Page 1

Cooling strategies for IT equipment

Technology brief

Introduction ......................................................................................................................................... 2

Limits of traditional cooling practices ...................................................................................................... 2

Free cooling strategies.......................................................................................................................... 4

Air-side economization ..................................................................................................................... 5

Water-side economization ................................................................................................................ 6

Benefits and disadvantages of free air cooling .................................................................................... 6

Air containment strategies ..................................................................................................................... 6

Cold-aisle containment ...................................................................................................................... 7

Hot-aisle containment ....................................................................................................................... 8

Closed-loop cooling systems .................................................................................................................. 9

HP Modular Cooling System .............................................................................................................. 9

HP Performance-Optimized Datacenter ............................................................................................. 11

Choosing the best cooling strategy ...................................................................................................... 12

Cooling decisions based on facility characteristics ............................................................................. 12

Cooling decisions based on room layout .......................................................................................... 13

Cooling decisions based on server density/power per rack ................................................................ 13

Managing data center cooling ............................................................................................................ 14

Managing ITE cooling with HP Systems Insight Manager .................................................................... 14

Managing the data center environment with HP Environmental Edge .................................................... 15

Conclusion ........................................................................................................................................ 15

For more information .......................................................................................................................... 16

Call to action .................................................................................................................................... 16

Page 2

ITE racks

Introduction

If you’re deploying the latest generation of information technology (IT) equipment or adding more

servers to a crowded data center, conventional data center cooling methods and systems will likely be

inadequate. The most effective cooling solution for any computing facility depends on the specific

characteristics of the facility, equipment layout, and server density.

This technology brief first explains limitations of traditional cooling practices. Then it describes a

range of systems you can choose from to modify or supplement your existing cooling system to get the

cooling capacity your data center requires.

