Page 1

Page 2

Page 3

HP Color LaserJet 2600n

Service Manual

Page 4

Copyright and License

FCC Class A Statement

Trademark Credits

© 2005 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained in this document

is subject to change without notice.

The only warranties for HP products and

services are set forth in the express

warranty statements accompanying such

products and services. Nothing herein

should be construed as constituting an

additional warranty. HP shall not be liable

for technical or editorial errors or omissions

contained herein.

Q6455-90930

Edition 1, 2/2005

This equipment has been tested and found

to comply with the limits for a Class A

digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to

provide reasonable protection against

harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential

area is likely to cause harmful interference,

in which case the user will be required to

correct the interference at his own

expense. The end user of this product

should be aware that any changes or

modifications made to this equipment

without the approval of Hewlett-Packard

could result in the product not meeting the

Class A limits, in which case the FCC

could void the user’s authority to operate

the equipment.

Adobe Photoshop® and PostScript are

trademarks of Adobe Systems Incorporated.

CorelDRAW™ is a trademark or registered

trademark of Corel Corporation or Corel

Corporation Limited.

Microsoft®, Windows®, MS-DOS®, and

Windows NT® are U.S. registered

trademarks of Microsoft Corporation.

Netscape™ and Netscape Navigator™ are

U.S. trademarks of Netscape

Communications Corporation.

TrueType™ is a U.S. trademark of Apple

Computer, Inc.

ENERGY STAR® and the ENERGY STAR

logo® are U.S. registered marks of the

United States Environmental Protection

Agency.

Page 5

Table of contents

1 Product information

Quick access to printer information.........................................................................................................2

Printer configuration................................................................................................................................3

Printer features........................................................................................................................................4

Walk around.............................................................................................................................................6

Front view (shown with optional Tray 3).................................................................................6

Back and side view.................................................................................................................7

Control panel...........................................................................................................................8

Understanding supplies status...............................................................................8

Understanding printer status..................................................................................8

Understanding control panel layout.......................................................................9

Software.................................................................................................................................................11

Supported drivers..................................................................................................................11

Software and supported operating systems........................................................11

Software for Windows...........................................................................................................11

Software for Macintosh.........................................................................................................12

Network software..................................................................................................................12

Uninstalling software.............................................................................................................12

Windows software................................................................................................12

Macintosh software..............................................................................................13

Print-media specifications......................................................................................................................14

General guidelines................................................................................................................14

Paper and print media...........................................................................................................14

Printing and storage environment.........................................................................................14

Envelopes.............................................................................................................................15

Labels....................................................................................................................................17

Transparencies.....................................................................................................................17

Media support tables.............................................................................................................17

Supported print media for Tray 1, Tray 2, and optional Tray 3............................17

Unsupported media (media to avoid)...................................................................18

2 Installation

Site preparation ....................................................................................................................................22

Operating environment ........................................................................................................22

Minimum system requirements ............................................................................................23

Requirements for PC systems ............................................................................23

Requirements for Macintosh systems (non-PostScript) .....................................23

Package contents .................................................................................................................................24

Install input devices ..............................................................................................................................25

ENWW iii

Page 6

Installing optional Tray 3 ......................................................................................................25

Loading Tray 1 .....................................................................................................................25

Installing supplies .................................................................................................................27

3 Managing and maintenance

Managing supplies ................................................................................................................................32

Life expectancies of supplies ...............................................................................................32

Checking and ordering supplies ..........................................................................................32

Storing supplies ...................................................................................................................33

Replacing and recycling supplies ........................................................................................33

HP policy on non-HP supplies .............................................................................................33

HP anti-counterfeit website ..................................................................................................33

Cleaning the printer ..............................................................................................................................34

To clean the printer at the printer .........................................................................................34

To clean the fuser using HP Toolbox ..................................................................................35

Cleaning spilled toner ..........................................................................................................35

Calibrating the printer ...........................................................................................................................36

To calibrate the printer at the printer ...................................................................................36

To calibrate the printer from the HP Toolbox .......................................................................36

Print cartridges ....................................................................................................27

To check status using the control panel .............................................................32

To check and order supplies using HP Toolbox .................................................32

Replacing the print cartridges .............................................................................33

4 Operational theory

Engine control system ..........................................................................................................................38

Basic sequence of operation ...............................................................................................38

Power-on sequence .............................................................................................................39

Motors and fans ...................................................................................................................39

Image formation system .......................................................................................................................41

Image formation process .....................................................................................................43

Developing stage .................................................................................................................45

Transfer stage ......................................................................................................................48

Separation stage ..................................................................................................................49

Fusing stage ........................................................................................................................49

Pickup and feed system .......................................................................................................................51

Manual feed slot pickup mechanism ...................................................................................53

Paper feed mechanism ........................................................................................................53

Skew correction by the registration shutter .........................................................................53

Jam detection .......................................................................................................................54

Solenoid, motor, and fan locations ......................................................................................55

Printed circuit assembly locations ........................................................................................55

250-sheet tray solenoid and printed circuit locations ..........................................................56

Service-only tools (SERVICE ONLY) ...................................................................................................58

Main motor failure detection ................................................................................40

Fan motor failure detection .................................................................................40

Latent image formation .......................................................................................44

Laser/scanner system .........................................................................................45

Print cartridge ......................................................................................................46

Transfer belt (ETB) ..............................................................................................47

iv ENWW

Page 7

General timing chart .............................................................................................................58

Printer calibration .................................................................................................................59

5 Removal and replacement

Overview................................................................................................................................................62

Service approach...................................................................................................................................63

Pre-service procedures.........................................................................................................63

Removal and replacement procedures.................................................................................................64

Print cartridge replacement...................................................................................................64

ETB removal and replacement.............................................................................................66

Fuser removal and replacement...........................................................................................74

Formatter removal and replacement....................................................................................82

DC controller removal and replacement...............................................................................86

Separation pad removal and replacement............................................................................88

Paper pickup roller removal and replacement......................................................................89

Control panel removal and replacement...............................................................................91

6 Troubleshooting

Troubleshooting process.......................................................................................................................98

Troubleshooting checklist.....................................................................................................98

Clearing jams ........................................................................................................................................99

Paper path............................................................................................................................99

Common causes of paper jams..........................................................................................100

Where to look for jams........................................................................................................101

Jams inside the printer........................................................................................................102

Input jams...........................................................................................................................103

Output jams.........................................................................................................................104

Wrapping jam......................................................................................................................105

Delivery stationary jam.......................................................................................................105

Start-up residual paper jam................................................................................................105

Door open jam....................................................................................................................106

Print problems......................................................................................................................................107

Getting information..............................................................................................................107

Tray 1.................................................................................................................103

Tray 2.................................................................................................................104

Jams in the top bin.............................................................................................104

Pickup delay jam................................................................................................105

Pickup stationary jam.........................................................................................105

Delivery delay jam..............................................................................................105

Control panel messages....................................................................................107

Alert and warning messages.............................................................107

Critical error messages.....................................................................108

Supplies messages...........................................................................109

Status messages...............................................................................112

Status log only messages.................................................................112

Reports menu.....................................................................................................113

Configuration page.............................................................................................114

Supplies Status page.........................................................................................116

Status log...........................................................................................................116

Service menu settings........................................................................................118

ENWW v

Page 8

Secondary service menu....................................................................................118

Printed image quality problems..........................................................................................119

Improving print quality........................................................................................119

Paper Types menu............................................................................119

Print Modes menu.............................................................................120

Print quality menu..............................................................................121

Understanding print-quality settings...................................................................121

To temporarily change print-quality settings.....................................122

To change print-quality settings for all future jobs............................122

Identifying and correcting printed image defects...............................................122

Print-quality checklist.........................................................................122

Paper handling issues........................................................................................................123

Wrong size/type media.......................................................................................123

Cannot select a tray or feature to use................................................................123

Performance problems.......................................................................................................123

Functional tests (SERVICE ONLY).....................................................................................................125

Engine test print..................................................................................................................125

