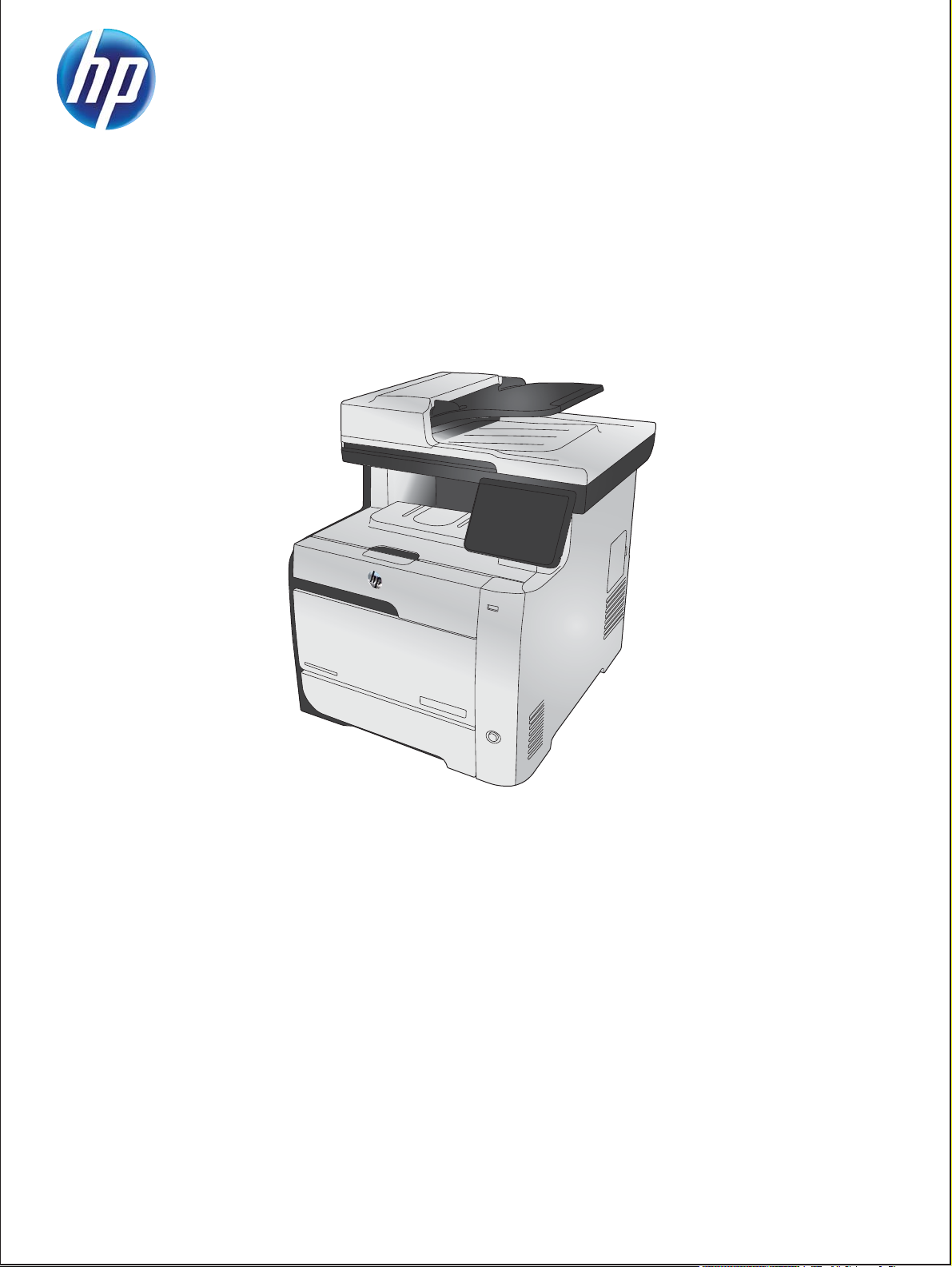

Page 1

LASERJET PRO 300 COLOR MFP

LASERJET PRO 400 COLOR MFP

Service Manual

M375

M475

Page 2

HP LaserJet Pro 300 color MFP M375

and HP LaserJet Pro 400 color MFP

M475 Printers

Service Manual

Page 3

Copyright and License

Trademark Credits

© 2012 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE863-90966

Edition 2, 5/2012

Microsoft®, Windows®, Windows® XP,

and Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

ENERGY STAR and the ENERGY STAR mark

are registered U.S. marks.

Page 4

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging

the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal

injury, catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 5

Table of contents

1 Removal and replacement ................................................................................................ 1

Removal and replacement strategy ............................................................................................. 2

Introduction .............................................................................................................. 2

Removal and replacement strategy .............................................................................. 2

Electrostatic discharge ............................................................................................... 3

Required tools ........................................................................................................... 3

Types of screws ........................................................................................................ 4

Service approach ..................................................................................................................... 5

Before performing service .......................................................................................... 5

After performing service ............................................................................................. 5

Post-service tests ........................................................................................................ 6

Test 1 (print-quality test) ............................................................................... 6

Test 2 (copy-quality test) .............................................................................. 6

Test 3 (fax-quality test; fax models only) ........................................................ 6