Limits of traditional cooling practices

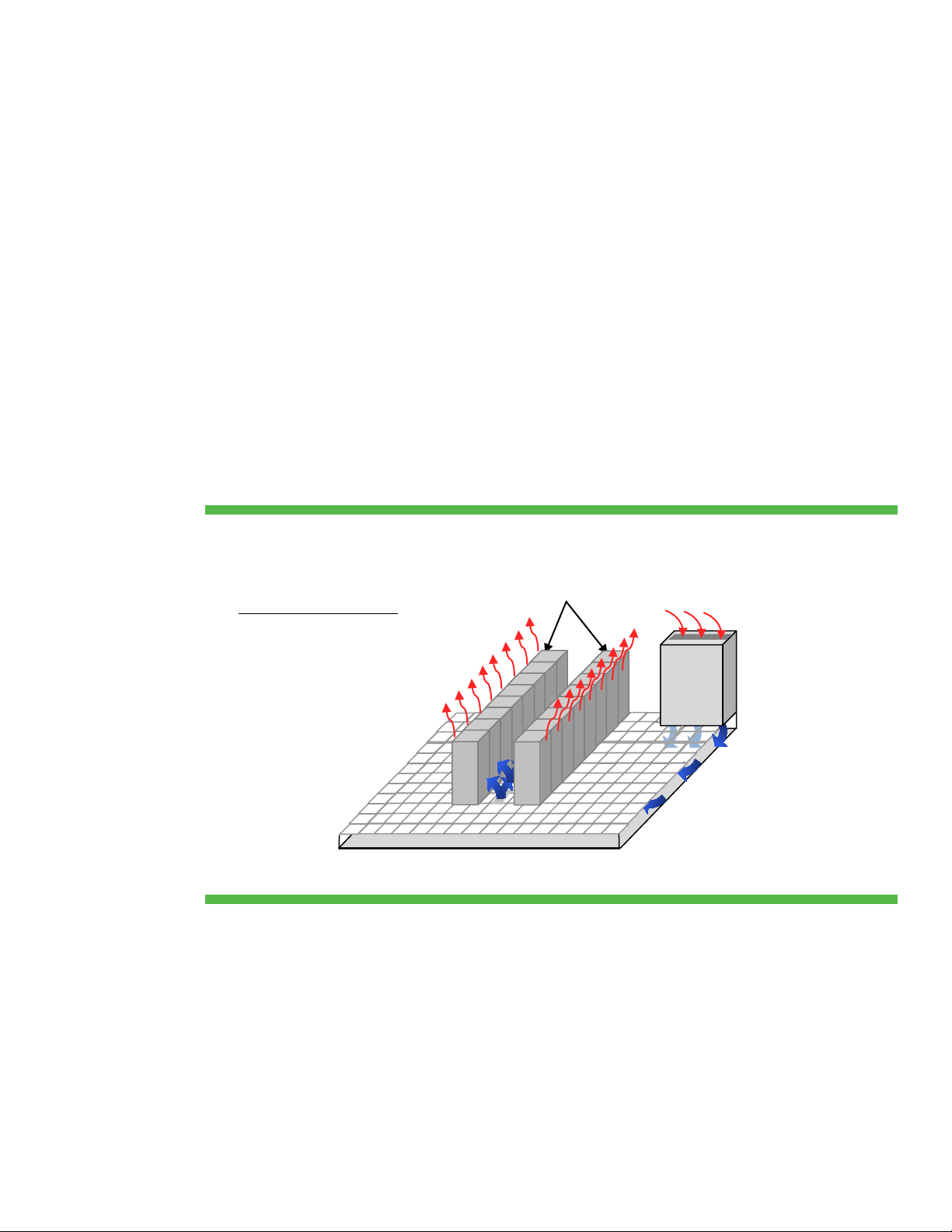

Enterprise data centers have most often used an open-area approach to cool racks of servers and

storage systems. With this approach, one or more computer room air handlers (CRAHs) are placed

on the periphery of the data center room. IT equipment (ITE) racks are arranged in a cold-aisle/hotaisle layout (Figure 1). Cool air is forced through a raised floor plenum and up through vented floor

tiles in the cold aisle toward the front of the ITE racks. The cool air is drawn through the ITE racks, and

warm air is vented out the rear of the racks and upward toward the ceiling. Air circulation works on

the basic strategy of providing cool air at the floor level and collecting warm air near the ceiling.

Figure 1: Traditional open-area data center cooling

Basic room requirement:

Raised floor

CRAH

The open-area strategy is generally adequate for racks using up to 10 kilowatts of power and lets

data centers scale relatively easily. However, some of the warm air mixes with the cool air, reducing

cooling system efficiency. Some equipment generates excessive heat, creating hot spots that need

supplemental cooling or specific air channeling. The typical remedy has been to set the cooling

system to run colder to compensate for the hot spot.

2

Page 3

(20 servers @ 423.9 W per server)

