Page 1

Service Gu ide

Publication Number 34970-90012 (order as 34970-90101 manual set)

Edition 3, March 2003

© Copyright Agilent Technologies, Inc. 1997-2003

For Safety information, Warranties, and Regulatory information,

see the pages following the Index.

Note: The schematics for the 34970A are available as a separate

downloadable PDF file from the Agilent web site at www.agilent. com.

Agilent 34970A

Data Acquistion / S witch Unit

Page 2

Page 3

Note: Unless otherwise indicated, this manual applies to all serial numbers.

The Agilent Technologies 34970A combines precision measurement

capability with flexible signal connections for your production and

development test systems. Three module slots are built into the rear

of the instrument to accept any combination of data acquisition or

switching modules. The combination of data logging and data

acquisition features makes this instrument a versatile solution for your

testing requirements now and in the future.

Convenient Data Logging Features

• Direct measurement of thermocouples, RTDs, thermistors, dc voltage,

ac voltage, resistance, dc current, ac current, frequency, and period

• Interval scanning with storage of up to 50,000 time-stamped readings

• Independent channel configuration with function, Mx+B scaling,

and alarm limits available on a per-channel basis

• Intuitive user interface with knob for quick channel selection,

menu navigation, and data entry from the front panel

• Portable, ruggedized case with non-skid feet

• BenchLink Data Logger Software for Microsoft

®

Windows

®

included

Warning

Flexible Data Acquisition / Sw itching Features

1

• 6

⁄

-digit multimeter accuracy, stability, and noise rejection

2

• Up to 60 channels per instrument (120 single-ended channels)

• Reading rates up to 600 readings per second on a single channel and

scan rates up to 250 channels per second

• Choice of multiplexing, matrix, general-purpose Form C switching,

RF switching, digital I/O, totalize, and 16-bit analog output functions

• GPIB (IEEE-488) interface and RS-232 interface are standard

• SCPI (Standard Commands for Programmable Instruments) compatib ility

The procedures in this manual are intended for use by qualified,

service-trained personnel only.

Agilent 34970A

Data Acquisition / S witch Unit

Page 4

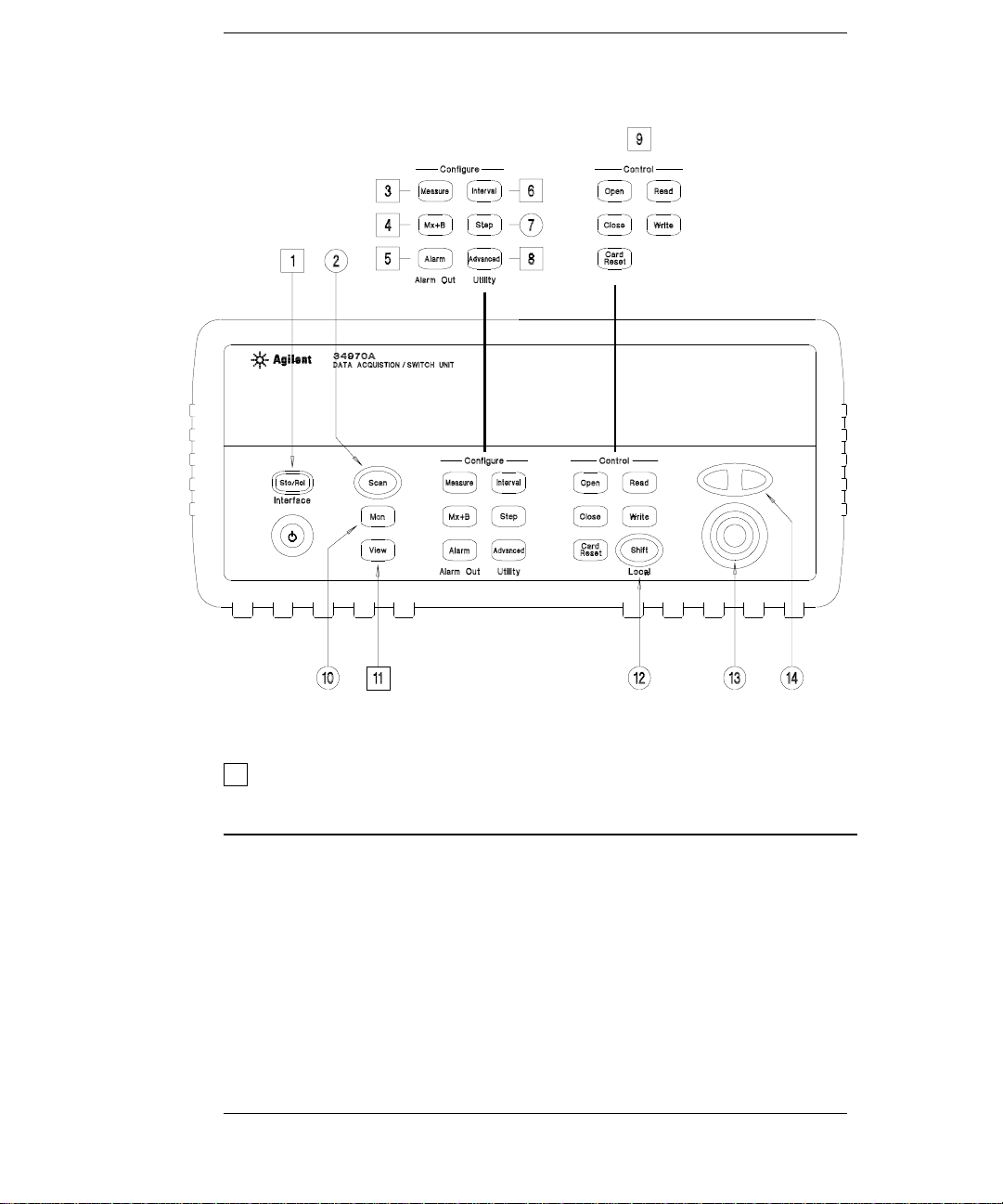

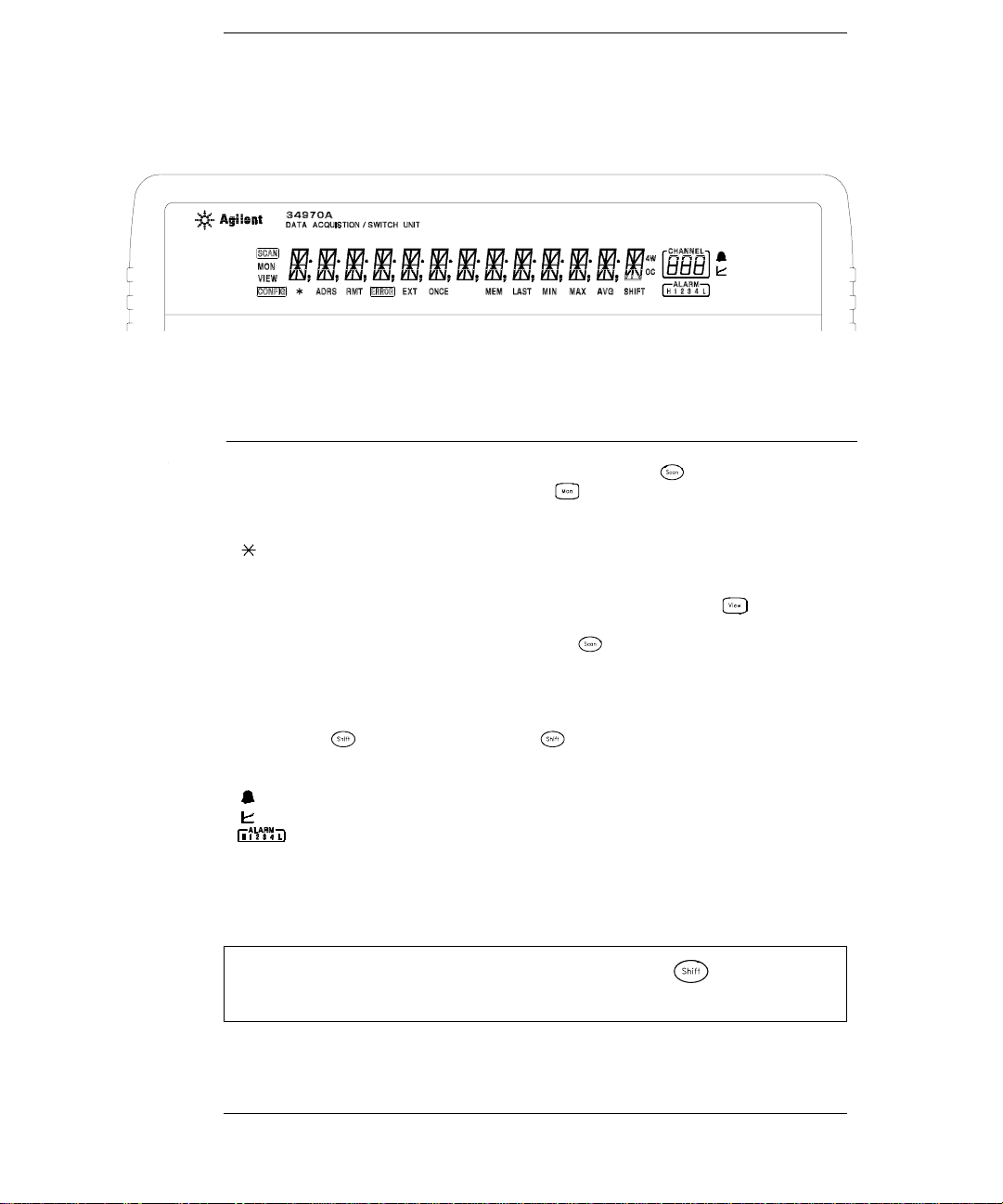

The Front Panel at a Glance

Denotes a menu key. S e e th e n ex t p a g e f or d et a il s on me nu o pe ra tio n .

1 State Storage / Remote Interface Menus

2 Scan Start / Stop Key

3 Measurement Configuration Menu

4 Scaling Configuration Menu

5 Alarm / Alarm Output Configuration Menu

6 Scan-to-Scan Interval Menu

7 Scan List Single Step/Read Key

8 Advanced Measurement / Utility Menus

9 Low-Level Module Contr ol Keys

10 Single-Channel Monitor On/Off Key

11 View Scanned Data, Alarms, Errors Menu

12 Shift / Local Key

13 Knob

14 Navigation Arrow Keys

2

Page 5

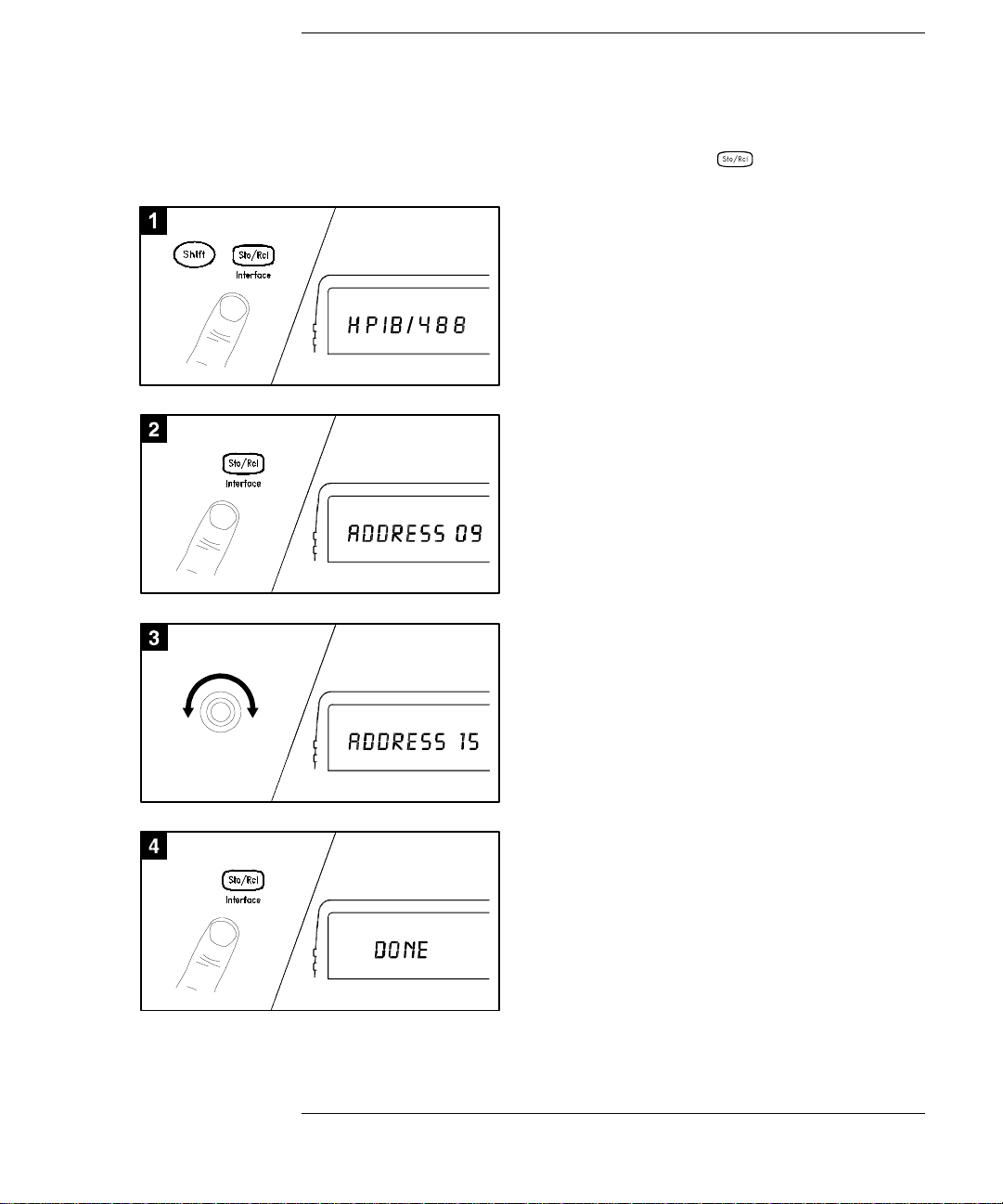

The Front-Panel Menus at a Glance

Several of the front-panel keys guide you through menus to configure

various parameters of the instrument (see previous page). The following

steps demonstrate the menu structure using the key.

1 Press the menu key. You are automatically

guided to the first level of the menu.

Rotate the knob to view the other choices

on the first level of the menu.

The menu will automatically timeout after

about 20 seconds of inactivity. You will be

returned to the operation in progress prior

to entering the menu.

2 Press the same menu key again to move

to the next item of the menu. Typically,

this is where you choose parameter values

for the selected operation.

3 Rotate the knob to view the choices on this

level of the menu. When you reach the end

of the list, rotate the knob in the opposite

direction to view all of the other choices.

The current selection is highlighted for emphasis.

All other choices are dimmed.

4 Press the same menu key again to accept the

change and exit the menu. A brief confirmation

message is displayed.

Tip: To review the current configuration of a specific menu, press the menu key several times.

A message

NO CHANGES is displayed when you exit the menu.

3

Page 6

Display Annunciators

SCAN

MON

VIEW

CONFIG

ADRS

RMT

ERROR

EXT

ONCE

MEM

LAST

MIN

MAX

SHIFT

4W

OC

Scan is in progress or enabled. Press and hold again to t urn of f .

Monitor mode is enabled. Press again to turn off.

Scanned readings, alarms, errors, or relay cycles are being viewed.

Channel configuration is in progress on displayed channel.

Measurement is in progress.

Instrument is addressed to listen or talk over the remote interface.

Instrument is in remote mode (remote interface).

Hardware or remote interface errors are detected. Press to read err o r s .

Instrument is configured for an external scan interval.

Scan Once mode is enabled. Press t o initiat e and hold key to disable.

Reading memory overflow; new readings will overwrite the oldest readings.

Viewed data is the last reading stored during most recent scan.

Viewed data is the minimum reading stored during most recent scan.

Viewed data is the maximum reading stored during most recent scan.

has been pressed. Press again to turn off.

4-wire function is in use on displayed channel.

Offset compensation is enabled on displayed channel.

Alarms are enabled on displayed channel.

Mx+B scaling is enabled on displayed channel.

HI or LO alarm condition has occurred on indicated alarms.

To review the display annunciators, hold down the key as you

turn on the instrument.

