Page 1

HP 4400 Enterprise Virtual Array Installation

Guide

Abstract

This guide describes how to install the HP 4400 Enterprise Virtual Array (EVA4400) and is intended for users with knowledge

of storage area networks and basic operating system commands and utilities.

The EVA4400 is customer self installable. However, you may purchase installation service by an HP-authorized service provider

if preferred. For more information, contact HP technical support in North America at 1-800-474-6836. Outside North America,

call HP technical support at the nearest location. Telephone numbers for worldwide technical support are listed on the HP

website: http://www.hp.com/support.

To assist you in installing the EVA4400, videos of the procedures have been produced. Go to the Services Media Library

website: http://www.hp.com/go/sml and navigate to your product to view these videos.

HP Part Number: 5697-1146

Published: September 2011

Edition: 8

Page 2

© Copyright 2008, 2011 Hewlett-Packard Development Company, L.P.

Confidential computer software. Valid license from HP required for possession, use, or copying. Consistent with FAR 12.211 and 12.212, Commercial

Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government under

vendor's standard commercial license.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Microsoft®, Windows®, Windows® XP, and Windows NT® are U.S. registered trademarks of Microsoft Corporation.

UNIX® is a registered trademark of The Open Group.

Printed in Puerto Rico

Page 3

Contents

1 Review and confirm your plans.....................................................................5

Overview................................................................................................................................5

Prerequisites.............................................................................................................................5

Plan your storage configuration..................................................................................................5

System and performance expectations....................................................................................6

RAID levels.........................................................................................................................6

HP P6000 Command View implementation..................................................................................7

2 Prepare your site........................................................................................8

Overview................................................................................................................................8

Provide adequate structural support for the floor...........................................................................8

Provide adequate clearance space and ventilation........................................................................8

Provide adequate and redundant sources of power.......................................................................9

Remove product from packaging.................................................................................................9

3 Install components....................................................................................10

Overview..............................................................................................................................10

Rack installation best practices.................................................................................................10

Attach the brackets for a longer chassis.....................................................................................11

Converting the rails.................................................................................................................12

Attach the rails.......................................................................................................................12

Install the enclosures...............................................................................................................14

Installing the hard drives into the drive bays...............................................................................16

Installing SFPs........................................................................................................................17

4 Connect cables and power cords...............................................................18

Overview..............................................................................................................................18

Cabling best practices.............................................................................................................18

Connecting the Fibre Channel cables........................................................................................18

Connecting device port Fibre Channel cables to the EVA (rear view).........................................18

Connecting Fibre Channel cables to the EVA (front end)..........................................................19

Connecting cables to an HSV300-S controller enclosure (front end)..........................................19

Labeling cables using labeling kit........................................................................................19

Connecting the power cords....................................................................................................19

5 Turn on power..........................................................................................20

Power on the devices...............................................................................................................20

Verify the operating status of the EVA........................................................................................20

Verify the operating status of the disk enclosures.........................................................................21

Verify the operating status of the Fibre Channel switches and adapters..........................................22

Installing Fibre Channel drivers.................................................................................................22

Configuring the embedded switch in an HSV300-S controller.......................................................22

Verify the operating status of the servers....................................................................................24

6 Connecting to the management module......................................................25

Overview..............................................................................................................................25

Connecting to the management module.....................................................................................25

Connecting through a public network...................................................................................25

Connecting through a private network..................................................................................26

Accessing HP P6000 Command View on the management module...............................................27

Changing the default operating mode.......................................................................................27

Accessing the HP P6000 Control Panel through HP P6000 Command View...................................28

Contents 3

Page 4

7 Configuring servers using HP P6000 SmartStart...........................................29

Configuring management servers using HP P6000 SmartStart.......................................................29

Configuring application servers for Windows using HP P6000 SmartStart......................................29

8 Using and monitoring your storage.............................................................30

Using your storage.................................................................................................................30

Firmware recovery .................................................................................................................30

HP Insight Remote Support software..........................................................................................30

9 Support and other resources......................................................................31

Contacting HP........................................................................................................................31

HP technical support..........................................................................................................31

Subscription service............................................................................................................31

Documentation feedback....................................................................................................31

Related information.................................................................................................................32

Documents........................................................................................................................32

HP websites......................................................................................................................32

Typographic conventions.........................................................................................................33

Customer self repair................................................................................................................33

Rack stability..........................................................................................................................34

Location of WWN and serial number........................................................................................34

A EVA4400 cabling diagrams......................................................................36

Connecting device port Fibre Channel cables to the EVA4400 (rear view)......................................36

Connecting Fibre Channel cables to the EVA4400 (front end).......................................................37

Connecting to the HSV300-S controller enclosure........................................................................39

4 Contents

Page 5

1 Review and confirm your plans

Overview

Before installing the EVA, HP recommends that you:

• Develop an installation and configuration plan for your environment.

• Review all videos and documentation.

• Determine if the EVA will be fabric-attached (connected to Fibre Channel switch) or

direct-attached (connected to Fibre Channel adapter in server). The EVA4400 is factory

configured for fabric-attached. To change to direct-attached mode, see “Connecting to the

management module” (page 25).

NOTE: Models of the EVA4400 with an embedded switch (also known as the HSV300-S

controller) are configured in fabric-attach mode and must remain fabric-attached.

Prerequisites

Prerequisites for using this product include:

• A Fibre Channel switch installed in your environment

• An equipment cabinet suitable for 2U sized enclosures

• A management server running Windows for HP P6000 Command View software (server-based

management)

• A management module running HP P6000 Command View software (array-based management)

• A CD-ROM drive attached to either the management server or the server attached to the

management module

Plan your storage configuration

Proper planning of the system storage and its subsequent performance is critical to a successful

deployment of the EVA. Improper planning or implementation can result in wasted storage space,

degraded performance, or inability to expand the system to meet growing storage needs. Planning

considerations include:

• System and performance expectations

• Striping methods

• RAID levels

• Hard drive sizes and types

• Spare drives

• Array sizing (capacity)

NOTE: For the minimum supported configuration, and other configuration information, see the

QuickSpecs document at: http://www.hp.com/go/eva4400

Overview 5

Page 6

System and performance expectations

To help determine the best way to configure your storage, rank the following three storage

characteristics in order of importance:

• Fault tolerance (high availability)

• I/O performance

• Storage efficiency

With your priorities established, you can determine which striping method and RAID level to use.

As highlighted in the following section, some configuration methods offer greater fault tolerance,

while other configuration methods offer better I/O performance or storage efficiency.

RAID levels

Vraid is the HP term for the implementation of RAID (Redundant Array of Independent Disks) storage.

Vraid is also referred to as redundancy in HP management software. Virtual disks with HP Vraid

use three key RAID methods: data striping, data mirroring, and parity error checking. Unlike

traditional RAID, all HP Vraid levels distribute data across all available physical disks.

Data striping improves speed by performing virtual disk I/O with an entire group of physical disks

at the same time. Mirroring provides data redundancy by storing data and a copy of the data.

Parity also provides data redundancy by storing data and the calculated parity for each stripe of

data. If a subset of the data on a physical disk becomes corrupt or the entire physical disk fails,

the data can be automatically recovered from redundancy so that data loss does not occur.

The EVA has four Vraid types: Vraid0, Vraid1, Vraid5, and Vraid6. Each Vraid type provides

unique I/O speed and has a different level of data redundancy, which directly effects the amount

of physical space used. Once a virtual disk is created, the Vraid type or level cannot be changed.

See Table 1 (page 6) for a comparison of the different RAID levels.

