Page 1

HP BladeSystem p-Class Enclosure

Installation Guide

March 2005 (Second Edition)

Part Number 354556-002

Page 2

© Copyright 2005 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

March 2005 (Second Edition)

Part Number 354556-002

Page 3

3

Contents

Planning the installation 7

Rack requirements................................................................................................................................7

Warnings, cautions, and importants..................................................................................................... 8

Space and airflow requirements......................................................................................................... 11

Temperature requirements ................................................................................................................. 12

Power requirements............................................................................................................................12

Grounding requirements ....................................................................................................................13

Installing HP BladeSystem p-Class enclosures 15

Installation overview.......................................................................................................................... 15

Measuring with the rack template...................................................................................................... 16

Installing the rack rails and cage nuts ................................................................................................ 16

Installing the HP BladeSystem p-Class 1U Power Enclosure rack rails................................. 17

Installing the rack rails (3U power supply and server blade enclosures)................................17

Installing the cage nuts ...........................................................................................................20

Installing HP BladeSystem p-Class enclosures into the rack............................................................. 20

Installing HP BladeSystem p-Class 1U Power Enclosures.....................................................21

Identifying HP BladeSystem p-Class 1U Power Supply Enclosure bays............................... 21

Installing an HP BladeSystem 1U Power Supply................................................................... 22

Installing HP BladeSystem p-Class 3U Power Enclosures.....................................................23

Identifying HP BladeSystem p-Class 3U Power Enclosure bays ...........................................23

Installing an HP BladeSystem 3U Power Supply................................................................... 24

Installing HP BladeSystem p-Class Server Blade Enclosures................................................ 25

Installing interconnects ......................................................................................................................25

Installing HP BladeSystem interconnect modules and RJ-45 patch panels............................26

Installing HP BladeSystem interconnect modules and interconnect switches........................27

Cabling and powering up the system 29

System cabling overview ...................................................................................................................29

Identifying HP BladeSystem p-Class 1U Power Enclosure components...........................................31

Identifying HP BladeSystem p-Class 3U Power Enclosure and Server Blade Enclosure components32

Installing power distribution devices ................................................................................................. 33

Installing a scalable bus bar kit...............................................................................................35

Installing a mini bus bar kit ....................................................................................................36

Installing a power bus box......................................................................................................36

Installing the power connectors.............................................................................................. 38

Cabling the management modules .....................................................................................................39

Page 4

4 HP BladeSystem p-Class Enclosure Installation Guide

Management cabling guidelines ............................................................................................. 39

Additional guidelines for a 42U solution................................................................................ 40

Connecting the management module cables........................................................................... 40

Connecting the HP BladeSystem p-Class 1U Management Link Cable.................................42

Connecting to iLO ..................................................................................................................43

Cabling the network to the system..................................................................................................... 43

Connecting the HP BladeSystem p-Class 1U DC power cable to the server blade enclosure ...........44

Connecting power cables to a mini bus bar........................................................................................44

Removing the mini bus bar cover...........................................................................................45

Connecting power cables to the mini bus bar......................................................................... 45

Replacing the mini bus bar cover ...........................................................................................46

Securing the mini bus bars......................................................................................................47

Connecting power cables to a scalable bus bar..................................................................................47

Removing the scalable bus bar covers.................................................................................... 48

Connecting power cables to the scalable bus bar....................................................................48

Replacing the scalable bus bar cover...................................................................................... 49

Securing the scalable bus bars................................................................................................50

Connecting the load-balancing signal cable ...........................................................................50

Connecting facility DC power to the power distribution bus bars .....................................................51

Installing the cable bracket ................................................................................................................52

Configuration examples .....................................................................................................................52

Scalable bus bar configuration example .................................................................................53

Two mini bus bar configuration example...............................................................................54

Redundant mini bus bar configuration example .....................................................................55

Full rack 42U solution with two pairs of mini bus bars.......................................................... 56

Configuring the Dynamic Power Saver.................................................................................. 57

Powering up the system .....................................................................................................................59

Powering up the system (HP BladeSystem p-Class 1U Power Enclosure).............................59

Powering up the system (HP BladeSystem p-Class 3U Power Enclosure).............................60

Powering up the system (facility DC).....................................................................................61

Completing the installation ................................................................................................................62

LEDs, buttons, and switches 63

LEDs ..................................................................................................................................................63

Server blade enclosure LEDs..................................................................................................63

Server blade management module LEDs................................................................................64

Power management module LEDs ......................................................................................... 65

HP BladeSystem p-Class 1U Power Enclosure LEDs............................................................ 67

HP BladeSystem p-Class 3U Power Enclosure LEDs............................................................ 69

HP BladeSystem p-Class 1U Power Supply LEDs.................................................................70

HP BladeSystem p-Class 3U Power Supply LEDs.................................................................71

Buttons and switches..........................................................................................................................71

Reset and UID buttons............................................................................................................72

Power configuration switches................................................................................................. 72

Page 5

Contents 5

Troubleshooting 77

Troubleshooting resources .................................................................................................................77

Important safety information..............................................................................................................77

Symbols on equipment ...........................................................................................................78

Warnings and cautions............................................................................................................79

Regulatory compliance notices 83

Regulatory compliance identification numbers..................................................................................83

Federal Communications Commission notice....................................................................................84

FCC rating label......................................................................................................................84

Class A equipment.................................................................................................................. 84

Class B equipment.................................................................................................................. 85

Declaration of conformity for products marked with the FCC logo, United States only...................85

Modifications .....................................................................................................................................86

Cables.................................................................................................................................................86

Canadian notice (Avis Canadien).......................................................................................................86

European Union regulatory notice .....................................................................................................87

Japanese notice...................................................................................................................................88

Power cord statement for Japan ......................................................................................................... 88

BSMI notice....................................................................................................................................... 88

Korean notice A&B ...........................................................................................................................89

Laser compliance ...............................................................................................................................89

Battery replacement notice.................................................................................................................90

Taiwan battery recycling notice......................................................................................................... 91

Electrostatic discharge 93

Preventing electrostatic discharge...................................................................................................... 93

Grounding methods to prevent electrostatic discharge ......................................................................94

Technical support 95

Before you contact HP....................................................................................................................... 95

HP contact information...................................................................................................................... 95

Acronyms and abbreviations 97

Index 103

Page 6

Page 7

7

Planning the installation

In this section

Rack requirements ..........................................................................................................................7

Warnings, cautions, and importants................................................................................................8

Space and airflow requirements ...................................................................................................11

Temperature requirements............................................................................................................12

Power requirements ......................................................................................................................12

Grounding requirements...............................................................................................................13

Rack requirements

The HP BladeSystem p-Class Server Blade Enclosure is compatible with the

following racks:

•

41U, 33U, and 25U HP Rack System/E

•

42U, 36U, and 22U Compaq branded 10000 and 9000 Series racks

NOTE: The system is optimized for 10000 Series racks.

•

Telco racks

•

Third-party rack cabinets that meet the following requirements:

– Width - 48.26 cm (19 in)

– Depth - 73.66 cm (29 in) between front and rear RETMA rails

– Clearance - 7.62 cm (3 in) minimum clearance between rear RETMA

rails and rear rack door to accommodate system cabling

– Open area - minimum of 65 percent open area to provide adequate airflow

through any rack front or rear doors

Page 8

8 HP BladeSystem p-Class Enclosure Installation Guide

Warnings, cautions, and importants

WARNING: To reduce the risk of personal injury or

damage to equipment, heed all warnings and cautions throughout

the installation instructions.

WARNING: To reduce the risk of personal injury or

damage to the equipment, be sure that:

The leveling jacks are extended to the floor. •

•

The full weight of the rack rests on the leveling jacks.

•

The stabilizing feet are attached to the rack if it is a single-rack

installation.

•

The racks are coupled together in multiple-rack installations.

•

Only one component is extended at a time. A rack may become

unstable if more than one component is extended for any

reason.

WARNING: To reduce the risk of personal injury or

equipment damage when unloading a rack:

At least two people are needed to safely unload the rack from

•

the pallet. An empty 42U rack can weigh as much as 115 kg

(253 lb), can stand more than 2.1 m (7 ft) tall, and may become

unstable when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp

from the pallet. Always handle the rack from both sides.

WARNING: To reduce the risk of personal injury or

equipment damage, be sure that the rack is adequately stabilized

before extending a component from the rack.

Page 9

Planning the installation 9

WARNING: The power enclosure and the server blade

enclosure are very heavy. To reduce the risk of personal injury or

damage to the equipment:

Observe local occupational health and safety requirements and

•

guidelines for manual material handling.

• • Remove hot-plug power supplies and server blades from their

enclosures before installing or removing the enclosures.

Use caution and get help to lift and stabilize enclosures during

installation or removal, especially when the enclosure is not

fastened to the rack.

WARNING: To reduce the risk of personal injury or

damage to the equipment, you must adequately support

enclosures during installation and removal.

WARNING: Always use at least two people to lift an

enclosure into the rack. If the enclosure is being loaded into the

rack above chest level, a third person must assist with aligning the

enclosure with the rails while the other two people support the

weight of the enclosure.

WARNING: Before installing an enclosure in the rack, be

sure that all hot-plug power supplies, server blades, and

interconnects are removed from the enclosure. Blanks can be left

in the enclosure.

WARNING: Be sure to install enclosures starting from the

bottom of the rack and work your way up the rack.

These symbols, on power supplies or systems,

indicate that the equipment is supplied by multiple sources of

power.

WARNING: To reduce the risk of injury from electric shock,

remove all power cords to completely disconnect power from the

system.

Page 10

10 HP BladeSystem p-Class Enclosure Installation Guide

Each power enclosure has two or more power supply cords. A

•

single rack or cabinet may contain more than one power

enclosure. Power may be supplied in a redundant fashion.

Removing any single source of power does not necessarily

remove power from any portion of the system. When

performing any service other than hot-plug module

replacement, you must completely disconnect all power to that

portion of the system.

• • When performing service procedures on server blade

enclosures, ensure that both A and B DC power feeds are

disconnected from the enclosure before servicing.

When performing service procedures on power enclosures,

shut off the circuit breakers to both A and B AC power feeds

and then disconnect both power cords from the wall outlet

before servicing.

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the drives and the internal system components to

cool before touching them.

WARNING: To reduce the risk of electric shock or damage

to the equipment, enter enclosures or perform service on system

components only as instructed in the user documentation.

WARNING: A risk of electric shock from high leakage

current exists. Before connecting the AC supply to the power

enclosures, be sure that the electrical outlets are properly

grounded (earthed).

CAUTION: Always be sure that equipment is properly

grounded and that you follow proper grounding procedures before

beginning any installation procedure. Improper grounding can result in

ESD damage to electronic components. For more information, refer to,

"Electrostatic Discharge (on page 93

CAUTION: When performing non-hot-plug operations, you

must power down the server blade and/or the system. Use caution

when performing other operations, such as hot-plug installations or

troubleshooting.

)."

Page 11

Planning the installation 11

CAUTION: Protect the equipment from AC power fluctuations

and temporary interruptions with a regulating facility UPS device. This

device protects the hardware from damage caused by power surges

and voltage spikes and keeps the system in operation during a power

failure.

IMPORTANT: Data on the dimensions and weights of HP BladeSystem

p-Class components can be found in the HP BladeSystem p-Class

System Maintenance and Service Guide. The same data can be

determined by using the online HP BladeSystem p-Class Sizing Utility.

