Page 1

HP Indigo 7000 Digital Press

User Guide

Page 2

HP Indigo 7000 Digital Press

User guide

Page 3

© 2008 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

HP, HP Indigo Press, HP Indigo Press RIP,

and HP ElectroInk are trademarks or

registered trademarks of HP.

Adobe® PostScript® is a trademark of

Adobe Systems Incorporated.

MS Windows® and Windows® are U.S.

registered trademarks of Microsoft Corp.

All other products or name brands are

trademarks of their respective holders.

The HP Indigo press' counter feature records

the number of impressions you make using

your press. The counter does not reflect any

previous use of the press or its age.

The HP Indigo press is a Class 1 Laser

Product containing high voltage power

supplies and laser light sources. There is no

danger to persons or equipment when the

system is operated in accordance with the

directions provided by HP in this and other

publications. All high voltage power supplies

and laser sources are located behind

protective covers. Warning labels are

attached to each protective cover. Do not

remove covers.

Part Number: CA394-00180

First Edition: May 2008

Page 4

Table of contents

1 About this user guide

Overview .............................................................................................................................................. 2

Conventions used in this guide ............................................................................................................ 4

2 Product overview

HP Indigo press .................................................................................................................................... 6

HP Indigo 7000 Digital Press ............................................................................................... 6

Press serial number ............................................................................................................. 7

General press specifications ................................................................................................................ 8

Printing rate ......................................................................................................................... 8

3 Safety

Overview ............................................................................................................................................ 10

Warning signs and labels ................................................................................................................... 11

Warning labels on the press .............................................................................................. 11

Warning signs .................................................................................................................... 12

Placement of warning labels .............................................................................................. 13

Safety devices .................................................................................................................................... 14

Material safety data sheets (MSDS) .................................................................................. 14

Fire extinguishing equipment ............................................................................................. 14

Eye wash stations .............................................................................................................. 14

Noise levels ....................................................................................................................... 14

Heat insulating tools .......................................................................................................... 14

Electrical safety .................................................................................................................. 14

Emergency power shutdown .............................................................................................................. 16

Door interlocks and warning indicators .............................................................................................. 19

Door interlocks ................................................................................................................... 19

Attention lights .................................................................................................................................... 21

Maintenance safety and emergency procedures ............................................................................... 23

Standby status ................................................................................................................... 23

Inching button .................................................................................................................... 23

Inch-safe method ............................................................................................................... 23

Press lockout procedure .................................................................................................... 24

Combustible and flammable liquids and fumes .................................................................................. 25

ENWW iii

Page 5

Isopropyl alcohol (IPA) ....................................................................................................... 25

Handling and storing imaging oil, inks, and IPA ................................................................ 25

Disposing of consumables and cleaning materials ............................................................ 25

Waste bottles ..................................................................................................................... 26

Additional information ........................................................................................................ 27

4 Operating the press

Turning the press on .......................................................................................................................... 30

Using the press .................................................................................................................................. 31

Using the control panel ....................................................................................................................... 32

Using the software ............................................................................................................. 32

Turning the press off .......................................................................................................................... 38

The control panel .............................................................................................. 32

Small press schematic ...................................................................... 32

Print job panel ................................................................................... 33

Main toolbar ...................................................................................... 34

Print controls ..................................................................................... 34

Working area ..................................................................................................... 37

Navigating in the working area ......................................................... 37

Virtual keyboards .............................................................................................. 37

5 Job handling

Managing jobs .................................................................................................................................... 40

Print Queue ........................................................................................................................ 40

Printing jobs ........................................................................................................................................ 41

Stage 1: Loading jobs ........................................................................................................ 41

Stage 2: Proofing ............................................................................................................... 41

Stage 3: Printing the full run .............................................................................................. 42

Job maintenance ................................................................................................................................ 43

Job disposition and retrieval .............................................................................................. 43

Editing job properties ......................................................................................................... 43

Image placement ............................................................................................................... 44

Editing job look-up tables (LUTs) ....................................................................................... 46

Screening ........................................................................................................................... 48

Inks “double-hit” printing .................................................................................................... 49

Linework and resolution ..................................................................................................... 50

6 Color management

Calibrating the press colors ................................................................................................................ 54

Color Calibration procedures .............................................................................................................. 55

Defining substrate-related color parameters ...................................................................................... 57

Optical density of substrates .............................................................................................. 57

Selecting a workflow for full color calibration and substrate-related parameters ............................... 59

iv ENWW

Page 6

Very high accuracy workflow ............................................................................................. 59

High accuracy workflow ..................................................................................................... 59

Normal accuracy workflow ................................................................................................. 59

Viewing last color calibration generation ........................................................................... 60

Determining substrate type ................................................................................................ 60

7 Substrate handling system

Overview ............................................................................................................................................ 66

Substrate specifications ..................................................................................................................... 67

Grain direction ................................................................................................................... 67

Sheet trimming ................................................................................................................... 68

Sheet size .......................................................................................................................... 68

Loading substrate into the feeder ....................................................................................................... 69

Monitoring status of substrates in drawers ......................................................................................... 70

Defining substrate type ....................................................................................................................... 71

Operating and unloading the stacker ................................................................................................. 73

Unloading a substrate stack .............................................................................................. 74

Defining stacker options ..................................................................................................................... 76

Adjusting stacker options ................................................................................................... 76

Clearing substrate jams ...................................................................................................................... 78

Removing a substrate jam at the external heating housing ............................................... 79

Maintaining the substrate transport system ........................................................................................ 84

Cleaning the substrate path ............................................................................................... 84

8 Operator routines

Maintenance routines ......................................................................................................................... 88

Lubricating the mechanical system .................................................................................................... 91

9 Ink system

Overview ............................................................................................................................................ 94

Replacing ink cans ............................................................................................................................. 95

Rebuilding the ink in a tank ................................................................................................................ 96

Draining ink tanks ............................................................................................................................... 98

Cleaning the ink pumps ...................................................................................................................... 99

Using the maintenance routine checklists ......................................................................... 88

Configuration file backup ................................................................................... 88

Practical tips for performing maintenance routines ............................................................ 89

Protecting substrate .......................................................................................... 89

IPA contamination ............................................................................................. 89

Water contamination ......................................................................................... 90

PIP protection .................................................................................................... 90

Replacing the lubrication can ............................................................................................. 91

ENWW v

Page 7

10 Binary ink developer (BID)

Overview .......................................................................................................................................... 104

Replacing the BID ............................................................................................................................ 106

Removing a BID ............................................................................................................... 106

Installing a new BID ......................................................................................................... 107

Returning a BID ............................................................................................................... 109

Adjusting the BID engage and disengage angle .............................................................................. 110

11 Blanket

Overview .......................................................................................................................................... 118

Replacing the blanket ....................................................................................................................... 119

Removing the old blanket ................................................................................................ 119

Installing a new blanket ................................................................................................... 121

Cleaning the blanket ......................................................................................................................... 122

Using the Print Cleaner wizard ........................................................................................ 122

Manually cleaning the blanket ......................................................................................... 122

Recovering the blanket surface ....................................................................................... 122

Using the automatic blanket cleaner page ....................................................................... 123

First transfer calibration .................................................................................................................... 125

Calibrating the pressure ................................................................................................... 125

Cleaning the ITM area ...................................................................................................................... 128

12 PIP

Overview .......................................................................................................................................... 130

Replacing the PIP Foil ...................................................................................................................... 131

Replacing the PIP underlayer ........................................................................................................... 133

13 Impression drum

Overview .......................................................................................................................................... 140

Replacing the impression paper ....................................................................................................... 141

Cleaning the grippers ....................................................................................................................... 143

14 Imaging oil

Overview .......................................................................................................................................... 146

Refilling the imaging oil tank ............................................................................................................. 147

Adding recycling agent ..................................................................................................................... 148

Replacing the imaging oil filters ........................................................................................................ 150

Cleaning the imaging oil cleanness sensor ...................................................................................... 15 2

Removing the old PIP foil ................................................................................................ 131

Installing a new PIP foil .................................................................................................... 131

Removing the old PIP underlayer .................................................................................... 133

Cleaning the PIP drum ..................................................................................................... 133

Installing the new PIP underlayer .................................................................................... 134

vi ENWW

Page 8

15 Utility cabinet

Overview .......................................................................................................................................... 156

