Page 1

May 1997 Edition

Split

Format

HP LaserJet Family

Quick Reference

Service Guide

Page 2

HP LaserJet

Family Quick

Reference

Service Guide

i

Page 3

Trademark Credits

PCL is a registered trademark of Hewlett-Packard Company.

Resolution Enhancement is a trademark of Hewlett-Packard Company.

Adobe and PostScript are registered trademarks of Adobe Systems, Inc. in the U.S. and other countries.

HP Vectra Personal Computer is a product of Hewlett-Packard Company.

IBM , IBM LAN Server and TokenRing are registered trademarks of International Business Machines

Corporation.

IBM PC is a product of International Business Machines Cor poration.

Microsof t is a U.S. registered trademark of Microsoft Corporation.

Micr os of t LA N M an age r and MS-DOS are U.S. registered trademarks of Microsoft Corporation.

Macintosh is a registered t rademark of Apple Computers Inc.

AppleTalk is a registered trademark of Apple Computers Inc.

3Com 3+ Op en an d 3Com are trademarks of 3Com Corporation.

Ethernet is a registered trademark of Xerox Corporation.

NetWare and Novel l are registered trademarks of Novell Corporation.

Ordering other Manuals

This

LaserJet Quick Reference Service Guide

LaserJet Service Engineer quickly troubleshoot common printer problems.

While this reference is intended to provid e all the information the Service

Engineer will need for on-site repair of HP LaserJet products, it is not i ntended

to replace the service manual for any HP LaserJet product . For detailed

information about the HP LaserJet Products described in this guide, see the

user’s or service manual for that product.

Servic e man uals for HP Laser Jet pr odu ct s are av ail able fro m

Hewlett-Packard’s Support Materials Organization (SMO). The Service Parts

Order Desk number is:

1-800-227-8164 (U.S. Only)

Outside U.S. contact local HP Sale s and Service office.

has been created to help the

ii

Page 4

Sect ion A

This section supports the following printers:

LaserJet 5/5M/5N

LaserJet 5P/5MP

LaserJet 6P/6MP

LaserJet 5L

LaserJet 5Si/5Si MX

LaserJet 5Si Mopier

LaserJet 6L

Minimal support is provided for the LaserJet Companion

iii

Page 5

iv

Page 6

Contents for Section A

1A E rro r Code s

Error listings, descriptions, and recommended actions.

2A Service Mo de

How to access Service Mode and related functions.

3A Power Supply Checks

DC voltages, test points, and tools.

4A I/O In form ation

Printer interface and cabling infor mation.

5A Media Specifications

Supported sizes and s pecifications fo r paper and special medi a.

6A Toner Cartridge Information

Cartridge weights, capacities, and potential service issues.

7A Printer Options and User Replaceable Parts

Support matrix and part numbers for access ories.

8A Service Parts

Selected high-usage replacement parts.

9A Service Notes Summary & Technical Tips

Some of the most common (o r troublesome) service issues.

10A Print Image Defects

Image defect samples, suspect causes, and remedies.

11A Wiring Diagr ams

Main wiring schematics.

12A Service/Support Resources and Training

How and where to get training, support, and materials.

13A LaserJet Companion Supplement

LaserJet Companion information and specifications.

v

Page 7

This guide provides:

Service tips and information for troubleshooting common problems.

Part number s and locati ons for common replacement parts.

Printer and media specifications.

Wiring diagrams that detail signal flow and show the interaction of the

different printer assemblies.

A guide to service support information from Hewlett-Packard.

This guide will be updated on a regular basis as the service needs change, as

new products are introduced, and as information becomes available.

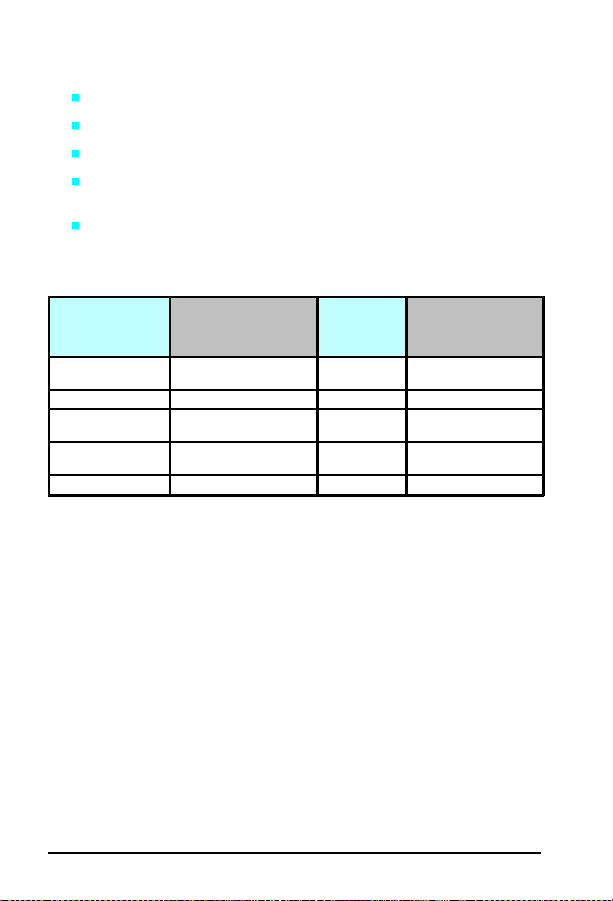

Reference

Name used

in this Guide

LJ 5P/5MP*/

6P/6MP*

LJ 5L C3941A 4K C3941-99001

LJ 5/5M*/5N C3916A/C3917A/

LJ 5Si/5SiMX*/

5Si Mopier

LJ 6L C3990A 6K C3990-90991

Model Number

C3150A/C3155A/

C3980A/C3982A

C3952A

C3166A/C3167A

C4076A/C4077A

Maximum

Pgs per

Month

12k C3980-90956

35K C3916-90984

100K C4077-90945

Service

Manual P art

Number

*Macintosh compatible.

vi

Page 8

1A

Error Codes

Error Codes

1A-1

Page 9

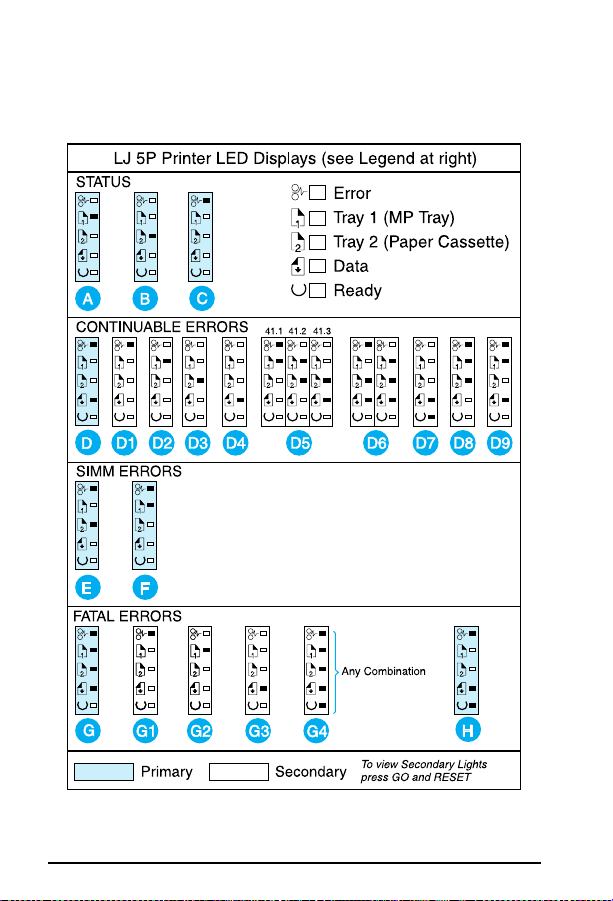

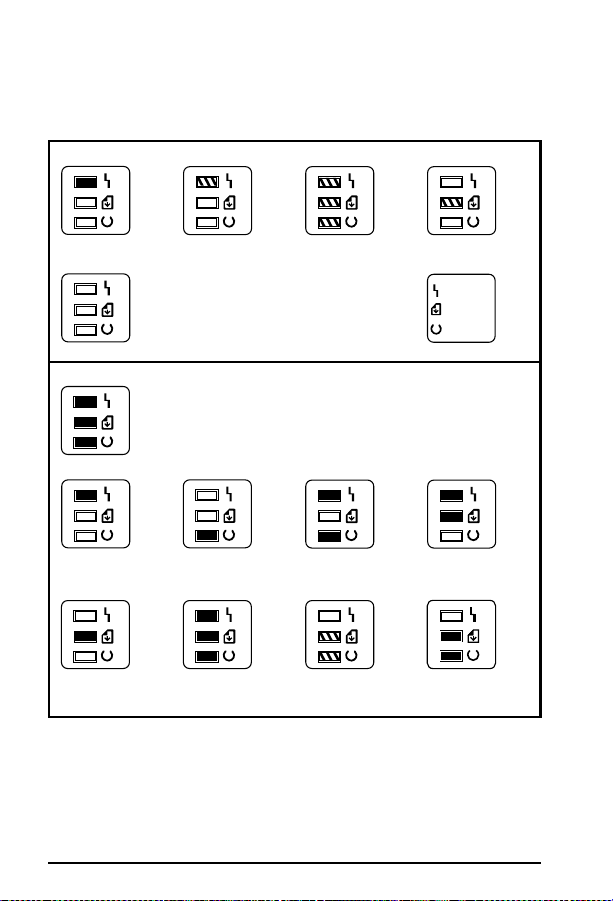

Error Codes

LJ 5P Printer LED Displays

For more details, refer to the page number list ed with each display letter .

If the error and data lights are both lit, simultaneously press [Go] and [Reset] to

display the Data Error pattern.

1A-2

Page 10

Error Codes

Legend (5P Display Lights)

STATUS MESSAGES

Paper Out (Tray 1)

A

(see page 1A-10)

Paper Out (Tray 2)

B

(see page 1A-10)

CONTINUABLE ERRORS

When the ERROR and DATA LEDs are on, press the Go and RESET

buttons. Follow the instructions for the secondary light patterns shown.

