Page 1

Product Category: Personal Computers

Marketing Name / Model

[List multiple models if applicable.]

HP RP9 G1 AiO Retail System, Model 9015

1.0 Items Requiring Selective Treatment

Quantity

in product

Printed Circuit Boards (PCB) or Printed Circuit

Assemblies (PCA)

With a surface greater than 10 sq cm

1

Batteries

All types including standard alkaline and lithium coin

or button style batteries

1

Mercury-containing components

For example, mercury in lamps, display backlights,

scanner lamps, switches, batteries

0

Liquid Crystal Displays (LCD) with a surface greater

than 100 sq cm

Includes background illuminated displays with gas

discharge lamps N/A

2

Cathode Ray Tubes (CRT)

N/A

0

Capacitors / condensers (Containing PCB/PCT)

N/A

0

Electrolytic Capacitors / Condensers measuring

greater than 2.5 cm in diameter or height

N/A

0

External electrical cables and cords

N/A

1

Gas Discharge Lamps

N/A

0

Plastics containing Brominated Flame Retardants

already listed as a separate item above)

N/A

0

Components and parts containing toner and ink,

including liquids, semi-liquids (gel/paste) and toner

Include the cartridges, print heads, tubes, vent

chambers, and service stations. N/A

0

Components and waste containing asbestos

N/A

0

Components, parts and materials containing

refractory ceramic fibers

N/A

0

Product End-of-Life Disassembly Instructions

Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions

for the disassembly of HP products to remove components and materials requiring selective treatme nt, as defined by EU

directive 2002/96/EC, Waste Electrical and Electronic Equipment (WEEE).

1.1 Items listed below are classified as requiring selective treatment.

1.2 Enter the quantity of items contained within t he product which require selective treatment in the right column, as

applicable.

Item Description Notes

weighing > 25 grams (not including PCBs or PCAs

of items

included

EL-MF877-00 Page 1

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 2

Components, parts and materials containing

radioactive substances

N/A

0

2.0 Tools Required

List the type and size of the tools that would typically be used to disassemble the product to a point whe re components

Tool Description

Tool Size (if

applicable)

T15 2.55-

3.00kgf.cm

2# 2.55-

3.00kgf.cm

Knife

Side Cutter

Star key wrench

3.0 Product Disassembly Process

and materials requiring selective treatment can be removed.

Hexagonal Screwdriver (T15)

Philips Screwdriver

Slotted Screwdriver

3.1 List the basic steps that should typically be f oll owed to remove components and materials requi ring selective treatment:

1. Disassembly process – Removing Back Cover

2. Disassembly process – Installing Wireless Card

3. Disassembly process –Installing DIMM

4. Disassembly process – Do not remove the HDD cage

5. Disassembly process -Remove the HDD cage

6. Disassembly process (CPU Installing)

7. Disassembly process (Installing back cover bracket)

8. Disassembly process (Assemble MCR, webcam, BIO reader (If necessary)

9. Disassembly process (MSR,Webcam,BIO)

10. Disassembly process (Assemble back cover)

11. Compact Stand Assembling (Without Power Supply)

12.

3.2 Optional Graphic. If the disassembly process is complex , insert a graphic illustration below to identify the items

contained in the product that require selective t reatment (with descriptions and arrows identifying locations).