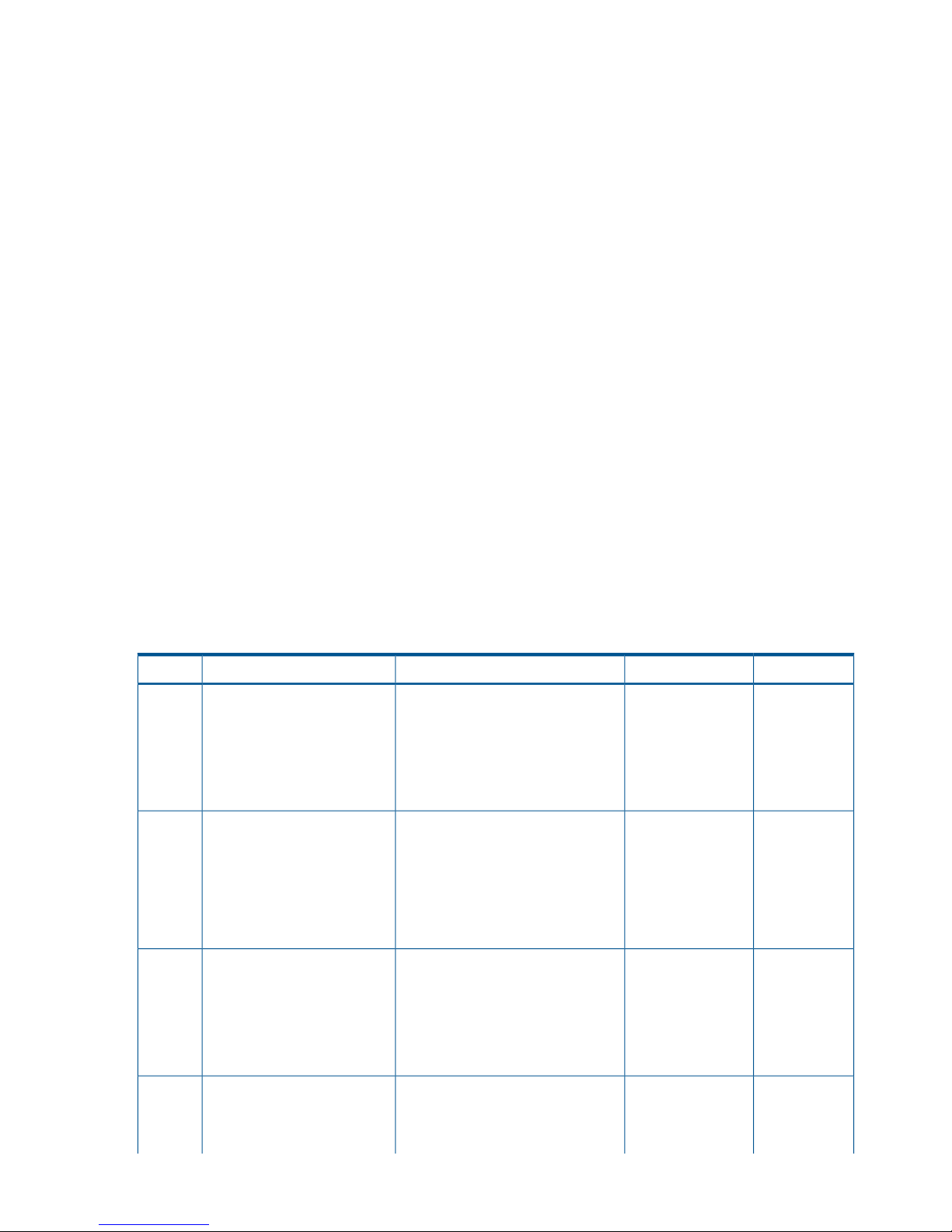

Table 1 Raid Level Comparison

RAID methodData redundancyBest practicesSummary

StripingNoneIMPORTANT: HP does not

recommend using Vraid0 for virtual

Vraid0 is optimized for I/O

speed and efficient use of

Vraid0

disks when high availability isphysical disk capacity, but

provides no data redundancy. required. Consider Vraid0 only for

noncritical storage. Vraid0 virtual

disks provide the best performance

for applications that use random I/O.

Striping and

mirroring

HighIn general, Vraid1 virtual disks

provide better performance

Vraid1 is optimized for data

redundancy and I/O speed,

Vraid1

characteristics over a wider range of

application workloads than Vraid5.

but uses the most physical disk

space.

IMPORTANT: Vraid1 uses

about 100% more physical

disk space than Vraid0.

Striping and

parity

MediumVraid5 virtual disks provide as good

or better performance than Vraid1

Vraid5 provides a balance of

data redundancy, I/O speed,

Vraid5

for applications that use sequentialand efficient use of physical

writes. Vraid5 has much lowerdisk space. Vraid5 uses about

random write performance in20% more physical disk space

than Vraid0. comparison to Vraid1, but has much

higher capacity efficiency.

Striping and

double parity

Very highPerformance characteristics of Vraid6

for random and sequential write

Vraid6 is similar to Vraid5, but

provides a higher level of

Vraid6

workloads will be slightly slower thanredundancy by storing two

Vraid5. Vraid6 provides the highestparity blocks per stripe instead

6 Review and confirm your plans

Page 7

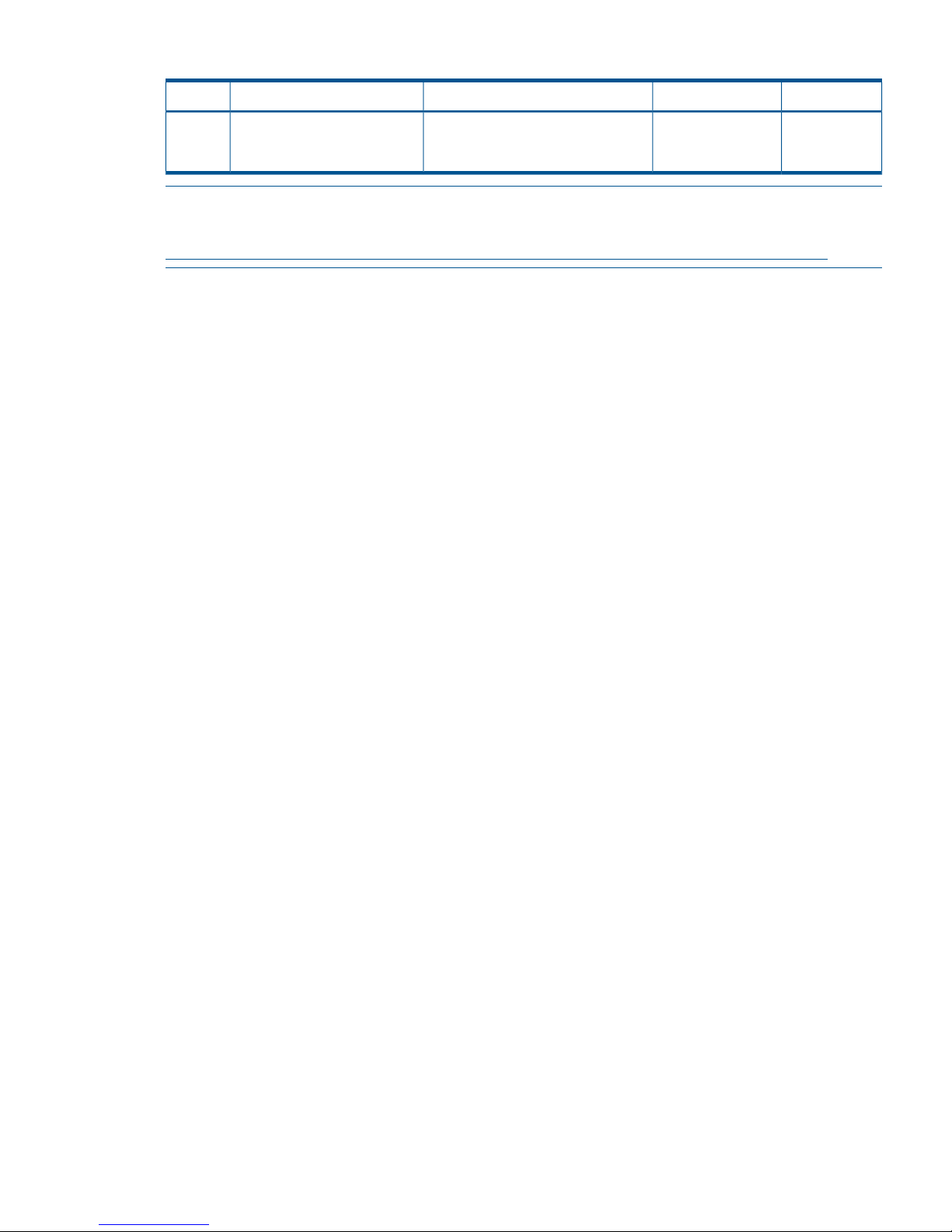

Table 1 Raid Level Comparison (continued)

RAID methodData redundancyBest practicesSummary

of one. Vraid6 uses 33% more

physical disk space than

Vraid0.

level of redundancy protection of all

the Vraid types.

NOTE: For best practice information, see the HP 4400 Enterprise Virtual Array configuration

best practices white paper available at:

http://h18006.www1.hp.com/storage/arraywhitepapers.html?jumpid=reg_R1002_USEN

HP P6000 Command View implementation

HP P6000 Command View can be implemented in two ways:

• Server-based management—HP P6000 Command View is installed on a management server

connected to the EVA, providing management of multiple HP EVA storage systems. All

components of the software suite (HP P6000 Command View, HP Command View EVAPerf,

HP Storage System Scripting Utility, SMI-S EVA) are installed. Server-based management is

applicable to all EVA models.

