Page 1

HP IndiChrome Ink Mixing System

User guide

Page 2

HP IndiChrome Ink Mixing System

User guide

Page 3

© 2006 Copyright

Hewlett-Packard

Development Company,

L.P.

Reproduction, adaptation,

or translation without prior

written permission is

prohibited, except as

allowed under the

copyright laws.

The information contained

herein is subject to change

without notice.

The only warranties for HP

products and services are

set forth in the express

warranty statements

accompanying such

products and services.

Nothing herein should be

construed as constituting

an additional warranty. HP

shall not be liable for

technical or editorial errors

or omissions contained

herein.

directions provided by HP

in this and other

publications. All high

voltage power supplies and

laser sources are located

behind protective covers.

Warning labels are

attached to each protective

cover. Do not remove

covers.

Part Number :

CA294-02222

First Edition:

December 2006

HP, HP Indigo Press,

HP Indigo Press RIP, and

HP ElectroInk are

trademarks or registered

trademarks of HP.

Adobe® PostScript® is a

trademark of Adobe

Systems Incorporated.

MS Windows® and

Windows® are U.S.

registered trademarks of

Microsoft Corp.

All other products or name

brands are trademarks of

their respective holders.

The HP Indigo press is a

Class 1 Laser Product

containing high voltage

power supplies and laser

light sources. There is no

danger to persons or

equipment when the

system is operated in

accordance with the

Printed in Israel.

Page 4

Contents

1 Introduction

User guide introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

User guide structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Conventions used in this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hardware configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Important system information and limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Safety and environment considerations

General warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Material Safety Data Sheets (MSDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Preventing eye irritation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrical safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Emergency power cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Flammable liquids and fumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Handling and storing imaging oil and inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Waste disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Getting started

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Detailed Automatic Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Starting the ink mixing system (IMS) software . . . . . . . . . . . . . . . . . . . . . . . . . . 27

HP IndiChrome Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Exiting the IMS software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 General procedures

Calibrating the electronic scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Calibrating the spectrophotometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Performing a full calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Performing the daily calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Draining the water from the dispensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adjusting the dispensing unit for the press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Measuring a color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Selecting a PANTONE

Save the Ink Definition file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Saving the color’s workspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Transferring the ink definition file to the press . . . . . . . . . . . . . . . . . . . . . . . . . . 46

All HP Indigo presses except for Indigo Sun computer-based presses . . . . 46

Indigo Sun computer-based presses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Preparing the basic inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Dispensing the ingredients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sealing the can . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Shaking the can . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Visually comparing the printed color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Adjusting the ink mix from the printed output . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Accurate match. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

®

color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ENWW

3

Page 5

Match can be improved by a fix can . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Fix can would add too much ink to the ink tank . . . . . . . . . . . . . . . . . . . . . . 55

Improvement possible by changing optical density . . . . . . . . . . . . . . . . . . . 56

Undoing and redoing a measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Changing the optical density (OD) spec value . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Improving visual match by changing illuminant. . . . . . . . . . . . . . . . . . . . . . . . . . 58

Comparing different ink mix results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Changing the ink on the press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5 Additional IMS procedures

Ready Mix colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Detailed Ready Mix Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Continuing work on a previously defined mix color . . . . . . . . . . . . . . . . . . . . . . . 68

Manual color mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Detailed Manual Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Mixing a custom color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Using L* a* b* target values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Measuring the color directly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Excluding a basic color from the ink mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Adding a new substrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Importing .mix files (including previous-version ink mix files) . . . . . . . . . . . . . . . 76

Exporting and deleting ink workspace files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Printing the color workspace details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Setting and displaying specific ink mix parameters . . . . . . . . . . . . . . . . . . . . . . 78

Color matching parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

HP Indigo press selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Ink print thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Color information summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Increase/decrease view of 2D color space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Zoom into 2D color space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Zoom by changing axes values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

View the 3D color space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4 Contents

6 Customizing the look of the HP IndiChrome window

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

HP IndiChrome window customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Changing the ink mix details panel background color . . . . . . . . . . . . . . . . . 85

Changing the 2D color space panel background color . . . . . . . . . . . . . . . . . 86

Changing the color name font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Displaying the 2D color space background bitmap . . . . . . . . . . . . . . . . . . . 87

Saving and loading the HP IndiChrome window customization . . . . . . . . . . . . . 87

Saving the customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Loading a customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Viewing and hiding the Toolbar and Status bar . . . . . . . . . . . . . . . . . . . . . . . . . 88

7 Help

Online help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Useful links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Program updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ENWW

Page 6

Appendix A Special options, basic concepts, and spare parts

(all presses)

Special options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Setting the mix precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Window menu item usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

How to use the IMS graphic window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Decreasing ink thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Using an old mix file for a new ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Basic concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Color space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

DE*94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Color gamut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

System file types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Can shaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Dispensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B Service and support

Index

ENWW

5

Page 7

6 Contents

ENWW

Page 8

1

Introduction

This chapter contains the following sections:

z

User guide introduction

z

User guide structure

z

Conventions used in this guide

z

System requirements

z

Hardware configuration

z

Consumables

z

Important system information and limitations

ENWW

7

Page 9

User guide introduction

It is often desirable to print with spot color inks in addition to the Cyan, Magenta, Yellow,

and Black (CMYK) process colors. The HP Indigo presses enable you to use such special

inks. The HP IndiChrome ink mixing system (IMS) gives you the capability of preparing

the special ink you require by mixing inks from a set of basic inks. Because the inks are

specially tailored to customer requirements, the inks are referred to as custom inks.

This user guide is suitable for the following HP Indigo presses and Indigo presses:

HP Indigo presses HP Indigo press 5000

Indigo presses UltraStream

User guide structure

This user guide is divided into the following chapters and appendices:

z

1. Introduction. Briefly describes the purpose of the HP IndiChrome ink mixing

system, explains the conventions used in this guide, lists the system requirements

and hardware configuration, lists the consumables that you can order from HP Indigo,

and gives relevant operating information.

z

2. Safety and environment considerations. Describes the safety precautions you

should take when operating the system.

z

3. Getting started. Shows you how to determine the workflow for ink mixing and how

to start and quit the HP IndiChrome ink mixing system software.

z

4. General procedures. Describes the procedures that are performed during the

various ink preparation steps: how to calibrate the electronic scale and

spectrophotometer, measure sample colors, adjust the air pressure of the dispensing

unit, prepare basic inks, dispense ingredients, and seal and shake cans.

z

5. Additional IMS procedures. Describes additional procedures and capabilities of

the HP IndiChrome ink mixing system software: including using Ready Mix colors,

continuing work on a previously defined mix color, manual color mixing, importing .mix

files, adjusting the view of the 2D color space and viewing the 3D color space.

z

Appendix A. Special options, basic concepts, and spare parts (all presses).

Explains special options and basic ink mixing concepts. A spare parts list is also

included.

Series

3000/4000/5000

and Indigo

UltraStream-based

HP Indigo press 3050

HP Indigo press 3000

HP Indigo press w3200

HP Indigo press ws4000

HP Indigo press ws4050

Publisher 4000

Series 1000/2000

and Indigo

TurboStream-based

HP Indigo press 1000

HP Indigo press ws2000

HP Indigo press s2000

TurboStream

Platinum

Omnius WebStream

Omnius MultiStream

Indigo Sun

computer-based

--

E-Print 1000

Omnius

Omnius CardPress

8 Chapter 1 Introduction

ENWW

Page 10

z

Appendix B. Service and support. Provides contact details for obtaining service

and support.

Conventions used in this guide

This guide uses the following documentation conventions:

z

Keyboard keys to press appear in all uppercase, for example: Press the SHIFT key.

z

Menu options appear in bold type, for example: From the File menu, click New.

z

Options in dialog boxes appear in bold type, for example: After selecting the options in

the Print dialog box, click OK.

z

References to other sections in the guide appear in quotes, for example: See

“Installation” on page 37.

z

Screen messages are displayed in a different font, for example: The Installation

Completed message appears.

ENWW

Conventions used in this guide 9

Page 11

Window sections

Often, a window is divided into sections. Each section has a name displayed at its top

border. A section may contain fields.

Section

Section

name

Fields within a section are referred to by first the section name, and then the field name,

separated by a slash (/). They appear in bold type. For example: enter a value in the

Target / L* field.

System requirements

z

HP IndiChrome ink mixing system software version 5.5.

z

HP Indigo press software version:

• For Indigo Sun computer-based presses, software version 4.0 or preferably 4.1.

• For Series 1000/2000 presses and TurboStream-based presses, software version

2.0 or higher.

• For Series 3000/4000/5000 presses and UltraStream-based presses, software

version 3.5 or higher.

• For HP Indigo press 5000, software version 7.0

z

Pentium® 133 MHz, or faster, computer; at least 16 MB RAM; Windows 95 or higher;

at least 5 MB free disk space; one free serial port; at least 16 bit or 64 K colors.

z

Operational Local Area Network (LAN): your computer and the HP Indigo press

computer must be nodes on the LAN.

This requirement is optional for Series 3000/4000/5000 presses, UltraStream-based

presses, Series 1000/2000 presses, and TurboStream-based presses.

Field

z

z

10 Chapter 1 Introduction

Compressed air (optional). The pressure/flow rate must be at least 4 bar/0.1 liter per

second, but no more than 10 bar.

The air tank must be equipped with an attached air hose. The end of the air hose

should have an attached female quick connector. The matching male quick connector

should have the standard 6.35 mm (0.25 inch) BSP thread. The male connector is

connected to the dispensing unit.

Work area that includes at least 2 by 0.7 m (6.56 by 2.3 ft) of tabletop space and at

least 0.7 by 1 m (2.3 by 3.28 ft) of floor space.

ENWW

Page 12

z

For Series 3000/4000/5000 and UltraStream-based presses, adequate space for the

BID washer. BID washer dimensions are:

width = 1.1 m (3.6 ft)

depth = 0.7 m (2.3 ft)

height = 1.2 m (3.94 ft)

z

Voltage: European kit: 235 VAC ±17 / 50 Hz

USA kit: 118 VAC ±8 / 60 Hz

Japanese kit: 103 VAC ±6 / 60 Hz, 115 VAC ±6 / 50 Hz

Hardware configuration

The HP IndiChrome ink mixing system contains the following hardware components:

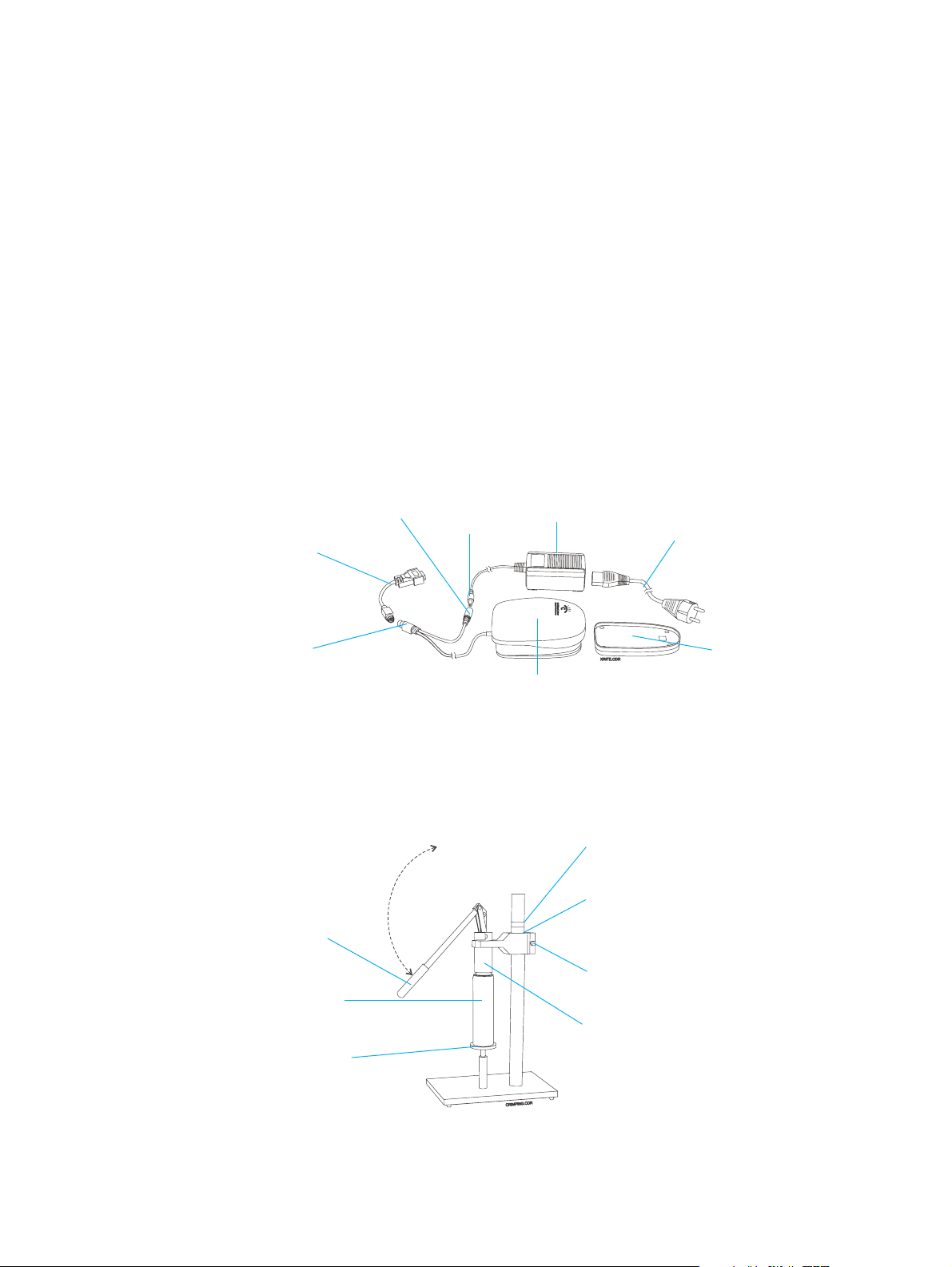

z

Spectrophotometer

The spectrophotometer measures colors. It is connected to a serial port on the

computer.

Second

plug

AC/DC

adapter

cord jack

AC/DC

adapter

Serial port

adapter

Main

connector

Spectrophotometer

Spectrophotometer components

z

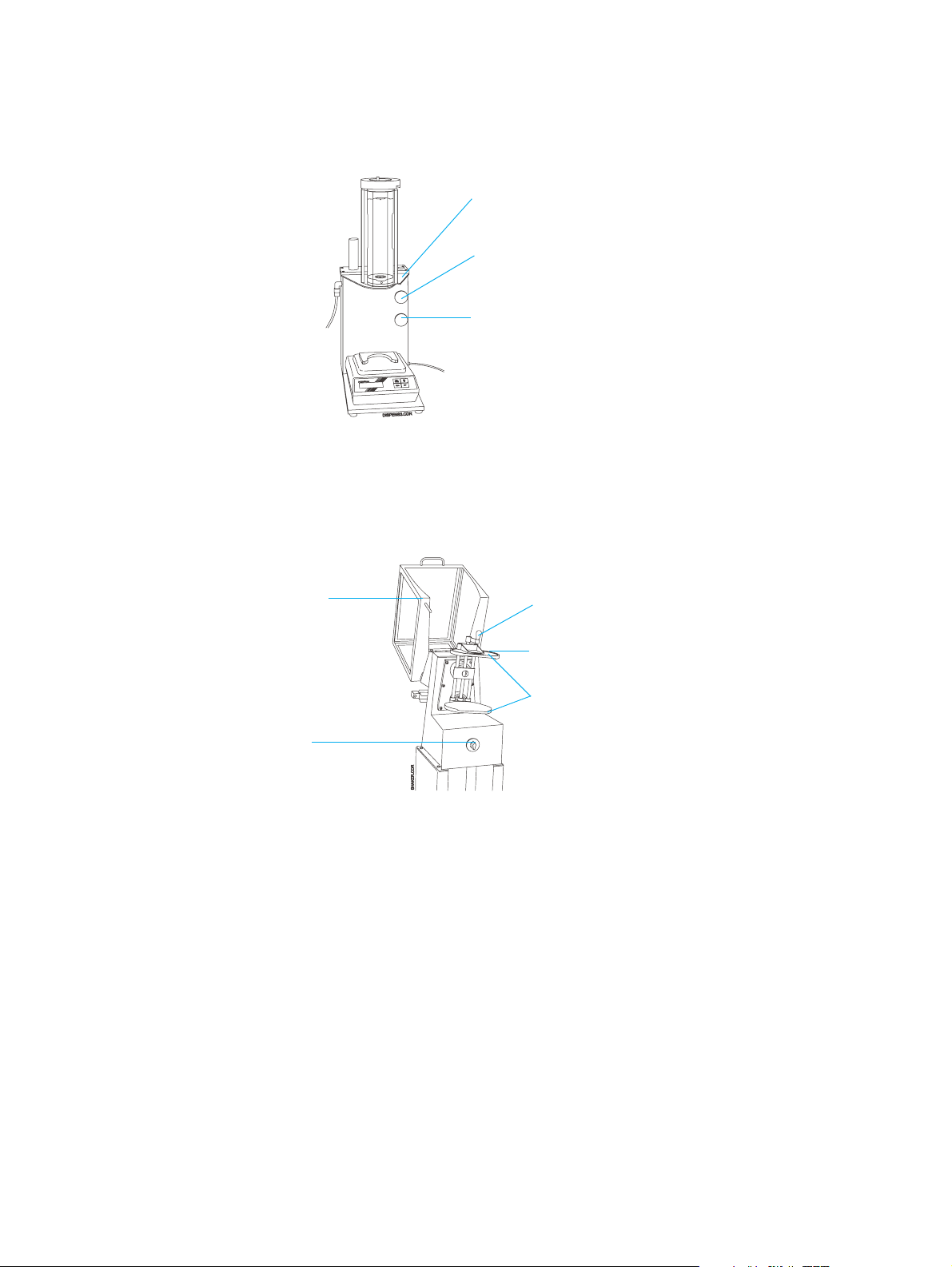

Crimper

The crimper seals the receiving can with a valve.

Lever

Power

cord

Calibration

reference

base

Series 3000/4000/5000 and

UltraStream-based level

Series 1000/2000,

TurboStream-based, and

Sun computer-based level

ENWW

Allen screw

Ink can

Crimper

Round

can base

Crimper

Hardware configuration 11

Page 13

Dispensing unit

z

The dispensing unit dispenses basic inks into a receiving can.

Dispensing

unit

Coarse button

Fine button

Dispensing unit

z

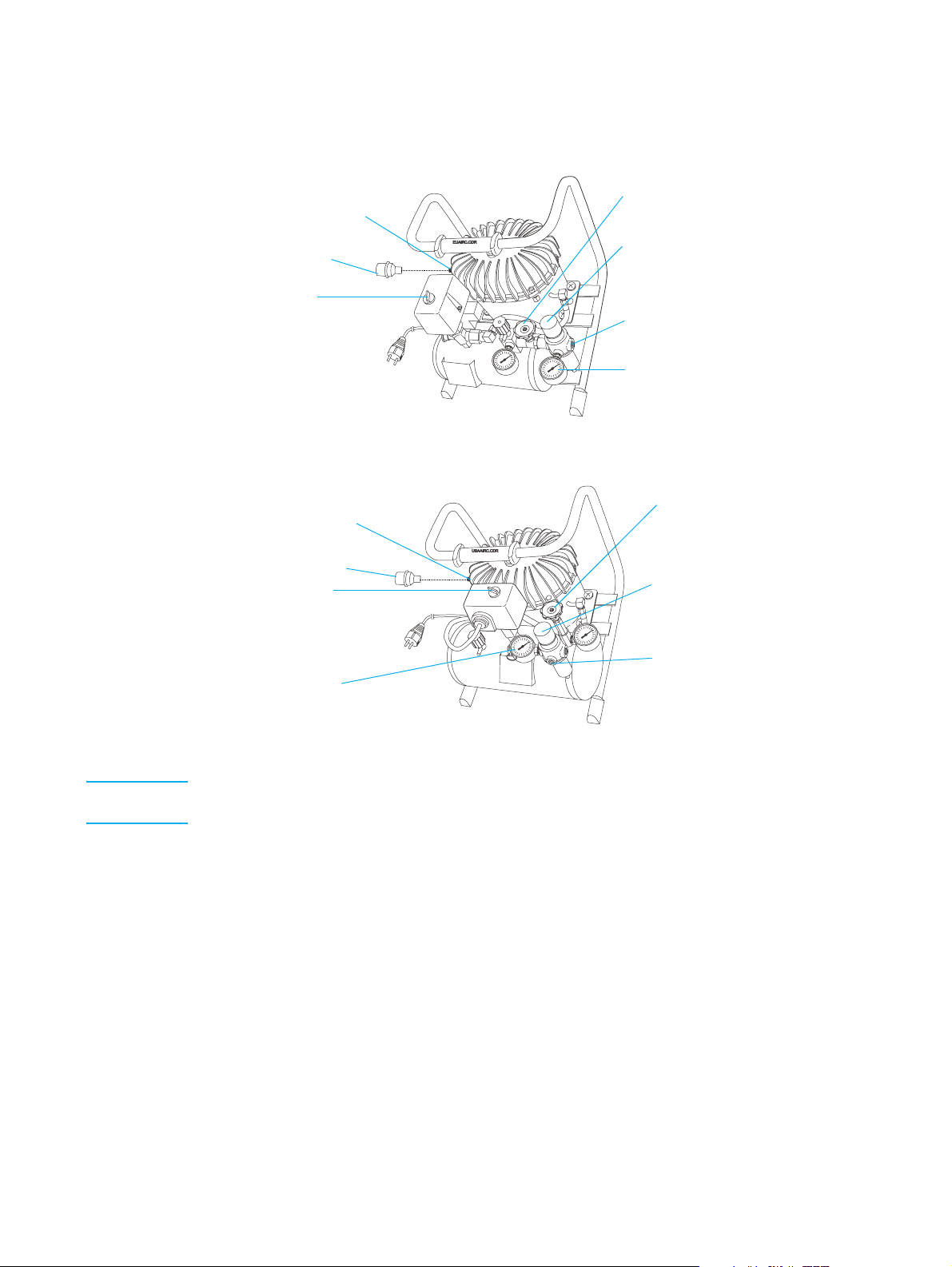

Shaker

The shaker thoroughly mixes the prepared custom ink can.

