Page 1

hp server rx4610

User Guide

Version 0501

Page 2

Notice

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be

liable for errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on equipment that is not

furnished by Hewlett-Packard.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of

this document may be photocopied, reproduced, or translated to another language without the prior written

consent of Hewlett-Packard Company.

®

is a registered trademark of ATI Technologies, Incorporated. Intel® and Pentium® are registered trademarks

ATI

of Intel Corporation. Microsoft

®

, Windows NT®, Windows 95® , Windows 2000® and Microsoft® Internet

Explorer are registered trademarks of Microsoft in the U.S. and other countries. Netscape Navigator

registered trademark of Netscape Communications Corporation in the U.S. and other countries. Symantec

registered trademark of Symantec, Incorporated. pcANYWHERE32 is a trademark of Symantec, Incorporated.

Symbios

Adobe Systems Incorporated. Torx

®

is a registered trademark of LSI Logic Corporation. Adobe® and Acrobat® are registered trademarks of

®

is a registered trademark of CamCar/Textron, Incorporated.

Itanium™ is a trademark of Intel Corporation. 3M is a trademark or registered trademark of 3M.

© Copyright 2001, Hewlett-Packard Company.

Audience Assumptions

®

is a

®

is a

This guide is for the person who installs, administers, and troubleshoots LAN servers. HewlettPackard Company assumes you are qualified in the servicing of computer equipment and trained in

recognizing hazards in products with hazardous energy levels.

ii

Page 3

Contents

1 Controls, Ports, and Indicators ......................................................................1

Introduction ........................................................................................................1

Front Panel ....................................................................................................1

Additional Front Panel Controls and Indicators .............................................3

Rear View ......................................................................................................7

Applying Power to the HP Server ....................................................................10

Powering-Up the HP Server ........................................................................10

Powering-Down the HP Server....................................................................10

Connecting AC Power to Multiple-Server Configurations............................ 11

2 Opening and Closing the HP Server ............................................................12

Introduction ......................................................................................................12

Mounting the Front Bezel ................................................................................. 12

Removing and Replacing the Front Bezel .......................................................12

Removing and Replacing the HP Server’s Main Cover.................................. 14

Tools Required ............................................................................................14

Removing the Top Cover............................................................................. 14

Replacing the Top Cover .............................................................................15

3 Installing Fans and Power Supplies ............................................................17

Introduction ......................................................................................................17

Tools and Supplies Needed.............................................................................17

Hot Swapping the 172 mm Fans .....................................................................18

Removing the 172 mm Fans .......................................................................18

Installing the 172 mm Fans .........................................................................19

Hot Swapping the 120 mm Fans .....................................................................19

Removing the 120 mm Fans .......................................................................19

Installing the 120 mm Fans .........................................................................20

Hot Swapping Power Supplies ........................................................................21

Determining Power Supply Status ............................................................... 22

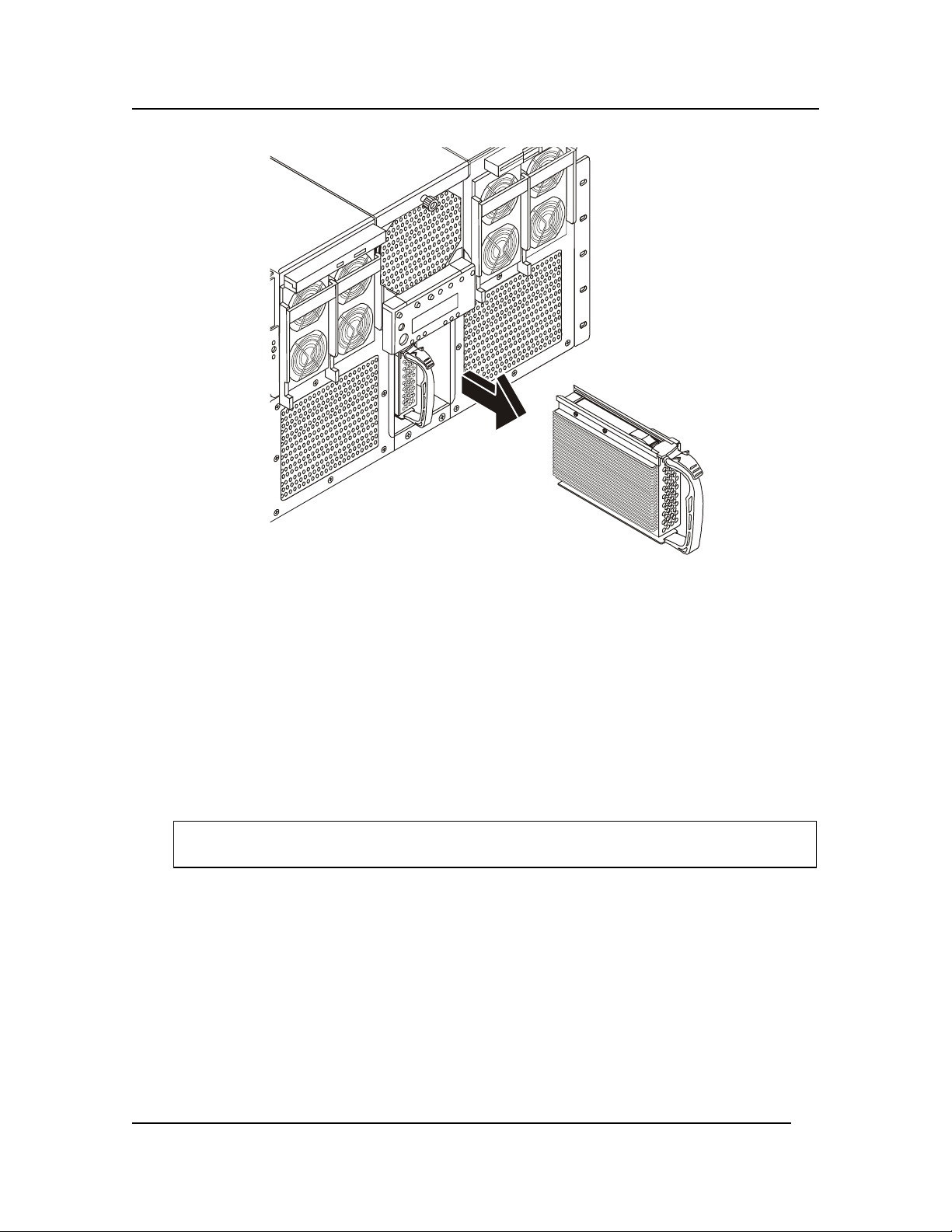

Removing a Power Supply ..........................................................................23

Installing a Power Supply ............................................................................24

4 Installing Mass Storage Devices ..................................................................25

Introduction ......................................................................................................25

Mass Storage Guidelines .................................................................................25

Boot Priority .................................................................................................25

Tools Required................................................................................................. 26

Installing a Hot Swap Hard Drive..................................................................... 26

Determining Drive Status............................................................................. 27

Removing a Hard Disk Drive .......................................................................27

Installing a Hard Disk Drive .........................................................................28

Installing Non-Hot Swap Drives .......................................................................29

iii

Page 4

Installing the Floppy Disk Drive ...................................................................29

Installing the DVD Drive ..............................................................................30

Connecting External SCSI Devices .............................................................32

Removing and Installing the Hard Disk Bay ....................................................32

Removing the Hard Disk Bay ......................................................................32

Installing the Hard Disk Bay ........................................................................33

Removing and Installing the SCSI Backplane .................................................34

Removing the SCSI Backplane ...................................................................34

Installing the SCSI Backplane Board........................................................... 34

Installing the Front Panel Board ......................................................................35

Removing the Front Panel Module ..............................................................35

Installing the Front Panel Board ..................................................................35

5 Installing Additional Memory........................................................................36

Introduction ......................................................................................................36

Tools Required ............................................................................................36

Memory Installation Guidelines ...................................................................36

Removing the Processor/Memory Complex ....................................................37

Removing the Memory Board DC-to-DC Converters ...................................... 38

Removing and Installing Memory Boards ........................................................39

Removing Memory Boards ..........................................................................39

Installing Memory Boards ............................................................................ 40

Installing and Removing DIMMs ......................................................................42

Installing DIMMs ..........................................................................................42

Removing DIMMs ........................................................................................44

Installing the Memory Board DC-to-DC Converters ........................................ 44

Installing the Processor/Memory Complex ......................................................45

6 Installing an Additional Processor............................................................... 46

Introduction ......................................................................................................46

Tools Required ............................................................................................46

Processor Configuration Guidelines ............................................................46

Removing the CPU Thermal Dummy .............................................................. 47

Installing an Additional Processor.................................................................... 48

Removing a Processor..................................................................................... 51

Installing a CPU Thermal Dummy ................................................................... 52

Installing the Processor Baseboard .................................................................52

Removing the Processor Baseboard...........................................................53

Installing the Board in a System with Three or Four Microprocessors........ 54

Installing the Board in a System with Two Microprocessors .......................55

7 Installing Accessory Boards ........................................................................57

Introduction ......................................................................................................57

Tested PCI Boards ......................................................................................57

Tools Required ............................................................................................57

Accessory Board Installation Guidelines ......................................................... 57

IRQ Settings ................................................................................................ 57

iv

Page 5

Boot Priority .................................................................................................58

Installing Accessory Boards............................................................................. 58

Installing a Hot Swap PCI Board .................................................................58

Installing a Non-Hot Plug PCI Board ...........................................................60

Removing Accessory Boards........................................................................... 63

Removing a Non-Hot Plug PCI Board .........................................................63

Removing a Hot Plug PCI Board .................................................................64

8 Server Management Boards .........................................................................65

Introduction ......................................................................................................65

Baseboard Management Controller (BMC) .................................................65

Intelligent Chassis Management Bus (ICMB) Controller ............................. 66

Hot Swap Controller (HSC) ......................................................................... 66

I/O Baseboard .................................................................................................. 68

Removing the I/O Baseboard ......................................................................68

Installing the I/O Baseboard ........................................................................70

Sideplane Board .............................................................................................. 71

Removing the Sideplane Board ................................................................... 71

Installing the Sideplane Board .....................................................................72

PCI Hot Plug LED Board.................................................................................. 72

Removing the PCI Hot Plug LED Board ......................................................72

Installing the PCI Hot Plug LED Board ........................................................73

Legacy I/O Board .............................................................................................74

Removing the Legacy I/O Board .................................................................74

Installing the Legacy I/O Board ...................................................................75

Changing the Legacy I/O Board Battery ..........................................................77

Power Distribution Board (T-Docking) .............................................................78

Removing the Power Distribution Board (T-Docking).................................. 78

Installing the Power Distribution Board (T-Docking).................................... 82

9 Connecting the Monitor, Keyboard, and Mouse ......................................... 84

Introduction ......................................................................................................84

10 Configuring the HP Server ...........................................................................86

Introduction ......................................................................................................86

Configuring the HP Server ...............................................................................86

Power-on Sequence and Power-on Self Test (POST)................................ 86

The Extensible Firmware Interface (EFI) Boot Manager .............................87

Server Management Configuration Utility.................................................... 92

Using BIOS Setup........................................................................................ 99

Using the SELViewer Utility....................................................................... 107

Using the SDR Viewer Utility .....................................................................112

Server Firmware ............................................................................................115

11 Troubleshooting.......................................................................................... 116

Introduction ....................................................................................................116

Common Installation Problems ...................................................................... 116

Troubleshooting Sequence........................................................................ 116

v

Page 6

HP Server rx4610 SEL Data Tables ..............................................................120

HP Server rx4610 Sensor Codes ..............................................................121

BIOS Error Codes\Messages ........................................................................ 125

Beep Codes ...................................................................................................129

Beep Codes and Interpretation.................................................................. 129

Types of Memory Tests .................................................................................131

First Row Memory Test.............................................................................. 131

Base Memory Test..................................................................................... 134

Extended Memory Test ............................................................................. 140

Memory Test Duration ...............................................................................143

Aborting the Memory Test .........................................................................144

Setup Dialog ..............................................................................................145

Memory Testing Error Codes\Messages ...................................................145

DIMMUTIL .................................................................................................148

12 Parts Information......................................................................................... 149

Exploded View – Hot Swap and Display........................................................149

Exploded View – Processor/Memory Access ................................................150

Exploded View – Processor/Memory Complex.............................................. 151

Exploded View – Server Management Boards.............................................. 153

Exploded View – Power Distribution Board and IDE Drives.......................... 154

Replaceable Parts List ...................................................................................155

Parts List Identifier .........................................................................................155

Appendix A Specifications ......................................................................... 158

Introduction ....................................................................................................158

Requirements ............................................................................................158

Video Display Modes .................................................................................160

Connector Pinouts and Boardset Locations ..................................................161

VGA Video Port .........................................................................................161

Keyboard and Mouse................................................................................. 162

Parallel Port ...............................................................................................163

Serial Ports A and B ..................................................................................163

Universal Serial Bus (USB) ....................................................................... 165

SCSI ..........................................................................................................166

IDE............................................................................................................. 167

PCI ............................................................................................................. 168

Information on Jumpers .................................................................................171

General Procedure to Change Jumper Settings ....................................... 171

Processor Baseboard Jumpers .................................................................171

Legacy I/O Board Jumpers........................................................................ 177

I/O Baseboard Jumpers............................................................................. 181

Power Distribution Board Jumpers (T-Docking) ........................................183

Determining DC-to-DC Status ...................................................................184

B Equipment Log and Configuration Worksheet .........................................186

Equipment Log ............................................................................................... 186

vi

Page 7

Index ..................................................................................................................188

vii

Page 8

Chapter 1: Controls, Ports, and Indicators

1 Controls, Ports, and Indicators

Introduction

Before operating the Server, familiarize yourself with the HP Server’s controls, ports, and indicators,

as shown in Figures 1-1 through 1-8.

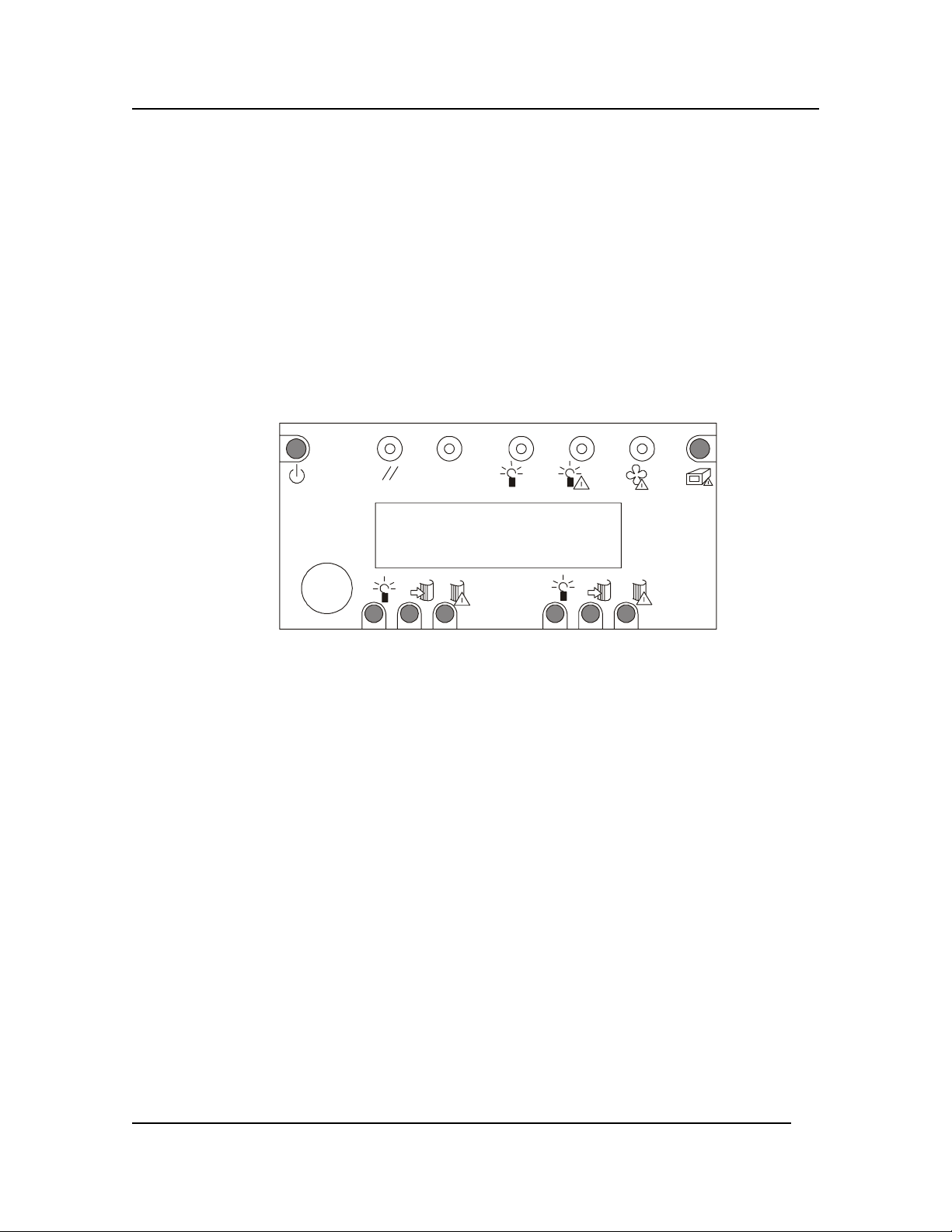

Front Panel

The front panel of the HP Server provides the controls and indicators commonly used when operating

the HP Server.

