Page 1

HP Latex 1500 Printer

User guide

Page 2

© Copyright 2016, 2017 HP Development

Company, L.P.

Edition 4

Legal notices

The information contained herein is subject to

change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be construed as

constituting an additional warranty. HP shall not

be liable for technical or editorial errors or

omissions contained herein.

Safety notice

Read and follow the operating and safety

instructions before starting the printer.

Trademarks

Microsoft® and Windows® are U.S. registered

trademarks of Microsoft Corporation.

Page 3

Table of contents

1 Introduction ............................................................................................................................................................................................... 1

Welcome to your printer ......................................................................................................................................................... 1

Documentation ......................................................................................................................................................................... 1

Safety precautions ................................................................................................................................................................... 2

Main components ................................................................................................................................................................... 11

Printer software ..................................................................................................................................................................... 13

Turn on the printer for the rst time ................................................................................................................................... 14

Turn the printer on and o ................................................................................................................................................... 14

Move the printer ..................................................................................................................................................................... 15

Printer status beacon ............................................................................................................................................................ 16

2 HP Internal Print Server ......................................................................................................................................................................... 17

Start the Internal Print Server .............................................................................................................................................. 17

Change the language of the Internal Print Server ............................................................................................................ 18

Change the units of measurement in the Internal Print Server ..................................................................................... 18

Set the Internal Print Server preferences .......................................................................................................................... 18

Internal Print Server menus ................................................................................................................................................. 21

Printer status and alerts ....................................................................................................................................................... 22

Update the rmware and the Internal Print Server .......................................................................................................... 23

3 RIP distribution ........................................................................................................................................................................................ 25

4 Printing workows integration ............................................................................................................................................................. 26

Introduction to JDF ................................................................................................................................................................. 26

Working with JDF .................................................................................................................................................................... 26

5 Handle the substrate ............................................................................................................................................................................. 32

Supported substrate types ................................................................................................................................................... 32

Supported HP substrates ..................................................................................................................................................... 34

Substrate tips .......................................................................................................................................................................... 37

Substrate congurations ...................................................................................................................................................... 39

ENWW iii

Page 4

Prepare to print ...................................................................................................................................................................... 40

The substrate edge holders ................................................................................................................................................. 42

Load a roll onto the spindle .................................................................................................................................................. 44

Load a roll into the printer .................................................................................................................................................... 45

Double-sided printing ............................................................................................................................................................ 55

Print a double-sided job with dual-roll ............................................................................................................................... 60

View information about the loaded substrate .................................................................................................................. 61

Unload a roll ............................................................................................................................................................................ 61

Output platen light ................................................................................................................................................................. 62

Substrate presets ................................................................................................................................................................... 63

Export multiple presets ........................................................................................................................................................ 63

Use a new substrate .............................................................................................................................................................. 64

Optimize for tiling ................................................................................................................................................................... 65

Prepare the printer for a new substrate ............................................................................................................................. 68

Create a new substrate preset with the Add New Substrate wizard ............................................................................. 68

Edit a substrate preset .......................................................................................................................................................... 70

Remove a substrate preset .................................................................................................................................................. 77

Online substrate manager .................................................................................................................................................... 77

Set the carriage beam position ............................................................................................................................................ 80

6 Create and manage print jobs .............................................................................................................................................................. 82

Add a new print job ................................................................................................................................................................ 82

Rotate a print job .................................................................................................................................................................... 87

Manage the print queue ........................................................................................................................................................ 87

Delete a print job .................................................................................................................................................................... 88

Image composition ................................................................................................................................................................ 89

7 Handle the ink system ......................................................................................................................................................................... 102

Ink system components ..................................................................................................................................................... 102

How to work with ink system components ..................................................................................................................... 104

8 Printer calibration ................................................................................................................................................................................ 126

Align the printheads ............................................................................................................................................................ 126

Possible diculties with printhead alignment ................................................................................................................ 130

Color calibration ................................................................................................................................................................... 134

Color consistency between dierent HP Latex printers ................................................................................................ 136

Color emulation of other printer models ......................................................................................................................... 136

Color proles ........................................................................................................................................................................ 138

Substrate-advance compensation ................................................................................................................................... 138

Calibrations specic to one substrate preset .................................................................................................................. 141

iv ENWW

Page 5

Recommended calibrations after particular events ...................................................................................................... 142

9 HP Print Care ......................................................................................................................................................................................... 143

Print Care diagnostics ......................................................................................................................................................... 144

10 Accessories ......................................................................................................................................................................................... 146

Compatibility table .............................................................................................................................................................. 146

Dual roll printing .................................................................................................................................................................. 146

In-line slitters ....................................................................................................................................................................... 149

Substrate saver .................................................................................................................................................................... 151

HP Latex Double-sided Day and Night Kit ....................................................................................................................... 155

Roll-to-Free-Fall Kit ............................................................................................................................................................. 156

Ink collector .......................................................................................................................................................................... 161

11 Hardware maintenance .................................................................................................................................................................... 182

Safety precautions .............................................................................................................................................................. 182

Maintenance resources ....................................................................................................................................................... 182

Summary of repairs kits and maintenances ................................................................................................................... 186

How to perform maintenance operations ....................................................................................................................... 191

How to turn the printer o and on for maintenance operations ................................................................................. 194

Weekly maintenance ........................................................................................................................................................... 197

450 liter maintenance ......................................................................................................................................................... 228

900 liter maintenance ......................................................................................................................................................... 243

When required ...................................................................................................................................................................... 264

12 Troubleshoot substrate issues ........................................................................................................................................................ 314

Loading issues ...................................................................................................................................................................... 314

Printing issues ...................................................................................................................................................................... 316

Dual roll printing issues ...................................................................................................................................................... 323

Print length issues ............................................................................................................................................................... 326

Collector issues .................................................................................................................................................................... 327

Slitter poor cutting quality ................................................................................................................................................. 328

13 Troubleshoot print-quality issues ................................................................................................................................................... 330

General advice ...................................................................................................................................................................... 330

Image quality inspection plot ............................................................................................................................................. 332

Basic and advanced troubleshooting ............................................................................................................................... 335

Advanced print-quality troubleshooting .......................................................................................................................... 336

ENWW v

Page 6

14 Troubleshoot ink cartridge and printhead issues ......................................................................................................................... 352

Ink cartridges ........................................................................................................................................................................ 352

Printheads ............................................................................................................................................................................. 353

Printhead cleaning roll errors ............................................................................................................................................ 358

15 Troubleshoot other issues ............................................................................................................................................................... 359

The printer does not start .................................................................................................................................................. 359

The printer does not print .................................................................................................................................................. 359

The printer cannot be restarted from the Internal Print Server ................................................................................... 359

The printer seems slow ...................................................................................................................................................... 359

Request to reinitialize the carriage ................................................................................................................................... 360

The Internal Print Server cannot detect the printer ....................................................................................................... 360

Print Care spontaneously restarts .................................................................................................................................... 360

Color calibration fails ........................................................................................................................................................... 360

16 When you need help ......................................................................................................................................................................... 361

HP Proactive Support .......................................................................................................................................................... 361

HP Customer Care ............................................................................................................................................................... 362

Service information ............................................................................................................................................................. 362

17 Printer specications ......................................................................................................................................................................... 364

Functional specications .................................................................................................................................................... 364

Physical specications ........................................................................................................................................................ 365

Memory specications ........................................................................................................................................................ 366

Power specications ........................................................................................................................................................... 366

Air supply requirements (pneumatic spindle) ................................................................................................................. 366

Ecological specications ..................................................................................................................................................... 367

Environmental specications ............................................................................................................................................. 367

Ventilation and air conditioning ......................................................................................................................................... 367

Acoustic specications ........................................................................................................................................................ 368

Appendix A Printer messages ............................................................................................................................................................... 369

Glossary ..................................................................................................................................................................................................... 373

Index ........................................................................................................................................................................................................... 376

vi ENWW

Page 7

1 Introduction

Welcome to your printer

The HP Latex 1500 Printer allows you to print signs and graphics on a wide range of exible materials up to 3.20

m (126 in) wide, and uses water-based HP Latex Inks to provide high quality, durable output.

●

High quality output, with rich colors, 1200 dpi resolution, and 12 picoliter drop size

●

Print on a wide range of substrates—including PVC banners, self-adhesive vinyls, papers, wall coverings,

PET lms, and textiles

●

Durable prints with outdoor display permanence of up to three years unlaminated, and up to ve years

laminated

●

Accurate and consistent color reproduction with automatic color calibration (built-in spectrophotometer)

●

Indoor-quality prints up to 45 m²/h (480 ft²/h)

●

HP Print Care maintenance scheduler and proactive maintenance alerts

●

At-a-glance monitoring on a busy production oor with internal print server alerts and status beacon

signals

●

Optional Double-Sided Day Night Kit, for printing double-side backlit applications on PVC banner and paper

●

Optional Dual Roll Kit, to maximize productivity and unattended printing when SAV and other substrates up

to 63 in (1.6 m)

Documentation

The following documents can be downloaded from http://www.hp.com/go/latex1500/manuals/.

●

Site preparation guide

●

Site preparation checklist

●

Installation guide

●

Introductory information

●

User's guide

●

Legal information

●

Limited warranty

ENWW Welcome to your printer 1

Page 8

See the Solutions Web site for information about new substrates, at http://www.hp.com/go/latex1500/

solutions/. A new Web-based Media Solutions Locator (http://www.hp.com/go/mediasolutionslocator) has been

developed to collect available substrate congurations for latex printers.

The Quick Response (QR) code images found in some parts of this guide provide links to additional video

explanations of particular topics. For an example of such an image, see Dual roll printing on page 146.

Safety precautions

Before using your printer, read the following safety precautions and operating instructions to make sure you use

the equipment safely.

You are expected to have the appropriate technical training and experience necessary to be aware of hazards to

which you may be exposed in performing a task, and to take appropriate measures to minimize the risks to

yourself and to others.

Operations must be supervised at all times.

General safety guidelines

WARNING! The information provided by the printer status light is only for functional information purposes and

is not related to any safety provision or safety states. Warning labels on the printer must be always considered

when operating the printer and prevail against any of the status indicated by the printer status lights.

●

Turn o the printer, using the Branch Circuit Breakers located in the building’s Power Distribution Unit

(PDU), and call your service representative (see HP Customer Care Centers on page 362) in any of the

following cases:

–

The power cord is damaged.

–

The drying or curing enclosures are damaged.

–

The printer has been damaged by an impact.

–

Liquid has entered the printer.

–

There is smoke or an unusual smell coming from the printer.

–

The printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter) has been

repeatedly tripped.

–

Fuses have blown.

–

The printer is not operating normally.

–

There is any mechanical or enclosure damage.

●

Turn o the printer using the Branch Circuit Breakers in either of the following cases:

–

During a thunderstorm

–

During a power failure

●

Take special care with zones marked with warning labels.

2 Chapter 1 Introduction ENWW

Page 9

Electrical shock hazard

WARNING! The internal circuits and drying and curing modules operate at hazardous voltages capable of

causing death or serious personal injury.

Turn o the printer using the Branch Circuit Breakers located in the building's Power Distribution Unit (PDU)

before servicing the printer. The printer must be connected to earth at mains outlets only.

To avoid the risk of electric shock:

●

Do not attempt to dismantle the drying and curing modules or e-cabinet during hardware maintenance

tasks. In that case, follow the instructions strictly.

●

Do not remove or open any other closed system covers or plugs.

●

Do not insert objects through slots in the printer.

●

Test the functionality of the Residual Circuit Breaker (RCCB) every year (refer to the procedure below).

NOTE: A blown fuse may indicate malfunctioning electrical circuits within the system. Call your service

representative (see HP Customer Care Centers on page 362), and do not attempt to replace the fuse yourself.