1.Description of the sample submitted for assessment

EL-MF877-00 Page 2

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 3

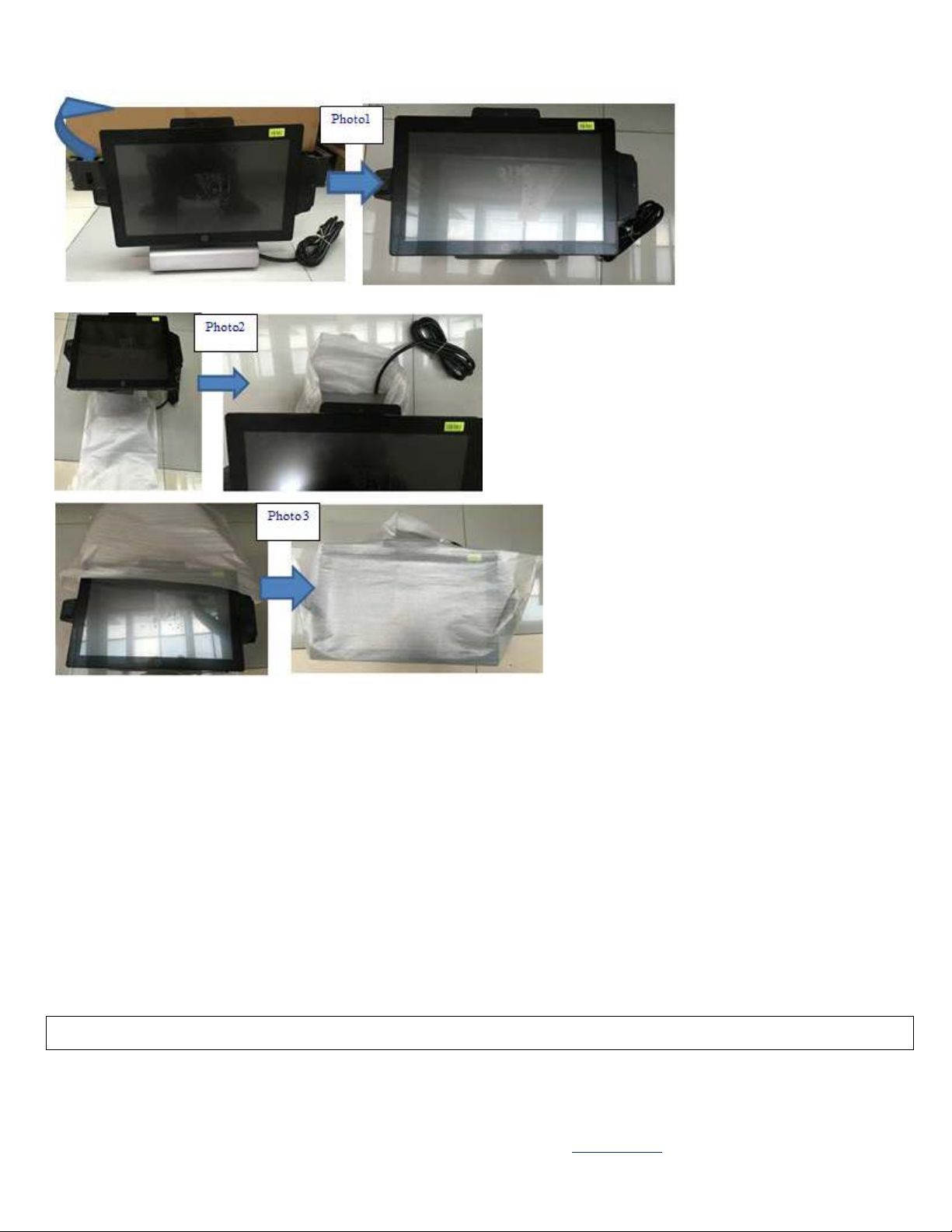

Disassembly process (Removing Back Cover)