Service mode functions (SERVICE ONLY).........................................................................................126

Cold reset............................................................................................................................126

NVRAM initializer................................................................................................................126

Super NVRAM initializer.....................................................................................................126

Restoring page counts and serial number..........................................................................127

Cleaning the ETB................................................................................................................127

Troubleshooting tools..........................................................................................................................128

Printer pages and reports...................................................................................................128

Demo page.........................................................................................................128

Configuration page.............................................................................................129

Event log............................................................................................................131

Supplies Status page.........................................................................................131

Fuser cleaning page...........................................................................................132

Print quality troubleshooting pages....................................................................132

Control panel messages (error codes)..............................................................132

Alert and warning messages.............................................................132

Critical error messages.....................................................................133

Supplies messages...........................................................................134

Status messages................................................................................................................137

Status log only messages...................................................................................................137

Service menu......................................................................................................................137

Restoring the factory-set defaults......................................................................138

To restore the factory-set defaults....................................................138

General print quality issues................................................................................................138

Solving issues with color documents..................................................................................142

HP Toolbox..........................................................................................................................................144

HP Toolbox.........................................................................................................................144

To view HP Toolbox...........................................................................................144

Troubleshooting tab...........................................................................................144

Print quality troubleshooting pages....................................................................................144

Printer calibration................................................................................................................144

Cleaning page.....................................................................................................................144

Configuration page..............................................................................................................145

vi ENWW

Page 9

Diagnostic resources...........................................................................................................................146

Reports menu.....................................................................................................................146

Network/Web diagnostics tools...........................................................................................146

Repetitive image defect ruler...............................................................................................................147

Firmware and software updates..........................................................................................................148

7 Parts and diagrams

Overview .............................................................................................................................................150

Assembly locations .............................................................................................................................154

Covers ................................................................................................................................................160

Internal assemblies .............................................................................................................................162

Input devices .......................................................................................................................................186

Diagrams ............................................................................................................................................208

Alphabetical parts list...........................................................................................................................209

Numerical parts list..............................................................................................................................230

Appendix A Product specifications

Physical specifications ........................................................................................................................252

Supplies specifications .......................................................................................................................253

Print cartridge life ...............................................................................................................253

Electrical specifications ......................................................................................................................254

Environmental specifications ..............................................................................................................255

Acoustical specifications .....................................................................................................................256

Appendix B Product warranty statements

Hewlett-Packard limited warranty statement ......................................................................................258

Print Cartridge Limited Warranty Statement ......................................................................................259

Appendix C Regulatory statements

Declaration of Conformity ...................................................................................................................262

Laser safety statement .......................................................................................................................263

Canadian DOC statement ..................................................................................................................264

VCCI statement (Japan) .....................................................................................................................265

Korean EMI statement ........................................................................................................................266

Finnish laser statement ......................................................................................................................267

Index....................................................................................................................................................................269

ENWW vii

Page 10

viii ENWW

Page 11

List of tables

Table 1-1 Printer features.................................................................................................................................4

Table 1-2 HP Color LaserJet 2600n printer software.....................................................................................11

Table 1-3 Envelope specifications..................................................................................................................15

Table 1-4 Envelope size ranges.....................................................................................................................16

Table 1-5 Tray 1 and Tray 2 specifications....................................................................................................17

Table 1-6 Optional Tray 3 specifications........................................................................................................18

Table 3-1 Print cartridge life ..........................................................................................................................32

Table 4-1 Basic operational sequence ..........................................................................................................38

Table 4-2 Motor specifications .......................................................................................................................40

Table 5-1 User-replaceable parts...................................................................................................................62

Table 6-1 Troubleshooting checklist...............................................................................................................98

Table 6-2 Status log only messages............................................................................................................112

Table 6-3 Configuration page.......................................................................................................................114

Table 6-4 Supplies Status page...................................................................................................................116

Table 6-5 Status log messages....................................................................................................................117

Table 6-6 Print modes for paper types.........................................................................................................120

Table 6-7 Extended print modes..................................................................................................................120

Table 6-8 Optimize menu.............................................................................................................................121

Table 6-9 Performance issues......................................................................................................................123

Table 6-10 Configuration page.......................................................................................................................129

Table 6-11 Supplies Status page...................................................................................................................131

Table 6-12 Status log only messages............................................................................................................137

Table 6-13 General print quality issues..........................................................................................................138

Table 6-14 Color document issues.................................................................................................................142

Table 6-15 Repetitive image defects..............................................................................................................147

Table 7-1 Available replaceable parts .........................................................................................................150

Table 7-2 Technical support Web sites .......................................................................................................152

Table 7-3 Accessories .................................................................................................................................152

Table 7-4 Assembly locations ......................................................................................................................155

Table 7-5 External panels and covers (1 of 2) ............................................................................................157

Table 7-6 External panels and covers (2 of 2) ............................................................................................159

Table 7-7 Upper assembly cover .................................................................................................................161

Table 7-8 Internal components (1 of 3) .......................................................................................................163

Table 7-9 Internal components (2 of 3) .......................................................................................................167

Table 7-10 Internal components (3 of 3) .......................................................................................................171

Table 7-11 Control panel assembly ...............................................................................................................175

Table 7-12 Main drive assembly ....................................................................................................................177

Table 7-13 Fuser assembly ...........................................................................................................................181

Table 7-14 PCB assembly location Tray 2 ....................................................................................................185

Table 7-15 Tray 2 input tray (cassette) .........................................................................................................187

ENWW ix

Page 12

Table 7-16 250-sheet input tray (cassette) ....................................................................................................191

Table 7-17 Tray 2 sheet input tray internal components ...............................................................................193

Table 7-18 Paper pick-up feeder assembly for Tray 2 ..................................................................................197

Table 7-19 Tray 3 input tray (cassette) .........................................................................................................201

Table 7-20 Paper pickup feeder assembly (Tray 3) ......................................................................................205

Table 7-21 Paper pickup feeder assembly (Tray 3) ......................................................................................207

Table 7-22 Alphabetical parts list...................................................................................................................209

Table 7-23 Numerical parts list.......................................................................................................................230

Table A-1 Printer specifications ...................................................................................................................252

Table A-2 Supplies specifications ................................................................................................................253

Table A-3 Print cartridge specifications .......................................................................................................253

Table A-4 Electrical specifications ...............................................................................................................254

Table A-5 Environmental specifications .......................................................................................................255

Table A-6 Acoustical specifications .............................................................................................................256

x ENWW

Page 13

List of figures

Figure 1-1 HP Color LaserJet 2600n printer......................................................................................................3

Figure 1-2 Front view (shown with optional Tray 3)...........................................................................................6

Figure 1-3 Back and side view...........................................................................................................................7

Figure 1-4 Transfer belt (ETB) and print cartridges...........................................................................................7

Figure 1-5 Model and serial number information...............................................................................................8

Figure 1-6 Control panel layout.......................................................................................................................10

Figure 1-7 Control panel display......................................................................................................................10

Figure 1-8 Envelope double side-seam construction......................................................................................16

Figure 2-1 Printer dimensions .........................................................................................................................22

Figure 2-2 Package contents ..........................................................................................................................24

Figure 4-1 Engine control system ...................................................................................................................39

Figure 4-2 Image formation system ................................................................................................................42

Figure 4-3 Image formation process ...............................................................................................................43

Figure 4-4 Latent image formation ..................................................................................................................45

Figure 4-5 Laser beam exposure ....................................................................................................................45

Figure 4-6 Developing stage ...........................................................................................................................46

Figure 4-7 Print cartridge structure .................................................................................................................47

Figure 4-8 ETB unit .........................................................................................................................................48

Figure 4-9 Transfer stage ...............................................................................................................................48

Figure 4-10 Separation stage ...........................................................................................................................49

Figure 4-11 Fusing stage ..................................................................................................................................49

Figure 4-12 Paper pickup and feed system ......................................................................................................52

Figure 4-13 Skew correction .............................................................................................................................54

Figure 4-14 Location of solenoids, motors, and fans .......................................................................................55

