Page 1

Table of Contents

Excel 10 W7761A Remote Input/Output

Device

CONTENTS

Introduction ...........................................................................................................................

Description of Devices ....................................................................................... 4

Control Application............................................................................................. 5

Control Provided................................................................................................. 5

Products Covered............................................................................................... 6

Organization of Manual...................................................................................... 6

Applicable Literature .......................................................................................... 6

Product Names .................................................................................................. 6

Agency Listings.................................................................................................. 7

Abbreviations and Definitions............................................................................. 7

Construction....................................................................................................... 9

Controllers..................................................................................................... 9

Performance Specifications...................................................................... 12

Wall Modules................................................................................................. 15

Configurations.................................................................................................... 16

Mixed-Output-Type Control........................................................................... 17

Occupancy Sensor........................................................................................ 17

Window Open/Closed Digital Input................................................................ 17

Wall Module Options ..................................................................................... 17

Dirty Filter Monitor......................................................................................... 17

Indoor Air Quality (IAQ) Override................................................................... 17

Application Steps ...........................................................................................................................

Overview ............................................................................................................ 18

Step 1. Plan The System.................................................................................... 18

Step 2. Determine Other Bus Devices Required................................................ 19

Step 3. Lay Out Communications and Power Wiring......................................... 19

E-Bus Layout................................................................................................. 19

Power Wiring................................................................................................. 21

Power Budget Calculation Example:......................................................... 21

Line Loss: ................................................................................................. 22

Step 4. Prepare Wiring Diagrams ...................................................................... 24

General Considerations................................................................................. 24

W7761A Devices........................................................................................... 24

E-Bus Termination Module............................................................................ 30

Step 5. Order Equipment.................................................................................... 33

Step 6. Configure Devices.................................................................................. 36

Step 7. Troubleshooting..................................................................................... 36

Troubleshooting Excel 10 Controllers and Wall Modules.............................. 36

Temperature Sensor and Setpoint Potentiometer Resistance Ranges......... 36

Alarms ........................................................................................................... 36

Broadcasting the Service Message............................................................... 37

W7761A Controller Status LEDs................................................................... 37

T7780 DDWM Bypass Pushbutton................................................................ 38

List of Figures ........................................................................................................................... 2

U.S. Registered Trademark

Copyright 1998 Honeywell Inc. • All Rights Reserved

LonWorks LonMark and LonMark l ogo are Regi stered

Trademarks of Echelon Corporat i on.

Fig. 1. Typical system overview......................................................................... 4

Fig. 2. Typical W7761A control application........................................................ 5

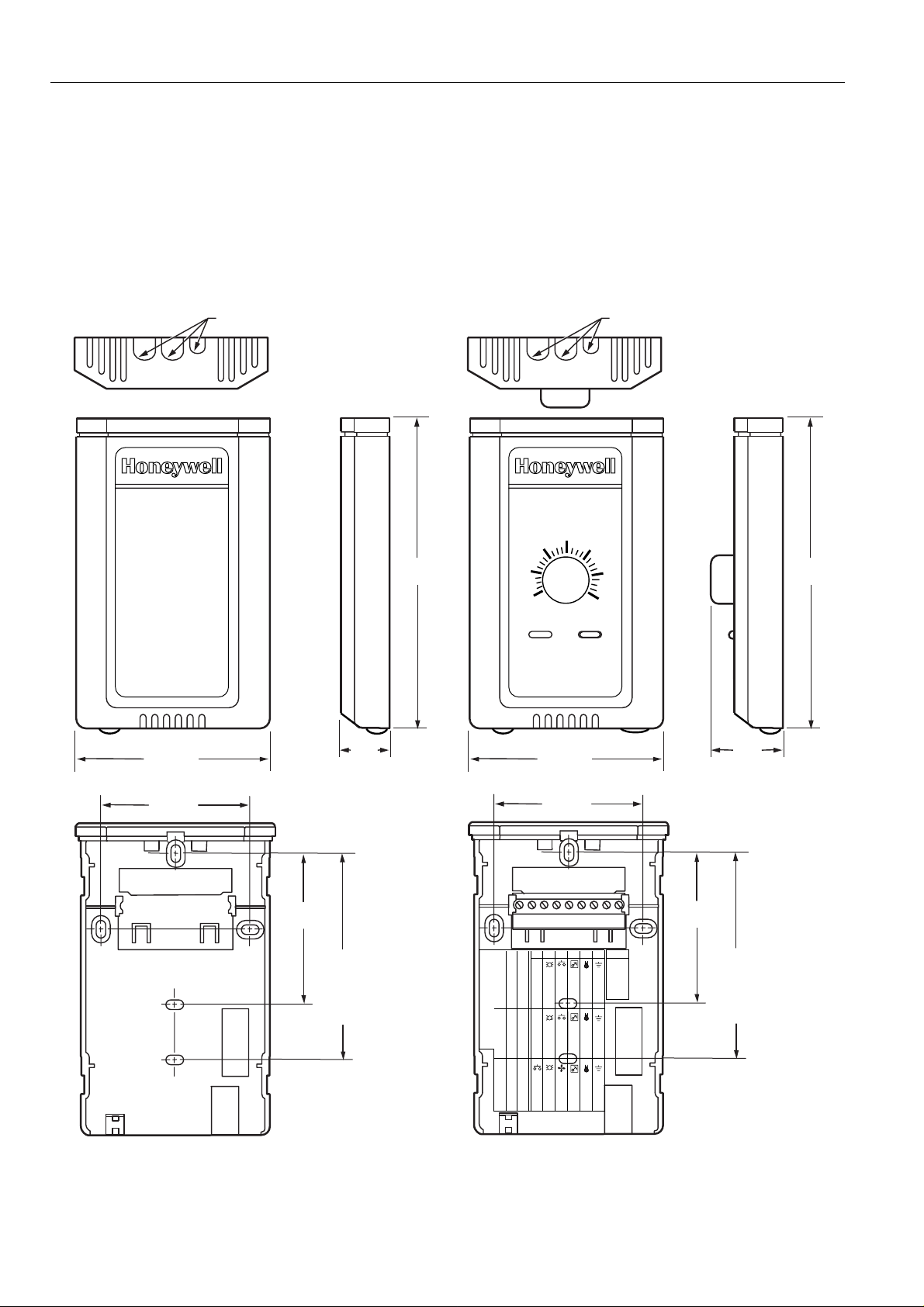

Fig. 3. Excel 10 W7761A Remote I/O Device. ................................................... 10

Fig. 4. W7761A construction.............................................................................. 11

74-2699

Page 2

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

Fig. 5. DIN rail adapters..................................................................................... 12

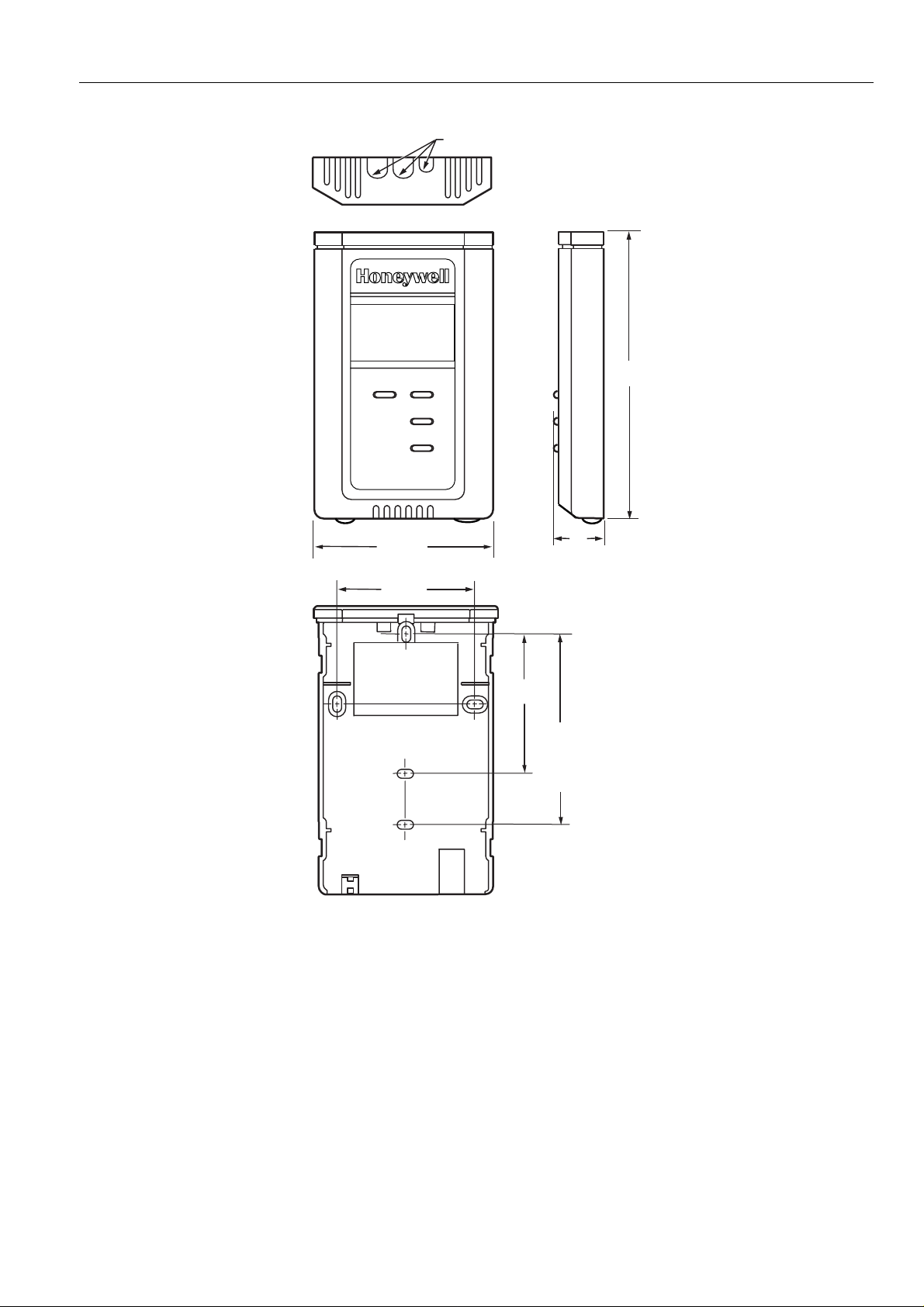

Fig. 6. T7770A,B,C,D construction (T7770A,C shown)..................................... 15

Fig. 7. T7780 construction................................................................................. 16

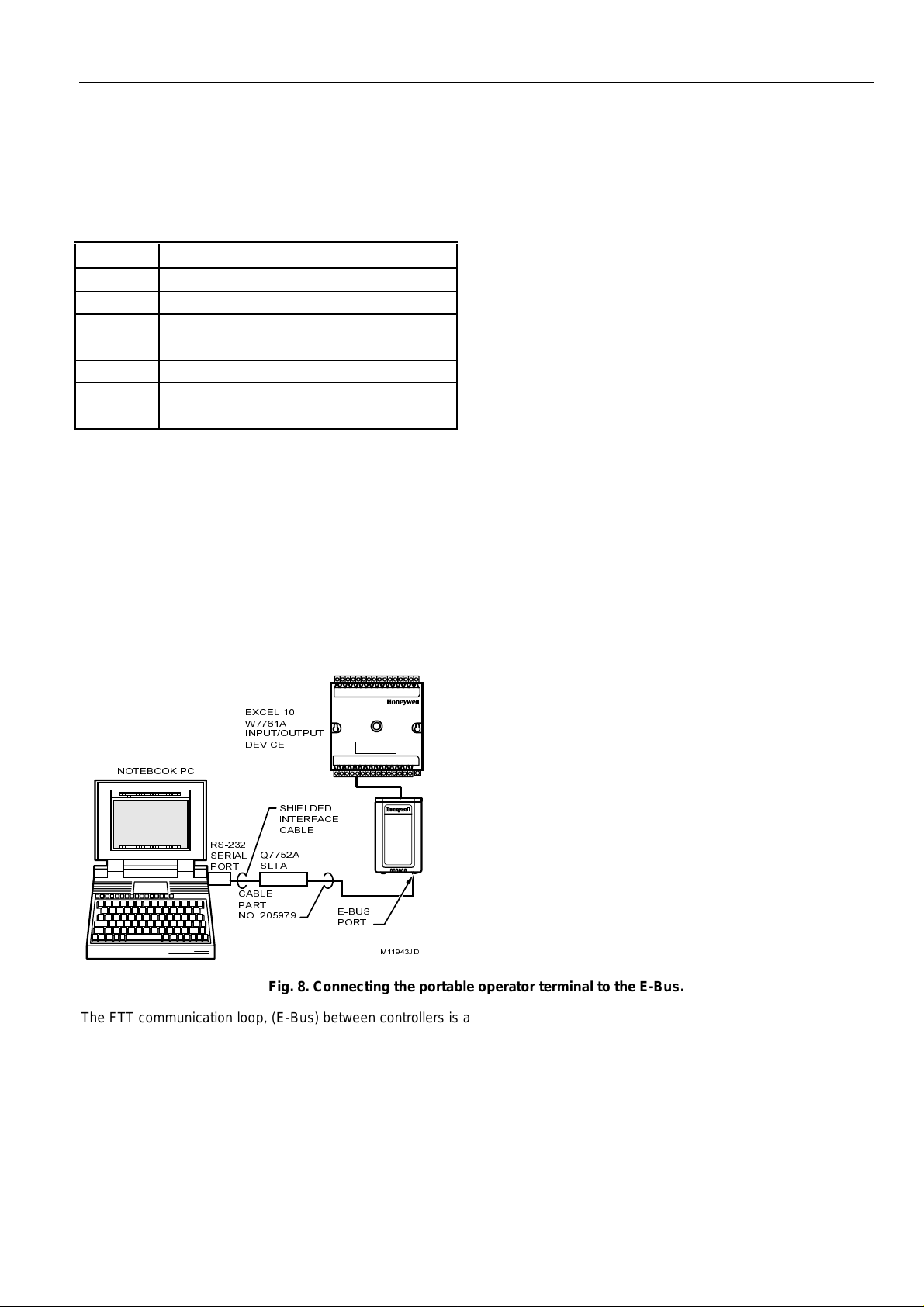

Fig. 8. Connecting the portable operator terminal to the E-Bus. ....................... 18

