Page 1

HP StorageWorks 1/8 G2 Tape Autoloader User and Service Guide

Abstract

This guide provides information on installing, configuring, upgrading, and troubleshooting the Tape Autoloader. This guide is

intended for system administrators and other users who need physical and functional knowledge of the Tape Autoloader.

HP Part Number: AK377-96020

Published: June 2012

Edition: Sixth

Page 2

© Copyright 2006, 2012 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be photocopied, reproduced, or

translated into another language without the prior written consent of Hewlett-Packard. The information is provided “as is” without warranty of any

kind and is subject to change without notice. The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

Intel, Itanium, Pentium, Intel Inside, and the Intel Inside logo are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the

United States and other countries.

Microsoft, Windows, Windows XP, and Windows NT are U.S. registered trademarks of Microsoft Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

Warranty

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Page 3

Contents

1 Features and overview................................................................................8

Autoloader options...................................................................................................................9

HP StorageWorks 1/8 G2 & MSL Encryption Kit......................................................................9

Command View TL TapeAssure..............................................................................................9

Interface specifications and requirements for parallel SCSI drives..................................................10

Parallel SCSI host bus adapters (HBAs).................................................................................10

Multiple LUN support.........................................................................................................10

Interface specifications and requirements for Fibre Channel drives.................................................11

Interface specifications and requirements for SAS drives...............................................................11

LTO-4 and later generation tape drives and encryption................................................................12

Using the Encryption Kit......................................................................................................12

Using application-managed encryption.................................................................................13

Front panel overview...............................................................................................................13

Back panel overview...............................................................................................................14

Tape drive LED.......................................................................................................................15

Controller health status indicator...............................................................................................16

2 Installing the Tape Autoloader....................................................................17

Preparing the host...................................................................................................................17

Planning the parallel SCSI configuration....................................................................................18

About parallel SCSI busses..................................................................................................18

Optimizing throughput........................................................................................................18

SCSI addresses..................................................................................................................18

Planning the SAS configuration.................................................................................................19

About SAS........................................................................................................................19

SAS cables and connectors.................................................................................................19

World Wide identifiers.......................................................................................................20

Planning the Fibre Channel configuration...................................................................................20

Direct connection...............................................................................................................20

SAN connection................................................................................................................20

Choosing a location...............................................................................................................20

Unpacking the shipping container............................................................................................21

Identifying product components................................................................................................21

Attaching the feet ..................................................................................................................22

Removing the shipping lock .....................................................................................................23

Mounting the device in a rack..................................................................................................24

Installing the Tabletop Conversion Kit........................................................................................25

Changing the SCSI address (parallel SCSI drives only).................................................................25

Connecting the parallel SCSI cable (parallel SCSI devices only)....................................................26

Connecting the Fibre Channel cables (Fibre Channel devices only)................................................27

Connecting the SAS cable (SAS devices only).............................................................................27

Powering on the device...........................................................................................................27

Configuring the device............................................................................................................28

Verifying the connection..........................................................................................................28

Labeling and loading the tape cartridges...................................................................................28

Verifying the installation..........................................................................................................29

Configuring additional features................................................................................................29

3 Tape cartridges and magazines.................................................................30

Tape cartridges......................................................................................................................30

Using and maintaining tape cartridges.................................................................................31

Labeling tape cartridges.....................................................................................................31

Contents 3

Page 4

Write-protecting tape cartridges...........................................................................................32

Read and write compatibility...............................................................................................33

Magazines............................................................................................................................33

4 Operating the Tape Autoloader..................................................................35

Remote management interface (RMI).........................................................................................35

Overview..........................................................................................................................35

Login................................................................................................................................36

Status pane.......................................................................................................................37

Getting help......................................................................................................................38

Identity ............................................................................................................................38

Viewing static device information....................................................................................38

Viewing static drive information.......................................................................................39

Viewing network information..........................................................................................41

Status...............................................................................................................................42

Viewing dynamic device information................................................................................42

Viewing dynamic drive information..................................................................................43

Viewing the tape cartridge inventory ...............................................................................45

Configuration....................................................................................................................46

Changing the system configuration..................................................................................46

Changing the drive configuration....................................................................................49

Changing the network configuration................................................................................50

Configuration: Network Management..............................................................................52

Configuring HP Systems Insight Manager for the Tape Autoloader..................................54

Changing the administrator password..............................................................................54

Setting the date and time...............................................................................................55

Setting error log mode...................................................................................................56

Setting event notification parameters................................................................................56

Saving and restoring the device configuration and restoring factory defaults..........................57

Operations.......................................................................................................................58

Moving media..............................................................................................................58

Updating the current media inventory..............................................................................59

Releasing and replacing the magazines...........................................................................59

Support............................................................................................................................60

Performing general diagnostics.......................................................................................60

HP Service - Service restricted.........................................................................................60

Determining and updating firmware ...............................................................................61

Rebooting the device.....................................................................................................61

Viewing logs................................................................................................................61

Cleaning the tape drive ................................................................................................62

Downloading a support ticket.........................................................................................62

Operator control panel (OCP)..................................................................................................64

LED indicators...................................................................................................................65

Autoloader home screen.....................................................................................................65

Operator control panel buttons............................................................................................66

Understanding the menu structure.........................................................................................67

Entering the administrator password................................................................................68

Unlocking the mailslot (Unlock Mailslot)................................................................................69

Status/Information.............................................................................................................69

Inventory (Status/Information > Inventory).........................................................................69

Autoloader information (Status/Information > Autoloader Information)..................................70

Drive information (Status/Information > Drive Information)..................................................71

Component status (Status/Information > Component Status)................................................71

Network information (Status/Information > Network Information).........................................71

Configuration....................................................................................................................72

4 Contents

Page 5

Changing the administrator password (Configuration > Change Admin Password).................72

Setting the number of reserved slots (Configuration > Set Reserved Slot Count)......................73

Configuring the mailslot (Configuration > Configure Mailslot)..............................................73

Bar code reporting format (Configuration > Barcode Format Reporting)................................73

Changing the SCSI address — parallel SCSI devices (Configuration > Change Drive)............74

Setting behaviors (Configuration > Autoloader Behavior)....................................................74

Setting the date and time (Configuration > Autoloader Date/Time)......................................75

Configuring network settings (Configuration > Configure Network Settings)...........................75

Configuring automatic cleaning (Configuration > Configure Auto Cleaning)..........................76

Restoring factory defaults (Configuration > Restore Defaults)................................................77

Saving and restoring the Autoloader configuration (Configuration > Save/Restore

Configuration)..............................................................................................................77

Operations.......................................................................................................................78

Unlocking, removing, and replacing magazines (Operations > Unlock Left or Right

Magazine)...................................................................................................................78

Cleaning the tape drive (Operations> Clean Drive)............................................................79

Moving tapes in the Autoloader (Operations > Move Tape)................................................80

Updating tape cartridge inventory (Operations > Perform Inventory).....................................80

Rebooting the Autoloader (Operations> Reboot Autoloader)...............................................81

Enabling password locks (Operations > Enable Autoldr Password Locks)...............................81

Support............................................................................................................................81

Powering a drive on or off (Support > Power On/Off Drive)................................................81

Running the demonstration (Support > Run Demo).............................................................82

Running the slot to slot test (Support > Run Slot To Slot Test)................................................82

Running the wellness test (Support > Run Wellness Test)......................................................82

Upgrading firmware (Support > Autoloader FW Upgrade, Support > Drive FW Upgrade)......83

Viewing logs (Support > Autoloader Error Log)..................................................................84

Downloading a support ticket (Support > Download Support Ticket).....................................84

Forcing the drive to eject a tape (Support > Force Drive To Eject Tape)..................................85

5 Troubleshooting........................................................................................86

Detection problems after installing a parallel SCSI device.............................................................86

Detection problems after installing a SAS device.........................................................................88

Fibre Channel connection problems..........................................................................................89

Operation problems................................................................................................................90

Performance problems.............................................................................................................95

Average file size................................................................................................................96

File system type.................................................................................................................96

Connection from the host server to the disks...........................................................................97

Operating system configuration.........................................................................................100

Windows...................................................................................................................100

Novell.......................................................................................................................101

Backup server..................................................................................................................101

Backup type....................................................................................................................101

File-by-file with a full-featured backup application............................................................102

File-by-file with a native application...............................................................................102

Disk image, flash, or sequential....................................................................................102

Database backup........................................................................................................102

Connection from the host server to the Autoloader................................................................102

Media............................................................................................................................103

Service and repair................................................................................................................104

Releasing the magazines manually.....................................................................................104

The wellness test...................................................................................................................104

Error codes..........................................................................................................................105

Finding error code information on the OCP.........................................................................106

Contents 5

Page 6

Finding error code information on the RMI..........................................................................106

Finding error code information on an L&TT support ticket or report..........................................107

Main error code descriptions.............................................................................................110

Error sub-code descriptions................................................................................................119

Drive error codes.............................................................................................................122

Warning events....................................................................................................................123

Configuration change events..................................................................................................126

Information events.................................................................................................................127

Using HP Library & Tape Tools to diagnose problems................................................................128

6 Upgrading and servicing the Tape Autoloader...........................................130

Possible tools needed............................................................................................................130

Removing and replacing a tape drive......................................................................................131

Removing and replacing a magazine......................................................................................133

Using the operator control panel........................................................................................133

Using the remote management interface.............................................................................133

Using the manual magazine release...................................................................................134

Removing and replacing the base chassis................................................................................134

Recording configuration settings.........................................................................................135

Removing the tape cartridge from the tape drive..................................................................135

Removing the cables, magazines, and tape drive ................................................................135

Removing the base chassis................................................................................................136

Unpacking the new chassis...............................................................................................136

Replacing the base chassis................................................................................................137

7 Support and other resources....................................................................139

HP technical support.............................................................................................................139

HP websites.........................................................................................................................139

Typographic conventions.......................................................................................................139

Customer Self Repair.............................................................................................................140

Subscription service..............................................................................................................140

HP-authorized reseller............................................................................................................141

A Technical specifications...........................................................................142

Physical specifications...........................................................................................................142

Environmental specifications...................................................................................................142

Regulatory specifications.......................................................................................................142

B Regulatory compliance and safety............................................................144

Regulatory compliance identification numbers..........................................................................144

Federal Communications Commission notice............................................................................144

FCC rating label..............................................................................................................144

Class A equipment......................................................................................................144

Class B equipment......................................................................................................144

Declaration of Conformity for products marked with the FCC logo, United States only...............145

Modification...................................................................................................................145

Cables...........................................................................................................................145

Canadian notice (Avis Canadien)...........................................................................................145

Class A equipment...........................................................................................................145

Class B equipment...........................................................................................................145

European Union regulatory notice...........................................................................................145

Japanese notices..................................................................................................................146

Japanese VCCI-A notice....................................................................................................146

Japanese VCCI-B notice....................................................................................................146

Japanese power cord statement.........................................................................................146

Korean notices.....................................................................................................................146

Class A equipment...........................................................................................................146

6 Contents

Page 7

Class B equipment...........................................................................................................147

Taiwanese notices.................................................................................................................147

BSMI Class A notice.........................................................................................................147

Taiwan battery recycle statement........................................................................................147

Laser compliance notices.......................................................................................................148

English laser notice..........................................................................................................148

Dutch laser notice............................................................................................................148

French laser notice...........................................................................................................148

German laser notice.........................................................................................................149

Italian laser notice............................................................................................................149

Japanese laser notice.......................................................................................................149

Spanish laser notice.........................................................................................................150

Recycling notices..................................................................................................................150

English notice..................................................................................................................150

Bulgarian notice..............................................................................................................150

Czech notice...................................................................................................................150

Danish notice..................................................................................................................151

Dutch notice....................................................................................................................151

Estonian notice................................................................................................................151

Finnish notice..................................................................................................................151

French notice...................................................................................................................151

German notice................................................................................................................152

Greek notice...................................................................................................................152

Hungarian notice.............................................................................................................152

Italian notice...................................................................................................................152

Latvian notice..................................................................................................................152

Lithuanian notice..............................................................................................................153

Polish notice....................................................................................................................153

Portuguese notice.............................................................................................................153

Romanian notice..............................................................................................................153

Slovak notice...................................................................................................................153

Spanish notice.................................................................................................................154

Swedish notice................................................................................................................154

Turkish notice..................................................................................................................154

Battery replacement notices...................................................................................................154

Dutch battery notice.........................................................................................................154

French battery notice........................................................................................................155

German battery notice......................................................................................................155

Italian battery notice........................................................................................................156

Japanese battery notice....................................................................................................156

Spanish battery notice......................................................................................................157

Power cords.........................................................................................................................157

C Electrostatic discharge............................................................................158

Preventing electrostatic damage..............................................................................................158

Grounding methods..............................................................................................................158

Glossary..................................................................................................159

Index.......................................................................................................162

Contents 7

Page 8

1 Features and overview

The Autoloader provides a compact, high-capacity, low-cost solution for simple, unattended data

backup. This unique design houses up to eight tape cartridges in a compact 1U form factor with

easy access to tape cartridges via two removable magazines and a configurable mailslot. Each

magazine can hold up to four cartridges.

The Autoloader can support Ultrium half-height tape drives. To see the tape drives currently available

for the 1/8 G2 Tape Autoloader, see the MSL QuickSpecs at www.hp.com/go/tape. For a list of

all supported configurations, go to www.hp.com/go/ebs.

The Autoloader is compatible with most operating systems and environments that support the SAS,

parallel SCSI, or Fibre Channel interfaces. However, the Autoloader requires either direct support

from the operating system or a compatible backup application to take full advantage of its many

features. To verify compatibility, go to www.hp.com/go/ebs.

The Autoloader uses the interface types described in Table 1 (page 8). The parallel SCSI Tape

Autoloader uses a single SCSI ID with two logical unit numbers (LUNs) — one for the tape drive

and the other for the robotic.