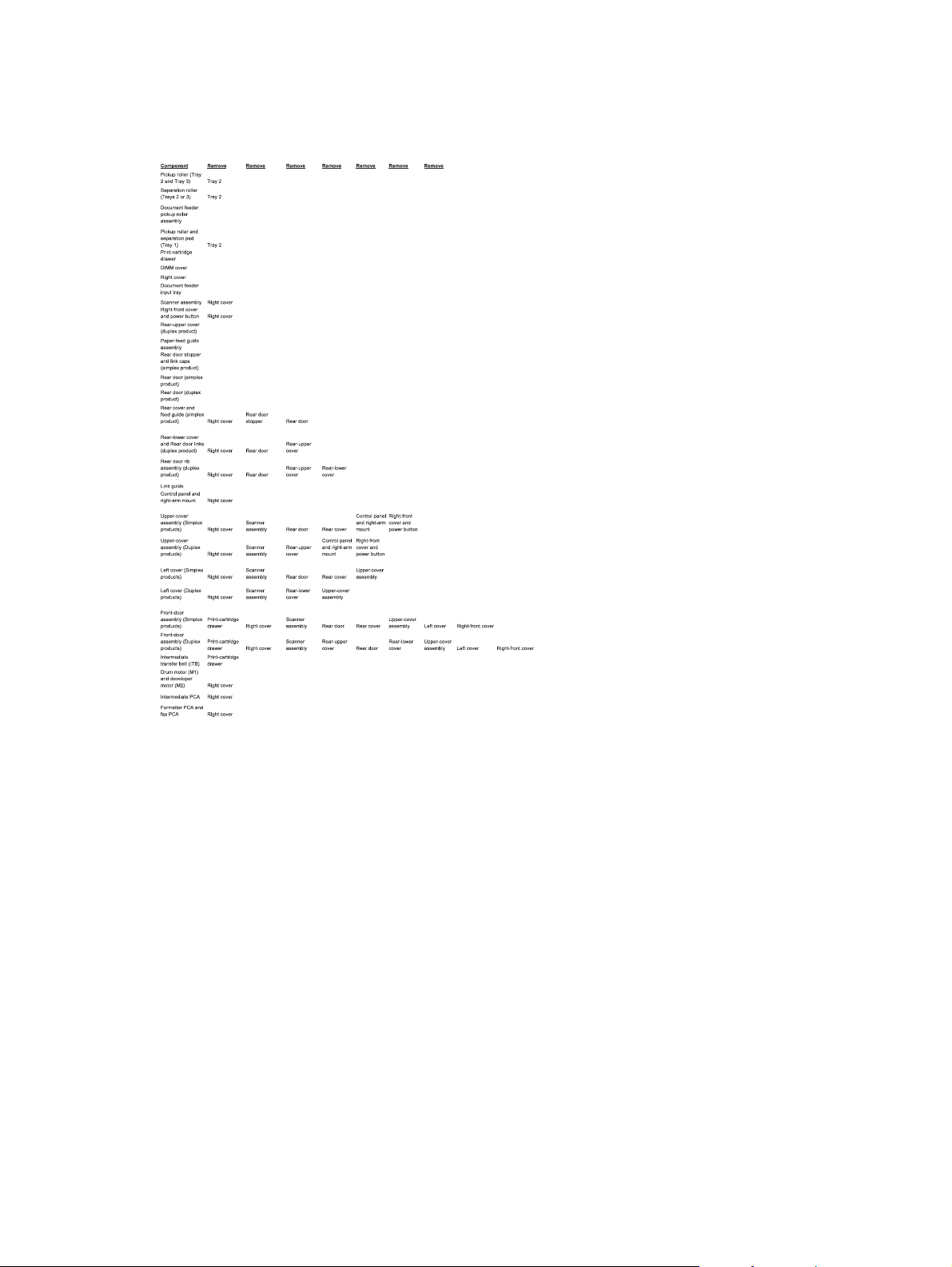

Parts removal order ................................................................................................... 7

Removal and replacement procedures ........................................................................................ 9

Rollers and pads ....................................................................................................... 9

Transfer roller ............................................................................................ 9

Pickup roller (Tray 2 and Tray 3) ................................................................ 10

Separation roller (Trays 2 or 3) .................................................................. 13

Reinstall the separation roller ...................................................... 15

Document feeder pickup roller assembly ..................................................... 16

Pickup roller and separation pad (Tray 1) ................................................... 17

Main assemblies ..................................................................................................... 20

Print-cartridge drawer ............................................................................... 20

DIMM cover ............................................................................................ 22

Right cover .............................................................................................. 23

Document feeder input tray ........................................................................ 25

Scanner assembly .................................................................................... 26

Right-front cover and power button ............................................................. 28

Rear-upper cover (duplex product) .............................................................. 30

Paper-feed guide assembly ........................................................................ 31

ENWW v

Page 6

Rear-door stopper and link caps (simplex product) ........................................ 32

Rear door (simplex product) ....................................................................... 33

Rear door (duplex product) ........................................................................ 35

Rear cover and feed guide (simplex product) ............................................... 37

Remove the rear cover and feed guide (simplex product) ................ 37

Rear-lower cover and rear-door links (duplex product) ................................... 41

Remove the rear-lower cover and rear-door links (duplex product) ... 41

Rear-door rib assembly (duplex product) ..................................................... 45

Remove the rear-door rib assembly (duplex product) ...................... 45

Link guide ............................................................................................... 47

Control panel and right-arm mount ............................................................. 48

Reinstall the control panel and right-arm mount ............................. 49

Upper-cover assembly ............................................................................... 51

Remove the upper-cover assembly ............................................... 51

Reinstall the upper-cover assembly ............................................... 53

Left cover ................................................................................................ 55

Remove the left cover ................................................................. 55

Reinstall the left cover ................................................................ 57

Front-door assembly ................................................................................. 58

Remove the front-door assembly .................................................. 58

Reinstall the front-door assembly .................................................. 63

Intermediate transfer belt (ITB) .................................................................... 65

Reinstall the ITB ......................................................................... 68

Drum motor (M1) and developer motor (M2) ............................................... 69

Reinstall the drum motor (M1) and developer motor (M2) ............... 74

Intermediate PCA ..................................................................................... 75

Formatter PCA and fax PCA ...................................................................... 76

Remove the formatter PCA and fax PCA ....................................... 76

Wireless PCA .......................................................................................... 79

DC controller PCA .................................................................................... 80

Remove the DC controller PCA .................................................... 81

Fuser-motor assembly ................................................................................ 83

Remove the fuser-motor assembly ................................................ 83

Reinstall the fuser-motor assembly ................................................ 86

High-voltage power-supply PCA ................................................................. 87

Remove the high-voltage power-supply PCA .................................. 87

Color-misregistration sensor assembly ......................................................... 90

Remove the color-misregistration sensor assembly .......................... 90

Reinstall the color-misregistration sensor assembly ......................... 92

Fan (FM1) ............................................................................................... 94

USB PCA (fax/memory-card models) .......................................................... 96

vi ENWW

Page 7

Remove the USB PCA ................................................................ 96

Duplex-reverse drive assembly ................................................................... 97

Remove the duplex-reverse drive assembly .................................... 97

Fuser .................................................................................................... 100

Remove the fuser ..................................................................... 101

Reinstall the fuser .................................................................... 106

Paper-delivery assembly .......................................................................... 107

Remove the paper-delivery assembly .......................................... 107

Tray cassettes and optional Tray 3 assembly ............................................................ 110

2 Solve problems ............................................................................................................. 111

Solve problems checklist ....................................................................................................... 112

Menu map .......................................................................................................................... 113

Troubleshooting process ........................................................................................................ 114

Pretroubleshooting checklist .................................................................................... 114

Power-on checks ................................................................................................... 115

Troubleshooting tools ............................................................................................................ 116

Component diagnostics .......................................................................................... 116

LED diagnostics ...................................................................................... 116

Network LEDs (network models only) ......................................... 116

Control panel LEDs .................................................................. 116

