HP designjet 2000cp, designjet 2500cp, designjet 2800cp, designjet 3000cp, designjet 3500cp schematic

...Page 1

HP DesignJet 2000CP

HP DesignJet 2500CP

HP DesignJet 2800CP

HP DesignJet 3000CP

HP DesignJet 3500CP

HP DesignJet 3800CP

Printers

Service Manual

Page 2

For HP Internal Use Only

Warranty

WARNING

E Copyright HewlettPackard Company 1998

This document contains

proprietary information that is

protected by copyright. All

rights are reserved. No part of

this document may be

photocopied, reproduced, or

translated into another

language without the prior

written consent of HewlettPackard Company.

First edition, March 1998

Second edition, Nov 1998

Third Edition, September 1999

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

regard to this material,

including, but not limited to,

the implied warranties of

merchantability and fitness

for a particular purpose.

Hewlett-Packard shall not be

liable for errors contained

herein or for incidental or

consequential damages in

connection with the furnishing,

performance, or use of this

material.

The procedures described in

this manual are to be

performed by HP-qualified

service personnel only.

Electrical Shock Hazard

Serious shock hazard leading

to death or injury may result if

you do not take the following

precautions:

D Ensure that the ac power

outlet (mains) has a

protective earth (ground)

terminal.

D Disconnect the Printer from

the power source prior to

performing any

maintenance.

D Prevent water or other

liquids from running onto

electrical components or

circuits, or through openings

in the enclosure.

Electrostatic Discharge

Refer to the beginning of

Chapter 8 of this manual, for

precautions you should take to

prevent damage to the Printer

circuits from electrostatic

discharge.

Technical Marketing, Barcelona Division

Hewlett-Packard Española, S.A.

Avda. Graells, 501

08190 Sant Cugat del Vallès

Spain

Safety Symbols

General definitions of safety

symbols are given

immediately after the table of

contents.

Page 3

Service Manual

HP DesignJet 2000CP

HP DesignJet 2500CP

HP DesignJet 2800CP

HP DesignJet 3000CP

HP DesignJet 3500CP

HP DesignJet 3800CP

Printers

Page 4

Using this Manual

Purpose

This manual contains information necessary to test, calibrate and service:

D HP DesignJet 2000CP printer (model C4703A)

D HP DesignJet 2500CP printer (model C4704A)

D HP DesignJet 2800CP printer (model C6085A)

D HP DesignJet 3000CP printer (model C4723A)

D HP DesignJet 3500CP printer (model C4724A)

D HP DesignJet 3800CP printer (model C6084A)

For information about using these printers, refer to the corresponding user

and quick-reference guides.

Readership

The procedures described in this manual are to be performed by

HP-certified service personnel only.

Part Numbers

Part numbers for plotter options, accessories and service parts are located in

chapter 7.

Conventions

This manual contains information for the color HP DesignJet 2000CP,

2500CP, 2800CP, 3000CP, 3500CP and 3800CP printers. Throughout this

Manual, these printers will be referred to as the HP DesignJet CP Series

Printers.

Concerning the hardware perspective, DesignJets 2800CP and 3800CP are

basically DesignJets 2000CP and 3000CP (respectively) connected with an

external Fiery RIP. Therefore, all information applicable to the DesignJets

2000CP/3000CP will also be applicable to DesignJets 2800CP/3800CP.

A small arrow ' is used to indicate other parts of the Service Manual or

User ’s Guide where you can find information related to the topic you are

consulting.

ii Using this Manual

HP DesignJet CP Series Printers

Page 5

Contents

Using this Manual ii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Symbols x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 T roubleshooting

Which Firmware relates to which Ink system? 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

How do I Check the Hard Disk Drive Version?

(Only applicable to HP DesignJet 2500CP/3500CP) 1-2. . . . . . . . . . . . . . . . . . . . . . .

Is the Printer Using the Latest Firmware Revision? 1-2. . . . . . . . . . . . . . . . . . . . . .

How do I upgrade the Firmware Revision on the Flash SIMM? 1-3. . . . . . . . . . . .

How do I upgrade the PostScript Revision on the Flash SIMM? 1-4. . . . . . . . . . . .

How can I Copy Firmware Data from One Flash SIMM

to a Second Flash SIMM? 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Can I do when a System Error Code Appears

on the Front-Panel Display? 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Have you performed a Service Test on the Failed Component/Assembly? 1-7. . . .

Have you Performed the Necessary Service Calibrations? 1-8. . . . . . . . . . . . . . . . .

What can I do to Solve Image Quality Problems? 1-8. . . . . . . . . . . . . . . . . . . . . . . . .

What can I do if the Carriage is Noisy? 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What can I do if the Service Station is Noisy? 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

What can I do if the Printer continuously rejects Printheads? 1-9. . . . . . . . . . . . . .

What can I do if the Printer has problems with Media Loading? 1-9. . . . . . . . . . .

What can I do if the Cover Sensors aren’t Working? 1-10. . . . . . . . . . . . . . . . . . . . . . .

What can I do if the “Switch Power Off / Check Printhead Path”

message appears when the Printer is about to cut or is cutting? 1-10. . . . . . . . . . . .

What can I do if the Bail Assembly does not lower all the way? 1-10. . . . . . . . . . . .

What can I do if the “Lens Maintenance” message

appears on the Front-Panel? 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Media Jams/Printhead Crashes 1-10. . . . . . . . . . . . . . . . . . . . . . . . .

What can I do if the Printer does not Power ON? 1-12. . . . . . . . . . . . . . . . . . . . . . . . .

What can I do if the Line Sensor has Problems Detecting Media? 1-12. . . . . . . . . .

What is the Ink System? 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Do I Troubleshoot the Ink System? 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Does the Customer have Mid-Print Refill Problems in

HP DesignJets 3500CP/3000CP? 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Do I Clean the Electrical Contacts? 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Do I Print some of the Internal Prints? 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Service Print 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Usage report 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The PostScript Config 1-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Navigate through the Front-Panel Menu on

HP DesignJets 2500CP and 2000CP 1-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP DesignJet CP Series Printers

iiiContents

Page 6

2 System Error Codes

System Error: 0000D8 XXXXXXXX 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010020 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010021 AXXXXXXX 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010022 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010023 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010024 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010030 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010031 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010032 000000XX 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010033 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010034 000X0000 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010035 0XABCDEF 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010036 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010036 0000XX00 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010037 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010038 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010039 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010040 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010041 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010042 0000000X 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010043 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010100 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010101 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010102 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010110 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010111 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010120 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 010121 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020000 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020001 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020002 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020003 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020004 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020005 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020006 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020010 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 020011 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 040xxx 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 040601 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 050000 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 060000 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 060100 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 060200 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 060300 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 060400 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 060500 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 07xxxx XXXXXXXX 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 08xxxx 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 080001 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error: 09xxxx 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv Contents

HP DesignJet CP Series Printers

Page 7

System Error: 090004 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Message: Ink System Error XX-YYYY 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 User Messages

User Messages for HP DesignJets 2500CP and 2000CP with Firmware

Version A.02.14 or Higher and HP DesignJets 3500CP and 3000CP 3-2. . . . . . . .

