Page 1

TM 11-6625-493-15

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

DS, GS, AND DEPOT MAINTENANCE

MANUAL

FREQUENCY COMPARATOR

CM-77A/USM

This copy is a reprint which includes current

pages from Changes 1 through 4.

HEADQUARTERS, DEPARTMENT OF THE ARMY

SEPTEMBER 1964

Page 2

Page 3

Changes in force C1, C3, and C4

Operators, Organizational, Direct Support,

General Support, and Depot

Maintenance Manual

FREQUENCY COMPARATOR CM977A/USM

(NSN 6625-00-080-7204)

TM 11-6625-493-15, 29 September 1964, is changed as follows:

The title of the manual is changed as shown above.

Page v, The Forms and Records paragraph is

superseded as follows:

TM 11-6625-493-15

C4

HEADQUARTERS

DEPARTMENT OF THE ARMY

ASHINGTON , DC, 9 May 1977

W

0-1. Forms and Records

a. Reports of Maintenance and Unsatisfactory

Equipment. Maintenance forms, records, and reports

which are to be used by maintenance personnel at all

maintenance levels are listed in and prescribed by

TM 38-750.

b. Report of Packaging and Handling Deficien-

cies. Fill out and forward DD Form 6 (Packaging Im-

provement Report) as prescribed in AR 70058/NAVSUPINST 4030.29/AFR 71-13/MCO

P4030.29A, and DSAR 4145.8.

c. Discrepancy in Shipment Report (DISREP) (SF

361). Fill out and forward Discrepancy in Shipment

Report (DISREP) (SF 361) as prescribed in AR 5538/NAVSUPINST 4610.33A/AFR

4610.19B and DSAR 4500.15

The Reporting of Errors paragraph is superseded as

follows:

75-18/MCO

0-2. Reporting of Errors

You can help improve this manual by calling atten tion to errors and by recommending improve-

ments and stating your reasons for the recommendations. Your letter or DA Form 2028 (Recommended

Changes to Publications and Blank Forms) should be

mailed direct to Commander, US Army Electronics

Command, ATTN: DRSEL-MA-Q, Fort Monmouth,

New Jersey 07703. A reply will be furnished direct to

you. After the Reporting of Errors paragraph, add

the following:

0-3. Administrative Storage

Administrative storage of equipment issued to and

used by Army activities shall be in accordance with

TM 740-90-1.

0-4. Destruction of Army Electronics

Materiel.

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM

750-244-2.

0-5. Reporting Equipment improve-

ment Recommendations (EIR)

EIR’s will be prepared using DA Form 2407 (Maintenance Request). Instructions for preparing EIR’s are

provided in TM 38-750, The Army Maintenance

Management System. EIR’s should be mailed direct

to Commander, US Army Electronics Command,

ATTN: DRSEL-MA-Q, Fort Monmouth, New Jersey

07703. A reply will be furnished direct to you.

Page 5-2, Table 5-1 is superseded as follows:

1

Page 4

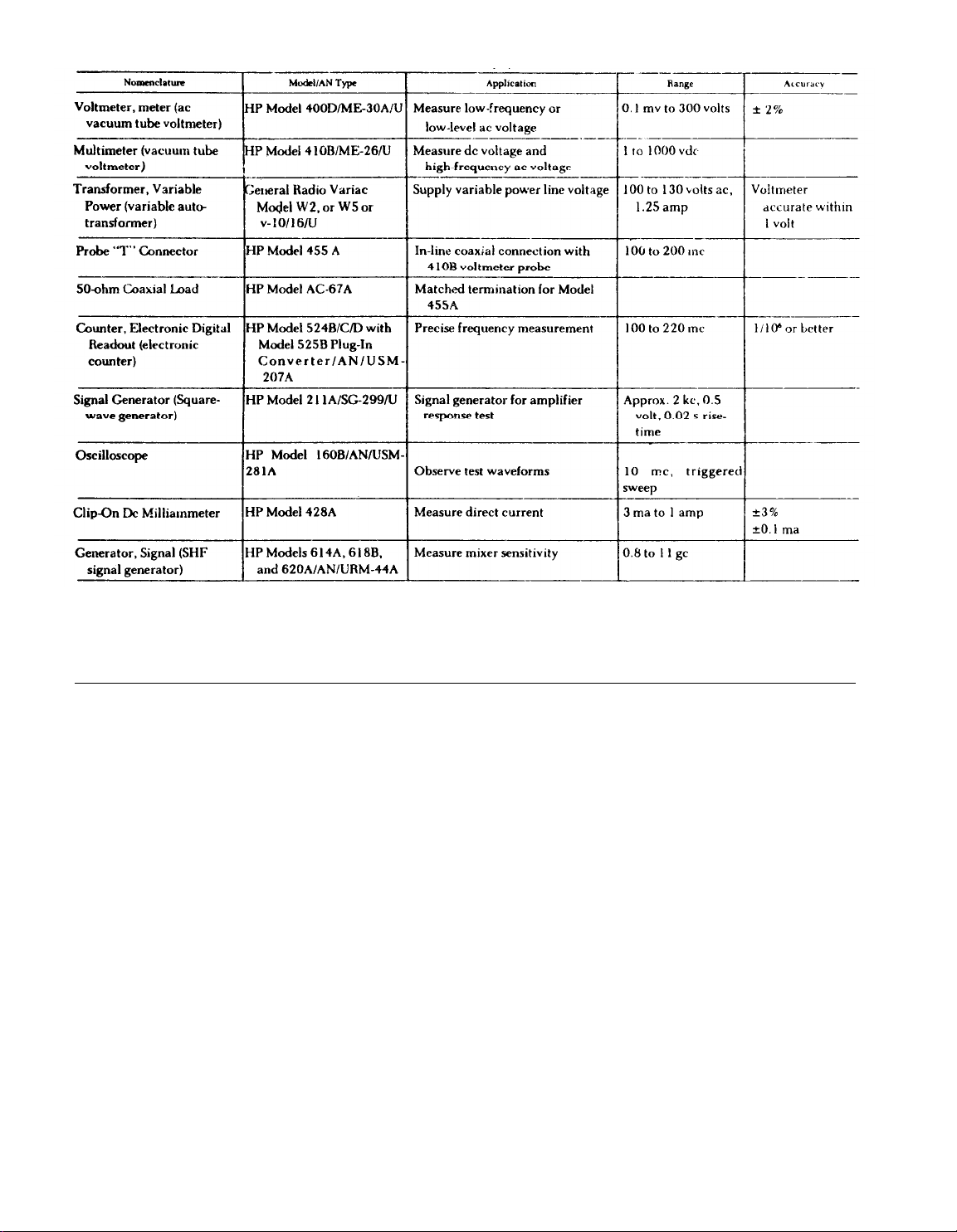

Table 5-1. Test Equipment

Page 5.1-1. Section V.I is superseded as follows:

SECTION V.1

PREVENTIVE MAINTENANCE INSTRUCTIONS

5.1-1. Scope of Organizational

Preventive Maintenance

Preventive maintenance is the systematic care, servicing, and inspection of equipment to prevent the occurrence of trouble, to reduce downtime, and to

assure that the equipment is serviceable.

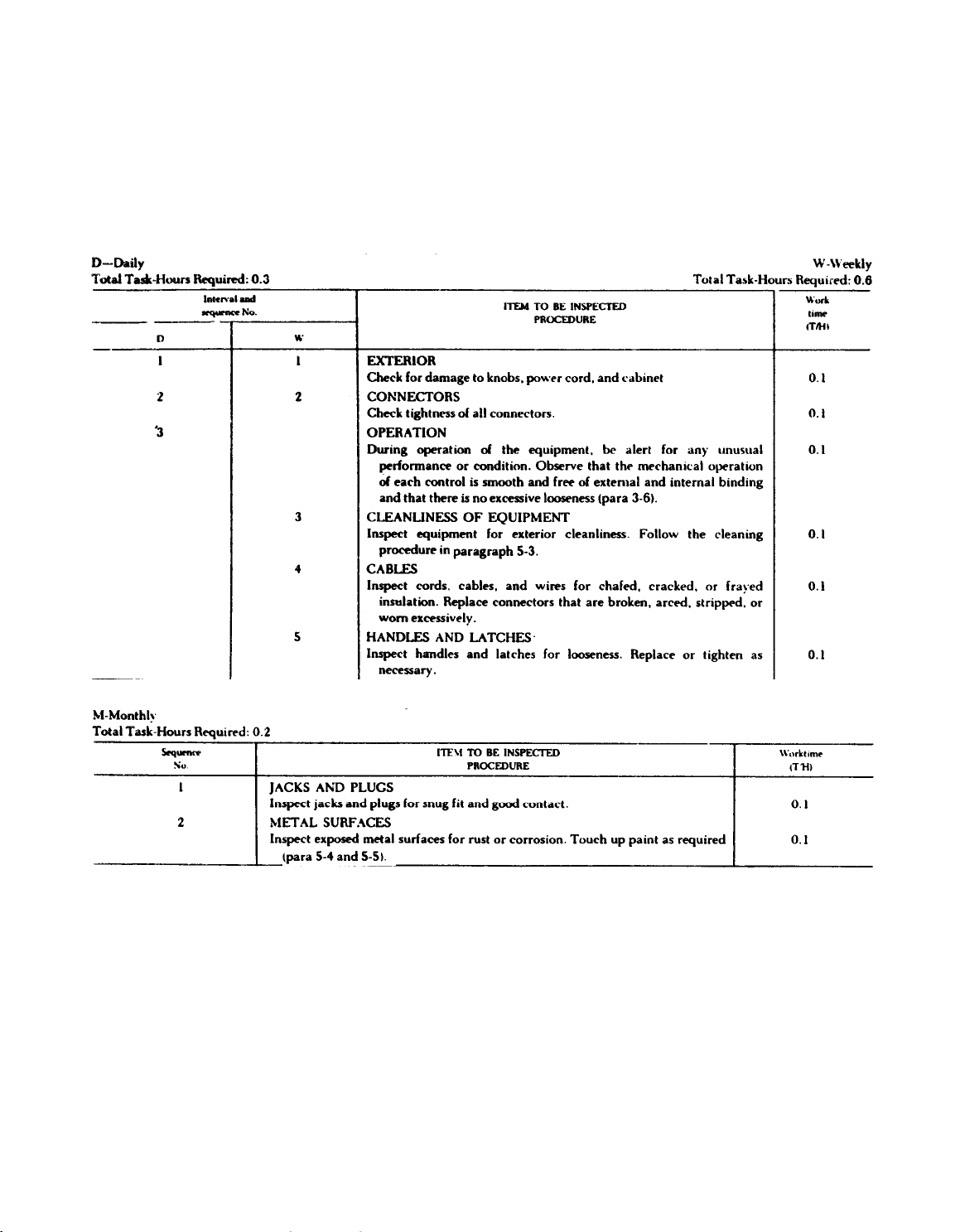

a. Systematic Care. The procedures given in

tables 5.1-1 and 5.1-2 cover routine systematic care

essential to proper upkeep and operation of the

equipment.

b. Preventive Maintenance Checks and Services.

The preventive maintenance checks and services

tables outline the functions to be performed at

specific intervals. These checks and services are

designed to maintain Army equipment in a combatserviceable condition; that is, in good physical and

operational condition. To assist organizational

maintenance personnel in maintaining combat serviceability, the table indicate what to check, how to

check, and the normal conditions. If the defect cannot be remedied by organizational maintenance personnel, higher category maintenance or repair is required. Records and reports of these checks and services must be made in accordance with TM 38-750.

5.1-2. Preventive Maintenance Checks

and Services Periods

Preventive maintenance checks and services of the

equipment is required on a daily, weekly, and

monthly basis as indicated in a and b below.

Whenever a normal indication is not observed during the performance of the daily, weekly, or monthly

preventive maintenance check, necessary corrective

action must be taken.

a. Daily and Weekly. Table 5.1-1 specifies the

preventive maintenance checks and services that

must be performed daily and weekly or when the

equipment is:

(1) Initially installed.

2

Page 5

(2) Reinstalled after return from higher cate

gory of maintenance and repairs have been performed.

(3) Maintained in a standby (ready for immedi-

ate operation) condition. Perform on a monthly

schedule.

ly 30 calendar days of 8-hour-per-day operation. Ad-

justment of the monthly preventive maintenance in-

terval must be made to compensate for any unusual

operating conditions. For example, if the equipment

is used 16 hours per day, the monthly preventive

(4) Returned to service from limited storage. maintenance checks and services should be per-

b. Monthly. Table 5.1-2 specifies the preventive

maintenance checks and services that must be per-

formed monthly. A month is defined as approximatc-

formed at 15-day intervals. ACM-77A maintained in

a standby condition requires monthly preventive

maintenance, but one in limited storage does not.

