Page 1

TM 9-6625-2469-15

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

GENERAL SUPPORT AND DEPOT MAINTENANCE

MANUAL [INCLUDING REPAIR PARTS]

POWER METER

[HEWLETT-PACKARD MODEL 432A]

[4931-436-4883]

THERMISTOR MOUNT

[HEWLETT-PACKARD MODEL 478A]

[6625-866-1955]

HEADQUARTERS, DEPARTMENT OF THE ARMY

DECEMBER 1969

Page 2

WE 20780

WARNING

HIGH VOLTAGE

is used in the operation of this equipment.

DEATH ON CONTACT

may result if personnel fail to observe safety precautions.

Learn the areas containing high voltage

in each piece of equipment.

Be careful not to contact high-voltage or 115-volt ac input connections

when installing or operating this equipment.

Before working inside the equipment, turn power off and ground points of

high potential before touching them.

Page 3

POWER METER

432A

SERIAL PREFIX: 914-

This manual applies directly to HP Model

432A Power Meters having serial prefix

number 914.

SERIAL PREFIXES NOT LISTED

For serial prefixes above 914, a “Manual

Changes” sheet is included with this manual.

For HP Model 432A with serial prefix below 914 refer to Appendix A.

Copyright

1501 PAGE MILL ROAD, PALO ALTO, CALIFORNIA,

HEWLETT-PACKARD COMPANY

1968

U.S.A

Page 4

(This manual contains copyright material.)

TM 9-6625-2469-15

TECHNICAL MANUAL )

)

No. 9-6625-2469-15)

THERMISTOR Mount (HEWLETT-PACKARD MODEL 478A)

HEADQUARTERS

DEPARTMENT OF THE ARMY

Washington, D.C.

(4931-436-4883)

(6625-866-1955)

22 December 1969

ii

Page 5

Table of Contents

List of Tables

POWER

TABLE OF CONTENTS

METER

432A

Model 432A

Section

GENERAL INFORMATION . . . . . . . . . . . . . . 1-1

I

1-1. Description . . . . . . . . . . . . . . . . . . . .1-1

1-5.

INSTALLATION . . . . . . . . . . . . . . . . . . . . . .2-1

II

2-1. Initial Inspection . . . . . . . . . . . . . .2-1

2-2. Mechanical Check . . . . . . . . . . . . 2-1

2-4.

2-6. Damage Claims . . . . . . . . . . . .2-1

2-9. Three-Conductor Power Cable . . . . 2-1

2-12. Primary Power Requirements . . . . 2-1

2-14.

2-16. Battery Installation. . . . . . . . . . . 2-1

2-17.

2-19.

2-21. Combining Case . . . . . . . . . . . .2-1

2-23. Adapter Frames . . . . . . . . . . .2-2

2-25. Repacking for Shipment . . . . . . . . . . 2-2

OPERATING INFORMATION.. . . . . . . . . . . 3-1

III

3-1.

3-4.

3-12.

3-17.

3-23.

3-27.

3-28.

3-30.

PRINCIPLES OF OPERATION . . . . . . . . . 4-1

IV

4-1.

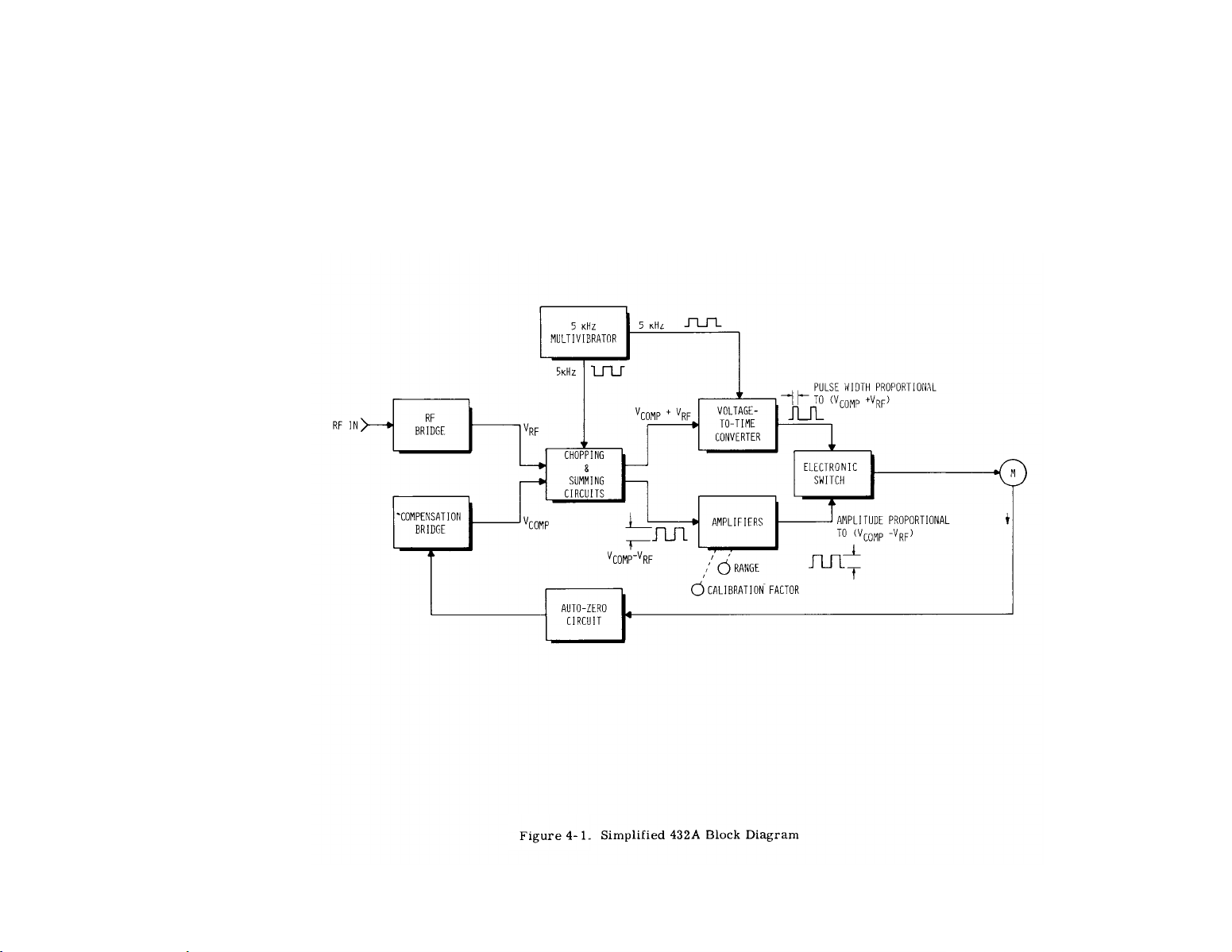

4-5. Functional Block Diagram . . . . . . . . 4-1

V

Instrument Identification . . . . . . . . . 1-1

Performance Checks . . . . . . . . . . 2-1

Internal Battery Operation . . . . . . . 2-1

Battery Storage . . . . . . . . . . . . . . 2-1

Rack Mounting . . . . . . . . . . . . . . . .2-1

Introduction . . . . . . . . . . . . . . . . . ...3-1

Controls, Connectors, and

Indicators . . . . . . . . . . . . . . . . . . ...3-1

Battery Operation . . . . . . . . . . . . . ..3-1

Microwave Power Measurement

Accuracy . . . . . . . . . . . . . . . . . . . ...3-2

Calibrator Factor and Effective

Efficiency . . . . . . . . . . . . . . . . . . ...3-2

Precision Power Measurement . . . 3-2

General . . . . . . . . . . . . . . . . . . . . . 3-2

Measurement Procedure . . . . . . 3-2

Simplified Description . . . . . . . . . . . . 4-1

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1. Introduction . . . . . . . . . . . . . . . . . . . . . 5-1

5-3.

Content . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-4. Performance Tests . . . . . . . . . . 5-1

5-6.

5-10. Test Equipment . . . . . . . . . . . . . . 5-1

5-12.

5-14. 432 A Performance Tests

Adjustments . . . . . . . . . . . . . . . . . 5-1

Service Information . . . . . . . . . . 5-1

with 8477A Calibrator. . . . . . . . . 5-1

Page Section

MAINTENANCE (Cont.)

V

5-15.

5-16. Meter Accuracy Test . . . . . . . . . 5-1

5-17.

5-18. Meter Linearity Check . . . . . . . 5-2

5-19.

5-20. Fine Zero Range Check . . . . . . 5-3

5-21. 432 Calibration without

5-24. Calibration Procedure 1 . . . . . . 5-3

5-26.

5-27.

5-29.

5-30. Top Cover Replacement . . . . . . 5-8

5-31.

5-32. Bottom Cover Replacement . . . 5-8

5-33. Adjustment Procedures . . . . . . . . . 5-8

5-34. Initial Setup . . . . . . . . . . . . . . . . . 5-8

5-35. Mechanical Meter Adjustment . 5-8

5-36. Bridge Amplifier Tests . . . . . . . 5-9

5-37. Meter and Recorder

5-38. Battery Charger Adjustment

5-39.

5-40. Isolating Trouble in Transistor

5-46. Out-of-Circuit Testing . . . . . . . 5-10

5-48. Component Replacement in

5-50.

5-52.

REPLACEABLE PARTS . . . . . . . . . . . . . ...6-1

VI

6-1.

6-3.

TROUBLESHOOTING. SCHEMATICS.

VII

AND COMPONENT tiCATIONS . . . . . . . . . 7-1

7-1. Introduction . . . . . . . . . . . . . . . . . ...7-1

7-5.

7-8. Schematics . . . . . . . . . . . . . . . . . . ...7-1

7-12. AIAl Auto Zero Assembly . . . . . . . 7-1

7-14. Test Conditions . . . . . . . . . . . . . . ...7-1

Page

Initial Setup . . . . . . . . . . . . . . . . . 5-1

Calibration Factor Test . . . . . . 5-2

Zero Carryover Test . . . . . . . . 5-2

8477A Calibrator . . . . . . . . . 5-3

Calibration Procedure 2 . . . . . .

Cover Removal and Replacement 5-8

Top Cover Removal . . . . . . . . . . 5-8

Bottom Cover Removal . . . . . . . 5-8

Output Calibration . . . . . . . 5-9

(Option 01 Only) . . . . . . . . . . 5-9

Battery Removal . . . . . . . . . . . . 5-10

Circuits . . . . . . . . . . . . . . . . . . . . 5-10

Etched Circuits . . . . . . . . . . . . . 5-13

Axial-Lead Components . . . . . . 5-13

Other Components . . . . . . . . . . . 5-13

Introduction . . . . . . . . . . . . . . . . . ...6-1

Ordering Information . . . . . . . . . . . . 6-1

Troubleshooting . . . . . . . . . . . . . . ...7-1

5-8

Number

1-1.

Specifications, . . . . . . . . . . . . . . . . . . . ...1-1

1-2.

Thermistor Mounts forthe 432A . . . . . . 1-2

Recommended Test Equipment . . . . . . . . 5-0

5-1.

Meter Accuracy Test . . . . . . . . . . . . . ...5-2

5-2.

Calibration Factor Test..... . . . . . . . . . 5-2

5-3.

5-4.

5-5.

5-6.

5-7.

6-1.

6-2.

6-3.

Performance Test Card... . . . . . . . . . . . 5-5

Out-of-Circuit Transistor Resistance

Measurements . . . . . . . . . . . . . . . . . . ...5-11

Etched Circuit Soldering’Equipment . . . 5-13

Safe Ohmmeter Range for Transistor

Resistance Measurements . . . . . . . . . . 5-13

Reference Designation Index . . . . . . . . . 6-2

Replaceable Parts . . . . . . . . . . . . . . . . ...6-12

Code List of Manufacturers . . . . . . . . . . 6-15

Title

LIST OF TABLES

Page

Number Title Page

7-1. Schematic Notes . . . . . . . . . . . . . . . . . ...7-2

7-2. Overall Troubleshooting . . . . . . . . . . . . . 7-5

7-3. RF Bridge Troubleshooting . . . . . . . . . . . 7-6

7-4.

7-5. Auto-Zero Troubleshooting. . . . . . . . . . . 7-7

7-6.

7-7. 5 kHz Multivibrator Troubleshooting . . 7-7

7-8. Range Amplifier Troubleshooting . . . . . 7-7

7-9.

7-10. Pulse Width Modulator and Meter

7-11. Power Supply Troubleshooting . . . . . . . . 7-9

iii

Compensation Bridge Troubleshooting.. 7-6

Chopping andSumm ing Circuit

Troubleshooting . . . . . . . . . . . . . . . . . ...7-7

Calibration Factor Amplifier

Troubleshooting . . . . . . . . . . . . . . . ..,. ..7-7

Troubleshooting . . . . . . . . . . . . . . . . ...7-7

Page 6

Model 432A

Number

1-1.

HP Model 432A Power Meter . . . . . . . . . . . . 1-0

1-2.

Instrument Identification . . . . . . . . . . . . . . . 1-1

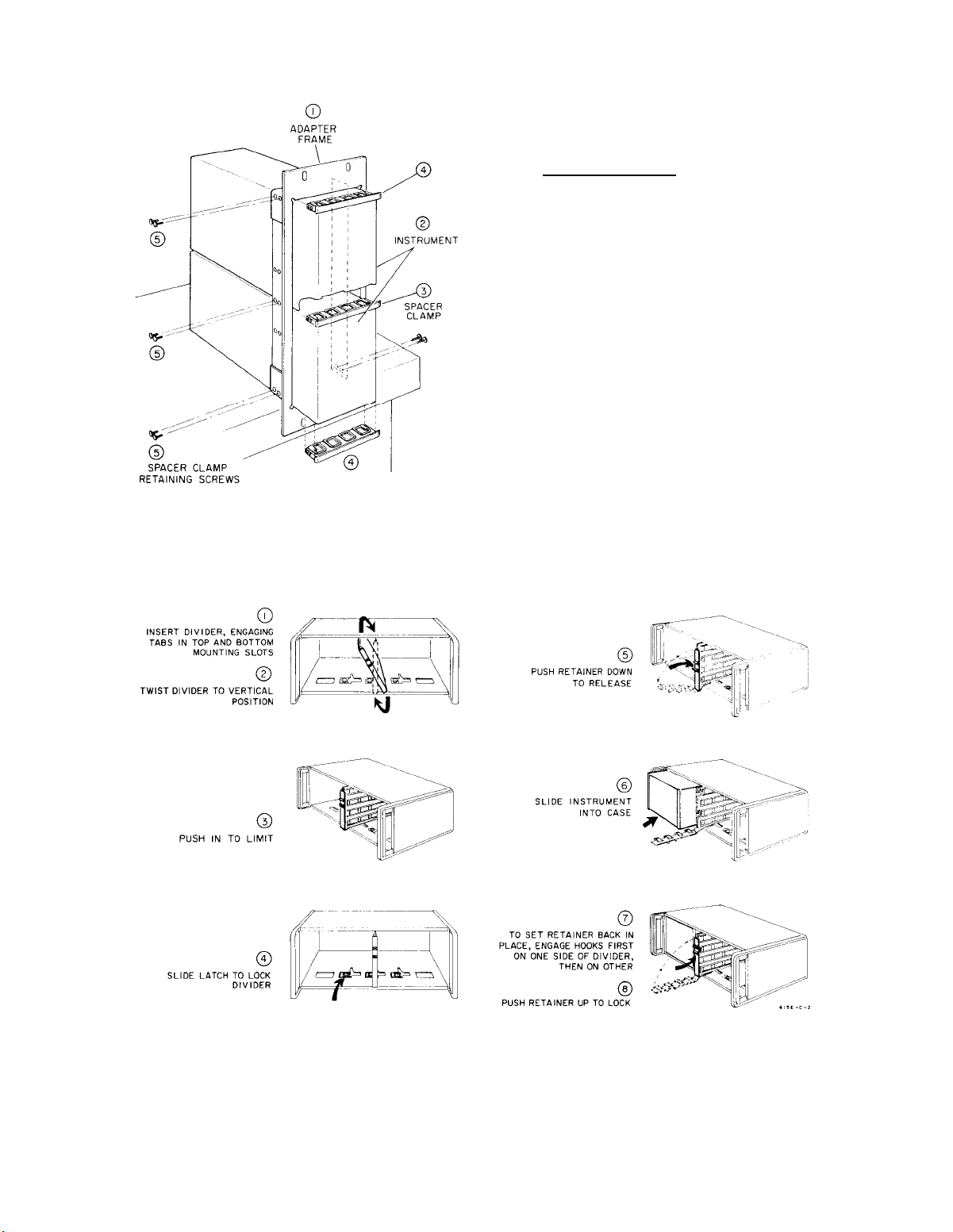

Sub- module Installation in Rack

2-1.

