Page 1

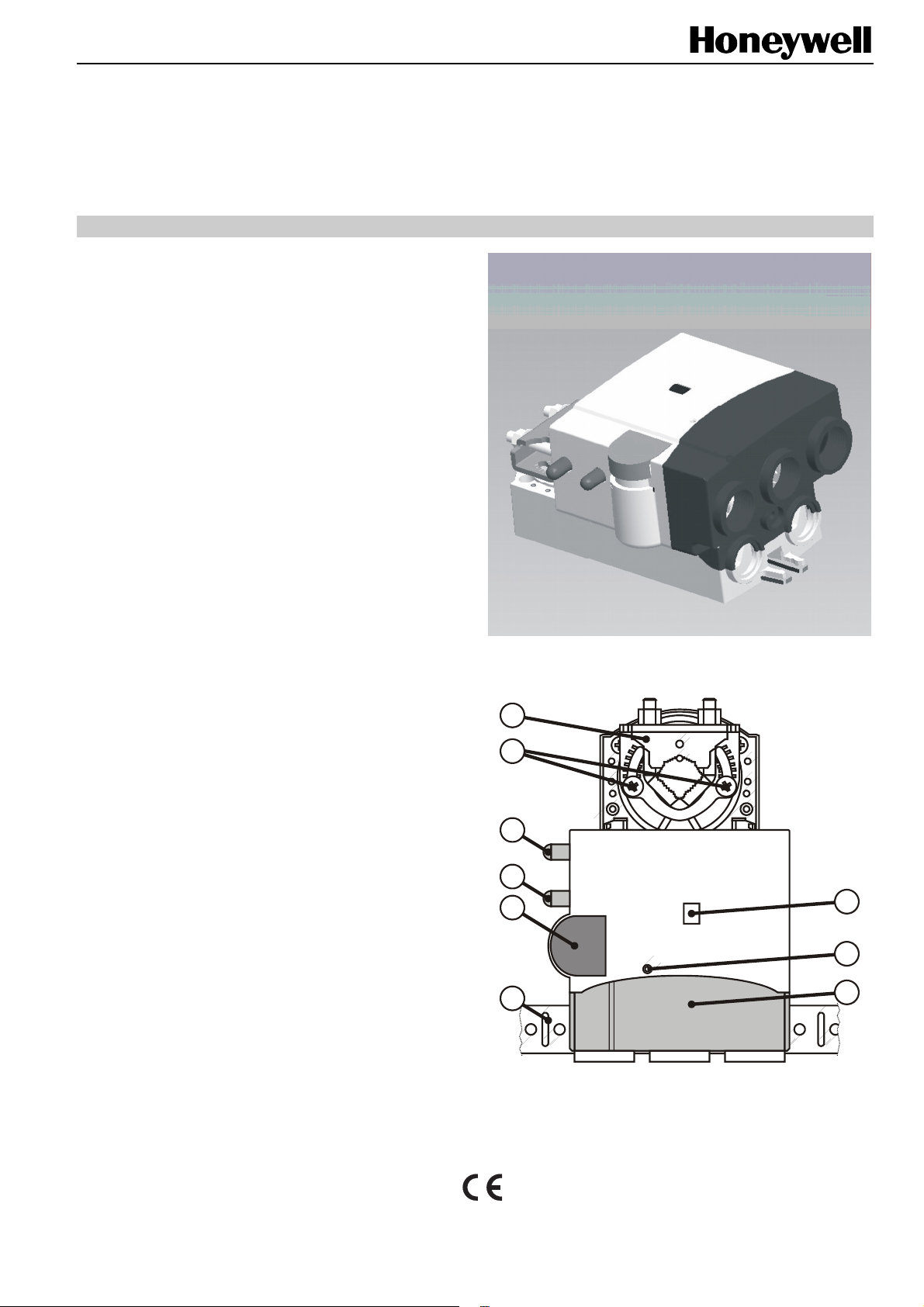

Excel 10

W7751H3007 VAV ACTUATORS

HONEYWELL EXCEL 5000 OPEN SYSTEM

BEFORE INSTALLATION

The W7751H Smart VAV Actuator consists of a factorycombined variable air volume (VAV) box controller and a

direct-coupled damper actuator with de-clutch mechanism.

The actuator/controller assembly is field-mounted to the VAV

box damper shaft similar to the mounting of a standard

actuator, and the controller wiring is terminated to the screw

terminals accessible inside the detachable wiring box. See

Fig. 2.

The W7751H's built-in actuator with de-clutch mechanism

allows the installer to manually open or close its built-in VAV

box damper without power or software tool.

The W7751H contains a Free Topology Transceiver (FTT)

LonMark® compliant controller containing a Microbridge flowthrough pressure sensor and communicates via the 78 kbaud

L

ONWORKS

The W7751H actuator mounts directly onto the VAV box

damper shaft and has up to 6 Nm torque, 95 degree stroke,

and 110 sec. timing at 50 Hz and 90 sec at 60 Hz.

If desired, the SSW2 Auxiliary Switch Kit (see "SSW2

Auxiliary Switch Kit for N05xx, N10xx Non-Spring Return

Direct-Coupled Damper Actuators – Installation Instructions",

Product Literature No.: MU1B-0284GE51) can be attached to

the W7751H. See also section "Optional Accessories" on

page 9.