Table 5.1-1. Daily and Weekly Preventive Maintenance Checks and Services

para 3-6

Table 5.1-2. Monthly Preventative Maintenance Checks and Services

para 5-4 and 5-5

5.1-3. Cleaning

Inspect the exterior of the equipment. The exterior

should be clean, and free from dust, dirt, grease, and

fungus.

a. Remove dust and loose dirt with a clean lint-

free cloth.

WARNING

The fumes of trichloroethane are toxic. Provide thorough ventilation whenever used.

paragraph 5-3

DO NOT USE NEAR AN OPEN FLAME.

Trichloroethane is not flammable, but exposure of the fumes to an open flame or hot

metal forms highly toxic phosgene gas.

b. Remove grease, fungus, and ground-in dirt

from the case; use a cloth dampened (not wet) with

trichloroethane. After cleaning, wipe dry with a

clean lint-free cloth.

c. Remove dust or dirt from plugs and jacks with

3

Page 6

a soft-bristled brush.

CAUTION

Do not press on the face (glass) of the

cathode ray tube when cleaning; the cathode

ray tube may become damaged.

d. Clean the front panel and control knobs; use a

soft clean lint-free cloth. If necessary, dampen the

cloth with water. Mild soap may be used for more effective cleaning.

cloth .

Wipe dry with a clean lint-free

5.1-4. Paints and Finishes

When the CM-77A/USM requires repainting,

refinishing, or touchup painting, refer to Federal

Standard No. 595a for a matching color. SB 11-573

lists. painting tools and miscellaneous supplies required for painting.

5.1-5. Touchup Painting Instructions

a. Refer to TB 43-0118 for instructions on paint-

ing and preserving Electronics Command equip-

ment. When touchup painting, a perfect match with

the exact shade of the original paint surface may not

be possible. This may be caused by changes such as

in the original pigment because of oxidation, and differences in manufacture. The prevention of corrosion

and deterioration is the most important consideration in touchup painting; appearance is secondary.

This, however, should not be construed to mean that

appearance of the equipment is not important.

Touckup painting should be accomplished neatly

and the quality of work should be good. Field inspection personnel should make allowances for slight color mismatch where minor touchup has been done,

but not for neglect, poor quality, or where the need

for refinishing is obvious.

b. Remove rust and corrosion from metal surfaces

by lightly sanding them with fine sandpaper. Brush

two thin coats of paint on the bare metal to protect it

from further corrosion.

Page i-2. Appendix 1 is superseded as follows:

APPENDIX A

REFERENCES

The following is a list of references that are available to the operator and organizational, DS, GS, and

depot maintenance personnel of Frequency Comparator CM-77A/USM:

DA Pam 310-4

DA Pam 310-7

SB 11-573

TB 43-180

TB 43-0118

TM 11-6625-200-15

TM 11-6625-258-14

TM 11-6625-274-12

TM 11-6625-316-12

TM 11-6625-320-12

TM 11-6625-366-15

TM 11-6625-412-15-1

Index of Technical Manuals, Technical Bulletins, Supply Manuals (Types 7, 8 and

9), Supply Bulletins, and Lubrication Orders.

US Army Index of Modification Work Orders.

Painting and Preservation Supplies Available for Field Use for Electronics

Command Equipment.

Calibration Requirements for the Maintenance of Army Materiel.

Field Instructions for Painting and Preserving Electronics Command Equipment

Including Camouflage Pattern Painting of Electrical Equipment Shelters

Operator’s, Organizational,

Multimeters ME-26A/U, ME-26B/U, ME-26C/U, and ME-26D/U.

Operator’s, Organizational, Direct Support, and General Support Maintenance

Manual: Signal Generators SG-299/U, SG-299A/U, SG-299B/U, SG-299C/U,

SC-299D/U and SG-299E/U.

Operator’s and Organizational Maintenance Manual: Test Sets, Electron Tube

TV-7/U, TV-7A/U, TV-7B/U, and TV-7D/U.

Operator’s and Organizational Maintenance Manual: Test Sets, Electron Tube

TV-2/U, TV-2A/U, TV-2B/U, and TV-2C/U.

Operator’s and Organizational Maintenance Manual: Voltmeter, Meter

ME-30A/U and Voltmeters, Electronic ME-30B/U, ME-30C/U, and ME-30E/U.

Operator’s, Organizational, EM, CS, and Depot Maintenance Manual: Multimeter

TS-352B/U.

Operator, Organizational, DS, GS, and Depot Maintenance Manual,

Repair Parts and Special Tools List: Radio Test Set AN/URM-44A.

DS, GS, and Depot Maintenance Manual:

Including

4

Page 7

TM 11-6625-700-14-1

TM 11-6625-1703-15

TM 38-750

TM 740-90-1

TM 750-244-2 Procedures for Destruction of Electronics Materiel to Prevent Enemy Use

Page i-3, Appendix II is superseded as follows:

Operator’s, Organizational, Direct Support, and General Support Maintenance

Manual Including Repair Parts and Special Tools List (Including Depot

Maintenance Repair Parts and Special Tools): Digital Readout Electronic

Counter AN/USM-207A (Serial Nos. 1A through 1100A).

Operator, Organizational, DS, GS, and Depot Maintenance Manual Including

Repair Parts and Special Tool Lists: Oscilloscope AN/USM-281A.

The Army Maintenance Management System (TAMMS).

Administrative Storage of Equipment

(Electronics Command).

APPENDIX C

MAINTENANCE ALLOCATION

Section I. INTRODUCTION

C-1. General

This appendix provides a summary of the

maintenance operations for CM-77A/USM. It authorizes categories of maintenance for specific maintenance functions on repairable items and components and the tools and equipment required to perform each function. This appendix may be used as an

aid in planning maintenance operations.

C-2. Maintenance Function

Maintenance functions will be limited to and defined

as follows:

a. Inspect. To determine the serviceability of an

item by comparing its physical, mechanical, and/or

electrical characteristics with established standards

through examination.

b. Test. To verify serviceability and to detect incipient failure by measuring the mechanical or electrical characteristics of an item and comparing those

characteristics with prescribed standards.

c. Service. operations required periodically to

keep an item in proper operating condition, i.e., to

clean (decontaminate), to preserve, to drain, to paint,

or to replenish fuel, lubricants, hydraulic fluids, or

compressed air supplies.

d. Adjust. To maintain, within prescribed limits,

by bringing into proper or exact position, or by setting the operating characteristics to the specified

parameters.

e. Align. To adjust specified variable elements of

an item to bring about optimum or desired performance.

f. Calibrate. To determine and cause corrections

to be made or to be adjusted on instruments or test

measuring and diagnostic equipments used in precision measurement. Consists of comparisons of two

instruments, one or which is a certified standard of

known accuracy, to detect and adjust any discrepancy in the accuracy of the instrument being compared.

g. Install. The act of emplacing, seating, or fixing

into position an item, part, module (component or

assembly) in a manner to allow the proper functioning of the equipment or system.

h. Replace. The act of substituting a serviceable

like type part, subassembly, or module (component

or assembly) for an unserviceable counterpart.

i. Repair. The application of maintenance serv-

ices (inspect, test, service, adjust, align, calibrate, re-

place) or other maintenance actions (welding, grind-

ing, riveting, straightening, facing, remachining, or

resurfacing) to restore serviceability to an item by

correcting specific damage, fault, malfunction, or

failure in a part, subassembly, module (component

or assembly), end item, or system. This function does

not include the trial and error replacement of run-

ning spare type items such as fuses, lamps, or elec-

tron tubes.

j. Overhaul. That maintenance effort (service/

action) necessary to restore an item to a completely

serviceable/operational condition as prescribed

by maintenance standards (i.e., DMWR) in appropriate technical publications. Overhaul is normally

the highest degree of maintenance performed by the

5

Page 8

Army. Overhaul does not normally return an item to

like new condition.

k. Rebuild. Consists of those services/actions

necessary for the restoration of unserviceable equipment to a like new condition in accordance with

original manufacturing standards. Rebuild is the

highest degree of materiel maintenance applied to

Army equipment. The rebuild, operation includes the

act of returning to zero those age measurements

(hours, miles, etc.) considered in classifying Army

equipments/components.

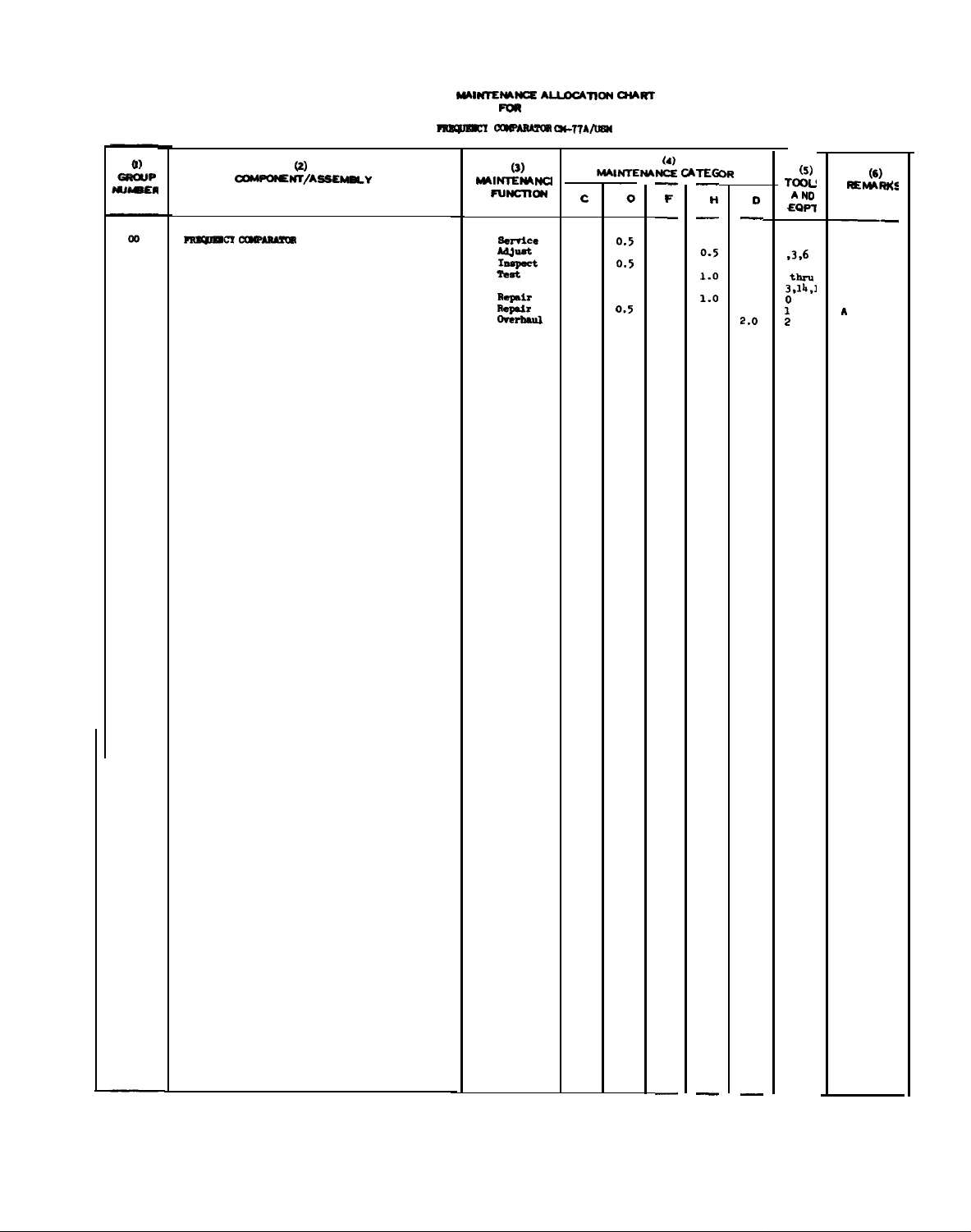

C-3. Column Entries

a. Column 1, Group Number. Column 1 lists

group numbers, the purpose of which is to identify

components, assemblies, subassemblies, and modules

with the next higher assembly.

b. Column 2, Component/Assembly. Column 2

contains the noun names of components, assemblies,

subassemblies, and modules for which maintenance

is authorized.

c. Column 3, Maintenance Functions. Column 3

lists the functions to be performed on the item listed

in column 2. When items are listed without maintenance functions, it is solely for purpose of having the

group numbers in the MAC and RPSTL coincide.

d. Column 4, Maintenance Category. Column 4

specifies, by the listing of a “work time” figure in the

appropriate subcolumn(s), the lowest level of maintenance authorized to perform the function listed in

column 3. This figure represents the active time required to perform that maintenance function at the

indicated category of maintenance. If the number or

complexity of the tasks within the listed maintenance

function vary at different maintenance categories,

appropriate “work time” figures will be shown for

each category. The number of task-hours specified by

the “work time” figure represents the average time

required to restore an item (assembly, subassembly,

component, module, end item or system) to a service-

able condition under typical field operating conditions. This time includes preparation time, troubleshooting time, and quality assurance/quality control

time in addition to the time required to perform the

specific tasks identified for the maintenance func-

tions authorized in the maintenance allocation cha

Subcolumns of column 4 are as follows:

C - Operator/Crew

O - Organizational

F - Direct Support

H - General Support

D - Depot

e. Column 5, Tools and Equipment. Column

specifies by code, those common tool sets (not in

dividual tools) and special tools, test, and supper

equipment required to perform the designated func

tion.

f. Column 6, Remarks. Column 6 contains an al

phabetic code which leads to the remark in section

IV, Remarks, which is pertinent to the item opposite

the particular code.