Safety

cover

Timer

knob

Shaker

Plate

adjusting

handle

Upper plate

Shaker

plates

12 Chapter 1 Introduction

ENWW

Page 14

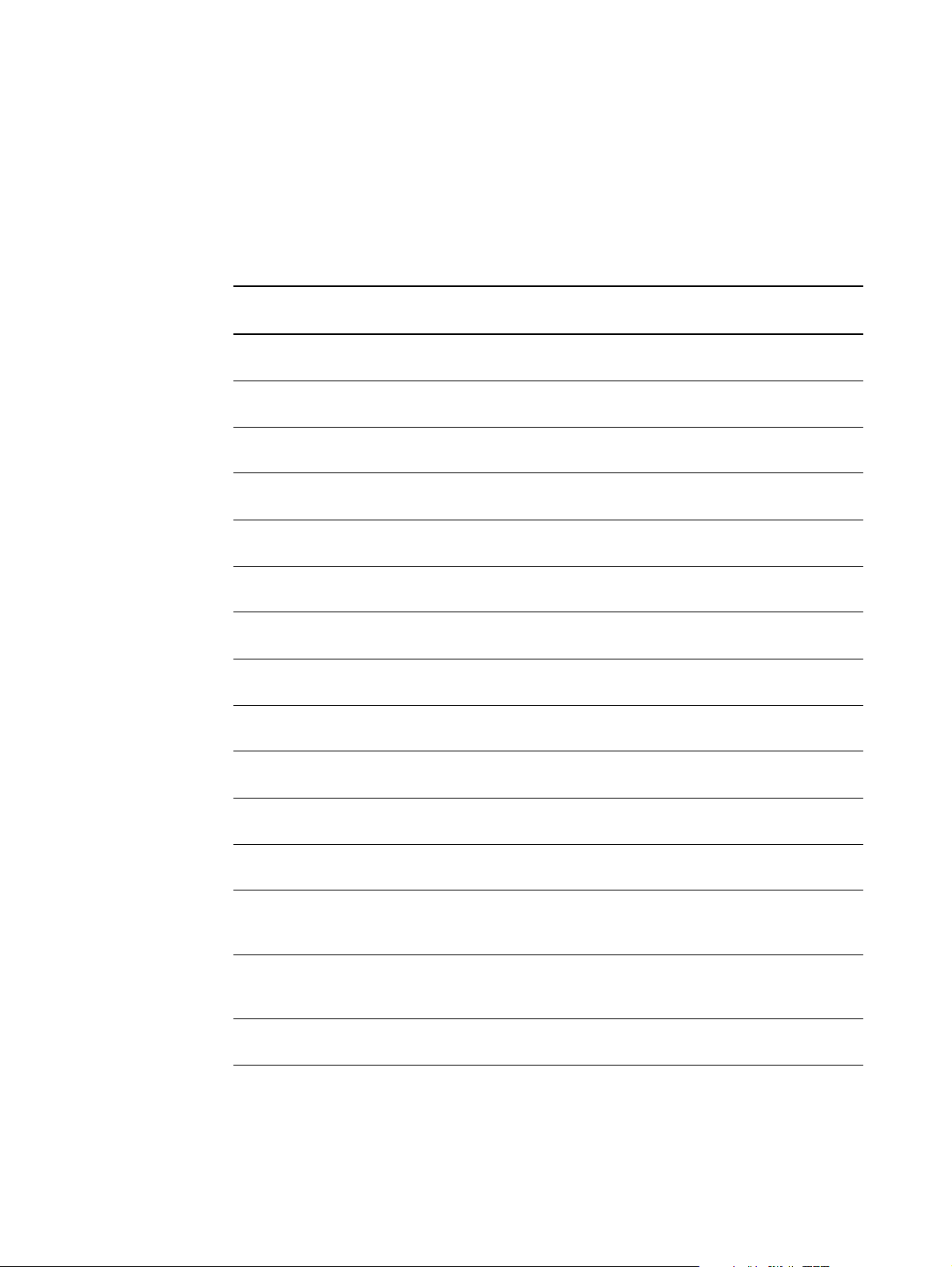

z

Air compressor

The air compressor is used for operating the dispensing unit.

Air inlet

Air filter

On/off

switch

European air compressor

Air inlet

Air filter

On/off

switch

Outlet

pressure

gauge

Air valve

Outlet

pressure

knob

Air outlet

Outlet

pressure

gauge

Air valve

Outlet

pressure

knob

Air outlet

USA / Japanese air compressor

Note The label on the on/off switch shows 250VAC. This value refers to the switch only and indicates

the upper limit of the supplied voltage.

ENWW

Hardware configuration 13

Page 15

Consumables

The following is a list of consumables that you can order from HP Indigo as the need

arises.

For Series 1000/2000 presses, Indigo TurboStream-based presses,

and Indigo Sun computer-based presses

Item Code Catalogue number Contents

HP ElectroInk:

Yellow Y MPS-2134-42 10 cans

Magenta M MPS-2133-42 10 cans

Cyan C MPS-2132-42 10 cans

Black K MPS-2131-42 10 cans

Orange 003 O MPS-2401-42 10 cans

Violet 065 V MPS-2465-42 10 cans

Bright Yellow 060 BY MPS-2460-42 10 cans

Blue 013 B MPS-2403-42 10 cans

Green 011 G MPS-2428-42 10 cans

Rhodamine 050 Rh MPS-2450-42 10 cans

Transparent 025 T MPS-2425-42 10 cans

Startup kit MKT-0510-41 Mixed cans (2) - MKT-0511-41

Empty cans (1) - MKT-0512-41

Mixed cans X MKT-0511-41 10 cans (O, V, BY, B, G, Rh, T, and

three empty cans)

Empty cans E MKT-0512-41 10 cans

14 Chapter 1 Introduction

ENWW

Page 16

For Series 5000 presses

Item Code Catalogue number Contents

Filter (for external filter kit) MFL-1901-01

HP ElectroInk:

Yellow Y Q4015A 10 cans

Magenta M Q4014A 10 cans

Cyan C Q4013A 10 cans

Black K Q4012A 10 cans

Orange 070 O Q4003A 10 cans

Violet 071 V Q4004A 10 cans

Bright Yellow 074 BY Q4007A 10 cans

Reflex Blue 075 RB Q4008A 10 cans

Green 072 G Q4005A 10 cans

Rhodamine 073 Rh Q4006A 10 cans

Transparent 076 T Q4009A 10 cans

Startup kit MKT-0510-51 Mixed cans (2) - MKT-0511-51

Empty cans (1) - MKT-0512-51

Mixed cans X MKT-0511-51 10 cans (O, V, BY, RB, G, Rh, T,

and three empty cans)

Empty cans E MKT-0512-51 10 cans

ENWW

Consumables 15

Page 17

For Series 3000/4000 presses and Indigo UltraStream-based presses

Item Code Catalogue number Contents

Filter (for external filter kit) MFL-1901-01

HP ElectroInk:

Yellow Y MPS-3134-43 10 cans

Magenta M MPS-3133-43 10 cans

Cyan C MPS-3132-43 10 cans

Black K MPS-3131-43 10 cans

Orange 070 O MPS-3135-43 10 cans

Violet 071 V MPS-3136-43 10 cans

Bright Yellow 074 BY MPS-3123-43 10 cans

Reflex Blue 075 RB MPS-3124-43 10 cans

Green 072 G MPS-3121-43 10 cans

Rhodamine 073 Rh MPS-3122-43 10 cans

Transparent 076 T MPS-3125-43 10 cans

Startup kit MKT-0510-51 Mixed cans (2) - MKT-0511-51

Empty cans (1) - MKT-0512-51

Mixed cans X MKT-0511-51 10 cans (O, V, BY, RB, G, Rh, T,

and three empty cans)

Empty cans E MKT-0512-51 10 cans

16 Chapter 1 Introduction

ENWW

Page 18

Important system information and limitations

z

The following procedures take some time to accomplish:

• Cleaning and preparing the ink tank may take between 40 and 60 minutes. You can

save 20 minutes on the Series 3000/4000/5000 or UltraStream-based press if you

use a replacement BID, ink pump, and ink tank.

• Ink formulation may take between 30 minutes (for one step) and 100 minutes (for

three to four steps).

z

Color accuracy:

• Gamut: In some cases, the target color may be outside the gamut of the

HP IndiChrome ink mixing system. This situation is characterized by having the

predicted best mix color differ from the target by a ∆E*

situation, the software guides you to achieve the mix that best resembles the target

color, regardless of what the predicted ∆E*

• Gloss: When the gloss of the target color sample is substantially different from the

printed color, it may be difficult to visually compare the two colors. For a glossier

target you can overcoat or laminate the printed sample with a glossy substance

before the comparison. You can even manually apply some imaging oil onto the

surface of the color to get the required temporary increase of the gloss or laminate

the sample with a transparent glossy scotch tape.

• Grey shades: In Sun computer-based presses with off-line densitometers, the LUT

of the custom color is the same as the LUT of Black. Therefore, the color shades

may not appear as linear as they should be.

• Double print: The HP IndiChrome ink mixing system software may suggest that

you formulate the ink for double printing. This occurs when the best mix color in

single print is not bright enough. If you print the separation of such ink twice, the

solid color effect is accurate but the color shades are not. Therefore, double print

should be used for printing solids only. If you double print shades, they are not

linear.

• Hot lamination: The printed colors may change during hot lamination, which may

be required when preparing PVC cards.

z

Mixing procedure:

• Ineffective mix: Some of the fix corrections may not improve the color. This reflects

the statistical nature of the corrective algorithm. In such cases, you may still expect

improvement of the color in successive corrections.

• Inaccurate mix: The color of the actual mix usually differs from the target color

more than the software prediction shows. This is mainly because of minute

contamination in the ink tank, inaccurate dispensing of the basic inks into the mix

can, and specific characteristics of the substrate in the print run. This is especially

true with colors that are outside the gamut.

• Precision in color adjustment: During the ink formulation stage, you are instructed

to correct the color by printing again with a modified optical density (OD) value.

Because of the limited precision of the color adjustment procedure, this instruction

may be repeated until the OD, as read by the spectrophotometer, is as required.

• Resending the ink parameter file: Do not send the ink parameter file to the press

more than once. If for some reason this has been done, you should use a first can

for recalibrating the ink density sensor.

94

is.

of more than zero. In this

94

ENWW

Important system information and limitations 17

Page 19

Resources:

z

• Initial ink amount: The amount of concentrated ink in the ink tank dispersion is

equivalent to almost one can. In order to print the job, you should prepare and

install at least one additional can. The weight of the ink in the can may be as small

as required for the print run. You must prepare at least one can of ink even if the

printing job consumes much less.

• Getting acquainted: To correctly operate the ink mixing system and take advantage

of its full range of features, experience and familiarity with the system is essential.

z

The following phenomena are caused by using Rhodamine ink:

• It causes the color of the squeegee (in Series 1000/2000, TurboStream-based, and

Sun computer-based presses) and the color of the developer (in Series

3000/4000/5000 and UltraStream-based presses) to change to yellow. However,

no deterioration of any other characteristics of the squeegee or developer is

expected.

• It causes an excess of particle residue to be found in the separator clean liquid and

on the blanket background.

Under normal circumstances, no degradation of print quality or machine reliability

is expected. When printing more than 1,000 pages with Rhodamine as one of the

separations or when printing with an ink mix containing a large percentage of

Rhodamine, slight contamination of other inks may occur. The expected color

shift will not be larger than ∆E*

94

= 1.5.

18 Chapter 1 Introduction

ENWW

Page 20

Safety and environment

2

considerations

This chapter contains the following sections:

z

General warning

z

Warning signs

z

Material Safety Data Sheets (MSDS)

z

Preventing eye irritation

z

Electrical safety precautions

z

Emergency power cutoff

z

Flammable liquids and fumes

z

Handling and storing imaging oil and inks

z

Waste disposal

EN

19

Page 21

General warning

WARNING! The HP IndiChrome ink mixing system should be operated only by personnel who have been

trained by an HP Indigo customer engineer. Operators should read and understand all operating

safety procedures presented here before attempting to use the system. Service and repairs

should be referred to an authorized customer engineer. Do not allow untrained personnel to

operate the HP IndiChrome ink mixing system. Follow the procedures properly at all times.

WARNING! If you have any questions regarding safe operation of the ink mixing system, cease operation

and contact HP Indigo.

Warning signs

Warning signs that clearly emphasize the dangers involved in operating and maintaining

the HP IndiChrome ink mixing system should be posted at the site.