NOTE: Any hardware driven by the triac outputs must have

® Network.

a min. current draw, when energized, of 25 mA at

24 Vac and a max. current draw of 770 mA.

INSTALLATION INSTRUCTIONS

Fig. 1. Excel 10 Smart VAV Actuator

1

2

MAIN FEATURES

Legend for Fig. 2:

1) Universal shaft adapter

2) Mechanical end limits (manually adjustable in increments

of 5.5°)

3) Air flow pick-up connector (-LO)

4) Air flow pick-up connector (-HI)

5) L

ONWORKS

6) Declutch button

7) L

ONWORKS

8) Detachable wiring box

9) Anti-rotation bracket

® U.S. Registered Trademark EN1B-0279GE51 R0707B

Copyright © 2007 Honeywell Inc. • All rights reserved

service LED

service pin

3

4

6

5

7

9

Fig. 2. W7751H main features

8

Page 2

EXCEL 10 W7751H SMART VAV ACTUATOR

INSTALLATION

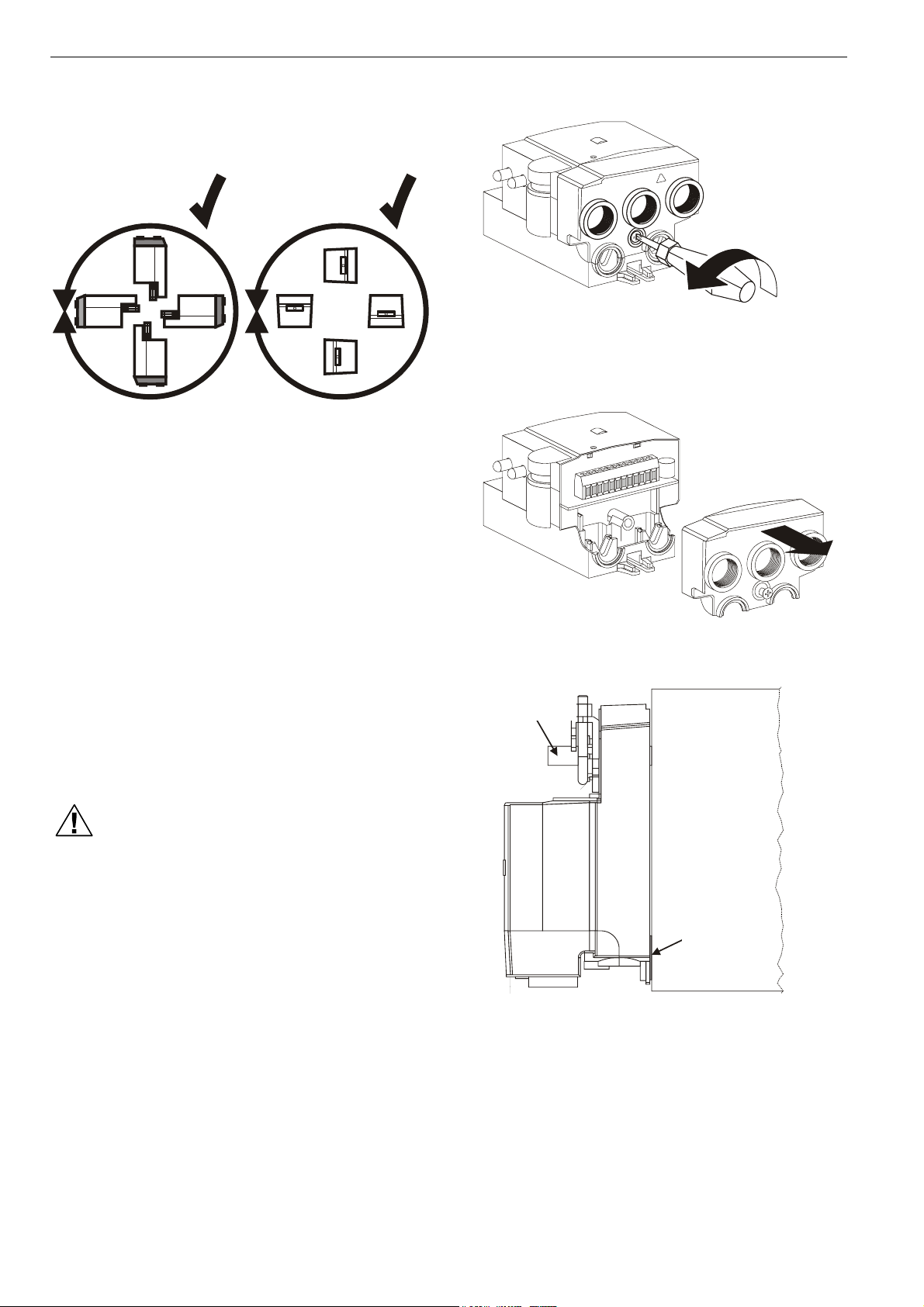

The W7751H provides IP40 in all mounting orientations.

IP40 IP40

360° 360°

2

1

1

1

0

1

9

8

7

6

5

4

3

2

1

Fig. 4. Opening wiring box (1)

Fig. 3. Permissible orientations providing IP40

Mount the W7751H on the damper shaft and allow clearance

for wiring, servicing, and module removal. Avoid mounting the

W7751H in areas where acid fumes or other corrosive vapors

can attack the actuator's metal parts, or in areas where

escaping gas or other explosive vapors are present. See Fig.

23 for mounting dimensions.

The W7751H is field-mounted to the VAV box damper shaft.

The W7751H actuator opens or closes a damper by driving

the damper shaft in either the counterclockwise (CCW) or

clockwise (CW) direction. If the W7751H is to be mounted

directly onto a damper shaft, use the mounting bracket and

screw included in the delivery.

The wiring of the W7751H controller is terminated to a screw

terminal block accessible inside the detachable wiring box.

See section "Wiring".

The W7751H actuator is shipped in the fully counterclockwise

(CCW) position (95 degrees). Mount the W7751H so that the

actuator is parallel with the VAV box damper housing.

CAUTION

Equipment damage hazard.

Mounting actuator unevenly with damper housing

can damage actuator.

Mount the actuator flush with the damper housing or

add a spacer between the anti-rotation bracket and

the VAV damper box housing (see Fig. 6).

