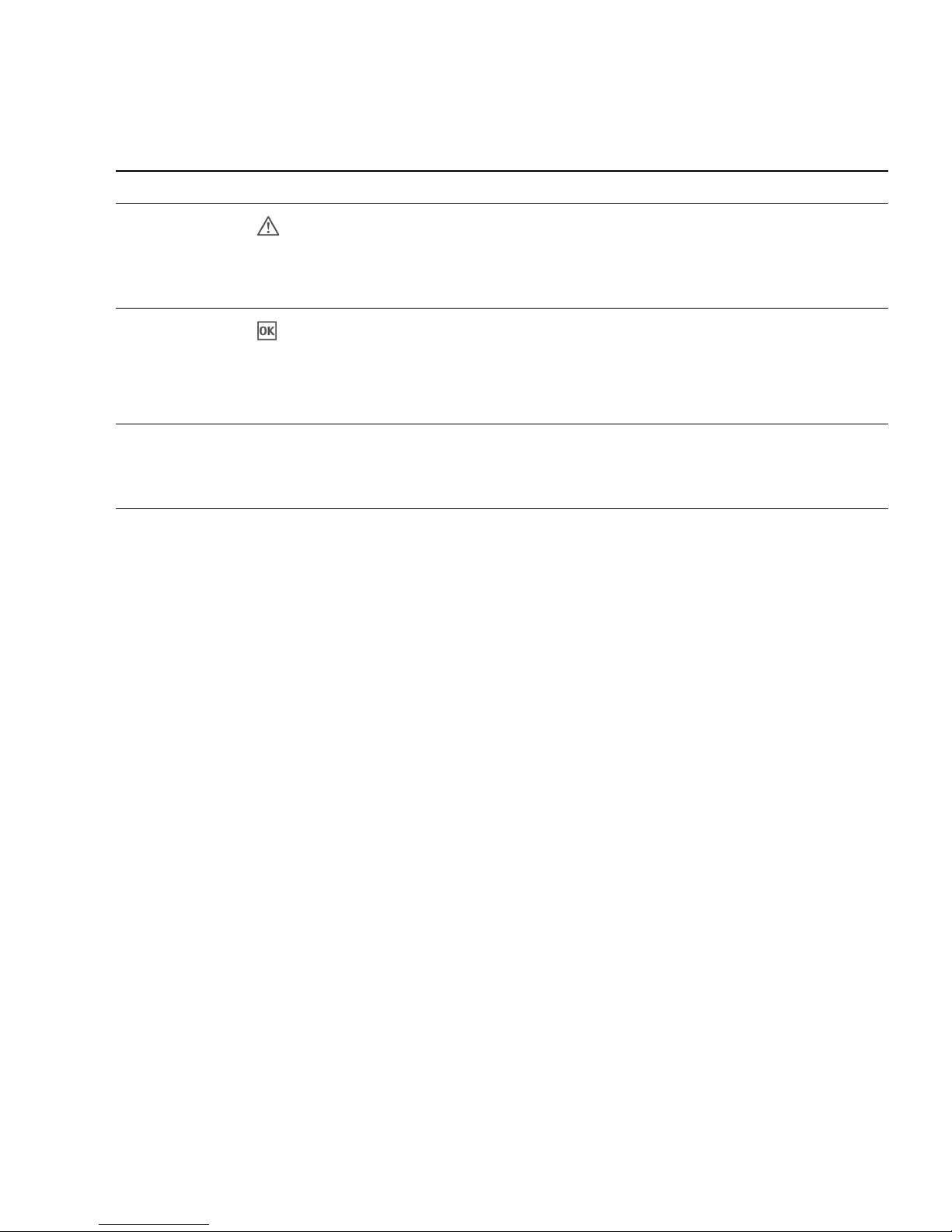

Figure 1-4 shows the ports and switches at the back of the drive enclosure.

Figure 1-4 Drive Enclosure Ports and Switches (Back View)

Table 1-7 describes the ports and switches on the back of the drive enclosure.