8.47 kW

20 servers

10 servers

4.23 kW

16.1 kW

8.0 kW

42 servers

21 servers

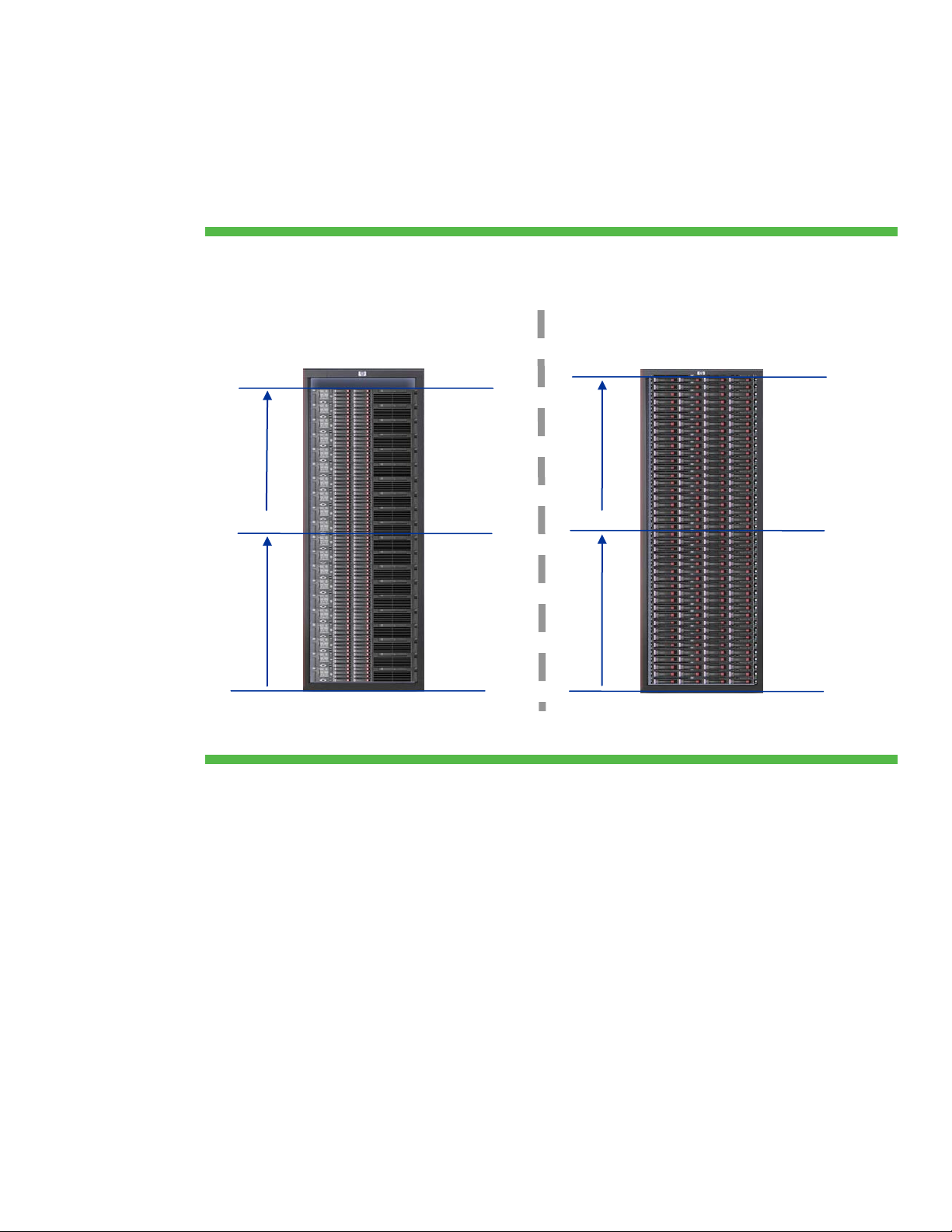

Server blade systems and 1U servers let you assemble high-density infrastructures; however, these

systems create much more heat per square foot of floor space and more hot spots. In instances like

this, the open-area approach cannot keep up with the demand for cool air.

Figure 2 compares two examples of server loading for a 42U rack. In Figure 2A, our rack contains

20 HP ProLiant DL380 G5 servers, each consuming approximately 424 watts for a total rack

consumption of 8.47 kW. In Figure 2B, our rack contains 42 dual-processor DL160 G6 servers

consuming 383 watts per server for a total rack consumption of over 16 kW of power.

Figure 2: Examples of power consumption in 42U IT equipment racks with different server loads

A: ProLiant DL380 G5 2U servers

Power

consumption

B: ProLiant DL160 G6 1U servers

(42 servers @ 383 W per server)

Power

consumption

Higher power consumption produces more heat. Virtually all power consumed by rack-mounted

equipment is converted to sensible heat, which increases the temperature in the environment. The

sensible heat load is typically expressed in British Thermal Units per hour (BTU/hr) or watts, where

1 W equals 3.413 BTU/hr. The rack’s heat load in BTU/hr can be calculated as follows:

Heat Load = Power [W] × 3.413 BTU/hr per watt

For example, the heat load for a ProLiant DL160 G6 server in a 2P configuration consuming

383 watts is calculated as follows:

383 W × 3.413 BTU/hr/W =1307 BTU/hr

This means that the heat load of our fully-loaded 42U rack of DL160 G6 servers is 54,901 BTU/hr. In

the United States, cooling capacity is often expressed in "tons" of refrigeration, which is derived by

dividing the sensible heat load by 12,000 BTU/hr per ton. Therefore, the cooling requirement for our

rack of DL160 G6 servers is computed as follows:

54,901 BTU/hr ÷ 12,000 BTU/hr per ton = 4.58 tons

3

Page 4

Cold/hot

24

32

Closed-loop

Supplemented

25

50

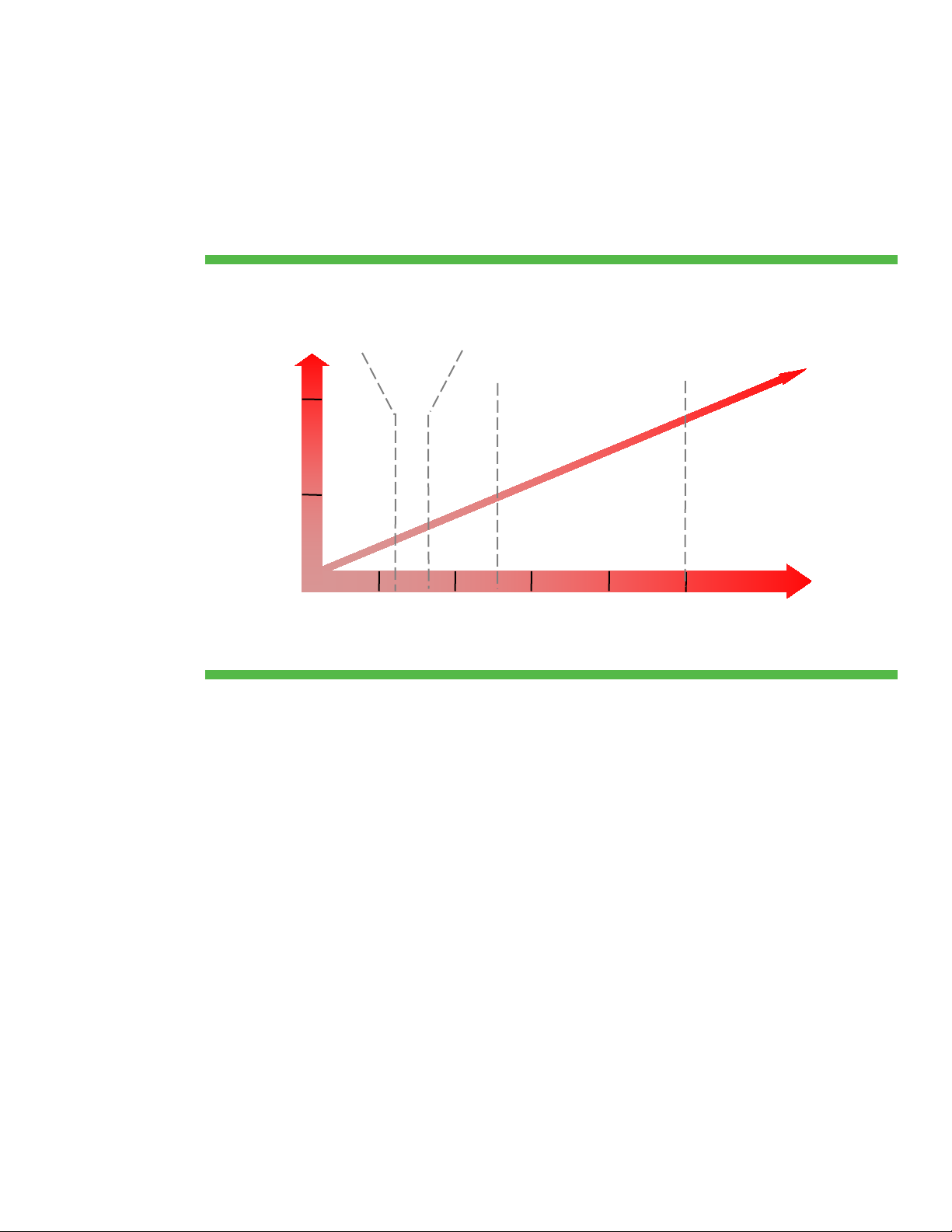

The increasing heat loads created by the latest server systems require more aggressive cooling

strategies than the traditional open-area approach. Such strategies include the following:

• Free cooling

• Air containment

• Closed-loop cooling

Figure 3 identifies cooling strategies and implementations based on kilowatts per rack and on the

server density per rack.

Figure 3: Cooling strategies based on server density/power per rack

data center

cooling

Traditional

open-area

cooling

aisle

containment

cooling

Chassis/component

level cooling,

future cooling

technologies

Density (nodes per rack)

8

16

40

Power (kW per rack)

Free cooling strategies

Free cooling strategies use ambient outside temperature to remove heat from inside a data center.

You can implement free cooling as either a primary or secondary system. Free cooling systems take

advantage of regional climate conditions for more efficient operation, but they do include mechanical

and electrical equipment. Free cooling is generally applied using one of two methods: air-side

economization or water-side economization.

4

Page 5

ITE racks

Air-side economization

Air-side economization uses a system of supply and return fans, filters, and dampers that maintain

positive air pressure with respect to the IT equipment exhaust, and positive data center air pressure

with respect to the outside. Air-side economization may also include supplemental cooling coils that

you can switch in and out of circuit as needed for changes in climate. You can implement air-side

economization as either a direct or indirect system. In direct air-side economization, outside air is

filtered, stabilized for relative humidity, and then delivered to the ITE racks (Figure 4). The ITE rack

layout and exhaust venting is similar to a hot-aisle containment strategy.

