Page 1

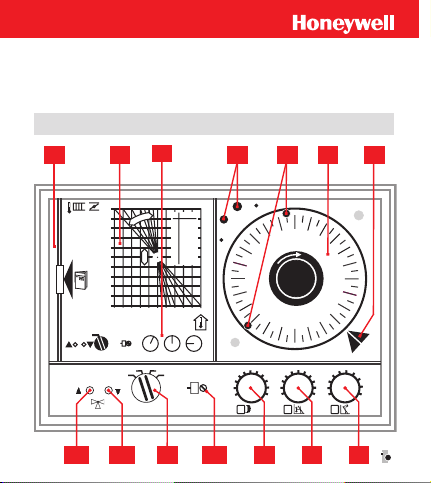

Comfort Compact Controller ZG 215N

OPERATION AND PUTTING INTO SERVICE

1476

%

ZG215N

auto

3

2

20 16 12 8 6 4 2 Xp

100

90

A

80

70

60

B

50

40

30

20

10

0

10 12 14 16 18 20 22 24 26 28 30

-8450

C

P1 ACB

5

A

20...90°C

2

1,4

4

2,8

6

4,2

8

5,5

10

7,0

12

8,2

14

9,6

16

10,9

18

12,4

20

13,9

°C

8311.7352

P1

L1 L2 P1

S

CBA

C

20

B

A

CB50266

Page 2

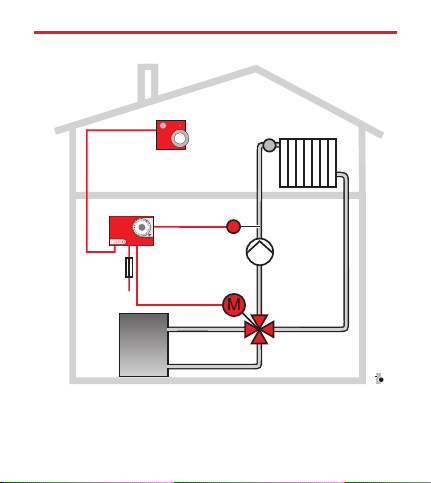

Hot Water Heating with Room Control

TW

ZG215N

////

ZG Control Unit

VM Servomotor

ZR Heating mixing valve

VF Flow sensor

VF

//

VM

////

TW Temperature selector

with room sensor

P Heating circuit pump

P

ZR

CBZG117.cdr

Page 3

Operation as a Heating Control

(Fig. left)

The remote control (TF) is composed of a temperature sensor

and atemperatureselector. (If desired also two separateddevices

can be used.)

The temperature sensor measures the actual room temperature.

n

The desired value for the room temperature is to be set on

n

the temperature selector.

On the basis of both of these values the control unit calculates the

necessary watertemperature (flow temperature).It is measured by

the flow sensor (VF). If the flow temperature differs from the set

value, the control unitadjusts themixing valve (ZR)with the ser

vomotor (VM) so that the right heat input is provided to the radi

ators.

Themixing valve determines the flow temperature by mixing the

hot water from the boiler with the colder return water.

Theheating circuit pump (P) provides for the circulation of the

hot water. It is not operated by the control unit.

Thetemperature selector (TF) is used as a remote control, e.g. if

the control unit is mounted in the cellar: by means of the selector

knob P2 the room temperature can be changed. With the party

switch S1 the night economy option can be suspended.

