Page 1

Excel 10

W7752D,E,F,G,J AND W7754K,L,M,N,P

FAN COIL UNIT CONTROLLERS

SYSTEM ENGINEERING

CONTENTS

Revision overview ....................................................................................................................................................................... 2

Introduction.................................................................................................................................................................................. 3

Description of Devices.............................................................................................. 3

Products Covered..................................................................................................... 4

Organization of Manual............................................................................................. 4

Applicable Literature................................................................................................. 4

Product Names......................................................................................................... 4

Control Application ................................................................................................... 4

Control Provided....................................................................................................... 5

Setpoints.............................................................................................................. 6

Bypass ................................................................................................................. 7

LED/LCD.............................................................................................................. 7

Energy-Saving Features ...................................................................................... 8

Occupancy Status................................................................................................ 8

Safety Features.................................................................................................... 9

Operating Modes ............................................................................................... 10

Agency Listings ...................................................................................................... 11

Construction ........................................................................................................... 11

Excel 10 W7752 FCU Controllers...................................................................... 11

Excel 10 W7754 FCU Controllers...................................................................... 11

Controller Performance Specifications .............................................................. 13

Configurations ........................................................................................................ 14

General .............................................................................................................. 14

Fan Type............................................................................................................ 14

Type of Heating and Cooling Equipment ........................................................... 15

Reheat Output.................................................................................................... 16

Digital Input........................................................................................................ 16

Excel 10 Wall Module Options........................................................................... 17

Abbreviations and Definitions ................................................................................. 18

Overview................................................................................................................. 19

Step 1. Plan the System ......................................................................................... 19

Application Steps ...................................................................................................................................................................... 19

® U.S. Registered Trademark

Copyright © 2003 Honeywell Inc. • All Rights Reserved

All Rights Reserved EN0B-0377GE51 R0703 (74-2961-5)

Step 2. Determine Other Bus Devices Required .................................................... 19

Step 3. Lay Out Communications and Power Wiring ............................................. 20

ONWORKS Layout.............................................................................................. 20

L

Power Wiring ..................................................................................................... 22

Step 4. Prepare Wiring Diagrams........................................................................... 22

General Considerations ..................................................................................... 22

Terminal Block Assignment and Wiring Example for the W7752 Controller...... 23

Terminal Block Assignment and Wiring for the W7754 Controller..................... 24

ONWORKS Termination ..................................................................................... 25

L

Step 5. Order Equipment........................................................................................ 26

Step 6. Configure Controllers ................................................................................. 28

General .............................................................................................................. 28

Output ................................................................................................................ 29

Input................................................................................................................... 30

Equipment Control ............................................................................................. 31

Fan..................................................................................................................... 31

Switching Levels ................................................................................................ 32

Zone Options ..................................................................................................... 32

Page 2

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Miscellaneous.....................................................................................................32

PID......................................................................................................................33

Commissioning ...................................................................................................33

ID Number ..........................................................................................................33

Excel 10 FCU Controller Point Mapping.............................................................33

Step 7. Troubleshooting ..........................................................................................35

Troubleshooting Excel 10 FCU Controllers and Wall Modules...........................35

Alarms ................................................................................................................35

Broadcasting the Service Message ....................................................................37

Manual Mode......................................................................................................37

Appendix A. Using E-Vision to Commission a Fan Coil Unit .................................................................................................38

Appendix B. Configuring for Master/Slave Operation.............................................................................................................39

Appendix C. Complete List of Excel 10 FCU Controller User Addresses .............................................................................41

Appendix D. Q7750A Excel 10 Zone Manager Point Estimating Guide.................................................................................82

Temperature Sensor Calibration .............................................................................38

Procedure ...........................................................................................................38

Output Configuration Options..................................................................................39

Input Configuration Options.....................................................................................39

Equipment Control Options .....................................................................................39

Zone Control Options ..............................................................................................39

Network Variable Binding ........................................................................................39

Approximate Memory Size Estimating Procedure...................................................82

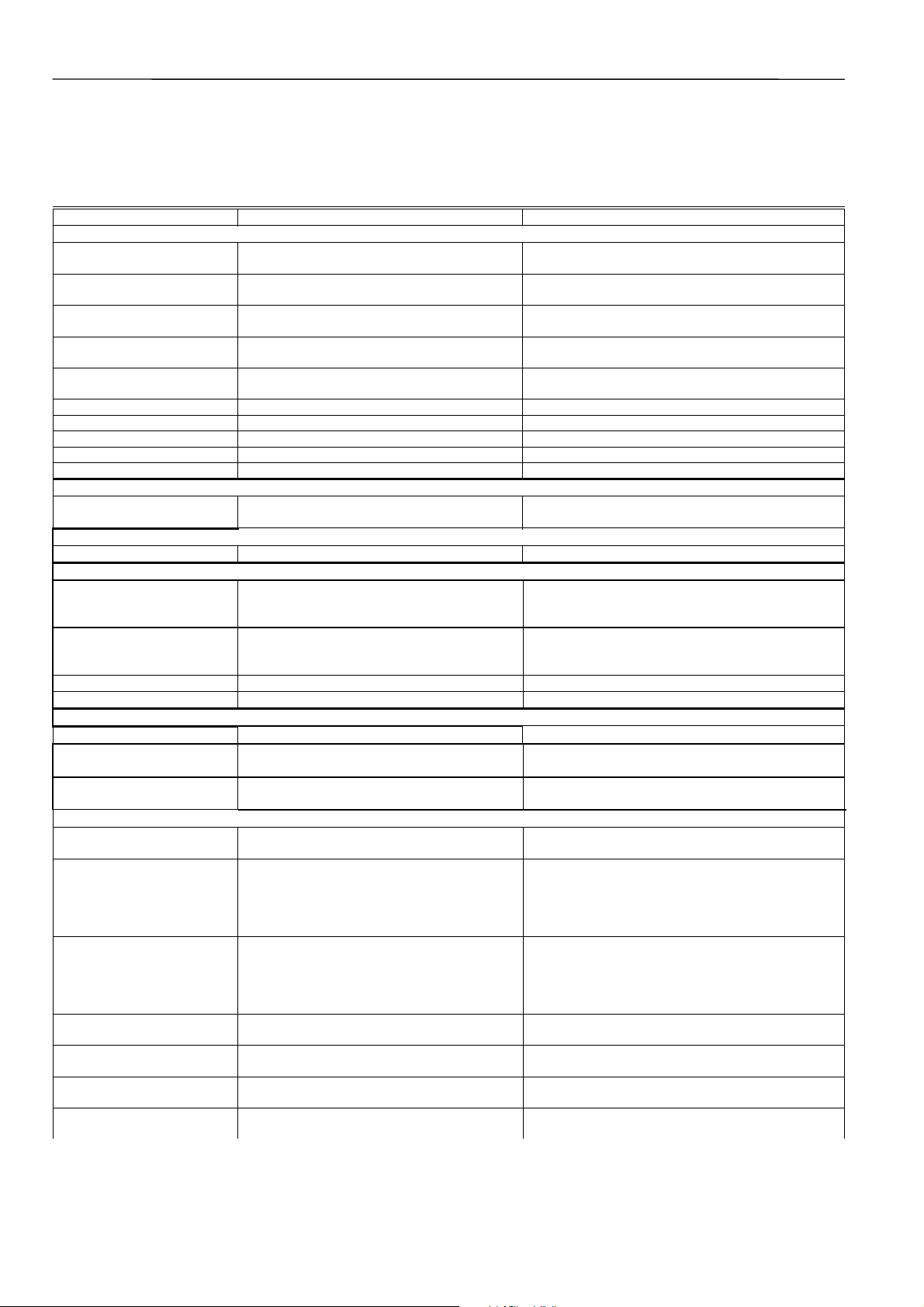

REVISION OVERVIEW

On the following pages changes have been made compared to the previous release of this document:

Page: Change:

EN0B-0377GE51 R0703 2

Page 3

EXCEL 10 FAN COIL UNIT CONTROLLER - SYSTEM ENGINEERING

INTRODUCTION

Description of Devices

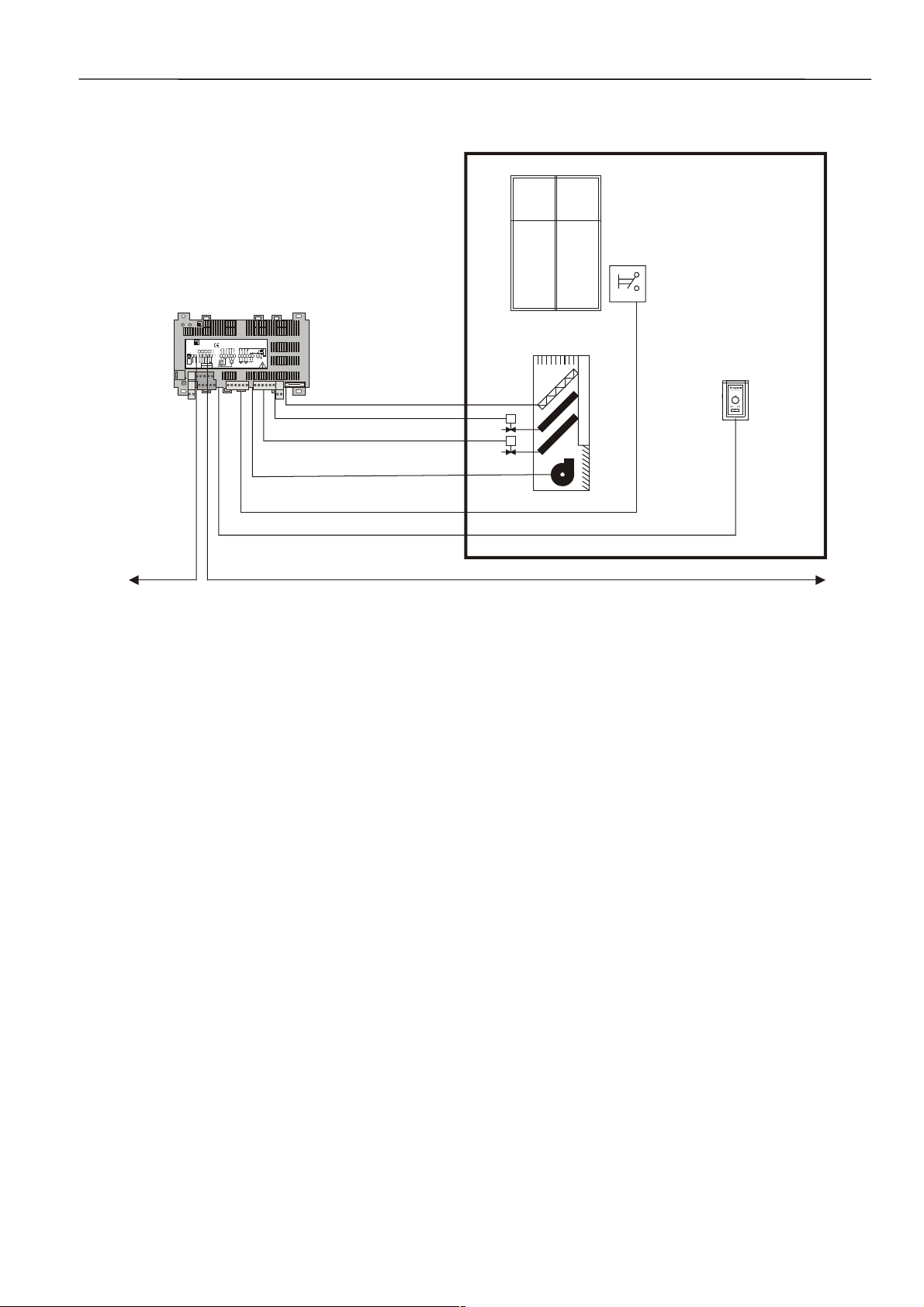

The W7752D,E,F,G,J and W7754K,L,M,N,P Fan Coil Unit

(FCU) Controllers all belong to the Excel 10 family product

line. FCU systems control the space temperature in a given

room by regulating the heating and/or cooling equipment

which control the temperature of the air delivered to that

space and the fan which controls air flow. Reheat coils are

often included at the fan coil unit. Excel 10 FCU controllers

are capable of stand-alone operation; however, optimum

functional benefits are achieved when the network

communication capabilities are used.

Excel 500

The zone controlled by the Excel 10 FCU controllers will

typically use an Excel 10 wall module with a temperature

sensor for space temperature measurement, analog setpoint

input, bypass push-button, and occupancy/unoccupancy

override. See page 4 for form numbers of Excel 10 wall

module literature for further information.

The Excel 500 can assume all of the Excel 10 FCU

controllers' scheduling functions. The number of Excel 10

FCU controllers on the L

ONWORKS network is determined by

the rules of LonWorks network design (see Table 10). Frontends can be either EBNI, SymmetriE, or SynOpsys,

depending upon the size and complexity of the connected

system.

PCLTA10

PCC10

Excel 10 W7754

FCU Controller

LonWorks network

ONUNUSED

UNUSED

W7754Kxxxx

0345

WALL MOD.

USED

+ -

RS1A

23D25

LON

Honeywell

DI2

USED

230 Vac, 50/60 Hz

D-71101 Schönaich

max. 5 VA unloaded

Made in Ger man y

GND9LED10FAN11DI2

triac

2 A10A

0.5 A

8

12

321

4 5 6

23247

1314

15 181716

1920

2122

2526

2A/M

IIIII I

DI1

SET

SENS

534

21

T7460 / T7560

LN

com

com

close

open

close

open

GND

230 V

fan

L

OUT1OUT2

230 V

N

230 Vac

Excel 10 W7752

FCU Controller

Excel 10

wall module

Fig. 1. Typical EXCEL 5000® System overview

Excel 10

wall module

3 EN0B-0377GE51 R0703

Page 4

EXCEL 10 FAN COIL UNIT CONTROLLER - SYSTEM ENGINEERING

Products Covered

This System Engineering Guide describes how to apply the

Excel 10 FCU controller and the accessories to typical FCU

applications. The specific devices covered include:

• W7752D,E,F,G, and J FCU Controllers.

• W7754K,L,M,N, and P FCU Controllers.

• T7460 Wall Modules.

• T7560 Wall Modules.

• for further products, see Appendices.

Organization of Manual

The Introduction and Application Steps 1 through 5 provide

the information needed to make accurate ordering decisions.

Application Step 6 and the Appendices include configuration

engineering that can be started using E-Vision software after

the devices and accessories are ordered. Application Step 7

is troubleshooting. Information provided in support of the use

of third-party L

ONWORKS communication packages to con-

figure FCU Controllers is found in the Appendices.

The organization of the manual assumes a project is being

engineered from start to finish. If you are adding to or

changing an existing system, the Table of Contents can

guide you to the relevant information.

Applicable Literature

The following is a list of documents containing information

related to the Excel 10 FCU Controller and the EXCEL 5000

System in general.

Form No. Title

EN0B-0376GE51 Excel 10 W7752D,E,F,G,J FCU

Controller Specification Data

EN1B-0250GE51 Excel 10 W7752D,E,F,G,J FCU

Controller Installation Instructions

EN1B-0251GE51 Excel 10 W7754K,L,M,N,P FCU

Controller Installation Instructions

74-3083 Excel 10 T7460 Wall Modules

Specification Data

95-7610 Excel 10 T7460 Wall Modules

Installation Instructions

74-3097 Excel 10 T7560 Wall Modules

Specification Data

95-7620 Excel 10 T7560 Wall Modules

Installation Instructions

74-2950 Excel 10 Q7750A, Excel 10 Zone

Manager Specification Data

95-7509 Excel 10 Q7750A Zone Manager

Installation Instructions.

95-7554 Excel 10 FTT/LPT 209541B

Termination Module Installation

Instructions

95-7510 Excel 10 Q7751A Router Installation

Instructions (US only)

95-7511 Excel 10 Q7752A Serial Interface

Installation Instructions (US only)

74-2588 Excel E-Vision User Guide

74-5587 Excel CARE User Guide

74-2039 XBS User’s Manual

74-5018 XBS Application Guide

Product Names

The W7752 Controller is available in five models:

• W7752D FCU Controller with 230 Vac power input and

with reheat relay.

• W7752E FCU Controller with 230 Vac power input without

reheat relay.

• W7752F FCU Controller with 115 Vac power input with

reheat relay.

• W7752G FCU Controller with 115 Vac power input without

reheat relay.

• W7752J FCU Controller with 100 Vac power input without

reheat relay.

The W7754 Controller is available in five models:

• W7754K FCU Controller with 230 Vac power supply, one

triac output, and one digital output for the low-voltage

Pulse-Width Modulated (PWM) control of a solid-state

relay employed in high-current electric reheat

applications

• W7754L FCU Controller with 24 Vac power supply and

two triac outputs

• W7754M FCU Controller with 230 Vac power supply

• W7754N FCU Controller with 230 Vac power supply and

two triac outputs

• W7754P FCU Controller with 230 Vac power supply, four

triac outputs, and an extra, fourth relay

The 2000-series FCU controllers can use any of the following

Excel 10 wall modules:

• T7460A with temperature sensor.

• T7460B with temperature sensor and setpoint adjustment.

• T7460C with temperature sensor, setpoint adjustment,

and bypass button and LED.

• T7460D with temperature sensor, setpoint adjustment and

5-position fan switch.

• T7460E with temperature sensor, setpoint adjustment,

bypass button and LED, and 3-position fan switch.

• T7460F with temperature sensor, setpoint adjustment,

bypass button and LED, and 5-position fan switch.

• T7560A with temperature sensor, unit enable button,

setpoint adjustment, bypass button, LCD display and

configurable fan override with up to five settings.

Other products:

• Q7750A Excel 10 Zone Manager.

• Q7751A Bus Router (US, only).

• Q7752A Serial Adapter (US, only).

• AK3781 L

ONWORKS (non-plenum): 22 AW G (0.325 mm

2

)

twisted pair solid conductor, non-shielded wire (one

twisted pair) (US, only).

• AK3782 L

ONWORKS (non-plenum): 22 AW G (0.325 mm

2

)

twisted pair solid conductor, non-shielded wire (two

twisted pairs) (US, only).

• AK3791 L

ONWORKS (plenum): 22 AW G (0.325 mm

2

)

twisted pair solid conductor, non-shielded wire (one

twisted pair) (US only).

• AK3792 L

ONWORKS (plenum): 22 AW G (0.325 mm

2

)

twisted pair solid conductor, non-shielded wire (two

twisted pairs) (US, only).

• C7608A Return Air Sensor (Europe, only).

Refer to the Table 15 (see section "Step 5. Order

Equipment") for complete listing of all available part numbers.

Control Application

FCU systems in commercial buildings control room

temperature through the control of heat and/or cold water

valves and fan speed. Electric reheat coils may also be used

in the system. The FCU Controller is located in the fan coil

unit and is typically connected to an Excel 10 wall module

which incorporates a temperature sensor, setpoint and fan

EN0B-0377GE51 R0703 4

Page 5

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

speed controls, and a bypass or override button. Fig. 2

shows a typical FCU control application.

Excel 10 W7754

FCU Controller

ONUNUSED

UNUSED

W7754Kxxxx

DI2

USED

GND9LED10FAN11DI2

8

321 4 5 6 23247

DI1

Honeywell

0345

230 Vac, 50/60 Hz

D-71101 Schönaich

max. 5 VA unloaded

Made in Germany

triac

2 A10A

0.5 A

12

131415 181716

192021 22

2526

2A/M

III II I

LN

com

com

close

open

close

open

SET

GND

230 V

fan

SENS

L

5342 1

OUT1OUT2

230 V

N

T7460 / T7560

230 Vac

WALL MOD.

