Page 1

Aruba 3810M Switches

Installation and Getting Started Guide

Number: 5998-8461a

Part

Published: June 2017

Edition: 2

Page 2

© Copyright 2011, 2016 Hewlett Packard Enterprise Development LP

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard Enterprise products and services

are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard Enterprise has no control over and is not

responsible for information outside the Hewlett Packard Enterprise website.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use, or copying. Consistent with FAR

12.211 and 12.212, Commercial Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed

to the U.S. Government under vendor's standard commercial license.

Acknowledgments

Microsoft® and Windows® are trademarks of the Microsoft group of companies.

Applicable Products

JL071AAruba 3810M 24G 1-slot Switch

JL072AAruba 3810M 48G 1-slot Switch

JL073AAruba 3810M 24G PoE+ 1-slot Switch

JL074AAruba 3810M 48G PoE+ 1-slot Switch

JL075AAruba 3810M 16SFP+ 2-slot Switch

JL076AAruba 3810M 40G 8 HPE Smart Rate PoE+ 1-slot Switch

JL084AAruba 3810M 4-port Stacking Module

JL078AAruba 3810M 1QSFP+ 40GbE module

JL079AAruba 3810M 2QSFP+ 40GbE module

JL083AAruba 3810M 4SFP+ module

JL088AAruba 3810 Switch Fan Tray

JL085AAruba X371 12VDC 250W PS

JL086AAruba X372 54VDC 680W PS

JL087AAruba X372 54VDC 1050W PS

J9578AAruba 3800/3810M 0.5m Stacking Cable

J9579AAruba 3800/3810M 3m Stacking Cable

J9665AAruba 3800/3810M 1m Stacking Cable

J9583AHPE X410 1U Universal 4-post Rack Mounting Kit

_______________________________________________________________________________________________________________________________________________________________________

Hewlett Packard Enterprise

3000 Hanover Street

Palo Alto, CA 94304

http://www.hpe.com/networking

Page 3

Contents

1 Introducing the 3810M switches..........................................................................6

Front of the Switches............................................................................................................................7

Network Ports..................................................................................................................................9

Management Ports........................................................................................................................11

Console Ports...........................................................................................................................11

Auxiliary (Aux) Port...................................................................................................................11

Switch and Port LEDs on Front of the switches............................................................................11

LED Mode Select Button and Indicator LEDs...............................................................................18

Reset and Clear Buttons...............................................................................................................19

Flex Port Slot and Module Support...............................................................................................20

Back of the Switches..........................................................................................................................20

Power Supplies..............................................................................................................................21

Power Connector...........................................................................................................................21

Stacking Module Slot.....................................................................................................................21

Fan Tray Assembly........................................................................................................................22

Out-of-Band Management (OOBM) Port.......................................................................................22

LEDs on the Back of the Switches................................................................................................22

3810M Stacking Module.....................................................................................................................23

Stacking Module LEDs..................................................................................................................24

Switch Features..................................................................................................................................25

2 Installing the Switch...........................................................................................28

Included Parts.....................................................................................................................................28

Installation Procedures.......................................................................................................................29

Summary.......................................................................................................................................29

Installation Precautions:................................................................................................................31

1. Prepare the Installation Site......................................................................................................31

2. Verify the Switch Boots Correctly..............................................................................................32

LED Behavior:..........................................................................................................................34

3. (Optional) Install the Stacking Module.......................................................................................34

Verifying the Module is Installed Correctly...............................................................................35

4. Installing the Flex Port Module..................................................................................................36

5. Mount the Switch.......................................................................................................................37

Rack or Cabinet Mounting........................................................................................................37

Rack Mounting the 3810M switch in a 2-post rack...................................................................38

Rack Mounting the 3810M switch in a 4-post rack...................................................................39

Horizontal Surface Mounting....................................................................................................40

6. (Optional) Installing the Stacking Cables..................................................................................41

7. (Optional) Installing Transceivers..............................................................................................41

Installing the transceivers:........................................................................................................41

Removing the transceiver:.......................................................................................................42

8. Connect the Switch to a Power Source.....................................................................................42

9. (Optional) Installing a Second Power Supply............................................................................43

PoE/PoE+ Operation................................................................................................................43

10. (Optional) Connect a Management console............................................................................44

Configuring the Management Console.....................................................................................44

Setting Up a Console Connection............................................................................................44

Console Cable Pinouts.............................................................................................................45

11. Connect the Network Cables...................................................................................................46

Using the RJ-45 Connectors....................................................................................................47

Connecting Cables to Transceivers.........................................................................................47

Stacking Information and Topologies..................................................................................................47

Contents 3

Page 4

Chain Topologies...........................................................................................................................48

Ring Topologies.............................................................................................................................50

Mesh Topologies............................................................................................................................51

Sample Network Topologies...............................................................................................................53

3 Getting Started With Switch Configuration........................................................58

Recommended Minimal Configuration................................................................................................58

Minimal Configuration Through the Console Port Connection...........................................................58

Where to Go From Here: Networked Connections.............................................................................60

Using the IP Address for Remote Switch Management.....................................................................61

Starting a Telnet Session...............................................................................................................61

Starting a Web Browser Session...................................................................................................61

4 Replacing Components.....................................................................................63

Replacing the Fan Tray.......................................................................................................................63

Replacing the Power Supply...............................................................................................................64

Replacing the Stacking Module..........................................................................................................65

Replacing the Flex Port Module..........................................................................................................66

5 Troubleshooting.................................................................................................68

Basic Troubleshooting Tips.................................................................................................................68

Diagnosing with the LEDs...................................................................................................................69

Proactive Networking..........................................................................................................................76

Hardware Diagnostic Tests.................................................................................................................77

Testing the Switch by Resetting It..................................................................................................77

Checking the Switch LEDs.......................................................................................................77

Checking Console Messages...................................................................................................77

Testing Twisted-Pair Cabling.........................................................................................................77

Testing Switch-to-Device Network Communications.....................................................................78

Testing End-to-End Network Communications..............................................................................78

Restoring the Factory Default Configuration.......................................................................................78

Downloading New Switch Software....................................................................................................79

Hewlett Packard Enterprise Customer Support Services...................................................................79

6 Specifications....................................................................................................80

Switch Specifications..........................................................................................................................80

Physical.........................................................................................................................................80

Electrical........................................................................................................................................80

Environmental................................................................................................................................81

Acoustics.......................................................................................................................................81

Safety............................................................................................................................................81

Connectivity Standards..................................................................................................................82

Stacking Module Specifications..........................................................................................................83

Physical.........................................................................................................................................83

Environmental................................................................................................................................83

Flex Port Specifications......................................................................................................................83

Physical.........................................................................................................................................83

Environmental................................................................................................................................84

7 Cabling and Technology Information.................................................................85

Cabling Specifications........................................................................................................................85

Technology Distance Specifications...................................................................................................87

Mode Conditioning Patch Cord...........................................................................................................88

Installing the Patch Cord.....................................................................................................................89

Twisted-Pair Cable/Connector Pin-Outs.............................................................................................89

Straight-Through Twisted-Pair Cable for 10 Mbps or 100 Mbps Network Connections................90

Cable Diagram.........................................................................................................................90

4 Contents

Page 5

Pin Assignments.......................................................................................................................91

Crossover Twisted-Pair Cable for 10 Mbps or 100 Mbps Network Connection............................91

Cable Diagram.........................................................................................................................91

Pin Assignments.......................................................................................................................92

Straight-Through Twisted-Pair Cable for 1000 Mbps Network Connections.................................92

Cable Diagram.........................................................................................................................92

Pin Assignments.......................................................................................................................93

8 Support and other resources.............................................................................94

Accessing Hewlett Packard Enterprise Support.................................................................................94

Before Calling Support..................................................................................................................95

Accessing updates..............................................................................................................................95

Websites.............................................................................................................................................95

Customer self repair...........................................................................................................................96

Remote support..................................................................................................................................96

Documentation feedback....................................................................................................................96

A Warranty and regulatory information.................................................................97

Warranty information...........................................................................................................................97

Regulatory information........................................................................................................................97

Belarus Kazakhstan Russia marking.............................................................................................97

Turkey RoHS material content declaration....................................................................................98

Ukraine RoHS material content declaration..................................................................................98

Index.....................................................................................................................99

Contents 5

Page 6

1 Introducing the 3810M switches

The Aruba 3810M are multiport switches that can be used to build high-performance switched

networks. These switches are store-and-forward devices offering low latency for high-speed

networking. The 3810M switches also support a field-replaceable Redundant Power Supply and

fan tray, Power over Ethernet (PoE/PoE+) technologies, full network management capabilities

and a flexible uplink port slot.

In addition, the 3810M switches support the FlexChassis Mesh feature for stacking the switches.

When 3810M Stacking Modules (JL084A) are installed in the switches, any combination of up

to ten 3810M switches can be stacked together via high-speed backplane cables to form a single

extended virtual switch. See Stacking Information and Topologies, and the HPE ArubaOS-Switch

Advanced Traffic Management Guide K/KA/KB.16.01 for more stacking information.

These switches are described in this manual:

PoE+ SwitchesNon-PoE Switches

Aruba 3810M 24G PoE+ 1-slot Switch (JL073A)Aruba 3810M 24G 1-slot Switch (JL071A)

Aruba 3810M 48G PoE+ 1-slot Switch (JL074A)Aruba 3810M 48G 1-slot Switch (JL072A)

Aruba 3810M 16SFP+ 2-slot Switch (JL075A)

Accessories List

Aruba 3810M 40G 8 HPE Smart Rate PoE+ 1-slot Switch

(JL076A)

Flex port ModulePower SupplyStacking Module

Aruba 3810M 4-port Stacking

Module (JL084A)

Aruba X371 12VDC 250W 100-240VAC

Power Supply (JL085A)

Aruba X372 54VDC 680W 100-240VAC

Power Supply (JL086A)

Power Supply (JL087A)

Aruba 3810M 1QSFP+ 40GbE module

(JL078A)

Aruba 3810M 2QSFP+ 40GbE module

(JL079A)

Aruba 3810M 4SFP+ module (JL083A)Aruba X372 54VDC 1050W 110-240VAC

This chapter describes these switches with the following information:

• Front of the switches:

Network Ports◦

◦ Management Ports

◦ LEDs

◦ Buttons

◦ Flex Port Slot

◦ Module Support

• Back of the switches:

Power Supplies and Power Connectors◦

◦ Fan Tray

◦ Out-of-Band Management (OOBM)

