Page 1

Wireless Room Thermostat

Installation and Operation

Y6630D1007

Page 2

Page 3

General safety instructions

Contents

1. General safety instructions.................................... 3

1.1. Commissioning the relay module HC60NG........... 3

2. Overview ............................................................... 4

2.1. Pre configured kit Y6630D1007............................. 4

2.2. Single provided devices......................................... 4

3. Installation ............................................................. 4

3.1. Installation relay module HC60NG ........................ 4

3.2. Installation room unit HCW 80............................... 6

4. Checking ...............................................................7

4.1. System check........................................................ 7

4.2. Radio transmission check......................................7

5. Teach-in (single devices only) ............................... 7

5.1. Assignment to the relay module HC60NG............. 7

5.2. Failed teach-in....................................................... 7

6. Communication loss.............................................. 7

7. Factory reset of relay module HC60NG................. 7

8. Particular features of the room unit HCW 80......... 8

8.1. Operation............................................................... 8

8.2. Limiting the adjustment range ............................... 8

8.3. Fixed control parameters....................................... 8

9. Changing batteries ................................................ 8

10. Appendix ............................................................... 9

10.1. Help with problems................................................ 9

10.2. Specifications HCW 80.......................................... 9

10.3. Specifications HC60NG......................................... 9

10.4. Device and function definition in accordance

with EN 60730-1.................................................... 9

10.5. WEEE directive 2002/96/EC – Waste Electrical

and Electronic Equipment directive ....................... 9

1. General safety

instructions

1.1. Commissioning the relay module

HC60NG

Danger

WARNING

WARNING

WARNING

Danger to life through electric

shock!

Contacts that are open are live.

► Ensure that the device is de-

energised.

► Have all the work carried out by

authorised qualified personnel.

► Observe the valid local regulations

during the installation.

Insufficient data transfer!

Interference of the relay module

HC60NG in the device through metallic

objects or further frequency devices.

► Mount the device with a distance of at

least 30 cm to metallic objects such

as wall boxes or boiler housings

according to the DECT standard, etc.

► Do not mount on metal wall boxes.

Damage to the device!

Short-circuiting through humidity and

moisture.

► Mount the device at a site that is

protected against humidity and

moisture.

Damage to exposed components!

Destruction of the electronic

components through electrostatic

discharges.

► Do not touch the components.

► Touch an earthed piece of metal to

discharge static electricity from your

body.

