Page 1

TM 11-6625-2820-14&P

TECHNICAL MANUAL

OPERATOR'S, ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

SIGNAL GENERATOR SG-735 / URM-165

(HEWLETT-PACKARD MODEL 8616A)

(NSN 6625-00-254-6671)

HEADQUARTERS, DEPARTMENT OF THE ARMY

JULY 1977

Page 2

d-

●

*

Page 3

TM 11-6625-2820-14&P

C2

CHANGE

HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 2

Washington, DC, 1 January 1988

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT

AND GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

(INCLUDING DEPOT MAINTENANCE REPAIR PARTS AND SPECIAL TOOLS)

FOR

SIGNAL GENERATOR SG-735/URM-165

(HEWLETT-PACKARD MODEL 8616A)

(NSN 6625-00-254-6671)

TM 11-6625-2820-14&P, 22 July 1977, is changed as follows:

Remove old pages and insert new pages as indicated below. New or changed material is indicated by a vertical bar

1.

in the margin of the page. Added or revised illustrations are indicated by a vertical bar adjacent to the identification

number.

Remove pages

Insert pages

iii and l-O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..iii and l-O

5-17 and 5-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-17 and 5-18

2. File this change sheet in the front of the publication for reference purposes.

Distribution authorized to the Department and DOD

for official use or for administration or operational purposes. This determination

was made on 1 October 1967. Other requests for this document will be referred

to Commander, US Army Communications-Electronics Command and Fort

Monmouth, ATTN: AMSE1-ME-P, Fort Monmouth, NJ 07703-5000.

contractors only

DESTRUCTION NOTICE – Destroy by any method that will prevent disclosure of

contents or reconstruction of the document.

Page 4

By Order of the Secretary of the Army:

Official:

R.L. DILWORTH

Brigadier General, United States Army

The Adjutant General

DISTRIBUTION:

To

be distributed in accordance with DA Form 12-36 literature

requirements for SG-735/URM-165.

CARL E. VUONO

General, United States Army

Chief of Staff

Page 5

TM 1 1-6425-2820-14&P

Cl

CHANGE

No. 1

HEADQUARTERS

DEPARTMENT OF THE ARMY

WASHINGTON, DC, 11 October 1978

Operator's, Organizational, Direct Support, and

General Support Maintenance Manual

Including Repair Parts and Special Tools Lists

(Including Depot Maintenance Repair Parts and Special Tools)

For

SIGNAL GENERATOR SG-735/URM-165

(HEWLETT-PACKARD MODEL 8616A)

(NSN 6626-00-254-6671)

This Changes is current as of 16 June 1978.

TM 11-6625-2820-14&P, 22 July 1977, is changed as follows:

1. The title is changed to read as shown above.

2. Remove old pages and insert new pages as indicated below.

3. New or changed material is indicated by a vertical bar in the margin of the page.

Remove Pages

i. ii, and iii

6-9 through 6-12

111-3 and III-4

IV-1 and IV-2 (unnumbered)

4.

File this change sheet in front of the publication for reference purposes.

Insert Pages

i through iv

6-9

111-3 and III-4

IV-1 through IV-31

Page 6

TM 11-6625-2820-14&P

By Order of the Secretary of the Army:

Official:

J.C. PENNINGTON

Brigadier General, United States Army

The Adjutant General

Distribution:

Active Army:

TSG (1)

USAARENBD (1)

USAINSCOM (2)

TRADOC (2)

DARCOM {2)

TECOM (2)

OS MAJ COMD (2)

USACC (2)

HISA (Ft Monmouth) (26)

Armies (1)

USASIGS (10)

Svc Colleges(1)

Ft Carson (5)

Ft Gillem (10)

Ft Huachuca (5)

Ft Richardson (CERCOM Ofc) (1)

WSMR(l]

USAERDAA (l)

USAERDAW (1)

Army Dep (1) except

LBAD (10)

SAAD (30)

SHAD (3)

(14)

TOAD

USA Dep (1)

Sig Sec USA Dep (1)

Units Org Under Fol TOE:

29-134

29-136

(1 cy each unit)

29-207

29-610

(2

copies each

unit)

BERNARD W. ROGERS

General, United States Army

Chief of Staff

ARNG:

None

USAR:

None

For explanation of abbreviations used, see AR 310-50.

U.S. GOVERNMENT PRINTING OFFICE: 1979-603-028/596

Page 7

This manual contains copyright material reproduced by permission of the Hewlett-Packard Company.

TM 11-6625-2820-14&P

ECHNICAL MANUAL

T

No. 11-6625-2820-14&P

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

(INCLUDING DEPOT MAINTENANCE REPAIR

SIGNAL GENERATOR SG-735/URM-165

HEADQUARTERS

DEPARTMENT OF THE ARMY

WASHINGTON, DC, 22 July 1977

PARTS AND SPECIAL TOOLS)

FOR

(HEWLETT-PACKARD MODEL 8616A)

( NSN 6625-00-254-6671 )

REPORTING OF ERRORS

You can improve this manual by recommending improvements using DA

Form 2028-2 located in the back of the manual. Simply tear out the self addressed form, fill it out as shown on the sample, fold it where shown, and drop

it in the mail.

If there are no blank DA Forms 2028-2 in the back of your manual, use the

standard DA Form 2028 (Recommended Changes to Publications and Blank

Forms) and forward to the Commander, US Army Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703.

In either case a reply will be furnished direct to you.

This manual is an authentication of the manufacturer’s commercial literature which, through usage, has been

found to cover the data required to operate and maintain this equipment. Since the manual was not prepared

in accordance with military specifications, the format has not been structured to consider levels of maintenance.

Change 1 i

Page 8

TM 11-6625-2820-14&P

SECTION

0 INTRODUCTION . . . . . . . . . . . . . . . . .

I GENERAL INFORMATION . . . . . . . .

1-1.

Introduction . . . . . . . . . . . . . . . .

1-6.

Supplementary Instruments . .

Instrument Options . . . . . . . . . .

1-9.

1-11. Instrument Identification. . . . .

1-13. Klystron Warranty Claim Sheet

II INSTALLATION . . . . . . . . . . . . . . . . . .

2-1. Incoming Inspection. . . . . . . . . .

Installation . . . . . . . . . . . . . . . . .

2-3.

2-6. Conversion to Rack Mount. . .

2-7.

2-9.

Air Filter Inspection . . . . . . . .

Power Requirement . . . . . . . . . .

2-11. Three Conductor Power Cable. .

2-14. Repackaging for Shipment . . . .

III OPERATION . . . . . . . . . . . . . . . . . . . . .

3-1. Introduction . . . . . . . . . . . . . . . .

3-3. Controls and Indicators . . . . . . .

3-5. Operating Procedures. . . . . . . . .

3-7.

Stabilized Source . . . . . . . . . . . . .

IV PRINCIPLES OF OPERATION . . . . .

4-1. Introduction . . . . . . . . . . . . . . . .

4-3. RF Oscillator . . . . . . . . . . . . . . . .

4-6. Pin Diode Modulator . . . . . . . . .

4-16. Modulation Circuits. . . . . . . . . .

4-18.

4-20.

4-22.

4-25.

ExternalPulse . . . . . . . . . . . .

Internal Square Wave. . . . . . .

Extemal AM . . . . . . . . . . . . . .

Internal Meter and Automatic

Level Control (ALC) . . . . . . . .

4-36. External Leveling . . . . . . . . . .

4-37. Regulated Power Supply. . . . . .

V MAINTENANCE . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . .

5-1.

Test Instruments Required. . . .

5-3.

Periodic Maintenance. . . . . . . . .

5-5.

5-6.

Cleaning the Air Filter . . . . . .

5-8. General Maintenance . . . . . . .

5-10.

Cover Removal . . . . . . . . . . . .

6-12. Troubleshooting. . . . . . . . . . . . .

5-14. Repair . . . . . . . . . . . . . . . . . . . . .

6-16. Klystron Removal and

Replacement . . . . . . . . . . . . . .

6-17.

6-18.

6-19.

Tube Removal . . . . . .. o.....

Tube Replacement . . . . . . . . .

RF Probe Removal and

Replacement . . . . . . . . . . . . .

6-20.

6-21.

6-22.

Probe Assembly Removal . . .

Probe Replacement. . . . . . . . .

Pin Modulator Removal and

Replacement . . . . . . . . . . . . . . . .

5-23.

5-25.

6-26

5-27.

Modulator Removal . . . . . . . .

Modulator Replacement. . . . .

Calibration . . . . . . . . . . . . . . . . .

Regulated Power-Supply

Adjustment . . . . . . . . . . . . . . .

6-28.

Frequency Tracking,

preliminary. . . . . . . . . . . . . . .

6-29.

Power Adjustment . . . . . . . . .

Page

0-1

1-1

1-1

1-1

1-1

1-1

1-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

3-1

3-1

3-1

3-1

3-1

4-1

4-1

4-1

4-1

4-3

4-3

4-3

4-4

4-5

4-6

4-6

5-1

6-1

5-1

5-1

6-1

6-1

5-1

6-1

5-6

5-6

6-6

6-6

5-6

5-6

6-7

5-9

5-9

5-9

6-9

6-9

5-10

5-10

Illus

Figure

S

ECTION

6-30.

RF Power Output

Adjustment . . . . . . . . . . . . . . .

5-31. Meter Amplifier . . . . . . . . . . .

5-32. Frequency Tracking, Final . . . .

6-33.

5-34.

5-35.

ALC Amplifier . . . . . . . . . . . . .

Pulse Modulation Adjust. . . .

Square-Wave Adjust . . . . . . .

5-35A. AM Adjust . . . . . . . . . . . . . . . . .

6-36. Performance Checks. . . . . . . . . .

5-38. Frequency Range and

Accuracy . . . . . . . . . . . . . . . . .

5-39. AFControl Check . . . . . . . . . .

5-40.

5-41.

6-42.

6-43.

Power Output Check. ., . . . . .

Leveled Output Check . . . . . .

Pin Diode On-Off Ratio. . . . . .

Internal Square-Wave

Check . . . . . . . . . . . . . . . . . . . .

5-44.

5-45.

External Pulse Check . . . . . . .

External AM Check . . . . . . . .

5-46. Measurement of Residual and

Incidental FM . . . . . . . . . . . . .

6-47. Cam Cable Replacement . . . . . . .

5-48.

5-49.

Tools Required . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . .

5-51. Low Pass Filter Replacement . .

5-52.

Tools Required . . . . . . . . . . . .

5-63. Procedure . . . . . . . . . . . . . . . .

5-65. Cavity Wiper Replacement . . . .

5-57.

5-59.

Parts Required . . . . . . . . . . . .

Replacement Procedure . . . . .

5-60. Frequency Drive Gear

Replacement . . . . . . . . . . . .

VI REPLACEABLE PARTS . . . . . . . . . . .

6-1.

Introduction . . . . . . . . . . . . . . . .

6-3.

Abbreviations . . . . . . . . . . . . . . .

6-5.

Replaceable Parts List. . . . . . . .

6-7.

APP

ENDIX

Ordering Instructions . . . . . . . .

0 REFERENCES . . . . . . . . . . . . . . ..D

I MANUAL CHANGES . . . . . . . . . . . . . .

SECTION

I-1.

Introduction . . . . . . . . . . . . . . . .

I-3.

Manual Changes . . . . . . . . . . . . .

I-6

Manual Changes Instructions . .

PPENDIX

A

II Illustrated Parts Identification . . . .

III MAINTENANCE ALLOCATION ... .

IV. ORGANIZATIONAL. DIRECT SUP-

PORT, AND GENERAL SUPPORT

MAINTENANCE REPAIR

PARTS AND SPECIAL

TOOLS LIST

(INCLUDING DEPOT

MAINTENANCE REPAIR

PARTS AND SPECIAL

TOOLS)

SECTION

I Introduction . . . . . . . . . . . . . . . . . . . . . .

II Repair Parts List . . . . . . . . . . . . . . . . . . .

Group

00 Signal Generator

SC 735/URM-165 . . . . . . . . . . . . . . . . .

Page Figure

Illus

6-10

5-12

5-12

5-13

5-14

5-14

5-14

5-14

5-14

5-14

5-15

5-15

5-15

5-15

5-17

5-17

5-18

5-18

5-18

5-18

5-21

5-21

5-21

6-21

5-21

5-21

5-24

6-1

6-1

6-1

6-1

6-1

0-1

i-1

i-1

i-1

i-3

ii- 1

III-1

IV-1

IV-6

IV-5

1

ii

Change 1

Page 9

TM 11-6625-2820-14&P

SECTION

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . .

HighVoltagePower Supply . . . . . . . . . .

Control Panel . . . . . . . . . . . . . . . . . . . . . .

Leveler Assembly . . . . . . . . . . . . . . . . . .

Low Pass FilterAssembly . . . . . . . . . . .

01 Circuit Card Assembly,

HighVoltagePower

Supply A100 . . . . . . . . . . . . . . . . . . . . .

02 Circuit Card Assembly,

Low Voltage and

Figure

1-1,

2-1.

3-1.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

6-9.

5-10.

Table

1-1.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

Mode 18616A SignalGenerator . . . . . . . . . . .

Conversion to RackMount . . . . . . . . . . . . . . .

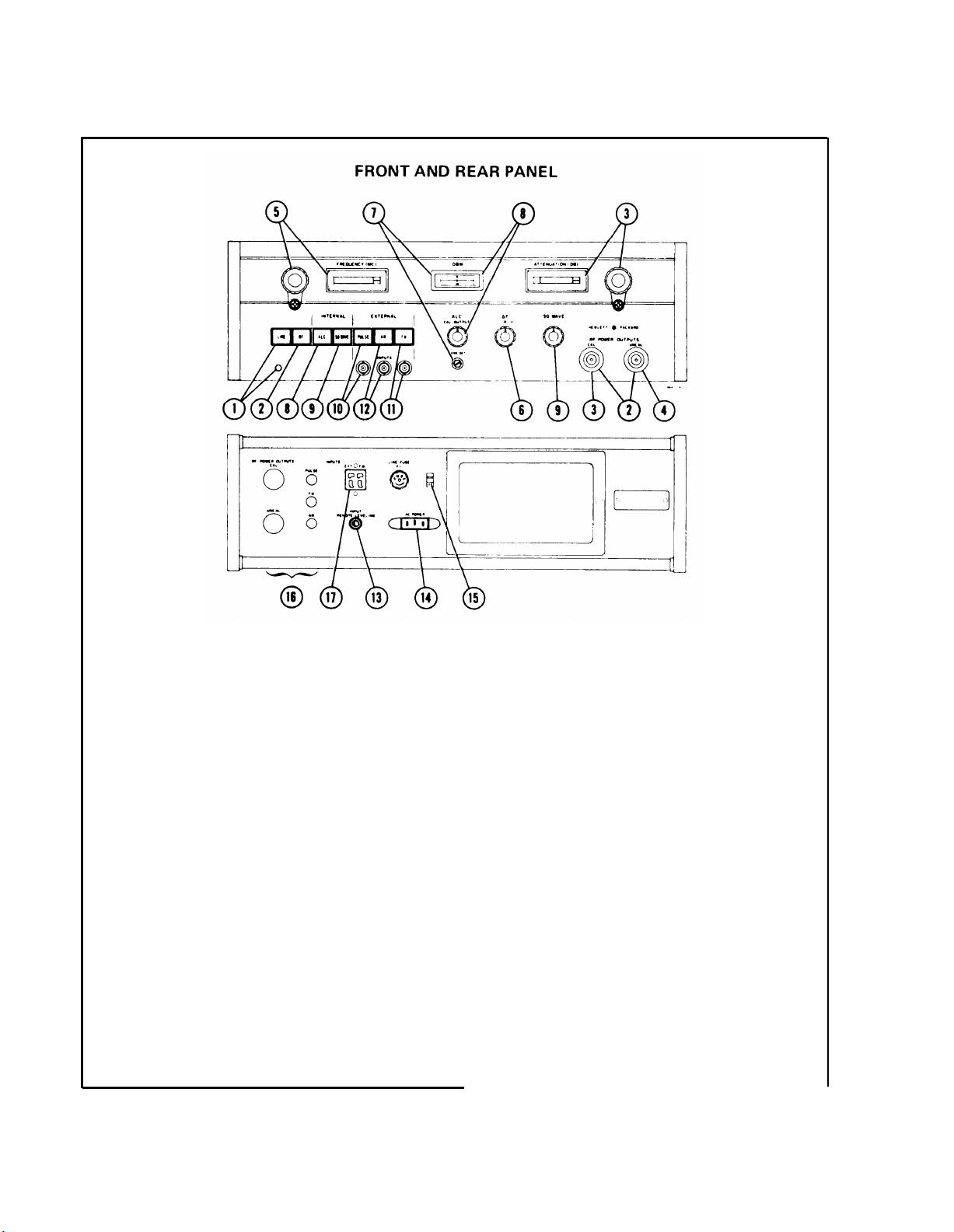

Front and Rear Panel Controls

and Indicators . . . . . . . . . . . . . . . . . . . . . . .

