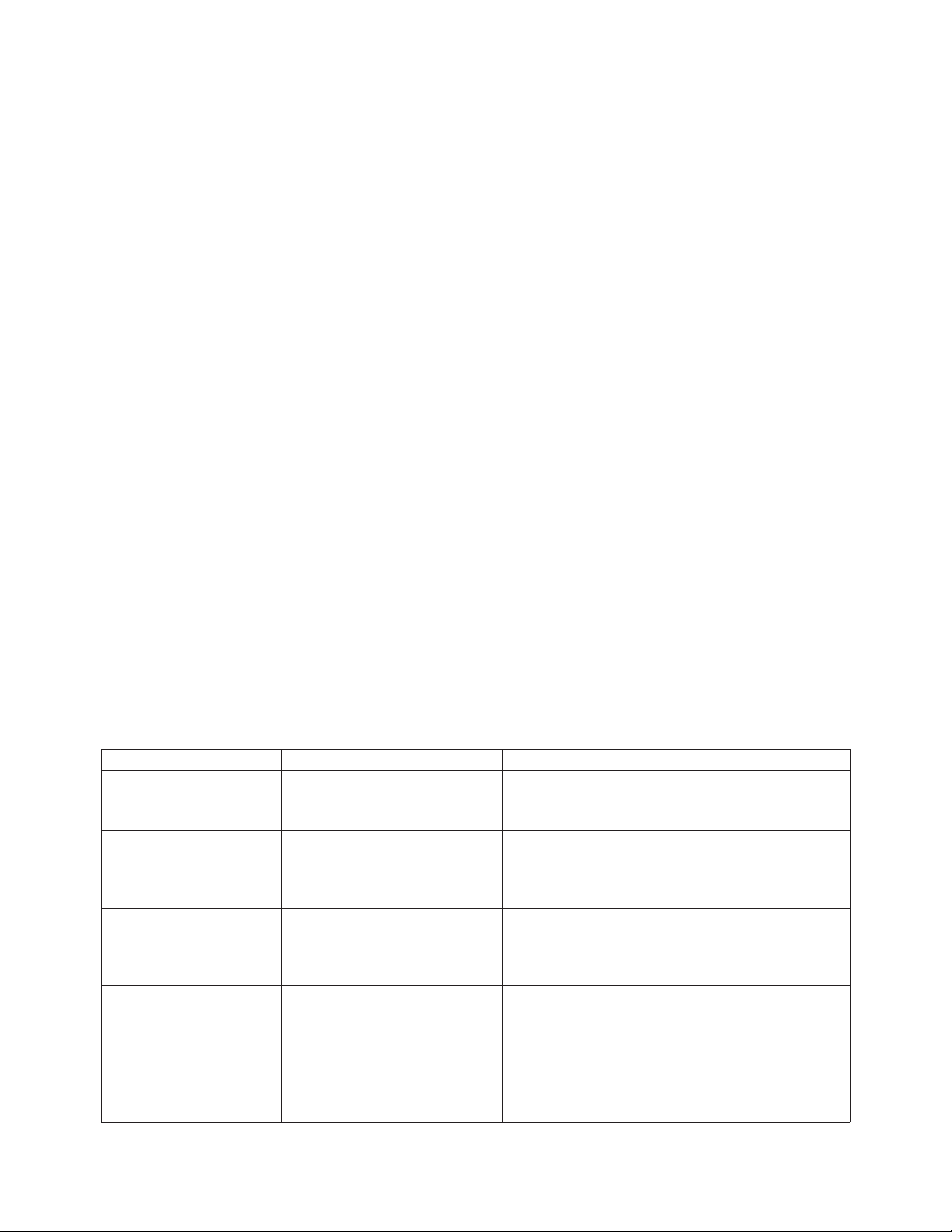

HP HFCT-5305 Datasheet

Gigabit Ethernet: 1.25 GBd

1300 nm Laser Transceiver

in Low Cost 1 x 9 Package Style

Preliminary Technical Data

HFCT-5305

Features

• Compliant with Proposed

Specifications for IEEE802-3 Gigabit Ethernet

• 1300 nm Trenched BH Laser

Source Technology

• Industry Standard 1 x 9

Package Style with Integral

Duplex SC Connector

• Class 1 Laser Safety

(Certification Pending)

• 3 km Links in 8/125 µm SMF

Cables

• 550 m Links in 62.5/125 µm

MMF Cables

• Single +5 V Power Supply

Operation and PECL Logic

Interfaces

• Wave Solder and Aqueous

Wash Process Compatible

• Designed and Manufactured

in an ISO 9000 Certified

Facility

Applications

• Host to Host Interface

Description

General Transmitter Section

The transmitter section consists

of a 1300 nm Laser in an eye safe

optical subassembly, (ELSA),

which mates to the fiber cable.

The ELSA is driven by a custom

silicon bipolar IC which converts

differential PECL logic signals,

ECL referenced to a +5 V supply,

into an analog Laser Diode drive

current.

