Page 1

SL500 (M852x) Tape

Library Installation an d

User’s Guide

Abstract

This manual describes how to install and use an M852x tape library on HP NonStop™

servers.

Product Version

N.A.

Supported Release Version Updates (RVUs)

This publication supports G06.31 and all subsequent G-series RVUs and H06.11 and

all subsequent H-series RVUs until otherwise indicated by its replacement publication.

Part Number Published

541531 -006 June 2007

Page 2

Document History

Part Number Product Version Published

541531-001 N.A. September 2005

541531- 002 N.A. Novembe r 2005

541531- 003 N.A. February 2006

541531- 004 N.A. February 2006

541531- 005 N.A. June 2006

541531- 006 N.A June 2007

Page 3

SL500 (M852x) Tape Library

Installation and User’s Guide

Index Figures Tables

What’s New in This Manual v

Manual Information v

New and Changed Information v

About This Manual vii

Notation Conventions vii

1. Overview of the T ape Library

Views and Locations 1-2

Physical Configurations 1-4

Capacities 1-9

Robotics Unit 1-11

Electronics 1-14

RLC Card 1-14

Interface Cards 1-14

Fans 1-14

Power System 1-15

Cartridge Access Port 1-15

Supported Tape Drives

LTO Ultrium 1-16

Audit of Tape Library

Safety Features

Cards and Power Supply

Robotics

Front Door

Interfaces

1-18

1-17

1-17

1- 17

1- 16

1- 17

2. Controls and Indicators

1- 17

Power Switch 2-1

Keypad 2-1

3. Library Operation

Automated Mode 3-1

Hewlett-Packard Company—541531-006

i

Page 4

Contents

Opening the Front Door (With Power) 3-1

Securing the Front Door (With Power) 3-1

Entering a Cartridge Through the CAP 3-1

Powering On the Tape Library 3-3

Powering Off the Tape Library 3-3

Manual Mode 3-4

Opening the Front Door (Without Power) 3-4

Securing the Front Door (Without Power) 3-5

Locate and Remove Cartridge 3-6

Insert Cartridges Into Slots 3-6

Inserting a Cartridge Into a Tape Drive 3-8

Removing a Cartridge From a Tape Drive 3-9

Removing a Cartridge From the Gripper Assembly 3-10

Replacing a Cleaning Cartridge 3-11

4. Cartridge Information

4. Cartridge Information

Handle Cartridges 4-1

Inspect Cartridges 4-1

Maintain Cartridges 4-2

Ultrium Cartridges 4-3

Apply Cartridge Labels 4-3

Valid Labels 4-3

Setting the Write-Protect Switch 4-6

5. Configuring the M8520 Tape Library for the NonStop S-Series

Server

Supported Connections 5-1

Adding the Control Path and the Data Path

ServerNet/DA

PMF CRU

5-1

5-3

5-1

6. Configuring the M8521 Tape Library for the Integrity NonStop

NS-Series Server

Supported Connection 6-1

Adding the Control Path and Data Path 6-1

7. Configuring the M8521 Tape Library for the NonStop S-Series

Server

Configuration Overview 7-1

Adding the Control Path and Data Path 7-3

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

ii

Page 5

Contents

A. Specifications

Tape Library Components Weights A-3

Tape Library Environment A-3

Power A-4

Safety and Compliance

Figures

Figure 1-1. Front View of Tape Library Components 1-2

Figure 1-2. Back View of Tape Library Components 1-3

Figure 1-3. Base Module Slots 1-5

Figure 1-4. Slots Locations for Firmware Slot Mapping 1-6

Figure 1-5. Slots Locations for SCSI Element Numbering Mapping 1-7

Figure 1-6. Slot Capacity for Back Wall of Cartridge Expansion Module 1-8

Figure 1-7. Robotics Components 1-12

A. Specifications

Figure 1-8. Hand Assembly 1-13

Figure 1-9. Supported Tape Drives 1-16

Figure 1-10. Tape Library Interfaces Locations 1-18

Figure 2-1. Buttons and Indicators 2-2

Figure 3-1. Sliding a Magazine Into a CAP 3-2

Figure 3-2. Lever Not in Parked Position 3-4

Figure 3-3. Door Locking Lever Extended 3-5

Figure 3-4. Moving Robotics Park Lever 3-6

Figure 3-5. Inserting Cartridges Into Slots 3-7

Figure 3-6. Inserting Cartridge Into Tape Drive 3-8

Figure 3-7.

Figure 3-8.

Figure 4-1. Ultrium Cartridge Components 4-3

Figure 4-2. LTO Cartridge Labels 4-4

Figure 4-3.

Figure 4-4.

Figure 7-1.

Figure A-1.

Location of Unload Button 3-9

Manual Release Screw 3-11

Ultrium Cartridge Label 4-5

Write-Protect Switch 4-6

Configuration Example 7-2

Library and Rack Dimensions A-1

Figure A-2. Tape Library and Rack Dimensions A-2

Figure A-3. Power Cabling A-6

Tables

Table 1-1. Cartridge Slot and Tape Drive Capacities 1-10

Table 1-2. LTO Generation 3 Specifications 1-16

Table 2-1. Keypad Buttons and Indicators 2-3

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

iii

Page 6

Contents

Table 4-1. LTO Cartridge Codes 4-4

Table 4-2. LTO Gen 1, Gen 2, and Gen 3 Cartridge Specifications 4-7

Table A-1. Library Component Weights A-3

Table A-2. Library Environment Specifications A-3

Table A-3. Power Cord and Receptacles A-4

Table A-4. Non-Country-Specific Cords A-4

Table A-5. Power for Library Without Tape Drives A-7

Table A-6. Power for Base Unit and Two LTO Tape Drives A-7

Table A-7. Power for Drive Expansion Module and Four LTO Tape Drives A-7

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

iv

Page 7

What’s New in This Manual

Manual Information

SL500 (M852x) Tape Library Installation and User’s Guide

Abstract

This manual describes how to install and use an M852x tape library on HP NonStop™

servers.

Product Version

N.A.

Supported Release Version Updates (RVUs)

This publication supports G06.31 and all subsequent G-series RVUs and H06.11 and

all subsequent H-series RVUs until otherwise indicated by its replacement publication.

Part Number Published

541531- 006 Jun e 2007

Document History

Part Number Product Version Published

541531-001 N.A. September 2005

541531- 002 N.A. Novembe r 2005

541531- 003 N.A. February 2006

541531- 004 N.A. February 2006

541531- 005 N.A. June 2006

541531- 006 N.A June 2007

New and Changed Information

The N1522A LTO gener ati on 2 SCSI tape driv e has bee n replace d by the N1523A LTO

generation 3 SCSI tape drive.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

v

Page 8

What’s New in This Manual

New and Changed Information

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

vi

Page 9

About This Manual

Notation Conventions

Hypertext Links

Blue underline is used to indicate a hypertext link within text. By clicking a passage of

text with a blue underline, you are taken to the location described. For example:

This requirement is described under Backup DAM Volumes and Physical Disk

Drives on page 3-2.

computer type. Computer type letters within text indicate C and Open System Services

(OSS) keywords and reserved words. Type these items exactly as shown. Items not

enclosed in brackets are required. For example:

myfile.c

italic computer type. Italic computer type letters within text indicate C and Open

System Services (OSS) variable items that you supply. Items not enclosed in brackets

are required. For example:

pathname

Change Bar Notation

Change bars are used to indicate substantive differences between this manual and its

preceding version. Change bars are vertical rules placed in the right margin of

changed portions of text, figures, tables, examples, and so on. Change bars highlight

new or revised information. For example:

The message types specified in the REPORT clause are different in the COBOL

environment and the Common Run-Time Environment (CRE).

The CRE has many new message types and some new message type codes for

old message types. In the CRE, the message type SYSTEM includes all

messages except LOGICAL-CLOSE and LOGICAL-OPEN.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

vii

Page 10

About This Manual

Change Bar Notation

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

viii

Page 11

1 Overvi ew of t he Tape Library

This section includes:

Views and Locations

Physical Configurations 1-4

Robotics Unit 1-11

Electronics 1-14

Fans 1-14

Power System 1-15

Cartridge Access Port 1-15

Supported Tape Drives 1-16

Audit of Tape Library 1-17

Safety Features 1-17

Interfaces 1-18

This section contains an overview of the major hardware components of the tape

library.

The tape library provides a highly adaptable storage platform made to specifically

consolidate, protect, and retain customer information. The tape library protects

customer’s investments by providing a cost-effective entry point and makes it easy to

grow the unit with expansion modules.

1-4

The tape library is a self-contained, fully automated tape cartridge storage system. It is

scalable and mounts into a 19-inch (483-millimeter) rack.

For each tape library:

The base module contains the robotics unit and the base unit:

•

The robotics unit has the robotic components and the keypad.

°

The base unit has 50 cartridge slots (including the reserved slots), one or two

°

tape drives, and a 5-slot cartridge access port (CAP).

Drive expansion modules and cartridge expansion modules can be added to a

•

standard rack to accommodate various slot and tape drive configurations.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-1