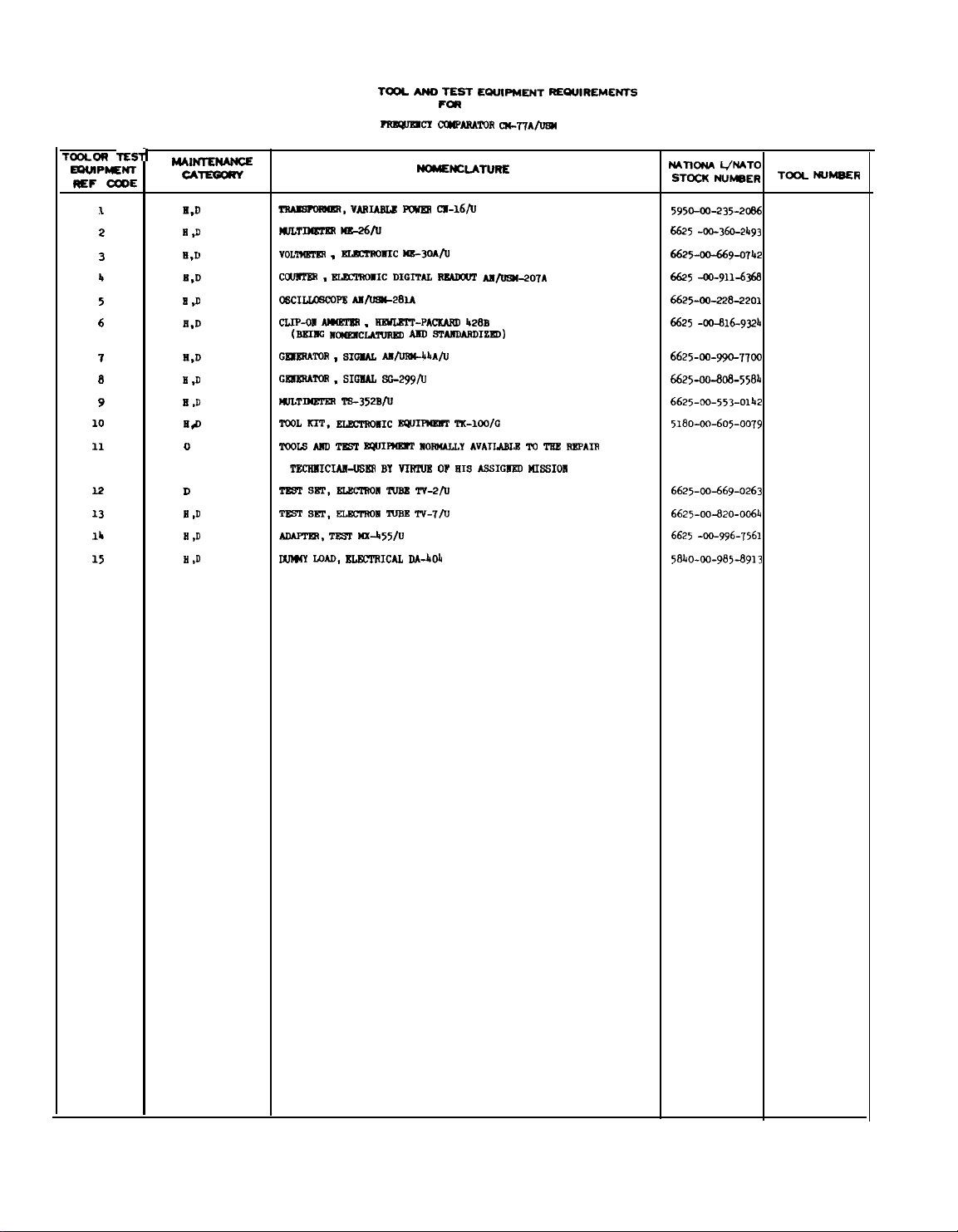

C-4. Tool and Test Equipment

Requirements (Sect. Ill)

a. Tool or Test Equipment Reference Code. The

numbers in this column coincide with the numbers

used in the tools and equipment column of the MAC.

The numbers indicate the applicable tool or test

equipment for the maintenance functions.

b. Maintenance Category. The codes in this column indicate the maintenance category allocated the

tool or test equipment.

c. Nomenclature. This column lists the noun

name and nomenclature of the tools and test equipment required to perform the maintenance functions.

d. National/NATO Stock Number. This column

lists the National/NATO stock number of the specific

tool or test equipment.

e. Tool Number. This column lists the manufacturer’s part number of the tool followed by the

Federal Supply Code for manufacturers (5-digit) in

parentheses.

C-5. Remarks (Sect. IV)

a. Reference Code. This code refers to the appropriate item in section II, column 6.

b. Remarks. This column provides the required

explanatory information necessary to clarify items

appearing in section II.

6

Page 9

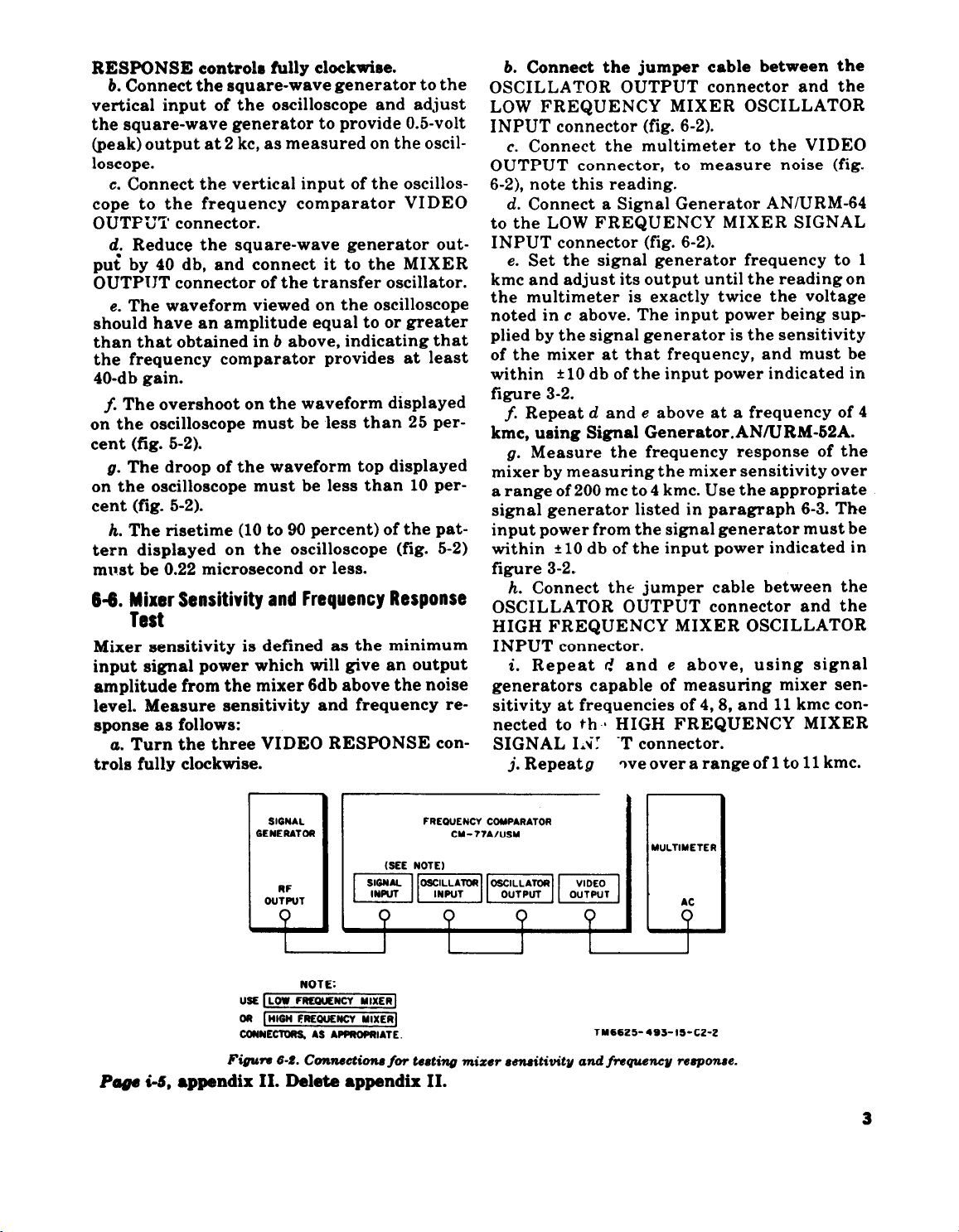

TM 11-6625-493-15

aMWO?#Em/AssWY

nEuJlacI CmmMlta

@

SECTION II

PRMM6CT CUSNWK#

Wlmllm’a=

Mlrmzmm

Fur4aloN

Gm-rAce

A4ijmt

Inspect

Test

Reqmlr

Rep8Ar

OTerhull

AA-lmmna’4 OiAwr

(M-77A-

(3)

c

—

0.5

0.5

0.5

(4)

—

o

F

—

MAlNTEw4& ~TEG

—

—

0.5

1.0

1.0

(5)

TOOU

A

0

No

+EQl=l

,3,6

thru

3,111,1

0

1

2

H

—

2.0

REM*S

—.

A

(6)

—

—

—

7

Page 10

TCUL

OR

E9UIPKNT

REF

10

11

32

13

lb

15

=E

1

2

3

b

5

6

7

a

9

TEslJ

mAINmmANuz

CATEGORY

E,D

n ,3

B,D

II,D

Ii ,D

E,D

li,D

H ,D

Ii ,D

Ha

0

D

E ,D

H ,D

H ,D

TM 11-6625-493-15

SECTION III.

TOOL

~CI

ANO

TEST

EWIPMSNT

FOR

CWPASATOR CU-77AfLRUl

REQuIREMENTS

NOMENCLATURE

~,

VM~ m cs.16/s

mJLTnQmHl M15-2&U

VOL’IW?2SS ,

c~ , 5RXli011C DIG~m ~

ELmrsosIc ME-3oAru

AI1/SBU-207A

~CILIOBCOPS AS-283A

CLIP-m

AMmm .

(Bs3ffi mxmcLAmmm

SWLEIT-PACKARD b28B

AMO W~DIZSO)

G=TOR , SIOSAL AE/UKl@4hA/U

G_TOS , SIOBAL 21i-299/O

KJLTIM?l’SS TB-352B/S

TOOL KIT,

BLB=2SOEIC ~

TIC-lCQ/G

‘KIDIS MD H IQIIIFUSI?2 IIOWY AVAILABLS ’111 ~ SXPAIR

TBCSSIC3AII-UBSS BY

H sm.

m sm.

SLEcmon mlul Tv-2/s

ELmrsoM mm Tv-7/u

VIRNS OF

HIS ABSIGIISD UIBSIOX4

ADAmm, m Kx-b55/u

tXJWY LOAD, SLW2RICAI, DA-kO~

NATION AUMTO

STOCK NUMSER

5950-DD-235-2DM

6625 -DD-360-2b93

6625-00-66$&0’1112

6625 -aJ-911-636s

6625-00-228-2201

6625 -cQ-s16-93211

6625-00-990-7700

6625-00-808-5584

6625-00-553-0142

5180-00-605-0079

662HM-669-0263

6625-00-820-0064

6625 -W996-7561

58b0-IxI-985-8913

TO(X NUMSER

8

Page 11

TM 11-6625-493-15

RSFERSN=

CaDs

A

SECTION IV.

