Page 1

HP LaserJet M1522 MFP Series

Service Manual

Page 2

Page 3

HP LaserJet M1522 MFP Series

Service Manual

Page 4

Copyright and License

© 2008 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Edition 1, 1/2008

Part number: CB534-90945

Trademark Credits

®

Adobe

, Acrobat®, and PostScript® are

trademarks of Adobe Systems Incorporated.

Microsoft

®

, Windows®, and Windows NT

®

are U.S. registered trademarks of Microsoft

Corporation.

®

UNIX

is a registered trademark of The Open

Group.

Page 5

Table of contents

1 Product information

Quick access to product information .................................................................................................... 2

Product comparison ............................................................................................................................. 3

Product features ................................................................................................................................... 4

Product walkaround .............................................................................................................................. 5

Front view ............................................................................................................................ 5

Back view ............................................................................................................................. 5

Interface ports ...................................................................................................................... 6

Control-panel ....................................................................................................................... 6

Serial number and model number location .......................................................................... 7

Software description ............................................................................................................................. 8

Supported operating systems .............................................................................................. 8

Supported printer drivers ..................................................................................................... 8

Software included with the product ...................................................................................... 8

Recommended installation for Windows ............................................................. 8

Express installation (USB or network) ................................................................. 9

Macintosh software ............................................................................................. 9

Software for Windows .......................................................................................................................... 9

HP ToolboxFX ..................................................................................................................... 9

Embedded Web server (EWS) .......................................................................................... 10

Software for Macintosh ....................................................................................................................... 10

HP Director ........................................................................................................................ 10

Macintosh Configure Device (Mac OS X v10.3, v10.4, and later) ..................................... 10

PDEs (Mac OS X v10.3, v10.4, and later) ......................................................................... 11

Uninstall software ............................................................................................................................... 11

Windows ............................................................................................................................ 11

Macintosh .......................................................................................................................... 11

Media specifications ........................................................................................................................... 12

Supported paper and print media sizes ............................................................................. 12

Supported paper types and tray capacity .......................................................................... 13

2 Installation

Site preparations ................................................................................................................................ 16

Operating environment ...................................................................................................... 16

Minimum system requirements .......................................................................................... 17

What was in the box ........................................................................................................................... 18

Install input devices ............................................................................................................................ 19

ADF input tray .................................................................................................................... 19

Priority input tray ................................................................................................................ 20

ENWW iii

Page 6

Install supplies .................................................................................................................................... 22

3 Maintenance

Manage supplies ................................................................................................................................ 26

Clean the product ............................................................................................................................... 30

Management tools .............................................................................................................................. 36

Tray 1 ................................................................................................................................. 21

Install the print cartridge .................................................................................................... 22

Life expectancies of supplies ............................................................................................. 26

Check and order supplies .................................................................................................. 26

Store supplies .................................................................................................................... 26

Replace supplies ............................................................................................................... 27

Print cartridge .................................................................................................... 27

HP policy on non-HP supplies ........................................................................................... 28

HP fraud hotline ................................................................................................................. 29

Clean the exterior .............................................................................................................. 30

Clean the flatbed scanner glass ........................................................................................ 30

Clean the scanner-cover backing ...................................................................................... 31

Clean the ADF pickup-roller assembly .............................................................................. 32

Clean the paper path ......................................................................................................... 34

Clean the paper path from HP ToolboxFX ........................................................ 34

Clean the paper path from the product control panel ........................................ 34

Calibrate the scanner ......................................................................................................... 34

Calibrate the scanner from HP ToolboxFX ....................................................... 35

Calibrate the scanner from the product control panel ....................................... 35

Information pages .............................................................................................................. 36

HP ToolboxFX ................................................................................................................... 37

View HP ToolboxFX .......................................................................................... 37

Status ................................................................................................................ 38

Event log ........................................................................................... 38

Alerts ................................................................................................................. 38

Set up status alerts ........................................................................... 38

Set up e-mail alerts ........................................................................... 38

Fax .................................................................................................................... 39

Fax tasks .......................................................................................... 39

Fax phone book ................................................................................ 39

Fax send log ..................................................................................... 41

Fax receive log ................................................................................. 41

Block Faxes ...................................................................................... 41

Help ................................................................................................................... 41

System Settings ................................................................................................ 42

Device information ............................................................................ 42

Paper handling ................................................................................. 43

Print quality ....................................................................................... 43

Paper types ...................................................................................... 43

System setup .................................................................................... 44

Service .............................................................................................. 44

Device polling ................................................................................... 44

Print Settings ..................................................................................................... 44

Printing ............................................................................................. 44

iv ENWW

Page 7

4 Operational theory

Basic operation ................................................................................................................................... 48

Scanner and ADF functions and operation ........................................................................................ 50

Internal components (base unit) ......................................................................................................... 54

Engine control system ........................................................................................................................ 55

Laser/scanner system ........................................................................................................................ 57

Pickup/feed/delivery system ............................................................................................................... 58

Image-formation system .................................................................................................................... 59

Fax functions and operation (fax models only) ................................................................................... 63

PCL 5e .............................................................................................. 45

PostScript ......................................................................................... 45

Network Settings ............................................................................................... 45

Embedded Web server ...................................................................................................... 45

Features ............................................................................................................ 45

Use HP Web Jetadmin software ........................................................................................ 46

Sequence of operation for the base unit ............................................................................ 48

Scanner functions ............................................................................................................. 50

Scanner operation ............................................................................................................. 51

ADF operation .................................................................................................................... 51

ADF paper path and ADF sensors ..................................................................................... 52

ADF jam detection ............................................................................................................. 53

Computer and network security features ........................................................................... 63

PSTN operation ................................................................................................................. 63

Receive faxes when you hear fax tones ............................................................................ 63

Distinctive ring function ...................................................................................................... 64

Fax by using Voice over IP services .................................................................................. 64

The fax subsystem ............................................................................................................. 65

Fax card in the fax subsystem ........................................................................................... 65

Safety isolation .................................................................................................. 65

Safety-protection circuitry .................................................................................. 65

Data path ........................................................................................................... 66

Hook state ......................................................................................................... 66

Downstream device detection ........................................................................... 66

Hook switch control ........................................................................................... 66

Ring detect ........................................................................................................ 67

Line current control ........................................................................................... 67

Billing- (metering-) tone filters ........................................................................... 67

Fax page storage in flash memory .................................................................................... 67

Stored fax pages ............................................................................................... 67

Advantages of flash memory storage ............................................................... 67

5 Removal and replacement

Removal and replacement strategy .................................................................................................... 70

Introduction ........................................................................................................................ 70

Removal and replacement warnings, cautions, notes and tips ......................... 70

Electrostatic discharge ...................................................................................... 71

Required tools ................................................................................................... 71

Before performing service .................................................................................................. 71

After performing service ..................................................................................................... 72

ENWW v

Page 8

Post-service tests .............................................................................................................. 73

Test 1 (print-quality test) ................................................................................... 73

Test 2 (copy-quality test) ................................................................................... 73

Test 3 (fax-quality test) ...................................................................................... 73

Parts removal order ........................................................................................................... 74

Scanner and ADF components .......................................................................................................... 75

ADF input tray .................................................................................................................... 75

Flatbed lid .......................................................................................................................... 76

Link assemblies and scanner support-frame springs ........................................................ 79

Control-panel bezel ............................................................................................................ 81

Control-panel assembly ..................................................................................................... 82

ADF separation pad ........................................................................................................... 83

ADF input-tray flag ............................................................................................................. 84

ADF pickup roller assembly .............................................................................................. 85

ADF scanner glass ............................................................................................................ 88

Scanner assembly ............................................................................................................. 90

Product base ...................................................................................................................................... 95

Print cartridge .................................................................................................................... 95

Separation pad (product base) .......................................................................................... 96

Pickup roller (product base) ............................................................................................... 97

Scanner cushions ............................................................................................................ 100

Media input tray ............................................................................................................... 101

Transfer roller .................................................................................................................. 103

Side covers ...................................................................................................................... 104

Print-cartridge door .......................................................................................................... 106

Rear cover and fuser cover ............................................................................................. 107