Page 12

Overview of the Tape Library

Views and Locations

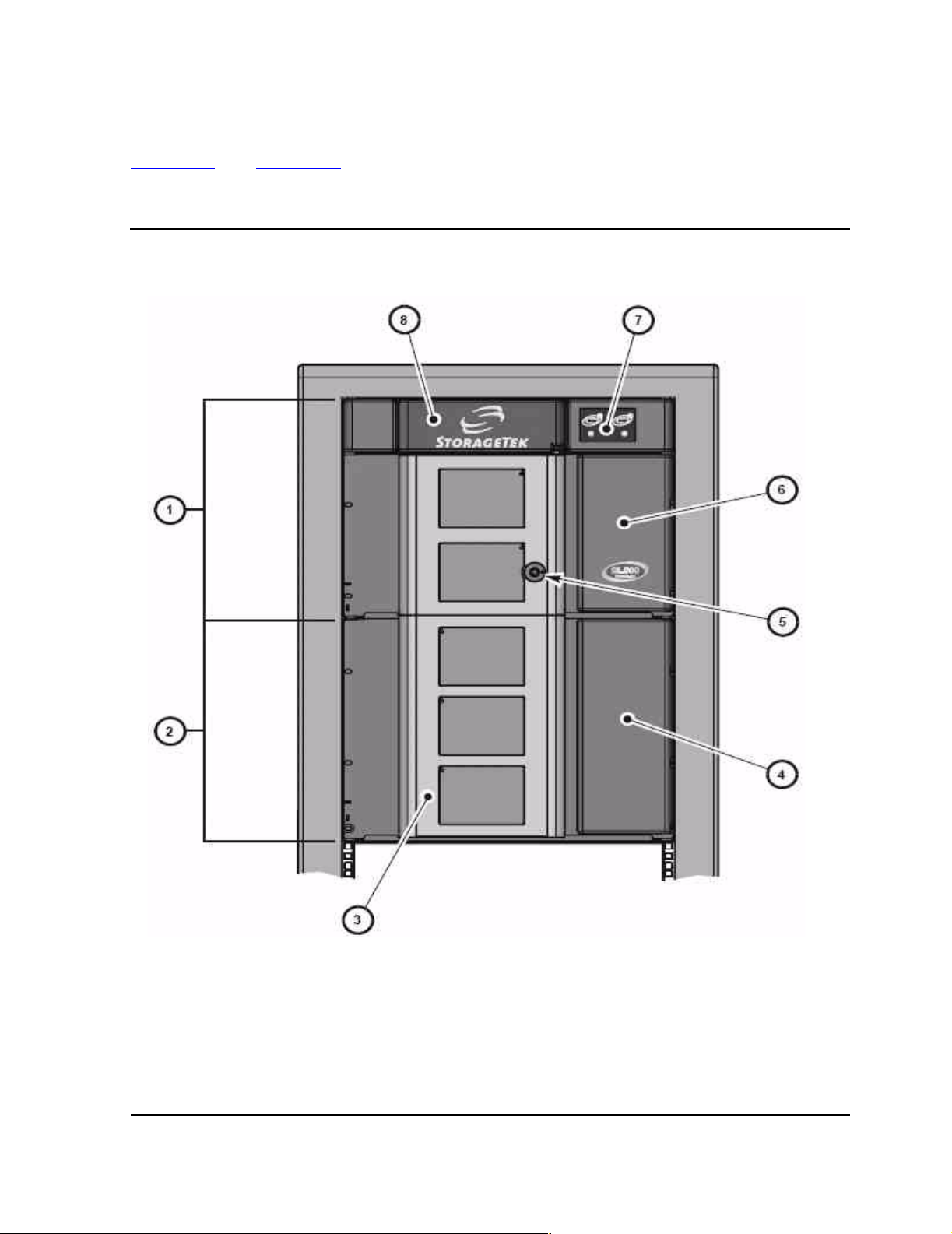

Figure 1-1 and Figure 1-2 show the tape library views and the locations of its

components.

