Page 1

HP ProLiant DL380 Generation 3 Server

User Guide

July 2003 (Third Edition)

Part Number 303130-003

Page 2

© 2003 Hewlett-Packard Development Company, L.P.

Microsoft, MS-DOS, Windows, and Windows NT are trademarks of Microsoft Corporation in the U.S. and

other countries.

Intel and Xeon are trademarks of Intel Corporation in the U.S. and other countries.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained

herein. The information in this document is provided “as is” without warranty of any kind and is subject to

change without notice. The warranties for HP products are set forth in the express limited warranty

statements accompanying such products. Nothing herein should be construed as constituting an additional

warranty.

July 2003 (Third Edition)

Part Number 303130-003

Audience Assumptions

This guide is for the person who installs, administers, and troubleshoots servers. HP assumes you

are qualified in the servicing of computer equipment and trained in recognizing hazards in

products with hazardous energy levels.

Page 3

3

Contents

Server Component Identification 9

Server Features.....................................................................................................................................9

Front Panel Components....................................................................................................................10

Front Panel LEDs and Buttons........................................................................................................... 11

Rear Panel Components..................................................................................................................... 13

Rear Panel LEDs and Buttons............................................................................................................ 15

System Board Components................................................................................................................ 17

System Maintenance Switch................................................................................................... 18

NMI Switch ............................................................................................................................18

Chassis ID Switch................................................................................................................... 19

DIMM Slots............................................................................................................................ 19

System Board LEDs........................................................................................................................... 20

System LEDs and Internal Health LED Combinations...................................................................... 22

SCSI Backplane Components ............................................................................................................ 24

SCSI Backplane LEDs....................................................................................................................... 25

Hot-Plug SCSI Hard Drive LEDs ......................................................................................................26

Hot-Plug SCSI Hard Drive LED Combinations.................................................................................28

Internal PCI Hot Plug LEDs and Button............................................................................................29

PCI Hot Plug LED Status Combinations ........................................................................................... 30

PCI Riser Cage LED.......................................................................................................................... 31

Remote Management Connector........................................................................................................ 31

Identifying Hot-Plug Fans.................................................................................................................. 32

Hot-Plug Fan LED ............................................................................................................................. 33

Power Converter Module LED .......................................................................................................... 34

Battery-Backed Write Cache Enabler LEDs...................................................................................... 34

Battery-Backed Write Cache Enabler LED Statuses .........................................................................35

Server Operations 37

Powering Up the Server ..................................................................................................................... 37

Powering Down the Server ................................................................................................................ 37

Extending the Server from the Rack ..................................................................................................38

Removing the Access Panel............................................................................................................... 40

Installing the Access Panel ................................................................................................................40

Removing the PCI Riser Cage ........................................................................................................... 40

Installing the PCI Riser Cage............................................................................................................. 42

Page 4

4 HP ProLiant DL380 Generation 3 Server User Guide

Server Setup 45

Optional Installation Services ............................................................................................................ 45

Rack Planning Resources................................................................................................................... 46

Optimum Environment ......................................................................................................................47

Space and Airflow Requirements ...........................................................................................47

Temperature Requirements..................................................................................................... 48

Power Requirements...............................................................................................................49

Electrical Grounding Requirements........................................................................................50

Rack Warnings................................................................................................................................... 50

Identifying the Contents of the Server Shipping Carton .................................................................... 51

Installing Hardware Options ..............................................................................................................52

Installing the Server into the Rack..................................................................................................... 52

Powering Up and Configuring the Server..........................................................................................62

Installing the Operating System......................................................................................................... 63

Registering the Server........................................................................................................................ 63

Hardware Options Installation 65

Introduction........................................................................................................................................ 65

Processor Option................................................................................................................................ 65

Memory Options ................................................................................................................................ 69

Online Spare Memory Configuration .....................................................................................70

DIMM Installation Guidelines................................................................................................ 70

Installing DIMMs ................................................................................................................... 71

Hot-Plug SCSI Hard Drive Options................................................................................................... 72

SCSI IDs................................................................................................................................. 72

Removing a Hard Drive Blank ............................................................................................... 73

Removing a Hot-Plug SCSI Hard Drive................................................................................. 74

Installing a Hot-Plug SCSI Hard Drive ..................................................................................74

Hot-Plug Tape Drive Option.............................................................................................................. 75

Battery-Backed Write Cache Enabler Option .................................................................................... 77

Redundant Hot-Plug Fans .................................................................................................................. 79

Installation Requirements .......................................................................................................81

Identifying Hot-Plug Fans ...................................................................................................... 81

Installing Redundant Hot-Plug Fans.......................................................................................82

Redundant Hot-Plug AC Power Supply Option................................................................................. 84

DC Power Supply Option ..................................................................................................................87

Expansion Board Options ..................................................................................................................91

Removing Expansion Slot Cover 1......................................................................................... 91

Removing Expansion Slot Covers 2 and 3 .............................................................................92

Installing a Non-Hot-Plug Expansion Board .......................................................................... 94

Installing PCI Hot Plug Expansion Boards............................................................................. 95

Server Cabling 99

Hot-Plug SCSI Hard Drive Cabling...................................................................................................99

Page 5

Contents 5

Integrated Simplex SCSI Cabling......................................................................................... 100

Integrated Duplex SCSI Cabling .......................................................................................... 101

PCI Simplex SCSI Cabling................................................................................................... 101

PCI Duplex SCSI Cabling .................................................................................................... 102

Installing the SCSI Terminator Board .................................................................................. 103

Removing the SCSI Terminator Board................................................................................. 104

CD-ROM Drive Cabling.................................................................................................................. 105

Diskette Drive Cabling..................................................................................................................... 106

Power Button/LED Cabling ............................................................................................................. 106

PCI Hot Plug Backplane Cabling..................................................................................................... 107

RILOE II Cabling ............................................................................................................................108

Internal Power Cabling .................................................................................................................... 108

External Storage Cabling ................................................................................................................. 109

Server Configuration and Utilities 111

ROM-Based Setup Utility................................................................................................................ 111

Using RBSU ......................................................................................................................... 112

Auto-Configuration Process ................................................................................................. 116

Boot Options......................................................................................................................... 117

Configuring Online Spare Memory ...................................................................................... 118

Re-Entering the Server Serial Number ................................................................................. 118

Redundant ROM Support................................................................................................................. 119

Safety and Security Benefits................................................................................................. 119

Access to Redundant ROM Settings..................................................................................... 119

ROMPaq Utility ............................................................................................................................... 120

System Online ROM Flash Component Utility ...............................................................................121

USB Support ....................................................................................................................................121

SmartStart Software ......................................................................................................................... 122

SmartStart Autorun Menu..................................................................................................... 122

SmartStart Scripting Toolkit................................................................................................. 123

Enterprise Diagnostics LX32 Utility ....................................................................................124

Drivers .............................................................................................................................................124

Option ROM Configuration for Arrays............................................................................................ 124

Management Agents ........................................................................................................................125

Insight Manager 7 ............................................................................................................................ 125

Automatic Server Recovery-2.......................................................................................................... 126

Survey Utility................................................................................................................................... 126

Integrated Management Log ............................................................................................................ 126

Server Specific Troubleshooting 129

Minimum Hardware Configuration..................................................................................................129

Server Error Messages ..................................................................................................................... 130

When the Server Does Not Start...................................................................................................... 130

Page 6

6 HP ProLiant DL380 Generation 3 Server User Guide

Diagnostic Steps............................................................................................................................... 132

Is the System Power LED Amber?....................................................................................... 134

Is the System Power LED Green? ........................................................................................ 135

Is the External Health LED Green? ...................................................................................... 135

Is the Internal Health LED Green? ....................................................................................... 136

Is the Monitor Displaying Information? ............................................................................... 137

Problems After Initial Boot.............................................................................................................. 137

System Cannot Load SmartStart........................................................................................... 138

SmartStart Fails During Installation ..................................................................................... 138

SmartStart Cannot Load Operating System.......................................................................... 139

ROMPaq Disaster Recovery ............................................................................................................ 139

Other Information Resources........................................................................................................... 140

Battery Replacement 141

Regulatory Compliance Notices 143

Regulatory Compliance Identification Numbers.............................................................................. 143

Federal Communications Commission Notice................................................................................. 144

FCC Rating Label................................................................................................................. 144

Class A Equipment ...............................................................................................................144

Class B Equipment ...............................................................................................................145

Declaration of Conformity for Products Marked with the FCC Logo, United States Only ............. 145

Modifications ...................................................................................................................................146

Cables............................................................................................................................................... 146

Mouse Compliance Statement..........................................................................................................146

Canadian Notice (Avis Canadien).................................................................................................... 146

European Union Notice.................................................................................................................... 147

Japanese Notice................................................................................................................................ 148

BSMI Notice ....................................................................................................................................148

Laser Device Notices ....................................................................................................................... 148

Laser Safety Warnings.......................................................................................................... 149

Compliance with CDRH Regulations................................................................................... 149

Compliance with International Regulations..........................................................................149

Laser Product Label.............................................................................................................. 149

Laser Information ................................................................................................................. 150

Battery Replacement Notice ............................................................................................................150

Electrostatic Discharge 151

Preventing Electrostatic Discharge .................................................................................................. 151

Grounding Methods to Prevent Electrostatic Discharge .................................................................. 152

Server Specifications 153

Server Specifications........................................................................................................................153

Environmental Specifications .......................................................................................................... 154

Page 7

Contents 7

Technical Support 155

Related Documents .......................................................................................................................... 155

HP Contact Information................................................................................................................... 155

Before You Contact HP ...................................................................................................................155

Acronyms and Abbreviations 157

Index 161

Page 8

Page 9

9

Server Component Identification

In This Section

Server Features ......................................................................................................................... 9

Front Panel Components ........................................................................................................10

Front Panel LEDs and Buttons ............................................................................................... 11

Rear Panel Components..........................................................................................................13

Rear Panel LEDs and Buttons ................................................................................................ 15

System Board Components ....................................................................................................17

System Board LEDs ...............................................................................................................20

System LEDs and Internal Health LED Combinations .......................................................... 22

SCSI Backplane Components................................................................................................. 24

SCSI Backplane LEDs............................................................................................................25

Hot-Plug SCSI Hard Drive LEDs........................................................................................... 26

Hot-Plug SCSI Hard Drive LED Combinations..................................................................... 28

Internal PCI Hot Plug LEDs and Button ................................................................................ 29

PCI Hot Plug LED Status Combinations................................................................................ 30

PCI Riser Cage LED...............................................................................................................31

Remote Management Connector ............................................................................................31

Identifying Hot-Plug Fans ...................................................................................................... 32

Hot-Plug Fan LED.................................................................................................................. 33

Power Converter Module LED...............................................................................................34

Battery-Backed Write Cache Enabler LEDs ..........................................................................34

Battery-Backed Write Cache Enabler LED Statuses.............................................................. 35

Server Features

The HP ProLiant DL380 Generation 3 server combines the latest Intel Xeon

processors with Hyper-Threading technology, PCI-X expansion slots, PCI Hot

Plug, Integrated Lights-Out (iLO), Online Spare Memory support, embedded

Smart Array 5i Plus Controller with optional transportable battery-backed write

cache, simplex/duplex SCSI backplane, dual integrated Gigabit NICs, optional

hot-plug redundant power and cooling, and rapid deploy rails for HP, Compaq

branded, telco, and third-party racks.

Page 10

10 HP ProLiant DL380 Generation 3 Server User Guide

For more information on the server, refer to the Documentation CD or the

QuickSpecs on the HP website

(http://h18000.www1.hp.com/products/servers/proliantdl380/

Front Panel Components

).