4

3

2

1

2

1

1

1

0

1

9

8

7

6

5

Fig. 5. Opening wiring box (2)

VAV b ox

damper shaft

VAV b ox

damper housing

spacer or washer

Fig. 6. Mounting W7751H with washer/spacer

Before mounting the W7751H onto the VAV box damper

shaft, do the following:

1. Ensure that the diameter of the damper shaft is within the

allowed limits (round: 8…16 mm, square: 6…13 mm).

EN1B-0279GE51 R0707B

2

Page 3

2. Ensure that the damper shaft has a length of at least

40 mm.

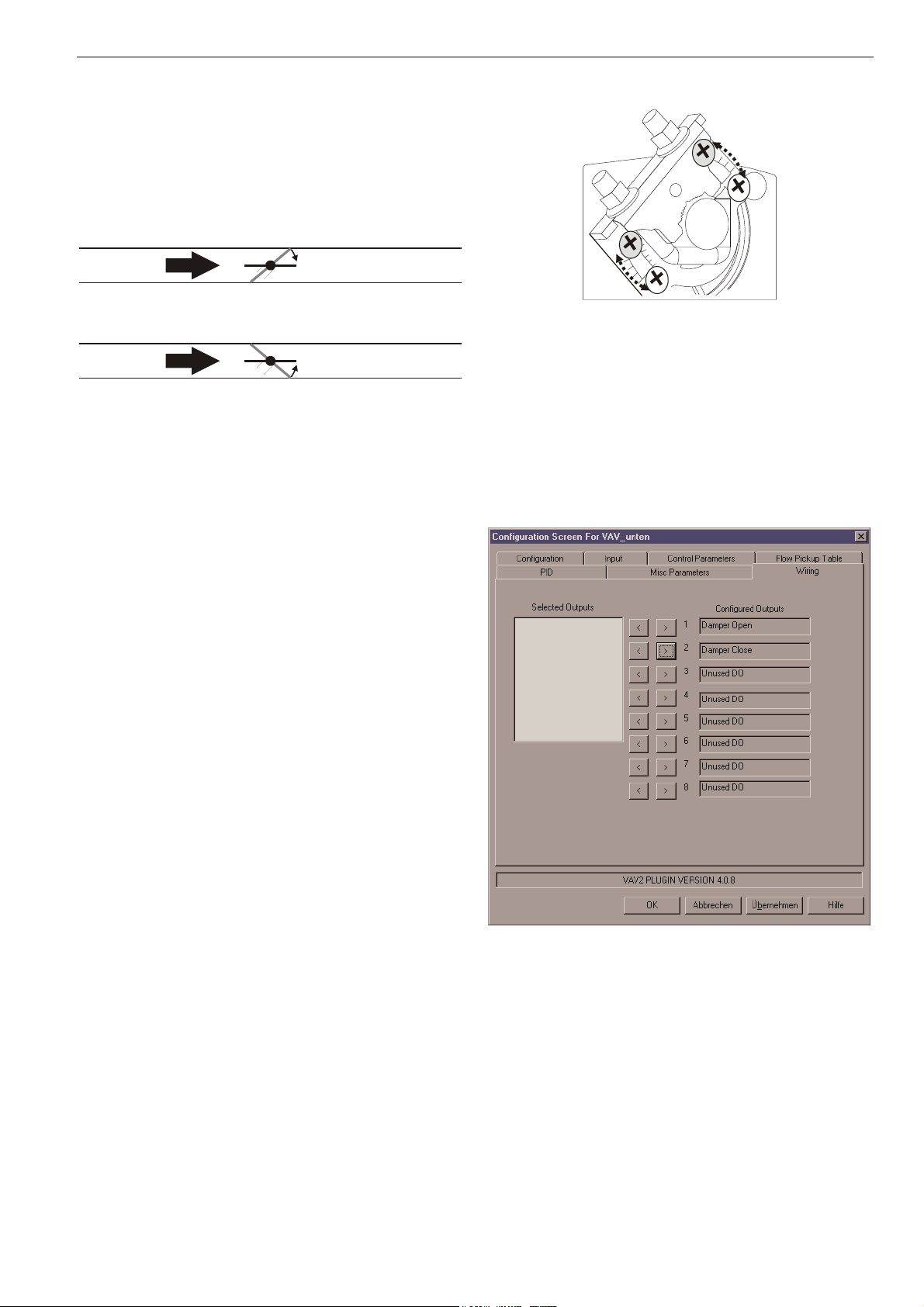

3. Determine the direction (CW or CCW) in which the

damper shaft rotates to open the damper (see Fig. 7).

4. Determine the angle of the damper opening (can be

adjusted in increments of 5.5°).

TYPE A DAMPER

COOLING

AIR FLOW

CW TO OPEN, CCW TO CLOSE

TYPE B DAMPER

COOLING

AIR FLOW

CCW TO OPEN, CW TO CLOSE

Fig. 7. Determining direction of rotation

The W7751H actuator is shipped in the fully counterclockwise

(CCW) position (95 degrees). The installation procedure

varies depending on the damper direction.

NOTE: Be aware that, until the W7751H is powered and the

damper is driven open, starting the fan system with

all the VAV box dampers closed can cause duct

over-pressurization and damage.

If Damper Rotates CW to Open

If the damper rotates clockwise (CW) to open, mount the

W7751H as follows:

1. Manually open the damper.

2. Push down the declutch button of the W7751H, and while

holding it down, manually rotate its shaft adapter fully to

the clockwise position.

3. Mount the W7751H to the VAV damper box and shaft.

4. Set the mechanical end limits of the W7751H (see Fig. 8).

When the W7751H closes, the damper will thus rotate

CCW until the mechanical end limits are reached.

If Damper Rotates CCW to Open

If the damper rotates counterclockwise (CCW) to open, mount

the W7751H as follows:

1. Manually open the damper.

2. Push the declutch button of the W7751H, and while

holding it down, manually rotate its shaft adapter fully to

the counterclockwise position.