Primary Light Pattern (see note)

D

Error 20 (Mem Overflow)

D1

(see page 1A-13)

Error 21(Print Overrun)

D2

(see page 1A-13)

Error 22(I/O Error)

D3

(see page 1A-14)

Error 40

D4

(see page 1A-16)

SIMM ERRORS

Remove all SIMMs and power cycle the printer. Retry operation. Replace

SIMMs one at a time to locate the defective module. Refer to the Service

Manual for details.

Error 53-0 ROM Error

E

(see note above)

Error 53-1 RAM Error

F

(see note above)

FATAL ERRORS

When the DATA, TRAY2, TRAY1, and ERROR LEDs are on, press the GO and

RESET buttons. Follow the instructions for the seconda ry light patterns shown.

Primary Light Pattern (see note)

G

Error 50 Fuser

G1

(see page 1A-18)

Error 57/58 (Main Mtr)

G2

(see pages 1A-21/22)

Printer Open (page 1A-8)

C

or

No Toner Cartridge (page

1A-8)

or

Paper Jam (page 1A-11)

Error 41.1, 41.2, 41.3

D5

(see page 1A-17)

Error 68, 68.1

D6

(see page 1A-26)

Error 51 (Beam Detect)

D7

(see page 1A-18)

Error 52 (Scanner

D8

Malfunction)

(see page 1A-19)

Error 55

D9

(see page 1A-21)

Error 61.1/62.1

G3

(see page 1A-22)

All other errors

G4

(see 79 Error, pg 1A-27)

Error 63 Service Error

H

(see page 1A-22)

1

A

1A-3

Page 11

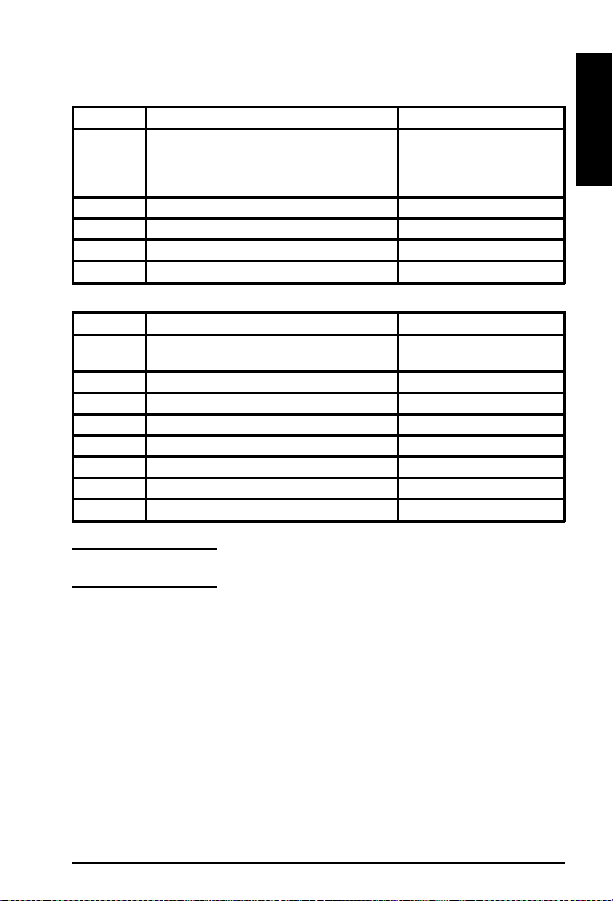

Error Codes

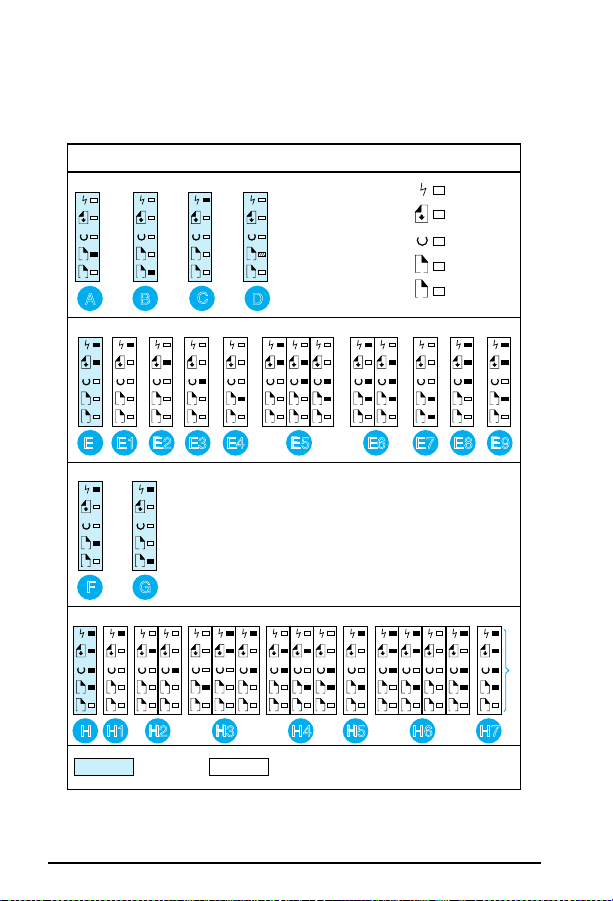

LJ 6P Printer LED Displays

For more details, refer to the page number list ed with each display letter .

If the error and data lights are both lit, simultaneously press [Go] and [Reset/Job

Cancel] to display the Data Err or pattern.

LJ 6P Printer LED Displays (see Legend at right)

STATUS

1

1

1

2

2

A

B

1

2

2

C

Tray 1

D

LED Blinking

CONTINUABLE ERRORS

1

1212121

2

E1 E2 E3 E4 E5 E7 E8 E9

E

2

121

12121212121

2

E6

SIMM ERRORS

1

1

2

2

G

F

FATAL ERRORS

11223

3

*

Error

Data

Ready

Tray 1

1

Tray 2

2

2

= Any other combination

121

H

1A-4

121

121

2

2

1

2

2

H1 H2 H3

Primary Secondary

121

2

2

121

2

2

2

1

1

H4 H5 H6 H7

To view Secondary Lights

press GO and RESET/JOB

CANCEL buttons simultaneously.

*

1

121

2

Page 12

Legend (6P Display Lights)

Error Codes

STATUS MESSAGES

Paper Out (Tray 1)

A

(see page 1A-10)

Paper Out (Tray 2)

B

(see page 1A-10)

CONTINUABLE ERRORS

When the ERROR and DATA LEDs are on, press the Go and RESET/JOB

CANCEL buttons. Follow the instructions for the secondary light patterns.

Primary Light Pattern (see note)

E

Error 20 (Mem Overflow)

E1

(see page 1A-13)

Error 21(Print Overrun)

E2

(see page 1A-13)

Error 22(I/O Error)

E3

(see page 1A-14)

Error 40

E4

(see page 1A-16)

SIMM ERRORS

Remove all SIMMs and power cycle the printer. Retry operation. Replace

SIMMs one at a time to locate the defective module. Refer to the Service

Manual for details.

Error 53-0 ROM Error

F

(see note above)

Error 53-1 RAM Error

G

(see note above)

FATAL ERRORS

When DATA, READY, TRAY1, and ERROR LEDs are on, press GO and

RESET/JOB CANCEL. Follow the instructions for the secondar y light patterns.

Primary Light Pattern (see note)

H

Error 50 Fuser

H1

(see page 1A-18)

Error 57/58 (Main Mtr)

H2

(see page 1A-21/22)

Error 61.x (x=1, 2, 3 SIMM)

H3

(see page 1A-22)

Printer Open (page 1A-8)

C

or

No Toner Cartridge (page

1A-8)

or

Paper Jam (page 1A-11)

Manual Feed (page 1A-30 )

D

Error 41.1, 41.2, 41.3

E5

(see page 1A-17)

Error 68, 68.1

E6

(see page 1A-26)

Error 51 (Beam Detect)

E7

(see page 1A-18)

Error 52 (Scanner

E8

Malfunction)

(see page 1A-19)

Error 55

E9

(see page 1A-21)

Error 62.x (x=1, 2, 3 SIMM)

H4

(see page 1A-23 )

Error 62.0

H5

(see page 1A-23 )

Error 63, 64, 64, 65

H6

(see page 1A-23 through 24)

All other errors

H7

(see pages 1A-26 through 30)

1

A

1A-5

Page 13

Error Codes

LJ 5L/6L Printer LED Displays

For more details, refer to the legend on the followi ng page, which will

refer you to recommended actions.

STATUS MESSAGES

A. Error LED is on.

*Unclearable error.

B. Error LED is

blinking.

C. All LEDs are

blinking.

D. Data LED is

blinking.

Error

Data

Ready

E. All LEDs are off. LED Legend

ERROR AND SERVICE MESSAGES

A. Error LED is on.

*Unclearable error.

E. Data LED is on. F. All LEDs are on. G. Data and

When all lights are on, there is a Service Error. Press and hold

the Front Panel Button to display the LED error code pattern.

The code will be shown only while the button is pressed. The

following pictures show the possible LED error patterns.

B. Ready LED isonC. Error an d

Ready LEDs are

on.

Ready LEDs are

blinking.

D. Error and Data

LEDs are on.

H. Formatter Error

* An unclearable error is not strictly a service message. It will appear without

all three lights being displayed first. See letter A in Status and Error sections.

1A-6

Page 14

Error Codes

5L LED Patterns for St at us and Error Messages

Status Messages

Item Description Recommended Action

A Paper Out

Door Open

No EP Cartridge

Paper Jam

B Memory Error See page 1A-13

C Incompatible Memory Card See page 1A-21

D Manual Feed See page 1A-29

E Sleep Mode See page 1A-28

Error an d Service Messages

Item Description Recommended Action

A Unclearable Error

Engine Error

B ROM/RAM Error See page 1A-20

C Fuser Error See page 1A-18

D Beam Error See page 1A-18

E Scanner Error See page 1A-19

F Formatter Error See page 1A-23

G F irmware Error See page 1A-29

H Formatter Error See page 1A-2223

See page 1A-10

See page 1A-8

See page 1A-8

See page 1A-11

See page 1A-30

See page 1A-16

1

A

Note

Before troubleshooting any Service Error, power

cycle the printer to see if the error persists.