Item Description

1 Hard drive bays

2 Bay for tape drive or hard drive and tape drive blank

3 Diskette drive

4 CD-ROM drive

Page 11

Server Component Identification 11

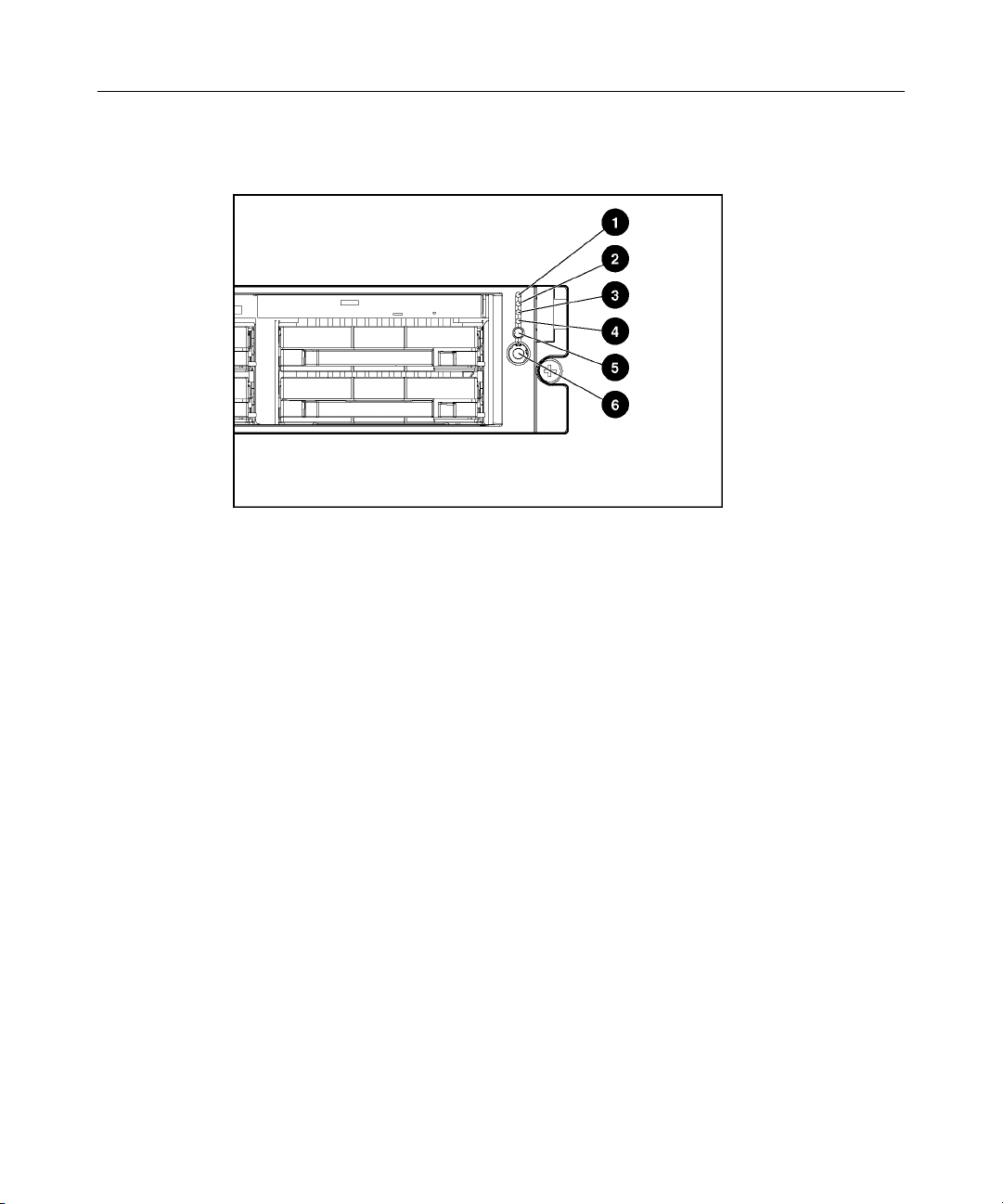

Front Panel LEDs and Buttons

Page 12

12 HP ProLiant DL380 Generation 3 Server User Guide

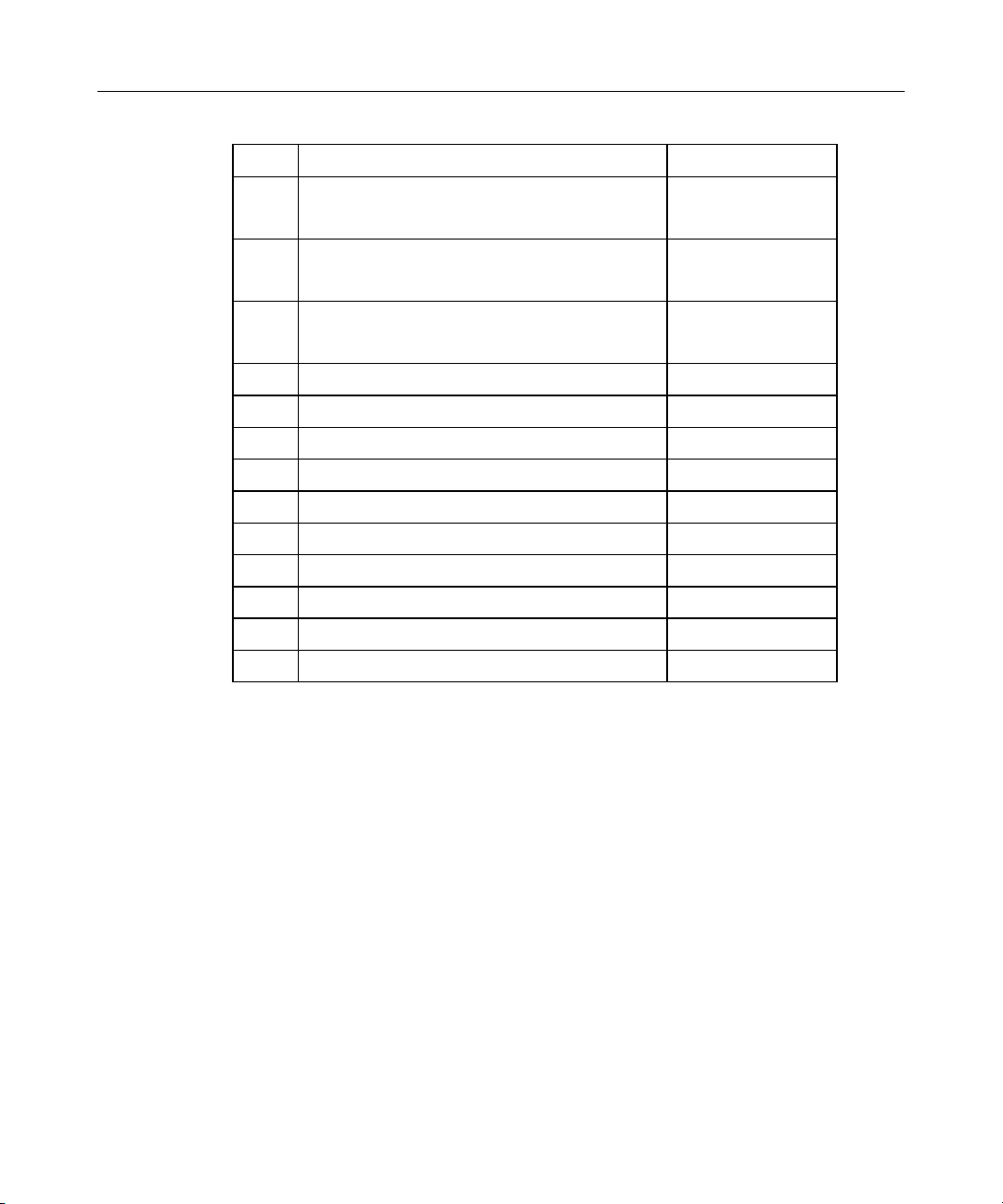

Item Description Status

1 Internal health LED Green = Normal

Amber = System degraded. Refer to system board LEDs to

identify component in degraded state.

Red = System critical. Refer to system board LEDs to identify

component in critical state.

2 External health LED

(power supply)

Green = Normal

Amber = Power redundancy failure

Red = Critical power supply failure

3 NIC 1 link/activity LED Green = Network link

Flashing = Network link and activity

Off = No link to network. If power is off, view the rear panel

RJ-45 LEDs for status.

4 NIC 2 link/activity LED Green = Network link

Flashing = Network link and activity

Off = No link to network. If power is off, view the rear panel

RJ-45 LEDs for status.