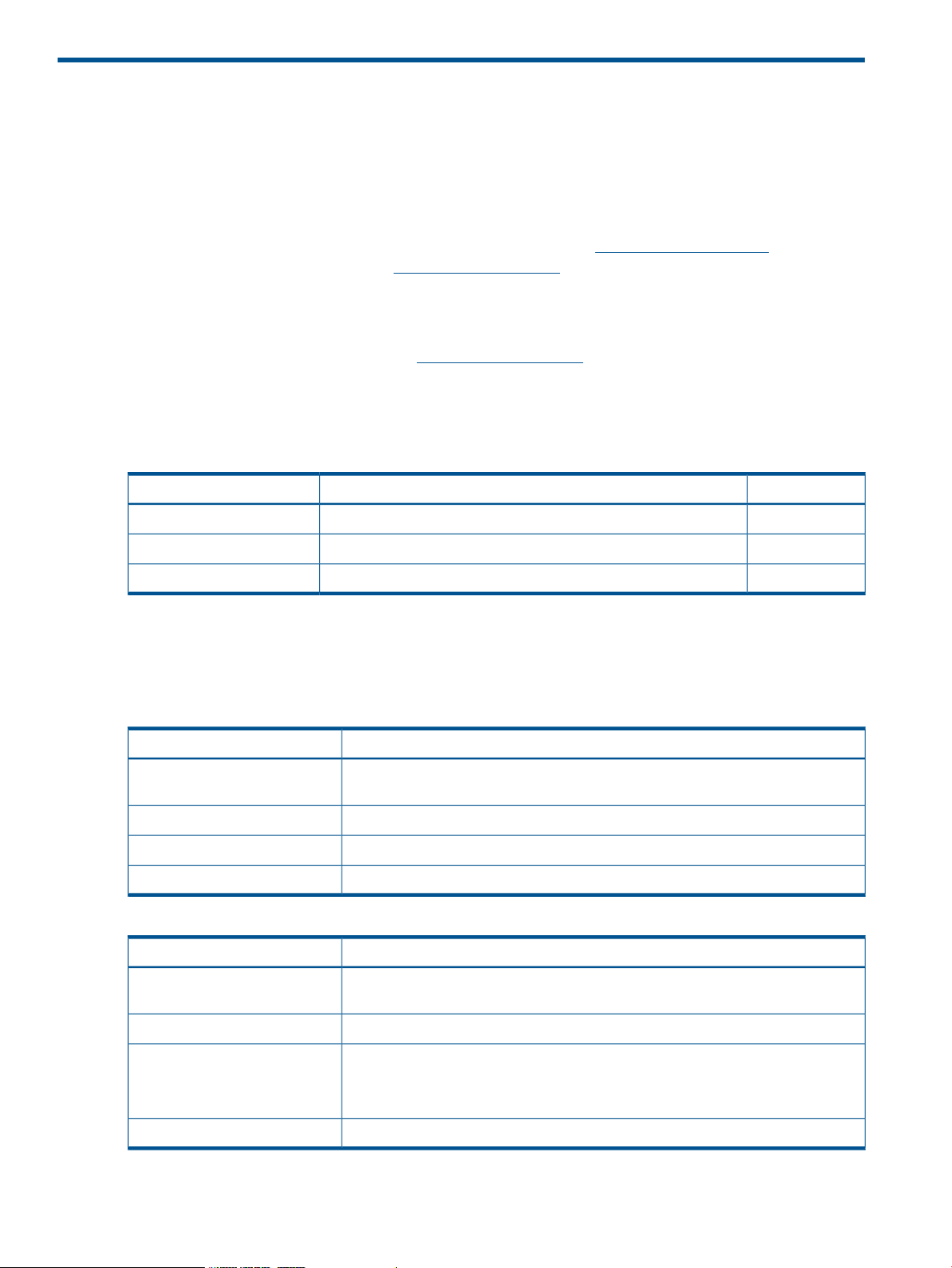

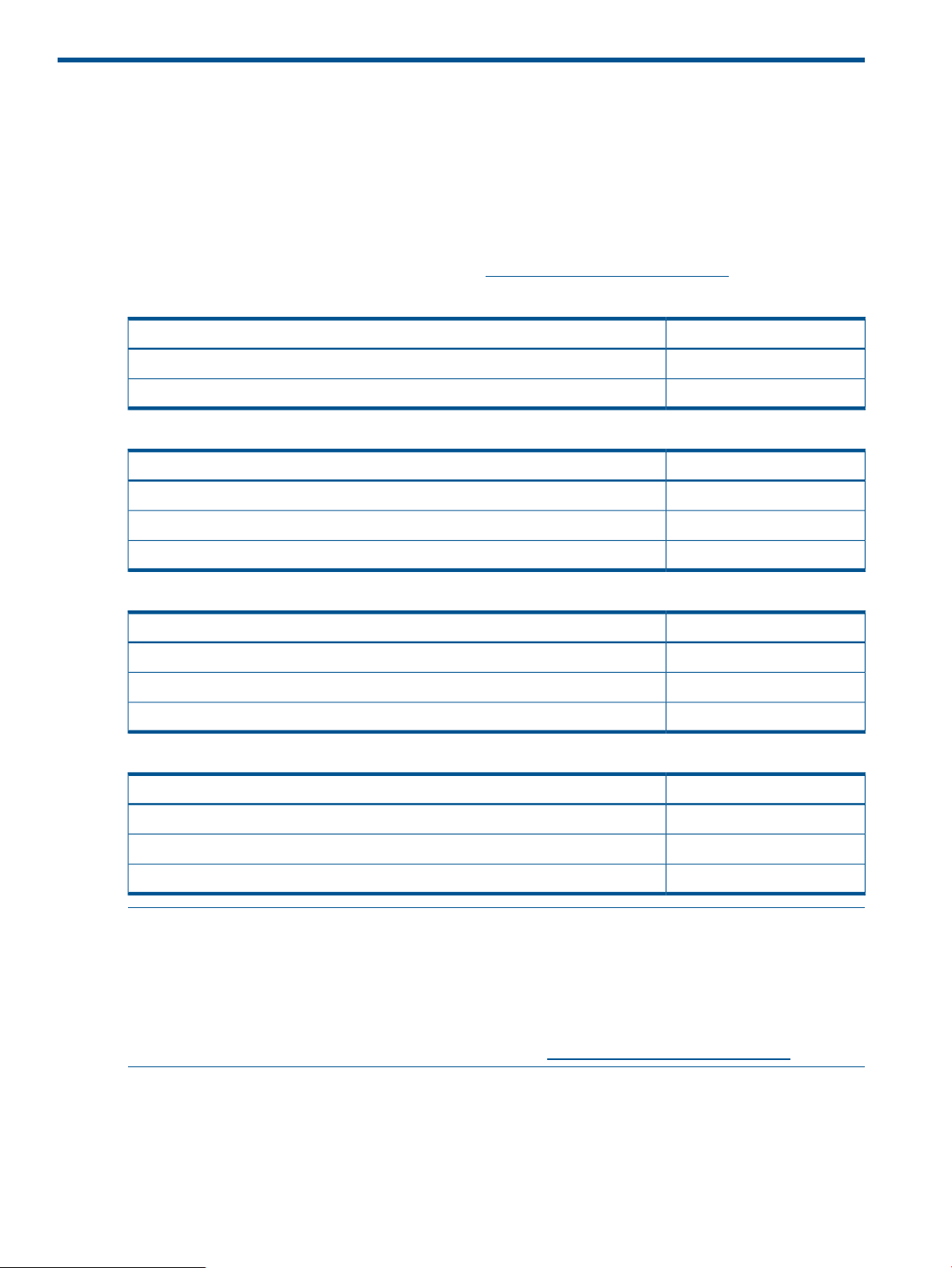

Table 1 Model and interface type

SCSI IDInterfaceLTO generation

4Ultra 160 SCSI LVD/SELTO-2

4Ultra 320 SCSI LVD, SASLTO-3, LTO-4

NAFibre Channel, SASLTO-5

Maximum storage capacity, maximum data transfer rates, and tape cartridges are specified in

Ultrium 448 1/8 G2 Tape Autoloader specifications (page 8), Ultrium 920 1/8 G2 Tape

Autoloader specifications (page 8), Ultrium 1760 1/8 G2 Tape Autoloader specifications

(page 9), and Ultrium 3000 1/8 G2 Tape Autoloader specifications (page 9).

Table 2 Ultrium 448 1/8 G2 Tape Autoloader specifications

SpecificationCharacteristic

Native: 1.6 TB (8 x 200 GB) Compressed (2:1): 3.2 TBMaximum storage capacity, 8

data cartridges

Native: 24 MB/s (86 GB/hr) Compressed (2:1): 48 MB/s (172 GB/hr)Maximum data transfer rate

HP LTO2 Ultrium 400 GB Data Cartridge, red, part number C7972AData cartridges

HP Ultrium universal cleaning cartridge, (50 cleans), orange, part number C7978ACleaning cartridge

Table 3 Ultrium 920 1/8 G2 Tape Autoloader specifications

SpecificationCharacteristic

Native: 3.2 TB (8 x 400 GB) Compressed (2:1): 6.4 TBMaximum storage capacity, 8

data cartridges

Native: 60 MB/s (215 GB/hr) Compressed (2:1): 120 MB/s (430 GB/hr)Maximum data transfer rate

8 Features and overview

HP LTO3 Ultrium 800 GB RW Data Cartridge , yellow, part number C7973AData cartridges

HP LTO3 Ultrium 800 GB WORM Data Cartridge , two-tone (yellow and white),

part number C7973W

HP Ultrium universal cleaning cartridge, (50 cleans), orange, part number C7978ACleaning cartridge

Page 9

Table 4 Ultrium 1760 1/8 G2 Tape Autoloader specifications

SpecificationCharacteristic

Native: 6.4 TB (8 x 800 GB) Compressed (2:1): 12.8 TBMaximum storage capacity, 8

data cartridges

Native: 80 MB/s (288 GB/hr) Compressed (2:1): 160 MB/s (576 GB/hr)Maximum data transfer rate

HP LTO4 Ultrium 1.6 TB RW Data Cartridge, green, part number C7974AData cartridges

HP LTO4 Ultrium 1.6 TB WORM Data Cartridge, two-tone (green and gray), part

number C7974W

HP Ultrium universal cleaning cartridge, (50 cleans), orange, part number C7978ACleaning cartridge

Table 5 Ultrium 3000 1/8 G2 Tape Autoloader specifications

SpecificationCharacteristic

Native: 12 TB (8 x 1.5 TB) Compressed (2:1): 24 TBMaximum storage capacity, 8

data cartridges

Native: 140 MB/s (504 GB/hr) Compressed (2:1): 280 MB/s (1,008 GB/hr)Maximum data transfer rate

HP LTO5 Ultrium 3 TB RW Data Tape, blue, part number C7975AData cartridges

HP LTO5 Ultrium 3 TB WORM Data Tape, two-tone (blue and gray), part number

C7975W

HP Ultrium universal cleaning cartridge, (50 cleans), orange, part number C7978ACleaning cartridge

Autoloader options

HP StorageWorks 1/8 G2 & MSL Encryption Kit

The Encryption Kit provides secure generation and storage of encryption keys. The Encryption Kit

may be used with any HP StorageWorks 1/8 G2 Tape Autoloader or the MSL2024, MSL4048,

MSL8048 and MSL8096 Tape Library with at least one LTO-4 or later generation tape drive. The

Encryption Kit cannot be used with the MSL6000.

The Encryption Kit includes two USB key server tokens. One key server token is available for use

as backup for the other.

To use the Encryption Kit, a key server token is inserted in the USB port on the back of the

Autoloader, and encryption is enabled and configured from the RMI.

The Encryption Kit supports your manual security policies and procedures by providing secure

storage for encryption keys. Access to the key server tokens and their backup files is protected with

user-specified passwords. You will need to create processes to protect the tokens and secure the

passwords.

IMPORTANT: When encryption is enabled with the Encryption Kit, the Autoloader will not use

encryption keys from other sources, such as a key management system or application software.

Disable encryption in applications writing to the Autoloader when encryption is enabled with the

Encryption Kit. Applications that attempt to control encryption while encryption is enabled with the

Encryption Kit will not be able to do so, which can cause backups or other write operations to fail.

Command View TL TapeAssure

HP StorageWorks Command View TL software provides a browser-based GUI for remote

management and monitoring of most HP libraries through a LAN. With Command View TL, you

can view and analyze the performance and health of the LTO-4 and LTO-5 tape drives and media

in multiple HP MSL2024, MSL4048, MSL8048, and MSL8096 Tape Libraries and 1/8 G2 Tape

Autoloader options 9

Page 10

Autoloaders at the same time. In addition, the information shown in TapeAssure is more extensive

than that shown in the RMI.

Command View TL software is installed on a management station. The management station can

also be used to manage HP StorageWorks EML and ESL Tape Libraries. For best performance, the

management station should be in the same physical location and on the same IP subnet as the

Autoloader. Command View TL software is available for download without charge from the HP

website at http://www.hp.com/support/cvtl.

For information on installing and using Command View TL, see the HP StorageWorks Interface

Manager and Command View TL User Guide, available from the HP website at http://

www.hp.com/support/cvtl.

Command View TL support is included in all Autoloader firmware that supports LTO-5 tape drives.

To find and download the most up-to-date firmware revision, visit the HP website at http://

www.hp.com/support.

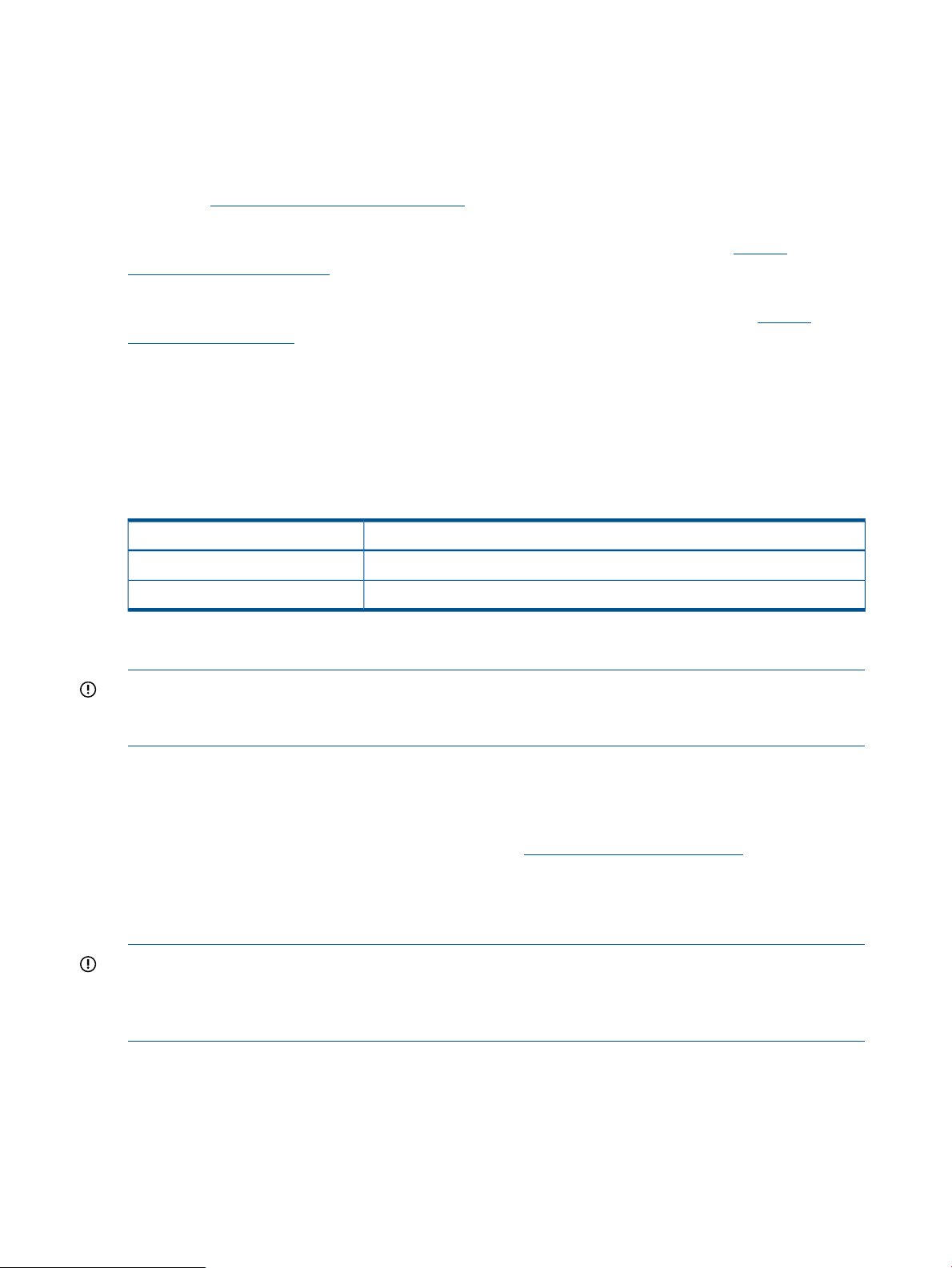

Interface specifications and requirements for parallel SCSI drives

The parallel SCSI Autoloaders use the SCSI interface types described in Table 6 (page 10). The

Autoloaders use a separate SCSI ID for each tape drive, with dual LUNs on the master drive's SCSI

ID to control the tape drive (LUN 0) and Autoloader robotic (LUN 1). HP recommends that each

Ultrium tape drive be put on its own bus when possible.

