Page 1

Page 2

HEWLETT-PACKARD

Technical Information from the Laboratories of Hewlett-Packard Company

JOURNAL

Contents-

processor-based

FEBRUARY 1981 Volume 32 • Number 2

A High-Purity, Fast-Switching Synthesized Signal Generator, by

phase noise and high frequency

Digital Control for a

Chisholm

Front-panel,

High-Performance

internal,

agility

are

Programmable Signal Generator, by Hamilton C.

and remote

usually

control

conflicting

of a complex instrument calls for a micro-

controller.

8662A Power-On and Self-Test Sequences, by Albert W.

Kovalick

Roland

requirements.

The ROM and RAM

Hassun

tests have some clever twists.

Low-Noise RF Signal Generator Design, by Dieter

liam J. Crilly, Jr., and Donald W.

Mathiesen

Scherer,

Bill S. Chan, Fred H.

Seven phase-locked loops and some innova-

tive techniques did the job.

A Switching Power Supply for a Low-Noise Signal Generator, by Gerald L Ainsworth

An

unusual

choice, because of switching noise, but the benefits outweighed the problems.

A High-Purity Signal Generator Output Section, by David L. Plan and Donald T.

This section

supplies

a low-noise output with unprecedented

level

accuracy.

Product Design for Precision and Purity, by Robert L DeVries Shielding and reliability

are major considerations.

Verifying High Spectral Purity and Level Accuracy in Production,

by

John W. Richardson

The question is how to test a state-of-the-art product without losing production-line efficiency.

Low

Ives,

Wil-

Borowski

In this Issue:

The quality of a precision laboratory signal generator is measured by how little noise and

spurious signals are present in its output along with the single-frequency signal that's

supposed to be there. No noise at all is an impossible ideal, but the subject of this issue, Model

| 8662A

I now available in its frequency range, which is 0.01 to 1280 megahertz.

I transmitters and receivers, and for testing this kind of equipment. In these systems, informaI tion is superimposed on a single-frequency carrier signal by modulating the carrier's

amplitude, frequency, or phase. A noisy carrier, one whose phase or amplitude jitters significantly, can severely

limit the performance of a system. Phase noise tends to be particularly troublesome, and so the measurement of

phase noise has become especially important. For phase-noise measurements, the 8662A is used as a stable

source with which to compare the equipment under test. These measurements are done in the development

laboratory, in production (where the 8662A's programmability makes automatic testing possible), and in

maintenance.

In receiver testing, an important measurement is adjacent channel selectivity, aimed at finding out how well a

receiver picks up a weak signal in one of its channels when there are strong interfering signals in adjacent

channels. A clean interfering signal is needed for this test so the performance that's measured is the receiver's

and not the signal generator's. Today, channels are being made narrower in an attempt to accommodate more

customers in an increasingly crowded electromagnetic spectrum. The narrower the channels, the cleaner the

test signal must be; hence the need for the 8662A.

Many applications lie above the 8662A's frequency range, but even in these cases, the 8662A's output can

often be multiplied to the needed frequency and still be clean enough, even though its phase noise is multiplied,

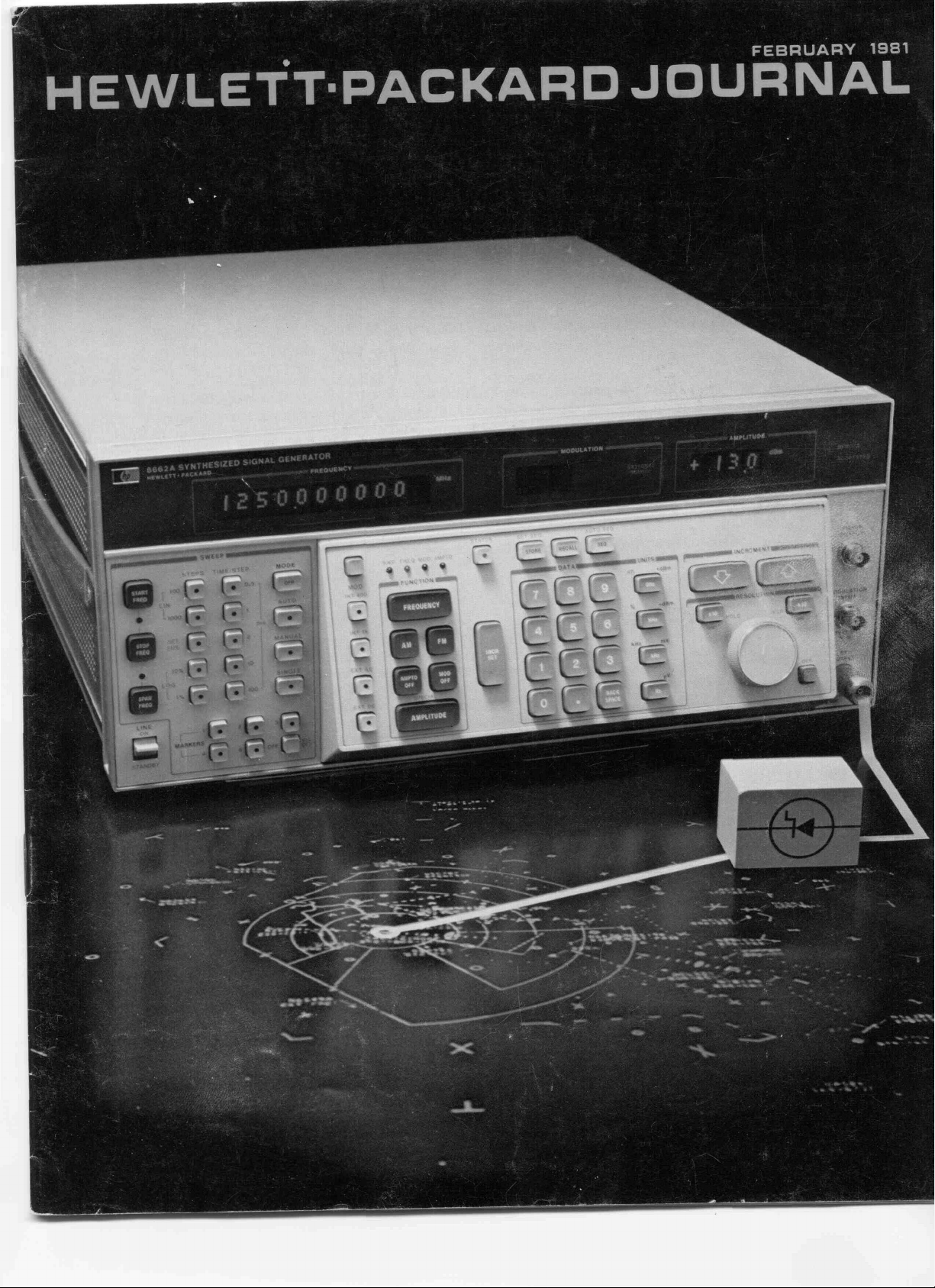

too. Our cover suggests an application like this. The 8662A feeds a step-recovery diode multiplier to provide the

transmitted signal in a pulsed Doppler radar system. (In practice, a pair of 8662As would be used to generate

both the transmitted signal and the receiver local oscillator signal). The radar scope in the foreground belongs to

the U.S. Federal Aviation Administration's Oakland TRACON (Traffic Control). This radar actually operates at

1030

MHz, within the 8662A's frequency range. We thank the FAA for letting us photograph it.

Synthesized

Signal Generator, comes as close to the ideal as any signal generator

Where are such super-clean, stable signals needed? Mostly in communications and radar

Illustrator, Nancy S. Vanderbloom • Administrative Services, Typography, Anne S. LoPresti • European Production Manager, Dick Leeksma

Editor, Richard P.

2 HEWLETT-PACKARD JOURNAL FEBRUARY 1981

Dolan

• Associate Editor, Kenneth A. Shaw • Art Director, Photographer, Arvid A. Danielson

©Hewlett-Packard

-R. P. Do/an

Company 1981 Printed in U.S.A.

Page 3

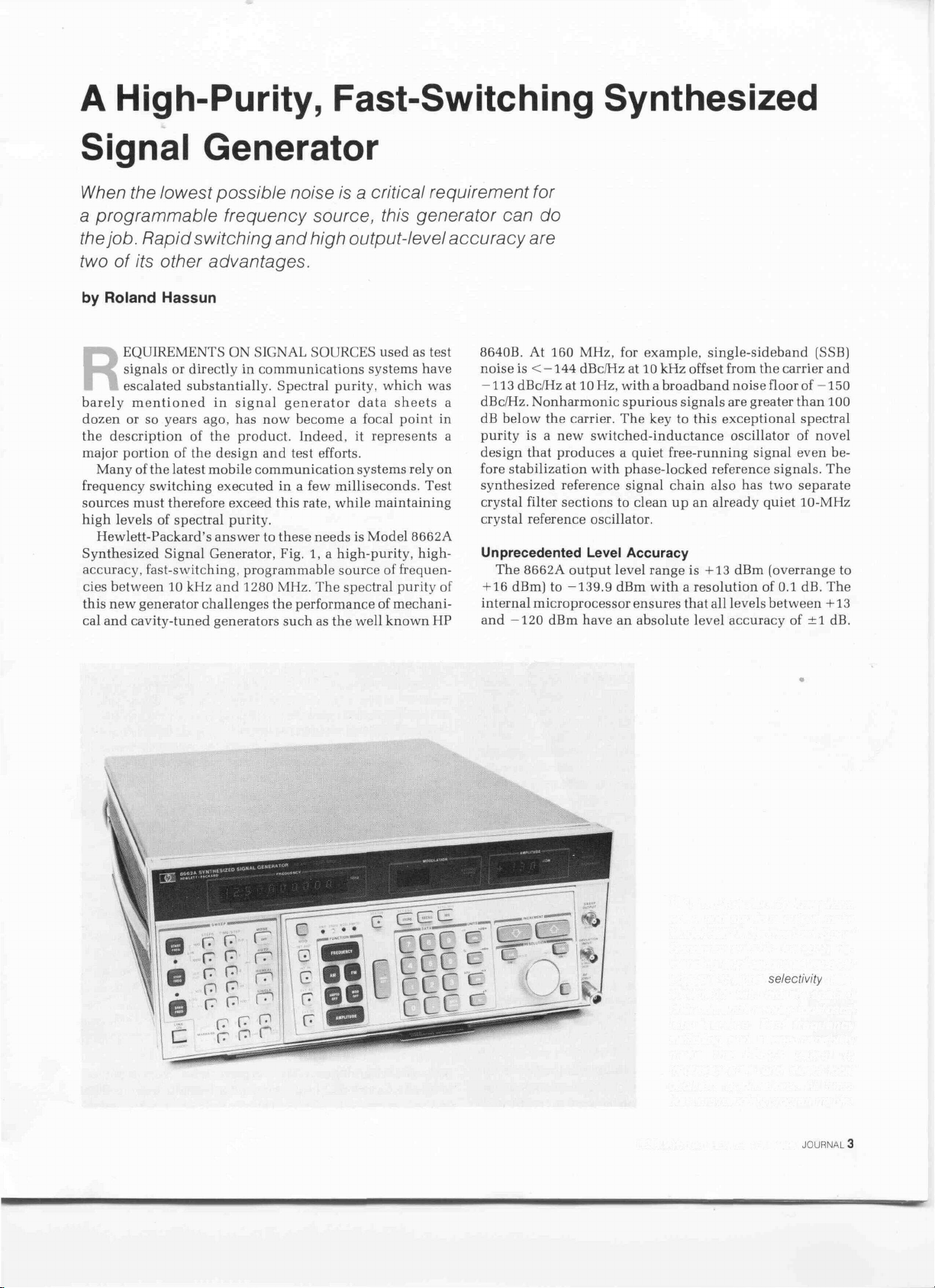

Fig. 1. Exceptionally low phase

noise and spurious output make

Model 8662A Synthesized Signal

Generator suitable for such demanding applications as receiver

adjacent channel

selectivity

measurements with closely spaced

channels and low-noise local oscil-

lator service. Fast frequency

switching and sweep capability

make the 8662A useful in

frequency-agile and swept local

oscillato applications. All functions are remotely programmable.