Product view

EL-MF877-00 Page 3

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 4

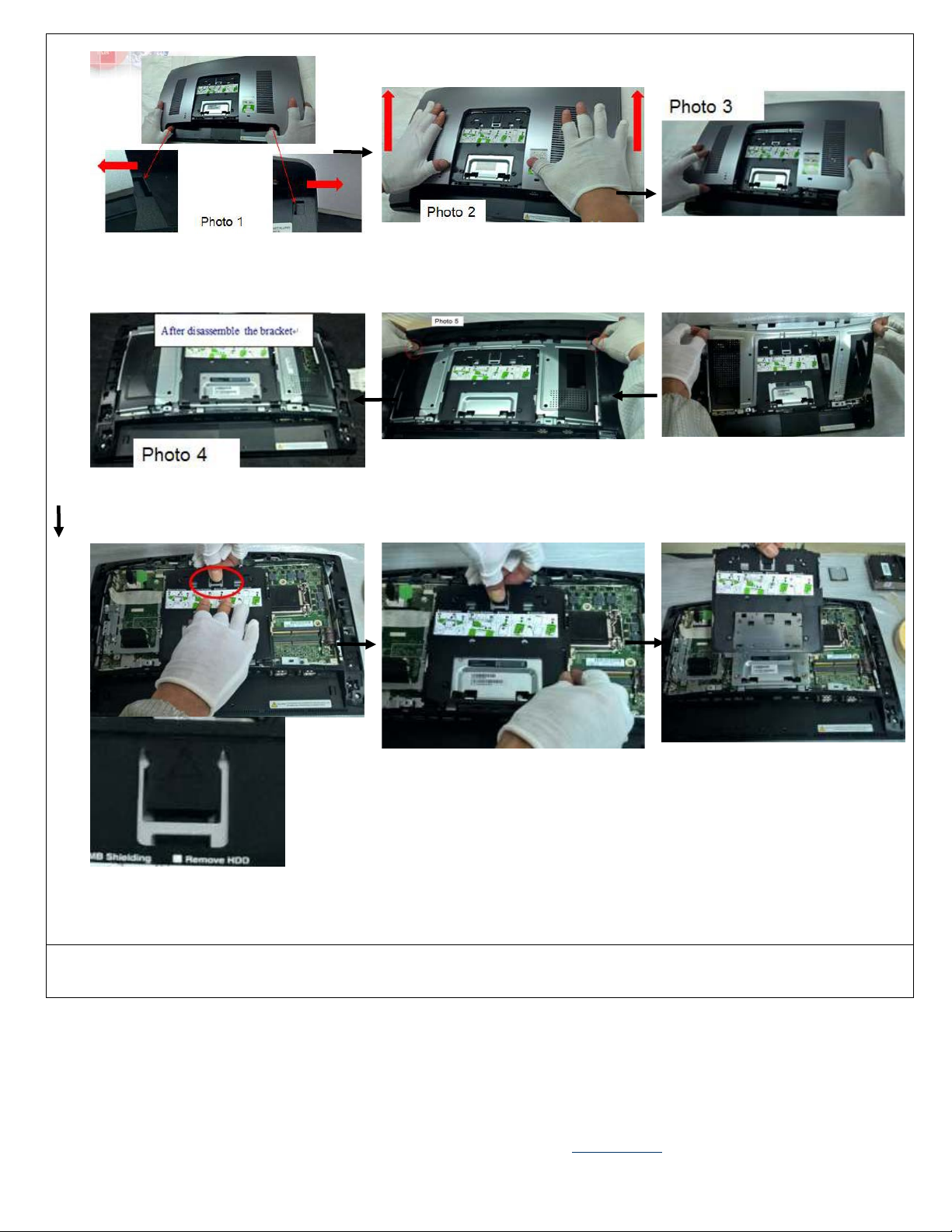

and 9.

Disassembly process (Installing Wireless Card)

Push the button on the middle bezel to

each side,see photo 1

Disassemble the

bracket, see photo 4

Disassemble the back cover by pulling

it upward and cover See photo 2.