-

-

Page 4

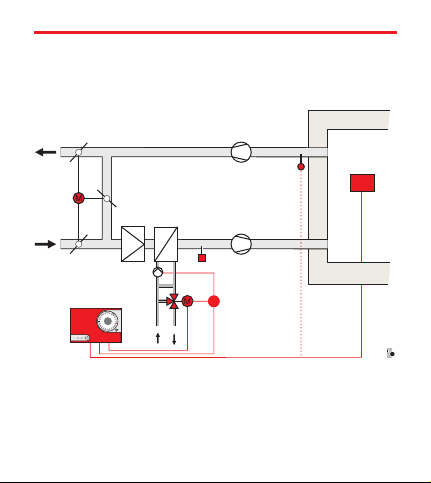

Air-handling system with mixing chamber

VM

ZG 215N

///

///

///

ZG Control Unit

VM Servomotor

ZR Heating mixing valve

LF

FT

Poti

LF Air duct sensor

TW Temperature selector

FT Frost protection thermo

//

TW

CB2283

-

Page 5

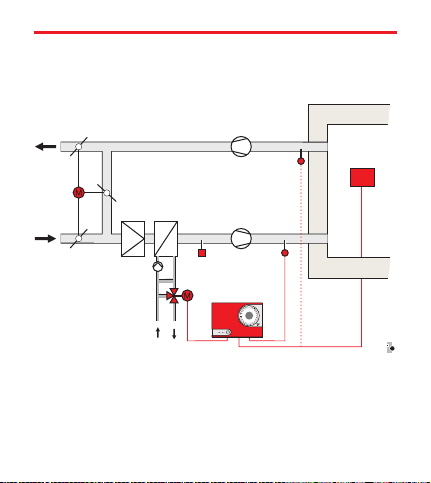

Air-handling system with heating coil

ZG Control Unit

VM Servomotor

ZR Heating mixing valve

LF

FT

LF

VM

ZG 215N

////////

LF Air duct sensor

TW Temperature selector

FT Frost protection thermo

//

TW

//

///

CB2286

-

Page 6

Operation as an Air-handling Control

(fig. left both

The operation of the air-handling control is basically the same as

for warm water heating. Instead of the flow temperature, the air

temperature in the supply duct is measured.

The control unit calculates the necessary heat demand and regula

tes the drivemotor sothatthe desired room temperature is reached.

Depending on the layout of the air-handling system, the drive mo

tor operates on a different part of the system:

In case of a mixing chamber system the blinds for the inco

n

ming and outgoing air are set.

In case of heating coil control the hot water temperature is

n

set for air heating.

In both oftypes ofsystem, the supply of heat isregulated so that the

room temperature setwith thetemperatureselector is maintained.

)

-

-

-

Page 7

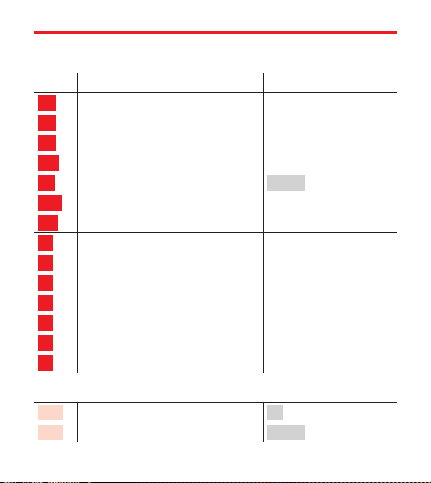

Operating and Display Components

Pos. Function Basic Setting

A

Proportional Range

B

Operating point setting

C Reduced Mode -8

P1 Sensitivity 5

S Operating mode selector auto

L1 “Hotter” LED (red)

L2 “Colder” LED (green)

1 Instructions compartment

2 Heating curve diagram

3 Basic Settings

4 Reserve trip pins

5 Inserted trip pins

6 Timer (optional)

7 Pointer for current time

Settings on the Temperature Selector

P2 Selector knob 0

S1 Party switch auto

4

50

Page 8

Operating mode selector

manu the controlunit is deactivated(the timer runs).The mixing

valve can be set manually (by hand). The pump is switched on.

auto Recommended setting for greater energysaving: automatic

change betweenday and reducedmode according to thetimer with

night switch-off.

Manual day mode, timer inactive.

Manual night mode according to the settings on the

setting knobs B minus C , the timer remains inactive.

LED’s

L1 L2

In themanu settings ofthe operating mode selector S there is no

LED display.

Both LED’s light up:

“neutral”

– mixing valve stops

only red LED lights up:

“hotter”

– mixing valve opens

only green LED lights up:

“colder”

– mixing valve closes

Page 9

Putting into service

Set the timer 6 with the current time.

n

Set the operating mode selector S to auto .

n

The remaining basic factory settings are printed under 3 on the

control unit.

Timer for reduced mode 6

With theaid of thetimer, the roomtemperature during idleperiods

can be reduced automatically to save on operating costs.

The timer has a built-in power reserve of approx. 60 hours thanks

to a rechargeable battery.

Changing the program

Factory settings: red pin 6:00, blue pin 22:00.

Pull out the trip pin and insert it again at the desired

n

switch-on time. Push in the trip pins until they reach the stop.

Owing to the different lengths, the trip

pins must always be inserted in ared/blue

alternate order. Thered trip pin switches

on day mode, while the blue pin activates

reduced mode.

CB5044.7.cdr

Page 10

In order tomake surethat the rooms are heated well inthe morning,

the heating system’sday mode should be activated betweenhalf an

hour and an hour before using the rooms.

Energy saving tip: Reduced mode can be activated

up to an hour before the room is left. The storage

capacity of the heating system and building is

enough to keep the rooms warm for some time.