5 UID LED button Blue = Activated

Flashing = System remotely managed

6 Power On/Standby

button/system power LED

Off = Deactivated

Green = System on

Amber = System shut down, but power still applied

Off = Power cord not attached or power supply failure

Page 13

Server Component Identification 13

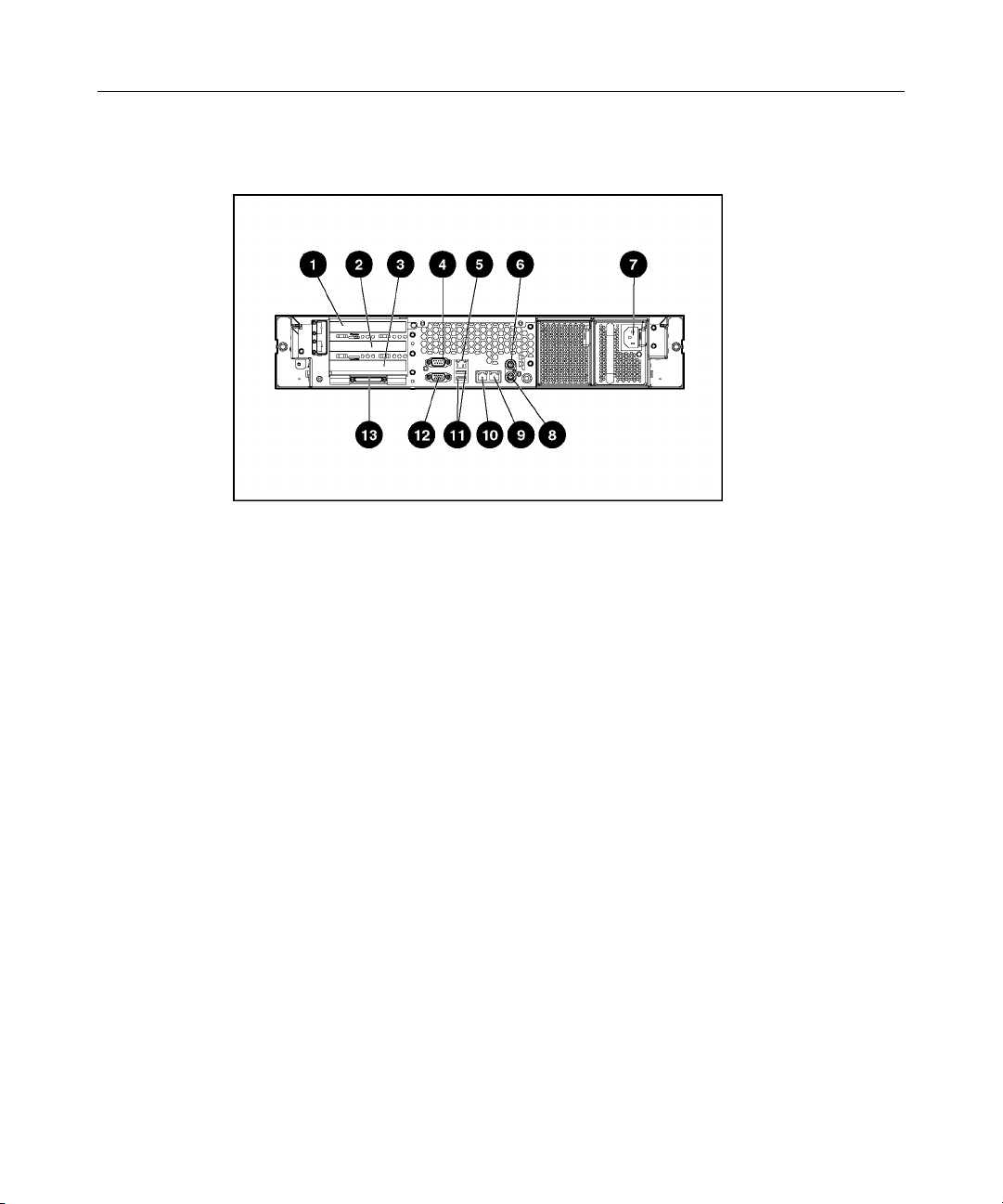

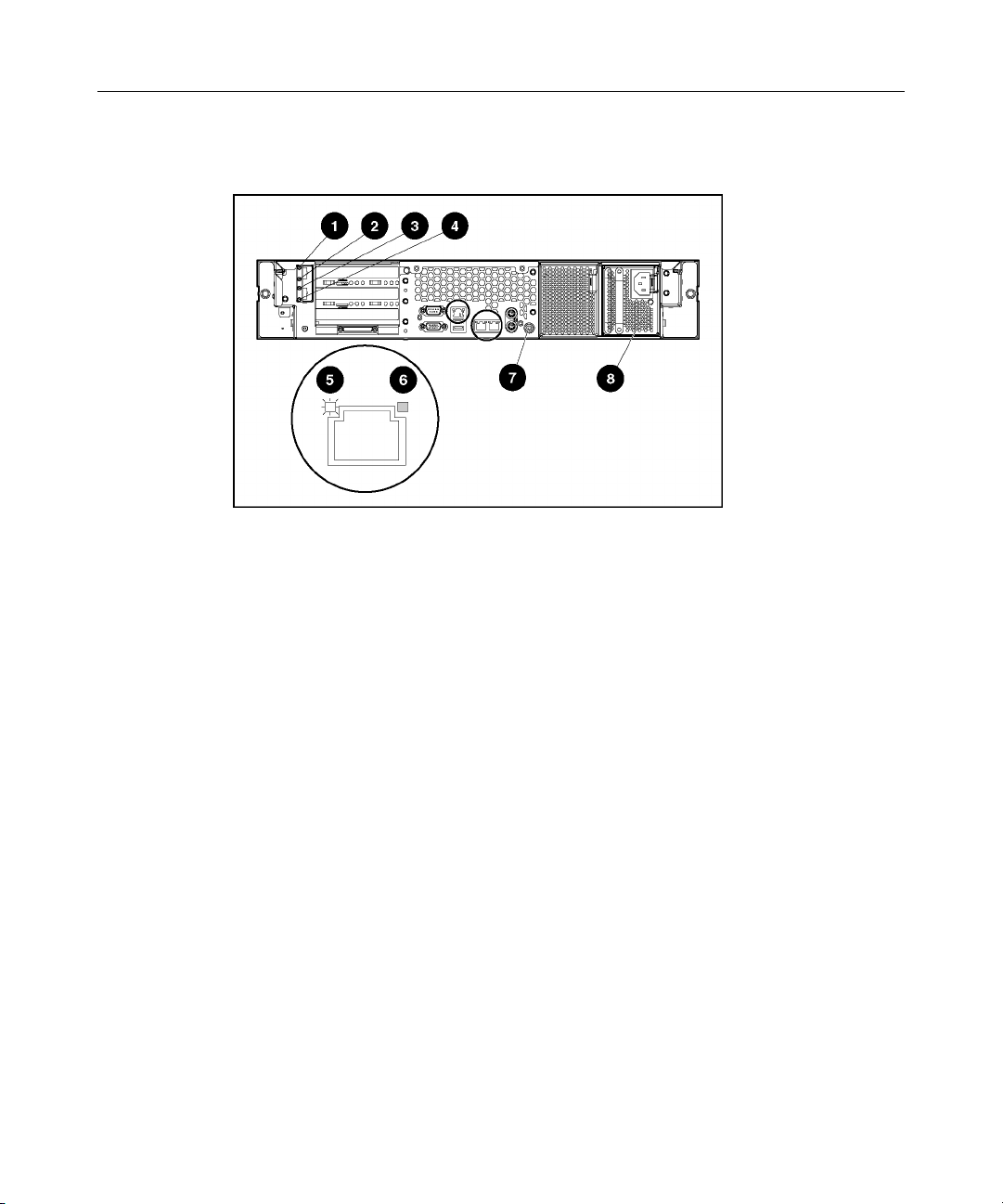

Rear Panel Components

Page 14

14 HP ProLiant DL380 Generation 3 Server User Guide

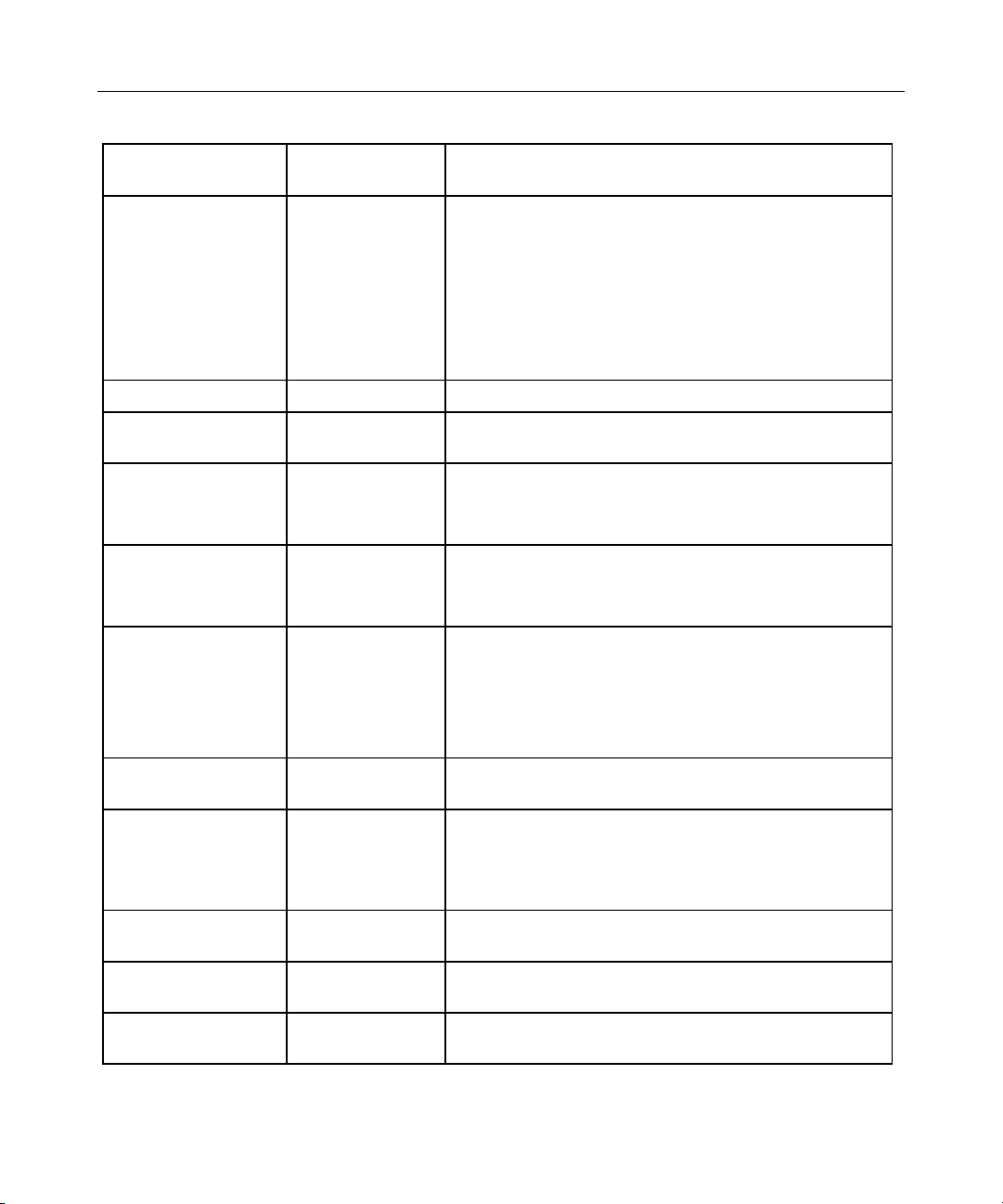

Item Description Connector Color

1 Hot-plug PCI-X expansion slot 3

(bus 6) 64-bit/100-MHz 3.3V

2 Hot-plug PCI-X expansion slot 2

(bus 6) 64-bit/100-MHz 3.3V

3 Non-hot-plug PCI-X expansion slot 1

(bus 3) 64-bit/133-MHz 3.3V

N/A

N/A

N/A

4 Serial connector Teal

5 iLO connector N/A

6 Mouse connector Green

7 Power cord connector N/A

8 Keyboard connector Purple

9 NIC 1 connector N/A

10 NIC 2 connector N/A

11 USB connectors Black

12 Video connector Blue

13 VHDCI SCSI connector (port 1) N/A

Page 15

Server Component Identification 15

Rear Panel LEDs and Buttons

Page 16

16 HP ProLiant DL380 Generation 3 Server User Guide

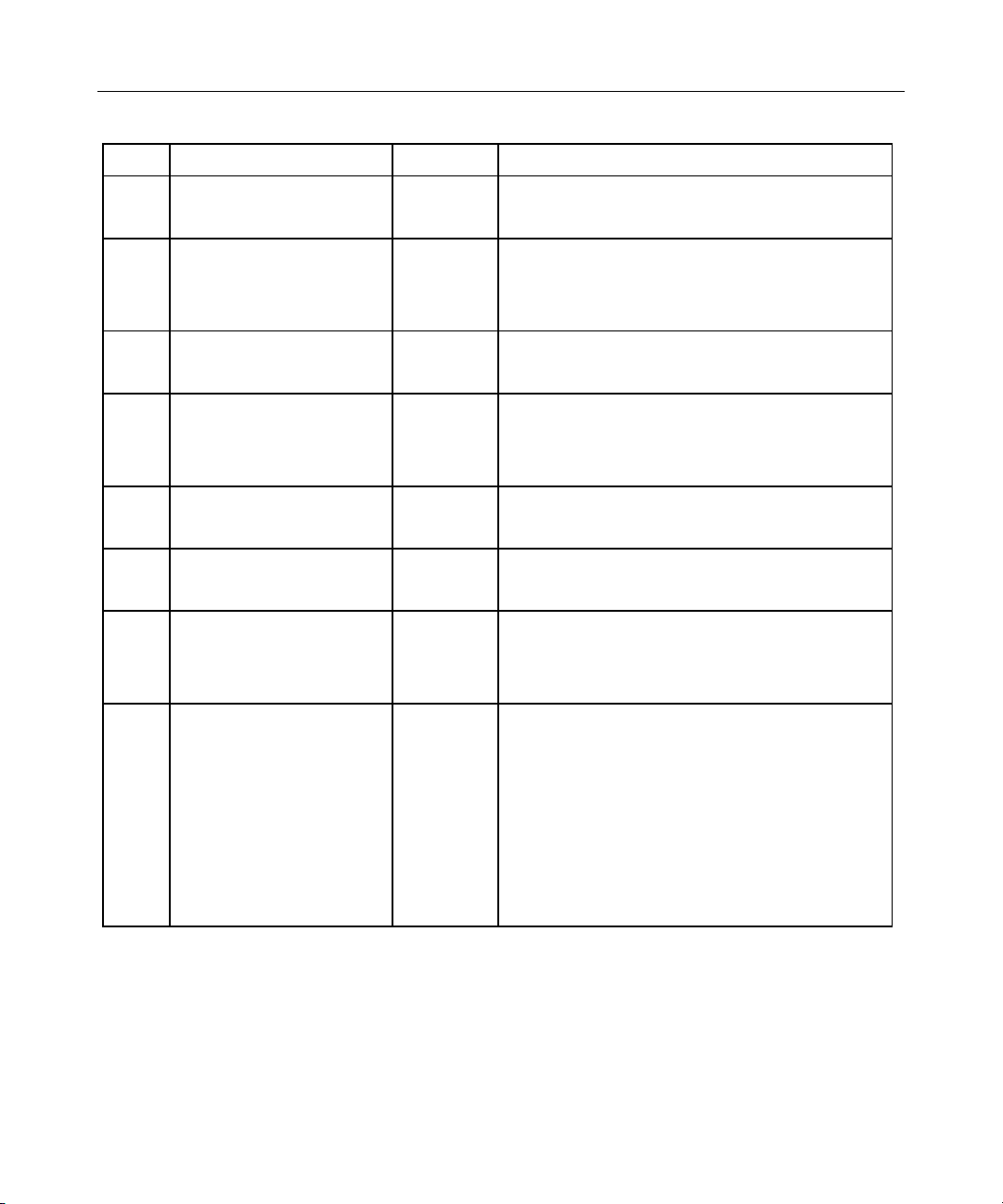

Item Description LED Color Status

1 PCI Hot Plug fault LED

(slot 3)

2 PCI Hot Plug power LED

(slot 3)

3 PCI Hot Plug fault LED

(slot 2)

4 PCI Hot Plug power LED

(slot 2)

Amber On = Expansion board failed

Off = Normal

Green On = Power is applied to the slot

Flashing = Power is cycling

Off = Power is not applied to the slot

Amber On = Expansion board failed

Off = Normal

Green On = Power is applied to the slot

Flashing = Power is cycling

Off = Power is not applied to the slot

5 RJ-45 link LED Green On = Linked to network

Off = Not linked to network

6 RJ-45 activity LED Green On or flashing = Network activity

Off = No network activity

7 UID LED button Blue On = Activated

Flashing = System remotely managed

Off = Deactivated

8 Power supply LED Green On = Power turned on and power supply

functioning properly

Off = One or more of the following conditions

exists:

•

AC power unavailable

•

Power supply failed

•

Power supply in standby mode

•

Power supply exceeded current limit

Page 17

Server Component Identification 17

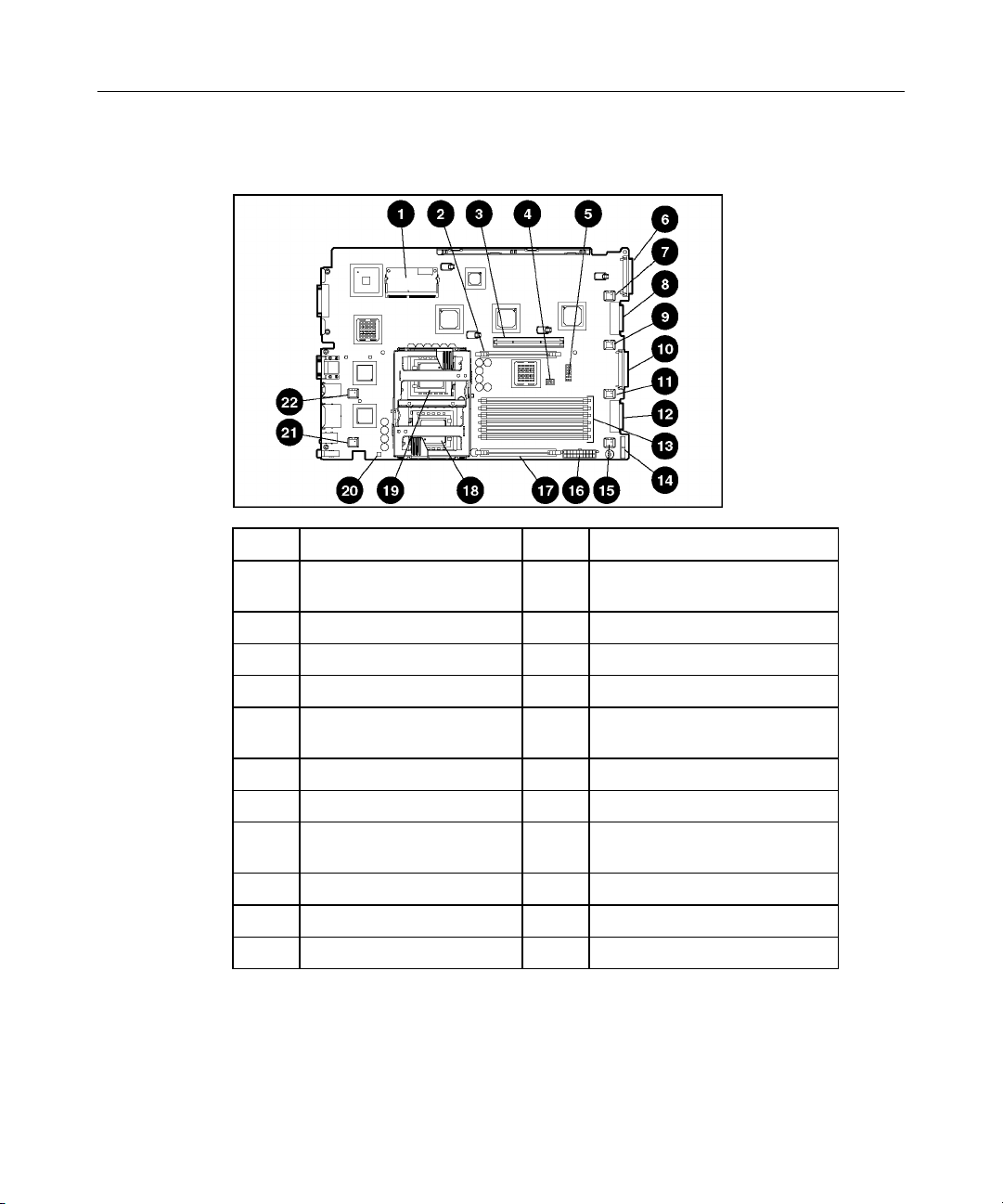

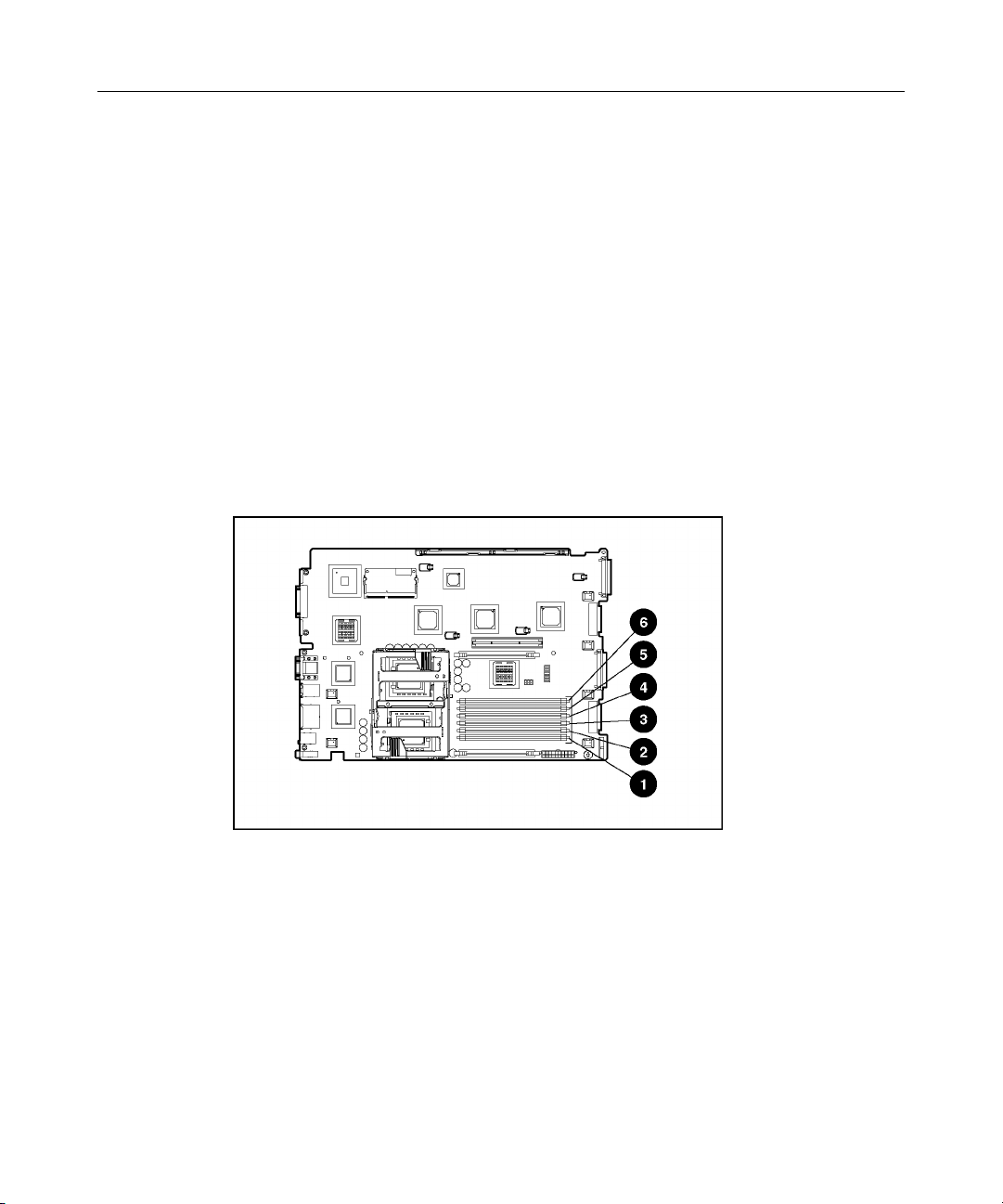

System Board Components

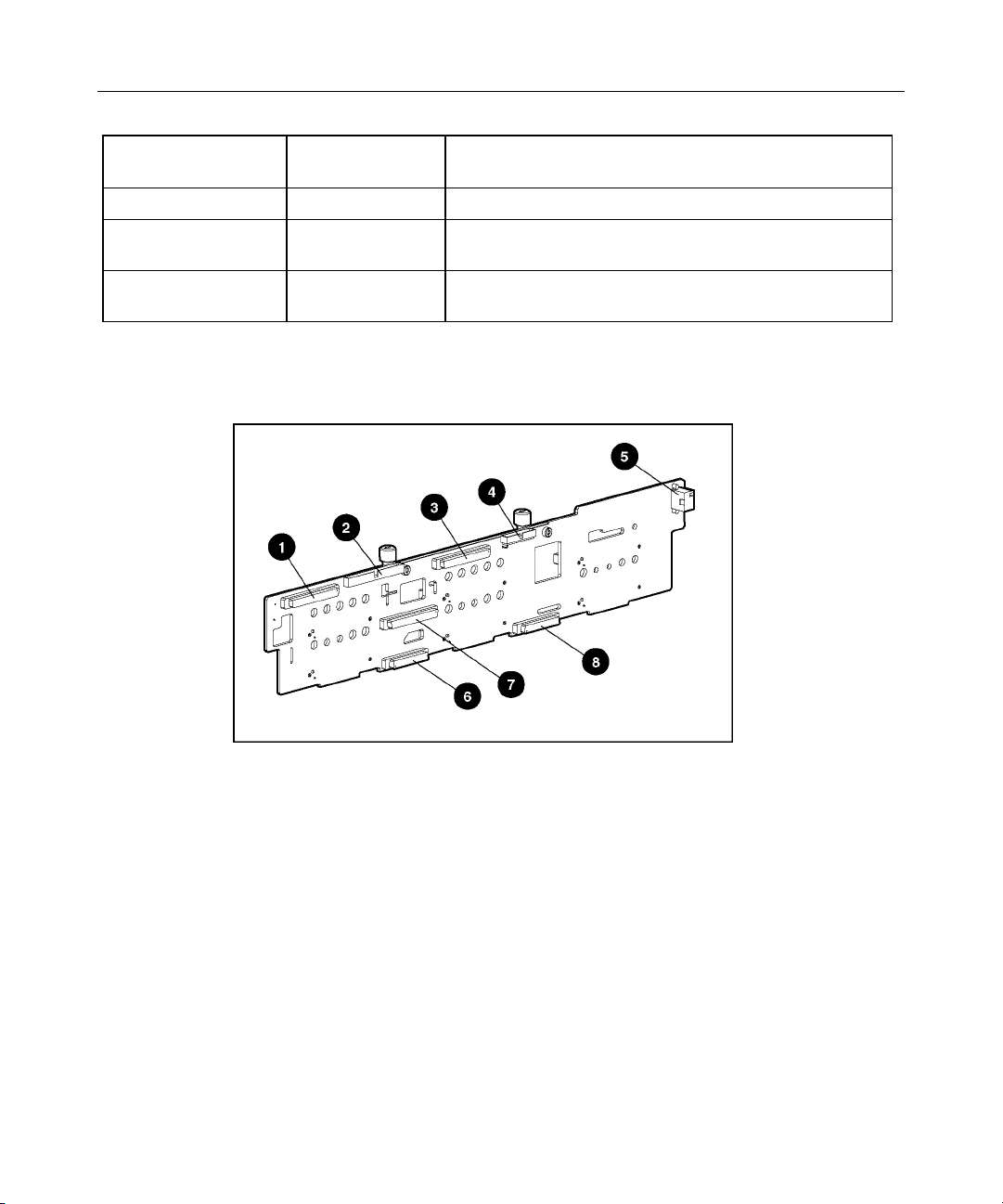

Item Description Item Description

1 Smart Array 5i Plus

Memory Module

2 PPM 2 slot 13 DIMM slots (1-6)

3 PCI riser cage connector 14 Power supply signal connector

4 Chassis ID switch 15 Fan 6 connector

5 System maintenance

switch

6 SCSI connector (port 2) 17 PPM 1 slot

7 Fan 3 connector 18 Processor 1 socket

8 CD-ROM drive system

connector

9 Fan 4 connector 20 NMI switch

10 SCSI connector (port 1) 21 Fan 2 connector

11 Fan 5 connector 22 Fan 1 connector

12 Diskette drive system

connector

16 System power connector

19 Processor 2 socket

Page 18

18 HP ProLiant DL380 Generation 3 Server User Guide

System Maintenance Switch

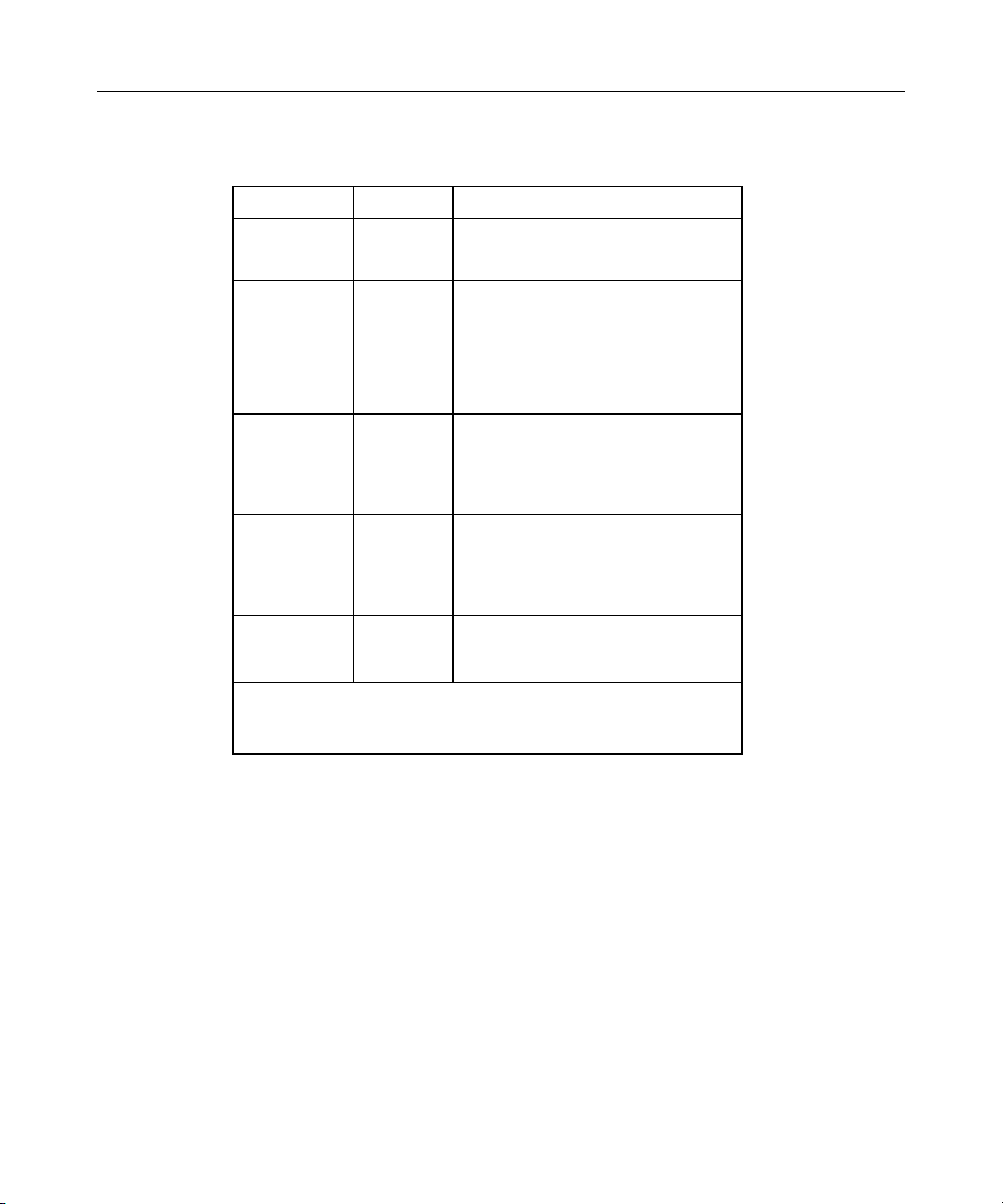

Position Default Function

S1 Off Off = iLO security is enabled.

On = iLO security is disabled.

S2 Off Off = System configuration can be

changed.

On = System configuration is

locked.

S3 Off Reserved

S4 Off Off = Booting from diskette is

controlled by RBSU.

On = Booting from diskette is

enabled and RBSU is overridden.

S5 Off Off = Power-on password is

enabled.

On = Power-on password is

disabled.

NMI Switch

S6 Off Off = No function

On = Clear NVRAM.*

* If you clear NVRAM, you must re-enter the server serial number

through RBSU ("Re-Entering the Server Serial Number" on page

118).

The NMI switch allows administrators to perform a memory dump before

performing a hard reset. Crash dump analysis is an essential part of eliminating

reliability problems, such as hangs or crashes in operating systems, device

drivers, and applications. Many crashes freeze a system, requiring you to do a

hard reset. Resetting the system erases any information that would support root

cause analysis.

Page 19

Server Component Identification 19

Systems running Microsoft Windows operating systems experience a blue screen

trap when the operating system crashes. When this happens, Microsoft

recommends that system administrators perform an NMI event by pressing a

dump switch. The NMI event enables a hung system to become responsive again.

Chassis ID Switch

The chassis ID switch on the system board is reserved for use by authorized

technicians only. Do not modify the switch setting.

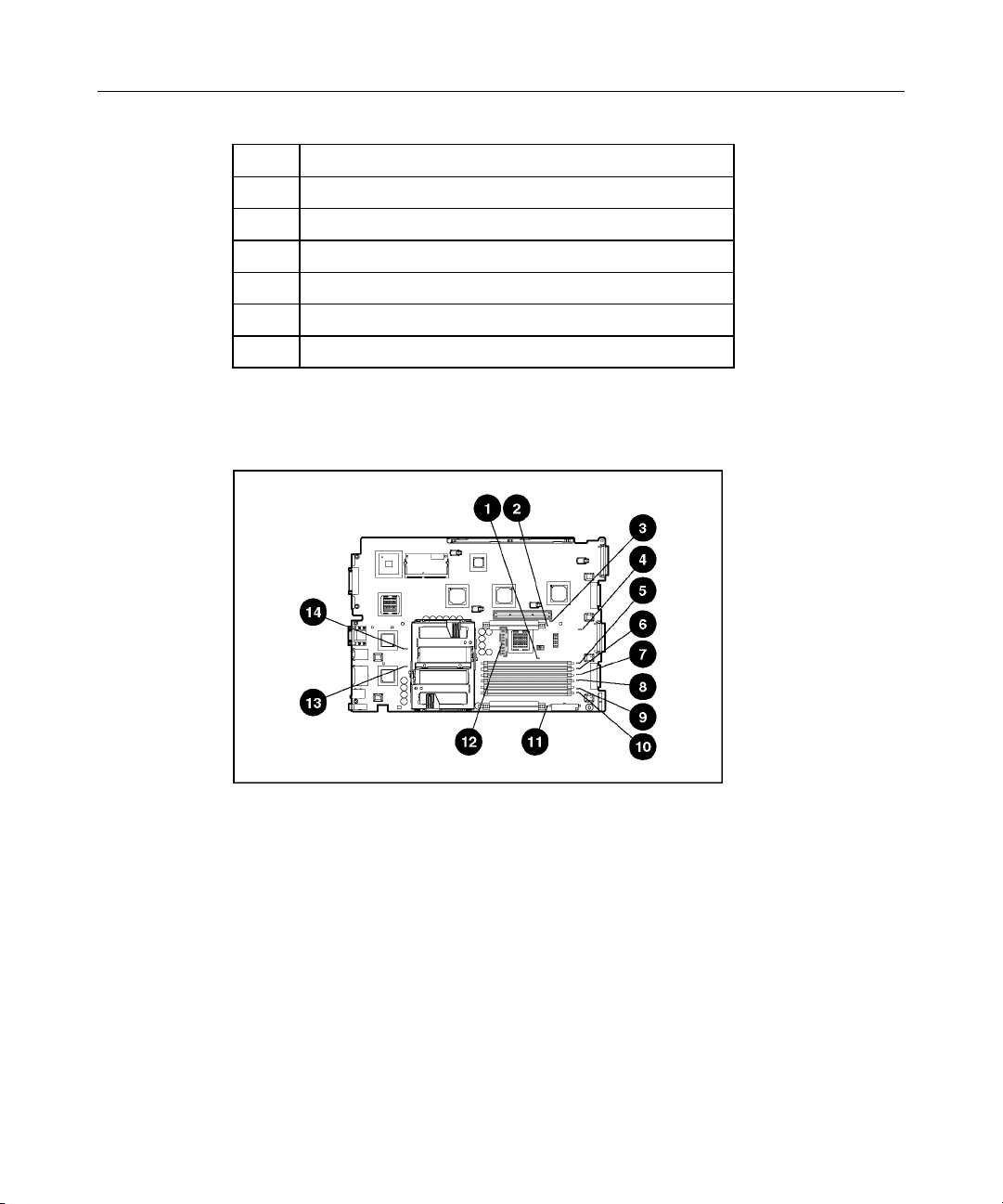

DIMM Slots

DIMM slots are numbered sequentially (1 through 6) and the paired banks are

identified by the letters A, B, and C.