The following texts are recommended:

z

To be operated by certified operators only.

z

Do not wear ties or other loose clothing or loose jewelry when operating and

maintaining the unit.

z

No smoking, open flames, or sources of ignition allowed!

z

Verify that the room is properly ventilated at all times.

z

Keep hands away from moving machine parts.

z

Ink and imaging oil are irritating to eyes and skin. Use rubber gloves.

z

Read and understand the MSDS sheets for the consumables used with the machine.

Material Safety Data Sheets (MSDS)

Material Safety Data Sheets (MSDS) are supplied for different HP ElectroInk colors and

the imaging oil.

You should keep the MSDS sheets that are supplied with the unit readily available in the

work area. These should be kept in a plastic folder for protection. The MSDS sheets

should be read, understood, and consulted for a full understanding of the consumables

being used with the machine.

20 Chapter 2 Safety and environment considerations

EN

Page 22

Preventing eye irritation

The HP IndiChrome ink mixing system uses inks and imaging oil that may irritate the skin

and eyes. In extreme cases of exposure, these substances may cause blindness.

As a precaution:

z

Wear protective eye covering. This is of particular importance during the custom ink

preparation.

z

Install eye wash stations within 7.6 m (25 ft) of areas where the ink and imaging oil

are handled, dispensed, or stored.

z

Provide eye wash liquid at the eye wash stations (available from most safety supply

companies) to comply with ANSI standard Z358.1-1990.

Electrical safety precautions

z

The shaker must be properly grounded at all times. Before operating the unit, ensure

that it is grounded in conformance with applicable electrical code standards for your

country/region. Do not operate the shaker if it is not properly grounded. If in doubt,

check with a licensed electrician or with your local HP Indigo office.

z

We recommend that you perform a weekly check of grounding cables.

Emergency power cutoff

Use one of the following methods to cut off power to the shaker in an emergency:

z

Pull the electric plug out of the wall.

z

Turn the timer to zero.

Flammable liquids and fumes

The HP IndiChrome ink mixing system uses flammable imaging oil. The following safety

procedures should be used when working with this substance:

z

Operate the unit in a well-ventilated room.

z

Do not smoke or introduce external sources of ignition such as pilot lights, open

flames, stoves, heaters, or halogen lights.

z

Avoid creating sparks (static, electrical, or mechanical) or introducing any

spark-producing equipment within 7.6 m (25 ft) of the system.

z

Clean up spills immediately after they occur and dispose of soaked cleaning materials

promptly in a covered waste bin.

EN

Preventing eye irritation 21

Page 23

Handling and storing imaging oil and inks

z

To avoid fire or explosion, store imaging oil and inks in a fireproof cabinet or in a

special combustible-liquids storage room. Only trained personnel should handle

imaging oil and inks. Refer to your local combustible material handling regulations.

z

When handling imaging oil and inks, wear safety glasses with side shields,

long-sleeved overalls, and protective gloves as indicated on the Material Safety Data

Sheets.

z

Do not drink or otherwise ingest imaging oil or inks.

Waste disposal

During the operation of the HP IndiChrome ink mixing system, you use consumables that

should be disposed of properly. Consult your local authorities to determine the correct

manner in which to dispose of the following wastes:

z

imaging oil and ink

z

spent ink cans

z

empty imaging oil containers

22 Chapter 2 Safety and environment considerations

EN

Page 24

3

Getting started

This chapter contains the following sections:

z

Overview

z

Detailed Automatic Workflow

z

Starting the ink mixing system (IMS) software

z

HP IndiChrome Wizard

z

To ol ba r

z

Exiting the IMS software

ENWW

23

Page 25

Overview

The HP IndiChrome Ink Mixing System (IMS) provides the following methods of

determining the ink weights required for producing a required color:

z

Automatic

z

Manual

z

Ready Mix

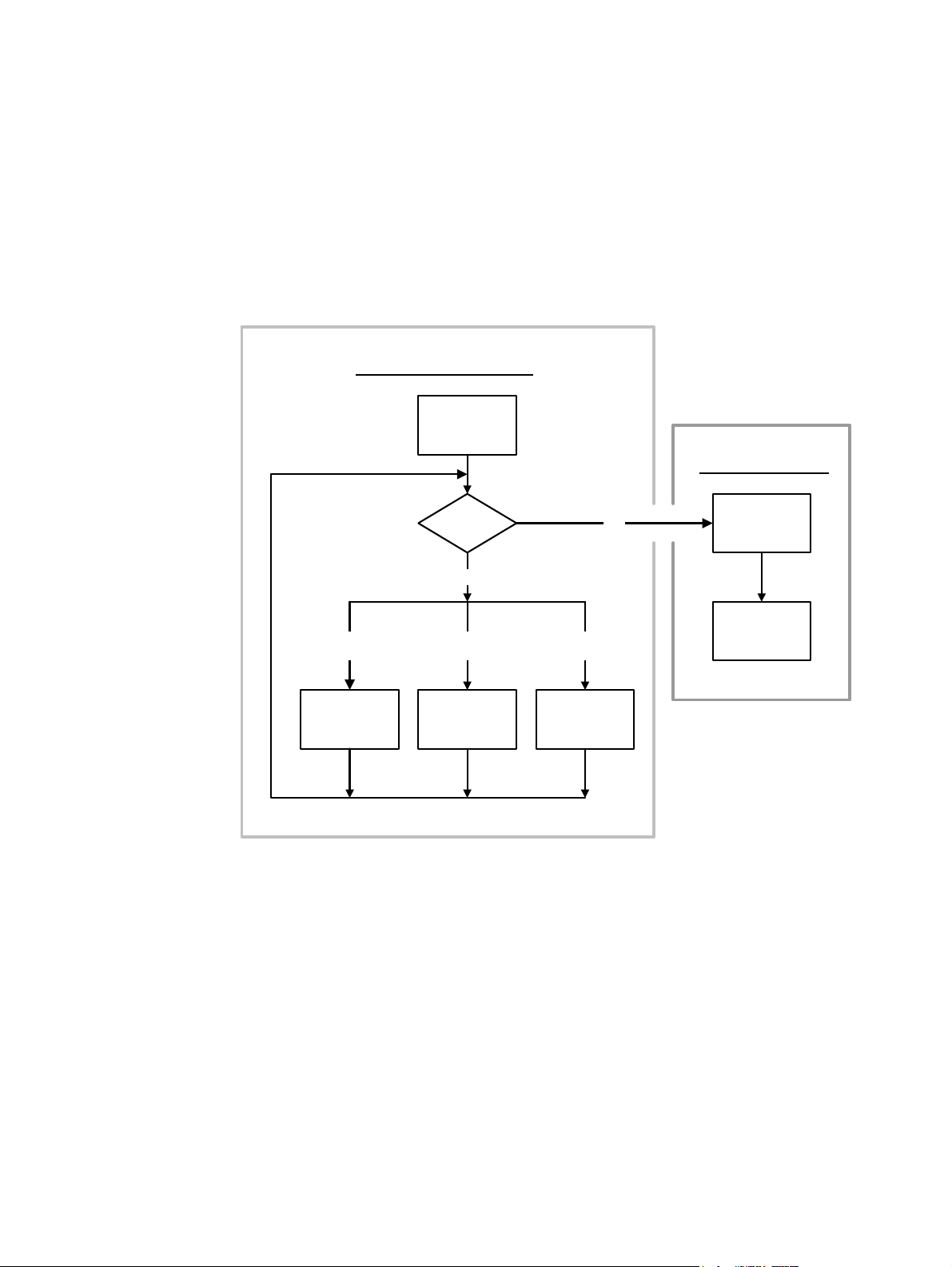

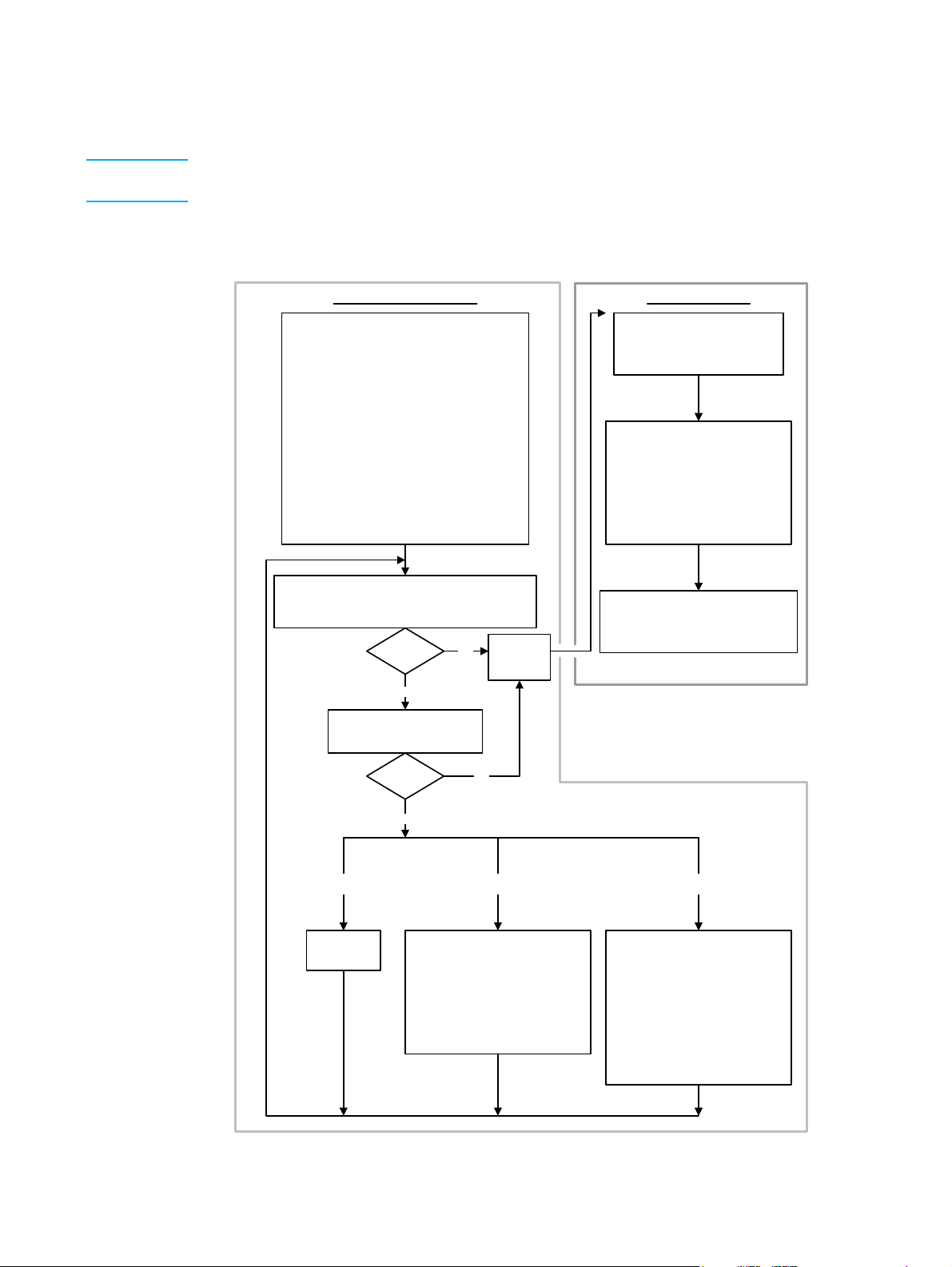

The Automatic method flow chart is displayed below.

INK FORMULATION

Prepare and test

first can

PRODUCTION

Prepare additional

cans

Prepare the RIP

for the digital print

Improve color by

changing OD

Change OD

spec value

Is color OK?

No

Improve color

with fix can

Prepare and test

fix can

Yes

Improve color with

new first can

Prepare and test

new first can

Ink formulation and production flow chart

In the Automatic method, you use the HP IndiChrome Ink Mixing System to prepare a

custom ink as follows:

1 Ink formulation:

a Determine (through measurement or PANTONE

®

color selection) the target color.

b Set the color match parameters (for example, substrate glossiness and type).

c Send the ink definition file to the HP Indigo press.

d Prepare and test a first can.