Table 1-7 Drive Enclosure Ports and Switches (Back)

Location Port/Switch Description

Power-andcooling module

Power switch On/Off toggle

Expansion

module

SAS In port 3-Gbps, 4-lane (12 Gbps total) subtractive ingress port used to

connect to a controller enclosure.

Expansion

module

SAS Out port 3-Gbps, 4-lane (12 Gbps total) table-routed egress port used to

connect to another drive enclosure.

Expansion

module

Service port Micro-DB9 port used by service personnel only.

Service port SAS Out port

Power switch

SAS In port

22 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Figure 1-5 shows the LEDs at the back of the drive enclosure.

Figure 1-5 Drive Enclosure LEDs (Back View)

Table 1-8 describes the LEDs on the back of the drive enclosure.

Table 1-8 Drive Enclosure LEDs (Back)

Location LED Color State Description

Power-andcooling module

AC Power Good Green Off AC power is off or input voltage is below

the minimum threshold.

On AC power is on and input voltage is normal.

Power -andcooling module

DC Voltage/

Fan Fault/

Service Required

Amber Off DC output voltage is normal.

On DC output voltage is out of range or a fan is

operating below the minimum required

RPM.

Expansion

module

SAS In port status Green Off The port is empty or the link is down.

On The port link is up and connected.

Expansion

module

Unit Locator White Off Normal operation.

Blink Physically identifies the expansion module.

Expansion

module

OK to

Remove

Not implemented.

AC Power Good

Service Required

DC Voltage/Fan Fault/

SAS In port status SAS Out port status

Unit Locator

OK to Remove

Fault/Service Required

OK

Chapter 1 System Components 23

Expansion

module

Fault/Service

Required

Amber On A fault has been detected or a service action

is required.

Blink Indicates a hardware-controlled power up or

a cache flush or restore error.

Expansion

module

OK Green Off Expansion module is not OK.

On Expansion module is operating normally.

Blink System is booting.

Expansion

module

SAS Out port

status

Green Off The port is empty or the link is down.

On The port link is up and connected.

Table 1-8 Drive Enclosure LEDs (Back) (Continued)

Location LED Color State Description

24 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

25

CHAPTER

2

Installing and Cabling Enclosures

This chapter describes how to install and cable enclosures. It contains the following

sections:

■ “Site Planning” on page 25

■ “Required Tools” on page 25

■ “Safety Precautions” on page 26

■ “Installation Checklist” on page 27

■ “Installing Enclosures Into a Rack” on page 28

■ “Attaching the Ear Caps” on page 32

■ “Connecting Controller and Drive Enclosures” on page 33

■ “Connecting AC Power” on page 36

■ “Testing the Enclosure Connections” on page 37

■ “Obtaining IP Values for Your Storage System” on page 38

■ “Correcting Enclosure IDs” on page 38

Site Planning

Make sure that the installation site adheres to all requirements and specifications as

described in “Environmental Requirements and Specifications” on page 71.

Required Tools

The installation procedures in this chapter require the following tools:

■ #2 Phillips screwdriver

■ Antistatic protection devices

26 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Safety Precautions

For your protection, observe the following safety precautions when setting up your

equipment:

■ Install the system in accordance with the local safety codes and regulations at the

facility site. Follow all cautions and instructions marked on the equipment.

■ Ensure that the voltage and frequency of your power source match the voltage

and frequency inscribed on the equipment’s electrical rating label.

■ Never push objects of any kind through openings in the equipment. Dangerous

voltages may be present. Conductive foreign objects could produce a short circuit

that could cause fire, electric shock, or damage to your equipment.

Note – Do not make mechanical or electrical modifications to the product. The

vendor is not responsible for the safety or regulatory compliance of a modified

product.

Caution – Two people are needed to lift and move the enclosure. Use care to avoid

injury. An enclosure with all drives installed can weigh 65 pounds (29.5 kilograms).

Caution – Electrostatic discharge can damage sensitive components. Be sure you

are properly grounded before touching a static-sensitive component or assembly.

Chapter 2 Installing and Cabling Enclosures 27

Installation Checklist

Table 2-1 outlines the steps required to install the enclosures and initially configure

the system. To ensure a successful installation, perform the tasks in the order they

are presented.