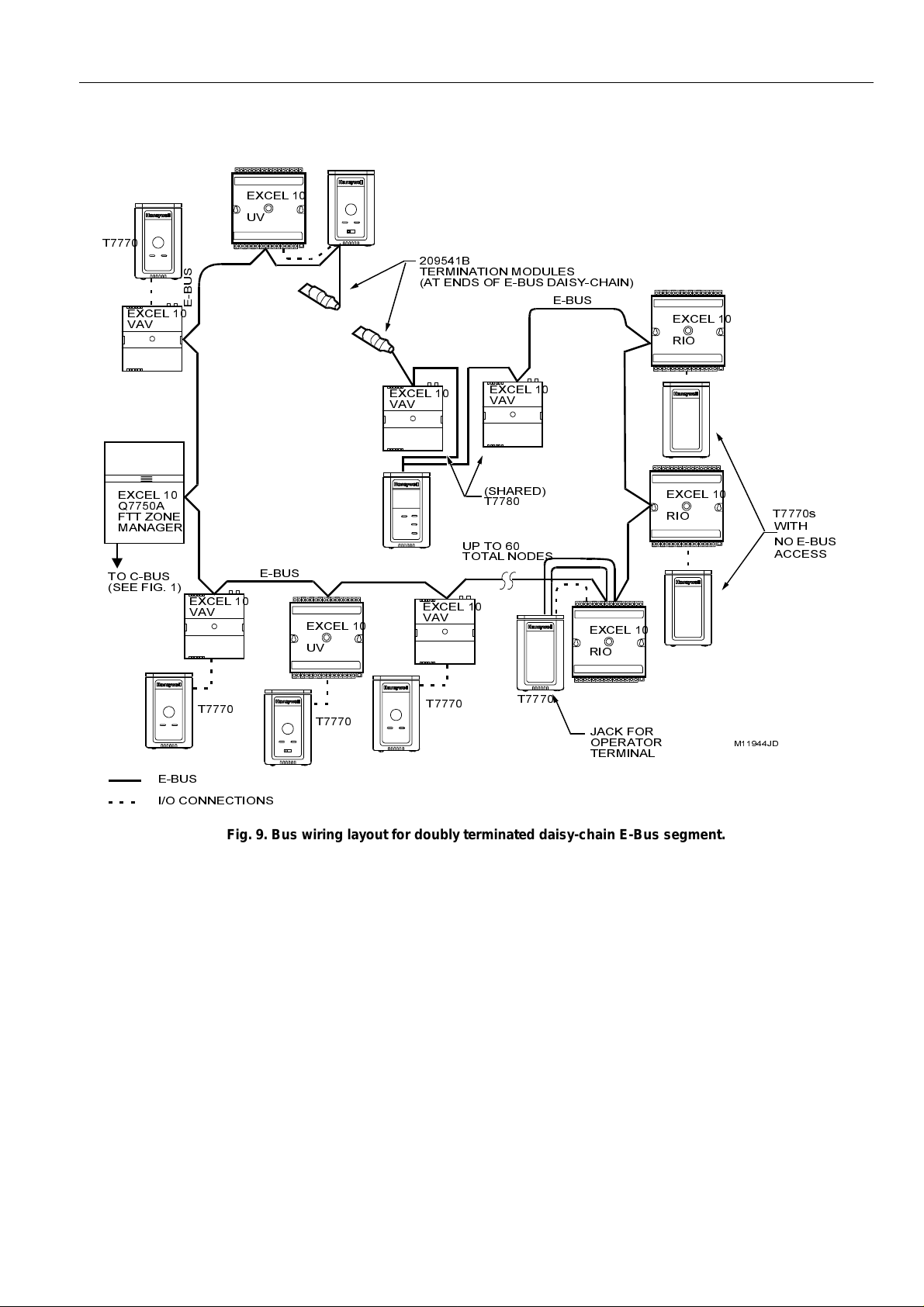

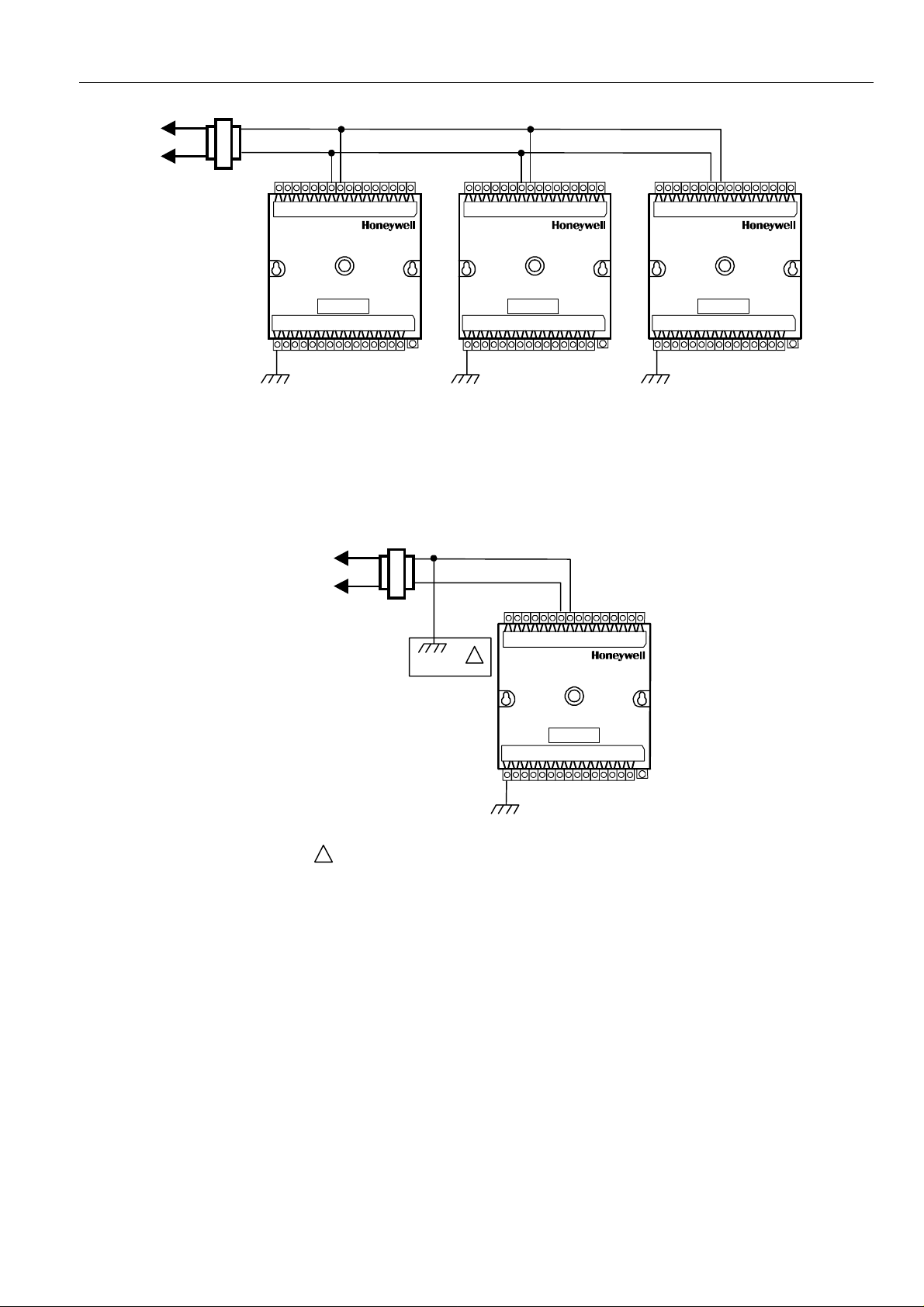

Fig. 9. Bus wiring layout for doubly terminated daisy-chain E-Bus segment..... 20

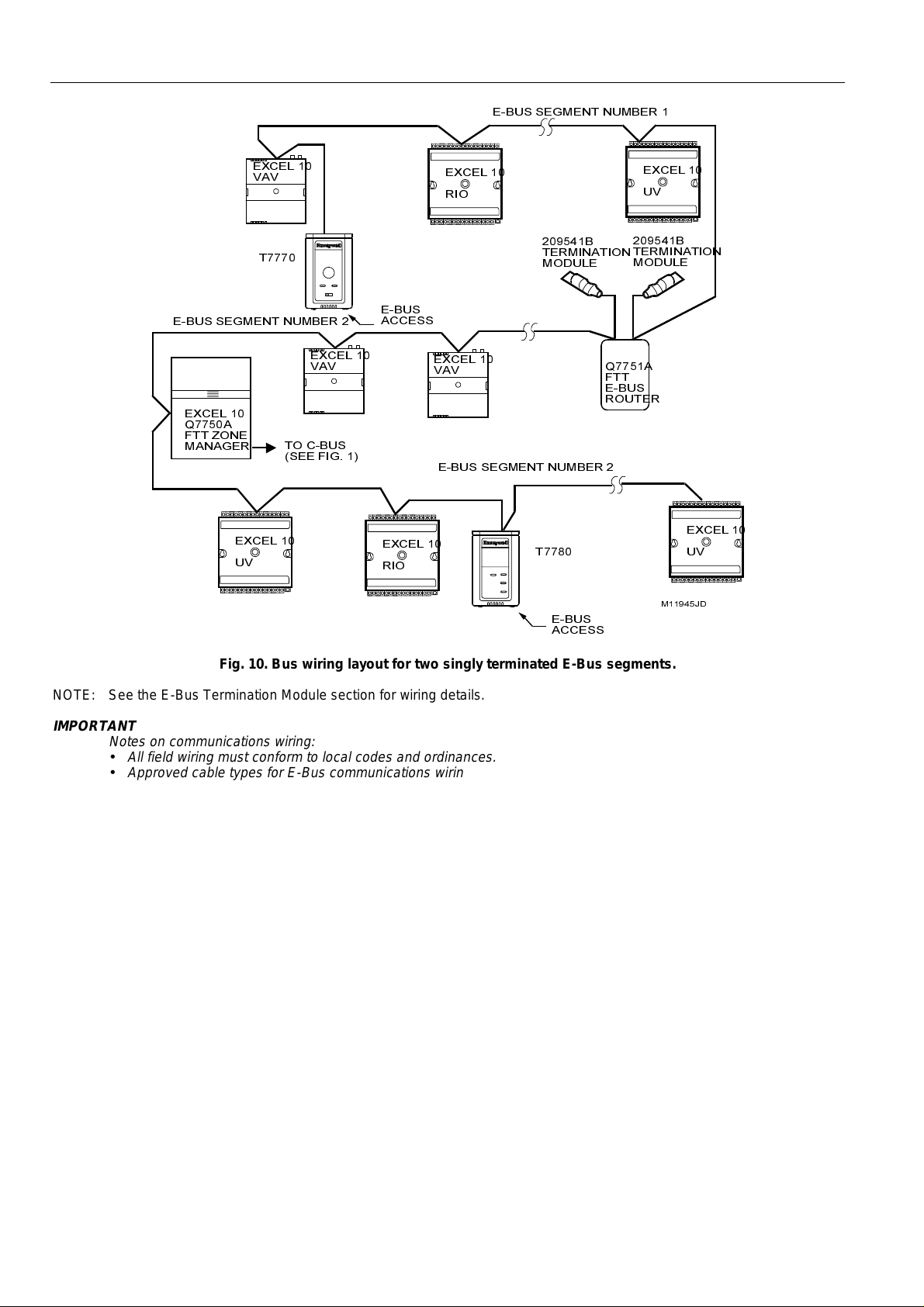

Fig. 10. Bus wiring layout for two singly terminated E-Bus segments............... 21

Fig. 11. NEMA class 2 transformer voltage output limits................................... 22

Fig. 12. Power wiring details for one Excel 10 per transformer......................... 22

Fig. 13. Power wiring details for two or more Excel 10s per transformer.......... 23

Fig. 14. Transformer power wiring details for one Excel 10 used in UL 1995

equipment (U.S. only)........................................................................................ 23

Fig. 15. Attaching two or more wires at terminal blocks.................................... 25

Fig. 16. Typical T7770A and C7770A wiring diagram....................................... 26

Fig. 17. Typical Humidity and Enthalpy (4 to 20 mA) sensor wiring diagram.... 27

Fig. 18. Typical Window and Occupancy sensor wiring diagram...................... 28

Fig. 19. Typical PWM Valve Actuator and miscellaneous fan control to W7761A.29

Fig. 20. Typical Pneumatic transducer to (Series 60 - Floating) W7761A......... 30

Fig. 21. Typical E-Bus termination module wiring diagrams.............................. 31

Fig. 22. E-Bus termination wiring options.......................................................... 32

Fig. 23. Temperature sensor resistance plots................................................... 36

Fig. 24. Location of the Service Pin Button. ...................................................... 37

Fig. 25. LED location on W7761A. .................................................................... 38

Fig. 26. Bypass pushbutton location on T7780 DDWM..................................... 39

List of Tables ...........................................................................................................................

Table 1. Agency Listings. .................................................................................. 7

Table 2. List Of Available Points........................................................................ 12

Table 3. Application Steps................................................................................. 18

Table 4. E-Bus Configuration Rules And Device Node Numbers...................... 19

Table 5. VA Ratings For Transformer Sizing..................................................... 22

Table 6. Field Wiring Reference Table.............................................................. 24

Table 7. W7761A I/O Description...................................................................... 25

Table 8. Excel 10 W7761A Device Ordering Information.................................. 33

Table 9. Excel 10 Alarms................................................................................... 37

Table 10. LED States. ....................................................................................... 38

Appendices ...........................................................................................................................