Disassemble the bracket by the red

circle marked position and take off

the bracket, see photo 5

Take off the rear cover, see photo 3

Lift up the bracket,see photo 6

Pressing the visa cover hook and push

it to the direction show in the photo 7,8

EL-MF877-00 Page 4

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 5

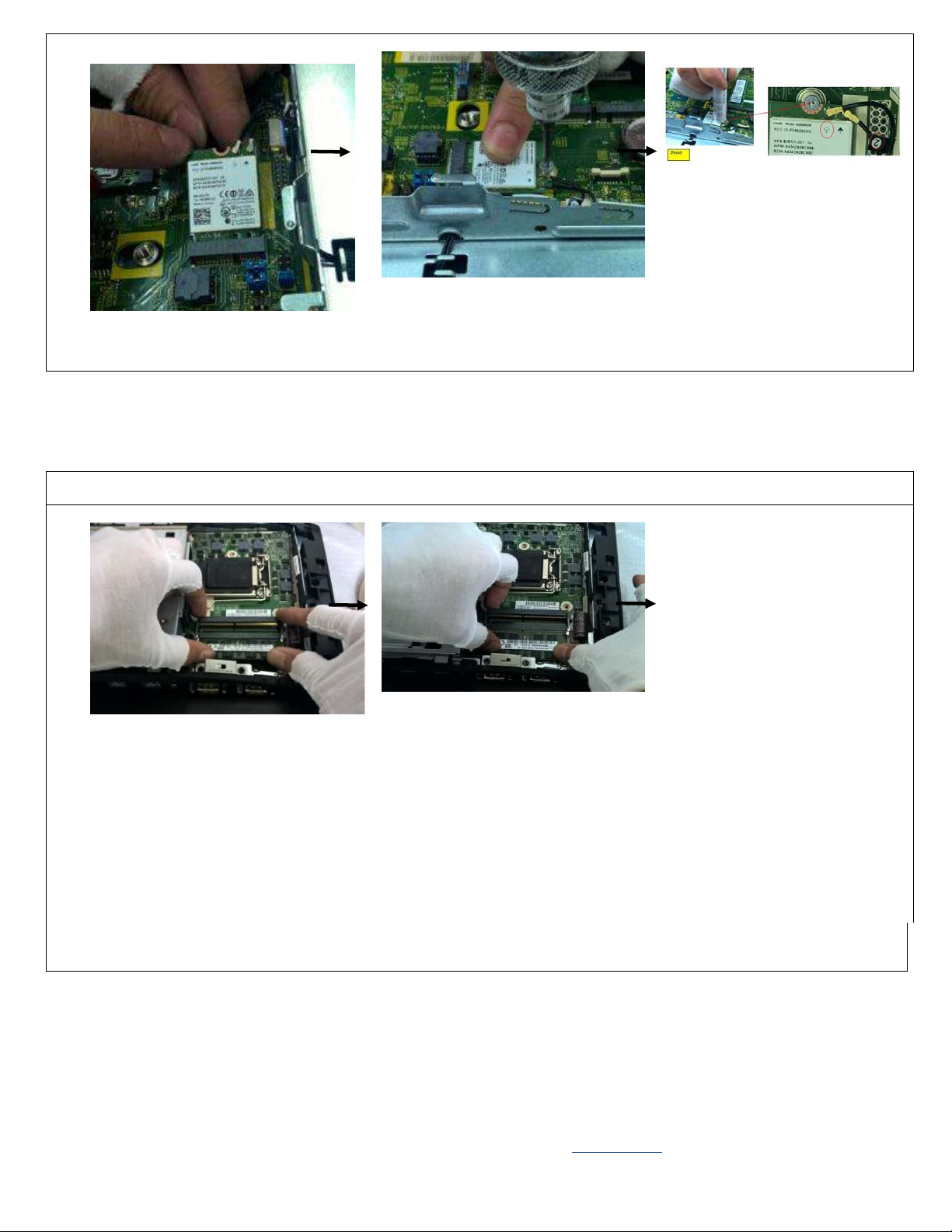

Install the wireless card atan angle of

45 degree.See photo 1

Screwdriver)See photo 2

Disassembly process (Installing DIMM)

at an angle of 45 degree.See photo 1

Disassembly process (Do not remove the HDD cage)

Fasten WIFI screw*1pcs as show in

photo 21.5 + /-0.2Kgf.cm Screw

driver: #1(Crosshead

Using pressing fixture to insert

cable in location“2”.Routing the

cable See photo3&4 Using pressing

fixture to insert cable in location“

1”.Routing the cable See photo3&4

Final cable routing for WLAN (

Photo 4)

Press the DIMM to confirm the DIMM

Take the DIMM and insert in DIMM slot

insert rightly See photo 2

EL-MF877-00 Page 5

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 6

0.3kgf.cm

photo 4

Unlocking the 2 screws on the HDD

bracket see photo 1(T15)3.0+/-

Lift up the HDD bracket horizontally

and take down the HDD bracket, see

photo 2,3

Assemble the first SSD Card to the

SSD1 mark connector, and fix the

SSD card to the unit by lock the

screw , see photo 3

Assemble the second SSD Card to the

SSD2 mark connector, and fix the SSD

card to theunit by lock the screw ,see

EL-MF877-00 Page 6

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 7

Disassembly process (Do not remove the HDD cage)