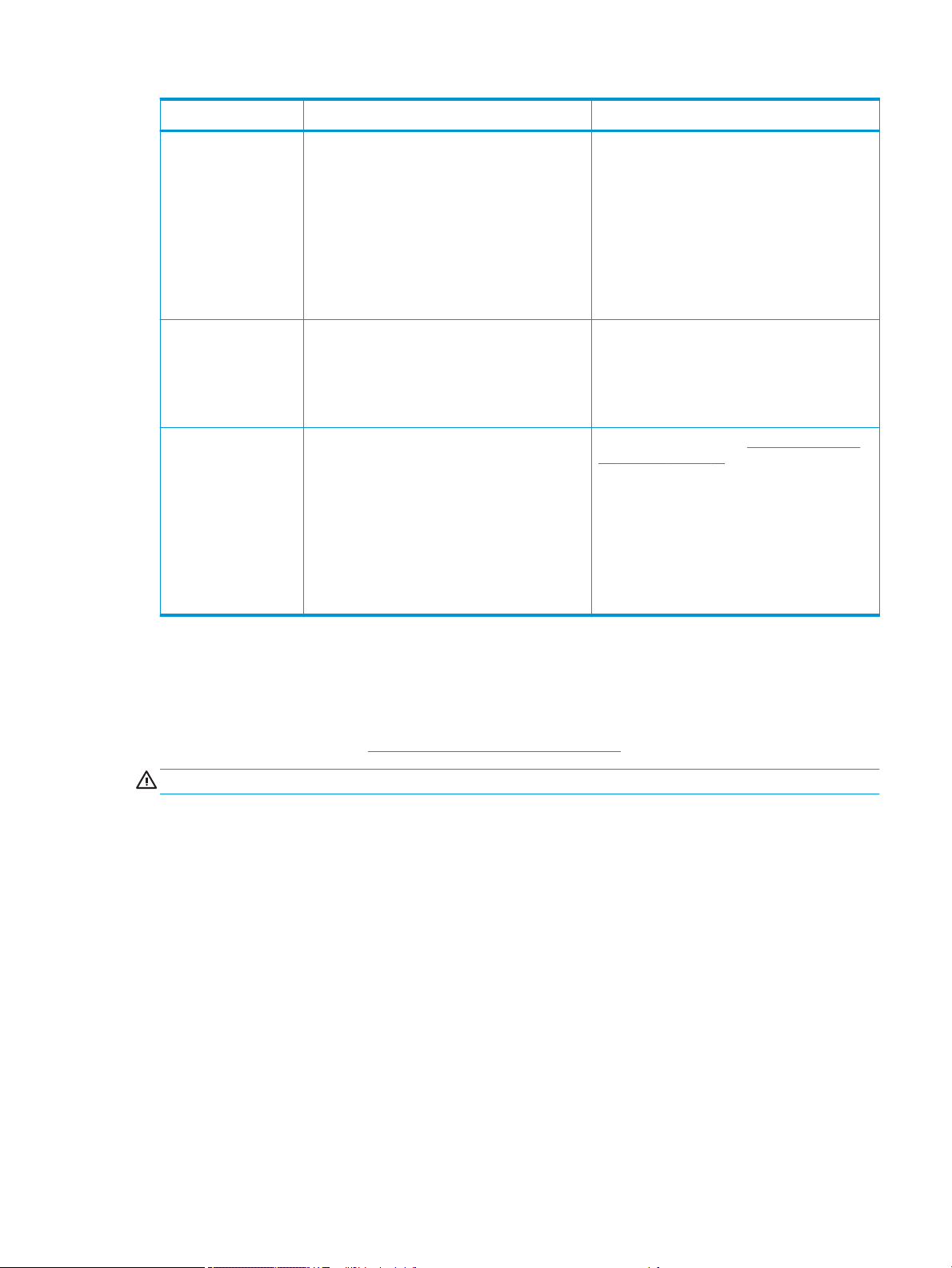

Checking the functionality of the Residual Circuit Breakers (RCCBs)

Following standard Residual Current Circuit Breaker (RCCB) recommendations, it is recommended that the RCCBs

are tested on a yearly basis. The procedure is as follows:

1. Turn o the built-in computer using the Internal Print Server’s Shutdown button (or, in Print Care, select

2. Once the computer is o, test that the RCCB works correctly by pressing the test button.

Heat hazard

The drying and curing subsystems of the printer operate at high temperatures and can cause burns if touched.

LED's array supports, beam and enclosures can reach high temperatures. To avoid the risk of burns, take the

following precautions:

●

●

●

Printer tools > Power options > Shutdown). Do not turn o the printer from the mains switch or the circuit

breakers.

CAUTION: The shutdown process takes some time to complete. Wait until the green Power Enabled light

is o before proceeding.

●

If the RCCB does not trip when the test button is pressed, this indicates that it has failed. The RCCB

must be replaced for safety reasons; call your service representative to remove and replace the RCCB.

●

If the RCCB trips, this indicates it is working correctly; reset the RCCB to its normal on state.

Do not touch the internal enclosures of the printer's drying and curing modules.

Take special care when accessing the substrate path.

Take special care with zones marked with warning labels.

●

Do not place objects covering LED's arrays supports, beam and enclosures.

●

Do not attempt to modify LED's array supports, beam and enclosures;

●

Remember to let the printer cool down before performing some maintenance operations.

ENWW Safety precautions 3

Page 10

Fire hazard

The drying and curing subsystems of the printer operate at high temperatures. Call your service representative if

the printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter) is repeatedly tripped.

To avoid the risk of re, take the following precautions.

●

●

●

●

●

●

●

●

Use the power supply voltage specied on the nameplate.

Connect the power cords to dedicated lines, each protected by a branch circuit breaker according to the

information detailed in the Site Preparations documentation.

Do not insert objects through slots in the printer.

Take care not to spill liquid on the printer. After cleaning, make sure all components are dry before using

the printer again.

Do not use aerosol products that contain ammable gases inside or around the printer. Do not operate the

printer in an explosive atmosphere.

Do not block or cover the openings of the printer.

Do not attempt to modify the drying or curing module, or the e-cabinet.

Ensure that the operating temperature of the substrate recommended by the manufacturer is not

exceeded. If this information is not available, ask the manufacturer. Do not load substrates that cannot be

used at an operating temperature above 125°C (257°F).

●

Do not load substrates with auto-ignition temperatures below 250°C (482°F). See note below. No ignition

sources are close to the substrate.

NOTE: Test method based on EN ISO 6942:2002; Evaluation of materials and material assemblies when

exposed to a source of radiant heat, method B. The test conditions, to determine the temperature when

the substrate starts ignition (either ame or glow) were: Heat ux density: 30 kW/m2, Copper calorimeter,

K type thermocouple.

●

Proper maintenance and genuine HP consumables are required to ensure that the printer operates safely

as designed. The use of non-HP consumibles (foams, lters, printhead cleaning roll, and inks) may present

a risk of re.

LED's array supports, beam and enclosures can reach high temperatures. To avoid the risk of re, take the

following precautions:

●

Take special care with zones marked with warning labels.

●

Do not place objects covering LED's arrays supports, beam and enclosures.

●

Take care not to spill liquid on the accessory. After cleaning, make sure all components are dry before using

the printer.

●

Do not attempt to modify LED's array supports, beam and enclosures.

Mechanical hazard

The printer has moving parts that could cause injury. To avoid personal injury, take the following precautions

when working close to the printer and (optional) In-line slitters.

4 Chapter 1 Introduction ENWW

Page 11

●

Keep your clothing and all parts of your body away from the printer's moving parts.

●

Avoid wearing necklaces, bracelets and other hanging objects.

●

If your hair is long, try to secure it so that it will not fall into the printer.

●

Take care that sleeves or gloves do not get caught in the printer's moving parts.

●

Avoid standing close to the fans, which could cause injury and could also aect print quality (by obstructing

the air ow).

●

Do not touch gears or moving rolls during printing.

●

Do not operate the printer with covers bypassed.

●

Do not touch In-line slitters during printing.

●

Handle In-line slitters with care and store them safely into their box when not used with the printer.

●

Risk of cutting your ngers! Uninstall the In-line slitters when manipulating the curing module or accessing

the substrate path.

●

Take care when using the air gun. When used for cleaning purposes, make sure to use it according to the

local regulations since additional safety provisions may apply.

WARNING! Be careful when you open the loading table, NEVER leave it unattended with both latches in the

open position. It may open inadvertently and cause serious injuries. Always check it has both latches closed

properly.

Light radiation hazard

UV radiation can be emitted from the LED's array in compliance with the requirements of the exempt group of

IEC 62471:2006 Photobiological safety of lamps and lamp systems. However, you are recommended not to look

directly for a long time at the output LEDs lights while they are on.

Sound pressure level

The sound pressure level could exceed 70 dB(A) in some print modes. Hearing protection may be required.

Chemical hazard

Safety data sheets identify ink ingredient and ventilation requirements to ensure any airborne exposure is

adequately controlled.

Current printer ink systems material safety data sheets are available at: http://www.hp.com/go/msds.

Air conditioning and ventilation should meet with local environmental and health and safety (EHS) guidelines and

regulations. To see more detailed information, please refer to the “Ventilation and air conditioning” section

included in the site preparation guide, available at: http://www.hp.com/go/latex1500/manuals.

Heavy substrate hazard

Special care must be taken to avoid personal injury when handling heavy substrates.

ENWW Safety precautions 5

Page 12

●

Handling heavy substrate rolls always requires two people. Care must be taken to avoid back strain and/or

injury.

●

Always use a forklift, pallet truck, or other handling equipment to lift substrates. The printer has been

designed to be compatible with many of these devices.

●

Always wear personal protective equipment including boots and gloves.

Ink and condensates handling

HP recommends that you wear gloves when handling ink and condensates system components.

Ventilation and air conditioning

As with all equipment installations, to maintain ambient comfort levels, air conditioning and ventilation in the

work area should take into account that the printer produces heat.

Air conditioning and ventilation should meet local environmental, health, and safety (EHS) guidelines and

regulations.

For a more prescriptive approach to adequate ventilation, refer to the ANSI/ASHRAE (American Society of

Heating, Refrigerating and Air-Conditioning Engineers) 62.1-2013 Ventilation for Acceptable Indoor Air Quality.

An example minimum exhaust rate of 2.5 L/s.m² (0.5 cfm/ft²) of fresh air for "copy, printing rooms" is specied.

NOTE: The ventilation and air conditioning units should not blow air directly onto the printer.

NOTE: Maintaining positive air pressure in the print production room will help prevent dust from entering the

room.

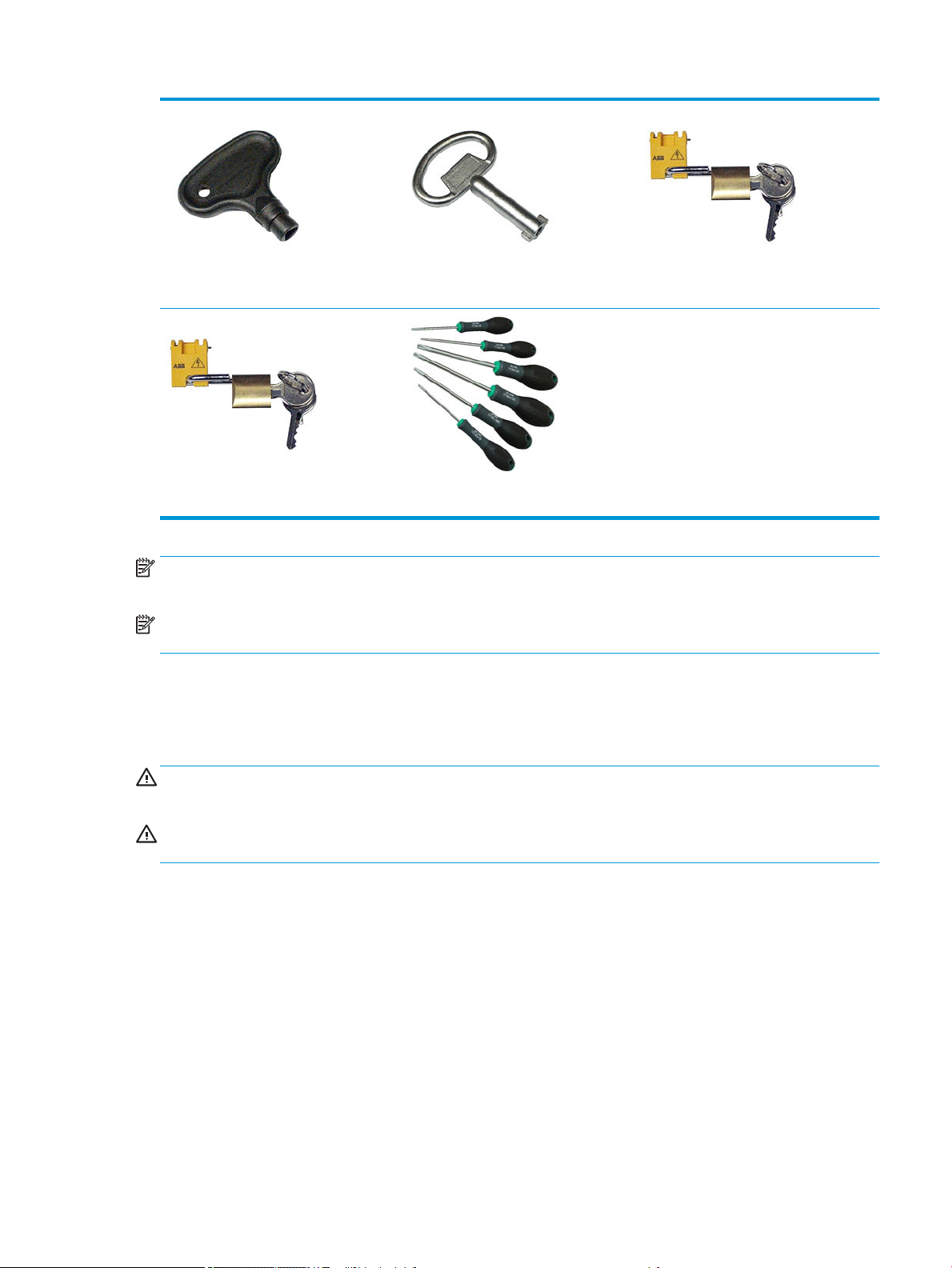

Use of tools and keys

●

Users: Daily operations including printer settings, printing, substrate loading, replacement of ink reservoirs,

and daily checks. Do not require any tool or maintenance key.

●

Maintenance personnel: Hardware maintenance tasks and replacement of printheads, lters, ink waste

bottles, foams, and printhead cleaning roll. Require maintenance key, and at screwdriver.

●

Service personnel: Any repair or maintenance operation, running diagnostics, and troubleshooting. Require

maintenance key, e-cabinet key, mains switch key, internal print server key, and torx screwdriver set.

6 Chapter 1 Introduction ENWW

Page 13

Maintenance key E-cabinet key Mains switch key

Internal Print Server key Torx screwdriver set

NOTE: During the installation of the printer, the designated personnel receive training for the safe operation

and maintenance of the printer. It is not allowed to use the printer without this training.

NOTE: After using the maintenance key to open a door, remember to lock it afterwards, and return the key to

safe and secure storage.

Warnings and cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent the printer

from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal injury or

death.