24 Chapter 3 Getting started

ENWW

Page 26

e If you are satisfied with the color, proceed to step 2 (Production).

If you are not satisfied with the color, the HP IndiChrome Ink Mixing System will

recommend improving the color in one of the following ways:

- If the color in the ink tank can be improved by adding a slightly different custom

ink, prepare and test a fix can.

- If the color in the tank cannot be improved by a fix can, prepare and test a new

first can.

- Changing the optical density at the press.

The HP IndiChrome Ink Mixing System repeats this step until you are satisfied with

the color.

2 Production: Prepare additional cans, prepare the press for printing with the custom

ink, and prepare the RIP (if necessary) to accept a print file with special colors.

In the Manual method, the HP IndiChrome Ink Mixing System does not determination the

ink weights. Thus the only possibility for correcting a color is through a fix can where the

ink weights used in the fix can is determined by the person preparing the color.

Note Once the Manual method is entered, there is no return to the Automatic (or Ready Mix) method.

In the Ready Mix method, the work in determining specific colors accurately has already

been done. Prepare a first can to calibrate the press and prepare additional cans for

production.

Note If you are not satisfied with the results of a Ready Mix color, you can change (fix) the color using

the Manual method.

ENWW

Overview 25

Page 27

Detailed Automatic Workflow

Note The detailed workflows for the Ready Mix and Manual methods are found on pages 67 and 70

respectively.

Reference the detailed flowchart only after reading the detailed instructions in this user

guide at least once.

INK FORMULATION PRODUCTION

Prepare additional cans

·

Prepare the first can

·

Determine the target color and substrat e type

·

Set the IMS color mixi ng parameters

·

Send/save the ink definition file to the pr ess

·

Mix the ink

Prepare the basic inks

Dispense the ingredients

Seal and shake the can

·

Prepare the press for test printing

Transfer the ink definition file

Clean the ink system

Assign ink parameters to the target ink tank

Add imaging oil

Add ink

Perform flush

Calibrate the ink density sensor

Specify the can capacity

·

Dispense the ingredients

·

Seal and shake the can

Prepare the press for printing with

the custom ink

·

Clean the ink system

·

Assign ink parameters to the t arget ink

tank

·

Change the OD spec value

·

Calibrate the ink density sensor

·

Perform color adjustment

·

Print and compare the printed color to the expecte d color

Perform color adjustment

Select the sample print for comparison

Visually inspect the printed color

colors match?

No

Spectrophotometric compari son of

the printed color

colors match?

No

Improve color

by changing OD

Change the OD

spec value

Prepare a fix can

·

·

Yes

Yes

Improve color

Mix the ink

Prepare the basic inks

Dispense the ingredients

Seal and shake the can

Prepare the press for test printing

Add ink

Perform flush

·

Conclude

ink

formulation

with fix can

Prepare the RIP for the digital print

Save the used custom ink

Improve color with

new first can

Prepare a new first can

·

Mix the ink

Prepare the basic inks

Dispense the ingredients

Seal and shake the can

·

Prepare the press for test printing

Remove the previous ink

Add imaging oil

Add ink

Perform flush

Calibrate the ink density sensor

Detailed Automatic ink formulation and production flow chart

26 Chapter 3 Getting started

ENWW

Page 28

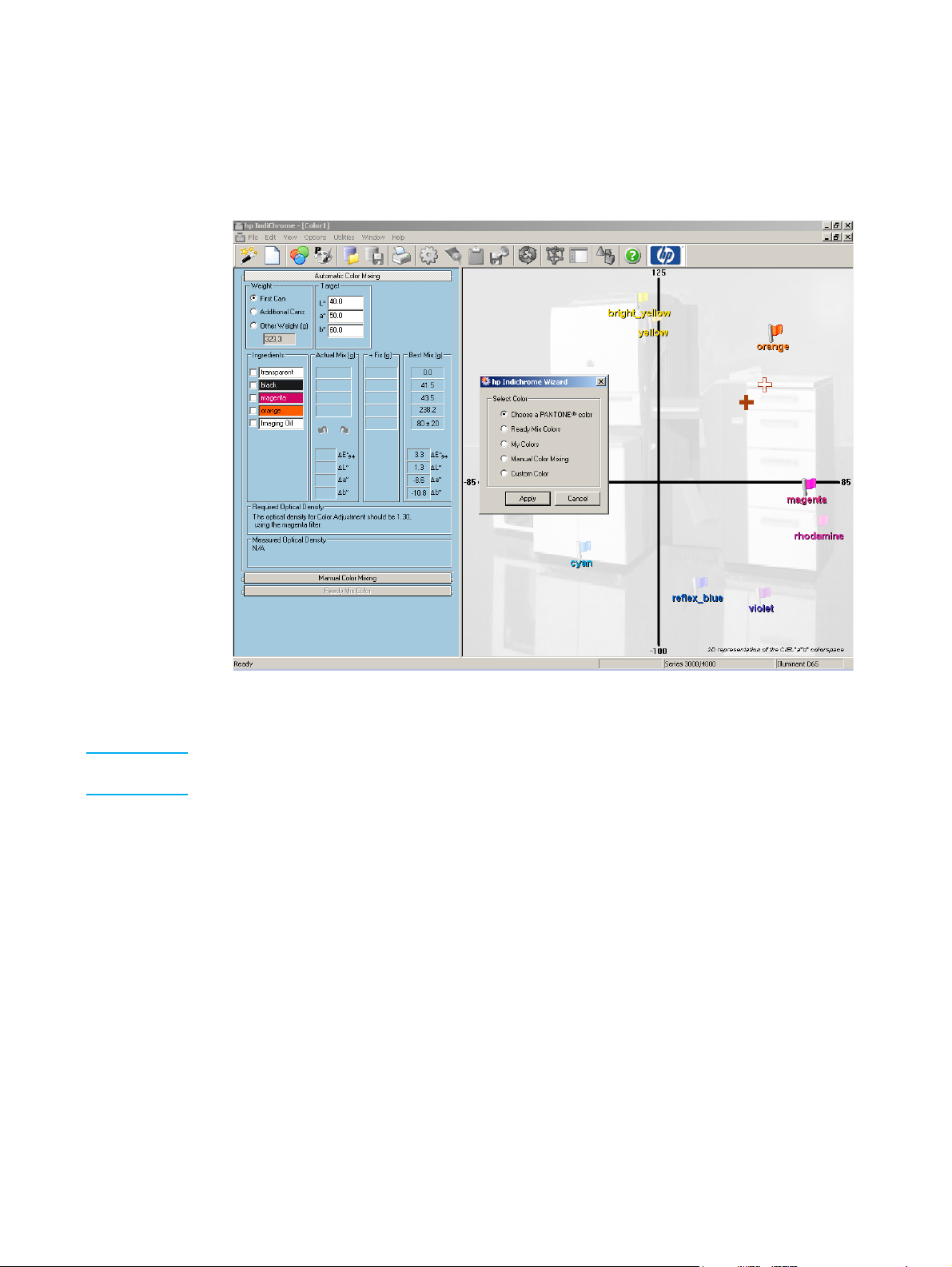

Starting the ink mixing system (IMS) software

To start the IMS software, double-click the Indimix V5.5 icon.

The following window appears:

hp IndiChrome window

The hp IndiChrome Wizard window is open when the IMS software starts.

Note If the X-Rite densitometer is not connected properly, a message appears informing you to

connect the densitometer, and restart the IMS software.

ENWW

Starting the ink mixing system (IMS) software 27

Page 29

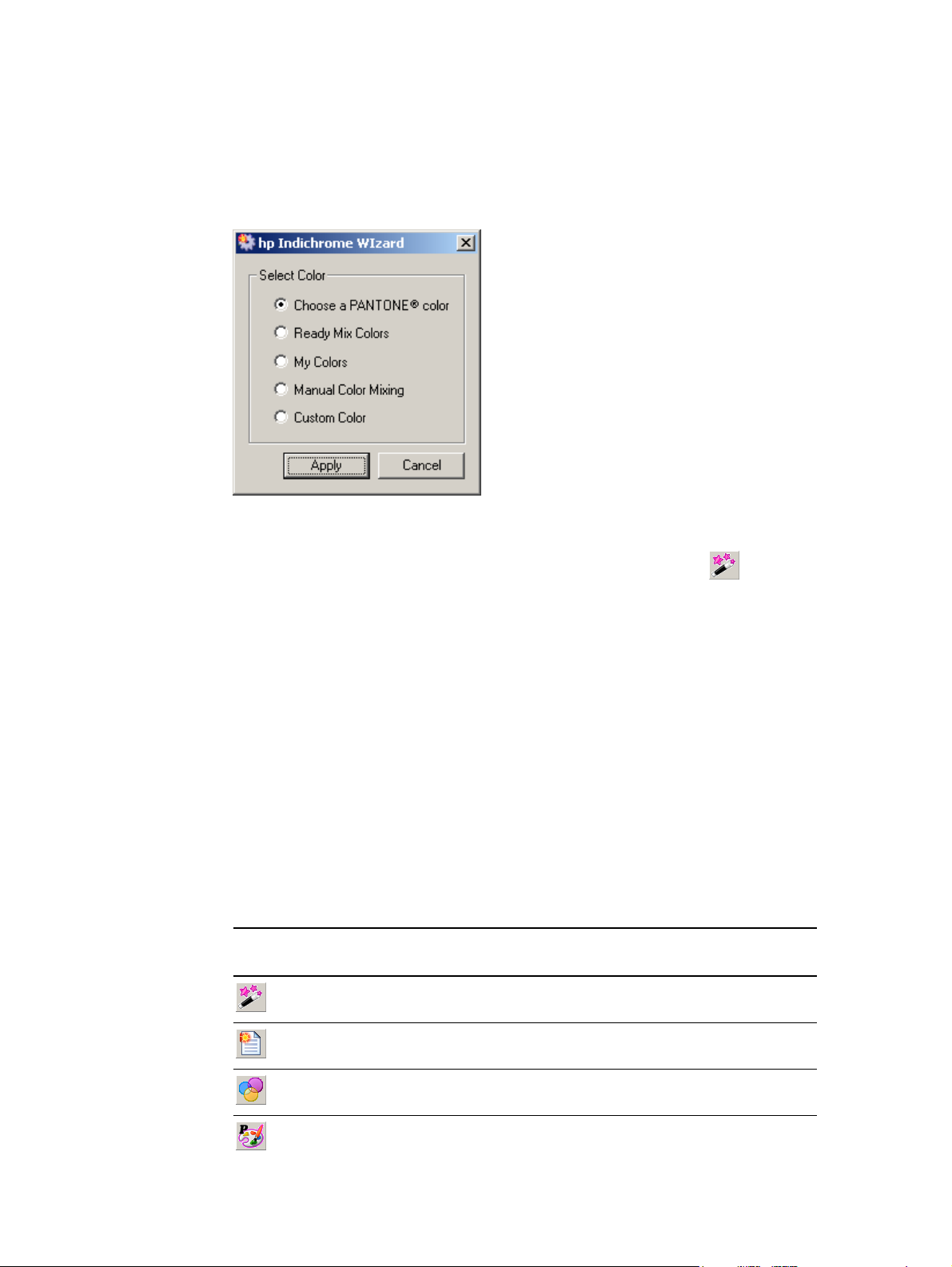

HP IndiChrome Wizard

The hp IndiChrome Wizard window provides access to the ink mixing procedure options

of the IMS software. It is especially useful when learning the MS software and to ensure

that the correct method is used for each ink mixing option.

hp IndiChrome Wizard window

The hp IndiChrome Wizard window opens when IMS software starts.

Toolbar

To open the hp IndiChrome Wizard window at other times, click the button.