TW replacement 6f knobs, fuse, and leap.

RSMARKS

REMARKS

9

Page 12

By Order of the Secretary of the Army:

Official:

PAUL T. SMITH

Major General, United States Army

The Adjutant General

Distribution:

Active Army

BERNARD W. ROGERS

General, United States Army

Chief of Staff

USASA (2)

COE (1)

TSG (1)

USAARENBD (1)

TECOM (2)

TRADOC (2)

OS Maj Comd (4)

USACC (4)

MDW (1)

Armies (2)

Corps (2)

Instl (2) except

Ft Gillem (10)

ARNG: State AC (3)

USAR: None

For explanation of abbreviations used, see AR310-50.

Ft Gordon (10)

Ft Huachuca (10)

Ft Carson (5)

SAAD (30)

LBAD (14)

TOAD (14)

SHAD (3)

HISA (Ft Monmouth) (33)

Ft Richardson (ECOM Ofc) (2)

Svc Colleges (1)

USASIGS (5)

USAICS (3)

USAADS (2)

USAFAS (2)

USAARMS (2)

USAIS (2)

USAES (2)

MAAG (1)

USARMIS (1)

USAERDAA (1)

USAERDAW (1)

Sig FLDMS (1)

Units org under fol TOE:-1 ea

11-500(AA-AC)

29-134

29-136

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

THIS MANUAL CONTAINS INFORMATION COPYRIGHTED BY

HEWLETT-PACKARD COMPANY.

TM 11-6625-493-15

TECHNICAL MANUAL )

NO. 11-6625-493-15 )

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section

I

II

III

GENERAL INFORMATION

1-1.

1-9. Differences in Instruments . . . . . . . . . . . . . . . . .

INSTALLATION

2-1.

2-3. Repacking for Shipment . . . . . . . . . . . . . . . . . . . . . .

2-5.

2-7. Operation from 115- or 230-Volt Line . . . . . . . . . . . . . . . . . . . .

2-10. Operation on Line Frequencies Higher than 120 Cycles

2-12. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING INSTRUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1.

3-3.

3-9.

3-12.

3-14.

3-16.

3-18.

3-26.

3-28.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Frequency . . . . . . . . . . . . . . . . . . . . . .

Measuring Fm Carrier Frequency and Limits of Frequency

Measuring Pulsed Rf Signals

Use of Frequency Control Connector . . . . . . . . . . . . . . . . . . . . . .

Extending the Operating Range from 12.4 Gc to 18 Gc . . . . .

Measuring Detailed Characteristics of Fm Signals . . . . . . . .

Generating Harmonics for Other Uses . . . . . . . . . . . . . . . . . . . . .

Measuring frequencies above 18 Gc . . . . . . . . . . . . . . . . .

)

Washington, D.C. 29 September 1964

DS, GS, and Depot Maintenance Manual

Frequency Comparator CM-77A/USM

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Per Second . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

HEADQUARTERS,

DEPARTMENT OF THE ARMY

Page

v

1-1

1-1

1-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

3-1

3-1

3-1

3-8

3-8

3-11

3-11

3-12

3-14

3-14

IV

V

THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Circuit Description . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1.

5-7.

5-9.

5-11.

5-13.

5-19.

5-21.

5-23.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3.

Cabinet Removal . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5.

Periodic Cleaning and Lubrication . . . . . . . . . . . . . . . .

Tube Replacement . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Test and Adjustment . . . . . . . . . . . . . . . . .

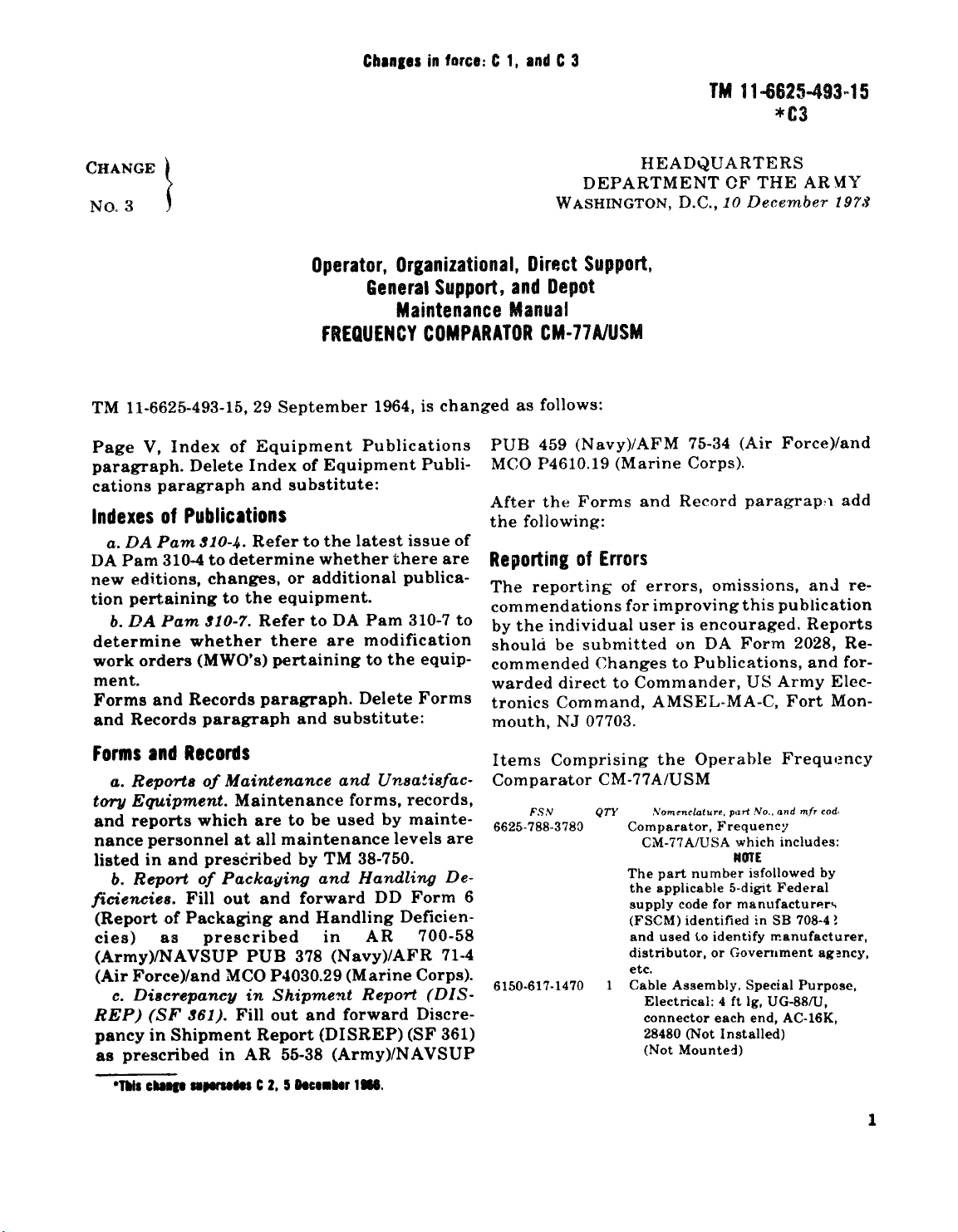

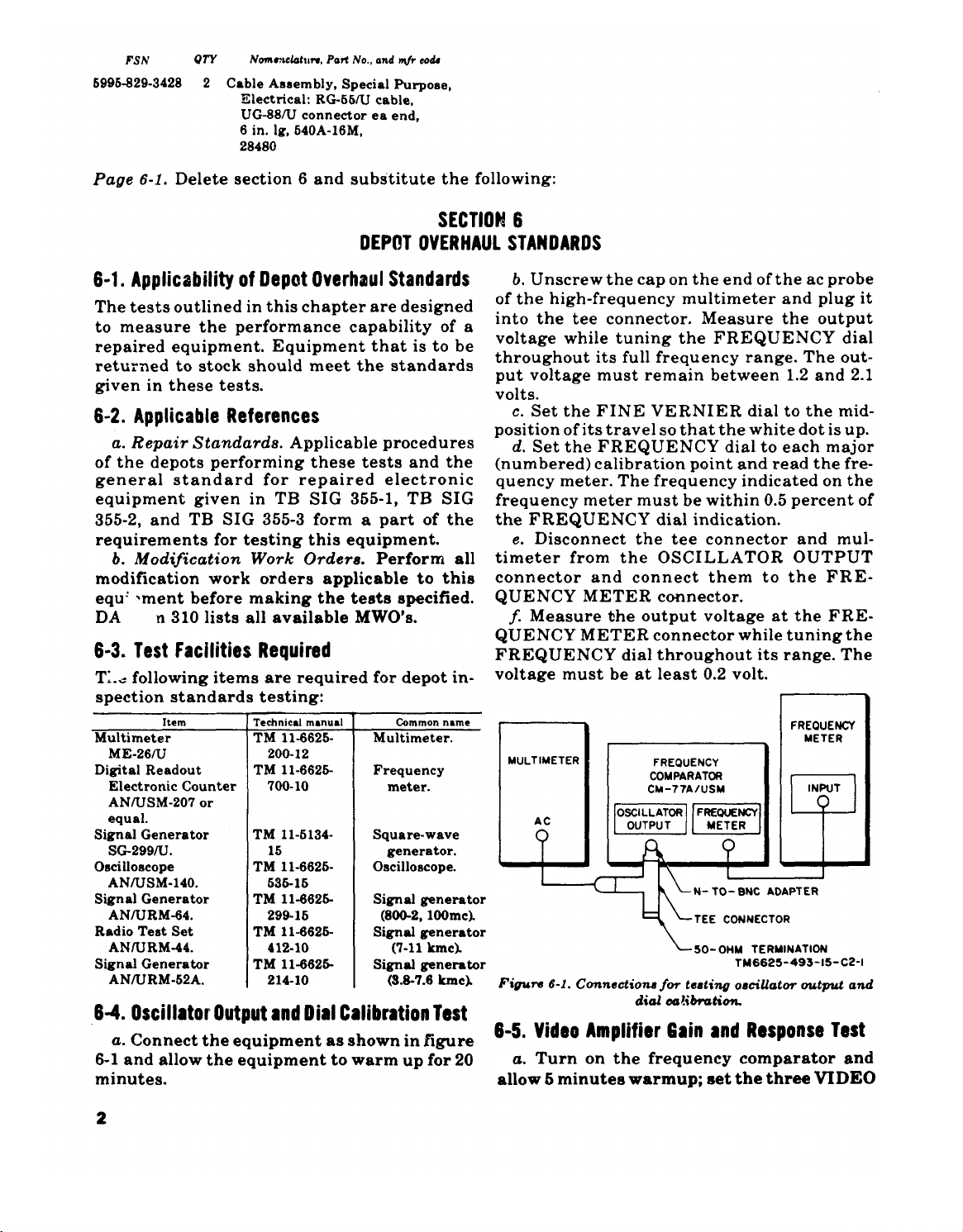

Testing Oscillator Output and Dial Calibration . . . . . . . . . .

Measuring Video Amplifier Gain and Response . . . . . . . . . . . . .

Centering Oscilloscope Trace . . . . . . . . . . . . . . . . . . .

4-1

4-1

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-3

5-4

5-5

i

Page 20

Section

Page

5-25.

5-27.

5-30.

5-35.

V.1

VI

APPENDIX I. REFERENCES

PREVENTIVE MAINTENANCE INSTRUCTIONS

5.1-1.

5.1-2.

5.1-3.

5.1-4.

5.1-5.

5.1-6.

5.1-7.

5.1-8.

5.1-9.

REPLACEABLE PARTS

6-1.

Measuring Mixer Sensitivity and Frequency Response . . . . . .

Replacing Parts in the Low Frequency Mixer . . . . . . . . . . . . . . 5-6

Replacing Parts in the High Frequency Mixer . . . . . . . . . . . . . 5-6

Harmonic Generator Assembly . . . . . . . . . . . . . . . . . . . . . . 5-7

Scope of Maintenance . . . . . . . . . . . . . . . . .... . . . . . . . .

Preventive Maintenance .. . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance Checks and Services Periods . . . . .