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury or

damage to the product.

ENWW Safety precautions 7

Page 14

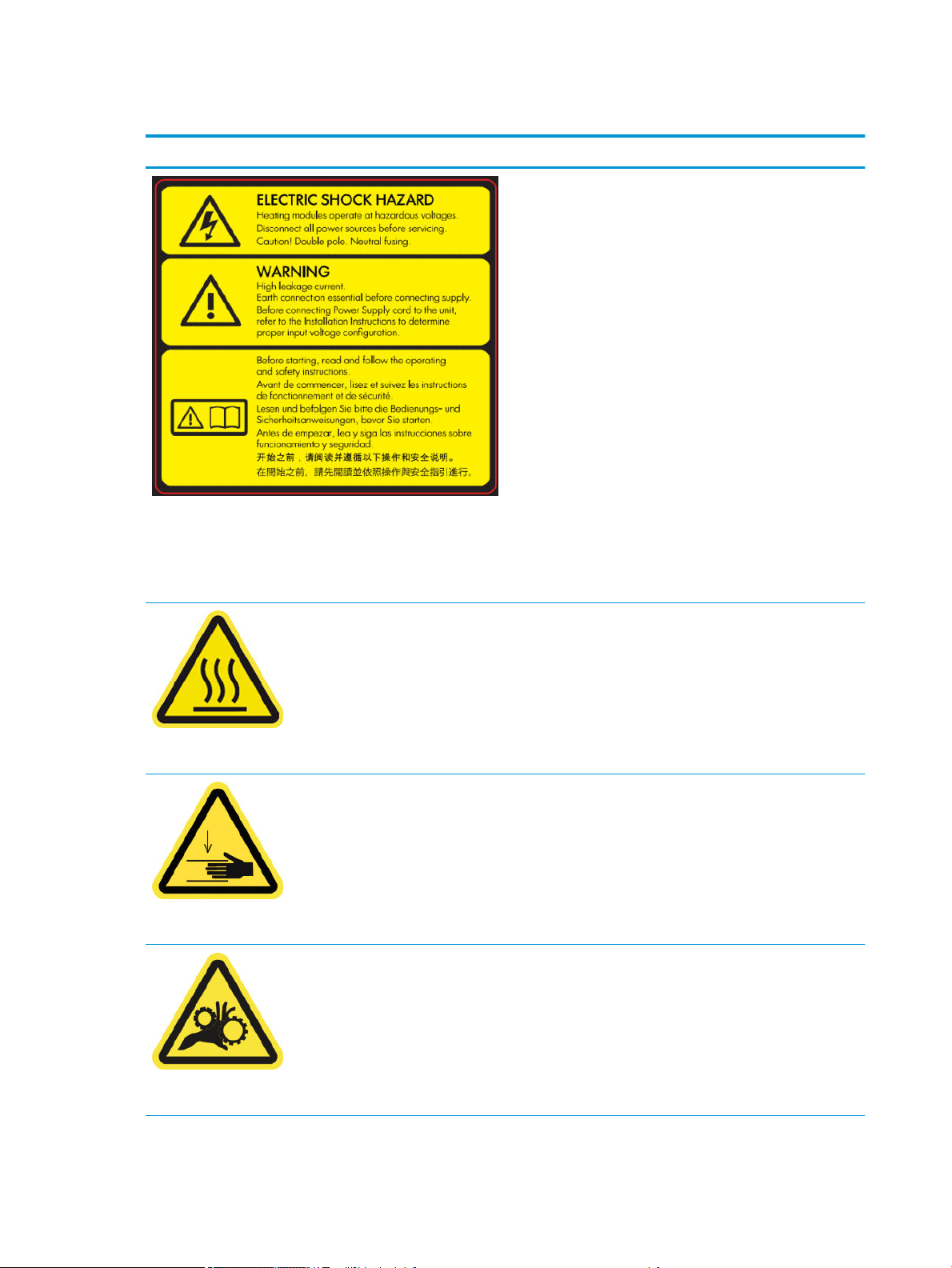

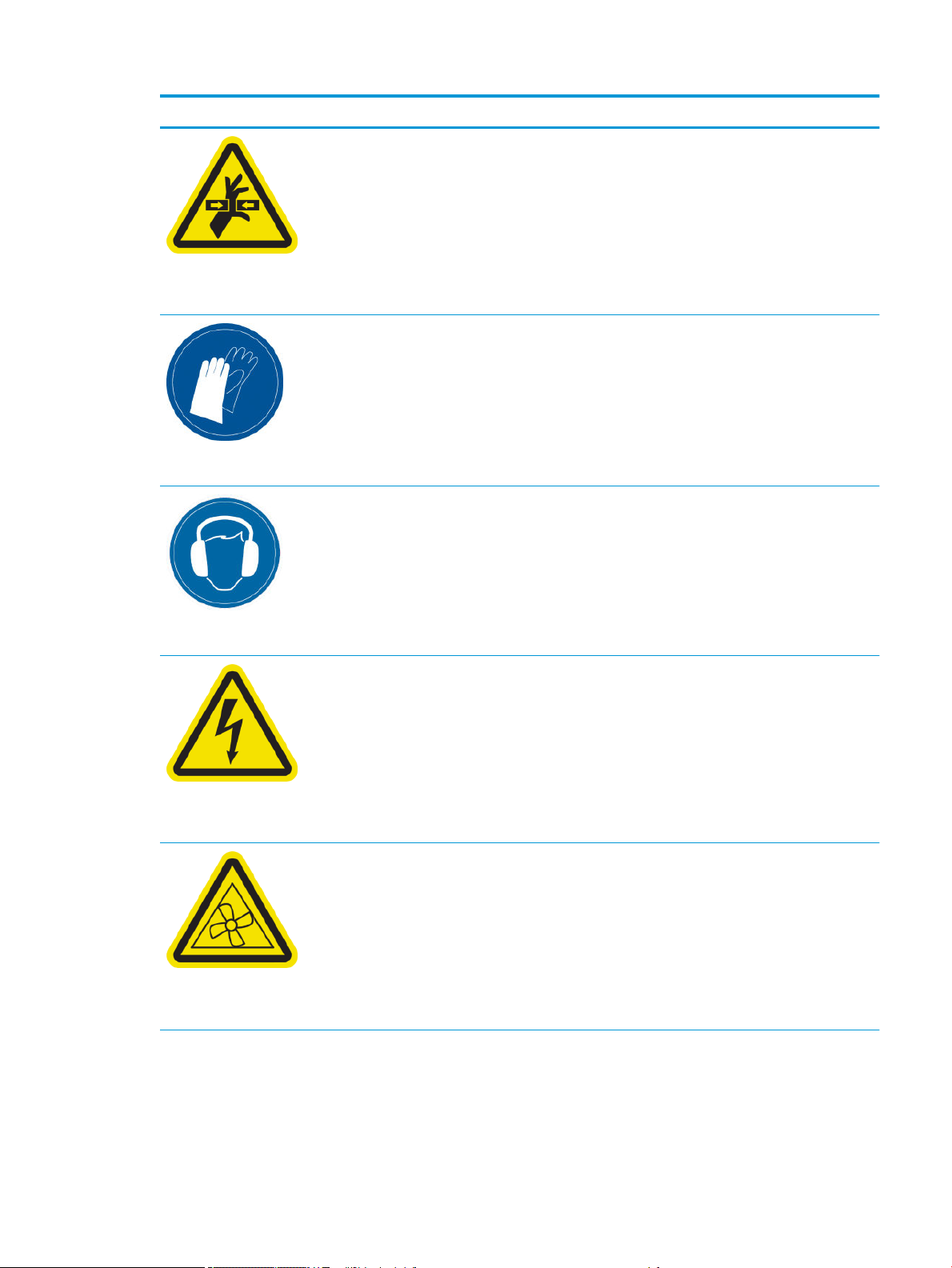

Warning labels

Label Explanation

Located on the e-cabinet.

Electric shock hazard

Heating modules operate at hazardous voltage. Disconnect power

source before servicing.

Caution! Double pole. Neutral fusing. Refer servicing to qualied

service personnel.

In case of operation of the fuse, parts of the printer that remain

energized may represent a hazard during servicing. Turn o the

printer using both Branch Circuit Breakers located in the building's

Power Distribution Unit (PDU) before servicing.

Warning

High leakage current. Current leakage may exceed 3.5 mA. Earth

connection essential before connecting supply. Equipment to be

connected to earthed mains only.

See installation instructions before connecting to the supply.

Ensure that the input voltage is within the printer's rated voltage

range. The printer requires up to two dedicated lines, each

protected by a branch circuit breaker according to site preparation

requirements.

Read and follow the operating and safety instructions before

starting the printer.

Located on the curing modules and universal support beam

Located on each side of substrate path, close to PPS gear

Risk of burns. Do not touch the internal enclosures of the printer's

drying and curing modules, universal support beam, and LED’s

array and enclosures when accessing substrate path.

Crush hazard. Do not touch PPS while moving. When substrate has

been loaded, the carriage descends into its normal position, and

could crush your hand or anything else left underneath it.

Risk of trapped ngers. Do not touch gears while moving. Danger

that your hands may become trapped between gearwheels.

Located on each side of substrate path, and close to PPS gear

8 Chapter 1 Introduction ENWW

Page 15

Label Explanation

Hazardous moving part. Keep away from moving carriage

printhead. When printing, the printhead carriage travels back and

forth across the substrate.

Located internally on substrate path and on printhead cleaning roll

(web wipe); for maintenance/service personnel only

You are recommended to wear gloves when handling ink cartridges,

printhead cleaning cartridges and the printhead cleaning container.

Located on ink waste bottle and web wipe

Sound pressure level could exceed 70dB(A) in certain print modes.

Hearing protection may be required.

Located on rear side on left cover

Located internally on heating modules and electrical cabinets; for

maintenance/service personnel only

Located internally, close to vacuum fan blades and Dryer PCA

cooling fan; for maintenance/service personnel only

Electric shock hazard. Disconnect power before servicing. Heating

modules and electrical cabinets operate at hazardous voltage.

Hazardous moving parts. Keep away from moving fan blades.

Internal close to Vacuum Fan Blades and Dryer PCA cooling fan.

ENWW Safety precautions 9

Page 16

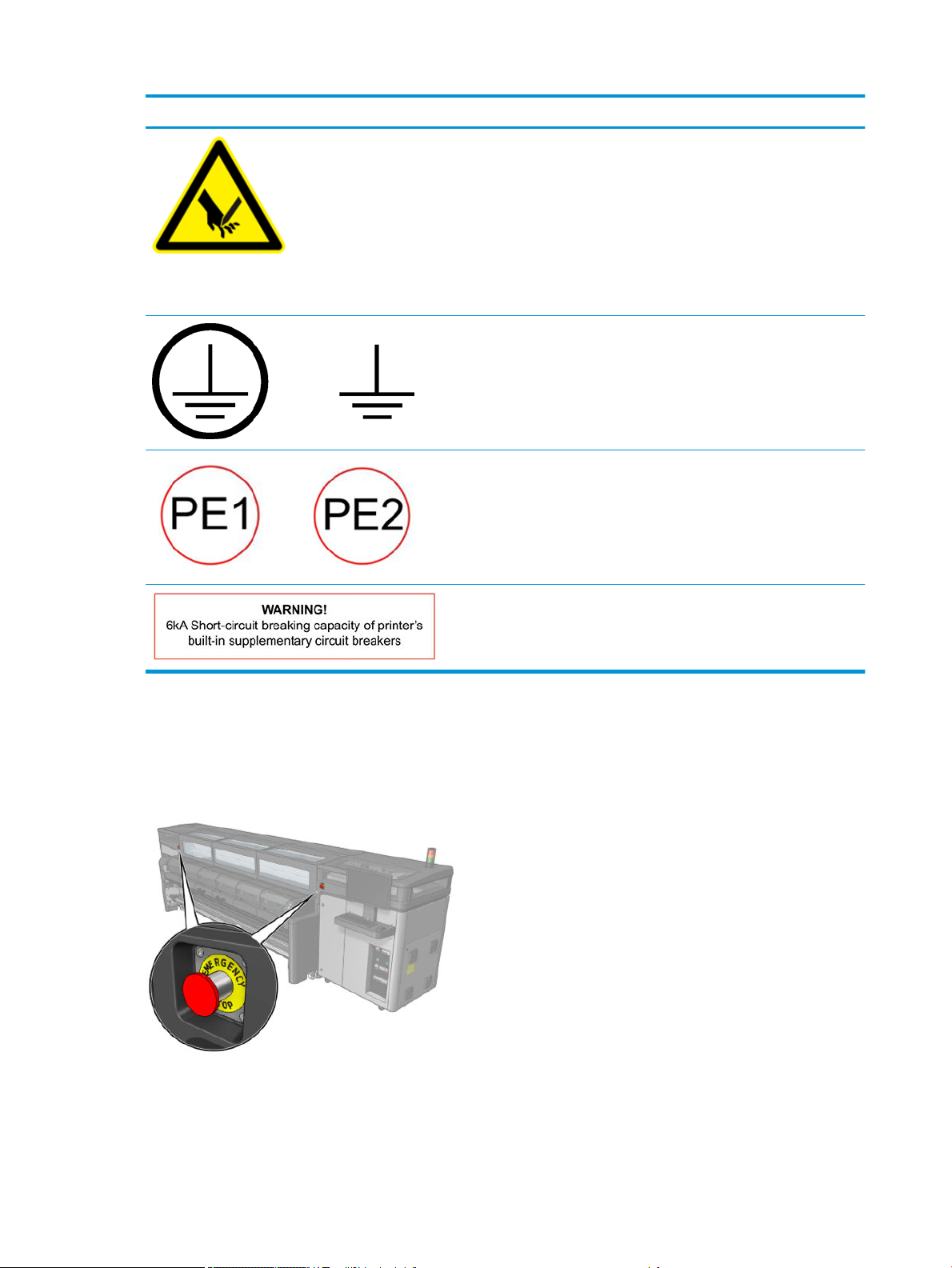

Label Explanation

Risk of cutting your ngers. Do not touch in-line slitters during

printing.

