Page 1

Errata

4338A Milliohmmeter Operating

Manual

04338-90030

June 1998

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Page 2

HP 4338B Milliohmmeter

Operation Manual

SERIAL NUMBERS

This manual applies directly to instruments with serial

number prex JP1KD, or rmware revision 1.01.

For additional important information about serial

numbers, read \Serial Number" in Appendix A.

HP Part No. 04338-90030

Printed in Japan June 1998

Third Edition

Page 3

Notice

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another

language without the prior written consent of the Hewlett-Packard Company.

Hewlett-Packard Japan, LTD.

Kobe Instrument Division

1-3-2, Murotani, Nishi-Ku, Kobe-shi,

Hyogo, 651-2241 Japan

c

Copyright 1996,1997,1998 Hewlett-Packard Japan, Ltd.

Page 4

HP 4338B

Manual Printing History

The manual's printing date and part number indicate its current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates that are incorporated

at reprint do not cause the date to change.) The manual part number changes when extensive

technical changes are incorporated.

March 1996

April 1997

June 1998

::::::: :::::: ::::::::: :::::::::::::: :::::: ::::::: ::::::: :::::: ::::::::: ::

::::: ::::::: ::::::::: ::::::::::::: ::::::: :::::: ::::::: ::::::: ::::::::: ::

:::::: ::::::: ::::::::: ::::::::::::: ::::::: ::::::: :::::: ::::::: ::::::::: :::

First Edition

Second Edition

Third Edition

iii

Page 5

HP 4338B

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with specic

WARNINGS

elsewhere in this manual may impair the protection provided by the equipment.

In addition it violates safety standards of design, manufacture, and intended use of the

instrument.

The Hewlett-Packard Company assumes no liability for the customer's failure to comply with

these requirements.

Note

HP 4338B comply with INSTALLATION CATEGORY II and POLLUTION

DEGREE 2 in IEC1010-1. HP 4338B are INDOOR USE product.

Note

LEDs in HP 4338B are Class 1 in accordance with IEC825-1.

CLASS 1 LED PRODUCT

Ground The Instrument

To avoid electric shock hazard, the instrument chassis and cabinet must be connected to a

safety earth ground by the supplied power cable with earth blade

.

DO NOT Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of ammable gasses or fumes

. Operation of any

electrical instrument in such an environment constitutes a denite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Component replacement and internal

adjustments must be made by qualied maintenance personnel. Do not replace components

with the power cable connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power and discharge

circuits before touching them.

DO NOT Service Or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of rendering rst

aid and resuscitation, is present.

DO NOT Substitute Parts Or Modify Instrument

Because of the danger of introducing additional hazards, do not install substitute parts

or perform unauthorized modications to the instrument. Return the instrument to a

Hewlett-Packard Sales and Service Oce for service and repair to ensure that safety features

are maintained.

iv

Page 6

HP 4338B

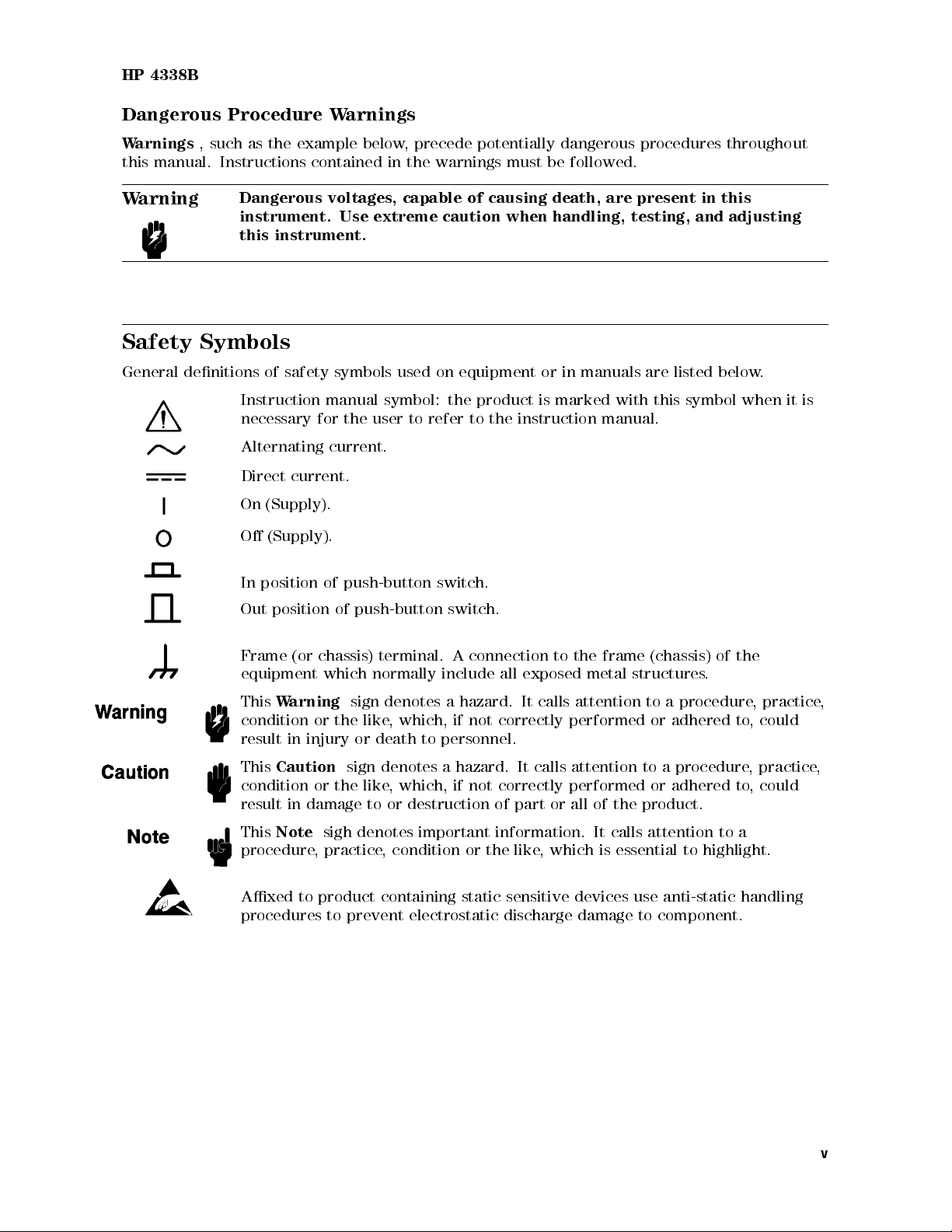

Dangerous Procedure Warnings

Warnings

, such as the example below, precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed.

Warning

Dangerous voltages, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing, and adjusting

this instrument.

Safety Symbols

General denitions of safety symbols used on equipment or in manuals are listed below.

Instruction manual symbol: the product is marked with this symbol when it is

necessary for the user to refer to the instruction manual.

Alternating current.

Direct current.

On (Supply).

O (Supply).

In position of push-button switch.

Out position of push-button switch.

Frame (or chassis) terminal. A connection to the frame (chassis) of the

equipment which normally include all exposed metal structures.

This

Warning

sign denotes a hazard. It calls attention to a procedure

condition or the like, which, if not correctly performed or adhered to

, practice,

, could

result in injury or death to personnel.

This

Caution

sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the product.

This

Note

sigh denotes important information. It calls attention to a

procedure, practice, condition or the like, which is essential to highlight.

Axed to product containing static sensitive devices use anti-static handling

procedures to prevent electrostatic discharge damage to component.

v

Page 7

HP 4338B

Certication

Hewlett-Packard Company certies that this product met its published specications at the

time of shipment from the factory. Hewlett-Packard further certies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institution's calibration facility, or to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects in material and

workmanship for a period of one year from the date of shipment, except that in the case of

certain components listed in

General Information

of this manual, the warranty shall be for the

specied period. During the warranty period, Hewlett-Packard Company will, at its option,

either repair or replace products that prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by

HP. Buyer shall prepay shipping charges to HP and HP shall pay shipping charges to return the

product to Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products

returned to HP from another country.

HP warrants that its software and rmware designated by HP for use with an instrument will

execute its programming instruction when property installed on that instrument. HP does not

warrant that the operation of the instrument, or software

, or rmware will be uninterrupted or

error free.

Limitation Of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modication or

misuse, operation outside the environmental specications for the product, or improper site

preparation or maintenance.

No other warranty is expressed or implied. HP specically disclaims the implied warranties

of merchantability and tness for a particular purpose.

vi

Page 8

HP 4338B

Exclusive Remedies

The remedies provided herein are buyer's sole and exclusive remedies. HP shall not be liable

for any direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available for

Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Oce.Addresses

are provided at the back of this manual.

vii

Page 9

Typeface Conventions

HP 4338B

Bold

Italics

Computer

4

HARDKEYS

NNNNNNNNNNNNNNNNNNNNNNNNNN

SOFTKEYS

Boldface type is used when a term is dened. For example:

icons

are

symbols.

Italic type is used for emphasis and for titles of manuals and other

publications.

Italic type is also used for keyboard entries when a name or a variable

must be typed in place of the words in italics.For example:

lename

type the name of a le such as

means to type the word

file1

copy

, to type a space, and then to

.

copy

Computer font is used for on-screen prompts and messages.

5

Labeled keys on the instrument front panel are enclosed in45.

NNNNN

Softkeys located to the right of the CRT are enclosed in

.

viii

Page 10

Contents

1. Getting Started

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview .... ...... ...... ........ ..... ..... 1-2

Features ...... ...... ........ ...... ...... . 1-2

Accessories Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Front Panel .. ...... ...... ...... ........ .... 1-4

Display .................................. 1-7

Rear Panel ................................ 1-8

Incoming Inspection ............................. 1-9

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Instruction for Cleaning ...... ...... ........ ...... .

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Use .............................

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9

1-10

1-12

1-12

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning ON the HP 4338B .........................

Using Front-Panel Keys ...........................

Direct Execution Keys . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toggle Keys .... ...... ...... ...... ...... ....

Selection Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Value Setup Keys .............................

Numeric Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum and Minimum Keys ......................

Left/Down and Right/Up Arrow Keys . . . . . . . . . . . . . . . . . . .

Back Space Key ...... ...... ...... ........ ...

1-12

1-13

1-14

1-14

1-14

1-14

1-15

1-15

1-16

1-17

1-17

ToPerform a Measurement .... ...... ....... ...... 1-18

Connecting a Test Fixture .......................... 1-19

Using the HP 16338A ...... ...... ...... ...... ... 1-19

To Reset HP 4338B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

ToPerform a SHORT Correction . . . . . . . . . . . . . . . . . . . . . . . .

To Select Measurement Parameter .. ...... ....... ...... .

To Select Auto Measurement Mode ......................

To Select Test Signal Level .. ...... ...... ...... ......

To Select Measurement Range ........................

Auto / Hold Range Mode ...... ...... ...... ........

Measurement Range Setting .... ...... ...... ...... ..

1-20

1-22

1-22

1-22

1-23

1-23

1-23

Contents-1

Page 11

2. Operating the HP 4338B

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Measurement Conguration ......................... 2-2

To Select the Measurement Time Mode ................... 2-2

To Set the Averaging Rate ......................... 2-2

To Set the Trigger Delay or Source Delay Time . . . . . . . . . . . . . . . . 2-2

To Set the Contact Check . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

To Set the Beeper Mode .......................... 2-4

To Save and Recall Instrument Settings .... ...... ...... ... 2-4

Making a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

To Trigger a Measurement .... ...... ...... ...... ... 2-6

To Use the Comparator Function ...................... 2-7

To Display Deviation Data .... ...... ...... ...... ... 2-8

To Set the Reference Value . . . . . . . . . . . . . . . . . . . . . . . . 2-8

To Select the Deviation Display Mode . . . . . . . . . . . . . . . . . . . 2-9

To Set the Display Mode and Display Digits ................. 2-10

To Change the Measurement Settings Display Mode .... ...... ... 2-11

To Lock Out the Front Panel Keys ...... ...... ..... .... 2-12

To Select the Local Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

To Set the HP-IB Address . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

To Print Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . .

ToTest the HP 4338B ............................

ToPerform a Self-Test ...........................

ToTest the Front Panel Keys' Functionality ...... ...... .....

If You Have a Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If the Display is Blank and the HP 4338B Appears Dead

...........

If an Error Message is Displayed ......................

If the HP 4338B does not Accept Any Key Input . . . . . . . . . . . . . . .

2-12

2-13

2-13

2-13

2-14

2-14

2-14

2-14

3. Function Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel .................................

Display ..................................

LINE Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chassis Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNKNOWN Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Auto Measurement Key ........................ 3-3

Level Key ...... ...... ....... ...... ..... 3-4

Measurement Parameter Key ...... ...... ........ . 3-5

Deviation Mode Key ...... ...... ........ ...

Measurement Time Key ........................

Show Setting Key ...........................

Display Mode Key ...... ...... ........ ....

Average Key .............................

Auto / Hold range Key ........................

Range Setup Key

......................... 3-6

Trigger Key ..............................

Trigger Mode Key

...... ...... ........ ...... .

Delay Key .............................

