Page 1

TM 11-6625-1538-15

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

OPERATOR, ORGANIZATIONAL, DS, GS, AND DEPOT

MAINTENANCE MANUAL

HEWLETT-PACKARD AC VOLTMETER AN/USM-265

(MODEL 400EL02) NSN 6625-00-935-4294

ME-459 (MODEL 400EL) NSN 6625-00-229-0457

ME-465 (MODEL 400E) NSN 6625-00-995-7716

This copy is a reprint which includes current

pages from Changes 1 and 2.

HEADQUARTERS, DEPARTMENT OF THE ARMY

MAY 1967

Page 2

WARNING

DANGEROUS VOLTAGES

EXIST IN THIS EQUIPMENT

Be careful when working on the power supplies and

their circuits, or on the 230-or 115–volt ac line

connections.

DO NOT TAKE CHANCES!

Page 3

TM 11-6625-1538-15

C2

CHANGE

HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 2

Washington, DC, 15 December 1983

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

GENERAL SUPPORT, AND DEPOT MAINTENANCE

MANUAL FOR

HEWLETT-PACKARD AC VOLTMETER AN/USM-265

(MODEL 400EL02) NSN 6625-00-935-4294

ME-459 (MODEL 400EL) NSN 6625-00-229-0457

ME-465 (MODEL 400E) NSN 6625-00-995-7716

TM 11-6625-1538-15, 11 May 1987, is changed as follows:

1. New or added material is indicated by a vertical bar in the margin of the page.

2. Added or revised illustrations are indicated by a vertical bar adjacent to the illustration identification number.

3. Remove old pages and insert new pages as indicated below.

Remove Pages

Insert Pages

i and ii

10.1 and 10.2

5-1 and 5-2

4. File this change sheet in front of the publication for reference purposes.

i and ii

10.1/(10.2 blank)

5-1 through 5-2.2

A-1/(A-2 blank)

Page 4

By Order of the Secretary of the Army:

Official:

ROBERT M. JOYCE

Major General, United States Army

The Adjutant General

DISTRIBUTION:

To be distributed in accordance with DA Form 12-34B, requirements for

TMDE.

JOHN A. WICKHAM JR.

General, United States Army

Chief of Staff

Page 5

TM 11-6625-1538-15

C1

CHANGE

HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 1

WASHINGTON,DC, 27 December 1979

Operator’s, Organizational, Direct Support,

General Support, and Depot Maintenance Manual

For

HEWLETT-PACKARD AC VOLTMETER AN/USM-265

(MODEL 400EL02) NSN 6625-00-935-4294

ME-459 (MODEL 400EL) NSN 6625-00-229-0457

ME-465 (MODEL 400E) NSN 6625-00-995-7716

TM 11-6625-1538-15, 11 May 1967, is changed as follows:

1. Title is changed as indicated above.

2. A vertical bar appears opposite changed material.

3. Remove and insert pages as indicated in the page list below:

Remove

iii and 1-0

None . . . . . . . . . . . . . . . . . . . . . . . . .

1-0.1

None . . . . . . . . . . . . . . . . . . . . . . .

4. File this change sheet in front of the manual for reference purposes.

By Order of the Secretary of the Army:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Insert

i and ii

1-0

1-0.1 and 1-0.2

D-1 through D-4

Official:

J. C. PENNINGTON

Major General, United States Army

The Adjutant General

DISTRIBUTION:

Active Army:

HISA (Ft Monmouth) (21) Svc Colleges (1)

USAINSCOM (2) USASIGS (5)

COE (1) USAADS (2)

TSG (1)

USAARENBD (1) USAARMS (2)

DARCOM (1)

TRADOC (2)

OS Maj Comd (4) USAICS (3)

TECOM (2)

USACC (4)

MDW (1)

Armies (2)

Corps (2)

ARNG: None

USAR: None

For explanation of abbreviations used, see AR 310-50.

USAFAS (2)

USAIS (2)

USAES (2)

MAAG (1)

USARMIS (1)

USAERDAA (1)

USAERDAW (1)

Fort Gordon (10)

E. C. MEYER

General, United States Army

Chief of Staff

Fort Carson (5)

Army Dep (1) except

LBAD (14)

SAAD (30)

TOAD (14)

SHAD (3)

Fort Gillem (10)

USA Dep (1)

Sig Sec USA Dep (1)

Fort Richardson (CERCOM Ofc) (2)

Units org under fol TOE:

(2 copies each unit)

29-207

29-610

Page 6

Page 7

This manual contains copyrighted material orginally prepared by the Hewlett-Packard Company.

TM 11-6625-1538-15

TECHNICAL M ANUAL

HEADQUARTERS

DEPARTMENT OF THE ARMY

ASHINGTON , DC, 11 May 1967

TM 11-6625-1538-15

W

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

GENERAL SUPPORT, AND DEPOT MAINTENANCE MANUAL

FOR

HEWLETT-PACKARD AC VOLTMETER AN/USM-265

(MODEL 400EL02) NSN 6625-00-935-4294

ME-459 (MODEL 400EL) NSN 6625-00-229-0457

ME-465 (MODEL 400E) NSN 6625-00-995-7716

SECTION I. GENERAL INFORMATION

ECTION II. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S

ECTION III. OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S

ECTION IV. THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S

SECTION

l-A.l. Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

lA.2. Consolidated index of Army publications and blank forms.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1A.3. Maintenance Forms, Records, and Reports

lA.4. Reporting Errors and Recommending Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-A.5. Reporting Equipment Improvement Recommendations (EIR)

l-A.6. Administrative Storge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l-A.7. Destruction of Army Electronics Materiel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1.

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4.

Options Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5.

Option 01(400E only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7.

0ption 02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9.

Instrument and manual Identification . . . . . . . . . . . . . . . . . . .

2-1.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3.

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5. Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,

2-7.

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10. Installation . . . . . . . .

2-12.

2-14.

2-16.

2-18. Repackaging for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1.

3-4.

3-6. Operating Instructions

3-7.

3-12.

3-14.

4-1.

4-8.

4-9.

4-12.

4-15.

4-20.

4-22. Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bench Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combination Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location of Controls and Indicators . . . . . . . . . . . . .

Standard 400E/EL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

400E with Option 01 . . . . . . . . . . . . . .

400E/EL with Option02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic Description (See Figure 6-l) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance Converter .

Meter Amplifier . . . .

Meter Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Output Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1.

Introduction . . . . . . . . . . .

5-3.

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

1-0.1

1-0.1

1-0.1

1-0.1

1-0.1

1-0.1

1-0.1

1-1

1-1

1-1

1-1

1-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

3-1

3-1

3-1

3-1

3-1

3-2

3-2

4-1

4-1

4-1

4-1

4-2

4-2

4-2

4-2

5-1

5-1

5-1

Change 2

i

Page 8

TM 11-6625-1538-15

5-4.1. Preventive Maintenance

5-4.2. Operator/Crew Preventive Maintenance Checks and Services

5-5.

Mechanical Zero Adjust (400E Only)

5-7.

Performance Checks Accuracy and Frequency Response Test . . . . . . . . . . . . . . . . . . . . . . . . .

5-19.

5-22. Alignment and Calibration Procedure . . . . . . .

5-24.

5-27.

5-29. AC Output Zero

5-31.

SECTION V.

ECTION VI.

S

APPENDIX A.

APPENDIX D.

SECTION I.

5-34. Troubleshooting

5-38. Power Supply

5-40.

5-46.

5-48. Adjustment of Factory Selected Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAMS

6-1.

Introduction

REFERENCES

MAINTENANCE ALLOCATION

INTRODUCTION

II.

MAINTENANCE ALLOCATION CHART FOR HEWLETT-PACKARD

AC VOLTMETER AN/USM-265, ME-459, and ME-465. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III.

TOOL AND TEST EQUIPMENT REQUIREMENTS FOR HEWLETT-PACKARD AC

VOLTMETER AN/USM-265,ME-459, AND ME-465 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMARKS (NOT APPLICABLE)

IV.

Chart

Input Impedance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bias Adjust

Calibration

Amplifiers

AC Output Circuit

Page

5-1

5-2

5-2

5-2

5-3

5-4

5-4

5-4

5-4

5-4

5-5

5-6

5-6

5-6

57

6-1

6-1

A-1

D-1

D-3

D-4

Number

1-1.

3-1.

3-2.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7. Impedance Converter Voltages

5-8.

5-9.

5-10.

Figure

1-1.

3-1.

3-2.

3-3.

4-1.

4-2.

5-1.

5-2.

5-3.

6-1.

6-2.

Specifications

Effect of Distortion on Average Responding Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Amplifier Gain

Required Test Equipment

Calibration Tolerances

l/3 Scale Tracking Tolerances (400E)

l/3 Scale Tracking Tolerances (4WEL)

Troubleshooting Guide

Power Supply Voltages

Meter Amplifier Voltages

AC Voltage Output Circuit

Factory Selected Components

Models 400E and 400EL AC Voltmeter

Location of Controls and Indicators

External Battery Connedion

Impedance Correction Graph

Simplified Block Diagram

Meter Bridge

Accuracy and Frequency Response Test Setup

Input Impedance Check

Location of Internal Adjustments

400E/EL Schematic Diagram and Location of Compnents

Location of Important Mechanical Parts

LIST OF TABLES

LIST OF ILLUSTRATIONS

Page

1-0

3-1

3-2

5-0

5-3

5-3

5-4

5-6

5-6

5-6

5-6

5-6

5-7

Page

1-0

3-0

3-1

3-3

4-1

4-2

5-2.1

5-4

5-5

6-3

6-4

ii

Change 2

Page 9

Page 10

TM 11-6625-1538-15

Section I

Figure 1-1 and Table 1-1

FIGURE l–l.

