HP 8566b Installation Manual

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support

your product. This manual is the best copy we could find; it may be incomplete

or contain dated information. If we find a more recent copy in the future, we will

add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. Our service centers may be able

to perform calibration if no repair parts are needed, but no other support from

Agilent is available. You will find any other available product information on the

Agilent Test & Measurement website, www.tm.agilent.com.

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and

chemical analysis businesses are now part of Agilent Technologies. We have

made no changes to this manual copy. In other documentation, to reduce

potential confusion, the only change to product numbers and names has been in

the company name prefix: where a product number/name was HP XXXX the

current name/number is now Agilent XXXX. For example, model number

HP8648A is now model number Agilent 8648A.

Installation

and

Verification Manual

HP 8566B Spectrum

Analyzer

Includes Option 400, Option 462,

and Option 857

HP Part No. 08566-90169

Printed in USA September 1993

Notice.

The information contained in this document is subject to change

without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing,

performance, or use of this material.

@

Copyright Hewlett-Packard Company 1993

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

1400 Fountaingrove Parkway, Santa Rosa CA, 95403-1799, USA

Certification

Hewlett-Packard Company certifies that this product met its

published specifications at the time of shipment from the factory.

Hewlett-Packard further certifies that its calibration measurements

are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Information

Warranty

Regulatory

Chapter [cross reference to location of declaration of conformity

noise information] contains regulatory information.

This Hewlett-Packard instrument product is warranted against defects

in material and workmanship for a period of one year from date of

shipment. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard. Buyer shall prepay

shipping charges to Hewlett-Packard and Hewlett-Packard

shipping charges to return the product to Buyer. However, Buyer shall

pay all shipping charges, duties, and taxes for products returned to

Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and firmware designated

by Hewlett-Packard for use with an instrument will execute

its programming instructions when properly installed on that

instrument. Hewlett-Packard does not warrant that the operation

of the instrument, or software, or firmware will be uninterrupted or

error-free.

shall

&

pay

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

. . .

III

Assistance

Product

agreements are available

Rw

Service Ome.

maintenance agreewmats

for Hewlett-FWkard

any assistance, contact your nearest

and other customer assistance

products.

Him&&t-Rzckard Sales

and

Safety Notes

Caution

Warning

Instruction

ManuaI

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument.

Caution denotes a hazard. It calls attention to a procedure that, if

not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note until

the indicated conditions are fully understood and met.

The instruction manual symbol. The product is marked with this

symbol when it is necessary for the user to refer to the instructions in

the manual.

iv

General Safety

Considerations

Warning

Warning

Caution

Before this

properly grounded through the protective conductor of the ac

power cable to a socket outlet provided with protective earth

contact.

Any interruption of the protective (grounding) conductor, inside

or outside the instrument, or disconnection of the protective

earth terminal can result in personal injury.

There are many points in the instrument which can, if contacted,

cause personal injury. Be extremely careful.

Any adjustments or service procedures that require operation

of the instrument with protective covers removed should be

performed only by trained service personnel.

Before this

instruct

instruct

is switched

on, make sure it has been

is switched on,

make sure its primary power

circuitry has been adapted to the voltage of the ac power source.

Failure to set the ac power input to the correct voltage could cause

damage to the instrument when the ac power cable is plugged in.

V

How to Use This

Manual

This manual uses the

following

conventions:

HP 8566B

Documentation

Description

HP 8566B Installation

and Verification

Manual

HP

8566B

and Programming

Operating

Manual

Front-Panel Ke

Screen Text This indicates text displayed on the instrument’s

Included with the HP Model 8566B spectrum analyzer are manuals:

The Installation and Verification, the Operating and Programming

Manual, and the Performance Tests and Adjustments Manual.

HP part number

Contents: General information, installation, specifications,

characteristics, and operation verification.

HP part number 08566-90040

Contents: Manual and remote operation, including complete syntax

and command description.

pocket-sized Quick Reference Guide, HP part number 59558970.

3

This represents a key physically located on the

instrument.

screen.

08566-90169

Accopanying

this manual is the seperate,

HP 8566B

Performance

Tests

and

Adjustments Manual

HP 8566B RF Section

Troubleshooting and

Repair Manual

HP 8566B IF-Display

Section

Troubleshooting and

Repair Manual

HP part number 08566-90168

Contents: Electrical performance tests and adjustment procedures.

HP part number 08566-90210 Contents: RF section service

information.

HP part number 08566-90085 Contents: IF-Display section service

information.

vi

Contents

1. General Information

What You’ll Find in This Chapter

Introducing

the

HP 8566B

...............

...........

Safety .......................

Accessories Supplied

Accessories Available

Options

......................

Instruments Covered by This Manual

Serial Numbers

...................

Calibration Cycle

HP-IB Address Selection

Bench Operation

Electrostatic Discharge Information

Static-Safe Accessories

Routine Maintenance

Cleaning the Display

Cleaning the RF Section’s Fan Filter

Replacing the RF Section’s Battery

Ordering Information

Direct Mail Order System

Direct Phone-Order System

Returning the Instrument for Service

................

................

........

..................

..............

..................

..........

...............

.................

................

.........

.........

.................

..............

.............

.........

Service lags ....................

Original Packaging

Other Packaging

Sales and Service Offices

.................

..................

...............

l-l

l-l

l-2

l-2

l-5

l-6

l-7

l-7

l-8

l-8

l-8

l-9

l-10

l-11

l-11

1-12

1-12

1-16

1-16

1-16

1-17

1-17

1-17

1-18

l-20

2. Instailation

What You’ll Find in This Chapter

...........

Safety .......................

Preparation for Use ..................

Initial Inspection

Operating Environment

Power Requirements

‘Ib

Install Standard Instruments

lb Install Option 908 and 913 Instruments

lb Install Option 010 Instruments

lb Set the HP-IB Address

From the Front Panel

From the HP-IB Bus

From the HP-IB Address

..................

...............

................

............

.......

...........

...............

................

................

Switch

...........

2-l

2-l

2-2

2-2

2-3

2-3

2-4

2-7

2-11

2-18

2-18

2-18

2-18

Contents-l

3. Specifications

Introduction .....................

Frequency ......................

Measurement Range

Displayed

Values

................

..................

Center Frequency ................

Frequency Span .................

Resolution

Resolution Bandwidth

Resolution Bandwidth (Option 462 6

.....................

......

dB*Bandwidthsj

Resolution Bandwidth (Option 462 Impulse

Bandwidth)

Bandwidth Shape

..................

.................

Spectral Purity ...................

Amplitude

Measurement Range

Displayed Values

Scale

Accuracy

Reference Lines Accuracy

Dynamic Range

Spurious Responses

Image, Multiple, and Out-of-Band Responses

Residual Responses

Gain Compression

Displayed Average Noise Level (Sensitivity)

......................

................

..................

......................

.....................

..............

...................

................

....

................

................

....

Amplitude Uncertainty ................

Table

Marker

Sweep

Footnotes

........................

........................

...................

Inputs ........................

RF INPUT

IF INPUT

.....................

.....................

outputs .......................

CAL OUTPUT

1STLOOUTPUT

SWEEP + TUNE OUTPUT

Options

.......................

: : : : : : : : : : : : : : : : : :

.............

400 Hz Power Line Frequency Operation Option 400.3-16

General

HP-IB Interface Functions

Environmental

Power Requirements

Humidity

EM1

X-Rays

Warm-Up Time

.......................

..............

...................

Temperature

Altitude

...................

.....................

................

......................

Operation

Storage

....................

.....................

........................

.......................

Serial Prefix 3004A and Above

Serial Prefix 3001A and Below

..........

..........

...................

Operation

....................