• 3810M Stacking Module

• Switch Features

6 Introducing the 3810M switches

Page 7

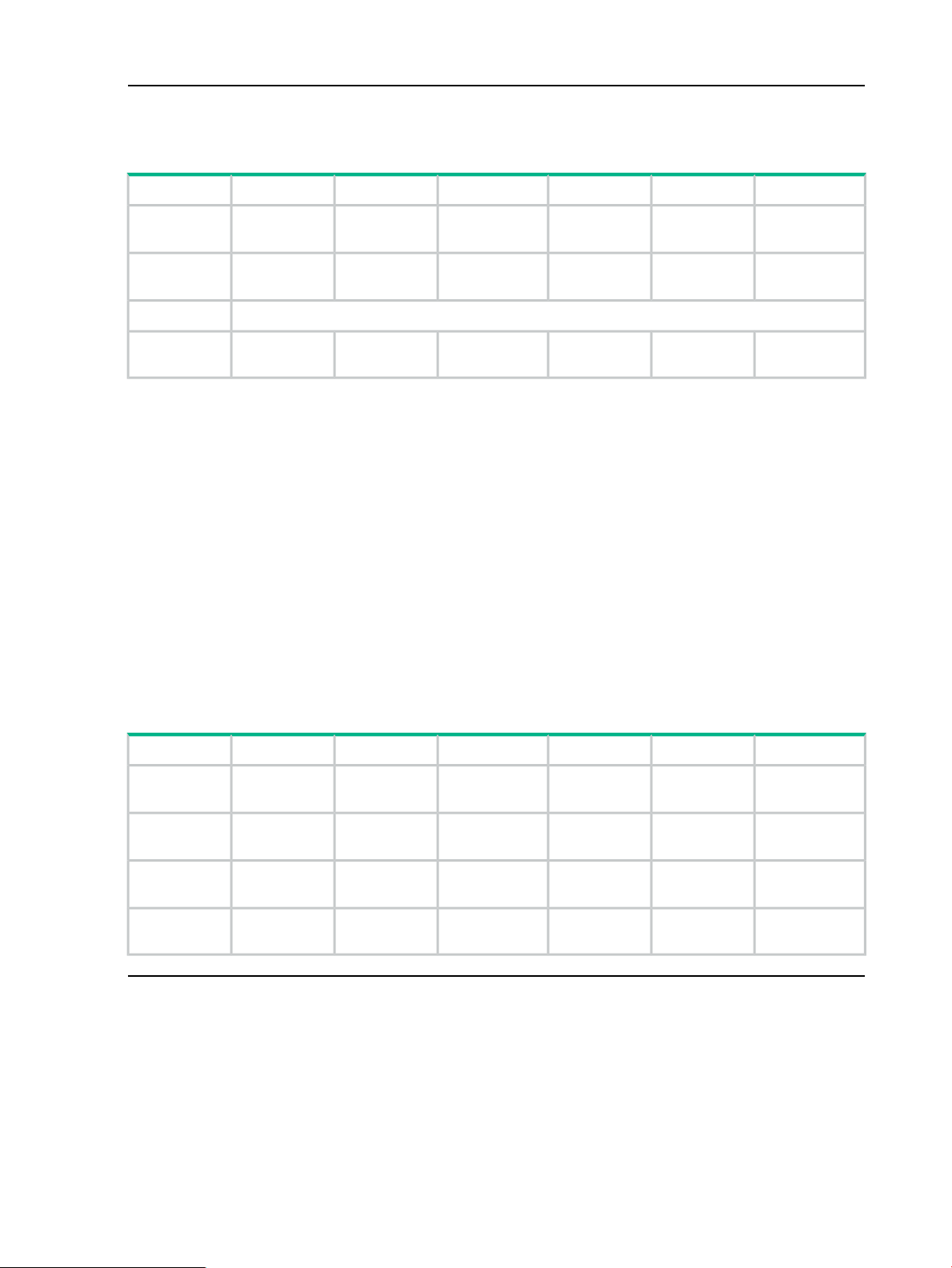

Front of the Switches

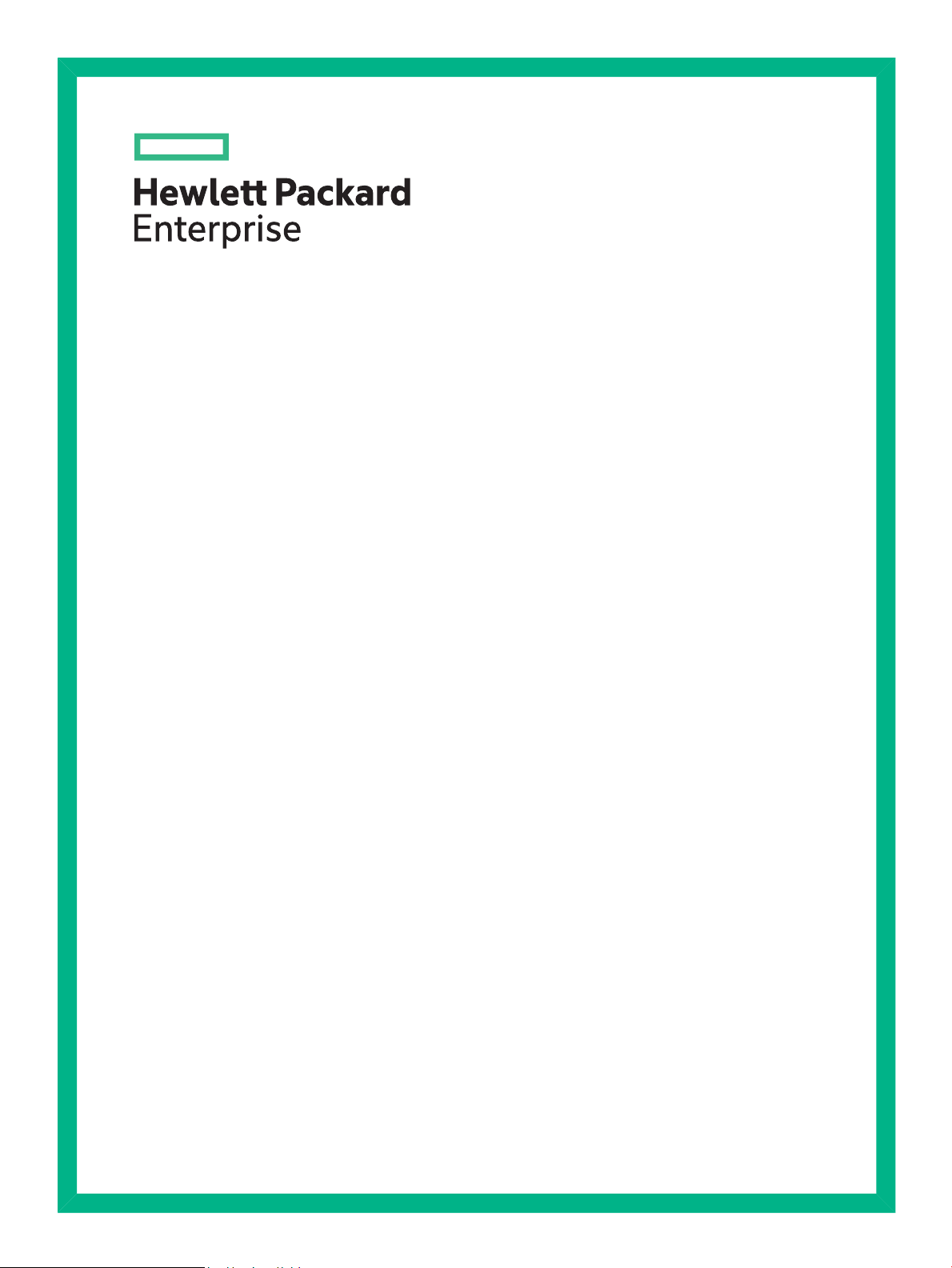

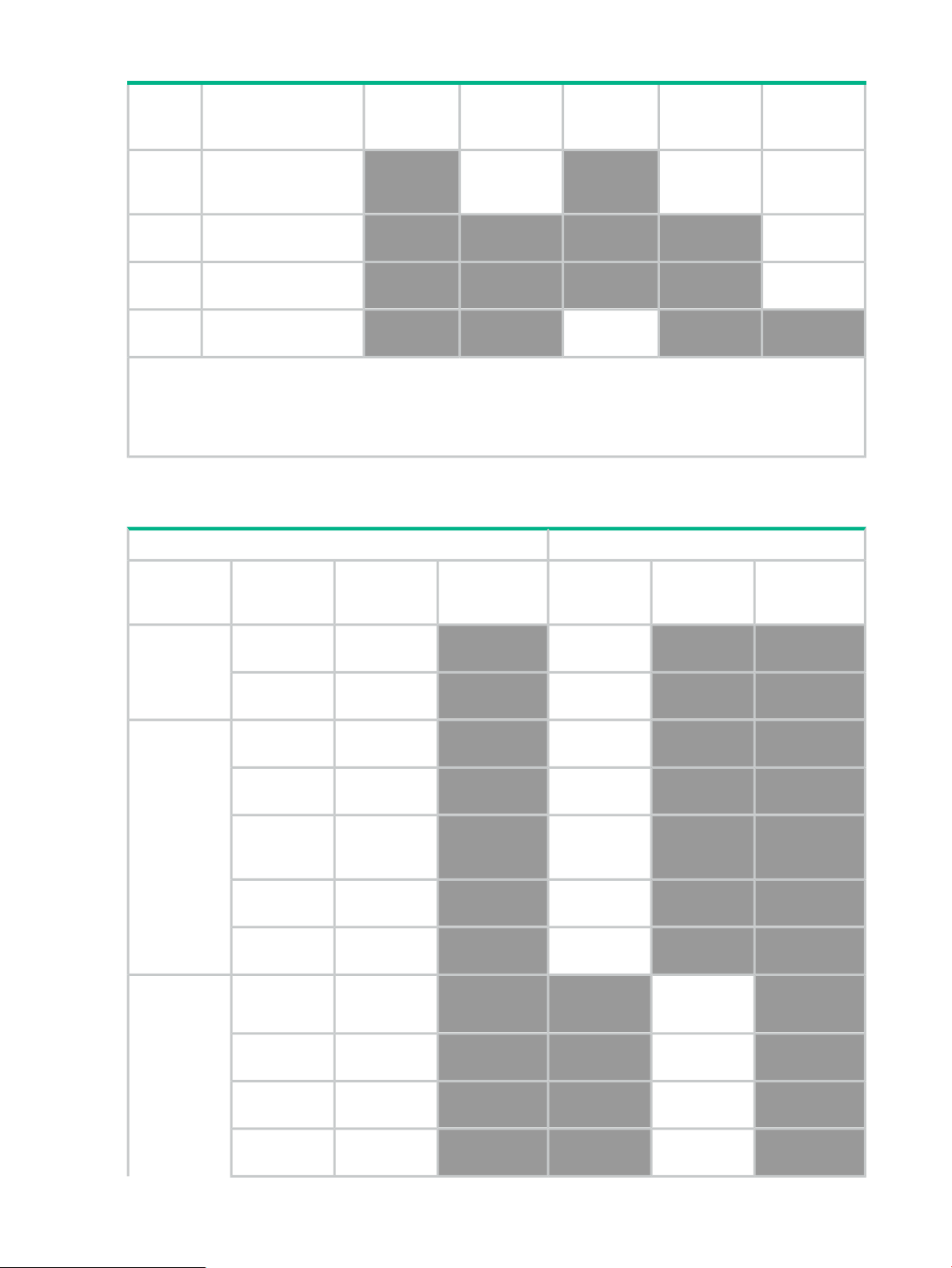

Figure 1 Front of all the 3810M Switches

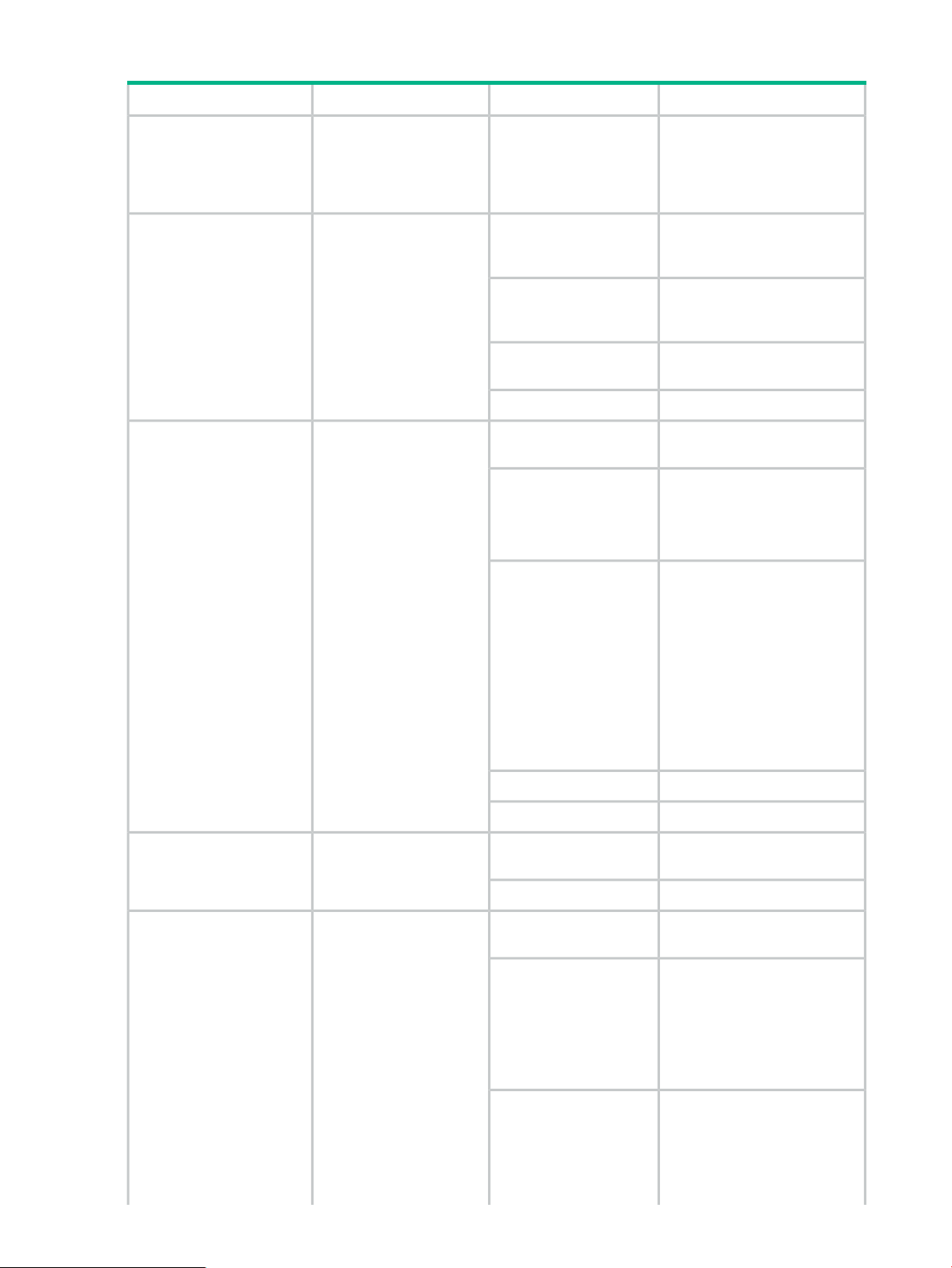

Table 1 Front of all the 3810M Switches Label and Description

DescriptionLabel

Aruba 3810M 24G 1-slot Switch (JL071A)1

Aruba 3810M 48G 1-slot Switch (JL072A)2

Aruba 3810M 24G PoE+ 1-slot Switch (JL073A)3

Aruba 3810M 48G PoE+ 1-slot Switch (JL074A)4

Aruba 3810M 16SFP+ 2-slot Switch (JL075A)5

Aruba 3810M 40G 8 HPE Smart Rate PoE+ 1-slot Switch (JL076A)6

Front of the Switches 7

Page 8

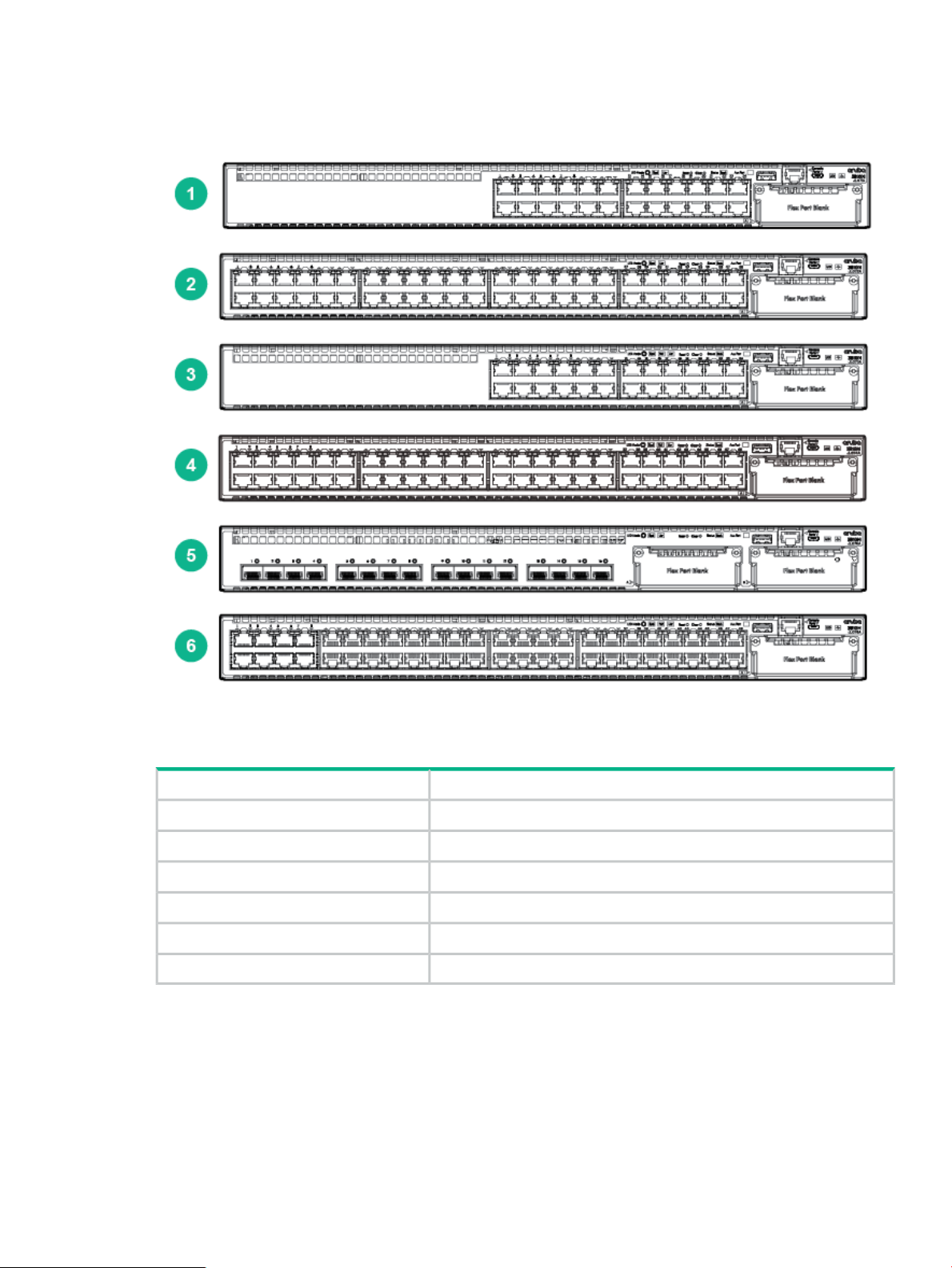

Figure 2 Front of 3810M Flex Port Modules

Table 2 3810M Flex Port Modules Label and Description

8 Introducing the 3810M switches

DescriptionLabel

Aruba 3810M 1QSFP+ 40GbE Module (JL078A)1

Aruba 3810M 2QSFP+ 40GbE Module (JL079A)2

Aruba 3810M 4SFP+ Module (JL083A)3

Port LEDs4

Flex Port Module Status LED5

Page 9

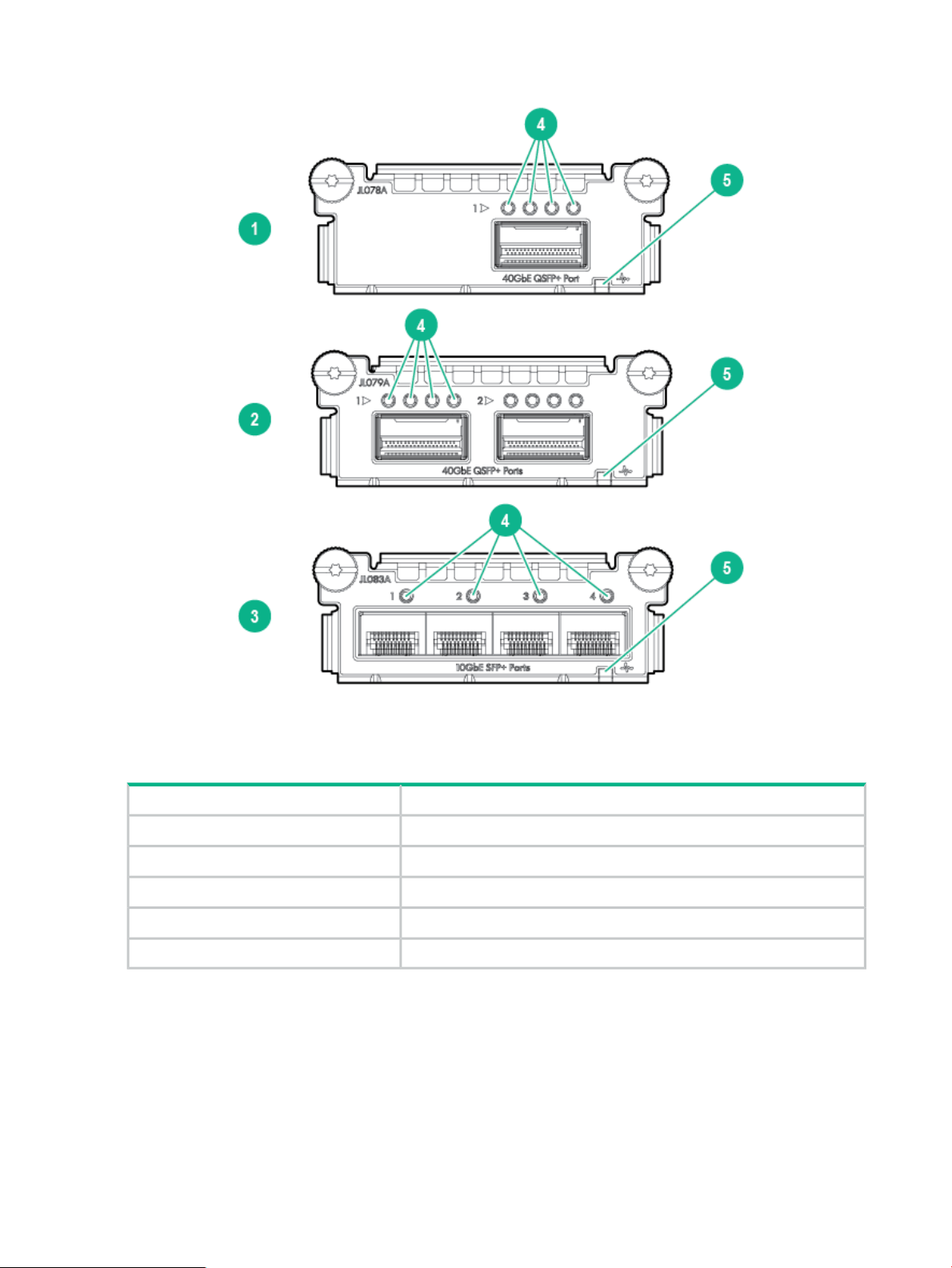

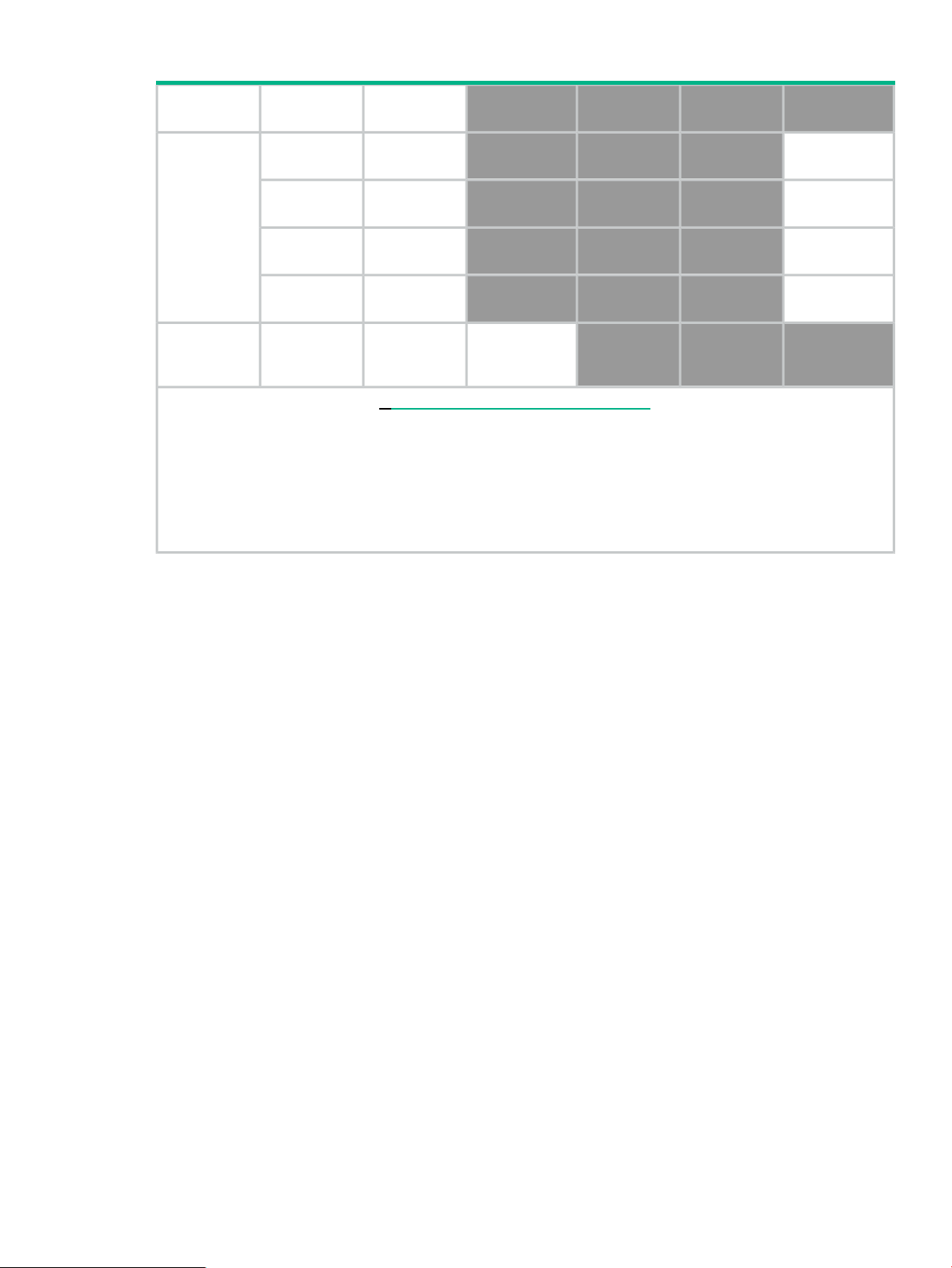

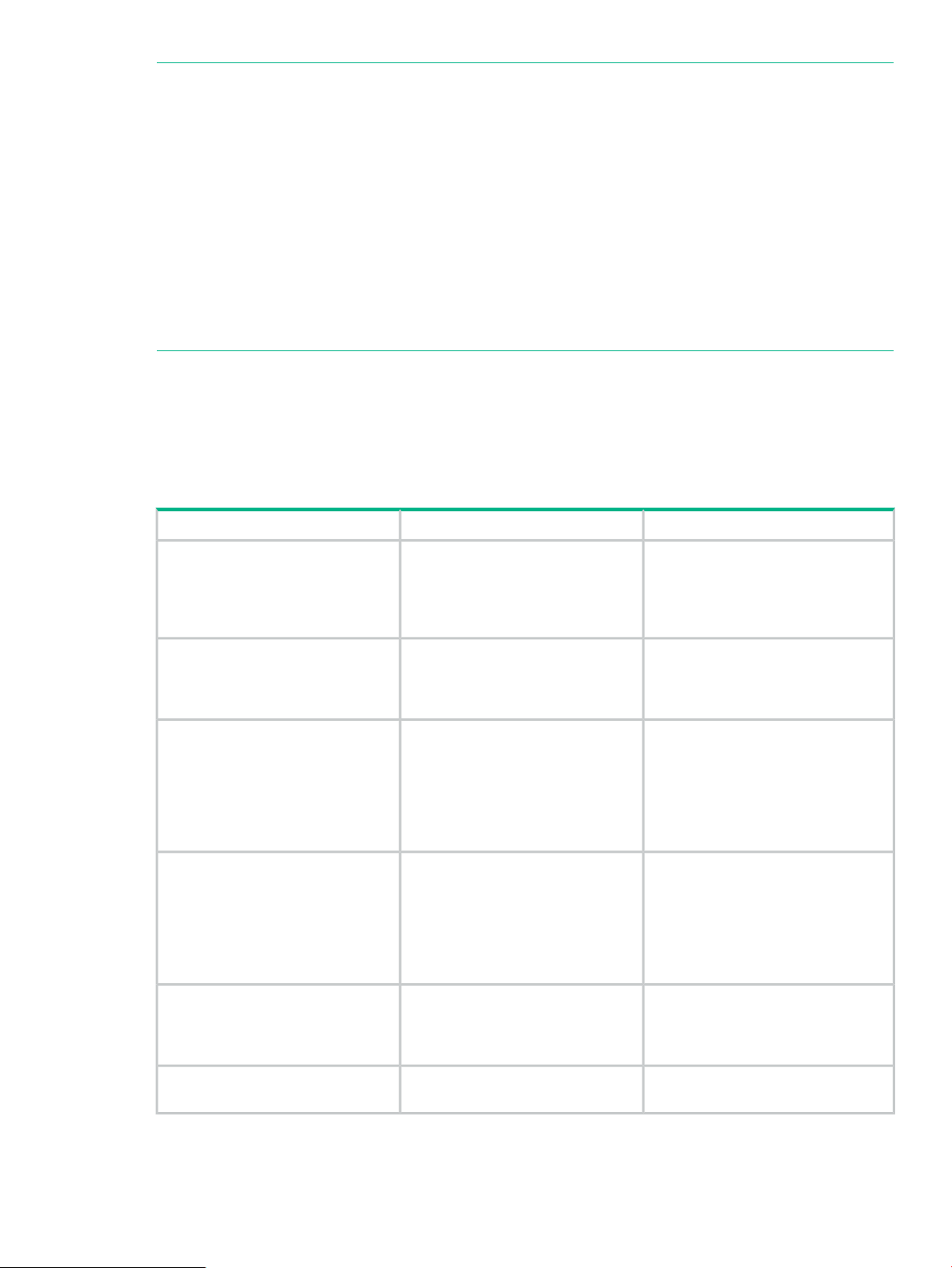

Figure 3 Example of 3810M Switches

Table 3 3810M Switches Labels and Description

Switch Port LEDs1

LED Mode button2

Speed, PoE*, Usr LEDs3

Reset, Clear buttons4, 5