• Array-based management—Beginning with HP Command View EVA 8.1, the EVA4400 is

shipped with HP P6000 Command View pre-installed on the management module within the

controller enclosure. Only one component of the software suite (HP P6000 Command View)

is installed. Array-based management is applicable to the EVA4400 only.

HP P6000 Command View implementation 7

Page 8

2 Prepare your site

Overview

Preparing your site means providing:

• Physical rack space for the equipment

• AC power for the EVA

• Proper ventilation and temperature conditions

• LAN or Fibre Channel cables to attach the EVA hardware to your network.

To ensure continuous, safe, and reliable operation of your equipment, place your system in an

approved environment.

Consider using the HP Enterprise Configurator (eCO) to help plan and configure racks and

rack-mountable devices. The eCO is available on the HP website:

http://h30099.www3.hp.com/configurator

Click Configure under Disk products.

Provide adequate structural support for the floor

Calculate the total weight of your equipment and verify that your site can support the weight.

Provide adequate clearance space and ventilation

Be sure to provide adequate clearance around the front and back of the racks. Provide at least

25 inches (63.5 cm) in the front of the rack to allow the doors to open fully and provide at least

30 inches (76.2 cm) in the rear of the rack to allow for servicing and airflow.

If there are unused spaces in your rack, attach blanking panels across those empty spaces to force

the airflow through the components instead of through the open spaces.

8 Prepare your site

Page 9

Provide adequate and redundant sources of power

Make sure that you have two high-line power feeds installed near your computer. These two power

sources usually come from the same external power grid, but occasionally may originate from

different grids or even entirely different sources.

For protection against a power-source failure, obtain and include two uninterruptible power supplies

in your installation.

For power consumption specifications, see the QuickSpecs document at:

http://www.hp.com/go/eva4400

Remove product from packaging

1. Remove product from boxes.

2. Verify that contents match your expectations and site requirements.

• EVA4400 controller enclosure should contain:

One 2U controller enclosure with two HSV300 or HSV300–S controller modules,

two power supply modules, two fan modules, and two battery modules installed.

◦

◦ Rack mounting hardware

◦ Two 2.0 meter FC copper cables

◦ Two power cords

◦ Installation documentation

◦ XCS controller software recovery CD

• Each FC disk shelf should contain:

◦ One 2U M6412 disk enclosure, two power supply modules, two fan modules, and

two battery modules.

◦ Rack mounting hardware kit

◦ Two 0.41 meter FC copper cables

◦ Two power cords

3. Inspect for damage.

If damage is present, contact your local HP representative.

Provide adequate and redundant sources of power 9

Page 10

3 Install components

Overview

Component installation includes:

• Rail kits

• Controller and disk enclosures

• Disk drives

NOTE: If you have ordered the factory integrated product, skip this chapter and go to “Turn on

power” (page 20).

Rack installation best practices

In addition to industry-standard recommendations, consider the following:

• Locate the heaviest items, such as uninterruptable power supplies (UPS) and additional disk

enclosures near the bottom of the rack.

• To make cabling easy, install the disk enclosures below the controller enclosure.

• Install similar components next to each other in the rack. Because enclosures, switches, and

servers are of differing depths, if you have more than one of a device, mount those devices

adjacent to one another to accommodate working behind the rack.

WARNING! To reduce the risk of personal injury or damage to the equipment, be sure that:

• At least two people lift the storage system during removal or installation, if the weight, exceeds

22.7 kg (50 lb). If the system is being loaded into the rack above chest level, a third person

MUST assist with aligning the system with the rails while the other two people support the

weight of the system.

• The leveling jacks on the rack are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component in a rack is extended at a time. A rack may become unstable if more

than one component is extended.

• To prevent damage and to ease insertion of the device into the rack, support the weight of

the device and keep it level when sliding it into the rack.

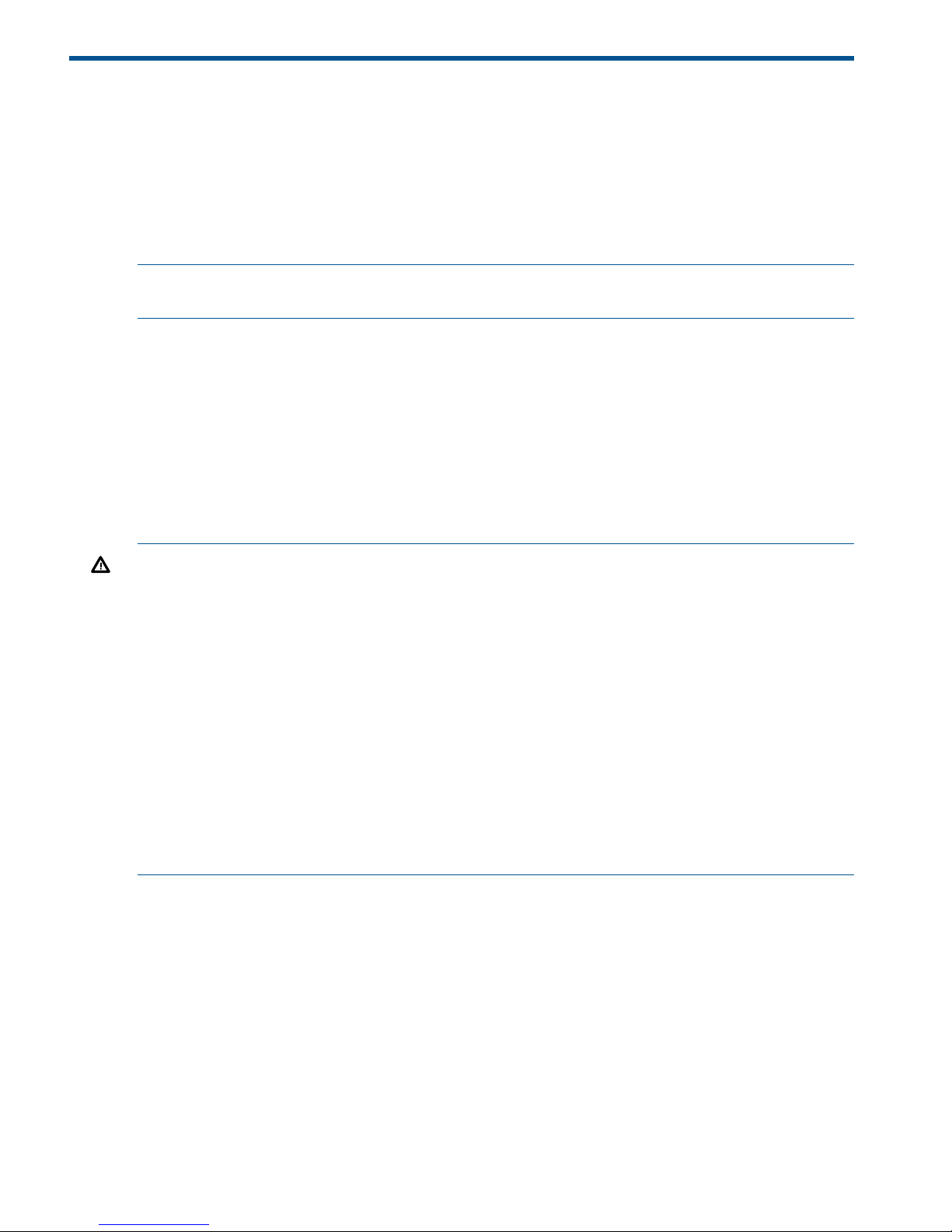

Review Figure 1 (page 11) before installing the EVA components in the rack.