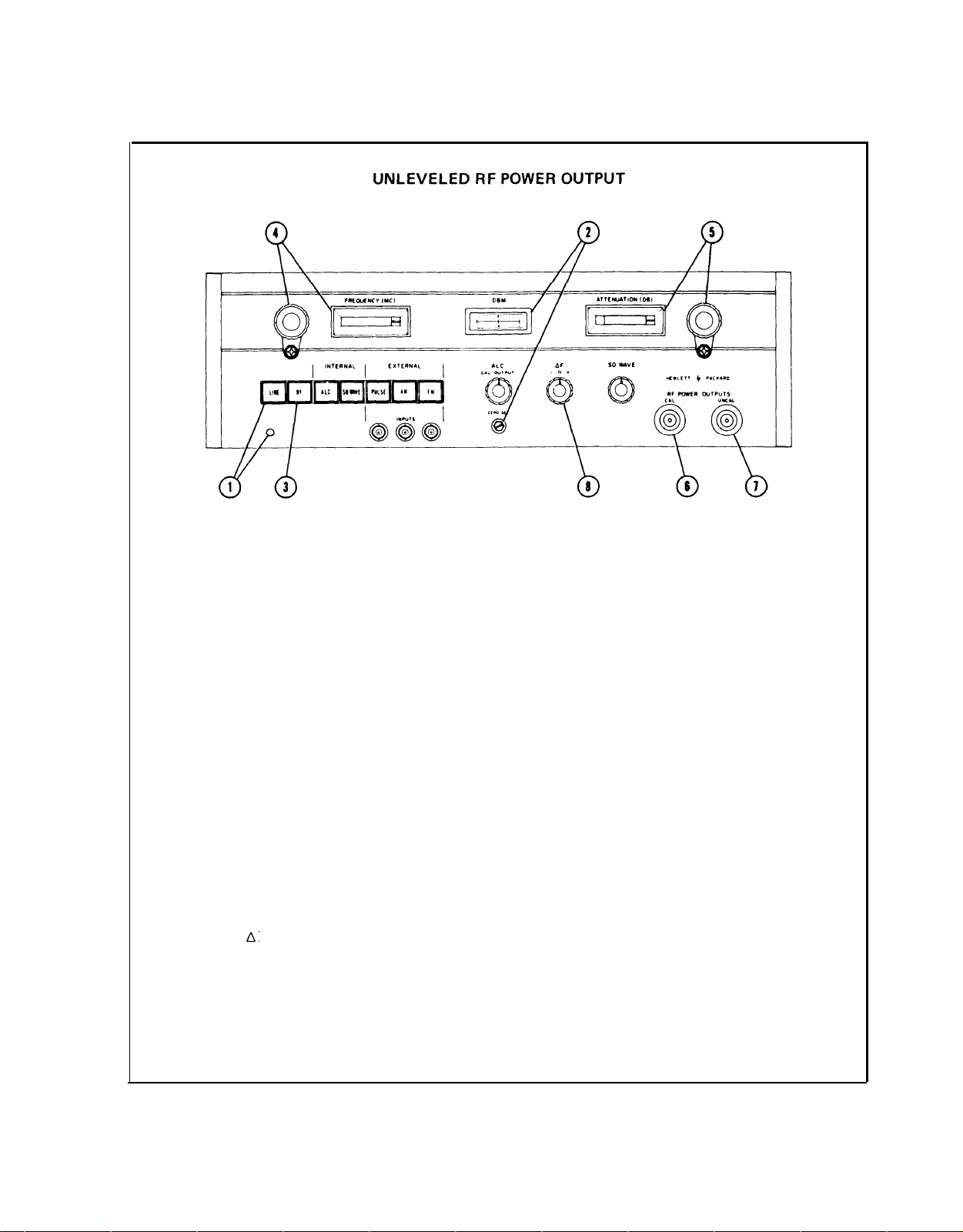

Unleveled RF Power Output . . . . . . . . . . . . . .

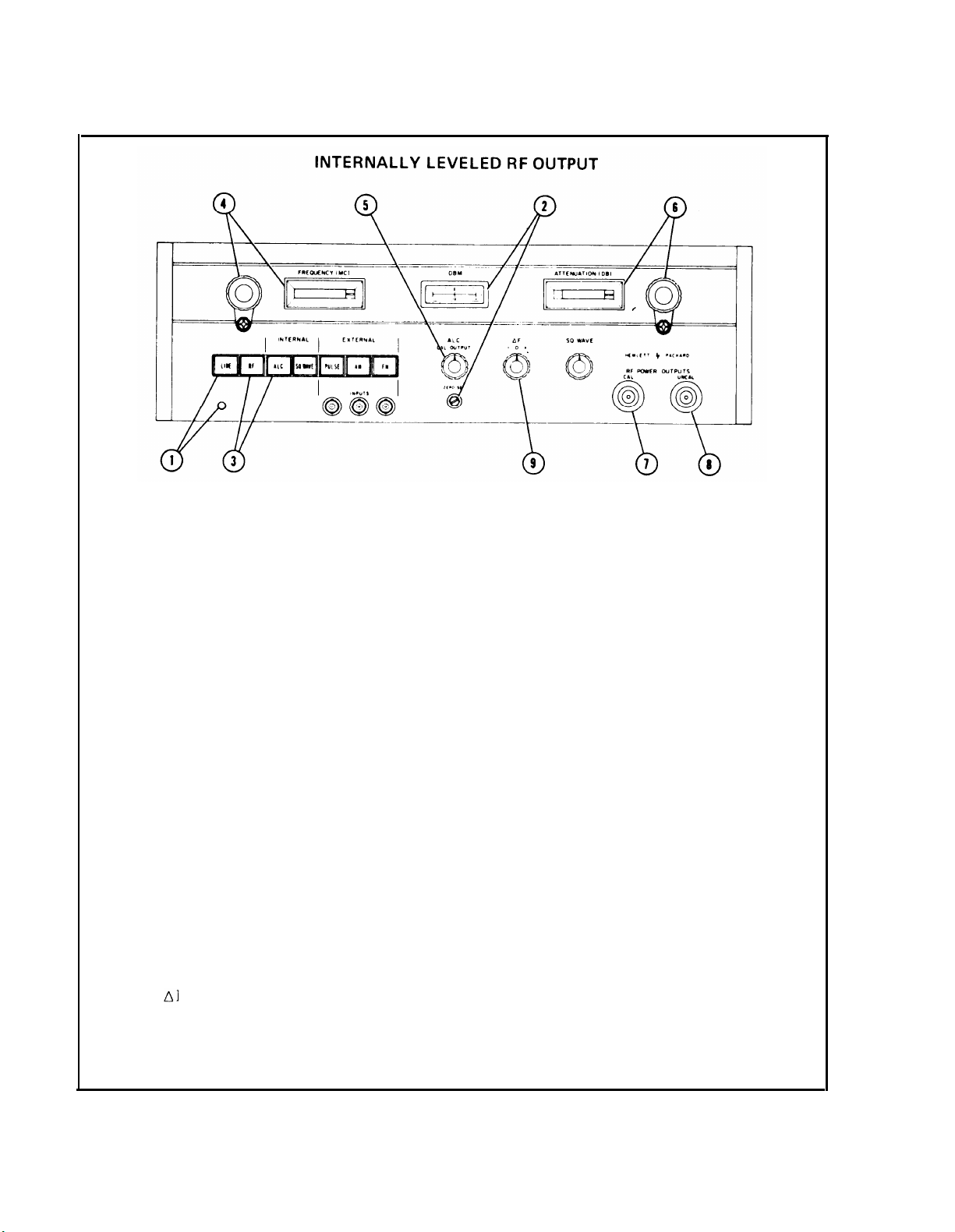

Internally-Leveled RFOutput . . . . . . . . . . . .

Externally-Leveled RF Output . . . . . . . . . . . .

Internal Square-Wave Modulation . . . . . . . . .

External Pulse Modulation . . . . . . . . . . . . . . .

External FM Modulation...... . . . . . . . . . .

External AM Modulation...... . . . . . . . . . .

Circuit Block Diagram . . . . . . . . . . . . . . . . . .

Simplified Block Diagram of PIN

Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Attenuator Unit . . . . . . . . . . . . . . . . . . . .

ALC Attenuator Unit . . . . . . . . . . . . . . . . . . .

Pulse ModulationCircuit . . . . . . . . . . . . . . . .

SquareWaveModulation Circuit . . . . . . . . . .

External AM Circuit . . . . . . . . . . . . . . . . . .

ALC and Meter Circuit . . . . . . . . . . . . . . . . . .

Series-RegulatedPower Supply . . . . . . . . . . .

Model 8616ABlock Diagram.. . . . . . . . . . . .

Cut-Away View of Klystron Cavity

and Klystron Assembly . . . . . . . . . . . . . . . .

RF Probe Assembly . . . . . . . . . . . . . . . . . . . .

PIN Modulator (Extemal View) . . . . . . . . . . .

Frequency Tracking Setup . . . . . . . . . . . . . . .

Frequency Tracking . . . . . . . . . . . . . . . . . . . .

Frequency and Power Measurement. . . . . . .

Internal Square Wave Check . . . . . . . . . . . . .

External Pulse Check........ . . . . . . . . . . .

External AM Check . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Required . . . . . . . . . . . . . . . .

Trouble Location . . . . . . . . . . . . . . . . . . . . . . .

Power SupplyAdjust . . . . . . . . . . . . . . . . . . .

Klystron Repeller Voltages . . . . . . . . . . . . . . .

Klystron Probe Adjust . . . . . . . . . . . . . . . . . .

ALC AmplifierAdjust . . . . . . . . . . . . . . . . . .

Illus

Page

IV-7

IV-9

IV-11

IV-15

IV-17

IV-19

Figure

7

ILLUSTRATIONS

Page

1-0

2-0

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

4-1

4-1

4-2

4-3

4-4

4-4

4-4

4-5

4-6

5-4

5-7

5-8

5-10

5-11

5-13

5-14

5-16

5-16

5-17

TABLES

Page

1-0

5-2

5-5

5-5

5-10

5-12

5-12

2

3

4

5

6

SECTION

ALC A500 . . . . . . . . . . . . . . . . . . . . . . . IV-23

03 Cavity Assembly . . . . . . . . . . . . . . . . . . . IV-27

04 Probe Assembly (No parts authorized)

SECTION

III Special Tools List

(Nonapplicable)

IV National Stock Number

and Part Number Index. . . . . . . . . . .

Figure

5-11.

5-12.

5-13.

5-14.

5-15.

5-16.

5-17.

5-18.

5-19.

5-20.

5-21.

A-1.

A-2.

B-1.

B-2.

B-3.

B-4.

B-5.

B-6.

B-7.

B-8.

Table

6-1.

6-2.

6-3.

A-1.

A-2.

A-3.

Top View, Cover Removed . . . . . . . . . . . . . . .

Residualand IncidentalFMChwk . . . . . . . .

ExplodedView-CamAsmmbly . . . . . . . . . . .

Low Pass FilterAsaembly Drawing . . . . . . . .

FormingtheCenter Conductor Fingers . . . . .

Modulation and Klystron Circuits . . . . . . . . .

ALCBoard (A500) . . . . . . . . . . . . . . . . . . . . . .

ALCCircuit . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulated +20Voltand Filament Supplies .

HighVoltageBoard(A100). . . . . . . . . . . . . . .

HighVoltagePower Supply . . . . . . . . . . . . . .

High VoltageBoard (A100). . . . . . . . . . . . . . .

Partial Schematic of Figure 5-17

ALC Circuit (Part of Change D) .......

HP Mode1 8616A, Signal Generator,

Generator Arrangement . . . . . . . . . . . . . . .

HP Model 8616A, Signal Generator,

Control Panel . . . . . . . . . . . . . . . . . . . . . . . .

HP Mode1 8616A, Signal Generator,

Cavity Assembly . . . . . . . . . . . . . . . . . . . . .

HP Mode1 8616A, Signal Generator,

Probe Assembly . . . . . . . . . . . . . . . . . . . . . .

HP Mode1 8616A, Signal Generator,

High Voltage Power Supply

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP Mode1 8616A, Signal Generator,

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . .

HP Mode1 8616A, Signal Generator,

Leveler Chassis . . . . . . . . . . . . . . . . . . . . . .

HP Mode1 8616A, Signal Generator,

Cabinet Assembly . . . . . . . . . . . . . . . . . . .

Reference Designations and Abbreviations .

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . .

Manufacturers Code List . . . . . . . . . . . . . . . .

Manual Changes by Serial Number . . . . . . . .

Manual Changes by Assembly . . . . . . . . . . . .

8616A Recommended Changes . . . . . . . . . . .