Memory card LED (memory-card models only) ............................. 116

Component tests ................................................................................................... 117

Control-panel tests .................................................................................. 117

Diagrams ............................................................................................................. 118

Plug/jack locations ................................................................................. 118

Location of connectors ............................................................................ 119

DC controller PCA ................................................................... 119

Location of major components ................................................................. 121

Major components .................................................................. 121

Motors and fans ...................................................................... 123

Rollers .................................................................................... 124

PCAs ..................................................................................... 125

Optional 250-sheet cassette ..................................................... 126

General timing diagram .......................................................................... 127

General circuit diagram .......................................................................... 128

CPU/ASIC diagrams .............................................................................. 129

HVT/Toner EMP diagram ........................................................................ 131

Driver PCA diagram ............................................................................... 132

Duplexer PCA diagram ........................................................................... 133

FSR diagram .......................................................................................... 134

ENWW vii

Page 8

Internal print quality test pages ............................................................................... 135

Print quality troubleshooting page ............................................................ 135

Print quality assessment page .................................................................. 135

Print the Configuration Page .................................................................... 135

Service page ......................................................................................... 135

Clean the paper path ............................................................................. 136

Print-quality troubleshooting tools ............................................................................ 136

Repetitive image defects .......................................................................... 136

Calibrate the product .............................................................................. 137

Control panel menus .............................................................................................. 137

Setup Menu ........................................................................................... 137

HP Web Services menu ............................................................ 138

Reports menu .......................................................................... 139

Quick Forms menu .................................................................. 140

Fax Setup menu ...................................................................... 141

System Setup menu .................................................................. 144

Service menu .......................................................................... 149

Network Setup menu ............................................................... 151

Function specific menus ........................................................................... 152

Copy menu ............................................................................ 152

Fax menu ............................................................................... 154

Scan menu ............................................................................. 156

USB Flash Drive ...................................................................... 157

Interpret control panel messages ............................................................................. 157

Control panel message types ................................................................... 157

Control panel messages .......................................................................... 157

10.100X Supply Memory Error ................................................. 157

49 Error, Turn off then on ......................................................... 158

50.x Fuser Error ...................................................................... 158

52 Scanner Error .................................................................... 158

57 Fan Error, Turn off then on ................................................... 159

79 Error Turn off then on .......................................................... 159

Black Cartridge Low ................................................................ 159

Black in wrong position ............................................................ 160

Black Very Low ....................................................................... 160

Canceled scan. Clear document ................................................ 160

Canceled send. Clear document ............................................... 160

Communication error. .............................................................. 161

Cyan Cartridge Low ................................................................ 161

Cyan in wrong position ............................................................ 161

Cyan Very Low ....................................................................... 161

viii ENWW

Page 9

Device error, press OK ............................................................ 162

Device is busy. Try again later .................................................. 162

Document feeder door is open. ................................................. 162

Document feeder jam. Clear and reload. ................................... 162

Document feeder mispick. Reload .............................................. 163

Door open .............................................................................. 163

Engine Communication Error .................................................... 163

Engine error. Press OK to continue. ........................................... 163

Fax is busy. Canceled send. ..................................................... 164

Fax is busy. Redial pending. ..................................................... 164

Fax receive error. .................................................................... 164

Fax Send error. ....................................................................... 165

Fax storage is full. Canceling the fax receive. ............................. 165

Fax storage is full. Canceling the fax send. ................................. 166

Fit to Page on flatbed only ........................................................ 166

Genuine HP supply installed ..................................................... 166

Incompatible <color> ............................................................... 166

Install [color] cartridge ............................................................. 166

Invalid driver Press OK ............................................................ 167

Invalid entry ........................................................................... 167

Jam in (area), Open door and clear jam .................................... 167

Jam in Tray 1, Clear jam and then press OK .............................. 167

Load paper ............................................................................ 167

Load Tray 1 <TYPE> <SIZE>, Press OK to use available media ..... 167

Load Tray 1, <PLAIN> <SIZE> / Cleaning mode, OK to start ....... 168

Load tray <X> Press [OK] for available media ............................ 168

Magenta Cartridge Low ........................................................... 168

Magenta in wrong position ...................................................... 168

Magenta Very Low .................................................................. 168

Manual Duplex Load Tray 1, Press OK ...................................... 169

Manual feed <SIZE> <TYPE>, Press OK to use available media .... 169

Memory is low. Press OK. ........................................................ 169

Memory is low. Try again later ................................................. 169

Memory low Only 1 copy made. Press OK to continue. ............... 170

Misprint, Press OK ................................................................... 170

No dial tone. .......................................................................... 170

No fax answer. Canceled send. ................................................ 170

No fax answer. Redial pending. ............................................... 171

No fax detected. ..................................................................... 171

Print failure, press OK. If error repeats, turn off then on. ............... 172

Remove shipping lock from <color> cartridge ............................. 172

ENWW ix

Page 10

Remove shipping locks from cartridges ...................................... 172

Replace [color] ....................................................................... 172

Scanner error #, Turn off then on .............................................. 172

Scanner reserved for PC scan ................................................... 173

Scanning error Cannot connect ................................................. 173

Settings cleared ...................................................................... 173

Unexpected size in tray # Load <size> Press [OK] ...................... 173

Unsupported <color> Press [OK] to continue ............................... 174

Used <color> in use ................................................................ 174

Used [color] installed, to accept press OK .................................. 174

Used supplies in use ................................................................ 174

Yellow Cartridge Low .............................................................. 174

Yellow in wrong position .......................................................... 175

Yellow Very Low ..................................................................... 175

Event-log messages ............................................................................................... 175

Print the event log ................................................................................... 176

Event log messages ................................................................................ 176

Clear jams .......................................................................................................................... 180

Common causes of jams ........................................................................................ 180

Jam locations ........................................................................................................ 180

Clear jams from the document feeder ...................................................................... 181

Clear jams in Tray 1 .............................................................................................. 183

Clear jams in Tray 2 .............................................................................................. 186

Clear jams in the fuser area ................................................................................... 187

Clear jams in the output bin .................................................................................... 188

Clear jams in the duplexer (duplexing models only) ................................................... 189

Solve paper-handling problems .............................................................................................. 191

The product picks up multiple sheets of paper ........................................................... 191

The product does not pick up paper ........................................................................ 191

Solve image-quality problems ................................................................................................ 192

Print quality examples ............................................................................................ 192

Color image defects .............................................................................................. 196

Clean the product ................................................................................................................ 198

Clean the pickup and separation rollers ................................................................... 198

Clean the paper path ............................................................................................ 198

Clean the paper path from the product control panel .................................. 198

Clean the scanner glass strip and platen .................................................................. 199