Figur e 1-1. Front View of Tape Library Components

Views and Locations

1. Base module

2. Drive ex pansion modu le

3. Library door

4. Drive ex pansion modu le cartridge a ccess port (CAP)

5. Library door lock

6. Base unit cartridge access port (CAP)

7. Keypad assembly

8. Robo tics unit

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-2

Page 13

Overview of the Tape Library

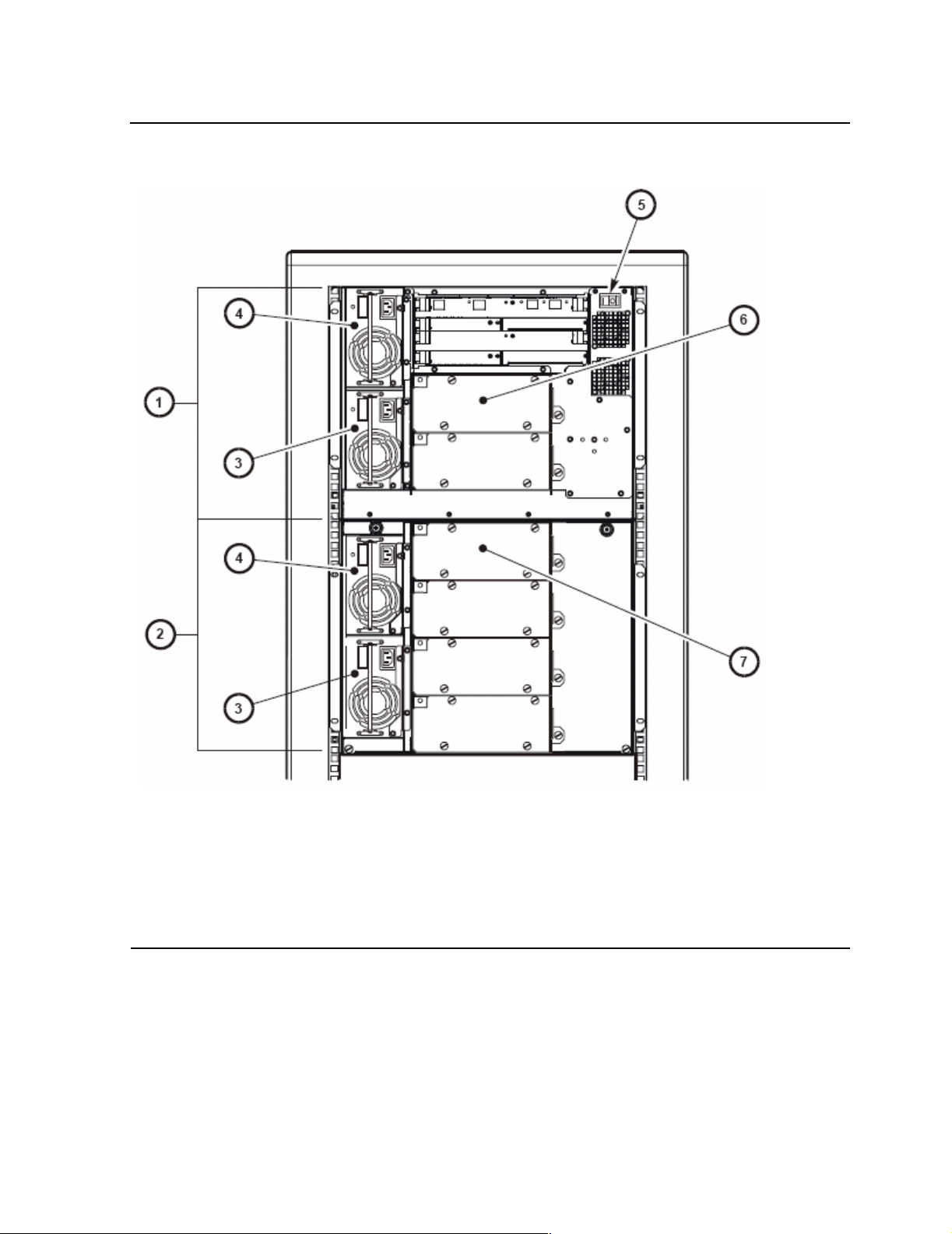

Figure 1-2. Back View of Tape Library Components

Views and Locations

1. Base module

2. Drive ex pans ion module

3. Redundant power supply

4. Standard power s upply

5. Library pow er switch

6. Tape drive 1 in b as e unit

7. Tape drive 1 in e xpa ns ion module

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-3

Page 14

Overview of the Tape Library

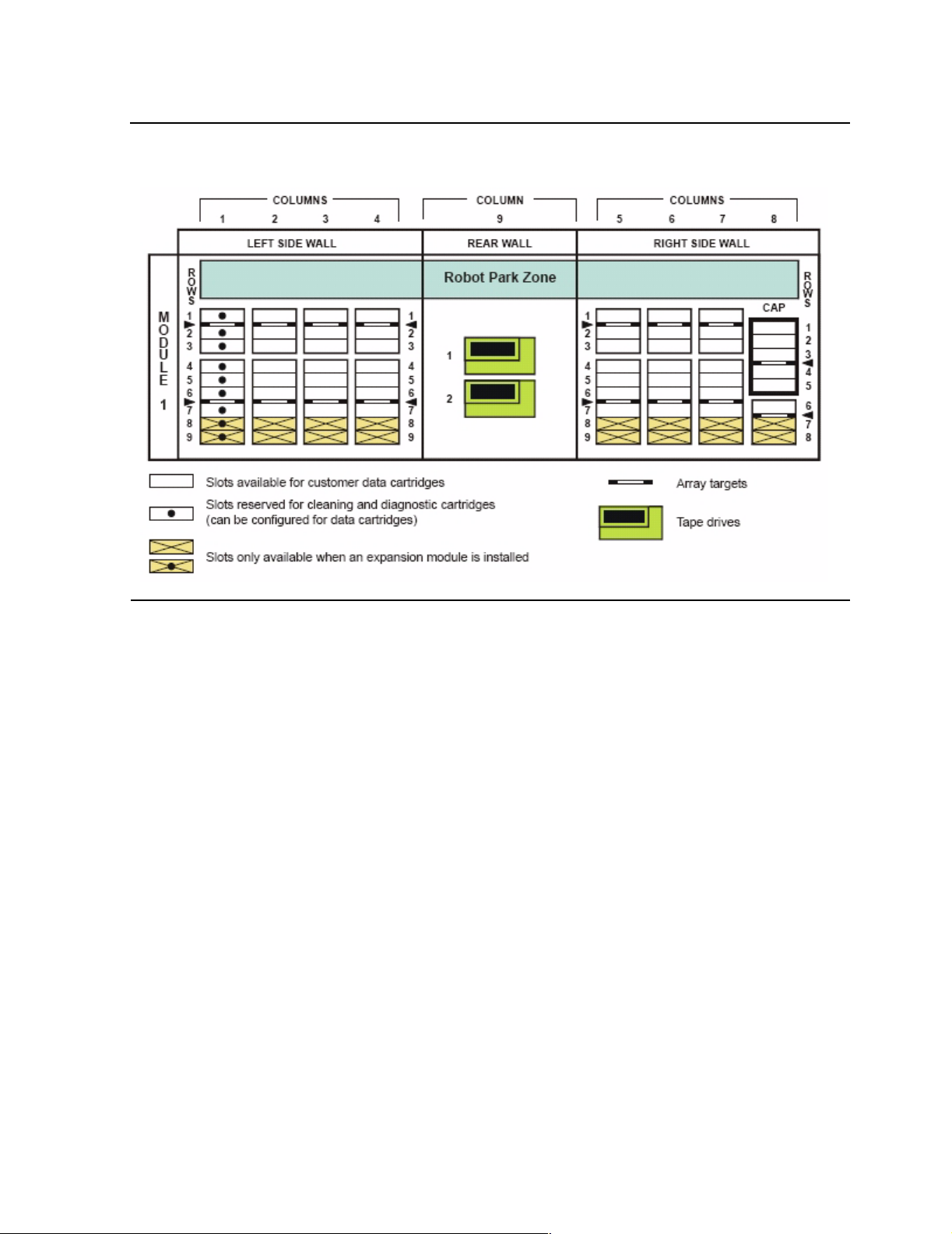

Physical Configurations

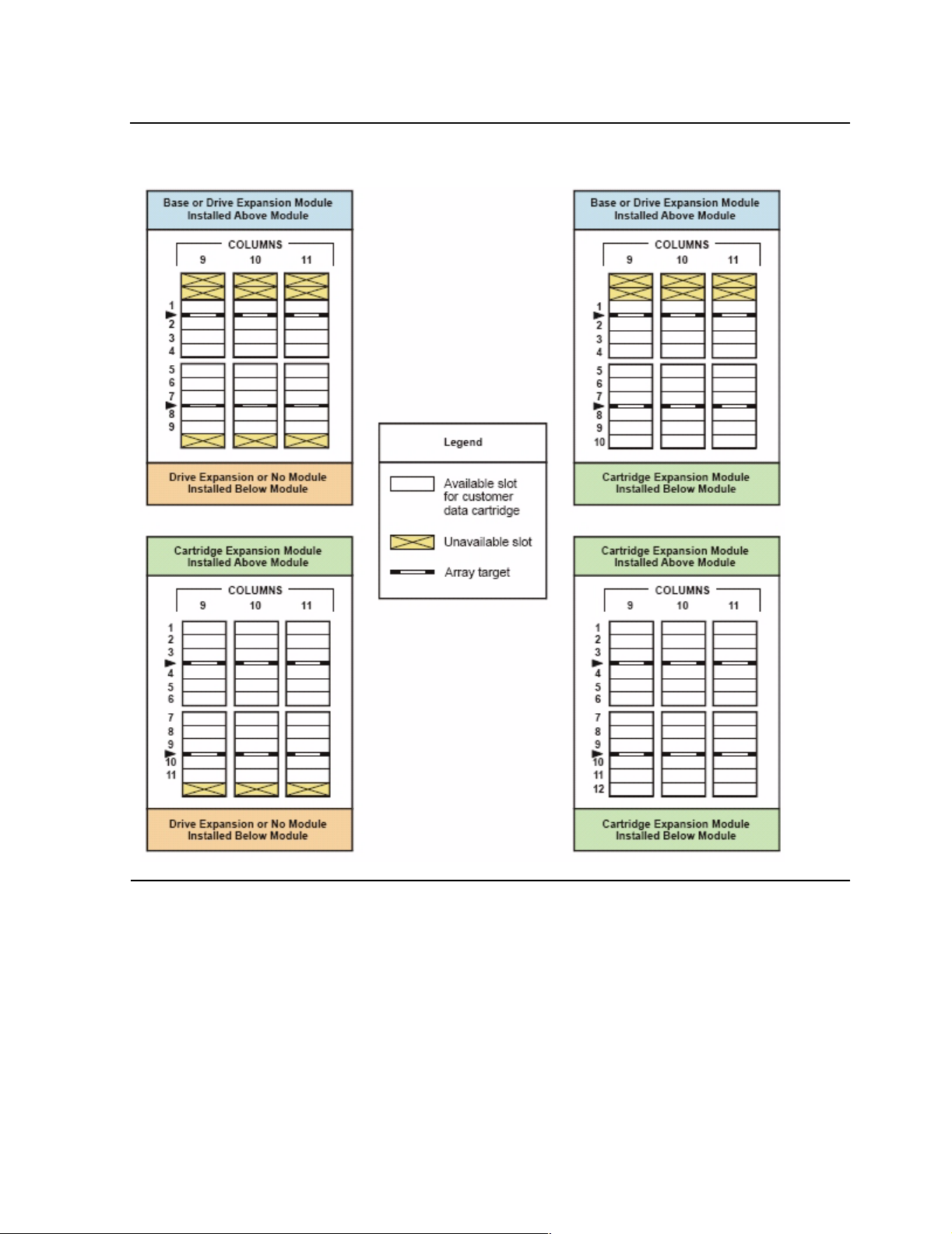

Figure 1-3 on page 1-5 shows a tape library with only a base module. Figure 1-4 on

page 1-6 shows a tape library with a base module that has nine reserved slots, one

drive expansion module, and one cartridge expansion module.

Figure 1-5 on page 1-7 shows a tape library with a base module that has two reserved

slots, one drive expansion module, and one cartridge expansion module.

Note. In Figure 1-5 on page 1-7, all s ix tap e drives are insta lled. When only s ome of the tape

drives are ins tal led, only those th at are powered-on receive SCSI address es , start ing with the

top-most tape d r ive.

The storage slot numbering begins with the first slot a fter t he reserved slots in column 1.

Figure 1-5

are config ured as storage slots, the top slot (row 1) would be 1. If the CAP in m odule 1 is

configured as storage slots, the top CAP slot (row 1) is 62 if there are two reserved slots as

shown, or 64 if no slots are re se rv ed.

Figure 1-6 on page 1-8 shows the slot capacity of a cartridge expansion module

according to which type of module is installed above and below it.

on pag e1-7 shows t w o r es erved s lots, but ther e c ould be mo re. If t he reser v ed slot s

Physical Configurations

The numbering scheme uses the tape library, module, row and column scheme. Four

integers are used to represent the cartridge and tape drive slots, as viewed from the

front of the tape library.

1. Library number (always 0)

2. Library module number 1 (top of rack) through 5 (bottom of rack)

3. Row number 1 through 9 (base module) or 1 through 12 (expansion module)

4. Column number 1 through 9 for base module and drive expansion module, 1

through 11 for cartridge expansion module

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-4

Page 15

Overview of the Tape Library

Figure 1-3. Base Module Slots

Physical Configurations

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-5

Page 16

Overview of the Tape Library

Figure 1-4. Slots L ocations for Firmware Slot Mapping

Physical Configurations

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-6

Page 17

Overview of the Tape Library

Figure 1-5. Slots Locations for SCSI Element Numbering Mapping

Physical Configurations

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-7

Page 18

Overview of the Tape Library

Figure 1-6. Slot Capacity for Back Wall of Cartridge Expansion Module

Physical Configurations

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-8

Page 19

Overview of the Tape Library

Capacities

Table 1-1 on page 1-10 shows the number of cartridge and tape drive slots available

depending on the type and number of modules installed.

Slot counts are based on the following assumptions:

Capacity includes reserved slots for diagnostic and cleaning cartridges.

•

Reserved slots (for cleaning and dia gnostic cart ridges) are located only in the base

•

module on the left side as you open the front door. These slots can be configured

for data cartridges if desired.

The base module has a 5-slot CAP; the drive expansion module (DEM) and

•

cartridge expan sion modu l e (CEM) each have tw o 5-slot CA Ps. These slot s can be

configured for data cartridges if desired.

When DEMs and CEMs are installed in the same library, the DEMs are above all of

•

the CEMs.

When you add an expansion module below an existing module, you increase the

capacity of the module directly above it by:

Capacities

Base module: +16 slots

•

CEM (when another CEM is below it): +10 slots

•

CEM (when a DEM is below it): +7 slots

•

DEM: +7 slots

•

When a CEM is installed below a base module or DEM, the top two rows on columns

9, 10, and 11 of the CEM are not accessible (-6 slots because of the tape drives).

The lowest module in the rack requires installation of the floor. The floor limits the

distance the robot can travel, which makes the bottom row(s) in the lowest module

inaccessible:

Base module: -16 slots

•

DEM: -7 slots

•

CEM (below another CEM): -16 slots (-10 slots on the lowest CEM, -6 slots on the

•

CEM above it)

CEM (below base module or DEM): -16 slots

•

Cartridge access ports:

Base module: 5 slots (one magazine)

•

Each DEM: 10 slots (two magazines)

•

Each CEM 10 slots (two magazines)

•

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-9

Page 20

Overview of the Tape Library

Table 1-1. Cartridge Slot and Tape Drive Capacities

Capacities

Modules Maximum Number of Tape Drives CAP

Slots

Total

Numb er of

Slots

2 6 10 14 18

Base Module 30 5 35

20 cartridge upgrade key 50 5 55

Adding one expansion module

Base module plus 1

100 15 115

limited DEM

Base module plus 1

143 15 158

DEM

Base module plus 1

170 15 185

CEM

Adding two expansion modules

Base module plus 2

227 25 252

limited D E Ms

Base module plus 1

254 25 279

DEM, 1 CEM

Base module plus 2

290 25 315

CEMs

Adding three expansion modules

Base module plus 3

DEMs

Base module plus 2

DEMs, 1 CEM

Base module plus 1

DEM, 2 CEMs

Base module plus 3

410 35 445

CEMs

Adding four expansion modules

Base module plus 4

DEMs

Base module plus 3

DEMs, 1 CEM

Base module plus 2

DEMs, 2 CEMs

Base module plus 1

DEM, 3 CEMs

Base module plus 4

530 45 575

CEMs

311 35 346

338 35 373

374 35 409

395 45 440

422 45 467

458 45 503

494 45 539

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-10

Page 21

Overview of the Tape Library

Robotics Unit

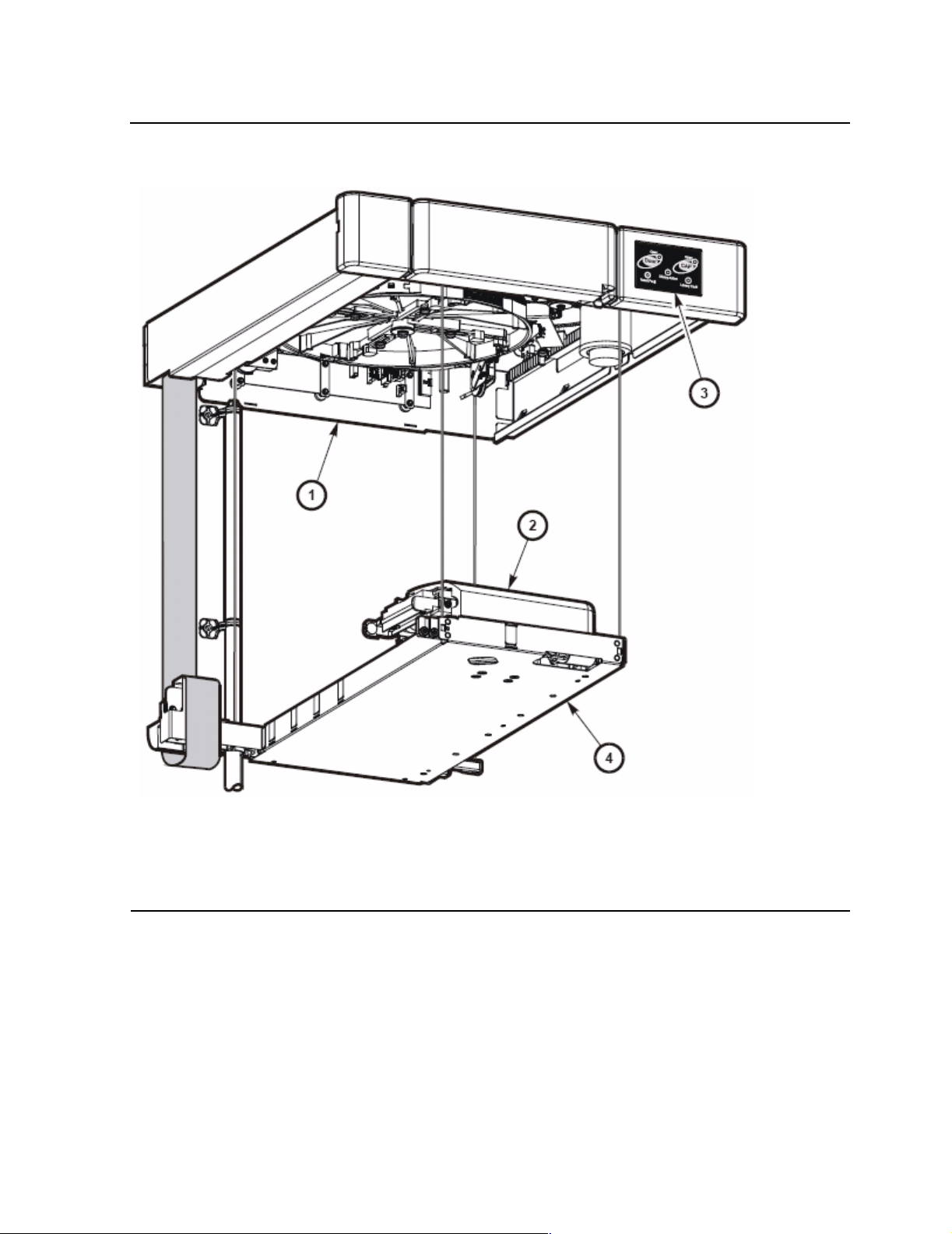

The robotics unit provides movement of cartridges among the storage slots, tape

drives, and cartridge access ports (CAPs). The three main robotic components are:

Z drive assembly

•

X table assembly

•

Hand assembly

•

The Z drive assembly uses the Z drive pulley to move the X table up and down to the

desired slot or tape drive. At the same time, the X carriage assembly (containing the

hand) moves the hand forward and backward; the wrist motor rotates the hand right

and left.