-hp- MODEL 400E/EL

Voltage Range:

in 12 ranges in 1, 3, 10 sequence. value for a step change.

-72 dbm to +52 dbm in 12 ranges with 10 dbm

between ranges. AC Power:

Frequency Range: 10 Hz to 10 MHz.

Calibration: Responds to absolute average value of

applied signal, calibrated in rms volts.

Input Impedance:

the 1 mv-1 v ranges and 10 megohms shunted by

8 pf on the 3 v-300 v ranges.

Amplifier AC Output: 150 mv rms for full scale

meter indication; output impedance 50 ohms, 10

Hz to 10 MHz (105 mv on the 1 mv range).

AC-DC Converter Output: 1 vdc output for full scale Shipping: 9 lbs. (4 kg).

meter deflection.

Output Resistance: 1000 ohms.

1 mv full scale to 300 v full scale

10 megohms shunted by 21 pf on

MODELS 400E AND 400EL AC VOLTMETERS

Table 1-1. Specifications

-hp- MODEL 400E/EL (Cont’d)

Response Time: 1 second to within 1% of final

approximately 5 watts.

Temperature Range: 0 to +55°C (except where noted

on accuracy charts).

External Battery Operation: Terminals are provided

on rear panel; positive and negative voltages between 35 v and 55 v are required; current drain

from each voltage is approximately 54 ma.

Weight:

Net: 6 lbs. (2, 7 kg).

Dimensions:

(165, 1 x 130,2 x 279,4 mm).

115 or 230 volts +10%, 50 to 1000 cps,

6-1/2” high, 5-1/8” wide, 11” deep

EL6625—1538—TM—CI—I

1-0

01788-1

Page 11

SECTION I

GENERAL INFORMATION

TM 11-6625-1538-15

1-A.1. SCOPE

This manual includes installation and operation

instruction and covers operator‘s, organizational,

direct support (DS), general support (GS), and

depot maintenance of the Hewlett-Packard AC

Voltmeter AN/USM-265 (Model 400EL02), ME-459

(Model 400EL), and ME-465 (Model 400E). The

repair parts and special tools list are located in

TM 11-6625-1538-24P.

1-A.2. CONSOLIDATED INDEX OF ARMY

PUBLICATIONS AND BLANK FORMS

Refer to the 1 test issue of DA Pam 310-1 to deter-

mine whether there are new editions, changed or

additional publications pertaining to the equipment.

MAINTENANCE FORMS, RECORDS,

1-A.3.

AND REPORTS

Reports of Maintenance and Unsatisfactory

a.

Equipment. Department of the Army forms

and procedures used for equipment maintenance will be those prescribed by TM

38-750, The Army Maintenance Management System.

Report of Packaging and Handling Defi-

b.

ciencies,

(Report of Discrepancy (ROD)) as prescribed in AR 735-11-2/DLAR 4140.55/

NAVMATINST 4355.73A/AFR 400-54/

MCO 430.3F.

c.

Discrepancy in Shipment Report (DISREP)

(SF 361). Fill out and forward Discrepancy

in Shipment Report (DISREP) (SF 361) as

prescribed in AR 55-38/NAVSUPINST

4610.33C/AFR 75-18/MCO P4610.19D/

DLAR 4500.15.

1-A.4.

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any

mistakes or if you know of a way to improve the

Fill out and forward SF 364

procedures, please let us know. Mail your letter or

DA Form 2028 (Recommended Changes to Publications and Blank Forms) direct to: Commander,

US Army Communications-Electronics Command

and Fort Monmouth, ATTN: DRSEL-ME-MP,

Fort Monmouth, New Jersey 07703.

In either case, a reply will be furnished direct to

you.

1-A.5. REPORTING EQUIPMENT IMPROVEMENT

RECOMMENDATIONS (EIR)

If your AC Voltmeter AN/USM-265 needs improvement, let us know. Send us an EIR. You, the user,

are the only one who can tell us what you don’t like

about your equipment. Let us know why you don‘t

like the design.

Deficiency Report). Mail it to Commander, US

Army Communications-Electronics Command and

Fort Monmouth, ATTN: DRSEL-ME-MP, Fort

Monmouth, New Jersey 07703. We’ll send you a

reply.

1-A.6. ADMINISTRATIVE STORAGE

Administrative Storage of Equipment issued to and

used by Army activities will have preventive maintenance performed in accordance with the PMCS

charts before storing. When removing the equipment from administrative storage the PMCS should

be performed to assure operational readiness. Disassembly and repacking of equipment for shipment

or limited storage are covered in paragraphs 2-18

through 2-21, and TM 740-90-1 Administrative

Storage of Equipment.

1-A.7. DESTRUCTION OF ARMY ELECTRONICS

MATERIEL

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM

750-244-2.

Put it on an SF 368 (Quality

Change 2

1-0.1/(1-0.2 blank)

Page 12

Page 13

TM 11-6625-1538-15

Model 400E/EL

In this manual, the international standard unit of frequency,

the Hertz, will be used rather than cycles per second.

1 Hertz (Hz) = 1 cycle per second

1-1. DESCRIPTION.

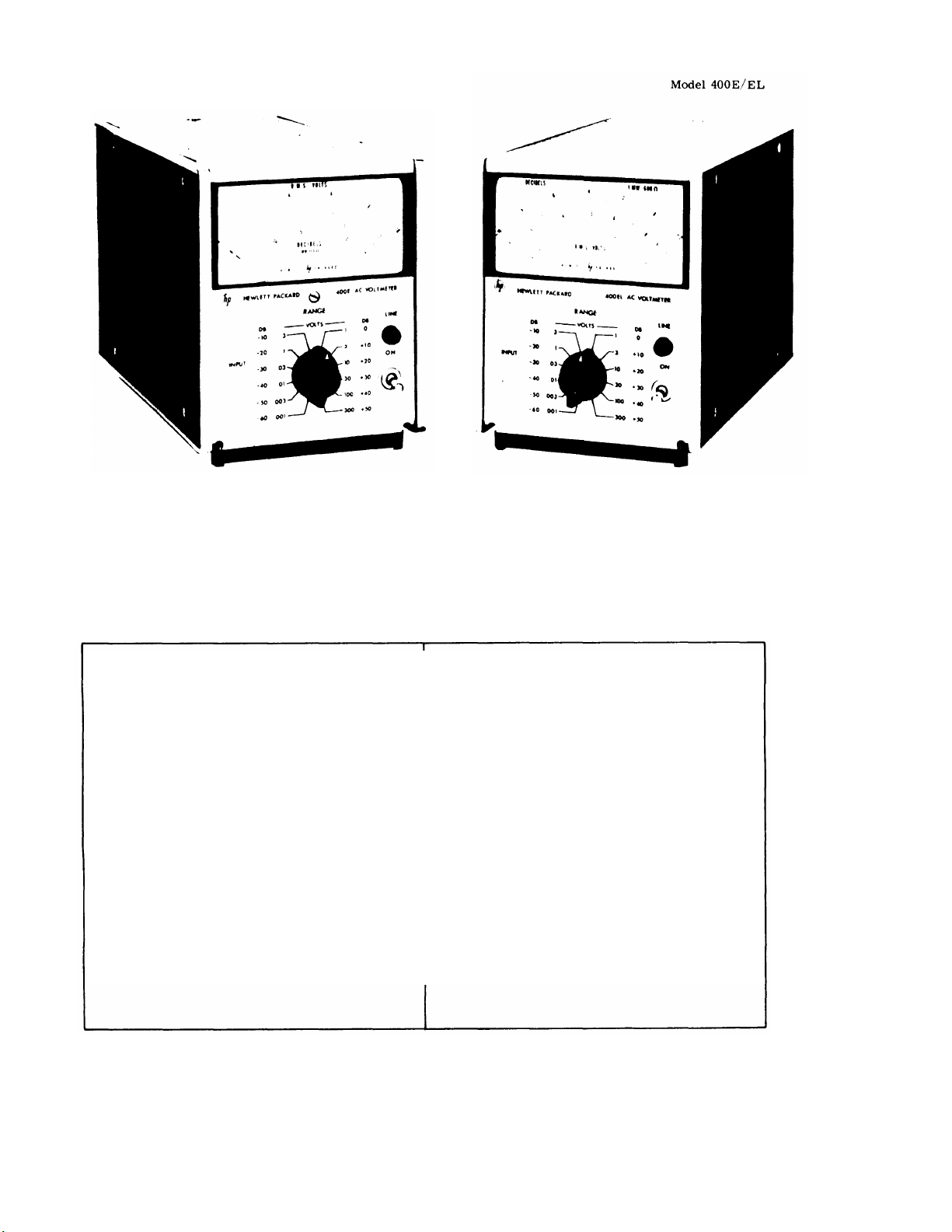

1-2. The -hp- Models 400E and 400EL are versatile

ac voltmeters and db meters. Both models can be

used as ac to dc converters or wideband amplifiers.

The Model 400E is primarily intended for voltage

measurements, whereas the Model 400EL is primarily

a db meter. However, both meters indicate both volts

and db. The 400E has a linear ac scale with a logarithmic db scale underneath, and the 400EL has a

linear db scale with a logarithmic ac scale underneath.

Since the difference in scales is the only difference

between the two instruments, this manual will use the

term 400E/EL in reference to both instruments.

1-3. Figure 1-1 shows both the Model 400E and the

Model 400EL. Table 1-1 is a list of specifications.