Assembling the HDD bracket to the unit

and lock the 2pcs screws, see photo 6

(T15)3.0+/-0.3kgf.cm

Assemble the first SSD Card to the

SSD1 mark(left position)connector

byone hand, and hold the

Mylar by another hand

see photo 1

Press the SSD to confirm it insert

rightly, and lock the screw to fix the SSD

on the MB, pull the Mylar aside at same

time, see photo 2

EL-MF877-00 Page 7

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 8

HDD Module Processing and

Installing(if necessary)

See photo 2

See photo 4

Disassembly process (Remove the HDD cage)

Do not remove the HDD cage

Remove the tape on the HDD cage See

photo 1

Slide the HDD holder

splinter and assemble

the HDD to the HDD

cage rightly

Take 4 screw to lock

the HDD,(#1)1.5+/-0.3kgf.cm

Insert the SATA cable

to the HDD

See photo 5

Plug the HDD screw holder to the

hold on HDD cage

See photo 3

Check the connector is

inserted rightly

See photo 6

EL-MF877-00 Page 8

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 9

Unscrew the 2 screws and remove

See photo4

See photo5

Disassembly process (CPU Installing)

the HDD bracket See photo 1 and

2

Take 4 screw to lock

the, (#1)1.5+/-

0.3kgf.cm

See photo 3

Install HDD in the unit

Check the Mylar connected to the MB

rightly, see photo 6

Insert the HDD SATA cable to HDD

EL-MF877-00 Page 9

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 10

Put the CPU onto the CPU socket

shown on heat sink,see photo 7and 8

Disassembly process (Installing visa cover)

vertical by fixture, see photo 3 and 4

Open the CPU cover and take off

the plastic cover, check whether

there is PIN bend issue,See photo

2 for the bend pin

Put the CPU onto the CPU socket

vertical by fixture, see photo 3 and

4

Locking the CPU holder, and during this

process, the CPU holder clip will drop

from the CPU holder,take clip away from

the MB, see photo 5 and 6

Lock the heat sink to MB, and lock the

3 screws based on the sequence

EL-MF877-00 Page 10

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 11

Disassembly process (Installing back cover bracket)

Disassembly process (Assemble MCR, webcam, BIO reader (If necessary)

Align the visa cover to the bracket

and press the clip to lock on to the

bracket see photo1

Push the rear cover to end , see picture 2

Confirm the visa cover locked well,

see photo 2 and 3

Double check the rear cover locked

well, see photo 4

Align the rear cover to the unit by

the two latch see photo 1

EL-MF877-00 Page 11

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 12

Disassembly process (MSR,Webcam,BIO)

Unscrew the 2 screws on the 3

dummy covers, see photo 1 and 2

Put one screwdriver head into the screw

hole and pull the dummy cover outward,

use same method to dissemble the 3

dummy covers

Assemble the Webcam, MSR,BIO

to the unit and lock the two screw

red marked See Photo 4 Confirm the

Webcam, MSR,BIO assembled rightly

see photo 5

Lock the 2 screws,see photo 6

EL-MF877-00 Page 12

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 13

After the MSR,Webcam, BIO

Compact Stand Assembling (Without Power Supply)

Disassembly process (Assemble back cover)

hooks are locked well See photo 4

assembled status,see photo 1

Put the back cover to the unit See

photo 1

Double check and confirm all the

EL-MF877-00 Page 13

Template Revision B

Push it towards

your self-direction

See photo 2

Assemble the back

cover to the unit,

and lock the hook

see photo 3

PSG instructions for this template are available at EL-MF877-01

Page 14

Assemble the bottom cover to the

stand,See photo 1~2

Assemble the stand to the unit

Lock each hook of the stand to the

unit VESA cover socket, 1 to 1, 2

to2 see photo 5

Assemble the bottom cover to the stand,

See photo 3

Check the 6 latches on the cover are no

damage, see photo 4

EL-MF877-00 Page 14

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Loading...

Loading...