Page 1

User Guide

hp rp7405/7410 Servers

Third Edition

Manufacturing Part Number: A6752-96008

21102

USA

© Copyright 2002

Page 2

Legal Notices

The information in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this manual, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be held

liable for errors contained herein or direct, indirect, special, incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Restricted Rights Legend. Use, duplication or disclosure by the U.S. Government is subject to restrictions

as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

HEWLETT-PACKARD COMPANY 3000 Hanover Street Palo Alto, California 94304 U.S.A.

Copyright Notices. ©copyright 1983-2002 Hewlett-Packard Company, all rights reserved.

Reproduction, adaptation, or translation of this document without prior written permission is prohibited,

except as allowed under the copyright laws.

ii

Page 3

1. Introduction

hp rp7405/rp7410 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cell Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

hp rp7405 Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Detailed hp rp7405/rp7410 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cell Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cells and nPartitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Package Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2. Installation

Unpacking the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unpacking a Racked Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unpacking a Non-Racked Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing Server Into the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installing the Cable Management Arm (CMA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing Add-On Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting AC Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

MP Core I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MP/SCSI Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LAN/SCSI Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Management Processor Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setting Up the CE Tool (PC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Standby Power and Logging in to the MP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Configuring LAN Information for the MP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Verifying Presence of the Cell Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Powering On the hp rp7405/rp7410 Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Selecting a Boot Partition using the Management Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Verifying the System Configuration using Boot Console Handler (BCH) . . . . . . . . . . . . . . . . . . . . . . . 46

Booting HP-UX using Boot Console Handler (BCH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Contents

3. Troubleshooting

Common Installation Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

The Server Does Not Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

The Server Powers On But Then Shuts Down with a Fault Light . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

hp rp7405/rp7410 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4. Removal and Replacement

Shutting Down nPartitions and Powering Off Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . 58

Shutting Down an nPartition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Powering Off Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Removing and Replacing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Removing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

iii

Page 4

Contents

Replacing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Removing and Replacing a Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing a Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Replacing a Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Removing and Replacing a CD/DVD Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Removing a CD/DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing a CD/DVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Removing and Replacing a Front Smart Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing a Front Smart Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Replacing a Front Smart Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Removing and Replacing a Rear Smart Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Removing a Rear Smart Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing a Rear Smart Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Removing and Replacing a PCI Smart Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Removing a PCI Smart Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Replacing a PCI Smart Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Removing and Replacing a Bulk Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Removing a BPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Replacing a BPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Removing and Replacing a PCI Power Module (Brick) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Removing a PCI Power Module (Brick) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Replacing a PCI Power Module (Brick) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Removing and Replacing the PCI Voltage Regulator Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Removing PCI VRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Replacing the PCI VRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Removing and Replacing a PCI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removing and Replacing a PCI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removing and Replacing the Mass Storage Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Removing the Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Replacing the Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Removing and Replacing a MP/SCSI Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Removing a MP/SCSI board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Replacing a MP/SCSI Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

A. Replaceable Parts

B. System Specifications

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

System AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Temperature and Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Typical Power Dissipation and Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

iv

Page 5

Acoustic Noise Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Air Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

C. Site Preparation

Electrical Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Electrical Load Requirements (Circuit Breaker Sizing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Power Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Sources of Electrical Disturbances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Power System Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Distribution Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Wire Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Raceway Systems (electrical conduits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Building Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Power Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Grounding Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Power Distribution Safety Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Cabinet Performance Grounding (High frequency Ground). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Equipment Grounding Implementation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

System Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Wiring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Data Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Environmental Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Computer Room Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Basic Air Conditioning Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Air Conditioning System Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Air Conditioning System Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Basic Air Distribution Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Air Conditioning System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Humidity Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Air Conditioning Ducts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Dust and Pollution Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Computer Room Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Lighting Requirements for Equipment Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Facility Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Floor Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Space Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Delivery Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Operational Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Zinc Particle Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Contents

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

v

Page 6

Contents

vi

Page 7

Tab les

Table 1. Revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Table 1-1. hp rp7405 Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1-2. hp rp7405-to-rp7410 Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1-3. hp rp7405/rp7410 DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 1-4. PCI Slot Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2-1. hp rp7405/rp7410 DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 3-1. Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 3-2. BPS LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 3-3. PCI Power Supply LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 3-4. System, Standby, and I/O Fan LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-5. SINC POST LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-6. OL* LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-7. OL* LEDs States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-8. MP Core I/O LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-9. LAN/SCSI LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 4-1. Front Smart Fan Assembly LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 4-2. Rear Smart Fan Assembly LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 4-3. Smart Fan Assembly LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 4-4. PCI Power Module LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table A-1. hp rp7405/rp7410 Field Replaceable Unit (FRU) List . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table B-1. hp rp7405/rp7410 Server Dimensions and Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table B-2. hp rp7405/rp7410 Component Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table B-3. Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table B-4. AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table B-5. System Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table B-6. Typical hp rp7405/rp7410 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table C-1. Computer Room Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table C-2. Effect of Humidity on ESD Charge Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table C-3. Floor Loading Term Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table C-4. Typical Raised Floor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