Front cover ....................................................................................................................... 109

Speaker assembly ........................................................................................................... 111

Formatter and fax card .................................................................................................... 113

Power supply ................................................................................................................... 114

Scanner support-frame .................................................................................................... 118

Laser/scanner assembly .................................................................................................. 121

Main motor ....................................................................................................................... 125

Fuser ................................................................................................................................ 128

Paper-pickup assembly ................................................................................................... 132

Drive-gear assembly and drive belt ................................................................................. 135

6 Problem solve

Problem-solving checklist ................................................................................................................. 138

Control-panel messages .................................................................................................................. 140

Alert and warning messages .......................................................................................... 140

Alert and warning message tables .................................................................. 140

Critical error messages .................................................................................................... 147

Critical error message-tables .......................................................................... 147

Clear jams ........................................................................................................................................ 149

Causes of jams ................................................................................................................ 149

Where to look for jams ..................................................................................................... 150

Clear jams from the ADF ................................................................................................. 151

Clear jams from the input-tray areas ............................................................................... 153

Clear jams from the output bin ......................................................................................... 155

vi ENWW

Page 9

Clear jams from the print-cartridge area .......................................................................... 156

Print problems .................................................................................................................................. 157

Print-quality problems ...................................................................................................... 157

Improve print quality ........................................................................................ 157

Print-quality settings ....................................................................... 157

Identify and correct print defects ..................................................................... 158

Print-quality checklist ...................................................................... 158

General print-quality issues ............................................................ 158

Scan problems ................................................................................................................................. 163

Solve scanned-image problems ...................................................................................... 163

Scan-quality problems ..................................................................................................... 165

Prevent problems ............................................................................................ 165

Solve scan-quality problems ........................................................................... 165

Copy problems ................................................................................................................................. 166

Prevent problems ............................................................................................................. 166

Image problems ............................................................................................................... 166

Media-handling problems ................................................................................................ 167

Performance problems .................................................................................................... 169

Fax problems (fax models only) ....................................................................................................... 170

General fax problem-solve ............................................................................................... 170

Problems receiving faxes ................................................................................................. 171

Problems sending faxes .................................................................................................. 174

Voice-call problems ......................................................................................................... 175

Media-handling problems ................................................................................................ 176

Performance problems .................................................................................................... 177

Functional checks ............................................................................................................................. 178

Engine test page .............................................................................................................. 178

Drum rotation test ............................................................................................................ 178

Half self-test functional check .......................................................................................... 179

Perform a half self-test check .......................................................................... 179

Perform other checks ..................................................................................... 179

Heating element check .................................................................................................... 180

High-voltage contacts check ............................................................................................ 180

Check the print-cartridge contacts ................................................................ 180

Check the high-voltage connector assembly .................................................. 181

Service-mode functions .................................................................................................................... 182

NVRAM initialization ........................................................................................................ 182

Super NVRAM initialization .............................................................................................. 182

Secondary service menu ................................................................................................. 182

Problem-solve tools .......................................................................................................................... 184

Product information pages and reports ............................................................................ 184

Configuration page .......................................................................................... 184

Supplies Status page ...................................................................................... 184

PCL, PCL 6, or PS font list .............................................................................. 184

Demo page ...................................................................................................... 185

Usage page ..................................................................................................................... 185

Menu map ........................................................................................................................ 185

Network report ................................................................................................................. 185

Fax reports ....................................................................................................................... 186

Fax activity log ................................................................................................ 186

ENWW vii

Page 10

Fax confirmation report ................................................................................... 186

Last call report ................................................................................................. 186

Phone book report ........................................................................................... 186

Billing-code report ........................................................................................... 188

HP ToolboxFX ................................................................................................................. 188

View HP ToolboxFX ........................................................................................ 188

Troubleshooting tab ........................................................................................ 188

Service menu ................................................................................................................... 189

Restore the factory-set defaults ...................................................................... 189

Clean the paper path ....................................................................................... 190

T.30 protocol trace .......................................................................................... 191

Archive print .................................................................................................... 191

Problem-solve diagrams ................................................................................................................... 192

Repetitive image defects ................................................................................................. 192

Interface ports .................................................................................................................. 193

ECU connectors ............................................................................................................... 194

Formatter PCA ................................................................................................................. 195

Fax card ........................................................................................................................... 196

Solenoid and motor .......................................................................................................... 197

Rollers .............................................................................................................................. 198

Sensors ............................................................................................................................ 199

Major components ........................................................................................................... 200

PCAs (base unit) .............................................................................................................. 201

Scanner and ADF ............................................................................................................ 202

Circuit diagram ................................................................................................................. 203

Firmware updates ............................................................................................................................. 204

Firmware update by using a flash executable file ............................................................ 204

7 Parts

Ordering information ......................................................................................................................... 206

Supplies and hinge tool .................................................................................................................... 206

Cable and interface accessories ...................................................................................................... 206

Whole unit replacement .................................................................................................................... 207

Control-panel bezels ........................................................................................................................ 211

Supplementry documentation and support ....................................................................................... 214

Parts lists and diagrams ................................................................................................................... 216

Types of screws ............................................................................................................... 217

ADF and scanner assemblies .......................................................................................................... 218

ADF internal components ................................................................................................................. 220

Assemblies ....................................................................................................................................... 222

External covers and panels .............................................................................................................. 224

Internal components (1 of 3) ............................................................................................................ 226

Internal components (2 of 3) ............................................................................................................ 228

Internal components (3 of 3) ............................................................................................................ 230

Alphabetical parts list ....................................................................................................................... 232

Numerical parts list ........................................................................................................................... 235

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 239

Customer self repair warranty service .............................................................................................. 240

viii ENWW

Page 11

Print cartridge limited warranty statement ........................................................................................ 241

Customer support ............................................................................................................................. 242

HP maintenance agreements ........................................................................................................... 242

Repacking the device ...................................................................................................... 242

Extended warranty ........................................................................................................... 242

Appendix B Specifications

Physical specifications ..................................................................................................................... 244

Electrical specifications .................................................................................................................... 244

Power consumption .......................................................................................................................... 244

Environmental specifications ............................................................................................................ 245

Acoustic emissions ........................................................................................................................... 245

Appendix C Regulatory information

FCC compliance ............................................................................................................................... 248

Environmental product stewardship program ................................................................................... 249

Protecting the environment .............................................................................................. 249

Ozone production ............................................................................................................ 249

Power consumption ......................................................................................................... 249

Toner consumption .......................................................................................................... 249

Paper use ........................................................................................................................ 249

Plastics ............................................................................................................................ 249

HP LaserJet print supplies ............................................................................................... 249

Return and recycling instructions ..................................................................................... 250

United States and Puerto Rico ........................................................................ 250

Non-US returns ............................................................................................... 250

Paper ............................................................................................................................... 250

Material restrictions .......................................................................................................... 25 0

Disposal of waste equipment by users in private households in the European Union ... . 251

Material Safety Data Sheet (MSDS) ................................................................................ 251

For more information ....................................................................................................... 252

Telephone Consumer Protection Act (United States) ...................................................................... 253

IC CS-03 requirements ..................................................................................................................... 253

EU statement for telecom operation ................................................................................................. 254

New Zealand telecom statements .................................................................................................... 254

Declaration of conformity .................................................................................................................. 255

Declaration of conformity .................................................................................................................. 256

Safety statements ............................................................................................................................. 257

Laser safety ..................................................................................................................... 257

Canadian DOC regulations .............................................................................................. 257

EMI statement (Korea) ..................................................................................................... 257

Laser statement for Finland ............................................................................................. 258

Substances table (China) ................................................................................................ 259

Multiple returns (two to eight cartridges) ........................................ 250

Single returns ................................................................................. 250

Shipping .......................................................................................... 250

Index ................................................................................................................................................................. 261

ENWW ix

Page 12

x ENWW

Page 13

List of tables

Table 1-1 Product guides ................................................................................................................................... 2

Table 1-2 Supported paper and print media sizes ........................................................................................... 12

Table 1-3 Supported envelopes and postcards ............................................................................................... 13

Table 4-1 Sequence of operation ..................................................................................................................... 48

