Page 1

HONEYWELL EXCEL 5000 OPEN SYSTEM

FEATURES

LONMARK® HVAC profile #8020

Stand-alone operation or on high-speed 78 kilobit

Uses Echelon LonTalk

FTT10A Transceiver

Direct connection of thermal actuators

Direct connection to fan switch

Direct and indirect connection to electrical heat

Factory-configured default parameters

Wide range of supported valves and actuators

Interlocks and time delays to protect equipment

Connected floating actuators exercised once a week

Slim design fits into narrow fan coil units

Terminals all on one side allow controllers to be

GENERAL

The W7754 is a configurable fan coil unit application

controller belonging to the Excel 10 product line for

maintained zones. The W7754 covers a wide range of fan coil

control applications and can operate as a stand-alone unit or

networked using the standard Echelon L

Interfaces are provided for a wide range of actuator types.

Heating systems can be water or electrical, and cooling

systems can be chilled water supply or compressors.

Extensive timing and interlock features make the W7754

especially suitable for systems using electrical heat and

compressors.

ONWORKS

®

bus.

Power supplied by power mains or 24 V

DESCRIPTION

The W7754K,P,Q Controllers provide room temperature

control for two- and four-pipe fan coil units with optional

electrical heating coils (W7754K and W7754P) and can

control single-, two-, or three-speed fans. The units are

provided with default configuration settings from the factory

and are fully operable upon installation. Using standard

Echelon configuration tools, the units can be configured with

job-specific settings. A variety of optional wall modules

interface with the units and provide any or all of the following:

setpoint adjustment, fan speed adjustment, and an occupancy

bypass button. All wall modules include a space temperature

sensor; however, a remote C7068A return air sensor can also

be used.