3. Mount the W7751H to the VAV damper box and shaft.

4. Set the mechanical end limits of the W7751H (see Fig. 8).

When the W7751H closes, the damper will thus rotate CW

until the mechanical end limits are reached.

EXCEL 10 W7751H SMART VAV ACTUATOR

Fig. 8. Setting the mechanical end limits

Reconfiguring to Match Rotation Direction

Using the LNS plug-in, the W7751H can be reconfigured to

match the direction the damper shaft rotates to open the

damper. Reconfigure the damper's direction of rotation to

"open" or "closed," according to your needs.

To change the damper direction from CW to CCW using the

LNS plug-in, proceed as follows.

1. Open the configuration part of the plug-in and select the

"Wiring" tab (see Fig. 9).

Fig. 9. Wiring tab (default configuration)

2. Then deselect the output configuration (see Fig. 10).

3

EN1B-0279GE51 R0707B

Page 4

EXCEL 10 W7751H SMART VAV ACTUATOR

fan startup. Use the de-clutch button to open the

W7751H's box damper only after the W7751H has

been powered down (this is to prevent overpressurization in the ductwork on fan startup). To

use the de-clutch button, press and hold down the

button (this disengages the motor). Turn the damper

shaft until the damper is open and then release the

button. When power is restored to the W7751H, it

synchronizes the damper actuator so that the

damper is in the correct position on startup.

Air Flow Pick-up

Connect the air flow pick-up to the two connectors on the

W7751H. See Fig. 12.

AIRFLOW DELTA-P PICK-UP

AIRFLOW

DIRECTION

Fig. 10. Deselecting the output configuration

3. Now, configure the outputs so that the W7751H operates

counterclockwise (CCW) (see Fig. 11).

Fig. 11. Configuring the W7751H to open CCW

The damper direction has now been reconfigured.

IMPORTANT

It is recommended that the dampers be left in an

"open" position after W7751H installation to avoid

the possibility of over-pressurizing the ductwork on

-LOW

+HIGH

Fig. 12. Air flow pick-up connections

NOTES:

• Use 6-mm outside diameter with 1-mm wall thickness

plenum-rated 1219 FR (94V-2) pneumatic tubing.

• Always use a fresh cut on the end of the tubing that

connects to the air flow pick-ups and the connectors on

the W7751H.

Connect the high pressure or upstream tube to the plastic

restrictor labeled (+ HI) or P1 and the low-pressure or downstream tube to the restrictor labeled (- LO) or P2. See labeling

in Fig. 12.

NOTE: If controllers are mounted in unusually dusty or dirty

environments, a 5-micron disposable air filter is recommended for the high-pressure line (marked as +)

connected to the air flow pick-up.

When twin tubing is used from the pick-up, split the pick-up

tubing a short length to accommodate the connections.

NOTES:

• The tubing from the air flow pick-up to the W7751H should

not exceed 0.914 m in length. Lengths much longer than

this can degrade the flow sensing accuracy.

EN1B-0279GE51 R0707B

4

Page 5

• To avoid damaging the air flow connectors, use caution

when removing tubing from them. Always pull straight

away from the connector; never remove by pulling at an

angle.