USED

+ -

RS1A

23D25

LON

wall

contact

Excel 10

wall module

LonWorks network

Fig. 2. Typical Excel 10 FCU control application

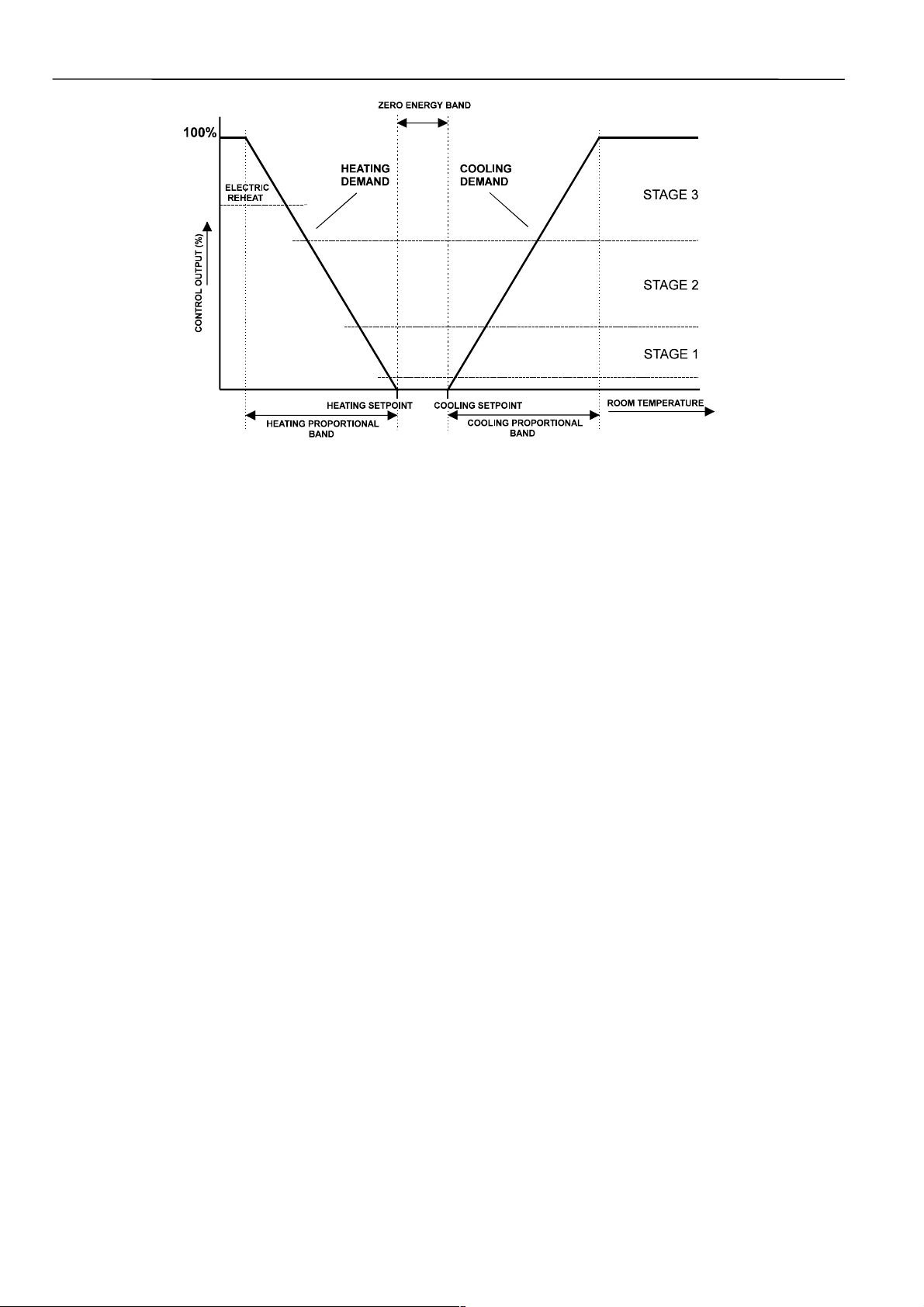

Control Provided

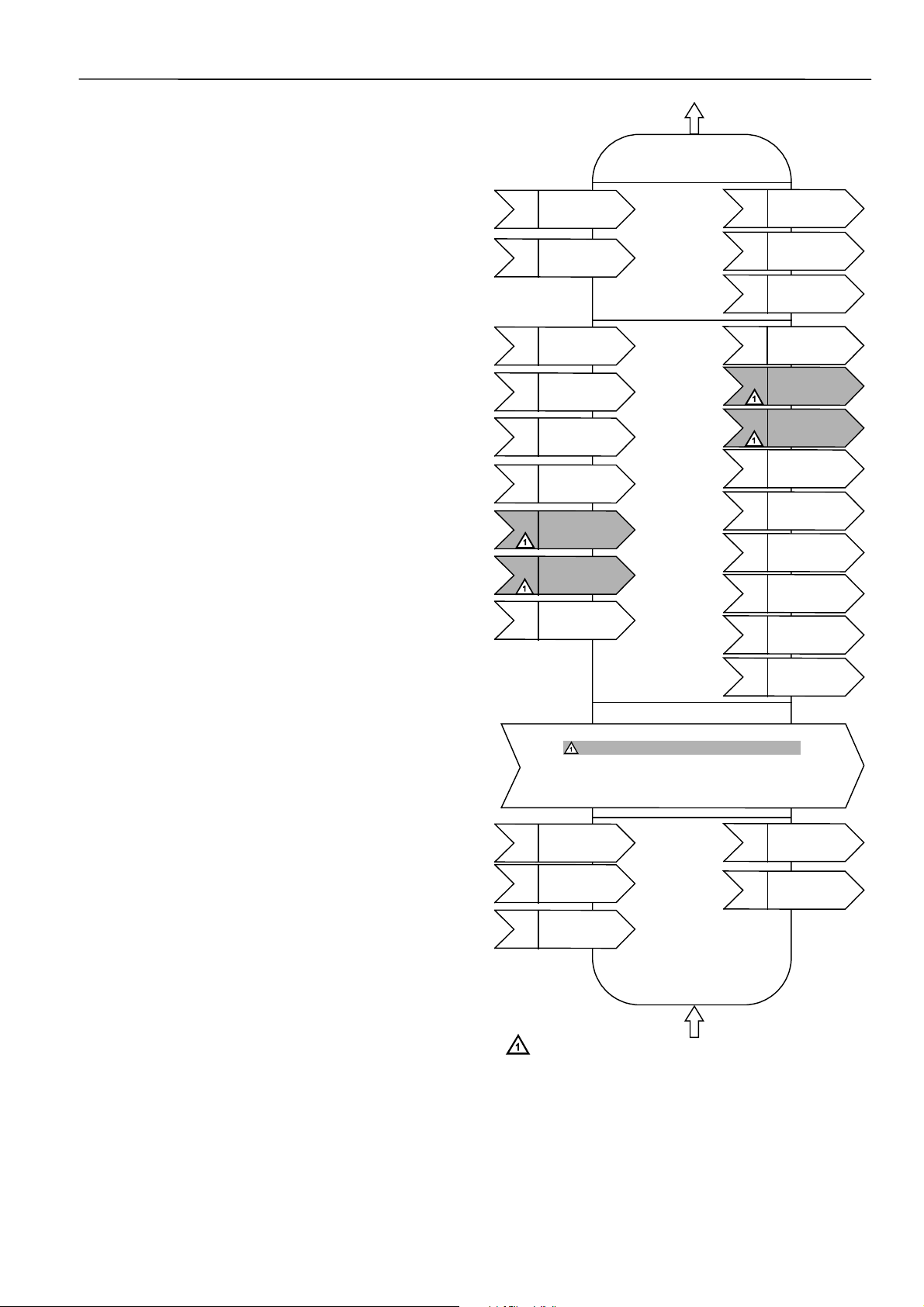

The Excel 10 FCU controllers provide room temperature control for two- and four-pipe fan coil units with optional electric

heating coil. The basic control sequence is shown in Fig. 3.

As space temperature falls below the heating setpoint, the

heating output is increased. As space temperature increases

above the cooling setpoint, the cooling output is modulated to

100%. Switching levels for staged heating/cooling and fan

speeds are configurable. The fan may still be configured to

run continuously during the zero energy band in the occupied

mode. Additional configurable fan control features include fan

min. ON and OFF times, run-up times, and overrun times.

The Excel 10 FCU controllers use a PID control algorithm

with which each of the three parameters can be configured.

There are additional configurable boost parameters

(HeatBoost and CoolBoost) which specify a range outside of

which the heating or cooling outputs are turned on fully for

faster response (for thermal actuators this specifies the control hysteresis). The controllers are delivered with factory

defaults for each of the parameters.

5 EN0B-0377GE51 R0703

Page 6

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Fig. 3. Control sequence diagram

Setpoints

Setpoint Knob

The Excel 10 FCU controllers may be connected to an Excel

10 wall module equipped with a setpoint knob. When

configured (UseWallModSpt), the value from the setpoint

knob is used to calculate the "occupied" setpoint for the

heating and the cooling modes. There are two options

(SptKnob) which determine how the setpoint used by the

control algorithm is calculated: "relative" (or "offset") and

"absolute middle". When configured for "relative", the Excel

10 wall module setpoint knob represents a number from

-9...+9 DDF(-5...+5 K) which is added to the configured

"occupied" and "standby" setpoints for the heating and the

cooling modes (SptCoolOcc and SptHeatOcc). When

SptKnob is set to "absolute middle", the setpoint knob

becomes the mid-point of the Zero Energy Band (ZEB)

extending between the "occupied" or "standby" setpoints for

the heating and the cooling modes. The range of the ZEB is

found by taking the difference between the "occupied" or

"standby" setpoints configured for the heating and the cooling

modes; in the case of "absolute middle", the current

"occupied" and "standby" setpoints are therefore found as

follows:

"occupied" setpoint:

SrcRmTempSptEff (in cooling mode) =

SrcRmTempSptHw + (SptCoolOcc - SptHeatOcc) / 2

SrcRmTempSptEff (in heating mode) =

SrcRmTempSptHw - (SptCoolOcc - SptHeatOcc) / 2

"standby" setpoints:

SrcRmTempSptEff (in cooling mode) =

SrcRmTempSptHw + (SptCoolStby - SptHeatStby) / 2

SrcRmTempSptEff (in heating mode) =

SrcRmTempSptHw - (SptCoolStby - SptHeatStby) / 2

SptKnobLowLim and SptKnobHiLim. In the case of absolute

"occupied" and "standby" setpoints, the setpoint knob still

represents the mid-point of the ZEB, even when set to either

of these limits. The actual setpoints are given by the

equations shown above. When the setpoint knob is configured to be "relative", the lowest actual "occupied" setpoint

allowed is equal to SptHeatOcc - SptKnobLowLim, and the

highest allowed is equal to SptCoolOcc + SptKnobHiLim. The

lowest and highest "standby" setpoints are found in an

analogous way.

Setpoint from Network

When not configured for UseWallModSpt, DestRmTempSpt

must be bound to another node that provides a setpoint.

When bound and when a valid update is received,

DestRmTempSpt is used with the appropriate ZEB:

ZEBoccupied = SptCoolOcc - SptHeatOcc

ZEBstandby = SptCoolStby - SptHeatStby

The "unoccupied" setpoint does not depend on

DestRmTempSpt at all.

Setpoint Offset

Third-party nodes may be bound to DestSptOffset in order to

shift the setpoint in the range of -18...+18 DDF (-10...+10 K).

When in the "unoccupied" mode, the remote setpoint knob is

ignored, and the configured setpoints for those modes are

used instead.

Setpoint Limits

Setpoints are limited to the range of 50...95°F (10...35°C).