Space and airflow requirements

To enable servicing and ensure adequate airflow, observe the following spatial

requirements when deciding where to install an HP branded, Compaq branded,

telco, or third-party rack:

•

Leave a minimum clearance of 63.5 cm (25 in) in front of the rack.

•

Leave a minimum clearance of 76.2 cm (30 in) in back of the rack.

•

Leave a minimum clearance of 121.9 cm (48 in) from the back of the rack to

the rear of another rack or row of racks.

HP BladeSystem servers draw cool air in through the front and expel warm air

through the rear of the enclosure. Therefore, the front of the rack enclosure must

be adequately ventilated to enable ambient room air to enter the enclosure, and

the rear of the enclosure must be adequately ventilated to enable the warm air to

escape from the enclosure.

IMPORTANT: Do not block the ventilation openings.

If the front of the rack is not completely filled with components, the remaining

gaps between the components can cause changes in the airflow, which can

adversely affect cooling within the rack. Cover these gaps with blanking panels.

CAUTION: Always use blanking panels to fill empty vertical

spaces in the rack. This arrangement ensures proper airflow. Using a

rack without blanking panels results in improper cooling that can lead to

thermal damage.

Page 12

12 HP BladeSystem p-Class Enclosure Installation Guide

Compaq branded 9000 Series racks provide proper server cooling from flowthrough perforations in the front and rear doors that provide 65 percent open area

for ventilation.

CAUTION: Always use blanks to fill empty spaces in

enclosures. This arrangement ensures proper airflow. Using an

enclosure without the proper blanks results in improper cooling that can

lead to thermal damage.

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the

rack in a well ventilated, climate-controlled environment.

The operating temperature inside the rack is always higher than the room

temperature and is dependent on the configuration of equipment in the rack.

Check the TMRA for each piece of equipment before installation.

CAUTION: To reduce the risk of damage to the equipment

when installing third-party options:

• • Do not permit optional equipment to impede airflow around the

equipment or to increase the internal rack temperature beyond the

maximum allowable limits.

Do not exceed the manufacturer’s TMRA.

Power requirements

WARNING: A risk of fire or damage to the equipment

exists.

Each AC power cord for the power enclosure has an electrical

rating based on the model and power supply configuration. The

rating is marked on the side of the enclosure.

Page 13

Planning the installation 13

It is important that the system be configured according to the

guidelines in the HP BladeSystem p-Class System Overview and

Planning white paper. Failure to follow these guidelines may result

in an overload of the electrical circuits feeding the power

enclosure.

When performing system upgrades, refer to the HP BladeSystem

p-Class System Overview and Planning white paper to be sure that

the new configuration does not overload the existing power

enclosure scheme.

Installation of this equipment must comply with local and regional electrical

regulations governing the installation of IT equipment by licensed electricians.

This equipment is designed to operate in installations covered by NFPA 70, 1999

Edition (National Electric Code) and NFPA-75, 1992 (code for Protection of

Electronic Computer/Data Processing Equipment). For electrical power ratings

on options, refer to the product rating label or the user documentation supplied

with that option.

WARNING: To reduce the risk of personal injury, fire, or

damage to the equipment, do not overload the AC supply branch

circuit that provides power to the rack. Consult the electrical

authority having jurisdiction over wiring and installation

requirements of your facility.

CAUTION: Protect the equipment from power fluctuations and

temporary interruptions with a regulating UPS. This device protects the

hardware from damage caused by power surges and voltage spikes and

keeps the equipment in operation during a power failure.

Grounding requirements

This equipment must be grounded properly for proper operation and safety. In

the United States, you must install the equipment in accordance with

NFPA 70, 1999 Edition (National Electric Code), Article 250, as well as any

local and regional building codes.

In Canada, you must install the equipment in accordance with Canadian

Standards Association, CSA C22.1, Canadian Electrical Code.

Page 14

14 HP BladeSystem p-Class Enclosure Installation Guide

In all other countries, you must install the equipment in accordance with any

regional or national electrical wiring codes, such as the International

Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore,

you must be sure that all power distribution devices used in the installation, such

as branch wiring and receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with this equipment, HP

recommends the use of a PDU that is either permanently wired to the building’s

branch circuit or includes a nondetachable cord that is wired to an industrial-style

plug. NEMA locking-style plugs or those complying with IEC 60309 are

considered suitable for this purpose. Using common power outlet strips to supply

power to this equipment is not recommended.

Page 15

15

Installing HP BladeSystem p-Class enclosures

In this section

Installation overview ....................................................................................................................15

Measuring with the rack template ................................................................................................16

Installing the rack rails and cage nuts...........................................................................................16

Installing HP BladeSystem p-Class enclosures into the rack .......................................................20

Installing interconnects.................................................................................................................25

Installation overview

To install an enclosure into the rack:

1. If you are installing the HP BladeSystem 3U power enclosure, use the rack

template ("Measuring with the rack template" on page 16

) to mark the

locations for power distribution devices.

2. Install the rack rails ("Installing the rack rails (3U power supply and server

blade enclosures)" on page 17

3. Install the cage nuts ("Installing the cage nuts" on page 20

IMPORTANT: You must install cage nuts for each power distribution

device (scalable bus bar or mini bus bar).

IMPORTANT: Be sure that the guiding fins on the enclosure seat

properly in the guiding groove on the rack rail.

) for each enclosure.

), if necessary.

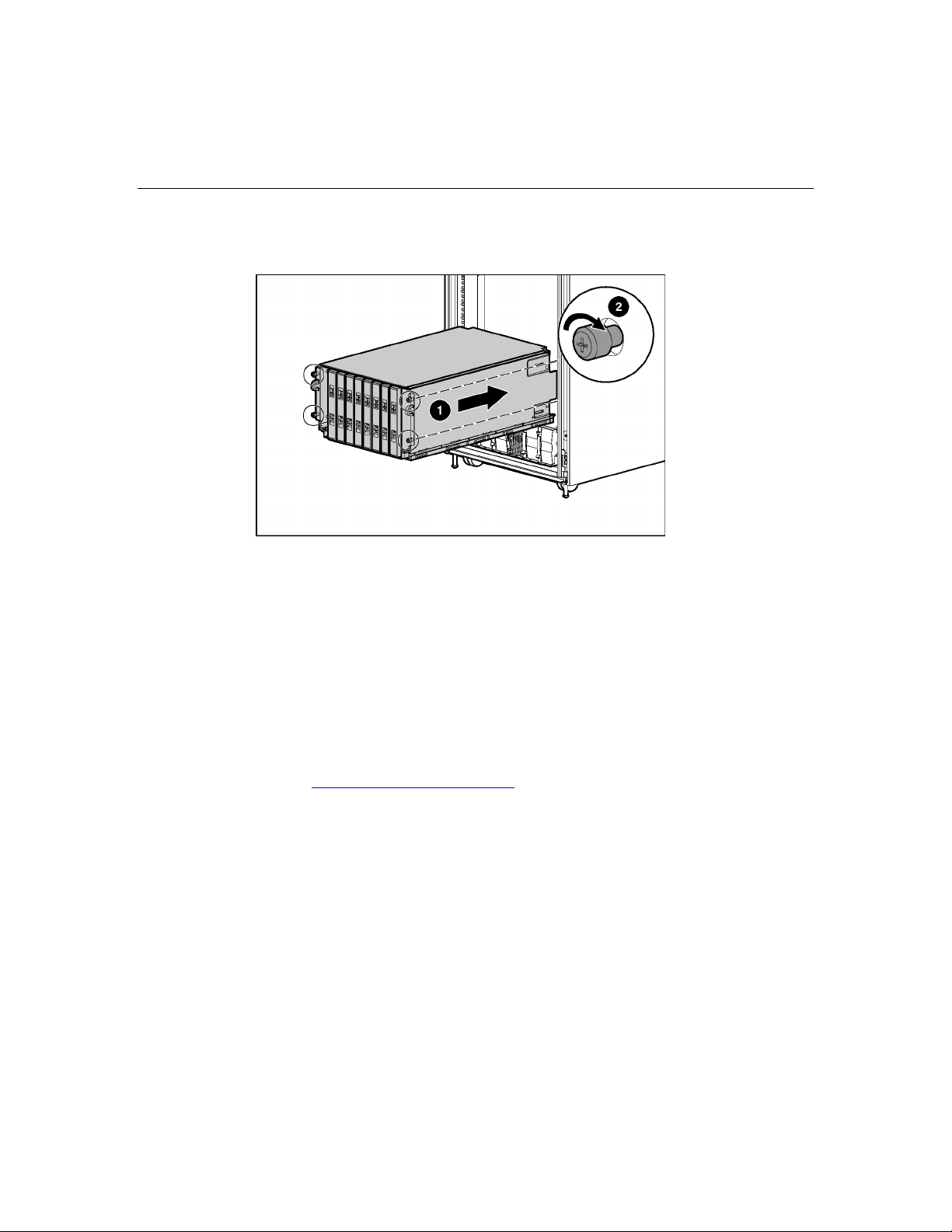

4. Position yourself at the front of the rack, and align the enclosure guiding fins

with the guiding groove in the rack rails.

5. Slide the enclosure fully into the rack.

6. Tighten the thumbscrews to secure the enclosure in the rack.

Page 16

16 HP BladeSystem p-Class Enclosure Installation Guide

Measuring with the rack template

NOTE: A rack template is not provided with the 1U power supply

enclosure.

Rack templates ship with the bus bars and provide detailed instructions on where

to position bus bar hinges and enclosure rack rails. Each power supply enclosure

kit and server blade enclosure kit includes rack rails recommended for that

enclosure. The rack rails that ship with the HP BladeSystem 3U Power Enclosure

and HP BladeSystem p-Class Server Blade Enclosure are identical.

When installing multiple enclosures, install the rack rails for one enclosure, then

install the enclosure. Repeat for each additional enclosure.

Installing the rack rails and cage nuts

You must install two rack rails to support each enclosure. Rack rails have the

following features:

• • Adjustable depth of 60.96 cm to 91.44 cm (24 in to 36 in)

IMPORTANT: For proper bus bar installation and clearance, the rack

rail depth must be set from 73.66 cm to 76.20 cm (29 in to 30 in).

Depth indicator, visible in the middle of the rail

Page 17

Installing HP BladeSystem p-Class enclosures 17

• "L" and "R" markings to identify left and right rack rails (from the front of

the rack)

CAUTION: Always plan the rack installation so that the

heaviest item is on the bottom of the rack. Install the heaviest item first,

and continue to populate the rack from the bottom to the top.

Installing the HP BladeSystem p-Class 1U Power Enclosure rack rails

The HP BladeSystem p-Class 1U Power Enclosure uses HP 1U Adjustable

Toolless Rails. Refer to the installation instructions that are included with the rail

hardware kit for detailed installation instructions. Cage nuts are not used with the

HP BladeSystem p-Class 1U Power Enclosure.

NOTE: Power distribution devices (scalable bus bar and mini bus bar)

are not required when installing the HP BladeSystem 1U Power

Enclosure. The power enclosure is designed to connect directly to one

server blade enclosure.