4

Page 7

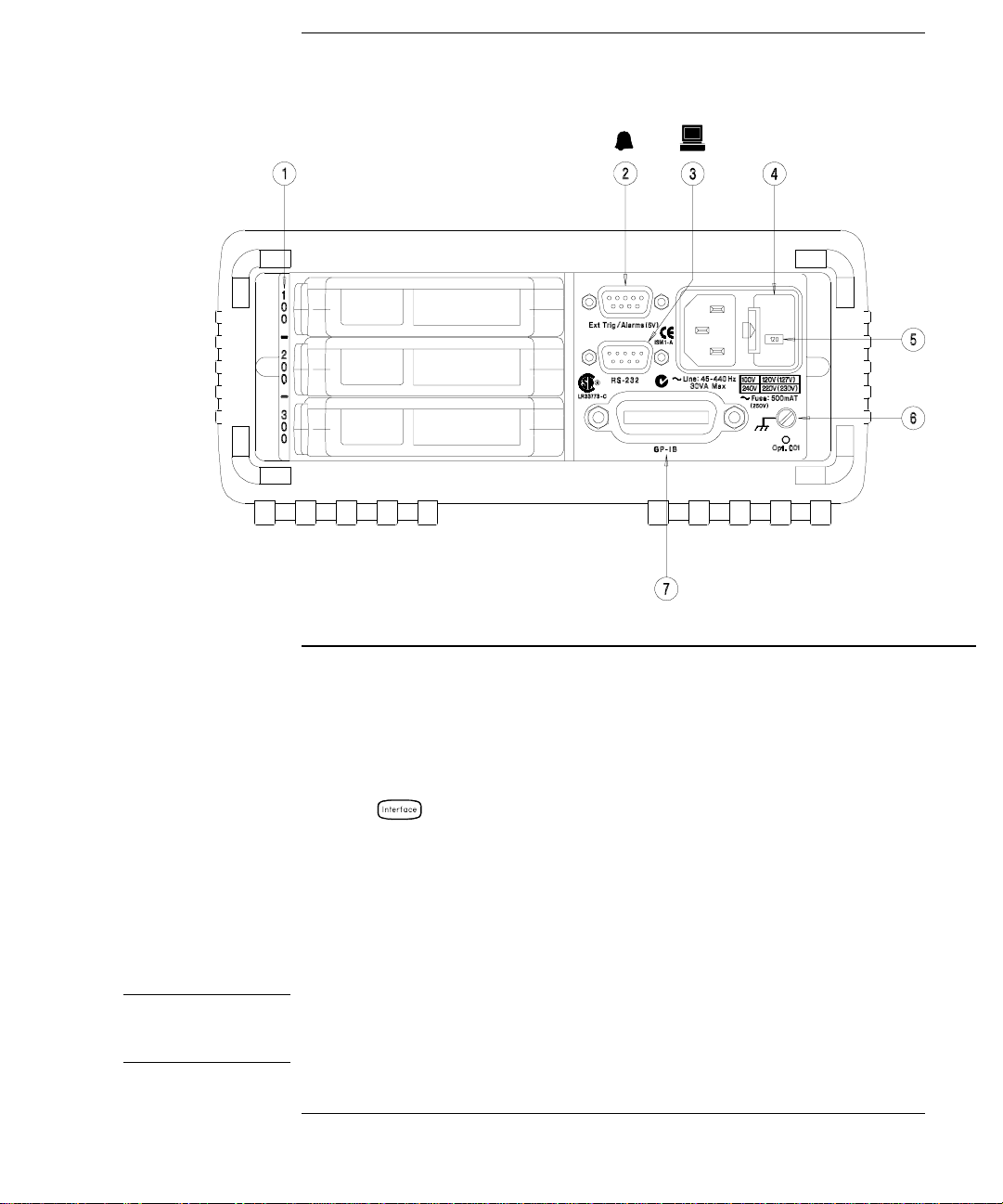

The Rear Panel at a Glance

WARNING

1 Slot Identifier (100, 200, 300)

2 Ext Trig Input / Alarm Outputs / Channel

Advance Input / Channel Closed Output

(for pinouts, see chapter 4 in User’s Guide)

3 RS-232 Interface Connector

Use the Menu to:

• Select the GPIB or RS-232 interface (see chapter 2 in User’s Guide).

• Set the GPIB address (see chapter 2 in User’s Guide).

• Set the RS-232 baud rate, parity, and flow control mode (see chapter 2 in User’s Guide).

4 Power-Line Fuse-Holder Assembly

5 Power-Line Voltage Setting

6 Chassis Ground

7 GPIB (IEEE-488) Interface Connector

For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

5

Page 8

The Plug-In Modules at a Glance

For complete specifications on each plug-in module, refer to the module

sections in chapter 1.

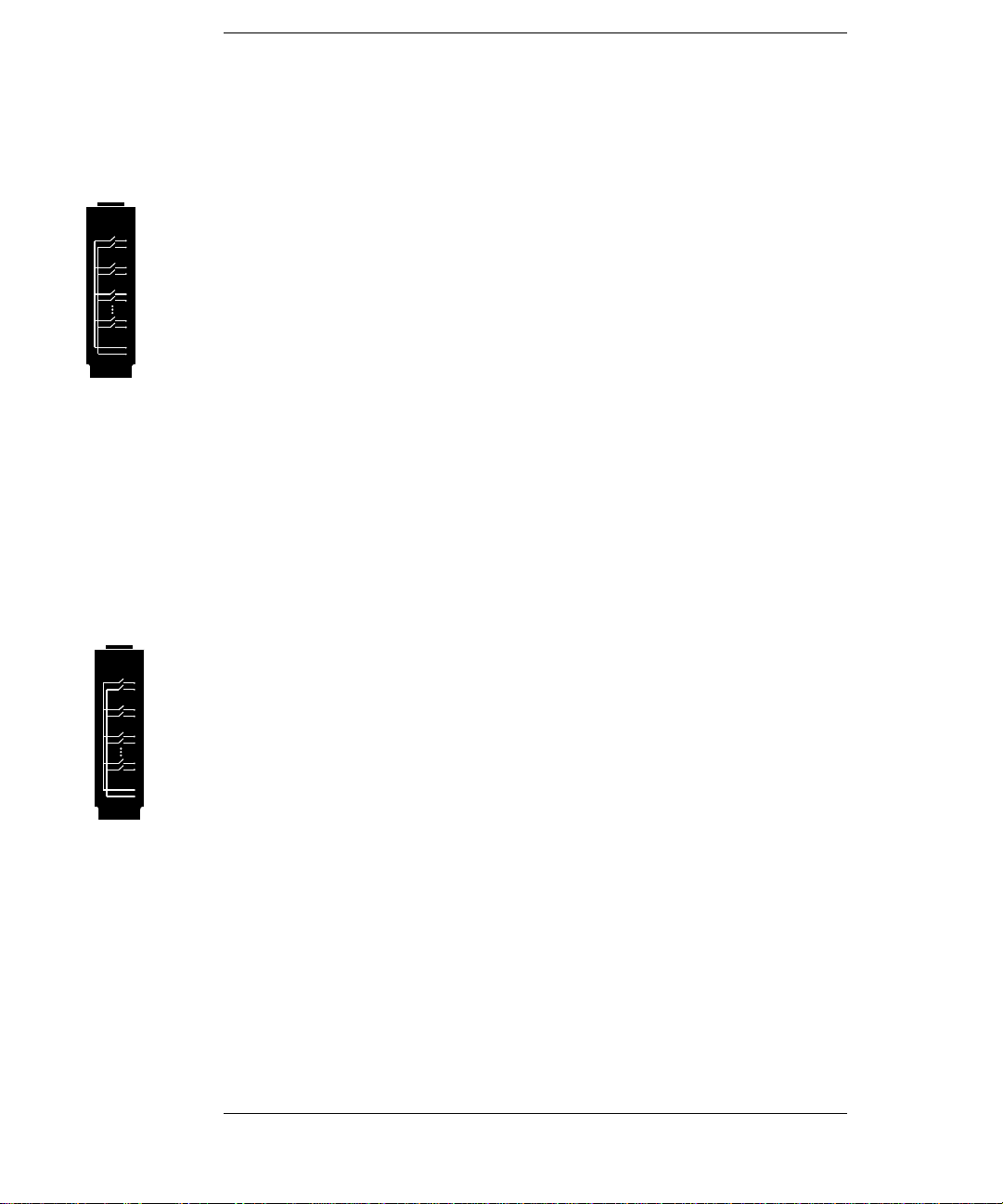

34901A 20-Channel Armature Multiplexer

• 20 channels of 300 V switching

• Two channels for DC or AC current measurements (100 nA to 1 A)

• Built-in ther mocouple reference junction

• Switching speed of up to 60 channels per second

• Connects to the internal multimeter

Each of the 20 channels switches both

fully isolated inputs to the internal multimeter. The module is divided

into two banks of 10 two-wire channels each. When making four-wire

resistance measurements, channels from Bank A are automatically

paired with channels from Bank B. Two additional fused channels are

included on the module (22 channels total) for making calibrated

AC current measurements with the internal multimeter (external shunt

resistors are not required). You can close multiple channels on this

module only if you have not configured any channels to be part of the scan

list. Otherwise, all channels on the module are break-before-make.

HI and LO inputs, thus providing

DC or

34902A 16-Channel Reed Multiplexer

• 16 channels of 300 V switching

• Built-in ther mocouple reference junction

• Switching speed of up to 250 channels per second

• Connects to the internal multimeter

Use this module for high-speed scanning and high-throughput

automated test applications. Each of the 16 channels switches both

HI and LO inputs, thus providing fully isolated inputs to the internal

multimeter. The module is divided into two banks of eight two-wire

channels each. When making four-wire resistance measurements,

channels from Bank A are automatically paired with channels from

Bank B. You can close multiple channels on this module only if you have

not configured any channels to be part of the scan list. Other wise, al l

channels on the module are break-before-make.

6

Page 9

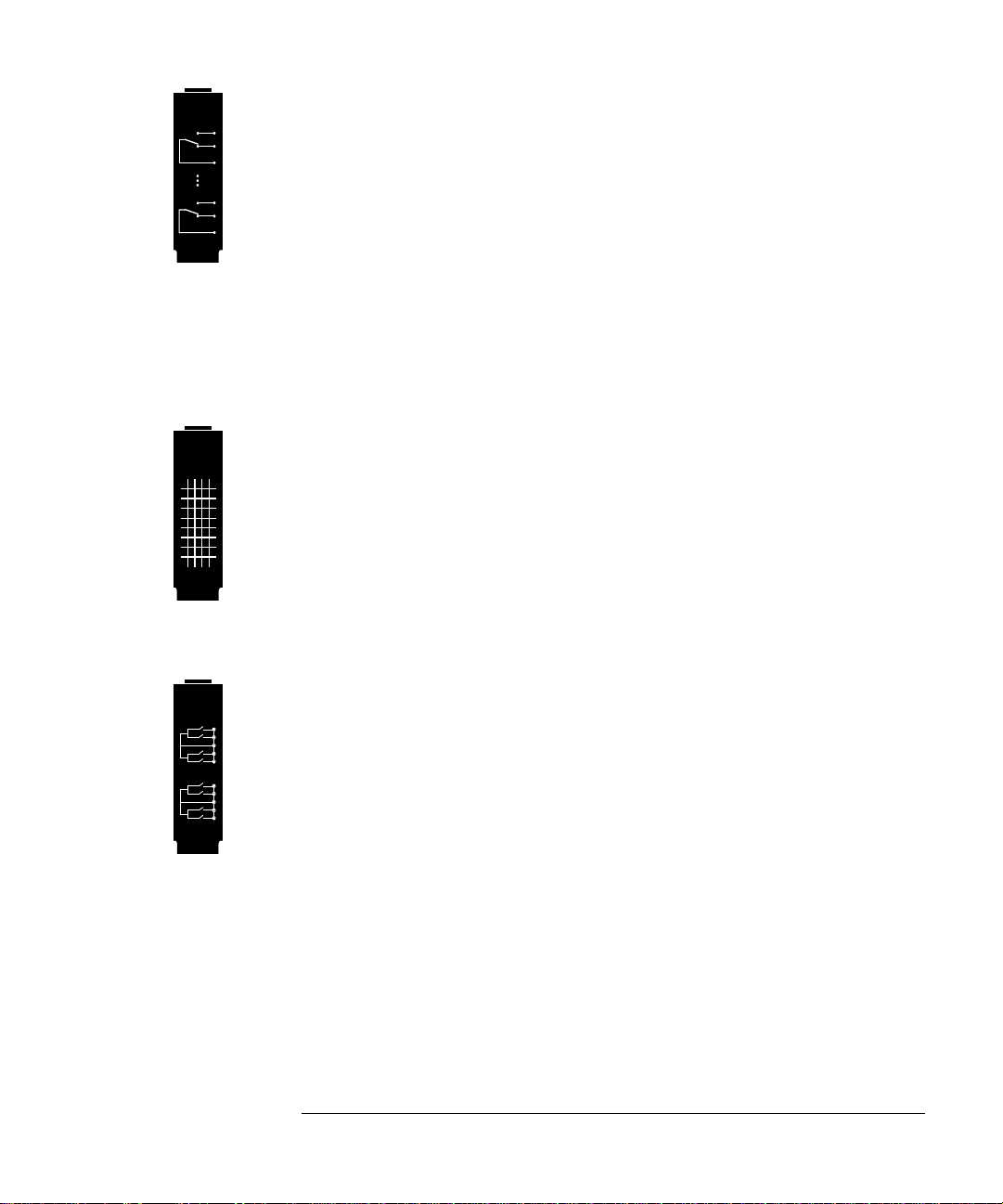

34903A 20-Channel Actuator / G eneral-Purpose Switch

• 300 V, 2 A actuation and switching

• SPDT (Form C) latching relays

• Breadboard area for custom circuits

Use this module for those applications that require high-integrity

contacts or quality connections of non-multiplexed signals. This module

can switch 300 V, 1 A (50 W maximum switch power) to your device

under test or to actuate external devices. Screw terminals on the module

provide access to the Normally-Open, Normally-Closed, and Common

contacts for each of the 20 switches. A breadboard area is provided near

the screw terminals to implement custom circuitry, such as simple

filters, snubbers, or voltage dividers.

34904A 4x8 Two-Wire Matrix Switch

• 32 two-wire crosspoint s

• Any combination of inputs and outputs can be connected at a time

• 300 V, 1 A switching

Use this module to connect multiple instruments to multiple points on

your device under test at the same time. You can connect rows and

columns between multiple modules to build larger matrices such as

8x8 and 4x16, with up to 96 crosspoints in a single mainframe.

34905/6A Dual 4-Channel RF Multiplexers

• 34905A (50Ω ) / 34906A (75Ω )

• 2 GHz bandwidth with on-board SMB connections

• 1 GHz bandwidth with SMB-to-BNC adapter cables provided

These modules offer wideband switching capabilities for high frequency

and pulsed signals. Each module is organized in two independent banks

of 4-to-1 multiplexers. Both modules offer low crosstalk and excellent

insertion loss performance. To create larger

cascade multiple banks together. Only one channel in each bank may be

closed at a time.

RF multiplexers, you can

7

Page 10

34907A Multifunction Module

• Two 8-bit Digital Input/Output ports, 400 mA sink, 42 V open collector

• 100 kHz Totalize input with 28 bits of resolution

• Two 16-bit, ± 12 V Calibrated Analog Outputs

Use this module to sense status and control external devices such as

solenoids, power relays, and microwave switches. For greater flexibility,

you can read digital inputs and the count on the totalizer during a scan.

34908A 40-Channel Single-Ended Multiplexer

• 40 channels of 300 V single-ended (common LO) switching

• Built-in thermocouple isothermal reference junction

• Switching speed of up to 60 channels per second

• Connects to the internal multimeter

Use this module for high-density switching applications which require

single-wire inputs with a common

to ensure that only one relay is connected at any time.

LO. All relays are break-before-make

8

Page 11

In This Book

Specifications Chapter 1 lists the technical specifications for the

mainframe and plug-in modules.

Quick Start Chapter 2 helps you get familiar with a few of the

instrument’s front-panel features.

Front-Panel Overview Chapter 3 introduces you to the front-panel

menus and describes some of the instrument’s menu features.

Calibration Procedures Chapter 4 provides calibration, verification,

and adjustment procedures for the instrument.

Theory of Operation Chapter 5 describes block and circuit level

theory related to the operation the instrument.

Service Chapter 6 provides guidelines for returning your instrument

to Agilent Technologies for servicing, or for servicing it yourself.