POWER

RESET INT SYS PWR PWR FAN GEN

LCD DISPLAY

PWR PWR ACTIVEACTIVE FAIL FAIL

Figure 1-1. Front Panel

Table 1-1 provides the front panel power switch and its associated LED indicator definitions.

1

Page 9

Chapter 1: Controls, Ports, and Indicators

Table 1-1. Control Panel Switch and Indicators

Control / Indicator Description

Power On/Off

Reset

INIT

System Power LED

(Green)

Power Fail LED

(Amber)

Fan Fail LED (Amber)

General Fault LED

(Amber)

Front Panel LCD

This button turns the HP Server power On or Off. The

+12 V standby voltage is On whenever the server power

cords are plugged in.

When pressed, it resets the server and causes the power on

self-test (POST) to run.

When pressed, the system performs a crash dump provided

the dump is supported by the operating system.

When lit continuously, it indicates the presence of DC

power in the server. When not lit, it indicates power is

turned off or the power source is disrupted.

When lit continuously, it indicates a power failure.

When flashing, it indicates a fan failure.

When lit continuously, it indicates a hot plug PCI fault.

It displays information about the processor type and the

POST codes.

2

Page 10

Chapter 1: Controls, Ports, and Indicators

A

Additional Front Panel Controls and Indicators

The input and storage devices provide additional front panel controls and indicators, which give

control and operational status to the respective device.

DVD Drive

The server supports a slimline IDE DVD drive. This peripheral mounts directly above the top-left

power bay on the front of the chassis. The drive is mounted on a removable tray that facilitates

system assembly and service.

Open/Close Button

POWER

RESET INT SYS PWR PWR FAN GEN

LCD DISPLAY

PWR PWR ACTIVE ACTIVE FA IL FAIL

Figure 1-2. DVD Drive

Table 1-2. HP DVD Drive

Control Indicator Description

Open/Close Button

Activity LED

When pressed, it opens or closes the DVD tray.

When lit, it indicates the drive is in use.

ctivity LED

3

Page 11

Chapter 1: Controls, Ports, and Indicators

A

Diskette Floppy Drive

The server supports a slimline IDE diskette drive for 1.44 MB and 120 MB media. This half-inch

slimline peripheral mounts directly above the top-right power bay on the front of the chassis. The

drive is mounted on a removable tray that facilitates system assembly and service.

ctivity

LED

Ejector

Button

POWER

RESET INT SYS PWR PWR FAN GEN

LCD DISPLAY

PWR PWR ACTIVE A CTIVE FAI L FAIL

Figure 1-3. Drive

Table 1-3. Floppy Diskette Drive

Control Indicator Description

Activity LED

Ejector Button

When lit, it indicates the drive is in use.

When pressed, it ejects the diskette.

4

Page 12

Chapter 1: Controls, Ports, and Indicators

SCSI Hard Drives

The server supports up to two hot-swap drive carriers containing standard 1-inch high by 3.5-inchwide LVDS SCSI hard drives. As part of the hot-swap implementation, drive carriers with integral

heat sinks house the drives. Each drive is mounted in a carrier with four fasteners and the carrier

snaps into the hard drive bay. When a carrier is seated properly in the bay, it snaps into place and

leaves the locking handle exposed to the front of the chassis. Drives can consume up to 24 watts of

power and must be specified to run at a maximum ambient temperature of 40 ° C (104 ° F).

POW ER

Power LED

Drive Active

Failure LED

RESET INT SYS PWR PWR FA N GEN

LCD DISPLAY

PWR PWR ACTIVEACTIVE FAIL FAIL

POWER

RESET INT SYS PWR PWR FAN GEN

LCD DISPLAY

PWR PWR ACTIVEACTIVE FAIL FAIL

Figure 1-4. SCSI Drive Indicators on the Front LED Panel

Table 1-4. SCSI Drives

Control Indicator Description

Failure LED

Drive Active

Power LED

Drive Power LED

(Green)

Drive Active LED

(Green)

Drive Fail LED

(Amber)

When lit continuously, it indicates the presence of

the drive and power to the drive.

When lit, it indicates drive activity.

When lit continuously, it indicates an asserted fault

status on one or more hard disk drives. When

flashing, it indicates a drive reset in progress.

5

Page 13

Chapter 1: Controls, Ports, and Indicators

Power Supplies

The chassis can be configured with three to four power supplies. Each power supply has a dual rating

of 800W minimum over an input range of 180-264VAC and 700W minimum over an input range of

90-132VAC. Each supply is designed to minimize EMI and RFI. Each power supply also has selfcontained fans for cooling.

The DC output voltages of each power supply are:

• +48 V

• +12 V standby

Each supply docks into a 28-pin connector on the front of the Power Distribution Board (T-Docking

board).

Power Supply Indicators

POWER

RESET INT SYS PWR PWR FAN GEN

LCD DISPLAY

PWR PWR ACTIVE ACTIVE FA IL FA IL

Figure 1-5. Power Supply Indicators

Table 1-5. LEDs for Power Supplies

Control Indicator Description

Power LED

(Green)

When lit continuously, it indicates the power

supply DC outputs are on and OK. Blinking

indicates the power supply is on standby. Off

indicates there is no power to the power supply.

Predictive Fail LED

(Amber)

Fail LED

(Amber)

A blinking LED indicates that the power supply

will soon fail.

When lit continuously, it indicates that the power

supply has failed and is not supplying output.

When blinking, it indicates that the power supply

has reached its current limit.

6

Page 14

Chapter 1: Controls, Ports, and Indicators

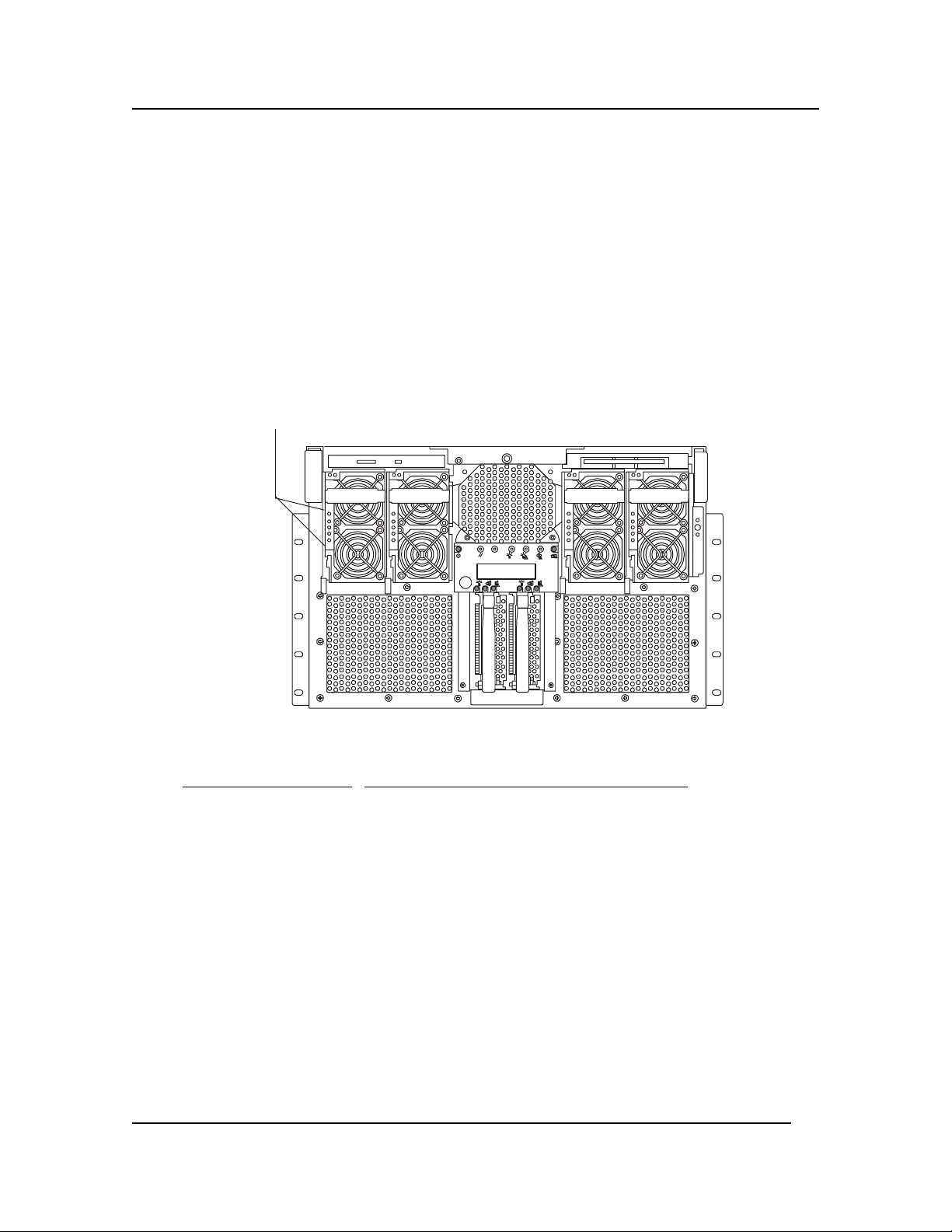

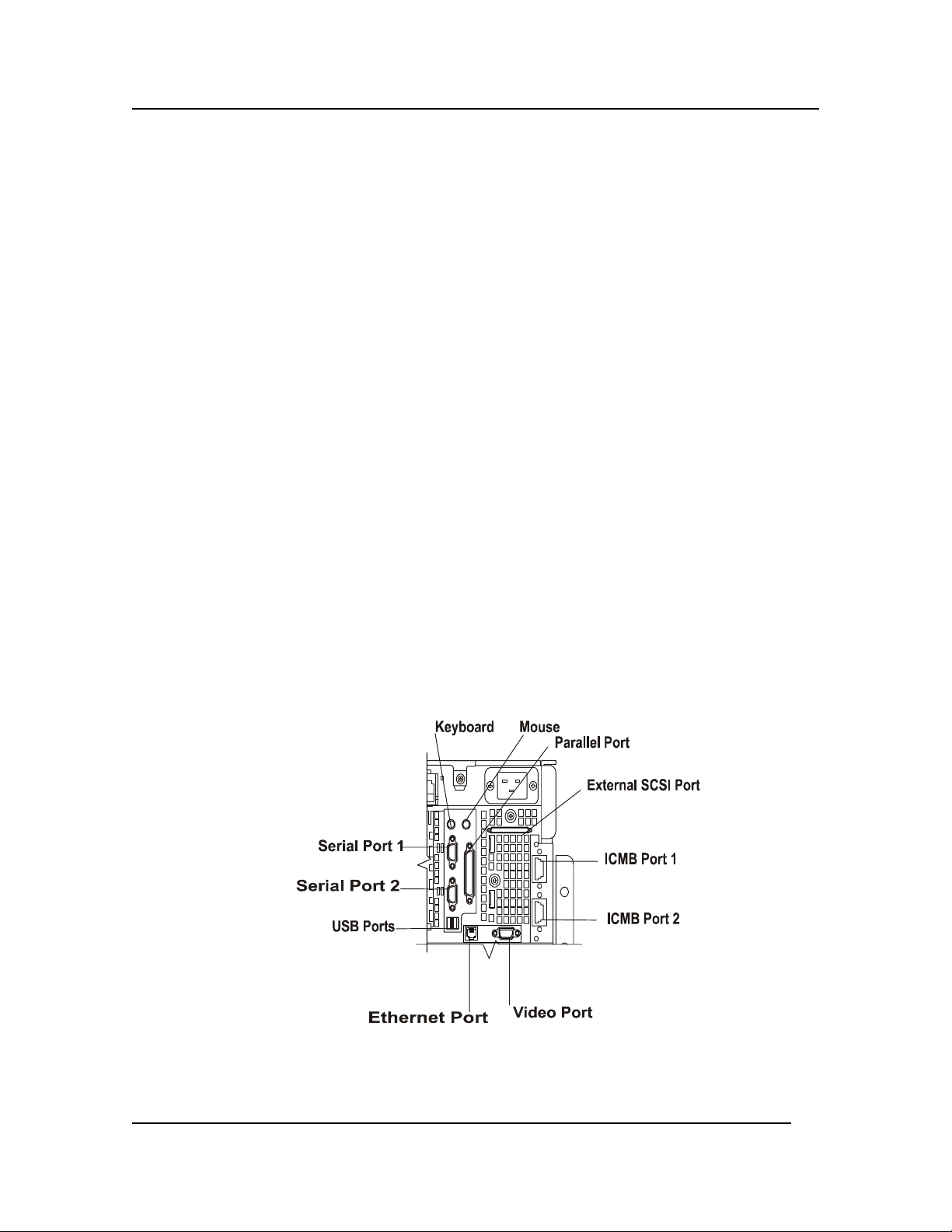

Rear View

The ports and connectors at the rear are listed below and shown in Figure 1-6. Figure 1-6 provides a

detailed view of the Legacy I/O panel that resides in the upper-right corner of the rear panel.

• The power connector accepts a standard power cable to connect the

HP Server with the site power supply.

• Ten PCI add-in board expansion slots are available. Eight are hot plug and two are non-hot

plug.

• Each hot plug PCI has status LEDs.

• The mouse port accepts a standard mouse with a PS/2 connector.

• The keyboard port accepts a standard keyboard with a 6-pin PS/2 connector.

• Two USB ports, 0 and 1, with 4 pin connectors are provided for printers, scanners, and

external modems.

• The LAN port is included as an embedded controller based on Intel's 82559 10/100 BaseT Fast

Ethernet controller. It has a RJ-45 LAN connector and two LEDs to indicate LAN speed and

valid connection.

• The two Serial Ports are standard 9-pin RS-232 connectors.

• The Parallel Port is a standard PS/2 compatible parallel port with a 25 pin bi-directional

subminiature D connector.

• There are two Interchassis Management Bus (ICMB) connectors, ports 1 and 2.

• The 15 pin video connector is Super VGA compatible.

• The optional external SCSI port provides access to external SCSI devices.

Figure 1-6. Rear Panel and Ports

7

Page 15

Chapter 1: Controls, Ports, and Indicators

Legacy I/O Panel

This board contains all legacy I/O connections and plugs into an edge connector on the I/O baseboard.

NOTE The keyboard and mouse connector must be plugged into the correct ports or the

server will not boot.

8

Page 16

Chapter 1: Controls, Ports, and Indicators

PCI LEDs

Each PCI slot has four indicator LEDs: two on the outside and two on the inside of the system. The

two LEDs for each slot: one amber and one green are visible from the rear (also inside) of the HP

Server, as shown in Figure 1-7. Eight of the ten PCI slots can be individually powered down through

the respective NOS or supported GUI utility, without powering down the entire HP Server, if the

board has a Hot Plug compliant driver.

Status Indicators for PCI Cards

Figure 1-7. Status Indicators for PCI Boards

9

Page 17

Chapter 1: Controls, Ports, and Indicators

Applying Power to the HP Server

Before applying power to the HP Server, verify that the keyboard and mouse are connected to the

proper ports. The server will not boot without these devices. Turning on the monitor prior to

powering on the HP Server allows proper auto-configuration of the video output as it boots.

Powering-Up the HP Server

To power-up the rx4610, complete the following procedure:

NOTE Turn on power to the monitor connected to the HP Server before you power-on the

Server. This allows proper

auto-configuration of video output of the Server as it boots.

1. Make sure that the monitor, keyboard, and mouse have been connected to the proper ports on

the rear panel of the server.

2. Remove the drive protection card, if present, from the diskette drive.

3. Plug in the power cord for the monitor and turn it on.

4. Plug the female ends of the server AC power cords into the input receptacle on the back of the

chassis.

5. Plug the male ends of the server AC power cords into grounded,

three-pronged AC power outlet.

6. Slide the server into the rack.

7. If the server does not come on when you plug it into the AC outlet, press the on/off power

switch on the front panel.

8. Verify that the power-on light on the front panel is lit. After a few seconds, the power-on self

test (POST) begins.

When you press the power button on the control panel, the Server powers up and loads the

operating system. The system runs a set of power on self tests (POST) during this process. For

details refer to Chapter 11, "Troubleshooting."

Powering-Down the HP Server

To power-down the HP Server, complete the following procedure:

1. Log off all users and, if necessary, back up the system files.

◊ Schedule the power down for a time when the Server being down will affect the fewest

users.

◊ If you will be doing any kind of hardware or software upgrade, ensure the Server's data has

been backed up.

◊ Follow instructions in your network operating system (NOS) documentation to gracefully

shut down all networking software and applications.

WARNING The power supply will continue to provide standby current to the HP Server until

the power cable is disconnected from the rear panel.

10

Page 18

Chapter 1: Controls, Ports, and Indicators

2. Logoff and exit the operating system. The following prompt appears:

Shell>

3. At the Shell> prompt, press and hold the Power button for several seconds. Holding the Power

button in for several seconds will power down the server.