Appendix A. Using E-Vision for Commissioning W7761A Controllers............... 39

SENSOR CALIBRATION.............................................................................. 39

CUSTOM MAPPING ..................................................................................... 39

ADDING ANALOG INPUTS - ENTHALPY (4 to 20 mA)........................... 39

ADDING OTHER VOLTAGE/CURRENT SENSORS............................... 40

Table A-1. Default PID Parameters.......................................................... 41

ADDING DIGITAL INPUTS...................................................................... 41

Table A-2. Supported Digital Input Types................................................ 41

ADDING DIGITAL OUTPUTS.................................................................. 41

Table A-2. Supported Digital Output Types ............................................. 42

Appendix B. Sequences of Operation. .............................................................. 42

Common Operations..................................................................................... 42

Room Temperature Sensor (RmTemp) ................................................... 42

Window Sensor (StatusWndw)................................................................ 43

Dirty Filter Monitor.................................................................................... 43

Series 60 Modulating Control................................................................... 43

Pulse Width Modulating (PWM) Control.................................................. 43

Indoor Air Quality (IAQ) Override............................................................. 43

Appendix C. Complete List of Excel 10 W7761A Remote I/O Device User

Addresses.......................................................................................................... 44

Table C0. Engineering Units For Analog Points........................................... 44

Table C1.Input/Output Points. ...................................................................... 46

Table C2. Control Parameters...................................................................... 56

Table C3. Status Points................................................................................ 58

Table C4. Configurations Parameters. ......................................................... 64

Table C5. Direct Access And Special Points................................................ 70

Appendix D. Q7750A Excel 10 Zone Manager Point Estimating Guide. ........... 71

Approximate Memory Size Estimating Procedure........................................ 71

Fig. D-1 Point capacity estimate for Zone Manager................................. 71

Appendix E. Sensor Data for Calibration........................................................... 72

Resistance Sensors...................................................................................... 72

Voltage/Current Sensors. ............................................................................. 74

2 74-2699

Page 3

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

INTRODUCTION

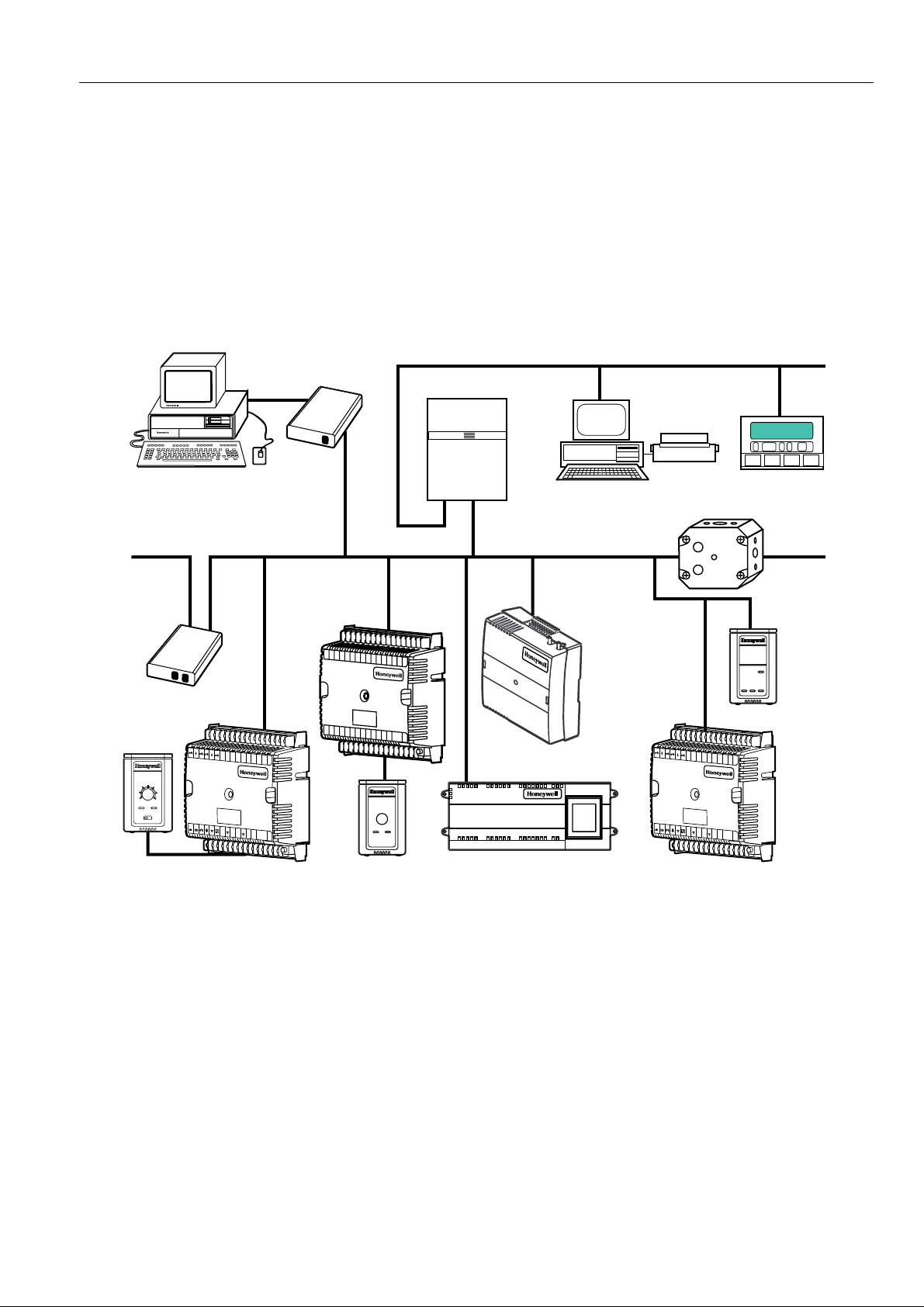

Description of Devices

The W7761A, Excel 10 Remote Input/Output device, provides auxiliary inputs and outputs for use with an Excel 10 Zone

®

Manager and Excel 10 controllers over the Echelon

®

tool. The W7761A device uses Echelon

LonWorks® communication technology and a new free topology twisted pair

transceiver (FTT) for greater network installation flexibility. The Excel 10 RIO device can be combined with the Excel 10 Zone

Manager (FTT), other Excel Controllers, and the Excel Building Supervisor, to provide a complete and low cost control solution

for small to large commercial buildings.

The Q7750A Excel 10 Zone Manager is a communications interface that allows devices on the E-Bus network to communicate

with devices on the standard EXCEL 5000® System C-Bus. Fig. 1 shows an overview of a typical system layout. The Q7750A

also provides some control and monitoring functions.

Q7752A

FTT E-BUS

SERIAL

ADAPTER

PERSONAL COMPUTER TOOLS

E-VISION

CARE

FTT E-BUS COMMUNICATIONS NETWORK

LonWorks®E-Bus. These I/O points are configured with the E-Vision

C-BUS COMMUNICATION NETWORK

EXCEL 10

Q7750A

FTT ZONE

MANAGER

C-BUS TO E-BUS

INTERFACE DEVICE

FTT E-BUS COMMUNICATIONS NETWORK

EXCEL BUILDING SUPERVISOR

EXCEL 500

Q7740A

2-WAY

REPEATER

Q7751A

FTT

E-BUS

ROUTER

EXCEL 10

T7770E

WALL

MODULE

65

60

55

auto 0 1

31 30 29 28 27 26 25

DI-4GND

DI-3

DI-2GND DI-1

70

75

80

85

E

LED

BYPASS

SNSR

GND

1234567 891011121314

EXCEL 10 W7753A UNIT

VENTILATOR CONTROLLER

EXCEL 10

W7750B

CVAHU

CONTROLLER

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

1234567 89101112131415J3

24

23 22 21 20 19 18 17

24

24

1

16

VAC

2

3

4

VAC

5

COM

6

OUT

7

OUT

8

OUT

OUT

OUT

OUT

OUT

OUT

GND

SET PT

AI-1

GND

A1-2

AI-3

GND

AI-4

OHM

22VDC

OHM

E-BUS

V/mA

E-BUS

V/mA

OUT

JACK

15

J3

EXCEL 10 T7770

WALL MODULE

EXCEL 10 W7752 FTT FAN

COIL UNIT CONTROLLER

EXCEL 10 W7751F

PANEL PLENUM

MOUNT VERSION

VARIABLE AIR

VOLUME

CONTROLLER

FTT E-BUS

COMMUNICATIONS

NETWORK

31 30 29 28 27 26 25

DI-4GND

DI-3

DI-2GND DI-1

E

LED

BYPASS

SNSR

GND

SET PT

GND

1234567 891011121314

24

24

24

VAC

VAC

COM

AI-1

GND

OHM

23 22 21 20 19 18 17

1

2

3

4

5

OUT

OUT

OUT

OUT

OUT

A1-2

AI-3

GND

AI-4

22VDC

OHM

V/mA

V/mA

OUT

EXCEL 10

T7780

DIGITAL

DISPLAY

WALL

MODULE

EXCEL 10

16

6

7

8

OUT

OUT

OUT

E-BUS

E-BUS

JACK

15

J3

REMOTE

INPUT/

OUTPUT

DEVICE

M12884

Fig. 1. Typical system overview.

3 74-2699

Page 4

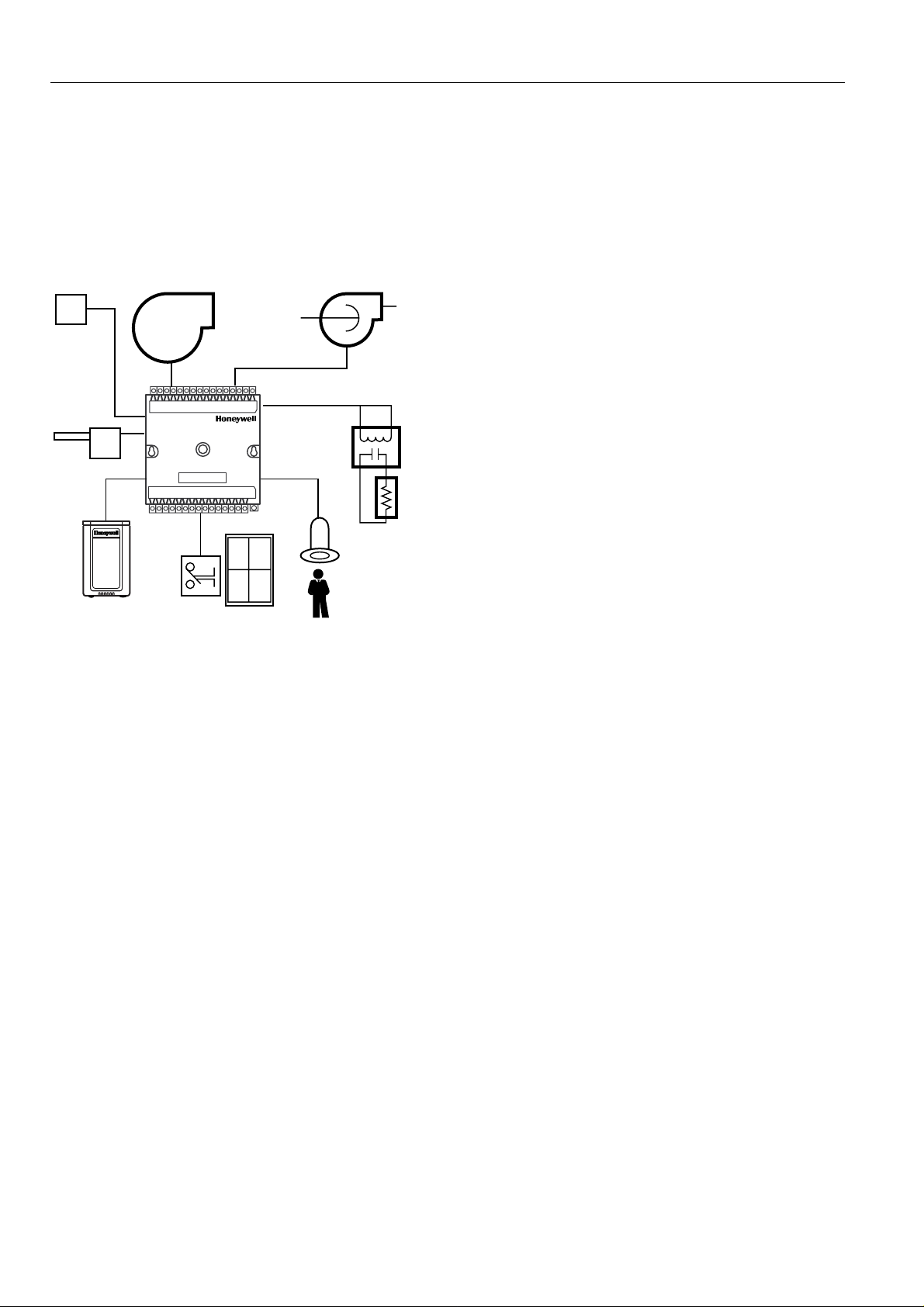

Control Application

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

The W7761A, Excel 10 Remote Input/Output device, provides auxiliary inputs and outputs for use with an Excel 10 Zone

®

Manager and Excel 10 controllers over the Echelon

LonWorks®E-Bus. The W7761A Remote Input/Output Device can be

connected to outdoor air temperature and humidity sensors that can be used by other Excel 10 controllers on the E-Bus or

Excel 5000 controllers on the C-Bus through the Excel 10 Zone Manager. This would allow the controllers to use their physical

inputs for monitoring other elements such as return humidity, IAQ, etc. to achieve better control. The W7761A can be used to

average many space temperature sensors that are located in a zone that is controlled by the W7750 Constant Volume AHU

Controller. The W7761A device has 8 Digital Outputs which may be Discrete, Modulating or Floating. For example, this allows

the control of lighting zones, miscellaneous exhaust or ventilation fans, miscellaneous pumps, and can enable freeze

protection. See Fig. 2.

OA

HUMIDITY

TEMPERATURE

EXCEL 10 T7770

WALL MODULE

OA

MISC.

FANS

WINDOW CONTACT

EXCEL 10

W7761A

REMOTE

INPUT/OUTPUT

PUMPS

LIGHTING

CONTROL

OCCUPANCY

SENSOR

M12885

Fig. 2. Typical W7761A control application.

Control Provided

The W7761A was not intended to control staged or modulating heating/cooling coils, mixed air economizer dampers, or system

fan/heat pump units. The W7761A contains inputs and outputs, but no control software. All control that would be associated

with the inputs and outputs in the W7761A would be accomplished though the Excel Zone Manager and would not be suitable

for VAV control, temperature control, or any control function that would require less than a 30 second update rate.

Products Covered

This System Engineering Guide describes how to apply the W7761A Excel 10 Remote Input/Output Device and related

accessories to typical applications. The specific devices covered include:

W7761A Remote I/O device.

•

T7770 A through D Wall Modules.

•

Q7750A Excel 10 Zone Manager.

•

Q7751A Router (FTT to FTT only).

•

Q7752A Serial Interface Adapter.

•

Q7740A,B Repeaters (2-way and 4-way).

•

209541B FTT Termination Module.

•

Organization of Manual

This manual is divided into three basic parts: the Introduction, the Application Steps, and the Appendices that provide

supporting information. The Introduction and Application Steps 1 through 5 provide the information needed to make accurate

material ordering decisions. Application Step 6 and the Appendices include configuration engineering that can be started using

Excel E-Vision PC Software after the devices and accessories are ordered. Application Step 7 is troubleshooting.

The organization of the manual assumes a project is being engineered from start to finish. If an operator is adding to, or is

changing an existing system, the Table of Contents can provide the relevant information.

Applicable Literature

The following list of documents contains information related to the Excel 10 W7761 Remote I/O Device and the EXCEL 5000®

System in general.

Form No. Title

4 74-2699

Page 5

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

74-2698 Excel 10 W7761A Device Specification Data

74-2956 Excel 10 W7750A,B Controller Specification Data

74-2697 T7770A through G Wall Module Specification Data

74-2955 T7780 Digital Display Wall Module Specification Data

74-2950 Excel 10 Q7750A, Zone Manager Specification Data

74-2952 Excel 10 Q7751A Router Specification Data

74-2954 Excel 10 Q7752A Serial Interface Specification Data

74-2858 Excel 10 Q7740A,B FTT Repeaters Specification Data

95-7539 Excel 10 W7761A Device Installation Instructions

95-7521 Excel 10 W7750A,B Controller Installation Instructions

95-7538 T7770 Wall Module Installation Instructions

95-7558 T7780 Digital Display Wall Module Installation Instructions

95-7509 Excel 10 Q7750A Zone Manager Installation Instructions

95-7510 Excel 10 Q7751A Router Installation Instructions

95-7511 Excel 10 Q7752A Serial Interface Installation Instructions

95-7516 Excel 10 SLTA Connector Cable Installation Instructions

95-7555 Excel 10 Q7740A,B FTT Repeaters Installation Instructions

95-7554 Excel 10 209541B FTT Termination Module Installation Instructions

74-2588 Excel E-Vision User’s Guide

74-5587 CARE User’s Manual

74-5577 CARE Icon Guide

74-2039 XBS User’s Manual

74-5018 XBS Application Guide

Product Names

The W7761A Remote I/O Device is available in one model:

W7761A

•

The T7770 Wall Module is available in five models:

T7770A1xxx

•

20Kohm NTC to a linearized version of a 20 Kohm NTC used with the W7751A,C,E,G).