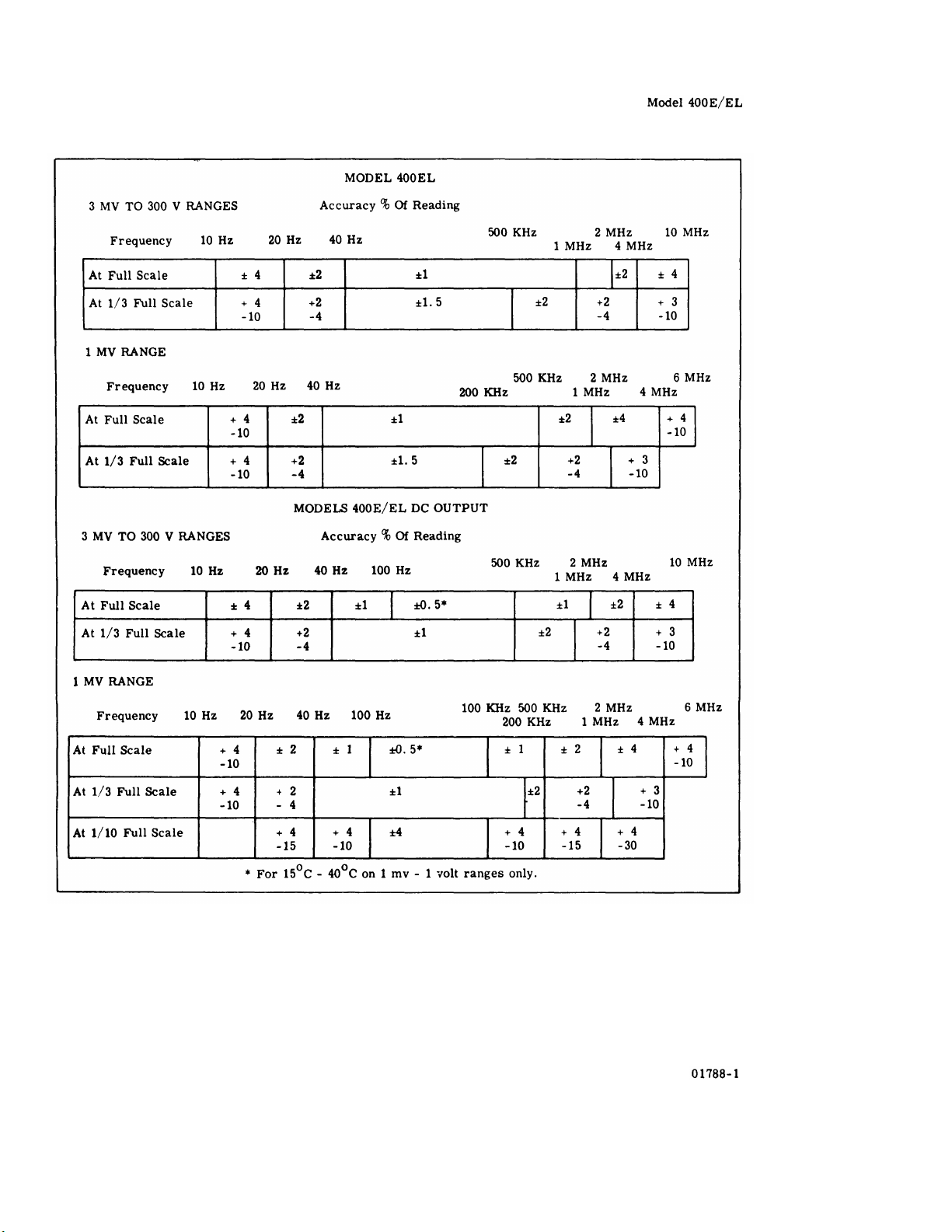

Paragraphs 1-1 to 1-11 and Table 1-1 (Cont’d)

NOTE

1-7. OPTION 02.

1-8. Option 02 adds a relative reference adjustment

to the 400E/EL. The REL. REF. control allows a continuous reduction in sensitivity by a maximum of 3

db in order to make relative voltage or db measurements.

1-9. INSTRUMENT AND MANUAL

IDENTIFICATION.

1-10. Hewlett-Packard instruments are identified by

a two-section, eight-digit serial number (000-00000).

Section I

1-4. OPTIONS AVAILABLE.

1-5. OPTION 01 (400E Only).

1-6. Option 01 places the db scale uppermost for

greater resolution when making db measurements.

Table 1-1. Specifications (Cent’d)

1-11. If the first three digits of the two-section, eight-

digit serial number are prefixed with an E or G, your

instrument was produced in Europe. An E000-00000

serial number indicates that the instrument was manufactured in England; a G000-00000 serial number indicates that the instrument was manufactured in Germany.

01788-1

1-1

Page 14

TM 11-6625-1538-15

Section 1

Table 1-1 (Cont’d)

Table 1-1. Specifications (Cont‘d)

1-2

Page 15

Model 400E/EL

TM 11-6625-1538-15

Section II

Paragraphs 2-1 to 2-21

SECTION II

INSTALLATION

2-1. INTRODUCTION.

2-2. This section contains information and instructions necessary for the installation and shipping of the

Model 400E and 400EL voltmeters. Included are initial inspection procedures, power and grounding requirements, installation information, and instructions

for repackaging for shipment.

2-3. INITIAL INSPECTION.

2-4. This instrument was carefully inspected both

mechanically and electrically before shipment. It

should be physically free of mars or scratches and in

perfect electrical order upon receipt. To confirm

this, the instrument should be inspected for physical

damage in transit. Also check for supplied accessories,

and test the electrical performance of the instrument

using the procedure outlined in Paragraph 5-7.

Report any damage or deficiencies in

accordance with paragraph

1-A. 3.

2-5. POWER REQUIREMENTS.

2-6. The Model 400E/EL can be operated from any

source of 115 or 230 volts at 50 to 1000 cycles or from

two 35 to 55 volt batteries connected to the rear panel

BATTERY terminals.

the rear panel selects the desired line voltage. Power

dissipation is 5 watts maximum.

The 115/230 v slide switch on

2-7. GROUNDING REQUIREMENTS.

2-8. To protect operating personnel, the National

Electrical Manufacturers’ Association (NEMA) recom-

mends that the instrument panel and cabinet be

grounded. All Hewlett- Packard instruments are

equipped with a three-conductor power cable which,

when plugged into an appropriate receptacle, grounds

the instrument.

three-prong connector is the ground wire.

2-9. To preserve the protection feature when operating the instrument from a two-contact outlet, use a

three-prong to two-prong adapter and connect the

green pigtail on the adapter to ground.

The offset pin on the power cable

2-10. INSTALLATION.

2-11. The Model 400E/EL is fully transistorized;

therefore, no special cooling is required. However,

the instrument should not be operated where the

ambient temperature exceeds 55°C (131°F) or the

relative humidity exceeds 95%.

2-12. BENCH MOUNTING.

2-13. The Model 400E/EL is shipped with plastic feet

and tilt stand in place, ready for use as a bench instrument.

2-14. RACK MOUNTING.

2-15. The Model 400E/EL may be rack mounted by

using an adapter frame (-hp- Part No. 5060-0797).

01788-1

The adapter

combination

mounted only.

2-16. COMBINATION MOUNTING.

2-17. The Model 400E/EL may be mounted in combi-

nation with other submodular units by using a Combining Case (-hp- Model 1051A or 1052A). The Combining Case is a full-module unit which accepts various

combinations of submodular units. Being a full- module

unit, the combining case can be bench or rack mounted

and is analogous to any full-module instrument.

2-18. REPACKAGING FOR SHIPMENT.

2-l9. The following paragraphs contain a

general guide for repackaging of the

equipment.

original container is to be used;

paragraph 2-21 if it is not.

2-20. If

follows:

a.

b.

2-21, If

as follows:

a.

b.

c.

d.

frame is a rack frame that accepts any

of submodular units. It can be rack

Refer to paragraph 2-20 if the

original container is to be used, proceed as

Place equipment in original container.

Make sure that container is well

sealed with strong tape or metal bands.

original container is not to be used, proceed

Wrap instrument in heavy paper or plastic before placing in an inner container.

Place packing material around all sides of

instrument and protect panel face with cardboard strips.

Place instrument and inner container in a

heavy carton or wooden box and seal with

strong tape or metal bands.

Mark shipping container with “DELICATE

INSTRUMENT,” “FRAGILE” etc.

2-1

Page 16

TM 11-6625-1538-15

Section III

Figure 3-1

Model 400E/EL

1 400E Scale: Indicates magnitude of applied sig-

nal in volts and dbm. Option 01 places the dbm

scale uppermost for greater resolution. 0 dbm

= 1 mw in 600

2 400EL Scale: Indicates magnitude of applied sig-

nal in volts and dbm. Dbm scale is linear. and

voltage scales are logarithmic. This arrangement allows better resolution for db reading. O

dbm = 1 mw in 600

3 AC INPUT BNC input jack connects signal to

be measured.

4 REL. REF Adjust (Option 02): Lowers sensi-

tivity of meter by 3 db. Fully clockwise ABSO-

LUTE position retains full meter sensitivity.

This control is used to vary meter indication

with a given input in order to make relative

readings easier.

5 RANGE Selector: Selects full scale reading of

meter. Dbm reading on scale adds algebraically

to DB setting of RANGE selector.

Ω.

Ω.

Figure 3-1.

Location of Controls and Indicators

3-0

6 Line ON Toggle Switch Applies primary power.

7 LINE Indicator Lamp: Indicates application of

primary power.

8 FUSE: 1/8 amp. Protects instrument against

current overload.

9 115 230 Volt Slide Switch: Selects 115 or 230

volts ac for line operation.

10 PRIMARY POWER CONNECTOR: Line voltage

is applied through this connector.

11 AC OUTPUT: Ac amplifier output. Output im-

pedance is 50

12 DC OUTPUT: Ac to dc converter output. Dc

voltage is proportional to percentage of meter

deflection. Output impedance is 1000

13 BATTERY VOLTAGE Terminals: 400E/EL may

be powered by connecting two 35 to 55 volt batteries to these terminals.