The value of the setpoint knob (SrcRmTempSptHw) is limited

to the range provided by the configuration parameters

EN0B-0377GE51 R0703 6

Page 7

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

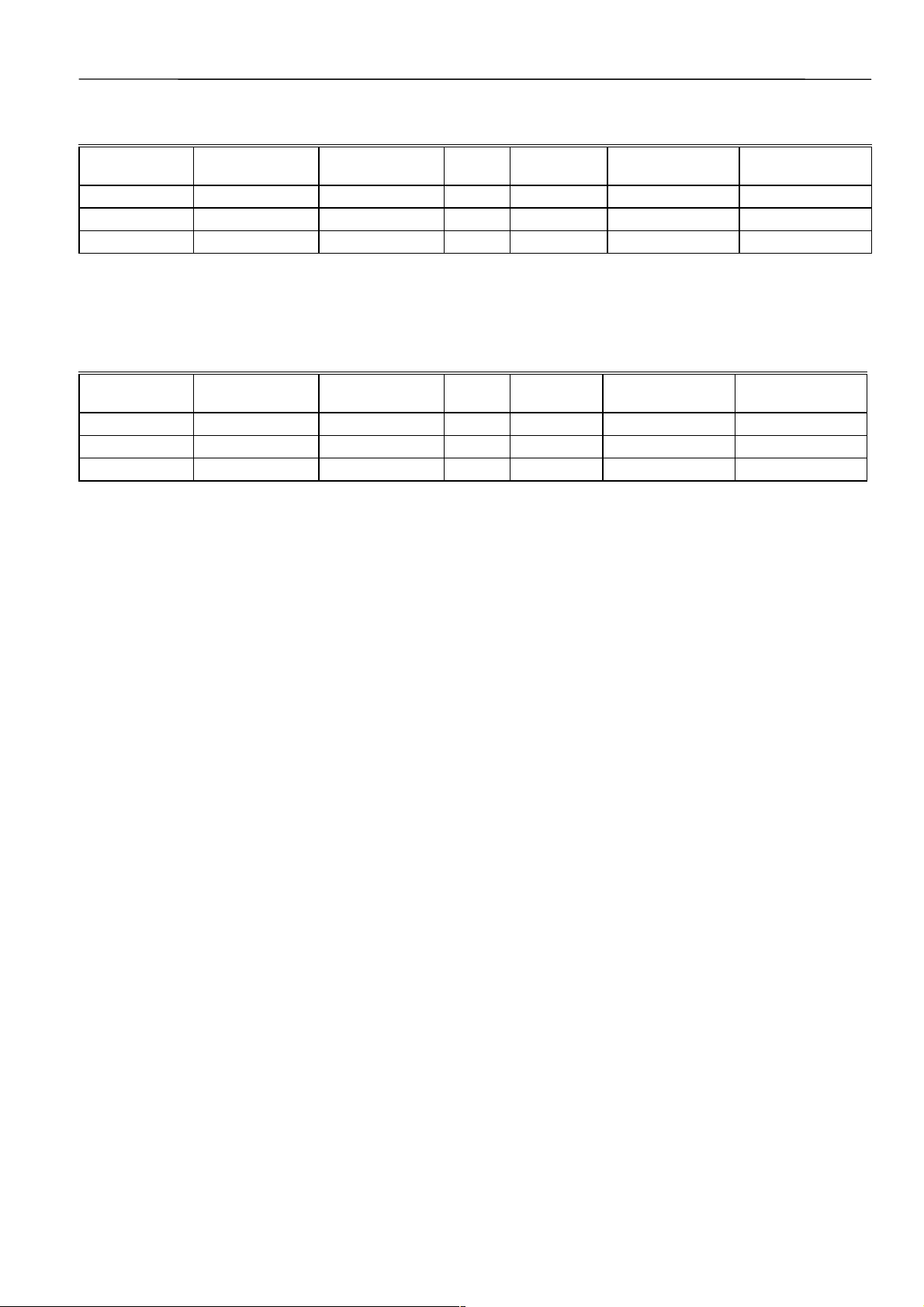

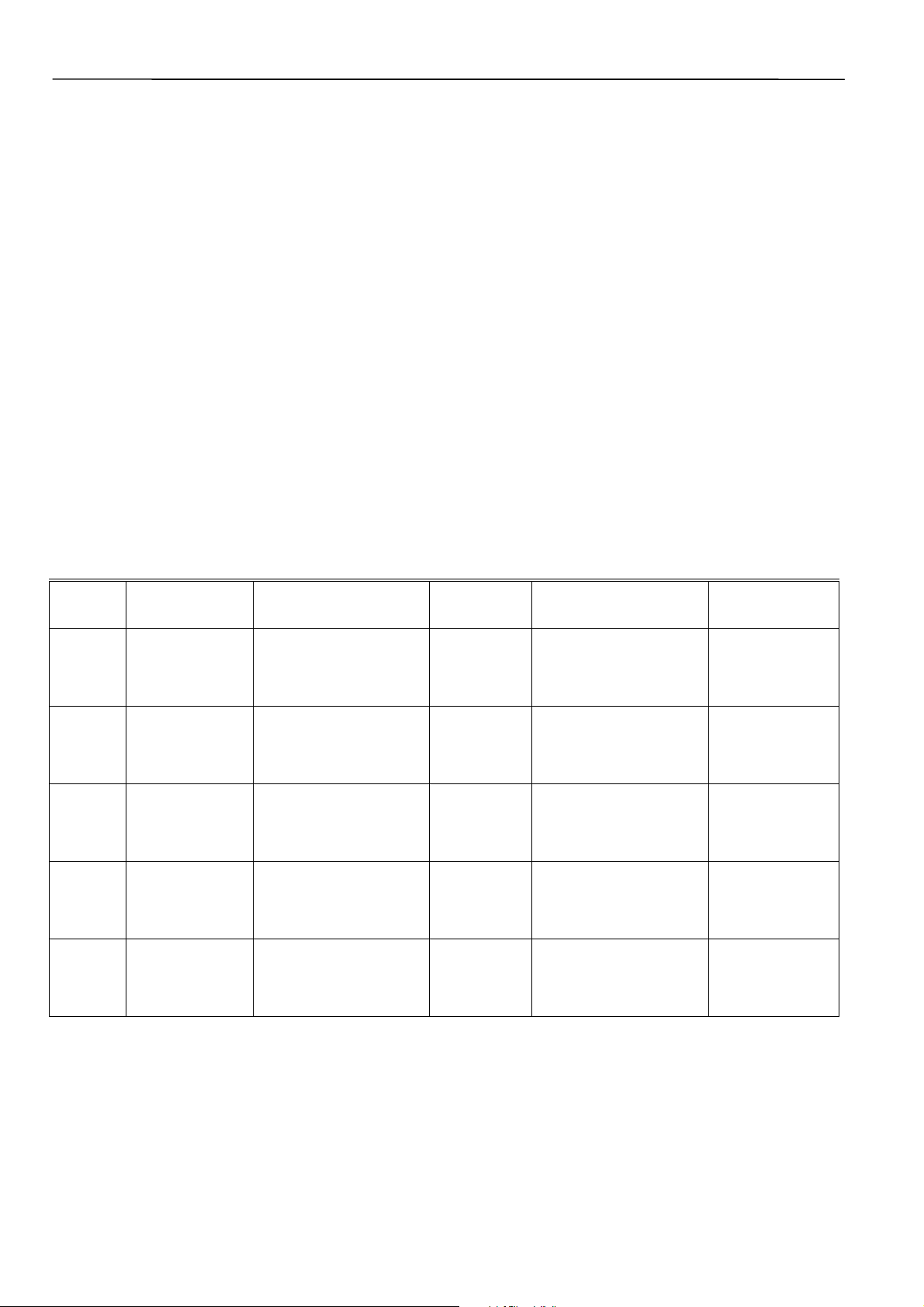

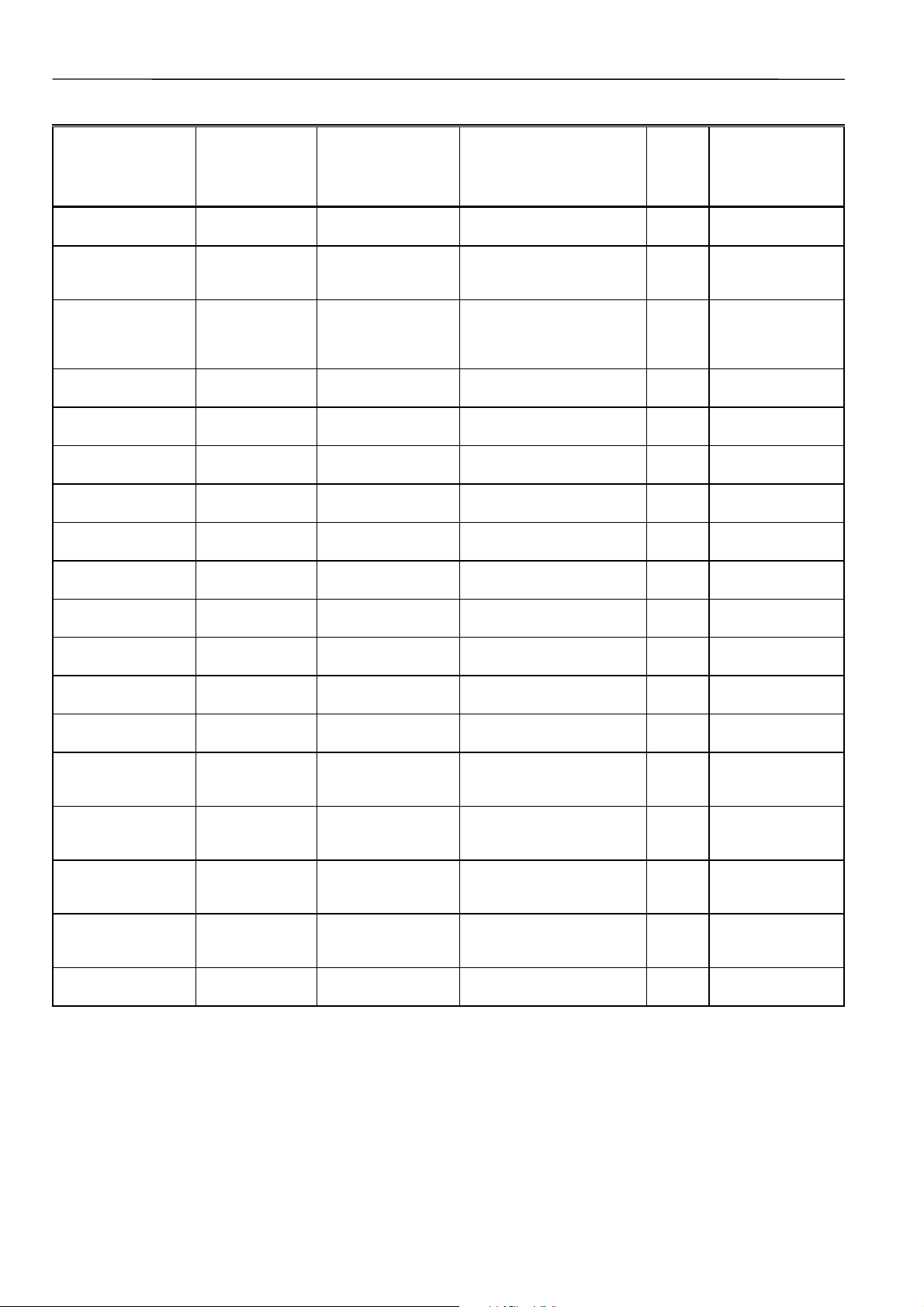

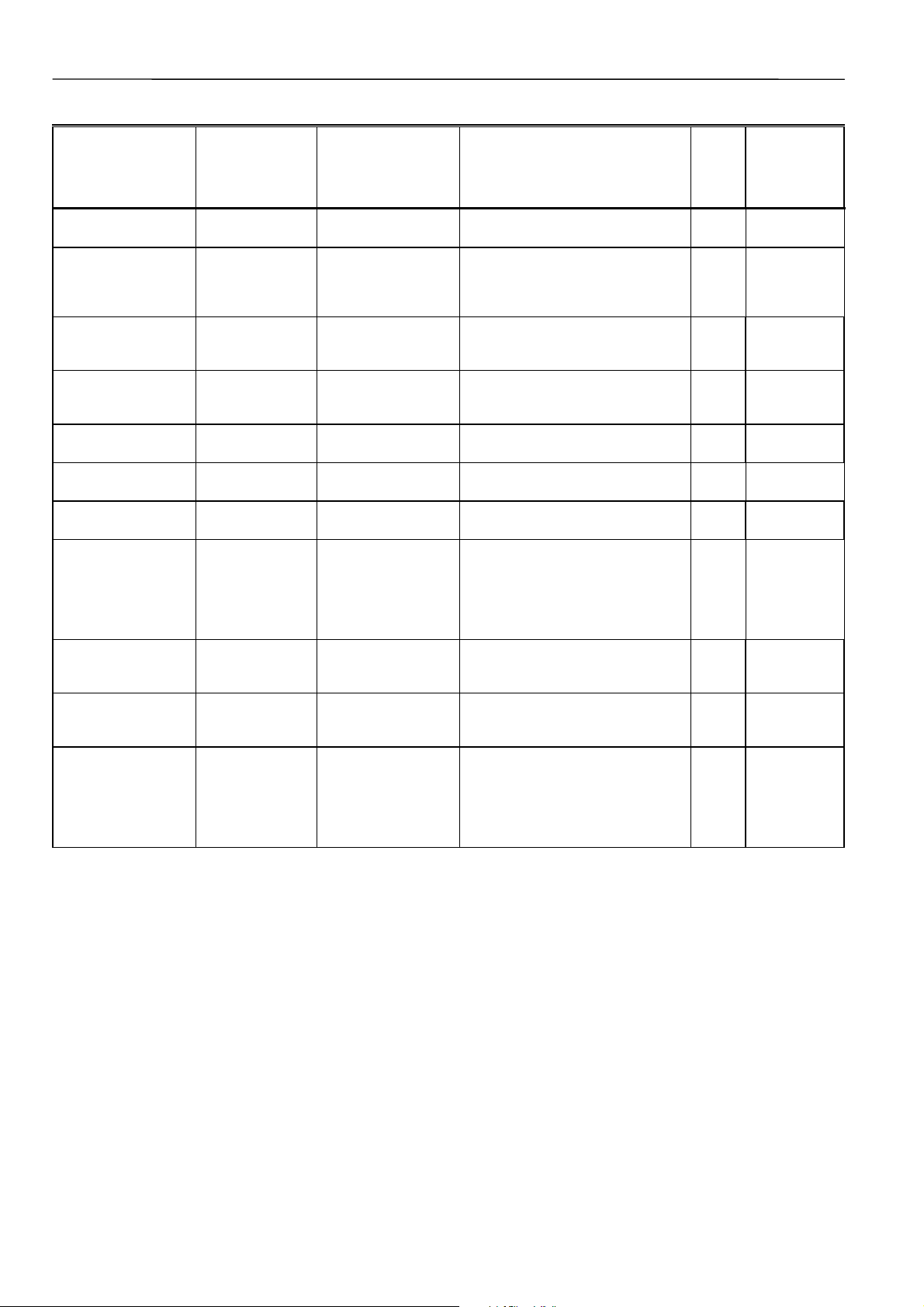

Table 1. Example setpoint values based upon default configuration – "absolute middle" setpoint knob (°C)

occupancy

mode

"occupied" 23 21 2 21 22 20

"standby" 25 19 6 21 24 18

"unoccupied" 28 16 12 X 28 16

NOTES:

1. Sample value shown. Limited by default configuration settings to the range of 12...30°C.

2. Limited to the range of 10...35°C.

3. = setpoint knob + (ZEB/2)

4. = setpoint knob – (ZEB/2)

Table 2. Example setpoint values based upon default configuration - Relative setpoint knob (°C)

occupancy

mode

"occupied" 23 21 2 -2 21 19

"standby" 25 19 6 -2 23 17

"unoccupied" 28 16 12 X 28 16

NOTES:

1. Sample value shown. Limited by default configuration settings to the range of -5...+5°C.

2. Limited to the range of 10...35°C.

3. = configured cooling setpoint + setpoint knob

4. = configured heating setpoint + setpoint knob

Bypass

Bypass Mode

During periods scheduled as being unoccupied, the Excel 10

wall module's bypass push-button may be used to force the

FCU controller into the "occupied" mode. The FCU controller

can also be forced into the "occupied" mode by means of a

ONWORKS network command (DestManOcc set to

L

OC_BYPASS). The controller will then remain in "bypass"

mode until:

1. The bypass timer has timed out, or

2. The user again presses the Excel 10 wall module's

bypass push-button, thus cancelling the "bypass"

mode, or

3. The occupancy schedule (DestSchedOcc network

input) switches the mode to "occupied".

4. The network input DestManOcc is set to OC_NUL.

The Excel 10 wall module indicates the current bypass mode

status (see Excel 10 wall module literature for further

information).

Bypass Timer

When the "bypass" mode has been activated, the bypass

timer is set to BypTime (default of 180 minutes), at the end of

which the mode will revert to its original state (see Excel 10

wall module literature for further information).

Continuous Unoccupied Mode

The "continuous unoccupied" mode is entered when an Excel

10 wall module is configured to allow it and if :

• (in the case of the T7460) the bypass button is pressed for

four to seven seconds (until the LED blinks),

• (in the case of the T7560) the bypass button is pressed for

more than five seconds (until the flashing moon appears).

configured

cooling setpoint

configured

cooling setpoint

configured

heating setpoint

configured

heating setpoint

ZEB

ZEB

setpoint

knob

setpoint

1

knob

effective cooling

1

effective cooling

setpoint

setpoint

2,3

2,3

effective heating

setpoint

effective heating

setpoint

The FCU controller can also be forced into the "continuous

unoccupied" mode by means of a L

ONWORKS network

command (DestManOcc set to OC_UNOCCUPIED). The

FCU controller will then remain in this mode indefinitely, or

until the bypass button is pressed to exit the mode or a

network command is sent to clear the mode.

Bypass Push-Button

The FCU Controller may be connected to an Excel 10 wall

module equipped with a bypass push-button. There are three

ways to configure the bypass push-button (see Table 17 for

further information):

NONE

BYPASS_UNOCCUPIED

BYPASS_ONLY

Override Priority

The FCU Controller can be configured to arbitrate overrides

coming from the bypass push-button and the L

ONWORKS

network. There are two possible states which have the

following meanings:

LAST_WINS specifies that the last command received

from either the wall module or DestManOcc determines

the effective override state.

NETWORK_WINS specifies that when DestManOcc is not

OC_NUL, then the effective occupancy mode is

determined by DestManOcc regardless of the wall

module override state.

LED/LCD

LED Override

The wall module’s LED indicates that the FCU controller is

being overridden by either the bypass button or the

ONWORKS network.

L

• LED ON "override bypass"

2,4

2,4

7 EN0B-0377GE51 R0703

Page 8

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

• One flash per second "override unoccupied"

• Two flashes per second "override standby" or

"occupied"

• LED OFF no override

• Four flashes per second The controller is responding

ONWORKS network management wink command.

to a L

LED Occupancy

The wall module’s LED indicates the effective occupancy

mode.

• LED ON effective "occupied" or effective "bypass"

• One flash per second effective "standby"

• LED OFF effective "unoccupied"

• Four flashes per second The controller is responding

ONWORKS network management wink command.

to a L

LCD Display

This mode is used only for T7560 Wall Modules. The

occupancy mode is represented by the following symbols:

effective "occupied" or effective "bypass"

effective "standby"

effective "unoccupied"

Controller is OFF

and Controller is OFF, frost protection is enabled.

Flashing symbols indicate the "override" mode:

override "occupied" or override "bypass"

override "standby"

override "unoccupied"

The controller is responding to a LONWORKS network

management wink command.

Energy-Saving Features

The "Standby" Mode

The digital input for reading input from an occupancy sensor

(usually a motion detector) provides the FCU controller with a

means to enter an energy-saving standby mode whenever

there are no people in the room. The "standby" mode occurs

when the scheduled occupancy mode is "occupied" but the

occupancy sensor indicates that the room is nevertheless

currently unoccupied. If no occupancy sensor is directly connected to the FCU controller, an occupancy sensor from

another node may be bound to the network input

DestOccSensor. The FCU controller can also be forced into

the "standby" mode by means of a L

command (DestManOcc set to OC_STANDBY). When in the

"standby" mode, the FCU Controller uses the "standby"

setpoints configured for the heating and the cooling modes

(SptHeatStby or SptCoolStby).

ONWORKS network

used by binding it to DestWindow. Frost protection remains

active. Normal temperature control resumes when the

window closes.

Demand Limit Control

When a high-electrical-demand signal is received from an

energy management system via the L

ONWORKS network

(DestDlcShed), the FCU controller uses DlcStptBump to shift

the current setpoint (down for heating and up for cooling) by

the configured value to save energy.

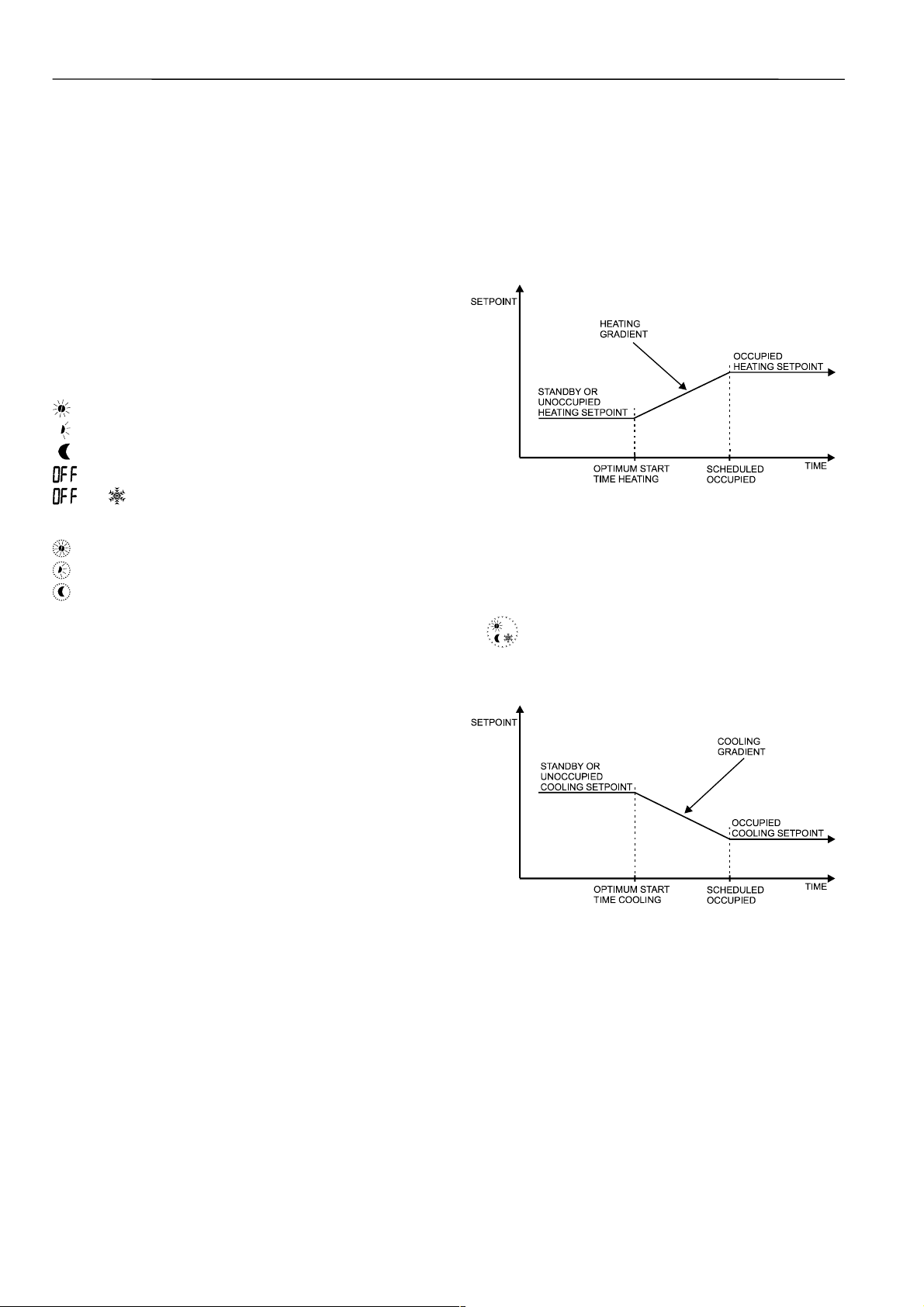

Fig. 4. Optimum start (heating)

Optimum Start Gradients

There are two parameters, RecRampCool and

RecRampHeat, that can be configured to cause the cooling

and heating setpoints respectively to ramp up to their

occupied settings from their unoccupied or standby settings

prior to scheduled occupancy. The FCU controller

uses the configured rates to determine the optimum

time to start increasing the heating or cooling

demand. See the following figures. The configuration

parameters are in K/hour.

Fig. 5. Optimum start (cooling)

Window Sensor

The digital input for reading input from a window contact

provides the FCU controller with a means to disable its temperature control activities if someone has opened a window

or door in the room. If no window sensor is directly connected

to the FCU controller, the sensor from another node may be

EN0B-0377GE51 R0703 8

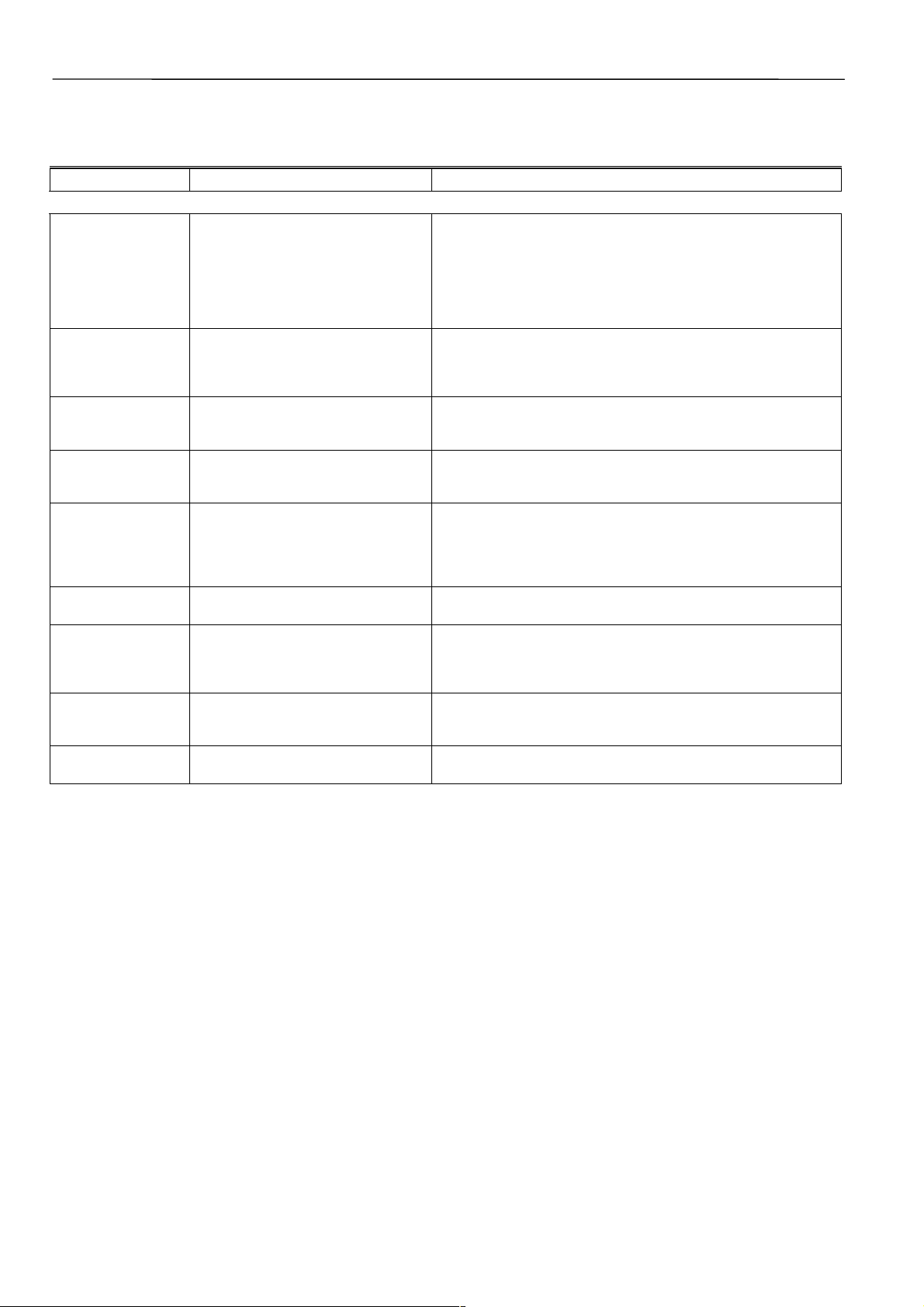

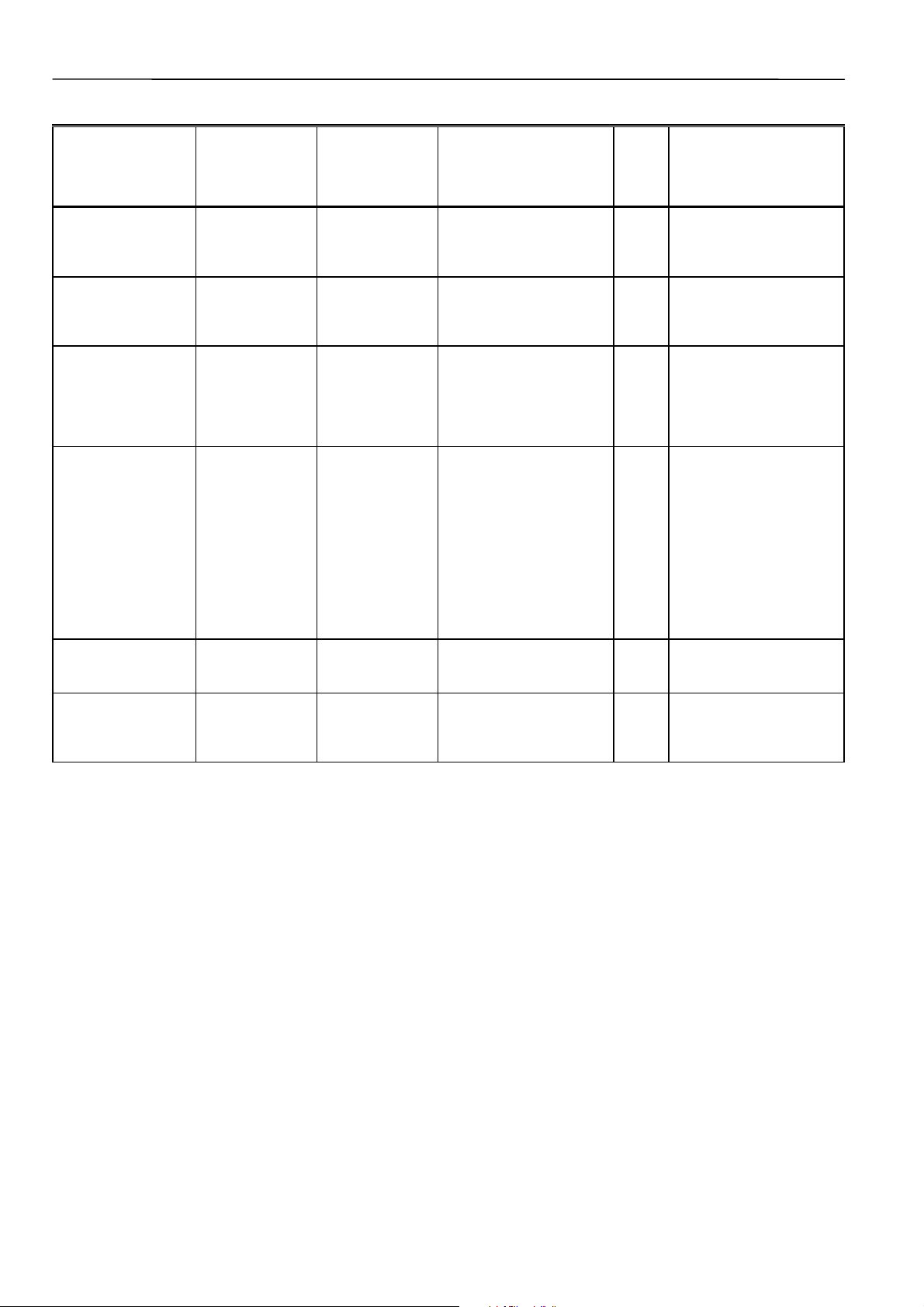

Occupancy Status

The occupancy status is determined based upon Table 3.