Table 4-2 Power-on sequence ......................................................................................................................... 49

Table 6-1 Alert and warning messages ......................................................................................................... 140

Table 6-2 Critical error messages .................................................................................................................. 147

Table 6-3 Repetitive image defects ................................................................................................................ 192

Table 6-4 ECU connectors ............................................................................................................................. 194

Table 6-5 Formatter connectors ..................................................................................................................... 195

Table 6-6 Fax card ......................................................................................................................................... 196

Table 6-7 Solenoid and motor ........................................................................................................................ 197

Table 6-8 Rollers ............................................................................................................................................ 198

Table 6-9 Sensors .......................................................................................................................................... 199

Table 6-10 Major components ........................................................................................................................ 200

Table 6-11 PCAs (base unit) .......................................................................................................................... 201

Table 6-12 Scanner and ADF ......................................................................................................................... 202

Table 7-1 Whole unit replacement, product bundle CC372A ......................................................................... 207

Table 7-2 Whole unit replacement, product bundle CB534A ......................................................................... 209

Table 7-3 Control-panel bezels (HP LaserJet M1522n) ................................................................................. 211

Table 7-4 Control-panel bezels (HP LaserJet M1522nf) ................................................................................ 212

Table 7-5 Documentation ............................................................................................................................... 214

Table 7-6 Scanner and ADF assemblies ........................................................................................................ 219

Table 7-7 ADF internal components ............................................................................................................... 221

Table 7-8 Assemblies ..................................................................................................................................... 223

Table 7-9 External covers and panels ............................................................................................................ 225

Table 7-10 Internal components (1 of 3) ........................................................................................................ 227

Table 7-11 Internal components (2 of 3) ........................................................................................................ 229

Table 7-12 Internal components (3 of 3) ........................................................................................................ 231

Table 7-13 Alphabetical parts list ................................................................................................................... 232

Table 7-14 Numerical parts list ....................................................................................................................... 235

Table B-1 Physical specifications ................................................................................................................... 244

Table B-2 Electrical specifications .................................................................................................................. 244

Table B-3 Power consumption (average, in watts) ....................................................................................... 244

Table B-4 Environmental specifications ........................................................................................................ 245

Table B-5 Acoustic emissions ....................................................................................................................... 245

ENWW xi

Page 14

xii ENWW

Page 15

List of figures

Figure 2-1 Operating environment ................................................................................................................... 16

Figure 4-1 System block diagram ..................................................................................................................... 48

Figure 4-2 Optical system ................................................................................................................................ 50

Figure 4-3 ADF paper path ............................................................................................................................... 52

Figure 4-4 Cross-section of printer ................................................................................................................... 54

Figure 4-5 Engine control system ..................................................................................................................... 55

Figure 4-6 Engine-control-system circuit diagram ............................................................................................ 56

Figure 4-7 Laser/scanner system ..................................................................................................................... 57

Figure 4-8 Pickup/feed/delivery system ........................................................................................................... 58

Figure 4-9 Image-formation system ................................................................................................................. 59

Figure 4-10 Primary charging ........................................................................................................................... 59

Figure 4-11 Developing .................................................................................................................................... 60

Figure 4-12 Transfer ......................................................................................................................................... 61

Figure 4-13 Separation ..................................................................................................................................... 61

Figure 4-14 Fusing ........................................................................................................................................... 61

Figure 4-15 Drum cleaning ............................................................................................................................... 62

Figure 5-1 Phillips and pozidrive screwdriver comparison ............................................................................... 71

Figure 5-2 Parts removal order for the scanner and ADF ................................................................................ 74

Figure 5-3 Parts removal order for the product (product base) ........................................................................ 74

Figure 5-4 Remove the ADF input tray ............................................................................................................. 75

Figure 5-5 Remove the flatbed lid (1 of 5) ........................................................................................................ 76

Figure 5-6 ADF cover correctly installed .......................................................................................................... 76

Figure 5-7 Remove the flatbed lid (2 of 5) ........................................................................................................ 77

Figure 5-8 Remove the flatbed lid (3 of 5) ........................................................................................................ 77

Figure 5-9 Remove the flatbed lid (4 of 5) ........................................................................................................ 78

Figure 5-10 Remove the flatbed lid (5 of 5) ...................................................................................................... 78

Figure 5-11 Remove the link assemblies and scanner support-frame springs (1 of 4) .................................... 79

Figure 5-12 Remove the link assemblies and scanner support-frame springs (2 of 4) .................................... 79

Figure 5-13 Remove the link assemblies and scanner support-frame springs (3 of 4) .................................... 80

Figure 5-14 Remove the link assemblies and scanner support-frame springs (4 of 4) .................................... 80

Figure 5-15 Remove the control-panel bezel ................................................................................................... 81

Figure 5-16 Remove the control-panel assembly (1 of 2) ................................................................................ 82

Figure 5-17 Remove the control-panel assembly (2 of 2) ................................................................................ 82

Figure 5-18 Remove the ADF separation pad ................................................................................................. 83

Figure 5-19 Remove the ADF input-tray flag .................................................................................................... 84

Figure 5-20 Replacing the ADF pickup roller assembly (1 of 6) ....................................................................... 85

Figure 5-21 Replacing the ADF pickup roller assembly (2 of 6) ....................................................................... 85

Figure 5-22 Replacing the ADF pickup roller assembly (3 of 6) ....................................................................... 86

Figure 5-23 Replacing the ADF pickup roller assembly (4 of 6) ....................................................................... 86

ENWW xiii

Page 16

Figure 5-24 Replacing the ADF pickup roller assembly (5 of 6) ....................................................................... 87

Figure 5-25 Replacing the ADF pickup roller (6 of 6) ....................................................................................... 87

Figure 5-26 Remove the ADF scanner glass (1 of 3) ....................................................................................... 88

Figure 5-27 Remove the ADF scanner glass (2 of 3) ....................................................................................... 88

Figure 5-28 Remove the ADF scanner glass (3 of 3) ....................................................................................... 89

Figure 5-29 Remove the scanner assembly (1 of 10) ...................................................................................... 90

Figure 5-30 Remove the scanner assembly (2 of 10) ...................................................................................... 90

Figure 5-31 Remove the scanner assembly (3 of 10) ...................................................................................... 91

Figure 5-32 Remove the scanner assembly (4 of 10) ...................................................................................... 91

Figure 5-33 Remove the scanner assembly (5 of 10) ...................................................................................... 92

Figure 5-34 Remove the scanner assembly (6 of 10) ...................................................................................... 92

Figure 5-35 Remove the scanner assembly (7 of 10) ...................................................................................... 93

Figure 5-36 Remove the scanner assembly (8 of 10) ...................................................................................... 93

Figure 5-37 Remove the scanner assembly (9 of 10) ...................................................................................... 94

Figure 5-38 Remove the scanner assembly (10 of 10) .................................................................................... 94