Figure 4: Air-side economization (direct method)

Exhaust

Input

Filters/fans

Filter/fan

Exhaust

air to

outside

Air from

outside

Room requirements:

Air circulation system built into facility

Air-side economization using the direct method is more applicable in cool regions where outside air

requires little or no refrigeration.

With indirect air-side economization, outside air cools data center air through an air-to-air heat

exchanger. This method uses two air circulation circuits: one for outside air and one for inside air.

Outside air is collected, cooled, and then used to cool re-circulated indoor air in a heat exchanger

that is common to both air circulation circuits. The two air circuits share the heat exchanger, but

indoor and outside air flows are segregated. Even though it requires two fan systems, indirect air-side

economization can be more energy efficient and may be the preferred method for warmer climates.

5

Page 6

Water-side economization

Water-side economization uses a cooling tower as either the primary or supplementary means of

cooling the chilled water supply for an air conditioning system. In a typical data center application

(Figure 5), a cooling tower cools water in the condenser circuit, which in turn cools the chilled water

in a common heat exchanger. The purpose of the external heat exchanger is to take the load off the

CRAH, which can consume significant energy if the cooling load is high.

Figure 5: Water-side free cooling

ITE racks

(cooling load)

Chiller

pump

CRAH

Cooling tower

Heat

exchanger

Condenser

pump

Figure 5 shows water-side free cooling for a data center using cold-aisle containment. Water-side free

cooling can also be used to supplement other cooling configurations.

Benefits and disadvantages of free air cooling

By using outside air to avoid or limit CRAH use, free-air cooling can significantly reduce a data

center’s energy requirements. However, free-air cooling systems require full integration with the facility

system and must be carefully designed and adjusted to the data center’s regional location.

Air containment strategies

Air containment strategies separate cold supply air from warm return air to maximize air handler

efficiency. Selecting an air containment strategy generally depends on whether there is a raised floor

or dropped ceiling, and/or the ability to meet fire codes. You can use one of two containment

strategies:

• Cold-aisle containment

• Hot-aisle containment

6

Page 7

ITE racks

Cold-aisle containment

In a cold-aisle containment system, two ITE rows face front-to-front, with the cold air coming up

through vented floor tiles of the common aisle. Cold air is isolated from the rest of the room air with

curtains and/or Plexiglas panels (Figure 6). This ensures that only cold air is drawn into the ITE racks.

The warm exhaust air exits the rear of the racks and is collected conventionally by the CRAHs.

Figure 6: Cold-aisle containment strategy

Basic room requirement:

Raised floor

CRAH

Cold-aisle containment is generally the easiest strategy to implement in a data center. There are no

restrictions for cable trays above the racks, and IT systems are easily scalable. But because much of

the data center room is at the hot air stream temperature, cold air meant to cool personnel in the

room will mix with the warm air from the ITE racks, resulting in cooler air returned to the CRAH. Low

return-air temperature can reduce cooling system efficiency, causing it to use shorter compressor

cycles and/or re-adjust the chilled-water flow more often.

If you retro-fit an existing data center with an air containment strategy, you must adhere to fire codes.

Fire suppression systems must have access to the face of the ITE racks.

7

Page 8

ITE racks

Air duct

Hot-aisle containment

In a hot-aisle containment system, two ITE rows are positioned back-to-back. As illustrated in Figure 7,

the warm air exhausts into a common aisle area that is isolated from the rest of the room by doors

and vertical ducts. The warm exhaust air is directed up to a dropped ceiling plenum and back to the

CRAH.

Figure 7: Hot-aisle containment with dedicated ductwork

Basic room requirement:

Dropped ceiling

CRAH

A variation of hot-aisle containment uses a

vertical air duct that vents exhaust air from

the rear area of an ITE rack to a dropped

ceiling air plenum. The HP 10K-G2 Series

42U Rack Air Duct Kit (Figure 8) can be

the answer for an individual rack or in

environments where full hot-aisle

containment is not practical from a

maintenance perspective.

Hot-aisle containment eliminates the

mixing of hot and cold air, thus ensuring

that only exhaust air returns to the CRAH.

This allows the air conditioning system to

operate more efficiently than cold-aisle

containment systems.

The disadvantage of hot-aisle containment, particularly in facilities without

raised flooring, is the lack of cold air

pressurization that helps direct air to the

front of the IT racks.