vii

Page 8

Table s

viii

Page 9

Figures

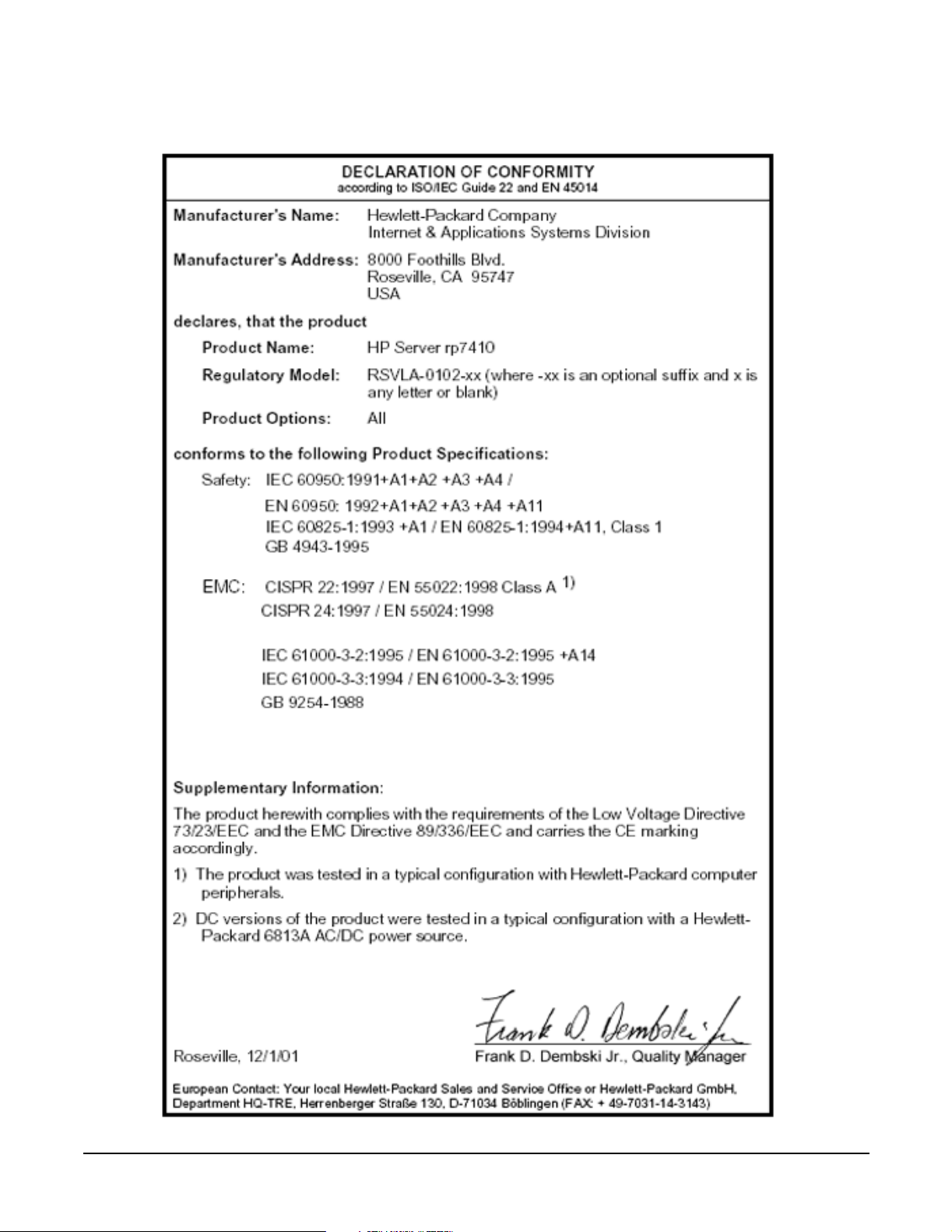

Figure 1. Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Figure 2. Japanese RFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Figure 3. Korean RFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Figure 4. Taiwan Area EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Figure 5. C-Tick Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Figure 1-1. hp rp7405/rp7410 Server (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 1-2. hp rp7405/rp7410 Server (without front bezel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 1-3. hp rp7410 8-Way Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 1-4. Cell Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1-5. Cell Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1-6. Memory Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 1-7. Internal Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 1-8. System Backplane Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 1-9. I/O Subsystem Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 1-10. Right-Front View of hp rp7405/rp7410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 1-11. Left-Rear View of hp rp7405/rp7410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2-1. Removing the Polystraps and Cardboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2-2. Removing the Shipping Bolts and Plastic Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-3. Preparing to Roll Off the Pallet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-4. Securing the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-5. RONI Lifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 2-6. Server with Shipping Box Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 2-7. Remove Cushions for Lift Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 2-8. Raising a Server Off the Pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 2-9. Lifting the Server to the Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 2-10. Positioning the Lift handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2-11. Inserting the Pins Into the Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-12. Lift Handles Mounted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-13. Lifting the Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-14. Cable Management Arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-15. Attaching CMA to Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-16. Attaching CMA to the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2-17. Embedded Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 2-18. Cell Board (Two processors and CC Shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 2-19. DIMM Loading Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 2-20. Power Cord Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 2-21. Power Source vs. Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 2-22. Front Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 2-23. MP Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 2-24. The lc Command Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 2-25. The ls Command Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 2-26. The du Command Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 4-1. Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ix

Page 10

Figures

Figure 4-2. Top Cover Retaining Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 4-3. Disk Drive Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 4-4. Disk Drive Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 4-5. CD/DVD Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 4-6. CD/DVD Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 4-7. CD/DVD Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 4-8. Front Smart Fan Assembly Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 4-9. Front Fan Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 4-10. Rear Smart Fan Assembly Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 4-11. Rear Fan Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 4-12. PCI Smart Fan Assembly Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 4-13. PCI Smart Fan Assembly Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 4-14. BPS Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 4-15. BPS Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 4-16. PCI Power Module Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 4-17. PCI Power Module Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 4-18. Locating the VRMs on PCI Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 4-19. PCI Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 4-20. PCI Gate Detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 4-21. Locating Internal Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 4-22. Locating the Mass Storage Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 4-23. Mass Storage Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 4-24. MP/SCSI Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 4-25. MP/SCSI Detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure B-1. Airflow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure C-1. Raised Floor Ground System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure C-2. Cabinet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure C-3. Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

x

Page 11

Preface

Page 12

Revision History

Table 1 Revisions

Revision Part Number Release Date Description

Third A6752-96008 November 2002 Corrected power cord and power reqirements section.

Corrected DIMM oading order. Other general

corrections.

Second A6752-96002 August 2002 Changed title, revised entire book

First A6752-91001 February 2002 Initial release

viii

Page 13

Notational Conventions

WARNING Warnings highlight procedures or information necessary to avoid injury to

personnel. The warning should tell the reader exactly what will result from what

actions and how to avoid them.

CAUTION A caution highlights procedures or information necessary to avoid damage to equipment,

damage to software, loss of data, or invalid test results.

NOTE A note highlights supplemental information.

ix

Page 14

Safety and Regulatory

Regulatory Model: RSVLA-0102

For your protection, this product has been tested to various national and international regulations and

standards. The scope of this regulatory testing includes electrical/mechanical safety, radio frequency

interference, acoustics, and know hazardous materials.Where applicable, approvals obtained from third-party

test agencies are shown on the product label.