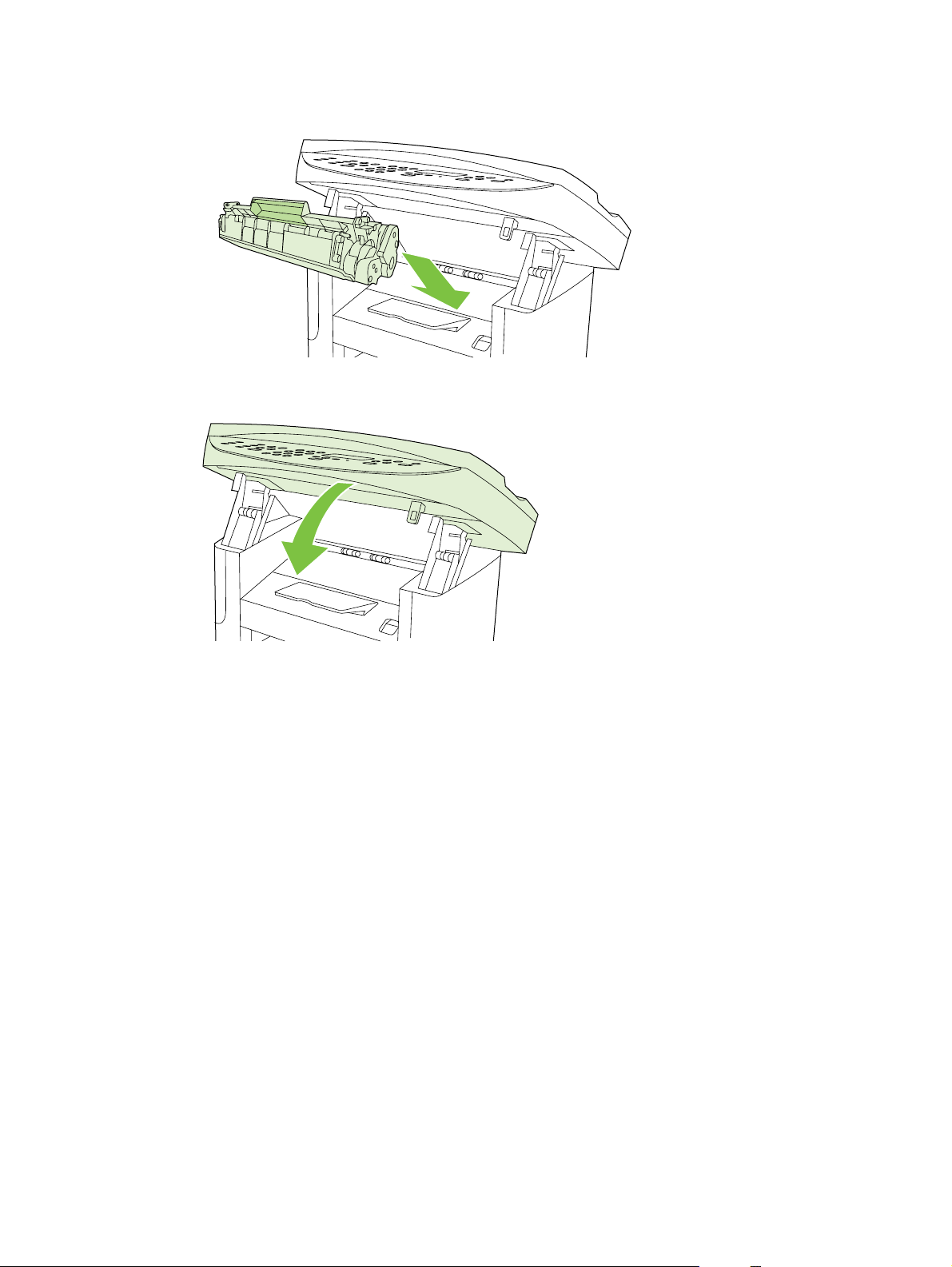

Figure 5-39 Remove the print cartridge (1 of 2) ............................................................................................... 95

Figure 5-40 Remove the print cartridge (2 of 2) ............................................................................................... 95

Figure 5-41 Remove the product separation pad (1 of 2) ................................................................................ 96

Figure 5-42 Remove the product separation pad (2 of 2) ................................................................................ 96

Figure 5-43 Remove the product pickup roller (1 of 5) ..................................................................................... 97

Figure 5-44 Remove the product pickup roller (2 of 5) ..................................................................................... 97

Figure 5-45 Remove the product pickup roller (3 of 5) ..................................................................................... 98

Figure 5-46 Remove the product pickup roller (4 of 5) ..................................................................................... 98

Figure 5-47 Remove the product pickup roller (5 of 5) ..................................................................................... 99

Figure 5-48 Installing the scanner cushions ................................................................................................... 100

Figure 5-49 Remove the media input tray (1 of 3) ......................................................................................... 101

Figure 5-50 Remove the media input tray (2 of 3) ......................................................................................... 101

Figure 5-51 Remove the media input tray (3 of 3) ......................................................................................... 102

Figure 5-52 Remove the transfer roller .......................................................................................................... 103

Figure 5-53 Remove the side covers (1 of 4) ................................................................................................. 104

Figure 5-54 Remove the side covers (2 of 4) ................................................................................................. 104

Figure 5-55 Remove the side covers (3 of 4) ................................................................................................. 105

Figure 5-56 Remove the side covers (4 of 4) ................................................................................................. 105

Figure 5-57 Remove the print-cartridge door (1 of 2) ..................................................................................... 106

Figure 5-58 Remove the print-cartridge door (2 of 2) ..................................................................................... 106

Figure 5-59 Remove the rear cover and fuser cover (1 of 3) ......................................................................... 107

Figure 5-60 Remove the rear cover and fuser cover (2 of 3) ......................................................................... 107

Figure 5-61 Remove the rear cover and fuser cover (3 of 3) ......................................................................... 108

Figure 5-62 Remove the front cover (1 of 4) .................................................................................................. 109

Figure 5-63 Remove the front cover (2 of 4) .................................................................................................. 109

Figure 5-64 Remove the front cover (3 of 4) .................................................................................................. 110

Figure 5-65 Remove the front cover (4 of 4) .................................................................................................. 110

Figure 5-66 Remove the speaker assembly (1 of 2) ...................................................................................... 111

Figure 5-67 Remove the speaker assembly (2 of 2) ...................................................................................... 111

Figure 5-68 Remove the formatter ................................................................................................................. 113

Figure 5-69 Remove the power supply (1 of 7) .............................................................................................. 114

Figure 5-70 Remove the power supply (2 of 7) .............................................................................................. 115

Figure 5-71 Remove the power supply (3 of 7) .............................................................................................. 115

Figure 5-72 Remove the power supply (4 of 7) .............................................................................................. 116

Figure 5-73 Remove the power supply (5 of 7) .............................................................................................. 116

xiv

ENWW

Page 17

Figure 5-74 Remove the power supply (7 of 7) .............................................................................................. 117

Figure 5-75 Remove the power supply (7 of 7) .............................................................................................. 117

Figure 5-76 Remove the scanner support-frame (1 of 5) ............................................................................... 118

Figure 5-77 Remove the scanner support-frame (2 of 5) ............................................................................... 119

Figure 5-78 Remove the scanner support-frame (3 of 5) ............................................................................... 119

Figure 5-79 Remove the scanner support-frame (4 of 5) ............................................................................... 120

Figure 5-80 Remove the scanner support-frame (5 of 5) ............................................................................... 120

Figure 5-81 Remove the laser/scanner (1 of 7) ............................................................................................. 121

Figure 5-82 Remove the laser/scanner (2 of 7) ............................................................................................. 122

Figure 5-83 Remove the laser/scanner (3 of 7) ............................................................................................. 122

Figure 5-84 Remove the laser/scanner (4 of 7) ............................................................................................. 123

Figure 5-85 Remove the laser/scanner assembly (5 of 7) ............................................................................. 123

Figure 5-86 Remove the laser/scanner assembly (6 of 7) ............................................................................. 124

Figure 5-87 Remove the laser/scanner assembly (7 of 7)Remove the laser/scanner assembly (7 of 7) ....... 124

Figure 5-88 Remove the main motor (1 of 4) ................................................................................................. 125

Figure 5-89 Remove the main motor (2 of 4) ................................................................................................. 126

Figure 5-90 Remove the main motor (3 of 4) ................................................................................................. 126

Figure 5-91 Remove the main motor (4 of 4) ................................................................................................. 127

Figure 5-92 Remove the fuser (1 of 6) ........................................................................................................... 128

Figure 5-93 Remove the fuser (2 of 6) ........................................................................................................... 129

Figure 5-94 Remove the fuser (3 of 6) ........................................................................................................... 129

Figure 5-95 Remove the fuser (4 of 6) ........................................................................................................... 130

Figure 5-96 Remove the fuser assembly (5 of 6) ........................................................................................... 130

Figure 5-97 Remove the fuser assembly (6 of 6) ........................................................................................... 131

Figure 5-98 Remove the paper-pickup assembly (1 of 4) .............................................................................. 132

Figure 5-99 Remove the paper-pickup assembly (2 of 4) .............................................................................. 133

Figure 5-100 Remove the paper-pickup assembly (3 of 4) ............................................................................ 133

Figure 5-101 Remove the paper-pickup assembly (4 of 4) ............................................................................ 134