Page 20

20 HP ProLiant DL380 Generation 3 Server User Guide

Item Description

1 DIMM slot 1A

2 DIMM slot 2A

3 DIMM slot 3B

4 DIMM slot 4B

5 DIMM slot 5C

6 DIMM slot 6C

System Board LEDs

Page 21

Server Component Identification 21

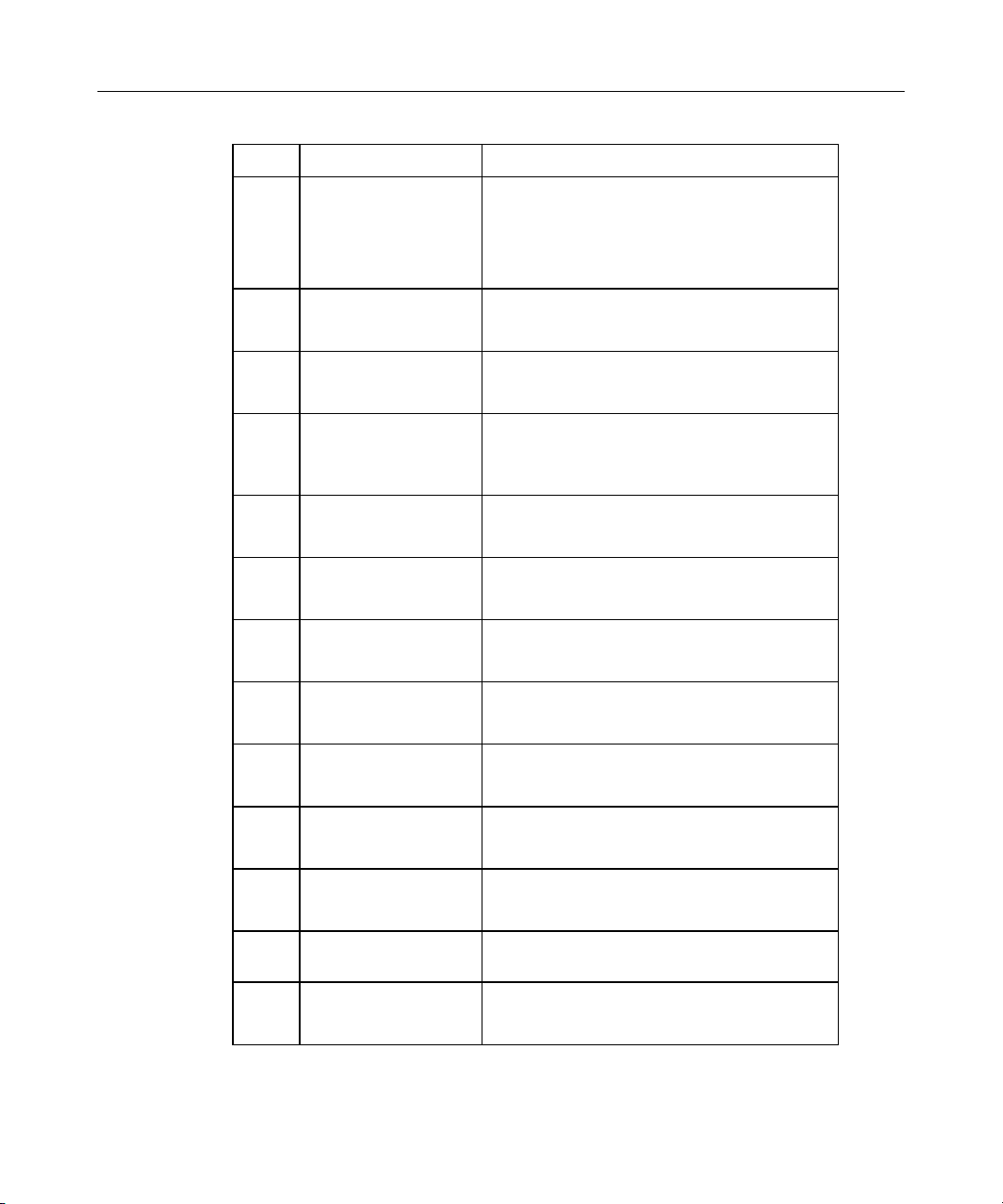

Item LED Description Status

1 Online spare memory Amber = Failover, online spare memory in

use

Green = Enabled, but not in use

Off = Disabled

2 PPM 2 failure Amber = PPM failed

Off = Normal

3 Riser interlock Amber = PCI riser cage not seated

Off = PCI riser cage is seated

4 Overtemperature Amber = Cautionary or critical temperature

level detected

Off = Temperature OK

5 DIMM 6C failure Amber = Memory failed

Off = Normal

6 DIMM 5C failure Amber = Memory failed

Off = Normal

7 DIMM 4B failure Amber = Memory failed

Off = Normal

8 DIMM 3B failure Amber = Memory failed

Off = Normal

9 DIMM 2A failure Amber = Memory failed

Off = Normal

10 DIMM 1A failure Amber = Memory failed

Off = Normal

11 PPM 1 failure Amber = PPM failed

Off = Normal

12 iLO diagnostic LEDs Refer to the HP Integrated Lights-Out User

Guide on the Documentation CD.

13 Processor 1 failure Amber = Processor failed

Off = Normal

Page 22

22 HP ProLiant DL380 Generation 3 Server User Guide

Item LED Description Status

14 Processor 2 failure Amber = Processor failed

Off = Normal

System LEDs and Internal Health LED Combinations

When the internal health LED on the front panel illuminates either amber or red,

the server is experiencing a health event. Combinations of illuminated system

LEDs and the internal health LED indicate system status.

The front panel health LEDs indicate only the current hardware status. In some

situations, Insight Manager 7 may report server status differently than the health

LEDs because the software tracks more system attributes.

Page 23

Server Component Identification 23

System LED and

Color

Internal Health

LED Color

Status

Processor failure,

socket X (Amber)

Amber Processor in socket X is in a pre-failure condition.

Processor failure,

both sockets (Amber)

PPM failure, slot X

(Amber)

DIMM failure, slot X

(Amber)

Amber •

Red One or more of the following conditions may exist:

•

Processor in socket X has failed.

•

Processor in socket X failed over to the offline spare.

•

Processor X is not installed in the socket.

•

Processor X is unsupported.

•

ROM detects a failed processor during POST.

Red Processor types are mismatched.

Red • • PPM in slot X has failed.

PPM is not installed in slot X, but the corresponding

processor is installed.

Red • • DIMM in slot X has failed.

DIMM in slot X is an unsupported type, and no valid

memory exists in another bank.

DIMM in slot X has reached single-bit correctable

error threshold.

•

DIMM in slot X is in a pre-failure condition.

•

DIMM in slot X is an unsupported type, but valid

memory exists in another bank.

DIMM failure, all slots

in one bank (Amber)

Overtemperature

(Amber)

Riser interlock

(Amber)

Online spare memory

(Amber)

Power converter

module (Amber)

Red No valid or usable memory is installed in the system.

Red • • The Health Driver has detected a cautionary

temperature level.

The server has detected a hardware critical

temperature level.

Red PCI riser cage is not seated.

Amber Bank X failed over to the online spare memory bank.

Red Power converter module has failed.

Page 24

24 HP ProLiant DL380 Generation 3 Server User Guide

System LED and

Color

Fan (Amber) Amber Redundant fan has failed.

Red The minimum fan requirements are not being met. One

SCSI configuration

error (Amber)

Internal Health

LED Color

Red SCSI cabling or terminator configuration is incorrect for

Status

or more fans have failed or are missing.

SCSI backplane.

SCSI Backplane Components

Page 25

Server Component Identification 25

Item Description

1 SCSI connector (port 2)

2 CD-ROM drive connector

3 SCSI connector (port 1)

4 Diskette drive connector

5 Power connector

6 CD-ROM drive system connector

7 SCSI connector (used with a jumper or terminator

board)

8 Diskette drive system connector

SCSI Backplane LEDs

Page 26

26 HP ProLiant DL380 Generation 3 Server User Guide

Item LED Description Status

1 SCSI configuration On = Simplex

Off = Duplex

2 SCSI configuration error On = SCSI cabling or terminator

configuration is incorrect

Off = SCSI cabling or terminator

configuration is correct

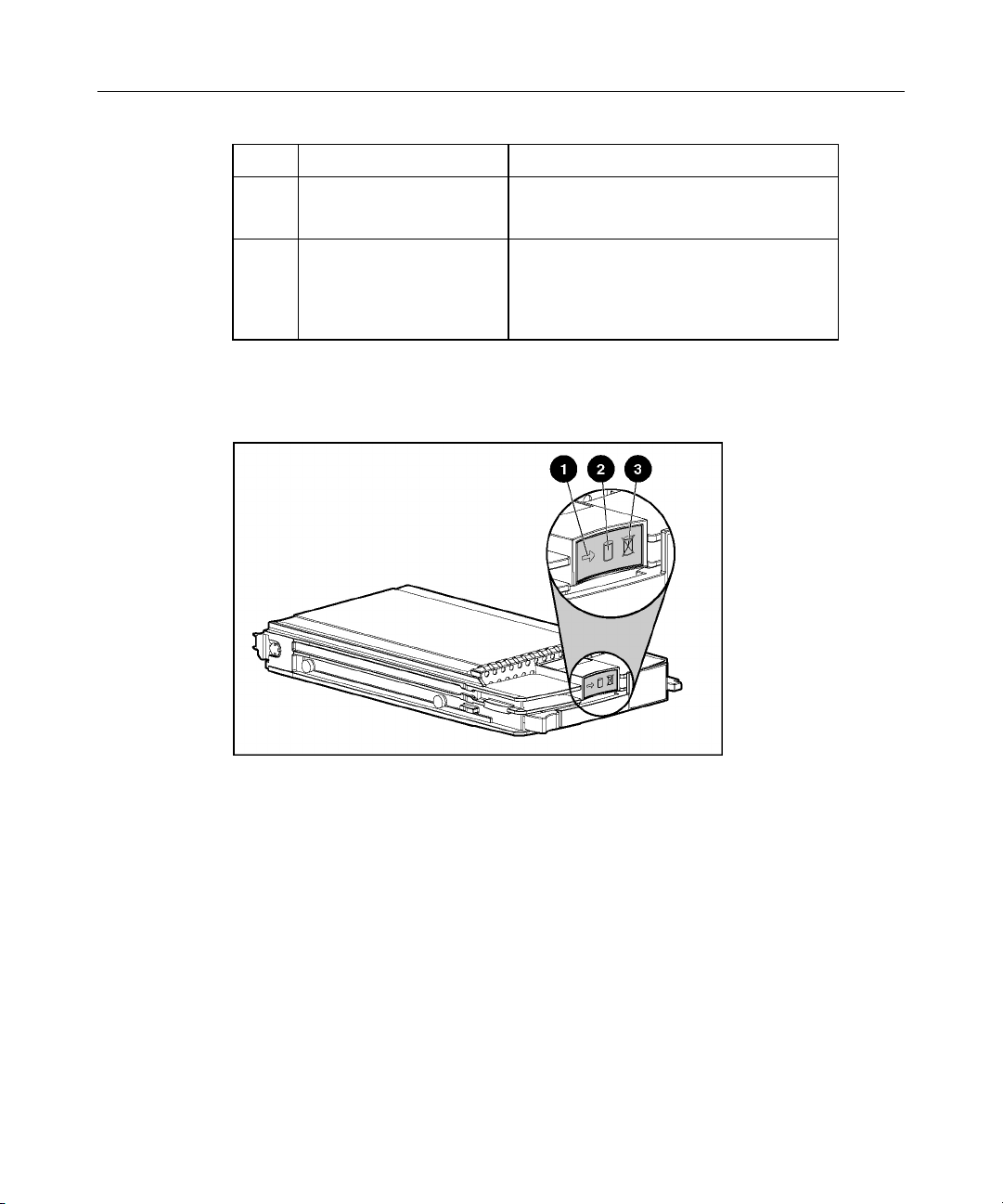

Hot-Plug SCSI Hard Drive LEDs

Page 27

Server Component Identification 27

Item LED Description Status

1 Activity status On = Drive activity

Flashing = High activity on the drive or

drive is being configured as part of an

array.

Off = No drive activity

2 Online status On = Drive is part of an array and is

currently working.

Flashing = Drive is actively online.

Off = Drive is offline.

3 Fault status On = Drive failure

Flashing = Fault-process activity

Off = No fault-process activity

Page 28

28 HP ProLiant DL380 Generation 3 Server User Guide

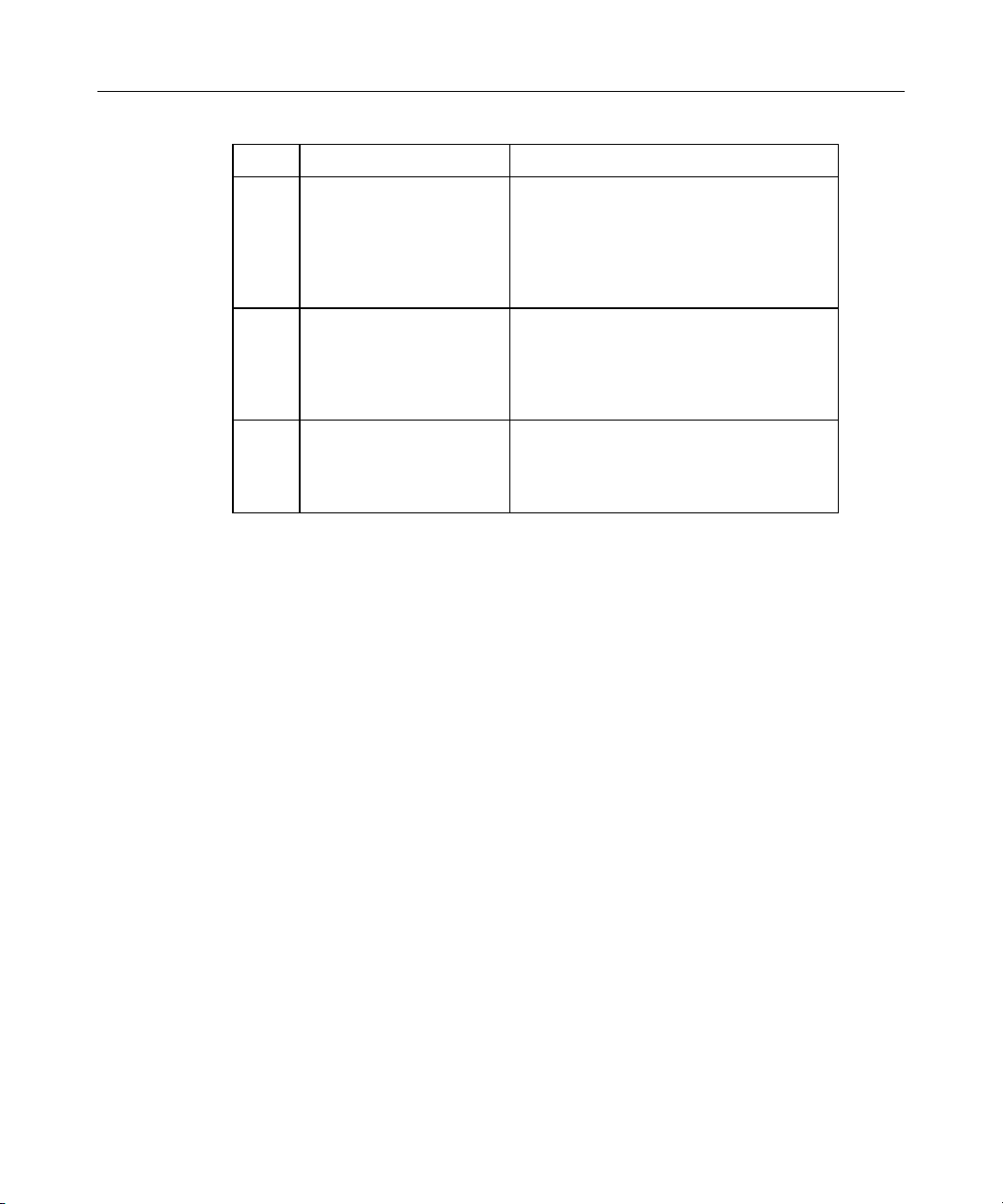

Hot-Plug SCSI Hard Drive LED Combinations

Activity

LED (1)

Online

LED (2)

Fault

LED (3)

Interpretation

On, off,

or

flashing

On, off,

or

flashing

On or

flashing

On Off Off

Flashing Flashing Flashing

Off Off On The drive has failed and been placed offline.