Table 6 Parallel SCSI interface types

SCSI InterfaceLTO generation

Ultra 160 SCSI LVD/SELTO-2

Ultra 320 SCSI LVDLTO-3, LTO-4

The parallel SCSI Autoloader incorporates a wide SCSI-2 or SCSI-3 Low-Voltage Differential (LVD)

SCSI bus. Make sure your SCSI host adapter or controller supports these standards.

IMPORTANT: The Tape Autoloader is NOT compatible with a high-voltage differential (HVD)

SCSI bus. Do not put the Autoloader on a narrow (50-pin) parallel SCSI bus because doing so will

severely degrade performance.

Parallel SCSI host bus adapters (HBAs)

For optimum performance, place the Autoloader on its own SCSI bus with a host bus adapter that

can transfer data as fast as the Autoloader can read and write. The HBA must also be supported

by your operating system. Refer to the EBS matrix at http://www.hp.com/go/ebs for current HBA

compatibility information.

• For LTO-3 or LTO-4 tape drives, use an Ultra 320 HBA.

• For LTO-2 tape drives, use an Ultra 320 or Ultra 160 HBA.

IMPORTANT: Do not connect an Ultrium tape drive to an SE SCSI bus, as it severely degrades

Autoloader performance. A single-ended SCSI host bus adapter severely degrades Autoloader

performance and limits cable length. Also, if any SE devices are on the SCSI bus, all of the devices

on the bus slow down to SE speed, severely degrading performance.

Multiple LUN support

The Autoloader uses a single SCSI ID and two logical unit numbers (LUN). LUN 0 controls the tape

drive and LUN 1 controls the robotic. The Autoloader requires an HBA that supports multiple LUNs.

If multiple LUN support is not enabled, the host computer cannot scan beyond LUN 0 to discover

the Autoloader. It just sees the tape drive.

10 Features and overview

Page 11

Parallel SCSI HP Smart Array controllers, RAID controllers, and most on-board HBAs do not support

multiple LUNs. Refer to the EBS matrix at http://www.hp.com/go/ebs for current HBA compatibility

information.

IMPORTANT: The Autoloader requires an HBA that supports multiple LUNs, which is also called

“LUN scanning.”

Interface specifications and requirements for Fibre Channel drives

The Fibre Channel tape drive can be connected directly to the server with a host bus adapter (HBA)

or through a storage area network (SAN).

Table 7 FC drive interface speeds

Supported speedsLTO generation

2 Gb, 4 Gb, 8 GbLTO-5

If you plan to connect the Autoloader directly to the server, you will need a 2 Gb, 4 Gb, or 8 Gb

Fibre Channel HBA. An 8 Gb HBA is recommended for LTO-5 tape drives for optimal performance.

Check the EBS matrix at www.hp. com/go/ebs to verify that your HBA is supported on your server

and qualified for the Autoloader.

In a SAN installation, all switches between the host and the Autoloader must be of the appropriate

type. For example, a 2 Gb switch in the path may result in performance degradation when backing

up highly compressible data to a 4 Gb tape drive. Configure zoning so only the backup servers

may access the Autoloader.

Interface specifications and requirements for SAS drives

The server must have an HP or third party SAS host bus adapter with an external connector.

Table 8 SAS drive interface speeds

Supported speedsLTO generation

1.5 Gb, 3 GbLTO-3, LTO-4

1.5 Gb, 3 Gb, 6 GbLTO-5

The device uses multiple LUNs to communicate with the Autoloader. Most SAS RAID controllers do

not support multiple LUNs. Check the EBS matrix at www.hp.com/go/ebs to find a SAS HBA that

is supported on your server and qualified with the Autoloader.

Most SAS HBA ports provide four SAS channels. The Autoloader only uses one channel. The HP

cable supplied with the Autoloader has one connector on each end, using only one of the four

channels. To use the other channels, you can purchase a SAS fanout cable, which will connect up

to four SAS tape drives to a single HBA port. When using a different cable, verify that the mini-SAS

connector for the tape drive end is keyed for location 4.

CAUTION: High quality SAS cables rated at the transfer rate of the SAS components are required.

Always verify that the SAS cable you are using is rated for the data transfer speed of the interface

of your components. SAS cables described as "equalized" may not support 6 Gb/s data rates

and should not be used with LTO-5 tape drives unless these cables are verified for 6 Gb/s data

rates. For optimum performance, only use HP cables of the length specified as qualified for your

products.

See About SAS (page 19) for more information about SAS.

Interface specifications and requirements for Fibre Channel drives 11

Page 12

LTO-4 and later generation tape drives and encryption

The LTO-4 and later generation tape drives include hardware capable of encrypting data while

writing data, and decrypting data when reading. Hardware encryption can be used with or without

compression while maintaining the full speed and capacity of the tape drive and media.

Encryption is the process of changing data into a form that cannot be read until it is deciphered

with the key used to encrypt the data, protecting the data from unauthorized access and use. LTO

tape drives use the 256-bit version of the industry-standard AES encrypting algorithm to protect

your data.

To make use of this feature you need:

• The HP StorageWorks 1/8 G2 & MSL Encryption Kit or a backup application that supports

hardware encryption.

• LTO-4 or LTO-5 media; no encryption will be performed when writing LTO-3 and earlier

generations of tape.

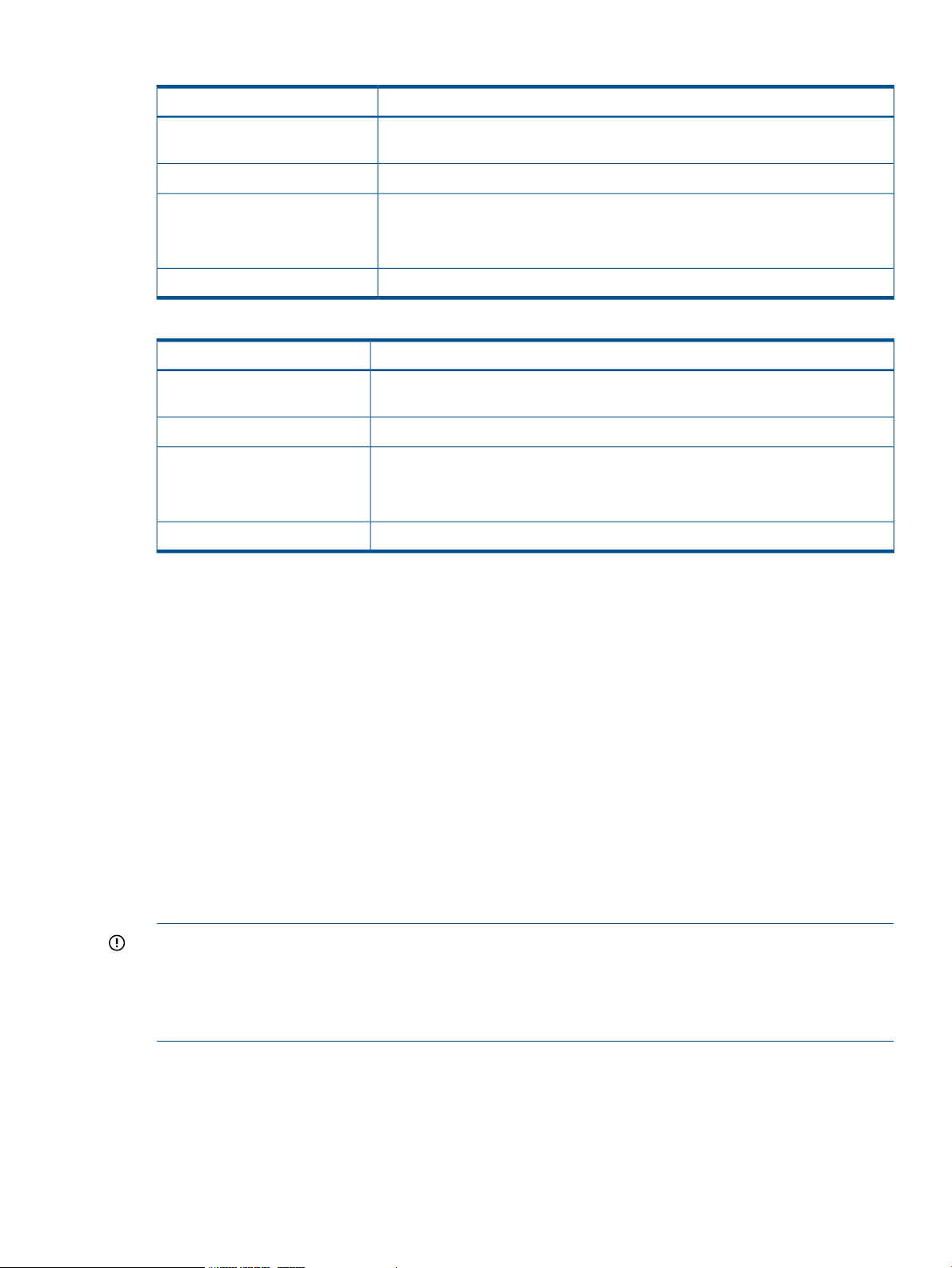

Table 9 Backward read compatibility

LTO-5 driveLTO-4 drive

IncompatibleIncompatibleLTO-1 media

IncompatibleRead onlyLTO-2 media

Read onlyRead/Write (no encryption)LTO-3 media

Your company policy will determine when you need to use encryption. For example, it may be

mandatory for company confidential and financial data, but not for personal data. Company policy

will also define how encryption keys should be generated and managed. Backup applications that

support encryption will generate a key for you or allow you to enter a key manually.

Using the Encryption Kit

The Encryption Kit includes two USB key server tokens. One key server token is available for use

as a backup for the other. Alternatively, you can save the encryption keys to a file and store that

file in a safe location.

To use the Encryption Kit, a key server token is inserted in the USB port on the back of the

Autoloader, and encryption is enabled and configured from the RMI.

The Encryption Kit supports your manual security policies and procedures by providing secure

storage for encryption keys. Access to the key server tokens and their backup files is protected with

user-specified passwords. You will need to create processes to protect the tokens and secure the

passwords.

Read/WriteRead/WriteLTO-4 media — unencrypted

Read/Write with encryption keyRead/Write with encryption keyLTO-4 media — encrypted

Read/WriteIncompatibleLTO-5 media — unencrypted

Read/Write with encryption keyIncompatibleLTO-5 media — encrypted

IMPORTANT: When encryption is enabled with the Encryption Kit, the Autoloader will not use

encryption keys from other sources, such as a key management system or application software.

Disable encryption in applications writing to the Autoloader when encryption is enabled with the

Encryption Kit. Applications that attempt to control encryption while encryption is enabled with the

Encryption Kit will not be able to do so, which can cause backups or other write operations to fail.

See the Encryption Kit user guide for additional information on using the Encryption Kit.

12 Features and overview

Page 13

Using application-managed encryption

Hardware encryption is turned off by default and is switched on by settings in your backup

application, where you also generate and supply the encryption key. Your backup application

must support hardware encryption for this feature to work. See http://www.hp.com/go/ebs for

an up-to-date list of other suitable backup software.

NOTE: The Autoloader can only obtain encryption keys from one source. Using the Encryption

Kit will prevent application-managed encryption.

Encryption is primarily designed to protect the media once it is offline and to prevent it being

accessed from another machine. You will be able to read and append the encrypted media without

being prompted for a key as long as it is being accessed by the machine and application that first

encrypted it.

There are two main instances when you will need to know the key:

• If you try to import the media to another machine or another instance of the backup application

• If you are recovering your system after a disaster

NOTE: Encryption with keys that are generated directly from passwords or passphrases may be

less secure than encryption using truly random keys. Your application should explain the options

and methods that are available. Please refer to your application's user documentation for more

information.

If you are unable to supply the key when requested to do so, neither you nor HP Support will be

able to access the encrypted data.

This guarantees the security of your data, but also means that you must be careful in the management

of the encryption key used to generate the tape.

CAUTION: You should keep a record or backup of your encryption keys and store them in a

secure place separate from the computer running the backup software.

For more information about AES encryption, encryption keys, and using hardware encryption with

your HP Ultrium tape drive, see the White Papers on http://h18006.www1.hp.com/storage/

tapewhitepapers.html.

For detailed instructions about enabling encryption please refer to the documentation supplied with

your backup application or with the HP StorageWorks 1/8 G2 and MSL Encryption Kit. This will

also highlight any default states, for example when copying tapes, that may need changing if

using encrypted tapes.