DescriptionLabel

* PoE Mode LED is present only on switch models that support PoE.

Network Ports

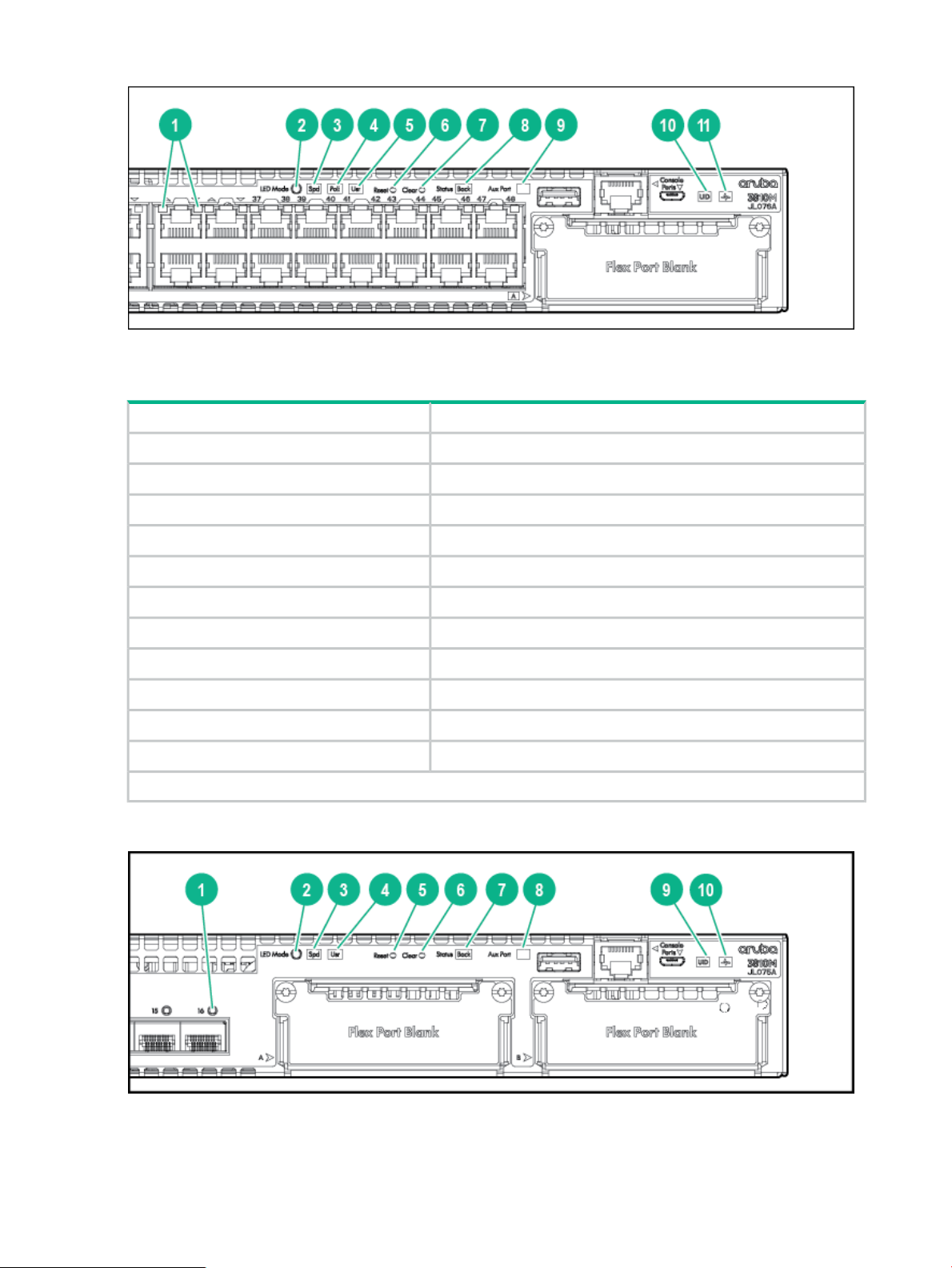

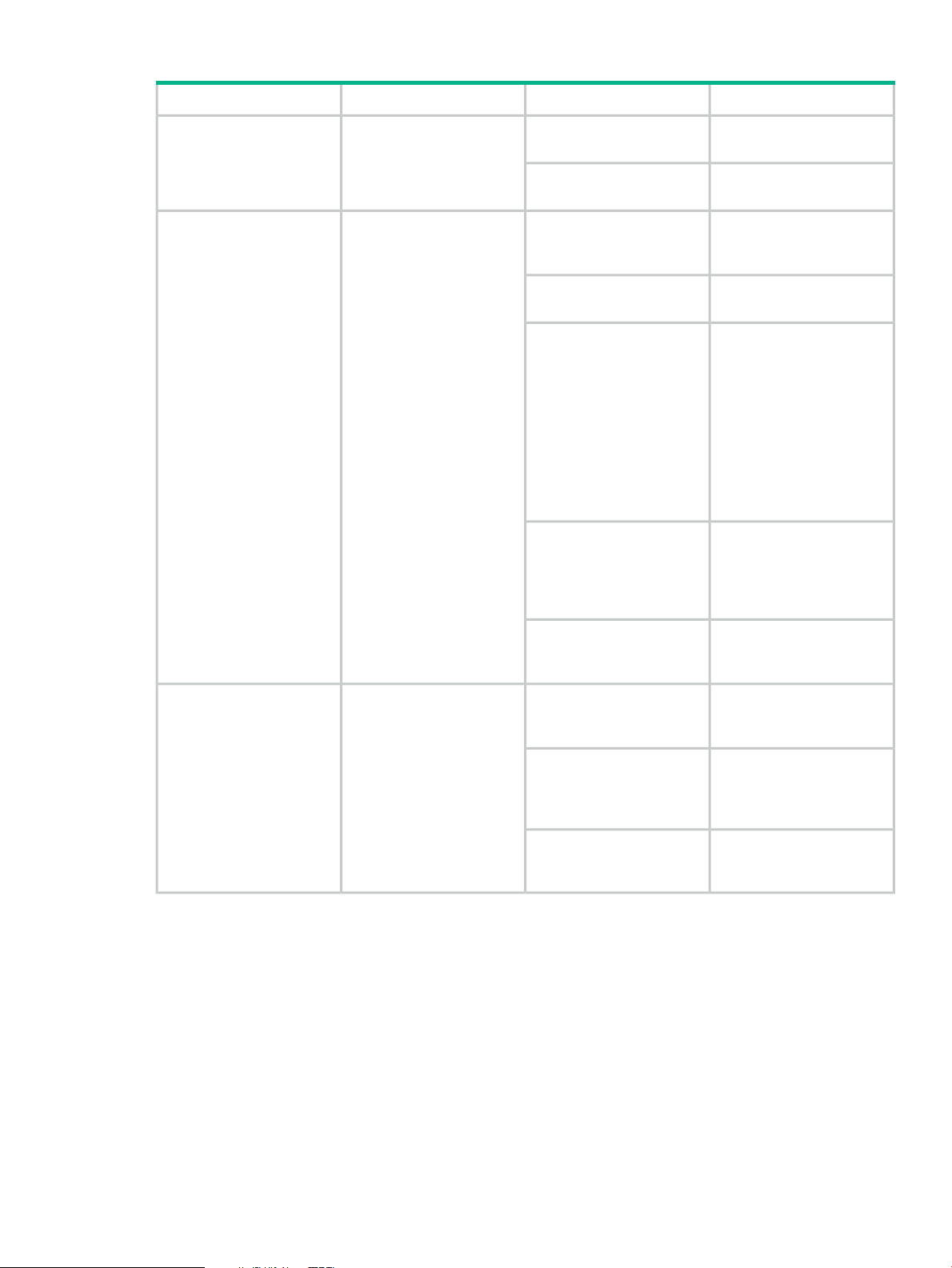

Table 4 Network Ports

Product

number

JL071A

Model name

Aruba 3810M 24G 1-slot

Switch

Back Module Status LED6

Aux port status LED7

USB/Auxiliary Port8

RJ Serial Console9

Micro USB Console10

Global Status, Unit Identification LEDs11

Flex port Module expansion slot12

10/100/1000Base-T RJ-45 Ports13

10/100/1000

non-PoE

RJ-45 ports

24

10/100/1000

PoE/PoE+

1

RJ-45 ports

SFP+ Ports

1

2

40GSmartRate

JL072A

JL073A

JL074A

JL075A

Aruba 3810M 48G 1-slot

Switch

Aruba 3810M 24G PoE+

1-slot Switch

Aruba 3810M 48G PoE+

1-slot Switch

Aruba 3810M 16SFP+

2-slot Switch

48

24

48

16

Front of the Switches 9

Page 10

Table 4 Network Ports (continued)

Product

number

Model name

10/100/1000

non-PoE

RJ-45 ports

10/100/1000

PoE/PoE+

1

RJ-45 ports

SFP+ Ports

1

2

40GSmartRate

Aruba 3810M 40G 8

JL076A

HPE Smart Rate PoE+

840

1-slot Switch

JL078A

JL079A

JL083A

Aruba 3810M 1QSFP+

40GbE module

Aruba 3810M 2QSFP+

40GbE module

Aruba 3810M 4SFP+

module

4

1

2

Notes:

1

All RJ-45 ports support “Auto-MDIX”, which means you can use either straight-through or crossover twisted-pair

cables to connect network devices to the switch.