Excel 10

W7754K,P,Q FCU CONTROLLERS

SPECIFICATION DATA

Echelon® LONWORKS© network

positioned at back of fan coil unit

®

protocol

® U.S. Registered Trademark

Copyright © 2010 Honeywell Inc. • All Rights Reserved EN0B-0453GE51 R0110

Page 2

W7754K,P,Q FCU CONTROLLERS

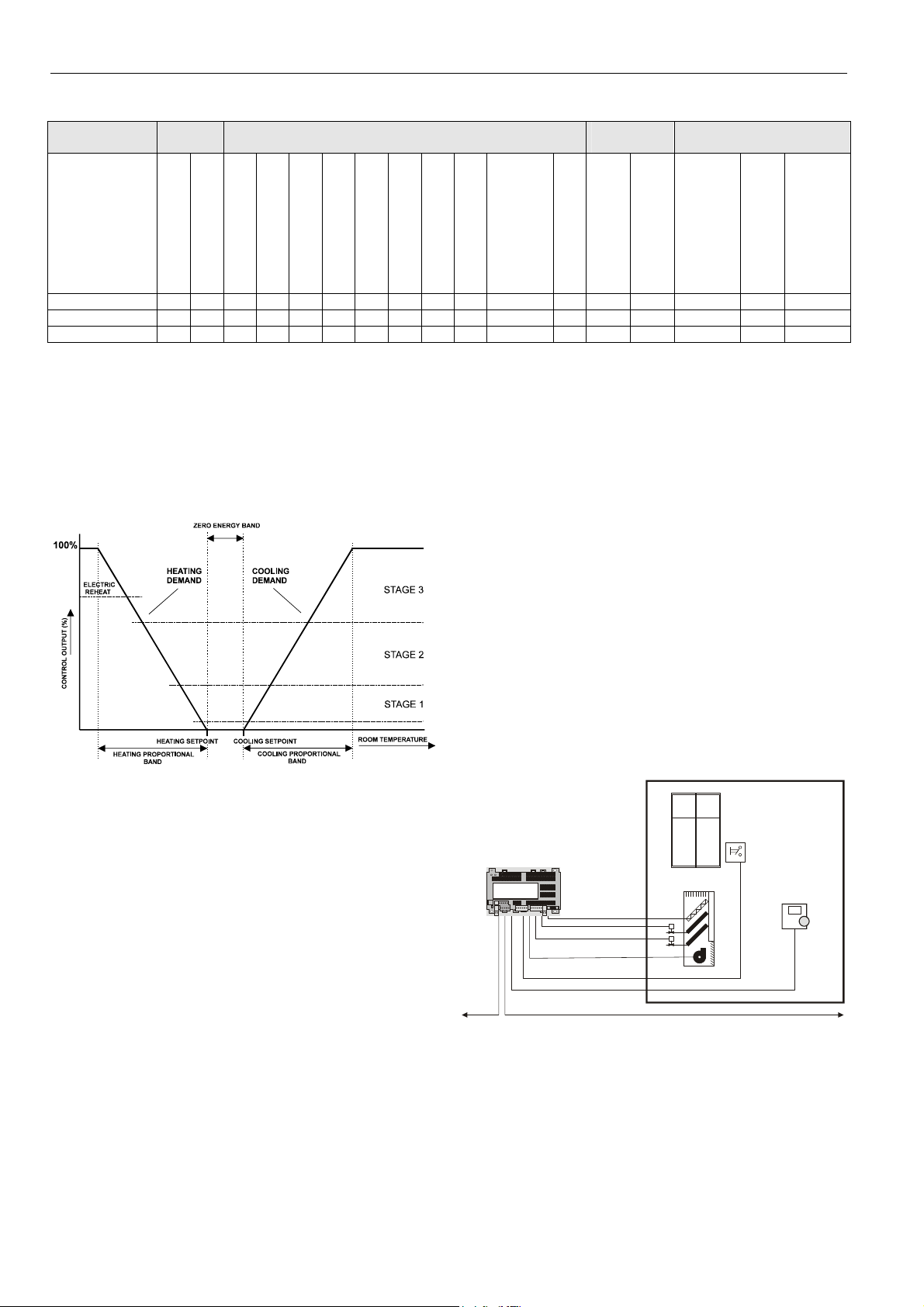

Table 1. Overview of equipment (by model)

OS Number

power

supply

digital outputs

digital

inputs

analog inputs

relay

relay

relay

rd

th

triac (open OUT1)"

triac (close OUT1)

triac (open OUT2)

triac (close OUT2)

low-voltage PWM

control of solid-

state relay

LED

configurable digital

input

digital input

(window contact)

AI (fan speed +

occupancy override

switches)

analog input (room

sensor)

analog input (set-

point adjustment

3

4

switch)

230

24

relay

st

1

nd

2

W7754K1001 X X X X X X X X X X X X

W7754P1000 X X X X X X X X X X X X X X X

W7754Q1008 X X X X X X X X X X X X X X X

Sequences

Heat and cool sequences can be selected to be active or not

active, giving a total of eight different sequence options (each

can be with or without fan control):

Heat, only

Cool, only

Heat/cool changeover

Heat and cool sequence

All of the above, plus electrical reheat.

"Unoccupied" Mode

This mode is used for longer unoccupied periods, such as at

night or during weekends and holidays.

Window Open

If the controllers are configured for window open detection,

they automatically disables heat and cool control until the

window is closed again. Frost protection remains active.

Frost Protection

If the temperature drops below 46°F (8°C), the controllers

enable the heating circuit as frost protection.

Smoke Control

The fan can be turned ON or OFF by network command for

smoke control.

Fan Failure

When configured with an air flow detector, the controllers

protect equipment by disabling the system when the fan fails.

Changeover

The controllers operate two-pipe fan-coil units configured with

a changeover input.

Fig. 1. Operational sequence

Modes of Operation

The units have the following modes of operation.

"Occupied" Mode

This is the normal operating condition for a room or zone

when it is occupied. The controllers can be switched into this

mode by a network command, by the room occupancy sensor, or by a bypass button on the wall module. In the

"occupied" mode, the fan is controlled by the setting of the fan

speed switch on the wall module or, when the switch is set to

“auto,” by the control algorithm. The fan can be configured to

remain ON or turn OFF during the zero energy band.

"Standby" Mode

The "standby" mode saves energy by reducing heating or

cooling demand during periods where the room is temporarily

unoccupied. In this mode, the fan is switched OFF within the

zero energy band.

e.g. Excel 10 W7754

FCU Controller

LonWorks network

Honeywell

D-71101 Schönaich

Made in Germany

Fig. 2. Typical application

window

contact

Excel 10

wall module

EN0B-0453GE51 R0110

2

Page 3

W7754K,P,Q FCU CONTROLLERS

SPECIFICATIONS

Models

All three models are equipped with a minimum of three relays,

one LED digital output, three digital inputs, and two analog

inputs.