4. Disconnect the power cords from the power source.

Normally this completes the power-down procedure.

Connecting AC Power to Multiple-Server Configurations

The HP Server temporarily draws a large "inrush current," when first connected to an AC power

source. This also occurs when the Server is in a standby mode (power is turned off, but the power

cord is plugged into AC power). The inrush current is much greater than the Server's normal operating

current and generally, the AC power source can handle the normal inrush current.

However, if you install several HP Servers on one circuit, precautions are necessary. If there is a

power failure and power is then restored, all the servers immediately begin to draw inrush current at

the same time. If the circuit breakers on the incoming power line have insufficient capability, the

breaker may trip and thus prevent the servers from powering up.

11

Page 19

2 Opening and Closing the HP Server

Introduction

This chapter describes how to remove and replace the front bezel and the HP Server's main cover.

Mounting the Front Bezel

The front handles, if not already installed on the HP Server, should be attached to the front of the HP

Server before mounting the bezel.

1. Place the handles into the slots on the front of the HP Server on each edge, as shown in the

figure below.

2. Insert the screws through the bracket into the top hole of each group of three holes on the front

sides of the HP Server. Repeat this procedure for both handles.

3. Hold the bezel in front of the HP Server.

4. Press the bezel firmly into place.

You should hear several clicks as the bezel snaps into place on the bracket.

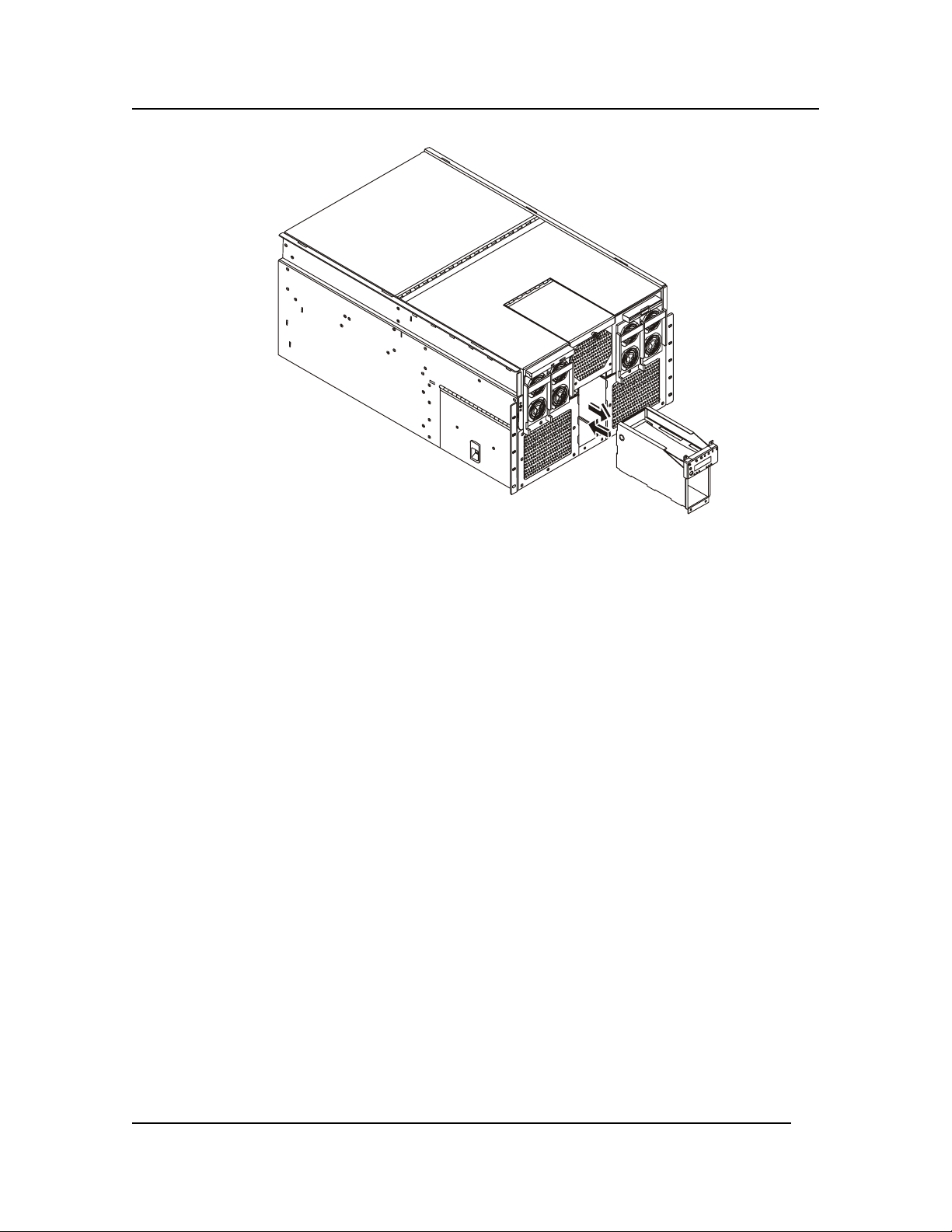

Removing and Replacing the Front Bezel

The bezel is packed in the top tray.

1. To remove the bezel, pull it straightforward off the chassis.

This exposes the power supplies, mass storage devices, and fans.

2. To replace the bezel, press it back onto the chassis, allowing it to snap into place. See Figure

2-1.

12

Page 20

Chapter 2: Opening and Closing the HP Server

Figure 2-1. Removing and Replacing the Front Bezel

13

Page 21

Chapter 2: Opening and Closing the HP Server

Removing and Replacing the HP Server’s Main Cover

The server comes with a removable top cover. Removal of this cover is necessary when installing or

removing many components. You do not have to remove the top cover when removing or installing

PCI hot plug and non-hot plug adapter boards, the Legacy I/O board, fans, hard drives, power

supplies, or components inside the Processor/Memory Complex.

WARNING Before removing the cover, always disconnect the power cord and unplug the

Ethernet cables. Disconnect the power cord to avoid exposure to high energy

levels that may cause burns when parts are short-circuited by metal objects such

as tools or jewelry.

Make sure that the rack is anchored securely so that it does not tip when the server

is extended from the rack.

CAUTION For proper cooling and airflow, do not operate the server with the cover off.

Always reinstall the cover before turning on the server.

Tools Required

The following tools may be required to remove and replace the cover.

• Phillips screwdriver #2 (cross-head )

• Small flat-bladed screwdriver

• Jumper removal tool

• Anti-static wrist strap

Removing the Top Cover

To remove the cover, follow these steps:

1. Turn off all peripheral devices connected to the server.

2. Power down the server by pressing and holding the Power button on the Front Control Panel.

You may have to hold the Power button down for several seconds.

3. Disconnect the power cords and any Ethernet line.

4. Pull the server out of the rack.

5. Loosen the thumbscrew at the front of the chassis that secures the 120 mm fan bay and fold the

fan cover open.

6. Loosen the two thumbscrews that secure the top cover to the rear of the chassis and fold the

rear half of the top cover open.

7. Loosen the screw that secures the non-hot plug PCI adapter board cover and remove that

cover.

8. Place your hands on the sides of the chassis near the hinge of the rear part such that your

thumbs can aggressively slide the entire top cover toward the rear of the chassis. Sliding the

14

Page 22

Chapter 2: Opening and Closing the HP Server

cover in this direction disengages the hooks on both sides of the top cover from the chassis

housing.

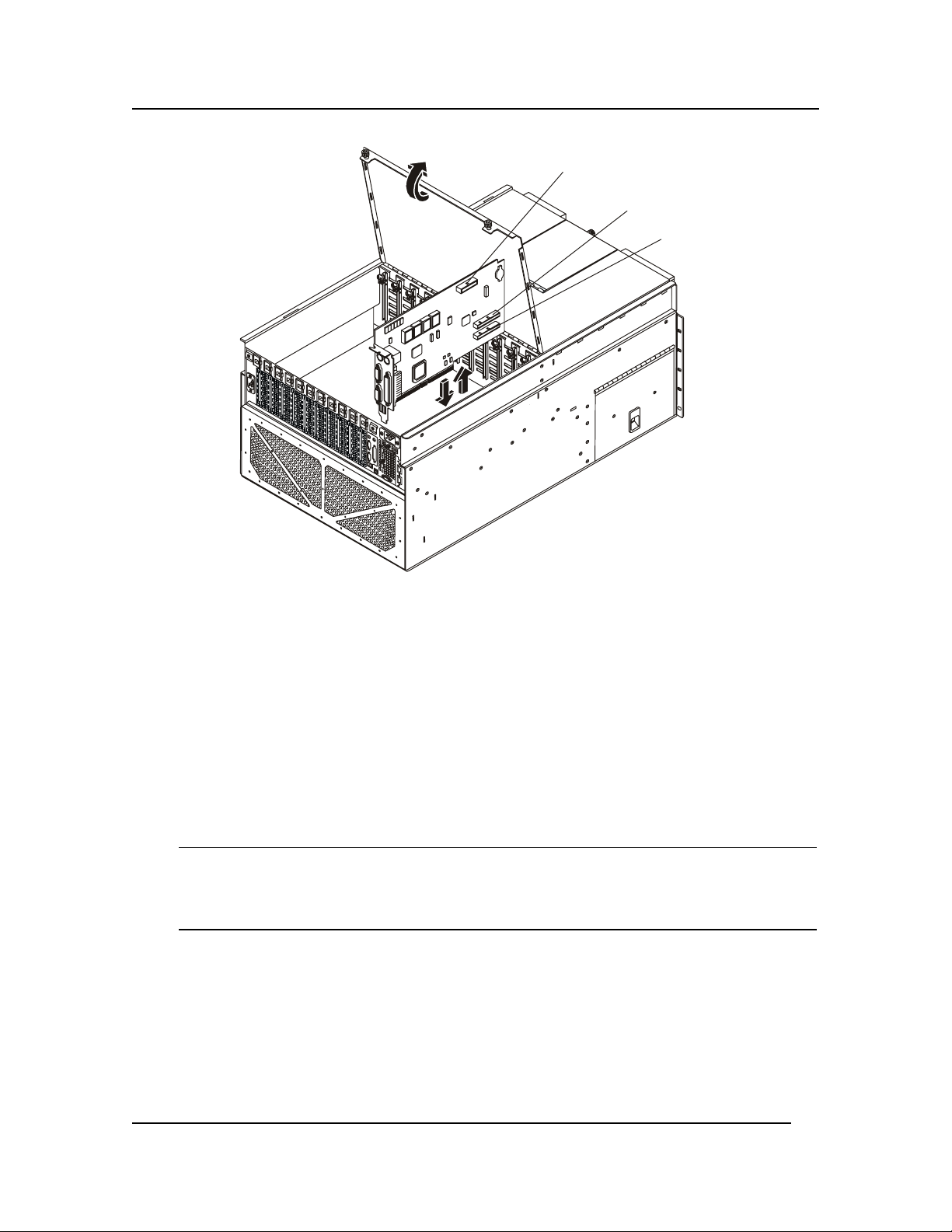

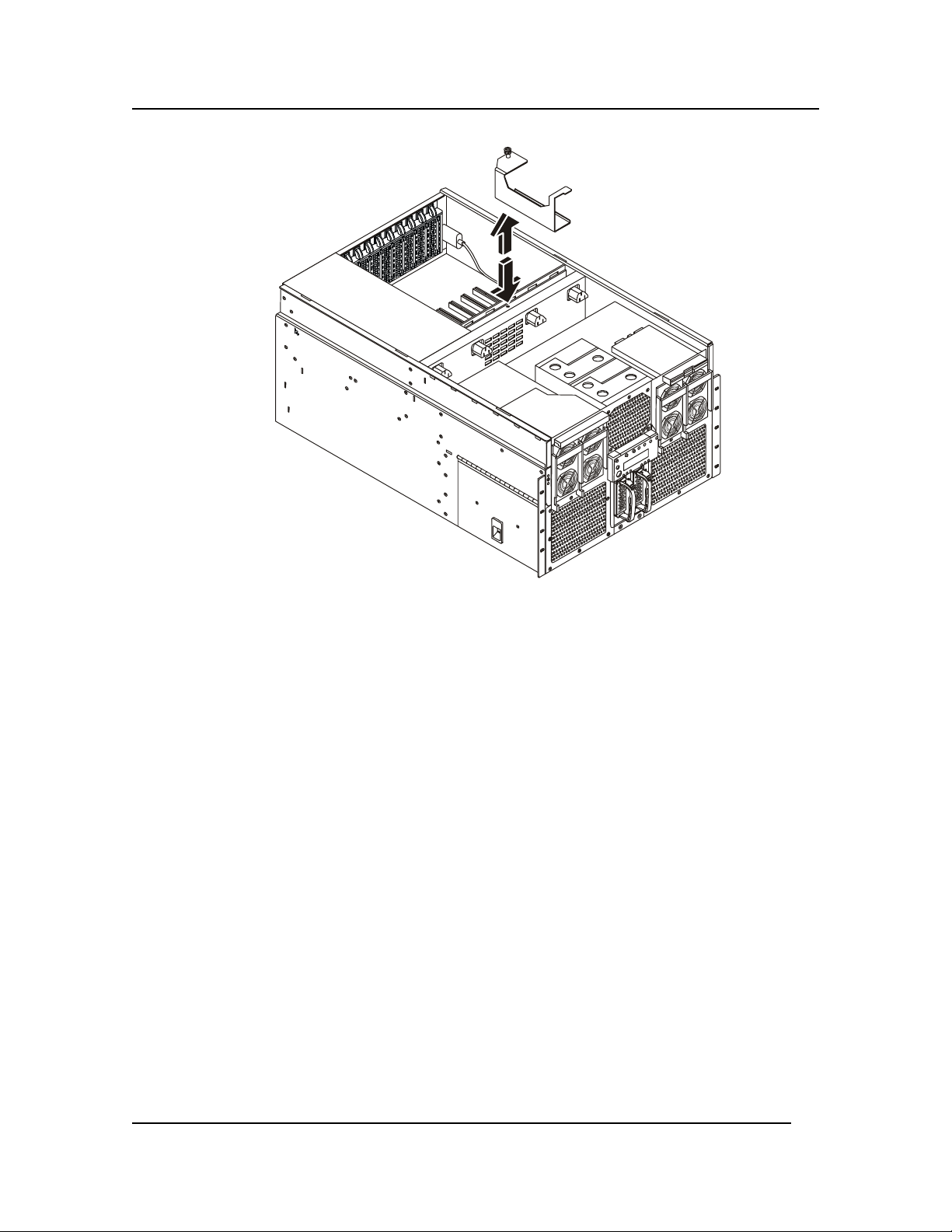

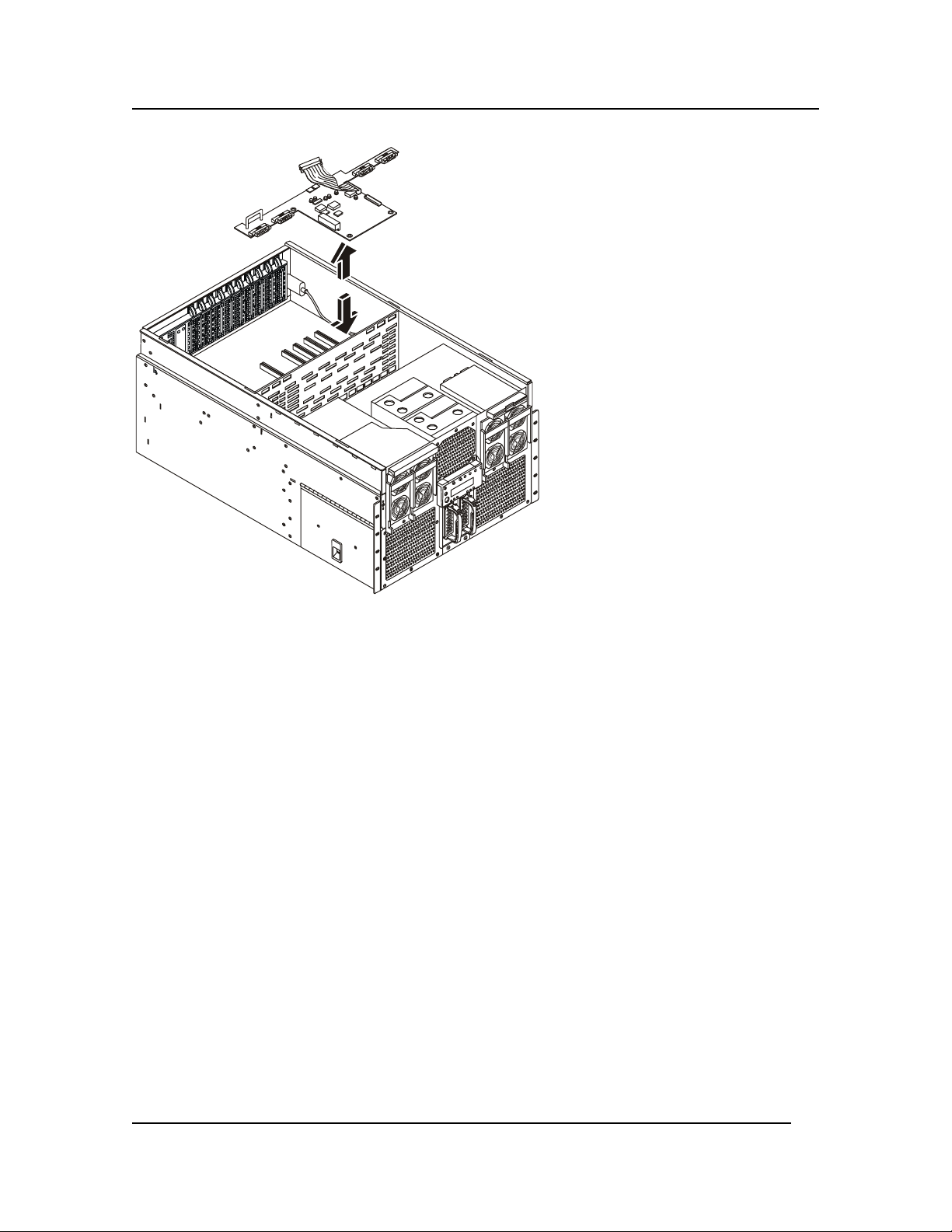

Figure 2-2. Removing the Cover

9. Lift the top cover off the chassis.

Replacing the Top Cover

To replace the cover, complete these steps:

1. Provide ESD protection by wearing an antistatic wrist strap attached to chassis ground of the

system when handling components.

