Page 1

BEFORE INSTALLATION

The Excel 10 Hydronic Controller is available in the following

two models:

1. W7762A—with integral setpoint adjustment.

2. W7762B—no integral setpoint adjustment.

Excel 10

W7762A,B HYDRONIC CONTROLLERS

INSTALLATION INSTRUCTIONS

Wiring

All wiring must comply with applicable electrical codes and

ordinances. Refer to job or manufacturers’ drawings for

details.

The models all have similar housings and mounting

procedures.

IMPORTANT

It is recommended that devices be kept at room

temperature for at least 24 hours before applying

power to allow any condensation resulting from low

shipping/storage temperatures to evaporate.

INSTALLATION

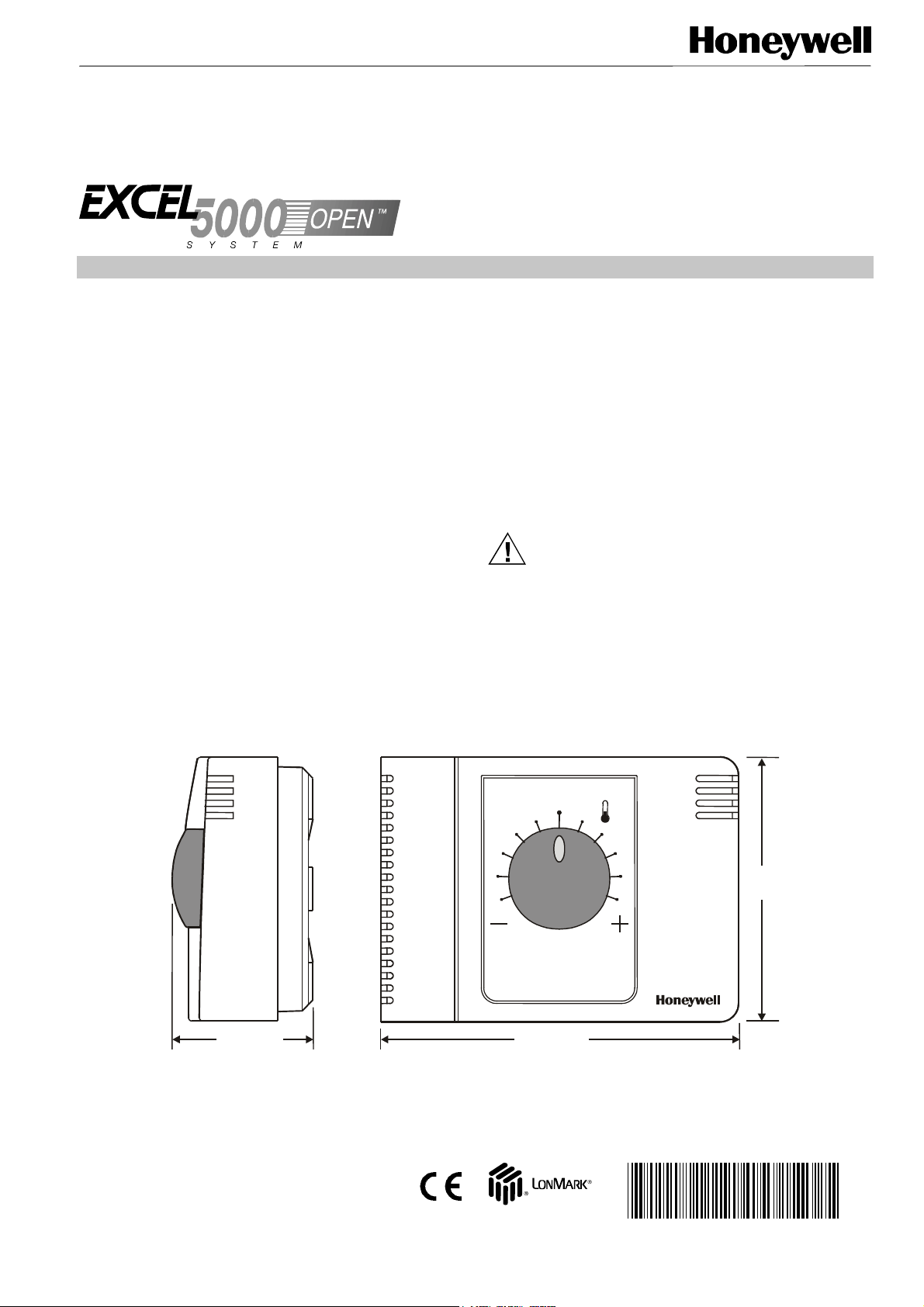

W7762 Hydronic Controllers can be mounted on a panel or

wall or onto a standard 60-mm wall outlet box using No. 6

(3.5 mm) screws. See Fig. 1 for outside dimensions and

Fig. 2 for subbase mounting dimensions.