Replaceable Parts Chapter 7 contains detailed parts lists for the

mainframe and plug-in modules.

Schematics Chapter 8 contains the instrument’s block diagram,

schematics, disassembly drawings, and component locator drawings.

If you have questions relating to the operation of the 34970A,

call 1-800-452-4844 in the United States, or contact your nearest

Agilent Technologies Sales Office.

If your 34970A fails within three years of original purchase, Agilent will

repair or replace it free of charge. Call 1-877-447-7278 and ask for

“Express Exchange.”

9

Page 12

Contents

Contents

Chapter 1 Specifications

DC, Resistance, and Temperature Accuracy Specifications 16

DC Measurement and Operating Characteristics 17

AC Accuracy Specifications 18

AC Measurement and Operating Characteristics 19

Measurement Rate s an d Sys t em Char a c ter i sti c s 20

Module Specifications 21

BenchLink Data Logger Soft ware Specifications 24

Product and Module Dimensions 25

To Calculate Total Measurement Error 26

Interpreting Internal DMM Specifications 28

Configuring for Highest Accuracy Measurements 31

Chapter 2 Quick Start

To Prepare the Instrument for Use 35

To Connect Wiring to a Module 36

To Set the Time and Date 38

To Configure a Measurement Channel 39

To Monitor a Single Ch an ne l 40

To Close a Channel 41

If the Instrument Does Not Turn On 42

To Adjust the Carrying Handle 44

To Rack Mount the Instrument 45

Chapter 3 Front-Panel Overview

Front-Panel Menu Reference 49

To Unsecure for Calibration 51

To Secure Against Cali br a tio n 51

To Change the Security Code 52

Error Messages 52

To Perform a Zero Adjustment 53

To Apply Mx+B Scaling to Measurements 54

To Read the Relay Cycle Count 55

To Read a Digital Input Port 56

To Write to a Digital Output Port 57

To Read the Totalizer Count 58

To Output a DC Voltage 59

10

Page 13

Contents

Chapter 4 Calibration Procedures

Agilent Technologies Calibration Services 63

Calibration Interval 63

Adjustment is Recommended 63

Time Required for Calibration 64

Automating Calibration Procedures 64

Recommended Test Equipment 65

Input Connections 66

Calibration Security 67

To Unsecure the Instrument Without the Security Code 68

Calibration Message 69

Calibration C o unt 69

Calibration Pr ocedure 70

Aborting a Calibration in Progress 70

Test Considerations 71

Performance Verification Tests 72

Self-Test 73

Quick Performanc e Check 74

Performance Verification Tests 74

Internal DMM Verification Tests 75

Zero Offset Verification 75

Gain Verification 77

Optional AC Performance Verification Tests 80

Internal DMM Adj ustments 81

Zero Adjustment 81

Gain Adjustment 82

–10 Vdc Adjustment Pro cedure (Optional) 85

Plug-in Mo dule Test Consideration s 87

Relay Verification 88

Relay Cycle Count 88

34901A Relay Contact Resistan ce V eri fication (Optional) 89

34902A Relay Contact Resistan ce V eri fication (Optional) 96

34903A Relay Contact Resistan ce V eri fication (Optional) 101

34904A Relay Contact Resistan ce V eri fication (Optional) 102

34905A/06A Relay Contact Resistance Verification (Optional) 105

34908A Relay Contact Resistan ce V eri fication (Optional) 106

Thermocouple Reference Junction (Optional) 112

Thermocouple Reference Junction Verificati on 112

Thermocouple Reference Junction Adjustments 113

34907A Analog Ou tput 114

Analog Output Verification Test 114

Analog Output Adjustment 115

Contents

11

Page 14

Contents

Contents

Chapter 5 Theory of Operation

System Block Diagram 119

Floating Logic 120

Memory 123

Earth-Referenced Logic 124

Power Supplies 125

Front Panel 127

Backplane 128

Analog Bus 128

Digital Bus 128

Internal DMM 129

DMM Block Diagram 129

Input 130

Input Amplifier 131

Ohms Current Source 133

AC Circuit 134

A-to-D Converter 136

Switch Modules 138

Switch Module Control 138

Relay Drivers 140

34901A 142

34902A 144

34903A 146

34904A 147

34905A/34906A 148

34908A 149

Multifunction Mo d ul e 151

Multifunction Control 151

Totalizer 153

Analog Output 154

Digital I/O 155

Chapter 6 Service

Operating Checklist 159

Is the instrument inope rat i v e? 159

Does the instrument fail self-test? 159

Is the Current measurement function inoperative? 159

Types of Service Available 160

Standard Repair Service (worldwide) 160

Express Exchange (U.S.A. only) 160

Repackaging for Shipment 161

Cleaning 161

Electrostatic Discharge (ESD) Precautions 162

Surface Mount Repair 162

To Replace the Power-Line Fuse 163

12

Page 15

Contents

Chapter 6 Service (continued)

Troubleshoot i ng Hi nt s 163

Unit is Inoperative 163

Unit Reports Error 705 164

Isolating to an Assembly 164

Unit Fails Self-Test 164

Power Supplies 165

Self-Test Procedures 167

Power-On Self-Test 167

Complete Self-Test 167

Plug-in Module Self-Test 167

Self-Tests 168

Battery Check and Replacement 172

To Verify the Battery 173

To Replace the Battery 173

Disassembly 174

General Disassembly 175

Internal DMM Disassembly 176

Front-Panel Chassis Disassembly 177

Additional Disassembly 178

Plug-in Module Disassembly 179

Chapter 7 Replaceable Parts

Replaceable Parts 182

To Order Replaceable Parts 182

34970A Mainframe 183

34970-66501 Main PC Assembly (A1) 184

34970-66502 Front-Panel and Keyboard PC Asse mb ly (A2) 189

34970-66503 Backplane PC Assemb ly (A 3) 190

34970-66504 Internal DMM PC Assembly (A4) 191

34901A 20-Channel Multiplexer 196

34902A 16-Channel Multiplexer 200

34903A 20-Channel Actuator 202

34904A 4x8 Matrix 204

34905A/34906A RF Multiplexer 207

34907A Multifunction Modul e 209

34908A 40-Channel Multiplexer 213

Manufacturer’s List 216

Contents

13

Page 16

Contents

Contents

Chapter 8 Schematics

Agilent 34970A System Block Diagram 221

A1 Component Locator (top) 222

A1 Component Locator (bottom) 223

A1 Power Supply Schematic (Sheet 1 of 4) 224

A1 Floating Logic Schematic (Sheet 2 of 4) 225

A1 Earth Referenced Logic Schematic (Sheet 3 of 4) 226

A1 Memory Schematic (Sheet 4 of 4) 227

A2 Component Locator 228

A2 Display and Keyboard Schematic 229

A3 Component Locator 230

A3 Backplane Schematic 231

A4 Component Locator (top) 232

A4 Component Locator (bottom) 233

A4 Input and Protection Schematic (Sheet 1 of 4) 234

A4 Input Amplifier and Ohms Cu rr en t Sch em ati c (Sheet 2 of 4) 235

A4 AC Schematic (Sheet 3 of 4) 236

A4 A/D Converter Schematic (Sheet 4 of 4) 237

34901A 20-Channel M ul tipl exe r Compo ne nt Loc a t or 238

34901A 20-Channel Multiplexer Schematic (Sheet 1 of 5) 239

34901A 20-Channel Multiplexer Schematic (Sheet 2 of 5) 240

34901A 20-Channel Multiplexer Schematic (Sheet 3 of 5) 241

34901A 20-Channel Multiplexer Schematic (Sheet 4 of 5) 242

34901A 20-Channel Multiplexer Schematic (Sheet 5 of 5) 243

34902A 16-Channel M ul tipl exe r Compo ne nt Loc a t or 244

34902A 16-Channel Multiplexer Schematic (Sheet 1 of 4) 245

34902A 16-Channel Multiplexer Schematic (Sheet 2 of 4) 246

34902A 16-Channel Multiplexer Schematic (Sheet 3 of 4) 247

34902A 16-Channel Multiplexer Schematic (Sheet 4 of 4) 248

34903A 20-Chann el Actu at o r Compo ne nt Locator 249

34903A 20-Channel Actuator Schematic (Sheet 1 of 3) 250

34903A 20-Channel Actuator Schematic (Sheet 2 of 3) 251

34903A 20-Channel Actuator Schematic (Sheet 3 of 3) 252

34904A 4x8 Matri x Compo ne nt Loc a tor 253

34904A 4x8 Matrix Schematic (Sheet 1 of 3) 254

34904A 4x8 Matrix Schematic (Sheet 2 of 3) 255

34904A 4x8 Matrix Schematic (Sheet 3 of 3) 256

34905A/34906A R F Mul t ipl exe r Co mpone nt Loc a tor 257

34905A/34906A RF Multiplexer Schematic (Sheet 1 of 2) 258

34905A/34906A RF Multiplexer Schematic (Sheet 2 of 2) 259

34907A Multifun c tio n Mo dul e Com p on en t Locato r 260

34907A Multifunction Modul e Sc hema t ic (S he et 1 of 5) 261

34907A Multifunction Modul e Sc hema t ic (S he et 2 of 5) 262

34907A Multifunction Modul e Sc hema t ic (S he et 3 of 5) 263

34907A Multifunction Modul e Sc hema t ic (S he et 4 of 5) 264

34907A Multifunction Modul e Sc hema t ic (S he et 5 of 5) 265

34908A 40-Channel M ul tipl exe r Compo ne nt Loc a t or 266

34908A 40-Channel Multiplexer Schematic (Sheet 1 of 3) 267

34908A 40-Channel Multiplexer Schematic (Sheet 2 of 3) 268

34908A 40-Channel Multiplexer Schematic (Sheet 3 of 3) 269

14

Page 17

1

• DC, Resistance, and Temperature Accuracy Specifications, on page 16

• DC Measurement and Operating Characteristics, on page 17

• AC Accuracy Specifications, on page 18

• AC Measurement and Operating Characteristics, on page 19

• Measurement Rates and System Characteristics, on page 20

• Module Specifications:

34901A, 34902A, 34908A, 34903A, 34904A, on page 21

34905A, 34906A, on page 22

Typical AC Performance Graphs, on page 23

34907A, on page 24

• BenchLink Data Logger Software Specifications, on page 24

• Product and Module Dimensions, on page 25

• To Calculate Total Measurement Error, on page 26

• Interpreting Multimeter Specifications, on page 28

• Configuring for Highest Accuracy Measurements, on page 31

1

Specifications

Page 18

Chapter 1 Specifications

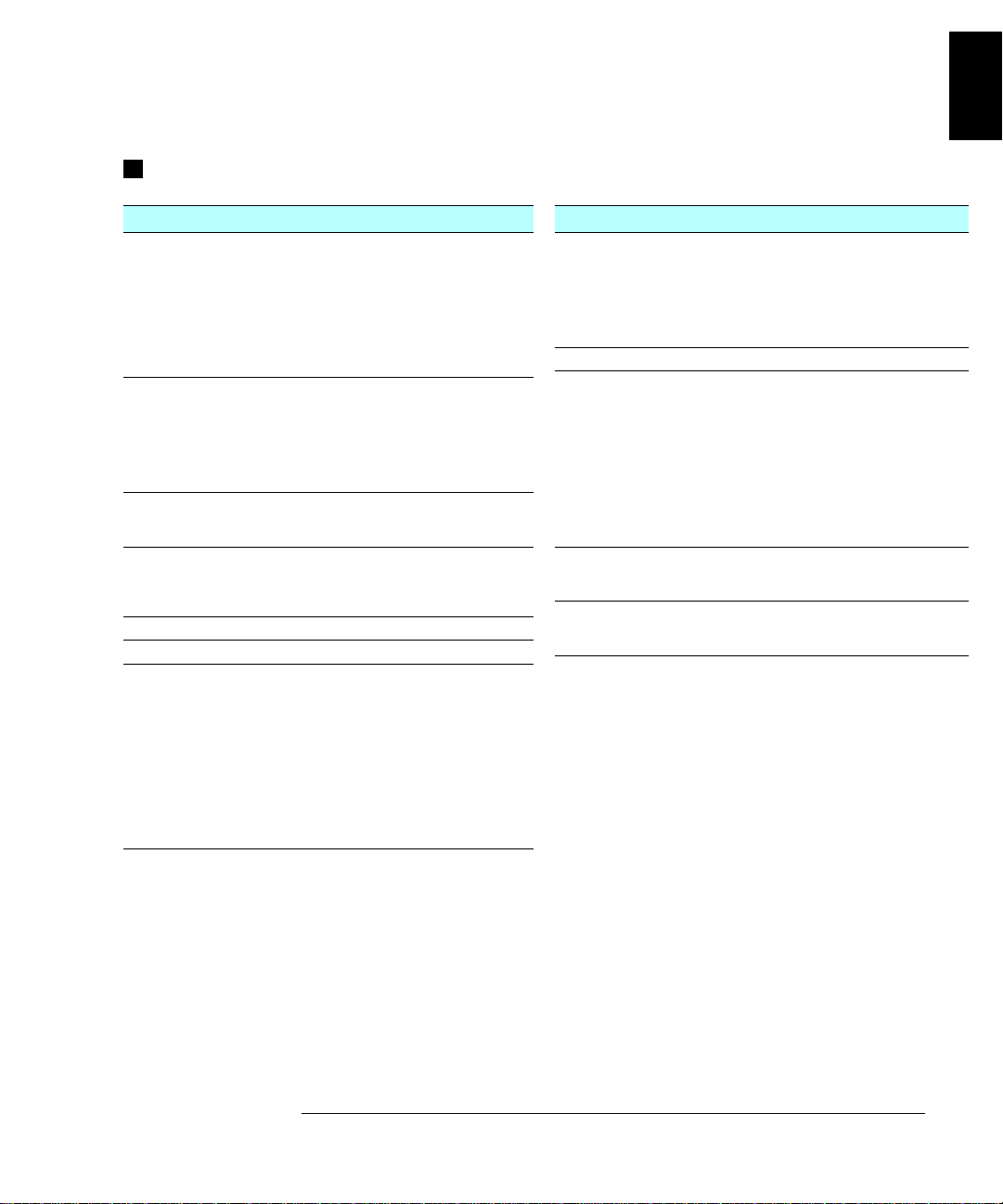

DC, Resistance, and Temperature Accuracy Specifications

DC, Resistance, and Temperature Accura cy Specifications

± ( % of reading + % of range )

[1]

Includes measurement error, switching error, and transducer conversion error

Function Range

[3]

Test Current or

Burden Voltage

DC Voltage 100.0000 mV

1.000000 V

10.00000 V

100.0000 V

300.000 V

Resistance

DC Current

34901A Only

Temperature

Thermocouple

RTD R

[4]

[6]

100.0000 Ω

1.000000 kΩ

10.00000 kΩ

100.0000 kΩ

1.000000 MΩ

10.00000 MΩ

100.0000 MΩ

10.00000 mA

100.0000 mA

1.000000 A

Type

B

E

J

K

N

R

S

T

from 49Ω

0

to 2.1 kΩ

1 mA current source

1 mA

100

10

µA

µA

5

500 nA

500 nA || 10 M

< 0.1 V burden

< 0.6 V

< 2 V

1100

-150

-150

-100

-100

300

400

-100

-200°C to 600°C 0.06°C0.003°C

Thermistor 2.2 k, 5 k, 10 k -80

µA

Ω

Best Range Accuracy

°C to 1820°C

°C to 1000°C

°C to 1200°C

°C to 1200°C

°C to 1300°C

°C to 1760°C

°C to 1760°C

°C to 400°C

°C to 150°C 0.08°C0.002°C

[2]

24 Hour

23 °C ± 1 °C

0.0030 + 0.0035

0.0020 + 0.0006

0.0015 + 0.0004

0.0020 + 0.0006

0.0020 + 0.0020

0.0030 + 0.0035

0.0020 + 0.0006

0.0020 + 0.0005

0.0020 + 0.0005

0.002 + 0.00 1

0.015 + 0.00 1

0.300 + 0.01 0

0.005 + 0.010

0.010 + 0.004

0.050 + 0.006

[5]

1.2

°C

1.0

°C

°C

1.0

1.0

°C

1.0

°C

°C

1.2

1.2

°C

1.0

°C

90 Day

23 °C

± 5 °C

0.0040 + 0.0040

0.0030 + 0.0 00 7

0.0020 + 0.0 00 5

0.0035 + 0.0 00 6

0.0035 + 0.0 03 0

0.008 + 0.004

0.008 + 0.001

0.008 + 0.001

0.008 + 0.001

0.008 + 0.001

0.020 + 0.001

0.800 + 0.010

0.030 + 0.020

0.030 + 0.005

0.080 + 0.010

23 °C

0.0050 + 0.0040

0.0040 + 0.0 00 7

0.0035 + 0.0 00 5

0.0045 + 0.0 00 6

0.0045 + 0.0 03 0

0.010 + 0.004

0.010 + 0.001

0.010 + 0.001

0.010 + 0.001

0.010 + 0.001

0.040 + 0.001

0.800 + 0.010

0.050 + 0.020

0.050 + 0.005

0.100 + 0.010

Extended Range Accuracy

400

°C to 1100°C

-200

°C to -150°C

°C to -150°C

-210

-200

°C to -100°C

-200

°C to -100°C

°C to 300°C

-50

-50

°C to 400°C

-200

°C to -100°C

1 Year

± 5 °C

1.8

°C

1.5

°C

°C

1.2

1.5

°C

1.5

°C

°C

1.8

1.8

°C

1.5

°C

[5]

Temperature

Coefficient /°C

0 °C – 18 °C

28 °C – 55 °C

0.0005 + 0.0005

0.0005 + 0.0001

0.0005 + 0.0001

0.0005 + 0.0001

0.0005 + 0.0003

0.0006 + 0.0005

0.0006 + 0.0001

0.0006 + 0.0001

0.0006 + 0.0001

0.0010 + 0.0002

0.0030 + 0.0004

0.1500 + 0.0002

0.002 + 0.0020

0.002 + 0.0005

0.005 + 0.0010

0.03

°C

0.03

°C

°C

0.03

0.03

°C

0.03

°C

°C

0.03

0.03

°C

0.03

°C

1

⁄

[1] Specifications are for 1 hour warm up and 6

[2] Relative to calibration standards

digits

2

[3] 20% over range on all ranges except 300 Vdc and 1 Adc range s

[4] Specifications are for 4-wire ohms function or 2-wire ohms using Scaling to remove the offset.