2-2.

3-1.

3-2.

3-3.

3-4.

4-1.

4-2.

4-3.

4-4.

4-5.

5-1.

5-2.

5-3.

5-4.

Adapter Frame . . . . . . . . . . . . . . . . . ...2-2

HP Model 1051A Combining Case

Instrument Installation . . . . . . . . . . . ...2-2

Precision Power Measurements . . . . . . . . . . 3-3

Front Panel Controls, Connectors

and Indicators . . . . . . . . . . . . . . . . . . . . ...3-4

Rear Panel Controls and Connectors . . . . . . 3-6

Turn On and Zeroing Procedure . . . . . . ...3-8

Model 432A Simplified Block Diagram. . . . 4-0

Model 432A Block Diagram. . . . . . . . . . . . ...4-3

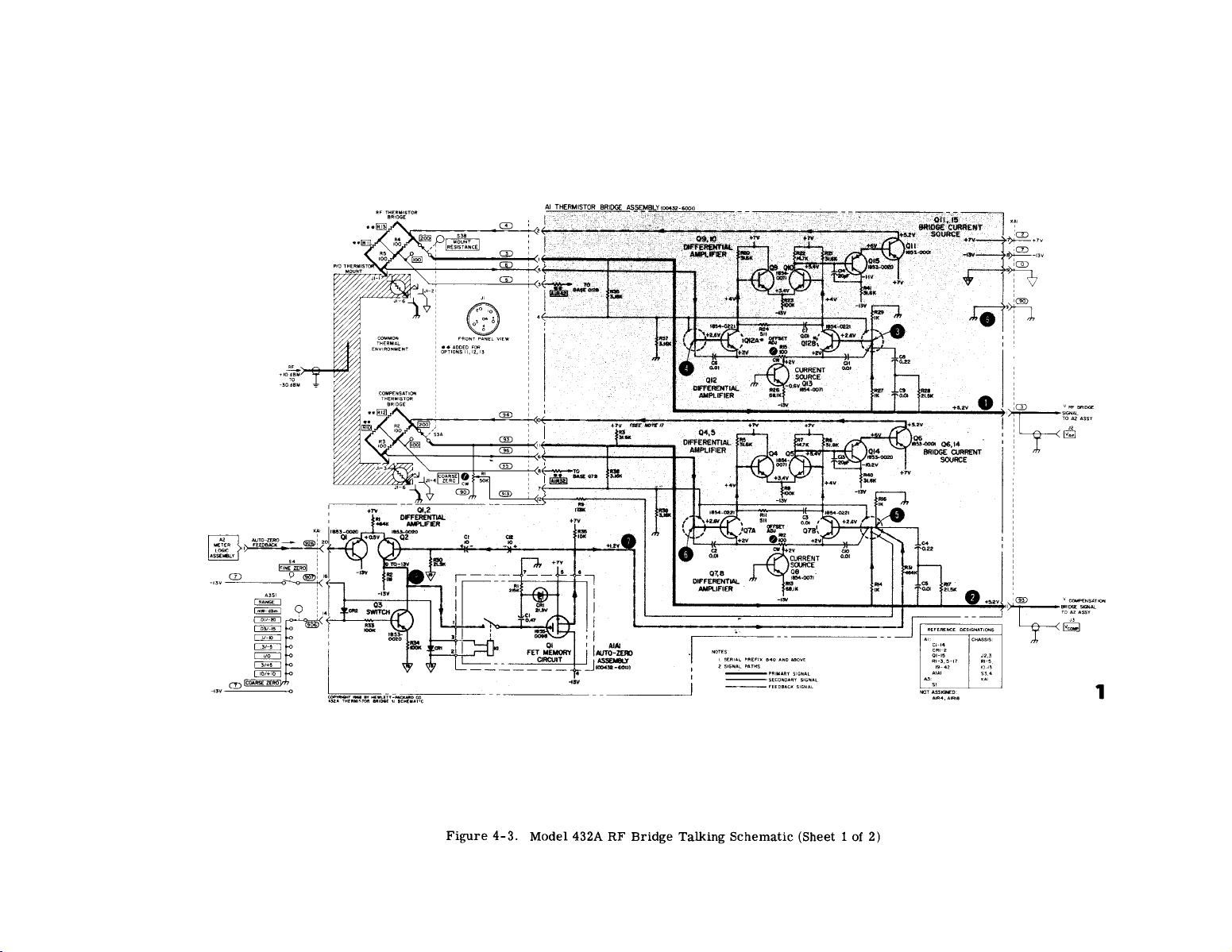

Mode1 432A RF Bridge Talking Schematic. . 4-4

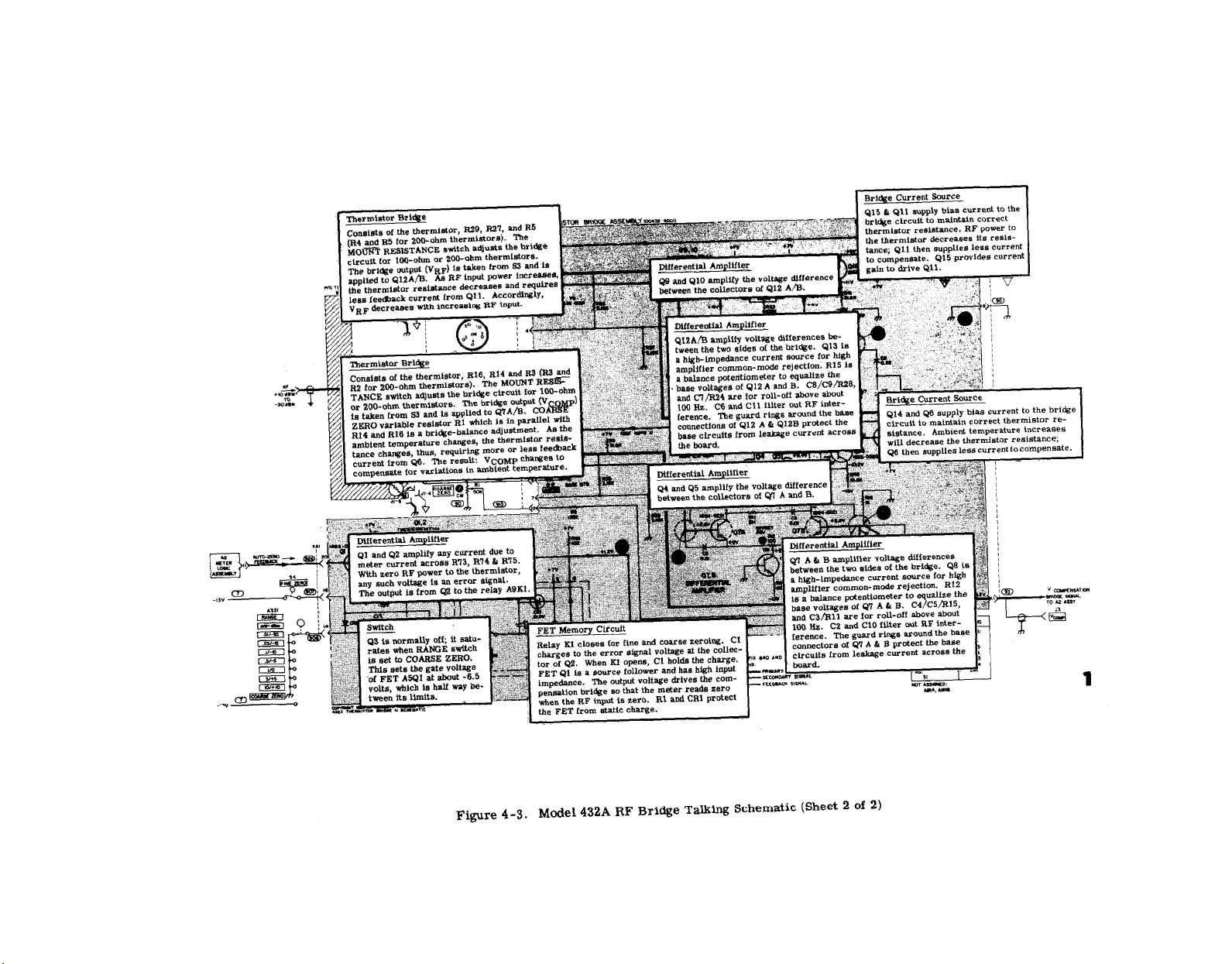

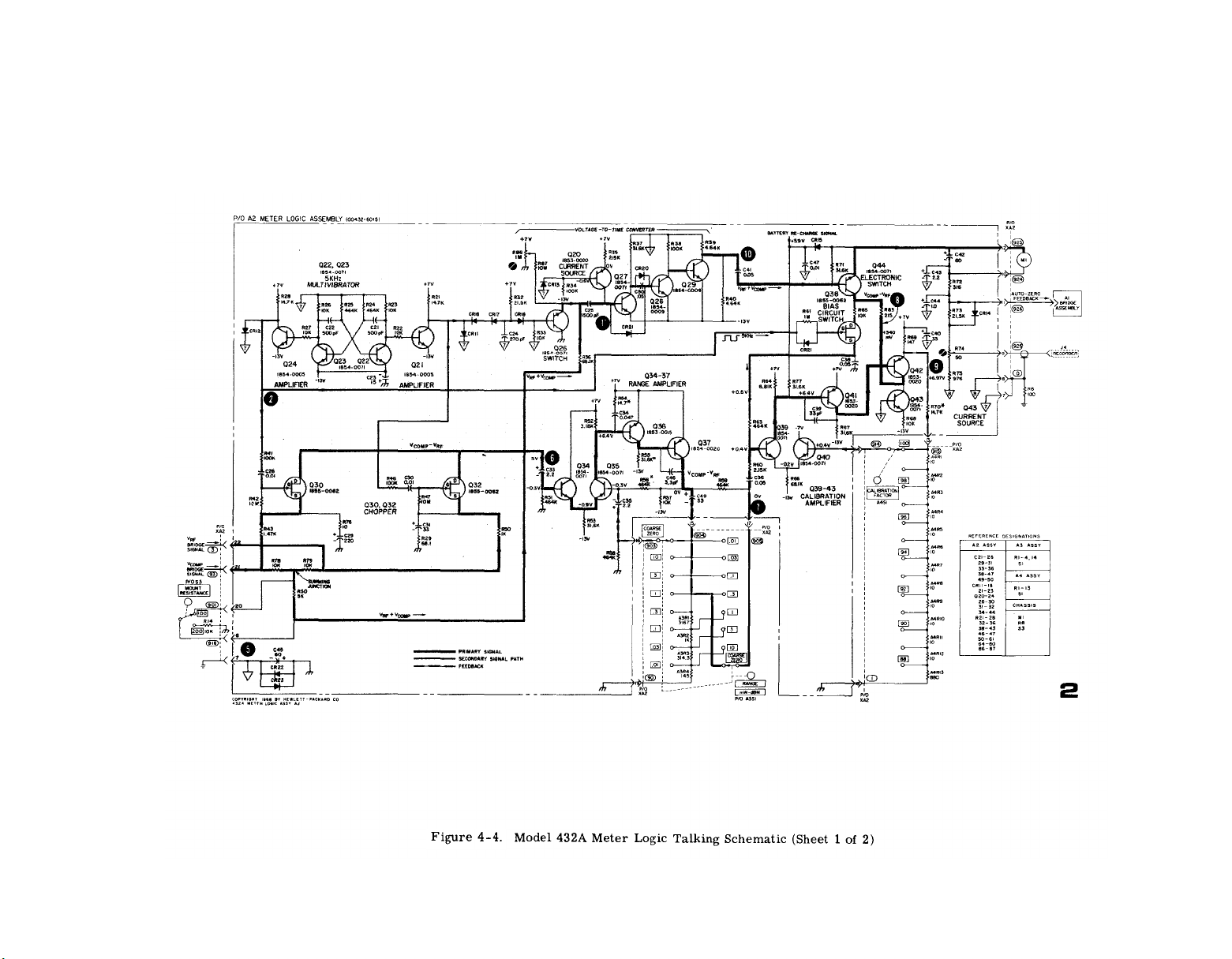

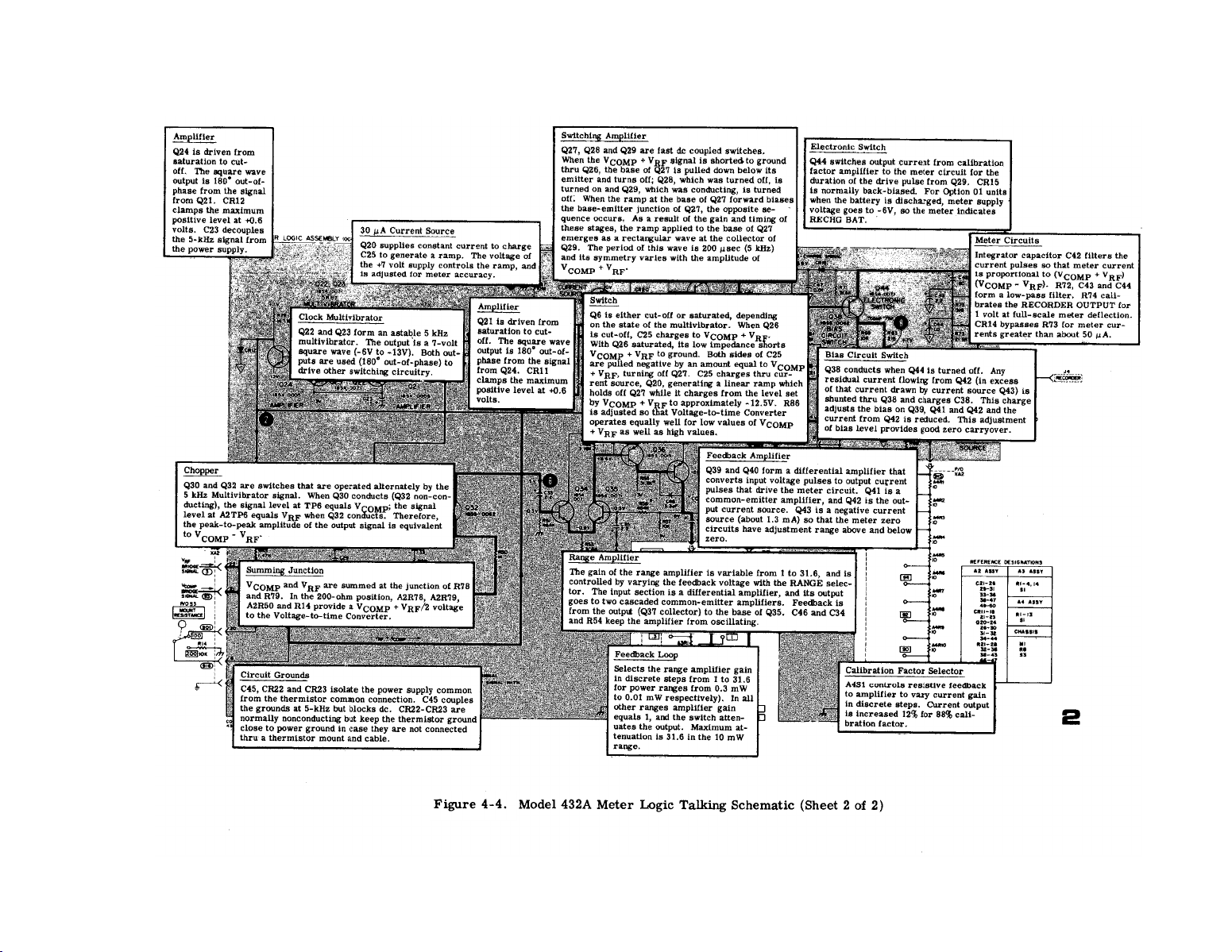

Model 432A Meter Logic Talking

Schematic . . . . . . . . . . . . . . . . . . . . . . . . ...4-6

Model 432A Power Supply Talking

Schematic . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Check and Adjustment Test Setup . . . . . . . . . 5-1

Zero Carryover Test Setup . . . . . . . . . . . . . . 5-3

Bridge Amplifier Test,... . . . . . . . . . . . ...5-10

Transistor Biasing and Operating

Chmacteristics . . . . . . . . . . . . . ...5-12

LIST OF ILLUSTRATIONS

Page

Number

7-1. Servicing Block Diagram . . . . . . . . . . . . 7-3

Model 432A Top Internal View . . . . . . . . . . . 7-4

7-2.