4 Service Tests

Introduction 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics - Self Test 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialization Sequences 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Tests (Diagnostics) 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering the Service Tests (Diagnostics) Menu System 4-5. . . . . . . . . . . . . . . .

D01. Electronics 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D02. Line Sensor 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D03. Carriage Axis (Y-axis) 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D04. Media Axis (X-axis) 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D05. Service Station 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D06. Refill 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D07. Front Panel 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D08. Sensors 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D09. MIO Presence 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D10. Cutter 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D11. Bail 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D12. Image Quality 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D13. Printhead ID 4-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D14. Printhead Continuity 4-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D15. Clean Roller 4-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D16. Erase EEROM 4-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D17. Reset Counters 4-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D19. Hard Disk Drive Revision (Only 2500CP/3500CP) 4-31. . . . . . . . . . . . . . .

5 Service Calibrations

Service Calibrations 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering the Service Calibrations Menu System 5-5. . . . . . . . . . . . . . . . . . . . . .

C01. Carriage 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C02. Refill 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C03. Line Sensor 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C04. Service Station 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C05. Printheads Alignment 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C06. Printheads Check 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C07. Color Calib. (Only available in DesignJet 2500CP/3500CP printer) 5-15.

C08. Service Accuracy 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C09. Maintenance 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C10. Font Type Set (Only available in DesignJet 2500CP/3500CP printer)

5-19

HP DesignJet CP Series Printers

vContents

Page 8

6 Image Quality

Image Quality Troubleshooting Checklist 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Modes 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Quality Print 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Image Quality Print 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Producing the Image Quality Print 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analyzing the Image Quality Print 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Printing Defects Found in the Image Quality Print 6-17. . . . . . . . . . . . . . . . .

Media 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Quality Problems 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Parts List

Printer Support (HP DesignJets 2500CP and 2000CP Only) 7-4. . . . . . . . . . . . . . .

Printer Support (HP DesignJets 3500CP and 3000CP Only) 7-6. . . . . . . . . . . . . . .

Right Hand Cover Area 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left Hand Cover Area 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Rear (HP DesignJets 2500CP and 2000CP Only) 7-12. . . . . . . . . . . . . . . . . .

Printer Rear (HP DesignJets 3500CP and 3000CP Only) 7-14. . . . . . . . . . . . . . . . . .

Electronics Module (Internal) 7-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-axis Assembly 7-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elevator Assembly 7-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refill Assembly 7-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage Assembly 7-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roll Cover Area 7-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Station Assembly Area 7-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X-axis Motor Assembly 7-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Roller Area (HP DesignJets 2500CP and 2000CP Only) 7-36. . . . . . . . . . . . .

Drive Roller Area (HP DesignJets 3500CP and 3000CP Only) 7-38. . . . . . . . . . . . .

Entry Platen Area 7-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pincharm Assembly 7-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refill Interconnect PCA and Cutter Assembly 7-44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Button (HP DesignJets 3500CP and 3000CP Only) 7-46. . . . . . . . . . . . . . . . .

Compatible Documentation 7-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Overlays (HP DesignJets 2500CP and 2000CP Only) 7-51. . . . . . . . . .

Front Panel Overlays (HP DesignJets 3500CP and 3000CP Only) 7-51. . . . . . . . . .

Interface Cables 7-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug-in memory (DRAMM SIMM) 7-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ink Delivery Systems 7-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Removal and Installation

Introduction 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge (ESD) Precautions 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics Module 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi Contents

HP DesignJet CP Series Printers

Page 9

Additional Rear Cover

(Only applicable to HP DesignJets 3500CP and 3000CP) 8-10. . . . . . . . . . . . . . . . . .

Removal 8-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard Disk Drive, Power Switch Cable 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window and Top Cover 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left Hand Cover and Left Hand Trim Assembly 8-18. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Right Hand Cover and Right Hand Trim Assembly 8-21. . . . . . . . . . . . . . . . . . . . . . .

Removal 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel and Stand-by Button 8-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Station Assembly and Service Station Flag 8-26. . . . . . . . . . . . . . . . . . . . . . .

Removal of the Service Station Assembly 8-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal of the Service Station Flag. 8-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the Service Station Assembly 8-27. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the Service Station Flag 8-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Primer Assembly (Only Applicable to HP DesignJets 2500CP/2000CP) 8-29. . . . . . . .

Removal 8-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Strip 8-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing Cable 8-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-Axis Belt 8-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage Assembly 8-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-Axis Motor Assembly 8-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutter Assembly (Only Applicable to HP DesignJets 2500CP and 2000CP) 8-48. . . .

Removal 8-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutter Assembly (Only Applicable to HP DesignJets 3500CP and 3000CP) 8-50. . . .

Removal 8-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elevator Assembly 8-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP DesignJet CP Series Printers

viiContents

Page 10

Refill Assembly 8-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bail Assembly and Star Wheel Assemblies 8-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starguard Assembly 8-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bail Stepper Motor 8-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refill Interconnect PCA 8-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X-Axis Assembly 8-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overdrive Assembly and Drive Roller

(Only Applicable to HP DesignJets 2500CP and 2000CP) 8-69. . . . . . . . . . . . . . . . . .

To remove the Drive Roller only 8-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the drive roller 8-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the overdrive assembly 8-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overdrive Assembly and Drive Roller

(Only Applicable to HP DesignJets 3500CP and 3000CP) 8-72. . . . . . . . . . . . . . . . . .

To remove the Drive Roller only 8-72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the drive roller 8-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the overdrive assembly 8-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entry Platen 8-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roll Cover and Roll Feed Assemblies 8-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pincharm Assemblies, Pincharm Shaft and Pincharm Sensor 8-84. . . . . . . . . . . . . .

Removal of the pincharm sensor 8-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal of the pincharm assemblies and the pincharm shaft. 8-84. . . . . . . . . .

Installation of the pincharm sensor. 8-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the pincharm assemblies and the pincharm shaft. 8-85. . . . . . .

Interconnect Cables 8-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal of the refill interconnect cable. 8-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal of the service station interconnect cable. 8-87. . . . . . . . . . . . . . . . . . . . .

Installation of the service station interconnect cable 8-88. . . . . . . . . . . . . . . . . . .

Installation of the refill interconnect cable 8-88. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Button (Only Applicable to HP DesignJets 3500CP and 3000CP) 8-90. . . .

Removal 8-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Preventive Maintenance

Moisture on the Printer 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii Contents

HP DesignJet CP Series Printers

Page 11

Noisy Carriage Bushing 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt Swelling 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Printer 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Cleaning 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Drive Roller 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Electrical Contacts? 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scheduled Maintenance 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level of Printer Usage 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance Kit - Part Number C4704-60198 9-5. . . . . . . . . . . . . .

Y-axis Maintenance Parts 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Functional Overview

DesignJet 2500CP-PostScript SKU 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DesignJet 2000CP-RTL SKU 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Circuit Assemblies (PCA) 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-Axis Assembly 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-axis belt and Y-axis belt tensioner 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-axis motor assembly 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Strip 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing cable 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Station Assembly 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Primer Assembly 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refill Assembly 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elevator Assembly 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X-Axis Assembly 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics Module 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stepper Motors 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensors 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Sensor 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Sensors 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Interface Sensors 10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX - Reinstalling the Fiery Box

HP DesignJet CP Series Printers

ixContents

Page 12

General Definition of Safety Symbols

International caution symbol (refer to manual): the product is

marked with this symbol when it is necessary for the user to refer

to the instruction manual in order to protect against damage to the

instrument.