The hand assembly contains the wrist hub assembly, gripper assembly, and bar-code

scanner. The gripper assembly has fingers that grasp the sides of the cartridge. If the

library loses power while a cartridge is between the fingers, the manual release screw

is used to remove the cartridge. A worm gear can be used to rotate the hand to the

correct position to access the manual release screw.

Robotics Unit

For safety purposes, the robotics will be parked in the robotics unit when the front door

is opened or when the Open Door button is pressed on the keypad. Parked means

that the robotics components are fully retracted into the robotics unit at the top of the

library. To verify the robot is parked, look at the lever in the cutout beneath the facade

and to the bottom left of the keypad, the lever should be to the left.

The robotics unit is accessible from the front of the rack.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-11

Page 22

Overview of the Tape Library

Figure 1-7. Robotics Components

Robotics Unit

1. Z dri v e as s embly

2. Hand ass embly

3. Keypad assembly

4. X table assembly

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-12

Page 23

Overview of the Tape Library

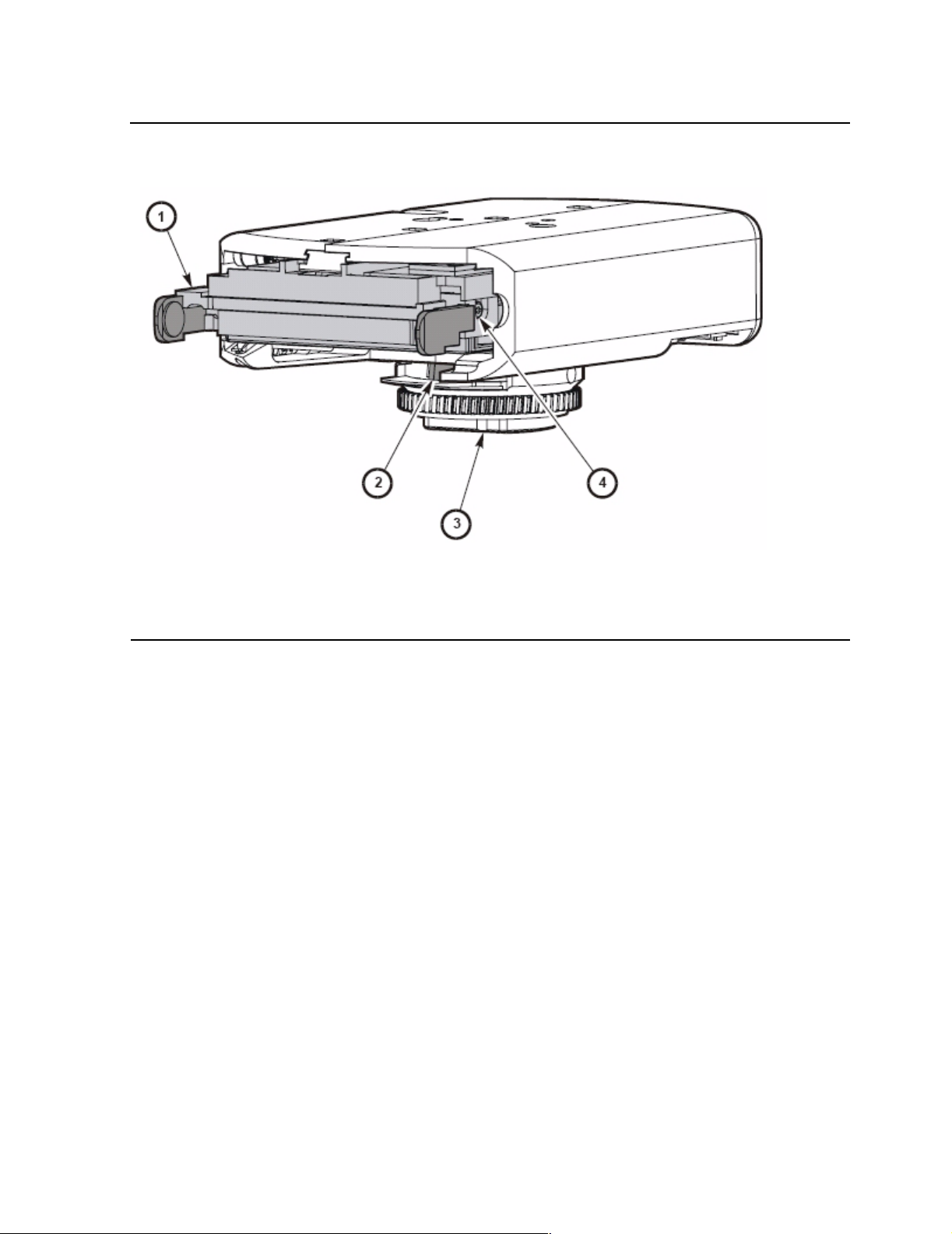

Figure 1-8. Hand Assembly

Robotics Unit

1. Gripper

2. Bar-code scanner

3. Wrist hub

4. Finger release screw

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-13

Page 24

Overview of the Tape Library

Electronics

The electronics consists of the control path and robotic cards in the base unit.

Communications include:

Command line interface (CLI) over an RS232 port

•

Public Ethernet port (The private port is for future use)

•

Point to point library/tape drive RS232 interface

•

Control path card for LVD SCSI or SCSI over Fibre Channel

•

Sensors include:

Card temperature

•

Fan operational

•

Power safe

•

Electronics

Tape drive present

•

Tape drive fault LED

•

RLC Card

The RLC card is the processor card. It contains all the necessary hardware to maintain

the robotics, interfaces, servo and vision control, and the door/CAP sensor status.

Interface Cards

The MPW card is the LVD SCSI interface card. The MPU2 card is the Fibre Channel

interface card.

Fans

The fans provide cooling for the library el ect ronics. Th e ta pe driv es and power supplie s

contain their own fans.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-14

Page 25

Overview of the Tape Library

Power System

The base unit has one standard power supply. A second supply can be ordered and

installed to provide redundant power to the module components. Each supply should

be plugged into a separate circuit and powered on to provide redundant power. If one

supply fails, the second supply automatically provides power.

A single power switch on the back of the tape library is used to power on or power off

all the power supplies in the rack:

The ON position is 1.

•

The OFF position is 0.

•

Cartridge Access Port

The cartridge access port (CAP) can be used to add cartridges to the tape library, or

remove cartridges from the tape library without interrupting normal robotic operation.

The CAP in the base module has one five slot magazine; the CAP in the drive

expansion module has two five slot magazines.

Power System

Although the CAPs are not physically connect ed, they are logical ly conne cted. If any of

the CAPs are open, the CAP LED on the keypad will be on, alerting the operator to

take action to close the CAP. If all of the CAPs are closed, the CAP LED will be off.

You can use the keypad on the robotics unit to issue a command for the robot to

unlock the CAP.

The CAP has two settings, ALLOW and PREVENT. ALLOW is the default setting after

you power on or reset the tape library. The following table shows how these settings

affect the CAPs.

CAP Condition ALLOW PREVENT

All of the CAPs are

closed.

Any of the CAPs

are open.

When you press the CAP

button all of the CAPs in the

rack will open.

The librar y firmware turns on

the CAP LED.

When you press the CAP

button, any CAP that is not

open in the rack will open.

When you press the CAP

button, the action is ignored

and all the CAPs remain

closed.

When you press the CAP

button, the action is ignored

and all of the CAPs remain

in their individual current

state of open or closed.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-15

Page 26

Overview of the Tape Library

Supported Tape Drives

The tape library can accommodate from 1 to 14 tape drives. The LTO generation 3

tape drives supports Ultrium 3 media, Ultrium 2 media, and Ultrium 1 media (read

only).

Figure 1-9. Supported Tape Drives

Product Number Description

N1523A LTO Gen er ation 3 tape dri v e w ith SCSI I nterfac e for NonStop S-series

servers

M8504 LTO Gene ration 3 tape drive with a Fibre C hannel interfac e f or

Integrity NonStop NS-series servers

LTO Ultrium

Linear-Tape Open (LTO) is a set of tape data format standards created to enable data

interchange among different LTO Ultrium tape drive vendors. These LTO Ultrium

standards allow data cartridges to be shared.

Supported Tape Drives

Table 1-2. LTO Generation 3 Specifications

Specification Performance

Capacity, native (unco m pressed) 400 gigab y te s

Capacity (compressed) 800 gigabytes

Data transfer rate, native (uncompress ed) 80 mega by t es per second

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-16

Page 27

Overview of the Tape Library

Audit of Tape Library

An audit is the method by which the tape library keeps track of all cartridge locations

within the unit. An audit occurs when you:

Power on the library

•

Open and close the front door

•

Close the CAP (CAP slots only)

•

Initialization occurs when the tape library is powered on or when the front door is

opened and closed. During initialization, the RLC card applies voltage to the motors

(gripper, reach, wrist, and Z drive). The robotic components ranges of motion are

tested, the targets and labels are read for calibration purposes, and the slots are

audited for cartridge VOLIDs. This information is stored on the RLC card.

Note.

When an audit occurs, the tapes in the tape drives are not audited.

•

Audit of Tape Library

If you manually exchange a cartridge from a tape drive for one in storage, you must update

•

the tape management database or an e rror will occur.

The bar code scanner on the hand assembly reads the labels on the cartridges.

Safety Features

The following subsections describe the safety features that are incorporated into the

tape library.