Figure 4-15 Location of printed circuit assemblies ...........................................................................................56

Figure 4-16 Location of 250-sheet tray solenoid and printed circuit assembly ................................................57

Figure 6-1 Paper path......................................................................................................................................99

Figure 6-2 Jam locations and stages.............................................................................................................101

Figure 6-3 Tray 2 input jam label...................................................................................................................104

Figure 6-4 Engine test print switch................................................................................................................125

Figure 7-1 Assembly location diagram .........................................................................................................154

Figure 7-2 External panels and covers (1 of 2) ............................................................................................156

Figure 7-3 External panels and covers (2 of 2) ............................................................................................158

Figure 7-4 Upper cover assembly .................................................................................................................160

Figure 7-5 Internal components (1 of 3) .......................................................................................................162

Figure 7-6 Internal components (2 of 3) .......................................................................................................166

Figure 7-7 Internal components (3 of 3) .......................................................................................................170

Figure 7-8 Control panel assembly ...............................................................................................................174

Figure 7-9 Main drive assembly ....................................................................................................................176

Figure 7-10 Fuser assembly ...........................................................................................................................180

ENWW xi

Page 14

Figure 7-11 PCB assembly location (Tray 2) ..................................................................................................184

Figure 7-12 Tray 2 input tray (cassette) .........................................................................................................186

Figure 7-13 250-sheet input tray (cassette) ....................................................................................................190

Figure 7-14 Tray 2 input tray internal components .........................................................................................192

Figure 7-15 Paper pick-up feeder assembly for Tray 2 ..................................................................................196

Figure 7-16 Tray 3 input tray (cassette) .........................................................................................................200

Figure 7-17 Paper pickup feeder assembly (Tray 3) ......................................................................................204

Figure 7-18 PCB assembly location optional Tray 3 ......................................................................................206

Figure 7-19 General circuit diagram ...............................................................................................................208

Figure C-1 VCCI statement ...........................................................................................................................265

Figure C-2 Korean EMI statement .................................................................................................................266

xii ENWW

Page 15

1 Product information

This section provides information about the following topics:

Quick access to printer information

●

Printer configuration

●

Printer features

●

●

Walk around

Software

●

●

Print-media specifications

ENWW 1

Page 16

Quick access to printer information

User guide

Contains detailed information for using the printer and troubleshooting problems. This guide is

available in two formats on the CD-ROM that came with the printer: in PDF format for printing and

HTML format for online viewing. It is also available through the HP Toolbox software.

Getting started guide

Provides step-by-step instructions for installing and setting up the printer.

HP Toolbox

Use to check the printer status and settings and to view troubleshooting information and online

documentation.

Embedded Web server

Use to view and configure printer settings and networking information.

2 Chapter 1 Product information ENWW

Page 17

Printer configuration

HP Color LaserJet 2600n

The HP Color LaserJet 2600n printer is available in the configuration described below.

Figure 1-1 HP Color LaserJet 2600n printer

The HP Color LaserJet 2600n printer is a four-color laser printer that prints eight pages per minute

(ppm) in both monochrome (black and white) and color.

■ Trays. The printer comes with a single sheet priority feed slot (Tray 1) and a universal tray

(Tray 2) that holds up to 250 sheets of various paper types and sizes or 10 envelopes. It

supports an optional 250-sheet paper tray (optional Tray 3).

■ Connectivity. The printer provides a Hi-Speed Universal Serial Bus (USB) 2.0 port for

connectivity and an HP built-in internal print server for connecting to a 10/100Base-T network.

■ Memory. The printer contains 16 megabytes (MB) of synchronous dynamic random access

memory (SDRAM). No additional memory can be added.

ENWW Printer configuration 3

Page 18

Printer features

Table 1-1 Printer features

Feature HP Color LaserJet 2600n printer

Color printing

Fast print speed ■ Prints in black on letter-size paper up to 8 ppm and on

Excellent print quality

Ease of use ■ Few supplies to order. Supplies are easy to install.

Flexible paper handling

■ Provides laser printing in full color by using the four

process colors: cyan, magenta, yellow, and black

(CMYK).

A4-size paper up to 8 ppm. Prints in color on A4/letter at

8 ppm.

■ ImageREt 2400 provides 2400 dpi equivalent color

quality through a multilevel printing process.

■ True 600 by 600 dots per inch (dpi) text and graphics.

■ Adjustable settings to optimize print quality.

■ The HP UltraPrecise print cartridge has a finer toner

formulation that provides sharper text and graphics.

■ Convenient access to printer information and settings by

using the HP Toolbox software.

■ Convenient access to all supplies and to the paper path

through the front door.

■ Trays 1 and 2 for letterhead, envelopes, labels,

transparencies, custom-sized media, postcards,

HP LaserJet glossy paper, HP LaserJet Tough paper,

heavy paper, and HP Laser Photo paper.

■ A 125-sheet top output bin.

■ Print on Both Sides (manually).

Interface connections

Energy savings

Economical printing ■ N-up printing (printing more than one page on a sheet)

■ Hi-Speed USB 2.0 port.

■ The HP Color LaserJet 2600n printer includes an

HP built-in internal print server for connecting to a

10/100Base-T network.

■ The printer automatically conserves electricity by

substantially reducing power consumption when it is not

printing.

■ As an ENERGY STAR® partner, Hewlett-Packard

Company has determined that this product meets

ENERGY STAR® guidelines for energy efficiency.

ENERGY STAR® is a U.S. registered service mark of

the United States Environmental Protection Agency.

and Printing on Both Sides features save paper.

4 Chapter 1 Product information ENWW

Page 19

Table 1-1 Printer features (continued)

Feature HP Color LaserJet 2600n printer

Supplies

Accessibility

Expandability ■ Optional Tray 3. This 250-sheet universal tray reduces

Memory

■ A Supplies Status page with print cartridge gauges that

show the supply levels that remain. For HP supplies only.

■ No-shake cartridge design.

■ Authentication for HP print cartridges.

■ Internet-enabled, supplies-ordering capability.

■ Online user guide that is compatible with text

screen-readers.

■ All doors and covers can be opened by using one hand.

how often you have to add paper to the printer. Only

one additional 250-sheet tray can be installed on the

printer.

■ 16 MB of DRAM.

NOTE No additional memory can be added.

ENWW Printer features 5

Page 20

Walk around

The following illustrations identify the locations and names of key components of this printer.