T7770A2xxx

•

T7770B

•

network connection for use with all Excel 5000 controllers (except W7751A,C,E,G).

T7770C

•

button and LED, and E-Bus network connection for use with all Excel 5000 controllers (except W7751A,C,E,G).

T7770D

•

LED, and E-Bus network connection for use with all Excel 5000 controllers (except W7751A,C,E,G).

Only one PT3000 sensor is supported with the W7761A device.

The T7780 Digital Display Wall Module (DDWM) is available in one model:

T7780

•

mode/speed selection for all Excel 10 controllers (except W7751 A,C,E,G).

Other products:

Q7750A

•

Q7751A

•

Q7752A

•

Q7740A,B

•

209541B

•

• ML6161

• M6410A

ML684A

•

MMC325-010

•

MMC325-020

•

ML6464A

•

ML6474

•

ML6185A

•

ML7984B

•

• EL7680A1008

• EL7628A1007

• EL7611A1003

• EL7612A1001

Refer to Table 8 in Application Step 5. Order Equipment for a complete listing of all available part numbers.

NOTE: The Q7750A Zone Manager is referred to as (E-Link) in internal software and CARE.

Remote Input/Output Device.

Wall Module with temperature sensor only Wall Module with temperature sensor and E-Bus network connection.

Wall Module with temperature sensor—(current feature that can be used with the RIO Device), setpoint, and E-Bus

Wall Module with temperature sensor—(current feature that can be used with the RIO Device), setpoint, Bypass

Wall Module with temperature sensor—(current feature that can be used with the RIO Device), Bypass button and

NOTE: The T7770B,C Models are available with a relative scale plate adjustable in E-Vision °F (± 5°C).

DDWM displays and provides space temperature, setpoint, Occ/Unocc override, Application Mode, and Fan

Excel 10 Zone Manager.

Bus Router.

Serial Adapter.

FTT Repeaters.

FTT Termination Module.

Series 60 Damper Actuator.

Series 60 Valve Actuator (use with V5812 or V5813 Valves).

Series 60 Versadrive Valve Actuator (use with V5011 and V5013 Valves).

Transducer, Series 60 to pneumatic 0 to 10 psi.

Transducer, Series 60 to pneumatic 0 to 20 psi.

Direct Coupled Damper Actuator, 66 lb-in. torque, Series 60.

Direct Coupled Damper Actuator, 132 lb-in. torque, Series 60.

Direct Coupled Damper Actuator, Spring Return, Series 60.

Direct Coupled Valve Actuator, PWM (use with V5011 or V5013F,G Valves).

Wall Module Infrared Occupancy Sensor.

Ceiling Mounted Infrared Occupancy Sensor.

Ultrasonic Occupancy Sensor.

Ultrasonic Occupancy Sensor.

not applicable to the RIO device

(jumper switches the sensor from

5 74-2699

Page 6

Agency Listings

g

Table 1 provides information on agency listings for Excel 10 products.

Table 1. Agency Listings.

Device Agency Comments

W7761A Input/Output Device

T7770A through D Wall Modules

T7780 DDWM

Q7750A Excel 10 Zone Manager

Q7751A,B Router,

Q7752A Serial Adapter

Q7740A,B FTT Repeaters

UL Tested and listed under UL916 (file number E87741).

cUL Listed (E87741).

CE General Immunity per European Consortium Standards EN50081-1 (CISPR

22, Class B) and EN 50082-1:1992 (based on Residential, Commercial, and

Light Industrial).

EN 61000-4-2: IEC 1000-4-2 (IEC 801-2) Electromagnetic Discharge.

EN 50140,

EN 50204: IEC 1000-4-3 (IEC 801-3) Radiated Electroma

EN 61000-4-4: IEC 1000-4-4 (IEC 801-4) Electrical Fast Transient (Burst).

Radiated Emissions and Conducted Emissions:

EN 55022: 1987 Class B.

CISPR-22: 1985.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing

Device. Operation in a residential area can cause interference to radio or TV

reception and require the operator to take steps necessary to correct the

interference.

UL (Not applicable.)

CSA (Not applicable.)

FCC (Not applicable.)

CE Emissions; EN50081-1, En55022 (CISPR Class B), Immunity 50082-1

UL &cUL Tested and listed under UL916, S8L9 Energy Management Equipment.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing

Device.

UL Tested and listed under UL916, file number S4804 (QVAX, PAZY).

CSA Listing pending.

FCC Complies with requirements in FCC Part 15 rules for a Class A Computing

Device. Operation in a residential area can cause interference to radio or TV

reception and require the operator to take steps necessary to correct the

interference.

UL UL1784.

CSA Listed.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing

Device.

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

netic Field.

Abbreviations and Definitions

AHU

- Air Handling Unit; the central fan system that includes the blower, heating equipment, cooling equipment, ventilation

air equipment, and other related equipment.

CO

- Carbon Monoxide. Occasionally used as a measure of indoor air quality.

CO2

- Carbon Dioxide. Often used as a measure of indoor air quality.

CARE

- Computer Aided Regulation Engineering; the PC based tool used to configure C-Bus and E-Bus devices.

C-Bus

-Honeywell proprietary Control Bus for communications between EXCEL 5000® System controllers and components.

CPU

- Central Processing Unit; an EXCEL 5000® System controller module.

cUL

- Underwriters Laboratories Canada.

CVAHU

-Constant Volume AHU; refers to a type of air handler with a single-speed fan that provides a constant amount of

supply air to the space it serves.

6 74-2699

Page 7

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

DDF

- Delta Degrees Fahrenheit.

D/X

- Direct Expansion; refers to a type of mechanical cooling where refrigerant is (expanded) to its cold state, within a

heat-exchanging coil that is mounted in the air stream supplied to the conditioned space.

E-Bus

- Honeywell implementation of Echelon® LonWorks® network for communication among Excel 10 Controllers.

E-Bus Segment

Echelon®

Economizer

E-Link

EEPROM

EPROM

Excel 10 Zone Manager

Firmware

router.

conditions, fresh air can be used to supplement the mechanical cooling equipment. Because this action saves energy,

the dampers are often referred to as

EMI

- Electromagnetic Interference; electrical noise that can cause problems with communications signals.

- Refers to the Q7750A Zone Manager. This name is used in internal software and in CARE software.

EMS

- Energy Management System; refers to the controllers and algorithms responsible for calculating optimum operational

parameters for maximum energy savings in the building.

and factory calibration information.

- Erasable Programmable Read Only Memory; the firmware that contains the control algorithms for the Excel 10

Controller.

also has the functionality of an Excel 100 Controller, but has no physical I/O points.

NOTE: The Q7750A Zone Manager can be referred to as E-Link in the internal software, CARE.

FCU

- Fan Coil Unit.

- An E-Bus section containing no more than 60 Excel 10s. Two segments can be joined together using a

- The company that developed the LON® bus and the Neuron® chips used to communicate on the E-Bus.

- Refers to the mixed-air dampers that regulate the quantity of outdoor air that enters the building. In cool outdoor

economizer dampers

- Electrically Erasable Programmable Read Only Memory; the variable storage area for saving user setpoint values

- A controller that is used to interface between the C-Bus and the E-Bus. The Excel 10 Zone Manager

- Software stored in a nonvolatile memory medium such as an EPROM.

.

Floating Control

Level IV

NEMA

Node

pulse the actuator open, and another digital output to pulse it closed.

FTT

- Free Topology Transceiver.

IAQ

- Indoor Air Quality. Refers to the quality of the air in the conditioned space, as it relates to occupant health and

comfort.

I/O

- Input/Output; the physical sensors and actuators connected to a controller.

I x R

- I times R or current times resistance; refers to Ohm’s Law: V = I x R.

K

- Degrees Kelvin.

- Refers to a classification of digital communication wire. Formerly known as UL Level IV, but

Category IV cable. If there is any question about wire compatibility, use Honeywell-approved cables (see Step 5 Order

Equipment section).

NEC

- National Electrical Code; the body of standards for safe field-wiring practices.

- National Electrical Manufacturers Association; the standards developed by an organization of companies for safe field

wiring practices.

- A Communications Connection on a network; an Excel 10 Controller is one node on the E-Bus network.

NV

- Network Variable; an Excel 10 parameter that can be viewed or modified over the E-Bus network.

PC

- An IBM compatible Personal Computer with 386 or higher processor and capable of running Microsoft® Windows™

Version 3.1.

- Refers to Series 60 Modulating Control of a valve or damper. Floating Control utilizes one digital output to

not

equivalent to

Pot

- Potentiometer. A variable resistance electronic component located on the T7770B,C Wall Module; used to allow useradjusted setpoints to be input into the Excel 10 Controller.

7 74-2699

Page 8

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

PWM

- Pulse Width Modulated output; allows analog modulating control of equipment using a digital output on the controller.

RTD

- Resistance Temperature Detector; refers to a type of temperature sensor whose resistance output changes according

to the temperature change of the sensing element.

RIO

- Remote Input/Output Device. Provides auxiliary inputs and outputs for use with an Excel 10 Zone Manager and Excel

10 controllers.

Subnet

W7750

W7751

W7752

W7753

W7761

Wall Module

- An E-Bus segment that is separated by a router from its Q7750A Zone Manager.

TOD

- Time-Of-Day; the scheduling of Occupied and Unoccupied times of operation.

TPT

- Twisted Pair Transceiver.

UV

- Unit Ventilator Controller.

VA

- Volt Amperes; a measure of electrical power output or consumption as applies to an ac device.

Vac

- Voltage alternating current; ac voltage rather than dc voltage.

VAV

- Variable Air Volume; Refers to either a type of air distribution system, or to the W7751 Excel 10 VAV Box Controller

that controls a single zone in a variable air volume delivery system.

VOC

- Volatile Organic Compound; refers to a class of common pollutants sometimes found in buildings. Sources include

out-gassing of construction materials, production-line by-products, and general cleaning solvents. A VOC is

occasionally used as a measure of indoor air quality.

-The model number of the Excel 10 CVAHU Controllers (also see CVAHU).

-The model number of the Excel 10 VAV Box Controllers (also see VAV).

-The model number of the Excel 10 FCU Controllers (also see FCU).

-The model number of the Excel 10 UV Controllers (also see UV).

-The model number of the Excel 10 RIO Device (also see RIO).

- The Excel 10 Space Temperature Sensor and other optional controller inputs are contained in the T7770 or

T7780 Wall Modules. See Application Step 5. Order Equipment for details on the various models of Wall Modules.

XBS

- Excel Building Supervisor; a PC based tool for monitoring and changing parameters in C-Bus devices.

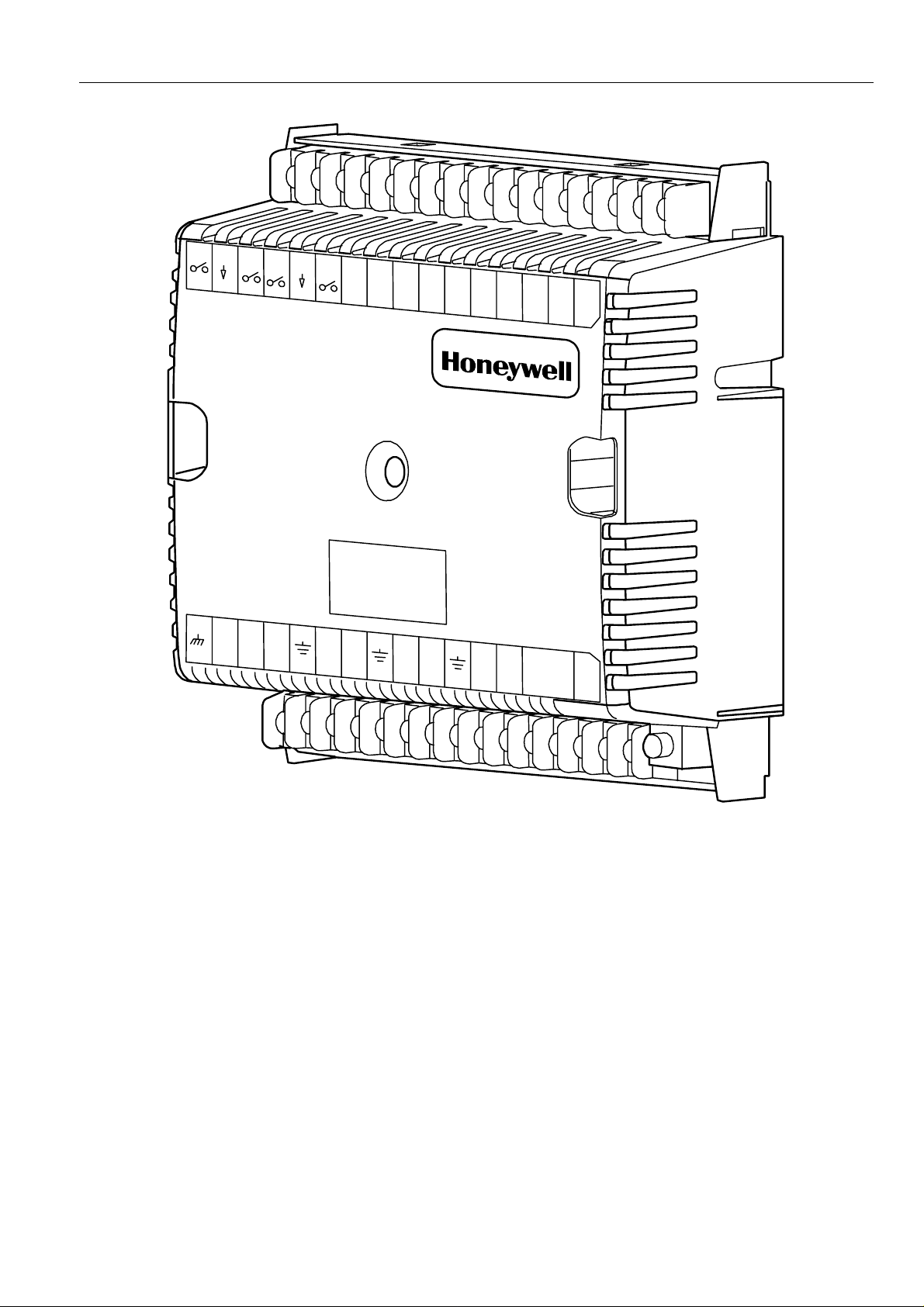

Construction

Controllers

The Excel 10 W7761A RIO Device is available in one model. It contains 4 resistive inputs that can be configured for either

20Kohm NTC or PT3000 sensors, 2 voltage or current inputs, 4 digital inputs and 8 Digital Outputs (Triacs) which may be

Discrete (maintained or momentary), Modulating (PWM) or Floating.