10 Install components

Page 11

Figure 1 Typical EVA installed in rack (preferred layout)

1. Controller enclosure

2. Disk enclosures

3. PDU (at rear of enclosure)

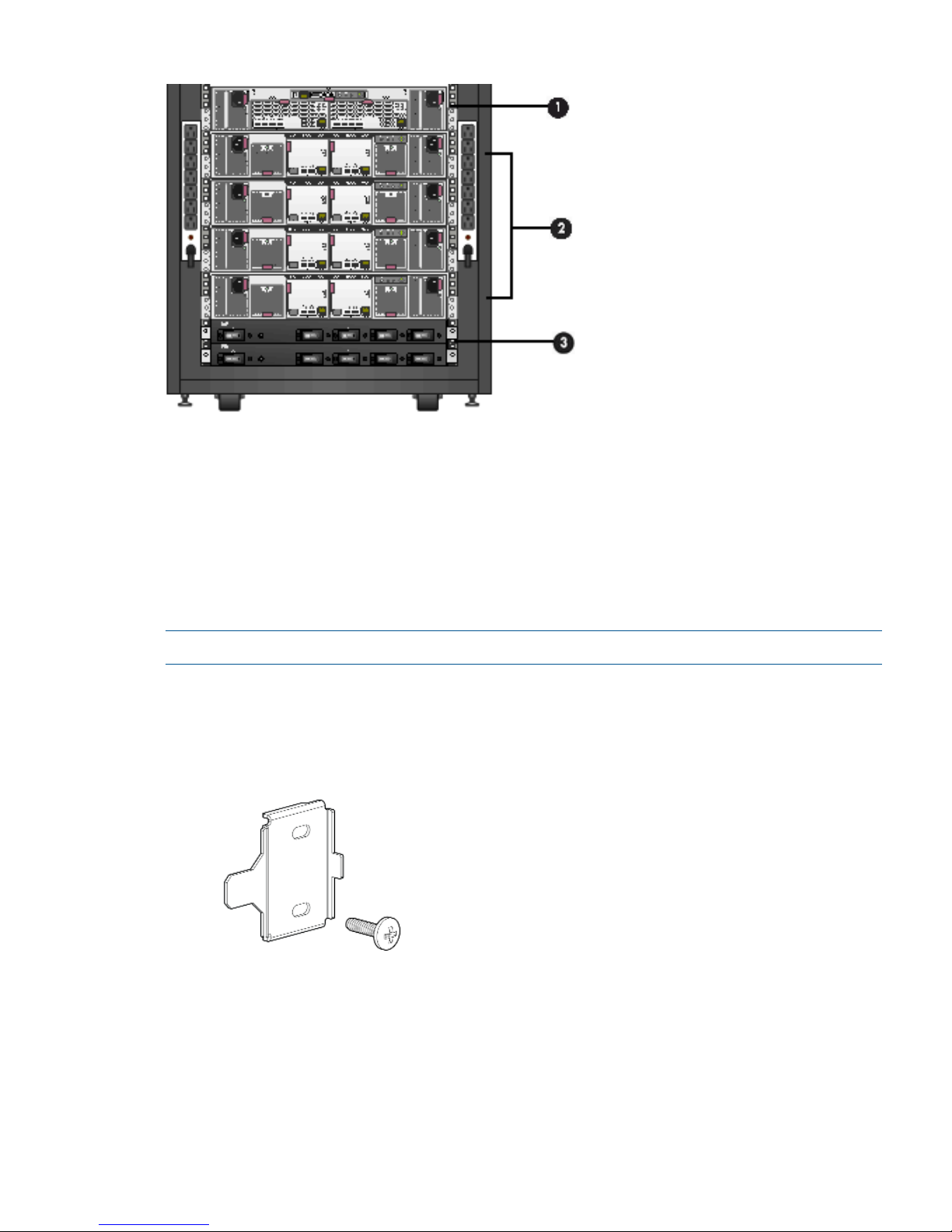

Attach the brackets for a longer chassis

If you are installing a longer chassis into your cabinet, such as for the controller enclosure, you

must remove the shipping retaining bracket and install the smaller brackets supplied in the accessory

kit.

NOTE: A No. 2 Phillips head screwdriver is required for this procedure.

1. Remove the existing thumbscrew and shipping retaining bracket from the rear of the rail.

2. Insert a screw through the bottom hole of the new bracket and loosely secure the bracket to

the rear of the rail.

Figure 2 Inserting screw into the new bracket

Attach the brackets for a longer chassis 11

Page 12

Figure 3 Attaching the brackets

3. Repeat Step 1 and Step 2 for the remaining rail.

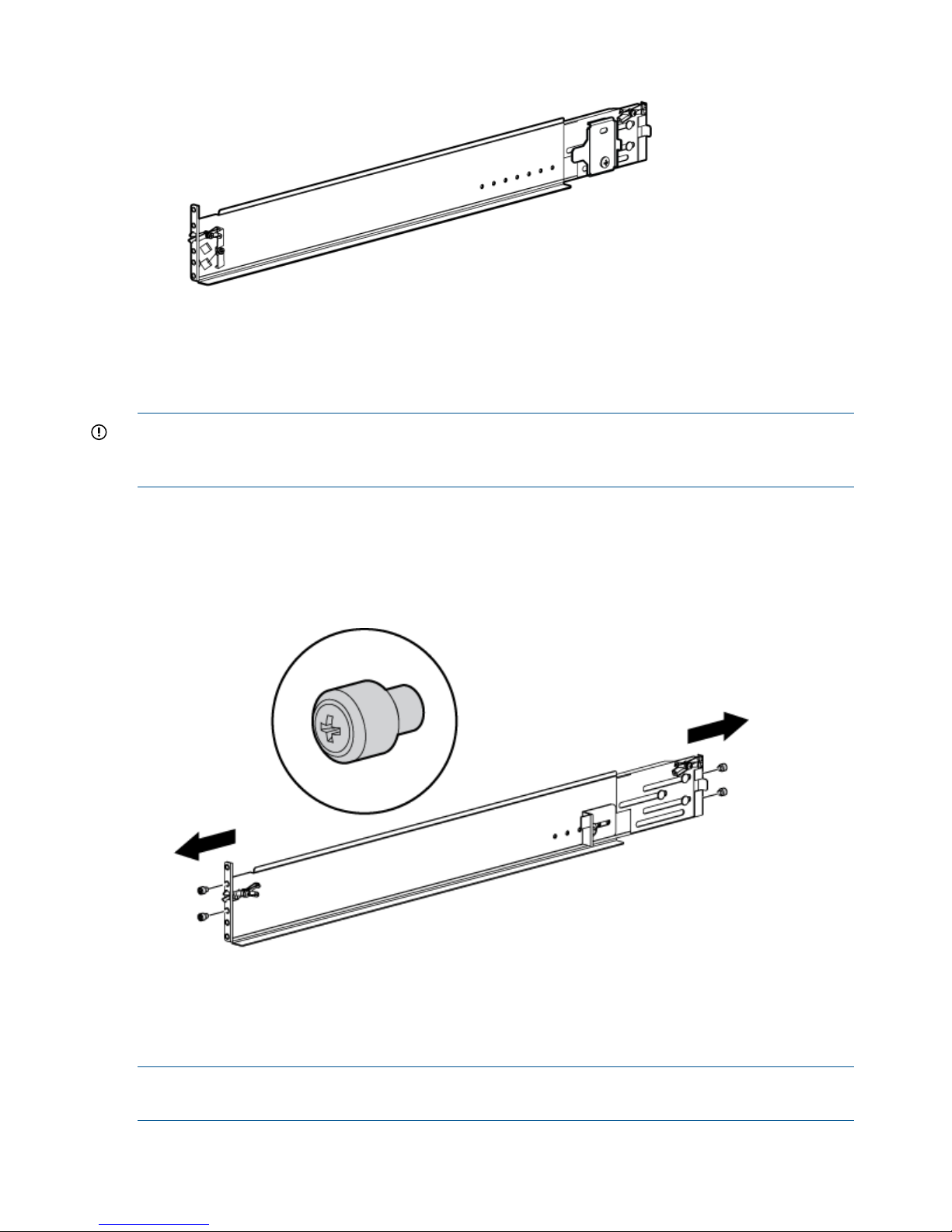

Converting the rails

The rail kit supplied with the disk enclosure comes configured for square-hole racks.

IMPORTANT: Do not remove the pins from the ends of the rails unless you are converting the

rails for use in round-hole racks. These load-bearing pins are designed to fit through the holes

without being removed.

To convert the rails for a round-hole rack:

1. Locate the bag of eight round-hole pins included in the rail kit.

2. Use a No. 2 Phillips screwdriver to remove the standard pins from the front and back of the

left and right rails (four pins on each rail).

Figure 4 Configuring the rails

3. Insert the round-hole pins into the eight holes on the rails where the standard pins were

removed.

Attach the rails

NOTE: The left and right rails are designated by the letters R (right) and L (left) stamped in the

metal on the front of the rack.

12 Install components

Page 13

Consider the following when installing the rails:

• Installing the rails does not require any tools for assembly.

• HP recommends that you install all the rail kits before installing any other components.

• Ensure that the rails are level before installing any other components.

WARNING! Before you begin, ensure that the rack is sufficiently stable. If provided, lower the

rack leveler feet and make sure any required stabilizers are installed. If provided, extend the anti-tip

device. Failure to extend the anti-tip device could cause personal injury or damage if the rack tips

over.