FEBRUARY 1981 HEWLETT-PACKARD

JOURNALS

Page 4

Spectral Purity

Spectral purity is a measure of how much the spectrum of the

output of a signal generator deviates from that of a pure sine wave.

Factors affecting spectral purity are:

• Phase noise, manifested as random fluctuations of zero crossings in the time domain and spectrum spreading in the fre-

quency domain

• AM noise, manifested as envelope fluctuations in the time domain and spectrum spreading in the frequency domain

•

Nonharmonically

called spurs

• Harmonically related sidebands caused by harmonic

distortion.

Phase noise is of particular importance in establishing the limits

of many modern communications systems. Harmonic distortion,

on the other hand, is not an important factor for the great majority

of applications in communications systems. It can be substan-

tially reduced by means of simple low-pass filtering.

AM noise levels are generally at least

levels in most signal sources. Furthermore, many operating systems rely on angle modulation (phase or frequency) and are

therefore not sensitive to AM noise.

Discrete sidebands can cause both amplitude and phase

modulation but occupy a much more restricted portion of the

spectrum than random modulation caused by random phase and

amplitude fluctuations.

The total unwanted power occupying a particular communication channel consists of the sum of the power in the discrete

sidebands plus the integral of the noise power in the channel

bandwidth. Both components therefore need to be minimized.

Phase Noise

The spectrum spreading of the carrier that is caused by the

existence of phase noise extends from less than 1 Hz offset from

the carrier to wherever the effect of additive

active device

MHz away from the carrier. Close-in phase noise is understood to

include offsets within 5 kHz of the carrier, while far-out phase

noise is understood to be that beyond 5 kHz.

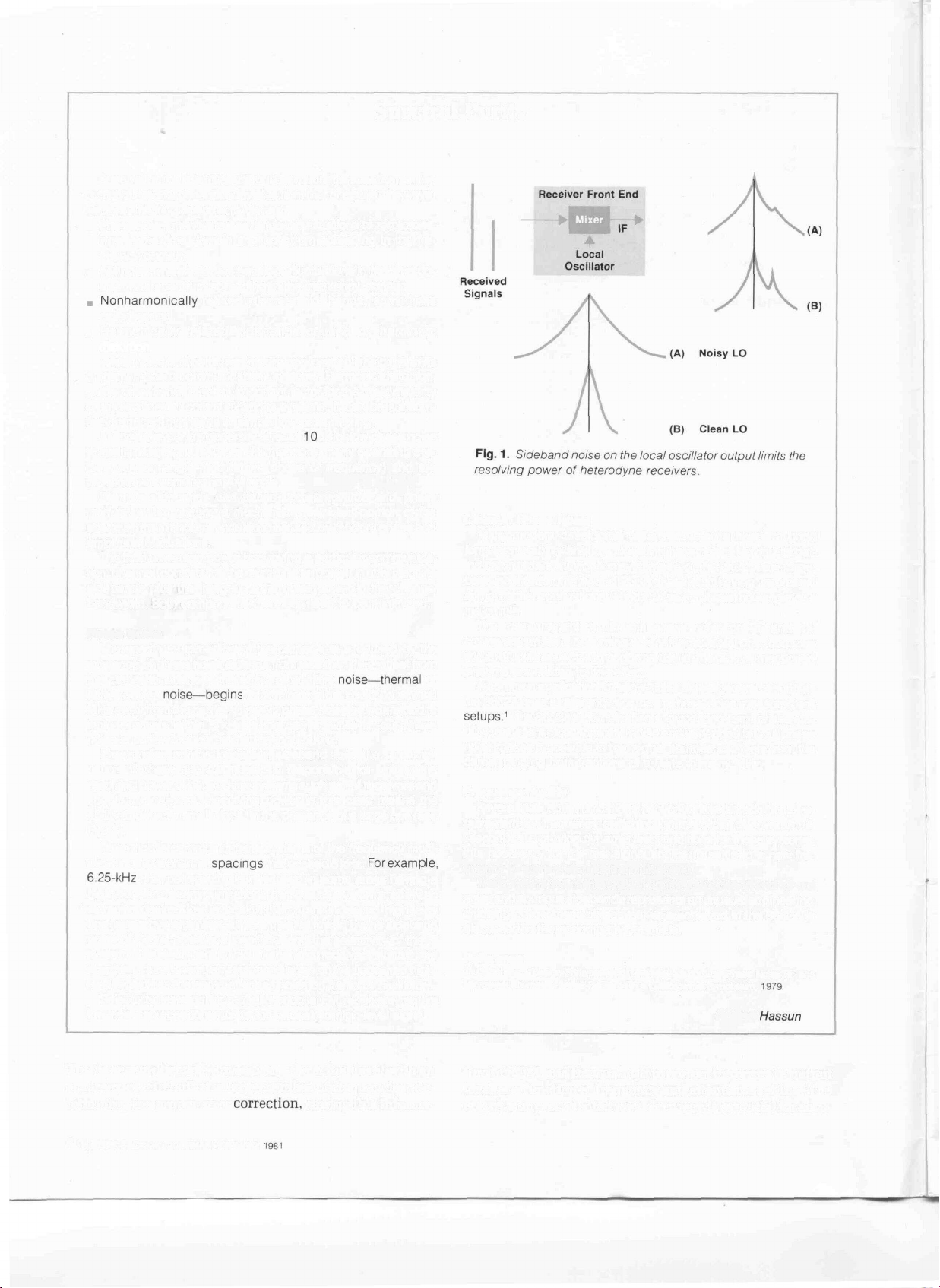

Phase noise, or more generally, sideband noise (i.e., a combi-

nation of phase and AM noise), is responsible for limiting the

resolving power of heterodyne systems such as FM receivers and

spectrum analyzers. Resolving power in this case means the

ability to detect a small signal in the presence of a large one (see

Fig.

1).

Most mobile communications systems of the frequency multi-

plex kind have channel

6.25-kHz

high density of communications traffic. The system's ability to

extract a desired low-level signal from an undesired high-level

one (a nearby transmitter, for example) is limited by the sideband

noise of the receiver local oscillator and the selectivity of the IF

system. It is assumed in Fig. 1 that the received signals are

spectrally pure. In fact, any sideband noise on the undesired high-

level signal has the same effect as noise on the local oscillator.

low-noise sources to simulate the undesired high-level signal.

channel spacing is now used in some areas having a

Selectivity tests on high-quality mobile FM receivers require

related discrete sidebands, sometimes

10

dB below phase noise

noise—thermal

noise—begins

to dominate. This could be several

spacings

that exceed 5 kHz.

or

Forexample,

Close-in Phase Noise

Many modern developments have created a need for good

long-term stability and low close-in phase noise. Moving-targetindicator radars, navigation systems (e.g., Navstar), very-large-

baseline interferometry and PSK (phase-shift keying) represent

some of the applications where close-in phase noise plays a

major role.

The measurement of close-in phase noise on RF and microwave sources is becoming a very fundamental one, because

some crucial aspects of performance in the above-mentioned

systems are related to this effect.

A common application for a low-noise signal generator such as

the 8662A is as a reference source in phase-noise measurement

setups.1 The 8662A's combination of good long-term phase sta-

bility, excellent close-in phase noise and very good far-out phase

noise makes it possible to test signal sources at offsets from the

carrier ranging from fractions of a hertz to many MHz.

Frequency Agility

Several new communications networks have an additional requirement for frequency switching on the order of several milliseconds. To provide dynamic test conditions for these systems,

it is necessary for the test signal source to settle to a new frequency in somewhat under a millisecond.

The combination of this level of agility, low close-in and far-out

noise and spurious sidebands represents an unusual engineering

challenge. How these objectives were achieved in the 8662A is

discussed in the accompanying article.

Reference

1. D. Scherer, "Design Principles and Test Methods for Low Phase Noise RF and

Microwave Sources," Hewlett-Packard RF and Microwave Symposium,

-Roland

1979.

Hassun

This is accomplished by measuring the actual level with an

accuracy of ±0.5 dB at a large number of frequencies, de-

termining the proper error

4 HEWLETT-PACKARD JOURNAL FEBRUARY

correction,

'

storing this informa-

tion in ROM, and then using it to correct the errors in output

level as a function of frequency and attenuator setting. The

8662A's unprecedented level accuracy is essential for accu-

Page 5

rate receiver sensitivity measurements.

Although primarily designed for high signal purity, the

8662A's indirect-type oscillator switches frequency with a

typical 12 ms total switching time (to within 100 Hz). RF

settling time is 0.5 ms. For testing frequency-agile receiv-

ers, a special learn mode may be used with the HP-IB*

programming bus to drive frequencies directly from the

bus, with

500-ju.s

switching speed.

All other front-panel functions are programmable via the

HP-IB, which is a standard feature. The microprocessor also

provides powerful diagnostic and error routines to aid the

user and service routines to aid in maintenance.

Flexible Control

A major design objective of the front-panel layout was to

improve measurement efficiency so that engineering and

production test productivity could be increased. Key func-

tions are grouped centrally. Frequencies are key-set to 0.1

Hz (or 0.2 Hz) and levels to

0.1

dB resolution. Values can be

incremented or decremented with up/down keys or a rotary

knob after keying in the desired step size. A store/recall

function allows up to nine complete front-panel control

settings to be retained and recalled singly or in a sequence

of up to 10 steps.

Most increment and sequence steps can be triggered by

rear-panel inputs. A series of pins available on a rear-panel

connector allows certain commands to be executed when

one of the pins is connected to ground (a debounce circuit is

provided internally) or pulsed with a negative-going TTL-

compatible pulse of at least

5-/us

duration. This allows out-

puts to be tied back to inputs directly, thus creating a sequential system, or through decision-making logic. For

example, if the sweep output is tied to the step-up pin, the

whole frequency range of the 8662A can be sequentially

swept in specified increments. If a detector circuit and some

logic are also used, then the sweeping action can be stopped

whenever a signal is detected.