3-1

3-2

3-2

3-3

3-3

3-5

3-5

3-5

3-6

3-6

3-6

3-6

3-7

3-7

Contents-2

Page 12

Local Key ............................... 3-8

Address Key

............................ 3-8

Save Key ............................. 3-8

Recall Key ............ ...... ...... ...... 3-9

Primary and Secondary comparator limit Key

Left/Down Arrow Key and Right/Up Arrow Key

0, 1, . . . , 9,0(minus), .(point) Key

... ......... 3-9

............ 3-9

...... .... 3-9

Enter Key ............................... 3-9

BLUE Shift Key

............................ 3-9

Engineering units Key .... ...... ....... ...... .. 3-10

Back Space Key ............................ 3-10

Minimum Key

Maximum Key

...... ...... ....... ...... .. 3-10

........................... 3-10

Comparator Key ...... ...... ........ ...... 3-10

Contact Check Key ........................ 3-11

Short Key .............................

Key Lock Key ...........................

Reset Key ...... ...... ...... ........ ...

Conguration Key ...... ...... ........ .....

Rear Panel .................................

External Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11

3-11

3-12

3-12

3-14

3-14

LINE Fuse Holder .... ...... ...... ..... .....

LINE Voltage Selector ...........................

Serial Number Plate .. ...... ...... ........ ......

Power Cord Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handler Interface .............................

Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP-IB Interface .......... ...... ........ ...... 3-18

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Overall Measurement Theory . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Test Signal Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Actual Signal Level across DUT . . . . . . . . . . . . . . . . . . . . . . 3-22

Limitation of Test Level .... ...... ...... ..... ....

4. Remote Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started ........ ...... ...... ...... .....

Input/Output Statements . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading the HP-IB Address . . . . . . . . . . . . . . . . . . . . . . . . .

Sending a Remote Command .... ...... ...... ........

Returning to the Local Mode ...... ...... ....... ..... 4-3

Query Commands ............................. 4-3

Getting Data from the HP 4338B ........ ...... ........

To Control the HP 4338B from an External Computer

............

To Set Up the HP 4338B ...........................

To Reset the HP 4338B . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-15

3-15

3-15

3-15

3-15

3-16

3-16

3-22

4-1

4-2

4-2

4-2

4-2

4-3

4-4

4-5

4-5

Contents-3

Page 13

To Set the LINE Frequency . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

ToPerform the SHORT Correction . . . . . . . . . . . . . . . . . . . . . 4-5

To Select the Measurement Parameter . . . . . . . . . . . . . . . . . . . 4-5

To Select the Auto Measurement Mode .................. 4-6

To Select the Measurement Range . . . . . . . . . . . . . . . . . . . . . 4-6

To Select the Test Signal Level ...................... 4-6

To Set the Measurement Time Mode . . . . . . . . . . . . . . . . . . . . 4-6

To Set the Averaging Rate ...... ...... ..... ...... . 4-7

To Set the Delay Time .. ...... ...... ...... ...... 4-7

To Set the Beeper Mode .... ...... ...... ...... ... 4-7

To Use Comparator Function .... ...... ...... ..... ... 4-8

To Display a Deviation Measurement .... ...... ...... .... 4-8

ToWait Until Previously Sent Commands are Completed ........... 4-8

To Get the Current Instrument Settings ................... 4-9

To Save and Recall Instrument Settings .... ...... ...... ... 4-9

To Trigger a Measurement .......................... 4-10

To Retrieve Data Eciently .......... ...... ...... ... 4-12

To Transfer Data Using the Real Data Format ........ ...... .. 4-12

To Use a Data Buer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Other Features ............................... 4-13

To test the HP 4338B . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Report the Instrument's Status . . . . . . . . . . . . . . . . . . . . . .

If You Have a Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If the HP 4338B Hangs Up When You Send

ABORt

Command .........

4-13

4-13

4-15

4-15

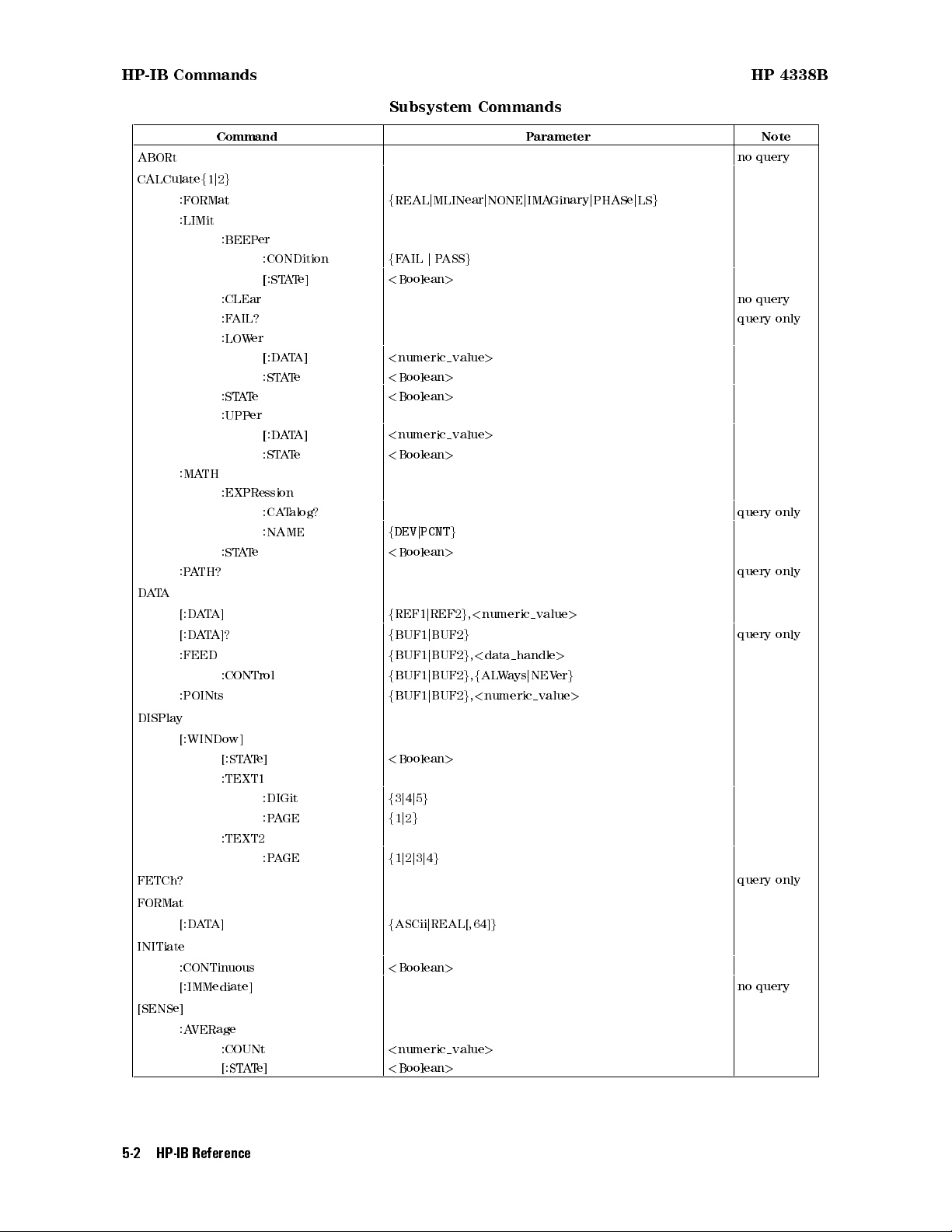

5. HP-IB Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP-IB Commands ..............................

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subsystem Commands ...........................

Subsystem Command Tree ..........................

Program Message Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . .

Case .... ...... ...... ...... ..... ...... ..

Program Message Terminator . . . . . . . . . . . . . . . . . . . . . . . .

Subsystem Command Syntax . . . . . . . . . . . . . . . . . . . . . . . .

Common Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Parameters ................................ 5-5

Parameter Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Sux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Multiple Messages ............................. 5-7

Query and Response Message Syntax ...... ...... ....... .

Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notations .................................

ABORt Command ..............................

:ABORt ...... ...... ...... ........ ...... ..

CALCulate Subsystem ............................

:CALCulate1:FORMatfREALjMLINear

:CALCulate2:FORMatfNONEjIMAGnaryjPHASejLS

g

g

........ 5-11

:CALCulatef1j2g:LIMit:BEEPer:CONDitionfFAILjPASSg.......... 5-11

:CALCulatef1j2g:LIMit:BEEPer[:STATe]fONjOFFj1j0g.......... 5-12

:CALCulatef1j2g:LIMit:CLEar . . . . . . . . . . . . . . . . . . . . . . . .

:CALCulatef1j2g:LIMit:FAIL? . . . . . . . . . . . . . . . . . . . . . . . .

:CALCulatef1j2

:LIMit:LOWer[:DATA]<numeric value>...... .....

g

:CALCulatef1j2g:LIMit:LOWer:STATefONjOFFj1j0g...... .....

:CALCulatef1j2g:LIMit:STATefONjOFFj1j0g..............

5-1

5-1

5-1

5-1

5-4

5-5

5-5

5-5

5-5

5-7

5-8

5-8

5-9

5-9

5-10

5-12

5-12

5-12

5-13

5-13

Contents-4

Page 14

:CALCulatef1j2g:LIMit:UPPer[:DATA]<numeric value>...... ..... 5-13

:CALCulatef1j2g:LIMit:UPPer:STATefONjOFFj1j0g...... ..... 5-13

:CALCulatef1j2g:MATH:EXPRession:CATalog? . . . . . . . . . . . . . . . . 5-13

:CALCulatef1j2g:MATH:EXPRession:NAMEfDEVjPCNTg...... ... 5-14

:CALCulatef1j2g:MATH:STATefONjOFFj1j0g.............. 5-14

:CALCulatef1j2g:PATH? .... ...... ...... ...... .... 5-14

DATA Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

:DATA[:DATA]fREF1jREF2g,<numeric value>.............. 5-15

:DATA[:DATA]?fBUF1jBUF2g...................... 5-16

:DATA:FEEDfBUF1jBUF2g,<data handle>............... 5-16

:DATA:FEED:CONTrolfBUF1jBUF2g,fALWaysjNEVerg...... ... 5-17

:DATA:POINtsfBUF1jBUF2g,<numeric value>.............. 5-17

DISPlay Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

:DISPlay[:WINDow][:STATe]fONjOFFj1j0g............... 5-18

:DISPlay[:WINDow]:TEXT1:DIGitf3j4j5g.................. 5-18

:DISPlay[:WINDow]:TEXT1:PAGEf1j2g...... ...... ...... 5-18

:DISPlay[:WINDow]:TEXT2:PAGEf1j2j3j4g................. 5-18

FETCh? Query .......... ...... ...... ..... .... 5-19

:FETCh? ................................. 5-19

FORMat Subsystem ............................. 5-20

:FORMat[:DATA]fASCiijREAL[,64]

g

...... ..... ........

INITiate Subsystem .. ...... ...... ..... ...... ....

:INITiate[:IMMediate] ...........................

:INITiate:CONTinuousfONjOFFj1j0g..................

SENSe Subsystem ..............................

[:SENSe]:AVERage:COUNt<numeric value>...... ...... ....

[:SENSe]:AVERage[:STATe]fONjOFFj1j0g................

[:SENSe]:CORRection:COLLect[:ACQuire] STANdard2 .. ...... ....

[:SENSe]:CORRection:COLLect:METHod REFL1 .. ...... ...... .

[:SENSe]:CORRection:DATA? STANdard2 .. ...... ...... ....

[:SENSe]:CORRection[:STATe]fONjOFFj1j0

g

..............

[:SENSe]:FIMPedance:APERture<numeric value>[MSjS] ..........

[:SENSe]:FIMPedance:CONTact:VERifyfONjOFFj1j0g...... ...... .

[:SENSe]:FIMPedance:RANGe:AUTOfONjOFFj1j0g...........

5-20

5-21

5-21

5-21

5-22

5-22

5-22

5-22

5-23

5-23

5-23

5-23

5-24

5-24

[:SENSe]:FIMPedance:RANGe[:UPPer]<numeric value>[MOHMjOHMjKOHM] . 5-24

[:SENSe]:FUNCtion<sensor function>...... ...... ....... 5-24

SOURce Subsystem ............................. 5-25

:SOURce:CURRent[:LEVel][:IMMediate][:AMPLitude]<numeric value>[UAjMA] 5-25

:SOURce:CURRent[:LEVel][:IMMediate][:AMPLitude]:AUTOfONjOFFj1j0

g

5-25

STATus Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

:STATus:OPERation[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . .

:STATus:OPERation:CONDition? ...... ...... ....... ...

:STATus:OPERation:ENABle<numeric value>...... ...... ...

:STATus:PRESet .. ...... ...... ...... ...... ....

:STATus:QUEStionable[:EVENt]? ......................

:STATus:QUEStionable:CONDition? .....................