Mode1 432A Waveforms . . . . . . . . . . . . ...7-4

7-3.

Mode1 432A Test Point Locations . . . . . . . . 7-5

7-4.

Model 432A Bottom View,

7-5.

7-6.

7-7.

7-8.

7-9. RF and Compensation Bridge

7-10. Mode1 432A Switches . . . . . . . . . . . . . . ...7-12

7-11. A2 Meter Logic Assembly,

7-12. Meter Logic Schematic Diagram . . . . . . . . . 7-13

7-13. A2 Meter Logic Assembly, Power

7-14. A7 Battery Charging Circuit (Option 0l)

7-15. Power Supply, Schematic Diagram . . . . . .7-l5

7-16. Thermistor Cable Wiring Diagram . . . . . . . 7-16

A1-1. A2 Meter Logic, Component Locations . .. A1-2

A1-2. A2 Meter Logic Assembly, Power

A1-3. Meter Logic Schematic Diagram . . . . . . .. A1-3

Component Locations . . . . . . . . . . . . ...7-6

Mode1 432A Front Panel Interior . . . . . . . 7-6

Al Bridge Assembly,

Component Locations . . . . . . . . . . . . . . . 7-10

Mode1 432A Rear Panel Interior . . . . . . . . . 7-10

Schematic Diagram . . . . . . . . . . . . ...7-11

Component Locations . . . . . . . . . . . . . . 7-13

Supply Component Locations . . . . . . . 7-15

Component Locations . . . . . . . . . . . . 7-15

Supply, Component Locations . . . . . . .A1-2

List of Illustrations

Page

APPENDIX A.

B. BASIC ISSUE ITEMS LIST

C.

D.

MANUAL CHANGES

--------------------------------

-----------------------------

MAINTENANCE ALLOCATION CHART

REPAIR PARTS LIST

-------------------------------

------------------

Al-1

B1-1

C1-1

D1-1

iv

Page 7

GENERAL INFORMATION

1.

Introdution

4.

Incoming Inspection

-------------

------------------

--------

OPERATION ---------------------

7.

Precautions -------------

8.

Mechanical Shock

10.

Biasing Thermistors -----

11.

Minimum Input

13.

Average Power

14.

Pulse Energy and Peale

Power 478A/432

15.

Pulse Energy and Peak

Power 478A/431

19.

Drift Precaution --------

21.

Zero-Set

RF Power Turned Off For

23.

- ---------- -- - - -

---------

--------------

-------- -----

---------

------ --

Zero-Set ---------------

25.

Thermistor Mount Dis-

connected For Zero-

------------------

Set

26.

478A/431

478A/432 ----------------

30.

31.

Mount Calibration Data --

33.

-Calibration Factor ------

35.

Effective Efficiency ----

37.

Calibration Data

Application

39

Thermoelectric Effect ---

.

43.

Thermoelectric Effect

- - - --- - ------ - --

--- - --- - - - -

Error Correction

478A/431

45.

Thermoelectric Error

478A/432

OPERATING PRINCIPLES

-------- ---------

---------------

------- ---

47. Circuit Description -----

52. 431-Power Meter

Detection . . . . . . . . . . . . .

54.

432 Power Detection -----

MAINTENANCE

56. Mechanical Shock

58.

Check On Thermistor

60.

Repair

71.

Thermistor Assembly Re-

-------- -------- ----

Match

---------------------

--------------------

---------

placement Procedure ---

75.

Removal Procedure -------

76.

Installation Procedure --

Page

8-1

8-1

8-2

8-2

8-2

8-2

8-2

8-2

8-2

8-2

8-3

8-3

8-3

8-3

8-4

8-4

8-4

8-5

8-5

8-5

8-5

8-5

8-6

8-5

8-5

8-5

8-6

8-6

8-6

8-6

8-6

8-7

8-8

8-9

8-9

Number Title

1

2

Specifications

Methods of Switching Off

RF Output of Various HP

Signal Generators

3

Parts Furnished in

Thermistor Assembly

Replacement Kit, HP

00478-600------------------

List of ILLUSTRATIONS

Number

1

Maximum Power Meter Read-

ing vs PRF for Pulses

Shorter than 250 u s ----

2

Maximum Power Meter Read-

ings vs Duty Cycle for

Pulses Longer than

250 u s ----------------

3

3 Maximum Power Meter Read-

ing vs Square and Sine

Wave Frequency ----------

4

Source Impedance Shunting

One RF Thermistor

Mount ------ -------------

5

Schematic Diagram of a

Model 478A Thermistor

Mount when Connected to

a 431 Power Meter --------

6

Schematic

Model 478A Thermistor

Mount when Connected to

a 4,82 Power Meter ----

7

Check on Model 478A

Thermistor Resistance

Match

8

9

Thermistor Compensation --Model 478A Thermistor

Mount Assembly ----------

10

HP Model 478A Printed

Circuit A

LIST OF TALBLES

-- - ---------

Diagram of a

------- ------ -

SSy Wiring -----

-------

Page

8-2

8-4

8-8

Page

8-3

8-3

8-3

8-4

8-5

---

8-7

8-7

8-8

8-9

8-10

v

Page 8

Section I

Model 432A

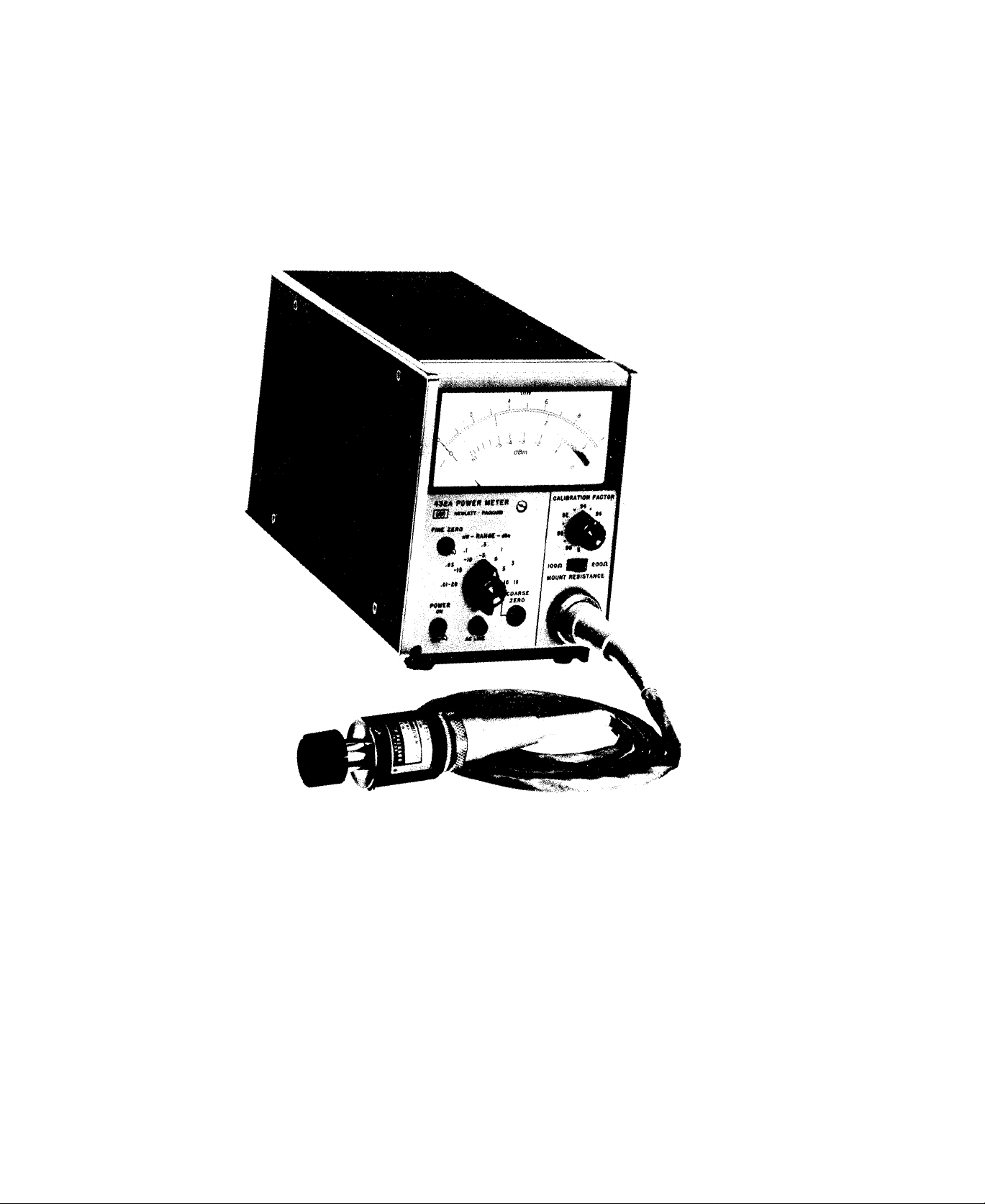

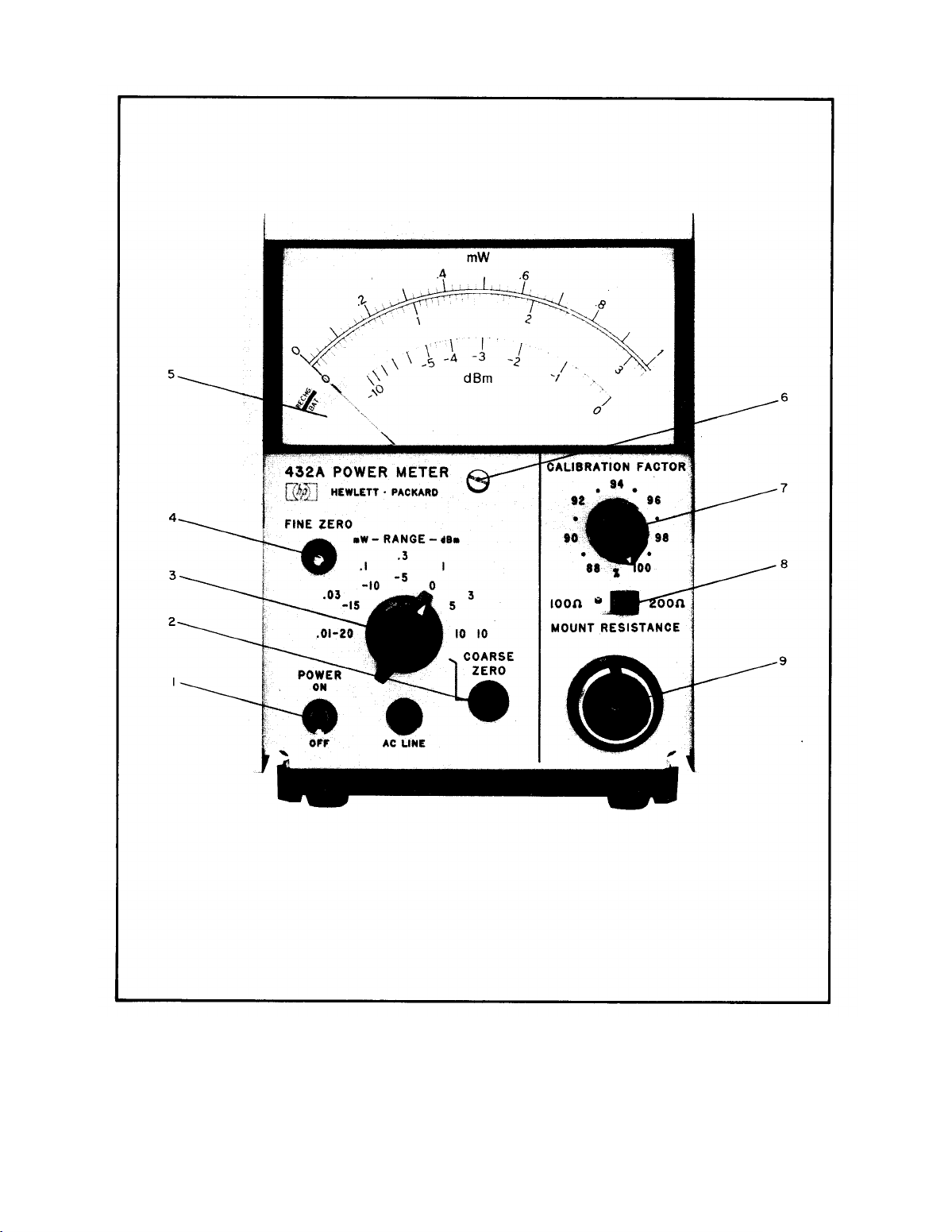

Figure 1-1. HP Model 432A POWER METER

vi

Page 9

Model 432A Section I

SECTION I

GENERAL INFORMATION

1-1. DESCRIPTION.

1-2. The Hewlett-Packard Model 432A Power Meter,

with HPtemperature -compensated thermistor mounts,

measures RF power from 10 microwatt (-20 dBm)

to 10 milliwatts (+10dBm) full scale with 1% of full

scale accuracy from 10 MHz to 40 GHz. With a selector switch, the instrument normalizes the power

meter reading to compensate for the Calibration Factor

of a thermistor mount used for a given measurement.

For portable operation, Option 01 instruments have a

rechargeable nickel-cadmium battery. See Table 1-1

for complete specifications.