Powerful sweep capability that preserves synthesizer

stability, resolution, and accuracy makes the 8662A ideal

for characterizing high-stability components such as crys-

tal filters. Start/stop or span sweeps can be selected. Five

key-set markers plus linear or log sweep are available. By

using the sequence

function,

multiple sweeps can be ob-

served simultaneously.

Full signal-generator capability is provided, with high-

performance AM and FM modulation. AM rates to 40 kHz

are possible depending on modulation depth and carrier

frequency. FM deviations to 200 kHz and rates to 100 kHz

are available for external modulation inputs. A 400 or

1000-Hz

Architecture

internal source can be selected.

The architecture of the 8662A reflects the major design

goals, which included low phase noise close to the carrier

(less than 5 kHz offsets), low phase noise far from the car-

rier, submillisecond frequency switching speeds, spurious

sidebands more than 90 dB below the carrier,

0.1-Hz

fre-

quency resolution, and quality modulation capability.

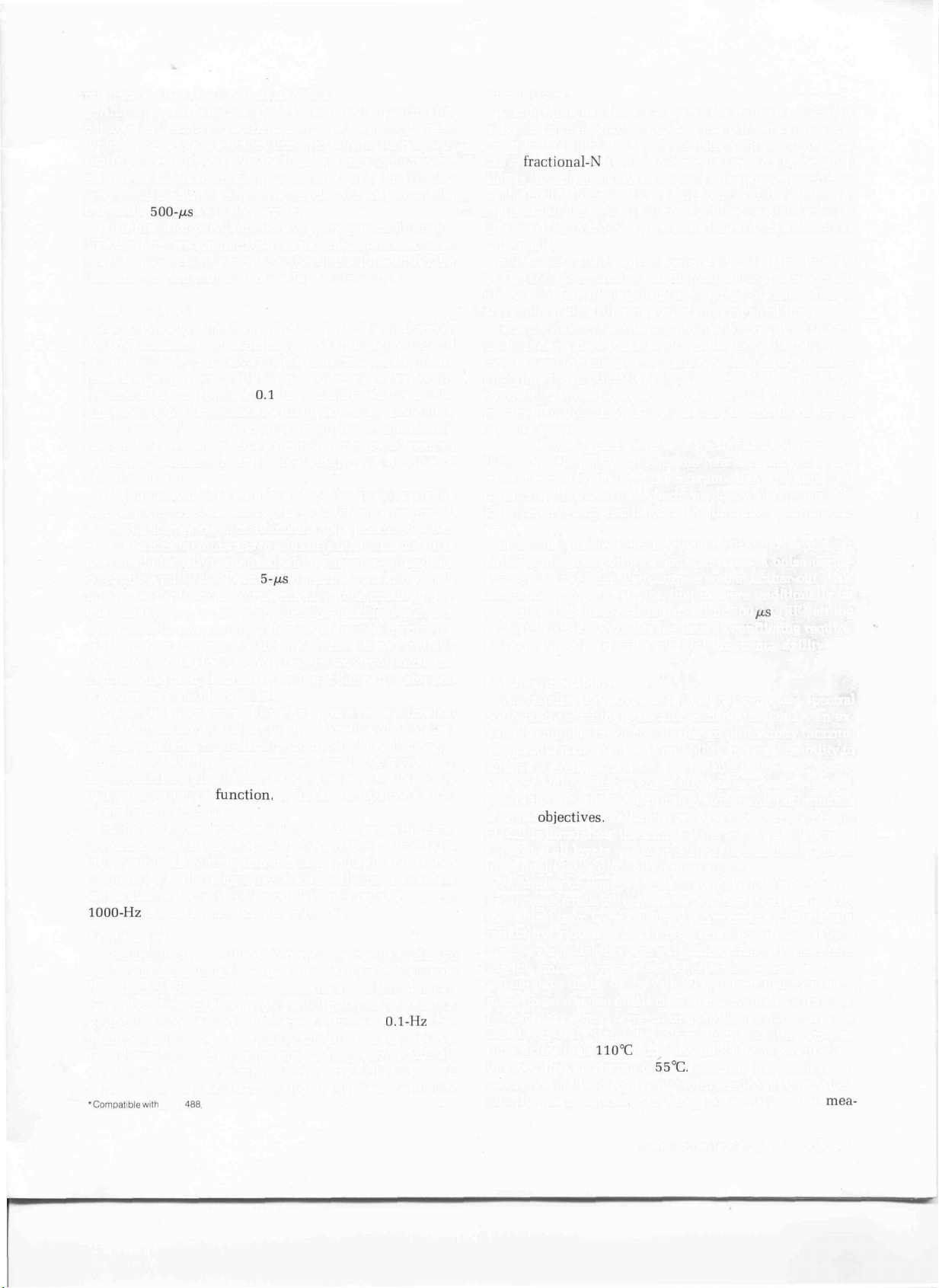

The phase-locked loop approach to frequency synthesis

was chosen because these objectives could be met with

a lower level of product complexity. Fig. 2 is the 8662A

•Compatible

with

IEEE

488

block diagram.

Divide ratios have been chosen so that noise on any of the

reference signals going into the phase detectors does not

undergo multiplication by more than 2 at the output. The

use of

fractional-N

divider techniques (see article, page 12)

allows the achievement of a specific frequency resolution

while maintaining a wider loop bandwidth (leading to

higher switching speed) than would be possible without

the use of fractional-N. At the same time, the divide ratio is

kept small.

Sidebands caused by reference signals leaking into the

VCOs (voltage-controlled oscillators) are kept below -100

dBc on the output signal in the majority of cases. This is

accomplished by filtering, isolation, and shielding.

The provision of frequency modulation required the ad-

dition of two phase-locked loops in the block diagram. One

loop is used to generate the frequency modulated signal by

applying the modulating signal to the VCO. The loop

bandwidth is less than the lowest modulating signal frequency. The other loop is used to sum the modulated signal

into the system.

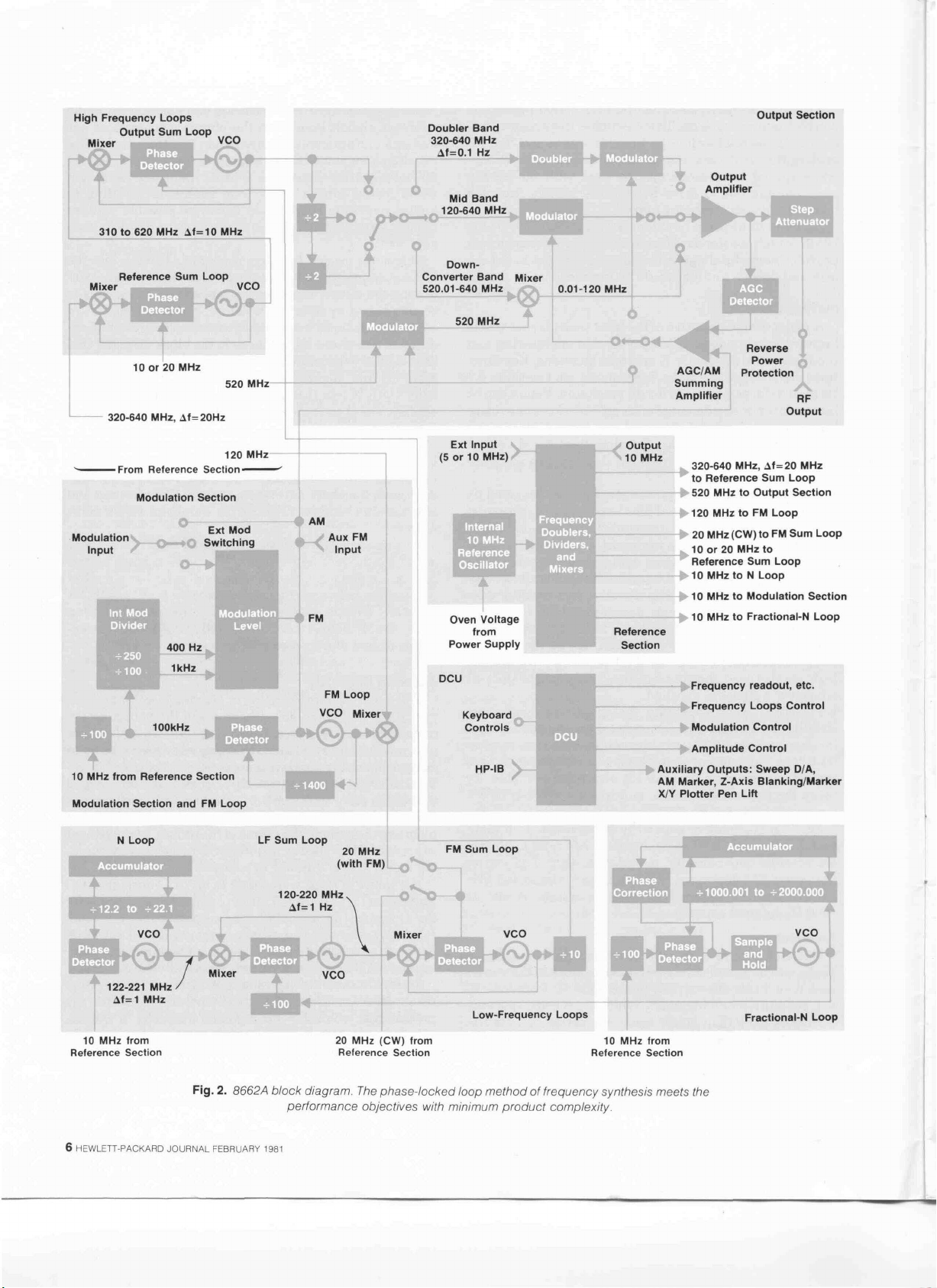

Fig. 3 shows typical 8662A single-sideband phase noise.

Below 10 kHz, phase noise of the reference section domi-

nates. From 10 to 500 kHz the reference loop and sum loop

determine the phase noise performance, while beyond 500

kHz the sum loop oscillator is the dominant phase noise

source.

This noise profile indicates that the HP 8662A is not only

an RF synthesizer with exceptional close-in noise perfor-

mance, but that it can also compete well at farther-out offset

frequencies where cavity oscillators were traditionally far

superior. With its switching speed of 500

/us

(RF settling

time), the HP 8662A meets the usually conflicting require-

ments of low phase noise and high frequency agility.

Assuring Reliability

The required improvements in signal generator spectral

purity and switching speed have made the 8662A an ex-

tremely complex product. The design philosophy for com-

plex products must include reliability and serviceability to

achieve operating cost levels acceptable to the user. There-

fore, reliability and serviceability goals were an integral

part of the early 8662A definition along with performance

and cost

objectives.

Reliability was the subject of significant

planning throughout the course of the project. Management

support at all levels was inspirational in steadfastly pursu-

ing a goal that is difficult to measure.