Frequency Reference ...............

3-l

3-l

3-l

3-l

3-l

3-2

3-3

3-3

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-5

3-6

3-6

3-6

3-6

3-7

3-8

3-8

3-8

3-10

3-12

3-13

3-14

3-14

3-14

3-14

3-15

3-15

3-15

3-15

3-16

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-17

3-19

3-19

3-19

Contents-2

Weight

Dimensions

4. Performance Characteristics

Frequency

Resolution

Spectral Purity

Stability

Amplitude

.......................

.....................

......................

.....................

...................

Noise Sidebands

Power-Line Related Sidebands

.................

...........

......................

Residual FM

Drift

.......................

...................

......................

Third Order Intermodulation Distortion

Third Order Intercept

Synthesis-Related Spurious Sidebands

Input Attenuator Uncertainties

RF Gain Uncertainty

Inputs

........................

IF INPUT

RF INPUT

VIDEO INP

IF INP

.....................

.....................

.....................

.......................

EXT TRIGGER

FREQREFERENCEEXT

outputs

.......................

Display Outputs

Recorder Outputs

SWEEP

VIDEO

PENLIFT

......................

.......................

......................

21.4 MHz IF OUTPUT

FREQ REFERENCE INT

10MHzOUT

VIDEO OUT

....................

....................

(TOI)

.............

........

...........

................

...................

..............

..................

..................

................

...............

IF OUT

IF OUTPUT’ : : : : : : : : : : : : : : : : : : : :

General

.......................

Acoustic Noise Emission/ Geraeuschemession

Function Descriptions

Sweep

.......................

Sweep Time

Zero Frequency Span

Marker

.....................

Video Bandwidth

Cathode Ray Tube

Instrument State Storage

Remote Operation

.................

...................

..............

.................

................

.............

................

.......

.....

3-19

3-20

4-l

4-l

4-l

4-l

4-l

4-3

4-3

4-3

4-4

4-4

4-4

4-5

4-5

4-5

4-6

4-6

4-6

4-7

4-7

4-7

4-8

4-8

4-8

4-8

4-8

4-9

4-9

4-9

4-9

4-9

4-10

4-10

4-10

4-10

4-10

4-11

4-11

4-11

4-11

4-11

4-11

4-12

4-12

4-12

Contents-3

5. Operation Verification

What You’ll Find in This Chapter

Test System Configuration

Equipment Connections

Program Loading

...................

Program Operation

HP-IB Addresses

Error Messages

Test Descriptions

...................

....................

...................

...............

................

..................

1. Input Attenuator Switching Check

...........

........

2. IF Gain Uncertainty ...............

3.

Scale

Fidelity (Log) ...............

4.

Scale

Fidelity (Linear)

5. Log

Scale

Switching Uncertainty

6. Resolution Bandwidths

..............

.........

..............

6. Impulse and Resolution Bandwidths (Option 462

Impulse Bandwidth)

7. Line Related Sidebands

8. Average Noise Level

9. Residual Responses

10. Sweep + Tune Out Accuracy

11. Second Harmonic Distortion

12. Frequency Span Accuracy

13. Gain Compression

14. Frequency Response

...............

.............

...............

...............

..........

...........

............

...............

..............

15. Third Order Intermodulation Distortion

16. Calibrator Output Amplitude Accuracy

17. First LO Output Power

.............

.....

......

5-1

5-4

5-5

5-6

5-7

5-8

5-9

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

5-17

5-18

5-19

5-20

5-21

5-22

5-23

5-24

5-25

5-26

5-27

Contents-4

Figures

l-l. HP 8566B with Accessories Supplied

l-2. AC Power Cables Available

l-3. Typical

Serial

Number Label

l-4. Static-Safe Workstation

l-5. Display Bezel Screws

................

l-6. Removing the Bottom Cover

.............

............

...............

............

l-7. Location of Al5 Controller Assembly

l-8. Location of Battery on Al5 Controller Assembly

l-9. Factory Packaging Materials for each Section

2-l. Rear-Panel Cable Connections

............

2-2. Voltage Selector Board and Fuse

2-3. Removing the Handles and Trim

2-4. Removing the Information-Card Tray

2-5. Attach the Rack Mount Flanges

2-6. Voltage Selector Board and Fuse

2-7. Rear-Panel Cable Connections

............

2-8. Removing the Handles and Trim

2-9. Removing the Information-Card Tray

2-10. Attaching the Rack Handles and Flanges

2-l 1. Rear-Panel Cable Connections

............

2-12. Voltage Selector Board and Fuse

2-13. Attaching

the

Inner-Member Brackets

2-14. Slide Adapter for Non-HP System Rack Cabinets

2-15. Removing the Bottom Cover

............

2-16. Location of Al5 Controller Assembly

.........

........

...

.....

...........

...........

........

...........

...........

...........

........

.......

...........

........

...

........

2-17. Address Switch (Shown In Factory Preset Position) . .

2-18. Address Switch Set to 4

...............

3-l. Specified Average Displayed Noise Level, 100 Hz to 2.5

GHz

Non-preselected Tuning Range

3-2. Specified Average Displayed Noise Level, 2.0

GHz

Preselected Tuning Range

3-3. Instrument Dimensions with Handles

3-4. Instrument Dimensions without Handles

4-l. Typical Spectrum Analyzer Resolution

........

GHz

to 22

..........

........

.......

........

4-2. Single Sideband Noise Normalized to 1 Hz BW versus

Offset from Carrier

4-3. Typical SSB Noise at 5.0

...............

GHz

Center Frequency

Normalized to 1 Hz BW versus Offset from Carrier

and Analyzer Resolution. May be Limited by

Average Noise Level.

4-4. Typical Optimum Dynamic Range

5-l.

Dual

Bus (MTS) System Connection

5-2. Single Bus System Connection

5-3. RF Input and Calibration Controls

..............

..........

.........

............

..........

l-3

l-4

l-8

l-9

l-11

1-13

1-13

1-14

1-18

2-4

2-5

2-7

2-8

2-8

2-9

2-10

2-11

2-12

2-12

2-13

2-14

2-15

2-16

2-19

2-19 .

2-20

2-21

3-9

3-9

3-20

3-20

4-l

4-2

4-3

4-4

5-5

5-6

5-8

Contents-5

lhbles

1 -

1. Static-Safe Accessories

...............

l-2. Factory Packaging Materials .............

l-3. Hewlett-Packard Sales and Service Offices

......

2-l. Decimal and Binary Address Codes .........

5-l. Tests Performed

5-2.

Tests Not Performed

5-3.

5-4.

Equipment Summary

HP-IB Addresses

..................

................

................

..................

l-10

1-18

1-21

2-22

5-2

5-3

5-4

5-8

Contents-6

General Information

1

What You’ll Find in

This Chapter

This chapter introduces you to the HP 8566B spectrum analyzer

and its options and accessories. Refer to Chapter 2 for information

on inspecting and installing the HP 8566B. Refer to Chapter 3 and

Chapter 4 for a complete listing of instrument specifications and

characteristics. Refer to Chapter 5 for Operation Verification.

Introducing the HP 8566B

Safety ...........................................................

Accessories Supplied

Accessories Available

Options

Instruments Covered by This Manual

Serial

Calibration Cycle

HP-IB Address Selection

Bench Operation

Electrostatic Discharge Information

Static-Safe Accessories

Routine Maintenance

Cleaning the Display

Cleaning the RF Section’s Fan Filter

Replacing the RF Section’s Battery

Ordering Information

Returning the Instrument for Service

Service

Original Packaging

Other Packaging

Sales and Service Offices

..........................................................

Numbers

..............................................

..............................................

Tags

..................................................