2

SFP+ ports support 100Mb (100-FX and 100-BX), 1G SFP and 10G SFP+ transceivers.

These products also support optional network connectivity:

Table 5 Optional Network Connectivity, Speeds and Technologies

Transceiver Form-Factor and Connector

1

100 Mbps

1 Gbps

100-FX

100-BX

1000-T

1000-SX

1000-LX

1000-LH

1000-BX

10-Gig

Direct Attach

CablingTechnologySpeed

Fiber

(multimode)

Fiber (single

mode)

Copper

(twisted-pair)

Fiber

(multimode)

Fiber

(multimode or

single mode)

Fiber (single

mode)

Fiber (single

mode)

Copper

(twinaxial)

Flex Module

Connector

SFP

("mini-GBIC")

Connector

LC

LC

RJ-45

LC

LC

LC

LC

QSFP+ConnectorSFP+Connector

Not

Applicable

10-Gig SR

10 Gbps

10-Gig LRM

10-Gig LR

10 Introducing the 3810M switches

Fiber

(multimode)

Fiber

(multimode)

Fiber (single

mode)

LC

LC

LC

Page 11

Table 5 Optional Network Connectivity, Speeds and Technologies (continued)

10-Gig ER

40-Gig Direct

Attach 1/3/5 m

40-Gig SR4

40 Gbps

40-Gig ESR4

40-Gig LR4

Smart Rate

1/2.5/5/10

Gbps

1

For supported transceivers, visit http://www.hpe.com/networking/support .

• In the first textbox, type J4858 (for 100-Mb and Gigabit information), J8436 (for 10-Gigabit information), or JH231

(for 40–Gigabit information).

• Select any of the products that display in the dropdown list.

• Select Support Center. Then click on Manuals, followed by View All to and find the Transceiver Support

Matrix.

For technical details of cabling and technologies, see Cabling and Technology Information.

Smart Rate

Fiber (single

mode)

Copper

(twinaxial)

Fiber

(multimode)

Fiber

(multimode)

Fiber (single

mode)

Copper

(twisted pair)

Not Applicable

MPO

MPO

LC

RJ-45

Management Ports

Console Ports

There are two serial console port options on the switch, an RJ-45 or Micro USB. These ports are

used to connect a console to the switch either by using the RJ-45 serial cable supplied with the

switch, or a standard Micro USB cable (not supplied). The Micro USB connector has precedence

for input, so if both cables are plugged in, the console output is echoed to both the RJ and

Micro-USB ports. But, the input is only accepted from the Micro-USB.

For more information on the console connection, see “10. (Optional) Connect a Management

console” (page 44). The console can be a PC or workstation running a VT-100 terminal emulator,

or a VT-100 terminal.

Auxiliary (Aux) Port

An auxiliary port for processing a USB command file or downloading switch software code. This

port uses a USB Type A connector, but does not comply with all USB protocols and standards.

Switch and Port LEDs on Front of the switches

• Front of Switch Status and Mode LED Behavior describes the switch chassis and Flex Port

status LEDs and also the Switch Mode LEDs.

• Table 9 (page 15) describes the switch Port LEDs and their different mode behaviors.

Front of the Switches 11

Page 12

Figure 4 Switch and Port LEDs for JL071A, JL072A, JL073A*, JL074A*, and JL076A*

Table 6 Switch and Port LEDs Label and Description for JL071A, JL072A, JL073A*, JL074A*,

and JL076A*

DescriptionLabel

Switch Port LEDs1

LED Mode button2

Speed LED3

PoE LED*4

Usr LED5

Reset button6

Clear button7

Back Module status LED8

Aux Port status LED9

Unit Indentification LED10

Global status LED11

* PoE LED is present only on PoE switches.

Figure 5 Switch and Port LEDs for JL075A

12 Introducing the 3810M switches

Page 13

Table 7 Switch and Port LEDs Label and Description for JL075A

DescriptionLabel

Switch Port LEDs1

LED Mode button2

Speed LED3

Usr LED4

Reset button5

Clear button6

Back Module status LED7

Aux Port status LED8

Unit Identification LED9

Global status LED10

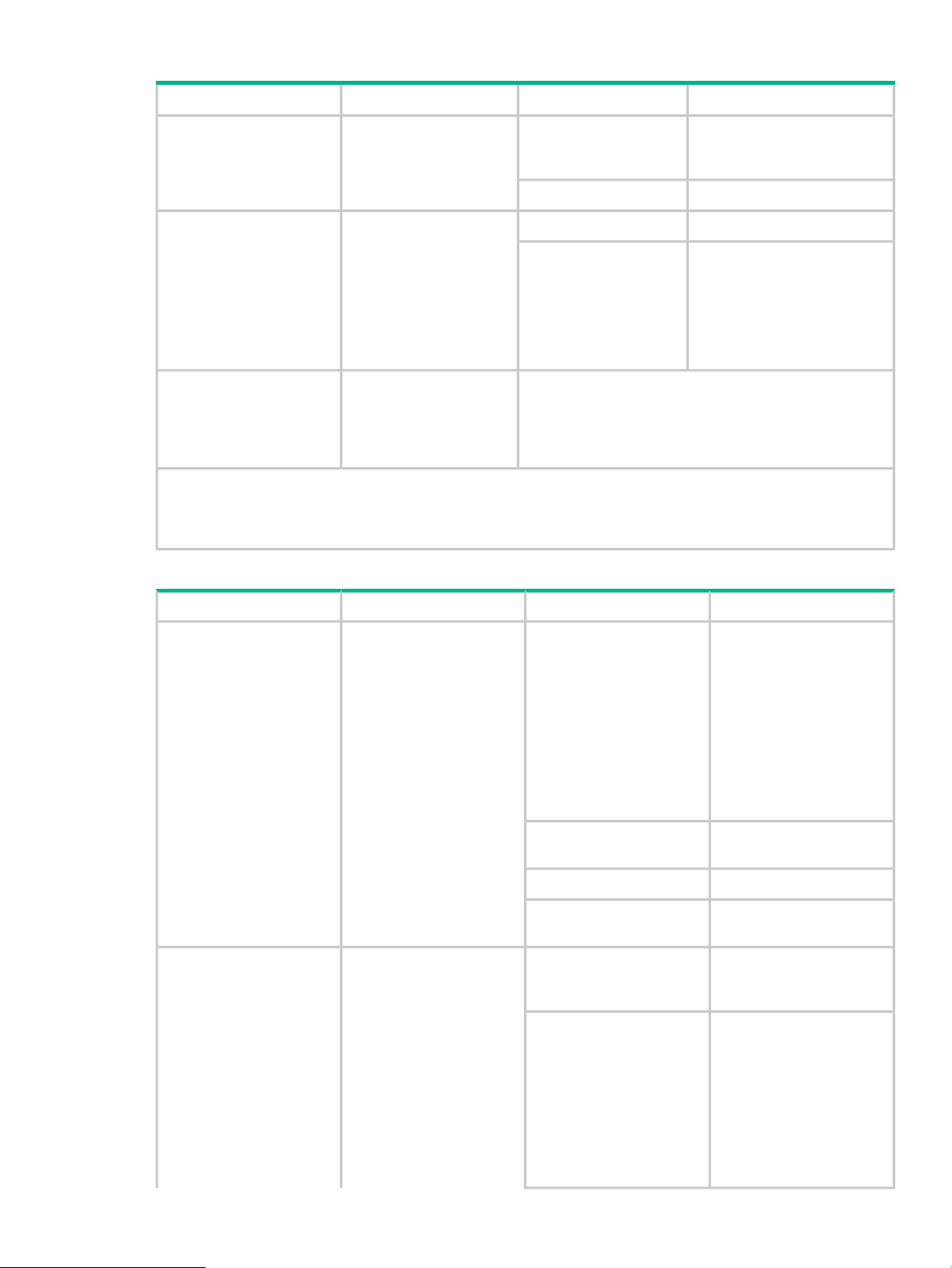

Table 8 Front of Switch Status and Mode LED Behavior

MeaningStateFunctionSwitch LEDs

Global Status

UID (Unit Identification)

the switch.

Self-Test Status

Switch/Port Fault Status

is used to help you to

a rack or collection of

products.

On GreenInternal Power Status of

Slow Flash Green*

Slow Flash Orange*

On Orange

On or Slow Flash**The Unit Identification LED

The Switch has passed self-test

and is powered up normally.

The switch self-test and

initialization are in progress

after the switch has been power

cycled or reset. The switch is

not operational until this LED

stops blinking green.

A fault or self-test failure has

occurred on the switch, one of

the switch ports, a module in

the rear of the switch, or the

fan. The Status LED for the

component with the fault will

blink simultaneously.

If this LED is on orange for a

prolonged time, the switch has

encountered a fatal hardware

failure, or has failed its self-test.

The unit is not receiving power.Off

The “chassislocate” command

allows you to blink or turn on

the LED for a specified numberidentify a particular unit in

of minutes (1-1440). The default

is 30 minutes.

Back Module Status

components installed in

the back of the unit.

Off

On GreenStatus of modular

Slow Flash Orange*

LED will turn off after the

timeout period has expired.

Normal operation: All modular

components installed in the

back of the unit are functioning

correctly.

One of the modules inserted

from the back of the chassis

(power supply, fan tray, or

Front of the Switches 13

Page 14

Table 8 Front of Switch Status and Mode LED Behavior (continued)

stacking module) has failed self

test or is experiencing a fault

condition. Flashes

simultaneously with the Global

Status LED flashing orange.

MeaningStateFunctionSwitch LEDs

Aux Port Activity

Flex Port Module Status

the Aux Port which is used

for processing a USB

command file or

downloading switch

software code.

module.

Solid GreenIndicates data transfer on

Green Flicker

Slow Flash Orange*

On GreenStatus of Flex Port

Slow Flash Orange*

Fast Flash Orange**

USB installed and successfully

initialized, and mounted, but no

data transfer.

Data transfer is in progress. Do

not remove installed device until

data transfer is complete

The USB device that is installed

is unsupported or faulted.

No USB installed.Off

Flex Port module operating

correctly.

Flex Port module has

experienced a fault.

The Global Status LED should

be flashing synchronously.

Flex Port module or one or

more of its ports is/are

experiencing an alert condition.

Alert conditions include that an

unsupported cable has been

installed in the module or that

the Flex Port module has been

installed while the switch was

powered on (hot-swapped) and

the switch needs to be rebooted

to support the module.

Speed Mode Selected

Power over Ethernet (PoE)

Mode Selected***

14 Introducing the 3810M switches

LEDs are showing port

speed information.

LEDs are showing PoE

status information.

OnIndicates when the Port

On GreenIndicates when the Port

On Orange

Slow Flash Orange*

No power.Off

No ModuleNo Present

Speed Mode is selected. Port

LEDs indicate port speed.

Speed mode not selected.Off

PoE Mode is selected. Port

LEDs show PoE information.

PoE Mode is selected and a

port also has a PoE error. The

Global Status LED and the LED

corresponding to the port with

the error will be flashing orange.

The rest of the Port LEDs will

display normal PoE status.

PoE Mode has NOT been

selected and a port has a PoE

error. LED will be flashing

orange simultaneously with the

Global Status LED and the LED

corresponding to the port with

Page 15

Table 8 Front of Switch Status and Mode LED Behavior (continued)

the error. The rest of the Port

LEDs will display normal PoE

status.

PoE mode is not selected.Off

MeaningStateFunctionSwitch LEDs

User Mode Selected

the Port LEDs are

displaying stack

information and status.

See Port LEDs and Mode

Behavior. When stacking

is disabled, this mode is

reserved for future use.

Save Power Mode Selected

* The slow blink behavior is an on/off cycle once every 1.6 seconds, approximately.

** The fast blink behavior is an on/off cycle once every 0.5 seconds, approximately.

*** Applies only to 3810M switches that support PoE/PoE+.

This mode is indicated by ALL the switch indicator LEDs

being off, except for the Global Status LED. This display

occurs only if the switch has been configured with the

savepower led command. See the Management and

Configuration Guide for more information on that command

Table 9 Port LEDs and Mode Behavior

Port LEDs

for the port as selected by

the LED Mode select

button.

When transceivers and

SFPs are installed, this LED

is also used to indicate that

the installation has occurred

by going on for two seconds

then off.

Activity/LinkTo display the information

User Mode is selected.On GreenWhen stacking is enabled,

User mode not selected.Off

MeaningState/ModeFunctionSwitch LEDs

Shows port Activity and Link

status.

This is the DEFAULT. There

is no dedicated mode LED

indicating this mode.

The Mode LED function

should return to this

selection 10 minutes after

the last press of the LED

Mode button.

Activity/Link Mode Selected

Link status and network

activity information

simultaneously.

Activity/Link Mode is the

default mode and is in effect

unless another LED mode

has been selected.

Speed

User

Half-Bright GreenPort LEDs are displaying

Activity Flicker Green

Shows port speed

configuration.

Shows PoE information.PoE

Shows User selectable User

behavior.

The port is enabled and

receiving a Link indication

from the connected device.

The percentage of time that

the LED is full-bright is

roughly proportional to the

percentage of full bandwidth

utilization of the port.

Half-Bright Green port Link

indication remains on as

Activity flickers from

half-bright to full-bright.

Front of the Switches 15

Page 16

Table 9 Port LEDs and Mode Behavior (continued)

MeaningState/ModeFunctionSwitch LEDs

Speed Mode Selected

the connection speed at

which each port is

operating.

Slow Flash Orange*

Off

Fast Flash Green**Port LEDs are displaying

On Green

Triple Blink Green

Double Blink Green

Slow Flash Green*

Off

The corresponding port has

failed its self-test. Flashes

simultaneously with the

Global Status LED flashing

orange.

The Port is disabled, not

connected, or not receiving

link.

The port is operating at 40

Gbps.

The port is operating at 10

Gbps.

The port is operating at 5

Gbps. (HPE SMART RATE

ports only)

The port is operating at 2.5

Gbps. (HPE SMART RATE

ports only)

The port is operating at 1

Gbps.

The port is not Linked, or is

operating at 10 or 100

Mbps.

PoE Mode Selected

User Mode Selected

PoE information.

in stacked configurations.

Used to display the number

of members in a stack and

their current status.

The status information is

sticky and if a unit’s status

changes while in USER

mode, you must exit and

re-enter USER mode to get

the updated status.

On GreenPort LEDs are displaying

Fast Flash Orange**

Slow Flash Orange*

Off

On GreenMode currently active only

Slow Flash Green*

Fast Flash Green**

On Orange

The port is providing PoE

power.

PoE is disabled on the port.On Orange

The port is denied power or

is detecting an external PD

fault.

The port has an internal

hardware failure. Flashes

simultaneously with the

Global Status LED flashing

orange.

The port is not providing

PoE power.

Stack Member exists in the

stack and is operational.

Indicates the Member # of

the chassis.

Indicates the Member # of

the Commander of the

stack.

Stack Member is currently

booting or has a fault that is

preventing it from

communicating.

16 Introducing the 3810M switches

Page 17

Table 9 Port LEDs and Mode Behavior (continued)

MeaningState/ModeFunctionSwitch LEDs

Slow Flash Orange*

Fast Flash Orange**

Off

* The slow blink behavior is an on/off cycle once every 1.6 seconds, approximately.