On or off Flashing A predictive failure alert has been received for this drive.

Replace the drive as soon as possible.

On Off The drive is online and is configured as part of an array.

If the array is configured for fault tolerance and all other drives in

the array are online, and a predictive failure alert is received or a

drive capacity upgrade is in progress, you may replace the drive

online.

Flashing Off

Do not remove the drive. Removing a drive may terminate the

current operation and cause data loss.

The drive is rebuilding or undergoing capacity expansion.

Do not remove the drive.

The drive is being accessed, but (1) it is not configured as part of

an array; (2) it is a replacement drive and rebuild has not yet

started; or (3) it is spinning up during the POST sequence.

Do not remove the drive. Removing a drive may cause data

loss in non-fault-tolerant configurations.

Either (1) the drive is part of an array being selected by an array

configuration utility; (2) Drive Identification has been selected in

Insight Manager; or (3) drive firmware is being updated.

You may replace the drive.

Off Off Off Either (1) the drive is not configured as part of an array; (2) the

drive is configured as part of an array, but it is a replacement drive

that is not being accessed or being rebuilt yet; or (3) the drive is

configured as an online spare.

If the drive is connected to an array controller, you may replace

the drive online.

Page 29

Server Component Identification 29

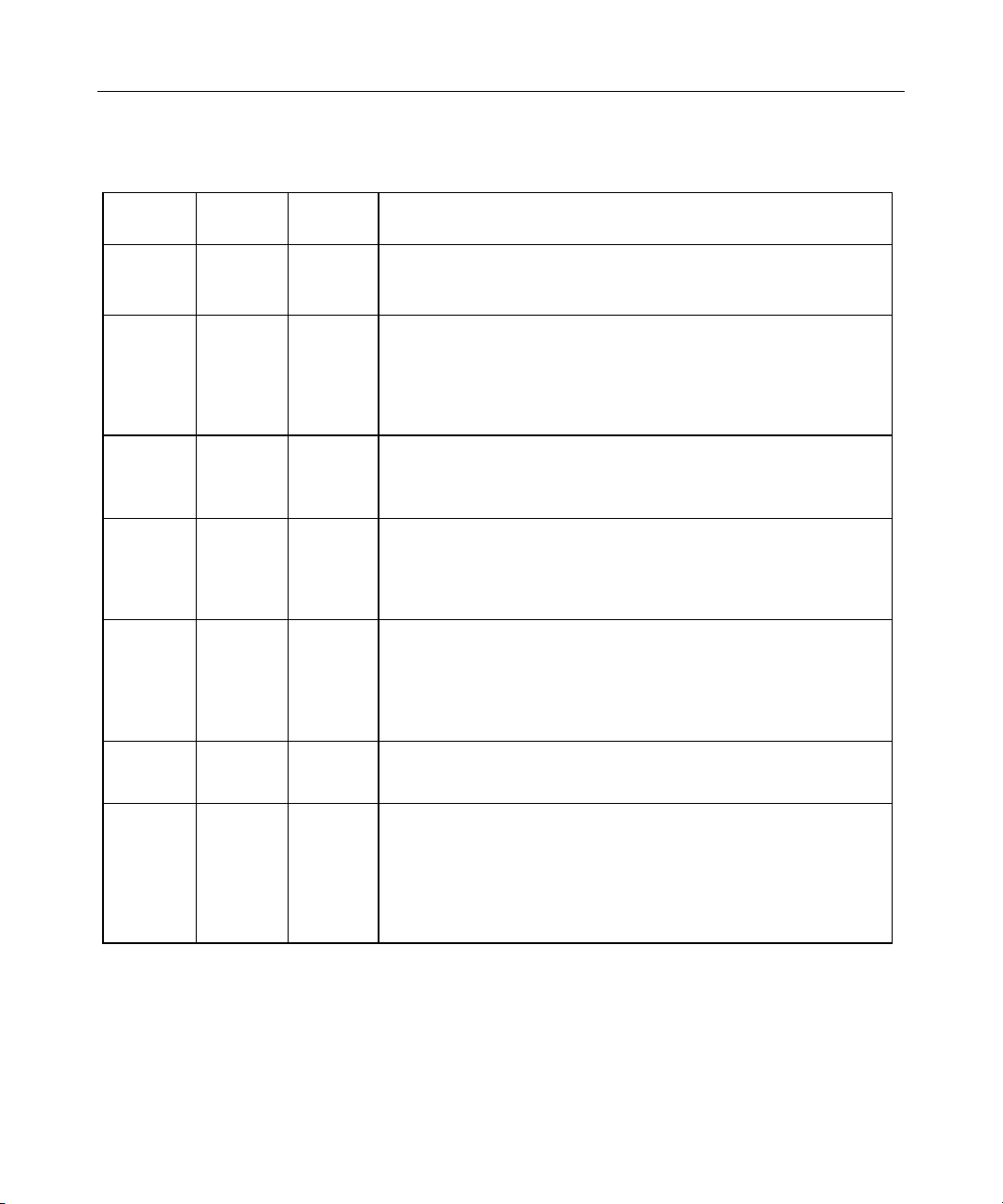

Internal PCI Hot Plug LEDs and Button

Item Description Status

1 Fault LED

(Amber)

2 Power LED

(Green)

3 PCI Hot Plug

button

On = Expansion board failed.

Off = Normal

On = Power is applied to the slot.

Flashing = Power is cycling.

Off = Power is not applied to the

slot.

N/A

Page 30

30 HP ProLiant DL380 Generation 3 Server User Guide

PCI Hot Plug LED Status Combinations

Power LED

(Green)

On Off No The power to the slot is on and the slot is functioning

On On No The power to the slot is on, but the slot needs attention for a

Flashing On or off No The power to the slot is being turned off or on, which may

Off On Yes The power to the slot is off, but the slot needs attention for a

Off Off Yes The power to the slot is off.

Fault LED

(Amber)

OK to

open?

Slot Status

normally. Do NOT open the slot release lever.

possible problem with the slot, board, or driver. DO NOT

open the slot release lever.

Examine the logs and Insight Manager 7. If the expansion

board is faulty, remove or replace the board.

take several seconds. DO NOT open the slot release lever.

To cancel the operation, press the PCI Hot Plug button.

possible problem with the slot, board, or driver.

Page 31

Server Component Identification 31

PCI Riser Cage LED

CAUTION: To prevent damage to the server or expansion

boards, power down the server and remove all AC power cords before

removing or installing the PCI riser cage.

Status

On = AC power connected

Off = AC power disconnected

Remote Management Connector

The 30-pin remote management connector, located on the PCI riser cage, is used

to cable the Remote Insight Lights-Out Edition II option. For more information,

refer to "RILOE II Cabling (on page 108)" or the Remote Insight Lights-Out

Edition II User Guide on the Documentation CD.

Page 32

32 HP ProLiant DL380 Generation 3 Server User Guide

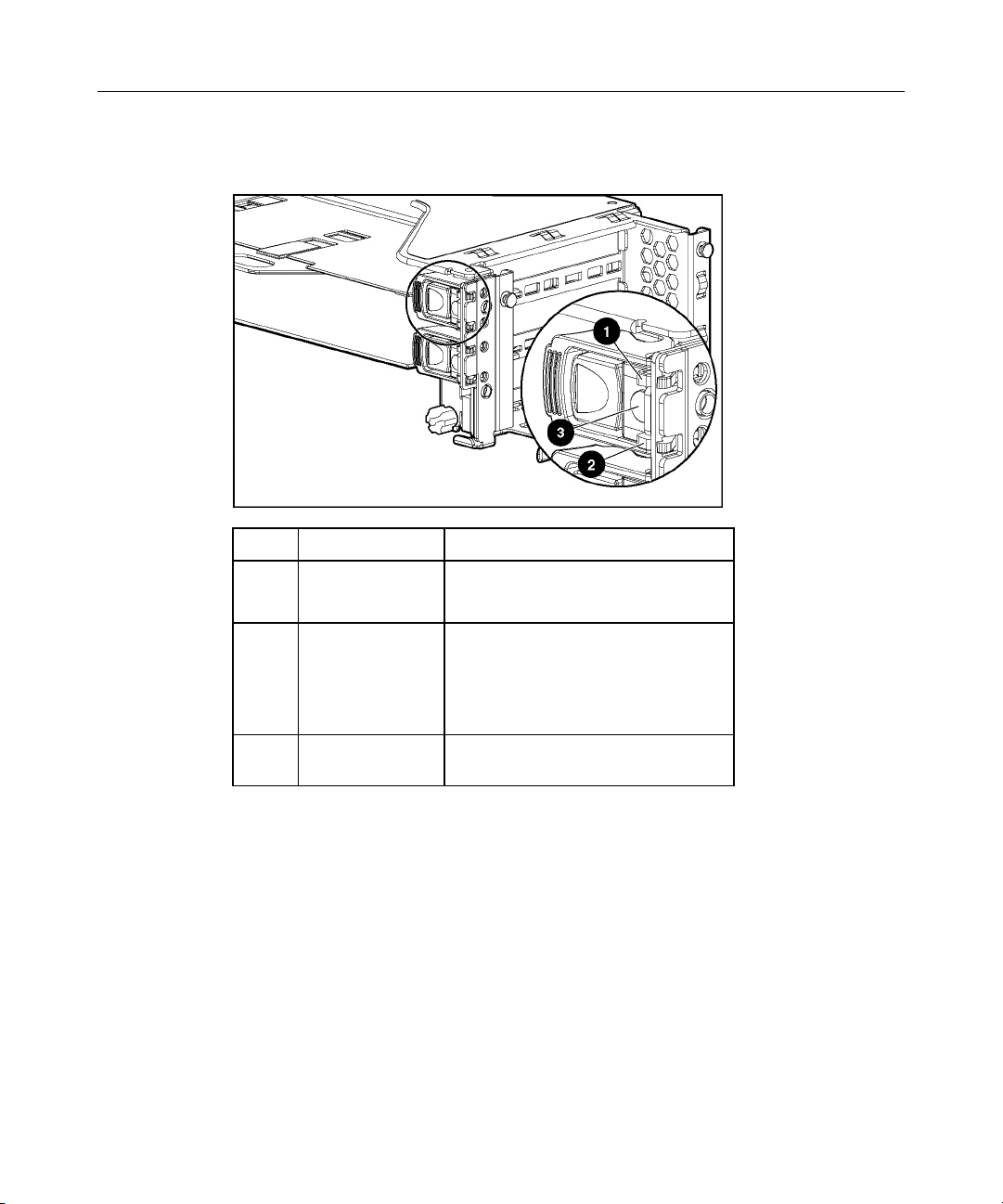

Identifying Hot-Plug Fans

Page 33

Server Component Identification 33

Item Description Zone Configuration

1 Fan 1 Processor Redundant

2 Fan 2 Processor Primary

3 Fan 3 I/O Redundant

4 Fan 4 I/O and processor Primary (shared)

5 Fan 5 Processor Primary

6 Fan 6 Processor Primary

7 Fan 7 Power supply and

8 Fan 8 Power supply Redundant

Hot-Plug Fan LED

Status

Primary (shared)

processor

Green = Operating normally

Amber = Failed

Off = No power

Page 34

34 HP ProLiant DL380 Generation 3 Server User Guide

Power Converter Module LED

Status

Amber = Failed

Off = Operating normally

Battery-Backed Write Cache Enabler LEDs

Page 35

Server Component Identification 35

Item LED Color

1 Amber

2 Green

For LED status information, refer to "Battery-Backed Write Cache Enabler LED

Statuses (on page 35)."

Battery-Backed Write Cache Enabler LED Statuses

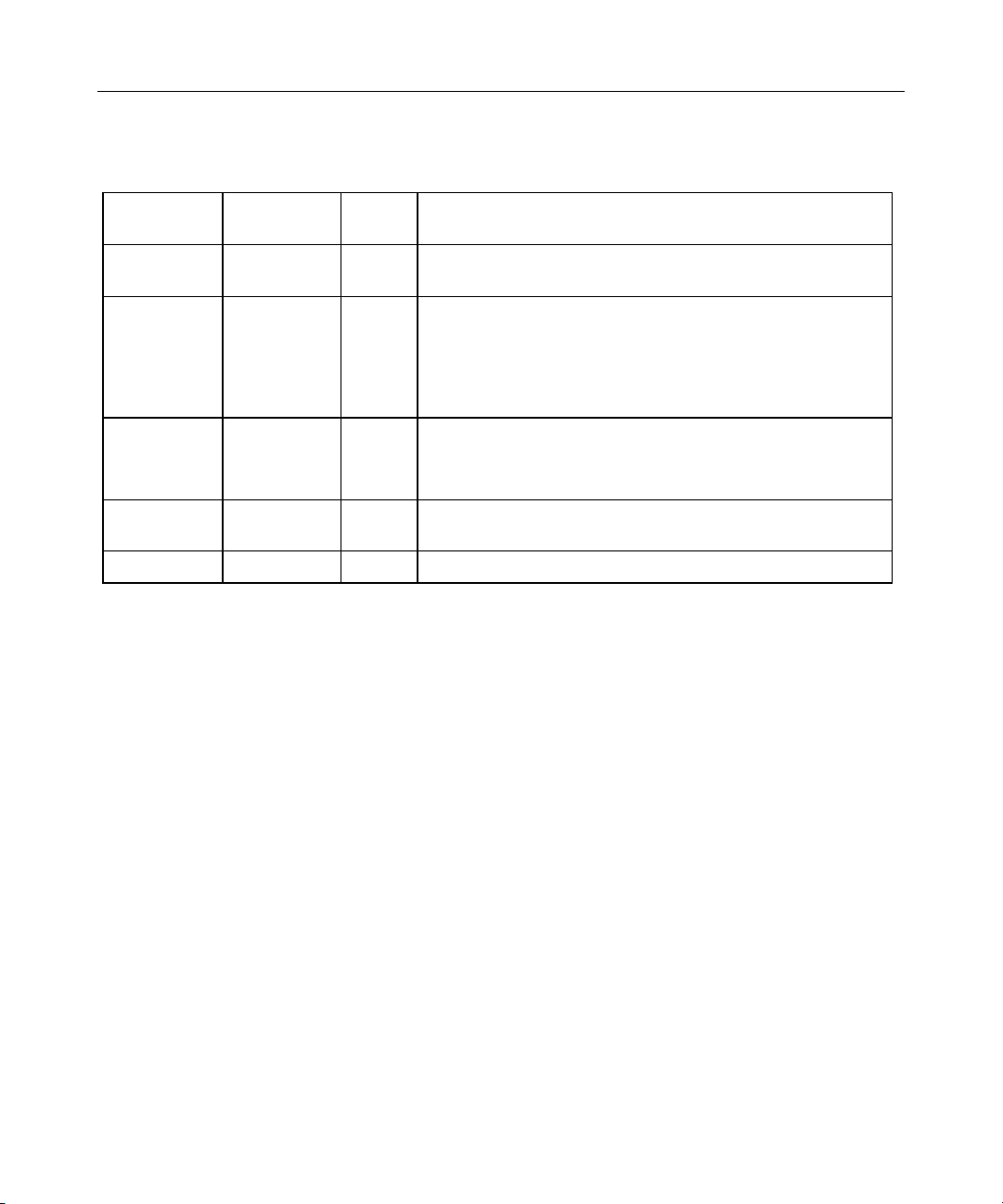

Server Status LED Status Battery Module Status

Server is on and has normal run

Green = On Fast charging

time

Green = Off Trickle charging

Amber = On A short exists in the connection of one or more

of the four button cells within the battery

module

Amber = Blinking An open exists in the circuit between the

positive and negative terminals of the battery

module

Amber = Off Normal

Server is on and is in the first 30

seconds after power up

Server is off and is in data

retention mode

Green = On

Amber = On

Amber = Blinking every

15 seconds

Temporary lock-out state; data was lost due to

cable being detached

User data held in write cache is being backed

up

Page 36

Page 37

37

Server Operations

In This Section

Powering Up the Server.......................................................................................................... 37

Powering Down the Server.....................................................................................................37

Extending the Server from the Rack....................................................................................... 38

Removing the Access Panel ...................................................................................................40

Installing the Access Panel .....................................................................................................40

Removing the PCI Riser Cage................................................................................................ 40

Installing the PCI Riser Cage .................................................................................................42

Powering Up the Server

To power up the server, press the Power On/Standby button.

