Page 1

Put Bar Code Here

Y8150 Fresh Air Ventilation System,

W8150 Fresh Air Ventilation Control

PRODUCT DATA

FEATURES

• Designed to help meet local ventilation codes and

standards, including ASHRAE 62.2-2010 standard,

“Ventilation and Acceptable Indoor Air Quality in

Low-Rise Residential Buildings.”

• Microcontroller optimizes the air delivery schedule to

make efficient use of normal HVAC run times.

• Easy-to-use input dials allow customized ventilation

for each installation.

• Test mode that includes immediate feedback to

installer to confirm that air delivery requirements of

selected ventilation standard are being met.

• Economical supply-only ventilation; works with forced

air system.

• Can be used with other equipment, such as an HRV/

ERV, for balanced ventilation.

APPLICATION

The Y8150 Fresh Air Ventilation System, W8150 Fresh Air

Ventilation Control provide fresh air to a home. The control

operates a fresh air intake damper and, when necessary,

activates the main HVAC blower to efficiently meet ASHRAE

ventilation rates.

IMPORTANT

Please read these instructions and keep them in your

records.

68-0282-07

Page 2

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

SPECIFICATIONS

Y8150 includes:

W8150A Fresh Air Ventilation Control.

EARD6 Fresh Air Damper.

AT120B Transformer.

Mounting hardware for control.

Homeowner information label.

W8150 includes:

W8150 Fresh Air Ventilation Control.

Mounting hardware for control.

Homeowner information label.

Control (W8150A):

Power Supply: 20-30 Vac, 60 Hz.

Power Consumption: 3.5 VA at 24 Vac.

Thermostat Fan Load: 10 mA resistive at 24 Vac.

Thermostat Heat Load: 10 mA resistive at 24 Vac.

Remote Terminals: 10 mA resistive at 24 Vac.

Relay Contacts:

Fan: 1.5A full load, 7.5A locked rotor at 24 Vac.

Damper: 0.6A inductive, 3.1A locked rotor at 24 Vac.

Auxiliary: 0.5A inductive, 2.5A locked rotor at 24 Vac.

Damper (EARD6): 24 Va c , 1 2 VA , 6 0 H z .

Operation: Power-open, spring-closed.

Diameter: 6 in.