Clean the document feeder pickup rollers and separation pad .................................... 200

Clean the touch screen .......................................................................................... 201

Solve performance problems ................................................................................................. 202

Factors affecting print performance ......................................................................... 202

x ENWW

Page 11

Print speeds ........................................................................................... 203

The product does not print or it prints slowly ............................................................. 204

The product does not print ....................................................................... 204

The product prints slowly ......................................................................... 205

Solve product connectivity problems ....................................................................................... 206

Solve direct-connect problems ................................................................................. 206

Solve network problems ......................................................................................... 206

Poor physical connection ......................................................................... 206

The computer is using the incorrect IP address for the product ...................... 206

The computer is unable to communicate with the product ............................ 207

The product is using incorrect link and duplex settings for the network .......... 207

New software programs might be causing compatibility problems ................ 207

The computer or workstation might be set up incorrectly .............................. 207

The product is disabled, or other network settings are incorrect .................... 207

Solve wireless network problems ............................................................................. 207

Wireless connectivity checklist ................................................................. 208

The control panel displays the message: The wireless feature on this product

has been turned off ................................................................................ 208

The product does not print after the wireless configuration completes ............ 208

The product does not print, and the computer has a third-party firewall

installed ................................................................................................ 209

The wireless connection does not work after moving the wireless router or

product ................................................................................................. 209

Cannot connect more computers to the wireless product .............................. 209

The wireless product loses communication when connected to a VPN ........... 210

The network does not appear in the wireless networks list ........................... 210

The wireless network is not functioning ...................................................... 210

Service mode functions ......................................................................................................... 211

Service menu ........................................................................................................ 211

Service menu settings .............................................................................. 211

Secondary service menu ........................................................................................ 211

Open the secondary service menu ............................................................ 212

Secondary service menu structure ............................................................. 212

Product resets ....................................................................................................... 213

Restore the factory-set defaults ................................................................. 213

NVRAM initialization .............................................................................. 213

Solve fax problems ............................................................................................................... 215

Fax troubleshooting checklist .................................................................................. 215

Fax error messages ............................................................................................... 217

Communication error. ............................................................................. 217

Document feeder door is open. Canceled fax. ........................................... 217

ENWW xi

Page 12

Fax is busy. Canceled send. .................................................................... 217

Fax is busy. Redial pending. .................................................................... 218

Fax receive error. ................................................................................... 218

Fax Send error. ...................................................................................... 219

Fax storage is full. Canceling the fax receive. ............................................ 219

Fax storage is full. Canceling the fax receive. ............................................ 219

Fax storage is full. Canceling the fax send. ................................................ 220

No dial tone. ......................................................................................... 220

No fax answer. Canceled send. ............................................................... 220

No fax answer. Redial pending. .............................................................. 221

No fax detected. .................................................................................... 221

Troubleshoot fax codes and trace reports ................................................................. 223

View and interpret fax error codes ........................................................... 223

Fax trace report ..................................................................................... 224

Fax logs and reports .............................................................................................. 224

Print all fax reports ................................................................................. 225

Print individual fax reports ....................................................................... 225

Set the fax error report ............................................................................ 226

Change error correction and fax speed ................................................................... 226

Set the fax-error-correction mode .............................................................. 226

Change the fax speed ............................................................................ 227

Solve problems sending faxes ................................................................................. 227

An error message displays on the control panel ......................................... 227

The Communication error. message displays .............................. 227

No dial tone. .......................................................................... 228

The Fax is busy. message displays ............................................ 229

The No fax answer. message displays ....................................... 229

Document feeder paper jam ..................................................... 230

The Fax storage is full. message displays ................................... 230

Scanner error ......................................................................... 230

The control panel displays a Ready message with no attempt to send the fax . 230

The control panel displays the message "Storing page 1" and does not

progress beyond that message ................................................................. 231

Faxes can be received, but not sent .......................................................... 231

Unable to use fax functions from the control panel ...................................... 231

Unable to use speed dials ....................................................................... 232

Unable to use group dials ....................................................................... 232

Receive a recorded error message from the phone company when trying to

send a fax ............................................................................................. 232

Unable to send a fax when a phone is connected to the product .................. 233

Solve problems receiving faxes ............................................................................... 234

xii ENWW

Page 13

The fax does not respond ........................................................................ 234

The fax has a dedicated phone line ........................................... 234

An answering machine is connected to the product ..................... 234

A telephone handset is connected to the product ......................... 235

The Answer Mode setting is set to the Manual setting ................... 235

Voice mail is available on the fax line ........................................ 235

The product is connected to a DSL phone service ........................ 236

The product uses a fax over IP or VoIP phone service ................... 236

An error message displays on the control panel ......................................... 237

The No fax detected. message displays ..................................... 237

The Communication error. message displays .............................. 237

The Fax storage is full. message displays ................................... 238

The Fax is busy. message displays ............................................ 238

A fax is received but does not print .......................................................... 239

The Private Receive feature is on ............................................... 239

Sender receives a busy signal .................................................................. 239

A handset is connected to the product ........................................ 239

A phone line splitter is being used ............................................. 239

No dial tone .......................................................................................... 239

Cannot send or receive a fax on a PBX line ............................................... 239

Solve general fax problems .................................................................................... 240

Faxes are sending slowly ........................................................................ 240

Fax quality is poor ................................................................................. 241

Fax cuts off or prints on two pages ........................................................... 241

Product updates ................................................................................................................... 243

3 Parts and diagrams ...................................................................................................... 245

Order parts by authorized service providers ............................................................................ 246

Orderable parts .................................................................................................... 246

Whole unit replacement ......................................................................................... 246

Related documentation and software ....................................................................... 247

Supplies and accessories ....................................................................................... 247

Service parts ........................................................................................................ 247

How to use the parts lists and diagrams .................................................................................. 248

Scanner and document feeder main assemblies ....................................................................... 250

Covers ................................................................................................................................ 252

Internal assemblies ............................................................................................................... 254

Internal assemblies (1 of 5) ..................................................................................... 254

Internal assemblies (2 of 5) ..................................................................................... 256

Internal components (3 of 5) ................................................................................... 258

Internal assemblies (4 of 5) ..................................................................................... 260

ENWW xiii

Page 14

Internal assemblies (5 of 5) ..................................................................................... 262

Internal assemblies (simplex models) ........................................................................ 264

Internal assemblies (duplex models) ......................................................................... 266

PCAs ................................................................................................................... 268

Input device(s) ..................................................................................................................... 270

250-sheet paper feeder (optional Tray 3) ................................................................. 270

Alphabetical parts list ........................................................................................................... 272