Page

IV-28

Illus

Figure

8

9

Page

5-19

5-20

5-20

5-22

5-24

5-27

5-29

5-29

5-31

5-33

5-33

i-4

i-6

ii- 3

ii-5

ii- 7

ii-9

ii-11

ii-13

ii-15

ii-17

Page

6-2

6-4

6-9

i-2

i-2

i-7

Change 1 iii

Page 10

Page 11

TM 11-6625-2820-14&P

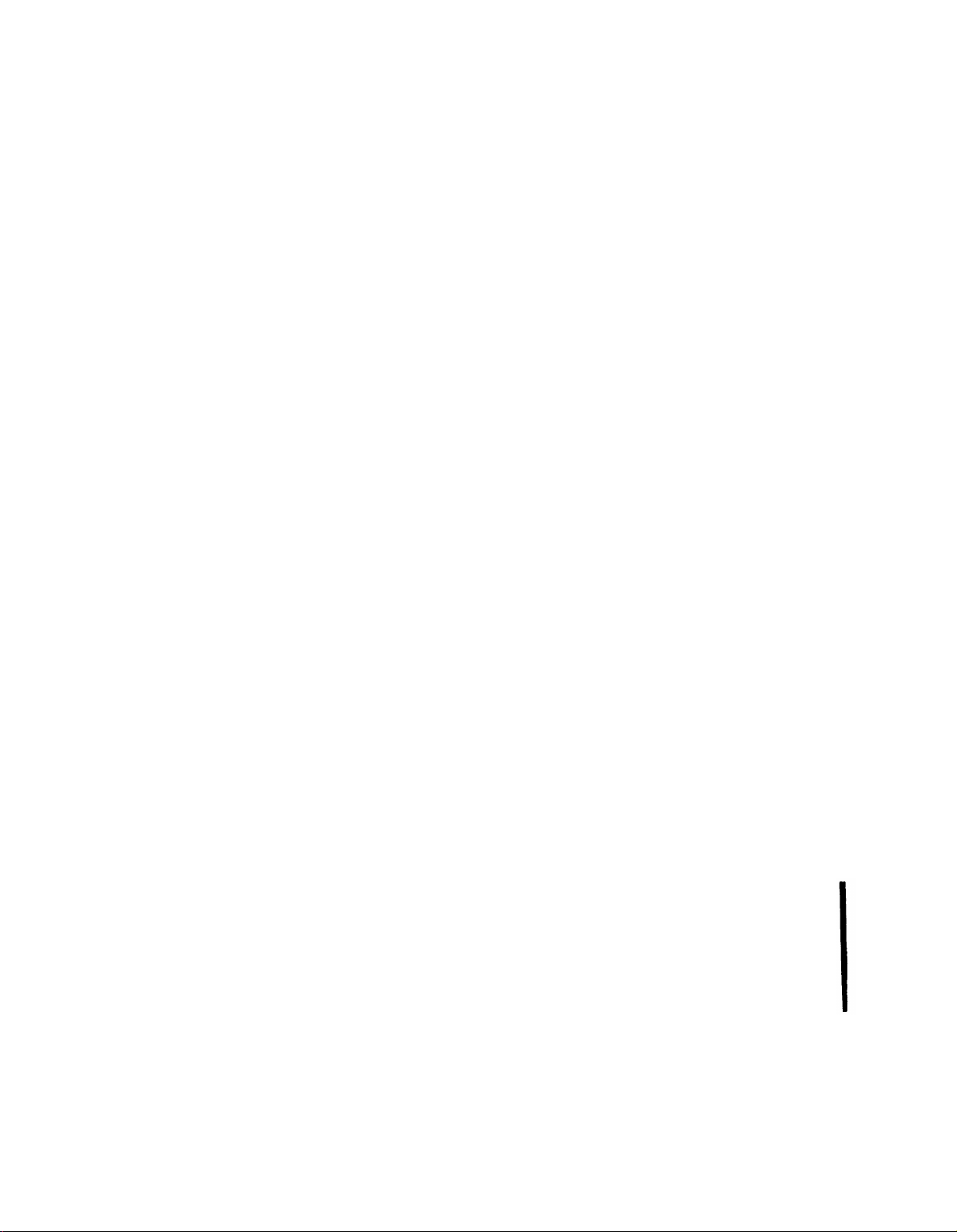

Figure 1-1. Model 8616A Signal Generator

Table 1-1. Specifications

Frequency Range:

4500 MHz.

Vernier:

MHz for fine tuning.

Frequency Calibration Accuracy:

Frequency Stability:

ambient temperature, less than 2500 Hz peak residual

FM, in a 10 kHz bandwidth, negligible incidental FM

in pulse and AM operation for attenuator settings below —10 dB. 0.003% change for line voltage variation

of ±10%.

RF output power:

3000 to 4500 MHz into a 50 load. Output attenuation dial directly calibrated in dBm from 0 to –127

dBm. A second uncalibrated output (approximately

0.5 mW) is provided on the front panel.

RF Output Power Accuracy (with respect to attenuation

dial:

Attenuator Accuracy:

–10 to –127 dBm: ±2 dB ±.06 dB/10 dB.

Leveled Output:

attenuation setting below 0 dB; ±l.0 dB.

Internal Impedance:

Modulation:

pulse.

Internal Square Wave:

cies available on special order.

External Pulse:

to +100V peak input.

F control has a range of approximately 1.5

±1.0 dB + attenuator accuracy (0 to –127 dBm).

direct reading within 2 MHz 1800 to

±10 MHz.

Approx. 0.005%/°C change in

+10 dBm (10 mW) +3 dBm from

for attenuation dial settings of

over entire frequency range at any

500; SWR less than 2.0.

On-off ratio at least 20 dB for square wave,

950 to 1050 Hz. Other frequen-

50 Hz to 50 kHz; 2 µsec rise time max +20

External AM:

External FM:

a. Front panel connector capacity-coupled to repeller

of klystron.

b. Four terminal rear panel connector (CinchJones

type S304AB) is DC-coupled to repeller of klystron.

Mode width between 3 dB points varies as follows: from

minimum of about 4 MHz to 5.5 MHz between 1800

and 3000 MHz to a maximum of about 8.5 MHz between 3000 and 4500 MHz; klystron sensitivities are

about 100, 50, 200 and 100 kHz/V, respectively.

Power Source:

imately 125W.

Dimensions:

Weight:

DC to 1 MHz.

115 or 230V ±l0%, 50 to 60 Hz, approx-

net 48 lb. (22 kg).

1-0

Change 2

Page 12

Page 13

SECTION I

GENERAL INFORMATION

TM 11-6625-2820-l4&P

1-1. INTRODUCTION

1-2. The Model 8616A Signal Generator provides

RF power in the 1800- to 4500-MHz range. The

instrument produces an RF power output of at

least 2 mW. Output frequency and attenuation are

read directly on digital dials, and fine frequent y

changes can be made by means of the front-panel

A F control. Complete specifications are given in

Table 1-1. The 8616A is shown in Figure 1-1.

1-3. The instrument has two power output con-

nectors which supply RF power simultaneous y.

One output provides at least 10 mW (2 mW from

3000 to 4500 MHz) of power and may be leveled.

When in the leveled output mode of operation and

the output is 0 dBm or less, the RF output is held

quite constant across the band without resetting

the attenuator or power monitor. The other output

connector provides an uncalibrated output of at

least 0.5 mW. A wave-guide-beyond-cutoff attenuator, which is referenced to the RF output, accurately attenuates the calibrated RF power output

from O to –127 dBm.

1-4. RF power output can be internally squarewave modulated. In addition, the RF power can be

externally AM, FM, or pulse modulated. An external ALC (automatic level control) input which can

be used for remote leveling loop control and an

external DC-coupled FM input which can be used

for external AFC is also provided.

1-5. PIN diode attenuators are used for leveling,

square wave, pulse, and amplitude modulation. The

PIN attenuator is an absorption device that can be

electrically controlled to attenuate RF power. A

sampling loop which includes a PIN diode attenuator compensates for changes in RF power output

to hold the RF power output nearly constant.

1-6. SUPPLEMENTARY INSTRUMENTS

1-7. Two instruments capable of extending the

operating parameters

8403A and the Model 2650A. The Model 8403A

Modulator produces output pulses with 30 to 40

of the generator are the

nanosecond rise and decay time characteristics.

Pulse outputs are accurately variable in frequency,

width, and delay. Amplitude modulation is available with frequency responses to 10 MHz for sine

waves. Square-wave frequency capability is accurately available. The modulator also provides sync

and delayed-sync outputs.

1-8. The Model 2650A Oscillator Synchronizer

may be used directly to stabilize all internal cavity

reflex klystron signal generators. Short-term stability is one part in 108/sec, and long-term stability

is one part in 106/week over 0 to 50 degrees

centigrade.

1-9. INSTRUMENT OPTIONS

1-10. In addition to the standard instrument, the

option 01 is available. The option 01 instrument

has its input connectors located on both the front

and rear panel and its output connectors located

on, the rear panel; in all other respects it is the same

as the regular signal generator.

1-11. INSTRUMENT IDENTIFICATION

1-12, Hewlett-Packard uses a ten digit serial number (on instrument rear panel) to identify instruments. The first four numbers and letter are the

serial prefix number and the last five digits are

unique to a specific instrument. If the serial prefix

on your instrument does not appear on the title

page of this manual, there are differences between

the manual and your instrument which are described in a Manual Change sheet included with the

manual. If the change sheet is missing, it may be

obtained, on request, from your nearest Hewlett-

Packard office.

1-13. KLYSTRON WARRANTY CLAIM SHEET

1-14. The klystron

klystrons purchased

guaranteed as set forth in the CONDITIONS OF

WARRANTY FOR KLYSTRON TUBES which is

found on the next to last page of this manual.

supplied and replacement

from Hewlett-Packard are

1-1

Page 14

TM 11-6625-2820-14&P

2-0

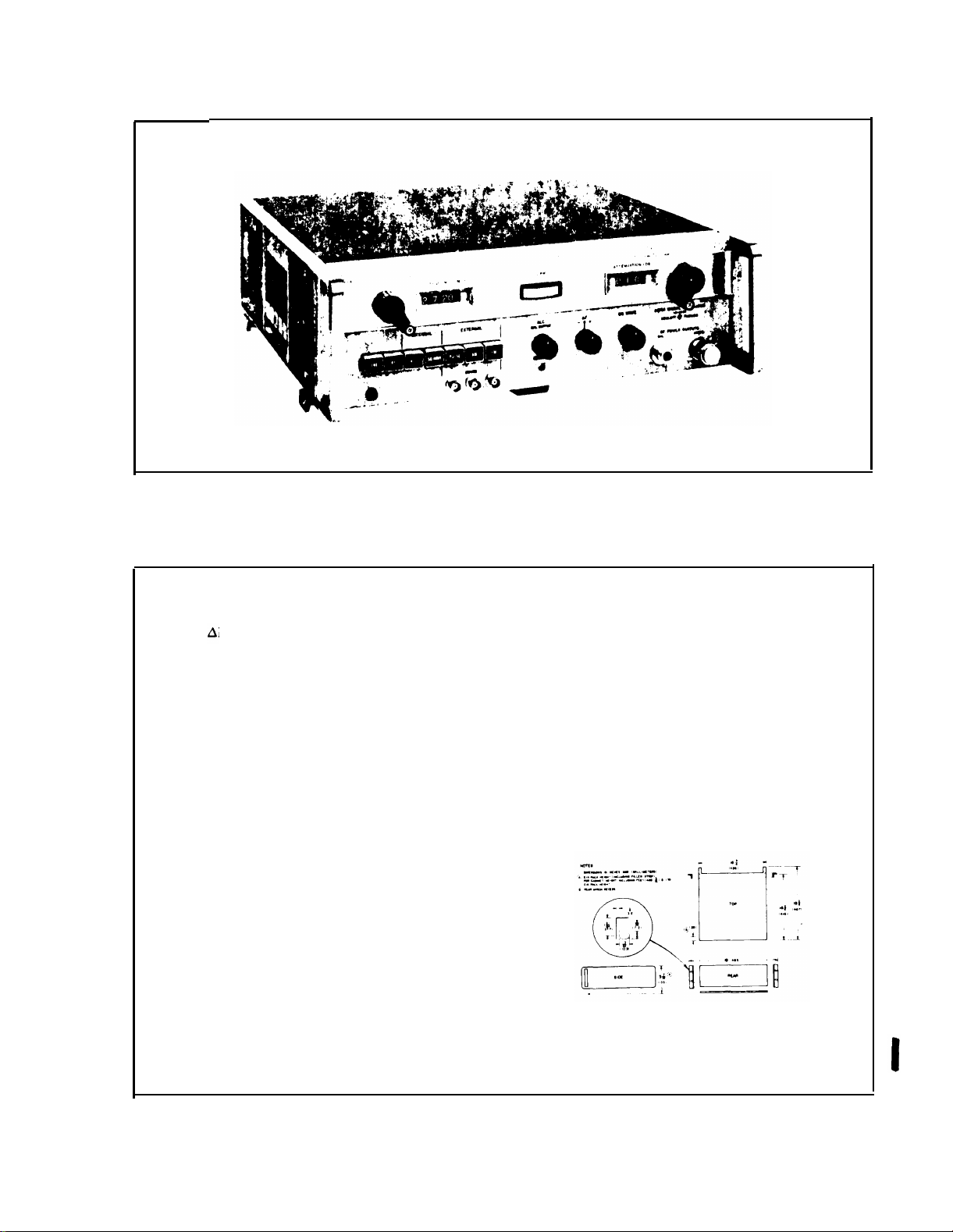

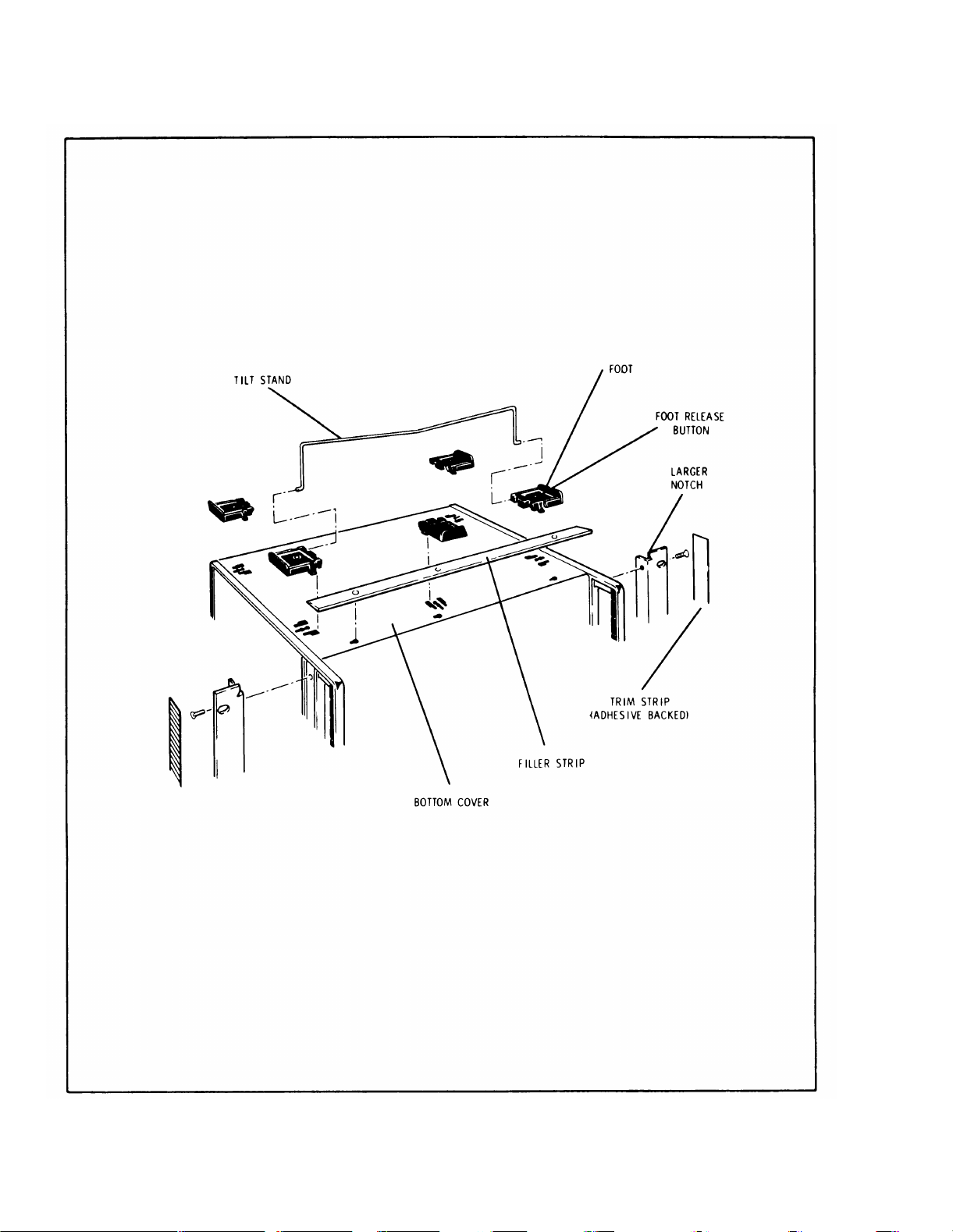

Figure 2-1. Conversion to Rack Mount

Page 15

SECTION II

INSTALLATION

TM 11-6625-2820-14&P

2-1.