A number of steps were taken to make a substantial im-

provement in reliability. A series of educational sessions for

the project team were held by the corporate and divisional

reliability groups. The strong commitment of all team

members to reliability was a significant factor in maintain-

ing the emphasis over a period of several years.

The main thrust of the reliability effort in the develop-

ment phase was the creation of an environment within the

product that would favor component longevity. It was de-

cided very early to limit semiconductor junction tempera-

tures to less than

the specified maximum of

110°C

when the ambient temperature is at

55°C.

Junction temperature is a

parameter that is directly related to semiconductor failure

rate. It was measured by making body temperature

mea-

FEBRUARY 1981 HEWLETT-PACKARD JOURNAL 5

Page 6

Page 7

surements

using thermocouples on well over 100 components at several stages throughout the development cycle.

Junction temperature was then computed with the knowl-

edge of the power dissipated in the device and its published

junction-to-body thermal resistance. The goal was met with

the exception of a microwave transistor chip used in the

output amplifier, whose junction temperature can reach

125°C (computed) in the very worst case. The use of a

high-efficiency switching regulated power supply that

saves approximately 70W and a carefully planned thermal

design approach were necessities in achieving the junction

temperature goal.

Another step taken was the reduction of electrical stress

on the components used. Power dissipation, voltage and

current were checked on all transistors and passive compo-

nents. The reliability group helped establish safe derated

limits to which the designers adhered. Design margins on

such crucial parameters as phase-locked loop acquisition

ranges were made very substantial.

Humidity and condensation tests carried out in the

course of a battery of environmental tests revealed some

harmful chemical action. Growth of a clear, amorphous,

nonconducting substance gave rise to intermittent contact

between printed circuit board connector fingers and their

sockets. The microprocessor-based controller was espe-

cially vulnerable to this, since missing a single pulse can

change a legitimate instruction to an unintelligible stream

of information. A task force consisting mainly of product

assurance and printed circuit board processing groups

traced the problem to contaminants in the water used in

the wash cycle. They were eliminated and the problem

went away.

A number of assemblies containing novel designs were

put through life tests. This included prolonged periods of

operation at elevated ambient temperature

(55°C).

Two of

four switched reactance oscillators exhibited identical fail-

ure modes on the tenth and eleventh days of testing. A thin

layer of insulation was punched through causing a

mal-

function. The condition was corrected. The life tests proved

very useful in identifying a number of systematic problems

that generally only show up after lengthy periods of time

and may not be diagnosed as problems when not viewed in

the context of a disciplined test.

Furthermore, a sufficient number of prototypes were

built, operated almost continuously, and exercised

whenever possible to uncover weaknesses. This intensive

search for problems proved quite effective.

Most of the semiconductors used in the product are

burned in according to a program developed by HP's Stanford Park Division product assurance group. A 5:1 reduc-

tion in failure rate has been observed in a pilot program.

Failures detected are carefully analyzed and when systematic patterns emerge, the suppliers of the faulty devices

are notified.

Acknowledgments

The 8662A was a large project that spanned a considerable period of time. Many people have contributed to it in

various disciplines. The reliability of the product has benefitted both in planning and execution from the close involvement of the Stanford Park Division Reliability Group

under the leadership of Julius Trager, especially Randy

White and Charles Sallsey. Bill Whitney's leadership and

Gary Sprader's inputs were very valuable in the field of

serviceability. Introduction to manufacturing was planned

and organized by Bob

Ickes.

The long involvement of Marilyn Lawrence and Tom Cottrell as test technicians, together

with the assembly team of Shirley Flock and Edna Fleck,

was much appreciated by the R&D team. Marketing activity

was managed by Mike Gallagher. Original product defini-

tion benefited from the inputs of Ned Barnholt, Marc Saun-

ders and

Wally

Rasmussen. The development project took

place in the Stanford Park Division R&D lab managed by

John Page and was part of Brian Unter's R&D section re-

sponsibility. I also wish to acknowledge John Hasen's many

contributions as a member of the design team, especially in

the later stages of the project.

Roland Hassun

Roily

Hassun received his BSEE degree

from the Politecnico di

and his

MSEE

State University at San Jose in 1963.

He's also done graduate work at Stanford University.

he worked on the

studies on transistor noise, designed

synthesizers, and ultimately served as

project manager for the 8662A Signal

Generator. He's lectured on synthesizers and spectral purity on three

continents in three languages. This arti-

cle is his third contribution to the HP

Journal. A member

Computer Society, and

committee

nis, bridge and spy novels. He's interested in world affairs and has

served as an officer of a large philanthropic organization, receiving its

leadership award.

for

the IEEE's 1981 western convention. Roily enjoys ten-

AFCEA,

FEBRUARY

he's vice chairman of the program

1981

HEWLETT-PACKARD

Milano

degree from California

After

joining

41OC

of

the IEEE, the IEEE

in 1960

HP

in

1961,

Voltmeter, did

JOURNAL?

Page 8

Digital Control for a

High-Performance

Programmable Signal Generator

by Hamilton C. Chisholm

CURRENT PRODUCTION INSTRUMENT, the

Hewlett-Packard 8660A Synthesized Signal Gen-

A

erator, successfully demonstrates the concept of

keyboard control of a signal generator. By means of the

Hewlett-Packard Interface Bus

means of solving many instrumentation problems calling

for remote control. This previous development served as a

guide in the planning of the 8662A Synthesized Signal

Generator. Many enhancements were developed to pro-

vide full control of all parameters. The panel arrangement

provides the operator with easily understood parameter

control. Interaction with a responding parameter display

reinforces the learning of short key sequences. Where func-

tion control is not obvious from the front panel, a pullout

card beneath the instrument quickly provides assistance.

The

8662A

is basically a signal source of sinusoidal fre-

quencies with exceptional purity. With the addition of

amplitude control and selectable amplitude and frequency

modulation, the source becomes a signal generator. With

step time and step frequency control, the generator is en-

(HP-IB),*

it also provides a

hanced with frequency sweeping capabilities.

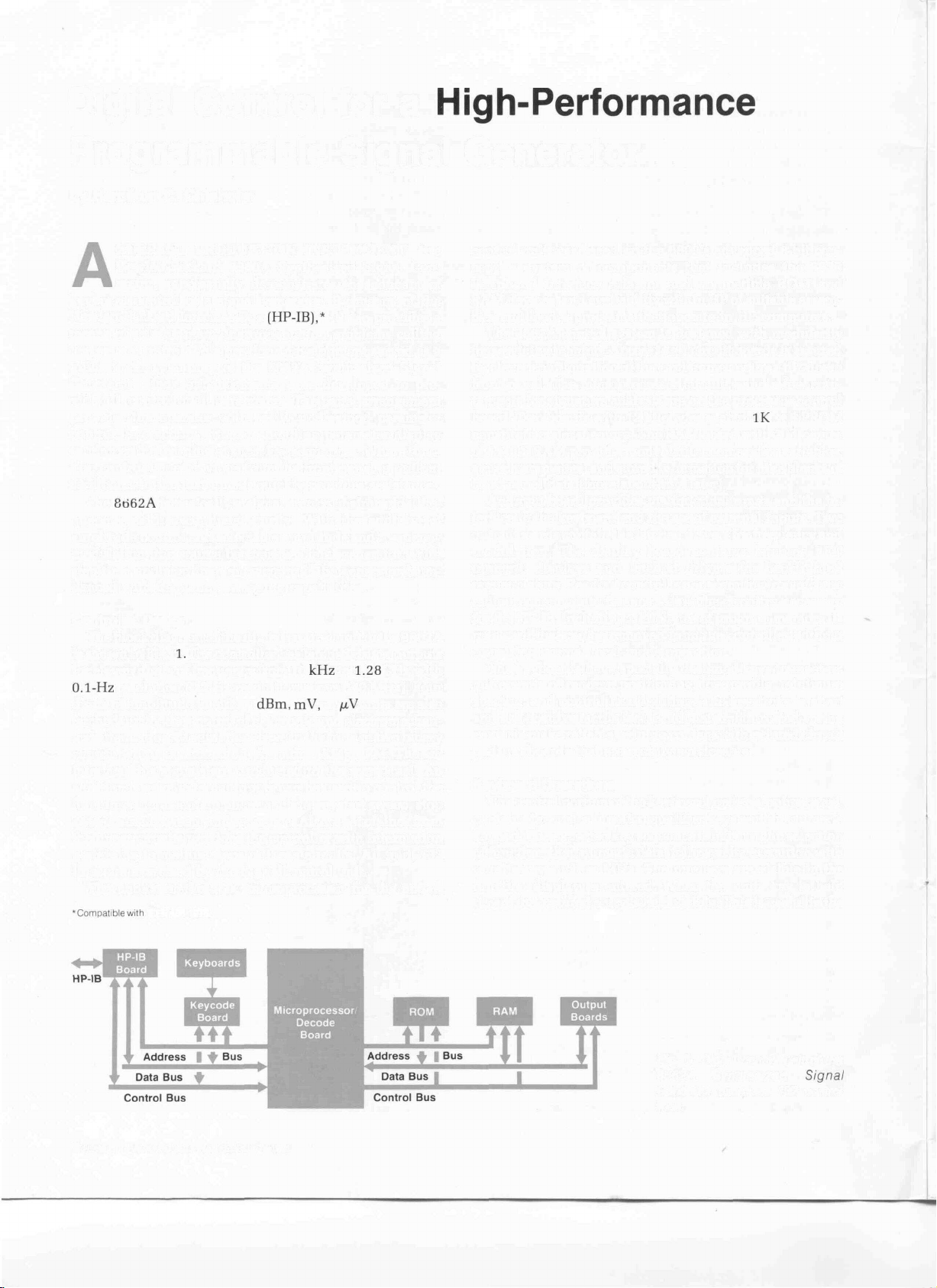

Controller Design

The block diagram of the digital control unit of the 8662A

is shown in Fig.

for eleven digits of frequency from 10

0.1-Hz

resolution (0.2-Hz resolution above 640 MHz). Four

digits of amplitude in either

latched out for the control of electronic and electromechan-

ical attenuation. Modulation drive in the form of two binary

control words is latched out for either AM or FM. The HP

Interface Bus signals are conducted to the rear panel. An

additional set of external inputs can be used to control the

functions increment up, increment down, start sweep, stop

sweep, single sweep, and sequence. Also, a set of lines from

1.

The controller has latched driver outputs

kHz

to

1.28

GHz with

dBm,

mV,

or

fj,V

units are also

the linear circuits provides the controller with information

pertaining to malfunctions of these circuits. All told, 132

lines are exercised by the digital control unit.

The choice of the 6800 microprocessor for the 8662A

•Compatible

with

IEEE 488-1978.

control unit was based on the 6800's advanced 8-bit concept, a system of components that includes the 6820

Peripheral Interface Adaptor and compatible ROM and

RAM devices, and availability within HP of suitable assem-

bler and loader programs that operate in HP computers.