1A-7

Page 15

Error Codes Clear Jam Staple

Optional Output Bin X

Error Code Tables (LJ 5 series and newer)

Clear Jam Staple

Option al Ou tput Bin X

5 Si Mopier

1. Clear the jam.

2. Check the staple cartridge.

3. Check stapler and cabling.

4. Check Stapling Unit Control PCA.

5. Replace the entire Stapling Unit as required.

Close P rinter Cove r/Pr inter Open

All Printers

1. Printer Door open.

Check that toner cart ridge is full y seated and tha t the covers are fir mly

clos ed.

2. Defective DC Power Supply.

3. Defective DC Controller.

4. Actuator or tab missing or broken.

5. Defective Paper Control PCA.

Install Toner Cartridge/No Cartridge

All Printers

1. Reseat or install new toner cartridge.

2. Dirty or defective High Voltage contacts.

3. Defective High Voltage Power Supply.

5

1. Defective DC Controller.

Install T r ay 2

5

1. Lower Cassette (T ray 3) selected and printer detected Paper Cassette

(Tray 2) not installed.

Install or reseat PC (Tray 2), which is the paper guide for the LC (Tray 3).

2. Improperly fitted PC.

Firmly rese at t he PC.

1A-8

Page 16

Error Codes Out of Staples Optional Output X

Out of Staples Optional Output X

5Si Mopier

1. Re pla ce th e st apl e ca rtri dge .

2. If message continues after cartrige has been replaced, check stapler,

T op Cover Assembly, and cabling.

3. Check Stapling Unit Control PCA.

4. Replace the entire Stapling Unit as required.

Output Operation Condition x.yy

5Si Mopier

x= output device number

yy=condition code

For the Multi-Bin Mailbox:

01 = Face-Up Tray not installed

Note: Refer to the 2000-Sheet Input Unit and Multi-Bin Mailbox/Mailbox

with Stapler T rouble shooting Chec ks for more info rmation.

Remove Paper Jam

5

1. See 13 Paper Jam — All Printers

2. Rear Door open.

3. Broken or missing Cassette Paper Out Sensor Flag.

4. 500 sheet lower cassette not properly adjusted (see Service Note

C2001A-01A)

Adjust tr ay follo wing ser vice no te.

5. Check transfer roller to ensure it is seated properly.

6. Bad Input Sensor (PS1), Fuser Exit Sernosr (PS3), or with jams from

the MP T ra y (T ray 1), bad Pape r En d Se nsor (PS5 ).

1

A

Staple Limit Reached

5Si Mopier

1. Send only print jobs of 20 pages or less to the stapler.

Stapler Align Error

5Si Mopier

1. Remove the paper from the stapler and resend the job.

1A-9

Page 17

Error Codes Stapler Malfunction

Stapler Malfunction

5Si Mopier

1. Clear the stapler jam and resend the job.

Stapler Supply Out

5Si Mopier

1. Load a new staple cartridge.

Toner Low

5/5Si

1. Toner is uneven in cartridge.

2. Malfunctioning Toner Cartridge contact points.

3. Defective HV Power Suppl y.

Tray x Emp ty/x L oad/Pap er Out

ALL Printers

1. Paper or Paper T ray empty or not seated correctly.

2. Sensor Arm stuck or broken.

3. Defective tray size sensing or configuration.

V erify tra y tabs and swit ches at right re ar (or right front) of tray slot o r

configure tray from control panel.

4. Defective Paper Control/Sensor PCA.

W armin g Up

5/5Si

1. Separate all accessories.

2. Power cycle the printer.

3. Defective formatter.

4. Defective DC Controller.

5. Defective power supply.

1A-10

Page 18

Error Codes 13 Paper Jam/Remove Paper Jam

13 Pape r J am/Rem ove Paper Jam

ALL Printers

1. Out of spec media.

2. Dirty or obstructed paper path.

Clean paper path components, check transfer roller is seated properly.

3. Worn Pickup (or other) Rollers and/or Separation Pad.

4. Wrong length paper or incorrect software paper size selected.

5. Defective Exit Sensor or flag.

6. Defective Input (paper out) Sensor doesn’t sense paper out.

7. Paper Casse ttes not c orr ectly load ed.

8. Bad solenoid operation.

V erify proper solenoid operation and replace as necessary.

9. Bad gear(s) or gears not meshing in drive train.

Repl ace bad gear s, ch eck tone r car tri dge gears for da mage .

10. Bad Main Motor or Drive Circuit.

11. Bad Delivery Mechanism or coupler gear to main drive.

12. Bad Main Motor Drive Circuitry.

13. Defective DC Controller.

5P/6P

1. Paper fragment under oblique rollers (top or front).

Remove rollers and clear out paper.

5L/5P/6P

1. If all flags move properly and connectors are seated and the error

persists, replace the DC Conroller .

13.x Pa per J am

5 Si

Note: When troubleshooting the LJ 5 Si, always troubleshoot the error log

message. See the LJ 5 Si Service Manual for detailed error log information.

X=Locat ion o f jam

=Non-specific jam

0

=Paper feed/paper late jam—paper late arriving at PS 2; lo cated in

1

paper pickup unit. Inspect paper path. Verify flag movement.

=Paper feed 2 paper late jam—paper late arriving at PS 2, which is the

2

registration photo sensor. Remove toner and lift up green lever to access

sensor flag. Verify flag movement.

=Fuser output paper late jam—paper late arriving at PS 1403, which is

3

in th e fusin g ass embl y . V e rif y flag mov eme nt.

1

A

1A-11

Page 19

Error Codes 18 MIO Not Ready

4=Fuser output paper stopped jam

5, 6=Duplex module paper jam. PS 1402 face-down delivery photo

sensor is located in the face-down delivery assembly . Inspect diverter

drive assembly. V erify paper path from fuser to top of face-down bin is

clear and fl ag mov es f reely.

7-10= Duplex module paper jam. Paper is diverted to the duplex

module after leaving the fusing assembly. Paper is turned around in the

duplexer and refed into the printer’s paper path. Reseat the duplex

module. If problems persist, replace the complete duplex assembly.

11=External input device paper jam

If the control panel displays a 13.1 1 Paper Jam message, the printer will

list additional error codes in the error log. These can be printed or viewed.

2000 Sheet Input Tray Paper Jam Error is related to the first device in the

C-Link daisy chain. In the supported configuration this device should be

the 2000-sheet high-capacity tray. Ver ify that Tr ay 4 lifts to its feed

position. Inspect flags in vertical transfer door.

12=External output device paper jam

If the control panel displays a 13.12 Paper Jam message, the printer will

list additional error code s in the error log. These can be printed or viewed.

Multi-Bin Mailbox/stapl er paper jam. Error is related to th e second or

third device on the C-Link daisy chain. In the supported configuration,

this second device should be the Multi-Bin Mailbox. Verify that all bins

are in position and the “scan bar” is complete. V erif y that the Multi-Bin

Mailbox completes its power up sequence. In the supported

configuration, the stapler is the third device in the C-Link daisy chain.

V erify the st apler completes its power- up sequence.

13=Fuser accordion jam. Inspect paper path before and after fuser.

14=Printer could not auto eject paper. Inspect entire paper path for

paper or debris.

18 MIO Not Rea dy

5/5Si

1. Printer is not connect ed to active LAN.

Connect printer to LAN or terminate connection using a BNC

T-Connector with two 50 Ohm resistors.

2. MIO card is misaligned or defective.

Reseat or replace MIO card.

1A-12

Page 20

Error Codes 18 MIO Init

18 MI O Init

5/5Si

1. Error message remains after 5 minutes.

Check network card or host.

20 Error/Mem Overflow

ALL Printers

1. Large print job exceeding memory capacity.

V erify SIMMs seate d. Add mem ory , re move soft fonts, d ecrease

resolution, or simplify print job. Adjust image adapt and page protect

settings, if available.

5

1. Too much data or data too complex.

Turn image adapt and page protect to ON or AUTO (can be set within the

Remote C ontrol Panel). Press [GO] to resume print ing.

5L/6L

1. Set Enhanced I/O to Auto Mode (PCL mode).

Resend print job. If Auto-Cont inue variable is on with in PJL, the printer

will continue to print after 10 seconds. If off, press the Front Panel Button

to continue printing.

21 Error/Print Overrun

ALL Printers

1. Too complex print job.

Simplify print job or add memory.

5Si

1. Too complex print job.

Enable Page Protect from Cont rol Panel and from softw are (may require

additional memory).

5

1. Too much data or data too complex.

Turn i mage adapt and page protect to ON or AUTO (c an be set wi thi n the

Remote Control Panel). Press [GO] to resu me printing.

5P/5L/6P/6L

1. Use remote control panel to turn Page Protect to Auto or On.

1

A

1A-13

Page 21

Error Codes 22 Error/ I/O Config Error/Par I/O Error / MIO Error

22 Error/ I/O Config Error/Par I/O Error / MIO

Error

ALL Printers

1. I/O config for the computer or printer is incorrect.

Refer to manual for proper configuration.

2. Wrong or damaged I/O Cable.

Replace I/O cable with specified cable (IEEE1284).

3. Computer is powered off.

Power computer on.

4. Damaged printer I/O port.

Replace I/O PCA or Formatter .

5P , 5, 6P

1. The computer and printer are not communicating because of improper

signal protocols. Indicates a loose cable connection or a bad or poor

quality cable.

Reseat the cable and make sure you are using a high-quality cable (IEEE

1284).

5Si

1. Using a non-HP MIO device.

Repl ac e w it h a H P M IO d e vi ce .

23 I/O Not Rea dy

ALL Printers

1. I/O card is unable to accept data or is not connected to the network.

Check I/O Ca rd s eating an d rep lace if nece ssary.

24 Job Memory Full

ALL Printers

1. Complex printer job.

Add memory or simplify print job.

25 XXXMem Full

ALL Printers

1. Complex printer job.

Add memory or simplify print job.

1A-14

Page 22

Error Codes 30 PS Error 16

30 PS Er ror 16

ALL Printers

1. An I/O time out or prom pt for use r in teraction (e.g., man ual feed) has

been exceeded.

Check I/O connections and whether media requests are being made.

30 PS Er ror 22 or 25

ALL Printers

1. Unexpected PostScript firmware error .

Replace PostScript SIMM.