Figure 5-102 Remove the Drive-gear assembly and drive belt (1 of 4). ........................................................ 135

Figure 5-103 Remove the Drive-gear assembly and drive belt (2 of 4). ........................................................ 135

Figure 5-104 Remove the Drive-gear assembly and drive belt (3 of 4). ........................................................ 136

Figure 5-105 Remove the Drive-gear assembly and drive belt (4 of 4). ........................................................ 136

Figure 6-1 Print-cartridge high-voltage connection points (right side) ............................................................ 180

Figure 6-2 Print-cartridge high-voltage connection points (left side) .............................................................. 181

Figure 6-3 ECU connectors ............................................................................................................................ 194

Figure 6-4 Formatter connectors .................................................................................................................... 195

Figure 6-5 Fax card connectors ..................................................................................................................... 196

Figure 6-6 Solenoid and motor ....................................................................................................................... 197

Figure 6-7 Rollers ........................................................................................................................................... 198

Figure 6-8 Sensors ......................................................................................................................................... 199

Figure 6-9 Major components ........................................................................................................................ 200

Figure 6-10 PCAs (base unit) ......................................................................................................................... 201

Figure 6-11 Scanner and ADF ....................................................................................................................... 202

Figure 6-12 Circuit diagram ........................................................................................................................... 203

Figure 7-1 Scanner and ADF assemblies ...................................................................................................... 218

Figure 7-2 ADF internal components ............................................................................................................. 220

Figure 7-3 Assemblies .................................................................................................................................... 222

Figure 7-4 External covers and panels .......................................................................................................... 224

Figure 7-5 Internal components (1 of 3) ......................................................................................................... 226

Figure 7-6 Internal components (2 of 3) ......................................................................................................... 228

ENWW xv

Page 18

Figure 7-7 Internal components (3 of 3) ......................................................................................................... 230

xvi ENWW

Page 19

1 Product information

Quick access to product information

●

Product comparison

●

Product features

●

Product walkaround

●

Software description

●

Software for Windows

●

Software for Macintosh

●

Uninstall software

●

Media specifications

●

ENWW 1

Page 20

Quick access to product information

Use the following Web site to find information about the product.

www.hp.com/support/ljm1522

●

Table 1-1 Product guides

Guide Description

HP LaserJet M1522 MFP Getting

Started Guide

HP LaserJet M1522 MFP Series

User Guide

HP ToolboxFX To check the product status and settings, and to view problem-solving information and online

Online Help Provides information about options that are available in the printer drivers. To view a Help

Provides step-by-step instructions for installing and setting up the product.

Provides detailed information for using the product and problem-solving. Available on the

product CD or in Program Group if the software is installed on a computer.

documentation, use the HP ToolboxFX. You must have performed a complete software

installation in order to use the HP ToolboxFX. See the user guide for more information about

software installation.

file, open the online Help through the printer driver.

2 Chapter 1 Product information ENWW

Page 21

Product comparison

The product is available in the following configurations.

HP LaserJet M1522n MFP HP LaserJet M1522nf MFP

Prints letter-size pages at speeds up to 24 pages per

●

minute (ppm) and A4-size pages at speeds up to 23 ppm.

PCL 5 and PCL 6 printer drivers and HP postscript level 3

●

emulation.

Priority input tray holds up to 10 sheets of print media.

●

Tray 1 holds up to 250 sheets of print media or 10

●

envelopes.

Hi-Speed USB 2.0 port and 10/100 Base-T network port.

●

64-MB random-access memory (RAM).

●

Flatbed scanner and 50-page automatic document

●

feeder (ADF).

HP LaserJet M1522n MFP, plus:

V.34 fax modem and 4-megabyte (MB) flash fax-storage

●

memory.

Two RJ-11 fax phone line ports

●

ENWW Product comparison 3

Page 22

Product features

Performance

Print quality

Fax (fax models only)

Copy

Scan

Networking

Printer driver features

Prints up to 24 ppm (letter) or 23 ppm (A4).

●

600 x 2 dots per inch (dpi) with Resolution Enhancement Technology (RET).

●

Adjustable settings to optimize print quality.

●

The HP UltraPrecise print cartridge has a finer toner formulation that provides sharper text

●

and graphics.

Full-functionality fax capabilities with a V.34 fax; includes a phone book, fax/tel, and

●

delayed-fax features.

Includes ADF that allows faster, more efficient copy jobs with multiple-page documents.

●

The product provides 1,200 pixels per inch (ppi), 24-bit full-color scanning from letter/A4-

●

size scanner glass.

The product provides 300 ppi, 24-bit full-color scanning from the automatic document

●

feeder (ADF).

Includes an ADF that allows faster, more efficient scan jobs with multiple-page documents.

●

TCP/IP

●

IPv4

◦

IPv6

◦

Fast printing performance, built-in Intellifont and TrueType scaling technologies, and

●

advanced imaging capabilities are benefits of the PCL 6 printer language.

Interface connections

Economical printing

Supplies

Accessibility

Hi-Speed USB 2.0 port.

●

10/100 Base-T ethernet network port (RJ-45).

●

RJ-11 fax/phone cable ports (fax models only).

●

N-up printing (printing more than one page on a sheet).

●

EconoMode setting.

●

A supplies status page that displays the amount of life remaining in the print cartridge.

●

The product ships with a 1,000-page (average yield) starter cartridge. The average yield

●

for replacement cartridges is 2,000 pages.

Authentication for HP print cartridges.

●

Enabled supplies-ordering capability.

●

Online user guide that is compatible with text screen-readers.

●

Print cartridges can be installed and removed by using one hand.

●

All doors and covers can be opened by using one hand.