Ω.

Ω.

01788-1

Page 17

Model 400E/EL

TM 11-6625-1538-15

Section III

Paragraphs 3-1 to 3-8 and Table 3-l and Figure 3-2

SECTION Ill

OPERATING INSTRUCTIONS

3-1. INTRODUCTION.

3-2. The Model 400E/EL is primarily an ac voltmeter

and db meter, but it can be used as an ac to dc converter or as a wide band amplifier.

3-3. This section explains the controls of the 400E/EL

and outlines the operating procedures for each mode

of operation.

3-4. LOCATION OF CONTROLS AND

INDICATORS.

3-5. Figure 3-1 shows the location of each of the

400E/EL controls and explains the function of each.

3-6. OPERATING INSTRUCTIONS.

3-7. STANDARD 400 E/EL.

3-8. AC VOLTMETER.

NOTE

Since the 400E/EL is average responding and rms calibrated, any

distortion will affect the accuracy

of the measurement. Table 3-1

shows the errors caused by distortion.

Table 3-1. Effect of Distortion on Average Respond-

ing Meter

b. To operate the Model 400E/EL with battery

power, connect two 35 to 55 volt batteries as

shown in Figure 3-2. Since the front panel

LINE switch has no effect during battery

operation, the switch in Figure 3-2 can be

used as a convenient method of disconnecting

the batteries when the instrument is not in use.

Figure 3-2. External Battery Connection

a. Ensure that 115-230 vac slide switch on the

rear panel matches line voltage used, and

connect power to the instrument. Mechanically

zero the instrument using the procedure outlined in Paragraph 5-5.

01788-1

Turn line ON toggle switch to up position.

c.

LINE lamp will glow.

d.

Select approximate range of signal to be measured.

DO NOT APPLY MORE THAN

600 VOLTS TO INPUT. DO NOT

OVERLOAD THE .001 THROUGH

1 VOLT RANGES WITH MORE

THAN 300 VOLTS AT FREQUENCIES BELOW 300 KC OR

WITH MORE THAN 64 VOLTS

AT FREQUENCIES ABOVE 300

KC. IF ANY OF THESE OVER-

LOADS ARE EXCEEDED, THE

INSTRUMENT MAY BE DAMAGED.

e.

Connect signal to be measured to INPUT terminals, and read the rms voltage on the scale.

3-1

Page 18

TM 11-6625-1538-15

Section III

Paragraphs 3-9 to 3-16 and Table 3-2

3-9. DB METER.

a. To make a db or dbm measurement, follow

steps a through e in Paragraph 3-8, and add

the scale reading to the RANGE setting. For

example: If the scale reading is +1.5 and the

RANGE is -30 db, the final measurement is

-28.5 db.

b. The 400E/EL db scale is calibrated in dbm.

0 dbm is equivalent to 1 milliwatt dissipated

by a 600 ohm load. Consequently, any dbm

measurements must be made across a total

impedance of 600

other impedances will be in db, but not dbm.

To convert a db reading to dbm, use the Im-

c.

pedance Correction Graph (Figure 3-3). For

example: To convert a +30 db reading made

across 50

on the bottom of the graph. Follow the impedance line to the heavy black line and read

the meter correction at that point. The correction for 50

rected reading is +40.5 dbm.

3-10. AC TO DC CONVERTER.

a. Follow steps a through e in Paragraph 3-8.

b. Connect the rear panel DC OUTPUT terminals

to a dc measuring device with a high input

impedance, The dc output resistance is 1000

Ω; and if it is loaded, the dc output signal will

be inaccurate.

c. The dc output is a 0 to 1 volt signal propor-

tional to the percentage of 400E/EL meter

deflection.

3-11. WIDE BAND AC AMPLIFIER.

a. Follow turn-on steps a through c in Para-

graph 3-8.

b. Select approximate range of input on RANGE

switch.

c. Connect SIGNAL to be amplified to INPUT

terminals.

Ω to dbm, locate the load impedance

Ω is +10.5 dbm, and the cor-

Measurements across

Ω.

Model 400E/EL

d. Connect a 50

AC OUTPUT connector.

e. The gain of the amplifier depends on the

RANGE selection. On the 0.1 volt range and

below, the 400E/EL amplifies the input; and

on the 0.3 volt range and above, it attenuates

the input.

maximum output is 105 mv.

ranges, the maximum output is 150 mv.

Table 3-2 shows the ac amplifier gain for

each range setting.

Table 3-2. AC Amplifier Gain

3-12. 400E WITH OPTION 01.

3-13. Operation of the 400E with Option 01 is essentially the same as operation of the standard 400E.

The db scale reads from -15 to +2 instead of from -12

to +2, and is placed at the top of the scale for better

resolution.

3-14. 400E/EL WITH OPTION 02.

3-15. Option 02 adds a relative reference adjustment

to the 400 E/EL. This adjustment allows a continuous

reduction in sensitivity by 3 db. Use the REL. REF

adjustment to set the meter at any convenient reference (0 db for example) in order to make relative

readings easier. When the REL. REF adjustment is

in the fully clockwise ABSOLUTE position, it has no

effect on the meter sensitivity.

3-16. In all other respects, operation of an Option 02

instrument is the same as operation of a standard

Model 400E/EL.

Ω amplifier load to rear panel

On the 0.001 volt ranges, the

On all other

3-2

01788-1

Page 19

TM 11-6625-1538-15

Model 400E/EL

Section III

Figure 3-3

01788-1

Figure 3-3.

Impedance Correction Graph

3-3

Page 20

Page 21

TM 11-6625-1538-15

Model 400E/EL

SECTION IV

THEORY OF OPERATION

4-1. GENERAL.

4-2. The 400E/EL is a solid state, average respond-

ing, rms calibrated voltmeter. It also has applications as an ac to dc converter and a wide band amplifier. Figure 4-1 shows a simplified block diagram

of the instrument.

4-3. When relay K1 is closed, the input is not attenuated; and when K2 is closed, the input is attenuated

by 50 db. On the 0.001 through 1 volt ranges, K1 is

closed and K2 is open.

on the 3 through 300 volt range. The entire Input Attenuator assembly is shielded, and the relays are

operated remotely by voltages applied through the

RANGE switch. Variable capacitor A1C2 is adjusted

on the 3 volt range with a 3 volt 100 KHz input in order

to shape the frequency response of the Input Attenuator.

4-4. The signal from the input attenuator is applied

to the impedance converter. The impedance converter

is a unity gain, feedback stabilized amplifier that

matches the high Impedance of the Input Attenuator to

the much lower impedance of the post attenuator.

4-5. The Post Attenuator attenuates the output of the

Impedance Converter by 10 db for each step of the

RANGE switch. On the 3 volt range, the Post Attenuator is switched back to the 30 db position, and

then it attenuates 10 db per step on the higher ranges.

Variable capacitor S2C2 is adjusted on the .003 volt

range with a 3 mv 8 MHz input to adjust the 8 MHz

response of the .003 volt range. With a full scale

input on any range except the .001 volt range, the

output of the Post Attenuator should be 3 mv. On the

.001 volt range, the output should be 1 mv.

K2 is closed and K1 is open

Paragraphs 4-l to 4-ll and Figure 4-1

4-6. The Meter Amplifier is a four-stage, high-gain

amplifier utilizing both ac and dc feedback for gain

stabilization. The Meter Bridge, connected in the ac

feedback path of the meter amplifier, converts the ac

output of the amplifier to a dc voltage proportional

to its average value.

A1C28 and A1R38 adjust the gain of the amplifier so

that the meter will read rms volts. A1R28 is adjusted at 400 Hz, and A1C28 is adjusted at 10 MHz.

4-7. The DC Output is a 0-1 volt level that is proportional to percentage of meter deflection. R2 is adjusted to calibrate the dc output. The AC Amplifier

samples the ac feedback and generates O to 150 mv

ac output that is directly proportional to meter deflec t ion.

4-8. SCHEMATIC DESCRIPTION

(See Figure 6-1).

4-9. IMPEDANCE CONVERTER.

4-10. The impedance converter, located on the main

voltmeter board (A2), matches the high impedance of

the input attenuator to the relatively low impedance

of the Post Attenuator. Breakdown diodes A2CR17

and 18 bias diodes A2CR9 and 10 at +5 and -5 volts

respectively. A2CR9 and 10 limit the input to 10 volts

peak-to-peak, providing overload protection. Fuse

A2F1 protects the instrument against destructive

overloads.

4-11. A field-effect transistor (A2Q5) is used in the

input stage of the impedance converter because of its

characteristically high input impedance and good frequency response. The output is taken from the emitter

This dc voltage drives the meter.

Section IV

01788-1

Figure 4-1. Simplified Block Diagram

4-1

Page 22

TM 11-6625-1538-15

Section IV

Paragraphs 4-12 to 4-24 and Figure 4-2

circuit of A2Q7 and applied to the post attenuator and

then applied to the meter amplifier. The solid black

lines on the schematic show the signal path, and the

broken lines show the feedback paths. A2R17 adjusts

the dc bias of the impedance converter.

4-12. METER AMPLIFIER.

4-13. The meter amplifier amplifies its input signal

by a fixed gain on all ranges except the .001 volt

range. The amplifier itself is a four-stage, dc coupled

amplifier with a cascode-coupled final stage (A2Q12

and 13). Dc feedback is coupled from the emitter of

A2Q12 back to the base of A2Q9. Breakdown diodes

A2CR12, 13 and 14 establish fixed dc bias levels in

the amplifier.

4-14. The output from the collector of A2Q13 is coupled

through the Meter Bridge and fed back to the emitter

of A2Q9. A2C28 in the feedback circuit adjusts the

amount of feedback at the high end of the frequency

range, and A2R38 adjusts the feedback at the low end.