30 PS Error XX (All Other)

ALL Printers

1. PCL file being sent to printer while in PostScrip t mode or bad

PostScript file or application error.

Check configuration, applicat ion, and print fil es.

30.1.1 Disk Failure

5 Si

1. Optional di sk failed self tes t.

Press [ Select] to continue.

40 Err or (data trans fer e rro r)

ALL Printers

1. Computer and printer may be set to different baud rates.

Refer to manual to reset baud rates.

2. Computer is powered off.

Power computer on.

3. Unseated or defective MIO card.

Remove, reseat , or repla ce MIO card.

4. Indicates an abnormal connection break occurred while transferring

data from the computer.

Press [Continue] or [GO] on the printe r to clear the error message.

1

A

1A-15

Page 23

Error Codes 40.x MIO Error

40.x MI O Err or

5Si

1. Add normal connection break in the specified MIO card occured.

If x=1; HP MIO port 1 (upper slot)

If x=2; HP MIO port 2 (lower slot)

Press [Select] to continue or power cycl e the printer . If the error pers ists,

repl ace MI O card .

41 Error (temporary print engine failure)

ALL Printers

1. Momentary error.

Reset by pressing the [Continue] or [Go] key.

5P/6P

1. A temporary error occurred while printing.

This error most commonly occurs when the printer picks two sheets of

paper at once. The page containing the error is reprinted automatically.

Remove the page from the output tray and press [GO] on the printer.

5L/6L

1. Temporary Error

Power cycle the printer . If the error persists, reseat the Formatter to the

DC Controll er PCA.

2. Engine Error

Replace the Formatte r PCA. If the error pers ists, replace the DC

Controller PCA.

41.x Error

5, 5S i

1. If x= 1; Defective connections.

Reseat J205, J206, J207 and Laser/Scanner connections.

2. If x=2; Beam Detect malfuction.

Reseat connectors, including laser scanning assembly.

3. If x=3; Paper size selection does not match installed paper or paper

multifeed.

Check for paper jams, multifeeds, or missfeeds.

Insert correct siz e paper .

One of the cassettes is overfull or improperly adjusted.

4. If x=4; Sync error.

Reseat DC Controller and Formatter connections.

1A-16

Page 24

Error Codes 50 Error / 50 Service (Fuser Malfunction)

5. If x=5; Video sync or undetermined error.

Reseat DC Controller and Formatter connections.

50 Error / 50 Service (Fuser Malfunction)

ALL Printers

1. Temporary error.

Power off for 20 mi nutes to clear tem porary 50 Error .

2. Low/unstable power (e.g. brownout).

Locate/verify stable power source.

5

1. Defective Fuser or Pwer Supply.

Replace Fuser followed by P ower Supply if probem persists.

2. Temporary error.

Short C202 (LJ 4) or C205 (LJ 4 Plus) on the DC Controller to bypass

Error 50 time delay .

5P/6P

1. Defective Fuser.

2. Defective DC Controller.

5L/6L

1. Check the r esistan ce betw een pins 1 and 2 from co nnector J102 of the D C

Controller and the Thermistor .

If no r esist ance, rep lace t he heati ng el emen t. If resis tan ce is c orr ect,

repl ace th e DC C ontr ol ler .

50.x Fuser Error

5Si

1. Fuser malfunction.

If x=1; Fuser low t emperature fa ilure.

If x=2; W arm up fa ilure.

If x=3; Over temperature failure.

If x=4; Bad fuser.

Power printer off for 20 mintues, then back on.

V erify th e fuser is inst alled correct ly and fully se ated.

Reseat or repla ce the fuser ca ble assembly .

1

A

1A-17

Page 25

Error Codes 51 Error (loss of beam detect)

51 Error (loss of beam detect)

5

1. Faulty Laser/Scanner Cable Connectors.

2. Defective Laser/Scanner Assembly.

5P , 5L,6P , 6L

1. Temporary error.

Power-cycle the printer .

2. Laser/Scanner Assembly not seated.

3. Defective Laser/Scanner Assembly.

Replace the Laser/Sc anner Assembly (or cable —5L only).

4. Defective DC Controller PCA (5L, 5SI only)

51.x E rror

5Si

1. Laser subsystem problem.

If x=1; Beam detect malfunction.

If x=2; Laser malfunction.

Press [Select] to resume operation. (If AU T OCONT=ON)

If error persists:

Check cable from DC C ontr ol ler t o la ser scan ner .

Repl ace la ser scanne r ass embl y .

Repl ace DC C ont roll er P CA.

52 Error (incorrect scanner speed)

5

1. Faulty Laser/Scanner Cable.

2. Defective Laser/Scanner Assembly.

5P , 5L, 6P , 6L

1. Temporary error.

Power-cycle the printer .

2. Improperly fitted Scanning Assembly.

3. Scanner cable problem.

4. Defective Laser/Scanner Assembly.

5. Defective DC Controller PCA.

1A-18

Page 26

52.x E rror

5Si

1. Scanner subsystem problem.

If x=1; Scanner startup failure.

If x=2; Scanner rotatio n failure.

Switch the printer off and back on.

If the error conti nues:

Check cable from DC Control ler to lase r scanner assem bly .

Repl ace la ser scanne r ass embl y .

Repl ace DC C ont roll er P CA.

53.XY . ZZ Error

5/5Si/5P/6P

1. SIMM malfunction.

T able 1-1 53.XY .ZZ Error fo r 5, 5Si

X (Hardware Type)

x=0, ROM 0=Unsupported memory

x=1, RAM

x=2, Flash

Y (Hardware Device)

y=0 Internal mem.

(Formatter PCA)

y=1 SIMM Slot 1

y=2 SIMM Slot 2

y=3 SIMM Slot 3

y=4 SIMM Slot 4

ZZ (Error Nu mber)

1=Unrecognized memory

2=Unsupported mem. size

3=Failed RAM test

4=Exceeded max RAM size

5=Exceeded max ROM size

6=Invalid SIMM speed

7=SIMM report ing info. incorrectly

8=SIMM RAM parity error

9=SIMM ROM mapped to an unsupported address

10=SIMM address conflict

11=ROM out of bounds

12=Could not make temporary mapping

Error Codes 52.x Error

1

A

5L/6L

1. An error has been found in the RAM or ROM.

Power-cycle the printer .

2. Defective or incompatible memory card.

Power off the printer, remove any additional memory, then power back

on. If the message cle ars replace th e memory card.

3. Defective Formatter PCA.

5, 5P , 5Si, 6P

1. SIMM malfunction.

V erify S IMM board is inst alled correct ly .

Repl ace th e SIM M tha t cau sed th e err or .

1A-19

Page 27

Error Codes 54 Error

54 Error

5Si

1. Defective Duplexer.

Repl ace dup le xer .

55 Error (internal communication pr oblem)

ALL Printers

1. Loose/bad cable.

2. Defective DC Controller PCA.

3. Defective Formatter PCA.

4. Defective Paper Input PCA.

5. Defective Main Motor.

56.x Error

5Si

1. Invalid input source or output destination has been selected.

If x=1; invalid input source.

If x=2; invalid output destination.

Check input and output devices.

Reselect a valid device.

57 Error

5L/6L

1. Incompatible memory card.

Remove card and replace it with a 1, 2, 4, or 8 MB, 5V , 70 nsec. or faster

card.

5, 5P , 6P

1. Main motor not fuctioning properly.

Check for any binding in motor or gear train. Check connection to DC

Controller , then repl ace main motor or DC Con troller as nece ssary .

1A-20

Page 28

Error Codes 57.x Service

57.x Ser vice

5Si

1. Faulty Fan Mot or x.

Check Fan number x, main or duplexor fan, and replace if necessary.

5

1. Main Motor Fa ilure .

58 Servic e

5, 5P , 6P

1. Improperly fitted Fan Cable.

Check/reseat Fan Cable.

2. Defective Fan.

58.x Printer Error

5Si

1. Tray lifter malfunction.

If x=1; Tray 2 lifter malfunction.

If x=2; Tray 3 lifter malfunction.

If x=3; Tray 1 lifter malfunction.

If x=4; Tray 4 lifter malfunction.

Press [ Sele ct ] to co nt inue .

Repair or replace tray/lif ter .

59.x Printer Error

5Si

1. Main motor malfuncti on.

If x=1; Main motor startu p failure.

If x=2; Main motor rot ation failure .

Switch the printer off, then back on.

If the message persists:

Check cabling between the main motor and DC Controller.

Repl ace th e main mot or .

Repl ace th e DC C ontr ol ler .

1

A

1A-21

Page 29

Error Codes 61.x Service

61.x Ser vice

ALL Printers

1. Improperly fitted SIMM in slot x.

2. Defective SIMM in slot x.

3. Defective Formatter.

Note: If x=0, SIMM slot counldnot be determined.

62.x Service / Printer Error

ALL Printers

1. Improperly fitted SIMMs or Font Cartridge.

2. Defective Internal Memory. (x=0)

Repl ace For mat ter PCA.

3. Defective SIMM Slot X.

63 Servic e

5, 5P , 6P

1. Defective Formatter PCA.

Replace Formatter PC A.

5L/6L

1. Defective Formatter PCA.

Power cycle the printer. Disconnect the parallel I/O cable and run a self

test. If the error persists , replace the Format ter PCA.

64 Servic e / Printe r Err or

ALL Printers

1. Defective Formatter PCA.

5Si

1. Defective DC Controller PCA.

65 Servic e

All Printers

1. Defective Formatter PCA.

1A-22

Page 30

Error Codes 65 Printer Error

65 Printer Error

5, 5Si, 5P , 6P

1. Indicates a dynamic RAM error .

Switch the printer off, then back on.

If the message persists, replace the Formatte r PCA.

66.x.yy D evice Error

5Si

If the control panel displays a 66.x.yy Device Error message, the printer

will list addition al error codes in the error log . These can be printed or

viewed .

Indicates a paper handling error. Printer is unable to communicate with

the external paper handling PCA. Verify C-Link cables are installed

correctly . Print the PCL Configu ration Page and note which installed

devices are not present on the Configuration Page.

x=paper handling device

0=external paper handling PCA (EPH)

1=first device attached to EPH

2=second device attached to EPH

3=third device attached to EPH

4=fourth device attached to EPH

5=fifth device attached to EPH

Switch the printer and paper handling devices off, then on. If the message

persists:

yy=paper handling device error code

1

A

If yy=1-22, 24:

Check cabling between the printer and the device.