** The fast blink behavior is an on/off cycle once every 0.5 seconds, approximately.

*** Applies only to 3810M switches that support PoE/PoE+.

Stack Member is in a known

fault condition (i.e. Fan fault,

PSU fault, etc.).

The Global Status LED on

all stack members will also

Slow Flash Orange.

Stack Member is in a Alert

condition (i.e. Overtemp,

PoE Over subscript, etc.).

The Global Status LEDs on

all stack members will

remain in normal

operational.

Stack Member does not

exist in the stack

configuration.

Front of the Switches 17

Page 18

Example 1 Example of USER mode behavior

Assume you have a 4-member stack, in a ring topology, with member numbers 1, 2, 3 and 5.

Member 1 is the commander and member 3 is rebooting. In USER mode, the members will show

the following on their port LEDs:

Port 6-10 LEDsPort 5 LEDPort 4 LEDPort 3 LEDPort 2 LEDPort 1 LED

Member 1

Member 2

Member 5

Green

Fast Flash

Green

Going through normal boot up sequencingMember 3

Green

Green

OffOn OrangeOn GreenFast Flash

Green

OffOn GreenOffOn OrangeOn GreenFast Flash

OffOn GreenOffOn OrangeSlow Flash

OffSlow Flash

Looking at any member, you can see that there are 4 members defined in the stack configuration,

with member numbers 1, 2, 3, and 5 because these are the LEDs that are lit. The port 4 LED is

off, indicating that this member number is not defined in the stack.

On all members, Port 1 LED is fast flashing, indicating that member 1 is the commander of the

stack. Port 3 LED is on orange, indicating either that 3 is rebooting or not communicating because

of an unknown fault.

When looking at member 1, only Port 1 LED is fast flashing green. This indicates that this unit

is member 1 and is the commander.

When looking at member 2, the port 2 LED is slow flashing green, indicating that unit is member

number 2. Likewise on member 5, the port 5 LED is slow flashing green, indicating that unit is

member 5.

Member 3 will be going through the normal boot LED boot up sequence. When it has completed

booting and joined the stack, if you exit and re-enter USER mode, the members show the following

on their port LEDs:

Member 1

Green

Member 2

Member 3

Member 5

Fast Flash

Green

Green

Green

Green

On GreenFast Flash

Green

LED Mode Select Button and Indicator LEDs

The state of the Mode LEDs is controlled by the LED Mode select button. The current view mode

is indicated by the Mode LEDs next to the button. Press the button to step from one view mode

to the next. See the LED information in Front of Switch Status and Mode LED Behavior for

standalone switches.

Port 6-10 LEDsPort 5 LEDPort 4 LEDPort 3 LEDPort 2 LEDPort 1 LED

OffOn GreenOffOn GreenOn GreenFast Flash

OffOn GreenOffOn GreenSlow Flash

OffOn GreenOffSlow Flash

OffOn GreenOn GreenFast Flash

Green

OffSlow Flash

18 Introducing the 3810M switches

Page 19

Stacking Notes:

• For 3810M switches that are in a stack, the Mode select button on every switch in the stack

controls the LED mode for all the switches in the stack. Using the Mode select button on

one switch in the stack changes the LED mode for the entire stack.

• If there is a combination of PoE/PoE+ switches and non-PoE switches in the stack, when

any of the Mode select buttons is pressed to put the stack into PoE mode, the non-PoE

switches indicate no PoE support by not illuminating any of the Mode indicator LEDs or any

of the port LEDs.

• If any of the switches in the stack are configured with the Save Power LED feature, then

the default LED Mode for the whole stack becomes the Save Power display (all LED Mode

indicator LEDs are off), but only the stack members on which that feature is configured

display the other characteristics of that feature (all LEDs Off except for the Power LED).

Reset and Clear Buttons

The Reset and Clear buttons are recessed from the front panel (to protect them from being

pushed accidentally) and are accessible through small holes on the top of the front panel. Use

pointed objects, such as unbent paper clips, to push them.

The Reset and Clear buttons are used singly or in combination, as follows:

This will happen:Do this:To accomplish this:

(Standalone switch)

Hard Reset

(Standalone switch)

(Stacked switch)

Hard Reset

(Stacked switch)

Delete console and management

access passwords

Press and release the Reset buttonSoft Reset

Press and hold the Reset button for

more than 5 seconds (until all LEDs

turn on), then release.

more than 5 seconds (until all LEDs

turn on), then release.

Press Clear button for more than 5

seconds, but within 15 seconds (in

btw 5 - 15 seconds)

The switch operating system is cleared

gracefully (such as data transfer

completion, temporary error conditions

are cleared), then reboots and runs

self tests.

The switch reboots, similar to a power

cycle. A hard reset is used, for

example, when the switch CPU is in

an unknown state or not responding.

Same as a standalone switch, except:Press and release the Reset buttonSoft Reset

• If action happened on the

Commander, the Standby switch

will become Commander.

• If action happened on the Standby,

a new Standby will be elected.

Same as a standalone switch, except:Press and hold the Reset button for

• If action happened on the

Commander, the Standby switch

will become Commander.

• If action happened on the Standby,

a new Standby will be elected.

Clears all passwords. Will flash Global

Status Green LED, after 5 seconds has

expired to indicate passwords have

cleared.

Turn off UID LED

Clears the UID LED.Press Clear button and release within

5 seconds (in btw 0.5 - 5 seconds)

Front of the Switches 19

Page 20

This will happen:Do this:To accomplish this:

Restore the factory default

configuration

Note: These buttons are provided for your convenience. If you are concerned with switch security though, you should

make sure that the switch is installed in a secure location, such as a locked wiring closet. You can also disable these

buttons by using the front-panel-security command. See the 3810M Management and Configuration Guide for a

description of that command.

1. Press Clear and Reset

simultaneously.

2. While continuing to press Clear,

release Reset.

3. When the Global Status LED

begins to fast flash orange (after

approximately 5 seconds), release

Clear.

Flex Port Slot and Module Support

The 3810M family of switches features a module slot(s) that allows the user to customize the

uplink ports on the switch. Depending on the switch model, the slot supports either 40Gbps or

80Gbps of maximum bandwidth and therefore, not all modules are supported in all slots. See

Switch Module/Support Matrix, for the switch module/support matrix.

NOTE: The unsupported modules are mechanically prevented from installing into unsupported

slots.

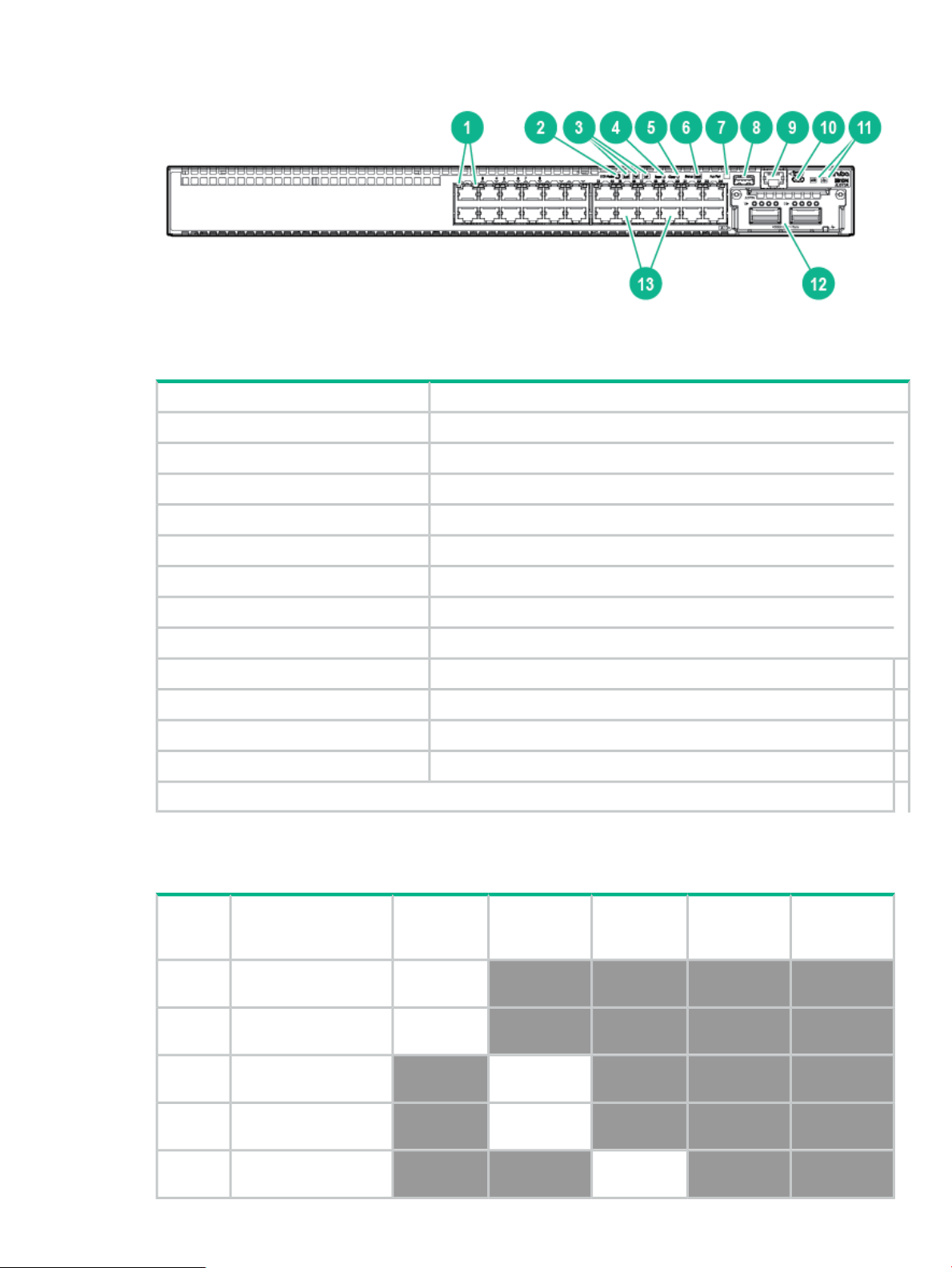

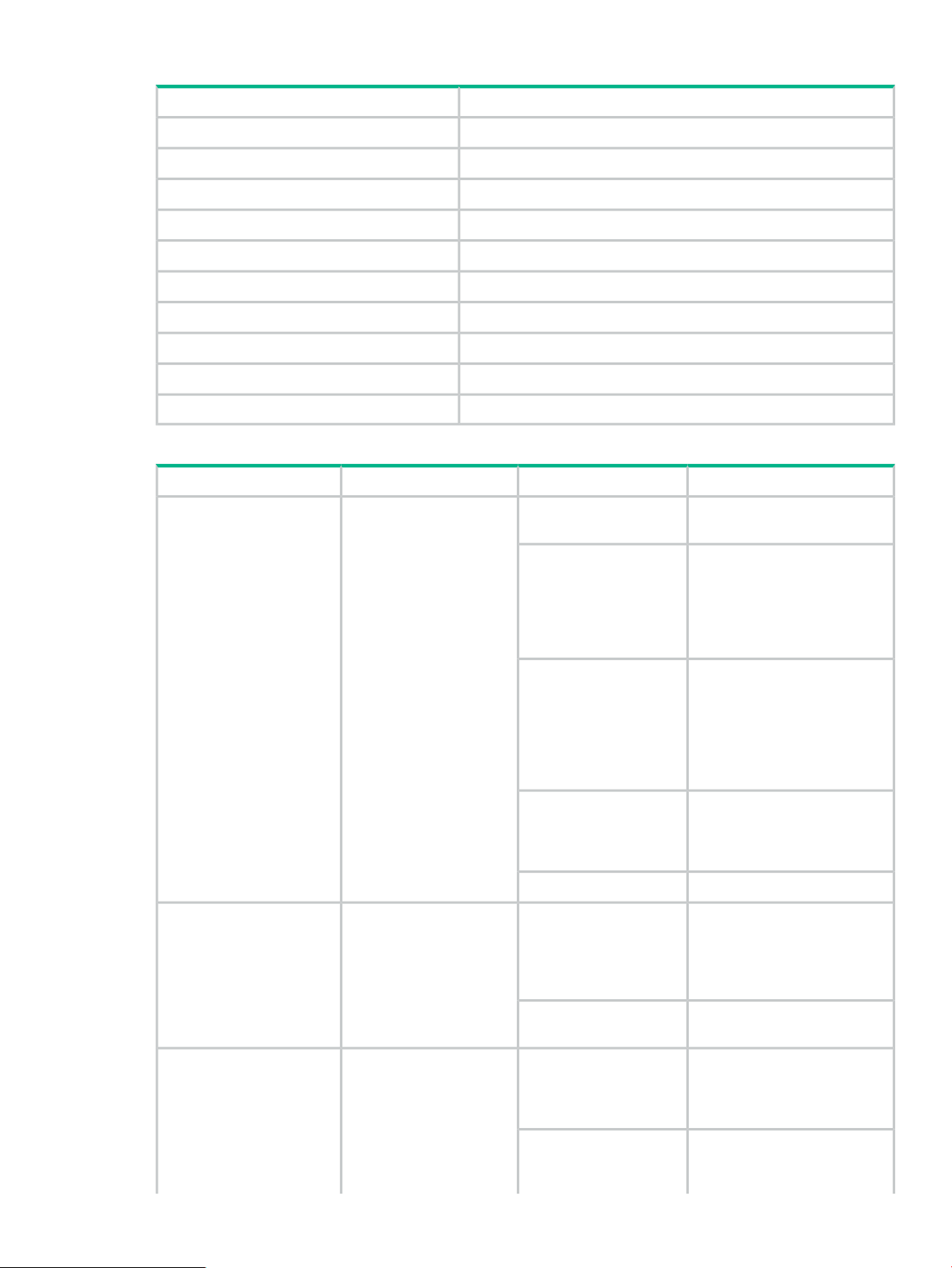

Table 10 Switch Module/Support Matrix

The switch removes all configuration

changes, restores the factory default

configuration, and runs self test.

JL071A Aruba 3810M 24G 1-slot

Switch

JL072A Aruba 3810M 48G 1-slot

Switch

JL073A Aruba 3810M 24G PoE+

1-slot Switch

JL074A Aruba 3810M 48G PoE+

1-slot Switch

JL075A Aruba 3810M 16SFP+ 2-slot

Switch

JL076A Aruba 3810M 40G 8SR PoE+

1-slot Switch

Back of the Switches

The back of all the 3810M switches is the same.