INCOMING INSPECTION

2-2.

This instrument was inspected both mechani-

cally

and electrically before shipment. To confirm

this,

the instrument should be inspected for physi-

cal damage in transit.

accessories, and test the electrical performance of

the instrument, using the procedure outlined in

Paragraph 5-36. If there is damage or deficiency,

see the warranty on the inside rear cover of this

manual.

2-3. INSTALLATION

2-4. The Model 8616A is delivered as a cabinet

mount instrument. A kit is supplied with the

instrument for conversion from cabinet to rack

mount.

2-5. Whether the instrument is cabinet- or rack-

mounted, provision should be made for adequate

circulation of air around the instrument. The instrument cooling fan is located at the rear of the

instrument and louvers are located on instrument

side panels. Proper air circulation is most impor-

tant at the sides and rear of the instrument.

IF FAN IS NOT OPERATING, THE

INSTRUMENT SHOULD NOT BE

OPERATED.

2-6. Conversion to Rack Mount

a.

Remove trim strip on sides of instrument

(refer to Figure 2-1).

Also check for supplied

2-7. Air Filter Inspection

2-8. The Model 8616A uses forced-air cooling to

maintain tolerable temperature within the instrument. Incoming air is filtered through a special

filter at the rear of the instrument. The air filter

should be checked periodically and if dirty,

cleaned. Refer to Paragraph 5-6 for air filter maintenance.

2-9. POWER REQUIREMENT

2-10. The Model 8616A can be operated from a

115 or 230V, 50 to 60 Hz source. A two-position

slide switch (LINE VOLTAGE ) at the rear of the

instrument selects AC operation mode. The line

voltage at which the instrument is set to operate

appears on the slider of the switch. A 2 ampere

standard fuse is used for 115V operation; a 1

ampere standard fuse is used for 230V operation.

2-11. THREE-CONDUCTOR POWER CABLE

2-12. To protect operating personnel, the National

Electrical Manufacturer’s Association (NEMA)

recommends that the instrument panel and cabinet

be grounded. This instrument is equipped with a

three-conductor power cable which, when plugged

into an appropriate receptacle, grounds the instrument. The offset pin on the power cable threeprong connector is the ground wire.

2-13. The protection provided by grounding the

instrument cabinet may be lost if any power cable

other than the three-pronged type is used to couple

the ac line voltage to the instrument.

b. Remove tilt stand by pressing two sides of

stand toward center of instrument and lifting it

out.

c. Remove five feet at bottom of instrument. Press button in center of each foot, slide

them toward center of instrument, and lift out.

d. Place rack mounting flanges (two) where

trim strips were and secure with screws provided.

e.

Add filler strip to bottom of instrument.

f.

Rack mounting under

conditions must be supplemented with additional

support at rear.

severe vibration

2-14. REPACKAGING FOR SHIPMENT

2-15. The following list is a general guide for

repackaging an instrument for shipment. However,

if you have any questions, contact your local HP

field office.

If possible, use the original container de-

a.

signed for the instrument. If a carton and packing

materials are desired, they can be ordered from

your local HP field office.

b. The instrument is supported by four poly-

ethylene supports fitted to the instrument height:

one support located at each corner.

2-1

Page 16

TM 11-6625-2820-14&P

NOTE

If the instrument is to reshipped to the

Hewlett-Packard Company for service or

repair, attach to the instrument a tag

identifying the instrument by owner,

model, and full serial number, and indicating the service or repair to be accomplished. In any correspondence, refer to

the instrument by model number and

complete serial number.

2-2

Page 17

SECTION Ill

OPERATION

TM 11-6625-2820-14&P

3-1. INTRODUCTION

3-2. The Model 8616A can provide 1.0 mW of

leveled power across its frequency range (RF outputs leveled to within ±1.0 dB can be obtained

across the band for attenuator setting of 0 dB or

less). Output power can be attenuated to –127 dB.

When operating unleveled, attenuation reference is

the klystron power output; when operating leveled,

attenuation reference is output reference setting.

Internal square-wave modulation is available from

950 to 1050 Hz. External FM, AM, and pulse

modulation voltages also can be used. Two or three

modulation modes of operation can be applied to

the instrument simultaneously; push-button controls select the mode of operation. External modulation signal inputs are located directly below the

modulation to which they apply.

RF power in excess of approximately

125 mW should never be applied to RF

power output

damage could result.

3-3. CONTROLS AND INDICATORS

3-4. Front and rear panel controls and connectors

are shown in Figure 3-1. Each control and connector is identified with a numbered call-out, and an

explanation of the function, given in the accompanying text, is keyed to the call-out number.

connectors as internal

3-5. OPERATING PROCEDURES

3-6. The operating procedures Figures 3-2 through

3-8) give step-by-step procedures for the various

modes of operation.

obtaining the following leveled and unleveled outputs: CW, square-wave modulated (modulating

voltage supplied internally, and FM, AM, and

pulse-modulated (modulating voltage supplied

externally ). Steps of each procedure are numbered

according to the sequence in which they are to be

performed, and any control or connector used is

identified with the number of the step in which it

is used.

3-7. STABILIZED SOURCE

3-8. To use an 2650A Oscillator Synchronizer

with the Signal Generator, proceed as follows:

The rear panel connector EXT FM (J201)

a.

is a Cinch-Jones type S304AB. Connection between this jack and J5 of the 2650A must be made

as follows:

Pin 3, J201, to Pin E, J5, 2650A

Pin 4, J201, to Pin F, J5, 2650A

Pin 1, J201, to Pin G, J5, 2650A

Pin 2, J201, no connection

Connect RF output from UNCAL

b.

OUTPUT connector on Model 8616A to OSCILLATOR INPUT connector on Model 2650A. Depress EXTERNAL FM button on Model 8616A

and proceed as explained in the instruction manual

for the Model 2650.

Instructions are given for

3-1

Page 18

TM 11-6625-2820-14&P

1.

LINE. Connects primary power to instrument;

lamp glows.

RF. Applies power to RF POWER OUTPUTS.

2.

ATTENUATION (dB). Sets RF power level at

3.

CAL RF POWER OUTPUT.

4.

UNCAL RF POWER OUTPUT.

mately 0.5 mW unleveled and unattenuated RF

power.

FREQUENCY (MHz). Sets

5.

F. Permits small deviations from FREQUENCY

6.

setting (±1.5 MHz).

ZERO SET. Adjust for zero indication on dBM

7.

meter (with RF turned off).

ALC. Levels calibrated RF output; used to set a

8.

reference on dBm meter.

INTERNAL SQ WAVE.

9.

PUT. SQ WAVE control adjusts modulation frequency.

Modulates CAL RF OUT-

Provides approxi-

RF frequency.

EXTERNAL PULSE.

10.

pulse input will provide modulation voltages re-

quired to pulse modulate CAL RF OUTPUT.

Positive pulses turn RF “ON

11.

EXTERNAL FM. AC

FM input will provide frequency modulation of

both CAL and UNCAL outputs.

12.

EXTERNAL AM.

input will provide modulation voltages required to

AM modulate CAL RF OUTPUT.

13.

INPUT REMOTE LEVELING. Input jack for

external leveling loop voltage applied to level

generator CAL RF POWER OUTPUT.

14.

LINE. Male receptacle which connects to the

power cord.

LINE VOLTAGE. Arranges input power trans-

15.

former to accept either 115 or 230 volt, 50 to 60

Hz primary power input.

16.

OPTION 01.

on rear panel (input connectors also located on

front panel).

17.

EXT FM:

lystron for stabilization of output frequency.

Input and output connectors located

Four terminal connector DC-coupled to

Positive pulses to external

voltages applied to external

Signals applied to external AM

3-2

Figure 3-1. Front and Rear Panel Controls and Indicators

Page 19

TM 11-6625-2820-14&P

Depress LINE; lamp glows,

1.

Note meter pointer on dBm meter.

2.

Depress RF; there should be some deflection of dBm meter pointer.

3.

When RF button is depressed, meter pointer will fluctuate from

approximately +1 dBm at low frequency to +4 dBm or more at high

frequency.

4.

Set FREQUENCY (MHz) to desired frequency.

The ATTENUATION (dB) knob will attenuate RF power at CAL RF POWER OUTPUT.

5.

Take unleveled but attenuable RF power at CAL RF POWER OUTPUT.

6.

Take unleveled and unattenuable RF power at UNCAL RF POWER OUTPUT.

7.

8.

Use A F control when a small deviation from FREQUENCY (MHz) setting is desired.

F control should be centered when not in use.

indicating heater and high voltage are applied.

NOTE

NOTE

Figure 3-2. Unleveled RF Power Output

3-3

Page 20

TM 11-6625-2820-14&P

1.

Depress LINE.

Check that meter pointer on dBm meter is on ZERO SET mark; if not, adjust accordingly.

2.

Depress RF and INTERNAL ALC; there should be some deflection of dBm meter pointer.

3.

4.

Set FREQUENCY (MHz) low frequency.

Adjust ALC CAL OUTPUT control for desired dBm reference on dBm meter. The ALC system

5.

holds RF output power across the band to within ±1.0 dB for levels of 0 dBm or less. The

most common reference used is —10 dBm because the attenuated RF output power can be read

directly from attenuator readout. Leveled RF output power can be obtained across the band;

however, ATTENUATION (dB) will not accurately calibrate above –10 dBm.

NOTE

Power may be leveled above 0 dBm over that portion of the band where

the desired power is available.

6.

Set ATTENUATION (dB) to desired attenuation. The RF power level at CAL RF POWER

OUTPUT is the algebraic sum of the dBm meter setting and of the ATTENUATION (dB)

setting.

Take leveled and attenuable RF power available at CAL RF POWER OUTPUT.

7.

Take unleveled and unattenuable RF power at UNCAL RF POWER OUTPUT.

8.

9.

Use F control when a small deviation from FREQUENCY (MHz) setting is desired.

3-4

Figure 3-3. Internally-Leveled RF Output

Page 21

TM 11-6625-2820-14&P

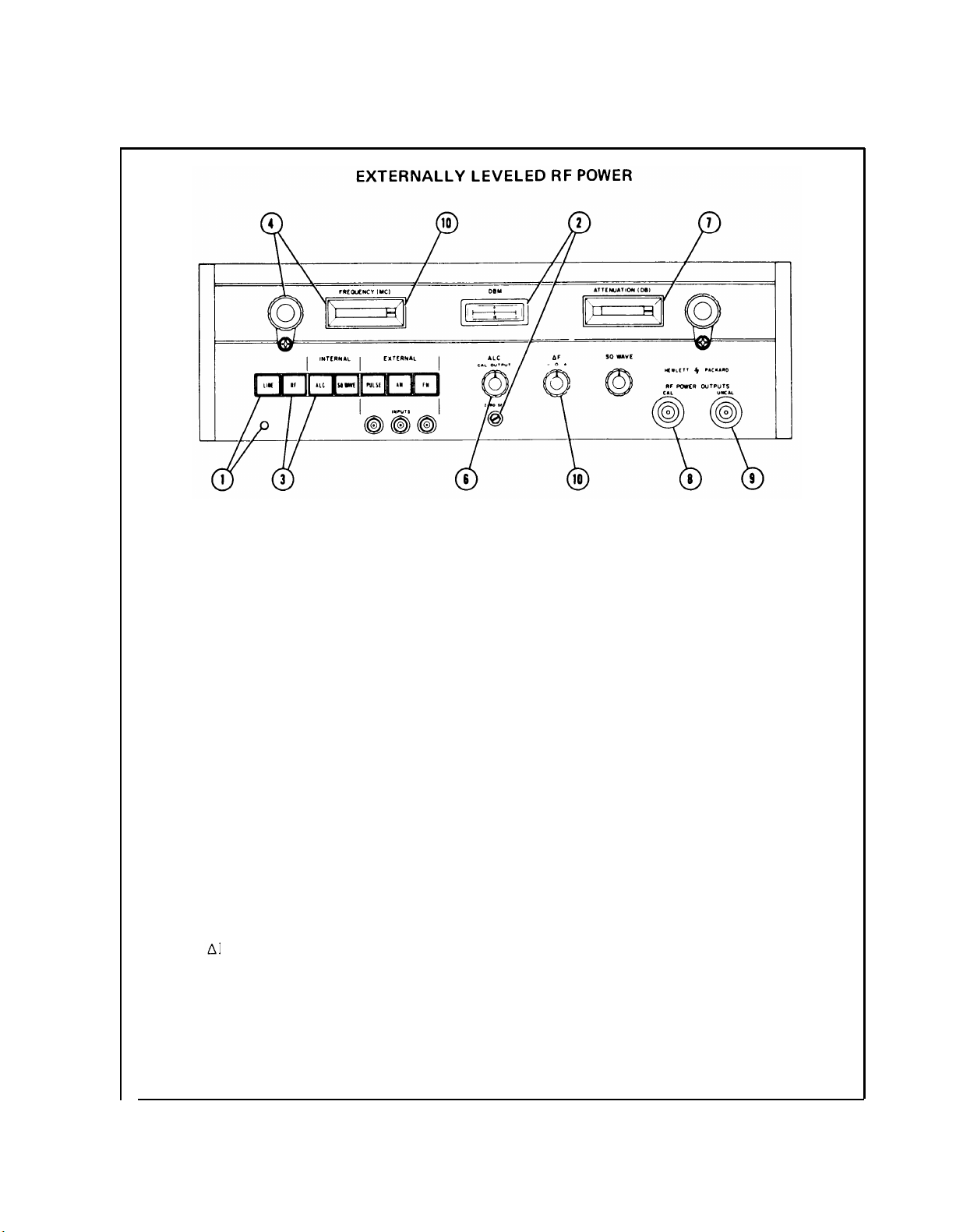

Depress LINE.

1.

Check that meter pointer on dBm meter is on ZERO SET mark.

2.

Depress RF and INTERNAL ALC.

3.

Set FREQUENCY for 1800 MHz.

4.

With a directional coupler connected between CAL output and the load, and as close to the

5.

load as possible, sample and detect incident power and apply the detected signal to INPUT

REMOTE LEVELING phone jack connection (rear panel). Approximately 40 mV but not

more than 240 mV is necessary.

Adjust ALC CAL OUTPUT for desired reference on dBm meter. This reference point may vary

6.

from that used with internal leveling due to different detector sensitivities.

Adjust ATTENUATION (dB) for desired attenuation.

7.

unless a 0 dBm reference has been set while monitoring with a power meter.

Take leveled and attenuable RF power available at CAL RF POWER OUTPUT.

8.

Take unleveled and unattenuable RF power at UNCAL RF POWER OUTPUT.

9.

Use F control when a small deviation horn FREQUENCY (MHz) setting is desired.

10.