1. On the rear of the rail, squeeze the scissor latch (1, Figure 5 (page 13)) together to insert the

rail and pins through the rack holes (2) until the latch engages.

Figure 5 Attaching the rear rail

2. On the front of the rail, pull the locking latch to release the scissors latch (1, Figure 6 (page

14)) and squeeze the scissors latch together to insert the rail and pins through the rack upright

holes (2) until the latch engages (3).

Attach the rails 13

Page 14

Figure 6 Attaching the front rail

3. Loosen the locking nut (1, Figure 7 (page 14)) on the shipping retaining bracket (2) and slide

the bracket to the farthest position on the rear of the rail. This moves the bracket out of the

way to allow you to install the chassis in the rails.

NOTE: Figure 7 (page 14) shows a disk enclosure rail and bracket. If you are installing a

longer chassis into your cabinet, such as a chassis for a controller enclosure, see “Attach the

brackets for a longer chassis” (page 11) for additional information.

Figure 7 Locking nut and retaining bracket

4. After attaching the rail, grab and move the rail gently to be sure it is firmly engaged in the

rack and that all latches are engaged in the rack holes.

5. Repeat Step 1 through Step 4 for the other rail.

Install the enclosures

To install disk and controller enclosures:

1. Remove the bezels installed over the thumbscrews on the front of the enclosure (Figure 8 (page

15)).

14 Install components

Page 15

Figure 8 Removing bezels from enclosure

2. Align the enclosure with the rails and slide it into the rack (Figure 9 (page 15)).

Figure 9 Installing an enclosure (view from front of rack)

3. Continue sliding the enclosure into the rack until the front edge is flush with the front of the

rack (1, Figure 10 (page 16)). Tighten the enclosure thumbscrews into the rack (2) taking care

not to strip the thumbscrews.

Install the enclosures 15

Page 16

Figure 10 Securing the rear of the enclosure in the rack (view from front of rack)

4. Reattach the front bezel covers.

5. At the rear of the rack, loosen the thumbscrew on the shipping retaining bracket (1,

Figure 11 (page 16)) and slide the bracket forward (2) until the tab engages the slot in the

chassis. Tighten the thumbscrew on the bracket.

Figure 11 Securing the rear of the enclosure (view from rear of rack)

6. Repeat 1 through 5 to install the controller enclosures.

Installing the hard drives into the drive bays

After the disk enclosures are secured in the rack, install the hard drives into the drive bays. Drives

must be installed in the proper bay sequence (see Figure 12 (page 17)) in the enclosures for

optimum HP P6000 Command View performance and data integrity.

For example, if you have four enclosures, and eight drives, you should install four drives into bay

1 of each enclosure and four drives into bay 2 of each enclosure. Do not install all the drives into

enclosure 1 and leave the other enclosures empty.

16 Install components

Page 17

Figure 12 Disk drive numbering

CAUTION: Install hard drives in the enclosures only after securing the enclosures in the rack:

• An enclosure populated with hard drives is too heavy to lift safely.

• Movement of an enclosure during installation might damage the internal storage media of

installed hard drives.

CAUTION: Follow industry-standard practices when handling hard drives. Internal storage media

can be damaged when drives are shaken, dropped, or roughly placed on a work surface. When

installing a hard drive, make sure it is fully seated in the drive bay. To remove a hard drive, press

the release button and pull the drive only slightly out of the enclosure. Then, to allow time for the

internal disk to stop rotating, wait approximately 10 seconds before completely removing the drive

from the enclosure.

To install the hard drives:

1. Insert the disk drive into the drive bay (1, Figure 13 (page 17)) until it clicks, locking the drive.

2. Rotate the drive lever to the right (2, Figure 13 (page 17)) until it locks.

Figure 13 Installing drives into the enclosures

Installing SFPs

The HSV300-S controller uses Small Form Factor Pluggable (SFPs) transceiver modules on the FC

ports. Four SFPs are factory installed in the HSV300-S, but you will need to install additional SFPs

if you plan to use more than four switch ports. If you purchased extra SFPs, install them now,

following the instructions shipped with the SFPs.

NOTE: The HSV300-S requires 4 Gb or higher SFPs.

Installing SFPs 17

Page 18

4 Connect cables and power cords

Overview

NOTE: If you have ordered the factory integrated product, skip this section and go to “Turn on

power” (page 20).

To connect cables and power cords:

1. Read the cabling best practices.

2. Attach Fibre Channel and/or LAN cables to controller, drives, and servers.

3. Label all cables using the supplied cable labeling kit.

4. Plug in all power cables.

Cabling best practices

• Use the shortest possible cable between devices. Shorter cables are easier to manage and

route along the back of the rack. In addition, shorter cables reduce the possibility of signal

degradation that may occur over longer distances.

• Gather the cables in the rear of the EVA to ensure that the cabling in the back of the rack

system does not interfere with system operation or maintenance. Bind the cables loosely with

cable ties and route the excess cables out of the way, along the side of the rack. When the

cables are tied together and routed down the side of the rack, system components and

indicators are easily visible and accessible.

• Attach a label near both ends of each cable to identify the device connected to that cable.

Include the device type, device name, port, or other information that you think will be helpful.

• Use colored markers to color code both ends of each cable, to help you visually identify a

particular cable without having to read or locate the label.

• In multipath configurations, you may want to loosely bind the matching pair of cables

connecting devices.

Connecting the Fibre Channel cables

To connect the EVA to the SAN, use standard Fibre Channel cables, observing the following caution

for good cabling-handling practices.

CAUTION: Use appropriate precautions when handling Fibre Channel cables:

• Touching the end of a Fibre Channel cable will either damage the cable or cause performance

problems, including intermittent difficulties accessing the storage.

• Whenever a Fibre Channel cable is not connected, replace the protective covers on the ends

of the cable.

• Make certain that the Fibre Channel cables are installed and supported so that no excess

weight is placed on the connectors. This prevents damage to the connector and cable. Excess

cable should be loosely coiled and tied out of the way, being careful not to coil the cable in

a tight loop. The minimum bend radius is 25 mm for 50, 62.5, and 9 micron fiber optic cable.

Connecting device port Fibre Channel cables to the EVA (rear view)

See Figure 24 (page 36) and Figure 25 (page 37) in Appendix A.

18 Connect cables and power cords

Page 19

Connecting Fibre Channel cables to the EVA (front end)

See Figure 26 (page 38) and Figure 28 (page 39) in Appendix A for front end connections with

server-based management. See Figure 27 (page 38) and Figure 29 (page 39) in Appendix A for

front end connections with array-based management.

Connecting cables to an HSV300-S controller enclosure (front end)

See Figure 30 (page 40) for server-based management or Figure 31 (page 40) for array-based

management in Appendix A.

Labeling cables using labeling kit

Label each end of each cable using the materials in the supplied labeling kit.

Connecting the power cords

WARNING! To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• To remove power to the equipment, unplug the power cord from the power supply.

• Route the power cord so that it is not likely to be walked on or pinched by items placed against

it. Pay particular attention to the plug, electrical outlet, and the point where the cord is attached

to the EVA.

To protect your system from power failure related downtime, each EVA ships with a redundant

power supply. See Table 2 (page 19) to determine the best method for connecting your power

supplies to your power source to eliminate downtime due to power-related failure.

When connecting the power cables, use the power cables shipped with the EVA. After power is

supplied to the EVA, the power supply automatically senses the input voltage and the power supply

LED illuminates as solid amber.

Table 2 Power cable connections

Level of ProtectionConnection Method

Protects you from downtime when one of the EVA power supplies fails.

The remaining power supply/fan module can operate the EVA until you install a

replacement module.

EVA power supplies connected to

one power source

Protects you from downtime when one of the EVA power supplies fails.

Protects you from data loss when one of your power sources fails, due to a pulled

cable or tripped breaker.

EVA power supplies connected to

two separate power sources

The remaining power source can power the EVA until the failed power source is

restored or relocated.

Depending on the cause and duration of the power outage, you can use this time

to properly shut down your storage sub-system.

Protects you from downtime when one of the EVA power supplies fails.

Protects you from data loss when one or both of your power sources fails, due to

a pulled cable, tripped breaker, or local power outage.

EVA power supplies connected to:

• Two uninterruptible power

supplies

The remaining power source or the UPS will power the EVA until power is restored

to the source. Depending on the cause and duration of the power outage, you

can use this time to properly shut down your storage sub-system.

• Two separate power sources

For more information about power sources, see the HP 4400 Enterprise Virtual Array User Guide.

Connecting the power cords 19

Page 20

5 Turn on power

Power on the devices

After the EVA and its disk enclosures are installed and connected to the SAN, power up all of the

devices in the SAN and verify that they are operating properly.