Numerical parts list .............................................................................................................. 275

Appendix A Service and support ..................................................................................... 279

Hewlett-Packard limited warranty statement ............................................................................. 280

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement .................. 282

Data stored on the print cartridge ........................................................................................... 283

End User License Agreement .................................................................................................. 284

OpenSSL ............................................................................................................................. 287

Customer support ................................................................................................................. 288

Appendix B Product specifications ................................................................................... 289

Physical specifications .......................................................................................................... 290

Power consumption, electrical specifications, and acoustic emissions .......................................... 290

Environmental specifications .................................................................................................. 290

Appendix C Regulatory information ................................................................................. 291

FCC regulations ................................................................................................................... 292

Environmental product stewardship program ........................................................................... 292

Protecting the environment ...................................................................................... 292

Ozone production ................................................................................................. 292

Power consumption ............................................................................................... 292

Toner consumption ................................................................................................ 293

Paper use ............................................................................................................. 293

Plastics ................................................................................................................. 293

HP LaserJet print supplies ....................................................................................... 293

Return and recycling instructions ............................................................................. 293

United States and Puerto Rico .................................................................. 293

Multiple returns (more than one cartridge) .................................. 294

Single returns .......................................................................... 294

Shipping ................................................................................ 294

Non-U.S. returns .................................................................................... 294

Paper .................................................................................................................. 295

Material restrictions ............................................................................................... 295

xiv ENWW

Page 15

Disposal of waste equipment by users in private households in the European Union ...... 295

Chemical substances ............................................................................................. 296

Material Safety Data Sheet (MSDS) ......................................................................... 296

For more information ............................................................................................. 297

Declaration of conformity ...................................................................................................... 298

Declaration of conformity (wireless models) ............................................................................. 300

Certificate of volatility ........................................................................................................... 302

Types of memory ................................................................................................... 302

Volatile memory ..................................................................................... 302

Non-volatile memory .............................................................................. 302

Safety statements ................................................................................................................. 303

Laser safety .......................................................................................................... 303

Canadian DOC regulations .................................................................................... 303

VCCI statement (Japan) .......................................................................................... 303

Power cord instructions .......................................................................................... 303

Power cord statement (Japan) ................................................................................. 303

EMC statement (Korea) .......................................................................................... 304

Laser statement for Finland ..................................................................................... 304

GS statement (Germany) ........................................................................................ 305

Substances Table (China) ....................................................................................... 305

Restriction on Hazardous Substances statement (Turkey) ............................................. 305

Restriction on Hazardous Substances statement (Ukraine) ........................................... 305

Additional statements for telecom (fax) products ....................................................................... 306

EU Statement for Telecom Operation ....................................................................... 306

New Zealand Telecom Statements ........................................................................... 306

Additional FCC statement for telecom products (US) .................................................. 306

Telephone Consumer Protection Act (US) .................................................................. 307

Industry Canada CS-03 requirements ...................................................................... 307

Vietnam Telecom wired/wireless marking for ICTQC Type approved products ............. 308

Additional statements for wireless products .............................................................................. 309

FCC compliance statement—United States ................................................................ 309

Australia statement ................................................................................................ 309

Brazil ANATEL statement ........................................................................................ 309

Canadian statements ............................................................................................. 309

European Union regulatory notice ........................................................................... 309

Notice for use in France ......................................................................................... 310

Notice for use in Russia ......................................................................................... 310

Korean statement .................................................................................................. 310

Taiwan statement .................................................................................................. 311

Vietnam Telecom wired/wireless marking for ICTQC Type approved products ............. 311

ENWW xv

Page 16

Index ............................................................................................................................... 313

xvi ENWW

Page 17

List of tables

Table 1-1 Common fasteners ................................................................................................................. 4

Table 2-1 Major components ............................................................................................................. 121

Table 2-2 Solenoid, sensors, and motors .............................................................................................. 123

Table 2-3 Rollers ............................................................................................................................... 124

Table 2-4 PCAs ................................................................................................................................ 125

Table 2-5 Optional 250-sheet cassette ................................................................................................. 126

Table 2-6 Repetitive image defects ...................................................................................................... 136

Table 2-7 Event-log messages ............................................................................................................. 176

Table 2-8 Event-log-only messages ...................................................................................................... 178

Table 2-9 Secondary service menu ...................................................................................................... 212

Table 3-1 Order parts, accessories, and supplies .................................................................................. 246

Table 3-2 Pro 300 Color MFP M375nw .............................................................................................. 246

Table 3-3 Pro 400 Color MFP M475dn ............................................................................................... 246

Table 3-4 Pro 400 Color M475dw ..................................................................................................... 246

Table 3-5 Related documentation and software .................................................................................... 247

Table 3-6 Scanner and document feeder main assemblies ..................................................................... 251

Table 3-7 Covers

Table 3-8 Internal assemblies (1 of 7) .................................................................................................. 255

Table 3-9 Internal assemblies (2 of 7) .................................................................................................. 257

Table 3-10 Internal assemblies (3 of 7) ................................................................................................ 259

Table 3-11 Internal assemblies (4 of 7) ................................................................................................ 261

Table 3-12 Internal assemblies (5 of 7) ................................................................................................ 263

Table 3-13 Internal assemblies (simplex models) ................................................................................... 265

Table 3-14 Internal assemblies (duplex models) .................................................................................... 267

Table 3-15 PCAs .............................................................................................................................. 269

Table 3-16 250-sheet paper feeder (optional Tray 3) ............................................................................ 271

Table 3-17 Alphabetical parts list ....................................................................................................... 272

Table 3-18 Numerical parts list ........................................................................................................... 275

Table B-1 Physical specifications ......................................................................................................... 290

Table B-2 Environmental specifications

1,2

........................................................................................................................... 253

1

............................................................................................... 290