Daily Preventive Maintenance Checks and Services

chart

Weekly Preventive Maintenance Checks and Services

chart

Monthly Preventive Maintenance Checks and Services

chart

Quarterly Preventive Maintenance Checks and

Services Chart

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touchup Painting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

II. MAINTENANCE ALLOCATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .

5-5

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.5.1-1

5.1-1

5.1-1

5.1-1

5.1-3

5.1-4

5.1-5

5.1-6

5.1-7

5.1-7

6-1

i-2

i-3

ii

Page 21

Model 540B

List of Illustrations

List of Tables

LIST OF ILLUSTRATIONS

Figure

Model 540B, Front View . . . . . . . . . 1-1

1-1.

1-2.

Diagram of Panel Connections and

Functional Groups . . . . . . . . . . . . 1-3

Power Transformer Primary Winding . 2-1

2-1.

Measuring CW and FM Signals . . . . 3-0

3-1.

Typical Mixer Input Sensitivity . .. 3-1

3-2.

3-3.

Controls, Indicators and Connectors . . 3-2

Typical Sequence of Oscilloscope Patterns

3-4.

Obtained as Difference Frequency is

Reduced to Zero, with a Stable CS

Input Signal . . . . . . . . . . . . . . . 3-4

Typical Oscilloscope Patterns Obtained

3-5.

when CW Input Signal has some

Frequency Deviation . . . . . . . . . . . 3-4

Nomograph for Determining a Harmonic

3-6.

Number of an Unknown Frequency Between

400 MC and 2 GC from Two Adjacent

Frequencies Obtained with the 540B. . 3-6

Nomograph for Determining a Harmonic

3-7.

Number of Unknown Frequency Between

2 and 5 GC from Two Adjacent Fre-

quencies Obtained withthe 540B . . . . . 3-7

Typical Oscilloscope Patterns Obtained

3-8.

when Input Signal is Frequency-

Modulated . . . . . . . . . . . . . . . . 3-8

Measuring Pulse-Modulated RF Signals. 3-9

3-9.

Typical Patterns Obtained on External

3-10.

Synchronized Oscilloscope, when meas-

ing Pulse-Modulated RF Signals . . . . . 3-10

Page

Figure

Typical Patterns Obtained on External

3-11.

3-12.

3-13.

3-14.

3-15.

3-16.

4-1.

Synchronized Oscilloscope when the

Pulse Presentations of Figure 3-10

are Differentiated at the Oscilloscope

Input . . . . . . . . . . . . . . . . . . . . .

Effect of Resistance Connected Across

FREQUENCY CONTROL Connector. .

Effect of Voltage Connected Across

FREQUENCY CONTROL Connector .

Making Measurements at Frequencies

between 12.4 and 18 GC . . . . . . . . . .

System To Measure Frequency Modu-

lation Characteristics . . . . . . . . . .

Design Information for a Simple

Three-Section Low -Pass Filter . . . .

Transfer Oscillator Block Diagram . .

Location of Measurement and Adjust-

5-1.

ment Points . . . . . . . . . . ..

Waveform Definitions . . . . . . . . . . .

5-2.

Low Frequency Harmonic Mixer . . . .

5-3.

High Frequency Harmonic Mixer . . . .

5-4.

Harmonic Generator . . . . . . . . . . . .

5-5.

Oscillator Assembly . . . . . . . . . . . .

5-6.

Chassis Board, Parts Location . . . .

5-7.

Resistor Board, Parts Location . . . .

5-8.

Voltage and Resistance Diagram . . . .

5-9.

Power Supply, Schematic Diagram. . .

5-10.

Oscillator, Schematic Diagram . . . . .

5-11.

Page

.. 3-10

.. 3-11

.. 3-11

.. 3-12

.. 3-13

.. 3-15

.. 4-1

. . 5-3

. . 5-5

. . 5-6

. . 5-6

. . 5-7

. . 5-8

. .

5-9

. . 5-10

. . 5-11

. .

5-12

5-13

LIST OF TABLES

Number

1-1. Specifications . . . . . . . . . . . . . . .1-2

3-1. Function of Controls, Indicators, and

5-1.

5-2.

5-3. Trouble Localization . . . . . . . . . . 5-5

6-1. Reference Designator . . . . , . . . 6-2

6-2. Replaceable Parts . . . . . . . . . .6-7

Connectors . . . . . . . . . . . . 3-2

Test Equipment . . . . . . . . . . 5-2

Adjustments Required when Tubes

are Replaced . . . . . . . . . . . . . . .5-4

Page

iii

Page 22

Section I

Figure 1-1

Model 540B

iv

Figure 1-1. Model 540B, Front View

Page 23

TM 11-6625-493-15

FOREWORD

Cl

Throughout this manual, reference is made to Model 540B Transfer

oscillator which is a commercial designation and is identical with Frequency

comparator CM-77A/USM. This is a first-edition manual containing preliminary

and unreviewed information compiled by the manufacturer of the equipment.

Judicious caution should be exercised in using the information in this

manual until it is replaced by a revised edition.

Index of Equipment Publications

Refer to the latest issue of DA Pam 31C-4 to determine whether there are

new editions, changes, or additional publications pertaining to the

equipment. Department of the Army Pamphlet No. 310-4 is an index of current

technical manuals, technical bulletins, supply manuals, supply bulletins,

lubrication orders, and modification work orders available through publications supply channels. The index lists the individual parts (-10, -20, -35P,

etc) and the latest changes to and revisions of each equipment publication.

Forms and Records

Reports of Maintenance and Unsatisfactory Equipment. Use equipment

forms and records in accordance with instructions in TM 38-750.

Report of Damaged or Improper Shipment. Fill out and forward DDForm 6

(Report of Damaged or Improper Shipment) as prescribed in AR 700-58 (Army),

NAVSANDA Publication 378 (Navy), and AFR 71-4 (Air Force).

Reporting of Equipment Manual Improvements. The direct reporting, by

the individual user, of errors, omissions, and recommendations for

improving this equipment manual is authorized and encouraged. DA Form 2028

till be used for reporting these improvements. This form may be completed

by using pencil, pen, or typewriter.

triplicate and forwarded by the individual using the manual.

DA Form 2028 will be completed in

The original

and one copy will be forwarded direct to: Commanding General, U. S. Army

Electronics Command, ATTN: AMSEL-MR-(NMP)-MA,

Fort Monnouth, New Jersey

07703.

v

Page 24

Page 25

Model 540B Section I

Paragraphs 1-1 to 1-10

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION.

1-2.

PURPOSE AND USE. The Hewlett - Packard

Model 540B Transfer Oscillator is an electronic frequency-measuring instrument which, extends the frequency measurement range of the Hewlett - Packard

524 and 5243 series of electronic frequency counters

into the microwave region. The transfer oscillator frequency counter combination measure frequencies

up to 12.4 gigacycles (gc), or with an external mixer,

up to 18 gc, with near-counter accuracy. The Model

540B can also be used without a frequency counter to

measure frequency below 4 gc within about ± 1/2%.

1-3. The method used in the Model 540B Transfer

Oscillator to determine frequency is to zero-beat the

unknown input signal with a harmonic of an extremelystable signal generated in the 540B, and to measure

the 540B fundamental frequency on a counter. Multi-

plying the counter readout by the number of the har-

monic causing the zero-beat gives the input signal frequency. The harmonic number is determined either

from previous knowledge of the input frequency or by

computation. The zero-beat is displayed on the 540B

internal oscilloscope. Typical difference-frequency

displays obtained are shown in figures 3-4 and 3-5.

1-4.

The visual dieplay of the difference frequency

between two signals permits reading microwave carrier frequencies to very close tolerance while the

signal is being amplitude- or frequency-modulated,

or when it contains troublesome e amounts of noise. It

also permits measuring the incidental frequency modulation in amplitude-modulated carriers, the residual

frequency modulation in cw signals and the center frequency and Iimits of deviation in frequency-modulated

signals. When the 540B is used in conjunction with an

external oscilloscope, the carrier frequency of rf

pulses can also be measured to high accuracy. Typical

beat-frequency displays of pulse-modulated carriers

are shown in figures 3-10 and 3-11.

1-5. ACCURACY OF MEASUREMENT. The stability

of the transfer oscillator and the precision with which

it can be adjusted are sufficient that the high accuracy

and resolution of the electronic counters used for readout are utilized over the entire frequency range. Accuracies up to 1 part per million may be expected with

cw signals that are very stable and noise-free. Few

radio-frequency (rf) signals are stable enough to be

measured with such accuracy. Thus, the instability

of the signal being measured is usually the greatest

accuracy-limiting factor.

1-6. When measuring pulsed signals, accuracy de-

pends to some extent on pulse length because measurement can take place only during the pulse. Typical

accuracy obtainable when measuring a stable, pulsed

carrier of 1000 mc is approximately 3 parts per million for a 10-microsecond pulse duration and 10 parts

per million for a 2. 5-microsecond pulse.

1-7. DESCRIPTION OF EQUIPMENT. The trans-

fer oscillator is a single-unit, cabinet-mounted in-

strument.

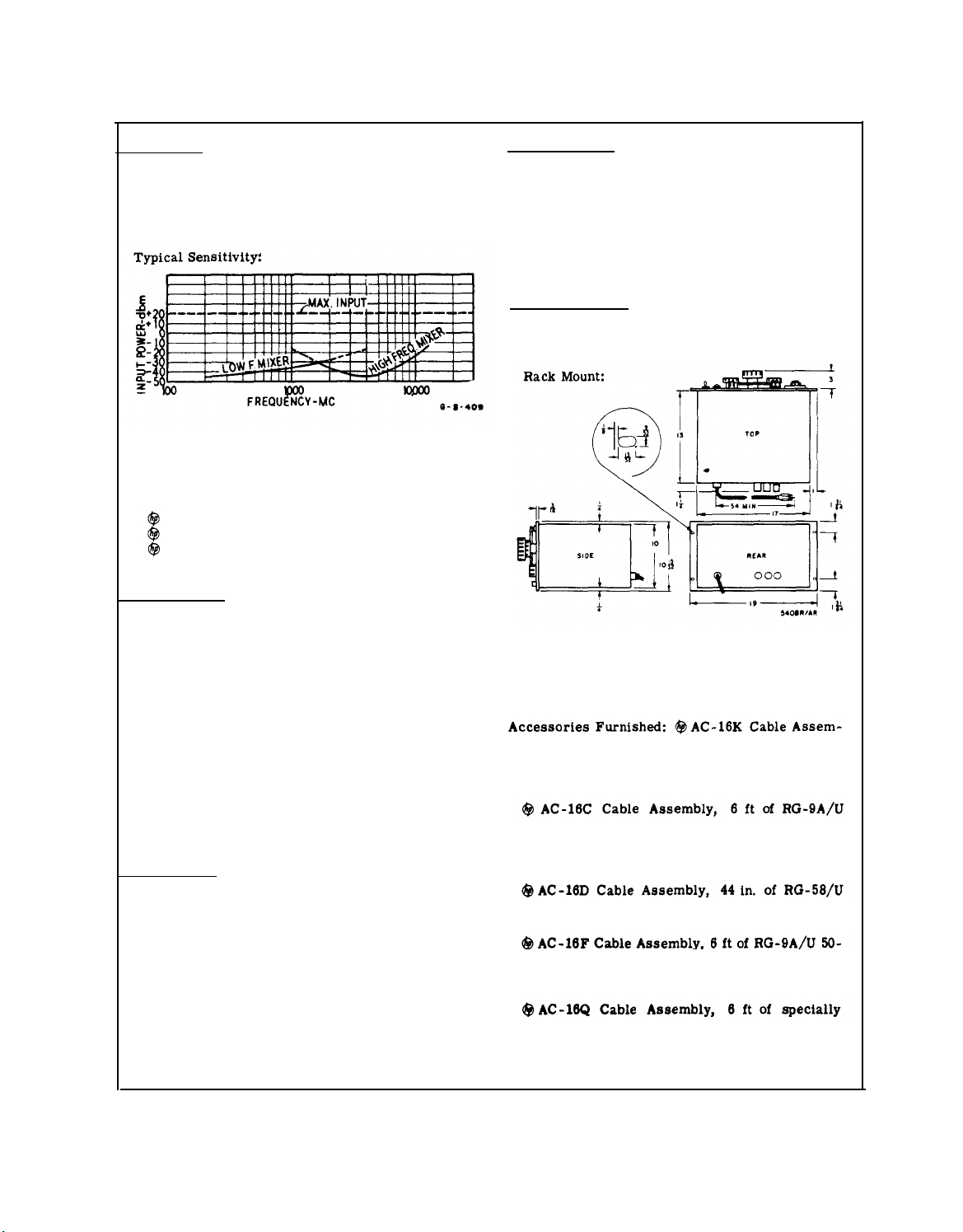

The electronic circuitry haa four main

groups which can be interconnected by front panel

jumpers for a variety of measurement applications.