3

Page 4

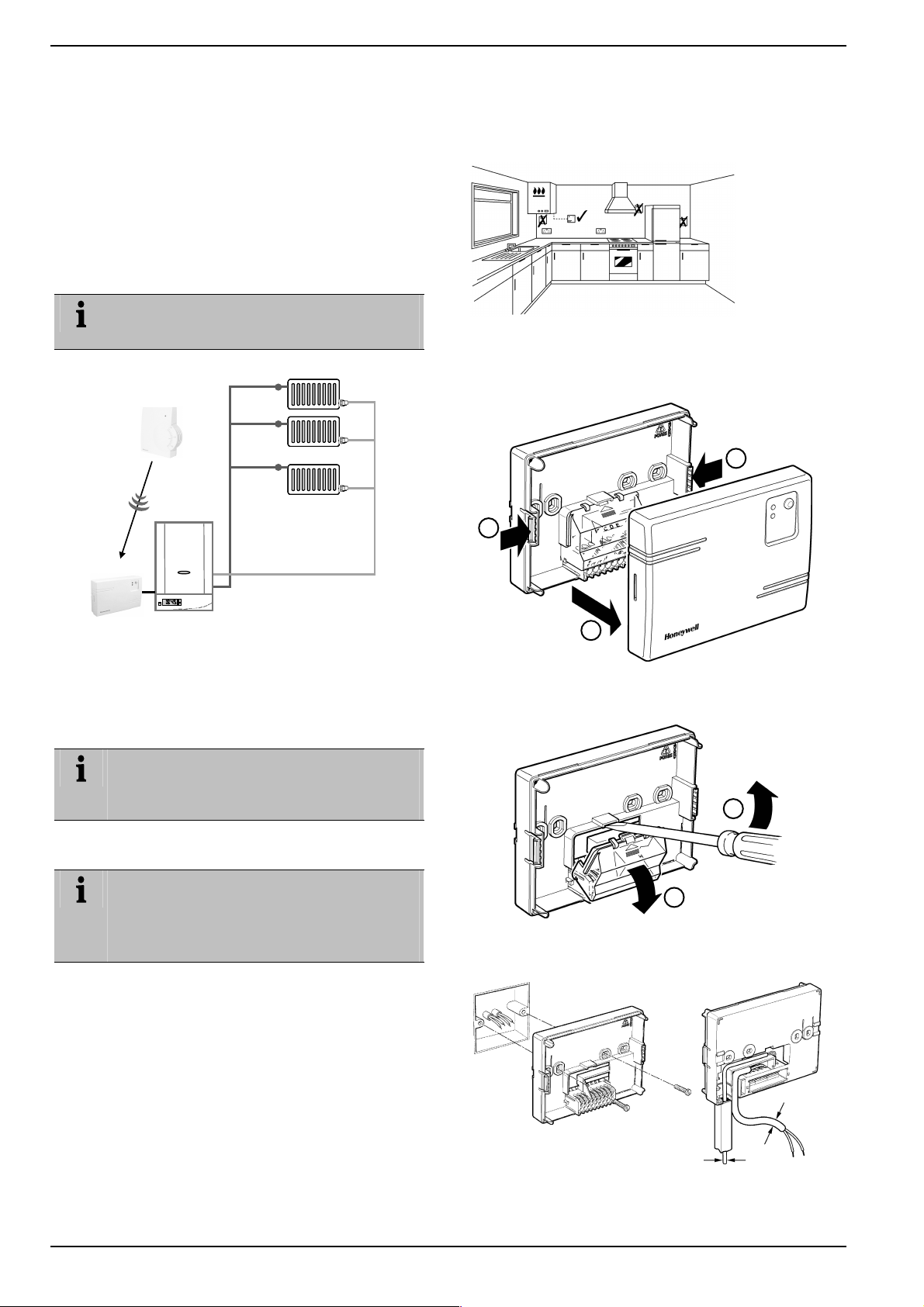

Overview

2. Overview

The room unit HCW 80 is used for intelligent room

temperature control in combination with the relay module

HC60NG. It can be used to control gas and oil boilers, a

variety of valves and actuators or electrical heating systems.

No wiring to the room unit HCW 80 is required.

Because of the simple HCW 80 analogue user interface with

absolute set point temperature scale the room set point

temperature can be easily adjusted.

The room unit and the relay module provide reliable RF

communication technology on 868 MHz frequency.

The HCW 80 and HC60NG are already teachedin (bounded). They are provided as pre

configured kit for fast installation (plug and play).

Zone 1

Wireless Room Thermostat

HCW80

Example radiator control

3. Installation

3.1. Installation relay module HC60NG

Fig. 2: Positioning the relay module HC60NG

► Follow the installation diagrams to install and connect the

power supply to the relay module HC60NG.

1

1

Relay module

HC60NG

Boiler

Fig. 1: Application of the wireless room thermostat

2.1. Pre configured kit Y6630D1007

· 1 HCW 80 (room unit)

· 1 HC60NG (relay module)

· 2 AA batteries, 1.5 V, type LR6

The kit Y6630D1007 is provided pre-bounded.

The room unit HCW 80 is already assigned to the

relay module HC60NG. The teach-in is not

required in this kit.

2.2. Single provided devices

Single provided devices must be teached-in as

described in section “5 Teach-in (single devices

only)”.