Cards and Power Supply

The RLC card or SCSI (MPW) interface card, and the power supply are housed inside

protective modules to prevent you from coming into contact with hazardous voltages

and sensitive electronics.

Robotics

The software parks the robot by retracting it into the robotics unit module before the

front door can be opened to prevent the robot from being damaged.

When the front door is opened, power is removed from the robot.

Front Door

The front door must be opened with a key to ensure that the data is secure. If the door

is not fully closed, a sensor relays the condition to the software and the robot remains

disabled.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-17

Page 28

Overview of the Tape Library

Interfaces

The major tape library interfaces are:

Library control path support for LVD SCSI

•

Public 100BaseT ethernet port

•

CLI serial port for local access for service representative, manufacturing and

•

engineering (Not for customer use).

Environmental port for monitoring fans, tape drives, and power. This port is internal

•

and cannot be accessed by the customer.

Cartridge access ports and sensors for indicating a door open or closed condition.

•

Front door opened button (on keypad), key for opening door, sensor LED that

•

indicates door is closed and latched.

Figure 1-10. Tape Library Interfaces Locations

Interfaces

1. Private Ethernet port is for future use.

2. Eject OK (hot-swappable) LED, when on, indicat es th at th e R LC card can be removed.

3. Public E th ernet port is for r em ote service ac ce s s .

4. Fault LED indicates tha t th e c ontroller has det ec t ed a problem.

5. Reserved for future use.

6. Standby LED, wh en lit , indicates the RL C c ard (when two R LC c ards are installed) is in

standby mode (future feature).

7. CLI port is an RJ-45 serial port for service represen tativ es .

8. Active LE D , w hen lit, indicate s th is R LC c ard is active if two R LC cards are in s talle d. If

only one card is installed, the LED is always on (f ut ure feature) .

Each installed tape drive contains the following interfaces:

• Tape Transport Interface (TTI) receives commands form the RLC card.

Some exa m ples of signals th at are transferred over the TT I are “ready,”

“unloading,” “busy,” and “sense” information.

• The data path ca n have a single -port SCSI.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

1-18

Page 29

2 Control s and Indicators

This section includes:

Power Switch 2-1

Keypad 2-1

Power Switch

When the switch is in position 1 the tape library and tape dri ves are power ed on. When

the switch is in position 0 the tape library and tape drives are powered off.

Note. Earlier built tap e libraries had power supp lies t hat had individ ual power switc hes. Later

tape libraries have one pow er switch that co nt rols all power supplies in the rac k .

Keypad

The keypad is used to open the door, open the CAP, and notify the user if service is

required.

1. The Door Open button opens the tape library door. All doors function as one door

and can not be opened individually.

2. The CAP Open button opens all CAP doors.

3. The Library Active LED, if on, indicates the tape library is functioning properly. If

the Library Active LED is flashing, call your service representative.

4. If the Service Robot LED is on and flashing, call your service representative.

5. If the Service Required LED is on and flashing, call your service representative.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

2-1

Page 30

Controls and Indicators

Figure 2-1. Buttons and Indicators

Keypad

1. Door Open button 5. Service Required LED

2. Door Open LED 6. Library Active LED

3. CAP Open button 7. Service Robot LED

4. CAP Op en LED

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

2-2

Page 31

Controls and Indicators

Table 2-1. Keypad Buttons and Indicators

Buttons/Indicators Description

Service Robot Indicator

Libr ary Active Indicator

Service Required Indicator

LED is lit w hen the robot is not functioning. Replace

the robotics unit.

LED is normally solid gr een.

•

LED turns off w hen the tape libr ary ex periences

•

a failure. If it ne v er t urns on, an initialization or

power fai lure has occurred.

LED is normally solid gr een.

•

LED is lit when the tape library experiences a

•

non-robotic failure.

Keypad

Open Door Indicator

LED flashes amber when the Open Door button

•

is pressed.

LED is solid amber whe n t he robot is parked in

•

the roboti c s u nit .

LED flashes during init ialization and audit.

•

LED is not lit w hen the library is re ady for

•

customer use.

Button

When pressed:

1. Software allows the current job to complete. This

could take aw hile.

2. Software retracts the robot into the robotics unit

so that it will not be damag ed when you open

the door with the key.

Open CAP Indicator

LED is amber when any CAP doors are open

•

LED is not lit w hen all CAP doors are shut

•

LED fl as hes durin g audit

•

Button

Button is used to tell the robot to open the CAP

doors.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

2-3

Page 32

Controls and Indicators

Keypad

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

2-4

Page 33

3 Library Operation

This section includes:

Automated Mode

Manual Mode 3-4

Automated Mode

Automated mode is the normal operating mode of the tape library. The controlling

software instruct s the hand assembly to move cartridges among the stora ge sl ot s, tape

drives, and cartridge access port (CAP) without operator intervention.

Opening the Front Door (With Power)

To open the front door when tape library power exists:

1. Press the Open Door button on the keypad.

a. The software allows the current job to complete.

b. The software retracts the robot into the robotic unit to prevent the robot from

being damaged and to prepare it for servicing.

2. When the Open Door indicator turns on, use the key to open the door.

3-1

Securing the Front Door (With Power)

To secure the front door when tape library power exists, push it closed and use the key

to lock it.

Entering a Cartridge Through the CAP

The base module CAP contains a standard five slot magazine. The expansion module

CAP has two five slot magazines. The CAPs allow you to insert cartridges and remove

cartridges from the tape library.

To enter a cartridge into the CAP:

1. Be sure that the CAP Prevent/Allow state is set to Allow.

2. Press the CAP Open button on the keypad.

The robot opens the CAP door and the CAP Open LED is turned on.

3. Grip the handle of the magazine and slide it out of the CAP and onto the door.

Note. Do not rem ov e the magazine from the door. Leaving the mag az ine on the door rails

will allow th e m agazine to slide easier into th e C AP.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-1

Page 34

Library Operation

4. Place the cartridge into one of the magazine slots, making sure that the VOLID

label is visible and the hub of the cartridge is down.

5. Grip the handle and slide the magazine back into the CAP.

Figure 3-1. S liding a Magazine Into a CAP

Entering a Cartridge Through the CAP

6. Close the CAP door making sure that the door is securely latched.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-2

Page 35

Library Operation

Powering On t he Tape Library

To power on the librar y:

1. Close and lock the front door if the door is open.

2. Press the power switch (on the top right corner of the back of the library) to the ON

(1) position.

Powering Off the Tape Library

Caution. If you power off th e ta pe library without performing the following procedure, you risk

possible equipment or ca rt ridge damage or loss of data.

1. Make sure that all jobs have completed processing.

2. Make sure the tape library and tape drives are not in use.

3. Move the power on/off switch to the OFF position (0).

Powering On the Tape Library

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-3

Page 36

Library Operation

Manual Mode

This section describes the operation of the tape library in manual mode. Manual mode

occurs then the tape library is taken offline, or loses power, or the front door is opened.

Opening the Front Door (Without Power)

To open the front door when no tape library power exists:

Note. You must manually move the robotics park lever (beneat h the facade and to the bott om

left of the keypa d) t o t he left position so t hat you can ope n th e door with the k ey. Under nor m al

conditio ns , the lev er signifies th at th e robot is parked in si de the robotics unit at the top of th e

tape library, and the door can be safely opened. When no power exists, the robot is not actually

parked, but you will be able to open the door when you move the lever to the left.

Figure 3-2. Lever Not in Parked Position

Manual Mode

1. Press the power switch on the back of the tape library to the OFF position.

2. Remove the robotic facade from the top of the library by gently pulling the facade

from side to side to pull the ball studs away from the clips. You might have to use a

screwdriver to gently pry it off.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-4

Page 37

Library Operation

WARNING. Possible injury to finger: Make sure that your finger is completely to the left in the

next step so that it will not be pinched when the door locking lever extends as shown in the

lower picture.

Figure 3-3. Door Locking Lever Extended

Securing the Front Door (Without Power)

3. While using one hand to move the robotics park lever to the left, use your other

hand to unlock the door with the key.

Securing the Front Door (Without Power)

To secure the front door when no tape library power exists:

1. Remove the robotic facade from the top of the tape library by gently pulling the

facade from side to side to pull the ball studs away from the clips. You might have

to use a screwdriver to gently pry it off.

Caution. Possible component damage: Note the door locking lever protruding from the top of

the door. Do not let it hi t the robotics park lev er when you close the door.

2. While using one hand to move the robotics park lever to the left, use your other

hand to close the door.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-5

Page 38

Library Operation

Figure 3-4. Moving Robotics Park Lever

3. While still holding the door shut, release the robotics park lever.

Locate and Remove Cartridge

4. Use the key to lock the door. The robotics lever automatically moves to the right

when the door locking lever retracts.

Locate and Remove Cartridge

To locate a particular cartridge inside the tape library:

1. Open the door .

2. Locate the particular cartridge by its VOLID (volume ID) label and slot.

3. Remove the cartridge from the slot by sliding the cartridge out.

4. Close the tape library door.

Insert Cartridges Into Slots

Depending on the version and configuration of your tape library, some storage slots

cannot be used.

Note. You do not have to insert a cartridge into every storage slot. The tape library

automatic ally audits cartridges and empty slots as part of its in iti aliz ation routin e.

Caution. Inserting the cartridges correctly is critical for library operation. If you do not orient

the cartridges correct ly or do not insert th em all the way into th e s t orage slots, the tap e library

might fail. Make sure you insert the cartridges into the magazine.

1. Check the cartridges to make sure they are correctly labeled.

2. Insert as many cartridges into the tape library as you want and as your

configuration allows, making sure you seat them all the way into the storage slots.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-6

Page 39

Library Operation

Figure 3-5. Inserting Cartridges Into Slots

Insert Cartridges Into Slots

1. Wall of arrays slots

2. Cartridge

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-7

Page 40

Library Operation

Inserting a Cartridge Into a Tap e Drive

To manually insert a cartridge into a tape drive:

1. Obtain the VOLID label, location, and tape drive number from the server console.

2. Open the door .

3. Locate the cartridge.

Caution. Potential equipment d am age. You must ins ert the cartri dge properly or y ou will

damage the tape drive.

4. Hold the cartridge so that the VOLID is facing you and can be read from right to

left.

5. Insert the cartridge into the tape drive.

6. Close the tape library access door.

Inserting a Cartridge Into a Tape Drive

Figure 3-6. Inserting Cart rid ge I nto Tap e Dr ive

1. Cartridge

2. Drive

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-8

Page 41

Library Operation

Removing a Cartridge From a Tap e Drive

To manually remove a cartridge from a tape drive:

1. Open the door and locate the appropriate tape drive.

Caution. Possible data los s . Fa ilure to perfor m and wait appro x im at ely 12 seconds until the

operation completes.

2. Press the Unload button on the tape drive and wait approximately 12 seconds until

the operation completes.