Without Scaling, add 4

Ω additional error in 2-wire ohms function.

[5] 1 year acc uracy. For total measurement accuracy, add tempe r ature probe error.

[6] Thermocouple specifications not guaranteed when 34907A module is present

16

Page 19

Chapter 1 Specifications

DC Measurement and Operating Characteristics

DC Measurement and Operating Characteristics

1

DC Measurement Characteristics

[1]

DC Voltage

Measurement Method:

Continuously Integrating,

Multi-slope III A/D Converter

A/D Linearity :

0.00 02 % of reading + 0. 00 01 % of range

Input Resistance:

100 mV, 1 V, 10 V ranges

100 V, 300 V ranges

Input Bias Current:

Input Protection:

Selectable 10 M

Ω or >10 GΩ

10 MΩ ±1%

< 30 pA at 25

°C

300 V on all ranges

Resistance

Measurement Method:

Offset Compensation:

Max. Lead Resistance:

Input Protection:

Selectable 4-wi re or 2- wire O hms,

Current source reference to LO input

Selectable on 100

Ω, 1 kΩ, 10 kΩ ranges

10% of range per lead for 100

1 k

Ω ranges. 1 kΩ on all other range s

300 V on all ranges

DC Current

Shunt Resistance:

Input Protection:

5

Ω for 10 mA, 100 mA; 0.1Ω for 1A.

1.5A 250 V fuse on 34901A module

Thermocouple

Conversion:

Reference Junction Type:

Open T/C Check:

ITS-90 software compensation

Internal, Fixed, or External

Selectable per channel. Open > 5 k

RTD α = 0.00385 (DIN ) and 0 . 00 391

Thermistor 44004, 44007, 44006 series

Measurement Noise Rejection 60 Hz (5 0 Hz)

DC CMRR:

Integration Time

200 PLC / 3.33s (4s)

100 PLC / 1.67s (2s)

20 PLC / 333 ms (400 ms)

10 PLC / 167 ms (200 ms)

2 PLC / 33.3 ms (40 ms)

1 PLC / 16.7 ms (20 ms)

< 1 PLC

140 dB

Normal Mode Rejection

[4]

110 dB

[4]

105 dB

[4]

100 dB

[4]

95 dB

90 dB

60 dB

0 dB

[2]

[3]

Ω and

DC Operating Characteristics

[6]

Function

DCV, DCI, and

Resistance:

Single Channel Measurement Rates

Function

DCV, 2-Wire Ohms:

Thermocouple:

Digits

1

6

⁄

2

1

6

⁄

2

1

5

⁄

2

1

5

⁄

2

1

4

⁄

2

Resolution

1

6

⁄

(10 PLC)

2

1

5

⁄

(1 PLC)

2

1

⁄

(0.02 PLC)

4

2

0.1

°C (1 PLC)

[5]

Readings/s

0.6 (0.5)

6 (5)

60 (50)

300

600

[8]

Additional

Noise Error

0% of range

0% of range

0.001% of range

0.001% of range

0.01% of range

(0.02 PLC)

0.01

RTD, Thermistor:

0.1

°C (0.02 PLC)

1

°C (10 PLC)

°C (1 PLC)

Autozero OFF Operation

Following instrument warm-up at calibration temperature

and < 10 minutes, add 0.0002% range additional error + 5

Ω

Settling Considerations

Reading settling times are affected by source impedance,

low dielectric absorption characteristics, and input signal changes.

[1] 300 Vdc isolation voltage (ch-ch, c h-earth)

[2] For 1 k

[3] For power line frequency

[4] For power line frequency

For power line frequency

[5] Reading speeds for 60 Hz and (50 Hz) operation; autozero OFF

[6] 6

[7] Add 20

Ω unbalance in LO lead

1

⁄

digits=22 bits, 5

2

µV for DCV, 4 µA for DCI, or 20 mΩ for resistance

±0.1%

±1%, use 80 dB.

±3%, use 60 dB .

1

⁄

digits=18 bits, 4

2

1

⁄

digits=15 bits

2

[8] For fixed function and range, readings to memory,

scaling and alarms off, autozero OFF

[7]

[7]

Readings/s

6 (5)

57 (47)

600

57 (47)

220

6 (5)

57 (47)

220

±1 °C

µV.

17

Page 20

Chapter 1 Specifications

AC Accuracy Specifications

AC Accuracy Specifications

± ( % of reading + % of range )

[1]

Includes measurement error, switching error, and transducer conversion error

Function Range

[3]

Frequency

24 Hour

[2]

23 °C ± 1 °C

90 Day

23 °C

± 5 °C

1 Year

23 °C

± 5 °C

Temperature

Coefficient /°C

0 °C – 18 °C

28 °C – 55 °C

True RMS

AC Voltage

Frequency

and Period

True RMS

AC Current

34901A Only

100.0000 mV

[4]

to 100 V

300.0000 V 3 Hz – 5 Hz

[6]

100 mV

to

300 V

10.00000 mA

and

1.000000 A

100.0000 mA

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 20 kHz

20 kHz – 50 kHz

50 kHz – 100 kHz

100 kHz – 300 kHz

5 Hz – 10 Hz

10 Hz – 20 kHz

20 kHz – 50 kHz

50 kHz – 100 kHz

100 kHz – 300 kHz

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 40 Hz

40 Hz – 300 kHz

[4]

3 Hz – 5 Hz

5 Hz – 10 Hz

[4]

10 Hz – 5 kHz

[7]

3 Hz – 5 Hz

5 Hz – 10 Hz

10 Hz – 5 kHz

[5]

[5]

1.00 + 0.03

0.35 + 0.03

0.04 + 0.03

0.10 + 0.05

0.55 + 0.08

4.00 + 0.50

1.00 + 0.05

0.35 + 0.05

0.04 + 0.05

0.10 + 0.10

0.55 + 0.20

4.00 + 1.25

0.10

0.05

0.03

0.006

1.00 + 0.04

0.30 + 0.04

0.10 + 0.04

1.00 + 0.5

0.30 + 0.5

0.10 + 0.5

1.00 + 0.04

0.35 + 0.04

0.05 + 0.04

0.11 + 0.05

0.60 + 0.08

4.00 + 0.50

1.00 + 0.08

0.35 + 0.08

0.05 + 0.08

0.11 + 0.12

0.60 + 0.20

4.00 + 1.25

0.10

0.05

0.03

0.01

1.00 + 0.04

0.30 + 0.04

0.10 + 0.04

1.00 + 0.5

0.30 + 0.5

0.10 + 0.5

1.00 + 0.04

0.35 + 0.04

0.06 + 0.04

0.12 + 0.05

0.60 + 0.08

4.00 + 0.50

1.00 + 0.08

0.35 + 0.08

0.06 + 0.08

0.12 + 0.12

0.60 + 0.20

4.00 + 1.25

0.10

0.05

0.03

0.01

1.00 + 0.04

0.30 + 0.04

0.10 + 0.04

1.00 + 0.5

0.30 + 0.5

0.10 + 0.5

0.100 + 0.004

0.035 + 0.004

0.005 + 0.004

0.011 + 0.005

0.060 + 0.008

0.20 + 0.02

0.100 + 0.008

0.035 + 0.008

0.005 + 0.008

0.011 + 0.012

0.060 + 0.020

0.20 + 0.05

0.100 + 0.006

0.035 + 0.006

0.015 + 0.006

0.100 + 0.06

0.035 + 0.06

0.015 + 0.06

Additional Low Frequency Error for ACV, ACI (% of reading) Additional Error for Frequency, Period (% of reading)

Frequency

10 Hz - 20 Hz

20 Hz - 40 Hz

40 Hz - 100 Hz

100 Hz - 200 Hz

200 Hz - 1 kHz

> 1 kHz

AC Filter

Slow

0

0

0

0

0

0

AC Filter

Medium

0.74

0.22

0.06

0.01

AC Filter

Fast

—

—

0.73

0.22

0

0

0.18

0

Frequency

3 Hz - 5 Hz

5 Hz - 10 Hz

10 Hz - 40 Hz

40 Hz - 100 Hz

100 Hz - 300 Hz

300 Hz - 1 kHz

> 1 kHz

6

1

⁄

2

Digits

0

0

0

0

0

0

0

1

5

⁄

Digits

2

0.12

0.17

0.2

0.06

0.03

0.01

0

1

4

⁄

Digits

2

0.12

0.17

0.2

0.21

0.21

0.07

0.02

0.005

0.005

0.001

0.001

[1] Specifications are for 1 hour warm up and 6

[2] Relative to calibration standards

1

⁄

digits, Slow ac filter

2

[3] 20% over range on all ranges except 300 Vac and 1 Aac ranges

[4] For sinewave input > 5% of range. For inputs from 1% to 5% of range and < 50 kHz, add 0.1% of range additional error.

[5] Typically 30% of reading error at 1 MHz, limited to 1x10

8

V Hz

[6] Input > 100 mV. For 10 mV inputs, multiply % of reading error x 10.

[7] Specified only for inputs > 10 mA

18

Page 21

Chapter 1 Specifications

AC Measurement and Operating Characteristics

AC Measurement and Operating Characteristics

1

AC Measurement Characteristics

True RMS AC Voltage

Measurement Method:

AC-coupled True RMS – measures

the ac component of input with up

[1]

to 300 Vdc of bias on any range

Crest Factor :

Additional Crest Factor

Errors (non-sinewave):

Maximum 5:1 at Full Scale

[2]

Crest Factor 1-2: 0.05% of reading

Crest Factor 2-3: 0.15% of reading

Crest Factor 3-4: 0.30% of reading

Crest Factor 4-5: 0.40% of reading

AC Filter Bandwidth:

Slow

Medium

Fast

Input Impedance:

Input Protection:

3 Hz – 300 kHz

20 Hz – 300 kHz

200 Hz – 300 kHz

1 M

Ω ± 2%, in parallel with 150 pF

300 Vrms on all ranges

Frequency and Period

Measurement Method:

Voltage Rang es:

Gate Time:

Measurement Timeout:

True RMS AC Current

Measurement Method:

Reciprocal c ount i ng tec hni qu e

Same as AC Voltage function

1s, 100 ms, or 10 ms

Selectable 3 Hz, 20 Hz, 20 0 Hz LF li mit

Direct coupled to the fuse and

shunt. AC-coupled True RMS

measurement (measures the

ac component only)

5

Shunt Resistance:

Input Protection:

Measurement Noi se Rejection

Ω for 10 mA; 0.1Ω for 100 mA, 1A

1.5A 250 V fuse on 34901A module

[3]

AC CMRR: 70 dB

Measurement Considerations (Frequency and Period)

All frequency counters are susceptible to error when measuring

low-voltage, low-frequency signals. Shielding inputs from

external noise pickup is critical for minimizing measurement errors.

AC Operating Characteristics

Function

ACV, ACI:

1

6

Single Channel Measurement Rates

Function

ACV:

Frequency, Period:

[5]

Digits

1

6

⁄

2

1

6

⁄

2

1

6

⁄

2

1

6

⁄

2

⁄

2üxç31ç33 Çä 32é

Resolution

1

6

⁄

Slow (3 Hz)

2

1

6

⁄

Medium (20 Hz)

2

1

⁄

Fast (200 Hz)

6

2

1

6

⁄

2üxç31ç33 Çä 32é

1

6

⁄

Digits (1s gate)

2

1

⁄

Digits (1s gate)

6

2

1

5

⁄

Digits (100 ms)

2

1

5

⁄

Digits (100 ms)

2

1

4

⁄

Digits (10 ms)

2

1

4

⁄

Digits (10 ms)

2

[4]

Readings/s

7 sec/reading

1

[6]

8

10

[7]

100

[8]

[7]

[7]

[7]

[7]

AC Filter

Slow (3 Hz)

Medium (20 Hz)

Fast (200 Hz)

Fast (200 Hz)

Fast (200 Hz)

Readings/s

0.14

1

8

100

0.77

1

2.5

9

3.2

70

[1] 300 Vrms isolation voltage (ch-ch, ch-earth)

[2] For frequencies below 100 Hz, slow AC filter specified for

sinewave input only

[3] For 1 k

Ω unbalance in LO lead

[4] Maximum reading rates for 0.01% of ac step additional error.

Additional settling delay required when input dc level varies.

1

[5] 6

⁄

digits=22 bits, 5

2

[6] For external trigger or remote operation using default

1

⁄

digits=18 bits, 4

2

1

⁄

digits=15 bits

2

settling delay (Delay Auto)

[7] Maximum limit with default settling delays defeated

[8] For fixed function and range, readings to memory,

scaling and alarms turned off

19

Page 22

Chapter 1 Specifications

Measurement Rates and System Characteristics

Measurement Rates and System Characteristics

Single Channel Meas ure me nt Rate s

Function

DCV, 2-Wire Ohms:

Thermocouple:

RTD, Thermistor:

ACV:

Frequency, Period:

System Speeds

INTO Memory

Single Channel DCV

34902A Scanning DCV

34907A Scanning Digital Input

34902A Scanning DCV, scaling and 1 alarm fail

34907A Scanning Totalize

34902A Scanning T emperature

34902A Scanning ACV

34902A Scanning DCV/Ohms, alternate channels

34901A/34908A Scanning DCV

Resolution

1

⁄

(10 PLC)

6

2

1

5

⁄

(1 PLC)

2

1

4

⁄

(0.02 PLC)

2

0.1

°C (1 PLC)

(0.02 PLC)

0.01

°C (10 PLC)

0.1

°C (1 PLC)

°C (0.02 PLC)

1

1

⁄

Slow (3 Hz)

6

2

1

⁄

Medium (20 Hz)

6

2

1

⁄

Fast (200 Hz)

6

2

[3]

1

6

⁄

2

1

⁄

Digits (1s gate)

6

2

1

5

⁄

Digits (100 ms)

2

1

4

⁄

Digits (10 ms)

2

[4]

[3]

[1] [2]

Readings/s

6 (5)

53 (47)

490

49 (47)

280

6 (5)

47 (47)

280

0.14

1

8

100

1

9

70

Ch/s

490

250

250

220

170

160

100

90

60

INTO and OUT of Memory to GPIB or RS-232 (INIT, FETCh)

34902A Scanning DCV

34902A Scanning DCV with Time stamp

OUT of Memory to GPIB

[5]

Readings

Readings with Time stamp

Readings with all Format Options ON

180

150

800

450

310

OUT of Memory to RS-232

Readings

Readings with Time stamp

Readings with all Format Options ON

600

320

230

DIRECT to GPIB or RS-232

Single Channel DCV

34902A Scanning DCV

Single Channel MEAS DCV 10 or MEAS DCV 1

Single Channel MEAS DCV or MEAS OHMS

440

200

25

12

System Characteristics

Scan Triggering

Scan Count:

Scan Interval:

Channel Delay:

External Trig Delay:

External Trig Jitter:

Alarms

Alarm Outputs:

Latency:

Memory

Readings:

Time Stamp Resolution:

Relative

Absolute

States:

Alarm Queue:

General Specifications

Power Supply:

Power Line Frequency:

Power Consumption:

Operating Environment:

Storage Environment:

Weight (Mainframe):

Safety:

RFI and ESD:

Warranty:

[1] Reading speeds for 60 Hz and (5 0 Hz) operation; autozero OFF

[2] For fixed function and range, readings to memory,

scaling and alarms off, autozero OFF

[3] Maximum limit with default settling delays defeated

[4] Speeds are for 4

Using 115 kbaud RS-232 setting.