Handle in-line slitters with care and store them safely in their box

when not being used with the printer.

Located on each side of the in-line slitters and close to carriage

encoder strip

Identies the Protective Earth (PE) terminal for qualied electrician,

and bonding terminals for maintenance/service personnel only.

Earth connection essential before connecting supply.

Identies the Protective Earth (PE) terminal for qualied electrician,

and bonding terminals for maintenance/service personnel only.

Earth connection essential before connecting supply.

Emergency stop buttons

There are four emergency stop buttons distributed around the printer. If an emergency occurs, simply push one

of the emergency stop buttons to stop all printing processes. A system error message is displayed, and the fans

turn at maximum speed. Ensure that all emergency stop buttons are released before restarting the printer.

Identies the short-circuit breaking capacity of printer’s built-in

supplementary circuit breakers beside mains input terminal, for

qualied electrician and maintenance/service personnel only. Earth

connection essential before connecting supply.

10 Chapter 1 Introduction ENWW

Page 17

For safety reasons, access to the print zone is not permitted while printing is in progress. Therefore, if the

window or the loading table is opened, power to the carriage and to the drying and curing module is

disconnected. The print is cancelled and a system error may be displayed.

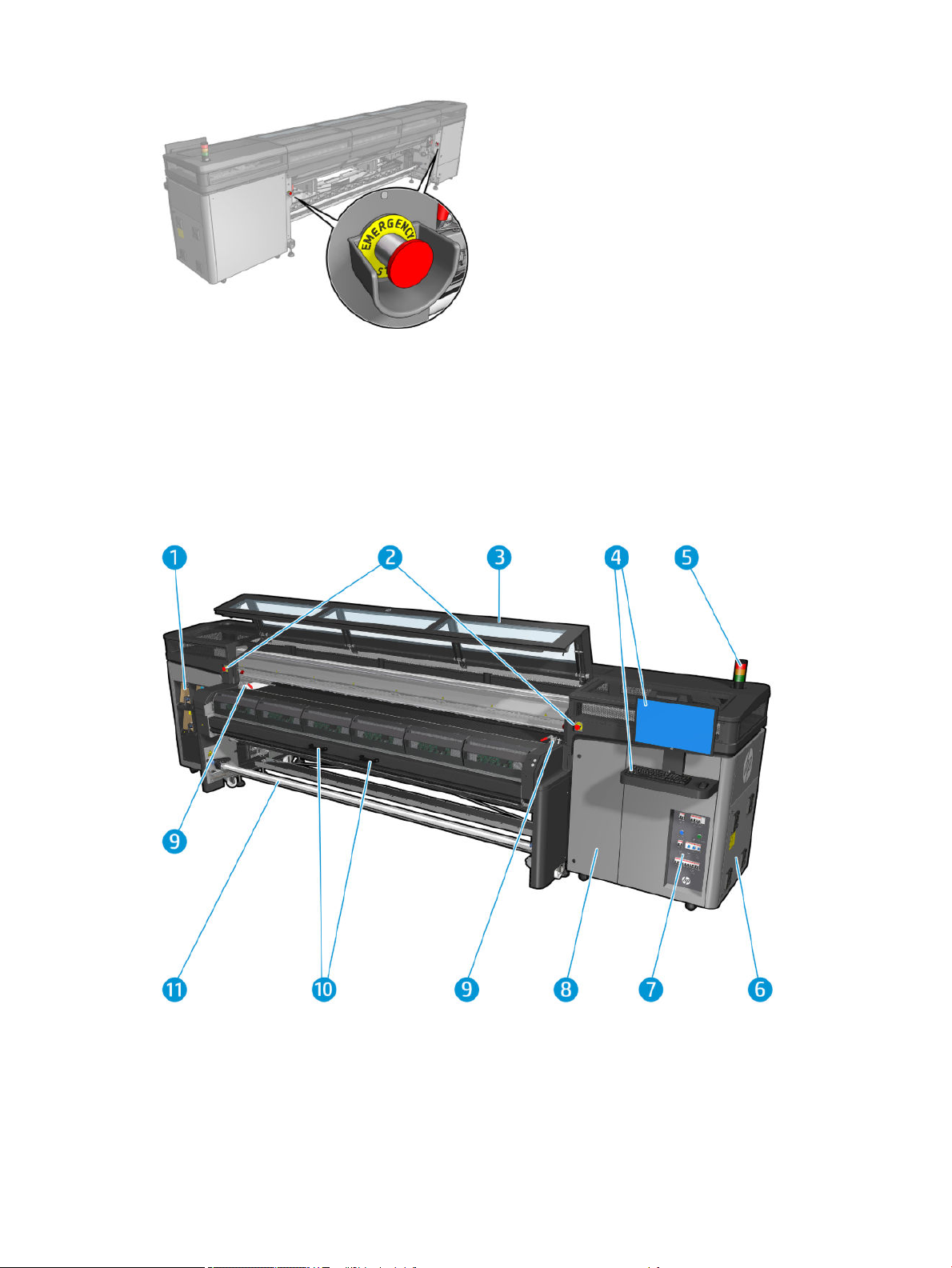

Main components

The following views of the printer illustrate the main components.

Front view

1. Ink cartridges

2. Emergency stop buttons

3. Front window for carriage and printzone access

4. Built-in computer

ENWW Main components 11

Page 18

5. Printer status beacon

6. E-cabinet

7. Power switches, lights, and circuit breakers

8. Printhead cleaning roll door

9. Curing module latches, one on each side

10. Curing module handles

11. Substrate output spindle

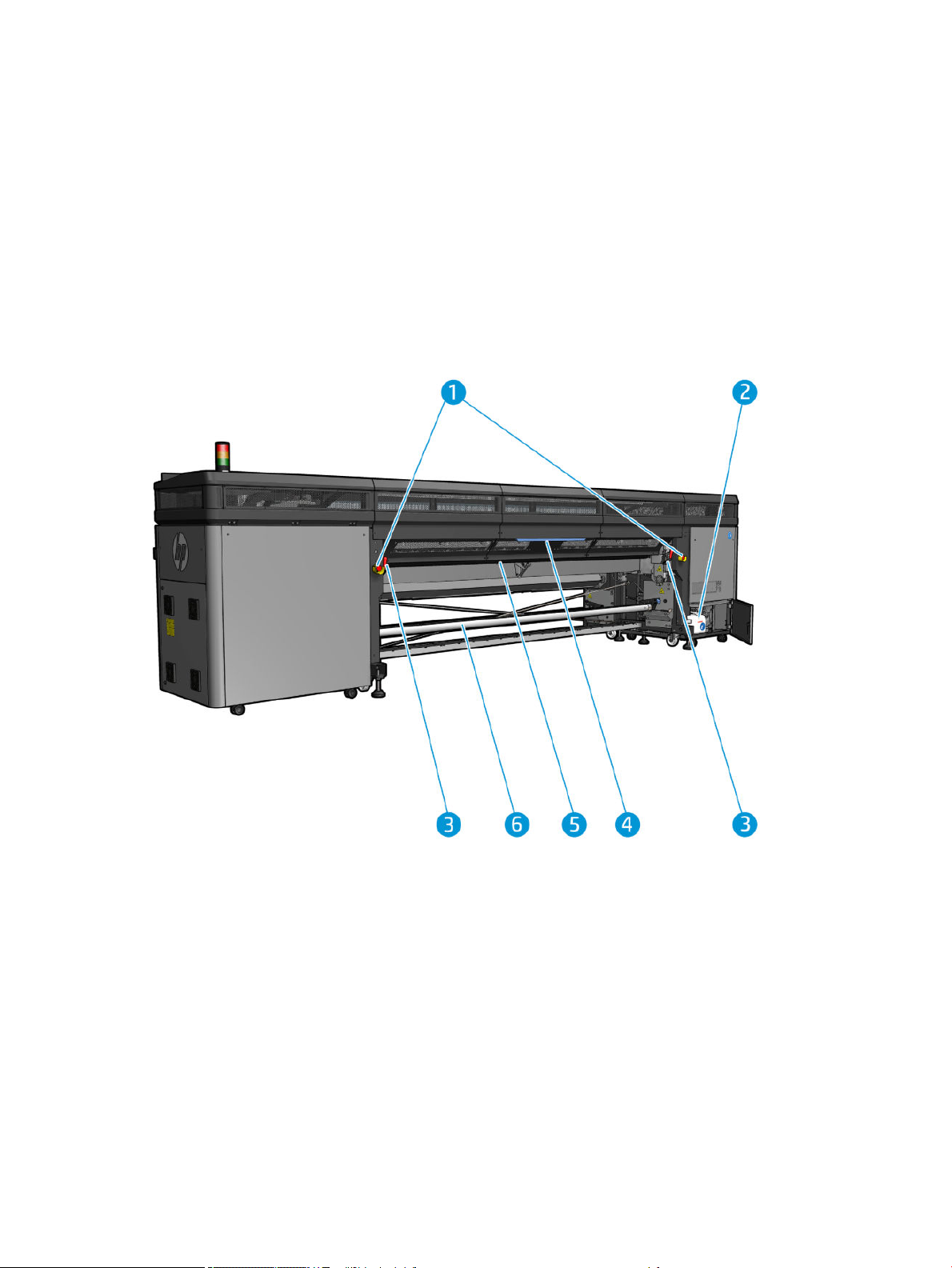

Rear view

1. Emergency stop buttons

2. Condensation collector bottle

3. Loading table latches, one on each side

4. Loading table

5. Drive roller

6. Substrate input spindle

12 Chapter 1 Introduction ENWW

Page 19

Carriage view

1. Optimizer printhead latch

2. Aerosol lters

3. Printhead

4. Color printhead latch

Printer software

Your printer requires the following software:

●

The HP Internal Print Server is provided with your printer and is already installed in the printer's built-in

computer. It displays printer alerts and a summary of printer status, manages print jobs, and must be used

to interact with the printer in various ways. See HP Internal Print Server on page 17.

●

The HP Print Care program is provided with your printer and is already installed in the printer's built-in

computer. It displays printer status and history in detail, and helps you to maintain the printer and solve any

problems that may arise. See HP Print Care on page 143.

●

A Raster Image Processor (RIP) should be run on a separate computer; it cannot be installed on the

printer's built-in computer. It is not provided with the printer and should be obtained separately. The printer

is JDF-enabled. If your RIP supports this interface, it can retrieve and display printer and job status.

ENWW Printer software 13

Page 20

Turn on the printer for the rst time

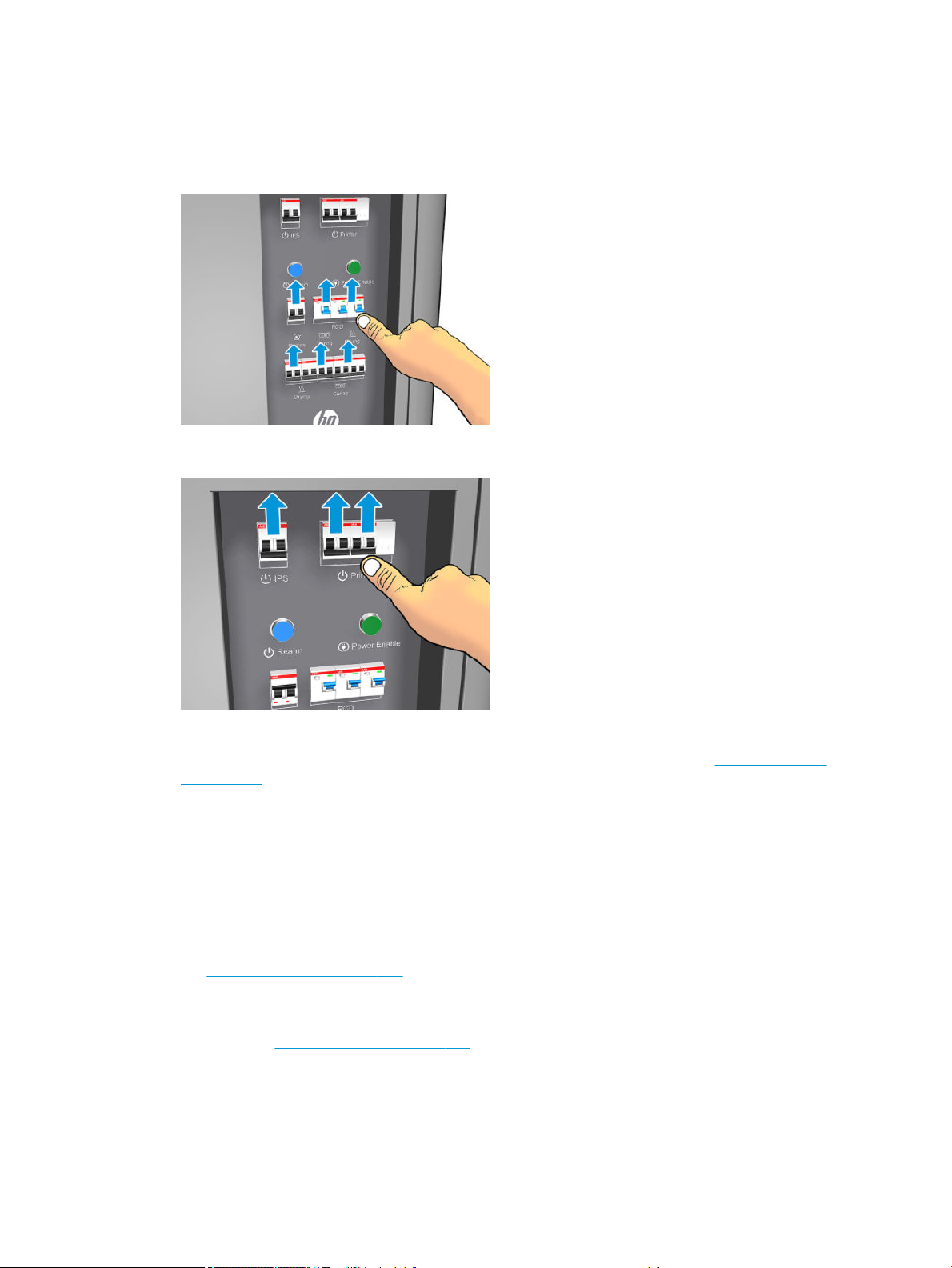

1. Make sure that the two bottom rows of circuit breakers at the front right of the printer are all in the up

position.