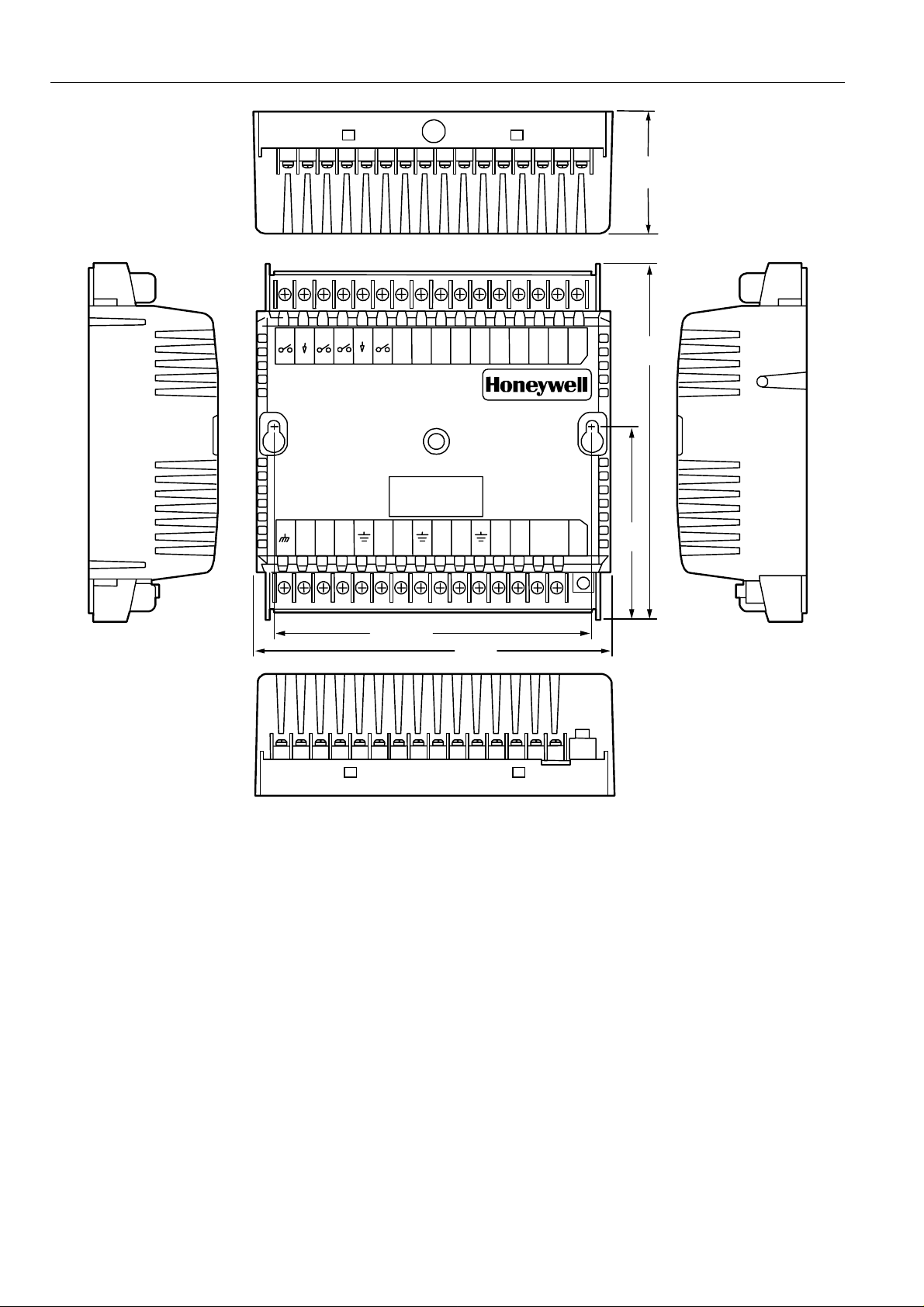

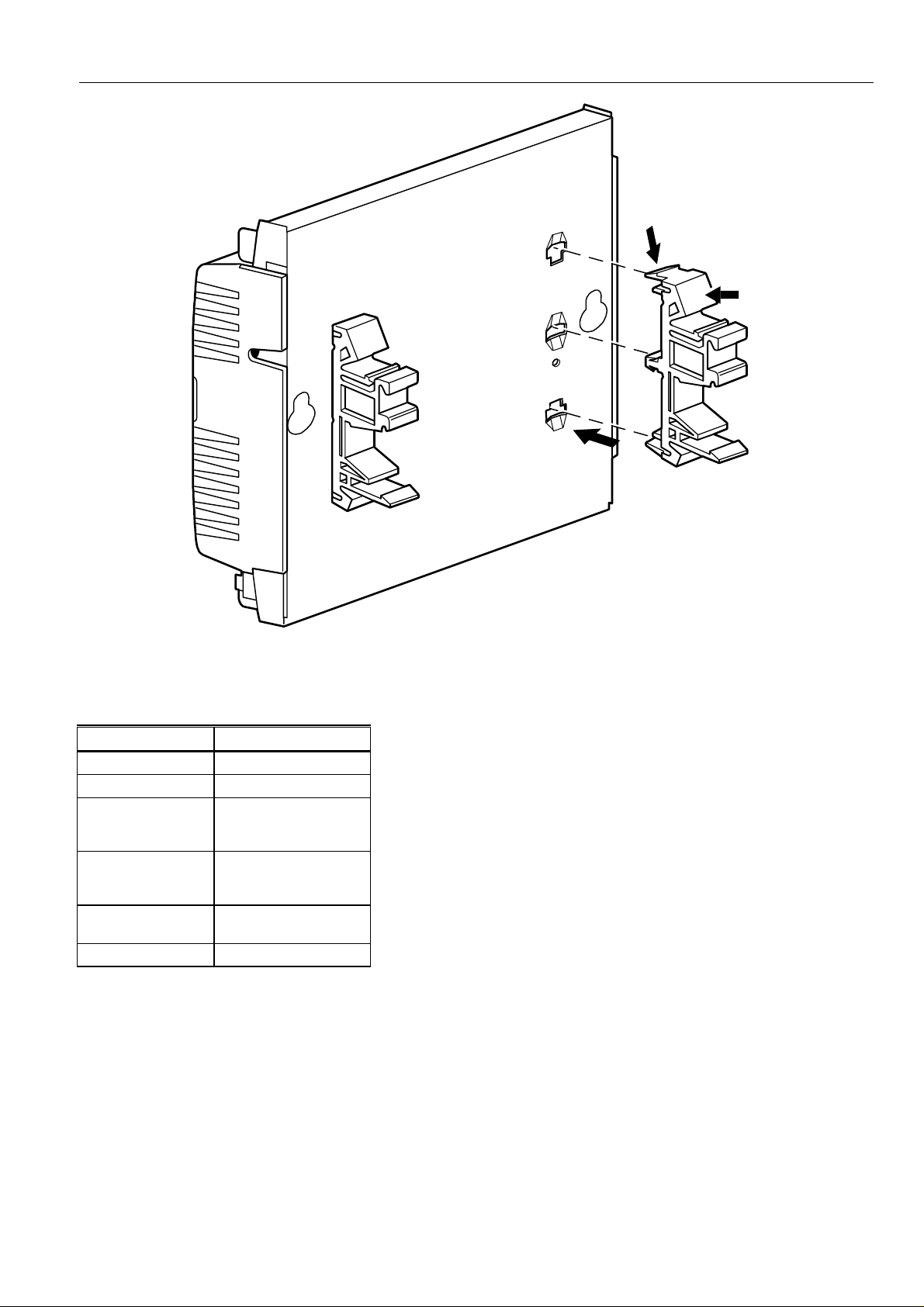

The W7761A consists of a single circuit board that is mounted in a sheet metal subbase and protected by a factory snap-on

cover. The device mounts with two screws (see Fig. 3 or 4). Using DIN rail adapters (see Fig. 5) they can also be snapped onto

standard EN 50 022 35 mm by 7.5 mm (1-3/8 in. by 5/16 in.) DIN rail. DIN rail is available through local suppliers. If using DIN

rail also purchase from Augat Inc. part number 2TK2D DIN rail (adapter) two each for every device (see Fig. 5). Wires are

attached to the screw terminal blocks on both sides of the device. Connection for operator access to the E-Bus is provided by

plugging the SLTA connector cable into the communications jack.

A channel in the cover allows the device status LED to be visible when the cover is in place. There are no field-serviceable

parts on the circuit board and, therefore,

The W7761A can be mounted in any orientation. Ventilation openings were designed into the cover to allow proper heat

dissipation regardless of the mounting orientation. See Fig. 3 and 4.

it is intended that the cover never be removed

.

8 74-2699

Page 9

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

W7761A

3

1

3

0

2

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

D

I-

4

G

N

D

D

I

-3

D

I-

2

G

N

D

D

I-1V

AC 24

V

AC 24

COM

O

U

T

1

O

U

T

0

1

9

1

8

1

7

1

6

2

O

U

T

3

O

U

T

4

O

U

T

5

O

U

T

6

O

U

T

7

O

UT

8

EGND

1

NOT

USED

2

NOT

USED

3

AI-1

OHM

GND

AI-2

AI-3

OHM

4

5

6

OHM

GND

AI-4

AI-5

OHM

7

8

9

1

V/mA

GND

AI-6

22

V

D

C

V/mA

0

1

1

1

2

E

B

US

O

U

T

1

3

1

4

E

B

U

S

JA

C

K

1

5

J

3

M1 0118

Fig. 3. Excel 10 W7761A Remote I/O Device.

9 74-2699

Page 10

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

2-1/8

(54)

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

VAC 24

VAC 24

OUT1 OUT2 OUT 3 OUT 4 OUT5 OUT 6 OUT7 OUT8

COM

AI-3

AI-4

AI-5

OHM

GND

OHM

V/mA

GND

AI-6

V/mA

22V DC

EBUS

OUT

EBUS

JACK

EGND

GNDGND

DI-1

DI-2DI-3DI-4

NOT

NOT

AI-1

AI-2

USED

GND

USED

OHM

OHM

1 2 3 4 5 6 7 8 9101112131415J3

5-3/16 (132)

6 (152)

3-1/16

(77)

5-5/8

(143)

Fig. 4. W7761A construction in in. (mm).

10 74-2699

M6856

Page 11

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

2

3

1

M6857

Fig. 5. DIN rail adapters.

The input/output points are summarized in Table 2.

Table 2. List Of Available Points.

W7761A

Digital Outputs 8 Triac Outputs

Digital Inputs 4

Analog Inputs 6

DC Power 20 Vdc available to

Floating (Series 60)

Control

PWM Control Heating or Cooling

Performance Specifications

Power:

24 Vac with a minimum of 20 Vac and a maximum of 30 Vac at either 50 or 60 Hz. The W7761A power consumption is 6 VA

maximum at 50 or 60 Hz. The W7761A is a NEC Class 2 rated device. This listing imposes limits on the amount of power the

product can consume or directly control to a total of 100 VA (U.S. only).

(4 Resistive and 2

Voltage/Current Inputs)

power optional sensors

(50 mA max.)

Heating or Cooling

The individual Triac outputs incorporate an internal common connection with the input power transformer. The Triacs provide a

switched path from the hot side (R) of the transformer through the load to the common of the transformer. The W7761A Device

must

design

Each individual Triac is rated 500mA at 30 Vac maximum. Under all operating conditions, the maximum load/source power

budget for the W7761A Device is 100 VA.

use the same power transformer for any loads connected to that device; see Fig. 19.

11 74-2699

Page 12

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

CPU:

Motorola or Toshiba 3150 Neuron processor, containing three eight-bit CPU’s. Each Neuron has a unique 48-bit network

identification number.

Memory Capacity:

64K ROM/PROM (6K reserved for network operations, 58K usable for control algorithm code).

512 bytes EEPROM.

2K RAM.

Specified Space Temperature Sensing Range:

45 to 99°F (7 to 37°C) with an allowable control setpoint range from 50 to 90°F (10 to 32°C) when initiated from the network

and 55 to 85°F (13 to 29°C) when configured and connected to T7770 Wall Modules or T7780 DDWM.

Communications:

The W7761A Device uses a transformer-coupled communications port with differential Manchester-encoded data at 78 kilobits

per second (kbs). The transformer-coupled communications interface offers a much higher degree of common-mode noise

rejection while ensuring dc isolation.

2

Approved cable types for E-Bus communications wiring is Level IV 22 AWG (0.34 mm

unshielded, twisted pair, solid conductor wire. For non-plenum areas, use Level IV 22 AWG (0.34 mm

AK3781 (one pair) or U.S. part AK3782 (two pair). In plenum areas, use plenum-rated Level IV, 22 AWG (0.34 mm

U.S. part AK3791 (one pair) or U.S. part AK3792 (two pair). (See Tables 6 and 8 for part numbers.) Contact Echelon Corp.

Technical Support for the recommended vendors of Echelon approved cables.

The Free Topology Transceiver (FTT) supports polarity insensitive free topology wiring. This frees the system installer from the

need to wire using a bus topology. Star, bus, mixed, and loop wiring are all supported by this architecture. The maximum E-Bus

length when using a combination of star, loop, and bus wiring (singly terminated) is 1640 ft (500m) with the maximum node-tonode length of 1312 ft (400m). In the event that the total wire length is exceeded, then a Q7740A 2-Way Repeater or a Q7740B

4-Way Repeater can be used to allow the number of devices to be spread out as well as increasing the length of wire over

which they communicate. The maximum number of repeaters per segment is one (on either side of the router). A Q7751A EBus Router can also be used to effectively double the maximum E-Bus length. The advantage of using the router is that it will

segregate traffic to a segment while when using the repeater, all traffic is repeated on each segment. When utilizing a doubly

terminated E-Bus structure, use a continuous daisy-chain with no stubs or taps from the main backbone, The maximum E-Bus

length is 4593 ft (1400m) with the maximum node-to-node length of 3773 ft (1150m).

) plenum or non-plenum rated

2

) such as U.S. part

2

) such as

FTT networks are very flexible and convenient to install and maintain, but it is imperative to carefully plan the network layout

and create and maintain accurate documentation. Unknown or inaccurate wire run lengths, node-to-node distances, node

counts, total wire length, and misplaced or missing terminators can cause poor network performance. Refer to E-Bus Wiring

Guidelines form, 74-2865 for complete description of network topology rules.

LonMark Functional Profile

W7761A Device supports the LonMark Preliminary Functional Profile for a Remote Input/Output Device.