...............................................

.........................................

............................................

..........................................

...........................

...............................................

........................................

..............................

........................................

............................................

...........................................

...........................

............................

............................................

...........................

.............................................

.........................................

..l- 5

..l-

..l-

l-10

. l-12

. l-13

1-13

l-14

1-14

. l-17

. l-18

..l-18

1

-

. l-19

l-21

l-2

l-2

l-2

l-6

l-7

l-8

8

l-9

9

18

Introducing the

HP 8566B

The HP 8566B spectrum analyzer is capable of measuring signals

from -135

22

GHz.

frequency range of the instrument can be extended, unpreselected,

to 110

commercially available mixers.

The HP 8566B is a complete, self-contained instrument that requires

only an external ac power source for operation. A set of two ac

power cables, suitable for use in the country to which the instrument

is originally shipped, are included with the instrument.

dBm

to

+30 dBm

The HP 8566B provides preselection from 2 to 22

GHz

using HP 11970 Series mixers, and to 325

over a frequency range of 100 Hz to

GHz

using other

General Information l-l

GHz.

The

Safety

Before installing or operating this instrument, you should familiarize

yourself with the safety marking on the instrument and the safety

instructions in the manuals. The instrument has been manufactured

and tested in accordance with international safety standards.

However, to ensure safe operation of the instrument and personal

safety of the user, the cautions and warnings in the manuals must be

followed. Refer to the summary of the safety information located

near the front of this manual.

Accessories Supplied

Figure l-l illustrates the instrument with the supplied accessories. In

accordance with international safety standards, both sections of this

instrument are equipped with three-wire ac power cables. Various

power cables are available to connect the HP 8566B to the types of ac

power outlets unique to specific geographic areas. See Figure l-2. The

cables appropriate for the area to which the instrument is originally

shipped are included with the instrument.

FRONT VIEW

I F-

Display

Sect ion

RF

Sect ion

REAR VIEW

h

1-2 General Information

IF- Display

Sect ion

RF Section

CABLES

Item

1

1ST

LO OUTPUT SMA termination

2

Front-panel IF semirigid jumper

3

BNC jumper cable (quantity 3)

4

Bus interconnect cable (W31)

5

Coax interconnect cable

6

Line power cables (2 each)

Figure l-l. HP 8566B with Accessories Supplied

Description HP Fart Number

1810-0118

85660-20101

85660-60117

85662-60220

(W30)

85662-60093

see Figure l-2

General Information

1.3

PLUG TYPE * *

CABLE

HP PART

NUMBER

I

PLUG

DESCRIPTION

I

CABLE

LENGTH

CM

(INCHES)

CABLE

COLOR

I

IN COUNTRY

FOR USE

250V

250V

II

FE%

0

-

250V

-

125V

0

ON Ed

0

-

250V

8120-1351

8120-1703

8120-1369 Straight*

8 120-0696 90°

8120-1689

8120-1692 go-

8120-1348

8120-1538

8120-1378

8 120-4753 Straight

8120-1521

8120-4754 9o”

8120-5182

8120-5181

Straight*

90”

Straight

Straight*

9on

Straight*

9o”

;traight*

JO0

BS1363A

NZSS198/ASCll

*

CEE7-Yl

NEMA5-15P

NEMA5-15P

NEMAS-15P

229 (90)

229 (90)

201 (79)

221 (87)

1

201 (79)

201 (79)

203 (80)

203 (80)

203 (80)

230 (90)

203 (80)

230 (90)

200 (78)

200 (78)

Mint Gray

Mint Gray

Gray

Gray

Mint Gray

Mint Gray

B I ock

Black

Jade Gray

Jade Gray

Jade Gray

Jade Gray

Jade Gray

Jade Gray

Great Britain,

Niger

Cyprus.

Singapore,

2 imbabwe

Argentina,

Australia,

New Zealand,

Mainland China

Iast

and West

!urope,

African

Jnited Arab

?epubl

(unpolarized in

nany nations)

United States

zanodo,

Japan (100 V or

200 V), Brazil,

Colombia, Mexico

Philippines,

Saudio

Taiwan

Israel

Central

Republic,

ic

Arabia,

ia,

-

*

Part number for plug is industry identifier for plug only. Number shown for cable is

HP Part Number for complete cable, including plug.

**

E = Earth Ground; L = Line; N = Neutral

FORMAT80

l-4

General Information

Figure l-2. AC Power Cables Available

Accessories Available

A number of accessories are available from Hewlett-Packard to help

configure the HP 8566B for your specific needs.

Preamplifiers

External Harmonic

Mixers

Microwave Power

Amplifier

Close-Field Probes

The HP 8447D preamplifier provides a

minimum of 26 dB gain from 100

1.3

GHz

to enhance measurements of very

kHz

to

low-level signals.

The HP 8449B preamplifier provides a

minimum of 28 dB gain from 1 to 26.5

GHz

to enhance measurements of very low-level

signals.

The HP 11970 Series harmonic mixers extend

the frequency range of the HP

110

GHz.

8566B

up to

The HP 11975A microwave power amplifier

boosts the LO power for external mixers. Its

frequency range is from 2 to 8

provides an output leveled to f 1

GHz,

dB.

and it

The HP 11940A and HP 11941A close-field

probes are small, hand-held,

electromagnetic-

field sensors. The probes can be used to

make repeatable, absolute, magnetic-field

measurements. When attached to a signal

source, the probes can be used to generate a

localized magnetic field for electromagnetic

interference

(EMI)

susceptibility testing. The

HP 11941A is specified over a frequency range

of 9

kHz

to 30 MHz. The HP 11940A operates

from 30 MHz to 1

GHz.

75

to 50 Ohm

Minimum-Loss Pad

Microwave Limiters

HP-IB Cable

Controllers

The minimum-loss pad (dc to 2.0

GHz),

HP part number 08568-60122, is a low-VSWR

resistive matching device for making

measurements in

The HP 11693A limiter protects

75-ohm

systems.

the

instrument input circuits from damage due

to high power levels. It operates over a

frequency range of 0.4 to 12.4

GHz

and is

rated 1 W continuous and 75 W peak power.

The HP 11867A limiter is similar to the

HP 11693A but has a frequency range of dc to

1.8

GHz

and is rated 10 W continuous and 100

W peak power.

Use HP

10833A/B/G/D

HP-IB cables.

The HP 8566B is fully HP-IB programmable.

The preferred controllers are HP 9000

Series 300 computers. Consult your local

Hewlett-Packard service representative for

other recommended controllers and available

software.

General Information

l-5

HP 85650A Quasi-Peak The HP 85650A adds to the spectrum

Adapter analyzer the resolution bandwidth filters and

quasi-peak detection capability specified by

CISPR. Together the quasi-peak adapter and

the spectrum analyzer provide many of the

elements needed for an EM1 receiver system.

HP

85685A

Preselector

RF

The HP

85685A

RF preselector can be used

with an HP 8566B to form a multi-purpose RF

test receiver. It improves spectrum analyzer

measurement sensitivity while providing

overload protection from out-of-band signals.

This enables low-level signals to be monitored

in the presence of high-level ambients. Its

frequency range is 20 Hz to 2

GHz.

Options

Troubleshooting and

Repair Manual

Service information for the HP 8566B is

available in the

and

Repair

HP 85660B Troubleshooting

Manual

and the

HP 85662A

Troubleshooting and I&pair Manual.

They include schematic diagrams, block

diagrams, component location illustrations,

circuit descriptions, repair procedures, and

troubleshooting information.

Service Kits

A service kit is available containing

troubleshooting and alignment accessories for

the HP 8566B. The kit includes a test cable

and extender boards. Order the kit as HP

part number 08566-60001. A combined kit,

HP part number 08566-60005, is available

containing accessories for both the HP 8566B

and HP

8568B

instruments.