Teach-in means the HCW 80 and HC60NG must

be RF bounded for communication.

2

Fig. 3: Opening the housing cover

1

2

Fig. 4: Removing the terminal covers

> 7 mm Æ

< 7 mm Æ

Fig. 5: Connecting the relay module to the power supply

4

Page 5

Installation

a. Burner (direct control) b. Combi boiler

Fig. 6: Wiring the terminal

Caution

Incorrect wiring!

► Install in accordance with local wiring

► Observe ambient temperature and

max. 2.5 mm

2

regulations.

current limits (see HC60NG wiring

label).

c. Zone valve

e. Thermal actuator

g. Electric actuator

d. Electric heater

f. Zone valve

h. Cooling device

Fig. 7: Wiring schemes

1

2

Fig. 8: Closing the terminal and housing cover

2

5

Page 6

Installation

3.2. Installation room unit HCW 80

WARNING

Insufficient data transfer!

Interference of the radio receiver in the

device through metallic objects or

further radio devices.

► Ensure there is sufficient distance to

metallic objects.

► Mount the device with a distance of at

least 1 m to radio devices such as

radio headphones, cordless phones

according to the DECT standard, etc.

► Select another installation site if the

radio interference cannot be rectified.

Fig. 9: Positioning the room unit HCW 80

► Place the room unit HCW 80 at the installation site.

► Remove the housing cover of the room unit HCW 80

(see Fig. 10

).

2

1

Fig. 10: Removing the housing cover

► Mark the drill holes according to the drilling template

(see Fig. 11).

Fig. 11: Drilling scheme (measurements in mm)

► Drill the holes.

► Screw on the room unit.

► Insert the supplied AA batteries with the correct battery

polarity (see Fig. 12).

Red LED

Send button

Fig. 12: Battery polarity and send button

The batteries have to be replaced when the red

LED at the room unit HCW 80 flashes (see

section “9 Changing batteries”).

► Place the housing cover in

position above and snap it down

(see Fig. 13).

Fig. 13: Placing housing

cover in position

6

Page 7

Checking

4. Checking

4.1. System check

► Adjust the set point of the room unit HCW 80 to 30 °C.

If the room temperature is >30 °C the relay module

HC60NG is switched on.

► Change the set point of the room unit HCW 80 to 5 °C.

If the room temperature is <5 °C the relay module

HC60NG is switched OFF.

4.2. Radio transmission check

The room unit HCW 80 can send a test signal to the

assigned relay module HC60NG in order to test the signal

strength.

► Keep the teach-in button of the HCW 80 pressed for at

least 15 sec until the red LED of the HCW 80 is OFF.

The HCW 80 is now in test mode and sends a test signal

every 5 sec.

The LED of the HCW80 flashes briefly at every test

signal the HCW 80 is sending.

The field strength is indicated by flashing of the red LED of

the HC60NG (1 = sufficient, 5 = strong).

► If the wireless communication is not successful

optimise the placement of the HCW80

The test mode is terminated automatically after

5 min. The test mode can also be terminated by

removing the batteries or by pressing the teachin button.

.

5. Teach-in (single devices

only)

The teach-in operation is required if the relay module

HC60NG and the room unit HW80 are not pre-bounded e.g.

new single devices or product replacement.

5.1. Assignment to the relay module

HC60NG

After the power up of the relay module HC60NG the red

LED will start to flash at 0,1 sec ON/ 0,9 sec OFF.

If this is not the case set the HC60NG into the reset mode

see section “7 Factory reset of relay module HC60NG”.

► Press and hold the teach-in button of the HC60NG for

5 sec to enter into the teach-in mode.

The red LED flashing at 0.5 sec ON/0.5 sec OFF

confirms the teach-in mode has been entered.

► Press the teach-in button of the HCW 80 to send the

binding signal to the HC60NG.

The red LED of the HC60NG is switched OFF to confirm

a successful teach-in operation.