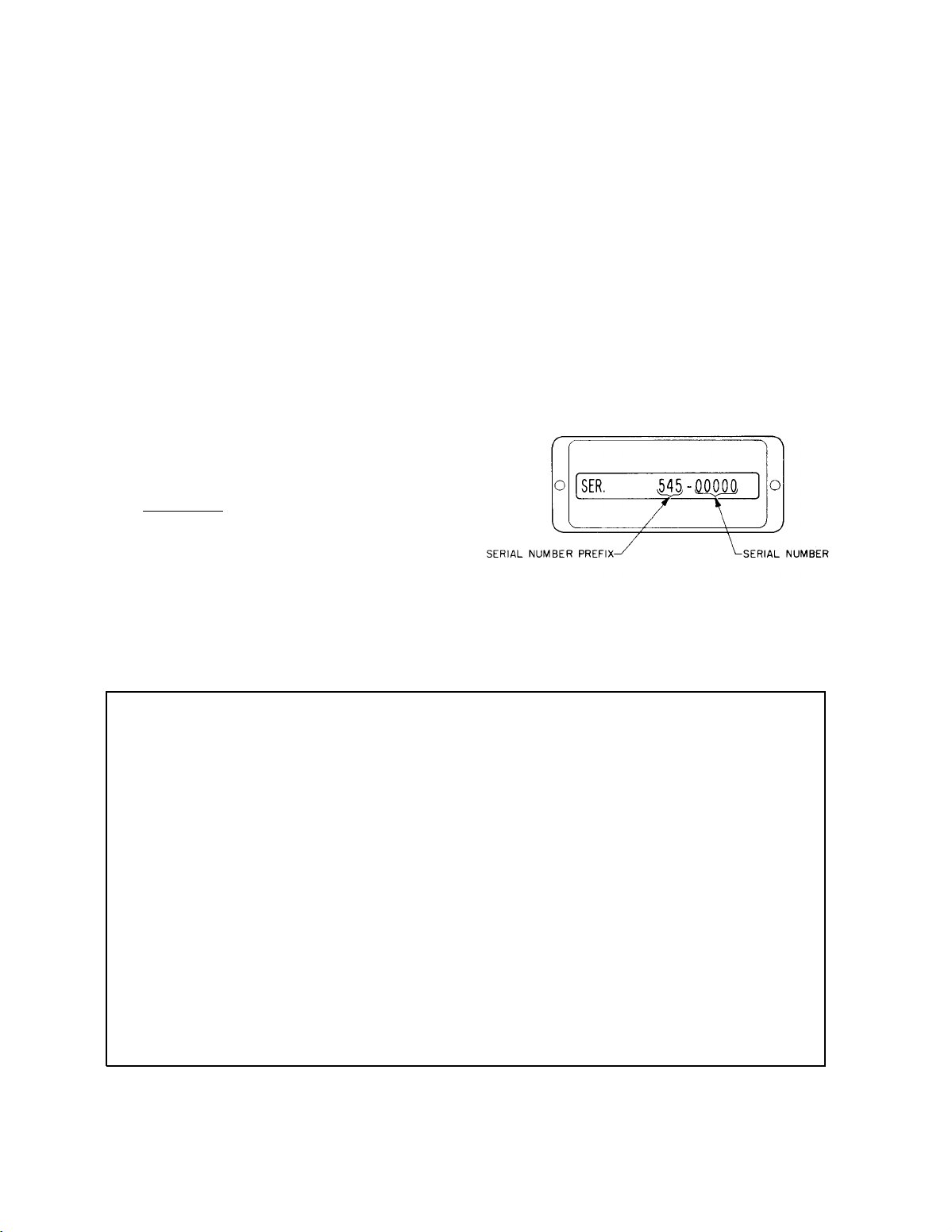

1-5. INSTRUMENT IDENTIFICATION.

1-6. Hewlett-Packard instruments are identified by

an 8-digit serial number. The first three digits are

the Serial Prefix. To properly match a manual with

the instrument to which it applies, the prefix on the

instrument must be the same as the pref ix at the front

of the manual. If the numbers are different, information is supplied either on yellow Manual Change

Supplements, or in an Appendix in the Manual. If the

change information is missing, contact your HP Sales

Office (Sales Offices are listed at the b a c k of the

Manual).

1-3. The Model 432A has provision for dc substitution

measurements and for power meter calibration. An

output is provided for recorders or digital voltmeter

readout.

1-4. Accessories, Two accessories are supplied with

the Model 432A Power Meter: a 7. 5-foot (2290 mm)

detachable power cable and a 5-foot ( 1520 mm) cable

that connects the thermistor mount to the meter. Ther mister mounts are available but not supplied with the

power meter (refer to Table 1-2). Table 1-1 lists

those accessories supplied and also those available. Figure 1-2. Instrument Identification

Table 1-1. Specifications

Instrument Type: Automatic, self -balancing power

Zero Carryover: Less than +0.5% of f u 11 scale

meterforuse with temperature -compensated ther - when zeroed on most sensitive range.

mister mount.

Power Range: 7 ranges with full-scale readings of

Fine Zero: Automatic, operated by toggle switch.

10, 30, 100, and 300 µW, 1, 3 and 10 mW; also

calibrated in dBm from -20 dBm to +10 dBm full

Recorder Output: 1.000 volt into open circuit cor scale in 5-dB steps. responds to full-scale meter deflection (1. O on

O,- 1 scale) +0.5%; 1000-ohm output impedance,

Accuracy:

+55

Calibration Factor Control: 13-position switch nor-

±1% of full scale on all ranges (+O°C, to

o

C).

BNC connector.

RFI: Meets all conditions specified in MIL-I-6181D.

realizes meter reading to account for thermistor

mount Calibration Factor. Power: 115 or 230 Vac ±10%, 50 to 400 Hz, 2-1/2

Range: 100% to 88% in l% steps.

watts. Optional rechargeable battery provides up

to 20 hours continuous operation. Automatic bat-

Thermistor Mount: External temperature -compen - tery recharge.

sated thermistor mounts required for operation

(see Table 1-2).

Weight: Net 6-1/2lb(3kg), shipping 9-1/4lb(4,2kg).

Meter: Taut -band suspension, individually com-

puter-calibrated, mirror-backed scales. Mini - Weight with Optional Battery Pack: Net 9-1/4 lb

watt scale more than 4-1 4 inches (108 mm) long.

(4,2 kg), shipping 12 lb (5,5 kg).

1-1

Page 10

Section I Model 432A

Table 1-1.

1-2

Table 1-2.

Page 11

Model 432A

Section II

Installation

SECTION II

INSTALLATION

2-1. INITIAL INSPECTION.

MECHANICAL CHECK.

2-2.

2-3. If damage to the shipping carton is evident, ask

that the carrier’s agent be present when the instrument

is unpacked. Inspect the instrument for mechanical

damage. Also check the cushioning material for signs

of severe stress.

2-4. PERFORMANCE CHECKS.

2-5. The electrical performance of the Model 432A

should be verified upon receipt. Performance checks

suitable for incoming inspection are given in Section V,

Maintenance.

2-6. DAMAGE CLAIMS.

2-7. If t h e instrument is mechanically damaged in

transit, notify the carrier and the nearest HewlettPackard field off ice immediately. A list of field offices

is at the back of this manual. Retain the shipping carton and padding material for the carrier’s inspection.

The field off ice will arrange for replacement or repair

of your instrument without waiting for claim settlements against the carrier,

2-8. Before shipment this instrument was inspected

and found free of mechanical and electrical defects.

If there is any def iciency, or if electrical performance

is not within specifications, notify your nearest Hewlett -Packard Sales and Service Off ice.

2-9. THREE-CONDUCTOR POWER CABLE.

To protect operating personnel, t h e National

2-10.

Electrical Manufacturers Association (NE MA) recommends that the instrument panel and cab in et be

grounded.

All Hewlett-Packard instruments are

equipped with a three-conductor power cable which,

when plugged into an appropriate receptacle, grounds

the instrument.

The off set pin on the power cable

three-prong connector is the ground wire.

2-11. To preserve the protection feature when oper-

ating the instrument from a two-connector outlet, use

a three-prong to two-prong adapter and connect the

green pigtail on the adapter to ground.

2-12. PRIMARY POWER REQUIREMENTS.

The Model 432A operates from 115 or 230 volts

2-13.

ac line voltage.

Line frequency may vary from 50 to

400 Hz. A slide switch on the rear panel is moved to

the correct position for the I in e voltage available.

Before operating the equipment, ensure that the fuse

installed in the instrument corresponds to the value

marked on the panel for the line voltage available ( 1/8

amp slow-blow).

2-14. INTERNAL BATTERY OPERATION.

Model 432A Option 01 instruments contain an

2-15.

internal battery and a battery charging assembly. By

connecting the 432A to an ac source, the battery may

be charged overnight. The battery can be maintained

in the charging state indefinitely without damage. It

will assume its full capacity, 1.25 ampere -hours, and

will not charge in excess of that. This enables the

instrument to operate for approximately 20 hours continuously without recharging.

2-16. BATTERY INSTALLATION.

a. Set power switch to off and remove power plug

from rear panel,

b. Remove top and bottom, and s i d e instrument

covers.

c. The battery is installed with the terminals toward

the right hand side of the instrument when faced from

the front. The two terminals on the battery fit into

spaces provided on the circuit board.

d. Using the retaining nuts, fasten the battery firmly

in place. Be careful not to short the battery terminals

at any time as this may cause battery cell damage.

e. Install Assembly A7, battery charging board, in

the space provided for it just ahead of the battery.

f. Reinstall instrument covers and adjust circuit.

Instrument is now ready for operation.

2-17. BATTERY STORAGE.

2-18. Store the battery at or below room temperature.

Extended storage at high temperature will reduce the

cell charge, but will not damage the battery if t h e

storage temperature is below 140” F. Install the battery in the instrument and recharge before using

Model 432A in battery operation.

2-19. RACK MOUNTING.

Model 432A is narrower than full-rack width.

2-20.

It is what is termed a sub-modular unit. When used

alone, the instrument can be bench mounted. When

used in combination with other sub-modular units it

may be bench or rack mounted. The HP 1051A and

1052A Combining Cases and Rack Adapter Frames are

designed specifically for this purpose.

2-21. COMBINING CASE.

2-22. A model 1051A Combining Case is shown in

Figure 2-1. This case is full rack width and accepts

varying combinations of submodular instruments. The

case, purchased separately, is provided with a rack

mount ing kit.

The combining case will hold three

2-1

Page 12

Section II

Installation

Model 432A

instruments the same size as the Model 432A. When

instruments are installed in the combining case, they

may be installed or removed individually.

2-23. ADAPTER FRAMES.

2-24. The 5060-0797 Adapter Frame is shown in Figure 2-2. The frame will accept a variety of submod ular units in a manner suitable for rack mounting.

Submodular units, in combination with anv necessarv

spacers are assembled within the frame.

A submod-

ular unit cannot be removed individually.

2-25. REPACKING FOR SHIPMENT.

Figure 2-1.

Sub -module Installation in

Rack Adapter Frame

2-26. When returning an instrument

Packard use the original packing material.

to HewlettIf the orig -

inal foam type packing material is not available, contact an authorized HP Sales Office for assistance. If

this is not possible, first protect the instrument surfaces by wrapping in heavy kraft paper or with sheets

of cardboard flat against the instrument, Protect the

instrument on all s i d e s using approximately 4“ of

packing material and pack in a durable container. Mark

the container clearly for proper handling and insure

adequately before shipping.

2-27. When an instrument is returned to HP for ser-

vice or repair, attach atagtothe instrument specifying

the owner and desired action. All correspondence

should identify the instrument by model number and

full eight -digit serial number.

2-2

Figure 2-2. HP Model 1051A Combining Case Instrument Installation

Page 13

Model 432A

Operating Instructions

Section III

SECTION Ill

OPERATING INFORMATION

3-1. INTRODUCTION.

3-2. The Model 432A Power Meter operates with HP

temperature-compensated thermistor mounts such as

the 8478B and 478A Coaxial, and 486A Waveguide

series. The frequency range of the 432A with these

mounts in 50-ohm coaxial systems is 10 MHz to 18 GHz;

in waveguide systems it is 2.6 GHz to 40 GHz. Fullscale power ranges are 10 microwatts to 10milliwatts

(-20 dBm to +10dBm). Extended measurements may

be made to 1 microwatt (-30 dBm). The total meas-

urement capacity of the instrument is divided into

seven ranges, selected by a f rent-panel RANGE switch.

3-3. This section describes general operating pro-

cedures and error analysis in microwave power messurement. Application Note 64, available on request

from Hewlett-Packard, is a detailed analysis of microwave power measurement problems and techniques.

3-4. CONTROLS, CONNECTORS, AND

INDICATORS.

3-5. The front and rear panel controls, connectors,

and indicators are explained in Figure 3-2. The des-

c riptions are keyed to the corresponding items which

are indicated on the figure.

3-6, The COARSE ZERO and FINE ZERO controls

zero the meter. Zero carry-over from the most sen-

sitive range to the other six ranges is within ± 0.5%.

When the RANGE switch is set to COARSE ZERO, the

meter indicates thermistor bridge unbalance, and the

front panel COARSE ZERO adjust is for initial bridge

balance. For best results, FINE ZERO the 432A on

the particular meter range in use.

3-7. The CALIBRATION FACTOR switch provides

discrete amounts of compensation for measurement

uncertainties related to SWR and thermistor mount

efficiency. The Calibration Factor value permits direct meter reading of the RF power delivered to an

impedance equal to the characteristic impedance (Z

of the transmission line between the thermistor mount

and the RF source. Calibration Factor values a r e

marked on the label of each 8478B, 478A, or 486A

Thermistor Mount.

For further details, see Para-

graph 3-23.

3-8. The MOUNT RESISTANCE switch on the front

panel compensates f o r t h r e e types of thermistor

mounts. Model 486A waveguide mounts can be used

by setting the MOUNT RESISTANCE switch to

100Ω

or 200Ω, depending on the thermistor mount used

(refer to Table 1-2). The

200Ω position is used with

Models 478A and 8478B Thermistor Mounts.

3-9. The rear-panel BNC connector lab e 1 ed RE-

CORDER provides an output voltage linearly propor tional to the meter current; 1 volt into an open cir-

cuit equals full- scale meter deflection. This voltage

is developed across a lK resistor; therefore, when

a recorder with a lK input impedance is connected to

the RECORDER output, approximately .5 volts will

equal full scale deflection. This loading of the RE-

CORDER output has no effect on the accuracy of the

432A panel meter.

3-10. A digital voltmeter can be connected to the rearpanel RECORDER output for more resolution of power

meter readings. When a voltmeter with input impedance greater than 1 megohm is connected to the RE-

CORDER output, 1 volt equals full scale deflection.

3-11. The 432A has two calibration jacks (V

vcomp) on the rear panel that can be used for precision power measurements.

Instrument error can

be reduced from ±1% ±(0.2% of reading +5µW) of

reading, depending on the care taken in measure-

and on the accuracy of auxiliary equipment.

ment,

For further information, see Paragraph 3-27.

3-12. BATTERY OPERATION,

3-13. The Model 432A Option 01 operates from battery

and conventional 115- or 230-volt line power. A rechargeable Nickel-Cadmium b a t t e r y is factoryinstalled in Option 01 instruments. The same battery

can be ordered and later installed in the basic instrument, thereby modifying the power meter to the Option

01 configuration. The battery installation kit (including

battery charging circuit ) may be ordered from the

nearest HP Sales Office.

3-14. It is recommended that the Model 432A be bat-

tery -operated for up to 8 hours, and then allowed to

recharge 8 hours, or overnight. Continuous battery

operation is possible for up to about 24 hours, but then

)

o

the battery must be recharged f o r about 24 hours.

3-15. The 432A automatically operates on its internal

batteries whenever the ac line power is disconnected

and the POWER switch is ON. When the battery ter-

minal voltage decreases far enough to f orce the power

supply voltage regulator out of regulation, then the

meter stops working and the meter indicator points to

the red RECHG BAT. To recharge the battery, simply

connect the 432A to ac line power, and turn it ON.