Safety in Material Handling

WARNING Do not lift the cabinet manually. To avoid physical injury you must use a mechanical

lifting device.

WARNING Use care when working with hazardous voltages. This equipment may be configured

with dual input line sources. Hazardous voltages and energy maybe present even

after the removal of a single input source. Trained service personnel must follow the

service guidelines.

WARNING Do not stand in front of the equipment as it is rolled off the pallet onto the ramps.

When removing the equipment from the shipping pallet, follow the guidelines

specified in the Installation Procedures section of the appropriate equipment

guides.

x

Page 15

Figure 1 Declaration of Conformity

xi

Page 16

USA Radio Frequency Interference

FCC Notice

The Federal Communications Commission (in 47 CFR Part 15 subpart B) has specified that the following

notice be brought to the attention of the users of this product.

NOTE This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

The user is cautioned that changes or modifications not expressly approved by Hewlett-Packard could result

in the equipment being noncompliant with FCC Class A requirements and void the user’s authority to

operated the equipment.

Japanese Radio Frequency Interference

VCCI

This equipment is in the Class A category information technology equipment based on the rules of Voluntary

Control Council For Interference by Information Technology Equipment (VCCI). When used in a residential

area, radio interference may be caused. In this case, user may be required to take appropriate corrective

actions.

Figure 2 Japanese RFI

xii

Page 17

Korean RFI Statement

Certification Number: E - AAAAA - BB - CCCC

• E: EMC registration

• AAAAA: equipment codes (RRL notice, 2000.10.26)

• BB: certification year

• CCCC: registration number

Figure 3 Korean RFI

Translation

Class A Equipment:

Please note that this equipment has been approved for business purpose with regards to electromagnetic

interference, if purchased un error for use in residential area, you may wish to exchange the equipment where

you purchase it.

Class B Equipment:

Please note that this equipment has been approved for non-business with regards to electromagnetic

interference. So, this equipment can be allowed to use all area as well as residential area.

European Union RFI Statement

This is a Class A product. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

Canada RFI Statement

This Class A digital apparatus complies with Canadian ICES-003.

Notice relative aux interférences radioélectriques (Canada)

Cet appareil numéric de la classe A est conforme à la norme NMB-003 du Canada.

xiii

Page 18

BSMI (Taiwan Area)

This product is fully compliant to CNS 13438 (CISPR 22: 1993) Class A. The EMC label is in the form shown

in Figure 4.

Figure 4 Taiwan Area EMC

NOTE Electrical practices and suggestions in this guide are based on North American practices. For

countries outside North America, local electrical codes will take precedence over North

American electrical codes.

An example would be the recommendation that the PE (protective earthing) conductor be green

with yellow stripes. This requirement is a North American directive and does not override the

local code requirements for a country outside North America.

Throughout this manual, the [LAHJ] acronym will be used to indicate Local Authority Has Jurisdiction.

Acoustics (Germany)

Acoustic Noise (A-weighted Sound Pressure Level LpA) measured at the bystander position, normal

operation, to ISO 7779: LpA = 59 dB.

Geräuschemission (Deutschland)

Lärmangabe (Schalldruckpegel LpA) gemessen am fiktiven Arbeitsplatz bei normalem Betrieb nach

DIN 45635, Teil 19: LpA = 59 dB.

IT Power System

This product has not been evaluated for connection to an IT power system (an AC distribution system having

no direct connection to earth according to IEC 60950).

TT, TN-C, and TN-C-S Power Systems

These products should not be connected to power systems that switch open the return lead when the return

lead also functions as the protective earth (PE). A separate PE ground wire must be connected to the

equipment at the designated PE terminal tie point.

xiv

Page 19

Installation Conditions

See installation instructions before connecting this equipment to the input supply.

Voir la notice d’installation avant de raccorder au réseau.

WARNING NORDIC Class 1 Equipment

Denmark: Før tilslutning af de øvrige ledere, se medfølgende

installationsvejledning.

WARNING NORDIC Class 1 Equipment

Sweden: Apparaten skall anslutas till jordat uttag, när den ansluts till ett nätverk.

Network Connected Equipment

The installation must provide a ground connection for the network equipment.

CAUTION Sweden: Apparaten skall anslutas till jordat uttang när deb abskuts till ett nätverk.

CAUTION Norway: Apparaten skall anslutas till jordat uttang nar deb abskuts till ett natverk.

xv

Page 20

Lithium Battery Caution

WARNING Observe the correct polarity when changing the lithium battery. There is a danger of

explosion if battery is installed incorrectly.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions and local

disposal requirements.

IMPORTANT Switzerland: Annex 4.10 of SR 814.013 applies to batteries.

Australian C-Tick Label

Figure 5 C-Tick Label

xvi

Page 21

Laser Safety

NOTE If a Fibre Channel I/O card is present, the following laser safety statement applies.

This product contains a laser internal to the Optical Link Module (OLM) for connection to the Fibre

communications port.

In the USA, the OLM is certified as a Class 1 laser product conforming to the requirements contained in the

Department of Health and Human Services (DHHS) regulation 21 CFR, Subchapter J. The certification is

indicated by a label on the plastic OLM housing.

Outside the USA, the OLM is certified as a Class 1 laser product conforming to the requirements contained in

IEC 60825-1:1993 and EN 60825-1:1994, including Amendment 11:1996.

NOTE If a DVD is present, the following laser safety statement applies.

This product contains a laser internal to the Digital Versatile Disc (DVD) housing.

In the USA, the DVD is certified as a Class 1 laser product conforming to the requirements contained in the

Department of Health and Human Services (DHHS) regulation 21 CFR, Subchapter J. The certification is

indicated by a label on the DVD housing.