2. Before installing the top cover, check that you have not left loose tools or parts inside the

system.

3. Check that cables, add-in boards, and other components are properly installed.

4. Make sure that the 120 mm fan cover is lifted and open.

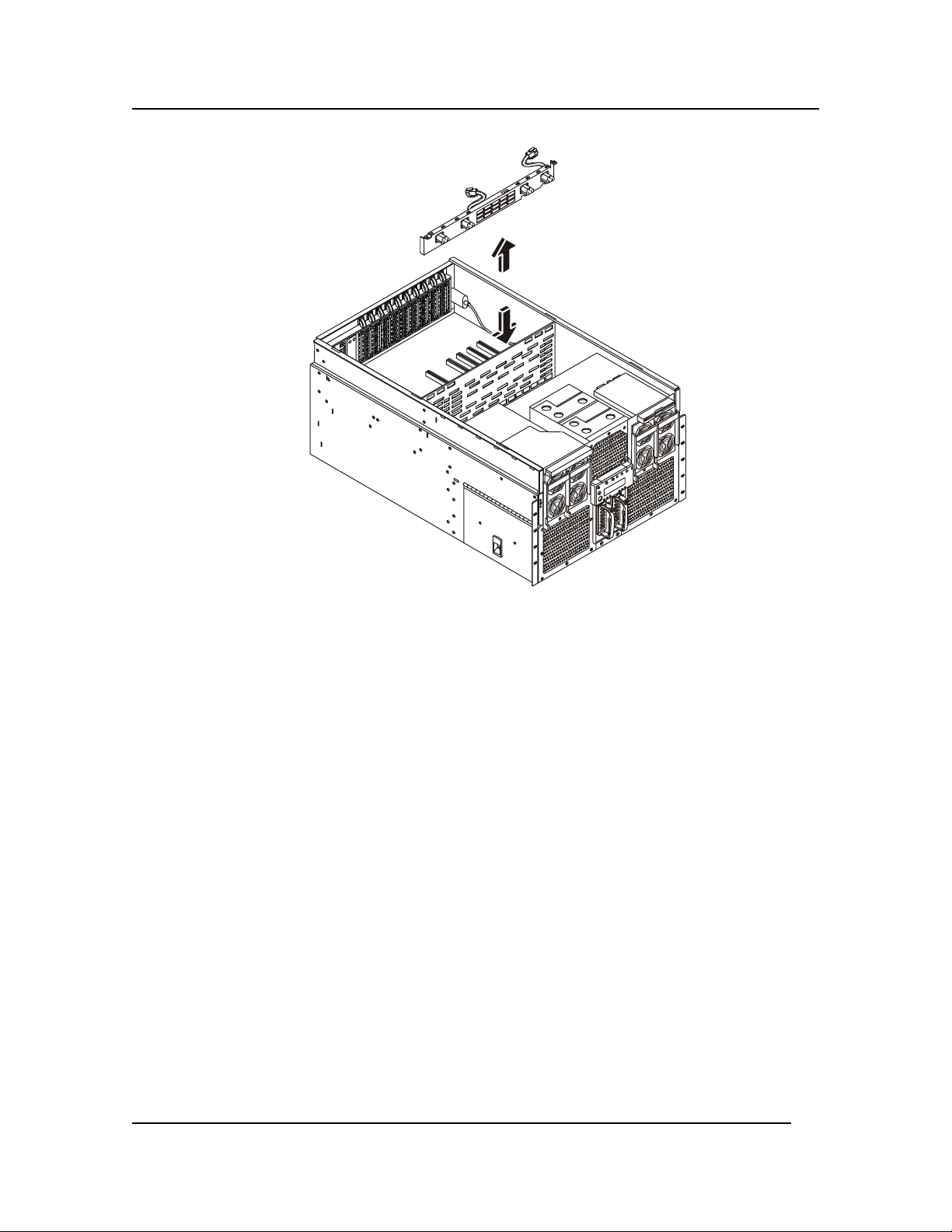

5. Fold the rear part of the top cover open and set it down on the chassis, aligning the hooks on

both sides of the front half of the cover.

6. Place your hands on the sides of the chassis near the hinge of the rear part such that your

thumbs can aggressively slide the entire top cover toward the front of the chassis. Sliding the

cover in this direction engages the hooks on both sides of the top cover into the chassis

housing.

15

Page 23

Chapter 2: Opening and Closing the HP Server

Figure 2-3. Replacing the Cover

7. Close the 120 mm fan cover and tighten the thumbscrew. If the door does not close then the

top cover hooks have not fully engaged into the chassis.

8. Replace the PCI adapter board cover and install the screw that secures it to the top cover.

9. Close the rear half of the top cover and tighten the two thumbscrews.

10. Push the chassis back into the rack.

11. Connect the keyboard, mouse, and monitor before powering up the system.

12. Power on any peripherals connected to the server that you shut down.

13. Power on the system.

16

Page 24

3 Installing Fans and Power Supplies

Introduction

The fans and power supplies used by the HP Server are hot swappable. The HP Server has four 172

mm fans located on each side of the chassis and two 120 mm cooling fans located on the top front of

the chassis. The server has a maximum of four 800 watt autoranging power supplies located in the

front of the chassis. This chapter describes the procedures necessary to remove and to replace these

components.

Tools and Supplies Needed

• Phillips (cross-head) screwdriver (#2 bit)

• Antistatic wrist strap (recommended)

• Pen or pencil

• Equipment Log

To record the model and serial numbers of the server, all installed options, and any other pertinent

information about the server, see Appendix B, “Equipment Log and Configuration Worksheet”.

WARNING Make sure that the rack is anchored securely, so it will not tip when the server

chassis is extended.

17

Page 25

Chapter 3: Installing Fans and Power Supplies

Hot Swapping the 172 mm Fans

The four 172 mm cooling fans are mounted in pairs on each side of the chassis. You can hot-swap

these fans without turning the server system power off. Each fan uses an amber LED located on the

fan’s casing to indicate the fan has failed. If it is a failed fan, the amber LED will be illuminated on

the front panel, and the amber LED on the failed fan itself will be illuminated. The individual fan

LEDs may be seen through view-ports in the fan covers

Removing the 172 mm Fans

To remove the 172 mm fan, complete the following steps:

1. Observe all standard safety and ESD precautions.

2. Slide the server out of the rack far enough to expose the fan-access doors near the front sides

of the chassis.

CAUTION Do not leave the door open for an extended time. Cooling of the system could be

reduced.

3. Slide the plastic latch on the fan cover upwards and pull the door open.

4. Grasp the fan assembly with the finger holes and pull it out.

LED Indicator

Figure 3-1. Removing the 172 mm Fans

18

Page 26

Chapter 3: Installing Fans and Power Supplies

Installing the 172 mm Fans

To install the 172 mm fan, complete the following procedure:

1. Lift the latch on the fan-access door and open the door.

NOTE Verify the connector orientation prior to installing the new fan.

2. Slide the new fan into place with the connector oriented to engage the socket inside of the fan

enclosure.

3. Push the fan assembly firmly into the enclosure to seat the connector.

4. Close the fan-access door and engage the latch by pushing it downward.

5. Slide the chassis back into the rack.

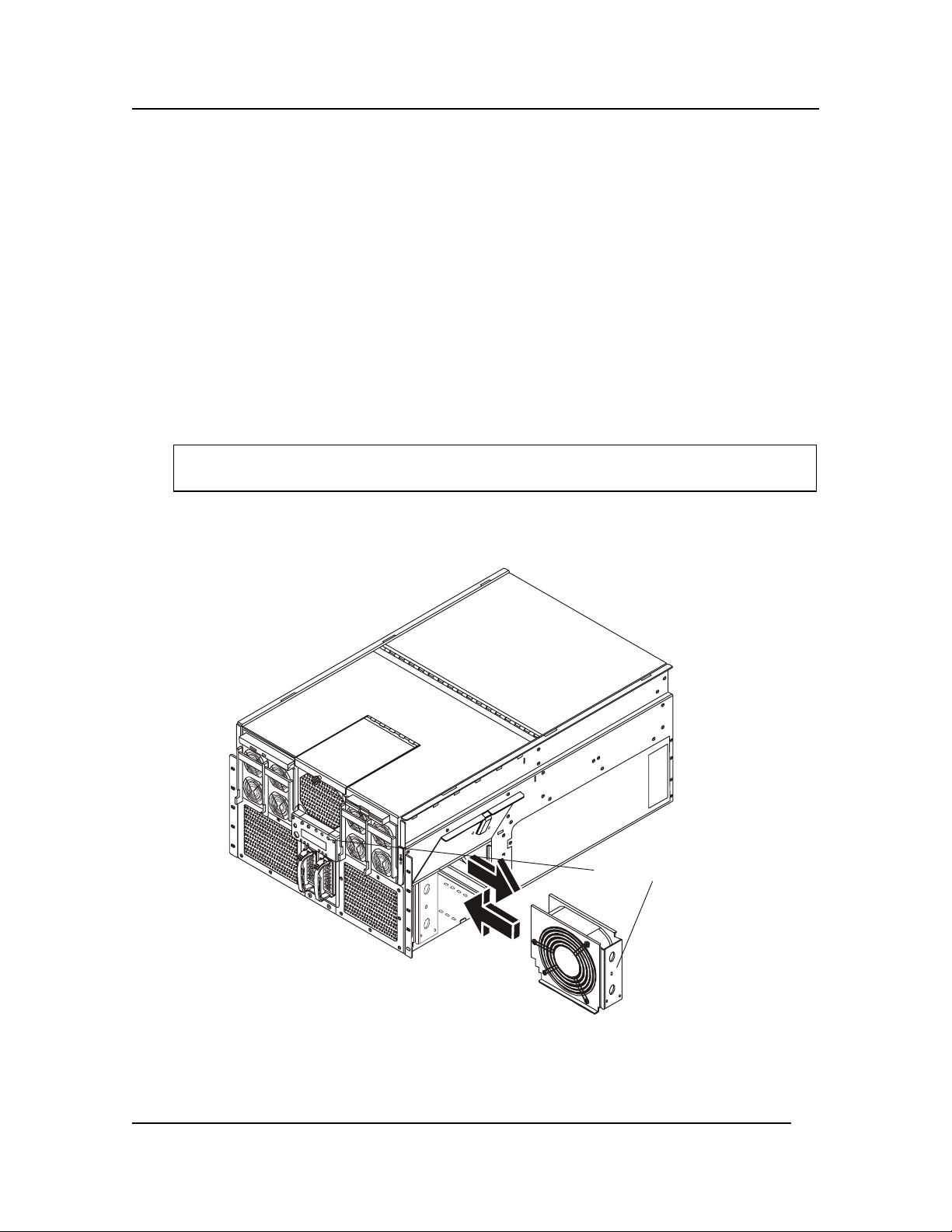

Hot Swapping the 120 mm Fans

The two 120 mm cooling fans are mounted on the top front of the chassis. These fans can be replaced

without shutting down power to the system. If it is a failed fan, the amber LED will be illuminated on

the front panel, and the amber LED on the failed fan itself will be illuminated. The individual fan

LEDs may be seen through view-ports in the fan covers

Removing the 120 mm Fans

To remove the 120mm fan, complete the following procedure:

1. Slide the server out of the rack far enough to expose the fan-access door on the top of the

chassis.

2. Unscrew the thumbscrew on the front of the fan-access door and lift the door open. If a fan

has failed, the amber LED light is illuminated.

CAUTION Do not leave the door open for an extended time. Cooling of the system could be

reduced

3. Grasp the fan assembly through the finger holes and pull the assembly out.

19

Page 27

Chapter 3: Installing Fans and Power Supplies

Figure 3-2. Removing the 120 mm Fans

Installing the 120 mm Fans

Follow these steps to install a 120 mm fan:

1. Slide the server out of the rack far enough to expose the fan-access door on the top of the

chassis.

2. Unscrew the thumbscrew on the front of the fan-access door and lift the door open.

3. Slide the new fan into place, with the connector oriented to engage the socket inside of the fan

enclosure.

4. Push the fan assembly firmly into the enclosure to seat the connector.

5. Close the fan-access door and tighten the thumbscrew.

6. Slide the chassis back into the rack.

20

Page 28

Chapter 3: Installing Fans and Power Supplies

Hot Swapping Power Supplies

The power system contains four 800-watt autoranging power supplies. The third bay’s power supply

from the left as you face the chassis serves a redundancy function for the server’s power supply

requirements.

CAUTION Because of chassis airflow disruption, the power supply bay should not be vacant

for more than five minutes when server power is on. Exceeding the five-minute

limit might cause system cooling to fall below the minimum required level and

possibly cause damage to system components.

NOTE The server requires a minimum of three power supplies to operate. If you have

only three power supplies operational, they must occupy the first, second, and

fourth power supply bays as you face the chassis. Figure 3-3 shows the power

supply installation order.

2

4

3

1

If only 3 power supplies

are operational, place a

filler panel over the fourth

bay in the installation order.

Figure 3-3. Power Supply Installation Order

21

Page 29

Chapter 3: Installing Fans and Power Supplies

Determining Power Supply Status

When the amber power supply failure LED on the front of the chassis turns on, determine which

power supply is defective by checking the three status LEDs on each supply. Each power supply has

three LEDs that both indicate whether power is supplied to the power supply and the health of the

power supply. The LEDs are ordered top to bottom on each power supply. Table 3-1 illustrates the

states indicated by the three LEDs.

Table 3-1. Power Supply LEDs

Power Supply Status

PWR

(Green)

(Top

Position)

PFAIL

(Amber)

(Middle

Position)

FAIL

(Amber)

(Bottom

Position)

No AC power to any power supplies Off Off Off

No AC power to a specific power supply Off Off On

AC present / Standby output on Blinking Off Off

DC outputs on and okay On Off Off

Power supply failure Off Off On

Current limit On Off Blinking

Predictive failure On Blinking /

Off

Latched

22

Page 30

Chapter 3: Installing Fans and Power Supplies

Removing a Power Supply

To remove a power supply, complete the following procedure:

1. Locate the power supply you want to remove.

2. Push the thumb latch to unlock the power supply handle and pull the handle down to undock

the supply.

CAUTION Any unused power supply slots must be covered with a blanking plug. Uncovered

slots can disrupt the air flow used for cooling the system.