Indicates dangerous voltage (terminals fed from the interior by

voltage exceeding 1000 volts must also be marked).

OR

OR

Protective conductor terminal. For protection against electrical

shock in case of a fault. Used with field wiring terminals to

indicate the terminal that must be connected to ground before

operating equipment.

Low-noise or noiseless, clean ground (earth) terminal. Used for a

signal common, as well as providing protection against electrical

shock in case of a fault. A terminal marked with this symbol must

be connected to ground in the manner described in the installation

(operating) manual, and before operating the equipment.

Frame or chassis terminal. A connection to the frame (chassis) of

the equipment, which normally includes all exposed metal.

Alternating current

Direct current

Alternating or direct current

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly performed

or adhered to, could result in personal injury.

x Contents

Take care not to cut yourself on the encoder strip inside the plotter.

The CAUTION sign denotes a hazard. It calls attention to an

operating procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in damage to or destruction

of part or all of the product.

HP DesignJet CP Series Printers

Page 13

1

T

roubleshooting

HP DesignJet CP Series Printers

1-1

Page 14

Introduction

This chapter will guide you through the relevant steps to take when

troubleshooting the printer.

Which Firmware relates to which Ink system?

A.01.XX - This firmware revision is applicable to HP DesignJets 2500CP

and 2000CP and means that the Printers can only use Imaging Inks.

A.02.XX - This firmware revision is applicable to HP DesignJets 2500CP

and 2000CP and means that the Printers can use both the Imaging Inks

and the new UV Durable Inks.

A.03.XX - This firmware revision is applicable to HP DesignJets 3500CP

and 3000CP and means that the Printers can use both the Imaging Inks

and the new UV Durable Inks.

A.04.XX - This firmware revision is applicable to all HP DesignJet CP

Series Printers and means that the Printers can use both the Imaging Inks

and the new UV Durable Inks.

How do I Check the Hard Disk Drive Version? (Only applicable to

HP DesignJet 2500CP/3500CP)

For HP DesignJet 2500CP - To check which Hard Disk Drive Version the

printer is using, print the PostScript Configuration using the front-panel

menu in Internal Prints / PostScript Config.

For HP DesignJet 3500CP - To check which Hard Disk Drive Version the

printer is using, use the front-panel menu in Utilities / Statistics / Disk Rev.

Is the Printer Using the Latest Firmware Revision?

Before spending time troubleshooting the problem by doing the various tests

or replacing parts (which may not need replacing), check which firmware

revision the printer is using. To check which firmware revision the printer is

using, use the front-panel menu in Utilities / Statistics / Code Rev. Some

problems which occurred in earlier firmware releases may have been solved

in later revisions. So if there is a new firmware revision then update the

Flash SIMM before replacing any parts. See below for information on

upgrading the Flash SIMM.

Remember that:

For the HP DesignJet 2000CP/3000CP, the first slot from the left

contains an 8MB SIMM with the firmware code inside.

For the HP DesignJet 2500CP/3500CP, the first slot from the left

contains an 8MB SIMM with the firmware code inside and the second

slot contains a 4 MB SIMM with the PostScript code inside.

1-2 Troubleshooting

HP DesignJet CP Series Printers

Page 15

How do I upgrade the Firmware Revision on the Flash SIMM?

You will need to have the Printer connected to a PC or a UNIX Workstation

with a Parallel cable. Download the latest Firmware Revision from the

Plotter Support WEB to your local drive and then follow these instructions:

1 Make sure the printer is switched OFF from the power switch on the back

of the printer and not from the standby button on the front of the printer.

2 Hold the CANCEL key down and switch the printer ON. Wait until the

message “Flash Programmer 1.X / Push to continue” is displayed on the

front-panel before releasing the CANCEL key.

3 Press the Down Arrow key and the message “Program Flash / Copy to

2nd Flash” is displayed on the front-panel.

4 Press the Up Arrow key and the message “Program 2nd Flash /

Program 1st Flash” is displayed on the front-panel.

5 Press the Down Arrow key and the message “Really Erase Yes / 1st

Flash? No” is displayed on the front-panel.

If you do not wish to continue press the Down Arrow key and the message

“Cancelled Program / Power off the board” is displayed on the front-panel.

Switch the Printer OFF from the power switch on the back of the printer.

6 Press the Up Arrow key and the message “Erasing Flash” is displayed.

THE DATA ON THE FLASH SIMM IS BEING ERASED AT THIS POINT.

DO NOT SWITCH OFF THE PRINTER BECAUSE IT WILL DAMAGE

THE FLASH SIMM.

7 When the data on the Flash SIMM is erased the message “Please

Download Binary Code” is displayed on the front-panel.

8 To download the firmware data to the Flash SIMM follow these instructions:

If using a UNIX Workstation, type:

$ cat filename > device.file

Substitute “filename” with the name of the file that contains the firmware

data which you downloaded from the Plotter Support WEB. Substitute

“device.file” with the name of your Workstation parallel device file.

If using a PC, type in MS-DOS:

C:\> copy /b filename lpt1:

Substitute “filename” with the name of the file that contains the

firmware data which you downloaded from the Plotter Support WEB.

Substitute “lpt1” with name of the parallel port that you have your

Printer connected to on the PC.

Troubleshooting

HP DesignJet CP Series Printers

1-3

Page 16

9 While the firmware data is being received by the printer, the message

“Receiving Binary Code” will be displayed on the front-panel.

THE DATA IS BEING DOWNLOADED ONTO THE FLASH SIMM AT

THIS POINT. DO NOT SWITCH OFF THE PRINTER BECAUSE IT WILL

DAMAGE THE FLASH SIMM.

10 When the Flash SIMM is completely programmed, the message “Finished

Programming / Power OFF the board” will be displayed on the front-panel.

11 Switch the Printer OFF from the power switch on the back of the printer.

12 Switch the Printer ON from the power switch on the back of the printer

and the Printer will start the initialization procedure.

13 When the message “Status/Ready” is displayed on the front-panel, check

that the new firmware revision has been correctly downloaded by using

the front-panel menu in Utilities / Statistics / Code Rev. The front-panel

should now show the new Firmware Revision of the Flash SIMM.

How do I upgrade the PostScript Revision on the Flash SIMM?

YOU ONLY NEED TO UPGRADE THE POSTSCRIPT SIMM IF THE

FIRMWARE CODE IS A.02.08 OR HIGHER.

1 Make sure the printer is switched OFF from the power switch on the

back of the printer and not from the standby button on the front of the

printer.

2 Install an additional 4MB Flash SIMM into the second slot.

3 Hold the CANCEL key down and switch the printer ON. Wait until the

message “Flash Programmer 1.X / Push to continue” is displayed on the

front-panel before releasing the CANCEL key.

If the Printer has problems starting up, the 8MB flash SIMM with the

firmware code has been incorrectly upgraded (it can be dead) or it is

incorrectly installed.

