Page 1

MSM415 RF Security Sensor

Quick Start Guide

Abstract

The MSM415 RF Security Sensor is a single-11n radio

security sensor that continuously scans the 2.4 and 5 GHz

bands to detect and counter-attack security threats for

802.11a/b/g/n wireless devices and APs. This document

describes how to install and initially configure the MSM415,

hereafter referred to as the sensor. The latest documentation

is available at www.hp.com/support/manuals.

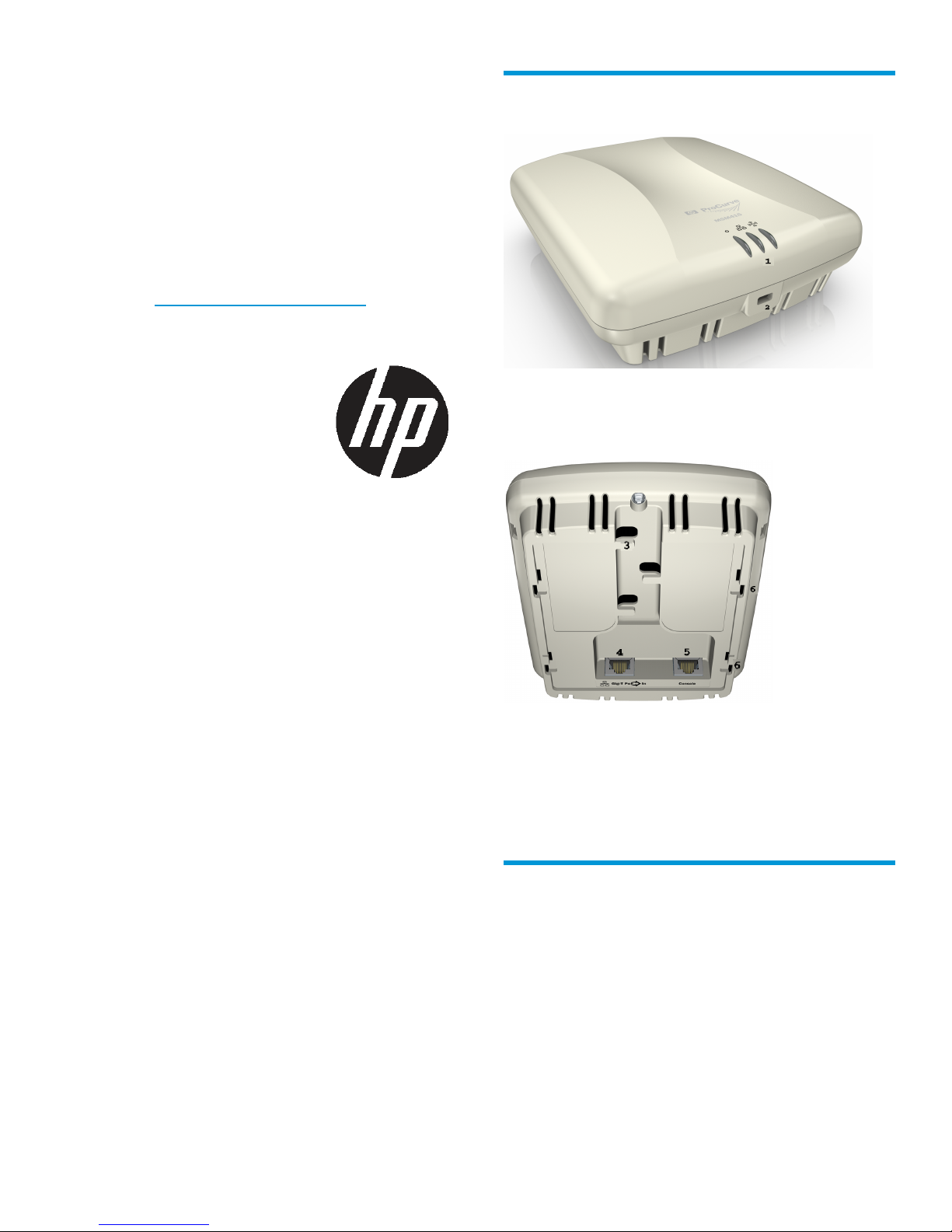

Hardware

1. Status LEDs

2. Lock tab

© Copyright 2015 Hewlett-Packard Development Company, L.P.