The controller can be mounted in any orientation desired.

Power

Input power provided must be 24 Vac (±20%), 50 or 60 Hz.

For US installation, power must come from an energy-limited

Class II Power Source (transformers must not exceed

100 VA). More than one W7762 Controller can be powered

by a single transformer.

CAUTION

Turn off power prior to connecting to or removing

connections from any terminals to avoid electrical

shock or equipment damage.

Use the heaviest gauge wire available, up to 14 AWG

(2.5 mm

wiring.

2)

with a minimum of 18 AWG (1.0 mm2) for all power

1-13/16 (46)

® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc.

All Rights Reserved

4-9/16 (116)

Fig. 1. Excel 10 Hydronic Controller outside dimensions in in. (mm).

3-3/8

(86)

95- 7563- 3

Page 2

W7762A,B HYDRONIC CONTROLLERS

ONIC CO

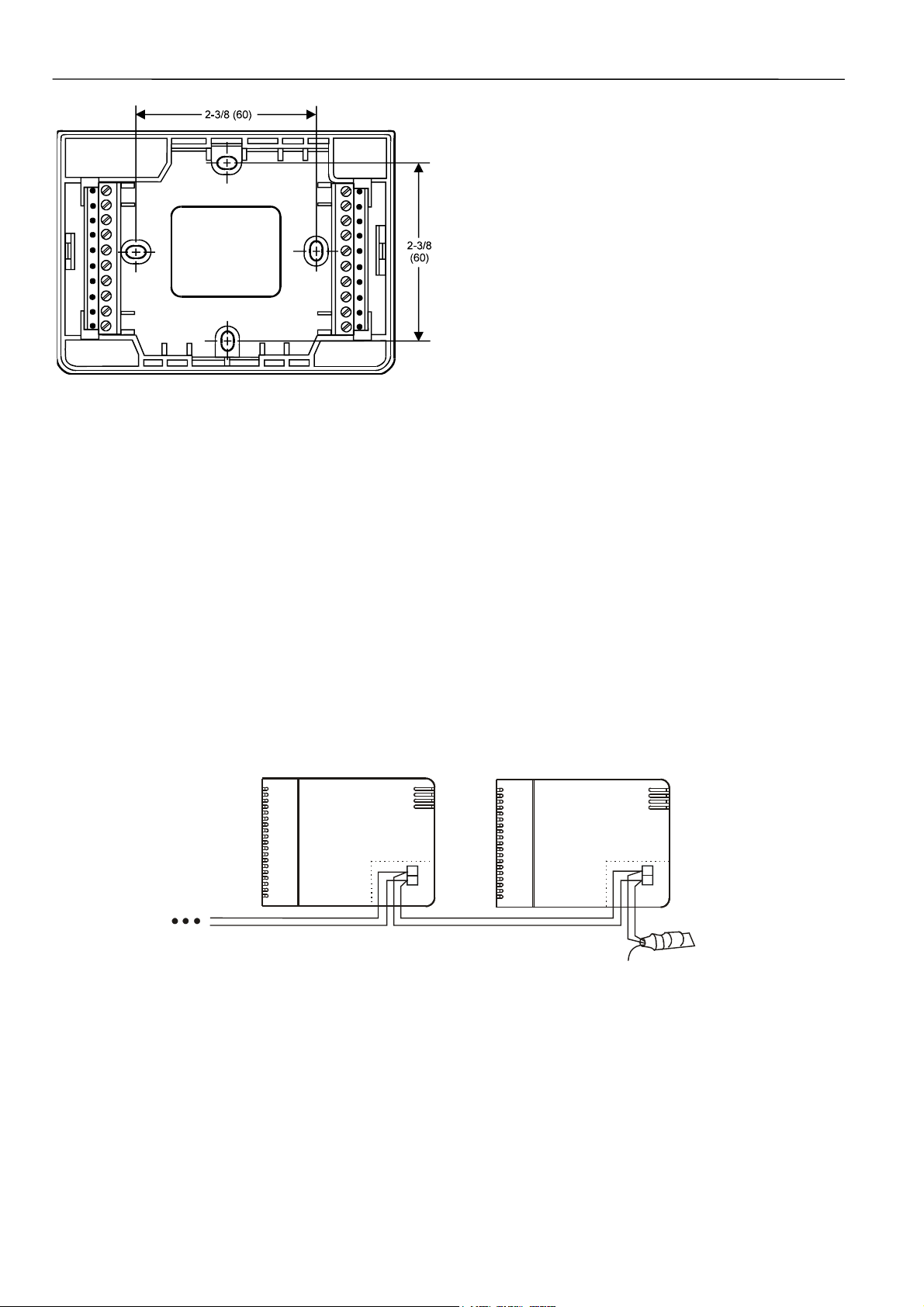

Fig. 2. Subbase mounting dimensions.

IMPORTANT (US only)

If the W7762 Controller is used on UL 1995 Heating

and Cooling Equipment and the transformer

primary power is more than 150 Vac, connect the

transformer’s secondary to earth ground. For these

applications, only one Excel 10 controller can be

powered by each transformer.

Communications

Wire the controller communications E-Bus using level IV 22

AWG (Belden part number 9D220150) or plenum-rated level

IV 22 AWG (Belden part number 9H2201504) nonshielded,

twisted pair, solid conductor wire. When possible, use

Honeywell AK3781, AK3782, AK3791, or AK3792 cable (US

part numbers). See E-Bus Wiring Practices, form number

74-2865, for more information including maximum lengths.

Pull the cable to each controller on the E-Bus and connect to

terminals 19 and 20.

The W7762 Hydronic Controller utilizes a free topology transceiver (FTT10A) Link Power compatible E-Bus that allows

daisy-chain, loop, and star network configurations or any

combination thereof. Depending upon the E-Bus configuration used, one or two termination modules, part number