●

4 Chapter 1 Product information ENWW

Page 23

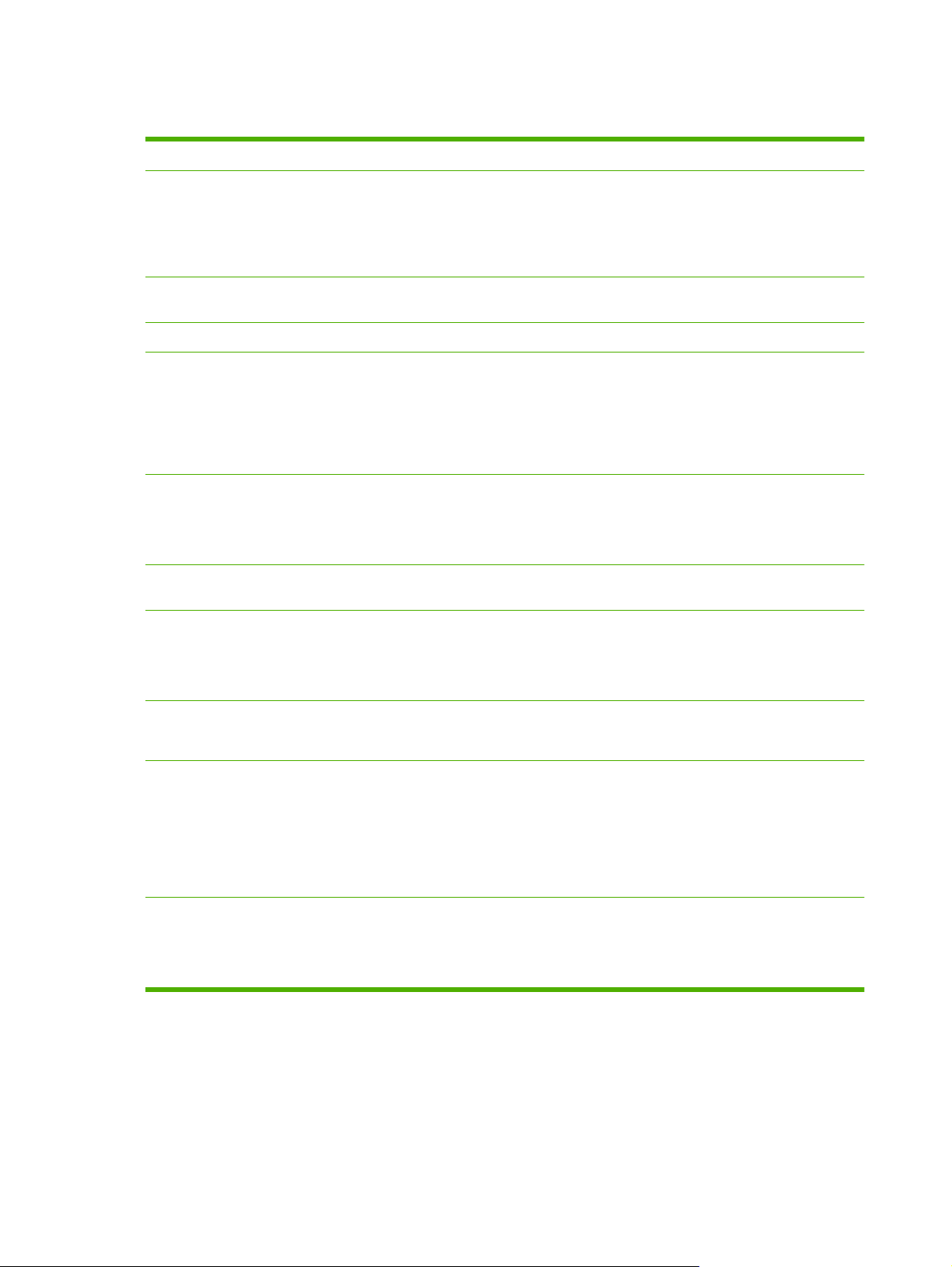

Product walkaround

Front view

7

1 Automatic document feeder (ADF) input tray

2 Automatic document feeder (ADF) output bin

3 Control panel

4 Print-cartridge door latch

5 Output bin

1

2

3

4

5

6

6 Priority input tray

7 Tray 1

Back view

8 Interface ports

9 Power switch

10 Power connector

11

10

9

8

7

11 Kensington lock

ENWW Product walkaround 5

Page 24

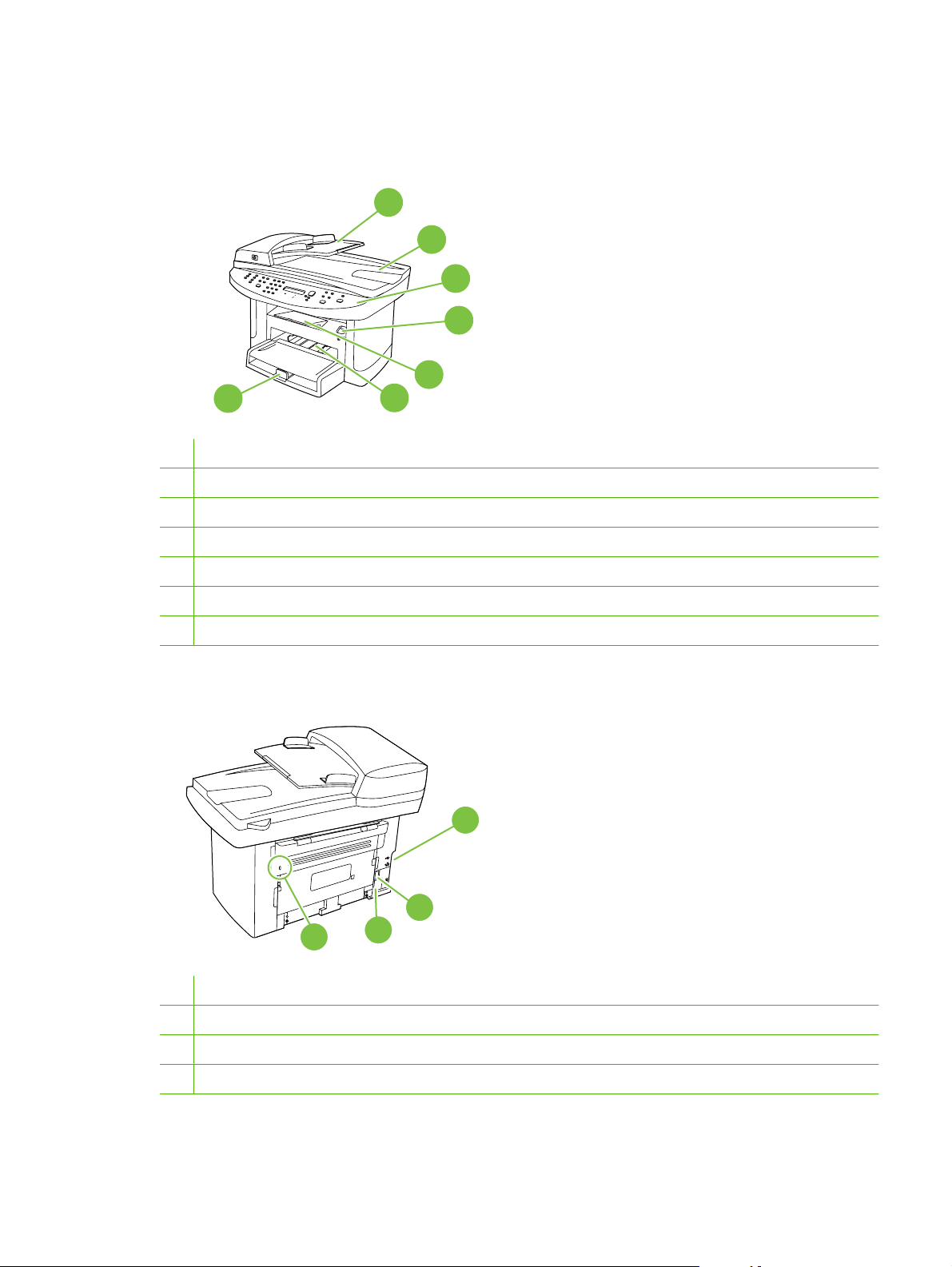

Interface ports

All models have a 10/100 Base-T (RJ-45) network port and a Hi-Speed USB 2.0 port. Fax models have

fax ports as well.