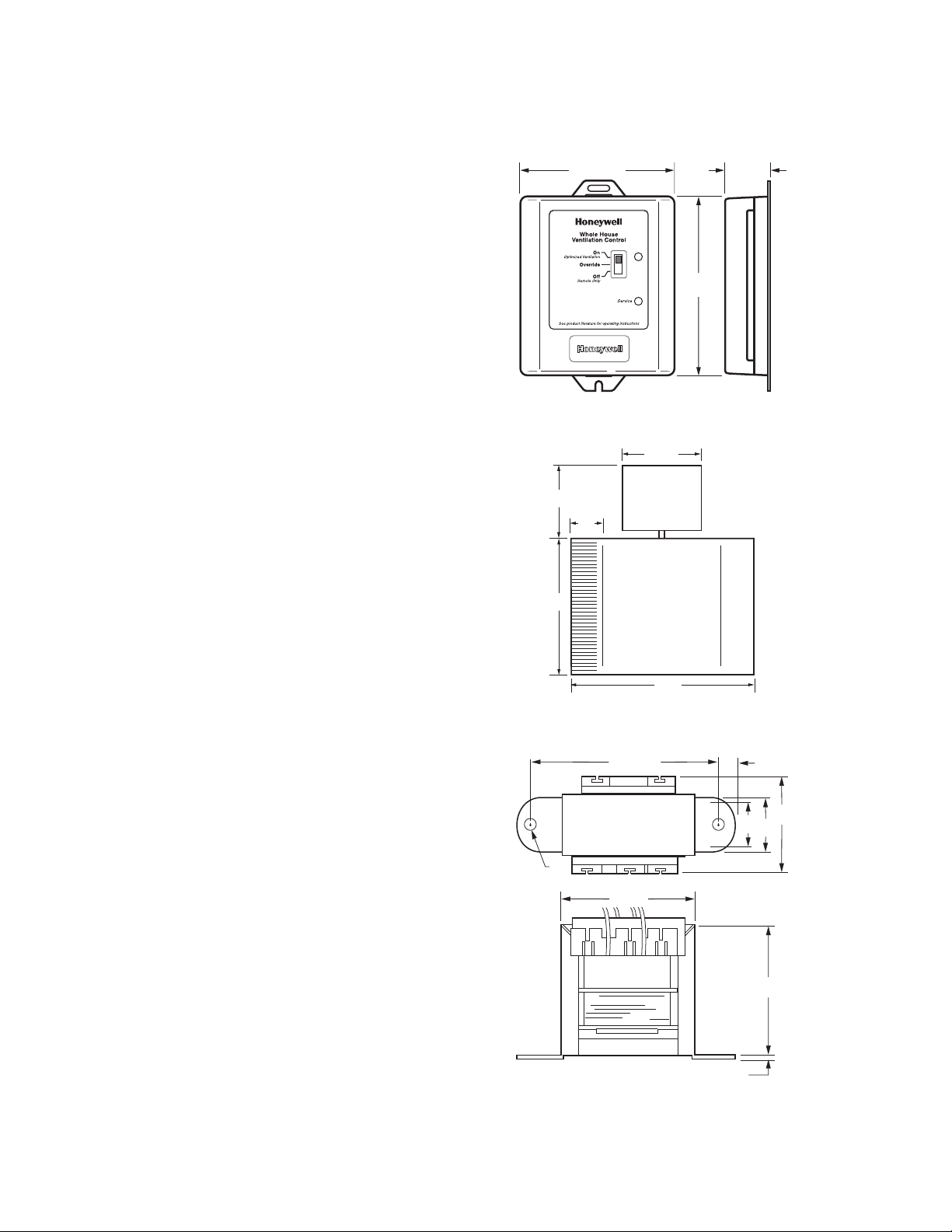

W8150A Ventilation Control dimensions in in. (mm).

3-3/8

(86)

4-3/16 (106)

1-1/2

(38)

3-1/2 (89)

5-3/4

(146)

1-1/4

(32)

M19988A

Transformer (AT120):

Input: 120 Vac.

Output: 27 Vac open circuit, 24 Vac full load at 20 VA.

Mounting: Foot mounted.

Temperature: -20 °F to 160 °F (-29 °C to 71 °C).

Humidity: 5 to 90% RH, noncondensing.

Input Setting Ranges:

Bedrooms: 2-5.

Area: 1000-4600 sq ft.

Vent Airflow: 40-160 cfm.

Composite Setting Resolution: +/- 12% of ASHRAE

62.2-2010, recommended ventilation for single-system setup.

AT120B Approvals: UL Component Recognized: Class 2,

File No. 14881.

Location: Device can be installed in unconditioned space.

Multiple devices can be installed when operating multiple

HVAC systems.

Dimensions: See device dimension diagrams.

6

(152)

8 (203)

M19989

EARD6 Fresh Air Damper dimensions in in. (mm).

3/16

(5)

1-3/4

(44)

15/16

1

(24)

(25)

1-5/8

(41)

3/16

2-13/16 (71)

(5)

1-7/8 (48)

68-0282—07 2

1/16 (2)

M22022

AT120B Transformer dimensions in in. (mm).

Page 3

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

1

F

G

2

R

C

C

C

3

C

H

4

W

5

G

T

6

7

8

9

10

11

12

BEDROOMS AREA (SQFT) VENT AIRFLOW (CFM)