[5] Assumes relative time format (time since start of scan)

[6] Storage at temperatures above 40

This ISM device complies with Cana dian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001

du Canada.

N10149

1 to 50,000 or continuous

0 to 99 hours; 1 ms step size

0 to 60 seconds/channel; 1 ms step size

< 300

µs; With Monitor On, < 200 ms

< 2 ms

4 TTL compatible. Select able TTL l ogic

HI or LO on Fail

5 ms (typical)

Battery Backed, 4 year typical life

50,000 readings

1 ms

1 s

5 instrument states

Up to 20 events

100 V / 120 V / 220 V / 240 V

45 Hz to 66 Hz automatically sensed

(12 W) 25 VA peak

Full accuracy for 0

Full accuracy to 80% R.H. at 40

°C to 70 °C

-40

°C to 55 °C

[6]

Net: 3.6 kg (8.0 lbs)

Conforms to CSA, UL-1244, IEC 1010 Cat I

CISPR 11, IEC 801/2/3/4

3 years

1

⁄

digits, delay 0, display off, autozero off.

2

°C will decrease battery life

[6]

±10%

°C

20

Page 23

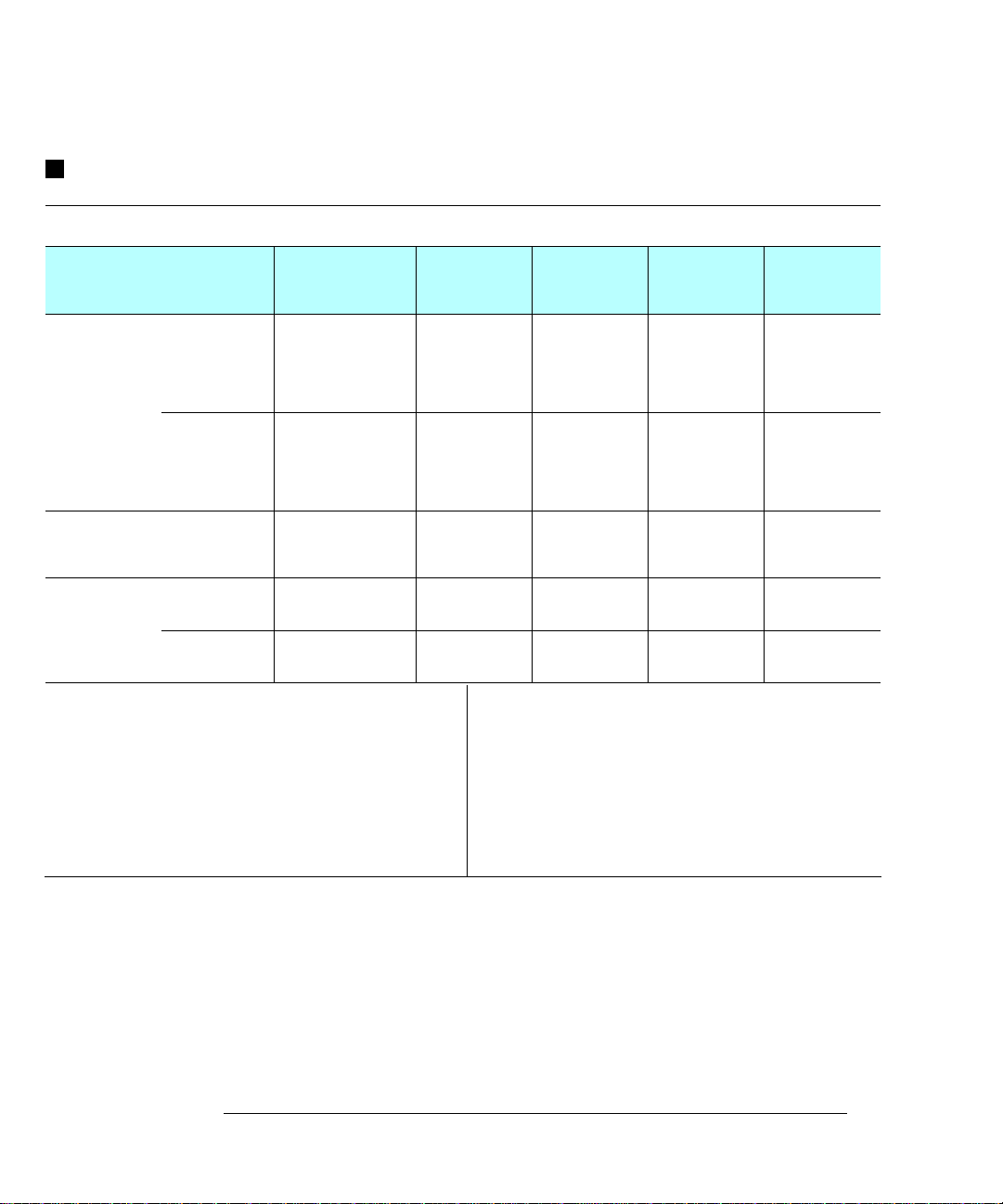

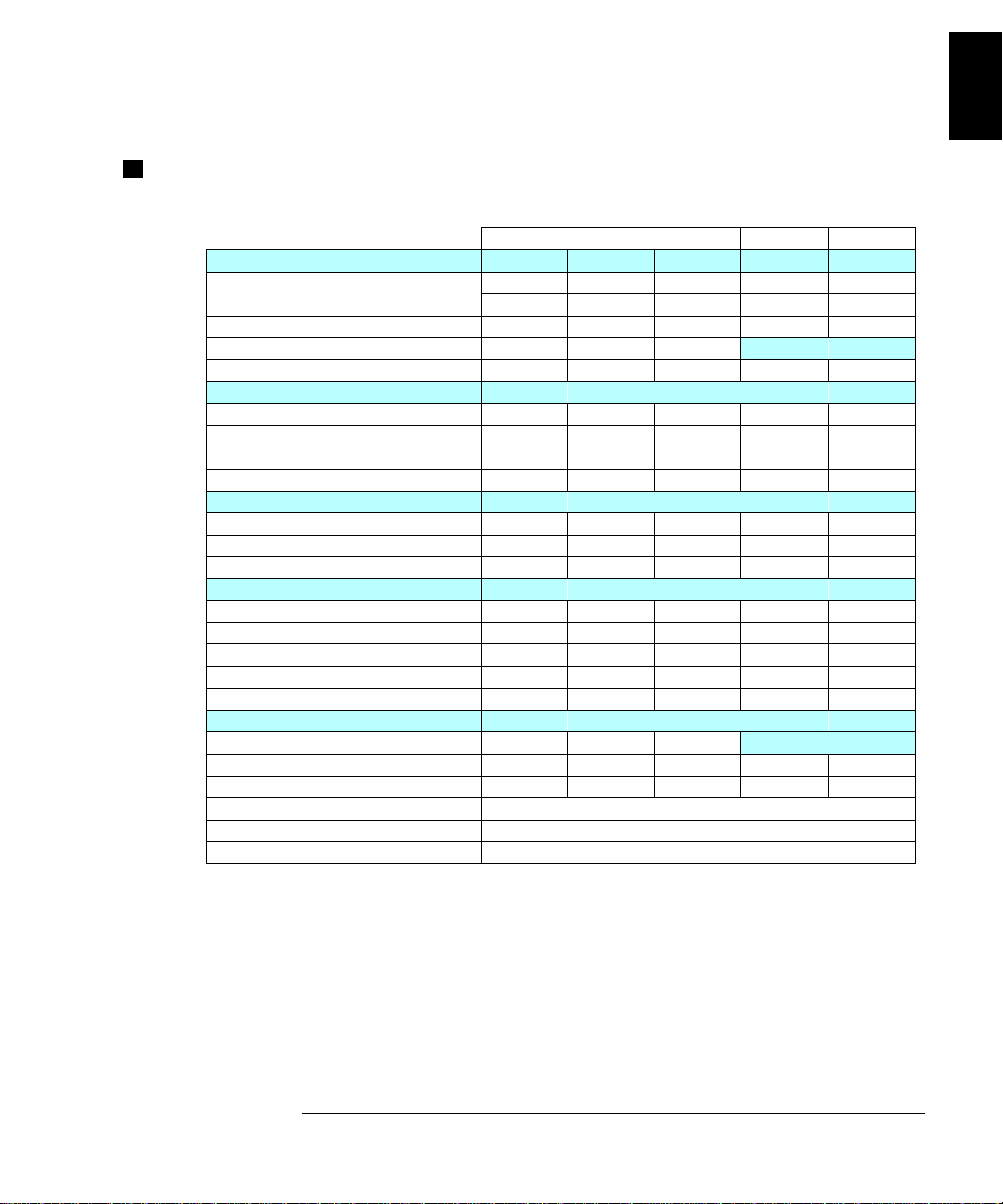

Chapter 1 Specifications

Module Specifications

Module Specifications

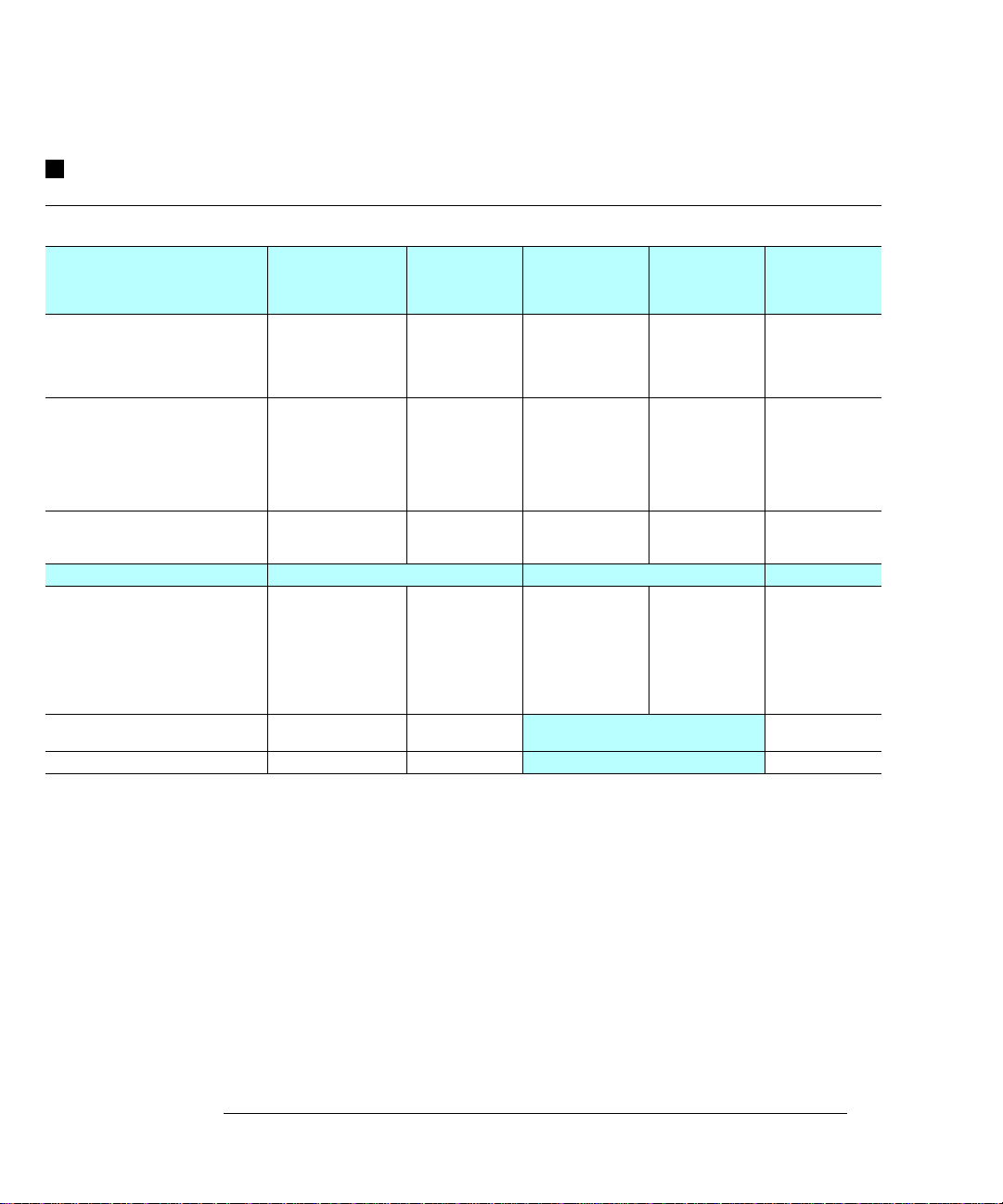

34901A, 34902A, 34908A, 34903A, 34904A

General 34901A

Number of Channels 20+2 16 40 20 4x8

2/4 wire 2/4 wire 1 wire SPDT 2 wire

Connects to Internal DMM Yes Yes Yes No No

Scanning Speed

Open/Close Speed 120/s 120/s 70/s 120/s 120/s

Maximum Input

Voltage (dc, ac rms) 300 V 300 V 300 V 300 V 300 V

Current (dc, ac rms ) 1 A 50 mA 1 A 1 A 1 A

Power (W, VA) 50 W 2 W 50 W 50 W 50 W

Isolation (ch-ch, ch-earth) dc, ac rms 300 V 300 V 300 V 300 V 300 V

DC Characteristi cs

Offset Voltage

Initial Closed Channel R

Isolation (ch-ch, ch-earth) > 10 GΩ > 10 GΩ > 10 GΩ > 10 GΩ > 10 GΩ

AC Characteristi cs

Bandwidth 10 MHz 10 MHz 10 MHz 10 MHz 10 MHz

Ch-Ch Cross Talk (dB)

Capacitance HI to LO < 50 pF < 50 pF < 50 pF < 10 pF < 50 pF

Capacitance LO to Earth < 80 pF < 80 pF < 80 pF < 80 pF < 80 pF

Volt-Hertz Limit

Other

T/C Cold Junction Accuracy

Switch Life No Load (typical) 100M 100M 100M 100M 100M

Switch Life Rated Load (typical)

Temperature Operating All Modules – 0

Temperature Storage All Modules – -20

Humidity (non-condensing) All Modules – 40

[1]

[2]

[2]

[3]

10 MHz -45 -45 -18

60 ch/s 250 ch/s 60 ch/s

< 3 µV< 6 µV< 3 µV< 3 µV< 3 µV

< 1Ω < 1Ω < 1Ω < 0.2Ω < 1Ω

10

[2] [5]

(typical) 0.8 °C0.8 °C0.8 °C

[6]

100k 100k 100k 100k 100k

Multiplexer Actuator Matrix

34902A 34908A 34903A 34904A

[4]

8

108 108 108 108

[7]

°C to 55 °C

°C to 70 °C

°C / 80% R.H.

-45 -33

1

1

⁄

[1] Speeds are for 4

[2] Errors included in the DMM measurement accuracy specifications

[3] 50

Ω source, 50Ω load

digits, delay 0, display off, autozero off. Using 115 kbaud RS-232 setting.

2

[4] Isolation within channel 1 to 20 or 21 to 40 banks is -40 dB

[5] Thermocouple specifications not guaranteed when 34907A module is present

[6] Applies to resistive loads only

[7] Thermocouple measurements not recommended with 34908A module due to common LO configuration.