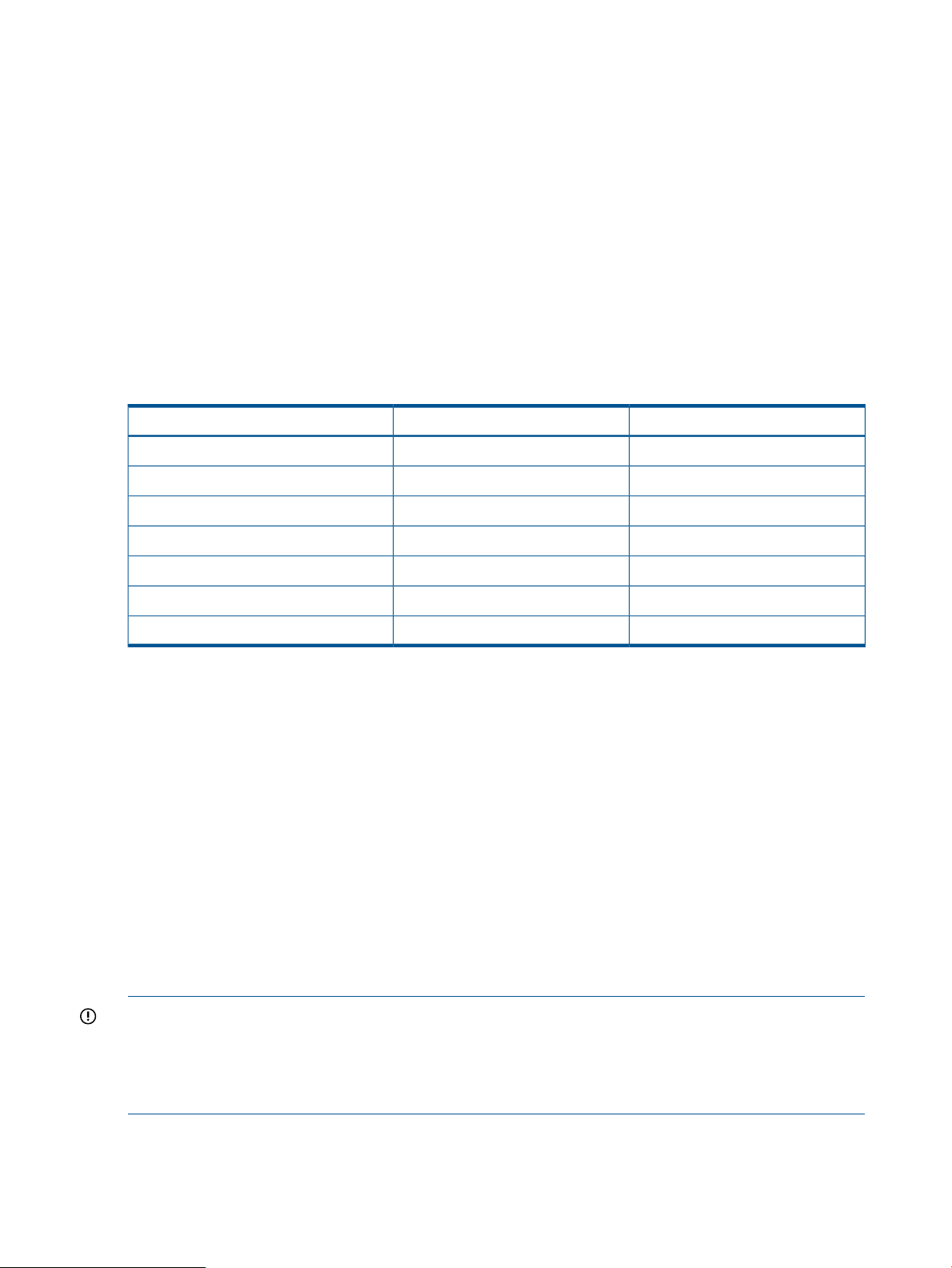

Front panel overview

The front panel provides access to the power button, operator control panel, left and right

magazines, LEDs, and the mailslot as shown in Figure 1 (page 14). See Operator control panel

(OCP) (page 64) for OCP functions.

Front panel overview 13

Page 14

Figure 1 Front panel overview

2. Mailslot1. Power button

4. Front panel LCD screen3. Front panel LEDs

6. Air vents5. Control buttons

7. Magazine

The operator control panel includes four LEDs that indicate system status information as shown in

Figure 2 (page 14).

Figure 2 Operator control panel LEDs

Ready. Illuminated when power is on. Blinking when there is tape drive or robotics activity.Green1.

Amber2.

Amber4.

Clean. Illuminated when the tape drive has determined that a cleaning cartridge should be used.

Cleaning is only necessary when the device directs you to do so. Additional cleaning is not

necessary.

Attention. Illuminated if the device has detected a condition that requires attention by the operator.Amber3.

Error. Illuminated if an unrecoverable error occurs. A corresponding error message displays on

the LCD screen (see Troubleshooting (page 86) for more information).

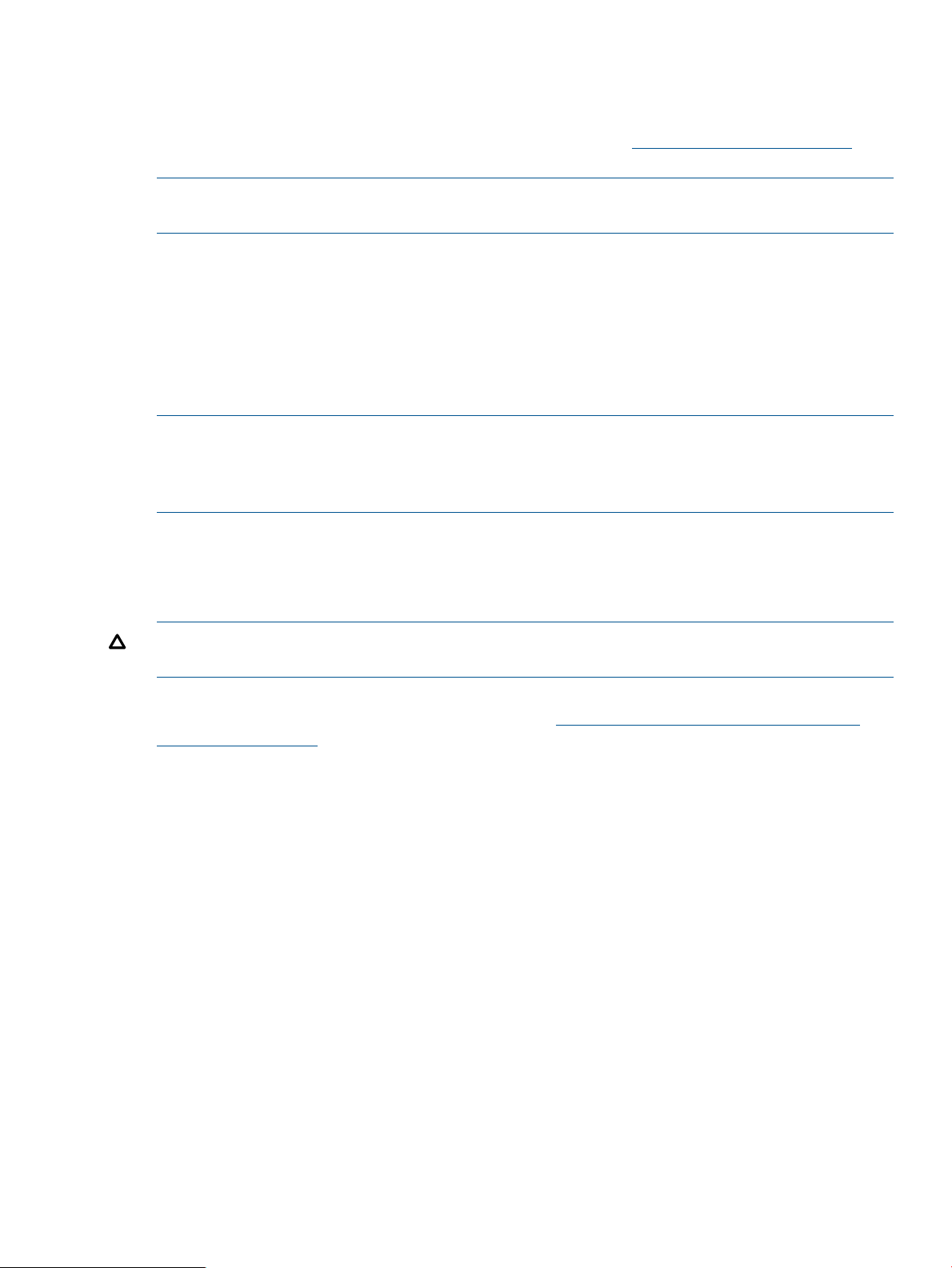

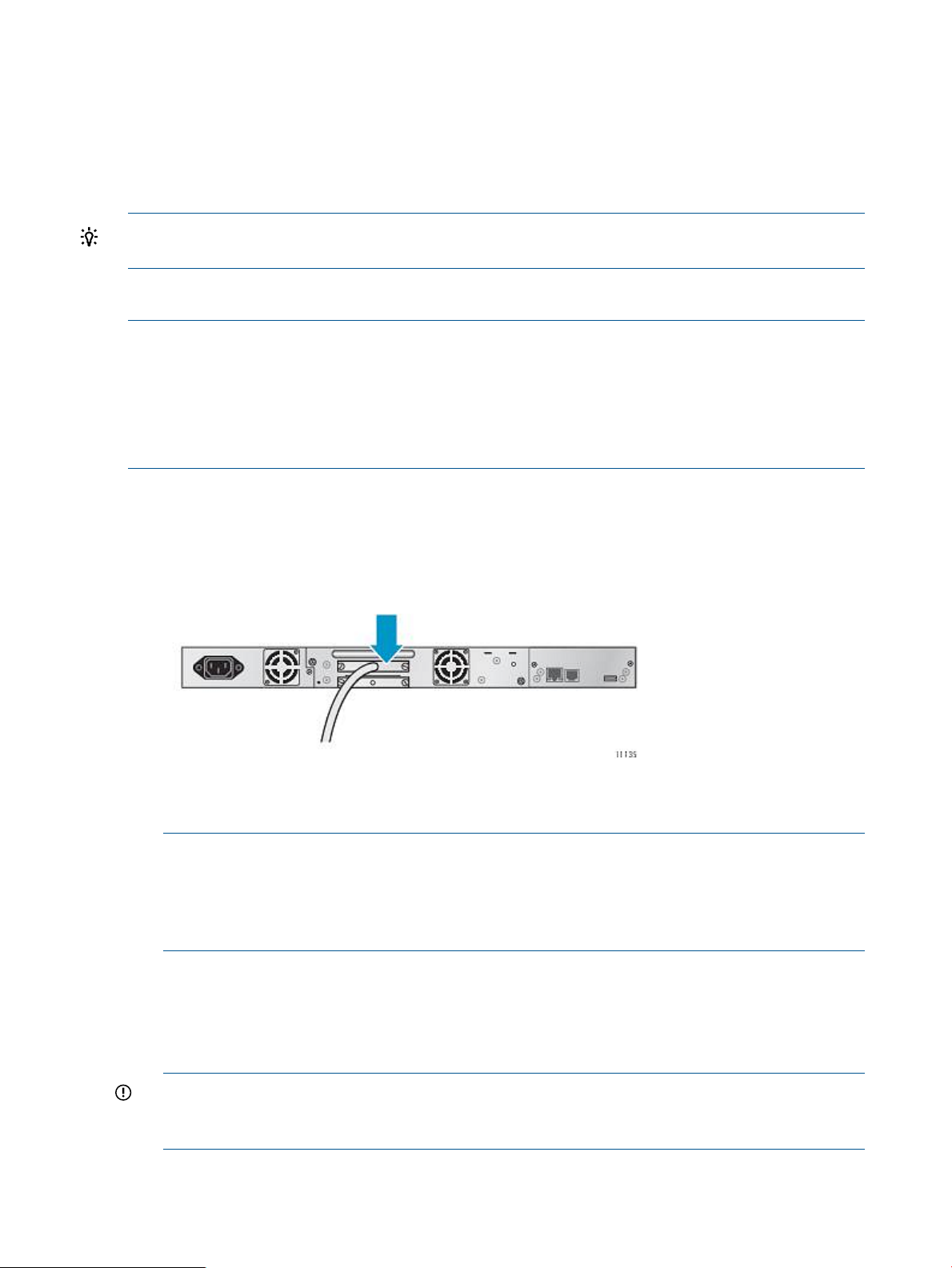

Back panel overview

The back panel provides access to the drive interface connectors, the tape drive, the power

connector, the Ethernet, serial and USB ports, and the magazine release holes as shown in

Figure 3 (page 14), Figure 4 (page 15), and Figure 5 (page 15).