Figure 3-4. Removing a Power Supply

3. Pull the power supply straight forward, out of the chassis. Set it aside.

23

Page 31

Chapter 3: Installing Fans and Power Supplies

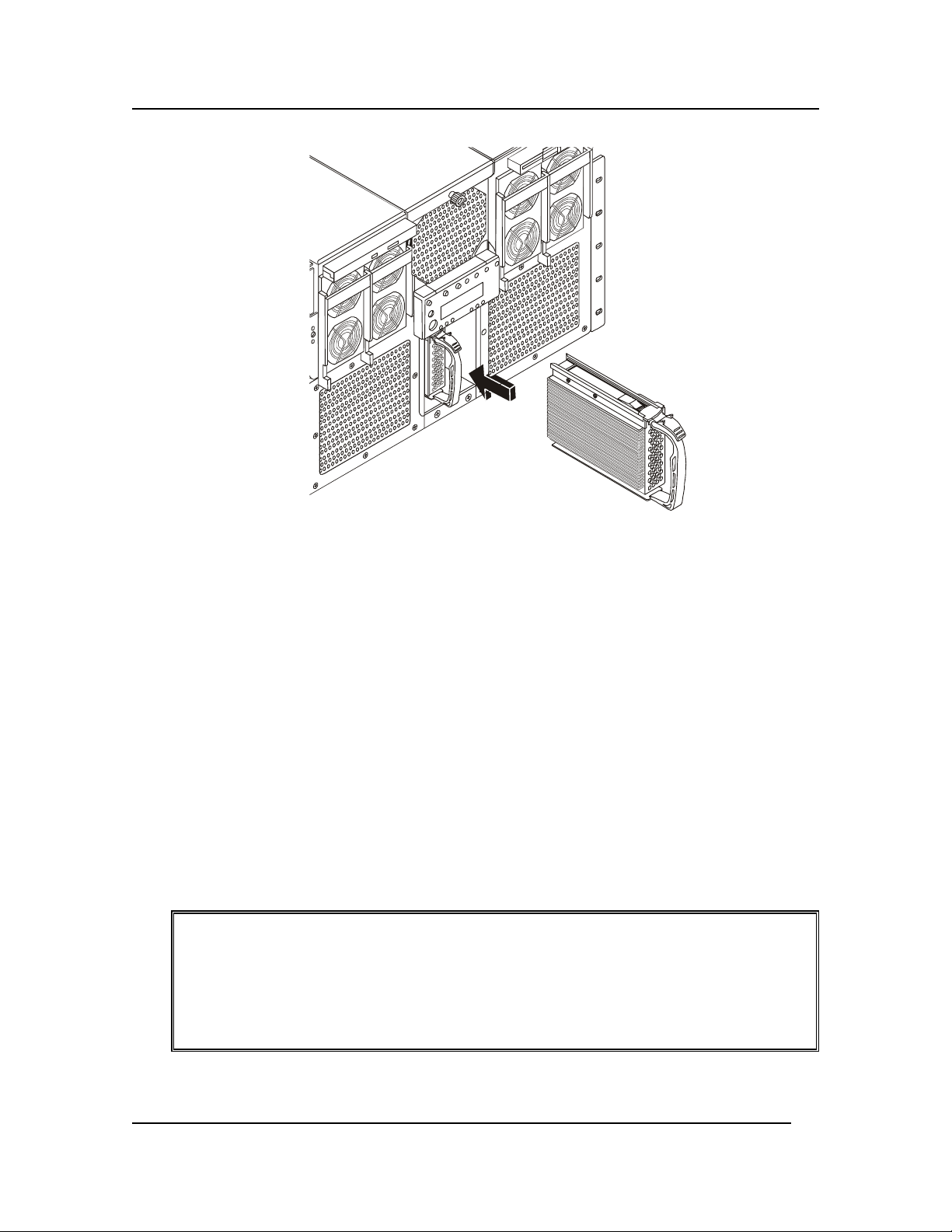

Installing a Power Supply

The power supply bay should not be vacant for more than five minutes when server power is on.

Disruption of the airflow may cause system cooling to fall below acceptable levels. To install the new

power supply, complete the following procedure:

1. Remove the new power supply from the protective packaging, and place it on an antistatic

surface.

2. Record the model and serial numbers of the power supply in your equipment log.

3. With the handle in the open position (pulled down), slide the replacement power supply into

the power supply bay until it stops.

4. Rotate the handle up and in to lock the power supply into place.

5. Check the new power supply LEDs to verify proper functioning.

24

Page 32

4 Installing Mass Storage Devices

Introduction

The HP Server comes standard with a DVD and a floppy diskette drive. The internal mass storage

cages support a maximum of two hot swap drive carriers. Each carrier can house a standard one inch

high by three and half inch wide SCSI-2 or SCSI-3 hard drive. The internal SCSI drives are mounted

to the carriers using four screws.

Mass Storage Guidelines

• General Guidelines

◊ Use care when unpacking and handling the SCSI disk drives.

The hard disk drives are very susceptible to mechanical shock and can be easily damaged

by a drop as short as one-quarter of an inch. If the drop would crack an egg, it will damage

the drive.

◊ Do not stack drives.

◊ The HP Server is internally limited to 2 SCSI disk drives

• IDE Devices

◊ The diskette drive and DVD drive are standard on all models of the HP Server. They are

housed in two piece drive carrier assemblies that rest on the chassis surface. They are

accessible when the top cover is removed. See Figures 4-3 and 4-4.

◊◊◊◊ The Legacy I/O board contains the PCI-enhanced IDE interface with two IDE buses. The

primary IDE 0 bus supports the diskette drive and the secondary IDE 1 bus supports the

DVD drive.

Refer to "System Board Layout" in Appendix A, "Specifications."

• SCSI Device Selection

◊◊◊◊ A Qlogic ISP12160A Ultra3 SCSI chip is a highly integrated bus master, dual-channel

SCSI I/O processor for SCSI initiator and target applications. The chip supports dual

channel, Ultra3 (160) SCSI functionality and is pin compatible with QLogic’s ISP12160

Ultra3 SCSI processor as well as QLogic’s ISP1280 dual SCSI processor.

◊◊◊◊ Use only low-voltage differential (LVD) SCSI devices.

Boot Priority

The HP Server's boot order should be considered when selecting a PCI slot on the system board. This

is especially important if you are installing a board that requires an early number in the boot order.

The board's boot priority is set by its slot location in the boot order.

By default the HP Server searches for boot devices in this order:

1. SCSI

2. PM

3. SM

25

Page 33

Chapter 4: Installing Mass Storage Devices

4. PS

5. Other Boot Devices

IDE DVD drive

Flexible disk drive

6. PCI slot 1

7. PCI slot 2

8. PCI slot 3

9. PCI slot 4

10. PCI slot 5

11. PCI slot 6

12. PCI slot 7

13. PCI slot 8

14. PCI slot 9

15. PCI slot 10

The SCSI controller chip interfaces the PCI bus to two Ultra3 SCSI buses and contains an onboard

RISC processor. The RISC processor is a fully autonomous device, capable of managing multiple I/O

operations and associated data transfers from start to finish without host intervention. It provides

power management feature support in accordance with the PCI Bus Power Management Interface

Specification.

NOTE The boot order can be changed using the Server's (BIOS) Setup Utility and the

Qlogic SCSI Utility. Refer to Chapter 10, "Configuring the HP Server" for more

information.

Tools Required

The following tools are required for the removal and installation of mass storage devices in the HP

Server:

• Phillips (cross-head) screwdriver (#2).

• Small flat-bladed screwdriver.

• Jumper-removal tool or needle-nosed pliers.

• Antistatic wrist strap and conductive foam pad (recommended).

• Pen or pencil.

• Equipment log: to record the model and serial numbers of components.

Installing a Hot Swap Hard Drive

The HP Server supports a variety of single-ended SCSI SCA-type hard disk drives. The area of the

chassis below the system’s controls and indicators on the front panel houses up to two 3.5-inch bays.

Each bay can contain a single industry-standard SCSI-2 or SCSI-3, one-inch high hard disk drive

26

Page 34

Chapter 4: Installing Mass Storage Devices

from the factory. The procedures in this section describe how to determine drive status, remove a

faulty drive, and install a new drive.

Determining Drive Status

Status LEDs arranged in sets of three over each of the two Hard Disk Bays monitor the status of each

drive.

Table 4-1. SCSI Drive Status LED Descriptions

SCSI drive present

with power on

Green LED

Left

On Off Off Drive is present with

On Blinking Off Drive is present with

Off Off On Steady amber fault light

On

Off Slow Blinking Drive SHOULD NOT be

Off

Off Off There is no drive installed

SCSI drive

active

Green LED

Middle

SCSI drive

faulty*

Amber LED

Right

Description and Action

(If Required)

power.

power and is being

accessed.

indicates drive has a

problem.

replaced at this time. A

slowly blinking amber

fault light indicates that a

drive that has just been

replaced is in recovery

mode (drive array being

rebuilt). Power to drive is

on.

in the bay.

Removing a Hard Disk Drive

To remove a hard disk drive from the disk bay, complete the following procedure:

1. Look at the amber LEDs above the hard disk bays to determine which drive is bad. See Table

4-1 for information on how to interpret the LEDs.

2. Remove the plastic bezel on the front of the server.

3. Depress the drive carrier latch of the bad drive, and use the handle to pull the assembly toward

you to disengage the drive from the backplane connector.

27

Page 35

Chapter 4: Installing Mass Storage Devices

Figure 4-1. Removing a Hard Disk Drive

4. Carefully slide the assembly out of the bay, and place it on an antistatic surface.

Installing a Hard Disk Drive

Hard disk drives are packaged in their drive carriers for immediate installation. They require no

assembly and may be installed without the use of any tools. To install the hard disk drive, complete

the following procedure:

1. Remove the plastic bezel on the front of the server.

2. Orient the new drive’s carrier and drive assembly in front of the bay guide rails so that the

latch is toward the top. Make sure that the carrier is placed correctly into the guide rails to

avoid damage.

CAUTION Do not press on the perforated metal bracket of the carrier when you push the

assembly into the bay, or you may damage the metal fingers of the bracket.

3. While grasping only the drive carrier handle, firmly push the assembly into the bay until the

drive docks with the backplane connector and the carrier latch locks.

28

Page 36

Chapter 4: Installing Mass Storage Devices

Figure 4-2 Hot Swapping a SCSI Drive

4. Replace the plastic bezel on the front of the server.

Installing Non-Hot Swap Drives

The HP Server supports a slimline IDE diskette drive for 1.44 MB and 120 MB media and a DVD

drive. Both drives are part of the standard configuration and mount directly above the power bays on

the front of the chassis. The drives are mounted on removable trays that facilitate system assembly

and service. The server must be powered down to install these drives.

Installing the Floppy Disk Drive

The floppy disk drive is housed in a two-piece drive carrier assembly that rests on the chassis surface.

The assembly is accessible when the top cover is removed. The following procedures describe how to

remove and install the drive.

Removing the Floppy Diskette Drive

To remove the floppy diskette drive, complete the following procedure:

1. Observe all safety and ESD precautions whenever you remove the cover from the HP Server.

WARNING Before removing the top cover, always disconnect the power cord and unplug the

Ethernet cables. Disconnect the power cord to avoid exposure to high energy

levels that may cause burns when parts are short-circuited by metal objects such

as tools or jewelry.

The power switch does NOT turn off the standby power. Disconnect the power

cord from the HP Server before handling components.

2. Remove the top cover as described in “Removing and Replacing the HP Server’s Main Cover”

in Chapter 2.

29

Page 37

Chapter 4: Installing Mass Storage Devices

3. Disconnect the drive’s data and power cables from cable adapter PCB at the rear of the drive.

4. Loosen the thumbscrew found at the rear of the drive carrier assembly.

5. Slide the drive and the drive carrier assembly toward the rear of the chassis so that the front

part of the drive clears the opening in the chassis.

6. Remove the drive carrier assembly with the drive in it from the chassis.

7. Place the drive in an antistatic protective wrapper if you are not reinstalling the same drive.

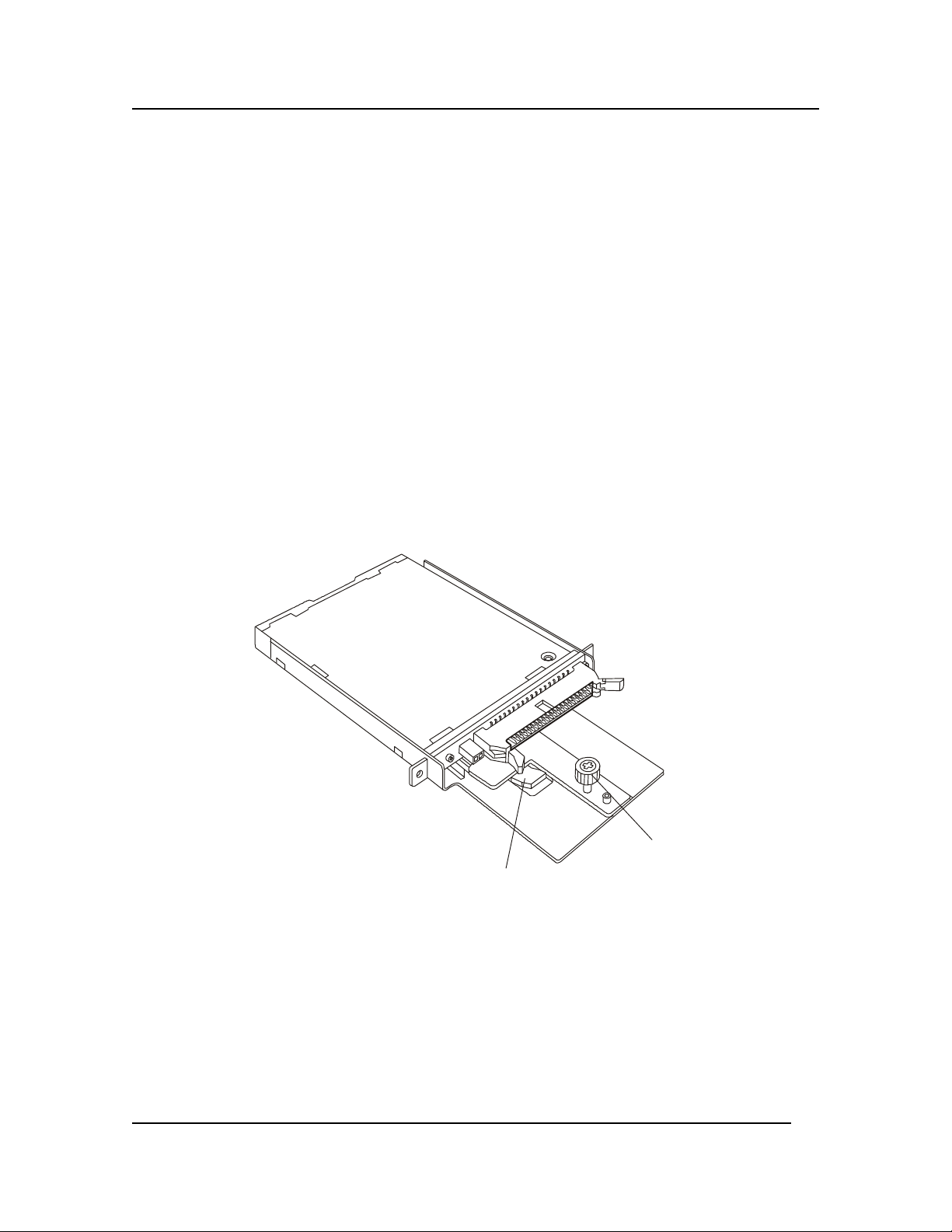

Installing the Floppy Disk Drive

To install the new floppy diskette drive, complete the following steps:

1. Remove the new drive assembly from its protective wrapper, and place it component-side up

on an antistatic surface.

2. Record the drive model and serial numbers in your equipment log.

3. Pick up the entire drive carrier assembly, being careful that you keep the pieces together, and

place it on the chassis surface just inside the drive slot.

4. Grasp the sides of the drive and drive carrier assembly and slide it forward such that the front

part of the drive comes through the opening in the chassis. Make sure that the thumbscrew at

the rear of the drive carrier assembly aligns with the hole in the surface of the chassis.

Thumbscrew

Tab

Figure 4-3. Diskette Drive

5. Tighten the thumbscrew at the rear of the drive carrier assembly.

6. Install the drive’s data and power cables into the cable adapter PCB.

7. Install the top cover.

Installing the DVD Drive

The DVD Drive is housed in two-piece drive carrier assembly that rests on the chassis surface. The

drive carrier assembly is accessible when the top cover is removed. The following sections describe

how to remove and install the drive.

30

Page 38

Chapter 4: Installing Mass Storage Devices

Removing the DVD Drive

To remove the DVD drive, complete the following procedure:

1. Observe the safety and ESD precautions at the beginning of this chapter.

2. Remove the top cover as described in “Removing and Replacing the HP Server’s Main Cover”

in Chapter 2.

3. Disconnect the drive’s data and power cables from the drive cable adapter PCB at the rear of

the drive.

4. Loosen the thumbscrew found at the rear of the drive carrier assembly.

5. Slide the drive and drive carrier assembly towards the rear of the chassis so that the front part

of the drive clears the opening in the chassis.