21

Page 24

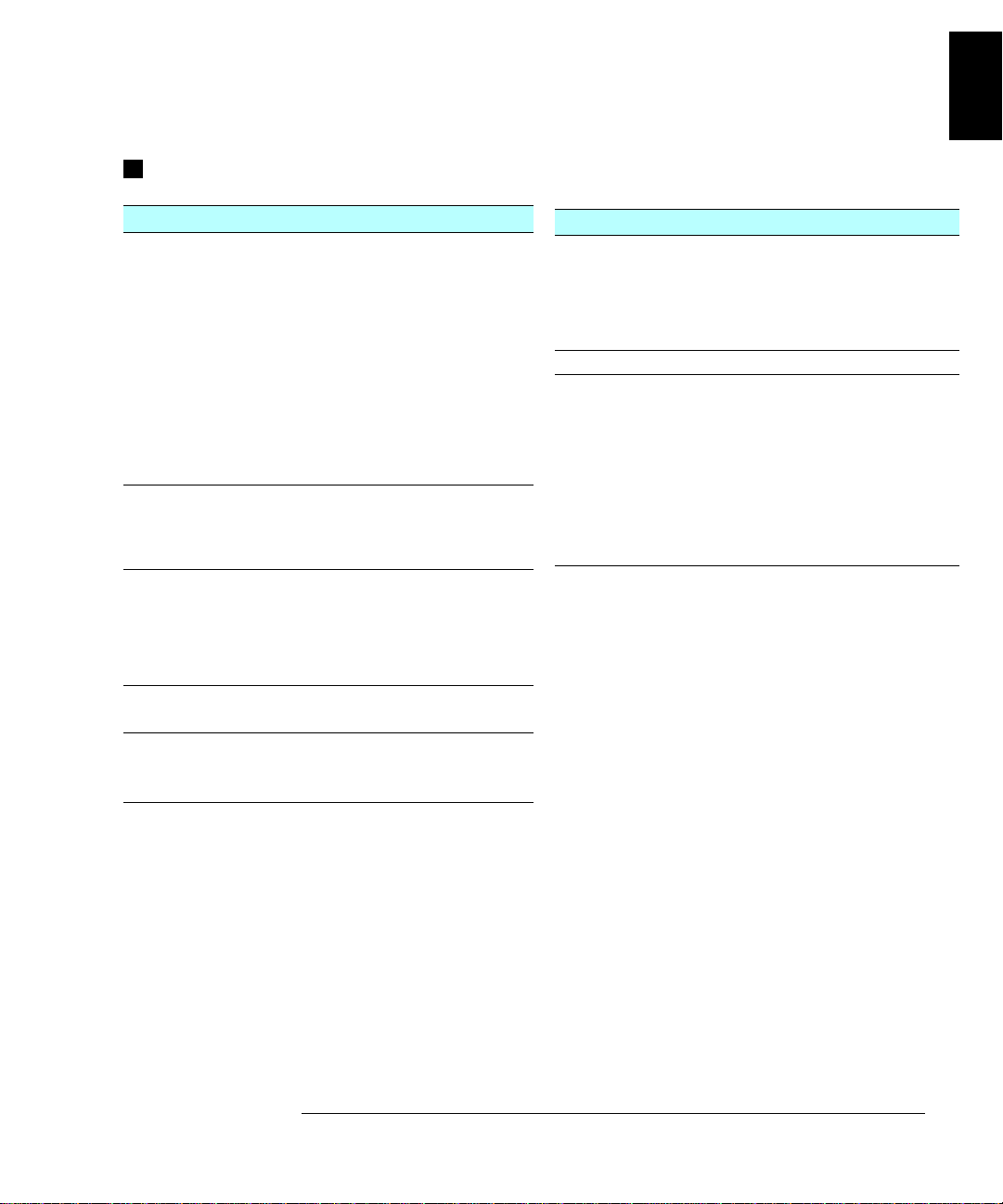

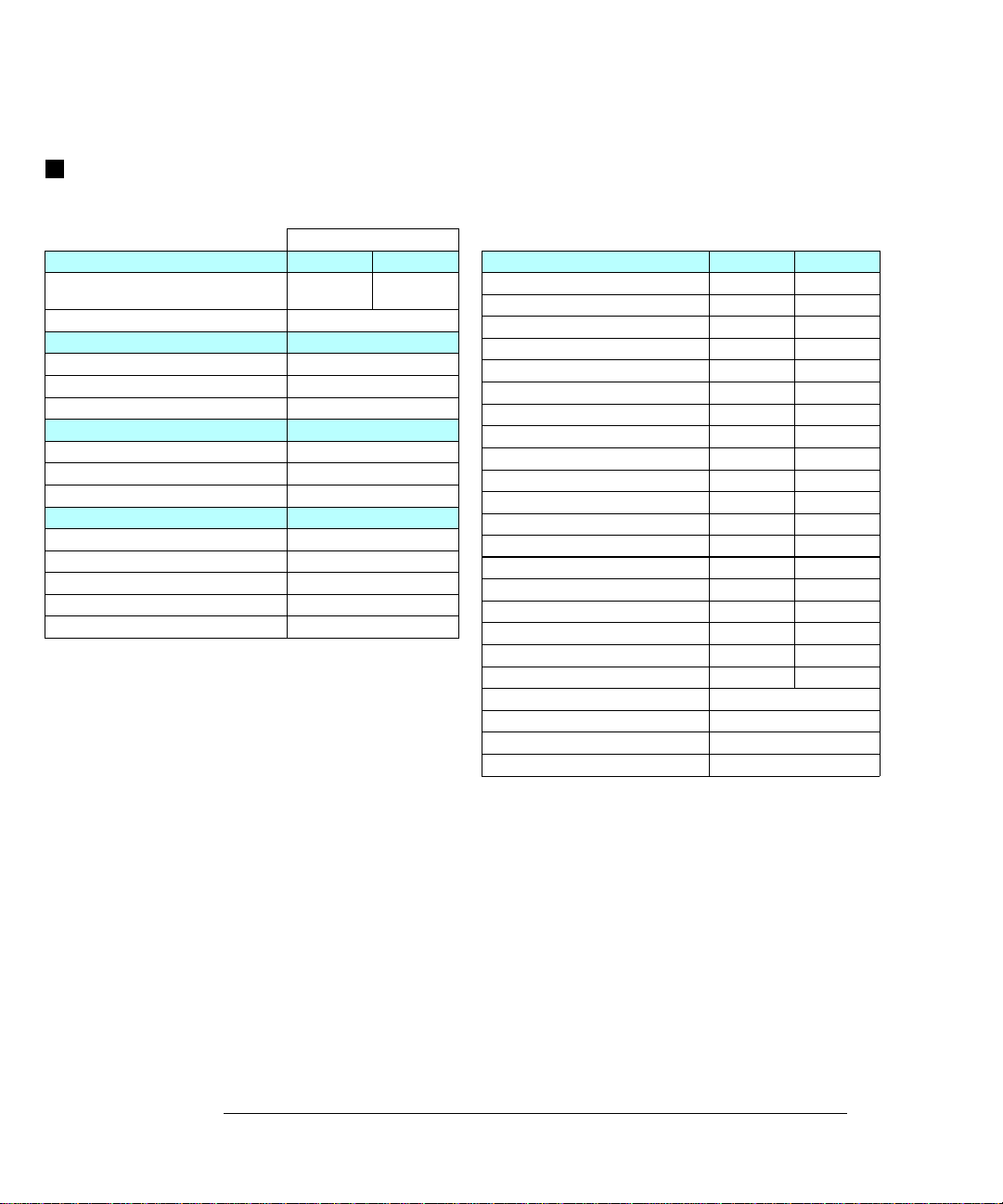

Chapter 1 Specifications

Module Specifications

Module Specifications

34905A, 34906A

RF Multiplexer

General 34905A 34906A

Number of Channels Dual 1x4

Open/Close Speed 60/s

Maximum Input

Voltage (dc, ac rms) 42 V

Current (dc, ac rms) 0.7 A

Power (W, VA) 20 W

DC Characteristi cs

Offset Voltage

Initial Closed Channel R

Isolation (ch-ch, ch-earth) > 1 GΩ

Other

Switch Life No Load (typical) 5M

Switch Life Rated Load (ty pical)

Temperature Operating 0

Temperature Storage -20

Humidity (non-condensing) 40

[1]

[1]

50

[2]

Dual 1x4

Ω

< 6 µV

< 0.5Ω

100k

°C to 55 °C

°C to 70 °C

°C / 80% R.H.

75

Ω

The ac performance graphs are shown on the following page.

AC Characteristics 34905A 34906A

Bandwidth

Insertion Loss (dB) 10 MHz -0.1 -0.1

100 MHz -0.4 -0.4

500 MHz -0.6 -0.5

1 GHz -1.0 -1.0

1.5 GHz -1.2 -1.5

2 GHz -3.0 -2.0

SWR 10 MHz 1.02 1.02

100 MHz 1.05 1.05

500 MHz 1.20 1.25

1 GHz 1.20 1.40

1.5 GHz 1.30 1.40

2 GHz 1.40 2.00

Ch-Ch Cross T a lk (dB)

100 MHz -85 -75

500 MHz -65 -65

1 GHz -55 -50

1.5 GHz -45 -40

2 GHz -35 -35

Risetime < 300 ps

Signal Delay < 3 ns

Capacitance HI to LO < 20 pF

Volt-Hertz Limit 10

[3]

2 GHz 2 GHz

[4]

10 MHz -100 -85

10

[1] Errors included in DMM meas ur ement a ccur acy sp eci f ica tio ns

[2] Applies to resistive loads only

[3] Bandwidth direct to module SMB connectors

[4] 50

Ω source, 50Ω load

22

Page 25

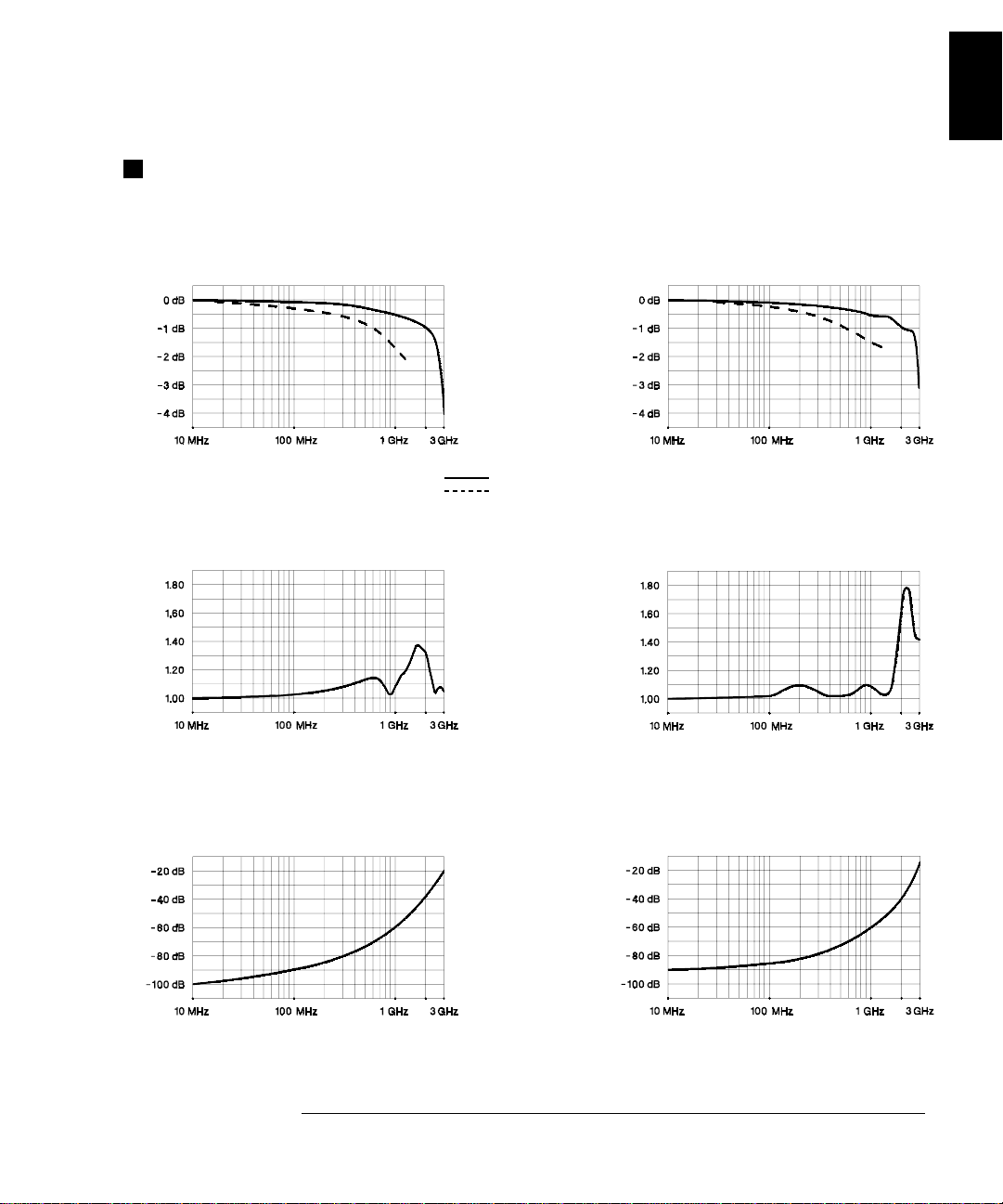

Chapter 1 Specifications

Typical AC Performance Graphs

Typical AC Performanc e Gr aphs

34905A, 34906A

1

Insertion Loss (50Ω)

VSWR (50Ω)

Direct to Module

Using provided adapter cables

Insertion Loss (75Ω)

VSWR (75Ω)

Crosstalk (50Ω)

Crosstalk (75Ω)