HP Part Number: 5998-7420

Published: February 2015

Edition: 1

*5998-7420*

3. Cable channel

4. Ethernet port (Port 1)

5. Console port

6. Mounting bracket tab slots

Package contents

MSM415, mounting bracket, two mounting screws

with wall anchors, and documentation.

Page 1

Page 2

Ports

Ethernet port (Port 1): Auto-sensing 10/100/1000

Base-T Ethernet port with RJ-45 connector. This port

supports Power over Ethernet (PoE) 802.3af.

Console port: Standard console (serial) port with an

RJ-45 connector.

Caution: Never connect the console port to an Ethernet

switch or PoE power source. This may damage the

sensor. Connect it only to other serial ports via an

RJ-45 to DB-9 adapter or equivalent.

Radios and Antennas

The sensor contains an integrated single 802.11n

Draft 2 compliant radio with an internal three-element,

dual-band MIMO antenna.

there is one wireless interface used for both 2.4 GHz

and 5 GHz, some states are overlapping.

DescriptionRadioEthernetPower

OnOnOn

OnOn

Flashing

quickly

The sensor is receiving power and

is working normally. The sensor is

also connected to the HP RF

Manager server.

• The sensor is performing

troubleshooting on

802.11b/g/n.

• The sensor is performing

troubleshooting on

802.11a/n.

• The sensor is performing

troubleshooting on 802.11a/n

and 802.11b/g/n.

• The sensor is performing

troubleshooting on 802.11a/n

and intrusion prevention on

802.11b/g/n.