Draining water and process oily waste ............................................................................................. 157

Draining the oil-water separator ....................................................................................................... 159

16 Cleaning station

Overview .......................................................................................................................................... 162

Cleaning the cleaning station blade ................................................................................................. 163

Rotating and replacing the cleaning station blade ............................................................................ 165

Removing the cleaning station ......................................................................................... 165

Installing the cleaning station ........................................................................................... 166

Replacing the sponge roller .............................................................................................................. 167

17 Charge Roller Assembly

Overview .......................................................................................................................................... 172

Charge roller maintenance procedures ............................................................................................ 173

Removing and replacing the charge roller ....................................................................... 173

Replacing the charge roller .............................................................................................. 173

Replacing the carbon brushes ......................................................................................... 174

Cleaning the charge roller ............................................................................................... 175

18 Pre-transfer erase (PTE)

Overview .......................................................................................................................................... 178

Cleaning the PTE ............................................................................................................................ 179

19 Exit Roller

Overview .......................................................................................................................................... 182

Cleaning the exit roller ...................................................................................................................... 183

20 Pre-heater

Overview .......................................................................................................................................... 186

Removing the pre-heater housing .................................................................................................... 187

21 Chiller Operation and Maintenance

Overview .......................................................................................................................................... 190

Chiller type ....................................................................................................................... 190

Warnings .......................................................................................................................................... 191

Operating conditions ........................................................................................................................ 192

Control panel .................................................................................................................................... 193

Components of the control panel ..................................................................................... 193

Control thermostat ........................................................................................................... 194

Maintenance ..................................................................................................................................... 196

ENWW vii

Page 9

Weekly ............................................................................................................................. 196

Monthly ............................................................................................................................ 196

Yearly ............................................................................................................................... 196

Appendix A Supplies and jigs

Imaging supplies .............................................................................................................................. 198

User maintenance supplies .............................................................................................................. 199

User tools and jigs ............................................................................................................................ 200

General supplies .............................................................................................................................. 201

Accessories ..................................................................................................................... 201

Substrate treatment ......................................................................................................... 201

Appendix B Service and support

Glossary ........................................................................................................................................................... 205

Index ................................................................................................................................................................. 209

viii ENWW

Page 10

1 About this user guide

Welcome to the HP Indigo 7000 Digital Press. This preface provides an overview of the user guide

contents and explains conventions used in this guide.

This preface contains the following sections:

Overview

●

Conventions used in this guide

●

ENWW 1

Page 11

Overview

This user guide assumes that you are familiar with the basic Windows environment and that you have

basic Windows skills, such as using a mouse and selecting menu items. If you do not, please see the

Windows documentation that came with the computer.

This user guide also assumes that you have participated in the HP Indigo press operator course, and

are familiar with the printing process.

The user guide contains the following information:

About this user guide: Provides an overview of the user guide contents and explains conventions

●

used in this guide.

Product overview: Provides an overview and specifications of the HP Indigo 7000 Digital

●

Press.

Safety: Provides important safety information for using the HP Indigo 7000 Digital Press.

●

Operating the press: Provides an overview of press operations basics.

●

Job handling: Describes the job management and maintenance process on the press.

●

Color management: Describes the color management and adjustment procedures.

●

Substrate handling system: Describes loading, unloading, adjustment and maintenance of the

●

substrate transport system.

Operator routines: Provides an overview and practical tips for performing operator maintenance

●

routines and mechanical system lubrication.

Ink system: Describes replacement and maintenance of the HP ElectroInk system.

●

Binary ink developer (BID): Provides BID maintenance and replacement procedures.

●

Blanket: Describes replacement and maintenance of the blanket.

●

PIP: Describes PIP replacement procedures.

●

Impression drum: Describes the impression paper replacement procedure.

●

Imaging oil: Describes maintenance and replacement procedures for the imaging oil system.

●

Utility cabinet: Provides utility cabinet maintenance procedures.

●

Cleaning station: Describes the cleaning station maintenance procedures.

●

Charge Roller: Describes the charge roller maintenance procedures.

●

Pre-transfer erase (PTE): Describes PTE maintenance procedures.

●

Exit roller: Describes exit roller cleaning and maintenance procedures.

●

Pre-heater: Describes pre-heater element cleaning and housing removal procedures.

●

Chiller Operation and Maintenance: Provides inspection and maintenance procedures for the

●

press chiller.

Glossary: Provides definitions of terms used throughout the HP Indigo 7000 Digital Press

●

documentation set.

2 Chapter 1 About this user guide ENWW

Page 12

Supplies and jigs: Provides information on the press imaging, maintenance, and general supplies.

●

Service and support: Provides customer care center service and support contact information.

●

ENWW Overview 3

Page 13

Conventions used in this guide

This guide uses the following documentation conventions:

Elements in the graphical user interface (GUI) which you must select or click, are indicated in bold

●

type, for example: On the File menu, click New.

Other elements in the GUI, such as Window names, appear in italics. For example: After selecting

●

the options in the Print window, click OK.

References to other sections in the guide appear in quotes, for example: See the “Installation” on

●

page 37.

4 Chapter 1 About this user guide ENWW

Page 14

2 Product overview

This chapter contains the following sections:

HP Indigo press

●

General press specifications

●

ENWW 5

Page 15

HP Indigo press

The HP Indigo 7000 Digital Press is a sheet-fed digital offset color press that incorporates the patented

HP ElectroInk liquid ink technology and high-speed electronic imaging to produce fully-finished, highquality color prints. The press features an intuitive and user-friendly interface, provides diagnostic

screens that take the guess work out of printing.