The four groups are shown in the block diagram in

figure 1-2, and listed below:

a. Oscillator Section. An internal oscillator generates a frequency from 100 to 220 mc, which is continuously adjustable by front panel controls. This

frequency is applied to frequency mixers and to an

external frequency counter for accurate frequency

indication.

b. Frequency Mixers. There are two mixers, a

low frequency mixer for input signals from about 10

mc to 5 gc and a high frequency mixer for input sig-

nals from 1 gc to 12.4 gc. The oscillator output is

connected to the proper mixer through a front panel

jumper. The mixer generates harmonics of the oscil-

lator signal which beat with the input signal and pro-

duce low-frequency beat signals which constitute the

mixer output.

c. Amplifier-Oscilloscope Section The amplifier

amplifies the mixer output to display the beat frequency on the built-in oscilloscope. The amplified

mixer output is also available for display on an external oscilloscope.

With the mixer output being

displayed on the oscilloscope, the frequency of the

oscillator can be adjusted until one of its harmonica

produces a zero-beat indication. The zero-beat indi-

cation on the oscilloscope differs in shape as different

types of signals having varying amounts of modulation

or noise are measured.

d. Harmonic Generator. This separate harmonic

generator section may be used to produce higherorder harmonics of the oscillator frequency for external amplification and use.

1-8.

ACCESSORIES FURNISHED. The Model 540B

Transfer Oscillator includes as part of the equipment

a 6-inch coaxial cable jumper with type BNC connectors for use in programming connections between the

jacks on the front panel, and a 4-foot coaxial cable

with type BNC connectors for connecting the transfer

oscillator to the electronic counter.

1-9. DIFFERENCES IN INSTRUMENTS.

1-10. This manual applies directly to 540B Transfer

Oscillators having the serial-number prefix 234. The

manual with the following changes aleo applies to 540B

Transfer Oscillators having serial-prefix numbers

128, 046, 015, 008, and the earlier prefix 129 for

serials between 101 and 597.

00161-2

1-1

Page 26

Section I

Table 1-1

Model 540B

Table 1-1. Specifications

GENERAL

Frequency Range: 10 mc to at least 12.4 gc

Type of Input Signal: CW, AM, FM, or pulse

Maximum Input: 100 mw

Accuracy: Depends on character of unknown sig-

nal, accuracy of comparison, and accuracy with

which fundamental is measured. See discussion

in text.

Auxiliary Equipment:

Model 524 Sertes Electronic Counter

Model 525B Frequency Converter Unit

Model 150A Oscilloscope (for pulse measure-

m ent)

OSCILLATOR

Fundamental Frequency Range: 100 mc to 220 mc

OSCILLOSCOPE

Frequency Range: 100 cps to 200 kc

Vertical Deflection Sensitivity: 5 mv rms per inch

Horizontal Sweep:

External, 1 volt per inch, 20 cps to 5 kc

Internal, power supply frequency with phase

control

MISCELLANEOUS

Dimensions:

Cabinet Mount: 20-3/4 in. wide, 12-1/2 in. high,

15-1/4 in. deep

Harmonic Frequency Range: Above 12.4 gc

Stability: Less than 0.002% change per minute after

30 minutes warmup

Dial: Six-inch diameter, calibrated in l-me in-

crements. Accuracy ± 1/2%

Vernier Dial:

Mechanical - approximately 9:1

Electrical -

approximately ± 125 parts/million

Output: Approximately 2 volts into 50 ohms. Ad-

justed for optimum crystal harmonic generation.

AMPLIFIER

Gain: Adjustable, 40 db maximum

Bandwidth: 100 cycles to 2 megacycles

High Frequency Control: 3-db point adjustable from

below 1 kc to above 2 mc

Low Frequency Control: 3-db point switched from

100 cycles to below 10 kc, then continuously adjustable to above 400 kc

Maximum Undistorted Output: 1 volt rms usable

signal across 1000-obm load

1-2

Weight: Cabinet Mount: 42 lb, shipping 53 lb

Rack Mount:

35 lb, shipping 50 lb

Power Supply: 115 or 230 volts ± 10%, 50 to 1000

cps, approximately 110 watts

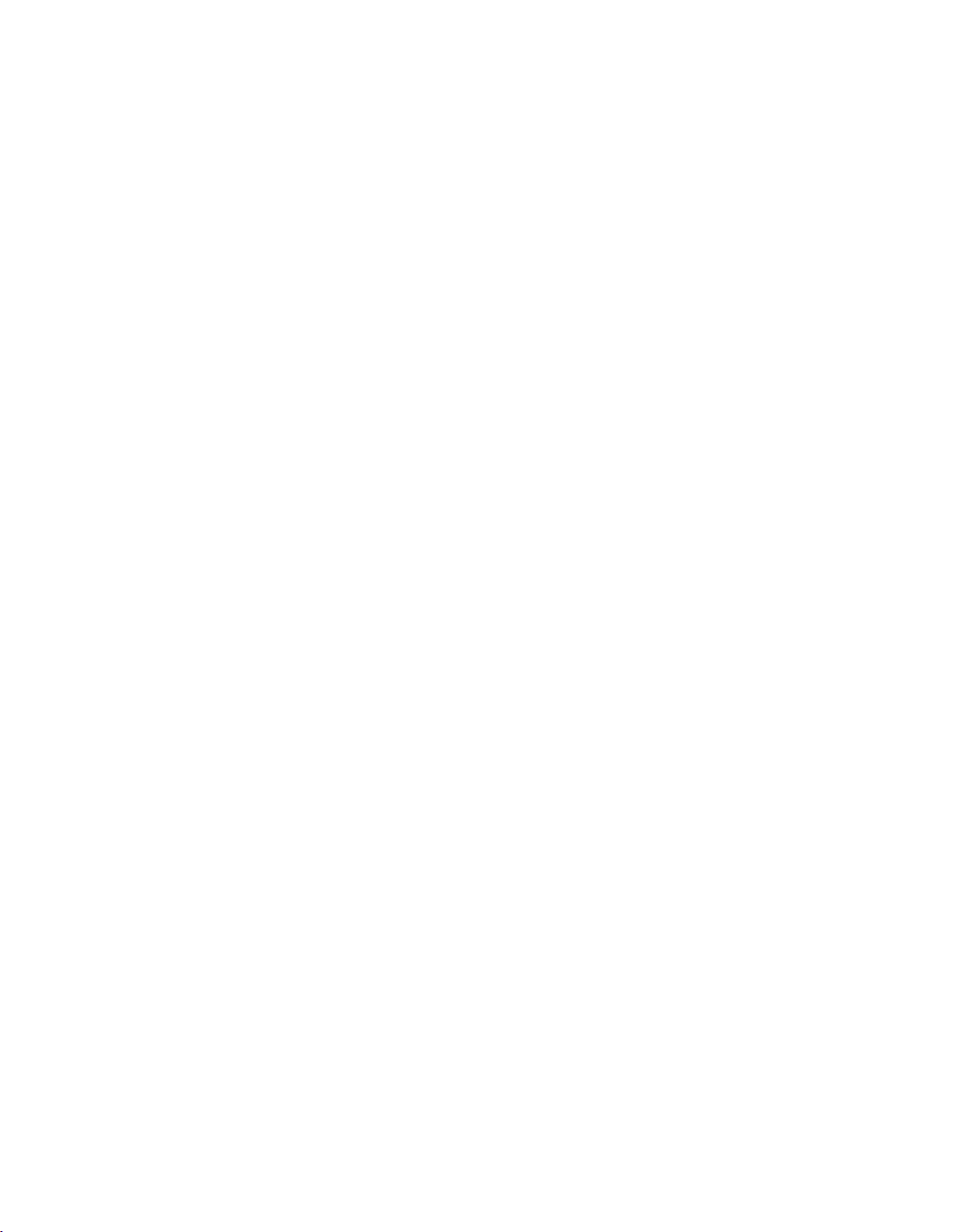

bly, 3 ft of RG-58/U 50-ohm coaxial cable termi-

nated at each end with UG-88/U type BNC male

connectors

Accessories Available:

50-ohm coaxial cable terminated at one end with

a UG-21B/U type male connector and with a UG-

23 B/U type N female connector at the other. (For

use at frequencies below 4000- mc. )

50-ohm coaxial cable terminated at one end only

with a UG-88/U type N BNC male connector

ohm coaxial cable terminated at each end with

UG-21B/U type N male. connectors.

(For use

at frequencies; below 4000 mc. )

treated RG-9A/U 50-ohm coaxial cable terminated at each end with UG-21B/U type N male

connectors.

Each cable is tested and selected

for minimum vswr at frequencies above 4000 mc.

00161-2

Page 27

Model 540B

Section I

Paragraph 1-11

Figure 1-2. Diagram of Panel Connections and Functional Groups

1-11. To adapt this manual to instruments with other

instrument serials, make changes as follows:

Instrument Serial No.

129-01577 to 128-02701

046-01191 to 046-01516

015-00698 to 015-01190

008-598 to 008-697

129-00101 to 128-00597

Change No.

1, 2

1, 2

1, 2, 3

1, 2, 3

1, 3, 4

1. S4. Delete slide switch from schematic diagram,

parts lists, table 3-1. Refer to paragraph 2-9 for

details.

Q1, R76, R77, C49. Delete these parts from sche-

matic diagram, parts lists, and replace with R2,

Resistor, fixed, composition, 1200 ohms ± 10%,

2. Gear, frequency drive, large driving; change stock

number in parts lists to G36-H.

Gear, frequency drive, large spring loading; change

stock number in parts lists to G24-G.

Window, frequency dial; change stock number in

parts lists to G99-H.

3.

L8. Delete choke from schematic diagram and

parts Mats. Replace with wire jumper connected

to junction of J13 and L5.

4.

Regulated B+ at Vll pins 3 and 6; change to +225

volts, Decrease by about 7% the values of all tube

socket voltages listed for all tubes except V6, V8,

V10, Vll, V12, and V13.

R12. Change value to 27,000 ohms,

0690-2731.

R17. Change value to 1800 ohms,

0687-1821.

C47. Change value to 470 pf,

0027,

Gear, frequency drive, large driving; change

stock No. in parts lists to 200AB-36B.

Gear, frequency drive, large spring loading; change

stock No. in parts lists to 200AB-36C.

00161-1

1-3/1-4

Page 28

Page 29

Model 540B

Paragraphs 2-1 to 2-13

Section II

SECTION II

INSTALLATION

2-1. UNPACKING AND INSPECTION

2-2.

Unpack the Transfer Oscillator upon receipt

and inspect it for signs of physical damage such as

scratched or dented surfaces, bent or broken projections, etc.

operation of the instrument as a further check for

damage in shipment. Preserve the packing materials

and case for future reshipment. The materials are

designed to give best protection against normal shipping hazards.

2-3. REPACKING FOR SHIPMENT.

2-4. If possible use original packing materials and

carton for repacking. If it is not available, first wrap

instrument in plastic of smooth, heavy paper to pro-

tect surface against scratching. Use liberal quantity

“stuffing” between entire instrument and heavy

of

shipping carton or box. The stuffing materials should

be firm, should prevent motion of the instrument in

the container, and absorb vibration as much as pos-

sible. Seal the shipping carton with steel bands or

heavy tape.

"DELICATE INSTRUMENT”.

2-5. POWER CABLE.

2-6. The Transfer Oscillator is equipped with a

three-conductor power cable which, when plugged into

the appropriate receptacle, grounds the instrument

chassis. The offset round pin on the plug is the ground

connection. To preserve the ground connection when

using a three-pin to two-pin adapter in a two-pin re-

ceptacle, connect the green pigtail lead on the adapter

to ground (the receptacle mounting box may provide

a good ground connection).

Mark the shipping box “FRAGILE” -

When possible, also attempt

and install the jumper marked “230 v“. The connections are easily made on a tie strip mounted next to

the power transformer.

Figure 2-1. Power Transformer Primary Winding

2-10. OPERATION ON LINE FREQUENCIES

HIGHER THAN 120 CYCLES PER SECOND

2-11. The Transfer Oscillator can be operated on any

frequency from 50 to 1000 cycles per second. The in-

ternal sweep for the front-panel oscilloscope gives

adequate phase control with line frequencies up to 120

cps. Above this line frequency, the proper degree of

phase control can still be obtained by decreasing the

value of C24 according to the following equation:

For example: with 400 cps line frequency,

2-7. OPERATION FROM 115- OR 230-VOLT LINE.