1. Apply power to the power distribution unit (PDU) in the rack:

• If the controller enclosure was shipped with the power button in the ON position, the

controller enclosure and connected disk enclosures will automatically power on. Otherwise,

press the power/standby button on the front panel of the controller enclosure.

• When the controller enclosure is powered on, the LED for the power/standby buttons

changes from amber to solid green.

• Wait for a solid green LED on each disk enclosure to ensure that each enclosure has

successfully powered on.

2. Apply power to each external Fibre Channel switch.

3. Wait (up to five minutes) for the EVA to complete its startup routine and for the Fibre Channel

switches to boot.

4. Apply power to the servers in the SAN with access to the EVA, start the operating system,

and log on as administrator.

CAUTION: When you power on the server, the monitor may display a “New Hardware

Found” message and to a prompt to install an HBA driver. Cancel out of this window to prevent

the installation of an unsupported HBA driver.

5. Verify that each component in the SAN is operating properly as described in the following

sections.

Verify the operating status of the EVA

To verify the operating status of the EVA, view the LEDs on the EVA.

Each module of the EVA is equipped with an LED display (Figure 14 (page 21)). See Table 3 (page

21) for LED information. The enclosure external health LED (2) on the panel should be lit when the

unit is operating properly. Check the LEDs located on the enclosure first before checking the LEDs

on individual replaceable units in the EVA.

20 Turn on power

Page 21

Figure 14 EVA4400 front panel LEDs

Table 3 EVA4400 status lights during startup

Fault conditionOperating conditionStartup conditionLED functionNumber

N/AOff—Blinking if turned

on remotely

Blinking blueUID (Unit ID)1

GreenBlinking greenEnclosure external health2

Blinking amberOffOffEnclosure fault warning3

Amber—Indicates link

lost

GreenSolid amberLink to host4

Blinking

green—Indicates

GreenSolid amberFan condition5 (2 LEDs)

charging or defective

FRU

Blinking

amber—Indicates

defective FRU

GreenSolid amberBattery condition6 (2 LEDs)

If the LED patterns described in Table 3 (page 21) are not illuminated:

• Check your cable connections between the device and the EVA.

• Check the availability of your power source.

• Review the installation procedures.

• Remove and reinsert the module.

Verify the operating status of the disk enclosures

To verify that the disk enclosures and hard drives are operating properly, view the enclosure and

hard drive LEDs and compare them with the patterns described in the documentation for these

devices. If the LEDs indicate a fault, see the HP 4400 Enterprise Virtual Array User Guide.

Verify the operating status of the disk enclosures 21

Page 22

Figure 15 Rear and front view of the disk enclosure

Verify the operating status of the Fibre Channel switches and adapters

To verify that your switches are operating properly, view the switch LEDs and compare them with

the patterns described in the documentation for these devices. If the LEDs indicate a fault, see the

documentation that came with the switch for help.

Optional Step: If you will be using Fibre Channel to attach the EVA to your existing servers, you

must install Fibre Channel adapters in those servers and test the Fibre Channel adapters prior to

installing HP P6000 Command View.

Ensure that you have the correct quantity and length of Fibre Channel cables available to attach

your servers to the EVA.

Installing Fibre Channel drivers

If you are using Windows, the HP P6000 SmartStart software automatically loads the required

Fibre Channel drivers. This occurs during this installation process when you run HP P6000

SmartStart.

For other operating systems, load the drivers as directed in (Configuring application servers) in

the HP 4400 Enterprise Virtual Array User Guide.

Configuring the embedded switch in an HSV300-S controller

The embedded switch in an HSV300-S controller has a default IP addresses that may not be visible

in your network. Any configuration changes must be made to both embedded switches in an

HSV300-S controller enclosure. This process involves connecting a cable from the Ethernet port of

each switch to a laptop computer and supplying switch addresses that are valid for your network.

NOTE: For complete switch configuration and management instructions, see the HP Fabric OS

6.1.x administrator guide at: http://www.hp.com/support/manuals. Under Storage, click Disk

Storage Systems and then click HP 4400 Enterprise Virtual Array under EVA Disk Arrays.

To configure an embedded switch in an HSV300-S controller:

1. Obtain a laptop and an Ethernet cable (straight-through or crossover type), and change the

IP address of the laptop to have an address in the same IP range as the embedded switch (for

example 10.77.77.79, with a subnet mask of: 255.255.255.0).

22 Turn on power

Page 23

NOTE: The embedded switch has an MDI-X port that supports straight-through or crossover

Ethernet cables. Use a Cat 5e or greater cable.

If needed, you can connect directly to the switch using the console port (2, Figure 16 (page

23)) and the provided console cable (manufacturing part number 259992–001). You may

need a USB adapter for this cable if your laptop does not have a serial port.

2. Connect the Ethernet port (2, Figure 16 (page 23)) of the embedded switch to the laptop.

Figure 16 HSV300-S rear view

1. Console port

2. Ethernet port

3. Browse to http://10.77.77.77 for the Controller 1 switch.

NOTE: Fibre Channel switches are referred to as left slot switch and right slot switch in

Brocade Web Tools.

The switch management GUI (Brocade Web Tools) appears (Figure 17 (page 24)).

Configuring the embedded switch in an HSV300-S controller 23

Page 24

Figure 17 Switch Management GUI

4. Change the IP address and other settings of the switch as appropriate for your network. You

may also rename the switch or perform other configuration activities at this time.

5. Remove the Ethernet cable from the first switch and connect the cable to the Ethernet port (2,

Figure 16 (page 23)) of the other embedded switch. Browse to http://10.77.77.78 for

the Controller 2 switch and repeat 4.

NOTE: If you are renaming or performing other configuration activities on the Controller 2

switch, be aware that two switches cannot have the same domain ID in the same fabric.

Verify the operating status of the servers

Although the EVA is not yet visible to the server, verify that the server is operating properly. A

simple test is to verify that your operating system loaded and then open a software application or

your browser.

If your server is not operating properly, see the documentation that came with the server for help.

24 Turn on power

Page 25

6 Connecting to the management module

Overview

This chapter describes several optional procedures. Complete the procedures in this chapter if any

of the following situations apply. Otherwise, continue with “Configuring servers using HP P6000

SmartStart” (page 29).

• Run HP P6000 Command View from the management module, which eliminates the requirement

for a management server.

• Change the default operating mode (via the HP P6000 Control Panel) for a direct connect

configuration.

• Access the HP P6000 Control Panel to view array state and status information and edit basic

configuration settings. See the HP P6000 Control Panel user guide for more information.

The management module has an MDI-X port that supports straight-through or crossover Ethernet

cables. Use a Cat 5e or greater cable to connect the management module from its Ethernet jack

(1, Figure 18 (page 25)) to the management server.

Figure 18 management module

1. Status LEDs

2. Ethernet jack

3. Reset button

Connecting to the management module

You can connect to the management module through a public or a private network.

NOTE: To aggregate additional HP Command View servers into a SPoG (Single Pane of Glass)

when the servers reside on a different IP network from the SPoG web server, some additional

configuration settings may be needed. To configure the system if the HP Command View servers

reside on a different network and you would like them visible in the SPoG, see Discovery URI under

Discovery configuration settings in the HP Management Integration Framework Administrator Guide.

If you use a laptop to connect to the management module, configure the laptop to have an address

in the same IP range as the management module (for example 192.168.0.2, with a subnet mask

of 255.255.255.0).

Connecting through a public network

1. Initialize the EVA4400 storage system, using HP P6000 SmartStart or HP P6000 Command

View.

2. If it is currently connected, disconnect the public network LAN cable from the back of the

management module in the controller enclosure.

3. Press and hold the recessed Reset button (3, Figure 18 (page 25)) for 4 to 5 seconds. If you

are running HP Command View EVA 9.3 or later, the green LED on the management module

(1, Figure 18 (page 25)) blinks to indicate the configuration reset has started. The reset may

take up to 2 minutes to complete. When the reset is completed, the green LED turns solid. This

Overview 25

Page 26

sets IP addresses of 192.168.0.1/24 (IPv4) and fd50:f2eb:a8a::7/48 (IPv6). If you are

running a version earlier than HP Command View EVA 9.3 on the management module, the

amber LED will flash momentarily when the reset is completed.

IMPORTANT: At initial setup, you cannot browse to the HP P6000 Control Panel until you

perform this step.

4. Do one of the following:

• Temporarily connect a LAN cable from a private network to the management module.

• Temporarily connect a laptop computer to the management module using a LAN patch

cable.