Powering Down the Server

WARNING: To reduce the risk of personal injury, electric

shock, or damage to the equipment, remove the power cord to

remove power from the server. The front panel Power On/Standby

button does not completely shut off system power. Portions of the

power supply and some internal circuitry remain active until AC

power is removed.

IMPORTANT: If installing a hot-plug device, it is not necessary to

power down the server.

1. Back up the server data.

2. Shut down the operating system as directed by the operating system

documentation.

3. If the server is installed in a rack, press the UID LED button on the front

panel (1). Blue LEDs illuminate on the front and rear panels of the server.

Page 38

38 HP ProLiant DL380 Generation 3 Server User Guide

4. Press the Power On/Standby button to place the server in standby mode (2).

When the server activates standby power mode, the system power LED

changes to amber.

5. If the server is installed in a rack, locate the server by identifying the

illuminated rear UID LED button.

6. Disconnect the power cords.

The system is now without power.

Extending the Server from the Rack

1. Loosen the thumbscrews that secure the server faceplate to the front of the

rack.

2. Extend the server on the rack rails until the server rail-release latches engage.

Page 39

Server Operations 39

WARNING: To reduce the risk of personal injury or

equipment damage, be sure that the rack is adequately stabilized

before extending a component from the rack.

WARNING: To reduce the risk of personal injury, be

careful when pressing the server rail-release latches and sliding

the server into the rack. The sliding rails could pinch your fingers.

3. After performing the installation or maintenance procedure, slide the server

back into the rack:

a. Press the server rail-release latches and slide the server fully into rack.

b. Secure the server by tightening the thumbscrews.

Page 40

40 HP ProLiant DL380 Generation 3 Server User Guide

Removing the Access Panel

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the drives and the internal system components to

cool before touching them.

CAUTION: Do not operate the server for long periods without

the access panel. Operating the server without the access panel results

in improper airflow and improper cooling that can lead to thermal

damage.

1. Power down the server if performing a non-hot-plug installation or

maintenance procedure ("Powering Down the Server" on page 37).

2. Extend the server from the rack, if applicable ("Extending the Server from

the Rack" on page 38).

3. Lift up on the hood latch handle and remove the access panel.

Installing the Access Panel

1. Place the access panel on top of the server with the hood latch open. Allow

the panel to extend past the rear of the server approximately 1.25 cm (0.5 in).

2. Push down on the hood latch. The access panel slides to a closed position.

Removing the PCI Riser Cage

CAUTION: To prevent damage to the server or expansion

boards, power down the server and remove all AC power cords before

removing or installing the PCI riser cage.

1. Power down the server ("Powering Down the Server" on page 37).

2. Extend the server from the rack, if applicable ("Extending the Server from

the Rack" on page 38).

3. Remove the access panel ("Removing the Access Panel" on page 40).

Page 41

Server Operations 41

4. Disconnect any internal or external cables connected to any existing

expansion boards.

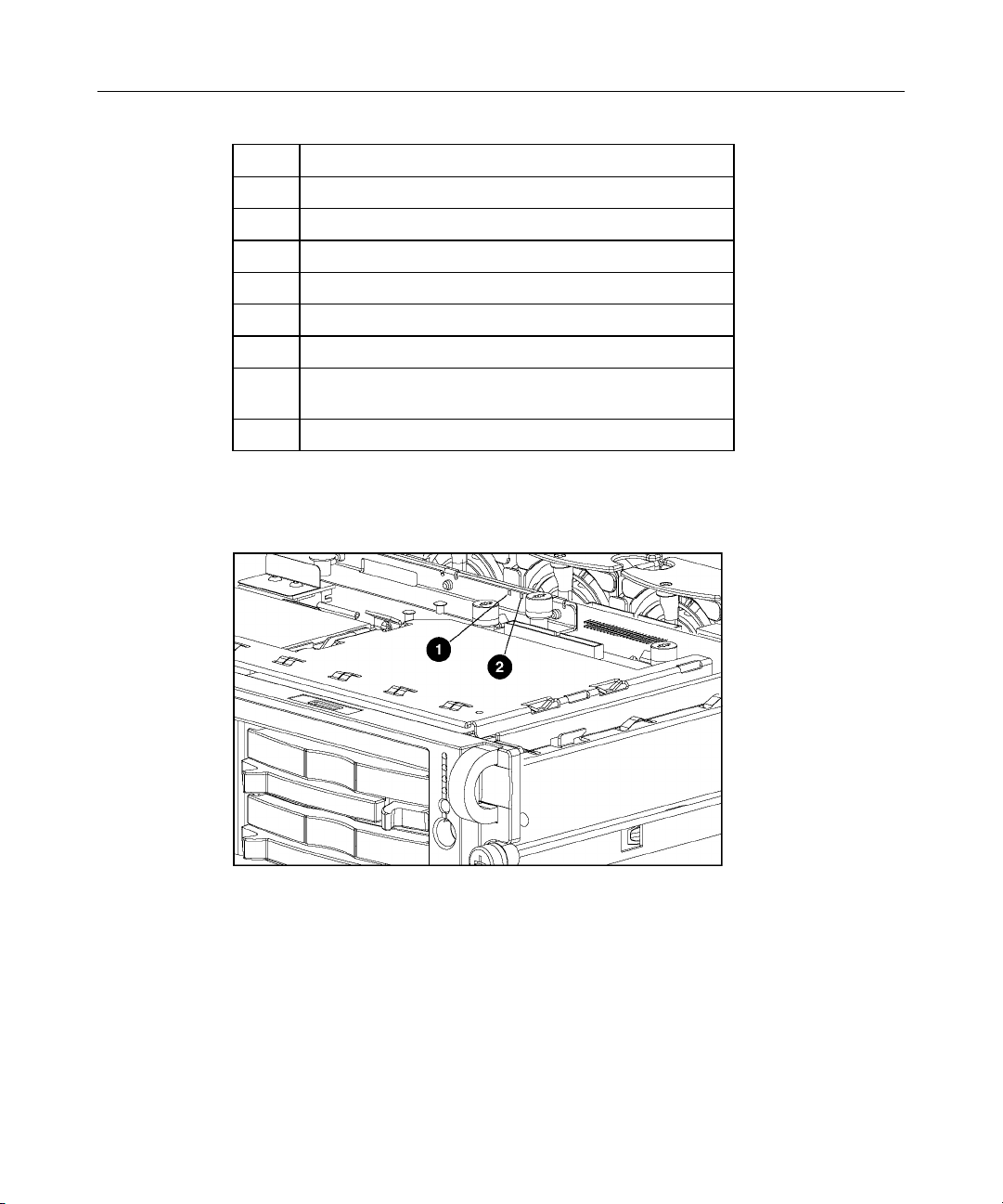

5. Lift the PCI riser cage thumbscrews (1) and turn them counter-clockwise (2).

6. Remove the PCI riser cage (3).

Page 42

42 HP ProLiant DL380 Generation 3 Server User Guide

Installing the PCI Riser Cage

CAUTION: To prevent damage to the server or expansion

boards, power down the server and remove all AC power cords before

removing or installing the PCI riser cage.

1. Align the PCI riser cage with the chassis and slide it into place.

2. Tighten the thumbscrews to secure the PCI riser cage:

a. Lift the thumbscrew knobs (1).

b. Turn the thumbscrews clockwise while pressing down, until tightened

(2).

Page 43

Server Operations 43

c. Turn the thumbscrews counterclockwise to lower thumbscrew knobs (3).

Page 44

Page 45

45

Server Setup

In This Section

Optional Installation Services................................................................................................. 45

Rack Planning Resources .......................................................................................................46

Optimum Environment ........................................................................................................... 47

Rack Warnings .......................................................................................................................50

Identifying the Contents of the Server Shipping Carton.........................................................51

Installing Hardware Options................................................................................................... 52

Installing the Server into the Rack .........................................................................................52

Powering Up and Configuring the Server ..............................................................................62

Installing the Operating System .............................................................................................63

Registering the Server ............................................................................................................63

Optional Installation Services

You may choose to have HP install the system. The installation service can be

purchased as a Care Pack packaged service or as a customized service agreement

to meet your specific requirements. Some of the Care Pack services are as

follows:

•

Hardware installation services

•

Hardware and operating system installation for ProLiant servers

•

Installation and start-up services for some operating systems

•

Installation and start-up services for Insight Manager

This optional hardware installation service is available in all countries where HP

has a direct or indirect service presence. The service may be ordered from and

provided by an authorized service reseller or, in the United States only, the

service may be ordered by calling 1-800-652-6672. In the United States, HP

makes all the arrangements to have the system installed by qualified guaranteed

service providers. For more information, refer to the HP website

(http://www.hp.com/hps

).

Page 46

46 HP ProLiant DL380 Generation 3 Server User Guide

For a list of operating systems, supported by the server, refer to the HP website

(ftp://ftp.compaq.com/pub/products/servers/os-support-matrix-310.pdf

Rack Planning Resources

The rack resource kit ships with all HP branded or Compaq branded 9000,

10000, and H9 series racks. A summary of the content of each resource follows:

• The Rack Builder Pro Configuration Tool enables you to simulate potential

rack configurations based on your input and provides the following

information:

− Graphical preview of properly configured racks

− Site planning data, including power requirements, cooling mandates, and

physical specifications

− Ordering information, including required components, part numbers, and

appropriate quantities

For more information, refer to the HP website

(http://www.hp.com/products/servers/platforms

).

).

• • The Installing Rack Products video provides a visual overview of operations

required for configuring a rack with rack-mountable components. It also

provides the following important configuration steps:

− Planning the site

− Installing rack servers and rack options

− Cabling servers in a rack

− Coupling multiple racks

The Rack Products Documentation CD enables you to view, search, and print

documentation for HP and Compaq branded racks and rack options. It also

helps you set up and optimize a rack in a manner that best fits your

environment.

If you intend to deploy and configure multiple servers in a single rack, refer to

the white paper on high-density deployment on the HP website

(http://www.hp.com/products/servers/platforms

).

Page 47

Server Setup 47

Optimum Environment

When installing the server in a rack, select a location that meets the

environmental standards described in this section.

Space and Airflow Requirements

To allow for servicing and adequate airflow, observe the following space and

airflow requirements when deciding where to install a rack:

•

Leave a minimum clearance of 63.5 cm (25 in) in front of the rack.

•

Leave a minimum clearance of 76.2 cm (30 in) behind the rack.

•

Leave a minimum clearance of 121.9 cm (48 in) from the back of the rack to

the back of another rack or row of racks.

HP servers draw in cool air through the front door and expel warm air through

the rear door. Therefore, the front and rear rack doors must be adequately

ventilated to allow ambient room air to enter the cabinet, and the rear door must

be adequately ventilated to allow the warm air to escape from the cabinet.

CAUTION: To prevent improper cooling and damage to the

equipment, do not block the ventilation openings.

When there is vertical space in the rack not filled by a server or rack component,

the gaps between the components cause changes in airflow through the rack and

across the servers. Cover all gaps with blanking panels to maintain proper

airflow.

CAUTION: Always use blanking panels to fill empty vertical

spaces in the rack. This arrangement ensures proper airflow. Using a

rack without blanking panels results in improper cooling that can lead to

thermal damage.

The 9000 and 10000 Series racks provide proper server cooling from flowthrough perforations in the front and rear doors that provide 64 percent open area

for ventilation.

Page 48

48 HP ProLiant DL380 Generation 3 Server User Guide

CAUTION: When using a Compaq branded 7000 Series rack,

you must install the high airflow rack door insert [P/N 327281-B21 (42U)

or P/N 157847-B21 (22U)] to provide proper front-to-back airflow and

cooling.

CAUTION: If a third-party rack is used, observe the following

additional requirements to ensure adequate airflow and to prevent

damage to the equipment:

• • Front and rear doors—If the 42U server rack includes closing front

and rear doors, you must allow 5,350 sq cm (830 square inches) of

holes evenly distributed from top to bottom to permit adequate

airflow (equivalent to the required 64 percent open area for

ventilation).

Side—The clearance between the installed rack component and the

side panels of the rack must be a minimum of 7 cm (2.75 inches).

Temperature Requirements

To ensure continued safe and reliable equipment operation, install or position the

system in a well-ventilated, climate-controlled environment.

The maximum recommended ambient operating temperature (TMRA) for most

server products is 35°C (95°F). The temperature in the room where the rack is

located must not exceed 35°C (95°F).

CAUTION: To reduce the risk of damage to the equipment

when installing third-party options:

• • Do not permit optional equipment to impede airflow around the

server or to increase the internal rack temperature beyond the

maximum allowable limits.

Do not exceed the manufacturer’s TMRA.

Page 49

Server Setup 49

Power Requirements

Installation of this equipment must comply with local and regional electrical

regulations governing the installation of information technology equipment by

licensed electricians. This equipment is designed to operate in installations

covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992

(code for Protection of Electronic Computer/Data Processing Equipment). For

electrical power ratings on options, refer to the product rating label or the user

documentation supplied with that option.

WARNING: To reduce the risk of personal injury, fire, or

damage to the equipment, do not overload the AC supply branch

circuit that provides power to the rack. Consult the electrical

authority having jurisdiction over your facility’s wiring and

installation requirements.

