Page 1

Agilent

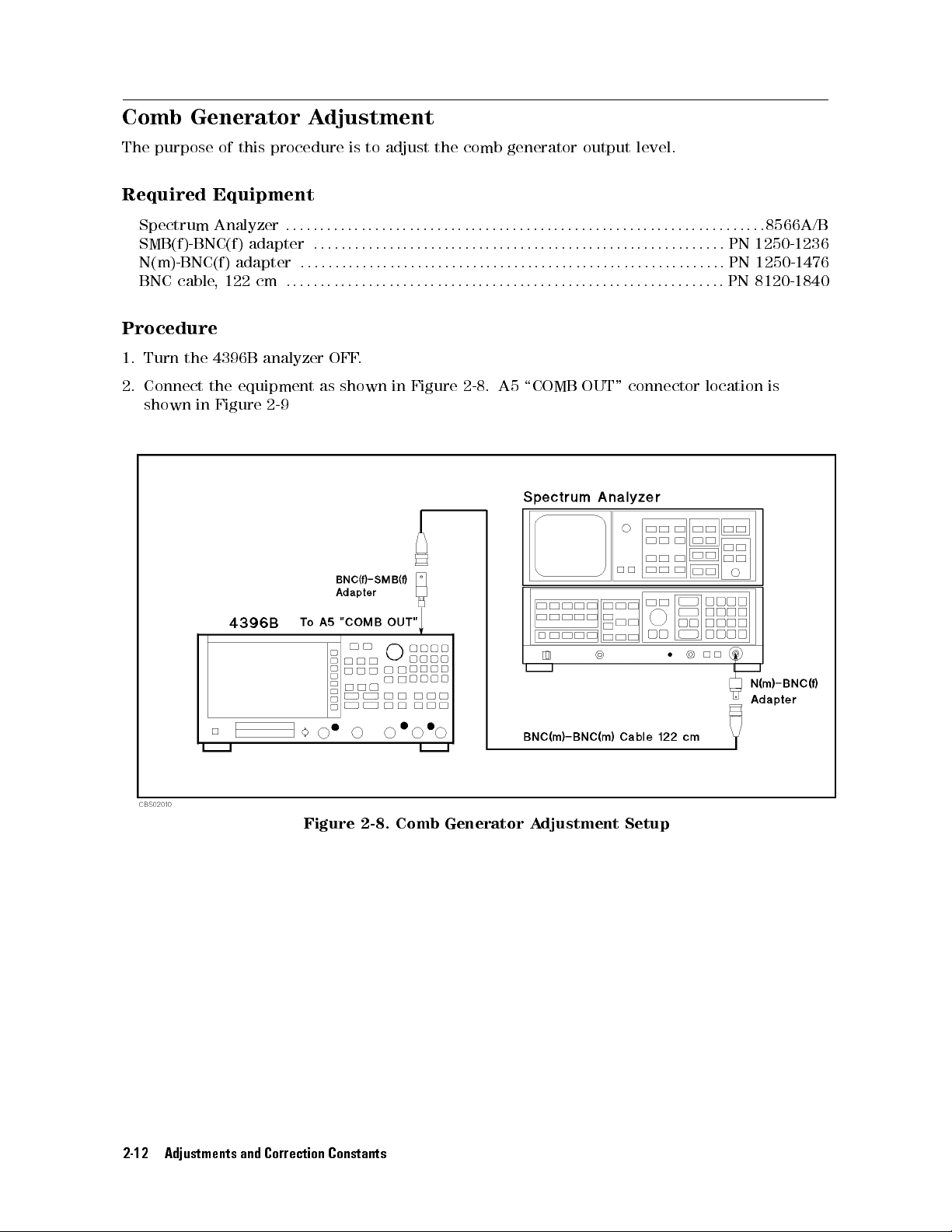

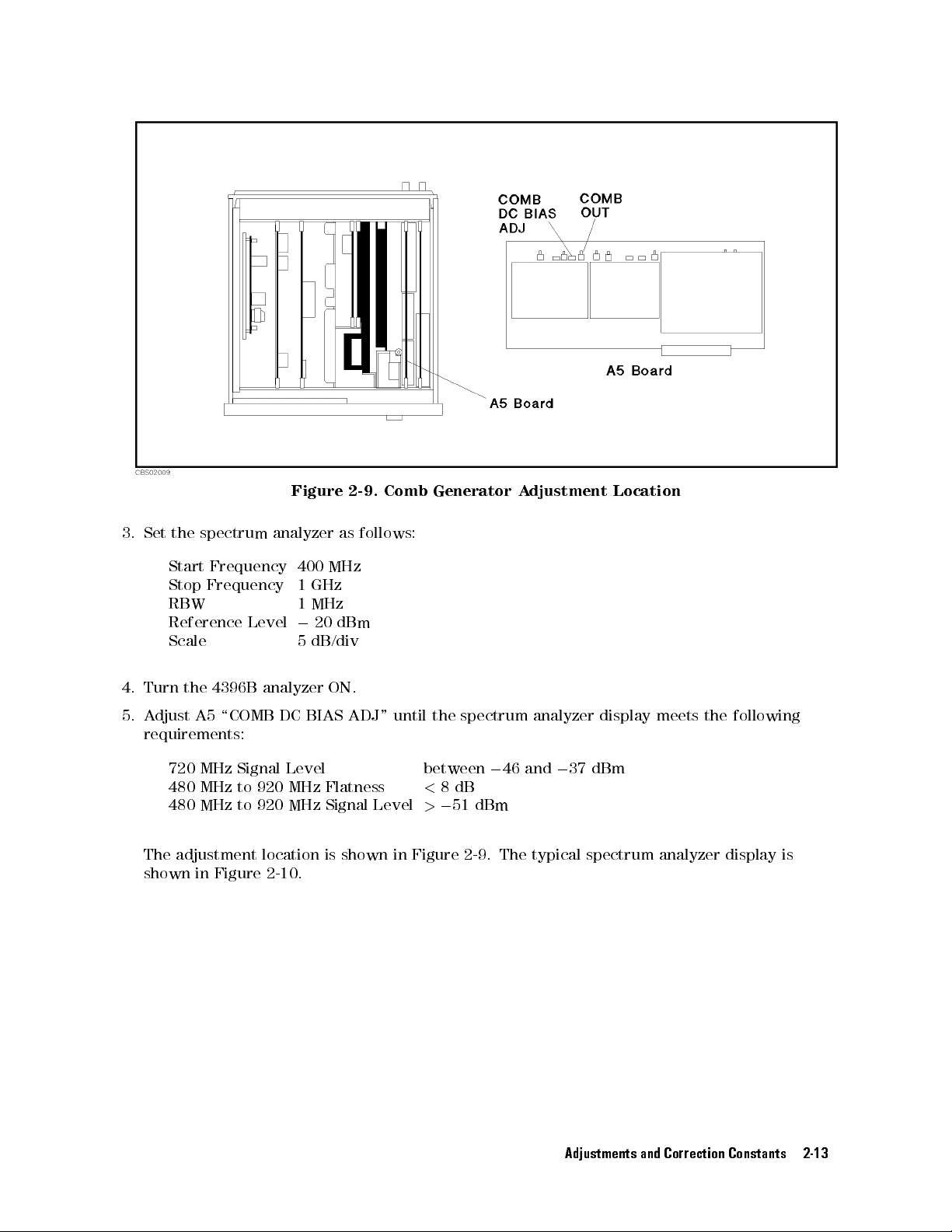

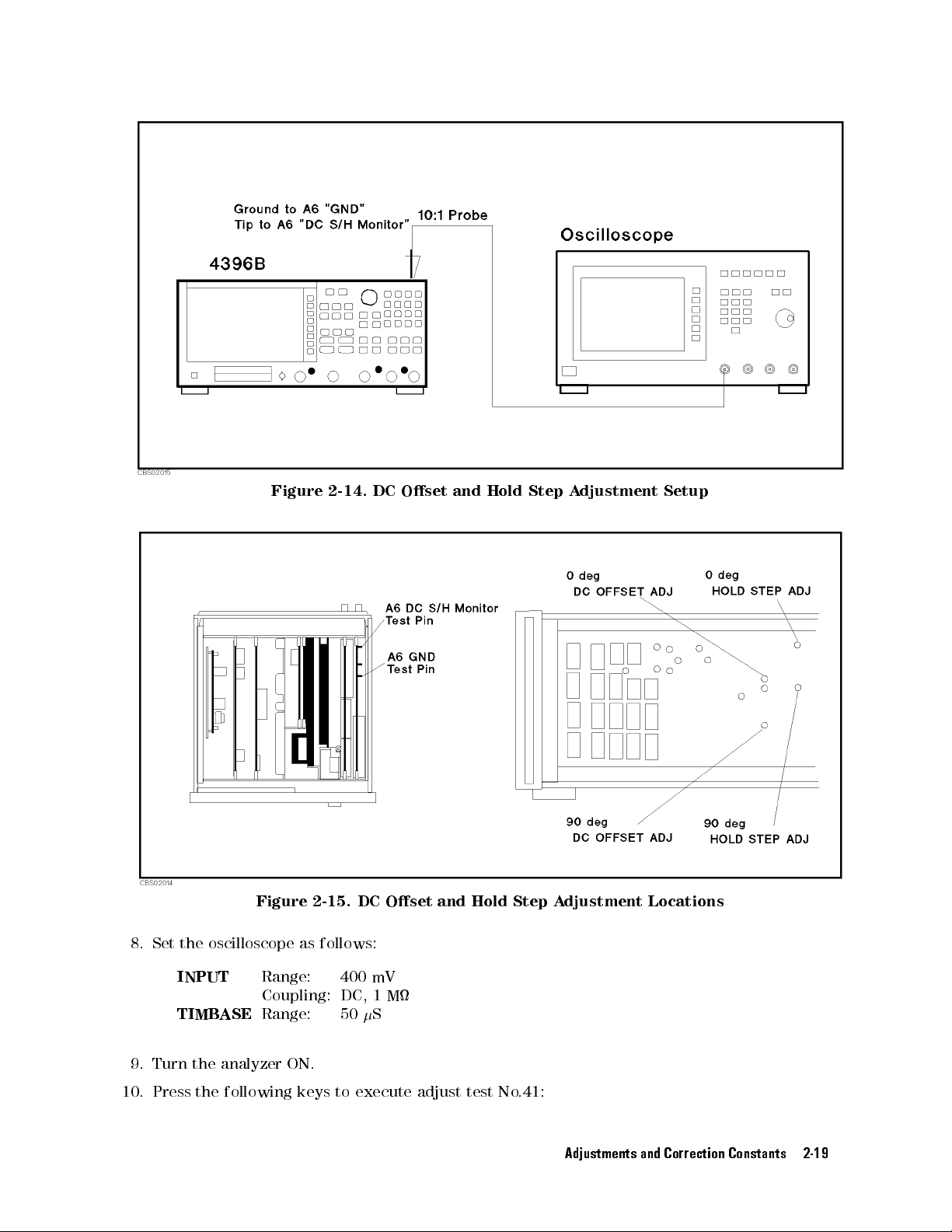

4396B Network/Spectrum/Impedance

Service Manual

Analyzer

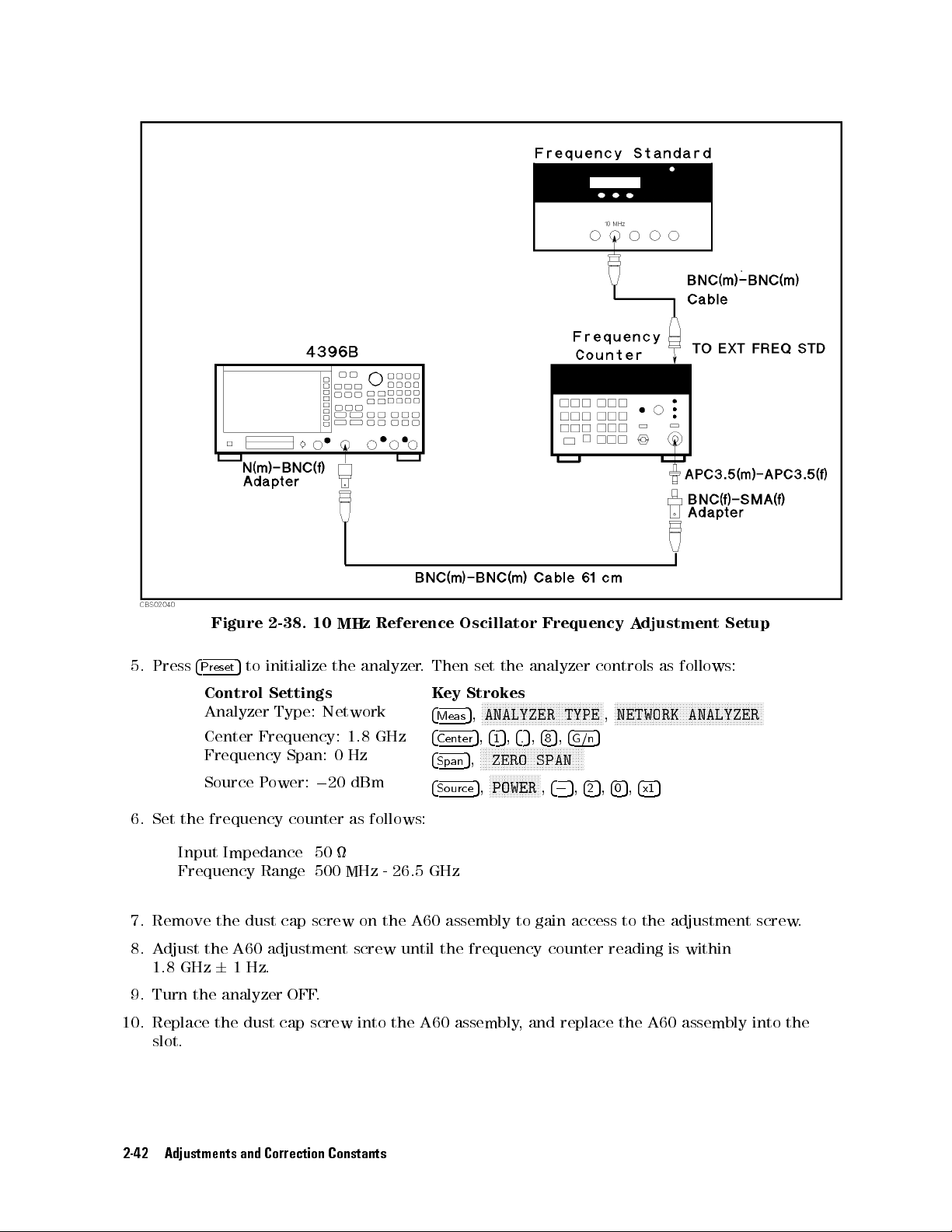

This

number

F

manual

or

additional

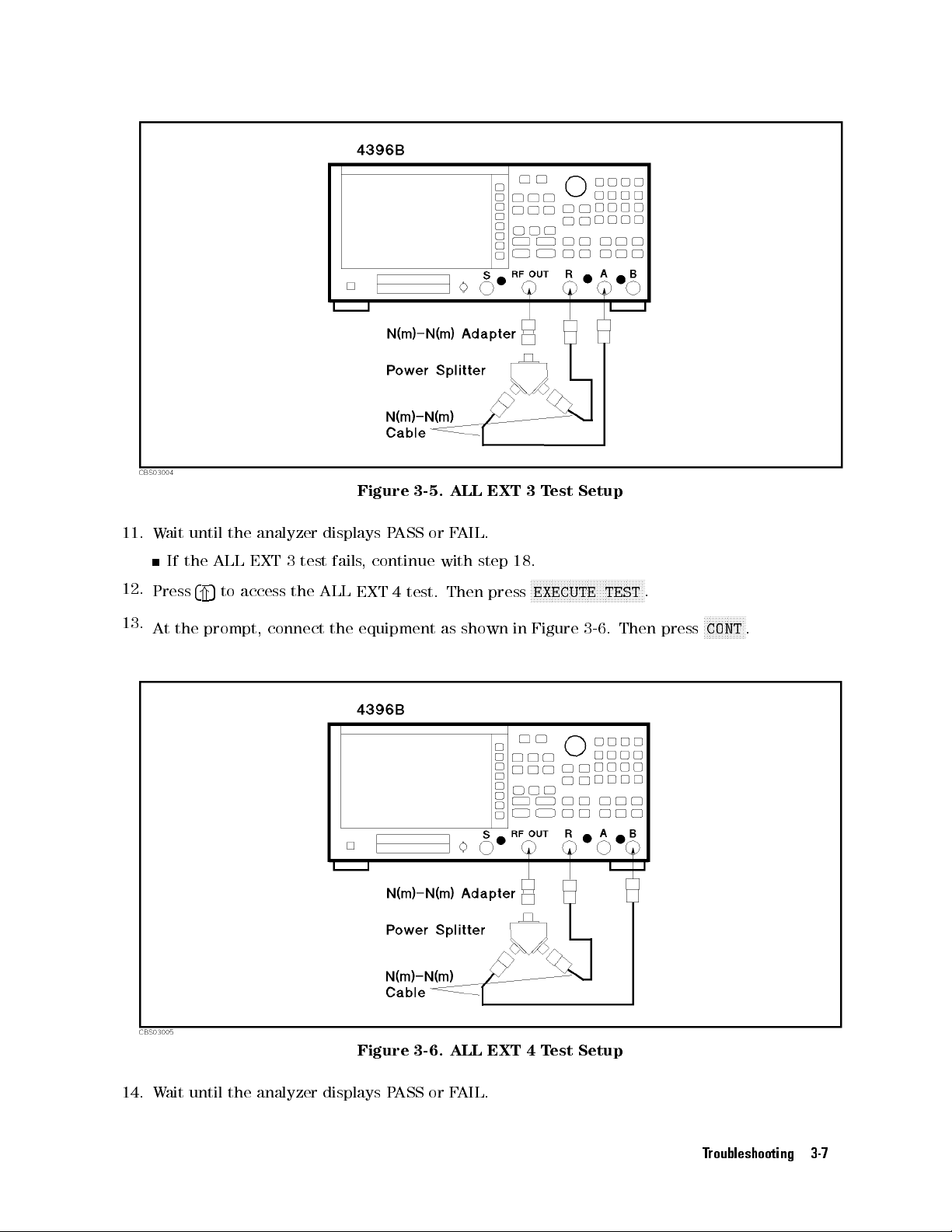

numbers

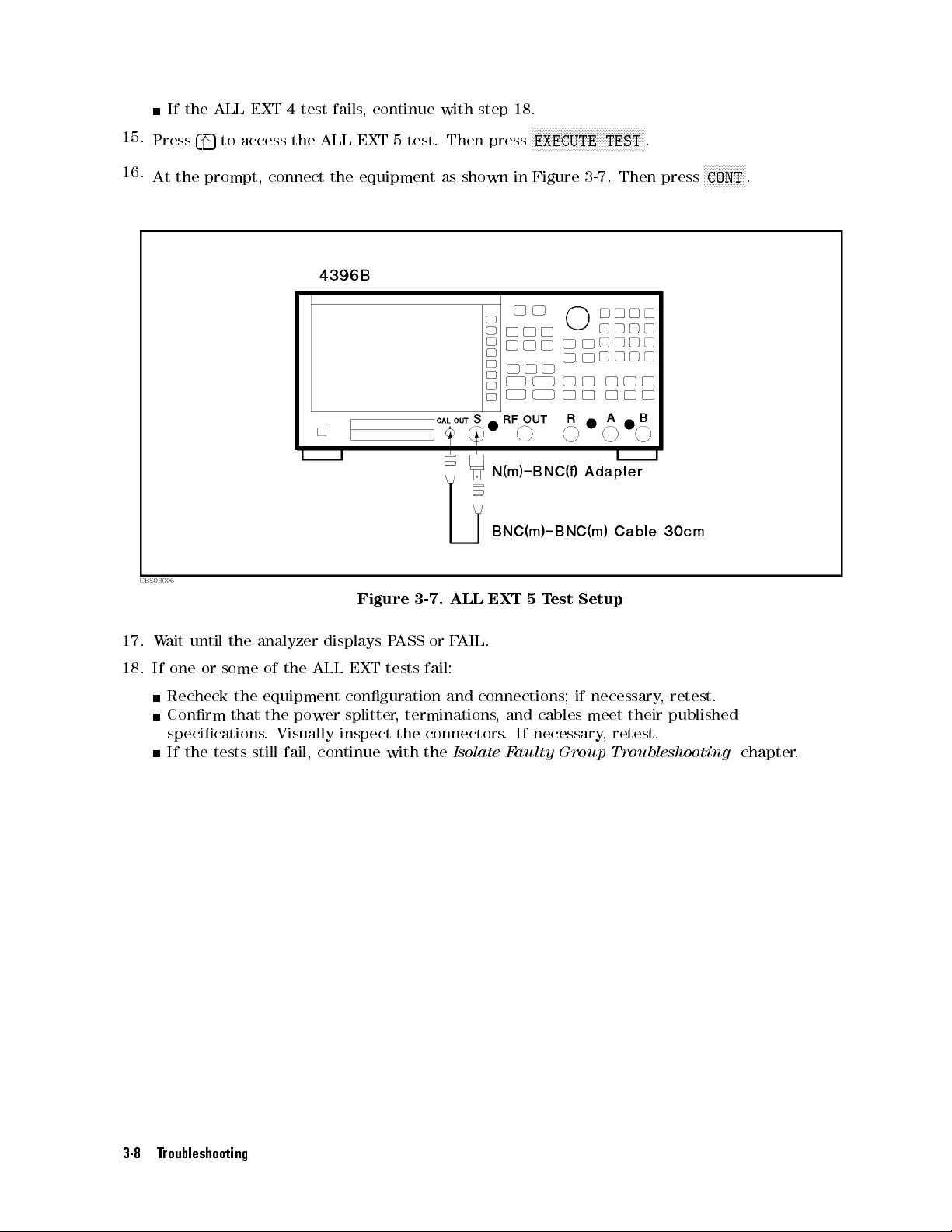

applies

prex

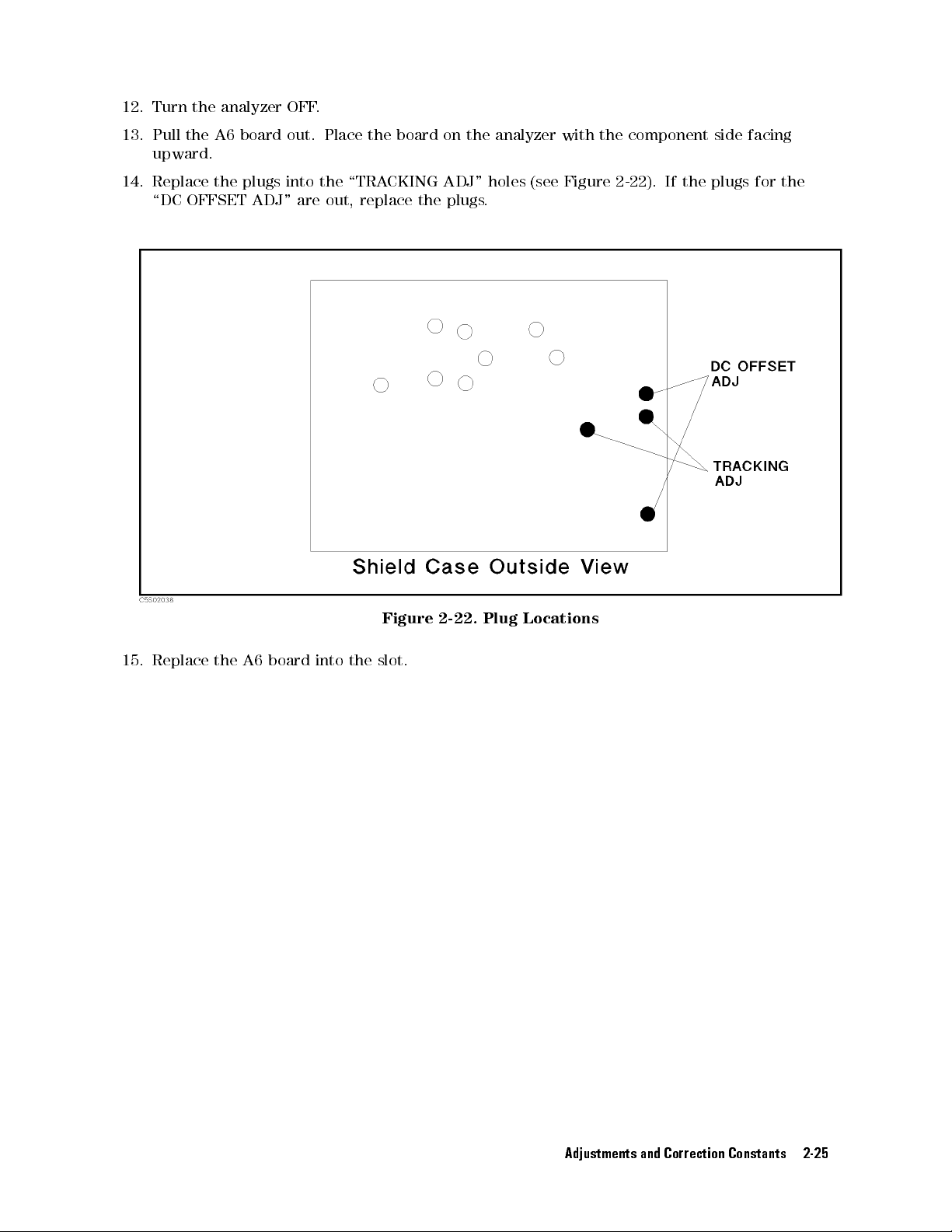

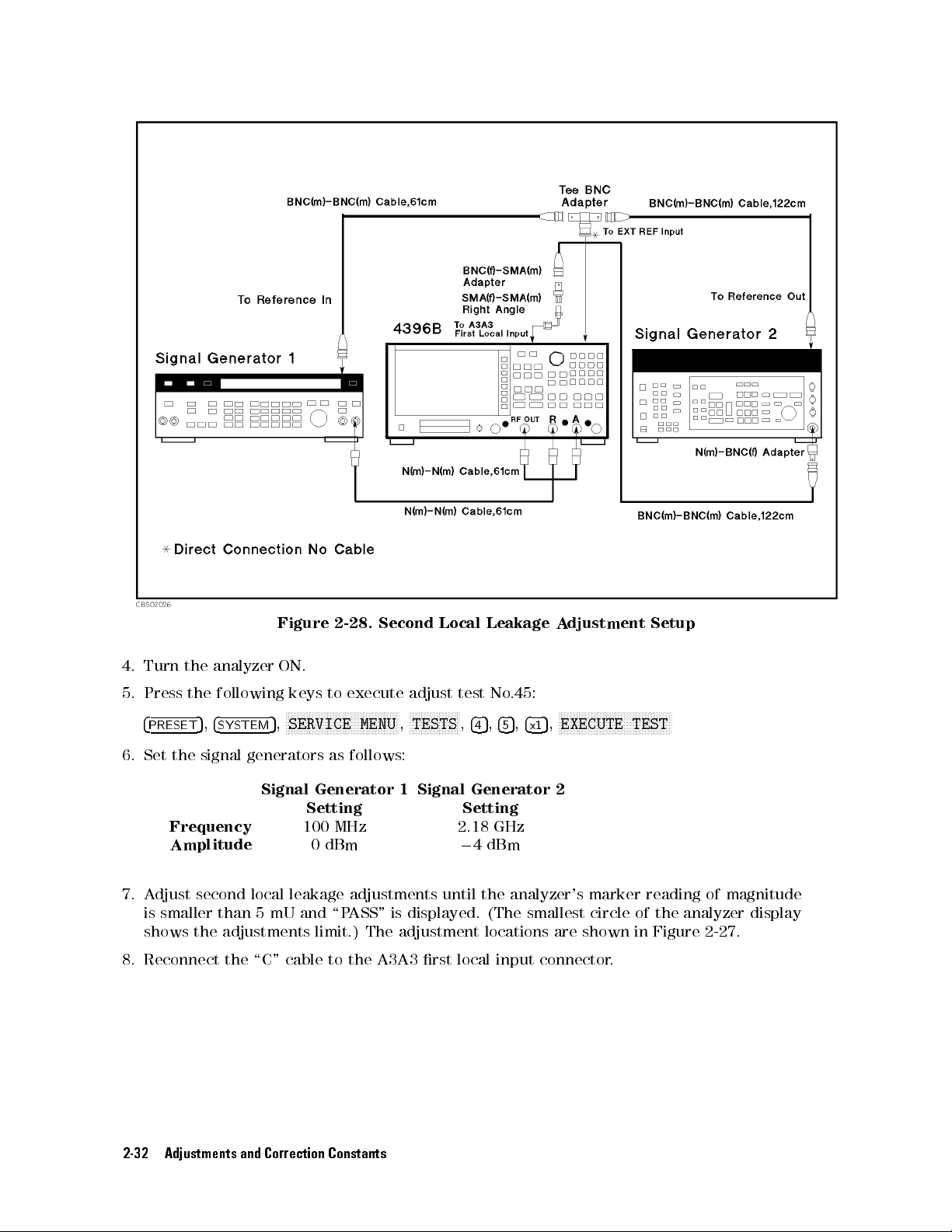

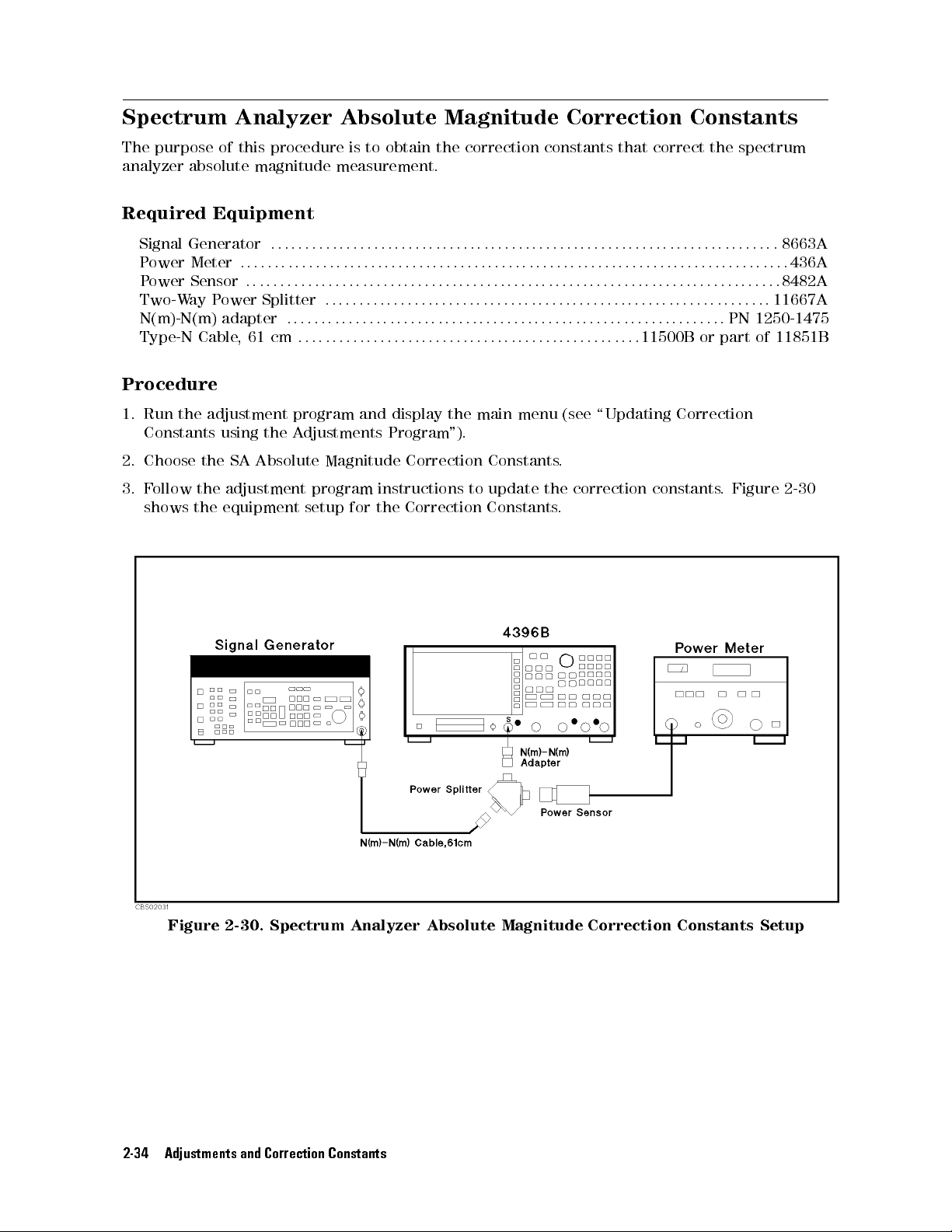

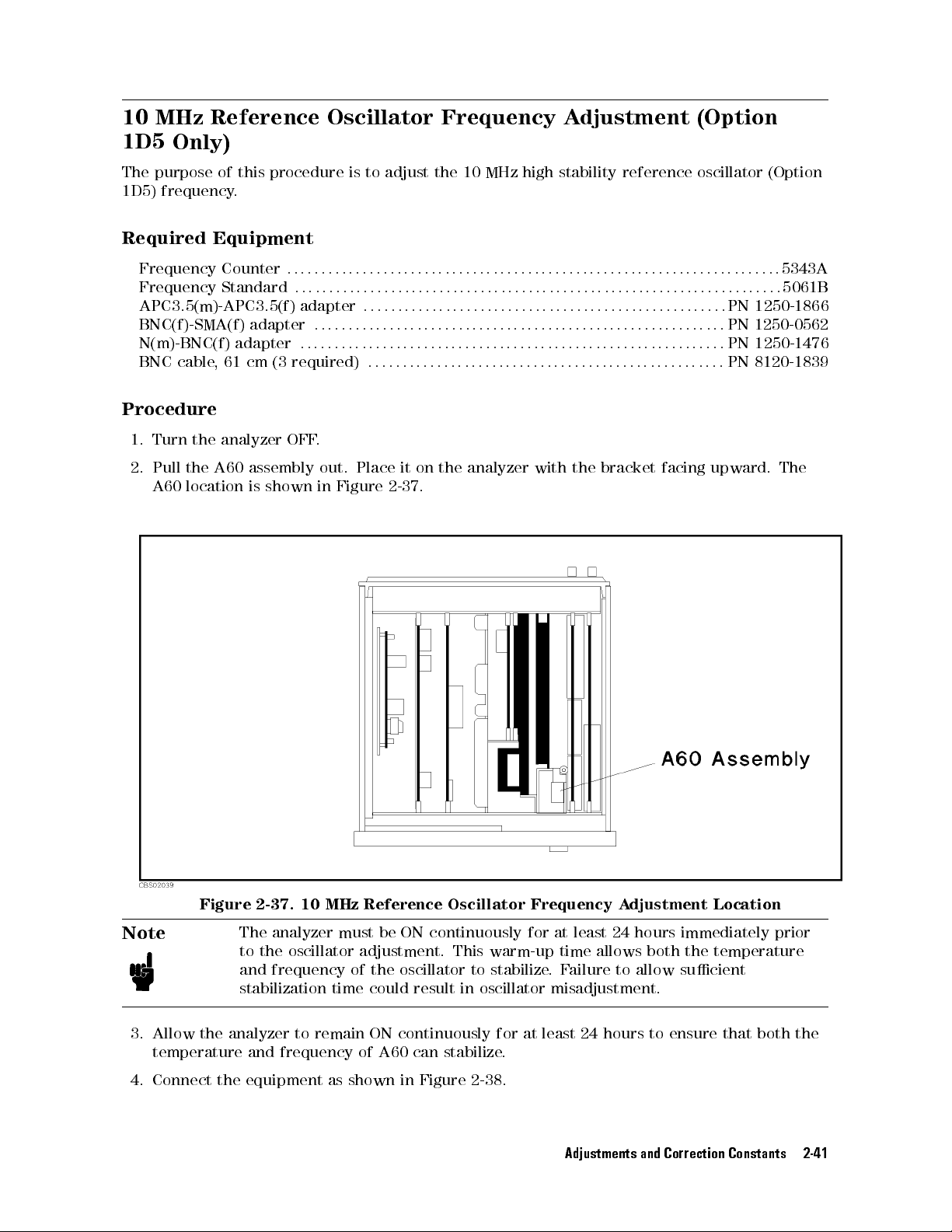

,

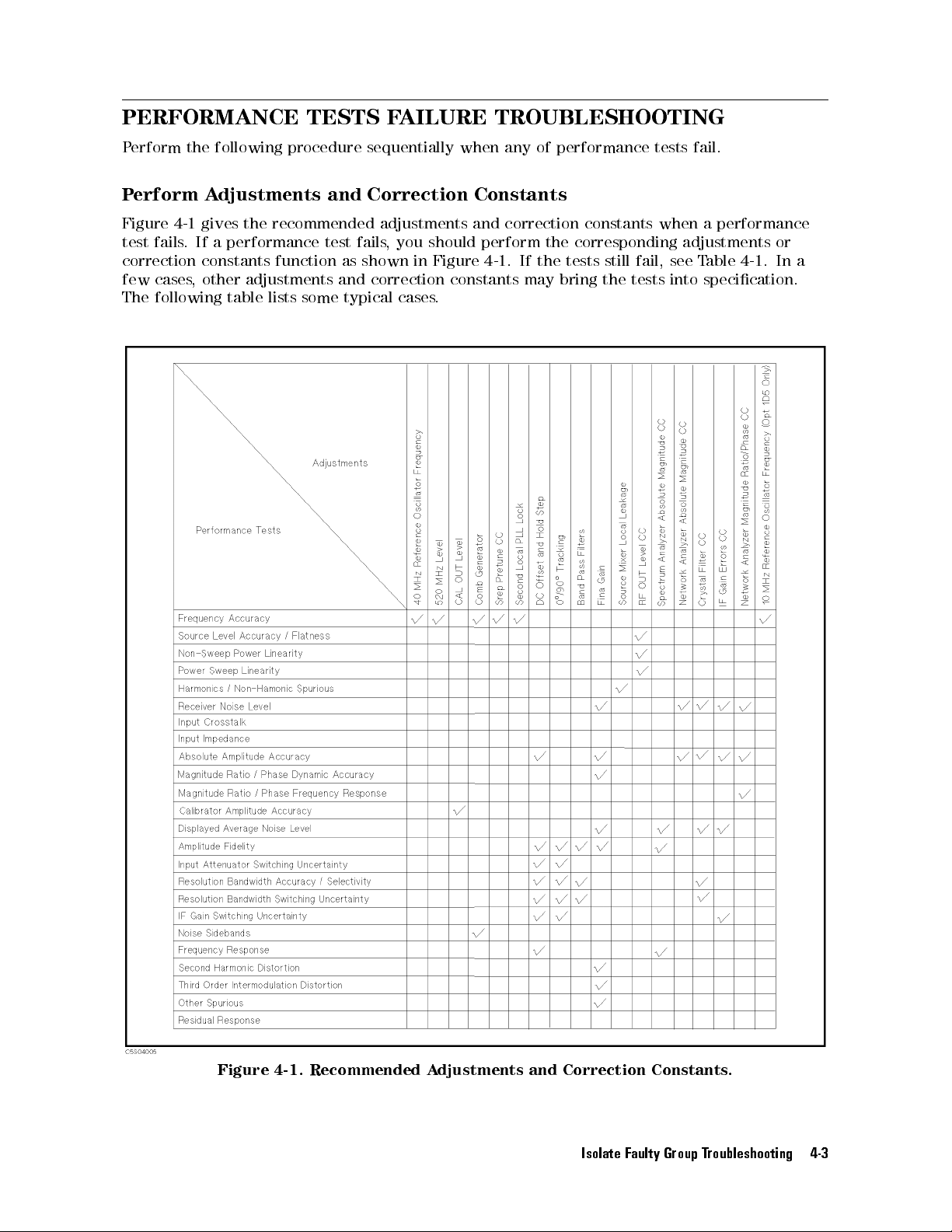

read

SERIAL

directly

JP1KD

,

important

\Serial

NUMBERS

to

instruments

or

rmware

information

Number"

with

revision

about

in Appendix

serial

1.00.

serial

A.

Agilent Part No. 04396-90121

Printed in Japan March 2001

Third Edition

Page 2

Notice

The

information

This

document

reserved.

language

contains

No

part

without

contained

proprietary

of

this

the

prior

in

this

document

written

document