Check the me chan ical int erf ace bet wee n the print er a nd th e devi ce.

Replace the external paper handling PCA.

If yy=23:

Check cabling and mechanical interface between printer and device.

Replace the external paper handling PCA.

Repeat steps 1 and 2 to isolate defective device.

Repai r or r epl ace d efect iv e devi ce.

If yy=31:

Printer not supported by paper handling device 1.

1A-23

Page 31

Error Codes 67 Service / Printer Error

If yy=32:

Printer not supported by paper handling device 2.

If yy=33:

Printer not supported by paper handling device 3.

If yy=34:

Printer not supported by paper handling device 4.

If yy=35:

Printer not supported by paper handling device 5.

For error codes 31-35: Verify that the device is supported.

If device is supported, follow steps under yy=23.

If yy=41:

Device 1 reports invalid configuration.

If yy=42:

Device 2 reports invalid configuration.

If yy=43:

Device 3 reports invalid configuration.

If yy=44:

Device 4 reports invalid configuration.

If yy=45:

Device 5 reports invalid configuration.

For error codes 41-4 5:

V erify proper configuration for device.

If configuration is correct, follow steps under yy=23.

67 Servic e / Printe r Err or

5

1. Defective Formatter PCA.

Reseat any accesso ries. If erro r persists, re place Forma tter PCA.

5Si

1. FRU’s not ins talled pro perly .

Reinstall FRU’ s.

1A-24

Page 32

Error Codes 68 Error / Service

68 Error / Service

ALL Printers

1. Defective Formatter PCA.

5, 5P , 5 Si, 6P

1. (68 Error) - error in NVRAM.

Check Control Panel setting s. Replace Formatter if p roblem persists.

5, 5S i

1. (68 SERVICE) -NVRAM full.

Cycle printer power . If probl em persists, perform NVRAM initia lization

by holding down the [Item] (or {Job Cancel] on the LJ 5) while powering

on the printer. All Control Panel settings (including Service Mode

settings) will require resetting following this procedure.

5P/6P

1. (68 SERVICE) -NVRAM full.

Perform a NVRAM initialization by holdin g down the RESET button for

more than 20 seconds while powering on the printer.

69 Servic e

ALL Printers

1. Defective I/O PCA.

Remove optional I/O PCA, then re-test.

2. Defective Formatter PCA.

Replace Formatter PC A.

70-71 E rr or

ALL Printers

1. Personality cartridge in SIMM slot incompatible.

5Si

1. Faulty MIO cards.

1

A

72 Servic e

ALL Printers

1. Defective Formatter PCA.

Replace Formatter PC A.

1A-25

Page 33

Error Codes 79 Service

79 Servic e

ALL Printers

1. Software/drivers, Memory PCA’ s, Font-Macro-Personality,

Cartridges, optional I/O cards. Defective toner cartridge.

Remove any accessories (font cartridges, memory PCAs SIMMs etc.)

plugged in to the Formatter and reprint file. If problem persists verify

proper setup with application vendor.

2. Defective Formatter PCA.

5 SI

Unrecoverable firmware error occurred.

1. Cycle power .

2. Reseat or replace the interface cable and cycle power.

3. Remove the SIMMs one at a time and cycle power .

4. Remove the MIO Card(s) one at a time and cycle power.

5. T ry using the pa rallel inte rface, if possib le.

6. With the MIO cards out of the printer , perform a COLD RESET.

7. If error continues, replace the formatter. Write down the page count

and serial number.

80 MIO Failu re

ALL Printers

1. Improper MIO connection.

Inspect pins on formatter MIO connection.

2. Defective MIO Card.

3. Defective Formatter PCA.

81 Error

ALL Printers

1. Defective Formatter PCA

89 PostScript ROM Failure

ALL Printers (except 5L and 6L)

1. Bent / broken pins on PostScript ROMs.

Inspect PostScript ROMs/SIMM for bent or broken pins.

2. Improperly located ROMs/SIMM.

Check that ROMs/ SI MM are i n cor rect loc ati on and ori ent ati on.

1A-26

Page 34

Error Codes All LEDs off (blank display).

3. Temporary error.

Cycle P ower .

4. Defective PostScript ROMs/SIMM.

All LEDs off (blank display).

5L/6L

1. Printer is in Sleep Mode.

Press Front Panel Button or open the EP Door

2. No power is supplied to printer.

Check power cord connections and power source.

3. Determine if print engine is functional.

Print an engine test; if successful, replace Formatter PCA.

4. Defective Contr ol Panel PCA cabl e.

5. Chec k f u ses o n DC C ont ro ll er.

6. Defective Formatter PCA.

7. Defective DC Controller.

All LEDs on (without pressing the front panel

button).

5L/6L

1. This is a service error .

Press down on the front panel button to display the error LED code. This

code will be shown only while the button is pressed.

2. All LEDs remain on while pressing the front panel button.

Cycle power . If error pers ists, replace the formatter .

Blank Display

ALL Printers

1. No power.

Check AC and DC volt ages .

2. Defective display panel, related cabling, or drive circuitry.

Check input voltages which illuminate the Display Panel.

3. Faulty display, cable, Formatter , or DC Controller.

1

A

1A-27

Page 35

Error Codes Data and Ready LEDs are blinking

Data an d Ready L EDs are blinki ng

5L/6L

1. Firmware Error

Note the LED pattern, Bi-Tronics error code, printer condition, data sent,

and any other information that may help isolate the error . Contact

HP technical support with this information.

Data LED is blinking

5L/6L

1. The printer is set to manual feed.

Insert paper into the manual feed slot. Ensure correct paper is loaded in

the printer . Press and release the Front Panel Button. If manual feed is

not desired, turn off the setting in the software application.

2. Printer is stuck on manual fe ed

Press the front panel button to override the manual feed request and to

feed paper from the paper casset te.

3. Defective Input Paper Sensor (PS1) or defective Front Oblique Roller

Assemb ly .

Replace PS1 or Fro nt Obli que Roller Ass embly .

Displa y Is All Bloc k Chara cters

ALL Printers

1. Display cable defective or disconnected.

Reseat or replace Display Panel cable.

2. Defective C ontro l Pa nel.

3. Defective Formatter PCA.

Check and re plac e as ne ede d.

Error LED is on co ntinuously

5L, 6L

1. Power cycle the printer.

2. Bad connection between formatter and AC Controller.

3. Defective formatter.

4. Defective AC controller.

1A-28

Page 36

Error Codes Tray 1 LED is Blinking

T ray 1 LED is Blink ing

6P

1. The printer is set to manual feed. Insert paper into Tray 1 and press the

GO button.

1

A

1A-29

Page 37

Error Codes Tray 1 LED is Blinking

1A-30

Page 38

2A

Service Mode

Service Mode

2A - 1

Page 39

Service Mode

The following can be executed while in the Service Mode

Print a Service Mode Self Test.

Verify the Page Count. (The page count is also displayed on the

standard self test.)

Set the Page Count.

Set the Cold Reset Default (LJ 5). This sets the factory default paper

size. Use when replacing non-U.S. Formatters.

Set the Diagnostic Function (LJ 5). On/Off (for software developers

use only).

Demo Page=On/Off (LJ 5). Removes the Demo Page option from the

self test menu.

The following illustrates the procedure used to initiate Service Mode.

A

PowerOff Printer

Hold Keys Down Simultaneously While Powering Printer On Press Keys Sequentially

B

B

B

LJ 5

Menu + Value +

(Power)

D

LJ5is now in Servicemode.

EC

LJ 5Si

LJ5Si

Mopier

Figure 2-1

Items + Select(Power)

Notes:

Service Mode not available on the LJ 5L.

Service Mode in the LJ 5P can only be done via software (PJL commands).

Please consult the Service Manual.

Howto access Service Mode

1. Power off theprinter (A).

2. Press thetwoor threekeys referenced (B) simultaneously, whilepoweringtheprinteron (C).

3. Press key (D) if required.

4. Press key (E) if required.

After a few seconds the printer's display should say "Service Mode".

6L, 5P, 6P

,

Accessing Service Mode

LJ5Si is now in

Servicemode.

EC

EC

There is no Service Mode or NVRAM on the LaserJet 5L, 6L, 5P , or 6P

printers. These page counts are retained only while plugged in; page count is

lost when the printer is unplugged.

2A - 2

Page 40

Service Mode

Setting the Page Count

(except on the LJ 5L, 5P, 6P, 6L)

The page count is stored in the printer’s Non-Volatile Memory . If it becomes

necessary to replace the Formatter PCA, the page count should be reset to the

printer’s original page count to reflect the age of the print engine. Use the

following procedure to set the page count.

1 When 00 S MODE

to modify the page count.

2 PA GES=XXXXXX will be displayed.

currently stored in the printer’s Non-V ola tile Memory . The underlined

character denotes the cursor position.

3 Press [+] (or [AL T] [- ]) to scroll unti l the correct valu e is displayed for the

underlined digit.

4 Press the [ENTER] key to select the corre ct value. The cursor will

automatically move one place to the right.

5 Set each digit in the same manner. When the last digit’ s value has been

selected, the display will return to 00 SMODE or SERVI CE MODE.

6 Press the [ON LINE] key to exit Service Mode.

or SERVI CE MODE is displayed, click the [MENU] key

XXXXXX represents the page count

Setting the Cold Reset Default Paper Size

The initial default paper size f or the Formatter PCAs in Eur ope is A4. When

replacing Formatte rs whose default is set for A 4, (Europe an Formatters), s et the

customization variable to A4. When the cu stomization variable is set to A4, t he

Cold Reset procedure can not reset the paper size to Letter . T o set th e

custom iz ati on var iab le:

(LJ 5 Only)

1 Turn off the printer.

2 Hold the Go key down while powering ON the printer.

3 The message FACTORY DEFAULT S BEI NG RES T ORE D is displayed. The

Cold Reset does not take effect u ntil the REA D Y message is displayed.

4 When the REA DY message is displayed, the default settings have been

returned to the factory defaults and the printer is ready to accept new

settings.