1 Hi-Speed USB 2.0 port

2 Network port

3 Fax ports (fax models only)

1

2

3

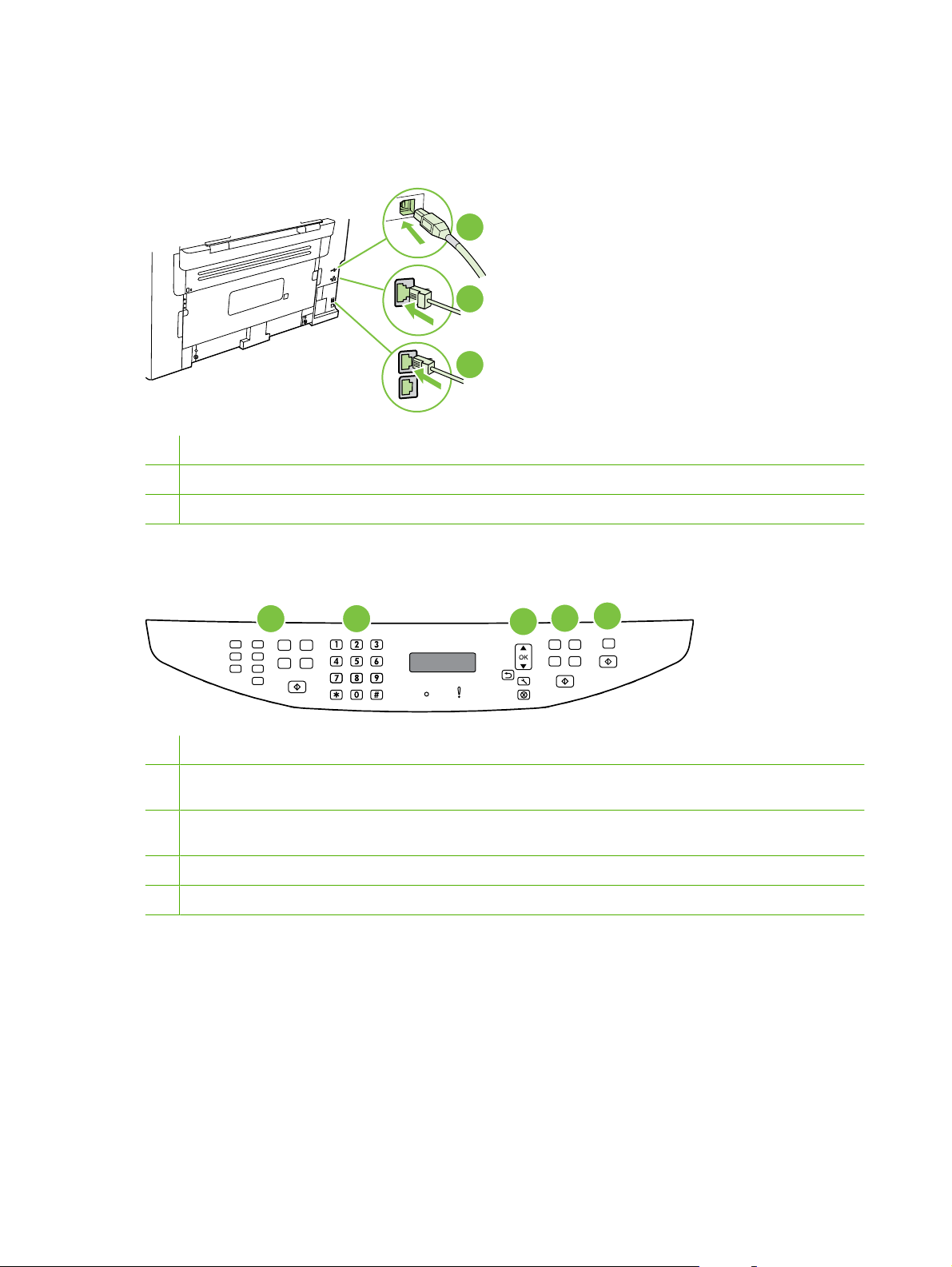

Control-panel

1 Fax controls (fax models only). Use the fax controls to change commonly used fax settings.

2 Alphanumeric buttons. Use the alphanumeric buttons to type data into the product control-panel display and dial

telephone numbers for faxing.

3 Setup and cancel controls. Use these controls to select menu options, determine the product status, and cancel the

current job.

4 Copy controls. Use these controls to change commonly used copy settings and to start copying.

5 Scan controls. Use these controls to scan to e-mail or to a folder.

1

2

3

4

5

6 Chapter 1 Product information ENWW

Page 25

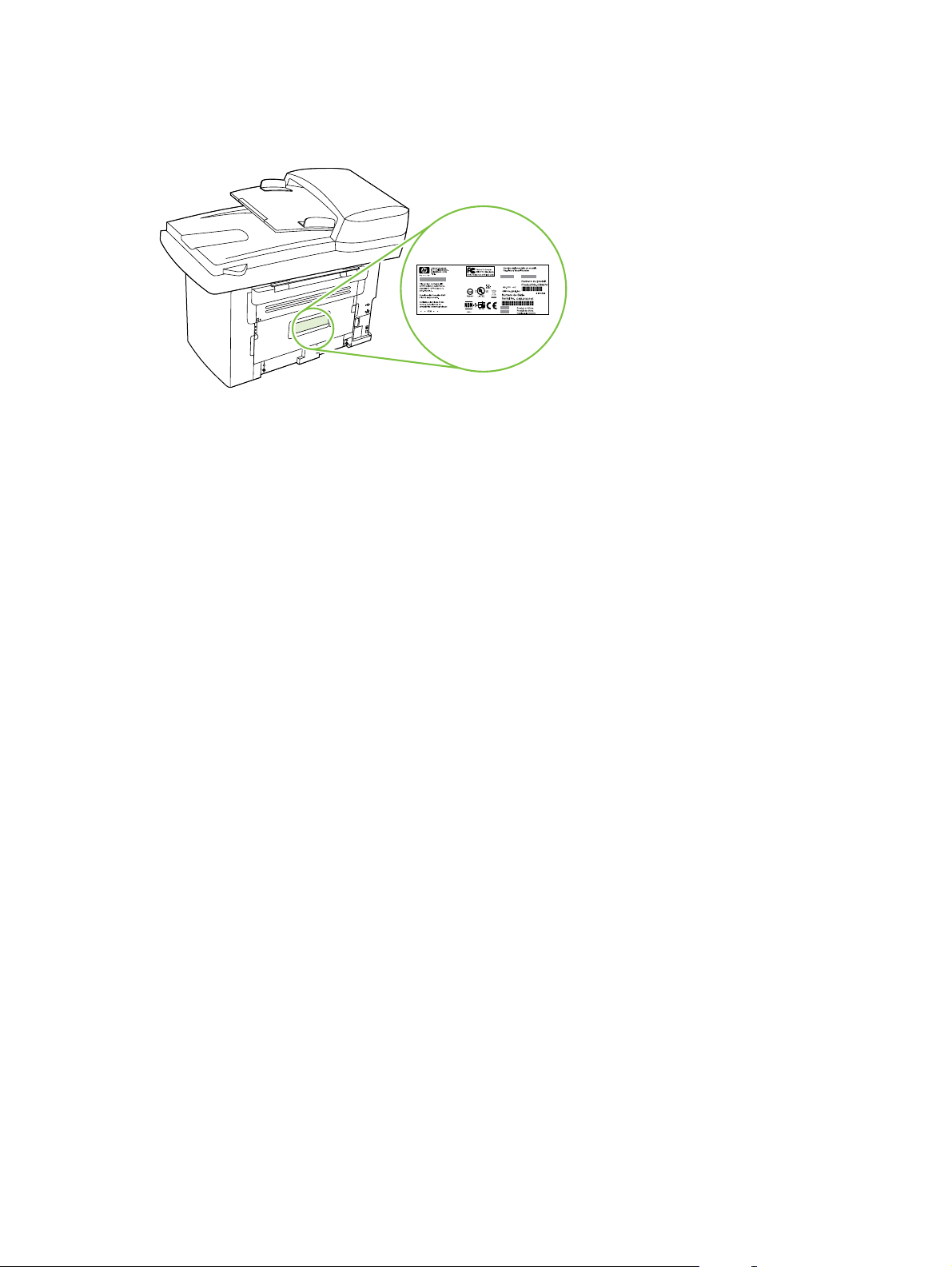

Serial number and model number location

The serial number and product model number label is on the back of the product.

ENWW Product walkaround 7

Page 26

Software description

Supported operating systems

The product supports the following operating systems:

Full software installation

Windows XP (32-bit and 64-bit)

●

Windows Vista (32-bit and 64-bit)

●

Mac OS X v10.3, v10.4, and later

●

NOTE: For Mac OS X v10.4 and later, PPC and Intel Core Processor Macs are supported.