2. Turn the main switch to the on position, and also turn on the PC switch beside it.

3. Check that all three green lights are on. In normal operation these lights should always be on. If any of

them are o, check the Internal Print Server in case there is a system error, and see Printer messages

on page 369 or check with your electrician.

4. Wait for the Internal Print Server to tell you that the printer is waiting for rearm.

5. Perform a visual check of the printer.

6. Press the blue rearm button at the front right of the printer. This enables all of the printer's high-power

subsystems.

7. Check that the printer-enabled green light turns on. In normal operation this light should always be on. If at

any time you notice that this light is o, check the Internal Print Server in case there is a system error, and

see Printer messages on page 369.

8. Wait for the Internal Print Server to indicate that the printer is ready. This can take several minutes. When

initialization is complete, the Internal Print Server displays a Ready message. If a system error message is

displayed, see Printer messages on page 369.

Turn the printer on and o

The printer has three power-o levels. Each of them goes deeper, until you reach complete shutdown at level 3.

14 Chapter 1 Introduction ENWW

Page 21

Level Turn o Turn on

1: Major power

electronics and engine

o.

2: All printer systems o

(recommended).

3: All printer systems and

Internal Print Server o.

Wait for the Internal Print Server to indicate that the

printer is ready, then turn o the high-power

subsystems by pressing the shutdown icon near the

top left corner of the screen. Wait until the Internal

Print Server reports that it has lost its connection to

the printer.

NOTE: After the printer electronics have been

turned o at the Internal Print Server, the fans turn at

maximum speed for safety reasons. This is normal

behavior and not a cause for concern.

After completing level 1, turn o the main switch. The

fans should stop.

After completing level 2, shut down the Internal Print

Server from the Windows Start button, and wait until

you see a black screen with the message No input

signal.

CAUTION: The computer may be damaged if it is

turned o incorrectly.

Once the Internal Print Server is completely o and

you see No input signal on the screen, turn o the

computer power switch.

Click the Wake Up button up in the top left corner of

the Internal Print Server window, and wait for the

printer to turn on the high-power systems.

When prompted, press the blue rearm button at the

front right of the printer.

After completing level 1, turn on the main switch, and

ensure that the circuit breaker beside it is on.

When prompted, press the blue rearm button and

wait for the Internal Print Server to announce that the

printer is Ready.

After completing level 2, see Turn on the printer for

the rst time on page 14.

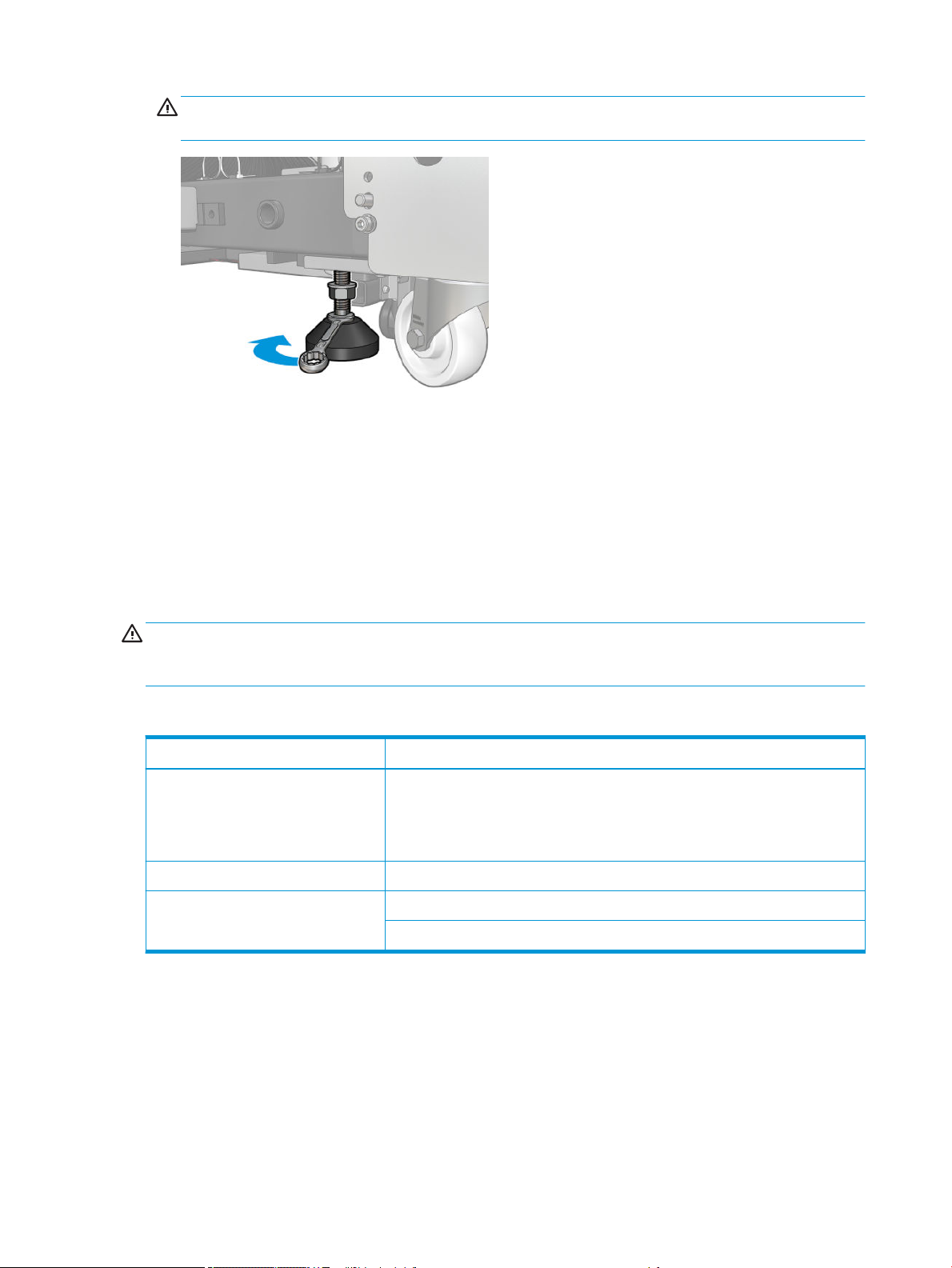

Move the printer

If you wish to move the printer a short distance on the same site, across a horizontal oor with no steps and no

slopes of more than 3% inclination, see the following instructions. For more dicult movement operations, call

your service representative (see HP Customer Care Centers on page 362).

CAUTION: Slopes steeper than 3% may cause serious damage to the printer.

1. Turn o the printer.

2. Disconnect all power and network cables from the printer.

3. Raise the feet gradually, applying two turns each time to each foot so that the wheels (A) touch the ground.

To raise a foot:

a. Use a 24mm (15/16 in) open end wrench to unlock the nut at the top of the foot.

b. Rotate the nut manually down the bolt. Leave about 2cm (0.8 in) clearance at the bottom between

nut and foot.

c. Use a 16mm (5/8 in) open end wrench to rotate the foot upwards. Use the at hexagonal faces at the

bottom of the bolt to t the wrench.

d. Raise the foot as far as the bolt allows.

e. Use the 24mm (15/16 in) open end wrench to lock the nut again.

ENWW Move the printer 15

Page 22

CAUTION: Take care to raise the feet as high as you can. They may break if they touch the ground while

the printer is in motion.

4. Push the printer from the outside corners of the main body. Remember to avoid slopes steeper than 3%.

5. Once the desired destination is reached, reverse the process described above to secure the printer in

position.

After moving the printer, you may in some cases need an electrician to reconnect the power cables. You may

also need to recongure the network, from the printer's built-in computer and from the RIP computer. See the

Installation Guide for more details, including the minimum space required around the printer.

Printer status beacon

CAUTION: The information provided by the printer status beacon is for functional information purposes only,

and is not related to any safety provision, or safety states. Warning labels on the printer must be always

considered when operating the printer, and they prevail over any status indicated by the printer status beacon.

Printer status beacon messages mean:

Color Description

Red Unexpected printing interruption. A job that had started to print stopped unexpectedly and

Orange Warning alert present in the IPS

Green Idle

appears as Failed. Attention required.

An UI user conrmation appears in the IPS window. When attended to, the red color in the

beacon changes to reect the state of the printer.

Printing

16 Chapter 1 Introduction ENWW

Page 23

2 HP Internal Print Server

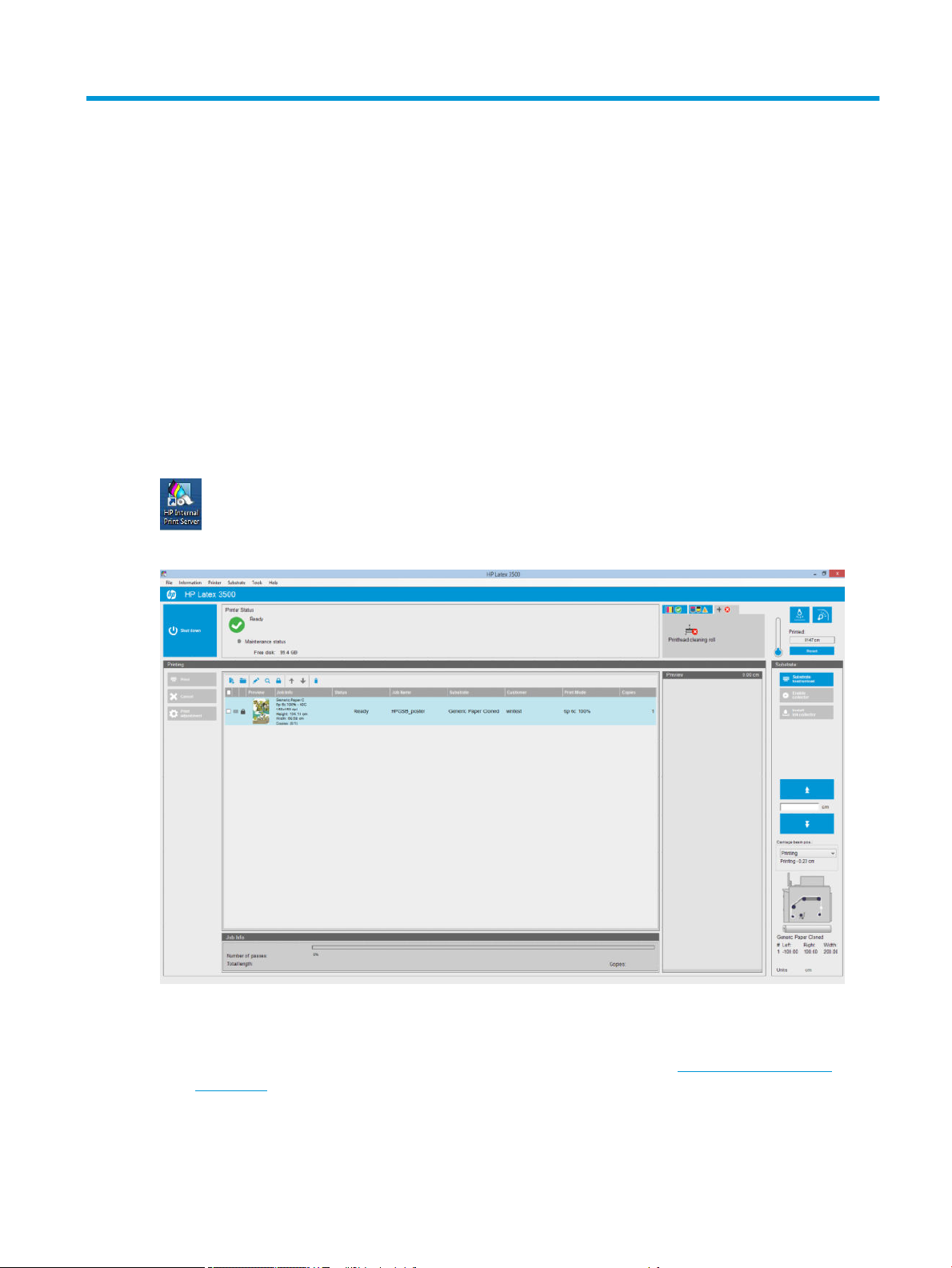

Start the Internal Print Server

The Internal Print Server starts automatically with Windows, and runs continually, in the background if not in the

foreground.