Outside the USA, the DVD is certified as a Class 1 laser product conforming to the requirements contained in

IEC 60825-1:1993+A1 and EN 60825-1:1994+A11.

xvii

Page 22

xviii

Page 23

1 Introduction

The hp rp7410 is a member of Hewlett-Packard’s business-critical computing platform family: a mid-range,

mid-volume server, positioned as an upgrade to the current N-Class product in the PL-1X product line. It

provides increased performance over its predecessor but in a smaller volume. Its shallower depth allows it to

fit in a standard rack. In addition to the hp rp7410, Hewlett-Packard offers a series of cost-effective servers

based on the hp rp7410 with somewhat less performance. See “hp rp7405 Servers” on page 5.

Chapter 1

1

Page 24

Introduction

hp rp7405/rp7410 Overview

hp rp7405/rp7410 Overview

The hp rp7405/rp7410 is a 10U, 8-way SMP, rack-mount server that accommodates up to 32 GB of memory (64

GB available at a later date); PCI-4X I/O; and internal peripherals including disks and DVD/tape. Its high

availability features include N+1 hot-pluggable fans and power, redundant power cords, and hot-pluggable

PCI cards and internal disks. It uses the PA8700 PA-RISC processors.

Figure 1-1 hp rp7405/rp7410 Server (front view)

2

Chapter 1

Page 25

Figure 1-2 hp rp7405/rp7410 Server (without front bezel)

Introduction

hp rp7405/rp7410 Overview

Improvements over its predecessor, N4000, include:

• Better availability and up time

• Depth optimized (shallower, fewer racking issues)

• Performance density increase

• Performance increase

• Internal removable media

• More internal disks

• Optimal power cord quantity (2 min., 4 max)

• Enabled for cell hot-plug, dual-partition, dual and/or redundant MP Core I/O

• More PCI slots (up to 16)

• Upgradeable to PCI-X

• Superset of MP Core I/O functionality

Cell Board

The cell board contains the processors, main memory, and the CC ASIC that interfaces the processors and

memory to the off-board I/O. The CC provides a crossbar connection, which allows communication with other

cell boards in the system. It connects to the PDH and SINC hardware. Each cell board holds up to 16 DIMMS.

There can be one or two cell boards installed in a server. The cell boards have hot-plug capability.

Chapter 1

3

Page 26

Introduction

hp rp7405/rp7410 Overview

System Backplane

The system backplane comprises the system clock generation logic, the system reset generation logic,

DC-to-DC converters, power monitor logic, and two Local Bus adaptor (LBA) link-to-PCI converter ASICs. It

also includes connectors for attaching the cell boards, PCI backplane, MP Core I/O MP/SCSI boards, SCSI

cables, bulk power, chassis fans, front panel display, intrusion switches, and the system scan card. Unlike

Superdome or the rp8400, there are no XBC chips on the system backplane. The “crossbar-less” back-to-back

CC connection increases performance and reduces costs.

There are only two sets of cell board connectors, because the server has only two cells

Also, only half of the MP Core I/O board set connects to the system backplane. The MP/SCSI boards plug into

the backplane, while the LAN/SCSI boards plug into the PCI Backplane.

I/O Subsystem

All of the I/O is integrated into the system by way of the PCI busses. The CC on each cell board communicates

with one SBA over the SBA link. The SBA link consists of both an inbound and an outbound link with an

effective bandwidth of approximately 1 GB/sec. The SBA converts the SBA link protocol into “ropes”. SBA can

support up to 16 of these high-speed bi-directional links for a total aggregate bandwidth of approximately 4

GB/sec. The LBA acts as a bus bridge, supporting either one or two ropes, and capable of driving either

PCI-2x Turbo (33 MHz x 64 bits) or PCI-4 Twin Turbo (66 MHz x 64 bits) respectively.

4

Chapter 1

Page 27

Introduction

hp rp7405 Servers

hp rp7405 Servers

Hewlett-Packard offers a cost-effective server based on the hp rp7410 by employing a reduced number of

processors, memory, core I/O, or power supplies as indicated in Table 1-1.These servers provide a somewhat

reduced performance than the fully functional hp rp7410 servers.

Table 1-1 hp rp7405 Servers

Server Product Number Description

rp7405 2-way system A7111A Includes rp7405 SMP base system, two 650-MHz PA-RISC

processors, 4-GB memory (2 x 2GB memory modules), two

73-GB 10k internal disks, one DVD drive, one cell board, one

core I/O, and two power supplies

rp7405 4-way system A7112A Includes rp7405 SMP base system, four 650-MHz PA-RISC

processors, 8-GB memory (4 x 2 GB memory modules), four

73-GB 10k internal disks, one DVD drive, two cell boards,

two core I/O, and two powers supplies

rp7405 8-way system A7113A Includes rp7405 SMP base system, eight 650-MHz PA-RISC

processors, 16-GB memory (8 x 2 GB memory modules), four

73-GB 10k internal disks, one DVD drive, two cell boards,

two core I/O, and two power supplies

These servers may be upgraded with additional processors/cell boards, memory, core I/O, etc. according to the

corporate price list.

In addition, these servers may be upgraded to fully functional hp rp7410 servers with the kits given in

Tab le 1- 2 .

Table 1-2 hp rp7405-to-rp7410 Upgrades

Kit Description Upgrade Part Number

Upgrade kit from 2-way rp7405 to rp7410 750 MHz upgrade A7144A

875 MHz upgrade A7145A

Upgrade kit from 4-way rp7405 to rp7410 750 MHz upgrade A7146A

875 MHz upgrade A7147A

Upgrade kit from 8-way rp7405 to rp7410 750 MHz upgrade A7148A

875 MHz upgrade A7149A

Chapter 1

5

Page 28

Introduction

Detailed hp rp7405/rp7410 Description

Detailed hp rp7405/rp7410 Description

Figure 1-3 hp rp7410 8-Way Block Diagram

6

Chapter 1

Page 29

Introduction

Detailed hp rp7405/rp7410 Description

Cell Board

The cell board contains the processors, main memory, and the cell controller (CC) ASIC that interfaces the

processors and memory to the off-board I/O. Shown in Figure 1-4 is the CC. This is the heart of the cell board.

The CC provides a crossbar connection, which allows communication with other cell boards in the system. It

connects to the PDH and SINC hardware. Each cell board holds up to 16 DIMMs. There can be one or two cell

boards installed in an system. The cell boards have hot-plug capability.