Manual override may come from the network input

DestManOcc or from the bypass push-button.

Page 9

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

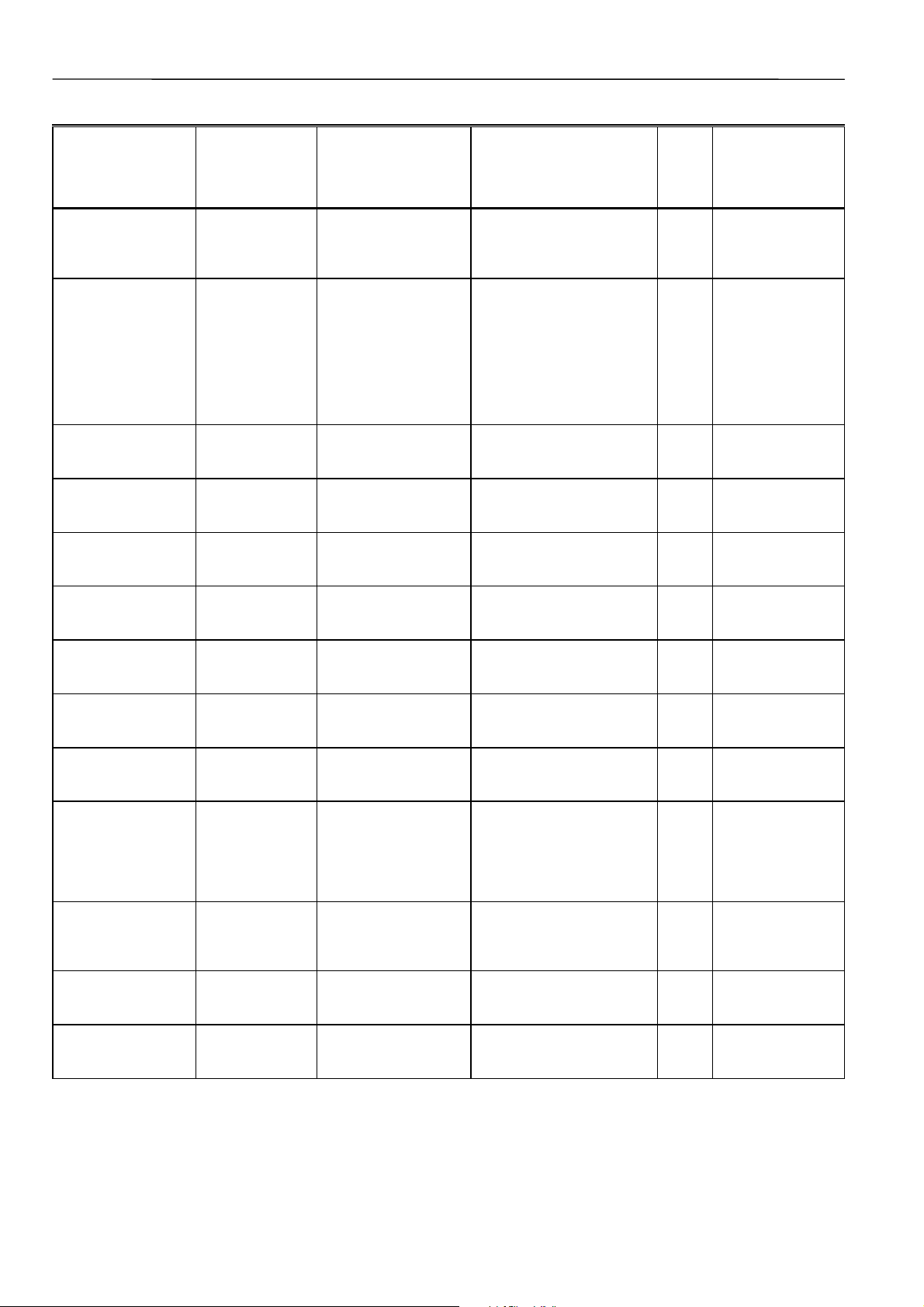

Table 3. Effective Occupancy Mode Arbitration

scheduled occupancy mode occupancy sensor status manual override status effective operating mode

"occupied" room occupied not assigned OC_OCCUPIED

"occupied" room not occupied not assigned OC_STANDBY

X X "occupied" OC_OCCUPIED

X X "unoccupied" OC_UNOCCUPIED

X X "standby" OC_STANDBY

"occupied" X "standby" OC_OCCUPIED

"standby" X not assigned OC_STANDBY

"standby" X "standby" OC_OCCUPIED

"unoccupied" X not assigned OC_UNOCCUPIED

"unoccupied" X "standby" OC_BYPASS

X=Don't care

Safety Features

Frost Protection

If the room temperature falls below 46.4°F (8°C), the FCU

controller enables the heating circuit to ensure frost protection and an alarm is issued. When the temperature rises

above 48.2°F (9°C) again, the heating circuit is turned OFF

again.

Smoke Control

The FCU controller will respond to L

emergency commands by switching OFF heating/cooling

outputs and switching OFF the fan (depressurize) or

switching ON the fan at its highest speed (pressurize). An

alarm is issued for any emergency commands

ONWORKS network

Fan Failure Protection

When configured with an airflow detector, the FCU controller

protects equipment by switching OFF heating / cooling

outputs and issuing an alarm when the fan fails.

Fan Interlocks

The FCU controller can be configured such that heating

and/or cooling outputs are never ON unless the fan is

running. A fan run-up time can be configured to turn ON the

fan prior to the heating/cooling outputs being switched ON,

and a fan overrun time can be configured to keep the fan

running for a period of time after the heating/cooling outputs

are switched OFF.

9 EN0B-0377GE51 R0703

Page 10

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

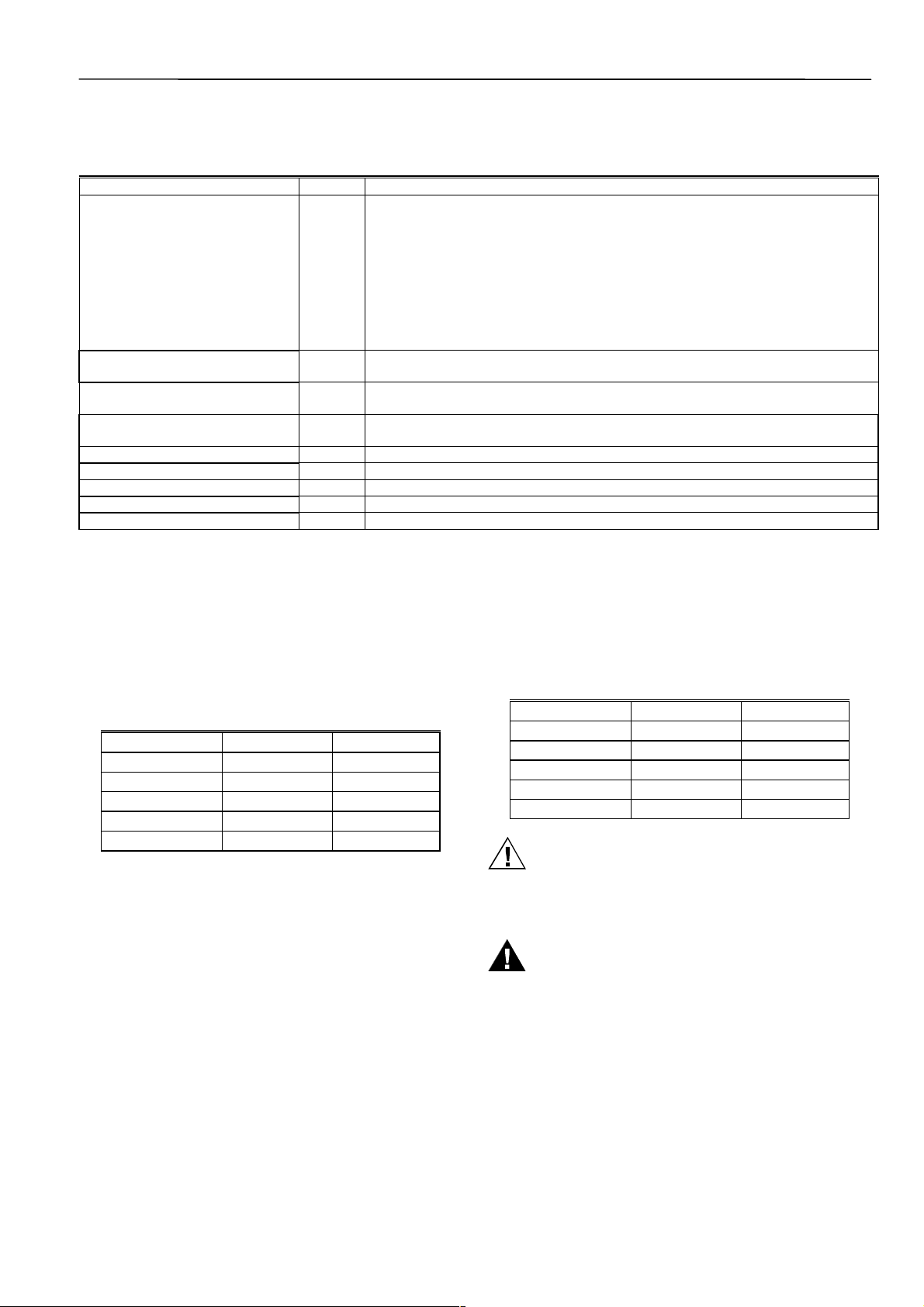

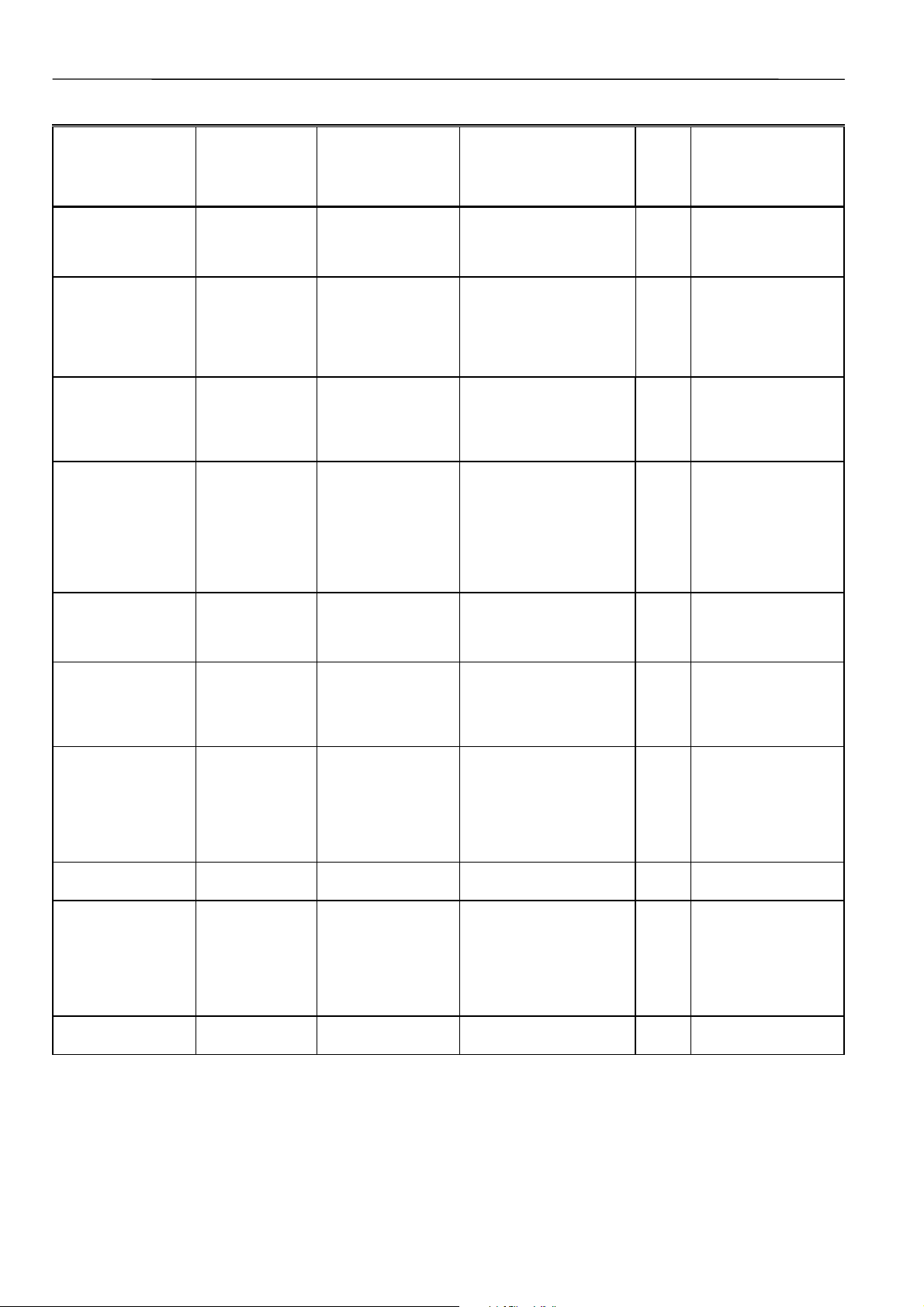

Operating Modes

The possible modes of operation are listed in Table 4.

Table 4. Modes of Operation for Excel 10 FCU Controller

mode description events causing a controller to switch to this mode

operational modes (user address: SrcFcuModeS)

START-UP AND

WAIT

FLOATING

OUTPUTS SYNCH

COOLING The FCU controller is controlling in

HEATING The FCU controller is controlling in

MANUAL MODE The control algorithms stay active

FACTORY TEST Control algorithm is disabled; a

DISABLED Control algorithms are terminated,

PRESSURIZE Heating/cooling outputs are switched

DEPRESSURIZE Heating, cooling and fan outputs are

Control algorithms are disabled.

Outputs stay in their initial positions.

Physical inputs are periodically read

and digital filtering of analog inputs is

turned OFF to speed up settling time.

Input NVs are received and output

NVs are sent periodically.

The FCU controller drives the floating

control valves to their initial positions

and then transitions to one of the

control modes.

the cooling mode.

the heating mode.

and outputs are controlled automatically until set individually to test

positions using the network input

nviTest.

special factory test program runs.

outputs are turned OFF (turn-OFF

sequences and interlocks are active).

Frost protection is disabled.

OFF, and the fan is switched ON at

its highest speed.

switched OFF.

This is the first mode after an application restart.

When the effective occupancy changes to "unoccupied" or

"standby", after start-up, after 24 hours since the last positioning,

or after each positioning to 0%, the FCU controller transitions to

this mode.

Input NV (DestHvacMode) has a value of HVAC_COOL or

HVAC_AUTO and the space temperature is above the cooling

setpoint.

Input NV (DestHvacMode) has the value of HVAC_HEAT or

HVAC_AUTO and the space temperature is below the heating

setpoint.

Input NV (DestManMode) has value of MODE_MANUAL.

This mode is for factory testing, only.

Input NV (DestManMode) has a value of MODE_DISABLED.

Input NV (DestEmerg) containing smoke control signal from C-

Bus has the value of EMERG_PRESSURIZE.

Input NV (DestEmerg) containing smoke control signal from C-

Bus has the value of EMERG_DEPRESSURIZE.

EN0B-0377GE51 R0703 10

Page 11

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Agency Listings

Table 5 provides information on agency listings for Excel 10 FCU Controller products.

Table 5. Agency listings

device agency comments

W7752D to J

FCU Controller

W7752D to J

FCU Controller

W7752D to G

FCU Controller

W7752D to G

FCU Controller

W7754K FCU Controller ??? ???

W7754L FCU Controller ??? ???

W7754M FCU Controller ??? ???

W7754N FCU Controller ??? ???

W7754P FCU Controller ??? ???

CE General Immunity per European Consortium standards EN50081-1 (CISPR 22

Class B) and EN 50082-1:1992 (based on Residential, Commercial, and Light

Industrial).

EN 61000-4-2 IEC 1000-4-2 (IEC 801-2) Electromagnetic Discharge.

EN 50140, EN 50204 IEC 1000-4-3 (IEC 801-3) Radiated Electromagnetic Field.

EN 61000-4-4 IEC 1000-4-4 (IEC 801-4) Electrical Fast Transient (Burst).

Radiated Emissions and Conducted Emissions.

EN 55022:1987 Class B.

CISPR-22: 1985.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing

Device.

UL Tested and listed under UL 916 (file number E87744).

Ambient Temperature Rating: 32...122 °F (0...50 °C).

cUL Tested and listed under UL 916 (file number E87744).

Ambient Temperature Rating: 32...122 °F (0...50 °C).

Construction

Excel 10 W7752 FCU Controllers

The Excel 10 W7752 FCU Controller is available in five basic

models, each with two different possibilities for L

transceivers. All of these controllers are mains-powered, and

two models are equipped with an additional high-power relay

for applications with electric reheat. Table 6 shows the

differences between models.

Table 6. Excel 10 W7752 FCU Controller models

OS number Power input Reheat relay

W7752D2007 230 Vac X

W7752E2004 230 Vac

W7752F2002 115 Vac X

W7752G2000 115 Vac

W7752J2003 100 Vac

All wiring connections to the controllers are made at screw

terminal blocks accessible beneath a plastic safety cover.