The teach-in mode is terminated automatically after 5 min.

5.2. Failed teach-in

If the teach-in has failed:

► See section “5.1 Assignment to the relay module

HC60NG”.

► Improve the data transfer.

Improving the data transfer

► When selecting the operating site of each device ensure

that the distance to radio devices such as radio

headphones, cordless phones, etc. according to the DECT

standard amounts to at least 1 m.

► Do not install the devices over metallic wall connecting

sockets and at least 30 cm away from the cover of the heat

generator.

► Correct the installation site of the room unit HCW 80 if

necessary.

6. Communication loss

When the RF communication is lost for a period of 1 h, the

red LED of the relay module HC60NG is ON to indicate that

no RF messages have been received during the last hour.

When RF communication is re-established the relay module

HC60NG will automatically return to normal operation mode.

See chapter “10 Help with problems” for possible cause and

problem solving.

7. Factory reset of relay

module HC60NG

► Keep the button of the HC60NG pressed for at least

15 sec.

The resetting was successful when the red LED flashes

rapidly (1/9 ON/OFF).

After the factory reset the HC60NG looses the

communication with the HCW 80.

See section “5 Teach-in (single devices only)” for

new teach-in.

7

Page 8

Particular features of the room unit HCW 80

8. Particular features of the

room unit HCW 80

8.1. Operation

The room set point temperature can be set easily at the set

point adjuster by means of an adjustment dial. The room set

point range is from 10 °C to 30 °C including the frost

protection setting

The HCW 80 simulates a mechanical thermostat by LED

indication as follows:

The red LED at the HCW 80 will be switched ON for 4 sec if

the deviation between the set point and the room

temperature is >1°C. If the deviation is <1 °C the red LED is

flashing for 4 sec. Respectively the relay module HC60NG

will be switched ON or OFF.

Fig. 14: Room unit HCW 80 (settings on the scale in °C)

► Select the desired room temperature set point at the

adjustment dial (see Fig. 14).

8.2. Limiting the adjustment range

You can limit the adjustment range that can be used at the

adjustment dial.

► Remove the housing cover (see Fig. 10, Page 6).

(5 °C).

► Place the two small pins into the holes of the adjustment

dial in order to limit the adjustment range (see Fig. 15).

Orientate yourself on the basis of the inner scale:

In Fig. 15, the pins are inserted so that the adjustment dial

can only be adjusted in the range of 19 °C to frost

protection

(lower limit) and 19 °C to 30 °C (higher limit)

around the value 19 °C.

► Turn the adjustment dial clockwise until it stops.

► Check whether the adjustment dial is in the position shown

in Fig. 14.

► If appropriate, put the adjustment back in, rotated by 180°

until it has the position shown.

► Turn the adjustment dial to position 19.

► Place the housing cover in position above and snap it

down (see Fig. 13, Page 6).

8.3. Fixed control parameters

The following parameters will be used for the control:

Parameter Factory setting Remark

Minimum ON

time

1 minute Minimum power up

time within the cycle

Cycle rate 6 cycles per hour Pulse width

modulation per hour

9. Changing batteries

Change the batteries if the red LED of the room unit

HCW 80 flashes and the device is not in test mode.

► Remove the housing cover of the HCW 80 (see Fig. 10,

Page 6).

► Remove the batteries.

Disposal of the batteries according to the local

statutory requirements and not with the used

► Insert the batteries with the right polarity into the battery

► Place the housing cover on at the top and latch it in

domestic refuse.

Always replace both batteries together. Only use

1.5 V batteries of the type LR06, AA.

compartment (see Fig. 12, Page 6).

downwards (see Fig. 13, Page 6).