Module Support

JL083A 4SFP+JL079A 2QSFP+JL078A 1QSFP+Switch Model

YesNoYes

YesYesYes

YesNoYes

YesYesYes

YesNoYes

YesYesYes

20 Introducing the 3810M switches

Page 21

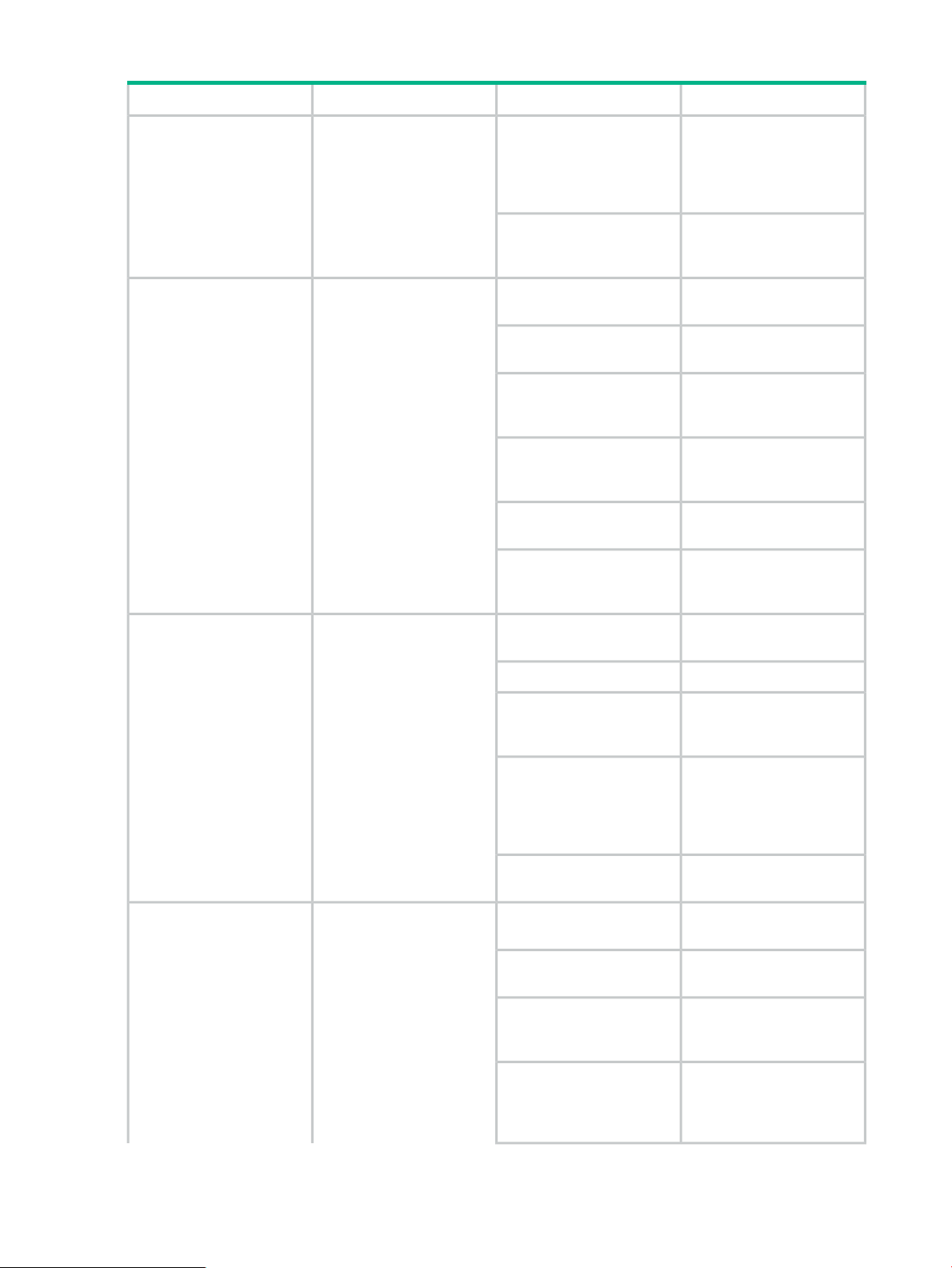

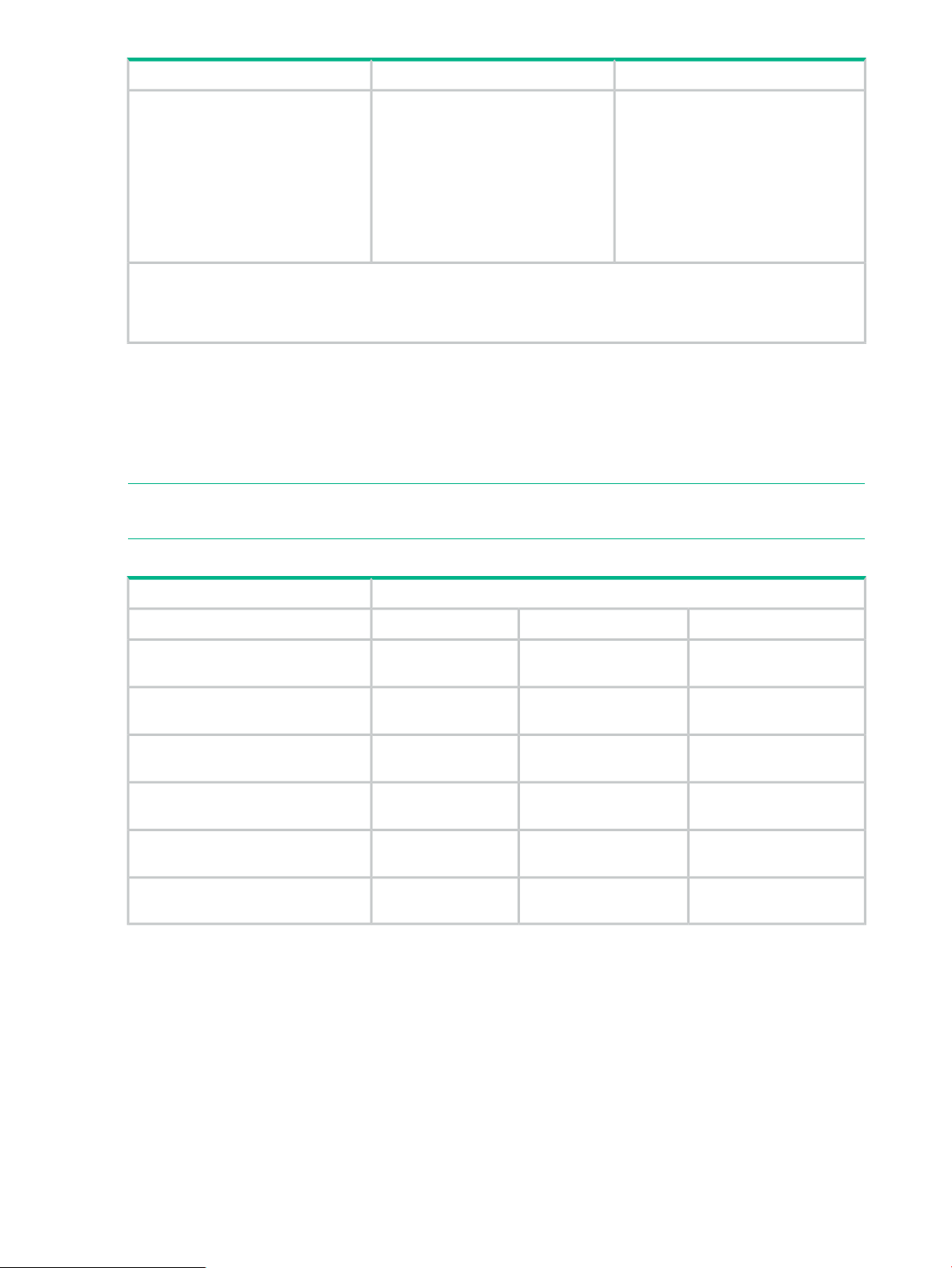

Figure 6 Back of the 3810M Switches

Table 11 Back of the 3810M Switches Label and Description

DescriptionLabel

Fan Status LED1

Stacking Module Slot2

Management/OOBM port3

AC Power connector/Power Supply slot 14

Power Supplies

There are three power supplies that can be installed into the 3810M switches:

• Aruba X371 12VDC 250W 100-240VAC Power Supply (JL085A)—A 250 watt power supply

for the non-PoE switches. This power supply does not provide any PoE power, and is keyed

so that it will not fit into the power supply slots of 3810M PoE+ switches.

• Aruba X372 54VDC 680W 100-240VAC Power Supply (JL086A)—A 680 watt power supply

for 3810M PoE+ supported switches. This power supply offers up to 370 watts of PoE+

power, and is keyed so that it does not fit into the power supply slots of non-PoE+ 3810M

switches.

• Aruba X372 54VDC 1050W 110-240VAC Power Supply (JL087A)—A 1050 watt power

supply for 3810M PoE+ supported switches. This power supply offers up to 740 watts of

PoE+ power, and is keyed so that it does not fit into the power supply slots of non-PoE+

3810M switches.

For more power supply information see 9. (Optional) Installing a Second Power Supply.

Power Connector

The 3810M switches do not have a power switch. They will power on when either one or both

power supplies are connected to an active AC power source.

Redundant Power Supply slot 25

Stacking Module Slot

Each of the 3810M switches has one module slot that can accept the 3810M Stacking Module

that provides high-speed connectivity to other 3810M switches. Only the 3810M switches support

this module.

Back of the Switches 21

Page 22

Fan Tray Assembly

The 3810M switches have a field-replaceable fan tray. If necessary, the fan tray can be replaced

while the switch is operating. For more information, see Replacing the Fan Tray.

Out-of-Band Management (OOBM) Port

This RJ-45 port is used to connect a dedicated management network to the switch.

LEDs on the Back of the Switches

This section describes the LEDs on the back of the switch. When the Back LED on the front of

the unit is blinking a fault, the user can then look at the back of the switch to find the corresponding

blinking LED for the faulted module.

Figure 7 LEDs on the Back of Switches

Table 12 Back of the 3810M Switches LED Labels and Description

DescriptionLabel

Unit Identification LED1

Fan Status LED2

OOBM Port LED: Activity/Link3

Power Supply Status LEDs4

Table 13 LEDs on the Back of the Switch

On GreenStatus of Fan tray.Fan Status

Slow Flash Orange

Unit Identification

identify a particular unit in a

rack or collection of

products.

On or Slow FlashUsed to assist you to

MeaningStateFunctionSwitch LEDs

Normal operation: Fan tray

assembly is functioning

correctly.

One or more fans in the fan

tray is faulted.

The Global Status and Back

LEDs on the front of unit

must also be synchronized

and flashing orange.

The chassislocate

command allows you to

blink or turn on the LED for

a specified number of

22 Introducing the 3810M switches

Page 23

Table 13 LEDs on the Back of the Switch (continued)

MeaningStateFunctionSwitch LEDs

OOBM Port LED:

Activity/Link

This LED is a copy of the

UID LED on the front of the

chassis.

port status of OOBM

Off

Half-Bright GreenDisplay Activity/Link and

On Green

Activity Flicker Green

Slow Flash Orange

minutes (1-1440). The

default is 30 minutes.

The LED turns off after the

timeout period has expired.

The port is enabled and

receiving a Link indication

from the connected device.

The port is experiencing

high bandwidth utilization.

The percentage of time that

the LED is full-bright is

roughly proportional to the

percentage of full bandwidth

utilization of the port. Even

just one packet will trigger

a visible full-bright flicker.

Half-Bright Green port Link

indication remains on as

Activity flickers from

half-bright to full-bright.

The port has failed its

self-test. Flashes

simultaneously with the

Global Status LED flashing

orange.

PSU module Status

Looking at the back of the

unit, PSU1 is on the left and

PSU2 is on the right.

3810M Stacking Module

The 3810M 4-port Stacking Module (JL084A) is a component you can add to an 3810M Switch

to provide high-speed stacking connections to other 3810M switches. See Stacking Information

and Topologies, and the HPE ArubaOS-Switch Advanced Traffic Management Guide

K/KA/KB.16.01 for more information about stacking configuration and operation.

Off

On GreenStatus of PSU

Slow Flash Green

Off

The port is disabled, not

connected, or not receiving

link.

The power supply has valid

AC input and valid DC

outputs.

Either the power supply has

an internal fault, or switch

has a fault that is causing

power supply to cycle on/off.

The power supply has an

invalid AC input, or invalid

DC outputs.

3810M Stacking Module 23

Page 24

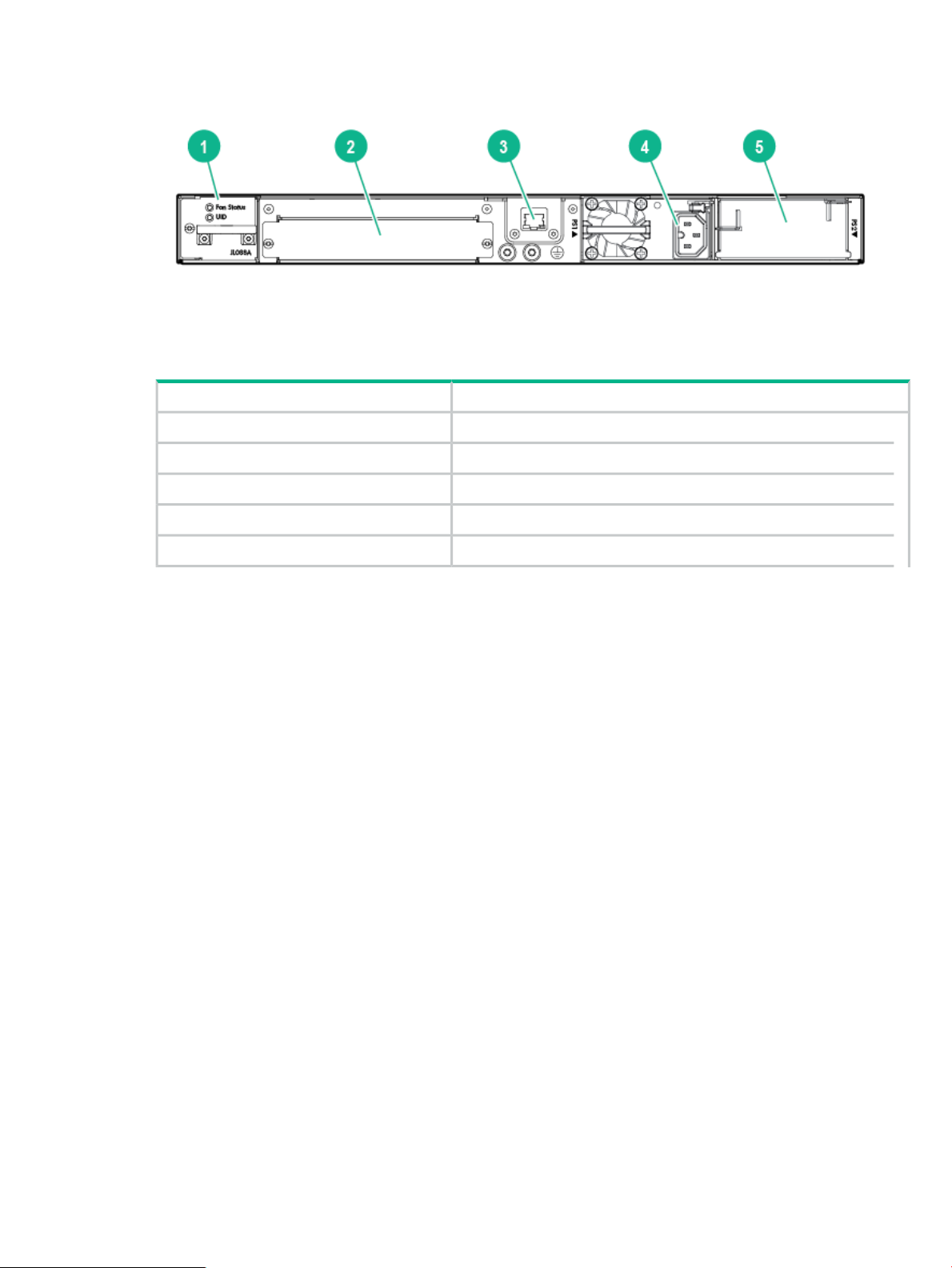

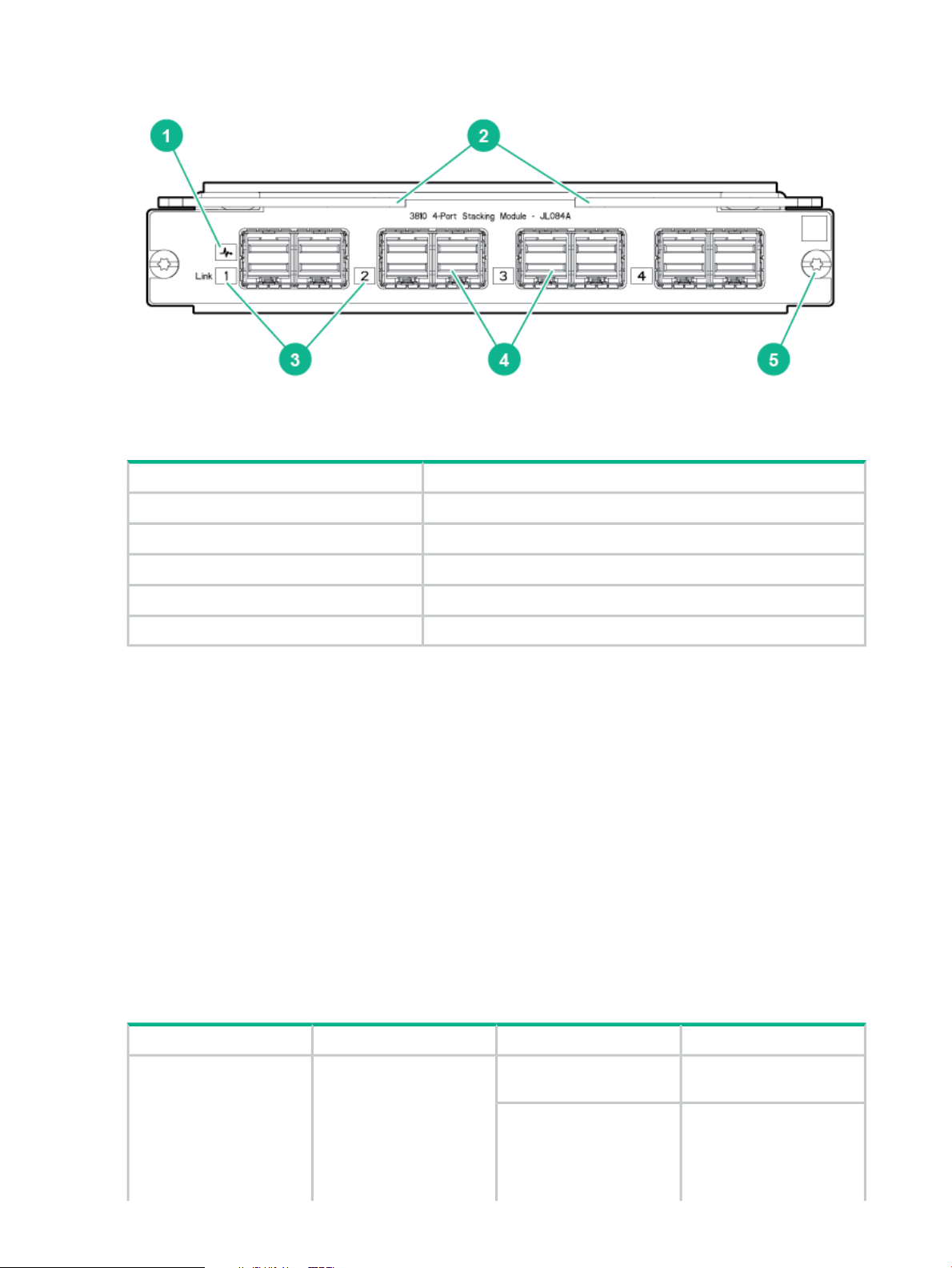

Figure 8 Front of 3810M 4-Port Stacking Module

Table 14 Front of 3810M 4-Port Stacking Module Label and Description

DescriptionLabel

Stacking Module Status LED1

The 3810M 4-Port Stacking Module JL084A has the following features:

• Four stacking connectors for connecting the 3810M switch to other 3810Ms in a stacked

topology (chain, ring, or mesh). Any of these available stacking cables can be used for these

connections:

◦ Aruba 3800/3810M 0.5m Stacking Cable (J9578A)

◦ Aruba 3800/3810M 3m Stacking Cable (J9579A)

◦ Aruba 3800/3810M 1m Stacking Cable (J9665A)

• LEDs, described in Table 15.