Figure 3 Back panel overview with parallel SCSI tape drive

2. Fan vent1. Power connector

4. Magazine release hole3. Tape drive

6. Serial port (Factory use only)5. Ethernet port

8. Shipping lock storage location7. USB port

14 Features and overview

Page 15

9. 68–pin parallel SCSI connector

11. Tape drive LED

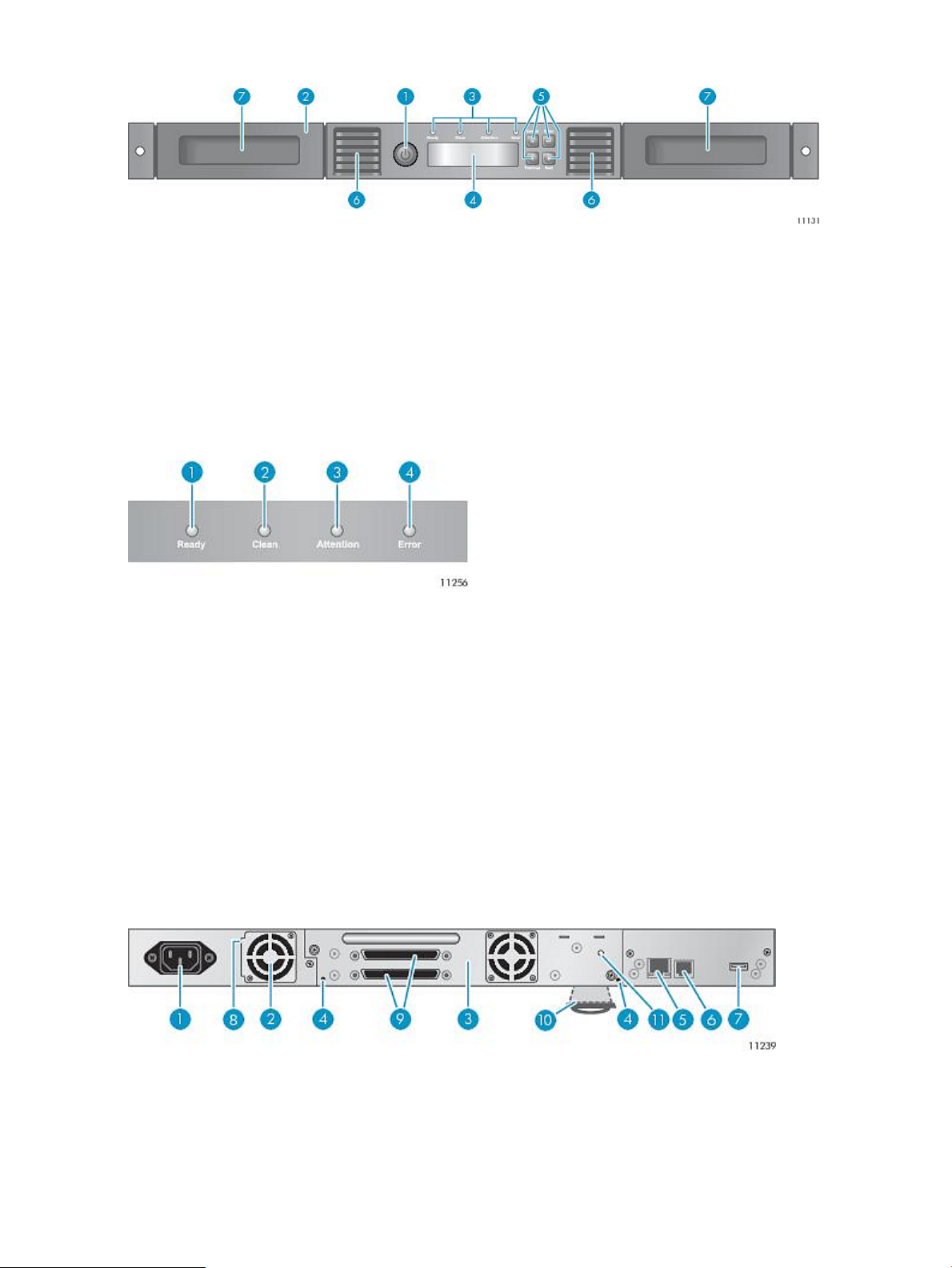

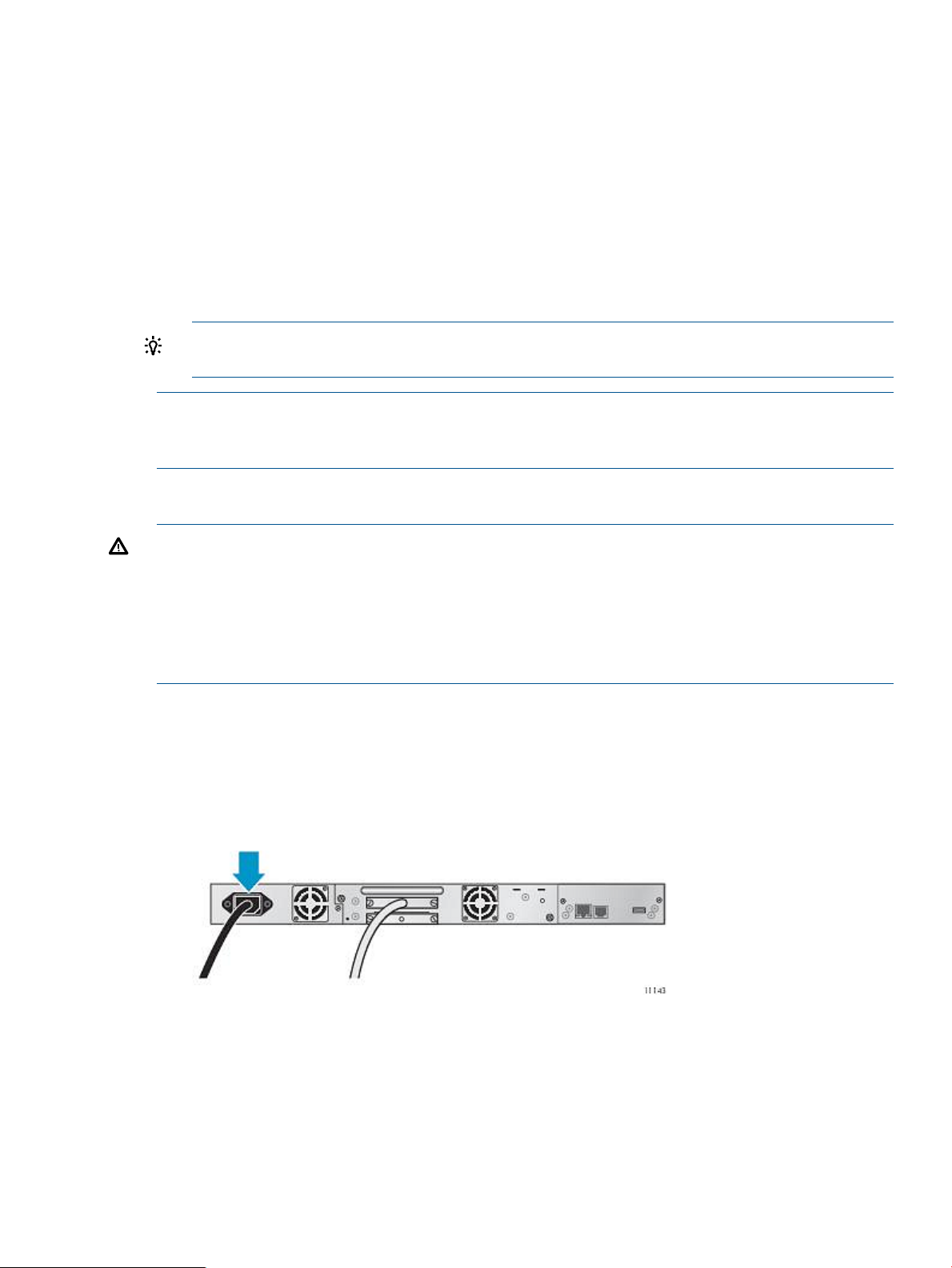

Figure 4 Back panel overview with SAS tape drive

9. SAS port

Figure 5 Back panel overview with FC tape drive

10. Pull-out tab containing the serial number and other

product information.

2. Fan vent1. Power connector

4. Magazine release hole3. Tape drive

6. Serial port (Factory use only)5. Ethernet port

8. Shipping lock storage location7. USB port

10. Pull-out tab containing the serial number and other

product information.

12. Tape drive Ethernet port (LTO-5 only)11. Tape drive LED

9. FC port

The device requires a 110/220 volt AC power connection.

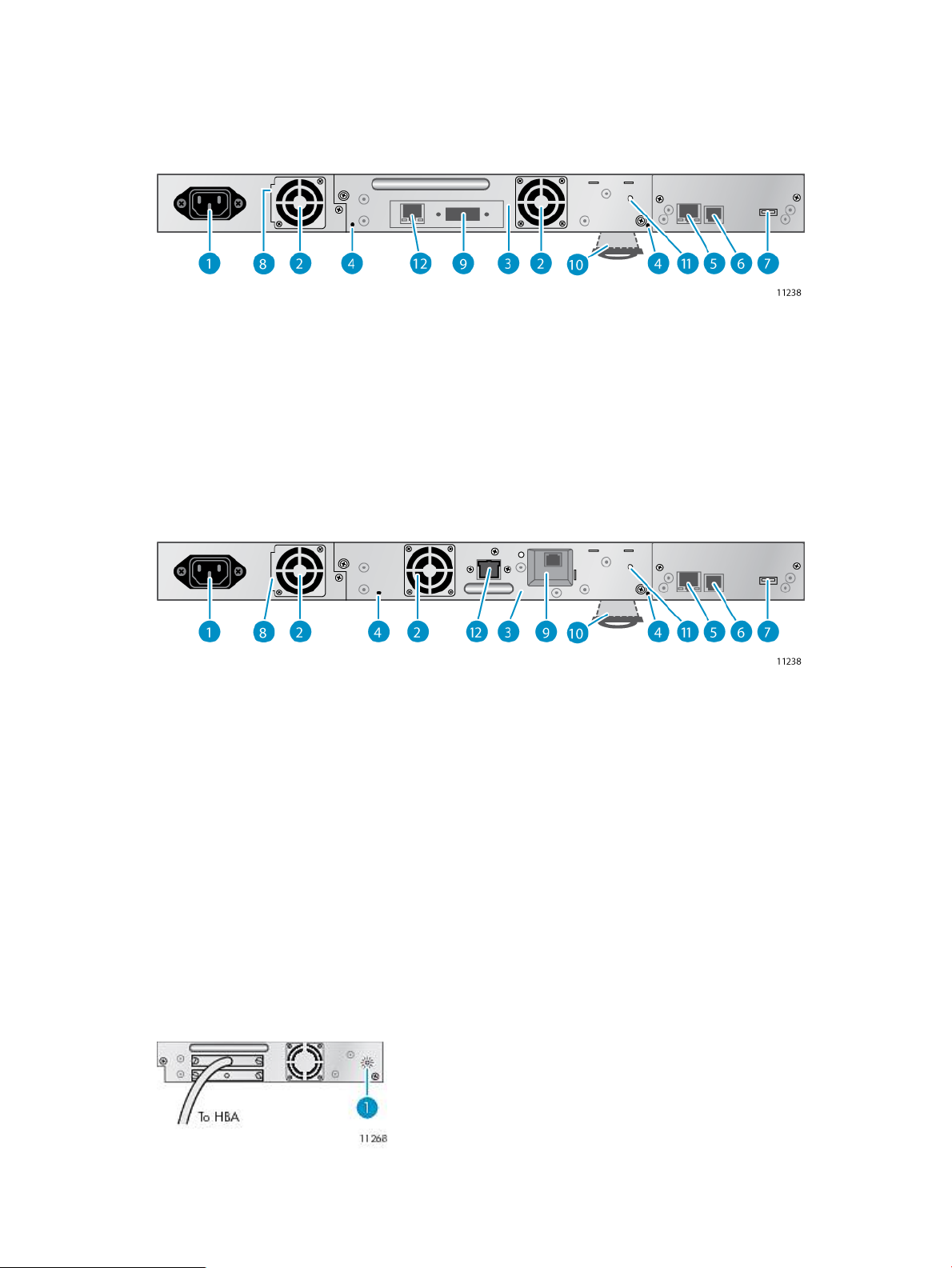

Tape drive LED

Each tape drive has a green LED, which indicates that the tape drive is powered on (see

Figure 6 (page 15)).

Figure 6 Tape drive LED

2. Fan vent1. Power connector

4. Magazine release hole3. Tape drive

6. Serial port (Factory use only)5. Ethernet port

8. Shipping lock storage location7. USB port

10. Pull-out tab containing the serial number and other

product information.

12. Tape drive Ethernet port (LTO-5 only)11. Tape drive LED

1. Tape drive LED

Tape drive LED 15

Page 16

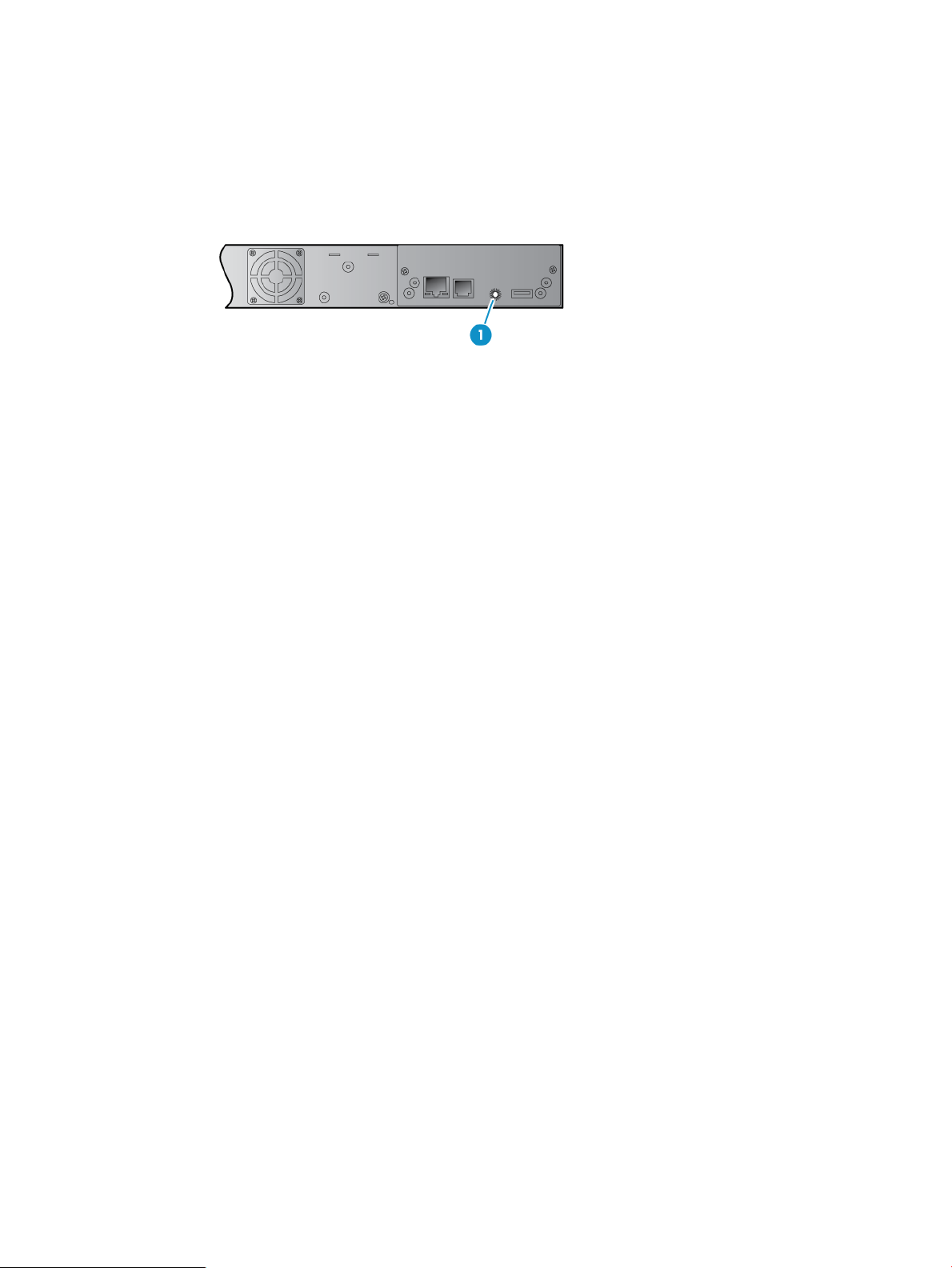

Controller health status indicator

The controller health status indicator is a green LED that pulses on and off in approximately one

second cycles during normal operation. The LED is located on the back of the device in the lower

right corner, as shown in Controller health status indicator location (page 16).

Figure 7 Controller health status indicator location

1. Controller health status LED

16 Features and overview

Page 17

2 Installing the Tape Autoloader

This chapter contains the information you need to install and configure your Tape Autoloader. The

installation steps are:

• Preparing the host

• Planning the SCSI configuration, Planning the SAS configuration, or Planning the Fibre Channel

configuration

• Choosing a location

• Unpacking the shipping container

• Identifying product components

• Attaching the feet

• Removing the shipping lock

• Mounting the device in a rack

• Installing the Tabletop Conversion Kit

• Changing the SCSI address

• Connecting the SCSI cable (parallel SCSI devices only)

• Connecting the Fibre Channel cables (Fibre Channel devices only)

• Connecting the SAS cable (SAS devices only)

• Powering on the device

• Configuring the device

• Verifying the connection

• Labeling and loading the tape cartridges

• Verifying the installation

• Configuring additional features

Preparing the host

IMPORTANT: Use proper procedures to prevent electrostatic discharge (ESD) (see Appendix:

Electrostatic discharge (page 158)). Use wrist-grounding straps and anti-static mats when handling

internal components.