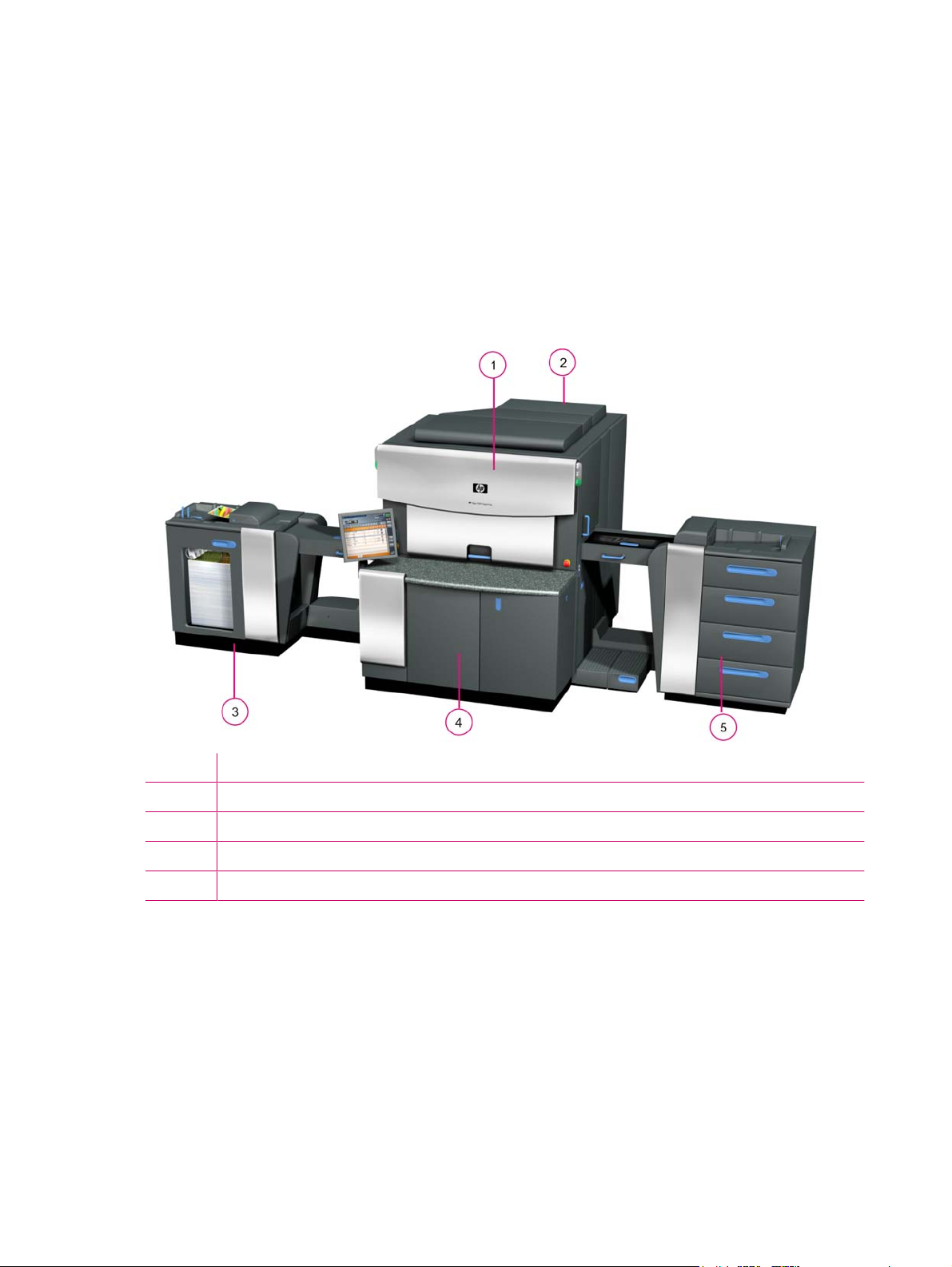

HP Indigo 7000 Digital Press

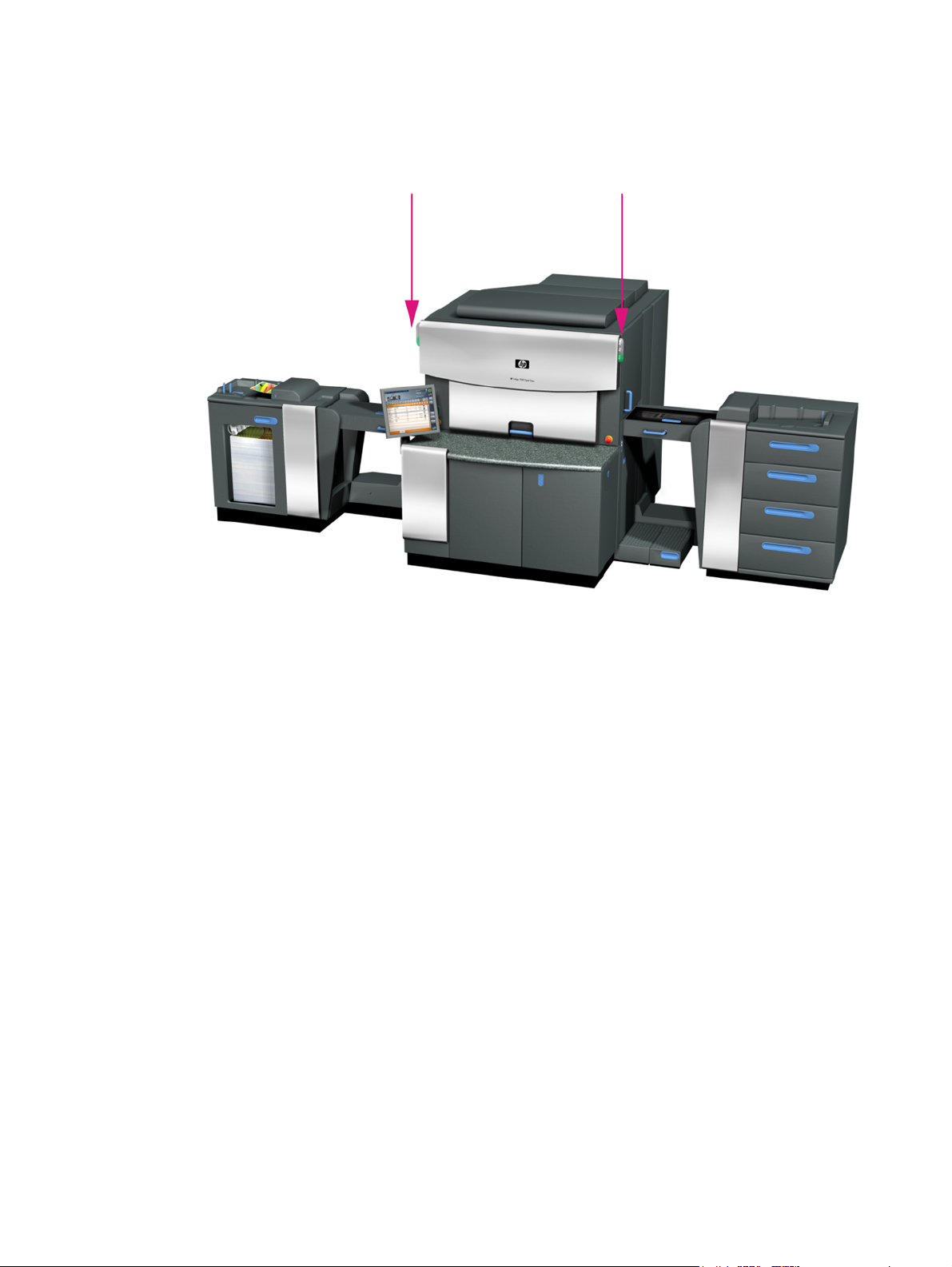

The press consists of five basic elements: the printing engine, ink cabinet, utility cabinet, feeder, and

stacker.

Figure 2-1 HP Indigo 7000 Digital Press

1 Printing engine

2 Utility cabinet

3 Stacker

4 Ink cabinet

5 Feeder

6 Chapter 2 Product overview ENWW

Page 16

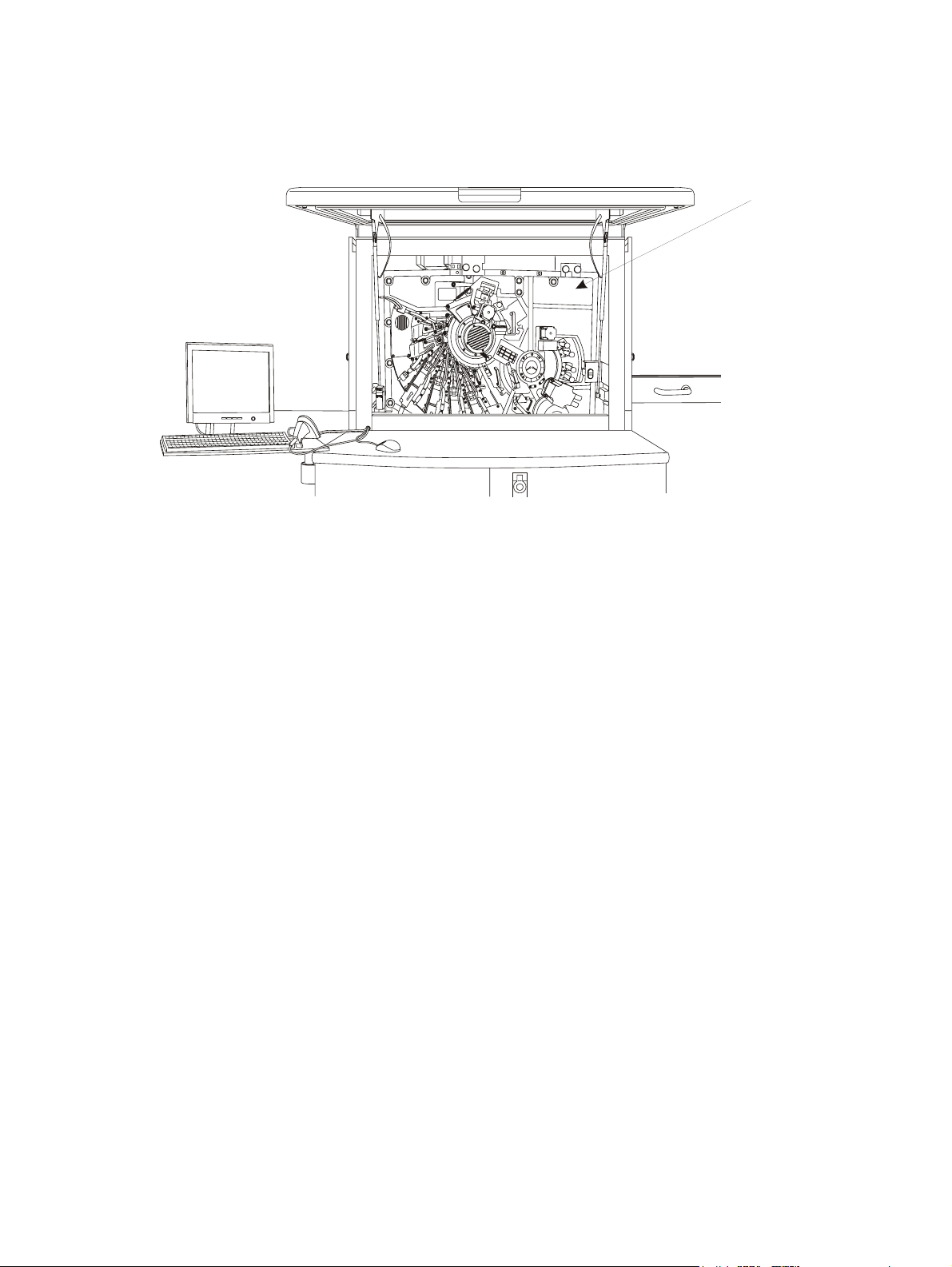

Press serial number

The press serial number is on the front of the press behind the front door.