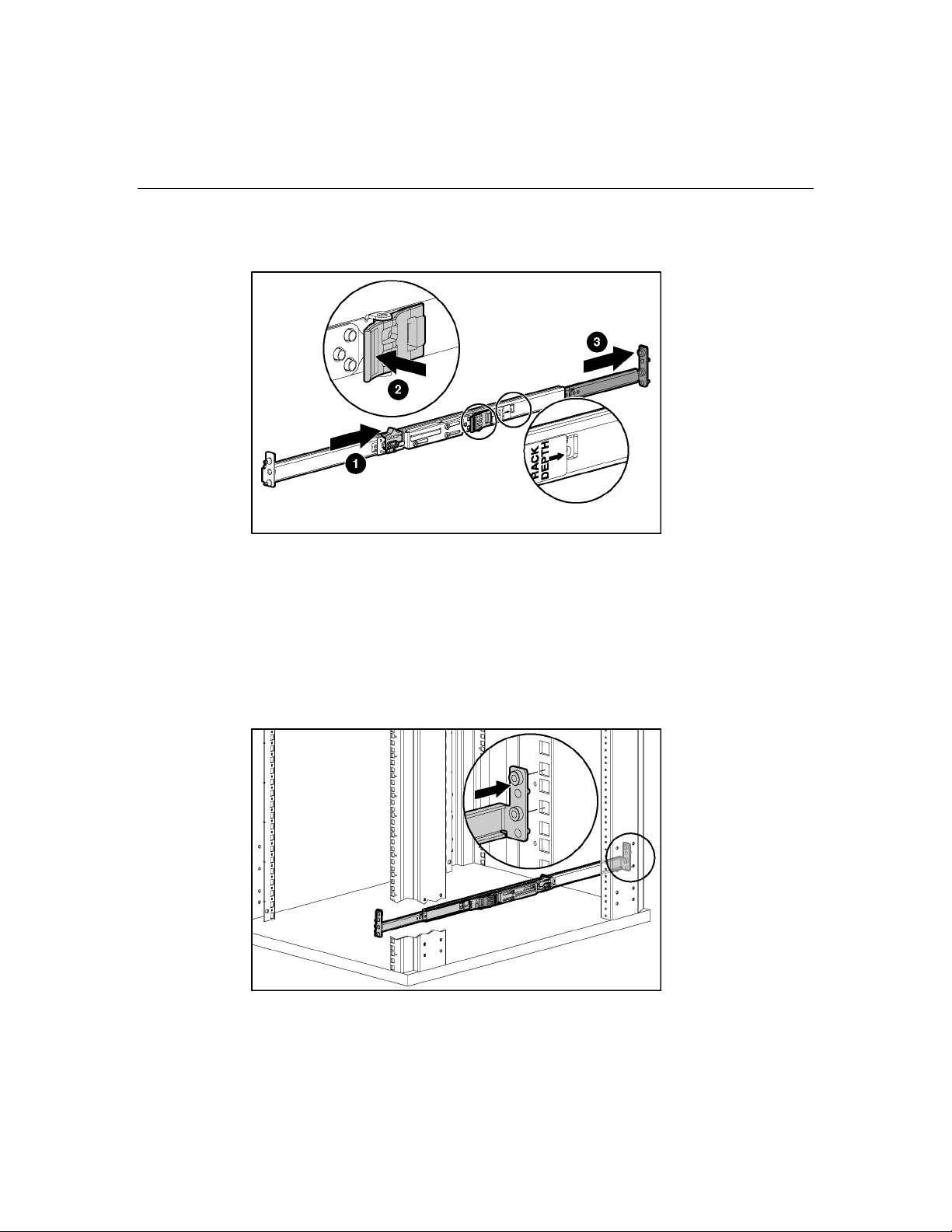

Installing the rack rails (3U power supply and server blade enclosures)

1. Adjust the rack rails to fit the rack, using the numbers on the rack rail as a

guide.

Page 18

18 HP BladeSystem p-Class Enclosure Installation Guide

NOTE: The depth of an HP or a Compaq branded rack (29 in) is clearly

indicated on the rack rails.

IMPORTANT: Numbers on the rack rail provide a gross adjustment of

the depth of the rack rail. You may need to adjust the rack rail depth

again to ensure a proper fit.

2. Install the right rack rail into the rack:

NOTE: Identify the left (L) and right (R) rack rails by markings stamped

into the sheet metal.

a. Insert the rear of the right rack rail into the rack at the marks you made

when measuring with the template.

Page 19

Installing HP BladeSystem p-Class enclosures 19

b. Compress the spring-loaded rack rail toward the rear of the rack.

c. Using the marks you made when measuring with the template, align the

front of the right rail with the holes and release the rail, allowing it to

lock into position.

d. Engage the locking gear.

CAUTION: Rack rails must be installed as tightly as possible.

Failure to obtain a proper fit may result in damage to equipment.

3. Repeat the preceding step for the left rack rail.

IMPORTANT: To ease installation, install all cage nuts for enclosures,

bus bar hinges, and cable brackets before installing the remaining

infrastructure.

4. Using the marks you made when measuring with the template, install the

cage nuts ("Installing the cage nuts" on page 20

) for enclosures, bus bar

hinges, and the cable bracket.

IMPORTANT: In AC power configurations, the bottom hinges for each

bus bar are installed on the ends of the power enclosure rack rails. The

rails have extrusions to align the hinges and holes to accept the screws.

In facility DC power configurations, you must install cage nuts to support

the bottom hinges. Refer to the template for hinge locations.

Page 20

20 HP BladeSystem p-Class Enclosure Installation Guide

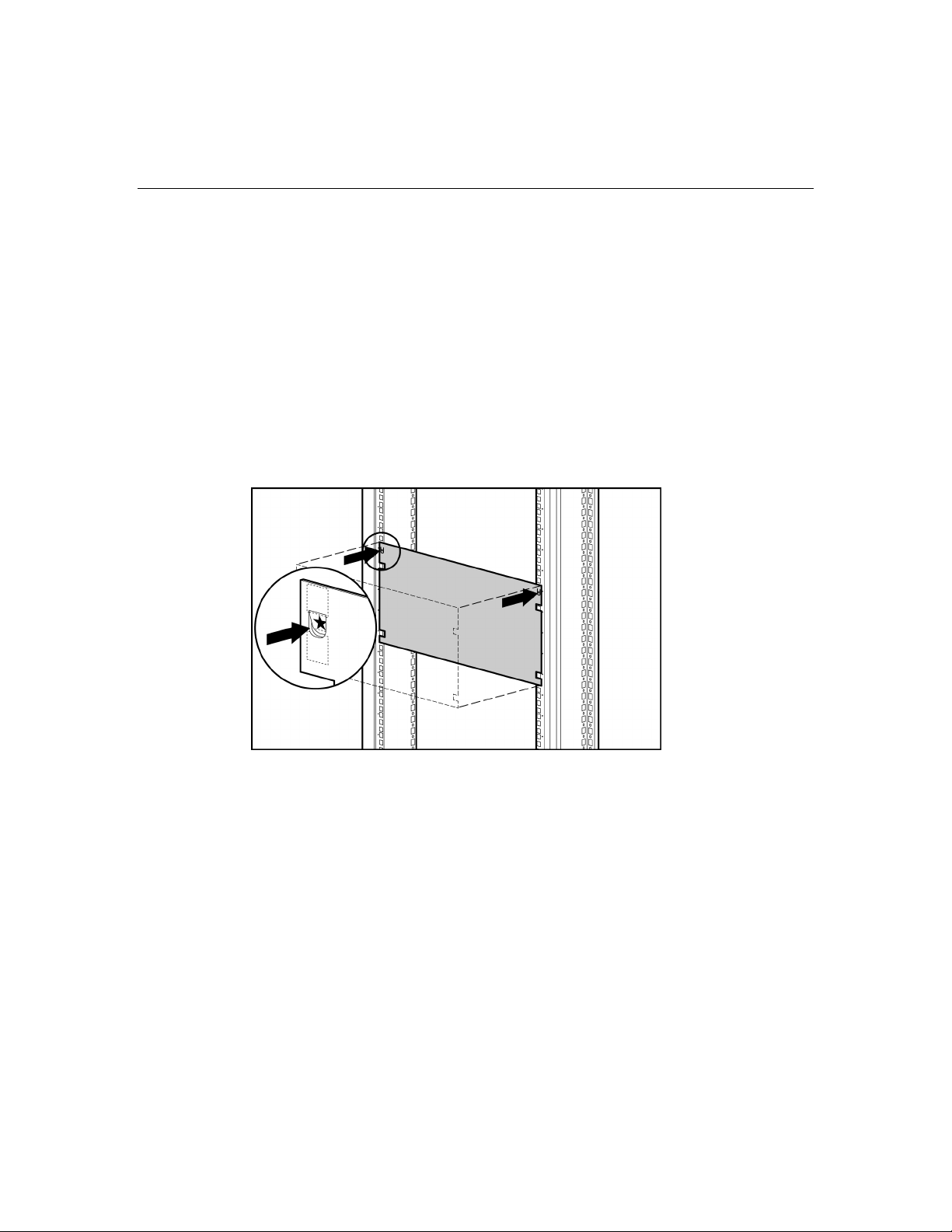

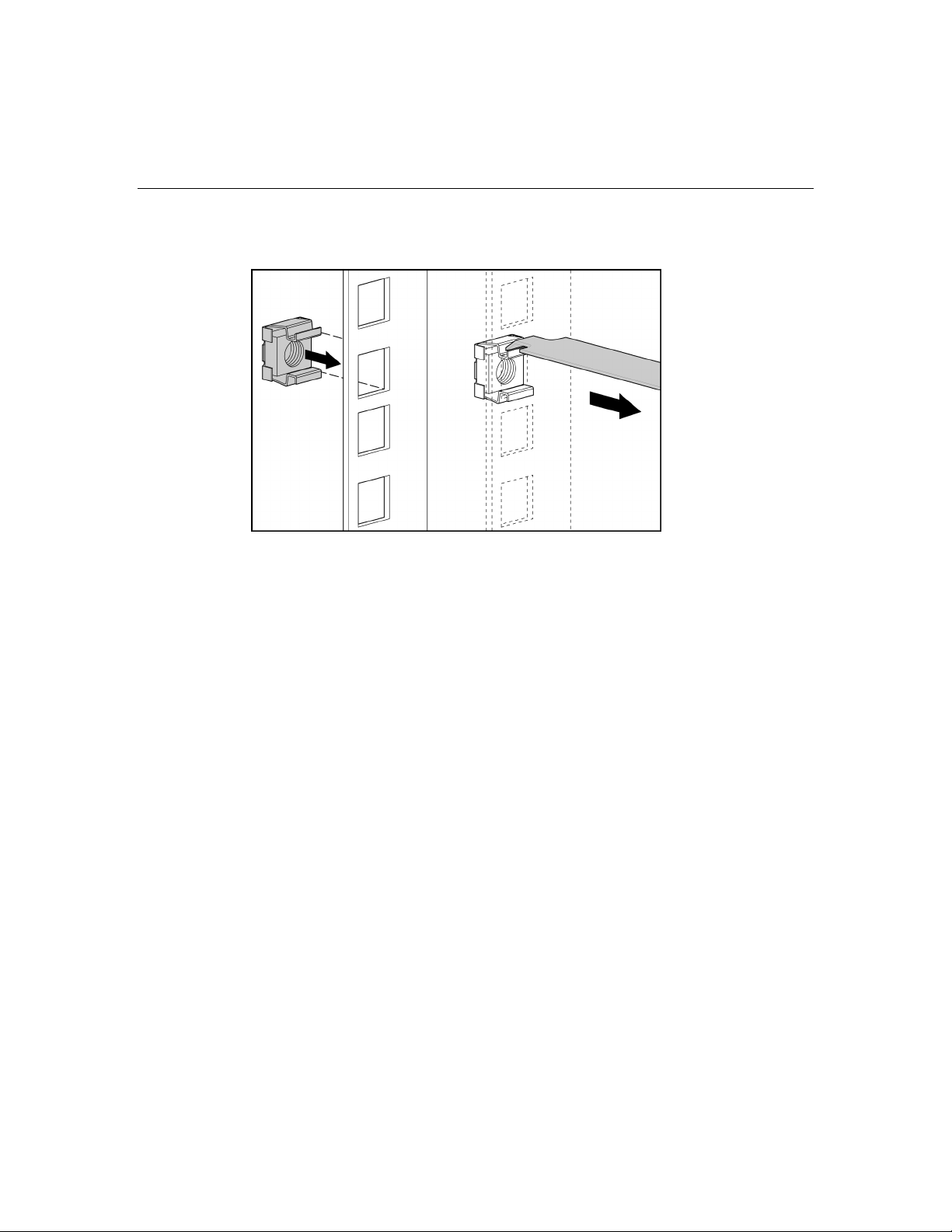

Installing the cage nuts

Installing HP BladeSystem p-Class enclosures into the rack

NOTE: Install all server blade enclosures before installing power

distribution devices at the rear of the rack.