Stacking Module LEDs

The following LEDs are located on the 3810M Stacking Module itself and are only viewable from

the rear of the switch.

Extractor Handles2

Link LEDs3

Stacking Connectors4

Retaining Screw5

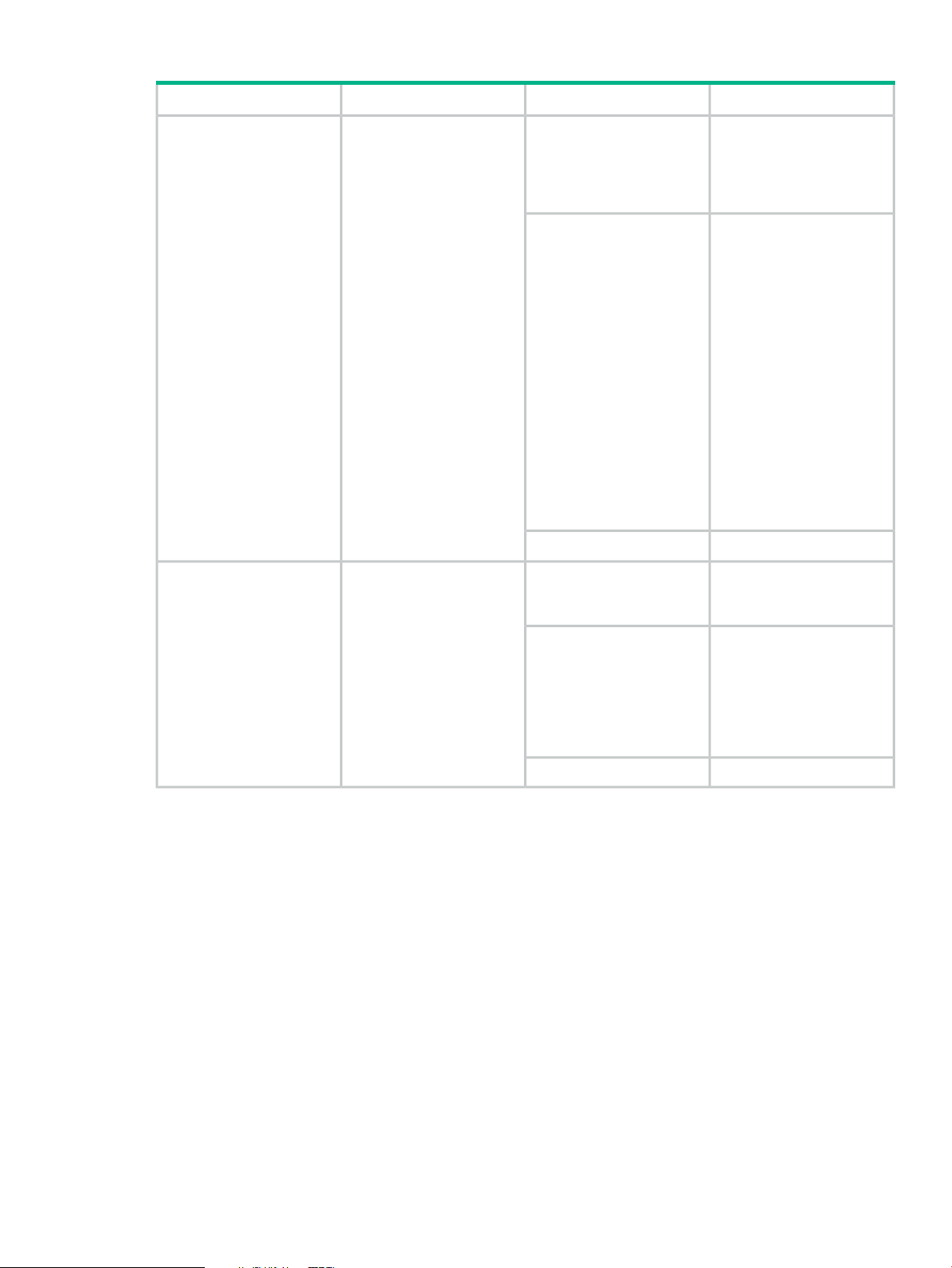

Table 15 Stacking Module LEDs

24 Introducing the 3810M switches

On GreenStatus of Stacking moduleStacking Module Status

Slow Flash Orange

DescriptionModeFunctionName

Stacking module operating

correctly.

Stacking module has

experienced a fault, or one

or more of the module ports

has experienced a fault. The

1.6 seconds cycle flash

Page 25

Table 15 Stacking Module LEDs (continued)

DescriptionModeFunctionName

should be synchronized with

the switch Global Status

LED. The Global Status and

Back LED should also be

flashing.

Stacking Link Status

port indicates the port is

enabled, connected and

detects a signal from the

attached device.

Fast Flash Orange

On GreenThe Link LED per stacking

Slow Flash Orange

Stacking module or one or

more of its ports is

experiencing an alert

condition.

Alert conditions include that

an unsupported cable has

been installed in the module

or that the stacking module

has been installed while the

switch was powered on

(hot-swapped) and the

switch needs to be rebooted

to support the module.

The BACK LED should be

flashing and the Global

Status LED should NOT be

flashing.

No PowerOff

The port is enabled and

receiving a link indication

from the connected device.

Port Failed POST or cable

fault. Module Status LED on

the stacking module and

Global Status and Back

LED on front of unit should

also be synchronized and

flashing orange.

Switch Features

The features of the 3810M switches include:

• Combinations of fixed 10/100/1000-T, HPE SMART RATE and SFP/SFP+ ports, as described

under Network Ports.

• Selected switch models feature HPE SMART RATE ports and provide 1Gbps, 2.5Gbps,

5Gbps and 10Gbs connectivity. See the appendices for cabling recommendations and

requirements.

• All switch models feature either 1 or 2 Flex Port Module slots, that allow configuration with

either 10G SFP+ or 40G QSFP+ ports, as described in Flex Port Slot and Module Support.

• One module slot is provided in the back of the switches to support a stacking module to

provide connectivity to other 3810M switches with stacking modules. See Stacking

Information and Topologies, the HPE ArubaOS-Switch Advanced Traffic Management Guide

K/KA/KB.16.01 for more information about stacking.

• Power over Ethernet (PoE+) operation—Aruba 3810M 24G PoE+ 1-slot Switch (JL073A),

Aruba 3810M 48G PoE+ 1-slot Switch (JL074A) and Aruba 3810M 40G 8 HPE Smart Rate

PoE+ 1-slot Switch (JL076A) switches are IEEE 802.3at standard compliant and provide up

No cable plugged in.Off

Switch Features 25

Page 26

to 30W per port to power IP phones, wireless access points, indoor web cameras, and more.

For more information, see the HPE Power over Ethernet (PoE/PoE+) Planning and

Implementation Guide, available from http://www.hpe.com/networking/support.

The switches support 802.3af and 802.3at standard devices and some pre-standard PoE

devices. For a list of these devices, see the FAQs (Frequently Asked Questions) for your

switch model. PoE is enabled by default. (For instructions, see the 3810M Management and

Configuration Guide for your switch at http://www.hpe.com/networking/support.

• The option to have one or two internal power supplies.

A second power supply supports redundant system power and/or redundant/additional PoE

power. If one of the internal power supplies fails, the second power supply immediately

provides the power necessary to keep the switch running, including PoE+ power on an

allocated basis.

If maximum PoE+ power is used on the 48 port PoE+ switch, the second power supply is

needed for PoE+ power but there is no PoE power redundancy. However, system power is

always maintained. On a power supply failure, the system drops the PoE power on ports

based on user priority, to maintain system power. For more information on Power Supplies,

see Power Supplies.

• Plug-and-play networking—all ports are enabled by default—just connect the network cables

to active network devices and your switched network is operational.

• Auto MDI/MDI-X on all twisted-pair ports (10/100/1000 and 10GBase-T), meaning that all

connections can be made using straight-through twisted-pair cables. Cross-over cables

are not required, although they will also work. The pin operation of each port is automatically

adjusted for the attached device: if the switch detects that another switch or hub is connected

to the port, it configures the port as MDI; if the switch detects that an end-node device is

connected to the port, it configures the port as MDI-X. (See the appendices for recommended

or required cabling.)

• Automatic learning of the network addresses in each switch’s 64000-address forwarding

table, (with configurable address aging value).

• Automatically negotiated full-duplex operation for the 10/100/1000 RJ-45 ports when

connected to other auto-negotiating devices—the SFP/SFP+ ports always operate at full

duplex.

• Easy management of the switch through several available interfaces:

Console interface—A full featured, easy to use, VT-100 terminal interface for

◦

out-of-band or in-band switch management.

◦ Web browser interface—An easy to use built-in graphical interface that can be accessed

from common web browsers.

◦ IMC—An SNMP-based, graphical network management tool that you can use to manage

your entire network.

• Support for the Spanning Tree Protocol to eliminate network loops.

• Support for up to 4096 IEEE 802.1Q-compliant VLANs so you can divide the attached end

nodes into logical groupings that fit your business needs.

• Support for many advanced features to enhance network performance—for a description,

see the 3810M Management and Configuration Guide at http://www.hpe.com/networking/

support.

• Ability to update the switch software. Software updates are routinely available from Hewlett

Packard Enterprise.

26 Introducing the 3810M switches

Page 27

• An auxiliary port (USB Type A connector) for processing a USB command file and updating

switch software.

• Low power operation:

◦ Ports on a switch or stack member may be set to operate at reduced power.

◦ Port status LEDs may be turned off.

◦ RJ-45 ports will operate at reduced power if the port is not connected (link partner is

not detected).

Switch Features 27

Page 28

2 Installing the Switch

This chapter shows how to install the switch. The 3810M switches come with an accessory kit

that includes the brackets for mounting the switch in a standard 19-inch telco rack, in an equipment

cabinet, and with rubber feet that can be attached so the switch can be securely located on a

horizontal surface. The brackets are designed to allow mounting the switch in a variety of locations

and orientations. For other mounting options contact your local Hewlett Packard Enterprise

authorized network reseller or Hewlett Packard Enterprise representative.

NOTE: If the switch is to be shipped in a rack, it can be mounted and shipped in a Hewlett

Packard Enterprise 10K rack using the HPE X410 Universal Rack Mounting Kit (J9583A).

Additionally, it can also be mounted in any four post rack using the HPE X410 Universal Rack

Mounting Kit (J9583A).

Included Parts

The 3810M switches have the following components shipped with them:

• Aruba Switch Quick Setup Guide

• Switch Safety and Regulatory sheet

• Warranty notice

• General Safety and Regulatory booklet

• Console cable

• Accessory kit

(5066-0651) for PoE+ 3810M switches(5069-5705) for Non-PoE+ 3810M switches

two mounting bracketstwo mounting brackets

eight 8-mm M4 screws to attach the mounting brackets

to the switch

four 5/8-inch number 12-24 screws to attach the switch

to a rack

eight 8-mm M4 screws to attach the mounting brackets

to the switch

four 5/8-inch number 12-24 screws to attach the switch

to a rack

four rubber feetfour rubber feet

• There are two warranty documents. One is HPN warranty and the other is EG warranty.

5998-8729 Warranty Statement and Software License◦

◦ 5998-8843 Aruba 3810M QSG/SRI

◦ 5998-8844 Read Me First

◦ 703828-026 EG Safety, Compliance, and Warranty Information

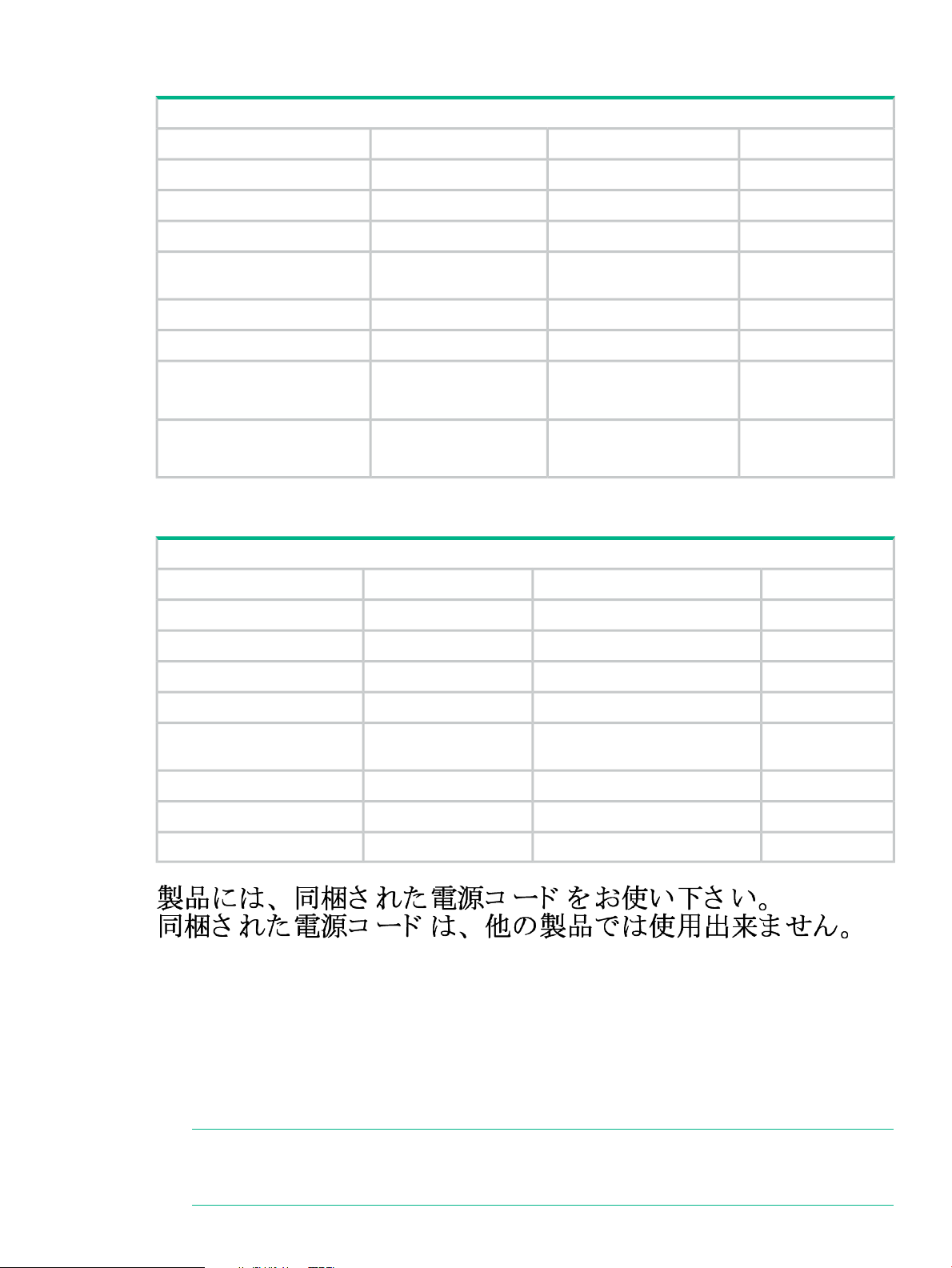

• Power cord, one of the following

28 Installing the Switch

Page 29

Power cord, one of the following:

Aruba 3810M PoE+ Switches

Kong/Singapore/Malaysia

Power cord, one of the following:

8121-0857Australia8121-0973North America

8121-1265Brazil8121-0941North America high line

8120-5336Europe/South Korea8121-1483South Africa/India

8121-1034China8121-1009Israel

8121-1481Argentina8120-5334United Kingdom/Hong

8120-8389Chile8120-5339Switzerland

8121-0671Thailand/Philippines8120-5340Danish

8121-1511Taiwan 15A8120-5338Japan high line

(JL086A, JL087A)(JL086A, JL087A)

8121-0967Taiwan 10A8120-5342Japan low line

(JL086A)(JL086A)

Aruba 3810M Non-PoE+ Switches

Korea

Installation Procedures

8120-4753Japan8120-6869Argentina

8120-6815Switzerland8121-0834Australia/New Zealand

8120-6813South Africa8121-1069Brazil

8121-0974Taiwan8120-6980Chile

8121-0668Philippines/Thailand8120-8707China

8120-6809UK/HongKong/Singapore/Malaysia8120-6811Continental Europe/South

8121-0973US/Canada/Mexico8120-6814Denmark

8121-0941North America high line8121-0780India

8121-1035Israel

Summary

1. Prepare the installation site (“ 1. Prepare the Installation Site” (page 31)). Ensure the

physical environment is properly prepared, including having the correct network cabling

ready to connect to the switch and having an appropriate location for the switch. See “

Installation Precautions:” (page 31) for some installation precautions.