4 Press the Down Arrow key and the message “Program Flash / Copy to

2nd Flash” is displayed on the front-panel.

5 Press the Up Arrow key and the message “Program 2nd Flash /

Program 1st Flash” is displayed on the front-panel.

6 Press the Up Arrow key and the message “Flash Size 8MB / 4MB” is

displayed on the front-panel. The printer is asking you if you want to

program a 4MB or 8MB SIMM.

7 Press the Down Arrow key and the message “Erasing Flash” is

displayed on the front-panel.

THE DATA ON THE FLASH SIMM IS BEING ERASED AT THIS POINT.

DO NOT SWITCH OFF THE PRINTER BECAUSE IT WILL DAMAGE

THE FLASH SIMM.

1-4 Troubleshooting

HP DesignJet CP Series Printers

Page 17

8 When the data on the Flash SIMM is erased the message “Please

Download Binary Code” is displayed on the front-panel.

9 To download the PostScript data to the Flash SIMM follow these

instructions:

If using a UNIX Workstation, type:

$ cat filename > device.file

Substitute “filename” with the name of the file that contains the

PostScript data which you downloaded from the Plotter Support

WEB. Substitute “device.file” with the name of your Workstation

parallel device file.

If using a PC, type in MS-DOS:

C:\> copy /b filename lpt1:

Substitute “filename” with the name of the file that contains the

PostScript data which you downloaded from the Plotter Support

WEB. Substitute “lpt1” with name of the parallel port that you have

your Printer connected to on the PC.

10 While the PostScript data is being received by the printer, the message

“Receiving Binary Code” will be displayed on the front-panel.

THE DATA IS BEING DOWNLOADED ONTO THE FLASH SIMM AT

THIS POINT. DO NOT SWITCH OFF THE PRINTER BECAUSE IT WILL

DAMAGE THE FLASH SIMM.

11 When the Flash SIMM is completely programmed, the message

“Finished Programming / Power OFF the board” will be displayed on the

front-panel.

12 Switch the Printer OFF from the power switch on the back of the printer.

13 Switch the Printer ON from the power switch on the back of the printer

and the Printer will start the initialization procedure.

14 When the message “Status/Ready” is displayed on the front-panel, check that

the new PostScript revision has been correctly downloaded by using the

front-panel menu in Utilities / Statistics / PS rev = PostScript. The

front-panel should now show the new PostScript Revision of the Flash

SIMM.

Troubleshooting

HP DesignJet CP Series Printers

1-5

Page 18

How can I Copy Firmware Data from One Flash SIMM to a Second

Flash SIMM?

This procedure can be used to copy Data from one Flash SIMM to another.

This is very useful when you have to update the Firmware Revision of

several Printers and is much faster than updating from the PC.

1 Make sure the printer is switched OFF from the power switch on the back

of the printer and not from the standby button on the front of the printer.

2 Remove the SIMM cover on the back of the Electronics Module.

3 Make sure that the master Flash SIMM is in the first slot from the left.

4 Install the 2nd Flash SIMM (that needs to be programmed) in the second

slot from the left. If a DRAM SIMM is installed in the 3rd slot, then

remove it first to allow more space to install the 2nd Flash SIMM.

5 Hold the CANCEL key down and switch the printer ON. Wait until the

message “Flash Programmer 1.X / Push to continue” is displayed on the

front-panel before releasing the CANCEL key.

6 Press the Down Arrow key and the message “Program Flash / Copy to

2nd Flash” is displayed on the front-panel.

7 Press the Down Arrow key and the message “Erasing Flash” is

displayed on the front-panel.

THE DATA ON THE SECOND FLASH SIMM IS BEING ERASED AT

THIS POINT. DO NOT SWITCH OFF THE PRINTER BECAUSE IT WILL

DAMAGE THE FLASH SIMM.

8 After a short while the message “Copying Binary Code” will be displayed on

the front-panel while the firmware data is being received by the printer.

THE DATA IS BEING DOWNLOADED ONTO THE SECOND FLASH

SIMM AT THIS POINT. DO NOT SWITCH OFF THE PRINTER

BECAUSE IT WILL DAMAGE THE FLASH SIMM.

9 When the Second Flash SIMM is completely programmed, the message

“Finished Programming / Power OFF the board” will be displayed on the

front-panel.

10 Switch the Printer OFF from the power switch on the back of the printer.

11 Remove the master Flash SIMM from the first slot from the left and

remove the 2nd Flash SIMM (that has just been programmed) from the

second slot from the left.

12 To verify if the Second Flash SIMM is programmed correctly, install the

2nd Flash SIMM in the first slot from the left and switch the Printer ON

from the power switch on the back of the printer. If the Printer initializes

correctly, then the Flash SIMM has been programmed correctly.

1-6 Troubleshooting

HP DesignJet CP Series Printers

Page 19

What Can I do when a System Error Code Appears on the

Front-Panel Display?

Chapter 2 contains a list of system error codes and their respective

descriptions and recommended corrective actions. Only try one

recommended action at a time and check if the error code has disappeared.

If you have an error code which is not documented in this Service Manual or

you have an error which you cannot resolve, then report the error to the HP

Response Center or the nearest HP Support Office. When reporting the

error, have the following information ready:

D Model and Serial Number of the printer.

D Which firmware revision the printer is using.

D The complete error number.

D The Service Print (Utilities / Service Tests).

D The Current configuration sheet.

D Which software application the customer is using (name, version, etc.).

D Is the problem reproducible by you?

D Additional comments about the usage, the setting, etc..

Have you performed a Service Test on the Failed

Component/Assembly?

If possible, always perform a Service Test on the component/assembly that

you are about to replace, just to make sure that is the component/assembly

that has failed. If the test on that component/assembly passes, you

should NOT replace it. For information on the Service Tests and how to

use them ' Chapter 4.