information

may

be

consent

is

subject

that

is

photocopied,

of

the

Agilent

to

change

protected

reproduced,

T

echnologies.

without

by

copyright.

or

notice

.

All

translated

rights

to

another

are

Agilent

T

echnologies

Component

1-3-2,

Hyogo

Murotani,

,

651-2241

T

est

Japan,

PGU-Kobe

Nishi-ku,

Japan

Ltd.

Kobe-shi,

c

Copyright Agilent Technologies Japan, Ltd. 1997, 2000, 2001

Page 3

Manual Printing

The

manual's

changes

at

reprint

technical

May

1997

June

when

do

changes

2000

printing

a

new

not

cause

:

:

::

::

:

:

:

:

::

edition

are

incorporated.

::

::

:

::

::

History

date

and part

is

the

date to

:

:

:

:

:

:

:

:

:

:

:

:

:

:

number indicate

printed. (Minor

change.)

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

::

corrections and

The manual

::

:

:

:

:

:

:

:

::

::

:

:

:

:

:

:

its current

part number

:

:

:

First

Second

edition. The

updates that

Edition

Edition

printing date

are incorporated

changes when

(part

number:

(part

number:

extensive

04396-90121)

04396-90121)

March

2001

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

Third

Edition

(part

number:

04396-90121)

iii

Page 4

Safety Summary

The

following

service

W

ARNINGS

In

addition

,

and

elsewhere

it

general

repair

violates

of

safety

this

safety

instrument.

The

A

gilent

requirements

T

echnologies

.

precautions must

instrument. F

in

this

manual

standards

assumes

ailure to

may impair

of design,

no liability

be observed

comply with

the protection

manufacture,

for the

customer's failure

during all

phases of

these precautions

provided by

and intended

operation,

or with

the equipment.

use of

to

comply

the

with

specic

these

Note

4396B

in

Note

LEDs

CLASS

Ground

To

avoid

safety earth

DO

Do not

electrical

Keep

The

electric

NOT

Operate

operate

instrument in

Away

Instrument

shock

ground

the

From

Operating personnel

adjustments

with

the

with

the

circuits

power

power

before

must

cable

cable

touching

be

comply

IEC1010-1.

in 4396B

1

LED

hazard,

by

the

supplied

In

An

instrument

such

Live

must not

made

by

connected.

removed.

them.

with

INST

4396B

are

are

Class

PRODUCT

the

instrument

power

Explosive

in

the

presence

an

environment

Circuits

remove

qualied

Under

T

o

avoid

ALLA

TION

INDOOR

1

in

accordance

chassis

cable

Atmosphere

of

constitutes

instrument

maintenance

certain

injuries

CA

TEGORY

USE

product.

and

with

earth

ammable

covers

.

personnel.

conditions

,

always

II

with

IEC825-1.

cabinet

blade

.

gasses

a

denite

Component

Do

,

dangerous

disconnect

and

POLLUTION

must

be

or

fumes

safety

replacement

not

replace

voltages

power

connected

.

Operation

hazard.

components

may

and

discharge

DEGREE

to

a

of

and

internal

exist

2

any

even

DO

NOT Service

Or

A

djust

Alone

Do not attempt internal service or adjustment unless another person, capable of rendering rst

aid and resuscitation, is present.