Timer with day program

The dayprogram is repeated every24 hours. Ifa (second) decrease

in temperature isdesired inthe course of the day to saveenergy, the

program needs tobe extended. Take the extra trippins 4 and insert

them at the desired time.

Example:

Desired time program

Normal temperature:

6:00 h to 8:00 h and 16:00 h to 22:00 h night decrease:

22:00 h to 6:00 h

day decrease: 8:00 h to 16:00 h

Position of the trip pins:

red pin 6:00 h – Start day mode (normal temperature)

blue pin 8:00 h – Start day decrease

red pin 16:00 h – Start day mode (normal temperature)

blue pin 22:00 h – Start night decrease

Page 11

Timer with week program

The timer has a changeable dial.

With the week program dialing a different heating program for

each weekday is possible.

The dial isprepared exfactory for the day program and,if required,

it can bechanged toweekprogram (see installation instructions).

Setting the right time

To set the time, the time dial is to be placed on the trip pins and

turned clockwise until the indication on the setting marker 7

matches with the current time.

Page 12

Optimization of the Settings

Basic Setting

(for hot water heating operating with temperature between

20 and 90 °C)

A è 4 B è 50 C è -8

During the regulation procedure open the radiator valves

n

completely. (Set the thermostat valves at the maximum va

lue).

If in the test room (room where the temperature sensor is

n

located) radiator valves are installed, these must be left

open always.

Close all windows and doors.

n

Proceed gradually by making only small changes.

n

Wait for the outcome of the change after each setting

n

(approx. 1 h).

Depending on the type of system – radiator/convector heating

(up to 90 °C), low temperature heating,air heating, mixing cham

ber regulation – and depending on the layout of the heating surfa

ces various flow or supply temperatures are needed to reach the

right room temperature – and hence also different settings on the

setting knobs.

-

-

-

Page 13

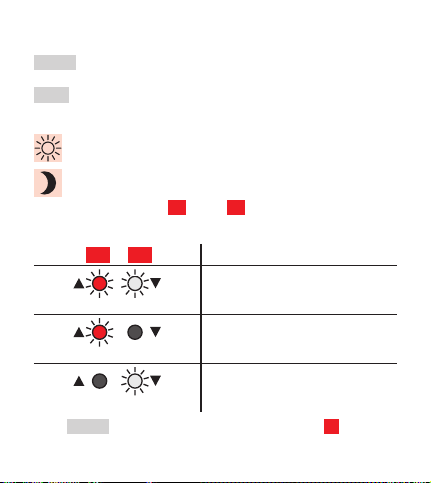

Proportional range: Setting knob

To makesure that thecontrol unit maintains the desired roomtem

perature, an operating range (regulation range) is to be given. The

operating rangedefines the relation betweenthe room temperature

and flow temperature or the setting of the regulating unit. Since

there is always a specific relation (proportion) between the room

and flow temperature in the operating range, it is also called

proportional rangeXp. For most 90/70 hotwater heating systems,

A è 4 is correct as the basic setting.

If with this setting (A è 4) aconstant room temperature is obtai

ned and the mixing valve position remains more or less the same

over a long period of time, no correction is necessary.

If, however, periodic room temperature oscillations occur, becau

se the mixing valve opens and closes intermittently, a larger pro

portional range is to be set (e. g. A è 5).

Description of the Operating Diagram

With the setting knob A the proportional range can be set. The

numeric value seton setting knob A means a proportionalrange in

% (or°C) for an operating rangeof the actuator of 0 to 100 %. The

smaller the numeric value on the setting knob A , the steeper the

operating characteristic curve of the regulation is. A steep opera

ting characteristic curve implies that already at a small room tem

perature oscillation a relatively intense heat convection to the

room occurs.

A

-

-

-

-

-

-

Page 14

With large numeric values on the setting knob A the operating

characteristic curve of the control unit is more level. For a small

deviation in the set room temperature, the supply of heat to the

room is hence changed only slightly and for fine dosing.

All the characteristic curves split in the operating pointto indicate

the rotation of the operating characteristic curve when turning the

setting knob A .The illustrated characteristiccurves A è 4 and

A è 9,5 correspond to the setting values 4 and 9.5 on the set

ting knob A . The operating point (settable with setting knob B )

is to be located for usual heating modes halfway between the lar

gest required and the least possible heating flow temperature.