Page 21

Installing HP BladeSystem p-Class enclosures 21

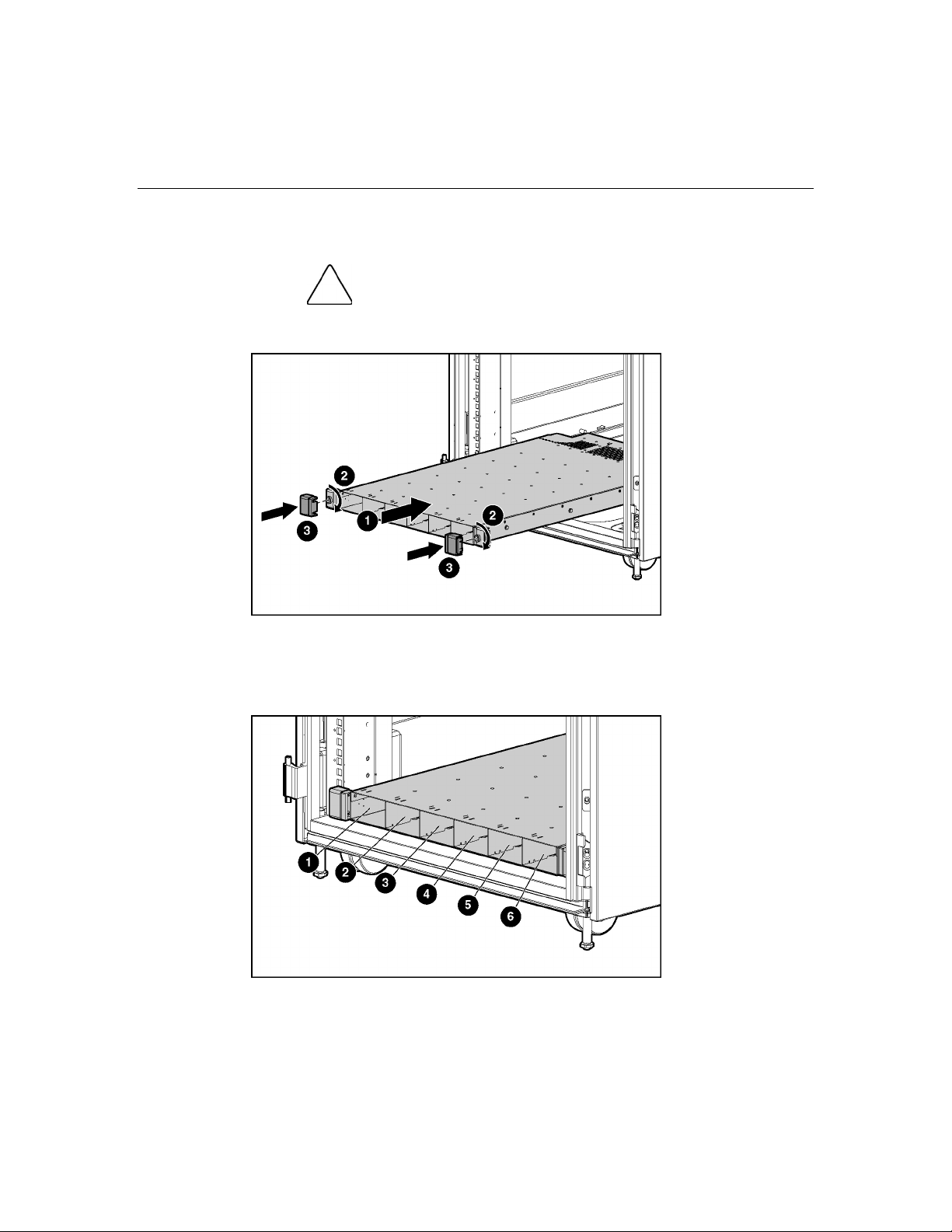

Installing HP BladeSystem p-Class 1U Power Enclosures

CAUTION: Always plan the rack installation so that the

heaviest item is on the bottom of the rack. Install the heaviest item first,

and continue to populate the rack from the bottom to the top.

Identifying HP BladeSystem p-Class 1U Power Supply Enclosure bays

Page 22

22 HP BladeSystem p-Class Enclosure Installation Guide

Item Description Configuration

1 Power supply bay 1 Bus A

2 Power supply bay 2 Bus A

3 Power supply bay 3 Bus A

4 Power supply bay 4 Bus B

5 Power supply bay 5 Bus B

6 Power supply bay 6 Bus B

Installing an HP BladeSystem 1U Power Supply

If necessary, remove the power supply blank.

NOTE: Order the appropriate AC power cord if you are not using the

PDU solution to provide power to the equipment.