6. Place the drive in an antistatic protective wrapper if you are not reinstalling the same drive.

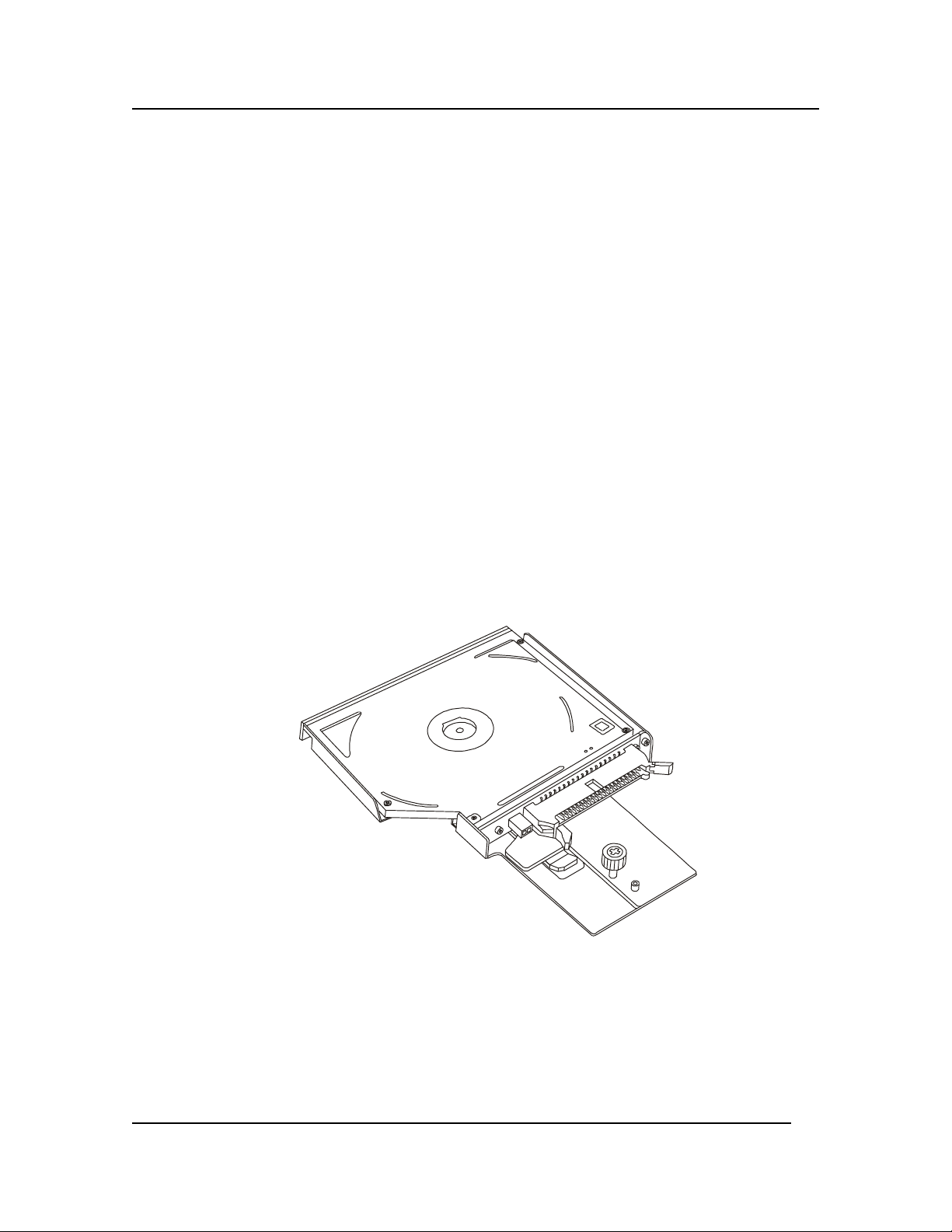

Installing the DVD Drive

To install the new DVD drive, complete the following steps:

1. Remove the new drive from its protective wrapper, and place it face down on an antistatic

surface.

2. Record the drive model and serial numbers in your equipment log.

3. Pick up the DVD drive and drive carrier assembly and place it face up (carrier side down) on

the chassis such that the front of the drive is aligned with the opening in the front of the

chassis.

Figure 4-4. Installing the DVD

4. Grasp the sides of the drive and drive carrier assembly and slide it forward such that the front

part of the drive comes through the opening in the chassis. Make sure that the thumbscrew at

the rear of the drive carrier assembly aligns with the hole in the surface of the chassis.

5. Tighten the thumbscrew at the rear of the drive carrier assembly.

6. Connect the drive’s data and power cables.

31

Page 39

Chapter 4: Installing Mass Storage Devices

7. Install the top cover as described in “Removing and Replacing the HP Server’s Main Cover” in

Chapter 2.

Connecting External SCSI Devices

The second SCSI channel B is connected directly to the external VHD (Very High Density) 68-pin

SCSI connector on the rear panel. All external SCSI devices are connected to the HP Server using this

external connector, but the external SCSI devices must provide the necessary termination at the end of

the SCSI chain. If no external devices are connected, then no termination is required. The internal

SCSI controller terminates channel B electrically, if no external devices are sensed at the connector.

Please consult the product update information for the latest approved adapters on the following HP

website:

http://www.hp.com

Removing and Installing the Hard Disk Bay

The Hard Drive Bay provides mounting features for two hot swap hard drives, the Front Panel

Interface board, and the Hot Swap Backplane board. You can easily remove and install the bay from

the chassis by removing the front bezel and four mounting screws.

Removing the Hard Disk Bay

To remove the Hard Disk Bay, complete the following procedure:

1. Turn off the system by using the power on/off switch on the front of the chassis and remove

both AC power cords.

2. Remove the front bezel.

3. Remove each hard disk drive from the drive bay by first grasping its handle and depressing the

drive locking tab, and then sliding the drive out of the bay.

4. Remove the four #2 Phillips screws from the top and bottom of the drive bay.

5. Grasp the bay by the Front Panel display housing and gently pull the drive bay out of the

chassis.

Figure 4-5. Hard Disk Bay

32

Page 40

Chapter 4: Installing Mass Storage Devices

Installing the Hard Disk Bay

To install the Hard Disk Bay, complete the following steps:

1. Turn off the system by using the power on/off switch on the front of the chassis and remove

both AC power cords.

2. If the front bezel is not already removed, remove the bezel.

3. Align the Hard Disk Bay such that the connector side is facing into the chassis and push the

bay into the front of the chassis.

4. Ensure the drive bay seats into the front connector on the Power Distribution Board (TDocking Board).

5. Replace the four screws at the top and bottom of the bay.

6. Replace any disk drives into drive bay as required.

7. Replace the Front Bezel.

33

Page 41

Chapter 4: Installing Mass Storage Devices

Removing and Installing the SCSI Backplane

The SCSI Backplane resides on the back of the Hard Drive Bay. It is accessed by removing the Hard

Disk Bay.

Removing the SCSI Backplane

To remove the SCSI Backplane, complete the following steps:

1. Remove the Hard Disk Bay as described in “Removing the Hard Disk Bay” earlier in this

chapter.

2. Disconnect the LCD panel cable from the SCSI Backplane.

3. Remove the cap stabilizer retaining screw and the cap stabilizer. These two items will be used

on the new board.

4. Remove the three screws that secure the SCSI Backplane to the Hard Disk Bay.

5. Carefully place the SCSI Backplane on a clean, anti-static work surface or in anti-static

packaging.

Figure 4-6. Removing the SCSI Backplane

Installing the SCSI Backplane Board

To install the SCSI Backplane Board, complete the following procedure:

1. Carefully align the SCSI Backplane in the slots to the rear of the Hard Disk Bay. Be sure that

the four holes in the SCSI Backplane align with the holes and alignment pin in the bay.

2. Secure the SCSI Backplane to the bay by tightening the three screws.

3. Connect the Front Panel cable to the SCSI Backplane. Open the cable connector lock tabs to a

4. Position the cap stabilizer and secure it with the cap stabilizer retaining screw.

5. Install the Hard Drive Bay as described in “Installing the Bay” earlier in this chapter.

c

45

angle before inserting the cable.

34

Page 42

Chapter 4: Installing Mass Storage Devices

Installing the Front Panel Board

The Front Panel Board displays server information. The module is attached to the front of the Hard

Disk Bay, which must first be removed to gain access to the Front Panel Board.

Removing the Front Panel Module

To remove the Front Panel module, complete the following procedure:

1. Turn off the system by using the power on/off switch on the front of the chassis and remove

both AC power cords.

2. Remove the Hard Disk Bay from the chassis as described in “Removing the Hard Disk Bay”

earlier in this chapter.

3. Disconnect the cable to the Front Panel Board that is attached to the front of the Hard Disk Bay

by squeezing the cable retention levers together. You do not have to remove the rear part of

the cable.

4. Remove the two screws securing the Front Panel Board to the front panel mounting on the

Hard Disk Bay. These screws are located on the inside of the Front Panel Board.

5. Remove the Front Panel Board from the Hard Disk Bay assembly and place it on an ESD

protected work surface.

2. Remove the two screws.

Figure 4-7 The Front Panel Board

1. Disconnect the cable.

Installing the Front Panel Board

To install the new Front Panel Board, complete the following steps:

1. Using two Phillips screws, secure the new Front Panel Board to the Hard Disk Bay.

2. Connect the front part of the Front Panel Board data cable to the connector on the new Front

Panel Board.

3. Install the Hard Disk Bay into the chassis as described in “Installing the Hard Disk Bay”

above.

35

Page 43

5 Installing Additional Memory

Introduction

This chapter provides the procedures for opening the Processor/Memory Complex, installing a

memory board, installing DIMMs, and installing memory board DC-to-DC converters.

Tools Required

Use an anti-static service kit (3M 8501/8502/8503 or equivalent). This kit includes a static-dissipating

work surface, a chassis clip lead, and a wrist strap.

Memory Installation Guidelines

Each Memory Board can support from 1 GB to 32 GB. The server supports up to 64 GB of system

memory.

• Use only HP DIMMs, which are 3.3V, 168-pin, PC100, buffered SDRAM DIMMs in 256 MB,

512 MB, or 1 GB modules.

• DIMMs must be installed in the order indicated by the numbered slots on the memory board in

groups of four. Verify that the same size DIMM is used in any given group of four by using

the same HP part number.

• To ensure optimum performance when two memory boards are installed, the memory on each

board should be equal.

• Ensure both latches close on the DIMM when completely installed.

• When handling DIMMs, observe anti-static precautions to avoid damage.

36

Page 44

Chapter 5: Installing Additional Memory

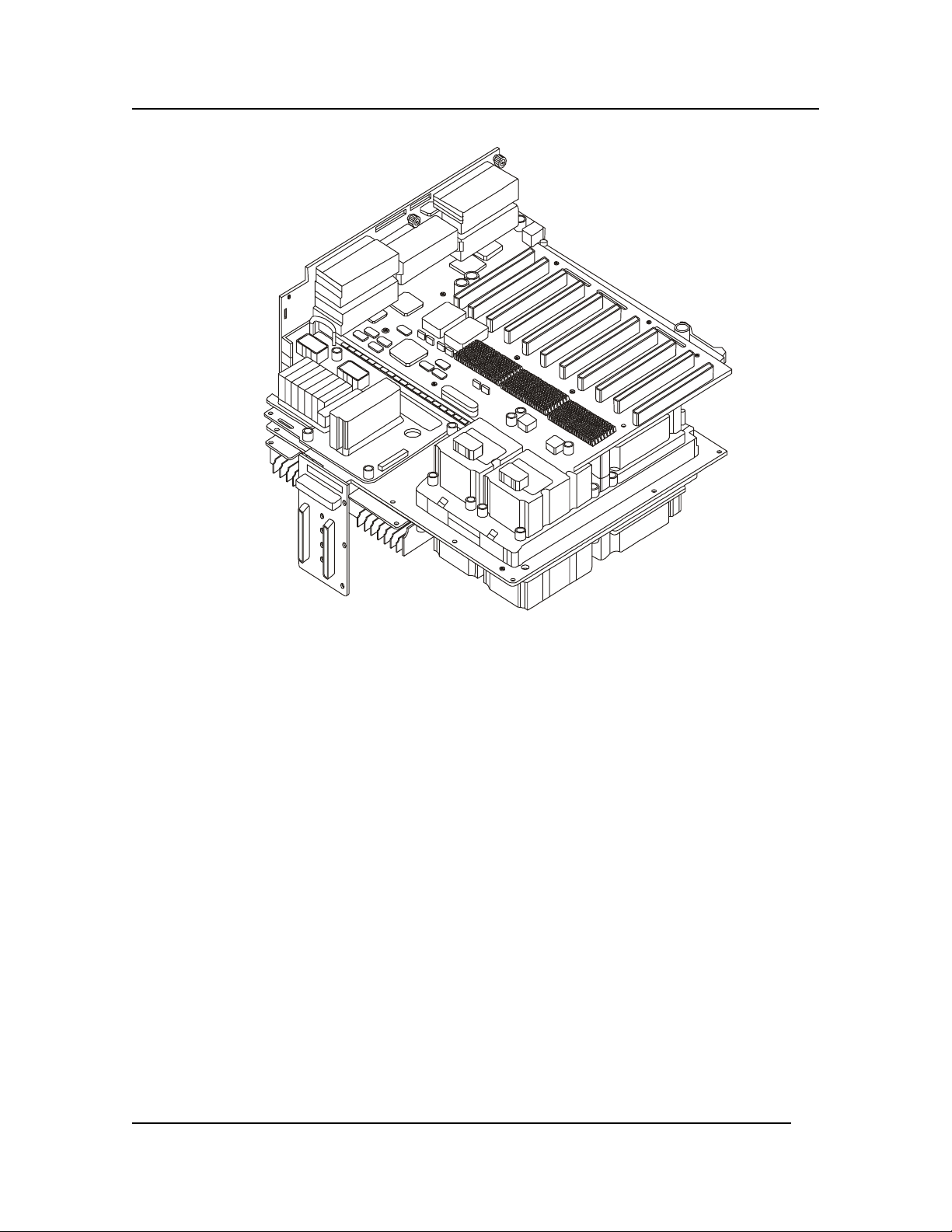

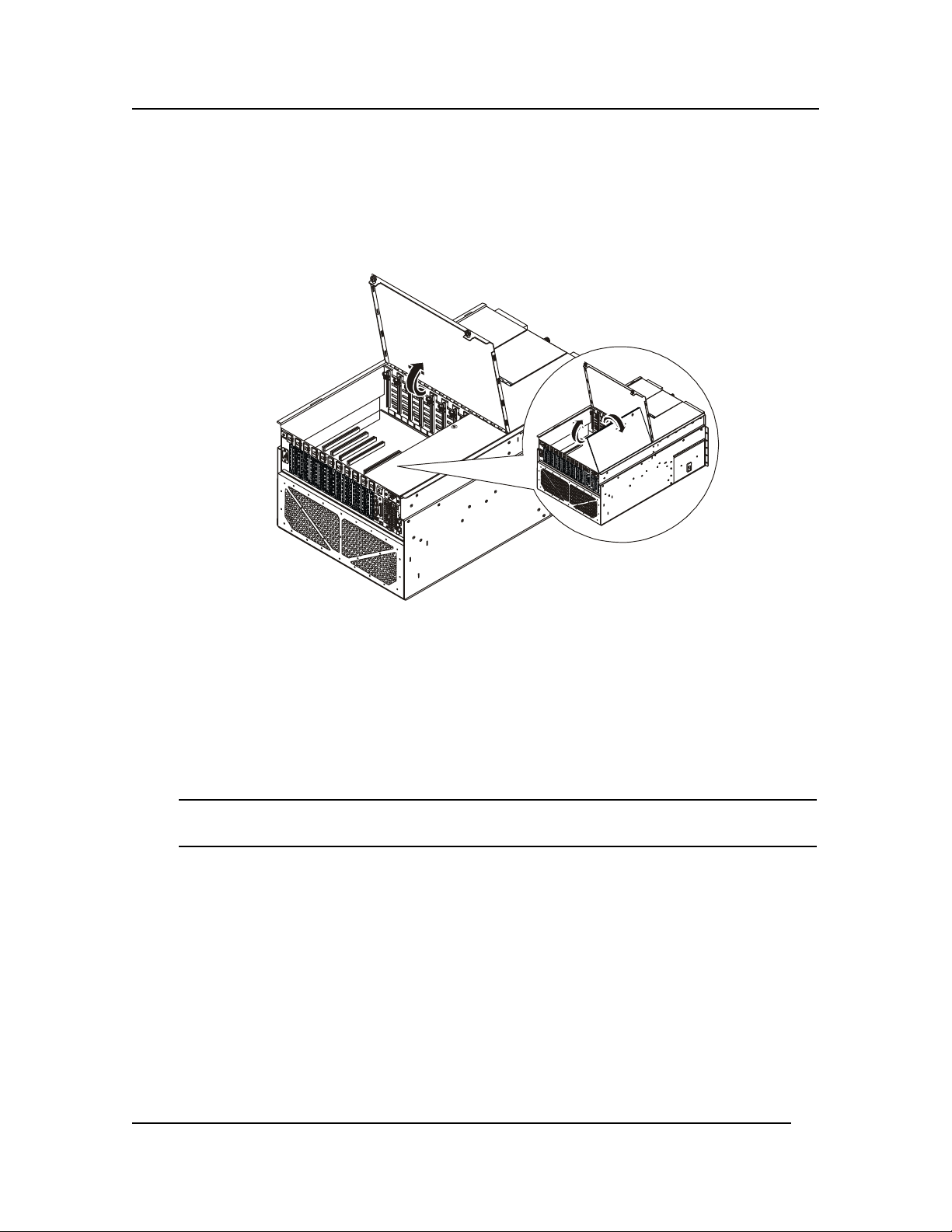

Removing the Processor/Memory Complex

The Processor/Memory Complex mounts memory boards to the processor board and forms a module

that you can remove from the main system chassis. To access this module, you need to remove the

access door on the side of the chassis and remove the four screws on the left side of the chassis to

slide the Processor/Memory Complex out of the system.

1. If the system is already installed and working, power down the system. Refer to Chapter 1,

"Controls, Ports, and Indicators."

WARNING The power supply will continue to provide standby current to the HP Server until

the power cable is disconnected. Before removing the cover, always disconnect

the power cord and unplug the Ethernet cables. Disconnect the power cord to

avoid exposure to high energy levels that may cause burns when parts are shortcircuited by metal objects such as tools or jewelry.

2. Disconnect the power cables and any external cables connected to the system.

If necessary, label each cable to expedite re-assembly.