5. Browse to https://192.168.0.1:2373 or https://[fd50:f2eb:a8a::7]:2373/and

log in as an HP administrator. HP recommends that you either change or delete the default

IPv4 or IPv6 addresses to avoid duplicate address detection issues on your network. The default

user name is admin. No password is required. The HP P6000 control panel GUI appears.

IMPORTANT: The HP P6000 Control Panel previously used port 2372 but now uses 2373.

If you change the password for the administrator or user account for the HP P6000 Control

Panel, be sure to record the new passwords since they cannot be cleared without resetting

the management module. HP recommends that you change the default passwords.

6. Select Administrator Options > Configure Network Options.

7. Enter an IP address and other network settings that apply.

NOTE: The management module firmware reserves IP addresses for internal communications.

If you are using HP Command View EVA 9.2 or earlier, the reserved IP addresses are 10.0.0.1

through 10.0.0.3. Later versions of the management module firmware will also use these

addresses if the array has older controller firmware loaded. The latest versions of controller

and management module firmware, however, use the reserved IP address range from

10.253.251.230 through 10.253.251.249. The management module cannot be configured

to use these addresses, nor can it communicate with external systems that fall within the reserved

address range (for example, web client, router, DNS server, and so on).

8. Click Save Changes.

The new IP address is stored and remains in effect, even when the storage system is later shut

down or restarted. The IP address changes immediately, causing you to lose connectivity to

the HP P6000 Control Panel.

IMPORTANT: The new IP address will be lost if the storage system is later uninitialized or

the management module is reset.

9. Remove the LAN cable connecting to the private network and reconnect the cable to the public

network.

10. From a computer on the public network, browse to https://newly configured ip

address:2373 and log in. The HP P6000 control panel GUI appears.

Connecting through a private network

1. Press and hold the recessed Reset button (3, Figure 18 (page 25)) for 4 to 5 seconds. If you

are running HP Command View EVA 9.3 or later, the green LED on the management module

(1, Figure 18 (page 25)) blinks to indicate the configuration reset has started. The reset may

take up to 2 minutes to complete. When the reset is completed, the green LED turns solid. This

sets IP addresses of 192.168.0.1/24 (IPv4) and fd50:f2eb:a8a::7/48 (IPv6). If you are

26 Connecting to the management module

Page 27

running a version earlier than HP Command View EVA 9.3 on the management module, the

amber LED will flash momentarily when the reset is completed.

2. Browse to https://192.168.0.1:2373 and log in as an HP administrator. HP recommends

that you either change or delete the default IPv4 or IPv6 addresses to avoid duplicate address

detection issues on your network. The default user name is admin. No password is required.

The HP P6000 control panel GUI appears.

IMPORTANT: At initial setup, you cannot browse to the HP P6000 control panel until you

perform this step.

3. Select Administrator Options > Configure Network Options.

NOTE: The management module firmware reserves IP addresses for internal communications.

If you are using HP Command View EVA 9.2 or earlier, the reserved IP addresses are 10.0.0.1

through 10.0.0.3. Later versions of the management module firmware will also use these

addresses if the array has older controller firmware loaded. The latest versions of controller

and management module firmware, however, use the reserved IP address range from

10.253.251.230 through 10.253.251.249. The management module cannot be configured

to use these addresses, nor can it communicate with external systems that fall within the reserved

address range (for example, web client, router, DNS server, and so on).

4. Enter an IP address and other network settings that apply.

5. Click Save Changes.

The new IP address is stored and remains in effect, even when the storage system is later shut

down or restarted. The IP address changes immediately, causing you to lose connectivity to

the HP P6000 Control Panel.

IMPORTANT: The new IP address will be lost if the storage system is later uninitialized or

the management module is reset.

The new IP address is stored and remains in effect, even when the storage system is shut down

or restarted.

NOTE: If you uninitialize the storage system, wait one minute before reinitializing or you

may lose the IP address.

6. From a computer on the private network, browse to https://newly configured ip

address:2373 and log in. The HP P6000 control panel GUI appears.

Accessing HP P6000 Command View on the management module

To access HP P6000 Command View on the management module complete the following:

1. Click Launch HP P6000 Command View.

2. Click Use management module server.

The logon window appears.

3. Enter the username and password for accessing HP P6000 Command View.

Changing the default operating mode

By default, the EVA4400 is shipped to operate in a Fibre Channel switch environment and is

configured in fabric mode. If you choose to connect the EVA4400 directly to a server, you must

change the default operating mode of the EVA4400 to direct mode. If you do not change this

mode, the EVA4400 will be unable to communicate with your server. Use the HP P6000 Control

Panel to change the default operating mode.

Accessing HP P6000 Command View on the management module 27

Page 28

NOTE: Change your browser settings for the HP P6000 Control Panel window as described in

the HP P6000 Command View Installation Guide. You must have administrator privilege to change

the settings in the HP P6000 Control Panel.

To change the default operating mode:

1. Connect to the management module using one of the methods described in “Connecting

through a public network” (page 25) or “Connecting through a private network” (page 26).

2. Log into the HP P6000 Control Panel as an administrator. The default username is admin and

the password field is blank. For security reasons, change the password after you log in.

3. Select Administrator Options > Configure controller host ports.

The HP P6000 Control Panel is displayed (Figure 19 (page 28)).

Figure 19 HP P6000 Control Panel Configure controller host ports page

4. In the Topology box, select Direct from the dropdown menu.

5. Click Save Changes.

6. Change the default operating mode for the other controller.

7. Close the HP P6000 Control Panel and remove the Ethernet cable from the server.

Accessing the HP P6000 Control Panel through HP P6000 Command View

1. Select the EVA4400 storage system you want to access.

2. Select Hardware > Controller Enclosure > Management Module.

3. Click Launch HP P6000 Control Panel.

On rare occasions, the Launch HP P6000 Control Panel button may not appear due to invalid

array state or if the management module IP address is unknown to HP P6000 Command View.

28 Connecting to the management module

Page 29

7 Configuring servers using HP P6000 SmartStart

Configuring management servers using HP P6000 SmartStart

Use this procedure if you are connecting the EVA4400 to a management server for server-based

management. To complete array configuration for array-based management, see “Completing the

array configuration” in the HP P6000 Command View Installation Guide.

1. Insert the HP P6000 SmartStart CD in the drive of the management server. The HP P6000

SmartStart tool runs automatically.

2. Read the conceptual information and browse the online help.

3. Click Configure as Management Server on the display (Figure 20 (page 29)).

4. Follow the prompts to configure this system as your management server.

Figure 20 Configure as management server option

Configuring application servers for Windows using HP P6000 SmartStart

1. Insert the HP P6000 SmartStart CD in the drive of an application server. This may be the same

server as your management server.

The HP P6000 SmartStart tool runs automatically.

2. Select one of the options shown in Figure 21 (page 29) to initially configure the application

server or to create and mount additional storage volumes:

Figure 21 Configure storage initially or add storage

3. Repeat this configuration process for each server in your HP P6000 Command View

configuration.

NOTE: To configure non-Windows application servers, see "Configuring application servers"

in the HP 4400 Enterprise Virtual Array User Guide. See Related information for document

location.

Configuring management servers using HP P6000 SmartStart 29

Page 30

8 Using and monitoring your storage

Using your storage

To use the storage you have installed:

1. Start a server application.

2. Browse to a file system window and verify the drive letter of the virtual drive you have created.

Firmware recovery

A recovery CD containing the original XCS firmware installed on the array is shipped along with

your EVA4400. The CD is only needed for recovery purposes. The latest firmware can be found

on the HP software depot web page: http://h20392.www2.hp.com/portal/swdepot/index.do

HP Insight Remote Support software

HP strongly recommends that you install HP Insight Remote Support software to complete the

installation or upgrade of your product and to enable enhanced delivery of your HP Warranty,

HP Care Pack Service or HP contractual support agreement. HP Insight Remote Support supplements

your monitoring, 24x7 to ensure maximum system availability by providing intelligent event

diagnosis, and automatic, secure submission of hardware event notifications to HP, which will

initiate a fast and accurate resolution, based on your product’s service level. Notifications may be

sent to your authorized HP Channel Partner for on-site service, if configured and available in your

country. The software is available in two variants:

• HP Insight Remote Support Standard: This software supports server and storage devices and

is optimized for environments with 1-50 servers. Ideal for customers who can benefit from

proactive notification, but do not need proactive service delivery and integration with a

management platform.

• HP Insight Remote Support Advanced: This software provides comprehensive remote monitoring

and proactive service support for nearly all HP servers, storage, network, and SAN

environments, plus selected non-HP servers that have a support obligation with HP. It is

integrated with HP Systems Insight Manager. A dedicated server is recommended to host both

HP Systems Insight Manager and HP Insight Remote Support Advanced.