Troubleshooting

HP DesignJet CP Series Printers

1-7

Page 20

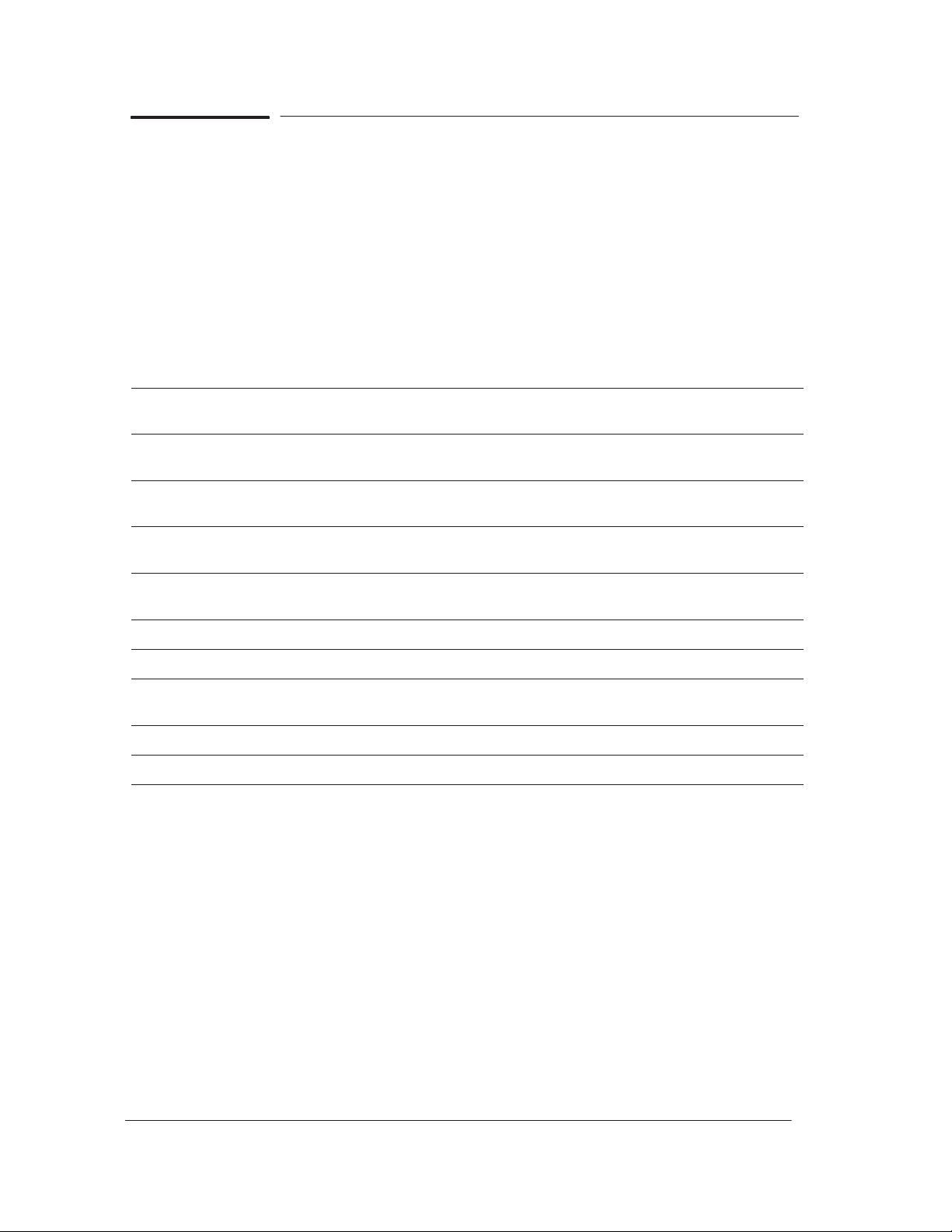

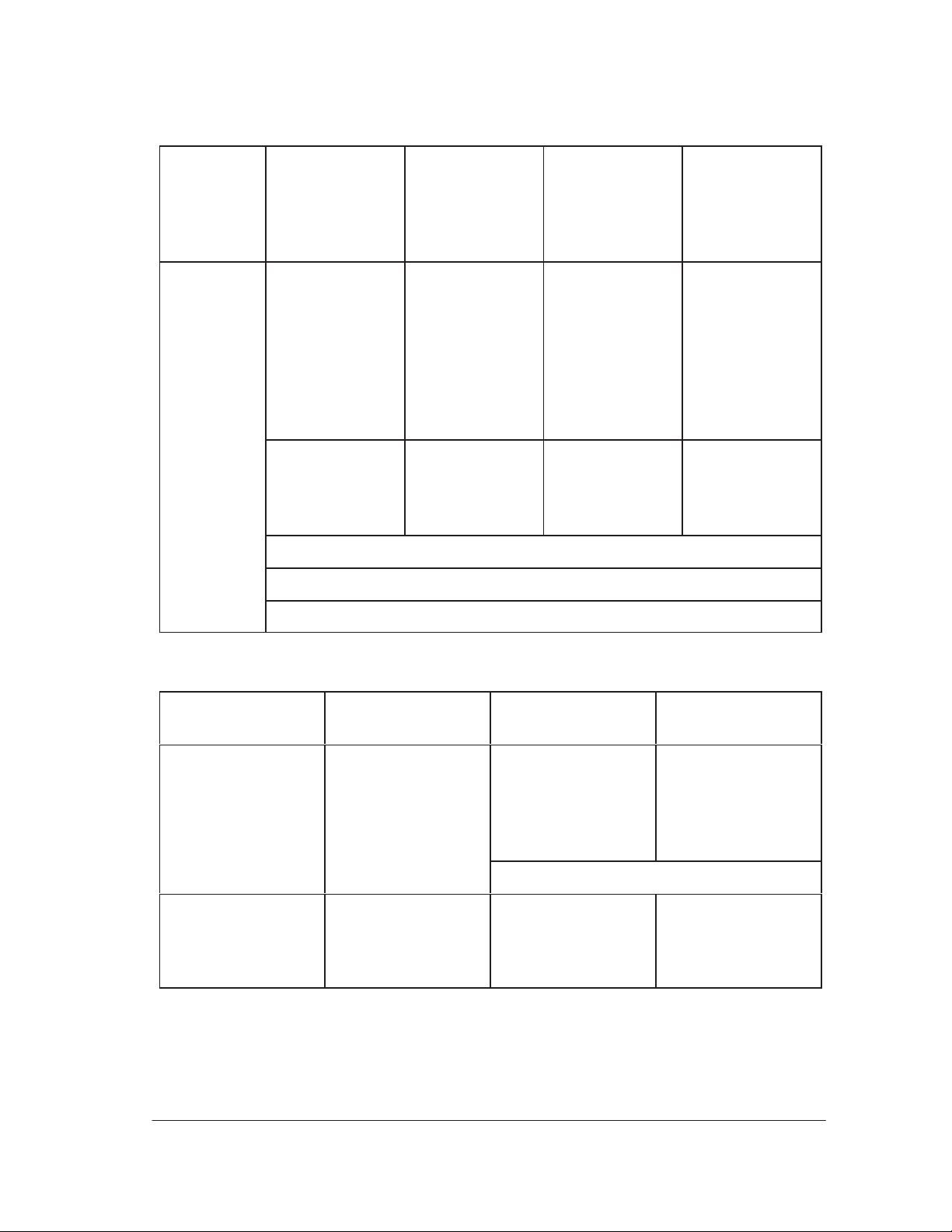

Have you Performed the Necessary Service Calibrations?

Is the printer calibrated correctly after replacing a component? Refer to the

table below to determine when a calibration is required. For information on

the Service Calibrations and how to use them Chapter 5.

REMEMBER THAT CERTAIN CALIBRATIONS ARE REQUIRED

EVEN IF AN ASSEMBLY HAS BEEN DISASSEMBLED TO GAIN

ACCESS TO ANOTHER ASSEMBLY OR COMPONENT.

Calibrations To Be Done

When Required

Electronics Module is

replaced

Carriage is disassembled or

replaced

Refill Assembly is

disassembled or replaced

X-axis Assembly is

disassembled or replaced

Drive Roller is

disassembled or replaced

Banding Problem No No Yes Yes Yes No Yes No No

Edge Detect Problem No No Yes No No No No No No

Misalignment between

Colors

Color Accuracy Problem No No Yes No No Yes No No No

Nozzles Out or Misdirected No No No No Yes No No No No

C01 C02 C03 C05 C06 C07 C08 C09 C10

Yes Yes Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes No No

No Yes No Yes No Yes No No No

No No No No No No Yes No No

No No No No No No Yes No No

No No Yes Yes Yes No Yes No No

What can I do to Solve Image Quality Problems?