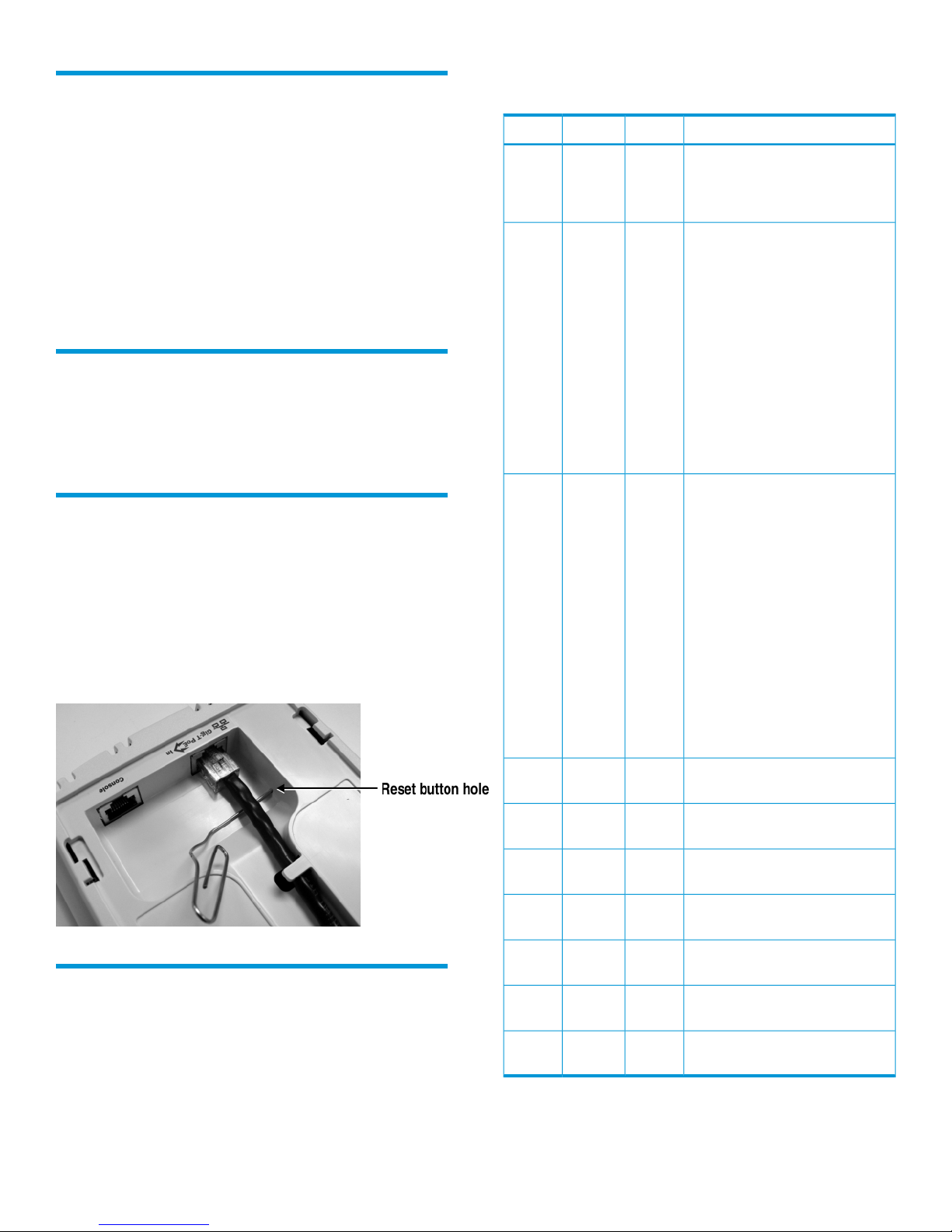

Reset button

The reset button is accessible via a hole on the bottom

of the sensor. To perform a reset, the unit must be

powered. Insert a paper clip under the cable and into

the reset button hole at the precise angle shown. Press

and quickly release the button to reset the sensor. To

reset the sensor to factory defaults, press the button

until the status LEDs flash three times, then release.

On

slowly

Flashing

quickly

Flashing

slowly

OnOn

Flashing

slowly

quickly

slowly

Flashing

slowly

slowly

—OnFlashing

—Flashing

—Flashing

• The sensor is performing

intrusion prevention on

802.11b/g/n.

• The sensor is performing

intrusion prevention on

802.11a/n.

• The sensor is performing

intrusion prevention on

802.11a/n and

troubleshooting on

802.11b/g/n.

• The sensor is performing

intrusion prevention on

802.11a/n and

802.11b/g/n.

The sensor upgrade is in progress.Flashing

The sensor is unable to get

Ethernet link.

The sensor did not receive a valid

IP address via the DHCP.

The sensor is unable to connect to

the RF Manager server.

Status LEDs

The following table indicates various MSM415 Sensor

states using the LEDs on the sensor device. Because

Page 2

slowly

slowly

On—Flashing

——Flashing

OffOffOff

There is an error on wireless

interface of the sensor.

The sensor is experiencing a

software error.

The sensor is not powered on or

it is in the process of starting up.

Page 3

Installing the sensor

Powering the sensor

Caution: Professional installation required. Prior to

installing or using the sensor, consult with a

professional installer trained in RF installation and

knowledgeable in local regulations including building

and wiring codes, safety, channel, power,

indoor/outdoor restrictions, and license requirements

for the intended country. It is the responsibility of the

end user to ensure that installation and use comply

with local safety and radio regulations.

Important: To prevent abuse and intrusion by

unauthorized personnel, it is extremely important to

install sensors such that it is difficult to unplug the

devices from the network or from the power outlet.

Cabling: You must use the appropriate cables, and

where applicable for your region, surge protection.

For compliance with EN55022 Class-B emissions

requirements use shielded Ethernet cables. Cables with

large boots may not insert into the RJ-45 connectors

properly. HP recommends that you do not use such

cables.

Plenum installation: The MSM415 and appropriate

cabling can be installed in a plenum (UL2043 rating).

The sensor should be installed with its top surface

facing the floor (similar orientation as in a ceiling

installation). However, it is left to a qualified installer

to determine how to install/secure the sensor in a

plenum in an appropriate and safe manner.

Plenum-rated cables and attachment hardware must

be used.

Safety: Take note of the following safety information

during installation.

The sensor can be powered by:

• A 10/100 or 10/100/1000 PoE-enabled switch.

Various PoE-enabled switches are available from

HP.

• An HP PoE 1-Port Power Injector (J9407A).

If the sensor will be powered by a user-supplied PoE

power injector, use only a gigabit-compatible power

injector. PoE injectors designed for 10/100 networks

only are not compatible with the sensor.

Mounting the bracket

The sensor can be mounted on a wall or a suspended

ceiling. In either case, the first step is to mount the

bracket, and the second step is to attach the sensor to

the bracket.

Mounting on a wall-mounted electrical box

1. Disconnect power and take any other needed

security precautions.

2. Remove the electrical box cover and any contents.

3. Pull the Ethernet cable down into the box, and

then through the hole in the bracket.

4. Hold the bracket against the box respecting the

UP indicator, and attach the bracket to the box

using appropriate countersunk screws.