Figure 2-2 Press serial number

7000_PREIPH-1-07

ENWW HP Indigo press 7

Page 17

General press specifications

Printing rate

Input job definition Press productivity

Color

Job type

A4 (1/0) 14,400 7,200

A4 (4/0) 7,200 14,400

A4 (1/1) 7,200 7,200

A4 (4/4) 3,600 14,400

1

1

(number of color separations on side 1 / number of color separations on side 2)

A4 pages/hour Separations/hour (impressions/hour)

Up to seven colors are supported:

Option 1 - four process colors (CMYK - cyan, magenta, yellow, and black), plus 3 spot colors.

●

Option 2 - HP IndiChrome process (six color process), plus 1 spot color.

●

8 Chapter 2 Product overview ENWW

Page 18

3Safety

This chapter contains the following sections:

Overview

●

Warning signs and labels

●

Safety devices

●

Emergency power shutdown

●

Door interlocks and warning indicators

●

Attention lights

●

Maintenance safety and emergency procedures

●

Combustible and flammable liquids and fumes

●

ENWW 9

Page 19

Overview

The safety information and procedures described in this chapter apply to operators and other personnel

working on or near the HP Indigo 7000 Digital Press. The safety procedures cover the press and the

area immediately surrounding the press.

Use the following guidelines:

The press must only be operated by personnel trained by HP or its authorized agents who are

●

thoroughly familiar with all the safety and maintenance procedures of the press.

Before you attempt to use the press, read and understand the safety procedures, including

●

environmental protection procedures.

NOTE: Call a customer care center for service and repair of the press. Do not attempt to service or

repair the press.

The HP Indigo 7000 Digital Press is NRTL approved and marked for use in the USA and

Canada.

Notice for the European Union:

This product complies with the following EU directives:

The Low Voltage Directive 2006/95/EC

●

The Machinery Directives 2006/42/EC

●

The EMC Directives 2004/108/EC

●

Compliance with these directives implies conformity to applicable harmonized European standards

(European Norms) which are listed on the Declaration of Conformity issued by Hewlett-Packard for this

product or product family.

The Declaration of Conformity can be found at www.hp.com/go/certificates

10 Chapter 3 Safety ENWW

Page 20

Warning signs and labels

Warning labels on the press

The following symbols appear on warning labels on the HP Indigo 7000 Digital Press:

Laser Hazard

DANGER. Invisible laser radiation may be present when doors are open and interlocks

are defeated. Avoid direct exposure to beam.

Laser Radiation

The lasers in the press emit radiation in the invisible range. The laser unit in the writing

head is enclosed in a protective housing and permits exit of the beam only at the writing

head window (aperture) to the PIP. Do not insert or allow any reflective objects to be

inserted in the path of the writing head window. Do not attempt to clean the writing head

window or look into the writing head window while the unit is operational.

Electrical Hazard

HAZARDOUS VOLTAGE. Will cause severe or fatal injury. Apply Lockout procedure.

Electrical Hazards

Before you start any maintenance procedure that involves an electrically powered

subsystem, make sure the subsystem is disconnected. If you are not sure that the

subsystem is turned off, turn off the main power switch. Always follow the lockout

procedure.

Live Current Hazard Alert

LIVE PARTS. Will cause severe or fatal injury. Apply Lockout procedure.

Entanglement Hazard Alert

WARNING. Open gears and mechanical parts. Can trap hands, fingers, clothing, and

cause serious injury. Stay well clear.

Pinch Hazard Alert

WARNING. Pinch points between rollers, wheels, and other parts can trap hands,

fingers, clothing, and cause serious injury. Stay well clear.

Mechanical Hazards

The press has a number of rotating parts and gripping devices (drums, gears, grippers,

and so on). Exercise special care when performing any maintenance work around these

parts. All repairs must be performed only by authorized customer engineers.

Do not climb into the substrate input or substrate exit for any reason. Doing so could be

dangerous.

Hot Surface Hazard

WARNING. Hot surface. Can cause burns. Do not touch.

Heat Hazards

ENWW Warning signs and labels 11

Page 21

The blanket and ITM drum become very hot during normal operation of the press, with

temperatures up to 110°C (230°F). Do not touch the ITM drum or external heater with

bare hands. Carelessness may cause burns. Wear thermal insulated gloves. Remove

old blankets with needlenose pliers.

The following warnings also appear on the press:

CAUTION! To reduce the risk of electric shock, the main disconnect should be locked in the off position before

servicing.

DANGER. Invisible laser radiation may be present when open and interlock defeated. Avoid direct exposure to

WARNING: Hazardous moving parts.

WARNING: Hazardous Voltage. Can cause damage.

WARNING: Hot surface. Can cause burns. Do not touch.

Emergency Stop Button

HIGH LEAKAGE CURRENT: Earth connection essential before connecting supply

MAIN EARTH CONNECTION LOCATED ON MAIN CHASSIS.

Warning signs

Post warning signs that clearly emphasize the dangers involved in operating and maintaining the press.

The following warnings are recommended:

This press is to be operated by properly trained and qualified operators only.

●

Do not wear ties, other loose clothing, or loose jewelry when operating and maintaining the unit.

●

Flammable vapors from heated imaging oil may be present!

●

No smoking, open flame, or sources of ignition allowed!

●

beam.

Make sure that the room is properly ventilated at all times. See the HP Indigo 7000 Digital Press

●

Site Preparation Guide.

Danger of pinching and crushing from moving press parts!

●

Keep hands away from moving press parts.

●

Access to Main Power switch must remain free at all times.

●

Do not operate the press with doors open.

●

Ink and imaging oil are irritating to eyes and skin. Use rubber gloves.

●

ITM drum and blanket are hot.

●

External heating lamps are hot.

●

Read and understand the material safety data sheets (MSDS) for consumables used with the press.

●

12 Chapter 3 Safety ENWW

Page 22

Placement of warning labels

Warning labels are placed in various locations on the press. Many of the warning labels on the press

are behind doors or covers and on parts that may be accessible only to authorized service personnel.

ENWW Warning signs and labels 13

Page 23

Safety devices

Material safety data sheets (MSDS)

MSDS are supplied for consumables, including the different HP ElectroInks, imaging oil and the imaging

agent, adhesion promoters, and adhesion promoter test fluids. Keep the MSDS readily available in the

work area. Read and consult them for your personal protection. Keep the MSDS in a protective plastic

cover.

Fire extinguishing equipment

The HP Indigo 7000 Digital Press generates combustible fumes and is also internally heated, a danger

of fire exists. Take the following precautions:

Position fire extinguishers in visible locations within 7.6 m (25 ft) of the press and any flammable

●

or combustible material storage areas.

Require regular inspection of the fire extinguishers (at least annually) and have designated

●

employees trained in their use. Employees should be retrained at least once a year.

Eye wash stations

The HP Indigo 7000 Digital Press uses inks and imaging oil that may be irritating to skin and eyes. In

extreme cases of exposure, these may cause blindness. Take the following precautions:

Install eye wash stations within 7.6 m (25 ft) of areas where the ink and imaging oil are handled,

●

dispensed, or stored.