Setting knob

A

Xp100in%2468101214161820

Xp 70 in °C 1.4 2.8 4.2 5.5 7.0 8.2 9.6 10.9 12.4 13.9

Xp 30 in °C 0.6 1.2 1.9 2.4 2.8 3.4 4.0 4.7 5.2 6.0

Xp 20 in °C 0.4 0.8 1.2 1.6 2.0 2.2 2.6 3.2 3.6 4.0

Setting of the operating point: Setting knob

With setting knob B the operating point of the operatingcharac

teristic point can be moved. The corresponding scale is planned in

“°C flow temperature” or “% valve position”. Basically, the

operating point is to be moved with setting knob B to the middle

of the system’s operating range. It is for example 45 °C for a hea

ting system in which the execution value matches the standard

2468101214161820

B

-

-

-

-

Page 15

design valueand which atthe lowest outdoortemperature requires

a maximum heating water temperature of approx. 70 °C and a mi

nimum temperatureof approx. 20 °C. Experience shows that most

systems are quite oversized. For the usual 70/50 radiator heating

systems, the basic setting B è 45 (instead of 50 °C) is correct.

Night decrease: Setting knob C

On setting knob C the size of the reduction to be triggered by the

timer isto be set. The settingof C gives a parallel shift ofthe ope

rating characteristic curve to the left (see dotted curve II). Thisle

ads toa decrease inthe room temperature.The scale divisionof C

corresponds toa room temperature decrease ofapprox. K (°C). “0”

means no decrease.

Example: C è -8 means that the nighttime room temperature

target valueis lower by 8 Kcompared to the daytime value,so that

the room temperature at night can decrease to approx. 8 K below

the set daytime temperature and hence

e. g. to 12 °C (20 °C −8 K = 12°C).

The recommendedsetting C at -8 makes it possibleto save quite a

lot of energywith a large nighttime decrease. In somebuildings the

rooms may become too cold.

In these cases, it is recommended to set a night decrease value of

about -5 or to switch on day mode earlier.

-

-

-

Page 16

Examples with other operating ranges:

1) Low temperature heating

n

maximum flow temperature 50 °C,

minimum flow temperature 20 °C,

average operating temperature (50 + 20):2=35°C;

The operating point of the operating characteristic curve is to

be set at 35 °C.

B è 35

A è 5

2) Ventilation and air conditioning systems:

n

maximum supply temperature 40 °C

minimum supply temperature 20 °C

average operating temperature (40 + 20):2=30°C

The operating point of the operating characteristic curve

is to be set at 30 °C.

B è 30

A è 10

3) Mixing chamber:

n

Valve setting AL 100 %, AL at

valve setting AL 0 %, AL to

B è 50

A è 8

( S1 è K, S2 è 1)

When using separated temperature sensors and target

value setting devices (TW 21...23), the function selector

on theback of the control unit S2 is tobe set always on

1 . Thesetarget valuesetting devicesare gaged in°C.

Page 17

Remote Control TF 22 (optional)

Setting the Room Temperature

On setting knob P2 the setting of the room temperature can be

fine-tuned. The normal settingis the room temperature set on con

trol unit(setting knob B ) (mainly 20°C to 22°C, the roomtempe

rature is not measured on the temperature selector). The scale on

the selector is divided from -7 to +7 and corresponds more or less

to the variation in degrees.

+ è Increasing the Room Temperature

– è Lowering the Room Temperature

The functioning of the selector knob P2 corresponds to the

functioning of the setting knob B on the control unit and gives a

parallel displacement of the heating curve along the oblique room

temperature axisindicated in thediagram. The valueson the selec

tor knob P2 and thesetting knob B are added on the controlunit:

S1

P2

-

-

-

Page 18

Examples B è 0 B è +1

Selector knob P2 -1 0 +1 +2 -1 0 +1 +2

Room temp. [°C] 19 20 21 22 20 21 22 23

If no temperature selector is available, the desired room tempera

ture can be set only on the setting knob B of the control unit.

Party switch S1

The temperature selector’sparty switchhasthe following settings:

auto automatic change to day mode or reduced mode

according to the timer

manual day mode, timer not active

manual night mode, timer not active

(the “night” duration mode is possible only if the

hours are set.)

If, for example, the heating is to stay open longer,

the Partyswitch is to be set on manual day mode.

Do not forget to switch back if the automatic mode is

to be activated again later on.

-

Page 19

Instructions for the Technician (only!)

Removing the Timer (see also the install. instructions)

Operating steps:

1. Pull out the instructions case.

n

2. Hold the timer by the two white stems and turn to the left

n

until the connector is released.

3. Remove the timer.

n

(To install the timer proceed in the opposite order.)