2

A

2A - 3

Page 41

Service Mode

(LJ 5Si)

1 Enter the Service Mode as described previously.

2 Press [MENUS] to acce ss the Service Menu.

3 Press [ITEMS] to step through the menu until COLD RESET

PAPER=LET T ER* is displayed.

4 Press [+] to toggle between Letter and A4 paper.

5 Press [SELECT] to activate your choic e.

6 Press [ON LINE] to exit Service Mode.

7 Perf orm a C old Reset to a cti vate new ch oi ce.

2A - 4

Page 42

3A

Power Supply Chec ks

Power Supply

Checks

3A - 1

Page 43

Power Supply Checks

LaserJet 5

Pin 1

3

2

45

6

TB 201

Figure 3A - 3

DC Power Supply Checks (LJ 5) TB201 on DC Controller

The operating voltages of the LJ 5 can be verified by:

1 Listening for the exhaust fan. A rotating fan indicates that the +5V dc and

the +24A V dc are present. (The fan runs on +24A V dc.)

2 Listen for the Main Motor . If the Main Motor runs, +24B V dc is enabled.

The 24A V dc must be present.

TB201

Voltage Color Pin Number

+5 V dc Brown 1,2

+24 V dc Red 3

Ground Blue 4, 5, 6

3A - 2

Page 44

Power Supply Chec ks

LaserJet 5P

The DC Power Supply circuitry, located on the DC Controller PCA, generates

+5V dc, and +12V dc, used as follows:

+5V dc:

Formatter PCA

Photosensors

DC Controller Circuitry

Laser/Scanner Assembly

+12V dc AS (after switch):

High Voltage Power Supply

Main Motor

+12V dc BS (before switch):

Solenoids

Fan (Through Laser/Scanner Assembly)

Fusing

heater

3

A

VBS=Voltage Before Switch

VAS=Voltage After Switch

Figure 3A - 4

LJ 5P Power System Block Diagram

3A - 3

Page 45

Power Supply Checks

LaserJet 5L/6L

The DC Controller PCA c oordinates all print e ngine activities, drives the laser,

and coordinates print data from the Formatter PCA with the image formation

process. The DC Controller also includes both ac and dc power supply and

distribution circuitry. The DC Controller controls the following systems and

functions:

Print Engine Control

Laser and Scanner Dri ve

Paper Motion Photosensors (Paper Out, Paper Registratio n, and Paper

Exit Sensors)

Motor

Power System

AC Power Distribution

DC Power Distribution

Overcurrent/Undervoltage Protection

SleepMode

High Voltage Power Distribution

AC Driver

Supply

+5V

+12V

Low-Voltage

Figure 3-5

3A - 4

DC Controller Loads

Page 46

Power Supply Chec ks

LaserJet 5Si

The AC and DC ppower supply circuits are contained in the Low V oltage

Power Supply (L VPS). Th e high voltages requir ed for image form ation are

generated by the High Voltage Power Supply (HVPS). The Low V oltage Power

Supply and Distribution System is illustrated below.

3

A

Figure 3-6

Low Voltage Power Distribution System

3A - 5

Page 47

Power Supply Checks

3A - 6

Page 48

4A

I/O Information

I/O Information

4A - 1

Page 49

I/O Information

Bidirectional Parallel Interface

(LJ 5, 5P, 5L, 5Si, 6P, 6L)

The Bidirectional parallel interface (IEEE-1284 Compliant) is compatible with

Centronics parallel inte rfaces. T o take advantage of its enhanced capabilit ies such as bidirectional communicati on - the following must be provide d:

Software application support for these features.

An IEEE-1284 compliant parallel cable with the correct pin

configuration (see below).

HP helped develop the IEEE-1284 sta ndard and is one of the first companies to

introduce products that are compliant with it. HP offers four IEEE-1284

compl ian t par all el c able s, sh own b elow :

IEEE-1284 Compliant Parallel Cable s

Part Number Length Connector Type

C2950A 2 meters Host A to printer B (large) connector

C2951A 3 meters Host A to printer B (large) connector

C2946A 3 meters Host A to printer C (small) connector

C2947A 10 meters Host A to printer C (small) connector

4A - 2

Page 50

I/O Information

RS-232-C/RS-422-A Serial Interface

Common Serial I/O Cables

The following serial cabl ing schematics are typical of IBM (AT/XT) and

compatible personal computers using the standard (9/25) pin serial RS-232C

interface.

Printer

(Male connector)

Chassis Ground

TD

RD

DSR

Sig Gnd

DTR

1

2

3

6

7

20

(Pins not shown are not used)

Computer

(Female Connector)

1 Chassis Ground

3RD

2TD

20 DTR

7 Sig Gnd

5 Clear to Send

6 DSR

Printer

(Male connector)

TD

RD

DSR

Sig Gnd

DTR

2

3

6

7

20

(Pins not shown are not used)

25 to 9-Pin Serial Adapter (P/N C2809A)

The pin-outs for the adapter are shown below:

Computer

(Female Connector)

2RD

3TD

4 DTR

5 Sig Gnd

6 DSR

8 Clear to Send

4

A

4A - 3

Page 51

I/O Information

Serial I/O Specifications

Handshaking Protocol

Data Format

Parity

Support e d Baud Rates

*LJ 5 & Newer: Supports to 57,600 Baud

RS-232-C: Xon/Xoff (software) and Data

Terminal Ready (hardware)

RS-422-A: Xon/Xoff (software) only

The signal logic or “sense” of the DTR line is

switchable to either active HIGH (the factory

default) or active LOW from the printer’s control

panel.

Asynchronous, with one start bit, eight data bits,

and one stop bit

Not used

300, 600, 1200, 2400, 4800, 9600, 19200,

57600*

Maximum I/O Cable Lengths

Serial RS-232

Parallel (non-IEEE 1284)

RS-422

50 feet (15 meters)

4000 feet (1,200 meters)

10 feet (3 meters)

Configuring the Computer’s Interface

The following information applies to IB M PC and compatible co mputer systems.

Use MS-DOS EDIT o r a simil ar pro gram to enter the appropr iate DOS M ODE

commands in the computer’s AUTOEXEC.BAT file. Step-by-step instructions

are provided in the printer’s Gettin g Started or Setting Up manual.

For parallel communication enter:

MODE LPT1:,,B (Note: change “B” to “P”if < DOS 4.0.)

For serial communication enter:

MODE COMn:9600,N,8,1,B (Note: change “B” to “P” if < DOS 4.0.)

MODE LPT1:=COMn

where n=1, 2 or 3 depending on which port is used

(that is, COM1, COM2 or COM3)

4A - 4

Page 52

I/O Information

Verifying Communication

MS-DOS

To verify communication between an MS DOS computer and an HP LaserJet

printer:

1 Power on the computer.

2 Pow er on the pr in ter.

3 W ait until th e printer displays 00 READY.

4 At the DOS prompt, type DIR >PRN and press [ENTER] key. (The

printer’s Form Feed light should illuminate.)

5 If necessary, take the printer off line and press the Form Feed key to eject

the page.

Infrared Communications (5, 5P, and 6P

Only)

The LaserJet 5, 5P , and 6P feature an infrare d (IR) port that is compliant with

the IrDA (Infrared Data Association) standard (though the LaserJet 5 requires

an additional tranceiver pod). Just above the port (located on the lower left

corner of the LJ 5P and LJ 6P or pod on the LJ 5) is a status light that indicates

when the port is activated.

Note

The IrD A stand ard for infrar ed co mmu nica tio ns

represents an emerging technology. Older

non-IrDA-compliant portable devices may not be

compatible with these printers.

Troubleshooting IR Printing Problems

IR printing problems may be caused by any of the several system components

or by lack of proper configuration. The followin g checklist will help determine

the source of the problem.

1 V erify the user is operating the printer and PC as described in the User’s

Manual: less than one meter between devices, and not more than +/-15

degrees from direct center.

2 V erify the host PC or laptop and the printer are IrDA-compliant and have

the necessary hardware components for IR communication.

4A - 5

4

A

Page 53

I/O Information

3 V erify the IR software has been loaded on the primary device (system

software from the PC manu facturer).

4 V erify the host PC or laptop is properly configured. Check the port

assignment, the IRQ level, and the base address value. Check both the

DOS AUTOEXEC.BA T and CONFIG.SYS files, and the Win dows

system configuration.

IR Test Tool

If all thes e elem ent s are p rop erl y inst all ed an d co nfi gur ed, us e the I R T e ste r to

test the IrDA protocol transmission and device operation. This tool for

troubleshooting IR communication problems has been developed by Genoa

Technology, Inc., in cooperation with Hewlett-Packard. The part number is

5062-4661 and can be ordered through HP Parts Direct Ordering (see inside

back cover).

To test the peripheral device:

1 Put the LaserJet printer in Ready Mode.

2 Press the “Peripheral T est” button on the tester. Th e LEDs on the tester

will sequence.

If the “P ASS” LED lights, the test was successful, indicating that

communication with the printer’s IR port is functioning normally. A self-test

page will print as a result of the test.

If the “TEST” LED goes out and the “P ASS” LED fails to ligh t, the printer’ s IR

port is not functioning correctly.

To te st the host computer:

1 Place the tester on a table in front of the PC’s IR port.

2 Press the “C omput er T est ” butto n. The teste r wil l seque nce the L EDs.

If the “P ASS” LED lights, the test was successful, indicating that

communication with the computer’s IR port is functioning normally.

If the “TEST” LED goes out and the “P ASS” LED fails to ligh t, the host’ s IR

port is not functioning correctly.

4A - 6

Page 54

5A

Media Specifications

Media

Specifications

5A - 1

Page 55

Media Specifications

Introduction

Media that does not meet the specifications listed below may increase the

incidents of paper jams, cause premature wear to the printe r, and increase repair

costs. Hewlett-Packard recommends testing of any print media before buying

large quantities.