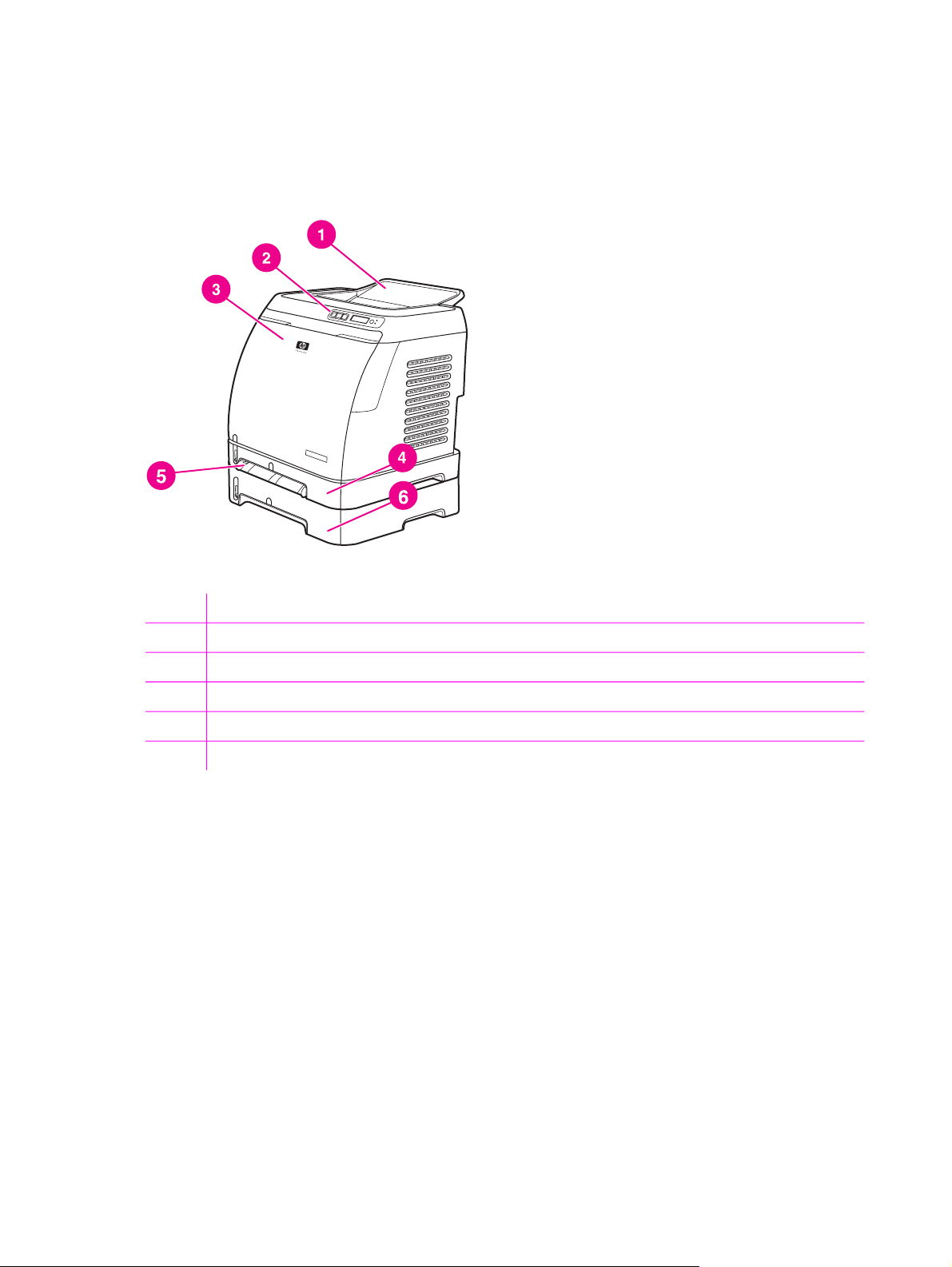

Front view (shown with optional Tray 3)

Figure 1-2 Front view (shown with optional Tray 3)

1 Output bin

2 Printer control panel

3 Front door

4 Tray 2 (250 sheets)

5 Tray 1 (single sheet priority feed slot)

6 Tray 3 (optional; 250 sheets)

6 Chapter 1 Product information ENWW

Page 21

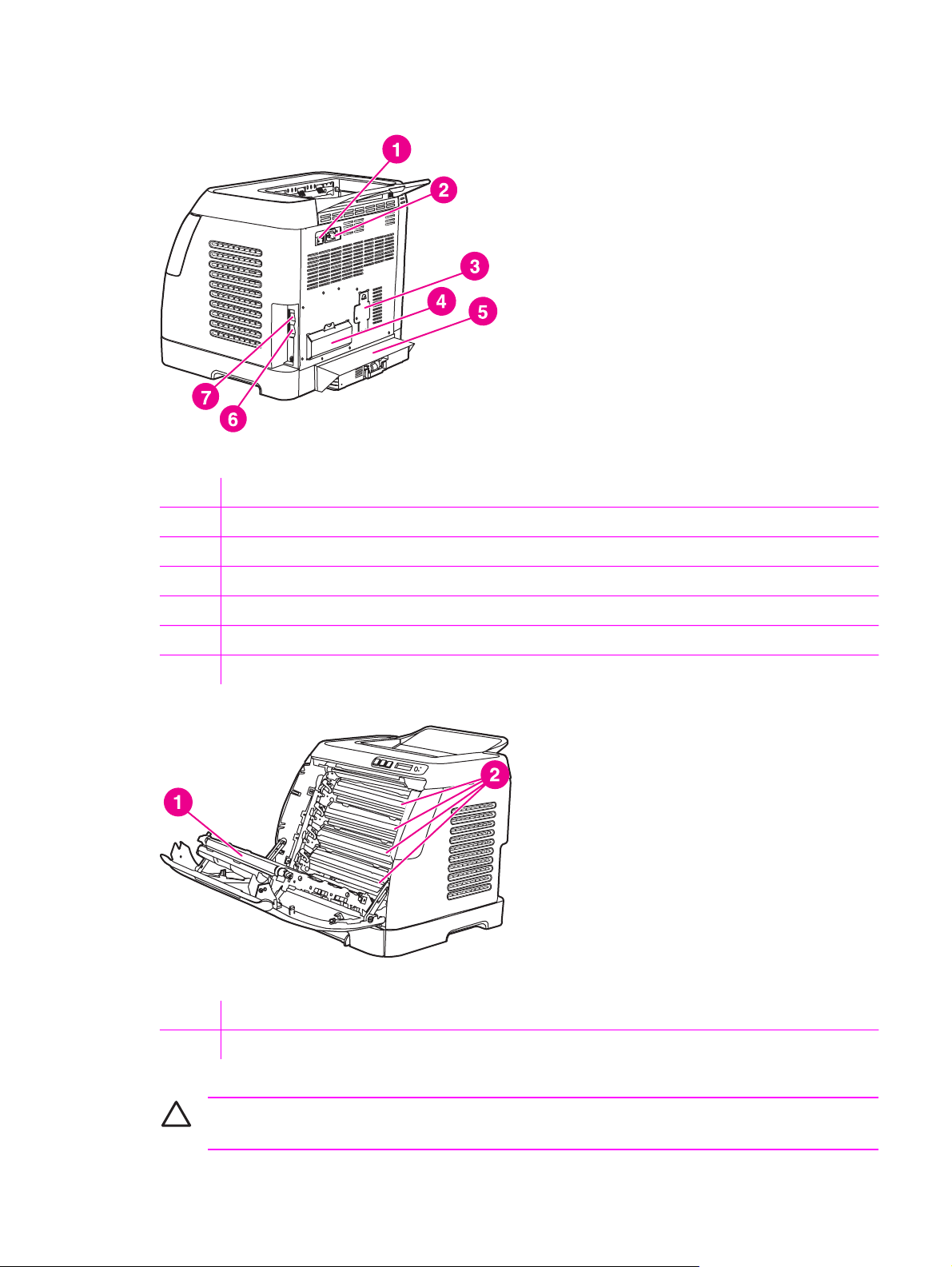

Back and side view

Figure 1-3 Back and side view

1 On/off switch

2 Power connection

3 Engine test button access door

4 Access door

5 Dust cover

6 HP built-in internal print server for connecting to a 10/100Base-T network

7 USB connection

Figure 1-4 Transfer belt (ETB) and print cartridges

1 Transfer belt (ETB)

2 Print cartridges

CAUTION Do not place anything on the transfer belt , which is located on the inside of the

front door. Otherwise, the printer may be damaged, adversely affecting print quality.

ENWW Walk around 7

Page 22

Model and serial number location

The model number and serial numbers are listed on identification labels located on the rear of the

printer. The model number is alphanumeric, such as Q6455A, for the HP Color LaserJet 2600n

printer. The serial number contains information about the country/region of origin, the printer version,

production code, and the production number of the printer.

Figure 1-5 Model and serial number information

Control panel

Understanding supplies status

The supplies gauges show the consumption levels of print cartridges (black, yellow, cyan, and

magenta).

Black, yellow, cyan, and magenta supplies status gauges

A ? appears instead of the consumption level when the level is not known. This can occur in the

following circumstances:

■ Missing cartridges

■ Incorrectly placed cartridges

■ Cartridges with an error

■ Some non-HP cartridges

The supplies gauge appears whenever the printer shows the Ready state with no warnings. It will

also appear when the printer shows a warning or error message concerning a print cartridge or

multiple supplies. If a supply is empty, the gauge will flash.