3-16. Battery Storage. Storage of the battery at or

below room temperature is best, Extended storage

at temperatures above room temperature will reduce

cell charge, but will not damage the battery; however,

the battery should not be stored where the tempera-

ture exceeds 60” C (+140° F).

RF and

3-1

Page 14

Section III

Operating Instructions

Model 432A

3-17. MICROWAVE POWER MEASUREMENT

ACCURACY.

3-18. A number of factors affect the overall accuracy

of power measurement.

The major sources of error

are mismatch error, RF losses, and instrumentation

error.

3-19. Mismatch Error.

In a practical measurement

situation, both the source and thermistor mount have

SWR, and the source is seldom matched to the ther mister mount unless a tuner is used. The amount of

mismatch loss in any measurement depends on the total

SWR present.

The impedance that the source sees is

determined by the acutal thermistor mount impedance,

the electrical length of the line, and the characteristic

impedance of the line, Z

.

o

3-20. In general, neither the source nor the thermistor mount has Z

are known only as reflection coefficients, mismatch

impedance, and the actual impedances

O

losses, or SWR. The power delivered to the thermis-

tor mount - and hence the mismatch loss - can only be

described as being somewhere between t w o limits.

The uncertainty of power measurement due to mismatch

loss increases with SWR. Limits of mismatch loss

are generally determined by means of a chart such as

the Mismatch Loss Limits charts in Application Note

64. The total mismatch 1 oss uncertainty in power

measurement is determined by algebraically adding

the thermistor mount losses to the uncertainty caused

by source and thermistor mount 2

3-21. RF Losses.

RF losses account for the power

match.

0

entering the thermistor mount but not dissipated in the

detection thermistor element.

Such losses may be in

the walls of a waveguide mount, the center conductor

of a coaxial mount, capacitor dielectric, poor connections within the mount, or due to radiation.

a load impedance equal to Z

relationship between indicated power and the power

, More accurately, the

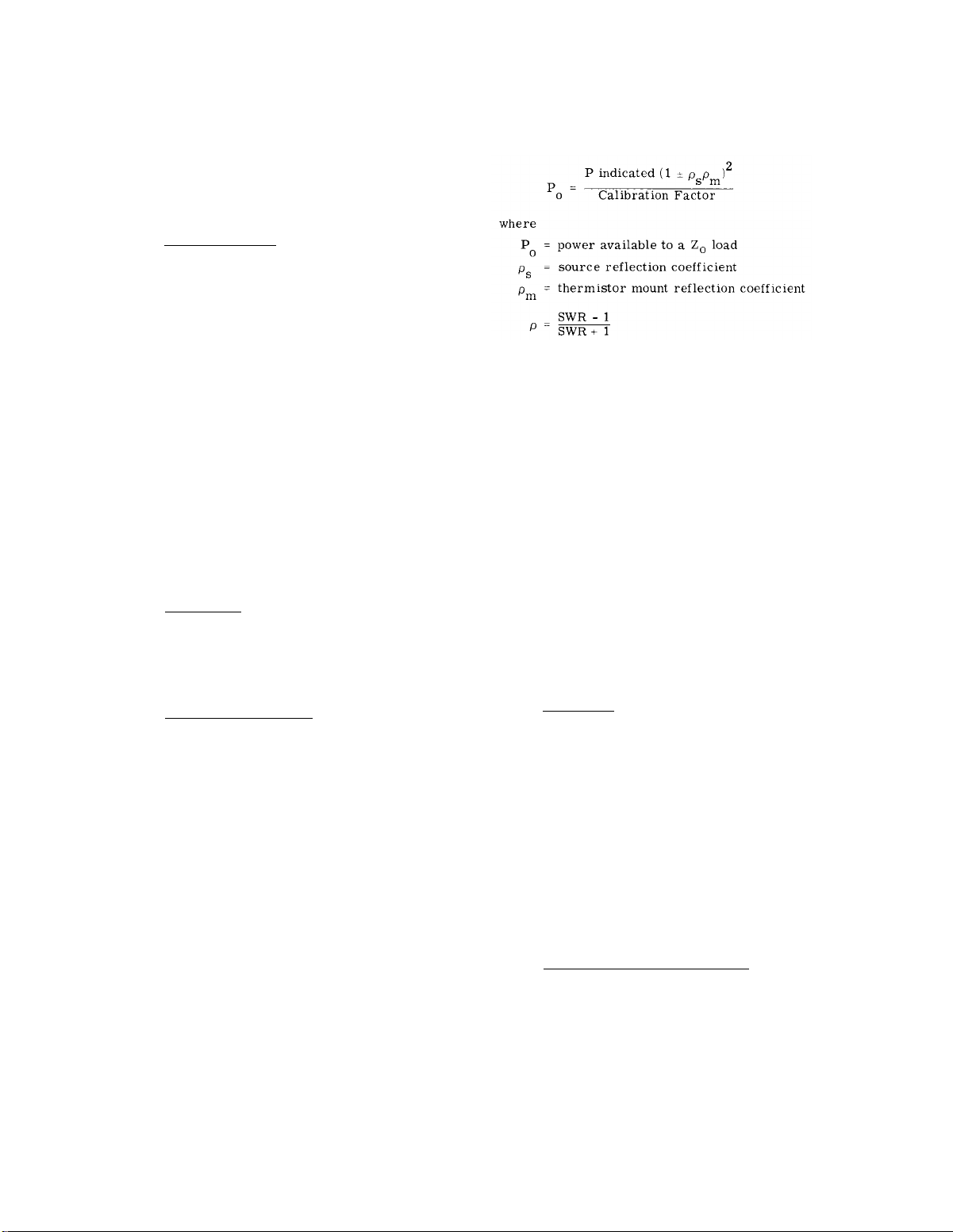

o

available to a Z. load is given by the following equation:

Calibration factor d o e s not compensate for source

VSWR, or for multiple reflections between the source

and the thermistor mount.

3-26. To minimize mismatch between the source and

the thermistor mount without a tuner, insert a low

SWR precision attenuator in the transmission line between the thermistor mount and the source. Since the

mount impedance (and corresponding SWR) deviates

significnatly only at the high and low ends of a microwave band, it is generally unnecessary to use a tuner.

A tuner or other effective means of reducing mismatch

error is recommended when the source SWR is high

or when more accuracy is required. For further details, there is a complete discussion of microwave

power measurement with emphasis on modern techniques, accuracy considerations and sources of error

available in Application Note 64.

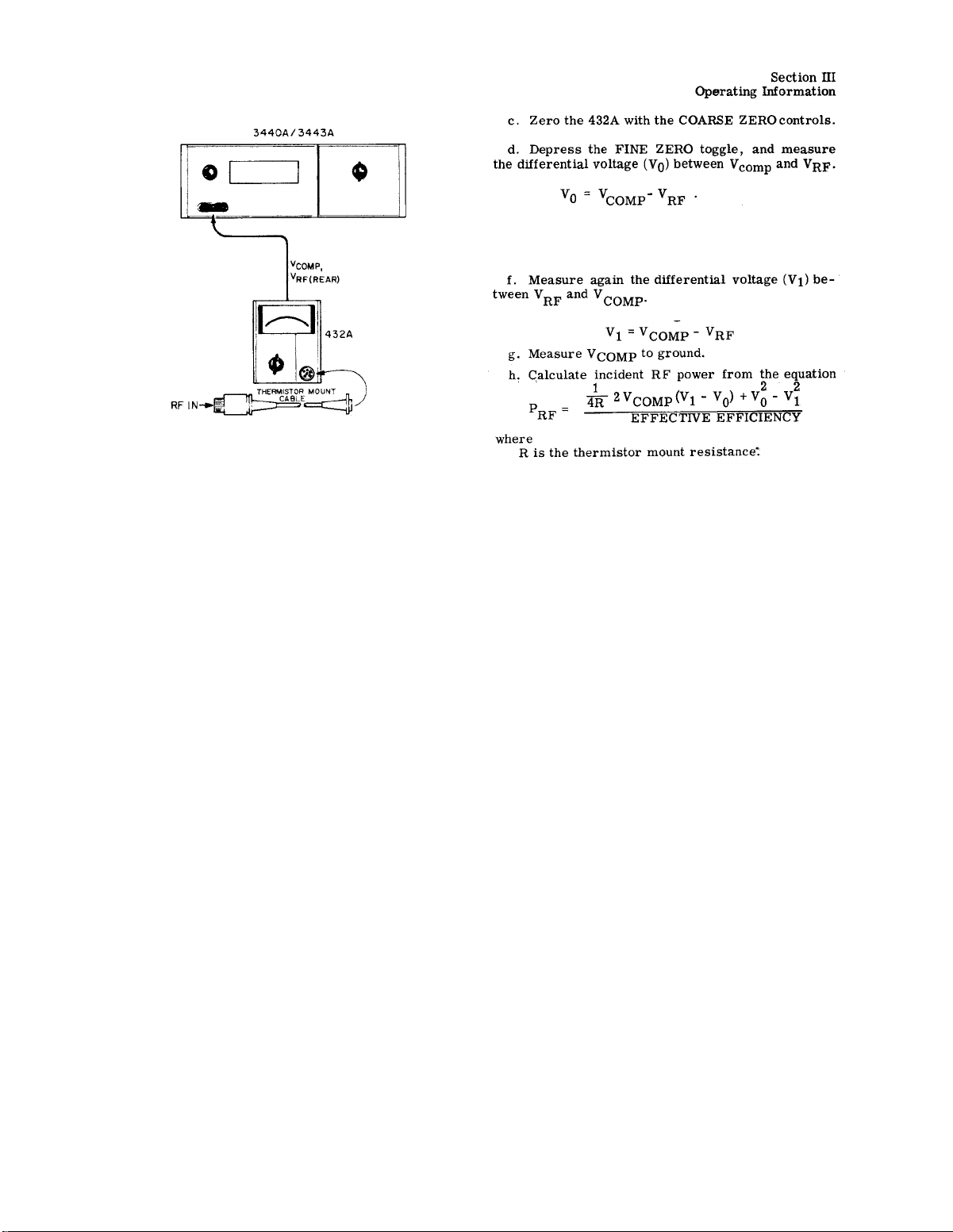

3-27. PRECISION POWER

MEASUREMENT.

3-22. Instrumentation Error. The degree of inability

of the instrument to measure the substitution power

supplied to the thermistor mount is called power meter

accuracy or instrumentation error. Instrumentation

error of the Model 432A is ±1% of full scale, O“C to

+55°c.

3-23. CALIBRATION FACTOR AND EFFECTIVE

EFFICIENCY.

3-24. Calibration factor and effective efficiency are

correction factors for improving power measurement

accuracy. Both factors are marked on every HP ther -

mister mount. Calibration factor compensates f o r

thermistor mount VSWR and RF losses whenever the

thermistor mount is connected to an RF source without

a tuner. Effective efficiency compensates for ther -

mister mount RF losses when a tuner is used in the

measurement system.

3-25. When the 432A CALIBRATION FACTOR selec tor is set to the appropriate factor indicated on the

thermistor mount, the power indicated by the meter

is the power that would be delivered by the source to

3-2

3-28. GENERAL.

3-29. Using precision instruments and careful procedures, measurement error can be reduced to ±0.2%

of reading +0.5 µW. The technique involves: 1) zero-

ing the bridge circuits and measuring the bridge amplifier output voltage difference with a digital voltmeter, then 2) connecting RF power to the thermistor

mount and then measuring the bridge amplifier output

voltage difference again, and 3) calculating the power

from ‘the two measurements. Figure 3-1 shows the

instrument setup for dc substitution measurement.

Use an HP Model 3440A DVM, with a 3443A Plug-in

Unit or a digital voltmeter with equivalent accuracy,

3-30. MEASUREMENT PROCEDURE.

a. Connect the DVM to the 432A rear panel Vcomp

and V

RF outputs.

Be sure that the digital voltmeter

input is isolated from chasses ground,

b. Turn off, or disconnect the RF power from the

thermistor mount.

Page 15

Model 432A

Section III

e. Release the FINE ZERO toggle, and turn on, or

reconnect the RF power to the thermistor ,mount.

Figure 3-1.

Precision Power Measurements

3-3

Page 16

Section III

General Information

Model 432A

3-4

Figure 3-2. Front Panel Controls, Connectors and Indicators (Sheet 1 of 2)

Page 17

Model 432A

Operating Information

Section III

1.

POWER. Instrument power ON/OFF switch;

connects either ac line voltage or internal bat- sion so that meter indicates zero. To adjust

tery (Option 01 only) to internal voltage regu - the zero:

later circuits. When ac power is on, optional

battery charging circuit operates.

2.

COARSE ZERO. Meter zero adjustment; set the indicator falls below zero and comes

the RANGE selector to COARSE ZERO, turn back up to zero again.

OFF the RF power, and adjust to zero the meter.

3.

RANGE. Power measurement range selector;

selects ranges from 0.01 to 10 milliwatts (-20

to +10dBm). COARSE ZERO setting is used

to zero meter with no power applied to ther -

mistor mount.

4. FINE ZERO. Electronic zero that balances

the compensation bridge with zero RF input.

To zero m e t e r during operation, close the

switch momentarily.

is not applied to the thermistor mount when the

FINE ZERO switch is depressed.

5.

Meter.

mount in milliwatts and dBm. To use the dBm

scale, note the value in dBm of the range in

use, and subtract from it the reading on the nectorfor 5-1/2 foot cable that connects to the

meter dBm scale.

Indicates power input to thermistor meter.

Be sure that RF power

6. Mechanical Meter Zero. Sets meter suspen-

a. Turn POWER switch off.

b. Turn the adjustment screw clockwise until

c. Turn the adjustment very slightly counter-

clockwise to free up tbe mechanism from

the adjusting peg.

CALIBRATION FACTOR. Amplifier gain com-

7.

pensation selector. Set to correspond to the

calibration factor printed on t h e thermistor

mount body. See Paragraph 3-23 for m o r e

information.

8.

MOUNT RESISTANCE. Se1ects resistance

equal to that of mount in use to balance bridges.

Table 1-2 lists Hewlett-Packard thermistor

mounts and resistances. Set with meter power

OFF, when mount is initially connected to the

9.

Thermistor Mount Cable Connector. Input con478A, 8478B, or 486A Thermistor Mounts.