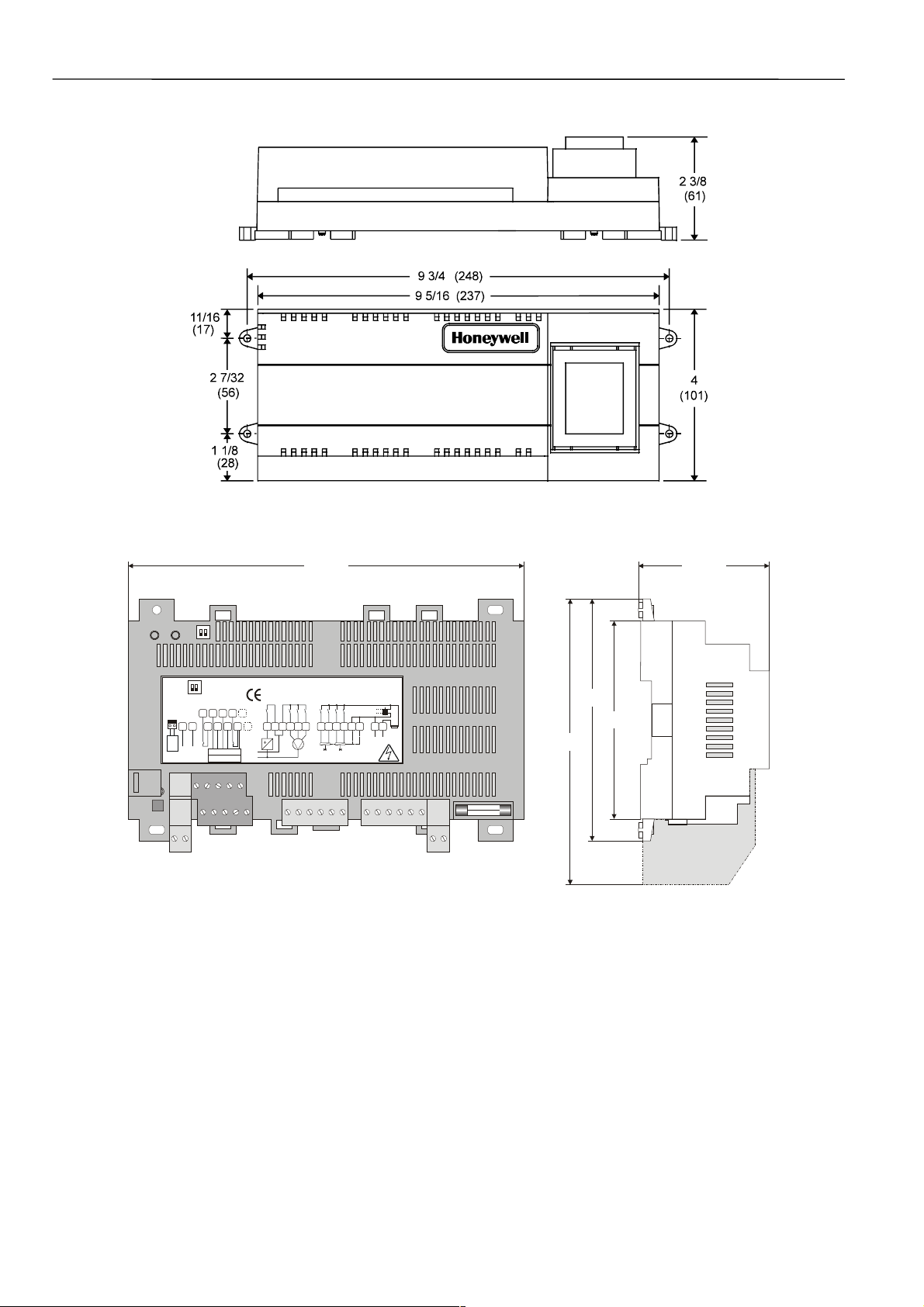

Mounting dimensions are shown in Fig. 6.

ONWORKS

Excel 10 W7754 FCU Controllers

The Excel 10 W7754 FCU Controller is available in five basic

models, each with two different possibilities for L

transceivers. Table 7 shows the differences between models.

Table 7. Excel 10 W7754 FCU Controller models

OS number Power input Reheat relay

W7754K1001 230 Vac X

W7754L1009 24 Vac

W7754M1007 230 Vac

W7754N1004 230 Vac

W7754P1000 230 Vac

ONWORKS

CAUTION

If FCU Controllers are mounted vertically and thermal

actuators are used, the transformer must not be

located below the electronics due to heating effects.

WARNING

Electrical Shock Hazard.

Mains power at terminal block can cause personal

injury or death. FCU Controllers must be mounted

inside their fan coil unit boxes to prevent access by

unauthorized personnel.

To reduce the risk of fire or electric shock, install in a

controlled environment relatively free of contaminants.

11 EN0B-0377GE51 R0703

Page 12

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Fig. 6. W7752 construction in inches (mm)

WALL MOD.

+ -

RS1A

59.5180

ONUNUSED

UNUSED

DI2

USED

USED

GND9LED10FAN11DI2

8

321 4 5 6 23247

DI1

SET

5342 1

T7460 / T7560

SENS

23D25

LON

12

GND

0345

230 V

W7754Kxxxx

230 Vac, 50/60 Hz

max. 5 VA unloaded

1314 15 181716

L

N

2 A10A

III II I

Honeywell

D-71101 Schönaich

Made in Germany

triac

0.5 A

1920 2122

close

fan

OUT1 OUT2

230 Vac

2526

2A/M

LN

com

com

open

open

close

230 V

Fig. 7. "7754 dimensions (in mm)

130

110

90

terminal protection

cover (optional)

EN0B-0377GE51 R0703 12

Page 13

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

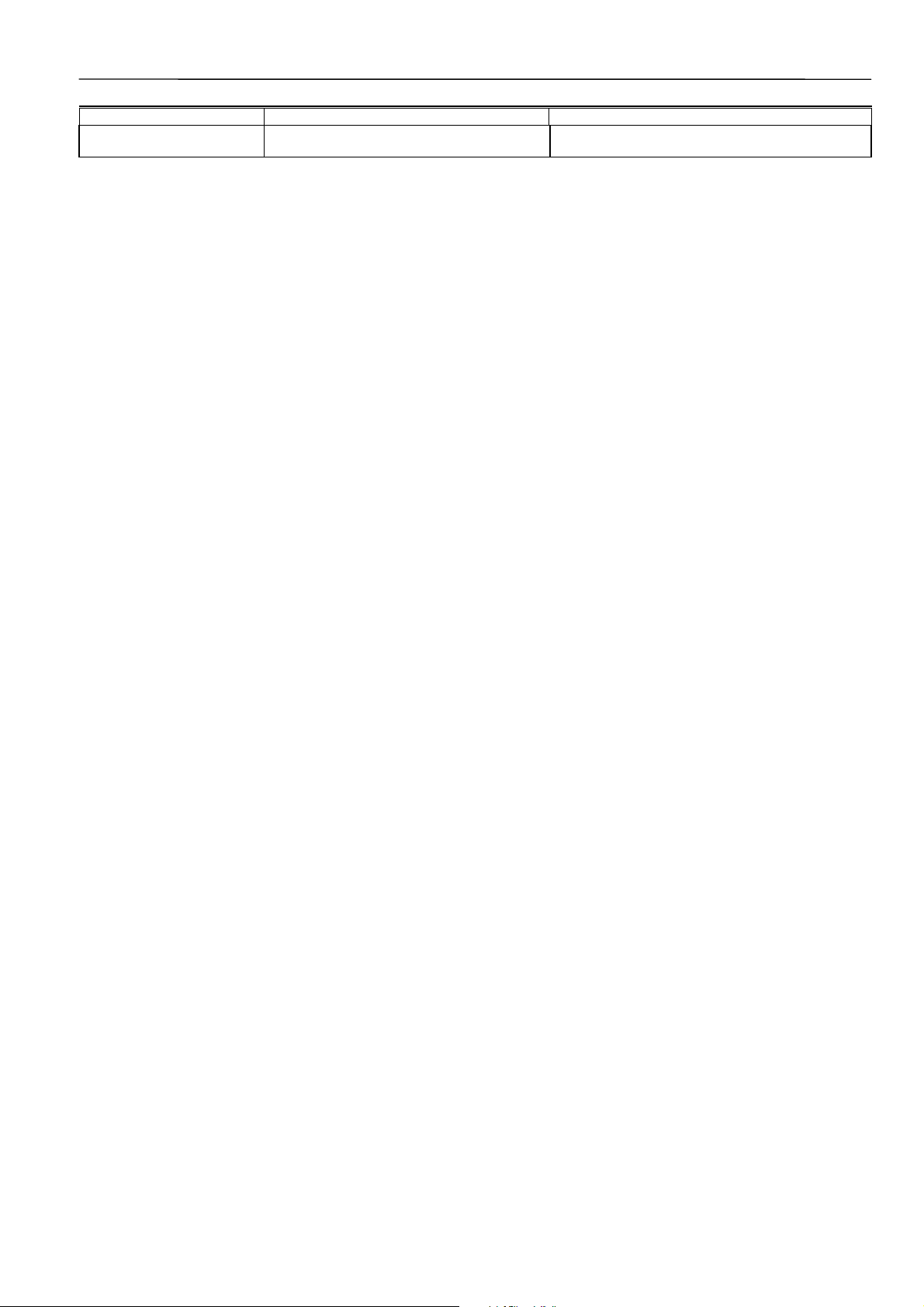

Controller Performance Specifications

Power:

W7752D and W7752E; W7754K,M,N,P

230 Vac +10%, -15%, 50/60 Hz.

W7752F and W7752G

115 Vac +10%, -15%, 50/60 Hz.

W7752J

100 Vac ±6%, 50/60 Hz.

W7754L

24 Vac ±20%, 50/60 Hz.

Operating Temperature:

32...122°F (0...50°C).

Shipping/Storage Temperature:

-40...+158°F (-40...+70°C).

Relative Humidity:

5% to 95% non-condensing

Inputs:

Temperature Sensor:

20k ohm NTC

Setpoint Potentiometer:

10k ohm

Digital Input:

Closed ≤ 400 ohms

Open ≥ 10 K ohms

Outputs:

Triac voltage range:

24 Vac ± 20%.

Triac max. current ratings:

250 mA continuous

650 mA surge for 30 sec.

IMPORTANT:

When any device is energized by a Triac, the device

must be able to sink a minimum of 15 mA. If nonHoneywell motors, actuators, or transducers are to be

used with Excel 10 FCU Controllers, compatibility must

be verified.

nviSpaceTemp

nv1

SNVT_temp_p

nviSetPoint

nv2

SNVT_temp_p

nviFanSpeedCmd

nv6

SNVT_switch

nviOccCmd

nv7

SNVT_occupancy

nviApplicMode

nv8

SNVT_hvac_mode

nviSetPtOffset

nv9

SNVT_temp_p

nviWaterTemp

nv10

SNVT_temp_p

nviDischAirTemp

nv17

SNVT_temp_p

nviEnergyHoldOff

nv18

SNVT_switch

Hardware

Output

Fan Coil Unit Controller

Object #8020

nvoHeatOutput

nv3

SNVT_lev_percent

Mandatory

Network

Variabl es

Optional

Network

Variabl es

nvoCoolOutput

nv4

SNVT_lev_percent

nvoFanSpeed

nv5

SNVT_switch

nvoTerminalLoad

nv11

SNVT_lev_percent

nvoLoadAbs

nv12

SNVT_power

nvoDischAirTemp

nv13

SNVT_temp_p

nvoReheat

nv14

SNVT_switch

nvoSpaceTemp

nv15

SNVT_temp_p

nvoEffectSetPt

nv16

SNVT_temp_p

nvoEffectOcc

nv19

SNVT_occupancy

nvoEnergyHoldOff

nv20

SNVT_switch

nvoUnitStatus

nv21

SNVT_hvac_status

Configuration Properties

nc49 - nciSndHrtBt SNVT_time_sec mandatory

nc52 - nciMinOutTm SNVT_time_sec optional

nc48 - nciRcvHrtBt SNVT_time_sec optional

nc17 - nciLocation SNVT_str_asc optional

nc60 - nciSetPnts

nc59 - nciNumValve

SNVT_temp_setpt

SNVT_count

mandatory

optional

Fan relays voltage range:

20 to 253 Vac

Fan relays max. current rating:

3 A

Electric reheat relay voltage range:

20 to 253 Vac

Electric reheat relay max. current rating:

10 A

6 A (UL916)

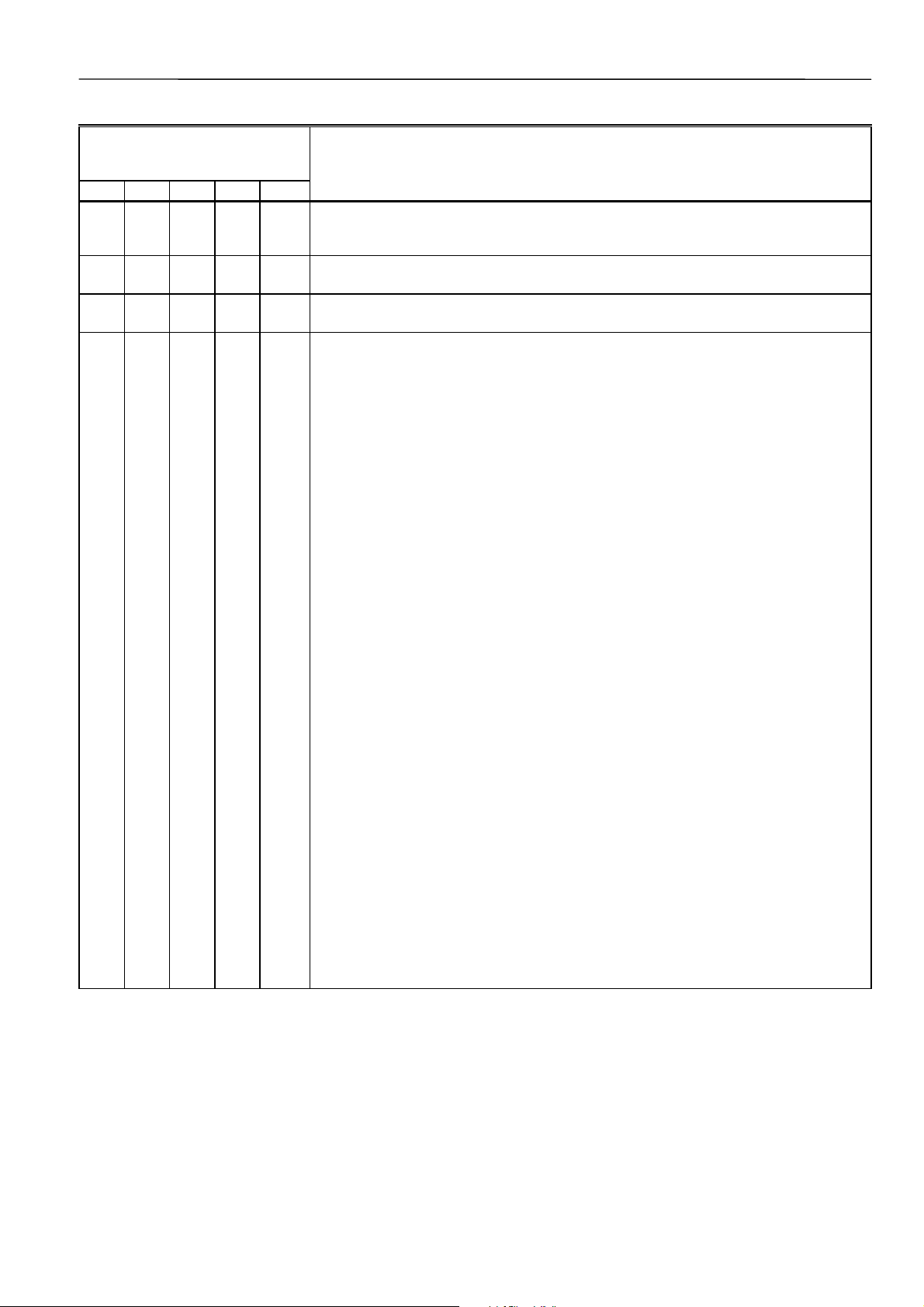

Interoperability

The W7752 Controllers use the LonTalk protocol. They

support the L

ONMARK Functional Profile # 8020 “Fan Coil Unit

Controller”, version 2.0. Fig. 8 shows the implementation

used.

nviSensorOcc

SNVT_Occupancy

Manufacturer

Defined

nvoSensorOcc

SNVT_occupancy

Section

nviEmerg

SNVT_hvac_emerg

nviReheatRelay

SNVT_switch

nvoDigitInState

SNVT_switch

Hardware

Input

NOT SUPPORTED.

Fig. 8. LONMARK FCU object profile

13 EN0B-0377GE51 R0703

Page 14

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

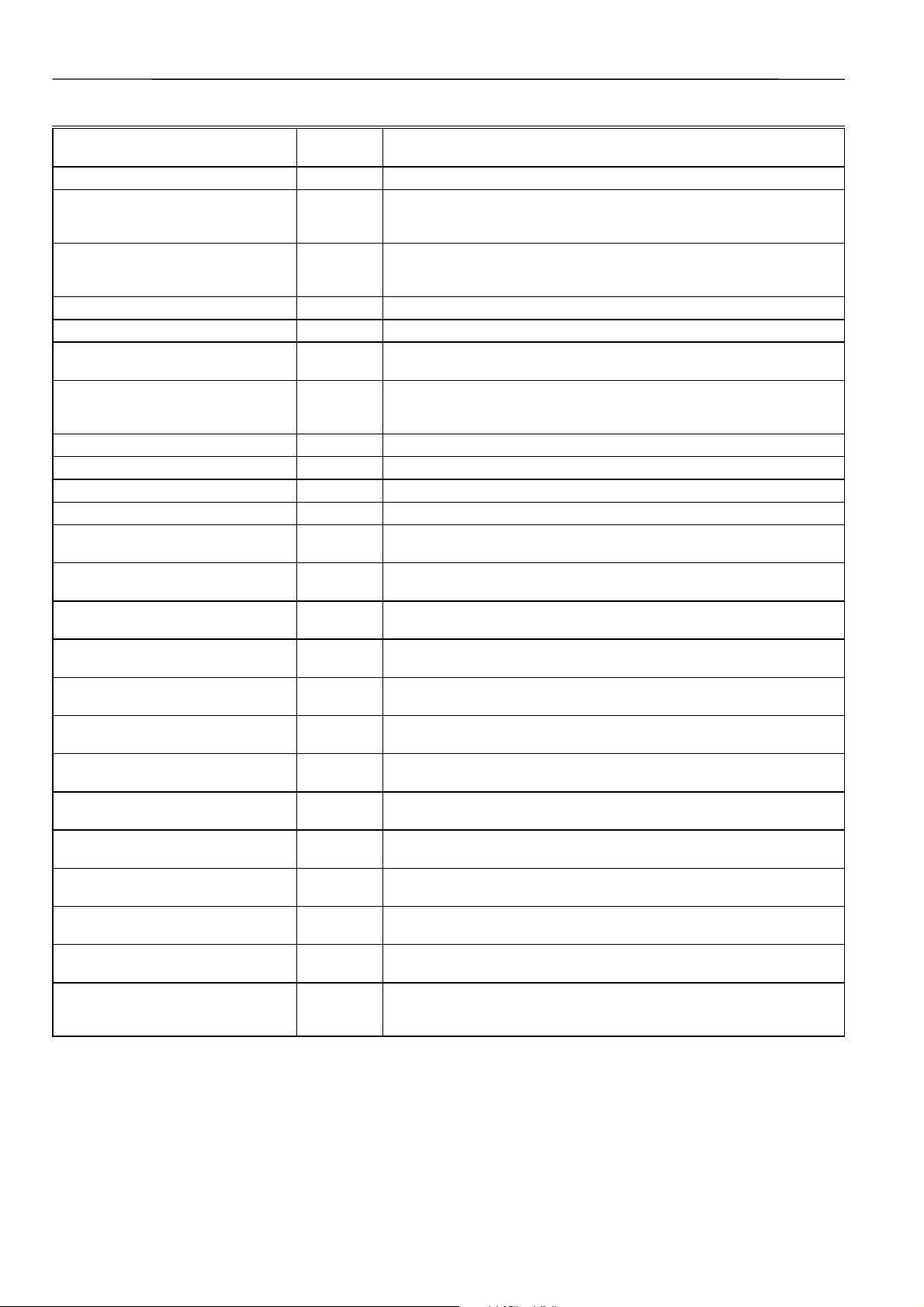

Configurations

General

The following sections provide an overview of the Excel 10

FCU Controller options related to inputs and outputs. See

section "Step 6. Configure Controllers" (page 28) for a

complete list of configuration options and defaults.