Figure 3-7. Location of Unload Button

Removing a Cartridge From a Tape Drive

3. Gently pull the cartridge from the tape drive.

4. Store the cartridge in an empty slot or outside the tape library.

Note. If you store the cartridge in an empty slot, you must reinitialize the tape library.

5. Close the tape library door.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-9

Page 42

Library Operation

Removing a Cartridge From the Gripper Assembly

Removing a Cartridge From the Gripper Assembly

The hand assembly can be in any position when the tape library loses power. Before

you can remove the cartridge, the hand assembly must be facing the front left arrays

and aligned with an empty slot.

If the hand assembly is facing right:

1. Gently turn the hand to the left.

2. Slide the hand assembly along the rail until the gripper is positioned across from

an empty slot and close to you.

3. Continue with the following steps.

If the hand assembly is facing left:

1. Turn the gripper belt to extend the gripper until the release screw is accessible.

2. Use a small, flat blade screwdriver to turn the screw 1/4 turn clockwise until the

cartridge is released.

3. Push the cartridge into a slot.

4. Gently push the gripper back into the hand.

5. Slide the hand assembly toward the back of the tape library.

6. Remove the cartridge from the slot, or leave it there.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-10

Page 43

Library Operation

Figure 3-8. Manual Release Screw

Replacing a Cleaning Cartridge

1. Gripper belt and pulley s

2. Gripper

3. Release screw

Replacing a Cleaning Cartridge

Cleaning cartridges have a limited life span. When the usage count exceeds its limit,

you must replace it with a new one.

To replace a cleaning cartridge:

1. Open the door .

2. Remove the expired cleaning cartridge from its reserved slot.

3. Insert the new cleaning cartridge into that slot.

4. Close the tape library door.

5. Wait until the initialization tests complete before performing another task.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-11

Page 44

Library Operation

Replacing a Cleaning Cartridge

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

3-12

Page 45

4 Cartri dge Info rm a tio n

This section includes:

Handle Cartridges 4-1

Inspect Cartridges 4-1

Maintain Cartridges 4-2

Ultrium Cartridges 4-3

Handle Cartridges

Improper handling of cartridges can result in loss of data or damage to a tape library

component.

To handle a cartridge correctly:

Make sure the leader is latched every time you pick up a cartridge.

•

Keep cartridges clean.

•

Inspect a cartridge be fore e ach use, a nd neve r put a d amag ed cartridge into a tape

•

drive or tape library.

Never pull tape from a cartridge.

•

Never open a cartridge.

•

Do not handle tape that is outside the cartridge; the tape edge might be damaged.

•

Do not expose the tape or cartridge to direct sunlight or moisture.

•

Do not expose a recorded cartridge to magnetic fields; this might destroy data on

•

the tape.

Inspect Cartridges

A defective or dirty cartridge can damage a tape drive. Always inspect a cartridge

before you insert it into a tape drive or a tape library. Look for:

Cracked or broken cartridge

•

Broken leader

•

Broken leader latch

•

Damaged write-protect switch

•

Liquid in the cartridge

•

Labels not firmly or neatly attached or extending over the cartridge edge

•

Any other obvious damage

•

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-1

Page 46

Cartridge Information

Maintain Cartridges

It is important to keep your tape cartridges in good condition. A defective or dirty

cartridge can damage a tape drive.

When you store a cartridge:

Leave it in its protective wrapping until you are ready to use it.

•

Choose a clean environment that duplicates the conditions of the room in which it

•

is used.

Make sure the cartridge has been in its operating environment for at least 24

•

hours.

When you clean a cartridge exterior:

Caution. Do not use certain solvents to remove labels or to clean cartridges because they can

damage th e c art ridges. Do not use ac etone, trichl oroethane, tolu ene, xylene, ben z ene, ketone,

methylet hy l k et one, methy lene chloride, et hy ldichloride, es t ers , et hy l ac etate, or similar

chemicals.

Maintain Cartridges

Wipe all dust, dirt, and moisture from the cartridge with a lint free cloth.

•

Use cleaning wipes that are saturated with isopropyl alcohol. Do not let any

•

solution touch the tape or get inside the cartridge.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-2

Page 47

Cartridge Information

Ultrium Cartridges

Figure 4-1. Ultrium Cartridge Components

Ultrium Cartridges

1. Write-protect switch (data cartridge has red switch, cleaning cartridge has gray switch)

2. Volume ID labe l (barcode to hu b s ide of cartridge)

3. Access door

4. Leader pin

Apply Cartridge La be ls

Cartridge labels reflect the cartridge media and usage. If your cartridges were not

ordered with labels already applied, you must apply them yourself. You must correctly

label all cartridges for tape library use.

Caution. Possible misread of volu m e number label: Make sure th e edges of the labels do not

curl. Curling causes th e c art ridges to stick in t he tape drive loa der and the robot t o m is read the

label.

Valid Labels

LTO cartridge labels have eight characters. The last two characters are the Media ID

(C1, C2, CU, L1, L2, or L3). CLN or DG are the first characters on the cleaning or

diagnostic label.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-3

Page 48

Cartridge Information

Table 4-1. LTO Cartridge Codes

Label Type of Cartridge

CLN plus C1 Cleaning cartridge for tape drives

CLN plus C U Univer sa l c leaning cartr idge

DG plus L Diagnos t ic c art ridge (Apply a D G label to a blan k d ata

L1 Generation 1 data cartridge

L2 G eneration 2 data cartridge

L3 Generation 3 data cartridge

Figure 4-2. LTO Cartridge Labels

Val id Labels

cartridg e t o be used for dia gnostic tests.)

When an audit occurs the tapes in the tape drives are not audited. Unlabeled

cartridges are not supported and will not be recognized by an audit.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-4

Page 49

Cartridge Information

Perform these steps before applying the label into the recessed area on the cartridge:

1. Make sure the cartridge has been at room temperature for at least 24 hours.

2. Clean the surface where the labels will be placed using a cleaning solution made

for this purpose.

3. Locate the type of label that you require.

4. Hold the cartridge so that the write-protect switch is toward you.

5. Attach the label to the cartridge as shown in Figure 4-3.

Figure 4-3. Ultrium Cartridge Label

Val id Labels

1. Volume number label

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-5

Page 50

Cartridge Information

Setting the Write-Protect Switch

You can set the write-protect switch so the cartridge is write enabled. To write-enable

the tapes, slide the switch to reveal the open lock symbol . In this position, the tape

drive can write as will as read data. This setting is recommended when inserting

cartridges into the tape library.

You can set the write-protect switch so that the cartridge is read only. Slide the switch

to reveal the symbol of a closed lock. In this position, the tape drive can only read data

from the tape but cannot write data to it.

Figure 4-4. Write-Protect Switch

Setting the Write-Protect Switch

1. Write-protect switch (D ata cartridge has red switch. C leaning cartr idge has gray swit c h. )

2. Write-enabled

3. Write-protected

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-6

Page 51

Cartridge Information

Table 4-2. LTO Gen 1, Gen 2, and Gen 3 Cartridge Specifications

Specification L3 Cartridge L2 Cartridge L1 Cartridge

Setting the Write-Protect Switch

Capacity, native

400 GB 200 GB 100 GB

(uncompressed)

Capacity

800 GB 400 GB 200 GB

(compressed)

Read and w rit e

5.9 m/s 5.9 m/s 4.0 m/s

tape speed

Sear ch and r ewin d

7.0 m/s 7.0 m/s 7.0 m/s

speed

Archival life 15–30 years 15-30 years 15-30 years

Numbe r of tracks 704 tr ac k s 51 2 t racks 384 tracks

Dimensions

Width

Height

Depth

Weight

107 mm (4.2 in.)

22.9 mm (0.9 in.)

102 mm (4.0 in.)

210.0 g (0.46 lb)

107 mm (4.2 in.)

22.9 mm (0.9 in.)

102 mm (4.0 in.)

210.0 g (0.46 lb)

107 mm (4 .2 in. )

22.9 mm (0.9 in.)

102 mm (4 .0 in. )

210.0 g (0.46 lb)

Temperature

(noncondensing)

Operating

10 to 40°C (50 to

104°F)

10 to 40°C (50 to

104°F)

10 to 40°C (50 to

104°F)

Shipping

Wet bulb

-23 to 49°C (-10 to

120°F)

26°C (7 8°F)

-23 to 49°C (-10 to

120°F)

26°C (78°F)

-23 to 49°C (-10 to

120°F)

26°C (78°F)

Humidity 20–80% 20-80% 20-80%

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-7

Page 52

Cartridge Information

Setting the Write-Protect Switch

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

4-8

Page 53

5

Configuring the M8520 Tape Library

for the NonStop S-Series Server

The section covers:

Supported Connections 5-1

Adding the Control Path and the Data Path 5-1

Supported Connections

You can attach the M8520 tape library (control path and data path) to a NonStop

S-series server using one of the following:

ServerNet/DA

•

IOMF CRU

•

PMF CRU

•

Note. The control path is used to control the robot and the data path is used to control the tape

drive or driv es .

Adding the Control Path and the Data Path

ServerNet/DA

To add the control path to the server configuration database, use the SCF ADD SCSI

command. Use the SCF ADD TAPE command to add the data path. Before issuing

these commands, check that the tape drive(s) and tape library are installed properly.

To add the control path:

-> SCF

-> ADD SCSI $M8520, SENDTO STORAGE, PRIMARYLOCATION

(1,1,51), PRIMARYSAC 1, SCSIID 5, PRIMARYCPU 0, BACKUPCPU 1

-> START SCSI $M8520

-> STATUS SCSI $M8520, DETAIL

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

5-1

Page 54

Configuring the M8520 Tape Library for the NonStop

S-Series Server

To add the data path:

-> SCF

-> ADD TAPE $N1523A, SENDTO STORAGE, LOCATION (1,1,55), SAC

1, DEVICEID 5, PRIMARYCPU 0, BACKUPCPU 1

-> START TAPE $N1523A

-> STATUS TAPE $N1523A, DETAIL

For complete details about the ADD and STATUS commands, including command

syntax, see the SCF Reference Manual for the Storage Subsystem.

ServerNet/DA

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

5-2

Page 55

Configuring the M8520 Tape Library for the NonStop

S-Series Server

PMF CRU

To add the control path to the server configuration database, use the SCF ADD SCSI

command. Use the SCF ADD TAPE command to add the data path. Before issuing

these commands, check that the tape drive or drives and the tape library are installed

properly.

To add the control path:

-> SCF

-> ADD SCSI $M8520, SENDTO STORAGE, PRIMARYLOCATION

(1,1,50), SCSIID 5, PRIMARYCPU 0, BACKUPCPU 1

-> START SCSI $M8520

-> INFO SCSI $M8520, DETAIL

To add the data path:

-> SCF

-> ADD TAPE $N1523A, SENDTO STORAGE, LOCATION (1,1,55),

DEVICEID 5, PRIMARYCPU 0, BACKUPCPU 1

PMF CRU

-> START TAPE $N1523A

-> STATUS TAPE $N1523A, DETAIL

For more information on the ADD and STATUS commands, see the SCF Reference

Manual for the Storage Subsystem.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

5-3

Page 56

Configuring the M8520 Tape Library for the NonStop

S-Series Server

PMF CRU

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

5-4

Page 57

6

Configuring the M8521 Tape Library

for the Integrity NonStop NS-Series

Server

The section covers:

Supported Connection 6-1

Adding the Control Path and Data Path 6-1

Supported Connection

You can attach the M8521 tape library (control path and data path) to a Fibre Channel

ServerNet adapter (FCSA) on an Integrity NonStop NS-series server.