Understanding printer status

Cancel Job button

■

When the Ready light is blinking, pressing

(C

ANCEL JOB

) cancels the current job.

■ When a supplies status gauge is blinking and the Attention light is on (indicating that a non-HP

supply has been installed), pressing

8 Chapter 1 Product information ENWW

(S

ELECT

) allows you to continue printing.

Page 23

CAUTION You might not receive any indication when a non-HP supply is empty. For more

information about using non-HP print cartridges, see

continue printing after the supply is empty, damage to the printer can occur. See

HP policy on non-HP supplies. If you

Hewlett-

Packard limited warranty statement.

Attention light

Generally, the Attention light blinks when the printer is out of paper, when a jam has occurred, or

when other problems that need attention occur.

The Attention light is on and one of the Supplies Status gauges is blinking the first time a non-HP

supply is installed.

Ready light

The Ready light is on when the printer is ready to print (experiencing no errors that prevent printing)

and blinks when it is receiving data to be printed.

Ready light and Select button

■

When the Ready light is on and the Attention light is blinking, pressing

(S

ELECT

print job after you load print media for a manual feed, or clears some errors.

■

When the Ready light is blinking, the front door has been opened and then closed. Press

(S

ELECT

) to return the printer to the Ready state. If you do not press (S

ELECT

), the printer

returns to the Ready state on its own.

Left and Right arrow buttons

Use the

EFT ARROW

) and (R

IGHT ARROW

) buttons to navigate through the printer control panel

(L

menus.

A Demo page can be printed by pressing the

EFT ARROW

) and (R

IGHT ARROW

) buttons

(L

simultaneously.

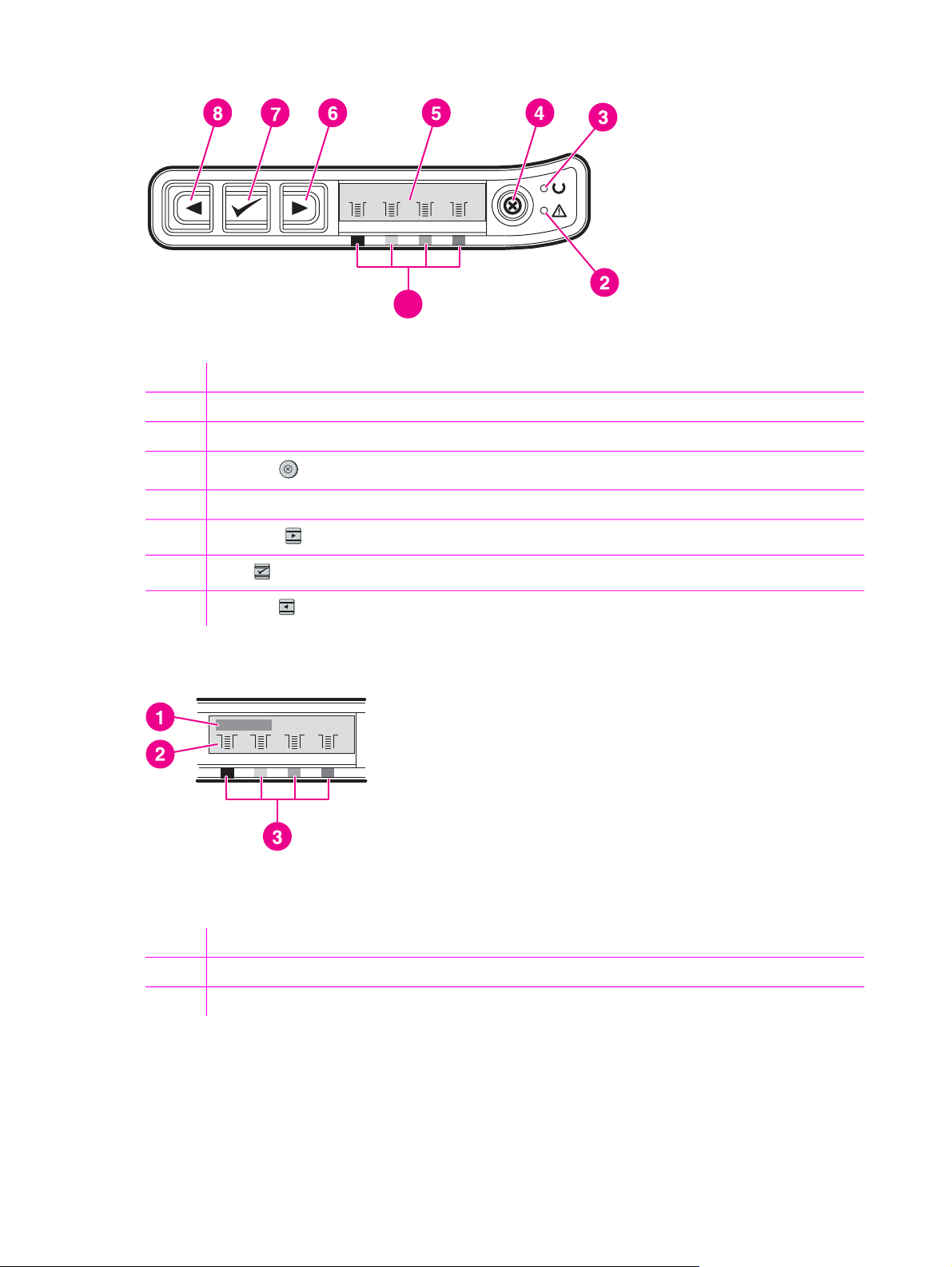

Understanding control panel layout

This section provides information about printer status and control panel layout.

Control panel layout

The printer contains the following lights and buttons on the control panel:

) continues the

ENWW Walk around 9

Page 24

Figure 1-6 Control panel layout

1 Color print cartridge indicators

2 Attention light (amber)

3 Ready light (green)

1

4

5 Message area

6

7

8

C

ANCEL JOB

R

IGHT ARROW

S

ELECT

L

EFT ARROW

button

button

button

button

Display

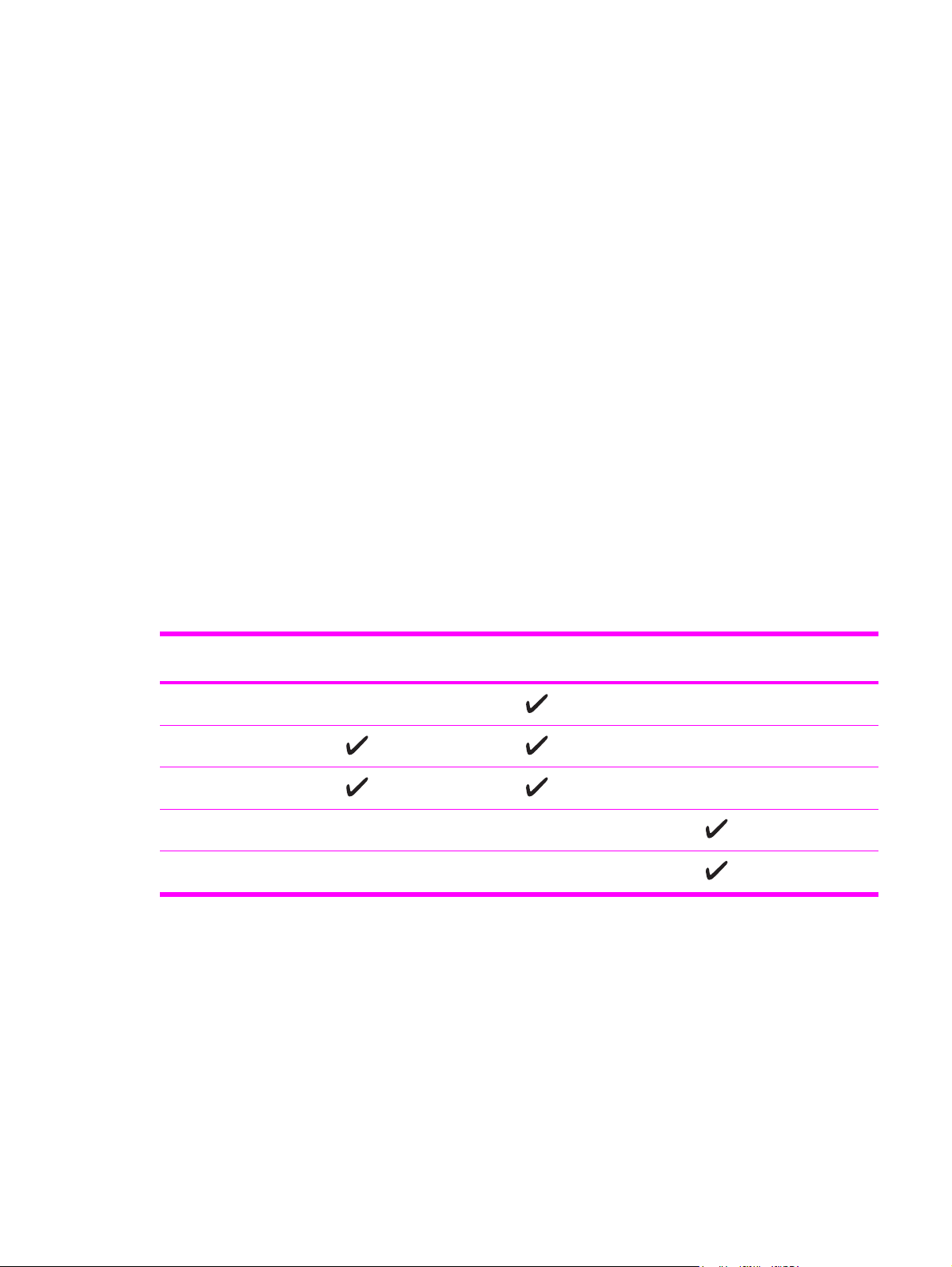

Figure 1-7 Control panel display

The printer display gives you information about the printer, job status, and levels of supplies.

1 Message area

2 Supplies gauges

3 Print cartridge colors are indicated from left to right: black, yellow, cyan, and magenta

10 Chapter 1 Product information ENWW

Page 25

Software

This section contains information about the software used with the HP Color LaserJet 2600n printer.

Supported drivers

Software and supported operating systems

For easy printer setup and access to the full range of printer features, HP strongly recommends that

you install the software that is provided. Not all software is available in all languages. See the Getting

Started Guide for installation instructions, and see the Readme file for the latest software information.

The most recent drivers, additional drivers, and other software are available from the Internet and

other sources.

The printer supports the following operating systems:

■ Microsoft® Windows® 98 Second Edition and Windows Millennium Edition (Me) (Add Printer

installation)

■ Microsoft® Windows® 2000 and Windows XP

■ Microsoft® Windows® Server 2003

■ Macintosh OS X v10.2 and later

The following table lists the software that is available for your operating system.

Table 1-2 HP Color LaserJet 2600n printer software

Feature Windows 98 Second

Edition, Me

Windows Installer

Windows printer driver

HP Toolbox software

Macintosh Installer

Macintosh printer drivers

Windows 2000 and XP Macintosh OS X v10.2 and

later

Software for Windows

When you install the software for Windows, you can directly connect the printer to a computer by

using a USB cable or you can connect the printer to the network by using HP built-in networking. See

the Getting Started Guide for installation instructions, and see the Readme file for the latest software

information.

The following software is available to all users of the printer, whether you connected the printer

directly to a computer by using a USB cable, or to the network through the HP built-in networking

internal print server.

ENWW Software 11

Page 26

Printer drivers

A printer driver is a software component that provides access to printer features and provides the

means for the computer to communicate with the printer.

Using Help

The printer driver has Help dialog boxes that can be activated from the Help button in the printer

driver, the F1 key on the computer keyboard, or the question mark symbol (?) in the upper-right

corner of the printer driver. These Help dialog boxes give detailed information about the specific

printer driver. Help for the printer driver is separate from the Help for your program.

HP Toolbox

You must perform a complete software installation to use the HP Toolbox.

The HP Toolbox provides links to printer status information and help information, such as the user

guide; and tools for diagnosing and solving problems. You can also view explanations and

animations on the control panel. See

Managing and maintenance for more information.

Software for Macintosh

The printer includes the following software for Macintosh computers.

Macintosh printer driver

When you install the software for Macintosh, you can directly connect the printer to a computer by

using a USB cable or you can connect the printer to the network by using HP built-in networking. If

you are connected via the network, you can configure your printer using the embedded Web server.

Network software

Supported networks

The HP Color LaserJet 2600n printer supports network printing on Windows and Mac systems.

Supported utilities/applications/tools

■ HP Color LaserJet 2600n HP Toolbox

For IP configuration, in HP Toolbox, select Device Settings, and then select the Networking

tab. For more information about the HP Toolbox, see

■ Embedded Web server (EWS)

If the printer is connected to a network, access the EWS by typing the printer IP address into the

address field of a Web browser, and then selecting the Networking tab.

HP Toolbox.

Uninstalling software

Uninstall software by using the following directions for your operating system.

Windows software

After a printing system installation, use the uninstall icon in the HP Color LaserJet 2600n printer

program group to select and remove any or all of the HP printing system components.

12 Chapter 1 Product information ENWW

Page 27

Starting the Uninstaller

1 Click Start, select Programs (All Programs for Windows XP) and choose HP.

2 In the HP Color LaserJet 2600n program group, click the HP Color LaserJet 2600n uninstall

icon.

3 The uninstaller guides you through removing the printing system components.

NOTE For driver-only (Add Printer/New Driver) installations, delete the printer icon from the

Printers folder (Windows 98 Second Edition, Windows Me, Windows 2000, and Windows XP).

Macintosh software

To remove the printer from your Macintosh use the following steps:

1 Open Print Center (v10.2) or Print Setup Utility (v10.3).

2 Select the printer name.

3 Select Delete.

ENWW Software 13

Page 28

Print-media specifications

This section contains information about specifications for the quality of print media, guidelines for

print media usage, and guidelines for print media storage.

General guidelines

Some print media might meet all of the guidelines in this manual and still not produce satisfactory

results. This problem might be the result of improper handling, unacceptable temperature and

humidity levels, or other variables over which Hewlett-Packard has no control.

Before purchasing large quantities of print media, always test a sample and make sure that the print

media meets the requirements specified in the HP LaserJet Printer Family Print Media Guide

available at

This printer accepts a variety of media, such as cut-sheet paper (including up to 100% recycled-fibercontent paper), envelopes, labels, transparencies, HP LaserJet glossy paper, HP LaserJet Tough

paper, HP LaserJet Photo paper, and custom-size paper. Properties such as weight, composition,

grain, and moisture content are important factors that affect printer performance and output quality.

Print media that does not meet the guidelines outlined in this manual can cause the following

problems:

http://www.hp.com/support/ljpaperguide.

CAUTION Using print media that does not meet HP specifications can cause problems for

the printer, requiring repair. This repair is not covered by the Hewlett-Packard warranty or

service agreements.

CAUTION Use only paper designed for laser printers. Paper for inkjet printers may damage

the printer.

■ Poor print quality

■ Increased jams

■ Premature wear on the printer, requiring repair

Paper and print media

For print-media specifications, see Media support tables.

Printing and storage environment

Ideally, the printing and media-storage environment should be at or near room temperature, and not

too dry or too humid. Remember that paper is hygroscopic; it absorbs and loses moisture rapidly.

Heat works with humidity to damage paper. Heat causes the moisture in paper to evaporate, while

cold causes it to condense on the sheets. Heating systems and air conditioners remove most of the

humidity from a room. As paper is opened and used, it loses moisture, causing streaks and

smudging. Humid weather or water coolers can cause the humidity to increase in a room. As paper is

opened and used it absorbs any excess moisture, causing light print and dropouts. Also, as paper

loses and gains moisture it can distort. This issue can cause jams.