The 8662A control system is designed with modularity

for servicing in mind. Access to all circuit boards is assured

by clever configuration of the card frame and by a tilt-down

front panel. The microprocessor circuitry and a few com-

ponents for signature analysis are on the processor control

board. Two boards with 12 kilobytes each of

constitute major memory. The RAM board with 2 kilobytes

of CMOS RAM provides nonvolatile memory for variables,

stored parameters, and stored information for nine blocks of

front-panel data (more about this later).

An input board provides malfunction inputs and the in-

terface to the keyboard and the set of external inputs. Two

output boards contain the latched drivers for frequency and

modulation. The display board contains latching LED

numeric displays and latched drivers for backlighted

nomenclature. Readout control is nonscanning to avoid any

radio frequency interference. All of the circuitry necessary

for the HP-IB, including 2 kilobytes of program memory, is

on a card that can be removed from the controller without

impairing normal local-mode operation.

The keyboards have specially designed keys to meet re-

quirements of random positioning, low profile, minimum

spacing, and control LED lighting. The keystroke is short

and has positive tactile feel. Gold plated, bifurcated spring

contacts make reliable, wiping contact with printed circuit

pads on boards that are readily serviceable.

Keyboard Operations

The central portion of the keyboard, on the sloping panel,

contains the major function qualifier keys and the numeric

keypad. The expected key sequence is left to right: selection

of function, then numeric data, followed by execution with

a units key such as MHz. The numbers are visible in the

function display as entered. When the units key is held

down, the justified entry is held visible. This is useful in the

IK

x 8 PROM

8 HEWLETT-PACKARD JOURNAL FEBRUARY 1981

Fig. 1. Digital control unit of the

8662A Synthesized

Generator exercises 132 control

lines.

Signal

Page 9

8662A Power-On and Self-Test

Sequences

by Albert W. Kovalick

With the introduction of microprocessor-based "smart" instruments, many conveniences were gained. However, some features of worth were lost. A typical instrument without a smart

controller has the ability to remember user settings by virtue of its

front-panel mechanical switches and dial settings. Most smart

instruments, on the other hand, require the user to key in most

front-panel settings each time power is switched on. An alternative is to use the HP-IB and program the instrument externally. For

simple stand-alone applications, however, manual initialization of

the instrument is a drawback.

The 8662A Synthesized Signal Generator solves this problem

by using a CMOS RAM powered by a battery to keep a record of

all front-panel settings. When the user turns off the synthesizer or

the power fails, the existing front-panel setting is saved. When

power is restored the last saved front-panel setting is restored.

Power-on Sequence

When the 8662A is switched on, a hardware power-on circuit

resets all hardware functions and causes the controller program

to begin. Before the settings are restored a checksum is com-

puted from the saved front-panel data. This is compared to a

reference checksum. If both checksums match, a software

routine restores all frequency, modulation, and amplitude settings. If the checksums disagree, RAM data has been altered.

This is unlikely, but it can occur if the battery discharges. In this

event, the first valid front-panel setting from the store/recall memory is recalled. If all nine settings contain altered data then a

default setting of 100 MHz and

RAM Testing

Testing of the entire 2K bytes of RAM is performed each time the

instrument is switched on. This power-on RAM test checks for

stuck bits in every RAM location without destroying any RAM data.

Before the test can begin, a small section or kernel of RAM is

tested. This kernel is needed to perform the larger 2K-byte test.

Each bit of RAM is now tested for the ability to

found faulty, a user code is displayed to indicate this. By use of a

special function code, a user may access this same test and run it

when desired.

A second, more extensive test is accessible by calling a routine

in the diagnostics ROM. It is different from the simpler test in three

ways. First, it checks for the case of multiple chips enabled.

Second, it tests for CMOS memory fade problems. Last, it tests for

row/column decoding errors internal to the chips. This test is

exhaustive. It runs for about

chips.

The test for multiple chips enabled must be performed before

decoding problems can be detected. If more than one RAM chip

is enabled, a read or write will affect more than the desired RAM.

The test is structured as follows.

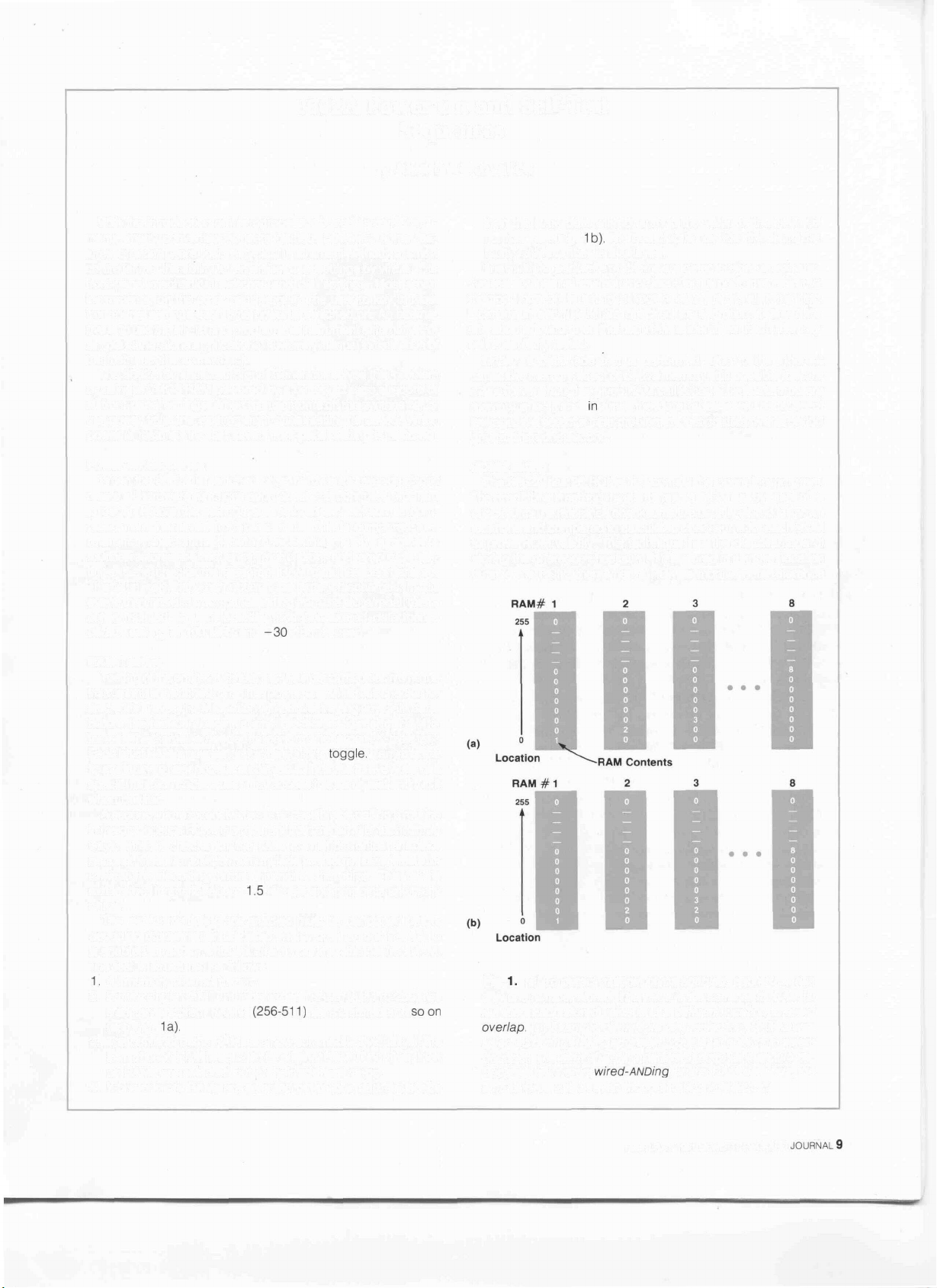

1.

All memory cleared to zero

2. Store a single RAM ID number in each RAM. RAM 1 (0-255) has

a solitary 1 stored. RAM 2

(see

Fig.

3. The contents of the RAMs are now summed individually. If the

sum of each RAM is equal to its original RAM ID number, then

no RAMs are selected out of their address range.

4. If one or more RAMs are selected out of their address space

1a).

-30

dBm is used.

toggle.

If any bits are

1.5

minutes and pinpoints any faulty

(256-511)

has a 2 stored and

soon

then the RAM data will not sum to the value of the RAM ID

number (see Fig.

faulty RAM number is displayed.

If no multiple read/write problems are detected then an exhaustive test for internal row/column decoding is performed. First, a

memory location is set to a known value. Next, all remaining

locations in each RAM are checked for alteration. If any data

alteration is found, then the bad RAM is identified. Each memory

1b).

The bad chip is now identified and the

cell is similarly tested.

Finally, a data fade test is performed. Due to the inherent

capacitive memory effect of CMOS memory, it is possible to store

a 1 or 0 even though a given RAM cell is bad. This is a temporary

memory effect, and

leakage. We detect a fade problem by testing data over a period

greater than one second.

ROM Testing

The 8662A has 26 ROMs that contain the operating program.

The traditional method used to test a ROM is by use of a

checksum. The reference checksums are usually stored in known

locations and compared to calculated checksums for each ROM

to prove ROM validity. This technique has the disadvantage of

storing the reference checksum. If it is stored in a known location

outside the ROM, then when a ROM is modified, its reference

Fig.

1.

(a) To detect multiple chips enabled, each RAM has

only one number stored. The value is the same as its RAM ID

number. Each stored value is at a different location to avoid

overlap,

(b) Example of multiple chip selection. RAM 3 was

selected during RAM 2 addressing due to a faulty chip select

decoder. The sum of RAM 3 data is 5, not 3 as it should be.

Because of inherent

sum of RAM 2 is 2, even though RAM 3 is selected.

in

time, the data fades away because of

wired-ANDing

on the RAM data bus, the

FEBRUARY 1981 HEWLETT-PACKARD

JOURNALS

Page 10

checksum must also be changed. Hence, two ROMs may need

changing. On the other hand, if each ROM has its checksum

stored within it, then an exact location is required and this may

interrupt the program code.

We have chosen to allocate the negative value of the checksum

dynamically. Suppose a sequence of assembly language code

could be produced that would not affect program operation and

would rarely, if ever, be produced by a programmer. A branch

around a

Once the program development is almost complete, this two-line

code segment

After assembly is complete the machine code is run through a

second program to locate the two-line segment. Next, this program computes the checksum of all ROM data excluding the NOP.

The NOP is then replaced by the two's complement of the

checksum. The controller program is not affected by this change

MOP

(no operation) falls into this category.

PROGRAM CODE

BRA +3

NOP

PROGRAM CODE

is

inserted roughly into the middle of each ROM.

due to the branch. Computing the checksum of a given ROM

yields zero as a result if all data is valid. The programmer never

needs to worry about the value of the checksum or the

location. To allow for easy ROM identification the actual value of

the total computed checksum can be one for ROM

ROM #2, and so on. This allows for easy detection of

ROMs.