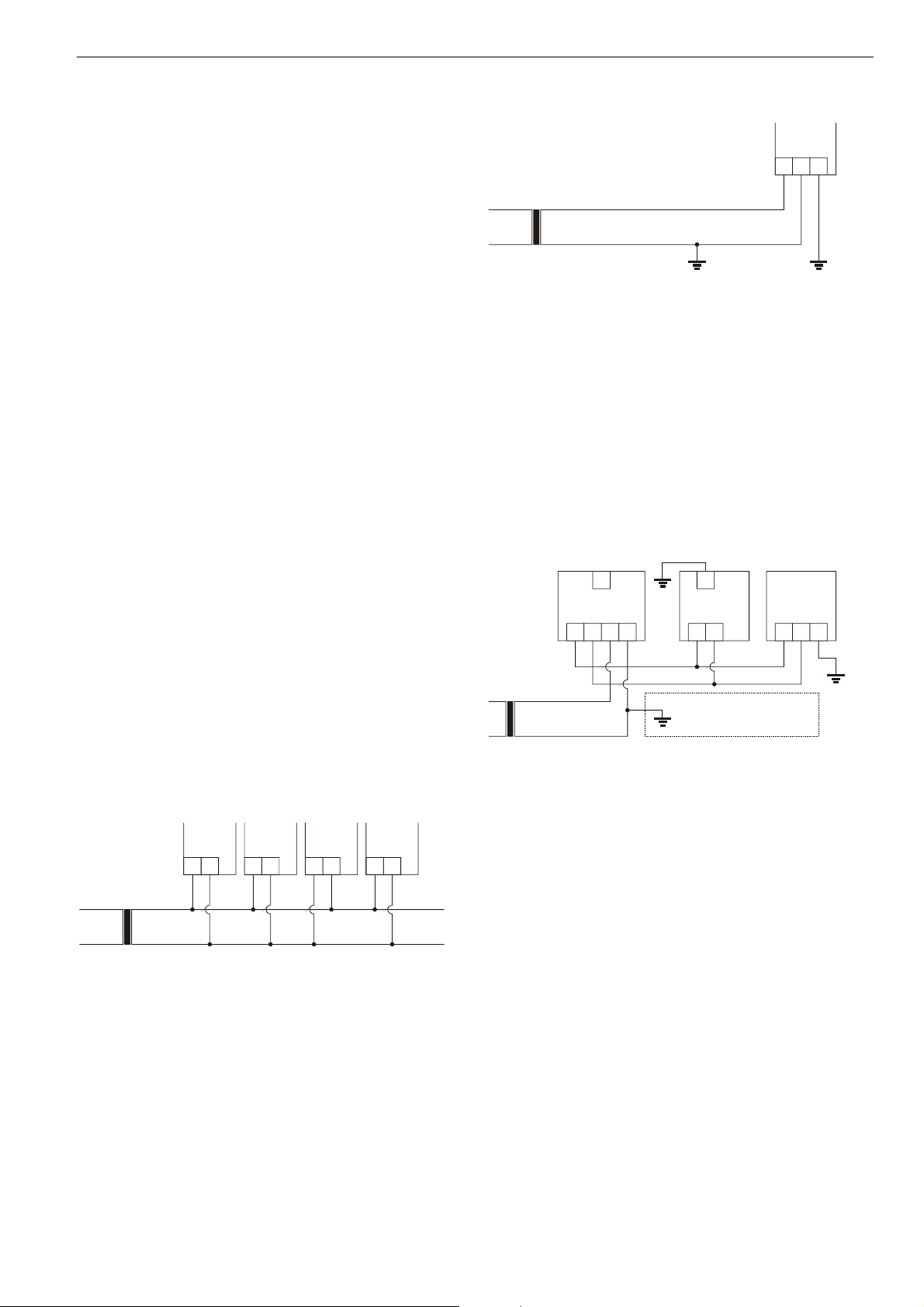

Wiring

All wiring must comply with applicable electrical codes and

ordinances, or as specified on installation wiring diagrams.

NOTES:

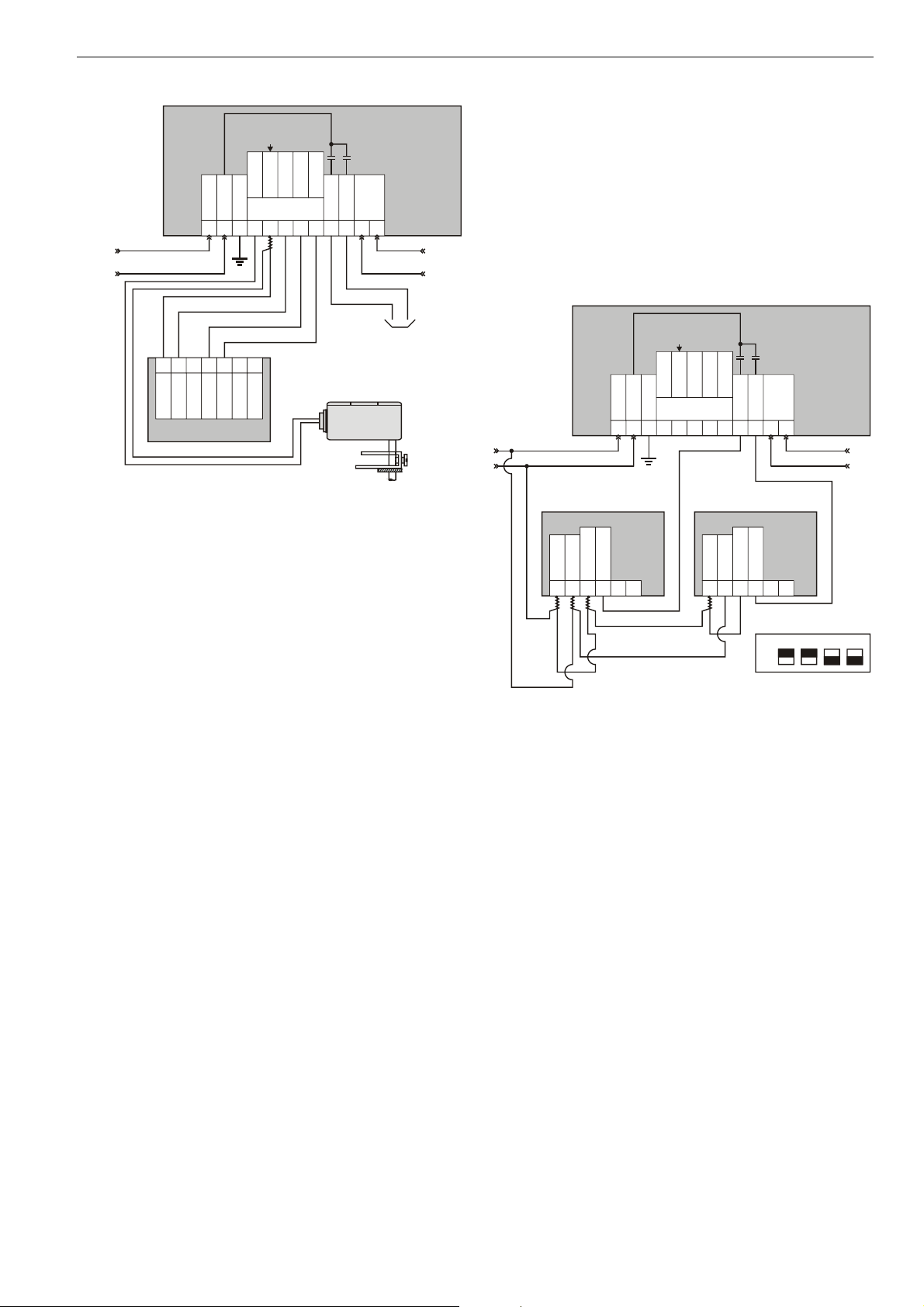

• 24 Vac power connections. Verify that multiple controllers

powered by the same transformer are wired with the

transformer secondary connected to the same input

terminal numbers on each W7751. See Fig. 13. Controller

configurations are not necessarily limited to three devices,

but the total power draw including accessories cannot

exceed 100 VA when powered by the same transformer.

For power wiring recommendations, refer to Excel 10

W7751B,D,F,H,J Variable Air Volume Controller –

Application Guide (Product Literature No.: 74-2949).

• In the case of multiple W7751H units operating from a

single transformer, the same side of the transformer

secondary must be connected to the same input terminal

in each W7751H and the ground terminals (terminal 3 of

the W7751H) must be connected to a verified earth

ground for each controller in the group. See Fig. 14.