ON

13

XFMR

R

C

REMOTE AUX DAMPER

M19990

20

19

18

17

16

15

14

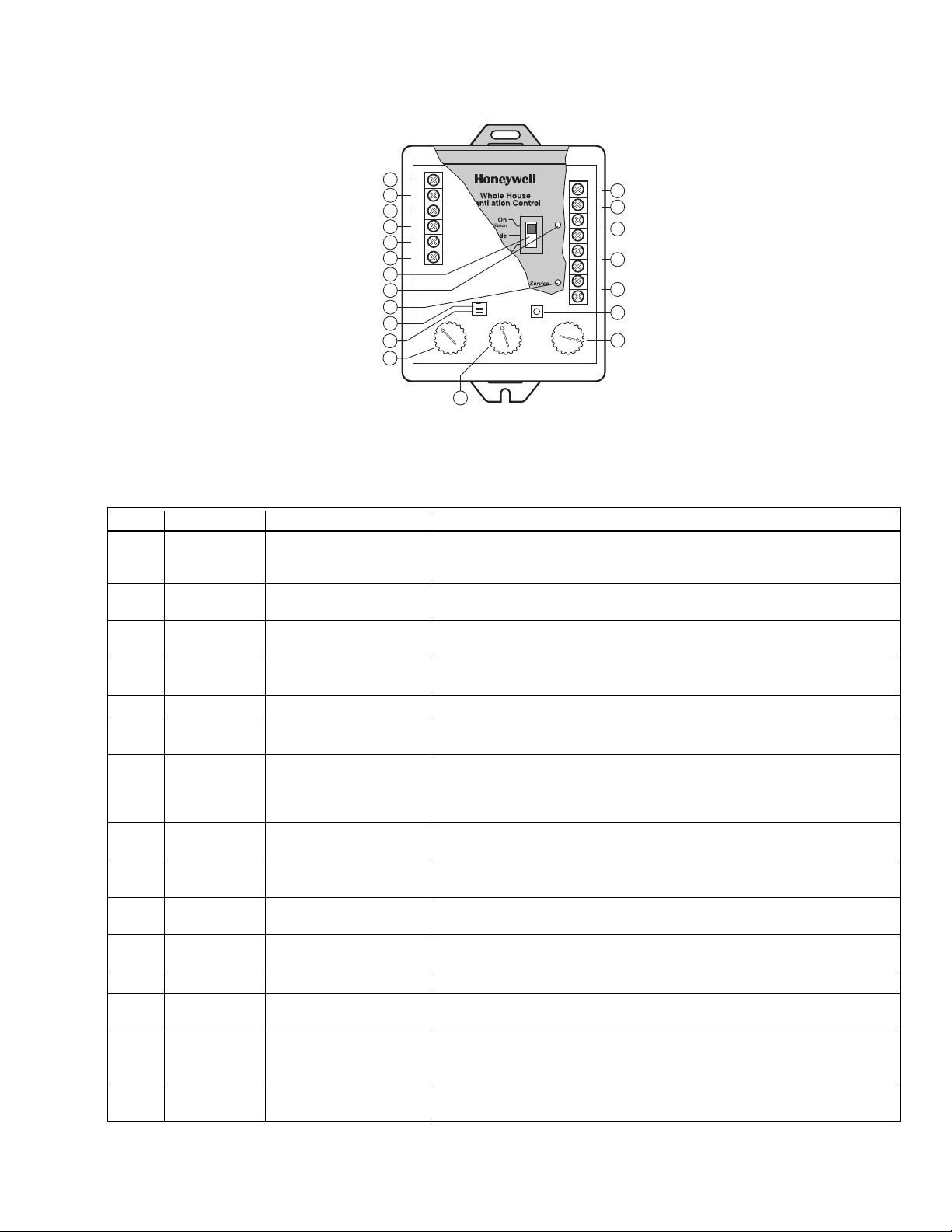

W8150 QUICK GUIDE

No. Name Description Function

1GF Equipment fan Allows W8150 to pass thermostat calls and, when necessary, turn on

2R

C 24 Vac cooling system

power

3C

C 24 Vac cooling system

common

H 24 Vac heating system

4C

common

5 W Heating Allows W8150 to monitor when heating is energized.

6GT Thermostat (or other

control) fan terminal

7 Switch On (optimal ventilation)

Override

Off (Remote Only)

8 Light Green Indicates device is powered and operating normally. Used in Test Mode to

9 Light Red Indicates the device is not operating normally. Used in Test Mode to signal

10 DIP1 Ventilation limit Choose between 60% (default) and 100% maximum fan run time allowed

11 DIP2 Ventilation standard Choose between ASHRAE 62.2 (default) and 62-1999 ventilation

12 BEDROOMS Number of bedrooms Used to calculate amount of ventilation necessary.

13 AREA

(SQ FT)

14 VENT

AIRFLOW

Square footage of

conditioned space

Air delivery rate through

fresh air duct.

(CFM)

15 Test Test button W8150 checks dial and switch settings, activates ventilation for up to three

system fan for ventilation. This should be the only connection to G on the

HVAC equipment.

Provides power to GF terminal to operate system fan, when necessary.

Allows W8150 to monitor when system fan is energized.

Allows W8150 to monitor thermostat heat calls when W is energized.

Allows W8150 to monitor when GT is energized. All external equipment that

controls the system fan should be wired to this terminal.

On (optimal ventilation) – W8150 ventilates, based on control settings.

Override – W8150 runs ventilation continuously.

Off (Remote Only) – W8150 supplies ventilation only when there is a

remote call.

signal if dial settings meet chosen standard.

if dial settings do not meet chosen standard.

by W8150 for ventilation.

standards.