NOTE: For steps 2 and 3 below, if an 3810M switch is powered on for the first time without

a stacking module installed, stacking will be disabled and that will be saved in the switch's

running configuration. For more information, see Stacking Information and Topologies.

Installation Procedures 29

Page 30

2. Verify the switch passes self test ( “ 2. Verify the Switch Boots Correctly” (page 32) ).

Plug the switch into a power source and observe that the LEDs on the switch’s front panel

indicate correct switch operation. When self test is complete, unplug the switch.

3. (Optional) Install the stacking module ( 3. (Optional) Install the Stacking Module).

4. (Optional) Install the Flex Port module (4. Installing the Flex Port Module).

5. Mount the switch ( “5. Mount the Switch” (page 37) ). The Switch can be mounted in the

19-inch telco rack, in an equipment cabinet, or on a horizontal surface.

6. (Optional) Install the stacking cables ( 6. (Optional) Installing the Stacking Cables). If

you have installed the module, you can now install up to four stacking cables and connect

them to other switches in the desired stacking topology.

7. (Optional) Install or remove SFP transceivers (mini-GBICs) (7. (Optional) Installing

Transceivers). Depending on the switch model purchased and optional Flex Port module

configuration, the switch can support SFP/SFP+ or QSFP+ transceivers. Depending on

where the switch is mounted, it may be easier to install the transceivers first. All transceiver

types can be installed or removed while the switch is powered on.

8. Connect the switch to a power source ( 8. Connect the Switch to a Power Source).

Once the switch is mounted, plug it into the nearby main power source.

9. (Optional) Install a second power supply ( 9. (Optional) Installing a Second Power

Supply). You may wish to use a second power supply with the switch to provide redundant

power or added PoE+ power.

10. (Optional) Connect a Management console (10. (Optional) Connect a Management

console). You may wish to modify the switch’s configuration, for example, to configure an

IP address so it can be managed using a web browser, from an SNMP network management

station, or through a Telnet session. Configuration changes can be made easily by using

the included console cable to connect a PC to the switch’s console port.

11. Connect the network cables (“ 11. Connect the Network Cables” (page 46)). Using the

appropriate network cables, connect the network devices to the switch ports.

At this point, the switch is fully installed. See the rest of this chapter if you need more detailed

information on any of these installation steps.

30 Installing the Switch

Page 31

Installation Precautions:

Follow these precautions when installing the 3810M switches.

WARNING!

• The rack or cabinet should be adequately secured to prevent it from becoming unstable

and/or falling over.

• Devices installed in a rack or cabinet should be mounted as low as possible, with the

heaviest devices at the bottom and progressively lighter devices installed above.

CAUTION:

• If the switch is to be shipped in a rack, it can be mounted and shipped in a Hewlett Packard

Enterprise 10K rack using the HPE X410 Universal Rack Mounting Kit (J9583A). Additionally,

it can be mounted in many 4-post racks using the HPE X410 Universal Rack Mounting Kit

(J9583A).

• Ensure the power source circuits are properly grounded, then use the power cord supplied

with the switch to connect it to the power source.

• If your installation requires a different power cord than the one supplied with the switch and

power supply, be sure the cord is adequately sized for the switch’s current requirements. In

addition, be sure to use a power cord displaying the mark of the safety agency that defines

the regulations for power cords in your country. The mark is your assurance that the power

cord can be used safely with the switch and power supply.

• When installing the switch, the AC outlet should be near the switch and should be easily

accessible in case the switch must be powered off.

• Ensure the switch does not overload the power circuits, wiring, and over-current protection.

To determine the possibility of overloading the supply circuits, add together the ampere

ratings of all devices installed on the same circuit as the switch and compare the total with

the rating limit for the circuit. The maximum ampere ratings are usually printed on the devices

near the AC power connectors.

• For safe operation, proper switch cooling, and reduction of electromagnetic emissions,

ensure that a slot cover is installed on any unused module or power supply slot.

• Do not install the switch in an environment where the operating ambient temperature might

exceed 45°C (113°F).

• Ensure the air flow around the sides and back of the switch is not restricted.

1. Prepare the Installation Site

Cabling Infrastructure - Ensure the cabling infrastructure meets the necessary network

specifications. See Cabling and Technology Information in the appendices for more information.

Installation Location - Before installing the switch, plan its location and orientation relative to

other devices and equipment:

• In the front of the switch, leave at least 7.6 cm (3 inches) of space for the twisted-pair and

fiber-optic cabling.

• In the back of the switch, leave at least 3.8 cm (1 1/2 inches) of space for the power cord.

If you are stacking the switches, you will need 20 to 23 cm (approximately 8 to 9 inches),

depending on the lengths of the stacking cables being used.

• On the sides of the switch, leave at least 7.6 cm (3 inches) for cooling, except if the switch

is installed in an open EIA/TIA rack.

Installation Procedures 31

Page 32

Figure 9 Air flow direction of the 3810M switches

2. Verify the Switch Boots Correctly

NOTE: For steps 2 and 3, if an 3810M switch is powered on for the first time without a stacking

module installed, stacking will be disabled and that will be saved in the switch's running

configuration. For more information, see Stacking Information and Topologies.

Before installing the switch in its network location, you should first verify it is working properly by

plugging it into a power source and verifying that it boots correctly.

32 Installing the Switch

Page 33

1. Connect the power cord supplied with the switch to the power connector on the back of the

switch, and then into a properly grounded electrical outlet.

Figure 10 Connecting the Power cord

NOTE: The 3810M switches do not have a power switch. They are powered on when the

power cord is connected to the switch and to a power source. For safety, the power outlet

should be located near the switch installation.

The switch automatically adjusts to any voltage between 100-240 (110–240 for JL087A

power supply) and either 50 or 60 Hz. No voltage range settings are required.

If your installation requires a different power cord than the one supplied with the switch, be

sure to use a power cord displaying the mark of the safety agency that defines the regulations

for power cords in your country. The mark is your assurance that the power cord can be

used safely with the switch.

2. Check the LEDs on the switch as described below.

Figure 11 Example of an 3810M-48-port PoE+ switch

Installation Procedures 33

Page 34

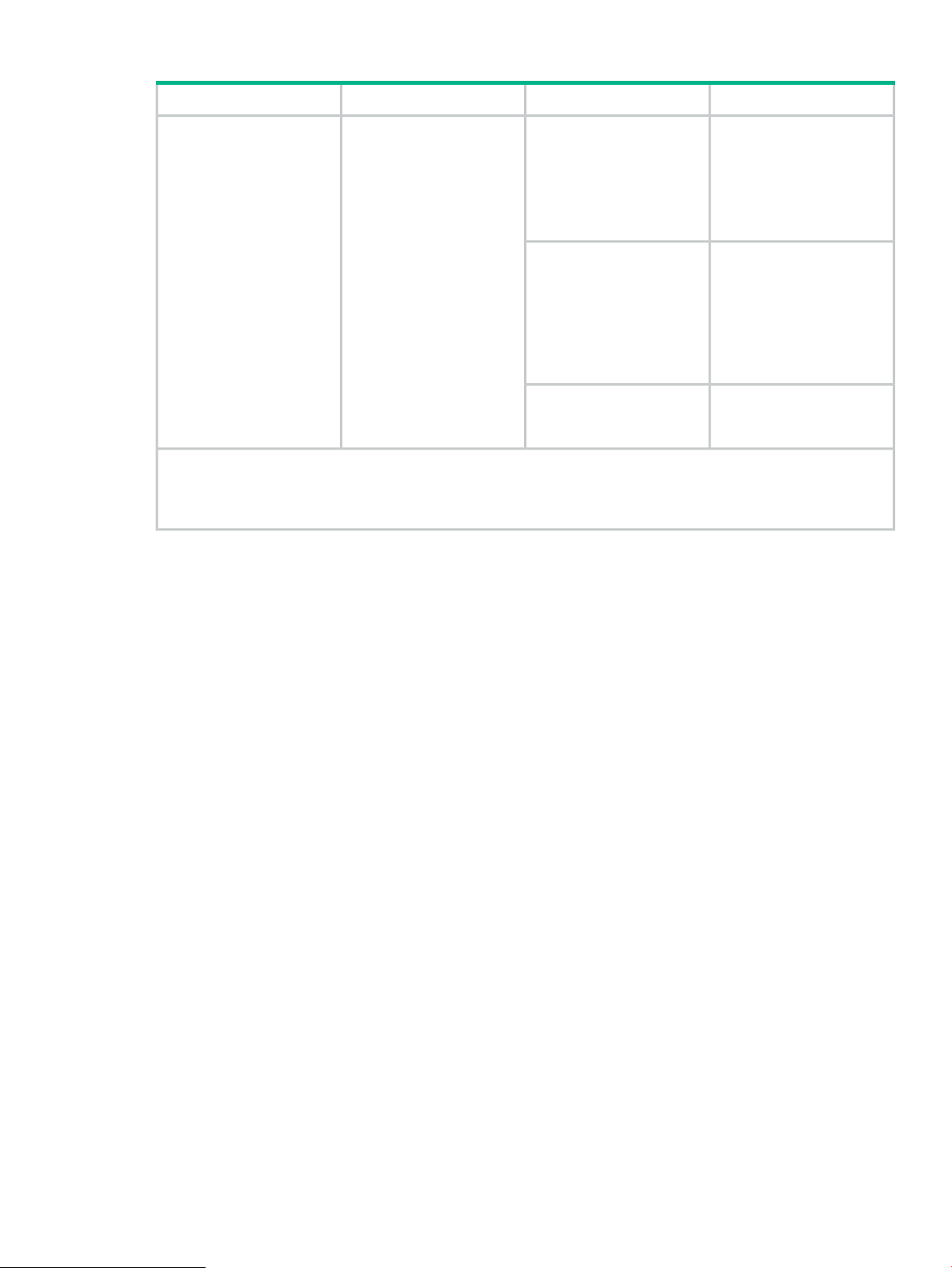

Table 16 Example of an 3810M-48-port PoE+ switch Label and Description

DescriptionLabel

Switch Port LEDs1

Mode LEDs2

When the switch is powered on, it performs its diagnostic self test and initialization. This boot

process, depending on switch model and configuration, takes approximately 1-2 minutes to

complete.

LED Behavior:

During the switch boot:

• The Global Status, UID, other Status and Mode LEDs, will initially turn on green and

bi-color LEDs will change to orange, then back to green.

• The Global Status LED will start blinking green, indicating the switch is going thru its self-test

and will continue to blink green until the switch if fully booted.

• The Port LEDs will come on green, turn orange, turn back to green, and then may blink on

and off during phases of the boot.

When the switch boots successfully, the LEDs display:

• Global Status and Back LEDs will be on solid green.

• Locator LED is off.

3

Back LED

Global Status and UID LEDs4

• Other status LEDs may be on or off depending on the switch configuration and the hardware

installed.

• The port LEDs go into their normal operational mode:

If the ports are connected to active network devices, the port LED may be on and

◦

behaves according to the LED mode selected. In the default LED mode (Activity/Link),

the LED should show half-bright green to indicate Link and be flickering full-bright green

to show network traffic.

◦ If the ports are not connected to active network devices, the port LED will stay off.

If the LED display is different than what is described above, especially if the Global Status LED

continues to blink green for more than 120 seconds or blinks orange continually, then the switch

boot has not completed correctly. Refer to “ Troubleshooting” (page 68) for diagnostic help.

3. (Optional) Install the Stacking Module

NOTE: Hot swapping the Stacking Module is not supported. If a module is installed with the

switch powered on, self-test of the module will not occur, the Back LED on the front of the switch

and the Module Status LED on the module will blink orange. The switch must be reset or power

cycled for the module to function. Only insert or remove a module during scheduled downtime

with the switch powered off.

1. Remove the cover plate.

2. Insert the module aligning with the guides in the slot.

3. Once the contacts have engaged, use the extractor handles to seat the module completely.

34 Installing the Switch

Page 35

4. Tighten the captive screws until they are snug – do not overtighten them.

Figure 12 Installing the Module

Verifying the Module is Installed Correctly

Observe the Back and Global Status LEDs on front of the switch, and the Module Status LED

on the module to verify module is installed properly.

Figure 13 Location of Module Status LEDs

Table 17 Location of Module Status LEDs Label and Description

DescriptionLabel

Back LED1

Global Status LED2

If the module is installed properly and the switch is powered on, the module undergoes a self

test during the normal switch boot up process. You can use the LEDs to determine that the

Installation Procedures 35

Page 36

module is installed properly and has passed the self test, as described in the “LED Behavior”

table Stacking Module LED Behavior.

Table 18 Stacking Module LED Behavior

Display for a Properly Installed ModuleLED

After boot-up sequencing, LEDs are on steady green.Global

Status and

Back LEDs

on front of

the switch

and Module

Status LED

on the

stacking

module

Link (for

each

stacking

port on the

module)

If stacking cables are connected to the module and to a Stacking Module on another powered on

3810M switch, the LED goes ON green to indicate the stacking port is enabled, connected, and detects

a signal from the attached switch.

4. Installing the Flex Port Module

1. Unscrew the two retaining screws on the blank filler and remove it.

2. Remove the new Flex Port module from its packaging, be careful not to touch any of the

circuitry on the board.

3. Insert the Flex Port module fully into the slot as shown in Install Flex Port Module. The face

plate of the module will be flush with the front face of the switch.

4. Engage the retaining screws and tighten them. Be sure, to not overtighten the screws.

5. Power on the switch and make sure the module passes its self test. See Flex Port LED Error

Indicators for the module LED behavior that indicates correct installation.

36 Installing the Switch

Page 37

Figure 14 Install Flex Port Module

5. Mount the Switch

After the switch passes self test, the switch is ready to be mounted in a stable location. The

3810M switches can be mounted in these ways:

• in a rack or cabinet

• on a horizontal surface

For other mounting options contact your local Hewlett Packard Enterprise authorized network

reseller or Hewlett Packard Enterprise representative.

Rack or Cabinet Mounting

These switches are designed to be mounted in any EIA-standard 2-post 19-inch telco rack or

4-post communication equipment cabinet.

WARNING! For safe operation, please read the mounting precautions on“ Installation

Precautions:” (page 31), before mounting a switch.

Equipment Cabinet Note:

The 12-24 screws supplied with the switch are the correct threading for standard EIA/TIA open

19-inch racks. If you are installing the switch in an equipment cabinet such as a server cabinet,

use the clips and screws that came with the cabinet in place of the 12-24 screws that are supplied

with the switch.

Complete step 1, and plan which four holes you will be using in the cabinet and install all four

clips. Then proceed to step 2.

Installation Procedures 37

Page 38

Rack Mounting the 3810M switch in a 2-post rack

1. Use a #1 Phillips (cross-head) screwdriver and attach the mounting brackets to the switch

with the included 8-mm M4 screws.

Figure 15 Attaching the mounting brackets to the switch

NOTE: The mounting brackets have multiple mounting holes and can be rotated allowing

for a wide variety of mounting options. These include mounting the switch so its front face