DO NOT Substitute P

Because of the danger of introducing additional hazards

arts Or Modify Instrument

, do not install substitute parts or

perform unauthorized modications to the instrument. Return the instrument to a Agilent

T

echnologies Sales and Service Oce for service and repair to ensure that safety features are

maintained.

iv

Page 5

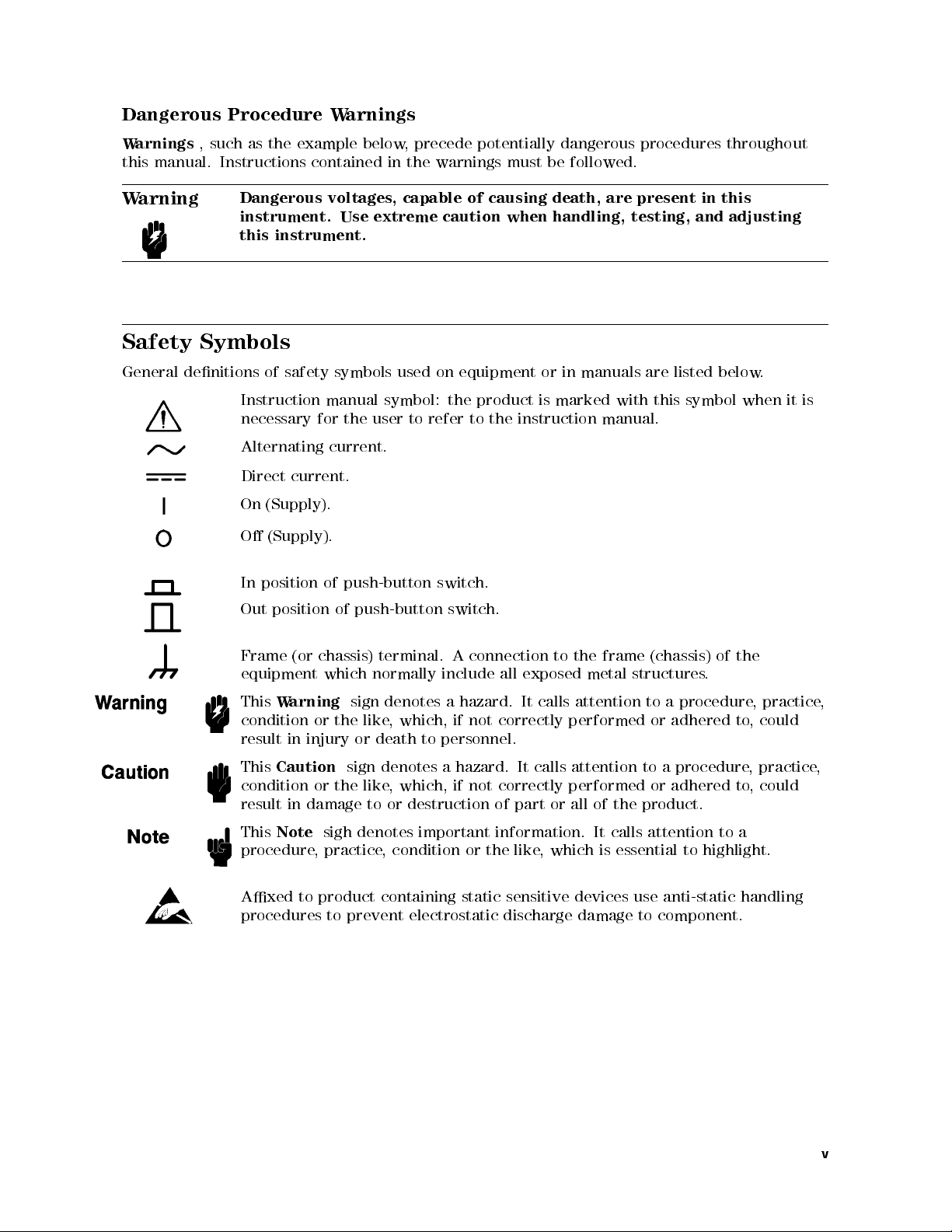

Dangerous

W

arnings

this

,

manual.

Procedure

such

as

the

Instructions

W

example

contained

arnings

below

in

,

precede

the

warnings

potentially dangerous

must

be followed.

procedures throughout

W

arning

Safety

General

Dangerous voltages

instrument. Use

this instrument.

Symbols

denitions

Instruction

necessary

Alternating

Direct

On

O

In

Out

of

safety

current.

(Supply).

(Supply).

position

position

symbols

manual

for

the

current.

of

push-button

of

push-button

, capable

of

extreme caution

used

on

equipment

symbol:

user

to

the

refer

product

to

switch.

switch.

causing

death,

when handling,

or

in

is

marked

the

instruction

are

manuals

with

manual.

present

testing,

are

listed

this

in

this

and

below

symbol

adjusting

.

when

it

is

Frame

equipment

This

condition

result

This

condition

result

This

procedure, practice

(or

chassis)

which normally

Warning

or the

in injury

Caution

or

in

damage

Note

sigh

terminal.

sign denotes

like,

which, if

or death

sign

the

like

to

to personnel.

denotes

,

which,

or

destruction

denotes important

, condition or the like

A

connection

include all

a

hazard.

not

correctly

a

hazard.

if

not

correctly

of

information.

exposed

It

calls

It

calls

part

or

, which

to

the

frame

metal

attention

performed

attention

performed

all

of

It

(chassis) of

structures

to

or

to

or

the

product.

calls

attention

a

a

is essential to highlight.

.

procedure

adhered

procedure

adhered

to

the

to

to

a

,

,

,

,

practice

could

practice

could

Axed to product containing static sensitive devices use anti-static handling

procedures to prevent electrostatic discharge damage to component.

,

,

v

Page 6

Certication

Agilent

of

T

echnologies

shipment

measurements

T

echnology

facilities

W

arranty

This

of

Agilent

,

to

other

workmanship

certain

specied

repair

F

or

Agilent

T

echnologies

pay

another

Agilent

T

echnologies

property

of

components

or

warranty

Technologies

all

shipping

country

T

echnologies

the

instrument,

period.

replace

installed

from

the

are

traceable

the

extent

International

T

echnologies

for

a

period

listed

During

products

service

.Buyer

shall

pay

charges

.

for

use

with

on

or

certies

factory

.

to

allowed by

instrument

of

in

General

the warranty

that

or

repair

shall prepay

shipping

,

duties

warrants

an

that

instrument.

software

that this

Agilent T

the

product met

echnologies further

United

States National

the Institution's

Standards Organization

one

year

product

from the

is

warranted against

date of

Information

period, Agilent

prove to

,

this

be defective

product

must

shipping

charges

,

and

that

instrument

,

or

to

taxes

its

software

will

Agilent

rmware

return

for

products

execute

T

will

and

echnologies

its published

Institute of

calibration facility

members.

shipment, except

of

this manual,

Technologies

.

be

returned to

charges

the

to

product

returned

rmware

its

programming

be

uninterrupted

specications at

certies that

Standards and

defects in

the warranty

will, at

a

service

Agilent

to

Buyer

to

Agilent

T

echnologies

.

designated

instruction

does

not

warrant

or

error

the time

its calibration

,or

to the

material and

that in

the

shall

its

option,

facility

designated

and

However

by

,

Buyer

T

echnologies

Agilent

when

that

the

free

.

calibration

case

of

be

for

either

Agilent

shall

from

operation

the

by

Limitation

The

foregoing

maintenance

misuse

,

preparation

No

other

implied

by

operation

or

warranty

warranties

Of

W

arranty

warranty

Buyer

shall

,

Buyer-supplied

outside

maintenance

is

expressed

of

merchantability

not

apply

the

environmental

.

or

to

software

implied.

and

defects

resulting

or

specications

A

gilent

tness

from

interfacing,

for

the

T

echnologies

for

a

particular purpose

improper

unauthorized

product,

specically

or

inadequate

modication

or

improper

disclaims

.

or

site

the

vi

Page 7

Exclusive Remedies

The

remedies

shall

not

whether

be

liable

based

provided

for

on

contract,

herein

any

direct, indirect,

Assistance

are buyer's

tort,

or

sole and

special, incidental,

any other

exclusive remedies

legal theory

or consequential

.

.A

gilent T

echnologies

damages,

Product

Agilent

F

or

any

A

ddresses

maintenance

T

echnologies

assistance

are

,

provided

agreements

products

contact

at

and

.

your

nearest Agilent

the

back

other

of this

customer

Technologies

manual.

assistance

Sales and

agreements

Service Oce

are

available

.

for

vii

Page 8

Typeface Conventions

Bold

Italics

Computer

4

HARDKEYS

N

NN

NN

NN

NN

N

N

N

N

N

N

N

N

N

N

N

SOFTKEYS

Boldface

symbols

Italic

publications

Italic

must

lename

type

Computer

5

N

N

N

N

N

N

Labeled

Softkeys located

type

type

be

the

type

.

is

is

typed

means

name

font

keys

used

.

also

is

on

used

in

to

of

is

the

used

place

a

used

to the

when

for

emphasis

for

of

type

the

le

such

for

instrument

right of

a

term

and

keyboard

the

words

word

as

file1

on-screen

front

the

is

for

entries

in

copy

prompts

CRT

dened.

titles of

italics

,

to

type a

.

panel

are

F

or example:

manuals and

when

a

.

F

or

space,

and

messages.

are

enclosed in

enclosed

name

or

example:

and then

N

NN

NN

in

icons

4

.

other

a

variable

copy

5

.

are

to

viii

Page 9

Documentation Map

The

following

manuals

are

available for

the analyzer

.

User's

Guide

The User's

make

basic

Guide walks

measurements,

measurement

T

ask

Reference

T

ask

Reference

step-by-step

instructions

Function Reference

The

Function

softkeys

system

Programming

The

analyzer

GPIB

Command

The

also

features

HP

Instrument

The

.

It

also

performance

Guide

Programming

and

Reference

GPIB

Command

provides

conform

B

ASIC

HP

Instrument

programming

provide

B

ASIC

Instrument

a

general

Programming

B

examples

helps

you

Reference

provides

,

and

Guide

describes

Reference

information

to

the

Manual

B

ASIC

language

,

programming

T

ASIC

Language

you through

explains commonly

.

After

you receive

to

learn

how

without

describes

concepts

all

information

some

topics

shows

how

how

HP

Instrument

provides

on

the

status

SCPI

standard).

Set,

User's

provide

Handbook

some

reference

echniques

,

HP

R

eference

system setup

used features

your analyzer

to

use

the

.

function

on

about

to

write

accessed

options and

the

and

B

ASIC

a

summary

reporting

introduces

helpful

hints

.

It

is

Instrument

.

and initial

, and

,begin

analyzer

.

This

from the

accessories available

analyzer's

use

works

of

structure

on

divided

B

ASIC

B

ASIC

with

all

you

getting

into

Interface

features.

available

and

to

three

power-on, shows

typical

with

manual

application

this

manual.

provides

front panel

, specications

program

the

the

the

analyzer

GPIB

the

trigger

HP

most

books

T

echniques

to control

..

commands

Instrument

use

,

HP

how to

simple

keys and

the

system

(these

B

from

it,

Instrument

,

and

.

It

ASIC

and

HP

,

P

erformance

The

specications

Service

T

P

erformance

Manual

est

Manual

.

(Option 0B

T

est

Manual

W only),

explains

how

to

verify

The Service Manual explains how to adjust, troubleshoot, and

This manual is option 0BW only

.

conformance

repair the instrument.

to

published

ix

Page 10

Page 11

Contents

1.

General

INTRODUCTION

ORGANIZATION

TABLE

2.

A

djustments

Introduction

Safety

Required

W

arm-up

Instrument Cover

Order

Updating

A

Controller

Updating

40

Required

Procedure

520

Required

Procedure

CAL

Required

Procedure

Comb

Required

Procedure

Step

Required

Procedure . . . . . . . . . . . . .

Second Local PLL Lock A

Required Equipment . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . .

DC

Required

Procedure .

0/90Tracking A

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Band Pass Filters Adjustments . ..... ...... ...... ...... 2-26

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Information

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

OF

SERVICE

OF

SERVICE

and

.