5-26

5-26

5-26

5-27

5-27

5-27

:STATus:QUEStionable:ENABle<numeric value>...... ...... .. 5-27

SYSTem Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-28

:SYSTem:BEEPer[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . 5-28

:SYSTem:BEEPer:STATefONjOFFj1

:SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:SYSTem:KLOCkfONjOFFj1j0

:SYSTem:LFRequency<numeric value>..................

:SYSTem:PRESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0g................. 5-28

j

g

....................

5-28

5-28

5-28

5-29

5-29

Contents-5

Page 15

TRIGger Subsystem ............................. 5-30

:TRIGger[:SEQuence1]:DELay<numeric value>[MSjS].. ...... .... 5-30

:TRIGger[:SEQuence1][:IMMediate] .. ........ ...... ..... 5-30

:TRIGger[:SEQuence1]:SOURcefBUSjEXTernaljINTernaljMANualg.... 5-30

:TRIGger:SEQuence2:DELay<numeric value>[MSjS] ............ 5-30

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

3

CLS ...... ...... ........ ..... ...... .... 5-31

3

ESE<numeric value>...... ...... ........ ..... . 5-31

3

ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

3

ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

3

IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

3

LRN? .................................. 5-31

3

OPC ................................... 5-31

3

OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

3

OPT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

3

RCL<numeric value>...... ...... ........ ..... . 5-32

3

RST ...... ...... ........ ..... ...... .... 5-32

3

SAV<numeric value>.......................... 5-32

3

SRE<numeric value>.......................... 5-32

3

SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

3

STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

TRG ...................................

3

TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

WAI .... ...... ...... ..... ........ ......

Status Reporting Structure . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Request (SRQ) ...........................

Status Byte Resister ............................

Standard Event Status Register . . . . . . . . . . . . . . . . . . . . . . .

Standard Operation Status Group . . . . . . . . . . . . . . . . . . . . . .

Operation Status Register .........................

Questionable Status Register ........................

Trigger System ........ ........ ...... ...... ...

HP 4338B Trigger System Conguration . . . . . . . . . . . . . . . . . . .

Idle State .... ...... ...... ........ ...... ..

Initiate State ..............................

5-33

5-33

5-33

5-33

5-34

5-34

5-35

5-36

5-37

5-38

5-38

5-39

5-39

5-39

5-40

Event Detection State .......................... 5-40

Sequence Operation State ........................ 5-40

Data Transfer Format ........ ...... ...... ...... .. 5-41

ASCII Format ............................... 5-41

REAL Format ............................... 5-42

6. Application Measurement

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Contact Resistance of Relays or Switches ...... ...... .. 6-2

Measuring Internal Resistance of Batteries . . . . . . . . . . . . . . . .

Contents-6

6-1

6-5

Page 16

7. Measurement Basics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

SHORT Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Measurement Range .... ...... ...... ........ ..... 7-2

Dry Circuit Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Extending Test Leads ............................ 7-3

8. General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Specications ................................ 8-2

Measurement Parameter .. ...... ...... ...... ...... 8-2

Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Measurement Range ............................ 8-2

Measurement Accuracy ...... ...... ........ ...... 8-3

Measurement Support Functions ...................... 8-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Supplemental Performance Characteristics ...... ...... ...... 8-7

9. Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Test Equipment ...............................

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment ...... ...... ...... ...... ......

Calculation Sheet .... ...... ........ ...... .....

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Cycle .... ...... ...... ...... ...... .

Test Signal Frequency Accuracy Test ....................

Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment .............................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Measurement Accuracy Test .... ...... ...... ...

Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment .............................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculation Sheet .... ...... ........ ...... ..... 9-9

Test Signal Frequency Accuracy Test ................... 9-9

Resistance Measurement Accuracy Test .................. 9-9

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Test Signal Frequency Accuracy Test ................... 9-10

Resistance Measurement Accuracy Test ..................

Functional Test ...............................

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment ...... ...... ...... ...... ......

Test Signal Level Functional Test ......................

Test Equipment .............................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handler Interface Functional Test.. ...... ...... ...... ..

Test Equipment ............................. 9-14

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Lock Function Test ........................

External Trigger Function Test .....................

Handler Interface Output Test ..................... 9-15

Functional Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1

9-2

9-2

9-2

9-2

9-3

9-3

9-4

9-4

9-4

9-4

9-6

9-6

9-6

9-6

9-10

9-11

9-11

9-11

9-12

9-12

9-12

9-14

9-14

9-14

9-14

9-16

Contents-7

Page 17

Test Signal Level Functional Test ..................... 9-16

A. Manual Changes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Change 1 ................................. A-2

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B. Handler Interface Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Input Signals ............................... B-4

Setting Up the Handler Interface Board . . . . . . . . . . . . . . . . . . . . B-5

Tools and Fasteners ............................. B-5

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Messages

Instrument Errors .... ...... ...... ........ ......Messages-2

HP-IB Errors ................................Messages-3

Index

Contents-8

Page 18

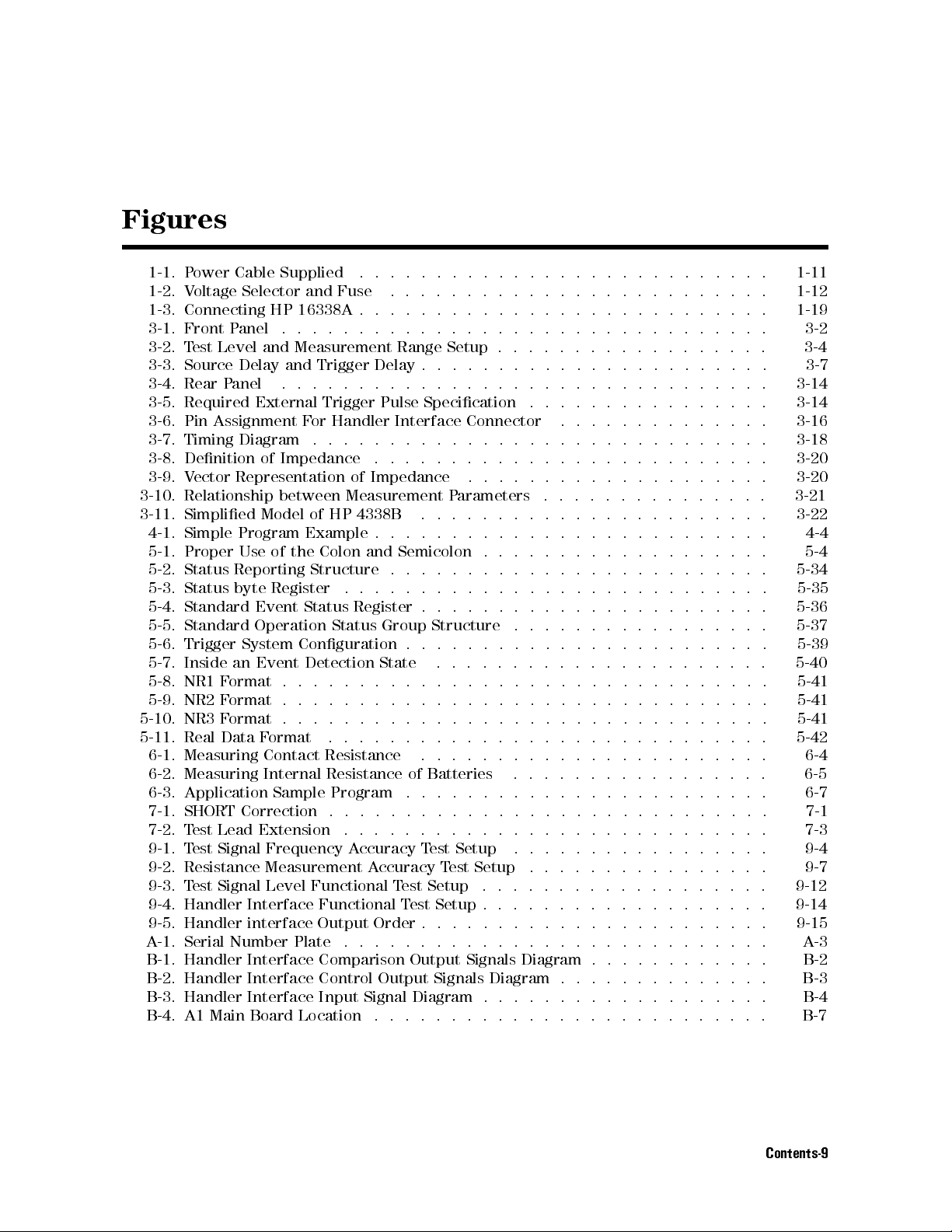

Figures

1-1. Power Cable Supplied ........................... 1-11

1-2. Voltage Selector and Fuse ......................... 1-12

1-3. Connecting HP 16338A . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

3-1. Front Panel ...... ........ ...... ...... ...... 3-2

3-2. Test Level and Measurement Range Setup . . . . . . . . . . . . . . . . . . 3-4

3-3. Source Delay and Trigger Delay . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-4. Rear Panel ................................ 3-14

3-5. Required External Trigger Pulse Specication .. ...... ...... .. 3-14

3-6. Pin Assignment For Handler Interface Connector .......... .... 3-16

3-7. Timing Diagram .............................. 3-18

3-8. Denition of Impedance .......................... 3-20

3-9. Vector Representation of Impedance .... ...... ...... ....

3-10. Relationship between Measurement Parameters ...............

3-11. Simplied Model of HP 4338B .......................

4-1. Simple Program Example . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1. Proper Use of the Colon and Semicolon . . . . . . . . . . . . . . . . . . .

5-2. Status Reporting Structure . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. Status byte Register ............................

5-4. Standard Event Status Register . . . . . . . . . . . . . . . . . . . . . . .

5-5. Standard Operation Status Group Structure .................

5-6. Trigger System Conguration . . . . . . . . . . . . . . . . . . . . . . . .

5-7. Inside an Event Detection State ......................

5-8. NR1 Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9. NR2 Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10. NR3 Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-11. Real Data Format .............................

6-1. Measuring Contact Resistance ....................... 6-4

6-2. Measuring Internal Resistance of Batteries ...... ...... ..... 6-5

6-3. Application Sample Program ........................ 6-7

7-1. SHORT Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2. Test Lead Extension ............................ 7-3

9-1. Test Signal Frequency Accuracy Test Setup .................

9-2. Resistance Measurement Accuracy Test Setup ................

9-3. Test Signal Level Functional Test Setup .... ...... ...... ...

9-4. Handler Interface Functional Test Setup . . . . . . . . . . . . . . . . . . .

9-5. Handler interface Output Order . . . . . . . . . . . . . . . . . . . . . . .

A-1. Serial Number Plate ...... ...... ........ ...... ..

B-1. Handler Interface Comparison Output Signals Diagram . . . . . . . . . . . .

B-2. Handler Interface Control Output Signals Diagram . . . . . . . . . . . . . .

B-3. Handler Interface Input Signal Diagram . . . . . . . . . . . . . . . . . . . B-4

B-4. A1 Main Board Location .......................... B-7

3-20

3-21

3-22

4-4

5-4

5-34

5-35

5-36

5-37

5-39

5-40

5-41

5-41

5-41

5-42

9-4

9-7

9-12

9-14

9-15

A-3

B-2

B-3

Contents-9

Page 19

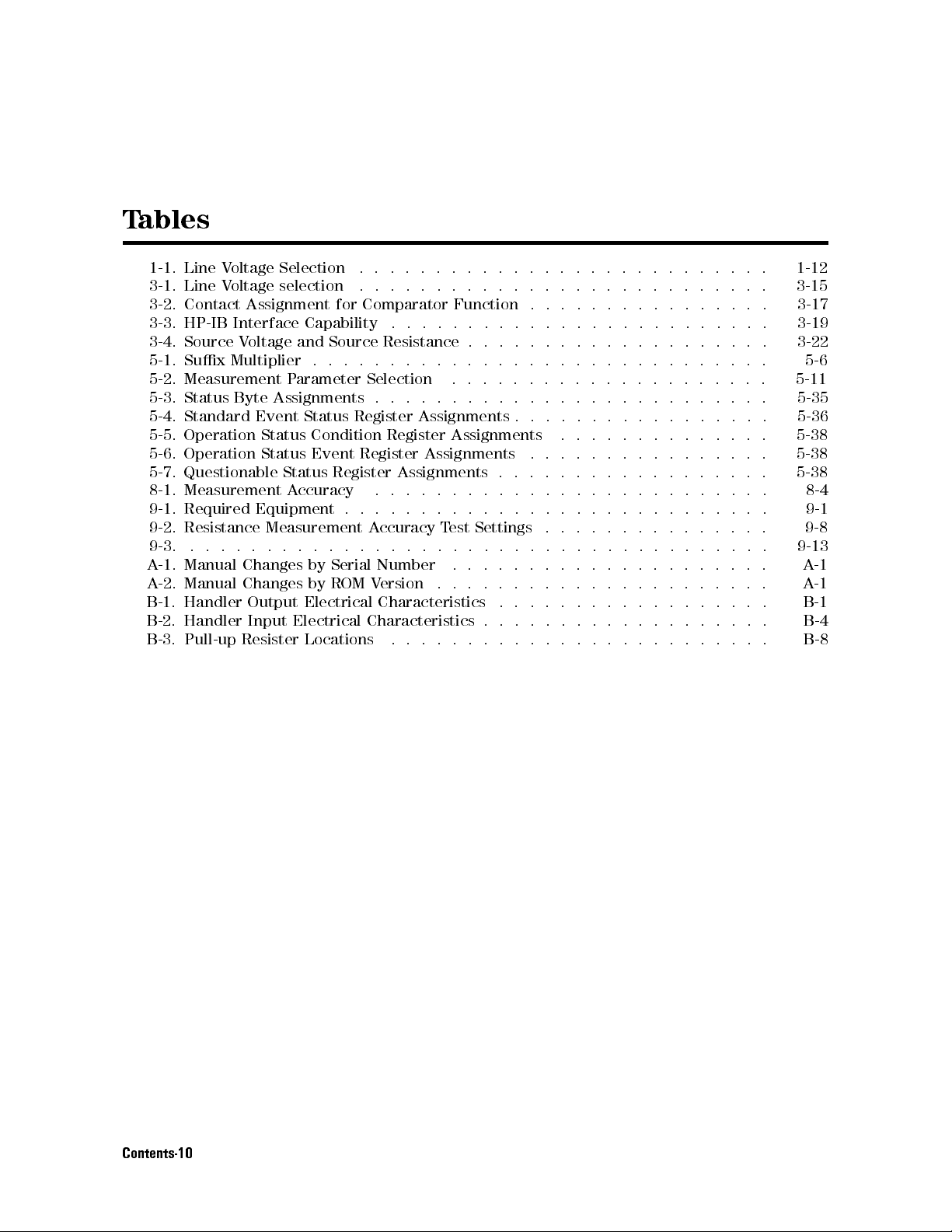

Tables

1-1. Line Voltage Selection .... ...... ...... ...... ..... 1-12

3-1. Line Voltage selection ........................... 3-15

3-2. Contact Assignment for Comparator Function . . . . . . . . . . . . . . . . 3-17