• If your network covers an area served by more

than one power distribution system, be sure all

safety grounds are securely interconnected.

• Network cables may occasionally be subject to

hazardous transient voltages (caused by lightning

or disturbances in the electrical power grid).

• Handle exposed metal components of the network

with caution.

• The sensor is powered-on when connected to a

PoE power source.

• The sensor and all interconnected equipment must

be installed indoors within the same building

(except for outdoor models/antennas), including

all PoE-powered network connections as described

by Environment A of the IEEE 802.3af standard.

Mounting directly on a wall

1. Respecting the UP indicator on the bracket, hold

the bracket against the wall at the desired

position. Mark two holes for the screws (wall

anchors) and one hole in the cutout area of the

bracket for the Ethernet cable.

2. Drill two holes for the wall anchors, typically 4.7

mm (3/16 inch) in diameter.

Page 3

Page 4

3. Drill a hole for the Ethernet cable. Alternatively,

you can feed the Ethernet cable from above and

through the sensor cable channel.

4. Insert the anchors and tap them flush with the wall

surface.

5. Pull the Ethernet cable through the hole in the wall

and the hole in the bracket.

6. Screw the bracket to the wall.

Mounting on a suspended ceiling

The sensor can be mounted on a suspended ceiling

with user-supplied T-bar clips or the equivalent. Use a

clip stud size of 3.5 mm (#8-32) with a maximum

length of 11mm (7/16 inch).

Connect the sensor to the network

This procedure assumes that RF Manager is already

running on your network. Add the DNS entry

wifi-security-server on all DNS servers. This

entry should point to the IP address of the server.

To connect the sensor to the network:

1. Ensure that DHCP is running on the subnet to

which the sensor will be connected.

2. Connect one end of the Network Interface cable

to the Ethernet port (port 1) on the sensor.

3. Connect the other end of the Network Interface

cable to an Ethernet jack that is connected to the

desired subnet.

Important: If DHCP is not enabled on a subnet,

sensors cannot connect to that subnet with zero

configuration.

4. Wait two minutes.

5. Observe the status LEDs on the sensor. If all LEDs

glow green, the sensor is operational and

connected to the server.

6. Log on to the HP RF Manager server through SSH.

Run the get sensor list command.

1. Attach two T-bar clips (not supplied) to the bracket

as illustrated. The clips must be attached to the

smooth outer side of the bracket.

2. Attach the bracket to the suspended ceiling T-bar

at the desired mounting position.

3. When the bracket is firmly attached to the T-bar,

cut a hole in the ceiling through the bracket

opening for the Ethernet cable.

4. Pull the Ethernet cable through the hole in the

bracket.

Attach the sensor to the bracket

1. Connect the Ethernet cable to the sensor Ethernet

port. Push excess cable back into the hole.

2. Position the sensor against the bracket so that the

bracket tabs fit into the tab slots on the back of

the sensor. Push the sensor against the bracket

and then pull down firmly so that it snaps onto

the bracket.

3. Verify that the sensor is firmly anchored before

letting go of it.

4. Optionally, secure the sensor to an immovable

object with a Kensington-type cable lock using

the hole below the status LEDs.

You will see a list of all sensors that are

recognized by the server.

Important: The sensor is configured and ready to go.

Check the console to ensure that this sensor has been

detected.

Specifications

Dimensions

power rating

Temperature

humidity

Maximum

altitude

Connectors

H: 4.93 cm (1.94 inch), W: 13.18 cm (5.19

inch), D: 15.65 cm (6.16 inch)

0.33 kg (0.72 lb)Weight

PoE 802.3afDC input

8WMaximum

Operating: 0°C to 50°C (32°F to 122°F)

Non-operating: -40°C to 70°C (-40°F to 158°F)

Operating: 5% to 95% (non-condensing)Relative

Operating: 3048 m (10,000 ft)

nl

Non-operating: 4572 m (15,000 ft)

One 10/100/1000 Mbps RJ-45 autosensing

port

Page 4

Page 5

Safety

model number

Complies with EN60950-1/IEC 60950-1, CSA

22.2 No. 60950-1, UL 2043, and UL 60950-1

standards.

MRLBB-0802Regulatory

Related information

For more information, see HP RF Manager Installation

and Getting Started Guide, HP RF Manager for

VMware Installation Guide, and HP RF Manager and

Sensors Management and Configuration Guide

available at www.hp.com/support/manuals.