Paper Sizes

Metric System

Size Metric Dimensions U.S. Dimensions

A0 841 x 1189 mm 33.1 x 46.8 in

A3 297 x 420 mm 11.7 x 16.5 in

A4 210 x 297 mm 8.3 x 11.7 in

A5 148 x 210 mm 5.8 x 8.3 in

B4 (ISO) 250 x 353 mm 9.8 x 13.9 in

B5 (ISO) 176 x 250 mm 6.9 x 9.8 in

Imperial (U.S.) S ystem

Size U.S. Dimensions

Ledger 11 x 17 in 279 x 432 mm

Legal 8.5 x 14 in 216 x 356 mm

Letter 8.5 x 11 in 216 x 279 mm

Executive 7.25 x 10.5 in 184 x 267 mm

JIS B4** 10.1 x 14.3 in 257 x 364 mm

JIS B5** 7.2 x 10.1 in 182 x 257 mm

J Postcard* 3.9 x 5.8 in 100 x 148 mm

J Double Postcard* 5.8 x 7.9 in 148 x 200 mm

* J - Japanes e

** JIS Japa nese In du stry S tand ar d

Metric D

Dimensions

5A - 2

Page 56

Media Specifications

Paper Specifications

Category Specifications

Acid Content: 5.5 pH to 8.0 pH

Basis Weight:

LJ 5 Tray 1 16-36 lbs (60-135 g/m2)

LJ 5P Paper Cassette

LJ 5L/6L Paper Output Bin

LJ 5 Tray 2

LJ 5Si Tray 2, Tray 3, Tray 4*

*(Opt. 2000 sheet feeder)

LJ 6P Tray 2

LJ 5 Tray 3 1 6-24 lbs (60-90 g/m2)

LJ 5L/6L, Front Output Slot

LJ 6P Tray 1

LJ 5Si, Tray 1 16-53 lbs (60 to 199 g/m2)

Caliper 3.0–7.0 mils (0.094–0.18 mm)

Curl

In ream Flat within 0.2 in. (5 mm)

Cut Edge Conditions Cut with sharp blades with no visible fray.

Fusing Compatibility M ust not scorch, melt, offset or release hazardous

Grain Long grain

Moisture Content 4% to 6% by weight

Smoothness 100–250 Sheffield

For complete pape r sp ecificatio ns for all LaserJet pri nters, s ee the LaserJet

Family Paper Specifications Guide, HP part number 5021-0368.

(5P may use media up to 42 lb with Sheffield rating

of 100 to 180 in the manual feed slot only)

16-28 lbs (60-105 g/m2)

16-43 lbs (60 to 163 g/m2)

emissions when heated to 200°C (392°F) for 0.1

second.

5A - 3

5

A

Page 57

Media Specifications

Paper Smoothness Comparisons

Smoothness is typically expressed in terms of Sheffield, Gurley, Bekk, or

Bendtsen units. HP LaserJet printers generally re quire a smoothness of

between 100-250 Sheffield.

Figure 5-1

5A - 4

Interrelation Among Air-Leak Smoothness Methods

Page 58

Media Specifications

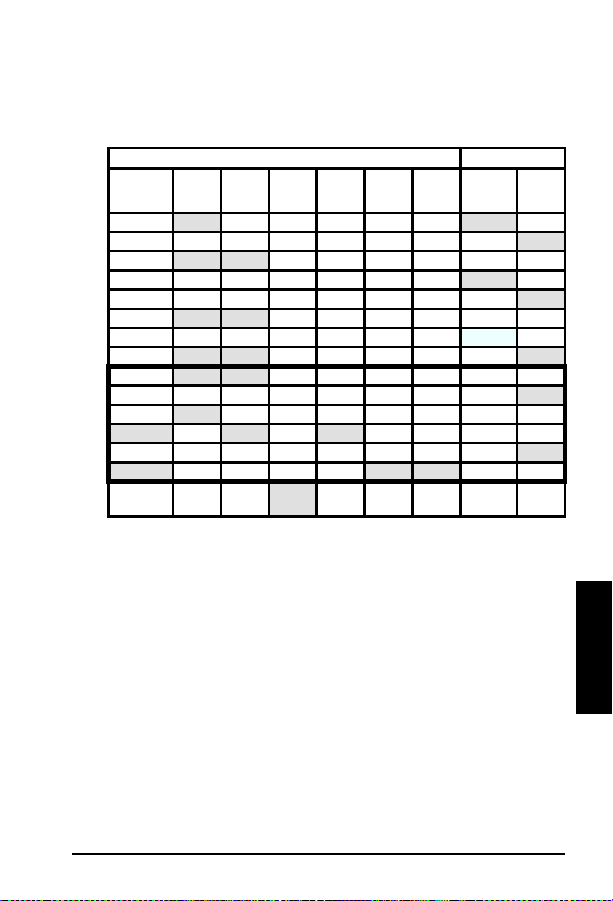

Paper Weight Equivalence Table

(Approximate)

Shaded areas indicate a standard weight for that grade.

US Weights (lb) or Thickness (mm) Metric Wt (g/m2)

PostCard *

thickness

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15**

* US Post Card measurements are approximate. Use for reference only.

** This media weight (row 15) may perform to your satisfaction but is beyond the printer’s

specifications. Printing with this media weight will not damage the printer.

Bond WtText

16 41 22 27 33 37 60 60

17 43 24 29 35 39 64 64

20 50 28 34 42 46 75 75

21 54 30 36 44 49 80 80

22 56 31 38 46 51 81 81

24 60 33 41 50 55 90 90

27 68 37 45 55 61 100 100

28 70 39 49 58 65 105 105

32 80 44 55 67 74 120 120

34 86 47 58 71 79 128 128

36 90 50 62 75 83 135 135

.18 39 100 55 67 82 91 148 148

.19 42 107 58 72 87 97 157 157

.20 43 110 60 74 90 100 163 163

.23 47 119 65 80 97 108 176 176

CoverWtBristol WtIndex WtTagWtEurope Japan

Book

Wt

5A - 5

5

A

Page 59

Media Specifications

Understanding Ream Labels

Standard ream and carton labels contain such standard information as:

A Grade

B Basis weight

C Size

D Printing surface (as indicated by the ream arrow)

E Basis weigh t (repeat ed)

F Grain (long or short)

G Number of sheets

AB C

GF E D

Figure 5-2

5A - 6

Ream Label Example

Page 60

Media Specifications

Paper Troubleshooting

Paper problems are sometimes difficult to detect. The following series of steps

will help isolate paper-induced problems versus printer problems:

Isolat e a paper path.

Isolat e a paper brand.

Isolate a paper type.

Evaluate paper user practices.

Evaluate environmental conditions.

Some simple tips:

Turn the paper over and print on the other s ide (this often corrects

excess paper curl.

Rotate the paper 180 (end for end) to feed a different leading edge (can

help correct for multi-sheet feeding problems).

Papers to Avoid

NCR self-carbon (or “carbonless” paper).

Paper that has been preprinted (such as letterhead) with ink that will not

withstand fuser heat (200°C/392°F for 0.1 second).

Plastic-fiber paper.

Embos sed paper .

Paper with cutouts or perforations.

Chemicall y treated paper.

Coated paper.

Synthetic paper.

Multi-part forms.

Odd size d pa pe r .

If your printer is having trouble with paper jams, multi-feeds, or misfeeds, use

HP’s paper: HP 20# Multi-Purpose Paper, part # 9300-2092; HP 24# LaserJet

Paper, part # 9300-2091.

5A - 7

5

A

Page 61

Media Specifications

General Tips

Paper Curl

Paper curl is the result of the heating process used to bond the print image

(toner) to the paper, combined with the path paper must negotiate through the

printer .

Actions that can be perfo rmed to reduce curl a re as follows:

1 Turn the paper over in the input tray. Some paper packages (ream) have

an arrow indicating the preferred printing side. Experiment to determine

which orientation yields the least curl.

2 Try a different output paper path (if available for your printer). Using the

“face-u p” o utp ut pa th may yiel d mor e acce pt able resul ts th an th e st andar d

“face-down” output tray. Note that the LJ 5, 5M, and 5N printers have no

alternative output paper path. Use the LJ 5L/6L Front Output Slot and

Paper Input Support if output is curled or wrinkled.

3 Protect the paper from adve rse environmental cond itions prior to use.

Paper designed for laser printing has an initial moisture content of 4-6%

which is maintained as long as it is stored properly . Once the paper h as

been removed from its packagin g, it will dry out or absorb additi onal

moisture, depending on the environment. Excess moisture in the paper

will increase the amount of curl.

4 Try a different type or brand of print media. Not all paper is designed for

laser printing.

Much of the paper curl induced by the laser printer’s fusing process will tend to

relax within the first 24 hours foll owing printing. However , the curl on the

leading edge of the page may remain more permanent because it tends to

remain in contact with the fusin g roller for longe r periods of time.

Consult your printer’s User’s Manual and the “HP LaserJet Printer Family

Paper Specification Guide,” part number 5021-0368 for more information.

5A - 8

Page 62

Media Specifications

Envelope Specifications

Category Specifications

Basis Weight 20 to 24 lbs (75 to 90 g/m2) single layer

Caliper 3.3 to 5.5 mils (0.084 to 0.14 mm) single layer thickness

Curl Less than 0.2 in. (5 mm) curl across entire surface.

Finishing Accurate, sharply creased folds with no more than

Fusing

Compatibility

Moisture Content 4% to 6% by weight

Paper Must meet all the normal paper specifications.

Smoothness 100 to 250 Sheffield

Envelope Sizes

Metric System

Size Metric Dimensions U.S. Dimensions

DL 110 X 220 mm 4.3 x 8.6 in

C5 162 x 229 mm 6.4 x 9.1 in

B5 176 x 250 mm 7.0 x 9.9 in

Imperial (U.S.) System

Size U.S. Dimensions Metric Dimensions

Commercial #10 4.1 x 9.5 in 105 x 241 mm

Monarch #7 3/4 3.9 x 7.5 in 98 x 191 mm

two thicknesses of paper at the leading edge.

Must not scorch, melt, offset or release hazardous

emissions when heated to 200°C (392°F) for 0.1 second.

Envelopes to Avoid

With clasps, snaps, or tie strings.

With transparent windows, holes, perforations, or cutouts.

Having a n open flap with adhes ive exposed.

Using pap er, inks, adhesives, or materi als that discolor, melt, offset or

release hazardous emissions when exposed to 200°C (392°F) for 0.1

second.

Extremely smooth, shiny, rough, textured, or deeply embossed.

Very rough, textured, or deeply embossed envelopes.

Damaged, wri nkled, or irreg ularly shaped.