Considerations

Equipment

for

A

djustments

Of

A

djustments

Correction

djustments

Keyboard

MHz

Reference

MHz

OUT

Generator

Pretune Correction

Oset and Hold Step A

3 MHz Band Pass Filter Adjustment.... ...... ...... .... 2-26

1 MHz BPF Band Width Adjustment . . . . . . . . . . . . . . . . . . . . 2-27

and

Requirement

Correction

Equipment

.

Level

Equipment

.

Level

Equipment

.

Equipment .

..

Equipment

Equipment........................

TEST

Correction

.

.

.

.

.

.

.

.

Removal .

.

Constants

Program

Mouse

Constants

Oscillator

.

.

.

.

.

.

A

djustment

.

.

.

.

.

.

A

djustment

.

.

.

.

.

.

A

djustment

..

..

.

..... ..... ...... ...... ...

djustment ...... ...

MANU

EQUIPMENT

.

.

.

.

.

.

.

.

.

and

..

.

.

.

.

.

.

Operation

.

.

Frequency

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

..

..

.

..

..

.

.

.

Constants .

.

.

.

djustment.. ...... ...... ...

djustment ...................

AL

Constants

.

.

.

.

.

.

.

.

.

.

.

.

Correction

.

.

.

.

.

.

.

using

the

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

Constants

.

.

.

.

.

.

.

.

A

djustments

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

djustment

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

..

..

.

.

.

...... ...... ...... ..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

Program

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

................

.

.

.

.

..

..

.

.

.

.

.

..

.

.

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

..

.

.........

.......

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.....

......

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

....

.

.

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

..

.

..

.

.

..

.

1-1

. 1-1

. 1-3

.

2-1

.

2-1

.

2-2

.

2-2

2-2

.

2-2

.

2-3

.

2-3

.

2-3

.

2-4

.

2-5

.

2-6

.

2-6

.

2-6

.

2-8

.

2-8

2-8

.

2-10

.

2-10

2-10

.

2-12

2-12

.

2-12

2-15

.

2-15

2-15

2-16

2-16

2-16

2-18

2-18

2-18

2-23

Contents-1

Page 12

Final

Gain A

Required

Procedure

Source

RF

Spectrum

Network

Crystal

IF

Network

10

Mixer Local

Required

Procedure

OUT

Required

Procedure

Required

Procedure

Required

Procedure

Required

Procedure

Gain

Required

Procedure

Required

Procedure

MHz

Required

Procedure

djustment .

Equipment .

..

Equipment .

..

Level

Correction

Equipment

.

.

Analyzer

Equipment

.

.

Analyzer

Equipment

.

.

Filter

Correction

Equipment

.

.

Errors

Reference

Correction

Equipment

.

.

Analyzer

Equipment

.

.

Equipment

.

.

.

.

.

.

Leakage

.

.

.

.

.

.

.

.

.

Absolute

.

.

.

.

.

Absolute

.

.

.

.

.

Constants

.

.

.

.

.

.

.

.

.

.

Magnitude

.

.

.

..

Oscillator

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

A

djustment

.

.

.

.

.

.

.

.

Constants

.

.

.

.

.

.

.

.

Magnitude

.

.

.

.

.

.

.

.

Magnitude

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

Constants

.

.

.

.

.

.

.

.

Ratio/Phase

.

.

..

..

.

.

Frequency

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

..

.

.

.

.

.

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

Correction

.

.

.

.

..

..

Correction

.

.

.

..

..

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

..

Correction

.

.

.

.

.

.

.

.

Adjustment

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

..

..

.

.

.

Constants

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Constants

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

..

..

.

.

.

.

.

..

..

..

..

..

..

.

..

..

..

..

..

..

.

.

.

..

..

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

Constants

.

.

.

.

.

.

.

.

.

.

(Option 1D5

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Only)

.

.

.

.

..

..

.

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

..

2-29

.

2-29

.

2-29

. 2-31

.

2-31

.

2-31

.

2-33

.

2-33

.

2-33

.

2-34

.

2-34

.

2-34

2-35

.

2-35

.

2-35

.

2-36

.

2-36

.

2-36

.

2-37

.

2-37

.

2-37

. 2-39

.

2-39

2-39

.

2-41

.

2-41

2-41

3.

Troubleshooting

INTRODUCTION

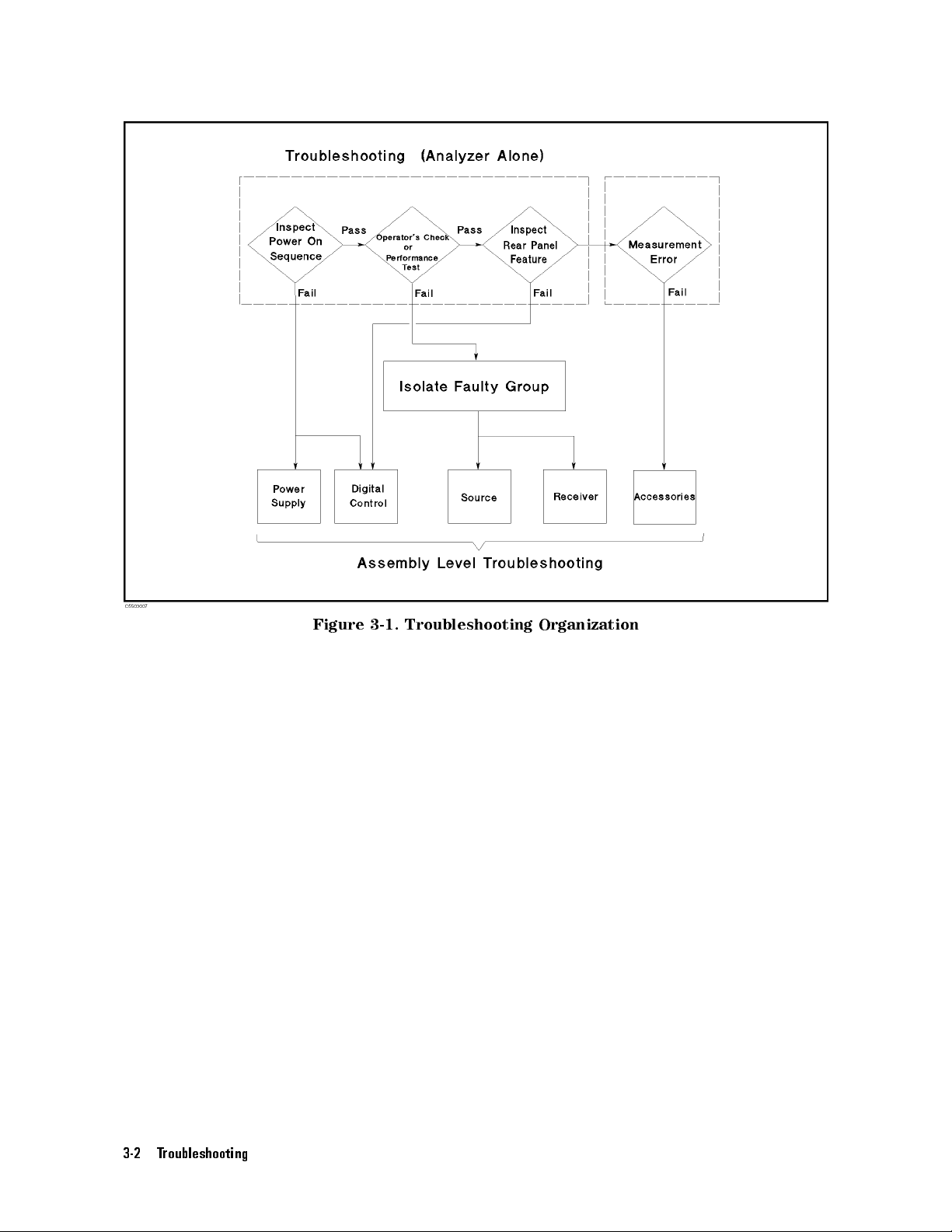

TROUBLESHOOTING

ST

ART HERE

INSPECT

Check

Check

Check

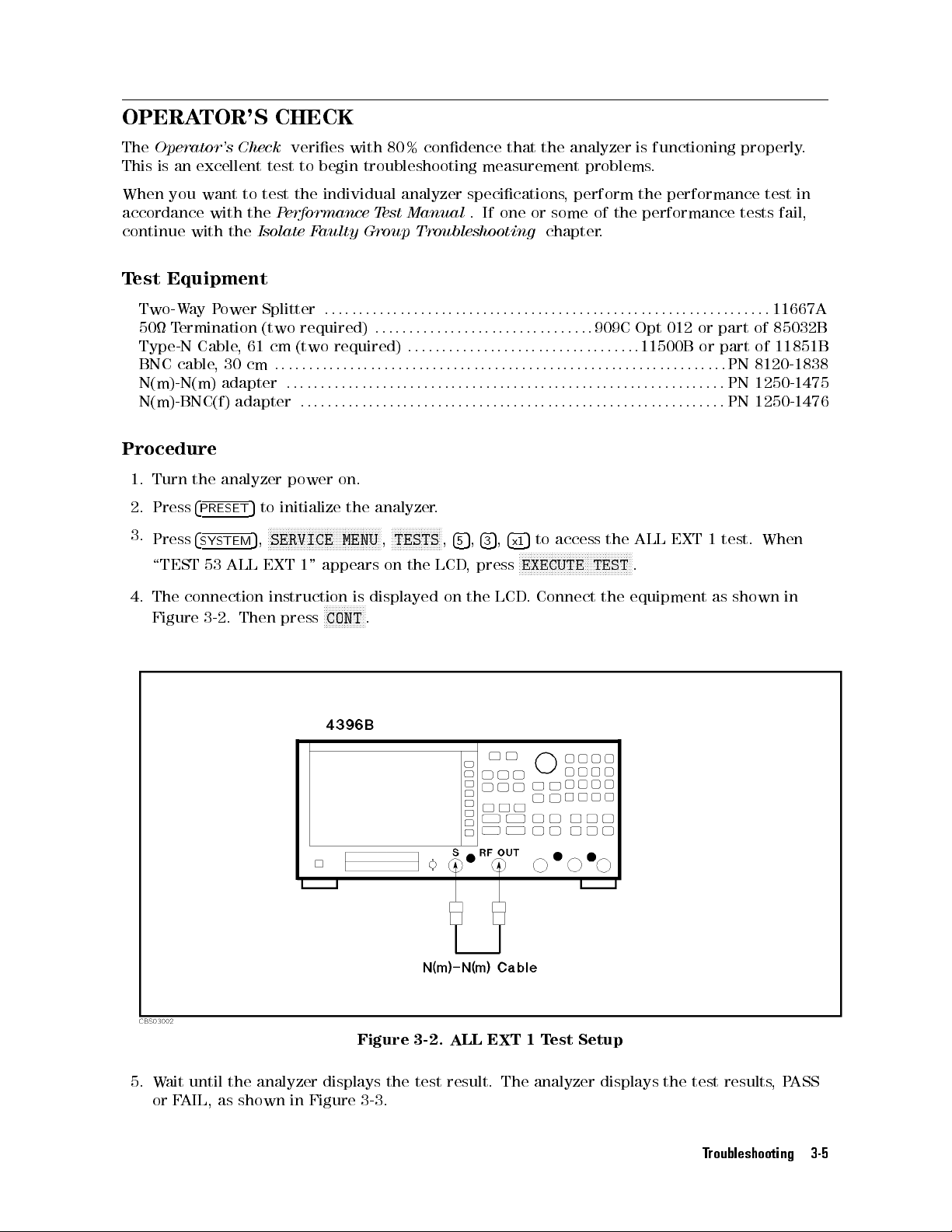

OPERA

T

est

Procedure

INSPECT

Check the GPIB Interface

Check the P

Check the mini DIN Keyboard Connector

4. Isolate F

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . .

OPERATOR'S CHECK F

Check RF OUT Frequency

Check RF OUT Power Level ........................ 4-2

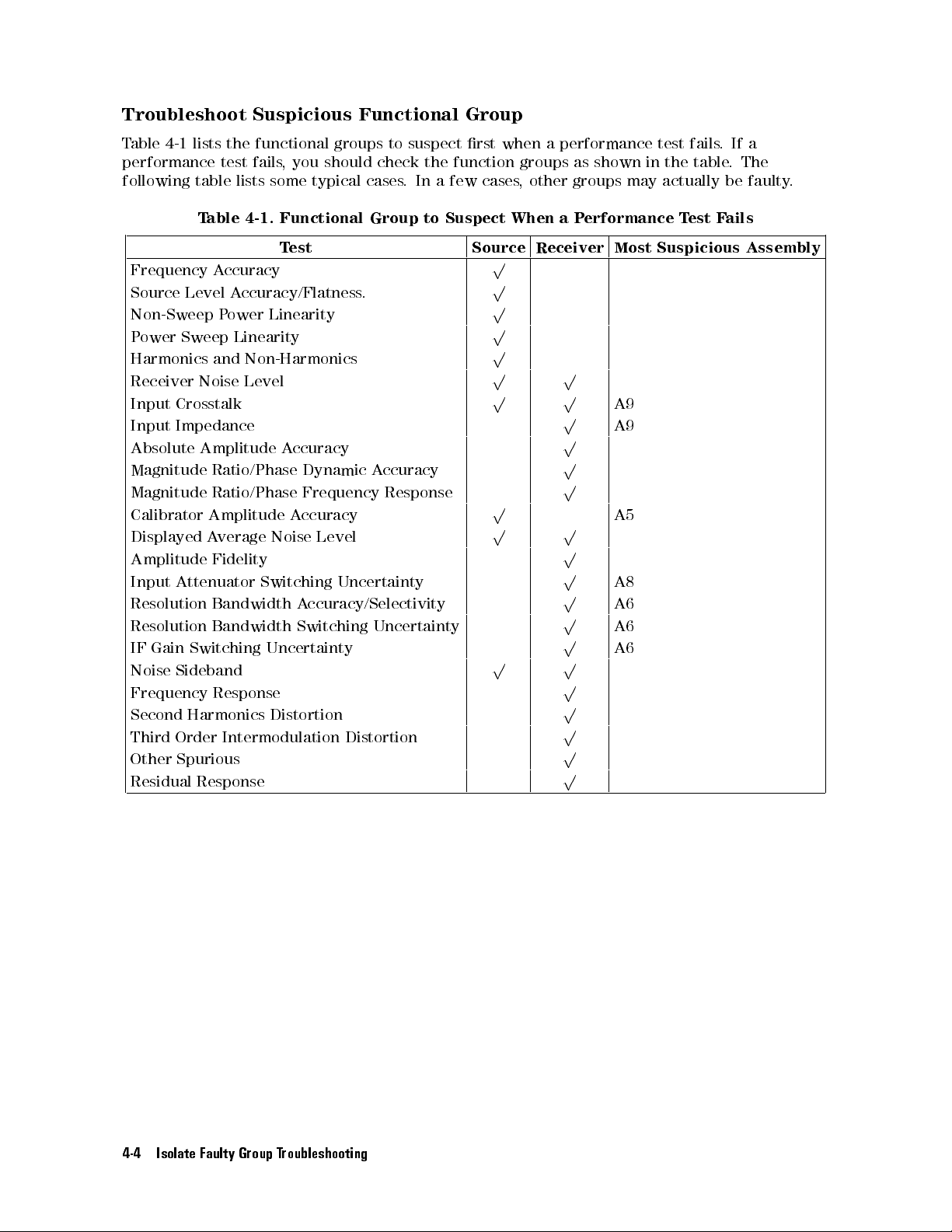

PERFORMANCE TESTS FAILURE TROUBLESHOOTING ...... ...... 4-3

Perform Adjustments and Correction Constants ..... ...... .... 4-3

Troubleshoot Suspicious Functional Group . . . . . . . . . . . . . . . . . . 4-4

THE

the

the

Error

TOR'S

Equipment

THE

aulty Group Troubleshooting

..

.

.

SUMMARY .

..

.

.

.

.

POWER

F

an

Front

Message

CHECK

.

.

REAR

arallel Interface

ON

.

.

.

.

.

P

anel

LEDs

.

.

.

.

.

.

.

.

.

.

.

P

ANEL

AILURE TROUBLESHOOTING

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

SEQUENCE

.

.

.

.

and

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

FEA

TURE

......

......

.....................

.

.

.

.

Displays

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

..

..

..

.

.

.

.

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...................

.... ...... ...... ..

......

...... ......

...... ...

.... ...... ...

.

.

.

.

..

.

..

.

.

..

.

..

.

.

.

.

..

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

....

.

.

.

.

.

.

.

.

.

.

.

.

3-1

.

3-1

.

3-3

.

3-4

.

3-4

.

3-4

.

3-4

.

3-5

.

3-5

. 3-5

.

3-9

3-9

3-9

3-9

4-1

4-2

4-2

Contents-2

Page 13

5.

Power

INTRODUCTION

ST

ART HERE

1.

Check Error

2.

Check the

3.

Check the

A50

4.

Check

Measure

5.

Check

6.

Run

Internal

FIND

OUT

1.

Check

2.

Check

FIND

OUT

1.

Disconnect

2.

Disconnect

3.

Disconnect

4.

Remove

FIND

OUT

1.

Check

2.

Check

3.

Disconnect

4.

Remove

TROUBLESHOOT

1.

Troubleshoot

2. Troubleshoot

TROUBLESHOOT

1.

Check the

2.

Check the

3.

Remove Assemblies

4.

Measure the

Supply Troubleshooting

..

.

.

.

.

.

.

.

.

.

.

.

.

.

F

an

A50

Shutdown

the

A1

the

A1

the

A2

the

Internal

T

est

WHY

THE

the

Line

the

A50

WHY

THE

the

the

the

Assemblies

WHY

THE

the

A40

the

A50

Cables

Assemblies

A40

A50 DC-DC

Messages

is

SHUTDOWN

LED

+5

+5

Eight

4:

A2

V

SHUTDOWN

Cable

Cable

Cable

Pre-Regulator

DC-DC

THE

the

the

THE A2

Pre-Regulator

A2 P

.

.

Rotating

.

.

.

VD

LED

VD

V

oltage

LEDs

T

est

4:

A2

POST

REGULA

F

AN

IS

NOT

oltage

,

Selector

A50

SHUTDOWN

from

from

from

.

.

.

A1

+5

VD

Converter .

on

the

A1 CPU

.

.

..

F

AN

AND

F

an

.

.

A50

DC-DC

POST-REGULA

Converter

..

.

ost

Regulator

.

.

.

.

.

.

.

.

.

.

.

.

LED

.

.

.

.

.

.

.

.

.

.

POST

ROT

Switch

LED

the

A50J1

the

A51J2

the

A1J10

.

.

.

LED

.

..

THE

..

.

Converter

.

.

.

.

Output

.

.

.

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

REGULA

TOR

A

TING

.

.

LED

.

.

IS

NOT

.

.

..

..

.

.

A50

.

.

TOR

.

.

.

.

.

.

TOR

.

.

.

.

.

..

Setting,

.

.

.

.

..

IS

OFF

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

ON

STEADILY

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

DC-DC CONVERTER

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

V

oltages

..

..

..

..

.

.

..

..

.

..

..

.

.

..

..

and

..

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

..

..

..

..

..

.

.

..

..

Fuse

..

.

..

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

..

..

.

..

..

..

..

..

..

..

.

.

.

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

5-1

.

5-3

.

5-3

.

5-3

. 5-3

.

5-4

.

5-5

.

5-5

.

5-5

.

5-6

.

5-7

.

5-8

.

5-8

.

5-8

.

5-9

.

5-9

.

5-9

.

5-9

.

5-9

.

5-10

.

5-10

.

5-10

.

5-11

.

5-12

.

5-13

.

5-13

.

5-14

.

5-16

. 5-16

. 5-16

5-16

.

5-16

6.

Digital

INTRODUCTION

A1

FIRMW

START HERE

TROUBLESHOOT THE A51 GSP and A52 LCD . . . . . . . . . . . . . . . . . 6-13

Control

CPU

Replacement

ARE

Ordering

Installing

1. Check the P

Check the

Check the A1 Eight LEDs

2.CheckErrorMessages........ ...... ....

Check the P

3. Check the A1 DRAM and Flash Memory

4. Check the A1 V

5. Check the A30 Front Keyboard ... ..... ...... ...... . 6-11

6. Check the A53 FDD . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

7. Check the A32 I-BASIC Interface and the mini DIN Keyboard ....... 6-12

1. Run the Internal Test 3: A51 GSP .... ...... ..... ..... 6-13

2. Check the A52 LCD(Liquid Crystal Display) . . . . . . . . . . . . . . . . 6-13

Troubleshooting

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

INST

ALLA

TION

the

Firmware

the

Firmware

.......

ower On Sequence . . . .

5

and

4

Ch 1

owerOnSelftest .................

olatileMemory..................

.

.

.

.

.

.

.

.

.

.

.

.

.

..

Diskette

.

.

5

4

Ch 2

.

.

.

.

..

..

..

..

.

.

..

.

.

.

.

.

.

.

.

.

...... ...... ...... ..... ..

..................

Operations . . . . . . . . . .

.................

................

..

.

.

.

..

..

..

.

..

..

..

..

..

.

.

.

.

..

.

.

.

...... ...

...... .

...... ..

......

.

.

.

.

.

.

.

.

.

.

.

....

.

.

.

.

.

.

6-1

.

6-3

.

6-4

.

6-4

.

6-4

6-6

6-6

6-6

6-6

6-7

6-7

. 6-10

6-11

Contents-3

Page 14

7.

Source Group

INTRODUCTION

SOURCE

Start

Check

Check

Check

Check

Check

Check

Check

ST

ART

CHECK

1.

Check

Check

2.

Check

3.

Check

4.

Check

5.

Check

6.

Check

CHECK

1.

Check

2.

Check

CHECK

1.

Check

CHECK

1.

Check

2. Check

CHECK

1.

Check the

CHECK

1.

Check A7

CHECK

Troubleshooting

..

.

.

.

.

.

.

GROUP TROUBLESHOOTING

Here .

A5 Synthesizer

A4A1 1st

an

A3A2

an

A7

A60

HERE

A5

A4A1

AN

A3A2

AN A3A3

A7 OUTPUT

THE A60

.

.

.

.

LO

Outputs

A3A1

ALC

2nd

LO

Outputs

A3A3

Source

Output

SYNTHESIZER

the

the

the

the

the

the

the

the

the

A3A1

the

the

the

Attenuator

High

Stability

.