2-8. The Transfer Oscillator may be operated on

either 115- or 230-volt line as selected by a slide

switch on the rear of the instrument chassis (earlier

models were not equipped with this switch and required

rewiring of the power transformer primary winding

as described below). The slide switch can be operated with a screwdriver; for operation on 115 volts,

slide switch down so that “115” is exposed; use a 1.25amp fuse. For 230-volt operation, slide switch down

so that “230” is exposed; use a O. 75-amp fuse.

2-9. For Transfer Oscillators having serial number

prefixes 129, 048, 015, and 008, the power transformer primary winding was connected as shown in

figure 2-1 for 115-volt operation. To connect for 230volt operation remove the jumpers marked “115 v“

00161-2

2-12. lNSTALLATION

2-13. No special operating precautions are necessary

for installing the Transfer Oscillator except when it is

to be operated near vibrating machinery. Even though

the precision oscillator in the Model 540B is not prone

to microphonics, its extreme resolution makes very

small frequency changes readily observable, and the

effects of vibration may become apparent. If vibrating

machines disturb frequency measurements, shockmount the Transfer Oscillator by placing the cabinet

model on shock-absorbing material

mounted, the mass of the rack is often sufficient to

reduce vibration to tolerable amounts.

rack-mounting the Transfer Oscillator are given in

Table 1-1, Specifications.

When rack-

Details of

2-1

Page 30

Section III

Figure 3-1

Model 540B

3-0

Figure 3-1. Measuring CW and FM Signals

Page 31

Model 540B

Paragraphs 3-1 to 3-5

Section III

SECTION Ill

OPERATING INSTRUCTIONS

3-1. INTRODUCTlON.

3-2. This section gives step-by-step procedures for

measuring the frequency of the three most common

types of microwave signals, continuous wave, frequency modulated and pulsed signals. The instructions

for measuring c-w signals are basic to all measurements made with the Transfer oscillator and must be

understood before proceeding with any other measurement technique.

special uses of the Transfer oscillator.

Apply no more than 100 milliwatt r-f power

to the Transfer oscillator Input connectors.

To do so will damage the mixer crystal diodes.

3-3. MEASURING FREQUENCY.

3-4. GENERAL. To measure the frequency of an

unknown signal applied to the input of the Transfer

Oscillator, tune the 540B fundamental frequency until

a harmonic of this fundamental beate with the input

signal, then measure the fundamental frequency on an

electronic counter (or read it from the FREQUENCY

dial) and multiply the fundamental by the number of the

harmonic which beat with the input signal; the product

is the frequency of the input signal. When measuring

an input signal for the first time, one of two conditions

exists: 1) the frequency of the input signal is known

approximately and the number of the harmonic causing

the beat can be determined by dividing the approximate

input signal frequency by the fundamental and rounding

off the answer to the nearest whole number; 2) the input

signal frequency is completely unknown and the number

of the harmonic that beats with it must be determined

by tuning the 540B to two adjacent fundamental frequen-

cies whose harmonics zero beat with the input signal,

and computing the number of the harmonic, and the

input frequency.

3-5. To measure the frequency of an input signal refer

to figures 3-1, 3-3 and Table 3-1, and proceed as

follows:

a. Plug in power cable and turn power switch to the

ON position.

b. Select the mixer section which includes the frequency of the signal to be measured. Connect the

jumper cable between the OSCILLATOR OUTPUT and

OSCILLATOR INPUT connectors of this mixer.

Instructions are aleo included for

CAUTION

e. Determine if the input signal level is above 100

milliwatts. If it ie, provide attenuation as shown in

figure 3-1.

CAUTION

DO NOT EXCEED 100 milliwatts to either

SIGNAL INPUT connector.

will destroy the crystal diodes in the mixer.

The minimum signal input power required

to make measurements at various frequencies is shown in figure 3-2.

The values obtainable with a particular mixer may vary

from the average values shown due to different crystal

efficiencies, etc. Generally variations as great as ± 10

db from tbe curves may occur at some frequencies.

*DBM means decibels referred to one milliwatt.

Figure 3-2. Typical Mixer Input Sensitivity

f. Connect the input signal to be measured to the

SIGNAL INPUT connector of the selected mixer.

g. Connect the electronic counter (Hewlett-Packard

Model 524 C/D or equivalent) to the FREQUENCY

METER connector.

h. If the input frequency is known approximately,

divide it by a harmonic number that gives a funda-

mental frequency in the range of the FREQUENCY

dial. Set the FREQUENCY dial to this frequency.

i. Using a 0.01 second counter gate time and minimum display time, tune the COARSE VERNIER control

until a vertical deflection is obtained on the oscillo-

scope. This deflection indicatee that some harmonic

of the transfer oscillator’s fundamental frequency is

sufficiently close to the input signal to produce a

difference-frequency within the bandwidth of the oscilloscope. If more than one such beat frequency is obtainable, use the highest fundamental. Tune as close

to zero beat as is convenient with the COARSE control.

Higher power

C. Set the HORIZ SWEEP INPUT switch on the rear

of the chassis to INT; set the line voltage selector to

the line voltage to be ueed.

d. Set the VIDEO RESPONSE-GAIN and HIGH FRE-

QUENCY controls to maximum clockwise position.

00161-2

j. Using a 0.01 second counter gate time and infinite

dieplay time, tune the FINE VERNIER control to reduce the difference-frequency to as close to zero as

the stability of the measured signal will allow. Press

the counter RESET bution at the instant an exact zero

beat is obtained. This allows the electronic counter

3-1

Page 32

Section III

Figure 3-3

Model 540B

Figure 3-3. Controls. Indicators. and Connectors

Table 3-1. Function of Controls, Indicators, and Connectors (Sheet 1 of 2)

1. ON switch.

In ON position, applies power to

instrument. In down position, removes power

from instrument.

2. POWER indicator light. Glows when power is

applied to instrument.

3. FREQUENCY dial.

Adjusts and indicates the

fundamental frequency generated by the internal

oscillator, in MEGACYLES, within 1/2 percent.

4. COARSE VERNIER dial.

Adjusts the FRE-

QUENCY dial at reduced speed.

3-2

FINE VERNIER dial.

5.

Adjusts the oscillator

frequency electrically +125 cycles per megacycle from the frequency indicated by the FREQUENCY dial.

6.

OSCILLATOR OUTPUT connector.

the fundamental frequency for connection tothe

Low Frequency or High Frequency Mixer, or

Harmonic Generator.

FREQUENCY METER connector. Supplies an

7.

output of the oscillator frequency for connection

to an external electronic counter.

Supplies

00161-2

Page 33

Model 540B

Section III

Table 3-1

Table 3-1. Function of Controls, Indicators, and Connectors (Sheet 2 of 2)

8. HIGH FREQUENCY MIXER OR LOW FREQUENCY OSCILLATOR INPUT connectors. Accepts the fundamental frequency from

the OSCILLATOR OUTPUT connector.

9. LOW FREQUENCY MIXER SIGNAL INPUT

connector. Accepts an input signal of 5 gc or

less whose frequency is to be measured. This

signal is mixed with harmonics of the oscillator

frequency and the resultant signal is supplied at

the MIXER OUTPUT connector.

10. HIGH FREQUENCY MIXER SIGNAL INPUT

connector. Accepts an input signal between 1

and 12.4 gc whoee frequency is to be measured.

This signal is mixed with harmonics of the oscillator frequency and the resultant signal is

supplied at the MIXER OUTPUT connector.

11. HARMONIC GENERATOR OSCILLATOR INPUT

connector. Accepts the signal from the OSCIL-

LATOR OUTPUT connector for generation of

higher-order harmonics obtainable at the HARMONIC OUTPUT connector. When the transfer

oscillator is used for frequency measurement,

the necessary harmonics are generated in the

mixer, and this harmonic generator section is

not used.

12. HARMONIC GENERATOR HARMONIC OUTPUT

connector.

Provides high-order harmonics of

the signal applied to the HARMONIC GENERA-

TOR OSCILLATOR INPUT connector. These

harmonics are for mixing with input signal frequencies above 12.4 gc using an external mixer.

The output of the external mixer is then applied

to the MIXER OUTPUT connector for display.

13. MIXER OUTPUT connector. Supplies the output signal from the Low or High Frequency

Mixer for use by external equipment these

mixer outputs are internally connected to the

amplifier-oscilloscope section for display).

This connector may also receive the output of

an external mixer for display on the internal

oscilloscope.

14. VIDEO OUTPUT BNC connector. Supplies the

amplified output of the mixers for use by ex-

ternal equipment. Gain and bandwidth are controlled by the three VIDEO RESPONSE controls.

15. VIDEO RESPONSE-GAIN control. Controls

amplification of the output from either internal

mixer or from an external mixer connected to

the MIXER OUTPUT jack, which drives the

oscilloscope sod is available at the VIDEO

OUTPUT connector.

16. VIDEO RESPONSE-HIGH FREQ control. Ad-

justs the frequency of the upper 3 db point of

the amplified mixer output signal to the oscilloscope and the VIDEO OUTPUT connector

from below 1 kc to above 2 mc.

NOTE: Although the signal available at the

VIDEO OUTPUT connector has a 2 mc bandwidth the oscilloscope responds only to frequencies up to approximately 200 kc.

17. VIDEO RESPONSE-LOW FREQ control. Adjusts the frequency of the lower 3 db point of

the mixer signal at the MIXER OUTPUT jack;

does not affect the bandwidth of the oscilloscope. At the extreme clockwise position, the

3 db point is switched to 100 cps. Moving off

the extreme CW position the 3 db point is

switched from 100

CPS to 10 kc, and then is

continuously adjustable to above 400 kc as the

control is turned counterclockwise.

18. FOCUS control.

Adjusts the focus of the os-

cilloscope trace.

19. INTENSITY control. Adjusts the intensity of

the oscilloscope trace.

20. HORIZ GAIN control. Adjusts speed to compress or widen the presentation.

21. 60 CYCLE PHASE control. Adjusts the phase

of the internal, power line frequency sweep to

position the zero-beat frequency indication in

the center of the screen.

22. HORIZ SWEEP INPUT toggle switch (on rear

panel).

In INT. position, provides a line-

frequency sine-wave sweep for the oscillo-

scope, with phase adjustable by the front panel

60 CYCLE PHASE control. In EXT. position,

allows a sweep signal to be provided from an

external source connected to HORIZ SWEEP

INPUT connector, and disables the front panel

60 CYCLE PHASE control.

23. HORIZ SWEEP INPUT BNC connector (on rear

panel). Accepts an external sweep signal.

External sweeps must have an external phase

control to position the zero-beat indication.

This is used to synchronize the sweep when

the carrier being measured is modulated at

a rate different from the power line frequency.

24. FREQUENCY CONTROL BNC connector (on

rear panel). Receives an externally-genetated,

adjustable voltage or resistance to adjust the

oscillator output frequency.

The maximum

frequency variation from this control ie less

than 0. 1%.

00161-1

3-3

Page 34

Section III

Paragraph 3-5 (contd)

to measure the, transfer oscillator fundamental frequency at a precise moment, then hold the display.

On stable signals the oscilloscope trace will resemble

figure 3-4. Absolute zero-beat will be obtained when

the oscilloscope trace collapses into the horizontal

Since the frequency of most signals measured

line.

is not stable enough to achieve this indication completely, various looped patterne are obtained as the

measured frequency drifts about the exact point of

zero-beat. Patterns such as illustrated in figure 3-5

are sufficiently close to zero-beat for most measurements, and are more practical to use than attempting

to obtain a perfect zero-beat. Adjust the characteristic of the pattern by adjusting the VIDEO RESPONSEGAIN and HIGH FREQ. controls as desired.

When a very stable cw signal is being measured, the

operator can initially adjust the transfer oscillator

frequency until a beat-frequency presentation similar

to A is obtained. As the operator refines the adjustment wfth the FINE VERNIER control, the oscilloscope

pattern changes as shown in B and then collapses to

almost-straight hortzontal lines, as shown in C when

the true zero-beat is obtained. In practice, few signals are sufficiently stable to permit the simple pattern

of C to be obtained. If the signal being measured has

some residual frequency modulation the beat frequency

patterns shown in figure 3-5 will be obtained.