3-3. HP-IB Interface Capability ......................... 3-19

3-4. Source Voltage and Source Resistance . . . . . . . . . . . . . . . . . . . . 3-22

5-1. Sux Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-2. Measurement Parameter Selection ..................... 5-11

5-3. Status Byte Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

5-4. Standard Event Status Register Assignments . . . . . . . . . . . . . . . . . 5-36

5-5. Operation Status Condition Register Assignments .. ...... ...... 5-38

5-6. Operation Status Event Register Assignments ...... ...... .... 5-38

5-7. Questionable Status Register Assignments . . . . . . . . . . . . . . . . . .

8-1. Measurement Accuracy ..........................

9-1. Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2. Resistance Measurement Accuracy Test Settings .... ...... .....

9-3. ......................................

A-1. Manual Changes by Serial Number .... ...... ........ ...

A-2. Manual Changes by ROM Version ......................

B-1. Handler Output Electrical Characteristics ..................

B-2. Handler Input Electrical Characteristics . . . . . . . . . . . . . . . . . . .

B-3. Pull-up Resister Locations .........................

5-38

8-4

9-1

9-8

9-13

A-1

A-1

B-1

B-4

B-8

Contents-10

Page 20

Getting Started

Introduction

This chapter provides the information necessary to get you started using your HP 4338B

Milliohmmeter. This chapter discusses the following topics:

Overview

Incoming Inspection

Ventilation Requirements

Instruction for Cleaning

Power Cable

Preparation for Use

Using Front-Panel Keys

Basic Operation

1

Getting Started 1-1

Page 21

Overview HP 4338B

Overview

HP 4338B Milliohmmeter is a precise, reliable, and high speed test tool for measuring low

resistance.

Features

Low and selectable test signal current: 1Ato10mA

Wide measurement range: 10 to 100 k

10 resolution

1 kHz ac measurement

High speed measurement: 34 ms

Built-in comparator

Auto measurement mode

Precise Low Resistance Measurement

Contact failure of electro-mechanical components in low current circuits is a key issue in

determining these components' reliability. The HP 4338B oers selectable low level ac

test signals (1A to 10 mA), so now low current conditions can be characterized. A high

resolution of 10 allows you to determine the slightest dierences in contact resistance

testing of relays, switches, connectors, PC board traces, and cables. The 1 kHz test signal

eliminates potential errors introduced by thermo-electric eects across the DUT contacts

.

The 1 kHz ac test signal is the best solution for evaluating the internal resistance of batteries

because it avoids dc energy consumption.

High Speed Measurements

The high speed (34 ms), built-in comparator, and HP-IB/handler interfaces makes it possible

to construct a measurement system using an automatic handler and an external computer to

minimize production test time.

Auto Measurement Mode

When performing gross continuity testing where the test signal level is not a signicant

factor in the test, the auto measurement function allows the HP 4338B to select the

appropriate test signal level and measurement range.

1-2 Getting Started

Page 22

HP 4338B Overview

Accessories Available

HP 16338A

HP 16064B

Test Lead Set

HP 16005B Kelvin Clip Lead (0.4 m, with large clip)

HP 16005C Kelvin IC Clip Lead (0.4 m, IC clip)

HP 16006A Pin-Type Probe Lead (0.4 m)

HP 16007A Alligator Clip Leads (0.4 m, with 2 red clips)

HP 16007B Alligator Clip Leads (0.4 m, with 2 black clips)

HP 16143B Mating Cable (0.6 m)

LED Display/Trigger Box (pass/fail display and trigger)

Getting Started 1-3

Page 23

Overview HP 4338B

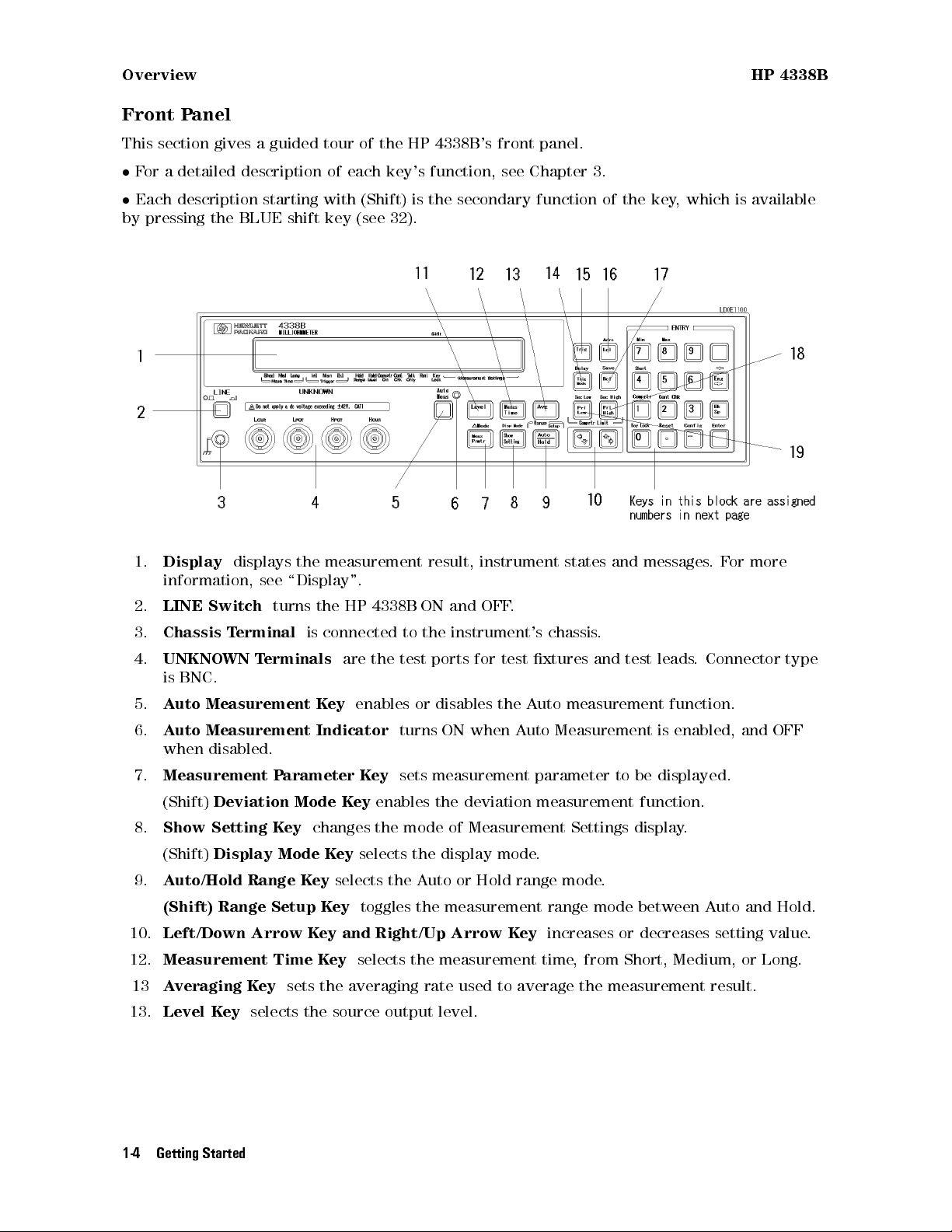

Front Panel

This section gives a guided tour of the HP 4338B's front panel.

For a detailed description of each key's function, see Chapter 3.

Each description starting with (Shift) is the secondary function of the key, which is available

by pressing the BLUE shift key (see 32).

1.

Display

displays the measurement result, instrument states and messages.For more

information, see \Display".

2.

LINE Switch

3.

Chassis Terminal

4.

UNKNOWN Terminals

turns the HP 4338B ON and OFF.

is connected to the instrument's chassis.

are the test ports for test xtures and test leads

is BNC.

5.

Auto Measurement Key

6.

Auto Measurement Indicator

enables or disables the Auto measurement function.

turns ON when Auto Measurement is enabled, and OFF

when disabled.

7.

Measurement Parameter Key

(Shift)

8.

Show Setting Key

(Shift)

9.

Auto/Hold Range Key

Deviation Mode Key

changes the mode of Measurement Settings display.

Display Mode Key

selects the Auto or Hold range mode.

(Shift) Range Setup Key

10.

Left/Down Arrow Key and Right/Up Arrow Key

12.

Measurement Time Key

13

Averaging Key

13.

Level Key

sets the averaging rate used to average the measurement result.

selects the source output level.

sets measurement parameter to be displayed.

enables the deviation measurement function.

selects the display mode.

toggles the measurement range mode between Auto and Hold.

selects the measurement time, from Short, Medium, or Long.

. Connector type

increases or decreases setting value.

1-4 Getting Started

Page 24

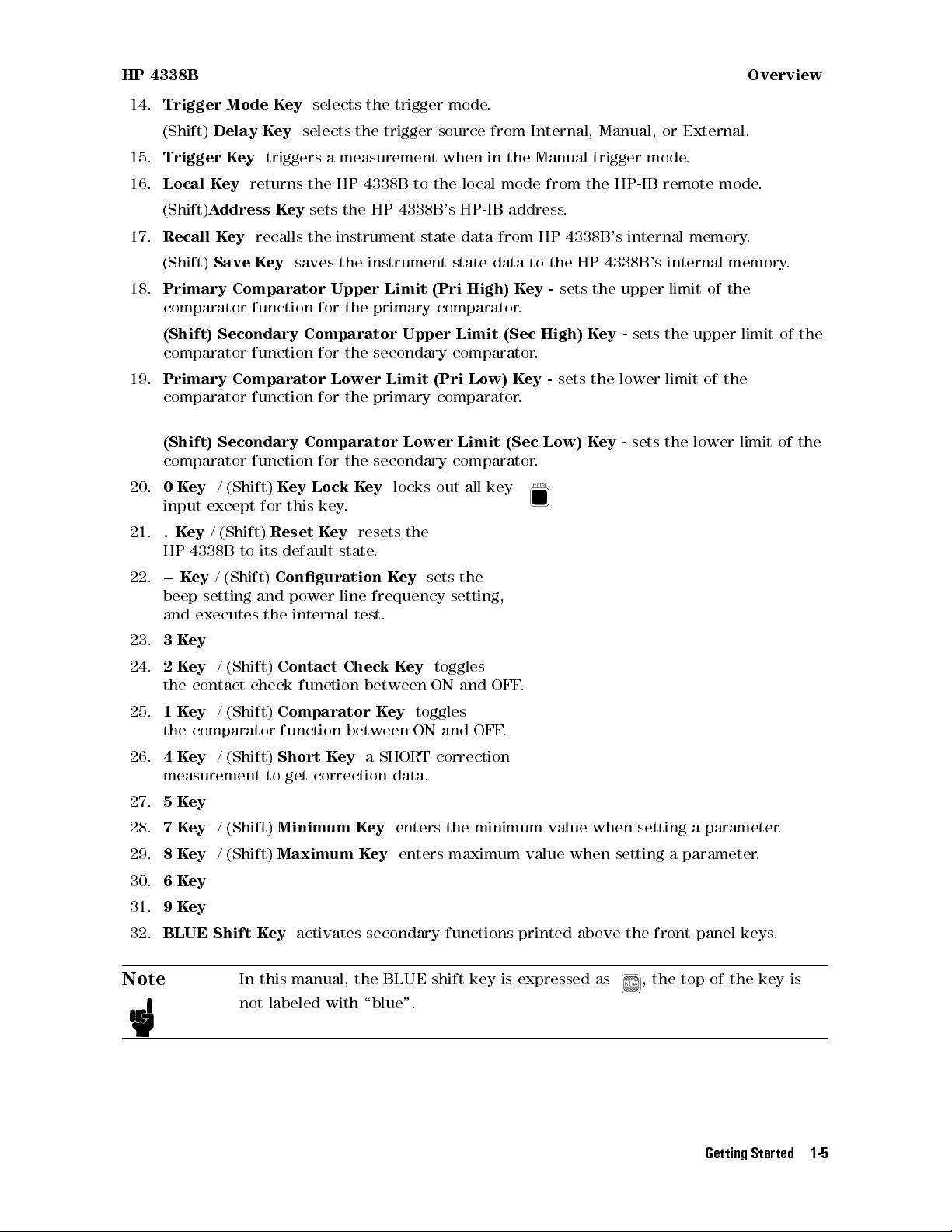

HP 4338B Overview

14.