Whenever an Image Quality problem appears, it is advisable to print the

Image Quality Print to help diagnose the problem. The Image Quality Print

will help you differentiate between possible printhead errors and other

problems such as incorrect front-panel selection, driver or RIP configuration

or mechanical problems. For information on solving Image Quality

problems Chapter 6.

1-8 Troubleshooting

HP DesignJet CP Series Printers

Page 21

What can I do if the Carriage is Noisy?

1 Dirty Carriage bushings. Remove dust particles from the Carriage

bushings and from the slider rods along which the Carriage moves. If

necessary, apply lubricant to the slider rods.

2 Check for a faulty Carriage. Perform the Carriage Axis Test page 4-12.

What can I do if the Service Station is Noisy?

1 Dirty Service Station slider rod. Remove dust particles from the Service

Station slider rod along which the Service Station moves. If necessary,

apply lubricant to the slider rod.

2 Check for a faulty Service Station. Perform the Service Station Test

page 4-16.

What can I do if the Printer continuously rejects Printheads?

1 Clean the contacts on the Printhead and in the Carriage using the Ink

Cleaner Part Number C6247A.

2 Remove all the Printheads from the Carriage and try installing just the

rejected Printhead. If the Printhead is still rejected then replace the

Printhead with a new one. If the new Printhead is not rejected then

check, one by one, if the other Printheads are rejected or not.

3 Perform the Printhead Continuity Test page 4-29.

4 Perform the Electronics Test page 4-7.

5 Replace the Trailing Cable page 8-36.

6 Replace the Carriage Assembly page 8-42.

What can I do if the Printer has problems with Media Loading?

On HP DesignJets 3500CP and 3000CP a new Media Button has been

installed to assist in Media Loading.

1 Check that the Media Sensor/Media Button is installed correctly.

2 Check if the cable for the Media Sensor/Media Button is connected correctly.

3 Check if the Pincharms are down (the Pincharm lever should be up).

4 Perform the Line Sensor calibration page 5-10.

5 If the media is continuously rejected during the media edge check, then

make sure that the Line Sensor is installed correctly. If necessary,

replace the Carriage Assembly page 8-42 .

6 Replace the Media Sensor/Media Button page 8-78.

7 Perform the Electronics Test page 4-7.

Troubleshooting

HP DesignJet CP Series Printers

1-9

Page 22

What can I do if the Cover Sensors aren’t Working?

1 Check if the faulty sensor is installed correctly.

2 Check if the cable for the faulty sensor is connected correctly.

3 Replace the faulty Sensor.

What can I do if the “Switch Power Off / Check Printhead Path”

message appears when the Printer is about to cut or is cutting?

1 Check the media path and clear it if necessary.

2 Perform the Cutter Test ' page 4-24.

3 Replace the Cutter Assembly ' page 8-48.

What can I do if the Bail Assembly does not lower all the way?

1 Check that there are no obstructions in the way of the Bail Assembly.

2 Perform the Bail Test ' page 4-25.

What can I do if the “Lens Maintenance” message appears on the

Front-Panel?

1 The Mark Encoder, on the Drive Roller, is dirty. Clean the Mark Encoder

first before trying anything else.

2 The lens cover, which is installed on the line sensor, is dirty. Replace the

lens cover ' Users Guide, Chapter 10 (Lens Maintenance).

Troubleshooting Media Jams/Printhead Crashes

The failure modes “media jam” and “head crash” are grouped together

because in many cases a media jam causes the media to lift up into the

carriage path and cause a head crash, thus causing many media jam

failures to be reported as head crashes.

1 Did the media jam occur when loading media?

D If the client has had media jams, it is common for pieces of media to

get stuck in the media path. Clear the media path.

2 Is the customer using non-HP media?

D The use of non-HP media can easily be the cause of media jams and

head crashes (especially head crashes because HP media is specially

formulated to avoid cockle, one of the primary causes of head

crashes). If the media is not HP approved, advise the customer to use

HP media and check to see if the problem now solved.

1-10 Troubleshooting

HP DesignJet CP Series Printers

Page 23

3 Is the client using Best Mode on Coated Media in high humidity?

In this particular case, head crashes could occur due to worst casing.

Recommend a change of media, print mode, or humidity conditions.

4 What is the Firmware Revision? (Only applicable to HP DesignJets

2500CP and 2000CP)

Must be A02.01 or more recent. If not, upgrade.

Explanation - In earlier releases of firmware a media jam/head

crash can be caused at the start of a plot. This can occur in the

“POME” pen alignment or closed loop color calibration, because

the leading edge of the media is brought back very close to the

Media Separator edge. If the edges cross, the media can lift up

when it is advanced, causing a media jam or head crash. It is more

likely to occur the more curled the media is.

5 Check the Media Separator (Only applicable to HP DesignJets

2500CP and 2000CP)

For units fabricated before Serial Numbers C4703A ESA7C04586 and

C4704A ESA7C10343. If the Media Separator is detaching do not

stick it down again, as it will detach again. Also, never reposition a

Media Separator, because it has an extremely tight positioning

tolerance. For Media Separators that are lifting off the Overdrive

Assembly, replace the entire Overdrive Assembly.

Explanation - The previous adhesive used under the Media

Separator can detach from the Overdrive Assembly. New

Overdrive Assemblies use a much better adhesive – it can be

easily differentiated from the old adhesive because it is white

instead of transparent. The Media Separator should never be

repositioned; it has an extremely tight tolerance. If it is too far

from the linear blade it can cause media crashes against the

Linear Blade. If it is too close it can cause media jams between the

leading edges of the media and the Media Separator.

6 Did the failure occur at the end of the media roll?

There are two known failure modes in this case. One is with Vinyl

media, in which case the end of the media was glued too strongly to the

roll, which can cause a head crash. The other is with Coated Media,

where some rolls have the final edge of the media bent in a “C” shape

which could cause a head crash when passing under the carriage. In

both cases the problem has been fixed and a new roll of media should

solve it.

Troubleshooting

HP DesignJet CP Series Printers

1-11

Page 24

7 Replace the Overdrive Assembly and the Clutch ' page 8-69.

D Explanation - For a unit fabricated before September of 1997 the

clutch could cause intermittent media jams. Refer to the applicable

Service Note. For a printer fabricated before July 1997 the linear

blade could be too high, causing media jams.

8 Check for missing/blocked starwheels or starwheel mount assemblies.

D Explanation - These parts can lead to media jams if missing or

blocked.

9 The Carriage is at the incorrect height in relation to the Drive Roller.

Perform the Refill Calibration ' page 5-9 and try to load the media

again.

D The refill station positioning must be checked afterwards since it is

affected. The refill station can be adjusted to accommodate the change

in Printhead Height. The specification for Printhead Height is 1.2 -

1.4mm. Printhead Heights higher than this can adversely affect print

quality.

What can I do if the Printer does not Power ON?