Albert W. Kovalick

Al

Kovalick joined HP in

receiving his MSEE degree from the

University

He's designed printer drive circuitry

for handheld and desktop cal-

culators and contributed to the design of the controller software and

power supply of the 8662A Signal

Generator. He's named as an inven-

tor on two patents and three pend-

ing patents. Al was born

Francisco and now lives in Santa

Clara, California. His wife, who

works in HP's R&D labs as a programmer, has also contributed an

article to the HP Journal. Al is active in his church and enjoys read-

ing, woodworking, racquetball, and recreational mathematics.

of California at Berkeley.

MOP

#1,

two for

misloaded

1974

after

in

San

frequency mode where the display may be configured for

sweep display while a new parameter is entered. Should the

operator begin an entry but not complete

it,

the display can

be restored by striking any function select key.

The

INCR

SET key is

common

to all

function

keys

and a

function key qualifies its use in entering increment values.

The justified value may be viewed on entry by holding the

units key down. An increment value may be viewed at any

time

by

selecting

the

function,

then

holding

the

INCR

SET

key down.

The right-hand position of the keyboard contains mod-

ifiers in the form of increment up and down keys and a

rotary control for manual tuning. The increment up and

down keys are qualified by the selected function. Holding

either key down will cause a succession of increments at a

rate

of two per

second.

The

rotary

RESOLUTION

control

is

enabled for every new function by pressing either the x 10 or

-MO

key. Holding either of these down will enable blinking

of a digit that denotes the resolution digit to which the

rotary control will apply. The digit may be moved by re-

peatedly keying

x10

or

-MO

to get ten times more or less

resolution.

The

increment

value

previously

entered

via the

INCR

SET

key may be used by the rotary control as its entry value. This

mode is enabled by pressing the blue key and then the

key,

which

has the

shifted

function

INCR

printed

beside

-MO

it.

Another useful mode is the separation of rotary control

operation from the increment key operation with respect to

function. For example, while in the amplitude mode, the

blue

key and

shift

key

HOLD

(x 10) are

pressed

in

succession.

Then when frequency is selected as the operating function,

the amplitude may be adjusted with the rotary control and

the frequency incremented with the increment up and

down keys.

Sweep Control

The left-hand keyboard contains all the sweep parameter

keys. Either a start/stop sweep or a span-type sweep may be

selected. Parameters are entered, for instance, by keying

START

FREQ,

numerics

and

units.

The start/stop sweep may be reversed by giving start a

larger frequency value than stop. The sweep step size and

step time keys indicate the selected value with integral

LEDs. Once selected, the values are remembered. A change

from span to start/stop sweep, with different step size and

time values, will be indicated by the LEDs in the keytops.

Execution

of

AUTO

or

SINGLE

sweep

will

cause a split

dis-

play in the frequency window, five digits for each of the two

frequency

parameters.

When

MANUAL

sweep

is

selected,

full eleven-digit sweep frequency display is presented.

Control of the sweep is provided by dedicated use of the

rotary knob in the right-hand portion of the keyboard. Any

signal generator parameter value may be changed while in

the sweeping mode.

Up to five digital sweep frequency markers are selectable.

Each marker is entered as a frequency. The rear-panel out-

put for sweep markers provides Z-axis beam intensifying

potential to give a bright CRT spot on an oscilloscope. Each

spot may be identified on the CRT by holding the selected

marker key down. Each marker may be moved on the CRT

by means of the increment keys or the rotary control. When

a marker key is held down, its frequency value is displayed.

Front-Panel Storage

To ease user operation of the 8662A, nine front-panel

configurations can be stored in memory. Each stored con-

figuration includes every parameter set on the front panel.

Thus at any time, any of several totally different panel

configurations can be recalled. This helps to reduce test

setup time.

a

10 HEWLETT-PACKARD JOURNAL FEBRUARY 1981

Page 11

Coupled with the store/recall feature is a sequence opera-

tion. A sequence is the order in which the user desires to

recall previously stored settings. For example, assume there

is a linear sweep in store 1, a logarithmic sweep in store 3

and a frequency modulated carrier in store 7. These may be

useful for a given series of tests. The sequence 137 can now

be stored in the sequence memory, and each time the SEQ

key is pressed the next front panel, as ordered by the sequence memory, will be recalled.

Status Indication

The 8662A features a STATUS key, which is

LED-lighted

to signal the operator. Whenever it lights up and the key is

pressed and held, a double-digit code appears in the frequency window. The code can be interpreted by referring to

the pullout card beneath the instrument. Status messages

may concern the condition of the crystal oven temperature,

or indicate that an external oscillator standard is being

used. Operator guidance messages are typically concerned

with parameters out of range for the operating conditions.

The status indicator flashes for malfunctions detected

internally. Examples are a loop unlock condition or a fault

detected by a circuit monitoring a set of interface lines. The

latter provide extensive information about approximately

80 lines passing between controller and mainframe circuits.

These give early indications of circuit or cabling failures.

Servicing

The operator may call for a check on ROM or RAM with a

special function key sequence. The ROM test (see page 9) is

based on checksum routines and responds in case of a ROM

1C

failure with a double-digit code in the

display,

defining

the failed part. The RAM test will do the same for some

bit-type failures. More subtle failures require more detailed

testing, which is available in servicing routines. The latter

are part of a switch selectable set, which also includes rou-

tines for signature analysis testing with the HP 5004A Signal

Analyzer. Basically, control unit servicing is performed

using signature analysis. For extreme conditions where the

instrument does not respond to power-on, a fundamental

free-run test permits checks of the microprocessor board,

which is the key to further operation. This can be done

without any other boards in the system, thus aiding discov-

ery of stuck address and data buses and control lines. With a

correctly operating processor board, the special diagnostics

ROM and a program select switch on the board are used to

select a routine to stimulate the other system boards. Signatures at significant circuit points quickly give direction to

the service person and lead to discovery of the offending

component on the failed system board.

Production Testing

Production testing of the 8662A control unit uses signature analysis techniques almost exclusively. These

techniques are aided by using an HP 9825 Computer as

memory for all the circuit mode signatures and as a testing

guide. The technician instructs the computer with inputs

defining the system board and the integrated circuit under

test. As the device pins are probed, the computer reads the

input signature via the HP 5004A with a special modification. A comparison is made with the known good signature

in memory. An audible beep announces that the signature is

good and the technician can proceed to the next node without looking away from the circuit. When an errant signature

is encountered, the computer prints out the node location

on its paper tape.

A further testing development uses the computer with a

special multiplexer that can select any one of over 200 lines.

Suitable cabling connects all the control output interface

lines into the multiplexer. Computer programs are accessed

for a series of tests that automatically monitor all the cabled

lines and record information on any failures. This test has

special merit, since it tests driving

circuits,

connectors, and

cables in the signal path, any of which can experience

difficulties in the assembly operations.

Acknowledgments

Many people contributed to the concept and design of the

control unit, which includes the front-panel display and

keyboard arrangement. The key members of the design staff

and their contributions were: Walt Jimison for

major

portions of the hardware design and associated software, Han

Park for major software contributions to the control of the

display, frequency sweeping, and sweep markers, Dan

Derby and Jim Stewart, industrial designers, for their important contributions to the subtleties of panel design, Bill

Thomas, production engineer, for a major effort in applying

signature analysis with calculator control to production

testing, and Lloyd

Marrugg,

production engineer, for devoted effort in the transfer of the controller from engineering to production, effectively coping with the training of

personnel. To Bill West goes a special thanks for a superlative effort in designing the

keyswitches

now used exten-

sively in Hewlett-Packard instruments.

Hamilton C. Chisholm

Ham Chisholm received his BEE degree in

1948

from the University of Minnesota. He designed some of the first

solid-state counters in

of the first integrated circuit counters in

1968.

He's

and is named inventor on several patents. With HP since

the 5590A Nuclear Sealer and served

as project leader

sections of the 8660A, 8660C, and

8662A Signal Generators. He has

served in the U.S. Air Force as a flight

navigator and is a member of the IEEE.

Ham enjoys gardening, photography,

camping, and skiing. A native of Minneapolis, Minnesota, he now

lives in Los Altos, California. He and his wife have a son and a

grandson.

published several papers

1954

and some

1966,

he worked on

for

the digital control

FEBRUARY 1981 HEWLETT-PACKARD JOURNAL 11

Page 12

Low-Noise RF Signal Generator Design

by

Dieter

Scherer,

Bill

S. Chan, Fred H.

Ives,

William J. Crilly, Jr., and Donald W. Mathiesen

N THE RF DESIGN of the 8662A Synthesized Signal

Generator, novel techniques had to be developed to

combine low phase noise and low spurious signals with

I

the usually conflicting goal of high frequency agility. The

design was governed by the following objectives:

• Excellent spectral purity. Phase noise and spurious

,

nals

were to be low enough to allow, for example, re-

ceiver

out-of-channel

with very pure cavity-tuned signal generators.

• High frequency agility. RF settling was to occur in less

than 500

• Economic frequency resolution.

be achieved with a minimum number of loops and

minimum parts count.

Fig. 2 on page 6 shows the basic blocks of the resulting RF

design. These include the following functional blocks:

• The reference section

• The reference sum loop

• The output sum loop

• The low-frequency loops

• The

• The doubler, dividers and down-converter of the output

section.

All frequencies are directly or indirectly generated from a

10-MHz crystal oscillator or an external 5 or 10-MHz refer-

ence source. The reference section transforms the 10-MHz

reference signal into an RF reference signal that can step

from 320 to 640 MHz in 20-MHz steps.

In the reference loop this spectrum is filtered and ex-

panded into a 310-to-620-MHz range with 10-MHz steps.

The output sum loop combines this with a 10-to-20-MHz

signal with

loops, yielding the 320-to-640-MHz baseband with 0.1-Hz

resolution. This band is then heterodyned, divided down

and doubled to produce the 10-kHz-to-1280-MHz output of

the synthesizer (see article, page 22).

/xs.

fractional-N

0.1-Hz

testing previously only possible

0.1-Hz

resolution was to

loop

steps generated in the low-frequency

sig-

Direct Synthesis Reference Section

The reference section provides the following group of

frequencies:

1. 320 to 640 MHz every 20 MHz.

2. A switched 520 MHz to the output section down-

converter.

3. Switched 20 and 120 MHz to the FM sum loop.

Fig.

1.

The reference section directly synthesizes low-noise

reference signals for the 8662A's phase-locked loops. The

320-to-640 MHz band is generated with a mixer and eight

frequencies, as shown.

12 HEWLETT-PACKARD JOURNAL FEBRUARY 1981

Fig. 2. 8662A reference section derives various frequencies

by multiplying, dividing, and mixing the output of the internal

crystal

reference oscillator or an external standard.

Page 13

4. A selectable 10 or 20 MHz to the reference sum loop.

5. 10 MHz distributed to five other sections.