Figure 1-4 Cell Controller

Figure 1-5 Cell Board

Chapter 1

7

Page 30

Introduction

Detailed hp rp7405/rp7410 Description

The hp rp7405/rp7410 has a 48V distributed power system and receives the 48V power from the system

backplane board. The cell board contains DC-to-DC converters to generate the required voltage rails. The

DC-to-DC converters on the cell board do not provide N+1 redundancy.

The cell board contains several major buses including:

• Runway buses for each of the four processors

• Two memory buses (one going to each half of the main memory array)

• Incoming and outgoing I/O bus that goes off board to a SBA chip

• Incoming and outgoing crossbar bus that goes off board to the other cell boards

• PDH bus that goes to the PDH/SINC circuitry

All of these buses come together at the CC chip.

Due to space limitations on the cell board the PDH/SINC circuitry resides on a riser board that plugs at a

right angle into the cell board. The cell board also includes clock circuits, test circuits and de-coupling

capacitors.

Figure 1-6 shows a simplified view of the memory subsystem. It consists of two independent access paths,

each path having its own address bus, control bus, data bus, and DIMMs. In practice, the CC runs the two

paths 180 degrees out of phase with respect to each other to facilitate pipelining in the CC. Address and

control signals are fanned out through register ports to the SDRAMs on the DIMMs.

Data transferred between the CC and SDRAM passes through custom VLSI circuits (M2) that are bit-sliced;

four form one 72-bit CC memory data bus. These circuits perform speed and width conversion between the

SDRAM and MID busses. They also perform the write (tag update) portion of a read-modify-write (RMW)

access. The CC memory data busses are bi-directional and run at 250 MT/s (million transfers per second).

These links are self-clocked in that a pair of clock strobes is passed along with the data so that phase

realignment can be done by the receiver.

Figure 1-6 Memory Subsystem

8

Chapter 1

Page 31

Introduction

Detailed hp rp7405/rp7410 Description

PDH Riser Board

The PDH riser board is a daughter card for the cell board. It contains a micro-processor memory interface

microcircuit, processor-dependent hardware (PDH) including the processor dependant code (PDC) Flash

memory, and a manageability micro-controller, called SINC, with associated circuitry. The PDH obtains cell

board configuration information from cell board signals and from the cell's LPM. See the PDH Riser Board

ERS for operational details.

The memory interface microcircuit is the heart of the PDH. It provides the CC access to the PDH space by a

4-bit, 50-75 MHz bus. This microcircuit also supports an interrupt mechanism to the CC that can interrupt a

processor for the PDH. It provides access to the FLASH ROM and scratch RAM memory chips together with

the external registers and an interface to an I

the system. It also controls system reset and initialization signals, as well as the low-level debugger (LDB)

port, UART, semaphore register, and GPIO pins. It is the primary master for a Serial Presence Detect bus.

The PDH supports up to 4 MB of address space for ROM (FLASH) to hold the PDC firmware.

The non-volatile memory and scratch RAM have been combined and placed in a 512KB battery-backed SRAM

DIMMs

Custom designed by Hewlett-Packard, each DIMM contains 36x4 SDRAM memory components similar to

PC-133 memory but qualified to run at 125MHz. They have an low-voltage TTL interface. The CEC does not

support traditional DRAMs.

2

C micro controller (SINC) that monitors sensors throughout

The hp rp7405/rp7410 supports DIMMs with 128, 256, 512, and 1024 Mbit devices. Table 1-3 shows each

DIMM supported with its associated capacity, the resulting total system capacity, and the memory component

density.

DIMMs must be loaded in sets of four at specific locations. For best performance, loading sets of eight DIMMs

is recommended.

Table 1-3 hp rp7405/rp7410 DIMMs

DIMM Capacity Total Capacity Memory Component Density

512 Mbyte 16 Gbytes 128 Mbit

1G Byte 32 Gbytes 256 Mbit

Main Memory Performance Latency to main memory is an important parameter in determining overall

system performance. With memory busses running at 125 MHz, the latency for a page hit is 8.5 cycles (68ns),

the latency for a page closed is 11.5 cycles (92ns), and the latency for a page miss is 14.5 cycles (116ns).

Cells and nPartitions

NOTE In the following discussion, the term “cell” refers to a cell board.

A cell board that has an I/O link to a bootable device and a console (usually supplied by an MP Core I/O card)

is a potential boot cell. The cell that contains the boot console I/O path is the called the root cell. Both cells are

potential root cells. The primary or default root cell in a single nPartition system is the bottom cell (cell 1).

An nPartition (also called a Protection Domain) is a cell(s) running the same OS and sharing processes and

memory space among the components. Each nPartition must have one root cell and may have both. The hp

rp7405/rp7410 has only two possible nPartition configurations: single or dual. The additional cell that may be

part of the nPartition does not require I/O links nor MP Core I/O cards.

Chapter 1

9

Page 32

Introduction

Detailed hp rp7405/rp7410 Description

In the single nPartition case, if two cells are present, either cell may be the root cell, assuming the both cells

have MP Core I/O functionality present. If only one cell is present, that cell is the root cell (and should be cell

1).

In the dual nPartition case (two cells required), each nPartition consists of one cell, and each cell must be a

root cell. The ability to interconnect two cells in one nPartition or isolate the cells in a dual nPartition system

provides system configuration flexibility. System partitioning is configured by the system management

processor.

Internal Disk Devices for hp rp7405/rp7410

As Figure 1-4 shows, in an hp rp7405/rp7410 cabinet the top internal disk drives connect to cell 1 through the

MP Core I/O for cell 1 (for 1/0/0/3/0.6) and the LAN/SCSI card in slot 1_8 (I/O chassis 1 slot 8, for

1/0/1/0/0/1/1.6). Both of the bottom disk drives (0/0/0/3/0.6 and 0/0/0/3/0.5) connect to cell 0 through the MP

core I/O for cell 0. A CD/DVD-ROM drive or DAT drive connects to cell 1 through the core I/O card for cell 1,

thus it can be accessed through the cell 1 nPartition only.