Figure 8: Hot-aisle containment with the HP 10K-G2 Series

42U Rack Air Duct Kit

Rack with

rear

extension kit

installed

Ceiling

Grid

Floor

Grid

8

Page 9

Closed-loop cooling systems

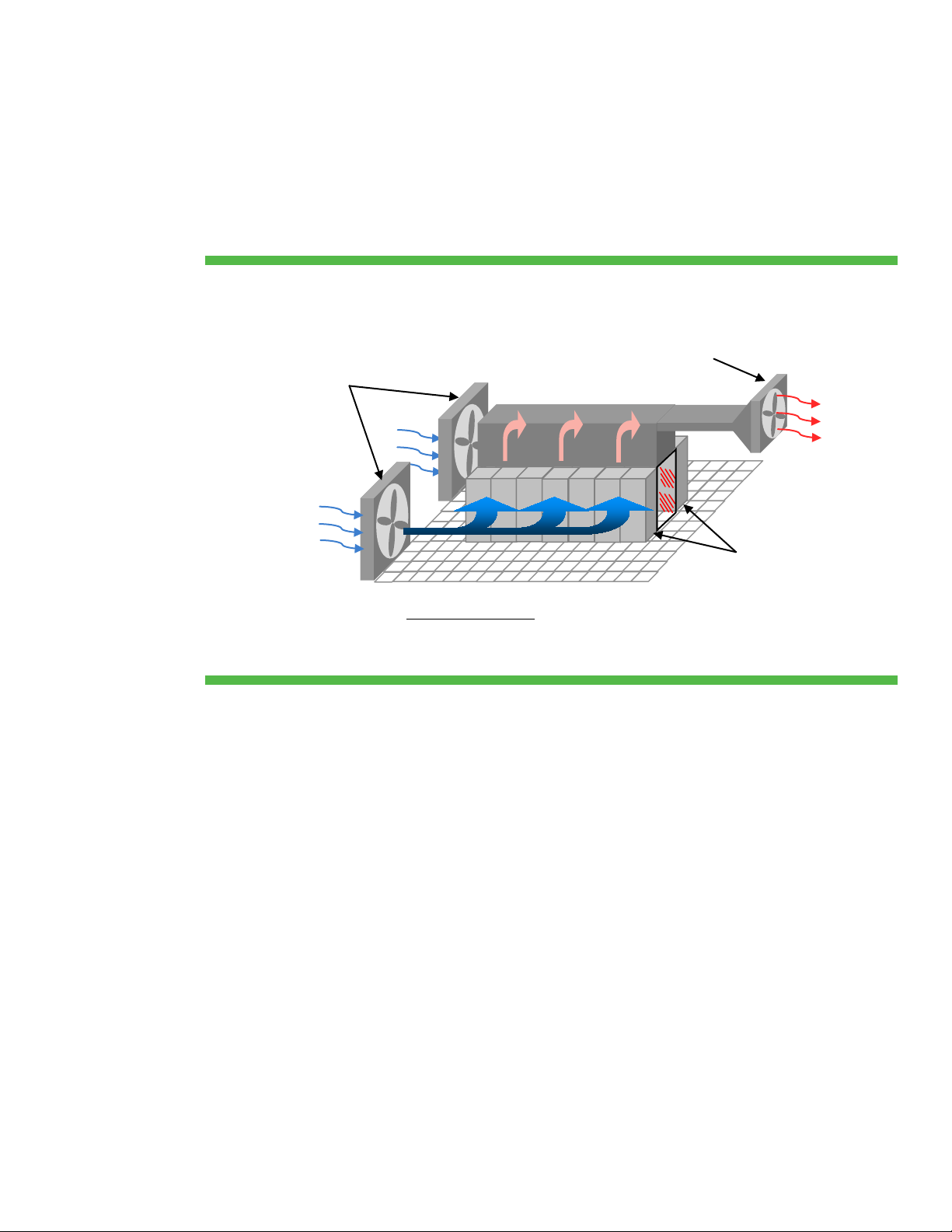

Closed-loop systems are designed specifically for cooling IT equipment. They are the best solution for

high-density systems consuming many kilowatts of power. These systems have separate cool air

distribution and warm air return paths that are isolated from the open room air. Closed-loop systems

typically use heat exchangers that use chilled water for removing heat created by IT equipment

(Figure 9).

Figure 9: Closed-loop cooling system

Basic requirement:

Chilled water supply

Heat

exchanger

Chilled

water

cooling

system

Heat

exchanger

Since they are self-contained, closed-loop cooling systems offer flexibility and are adaptable to a wide

range of locations and environments. Closed-loop cooling systems can also accommodate a wide

range of server and power densities.