Table 2-1 Installation Checklist

Step Installation Task Where to Find Procedure

1. Prepare the rack for installation. “Preparing the Rack” on page 28

2. Assemble the rackmount bracket kit and install the

controller enclosure and optional drive enclosures in

the rack.

“Assembling and Installing the

Rackmount Bracket Kit” on page 28

3. Attach the ear caps. “Attaching the Ear Caps” on page 32

4. Connect the enclosures. “Connecting Controller and Drive

Enclosures” on page 33

5. Connect the power cords. “Connecting AC Power” on page 36

6. Test the enclosure connections. “Testing the Enclosure Connections” on

page 37

7. Obtain IP values. “Obtaining IP Values for Your Storage

System” on page 38

8. Correct enclosure IDs, if necessary. “Correcting Enclosure IDs” on page 38

9. Install required host software and drivers, including:

• MSA2000 Family MPIO DSM

• MSA2000 Family SES Driver

“Host System Requirements” on page 39

10. Connect the data hosts. “Connecting Hosts” on page 39

11. Connect the management host. “Connecting Remote Management

Hosts” on page 40

12. Perform initial configuration tasks:

• Set management port IP properties on the

controller enclosure

• Verify that controllers and enclosures have the

latest firmware

• Set the date and time on the controller enclosure

• Configure host ports on the controller enclosure

• Create virtual disks and map volumes

• Test the configuration

“Configuring a System for the First

Time” on page 41

28 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Installing Enclosures Into a Rack

This section describes how to install the enclosures into a standard 19-inch rack

cabinet with a 28 to 36-inch (71.12 to 91.44-cm) depth.

Tip – To help you correctly identify the screws, keep all hardware items in plastic

bags until you are ready to use them.

Preparing the Rack

Before installing enclosures in a rack cabinet, ensure the rack is installed according

to its installation instructions and that the installation complies with local safety

codes.

1. Stabilize the rack as described in its documentation.

2. If the rack has casters, make sure the casters are locked to prevent the rack from

rolling.

3. Remove or open the top front panel and the vented back panel.

Assembling and Installing the Rackmount Bracket

Kit

Note – If the rackmount bracket kit you are installing includes assembly

instructions, use them in place of the instructions in this guide.