WARNING Make sure that the rack is anchored securely so that it does not tip when the server

is extended from the rack.

3. Pull the chassis out of the rack to expose the Processor/Memory Bay on the right side of the

chassis as you face its front.

4. Remove the four screws that secure the complex to the chassis. These screws are located on

the left side of the chassis as you face the front of the system.

5. Loosen the two-quarter turn screws on the left side of the Processor/Memory Complex cover

such that the cover springs open.

6. Grasp the cover and press it back toward the chassis as you shift the cover to the left. Shifting

the cover to the left clears the right side of the cover from behind the chassis side.

3

Figure 5-1. Opening the Processor/Memory Complex Bay Cover

7. Once the cover is clear, set it aside.

37

Page 45

Chapter 5: Installing Additional Memory

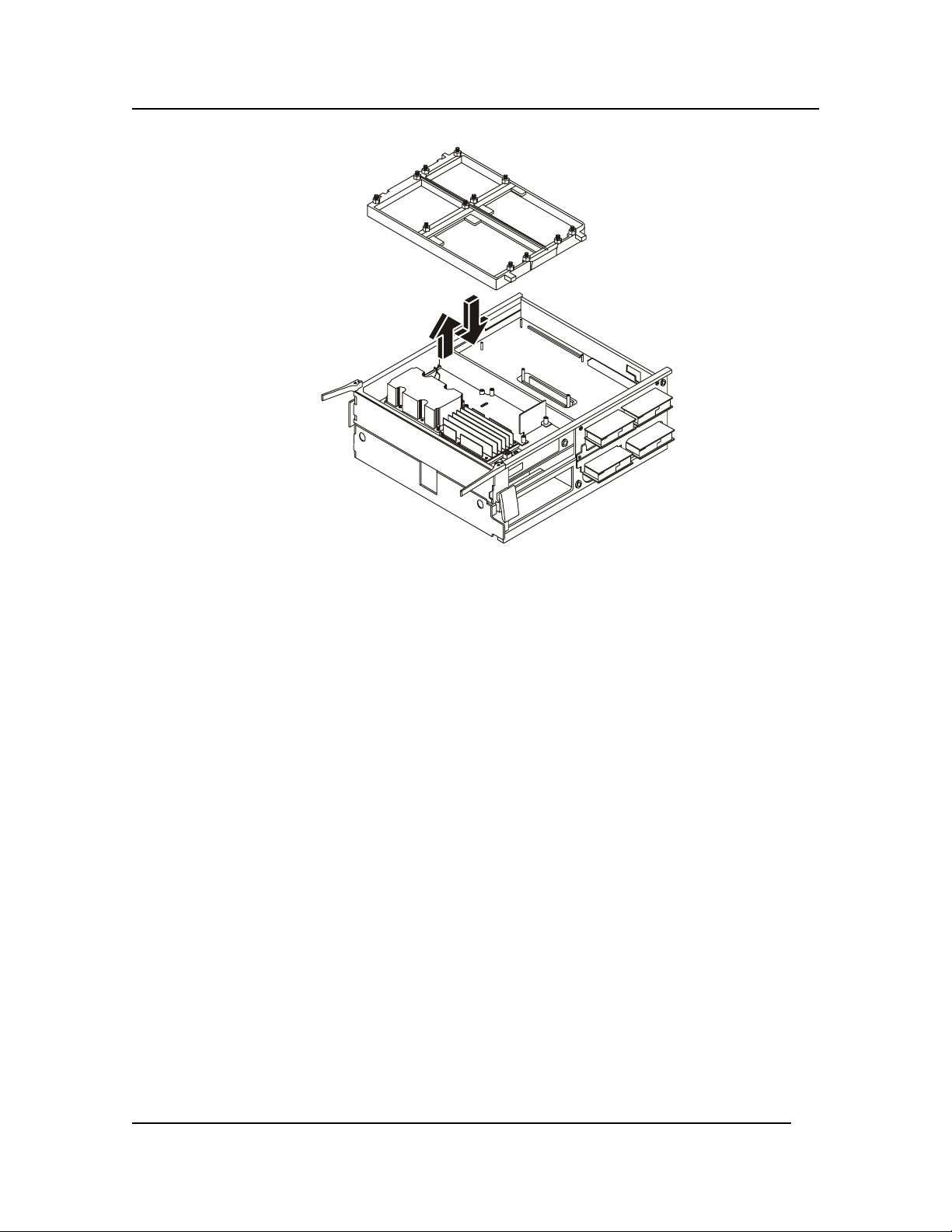

8. Rotate the two extraction levers on the sides of the module to eject it from the Sideplane board

connector.

Figure 5-2. Removing the Processor/Memory Complex

WARNING Fully loaded, the Processor/Memory Complex weighs 36 pounds (16.33 kg).

Minimally configured, this complex weighs 24 pounds (10.80 kg). Exercise

caution when lifting the complex out of the system.

9. Remove the complex from the bay and place it on a clean ESD protected surface.

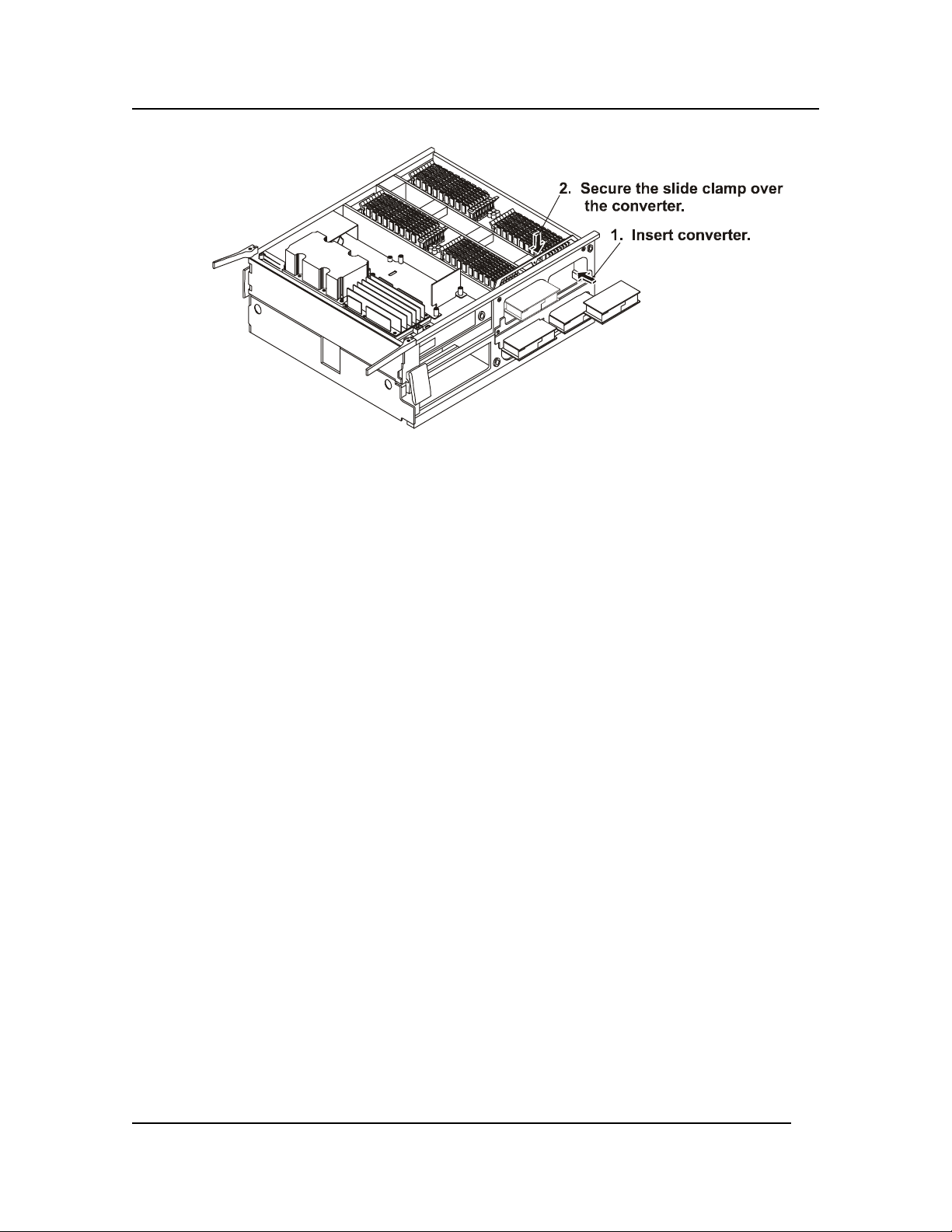

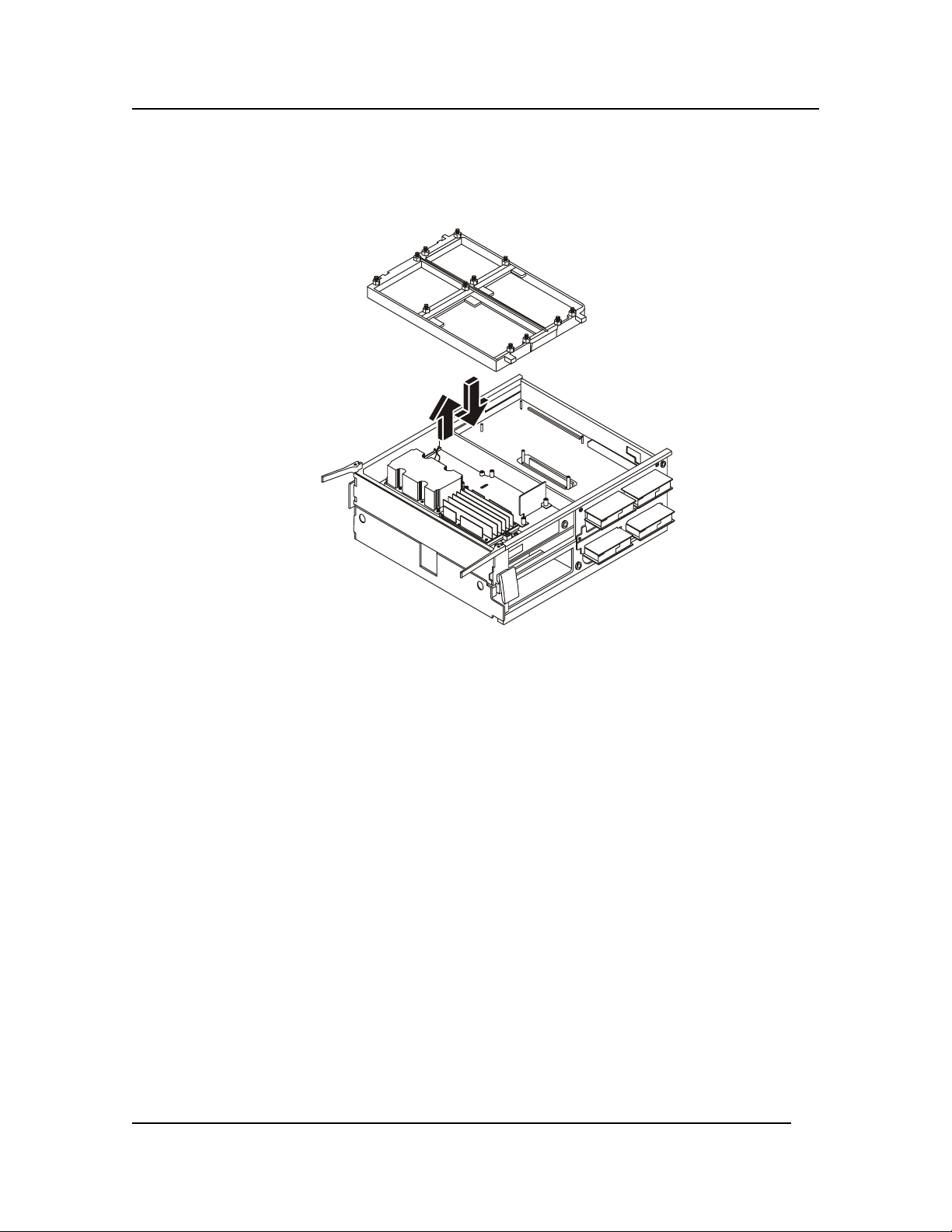

Removing the Memory Board DC-to-DC Converters

The Memory Board DC-DC Converters reside on the side of the Processor/Memory Complex inside

the system chassis. The server uses four converters to supply regulated power to the system. You can

access them by removing the Processor/Memory Complex and working from its side. The Memory

Board DC-to-DC Converters must be removed before the Memory Board can be replaced.

To remove the converters, complete the following procedure:

1. Observe the necessary safety and ESD precautions.

2. Remove the Processor/Memory Complex as described in “Removing the Processor/Memory

Complex” in Chapter 5.

3. Loosen the slide clamp screw that secures the converters but do not remove it. Loosening the

upper screw allows you to remove the upper converters, while loosing the lower screw allows

you to remove the lower converters.

4. With the converters to be removed located on the top of the unit, slide the clamp upward that

secures that pair of converters.

5. Pull each converter straight out from its socket. Be sure that you keep the converter level as

you remove it from its socket. Each converter has a keyed guide that is attached to the side of

the Processor/Memory Complex.

38

Page 46

Chapter 5: Installing Additional Memory

Figure 5-3. Memory Board DC-DC Converters

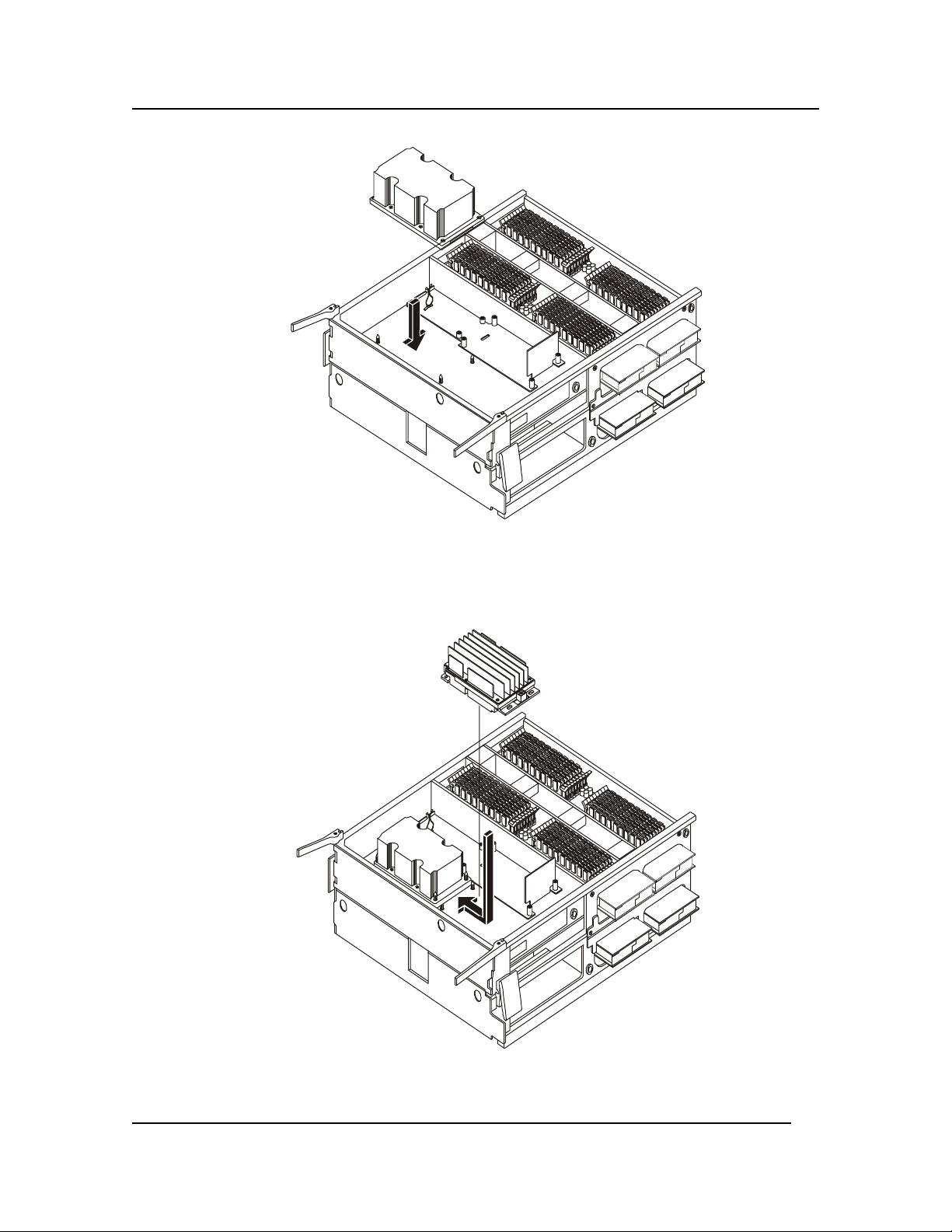

Removing and Installing Memory Boards

Two Memory Boards reside in the Processor/Memory Complex: one is on top of the complex and the

other underneath. You can remove or install these memory boards.