It was considered important that these frequencies be obtained with as low a noise contribution as achievable and

with undesired signals down 40 dB at the 320-to-640-MHz

reference output.

As Fig. 1 shows, the 320-to-640-MHz band may be generated with a mixer and eight frequencies. Using dc allows

the 320, 480, or 640-MHz signal to pass through the mixer.

Otherwise, two RF frequencies are generated

fir),

and the undesired frequency is eliminated by the refer-

(f^y = fLo

—

ence sum loop. Fig. 2 explains the generation of reference

signals in more detail.

Noise and Undesired Signals

Particular care was exercised in the design of the

amplifier and multiplier stages immediately following the

crystal oscillator to keep from degrading its noise performance. The amplifiers and doublers at higher frequencies

are not so critical since the phase noise of the 10-MHz

standard is increased by 6 dB each time the frequency is

doubled.

The multiplier selected is essentially a full-wave rectifier

circuit using Schottky diodes. This arrangement was

selected for the repeatability of low-noise performance, inherent rejection of the driving frequency (alleviating some

filtering problems), and convenience in generating a frequency at every octave of 10 MHz.

The amplifiers operate with low currents and high

voltages to keep the

1/f

noise current of the device low.

RF emitter degeneration decreases device nonlinearity,

which partly prevents 1/f noise from being converted to the

signal frequency.

The reference block has two stages of crystal filtering at

40 and 160 MHz. The filters serve the dual purpose of

removing 10 and 20-MHz sidebands not

rejected

by the

doublers and filtering the multiplied noise of the frequency

standard beyond approximately ±0.008% of center frequency. Multiplying 10 MHz to 640 MHz would result in a

36-dB phase-noise increase. The crystal filters must suppress the 10 and 20-MHz sidebands such that these

sidebands on the 520-MHz output are 90 dB below the

carrier, since they would be translated directly to the output

in the heterodyne band. Two-pole monolithic quartz filters

were chosen for their compactness and low cost.

A problem associated with the use of these narrow-band

filters is their high susceptibility to vibration. To combat

this problem, the filters are shock mounted on a separate,

small circuit board.

Sources of noise that contribute to the residual noise of

the reference section include the following:

Additive noise and 1/f noise in transistors, most prominently in the first stages of multiplication

• Leakage currents in capacitors and Schottky diodes

• Thermal effects on various materials

• Phase changes caused by cables and connectors

• Crystal filter noise and microphonic noise.

Noise of the reference section is typically

—110

dB below

the carrier at 10 Hz offset with the noise floor approximately

•148

dBc at 10 kHz and farther out.

Output

Fig. 3. The higher frequencies in the reference section are

switched by a form of ECL multiplexer using several monolithic

differential pairs connected to a common collector resistor.

Switching

It was necessary to find ways of switching frequencies

with a minimum of complexity since the reference section

uses direct synthesis. ECL multiplexers were found to have

inadequate pin-to-pin isolation. Discrete forms of PIN diode

switches require multiple diodes and drivers all properly

shielded. A form of ECL multiplexing using several

FEBRUARY 1981 HEWLETT-PACKARD JOURNAL 13

Page 14

r

Fig. 4. Simplified block diagram of the output sum loop, high-frequency voltage-controlled

oscillator (HF VCO), and ROM controller.

monolithic differential pairs connected to a common col-

lector resistor was found to be the most effective solution at

the highest frequencies. The schematic for this switch is

given in Fig. 3.

Isolation in the off state is approximately 35 dB for fre-

quencies up to 1 GHz. A switch is turned off by removing

the current from a differential pair, causing the transcon-

ductance to drop to a low value.

Inexpensive PIN diodes are used for the low-frequency

switches, since there is less off-state leakage due to

shunt capacitance. The driving circuit is a simple TTL

demultiplexer.

Reference and Output Sum Loops

The output signal of the reference section contains un-

wanted sidebands, multiples of 10

dBc. The reference loop acts as a narrow-band tracking

filter, cleaning up this spectrum with minimum degradation of its low-phase-noise quality. Summing 10 or

20 MHz also adds 10-MHz steps to the 310-to-620-MHz

output signal.

The output sum loop has similar input signals. It com-

bines the 310-to-620-MHz reference loop output with the

10-to-20-MHz signal stepping in

quirements on phase noise and switching speed are identi-

cal for both loops. Therefore, it was possible to use interchangeable phase-lock circuits and oscillators for both

MHz,

0.1-Hz

as high as -40

steps. The re-

14

HEWLETT-PACKARD JOURNAL FEBRUARY

1981

Fig. 5. The VCO in the output sum

loop is this

switched reactance oscillator. It

meets requirements of low phase

noise and low tuning sensitivity.

320-to-640-MHz

Page 15

loops. Fig. 4 shows a simplified block diagram of the output

sum loop including the VCO with its ROM control.

Starting with the high-frequency VCO, the output sum

loop is designed with two paramount

objectives.

First, low

phase noise of the free running oscillator is essential. In

phase-locked operation the phase noise of the VCO is sup-

pressed by the loop gain. Close to the band edge, where the

loop gain approaches zero, and outside the bandwidth,

VCO noise dominates. Second, low tuning sensitivity is

required to minimize the effect of unavoidable noise on

the tuning line of the VCO. These two

objectives

led to

the concept of the switched reactance oscillator pictured

in

Fig.

5.

The resonator consists of five inductor arrays. Switched

by a ROM in binary fashion, they provide 32 frequency

steps. A varactor tunes between the frequency intervals to

give continuous frequency coverage. Compared to a con-

ventional VCO with a varactor covering the entire

310-to-

640-MHz range, this switched scheme results in drastically

reduced tuning sensitivity. It also allows operating the varactor at high bias levels where its Q is maximal.

High Q of the total resonator, a prime requirement for low

phase noise, was further achieved by realizing the inductor

arrays as shorted transmission lines in a low-loss stripline

structure and by switching them with low-resistance PIN

diodes. Q varies between 150 and 250 over the frequency

range. The nature of the resonator also allows high RF

signal levels (±10V peak), fast switching, and precise pre-

tuning. The active circuit consists of a source follower feed-

ing a common-gate FET stage.

Single-sideband phase noise of the free running VCO in

a

1-Hz

bandwidth was measured as -120 to -130 dBc at

20 kHz offset, and -138 to 145 dBc at 100 kHz offset.

Lock Acquisition

Fig. 6 shows the working of the output sum loop in more

detail. The circuitry is divided into two major blocks which

relate to the two operating modes of the loop, lock acquisition and locked operation. The function of achieving lock

will be discussed before the locked loop circuitry.

The two phase detector references are limited in ECL

Fig. 6. Functional diagram of the output sum

loop.

FEBRUARY 1981 HEWLETT-PACKARD JOURNAL 15

Page 16

limiters to remove amplitude differences. These limiters

drive a phase detector consisting of a high-level mixer; they

also drive the frequency detector circuitry.

With the loop out of lock, the phase detector produces an

output containing a beat note at the difference between the

two input frequencies. This signal is filtered by a sevenMHz low-pass filter and an active

150-kHz

high-pass filter

to remove components other than the difference frequency.

It is then converted to TTL levels in a high-speed com-

parator circuit to trigger the

out-of-lock

digital dis-

criminator, diagrammed in Fig. 7.

The out-of-lock digital discriminator signals are derived

from the period of the beat note. Assume the D flip-flop is

reset. The beat note will clock monostable Ml on a rising

edge. Monostable Ml will go high one gate delay after the

rising edge of the beat note. Since this signal is also timing

the D flip-flop and monostable M2, they both stay in the

reset state. If the next rising edge comes after a time delay of

5

fj.s,

Ml will have already reset and the same state will

result. This case happens when the loop is within 200 kHz

of lock.

If the beat note happens with a period of less than 5

/AS

the

D flip-flop is set and the out-of-lock signal is produced by

the next rising edge of the beat note. The out-of-lock signal

controls several functions, one of which is to enable

monostable M2 to act as a digital discriminator, producing a

pulse of 400-ns width at the rate of the beat signal. At a rate

of

2.5

MHz (400-ns period) and higher, M2

will

be on all the

time. Below 2.5 MHz the duty cycle of the pulse signal out

of M2 will decrease proportionally with the period of the

beat signal. The average output voltage of the digital dis-

criminator is diagrammed in Fig. 8. This discriminator sig-

nal provides the magnitude of the feedback to steer the loop

into lock.

By digitally AND-gating the out-of-lock and dis-

criminator signals, a signal is produced to control a current

source and sink that rapidly charges or discharges the integrator capacitor to steer the loop into lock. With the loop

more than 2.5 MHz from lock the correction current is fully

on. The magnitude of the correction current decreases

proportionally as the loop approaches lock. With the loop

closer than 200 kHz, the out-of-lock signal disappears and

the entire block of lock acquisition circuitry is switched

off.

The phase-locked loop now rapidly completes lock acquisi-

tion, since the beat note is well within its capture range.

With the proportional feedback from the digital dis-

Fig. 7. The out-of-lock digital discriminator generates the

out-of-lock signal (OL) that controls several functions in the

output sum

the difference between the loop input and output frequencies.

loop.

It also produces a signal (D) that represents

.2 1 2 2.5

Beat Signal Frequency (MHz)

Fig. 8. Average value of the digital

a function of the beat or difference frequency between the

input and output of the output sum loop. This signal provides

the magnitude of the feedback to steer the loop into lock.

discriminator's

D output is

criminator the loop is able to acquire lock very rapidly for

any size frequency step. Total lock acquisition time is less

than 75

/us.

Locked Operation

Below the dotted line in Fig. 6 is the circuitry that is

active in locked operation. The phase detector output is

low-pass filtered and sent to the integrator. The output of

the integrator is summed with the pretune voltage in a

nonlinear shaper to compensate for the varactor tuning

curve of the VCO. This signal is sent through the loop gain

adjust circuit, which compensates for oscillator gain

changes caused by inductor changes when switching oscillator bands. The signal is then low-pass filtered again and

buffered to drive the VCO tune line.

With a locked loop there is no beat note from the phase

detector and the entire lock acquisition circuitry is put in a

static mode to eliminate spurious signals from this source.

The low-pass filtering of the phase detector signal is ac-

complished in three distinct filters. This allows an op-

timum balance between bandwidth and rejection to get

maximum suppression of spurious reference sidebands. All

spurious responses in the loop are below

-100

dBc.

The action of the pretune circuit, nonlinear shaper, and

loop gain adjust circuit allows precise control of the oscil-

lator. A loop bandwidth of 250 to 500 kHz can be main-

tained. To take advantage of this high loop bandwidth to

suppress close-in oscillator noise, each of the circuits in the

loop gain path had to be designed for low noise. An exam-

ple is the discrete integrating amplifier, which has two

low-noise transistors in its front end. Also, because of the

variation in VCO tuning sensitivity when switching inductor bands, the loop gain adjust circuitry serves a dual role. It

attenuates pretune circuit and shaper noise as well as controlling loop gain. The pretune circuit switches are designed with low-noise JFETs and the shaper is designed for

low noise.