Figure 1-7 Internal Disks

Drive 1-1

Path: 1/0/0/3/0.6

Drive 1-2

Path: 1/0/1/0/0/1/1.6

Removable media path

DVD: 1/0/0/3/1.2

DAT: 1/0/0/3/1.3

Drive 0-2

Path: 0/0/0/3/0.5

Drive 0-1

Path: 0/0/0/3/0.6

10

Chapter 1

Page 33

Introduction

Detailed hp rp7405/rp7410 Description

System Backplane

The system backplane comprises the system clock generation logic, the system reset generation logic,

DC-to-DC converters, power monitor logic, and two LBA link-to-PCI converter ASICs. It also includes

connectors for attaching the cell boards, PCI backplane, MP Core I/O MP/SCSI boards, SCSI cables, bulk

power, chassis fans, front panel display, intrusion switches, and the system scan card.

Figure 1-8 System Backplane Block Diagram

System backplane

MP Core I/O

MP/SCSI

PCI backplane

Cell board 0

MP Core I/O

MP/SCSI

Cell board 1

Cell boards are perpendicular

to the system backplane.

Bulk power supply

Only half of the MP Core I/O board set connects to the system backplane. The MP/SCSI boards plug into the

backplane, while the LAN/SCSI boards plug into the PCI backplane.

Clocks and Reset

The system backplane contains reset and clock circuitry that propagates through the whole system. The

central clocks drive all major chip set clocks. Therefore, these circuits represent a system wide single point of

failure.

I/O Subsystem

The cell board-to-I/O path runs from the CC to the SBA, from the SBA to the ropes, from the ropes to the LBA,

and from the LBA to the PCI buses. The CC on each cell board communicates with one SBA over the SBA

link. The SBA link consists of both an inbound and an outbound link with an effective bandwidth of

approximately 1 GB/sec. The SBA converts the SBA link protocol into “ropes.” The SBA can support up to 16

of these high-speed bi-directional rope links for a total aggregate bandwidth of approximately 4 GB/sec. The

LBA acts as a bus bridge, supporting either one or two ropes and capable of driving either PCI-2x Turbo (33

MHz x 64 bits) or PCI-4 Twin Turbo (66 MHz x 64 bits) respectively

Chapter 1

11

Page 34

Introduction

Detailed hp rp7405/rp7410 Description

.

Figure 1-9 I/O Subsystem Architecture

The server supports two internal SBAs. The SBAs generate 32 rope busses (16 per SBA). The 32 available

internal rope busses are divided in the following manner:

• Two ropes are routed as single rope bundles to support PCI-2x Turbo (264 MB/sec. bandwidth, 64-bit

transfers at 33 MHz) for the MP Core I/O boards for SCSI/LAN.

• Two ropes are routed as single rope bundles to two LBAs to support two slots operating at PCI-2x for

MP/SCSI.

• The remaining 28 ropes are bundled in two rope pairs to 14 LBAs to support 14 slots operating at PCI-4x

(528 MB/sec., 64-bit transfers at 66 MHz).

The hp rp7405/rp7410 uses Hewlett-Packard’s proprietary adaptive signaling concept, also known as the

Universal PCI slot concept (not to be confused with the Universal PCI card). Circuitry on the backplane

senses a standard connector, keyed for 5V, to determine the type of the cards inserted. The circuitry controls

the voltage rail supplied to the connector for powering the card’s I/O pads, VIO. The card can either be of the

5V only, or universal type. 5V only cards require VIO to be 5V, whereas universal cards operate 5V as well as

3.3V. To take advantage of the 66-MHz potential of universal cards, one must operate those cards at 3.3V. The

control circuitry on the backplane, therefore, provides 5V to the slot when a 5V-only card is present, or 3.3V

when a universal card is present. Firmware controls the setting of the slot’s clock rate.

12

Chapter 1

Page 35

Introduction

Detailed hp rp7405/rp7410 Description

This concept allows maximum connectivity for mainstream 5V-only, 33 MHz, 32 bit (PCI-1x) and 64-bit

(PCI-2x) cards, as well as full I/O bandwidth utilization through the use of 64-bit, 66 MHz (PCI-4x) universal

cards.

Table 1-4 PCI Slot Types

Slot# Device:

0_1 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_2 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_3 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_4 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_5 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_6 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_7 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

0_8 PCI-2x, Turbo 64-bit, 33 MHz, Adaptive Signaling, 5V connector, Hot Swap Slot.

1_1 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_2 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_3 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_4 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_5 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_6 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_7 PCI-4x, Twin Turbo 64-bit, 66 MHz, 3.3V-only, 3.3V connector, Hot Swap Slot.

1_8 PCI-2x, Turbo 64-bit, 33 MHz, Adaptive Signaling, 5V connector, Hot Swap Slot.

MP/SCSI MP Core I/O Board

The hp rp7405/rp7410 accommodates two sets of MP Core I/O functionality. Each MP Core I/O board set

consists of a MP/SCSI board and a Procurium LAN/SCSI board. At least one MP/SCSI board is required

(independent of partitions) An additional MP/SCSI board can be added as well (and is required in a dual

partition system). Both MP/SCSI boards are oriented vertically and plug into the system backplane. The

MP/SCSI board incorporates a dual Ultra160 SCSI controller and is hot pluggable.

Procurium LAN/SCSI Board

At least one Procurium LAN/SCSI board is required for the minimum system configuration; two are required

in a dual partition system. The Procurium board is a standard PCI form factor card with PCI card edge

connectors. The PCI backplane has one slot location reserved for the required Procurium board and another

that can accommodate either a Procurium board or any other supported add-in PCI card. The Procurium

board is hot pluggable.

Chapter 1

13

Page 36

Introduction

Detailed hp rp7405/rp7410 Description

Mass Storage (Disk) Backplane

Internal mass storage connections (to disks) are routed on the mass storage backplane, having connectors and

termination logic. All disks are hot pluggable. The hp rp7405/rp7410 accommodates one internal removable

media device. Therefore, only one power connector for a removable media device is required on the mass

storage backplane. The mass storage backplane incorporates a circuit that allows power to the internal

removable media device to be programmatically cycled.