23

Page 26

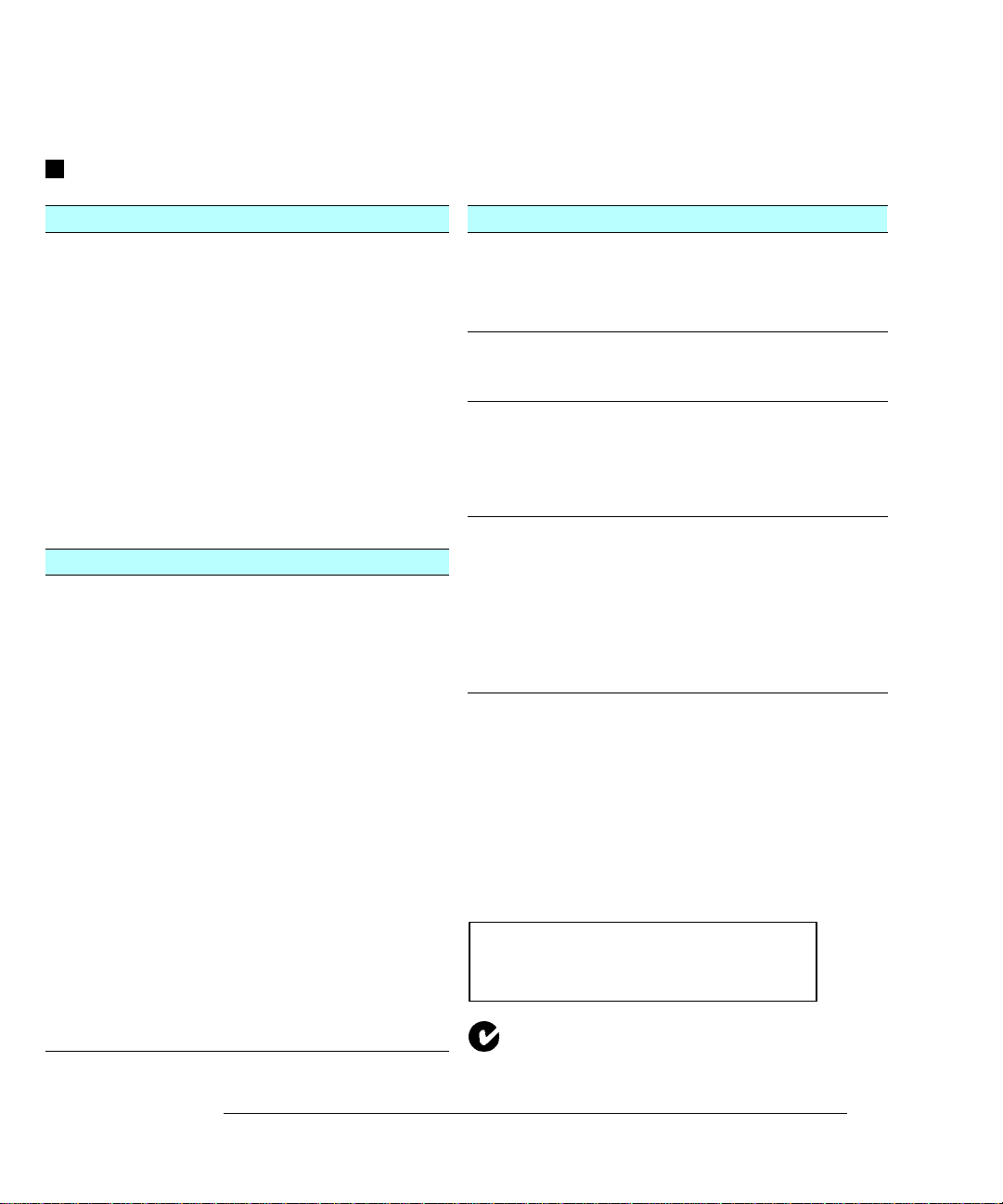

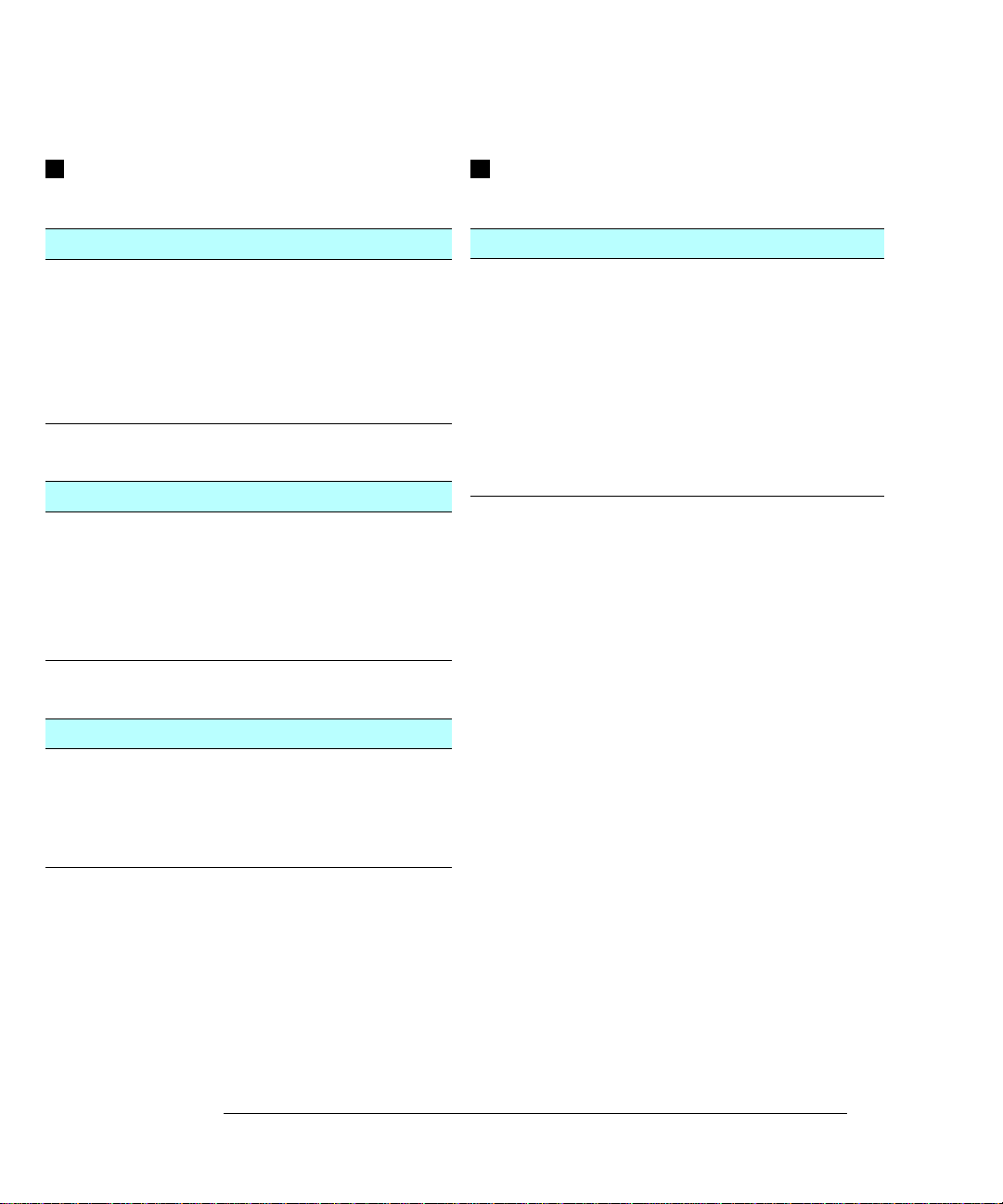

Chapter 1 Specifications

Module Specifications

Module Specifications

34907A

Digital Input / Output

Port 1, 2:

in(L):

V

V

in(H):

V

out(L):

out(H):

V

in(H) Max:

V

Alarming:

Speed

Latency

Read/Write Speed:

Totalize Input

Maximum Count:

Totalize Input:

Signal Level:

Threshold:

Gate Input:

Count Reset:

Read Speed:

8 Bit, input or output, non-isolated

< 0.8V (TTL)

> 2.0V (TTL)

< 0.8V @ Iout = - 400 mA

> 2.4V @ Iout = 1 mA

< 42V with extern al open dr ai n p ul l- up

Maskable pat ter n ma tc h or st at e ch an ge

4 ms (max) alarm sampling

5 ms (typical) to 34970A alarm output

95/s

26

2

- 1 (67,108,863)

100 kHz (max), rising or falling edge,

programmable

1 Vp-p (min)

42 Vpk (max)

0V or TTL, jumper selectable

TTL-Hi, TTL-Lo, or none

Manual or Read+Reset

85/s

Software Specifications

BenchLink Data Logge r

System Requirements

PC Hardware:

Operating System:

Computer Interfaces

GPIB:

LAN-to-GPIB:

RS-232 (Serial Port):

Performance

Scan and Save to Disk:

[1] Software provided on CD-ROM; includes utility to create

floppy disks for installation

[2] Interface and dr ive rs mus t be pu rch ase d a nd in st al le d se pa rat el y

[3] 90 MHz Pentium

[3]

®

, 20 MB RAM

(not included with Option 001)

[1]

486, 66 MHz, 16 MB RAM,

12 MB disk space

Windows

Windows NT

[2]

Agilent 82335B, 82340A/B/C,

82341A/B/C/D

National Inst r ument s A T-G PIB / TNT,

PCI-GPIB

Agilent E581 0A (Windows 98/Me/

NT/2000/XP Professional)

PC COM 1 to 4

100 ch/s, 2 strip charts displayed

®

3.1, Windows 95,

®

4.0

Analog Voltage (DAC) Output

DAC 1, 2:

Resolution:

I

out:

Settling Time:

Accuracy:

1 year

Temp Coefficient:

[1] Limited to 40 mA total for all three slots (six DAC channels)

±5 °C

±12V, non-isolated (earth referenced)

1 mV

10 mA max

1 ms to 0.01% of output

±(% of output + mV)

0.25% + 20 mV

±(0.015% + 1 mV) / °C

[1]

24

Page 27

Chapter 1 Specifications

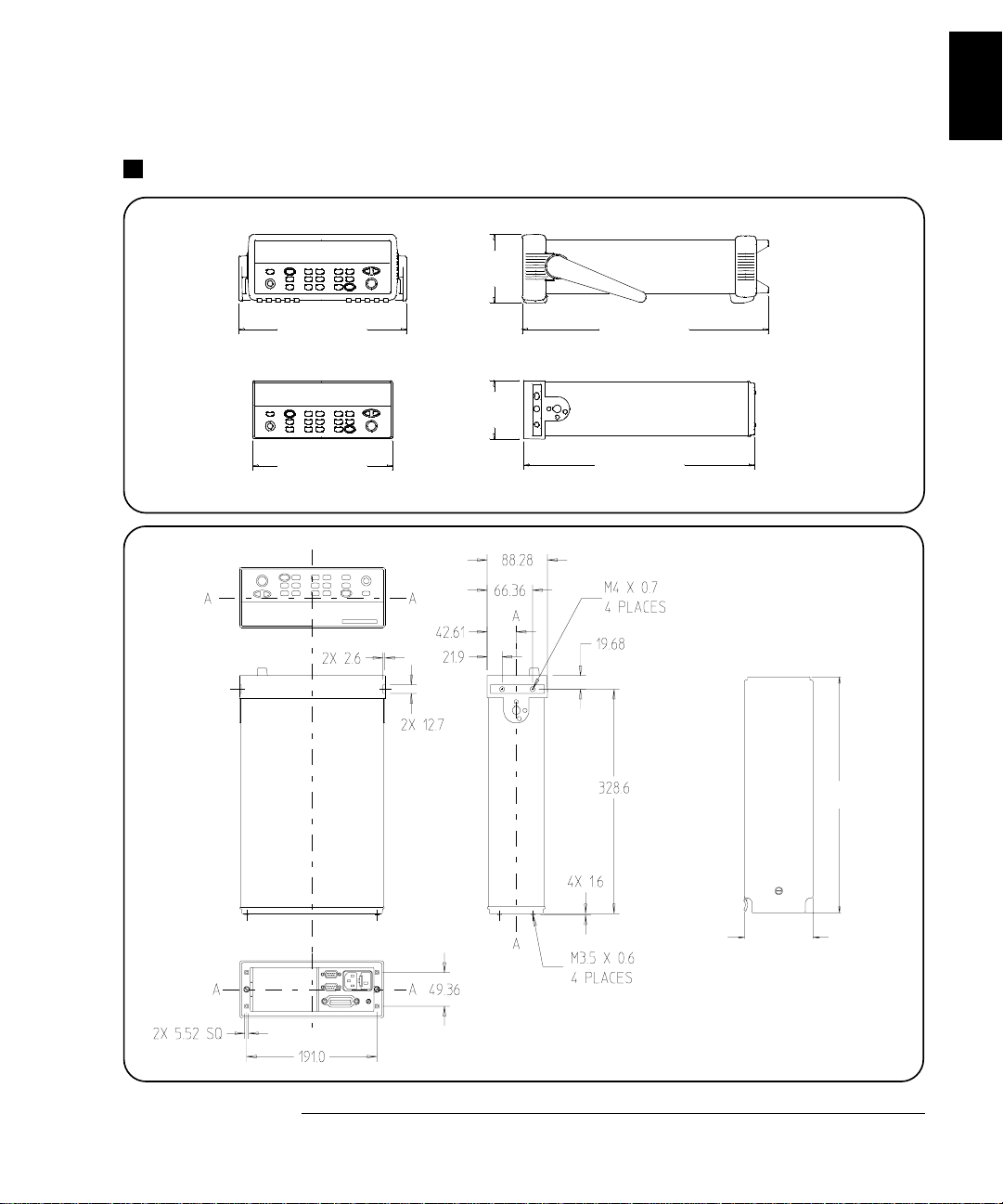

Product and Module Dimensions

Product and Module Dimensions

103.6 mm

1

254.4 mm

TOP

374.0 mm

88.5 mm

348.3 mm212.6 mm

Module

315.6

91.9

All dimensio ns are shown

in millimeters .

25

Page 28

Chapter 1 Specifications

To Calculate Total Measurement Error

To Calculate Total Measurement Error

Each specification includes correction factors which account for errors

present due to operational limitations of the internal

explains these errors and shows how to apply them t o your measurements.

Refer to “Interpreting Internal DMM Specifications,” starting on page

28, to get a better understanding of the terminology used and to help

you interpret the internal

DMM’s specifications.

DMM. This section

The internal

DMM’s accuracy specifications are expressed in the form:

(% of reading + % of range). In addition to the reading error and range

error, you may need to add additional errors for certain operating

conditions. Check the li st below to mak e sure you inc lude all mea surement

errors for a given function. Also, make sure you apply the conditions as

described in the footnotes on the specification pages.

• If you are operating the internal DMM outside the 23 °C ± 5 °C

temperature range specified, apply an additional temperature

coefficient error.

• For dc voltage, dc current, and resistance measurements, you may

need to apply an additional reading speed error.

• For ac voltage and ac current measurements, you may need to apply

an additional low frequency error or crest factor error.

Understanding the “ % of reading ” Error The reading error

compensates for inaccur acies that result from the function and range

you select, as well as the input signal level. The reading error varies

according to the input level on the selected range. This error is

expressed in percent of reading. The following table shows the reading

error applied to the internal

Range Input Level

DMM’s 24-hour dc voltage specification.

Reading Error

(% of reading)

Reading

Error Voltage

26

10 Vdc

10 Vdc

10 Vdc

10 Vdc

1 Vdc

0.1 Vdc

0.0015

0.0015

0.0015

≤ 150 µV

≤ 15 µV

≤ 1.5 µV

Page 29

Chapter 1 Specifications

To Calculate Total Measurement Error

Understanding the “ % of range ” Error The range error compensates

for inaccuracies that result from the function and range you select.

The range error contributes a constant error, expressed as a percent of

range, independent of the input signal level. The following table shows

the range error applied to the

DMM’s 24-hour dc voltage specification.

1

Range Input Level

10 Vdc

10 Vdc

10 Vdc

10 Vdc

1 Vdc

0.1 Vdc

Range Error

(% of range)

0.0004

0.0004

0.0004

Range

Error Voltage

≤ 40 µV

≤ 40 µV

≤ 40 µV

Total Measurement Error To compute the total measurement error,

add the reading error and range error. You can then convert the total

measurement error to a “percent of input” error or a “ppm (part-permillion) of input” error as shown below.

% of input error =

ppm of input error =

Example: Computing Total Measurement Error

Total Measurement Error

Input Signal Level

Total Measurement Error

Input Signal Level

× 100

× 1,000,000

Assume that a 5 Vdc signal is input to the DMM on the 10 Vdc range.

Compute the total measurement error using the 90-day accuracy

specification of

±(0.0020% of reading + 0.0005% of range).

Reading Error = 0.0020% x 5 Vdc = 100

Range Error = 0.0005% x 10 Vdc = 50

Total Error = 100

µV + 50 µV= ± 150 µV

=

± 0.0030% of 5 Vdc

=

± 30 ppm of 5 Vdc

µV

µV

27

Page 30

Chapter 1 Specifications

Interpreting Internal DMM Specifications

Interpreting Internal DMM Specifications

This section is provided to give you a better understanding of the

terminology used and will help you interpret the internal

specifications.

Number of Digits and Overrange

The “number of digits” specification is the most fundamental, and

sometimes, the most confusing characteristic of a multimeter.

The number of digits is equal to the maximum number of “9’s” the

multimeter can measure or display. This indicates the number of

full digits. Most multimeters have the ability to overrange and add

a partial or “

1

⁄

” digit.

2

DMM’s

For example, the internal

range. This represents six full digits of resolution. The internal

DMM can measure 9.99999 Vdc on the 10 V

DMM

can also overrange on the 10 V range and measure up to a maximum of

12.00000 Vdc. This corresponds to a 6

1

⁄

-digit measurement with 20%

2

overrange capability.

Sensitivity

Sensitivity is the minimum level that the multimeter can detect for a

given measurement. Sensitivity defines the ability of the multimeter to

respond to small changes in the input level. For example, suppose you

are monitoring a 1 mVdc signal and you want to adjust the level to

within

measurement would require a multimeter with a sensitivity of at least

1

range. You could also use a 4

For ac voltage and ac current measurements, note that the smallest

value that can be measured is different from the sensitivity. For the

internal

the selected range. For example, the internal

to 1 mV on the 100 mV range.

±1 µV. To be able to respond to an adjustment this small, this

µV. You could use a 6

DMM, these functions are specified to measure down to 1% of

1

⁄

-digit multimeter if it has a 1 Vdc or smaller

2

1

⁄

-digit multimeter with a 10 mVdc range.

2

DMM can measure down

28

Page 31

Chapter 1 Specifications

Interpreting Internal DMM Specifications

Resolution

Resolution is the numeric ratio of the maximum displayed value divided

by the minimum displayed value on a selected range. Resolution is

often expressed in percent, parts-per-million (ppm), counts, or bits.

For example, a 6

1

⁄

-digit multimeter with 20% overrange capability can

2

display a measurement with up to 1,200,000 counts of resolution.

This corresponds to about 0.0001% (1 ppm) of full scale, or 21 bits

including the sign bit. All four specifications are equivalent.