Other regulatory information

For important safety, environmental, and regulatory

information, see Safety and Compliance Information

for Server, Storage, Power, Networking, and Rack

Products, available at http://www.hp.com/support/

Safety-Compliance-EnterpriseProducts.

Belarus Kazakhstan Russia marking

Manufacturer and Local Representative Information

Manufacturer’s information:

• Hewlett-Packard Company, 3000 Hanover Street,

Palo Alto, California 94304, U.S.

Local Representative information Russian:

• HP Belarus: ИООО «Хьюлетт-Паккард Бел»,

220030, Беларусь, г. Минск, ул.

Интернациональная, 36-1, офис 722-723, тел.:

+375 (17) 392 28 18, факс: +375 (17) 392 28

21

• HP Kazakhstan: ТОО «Хьюлетт-Паккард (К),

050040, Казахстан, г. Алматы, Бостандыкский

район, ул. Тимирязева, 28В, 1 этаж, тел./факс:

+7 (727) 355 35 50, +7 (727) 355 35 51

• HP Russia: ЗАО “Хьюлетт-Паккард А.О.”,

125171, Россия, г. Москва, Ленинградское

шоссе, 16А, стр.3, тел/факс: +7 (495) 797 35

00, +7 (495) 287 89 05

Local Representative information Kazakh:

• HP Kazakhstan: ЖШС «Хьюлетт-Паккард (К)»,

Қазақстан, Алматы қ., Бостандық ауданы,

Тимирязев к-сі, 28В, тел./факс: +7 (727) 355

35 50, +7 (727) 355 35 51

Manufacturing Date – The manufacturing date is

included in the product serial number, CCYMPPPZZZ

(HP serial number format for this product). The

manufacturing date is indicated by YM in the serial

number, where Y indicates the year counting from

within each new decade, with 2010 as the starting

point, and M is the month when the unit was

manufactured. For example, 3A would indicate 3 for

2013 and A for the month of November. Following

this convention, 2010 is indicated by 0, 2011 by 1,

2012 by 2, 2013 by 3, and so forth. Months start at

1 for January, 2 for February, up to 9 for September.

0 (zero) is used for October, A for November, and B

for December.

Дата изготовления – Дата изготовления включена в

серийный номер изделия, CCYMPPPZZZ (формат

серийного номера HP для данного изделия). Дата

изготовления указана как YM в серийном номере,

где Y соответствует году с началом отсчета в каждом

новом десятилетии, начиная с 2010, а M

соответствует месяцу изготовления устройства.

Например, в обозначении 3A цифра 3 соответствует

2013 году, а A обозначает ноябрь. В соответствии

с данным принятым обозначением, 2010 год

указывается как 0, 2011 – как 1, 2012 – как 2,

2013 – как 3 и т. д. Месяцы обозначаются как 1

(январь), 2 (февраль) и т. д. до 9 (сентябрь). 0 (ноль)

обозначает октябрь, A обозначает ноябрь, а B

обозначает декабрь.

Жасалған күні – Жасалған күні CCYMPPPZZZ (осы

өнімге арналған HP сериялық нөмірінің пішімі)

пішіміндегі өнімнің сериялық нөмірінде қамтылады.

Жасалған күні сериялық нөмірдегі YM əріптерімен

көрсетіледі. Y əрпі 2010 жылдан басталатын жəне

əр он жылдан бастап есептелетін жылды көрсетеді

жəне M əрпі құрылғының жасалған айын білдіреді.

Мысалы, 3A таңбалары келісіні білдіреді: 3 – 2013

жылды жəне A қараша айын көрсетеді. Бұл əдіс

бойынша, 2010 жыл 0 санымен, 2011 жыл 1

санымен, 2012 жыл 2 санымен, 2013 жыл 3

санымен жəне т.т. көрсетіледі. Айларды 1 мен 9

аралығындағы сандар көрсетеді:1 саны қаңтар айы

үшін, 2 саны ақпан айы үшін жəне 9 саны қыркүйек

айы үшін. 0 (нөл) саны қазан айы үшін, A əрпі

қараша айы үшін жəне B əрпі желтоқсан айы үшін

қолданылады.

Page 5

Page 6

Documentation feedback

Send any errors, suggestions, or comments to

Documentation Feedback (docsfeedback@hp.com).

Page 6

Loading...

Loading...