Provide eye wash liquid at eye wash stations (available from most safety supply companies) that

●

complies with ANSI standard Z358. 1–1990.

Use safety glasses with side-shields and rubber gloves when handling ink and imaging oil (nitrile

●

disposable gloves are recommended).

Noise levels

During printing, the operator is exposed to a maximum of 80 dBA of audio noise with all service doors

and covers closed.

Heat insulating tools

The blanket, ITM drum, and external heating lamps become very hot during normal operation of the

press, with temperatures up to 165°C (355°F). Touching these parts could cause burns. Take the

following precautions when you work near the ITM drum or when you are replacing the blanket:

Wait until the drum cools to below 60°C (140°F) before performing maintenance procedures.

●

Do not place hands on the moving blanket. Use a tool to grip the blanket metal bar.

●

Electrical safety

The HP Indigo 7000 Digital Press must be properly grounded at all times. Before operating the unit,

ensure that it is grounded in conformance with the electrical code standards for your country/region (see

the HP Indigo 7000 Digital Press Site Preparation Guide for recommendations). If in doubt, check with

a licensed electrician or with your customer care center.

14 Chapter 3 Safety ENWW

Page 24

WARNING! Do not operate the press if it is not properly grounded. Perform a weekly check of

grounding cables.

If a cable has to be disconnected or reconnected during a maintenance procedure, you must electrically

turn off and lockout the press. Turn off the press by using the main power switch.

ENWW Safety devices 15

Page 25

Emergency power shutdown

The following can turn off all or some electrical power to the press:

Emergency Stop buttons: In an emergency, press one of the red Emergency Stop buttons to

●

stop all mechanical movement in the main engine.

Red Emergency Stop buttons on a yellow background are located at both sides of the front door,

and in other prominent locations on the press. When pressed, the button stops the press, and turns

off electrical power to most system components.

To turn off power: press the button down.

◦

To restore power: rotate the button clockwise to release.

◦

CAUTION: Some press components continue to receive power after an Emergency Stop button is

pressed.

NOTE: Pressing an Emergency Stop button during printing can cause damage to the PIP and blanket.

Figure 3-1 Emergency Stop button on right and left sides of front door

16 Chapter 3 Safety ENWW

Page 26

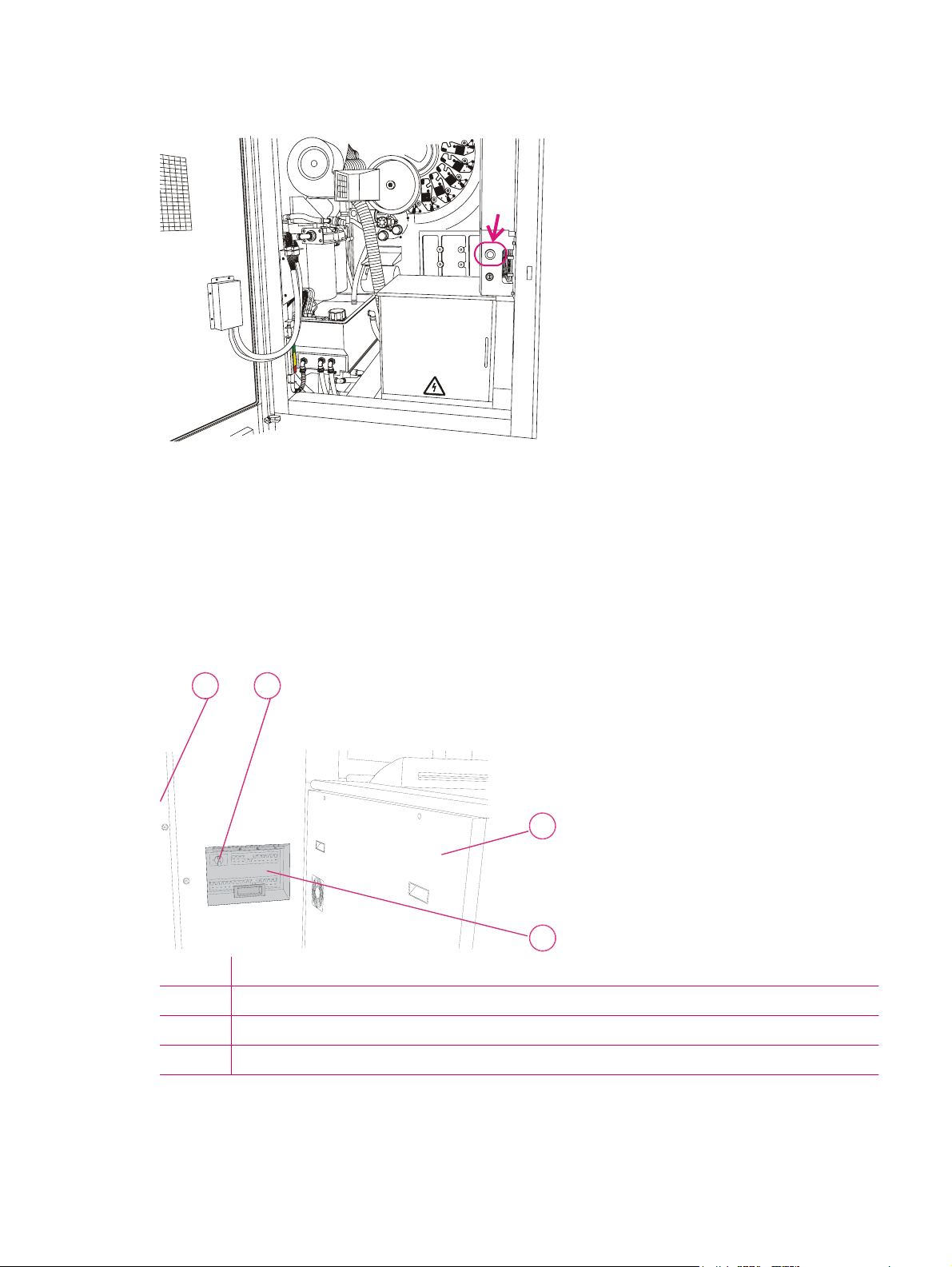

Figure 3-2 Emergency Stop button behind rear utility cabinet door

U

T

I

L

_

C

A

B

I

N

E

T

-

f

g

i

Main supply disconnect switch: The main supply disconnect switch is permanently connected to the

press via a conduit. A lockable disconnect device incorporated in the fixed wiring must be readily

accessible. The device must be rated according to the specifications shown in the HP Indigo 7000 Digital

Press Site Preparation Guide. This is an isolating device, which can be locked in the Off position to avoid

an unexpected startup or release of electrical power during servicing or maintenance.

Main power switch: The main power switch is located at the rear of the press. Access the main

●

power switch through the opening near the rear door. Raise the switch cover. Rotate the main

power switch to the left position to turn off all electrical power to the press engine.

Figure 3-3 Main power switch

12

P

R

E

I

P

H

_

0

1

7

6

A

-

f

i

g

1 Rear utility cabinet door

2 Main power switch at exit side, behind stacker unit

3 Stacker unit

4 Switch cover

3

4

ENWW Emergency power shutdown 17

Page 27

CAUTION: Always maintain free access to the main power switch, so that power can be immediately

turned off in an emergency.

The main power switch does not disconnect power to the power distribution unit (PDU).

Power Enable switch: The Power Enable switch is located on the upper left side of the press. The

●

switch turns off power to the press engine subsystems, except for the computer and ink cabinet.

To turn off power, put the Power Enable switch in the off position. To restore power, put the Power

Enable switch in the on position.

Figure 3-4 Power Enable switch

18 Chapter 3 Safety ENWW

Page 28

Door interlocks and warning indicators

Door interlocks

The HP Indigo 7000 Digital Press has interlocked doors and covers that stop the press and turn off

electrical power to system devices when these doors and covers are opened.

WARNING! Access to, and use of bypass keys is restricted to specifically trained and authorized

personnel. Do not disconnect or override any of these safety devices.