ENWW xvii

Page 18

List of figures

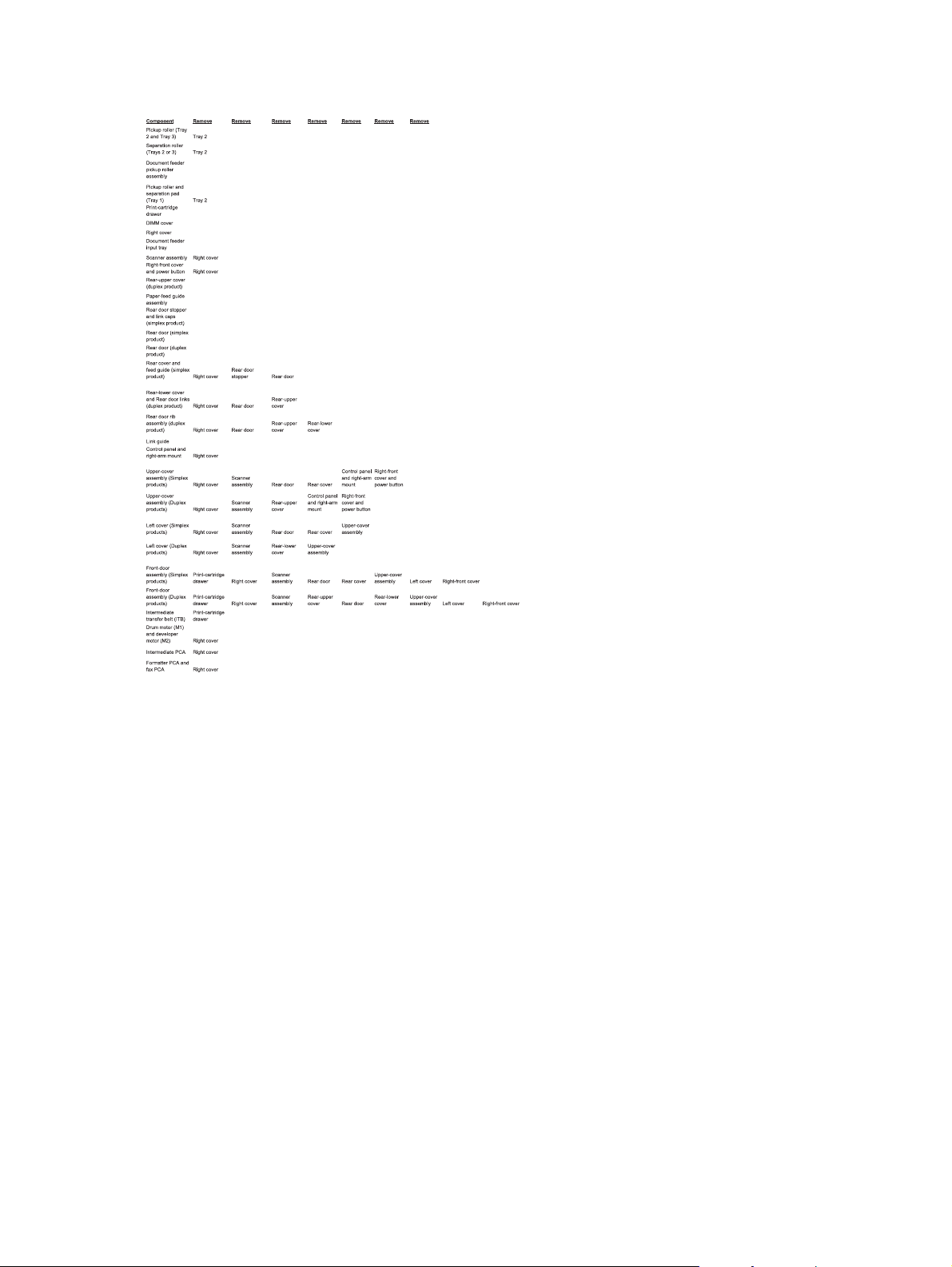

Figure 1-1 Phillips and pozidrive screwdriver comparison .......................................................................... 3

Figure 1-2 Parts removal order (1 of 2) .................................................................................................... 7

Figure 1-3 Parts removal order (2 of 2) .................................................................................................... 8

Figure 1-4 Remove the pickup roller (1 of 2) ........................................................................................... 11

Figure 1-5 Remove the pickup roller (2 of 2) ........................................................................................... 12

Figure 1-6 Remove the pickup roller (1 of 3) ........................................................................................... 13

Figure 1-7 Remove the separation roller (2 of 3) ..................................................................................... 14

Figure 1-8 Remove the separation roller (3 of 3) ..................................................................................... 14

Figure 1-9 Reinstall the separation roller ................................................................................................ 15

Figure 1-10 Remove the document feeder pickup roller assembly (1 of 2) .................................................. 16

Figure 1-11 Remove the document feeder pickup roller assembly (2 of 2) .................................................. 16

Figure 1-12 Remove the Tray 1 pickup roller (1 of 3) .............................................................................. 18

Figure 1-13 Remove the Tray 1 pickup roller (2 of 3) .............................................................................. 18

Figure 1-14 Remove the Tray 1 pickup roller (3 of 3) .............................................................................. 19

Figure 1-15 Remove the Tray 1 separation pad ...................................................................................... 19

Figure 1-16 Remove the print-cartridge drawer (1 of 3) ........................................................................... 20

Figure 1-17 Remove the print-cartridge drawer (2 of 3) ........................................................................... 20

Figure 1-18 Remove the print-cartridge drawer (3 of 3) ........................................................................... 21

Figure 1-19 Remove the DIMM cover .................................................................................................... 22

Figure 1-20 Remove the right cover (1 of 3) ........................................................................................... 23

Figure 1-21 Remove the right cover (2 of 3) ........................................................................................... 23

Figure 1-22 Remove the right cover (3 of 3) ........................................................................................... 24

Figure 1-23 Remove the document feeder input tray (2 of 2) .................................................................... 25

Figure 1-24 Remove the document feeder input tray (2 of 2) .................................................................... 25

Figure 1-25 Remove the scanner assembly (1 of 4) ................................................................................. 26

Figure 1-26 Remove the scanner assembly (2 of 4) ................................................................................. 26

Figure 1-27 Remove the scanner assembly (3 of 4) ................................................................................. 27

Figure 1-28 Re

Figure 1-29 Remove the rear-upper cover (1 of 2) ................................................................................... 30

Figure 1-30 Remove the rear-upper cover (2 of 2) ................................................................................... 30

Figure 1-31 Remove the feed assembly (1 of 2) ...................................................................................... 31

Figure 1-32 Remove the feed assembly (2 of 2) ...................................................................................... 31

move the scanner assembly (4 of 4) ................................................................................. 27

ENWW xix

Page 19

Figure 1-33 Remove the Rear-door stopper and link caps (simplex product) (1 of 2) .................................... 32

Figure 1-34 Remove the Rear-door stopper and link cap (simplex product) (2 of 2) ..................................... 32

Figure 1-35 Remove the rear door (simplex product) (1 of 4) .................................................................... 33

Figure 1-36 Remove the rear door (simplex product) (2 of 4) .................................................................... 33

Figure 1-37 Remove the rear door (simplex product) (3 of 4) .................................................................... 34

Figure 1-38 Remove the rear door (simplex product) (4 of 4) .................................................................... 34

Figure 1-39 Remove the rear door (duplex product) (1 of 4) ..................................................................... 35