Used to calculate amount of ventilation necessary.

Used to calculate amount of ventilation necessary.

minutes and provides feedback to validate if chosen standard can be met.

3 68-0282—07

Page 4

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

6

5

uto

(Remote Only)

No. Name Description Function

16 REMOTE Remote switch (two

terminals)

24 Vac powered contacts allow a remote switch closure to call for

ventilation.

17 AUX Auxiliary (two terminals) 24 Vac dry contacts allow W8150 to control an auxiliary device, such as

exhaust fan or HRV/ERV, with a call for ventilation.

18 DAMPER Damper (two terminals) 24 Vac powered contacts control fresh air damper.

19 XFMR C 24 Vac ventilation control

Supplies power to W8150 and damper from transformer provided.

common

20 XFMR R 24 Vac ventilation control

Supplies power to W8150 and damper from transformer provided.

power

INSTALLATION

A fresh air duct and damper must be installed between the

outdoors and the return side of the HVAC equipment. The

W8150 control will be mounted near the HVAC system and

wired between the thermostat and the fan control.

You will need…

• W8150 Fresh Air Ventilation Control.

• damper.

• transformer.

• insulated ductwork.

• outdoor weather hood.

• starting collar.

• access to 120 Vac power.

• airflow measuring tool.

TIPS:

• To meet ASHRAE 62.2-2010, system must have at least a

MERV 6 filter installed.

• In cold climates, balanced ventilation is recommended. An

exhaust fan or heat recovery ventilator can be used.

• Humid climates may require additional dehumidification

equipment.