Input/Output

Table 2. Input/output specifications

function/characteristics

1st digital

input

1st

analog

input

2nd

analog

input

1st digital

output

3rd

analog

input

2nd

digital

input

4th relay W7754P,Q only; permanently configured to

1st, 2nd,

and 3

relays

triac

outputs

2nd

digital

output

all models; configurable (using LNS plug-in) to

read input from hardwired window contact, occupancy sensor, etc.; suitable for dry contacts,

only; max. voltage at open contact = 5 Vdc

all models; permanently configured to read input from hardwired wall module's temperature

setpoint adjustment knob; enabled / disabled

using left DIP switch

all models; permanently configured to read input from hardwired wall module's room temperature sensor (for use with an NTC20k

sensor, only; accuracy [w/o sensor] = 0.5 °C at

25 °C); enabled/disabled using left DIP switch

all models; permanently configured to write output to LED of hardwired wall module; enabled /

disabled using left DIP switch; max. voltage =

5 Vdc; max. current = 5 mA

all models; permanently configured to read input from hardwired wall module's 3-speed fan

control knob and "occupancy override" button;

enabled / disabled using left DIP switch

all models; permanently configured to read input from window contact; enabled / disabled

using right DIP switch; suitable for dry contacts, only; max. voltage at open contact =

5 Vdc

write output to hardwired electrical reheat coil;

switching voltage = 24...230 Vac; switching

current = 0.05...10 A

all models; permanently configured to write out-

rd

put to hardwired 3-speed fan; switching voltage

= 24...230 Vac; switching current = 0.05...3 A

(max. 3 A for all three relays together)

number varies according to model: permanently

configured to write output to OUT1/2; switching

voltage = 230 Vac (230-V models) or 24 Vac

(24-V models), max. switching current = 0.5 A;

max. peak (10 sec) current = 1 A

W7754K, only; suitable for attachment to a

solid-state relay (max. voltage = 12 Vdc; max.

current = 12 mA at 10 Vdc) for low-voltage

PWM control in high-current electrical reheat

applications (see section "Accessories")

Power Supply

W7754K,P: 230 Vac +10%, -15%, 50/60 Hz

W7754Q: 24 Vac 20%, 50/60 Hz

Power Consumption

See Table 2.

Hardware Design

Processor: Neuron 3150® running at 5 MHz, with 2 kB

of RAM and 0.5 kB of EEPROM on chip.

Ext. memory: EPROM, 64 kB by 8.

Specified Sensing Temperature Range

32° to 104°F (0° to 40°C)

Approvals, Certifications, and Standards

Approvals and Certifications

CE-approved

Certified as per LonMark® Application Layer

Guidelines V 3.0, thus interoperable with all other

devices in open L

devices)

EUBAC-certified as follows:

W7754P1000:

W7754Q1008:

ONWORKS® networks (incl. 3

eu.bac

020885

Cert

eu.bac

020706

Cert

rd

-party

Classification according to EN60730-1

Environmental conditions: For use in home (residential,

commercial, and light-industrial)

environments

Pollution degree: Class 2

Protection against shock: Class 0 (without terminal cover)

Class II (with terminal cover)

Software class: Class A

Classification according to EN60529

(Degree of Protection Provided by Enclosures)

Without terminal cover: IP20

With terminal cover: IP30

Ambient Environmental Limits

Operating temperature: 0 … +50 °C at 5…90% r.H.

Storage temperature: -40 … +70 °C at 5…90% r.H.

W7754P1000, W7754Q1008 Temperature Control

Accuracy (CA)

(min. CA values requested by EUBAC for fan coil unit

applications: ≤ 1.4 K)

FCU heating mode: 0.5 K

FCU cooling mode: 0.2 K

Dimensions (W x L x H)

Without terminal cover: W x L x H = 110 x 180 x 60 mm

With terminal cover: W x L x H = 130 x 180 x 60 mm

Weight

W7754K,P: 420 g; W7754Q: 260 g

3

EN0B-0453GE51 R0110

Page 4

W7754K,P,Q FCU CONTROLLERS

Communications

The controllers use the LonTalk protocol. They support the

L

ONMARK Functional Profile # 8020 “Fan Coil Unit Controller”,

version 2.0. Fig. 6 shows the implementation used.

The recommended wire size to be used for the L

Bus is level IV 22 AWG (Belden part no. 9D220150) or

plenum rated level IV 22 AWG (Belden part no. 9H2201504)

non-shielded, twisted pair, solid conductor wire.

FTT networks can be in bus, star, loop or any combination of

these topologies.

ONWORKS

Mounting Options

The controllers are suitable for mounting on a standard rail

(DIN EN 50022-35 x 7,5), on walls/ceilings, as well as for

installation in wiring cabinets or fuse boxes.