This calibrates the amplifier gain at both ends of the

frequency range.

feedback circuit on the 0.001 volt range, boosting the

gain on that range.

of the amplifier.

4-15. METER BRIDGE.

4-16. Figure 4-2 shows a partial schematic of the

Meter Bridge.

amplifier output and supplies the dc current to drive

the meter. In order to use part of the meter bridge

output as the rear terminal dc output, the meter has

to be referenced to ground. Transistor A2Q14 ref-

erences the meter to ground.

4-17. During the positive half cycle, A2CR15 conducts.

Part of the current (solid line) goes through A2C34

into the feedback path, and part of the current goes

through A2R53 and the meter to ground. The current

through A2R53 turns on A2Q14, and A2Q14 draws

current from the positive supply. The current from

A2Q14 goes through A2C36 into the feedback path.

The current through A2Q14 and A2C36 is equal to the

current drawn through the meter, so the current out

of the bridge is equal to the current into the bridge.

4-18. During the negative half cycle, A2CR16 conducts

and draws current from the feedback path (dotted line).

Part of the current goes through A2C36 and A2CR16

into the amplifier, and part goes through A2R53 and

the meter to ground. The current through A2R53

turns on A2Q14, and the current from A2Q14 goes

through A2R54 and A2CR16 to the amplifier, Again

the current through the meter equals

A2R44 and 45 are switched into the

A2R31 adjusts the dc bias level

The meter bridge rectifies the ac

the current

Model 400E/EL

Figure 4-2.

through A2R54, and the current into the bridge equals

the current out.

4-19. Transistor A2Q14 replaces current drawn by

the meter, so the meter bridge is kept floating while

the meter is referenced to ground. The dc output,

taken across A2R65 and R2, is also referenced to

ground.

4-20. AC OUTPUT CIRCUIT.

4-21. The ac output circuit isolates the meter bridge

and amplifier from the ac output load. It consists of

two emitter followers (A2Q15 and Q16) connected in

cascade. A2R59 in the base circuit of A2Q15 zeroes the

output dc level at the ac output.

4-22. POWER SUPPLY.

4-23. The power supply produces regulated +26 volts

and -26 volts.

a reference voltage of 6.98 volts. Part of the power

supply output is applied to the base of A2Q2, and A2Q2

senses the difference between the supply output and

the reference.

emitter to base voltage of A2Q2 will change; and the

output of A2Q2 will change the current through A2Q1,

the regulator.

4-24. The negative regulator, A2Q3 and A2Q4, uses

the +26 volt output as a reference. Consequently, the

negative supply is dependent upon the positive supply.

Breakdown diode A2CR7 establishes

If the output voltage changes, the

Meter Bridge

4-2

01788-1

Page 23

Page 24

TM 11-6625-1538-15

Section V Model 400E/EL

Table 5-1

Table 5-1. Required Test Equipment

5-0

01788-1

Page 25

SECTION V

MAINTENANCE

TM 11-6625-1538-15

5-1. INTRODUCTION.

5-2. This section contains information necessary to

maintain the Model 400 E/EL. The following paragraphs describe the Preventive Maintenance, the

Performance Checks, the Calibration Procedures,

and the Troubleshooting Procedures.

5-3.

REQUIRED EQUIPMENT

5-4. Table 5-1 is a list of the equipment required to

properly maintain the Model 400E/EL. If the model

recommended in Table 5-1 is not available, a substitute may be used as long as it meets the required

specifications

5-4.1. PREVENTIVE MAINTENANCE

NOTE

Refer to TM 750-244-2 for proper

procedures for destruction of this

equipment to prevent enemy use.

a. Operator/crew preventive maintenance is

the systematic care, servicing and inspection

of equipment to prevent the occurrence of

trouble, to reduce downtime, and to maintain equipment in serviceable condition, To

be sure that your voltmeter is always ready

for your mission, you must do scheduled

preventive maintenance checks and services

(PMCS).

(1) BEFORE OPERATION, perform your B

PMCS to be sure that your equipment is

ready to go.

(2) When an item of equipment is reinstalled

after removal, for any reason, perform

the necessary B PMCS (para 5-4.2) to be

sure the item meets the readiness report ing criteria.

(3) Use the ITEM NO. column in the PMCS

table to get the number to be used in the

TM ITEM NO. column on DA Form 2404

(Equipment Inspection and Maintenance

Worksheet) when you fill out the form.

b. There are no organizational PMCS to be

performed.

c. Routine checks like CLEANING, DUSTING,

WASHING, CHECKING FOR FRAYED

CABLES, STOWING ITEMS NOT IN USE,

COVERING UNUSED RECEPTACLES,

CHECKING FOR LOOSE NUTS AND

BOLTS, AND CHECKING FOR COMPLETENESS, are not listed as PMCS checks.

They are things that you should do any time

you see they must be done. If you find a

routine check like one of those listed in your

PMCS, it is because other operators reported

problems with this item.

NOTE

When you are doing any PMCS or

routine checks, keep in mind the

warnings and cautions.

WARNINGS

Adequate ventilation should be

provided while using TRICHLOROTRIFLUOROETHANE. Prolonged breathing of vapor should

be avoided. The solvent should

not be used near heat or open

flame, the products of decomposition are toxic and irritating.

Since TRICHLOROTRIFLUOROETHANE dissolves natural oils,

prolonged contact with skin

should be avoided When necessary, use gloves which the solvent

cannot penetrate. If the solvent

is taken internally, consult a

physician immediately.

NOTES

The PROCEDURES column in

your PMCS charts instruct how to

perform the required checks and

services. Carefully follow these

instructions and, if tools are needed

or the chart so instructs, get

organizational maintenance to do

the necessary work.

If your equipment must be in

operation all the time, check those

items that can be checks and serviced without disturbing operation.

Make the complete checks and

services when the equipment can

be shut down.

d. Deficiencies that cannot be corrected must

be reported to higher category maintenance

personnel. Records and reports of preventive maintenance must be made in accordance with procedures given in TM

38-750.

NOTE

The checks in the interval column

are to be performed in the order

listed.

Change 2

5.1

Page 26

TM 11-6625-1538-15

5-4.2. OPERATOR/CREW PREVENTIVE MAINTENANCE

CHECKS AND SERVICES CHART

B — Before

Equipment is not

Ready/Available

Available equipment is

insufficient to support

the combat mission.

Item

No.

1

Interval

B

●

Item to be

Inspected

Mission

Essential

Equipment

Procedures – Check for and have

repaired or adjusted as

necessary

Check for completeness and satis-

factory condition of the equipment. Report missing items.

.

*Do this check before each deployment to a mission location.

be corrected before the mission starts, The check does not need to be done again until redeployment.

MECHANICAL ZERO ADJUST (400E Only).

5-5.

5-6. Before any performance checks or calibration

is begun, complete the mechanical zero adjustment

in the following steps:

Be sure the meter has been off for at least

a.

one minute,

Rotate mechanical adjustment screw CLOCK-

b.

WISE until meter pointer is to the left of zero

and moving upscale toward zero.

c.

Continue to rotate adjustment screw clockwise.

STOP when needle is exactly on zero. If needle overshoots, repeat step b.

When pointer is exactly over zero, rotate

d.

adjustment screw slightly COUNTERCLOCKWISE to relieve tension on suspension. If the

pointer moves to the left, repeat whole procedure, but make counterclockwise rotation

less.

5-7.

PERFORMANCE CHECKS.

5-8. The performance checks are ‘in cabinet’ tests

that compare the 400E/EL with its specifications.

These procedures can be used for both incoming inspection and periodic inspection.

5-9. ACCURACY AND FREQUENCY RESPONSE

TEST.

sponse of the test oscillator to within 0.2% over its

entire band. Construct the 0 to 10 mv Reference Sup

ply shown in Figure 5-1 and allow it at least 24 hours

to stabilize.

5-12. REFERENCE SUPPLY CALIBRATION.

5-13. Using the following procedure to calibrate the

thermal converter and reference supply.

a. Connect the dc standard, the 400E/EL, the

This will permit any existing problems to

NOTE

The test oscillator used must have

very low distortion (< 170). A

thermal converter and an average

responding circuit react differently

to distortion, and any distortion

present would create a calibration

error.

null voltmeter, the reference supply, and a

3 volt thermal converter as shown in Figure

5-1. Set switch S1 to position A connecting the dc standard output to the thermal

converter input. The reference supply and

the thermal converter are sensitive to variations in ambient temperature. Ensure that

the ambient temperature variations are

less than ±2.0°C.

If:

5-10. The accuracy and frequency response test compares the Model 400E/EL with its accuracy specifications over the entire frequency range. For this test,

a stable voltage reference and an extremely flat broad

band signal generator are needed.

5-11. The test setup in Figure 5-1 uses a thermal con-

verter with a null circuit to adjust the frequency re-

5-2

Change 2

NOTE

If a 400E/EL Option 02 instrument

is used, set the REL. REF adjustment to the fully clockwise ABSOL-

UTE position before making accuracy check.

Page 27

TM 11-6625-1538-15

Model 400E/EL

Figure 5-1. Accuracy and Frequency Response Test Setup

b. Set the dc standard output to +3.000 volts dc.

c. Using the null voltmeter, adjust the reference

supply until its output is within ±l.5 micro-

volt of the thermal converter output.

5-14. MODEL 400E/EL ACCURACY TEST.

5-15. Check the 400E/EL accuracy and frequency

response according to the following steps.

CAUTION

SET TEST OSCILLATOR OUTPUT TO MINIMUM BEFORE

CONNECTING. REDUCE OSCILLATOR OUTPUT BEFORE

CHANGING FREQUENCY RANGE

DO NOT ALLOW OSCILLATOR

OUTPUT TO EXCEED RATED

INPUT OF THERMAL CONVERTER.