Eye Safety Design

The ELSA is designed to be eye

safe under a single fault condition. To be eye-safe, only one of

two results can occur in the event

of a single fault. The transmitter

must either maintain a safe level

of output power or the transmitter should be disabled.

The ELSA contains a patented

optical fiber stub which restricts

the level of light emerging from

the connector port under all

conditions. Overdriving the laser

(even to destruction) cannot

produce enough light to violate

the IEC safe level. As a result the

HFCT-5305 is intrinsically eye

safe.

Receiver Section

The receiver includes an InP PIN

photodiode mounted together

with a custom silicon bipolar

transimpedance preamplifier IC

in an optical subassembly, OSA.

This OSA is mated to a custom

silicon bipolar circuit providing

post-amplification and

quantization.

The custom silicon bipolar circuit

also includes a Signal Detect

circuit which provides a PECL

logic high output upon detection

of a usable input optical signal

level. This single-ended lowpower PECL output is designed

to drive a standard PECL input

Preliminary Product Disclaimer

This preliminary data sheet is provided to assist you in the evaluation of engineering samples of the product which is under development

and targeted for release during 1997. Until Hewlett-Packard releases this product for general sales, HP reserves the right to alter prices,

specifications, features, capabilities, function, manufacturing release dates, and even general availability of the product at any time.

(5/97)

565

through a 10 Ω load instead of

the normal 50 Ω ECL load.

Regulatory Compliance

See the Regulatory Compliance

Table for the targeted typical

and measured performance for

these transceivers. As the

product design is completed,

full characterization testing

will be done to determine the

actual performance of the final

design.

The overall equipment design will

determine the level it is able to be

certified to. These transceiver

performance targets are offered

as a figure of merit to assist the

designer in considering their use

in equipment designs.

Electrostatic Discharge (ESD)

There are two design cases in

which immunity to ESD damage

is important.

The first case is during handling

of the transceiver prior to mounting it on the circuit board. It is

important to use normal ESD

handling precautions for ESD

sensitive devices. These precautions include using grounded

wrist straps, work benches, and

floor mats in ESD controlled

areas.

The targeted performance has

been shown to provide adequate

performance typical industry

production environments.

The second case to consider is

static discharges to the exterior

of the equipment chassis

containing the transceiver parts.

To the extent that the duplex SC

connector is exposed to the

outside of the equipment chassis

it may be subject to whatever

system level ESD test criteria that

the equipment is intended to

meet. The targeted performance

is more robust than typical

industry equipment practices

today.

Electromagnetic Interference

(EMI)

Most equipment designs utilizing

these high speed transceivers

from Hewlett-Packard will be

required to meet the requirements of FCC in the United

States, CENELEC EN55022

(CISPR 22) in Europe and VCCI

in Japan.

These transceivers, with their

shielded design, are targeted to

perform to the limits listed to

assist the designer in the

management of the overall

equipment EMI performance.

Immunity

Equipment utilizing these

transceivers will be subject to

radio-frequency electromagnetic

fields in some environments.

Regulatory Compliance

Feature Test Method Targeted Performance

Electrostatic Discharge MIL-STD-883C Class 1 (>500 V)

(ESD) to the Method 3015.4

Electrical Pins

Electrostatic Discharge Variation of IEC 801-2 Products of this type will typically withstand at

(ESD) to the least 25 kV without damage when the Duplex

Duplex SC Receptacle SC Connector Receptacle is contacted by a

Human Body Model probe.

Electromagnetic FCC Class A Typically provide a TBD dB margin to the noted

Interference (EMI) CENELEC EN55022 Class A standard limits when tested at a certified test

(CISPR 22A) range with the transceiver mounted to a circuit

VCCI Class I card without a chassis enclosure.

Immunity Variation of IEC 801-3 Typically show no measurable effect from a

3 V/m field swept from 10 to 450 MHz applied

to the transceiver without a chassis enclosure.

Eye Safety FDA CDRH 21-CFR 1040 Class Compliant per Hewlett-Packard Testing for all

1 IEC 825 Issue 1 1993: three requirements under normal operating

11 Class conditions. Fault condition testing pending

1 CENELEC EN60825 Class 1 completion of product development.

566

These transceivers have an

immunity to such fields due to

their shielded design.

provide Class 1 eye safety by

design. Hewlett-Packard has

tested the current transceiver

design is completed. HP will

obtain certification from outside

sources for eye safety.

design for compliance with the

Eye Safety

These 1300 nm Laser-based

transceivers are intended to

requirements listed below under

normal operating conditions and

will test for compliance under

fault conditions when the product

This performance will enable the

transceivers to be used without

concern for eye safety in the

same way that LED-based

transceivers are used today.