The following doors and covers are interlocked:

Stacker Printing engine Feeder

• Stacker top cover • Upper feed door • Feeder drawers

• Stacker front door • Lower feed door • Feeder upper feed door

• Ink cabinet door (disables air

compressor to ink cans only)

• Front door • Feeder vertical access door

• Bridge

Cleaning ECN door

• External heater cover

• Rear utility cabinet door

• Feeder to cover frame

If any of the doors or covers are opened, the interlock is activated and prevents operation of most

devices, such as the high-voltage power supply and the main motor. Opening a feeder door will not turn

off power to all parts of the feeder.

When you open an interlocked door :

The press status changes to Off.

●

The schematic illustration indicates that the door is open,

●

All opened interlocked doors and covers are indicated by• an open lock icon in the user interface.

ENWW Door interlocks and warning indicators 19

Page 29

Figure 3-5 Press schematic showing open interlock doors

20 Chapter 3 Safety ENWW

Page 30

Attention lights

Attention lights are located on the input and exit sides of the printing engine.

Figure 3-6 Attention lights

Attention lights consist of three colors that indicate the following when lit:

Green light:

●

Always on in Ready state

◦

Flashing in Printing and Getting Ready states

◦

Yellow light:

●

Always on for all errors and for warning LEDs

◦

Warnings flagged:

An ink can is empty

◦

Conductivity in one ink tank is high/low

◦

Color adjustment is needed

◦

Print cleaner is needed

◦

Cooler drain is almost full

◦

Stacker is 90% full

◦

Only 10% of substrate is left in the feeder

◦

Red light:

●

Flashing when the bypass key is inserted, and a buzzer will sound before the press starts to

◦

rotate.

ENWW Attention lights 21

Page 31

CAUTION: A flashing red light indicates that the bypass key is inserted, and a buzzer will sound before

the press starts to rotate.

22 Chapter 3 Safety ENWW

Page 32

Maintenance safety and emergency procedures

Standby status

Put the press in Standby by pressing the Standby button on the touch screen when the system is not

required to print, or is unattended. The press automatically goes into Standby after it has remained idle

for more than 20 minutes.

Inching button

Use the Inching button in maintenance procedures that require inching the drums. If any interlocked

doors are open, the press returns to the off state. The Inching button is enabled when the upper feed

sliding window is opened. During inching, the press is in Standby.

Figure 3-7 Inching button (feed side)

Inch-safe method

WARNING! Do not perform maintenance on rotating parts (such as drums) with a hand on a moving

part while the press is on slow roll (for example, pressing the Inching button).

Health and safety regulations require that you use the inch-safe method for maintenance procedures

where the PIP, ITM, and impression drums are required to rotate:

1. Press an Emergency Stop button to put the press into an inactive state with the power on.

2. Perform the necessary procedure (for example, cleaning).

3. Release the Emergency Stop button by rotating it. Press the Inching button to inch the press.

Immediately press an Emergency Stop button to put the press into a safe state before continuing

maintenance.

4. Continue inching the press, stopping the press (putting it into an inactive state), and servicing the

press part until the job is complete.

ENWW Maintenance safety and emergency procedures 23

Page 33

Press lockout procedure

Health and safety regulations require that you use the following lockout procedure before performing

maintenance procedures that do not require drum rotation.

Lockout means either locking an energy-isolating device (for example, a fuse box) to prevent the

activation of the press, or unplugging the press, with the plug under the exclusive control of the person

performing the service or maintenance.

Use the following lockout procedure whenever there is any risk of unexpected press activation:

1. Disconnect the press from all sources of electrical power by using the Main Power Supply

Disconnect switch (see

2. Lock the isolator switch in the off position to avoid an unexpected startup or release of electricity.

3. Turn off the external Uninterruptable Power Supply (UPS).

4. Allow 20 seconds for residual stored energy to dissipate after the press is turned off.

5. Before starting maintenance or servicing, use a power tester to ensure that points that are live

when the press is in normal operation are no longer live.

Figure 3-3 Main power switch on page 17).

24 Chapter 3 Safety ENWW

Page 34

Combustible and flammable liquids and fumes

Because the imaging oil used by the HP Indigo press is combustible (USDOT Class 3A), use the

following safety procedures:

Operate the press in a well-ventilated room (see the HP Indigo 7000 Digital Press Site Preparation

●

Guide). The press is equipped with ventilation fans. If they are not functioning, the unit enters an

error state and the press becomes inoperable.

Do not smoke or introduce an external source of ignition (such as pilot lights, open flames, stoves,

●

heaters, or halogen lights). Avoid creating sparks (static, electrical, or mechanical) or introducing

any spark-producing equipment within 7.6 m (25 ft) of the press.

Clean spills immediately after they occur, and dispose of dampened cleaning materials promptly

●

and properly in accordance with local regulations.

Isopropyl alcohol (IPA)

IPA is a highly volatile and flammable liquid (USDOT Class 1B). Do not apply it to hot surfaces or allow

its use near an open flame or sources of electrical sparks.

Use IPA for cleaning specified parts only. Clean with IPA only when the printing engine is off. When you

use IPA, wait two to three minutes after application to allow the IPA to evaporate before proceeding. If

you cannot tell if the IPA has evaporated, use your finger to feel for wetness.

Handling and storing imaging oil, inks, and IPA

Take the following precautions when handling or storing imaging oil, inks, and IPA:

Avoid fire hazards by storing imaging oil, inks, and IPA in fireproof cabinets or a special combustible

●

liquids storage room.

Allow only trained personnel to handle imaging oil, inks, and IPA.

●

Keep containers tightly closed at all times. If a container appears damaged, transfer the contents

●

to a dry, clean, and suitable container that can be tightly sealed.

When handling imaging oil and inks, wear safety glasses with side shields, long-sleeve overalls,

●

and protective gloves as indicated on MSDS.

Keep MSDS in solvent-proof envelopes at the press.

●

Carefully drain the air conditioner sump tank. Use a suitable receptacle and avoid splashing.

●

Do not ingest imaging oil, inks, IPA, or any waste fluids.

●

Refer to local combustible material handling regulations.

●

Disposing of consumables and cleaning materials

Dispose of the consumables and cleaning materials that you use in accordance with applicable

regulations. Consult with your local authorities to determine the correct manner in which to dispose of

the following wastes:

Process oily waste bottles

●

Imaging oil and ink

●

ENWW Combustible and flammable liquids and fumes 25

Page 35

Empty HP ElectroInk containers

●

Charge roller

●

Blankets

●

PIPs

●

Cleaning wipes dampened with imaging oil

●

Lint-free wipes or tissue paper contaminated with ink

●

Contaminated chemical-resistant gloves

●

Empty imaging oil containers

●

Oil filters

●

Ozone filters

●

NOTE: For disposal of items other than those listed above, contact your local customer care center.

Waste bottles

Two bottles used to store waste are located in the lower service door at the rear of the press. These

bottles are identified as follows:

Waste bottle #1—Process oily waste

●

Waste bottle #2—Water waste

●

Figure 3-8 Waste bottles (in lower service door at press rear)

12

L

O

W

E

R

_

U

T

I

L

_

D

O

O

R

1

-

f

i

g

1 Water waste bottle

2 Process oily waste bottle

26 Chapter 3 Safety ENWW

Page 36

Additional information

It you have any questions regarding safe operation of the HP Indigo 7000 Digital Press, do not continue

operation without contacting a customer care center. Additional MSDS are available upon request from

your customer care center.

ENWW Combustible and flammable liquids and fumes 27

Page 37

28 Chapter 3 Safety ENWW

Page 38

4 Operating the press

This chapter contains the following sections:

Turning the press on

●

Using the press

●

Using the control panel

●

Turning the press off

●

ENWW 29

Page 39

Turning the press on

1. Make sure the HP Indigo press Production Manager is turned on and active prior to turning the

press on.

2. On the press, raise the switch cover and turn on the Main Power switch at the rear of the press

3. Wait for the HP Indigo 7000 Digital Press software to appear on the screen (this can take several

minutes),

4. Push the Power Enable switch on the exit side of the press.

The press is now in Standby state.

Figure 4-1 main Power switch at press rear

12

P

R

E

I

P

H

_

0

1

7

6

B

-

f

i

g

1 Main power switch

2 Switch cover

Figure 4-2 Power Enable switch

30 Chapter 4 Operating the press ENWW

Page 40

Using the press

1. Make certain that all the subsystems are assembled on the press and that end of day routines were

performed the previous day.