Several options are available and can be ordered by option number

when you order the instrument. Some of the options are also

available as kits that can be ordered and installed after you have

received your HP 8566B.

Option 010

Rack Mount Slide Kit. This option supplies the

necessary hardware and installation instructions

for mounting an instrument on slides into a rack of

482.6 mm (19 inch) spacing. The heavy-duty slides

are designed specifically to support the weight of the

HP 8566B. Because of the weight of

the

HP

8566B,

approximately 50 kg (112 lb), the use of this option

is recommended. Option 010 is also available as a kit

(HP part number 5062-6407).

1-6 General Information

Option 080

Option 081

Option 400

Information Cards in Japanese

Information Cards in French

The standard HP 8566B requires that the power line

frequency be 50 or 60 Hz. Option 400 allows the

instrument to operate with a 400 Hz power line

frequency.

Option 462

This option provides 6 dB bandwidths for making

MIL-STD EM1 measurements. In addition to

enhancing instrument capability for MIL-STD

461D and 462D EM1 measurements, Option 462

spectrum analyzers can still make all commercial

EM1 and general-purpose measurements. Option

462 instruments with HP 85662A (top box) serial

prefixes below 3341A were compatible with MIL-STD

462A/B/C

(impulse bandwidths).

Option 857

Option 908

Option 910

Option 913

Option 915

The HP 8566B Option 857 is used in EMC receiver

applications. This option provides the cumulative

log fidelity and absolute amplitude performance

necessary for EMC receivers to meet their system

specs.

Rack Mount Flange Kit (to mount without handles).

This option supplies the necessary hardware and

installation instructions for mounting an instrument in

a rack of 482.6 mm (19 inch) spacing. Option 908 is

also available as a kit (HP part number 5062-3986).

Extra

HP 8566B Operating and Programming

Manual

and Adjustments Manual.

Rack Mount Flanges with Handles (handles provided).

This option supplies the

installation instructions for mounting an instrument

with handles in a rack of 482.6 mm (19 inch) spacing.

Option 913 is also available as a kit (HP part number

5062-3986).

This option supplies the HP 8566B troubleshooting

and repair manuals.

and an extra

HP

8566B Ryformance Ests

necessary

hardware and

Instruments Covered

by

This

Manual

Serial Numbers

This manual contains information for setting up and verifying

operation of HP

Option 400 (400 Hz operation), Option 857, or Option 462 (6

bandwidths or impulse bandwidths) installed. The procedures in this

manual can also be used to set up and verify the operation of HP

8566A spectrum analyzers that

spectrum analyzers through the installation of an HP 8566AB Retrofit

Kit (formerly the HP

Hewlett-Packard makes frequent improvements to its products to

enhance their performance, usability, or reliability. HP service

personnel have access to complete records of design changes to each

type of equipment, based

Whenever you contact Hewlett-Packard about your instrument, have

the complete serial number available to ensure obtaining the most

complete and accurate information possible.

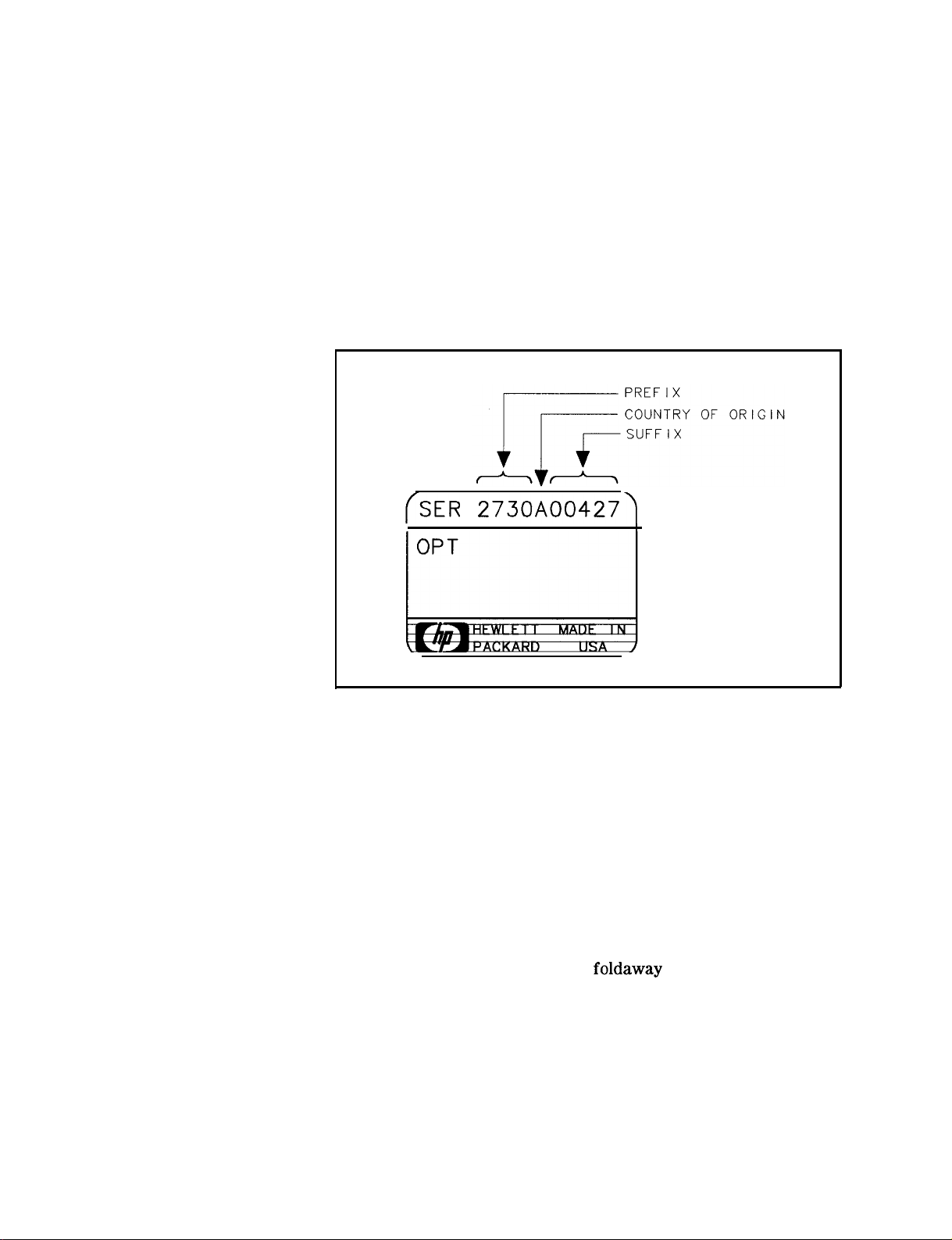

A serial number label is attached to the rear of each instrument

section. The serial number has two parts: the prefix (the first four

8566B

spectrum analyzers, including those with

have

been converted into HP 8566B

8566A+OlK

on the

Retrofit Kit).

equipment’s serial number.

dB

General Information 1-7

numbers and a letter), and the suffix (the last five numbers). See

Figure l-3.

The first four numbers of the prefix are a code identifying the date of

the last major design change incorporated in your instrument.

The letter identifies the country in which the instrument was

manufactured. The five-digit suffix is a sequential number and is

different for each instrument. Whenever you list the serial number

or refer to it in obtaining information about your instrument section,

be sure to use the complete number, including the full prefix and the

suffix.

Calibration Cycle

HP-IB Address

Selection

fsER

To ensure that the HP 8566B meets the specifications listed in Chapter

3, the operation verification listed in Chapter 5 should be performed

every 6 months.