Details for both versions are available at:

http://www.hp.com/go/insightremotesupport

To download the software, go to Software Depot:

http://www.software.hp.com

Select Insight Remote Support from the menu on the right.

30 Using and monitoring your storage

Page 31

9 Support and other resources

Contacting HP

HP technical support

For worldwide technical support information, see the HP support website:

http://www.hp.com/support

Before contacting HP, collect the following information:

• Product model names and numbers

• Technical support registration number (if applicable)

• Product serial numbers

• Error messages

• Operating system type and revision level

• Detailed questions

Subscription service

HP recommends that you register your product at the Subscriber's Choice for Business website:

http://www.hp.com/go/wwalerts

After registering, you will receive e-mail notification of product enhancements, new driver versions,

firmware updates, and other product resources.

Documentation feedback

HP welcomes your feedback.

To make comments and suggestions about product documentation, please send a message to

storagedocsFeedback@hp.com. All submissions become the property of HP.

Contacting HP 31

Page 32

Related information

Documents

For documents referenced in this guide, see the Manuals page on the Business Support Center

website:

http://www.hp.com/support/manuals

HP websites

• HP:

http://www.hp.com

• HP Storage:

http://www.hp.com/go/storage

• HP Partner Locator:

http://www.hp.com/service_locator

• HP Software Downloads:

http://www.hp.com/support/downloads

• Hp Software Depot:

http://www.software.hp.com

• HP Single Point of Connectivity Knowledge (SPOCK):

http://www.hp.com/storage/spock

• HP SAN manuals:

http://www.hp.com/go/sdgmanuals

32 Support and other resources

Page 33

Typographic conventions

Table 4 Document conventions

UsesConvention

Cross-reference links and email addressesBlue text: Table 4 (page 33)

Website addressesBlue, underlined text: http://www.hp.com

Bold text

• Keys that are pressed

• Text typed into a GUI element, such as a box

• GUI elements that are clicked or selected, such as menu and

list items, buttons, tabs, and check boxes

Text emphasisItalic text

Monospace text

• File and directory names

• System output

• Code

• Commands, their arguments, and argument values

Monospace, italic text

• Code variables

• Command variables

Emphasized monospace textMonospace, bold text

Indication that the example continues....

An alert that calls attention to important information that if not

understood or followed can result in personal injury.

WARNING!

An alert that calls attention to important information that if not

understood or followed can result in data loss, data corruption,

or damage to hardware or software.

CAUTION:

An alert that calls attention to essential information.

IMPORTANT:

An alert that calls attention to additional or supplementary

information.

NOTE:

An alert that calls attention to helpful hints and shortcuts.

TIP:

Customer self repair

HP customer self repair (CSR) programs allow you to repair your HP product. If a CSR part needs

replacing, HP ships the part directly to you so that you can install it at your convenience. Some

parts do not qualify for CSR. Your HP-authorized service provider will determine whether a repair

can be accomplished by CSR.

For more information about CSR, contact your local service provider or see the CSR website:

http://www.hp.com/go/selfrepair

Typographic conventions 33

Page 34

Rack stability

Rack stability protects personnel and equipment.

WARNING! To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install stabilizing feet on the rack.

• In multiple-rack installations, fasten racks together securely.

• Extend only one rack component at a time. Racks can become unstable if more than one

component is extended.

Location of WWN and serial number

For service and support purposes, the location of the controller serial number, world wide name

(WWN), and controller product number (after removing the controller front bezel) is shown in the

red circle in Figure 22 (page 34).

Figure 22 Location of WWN and serial number

NOTE: For products ordered as bundled products that contain multiple products, the product

number and serial number needed for service and support is shown in the circled area in

Figure 23 (page 35), callouts 3 and 4.

34 Support and other resources

Page 35

Figure 23 Location of WWN and serial number for bundled products

Location of WWN and serial number 35

Page 36

A EVA4400 cabling diagrams

This appendix contains cabling diagrams for common EVA4400 installation environments. If you

plan to configure the EVA4400 with an iSCSI device, see the HP P6000 iSCSI Connectivity User

Guide. See Related information for the location of this guide.

Connecting device port Fibre Channel cables to the EVA4400 (rear view)

This section shows two views of how to connect cables to the controller. Figure 24 (page 36) shows

the controller mounted on top of the disk shelves in the rack, and Figure 25 (page 37) shows the

controller with disk shelves mounted above and below it.

• For configurations with the controller above the disk enclosures, attach the cables to the EVA

as shown in Figure 24 (page 36).

NOTE: All controller device port A cabling must be plugged into the A I/O modules on all

enclosures. All controller B device port cabling must be plugged into the B I/O modules on

all enclosures.

Figure 24 Fibre Channel cabling for the EVA (rear view, top-mounted controller)

1. This cable connects controller 1, device port 1B (top left—Cntrl 1, DP1B) to I/O module B, port 2 (bottom

right—I/O B, P2).

2. This cable connects controller 2, device port 1A (top right—Cntrl 2, DP1A) to I/O module A, port 2 (bottom

left—I/O A, P2).

• For configurations with the controller between the disk enclosures, attach the cables to the

EVA as shown in Figure 25 (page 37).

NOTE: All controller device port A cabling must be plugged into the A I/O modules on all

enclosures. All controller B device port cabling must be plugged into the B I/O modules on

all enclosures.

36 EVA4400 cabling diagrams

Page 37

Figure 25 Fibre Channel cabling for the EVA (rear view, mid-mounted controller)

1. This cable connects controller 1, device port 1B (top left—Cntrl 1, DP1B) to I/O module B, port 2 (bottom

right—I/O B, P2).

2. This cable connects controller 2, device port 1A (top right—Cntrl 2, DP1A) to I/O module A, port 2 (bottom

left—I/O A, P2).

Connecting Fibre Channel cables to the EVA4400 (front end)

You can cable the front end of your EVA4400 either to external Fibre Channel switches or directly

to servers. See Figure 26 (page 38) and Figure 28 (page 39) for front end connections with

server-based management. See Figure 27 (page 38) and Figure 29 (page 39) for front end

connections with array-based management.

NOTE: The cabling diagrams in Figure 26 (page 38) through Figure 29 (page 39) require fabric

connect mode, which is the default as shipped.

Connecting Fibre Channel cables to the EVA4400 (front end) 37

Page 38

Figure 26 Cabling the controller to front end component—Fibre Channel to switch detail view with

server-based management

1. File server

2. Management server

3. Database server

4. Fiber channel switch

5. LED status indicators for cabling connections to disk enclosures. See Figure 24 (page 36) and Figure 25 (page 37)

for cabling connections.

Figure 27 Cabling the controller to front end components—Fibre Channel to switch detail view with

array-based management

1. File server

2. Database server

3. Fiber channel switch

4. LED status indicators for cabling connections to disk enclosures. See Figure 24 (page 36) and Figure 25 (page 37)

for cabling connections.

38 EVA4400 cabling diagrams

Page 39

Figure 28 Cabling the controller to front end components—Direct Fibre Channel to servers with

server-based management

1. Management server

2. Database server

3. LED status indicators for cabling connections to disk enclosures. See Figure 24 (page 36) and Figure 25 (page 37)

for cabling connections.

Figure 29 Cabling the controller to front end component—direct Fibre Channel to servers with

array-based management

1. File server

2. Database server

3. Indicates cabling connections to disk enclosures. See Figure 24 (page 36) and Figure 25 (page 37) for cabling

connections.

Connecting to the HSV300-S controller enclosure

The HSV 300-S controller enclosure includes a switch within each controller. The switches are

configured to be redundant during the manufacturing process. Figure 30 (page 40) and

Figure 31 (page 40) show an HSV300-S controller enclosure with external hosts connected to the

embedded Fibre Channel switches.

NOTE: Additional external switches can be connected to the HSV300-S controller enclosure.

Connecting to the HSV300-S controller enclosure 39

Page 40

Figure 30 HSV300-S controller enclosure in an embedded Fibre Channel switch configuration with

server-based management

1. Management server

2. Database server

3. Indicates cabling connections to disk enclosures. See Figure 24 (page 36) and Figure 25 (page 37) for cabling

connections.

Figure 31 HSV300-S controller enclosure in an embedded Fibre Channel switch configuration with

array-based management

1. File server

2. Database server

3. Indicates cabling connections to disk enclosures. See Figure 24 (page 36) and Figure 25 (page 37) for cabling

connections.

40 EVA4400 cabling diagrams

Loading...

Loading...