2. Put the press in Ready status. On the touchscreen, touch Get Ready. The press drums begin to

roll and the various subsystems power up. When the preset conditions are met, the press status

changes to Ready.

3. Load the substrate type for the first job to be printed (see

on page 69).

4. Load the job (see

5. Click Print or Proof.

6. Remove the printed sheets from the stacker. Check the output placement, color, etc. adjust if

necessary (see

7. When the job has finished printing, the press goes to Standby status.

8. When you have finished work for the day, turn the press off.

Printing jobs on page 41)

Editing job properties on page 43)

Loading substrate into the feeder

ENWW Using the press 31

Page 41

Using the control panel

The control panel is the main window from which you control the entire operation of the press.

Using the software

The software is the main screen from which you control the entire operation of the press.

Touch the required button or icon displayed on the screen to select an option. Some components are

read-only and are not sensitive to touch.

The main screen includes the following components which are always visible.

The control panel

●

Working area

●

The control panel

The control panel includes the following components:

1 Small press schematic

1

2

3

4

2 Print job panel

3 Main toolbar

4 Printing controls

Small press schematic

The small press schematic indicates the press status.

32 Chapter 4 Operating the press ENWW

Page 42

Using the Press Schematic

On the Main Menu, select Press Status, and Schematic.

The large Press Schematic panel is displayed indicating the current status of various parts of the press.

In the Press schematic panel, touch the various press parts to open the relevant part panel.

Figure 4-3 Press Schematic

Print job panel

The print job panel shows properties for the current job:

●

●

●

●

●

●

●

●

●

Touching the current job area opens the Copy/Sheet progress details for the current job.

Touching the next job area opens the Job Properties window for the next job.

Job name

Substrate name

Thumbnail of current job — select to display a full preview of the job

Number of sheets in the job

Number of copies printed and number of copies to be printed

Time left for the current job to finish printing

The next job to be printed

The status of the next job

Thumbnail of next job — select to display a full preview of the job

ENWW Using the control panel 33

Page 43

Main toolbar

The main toolbar is used to access the main menu and frequently used processes. The selection

appears in the working area.

The main toolbar includes the following buttons:

●

●

●

●

●

Main Menu — Enables access to all processes

— Displays the home window, and closes the current window.

Paused Processes — Allows you to switch between multiple paused processes. When more than

one application is paused, the number of paused processes is displayed in brackets. Touch the

arrow to open the drop-down list, and select a paused process.

— Opens a menu with additional main toolbar buttons, including customized buttons. This

button can be toggled to show or hide the menu.

— Changes to ToolTip mode. ToolTip mode displays the relevant tooltip when touching a

control button, and will not perform the relevant operation. This button can be toggled.

●

Print controls

The print controls are used to operate the press and to print jobs. The print controls also show the press

state.

— Opens the relevant help page for the current window in the working area.

34 Chapter 4 Operating the press ENWW

Page 44

1

2

3

4

5

6

1 Press state indicator

2 Error and warning indicators

3 Print buttons

4 Press status selector

5 Pause selector (idle)

6 Mode buttons

Press state indicator

Different press functions are possible only at defined press states.

The following press states exist:

Print

●

Getting Ready

●

Ready

●

Standby

●

Off

●

ENWW Using the control panel 35

Page 45

Error and warning indicators

The error and warning indicators display the number of unacknowledged messages. Touch the buttons

to open the list of the latest messages.

Print buttons

The print buttons control the operation of the press and jobs.

The following print buttons are available:

Print — Prints a single job.

●

When the press is in print state, this button changes to Pause. Touching this button, pauses the

job currently printing.

Proof — Prints a proof to the sample tray.

●

Sample — Prints a sample copy to the sample tray. While printing many copies of a job you cannot

●

print a proof, but you can print samples to check that print quality remains as good as the original

proof. Sample copies are not included in the number of copies for a job.

End Job — Ends the current job, and starts the next job.

●

Abort — Terminates the current job and stops printing.

●

Get Ready / Standby — Moves the press state from Standby to Ready; from Ready to Standby;

●

or from Get Ready to Standby.

NOTE: When working on a press with multiple stackers, all the print buttons are displayed with a

buzzer icon, and the controls are disabled prior to printing. Touching any print button activates the buzzer

alarm, indicating that the press is about to rotate at full speed. The print buttons are then enabled, and

the buzzer alarm stops

Mode buttons

The mode buttons control the print mode and the press mode when job printing is completed.

The mode buttons include:

●

●

At the completion of all print jobs in the print queue:

Idle — The press continues to rotate and moves to Pause state

◦

Suspend — The press stops rotating and moves to Ready state.

◦

36 Chapter 4 Operating the press ENWW

Page 46

At the end of each print job in the print queue:

Continuous — The press prints the next job automatically without stopping.

◦

Step — The press moves to Ready state, and only continues to next job when Print button is

◦

touched.

Working area

The working area of the touchscreen displays the currently running process. The processes are color

coded according to predefined groups to enable easy recognition. For examples green background

indicates wizards.

Navigating in the working area

The working area can include its own toolbar to enable navigation in the current process. Use the main

menu or main toolbar to navigate to other processes.

Virtual keyboards

A virtual keyboard appears when touching a button that requires text input. A virtual numeric keypad

appears when touching a button that requires number input.

ENWW Using the control panel 37

Page 47

Turning the press off

1. On the touch screen Main Menu, select Options, and Shut Down Computer. The Shut Down

Computer window appears.

2. Select Shut down the computer. Wait for the computer to completely shut down, this can take a

few minutes.

3. Turn off the Main Power switch at the rear of the press. The system is now shut down.

38 Chapter 4 Operating the press ENWW

Page 48

5 Job handling

This chapter contains the following sections:

Managing jobs

●

Printing jobs

●

Job maintenance

●

ENWW 39

Page 49

Managing jobs

Jobs are produced on the HP Indigo Production Manager, and sent to the press. On the press, Jobs

are managed using the Print Queue window. From the Print Queue you can view the status and

properties of all jobs, including:

The jobs currently printing

●

The jobs requiring preparation

●

Held jobs

●

Retained jobs saved in the system for a limited period of time

●

You can also view the job properties for each individual job.

Print Queue

The print queue is the default window in the touch screen working area. It shows the list of jobs to be

printed. Each job also contains information about the job parameters. Additional information about a

selected job can be seen by touching the Properties button.

Figure 5-1 Print Queue

40 Chapter 5 Job handling ENWW

Page 50

Printing jobs

To print jobs:

Load jobs in the Print Queue. The position of a job in the list depends on urgency, substrate type,

●

substrate thickness, number of colors in the job, or other job properties.

Arrange the jobs in the list to facilitate the workflow. For example, all jobs that use the same

●

substrate type or all jobs that use the same fifth and sixth color should be grouped and printed

consecutively.

Jobs are loaded and managed using the HP Indigo Press Production Manager.

Stage 1: Loading jobs

From the HP Indigo Production Manager, load jobs to the Loaded Jobs list. There are several ways to

load jobs to the list. Refer to the HP Indigo Production Manager user guide for details.

Make certain the job properties, number of copies, print range, and screen ruling are defined as

●

required.

Modify the properties if necessary. For more details, see

●

Stage 2: Proofing

1. In the Print Queue, select the job to print.

2. Click Proof. The press prints one copy of your job.

3. Evaluate the printed job.

Check for image placement in relation to the leading edge and to the left margin (see

●

5-5 Image placement on the sheet on page 45). Normally the image should be centered on

the narrow axis and 10 mm [0.39 inches] from the leading edge.

Check for color values. Compare with a previous print or a proof, if available. To modify color

●

values, use the Color Match tab or the Color Control in the Job Properties window.

Check image integrity, full ink coverage, right sheet sequence, and same image placement

●

for all jobs.

Editing job properties on page 43.

Figure

— For duplex jobs, check the front-to-back registration (see

registration on page 46).

— For multi-sheet jobs, make sure that the image placement is identical for all the job

sheets

— If necessary, move the job to the Held List, then open the Job Properties window,

click the Image Placement tab and make corrections.

Figure 5-6 Front-to-back

4. Print a second proof and evaluate it.

If there is a time delay between proof approval and the actual full run, print another proof

immediately before printing the full run, to make certain it matches the approved proof.