The instrument is shipped with the HP-IB address preset to 18 (ASCII

2R). The instrument stores this address in internal RAM memory

which is maintained by a lithium battery in STANDBY and when line

power is removed. This stored address can be changed from the

front panel or on switches located on the RF section’s Al5 controller

assembly. Refer to Chapter 2, Installation.

2730AOO427)

Figure 1-3. Typical Serial Number Label

Bench Operation

1-6 General Information

The instrument has plastic feet and foldaway tilt stands for

convenience in bench operation. The plastic feet are shaped to make

full-width modular instruments self-aligning when stacked. The

instrument is shipped with front handles attached for ease of moving.

Electrostatic

Discharge

Information

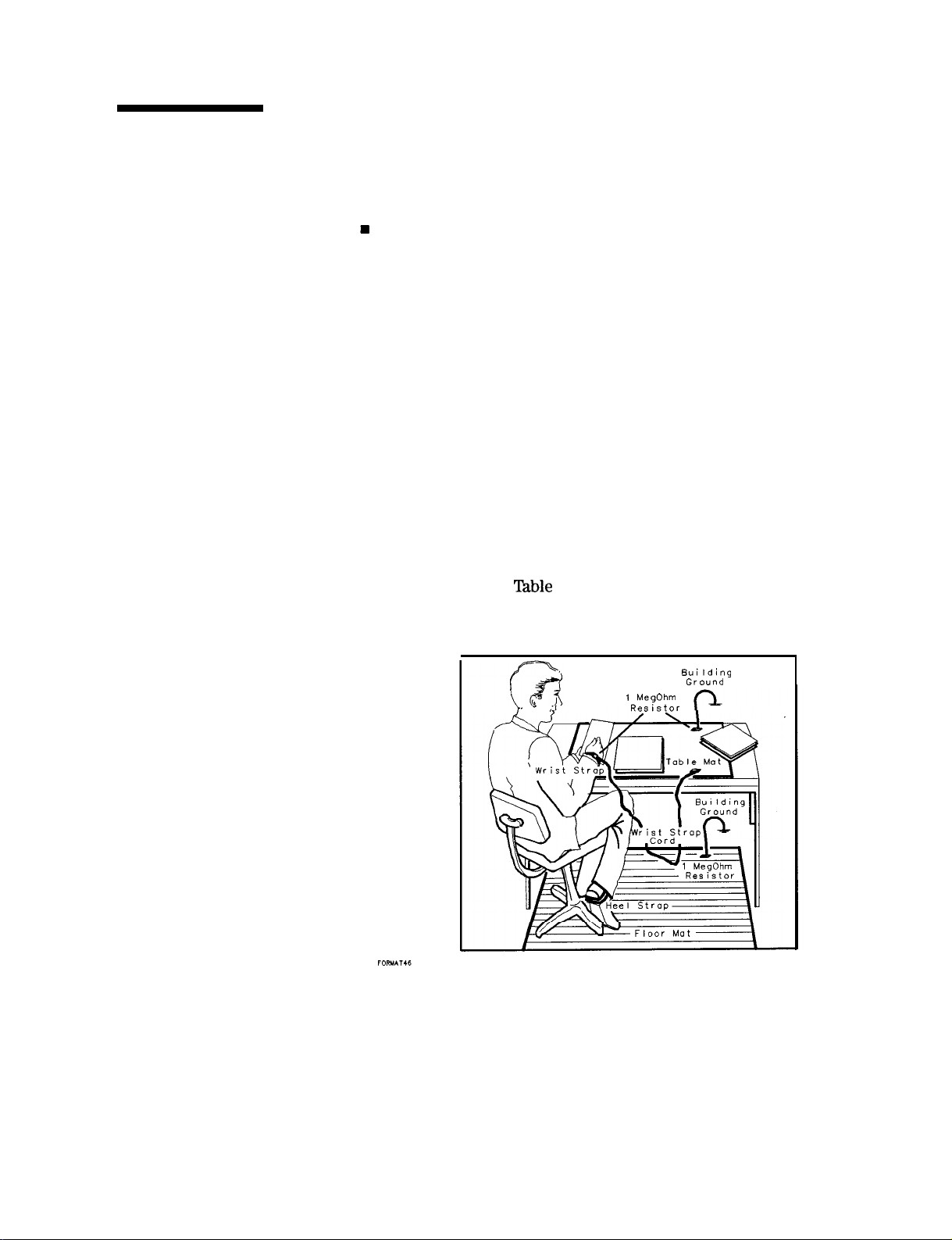

Electrostatic discharge (ESD) can damage or destroy electronic

components. Therefore, observe the following precautions:

n

Be sure

that

all instruments are properly earth-grounded to prevent

buildup of static charge.

H

Before connecting any coaxial cable to an instrument connector for

the first time each day, momentarily short the center and outer

conductors of the cable together.

n Personnel should be grounded with a resistor-isolated wrist strap

before touching the center pin of any connector and before

removing any assembly from the instrument.

n When replacing the instrument’s battery (refer to “Replacing the RF

Section Battery” in this chapter), be sure to observe the following:

q Perform the work at a static-safe workstation. See Figure l-4.

q

Store or transport PC boards only in static-shielding containers.

q Always handle board assemblies by the edges. Do not touch the

edge-connector contacts or trace surfaces with bare hands.

Figure l-4 shows an example of a static-safe work station. Two types

of ESD protection are shown: a) conductive table mat and wrist strap

combination, and b) conductive floor mat and heel strap combination.

The two types must be used together to ensure adequate ESD

protection. Refer to

Table

l-l for a list of static-safe accessories and

their part numbers.