Trigger Mode Key

(Shift)

15.

Trigger Key

16.

Local Key

(Shift)

17.

Recall Key

(Shift)

18.

Primary Comparator Upper Limit (Pri High) Key -

Delay Key

returns the HP 4338B to the local mode from the HP-IB remote mode.

Address Key

recalls the instrument state data from HP 4338B's internal memory.

Save Key

selects the trigger mode.

selects the trigger source from Internal, Manual, or External.

triggers a measurement when in the Manual trigger mode.

sets the HP 4338B's HP-IB address.

saves the instrument state data to the HP 4338B's internal memory.

sets the upper limit of the

comparator function for the primary comparator.

(Shift) Secondary Comparator Upper Limit (Sec High) Key

- sets the upper limit of the

comparator function for the secondary comparator.

19.

Primary Comparator Lower Limit (Pri Low) Key -

sets the lower limit of the

comparator function for the primary comparator.

(Shift) Secondary Comparator Lower Limit (Sec Low) Key

comparator function for the secondary comparator.

20.

0Key

/ (Shift)

Key Lock Key

locks out all key

input except for this key.

21.

.Key

/ (Shift)

Reset Key

resets the

HP 4338B to its default state.

22.0Key

/ (Shift)

Conguration Key

sets the

beep setting and power line frequency setting,

and executes the internal test.

23.

3Key

24.

2Key

the contact check function between ON and OFF

25.

1Key

/ (Shift)

/ (Shift)

Contact Check Key

Comparator Key

toggles

.

toggles

the comparator function between ON and OFF.

26.

4Key

/ (Shift)

Short Key

a SHORT correction

measurement to get correction data.

27.

5Key

28.

29.

30.

31.

7Key

8Key

6Key

9Key

/ (Shift)

/ (Shift)

Minimum Key

Maximum Key

enters the minimum value when setting a parameter.

enters maximum value when setting a parameter.

- sets the lower limit of the

32.

BLUE Shift Key

Note

activates secondary functions printed above the front-panel keys.

In this manual, the BLUE shift key is expressed as , the top of the key is

not labeled with \blue".

Getting Started 1-5

Page 25

Overview HP 4338B

33.

Engineering Unit Key

34.

Back Space Key

35.

Enter Key

terminates key entry.

enters the engineering units,p,n,, m, k, and M.

erases the last entered character when entering numeric values.

1-6 Getting Started

Page 26

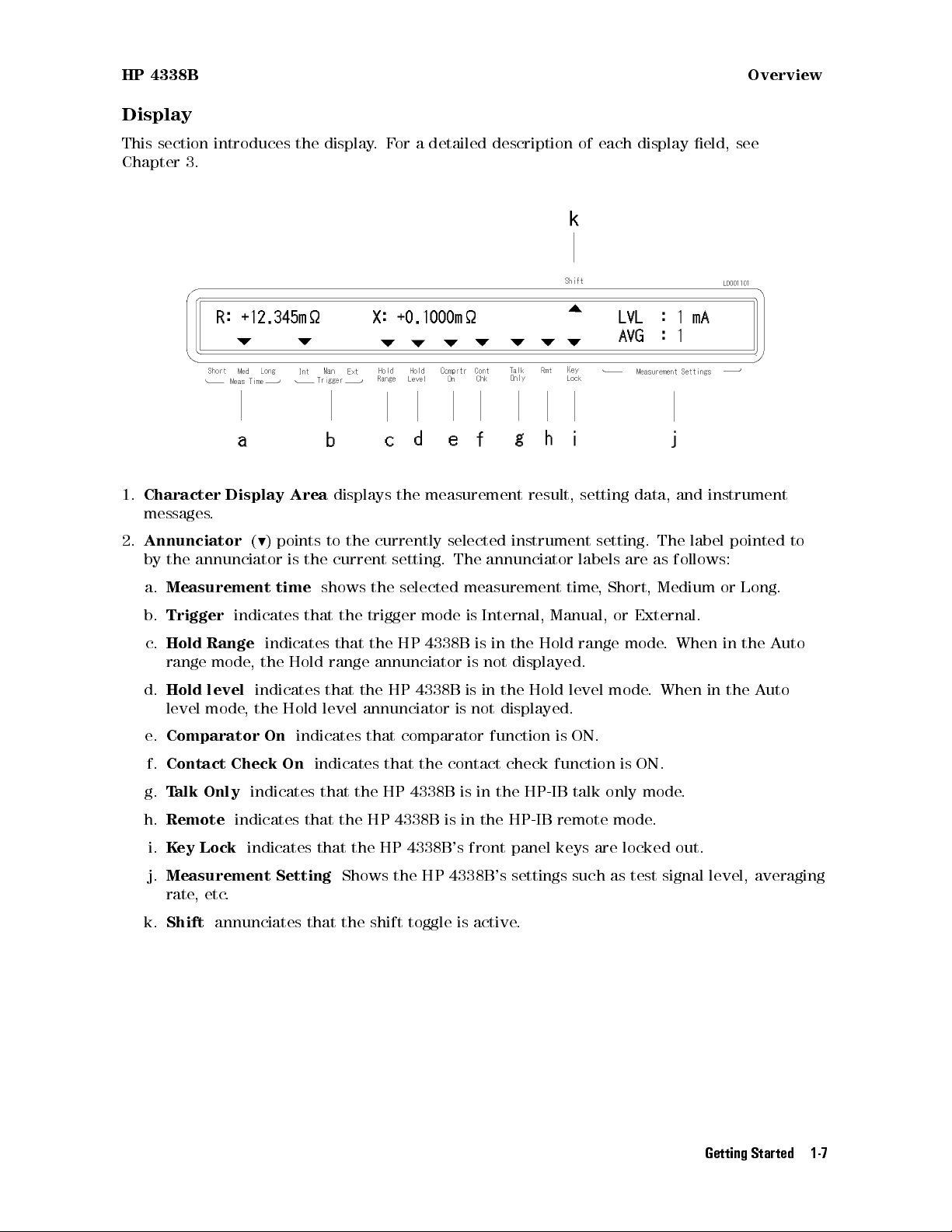

HP 4338B Overview

Display

This section introduces the display.For a detailed description of each display eld, see

Chapter 3.

1.

Character Display Area

displays the measurement result, setting data, and instrument

messages.

2.

Annunciator(9

) points to the currently selected instrument setting. The label pointed to

by the annunciator is the current setting. The annunciator labels are as follows:

a.

Measurement time

b.

Trigger

c.

Hold Range

indicates that the trigger mode is Internal, Manual, or External.

indicates that the HP 4338B is in the Hold range mode

shows the selected measurement time, Short, Medium or Long.

. When in the Auto

range mode, the Hold range annunciator is not displayed.

d.

Hold level

indicates that the HP 4338B is in the Hold level mode

. When in the Auto

level mode, the Hold level annunciator is not displayed.

e.

Comparator On

f.

Contact Check On

g.

Talk Only

h.

Remote

i.

Key Lock

j.

Measurement Setting

indicates that the HP 4338B is in the HP-IB remote mode.

indicates that the HP 4338B's front panel keys are locked out.

indicates that comparator function is ON.

indicates that the contact check function is ON.

indicates that the HP 4338B is in the HP-IB talk only mode.

Shows the HP 4338B's settings such as test signal level, averaging

rate, etc.

k.

Shift

annunciates that the shift toggle is active.

Getting Started 1-7

Page 27

Overview HP 4338B

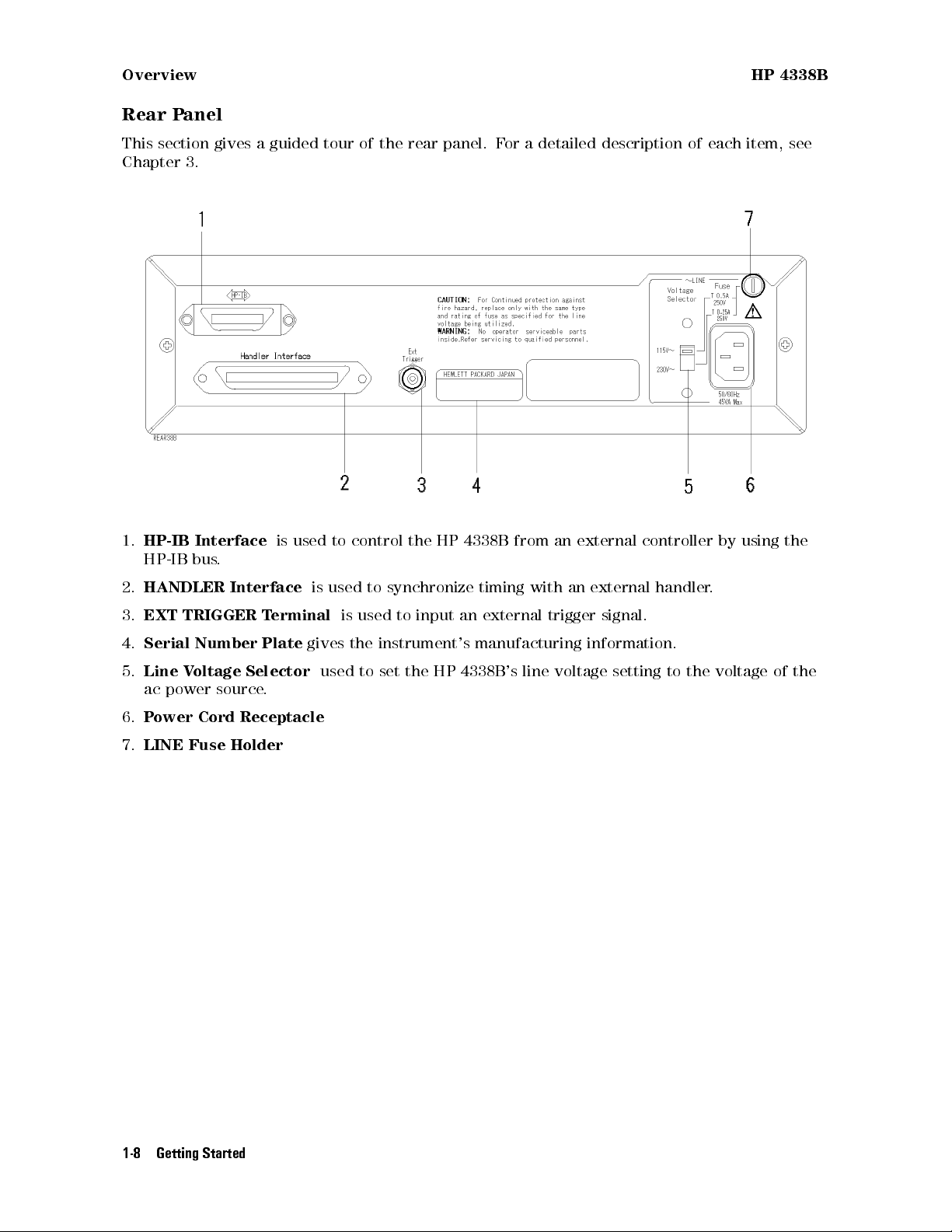

Rear Panel

This section gives a guided tour of the rear panel. For a detailed description of each item, see

Chapter 3.

1.

HP-IB Interface

HP-IB bus.

2.

HANDLER Interface

3.

EXT TRIGGER Terminal

4.

Serial Number Plate

5.

Line Voltage Selector

ac power source.

6.

Power Cord Receptacle

7.

LINE Fuse Holder

is used to control the HP 4338B from an external controller by using the

is used to synchronize timing with an external handler

is used to input an external trigger signal.

gives the instrument's manufacturing information.

used to set the HP 4338B's line voltage setting to the voltage of the

.

1-8 Getting Started

Page 28

HP 4338B Overview

Incoming Inspection

Warning

Inspect the shipping container for damage. If the shipping container or cushioning material

is damaged, it should be kept until the contents of the shipment have been checked for

completeness and the HP 4338B has been checked mechanically and electrically. The contents

of the shipment are as follows:

HP 4338B LCR Meter

Power Cable

Operation Manual(This Book)

User's Guide

If the contents are incomplete, if there is mechanical damage or defect, or if the analyzer does

not pass the power-on selftests, notify the nearest Hewlett-Packard oce. If the shipping

container is damaged, or the cushioning material shows signs of unusual stress

carrier as well as the Hewlett-Packard oce. Keep the shipping materials for the carrier's

inspection.