ENWW Printing jobs 41

Page 51

Stage 3: Printing the full run

1. Set the print mode on the control panel:

When it is set to Continuous, the job is unloaded at the end of the print run and the next job

●

in the Print Queue starts the print process.

When it is set to Step, the next job in the Print Queue is moved to the top of the Print Queue

●

and appears in the Now printing job field, but printing stops

Figure 5-2 Print mode selector

2. Change the press status to Ready.

3. Make certain the required substrate type for the subsequent job is loaded on the press.

4. On the control panel, click Print to print the full-run

42 Chapter 5 Job handling ENWW

Page 52

Job maintenance

Job maintenance activities are performed in the Job Properties window.

Job disposition and retrieval

Loaded jobs use large amounts of system space.

Do not keep unnecessary jobs on the system. The press will discard, save, save for a limited period of

time, or archive jobs that have been printed.

Define the disposition of a job after printing In the Job Properties window, General tab.

●

In the After Print Retain For section, type or select the period of time you need to retain a print

job.

To retrieve a retained job in the Job Manager window, click Job and Retain List.

●

Drag and drop the required job into either the Loaded Jobs list or the Print Queue.

Archive a job from the Job Manager window by clicking Job and Export. Save the job to a memory

●

storage device on the system, such as the DVD writer.

Retrieve jobs from the Job Manager window by clicking Job and Import. Access the required

●

directory or drive and select the job to be imported.

Editing job properties

Edit job properties in the Job Properties window.

Open the Job Properties window from the HP Press Production Manager—Press Job Manager. Rightclick a job in the Loaded Jobs panel, and select Job Properties.

The Job Properties window contains the following tabs:

General: Defines job related parameters such as number of copies, sheet range, duplexing, and

●

job retention.

Substrate: Used to define the substrate to be used for printing the selected job.

●

Stacking: Used to change stacking destination and the duplex orientation.

●

Image Placement: Used to change the position of images within the job.

●

Color Control: Used to change a job's color look-up table (LUT) - see below.

●

Color Match: Used to modify dot area and optical density of the separate colors.

●

ENWW Job maintenance 43

Page 53

Separations: Used for defining separations, screening, and ink order.

●

Linework and Resolution: Used to define resolution and linework settings such as adaptive

●

halftoning, line smoothing, and line thinning.

Figure 5-3 Job Properties—General

44 Chapter 5 Job handling ENWW

Page 54

Image placement

Corrections to image placement on the substrate for a specific job can be done from the Job

Properties window, Image Placement tab.

Correct the image placement in relation to the leading edge and the margins. Normally the image

●

should be centered on the narrow axis, and 10 mm (0.39 inches) from the leading edge.

For duplex jobs, you can correct the front to back registration.

●

Adjust identical image placement for multi-sheet jobs.

●

Figure 5-4 Job properties — Image placement tab

Figure 5-5 Image placement on the sheet

10 mm

(.39 inches)

XX

Image is centered

on the horizontal

axis (X=X)

ENWW Job maintenance 45

Page 55

Figure 5-6 Front-to-back registration

s

g

Front leading

2

1

Figure 5-7 Cross-run registration

Distance from left

margin to image is

equal throughout

the run

Front cross

marks

aligned with

back cross mark

Distance from leadin

edge to image is

equal throughout the

run

.

Editing job look-up tables (LUTs)

Job LUTs are used to change the printed dot size in relation to the dot size as defined in the original

graphics files. By editing LUTs, you can control the dot gain for every dot size individually.

46 Chapter 5 Job handling ENWW

Page 56

HP Indigo supplies several tailored LUTs, ranging from Linear to Chromalin, with Chromalin applying

the biggest dot gain. You can also create your own LUT or set a customized LUT as the default.

Figure 5-8 Different LUTs

yy

x

Chromalin Linear

x Dot size in graphic file

y Printed dot size

To create your own LUT, select Job Properties, and then select the Color Control tab. Use the Table

and Scales tab to modify the entire LUT, or change selected points.

Figure 5-9 Job Properties—Color Control

NOTE: LUT changes only apply to the selected job.

You can save the LUT to the LUT Library for use with other jobs.

You can control the 50 percent dot area from the job LUT panel.

ENWW Job maintenance 47

Page 57

To improve accuracy, adjust colors from the Color Control tab (Figure 5-9 Job Properties—Color

Control on page 47).

The solid, 100 percent optical density slider in the Job properties - Color Control window contains the

same parameter adjustments as those in the Job properties - Color Match window.

Color matching is used when you need to change the color intensity. Color matching is a fast but less

exact tool than LUT changes. With color matching, the entire gray scale shifts either up or down.

With color matching, you can define the new optical density value for the 100 percent dot area and for

the 50 percent dot area for each ink individually. Move the job to the Held Job list before attempting to

perform Color Match. These values are then saved as part of the job properties for future runs.

Figure 5-10 Job Properties—Color Match tab

Screening

Jobs can be printed with different screen rulings. The higher the screen ruling, the better the rendering

of detail.

Higher screen rulings are more demanding, because they require a more finely tuned press calibration.

Job screen can be defined in the Job Properties window, Separations tab.

HP Indigo supplies the following screen rulings:

Sequin — an average of 144 lines per inch (lpi), used for specific circumstances only

●

HDI-175 — an average of 175 lpi — default screen used for most jobs

●

HDI-180 — an average of 180 lpi

●

You can print a separation several times to enhance density.

48 Chapter 5 Job handling ENWW

Page 58

HP Indigo supplies you with alternative color order to support transparency printing.

Figure 5-11 Job Properties — Separations tab

Inks “double-hit” printing

Some Ink Mixing System inks require double-hit printing in order to achieve the required color saturation,

and this feature performs double-hit printing without screening artifacts (patterns).

The press will double-hit only the solid and high-saturation gray levels.

To access the double-hit feature:

ENWW Job maintenance 49

Page 59

Double-hit printing can be defined from the Job Properties window, Separations tab. Check the X2

box for the required color.

Figure 5-12 Double Hit check box

50 Chapter 5 Job handling ENWW

Page 60

Linework and resolution

Modify linework and resolution to print thinner lines and smoother fonts at a higher definition. Job

linework and resolution can be defined in the Job Properties, Linework and Resolution tab.

Check Adaptive Halftoning to smooth edges on gray-level areas

●

Check Line Smoothing to smooth lines in 400 dpi and 600 dpi jobs

●

Check Line Thinning and type a value in microns or use the slider to choose value

●

Figure 5-13 Job Properties — Linework and resolution tab

ENWW Job maintenance 51

Page 61

52 Chapter 5 Job handling ENWW

Page 62

6 Color management

This chapter contains the following sections:

Calibrating the press colors

●

Color Calibration procedures

●

Defining substrate-related color parameters

●

Selecting a workflow for full color calibration and substrate-related parameters

●

ENWW 53

Page 63

Calibrating the press colors

There are two ways of calibrating the press colors:

Short color calibration - offers high speed and economy.

●

Full color calibration - offers high accuracy and flexibility.

●

The short color calibration procedure is used to guarantee color repeatability between runs on the press.

It allows you to set the density of the solid ink layer and the density of three grey levels..

●

It fine tunes the compensation process for each PIP since PIP deterioration over time is a source

●

of color inaccuracies.

It is triggered automatically:

●

After a PIP replacement

◦

Every 10,000 impressions per substrate type, unless bypassed by the operator.

◦

Perform the short color adjustment procedure after replacing the blanket.

Perform the full color calibration when a particular screen, ink or substrate is changed.

The full color calibration calibrates 15 points on the dot gain curve.

The full color calibration is operated automatically every 20,000 impressions, or via a wizard.

54 Chapter 6 Color management ENWW

Page 64

Color Calibration procedures

To perform the short or full color calibration procedure:

1. On the press software menu, select Print Quality. The Print Quality panel opens.

2. Touch Color Calibration. The Color Calibration wizard opens.

3. Select the Short or Full color calibration type,

4. Select a method to run the calibration — Skip to print uses default substrate, screening and ink

parameters to run the calibration. Step by step allows you to customize the calibration parameters.

NOTE: When performing a Step by Step calibration, choose a the same substrate or a substrate

from the same group as the calibration substrate.

Figure 6-1 Color Calibration Wizard