Environmental:

Operating Temperature:

-40° to 150°F (-40° to 65.5°C).

Shipping Temperature:

-40° to 150°F (-40° to 65.5°C).

Relative Humidity:

5% to 95% noncondensing.

Vibration:

Rated V2 level compliant.

Inputs/Outputs:

The W7761A Unit supports the following hardware features:

• Four 20KNTC (1000 through 150,000 ohm) or PT3000 (250 through 12,000 ohm) resistive analog inputs.

• Two 0.2 to 10 VDC or 2 to 20 mA (user selectable) analog inputs.

• Four dry contact digital inputs.

• Eight 24 Vac Triac digital outputs (500 mA MAX).

• One 22 Vdc power supply for auxiliary devices with a maximum current of 50 mA.

Analog Inputs:

Space Temperature:

Type: RTD.

12 74-2699

Page 13

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

Supported Sensors: T7770A,B,C,D sensor—(current feature that can be used with the RIO Device) and T7780

DDWM.

Discharge Air Temperature:

Type: RTD.

Supported Sensors: C7100A1015*, C7770A1006, C7031B1033, C7031C1031, C7031D1062, C7031J1050,

C7031K1017.

Outdoor Air Temperature:

Type: RTD.

Supported Sensors: C7170A1002.

Return Air Temperature:

Type: RTD.

Supported Sensors: C7100A1015*, C7770A1006, C7031B1033, C7031C1031, C7031D1062, C7031J1050,

C7031K1017.

Mixed Air Temperature:

Type: RTD.

Supported Sensors: C7100A1015*, C7770A1006, C7031B1033, C7031C1031, C7031D1062, C7031J1050,

C7031K1017.

*The PT3000 sensor is not recommended for floating control (real time - discharge or return configured as space sensor).

The PT3000 sensor is intended for monitoring or differential (staged) control.

Outdoor Air Humidity:

Type: Voltage/Current.

Supported Sensors: C7600B1000 and C7600B1018 (2 to 10V), C7600C1008 (4 to 20mA).

Return Air Humidity:

Type: Voltage/Current.

Supported Sensors: C7600B1000 and C7600B1018 (2 to 10V), C7600C1008 (4 to 20mA).

Outdoor Air Enthalpy:

Type: Current.

Supported Sensors: C7400A1004 (4 to 20mA).

Return Air Enthalpy:

Type: Current.

Supported Sensors: C7400A1004 (4 to 20mA).

Air Filter Differential Pressure:

Type: Voltage.

Supported Sensors: Third party 2 to 10V, 0 to 5 inw ( 0 to 1.25 kPa) differential pressure sensors.

Space CO

Sensor:

2

Type: Voltage.

Supported Sensors: Third party 0 to 10V, 0 to 2000 ppm CO

Outdoor Air CO

Sensor:

2

sensors.

2

Type: Voltage.

Supported Sensors: Third party 0 to 10V, 0 to 2000 ppm CO

sensors.

2

Outdoor Air CO Sensor:

Type: Current.

Supported Sensors: Third party 4 to 20mA, 0 to 300 ppm CO sensor.

Monitor Sensor for network use:

Type: Voltage.

Supported Sensors: Third party 2 to 10V, 2 to 10 volts displayed.

Digital Inputs:

Dry-contact inputs are sensed using a 9 milliamp at 4.8 volts detection circuit. It is very important that the device used contains

high quality, noncorroding contacts with resistivity that does not degrade; that is, increase over time. Use noble metal (such as

gold or silver) or pimpled or sealed contacts to assure consistent, long-term operation.

Triac Outputs:

Triac Outputs on the RIO:

— Power ratings: 20 Vac to 30 Vac at 25 mA MIN to 500 mA MAX current for any voltage.

13 74-2699

Page 14

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

CAUTION

When any device is energized by a Triac, the device must be able to sink a minimum of 25 mA.

NOTE: Triacs sink current to the 24 Vac common (COM terminal on the W7761A); see Fig. 19 for wiring example.

IMPORTANT:

If non-Honeywell motors, actuators, or transducers are to be used with Excel 10 Controllers, Triac compatibility must

be verified (see previous NOTE).

Wall Modules

The T7770A,B,C,D Wall Module sensor—(current feature that can be used with the Excel 10 W7761A RIO Device). See Fig. 6.

KNOCKOUTS FOR EUROPEAN

APPLICATIONS

5-1/16

(128)

60

55

65

70

KNOCKOUTS FOR EUROPEAN

APPLICATIONS

75

80

85

5-1/16

(128)

3-5/32 (80)

2-3/8 (60)

2-3/8

(60)

T7770A1006

29/32

(23)

STANDARD

UTILITY

CONDUIT

BOX (2 X 4)

MOUNTING

HOLES

3-5/32 (80)

2-3/8 (60)

9 8 7 6 5 4 3 2 1

W7752

DIP Switch S4 Settings:

XL600-XL20

W7753

LED RETURN

1,3,5=on; 2,4=off 2,4=on; 1,3,5=off 1,2,3,4=on; 5=0ff

BYPASS

LED

LED

LED

2-3/8

(60)

E-BUS

SENSOR

GND

SENSOR

AL COM

E-BUS

SETPT

BYPASS/FAN BYPASS/FAN

SETPT

T7770C

FAN

SETPT

SENSOR

GND

1-1/4

(32)

STANDARD

UTILITY

CONDUIT

BOX (2 X 4)

MOUNTING

HOLES

M15119

Fig. 6. T7770A,B,C,D (T7770A,C shown) construction in in. (mm), sensor—(current feature that can be used with RIO

Device).

14 74-2699

Page 15

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

The T7780 DDWM for the Excel 10 Controllers (see Product Names section) is shown in Fig. 7.

3-5/32 (80)

KNOCKOUTS FOR EUROPEAN

APPLICATIONS

1

(25)

5-1/16

(128)

2-3/8 (60)

2-3/8

(60)

STANDARD

UTILITY

CONDUIT

BOX (2 X4)

MOUNTING

HOLES

M11391

Fig. 7. T7780 construction, subbase dimensions in in. (mm).

Configurations

Each W7761A device can control or monitor a variety of different types of mechanical equipment. The W7761A was not

intended to control staged or modulating heating/cooling coils, mixed air economizer dampers, or system fan/heat pump units.

The W7761A contains inputs and outputs, but no control software. All control that would be associated with the inputs and

outputs in the W7761A would be accomplished though the Excel Zone Manager and would not be suitable for VAV control,

temperature control, or any control function that would require less than a 30 second update rate.

It would be suitable to control miscellaneous exhaust or ventilation fans, lighting zones that are spread out through a building

which need to be linked to a start/stop time program through the Zone Manager or to enable freeze protection. The W7761A

device can be connected to outdoor air temperature and humidity sensors that can be used by other Excel 10 controllers on

the E-Bus or Excel 5000 controllers on the C-Bus through the Excel 10 Zone Manager. The W7761A can be used to monitor

Occupancy, Window, Dirty filter, Indoor air quality, and Smoke control sensors. This allows the controllers to use their physical

inputs for monitoring other elements such as return humidity, IAQ, etc. to achieve better control. The W7761A can be used to

15 74-2699

Page 16

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

average many space temperature sensors that are located in a zone that is controlled by the W7750 Constant Volume AHU

Controller.

Mixed-Output-Type Control

The W7761A Device can control mixed-output-types of applications such as PWM and staged control occurring simultaneously

with Series 60 Floating Control.

Occupancy Sensor

Excel 10 W7761A device can be connected to an occupancy sensor through a digital input. This is a device, such as a passive

infrared motion detector, that contains a dry contact (see following NOTE) closure to indicate whether or not people are present

in the space. The Excel 10 W7761A Device expects a contact closure to indicate the space is Occupied. See Fig. 18 in

Application Step 4, Prepare Wiring Diagrams, for details on wiring connections. This occupancy sensor can then be bound to

other Excel 10 controllers on the E-Bus or Excel 5000 controllers on the C-Bus through the Excel 10 Zone Manager. This

would allow the other Excel 10 controllers to use their physical inputs for monitoring other elements such as return humidity,

IAQ, etc. to achieve better control.

NOTE: The Excel 10 Controllers (W7750 CVAHU and W7761A RIO) have limited power available (only 9 mA at 4.8 volts) for

The recommended devices for use with the Excel 10 W7750 Controller and W7761A Device are the EL7628A1007 Ceiling

Mounted Infrared or the EL7680A1008 Wall Mounted Wide View Infrared Occupancy Sensors. If ultrasonic sensors are

required, the EL7611A1003 and the EL7612A1001 Occupancy Sensors are recommended. An EL76XX Power Supply/Control

Unit is required for use with these occupancy sensors. The EL7630A1003 can power up to four sensors, and is multi-tapped for

several line voltages. The EL7621A1002 can power three sensors and it connects to 120 Vac line voltage. The EL7621A1010

can also power three sensors but it connects to 277 Vac line voltage.

checking the digital inputs for contact closures. It is very important that the device used contains high quality,

noncorroding contacts with resistivity that does not degrade; that is, increase over time. Use noble metal (such as

gold or silver), pimpled or sealed contacts to assure consistent, long-term operation.

Window Open/Closed Digital Input

Excel 10 W7761A device can be connected to a window sensor to indicate whether a window in the space was opened. The

Excel 10 W7761A device can be connected to a dry contact (see the NOTE for the Occupancy Sensor and Fig. 18 in

Application Step 4. Prepare Wiring Diagrams, for details) or a set of contacts wired in series (for monitoring multiple windows)

to verify that the window(s) are closed. This window(s) sensor can then be bound to other Excel 10 controllers on the E-Bus or

Excel 5000 controllers on the C-Bus through the Excel 10 Zone Manager. The algorithm in the other Excel 10 controllers

expects a contact closure to indicate the window is closed. If an open window is detected, the algorithm in the other Excel 10

controllers changes the mode of operation to FREEZE_PROTECT, which shuts down the control functions, and watches for

low space temperature conditions. The freeze protection setpoint is 46.4°F (8°C), and the frost alarm occurs at 42.8°F (6°C).

Wall Module Options

As previously discussed, there are five basic varieties of the T7770. There is one variety of the PT3000 sensor and the T7780

DDWM (see the Product Names and the Construction sections). The T7770A,B,C,D 20Kohm NTC sensor—(current feature

that can be used with the RIO Device) and one PT3000 sensor can be configured on any of the four resistive inputs. The

T7780 is an E-Bus node and would not be directly connected to the RIO Device.

Dirty Filter Monitor

The air filter in the air handler can be monitored by the W7761A RIO device and an alarm issued by the Zone Manager when

the filter media needs replacement. The two methods of monitoring the filter are:

1. Connecting a differential pressure switch to a digital input on the W7761A.

2. Wiring a 2-to-10V differential pressure sensor to a voltage input on the W7761A. If the analog input sensor is used, its

measured value 0 to 5 inw (0 to 1.25 kPa) is compared to a user-selectable setpoint. The comparison is done in the

Zone Manager —valid range: 0 to 5 inw (0 to 1.25 kPa), and the Dirty Filter alarm is issued when the pressure drop

across the filter exceeds the setpoint.

Indoor Air Quality (IAQ)

The Excel 10 W7761A device can monitor IAQ using one of two different methods of detecting poor air quality. The first is with

an IAQ switch device connected to a digital input on the W7761A, where a contact closure indicates poor air quality, and an

alarm can be issued by the Zone Manager. The device can detect poor air quality using any desired measure such as CO

VOC, CO, etc. The second method, is through an analog input that connects to a CO

from this sensor (0 to 2000 ppm) is compared to a user-selectable setpoint (the comparison is done in the Zone

of CO

2

Manager —valid range: 0 to 2000 ppm), and an IAQ alarm can be issued when the CO

sensor that is connected to the W7750 RIO, can be bound to other W7750 CVAHU Excel 10 controllers on the E-Bus.

16 74-2699

sensor (0 to 10V). The measured value

2

level exceeds the setpoint. The IAQ

2

,

2

Page 17

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

APPLICATION STEPS

Overview

The seven application steps shown in Table 3 are planning considerations for engineering an Excel 10 W7761 Remote

Input/Output Device. These steps are guidelines intended to aid understanding of the product I/O options, bus arrangement

choices and the Excel 10 W7761A Devices role in the overall EXCEL 5000® System architecture.

Step No. Description

1 Plan The System

2 Determine Other Bus Devices Required

3 Lay Out Communication and Power Wiring

4 Prepare Wiring Diagrams

5 Order Equipment

6 Configure Devices

7 Troubleshooting

Step 1. Plan The System

Plan the use of the W7761A Devices according to the job requirements. Determine the location, functionality and sensor or

actuator usage. Verify the sales estimate of the number of W7761A Devices and the number and type of output actuators and

other required accessories.

When planning the system layout, consider potential expansion possibilities to allow for future growth. Planning is very

important to be prepared for adding HVAC systems and controllers in future projects.

T7770A,B,C,D Wall Modules (sensor—current feature that can be used with the RIO Device)can be installed as either

hardwired I/O-only devices or additional wiring can be run to them (for the E-Bus network ) to allow a CARE/E-Vision operator

terminal to have access to the E-Bus. The application engineer needs to determine how many wall modules or other input

sensors are required. This information is required during installation to ensure that the proper number and type of wires are

pulled to the wall modules, and the building operators are informed about where they can plug in to the E-Bus network with a

portable operator terminal (see Fig. 8 through 10).

Table 3 . Application Steps.

(;&(/

:$

,1387287387

'(9,&(

127(%22. 3&

6+,(/'('

,17(5)$&(

56

6(5,$/

3257

&$%/(

4$

6/7$

&$%/(

3$57

12

(%86

3257

0-'

Fig. 8. Connecting the portable operator terminal to the E-Bus.

The FTT communication loop, (E-Bus) between controllers is a free topology wiring scheme that supports star, loop, and/or bus

wiring. Refer to the E-Bus Wiring Guidelines form, 74-2865 for complete description of network topology rules. See Application

Step 3. Lay Out Communications and Power Wiring, for more information on bus wiring layout, and see Fig. 16 through 19 in

Application Step 4. Prepare Wiring Diagrams, for wiring details.

The application engineer must review the Direct Digital Control (DDC) job requirements. This includes the Sequences of

Operation for the Excel 10 controllers, and for the system as a whole. Usually there are variables that must be passed between

the W7750 (CVAHU), Q7750A Zone Manager, W7761 (RIO), and other Excel 10 controller(s), or central plant controller(s) that

are required for optimum system-wide operation. Typical examples are the TOD Occ/Unocc signal, the outdoor air

temperature, demand limit control signal, and smoke control mode signal.

17 74-2699

Page 18

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

It is important to understand these interrelationships early in the job engineering process to ensure implementing when

configuring the controllers. (See Application Step 6. Configure Devices, for information on the various Excel 10 parameters and

on Excel 10 point mapping.)