To avoid hazardous electrical shock, do not turn on the HP 4338B when

there are signs of shipping damage to any portion of the outer enclosure

(for example, covers, panel, or display)

, notify the

Ventilation Requirements

To ensure adequate ventilation, make sure that there is adequate clearance of at least 400 mm

behind, 100 mm sides and 15 mm above.

Instruction for Cleaning

For cleaning, wipe with soft cloth that is soaked with water and wrung tightly without undue

pressure.

Getting Started 1-9

Page 29

Overview HP 4338B

Power Cable

In accordance with international safety standards, this instrument is equipped with a

three-wire power cable. When connected to an appropriate ac power outlet, this cable grounds

the instrument frame. The type of power cable shipped with each instrument depends on the

country of destination. Refer to Figure 1-1 for the part numbers of the power cables available.

Warning

For protection from electrical shock, the power cable ground must not be

defeated. The power plug must be plugged into an outlet that provides a

protective earth ground connection.

1-10 Getting Started

Page 30

HP 4338B Overview

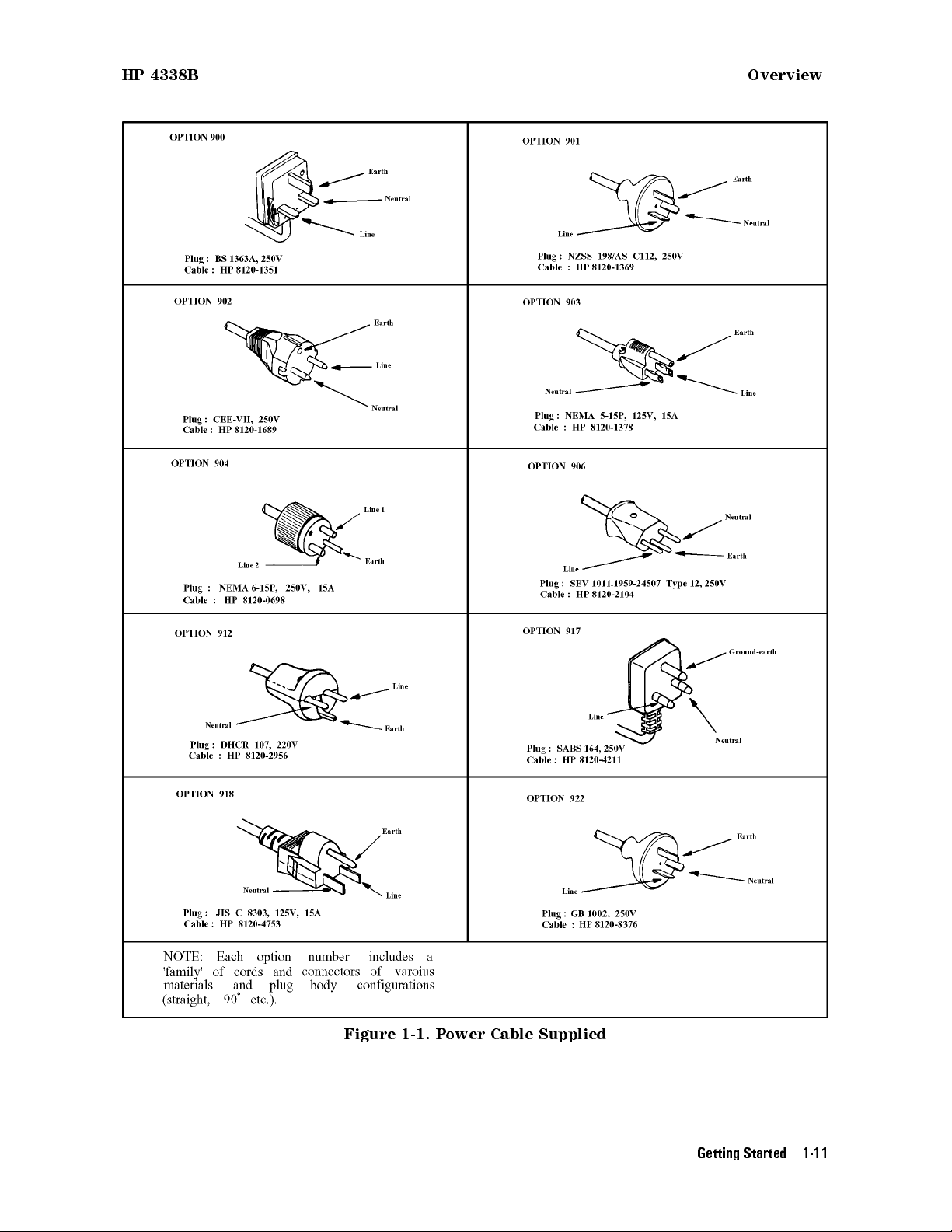

Figure 1-1. Power Cable Supplied

Getting Started 1-11

Page 31

Preparation for Use HP 4338B

Preparation for Use

Before you use the HP 4338B, you must set the HP 4338B to match the available power line

voltage and frequency.

set line voltage | see \Power Requirements".

set line frequency | see \Turning ON the HP 4338B".

Power Requirements

The HP 4338B's power source requirements are as follows:

Power Line Voltage :

PowerLine Frequency :

Power Consumption :

100/120/220/240 Vac(610%)

47 to 66Hz

45 VA maximum

Conrm that the LINE Voltage Selector on rear panel is set to match the power line voltage

before plugging in the HP 4338B. Refer to Figure 1-2

1. Conrm that the power cable is disconnected.

2. Slide the LINE V

oltage Selector on the rear panel to match your power line voltage

. When

your power line voltage is 100/120 Vac(610%), slide the Selector to 115 V. When your power

line voltage is 220/240 Vac(610%), slide the Selector to 230 V. See Figure 1-2.

Fuse

Use the fuse shown in Table 1-1. If you require the fuse, contact the nearest Hewlett-Packard

sales oce.

The fuse can be replaced by turning the fuse holder shown in Figure 1-2 counterclockwise until

the fuse holder pops out with a minus screw driver

.

Figure 1-2. Voltage Selector and Fuse

Table 1-1. Line Voltage Selection

Voltage Selector Power Line

115V 100/120Vac(610%) UL/CSA type, Time delay 0.5A 250V

230V 220/240Vac(610%) UL/CSA type, Time delay 0.25A 250V

1-12 Getting Started

Required Fuse

Voltage

(HP part number 2110-0202)

(HP part number 2110-0201)

Page 32

HP 4338B Preparation for Use

Turning ON the HP 4338B

1. Connect the power cable to the power cord receptacle on the rear panel.

2. Push the LINE switch in. The HP 4338B will emit a beep when it turns ON and perform the

self test. (If any message is displayed, see \Error Messages" in the back of this manual.) The

HP 4338B will be ready for operation after a message like the one shown in the following

gure is displayed.

3. Conrm that the power line frequency setting is correct.

a. Press . The following menu is displayed.

b. Press until the

A blinking item is selected.

c. If the setting does not match the ac line frequency, press

between

d. Press two times to exit this menu.

The power line frequency setting is stored and does not change after reset or on power-o.

Once you set it, you do not need to set the line frequency again as long as the same power line

frequency is being used.

50 Hz

and

Line

blinks, then Press .

60 Hz

.

to toggle the setting

Getting Started 1-13

Page 33

Using Front-Panel Keys HP 4338B

Using Front-Panel Keys

The HP 4338B has four types of keys as follows:

Direct Execution Keys

Toggle Keys

Selection Keys

Value Setup Keys

This section describes how to use the HP 4338B's front panel keys.

Note

If you want to exit an operation and go back to the measurement display, press

several times.

Direct Execution Keys

Pressing a direct execution key will cause the pressed key's function to be performed

immediately.For example,

Press

, and the HP 4338B's front panel keys are locked out.

Toggle Keys

Pressing a toggle key will switch between several conditions

. An annunciator will indicate the

current condition. For example,

Press

, and the

Meas Time

annunciator(9) alternately points to the current setting

(Short, Med or Long).

Selection Keys

Pressing a selection key will display the selection display. The blinking item is the one

currently selected. By using

, , or the selection key itself, the selected (blinking) items

can be changed.

For example, to perform the self test,

1. Press .

2. Press to blink

3. Press

Exit

is blinking.

Test

.

. The self test will start immediately. After the test is nished, the HP 4338B will

display any existing error code, and return to the menu.

4. Select

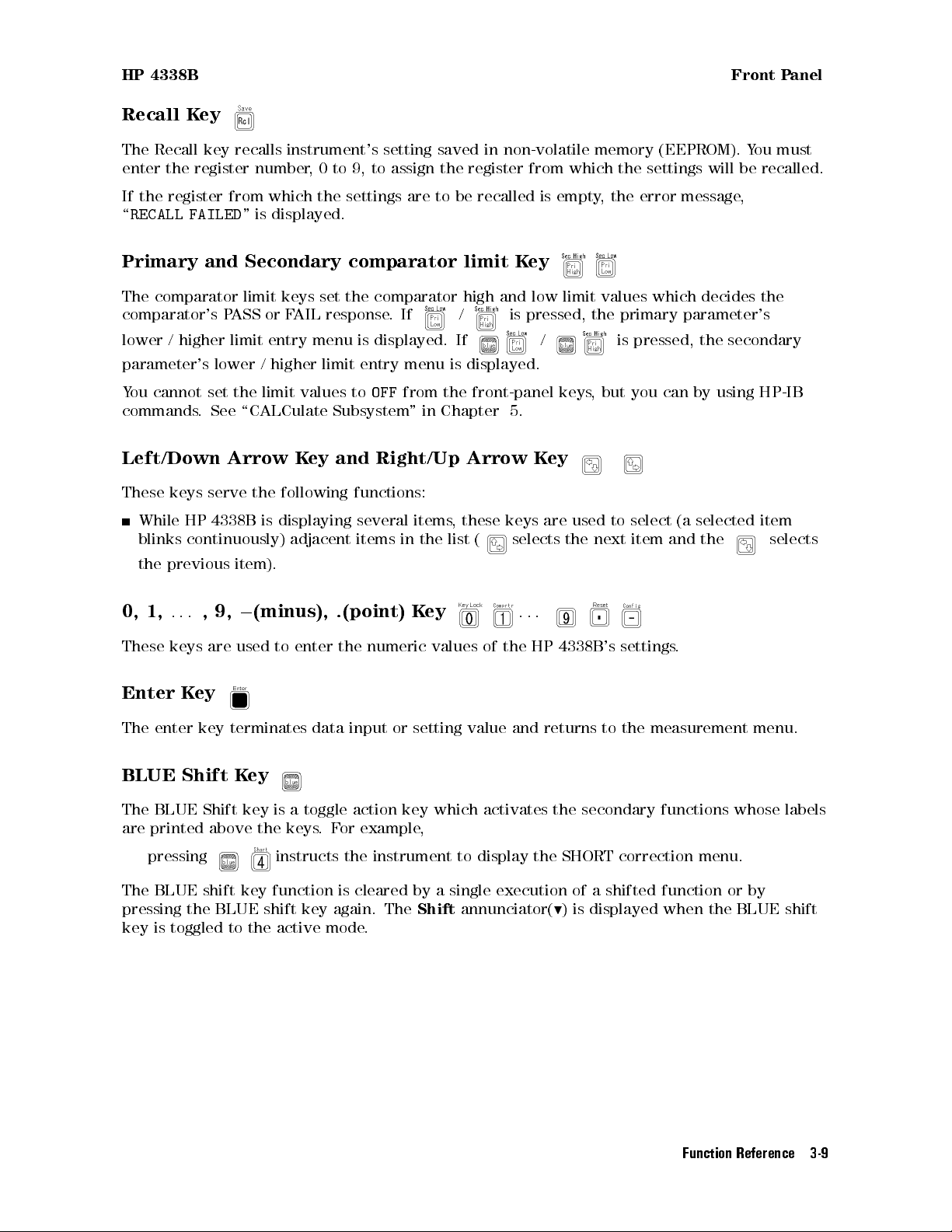

Exit

and press

to exit the menu.