The following ink mixing procedures are available:

z

Choosing a PANTONE® color (see page 37)

z

Ready Mix Colors (see page 64)

z

My Colors (see page 68)

z

Manual Color Mixing (see page 69)

z

Custom Color (see page 71)

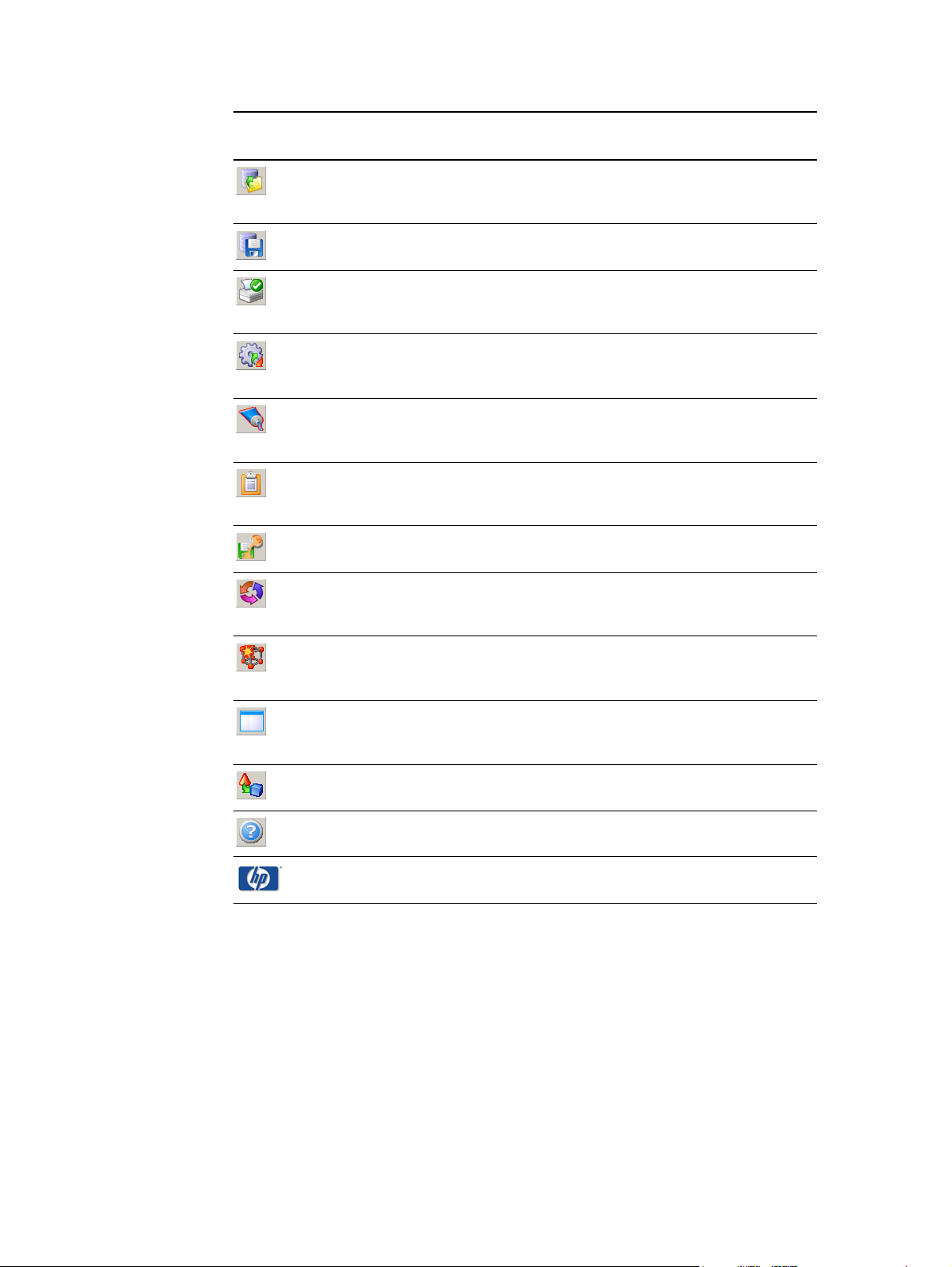

The following buttons are available on the IMS Toolbar:

IMS Toolbar Buttons

Button Meaning Details

Open the hp IndiChrome wizard See "HP IndiChrome Wizard" on page 28.

28 Chapter 3 Getting started

Start a new color See "Measuring the color directly" on page 72.

Load a Ready Mix color See "Ready Mix colors" on page 64.

®

Choose a PANTONE

color See "Selecting a PANTONE® color" on page 37.

ENWW

Page 30

Button Meaning Details

Access the color environments

previously defined

Save the color environment See "Saving the color’s workspace" on page 44.

Print the 2D color environment See "Printing the color workspace details" on

Set the color matching

parameters

Set the thickness of the ink

layer

Display a summary of the color

information

Save the ink definition file See "Save the Ink Definition file" on page 43.

Checks for better results with

different illuminants

See "Continuing work on a previously defined

mix color" on page 68.

page 77.

See "Color matching parameters" on page 78.

See "Ink print thickness" on page 79.

See "Color information summary" on page 80.

See "Improving visual match by changing

illuminant" on page 58.

Set the axis range displayed in

the 2D color space

Show/Hide the ink mix details

panel

Display the 3D color space See "View the 3D color space" on page 82.

Display the help topics See "Online help" on page 90.

Program update See "Program updates" on page 90.

See "Zoom by changing axes values" on page

81.

See "Increase/decrease view of 2D color space"

on page 80.

ENWW

Toolbar 29

Page 31

Exiting the IMS software

To exit the IMS software, do the following steps:

1 On the File menu, click Exit. The Are you sure message appears.

Are you sure message

2 Click Yes.

If you changed any of the parameters affecting an ink mix, the following message

appears for each affected workspace:

Save changes message (example)

To save the changes, click Ye s , and click Save in the Save My Colors window.

30 Chapter 3 Getting started

ENWW

Page 32

4

General procedures

This chapter contains the following sections:

z

Calibrating the electronic scale

z

Calibrating the spectrophotometer

z

Draining the water from the dispensing unit

z

Adjusting the dispensing unit for the press

z

Measuring a color

z

Selecting a PANTONE® color

z

Transferring the ink definition file to the press

z

Preparing the basic inks

z

Dispensing the ingredients

z

Sealing the can

z

Shaking the can

z

Visually comparing the printed color

z

Adjusting the ink mix from the printed output

z

Undoing and redoing a measurement

z

Changing the optical density (OD) spec value

z

Comparing different ink mix results

z

Changing the ink on the press

ENWW

31

Page 33

Calibrating the electronic scale

Calibrate the electronic scale once a day.

1 Connect the scale to a power source, and press the On button. Allow a one-minute

warm up period.

Note Do not put the adjusting weight on the scale.

Adjusting

weight

Weighing

pan

LCD

display

Adjusting weight and scale

2 Press and hold the Cal/Mode button until the exact size (500.0) of the adjusting

weight appears flashing on the LCD display.

Note It may take up to two seconds for the scale to show results.

3 Press the Off button. The message CAL 0 appears on the display.

4 Place the adjusting weight in the center of the weighing pan. After a short while, the

message CAL F appears on the display for a short time.

The exact weight of the adjusting weight (that is, 500.0) should appear on the display

shortly afterwards.

If an adjusting error occurs or the wrong adjusting weight is used, the message

CAL E appears on the display. In this case, repeat this calibration procedure.

Cal/Mode

button

On button

Off button

5 Put the 500 g adjusting weight in a safe place.

32 Chapter 4 General procedures

ENWW

Page 34

Calibrating the spectrophotometer

Performing a full calibration

Before using the spectrophotometer for the first time, and once a month thereafter,

perform a full calibration as follows:

1 From the Utilities menu, click Calibrate Spectrophotometer, and Full Calibration.

2 Follow the instructions in the series of message windows that appear, clicking OK

after each message window.

Note For the Black Calibration test, make sure that you measure the dark area until the four vibrating

measurements end completely. This takes approximately 15 seconds.

If the Black calibration successful and the White calibration

successful messages appear on the screen, the full calibration was successful. If

not, repeat this procedure one more time before calling the customer engineer.

Performing the daily calibration

Calibrate the spectrophotometer once a day.

1 From the Utilities menu, click Calibrate Spectrophotometer, and Frequent

Calibration.

2 Follow the instructions in the window that appears.

Note For the White Calibration test, make sure that you measure the white reference area until the

single vibrating measurement ends completely. This takes approximately two seconds.

If the Calibration successful message appears on the screen, the daily

calibration was successful. If not, repeat this procedure one more time before calling

the customer engineer.

ENWW

Calibrating the spectrophotometer 33

Page 35

Draining the water from the dispensing unit

The dispensing unit removes water from the compressed air as it enters the unit. The

water should be drained at the end of each work day.

To drain the water from the dispensing unit, do the following:

1 Close the compressed air valve on the air compressor or compressed air pipe

(whichever you are using).

Transparent

safety door

Draining the dispensing unit

Dispensing

unit

Coarse

button

Water drainage

tube

Water

container

2 Close the transparent safety door.

3 Press and hold the Coarse button until all the excess air goes out of the dispenser.

4 Release the Coarse button. The water drains into the water container.

5 Empty the water container.

34 Chapter 4 General procedures

ENWW

Page 36

Adjusting the dispensing unit for the press

The Series 3000/4000/5000 and UltraStream-based presses use ink cans that are taller

than those used by the Series 1000/2000, TurboStream-based, and Sun computer-based

presses. Consequently, the dispensing unit must be adjusted to the height of the ink cans

used by the press for which you are preparing custom ink.

The dispensing unit can accommodate two nozzles: a short one for the Series

3000/4000/5000 and UltraStream-based presses and a long one for the Series

1000/2000, TurboStream-based, and Sun computer-based presses. The nozzle is

screwed onto the top can holder.

Long nozzle

Short nozzle

Ring

holder

Weighing

pan

P

S

I

D

Can holder

(top)

Nozzle

Nozzle

storage hole

Spacer ring

(Series 1000/2000,

TurboStream-based, and

Sun computer-based only)

R

D

C

.

L

Z

O

N

Adjusting the dispensing unit

When dispensing to an empty Series 3000/4000/5000 or UltraStream-based ink can,

place it directly on the weighing pan. When dispensing to an empty Series 1000/2000,

TurboStream-based, or Sun computer-based ink can, place it on a spacer ring on the

electronic scale weighing pan.

Note The nozzle that is not in use can be stored in the nozzle storage hole. Adapter rings (used when

shaking cans) that are not being used can be stored on the ring holder.

ENWW

Adjusting the dispensing unit for the press 35

Page 37

Measuring a color

The spectrophotometer samples color data from any clean, dry surface that is reasonably

flat and smooth. The target eye should be able to rest flat and steady on the sample area.

Because the opening is just 6 mm (0.24 inch) in diameter, it can rest sufficiently flat on

many curved surfaces.

As a general rule, surfaces with bulky, rough, or loose-weave textures do not provide good

results.

Head

Shoe

Spectrophotometer

To measure a color:

1 Clear the sample surface of any dirt, dust, or moisture.

Tar g e t e y e

White reference

area

Calibration

reference base

2 Place the spectrophotometer shoe directly on the surface, aligning the target eye

opening over a continuous patch of the desired color.

3 Press the spectrophotometer head down onto the shoe, and hold it closed.

4 Hold the head down until the spectrophotometer stops vibrating. Make sure that you

hold the spectrophotometer still for the entire measurement. Any movement affects

the reading accuracy.

5 Raise the spectrophotometer off the sample area, and carefully return it to its base.

36 Chapter 4 General procedures

ENWW

Page 38

Selecting a PANTONE® color

Instead of measuring a color using the spectrophotometer, you can select the PANTONE

color from a color list (if you know its name). The colors in the list are exactly the same as

those found in the PA NT ON E

or metallic colors.