We offer two closed-loop cooling systems:

• HP Modular Cooling System

• HP Performance-Optimized Datacenter

HP Modular Cooling System

The HP Modular Cooling System (MCS) Generation 2 (G2) is a closed-loop system contained within a

modified HP 10000 Series G2 rack. Using a chilled water supply and integrating a heat exchanger,

the HP MCS G2 can cool IT equipment consuming up to 35 kW. The system is entirely self-contained.

9

Page 10

The HP MCS G2 supports the front-to-back cooling principle. It evenly distributes cold supply air at the

front of each rack so components receive adequate supply air regardless of their position or density.

Warm exhaust air collects in the rear of the rack. Fans direct it into the heat exchanger where it is

cooled and re-circulated to the front of the rack. Condensation flows through a discharge tube to a

tray integrated in the base assembly. The HP MCS G2 can be configured to cool 35 kW of

equipment in a single rack or two racks of 17.5 kW each (Figure 10).

Figure 10: HP MCS G2 system

Single Rack Configuration

The HP MCS G2 includes an Automatic Emergency Door Release Kit designed to open the front and

rear doors in case of a sudden temperature increase. The open doors let ambient air cool the

equipment.

Dual Rack Configuration

Flexible installation capabilities allow you to place the HP MCS G2 in locations not originally

intended for IT equipment or in older data centers not designed for high-density, high-kilowatt systems.

HP MCS chilled water requirements

There are three potential sources of chilled water for the HP MCS G2:

• Direct connection to the building’s chilled water system

• A dedicated chilled water system

• A water-to-water heat exchanger unit connected to a chilled water system or building water system

The HP MCS G2 connects directly to the facility’s chilled water supply. When it is necessary to isolate

the fluid supply/return loop from the main building water system, we recommend using a separate

water-to-water heat exchanger. The heat exchanger provides easier control and monitoring of water

quality. It also lets you maintain a higher water temperature to reduce condensation.

10

Page 11

HP MCS cooling requirements

The HP MCS G2 adds minimal heat to the room because most of the heat generated inside the

cabinet is removed through the chilled water loop. It exchanges a small amount of air with the room

during normal operation. Depending on the room temperature, rack power consumption, and system

configuration, up to 10 percent of the total internal heat load may pass into the room.

In anticipation of future heat loads, isolated-loop chilled water piping should be designed and

installed to support the following:

• Specific heat load increments of 17.5 or 35kW

• The specific number of HP Modular Cooling Systems per row or loop

• Other site build-out planning parameters

As cooling, rack space, and equipment density requirements increase, additional HP MCS G2

systems can be quick-coupled into the isolated chilled water system.

the links provided in the “For More Information” section at the end of this document.

For detailed information, refer to

HP Performance-Optimized Datacenter

The HP Performance-Optimized

Datacenter (POD) (Figure 11) is a

containerized data center with power,

cooling, and IT equipment preinstalled. It has a complete closed-loop

cooling system. HP PODs are

available as 20-foot or 40-foot

containers. The 20-foot HP POD

2000c can contain up to ten 50U

19-inch industry-standard racks for a

maximum power capacity of 290

kilowatts non-redundant or 145

kilowatts redundant.

Figure 11: HP POD 2000c

The 40-foot maximum-density HP POD

4000c can contain twenty-two 50U,

19-inch industry-standard racks for a

maximum power capacity of 600

kilowatts non-redundant or 380

kilowatts redundant.

With close-coupled temperature

control, you can use higher chilled

water supply temperatures to reduce

power consumption of the chilled

water supply.

11

Page 12

The HP POD supports HP or any third-party IT equipment that conforms to 19-inch industry-standard

mounting and front-to-back air flow. The only requirements at the location of installation are as

follows:

• Utility power:

2 x 480 V/3-phase delta, 400 A, 50-60 Hz

• Communications

• Chilled water:

Flow rate:

HP POD 2000c; 120 gpm

HP POD 4000c; 240 gpm

Maximum inlet temperature: 55º F – 75º F (12º C – 24º C)

HP PODs can be installed inside existing buildings or outdoors. They can be used to expand an

existing data center or can become the basis for a new data center.

Choosing the best cooling strategy

We do not recommend a specific cooling strategy as the best strategy for all data center

environments. The optimum cooling strategy depends on factors such as facility characteristics, room

mapping, power consumed per rack, and server density.