1-14 Getting Started

Page 34

HP 4338B Using Front-Panel Keys

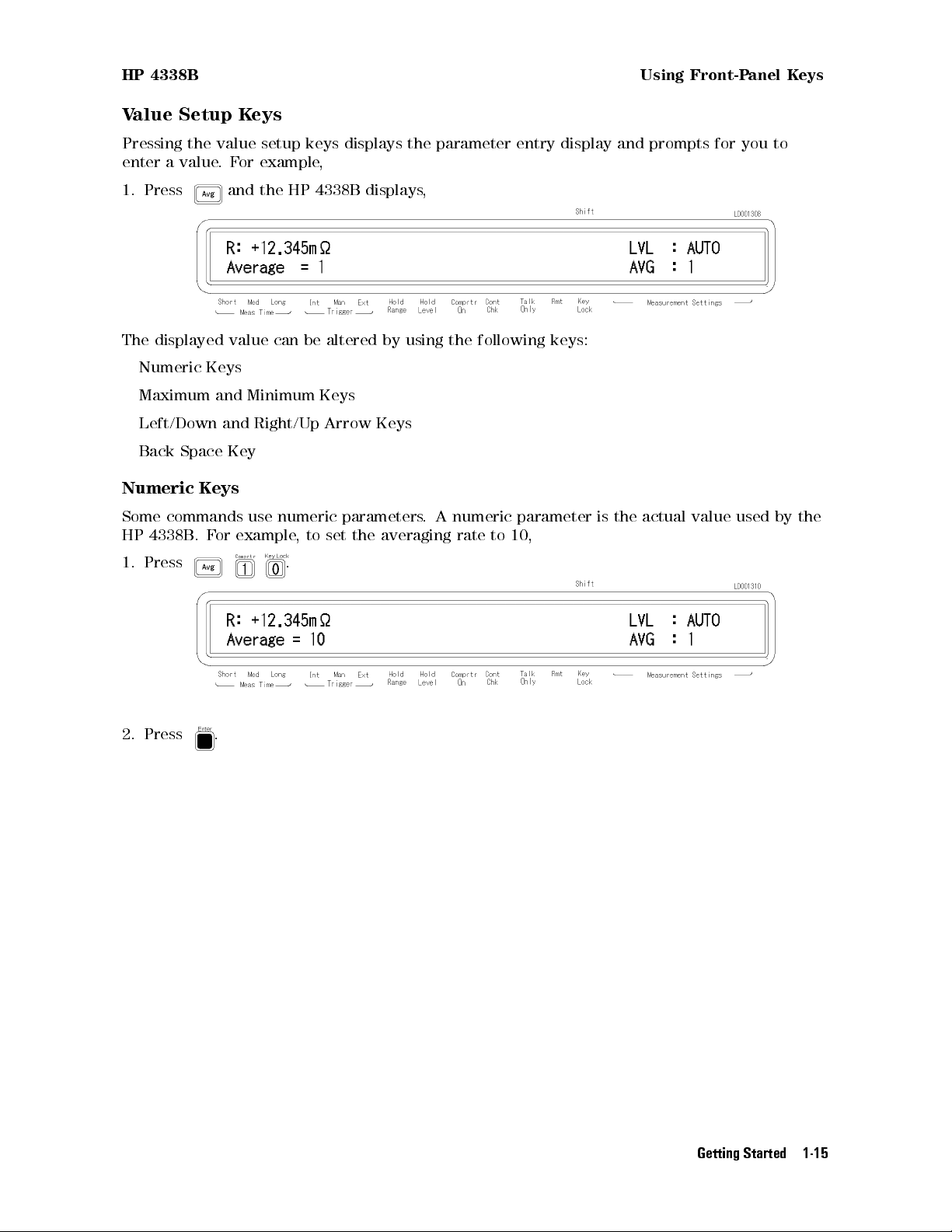

Value Setup Keys

Pressing the value setup keys displays the parameter entry display and prompts for you to

enter a value.For example,

1. Press and the HP 4338B displays,

The displayed value can be altered by using the following keys:

Numeric Keys

Maximum and Minimum Keys

Left/Down and Right/Up Arrow Keys

Back Space Key

Numeric Keys

Some commands use numeric parameters. A numeric parameter is the actual value used by the

HP 4338B. For example, to set the averaging rate to 10,

1. Press

2. Press .

.

Getting Started 1-15

Page 35

Using Front-Panel Keys HP 4338B

You can also enter numeric parameters using engineering units.

1. Press

2. Press

3. Press and the engineering unit will be displayed with

displayed.

4. Press more several times and the engineering units are displayed alternately in

increasing order.

5. Press

. The comparator limit menu is displayed.

.

100

.For example

, and the engineering unit previously displayed will be displayed again.

100K

will

6. Press to enter the value and exit this menu.

Note

Maximum and Minimum Keys

These keys enter the maximum and minimum numeric value in place of using the numeric

keys.For example,

1. Press

2. Press to enter the value and exit this menu.

Before you press , the previous setting is still the current setting, even

though the displayed value has changed. If you press a key other than one of

the keys in ENTRY block before pressing , the setting will not change and

the displayed value will be discarded.

and you will get the maximum value of averaging rate (256).

1-16 Getting Started

Page 36

HP 4338B Using Front-Panel Keys

Left/Down and Right/Up Arrow Keys

Increments or decrements numeric entry.For example,

1. Press

2. Press several times and conrm a change in value.

3. Press

Back Space Key

Erases the last entered character, and cancels the input value.For example,

1. Press

2. Press .

3. Press .

to bring up the HP-IB address setup display.

to exit the setup display.

to select comparator limit menu.

Last entered4is erased.

Getting Started 1-17

Page 37

Connecting a Test Fixture HP 4338B

ToPerform a Measurement

The following procedure is commonly used to perform a measurement using the HP 4338B:

1. Conguration setup

2. Turning on the HP 4338B

3. Connecting DUT to test xture

4. Correction

5. Setting parameters

6. Measurement

This section provides the basic measurement procedure for using the HP 4338B. Follow the

instructions and get to know about the HP 4338B.

To Connect Test Fixture

To Reset HP 4338B

ToPerform Short Correction

To Select Measurement Parameter

To Select Auto Measurement Mode

To Select Measurement Range

To Set Test Voltage

Caution

Note

DO NOT apply a dc voltage exceeding642 V to UNKNOWN terminals, or input

circuit of the HP 4338B will be destroyed.

If you have any problems operating the HP 4338B, see \If Y

in Chapter 2.

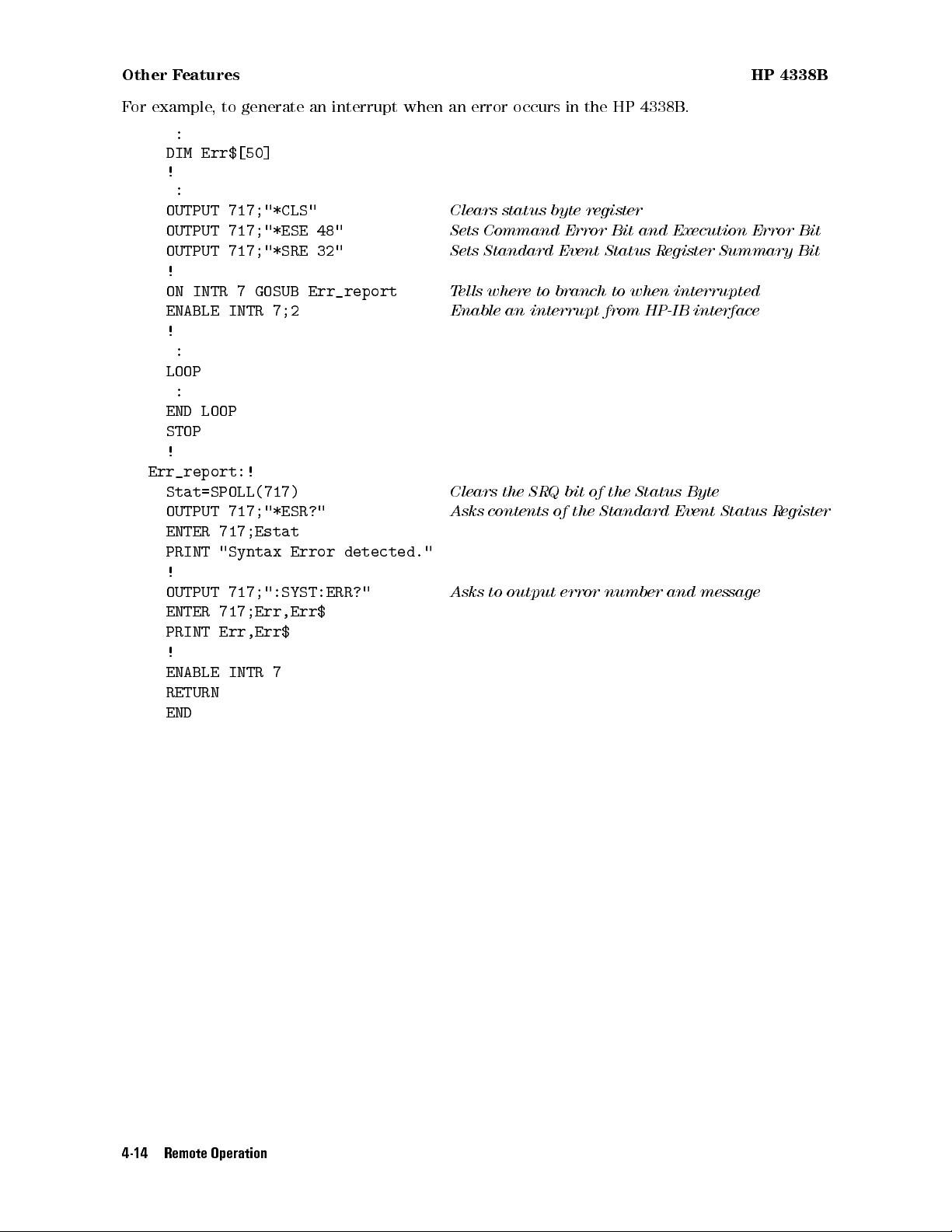

ou Have a Problem"

1-18 Getting Started

Page 38

HP 4338B To Reset HP 4338B

Connecting a Test Fixture

The following describes the available test xtures for the HP 4338B and their connection to the

HP 4338B.

Note

Using the HP 16338A

The HP 16338A test lead set contains four types of test leads, which are used depending on the

DUT type.

The HP 16338A Test Lead set is available for the HP 4338B. Other xtures

must NOT be used with the HP 4338B, even if the UNKNOWN terminals

physically match a test xture's connector spacing because the terminals'

conguration is dierent.

Figure 1-3. Connecting HP 16338A

Getting Started 1-19

Page 39

ToPerform a SHORT Correction HP 4338B

To Reset HP 4338B

Resetting the HP 4338B sets its settings to their default states.

1. Press

2. Press to select

to select the reset menu.

Yes(Yes

blinks), then press .

The HP 4338B is now set to the default state.For more information about the default state,

refer to \Reset Key

" in Chapter 3.

ToPerform a SHORT Correction

Correction is used to cancel the residual errors of the cables and the test xture

correction cancels residual impedance in series with the DUT

.

. The SHORT

1. Connect the electrodes of xture to obtain a SHORT condition.

Note

The SHORT condition is obtained by using a shorting bar

, or by connecting

the test leads together.For details on making a good SHORT, see the manual

supplied with the test xture being used.

2. Press

3. Press or until

. The SHORT correction menu is displayed.

ShortMeas

blinks, and press . The SHORT correction is in

progress, and the following message is displayed.

After a short time, the HP 4338B will display the message

"Short Correction Complete"

and return to the normal display.

If the SHORT impedancejZsjis NOT less than 10 , which is unsuitable for use as the SHORT

correction data, the HP 4338B will display the following warning message

.

,

1-20 Getting Started

Page 40

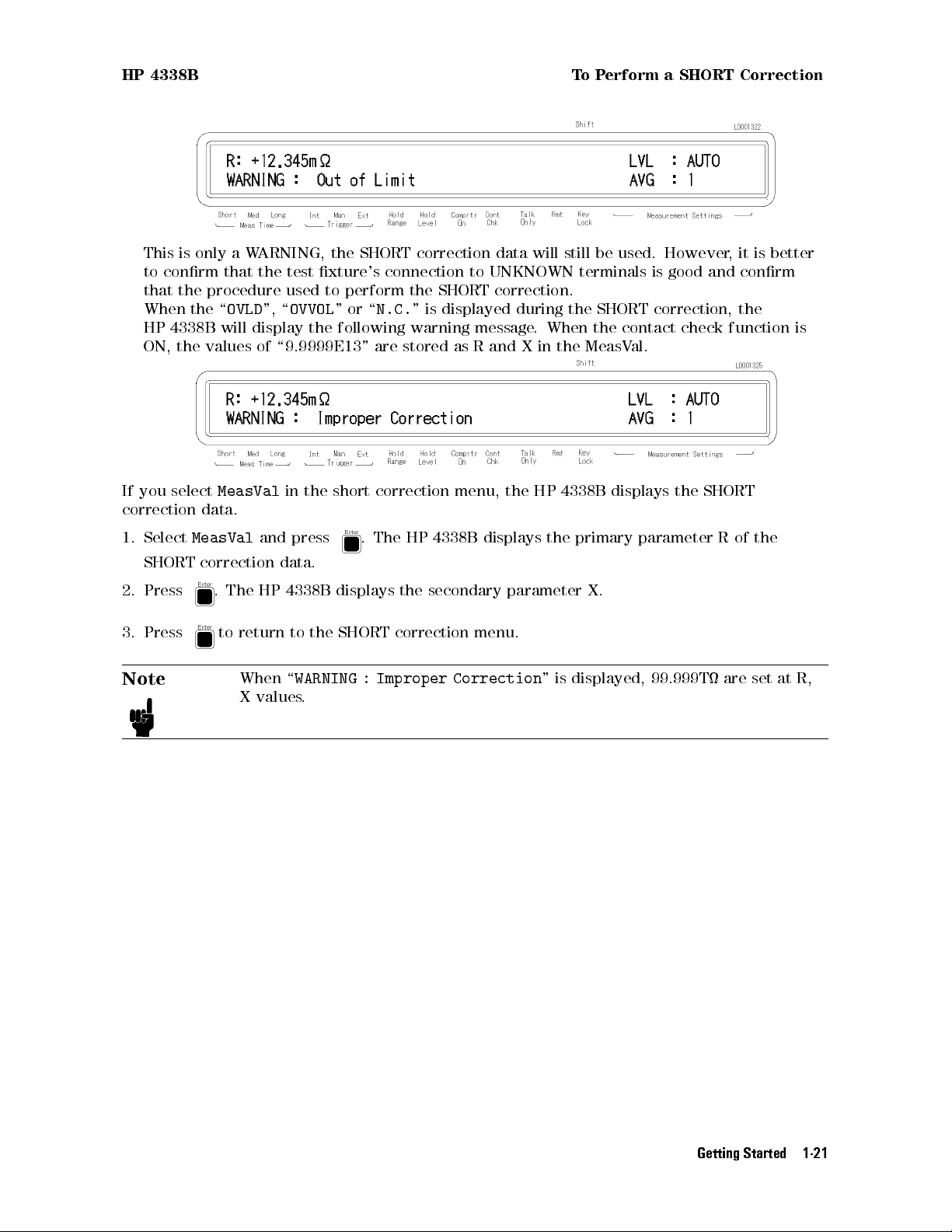

HP 4338B ToPerform a SHORT Correction

This is only a WARNING, the SHORT correction data will still be used. However, it is better

to conrm that the test xture's connection to UNKNOWN terminals is good and conrm

that the procedure used to perform the SHORT correction.