Follow these general steps:

• If the host server is connected to a network, check with the system administrator before powering

off the computer.

• For parallel SCSI Autoloaders, install a parallel SCSI host bus adapter (HBA) that supports

multiple LUNs. Refer to the manuals for the host computer and the HBA for installation

information. See Parallel SCSI host bus adapters (HBAs) (page 10) for HBA requirements.

• For SAS Autoloaders, install a SAS host bus adapter (HBA) with an external SAS connector

that supports multiple LUNs. Refer to the manuals for the host computer and the HBA for

installation information. See Planning the SAS configuration (page 19) for configuration

requirements.

• For Fibre Channel Tape Autoloaders, install an FC host bus adapter (HBA) or verify that you

have sufficient ports available on a compatible Fibre Channel switch. See Planning the Fibre

Channel configuration (page 20) for configuration requirements.

Preparing the host 17

Page 18

• Install application software and compatible drivers on the host computer. See the application

software manuals for installation and configuration information.

• Make sure multiple LUN support is enabled on the host computer. See Multiple LUN

support (page 10).

Planning the parallel SCSI configuration

If the host computer will have multiple parallel SCSI devices, you must decide how they will be

configured into one or more parallel SCSI busses.

About parallel SCSI busses

A parallel SCSI bus consists of the host bus adapter (HBA), the parallel SCSI devices, the parallel

SCSI cables, and the terminators. The HBA and devices are connected in a chain, with each device

connected to the next. The last device must have a SCSI terminator. Each device in the chain must

have a unique SCSI address (SCSI ID).

Complex devices, such as the Autoloader, assign sub-addresses, called logical unit numbers (LUNs),

to different parts of the device. The HBA and operating system must support multiple LUNs, also

called LUN scanning, for the application software to operate the Autoloader. HP Smart Array

controllers, most third-party RAID controllers, and many on-board SCSI controllers do not support

multiple LUNs.

An HBA might have one or two channels, with each channel supporting one parallel SCSI bus.

Check to see how many channels the HBA has and what devices are already connected to the

HBA. Some devices, such as parallel SCSI disk drives, could be inside the server.

The devices on a parallel SCSI bus share bandwidth so be careful about which devices you put

together on a bus. Also, putting a single-ended (SE) SCSI device on the bus will slow all of the

devices on the bus down to SE speed. Check each device's interface specifications to see what

kind of parallel SCSI interface it has.

Optimizing throughput

If possible, put the Autoloader on its own parallel SCSI bus. This will give you the best performance

and easiest installation.

If a tape drive must share a parallel SCSI bus with one or more other devices, follow these guidelines

to plan your parallel SCSI busses for the highest performance:

• Do not put a tape drive on the same parallel SCSI bus as a disk drive because the system and

backup performance will be slow when data is written from the hard drive to tape or from

tape to the hard drive.

• Do not put a tape drive on the same parallel SCSI bus as a disk array because the disk and

the tape drive performance will be affected, most RAID controllers do not support multiple

LUNs, and the data on the disk array could become corrupted.

• Avoid putting an SE SCSI device on the same bus as a tape drive because the SE device will

slow the tape drive to SE speed and reduce the allowable cable length.

SCSI addresses

Verify that each device on the bus has a unique SCSI address (SCSI ID). The pre-configured SCSI

address for the Autoloader is 4. If 4 is already used for another device, you will need to change

the SCSI address of the Autoloader during the installation process.

NOTE: The HBA also has a SCSI address, which is typically 7.

NOTE: Use the HP Library & Tape Tools to check your server's parallel SCSI configuration. The

HP Library & Tape Tools utility is available without cost at www.hp.com/support/TapeTools.

18 Installing the Tape Autoloader

Page 19

Planning the SAS configuration

The key steps in planning the SAS configuration are obtaining a suitable HBA and cable.

The Autoloader uses two SCSI logical unit numbers (LUNs) and requires an HBA with multiple LUN

support. Most HP SAS RAID controllers support Tape Libraries; many non-HP SAS RAID controllers

to not support Tape Libraries. To verify the specifications of your HBA or find a list of compatible

HBAs, review the compatibility matrix on the Enterprise Backup Solutions web site at: http://

www.hp.com/go/ebs.

CAUTION: Do not connect the Autoloader to a SAS RAID controller unless the EBS matrix shows

that the controller is qualified with the Autoloader. The server might not be able to boot when the

Autoloader is connected to a non-supported SAS RAID controller.

About SAS

Serial Attached SCSI (SAS) is a computer bus technology mainly used to transfer data to and from

storage devices, including disk drives and tape drives. SAS-1 (LTO-4) is designed to transfer data

at 3 Gb/sec, which is comparable to the speed attained by Ultra320 SCSI. SAS-2 (LTO-5) is

designed to transfer data at 6 Gb/sec.

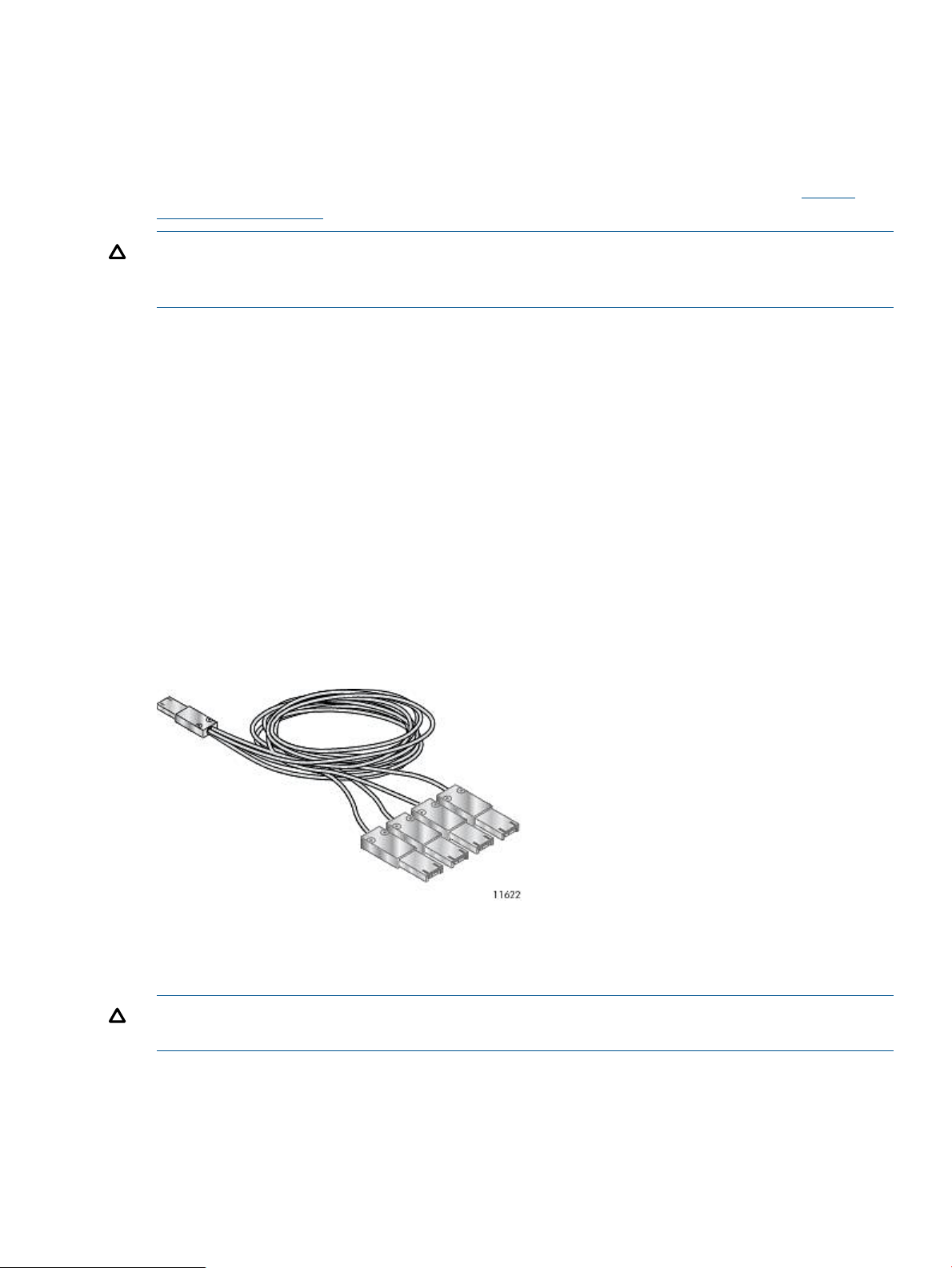

SAS cables and connectors

SAS uses serial connections, with a direct connection between the host server and each of the

storage devices. This eliminates the need to configure SCSI busses and assign SCSI IDs, as is

required for parallel SCSI devices.

Most SAS HBA ports have four SAS channels. A tape drive uses one channel, so each HBA port

can support up to four tape drives. You can use a cable with one connector on each end, but only

one channel will be used. To use the other channels, you can purchase a SAS fanout cable with

a connector for each tape drive, as shown in Example SAS fanout cable (page 19).

Figure 8 Example SAS fanout cable

The Autoloader has a mini-SAS connector on the tape drive. The connector is keyed in location 4,

which is the standard location for end devices. If you use a cable other than the one supplied with

the product, verify that it is keyed in location 4.

CAUTION: Mini-SAS connectors are keyed. Do not force a SAS cable's mini-SAS connector into

the tape drive mini-SAS connector because it might be keyed differently.

Planning the SAS configuration 19

Page 20

SAS signal rates require clean connections and a minimum number of connections between the

HBA and the device. Do not use adapters or converters between the HBA and the device. HP

recommends a maximum SAS cable length of six meters.

CAUTION: High quality SAS cables rated at the transfer rate of the SAS components are required.

Always verify that the SAS cable you are using is rated for the data transfer speed of the interface

of your components. SAS cables described as "equalized" may not support 6 Gb/s data rates

and should not be used with LTO-5 tape drives unless these cables are verified for 6 Gb/s data

rates. For optimum performance, only use HP cables of the length specified as qualified for your

products.

World Wide identifiers

A SAS tape drive is identified by a unique identifier called a World Wide Name (WWN) or World

Wide Identifier (WWID). The Autoloader assigns the World Wide identifier to the drive bay. When

a tape drive is replaced, the World Wide identifier is re-assigned to the new tape drive.

Planning the Fibre Channel configuration

You can connect the Autoloader directly to the server with a host bus adapter (HBA) or indirectly

through a storage area network (SAN) with a switch.

Direct connection

If you plan to connect the Autoloader directly to the server, you will need a 2 Gb, 4 Gb, or 8 Gb

Fibre Channel HBA. An 8 Gb HBA is recommended for LTO-5 tape drives for optimal performance.

Check the EBS matrix at www.hp. com/go/ebs to verify that your HBA is supported on your server

and qualified for the Autoloader.

A server that uses Fibre Channel disks needs at least two FC ports. Using the same port for disk

and tape access will cause performance degradation.

SAN connection

All switches between the host and the Autoloader must be of the appropriate type. A 2 Gb switch

in the path may result in performance degradation when backing up highly compressible data.

Configure zoning on the Fibre switch so only the backup servers may access the Autoloader. See

the switch manual for information on zoning.

Choosing a location

If you plan to mount the device in a rack, select an open rack location, ideally near the center of

the rack or higher, with access to the host server and a power outlet. You may also set the

Autoloader on a shelf in the rack. In this case you must attach the feet during the installation process.

If you plan to set the Autoloader on a table, select a level area large enough to support both edges

of the Autoloader with access to the host server and a power outlet.

Choose a location that meets the criteria shown in Location criteria (page 20):

Table 10 Location criteria

Tabletop requirements

20 Installing the Tape Autoloader

DefinitionCriteria

The Autoloader can only be placed on a flat surface if the support feet have been properly

applied or the Autoloader is mounted in the optional tabletop conversion cover. Select a

location that is flat, sturdy, and close to the host server. Ensure that all of the feet on the

Autoloader or tabletop conversion cover will be supported.

Do not place the device on the floor or other carpeted surface.

Page 21

Table 10 Location criteria (continued)

DefinitionCriteria

Do not place the Autoloader on its sides or upside down. Do not put anything on top of the

Autoloader unless the optional tabletop conversion cover is installed. The tabletop conversion

cover can support up to 15 kg (33 lb).

HP Rack 5000, 10000 Series, HP Rack System/ERack requirements

1U when mounted in the optional rack railsRack space

requirements

10-35º C (50-95º F)Room temperature

AC power voltage: 100-127 VAC; 200-240 VACPower source

Line frequency: 50-60 Hz

Place the device near an AC outlet. The AC power cord is the product's main AC disconnect

device and must be easily accessible at all times.

11.5 kg (25.4 lb)Weight without media

13.1 kg (28.9 lb)Weight with media

Air quality

The device should be placed in an area with minimal sources of particulate contamination.

Avoid areas near frequently used doors and walkways, stacks of supplies that collect dust,

printers, and smoke-filled rooms.

Excessive dust and debris can damage tapes and tape drives.

20-80 percent relative humidity non-condensingHumidity

Back: Minimum of 15.4 cm (6 inches)Clearance

Front: Minimum of 30.8 cm (12 inches)

Sides: Minimum of 5.08 cm (2 inches)

Unpacking the shipping container

Before you begin, clear a level work surface near where you will place the Autoloader.

CAUTION: If the temperature in the room where the device will be installed varies by 15º C (30º

F) from the room where it was stored, allow it to acclimate to the surrounding environment for at

least 12 hours before unpacking it from the shipping container.

Unpacking the Tape Autoloader:

1. Inspect the container for shipping damage. If you notice any damage, report it to the shipping

company immediately.

2. Open the shipping container and remove the packaging foam and accessories that cover the

device.

3. Lift the device out of the carton, place it on the work surface.

CAUTION: Do not place the Autoloader on either end or its sides as this may damage it.

4. Remove any other accessories from the shipping container. Save the packaging materials for

future use.