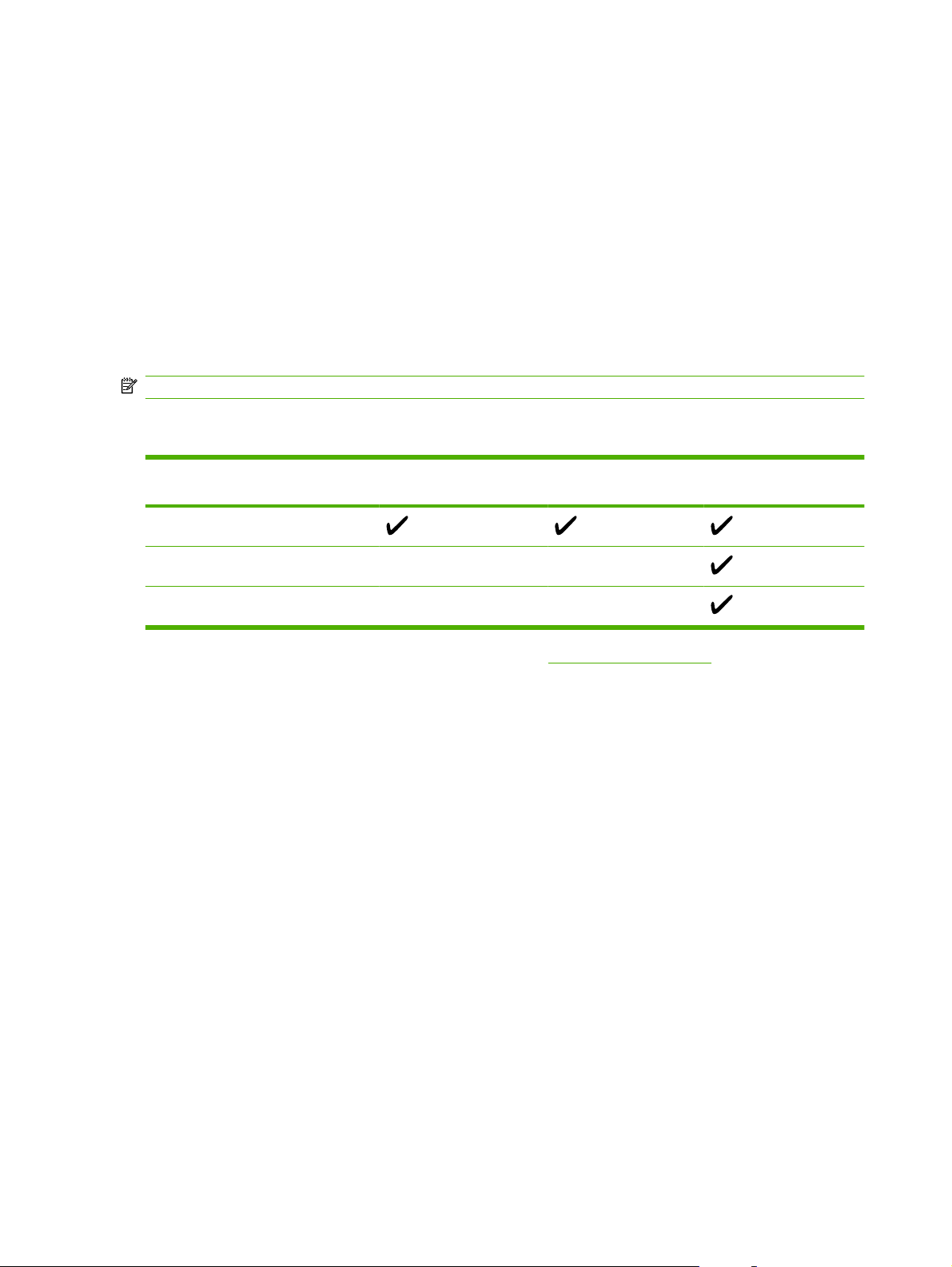

Supported printer drivers

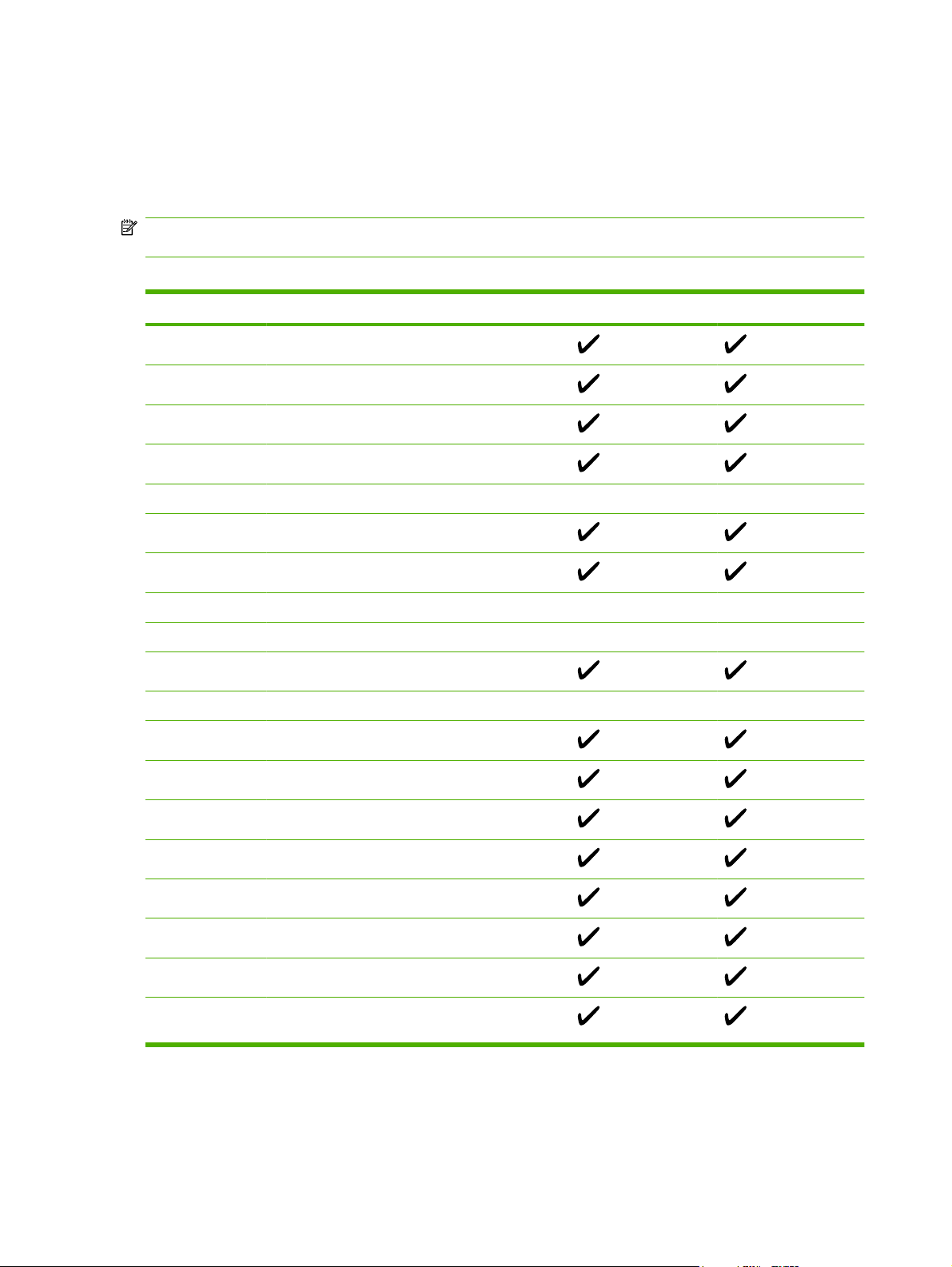

Operating system PCL 5 PCL 6 HP postscript level 3

Windows

Mac OS X v10.3, v10.4, and later

2

Linux

1

Driver can be installed by using the Microsoft Add Printer wizard, too.

2

For Linux, download the HP postscript level 3 emulation driver from www.hp.com/go/linuxprinting.

Print and scan driver

Windows 2000

●

Windows 2003 Server (32-bit)

●

1 1

Printer driver only

Linux (Web only)

●

UNIX model scripts (Web only)

●

emulation

The printer drivers include online Help that has instructions for common printing tasks and also describes

the buttons, checkboxes, and drop-down lists that are in the printer driver.

Software included with the product

There are several options for completing a recommended install. Easy Install will complete the

installation with default settings. Advanced Install allows you to select custom settings and choose the

components that are installed.

Recommended installation for Windows

HP drivers

●

PCL 6 printer driver

◦

Scan driver

◦

HP MFP software

●

HP ToolboxFX

◦

HP LaserJet Scan program

◦

HP Send Fax program and driver

◦

8 Chapter 1 Product information ENWW

Page 27

HP Fax Setup Wizard

◦

Uninstall program

◦

HP Update program

●

HP Customer Participation Program

●

Shop for HP Supplies program

●

Other programs

●

Readiris OCR (not installed with other software; separate installation is required)

◦

Express installation (USB or network)

The following software is included with an Express installation:

PCL 6 printer driver

●

Scan driver

●

NOTE: Express installation supports faxing by using the control panel.

NOTE: PCL 5 and HP postscript level 3 emulation drivers can be installed using the Microsoft Add

Printer wizard.

Macintosh software

HP Product Setup Assistant

●

HP Device Configuration

●

HP Uninstaller

●

HP LaserJet software

●

HP Scan

◦

HP Director

◦

Fax program

◦

Scan to e-mail program

◦

HP Photosmart

◦

Software for Windows