1 Check that the power cord is connected correctly.

2 Check that the Flash SIMM is installed correctly in the correct slot (the

first slot from the left) at the back of the Printer.

3 On the Main PCA, in the Electronics Module, there are other fuses that

are not controlled by the firmware so that, if they are burnt, they can

cause a no-power-up problem. It is recommended to check the

resistance of the motors in a no-power-up situation before

installing a new Electronics Module. If you have a short in one

motor, you will burn the new Electronics Module.

4 Try to disconnect all the cables, apart from the Front Panel Cable, from

the Electronics Module and then try to power ON the Printer again. If

nothing appears on the front-panel display, then replace the Electronics

Module ' page 8-6. If the Printer does Power On with the cables

disconnected, then the problem must be with another component of the

Printer. To find the faulty component, power OFF the Printer and

connect one of the cables and power ON again. Once the faulty

component is connected, it will not allow the Printer to power ON. This

component should then be replaced.

What can I do if the Line Sensor has Problems Detecting Media?

1 Excessive ink deposits on the drive-roller surface can fool the sensor by

reflecting the light. Clean the drive-roller ' page 9-3.

1-12 Troubleshooting

HP DesignJet CP Series Printers

Page 25

2 The lens cover, which is installed on the line sensor, is dirty. Replace the

lens cover Users Guide, Chapter 10 (Lens Maintenance).

3 The Line Sensor is not calibrated correctly. Perform the Line Sensor

calibration page 5-10.

4 The Line Sensor is installed incorrectly. Try to reinstall it and make sure

that it is connected and seated correctly. If the problem continues,

replace the Carriage Assembly page 8-42.

Troubleshooting

HP DesignJet CP Series Printers

1-13

Page 26

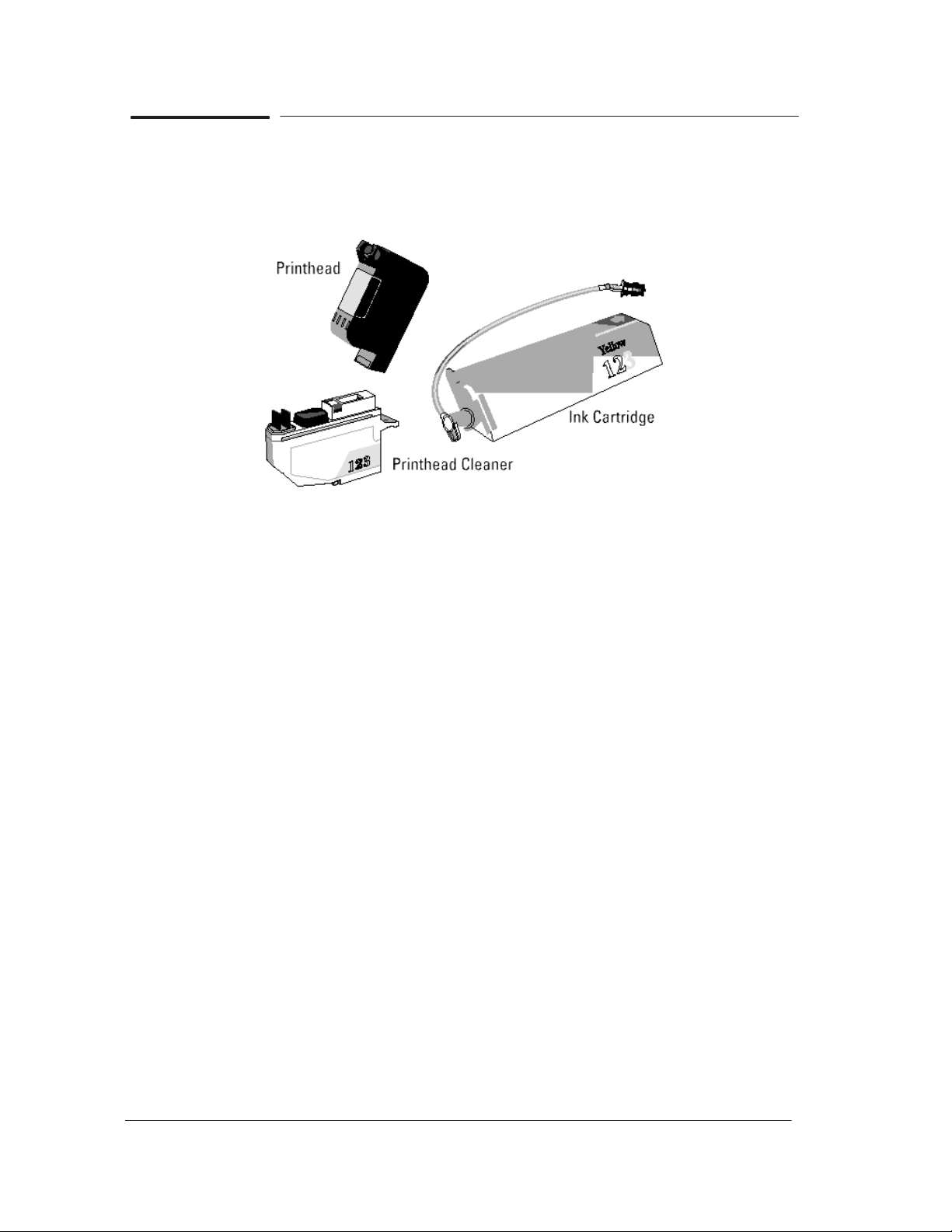

What is the Ink System?

For each of the four colors of ink in your printer ’s ink system, there are

three separate components that work together as a system. The components

for each ink color are color-coded to help you install them correctly.

Ink Cartridge

The ink cartridges are a large-capacity ink supply from which the

printheads are refilled whenever the ink volume in the printhead drops

below a minimum level.

Printhead

The printhead has a 600 dpi thermal inkjet head for firing ink droplets onto

the media and a reservoir which holds enough ink for a large number of

prints. The actual number of prints between refills depends on the size and

type of images you are printing.

Printhead Cleaner

The printer uses the printhead cleaner to clean and maintain the printhead

to ensure the best possible image quality, and to seal the printhead when it

is not in use to prevent it from drying out.

How Do I Troubleshoot the Ink System?

1 If the error message IInk system IncompltI appears on the

front-panel it means that the ink cartridge valve has been disconnected,

so:

D If this is the first failure try to REINSTALL the failing Ink System.

D If the failure has been very frequent REPLACE the failing Ink

System (The valve could be damaged).

If this doesn’t solve the problem, continue with the following process.

1-14 Troubleshooting

HP DesignJet CP Series Printers

Page 27

2 Reinstall the Ink Delivery System as follows:

1 Remove the four printheads from the carriage. On the front panel you

will see the four squares representing the printheads flashing.

2 Clean the electrical contacts using the Ink Cleaner Part Number

C6247A.

3 Reinstall all the printheads, one by one, checking on the front panel

that the squares representing the reinstalled printheads are steady.

D DO NOT INSERT THE NEXT PRINTHEAD UNTIL THE

PRINTER HAS ACCEPTED THE CURRENT PRINTHEAD.

D If, even after the electrical contacts have been cleaned, the

printhead is not accepted REPLACE THE COMPLETE INK

SYSTEM (Printhead/Head Cleaner/Ink Cartridge) for this color.