Package Description

Dimensions

The dimensions of the hp rp7405/rp7410 are as follows:

• Width: 44.45 cm (17.5 inches), constrained by EIA standard 19 inch racks.

• Depth: Defined by cable management constraints to fit into standard 36 inch deep racks (Rittal/Compaq,

Rosebowl I):

25.5 inches from front rack column to PCI connector surface:

26.7 inches from front rack column to MP Core I/O connector surface

30 inches overall package dimension, including 2.7 inches protruding in front of the front rack columns.

• Height: 10U – 5.4 cm = 43.91 cm (17.287 inches). This is the appropriate height for a product that

consumes 10U of rack height while allowing adequate clearance between products directly above and

below this product. Fitting four server units per 2 m rack and upgrade of current 10U height products in

the future are the main height constraints.

System Chassis

The mass storage section located in the front allows access to removable mass storage devices without

removal of the bezel (not shown.) This is especially helpful when the system is mounted in the lowest position

in a rack. The mass storage bay accommodates one 5.25-inch removable media device and up to four 3.5-inch

hard drives. The front panel display board, containing LEDs and the system power switch, is located directly

above the 5.25-inch removable media bay.

Below the mass storage section and behind a removable bezel are two PCI DC-to-DC power converters.

The bulk power supply section is partitioned by a sealed metallic enclosure located in the bottom of the

package. This enclosure houses the 2N fully redundant BPSs.

14

Chapter 1

Page 37

Figure 1-10 Right-Front View of hp rp7405/rp7410

Front panel

display board

Introduction

Detailed hp rp7405/rp7410 Description

PCI cards

Cell boards

PCI DC-to-DC

converters

Bulk powers supplies

The PCI I/O card section, located towards the rear, is accessed by removing the top cover.

The PCI OLR fan modules are located in front of the PCI cards. These six 9.2 cm fans are housed in plastic

carriers. They are configured in two rows of three fans.

The MP/SCSI MP Core I/O boards are positioned vertically at the rear of the chassis.

The PCI card bulkhead connectors are located in the top rear portion of the product volume.

Four OLR system fan modules, externally attached to the chassis, are 15 cm (6.5-inch) fans. Two fans are

mounted on the front surface of the chassis and two are mounted on the rear surface.

Redundant line cords attach to the floating AC connector module at the bottom rear. Two 20-amp cords are

required to power the server. Two additional line cords provide redundancy.

Slide

A cable harness that connects from the rear of the BPSs to the system backplane provides DC power

distribution.

Access the system backplane is accomplished by removing the left side cover. The system backplane inserts by

a guide/insertion mechanism using a single large jack screw assembly.

SCSI ribbon-cable assemblies route from the mass storage area to the backside of the system backplane and

to the Procurium PCI MP Core I/O card.

Chapter 1

15

Page 38

Introduction

Detailed hp rp7405/rp7410 Description

Cell boards are accessed from the right side of the chassis behind a removable side cover.

Figure 1-11 Left-Rear View of hp rp7405/rp7410

System backplane

MP Core I/O MP/SCSIs

16

Chapter 1

Page 39

2 Installation

Chapter 2

17

Page 40

Installation

Unpacking the Server

Unpacking the Server

Hewlett-Packard shipping containers are designed to protect their contents under normal shipping

conditions. After the equipment arrives, carefully inspect each carton for signs of shipping damage. A tilt

indicator is installed on each carton shipped. The beads in the indicator will roll to the upper position if the

container has been tilted to an angle that could cause equipment damage. The tilt indicator itself will have

two windows and each window under normal conditions will show four beads present. If a carton has been

mishandled, accidentally dropped, or knocked against something, the tilt indicator will indicate missing

beads. If damage is found, document the damage with photographs and contact the transport carrier

immediately.

Examine the server cabinet for visible shipping damage. After unpacking the cabinet, check for damage that

may have been obscured by the shipping container. If damage is found after visual inspection, document the

damage with photographs and contact the transport carrier immediately.

If the equipment has any damage, a damage claim form must be obtained by the customer from the shipping

representative. The customer should complete the form and return it to the shipping representative.

NOTE The server may come already racked, or ready for rack installation.

Unpacking a Racked Server

This section contains information pertaining to unpacking the cabinet.

WARNING Wear protective glasses while cutting the plastic bands around the shipping

container. These bands are under tension. When cut, they can spring back and cause

serious eye injury.

NOTE Position the pallet allowing for enough space to roll the cabinet off the pallet before starting.

Remove the cabinet using the following procedure:

Step 1. Cut the polystrap bands around the shipping container.

Step 2. Lift the cardboard top cap from the shipping box. See Figure 2-1.

Step 3. Remove the corrugated wrap from the pallet.

Step 4. Remove the packing materials.

18

Chapter 2

Page 41

Installation

Unpacking the Server

CAUTION The plastic wrapping material should be cut off rather than pulled off. Pulling the

plastic covering off represents an ESD hazard.

Figure 2-1 Removing the Polystraps and Cardboard

Chapter 2

19

Page 42

Installation

Unpacking the Server

Step 5. Remove four bolts holding down the ramps and remove the ramps. See Figure 2-2.

Figure 2-2 Removing the Shipping Bolts and Plastic Cover

20

Chapter 2

Page 43

Unpacking the Server

Step 6. Remove the six bolts from the base attaching the rack to the pallet. See Figure 2-3.

Figure 2-3 Preparing to Roll Off the Pallet

Installation

WARNING Make sure that the leveling feet on the rack are raised before you roll the

rack down the ramp and any time you roll the rack on the casters. Use

caution when rolling the cabinet off the ramp. A single server in the cabinet

weighs approximately 400 pounds. It is strongly recommended that two

people roll the cabinet off the pallet.

Chapter 2

21

Page 44

Installation

Unpacking the Server

Securing the Cabinet

Once in position, secure and stabilize the cabinet using the leveling feet at the corners of the base and install

the anti-tip mechanisms on the bottom front and rear of the rack.