If for some reason it has stopped running, or its window is not visible, you can start it from the Windows Start

menu or by double-clicking its icon on the desktop.

When it starts, the main screen appears.

In the main screen:

●

You can shut down the printer by pressing the Shut down button at the top left.

●

The top central pane shows the printer status and maintenance status. See Printer status and alerts

on page 22.

●

The thermometer to the right of the status pane shows the curing temperature.

ENWW Start the Internal Print Server 17

Page 24

●

To the right of the thermometer, you can see a summary of the status of the ink cartridges, the printheads,

and the printhead cleaning roll.

●

The System Preheat button preheats the whole system in printer ready status. It is useful for cold

environments to avoid time-out errors during warm-up. It enables drying and curing to slowly preheat the

system. Heating duration can be set from 1 to 60 minutes in Tools > Preferences > Additional Settings.

●

The Printing pane occupies most of the window, and includes:

–

The Print, Cancel, and Print adjustment buttons

–

The job queue

–

The print preview and job settings

●

The Substrate pane includes the Substrate load/unload, Enable collector, and move carriage beam buttons;

and information about how the current substrate is loaded.

Change the language of the Internal Print Server

When the Internal Print Server starts, it uses the language selected in the Windows Regional and Language

Options. To change the selected language:

1. Open the Control Panel from the start menu.

2. If you are using the Category View of the Control Panel, open the Clock, Language, and Region category.

3. Open the Regional and Language Options.

4. In the Formats tab, change the current format to correspond with the language you want.

5. Press the OK button.

The change takes eect when Windows is restarted.

Change the units of measurement in the Internal Print Server

To change the units of measurement in the Internal Print Server, select the Tools > Preferences > Units. You can

change the units of length and temperature.

Set the Internal Print Server preferences

To change the Internal Print Server's preferences, select Preferences from the Tools menu. In the Preferences

window, you will see four tabs.

18 Chapter 2 HP Internal Print Server ENWW

Page 25

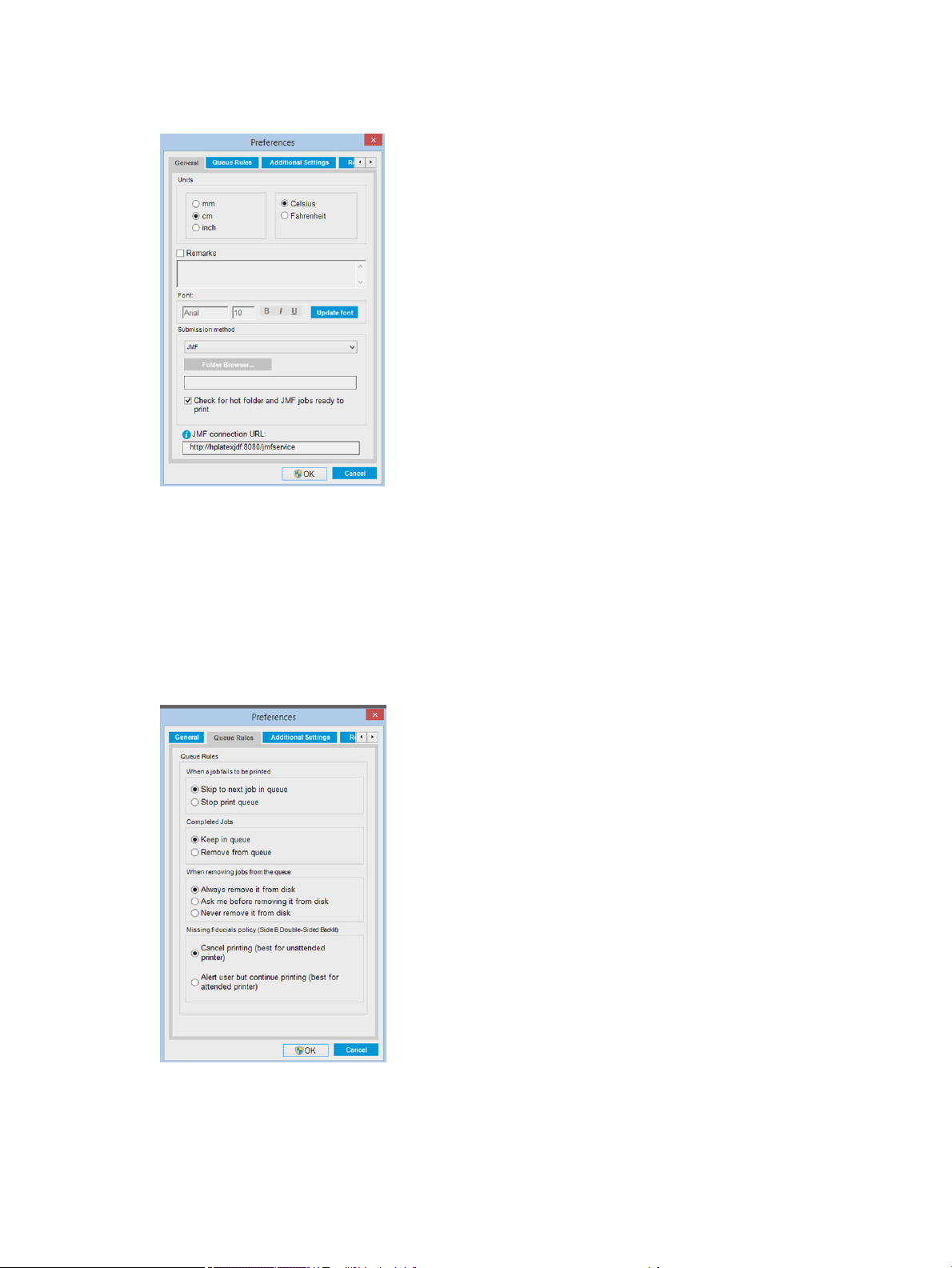

General tab

●

●

●

Units of length and temperature

Remarks (to add as a footer to the printed le)

Font of footer text

●

Hot folder

●

JMF connection url

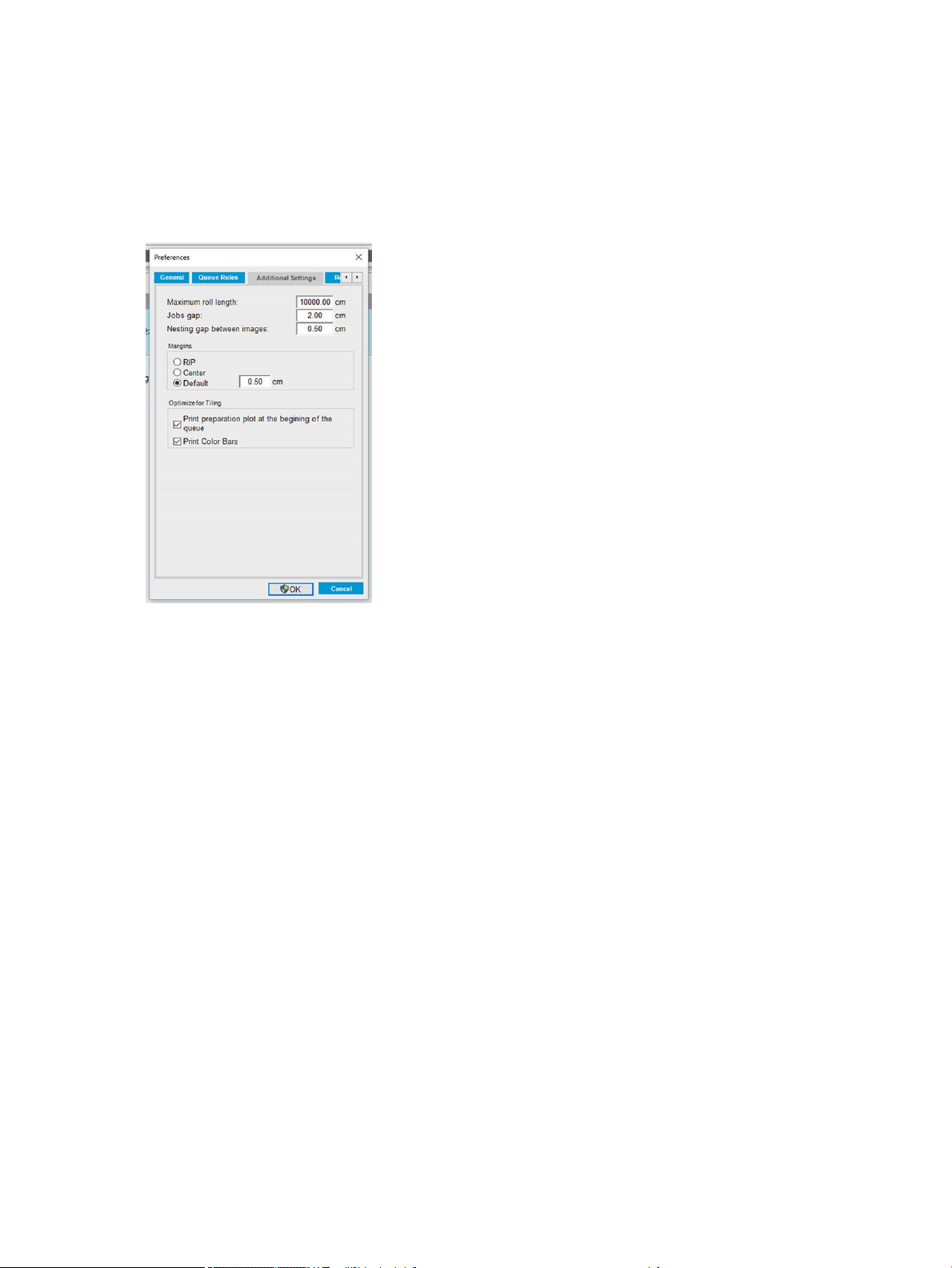

Queue Rules tab

ENWW Set the Internal Print Server preferences 19

Page 26

●

Action when job fails

●

Action when job has been printed

●

Action when job is removed from the queue

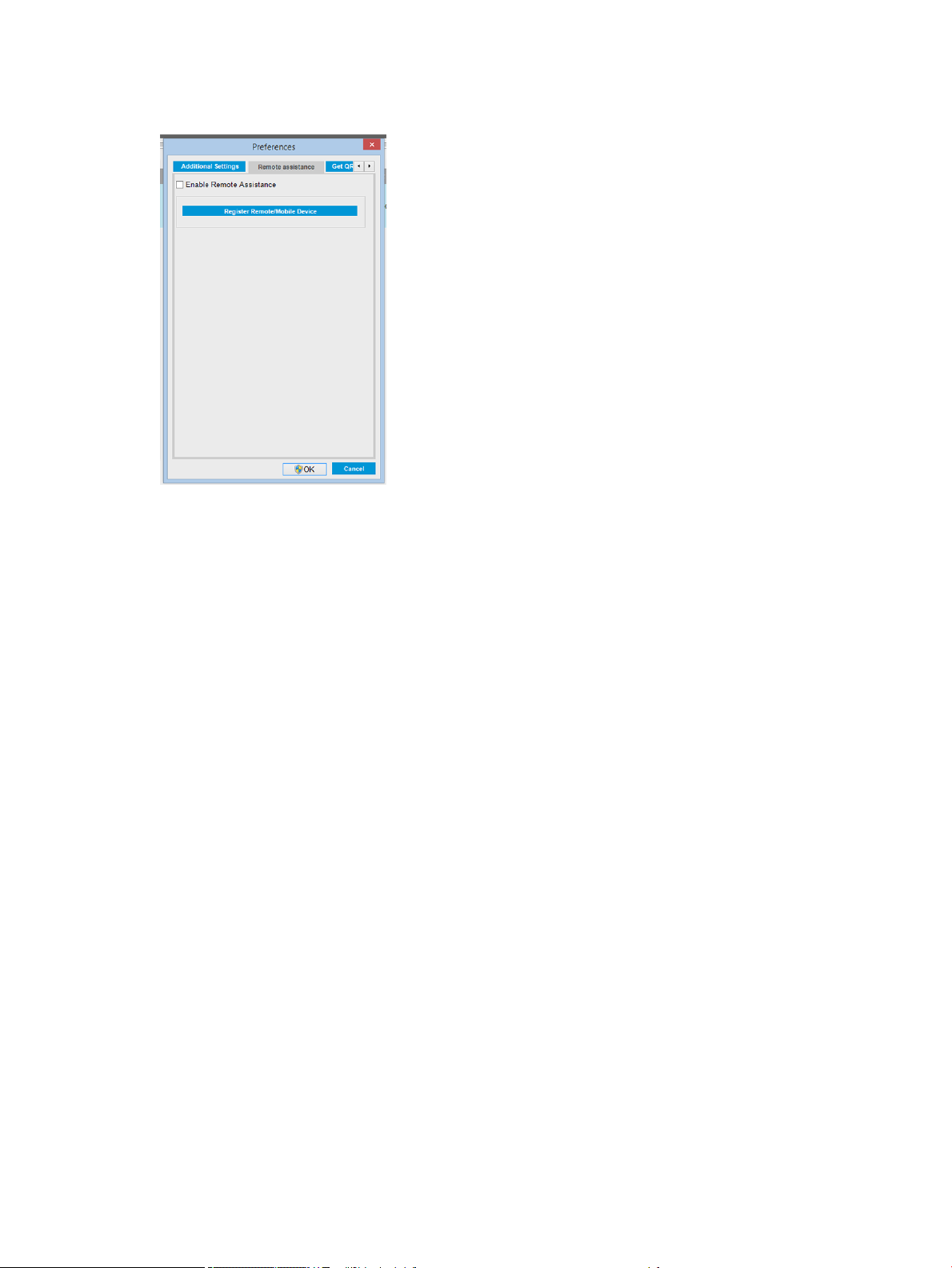

Additional Settings tab

●

Maximum roll length

●

Gap between jobs

●

Nesting gap between images

●

Margins:

–

RIP: Margins are set as dened in the RIP.