Building

1 MegOhm

Resistor

Ground

Figure 1-4. Static-Safe Workstation

General Information l-9

Static-Safe

Accessories

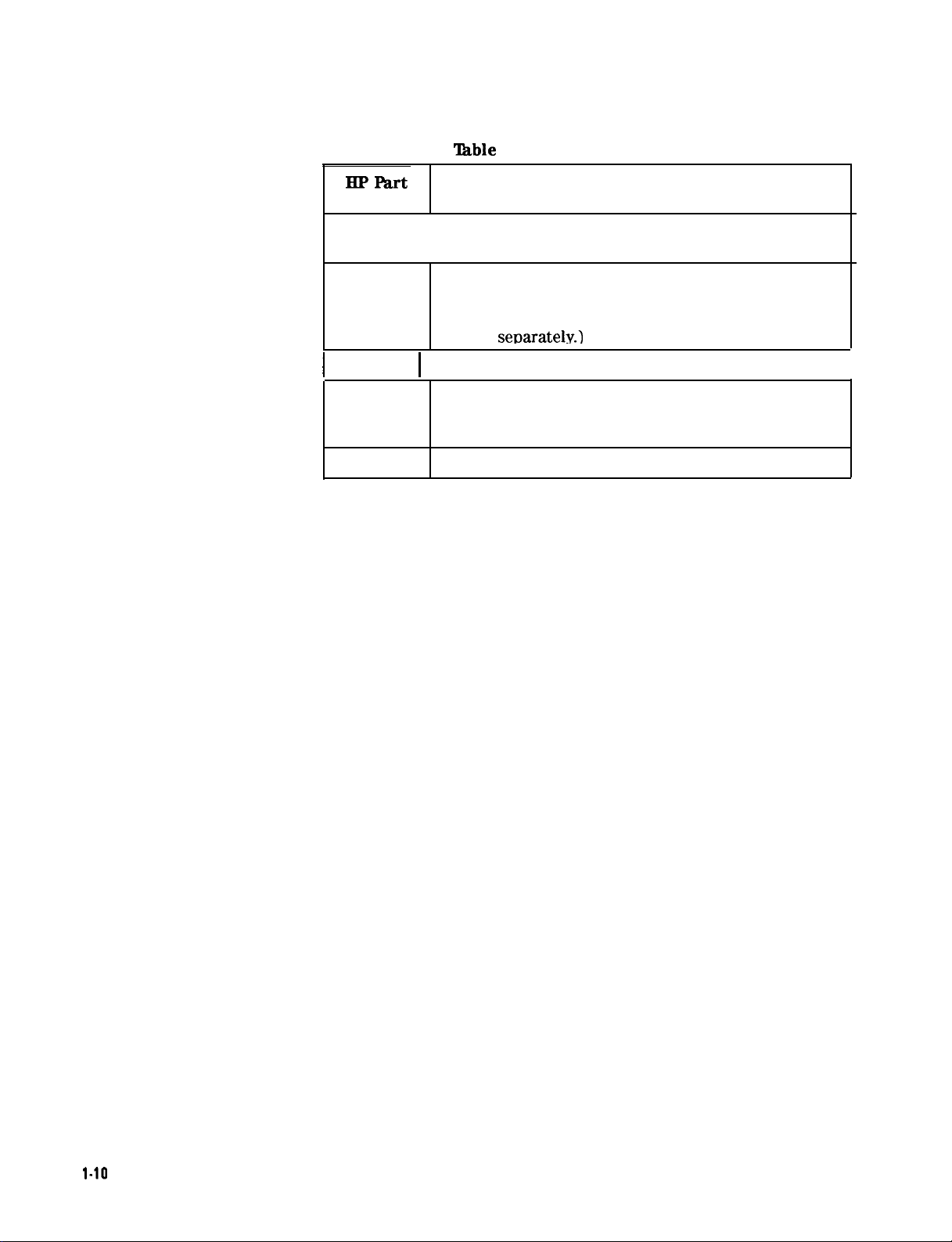

‘able

l-l. Static-Safe Accessories

HPFart

Number

Description

Order the following through any Hewlett-Packard Sales and Service

Office

9300-0797

Set includes: 3M static control mat 0.6 m x 1.2 m (2 ft

x 4 ft) and 4.6 cm (15 ft) ground wire. (The wrist-strap

and wrist-strap cord are not included. They must be

ordered

1

9300-0980 1 Wrist-strap cord 1.5 m (5 ft)

9300-1383

Wrist-strap, color black, stainless steel, without cord,

separatelv.)

has four adjustable links and a 7 mm post-type

connection.

9300-1169

ESD heel-strap (reusable 6 to 12 months).

I

l-10

General Information

Routine

Maintenance

Cleaning the Display

Caution

The inside surface of the glass CRT shield is coated with a thin

metallic film that can be easily damaged. To clean the glass CRT

shield, use thin-film cleaner (HP part number 8500-2163) and a

lint-free cloth. lb clean the inside surface of the display glass, remove

the

glass CRT shield using the following procedure:

1. Disconnect the ac line power from the instrument sections.

2. Remove the two screws securing the display bezel and CRT glass

shield to the front panel. These screws are located on the bottom

edge of the bezel. See Figure l-5.

While removing the two bezel screws, use caution to prevent the glass

from falling.

3. Remove the bezel and CRT glass shield.

\

Bezel Screws

Figure 1-5. Display Bezel Screws

4. Clean the glass using the thin-film cleaner and a lint-free cloth.

5. Replace the glass shield. Place the side of the glass that has the

silver edge towards the CRT.

6. Replace the bezel and two screws.

General Information

l-11

Cleaning the RF

Section’s Fan Filter

The fan on the RF section has a air filter that should be regularly

inspected and cleaned. lb clean the air filter, perform the following:

1. Disconnect the ac line power from the RF section.

2. Remove the four screws securing the filter cover to the fan on the

RF Section. Remove the filter.

Replacing the RF

Section’s Battery

Warning

Warning

3. Clean

the

filter using mild soap and water. Dry the filter

thoroughly. If it is damaged, replace it with a new filter (HP part

number 85660-00049).

4. Replace the filter and its cover.

The RF section’s Al5 controller assembly has a battery for

maintaining internal RAM memory. This memory is primarily used

for storing instrument states, error correction data, and

DLPs

(downloadable programs). Under normal conditions, the battery

should typically last a minimum of 3 years. Refer to the HP

Troubleshooting and

Repair

Manual for the HP part number. Use the

8566023

following procedure to replace the battery.

Battery

or attempt to recharge this battery. Dispose of discharged

battery in a safe manner.

Changing the battery

requires the removal of the RF’ Section’s protective bottom cover.

This should be performed only by a qualified service person.

Refer all such servicing of the instrument to qualified service

persons.

BTl

contains lithium iodide. Do not incinerate, puncture,

BTl

on the Al5 controller assembly

Caution

ESD (electrostatic discharge) can damage or destroy electronic

components. Work at a static-safe workstation when replacing the

battery.

