Page 1

Ê

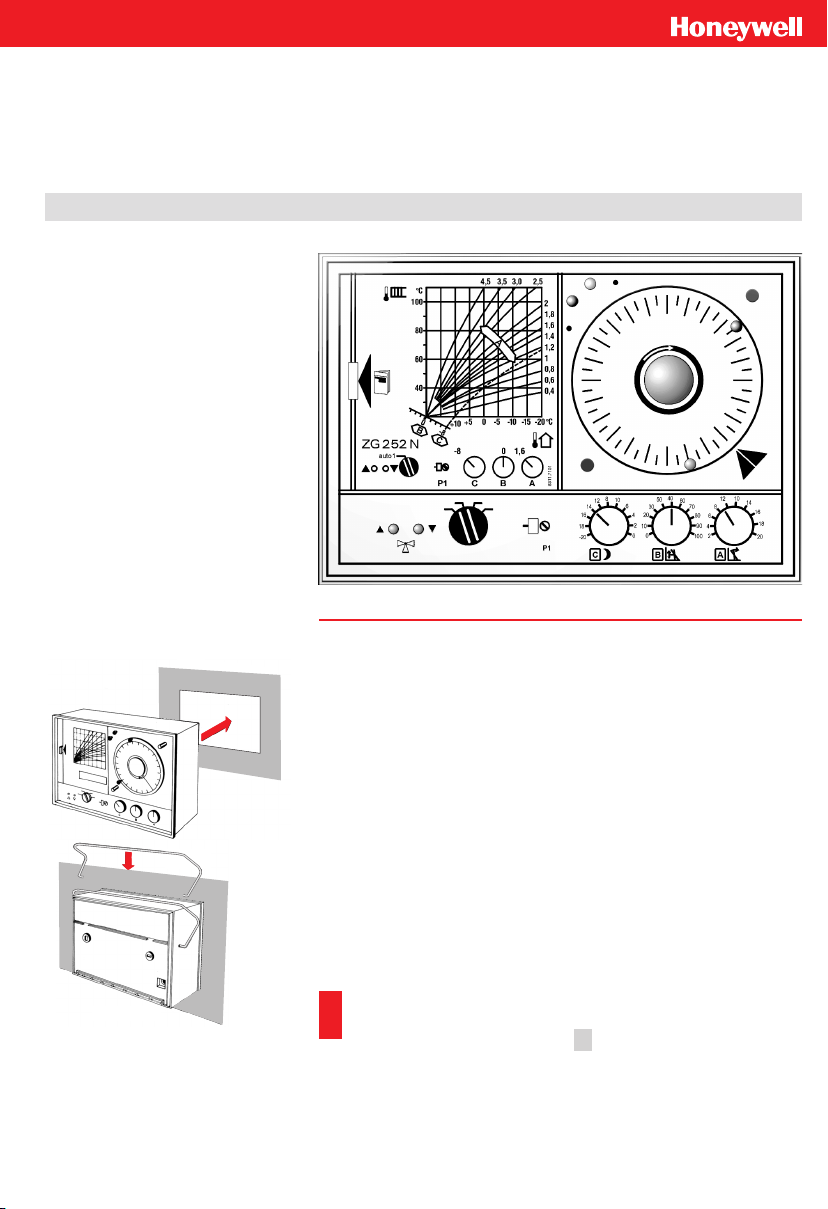

Compact control units

ZG 215N / 215 VN / 252 N

MOUNTING INSTRUCTIONS

Mounting of the Control Unit

It can be mounted in any dry room, e. g. the boiler room. The device

can be mounted either in a cubicle door or on the wall.

Maximum permissible ambient temperature: 45 °C.

Ë

Door Mounting

Ê The casing cover isheldby a snap hinge closure.Press it inthe di

rection of the arrow on the left side and pull out.

Ë Insert the control unit in the dedicated door opening

(183 x 126 mm).

Ì Expand the retaining clips at the ends and insert in the relevant

holes. Fix into place the retaining clips by pressing down in the

fastening position.

Í Execute the electrical connection in the base (see the next page).

Then put on the base.

Important:

If the heating system is empty, the ZG 252N’s operating mode

selector is to be positioned on 2 . By doing so, the circulation

pump is deactivated and protected against dry-running.