Step 2. Determine Other Bus Devices Required

A maximum of 62 nodes can communicate on a single E-Bus segment. Each W7761A (RIO), W7750 (CVAHU), W7751 (VAV)

Controller or T7780 Wall Module constitutes one node. If more nodes are required, a Q7751A Router is necessary. Using a

router allows up to 125 nodes, divided between two E-Bus segments. The router accounts for two of these nodes (one node on

each side of the router); a Q7750A Excel 10 Zone Manager takes one node and two nodes are available for operator terminal

nodes, leaving 120 nodes available for Excel 10 Controllers and T7780 Wall Modules. All 120 controllers and T7780 Wall

Modules are able to talk to each other through the router. A Q7750A Excel 10 Zone Manager is required to connect the E-Bus

to the standard EXCEL 5000® System C-Bus. Each Excel 10 Zone Manager can support no more than 120 Excel 10

Controllers and T7780 Wall Modules. This limit is set in the Excel 10 Zone Manager database as an absolute maximum.

Each E-Bus segment is set up with two unused nodes to allow for a CARE/E-Vision or Hand Held Tool (HHT) to be connected

to the E-Bus. Multiple CARE/E-Vision or HHT terminals can be connected to the bus at the same time. Table 4 summarizes the

E-Bus segment configuration rules.

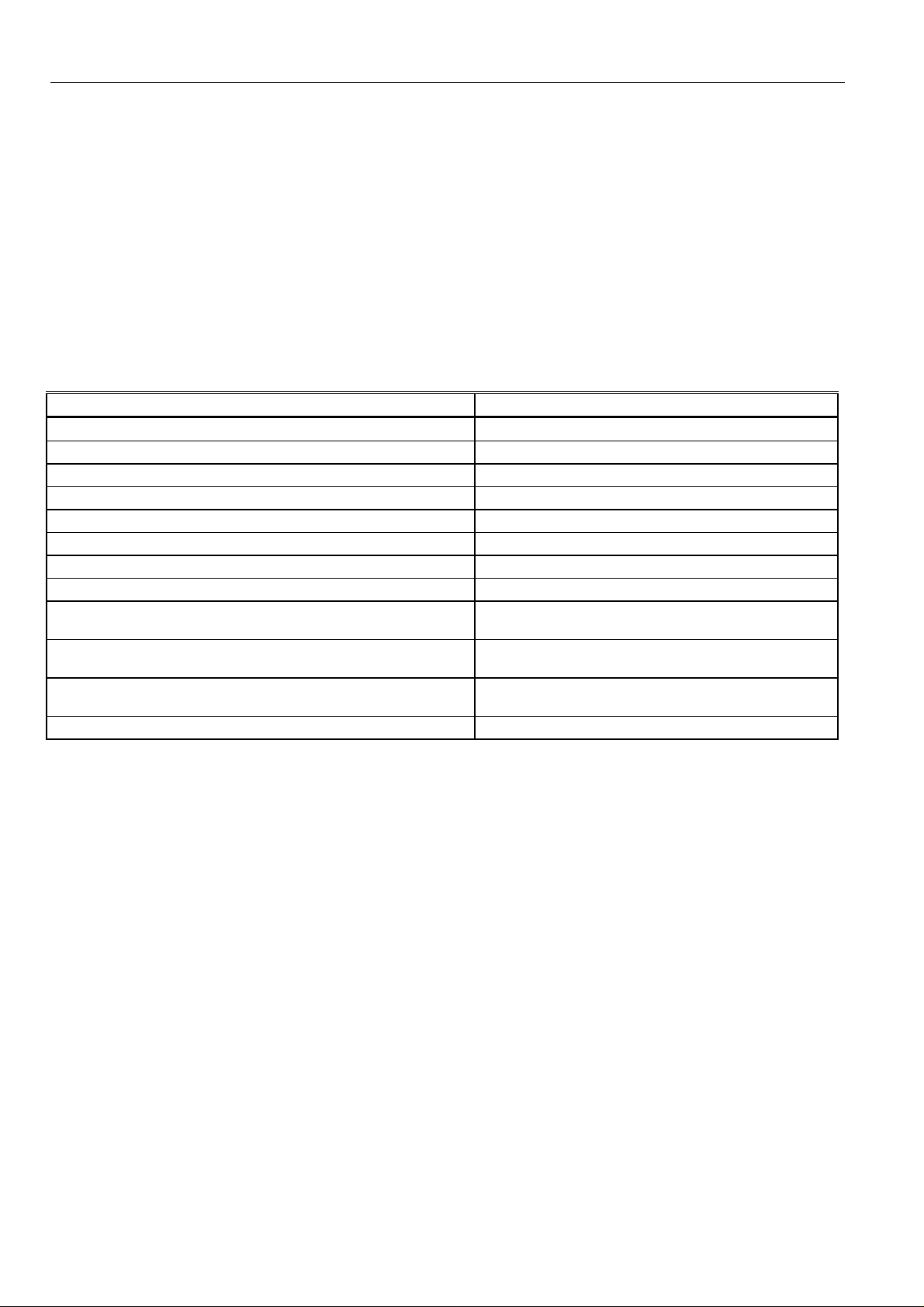

Table 4 . E-Bus Configuration Rules And Device Node Numbers.

One E-Bus Segment Example Maximum Number of Nodes Equals 62

One Q7750A Excel 10 Zone Manager 1 node

Port for operator terminal access (CARE/E-Vision or HHT) 1 node

Maximum number of Excel 10s and T7780s 60 nodes (Only T7780 Wall Modules are E-Bus nodes)

Total 62 nodes

Two E-Bus Segments Example Maximum Number of Nodes Equals 125

One Q7750A Excel 10 Zone Manager 1 node

One Q7751A Router 2 nodes (1 in each Bus Segment)

Ports for operator terminal access (two CARE/E-Vision or HHT

terminals)

Maximum number of Excel 10s and T7780s in segment number

Maximum number of Excel 10s and T7780s in segment number

Refer to the E-Bus Wiring Guidelines form, 74-2865 for complete description of network topology rules and the maximum wire

length limitations. If longer runs are required, a Q7740A 2-way or Q7740B 4-way repeater can be added to extend the length of

the E-Bus. A Q7751A Router can be added to partition the system into two segments and effectively double the length of the

E-Bus. Only one router is allowed with each Excel 10 Zone Manager and each network segment can have a maximum of 1

repeater. In addition, all E-Bus segments require the installation of a Bus Termination Module for a singly terminated E-Bus or

two Bus Termination Modules for a doubly terminated E-Bus. For more details on E-Bus termination, refer to the E-Bus Wiring

Guidelines form, 74-2865, or see Application Step 3. Lay Out Communications and Power Wiring, and the E-Bus Termination

Module subsection in Application Step 4.

2 nodes (1 in each Bus Segment)

60 nodes (Only T7780 Wall Modules are E-Bus nodes)

one

60 nodes (Only T7780 Wall Modules are E-Bus nodes)

two

Total 125 nodes

Step 3. Lay Out Communications and Power Wiring

E-Bus Layout

The communications bus, E-Bus, is a 78-kilobit serial link that uses transformer isolation and differential Manchester encoding.

Approved cable types for E-Bus communications wiring is Level IV 22 AWG (0.34 mm

unshielded, twisted pair, solid conductor wire. For nonplenum areas, use Level IV 22 AWG (0.34 mm

AK3781 (one pair) or U.S. part AK3782 (two pair). In plenum areas, use plenum-rated Level IV, 22 AWG (0.34 mm

U.S. part AK3791 (one pair) or U.S. part AK3792 (two pair). See Tables 9 and 10 for part numbers. Contact Echelon Corp.

Technical Support for the recommended vendors of Echelon approved cables. The FTT communications bus, E-Bus,

supports a polarity insensitive, free topology wiring scheme that supports star, loop, and/or bus wiring.

E-Bus networks can be configured in a variety of ways, so refer to the E-Bus Wiring Guidelines form, 74-2865 for a complete

description of network topology rules and Table 4. Fig. 9 and 10 depict two typical E-Bus network topologies; one as a singly

terminated bus segment that has 60 nodes or less, and one showing a doubly terminated segment. The bus configuration is

set up using the Network Manager tool from within CARE (see the CARE User’s Manual form, 74-5587 or Excel E-Vision

User’s Guide form, 74-2588).

2

) plenum or non-plenum rated

2

), such as U.S. part

2

) such as

18 74-2699

Page 19

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

NOTE: For wiring details see the E-Bus Termination Module subsection in Step 4. For wall module wiring, US part AK3782

(non-plenum) or US part AK3792 (plenum) can be used. These cables contain two twisted pairs (one for the run down

to the wall module, and one for the run back up to the controller) for ease of installation.

(;&(/

89

7

%

7(50,1$7,21 02'8/(6

$7 (1'6 2) (%86 '$,6<&+$,1

(;&(/

9$9

(;&(/

4$

)77 =21(

0$1$*(5

72 &%86

6(( ),*

(%86

(;&(/

9$9

(%86

(;&(/

89

(;&(/

9$9

(;&(/

9$9

(;&(/

9$9

6+$5('

7

83 72

727$/ 12'(6

(%86

(;&(/

5,2

(;&(/

5,2

(;&(/

5,2

7V

:,7+

12 (%86

$&&(66

7

(%86

,2 &211(&7,216

Fig. 9. Bus wiring layout for doubly terminated daisy-chain E-Bus segment.

7

7

7

-$&. )25

23(5$725

7(50,1$/

0-'

19 74-2699

Page 20

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

(%86 6(*0(17 180%(5

(;&(/

9$9

7

(%86 6(*0(17 180%(5

(;&(/

9$9

(;&(/

4$

)77 =21(

0$1$*(5

(;&(/

89

72 &%86

6(( ),*

(%86

$&&(66

(;&(/

5,2

(;&(/

5,2

%

7(50,1$7,21

02'8/(

(;&(/

9$9

(%86 6(*0(17 180%(5

7

(%86

$&&(66

(;&(/

89

%

7(50,1$7,21

02'8/(

4$

)77

(%86

5287(5

(;&(/

89

0-'

Fig. 10. Bus wiring layout for two singly terminated E-Bus segments.

NOTE: See the E-Bus Termination Module section for wiring details.

IMPORTANT

Notes on communications wiring:

All field wiring must conform to local codes and ordinances.

•

Approved cable types for E-Bus communications wiring is Level IV 22 AWG (0.34 mm2) plenum or non-plenum

•

rated unshielded, twisted pair, solid conductor wire. For nonplenum areas, use Level IV 22 AWG (0.34 mm

as U.S. part AK3781 (one pair) or U.S. part AK3782 (two pair). In plenum areas, use plenum-rated Level IV, 22

AWG (0.34 mm

2

) such as U.S. part AK3791 (one pair) or U.S. part AK3792 (two pair). See Tables 9 and 10 for part

2

), such

numbers. Contact Echelon Corp. Technical Support for the recommended vendors of Echelon approved

cables.

Unswitched 24 Vac power wiring can be run in the same conduit as the E-Bus cable.

•

Do not use different wire types or gauges on the same E-Bus segment. The step change in line impedance

•

characteristics causes unpredictable reflections on the bus. When using different types is unavoidable, use a

Q7751A Router at the junction.

In noisy (high EMI) environments, avoid wire runs parallel to noisy power cables, or lines containing lighting

•

dimmer switches, and keep at least 3 in. (76 mm) of separation between noisy lines and the E-Bus cable.

Make sure that neither of the E-Bus wires is grounded.

•

Power Wiring

A power budget must be calculated for each Excel 10 W7761 Device to determine the required transformer size for proper

operation. A power budget is simply the summing of the maximum power draw ratings (in VA) of all the devices to be controlled

by an Excel 10 W7761 Device. This includes the device itself, the equipment actuators (ML6161, or other motors) and various

contactors and transducers, as appropriate, for the Excel 10 configuration.

Power Budget Calculation Example

The following is an example power budget calculation for a typical W7761A Excel 10 Device.

Device VA Information Obtained from the

Excel 10 W7761 6.0 VA W7761

Device Specification Data

20 74-2699

Page 21

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

ML6161 2.2 VA TRADELINE®

Damper Actuator Catalog

R8242A 21.0 VA TRADELINE®

Contactor for fan Catalog in-rush rating

M6410A Steam 0.7 VA TRADELINE®

Heating Coil Valve Catalog, 0.32A at 24 Vac

The Excel 10 System example requires 29.9 VA of peak power; therefore, a 40 VA AT72D Transformer is able to provide

ample power for this device and its accessories. Alternatively, a 75 VA AT88A Transformer could be used to power two Excel

10 Systems of this type, or a 100 VA AT92A Transformer could be used to power three of these controllers and meet NEC

Class 2 restrictions (no greater than 100 VA). See Fig. 12 through 14 for illustrations of power wiring details. See Table 5 for

VA ratings of various devices.

W7761A Excel 10 W7761 Device 6.0

ML6161A/B Damper Actuator, 35 lb-in. 2.2

R8242A Contactor 21.0

R6410A Valve Actuator 0.7

MMC325 Pneumatic Transducer 5.0

ML684 Versadrive Valve Actuator 12.0

ML6464 Damper Actuator, 66 lb-in. 3.0

ML6474 Damper Actuator, 132 lb-in. 3.0

ML6185 Damper Actuator SR 50 lb-in. 12.0

TOTAL: 29.9 VA

Table 5 . VA Ratings For Transformer Sizing.

Device Description VA

For contactors and similar devices, the in-rush power ratings should be used as the worst case values when performing power

budget calculations. Also, the application engineer must consider the possible combinations of simultaneously energized

outputs and calculate the VA ratings accordingly. The worst case, that uses the largest possible VA load, should be determined

when sizing the transformer.

Line Loss

Excel 10 Controllers must receive a minimum supply voltage of 20 Vac. If long power or output wire runs are required, a

voltage drop due to Ohms Law (I x R) line loss must be considered. This line loss can result in a significant increase in total

power required and thereby affect transformer sizing. The following example is an I x R line-loss calculation for a 200 ft (61m)

run from the transformer to a W7761 Device drawing 37 VA using 18 AW G (1.0 mm

2

) wire.