Chapter 2 Installing and Cabling Enclosures 29

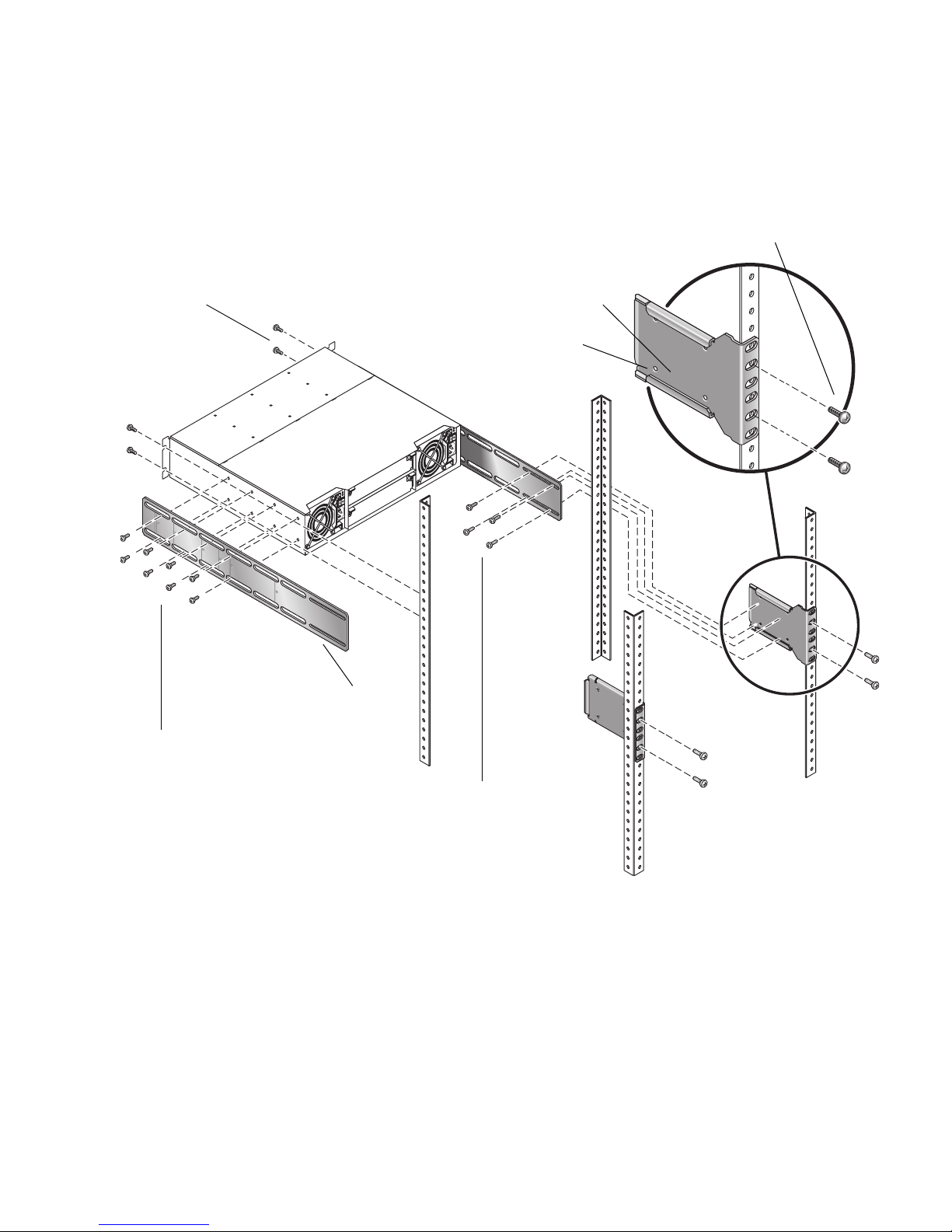

Figure 2-1 provides a visual overview of the rackmount kit assembly components

and corresponds to the steps that follow.

Figure 2-1 Overview of Standard 19-Inch EIA Rackmounting Components

#10-32 x 5/8 truss screws

Threaded PEMs (4)

Rear bracket connected to rack

#10-32 x 5/8 truss screws

Side bracket

(Step 6)

(Step 5)

(Step 8)

(Step 9)

#8-32 x 3/16 flathead screws

#8-32 x 1/4 panhead screws

30 HP StorageWorks 2012sa Modular Smart Array user guide • May 2008

Use the following procedure and refer to Figure 2-1 to install each enclosure into

the rack.

Note – If the rackmount bracket kit you are installing includes assembly

instructions, use them in place of the instructions in this guide.

When positioning an enclosure in the rack, do not block the air vents at the front or

back of the enclosure.

Caution – If you only have one person to perform the installation, remove the

power and cooling modules and drive modules from an enclosure before

installation, and use the optional nylon front support brackets. If possible, position

the enclosure on top of another device or shelf in the rack to hold the enclosure as

you attach the front brackets.

1. Considering your system configuration and weight distribution in the rack,

determine where you will install each enclosure in the rack.

2. Confirm that you have cables of adequate length to connect to hosts and to power

outlets.

3. (Square-cut European-style racks only) Insert the cage nuts in the corresponding

holes on the front and rear of the rack.

4. (Optional-one person installation) Screw the front support nylon brackets into

position on the rack face using #10-32 x 5/8 screws (two per bracket).

These brackets enable one person to easily position and support the front of the

enclosure in the rack during installation.

5. Attach the side brackets to each side of the enclosure using #8-32 x 3/16 flathead

screws (four to eight on each side). The right and left side brackets are identical.

Note – To allow adjustment of the brackets, do not tighten the screws completely

until the enclosure is mounted in the rack.

a. Use the alignment marks (Figure 2-2) stamped into the side brackets to position

the brackets and screws. The alignment marks show depth in inches.

Determine the depth you require and align the rear-most alignment mark on the

side bracket with the rear-most threaded holes on the enclosure. Make sure that

the alignment mark corresponding to the depth you want lines up with both the

top and bottom holes.

Loading...

Loading...