–

Center: The image is horizontally centered on the loaded substrate.

–

Default: The default margins are set to 5.0 mm (0.02 in). You can dene the default left margin in the

Job Properties window.

●

Heating duration

●

Optimize for tiling:

–

Print preparation plot at the beginning of the queue.

–

Print color bars.

20 Chapter 2 HP Internal Print Server ENWW

Page 27

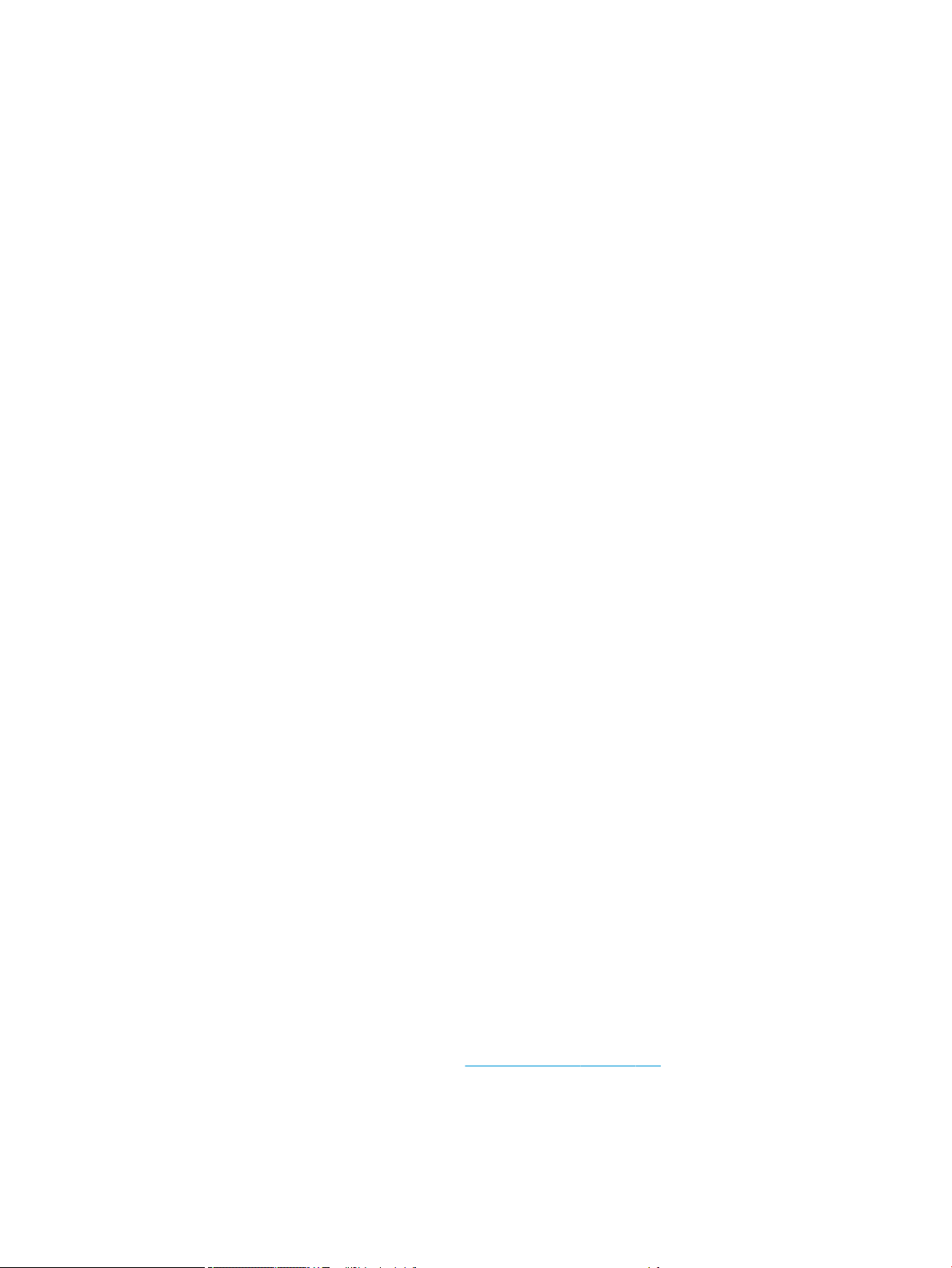

Remote Assistance tab

●

Enable remote assistance

●

Enable proxy server and give details

●

Register Remote/Mobile Device

Internal Print Server menus

The Internal Print Server provides the following menus.

ENWW Internal Print Server menus 21

Page 28

The File menu

The Information menu

The Printer menu

●

Add New Job

●

Add Existing Job

●

Edit Job

●

Delete Job

●

Exit

The Substrate menu

●

Load/Unload

●

Settings

●

Create

●

Edit

●

Clone

●

Optimize for tiling

●

Rename

●

Remove

●

Alerts

●

Supplies

●

Service information

The Tools menu

●

Preferences

●

HP Scitex Print Care

●

HP Proactive Support

●

Firmware update

●

Wake up

●

Shut down

●

Reinitialize carriage

●

Printing adjustments

●

Printhead alignment

●

Printhead cleaning

●

Replace printheads

●

Replace cleaning roll kit

●

Advance calibration

●

Enable/Disable collector

The Help menu

●

About

●

User's guide

●

Color calibration

●

Presets management

●

Search substrate online

Printer status and alerts

The Internal Print Server displays the general status of the printer, the maintenance status, the loaded substrate,

and the ink system.

The printer can communicate the following types of alerts:

Printer status

●

Errors: When the printer is unable to print.

●

Warnings: When the printer needs attention for an adjustment, such as a calibration, preventive

maintenance or ink cartridge replacement.

A summary list of printer alerts appears in the main window of the Internal Print Server. To display a more

complete and detailed list, select Information > Alerts.

For more information about a particular alert, see Printer messages on page 369.

22 Chapter 2 HP Internal Print Server ENWW

Page 29

Maintenance status

●

Green light: No maintenance is needed.

●

Yellow light: Maintenance procedure date is approaching. Press the yellow button to check Print Care for

details. See HP Print Care on page 143.

●

Orange light: Maintenance is required. Press the orange button to check Print Care for details.

●

Red light: Maintenance is required urgently. Press the red button to check Print Care for details.

●

Grayed out: Print Care is not running. Press the orange button.

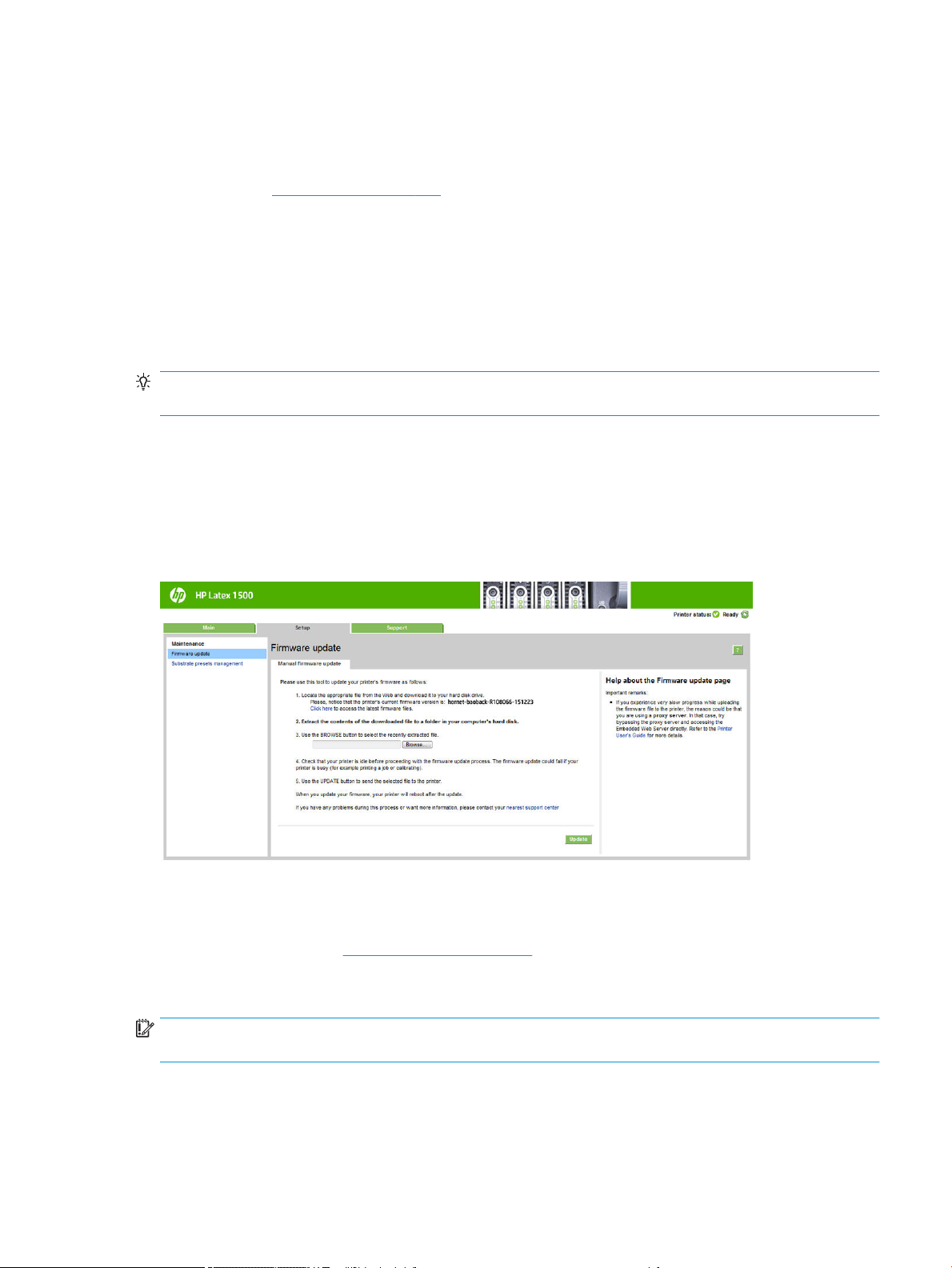

Update the rmware and the Internal Print Server

TIP: When updating the rmware and the Internal Print Server, rst update the rmware and then the Internal

Print Server.

Update the rmware

From time to time rmware updates will be available from HP that increase the printer's functionality and

enhance its features.

Firmware updates can be downloaded from the Internet and installed in your printer using the Internal Print

Server: select Firmware update from the Tools menu.

Follow the instructions on your screen to download the rmware le and store it on your hard disk. Then select

the downloaded le and click Update.

The rmware includes a set of the most commonly used substrate presets. Extra substrate presets can be

downloaded separately; see Substrate presets on page 63.

Update the Internal Print Server

IMPORTANT: Remove the previous version of the Internal Print Server in the printer's built-in computer before

installing the new version.

1. Remove the current version of the Internal Print Server through the control panel. Select Uninstall Internal

Print Server Application (this deletes any current job in the queue, but not ripped les).

2. Download the le to the built-in computer's hard disk (but not to the desktop).

ENWW Update the rmware and the Internal Print Server 23

Page 30

3. Unzip/extract the les HPIPS.msi and Setup.exe.

4. Run the le Setup.exe and follow the onscreen instructions until the new software is installed.

Update the HP IPS Services

IMPORTANT: Remove the previous version of the Internal Print Server in the printer's built-in computer before

installing the new version.

1. Remove the current version of the Internal Print Server through the control panel. Select Uninstall Internal

Print Server Application

2. Download the le to the built-in computer's hard disk (but not to the desktop).

3. Unzip/extract the les HPIPSServices.msi and Setup.exe.

4. Run the le Setup.exe and follow the onscreen instructions until the new software is installed.

.

24 Chapter 2 HP Internal Print Server ENWW

Page 31

3 RIP distribution

HP RIP Certication dierentiates the RIP partners who reach a specic and superior level of integration,

compatibility, and performance with the HP Latex 1500 Printer.

HP has increased the functionalities and RIPs certied for the HP Latex 1500 Printer.

The compatibility support matrix below presents the certied RIP partners and versions. As well as the dierent

functionalities supported by each specic RIP partner, all certied RIP partners support, at least, all the

mandatory functionalities. You can nd more information on the HP Latex Knowledge center via the following

link: http://h20435.www2.hp.com/t5/HP-Latex-Blog/Certied-RIPs-to-enable-seamless-integration-with-HP-

Latex-1500/ba-p/298577.

ENWW 25

Page 32

4 Printing workows integration

Introduction to JDF

What is JDF?

JDF is a software method by which devices from a variety of vendors and manufacturers can interoperate

together. It uses a text-based language known as XML that is compliant with many devices and workow

controllers in varying vertical print markets.

JDF implementation is typically based upon an MIS system to be use for job scheduling, submission, accounting,

and costing. An integrator typically interfaces an MIS system to the devices that are present in a workow

through JDF technology.

JMF is a communication protocol (based upon the JDF specication) that allows devices to communicate job

status information and other real-time job metrics and parameters. It can be used to poll a device for status or to

watch a device at regular intervals.