Page 23

Installing HP BladeSystem p-Class enclosures 23

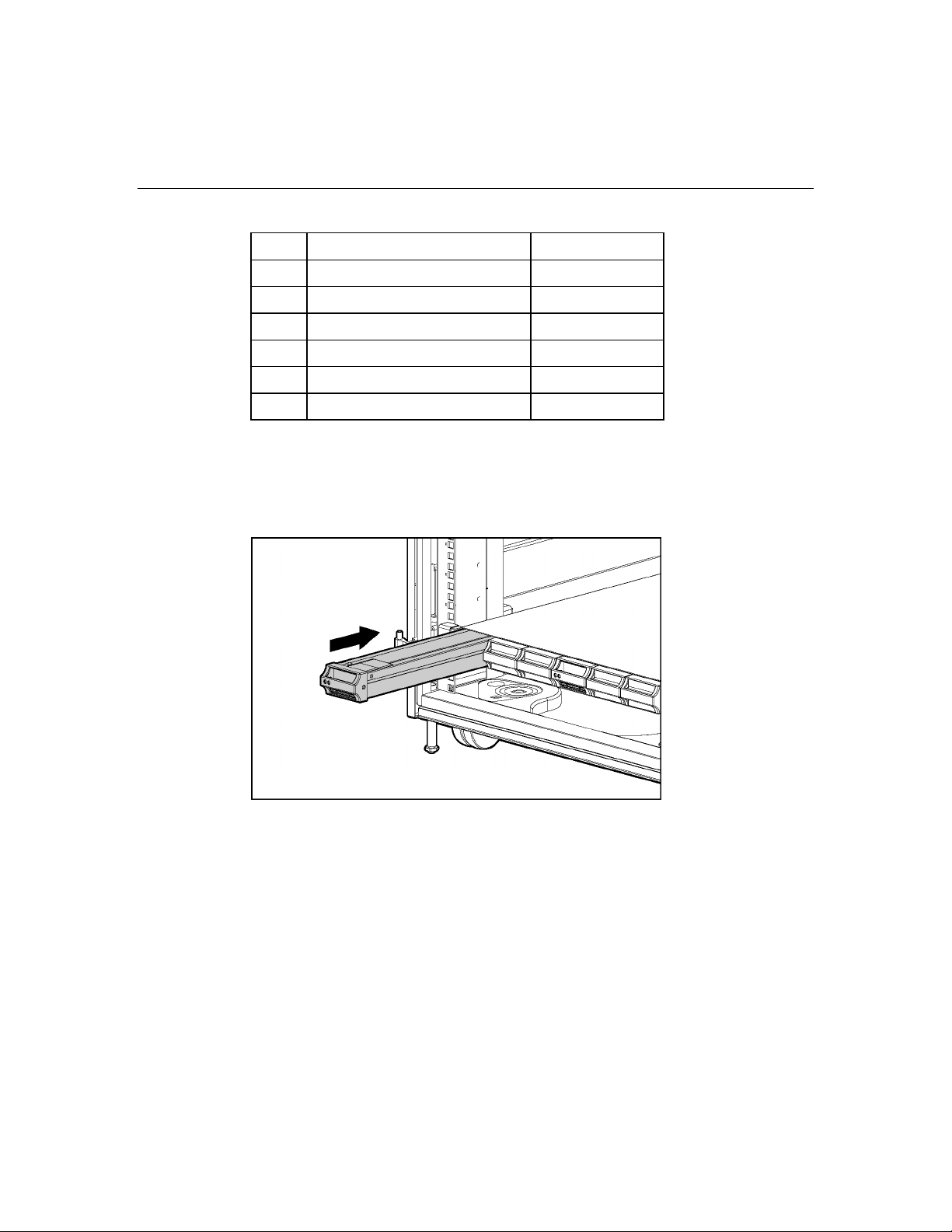

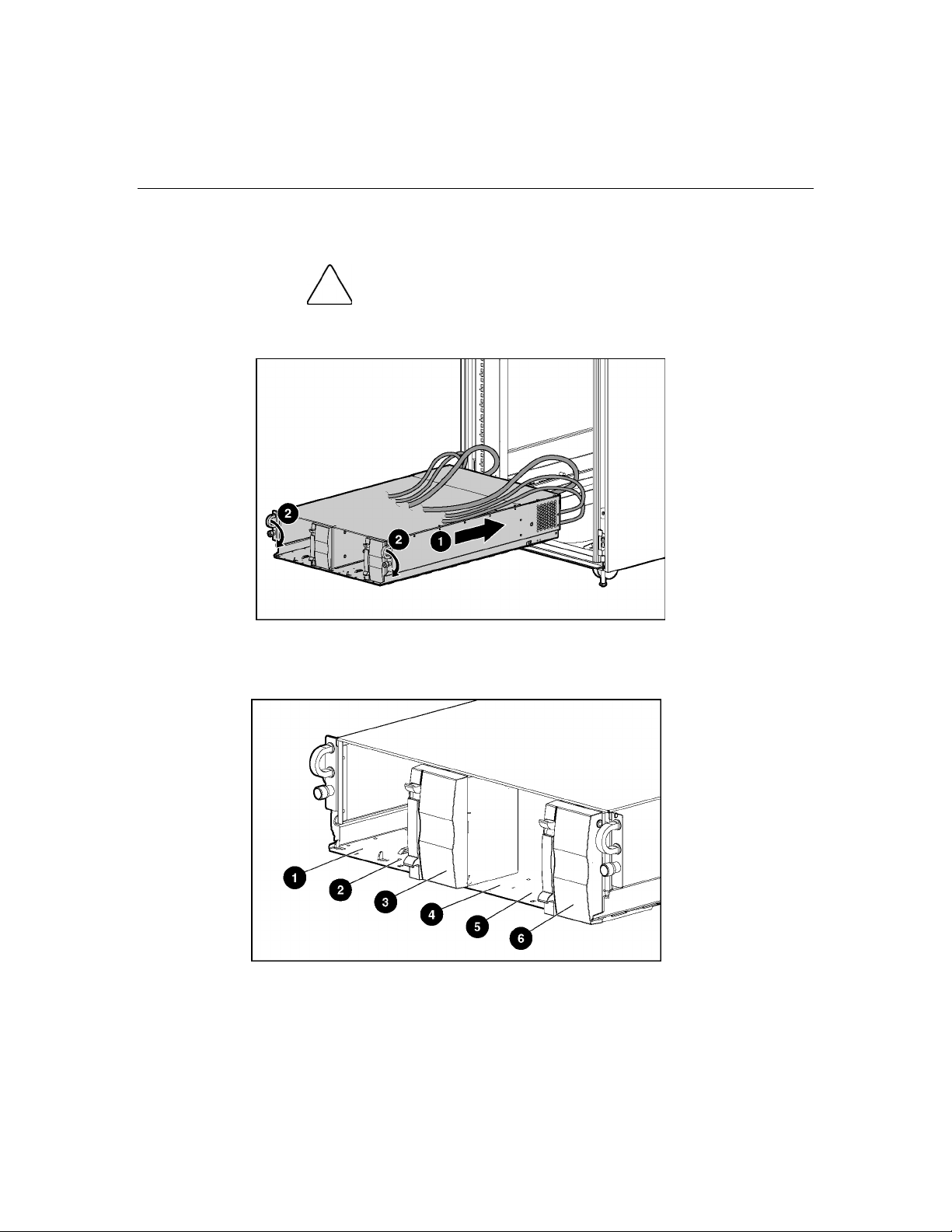

Installing HP BladeSystem p-Class 3U Power Enclosures

CAUTION: Always plan the rack installation so that the

heaviest item is on the bottom of the rack. Install the heaviest item first,

and continue to populate the rack from the bottom to the top.

Identifying HP BladeSystem p-Class 3U Power Enclosure bays

Page 24

24 HP BladeSystem p-Class Enclosure Installation Guide

Item Description Configuration

1 Power supply bay 1 Bus A

2 Power supply bay 2 Bus A

3 Power supply bay 3 Bus A

4 Power supply bay 4 Bus B

5 Power supply bay 5 Bus B

6 Power supply bay 6 Bus B

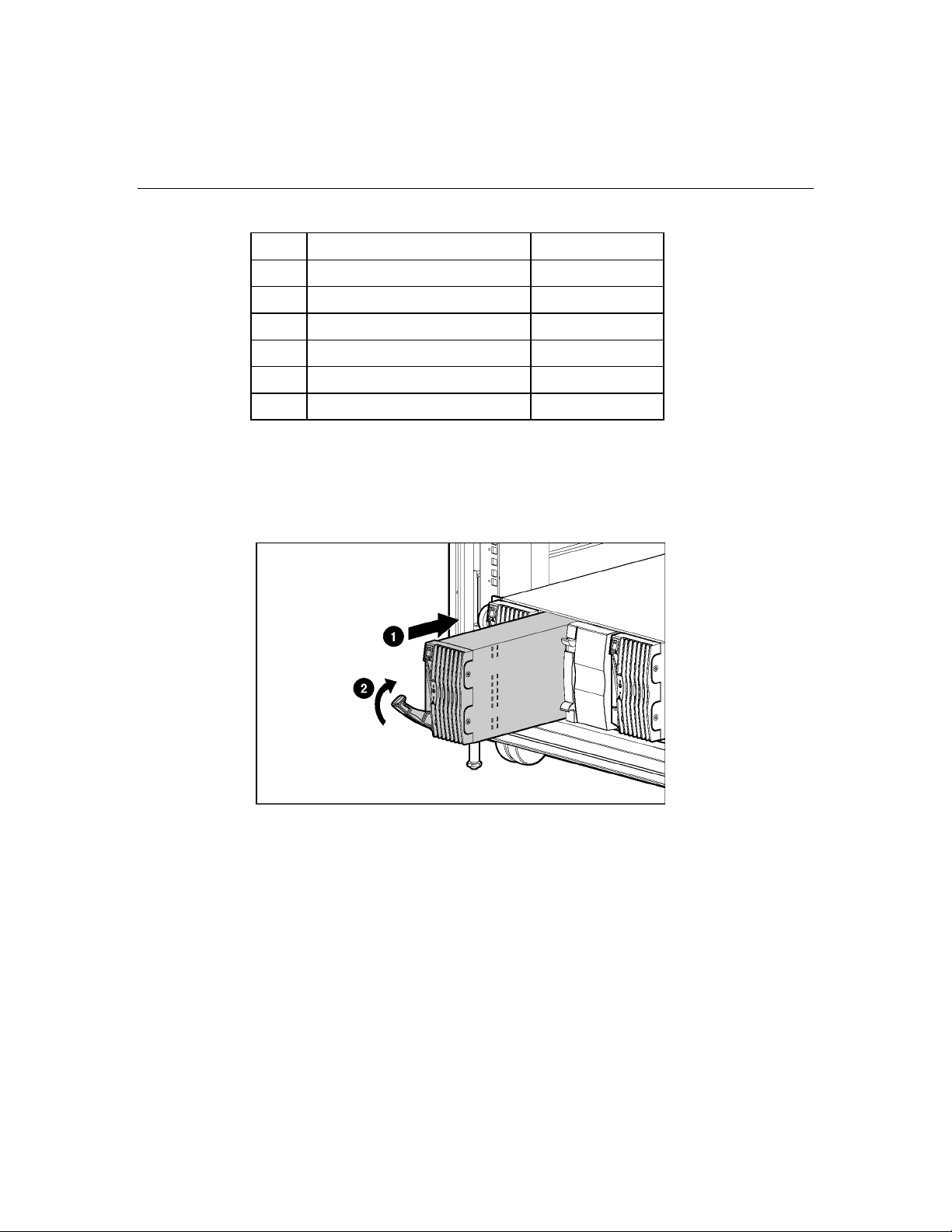

Installing an HP BladeSystem 3U Power Supply

If necessary, remove the power supply blank.

Page 25

Installing HP BladeSystem p-Class enclosures 25

Installing HP BladeSystem p-Class Server Blade Enclosures

Installing interconnects

Each server blade enclosure requires a pair of interconnects and server blades to

provide network access for data transfer. The leftmost and rightmost bays of each

server blade enclosure are interconnect bays.

IMPORTANT: Interconnect options vary. A server blade enclosure

requires a pair of interconnects of the same type. Do not mix two types

of interconnects in the same enclosure. Refer to the documentation that

ships with the interconnect option or server blade option you have

selected. Additional information is available at the HP website

(http://www.hp.com/go/bizsupport

).

Page 26

26 HP BladeSystem p-Class Enclosure Installation Guide

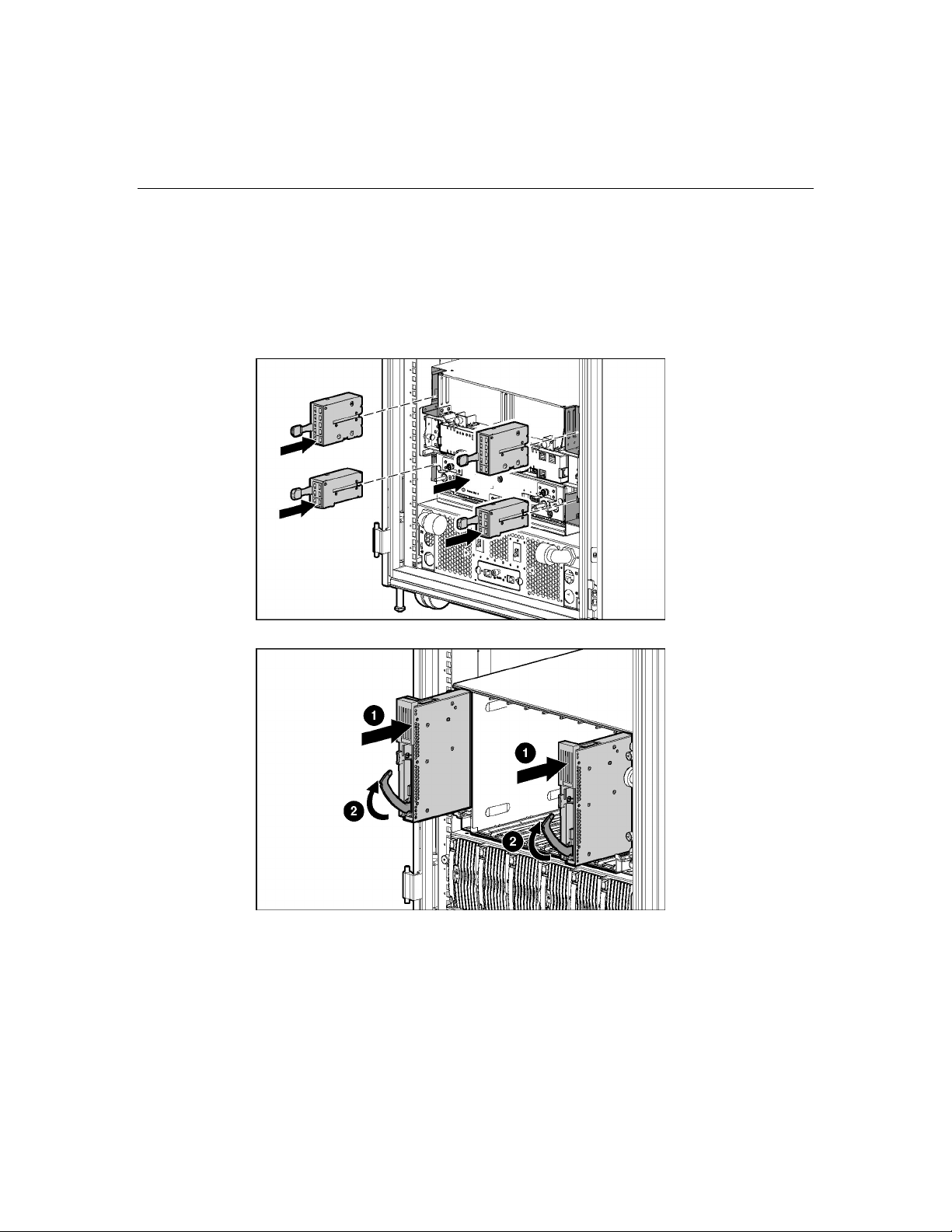

Installing HP BladeSystem interconnect modules and RJ-45 patch panels

NOTE: Always install the interconnect modules in the rear of the server

blade enclosure before installing the switch or patch panel in the front of

the server blade enclosure.