-

Page 2

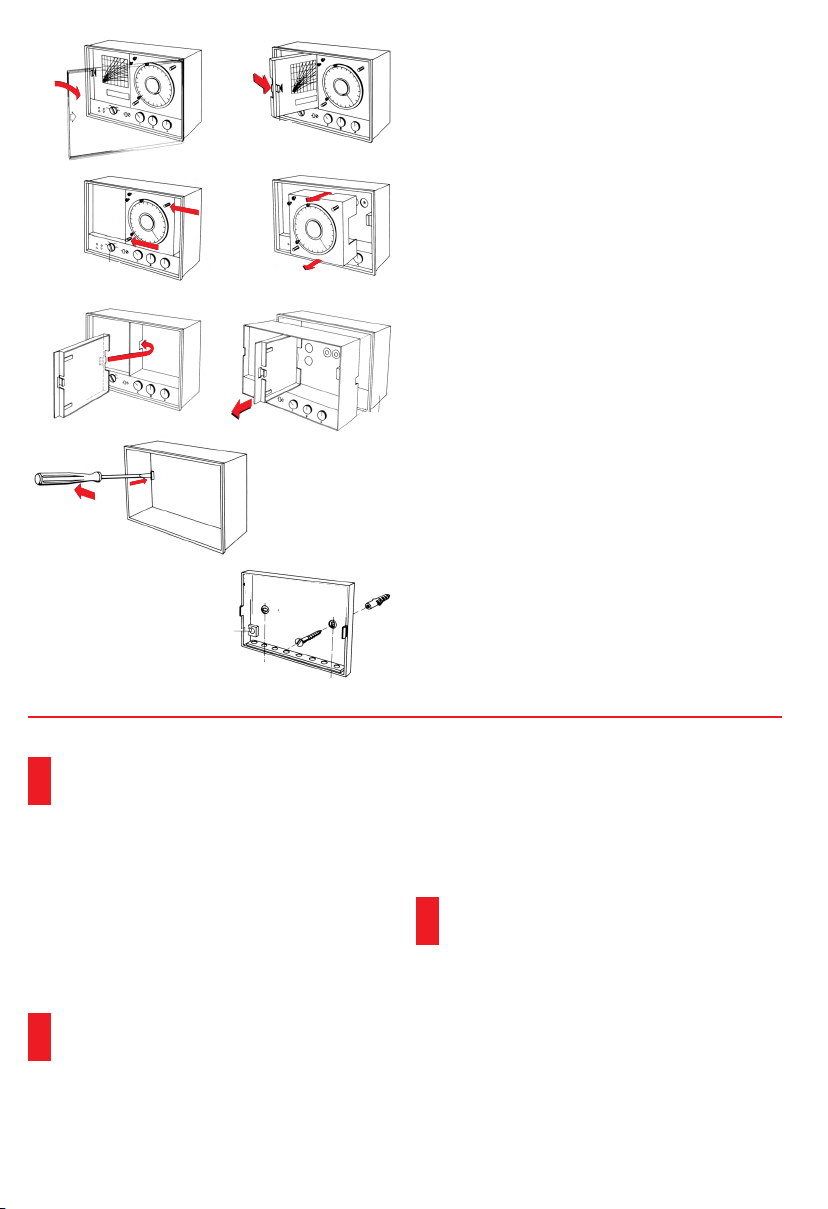

ÊË

ÌÍ

ÎÏ

Ð

Wall mounting

Ê The casing cover is held by a snap hinge closure.

Press it in the direction of the arrow on the left

side and pull out.

Ë Hold the discharge compartment by the handle

and turn out to the right by exerting a light pres

sure. The instructions manual is kept here.

Ì Press the timer on bothpin inthe direction of the

arrow.

Í Pull out the timer.

Î Hang the slide of the instructions case in the

relevant recess of the insert.

Ï Pull the controller insert out of the casing with

the aid of the slide on the instructions case.

Ð Press the left lock pinto theleft witha screwdri

ver; by doing so, the case is freed from the devi

ce’s base.

Ñ Mount the device’s base with two 0.4 mm Æ

screws and dowels horizontally on the wall.

The assembly is to be carried out in the opposite

order.

-

-

-

Ñ

Electrical Connections

The electrical connections are to be carried

out by a technician!

Cross sections

n

Left terminal strip (base):

230 V AC 1.5 mm²

(connection to the control unit, servomotor,

pump)

n

Right terminal strip (base):

18 V DC >= 0.75 mm²

(connection to the sensors and selectors)

The 18 V lines are to be laid separately from

the 230 V lines. Use shielded cablesin the pre

sence of intense HF disturbance fields!

Wiring

The single accessory parts are to be connected ac

cording to the wiring diagram on the back of the ca

sing of this device model. When using the ZG 252N

in low temperature heating systems (e.g. floor hea

ting) an additional thermostat is recommended to

provide separate over-temperature limitation. With

230 V/50 Hz the servomotor and circulation pump

require the jumper from terminal 5 to 6.

The local regulations on earthing and

resetting are to be followed carefully

when connecting the device.

Earlier temperature selector and sensor versions

without additional letters A (e. g. TW 20, RF 20,

TF 20, etc.) have the same electrical connections

and the same resistance values as the device

-

versions with with additional letter A.

Noise suppression

Our control units are all provided with noise sup

pression.