Table 8. Hardware options summary

option possible configurations

fan type no fan

fan interlock enabled

FCU system type two-pipe

output 1 actuator type floating

output 2 actuator type floating

valve direction direct

reheat none

digital input not used

wall module option local

temperature sensor

type

NOTE:

1

The floating-mid option is only for changeover applications

and uses only one of the two outputs.

one-speed

two-speed

three-speed

disabled

four-pipe

floating mid (one for heat/cool)

one-stage

two-stage

three-stage

PWM

thermal

floating mid (one for heat/cool)

one-stage

two-stage

three-stage

PWM

thermal

reverse

reheat (W7752D and F only)

free use (W7752D and F only)

W7754?

window closed

occupied sensor

air flow detector

cool changeover

window open

unoccupied sensor

no air flow

heat changeover

movement

no movement

shared

none

NTC non-linearized

1

1

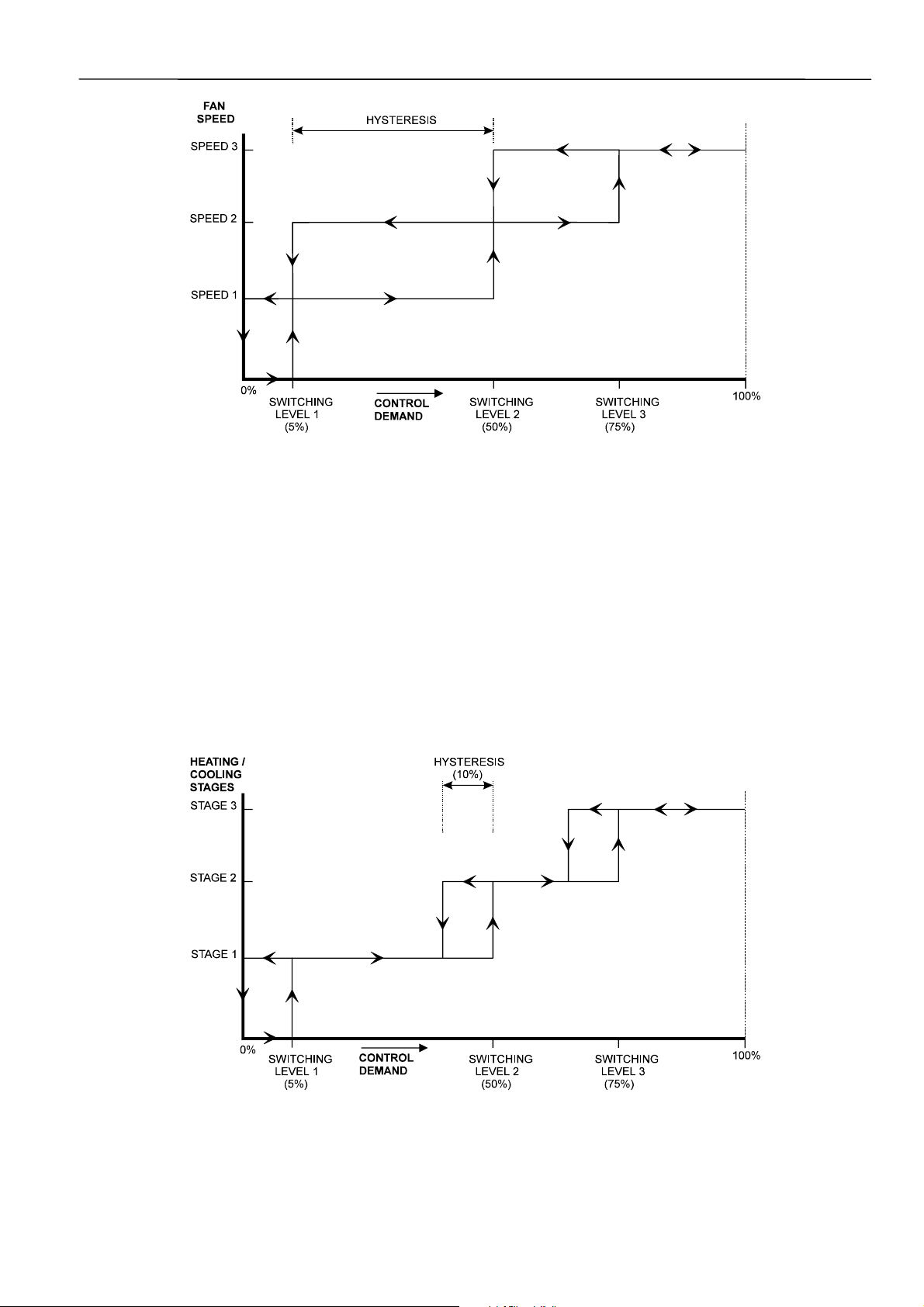

Fan Type

Each fan coil unit controlled by an FCU controller can have a

fan with up to three different speeds or no fan at all. Multispeed fans are switched at the same switching levels as

multi-staged heating control points (see Fig. 9). For example,

a three-speed fan will switch ON its first speed at the same

control level as the first stage of heating or cooling up until

the second stage of heating or cooling where the second fan

speed will switch ON. A two-stage fan will switch with the first

two stages of a 3-stage heating or cooling system. Likewise,

a single-speed fan will turn ON at the first stage of any multistaged system. Conversely, a multi-speed fan may follow

multiple switching levels even for single-staged, floating,

PWM, or thermal actuator-based systems.

Hysteresis

The hysteresis for fan speed extends to the next lower

switching level (or a control level of 0) as is shown in Fig. 9.

For example, the second fan speed will remain ON until the

control level falls below the switching point for the first fan

speed. Min. ON and OFF times can be configured and will

apply to all fan switching points.

Interlock

A fan interlock can be configured which prevents heating or

cooling outputs from being turned ON in the event of a fan

failure (where an air flow detector is installed to detect fan

failure). When fan interlock is configured, run-up and overrun

times can be configured to delay switching ON the heating or

cooling equipment after switching ON the fan and delay

switching OFF the fan after the heating or cooling equipment

is switched OFF.

The fan can be configured to run continuously during the

zero energy band during occupied periods.

EN0B-0377GE51 R0703 14

Page 15

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Fig. 9. Three-speed fan switching and hysteresis, cooling mode (defaults for switching levels shown)

Type of Heating and Cooling Equipment

The FCU controller can operate with either two-pipe or fourpipe systems. A two-pipe system requires a changeover input

to the controller (hardware or network input).

The FCU controller can operate with a variety of actuators for

heating and cooling equipment. Floating actuators can be

used which will require specifying the valve run time during

configuration of the controller. Valve action can be configured

as either direct or reverse. When in a two-pipe system with a

changeover input, a floating actuator can be used which has

the middle position (50%) as the zero energy position. The

cool range is then 0 to 50% and the heat range 50 to 100%.

The output must be configured as floating-mid.

Multi-stage systems can be controlled with up to three

different stages of heating/cooling control. Switching levels

are specified in % of control level (see Fig. 10) as is a

hysteresis setting which applies to all switching levels.

Heating and cooling switching levels and hysteresis are

specified separately. Min. OFF times can be configured, and

for one-, two- and three-stage systems, a min. ON time can

also be configured.

PWM electronic valves and thermal actuators can also be

connected and can be configured as either direct or reverse

action. The cycle time must be specified during configuration.

In the case of PWM valves, the zero and full positions must

also be configured.

Fig. 10. Three-stage heating/cooling switching (defaults for switching levels and hysteresis shown)

15 EN0B-0377GE51 R0703

Page 16

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

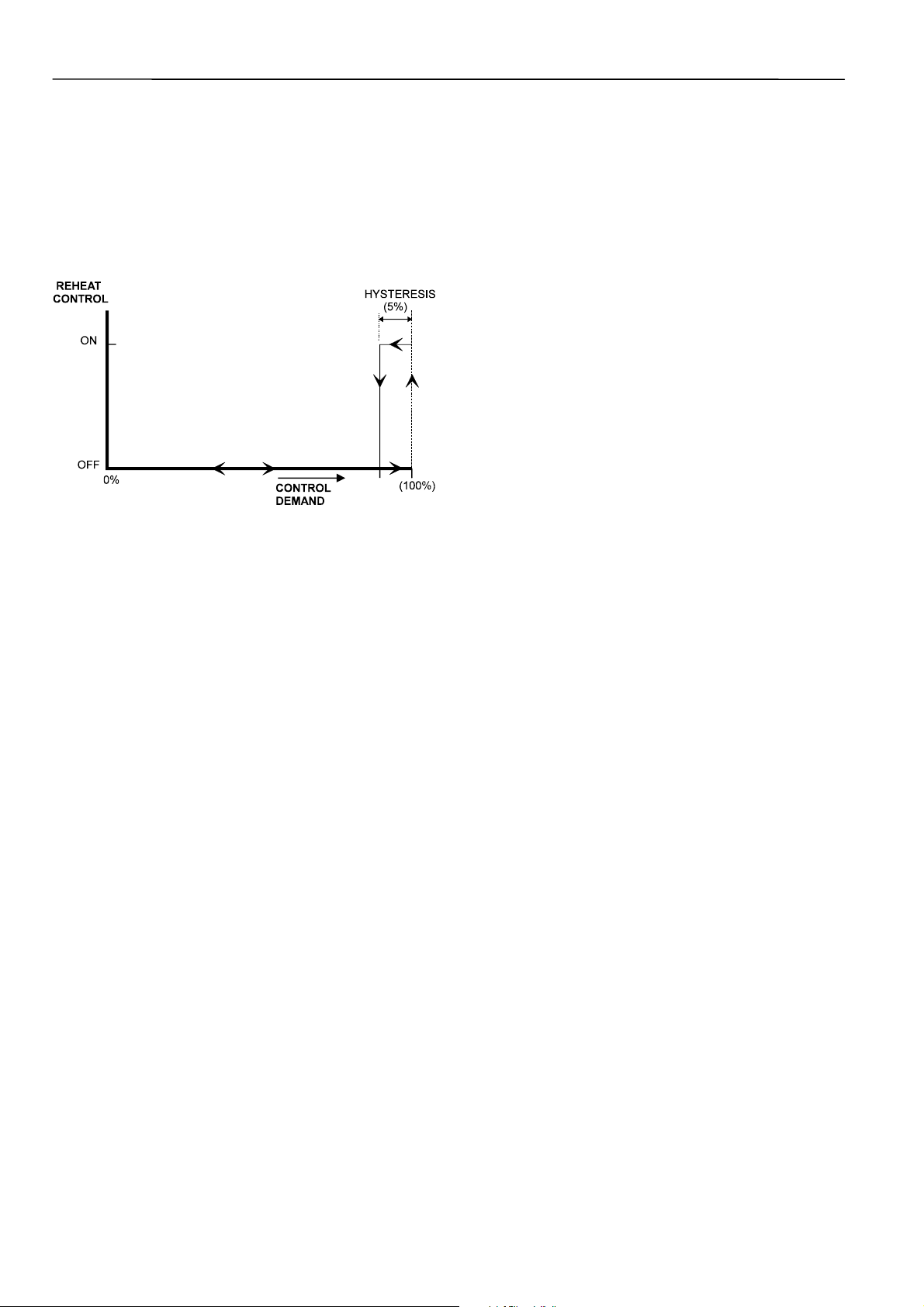

Reheat Output

W7752D and F Controllers have an additional high-current of

10 A max. (UL916: 6 A max.) output relay to control an electric reheater (refer to Fig. 2 for sample application). The

reheat output has its own switching level and hysteresis

settings (see Fig. 11). The reheat relay may also be used as

an auxiliary output for other purposes, in which case the

W7752 must be configured to specify that the output is under

the control of the L

control algorithm.

Fig. 11. Reheat switching and hysteresis (defaults

ONWORKS network, and not of the FCU

shown)

Digital Input

There is a single digital input in the W7752 Controller which

may be configured to accommodate an occupancy sensor, a

window open/closed contact, an air flow detector (for fan

failure detection), or a changeover input. It is possible to

configure this input for either normally-open or normallyclosed contacts for any of the switches.

The control algorithm in the Excel 10 FCU controller uses the

occupancy sensor, if configured, to determine the effective

occupancy mode (see Table 3). If the Time Of Day (TOD)

schedule indicates an occupied state, and the eccupancy

sensor contact is closed, the effective occupancy mode will

be "occupied". However, if the TOD schedule indicates an

occupied state and the occupancy sensor contact is open,

then the effective occupancy mode will be "standby". The

control algorithm will then control according to the "standby"

setpoints configured for the heating and the cooling modes.

Configuring the digital input for movement or no movement

(dependent upon normally-open or normally-closed contacts)

adds a delay of 15 minutes to the occupancy sensor such

that the space is considered occupied until 15 minutes has

elapsed since the last movement is detected.

If the digital input is configured to read input from a window

open/closed contact, heating, cooling, and fan control will be

disabled while the window is detected open. Frost protection

will be enabled. A set of contacts may be wired in series for

multiple windows. If the window open/closed contact is not

configured, a one-to-one association (binding) of the window

sensor from another controller on the L

can be made. A locally-wired contact can also be used in

combination with the network input, the result being a logical

OR of the inputs.

If the digital input is configured to read input from an air flow

detector (fan status), heating and cooling control will be

disabled for a fan failure (fan ON and no air flow detected).

The input may also be configured for changeover for a twopipe system.

NOTE: The Excel 10 FCU Controller has limited power

available (only 1.5 mA/4.8 V) for checking the digital

input for contact closures. Ensure that contacts

used remain within the specified resistance

tolerance range (closed ≤ 400 ohms) even when

aged.

ONWORKS network

EN0B-0377GE51 R0703 16

Page 17

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Excel 10 Wall Module Options

A typical FCU installation will include an Excel 10 wall

module containing a 20k ohm NTC room temperature sensor

and additional features depending on the wall module type

(see Excel 10 wall module literature for further information).

The FCU controller can use a return air sensor rather than

the sensor in the wall module if it is wired to the wall module

sensor input. Setpoint adjustments can be configured as

relative or absolute, and upper and lower limits can be set. A

configuration option for the fan speed switch allows it to be

disabled if not required. The bypass button can be configured

to override the control mode to "occupied" for a configurable

bypass time and to override the control mode to

"unoccupied" for an indefinite time, or it may be configured to

only override to "occupied". The button may also be used to

cancel the override.

Common Temperature Control (Master/Slave Controllers)

When one or more FCU controllers serve a common area

and a single temperature sensor is to be used, a

master/slave arrangement can be configured. One Excel 10

FCU Controller is configured for the local wall module with

the desired options. The other Excel 10 FCU Controller(s) will

be configured without wall modules and with certain network

variables bound with the master controller. Refer to

Application Step 6 of this document for more details.

IMPORTANT

The slave units must have the same HVAC equipment

connected to it as the master units.

The slave units will not use any internal temperature

setpoints or control algorithms. The master controller

determines heating/cooling output based upon setpoints

and occupancy and L

ONWORKS network command

mode status and communicates this to the slave via the

ONWORKS network.

L

17 EN0B-0377GE51 R0703

Page 18

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Abbreviations and Definitions

CARE Computer Aided Regulation Engineering;

C-Bus Honeywell proprietary Control Bus for

CPU Central Processing Unit; an EXCEL 5000

Echelon

EMS Energy Management System; refers to the

EEPROM Electrically Erasable Programmable Read

EPROM Erasable Programmable Read Only

E-Vision PC-based tool used for configuration and

Excel 10 Zone Manager - A controller that is used to

Firmware Software stored in a nonvolatile memory

the PC based tool used to configure C-Bus-

Bus devices.

communications between EXCEL 5000

System controllers and components.

System controller module.

®

The company that developed the

ONWORKS

L

®

network and the Neuron

chips used to communicate on it.

EMI Electromagnetic Interference; electrical

noise that can cause problems with

communications signals.

controllers and algorithms responsible for

calculating optimum operational

parameters for max. energy savings in the

building.

Only Memory; the variable storage area for

saving user setpoint values and factory

calibration information.

Memory; the firmware that contains the

control algorithms for the Excel 10 FCU

Controller.

commissioning of Excel 10 devices.

interface between the C-Bus and the

ONWORKS network. The Excel 10 Zone

L

Manager also has the functionality of an

Excel 100 Controller, but has no physical

I/O points. (Note: The Q7750A Zone

Manager may be referred to as E-Link.)

medium such as an EPROM.

I/O Input/Output; the physical sensors and

actuators connected to a controller.

I x R I times R or current times resistance; refers

to Ohms Law: V = I x R.

K Kelvin.

LiveCARE The PC based tool used to monitor and

®

ONWORKS Echelon® LONWORKS® network for

L

®

change parameters in C-Bus devices.

communication among Excel 10 FCU

controllers.

NEC National Electrical Code; the body of

®

standards for safe field-wiring practices.

NEMA National Electrical Manufacturers

Association; the standards developed by an

organization of companies for safe field

wiring practices.

NV Network Variable; an Excel 10 FCU

controller parameter that can be viewed or

modified over the L

ONWORKS network.

OEM Original Equipment Manufacturer; the

company that builds the fan coil units.

PC Personal Computer.

Pot Potentiometer. A variable resistance

electronic component located on Excel 10

wall modules. Used to allow user-adjusted

Setpoints to be inputted into the Excel 10

FCU Controller.

segment A L

ONWORKS section containing no more

than 60 Excel 10s. Two segments can be

joined together using a router.

Subnet An L

ONWORKS segment that is separated

by a router from its Q7750A Zone Manager.

TOD Time-Of-Day; the scheduling of Occupied

and Unoccupied times of operation.

VA Volt Amperes; a measure of electrical

power output or consumption as applicable

to an ac device.

Vac Voltage alternating current; ac voltage as

opposed to dc voltage.

XBS Excel Building Supervisor; a PC based tool

for monitoring and changing parameters in

C-Bus devices.

EN0B-0377GE51 R0703 18

Page 19

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

APPLICATION STEPS

Overview

Steps one through seven, see Table 9, address considerations for engineering an Excel 10 FCU System. These

steps are guidelines intended to aid understanding of the product I/O options, bus arrangement choices, configuration

options and the Excel 10 FCU Controllers’ role in the overall

EXCEL 5000

Step No. Description

Step 1. Plan the System

Plan the use of the FCU controllers according to the job

requirements. Determine the location, functionality and

sensor or actuator usage. Verify the sales estimate of the

number of FCU controllers and wall modules required for

each model type. Also check the number and type of output

actuators and other accessories required.

When planning the system layout, consider potential expansion possibilities to allow for future growth. Planning is

very important to be prepared for adding HVAC systems and

controllers in future projects.

®

System architecture.