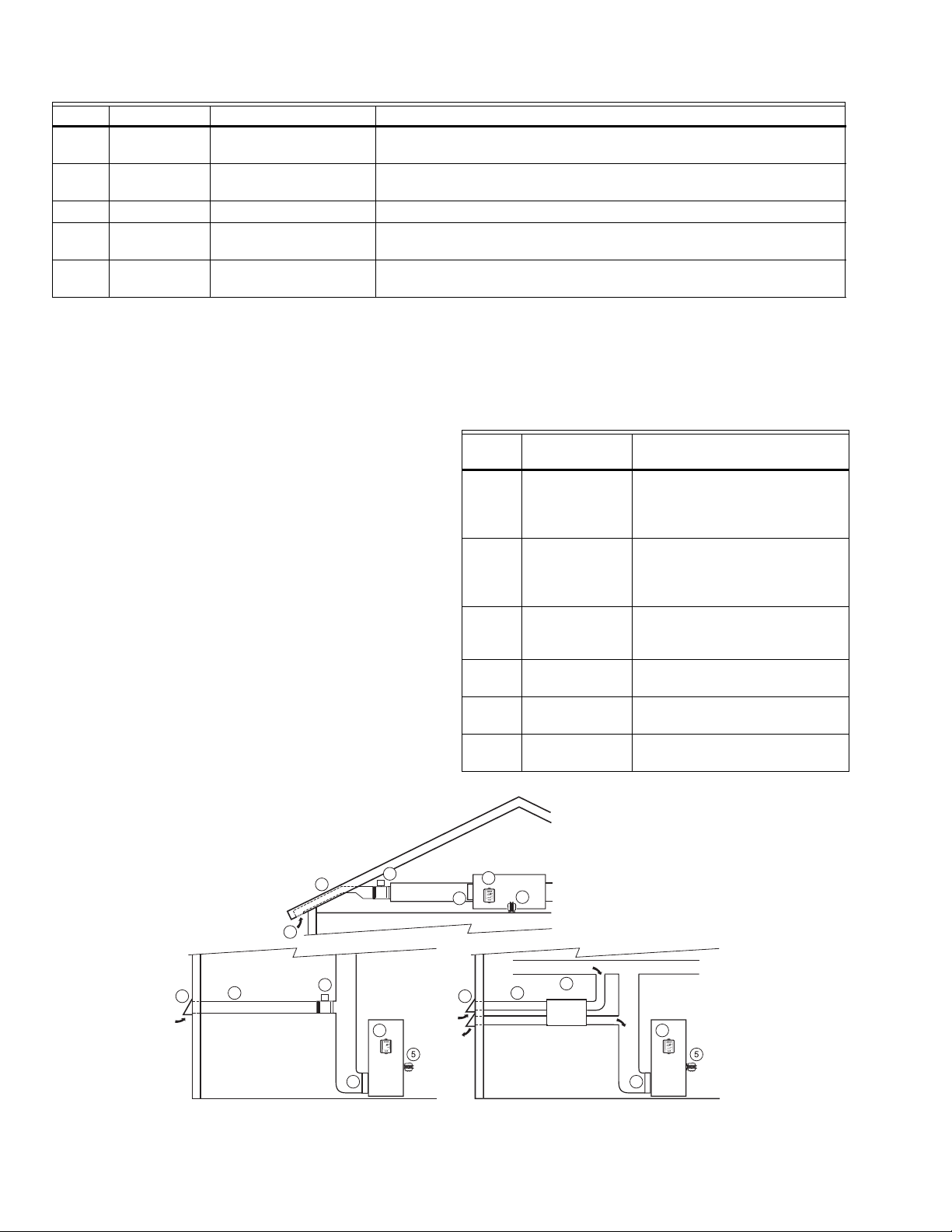

Choosing a location…

When choosing locations for equipment, duct connections,

and fresh air intake, be sure to consult local code

requirements.

Device

Number Component Location

1 Fresh air intake Install away from known sources

of pollutants such as auto

exhaust, dryer vent exhaust or

chimney smoke.

2 Fresh air duct Install between weather hood and

upstream of equipment filter and

downstream of any duct-mounted

sensor.

3 Damper Install damper in fresh air duct,

where convenient. Optionally,

install heat recovery ventilator.

4 Control Locate the control for convenient

access and for easy wire routing.

5 Transformer Locate where convenient for line

voltage connection.

6 Filter Locate filter downstream of fresh

air intake.

TYPICAL ATTIC

INSTALLATION

2

1

1

68-0282—07 4

2

TYPICAL BASEMENT

INSTALLATION

3

3

6

1

V

nili

n nrl

A

6

2

TYPICAL HRV/ERV

3

HRV/ERV

INSTALLATION

M19993

Page 5

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

CAUTION

Installing fresh air damper, ducting,

and control…

1. Disconnect power from HVAC system.

2. Install the weather hood, ducting, and damper following

local practices. Be sure all duct and insulation seams

are tightly sealed.

3. Mount the transformer and control.

TIPS:

• In general, larger ducting allows higher airflow, minimizes

additional fan run time and may be needed for larger

homes.

• Installing a damper directly to the return duct may be

convenient to support the damper and reduce ducting.

• Fresh air connection should be downstream of sensors

(such as a humidistat) in return air plenum.

• The EARD6 end stops can be used to reduce the amount

of airflow in the duct. To prevent complete opening, loosen

(but do not remove) the wing nut and move the upper lever

until the desired position is reached. Tighten the wing nut.

Keep the lower lever in the position shown.

Wiring the control…

Electrical Hazard.

Can cause personal injury or equipment damage.

Disconnect power to all systems before beginning

installation.

1. Wire the control. See wiring diagrams in Fig. 1-10 as

listed below. All wiring must comply with local codes,

ordinances, and regulations.

2. Reapply power to system and control.

TIP:

• Control package allows wire routing through side slots and

bottom openings.

System Hookup Diagrams Fig. No. Page No.

Single transformer, conventional 1 10

Dual transformer, conventional 2 10

Multi-stage, conventional 3 10

Heat pump without emergency heat 4 10

Heat pump with emergency heat 5 11

UPPER LEVER

WING NUT

LOWER LEVER

M20155

Accessory Hookup Diagrams Fig. No. Page No.

Wiring with a PC8900 Thermostat 6 11

Wiring with a remote switch/timer 7 11

Wiring to an HRV/ERV 8 11

Wiring an exhaust fan 9 11

Wiring a fan for a steam humidifier 10 12

5 68-0282—07

Page 6

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

Measuring airflow…

1. Make sure all HVAC system air filters are clean and

installed.

2. Push Test button:

• Control opens damper and turns on HVAC fan for

three minutes.

• A red or green light is flashing; you can now measure

airflow.

3. Follow instrument instructions for measuring airflow.

TIPS:

• You can exit the test mode at any time by pressing the test

button again.

• See Conversion Table (located after wiring diagrams) for

quick area and airflow setting conversions.

• For future reference, record the air flow on the inside of the

device cover.

• Pitot Tubes and flow measuring stations are commonly

used airflow measuring devices.

About the control settings…

Dial Settings

These settings allow the installer to customize the control to

meet the ventilation requirements for the home.