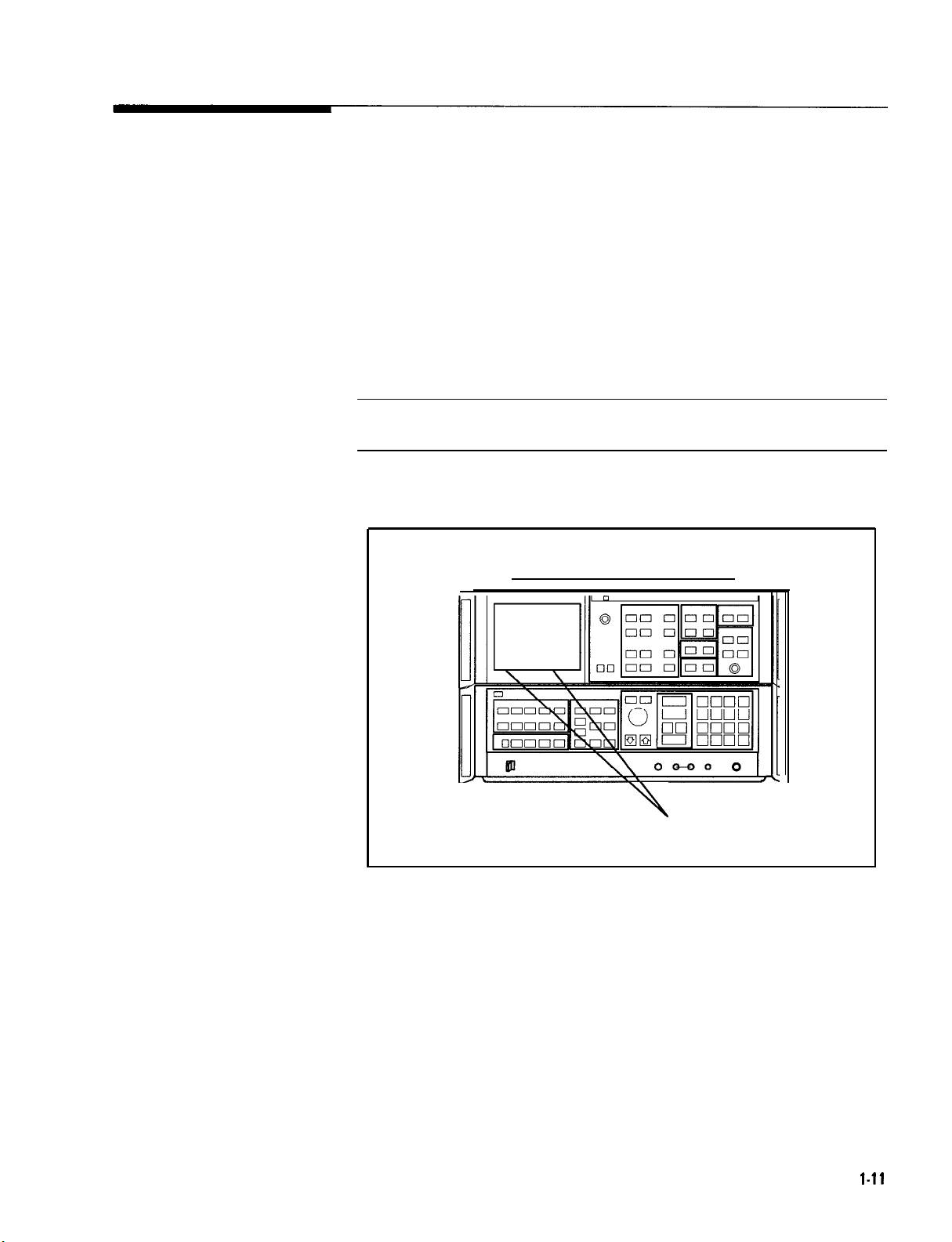

1. Place the HP

8566B

on a static-safe workstation. Refer to

“Electrostatic Discharge Information” in this chapter.

2. Disconnect the ac line power from the instrument sections. Place

the HP 8566B RF section upside down on the work surface so the

bottom of the RF section faces up.

3. Using a Pozidriv screw driver, remove the two bottom RF-Section

rear-panel bumpers. See Q) in Figure l-6.

1-12 General Information

TOP DOWN

Figure 1-6. Removing the Bottom Cover

4. Back out screw Q (Figure l-6) causing the cover to unseat from

the front frame. When the cover is clear of the front frame, lift

the cover up to remove it.

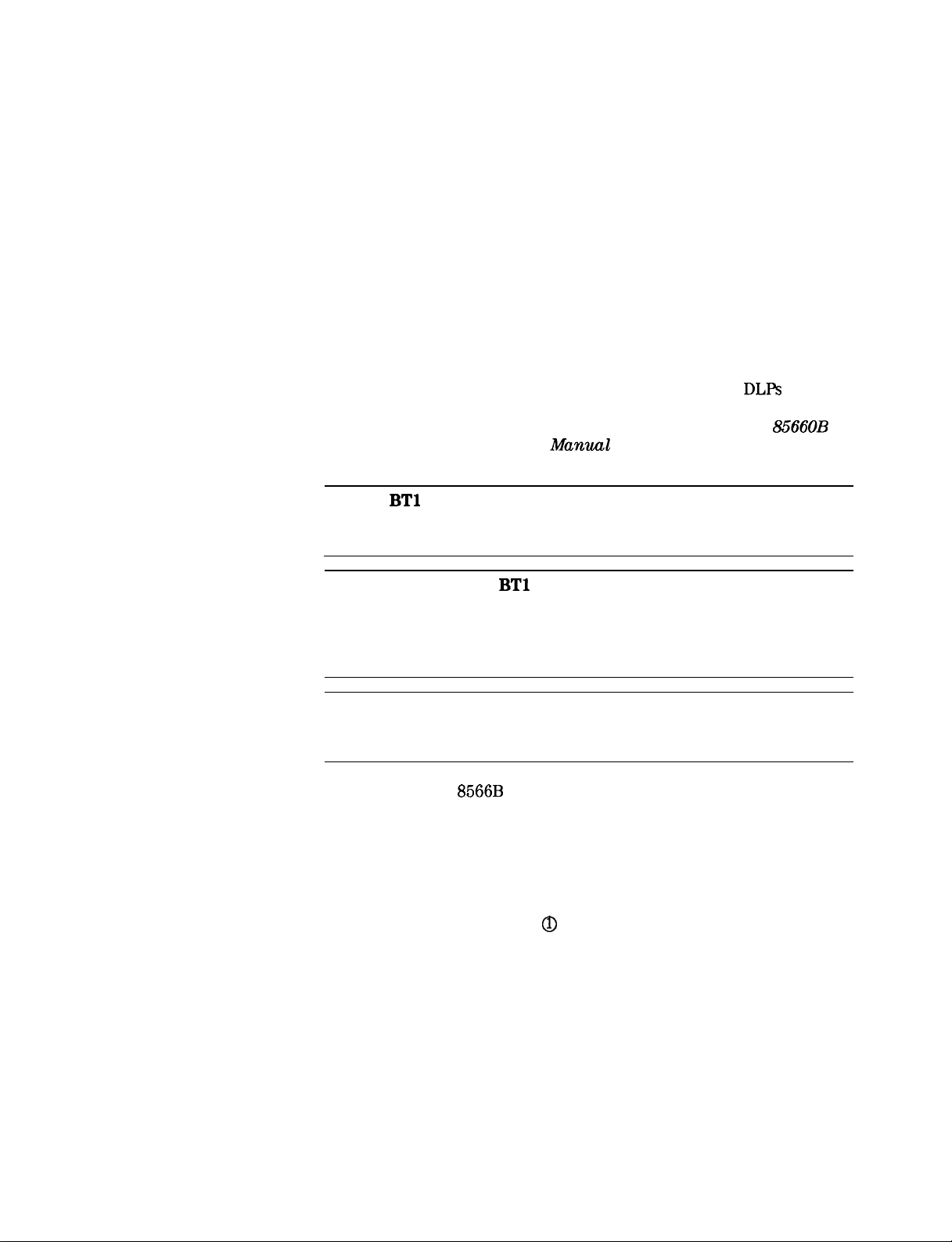

Al5 CONTROLLER

ASSEMBLY

Figure 1-7. Location of Al5 Controller Assembly

General Information l-13

5. Remove the cover from the Al5 controller assembly. See

Figure l-7.

6. Remove the Al5 controller assembly. Locate the battery on the

Al5 assembly. Figure 1-8 shows the location of the battery.