Page 27

Installing HP BladeSystem p-Class enclosures 27

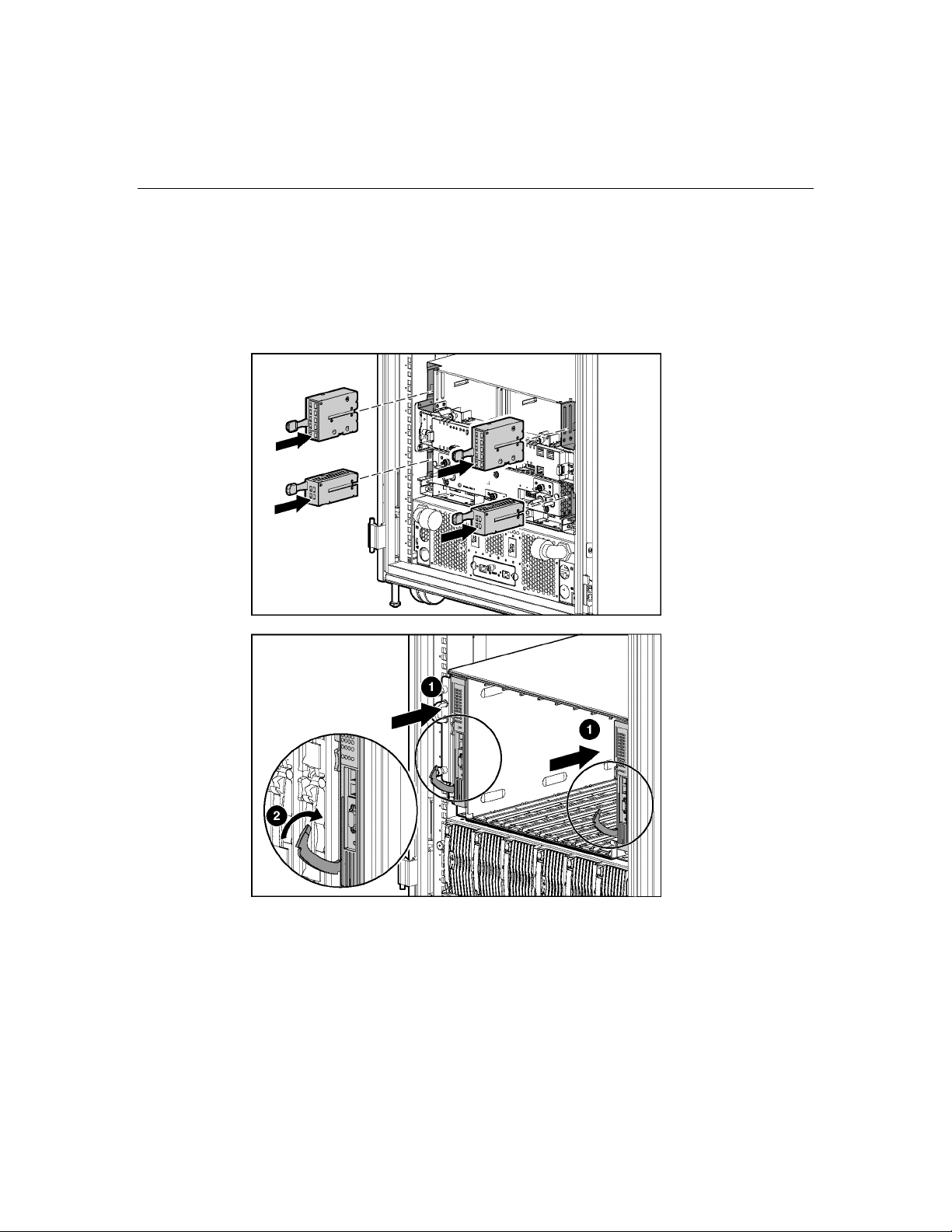

Installing HP BladeSystem interconnect modules and interconnect switches

NOTE: Always install the interconnect modules in the rear of the server

blade enclosure before installing the switch or patch panel in the front of

the server blade enclosure.

Page 28

Page 29

29

Cabling and powering up the system

In this section

System cabling overview..............................................................................................................29

Identifying HP BladeSystem p-Class 1U Power Enclosure components.....................................31

Identifying HP BladeSystem p-Class 3U Power Enclosure and Server Blade Enclosure

components...................................................................................................................................32

Installing power distribution devices............................................................................................33

Cabling the management modules................................................................................................39

Cabling the network to the system ...............................................................................................43

Connecting the HP BladeSystem p-Class 1U DC power cable to the server blade enclosure .....44

Connecting power cables to a mini bus bar..................................................................................44

Connecting power cables to a scalable bus bar ............................................................................47

Connecting facility DC power to the power distribution bus bars ...............................................51

Installing the cable bracket...........................................................................................................52

Configuration examples................................................................................................................52

Powering up the system................................................................................................................59

Completing the installation...........................................................................................................62

System cabling overview

After all system hardware is installed, cable the components. Refer to the HP

ProLiant BL System Best Practices Guide on the Documentation CD or the HP

website (http://www.hp.com

WARNING: To reduce the risk of electric shock or injury

due to high-current electrical energy, be sure that all power is

completely disconnected at the source before beginning any

power connections to the power bus bars or power bus box.

To cable the system:

1. Cable the management modules. Refer to "Cabling the management modules

(on page 39

)."

) for HP recommendations on cable ordering.

Page 30

30 HP BladeSystem p-Class Enclosure Installation Guide

2. Connect the network cables to the interconnects. Refer to the documentation

that came with the interconnects or to the HP ProLiant BL System Best

Practices Guide on the Documentation CD or on the HP website

(http://www.hp.com/go/bizsupport

WARNING: Be sure that all circuit breakers are locked in

the off position before connecting any power components.

).

3. If you are using a facility AC power source, complete the following steps:

a. If you are installing the HP BladeSystem p-Class 1U Power Enclosure,

connect the power cables from the power enclosure to the server blade

enclosure. Refer to "Connecting the HP BladeSystem p-Class 1U DC

Power Cable to the server blade enclosure (on page 44

b. If you are installing the HP BladeSystem p-Class 3U Power Enclosure in

a scalable bus bar configuration or Mini Bus Bar Dual Power Box

configuration, connect the load-balancing signal cable between power

enclosures. Refer to "Connecting the load-balancing signal cable (on

page 50

)."

c. Connect the bus bars or power bus boxes to the enclosures. Refer to

"Installing power distribution devices (on page 33

power couplers ("Installing the power connectors" on page 38

)."

)" and "Installing the

)."

4. If you are using a facility DC power source:

a. Connect the grounding cable to the server blade enclosures. Refer to

"Connecting facility DC power to the power distribution bus bars (on

page 51

)."

b. Install the facility DC cables. Refer to the documentation that ships with

the Facility DC Cable Kit.

c. Connect the bus bars or power bus boxes to the enclosures. Refer to

"Installing power distribution devices (on page 33

power couplers ("Installing the power connectors" on page 38

)" and "Installing the

)."

d. Install the cable bracket. Refer to the documentation that ships with the

brackets.

5. Connect to your facility AC or DC power source and power up the system.

Refer to the "Powering up the system (on page 59

)."

Page 31

Cabling and powering up the system 31

Identifying HP BladeSystem p-Class 1U Power Enclosure components

Item Description Cable type

1 DC output power connector for bus B DC power

cable

2 AC input power connector for bay 6 PDU power

cord

3 AC input power connector for bay 5 PDU power

cord

4 AC input power connector for bay 4 PDU power

cord

5 Power enclosure management link

connector (to enclosure below, if

necessary)

6 Power management module service

port

7 Power enclosure management link

connector (to server enclosure

above)

8 AC input power connector for bay 3 PDU power

RJ-45

management

link cable

—

RJ-45

management

link cable

cord

Page 32

32 HP BladeSystem p-Class Enclosure Installation Guide

Item Description Cable type

9 AC input power connector for bay 2 PDU power

cord

10 AC input power connector for bay 1 PDU power

cord

11 DC output power connector for bus A DC power

cable

Identifying HP BladeSystem p-Class 3U Power Enclosure and Server Blade Enclosure components

Item Description Cable type

1 Power zone configuration switch —

2 Server blade management link

connectors (top to enclosure above,

bottom to enclosure below)

3 iLO connector RJ-45

4 DC power input connectors for bus

A

5 Server blade enclosure grounding

cable screw

RJ-45

management

link cable

DC power

cable

—

Page 33

Cabling and powering up the system 33

Item Description Cable type

6 AC input power connector for bus A AC power

cord

7 DC output power connector for bus

A

8 Power enclosure grounding cable

screw

9 Power management link connectors

to enclosure above

10 Power management module service

port

11 Power enclosure AC circuit breakers

(to hot-plug power supplies) for bus

B (left) and bus A (right)

12 Power management link connectors

to enclosure below

13 DC output power connector for bus B DC power

14 Load balancing signal cable —

15 AC input power connector for bus B AC power

16 DC power input connectors for bus B DC power

DC power

cable

—

RJ-45

management

link cable

—

—

RJ-45

management

link cable

cable

cord

cable

17 Server blade management module

service port

—

Installing power distribution devices

NOTE: Power distribution devices (scalable bus bar and mini bus bar)

are not required when installing the HP BladeSystem 1U Power

Enclosure. The power enclosure is designed to connect directly to one

server blade enclosure.

NOTE: Other power distribution options may exist for the server blade.

Refer to the specific power distribution documentation for more

information.

Page 34

34 HP BladeSystem p-Class Enclosure Installation Guide

Solution Power

enclosures

supported

Server blade

enclosures

supported

Maximum

rack space

occupied

Scalable bus

2 5 36U

bar

Mini bus bar 1 3 21U

Mini bus bar* 2 3 24U

Power bus box 1 1 9U

* A Mini Bus Bar Dual Power Box supports two power enclosures attached to the mini bus

bar to enable a redundant AC power configuration.

Two mini bus bar configurations, each with one power enclosure and three server

blade enclosures, can be installed one above the other to fully populate a 42U

rack.

NOTE: Scalable and mini bus bars attach to the rack in the same

manner.

Page 35

Cabling and powering up the system 35

Installing a scalable bus bar kit

NOTE: Use the location marks made when you measured the rack with

the rack template.

Page 36

36 HP BladeSystem p-Class Enclosure Installation Guide

Installing a mini bus bar kit

NOTE: Use the location marks made when you measured the rack with

the rack template.

Installing a power bus box

WARNING: If using facility DC power, cables must be

connected by a licensed electrician or trained service personnel

familiar with high-power circuitry.

Page 37

Cabling and powering up the system 37

WARNING: Be sure that all circuit breakers are locked in

the off position before connecting any power components.

Page 38

38 HP BladeSystem p-Class Enclosure Installation Guide

Installing the power connectors

The power connectors are positioned to line up to adjacent server blade

enclosures.

WARNING: If using facility DC power, cables must be

connected by a licensed electrician or trained service personnel

familiar with high-power circuitry.

Page 39

Cabling and powering up the system 39

WARNING: Be sure that all circuit breakers are locked in

the off position before connecting any power components.

Cabling the management modules

The server blade management modules and power management modules are

cabled together in daisy-chain fashion to provide the management link. Each

management module has two management link connectors: one to connect to

enclosures above and one to connect to enclosures below. Cabling the

management modules enables the system to identify rack topology for power and

data management.

CAUTION: Do not install NIC cabling or telephone cabling into

the management link connectors; these devices are not supported.

When deploying the HP BladeSystem 1U Power Enclosure and attached server

enclosure into an existing installation, it is necessary to upgrade all management

module firmware on all enclosures to the latest version.

Management cabling guidelines

Observe the following guidelines for cabling the management modules.

Page 40

40 HP BladeSystem p-Class Enclosure Installation Guide

On the server blade management module:

•

The upper Management Link connects to the upper enclosure.

•

The lower Management Link connects to the lower enclosure.

•

The iLO port connects to the iLO network.

On the power management module:

•

The right management link connector connects to enclosures above the

module.