Model 540B

When the frequency of the unknown signal vanes

slightly (has some residual frequency modulation),

the difference or beat frequency viewed on the oscilloscope also varies, and the exact zero-beat indication till be in the center of a band of difference frequencies all shown simultaneously on the oscilloscope

screen.

indications obtained with signals with varying amounts

of residual frequent y modulation. Parts A and B

show two typical beat-frequency responses from

signals containing very minor amounts of frequency

deviation; part C is the result obtained with a signal

having a larger amount of frequency deviation. The

exact zero-beat point is where the lines in the pattern become expanded horizontally.

responses are obtained, notice first, that a low-beat

frequency is approached, and then the exact zero-beat

point begins to appear. This point moves about on

the screen presentation and then disappears. Note

that the zero-beat is traced twice per sweep, once in

each direction, because the oscilloscope sweep is a

sine wave. The 60 CYCLE PHASE control can be

used to superimpose the two zero-beat traces in the

center of the screen, if the residual frequency modu-

lation occurs at power line frequency. If the zerobeat traces cannot be stopped in one place, refer to

paragraph 3-5 k for instructions for connecting an

external synchronizing signal.

This figure shows examples of zero-beat

When such

Figure 3-4. Typical Sequence of Oscilloscope

Patterns Obtained as Difference Frequency is

Reduced to Zero, with a Stable CS Input Signal

k. The 60 CYCLE PHASE control can be adjusted

to position the zero beat point in the center of the

screen, provided the residual frequency modulation

occure at the power line frequency. If the zero beat

cannot be positioned with the 60 CYCLE PHASE con-

trol, frequency of the residual modulation on the car-

rier is different from the power line frequency. In

thie case the zero-beat point is determined from the

wideet zero-beat indication obtainable in the pattern

that will sweep across the screen. If it ie necessary

to etop the pattern in one place f or adequate measurement, apply to the rear HORIZ SWEEP INPUT connector a signal of the same frequency as the residual

modulation of the cw input. Switch the HORIZ SWEEP

INPUT switch to the EXT. position. The oscilloscope

horizontal sweep will now be synchronized with the

residual modulation of the cw input signal, and the

pattern will be stable. If the residual frequency-

3-4

Figure 3-5. Typical Oscilloscope Patterns

Obtained when CW Input Signal has some

Frequency Deviation

modulation is accompanied bv the amplitude modulation, the amplitude of the overall pattern on the

oscilloscope will be altered without affecting readability or resolution. Amplitude modulation is indicated by a difference in amplitude of the pattern at

the forward and backward traces on the oscilloscope.

If the amplitude modulation occurs at the power line

frequency, the phase control can be adjusted to superimpose the two traces and produce the familiar

trapezoid associated with amplitude modulation. To

measure the residual or the incidental frequency

modulation, see paragraph 3-9.

1. Record the reading on the FREQUENCY dial, or

the number displayed on the Model 524 C/D Frequency

Counter (add the mixing frequency indicated on the

Model 525B Frequency Converter, in accordance with

the frequency converter instruction manual). The

00161-1

Page 35

Paragraphs 3-6 to 3-8

Section III

counter reading is a more exact measurement of the

fundamental frequency being generated by the transfer oscillator.

m. If the input frequency is known well enough that

there can be no ambiguity between harmonics, divide

it by the transfer oscillator fundamental frequency

and round off the answer to the nearest even number.

This is the number of the harmonic that beats with

the input signal. If there is any ambiguity about the

harmonic number, determine the exact harmonic in

steps o through s.

n. Multiply the FREQUENCY dial reading or the

counter indication by the harmonic number to obtain

the exact frequency of the input signal.

o. Slowly increase or decrease the fundamental

frequency until the next adjacent fundamental is found

whose harmonic produces a zero-beat indication.

Watch the oscilloscope closely to assure that a weak

indication of a zero-beat is not passed unnoticed,

Record this fundamental frequency.

p. Using the appropriate nomograph in figures 3-6

and 3-7, locate the higher fundamental frequency recorded in steps 1 and o on the left column and the

lower fundamental frequency recorded above on the

center column.

q. Place a straight-edge across the two points and

intersecting the right hand column. The point of in-

tersection on the right-hand column indicates the

number of harmonic that beats with the input signal

when the FREQUENCY dial is tuned to the higher of

the two fundamental frequencies used.

r. If further assurance of accuracy is required,

such as with input signals containing large amounts

of noise, or if the input frequency is above or below

those included in the nomography, use the first of the

following equations to determine the input frequency,

and the second or third equations to determine the

harmonic.

Equation 1:

Equation 2:

Equation 3:

Note

To obtain accurate answers with the above

equations, the fundamental frequencies must

be read to 0.01% or better. In case the input signal being measured does not have this

order of stability, it may be necessary to

take the average of several fundamental fre quency readings for each beat-producing harmonic.

read to 0.01% or better, the necessary division or multiplication can be carried out in

longhand if highest accuracy is required, or

with a slide rule if this degree of accuracy is

satisfactory.

S

. To check the calculation performed in the step

With the fundamental frequencies

above, measure the next adjacent fundamental whose

harmonic produces a zero-beat indication. Recalculate, using the previously measured adjacent fundamental frequency.

Figures 3-6 and 3-7 are nomography of the

3-6.

equations given in step r of paragraph 3-5. They are

useful if the input frequency is between 400 and 5000

megacycles and can be determined from two adjacent

transfer oscillator fundamental frequencies which produce zero-beat indications. In the nomograph, f

the unknown frequency, f

transfer oscillator frequencies whose harmonics produce zero-beat indications; f

To use the nomograph, locate two adjacent fundamental

is the higher of two adjacent

1

is the lower frequency.

2

x

frequencies which zero-beat with the unknown input

signal. Find the higher of these two frequencies in

left-hand column, the lower in the center column; place

a straight-edge across these two points. The point

where the straight-edge intersects the right-hand

column ie the number of the harmonic which beats

when the transfer oscillator is tuned to fl,

with f

x

Multiply f

quency of the input signal (f

by the harmonic number to obtain the f re -

1

).

x

3-7. Transfer oscillator fundamental frequency can

be read directly from the FREQUENCY dial with 1/2%

accuracy. The dial reading can be used in the above

equations for frequencies up to about 2000 megacycles,

where low-order harmonics are used and the multiplied inaccuracy is reduced. To use the equations

above 2000 mc the electronic counter must be used to

read the fundamental frequency with sufficient accuracy to identify adjacent harmonics. However, if the

harmonic which produces a beat frequency is already

identified,

unknown frequencies above 2000 mega-

cycles can be measured to 1/2% accuracy by reading

the fundamental frequency directly from transfer os-

cillator FREQUENCY dial.

is

= frequency of unknown input signal

= two adjacent fundamental frequencies

f

l

whose harmonics produce zero beat

= harmonic number of f

N

1

N2 = harmonic number of f

00161-1

higher fundamental,

lower fundamental

1

2

3-8. The beat frequencies produced by the mixers

in thie instrument are suitable only for frequency

measurement as described in this manual.

These

outputs are not suitable for amplitude measurements

because the mixers are designed for best frequency

coverage rather than calibrated amplitude responses.

A suitable external mixer must be used for applications where mixer output amplitude measurements

are made.

3-5

Page 36

Section III

Figure 3-6

Model 540B

3-6

Figure 3-6. Nomograph for Determining a Harmonic Number of an

Unknown Frequency Between 400 MC and 2 GC from Two

Adjacent Frequencies Obtained with the 540B

Page 37

Model 540B

Section III

Figure 3-7

Figure 3-7. Nomograph for Determining a Harmonic Number of

Unknown Frequency Between 2 and 5 CC from Two

Adjacent Frequencies Obtained with the 540B

3-7

Page 38

Section III

Paragraphs 3-9 to 3-13

3-9. MEASURING FM CARRIER FREQUENCY

AND LIMITS OF FREQUENCY DEVIATION.

3-10. To obtain readable zero-beat patterns when

measuring the center-frequency and the limits of fre -

quency deviation in frequency-modulation carriers,

the oscilloscope in the Model 540B must be swept by

a signal of the same frequency that modulates the

carrier,

swept at the power line frequency. If the carrier being

measured must be frequency-modulated at a rate different from the power-line frequency, this frequency

signal must also be applied to the HORIZ SWEEP INPUT connector on the rear of the transfer oscillator

chassis and the HORIZ SWEEP INPUT switch must be

set to the EXT. position.

modulation which results in simple zero-beat presentations; non-sinusoidal modulation gives complex

oscilloscope pictures.

3-11. When an external sweep input signal is used,

the 60 CYCLE PHASE control on the front panel is

inoperative, and it may be necessary to externally

adjust the phase of the sweep input signal to produce

a stationary pattern such as shown in figure 3-8. The

oscilloscope presentation obtained when measuring

a frequency-modulated signal indicates much great er

deviationtban when a cw signal with residual frequency

modulation was measured. The width of the zero-beat

point appears much smaller in relation to the full

oscilloscope pattern, as shown in figure 3-8. Make

measurements as follows:

a. Perform steps a through s of paragraph 3-4 to

measure the carrier frequency. Refer to figure 3-8

for typical oscilloscope patterns.

b. Position the zero-beat pattern for the carrier

frequency in the center of the oscilloscope screen.

c. With the FINE VERNIER control adjust the zerobeat indication slowly to one side of the oscilloscope

screen, as shown in figure 3-8, parts B and C. This

is either the lowest or highest frequency present in

the carrier.

d. Compute this frequency as directed in paragraph

3-4, steps 1 through s.

e. Adjust the zero-beat to the opposite side of the

oscilloscope, which corresponds to the limit of deviation on the opposite side of the carrier frequency.

f. Compute frequency as in step d.

3-12. MEASURING PULSED RF SIGNALS.

3-13. The carrier frequency of pulsed rf signals is

measured by displaying a single pulse from the pulse

train as shown in figures 3-10 and 3-11, and adjust-

ing the transfer oscillator until a harmonic produces

a zero-beat indication with the carrier during the

pulse. To observe a single pulse from the pulse train,

an external oscilloscope with triggered sweep must

be used instead of the transfer oscillator oscilloscope.

Proceed as follows:

a. If the pulse width is greater than one micro-

second, connect the VIDEO OUTPUT connector of the

The Model 540B oscilloscope is internally

Use sine-wave frequency

Model 540B

When a frequency modulated signal is being meas-

ured, the beat frequency varies at tbe rate of the

frequency modulation and it is not possible to reduce

the zero-beat indication to a simple horizontal line

as in figure 3-11; instead, the zero-beat indication

aPPears in the center of a band of difference frequen cies similar to those of figure 3-5, but wfth the difference frequencies more tightly packed. The exact

zero-beat point is where the lines in the pattern become expanded horizontally. Parts A and D above

show the zero-beat indic atione prope rly superimposed

while the transfer oscillator is properly tuned to the

carrier center frequency. Tbe amplitude of the difference frequencies on either side of center in D is

decreased because the frequency deviation of the

carrier is so great that display of the difference

frequencies is limited by the bandwidth of the oscilloscope vertical amplifier. Parts B and C show the

presentation of the same signal as part A, as it

appears when the transfer oscillator is properly tuned

first to one limit of frequency deviation and then the

other, in making a measurement of maximum de-

viation above and below carrier frequency.

Figure 3-8.

when Input Signal is Frequency-Modulated

transfer oscillator to the vertical input jack of an

external oscilloscope with triggered horizontal sweep.

See figure 3-9 for a connection diagram.

b. If the pulse width is less than one microsecond,

connect the MIXER OUTPUT connector to an external

wideband amplifier, such as the@ Model 460 AR. Then

connect the output of the amplifier to the vertical in-

put jack of the oscilloscope. The external amplifier

is required because the mixer output contains frequencies beyond the passband of the transfer oscillator amplifier,

c. Connect the external sync jack of the oscilloscope

to the sync output of the pulsed carrier modulator. If

no suitable sync output is available a usable output

Typical Oscilloscope Patterns Obtained

3-8

00161-1

Page 39

Model 540B

Section III

Paragraph 3-13

Figure 3-9. Measuring Pulse-Modulated RF Signals

may be obtained by tapping off a portion of the pulsed

carrier at a suitable point, and detecting the pulse

envelope with a low-pass filter.

This envelope is

suitable for triggering the oscilloscope sweep.

d. Perform steps a through g of paragraph 3-5. For

pulse carriers it is best to be able to adjust the input

power to obtain at optimum oscilloscope pattern. If

too much input power is applied in pulsed if measurements, the detected video pulse may obliterate ths

desired beat frequency in the preeentaUon. Use only

enough power to obtain an easily read zero-beat.

e. If using the internal amplifier, turn all three

VIDEO RESPONSE controls on the transfer oscillator

fully clockwise for maximum gain and bandwidth.

00161-1

f. Adjust the input attenuator, initially, to provide

almost 100 milliwatts of power. It may be necessary

to reduce this input power to obtain an optimum zerobeat pattern.

g. Adjust the fundamental frequency of the transfer

oscillator to obtain the proper zero-beat pattern described below and illustrated in figure 3-10. The

unknown frequency consists of pulses of an rf carrier;