Table 9. Application steps

1 Plan the System

2 Determine Other Bus Devices Required

3 Lay out Communication and Power Wiring

4 Prepare Wiring Diagrams

5 Order Equipment

6 Configure Controllers

7 Troubleshooting

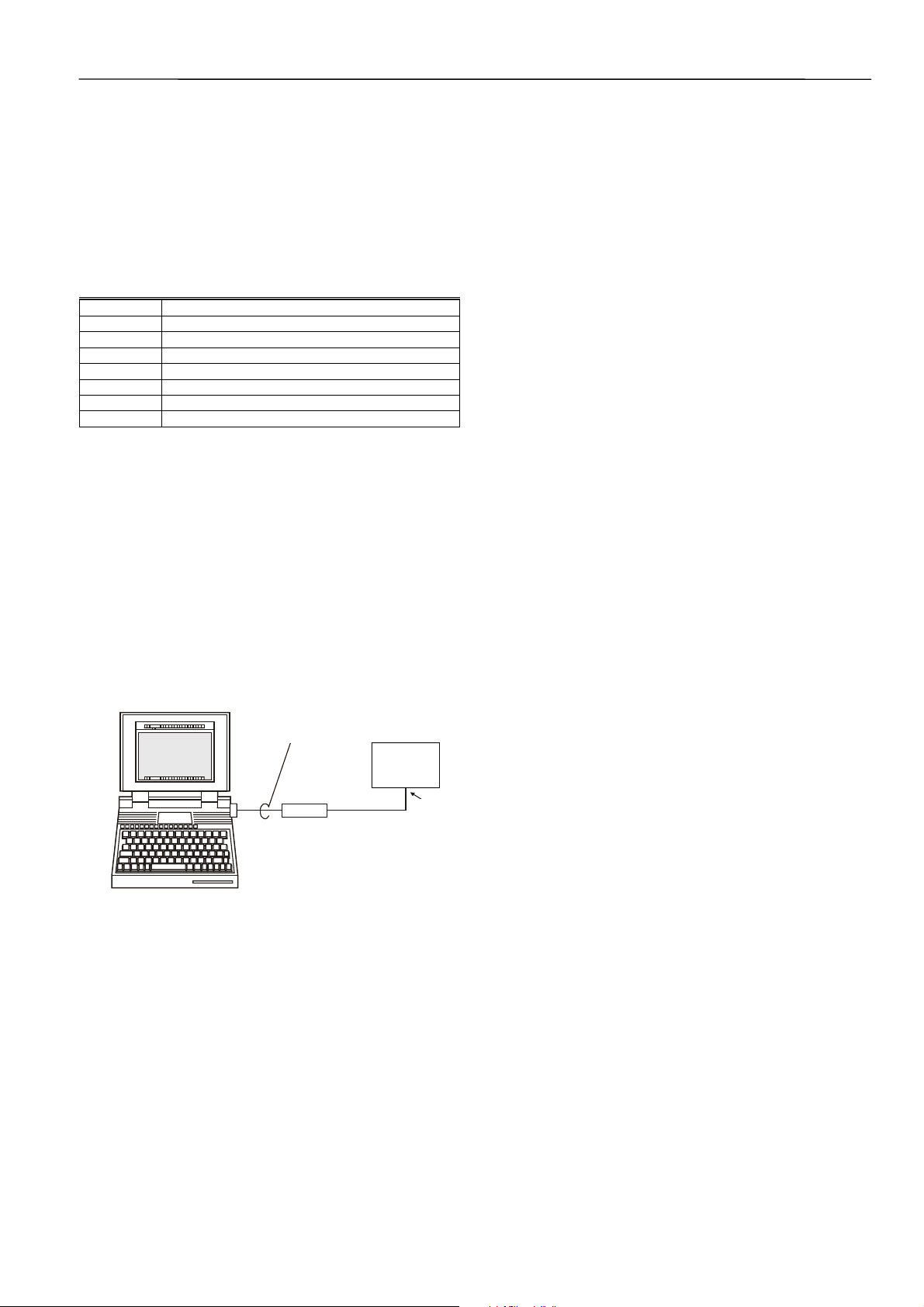

notebook PC

using E-Vision

shielded

interface

cable

Excel 10

FCU

RS-232

serial

port

SLTA

controller

LonWorks

port

The L

ONWORKS communication loop between controllers

must be laid out according to the guidelines applicable for

that topology. FCU Controllers use FTT technology which

allows daisy chain, star, loop or combinations of these bus

configurations. See section "Step 3. Lay Out

Communications and Power Wiring" (page 20) for more

information on bus wiring layout, and see Fig. 13, Fig. 14,

and Fig. 15 in section "Step 4. Prepare Wiring Diagrams"

(page 22) for wiring details.

It is important to understand the interrelationships between

FCU controllers on the L

ONWORKS network early in the job

engineering process to ensure their implementation when

configuring the controllers. (See section "Step 6. Configure

Controllers" [page 28] for information on the various Excel 10

FCU Controller parameters and on Excel 10 FCU Controller

point mapping.)

Step 2. Determine Other Bus Devices

Required

A max. of 62 nodes can communicate on a single LONWORKS

segment. If more nodes are required, a router is necessary.

Using a router allows up to 125 nodes, divided between two

ONWORKS segments. The router accounts for two of these

L

nodes (one node on each side of the router); a Q7750A Excel

10 Zone Manager can take one node and two slots are

available for operator terminal nodes, leaving 120 nodes

available for Excel 10 FCU Controllers. All 120 controllers are

able to communicate through the router. A Q7750A Excel 10

Zone Manager is required to connect the L

to the standard EXCEL 5000 System C-Bus. Each Excel 10

Zone Manager can support no more than 120 W7752s. This

is a limit set in the Excel 10 Zone Manager database and is

an absolute maximum.

ONWORKS segment is set up with two unused nodes to

Each L

allow for an E-Vision operator terminal to be connected to the

ONWORKS network. Multiple E-Vision terminals can be

L

connected to the bus at the same time. Table 10 summarizes

ONWORKS segment configuration rules.

the L

ONWORKS network

Fig. 12. Connecting the portable operator terminal to the

ONWORKS network

L

19 EN0B-0377GE51 R0703

Page 20

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Table 10. LonWorks configuration rules and device node numbers

One L

ONWORKS Segment Example max. number of nodes equals 62

one Q7750A Excel 10 Zone Manager 1 node

port for operator terminal access (E-Vision) 1 node

max. number of Excel 10 Controllers 60 nodes (wall modules are not LONWORKS nodes)

Total 62 nodes

Two LONWORKS Segments Example max. number of nodes equals 125

one Q7750A Excel 10 Zone Manager 1 node

one Q7751A Router 2 nodes (1 in each Bus Segment)

ports for operator terminal access (two E-Vision terminals) 2 nodes (1 in each Bus Segment)

max. number of Excel 10 Controllers in segment number one 60 nodes (wall modules are not LONWORKS nodes)

max. number of Excel 10 Controllers in segment number two 60 nodes (wall modules are not LONWORKS nodes)

Total 125 nodes

The max. length of an FTT LONWORKS segment is 4600 ft

(1400 m) for a daisy chain configuration or 1650 ft (500 m)

total wire length and (400 m) node-to-node for any other type

of configuration.

NOTE: In the case of FTT L

ONWORKS segments, the

distance from each transceiver to all other transceivers and to the termination must not exceed the

max. node-to-node distance. If multiple paths exist,

the longest one should be used for the calculation.

If longer runs are required, add a Q7751A Router to partition

the system into two segments. It is not legal to use more than

one router per Excel 10 Zone Manager.

In addition, all L

a Bus Termination Module. For an FTT L

ONWORKS segments require the installation of

ONWORKS segment,

one or two Termination Modules may be required depending

upon the bus configuration. See section "Step 3. Lay Out

Communications and Power Wiring" (page 20) and the

ONWORKS Termination Module subsection in section "Step

L

4. Prepare Wiring Diagrams" (page 22) for more details.

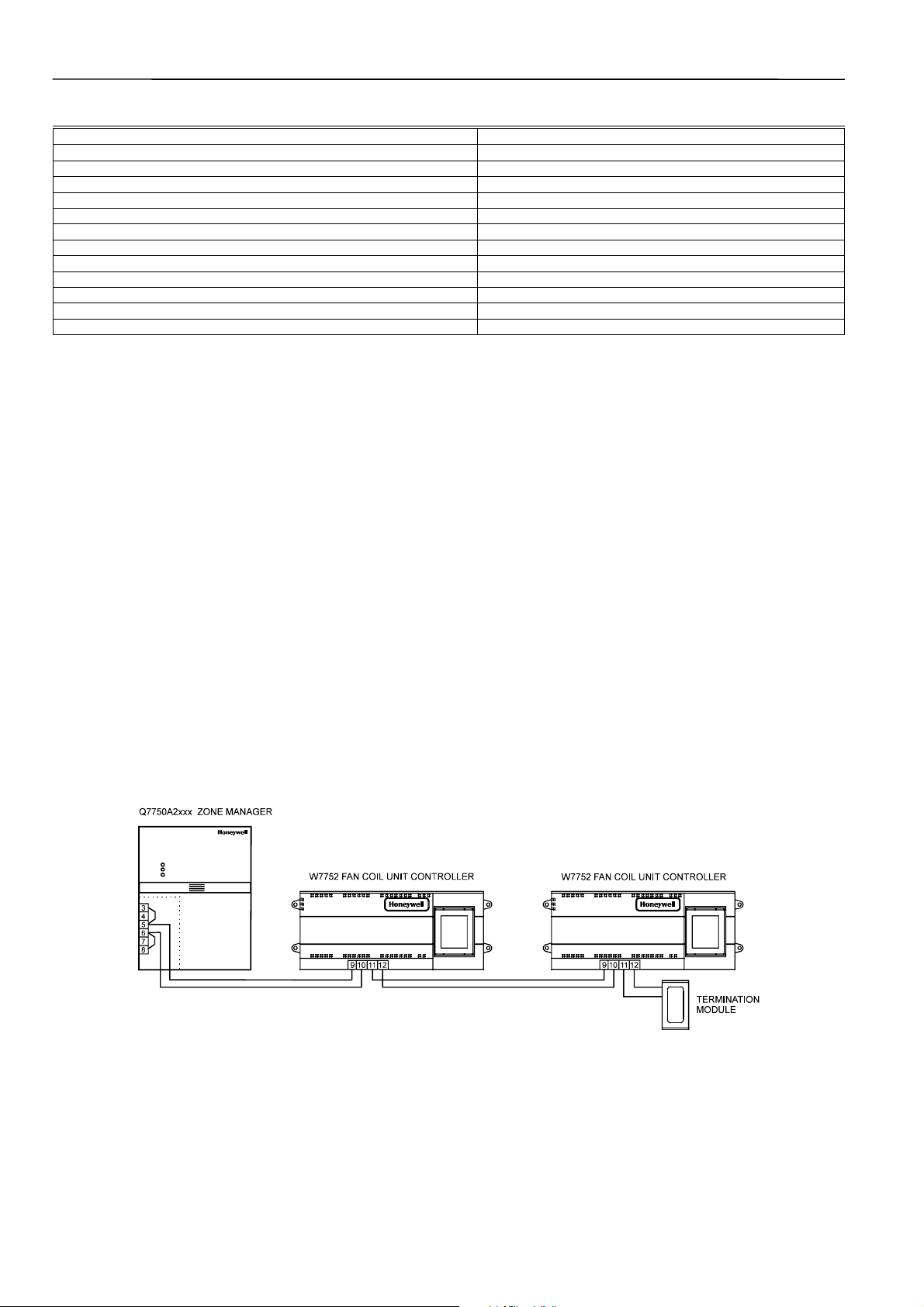

Step 3. Lay Out Communications and Power

Wiring

LONWORKS Layout

The communications bus, LONWORKS, is a 78-kilobit serial

link that uses transformer isolation and differential

Manchester encoding. Wire the L

AWG or plenum rated level IV 22 AWG non-shielded, twisted

pair, solid conductor wire as the recommended wire size (see

Table 11 for part numbers). An FTT L

in daisy chain, star, loop or any combination thereof as long

as the max. wire length requirements given in Step 2 are met.

NOTE: Due to the transformer isolation, the bus wiring does

not have a polarity; that is, it is not important which

of the two L

ONWORKS terminals are connected to

each wire of the twisted pair.

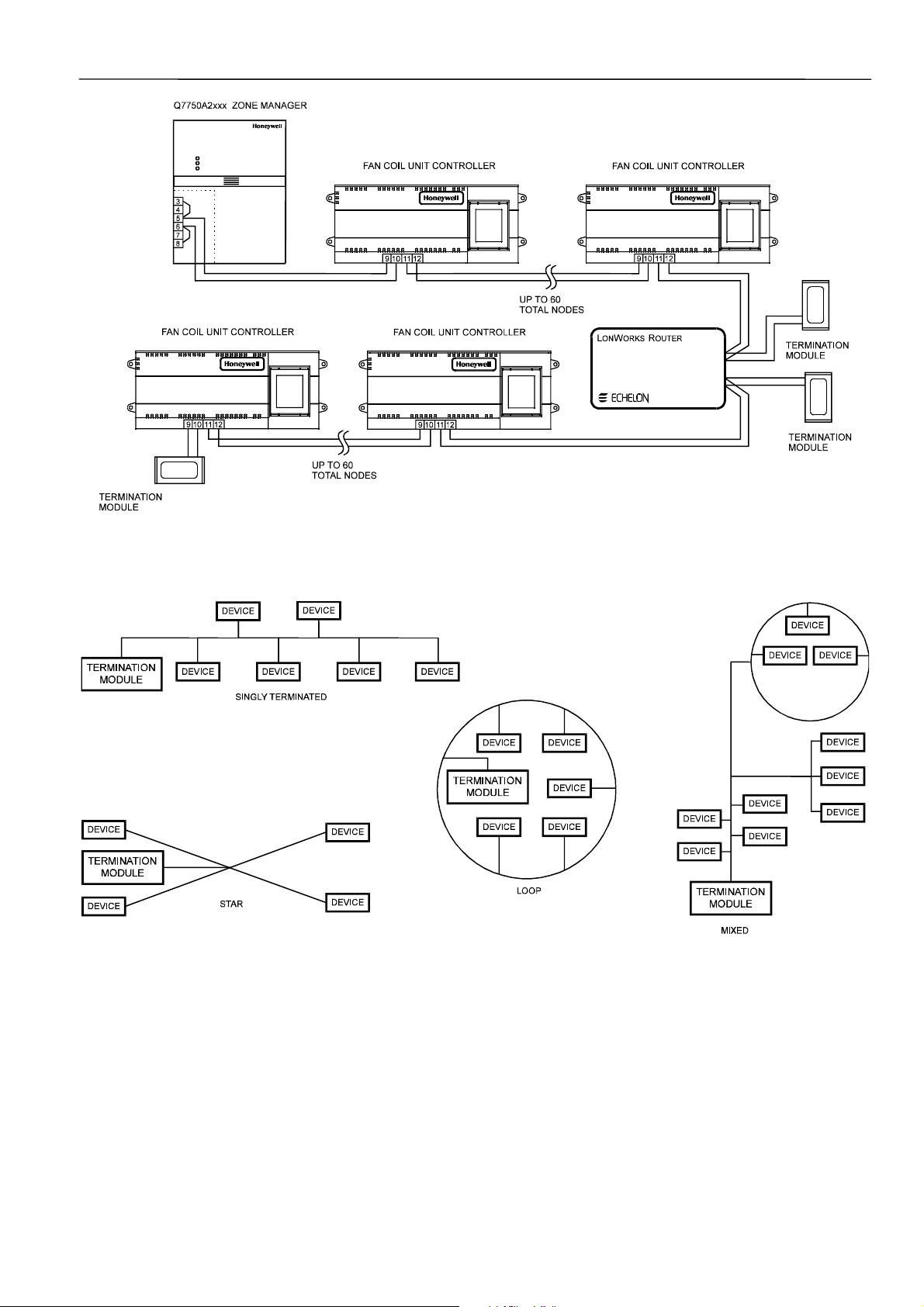

LONWORKS networks can be configured in a variety of ways,

but the rules listed in Table 10 always apply. Fig. 13 and Fig.

14 depict two typical daisy chain L

one as a single bus segment that has 60 nodes or less, and

one showing two segments. Fig. 15 shows examples of free

topology bus layouts using 2000-series devices. The bus

configuration is set up using the Network Manager tool from

within E-Vision (see the E-Vision User Guide).

ONWORKS using level IV 22

ONWORKS can be wired

ONWORKS network layouts;

Note: C7750A Zone Manager has internal termination module (with jumpers installed as shown).

Fig. 13. LONWORKS wiring layout for one daisy-chain network segment

EN0B-0377GE51 R0703 20

Page 21

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Fig. 14. LONWORKS wiring layout for two daisy-chain network segments

Fig. 15. Free topology LONWORKS layout examples

NOTE: See section "L

ONWORKS Termination" on page 25

for additional details.

IMPORTANT

Notes on Communications Wiring:

• All field wiring must conform to local codes and

ordinances.

• Do not use different wire types or gauges on the

ONWORKS segment. The step change in

same L

line impedance characteristics would cause

unpredictable reflections on the L

ONWORKS net-

work. When using different types is unavoidable,

use a Q7751A Router at the junction.

21 EN0B-0377GE51 R0703

Page 22

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

• Do not use shielded cable for LONWORKS wiring

runs. The higher capacitance of the shielded

cable will cause degradation of communications

throughput. In noisy (high EMI) environments,

avoid wire runs parallel to noisy power cables, or

lines containing lighting dimmer switches, and

keep at least 3 in. (76 mm) of separation

between noisy lines and the L

• Make sure that neither of the L

grounded.

Power Wiring

IMPORTANT

Notes on Power Wiring:

• All field wiring must conform to local codes and

ordinances.

• Use the heaviest gauge wire available, up to

14 AWG (2.0 mm

(1.0 mm

connections.

• To minimize EMI noise, do not run Triac and/or

relay output wires in the same conduit as the

input wires or the L

loop.

ONWORKS cable.

ONWORKS wires is

2

2

) for all power and earth ground

) with a minimum of 18 AWG

ONWORKS communications

• To comply with CE requirements, in the case of

devices having a voltage range of 50 to 1000

Vac or 75 and 1500 Vdc which are not provided

with a supply cord and a plug or with other

means for disconnection from the supply having

a contact separation of at least 3 mm in all poles,

the means for disconnection must be

incorporated in the fixed wiring.

Step 4. Prepare Wiring Diagrams

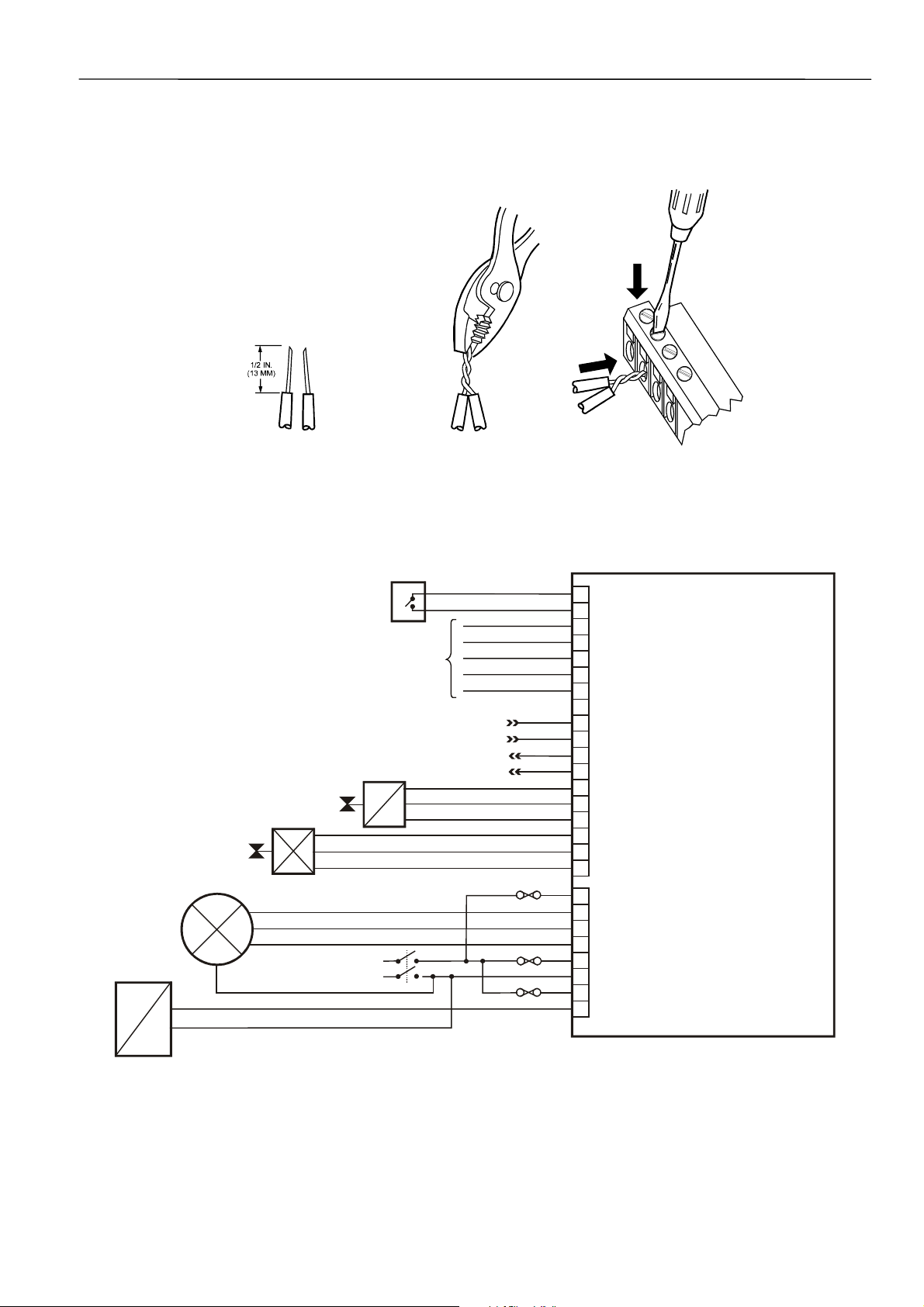

General Considerations

The purpose of this step is to assist the application engineer

in developing job drawings to meet job specifications. Wiring

details for the W7752 FCU Controller are shown in Fig. 17.

Table 12 gives additional details for output connections.

NOTE: For field wiring, when two or more wires are to be

attached to the same connector block terminal, be

sure to twist them together. Deviation from this rule

can result in improper electrical contact. See Fig.