Benets of working with JDF for le submission

JDF can be useful in providing an accurate MIS-driven way to know the job status of content as well as when a

device has completed a job. Since the role of an MIS is to track, schedule and cost-account for a job, JDF/JMF

allows for a simple way to interface devices to an MIS for this task.

JDF and JMF can be used to be able to analyze and later perform accounting principles upon work created in a

JDF workow. A detailed analysis can be performed after a day or series of jobs to see the prot margin of a job,

the costs and materials consumed, as well as inventory control and stock consignment.

HP is a partner member of the CIP4 organization, and you can obtain many more details about JDF at the CIP4

www site at http://www.cip4.org.

Working with JDF

Creating JDF job tickets

JDF Implementations typically use an MIS system to control and monitor a JDF/JMF workow. The MIS can then

monitor a device’s status, can track time and consumables and provide interfacing with counting and inventory

control modules integrated into an MIS. An MIS is typically the origin of a JDF job and resultant ticket. JMF

communication can be used to send that ticket information to production milestones. An MIS is typically the

origin of a JDF job and resultant ticket. JMF communication can be used to send that ticket information to

production milestones.

26 Chapter 4 Printing workows integration ENWW

Page 33

What information is captured by the HP Latex 1500 printer series and what can be

communicated by JMF to an MIS?

The printer implements a subset of the JDF 1.5 specication, using JMF. This allows it to communicate printerstatus, and notications together with job status, job ink, and substrate consumption to external applications.

NOTE: It is important to consider the fact that the RIP is capable of combining several jobs into one for the

purpose of substrate optimization, and nishing. In this example, the printer sees the print as one job. In this

situation, the MIS should query the RIP for the status of each individual job on the nest.

The RIP application can retrieve substrate and consumable tracking to report back to MIS.

Guidelines for Integration

How to integrate the HP Latex 1500 printer series into CALDERA RIP

CALDERA RIP can take advantage of the JDF interface in the printer by selecting the option on the printer driver

setup. Once the JDF interface is enabled, the RIP will display printer status and notications together with job

status, job ink and substrate consumption.

In order to activate this functionality in the CALDERA RIP, you need to type the printer's JMF url in the JDF area of

the printer conguration dialog (IPS URL). Please, make sure you have the latest driver available from the

CALDERA Website.

Once congured, you can display the printer status by opening the info window in the print client, and opening

the spooler for the job status.

ENWW Working with JDF 27

Page 34

To obtain the JMF URL: Go to the IPS PC, on the Internal Print Server SW, and then Tools>Preferences>General.

If there are problems using the printer’s hostname, switch to the printer’s IP using the HP Latex 1500 System

Conguration Tool. For more details refer to the Service Manual or talk to your network administrator to solve

hostname resolution.

How to integrate the HP Latex 1500 printer series into ONYX RIP

ONYX can take advantage of the JDF interface in the printer by selecting the option on the printer driver setup.

Once the JDF interface is enabled, the RIP will display printer status and notications together with job status, job

ink and substrate consumption.

In order to activate this functionality in the ONYX RIP, you need to type the printer's JMF url in the JDF area of the

printer conguration dialog (JDF URL). Please, make sure you have the latest driver version from the ONYX

Download manager.

Once congured, you can display the printer and job status opening the info window in the RIP queue.

28 Chapter 4 Printing workows integration ENWW

Page 35

To obtain the JMF URL: Go to the IPS PC, on the Internal Print Server SW, and then Tools>Preferences>General.

If there are problems using the printer’s hostname, switch to the printer’s IP using the HP Latex 1500 System

Conguration Tool. For more details refer to the Service Manual or talk to your network administrator to solve

hostname resolution.

Job submission methods

The HP Latex 1500 supports two le submission methods (in addition to open a le directly in HP IPS UI):

Select the submission method within the Preference dialog in HP IPS Tools>Preferences>General, in the Submit

method drop down list:

ENWW Working with JDF 29

Page 36

Hotfolder: Select a shared folder in the HP IPS PC and the RIP copies the output job there, the IPS automatically

loads jobs into the queue.

NOTE: The shared folder should be the same as the one congured in the RIP.

JMF: The RIP sends the location of the job via a JMF command and the IPS automatically looks for the les there

and loads them directly into the printer queue.

Not specify: Load the le manually in the IPS File>Open.

Removing a queued job from the RIP:

Remove a job from the IPS/printer queue directly via the RIP interface, but only if it was submitted using the JMF

method.

How to integrate the HP Latex 1500 printer series into an MIS system or production control software

Specic RIP/MIS implementations will require vendor specic congurations.

MIS or Production Control Software applications can retrieve printer status and notications together with job

status, job ink and substrate consumption, from the printer via the HP JDF/JMF Interface. It is also possible to

remove a job in the printer queue via the HP JDF/JMF Interface.

As explained in the previous section, if the RIP combines several jobs into one before sending it to the printer, the

recommendation is to connect the MIS or Production Control software to the RIP instead of the IPS in order to get

the grouped jobs’ individual job status.

Be sure to assign unique names to each job in order to identify them on the gathered information from the

printer.

30 Chapter 4 Printing workows integration ENWW

Page 37

If you are using CALDERA 10.2 RIP, then the MIS can communicate using the Caldera Nexio module. Caldera

Nexio is a tool that connects the Caldera RIP and other third-party software using standard JDF/JMF protocols,

making it possible to produce automatic sequences of actions that speed up production and advanced reports to

improve operations. Please, contact CALDERA for further information.

ONYX customers wishing to integrate with MIS solutions can use the ONYX Connect module to communicate via

JDF. ONYX Connect does not currently support JMF. Please contact ONYX for further information.

If you are using another RIP solution, please contact your specic RIP vendor for JDF/JMF conguration and

interface guidelines.

MIS vendors or customers that would like to integrate the printer with a solution directly, can obtain the HP

specically supported JDF Software Development Kit from the HP Solutions Portal: https://developers.hp.com/

lfp-enroll.

ENWW Working with JDF 31

Page 38

5 Handle the substrate

Supported substrate types

The following substrate types are compatible with your printer. For specic substrate settings and proles, see

the Online substrate manager on page 77.

Self-adhesive vinyl

●

Cast self-adhesive vinyl

●

Calendered self-adhesive vinyl

●

Perforated self-adhesive vinyl

●

Transparent self-adhesive vinyl

PVC banner

Paper

●

Reective self-adhesive vinyl

●

Frontlit banner

●

Backlit banner

●

Scrim banner

●

Scrimless banner

●

Mesh banner with liner

●

Blockout banner

●

Truck curtain banner or tarpaulin

●

Coated paper

●

Uncoated paper

●

Photo paper

●

Photorealistic paper

●

Blue-back paper

●

Self-adhesive paper

32 Chapter 5 Handle the substrate ENWW

Page 39

PP and PE lm and banner

●

Polypropylene (PP) lm

●

Synthetic paper (such as Yupo)

●

Tyvek

●

Coated PE/HDPE (polyethylene) banner

PET lm

●

Polyester (PET) backlit lm

●

Polyester (PET) frontlit lm

●

Polyester (PET) grey-back lm

Textile

To check the porosity of your substrate, see Check the porosity of your substrate on page 34.

●

Polyester textile and fabric

●

Textile banner

●

Backdrops

Wall covering

●

Textile mesh with liner

●

Frontlit textile with liner if porous

●

Backlit textile with liner if porous

●

Canvas

●

Flag and voile with liner

●

Cotton textile

●

Self-adhesive textile

NOTE: This is an application example, not a selectable category.

●

Paper wall covering or wallpaper

●

PVC wall covering

●

Pre-pasted wall covering

●

Non-woven wall covering

●

Textile wall covering

●

Self-adhesive wall covering

ENWW Supported substrate types 33

Page 40

Check the porosity of your substrate

1. If the printer has any substrate loaded, unload it.

2. Cut a piece of self-adhesive vinyl white gloss 15 × 50 mm (0.6 × 2 in) in size.

3. Stick it to the platen, covering the substrate-advance sensor.

4. Load the substrate that you want to check.

5. Open your RIP software.

6. Obtain the test le from the printer’s built-in computer: C:\Users\hplatex\Documents\HP IPS

\InkTrespassingCheck\Ink_trespassing_check.pdf.

7. Print the test le using the number of passes and substrate preset that you intend to use in future with this

substrate (or a similar prole in terms of ink limit).

8. Unload the substrate.

9. Remove the strip of self-adhesive vinyl from the platen.

10. Look at the self-adhesive vinyl you have taken from the platen.

●

If the strip is completely white (has no ink on it), the tested substrate is non-porous and may be used

for printing as described in this guide.

11. Clean the print zone, see Clean the print zone on page 198.

Supported HP substrates

Category Substrate

HP Banners

HP Self-adhesive

Materials

HP HDPE Reinforced Banner

203 microns (8 mil) • 180 g/m2 (5 oz) • 45,7 m (150 ft)

HP Everyday Matte Polypropylene, 3-in Core

203 microns (8 mil) • 120 g/m² • 61 m (200 ft)

HP Air Release Adhesive Gloss Cast Vinyl

Without liner: 50 microns (2 mil) • 100 g/m² • 45,7 m (150 ft)

With liner: 241 microns (9.5 mil) • 260 g/m² • 45,7 m (150 ft)

HP One-view Perforated Adhesive Window Vinyl

Without liner: 165 microns (6.5 mil) • 155 g/m² • 50 m (164 ft)

With liner: 406 microns (16 mil) • 288 g/m² • 50 m (164 ft)

Automatic

printhead

alignment

NO NO Trade show and event

YES YES Trade show and event

YES YES Trade show and event

NO NO Fleet graphics and vehicle

Color

calib. Applications

displays, POP and retail

displays, Banners

displays, POP and retail

displays, Posters and

photo enlargements,

Banners

displays, Fleet graphics

and vehicle wraps,

Signage

wraps, Window graphics,

POP and retail displays

34 Chapter 5 Handle the substrate ENWW

Page 41

Category Substrate

Automatic

printhead

alignment

Color

calib. Applications

HP Films

HP Permanent Gloss Adhesive Vinyl

Without liner: 121 microns (4.8 mil) •150 g/m² • 100 g/m² • 45,7

m (150 f • 91,4 m (300 ft)

With liner: 266 microns (10.5 mil) • 280 g/m² • 45,7 m (150 ft •

91,4 m (300 ft)

HP Permanent Matte Adhesive Vinyl

Without liner: 121 microns (4.8 mil) •150 g/m² • 45,7 m (150 f •

91,4 m (300 ft)

With liner: 266 microns (10.5 mil) • 280 g/m² • 45,7 m (150 ft •

91,4 m (300 ft)

HP Premium Removable Gloss Adhesive Vinyl

Without liner: 96 microns (3.8 mil) • 136 g/m² • 45,7 m (150 f)

With liner: 284 microns (11.2 mil) • 298 g/m² • 45,7 m (150 ft)

HP Everyday Adhesive Matte Polypropylene, 3-in Core

Without liner: 180 microns (7.1 mil) • 120 g/m² • 30,5 m (100 ft)

With liner: 215 microns (8.5 mil) • 168 g/m2 ² • 30,5 m (100 ft)

HP Backlit Polyester Film

220 microns (8.7 mil) • 285 g/m² • 30,5 m (100 ft)

YES YES Trade show and event

displays, Signage, POP

and retail displays

YES YES

YES YES

YES YES Trade show and event

displays, Signage, POP

and retail displays,

Banners

NO NO Trade show and event

displays, Backlit displays,

POP and retail displays,

Posters and photo

enlargements

HP Fabrics

HP Papers/

Photographic

Papers

HP Light Fabric

381 microns (15 mil) • 218 g/m2 (6.2 oz) • 45,7 m (150 ft)

HP PVC-Free Wall Paper

177 microns (7 mil) • 175 g/m² • 30,5 m (100 ft) • 91,4 m (300

ft)

HP PVC-free Durable Smooth Wall Paper

431 microns (17 mil) • 290 g/m2 • 30,5 m (100 ft)

HP White Satin Poster Paper

165 microns (6.5 mil) • 136 g/m² • 61 m (200 ft)

HP Photo-realistic Poster Paper

205 microns (8.1 mil) • 205 g/m² • 61 m (200 ft)

HP Premium Poster Paper

228 microns (9 mil) • 200 g/m2 • 61 m (200 ft)

NO NO Trade show and event

displays, POP and retail

displays, Textiles (fabric

printing), Banners, Interior

decorations

YES YES Trade show and event

displays, Posters and

photo enlargements,

Interior decorations

YES YES

YES YES Trade show and event

displays, Backlit displays,

POP and retail displays,

Posters and photo

enlargements, Billboards

YES YES Trade show and event

displays, POP and retail

displays, Posters and

photo enlargements

YES YES

ENWW Supported HP substrates 35

Page 42

Category Substrate

Automatic

printhead

alignment

Color

calib. Applications

HP Blue Back Billboard Paper

165 microns (6.5 mil) • 123 g/m2 • 80 m (262 ft)

HP Universal Heavyweight Coated Paper, 3-in Core

172 microns (6.8 mil) • 131 g/m2 (33 lbs) • 61 m (200 ft)

HP Super Heavyweight Plus Matte Paper, 3-in Core

264 microns (10.4 mil) • 210 g/m2 (55 lb) • 61 m (200 ft)

HP Professional Gloss Photo Paper

248 microns (9.8 mil) • 275 g/m2 • 30,5 m (100 ft)

HP Professional Satin Photo Paper

248 microns (9.8 mil) • 275 g/m2 • 30,5 m (100 ft)