Figure 1-40 Remove the rear door (duplex product) (2 of 4) ..................................................................... 35

Figure 1-41 Remove the rear door (duplex product) (3 of 4) ..................................................................... 36

Figure 1-42 Remove the rear door (duplex product) (4 of 4) ..................................................................... 36

Figure 1-43 Remove the rear cover and feed guide (simplex product) (1 of 6) ............................................ 37

Figure 1-44 Remove the rear cover and feed guide (simplex product) (2 of 6) ............................................ 38

Figure 1-45 Remove the rear cover and feed guide (simplex product) (3 of 6) ............................................ 38

Figure 1-46 Remove the rear cover and feed guide (simplex product) (4 of 6) ............................................ 39

Figure 1-47 Remove the rear cover and feed guide (simplex product) (5 of 6) ............................................ 40

Figure 1-48 Remove the rear cover and feed guide (simplex product) (6 of 6) ............................................ 40

Figure 1-49 Remove the rear- lower cover and rear-door links (duplex product) (1 of 6) ............................... 41

Figure 1-50 Remove the rear-lower cover and rear-door links (duplex product) (2 of 6) ................................ 42

Figure 1-51 Remove the rear-lower cover and rear-door links (duplex product) (3 of 6) ................................ 42

Figure 1-52 Remove the rear-lower cover and link-guides (duplex product) (4 of 6) ..................................... 43

Figure 1-53 Remove the rear-lower cover and link-guides (duplex product) (5 of 6) ..................................... 43

Figure 1-54 Remove the rear-lower cover and rear-door links (duplex product) (6 of 6) ................................ 44

Figure 1-55 Remove the rear-door rib assembly (duplex product) (1 of 3) .................................................. 45

Figure 1-56 Remove the rear-door rib assembly (duplex product) (2 of 3) .................................................. 46

Figure 1-57 Remove the rear-door rib assembly (duplex product) (3 of 3) .................................................. 46

Figure 1-58 Replace the link guide (simplex products) ............................................................................. 47

Figure 1-59 Replace the link guide (duplex products) .............................................................................. 47

Figure 1-60 Remove the control panel and right-arm mount (1 of 3) .......................................................... 48

Figure 1-61 Remove the control panel and right-arm mount (2 of 3) .......................................................... 48

Figure 1-62 Remove the control panel and right-arm mount (3 of 3) .......................................................... 49

Figure 1-63 Reinstall the co

Figure 1-64 Reinstall the control panel and right-arm mount (2 of 2) .......................................................... 50

Figure 1-65 Remove the upper-cover assembly (1 of 3) ............................................................................ 51

Figure 1-66 Remove the upper-cover assembly (2 of 3) ............................................................................ 52

Figure 1-67 Remove the upper-cover assembly (3 of 3) ............................................................................ 52

Figure 1-68 Reinstall the upper-cover assembly (1 of 3) ........................................................................... 53

Figure 1-69 Reinstall the upper-cover assembly (2 of 3) ........................................................................... 53

Figure 1-70 Reinstall the upper-cover assembly (3 of 3) ........................................................................... 54

Figure 1-71 Remove the left cover (1 of 3) ............................................................................................. 55

Figure 1-72 Remove the left cover (2 of 3) ............................................................................................. 56

Figure 1-73 Remove the left cover (3 of 3) ............................................................................................. 56

ntrol panel and right-arm mount (1 of 2) .......................................................... 49

xx ENWW

Page 20

Figure 1-74 Reinstall the left cover (1 of 2) ............................................................................................. 57

Figure 1-75 Reinstall the left cover (2 of 2) ............................................................................................. 57

Figure 1-76 Remove the front-door assembly (1 of 10) ............................................................................. 58

Figure 1-77 Remove the front-door assembly (2 of 10) ............................................................................. 59

Figure 1-78 Remove the front-door assembly (3 of 10) ............................................................................. 59

Figure 1-79 Remove the front-door assembly (4 of 10) ............................................................................. 60

Figure 1-80 Remove the front-door assembly (5 of 10) ............................................................................. 60

Figure 1-81 Remove the front-door assembly (6 of 10) ............................................................................. 61

Figure 1-82 Remove the front-door assembly (7 of 10) ............................................................................. 61

Figure 1-83 Remove the front-door assembly (8 of 10) ............................................................................. 62

Figure 1-84 Remove the front-door assembly (9 of 10) ............................................................................. 62

Figure 1-85 Remove the front-door assembly (10 of 10) ........................................................................... 63

Figure 1-86 Reinstall the front-door assembly (1 of 2) .............................................................................. 63

Figure 1-87 Reinstall the front-door assembly (2 of 2) .............................................................................. 64

Figure 1-88 Remove the ITB (1 of 6) ...................................................................................................... 65

Figure 1-89 Remove the ITB (2 of 6) ...................................................................................................... 65

Figure 1-90 Remove the ITB (3 of 6) ...................................................................................................... 66

Figure 1-91 Remove the ITB (4 of 6) ...................................................................................................... 66

Figure 1-92 Remove the ITB (5 of 6) ...................................................................................................... 67

Figure 1-93 Remove the ITB (6 of 6) ...................................................................................................... 67

Figure 1-94 Reinstall the ITB ................................................................................................................. 68

Figure 1-95 Remove motor M1 and motor M2 (1 of 6) ............................................................................ 69

Figure 1-96 Remove motor M1 and motor M2 (2 of 6) ............................................................................ 70

Figure 1-97 Remove motor M1 and motor M2 (3 of 6) ............................................................................ 71

Figure 1-98 Remove motor M1 and motor M2 (4 of 6) ............................................................................ 72

Figure 1-99 Remove motor M1 and motor M2 (5 of 6) ............................................................................ 72

Figure 1-100 Remove motor M1 and motor M2 (6 of 6) .......................................................................... 73

Figure 1-101 Reinstall the motor M1 and motor M2 wire-harness retainer .................................................. 74

Figure 1-102 Remo

Figure 1-103 Remove the Intermediate PCA (2 of 2) ................................................................................ 75

Figure 1-104 Remove the formatter (1 of 4; base model) ......................................................................... 77

Figure 1-105 Remove the formatter (2 of 4; fax model) ............................................................................ 77

Figure 1-106 Remove the formatter (3 of 4; base model) ......................................................................... 78

Figure 1-107 Remove the formatter (4 of 4; fax model) ............................................................................ 78

Figure 1-108 Remove the wirelss PCA (1 of 2) ....................................................................................... 79

Figure 1-109 Remove the wirelss PCA (2 of 2) ....................................................................................... 79

Figure 1-110 Remove the DC controller PCA (1 of 2) .............................................................................. 81