Battery

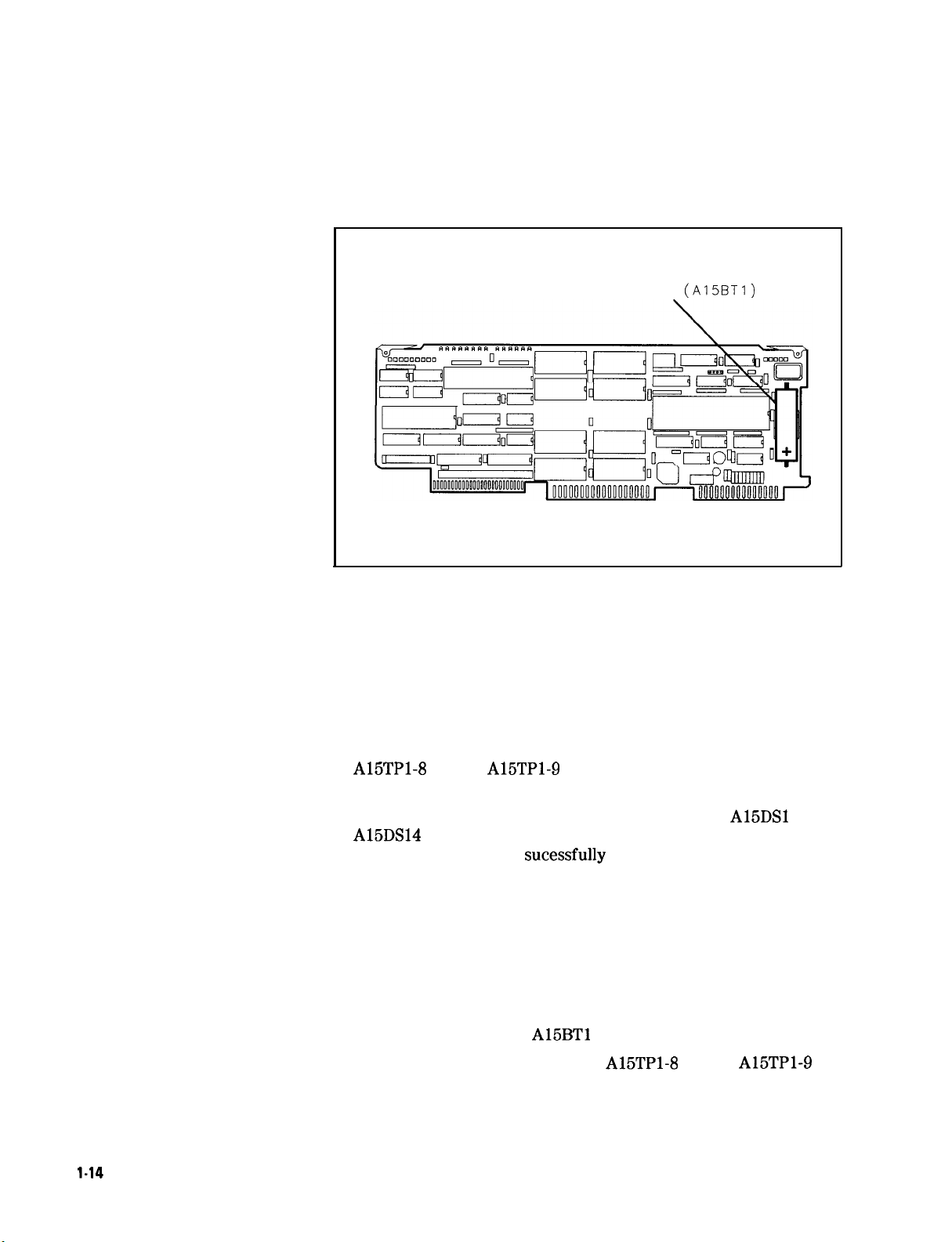

Figure 1-8. Location of Battery on Al5 Controller Assembly

(A15BTl)

7. Replace the battery with a new one (HP part number 1420-0331).

Be sure to install the battery with

the

polarity shown in

Figure l-8.

8. Replace the Al5 controller assembly.

9. Reconnect the power cables to the IF and RF sections.

l-14

General Information

10. Connect a jumper wire between the Al5 controller test points

A15TPl-8

T3 and

A15TPl-9

ST (to erase and initialize Al5

controller nonvolitile memory).

11. Set LINE switch to ON. The Al5 controller LED’s

A15DS14

the Al5 controller has

should all turn on, then turn off, sequentially, indicating

sucessfully

executed self-test. If they do

A15DSl

through

not the Al5 controller might be damaged or improperly installed.

In addition, all front panel LED’s should turn on momentarily,

indicating the HP 8566B has performed its’ power-on pretest.

In addition to normal HP 8566B power-up HP-IB address and

firmware revision information, a BATTERY flag should appear on

the CRT, indicating that information previously stored in

the Al5

controller nonvolitile memory has been lost or erased. Normally

the BATTERY flag appears after several years of use to indicate

that the lithium battery

12. Remove the jumper wire between

13. Set the LINE switch to STANDBY

A15BTl

needs to be replaced.

A15TPl-8

and

T3 and

A15TPl-9

then to ON. The HP 8566B

should power up normally, without any flags displayed on the

CRT.

ST.

14. Set the LINE switch to STANDBY and remove the power cable

from the rear of the RF section.

15. Install the controller cover.

16. Replace the RF section bottom cover and the two rear feet.

17. Place the HP 8566B top side up and reconnect the power cable to

the RF section.

18. Set the LINE switch to ON and allow a 2-hour warm-up.

19. Recalibrate the instrument with the following steps. (For a more

complete description of the calibration, refer to the HP

8566B

Operating and Programming Manual.)

Connect the front-panel CAL OUTPUT signal to the RF INPUT.

a.

Press

b.

cm]

adjust for a marker amplitude of -10.00

Press (RECALL) @, and then adjust the front-panel FREQ ZERO

C.

@, and then adjust the front-panel AMPTD CAL

dBm.

adjust for maximum signal amplitude.

Press (SHIFT_) [FREQUENCY SPAN) w

d.

data in the instrument’s memory.

to load the error correction

General Information

l-15

Ordering

Information

Parts can be ordered from any Hewlett-Packard Sales and Service

Office. Refer to

order a part or assembly, quote

‘fable

l-3 for a listing of sales and service offices. lb

the

Hewlett-Packard part number,

indicate the quantity required, and address the order to the nearest

Hewlett-Packard Office.

To

order a part that is not listed in the replaceable parts table, include

the instrument model number, the description and function of the

part, and the number of parts required. Address the order to the

nearest Hewlett-Packard Sales and Service Office.

Direct Mail Order

System

Direct Phone-Order

System

Within the USA, Hewlett-Packard can supply parts through a direct

mail

order system. Advantages of using the system are as follows:

n Direct ordering and shipment from the HP Support Materials

Organization in Roseville, California.

n

No maximum or minimum on any mail order. (There is a minimum

order amount for parts ordered through a local Hewlett-Packard

Sales and Service Office when the orders require billing and

invoicing.)

n Prepaid transportation. (There is a small handling charge for each

order.)

n

No invoices.

‘lb provide these advantages, a check or money order must accompany

each order. Mail-order forms and specific ordering information is

available through your local Hewlett-Packard Sales and Service Office.

Within the USA, a phone order system is available for regular and

hotline replacement parts service. A toll-free phone number is

available, and Mastercard and Visa are accepted.

Regular Orders: The toll-free phone number, (800) 227-8164, is

available 6 AM to 5 PM, Pacific time, Monday through Friday. Regular

orders have a 4 day delivery time.

l-16

General Information

Hotline Orders: Hotline service for ordering emergency parts is

available 24 hours a day, 365 days a year. There is an additional

hotline charge to cover

the

cost of freight and special handling.

The toll-free phone number, (800) 227-8164, is available 6 AM to 5 PM,

Pacific time, Monday through Friday and (916)

785-8HOT

is available

after-hours, weekends, and holidays. Hotline orders are normally

delivered the following business day.

Returning the

Instrument for

Service

The instrument may be shipped in environments within the following

limits:

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to

Humidity . . . . . . . . . . . . . . . . . . . . . . . . 5% to 90% at 0” to 40°C

Altitude . . . . . . . . . . . . . . . .

The instrument should be protected from temperature extremes which

might cause condensation within the instrument.

Up to 15,240 meters (50,000 feet)

+75OC

Service

T&gs

Original Packaging

Note

If you are returning the instrument to Hewlett-Packard for servicing,

fill in and attach a blue service tag to each instrument section.

Service tags are supplied at the end of this chapter.

Please be as specific as possible about the nature of the problem. If

you have recorded any error messages that appeared on the screen or

have any other specific data on the performance of the instrument,

please send a copy of this information with the instrument.

lb protect the front panel, the front handles must be attached to each

instrument section before shipping.

It is recommended that the original factory packaging materials be

retained for use when shipping the instrument. Because the combined

weight of the two instrument sections is approximately 50 kg (112 lb),

do not package the instrument sections fastened together as one unit.

The instrument sections must be separated and packaged in separate

containers. Pack each section in the original factory packaging

materials if they are available (see Figure l-9). Refer to

the part numbers of items listed in the figure. Original materials are

available through any Hewlett-Packard Sales and Service Office.

Table

l-2 for

General Information 1-17

Loading...

Loading...