Note. The contro l pat h is used to contro l th e robot, and the data path is used to co nt rol the

tape drive or driv es .

Adding the Control Path and Data Path

Note. To obtain the portname numbers for your control path and data path, contact a service

representative from STK. The portname numbers used in this section are examples only.

To add the control path, issue this SCF command:

SCF> ADD SCSI $device, SENDTO STORAGE, PRIMARYLOCATION

(group, module, slot), PRIMARYSAC sac-id, LUN lun-id,

PRIMARYPORT 64-bit-portname

Example:

SCF> ADD SCSI $M8521, SENDTO STORAGE, PRIMARYLOCATION

(110,2,2), PRIMARYSAC 2, LUN 0, PRIMARYPORT 1234567891234567

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

6-1

Page 58

Configuring the M8521 Tape Library for the Integrity

NonStop NS-Series Server

To add the data path:

Note. WWN (portname) for ea ch port is labeled on the back of each tape driv e.

1. In SCF, issue this command:

SCF> ADD TAPE $tape, SENDTO STORAGE, LOCATION (group, module,

slot), SAC sac-id, PORTNAME 64-bit-portname, LUN lun-id

Example:

SCF> ADD TAPE $M8504, SENDTO STORAGE, LOCATION (110,2,2), SAC

2, LUN 0, PORT 50060B00002E69CD

Note. The LUN ( logical unit num ber) for all Fibre C hannel tape storage devices d irectly

attached t o t he N onStop NS-series se rv er is 0.

2. To start the tape drive on the server, issue this command in SCF:

SCF> START TAPE $tape

Example:

Adding the Control Path and Data Path

SCF> START TAPE $M8504

For complete details about the ADD and STATUS commands, including command

syntax, see the SCF Reference Manual for the Storage Subsystem.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

6-2

Page 59

7

Configuring the M8521 Tape Library

for the NonStop S-Series Server

The section covers:

Configuration Overview 7-1

Adding the Control Path and Data Path 7-3

Configuration Overview

You can attach the tape library (control path and data path) to a NonStop S-series

server via an IOAM enclosure. The tape library attaches to the FCSA (Fibre Channel

ServerNet adapter) in the IOAM enclosure. The ServerNet switch board on the IOAM

enclosure connects to a MSEB (Modular ServerNet Expansion Board) on a NonStop Sseries server via a fiber-optic cable. Figure 7-1 on page 7-2 shows a configuration

example of the tape library connected to a NonStop S-series server via an IOAM

enclosure.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

7-1

Page 60

Configuring the M8521 Tape Library for the NonStop

S-Series Server

Figure 7-1. Configuration Example

Fiber-optic

Cable

IOAM

Enclosure

MSEBs

Configuration Overview

ServerNet

Switch Board

Fibre Channel

ServerNet

Adapters (FCSAs)

Control

Path

Data

Path

Fiber-optic

Cables

NonStop Modular Rack Tape Library

S-Series (Rear View)

System

Note. The contro l pat h is used to contro l th e robot, and the data path is used to co nt rol the

tape drive (M8504).

For more information on the IOAM enclosure, see the Modular I/O Installation and

Configuration Guide.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

7-2

Page 61

Configuring the M8521 Tape Library for the NonStop

S-Series Server

Adding the Control Path and Data Path

Adding the Control Path and Data Path

Note. To obtain the portname numbers for your control path and data path, contact a service

representative from STK. The portname numbers used in this section are examples only.

To add the control path, issue this SCF command:

SCF> ADD SCSI $device, SENDTO STORAGE, PRIMARYLOCATION

(group, module, slot), PRIMARYSAC sac-id, LUN lun-id,

PRIMARYPORT 64-bit-portname

Example:

SCF> ADD SCSI $M8521, SENDTO STORAGE, PRIMARYLOCATION

(110,2,2), PRIMARYSAC 2, LUN 0, PRIMARYPORT 1234567891234567

To add the data path:

Note. WWN (portname) for ea ch port is labeled on the back of each tape driv e.

1. In SCF, issue this command:

SCF> ADD TAPE $tape, SENDTO STORAGE, LOCATION (group, module,

slot), SAC sac-id, PORTNAME 64-bit-portname, LUN lun-id

Example:

SCF> ADD TAPE $M8504, SENDTO STORAGE, LOCATION (110,2,2), SAC

2, LUN 0, PORT 50060B00002E69CD

Note. The LUN ( logical unit num ber) for all Fibre C hannel tape storage devices d irectly

attached to the IOAM enclosure is 0.

2. To start the tape drive on the server, issue this command in SCF:

SCF> START TAPE $tape

Example:

SCF> START TAPE $M8504

For complete details about the ADD and STATUS commands, including command

syntax, see the SCF Reference Manual for the Storage Subsystem.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

7-3

Page 62

Configuring the M8521 Tape Library for the NonStop

S-Series Server

Adding the Control Path and Data Path

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

7-4

Page 63

A Specifications

The next pages provide tape library, tape drive, and cartridge specifications.

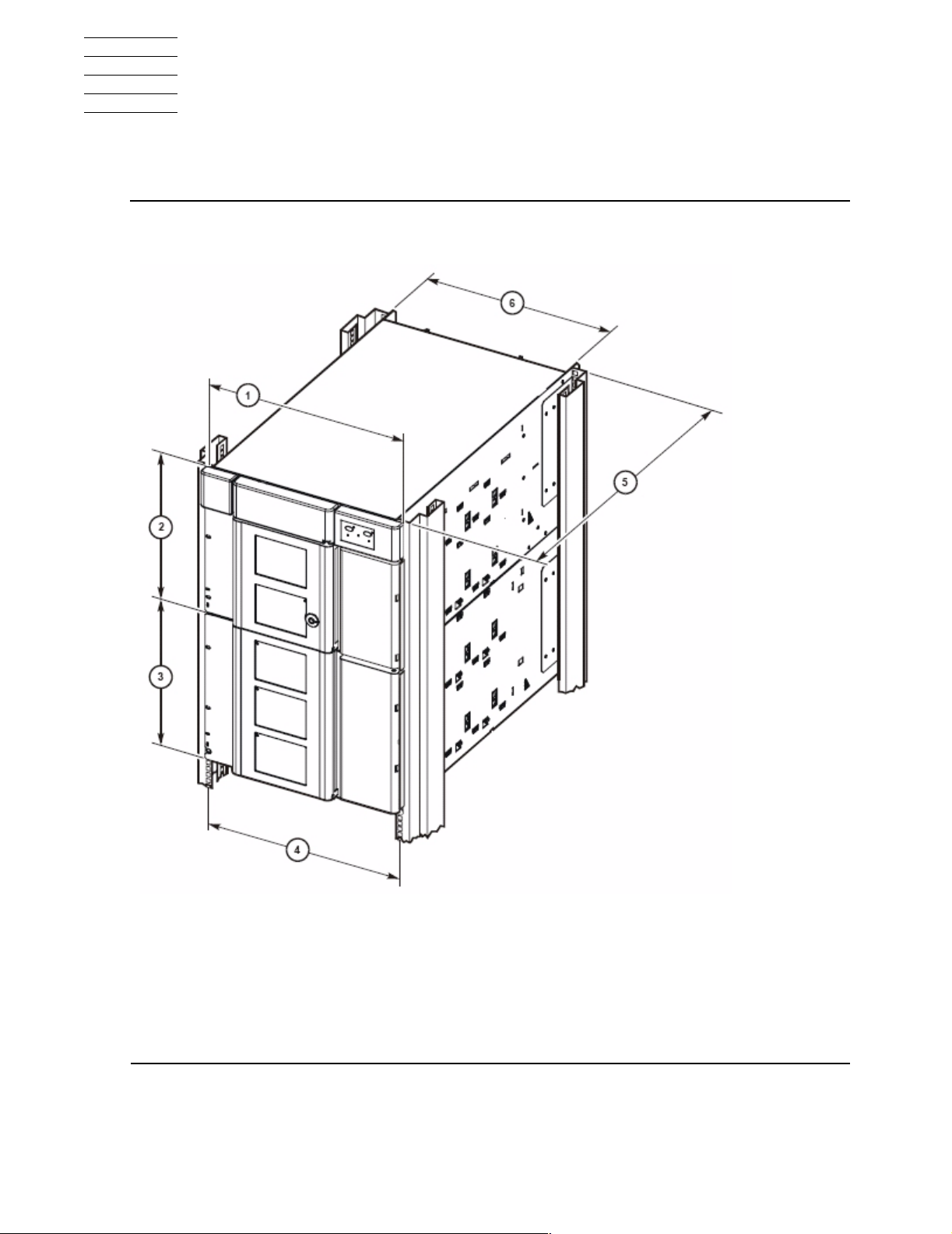

Figure A-1. Library and Rack Dimensions

1. 48.3 cm (19.0 in.) width of front of base module with flange

2. 35.6 cm (14.0 in.) height of base module

3. 35.6 cm (14.0 in.) heig ht of ex pans ion module

4. 46.5 cm (18.3 in.) distance between rack holes

5. 60.9 cm (24.0 in.) to 86.4 cm (34.0 in.), optimally 74 cm (29 in.) front to

rear rack mounting distance

6. 44.5 cm (17.5 in.) width of back of base module

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-1

Page 64

Specifications

Figure A-2. Tape Library and Rack Dimensions

1. 60.9 cm (2 ft) minimum service clearance behind the library or rack

2. 81.0 cm (31.9 in.) depth of base module from front mounting plane to

back of tape dri ve s

3. 76.2 cm (30.0 in.) depth of base module

4. 3.8 cm (1.5 in.) depth of front door, required clearance

5. 5.3 cm (2.1 in.) depth of front door and unique latch hardware

6. 5.9 cm (2.3 in.) key depth

7. 24.1 cm (9. 5 in.) front door opening clearance

8. 60.9 cm (2 ft) minimum front service clearance

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-2

Page 65

Specifications

Tape Library Components Weights

Tape Library Components Weights

This table lists the weights of the tape library, tape drives and trays, and cartridges.