•

The left management link connector connects to enclosures below the

module.

Additional guidelines for a 42U solution

Observe the following additional guidelines for configuring a full-rack 42U

solution with two pairs of mini bus bars:

•

You must set the power configuration switches to establish the two power

zones. Refer to Power configuration switches (on page 72

) in this guide.

• You must cable the power management module in zone 2 (upper pair of mini

bus bars) to both adjacent server blade management modules, above and

below. This connection enables system management to establish a full-rack

topology.

Connecting the management module cables

NOTE: This section applies only to systems that are configured with an

enhanced server blade enclosure.

Page 41

Cabling and powering up the system 41

NOTE: Management modules are used only for information

management (asset tracking, for example). Disconnecting the

management module cabling does not affect system operation.

IMPORTANT: Improper cabling causes all the management link

connector LEDs on the management modules to flash.

Be sure the power configuration switches are set properly if you have a full-rack

solution with two pairs of mini bus bars. Refer to Power Configuration Switches

(on page 72

) in this guide.

Page 42

42 HP BladeSystem p-Class Enclosure Installation Guide

Connecting the HP BladeSystem p-Class 1U Management Link Cable

When deploying the HP BladeSystem 1U Power Enclosure and attached server

enclosure into an existing installation, it is necessary to upgrade all management

module firmware on all enclosures to the latest version.

IMPORTANT: In installations configured with the HP BladeSystem 1U

Power Enclosures and Power Supplies, the power zones are calculated

dynamically using the topology information from all the connected

enclosures. Disregard the power zone switch and LEDs on the

HP BladeSystem 1U Power Enclosure.

If deploying the HP BladeSystem 1U Power Enclosure into a rack installation

with other HP BladeSystem Enclosures, the enclosures can be connected to each

other with management link cables to identify rack topology. Refer to the

"Configuring the dynamic power saver (on page 57

)" section in this document.

Page 43

Cabling and powering up the system 43

Connecting to iLO

NOTE: This section applies only to systems that are configured with an

enhanced server blade enclosure.

Cabling the network to the system

Cable the interconnects to the network. Refer to the supporting documentation

for specific details on cabling the interconnects.

Page 44

44 HP BladeSystem p-Class Enclosure Installation Guide

Connecting the HP BladeSystem p-Class 1U DC power cable to the server blade enclosure

Connecting power cables to a mini bus bar

Connect the power cables to the mini bus bar.

Page 45

Cabling and powering up the system 45

Removing the mini bus bar cover

Connecting power cables to the mini bus bar

WARNING: If using facility DC power, cables must be

connected by a licensed electrician or trained service personnel

familiar with high-power circuitry.

Page 46

46 HP BladeSystem p-Class Enclosure Installation Guide

NOTE: If you are connecting two HP BladeSystem 3U Power

enclosures to mini bus bars, refer to the HP BladeSystem Mini Bus Bar

Dual Power Kit Installation Instructions or to the HP BladeSystem

p-Class Enclosure Installation Guide.

Replacing the mini bus bar cover

Page 47

Cabling and powering up the system 47

Securing the mini bus bars

Connecting power cables to a scalable bus bar

Connect the DC power cables to the scalable bus bar.

Page 48

48 HP BladeSystem p-Class Enclosure Installation Guide

Removing the scalable bus bar covers

WARNING: If using facility DC power, cables must be

connected by a licensed electrician or trained service personnel

familiar with high-power circuitry.

Connecting power cables to the scalable bus bar

Page 49

Cabling and powering up the system 49

Replacing the scalable bus bar cover

Page 50

50 HP BladeSystem p-Class Enclosure Installation Guide

Securing the scalable bus bars

Connecting the load-balancing signal cable

When a power zone is configured with two HP BladeSystem 3U Power

Enclosures, the load-balancing signal cable must be used to enable the power

enclosures to balance their power output for the system power demand in that

power zone.

IMPORTANT: If the load-balancing signal cable is not installed, the

management software issues alerts.

Page 51

Cabling and powering up the system 51

IMPORTANT: If the configuration does not include HP BladeSystem

p-Class 3U Power Enclosures, no load-balancing signal cables are

necessary.

Connecting facility DC power to the power distribution bus bars

Install the facility DC cable option kit. Refer to the documentation that ships with

that kit.

The grounding cable satisfies enclosure-to-enclosure grounding requirements in

facility DC power environments. Each type of bus bar supports a different

number of enclosures; therefore, each Facility DC Cable Option Kit contains a

grounding cable to support the appropriate number of enclosures.

WARNING: The ground cable must be connected to each

enclosure in the rack and to a suitable ground (earth) terminal

located within the rack or cabinet. The terminal in the rack must be

connected to a suitable building ground (earth) terminal in

accordance with local, regional, or national electrical codes or

regulations. Do not rely on the rack or cabinet chassis to provide

adequate continuity of the rack ground connection.

Page 52

52 HP BladeSystem p-Class Enclosure Installation Guide

WARNING: If using facility DC power, cables must be

connected by a licensed electrician or trained service personnel

familiar with high-power circuitry.

To connect the grounding cable:

1. Insert the mounting screw through the grounding cable lead and into the

enclosure (1).

2. Tighten the mounting screw to secure the grounding cable to the enclosure

(2).

3. Repeat steps 1 and 2 as needed for the configuration until all enclosures in

the rack are connected by the grounding cable.

4. Connect the lower end of the grounding cable to the facility grounding

connection.

Installing the cable bracket

Install the cable bracket (optional) provided with each power distribution kit.

Configuration examples

Refer to the following examples for typical HP BladeSystem configurations:

Page 53

Cabling and powering up the system 53

• Scalable bus bar configuration example (on page 53)

• Two mini bus bar configuration example (on page 54)

• Redundant mini bus bar configuration example (on page 55

• Full rack 42U solution with two pairs of mini bus bars (on page 56)

• Configuring the Dynamic Power Saver (on page 57)

Scalable bus bar configuration example

CAUTION: Always use blanking panels to fill empty vertical

spaces in the rack. This arrangement ensures proper airflow. Using a

rack without blanking panels results in improper cooling that can lead to

thermal damage.

)

Page 54

54 HP BladeSystem p-Class Enclosure Installation Guide

CAUTION: Always use blanks to fill empty spaces in

enclosures. This arrangement ensures proper airflow. Using an

enclosure without the proper blanks results in improper cooling that can

lead to thermal damage.

Two mini bus bar configuration example

CAUTION: Always use blanking panels to fill empty vertical

spaces in the rack. This arrangement ensures proper airflow. Using a

rack without blanking panels results in improper cooling that can lead to

thermal damage.

Page 55

Cabling and powering up the system 55

CAUTION: Always use blanks to fill empty spaces in

enclosures. This arrangement ensures proper airflow. Using an

enclosure without the proper blanks results in improper cooling that can

lead to thermal damage.

Redundant mini bus bar configuration example

The configurations illustrated in this document are non-redundant AC mini bus

bar configurations. To obtain AC redundancy, you need the AC redundant mini

bus bar box. Refer to the documentation supplied with the AC redundant mini

bus bar box and to the HP ProLiant BL System Best Practices Guide.

Page 56

56 HP BladeSystem p-Class Enclosure Installation Guide

Full rack 42U solution with two pairs of mini bus bars

Observe the following additional guidelines for configuring a full-rack 42U

solution with two pairs of mini bus bars:

• • Set the power configuration switches to establish the two power zones.

Cable the power management module in zone 2 (upper pair of mini bus bars)

to both adjacent server blade management modules, above and below. This

connection enables system management to establish a full rack topology.

Page 57

Cabling and powering up the system 57

Item Description

1 Power zone 2

2 Zone 2 switches in the up (secondary) position

3 Power zone 1

4 Zone 1 switches in the down (default) position

IMPORTANT: In installations configured with the HP BladeSystem 1U

Power Enclosures and Power Supplies, the power zones are calculated

dynamically using the topology information from all the connected

enclosures. Disregard the power zone switch and LEDs on the

HP BladeSystem 1U Power Enclosure.

For more information on configuring the power zones, refer to the HP ProLiant

BL System Best Practices Guide.

Configuring the Dynamic Power Saver

NOTE: The Dynamic Power Saver is a feature of the HP BladeSystem

p-Class 1U Power Supply Enclosure.

NOTE: The Dynamic Power Saver configures the available power

supplies to operate at maximum efficiency.

When the Dynamic Power Saver feature is enabled, the total enclosure power

consumption is monitored in real time. Power supplies are placed in a standby

condition when the power demand from the server enclosure is low. When power

demand increases, the standby power supplies instantaneously deliver the

required power. This enables the enclosure to operate at optimum efficiency.

Page 58

58 HP BladeSystem p-Class Enclosure Installation Guide

To configure the Dynamic Power Saver, remove the power enclosure

management module.

Use the following figure and table to identify the Dynamic Power Saver switch

location and function.

Position Function

1 Dynamic Power Saver disabled (default)

2 Dynamic Power Saver enabled

Page 59

Cabling and powering up the system 59

Position Function

3 Reserved (off=default)

Powering up the system

WARNING: Be sure that all circuit breakers are locked in

the off position before connecting any power components.

Refer to the following procedures to power up your HP BladeSystem installation:

• Powering up the system (HP BladeSystem p-Class 1U Power Enclosure) (on

page 59

• Powering up the system (HP BladeSystem p-Class 3U Power Enclosure) (on

page 60

• Powering up the system (facility DC) (on page 61)

)

)

Powering up the system (HP BladeSystem p-Class 1U Power Enclosure)

NOTE: Order the appropriate AC power cord if you are not using the

PDU solution to provide power to the equipment.

If you have installed the 1U power enclosure:

1. Be sure all power supplies are seated in the power enclosure.

2. Connect each PDU Power Cord to the power enclosure.

3. Connect each PDU Power Cord to the PDU.

4. Connect the PDU to the facility power connection.

5. Apply power to the facility power connection, if necessary.

6. Be sure that the hot-plug power supply LEDs and power enclosure DC power

LEDs are illuminated green. Refer to "LEDs, buttons, and switches (on page

)" or to the documentation included with the HP BladeSystem p-Class 1U

63

Power Enclosure.

Page 60

60 HP BladeSystem p-Class Enclosure Installation Guide

7. Be sure that the server blade enclosure DC power LEDs are illuminated

green. Refer to "LEDs, buttons, and switches (on page 63

)" or to the

documentation included with the HP BladeSystem p-Class Server Blade

Enclosure.

Power is now applied to all system hardware.

Powering up the system (HP BladeSystem p-Class 3U Power Enclosure)

If you have installed the HP BladeSystem p-Class 3U Power Enclosure:

1. Be sure all power supplies are seated in the power enclosure.

2. Connect the power cords to the AC power source.

3. Apply power to the facility power connection, if necessary.

4. Unlock the circuit breakers on the power enclosure.

5. Toggle the switches to the on position. This action applies AC power to the

hot-plug power supplies.

6. Lock the switch in the on position.

Page 61

Cabling and powering up the system 61

7. Be sure that the hot-plug power supply LEDs, power enclosure DC power

LEDs, and bus bar power LEDs are illuminated green. Refer to the "LEDs,

buttons, and switches (on page 63

)" or to the documentation included with

the HP BladeSystem p-Class 3U Power Enclosure.

8. Unlock the circuit breaker switches on the bus bars or power bus boxes and

toggle the switches to the on position. This action applies DC power to the

server blade enclosures.