Controller configurations are not necessarily limited to

three devices, but the total power draw including

accessories cannot exceed 100 VA when powered by the

same transformer. For power wiring recommendations,

refer to Excel 10 W7751B,D,F,H,J Variable Air Volume

Controller – Application Guide (Product Literature No.: 74-

2949).

• All loads on a W7751H must be powered by the same

transformer that powers the W7751H.

• Keep the earth ground connection (terminal 3) wire run as

short as possible. See Fig. 14.

• Do not connect the analog ground (terminal 5) to the earth

ground. See Fig. 15.

W7751H W7751H W7751H W7751H

21 21 21 21

24 VAC

50/60 Hz

COM

Fig. 13. Wiring multiple W7751 units (with transformer

secondary connected to same input terminal numbers)

X

EXCEL 10 W7751H SMART VAV ACTUATOR

W7751H

231

24 VAC

50/60 Hz

COM

Fig. 14. Earth grounding

Power

The 24 Vac power from an energy-limited Class II Power

Source must be provided to each W7751H. To conform to

Class II restrictions, transformers must not be larger than 100

VA.

IMPORTANT

Power must be OFF prior to connecting to or

disconnecting from output terminals 9 and 10.

Use the heaviest gauge wire available, up to 2.0

mm2 with a minimum of 1.0 mm

2

, for all power and

earth ground wiring. For non-plenum, open areas,

run cables exposed (or in conduit, if required).

2832

W7751D,F

24V 24VCOM COM

234

24 VAC

50/60 Hz

W7751B

W7751H

9110

IF THE W7751H IS USED IN UL 1995

EQUIPMENT AND THE PRIMARY

POWER IS MORE THAN 150 V,

GROUND ONE SIDE OF TRANSFORMER SECONDARY.

231

Fig. 15. Power wiring for multiple controllers

NOTES:

• Unswitched 24 Vac power wiring can be run in the same

conduit as the L

ONWORKS

® network cable.

• Maintain a 76-mm separation between triac outputs and

L

ONWORKS

® network wiring throughout the installation.

Communications

See Chapter "LonWorks System Engineering" of Excel

50/500 LonWorks Mechanisms – Interface Description

(Product Literature No.: EN0B-0270GE51) for a complete

description of L

cable types for L

is Level IV 0.34 mm

twisted pair, solid conductor wire. For non-plenum areas, US

part AK3781 (one pair) or US part AK3782 (two pair) can be

uses. In plenum areas, US part AK3791 (one pair) or US part

AK3792 (two pair) can be used. Communications wiring can

be run in a conduit, if needed, with non-switched 24 Vac or

sensor wiring. Only one router is allowed with each Excel 10

ONWORKS

ONWORKS

® network topology rules. Approved

® network communications wiring

2

plenum or non-plenum rated unshielded,

5

EN1B-0279GE51 R0707B

Page 6

EXCEL 10 W7751H SMART VAV ACTUATOR

V

Zone Manager, and each network segment can have a

maximum of one repeater.

Pull the cable to each device on the L

ONWORKS

® network and

connect to communication terminals 11 and 12 of the

W7751H.

Notes on Communications Wiring:

• All field wiring must conform to local codes and

ordinances (or as specified on the installation drawings).

• Approved cable types for LONW

munications wiring is Level IV 0.34 mm

ORKS

® network com-

2

plenum or nonplenum rated unshielded, twisted pair, solid conductor

wire. For non-plenum areas, US part AK3781 (one pair) or

US part AK3782 (two pair) can be used. In plenum areas,

US part AK3791 (one pair) or US part AK3792 (two pair)

can be used.

• Unswitched 24 Vac power wiring can be run in the same

conduit as the L

ONWORKS

® network cable.

• Do not bundle output wires with sensor, digital input or

LONW

ORKS

® network wires.

• Ensure that neither L

ONWORKS

® bus wire is grounded.

• In noisy (high EMI) environments, avoid wire runs parallel

to noisy power cables, motor control centers, or lines containing lighting dimmer switches, and keep at least 76 mm

of separation between noisy lines and the L

ONWORKS

®

network cable.

• Do not use different wire types or gauges on the same

L

ONWORKS

® bus segment: Step changes in line impedance characteristics cause unpredictable reflections

on the L

• For L

ONWORKS

ONWORKS

® bus.

termination, use an XAL-Term or a

209541B termination module.

Verify Termination Module Placement

The installation wiring diagrams should indicate the locations

for placement of termination module(s). See Chapter

"LonWorks System Engineering" of Excel 50/500 LonWorks

Mechanisms – Interface Description (Product Literature No.:

EN0B-0270GE51). Correct placement of the termination

module(s) is required for proper L

ONWORKS

® network

communications.

Wiring Details

Wire to the terminal blocks as follows:

1. Strip 5 mm insulation from the conductor

2. Insert the wire into the required terminal location and

tighten the screw to complete the termination.

NOTE: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available, up

to 14 AWG (2.0 mm2), with a minimum of 18 AWG

(1.0 mm

NOTE: With the exception of 2.0 mm2, if inserting two or

more wires into one terminal location, use end

sleeves. Deviation from this rule can result in

improper electrical connection.

2

).