Figure 3-2. Front Panel Controls, Connectors and Indicators (Sheet 2 of 2)

3-5

Page 18

Section III

Operating Information

Model 432A

3-6

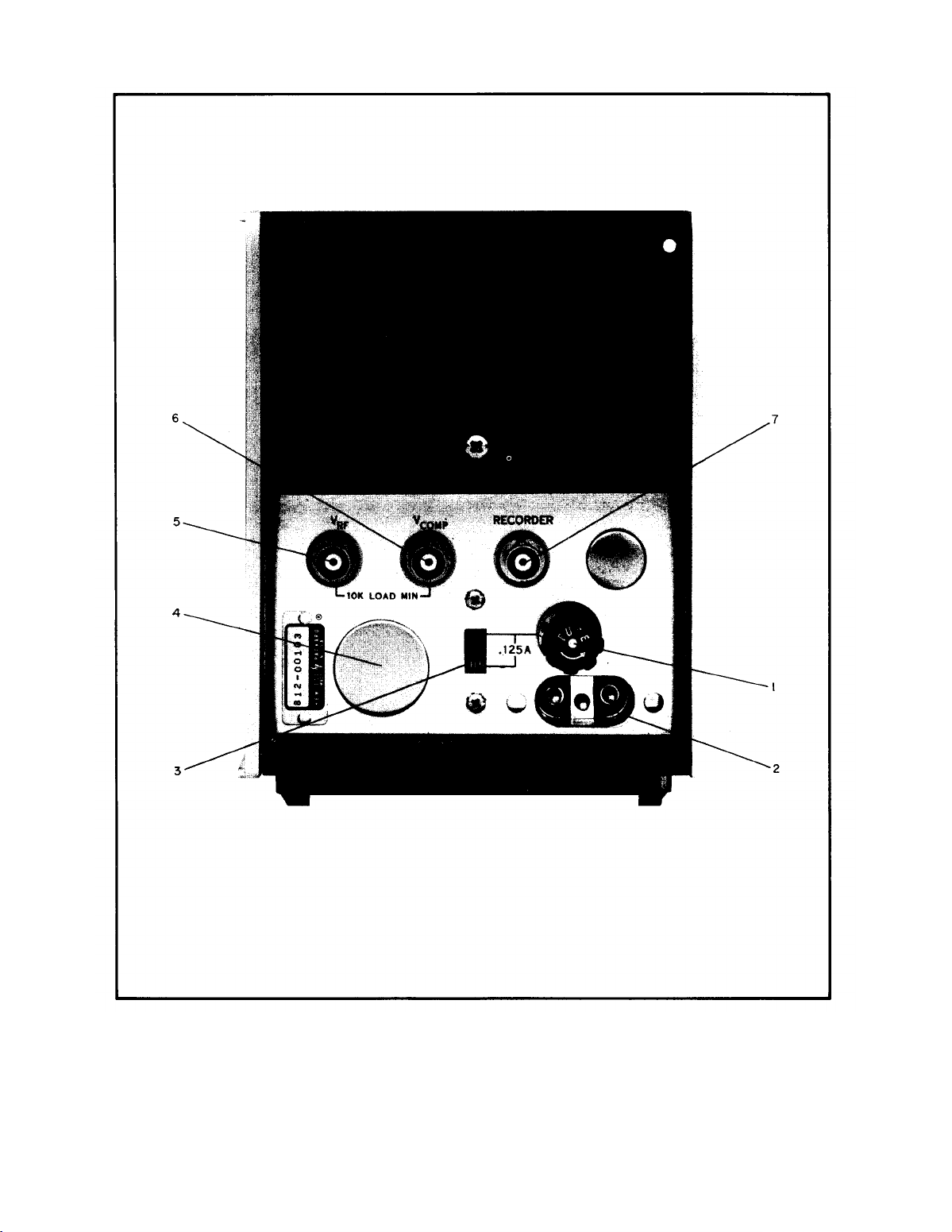

Figure 3-3. Rear Panel Controls and Connectors (Sheet 1 of 2)

Page 19

Model 432A

Operating Information

Section III

1,

Line Fuse. For 115 Vac or for 230 Vac use

1/8 amp slow-blow fuse.

2. Power Cord Input. Use power cord provided,

HP 8120 -00?8. Line power limits are 115/230

Vat, 50-400 Hz. Check FUSE rating and

PO-

sition of line voltage slide switch before connetting power.

Line Voltage Slide Switch: Set to line voltage

3.

avallable (115 or 230 Vat, 50-400 Hz).

4.

Mounting Hole for Option 02 Model Power

Meters.

Thermistor mount cable connector meter. Output impedance is approx.

installed and wired in parallel with f rent-panel

connector. Only one mount at a time may be

used with the power meter.

VRF Input. Connected directly to RF bridge.

5.

Used for calibrating power meter with HP 8477A

Power Meter Calibrator. Also used for precision power measurements.

VCOMP Input. Connected directly to compen-

6.

sation bridge. Used for calibrating power meter

with HP 8477A Power Meter Calibrator. Also

used for precision power measurements.

RECORDER OUTPUT. Voltage f r o m meter

7.

circuit to be used for recorder or digital volt-

1000Ω.

Figure 3-3. Rear Panel Controls and Connectors (Sheet 2 of 2)

3-7

Page 20

Section III

Operating Information

Model 432A

3-8

Figure 3-4. Turn On and Zeroing Procedure (Sheet 1 of 2)

Page 21

Model 432A

Operating Information

1. Connect the thermistor mount and cable to 5. Set the RANGE selector to COARSE ZERO and

THERMISTOR MOUNT connector. Refer to then zero the meter with the COARSE ZERO

Table 1-2 for recommended thermistor mounts screwdriver adjustment.

and their frequency ranges.

Note

2.

Meter Mechanical Zero:

a. With the instrument turned off, rotate the

meter adjustment screw clockwise until the

pointer approaches the zero mark from the

left.

b. Continue the clockwise rotation until the

The power meter should be zeroed with the

RF power source turned off, or the mount

disconnected from the source.

6. Set the range selector to the 0.01 mW range;

then depress the FINE ZERO switch until the

meter indicates zero.

pointer coincides with the zero mark. If

the pointer overshoots, continue rotating

the adjustment screw clockwise until the

pointer once again approaches the zero mark

Range-to-range zero carryover is 1 ess

Note

from the left. than ±0.5% if the meter zero has been ad-

C. Rotate the adjustment screw about three de-

grees counterclockwise to disengage screw

adjustment from the meter suspension.

justed (step 2 above), and the instrument

has been properly zero-set on the sensi -

tive range. For maximum accuracy, zero-

set the power meter on the range to be

used.

3.

Set the MOUNT RES switch to correspond to

the operating resistance of thermistor mount

used.

4,

Turn the 432A POWER switch ON. For battery

operation, the AC LINE indicator does not turn

on.

Set CALIB FACTOR switch to correspond to

7.

Calibration Factor imprinted on HP thermistor

mount label.

8.

Apply RF power to the thermistor mount. Power

is indicated on the meter directly in mW or dBm.

Section III

Figure 3-4. Turn On and Zeroing Procedure

3-9

Page 22

4-0

Section IV

Principles of Operation

Figure 4-1.

Model 432A

Page 23

Model 432A

Principles of Operation

Section IV

SECTION IV

PRINCIPLES OF OPERATION

4-1. SIMPLIFIED DESCRIPTION

4-2. The HP 432A Power Meter consists of two major

sections:

the bridge and meter logic assemblies, The

instrument also contains an auto zero circuit which

provides for automatic zeroing on any range. A simplified Mock diagram of the HP 432A is shown in

Figure 4-1.

4-3. The bridge section contains circuits which form

two self-balancing bridge circuits when a suitable

thermistor mount is connected to the 432A. Each

bridge is automatically brought to balance by the

action of a high gain dc amplifier feeding power to the

top of the bridge, The voltage at the top of the RF

bridge V

RF is responsive to both input RF power and

ambient temperature changes.. The voltage at the top

of the compensation bridge, V

only to ambient temperature changes. Knowing V

COMP is responsive

RF

and VCOMP, the RFpower can be calculated.

4-4. The meter logic section processes V

V

COMP to produce a meter current proportional to

RF power. The sum (V

RF + VCOMP) controls the

width of 5 kHz pulses. The difference (V

RF and

COMP - VRF)

is chopped, amplified and fed to an electronic switch

actuated by the controlled width pulses. Therefore,

the meter current is pulses of variable height and

width with the meter indicating the average current.

(This process produces a meter current proportional

to (V

RF + VCOMP) (VRF - VCOMP ). Paragraph 4-10

explains why this is necessary.

4-8. If ambient temperature causes changes in the

thermistor resistance, the bridge circuits respond by

applying an error voltage to the bridges to maintain

bridge balance.

The voltage at the top of the RF

bridge is dependent upon both ambient temperature

and the RF input. The voltage at the top of the compensation bridge is dependent upon the ambient temperature only. The power meter reading is brought to

zero with no applied RF power by making V

COMP

equal to VRF so (VCOMP - VRF) equals zero. Since

ambient temperature causes both thermistors to respond similarly, there will be no net difference between the amplifier output voltages. Therefore, any

difference in output voltages from the bridges is now

due to RF power absorbed by the thermistor mount.

4-9. The RF bridge voltage, V

tion bridge voltage, V

COMP, contain the “RF power”

RF, and the compensa-

information. To provide a meter reading proportional

to RF power the dc voltages (V

RF, VCOMP) must be

further processed by the meter logic circuits.

4-10. The required processing is derived as follows:

P. is absorbed power needed by the RF thermistor

to bring its resistance to R ohms (100 or 200 ohms).

P. consists of two components: RF power from the

signal source to be measured and dc power supplied

by the 432A. The self balancing action of the bridge

circuit automatically adjusts the dc power so that the

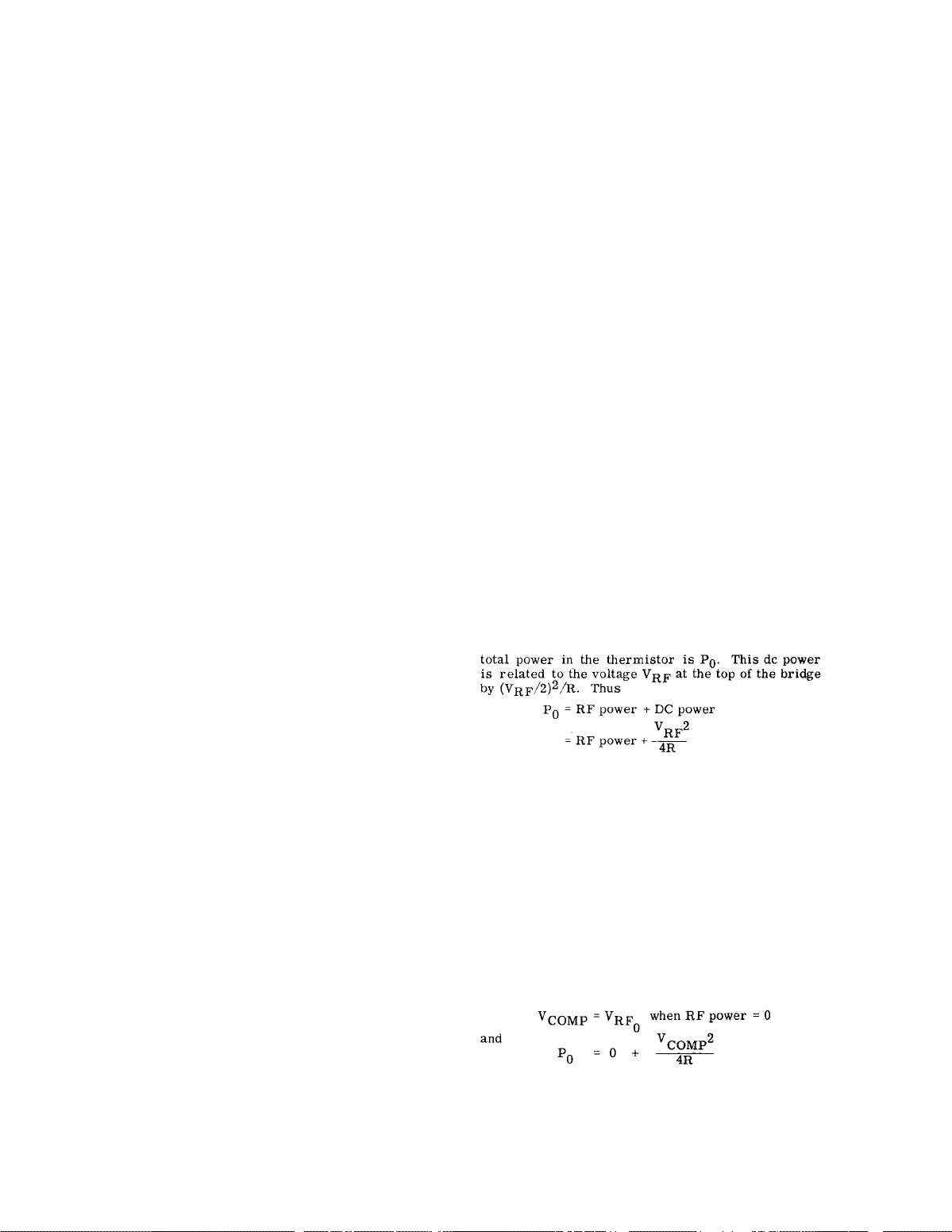

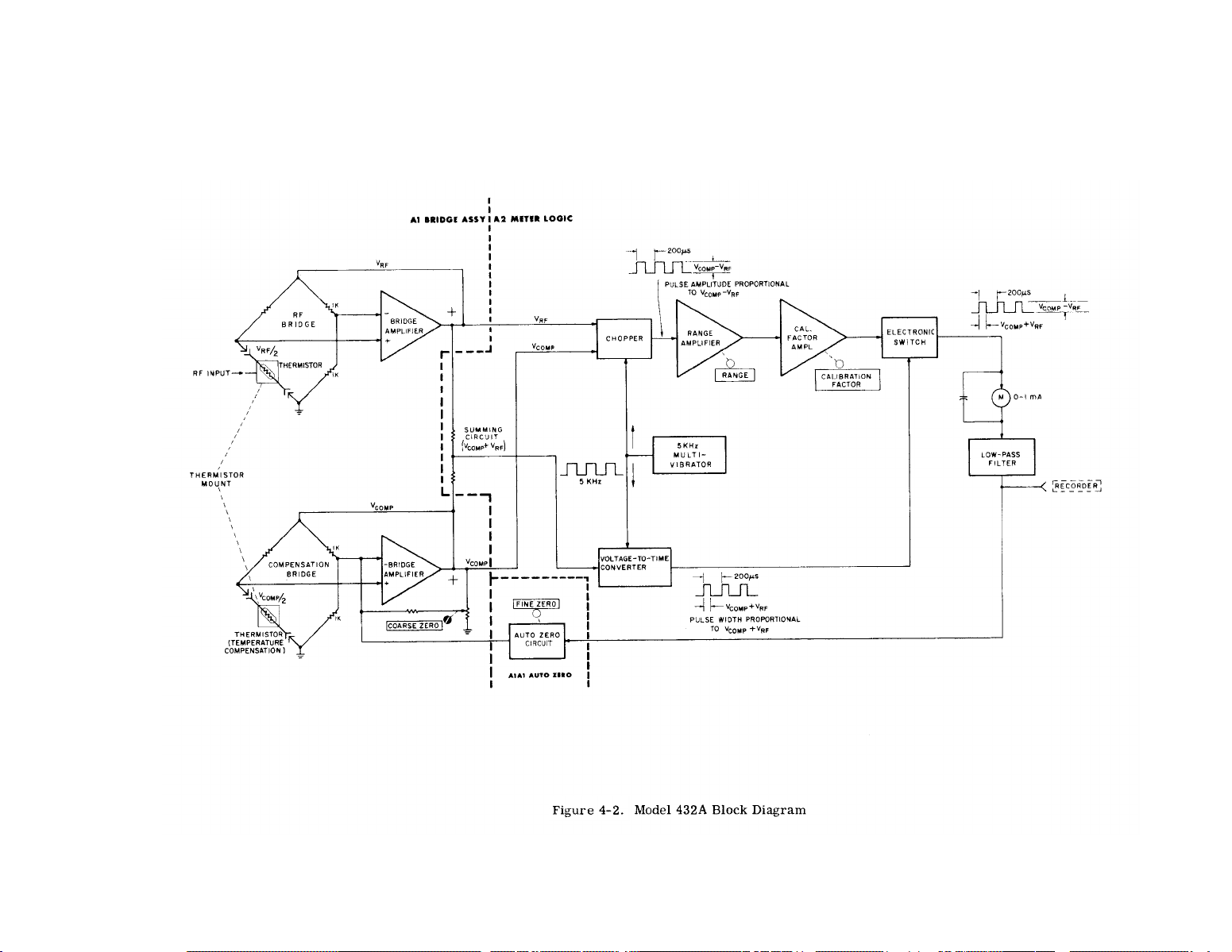

4-5. FUNCTIONAL BLOCK DIAGRAM

4-6. A functional block of the 432A power meter is

shown in Figure 4-2. The instrument comprises two

major assemblies: bridge assembly Al and meter

logic assembly A2.