D If, after inserting a NEW Ink System, the printhead is not

accepted, the problem may be with the printer. Replace the

Carriage Assembly ' 8-42.

4 If you have reinserted the four printheads and the printer has

accepted them continue reinstalling the head cleaners.

5 Remove and reinstall the ink cartridge valves, one by one, checking

on the front panel that the squares representing the reinstalled ink

cartridge are steady.

D If the ink cartridge is not accepted, REPLACE THE COMPLETE

INK SYSTEM (Printhead/Head Cleaner/Ink Cartridge) for this

color.

D If, after reinserting the NEW Ink System, the ink cartridge is not

accepted, the problem may be with the printer. Make sure that the

Refill Assembly cable is not damaged and is correctly connected to

the Interconnect PCA. If the cable is correctly connected and is not

damaged then replace the Refill Assembly ' page 8-55.

3 If the problem is fixed, but it reappears frequently, contact a HP dealer

for a replacement (the Ink System may be damaged.)

Troubleshooting

HP DesignJet CP Series Printers

1-15

Page 28

Does the Customer have Mid-Print Refill Problems in

HP DesignJets 3500CP/3000CP?

New Refill Features in HP DesignJet CP Series (in the case of

DesignJets 2X00CP, the firmware release must be at least A.04.05)

1 Adaptive trigger. The printer looks for low density places to stop and

refill in the print where it will be less noticeable. This feature becomes

active when 75% of the ink in the printhead has been used up. RIP’s

may have disabled this feature, or enabled it at a different ink level.

2 Slightly more useable ink for Imaging printheads. There is an

additional 10% of usable ink.

3 New refill type selections. User can select from three different refill

types through the front panel (Device Setup / Refill=). RIP’s may

support these selections, too:

Type A is similar to what HP DesignJet 2xxxCP does at refill.

Type B finishes the print to a clean edge before refilling.

Type C does a quicker, more frequent refill.

The Default type makes the correct selection for HP media types.

When using non-HP medias, the following settings are probably best:

Glossy - B or C Coated - A or B Backlit - B or A

4 Additional printhead servicing and warming activities are done during

refills, which improves the quality over the 2xxxCP. The user may notice

some new servicing (i.e. noises) at mid-page refills.

5 “Big print” feature. When a refill happens during a large print, the

printer will automatically refill again at the end of the print, to make

sure the maximum ink is available for the next print, which might also

be expected to be large. The user is unlikely to notice this difference in

behavior, since the printer often refills at the end of large pages.

Working with refill problems

General tips:

Check media type is loaded correctly.

Check refill type is set to default.

Try a higher image quality setting for better performance.

Check user’s expectations - refill performance is not always “perfect”, but

almost always is acceptable for poster-type applications. Photo medias

are the most sensitive to defects.

1-16 Troubleshooting

HP DesignJet CP Series Printers

Page 29

Troubleshooting Table 1

Problem

Solutions

Hazy stripe in

dark or black

area with

Hi/Semi Gloss

Light line,

any media

High Gloss/

Semi Gloss

Photo

problems

Photo

Check that

black contains

undercolor

Try higher

image quality

setting

Try higher

image quality

setting

(send RGB to

printer, or add

33% CMY to

black areas

yourself)

Make sure

type B or

default refill

is selected

Switch

between Type

A and B

refills

Make sure

type B or

default refill

is selected

Use higher image quality settings

Use a LOWER image quality setting

Non-HP

medias

Try different

refill types

A,B or C

Use higher

image quality

settings

Use HP media

Troubleshooting Table 2

Problem

Missing color

PRIOR to refill

Reason Printhead is out

of ink (but got a

little more when

it refilled)

Solution Replace

printhead

Missing nozzles

AFTER refill

Error hiding

does not work in

Poor start-up

AFTER refill

Occasional

occurrence

the first swath

after a type B

refill

First swath after a Type B refill

None/ replace

printhead

Check

printheads/

recover

printheads

Troubleshooting

HP DesignJet CP Series Printers

1-17

Page 30

Refill Avoidance Tips

Printer:

1 Try to “top off” printheads before large prints with “Refill Now” option in

Front Panel (Image Quality / Printhead Service / Refill now). If a refill

happened at the end of the last print (usually happens with big prints),

this is not necessary.

2 If you have just canceled a print, you may need to use the “refill now”

option to guarantee the maximum ink available for the next print.

Print Composition Tips:

1 Don’t try to nest more than 15 ft^2 of prints.

2 If the print is lighter in color at one end, rotate print so that it is the last

part to be printed. Refills are less noticeable in light prints.

3 If possible, lighten background colors or use a gradient in place of a solid

fill.

4 Textured areas make refills less noticeable than “flat” color areas.

How Do I Clean the Electrical Contacts?

The problem.

The printer fires drops by sending electrical signals from the printhead

carriage to the printhead through the electrical contacts present on the

carriage and on the printheads. The problem is that when you load the

printheads into their stalls, sometimes some ink goes over the carriage

electrical contacts, and when the printhead is installed over the printhead

electrical contacts. When the printer prints, some ink goes to the bottom of the

electrical contacts. This causes electrical continuity problems that can be fixed

very easily.

The solution.

A new tool has been created especially to clean the electrical contacts and is

called the Ink Cleaner (Part Number C6247A - includes the instructions).

1-18 Troubleshooting

HP DesignJet CP Series Printers

Page 31

How Do I Print some of the Internal Prints?

The Service Print

The purpose of the Service Print is to give information about the operating

conditions, Usage Level, Serviceability and the MIO Configuration. This

Print is very useful when troubleshooting the Printer, as it gives you

information regarding the firmware revision, the last system error and the

internal sensors.

If the EEROM is cleared, you will loose all the information on the

Service Print (including the MIO Configuration).

Print the Service Print as follows:

Load media (A4 minimum) before printing the Service Print.

1 In the Utilities submenu, scroll to “Service Tests” and press Enter.

SERVICE TESTS

Service print

2 Scroll to “Service Print” and press Enter.

3 The Service Print will then be printed.

Troubleshooting

HP DesignJet CP Series Printers

1-19

Page 32

The Usage report

The purpose of the Usage Report is to give information about some of the

Internal Counters which can help you to know the usage of the Printer.

If the EEROM is cleared, the counters will be reset to zero.

Print the Usage Report as follows:

Load media (A4 minimum) before printing the Usage Report.

1 In the Internal Prints submenu, scroll to “Usage Report” and press

Enter.

INTERNAL PRINTS

Usage Report

2 The Usage Report will then be printed.

1-20 Troubleshooting

HP DesignJet CP Series Printers

Page 33

The PostScript Config

The purpose of the PostScript Config is to give information about the

internal Hard Disk, Internal Fonts and the PostScript part of the

front-panel configuration.

Print the PostScript Config as follows:

Load media (A4 minimum) before printing the PostScript Config.

1 In the Internal Prints submenu, scroll to “PostScript Config” and press

Enter.

INTERNAL PRINTS

PostScript Config

2 The PostScript Config will then be printed.

Troubleshooting

HP DesignJet CP Series Printers

1-21

Page 34

How to Navigate through the Front-Panel Menu