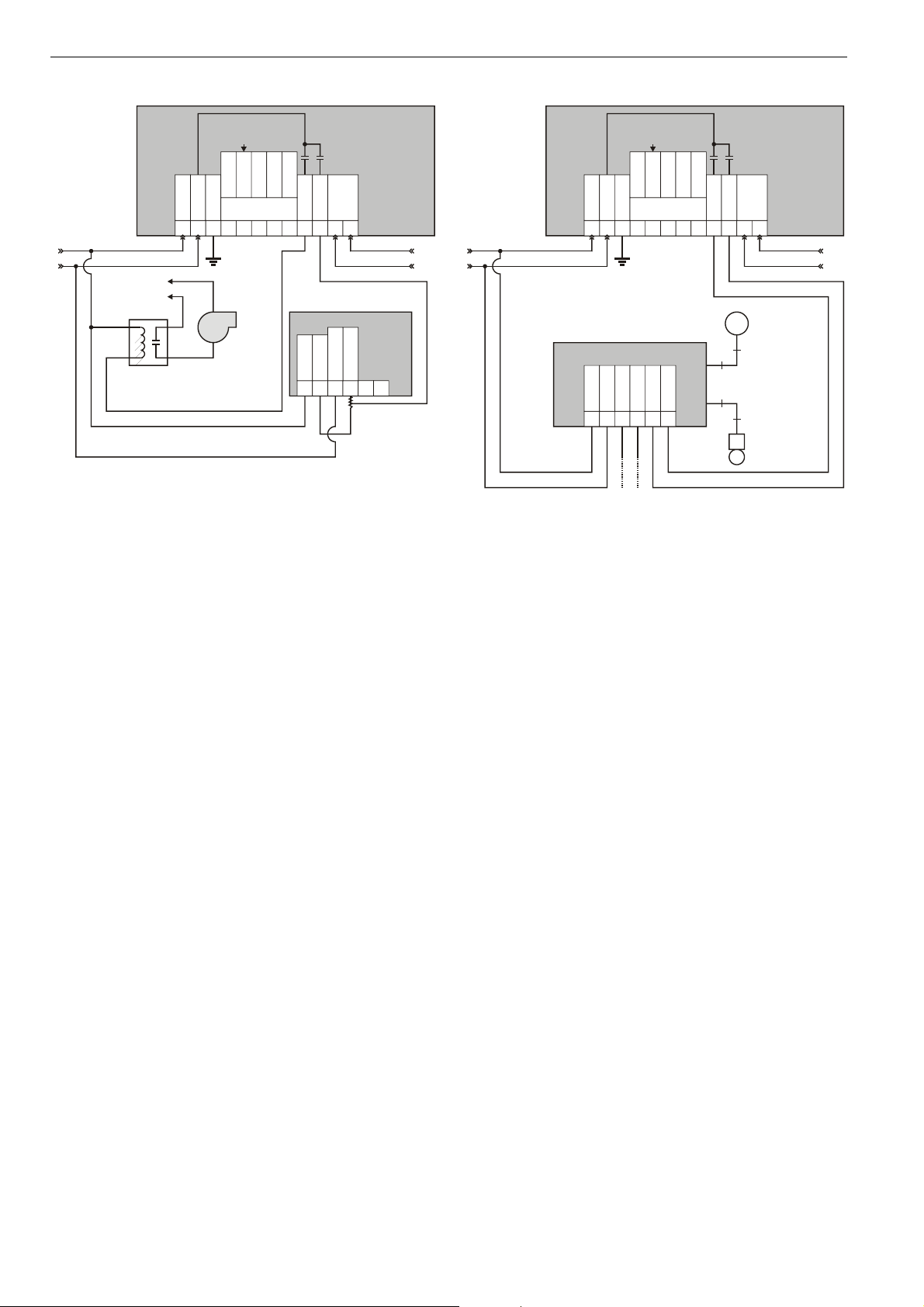

Fig. 16 through Fig. 21 provide detailed wiring diagrams for

the W7751H. See the installation diagrams for specific wiring.

NOTE: Ensure that the wall module's Configuration DIP

Switch is set as shown in Fig. 19. Switches 1 through

3 set the timing of the valve actuator to match the

W7751H outputs (minimum of 0.1 s, with a max. time

of 25.6 s). Switch 4 determines the action of the

actuator (OFF = Direct Acting, ON = Reverse

Acting).

TRIAC

NOT EARTH

GROUND

EQUIVALENT

CIRCUIT

W7751H

LED

GND

BYPASS

SENSOR

SET PT

24VAC

COM

21

MODULE

EARTH

3

4

WALL

765

8

OUT1

9 10

OUT2

1112

LON

24VAC COMM IN

5

1 234

COM

SENSOR

6 7

OPEN SIGNAL

LED

BYP/FAN

LED/RTN

BYP/RTN

SET PT

CLOSED SIGNAL

T7460E

STEM

UP

ALVE ACTUATOR

COM

STEM

DOWN

Fig. 16. W7751H modulating reheat valve wiring diagram

TRIAC

NOT EARTH

GROUND

EQUIVALENT

CIRCUIT

W7751H

LED

GND

BYPASS

SENSOR

SET PT

24VAC

COM

21

EARTH

MODULE

3

4

WALL

765

8

OUT1

9 10

OUT2

1112

LON

24VAC COMM IN

1 234

COM

SENSOR

SET PT

T7460E

STAGE 1

5

6 7

LED

BYP/FAN

LED/RTN

BYP/RTN

LINE POWER

STAGE 2

Fig. 17. W7751H two-stage reheat wiring diagram

EN1B-0279GE51 R0707B

6

Page 7

EXCEL 10 W7751H SMART VAV ACTUATOR

*

TRIAC

NOT EARTH

GROUND

EQUIVALENT

CIRCUIT

W7751H

LED

GND

BYPASS

SENSOR

SET PT

WALL

COM

24VAC

EARTH

MODULE

5

3

21

24VAC COMM IN

1 2 3 456

BYP/FAN

SET PT

LED

BYP/RTN

COM

SENSOR

76

4

8

*

7

TEMPERATURE SENSOR

LED/RTN

OUT1

OUT2

9 10

1112

MODULATING OR

STAGED REHEAT

LF20 DUCT

LON

WIRED FOR

T7460E

TO ASSURE PROPER ELECTRICAL CONTACT, WIRES

MUST BE TWISTED TOGETHER BEFORE INSERTION.