Auto zero circuit Al Al, which

provides for automatic zeroing of the instruemtn, is

included as part of logic assembly Al.

4-7. The thermistor bridges are biased with direct

current from the bridge amplifiers.

Each bridge

amplifier supplies enough heating current to br ing the

thermistor resistance to 100 or 200 ohms, depending

upon the setting of the MOUNT RESISTANCE switch

on the 432A. If one of the thermistor bridges is unbalanced due to incorrect thermistor resistance, an

error voltage occurs and is amplified by the bridge

amplifier. The error voltage is applied to the top of

the bridge and changes the power dissipation of the

negative temperature coefficient thermistor.

The

change of power dissipation causes the resistance to

the thermistor to change in the direction required to

balance the bridge. Application of RF power to the

RF bridge heats the thermistor and lowers its resis-

tance. The bridge circuit responds by reducing the

dc voltage applied to the top of the bridge thus main-

taining bridge balance.

4-11. RFpower can redetermined by measuring VRF

with and without applied RF power and then doing

some arithmetic. But this power measuring scheme

is neither convenient nor temperature compensated

(since P. changes with temperature). The 432A introduces another thermistor bridge circuit exposed

to the same ambient temperature but not RF power.

This circuit includes adjustments (COARSE and FINE

ZERO) so that the dc voltage V

bridge can be set equal to V

RF and compensation thermistors, V

power) and V

erature fluctuation.

COMP remain equal with ambient temp-

They cliff er only when the RF

COMP at the top of its

RF. Assuming matched

RF

(with no RF

O

power to be measured is applied to the RF thermistor.

Thus, we have

4-1

Page 24

Section IV

Principles of Operation

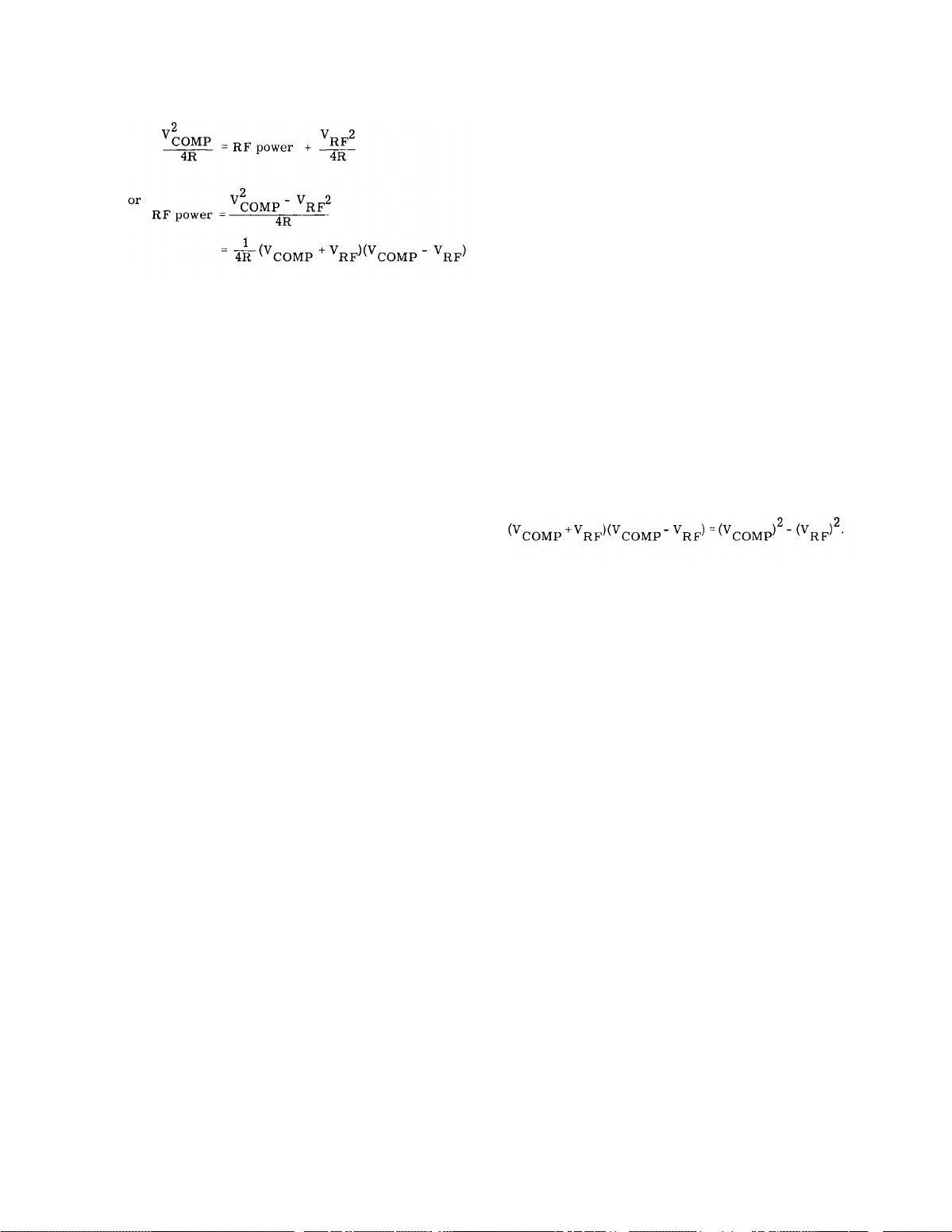

Combining equations, we have

4-12. Thus an RF power measurement reduces to

setting V

COMP = V RF

measuring V

COMP and VRF, and computing with the

(with zero RF power) initially,

O

above formula. The 432A carries out the computation

by forming the indicated sum and difference, perform-

ing the multiplication and displaying the result on a

meter.

4-13. The meter logic circuits change the two dc

voltages to two pulse signals which contain all the RF

power information. One of the signals will be a square

wave whose amplitude is proportional to V

RF. The other signal will have a pulse width pro-

V

portional to V

4-14. The V

-

COMP

= VRF .

COMP-VRF signal is obtained by taking

COMP -

the dc voltage outputs from the Al assembly and applying them to a chopper circuit. This chopper cir-

cuit is driven by a 5-kHz multivibrator. The output

of the chopper is a square wave signal whose amplitude is proportional to V

COMP - VRF. The output of

the chopper is coupled to the range amplifier and then

to the calibration factor amplifier. The amplification

that the signal receives in these two amplifiers depends upon the setting of the RANGE switch and the

CALIBRATION FACTOR switch.

The output of the

calibration factor amplifier is V. This current is fed

to the electronic switch. A square wave current with

amplitude proportional to (V

COMP - VRF).

Model 432A

4-15. The V

COMP + VRF signal is obtained by taking

the two dc voltages from Al assembly through a summing circuit and feeding this voltage to a voltage-totime converter.

The voltage-to-time converter is

driven by a 5-kHz multivibrator. The output of the

voltage-to-time converter is a signal whose pulse

width is proportional to the sum of V

COMP + VRF.

This signal controls the electronic switch. From the

COMP - VRF and V COMP + VRF inputs, the elec-

V

tronic switch provides a 5-kHz pulse train whose amp-

litude is proportional to V

width is proportional to V

COMP-VRF and whose pulse

COMP + VRF. The pulse

width is always 90 msec or less.

4-16. The bias circuit switch and filter provides a

zero current reference for the meter circuit. This is

accomplished by controlling the dc bias to the first

stage of the calibration factor amplifier. This circuit,

in effect, restores the dc component to the square wave

which has been amplified by ac coupled amplifiers.

4-17. The meter is 0-1 mA, full-scale meter that

has a capacitor across its terminals. The capacitor

integrates the output pulses from the current switch

so the current into the meter is proportional to the

time average of the input pulses. That is, the input

current to the meter is proportional to the product of

4-18. The output from the meter is further filtered so

the voltage at the rear panel RECORDER output is

suitable for use with either a digital voltmeter or X-Y

recorder. The RECORDER output voltage is returned

to the compensation bridge through the automatic zero

circuit when the FINE ZERO switch is depressed.

The automatic zero circuit holds a correction voltage

at the input of the compensation bridge amplifier, so

when the RF is zero, the meter indication will also

be zero.

4-2

Page 25

Model 432A

4-3

Principles of Operation

Section IV

Figure 4-2.

Page 26

4-4

Section IV

Principles of Operation

Figure 4-3.

Model 432A

Page 27

Model 432A

4-5

Figure 4-3.

Principles of Operation

Section

IV

Page 28

4-6

Section IV

Principles of Operation

Figure 4-4.

Model 432A

Page 29

Model 432A

4-7

Principles of Operation

Section IV

Figure 4-4.

Page 30

4-8

Section IV

Principles of Operation

Figure 4-5.

Model 432A

Page 31

Model 432A

4-9

Principles of Operation

Section IV

Figure 4-5.

Page 32

Section V

Maintenance

Model 432A

Table 5-1.

5-0

Figure 5-2

Page 33

Model 432A

SECTION V

MAINTENANCE

5-1. INTRODUCTION.

5-2. This section provides information for perfor mance testing, adjusting, troubleshooting and repairing

the 432A Power Meter.

instrument to be checked for conformance to specifications. If performance is not within specifications,

adjust or troubleshoot the instrument.

5-3. CONTENT.

5-4. PERFORMANCE TESTS .

5-5. The procedures test power meter performance

for incoming inspection, periodic evaluation, calibration and troubleshooting, Specifications in Table 1-1

are the performance standards. If the power meter

fails to meet any of the performance test specifications. refer to the troubleshooting diagrams.

Performance tests allow the

Section V

Maintenance

Figure 5-1. Check and Adjustment Test Set -up

5-6. ADJUSTMENTS

5-7. Procedures describe the adjustments necessary

to calibrate the power meter. Adjust the power meter

only when it is determined that the meter is out of

adjustment, and not malfunctioning due to a circuit

failure.

5-8. To avoid errors due to possible ground loop currents, isolate the power meter from ground used for

other auxiliary equipment. A power plug adapter that

removes the ground connection at the line outlet can

be used to isolate the power meter.

5-9. Several circuit components are factory-selected

to meet specific circuit requirements. The factory

selected parts are indicated on the schematic diagrams.

5-10. TEST EQUIPMENT.

5-11. Instruments and accessories required for ad-

justing and testing the power meter are listed and

briefly described in Table 5-1. Instruments used to

maintain the instrument must m e e t or exceed the

specifications given.

5-12. SERVICE INFORMATION.

5-13. Service information in the f o r m of troubleshooting, waveforms, schematics, and component 10cations are given in Section VII. Also, an overall system block diagram is included which contains keyed

numbers corresponding to the test points.

5-14. 432A

PERFORMANCE TESTS

WITH 8477A CALIBRATOR

5-15.

INITIAL SET-UP.

a. Connect the 8477A outputs to the 432A inputs as

shown in Figure 5-1. Use appropriate test equipment

as listed in Table 5-1.

b. If necessary, mechanically zero the meter move-

ment as follows:

(1) With instrument turned off, rotate meter adjust-

ment screw clockwise until pointer approaches

zero mark from the left.

(2) Continue rotating clockwise until pointer coin-

cides with zero mark. If pointer overshoots,

continue rotating adjustment screw clockwise

until pointer once again approaches zero mark

from the left.

(3) Rotate adjustment screw about three degrees

counterclockwise to disengage screw adjustment

from meter suspension.

5-16. METER ACCURACY TEST.

a. Set the 8477A Calibrator controls as follows:

POWER . . . . . . . . . . . . . . . . . . . . . . . . . .. 0.0lmW

FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

ZERO/TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ZERO

b. Set the 432A controls as follows:

MOUNT RESISTANCE.. . . . . . . . . . . . . . . . . . .

RANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.0lmW

POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ON

CALIBRATION FACTOR . . . . . . . . . . . . . . . . . . . ...100%

200Ω

..200Ω

5-1

Page 34

Section V

Maintenance

Model 432A

c. Adjust 8477A ZERO knob for 0 volts

cation on the DVM.

d. Set the 8477A controls as follows:

POWER . . . . . . . . . . . . . . . . . . . . . . . .

ZERO/TEST . . . . . . . . . . . . . . . . . . . . . . . . .

e. The digital voltmeter should indicate 1000 ±10

millivolts.

f. The 432A meter should indicate full scale ±1/2

division.

g. Repeat steps d through f for each of the other

ranges. Set the power meter range selector to the

position indicated in Column 1 of Table 5-2, and set

the 8477A meter reading selector to the corresponding

position indicated in Column 2 of Table 5-2. In each

case, the meter indications should correspond to those

shown in Table 5-2, Columns 3 and 4.

Table 5-2. Meter Accuracy Test

±2 mV indi -

.. 0.01mW

TEST

. . . . .

f. Repeat steps d and e for each position of the

CALIBRATION FACTOR selector. In each case, the

digital voltmeter should indicate the voltage shown in

the second column of Table 5-3 for the CALIBRATION

FACTOR shown in the first column.

Table 5-3. Calibration Factor Test

5-17. CALIBRATION FACTOR TEST.

a. Set 432A controls as follows:

RANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAL FACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOUNT RESISTANCE . . . . . . . . . . . . . . . . . . . ...2000

b. Set 8477A controls as follows:

FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ZERO/TEST Switch . . . . . . . . . . . . . . . . . . . . . . . .. TEST

POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.lmW

c. Set 8477A ZERO control sothatthe digital volt-

meter reads 1000 ±2 mV.

d. Set the calibration factor selector to 89%.

e. The digital voltmeter should indicate 989 ±10

millivolts.

0.1 mW

.88%

..200Ω

5-18. METER LINEARITY CHECK.

a. Set the 8477A POWER (MW) selector to 1 mW,

and FUNCTION to

b. Set the 432A RANGE selector to 3 mW, MOUNT

RESISTANCE to

c. The 432A meter should indicate 1 mW ±1/2

division.

d. Set the 8477A POWER (MW) selector to 2 mW.

e. The 432A meter should indicate 2

division.

f. Set the 8477A POWER (MW) selector

g. The 432A m e t e r should indicate 3

division.

5-19. ZERO CARRYOVER TEST.

a. Disconnect the 432A from the 8477A.

b. Turn the 432A power OFF, and connect the ther -

mister mount cable to a thermistor mount.

200Ω, ZERO/TEST switch to TEST.

200Ω.

mW ±1/2

to 3 mW.

mW ±1/2

5-2

Page 35

Model 432A

Figure 5-2. Zero Carryover Test Setup

c.

Set the

432A Power Meter MOUNT RESISTANCE

selector to the resistance shown on the thermistor

mount,

d. Turn ON the 432A power.

e. Connect 141A through ftiltering network to rear

of 432A as shown in Figure 5-2.

Set 141A controls

as follows:

INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DC

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . .

SWEEPT ICE . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGGER LEVEL . . . . . . . .

max clockwise (free run)

1 mV/cm

2 see/cm

f. Zero the 432A as follows:

1) Set the RANGE selector maximum cw to

COARSE ZERO.

2) Set the COARSE ZERO screwdriver adjust so

that the meter indicates zero.