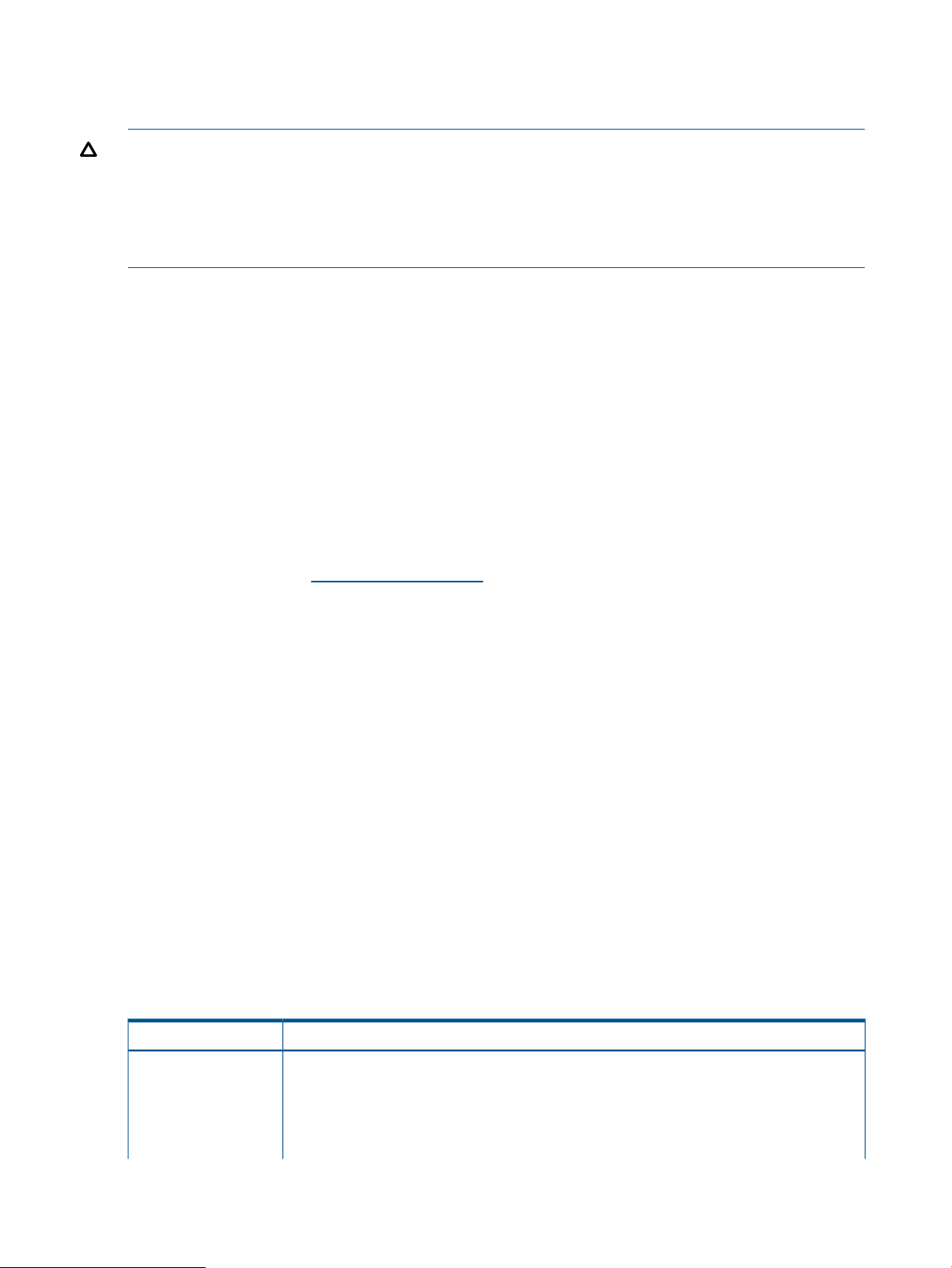

Identifying product components

Confirm that you received the product components shown in Product components (page 22).

Unpacking the shipping container 21

Page 22

Figure 9 Product components

1. Autoloader

7. HP OpenView Data Protector Express Single Server

Edition CD

Attaching the feet

If you plan to mount the Autoloader in a rack or in the optional Tabletop Conversion Cover, skip

this step and continue with Removing the shipping lock (page 23).

CAUTION: The Autoloader must be supported under both side edges to operate properly. If the

Autoloader is not mounted in a rack or in the tabletop conversion kit, you must apply the feet.

Do not put anything on top of the Autoloader. Weight on top of the Autoloader can prevent the

robotic inside from moving properly. If you must place items on top of the Autoloader, install it in

the optional tabletop conversion cover, which can support up to 15 kg (33 lb).

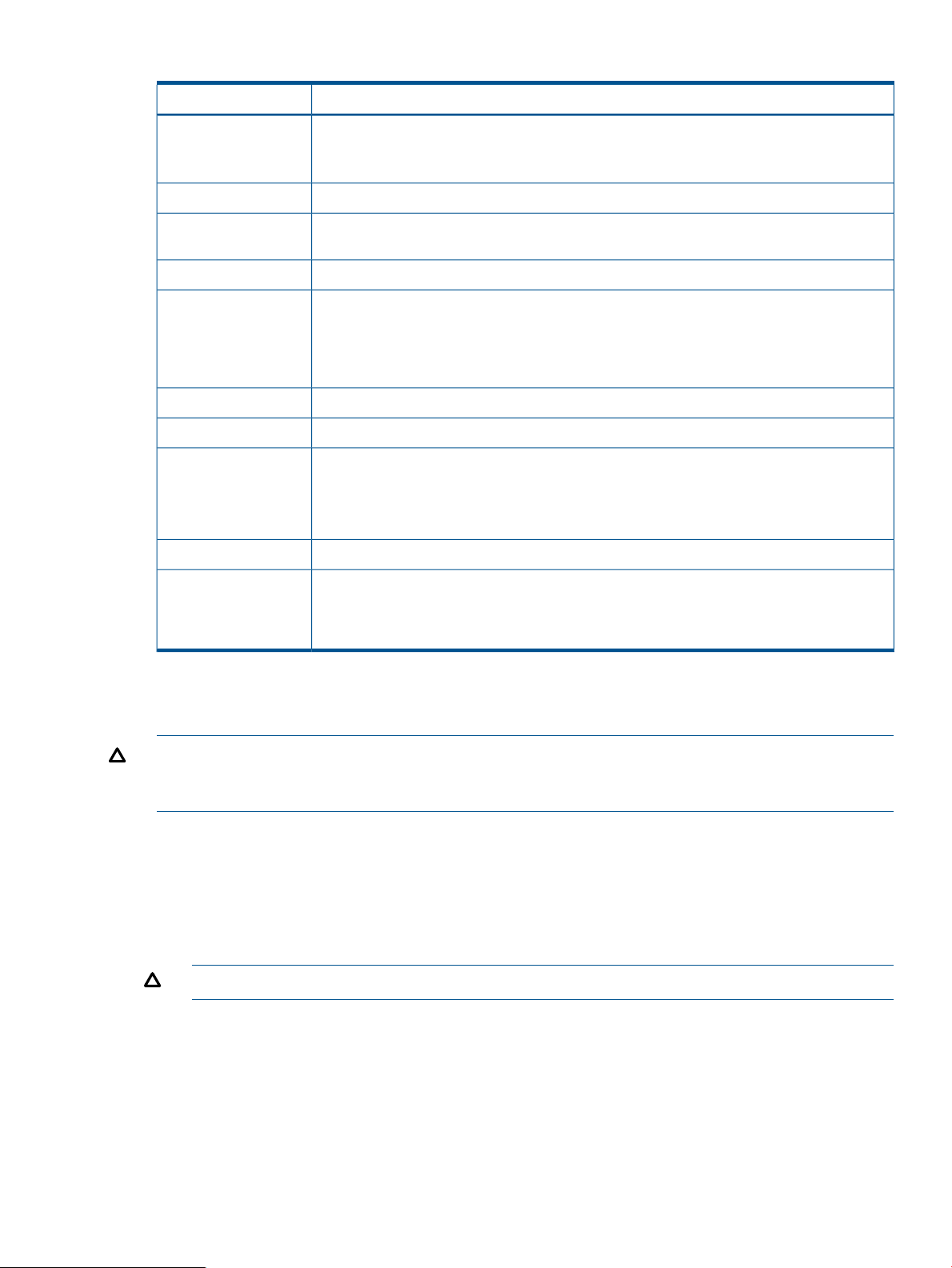

You need the six support feet from the accessory package for this procedure.

To attach the feet:

1. Verify that there are no tape cartridges in the Autoloader.

IMPORTANT: The Autoloader may be damaged if it is turned over with tape cartridges in

the magazines or robot. If the Autoloader has been used before, use the manual magazine

release to remove the cartridges from the magazines (see Using the manual release (page 134).

2. Parallel SCSI or SAS interface cable (parallel SCSI and

SAS Autoloaders only)

4. Product documentation3. SCSI terminator (parallel SCSI Autoloaders only)

6. Six support feet5. Ethernet cable

2. With another person, gently turn the Autoloader over and set it on its back.

3. Locate the six inscribed foot location lines on the bottom of the Autoloader.

4. If the Autoloader is not new, clean the foot locations with a damp paper towel.

5. Peel the backing paper off each foot and apply it within a set of foot location lines (see

Attaching the feet to the bottom of the Autoloader (page 23)).

6. With another person, gently turn the Autoloader over and set it on its feet.

22 Installing the Tape Autoloader

Page 23

Figure 10 Attaching the feet to the bottom of the Autoloader

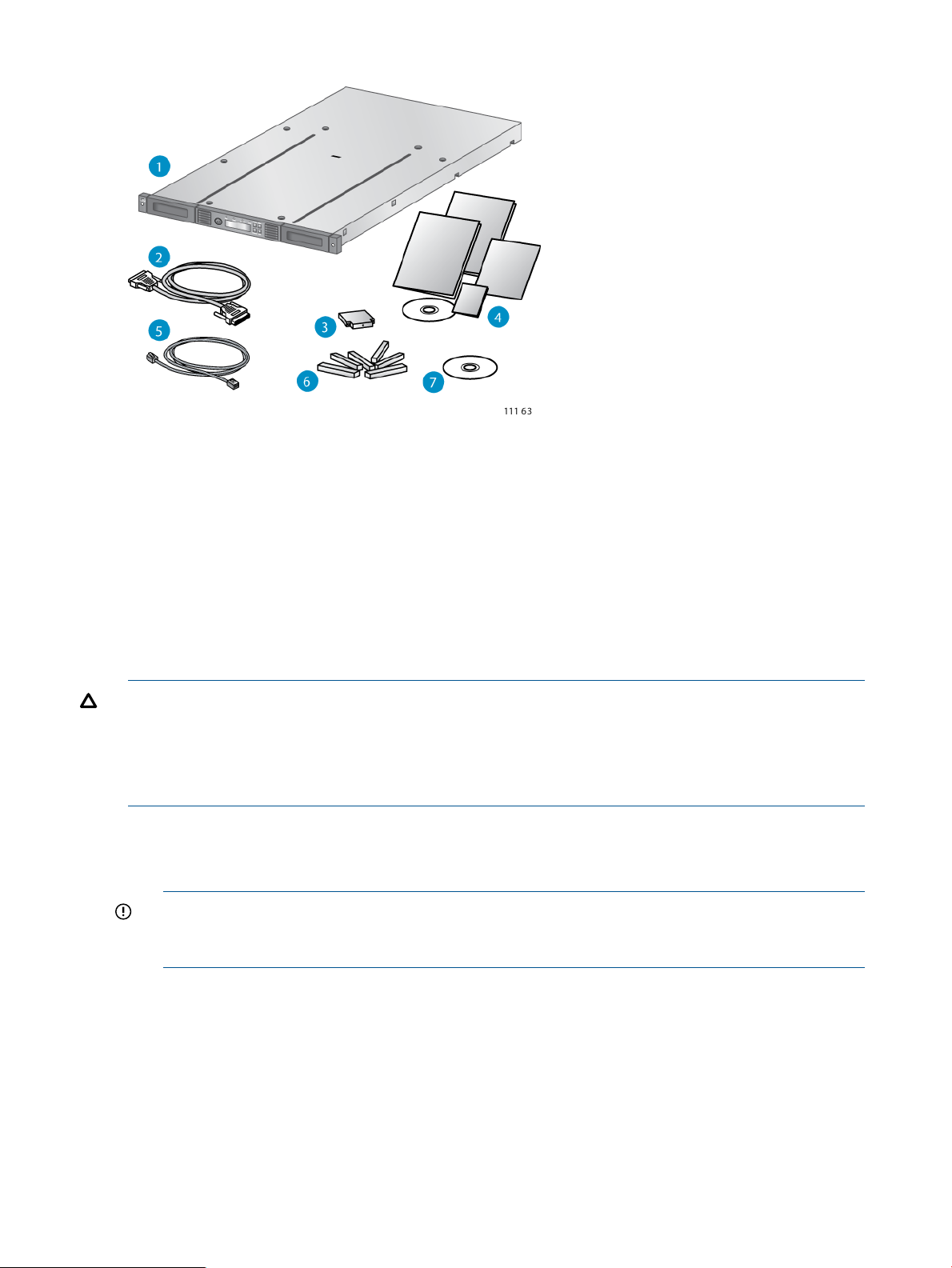

Removing the shipping lock

The shipping lock prevents the robotic transport mechanism from moving during shipment. You

must remove the shipping lock before powering on the device. The shipping lock is held in place

with a piece of tape and is located in the top center of the device. After the shipping lock is

removed, it should be stored on the back panel of the device for future use.