To select the PANTONE

1 From the hp Indichrome Wizard window, select Choose a PANTONE

Apply. The PANTONE

Alternatively, click the button or from the Edit menu, click PANTONE

Simulations.

®

color, perform the following steps:

®

®

Color Formula Guide. The list does not contain fluorescent

®

color and click

Color Simulations window appears.

®

Color

PAN TO NE

®

Color Simulations window

Note If an "(R)" (the letter R within parentheses) appears next to the PANTONE® color name, the

color is available as a Ready Mix color (see "Ready Mix colors" on page 64).

2 If your PA NTO N E

®

Color Formula Guide is dated year 2000 or later, select the

IMS 5.2 compatible color option. Otherwise, select the IMS 4.1 compatible color

option.

3 Type the PANTONE

®

color name in the PANTONE field, or scroll and select the color

from the list.

4 Select the Coated, Uncoated, or Matte option. Choose whichever type most closely

matches the substrate.

ENWW

Selecting a PANTONE® color 37

Page 39

Note "Uncoated" is for substrates similar in gloss to copy paper. Matte can be used for substrates like

PVC.

If you use a 75° glossmeter, you can determine the gloss level as follows:

• above 50 percent gloss, click Glossy

• 15 to 50 percent gloss, click Matte

• below 15 percent gloss, click Uncoated.

5 Click Apply. If Uncoated was selected, the following message is displayed:

Very Matte Warning message

If the Configure Color Matching Parameters window appears, continue with step 8.

6 If the ink mix only matches the target color under specific lighting conditions, the

Warning! Metameric window appears.

Warning! Metamerism window

Two colors are considered metameric if under a specified illuminant, they appear

equivalent to the average eye. Under a different illuminant, the colors may vary.

Select the relevant illuminant, and click Apply:

• Outdoor lighting

• Indoor lighting

• Other illuminant

38 Chapter 4 General procedures

ENWW

Page 40

A selection of Outdoor lighting or Indoor lighting is matched in the Illuminant section of

the Configure Color Matching Parameters window (see step 8).

Note The level of metamerism is defined as the absolute difference between the following:

• The difference between the target and custom colors under "warm” light, such as an

incandescent light.

• The difference between the target and custom colors under “cold” light, such as D

If the level of metamerism is greater than the mix precision, the Metamerism warning window

appears. (See ‘Setting the mix precision’ on page 94 for an explanation of mix precision.)

7 If the target color is out-of-gamut at the regular thickness of the ink layer, the Increase

Thickness window appears. You can improve the color match by printing with a

greater ink thickness.

65

.

Increase Thickness window

Select the relevant ink thickness as follows, and click OK:

• Regular thickness refers to a single print of the custom color separation.

• Double print means that the custom color is required to be printed twice. The color

adjustment runs in single print mode, and the optical density (OD) spec reflects

this.

• Increase thickness refers to a single print with the ink thicknesses (minimum and

maximum) increased (the OD values are increased by 0.1).

The Configure Color Matching Parameters window appears.

ENWW

Selecting a PANTONE® color 39

Page 41

Configure Color Matching Parameters window

8 In the Illuminant section, select the type of lighting conditions that your customers use

to check their printed output.

9 In the Observer section, select the spectrophotometer's angle of measurement. The

default is 10°.

Note The practical difference between 10° and 2° is insignificant.

10 In the Color Difference section, select the parameter to be used to indicate the color

difference between the best or actual mix and the target color. See "∆E*

96 for an in-depth explanation of ∆E*

94

.

11 The Level of Gloss parameter contents matches the choice made in step 4. Select a

different value only if necessary.

12 Click the Substrates drop-down list. If the substrate is white, click Default substrate. If

the substrate is other than white, do one of the following:

• Select the substrate from the list that most closely matches your substrate.

• Add a new substrate (refer to "Adding a new substrate" on page 74).

" on page

94

40 Chapter 4 General procedures

ENWW

Page 42

13 Select the type of press on which this color will be installed.

If the press is one of the following, select the operating system of the press:

• Series 3000/4000

• Series 1000/2000

• Indigo TurboStream-based

HP Indigo Press section with Press Windows Version displayed

14 Click Apply. The Save Workspace message displays.

Save workspace dialog box

15 Click Yes. The Save My Colors window displays.

ENWW

Selecting a PANTONE® color 41

Page 43

Save My Colors window

The Save My Colors window provides a file name for the workspace of the mix color.

This name is the combination of the PANTONE

®

color name, the coating of the

substrate, and the press type.

You can edit the default file name. For example, if the mix color is to be printed using a

double print, edit the file name to indicate this requirement. This will ensure that the

name of the ink file will indicate to the operator that a double print is required.

16 Click Save.

Note For details on the Export File and Delete File procedures available from the Save My Colors

window, see "Exporting and deleting ink workspace files" on page -77.

42 Chapter 4 General procedures

ENWW

Page 44

Save the Ink Definition file

The HP Indigo press contains a separate ink definition file for each ink that is used. You

must save the ink definition file of the new custom ink to a network drive or to a disk so

that it is accessible by the HP Indigo press computer.

1 From the Utilities menu, click Save Ink Definition File; or click the button. The

Save Ink Definition File window appears.

Save Ink Definition File window

The Save Ink Definitions File window provides a file name for the ink definition file.

This name is the combination of the PANTONE

can edit the default file name.

Note The My Colors default location is C:\Program Files\IMS. This location can be opened by clicking

on Utilities, and Open Ink Definition File Folder.

2 Click Save. The following message appears:

Ink Definition File Created message

Note The filter color, mentioned in the message, is the filter with which the in-line densitometer

measures the custom color. If your press uses an off-line densitometer, the preferred filter color

appears in the Color Adjustment window.

®

color name and the press type. You

ENWW

Selecting a PANTONE® color 43

Page 45

3 Click OK. The following message appears:

Check imaging oil conductivity message

4 Click OK.

If the color is to be double printed, the following message appears:

Remember to double print message

Click OK.

Note Saving the ink definition file changes the color’s workspace. Stopping work on this color at this

time will generate a message to save changes to the color.

Saving the color’s workspace

1 From the File menu, click Save; or click the button. The Save My Colors window

displays.

44 Chapter 4 General procedures

ENWW

Page 46

Save My Colors window

2 Click Save. If the workspace was already saved under that file name, the following

message is displayed:

File Already Exists window

To continue with saving the workspace, click Yes.

ENWW

Selecting a PANTONE® color 45

Page 47

Transferring the ink definition file to the press

All HP Indigo presses except for Indigo Sun computer-based presses

1 (On the press) From the Options menu, click Ink List. The Ink List window appears.

2 Click Import. The Import ink definition window appears.

3 Select the network directory in which you saved the ink definition file on the IMS

computer.

If you saved the ink definition file to a disk and you want to load the file from that disk,

insert the disk into the press computer, and in this step select 3¾ Floppy (A:).

Note To see only the ink definition files, select On-Site Mixing (*.osm) in the Files of type field.

4 Select the ink definition file. The file must have the .osm extension.

5 Click Open.

6 Click Close.

Indigo Sun computer-based presses

1 Login (User Mode) as Supervisor to access the necessary options.

2 From the Config menu, click Colors Data Base. The Colors Data Base window

appears.

3 Click OnSite DB.

4 Click Read.

Note If the ink name that you sent from the IMS software already exists in any of the databases on

the press, the software automatically appends a number (1, 2, 3, and so on) to the ink name.

5 Select the ink definition file from the OnSite DB list, and click Add to Local Colors

DB. The selected file is added to the Local Colors DB list.

6 Click Quit to close the Color Data Base window.

46 Chapter 4 General procedures

ENWW

Page 48

Preparing the basic inks

1 Look at the Ingredients list to see which basic inks are needed for the target color

that you want to print.

Ingredients list

2 Place at least one can of each basic ink into the shaker. There should be no more

than four cans in the shaker.

Note The only cans that need shaking are those that have not been shaken in the past 24 hours.

Note If a basic ink can has been used previously, some imaging oil may spill out of the can during

shaking. To prevent this, wipe the bottom of the can with a tissue and cover the hole at the

bottom of the can with adhesive tape.

3 Operate the shaker to ensure that each basic ink is of uniform concentration.

See “Shaking the can” on page 51 for a detailed description of how to operate the

shaker.

ENWW

Preparing the basic inks 47

Page 49

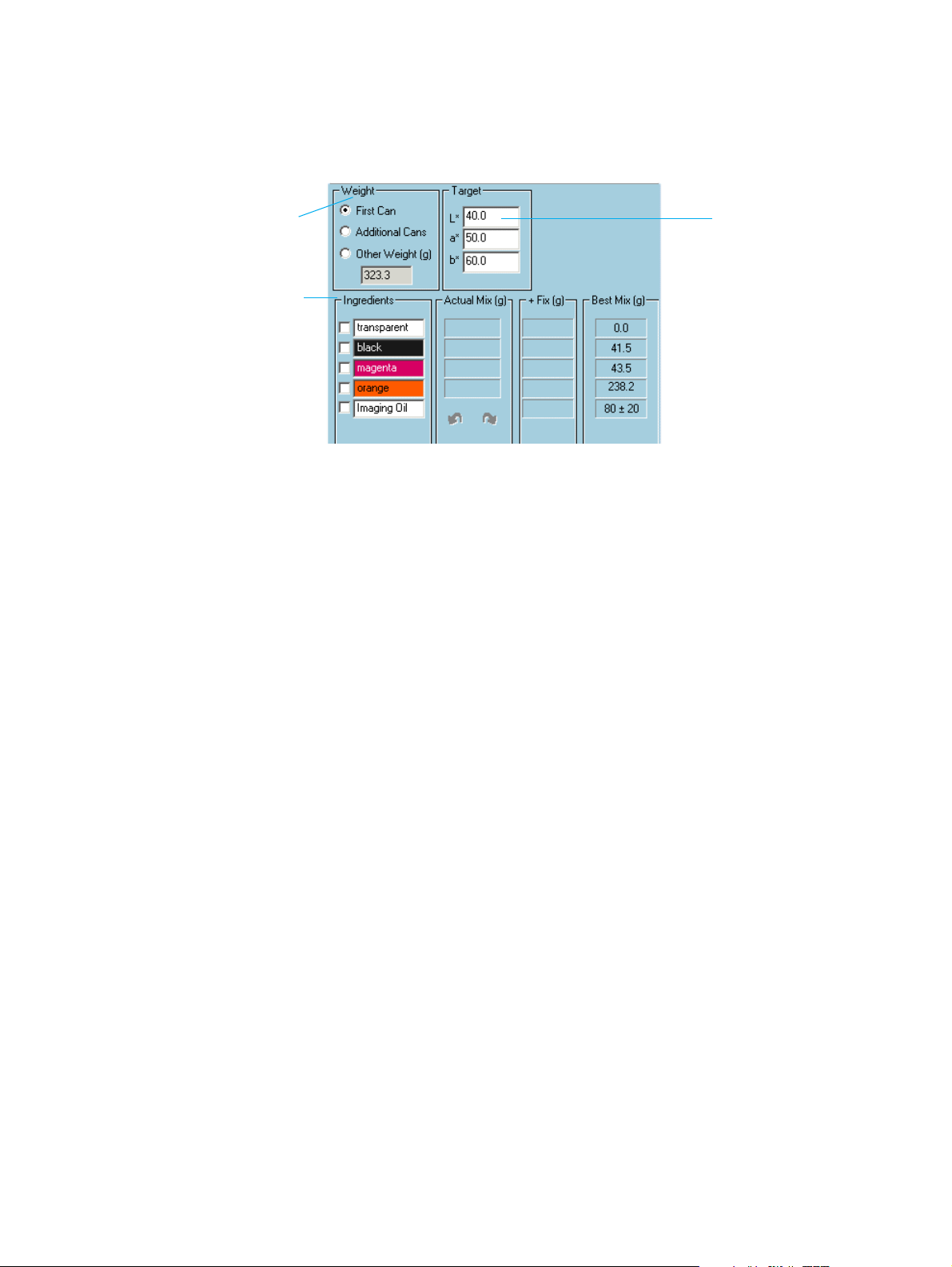

Dispensing the ingredients

Note For a first can, new first can, and additional cans, use the weights shown in Best Mix (g). For

a fix can, use the weights shown in +Fix (g).