The attenuator is not direct reading

Figure 3-4. Externally-Leveled RF Power

3-5

Page 22

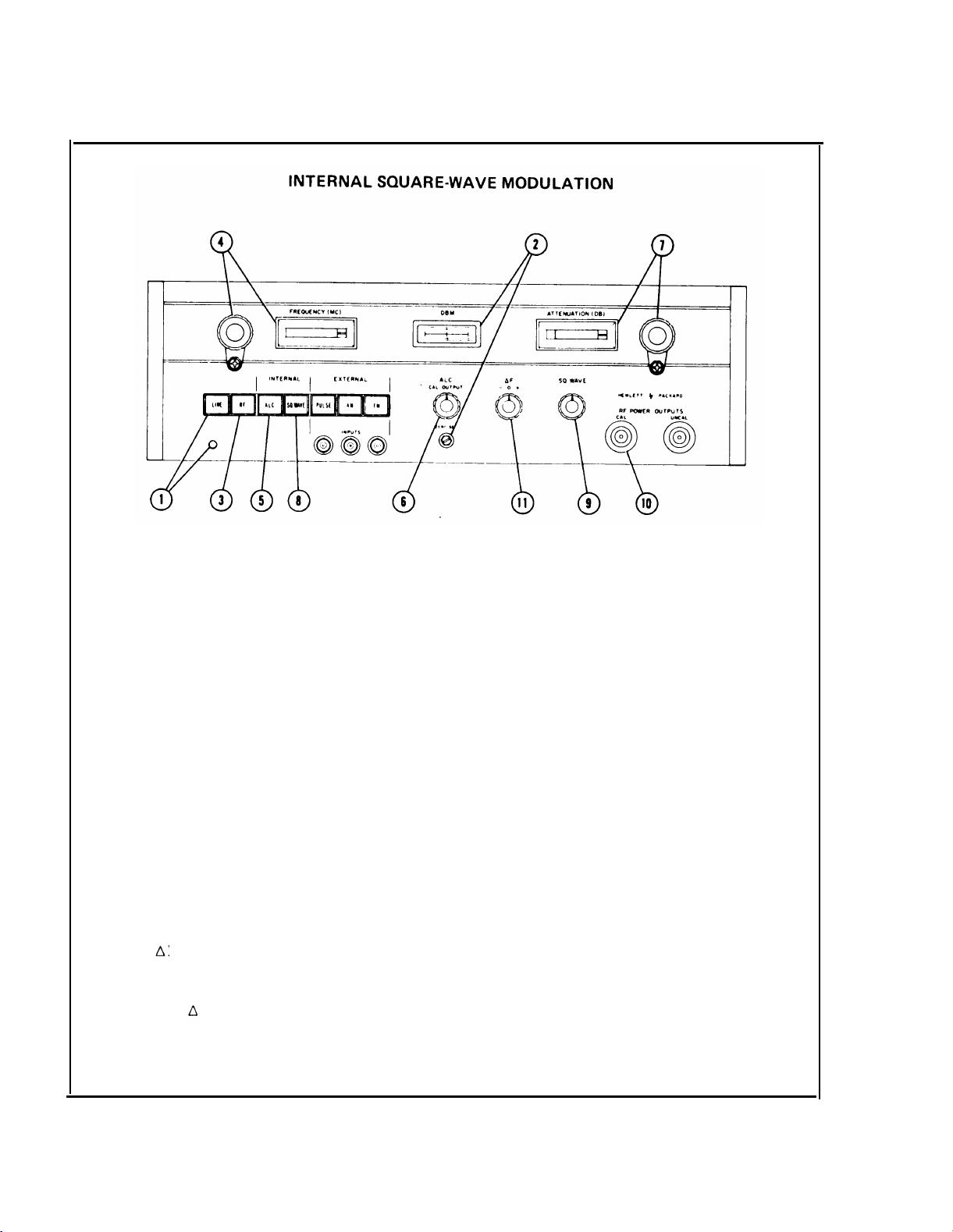

TM 11-6625-2820-14&P

1. Depress LINE.

NOTE

When unleveled power is to be modulated, omit steps 2, 5 and 6.

2. Check that meter pointer on dBm meter is on ZERO SET mark.

3. Depress RF.

4. Set FREQUENCY (MHz).

5. Depress INTERNAL ALC.

6. Adjust ALC CAL OUTPUT for desired dBm reference on dBm meter.

7. Set ATTENUATION dB.

8. Depress SQ. WAVE.

9. Adjust SQ WAVE for desired modulation frequency.

10. Take leveled and attenuable RF power output at CAL RF POWER OUTPUT.

11. Use F control when a small deviation from FREQUENCY MHz setting is desired.

NOTE

F control should be centered when not in use.

3-6

Figure 3-5. Internal Square- Wave Modulation

Page 23

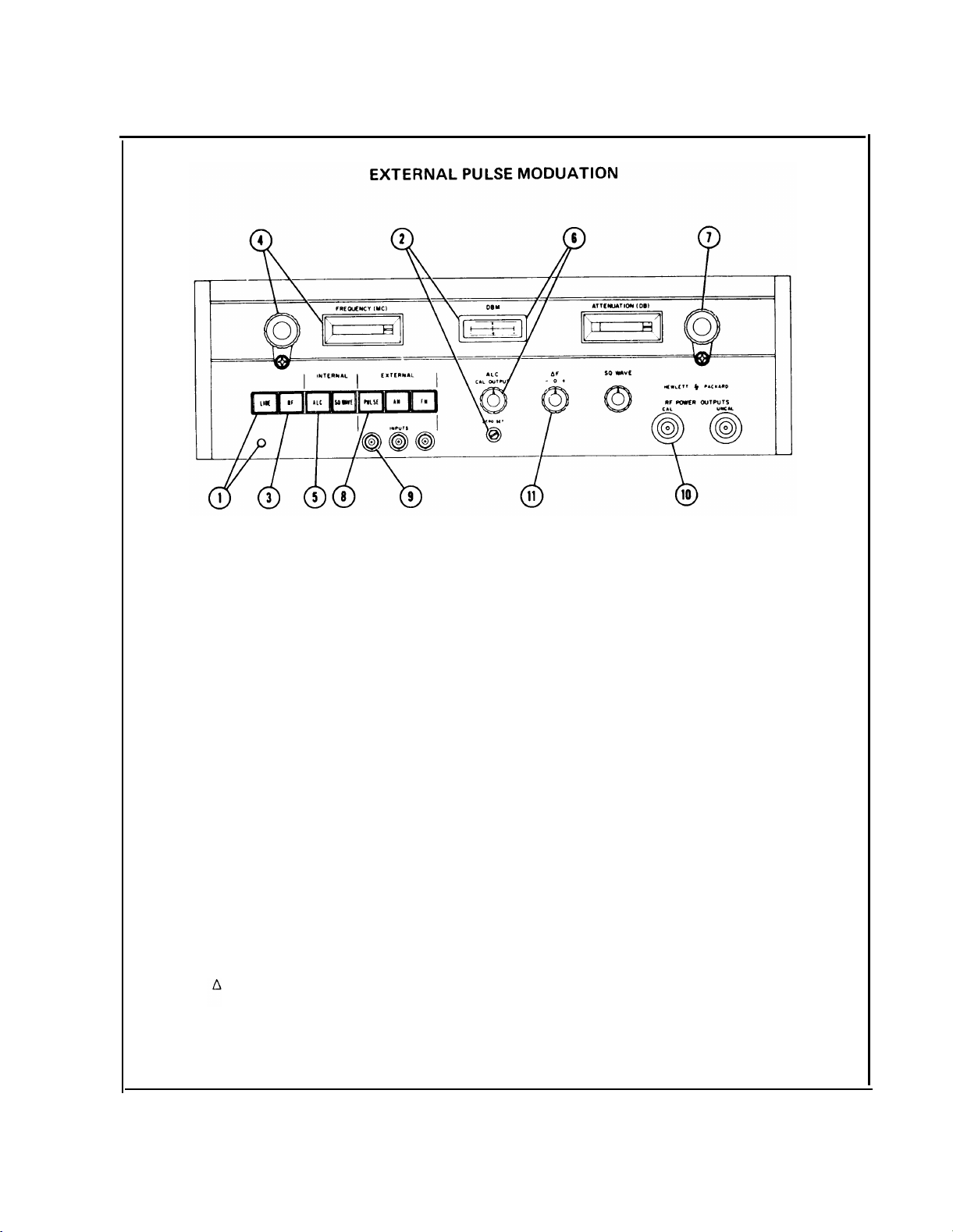

TM 11-6625-2820-14&P

1. Depress LINE.

NOTE

If external pulse modulation of unleveled power is desired, omit steps 2,

5and6.

2. Check that meter pointer on dBm meter is on ZERO SET mark.

3. Depress RF.

4. Set FREQUENCY (MHz).

5. Depress INTERNAL ALC.

6. Adjust ALC CAL OUTPUT for desired dBm reference on dBm meter.

7. Set ATTENUATION (dB) as desired.

8. Depress EXTERNAL PULSE.

9. Apply +20 to +100V 50 Hz to 50 kHz positive pulse modulating signal to EXTERNAL PULSE

INPUT.

10. Take leveled and attenuable pulse modulated RF power output at CAL RF POWER OUTPUT.

11. Use F control when a small deviation from FREQUENCY (MHz) setting is desired.

Figure 3-6. External Pulse Modulation

3-7

Page 24

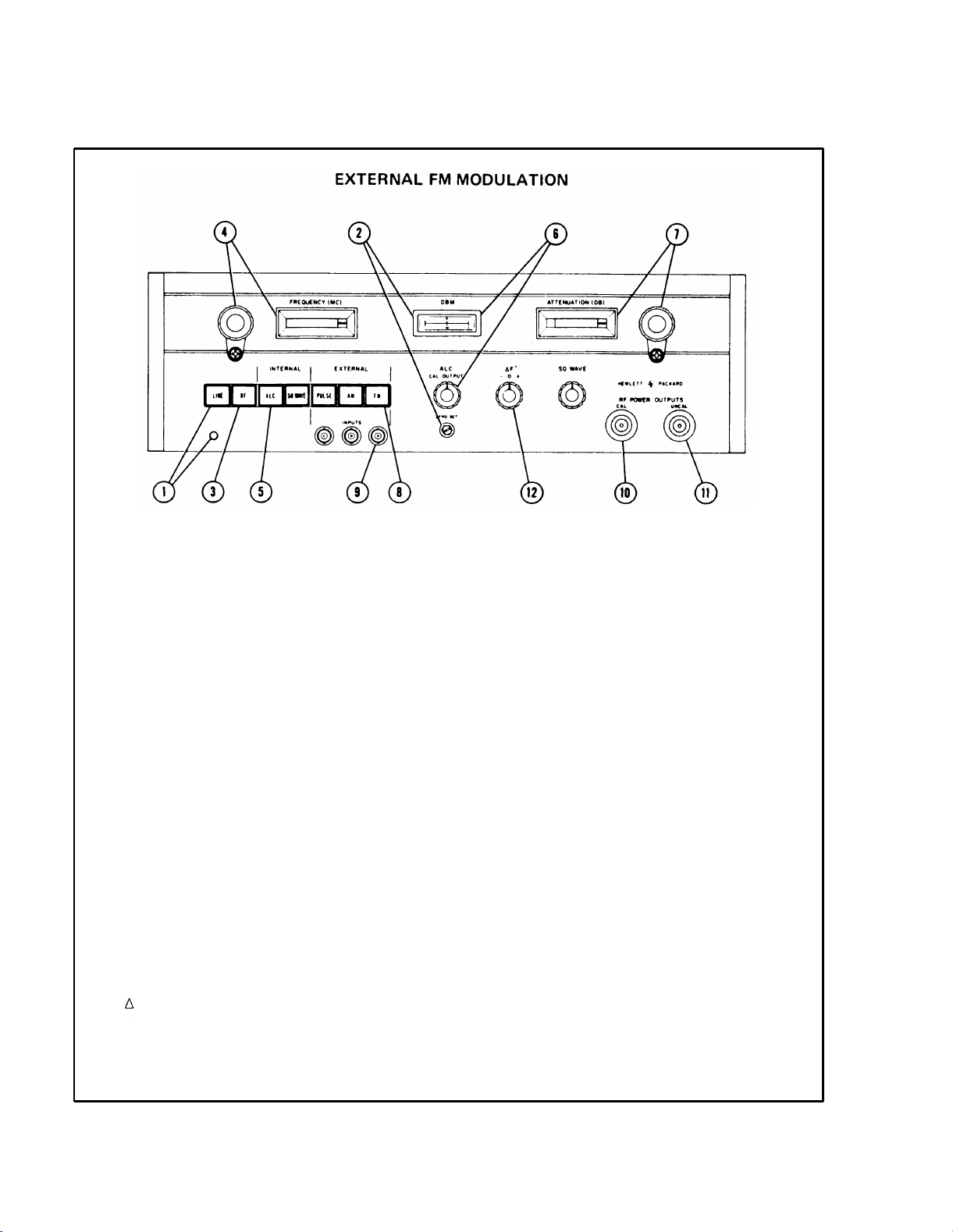

TM 11-6625-2820-14&P

Depress LINE.

1.

If external FM modulation of unleveled power is desired, omit steps 2, 5, and 6.

NOTE

Check that meter pointer on dBm meter is on ZERO SET mark.

2.

Depress RF.

3.

Set FREQUENCY (MHz).

4.

Depress INTERNAL (ALC).

5.

Adjust ALC CAL OUTPUT for desired dBm reference on dBm meter. The ALC system holds

6.

the RF output power across the band to within limits at frequencies up to 1 kHz provided the

FM voltages are small enough to maintain operation in the center of the mode. The most

common reference used is —10 dBm because the attenuator RF output power can be read

directly from attenuator readout.

NOTE

Power may be leveled above 0 dBm over that portion of the band where the desired power is available.

Set ATTENUATION (dB).

7.

Depress EXTERNAL FM.

8.

Apply modulating signal to EXTERNAL FM INPUT (front or rear panel).

9.

Take leveled and attenuable frequency modulated RF power output at CAL RF POWER

10.

OUTPUT.

Take unleveled FM-modulated RF power at UNCAL RF POWER OUTPUT.

11.

F control should be centered so that the klystron will operate in the center of the mode.

12.

3-8

Figure 3-7. External FM Modulation

Page 25

TM 11-6625-2$20-14&P

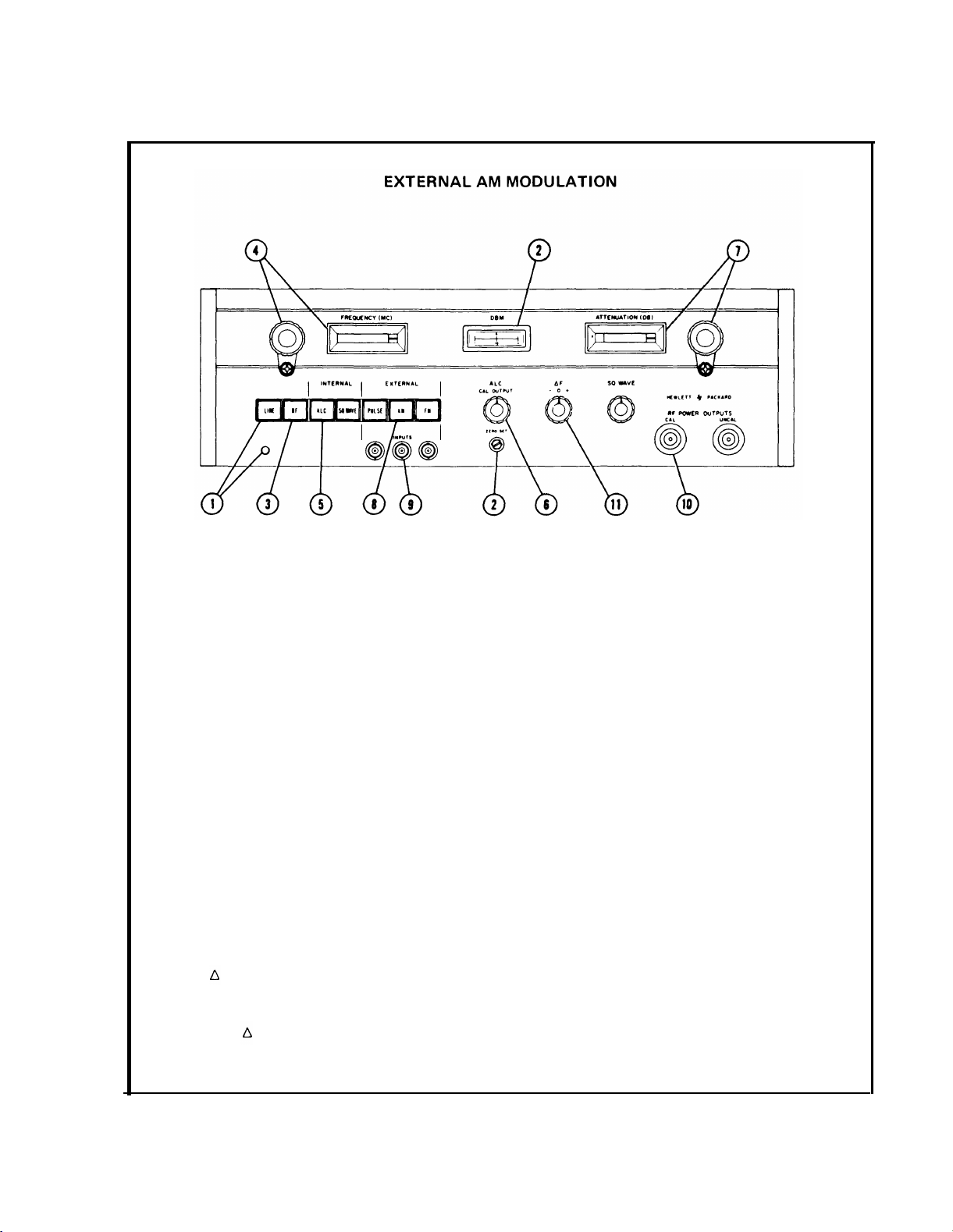

1. Depress LINE.

2. Check that meter pointer on dBm meter is on ZERO SET mark.

3. Depress RF.

4. Set FREQUENCY (MHz).

NOTE

If AM modulation of unleveled power is desired, omit steps 5 and 6 and

proceed to step 7. Also, unleveled power can be AM-modulated with a

dc coupled audio signal.