-

-

-

Page 3

Checking the Control System

n

Before putting the system into service, check

whether the control device is connected as illu

strated in the wiring diagram.

n

The servomotor’s sense of rotation can be deter

mined by setting the control unit’s operating

mode selector on ”auto“ for ZG 252N or ”auto“

for ZG 215N / ZG 215VN and by changing the

room target value on setting knob B (ZG 252N)

or on the TW/TF (ZG 215N / ZG 215VN).

Setting knob B

or TW / TF

Turn towards + Red Opens

Turn towards – Green Closes

If the sense of rotation is wrong, invert termi

nals 10 and 11 on the left-hand of the terminal

strip.

Connecting the Potentiometer

If a potentiometer is used as feedback with the

ZG 215N instead of the flow sensor VF 20, also ter

minals 4 and 5 on the right-hand are to be inverted

besides terminals 10 / 11 if the sense of rotation of

the actuator (mixer, ventilation valves), is wrong.

When opening the actuator the resistance between

terminals 3 / 4 of the motor must belower, while the

resistance between terminals 4 / 5 of the motor

amounts always to 10 kW.

Pump Activation in the ZG 215N

If no heat input is required, thecirculation pumpcan

be switched off by means of an auxiliary switch in

the motor. The auxiliary switch makes sure that the

circulation pump is switched off when the mixer is

closed.

LED

Display

Servomotor

Checking the Temperature Sensors and

-

-Selectors

By measuring theresistance itcan bechecked whet

her the temperature sensors and selectors are con

nected correctly.

(The indicated terminal numbers refer to the mar

kings on the sensors and selectors.)

Temperature Sensor AF20, VF 20, VF 20A

Resistance values (R) at ambient temperature (t)

t [°C] -20 -10 0 +20 +25 +30 +70 +90

R[kW] 220 122 70 25 20 16 3,1 1,5

Temperature Selector TW 20A, TF 20A

Setting on the Selector Resistance [kW]

-

Right stop (+12) 147 100 47

Left stop (-12) 100 147 47

between the terminals

1/2 1/3 2/3

Temperature Selectors TF 22 and TFU 22

-

Setting on the selector Resistance [kW]

Right stop (+7) 28.7 4,8 0

Left stop (-7) 69.8 13.8 0

between terminals1/ 3

auto day night

Temperature Selectors TW 21A...TW 23A

Setting on the Selector Resistance [kW]

between the terminals

1/2 1/3 2/3

TW 21A (-15.. . +15°C)

TW 22A (0...+30 °C) 58 68 10

TW 23A (20..+70 °C) 26 27 9

35 45 10

-

-

-

TW 21A toTW 23A canbe connected only tothe

controllers ZG 215N / ZG 215VN.

Party switch

Resistance between terminals2/4onTW20Aor

TF 20:

Switch position ”Automatic“: ¥ (infinite)

Switch position ”Day mode“:0kW

Page 4

Terminal diagrams

230 V~ SELV

123456789

PE

ALTERNATIVE ALTERNATIVE

567 9

123

TW 21

TW 22

TW 23

10 11 12

123

12

123456789

VF1 PotiNL

ALTERNATIVE

RF 20

VF 20

LF 20

ZG 215 N

10 11 12

ext.

123456

TF 22

7 9 12 10

123456

U+

TFU 22

Protection against the

destruction of the com

ponents owing to elec

trostatic discharges:

These are to be discharged to an

earthed line (e.g.water line)befo

re they touch the components on

the controller board!

Attention! Before acces

sing the connection ter

CB50227F

minals, all the mains

supply circuits are to be

switched off.

-

-

-

-

-

230 V~ SELV

123456789

10 11 12

123

ALTERNATIVE ALTERNATIVE

5678

1234

TW 20

Centra Regelungstechnik

Honeywell AG

Böblinger Straße 17

D 71101 Schönaich

Telefon +49 (70 31) 637-01

Telefax +49 (70 31) 637-493

ZG 252 N

123456789

VF

AFNLPE

123456

TF 22

71210

123456

U+

TFU 22

10 11 12

ext.

ZG 252 N

7

...12

10 9

Hometronic

HCE 60

712

54

Hometronic

HCM 200

In case of fixed installa

tion an all-pole discon

nection device with at

leasta3mmcontact

opening is to be instal

led.

Reference

Operating instructions

ZG 252NV EN-2H0215 GE51

ZG 215NV EN-2H0216 GE51

ZG 215VN EN-2H0217 GE51

“Informationsschrift”

(Planning broschure in German)

L3 – Comfort-Kompakt-Regler

GE-0H 0327 GE51

[CBZG_MAE.VP]

CB50247F

-

-

-

EN 1H-0181 GE51 R1001 07157 562 http://www.honeywell.de/hga

Loading...

Loading...