ANY OVERLOAD MAY DESTROY

THERMAL CONVERTER.

:

a.

Set switch S-1 in figure 5-1 to position B, connecting the test oscillator to the thermal converter input. Connect the digital voltmeter to

the 400E/EL DC OUTPUT terminals.

b.

Set the 400E/EL Range Switch to 3 volts and

set the oscillator frequency to 10 Hz.

c.

Using the oscillator amplitude control as

coarse adjustment and resistor R4 (Figure 5-1)

as fine adjustment, increase the oscillator

amplitude until the thermal converter output

nulls the reference supply. Observe the

400E/EL meter indication and dc output.

d.

Repeat steps b and c for each frequency listed

in Table 5-2. If the 400E/EL is within speci-

fications, the meter indication and the dc out-

put will be within the tolerances listed in

Table 5-2.

e.

Repeat the procedure in Paragraph 5-1l using

a 1 volt thermal converter and a 1 volt output

from the dc standard.

f.

Repeat steps a through d in this paragraph

using the one volt thermal converter. Set the

400E/EL to the 1 volt range.

Change 2

5-2.1

Page 28

TM 11-6625-1538-15

5-16. RANGE TRACKING TEST.

5-17. The range tracking test checks the accuracy of

the 400E/EL with a 1/3 scale input over its entire

frequency range.

5-18. After verifying the full scale calibration with

the accuracy test in Paragraph 5-13, check the range

tracking with the following procedures.

a. Connect the dc standard, 3 volt thermal con-

verter, dc null voltmeter, and reference sup

ply as shown in Figure 5-1.

b. Set the dc standard output to +3.000 volts dc,

and adjust the reference supply output to null

the thermal converter output.

CAUTION

SET TEST OSCILLATOR OUTPUT

TO MINIMUM BEFORE CON–

NECTING. REDUCE OSCILLATOR

OUTPUT BEFORE CHANGING

FREQUENCY RANGE. DO NOT

5-2.2

Change 2

Page 29

Model 400E/EL

FREQUENCY Hz

10

40

100

1000

10 K

100 K

lM

2M

4M

10 M

TM 11-6625-1538-15

Paragraphs 5-19 to 5-20 and Tables 5-2 to 5-3

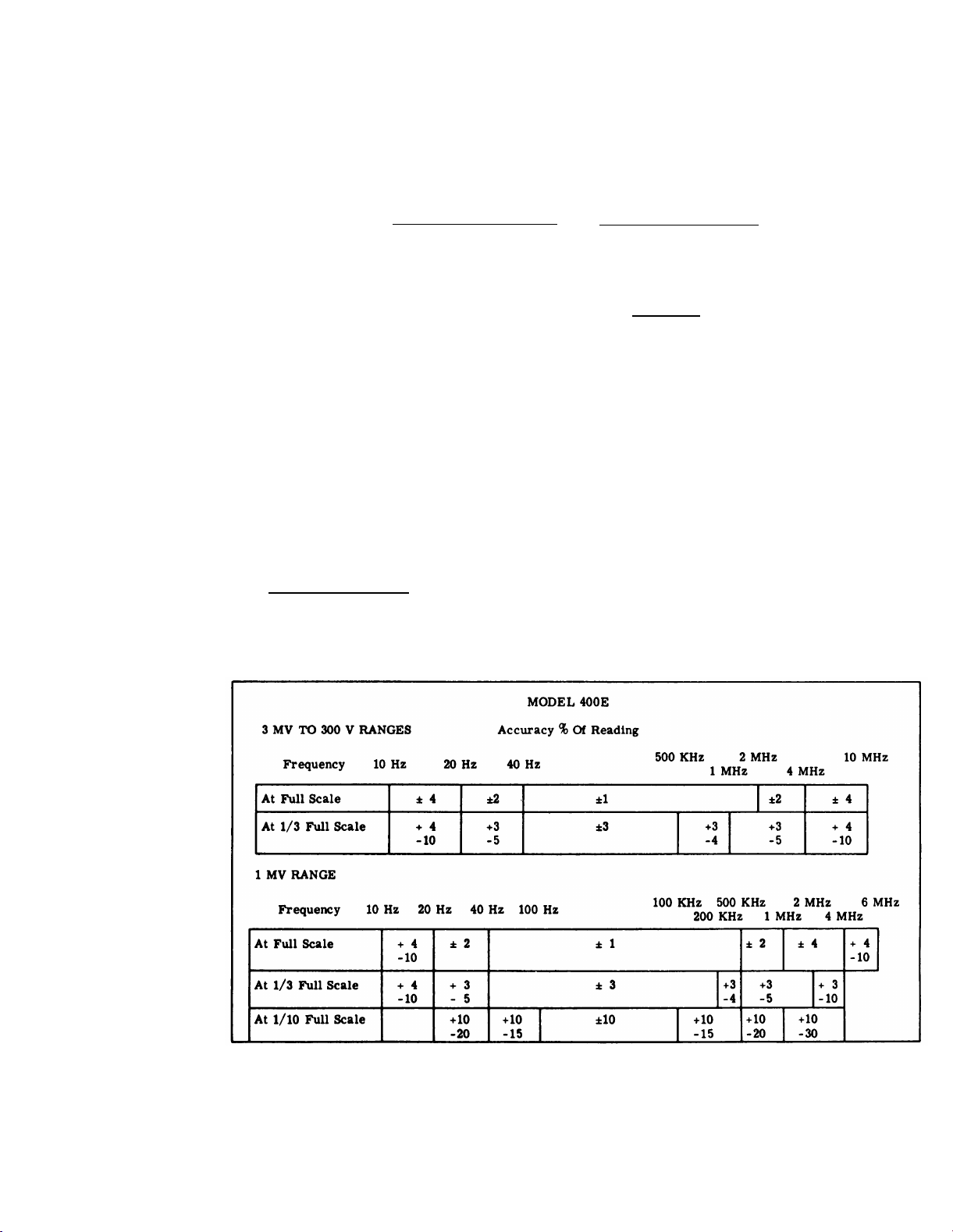

Table 5-2. Calibration Tolerant es

3 VOLT RANGE 1 VOLT RANGE

METER

READING OUTPUT

MIN

2.88 3.12 0.911 0.987

2.94 3.06

2.97 3.03

2.97 3.03

2.97 3.03 0.940 0.958 10 K 0.99

2.97

2.97 3.03

2.97 3.03 0.940 0.958 2M 0.99 1.01

2.94

2.88 3.12 0.911 0.987 10 M 0.96

MAX

3.03

3.06

DC

MIN

0.930 0.968

0.940

0.940

0.940 0.958 100 K 0.99 1.01

0.940

0.930 0.968

MAX

0.958

0.958

0.958 lM 0.99 1.01 0.990

FREQUENCY Hz

10

40

100

1000

4M 0.98

METER

READING OUTPUT

MIN

0.96 1.04 0.960

0.96

0.99

0.99

MAX

1.02

1.01 0.990

1.01

1.01

1.02 0.980

1.04

MIN

0.960

0.995

0.995

0.995

0.990

0.960

Section V

DC

MAX

1.040

1.020

1.010

1.005

1.005

1.005

1.010

1.010

1.020

1.040

c.

Disconnect the dc standard, and connect the

test oscillator, the digital voltmeter, and the

400E/EL as shown in Figure 5-1.

d.

Set the 400E/EL RANGE switch to 10 volts

and the oscillator to 10 Hz.

e.

Using the oscillator amplitude control as

coarse adjustment and resistor R4 as a fine

adjustment, set the oscillator output so that

the thermal converter output nulls the reference supply output.

f.

Repeat steps band c for each frequency listed

in Table 5-3 (400E) or Table 5-4 (400EL). If

the 400E/EL is within specifications, the meter

indication and the dc output will be within the

tolerances listed in the tables.

FREQUENCY Hz

100

1000

500 K

01788-1

ALLOW OSCILI.ATOR OUTPUT

TO EXCEED RATED INPUT OF

THERMAL CONVERTER. ANY

OVERLOAD MAY DESTROY 400E/EL to the 3 volt range.

THERMAL CONVERTER.

Table 5-3. 1/3 Scale Tracking Tolerances (400E)

10 VOLT RANGE

METER DC

READING OUTPUT

MAx MIN MAX

0.270

3.09

3.09 0.291 0.309

3.09 0.291

3.09

3.09

3.09

3.12 0.270 0.312

0.291

0.291

0.288

0.285

0.312

0.309

0.309 1000

0.309

0.309 500 K

0.309

0.309

10

40

10 K

lM

4M

10 M

MIN

2.70 3.12

2.85

2.91

2.91

2.91 3.09 0.291

2.91

2.88

2.85

2.70

g. Repeat steps a through fin this paragraph using

a 1 volt thermal converter and a +1.000 volt

dc output from the dc standard. Set the

5-19. INPUT IMPEDANCE CHECK.

5-20. INPUT RESISTANCE CHECK.

a.

Connect the 50

to the input of the 400E/EL.

Set the test oscillator and the 400E/EL to the

b.

3 volt range.

Hz, and adjust the output for a full scale indication.

c.

Connect a 100 K

oscillator output and the 400E/EL input as

shown in Figure 5-2.

The 400E/EL indication should not drop more

d.

than one small scale division from full scale.

This verifies an input resistance of 10 M

3 VOLT RANGE

FREQUENCY Hz READING OUTPUT

10

40

100

10 K

lM 0.96 1.03 0.304

4M 0.95 1.03 0.301

10 M 0.90

Ω output of the test oscillator

Set the oscillator output to 40

Ω resistor between the test

METER

MIN MAX

0.90 1.04 0.285 0.328

0.95 1.03 0.301 0.325

0.97 1.03

0.97

0.97 1.03 0.307 0.325

0.97 1.03 0.307

1.03

1.04 0.285 0.328

DC

MIN

0.307 0.325

0.307

MAX

0.325

0.325

0.325

0.325

Ω.