5. Depress INTERNAL ALC.

6. Adjust ALC CAL OUTPUT control for at least 3 dB of attenuation. Due to leveIing at the

frequency desired, the ALC system holds the RF output power across the band to within limits

except for variations due to an AM signal. The most common reference used is —3 dBm because

this allows AM signal to modulate the RF above (3 dB) this level.

7. Set ATTENUATION (dB).

8. Depress EXTERNAL AM.

9. Apply AM modulating signal to EXTERNAL AM INPUT (6 volts peak-to-peak).

10. Take AM-modulated and attenuable RF power output at CAL RF POWER OUTPUT.

11. Use F control when a small deviation from FREQUENCY (MHz) setting is desired.

NOTE

F control should be centered when not in use.

Figure 3-8. External AM Modulation

3-9/3-10

Page 26

Page 27

SECTION IV

PRINCIPLES OF OPERATION

TM 11-6625-2820-14&P

4-1. INTRODUCTION

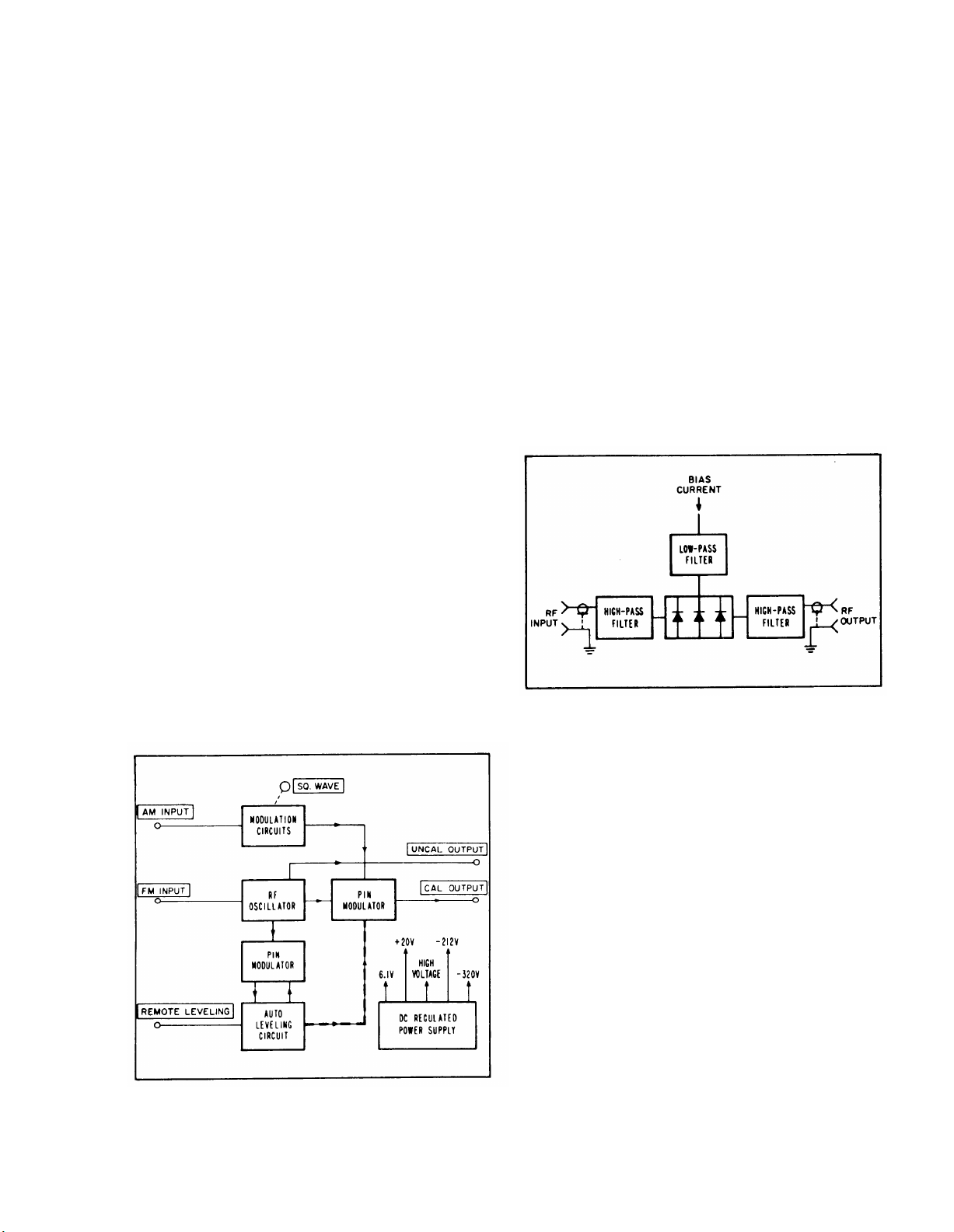

4-2. Basically the intrument includes a RF

Oscillator, PIN Diode Modulator, Automatic Leveling Circuit, Modulation Circuits, and Power Supply

as shown in Figure 4-1. The RF Oscillator is a

reflex klystron which always operates CW. The PIN

diode modulator is a current-controlled device that

attenuates RF power up to 20 dB or more. The

control circuits provide the modulation currents

required by the PIN modulator. The power supply

provides the regulated dc voltages required to

operate the circuits in the instrument.

4-3. RF OSCILLATOR

4-4. The RF Oscillator, which generates the RF

power, consists of a velocity-modulated tube

operating in an external resonant cavity. The tube

is a reflex klystron operating in the 1-3/4 and 2-3/4

modes.

4-5. The RF power output from the oscillator,

which may be CW or CW with FM, is obtained

from the resonant cavity by means of pickup

probes located in

which open into the resonant cavity. One of these

probes delivers RF power directly to the UNCALIBRATED RF OUTPUT connector, the other two

deliver RF power to the PIN modulator.

small sections of waveguide

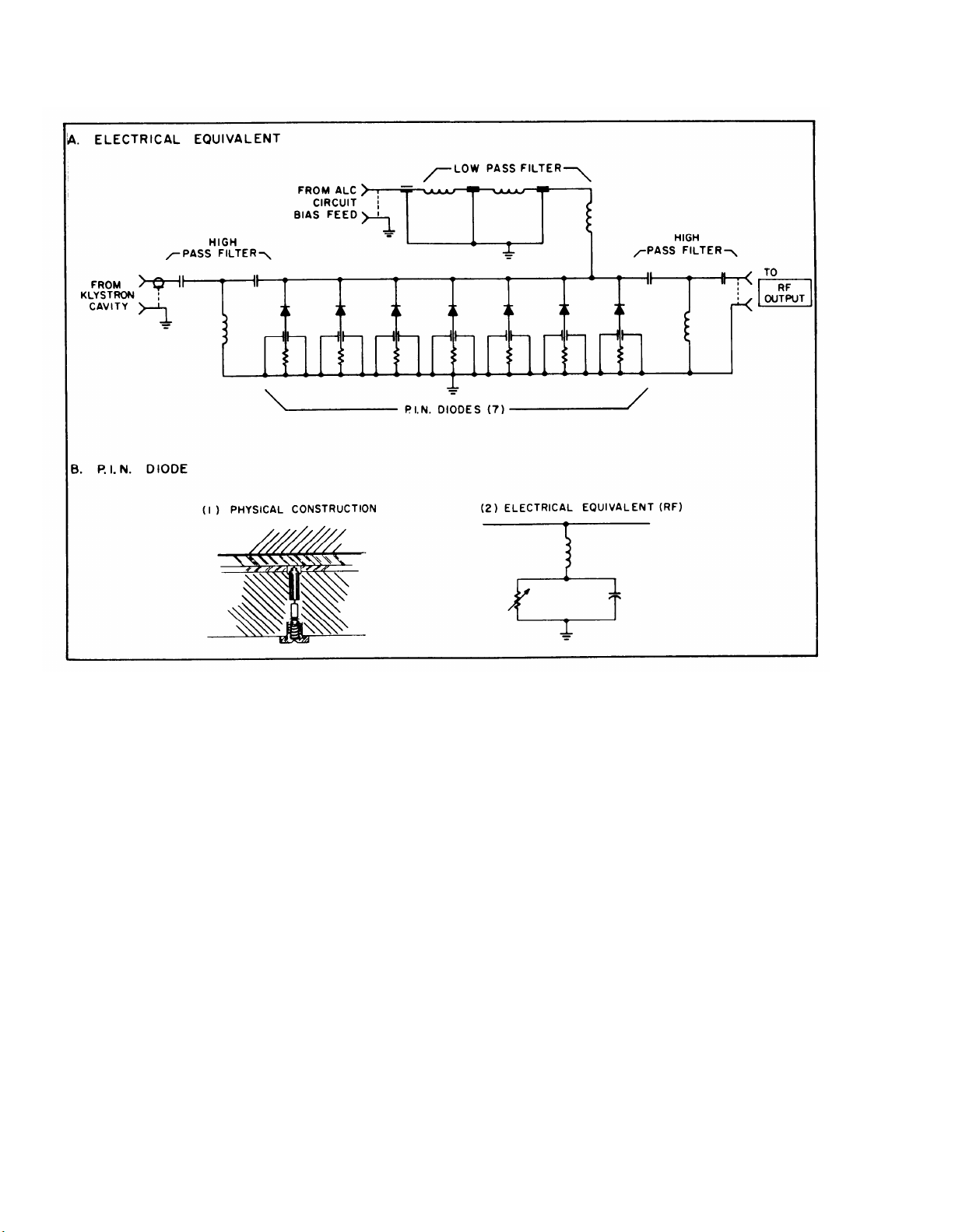

4-6. PIN DIODE MODULATOR

4-7. The PIN modulator, which is two nearly

identical units in one, is a high-speed, currentcontrolled absorption-type attenuator. One unit,

the RF attenuator unit, is shown in Figure 4-3. The

second unit, the ALC attenuator unit, is shown in

Figure 4-4. It is a comparison unit. A simplified

illustration of the modulator is shown in Figure

4-2. Each PIN diode unit includes a transmission

line, PIN diodes, low-pass filter, and high-pass

filters.

Figure 4-2. Simplified Block Diagram

of PIN Modulator

Figure 4-1. Circuit Block Diagram

4-8. The PIN diode is a slice of nearly Pure silicon

wafer in which the P and N traces are nearly equal.

P-type impurities are diffused from one side into

the wafer, and N-type impurities are diffused from

the other side, leaving a layer of intrinsic semiconductor (silicon) through the middle. Thus the

name, PIN diode. At frequencies below 100 MHz

the PIN diode rectifies the same as any other good

junction diode. However, at frequencies above 100

MHz, rectification efficiency drops rapidly because

of carrier storage in the intrinsic (I) layer.

4-9. When forward-bias current flows through the

PIN diode, holes and electrons are stored in the I

layer. The more the bias current, the larger the

amount of stored charge-carriers. When reverse bias

is applied, reverse current flows until the stored

carriers are depleted. During this period, the diode

impedance remains 10 w. Currents above several

hundred megacycles do not flow in the reverse

direction for a long enough time to remove those

charge carriers.

So, microwave currents

do not

4-1

Page 28

TM 11-6625-2820-14&P

Figure 4-3. RF Attenuator Unit

significantly change the instantaneous amount of

charge carriers stored, and there is negligible rectification.

4-10. There is, however, a resistance to microwave

current flow. This resistance is inversely

proportional to the number of charge carriers

stored in the I layer, and the number of charge

carriers, in turn, is proportional to the forward bias

current. By varying the bias on a diode from back

bias (no stored charge) to about 1/2 mA forward

bias, the resistance to microwave currents varies

from approximately 5000 ohms to 30 ohms.

4-11. Pin Diodes Mounted in a Transmission

Line.

works, consider a PIN diode mounted across a

transmission line that has a characteristic impedance of 50 ohms. When the diode is back-biased

to about 5000 ohms, the microwave signal on the

transmission line is unattenuated because 5000

ohms compared to 50-ohm line impedance has

little effect. However, when the diode is

To understand how a PIN modulator

4-2

forward-biased to about 30 ohms, most of the

microwave current will flow through the 30-ohm

diode instead of propagating down the 50-ohm

transmission line. This current through the 30-ohm

diode represents microwave energy dissipated as

heat. Consequently the diode actually absorbs

microwave energy.

4-12. Figures 4-3A and 4-4A show the schematic

of the PIN diode modulator used in the Model

8616A. The PIN modulator contains seven PIN

diodes which are placed at approximately 1/4

wavelength along each strip transmission line. The

1/4 wavelength at midband spacing results in the

lowest average SWR because reflection from one

diode will tend to be absorbed and cancelled by

the adjacent diode. The resistance in series with the

diodes reduces voltage to the diodes and thereby

protects the circuit.

4-13. Modulation input in the form of diode bias

is used to change attenuation of the PIN diodes.