Accuracy

Accuracy is a measure of the “exactness” to which the internal DMM’s

measurement uncertainty can be determined relative to the calibration

reference used. Absolute accuracy includes the Internal DMM’s relative

accuracy specification plus the known error of the calibration reference

relative to national standards (such as the U.S. National Institute of

Standards and Technology ). To be meanin gful, th e accur acy specifica tion s

must be accompanied with the conditions under which they are valid.

These conditions should include temperature, humidity, and time.

1

There is no standard convention among multimeter manufacturers for

the confidence limits at which specifications are set. The table below

shows the probability of non-conformance for each specification with the

given assumptions.

Specification

Criteria

Mean ± 2 sigma

Mean ± 3 sigma

Probability

of Failure

4.5%

0.3%

Variations in performance from reading to reading, and instrument

to instrument, decrease for increasing number of sigma for a given

specification. This means that you can achieve greater actual

measurement precision for a specific accuracy specification number.

The 34970A is designed and tested to meet performance better than

mean

±3 sigma of the published accuracy specifications.

29

Page 32

Chapter 1 Specifications

Interpreting Internal DMM Specifications

24-Hour Accuracy

The 24-hour accuracy specification indicates the internal DMM’s

relative accuracy over its full measurement range for s hort time

intervals and within a stable environment. Short-term accuracy is

usually specified for a 24-hour period and for a

range.

±1 °C temperature

90-Day and 1-Year Accuracy

These long-term accuracy specifications are valid for a 23 °C ± 5 °C

temperature range. These specifications include the initial calibration

errors plus the internal DMM’s long-term drift errors.

Temperature Coefficients

Accuracy is usually specified for a 23 °C ± 5 °C temperature range.

This is a common temperature range for many operating environments.

You must add additional temperature coefficient errors to the accuracy

specification if you are operating the multimeter outside a 23 °C

temperature range (the specification is per °C).

± 5 °C

30

Page 33

Chapter 1 Specifications

Configuring for Highest Accuracy Measurements

Configuring for Highest Accuracy Measurements

The measurement configurations shown below assume that the internal

DMM is in its Factory Reset state. It is also assumed that manual

ranging is enabled to ensure proper full scale range selection.

DC Voltage, DC Current, and Resistance Measurements:

• Set the resolution to 6 digits (you can use the 6 digits slow mode for

further noise reduction).

• Set the input resistance to greater than 10 GΩ (for the 100 mV, 1 V,

and 10 V ranges) for the best dc voltage accuracy.

• Use 4-wire ohms and enable offset compensation for the best

resistance accuracy.

AC Voltage and AC Current Measurements:

• Set the resolution to 6 digits.

1

• Select the slow ac filter (3 Hz to 300 kHz).

Frequency and Period Measurements:

• Set the resolution to 6 digits.

31

Page 34

32

Page 35

2

2

Quick Start

Page 36

Quick Start

One of the first things you will want to do with your instrument is to

become acquainted with the front panel. We have written the exercises

in this chapter to prepare the instrument for use and help you get

familiar with some of its front-panel operations.

The front panel has several groups of keys to select various functions

and operations. A few keys have a shifted function printed in blue below

the key. To perform a shifted function, press (the

will turn on). Then, press the key that has the desired label below it.

For example, to select the Utility Menu, press .

SHIFT annunciator

If you accidentally press , just press it again to turn off the

annunciator.

This chapter is divided into the following sections:

• To Prepare the Instrument for Use, on page 35

• To Connect Wiring to a Module, on page 36

• To Set the Time and Date, on page 38

• To Configure a Measurement Channel, on page 39

• To Monitor a Single Channel, on page 40

• To Close a Channel, on page 41

• If the Instrument Does Not Turn On, on page 42

• To Adjust the Carrying Handle, on page 44

• To Rack Mount the Instrument, on page 45

SHIFT

34

Page 37

Chapter 2 Quick Start

To Prepare the Instrument for Use

To Prepare the Instrument for Use

1 Check the list of supplied items.

Verify that you have received the following items with your instrument.

If anything is missing, contact your nearest Agilent Technologies Sales Office.

One power cord.

One User’s Guide.

This Service Guide.

One Quick Reference Guide.

Certificate of Calibration (if you ordered the internal DMM ).

Quick Start Kit (if you ordered the internal DMM):

• One RS-232 cable.

• BenchLink Data Logger Software CD-ROM.

• One J-type thermocouple and a flatblade screwdriver.

Any plug-in modules that you ordered are delivered in a separate

shipping container.

2

On/Standby

Switch

WARNING

Note that this switch

Standby only.

is

To disconnect the

mains from the

instrumen t , remove

the power cord.

2 Connect the power cord and turn on the instrument.

The front-panel display will light up briefly while the instrument

performs its power-on self-test. The

GPIB address is displayed.

The instrument initially powers up with all measurement channels

turned off. To review the power-on display with all annunciators

turned on, hold down as you turn on the instrument. If the

instrument does not turn on properly, see page 42.

3Perform a complete self-test.

The complete self-test performs a more extensive set of tests than those

performed at power-on. Hold down as you turn on the instrument

and hold down the ke y until you hear a long beep. The self-test will begin

when you release the key f ollowing the beep.

35

Page 38

Chapter 2 Quick Start

To Connect Wiring to a Module

To Connect Wiring to a Module

1 Remove the module cov er.

3 Route wiring through strain relief.

Cable Tie Wrap

(optional)

2 Connect wiring to the screw terminals.

20 AWG

Typical

6 mm

4 Replace the module cover.

5 Install the module into mainframe.

Channel Number:

Slot Channel

36

Wiring Hints...

• For detailed information on each module,

refer to the 34970A User’ s Guide.

• To reduce wear on the internal DMM relays,

wire like functions on adjacent channels.

• Use shielded twisted pair Teflon insulated

cables to reduce settling and noise errors.

• The diagrams on the next page show how to

connect wiring to a multiplexer module for

each measurement function.

Page 39

Chapter 2 Quick Start

To Connect Wiring to a Module

Thermocouple

Thermocouple Types: B, E, J, K, N, R, S, T

2-Wire Ohms / RTD / Thermistor

Ranges: 100, 1 k, 10 k, 100 k, 1 M, 10 M, 100 MΩ

RTD Types: 0.00385, 0.00391

Thermistor Types: 2.2 k, 5 k, 10 k

DC Voltage / AC Voltage / Frequency

Ranges: 100 mV, 1 V, 10 V, 100 V, 300 V

4-Wire Ohms / RTD

2

DC Current / AC Current

Valid only on channels 21 and 22 on the 34 9 0 1 A .

Ranges: 10 mA, 100 mA, 1A

Channel n (source) is automatically paired with

Channel n+10 (sense) on the 34901A or

Channel n+8 (sense) on the 34902A.

Ranges: 100, 1 k, 10 k, 100 k, 1 M, 10 M, 100 MΩ

RTD Types: 0.00385, 0.00391

37

Page 40

Chapter 2 Quick Start

To Set the Time and Date

To Set the Time and Date

All readings during a scan are automatically time stamped and stored in

non-volatile memory. In addition, alarm data is time stamped and

stored in a separate non-volatile memory queue.

Utility

Utility

1 Set the time of day.

Use and to select the field to modify and turn the knob to change

the value. You can also edit the

AM/PM field.

TIME 03:45 PM

2 Set the date.

Use and to select the field to modify and turn the knob to change

the value.

JUNE 01 2002

38

Page 41

Chapter 2 Quick Start

To Configure a Measurement Channel

To Configure a Measurement Channel

Use this general procedure to configure a measurement channel.

1 Select the channel.

Turn the knob until the desired channel is shown on the right side of

front-panel display. The channel number is a three-digit number;

the left-most digit represents the slot number (100, 200, or 300) and the

two digits on the right indicate the channel number (102, 110, etc.).

Note: You can use and to skip to the beginning of the previous

or next slot.

2 Select the measurement parameters for the selected channel.

Use the knob to scroll through the measurement choices on each level

of the menu. When you press to make your selection, the menu

automatically guides you through all relevant choices to configure a

measurement on the selected function. When you have finished

configuring the parameters, you are automatically exited from the menu.

The present selection (or default) is displayed in full bright for easy

identification. When you make a different selection, the new choice is

shown in full bright and it becomes the default selection. The order of

the choices always remains the same; however, you always enter the

menu at the present (full-bright) setting for each parameter.

2

Note: The menu will timeout after about 20 seconds of inactivity and

any changes made previously will take effect.

39

Page 42

Chapter 2 Quick Start

To Monitor a Single Channel

To Monitor a Single Channel

You can use the Monitor function to continuously take readings on a single

channel, even during a scan. This feature is used during front pa nel

calibration procedures.

1 Select the channel to be monitored.

Only one channel can be monitored at a time but you can change the

channel being monitored at any time by turning the knob.

2 Enable monitoring on the selected channel.

Any channel that can be “read” by the instrument can be monitored

(the

MON annunciator turns on). This includes any combination of

temperature, voltage, resistance, current, frequency, or period

measurements on multiplexer channels. You can also monitor a digital

input port or the totalizer count on the multifunction module.

To disable monitoring, press again.

40

Page 43

Chapter 2 Quick Start

To Close a Channel

To Close a Channel

On the multiplexer and switch modules, you can close and open individual

relays on the module. However, note that if you have already configured

2

any multiplexer channels for scanning, you cannot independently close

and open individual relays on that module.

1 Select the channel.

Turn the knob until the desired channel is shown on the right side of

front-panel display. For this example, select channel 213.

2 Close the selected channel.

3 Open the selected channel.

Note: will sequentially open all channels on the module in the

selected slot.

The table below shows the low-level control operations available for each

of the plug-in modules.

Plug-In Module

34901A 20-Channel Mux ••• •

34902A 16-Channel Mux ••• •

34908A 40-Channel Single-Ended Mux

34903A 20-Channel Actuator ••

34904A 4x8 Matrix ••

34905A Dual 4-Channel RF Mux (50

34906A Dual 4-Channel RF Mux (75

34907A Multifunction Module (DIO) •• •

34907A Multifunction Module (Totalizer) ••

34907A Multifunction Module (DAC) •

[1]

••• •

[2]

Ω )

Ω )

[2]

•

•

,

[1] Only one channel can be closed at a time on this module.

[2] Only one channel in each bank can be closed at a time on this module.

41

Page 44

Chapter 2 Quick Start

If the Instrument Does Not Turn On

If the Instrument Does Not Turn On

Use the following steps to help solve problems you might encounter

when turning on the instrument.

1 Verify that there is ac power to the instrument.

First, verify that the power cord is firmly plugged into the power

receptacle on the rear panel of the instrument. You should also make

sure that the power source you plugged the instrument into is

energized. Then, verify that the instrument is turned on.

The On/Standby switch is located on the lower left side of the front panel.

2 Verify the power-line voltage setting.

The line voltage is set to the proper value for your country when the

instrument is shipped from the factory. Change the voltage setting if

it is not correct. The settings are: 100, 120, 220, or 240 Vac.

Note: For 127 Vac operation, use the 120 Vac setting.

For 230 Vac operation, use the 220 Vac setting.

See the next page if you need to change the line-voltage setting.

3 Verify that the power-line fuse is good.

The instrument is shi pped from th e factor y with a 500 m A fuse ins talled .

This is the correct fuse for all line voltages.

See the next page if you need to replace the power-line fuse.

To replace the 500 mAT, 250 V fuse, order Agilent part number 2110-0458.

42

Page 45

Chapter 2 Quick Start

If the Instrument Does Not Turn On

1 Remove the power cord. Remove the

fuse-holder assembly from the rear panel.

3 Rotate the line-voltage selector until the

corr ect voltage appears in the window.

2 Remove the line-voltage selector from

the assembly.

Fuse: 500 mAT (for all line voltages)

Agilent Part Number: 2110-0458

4 Replace the fuse-holder assembly in

the rear panel.

2

100, 120 (127), 220 (230) or 240 Vac

Verify that the correct line voltage is selected and the power-line fuse is good.

43

Page 46

Chapter 2 Quick Start

To Adjust the Carrying Handle

To Adjust the Carrying Handle

To adjust the position, grasp the handle by the sides and pull outward.

Then, rotate the handle to the desired position.

44

Carrying PositionBenchtop Viewing Positions

Page 47

Chapter 2 Quick Start

To Rack Mount the Instrument

To Rack Mount the Instrument

You can mount the instrument in a standard 19-inch rack cabinet using

one of three optional kits available. Instructions and mounting

hardware are included with each rack-mounting kit. Any System II

instrument of the same size can be rack-mounted beside the 34970A.

Remove the carrying handle, and the front and rear rubber bumpers,

before rack-mounting the instrument.

To remove the handle, rotate it to the vertical p osition an d pull t he ends outward.

2

Front Rear (bottom view)

To remove the rubber bumper, stretch a corner and then slide it off.

45

Page 48

Chapter 2 Quick Start

To Rack Mount the Instrument

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061-9694 and

flange kit 5063-9212. Be sure to use the support rails inside the rack cabinet.

To install one or two instruments in a sliding support shelf, order shelf 5063-9255,

and slide kit 1494-0015 (for a single instrument, also order filler panel 5002-3999).

46

Page 49

3

3

Front-Panel

Overview

Page 50

Front-Panel Overview

This chapter introduces you to the front-panel keys and menu operation.

This chapter does not give a detailed description of every front-panel

key or menu operation. It does, however, give you a good overview of

the front-panel menu and many front-panel operations. See the Agilent

34970A User’s Guide for a complete discussion of the instrument’s

capabilities and operation.

This chapter is divided into the following sections:

• Front-Panel Menu Reference, on page 49

• To Unsecure for Calibration, on page 51

• To Secure Against Calibration, on page 51

• To Change the Security Code, on page 52

• Error Messages, on page 52

• To Perform a Zero Adjustment, on page 53

• To Apply Mx+B Scaling to Measurements, on page 54

• To Read the Relay Cycle Count, on page 55

• To Read a Digital Input Port, on page 56

• To Write to a Digital Output Port, on page 57

• To Read the Totalizer Count, on page 58

• To Output a DC Vo ltage, on page 59

48

Page 51

Chapter 3 Front-Panel Overview

Front-Panel Menu Reference

Front-Panel Menu Reference

This section gives an overview of the front-panel menus. The menus are

designed to automatically guide you through all parameters required to

configure a particular function or operation. The remainder of this

chapter shows examples of using the front-panel menus.

Configure th e measurement parameters on the displayed ch annel.

• Select measure me nt function (dc volts, oh ms, etc.) on the displaye d channel.

• Select transducer type for temperature measurements.

• Select units (°C, °F, or K) for temperature measurements.

• Select measureme nt rang e or au to ran ge .

• Select measureme nt resolution.

• Copy and paste measurement configuration to other ch an ne ls .

Configure the scaling parameters for the displayed channel.

• Set the gain (“M”) and offset (“B”) value for the displayed channel.

• Make a null measurement and store it as the offset value.

• Specify a custom la be l (RPM, PSI, etc.) for the displa ye d ch annel.

3

Configure al arms on the displayed channel.

• Select one of fou r ala rms to report alarm condit io ns on th e di sp la yed channel.

• Configure a hi gh lim it , lo w lim it , or bo th for the displayed chan ne l.

• Configure a bit pattern which will generate an alarm (for digital input channels).

Configure the four Alarm Outp ut ha rdw a re li ne s.

• Clear the state of the four alarm output lines.

• Select the “Latch” or “Track” mode for the four alarm output lines.

• Select the slope (ris in g or fa ll ing edge) for the four alarm out pu t lines.

Configure the event or action that controls the scan interval.

• Select the scan int erv al mod e (in te rva l, manual, external, or al arm) .

• Select the scan cou nt.

49

Page 52

Chapter 3 Front-Panel Overview

Front-Panel Menu Reference

Configure the advanced measurement features on displayed channel.

• Set the integration time for measurements on the displayed channel.

• Set the channel-to-channel delay for scanning.

• Enable/disabl e th e th erm oc ou pl e ch ec k fe ature (T/C measurement s only ).

• Select the refere nce ju nc ti on source (T/C measurement s on ly ).

• Set the low frequency limit (ac m easurements only).

• Enable/disable offset compensation (resistance measurements only).

• Select the binary or decimal mode for digital operations (34907A on ly ).

• Configure the to ta lizer reset mode (total iz er on ly ).

• Select which edge is detected (rising or falling) for totalizer operations.

Configure system-related instrument parameters.

• Set the real-time system clock and calendar.