Fig. 15: Limiting the adjustment range

8

Page 9

Appendix

10. Appendix

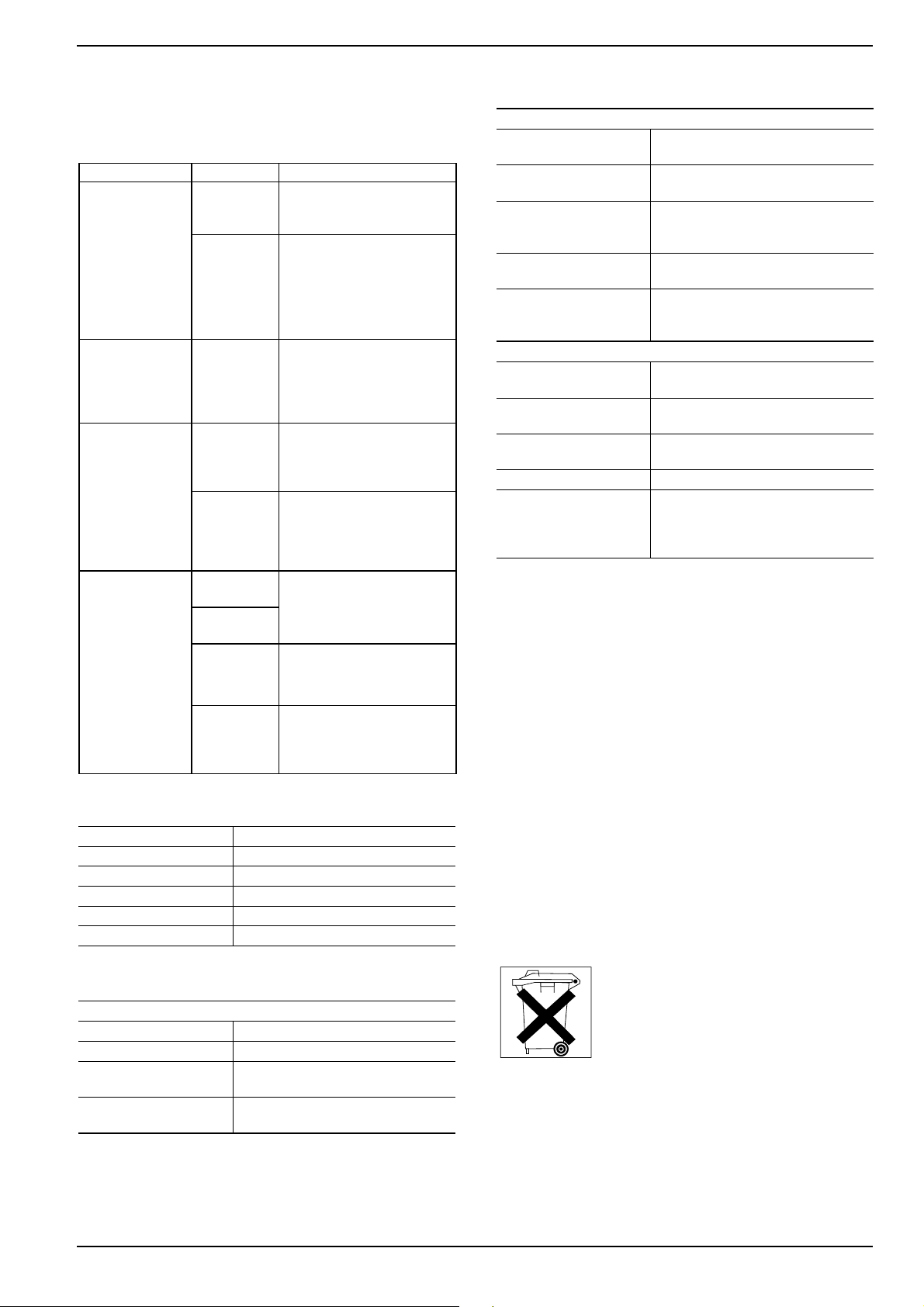

10.1. Help with problems

Problem Cause Remedy

Teach-in failed

HC60NG does

not react to set

point changes

on HCW 80

After teach-in

red LED is on

and green LED

is flashing once

every 3 sec

Red LED of the

HC60NG is on

10.2. Specifications HCW 80

Batteries 1.5 V, type LR06, AA

Frequency 868.3 MHz (transmitter)