When the \

HP 4338B will display the following warning message. When the contact check function is

ON, the values of \9.9999E13" are stored as R and X in the MeasVal.

OVLD

", \

OVVOL

"or\

N.C.

" is displayed during the SHORT correction, the

If you select

correction data.

1. Select

SHORT correction data.

2. Press . The HP 4338B displays the secondary parameter X.

3. Press to return to the SHORT correction menu.

Note

MeasVal

MeasVal

When \

X values.

in the short correction menu, the HP 4338B displays the SHORT

and press

WARNING : Improper Correction

. The HP 4338B displays the primary parameter R of the

" is displayed, 99.999T are set at R,

Getting Started 1-21

Page 41

To Select Measurement Range HP 4338B

To Select Measurement Parameter

1. Press

. The following menu is displayed.

2. Press or to select the dsesired parameter, then press .

R

R-X

R-L

Z-

To Select Auto Measurement Mode

The HP 4338B has an Auto Measurement Function which allows automatic selection of the

optimum measurement range and test signal level. To activate the auto measurement mode:

Press

The auto measurement indicator turns ON. If the

.

Hold Range

annunciator(9)or

Hold Level

annunciator(9) is displyed, the indicator turns o.

To Select Test Signal Level

The HP 4338B has ve test current levels | 1

addition to these selection, you can select also the auto level mode

A, 10A, 100A, 1 mA, and 10 mA. In

, in which the HP 4338B

automatically selects the optimum measurement test level. If the test level is set other than

the auto level mode, the

Hold Level

annunciator(9) is displayed.

To select the test level:

.

Auto

1. press

and available test signal levels are displayed.

2. Press or until the desired level blinks. If you want to select the auto level mode,

press

3. Press

or until

.

Auto

blinks.

1-22 Getting Started

Page 42

HP 4338B To Select Measurement Range

To Select Measurement Range

Auto / Hold Range Mode

The HP 4338B has two measurement range modes,Auto and Hold. The Auto mode changes

the measurement range automatically to t the measured value. The Hold mode xes the

measurement range.

To select the range mode,

Press

In Hold range mode, the

when the

Measurement Range Setting

1. Press . Measurement range menu is displayed.

2. Press or until the desired range is displayed.

3. Press .

Note

and the

Hold Range

Hold Range

Hold Range

annunciator is not displayed.

You may nd some measurement range cannot be set because the HP 4338B has

test signal level limitations for each measurement range setting. F

Figure 3-2.

annunciator(9) is alternately displayed and turned o.

annunciator is displayed. The Auto range mode is active

or details, see

Getting Started 1-23

Page 43

Page 44

Operating the HP 4338B

Introduction

This chapter provides step-by-step instructions for using the HP 4338B Milliohmmeter . This

chapter includes the following sections:

Measurement Conguration

Making a measurement

Testing the HP 4338B

If You Have a Problem

Refer to Chapter 3 for the description of each front panel key function.

2

Operating the HP 4338B 2-1

Page 45

Measurement Conguration HP 4338B

Measurement Conguration

This section discusses the HP 4338B's general conguration topics that apply to many or all

measurement functions.

To Select the Measurement Time Mode

The current measurement time mode setting (Short, Med or Long) is indicated by the

Meas Time

annunciator(9). To select the measurement time mode:

1. Press

until the measurement time mode is set to the desired mode.

To Set the Averaging Rate

To set the averaging rate :

1. Press .

2. Enter the desired value.

3. Press

to set the value and to exit.

The current setting is desplayed on the right side of the LCD display

is not displayed, press until it is displayed.

To Set the Trigger Delay or Source Delay Time

To set the trigger delay or the source delay time:

. When the current setting

1. Press

.

To set the trigger delay time:

Press

or until

Enter the desired value using the numeric keys

TrigDelay

blinks, and press .

, and press

When you want to exit without changing value, just press .

2-2 Operating the HP 4338B

.

Page 46

HP 4338B Measurement Conguration

To set the source delay time:

Press or until

Enter the desired value using the numeric keys, and press .

When you want to exit without changing value, just press

To display the current setting, press

side of the LCD display.

To Set the Contact Check

The

Cont Chk

contact check function is turned ON/OFF as follows:

To turn ON the contact check function:

Press

To turn OFF the contact check function:

annunciator(9) indicates the ON/OFF state of the contact check function. The

. The Cont Chk annunciator(9) is displayed.

SourceDelay

blinks, and press .

until the setting value is displayed on the right

.

Press

again. The Cont Chk annunciator(9) disappears.

Operating the HP 4338B 2-3

Page 47

Measurement Conguration HP 4338B

To Set the Beeper Mode

To set the beeper mode for the comparator result reporting:

1. Press

2. Select

3. Select the desired mode (

4. Select

To Save and Recall Instrument Settings

The HP 4338B can save and recall the instrument's settings

To save the current settings:

Beep

Exit

.

using or , and press .

Fail,PassorOff

using or , and press to exit.

) using or , and press .

.

1. Press

2. Enter the register number (0 to 9) that you want to save the settings into

3. Press to save.

Note

.

Record the register number that you saved into for further reference.

.

2-4 Operating the HP 4338B

Page 48

HP 4338B Measurement Conguration

To recall a setting.

1. Press .

2. Enter the register number (0 to 9) that you want to recall the settings from.

3. Press to recall.

Operating the HP 4338B 2-5

Page 49

Making a Measurement HP 4338B

Making a Measurement

To Trigger a Measurement

The HP 4338B has four trigger source modes: Internal, Manual, External, or Bus. The

annunciator shows which trigger source is selected.

Note

To Trigger Internally

1. Press

To Trigger Manually

1. Press until the

2. Press

To Trigger Externally

1. Connect the external trigger source to the EXT TRIGGER terminal on the HP 4338B's rear

panel.

2. Press

3. Apply a trigger signal to trigger the HP 4338B

The bus trigger mode can be set by HP-IB commands only. When the bus

trigger mode is selected, none of the Trigger annunciators are ON.

until the

when you want to trigger a measurement.

until the

Int

trigger annunciator(9) is ON.

Man

trigger annunciator(9) is ON.

Ext

trigger annunciator(9) is ON.

.

Trigger

2-6 Operating the HP 4338B

Page 50

HP 4338B Making a Measurement

To Use the Comparator Function

The comparator function can be used to sort DUTs based on their parameter values. The

Comprtr On

To set the limit values:

1. Select the parameter to be set by pressing or for the primary parameter, and

2. Enter the value using the numeric keys, and press to enter the value.

annunciator(9) tells whether the comparator function is set to ON or OFF.

or for the secondary parameter.

Note

To start sorting:

1. Press

To display the sorting results:

Press

Select

mode, and the comparison result is displayed.

When you want to set the limits only for the lower limit or the upper limit, or

the limits only for the primary parameter or the secondary parameter, set the

unnecessary parameter to OFF using the (setting the minimum value)

or the (setting the maximum value).

.

. The following menu is displayed.

Comprtr

using or . The display mode is set to the comparator result display

To stop sorting:

Press .

Operating the HP 4338B 2-7

Page 51

Making a Measurement HP 4338B

To Display Deviation Data

The1before the measurement parameter on the LCD display tells that the displayed value for

the parameter is the deviation value.

To Set the Reference Value

1. Press . The following menu is displayed.

2. Press or to select

To set by measuring the reference DUT:

a. Press

b. Then the secondary parameter reference setting menu (

Press

value as the secondary reference.

To set by entering a value:

a. Enter the primary parameter reference value using the numeric keys

When you want to exit without changing value, just press .

b. Enter the secondary parameter reference value using the numeric keys, and press .

regardless of the trigger mode, and the primary parameter is measured. Press

to set the measurement value as the primary reference

to measure the secondary parameter, and press to set the measurement

1RefEnt

, and press .

.

1Ref Secondary=

, and press

) is displayed.

.

When you want to exit without changing value, just press .

2-8 Operating the HP 4338B

Page 52

HP 4338B Making a Measurement

To Select the Deviation Display Mode

To select the deviation display mode (

3. To select the primary parameter deviation display mode, press

press .

Press or to select

4. To select the secondary parameter deviation display mode, press or to select

and press . The same menu as the primary parameter is displayed, and you can select

the mode (

Off, 1ABSor1

Off,1ABS

%) in the same manner as the primary parameter.

Off,1

,or1%),

,or1%, and press .

or to select

Pri

, and

Sec

,

Operating the HP 4338B 2-9

Page 53

Making a Measurement HP 4338B

To Set the Display Mode and Display Digits

If you press

or (

Off

: turns the display OFF) and press

To exit from this menu, select

If you select

using or , and press . After selecting the display digits, the HP 4338B returns to

the display mode selection menu.

Data

Digit

, the display mode selection menu appears. Select the desired mode using

: displays the measurement data,

.

Exit

and press .

, the display digits selection menu appears. Select the desired display digits

Comprtr

: displays the comparator results,

2-10 Operating the HP 4338B

Page 54

HP 4338B Making a Measurement

To Change the Measurement Settings Display Mode

Each time

is pressed, the current settings of the HP 4338B are displayed one after

another on the right side of the LCD display. The information displayed and the order of

display is as follows:

1. Test signal level and Averaging rate

2. Trigger delay time and Source delay time

3. Comparator limits of the primary parameter

4. Comparator limits of the secondary parameter

Operating the HP 4338B 2-11

Page 55

Making a Measurement HP 4338B

To Lock Out the Front Panel Keys

To lockout the keys:

Press

.

To unlock the keys:

Press again.

To Select the Local Mode

To return the HP 4338B to the local mode from HP-IB remote mode:

Press

.

To Set the HP-IB Address

1. Press

.

2. Enter the desired value, then press to set the value and to exit.

When you just want to show the current setting, just press .

To Print Measurement Data

To print the measurement data to an HP-IB compatible printer without using an external

controller:

1. Set the printer to listen-always mode.

2. Connect the HP-IB compatible printer to the HP 4338B's HP-IB port.

3. Turn the printer ON.

4. Set the HP 4338B's HP-IB address to 31 (talk only mode).

Press

.

The printer will begin printing the measurement data.

5. When you want to stop printing, change the HP 4338B's HP-IB address to an address other

than 31 (for example, 17, which is the default setting).

Press

.

2-12 Operating the HP 4338B

Page 56

HP 4338B ToTest the HP 4338B

ToTest the HP 4338B

ToPerform a Self-Test

The HP 4338B has a self-test function to check its basic performance.

1. Press

2. Select

Test

.

using or , then press to execute the self test. If any error message

is displayed, refer to \Error Messages".

3. Select

Exit

and press to exit.

ToTest the Front Panel Keys' Functionality

The HP 4338B has a service function to test the functionality of the front panel keys

, the

handler interface, the ROM, the RAM, and the EEPROM. This section describes how to test

the front panel key's functionality.For the handler interface test, refer to Chapter 9 for the

procedure. The other tests are for use by service personnel only

1. Press

2. Select

Svc

.

using or and press .

.

3. Select

KEY

using ,or and press .

4. Press the front panel key that you want to test.

For example, if you want to test , then press .

When the key functions properly,

KEY CODE:5 TRIGGER

is displayed; otherwise, there will be

no such display, the key is not functioning correctly. Contact your nearest Hewlett-Packard

oce.