Best Mix (g) and +Fix (g) lists

1 Verify that the appropriate nozzle is installed in the dispensing unit and that the

spacer ring is used if necessary. See “Adjusting the dispensing unit for the press” on

page 35 for details.

2 Before dispensing any ink, place an empty receiving can or fix bottle on the weighing

pan of the electronic scale in the dispensing unit.

WARNING! Verify that the diaphragm is at the bottom (closed) end of the new empty receiving can by gently

pushing down on it with the rounded end of a spatula.

Note A fix bottle is sometimes used instead of an empty receiving can when preparing a fix can.

3 Open the transparent safety door of the dispensing unit, and insert the first or next

ingredient can listed in the Ingredients list. Close the safety door.

4 Press the red Tare button on the scale’s base to set the scale to zero. Do this each

time before dispensing ink from the different ingredient cans.

5 Dispense the quantity of ink specified in the weight fields (Best Mix (g) or +Fix (g))

for the ingredient can that you inserted in the dispensing unit.

Transparent

safety door

Weighing

pan

Tare button

Dispensing

unit

Coarse

button

Fine button

Electronic

scale

Dispensing unit

48 Chapter 4 General procedures

ENWW

Page 50

To dispense the ink quickly and accurately, do the following:

a For rapid dispensing, press the Coarse and Fine buttons.

Release the Coarse button (but not the Fine button) 5 to 10 g before the desired

weight.

b To dispense the last few grams incrementally, press the Coarse button in short

spurts while still pressing the Fine button.

Note The dispensing of transparent ink should be accurate to 3 g. All other inks should be accurate

to 0.4 g. If the amount added was more than required, you may remove the excess ink from the

receiving can or fix bottle with the spatula or a clean stick.

If the amount of ink to dispense is very small (2 g or less), the following alternate

dispensing method may be used:

a Dispense some ink into an empty ink can cover.

b Using a clean spatula, take small amounts of ink from the can cover and put them

into the receiving can until the required amount of ink is reached.

CAUTION Beware of sudden ink spills.

6 (Optional) Click the box in the check list that corresponds to the ingredient that you

have finished adding to the receiving can.

ENWW

Ingredients list

7 If you are dispensing into a receiving can, repeat steps 2 through 5 for all the other

ingredients (but not the imaging agent) listed in the Ingredients list in the order they

appear in the list.

If you are dispensing into a fix bottle, repeat steps 2 through 5 for all the other

ingredients (but not the imaging oil or the imaging agent) listed in the Ingredients list

in the order they appear in the list.

8 If you are dispensing into a receiving can, remove it from the dispenser.

If you are dispensing into a fix bottle, leave it in the dispenser.

9 For a first can and a new first can, add to the receiving can the amount of imaging

agent as shown next to the Ingredients / Imaging Agent field.

Dispensing the ingredients 49

Page 51

Sealing the can

1 If the crimper is set to the Series 3000/4000/5000 and UltraStream-based level and

Spacer ring

you are sealing a Series 1000/2000, TurboStream-based, or Sun computer-based

can, place the spacer ring on the round can base.

Series 3000/4000/5000 and

UltraStream-based level

Spacer ring

Round

can base

2 Raise the crimper lever all the way up.

3 Put a valve on top of the prepared ink can.

Valve

Ink can

Valve and prepared ink can

4 Push the round can base down, and carefully insert the can into the can crimper.

Make sure that the top of the can enters the crimper completely and that the can is

centered and flat on the round can base (or spacer ring if it is used) and not tilted.

50 Chapter 4 General procedures

ENWW

Page 52

Crimper

5 Seal the can by pulling the crimper lever down as far as possible.

6 Raise the crimper lever, and remove the can.

Shaking the can

Crimper

Lever

Ink can

Safety

cover

Timer

knob

Shaker with safety cover open

To use the shaker, perform the following steps:

1 Open the safety cover.

2 To allow easy insertion of cans into the shaker, manually rotate the shaker plates until

they are horizontal.

3 Rotate the plate adjusting handle counterclockwise to raise the upper plate.

4 Place an adapter ring on the valve side of the can, and insert the can into the shaker

with the valve facing up.

Plate

adjusting

handle

Upper

plate

Shaker

plates

Note You may insert up to four cans in the shaker. Position the cans in the central area of the shaker

plates.

ENWW

Shaking the can 51

Page 53

Adapter

ring

Valve

Ink can

Ink can

5 Rotate the plate adjusting handle clockwise to lower the upper plate until it touches

the loosest can.

Rotate the plate adjusting handle clockwise 1 to 1.5 more turns.

6 Close the safety cover.

7 Rotate the timer knob to the number of minutes required: three minutes for first and fix

cans or four minutes for additional cans.

Note Rotating the timer knob operates the shaker. You can stop the shaker by rotating the timer knob

back to 0.

8 When the shaking stops, open the safety cover, raise the upper plate, and remove the

cans.

9 For additional cans, shake the cans a second time by reinserting the cans with the

valves facing down, and repeating steps 5 through 8.

Note Adapter rings that are not being used can be stored on the ring holder on the dispenser.

52 Chapter 4 General procedures

ENWW

Page 54

Visually comparing the printed color

Use a light box to compare the printed sample color to the target color. The light standard

should be identical to the standard that you chose in "Selecting a PANTONE

8) on page 40.

If you are satisfied with the color match, you can select Additional Cans on the hp

IndiChrome window, which supplies the ink weights for 500 g cans.

If you are not satisfied with the color match or if you want to determine the

spectrophotometric results of the print, proceed to the next section “Adjusting the ink mix

from the printed output.”

Adjusting the ink mix from the printed output

1 With the IMS software running, measure the printed color with a spectrophotometer.

The Spectral Measurement window appears.

®

color" (step

Spectral Measurement window

2 Verify that the Actual Mixture of Inks option is selected. If not, select it.

Note If the Target Color option is selected and the Actual Mixture of Inks option is unavailable (grayed

out), do the following:

a Click Cancel.

b Perform the procedure in ‘Save the Ink Definition file’ on page 43.

c Restart this procedure (“Adjusting the ink mix from the printed output”).

3 Click Apply. A message appears which reports one of the following color comparison

results:

• Accurate match

• Match can be improved by a fix can

• Fix can would add too much ink to the ink tank

• Improvement possible by changing optical density

ENWW

Visually comparing the printed color 53

Page 55

Accurate match

The following message appears:

Accurate color match report

Close the message and the Additional Cans window appears.

Note An accurate color match report can be followed by a fix can improvement message (see page

55).

Note When the difference between the colors is less than1.0, the Additional cans window appears

without a preliminary accurate color match report.

Additional cans window

The choice is as follows:

z

Select Stop improving the formulation . . . and click Apply – at this stage, you can now

create cans of required ink color. (In the software, the Weight changes to Additional

cans and Best Mix displays the ink weights required for creating the additional cans.)

z

Select Continue improving the formulation and click Apply – try to improve the color

match by changing the optical density value on the press. The change optical density

message appears (see page 56).

54 Chapter 4 General procedures

ENWW

Page 56

Match can be improved by a fix can

The following message appears:

Fix can improvement possible report

Close the message and prepare and install the fix can. Print a new sample page and start

the comparison again from ‘Adjusting the ink mix from the printed output’ on page 53.

Note If the fix can requires less than 25 grams of ink, you can use a test tube provided with the IMS

software to mix the required ink quantity with imaging oil, and pour the mix into the ink tank.

This will save you from using of a full ink can.

Fix can would add too much ink to the ink tank

The following message appears:

ENWW

Compromise window

The calculated ink weights needed to correct printed color would add to much ink to the

ink tank. The choice is as follows:

z

Select Make a compromise correction . . . and click OK – create a compromise fix can

that won’t put too much ink in the ink tank. (The software displays the ink weights for

the "compromise" fix can.) Prepare and install the fix can. Print a new sample page

and start the comparison again from ‘Adjusting the ink mix from the printed output’ on

page 53.

z

Select Mix a new First Can . . . and click OK – instead of trying to "fix" the ink mix, you

can create a new "first" can. (The software displays the ink weight for the new "first"

can.) Prepare and install the new first can. Print a new sample page and start the

comparison again from ‘Adjusting the ink mix from the printed output’ on page 53.

Adjusting the ink mix from the printed output 55

Page 57

Improvement possible by changing optical density

The following message appears:

Undo Measurement window

The choice is as follows:

z

Select To make the improvement . . . and click Apply – change (on the press) the

optical density spec value for the ink to the value given in the Undo Measurement

window (see Changing the optical density (OD) spec value on page 57) and print

another sample page. Measure the color again. (The software resets the ink weights

to the values they had before the measurement.)

z

Select Let the software try to mathematically account for the error in optical density

and click Apply – the software displays fix can ink weights. Prepare and install the fix

can. Print a new sample page and start the comparison again from ‘Adjusting the ink

mix from the printed output’ on page 53.

56 Chapter 4 General procedures

ENWW

Page 58

Undoing and redoing a measurement

Measuring the color of a sample that you printed on the HP Indigo press causes many

field values to change. For example, the actual mix and best mix values change.

If you want to undo all the changes associated with such a color

measurement, perform one of the following:

●

From the Edit menu, click Undo the Last Actual Mix.

●

Click Undo.

If you want to reapply all the changes undone by the Undo command,

perform one of the following:

●

From the Edit menu, click Redo the Last Actual Mix.

●

Click Redo.

Changing the optical density (OD) spec value

Perform this procedure if Undo Measurement window displays (described on page 56) and

you want to improve the color by changing the optical density spec value on the press.

1 From the Consumables menu, click Install Ink. The Ink Installation Manager window

appears.

2 Click Custom Auto Color Adjust, and click Next.

3 Click Setup.

4 Type the optical density value (as indicated in the Undo Measurement window) for the

custom ink.

5 Click OK.

6 Click Print.

If you use an off-line densitometer, make sure that you measure the optical density

(OD) with the optical filter specified in the Manual Color Adjustment window.

7 Record the Measured/OD of 100% value from the Custom Auto Color Adjustment

window.

Note The measured OD value is very important for future printing. Record the value in a safe place.

8 Click Finish.

9 Return to ‘Adjusting the ink mix from the printed output’ on page 53, and continue

from there.

ENWW

Undoing and redoing a measurement 57

Page 59

Improving visual match by changing illuminant

Note Save the color mix workspace before applying this procedure.

If you feel the visible match needs improvement, click and the Which color to add

window opens.

Which Color to Add window

Select the color that you believe will give the best improvement. The IMS system checks

all the color results against different illuminants and if possible will recommend a more

appropriate illuminant for the viewing environment.

If the following message appears, click OK and the system will continue the check against

another illuminant.

No spectral information for target message

58 Chapter 4 General procedures

ENWW

Page 60

If a more appropriate illuminant is found the Change Illuminant window opens.

Change Illuminant window

The recommendation is to change the current illuminant and the default illuminant. Click

Apply.

If no appropriate illuminant change is found, the following message appears:

No illuminant gives requested correction message

Click OK.

ENWW

Improving visual match by changing illuminant 59

Page 61

Comparing different ink mix results

After each measurement, the result location is added to the 2D color space and the fix

weights are available to change the resultant color. Each subsequent measurement is

labeled by number.

To compare different ink mix results, do the following steps:

1 Right-click on one of the measurement results required for the comparison, and select