209541B, may be required. Different connections to the

termination module are necessary depending upon whether it

is used in a singly- or doubly-terminated network configuration. See Excel 10 FTT/LPT 209541B Termination

Module Installation Instructions, form 95-7554.

NOTES:

— The E-Bus is insensitive to polarity, eliminating

installation errors due to miswiring.

— Do not bundle output wires with sensor, digital input or

communications bus wires. Maintain a minimum 3-in.

(76-mm) separation between E-Bus and Triac output and

power supply wiring.

— For installations, try to avoid areas of high electro-

magnetic noise (EMI).

— Some T7770 Wall Modules used with Hydronic con-

trollers have a daisy-chain connection for the E-Bus to

provide network access via built-in jack.

— For more information; see E-Bus Wiring Guidelines, form

number 74-2865.

Wall Modules

A variety of Excel 10 wall modules can be used with W7762

Hydronic Controllers. See T7460 Wall Modules Installation

Instructions, form number 95-7610; T7560 Digital Wall

Module Installation Instructions, form number 95-7620; and

T7770 Wall Modules Installation Instructions, form number

95-7538 for installation details.

NOTE: Wall Modules with fan speed switches must not be

used with W7762 controllers.

W7762 HYDRONIC CONTROLLER

19

20

Fig. 3. Termination module connection (daisy-chain network configuration).

95-7563-3 2

W7762 HYDR

NTROLLER

ORANGE

19

20

BROWN

TERMINATION

MODULE (209541B)

Page 3

W7762A,B HYDRONIC CONTROLLERS

Wiring Details

Connections to the Hydronic controllers are made at 2

internal terminal blocks accessible beneath the front cover.

No tools are required to remove the front cover. Simply pull

away from the subbase as shown in Fig. 4.

Fig. 4. Terminal cover removal.

IMPORTANT

Screw-type terminal blocks are designed to accept

no more than one 14 AWG (2.5 mm

Multiple wires that are 14 AWG (2.5 mm

2

) conductor.