Removing Memory Boards

Two memory boards exist, one plugged in to each side of the processor board (the top and the

underside of the Processor/Memory Complex). The following procedure describes the removal

process for either memory board. To remove the memory board, complete the following procedure:

1. Open and remove the Processor/Memory Complex.

2. If desired, remove the DIMMs from the memory board you are removing as described in

“Removing DIMMs” in Chapter 5.

3. Remove the DC-DC converters from the memory board as described in “Removing the

Memory Board DC-DC Converters” in Chapter 5.

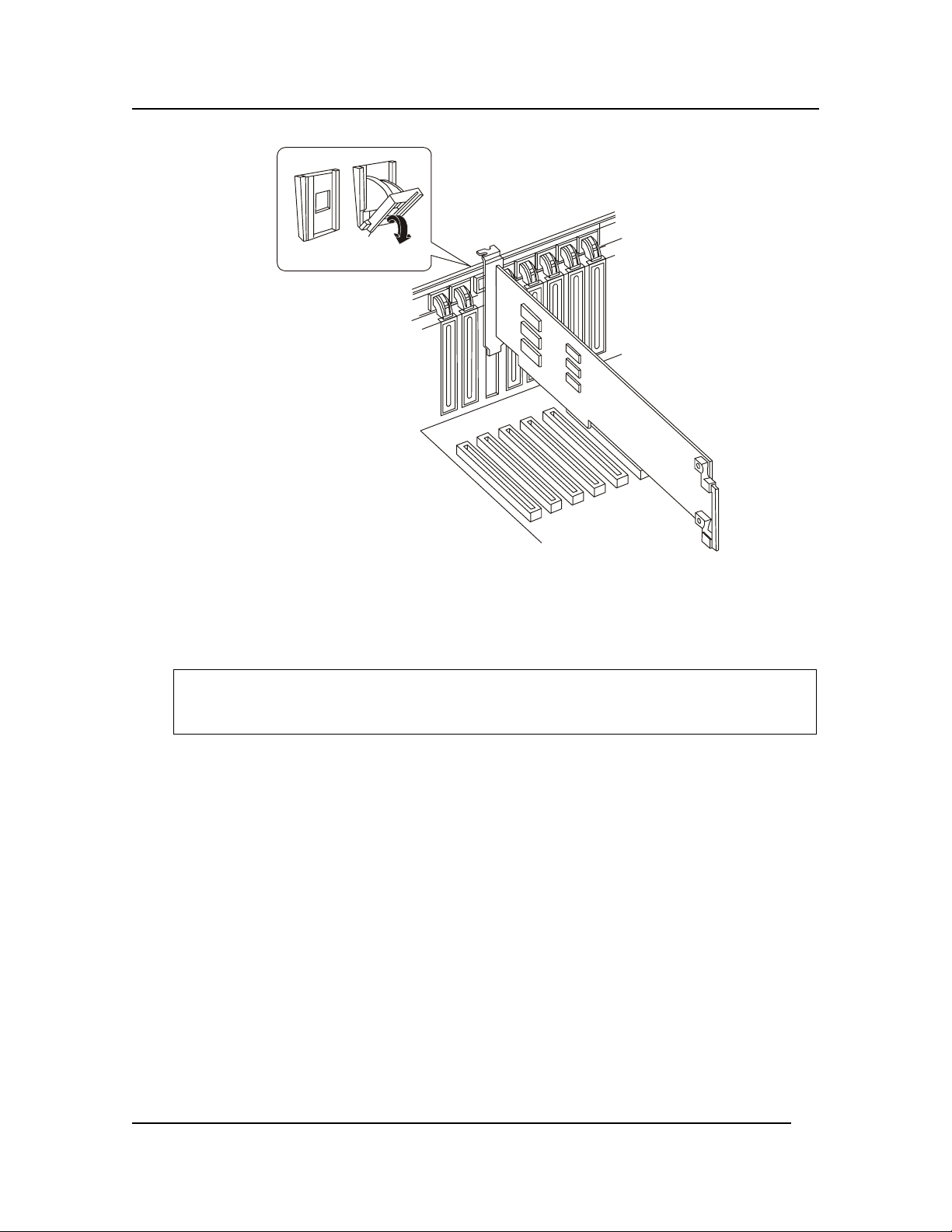

4. Loosen the two captive screws holding the sides of the memory board to the processor board.

Each of these screws secures a board clamp that runs along the length of the memory board.

5. Lift the board clamps out of the Processor/Memory Complex.

6. Loosen the two captive screws at the end of the handle that spans the middle of the Memory

Board.

7. Remove the bracket with the thumbscrew that locks the extraction levers.

8. Pull up on the extraction levers to disengage the memory board from the processor board.

NOTE Both extraction levers must be raised evenly while disengaging the memory from

the Processor Baseboard. The memory board must remain parallel to the Processor

Baseboard during extraction.

39

Page 47

Chapter 5: Installing Additional Memory

9. Place the memory board on a clean ESD-protected surface.

Figure 5-4. Memory Boards

Installing Memory Boards

Two memory boards exist, one plugged into each side of the Processor Baseboard (the top and the

underside of the Processor/Memory Complex). This procedure describes the installation process for

either memory board. To re-install the memory board or install a new board, complete the following

procedure:

1. Observe all safety and ESD precautions.

2. Remove the Processor/Memory Complex as described in “Removing the Processor/Memory

Complex” in Chapter 5.

3. With both extraction levers raised to engage the guide pins, place the memory board over the

Processor Baseboard connector and guide pins

4. Engage both guide pins at the same time. Ensure that the memory board remains parallel to

the Processor Baseboard.

NOTE Both extraction levers must be depressed evenly while inserting the Memory

Board. The Memory Board must remain parallel to the Processor Baseboard

during insertion.

5. Slowly depress the levers until the Memory Board connector fully engages.

40

Page 48

Chapter 5: Installing Additional Memory

6. Tighten the two captive screws at the end of the extraction handle.

7. Place the two board clamps along the sides of the memory board such that the screws align

with their respective holes.

8. Secure the two board clamps with the two board clamp screws.

9. Place the bracket with the thumbscrew that locks the extraction lever over the extraction levers

and tighten the screw.

10. Replace the DC-DC converters as described in “Installing the Memory Board DC-to-DC

Converters” in Chapter 5.

11. If you removed any DIMMs replace them as described in “Installing DIMMs” in Chapter 5.

Replace the Processor/Memory Complex as described in “Installing the Processor/Memory

Complex” in Chapter 5.

41

Page 49

Chapter 5: Installing Additional Memory

Installing and Removing DIMMs

The BIOS automatically detects, sizes, and initializes the memory array, depending on the type, size,

and speed of the installed DIMMs. It reports the memory size and allocation to the system through the

configuration registers. DIMMs reside in the Processor/Memory Complex and are accessible inside

the server chassis. To remove or install DIMMs you need to access the complex and follow the

installation order and groupings required for the DIMMs. It is not necessary to remove the memory

board from the complex.

Installing DIMMs

Please refer to the “Memory Installation Guidelines” earlier in this chapter before installing the

DIMMs. To install DIMMs, complete the following procedure:

CAUTION The memory modules are sensitive to static electricity and can be easily damaged

by improper handling. Do the following when handling the accessory kit:

• Leave the memory module in the anti-static container until you are ready to

install it.

• Always use an anti-static wrist strap and a grounding mat.

• Before you remove a memory module from the anti-static container, touch a

grounded, unpainted metal surface on the HP Server to discharge static

electricity.

1. If the system is already installed and working, power down the system.

Refer to Chapter 1, "Controls, Ports, and Indicators."

WARNING The power supply will continue to provide standby current to the HP Server until

the power cable is disconnected. Disconnect all power cables before servicing.

2. Disconnect the power cables and all external cables.

If necessary, label each one to aid in the re-assembly of the unit.

3. Remove the top cover from the HP Server.

Refer to Chapter 2, "Opening and Closing the HP Server."

4. Observe safety and ESD precautions when working with DIMMs.

5. Expose the memory boards by removing the Processor/Memory complex as described in

“Removing the Processor/Memory Complex” in Chapter 5.

CAUTION DIMM slots on the memory module must be installed only in groups of four.. The

number next to each DIMM slot corresponds to installation sequence. DIMMs

must be installed by groups of four and must be inserted in the indicated sequence

indicated on the memory board.

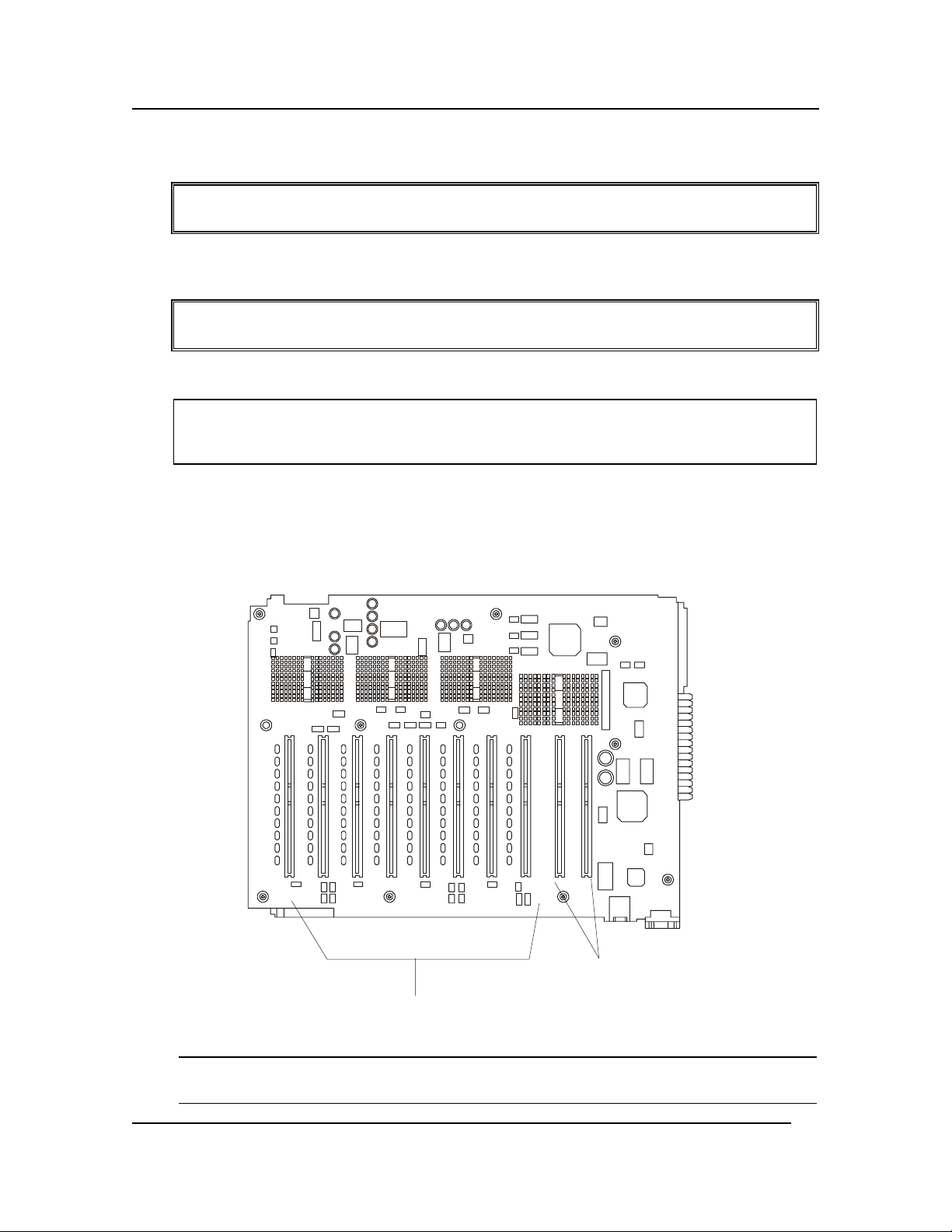

Remove the DIMM from its antistatic package. Align the two notches in the bottom edge of the

DIMM with the keyed socket on the memory board.

42

Page 50

Chapter 5: Installing Additional Memory

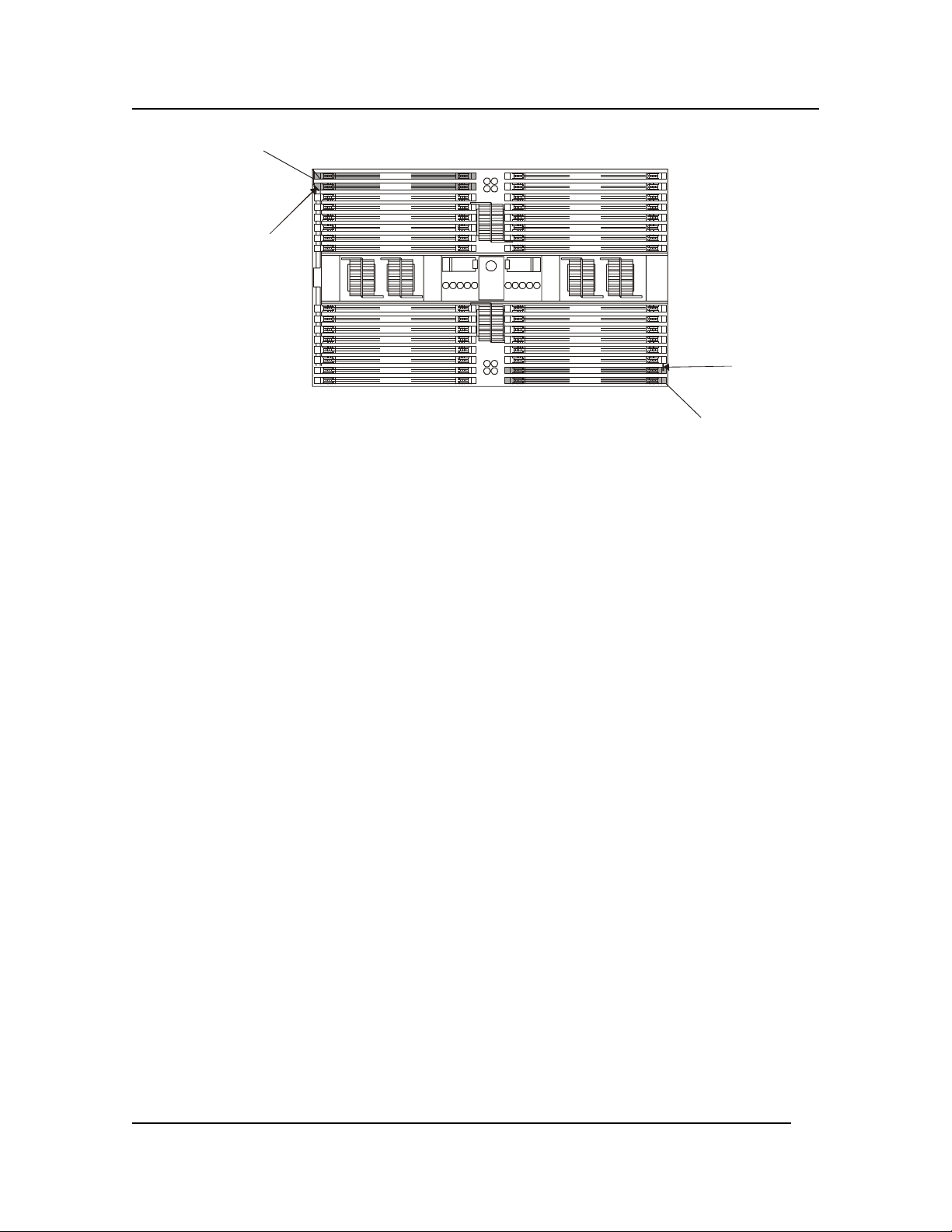

1

2

DIMM 1

DIMM 2

DIMM 9

DIMM 10

DIMM 17

DIMM 18

DIMM 25

DIMM 26

DIMM 5

DIMM 6

DIMM 13

DIMM 14

DIMM 21

DIMM 22

DIMM 29

DIMM 30

DIMM 32

DIMM 31

DIMM 24

DIMM 23

DIMM 16

DIMM 15

DIMM 8

DIMM 7

DIMM 28

DIMM 27

DIMM 20

DIMM 19

DIMM 12

DIMM 11

DIMM 4

DIMM 3

4

3

Figure 5-5. DIMM Installation Sequence

7. Insert the bottom edge of the DIMM into the socket and press down firmly until the DIMM is

seated correctly.

8. Push the plastic ejector levers on the socket ends to the upright position. Repeat the DIMM

installation steps for each DIMM you wish to install.

43

Page 51

Chapter 5: Installing Additional Memory

Removing DIMMs

You may need to remove a DIMM module to downsize your memory configuration or to replace a

defective DIMM.

1. If the system is already installed and working, power down the system.

Refer to Chapter 1, "Controls, Ports, and Indicators."

WARNING The power supply will continue to provide standby current to the HP Server until

the power cable is disconnected.

2. Disconnect the power cables and all external cables.

If necessary, label each one to support re-assembly.

3. Remove the top cover from the HP Server.

Refer to Chapter 2, "Opening and Closing the HP Server."

4. Remove the existing DIMM from its socket by gently pushing the plastic ejector levers out and

down.