As a result, paper storage and handling are as important as the paper-making process itself. Paper

storage environmental conditions directly affect the feed operation and print quality.

14 Chapter 1 Product information ENWW

Page 29

Care should be taken not to purchase more paper than can be easily used in a short time (about

three months). Paper stored for long periods can experience heat and moisture extremes, which can

cause damage. Planning is important to prevent damage to a large supply of paper.

Unopened paper in sealed reams can remain stable for several months before use. Opened

packages of paper have more potential for environmental damage, especially if they are not wrapped

with a moisture-proof barrier.

The media-storage environment should be properly maintained to ensure optimum printer

performance. The required condition is 20° to 24°C (68° to 75°F), with a relative humidity of 45% to

55%. The following guidelines should be helpful when evaluating the paper's storage environment:

■ Print media should be stored at or near room temperature.

■ The air should not be too dry or too humid (to moderate the hygroscopic properties of paper).

■ The best way to store an opened ream of paper is to rewrap it tightly in its moisture-proof

wrapping. If the printer environment is subject to extremes, unwrap only the amount of paper to

be used during the day's operation to prevent unwanted moisture changes.

■ Avoid storing paper and print media near heating and air conditioning vents or near windows and

doors that are frequently open.

Envelopes

Envelopes can be printed from Tray 1 or Tray 2. Select the type of envelope that you are using from

the Print dialog box or the printer driver.

In your program, set the margins for the envelope. The following table gives typical address margins

for a commercial #10 or DL envelope.

Table 1-3 Envelope specifications

Type of address Top margin Left margin

Return address 15 mm (0.6 inch) 15 mm (0.6 inch)

Delivery address 51 mm (2 inches) 89 mm (3.5 inches)

■ For the best print quality, position margins no closer than 15 mm (0.6 inch) from the edges of the

envelope.

■ Avoid printing over the area where the envelope seams meet.

Envelope storage

Proper storage of envelopes helps contribute to print quality. Envelopes should be stored flat. If air is

trapped in an envelope and creates an air bubble, then the envelope might wrinkle during printing.

Envelope construction

Envelope construction is critical. Envelope fold lines can vary considerably, not only between

manufacturers, but also within a box from the same manufacturer. Successful printing on envelopes

ENWW Print-media specifications 15

Page 30

depends upon the quality of the envelopes. When selecting envelopes, consider the following

components:

■

Weight: The weight of the envelope paper should not exceed 90 g/m

2

(24 lb) or jamming might

occur.

■ Construction: Before printing, envelopes should lie flat with less than 6 mm (0.25 inch) curl, and

should not contain air.

■ Condition: Envelopes should not be wrinkled, nicked, or otherwise damaged.

■ Temperature: Use envelopes that are compatible with the heat and pressure of the printer. This

printer fusing temperature is 210°C (410°F).

■ Size: Use only envelopes that are within the following size ranges.

Table 1-4 Envelope size ranges

Tray Minimum Maximum

Tray 1 or Tray 2 76 x 127 mm (3 x 5 inches) 216 x 356 mm (8.5 x 14 inches)

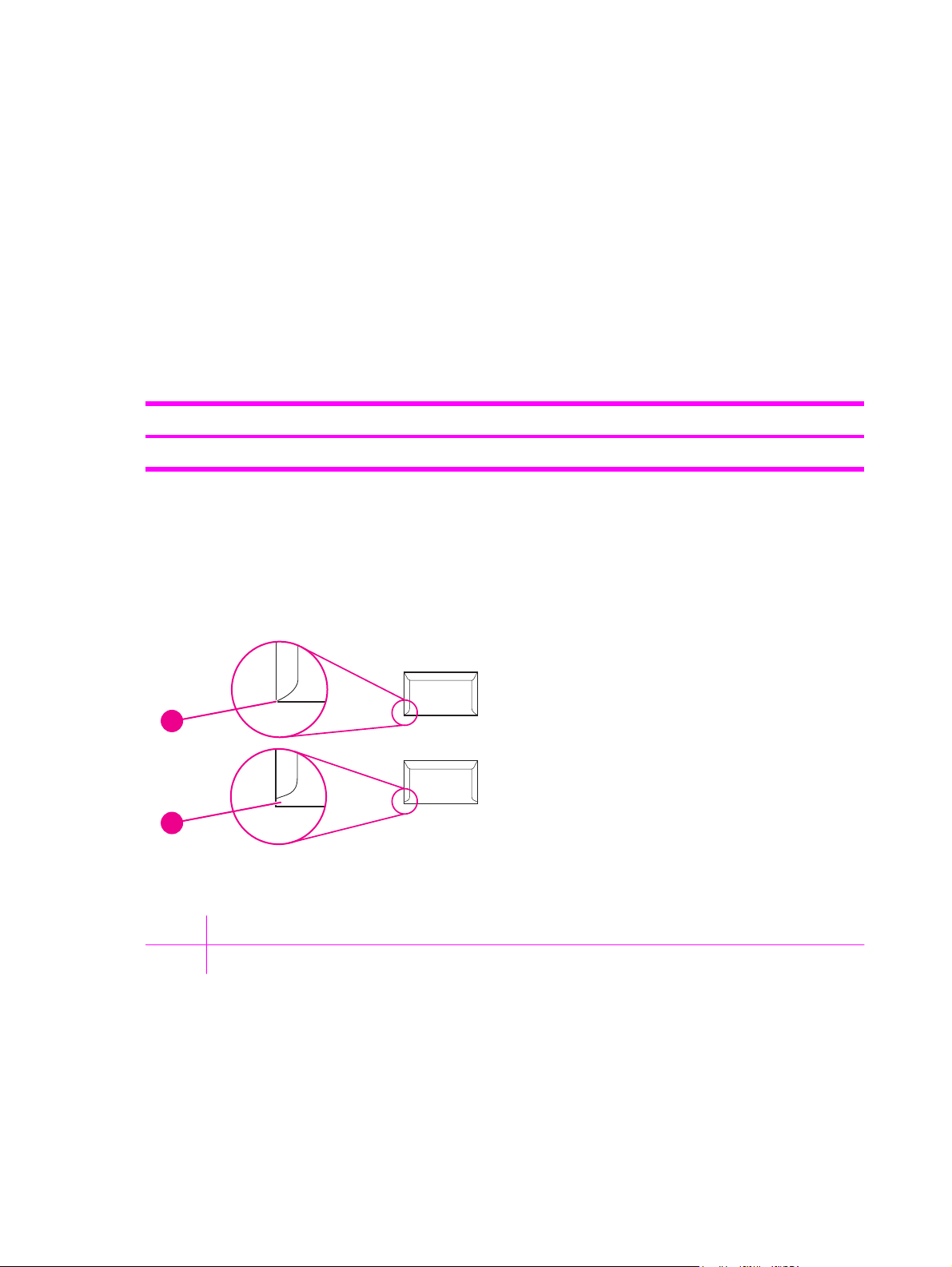

Envelopes with double side-seams

Double side-seam construction has vertical seams at both ends of the envelope rather than diagonal

seams. This style might be more likely to wrinkle. Be sure the seam extends all the way to the corner

of the envelope as illustrated below.

1

2

Figure 1-8 Envelope double side-seam construction

1 Acceptable

2 Unacceptable

Envelopes with adhesive strips or flaps

Envelopes with a peel-off adhesive strip or with more than one flap that folds over to seal must use

adhesives that are compatible with the heat and pressure in the printer. The extra flaps and strips

might cause wrinkling, creasing, or even jams and might damage the fuser.

16 Chapter 1 Product information ENWW

Page 31

Labels

Select the type of label that you are using from the Print dialog box or the printer driver.

CAUTION To avoid damaging the printer, use only labels that are recommended for laser

printers. To prevent serious jams, always use Tray 1 or Tray 2 to print on labels. Never print

on the same sheet of labels more than once or print on a partial sheet of labels.

When selecting labels, consider the quality of each component:

■ Adhesives: The adhesive material should be stable at 210°C (410°F), which is the printer fusing

temperature.