.

.

.

CAL

OUT

CAL

OUT's

INT

REF

FRA

C

N

STEP

OSC

520

MHz

EXT

REF

1ST

LO

OUTPUTS

1st

LO

OSC

1st

LO

OSC Signal

ALC

21.42

MHz

2ND

LO

OUTPUTS

2nd

Local

2.05858

SOURCE

A3A3

Control Signals

RF

ATTENU

HIGH ST

.

.

.

.

Outputs

Output

Output

Frequency

.

.

.

.

OUTPUTS

Signal

Spurious

Signal

OSC

Signal

Signal

Signal

Operation

Signal

OUTPUT

Signal .

Oscillator

GHz

Signal

OUTPUT

Signal

A

ABILITY

.

.

.

.

Control

.

.

.

.

TOR

.

.

.

.

.

.

SUMMARY

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Signals

Reference

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

at

A4A1J3

at A4A1J4

..

..

.

..

.

.

.

.

..

.

Signal

.

.

.

.

.

.

.

.

.

.

.

.

CONTROL

.

.

.

.

.

FREQUENCY

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

(Option

.

.

.

.

.

.

..

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

SIGNALS

.

.

.

REFERENCE

..

.

.

..

.

.

.

.

..

..

.

.

.

.

.

.

.

..

..

..

..

.

.

.

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

.

..

.

.

.

.

..

..

..

..

..

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

..

..

.

1D5)

.

..

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

..

..

..

.

.

.

.

.

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

..

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

..

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

..

.

.

.

.

. 7-3

.

.

. 7-3

.

.

.

.

.

.

.

..

.

. 7-4

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 7-32

.

.

7-1

7-3

7-3

7-3

7-3

7-4

7-4

7-5

7-7

7-7

7-8

7-9

7-11

7-13

7-16

7-18

7-19

7-19

7-21

7-23

7-23

7-26

7-26

7-27

7-30

7-30

7-32

7-34

8.

Receiver

INTRODUCTION

RECEIVER

Start

Check

Check

Check Signal Inputs to A4A2 Receiver RF . . .

START HERE

CHECK A8 INPUT A

CHECK A9 INPUT MUL

CHECK SIGNAL INPUTS TO THE A4A2 RECEIVER RF . . . . . . . . . . . . .

Check the Input Signal to A4A2J3

Check the Input Signal to A4A2J12 . . . . . . . . . . . . . . . . . .

Contents-4

Group

Here

A8

A9

Troubleshooting

.

.

.

GROUP

.

Output

Input

TROUBLESHOOTING

.

.

.

.

Attenuator

Multiplexer

........

TTENUATOR CONTROL SIGNALS

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

SUMMARY

.

.

.

.

.

.

.

.

.

.

.

..

Control

Control

.... ...... ...... ...... ..

TIPLEXER CONTROL SIGNALS . . . . . . . . . . . . .

Signals

Signals

.................

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

...... ...... ...

...

..........

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

....

...

8-1

8-3

8-3

8-3

8-3

8-3

8-4

8-5

8-7

8-9

8-9

8-9

Page 15

9.

Accessories

INTRODUCTION

VERIFY

Using

Large

Odd

INSPECT

INSPECT

V

erify

Inspect

Inspect

10.

Service

INTRODUCTION

SERVICE

N

N

N

N

N

TESTS

N

N

N

N

N

SERVICE

N

N

N

N

N

FIRMWARE

TESTS MENU

N

N

NN

NN

EXECUTE TEST

NN

NN

N

INTERNAL

N

N

N

N

N

EXTERNAL

N

N

N

N

N

ADJUSTMENT

N

N

N

N

N

DISPLAY

N

N

NN

N

ALL

N

N

N

N

N

MISC

T

est

Diagnostic

T

est Descriptions

Troubleshooting

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

9-1

OPERATIONS

75

Connectors

Spurious Signals

Appearing Opens

THE

CONNECTORS

THE

A

CCESSORIES

the

Probe

the

T

est

the

Calibration

V

erify

Shorts

K

ey

Menus

MENU

N

N

N

N

N

N

NN

NN

NN

.

.

.

N

N

N

N

N

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

EXT

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

TESTS

Status

N

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

INTERNAL

0: ALL

1: A1

2: A1

3: A51

4: A2

5: A6

6: A5 REFERENCE OSC

7: A5 FRA

8: A5 STEP OSC . . . . . . . . . . . . . . . . . .

9: A4A1 1ST LO OSC

10: A3A2 2ND LO OSC . . .

11: A3A1 DIVIDER

12: A6 3RD LO OSC

13: A3A1 SOURCE OSC

14: A6 3RD IF DC OFFSET . . . . . . . . . . . . . . . . . . . . . . . . 10-9

15: A6 SEQUENCER . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

16: A3A1 ALC .. ...... ..... ...... ...... .... 10-9

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

EXTERNAL TESTS

17: FRONT PANEL DIAG. ........................ 10-12

18: DSK DR FAULTISOL'N........................ 10-12

19: POWER SWEEP LINEARITY ..................... 10-12

N

CPU .

VOLA

POST REGULA

A/D

.

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

MODES

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

REVISION

..

N

N

N

N

NN

NN

NN

N

N

N

N

N

NN

NN

NN

N

N

N

N

N

N

N

N

N

N

TESTS

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

TESTS

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

TESTS

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

TESTS

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

TESTS

N

N

N

N

N

N

N

N

(

:DIAG:TEST

.

.

T

ests

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

TESTS

INT .

TILE MEMORY

GSP .

CONVERTER

CTIONAL N OSC . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

with

50

Connectors

in

the

Spectrum

and

Shorts

.

.

.

.

.

.

P

ower

Set

and

.

.

.

.

.

N

N

(

:DIAG:SERV:MODE

N

N

N

N

N

N

N

N

N

.

(

:DIAG:TEST:EXET

N

N

N

N

N

(

:DIAG:TEST

N

N

N

NN

(

:DIAG:TEST

N

N

N

N

N

N

N

N

N

N

N

(

:DIAG:TEST 48

N

N

(

:DIAG:TEST

.

.

..

N

N

NN

NN

N

N

N

N

.

.

..

.

.

.

.

.

.

.

.

.

.

Kit

.

.

.

Opens

.

.

.

N

N

N

N

.

N

(

:DIAG:TEST

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

(

:DIAG:FREV?

.

.

.

.

.

.

0

)

17

)

53

)

58

)

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

TOR .

..................

.....

....

............................ 10-9

..

.

.

.

.................

...... ...... ...... .....

...... ...... ...... .....

......

Measurement

in

the

Network

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

..

{ON|1}

)

.

.

.

.

).

.

.

.

)

.

.

41

)

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

......................

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

Measurement

.

.

.

.

.

..

..

.

.

.

.

..

..

.

.

.

..

..

..

.

.

..

..

..

.

.

.

.

.

.

..

.

..

..

..

.

..

..

..

.

..

..

..

.

.

.

.

.

.

.

.

.

.

)

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

...... ..... ...... ..

.

.

.

.

.

..

..

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

..

..

..

.

.

..

..

..

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

..

..

..

.

.

.

.

.

.

.

..

...... ..

...... ...

.........

........

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

..

.

9-2

9-2

. 9-2

. 9-2

.

9-3

.

9-4

.

9-4

.

9-5

.

9-5

.

9-5

.

10-1

.

10-3

10-3

.

10-3

.

10-3

.

10-4

. 10-4

.

10-4

.

10-5

.

10-5

.

10-5

.

10-5

.

10-5

. 10-5

.

10-6

.

10-7

.

10-7

.

10-7

.

10-7

. 10-7

.

10-8

10-8

.

10-8

10-8

10-8

10-9

10-9

10-9

10-9

10-9

10-9

Contents-5

Page 16

20:

OUTPUT A

21:

INPUT A

22:

RF TO

23:

STO

24:

S INPUT

25:

S INPUT

26:

S

INPUT

27:

FRA

CTION

28:

RF

TO

29:

NA

CROSST

30:

R

INPUT

31:

RANGING

32:

A/R

RA

33:

A

INPUT

34:

B/R

RA

35:

B

INPUT

36:

RESOLUTION

37:

IF

GAIN

38:

PHASE

39:

SPURIOUS

40:

X'T

N

N

N

ADJUSTMENT

41:

42:

43:

44:

45:

46:

47: 1

N

N

N

DISPLAY TESTS

48:

49:

50:

51:

52:

N

N

N

ALL

53:

54:

55:

56:

57: ALL EXT 5

NNNNNN

N

MISC TESTS

58: IMPED

SERVICE MODES MENU . . . . . . . . . . . . . . . . . . . .

NNNNNNNNNNNNNNN

N

BUS MEAS [OFF]

NNNN

NNNNNNNNNNNNNNNNNNNNNNNNN

CORRECTION CONSTANTS

NNNNNNNN

IF

NNNNNNN

NNNNNNNNNN

SYNTH

NNNNNNNNNNNNNNNNNNNN

SOURCE

Service Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

BUSMEASUREMENTMENU.... ..... ...... ...... .... 10-21

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

BUS MEAS on OFF(:DIAG:SERV:BUS:STAT {ON|OFF}

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DC BUS [OFF](:DIAG:SERV:BUS:DC<numeric>) .. ..... ...... 10-21

AL

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

N

DC

OFFST/HLD

0/90

FINAL

2nd

LO

SOURCE

3

MHZ

MHZ

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

TEST

TEST

TEST

TEST

TEST

N

N

N

N

N

N

N

N

N

NN

NN

NN

N

N

N

N

EXT

ALL EXT

ALL EXT

ALL EXT

ALL

NNNNNNNNNNNNNNNNNNNNNNNNN

NNNNNNNNNNNNNNNNNNNNNNNNN

..........

.................................. 10-19

.................................. 10-20

TTENUA

TTENU

S

L

VL

A

CROSST

COMPRESSION

RESIDU

NOISE

SPURIOUS

R

L

VL

ALK

COMPRESSION

.

TIO

A

COMPRESSION

TIO

A

CCURA

COMPRESSION

.

.

NOISE

.

FIL

TER

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

TESTS

DEG

TRA

GAIN

PLL

LOCK

MIXER

BPF

ADJ

BPF

N

N

N

N

N

N

EXT

NNNNNNNNNNNNNNNNNNNNNNNNN

ADJ

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

P

A

TTERN

P

A

TTERN

P

A

TTERN

P

A

TTERN

P

A

TTERN

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

TESTS

1 .

2 .

3 .

4

.....................

ANCE TEST KIT . . . . . . . . . . . . . . . . .

NNN

TOR .

A

TOR

&

FL

TNESS

ALK

&

.

CCURA

B

.

.

RESPONSE

NN

NN

N

N

N

CKING ADJ

ADJ

.

.

.

..... .....

.....

.

ALS

LEVEL

FL

TNESS

&

NOISE

.

.

.

CY

CY

ANDWIDTH

.

.

.

.

.

.

.

.

.

.

N

.

.

.

STEP

..

ADJ

LEAK

.

.

.

.

.

.

.

.

.

.

1

.

.

2

.

.

3

.

.

4

..

5

.

.

.

.

.

.

..

.

.

..

.

.

..

..

.

.

.

.

NNNNNNNN

....................

.........................

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ADJ .