CAUTION: Protect the server from power fluctuations and

temporary interruptions with a regulating uninterruptible power supply

(UPS). This device protects the hardware from damage caused by

power surges and voltage spikes and keeps the system in operation

during a power failure.

When installing more than one server, you may need to use additional power

distribution devices to safely provide power to all devices. Observe the following

guidelines:

•

Balance the server power load between available AC supply branch circuits.

•

Do not allow the overall system AC current load to exceed 80 percent of the

branch circuit AC current rating.

•

Do not use common power outlet strips for this equipment.

•

Provide a separate electrical circuit for the server.

Page 50

50 HP ProLiant DL380 Generation 3 Server User Guide

Electrical Grounding Requirements

The server must be grounded properly for proper operation and safety. In the

United States, you must install the equipment in accordance with NFPA 70, 1999

Edition (National Electric Code), Article 250, as well as any local and regional

building codes. In Canada, you must install the equipment in accordance with

Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all

other countries, you must install the equipment in accordance with any regional

or national electrical wiring codes, such as the International Electrotechnical

Commission (IEC) Code 364, parts 1 through 7. Furthermore, you must be sure

that all power distribution devices used in the installation, such as branch wiring

and receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple servers

connected to the same power source, HP recommends the use of a power

distribution unit (PDU) that is either permanently wired to the building’s branch

circuit or includes a nondetachable cord that is wired to an industrial-style plug.

NEMA locking-style plugs or those complying with IEC 60309 are considered

suitable for this purpose. Using common power outlet strips for the server is not

recommended.

Rack Warnings

damage to the equipment, be sure that:

•

•

•

•

WARNING: To reduce the risk of personal injury or

The leveling jacks are extended to the floor. •

The full weight of the rack rests on the leveling jacks.

The stabilizing feet are attached to the rack if it is a single-rack

installation.

The racks are coupled together in multiple-rack installations.

Only one component is extended at a time. A rack may become

unstable if more than one component is extended for any

reason.

Page 51

Server Setup 51

WARNING: To reduce the risk of personal injury or

equipment damage when unloading a rack:

At least two people are needed to safely unload the rack from

•

the pallet. An empty 42U rack can weigh as much as 115 kg

(253 lb), can stand more than 2.1 m (7 ft) tall, and may become

unstable when being moved on its casters.

•

Never stand in front of the rack when it is rolling down the ramp

from the pallet. Always handle the rack from both sides.

Identifying the Contents of the Server Shipping Carton

Unpack the server shipping carton and locate the materials and documentation

necessary for installing the server. All the rack-mounting hardware necessary for

installing the server into the rack is included with the rack or the server.

The contents of the server shipping carton include:

•

Server

•

Printed setup documentation, Documentation CD, and software products

•

Power cord

•

Rack-mounting hardware

In addition to these supplied items, you may need:

•

Application software diskettes

Page 52

52 HP ProLiant DL380 Generation 3 Server User Guide

• Options to be installed

Item Description

1 Server rails

2 Left and right standard rack rail assemblies

3 Cable management arm

4 Rack template

Installing Hardware Options

Install any hardware options before initializing the server. For options installation

information, refer to the option documentation. For server-specific information,

refer to "Hardware Options Installation (on page 65)."

Installing the Server into the Rack

Follow the steps in this section if you are installing the server into a rack with

square holes. If you are installing the server into a rack with round holes, order

the appropriate rack installation option kit, and then refer to the installation

instructions that ship with the option kit for more information.

Page 53

Server Setup 53

NOTE: The steps in this section work with most third-party racks with

square holes. If they do not work with the rack you are using, order the

option kit for racks with round holes.

If you are installing the server into a telco rack, order the appropriate option kit at

the RackSolutions.com website (http://www.racksolutions.com/hp

). Follow the

server-specific instructions on the website to install the rack brackets. After

installing the brackets, follow the steps in this section.

WARNING: When installing a server in a telco rack, be

sure that the rack frame is adequately secured to the top and

bottom of the building structure.

1. Mark the rack.

CAUTION: Always plan the rack installation so that the

heaviest item is on the bottom of the rack. Install the heaviest item first,

and continue to populate the rack from the bottom to the top.

Page 54

54 HP ProLiant DL380 Generation 3 Server User Guide

NOTE: Rack components are removed for clarity.

2. Secure each server rail to the server.

3. Secure the left and right standard rack rails to the appropriate side of the

rack.

4. Extend the slides from the standard rack rails, and then slide the server rails

into the slides.

Page 55

Server Setup 55

WARNING: To reduce the risk of personal injury or

equipment damage, be sure that the rack is adequately stabilized

before sliding the server rails into the rack rails.

CAUTION: Be sure to keep the server parallel to the floor

when sliding the server rails into the rack rails. Tilting the server up or

down could result in damage to the rails.

5. Press the rail-release latches and slide the server into the rack.

Page 56

56 HP ProLiant DL380 Generation 3 Server User Guide

WARNING: To reduce the risk of personal injury, be

careful when pressing the server rail-release latches and sliding

the server into the rack. The sliding rails could pinch your fingers.

6. Secure the server to the rack.

Page 57

Server Setup 57

7. Secure the cable management arm bracket to the server.

NOTE: Cable management arm is removed for clarity.

8. Secure the cable management bracket to the rail.

9. Connect peripheral devices to the server.

Page 58

58 HP ProLiant DL380 Generation 3 Server User Guide

WARNING: To reduce the risk of electric shock, fire, or

damage to the equipment, do not plug telephone or

telecommunications connectors into RJ-45 connectors.

IMPORTANT: If the RILOE II board is installed in the server, be sure

that you attach the video cable to the video connector on the rear of the

RILOE II board. The standard video connector on the server rear panel

is not used when the RILOE II board is installed. For more information,

refer to the HP Remote Insight Lights-Out Edition II User Guide on the

Documentation CD.

Page 59

Server Setup 59

Item Description Connector Color

1 Hot-plug PCI-X expansion slot 3

(bus 6) 64-bit/100-MHz 3.3V

2 Hot-plug PCI-X expansion slot 2

(bus 6) 64-bit/100-MHz 3.3V

3 Non-hot-plug PCI-X expansion slot 1

(bus 3) 64-bit/133-MHz 3.3V

4 Serial connector Teal

5 iLO connector N/A

6 Mouse connector Green

7 Power cord connector N/A

8 Keyboard connector Purple

9 NIC 1 connector N/A

10 NIC 2 connector N/A

11 USB connectors Black

12 Video connector Blue

13 VHDCI SCSI connector (port 1) N/A

N/A

N/A

N/A

10. Connect the power cord to the back of the server.

11. If you chose not to install the cable management arm, install the power cord

anchor.

Page 60

60 HP ProLiant DL380 Generation 3 Server User Guide

a. Secure the power cord anchor to the server, and then insert the tie wrap

into the groove on the power cord anchor.

NOTE: Peripheral device cables are removed for clarity.

b. Place the power cord across the tie wrap at the following locations:

21.59 cm (8.5 inches) from the end of the redundant power supply cord

27.94 cm (11 inches) from the end of the primary power supply cord

Page 61

Server Setup 61

NOTE: If using the power cord anchor, be sure to leave enough slack

in the power cord so that the redundant power supply can be removed

without disconnecting the power cord from the primary power supply.

c. Secure the tie wrap around the power cord to prevent accidental

disengagement.

12. Secure cables to the cable management arm.

13. Connect the power cord to the AC power source.

Page 62

62 HP ProLiant DL380 Generation 3 Server User Guide

WARNING: To reduce the risk of electric shock or damage

to the equipment:

Do not disable the power cord grounding plug. The grounding

•

plug is an important safety feature.

•

Plug the power cord into a grounded (earthed) electric outlet

that is easily accessible at all times.

•

Unplug the power cord from the power supply to disconnect

power to the equipment.

•

Do not route the power cord where it can be walked on or

pinched by items placed against it. Pay particular attention to

the plug, electric outlet, and the point where the cord extends

from the server.

Powering Up and Configuring the Server

To power up the server, press the Power On/Standby button.

While the server boots, RBSU and the ORCA utility are automatically

configured to prepare the server for operating system installation. To configure

these utilities manually:

•

Press the F8 key when prompted during the array controller initialization to

configure the array controller using ORCA. The array controller defaults to

RAID 0 with one drive installed and RAID 1 with more than one drive

installed.

•

Press the F9 key when prompted during the boot process to change the server

settings, such as the settings for language and operating system, using RBSU.

The system is set up by default for the English language and a Microsoft

Windows 2000 installation.

For more information on the automatic configuration, refer to the HP ROM-

Based Setup Utility User Guide located on the Documentation CD.

Page 63

Server Setup 63

Installing the Operating System

To operate properly, the server must have a supported operating system. For the

latest information on supported operating systems, refer to the HP website

(ftp://ftp.compaq.com/pub/products/servers/os-support-matrix-310.pdf

Two methods are available to install an operating system on the server:

• • SmartStart assisted installation—Insert the SmartStart CD into the CD-ROM

drive and reboot the server.

Manual installation—Insert the operating system CD into the CD-ROM drive

and reboot the server. This process may require you to obtain additional

drivers from the HP website (http://www.hp.com/support

).

Follow the on-screen instructions to begin the installation process.

For information on using these installation paths, refer to the SmartStart

installation poster in the ProLiant Essentials Foundation Pack, included with the

server.

).

Registering the Server

Register the server at the HP website (http://register.hp.com).

Page 64

Page 65

65

Hardware Options Installation

In This Section

Introduction ............................................................................................................................65

Processor Option ....................................................................................................................65

Memory Options..................................................................................................................... 69

Hot-Plug SCSI Hard Drive Options .......................................................................................72

Hot-Plug Tape Drive Option ..................................................................................................75

Battery-Backed Write Cache Enabler Option.........................................................................77

Redundant Hot-Plug Fans....................................................................................................... 79

Redundant Hot-Plug AC Power Supply Option .....................................................................84

DC Power Supply Option....................................................................................................... 87

Expansion Board Options....................................................................................................... 91

Introduction

If more than one option is being installed, read the installation instructions for all

of the hardware options and identify similar steps to streamline the installation

process.

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the drives and the internal system components to

cool before touching them.

properly ground the server before beginning any installation procedure.

Improper grounding can cause electrostatic discharge.

Processor Option

The server supports single- and dual-processor operation. With two processors

installed, the server supports boot functions through the processor installed in

processor socket 1. However, if processor 1 fails, the system automatically boots

from processor 2 and provides a processor failure message.

CAUTION: To prevent damage to electric components,

Page 66

66 HP ProLiant DL380 Generation 3 Server User Guide

The server uses PPMs as DC-to-DC converters to provide the proper power to

each processor. Each PPM must be installed in the slot adjacent to its processor.

CAUTION: To prevent thermal instability and damage to the

server, do not separate the processor from the heatsink. The processor,

heatsink, and retaining clip make up a single assembly.

CAUTION: To prevent possible server malfunction and

damage to the equipment, do not mix processors of different types.

IMPORTANT: If upgrading processor speed, update the system ROM

before installing the processor.

IMPORTANT: Processor socket 1 and PPM slot 1 must be populated

at all times or the server will not function properly.

IMPORTANT: Always install a PPM when you install a processor. The

system fails to boot if the PPM is missing.

To install a processor:

1. Power down the server ("Powering Down the Server" on page 37).

2. Extend the server from the rack, if applicable ("Extending the Server from

the Rack" on page 38).

3. Remove the access panel ("Removing the Access Panel" on page 40).

4. Open the processor retaining bracket.

Page 67

Hardware Options Installation 67

5. Release the processor locking lever.

CAUTION: Failure to open the processor locking lever

completely prevents the processor from seating during installation,

leading to hardware damage.

6. Install the processor.

Page 68

68 HP ProLiant DL380 Generation 3 Server User Guide

CAUTION: To prevent possible server malfunction or damage

to the equipment, be sure to completely close the processor locking

lever.

IMPORTANT: Processor 2 is oriented 180 degrees from processor 1.

7. Close the processor retaining bracket.

8. Open the latches on the corresponding PPM slot.

Page 69

Hardware Options Installation 69

9. Install the PPM.

NOTE: The appearance of compatible PPMs may vary.

10. Install the access panel ("Installing the Access Panel" on page 40).

Memory Options

You can expand server memory by installing PC2100 Registered DDR SDRAM

DIMMs. The system supports up to six DIMMs.

NOTE: The Advanced Memory Protection option in RBSU provides

additional memory protection beyond Advanced ECC. By default, the

server is set to Advanced ECC Support. Refer to "ROM-Based Setup

Utility (on page 111)," on the Documentation CD, for more information.

The server supports two types of memory configurations:

• • Standard memory configuration for maximum performance

− 2.4-GHz and 2.8-GHz models—up to 6 GB active memory (six 1-GB

memory modules)

− 3.06-GHz or greater models—up to 12 GB of active memory (six 2-GB

memory modules)

Online spare memory configuration for maximum availability

Page 70

70 HP ProLiant DL380 Generation 3 Server User Guide

− 2.4-GHz and 2.8 GHz models— up to 4 GB active memory and 2 GB

online spare memory

− 3.06-GHz or greater models—up to 8 GB of active memory and 4 GB of

online spare memory

Refer to "DIMM Slots (on page 19)" for DIMM slot locations and bank

assignments.

Online Spare Memory Configuration

In the online spare configuration, the ROM automatically configures the last

populated bank as the spare memory. If only banks A and B are populated,

bank B is the spare bank. If banks A, B, and C are populated, bank C is the spare

bank. If DIMMs in a non-spare bank exceed the limit for the single-bit

correctable errors threshold as defined by the Pre-Failure Warranty, the system

copies the memory contents of the failing bank to the spare bank. The system

then deactivates the failing bank and automatically switches over to the spare

bank.

For online spare memory support, you must observe the following guidelines:

•

The ROM must be up to date.

•

DIMMs installed in a spare bank must be of equal or greater capacity than

the DIMMs installed in other banks.

For example, if bank A is populated with two 256-MB DIMMs and bank B is

populated with two 512-MB DIMMs, bank C must be populated with two

512-MB or greater DIMMs in order for online spare memory support to

function properly.

After installing DIMMs, use RBSU to configure the system for online spare

memory support ("Configuring Online Spare Memory" on page 118).

DIMM Installation Guidelines

You must observe the following guidelines when installing additional memory:

•

Always install memory in pairs of two identical DIMMs.

Page 71

Hardware Options Installation 71

•

Install only PC2100 Registered DDR SDRAM DIMMs, 2.5 volts, 72 bits

wide, and ECC.

•

Install DIMMs with the same speed.

•

Install DIMMs into both slots within a single bank. Install DIMMs in order.

•

Upgrade memory by installing DIMM pairs into banks in sequential bank

order, starting with bank B.

For online spare memory support, you must also observe additional guidelines

("Online Spare Memory Configuration" on page 70).

Installing DIMMs