Table A-1. Library Component Weights

Components Weight

Base mod ule with 1 power supply, 2 tape

drives, and ro botics un it

Drive expans ion module (D EM) with 1

power supply and 4 tape drives

Cartridge expansion module (CEM) 44.2 pounds (20.1 kilograms)

Robotics unit 22.2 pounds (10.1 kilograms)

Power Supply 5.1 pounds (2.3 k ilograms)

LTO Ultrium ta pe drive and tra y a s sy 7. 9 pounds (3.6 k ilograms)

Tape drive tray assy without tape drive 3.4 pounds (1.5 kilograms)

LTO Ultrium cartridge 7.8 ounces (221 grams)

98 pounds (44.5 kilograms)

91 pounds (41.3 kilograms)

Tape Library Environment

This table lists the tape library environments specifications.

Table A-2. Library Environment Specifications

Operating Storage Transporting

Temperature +10 to +40ºC

(+50 to +104ºF)

Humidity 20 to 80% 10 to 95% 10 to 95%

Wet bulb (maximum

noncondensing)

Altitude -76 to 3,0 48 m (-250

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

+29.2ºC

(+84.5ºF)

to 10,000 ft)

+10 to +40 ºC

(+50 to +104ºF)

+35ºC

(+95ºF)

-76 to 3,048 m (-250

to 10,000 ft)

A-3

-40 to +60ºC

(-40 to +140 ºF)

+35ºC

(+95ºF)

-76 to 3,04 8 m (-250

to 10,000 ft)

Page 66

Specifications

Power

Note. The tape library is offered with redundant pow er in all the modules that hav e power

supplies in them.

The pow er cords are s hipped with the unit and are selected to ma tc h the geographical power

requirements of that area.

Power Cord Numbers and Receptacles

Power cord part numbers are listed by country in the following table. All cords are 3

meters (9.81 feet).

Table A-3. Power Cord and Receptacles

Input V oltage Country Part Number Receptacle Type

100 to 127 VAC U.S./ C anada 10083242 5-15R

Power

Japan 10083243 JIS C8303

200 to 240 VAC Aust ralia 10083244 AS 3112

Denmark 10083248 DEMKO107 / 10-1973

Europe 10083241 Schuko

Italy 10083245 CEI 23-16/V11

Korea 100 83657 KSC 8305

South Af rica 1008 3636 BS546

Switzerland 10083246 SEV 1011-S24507

United K ingdom 1008324 7 BS 1363/A

U.S./Canada 10083547 6-15R

Table A-4. Non-Count ry-Specific Cords

Descr i p tion Part Number

Cord, power, SJT, IE C 320, 14AWG, 100 to 127 VAC 10083617

Cord, SJ T, 16AW G, L6-15P, 250 VAC 1008 3639

Cord, 18, 3, SVT, 1mm, M/SH FRT 1008327 3

Cord, power, 3, F, IEC320 harmonized. The cord has

a plug on on e end that attaches to the library and

bare wires on the other. Buy the corr ec t end to

match your normal wall outlet and attach it to the

cord.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-4

10083302

Page 67

Specifications

Installing the Power Cords

WARNING. Possible bodily harm and equipment damage: The power cor d m us t not be

plugged in until the supply has been properly installed.

If your rack has a power distribution unit (PDU), plug each power cable from the power

supply receptacle to the PDU, and then plug the PDU cable to the wall receptacle.

If your rack does not have a PDU, plug each power cable from the power supply

receptacle to the wall receptac le.

Power Cord Numbers and Receptacles

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-5

Page 68

Specifications

Figure A-3. Power Cabling

1

Power Cord Numbers and Receptacles

2

3

1. To wall outlet or external power strip

2. To rack PDU, if present

3. From rack PDU (if present) to wall outlet

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-6

Page 69

Specifications

Power Specifications

These tables list power specifications for the modules and tape drives.

Table A-5. Power for Library Without Tape Drives

Input voltage 100-240 VAC, single phase

Frequenc y 50/50 Hz

Maximum library powe r co ns umption 1.4 A @ 12 0 V

Maximum heat output 614 Btu/h r

Voltage-amperes 180 VA

Table A-6. Power for Base Unit and Two LTO Tape Drives

Power Specifications

0.8 A @ 24 0 V

Two LTO Tape Dr ives

Input power 219 watts

Input v oltage -amperes 226 voltage-amperes

Input current (100 VAC) 2.3 amperes

Input current (120 VAC) 1.9 amperes

Input current (240 VAC) 0.9 amperes

Btu/hour 748 Btu/hr

Table A-7. Power for Drive Expansion Module and Four LTO Tape Drives

Four LTO Tape Drives

Input power 288 watts

Input voltage-amperes 297 voltage-amperes

Input c urrent (100 VAC) 3.0 amperes

Input c urrent (120 VAC) 2.5 amperes

Input c urrent (240 VAC) 1.2 amperes

Btu/ hour 983 Btu/hr

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-7

Page 70

Specifications

Power Specifications

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

A-8

Page 71

Safety and Compliance

This section contains three types of required safety and compliance statements:

Regulatory compliance

•

Waste Electrical and Electronic Equipment (WEEE)

•

Safety

•

Regulatory Compliance Statements

The following regulatory compliance statements apply to the products documented by

this manual.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio-frequency energy and, if not installed and used in accordance with the

instruction manual, may cause interference to radio communications. Operation of this

equipment in a residenti al area is likely to cause harm ful interfer ence in wh ich case the

user will be required to correct the interference at his own expense.

Any changes or modifications not expressly approved by Hewlett-Packard Computer

Corporation could void the user’s authority to operate this equipment.

Canadian Compliance

This class A digital apparatus meets all the requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique d e la classe A r especte toutes le s exigence s du R ègel ment sur

le matériel brouilleur du Canada.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

Statements-1

Page 72

Safety and Compliance

Korea MIC Compliance

Taiwan ( BSM I) Compliance

Regulatory Compliance Statements

Japan (VCCI) Compliance

This is a Class A product based on the standard or the Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this equipment is used in

a domestic environment, radio disturbance may occur, in which case the user may be

required to take corrective actions.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

Statements-2

Page 73

Safety and Compliance

European Union Notice

Products with the CE Marking comply with both the EMC Directive (89/336/EEC) and

the Low Voltage Directive (73/23/EEC) issued by the Commission of the European

Community.

Compliance with these directives implies conformity to the following European Norms

(the equivalent international standards are in parenthesis):

EN55022 (CISPR 22)—Electromagnetic Interference

•

EN55024 (IEC61000-4-2, 3, 4, 5, 6, 8, 11)—Electromagnetic Immunity

•

EN61000-3-2 (IEC61000-3-2)—Power Line Harmonics

•

EN61000-3-3 (IEC61000-3-3)—Power Line Flicker

•

EN60950-1 (IEC60950-1)—Product Safety

•

Laser Compliance

Regulatory Compliance Statements

This product may be provided with an optical storage device (that is, CD or DVD drive)

and/or fiber optic transceiver. Each of these devices contains a laser that is classified

as a Class 1 Laser Product in accordance with US FDA regulations and the IEC

60825-1. The product does not emit hazardous laser radiation.

W ARNING: Use the controls or adjustment s or performance of

procedures other than those specified herein or in the laser

product’s installation guide may result in hazardous radiation

exposure. To reduce the risk of exposure to hazardous

radiation:

Do not try to open the module enclosure. There are no

•

user-serviceable components inside.

Do not operate controls, make adjustments, or perform

•

procedures to the laser device other than those specified

herein.

Allow only HP Authorized Service technicians to repair

•

the module.

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug

Administration implemented regulations for laser products on August 2, 1976. These

regulations apply to laser products manufactured from August 1, 1976. Compliance is

mandatory for products marketed in the United States.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

Statements-3

Page 74

Safety and Compliance

SAFETY CAUTION

The following icon or caution statements may be placed on equipment to indicate the

presence of potentially hazardous conditions:

SAFETY CAUTION

DUAL POWER CORDS CAUTION:

“THIS UNIT HAS MORE THAN ONE POWER SUPPLY CORD.

DISCONNECT ALL POWER SUPPLY CORDS TO COMPLETELY

REMOVE POWER FROM THIS UNIT."

"ATTENTION: CET APPAREIL COMPORTE PLUS D'UN CORDON

D'AL I M EN TATI ON . D ÉBRANCHER TOUS LES CORDONS

D'ALIMENTATION AFIN DE COUPER COMPLÈTEMENT

L'ALIMEN TATION DE CET ÉQUIPEMENT".

DIESES GERÄT HAT MEHR ALS EIN NETZKABEL. VOR DER

WARTUNG BI T T E ALLE NETZKABEL AUS DER STECK D OSE

ZIEHEN.

Any surface or area of the equipment marked with these symbols

indicates the presence of electric shock hazards. The enclosed area

contains no operator-serviceable parts.

WARNING: To reduce the risk of injury from electric shock hazards, do

not open this enclosure.

NOT FOR EXTERNAL USE

CAUTION: NOT FOR EXTERNAL USE. ALL RECEPTACLES ARE FOR INTERNAL

USE ONL Y.

ATTENTION: NE PAS UTILISER A L’EXTERIEUR DE L’EQUIPEMENT

IMPORTANT: TOUS LES RECIPIENTS SONT DESTINES UNIQUEMENT A UN

USAGE INTERNE.

VORSICHT: ALLE STECKDOSEN DIENEN NUR DEM INTERNEN GEBRAUCH.

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

Statements-4

Page 75

Safety and Compliance

HIGH LEAKAGE CURRENT

To reduce the risk of electric shock due to high leakage currents, a reliable grounded

(earthed) connection should be checked before servicing the power distribution unit

(PDU).

Observe the following limits when connecting the product to AC power distribution

devices: For PDUs that have attached AC power cords or are directly wired to the

building power, the total combined leakage current should not exceed 5 percent of the

rated input current for the device.

“HIGH LEAKAGE CURRENT, EARTH CONNECTION ESSENTIAL BEFORE

CONNECTING SUPPLY”

“HOHER ABLEITSTROM. VOR INBETRIEBNAHME UNBEDINGT

ERDUNGSVERBINDUNG HERSTELLEN”

“COURANT DE FUITE E’LEVE’. RACCORDEMENT A LA TERRE INDISPENSABLE

AVANT LE RACCORD EMENT AU RESEAU”

Waste Electrical and Electronic Equipment (WEEE)

FUSE REPLACEMENT

CAUTION – For continued protection against risk of fire, replace fuses only with fuses

of the same type and the same rating. Disconnect power before changing fuses.

Waste Electrical and Electronic Equipment

(WEEE)

Information about the Waste Electrical and Electronic Equipment (WEEE) directive can

be accessed from the left navigation area of the NTL home page: select NonStop

Computing > Waste Electrical and Electronic Equipment (WEEE).

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

Statements-5

Page 76

Safety and Compliance

Safety

Safety information can be accessed from the left navigation area of the NTL home

page: select NonStop Computing>Important Safety Information. A document

window containing a binder of safety information, in several languages, appears. In the

document window, click a document title to open the safety information in another

language. Local HP support can also help direct you to your safety information.

Safety

SL500 (M852x) Tape Library Installation and User’s Gu id e—541531-006

Statements-6

Loading...

Loading...