Ventilation Standard

Building codes are different everywhere. The W8150

Ventilation Control can be configured to operate based on:

• ASHRAE 62.2.

• ASHRAE 62-1999

TIP:

• Clear understanding of local codes and practices is

required to make sure the ventilation system is installed

and configured correctly. Generally, ASHRAE 62.2 control

method is recommended and can meet many existing local

codes.

Code/Standard Setting

General Ventilation

Requirements

Washington State Energy

Code

Canadian Building Code* ASHRAE 62.2

Minnesota Energy Code 62-1999

2002 International

Residential Code

*In Canada, interlocking exhaust equipment

may be required for balanced ventilation.

ASHRAE 62.2

ASHRAE 62.2

62-1999

Ventilation Limit

This setting determines the maximum amount of time that the

fan runs for ventilation.

Ventilation Limit*

1

60%

ASHRAE 62.2

BEDROOMS

Setting ventilation limit and ventilation standard.

2

Ventilation

Standard

100%

62-1999

M22009

68-0282—07 6

Page 7

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

Honeywell

Golden Valley, MN 55422

50001159-001 Rev. A

W

8150A 1001

1

www.honeywell.com/yourhome

or call 1-800-468-1502

_________

area (sq. ft.)

R

ecor

d setting

s above

Ventilation Limit*

Ventilation

Standard

1260%

ASHRAE 62.2

100%

62-1999

Installer

Test

M19991

Para español ver las instrucciones

*See Instructions Voir mode d'emploi en français inclus

R

C

DMP

DMP

AUX

AUX

REM

REM

24 VAC

XFRM

HVAC

Stat

Damper

ERV/Fan

Timer/Switch

GF

RC

CC

CH

W

G

T

Patent Pending

_________

bedrooms

_________

airflow (cfm)

Date installed:________________________

W8150A 1001

_________

area (sq. ft.)

Record settings above

Ventilation Limit*

Ventilation

Standard

1

2

60%

ASHRAE 62.2

100%

62-1999

Installer

Test

R

C

DMP

DMP

AUX

AUX

REM

REM

24 VAC

XFRM

HVAC

Stat

Damper

ERV/Fan

Timer/Switch

G

F

R

C

C

C

C

H

W

G

T

_________

bedrooms

_________

airflow (cfm)

Date installed:________________________

Setting the control...

1. Be sure power is turned on.

2. Set the Ventilation Standard on the control.

3. Set the bedrooms dial.

4. Set the area (sq ft) dial.

5. Set the airflow (cfm) dial.

6. Press the test button and observe the lights:

Green light is flashing.

The dial settings meet the chosen standard.

Red light is flashing.

There is not enough fresh air delivered to meet the

requirements of the selected standard. See

Troubleshooting section.

7. Record settings on the label inside the cover as shown

in the diagram.

TIPS:

• Ventilation control reads new dial setting only when test

button is pushed or power is cycled. To ensure dial settings

are read, push test button after any changes are made.

• For single bedroom homes, set the bedrooms dial to 2 (this

may result in more ventilation than the minimum required).

• For homes having more than five bedrooms and only a

single ventilation system, set the bedrooms dial to 5 (this

may result in less ventilation than the minimum required).

• For conditioned square feet, set area (sq ft) dial to the

nearest value.

• For airflow, set airflow (cfm) dial to the nearest value.

• Vaulted ceilings do not need to be considered when setting

this control.

• For homes with multiple systems: Honeywell recommends

a ventilation control and fresh air intake for each system.

Measure ventilation airflow for each system independently.

Refer to Multi-system Setup Example for further details.

Customizing the ventilation control.

7 68-0282—07

Page 8

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

CHECKOUT

In this section, make sure the ventilation system is operating

correctly.

1. On thermostat, set Fan switch to Auto and System

switch to Off.

2. Set any remote switches throughout the house in the

Off position.

3. On the W8150, set the control switch to Off (remote

only).

4. Press Test button for two seconds to enter test mode:

• A light on the control begins flashing.

• The HVAC system fan comes on.

• The damper moves to the Open position.

5. Press the Test button again to exit test mode:

• No lights on the control are on.

• The HVAC system fan turns off.

• The damper returns to the closed position.

6. Return the thermostat, ventilation control, and remote

switches to the original settings.

7. Refer to Troubleshooting section, if needed.

TIP:

• W8150 Ventilation Control automatically exits test mode

after three minutes.