Figure 2-4 Securing the Cabinet

Unpacking a Non-Racked Server

NOTE Hewlett-Packard recommends the use of a lifter, such as a RONI Company model 17000 SP 400

lifting device, when moving a non-racked system, shown in Figure 2-5. If no lifter is available,

install the lift handle panels provided with the system.

Unloading with a Lifter

Use the following procedure to unload the server from the pallet using a lifter.

WARNING Use caution when using a lifter. Because of the weight of the server, it must be

centered on the lifter forks before raising it off the pallet to avoid injury.

Never extend more than one server from the same cabinet while installing or

servicing either an hp rp7405/rp7410 or another server product. Failure to follow

these instructions could result in the cabinet tipping over.

22

Chapter 2

Page 45

Figure 2-5 RONI Lifter

Installation

Unpacking the Server

Step 1. Follow the instructions on the outside of the server packaging to remove the banding and carton top

from the server pallet.

Figure 2-6 Server with Shipping Box Removed

Step 2. Remove all cartons from the pallet leaving only the server.

Chapter 2

23

Page 46

Installation

Unpacking the Server

Step 3. Observe Figure 2-7. Remove the two foam cushion for lift access.

Figure 2-7 Remove Cushions for Lift Access

Remove cushion

Remove cushion

Clearance for RonI lift is 28”x5”

Step 4. Insert the lifter forks under the server.

Step 5. Carefully roll the lift forward until it is fully positioned against the side of the server.

24

Chapter 2

Page 47

Step 6. Slowly raise the server off the pallet until it clears the pallet cushions.

Figure 2-8 Raising a Server Off the Pallet

Installation

Unpacking the Server

Step 7. Roll the lifter and server away from the pallet. Do not raise the server any higher than necessary

when moving it over to the rack.

Figure 2-9 Lifting the Server to the Rack

NOTE If you are installing the system in a rack, refer to the hp J1530A Rack Integration Kit

Installation Guide.

Chapter 2

25

Page 48

Installation

Unpacking the Server

Unloading with Lift Handle Panels

WARNING Use this procedure only if no Hewlett-Packard approved lift is available. This

procedure should only be attempted by two (2) authorized Hewlett-Packard service

people.

Before attempting this procedure, it is recommended that you first remove all Cell

Boards and AC power supplies. Instructions for removing these components can be

found in the Removal and Replacement chapter of the service manual. Check with

local safety regulations before attempting to move the system using the lift handle

panels.

Failure to observe these precautions can cause serious injury to personnel or

damage to equipment.

CAUTION Unpack the server in an ESD safe environment. Observe all ESD safety precautions before

attempting this procedure. Failure to follow ESD safety precautions could result in damage to

the server.

Step 1. Remove both side covers. If present, remove the front panel.

Step 2. Locate lift handles and remove from storage plate.

Step 3. Orient lift handle panels such that when installed, the handles hang downward at 90 degrees and

lock in a horizontal position during lifting.

Figure 2-10 Positioning the Lift handles

26

Chapter 2

Page 49

Installation

Unpacking the Server

Step 4. With one handle in each hand, install the pin end of the panel into the backside of the front rack

mount ears on the chassis.

Figure 2-11 Inserting the Pins Into the Rack

Step 5. Pull the spring plunger out, move the handles apart and install the shoulder washer end of the

panel into the keyway feature.

Figure 2-12 Lift Handles Mounted

Chapter 2

27

Page 50

Installation

Unpacking the Server

Step 6. Continue to pull the handles apart until the spring plunger snaps into final position. The spring

plunger will drop down into the recess position.

Step 7. Check that the handles are secure by pressing the handles together and moving back and forth.

Check to see if lift handle panel breaks free of chassis.

Step 8. Repeat the steps above for the other handle

Step 9. To lift the server, rotate the handles 90 degrees to horizontal position.

NOTE If you are installing the system in a rack, refer to the installation guide, hp J1530A,

rack installation kit (lower case intended).

Step 10. After moving the server, remove the lift handle panels from the chassis and reinstall the server

covers and front bezel. Refer to installation guide, hp J1530A, rack installation kit (lower case

intended).

Figure 2-13 Lifting the Server

Installing Server Into the Rack

Any hp rp7405/rp7410 server that is to be installed into a rack is shipped with equipment slides. With every

set of slides comes an installation guide: installation guide, hp J1530A, rack installation kit (lower case

intended). Follow the steps in this installation guide to determine where and how to place the server into the

rack.

28

Chapter 2

Page 51

Installation

Unpacking the Server

Installing the Cable Management Arm (CMA)

Once the server is installed in the rack, the CMA must be installed on the rear of the server. Follow the

instructions for installing the CMA can be found in the installation guide, hp J1530A, rack installation kit

(lower case intended).

Figure 2-14 Cable Management Arm

Cable Management Arm

Step 1. Attach CMA to the rack using T-25 Torx screws.

Figure 2-15 Attaching CMA to Rack

Chapter 2

29

Page 52

Installation

Unpacking the Server

Step 2. Attach the other end of the CMA to the server using the thumb screws that came with the CMA.

Figure 2-16 Attaching CMA to the Server

Installing Add-On Products

This section explains load orders and dependencies for add-on products. For physical installation procedures,

refer to that components replacement procedure in Chapter 4, “Removal and Replacement.”

If installing add-on products to an existing server, follow operating system backup and shutdown procedures

before powering off the server.

Cell Boards

The server requires at least one cell board to operate. Install the first cell board slot 1 (lower slot) and the

second cell board in slot 0 (upper). Cell Board 0 enables the PCI cards in Chassis 0 and Cell Board 1 enables

the PCI cards in Chassis 1.

MP Core I/O Cards

MP Core I/O consists of two cards that must be installed in pairs: the MP/SCSI and the LAN/SCSI.

The first (primary) set of MP Core I/O cards is installed as follows: MP/SCSI in MP/SCSI slot 1 (lower slot)

and LAN/SCSI in PCI slot 8 of Chassis 1 (from the rear, the extreme right-hand PCI slot).