Regulation Stability (Sensitivity)

The stability of the regulation can be modified with the setting

potentiometer P1 .

For the regulation technician:

By means of P1 set the proportional range of the PD control

unit. Recommended basic setting: P1 è 10.

In case of unstable regulation, set higher values.

Setting potentiometer (for special cases)

Below the timer you will find the two potentiometers P6

n

and P8 (see fig.). After removing the timer these can be set

with a screwdriver. The factory basic setting is correct in

most cases and needs to be reset only in special cases and

only by a technician.

Page 20

Potentiomer P6 : Minimum limit

n

In case of air-hand

ling systems minimum

outside air rates or mini

mum flow temperatures

are necessary. P6 deter

mines the minimum ope

ning of the setting valves

between 0...70 %. For

heating systems mini

mum flow temperatures

of 0...70 °C can be set.

Factory basic setting: P6 è 0

Potentiometer P8 : Feedback balancing

n

In heating systemswithout flow sensor (e. g. quantityregulation in

the flow)or in air-handlingsystems, the controlunite works witha

potentiometer feedback of the servomotor. Changes in special

cases, ife. g. with valveactuation the motor’sswitch-off point and

the valve’s cut-off point do not match.

Factory basic setting: P8 è 0

Changes are to be made only by specialized personnel!

Make sure that:

1. Shifting towards + the closing angle increases

– the regulating unit is closed further

2. Shifting towards – increases the opening angle

– the regulating unit is opened further

-

-

-

-

-

P8 P6

Page 21

Function switch S1 / S2

( S1 and S2 are located on the back of

the controller insert. To move thefuncti

on switch insert, remove it as described

in the installation instructions.)

Function switch S1

n

"Heating – Cooling"

In air-conditioning systems, the control

ler can be used also to regulate the cooling load. The feedback of

the setting value (valve position) to the controller is provided by

means of a potentiometer in the servomotor, instead of the flow

sensor.

S1 è H (Heating) = factory basic setting

S1 è K (Cooling)

In setting K the following mean:

LED display red – colder (greater cooling load)

LED display green – hotter (less cooling load)

Function switch S2 "Target Value Definition"

n

S2 è 2 (target value in the pro. range, like setting knob B )

S2 è 1 (Operating point is always at the target value)

Position 1 of the switch is appropriate for example for mixing

chamber or greenhouse regulations. With this setting the entire

operating characteristic curve goes only in one direction.

Position the setting knob B always on 50.

= factory basic setting

-

S1 S2

-

Page 22

Troubleshooting Checklist

Is the heat generator at the required temperature?

n

è Read the heat generator’s thermometer.

Is the burner ready?

n

Is the burner failure lamp on?

è If necessary, press the suppressor.

Was the temperature selector set by mistake?

n

Setting of the selector knob P1

Check the setting on the control unit.

n

Setting knobs BCand operating mode selector S .

Is the timer running? Is the displayed time correct?

n

è Check the time and switch-on point.

If the problem still has not been solved after checkingthe settings,

position the setting knob B on +7

The servomotor should now open the mixing valve and the red

LED L2 should light up. If this is not the case, the control system

has failed. Contact your heating technician.

Page 23

Manual mode

In case of the breakdown of the

heating mode regulation you can

proceed temporarily as follows:

1. Set the operating mode se

n

lector S on manu .

2. Open the mixing valve by

n

hand until the desired flow

and room temperatures are

reached.

CB5043.7.cdr

– The coupling incorporated in the mixing valve drive unit

provides for the release of the connection between the

motor and the mixing valve.

– Press firmly on the unlock key on the cover of the drive

unit and keep the key pressed (firmly!).

– Use the setting lever to set the mixing valve in the desi

red

position.

After eliminating the problem the mixing valve is set

again to the right position by the control unit in au

tomatic mode.

-

-

-

Page 24

Reference

Installation instructions

Compact Control Units ZG 215N / 215 VN / 252 N

EN 1H-0181 GE51

Operating Instructions

ZG 252N: EN-2H0215 GE51

ZG 215N: EN-2H0216 GE51

ZG 215V: EN-2H0217 GE51

“Informationsschrift”(Planning broschure in German)

L3 – Komfort-Compact Regler

GE-0H 0327 GE51

Centra Regelungstechnik http://www.honeywell.de/hga

Honeywell AG

Böblinger Straße 17

D 71101 Schönaich

Telefon +49 (70 31) 637-01

Telefax +49 (70 31) 637-493

Technical data may be changed without prior notice.

EN 2H-0216 GE51 R1001 7157 559

Loading...

Loading...