IMPORTANT: Only unlock circuit breakers for couplers that are

attached to a server blade enclosure.

9. Be sure that the server blade enclosure DC power LEDs are illuminated

green. Refer to "LEDs, buttons, and switches (on page 63

)" or to the

documentation included with the HP BladeSystem p-Class Server Blade

Enclosure.

NOTE: Circuit breakers continue to function in the event of an overload

condition even if they are locked.

IMPORTANT: Be sure to lock all the circuit breaker switches in the on

position. This action prevents anyone from accidentally powering down

the system.

Power is now applied to all system hardware.

Powering up the system (facility DC)

If you are using a facility DC power source:

1. Connect the power cables to the DC power source.

2. Apply power to the facility power connection, if necessary.

IMPORTANT: Only unlock circuit breakers for couplers that are

attached to a server blade enclosure.

3. Unlock the circuit breaker switches on the bus bars or power bus boxes and

toggle the switches to the on position. This action applies DC power to the

server blade enclosures.

IMPORTANT: Be sure to lock all the circuit breaker switches in the on

position. This action prevents anyone from accidentally powering down

the system.

NOTE: Circuit breakers continue to function in the event of an overload

condition even if they are locked.

Page 62

62 HP BladeSystem p-Class Enclosure Installation Guide

4. Be sure that the server blade enclosure DC power LEDs are illuminated

green. Refer to "LEDs, buttons, and switches (on page 63

documentation included with the HP BladeSystem p-Class Server Blade

Enclosure.

Power is now applied to all system hardware.

Completing the installation

To complete the BladeSystem installation, perform the following tasks:

•

Build the management environment.

•

Name the server blade enclosures.

•

Name the server blade components.

•

Update the component firmware.

•

Install operating systems on the server blades.

•

Deploy application software onto the server blades.

)" or to the

•

Establish the SAN environment (optional).

For more information, refer to the HP Remote Insight Lights-Out Edition User

Guide, the HP Remote Insight Lights-Out Edition II User Guide, or the

HP Integrated Lights-Out User Guide available at the Remote Management

website (http://www.hp.com/servers/lights-out

).

Page 63

63

LEDs, buttons, and switches

In this section

LEDs.............................................................................................................................................63

Buttons and switches ....................................................................................................................71

LEDs

Server blade enclosure LEDs

The system contains several sets of LEDs that indicate the status and settings of

hardware components. Use the following sections to determine the location and

functions of LEDs on system components.

For information about LEDs on server blades, interconnect modules, hard drives,

and other devices, refer to the documentation supplied with each device.

The server blade enclosure has two LEDs that provide the status of DC power

input. Use the following figure and table to identify LED locations and functions.

Page 64

64 HP BladeSystem p-Class Enclosure Installation Guide

Item LED Description Status

1 Bus B power Off = No power available

Green = Power available

Red = Polarity reversed

2 Bus A power Off = No power available

Green = Power available

Red = Polarity reversed

Server blade management module LEDs

The server blade management module has LEDs for identification, power status,

and management activity. Use the following figure and table to identify LED

locations and functions.

Item LED Description Status

1 Fault status LED Red = Fault process activity

Off = No fault process

activity

Page 65

LEDs, buttons, and switches 65

Item LED Description Status

2 Unit identification Blue = Identified

Off = No active remote

management

3 Power LED Off = No power

Green = Management

module is powered up

4/5 Power configuration Off/Green = Power zone 1

(default)

Green/Green = Power zone

2 (secondary)

6 Management link

activity LED

7 Management link LED Green = Network linked*

8 iLO activity Green = Activity

9 iLO Link Green = Network linked

* All management link connector LEDs flash on the server blade management modules

and power management modules when management modules are cabled improperly.

Amber = Activity*

Off = No link or activity

Off = No link

Off = No activity

Off = No link

Power management module LEDs

The power management module has LEDs for identification, power status, and

management activity.

IMPORTANT: If the power configuration switch is set improperly, all

power management module management link connector LEDs flash.

IMPORTANT: If management modules are cabled improperly, all

management link connector LEDs flash on all management modules.

Page 66

66 HP BladeSystem p-Class Enclosure Installation Guide

Use the following figure and table to identify LED locations and functions.

Item LED Description Status

1 Management link

activity LED

2 Management link LED Green = Network linked*

3 Power Off = No power

4 Fault status LED Red = Fault process activity

5 UID LED Blue = Identified

6/7 Power configuration Off/Green = Power zone 1

Amber = Network activity*

Off = No link or activity

Off = No link

Green = Management

module is powered up

Off = No fault process

activity

Off = Not identified

(default)

Green/Green = Power zone

2 (secondary)

Page 67

LEDs, buttons, and switches 67

* All management link connector LEDs flash on all management modules when

management modules are cabled improperly. Management link connector LEDs flash on

the power management module only when power configuration switches are set

improperly.

HP BladeSystem p-Class 1U Power Enclosure LEDs

Use the following figure and table to identify LED locations and functions.

Item LED Description Status

1 Bus B DC power

LED

2 Management link

activity LED

3 Management link

LED

4 Power LED Off = No power

Off = No DC power available

Green = DC power available

Amber flashing = Network

activity

Off = No link or activity

Green = Network linked

Off = No link

Green = Management module

is powered up

Page 68

68 HP BladeSystem p-Class Enclosure Installation Guide

Item LED Description Status

5 Fault status LED Red flashing = Fault process

activity

Off = No fault process activity

6 UID LED Blue = Identified

Off = No active remote

management

7, 8 Power zone LEDs See note 1

9 Management link

activity LED

Amber flashing = Network

activity

Off = No link or activity

10 Management link

LED

11 Bus A DC power

LED

1

Power zones are automatically configured based on the location of the enclosures in the

Green = Network linked

Off = No link

Off = No DC power available

Green = DC power available

rack and the management link connections. Disregard the power zone switch and LEDs

on the HP BladeSystem 1U Power Enclosure.

Page 69

LEDs, buttons, and switches 69

HP BladeSystem p-Class 3U Power Enclosure LEDs

The power enclosure has two LEDs, one for each bus, to indicate DC power

presence. Use the following figure and table to identify LED locations and

functions.

Item LED Description Status

1 Bus B DC power Off = No DC power available

Green = DC power available

2 Bus A DC power Off = No DC power available

Green = DC power available

Page 70

70 HP BladeSystem p-Class Enclosure Installation Guide

HP BladeSystem p-Class 1U Power Supply LEDs

The power supply has two LEDs to indicate the power supply status. Use the

following figure and table to identify LED locations and functions.

NOTE: The Dynamic Power Saver configures the available power

supplies to operate at maximum efficiency.

Condition Power LED (1) Fault LED (2)

No AC Off Off

AC available, power

supply in standby mode

Power supply on,

1

Flashing

(Green)

Off

Green Off

delivering power

Power supply fault

condition

1

This condition will occur when the Dynamic Power Saver is enabled.

2

To reset the power supply overload warning, remove AC power or hot-unplug and hot-

2

Off Amber

plug the power supply if more than one power supply in the enclosure is delivering power

to the server enclosure.

Page 71

LEDs, buttons, and switches 71

HP BladeSystem p-Class 3U Power Supply LEDs

The power enclosure has two LEDs, one for each bus, to indicate DC power

presence. Use the following figure and table to identify LED locations and

functions.

Item LED Description Status

1 Bus B DC power Off = No DC power available

2 Bus A DC power Off = No DC power available

Buttons and switches

The system contains switches that reset the systems, identify components of the

systems, and establish the power zone settings. Use the following sections to

determine the location and functions of these switches on system components.

For information about switches on server blades, interconnect modules, hard

drives, and other devices, refer to the documentation supplied with each device.

Green = DC power available

Green = DC power available

Page 72

72 HP BladeSystem p-Class Enclosure Installation Guide

Reset and UID buttons

Each management module contains a reset button and UID button. Use the

following figure and table to identify button locations and functions.

Item Description Function

1 Reset button Reinitializes management

2 UID button Toggles UID LED between on

Power configuration switches

IMPORTANT: In installations configured with the HP BladeSystem 1U

Power Enclosures and Power Supplies, the power zones are calculated

dynamically using the topology information from all the connected

enclosures. Disregard the power zone switch and LEDs on the

HP BladeSystem 1U Power Enclosure.

functions

and off

Page 73

LEDs, buttons, and switches 73

The server blade management modules and power management modules have a

two-position switch that identifies the use of single or multiple power zones in

the rack environment. In installations configured with HP BladeSystem p-Class

3U Power Supply Enclosures, you must set these switches at the time of

installation for the system to recognize multiple power zones and rack topology

properly.

The zone 1 switch setting is the default position. It is used for scalable bus bar,

single mini bus bar, and power bus box solutions. The zone 2 switch setting is

only used for a secondary power zone when you configure a full-rack 42U

solution with two pairs of mini bus bars.

Use the following figure and table to identify switch locations and functions.

Item Description Function

1 Reset switch Reinitializes management

functions

2 UID switch Toggles UID LED between on

and off

After the initial power-up, use the LEDs to verify correct switch settings. Refer

to the "Server blade management module LEDs (on page 64

management module LEDs (on page 65

)" sections in this guide.

)" and "Power

Page 74

74 HP BladeSystem p-Class Enclosure Installation Guide

IMPORTANT: All power configuration switches in the same zone must

be set to the same position. The system issues alerts and the

management link connector LEDs on the power management modules

flash when these switches are set improperly.

To set the switches for multiple power zones, use the following example and

figure.

Example: A full-rack 42U solution with two pairs of mini bus bars requires two

power zones. To distinguish the two power zones, set all the power configuration

switches on management modules in the upper zone (zone 2) to the up position;

the power configuration switches on the management modules in the lower zone

(zone 1) remain in the down (default) position.

Page 75

LEDs, buttons, and switches 75

Item

1 Power zone 2

2 Zone 2 switches in the up (secondary) position

3 Power zone 1

4 Zone 1 switches in the down (default) position

Page 76

Page 77

77

Troubleshooting

In this section

Troubleshooting resources............................................................................................................77

Important safety information........................................................................................................77

Troubleshooting resources

NOTE: For common troubleshooting procedures, the term "server" is

used to mean servers and server blades.

The HP ProLiant Servers Troubleshooting Guide provides simple procedures for

resolving common problems as well as a comprehensive course of action for

fault isolation and identification, error message interpretation, issue resolution,

and software maintenance.

To obtain the guide, refer to any of the following sources and then select the HP

ProLiant Servers Troubleshooting Guide.

•

The server-specific Documentation CD

•

The Business Support Center on the HP website

(http://www.hp.com/support

). You can find the guide by using the navigation

features on the HP website.

• The Technical Documentation website (http://www.docs.hp.com

Enterprise Servers, Workstations and Systems Hardware, and then the

appropriate server.

Important safety information

Familiarize yourself with the safety information in the following sections before

troubleshooting the server.

). Select

Page 78

78 HP BladeSystem p-Class Enclosure Installation Guide

Important safety information

Before servicing this product, read the Important Safety Information document

provided with the server.

Symbols on equipment

The following symbols may be placed on equipment to indicate the presence of

potentially hazardous conditions.

This symbol indicates the presence of hazardous

energy circuits or electric shock hazards. Refer all servicing to

qualified personnel.

WARNING: To reduce the risk of injury from electric shock

hazards, do not open this enclosure. Refer all maintenance,

upgrades, and servicing to qualified personnel.

This symbol indicates the presence of electric