16.

Table 11 lists wiring types, sizes, and length restrictions for

Excel 10 FCU Controller products.

Table 11. Field wiring reference table (US part numbers shown)

wire

function

LONWORKS

(plenum)

LONWORKS

(nonplenum)*

input

wiring,

sensors,

contacts

output

wiring,

actuators,

relays

power

wiring

recommended

min. wire size

AWG (mm

2

)

22 AWG

22 AWG

14 to 20 AWG

(2.0 to 0.5 mm

14 AWG (2.5 mm

(18 AWG (1.0

2

) acceptable

mm

for short runs)

14 AWG

(2.5 mm

2

)

construction

twisted pair solid

conductor, non-shielded.

twisted pair solid

conductor, non-shielded.

multi-conductor (usually

five-wire cable bundle); for

2

runs >100 ft (30 m),

)

twisted pair or shielded

cable is recommended.

2

)

any pair non-shielded (use

heavier wire for longer

runs).

any pair non-shielded (use

heavier wire for longer

runs).

specification

or

requirement

Level IV 140°F

(60°C) rating

Level IV 140°F

(60°C) rating

140°F (60°C)

rating

NEC Class 2

140°F (60°C)

rating

NEC Class 2

140°F (60°C)

rating

NOTE: PVC wire must not be used where prohibited by local fire regulations.

vendor wire type max. length ft (m)

Honeywell (US)

AK3791 (one twisted pair)

AK3792 (two twisted pairs)

See Step 2

(Europe: Belden

9H2201504)

Honeywell (US)

AK3781 (one twisted pair)

AK3782 (two twisted pairs)

See Step 2

(Europe: Belden

9D220150)

Standard thermostat wire 82.5 ft (25 m)

Honeywell (US)

AK3702 (18 AWG)

AK3712 (16 AWG)

200 ft (60 m)

AK3754 (14 AWG)

or equivalent

Honeywell (US)

AK3754 (14 AWG)

(twisted pair)

AK3909 (14 AWG) single

conductor or equivalent

Limited by line loss

effects on power

consumption.

(See Line Loss

subsection.)

EN0B-0377GE51 R0703 22

Page 23

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Terminal Block Assignment and Wiring Example for the W7752 Controller

Fig. 17 illustrates terminal block assignments and wiring for

an example Excel 10 W7752 FCU Controller installation. All

connections are made at terminal blocks. Table 12 lists

wiring information for wiring all of the possible actuator types.

REHEAT

+

1. STRIP 1/2 IN. (13 MM) FROM WIRES

TO BE ATTACHED AT ONE

TERMAINAL

Fig. 16. Attaching two or more wires at terminal blocks

OCCUPANCY SENSOR

CHANGEOVER CONTACT

AIRFLOW CONTACT

WINDOW CONTACT

MOTION SENSOR

WALL MODULE

CONNECTIONS

HEAT

COM

-

COOL

FAN

LO

MED

HI

RETURN

OPEN

CLOSE

POWER MAINS

2. TWIST WIRES TOGETHER WITH

PLIERS (A MINIMUM OF THREE

TURNS).

LONW

ORKS

NETWORK IN

L

ONWORKS

L

N

COM

+

OPEN

CLOSE

NETWORK OUT

3. CUT TWISTED END OF WIRES TO 3/16 IN. (5 MM) BEFORE

INSERTING INTO T ERMINAL AND TIGHTENI NG SCREW. THEN

PULL ON EACH WIRE IN ALL TERMINALS TO CHECK FOR GOOD

MECHANICAL CONNECTION.

W7752 FAN COIL UNIT CONTROLLER

D

G

N

D

1

T

A

D

G

I

I

L

N

I

P

U

T

4A

0.5A

16A

2

3

LED

SETPOINT

4

FAN / BYPASS

5

TEMP SENSOR

6

AGND

7

8

E-BUS IN

9

E-BUS IN

10

E-BUS OUT

11

12

E-BUS OUT

OUT 1 COM

13

OUT 1 OPEN

14

OUT 1 CLOSE

15

16

OUT 2 COM

OUT 2 OPEN

17

OUT 2 CLOSE

18

19

RELAY COM

20

RELAY 1

21

RELAY 2

22

RELAY 3

23

SUPPLY VOLT

24

SUPPLY VOLT

PWR RELAY IN (D,F MODELS ONLY)

25

26

PWR RELAY OUT (D,F MODELS ONLY)

Fig. 17. W7752 FCU Controller wiring example

23 EN0B-0377GE51 R0703

Page 24

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

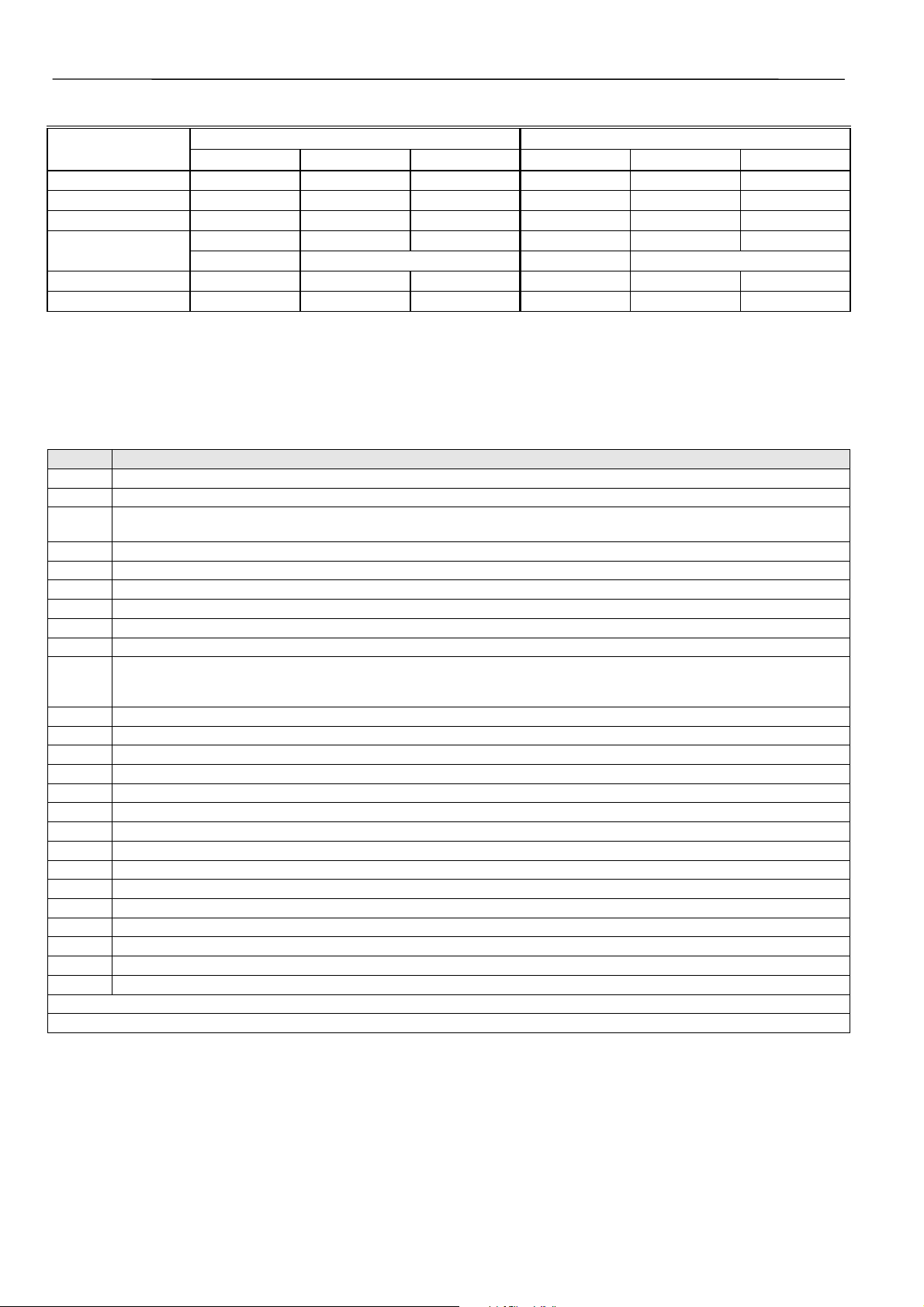

Table 12. Output assignments for various actuator types

Output type

13 14 15 16 17 18

Out 1 Terminal Out 2 Terminal

Floating 24 Vac open close 24 Vac open close

1-stage 24 Vac on/OFF — 24 Vac on/OFF —

2-stage 24 Vac stage 1 stage 2 24 Vac stage 1 stage 2

3-stage

24 Vac stage 1 stage 2 24 Vac stage 1 stage 2

stage 3 stage 3

PWM 24 Vac PWM — 24 Vac PWM —

Thermal 24 Vac on/OFF — 24 Vac on/OFF —

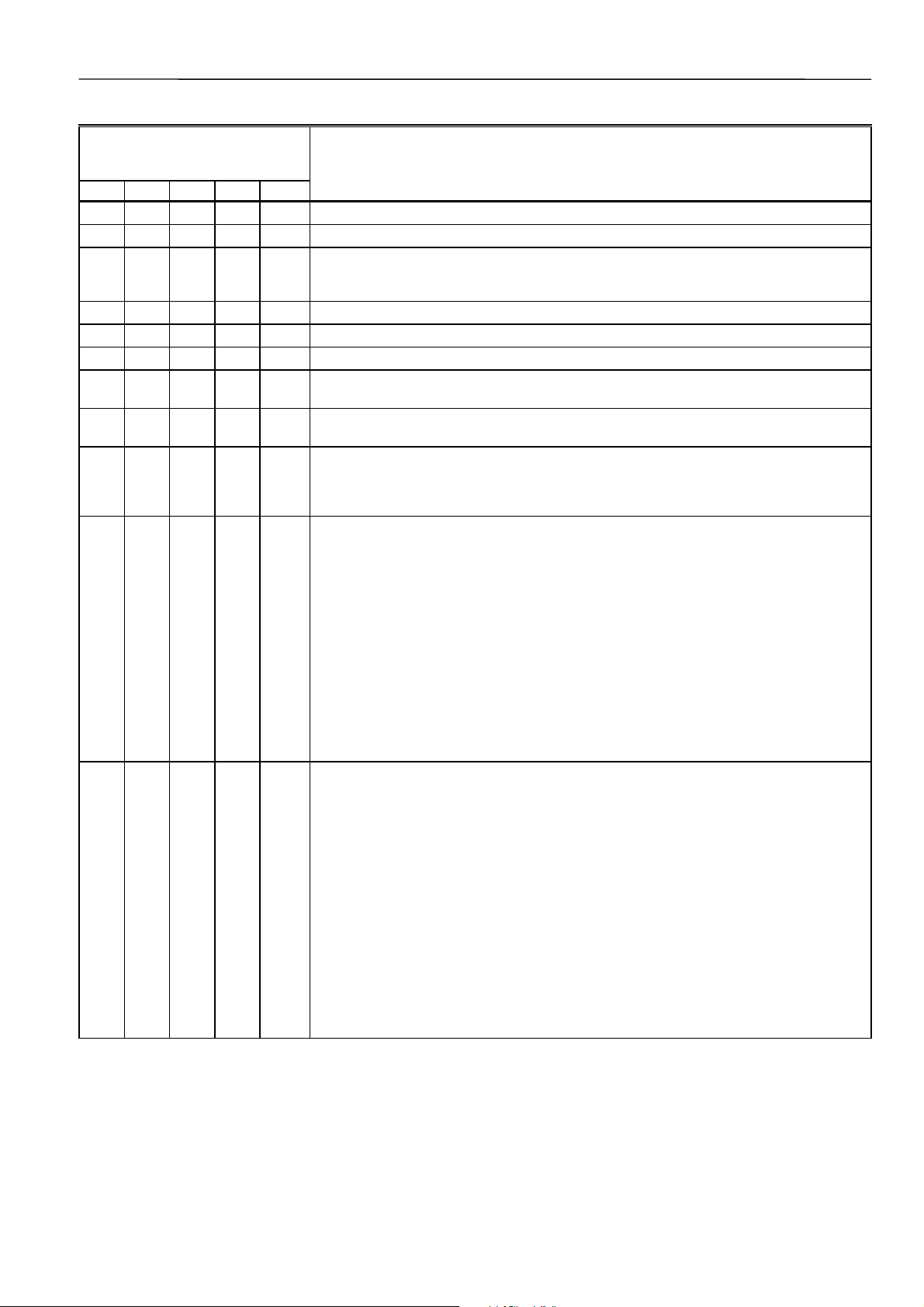

Terminal Block Assignment and Wiring for the W7754 Controller

Table 13 lists the terminals and their functions of the Excel 10 W7754 FCU Controller. In addition to connections made at

terminal blocks, there is an extra socket located to the left of the terminal blocks containing a digital output for the low-voltage

PWM control of a solid-state relay employed in high-current electric reheat applications. Table 13 lists wiring information for

wiring all of the possible actuator types.

Table 13. W7754 Controller, terminals and functions

term. # function

1 receiving/sending data on the LONWORKS network

2 receiving/sending data on the LONWORKS network

3 a digital input, configurable (using the LNS plug-in) to read input e.g. from a window contact, an occupancy sensor,

4 an analog input, permanently configured to read input from a wall module's temperature setpoint adjustment knob

5 an analog input, permanently configured to read input from a room temperature sensor.

6GND

7 not present

8GND

9 a digital output, permanently configured to write output switching the wall module's LED "on" or "OFF"

10 an analog input, permanently configured to read input on whether the wall module's 3-speed fan control knob has

11

12 not present

13+14 relay 4, permanently configured to switch a hardwired electrical reheat coil ON or OFF

15 common terminal for terminals 16, 17, and 18

16

17

18

19 a triac output, permanently configured to write output to OUT1, closing it

20 a triac output, permanently configured to write output to OUT1, opening it

21 a triac output, permanently configured to write output to OUT2, closing it

22 a triac output, permanently configured to write output to OUT2, opening it

23 a common terminal for terminals 19 and 20

24 a common terminal for terminals 21 and 22

25 the "N" terminal of the power supply

26 the "L" terminal of the power supply

(1)

This digital input can be enabled / disabled using the right DIP switch located on the top of the controller.

(2)

If all three relays (terminals 16, 17, and 18) are switched OFF, then the three-speed fan is switched OFF.

etc.

been set to AUTO, OFF, LOW, MEDIUM, or HIGH and whether the wall module's "occupancy override" button has

been pressed.

(1)

a digital input, permanently configured to read input on whether a window contact is "open" or "closed".

(2)

relay 3, permanently configured to write output to a three-speed fan, setting it to HIGH

(2)

relay 2, permanently configured to write output to a three-speed fan, setting it to MEDIUM

(2)

relay 1, permanently configured to write output to a three-speed fan, setting it to LOW

The triac outputs or relay outputs of the Excel 10 W7754 FCU Controller can be configured (using Honeywell's LNS plug-in) for

different functions.

You can configure the four triac outputs for connection to either a floating drive or to a thermal actuator. Once the outputs have

been configured, the corresponding devices can be directly connected to them.

EN0B-0377GE51 R0703 24

Page 25

EXCEL 10 FAN COIL UNIT CONTROLLER SYSTEM ENGINEERING

Table 14. Output assignments of Excel 10 W7754 FCU Controller for various actuator types

output type stage

19 20 21 22

floating -- close open close open

1-stage

0--OFF--OFF

1--ON--ON

0 OFF OFF OFF OFF

1 OFF ON OFF ON2-stage

2 ON OFF ON OFF

0 OFF OFF OFF OFF

3-stage

1 OFF ON OFF ON

2 ON OFF ON OFF

3 ONONONON

PWM -- -- PWM -- PW M

thermal -- -- ON/OFF -- ON/OFF

OUT1 OUT2

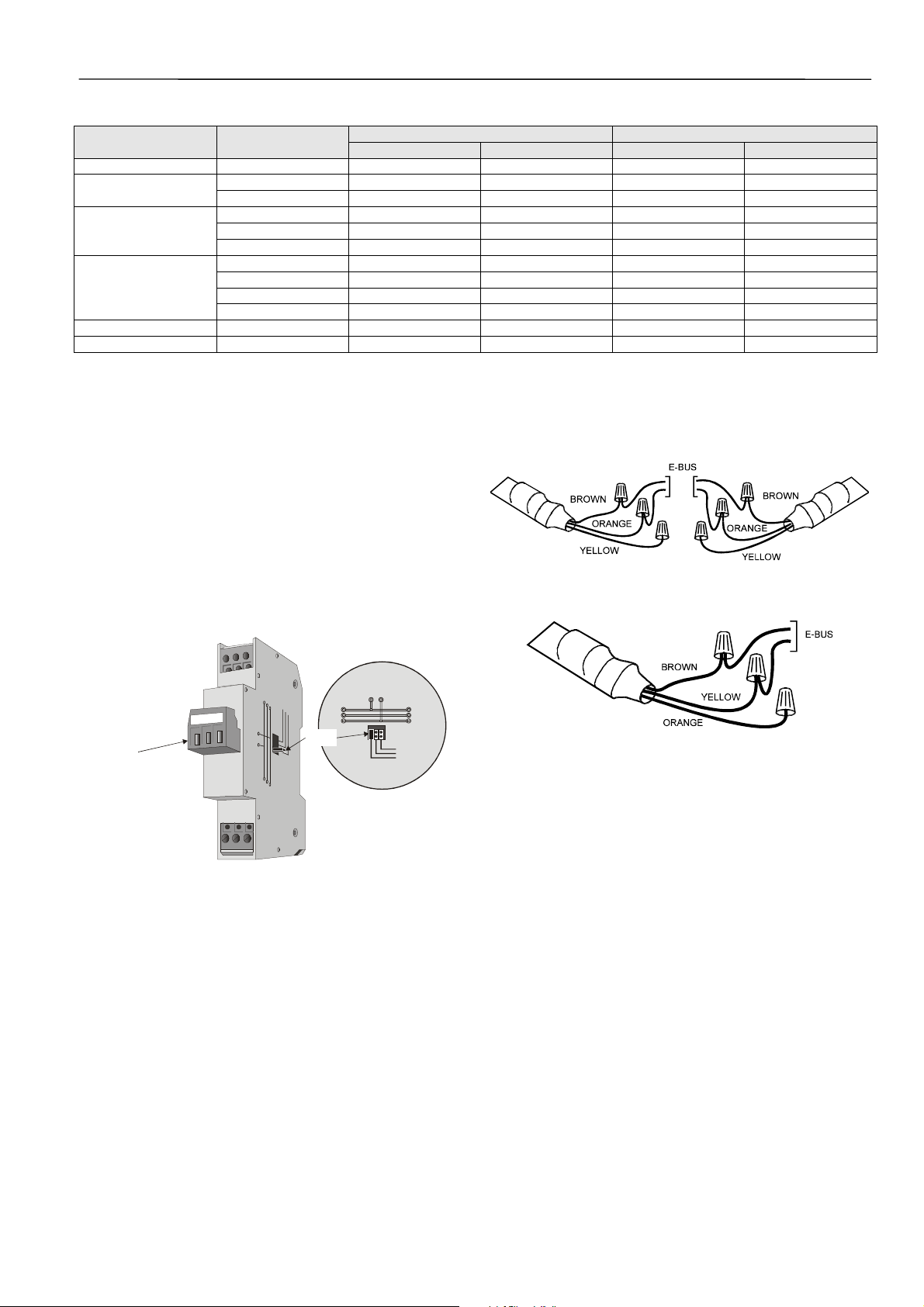

LONWORKS Termination

One or two LONWORKS terminations are required, depending

on the given LonWorks bus layout.

Double termination is required only when the network is a

daisy-chain configuration and the total wire length is greater

than 1640 ft (500 m). The max. lengths described in Step 2

must be adhered to for either a daisy chain or free topology

ONWORKS layout. See Fig. 19 for connection details for a

L

doubly terminated bus. See Fig. 20 for connection details for

a singly terminated bus.

Two different L

ONWORKS termination module, order no.: 209541B

• L

ONWORKS connection / termination module (mountable

• L

on DIN rails and in fuse boxes), order no.: XAL-Term

removable screw-type

3-pole terminal block

ONWORKS termination modules are available:

l

l

we

y

e

n

o

H

m

r

e

T

-

L

A

X

4

3

L

L

O

O

N

N

shield shield

plug-in

jumper

34

15

06

LON

Term in at io n

FTT/LPT Bus