The formula is:

Loss = [length of round-trip wire run (ft)] x [resistance in wire (ohms per ft)] x [current in wire (amperes)]

From specification data:

18 AWG twisted pair wire has 6.52 ohms per 1000 feet.

Loss = [(200 ft) x (2 - round-trip) x (6.52/1000 ohms per ft)] x [(37 VA)/(24V)] = 4.02 volts

This means that four volts are going to be lost between the transformer and the device; therefore, to assure the device receives

at least 20 volts, the transformer must output more than 24 volts. Because all transformer output voltage levels depend on the

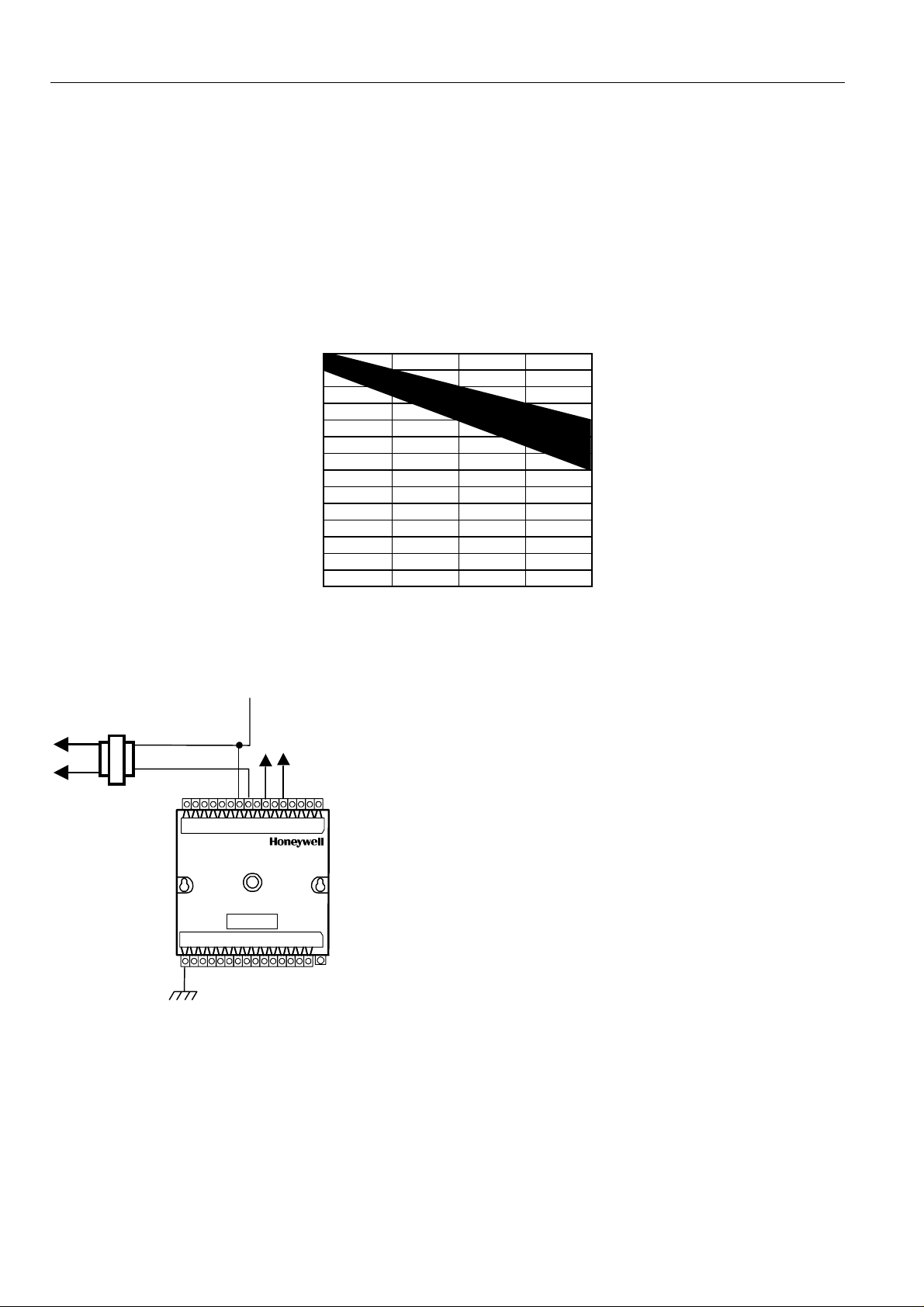

size of the connected load, a larger transformer outputs a higher voltage than a smaller one for a given load. Fig. 11 shows this

voltage load dependence.

In the preceding I x R loss example, even though the device load is only 37 VA, a standard 40 VA transformer is not sufficient

due to the line loss. From Fig. 11, a 40 VA transformer is just under 100 percent loaded (for the 37 VA device) and, therefore,

has a secondary voltage of 22.9 volts. (Use the lower edge of the shaded zone in Fig. 11 that represents the worst case

conditions.) When the I x R loss of four volts is subtracted, only 18.9 volts reaches the device, which is not enough voltage for

proper operation.

In this situation, the engineer basically has three alternatives:

1. Use a larger transformer; for example, if an 80 VA model is used, see Fig. 11, an output of 24.4 volts minus the four volt

line loss supplies 20.4V to the device. Although acceptable, the four-volt line-loss in this example is higher than

recommended. See the following

IMPORTANT

2. Use heavier gauge wire for the power run. 14 AWG (2.0 mm

using the preceding formula, gives a line-loss of only 1.58 volts (compared with 4.02 volts). This would allow a 40 VA

transformer to be used. 14 AWG (2.0 mm

.

2

) wire is the recommended wire size for 24 Vac wiring.

2

) wire has a resistance of 2.57 ohms per 1000 ft which,

3. Locate the transformer closer to the device, thereby reducing the length of the wire run, and the line loss.

The issue of line-loss is also important in the case of the output wiring connected to the Triac digital outputs. The same formula

and method are used. The rule to remember is to keep all power and output wire runs as short as practical. When necessary,

use heavier gauge wire, a bigger transformer, or install the transformer closer to the device.

IMPORTANT

21 74-2699

Page 22

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

No installation should be designed where the line loss is greater than two volts to allow for nominal operation if the

primary voltage drops to 102 Vac (120 Vac minus 15 percent).

To meet the National Electrical Manufacturers Association (NEMA) standards, a transformer must stay within the NEMA limits.

The chart in Fig. 11 shows the required limits at various loads.

With 100 percent load, the transformer secondary must supply between 23 and 25 volts to meet the NEMA standard. When a

purchased transformer meets the NEMA standard DC20-1986, the transformer voltage-regulating ability can be considered

reliable. Compliance with the NEMA standard is voluntary.

The following Honeywell transformers meet this NEMA standard:

Transformer Type VA Rating

AT20A 20

AT40A 40

AT72D 40

AT87A 50

AK3310 Assembly 100

27

26

25

24

23

22

21

20

19

18

SECONDARY VOLTAGE

17

16

15

14

0 50 100 150

% OF LOAD

Fig. 11. NEMA class 2 transformer voltage output limits.

200

M993

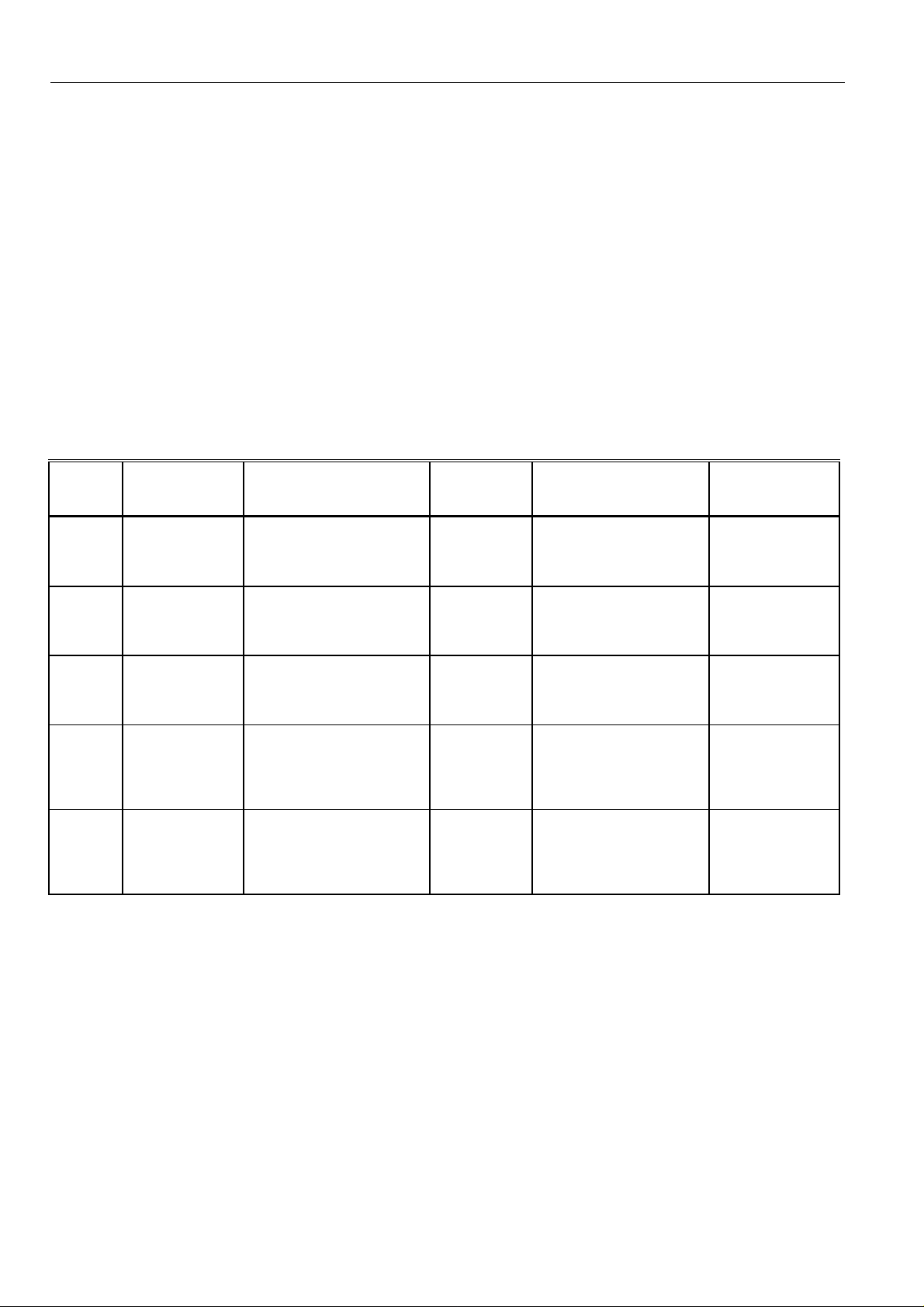

Attach earth ground to W7761 Device terminal 1. See Fig. 12, 13 and 14, 16 through 20.

TRIAC`

COMMON

TRANSFORMER

CONNECT POWER TO `

TERMINALS 24 AND 25

W7761A

1

EARTH`

GROUND

TRIAC LINES`

TO ACTUATORS`

ANDCONTACTORS

20222425

M10089

Fig. 12. Power wiring details for one Excel 10 per transformer.

22 74-2699

Page 23

TRANSFORMER

LINEVOLTAGE

`

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

120/240 VAC

IMPORTANT

If the W7761A Device is used on Heating and Cooling Equipment (UL 1995 US only) devices and the transformer

primary power is more than 150 volts, connect the transformer secondary to earth ground, see Fig. 14.

24VAC

W7761A W7761A W7761A

2425

1

EARTH`

GROUND

1

EARTH`

GROUND

2425

1

EARTH`

GROUND

Fig. 13. Power wiring details for two or more Excel 10s per transformer.

GREATER`

THAN 150 VAC

24 VAC

TRANSFORMER

W7761A

2425

M10090

Fig. 14. Transformer power wiring details for one Excel 10 used in UL 1995 equipment (U.S. only).

IMPORTANT

Notes on power wiring:

•

•

•

•

•

•

•

EARTH`

GROUND

1` IF THE W7761 CONTROLLER IS USED IN UL 1995 EQUIPMENT AND `

THEPRIMARYPOWERISMORETHAN150VOLTS,GROUNDONE`

SIDE OF TRANSFORMER SECONDARY.

1

1

EARTH`

GROUND

M10088

All field wiring must conform to local codes and ordinances.

To maintain NEC Class 2 and UL ratings, the installation must use transformers of 100 VA or less capacity.

For multiple controllers operating from a single transformer, the same side of the transformer secondary must be

connected to the same input terminal in each device and the ground terminals (1 on the W7761A) must be

connected to a verified earth ground for each device in the group. See Fig. 13. (Device configurations are not

necessarily limited to three devices per transformer.)

For the W7761A Device (which has Triac outputs), all output devices must be powered from the same transformer

as the one powering the Excel 10 W7761A Device.

Use the heaviest gauge wire available, up to 14 AWG (2.0 mm2) with a minimum of 18 AWG (1.0 mm2) for all

power and earth ground connections.

To minimize EMI noise, do not run Triac output wires in the same conduit as the input wires or the E-Bus

communications loop.

Unswitched 24 Vac power wiring can be run in the same conduit as the E-Bus cable.

23 74-2699

Page 24

EXCEL 10 W7761A INPUT/OUTPUT DEVICE

Make earth ground connections with the shortest possible wire run using 14 AWG (2.0 mm2) wire. A good earth

•

ground is essential for W7761A operation. Ideally, connect the earth ground to the ground bus at a motor control

center or circuit breaker panel. However, if the nearest ideal earth ground is inaccessible, consider an alternate

source for earth ground. Metal water pipe is generally a good ground, but do not use sprinkler pipe if prohibited by

local codes. Attention must be given when duct work, conduit, or rebar are to be considered as ground sources. It

is the responsibility of the installer to assure that these structures are tied back to a known earth ground.

Step 4. Prepare Wiring Diagrams

General Considerations

The purpose of this step is to assist the application engineer in developing job drawings to meet job specifications. Wiring

details are included for the W7761A device the T7770A,B,C,D wall module (sensor—current feature that can be used with the

RIO Device) and the T7780 DDWM. The drawings detail I/O, power, and communication bus wiring connections.

NOTE: For field wiring, when two or more wires are to be attached to the same connector block terminal, be sure to twist

them together. Deviation from this rule can result in improper electrical contact. See Fig. 15.

2

The connector block terminals on the W7761A and on the T7770 accept 14 through 22 AWG (2.0 to 0.34 mm

) wire. Table 6

lists wiring types, sizes, and length restrictions for Excel 10 products.

Table 6 . Field Wiring Reference Table.

Wire

Function

E-Bus

(Plenum)

Recommended

Minimum Wire

Size AWG (mm

22 AWG

(0.34 mm

2

)

2

) Construction

Twisted pair solid conductor,

nonshielded or Echelon

approved shielded cable.

Specification

or

Requirement Vendor Wire Type

Level IV 140°F

(60°C) rating

Honeywell

AK3791 (one twisted pair)

AK3792 (two twisted pairs)

Maximum Length

ft (m)

Refer to E-Bus

Wiring Guidelines

for maximum

length

E-Bus

(NonPlenum)

22 AWG

(0.34 mm

2

)

Twisted pair solid conductor,

nonshielded or Echelon

approved shielded cable.

Level IV 140°F

(60°C) rating

Honeywell

AK3781 (one twisted pair)

AK3782 (two twisted pairs)

Refer to E-Bus

Wiring Guidelines

for maximum

length

I

nput

Wiring

Sensors

Contacts

Output

Wiring

Actuators

Relays

Power

Wiring

18 to 22 AWG

(1.0 to 0.34 mm

14 AWG (2.0

2

)

mm