Accessories

Excel 10 T7460 Wall Modules

Excel 10 T7560 Wall Modules

Excel 10 FTT/LPT 209541B Termination Module

C7068A Return Air Sensor (Europe, only)

M7410C Small Electric Linear Valve Actuator (Europe,

only)

Z100 Thermoelectric Actuator (Europe, only)

XAL-COV-L Terminal Protection Covers (8 pcs. bulk)

Solid-state relay from Carlo Gavazzi (part no.:

RS1A23D25-P64) with 40-cm cable and plug, for

230 Vac and max. 25 A (AC

XAL-Term, L

for DIN rail

ONWORKS connection/termination module

rms

)

EN0B-0453GE51 R0110

4

Page 5

W7754K,P,Q FCU CONTROLLERS

+ -

RS1A

23D25

21 4

LON

GND9LED10FAN11DI2

8

5

3

DI1

SET

SENS

5

3

42 1

T7460 / T7560

12

6 23

7

GND

L

230 V

N

3A

131415 18

16

17

III II I

fan

1920

Fig. 3. W7754K sticker with input/output details

21 4

LON

GND9LED10FAN11DI2

8

5

3

DI1

SET

SENS

5

3

42 1

T7460 / T7560

12

6 23

7

GND

L

230 V

N

3A10A

131415 18

16

17

III II I

fan

1920

open

close

OUT1 OUT2

230 Vac

Fig. 4. W7754P sticker with input/output details

21 4

LON

GND9LED10FAN11DI2

8

5

3

DI1

SET

SENS

5

3

42 1

T7460 / T7560

12

6 23

7

GND

L

230 V

N

3A10A

131415 18

16

17

III II I

fan

1920

open

close

OUT1 OUT2

24 Vac

Fig. 5. W7754Q sticker with input/output details

CAUTION

In order to conform to IP30, when installed on walls or

ceilings, the unit must be equipped with the optional

terminal protection cover.

Ho ne ywe l l

D-71101 Schönaich

Made in Germany

triac

0.5 A

2526

24

2122

com

com

open

OUT2

230 Vac

Ho ne ywe l l

D-71101 Schönaich

Made in Germany

2122

open

close

Honeywell

D-71101 Schönaich

Made in Germany

2122

open

close

triac

0.5 A

triac

0.5 A

230 V

2526

24

com

com

230 V

2526

24

~~

com

com

24 Vac

Hardware

Output

Fan Coil Unit Controller

Object #8020

F2.5H

LN

F2.5H

LN

F2.5H

nviSpaceTemp

nv1

SNVT_temp_p

nviSetPoint

nv2

SNVT_temp_p

nviFanSpeedCmd

nv6

SNVT_switch

nviOccCmd

nv7

SNVT_occupancy

nviApplicMode

nv8

SNVT_hvac_mode

nviSetPtOffset

nv9

SNVT_temp_p

nviWaterTemp

nv10

SNVT_temp_p

nviDischAirTemp

nv17

SNVT_temp_p

nviEnergyHoldOff

nv18

SNVT_switch

Mandatory

Network

Variables

Optional

Network

Variables

nvoHeatOutput

nv3

SNVT_lev_percent

nvoCoolOutput

nv4

SNVT_lev_percent

nvoFanSpeed

nv5

SNVT_switch

nvoTerminalLoad

nv11

SNVT_lev_percent

nvoLoadAbs

nv12

SNVT_power

nvoDischAirTemp

nv13

SNVT_temp_p

nvoReheat

nv14

SNVT_switch

nvoSpaceTemp

nv15

SNVT_temp_p

nvoEffectSetPt

nv16

SNVT_temp_p

nvoEffectOcc

nv19

SNVT_occupancy

nvoEnergyHoldOff

nv20

SNVT_switch

nvoUnitStatus

nv21

SNVT_hvac_status

Configuration Properties

nc49 - nciSndHrtBt SNVT_time_sec mandatory

nc52 - nciMinOutTm SNVT_time_sec optional

nc48 - nciRcvHrtBt SNVT_time_sec optional

nc17 - nciLocation SNVT_str_asc optional

nc60 - nciSetPnts

nc59 - nciNumValve

nviSensorOcc

SNVT_Occupancy

nviEmerg

SNVT_hvac_emerg

nviReheatRelay

SNVT_switch

SNVT_temp_setpt

SNVT_count

Manufacturer

Defined

Section

mandatory

optional

nvoSensorOcc

SNVT_occupancy

nvoDigitInState

SNVT_switch

Hardware

NOT SUPPORTED.

Fig. 6. L

Input

ONMARK object details

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich / Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0453GE51 R0110

Loading...

Loading...