Figure 1-111 Remove the DC controller PCA (2 of 2) .............................................................................. 82

Figure 1-112 Remove the fuser-motor assembly (1 of 6) ........................................................................... 83

Figure 1-113 Remove the fuser-motor assembly (2 of 6) ........................................................................... 84

Figure 1-114 Remove the fuser-motor assembly (3 of 6) ........................................................................... 84

ve the Intermediate PCA (1 of 2) ................................................................................ 75

ENWW xxi

Page 21

Figure 1-115 Remove the fuser-motor assembly (4 of 6) ........................................................................... 85

Figure 1-116 Remove the fuser-motor assembly (5 of 6) ........................................................................... 85

Figure 1-117 Remove the fuser-motor assembly (6 of 6) ........................................................................... 86

Figure 1-118 Reinstall the fuser-motor assembly ...................................................................................... 86

Figure 1-119 Remove the high-voltage power-supply PCA (1 of 5) ............................................................ 87

Figure 1-120 Remove the high-voltage power-supply PCA (2 of 5) ............................................................ 88

Figure 1-121 Remove the high-voltage power-supply PCA (3 of 5) ............................................................ 88

Figure 1-122 Remove the high-voltage power-supply PCA (4 of 5) ............................................................ 89

Figure 1-123 Remove the high-voltage power-supply PCA (5 of 5) ............................................................ 89

Figure 1-124 Remove the color-misregistration sensor assembly PCA (1 of 4) ............................................. 90

Figure 1-125 Remove the color-misregistration sensor assembly PCA (2 of 4) ............................................. 91

Figure 1-126 Remove the color-misregistration sensor assembly PCA (3 of 4) ............................................. 91

Figure 1-127 Remove the color-misregistration sensor assembly PCA (4 of 4) ............................................. 92

Figure 1-128 Reinstall the color-misregistration sensor assembly PCA (1 of 2) ............................................. 92

Figure 1-129 Reinstall the color-misregistration sensor assembly PCA (2 of 2) ............................................. 93

Figure 1-130 Remove the fan (FM1) (1 of 2) .......................................................................................... 94

Figure 1-131 Remove the fan (FM1) (2 of 2) .......................................................................................... 95

Figure 1-132 Remove the USB PCA (fax/memory-card models) ................................................................ 96

Figure 1-133 Remove the duplex-reverse drive assembly (1 of 4) .............................................................. 97

Figure 1-134 Remove the duplex-reverse drive assembly (2 of 4) .............................................................. 98

Figure 1-135 Remove the duplex-reverse drive assembly (3 of 4) .............................................................. 98

Figure 1-136 Remove the duplex-reverse drive assembly (4 of 4) .............................................................. 99

Figure 1-137 Remove the fuser (1 of 8) ............................................................................................... 101

Figure 1-138 Remove the fuser (2 of 8) ............................................................................................... 102

Figure 1-139 Remove the fuser (3 of 8) ............................................................................................... 102

Figure 1-140 Remove the fuser (4 of 8) ............................................................................................... 103

Figure 1-141 Remove the fuser (5 of 8) ............................................................................................... 103

Figure 1-142 Remove the fuser (6 of 8) ............................................................................................... 104

Figure 1-143 Remove the fuser (7 of 8) ............................................................................................... 104

Figure 1-144 Remove the fuser (8 of 8) ............................................................................................... 105

Figure 1-145 Reinstall the fuser ........................................................................................................... 106

Figure 1-146 Remove the paper-delivery assembly (1 of 4) .................................................................... 107

Figure 1-147 Remove the paper-delivery assembly (2 of 4) .................................................................... 108

Figure 1-

Figure 1-149 Remove the paper-delivery assembly (4 of 4) .................................................................... 109

Figure 1-150 Remove the tray cassettes and optional Tray 3 assembly (1 of 2) ......................................... 110

Figure 1-151 Remove the tray cassettes and optional Tray 3 assembly (2 of 2) ......................................... 110

Figure 2-1 Control-panel test .............................................................................................................. 117

Figure 2-2 DC controller connectors .................................................................................................... 119

Figure 2-3 Major components ............................................................................................................ 121

Figure 2-4 Motors and fans ................................................................................................................ 123

148 Remove the paper-delivery assembly (3 of 4) .................................................................... 108

xxii ENWW

Page 22

Figure 2-5 Rollers .............................................................................................................................. 124

Figure 2-6 PCAs ............................................................................................................................... 125

Figure 2-7 Optional 250-sheet cassette ................................................................................................ 126

Figure 2-8 Timing diagram ................................................................................................................. 127

Figure 2-9 Circuit diagram ................................................................................................................. 128

Figure 2-10 CPU diagram ................................................................................................................. 129

Figure 2-11 ASIC diagram ................................................................................................................. 130

Figure 2-12 HVT/Toner EMP diagram ................................................................................................. 131

Figure 2-13 Driver PCA diagram ........................................................................................................ 132

Figure 2-14 Duplexer PCA diagram .................................................................................................... 133

Figure 2-15 FSR diagram ................................................................................................................... 134

Figure 2-16 Control-panel test ............................................................................................................ 175

Figure 2-17 Control-panel test ............................................................................................................ 211

Figure 3-1 Scanner and document feeder main assemblies .................................................................... 250

Figure 3-2 External panels and covers ................................................................................................. 252

Figure 3-3 Internal assemblies (1 of 7) ................................................................................................. 254

Figure 3-4 Internal assemblies (2 of 2) ................................................................................................. 256

Figure 3-5 Internal assemblies (3 of 7) ................................................................................................. 258

Figure 3-6 Internal assemblies (4 of 7) ................................................................................................. 260

Figure 3-7 Internal assemblies (5 of 7) ................................................................................................. 262

Figure 3-8 Internal assemblies (simplex models) .................................................................................... 264

Figure 3-9 Internal assemblies (duplex models) ..................................................................................... 266

Figure 3-10 PCAs ............................................................................................................................. 268

Figure 3-11 250-sheet paper feeder (optional Tray 3) ........................................................................... 270

ENWW xxiii

Page 23

1 Removal and replacement

Removal and replacement strategy

●

Service approach

●

Removal and replacement procedures

●

ENWW 1

Page 24

Removal and replacement strategy

This chapter discusses the removal and replacement of field replaceable units (FRUs) only.

Replacing FRUs is generally the reverse of removal. Occasionally, notes and tips are included to

provide directions for difficult or critical replacement procedures.

not

HP does

Note the length, diameter, color, type, and location of each screw. Be sure to return each screw to its

original location during reassembly.

Incorrectly routed or loose wire harnesses can interfere with other internal components and can become