Page 29

TM 11-6625-2820-14&P

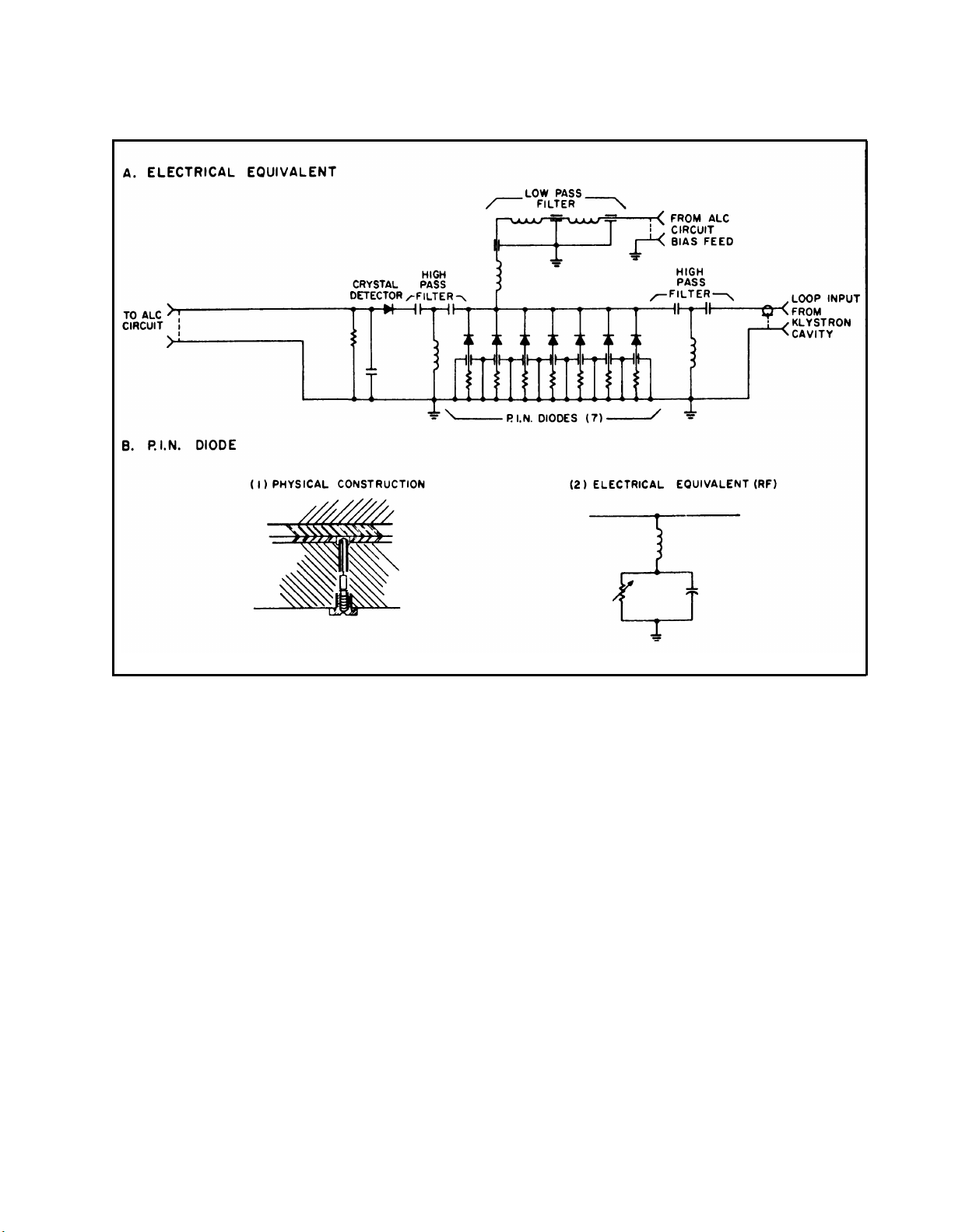

Figure 4-4. ALC Attenuator Unit

Changes in diode bias produce changes in RF

output level.

4-14. Modulation circuits external to the PIN

modulator are protected by a low-pass filter (Fig-

ures 4-3 and 4-4 ) which prevents RF leakage.

Leakage, if present, could cause erratic action in

the circuits driving the PIN modulator and also

cause RF interference.

4-15. The high-pass filters (Figures 4-3 and 4-4)

permit RF energy to enter and leave the diode strip

line, while keeping the low frequency modulating

signals from entering the RF circuits preceding or

following the PIN modulator.

4-16. MODULATION CIRCUITS

4-17. The arrangement of the modulation circuits

depends on the mode of operation. Mode of

operation switching is accomplished by depressing

the appropriate front-panel button.

4-18. External Pulse

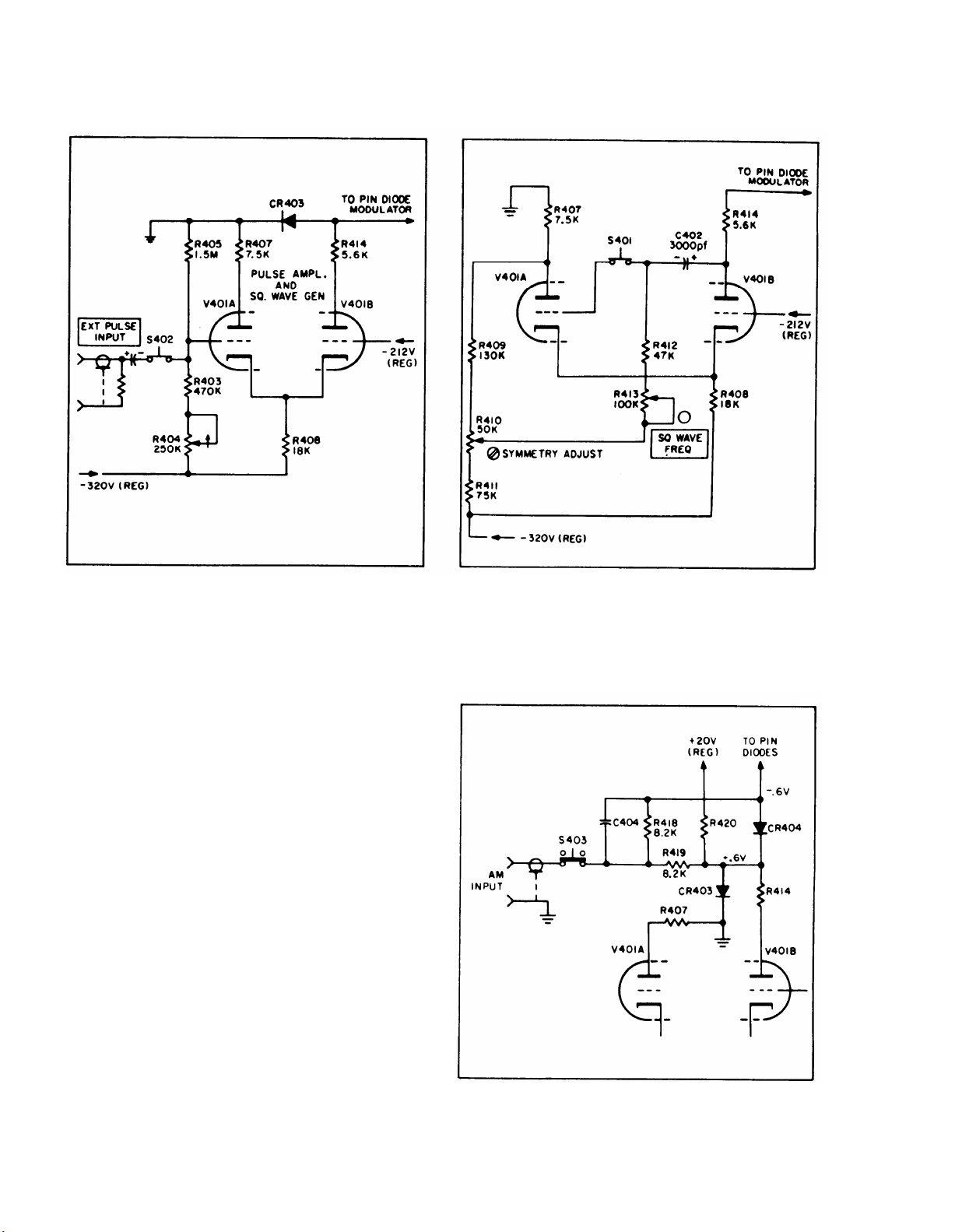

4-19. A simplified diagram of the circuits used in

the external pulse mode of operation is shown in

Figure 4-5. When the pulse button is depressed,

V401A is cut off, and V401B is conducting. The

conduction of V401 B draws current through the

PIN diodes in the REF attenuator unit; hence,

conduction of V401B forward biases the PIN

diodes causing the RF output to decrease by more

than 20 dB. A positive pulse applied to the exter-

nal pulse input turns V401A on, turns V401B off,

and allows RF power to pass through the PIN

diode attenuator with the RF output level clamped

to set level by CR403.

4-20. Internal Square Wave

4-21. A simplified diagram of the circuits used in

the internal square wave mode of operation is

shown in Figure 4-6. When V401B is conducting,

capacitor C402, is

discharging toward

4-3

Page 30

TM 11-6625-2820-14&P

Figure 4-5. Pulse Modulation Circuit

approximately

cut off. When C402 discharges sufficiently, V401 A

begins to conduct and biases V401 B off through

the common cathode resistor R408. This results in

C402 charging toward approximately –225 volts as

long as V401A conducts. When C402 charges

sufficiently however, the current in V401A becomes limited and V401B again conducts causing

V401A to cut off. The RC time constant of C402

is varied by R413, allowing frequency to be

changed from 950 to 1050 Hz. When V401B is

conducting the RF output is cut off by the PIN

diodes. The symmetry of the sqaure wave is ad-

justed by R410. R410 varies the voltage difference

across C402; by varying R410, the time for C402

to charge or discharge to a given potential is

controlled.

4-22. External AM

4-23. A simplified diagram

the external AM mode of

Figure 4-7. With the square

of operation off, V401B is cut off, causing conduction of CR403 which isolates the square wave

and pulse circuit from the AM input and the PIN

diodes. Diode CR403 does this by clamping the

–200 volts while holding V401A

of the circuits used in

operation is shown in

wave and pulse modes

Figure 4-6. Square Wave Modulation Circuit

voltage at the junction of R414 and CR404 at

approximately +0.6 volt. This back biases CR404

providing the isolation.

Figure 4-7. External AM Circuit

4-4

Page 31

TM 11-6625-2820-14&P

4-24. Since the PIN diode modulator is of the

absorption type, it is necessary to lower the average level of the RF carrier (CW power level) by an

amount equal to the peak level of the AM signal so

that the peak will not be clipped. The ALC CAL

adjust sets the power level of the RF carrier. The

external signal then increases or decreases the

attenuation to give amplitude modulation. When

the external signal goes positive, it increases the RF

out of the generator by reducing the current in the

PIN diodes. A negative signal causes an increase in

current in the PIN diodes, which causes a signal

level reduction up to approximately 20 dB on the

negative half cycle of the input depending on

peak-to-peak amplitude of the AM signal. For most

purposes this amount of signal reduction should be

sufficient since it very nearly approximates 10070

modulation. The amount of distortion, though

small, is dependent upon the percentage of modu-

lation: at 30% modulation the amount of distortion is almost unnoticeable; at 100% modulation

the distortion may be as great as 5 to 20%.

4-25. Internal Meter and Automatic Level Control

(ALC)

4-26. A simplified diagram of the ALC circuit is

shown in Figure 4-8. The meter amplifier is a dual

function circuit, performing both a leveling and/or

a power output monitoring function. RF power is

taken from the klystron cavity through the ALC

attenuator assembly (part of the PIN diode modulator) and delivered to the ALC circuit. The meter

amplifier monitors the power level and in leveled

operation with the ALC amplifier, maintains a

constant RF output.

4-27. Actual operation is as follows: RF power

from the klystron is coupled from a fixed probe in

the klystron cavity to the ALC attenuator (part of

the PIN diode modulator). The RF power is deli-

vered through a high-pass filter to the ALC diode

attenuator, then through another high-pass filter to

a crystal detector. The detected signal from CR701

is then delivered to a low-pass filter and to the

ALC circuit.

4-28. The crystal detector CR701 is arranged so

that the detected signal is negative in polarity. An

increase in RF level as the klystron is tuned across

the band will cause a more negative output. A

decrease in RF power from the klystron causes a

less negative output. The detected RF output level

from CR701 is then delivered to the base of

Q501A.

4-29. Consider the circuit operation when the RF

level from the klystron increases. An increase in

klystron output level causes a more negative signal

on the base of Q501A. The conduction of Q501A

decreases causing the collector of Q501A to go in a

positive direction. The positive signal goes through

Figure 4-8. ALC and Meter Circuit

4-5

Page 32

TM 11-6625-2820-14&P

the cathode follower, V401, and is applied to the

base of Q502, decreasing the conduction of Q502.

The collector of Q502 goes more negative.

4-30. A portion of the negative-going signal from

the collector of Q502 is applied to the base of

Q501B as negative feedback. The feedback factor

is determined by the ratio of R513 to R514. The

open loop gain of the meter amplifier (Q501 A/B,

Q502 and Q503) is sufficiently high so that the

closed loop gain is essentially a function of the

feedback factor and is, therefore, less dependent

upon the normal aging effects on the tubes and

transistors in the circuit.

4-31. The negative-going signal from Q502 is also

applied to the meter M501 for output indication.

The meter is protected against overload by the

breakdown diode CR501. If the internal ALC

switch, S601, is on, the negative-going output is

applied to the base of the differential amplifier,

Q601, causing a decrease in conduction. The

collector of Q601 will go more positive, causing an

increase in conduction of the emitter followers,

Q603 and Q604. This causes the emitter of Q604

to also become more positive. The positive-going

signal is applied to the bases of Q605 and Q606

increasing their conduction and causing both collectors to become more negative.

4-35. External Leveling

4-36. A simplified diagram of the ALC circuit is

shown in Figure 4-8. Operation of the external

leveling is the same as that described for internal

leveling with two exceptions. Operation of the

ALC circuit is such that the ALC attenuator (part

of the PIN diode modulator) will no longer be part

of the circuit; therefore, since the ALC attenuator

is removed from the overall circuit, the meter,

M501, will indicate a RF power level but not an

accurate measure of CAL RF OUTPUT power.

4-37. Regulated Power Supply

4-38. There are three regulated power supplies:

high voltage,

supplies are series-regulated types. The series regu-

lator is connected in series with the main load. The

output voltage is monitored and compared to a

reference voltage.

applied through a control amplifier to the series

regulator. This differential voltage changes the

effective resistance of the series regulator which in

turn holds the output voltage constant (see Figure

4-9).

+20 volts, and filament. All three

The voltage differential is

4-32. The collectors of Q605 and Q606 appear as

constant current sources, so the decrease in collector potential causes current to be drawn from the

PIN diodes. This increased bias current (increased

forward bias) reduces the RF power output to its

original level.

Q605 is delivered to the RF PIN diode attenuator

allowing less RF to pass through it also. The net

result is that an increase in klystron output causes

an increase of forward bias on the PIN diodes

which decreases the RF output.

4-33. Leveling Accuracy. For accurate leveling,

the ALC and RF pin diode attenuators must track

together as far as attenuation and frequency are

concerned. The adjustment of R614, R620, and

R621 provide for matching the attenuator charac-

teristics.

4-34. ALC Cal Output. The RF OUTPUT can be

controlled by adjusting the front panel ALC CAL

OUTPUT control which varies the bias on the base

of the differential amplifier, Q602, which in turn

changes the bias on the PIN diode attenuator.

The negative-going output from

Figure 4-9. Series-Regulated Power Supply

4-39. The high-voltage supply consists of two supplies which have been combined to obtain required

voltages. They are a —320 volt supply on which a

–350 volt supply has been stacked to provide a

total of -670 volts. Both supplies use voltage

doublers to drive series regulator circuits. Since this

is a combined circuit arrangement, the —320 volt

and —400 volt supplies are interdependent. There

is also a gas regulator tube, V105, connected to the

– 320 volt supply to provide a –212 volt regulated

source.

4-40. There are two low-voltage supplies. One

provides +20 volts DC for the ALC circuit, the

4-6

Page 33

TM 11-6625-2820-14&P

other 6.1 volts DC for filament operation. The +20

volt supply uses a voltage doubler and series

regulator, while the filament supply uses a halfwave rectifier and a series regulator.

4-7/4-8

Page 34

Page 35

SECTION V

MAINTENANCE

TM 11-6625-2820-14&P

5-1. INTRODUCTION

5-2. This section provides maintenance and service

information for the Model 8616A. Included in this

section is a performance check which may be used

to verify instrument operation (see Appendix II).

5-3. TEST INSTRUMENTS REQUIRED

5-4. Table 5-1 lists test equipment required for the

maintenance procedures discussed in this section.

Instruments other than those recommended may

be used, provided performance meets the basic

requirements given in Table 5-1.