TROUBLESHOOTING

Problem Possible cause What to do

Flashing red light

during test mode

(The current settings

do not meet the

selected ventilation

requirement)

Flashing red light

during normal

operation

No light on ventilation

control when switch

set to:

• On

• Override Off/

• Remote Only and a

remote switch is on.

HVAC fan does not

come on after pressing

Test button.

Not enough airflow • Measure airflow and check dial setting.

• See Problem: Not enough airflow.

Ventilation on-time limit

setting

Low voltage • Check the voltage from the transformer for at least 20 Vac. If voltage is

No power to control • Verify 24 volt input to R and C terminals on ventilation control.

Device malfunction • Cycle power off to control for ten seconds and recheck. If control does not

Wiring • Check wiring connections per appropriate system diagram.

HVAC system does not

have power

• If the device is set to 60%: Set the ventilation control to 100% maximum

on time. This allows the HVAC fan to run up to 100% of the time. It may be

preferable to increase airflow.

• If the device is set to 100%: There is not enough airflow through the

fresh air duct.

• Ventilation continues to occur according to the settings but chosen

standard may not be met.

OK, replace W8150 Control. If voltage is not OK, disconnect damper and

remote switch connections and check again. If voltage does not return to

at least 20 Vac, replace transformer.

• Check wiring connections per appropriate system diagram and replace

transformer, if necessary.

recover, replace ventilation control.

• Restore power to the HVAC system.

68-0282—07 8

Page 9

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

Problem Possible cause What to do

HVAC fan is running all

Device is set to override • Move switch to On position to allow for automatic operation.

the time

Remote switch is on • Adjust remote switch to desired position.

Thermostat Fan switch is

• Normal operation.

in On position

HVAC system is running

• Normal operation.

to satisfy heating or

cooling requirements.

Ventilation limit is set to

100% ventilation limit.

• Set ventilation limit to 60%. The control may not be able to meet the

recommended ventilation requirements.

• Increase ventilation airflow through fresh air duct and adjust settings.

Low ventilation air flow. • See Problem: Not enough airflow.

• Damper does not

open during

checkout or

• Damper does not

close.

Incorrectly wired. • Check wiring connections per appropriate wiring diagram.

Transformer output. • Verify 24 Vac applied to actuator.

Damper actuator motor

failure or mechanical

failure.

• Manually open damper and verify free movement; damper should return

to closed position when no power is applied.

• If damper moves freely but does not operate when 24 volts is applied,

replace damper actuator.

• If damper does not move freely, replace fresh air damper.

Cooling compressor

comes on when there

is no cooling call from

the thermostat.

Incorrectly wired. • Check wiring connections per appropriate system diagram.

• An isolation relay may be required when appliances are connected to the

G

T terminals on the ventilation control. (For an example, see wiring a fan

for a steam humidifier diagram.)

Not enough airflow Obstruction or duct size • Check for obstructions in the fresh air duct and weather hood.

• Check for kinks in ductwork.

• Make sure all manual dampers are fully open.

• Make sure the stops on the EARD damper allow it to open fully.

• Increase duct size.

• Add a booster fan to the fresh air duct.

NOTE: After any changes to the ductwork, repeat the Measuring Airflow

section.

9 68-0282—07

Page 10

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

WIRING DIAGRAMS

Consult thermostat Installation Instructions for alternate

terminal designations.

HVAC

HVAC

RCWYG

W8150A

G

F

R

C

C

C

C

H

W

G

T

RR

C

WYG

System

Heat

AM

Fan

Room

Tue

Wake

Auto

DST

M19994A

Fig. 1. Single transformer, conventional system.

HVAC

COOLINGHEATING

WR

RC CYG

W8150A

G

F

R

C

C

C

C

H

W

G

T

NOTE:

RR

C

Tue

Wake

WYG

System

Heat

AM

Fan

Room

Auto

DST

REMOVE FACTORY

INSTALLED JUMPER

BETWEEN C

ON W8150.

C AND CH

W1CRW

2Y1Y2

G

W8150A

G

F

R

C

C

C

C

H

W

G

T

W

1

CRCRW

2Y1Y2

AM

Room

Tue

DST

Wake

G

System

Heat

Fan

Auto

M19996

Fig. 3. Multi-stage conventional system.

HVAC

RCYGO

W8150A

G

F

R

C

C

C

C

H

W

G

T

R

C

R W Y G O/B

Wake

System

Heat

AM

Fan

Room

Tue

Auto

DST

M19997A

M19995A

Fig. 2. Dual transformer, conventional system.