Use of encapsulating adhesives that do not require moistening, but rely

instead on pressure to seal them.

5

A

5A - 9

Page 63

Media Specifications

Printer Malfunctions Due to Envelopes

Printer malfunctions caused by envelopes can best be avoided by the following

preve nti ve meas ur es:

Carefully feeding the envelope into the printer.

Being aware of envelope construction.

The fol lowi ng summ arize s pr event ati ve acti ons f or ea ch ca se.

Envelope Feeding

Envelopes may be manually fed through the printer or an envelope tray

or a feed er ma y be us ed.

Closely inspect the leading edge of the envelopes before feeding them

into the printer. Ensure the leading edge is flat. Watch for envelope

curl and dog ears. Flatten the leading edge of the en velope before

printing.

Be patient, in manual feed mode the printer displays a message when it

is ready to accept the next envelope. Always wa it for this message to

appear bef ore inserting th e next envelope.

Do not allow a large quantity of envelopes to accumulate in the output

tray.

On most printers, the rear (or front) output tray should be used when

available when printing envelopes not the top (face down) output.

Envelope Construction

Corner folds must be well-creased, with no more than two thicknesses

of paper.

Envelopes must lay flat.

Paper gr ain should be diagonal to the feed direction.

Adhesives must meet HP specifications for fusing compatibility.

Basis weight must not exceed 24 pounds.

Under no circumstances should envelopes have clasps, snaps, t i e

strings, or windows; nor should t hey use synthetic materials.

5A - 10

Page 64

Media Specifications

Label Specifications

Category Specifications

Adhesive Must not be on any external surfaces of the label

Caliper Must not exceed 0.007 in. (0.18 mm)

Curl In ream: flat within 0.2 in (5 mm)

Finishing Precision Cut sheet within 0.031 in. (0.79 mm) of nominal

Fusing Compatibility All adhesives, carrier sheets, top sheets, and

Packaging Moisture proof wrap to preserve properties.

Printer Malfunctions Due to Adhesiv e Labels

As with envelopes, printer malfunctions caused by adhesive labels can best be

avoided through prevention. To prevent paper jams and feed problems, labels

must:

Be cut long grain (as oppose d to short grain).

Totally cover the carrier sheet (no spaces between labels, or removed

labels).

Contain no excessive glue. (The adhesive should be acrylic-based

emulsion and should not come into direct contact with the printer.)

Meet HP specifications for fusing compatibility.

Meet HP specifications for caliper.

Have a carrier sheet that is not too smooth.

The flat paper path (manual feed slot and rear, or front, face-up

delivery door) is the recommended printing method.

before, during, or after printing. Label

construction and die-cutting must not allow

labels to peel off during transport, printing, or

fusing.

and 0.20° square.

other materials used in label construction must

be compatible with the heat and pressure of the

fusing process. Materials must not discolor,

melt, offset, or release hazardous emissions

when heated to 392°F (200°C) for 0.1 second.

5

A

5A - 11

Page 65

Media Specifications

Transparency Specifications

Category Specifications

Caliper 3.9 to 4.3 mils (0.100 to 0.110 mm)

Cutting Angle

Finishing Precision Cut sheet to within 0.03 in. (0.8 mm) of nominal

Fusing Compatibility Overhead transparency material must be

90° ± 0.2°

and ± 0.2° of square.

compatible with the heat and pressure of the

fusing process. Materials must not discolor,

melt, offset material, or release hazardous

emissions when heated to 392° F (200° C ) for

0.1 second.

Printer Malfu nctions Due to Transparen cies

To prev ent pri nter malf unc tio ns du e to t ran spar enci es:

Use the straightest paper path to avoid curling and other problems.

Use transparencies with the correct resistiv ity.

Use transparencies which meet HP specif ication s fo r f us ing

compatibility.

Remove each printed s heet from the tray and p lace it on a flat surface

before printing the next sheet.

HP Paper Training Video Tape

HP has developed a training video focusing on how paper is manufactured and

how the manufacturing process rela tes to its use in HP LaserJet Printers. Part

numbers are shown below.

The Paper Video explains the

manufacturing process.

5A - 12

Part No.

5961-0711 NTSC Version

5961-0712 PAL Version

Version

(VHS Format)

Page 66

6A

Toner Cartridge Information

Toner Car tridge

Information

6A - 1

Page 67

Toner Cartridge Information

Cartridge Weights/Page Counts

HP LaserJet Product Cartridge Full Weight Empty Weight Page Count

5L/6L C3906 A EP-A 730 gm (25. 7

5P/6P C3903A EP-V 9 20 gm (32. 8

5 92298A EP-E 150 0 gm (52 .9

5Si C3909A EP-W 3034 gm (1 06 .8

oz.)

oz)

oz)

oz)

630 gm (22 oz) 2 ,500

740 gm (26 oz) 4,000

1220 gm (43 oz) 6,800

2315 gm (81.5

oz)

@ 5%

Coverage

15,000

Potential Toner Cartridge Issues

Banding

When printing with a laser printer , the toner is appli ed across the page in

horizontal strips. The page is moved through the printer and toner is continually

applied. When printing text, or black pages a large amount of toner is deposited

on the page. As the amount of toner deposited on the page decreases, slight

speed variations become more apparent. As the resolution (dots per inch) and

the speed (pages per minute) increase, a variation in patt ern intensity may

appear on the page as lines or bands.

The bands are more visible in certain gray-scale patterns. High speed printers,

that are capable of printing high resolution grayscale patterns, are more likely to

display the p attern variat ions. C hanging t he gray-scale pat tern or re ducing the

resolution may si gnificant ly reduce t he amount o f banding t hat occurs.

Character Voids

Small gaps or voids may appear in some of the characters when printing on

media other than standard photocopier paper. These “character voids” occur

because some print media does not accept the transfer of toner as well as others.

To minimize the occurrence of character voids, avoid media with a rough finish.

Use media that is within Hewlett-Packard’ s paper specif ications listed in the

User’s Manual. If the finish is too rough, th e surface will consist of large

inconsistencies. If the finish is too smooth , toner will not adhere well.

Adjusting the print density may effect the severity of character voids.

6A - 2

Page 68

Toner Cartridge Information

Toner Cracking

When paper is folded and the crease happens to line up with a line of text it is

possible with certain types of paper for the text to break along the line, giving

the appearance of a white line through the text. Papers which do not meet the

smoothness (100-250 Sheffield, 100-500 Bendtsen) and/or W ax Pick (>11

Dennison) are likely to exhibit th is effect more than other s.

Toner in the HP LaserJet printer s is comprised of minute particles of pi gmented

plastic material (styrene) and iron oxide. When the toner is subjected to the

fusing temperature, these individual iron-impregnated plastic particles become

part of a larger plastic image on the page. When the printed page is

subsequently folded, the plastic image must also give, in some fashion, in order

to accommodate the fold. If the print image has been well -set into the paper ,

this resulting break in the plasti c will not be apparent. However, if the toner is

unable to adequately penetrate the paper fibers or if, in the process of folding

the paper, the paper fibers behind the toner break away from the page itself, the

result will be a “white line” through the image. There are several ways to

minimize this effect:

Ensure paper being used meets ALL of the specifications provided in

the HP LaserJet Printer Family Paper Specification Guide, part

number 5021-0368, in parti cular the smoothn es s and wax pick.

A lighter density setting will ensure that the toner image will be

comprised of less plastic material, thus minimizing the resulting effect

of trying to fold the toner image.

A lighter character stroke width might also help for the same reasons

given above.

MICR (Magnetic Ink Character Recognition) paper may fix toner

crackin g problems (see also HP MICR User’s Guide, HP part number

5091-3857).

Paper with a laid finish will normally cause problems when doing xerographic

(laser) printing, particularly due to its surface roughness. Relatively “stiff”

papers (as compared to a xerographic bond paper) are not ideal for folding in

the first place and again will present problems when attempting to do so with a

toner image applied to the surfa ce.

6A - 3

6

A

Page 69

Toner Cartridge Information

Post Image Transfer

After printing a document on an HP LaserJet printer, folding it, and sending it

through the mail, a portion of the print im age may be transferred to opposing

surfa ces o f the f old ed doc ume nt.

EXPLANATION:

The laser printing process uses a pigmented plastic powder (toner) to form a

print image that is first transferre d to a sheet of paper (or other print medium)

and th en me lte d (fus ed) o nt o the surfac e of t he p aper to for m a per mane nt

image. Though paper is usually thought of as being “soft”, it is actually quite

abrasive. When the printed page is folded, movement under pressure between a

paper surface and the toner image may cause the paper to abrade (scratch) the

toner, causing a transfer of the toner material onto the opposing surface of the

paper. This can be demonstrated by rubbing a print image against (or into) a

clean sheet of paper.

Some machinery, such as that used by the US Postal Service to sort mail, can

apply the necessary pressure and agitation to cause this toner image transfer

phenomenon.

RESOLUTION:

The potential for this problem can be significantly reduced by minimizing the

amount (or height) of toner used to produce the print image, using a paper that

is less abrasive, and/or ensuring optimal fusing of the toner (print) image to the

paper.

The amount of toner used to produce a print image is controlled by the print

density dial, slide, or Control Pane l settings in the HP LaserJet p rinters. The

print density should be adjusted for a LIGHTER image to reduce the amount

(height) of toner prone to abrasive transfer.

The HP LaserJet printers have been designed for optimum results with

xerographic (or “laser”) bond papers, such as XEROX 4024 photocopy paper.

The properties of this type of paper (surface roughness, composition, moisture

content, etc.) are such that the other causes of potential toner transfer are

minimized. Photocopy papers are typically less abrasive than other types of

paper (such as “writing bond”) and are also formulated to ensure optimal fusing

of the toner image. Using other types of paper will generally yield less than

optimal results in laser print ers. For help in selecting paper suitabl e for use in

the HP LaserJet printers, refer to the HP LaserJet Printer Family Paper

Specification Guide - part number 5021-0368. This guide can be ordered by

calling HP Parts Direct at 800-227-8164 in the U.S., or HP Distribution at

970-339-7009.

6A - 4

Page 70

Toner Cartridge Information

There is presently no way to entirely eliminat e the possibility of tone r transfer

due to the way in which laser printing is accomplished. However, using these

techniques should yield more satisfactory results and will often reduce the