5-5. PERIODIC MAINTENANCE

5-6. Cleaning the Air Filter

5-7. Inspect the air filter regularly and clean it

before it becomes dirty enough to restrict air flow.

Remove filter from instrument rear and

a.

wash it in warm water and detergent.

b. Dry filter thoroughly and

instrument.

5-8. GeneraI Maintenance

5-9. Other than periodic cleaning of

as mentioned above, the Model 8616A requires no

special preventive maintenance. We do suggest,

however, that every six months or so low pressure

air be used to blow any accumulated dust out of

the instrument.

5-10. Cover Removal

5-11. The Model 8616A is equipped with remov-

able top and bottom covers. The top cover exposes

wiring harnesses and the wired side of the powersupply circuit board.

hinged and may be opened out from the instrument when the top cover is removed. When the

power-supply circuit board is opened out from the

instrument, all of the adjustments and tests points

are accessible. The bottom cover exposes resistor

R613 and the wired side of the ALC circuit board.

The power-supply board is

remount on

the air filters

a.

Remove the four flathead screws from

cover.

b. Slide cover back and off instrument.

5-12. TROUBLESHOOTING

5-13. The following troubleshooting procedure

isolates the trouble to a stage. The procedure

should be performed generally in the sequence

given below.

When using an ohmmeter to measure

transistor forward and reverse resistance,

quite a bit of care must be used as almost

every ohmmeter has a few ranges that

supply enough current or voltage to damage a transistor. Before using any ohmmeter, measure the open-circuit voltage

(open-circuit voltage of each range should

not exceed 1.5 volts), and measure the

short-circuit current (current of each

range should not exceed 3 mA). If the

open-circuit voltage and or short-circuit

current exceeds 1.5 volts or 3 mA, respectively ON THE OHMMENTER RANGE

THAT YOU INTEND TO USE then the

ohmmeter will probably damage the transistor to be tested. For example: a DC

Multimeter cannot be used on the Rxl

and Rx10 range, but all other ranges are

perfectly safe.

POWER SUPPLIES. The high-voItage

a.

supply consists of two supplies which have been

combined to obtain the required voltages. They are

a —320 volt supply on which a —400 volt supply

has been stacked to provide a total high voltage

output of —720 volts. Both supplies use voltage

doublers to drive the regulator circuits. There is

also a gas regulator tube connected to the —320

volt supply to provide a —2.1 volt regulated source.

There are two low-voltage supplies. One provides

+20 volts DC for the ALC circuit, the other

provides 6.1 volts DC for filament operation. The

+20 volt supply uses voltage doublers; the 6.1 volt

supply uses half-wave rectifier and transistorized

series regulator circuits.

5-1

Page 36

TM 11-6625-2820-14&P

Table 5-1. Test Equipment Required

5-2

Page 37

TM 11-6625-2820-14&P

(1) LEVEL OUTPUT CHECK

“SOME OF THE MAINTENANCE AND

SERVICING OPERATIONS DESCRIBED

HEREIN ARE PERFORMED WITH

POWER SUPPLIED TO THE INSTRUMENT WHILE COVERS ARE RE-

MOVED.

PERFORMING THESE OPERATIONS.

LINE VOLTAGE IS ALWAYS PRESENT

ON TERMINALS INCLUDING THE

POWER INPUT CONNECTOR, FUSE

HOLDER, POWER SWITCH, ETC. IN

ADDITION, WHEN THE INSTRUMENT

IS ON, ENERGY AVAILABLE AT

MANY POINTS MAY RESULT IN PER-

SONAL INJURY OR DEATH WHEN

CONTACTED.”

Remove four #6 x 32 screws from top

(1)

cover and remove top cover.

Open out power-supply board by re-

(2)

moving two screws that secure board to

leveler assembly.

Connect ac power line to an ac power

(3)

source. Set slide switch at 115 volts ac or

230 volts ac as appropriate.

(4)

Connect a digital voltmeter in parallel and

make the proper measurements (see Table

5-3).

Use grounded meter for filament and

—400 volt measurement.

BE CAREFUL WHEN

(a) Set up Model 8616A as follows:

LINE . . . . . . . . . .

RF . . . . . . . . . . . depressed

ALC not depressed

ATTENUATION “ : : . . . . . 012

FREQUENCY . . . . . 1800 MHz

(b) Using a

measure voltage

Q501A (easiest access is rear

panel REMOTE LEVELING INPUT connector). Specification:

reading should equal 120 ± 2

mV. If voltage is not within

specification refer to paragraph

5-29 and adjust.

(c) With Model 8616A as in step a,

depress ALC button and set dBm

meter with ALC CAL OUTPUT

adjust to 0 dBm. Using dc millivolt meter measure voltage on

base of Q501A. Specification:

voltage should be approximately

100 mV.

(d) Set up power meter combination

for operation on the 3 mW range.

(e) Using power meter measure the

CAL RF OUTPUT of the Model

8616A across the entire fre-

quency range. Specification:

Level output should be constant

within ± 1.0 dB.

dc millivolt meter

depressed

on base of

b. TROUBLESHOOTING LOCATION

CHART. Check instrument trouble symptoms

against those listed in Table 5-2, Trouble Location.

ISOLATING TROUBLE TO A SPECIFIC

c.

CIRCUIT. Because each mode of operation uses

different circuit combinations (see Figure 5-1),

trouble can be isolated to a specific circuit by

checking the operation of each mode of operation

in logical order.

ISOLATING TROUBLE TO THE PIN

d.

MODULATOR. This procedure isolates trouble to

the PIN diode modulator box or to the instrument

circuitry.

(f) If level output is not within

specification refer to paragraph

5-28 and check and if necessary

adjust klystron repeller voltages

across frequency band.

(g) AIso, refer to paragraph 5-33 and

check and if necessary adjust the

ALC Amplifier for proper opera-

tion.

(h) Recheck signal generator leveled

output. If level output is still not

within

Table 5-2 eliminate cause of

specification refer to

5-3

Page 38

TM 11-6625-2820-14&P

5-4

Figure 5-1. Model 8616A Block Diagram

Page 39

Table 5-2. Trouble Location

TM 11-6625-2820-14&P

Table 5-3. Power Supply Adjust

5-5

Page 40

TM 11-6625-2820-14&P

trouble to either the PIN diode

modulator box or instrument circuitry.

(2) ON-OFF RATIO CHECK. Refer to

paragraph 5-42.

5-14. REPAIR

5-15. The etched circuit boards used in the 8616A

are of the plated-through type and consist of a base

board and conductor. The board does not include

funneled eyelets. The conductor material is plated

to the wall of the holes and thus the conductor is

effectively extended through the hole. This type of

board can be soldered from either the conductor or

component side of the board with equally good

results. The rules given below should be followed

when repairing a plated-through type etched circuit

board .

Avoid applying excessive heat when sol-

dering on the circuit board.

b. To remove a damaged component, clip

component leads near the component, then apply

heat, and remove the leads with a straight upward

motion.

outer truarc ring from the outer cover of the

klystron cavity (see Figure 5-2).

d. Remove outer cover. Remove inner truarc

ring holding klystron clamp housing in klystron

cavity.

Pull tube socket from klystron with a

e.

straight pull. Grasp klystron tube and remove from

cavity.

f.

Unscrew clamp nut, lift out clamp spacer,

and remove klystron (see Figure 5-2).

Remove waffle washer from cavity.

g

NOTE

Refer to paragraph 1-13

rant y claim instructions.

5-18. Tube Replacement

a. Reassemble new klystron, housing, spacer,

and nut.

b. Set klystron frequency drive at top end

(high frequency dial setting) for klystron centering.

for klystron war-

c. Use a special soldering iron tip to remove

components having multiple connections, such as

potentiometers, transformers, etc. Refer to Table

5-1 for type of soldering tip required.

d. Use a toothpick to free hole of solder

before installing a new component.

5-16. KLYSTRON REMOVAL AND REPLACE–

MENT

5-17. Tube Removal

BEFORE ATTEMPTING KLYSTRON

REMOVAL OR REPLACEMENT, BE

CERTAIN THAT LINE POWER IS COMPLETELY REMOVED FROM INSTRUMENT.

a. Remove panel cover on left (with

respect to front panel) side of instrument

(see Figure 5-2).

Set klystron frequency drive at top end

(4500 MHz frequency dial setting).

c. Using truarc pliers which are available in a

repair kit, HP Part No. 08614-800, remove the

Place waffle washer in klystron cavity.

c.

d. Insert klystron into klystron cavity.

Klystron should be inserted straight into

cavity. Insertion of klystron should require no unnecessary force; the klystron

should fit snugly but easily, into cavity.

Replace inner truarc ring on clamp hous-

e.

ing (if the klystron is properly in place the ring will

fit properly). Allow tube to be centered by center

conductor.

Install tube socket and outer cover.

f.

Place edge of truarc ring on outer cover

g.

and rotate until ring lies flat on cover and is easily

accessible with truarc pliers.

Refer to Calibration Checks (paragraph

h.

5-26) and make necessary adjustments.

5-19. RF PROBE REMOVAL AND REPLACE-

MENT

5-20. Probe Assembly Removal

5-6

Page 41

TM 11-6625-2820-14&P

Figure 5-2. Cut-A way View of Klystron Cavity and Klystron Assembly

BEFORE

ASSEMBLY REMOVAL OR REPLACEMENT,

POWER IS COMPLETELY REMOVED

FROM INSTRUMENT.

Remove top cover from instrument.

a.

b. Set FREQUENCY (MHz) drive to the

highest frequency setting (4500 MHz).

c.

Remove Attenuator access cover from

Klystron Cavity Casting and disconnect

assembly connectors from instrument.

d. Remove the cable assembly connector

from the defective RF probe cable. Be careful not

to lose any connector parts as they will be required

for reassembly.

Remove

e.

guide.

ATTEMPTING

BE CERTAIN THAT LINE

the probe cable from the cable

PROBE

cable

Remove the retaining screw holding the

f.

tuning carriage and remove the probe from the

casting.

The defective probe assembly should be

g.

returned to your local Hewlett-Packard Sales and

Service Office for repair or replacement (see list at

rear of manual).

5-21. Probe Replacement

THE

SHOULD BE HANDLED WITH CARE.

THE PROBLE SHOULD BE PLACED IN

A PROTECTIVE SHIELD WHEN HANDLING OR SHIPPING.

a.

insert the new probe into the Klystron Cavity

Casting and replace the probe retaining screw.

PROBE IS

To install a new probe assembly, carefully

FRAGILE AND

5-7

Page 42

TM

11-6625-2820-14&P

CARE MUST BE TAKEN NOT TO

DAMAGE THE RESISTIVE ELEMENT

ON THE PROBE END OR THE SPRING

WIPERS THAT MAKE CONTACT WITH

THE PROBE GUIDE TUBE.

f.

Trim the dielectric flush with the end of

the clamping body so that the center conductor is

bare.

Trim the center conductor protruding

g.

from the clamping body, then place the insulator

washer on the center conductor.

b. Insert the probe assembly through the

cable guide. Install the cable guide.

c.

Trim the insulation from the end of the

problem assembly cable (for RF UNCAL probe, 5/16

inch; for RF CAL and ALC probes, 1/4 inch).

d. Place cable assembly connector parts on

cable, with the exception of the clamping body,

and fold the braid upon the connector assembly

(see Figure 5-3).

Place the clamping body on the RF UN-

e.

CAL cable and screw the clamp nut and clamping

body together.

NOTE

After tinning center conductor the diameter may be too large to fit into the pin,

making it necessary to file the center

conductor to the proper diameter.

h. In preparing the ALC and CAL RF

probes, cut the inner conductor insulation about

1/8” from folded braid.

i.

Flatten inner conductor to approximately

1/8” wide and 1/32” thick.

Tin flattened conductor with solder and

j.

allow it to wick slightly.

5-8

Figure 5-3. RF Probe Assembly

Page 43

TM 11-6625-2820-14&P

k. Press end of inner conductor with

ensure good contact and smooth insertion

Cal.

Before connecting connector assembly in-

1.

to the instrument, connect an ohmmeter between

the probe center

measure the resistance across the range of the

attenuator. The resistance should be approximately

50 ohms ±5 ohms. If the probe is open or shorted

at any point, the probe is defective and should be

replaced.

m. Replace the connector assembly as it was

before disassembly. Connect the probe connector

to the instrument, making certain the center conductor makes good contact.

The probe installation is complete. Reas-

n.

sembly the instrument except for the front, right

side panel, which is removed when performing the

output power calibration adjustments.

5-22. PIN MODULATOR REMOVAL AND RE-

PLACEMENT

5-23. Modulator Removal

5-24. The PIN modulator CANNOT be repaired in

the field. If the PIN modulator is found to be

faulty, it should be returned for repair. Remove

the four screws holding the PIN modulator only.

Removal of screws holding the PIN diodes in place

can cause contamination of the PIN diodes, high

SWR, etc.

a. Remove power line from instrument.

b.

Remove top and bottom covers.

conductor and ground and

a file to

recepti-

f. (Referring to Figure 5-14 and paragraph

5-54) replace crystal diode body.

Disconnect ALC Bias Feed connections (1

g.

and 2 on A500 board) from ALC circuit board.

h. Remove three screws holding PIN modula-

tor in place.

i.

Remove PIN modulator from instrument.

Carefully pack PIN modulator in a con-

tainer and return to your local Hewlett-Packard

field office for repair or replacement.

5-25. Modulator Replacement

Replace three screws that hold PIN mod-

a.

ulator to instrument chassis.

b. Connect RF OUTPUT cable to J701.

Connect ALC Bias Feed connections to

ALC circuit board (A500).

d. Connect cable assembly connectors to

PIN diode modulator. (See CAUTION, paragraph

5-24).

e.

Place crystal diode into modulator; the

dark-coated side of crystal fits into the finger of

center conductor. WHEN INSTALLING CRY-

STAL, DO NOT FORCE TIP OF CRYSTAL INTO

CENTER CONDUCTOR AS FINGERS IN

MOUNT MAY BE DAMAGED OR BENT. Bending

or damaging center conductor fingers will cause

sporadic operation of the diode.

c. Place instrument on its side.

DO NOT HANDLE CRYSTAL DIODE,

CR701 NEEDLESSLY. A static charge

which builds up on a person, especially on

a cold, dry day must NEVER, be allowed

to discharge through element. When installing always touch casting first to insure

no difference in potential between hand

and casting.

d. (Referring to Figure 5-19 and paragraph

5-54) disconnect crystal diode, CR701, and crystal

diode body, P706, from PIN modulator.

e.

Disconnect cable assembly connectors

from the modulator (see Figure 5-3). Be careful

not to lose any disassembled parts as they will be

required for reassembly.

f. (Referring to Figure 5-14 and paragraph

5-54) replace crystal diode body.

5-26. CALIBRATION

5-27. Regulated Power-Supply Adjustment

Remove instrument top cover and open

out top circuit board (see paragraph 5-10).

b. Depress LINE button.

c.

Connect ac power line to an ac power

source. Set ac voltage at 115 or 230 volts as

appropriate.

d. Connect DC voltmeter digital and vacuum

tube voltmeter in parallel and make necessary

adjustments (see Table 5-3).

5-9

Page 44

TM 11-6625-2820-14&P

Use ungrounded meter for filament and

--400V measurement.

Figure 5-4. PIN Modulator (External View)

5-28. Frequency Tracking, Preliminary

tors; a fuse holder, and a power cord. Connected as

shown, this modulator provides a power line frequency modulation voltage continuously variable in

amplitude from 300 volts peak-to-peak, with phase

variable over a range of approximately 80 degrees,

plus a 6.3-volt AC output for oscilloscope sweep

control.

d. Apply external FM (60 cycles) and view