2

connected with a wire nut. Include a pigtail with this

wire group and attach the pigtail to the individual

terminal block.

Wire to the terminal blocks as follows:

1. Strip 1/2 in. (13 mm) insulation from the conductor.

2. Insert the wire in the required terminal location and

tighten the screw to complete the termination. Ensure

that the wire entering the terminal block does not extend above the numbered face of the terminal block to

avoid contact between the wires and the printed circuit

board on the underside of the front cover (see Fig. 6.)

) can be

Fig. 5. Mounting on wall outlet box.

Use a minimum wire size of 20 AWG (0.5 mm

2

) for all input /

output connections. The maximum length of all input/output

cables and wall module interface cables is 65 ft (20 m). Maintain 3 in. (76 mm) minimum spacing between signal lines 110 and Triac output and power supply wiring.

Fig. 8 illustrates the terminal assignments of the controllers.

Table 1 lists Triac output assignments for various actuator

types. Refer to job drawings for specific wiring diagrams.

Fig. 6. Terminal block connections.

IMPORTANT

When two or more wires are to be attached to the

same terminal, be sure to twist them together.

Deviations from this rule can result in improper

electrical contact. See Fig. 7. Local wiring codes

may take precedence over this recommendation.

3 95-7563-3

Page 4

W7762A,B HYDRONIC CONTROLLERS

1. STRIP 1/2 IN. (13 MM) FROM WIRES

TO BE ATTACHED AT ONE

TERMAINAL

OCCUPANCY SENSOR,

CHANGEOVER CONTACT,

AIRFLOW CONTACT,

WINDOW CONTACT,

MOTION SENSOR, etc.

6

T7560A,

T7460A,

T7460B, or

T7460E

WALL MODULE

5

4

3

2

1

Output type Out 1 Terminal Out 2 Terminal

Floating 24 Vac open close 24 Vac open close

1-stage 24 Vac on/off — 24 Vac on/off —

2-stage 24 Vac stage 1 stage 2 24 Vac stage 1 stage 2

3-stage 24 Vac stage 1 stage 2 24 Vac stage 1 stage 2

PWM 24 Vac PWM — 24 Vac PWM —

Thermal 24 Vac on/off — 24 Vac on/off —

2. TWIST WIRES TOGETHER WITH

PLIERS (A MINIMUM OF THREE

TURNS).

3. CUT TWISTED END OF WIRES TO 3/16 IN. (5 MM) BEFORE

INSERTING INTO T ERMINAL AND TIGHTENI NG SCREW. THE N

PULL ON EACH WIRE IN ALL TERMINALS TO CHECK FOR GOOD

MECHANICAL CONNECTION.

Fig. 7. Attaching two or more wires at terminal blocks.

W7762 HYDRONIC CONTROLLER

NOT USED

1

NOT USED

2

NOT USED

3

DIGITAL INPUT

4

DGND

5

LED

6

7

BYPASS

8

SETPT (for W7762B, only)

9

SENSOR

10

GND

24 VAC

24 VAC COM

OUT 1 COM

OUT 1 OPEN

OUT 1 CLOSE

OUT 2 COM

OUT 2 OPEN

OUT 2 CLOSE

E-BUS (LON)

E-BUS (LON)

24 VAC

11

24 VAC COM

12

COM

13

OPEN

14

CLOSE

15

COM

16

OP EN

17

CLO SE

18

19

20

LONWORKS NETWORK IN

LONWORKS NETWORK OUT

Fig. 8. Hydronic Controller terminal assignments.

Table 1. Output assignments for various actuator types.

13 14 15 16 17 18

stage 3 stage 3

120/240 VAC

HEAT

+

COOL

-

Home and Building Control Home and Building Control Home and Building Control Products

Honeywell Inc. Honeywell Limited-Honeywell Limitee Honeywell AG

Honeywell Plaza 155 Gordon Baker Road Böblinger Straβe 17

P.O. Box 524 North York, Ontario D-71101 Schönaich

Minneapolis, MN 55408-0524 M2H 3N7 Germany

USA Canada

http://www.honeywell.com http://www.honeywell.ca http://europe.hbc.honeywell.com

95-7563-3 Rev. 01-01 7157 351 printed in Germany Subject to change without notice

Loading...

Loading...