3) Set 432 ARANGE switch to .01 mW. Depress

the FINE ZERO switch. The meter indication

should to to zero without overshoot.

g. Rotate the RANGE switch clockwise, one step at

a time, while the oscilloscope is sweeping. On each

432 A range, the scope trace should be within .0lmW

divisions (±5 mV) from where it was on the .01 mWrange,

5-20. FINE ZERO RANGE CHECK.

a. Set the 432A RANGE selector to 0.3 mW. Leave

the thermistor mount connected to the cable, and the

MOUNT RESISTANCE selector set to correspond to

the resistance of the mount used.

b. Depress the FINE ZERO switch.

c. Slowly turn the COARSE ZERO screwdriver adjustment counterclockwise until the meter will no

longer zero. The FINE zero circuit is at one end of

its range.

d. Release FINE ZERO.

e. Set the COARSE ZERO screwdriver adjustment

so that the meter indicates full scale on the 0-3 scale

(0.3 ‘mW range).

Section V

Maintenance

f. Depress FINE ZERO switch (the fine zero circuit

is at the other end of its range). Meter should indicate

below 2 on the 0-3 scale. Record the indication.

g. Release FINE ZERO.

h. Rotate RANGE switch to COARSE ZERO position.

The fine zero circuit is now in the center of its range.

The meter reading should be (1.5 + reading of +1/2 of

reading in step f, ±0.1 on the 0-3 scale.

5-21. 432A CALIBRATION WITHOUT 8477A

CALIBRATOR

5-22. The 432A Power Meter can be calibrated without an 8477A Calibrator using a method similar to the

precision power method outlined in Paragraph 3-27.

5-23. A major difference between the two measurements is that external power need not be applied when

calibrating the instrument. Normally, in a stable environment, the V

output voltage remains con-

COMP

stant, not being affected by external RF power; only

the V

RF output varies during power measurement.

Since the power that the meter indicates is proportional to V

to indicate a power also by holding V

varying V

COMP and VRF, we can cause the meter

RF constant and

COMP. This is easily done on the 432A by

turning the COARSE ZERO control. Two calibration

procedures are given below.

5-24. CALIBRATION PROCEDURE 1.

a. Connect thermistor mount to power meter; let

instrument warm up for at least 10 minutes.

b. Select range which instrument is to be calibrated

on. Note: ranges below 0.3 mW require a precise

differential voltmeter capable of resolving 1 µV. The

HP 740B DC Standard/A Voltmeter, which has an accuracy of ±(0.005% of reading ±0.0004%ofrange ±1µV)

is recommended. A digital voltmeter is adequate for

the 1.0 mW and higher ranges.

c. Connect Differential Voltmeter (or DVM differentially) between the V

on the rear panel. See Figure 3-3 for location of V

and VCOMP outputs.

d. While pressing the FINE ZERO switch, measure

and record V

0. (V. is the difference of the bridge

voltages with no power applied. )

e. Turn COARSE ZERO control (on front panel)

clockwise to a convenient power, e.g., 9 on the zero to

10 scale or 2 on the 0 to 3 scale.

f. Differentially measure and record V

difference voltage between V

power applied.

g. Measure and record V

V

COMP jack is isolated from chassis ground; measure

from the center conductor of the BNC to the outer

conductor.

COMP and VRF output jacks

1. V1 is the

COMP and VRF with

COMP. Note that the

5-3

R

F

Page 36

Page 37

Model 432A

Section V

Maintenance

INSTRUMENT SERIAL NO.

DATE

TABLE 5-4. PERFORMANCE TEST CARD

Data in this test card corresponds to Performance Tests in

Paragraphs 5-16 through 5-20.

5-5

Page 38

Section V

Maintenance

Model 432A

TABLE 5-4. PERFORMANCE TEST CARD

Para. Measurement

Ref. Test

5-16

e

f

METER ACCURACY

0.01 mW applied; measure RECORDER OUT voltage

Meter indicates full-scale (0-1 scale)

Unit

mVdc

divisions

Repeat on remaining 432A power ranges:

e

f

e

f

e

f

e

f

e

f

Power applied: 0.03 mW

Meter indication (0-3 scale)

Power applied: 0.1 mW

Meter indication (0-1 scale)

Power applied: 0. 3 mW mVdc 938.8 958.8

Meter indication (0-3 scale)

Power applied: 1 mW

Meter indication (0-1 scale)

Power applied: 3 mW

Meter indication (0-3 scale)

mVdc

divisions -1/2

m.Vdc 990 1010

divisions -1/2

divisions -1/2

mVdc

divisions -1/2

mVdc

divisions

Min.

990

-1/2

Actual Max.

1010

+ 1,/2

938.8 958.8

+ 1,/2

+1/2

+1/2

990

1010

+ 1/2

938.8 958.8

-1/2

+1/2

e

f

5-17

i

Power applied: 10 mW

Meter indication (0-1 scale)

CALIBRATION FACTOR

Calibration Factor (%)

88

89

90

91 967

92 957

93

94

95

96

97

98

99

100

DVM Reading (mVdc )

1000

989

9’78

946

935

926

916

907

897

889

880

mVdc

divisions

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

mVdc

990

-1/2

990

1010

+ 1,/2

1010

979 999

968

957

947

936

925

916

906

988

977

967

956

945

936

926

897 917

887

879

907

899

870 890

5-6

Page 39

Model 432A

Section V

Maintenance

TABLE 5-4. PERFORMANCE TEST CARD

Para.

Ref.

5-18

c

e

g

5-19

d

Test

Unit

METER LINEARITY

1 mW applied, 3 mW scale: meter indicates 1 mW divisions

2 mW applied, 3 mW scale: meter indicates 2 mW divisions

3 mW applied, 3 mW scale: meter indicates 3 mW divisions

ZERO CARRY-OVER

Zero carry-over:

Measurement

Range (mW)

.01

.03 0 ±5 mVdc

.1

.3

1

3

10

Scope Indication

0 ±5 mVdc

0 ±5 mVdc

0 ±5 mVdc

0 ±5 mVdc

0 ±5 mVdc

0 ±5 mVdc mVdc

mVdc

mVdc -5

mVdc -5

mVdc -5

mVdc -5

mVdc

Min.

-1/2

-1/2

-1/2

-5

-5

-5

Actual Max.

+1/2

+1/2

+1/2

+5

+5

+5

+5

+5

+5

+5

5-20

f

g

FINE ZERO RANGE

Meter indication on 1-3 scale:

Meter indication on 1-3 scale: 1.5+ 1/2 reading

of step f.

divisions

divisions

1.75

2.0

1.5

5-7

Page 40

Model 432A

h. Calculate the power using the following formula?

where R is the resistance of the thermistor mount and

should be identical to the setting of the MOUNT RESISTANCE switch.

i. If calculated power is different from the value

that was set with the COARSE ZERO control, adjust

A2R6 so that the meter reads calculated power. If the

range of A2R6 is insufficient to set new power, it will

be necessary to change the value of A2R70.

j. Set COARSE ZERO so that meter reads one on

the 0 to 1’scale. Set A2R72 for 1.000 V±10 mV at the

RECORDER output jack on the rear panel.

5-25. There is a simpler form of the equation that

was used to calculate power in step h above. This

form ignores V

tween the two bridges with no power applied. How-

, the small voltage difference be-

o

ever, V. becomes negligible on the higher ranges,

that is, 1 mV and above, and can be ignored with little

decrease in accuracy. I’he simpler form is as follows:

5-26. CALIBRATION PROCEDURE 2.

a. Connect thermistor mount to power meter; let

instrument warm up for at least 10 minutes.

b. Select 1, 3, or 10 mW range.

c. Turn the COARSE ZERO control clockwise to

indicate some convenient on- scale reading.

d. Measure V

COMP and record. Note that VCOMP

jack is isolated from chassis ground; measure from

the center conductor of the BNC to the outer conductor.

e. Measure V

RF and record. Follow measurement

procedure in step d.

f. Measure and record V

COMP - VRF. This term

must be measured differentially, that is, one side of

the DVM connected to V

nected to V

RF. In this way the full resolution of the

COMP and the other side con-

DVM can be used.

g. Substituting the measured values into the above

formula, calculate the power,

h. If calculated power is different from the power

set with the COARSE ZERO control, adjust A2R6 so

that meter indicates that power. If the range of A2R6

is not great enough to set new power level, the value

of A2R70 will have to be changed.

i. Adjust COARSE ZERO so that meter reads 1 on

the O to 1 scale. Set A2R72 for 1.000 V ±10 mV at the

RECORDER output jack on the rear panel.

*This formula is accurate for on- scale readings; how-

ever, with no power applied (i. e., V

solveto P = O because of a deleted term + V

1 = V0) it does not

0. This

term can be neglected for any on-scale reading.

5-8

Section V

Maintenance

COVER REMOVAL AND

5-27.

REPLACEMENT.

The side covers can be removed and replaced

5-28.

independently of the top and bottom covers. Each side

cover is held in place by four screws retained by nuts

which are fastened to the side frames.

5-29. TOP COVER REMOVAL.

a. At the rear of the instrument, remove the screw

that retains the cover.

b. Grasp the cover from the rear, and slide it back

1/2 inch. Then tilt forward edge of the cover upward

and lift the cover from the instrument.

5-30. TOP COVER REPLACEMENT.

a. Rest the cover flat on the cast guides projecting

inward near the top of each side frame.

b. Slide t h e cover forward, allowing its forward

edge to enter the groove in the front panel.

c. Replace the cover retaining screw.

5-31. BOTTOM COVER REMOVAL.

a. Remove the retaining screw at the rear of the

cover.

b. Swing the tilt stand out to free the cover

c. Slide the cover rearward far enough to free the

forward edge.

d. Tilt the forward edge of the cover upward and

lift the cover from the instrument.

5-32. BOTTOM COVER REPLACEMENT.

a. Set the tilt stand out of the way of the cover

b. Rest the bottom cover flat on the cast guides

projecting inward near the bottom of each side frame.

c. Slide the cover forward on the guides so that the

formed portion at the rear of the cover slides over the

two short projections at the rear corner of each side

frame.

d. Replace the retaining screw.

5-33. ADJUSTMENT PROCEDURES.

5-34. INITIAL SETUP.

a. Remove the power meter side panels.

b. Connect the equipment as shown in Figure 5-1.

Refer to Table 5-1 for equipment specifications.

5-35. MECHANICAL METER ADJUSTMENT.

a. Whenthe meter is properly zero-set, the pointer

rests over the zero mark on the meter scale when the

instrument is:

(1) at normal operating temperature

(2) in its normal operating position

(3) turned off

Page 41

Section V

Maintenance

Model 432A

b. Set the pointer as follows to obtain best accuracy

and mechanical stability:

(1) Turn instrument off.

(2) Rotate the meter mechanical adjustment screw

clockwise until the meter pointer is to the left

of zero and moving up the scale toward zero.

Stop when the pointer is exactly over the zero

mark. If the pointer overshoots, repeat step 2.

(3) When the pointer is exactly on zero, rotate the

adjustment screw approximately 3 d e g r e es

counterclockwise. This frees the adjustment

screw from the meter suspension. If the pointer

moves during this step, repeat steps 2 and 3.

5-36. BRIDGE AMPLIFIER TESTS

a. Connect equipment as shown in Figure 5-3.

b. Compensation Bridge.

1. Connect 3440A/3443A between A1TP5 and

A1TP6 (using 10K isolation resistors).

2. Make the following settings:

RANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . .l0mW

MOUNT RESISTANCE . . . . . . . . . . . . . .

FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . .. SET

3. Adjust A1R12 (OFFSET ADJUST) for 0.0 ±0.1

mV dc reading on the digital voltmeter.

4. Change 8477A FUNCTION to CHECK. The

digital VM reading should not exceed ±0.4

mVdc.

c . RF BRIDGE

1. Connect DVM between A1TP3 and AlTP4

using 10

the leads.

3. Set 8477A FUNCTION to SET. Adjust A1R15

(OFFSET ADJUST) for DVM reading of 0.0

± 0.1 mVdc.

432A

..200Ω

8477A

κΩ isolation resistors in series with

4. Change 8477A FUNCTION to CHECK. The

reading should not exceed ±0.4 mVdc.

Note: Failure of the instrument to meet the specification of steps (4) of b and c above indicates insufficient

bridge gain. Refer to Table 7-3 or 7-4 in the trouble-

shooting section.

5-37. METER AND RECORDER OUTPUT

CALIBRATION

a. Connect the DVM to the 432A RECORDER output.

b. Set 8477A controls as follows:

FUNCTION . . . . . . . . . . . . . . . . . . . .

ZERO/TEST . . . . . . . . . . . . . . . . .. ZERO

POWER . . . . . . . . . . . . . . . . . . . . . . . 1mw

c. Set 432A controls as follows:

MOUNT RES . . . . . . . . . . . . . . . . . . .

RANGE . . . . . . . . . . . . . . . . . . . . . . . . . lmW

CAL FACTOR . . . . . . . . . . . . . . . . . . .

d. Adjust ZERO control on 8477A for DVM indica-

tion of 0.000 ±.00IV.

e. ZERO/TEST on 8477A to TEST

f. Adjust A2R6 in 432A for 432A meter reading of

1.0 mW ±.01 mW.

g. Adjust A2R74 in 432A for DVM reading of 1.0V

±.001V

h.

Change the following settings:

432A RANGE to 10 mW

8477A POWER (mW) to 10 mW and ZERO/

TEST to ZERO.

Note: When switching 432A to 10 mW or switching from 10 mW to any other range, the meter

will react slowly for a short period. This is due

to time constants in the instrument and is normal.

i.

Zero instrument as in step d and c.

200Ω

.200Ω

100%

Figure 5-3. Bridge Amplifier Test

Adjust A2R86 for DVM reading of 1.00 ±.00 IV.

j.

Return 432A RANGE and 8477A POWER switches

k.

to 1 mW and zero as before.

1. Adjust A2R6 for DVM reading of 1.000 ±.00 1V.

m. Perform the adjustments of steps h through 1

again until 432A reads 1 ±.010V (at recorder output)

on both 1 mW and 10 mW ranges.

n. Turn to the beginning of this section; verify that

the instrument meets its specifications by completing

the PERFORMANCE TESTS.

5-38. BATTERY CHARGER ADJUSTMENT

(OPTION 01 ONLY)

a.b.Remove the power meter top panel.

Connect 432A to ac line power and turn ON.

5-9

Page 42

Model 432A

c. Set A7R8 fully clockwise for maximum battery

charge rate.

d. With the digital voltmeter, measure the voltage

between A7TP1 and A7TP2.

e. Adjust A7R8 for digital voltmeter reading of 0.2

to 0.4 volts (20 to 40 mA through R3).

Section V

Maintenance

5-43. To check a transistor, first see if the emitterbase diode is forward-biased by measuring the voltage

difference between emitter and base. When using an

electronic voltmeter, do not measure directly between

emitter and base; there may be sufficient loop current

between the voltmeter lead to damage the transistor.

Instead, measure each voltage separately with respect

to a voltage common point (e.g. , chassis).

f. Disconnect the test equipment and power and re-

place the power meter top and side panels.

5-39. BATTERY REMOVAL

a. Remove the top cover.

b. Remove the two Phillips screws on the top rear

of the battery cover.

c. Lift off the battery cover.

d. Loosen the nuts on the battery binding posts.

e. Lift out the battery.

5-40.

ISOLATING TROUBLE IN TRANSISTOR

CIRCUITS.

5-41. General. The following information should help

determine if a transistor works. There are tests for

both in-circuit and out -of -circuit transistors, which

help to determine if a particular trouble is due to a

faulty transistor or some other component. See Figure 5-2.

5-42. hi-circuit Testing. Intransistor Circuit testing

the most important consideration is the transistor

base-emitter junction. Like the control g r id of a

vacuum tube, this is the control point in the transistor.

5-44. If the transistor base-emitter junction is

forward-biased, the transistor conducts. If the diode

is heavily forward-biased, the transistor saturates.