To remove and store the shipping lock:

1. Locate the tape and lock at the top of the device (see Shipping lock location (page 23)) .

Figure 11 Shipping lock location

2. Remove the tape, then remove the lock.

3. Store the lock on the back panel of the device (see Figure 12 (page 23)).

Figure 12 Shipping lock storage location

Removing the shipping lock 23

Page 24

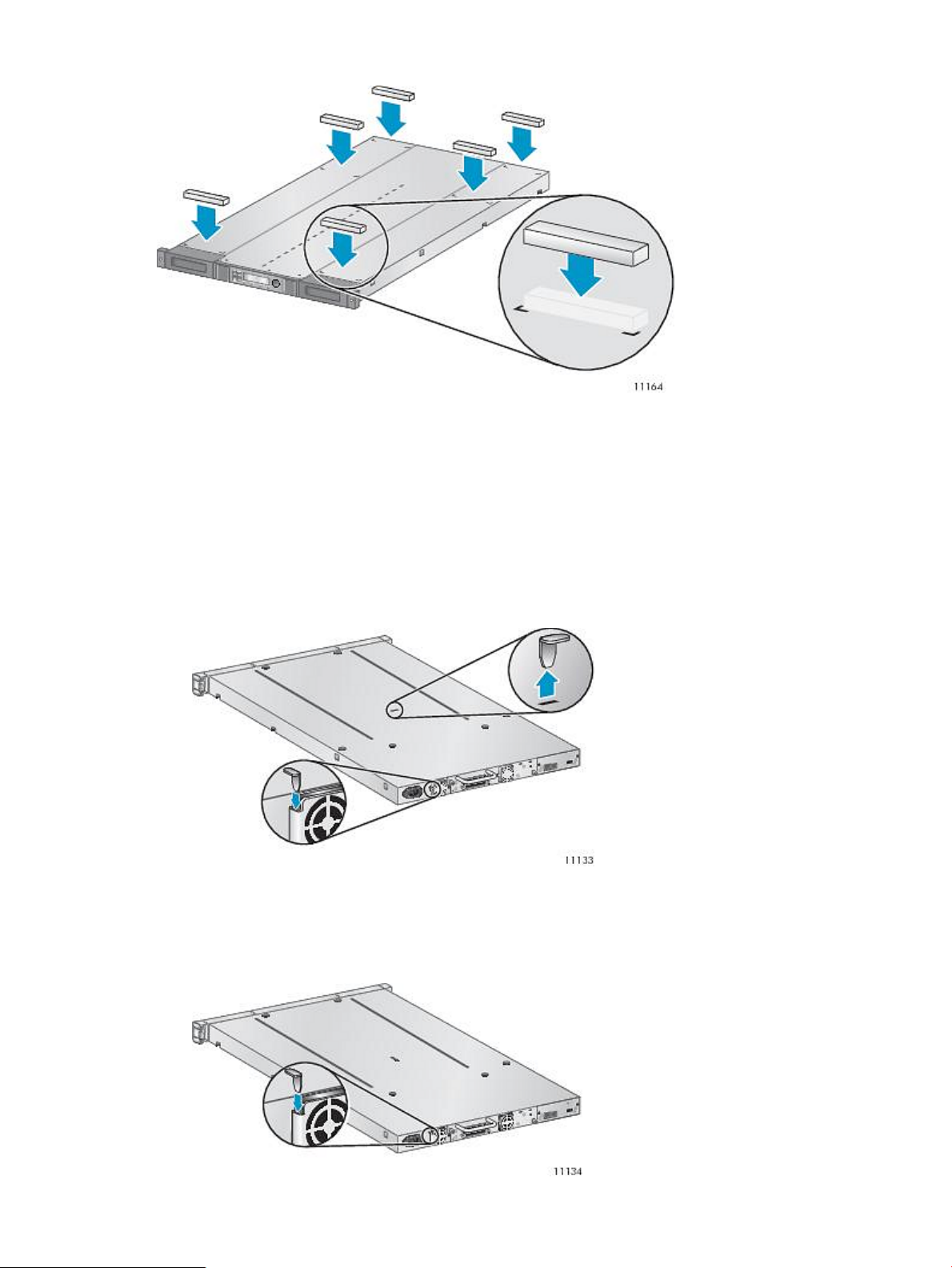

Mounting the device in a rack

If you plan to set the Autoloader on a table or rack shelf, skip this step and continue with Installing

the Tabletop Conversion Kit (page 25).

WARNING! The HP StorageWorks 1/8 G2 Tape Autoloader weighs 11.5 kg (25.4 lb) without

media and 13.1 kg (28.9 lb) with media (8 cartridges). When moving the Autoloader, to reduce

the risk of personal injury or damage to the Autoloader: 1) observe local health and safety

requirements and guidelines for manual material handing, 2) always remove all tapes to reduce

the overall weight of the Autoloader, and 3) obtain adequate assistance to lift and stabilize the

Autoloader during installation or removal.

The device easily installs into the HP Rack System/E, or the HP Rack 5000 or HP Rack 10000

series. You need a #2 and a #3 Phillips screwdriver for this procedure.

Unpack the rack kit and verify that it includes the following:

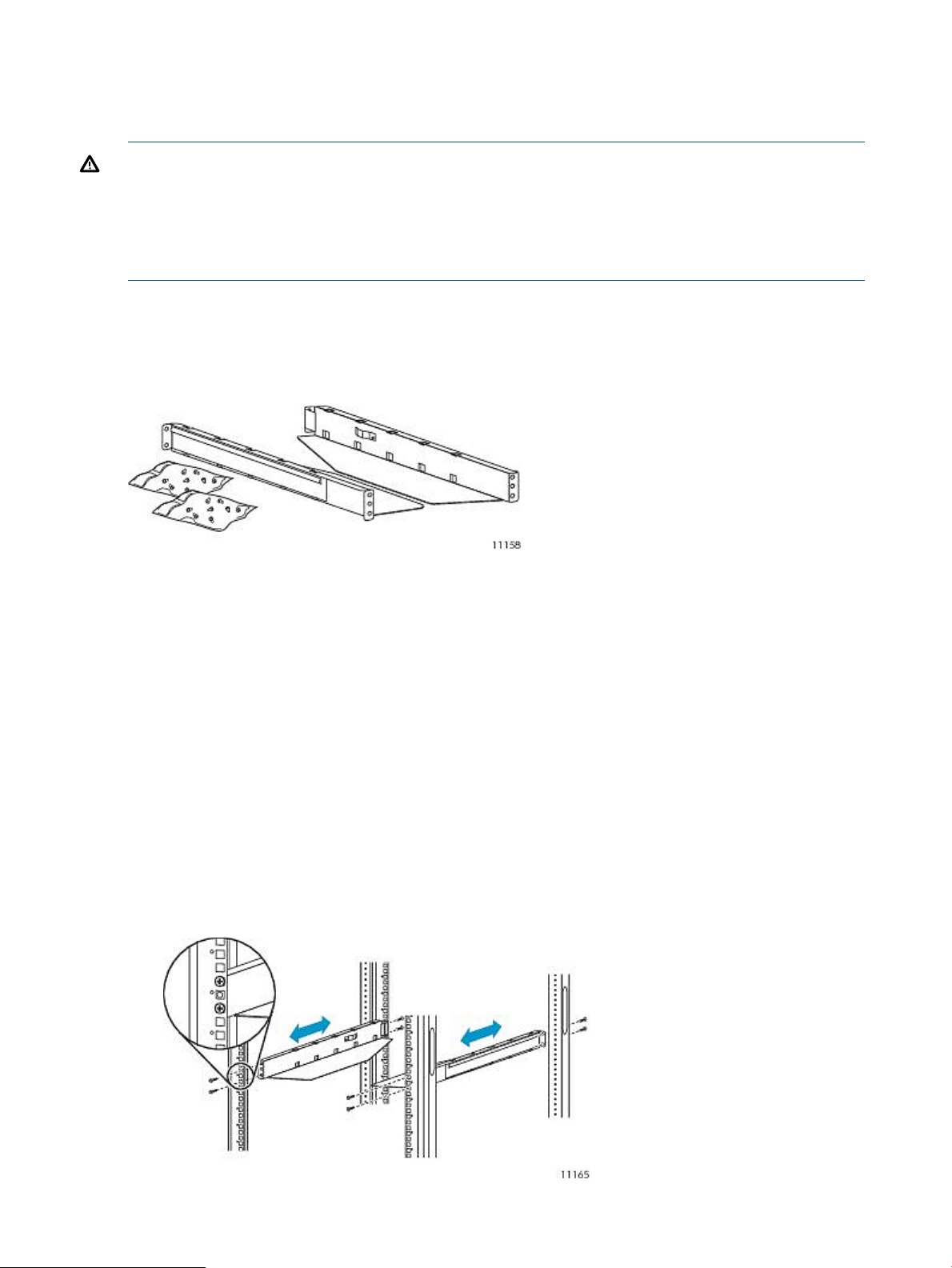

Figure 13 Rack kit

• Two rails

• Two bags of eight M6 screws.

Select the bag of screws appropriate for your type of rack.

• The HP Rack System/E rack has 7.1 mm round holes in the rack column. The packet for this

rack type is labeled HP Rack System/E.

• The HP Rack 5000 and 10000 series have 9.5 mm square holes in the rack column. The

packet for these rack types is labeled HP Rack 5000, 10000 Series.

To install the rails into the rack:

1. Using the screws for your rack type and a #3 Phillips screwdriver, secure one rail to each

side of the rack in your chosen rack location.

2. Secure the front of one rail to the front of the rack. Extend the rail to the depth of the rack and

secure the rail to the back of the rack. The front of the rails are straight and the back are

angled, as shown in Installing the rails into the rack (page 24).

Figure 14 Installing the rails into the rack

24 Installing the Tape Autoloader

Page 25

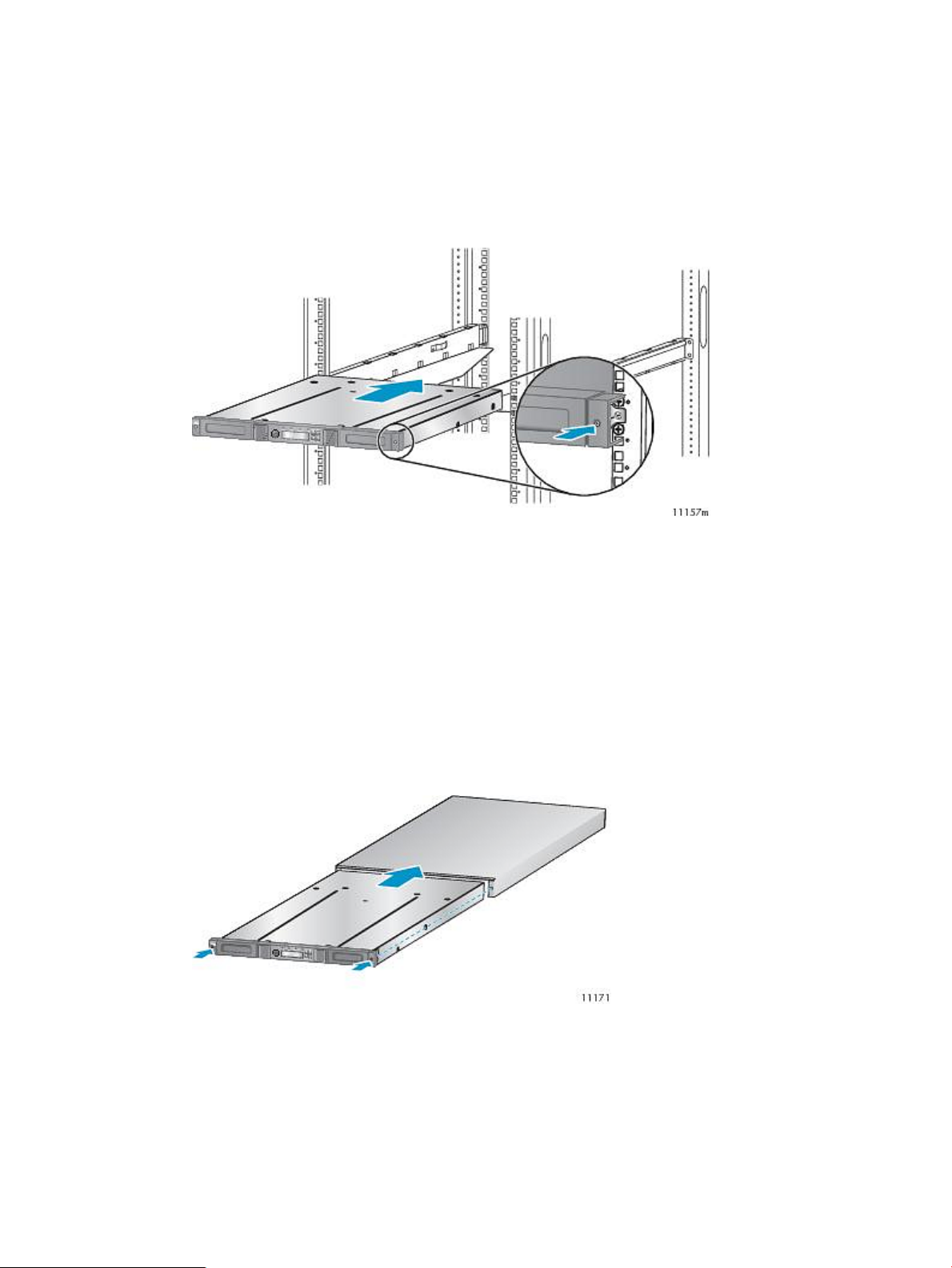

To install the device on the rails and into the rack:

1. Locate the captive screws on the front bezel (see Figure 15 (page 25)).

2. Slide the device onto the rails.

3. From the front of the device, secure the front bezel to the rack using a #2 Phillips screw driver

placed through the small holes in the mounting bracket to tighten the captive screws on each

side of the device.

Figure 15 Securing the Autoloader to the rack

Installing the Tabletop Conversion Kit

If you do not have the optional Tabletop Conversion Kit, skip this step and continue with Connecting

the SCSI cable (parallel SCSI devices only). The Rack to Tabletop Conversion Kit supports the

edges of the Tape Autoloader and is capable of holding 15 kg (33 lb).

To install the cover:

1. Place the cover on a flat, level surface behind the device.

2. Slide the device into the cover until the front panel of the device is aligned with the cover (see

Figure 16 (page 25)).

Figure 16 Installing the tabletop conversion cover

3. Tighten the captive screws on the front panel until the cover is secure.

Changing the SCSI address (parallel SCSI drives only)

If you have multiple parallel SCSI devices on the SCSI bus and another device is already using

SCSI ID 4, you must change the SCSI ID of the Autoloader.

To change the SCSI ID:

Installing the Tabletop Conversion Kit 25

Page 26

1. Plug the power cord into the power connector on the back panel and then plug the cord into

the power outlet.

2. From the front panel, push the round power button to power on the device.

3. From the front panel, set the new SCSI ID (see Changing the SCSI address — parallel SCSI

devices (Configuration > Change Drive) (page 74)).

4. Power off the device by depressing the power button on the front panel.

TIP: The SCSI ID can also be changed from the RMI Configure: Drive screen once the RMI is

configured. See Changing the drive configuration (page 49).

Connecting the parallel SCSI cable (parallel SCSI devices only)

NOTE: LTO-3 and LTO-4 tape drives are Ultra 320 SCSI LVD devices. Use only cables and

terminators specified for Ultra 320 or labeled as MultiMode. LTO-2 tape drives are Ultra 160 SCSI

LVD/SE devices; use only cables and terminators specified for Ultra 160 or Ultra 320, or labeled

as MultiMode.

NOTE: For optimal performance, a parallel SCSI tape drive should be the only device on the

bus.

To connect the parallel SCSI cable to the device:

1. HP recommends that the host server be powered off before attaching new devices.

2. Attach one end of the parallel SCSI cable (included in the accessory package) to one of the

connectors on the back panel of the tape drive (see Figure 17 (page 26)).

Figure 17 Attaching the parallel SCSI cable to the tape drive

3. Attach the other end of the parallel SCSI cable to the connector on the parallel SCSI host bus

adapter or to the connector on the previous device on the parallel SCSI bus.

NOTE: The host bus adapter should be Low Voltage Differential Signaling (LVDS). A