Cooling decisions based on facility characteristics

Table 1 shows a list of facility characteristics and probable cooling strategies.

Table 1. Cooling strategies based on facility characteristics

Facility characteristics Cooling strategy most easily adapted

No raised floor or

dropped ceiling

Raised floor only Cold aisle containment

Dropped ceiling only Hot aisle containment

Raised floor and

dropped ceiling

Free cooling or

closed-loop system

Depends on room layout of ITE racks/rows

12

Page 13

Cooling decisions based on room layout

If facility characteristics allow several cooling options, the rack layout can suggest which cooling

strategy should be used. Figure 12 compares two data center layouts, each with four rows of racks.

Figure 12A shows two pairs of rows with each pair facing each other to create two cold aisles and

three hot aisles. This layout lends itself to a cold-aisle cooling strategy since only two rows require

containment. Figure 12B shows a layout with only one pair of rows facing each other, resulting in

three cold aisles and two hot aisles. In this case, a hot-aisle containment strategy might be preferred

since only two rows require containment.

Figure 12: Cooling strategies based on room layout (top view)

A: Layout suggesting cold-aisle containment

Hot aisle Cold aisle

B: Layout suggesting hot-aisle containment

Cooling decisions based on server density/power per rack

Your room characteristics and data center layout can suggest a specific cooling strategy, but

equipment density and power consumption ultimately determine the best choice. We can make some

general assumptions:

• Traditional data center cooling is adequate for racks using up to 10 kW.

• Racks using 15 kW or more will likely require some form of containment strategy.

• Closed-loop cooling accommodates the widest range of server/power densities.

13

Page 14

Managing data center cooling

High-density data centers require close monitoring and management to achieve and maintain efficient

and economical cooling. We offer two solutions, HP Systems Insight Manager and HP Environmental

Edge, to manage and monitor cooling status. These tools can be used separately or together as a

comprehensive management solution.

Managing ITE cooling with HP Systems Insight Manager

HP Systems Insight Manager (SIM), a total management solution for data centers, lets you closely

monitor the thermal status of all racks by monitoring sensors within the racks and server chassis. The

resulting thermal status display (Figure 13) lets you identify possible cooling issues such as hot spots.

You can then take action such as adjusting the cooling system or, much more conveniently, using HP

SIM to control power consumption of servers in a specific location.

Figure 13: HP SIM screen showing the thermal status of IT racks

14

Page 15

Managing the data center environment with HP Environmental Edge

HP Environmental Edge technology helps you monitor two critical areas of the data center: power and

cooling. Using sensors with wireless radio modules and software running on an Environmental Edge

server, HP Environmental Edge measures, compiles, and analyzes data center power and cooling

data. By presenting a thermal map of the data center environment (Figure 14), HP Environmental

Edge technology lets you adjust for potential infrastructure issues to make the most of data center

capacity and reduce cooling costs.

Figure 14: HP Environmental Edge screen showing the thermal map of a data center

Conclusion

As data centers require more efficient cooling solutions, we at HP work diligently to provide solutions

to meet current and future needs. Since conditions vary from one data center to another, we provide a

full range of solutions that you can choose from to cool your computing environment efficiently.

15

Page 16

For more information

For additional information, refer to the resources listed below.

Resource description Web address

HP Rack and Rack Options

HP 10000 G2 Rack Air Duct Kit

HP Modular Cooling System

HP Performance Optimized Data Center

HP Systems Insight Software

HP Environmental Edge

http://h18004.www1.hp.com/products/servers/proliantstora

ge/racks/index.html

http://h18004.www1.hp.com/products/servers/proliantstora

ge/rack-options/rack-air-duct/index.html

http://h10010.www1.hp.com/wwpc/us/en/sm/WF05a/34

47589-3447589-3446285-3446371-3461917-

3657806.html

http://h18004.www1.hp.com/products/servers/solutions/dat

acentersolutions/pod/index.html?jumpid=reg_R1002_USEN

http://h18013.www1.hp.com/products/servers/management

/hpsim/index.html?jumpid=go/hpsim

http://h18004.www1.hp.com/products/servers/solutions/dat

acentersolutions/environmentaledge/index.html?jumpid=reg_R

1002_USEN

Call to action

Send comments about this paper to TechCom@HP.com

© Copyright 2010 Hewlett-Packard Development Company, L.P. The information contained herein is subject to

change without notice. The only warranties for HP products and services are set forth in the express warranty

statements accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

TC100904TB, September 2010

Loading...

Loading...