The result of these design considerations is an extremely

low phase-noise floor in the locked system. Excluding re-

ference phase noise, the phase-locked loop achieves a noise

floor of -140 to -143 dBc as close as 1 kHz to the carrier.

16 HEWLETT-PACKARD JOURNAL FEBRUARY 1981

Page 17

Fig. 9.

8662A

low-frequency section

has

four phase-locked loops and produces a signal from 10

to 20 MHz in

0.1-Hz

steps.

Low-Frequency Section

The

fine frequency steps

of

the

8662A

are synthesized

in

multiple loop system that produces a signal covering 10 to

20 MHz in

0.1-Hz

steps. Fig. 9 is the block diagram of the

low-frequency section.

The

10-to-20-MHz

signal is summed directly into the

output sum loop, so the spectral purity and frequency

switching time requirements are the same as those of the

320-to-640-MHz sum loop output. A well known tradeoff in

synthesizer design is between frequency resolution on the

one hand and spectral purity and frequency switching time

on the other. For indirect, or phase-locked loop synthesiz-

ers, this tradeoff occurs because the need to filter spurious

sidebands that are offset from the carrier by the frequency

resolution limits the maximum loop bandwidth. The

maximum loop bandwidth then limits the loop gain avail-

able to reduce oscillator noise sidebands. The frequency

switching speed is also determined by the loop bandwidth.

In the 8662A, a significant improvement to this tradeoff is

achieved by using a

fractional-N

loop with correction cir-

cuits that effectively cancel the spurious sidebands, rather

than filtering them with a phase-locked loop. By setting a

loop bandwidth that exceeds the minimum frequency resolution and employing digital-to-analog converters to cancel spurious signals at the phase detector, high resolution

and good spectral purity are achieved simultaneously.

At present, fractional-N loop technology is capable of

good spectral purity and switching speed. However, to ex-

ceed the signal quality of the output sum and reference

loops and reference section, the output of the fractional-N

loop must be divided down to 100 to 200 kHz, referred to the

output. As a signal's frequency is divided, phase noise

modulation is reduced by the divide number. As a result, a

100-to-200-MHz

a

1000 exhibits excellent spectral purity.

fractional-N loop signal after division by

Since the output sum loop requires 10 to 20 MHz and the

fractional-N loop provides only 100 to 200 kHz, a system of

two phase-locked loops is used to synthesize the increased

frequency range. This synthesis is accomplished with a first

loop that generates 122 to 221 MHz in 1-MHz steps and a

second loop that sums the fractional-N loop, after division

by 100, with the first loop. The result is a frequency cover-

ing 120 to 220 MHz in

1-Hz

steps. A third phase-locked loop

subtracts a 20-MHz signal that can have frequency mod-

ulation. The output of this loop is then 100 to 200 MHz in

1-Hz steps with frequency modulation capability. This

100-to-200-MHz signal is divided by ten, providing 10 to 20

MHz in

0.1-Hz

steps, with FM capability and excellent

spectral purity. By generating a signal at 100 to 200 MHz

and then dividing it by

ten,

a high loop bandwidth can be

maintained for these loops. Compared to a set of loops

operating at 10 to 20 MHz, the frequency switching time of

the higher-frequency loops is reduced by a factor of ten

because phase or frequency settling time is inversely pro-

portional to loop bandwidth.

Fractional-N Loop

The fractional-N loop of the 8662A provides the lower

six decades of frequency resolution. The fractional-N

technique1'2 is able to meet noise and switching speed

performance requirements that would otherwise require

three phase-locked loops. The output of the fractional-N

loop has a frequency of 100.0001 MHz to 200 MHz in

100-Hz

steps. This is divided by 1000, giving 0.1 Hz steps at

the output of the 8662A.

The loop has a bandwidth of approximately 9 kHz.

FEBRUARY 1981 HEWLETT-PACKARD JOURNAL 17

Page 18

DO,

D1,

Fig.

10.

Fractional-N loop provides the lower six decades of frequency

a frequency of

100.0001

to 200 MHz in 100-Hz steps. This is divided by 1000 to give

at the 8662A output.

D2 From DCU D3, D4, D5

resolution.

Its output has

0.1-Hz

steps

Worst-case switching transient time to within 1 MHz (1 kHz

at the 8662A output) of the final frequency is 250

/us.

Set-

tling occurs at a rate of about one decade reduction in offset

per 150

fractional-N

/us.

The single-sideband phase noise of the

loop is more than 10 dB below the instrument's

noise at its output, making the noise contribution of the

fractional-N loop less than 1 dB.

Although the fractional-N loop block diagram, Fig. 10, is

similar to conventional divide-by-N phase-locked loops,

there are many differences. The output frequency

phase-locked loop is N times the reference frequency

The fractional-N divider allows

than

fr.

A fractional-N divider is an integer frequency di-

f0 to have a step size less

(f0)

of a

(fr).

vider whose divide number (N) can be altered by one (N,

N+l

or

N,N-1)

the average divide number (M) for an

at a desired duty cycle (D). This makes

N.N-1

divider

a non-integer.

D = (Number of VCO cycles counted with

•^

(Total number of VCO cycles counted per base period)

M = N - D

The average output frequency is M times

also has spurs because the

instantaneous

N-l

per base period)

fr.

The output

frequency varies.

These spurs are caused by the phase shifting of the divider

output by changing N. The phase shifting results in ripple

on the output of the phase detector. The ripple can be

reduced by filtering, but this approach requires that the

loop bandwidth be less than the minimum step size. To

maintain fast switching in the 8662A, the ripple is reduced

by the following method, which does not require a narrow

loop bandwidth.

The time and amount of phase shift is determined by the

accumulator that generates the divider modulus control

signal at the desired duty cycle. The deviation of the

fractional-N divider output phase from a reference 100 kHz

that is due to the fractional-N process is known and is

corrected for. A correction circuit generates a signal that is

equal and opposite to this deviation. This is added to the

output of the phase detector. The resultant signal is sam-

pled once per reference period and is used to control the

voltage-controlled oscillator (VCO). This VCO control sig-

nal contains feedback information that removes the spuri-

ous ripple.

Fast switching speed is an important performance

characteristic of the 8662A. The fractional-N loop has

specific circuitry to address this need. Three major speedup circuit functions are performed: pretuning the VCO con-

trol voltage, phase detector transient reduction, and loop

gain (bandwidth) control.

A voltage-dependent variable-gain amplifier is used to

linearize the VCO tuning characteristic. The VCO is set in

4-MHz increments (4-kHz at 8662A output) by the digital

control unit by means of a digital-to-analog converter

(DAC). The DAC output is filtered for noise reduction.

When a DAC output change is detected the filter output is

speeded up by turning on a FET that is in shunt with the

series resistor of the filter.

18

HEWLETT-PACKARD

JOURNAL FEBRUARY

'

Page 19

To minimize the transient applied to the phase detector

filter (loop compensation) the phase detector is disabled,

the current summing amplifier offset bias is removed, and

the reference divider and fractional-N divider are halted in

a reset state. This is done while the pretune transient is

settling (20

/us,

two reference periods). After the pretune

settling time, the fractional-N loop is returned to normal

operation. The reference and fractional-N dividers are

started in phase. This insures that the first output of the

phase detector compares full reference and fractional-N

counter periods. This output then reflects the necessary

correction needed to lock the loop.

For fractional-N loop output frequencies 160 MHz and

higher, an attenuator in the phase detector is switched out.

This increases the loop gain and partially compensates for

the loop gain reduction that results from an increasing

divide

number.The

loop settling time is reduced as the loop

gain is increased.

122-to-221-MHz

Loop (N Loop)

The phase-locked loop that synthesizes 122 to 221 MHz

in 1-MHz steps with good spectral purity presented a

number of design challenges. The conventional approach

for such a loop is to lock a voltage-controlled oscillator to a

1-MHz reference. A programmable divider that covers 122

to

221

would then be required. Within the bandwidth of the

phase-locked

loop,

the output phase would follow the reference phase, multiplied by 221. This represents a degradation of reference phase noise sidebands of about 47 dB.

Even with the lowest-phase-noise dividers and phase detec-

tors available, excellent spectral purity cannot be achieved

with such a high divide number. The solution to this problem was to use a fractional-N divider that has divide numbers of 12.2 to

22.1

in steps of

0.1.

The reference frequency is

changed to 10 MHz and the output frequency steps are 0.1

times 10 MHz or 1 MHz. A phase noise enhancement

of

only

22.1 or 27 dB preserves excellent output spectral purity.

The spurious signals at multiples of 1 MHz are reduced by

placing a series of notch filters in the loop between the

phase detector and the VCO control voltage.

Fig.

12.

The low-frequency sum loop combines the output of

the

122-to-221-MHz

loop which, after division by 100, has a frequency of 1 to 2

MHz.

loop with the output of the fractional-N

The programmable divider in this loop is made up of a

12-to-23 integer divider and a separate circuit that controls

a fractional digit, so that a total divide number of 12.2 to

22.1 is obtained. This 12-to-23 integer divider presented a

substantial design challenge. Not only are MSI ECL count-

ers unable to operate at such a high frequency, but ECL

-MO/11

prescalers do not allow divide numbers of 12 to 23.

A variable-ratio prescale divider was developed using

SSI

and MSI ECL devices (Fig. 11).

The design is split into two parts, a variable-ratio pre-

scaler and a control for the modulus of the prescaler. Since

the lowest overall divide number is 12, and a relatively

simple prescaler was desired, division by 3 or 4 was

selected. For example, to divide by 13, the prescaler is

programmed to divide the input by 3 for three cycles of the

output of the prescaler and by 4 for one cycle of the output of

the prescaler. A total of 3

X34-4X l or 13 pulses are input

for every output pulse, and a division by 13 results. The

control circuit that selects the modulus of the divider is

critical because of the short time available to change the

modulus, about 10 nanoseconds. The control circuit uses a

shift register as a ring counter. The last flip-flop in the shift

register is used to detect a terminal state and load the shift

register from its parallel data inputs. One of the outputs

of the shift register is connected to the modulus of the

3-or-4 divider by a selector. The output of the selector is a

signal with programmable duty cycle and pulse length that

controls the number of divide-by-three or divide-by-four

cycles.

Fig. 11. This 12-to-23 integer divider is used in the phase-

locked

loop

that generates 122 to 221 MHz in

A separate circuit controls a fractional digit to give divide

numbers of 12.2 to

22.1.

1-MHz

steps.

Sum Loop

To combine the output of the 122-to-221-MHz loop, also

called the N loop, with the

l-to-2-MHz

fractional-N signal, a

sum loop is employed (Fig. 12). The oscillator output signal

is mixed with the N loop output to an IF equal to the

frequency of the fractional-N loop VCO divided by 100.

During frequency switching the IF can be well outside the

loop bandwidth, leaving the loop unable to lock. Two solu-

tions to this problem are required. One is a frequency detec-