■ Arrangement: Only use labels with no exposed backing between them. Labels can peel off

sheets with spaces between the labels, causing serious jams.

■ Curl: Before printing, labels must lie flat with no more than 13 mm (0.5 inch) of curl in any

direction.

■ Condition: Do not use labels that have wrinkles, bubbles, or other indications of separation.

Transparencies

Use only Tray 1 or Tray 2 to print on transparencies. Select Transparencies from the Print dialog

box or the printer driver.

The printer supports printing on color transparencies. Use only transparencies that are

recommended for use in laser printers.

Transparencies that are used in the printer must be able to withstand 210°C (410°F), which is the

printer fusing temperature.

CAUTION To avoid damage to the printer, use only transparencies that are recommended

for use in laser printers.

Media support tables

This section contains information about the sizes, weights, and capacities of paper and other print

media that each tray supports.

Supported print media for Tray 1, Tray 2, and optional Tray 3

This section contains information about the sizes, weights, and capacities of paper and other print

media that each tray supports.

Tray 1 and Tray 2 specifications

Table 1-5 Tray 1 and Tray 2 specifications

Tray 1 and Tray 2

Dimensions

1

Weight Capacity

2

Paper Minimum: 76 x 127 mm

(3 x 5 inches)

60 to 163 g/m

2

(16 to 43 lb) Single sheet of 75 g/m

(20 lb) paper for Tray 1

2

ENWW Print-media specifications 17

Page 32

Table 1-5 Tray 1 and Tray 2 specifications (continued)

Tray 1 and Tray 2

Dimensions

1

Weight Capacity

2

Maximum: 216 x 356 mm

Up to 250 sheets for Tray 2

(8.5 x 14 inches)

HP LaserJet glossy paper

and HP LaserJet photo paper

Same as the preceding

listed minimum and

maximum sizes.

75 to 163 g/m2 (20 to 43 lb)

Single sheet of HP LaserJet

glossy paper or HP LaserJet

photo paper for Tray 1

Up to 25 mm (0.99 inch)

stack height for Tray 2

HP Premium Cover paper

3

200 g/m2 (75 lb) cover

Single sheet of HP Cover

paper for Tray 1

Up to 25 mm (0.99 inch)

stack height for Tray 2

Transparencies and opaque

film

Thickness: 0.10 to 0.13 mm

(3.9 to 5.1 mils)

Single sheet of transparency

or opaque film for Tray 1

Up to 50 sheets for Tray 2

Labels

Thickness: up to 0.23 mm

(up to 9 mils)

Single sheet of labels for

Tray 1

Up to 25 mm (0.99 inch)

stack height for Tray 2

Envelopes

Up to 90 g/m2 (16 to 24 lb)

Single envelope for Tray 1

Up to ten envelopes for

Tray 2

1

The printer supports a wide range of standard and custom sizes of print media. Check the printer driver for supported sizes.

2

Capacity can vary depending on media weight and thickness, and environmental conditions.

3

Hewlett-Packard does not guarantee results when printing with other types of heavy paper.

Optional Tray 3 specifications

Table 1-6 Optional Tray 3 specifications

Optional Tray 3 (250–sheet

Dimensions

1

Weight

Capacity

tray)

Paper Minimum: 76 x 127 mm

60 to 163 g/m2 (16 to 43 lb)

Up to 250 sheets

(3 x 5 inches)

Maximum: 216 x 356 mm

(8.5 x 14 inches)

1

The printer supports a wide range of standard and custom sizes of print media. Check the printer driver for supported sizes.

2

Capacity can vary depending on media weight and thickness, and environmental conditions.

2

Unsupported media (media to avoid)

Avoid using the following media:

■ Paper that has been stapled. Staples left in reused paper will cause printer damage that will

require repairs that may not be covered under the warranty.

■ Sheets of labels that have been used more than once or partial sheets of labels

18 Chapter 1 Product information ENWW

Page 33

■ Labels that are not specifically recommended for laser printers

■ Labels that are separating from the backing sheet or are wrinkled or damaged in any way

■ Transparencies that are not specifically recommended for laser printers

■ Media that has been stored in a high-humidity environment

■ Labels with exposed glue or adhesive

ENWW Print-media specifications 19

Page 34

20 Chapter 1 Product information ENWW

Page 35

2 Installation

This chapter contains information about the following topics.

Site preparation

●

Package contents

●

Install input devices

●

ENWW 21

Page 36

Site preparation

Below are recommendations for the printer location and placement.

Operating environment

The printer must be kept in a proper location to maintain the performance level that has been set at

the factory. In particular, be sure that the environment adheres to the specifications listed in this

chapter.

The printer must have 2 inches of space above and around it.

Figure 2-1 Printer dimensions

1 Front view

2 Side view

Make sure the printer has the following:

■ A well-ventilated, dust-free area

■ As surface that will support up to 18 kg (40 lbs)

■ A constant temperature and humidity (Do not install near water sources, humidifiers, air

conditioners, refrigerators, or other major appliances.)

■ A hard level surface (not more than a 2° angle)

Make sure to keep the printer away from the following:

■ Direct sunlight, dust, open flames, or water

■ Direct flow of exhaust from air ventilation systems

■ Magnets and devices that emit a magnetic field

■ Areas subject to vibration

22 Chapter 2 Installation ENWW

Page 37

■ Walls or other objects. There must be enough space around the printer for proper access and

ventilation

Minimum system requirements

The minimum system requirements for the HP Color LaserJet 2600n printer are listed below:

■ 150 MB of free hard disk space

■ CD-ROM drive

■ Available USB or network port

NOTE Networking is only available on Windows 2000, Windows XP, and Macintosh.

Requirements for PC systems

■ Windows 98 SE and Me (driver only)

■ Windows 2000 and XP (32-bit Home and Professional)

■ 233 MHz processor with 64 MB RAM

Requirements for Macintosh systems (non-PostScript)

■ G3 processor (G4 processor recommended)

■ Mac OS X 10.2 and later

ENWW Site preparation 23

Page 38

Package contents

Figure 2-2 Package contents lists the package contents for the HP Color LaserJet 2600n.

Figure 2-2 Package contents

1 HP Color LaserJet 2600n

2 Output tray

3 Power cable

4 Dust cover

5 Getting Started Guide

6 Software and user documentation CD-ROM

24 Chapter 2 Installation ENWW

Page 39

Install input devices

Installing optional Tray 3

1 Turn off the power switch on the printer.

2 Unplug the power cable.

3 Place the printer on optional Tray 3, aligning the three (3) pegs on Tray 3 with the holes on the

printer.

Loading Tray 1

Tray 1 (the single sheet priority feed slot) prints single sheets of print media or a single envelope.

Use Tray 1 when feeding one sheet of paper, or one envelope, postcard, label, HP LaserJet glossy

paper, HP LaserJet Photo paper, or transparency. You can also use Tray 1 to print the first page on

different media than the rest of the document.

ENWW Install input devices 25

Page 40

For information about loading special print media such as envelopes, labels, and transparencies, see

Print-media specifications.

To load Tray 1

1 Media guides ensure that the media is correctly fed into the printer and that the print is not

skewed. Slide the media-width guides slightly wider than the print media.

2 Feed print media into Tray 1 with the side to be printed down, and the top, short edge in first.

Make sure that the media is inserted far enough into the printer for the paper feed mechanism to

grab the media. The paper will reach the sensor after 140 mm (5.5 inches) has been inserted.

The printer will then pause for .5 second before it pulls the paper into the printer. HP

recommends holding the paper on both sides when inserting.

NOTE Light weight paper may buckle if held only on the short (far) edge as it is inserted.

As paper is inserted, it trips the registration shutter. For light weight paper, holding it on

both sides near the slot increases the ability for the paper to appropriately trip this shutter.

26 Chapter 2 Installation ENWW

Page 41

Installing supplies

Print cartridges

When a print cartridge approaches the end of useful life, the control panel displays a message

recommending that you order a replacement. The printer can continue to print using the current print