5-3

Page 30

TM 11-6625-1538-15

Section V

Paragraphs 5-21 to 5-31 and Table 5-4 and Figure 5-2

Table 5-4. 1/3 Scale Tracking Tolerances (400 EL)

Model 400E/EL

FREQUENCY Hz

10

40

100

1000

,

10 K

500 K 2.94 3.06 0.294 0.306 500 K 0.98

10 M

lM

4M

10 VOLT RANGE

METER

READING

MIN MAX MIN

2.70

2.96

2.96

2.96

2.96

2.94 3.06 0.294

2.88

2.70

3.12

3.04 0.297 0.303

3.04

3.04 0.297 0.303

3.04

3.06 0.288

3.07 0.270 0.309 10 M 0.90

OUTPUT

0.270

0.297

0.297

DC

MAX MIN

0.312

0.303

0.303 10 K 0.98

0.306

0.306

FREQUENCY Hz READING OUTPUT

10

40

100

1000

lM

4M

3 VOLT RANGE

METER

MAX MIN

0.90 1.04 0.284 0.304

0.98 1.02 0.311

0.98 1.02 0.311

0.98 1.02

1.02 0.311 0.321

1.02 0.311 0.321

0.98

0.96

1.02 0.310 0.322

1.02 0.304 0.322

1.03 0.284 0.325

DC

0.311

MAX

0.321

0.321

0.321

5-21. INPUT CAPACITY CHECK.

a.

Connect a test oscillator, a 100 K

and the 400E/EL as shown in Figure 5-2. Insert the resistor lead directly into the BNC

connector on the 400E/EL, and connect the

ground lead to the outer shield of the 400E/EL

input connector. Do not use an adapter, as

any adapter will add input capacity.

With the 400E/EL on the 3 volt range, adjust

b.

the test oscillator for a full scale reading on

the 400E/EL at 40 Hz.

Increase the test oscillator frequency until

c.

the 400E/EL indication drops to 2.12 volts.

This should occur at a frequency of 180 KHz

or greater, verifying an input capacity of 8

pf or less on the 3 volt range.

d.

Repeat steps a and b with the 400E/EL on the

1 volt range.

Increase the test oscillator frequency until

e.

the 400E/EL indication drops to 0.707 volts.

This should occur at a frequency of 72 KHz

or greater, verifying an input capacity of 21

pf or less on the 1 volt range.

ALIGNMENT AND CALIBRATION

5-22.

PROCEDURE.

5-23. The calibration adjustments are “cover off”

procedures to adjust the 400E/EL to its performance

5-4

Figure 5-2. Input Impedance Check

Ω resistor,

specifications.

adjusted, refer to the Troubleshooting Procedures

(Paragraph 5-34). Figure 5-3 shows the location of

all the internal adjustments.

5-24. COVER REMOVAL.

5-25. To remove the top or bottom covers, remove

the Phillips screw at the rear of the cover, slide the

cover about 1 inch to the rear, and lift if off. To replace the cover, reverse the removal procedure.

5-26. To remove a side cover, remove the four Phillips

screws and lift it off.

5-27. BIAS ADJUST.

5-28. Connect a dc voltmeter (410C) to TP3 and adjust

A2R17 for -6.0 ±0.25 vdc. Connect a dc voltmeter

to TP4 and adjust A2R31 for +10.0 ±0.5 vdc.

5-29. AC OUTPUT ZERO.

5-30. Connect a dc voltmeter (410C) to TP5 and adjust

A2R59 for 0.0 ±0.050 vdc.

5-31. CALIBRATION.

If the instrument cannot be properly

NOTE

If a 400E/EL Otpion 02 is to be

calibrated, set the REL. REF

adjustment to the fully clockwise

ABSOLUTE position before beginning the calibration.

01788-1

Page 31

Model 400E/EL

TM 11-6625-1538-15

Section V

Paragraphs 5-32 to 5-35 and Figure 5-3

Figure 5-3. Location of Internal Adjustments

5-32. LOW AND HIGH FREQUENCY CALIBRATION.

a. Calibrate the reference supply in Figure 5-1

with a 1 volt thermal converter according to

the steps in Paragraph 5-10.

b.

Disconnect the dc standard and connect the

test oscillator, the 400E/EL, and the digital

voltmeter as shown in Figure 5-1. Set the

oscillator frequency to 400 Hz and the 400E/EL

to the 1 volt range. Using the amplitude control as coarse adjustment and R4 as fine adjustment, increase the oscillator output until

the thermal converter output nulls the ref-

erence supply.

Adjust A2R38 for a 400E/EL meter reading

c.

of 1.004.01 volts.

Adjust R2 for a digital voltmeter display of

d.

1.000 ±0.005 vdc.

e.

Lower test oscillator output and set frequency

to 10 MHz. Readjust oscillator amplitude

until thermal converter output nulls reference

Supply.

Adjust A2C28 for digital voltmeter display of

f.

1.000 ±0.04.

5-33. ATTENUATOR ALIGNMENT.

a. Use the setup shown in Figure 5-1 to align the

attenuator. Calibrate the reference supply

according to the procedures in Paragraph 5-10

using a 3 volt thermal converter.

01788-1

SET TEST OSCILLATOR OUTPUT

TO MINIMUM BE FORE CONNECTING. REDUCE OSCILLATOR

OUTPUT BEFORE CHANGING

FREQUENCY RANGE. DO NOT

ALLOW OSCILLATOR OUTPUT

TO EXCEED RATED INPUT OF

THERMAL CONVERTER. ANY

OVERLOAD MAY DESTROY

THERMAL CONVERTER.

b.

Disconnect the dc standard and connect the

test oscillator and 400E/EL as shown in Figure 5-1. Set the oscillator frequent y to 100

KHz and the 400E/EL to the 3 volt range.

Using the amplitude control as coarse adjustment and R4 as fine adjustment, increase the

oscillator output until the thermal converter

output nulls the reference supply.

Adjust A1C1 in the 400E/EL for a meter

c.

reading of 3.00 volts.

5-34.

5-35. When the 400E/EL operates improperly, first

determine if it is adjusted improperly or if a circuit

is malfunctioning by adjusting and calibrating the instrument according to the procedures in Paragraph 5-22.

with the troubleshooting steps.

TROUBLESHOOTING.

If calibration is impossible, proceed

5-5

Page 32

TM 11-6625-1538-15

Section V

Paragraphs 5-36 to 5-47 and Tables 5-5 to 5-9

5-36. Check the instrument for any obvious evidence

of trouble, such as loose or broken wires or broken

connectors. Check the printed circuit boards for

separations

clean.

5-37. First isolate the trouble to a particular circuit

using the block diagram (Figure 4- 1) and the schematic

(Figure 6- 1). Table 5-5 lists some likely troubles

and their probable causes. Then refer to the trouble-

shooting steps for that circuit.

No response to input.

Instrument will not up-

range above 1 volt, but

works on 1 volt range

and below.

Instrument will not

downrange below 3 v,

but works on 3 v range

and above.

TP3 voltage cannot be

properly adjusted.

or cracks and ensure that all pins are

NOTE

The test voltages shown in this

section are nominal. A tolerance

of ±5% is allowable.

Table 5-5. Troubleshooting Guide

SYMPTOM

PROBABLE TROUBLE

Fuse A2F1 open.

Relay K1 stuck closed.

Relay K2 stuck closed.

Impedance Converter

(A2Q5, 6, and 7).

Model 400E/EL

5-42. If the voltage at pin 22 is low, pull the wht/orn/

yel wire from pin 22,

the wire. It should be 3 mv. If the voltage on the

wire is proper, the trouble is in the meter amplifier

If it isn’t correct, the trouble is either in the Post

Attenuator or the Impedance Converter.

5-43. To check the Impedance Converter, measure the

ac voltage at its output (A2 pin 21). The output voltage

should be very close to the input voltage since the Im-

pedance Converter is a unity gain amplifier. With a

1 volt input, the output should be 0.98 volts ±0.02 volts.

5-44. Both the Impedance Converter and the meter

amplifier are internally dc coupled. If the dc voltages

anywhere in the amplifier are incorrect, the amplifier

won’t operate properly.

dc voltages is a good check of the amplifiers.

5-45. Tables 5-7 and 5-8 contain the dc voltages on

all of the transistors in the meter amplifier and the

Impedance Converter.

given transistor is wrong, the trouble is probably in

that transistor or its associated circuit.

Measure these dc voltages with

the in,put shorted. A dc voltmeter

with low input capacitance and

very high input resistance must

be used. The -hp- Model 410C

is recommended.

Table 5-7. Impedance Converter Voltages

and measure the ac signal at

Consequently a check of the

If the measured voltage on a

NOTE

properly adjusted.

5-38. POWER SUPPLY.

5-39. Check with a dc voltmeter (410C) at TP1 and

TP2 for +26 volts and -26 volts respectively. If the

TP voltages are improper, check the voltages listed

in Table 5-6. If the voltage for a given component

is wrong, the trouble is probably in that component

or its associated circuit.

Table 5-6.

COMPONENT

Collector Q1

Collector Q2

Emitter Q2

Base Q3

Collector Q3

Collector Q4

5-40. AMPLIFIERS.

5-41. Set the 400E/EL to the 1 volt range, and connect

a full scale input. With a sensitive ac voltmeter,

monitor the ac amplifier output at the negative side of

A2C34 or A2C36. The output should be 150 mv. If

it is not 150 mv, measure the ac voltage at A2 pin 22.