68-0282—07 10

Fig. 4. Wiring heat pump without emergency heat.

Page 11

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

M19999

W8900

REMOTE AUX DAMPER

C

R

XFMR

RH

RC

HUM

HUM

VNT

VNT

®

AT120

W8150A

EARD-6

NOTE:

CONFIGURE PC8900 SO ALL VENT PROGRAM

SETTINGS ARE OFF; THE VENT BUTTON ON THE

PC8900 THEN SERVES AS A REMOTE AND THE W8150

CONTROLS BACKGROUND VENTILATION.

0

0

0

0

BLUE

BLUE

HVAC

YCRW2EGO

W8150A

G

F

R

C

C

C

C

H

W

G

T

Y

1W1

CRW

Wake

2

E G O/B

System

Heat

AM

Fan

Room

Tue

Auto

DST

M19998A

Fig. 5. Wiring heat pump with emergency heat.

W8150A

V

entilation

C

ontro

Auto

Continuous

Off

(Remote Only)

V

entilation

C

ontro

AT12

C

l

Service

l

EARD-6

REMOTE AUX DAMPER

Fig. 7. Using a remote switch or timer.

W8150A

V

entilation

C

Auto

Continuous

Off

(Remote Only)

V

entilation

C

ontro

AT12

C

ontro

l

Service

l

1

HR150/ER150

RED BLACK

FAN TIMER

M22000

FAN TIMER

Fig. 6. Wiring with a PC8900.

NOTES:

– BALANCE THE HRV/ERV TO 160 CFM OR LOWER.

– SET VENTILATOR SPEED KNOB TO 0.

1

EARD DAMPER NOT USED WITH HRV/ERV.

M22001

Fig. 8. Wiring to an HRV/ERV.

REMOTE AUX DAMPER

AT12

EARD-6

FAN TIMER

EXHAUST FAN

120 VAC

R8222

RED

BLACK

L1

120

VAC

L2

M22002

W8150A

V

entilation

C

ontro

Auto

Continuous

Off

(Remote Only)

Service

V

entilation

C

ontro

AT12

R

C

l

l

REMOTE AUX DAMPER

Fig. 9. Wiring an exhaust fan.

11 68-0282—07

Page 12

Y8150 FRESH AIR VENTILATION SYSTEM, W8150 FRESH AIR VENTILATION CONTROL

Wake

Room

System

Fan

Heat

Auto

AM

DST

Tue

W1CRW

2Y1Y2

G

W

1

CRCRW

2Y1Y2

G

M22021A

G

F

R

C

C

C

C

H

W

G

T

HVAC

W8150A

HE440

FAN

R8222

BLACK

BLUE

BLUE

RED

•100 cfm.

CONVERSION TABLE

Area Airflow

sq ft sq m cfm lps

1000 93 40 19

1300 121 50 24

1600 149 60 28

1900 177 70 33

2200 204 80 38

2500 232 90 42

2800 260 100 47

3100 288 110 52

3400 316 120 57

3700 344 130 61

4000 372 140 66

4300 399 150 71

Fig. 10. Wiring fan for a steam humidifier.

4600 427 160 76

Multi-System Setup Example

Total square feet and bedrooms should be proportionately

split between the ventilation controls based on sq ft served by

each system regardless of where the bedrooms are located.

Example: 5,000 sq ft, six bedrooms:

System 1:

• serves 3200 sq ft,

• two bedrooms.

• fresh air intake measured at 127 cfm.

System 2:

• serves 1800 sq ft,

• four bedrooms

• fresh air intake measured at 98 cfm.

Set W8150 for System 1:

• 3100 sq ft,

• four bedrooms

• 130 cfm.

Set W8150 for System 2:

• 1900 sq ft,

• two bedrooms

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Airflow

cfm

6 in. duct

(15.2 cm)

fpm ms fpm ms

7 in. duct

(17.8 cm)

40 204 1.0 150 0.8

50 255 1.3 187 1.0

60 306 1.6 225 1.1

70 357 1.8 262 1.3

80 407 2.1 299 1.5

90 458 2.3 337 1.7

100 509 2.6 374 1.9

110 560 2.8 412 2.1

120 611 3.1 449 2.3

130 662 3.4 486 2.5

140 713 3.6 524 2.7

150 764 3.9 561 2.9

160 815 4.1 599 3.0

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

68-0282—07 T.D. Rev. 02-11

Printed in U.S.A.

Loading...

Loading...