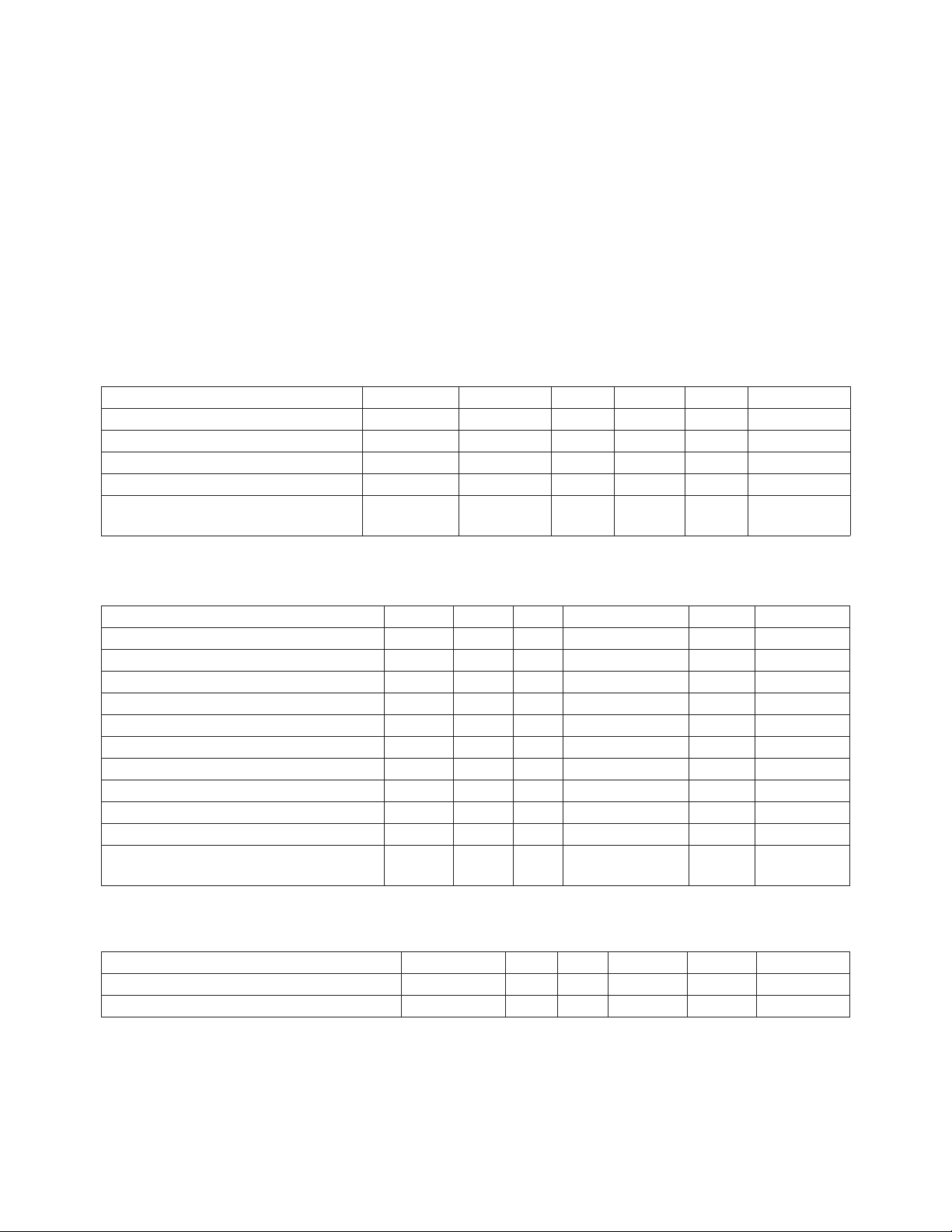

Absolute Maximum Ratings

Parameter Symbol Min. Typ. Max. Unit Reference

Storage Temperature T

Ambient Operating Temperature T

Supply Voltage V

Data Input Voltage V

Transmitter Differential Input V

S

A

CC

I

D

–40 +100 °C

–10 +80 °C

–0.5 7 V

–0.5 V

CC

V

See Table 1.4 V 1

Voltage Below

Recommended Operating Conditions

Parameter Symbol Min. Typ. Max. Unit Reference

Ambient Operating Temperature T

A

Relative Humidity RH 5 95 %

Supply Voltage V

CC

Power Supply Ripple TBD Hz/V

Power Supply Rejection TBD Hz/V

Transmitter Data Input Voltage - Low VIL-V

CC

Transmitter Data Input Voltage - High VIH-VCC–1.165 –0.880 V 2

Transmitter Differential Input Voltage V

Data Output Load R

Signal Detect Output Load R

D

DL

SDL

Conducted Noise on Data and Signal TBD Hz/V

Detect Outputs

0 +70 °C

4.75 5.25 V

pp

pp

–1.810 –1.475 V 2

0.3 See Table Above V

50 Ω 3

710 Ω 4

pp

Process Compatibility

Parameter Symbol Min. Typ. Max. Unit Reference

Hand Lead Soldering Temperature/Time T

Wave Soldering and Aqueous Wash T

Notes:

1. This is the maximum voltage that can be applied across the Differential Transmitter Data Inputs without damaging the ESD

protection circuit.

2. Compatible with 10 K, 10 KH and 100 K ECL and PECL signals.

3. The outputs are terminated to VCC - 2 V.

4. The outputs are terminated to ground.

SOLD/tSOLD

SOLD/tSOLD

+270/10 °C/sec.

+270/10 °C/sec.

567