Operating temperature 0 °C to 50 °C

Storage temperature –20 °C to 70 °C

Humidity 5 % to 90 % relative humidity

IP class 30

10.3. Specifications HC60NG

Electrical

Receiver power supply 230 V AC (+10 %, –15 %), 50 Hz

Switch type SPDT potential free

Output rating 24-230 V AC, 10 A resistive,

Wire access

(receiver only)

Batteries

inserted

incorrectly

Radio

connection

failure

HC60NG

and HCW

80 not

teached-in

Teach-in

procedure

incorrect/

incomplete

Position of

HCW 80

incorrect

Communication loss

RF signal

blocked

Batteries of

HCW 80

exhausted

HC60NG

and

HCW 80 not

teached-in

► Insert the batteries

correctly.

► Eliminate interference

sources (metal, wireless

devices).

► Correct installation site.

► Repeat the teach-in.

► Reset HC60NG.

► Follow the teach-in

procedure as described

in section “5”.

► Repeat the teach-in.

► Repeat the teach-in

keeping approx. 1 m

distance between HCW

80 and

HC60NG.

► Relocate the HCW 80

(see section “3.2”).

► Replace batteries in

HCW 80

(see section “9”).

► Follow the teach-in

procedure as described

in section “5”.

3 A inductive, 0.6 p.f.

From the rear (wall box mounting),

right an bottom

RF

RF operation band ISM (868.0-868.6) MHz,

1 % duty cycle

RF communication

range

RF communication

technology

Blocking immunity Receiver class 2 (ETSI EN300

RF binding method Factory pre-bound with the room

Environmental & Standard

Operating temperature 0 to 40 °C when relay load <8 A

Shipping & storage

temperature

Humidity Humidity range 0 to 90 % rh,

IP class 30

Meeting the following

standards

30 m in a residential building

environment

Short, high rate transmissions to

minimise air time and avoid

collisions

220-1 version 1.3.1)

unit HCW 80 (kit Y6630D1007

only)

0 to 30 °C when relay load >8 A

–20 to 55 °C

non-condensing

EN 60730-1 (1995), EN 55014-1

(1997), EN 55014-2 (1996), ETSI

EN 300 220-3 (2000), ETSI

EN 301 489-3 (2000)

10.4. Device and function definition in

accordance with EN 60730-1

· Purpose of the device is temperature controlling

· Device fulfills protection class 2

· Independently installable electronic control system

with fixed installation

· Type of action is type 1.8

· Temperature of ball thrust hardness test for

housing components 75 °C and for live parts such

as, for example, terminals 125 °C

· EMC emitted interference test at 230 V~, 50 HZ

maximum

· Pollution severity is 2

· Rated voltage is 4000 V (corresponding to

overvoltage category III)

· Software class is A

10.5. WEEE directive 2002/96/EC – Waste

Electrical and Electronic Equipment

directive

► At the end of the product life dispose of

the packaging and product in a

corresponding recycling centre.

► Do not dispose of the unit with the usual

domestic refuse.

► Do not burn the product.

9

Page 10

Page 11

Page 12

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Honeywell GmbH

Böblinger Straße 17

71101 Schönaich, Germany

Tel.: (++49) (0) 7031 637 01

Fax: (++49) (0) 7031 637 493

http://europe.hbc.honeywell.com

The right is reserved to make

modifications

This document is definitive for the enclosed product and replaces all previous publications.

Honeywell Inc. hereby declares that this device complies with the basic requirements and other relevant regulations of guideline 1999/5/EC. The declaration of

conformity of the product can be requested from the manufacturer.

EN1B-0344GE51 R1105A

Loading...

Loading...