The voltage at pin 22 should be 3 mv. If these two

voltage readings are correct, the meter amplifier and

meter bridge are operating properly.

- 13).

Power Supply Voltages

VOLTAGE

I

+39 v

+26. 5 v

+6.98 v

-0.6 v

-23.5 v

-39 v

5-6

TRANSISTOR E

Q5

Q6

Q7

Table 5-8. Meter Amplifier Voltages

TRANSISTOR

Q8

Q9

Q1O

Qll +1.25 v

Q12

Q13

Q14* - 0.45 v

5-46. AC OUTPUT CIRCUIT.

5-47. To check the ac output circuit, measure the dc

voltages at the points shown in Table 5-9. If a given

measured voltage is incorrect, the trouble is probably

in that component or its associated circuit.

Table 5-9. AC Voltage Output Circuit

TRANSISTOR

Q15 +0. 68 v

916 0

(S)-6 v

-15 v

- 6.7 v

* Cannot be measured.

E

+22. 25 v

+0.02 v

+ 8.2 v

+9

+0.27 v

* In bridge circuit.

E B

B

(G) *

-14.3v - 7.4v

- 7.4v

B

+23 v +25. 5 v

+0.57 v

+7.5 v +1.8 v

+1.8 v

+8

v

v

0

+ 0.02 v

+1.3 v

+0. 66 v

c

(D) 14. 4V

-21.5v

c

+7.5 v

+8 v

+0.27 v

-6.2 v

+26 v

c

+4. 6 V

+4. 6 V

01788-1

Page 33

TM 11-6625-1538-15

Model 400E/EL

5-48. ADJUSTMENT OF FACTORY SELECTED

COMPONENTS.

5-49. Certain components within the Model 400E/EL are

individually selected in order to compensate for slightly

varying circuit parameters. These components are

denoted by an asterisk (*) on the schematic, and the

typical value is shown.

function of the factory selected components and gives

instruct ions for their select ion.

components do not need to be changed unless another

associated component is changed. Replacement of a

transistor, for example, may require the changing

of a factory selected component.

Table 5-10 describes the

Normally, these

Paragraphs 5-48 to 5-49 and Table 5-10

Table 5-10. Factory Selected Components

COMPONENT FUNCTION AND SELECTION

A2C12*

A2C31*

A2R44*

S2C4*

56 to 110 pf. Adjusts 2 MHz re-

sponse of impedance converter.

With consistently high readings at

2 MHz on 1 volt range, decrease

A2C12.

18 to 22 pf. Adjusts 10 Hz re-

sponse on 3 volt range. With con-

sistently low readings at 10 Hz on

3 volt range, decrease A2C31.

110-182

sponse on the 1 mv range. With

consistently low readings, decrease A2R44.

1.8 to 6.8 pf. Adjusts 10 Hz response on 1 mv and 3 mv range.

With consistently high readings at

10 Hz on 3 mv or 1 mv range, decrease S2C4.

Ω. Adjusts 400 Hz re-

Section V

01788-1

5-7

Page 34

Page 35

TM 11-6625-1538-15

Model 400E/EL

SECTION VI

CIRCUIT DIAGRAMS

6-1. INTRODUCTION.

6-2. This section contains the circuit diagrams necessary for maintenance of the Model 400E/EL. A

Paragraphs 6-1 to 6-2

Section VI

schematic, a component location drawing, and a diagram of the RANGE switch are included. Location

grids are drawn on the more complicated diagrams

making the search for individual components easier.

01788-1

6-1

Page 36

TM 11-6625-1538-15

Section VI

Figure 6-1

Model 400E/EL

6-2

p/o Figure 6-1.

400E/EL Schematic Diagram and Location of Components

01789-1

Page 37

APPENDIX A

REFERENCES

TM 11-6625-1538-15

DA Pam 310-1

TM 11-6626-1538-24P

TM 38-740

TM 740-90-1

TM 750-244-2

Consolidated Index of Army Publications and Blank Forms.

Organizational, Direct Support, and General Support Maintenance Repair Parts

and Special Tools List for Voltmeters, AN/USM-265 (NSN 6625-00-935-

4294), ME-459 (6625-00-229-4457) and ME-465 (6625-00-995-7716).

The Army Maintenance Management System (TAMMS).

Administrative Storage of Equipment.

Procedures for Destruction of Electronics Materiel to Prevent Enemy Use.

Change 2

A-1/(A-2 blank)

Page 38

Page 39

APPENDIX D

MAINTENANCE ALLOCATION

Section I. INTRODUCTION

TM 11-6625-1538-15

D-1. General

This appendix provides a summary of the

maintenance operations for AC Voltmeter

AN/USM-265, ME-459, and ME-465. It au-

thorizes categories of maintenance for specific

maintenance functions on repairable items and

components and the tools and equipment required to perform each function. This appendix

may be used as an aid in planning maintenance

operations.

D-2. Maintenance Function

Maintenance functions will be limited to and

defined as follows:

a. Inspect. To determine the serviceability of

an item by comparing its physical, mechanical,

and/or electrical characteristics with established standards through examination.

b. Test. To verify serviceability and to detect

incipient failure by measuring the mechanical

or electrical characteristics of an item and

comparing those characteristics with prescribed

standards.

c. Service. Operations required periodically to

keep an item in proper operating condition, i.e.,

to clean (decontaminate), to preserve, to drain,

to paint, or to replenish fuel, lubricants, hydraulic fluids, or compressed air supplies.

d. Adjust. To maintain, within prescribed

limits, by bringing into proper or exact position,

or by setting the operating characteristics to the

specified parameters.

e. Align. To adjust specified variable elements

of an item to bring about optimum or desired

performance.

f. Calibrate. To determine and cause corrections to be made or to be adjusted on instruments or test measuring and diagnostic

equipments used in precision measurement.

Consists of comparisons of two instruments, one

of which is a certified standard of known

accuracy, to detect and adjust any discrepancy

in the accuracy of the instrument being compared.

g. Install.

fixing into

(component

the proper

system.

h. Replace. The act of substituting a service-

able like type part, subassembly, or module

(component or assembly) for an unserviceable

counterpart.

i. Repair. The application of maintenance

services (inspect, test, service, adjust, align,

calibrate, replace) or other maintenance actions

(welding, grinding, riveting, straightening,

facing, remachining, or resurfacing) to restore

serviceability to an item by correcting specific

damage, fault, malfunction, or failure in a part,

subassembly, module (component or assembly),

end item, or system.

.j. Overhaul.

(service/action) necessary to restore an item to a

completely serviceable/operational condition as

prescribed by maintenance standards (i.e.,

DMWR) in appropriate technical publications.

Overhaul is normally the highest degree of

maintenance performed by the Army. Overhaul

does not normally return an item to like new

condition.

k. Rebuild. Consists of those services/actions

necessary for the restoration of unserviceable

equipment to a like new condition in accordance

with original manufacturing standards. Rebuild is the highest degree of materiel maintenance applied to Army equipment. The rebuild

operation includes the act of returning to zero

those age measurements (hours, miles, etc.)

considered in classifying Army equipments/

components.

The act of emplacing, seating, or

position an item, part, module

or assembly) in a manner to allow

functioning of the equipment or

That maintenance effort

D-3. Column Entries

a. Column 1, Group Number. Column 1 lists

group numbers, the purpose of which is to

identify components, assemblies, subas-

semblies, and modules with the next higher

assembly.

Change1 D-1

Page 40

TM 11-6625-1538-15

b. Column 2, Component/Assembly. Column 2

contains the noun names of components, assemblies, subassemblies, and modules for which

maintenance is authorized.

c. Column 3, Maintenance Functions. Column

3 lists the functions to be performed on the item

listed in column 2. When items are listed without

maintenance functions, it is solely for purpose of

having the group numbers in the MAC and

RPSTL coincide.

d. Column 4, Maintenance Category. Column 4

specifies, by the listing of a “work time” figure in

the appropriate subcolumns(s), the lowest level

of maintenance authorized to perform the

function listed in column 3. This figure represents the active time required to perform that

maintenance function at the indicated category

of maintenance. If the number or complexity of

the tasks within the listed maintenance function vary at different maintenance categories,

appropriate “work time” figures will be shown

for each category. The number of task-hours

specified by the “work time” figure represent

the average time required to restore an item

(assembly, subassembly, component, module,

end item or system) to a serviceable condition

under typical field operating conditions. This

time includes preparation time, troubleshooting

time, and quality assurance/quality control time

in addition to the time required to perform the

specific tasks identified for the maintenance

functions authorized in the maintenance allocation chart. Subcolumns of column 4 are as

follows:

C

— Operator/Crew

O

— Organizational

F — Direct Support

H — General Support

D — Depot

e. Column 5, Tools and Equipment. Column 5

specifies by code, those common tool sets (not

individual tools) and special tools, test, and

support equipment required to perform the

designated function.

f. Column 6, Remarks. Not applicable.

D-4. Tool and Test Equipment Require-

ments (See Ill)

a. Tool or Test Equipment Reference Code. The

numbers in this column coincide with the

numbers used in the tools and equipment

column of the MAC. The numbers indicate the

applicable tool or test equipment for the main-

tenance functions.

b. Maintenance Category. The codes in this

column indicate the maintenance category

allocated the tool or test equipment.

c. Nomenclature. This column lists the noun

name and nomenclature of the tools and test

equipment required to perform the maintenance functions.

d. National/NATO Stock Number. This column

lists the National/NATO stock number of the

specific tool or test equipment.

e. Tool Number. Not applicable.

D-5. Remarks (See IV)

a. Reference Code. This code refers to the

appropriate item in section II, column 6.

b. Remarks. This column provides the re-

quired explanatory information necessary to

clarify items appearing in section II.

D-2

(Next printed page is D-3.)

Change 1