Fig. 18. W7751H discharge air sensing

CHECKOUT

Step 1. Wiring Connections

Inspect all wiring connections at the W7751H and the T7460

terminals, and verify compliance with installation diagrams. If

any wiring changes are required, first be sure to remove

power from the controller before starting work. Pay particular

attention to:

• Controller wiring: Be sure that each W7751H is wired

(terminal 3 on the W7751H) to a verified earth ground

using a wire run as short as possible with the heaviest

gauge wire available, up to 2.0 mm

1.0 mm2 for each controller in the group. See Fig. 15.

• Verify that triac wiring to external devices uses the proper

load power/24 Vac Hot terminal (terminal 1 on the

W7751H).

NOTE: All wiring must comply with applicable electrical

codes and ordinances. See the installation diagrams

for specific wiring.

Step 2. Startup

Broadcasting the Service Message

The Service Message allows a device on the LONW

network to be positively identified. The Service Message contains the device's ID number and, therefore, can be used to

confirm the physical location of a particular W7751H in a

building. There are two methods for broadcasting the Service

Message from the W7751H:

1. Operating the service pin on the W7751H: Insert a thin rod

(e.g. paper clip) into the service pin hole (see Fig. 2) and

push briefly; the Service Message will then be broadcast

on the network.

2

with a minimum of

ORKS

®

2. Using the wall module bypass button: By pressing the wall

module's bypass/override button for more than four

seconds, the W7751H will send the Service Message (this

functionality is supported in firmware version 1.2.15 and

higher). When employing this method, the occupancy

override state of the W7751H changes depending upon

how long the bypass/override button is pressed. For

example, if the button is pressed for six seconds, the

W7751H will send the Service Message and also enter

into the "continuous unoccupied" mode. To clear the

"continuous unoccupied" mode, the button must be

pressed briefly.

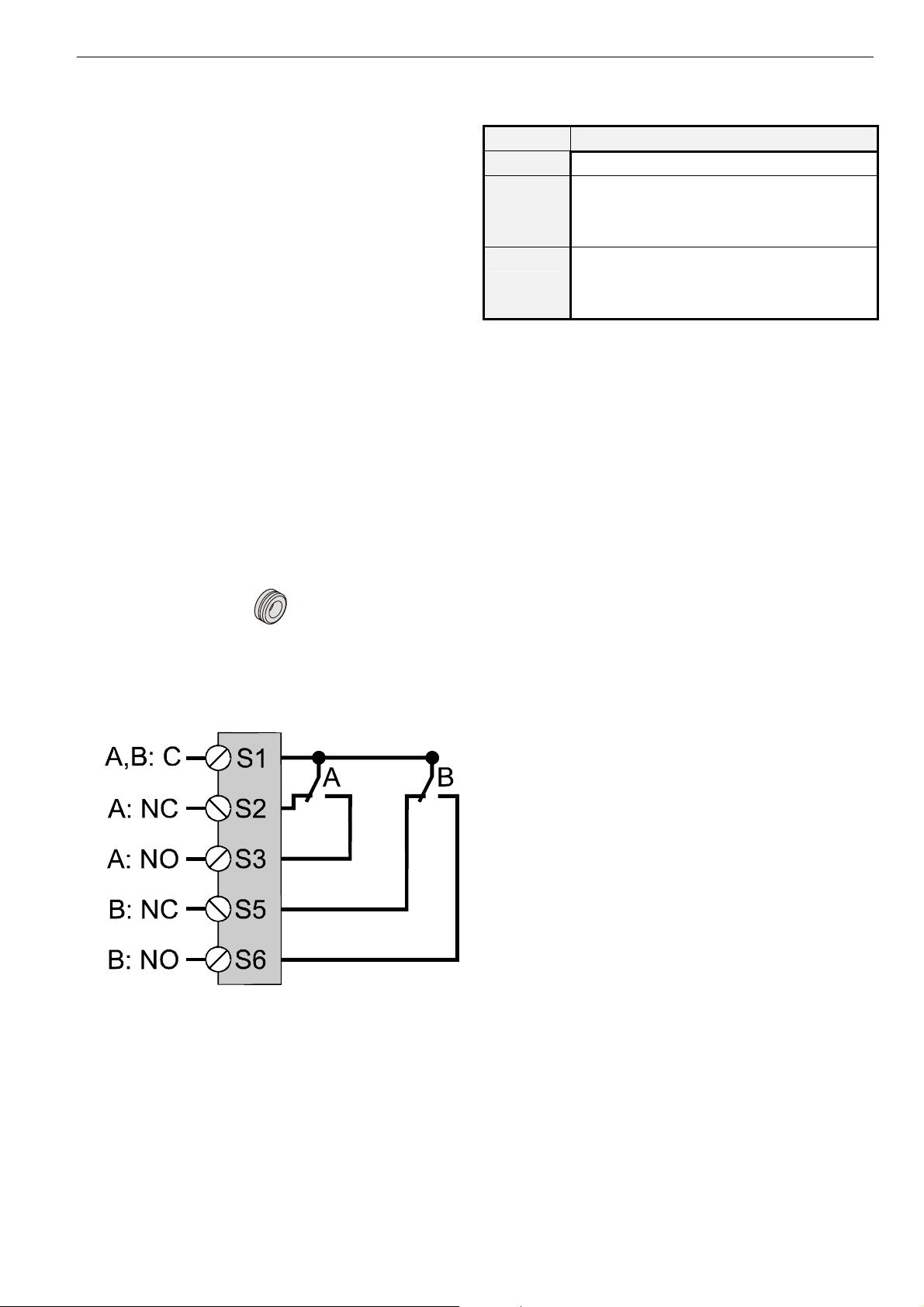

TRIAC

EQUIVALENT

CIRCUIT

LED

BYPASS

LON

OUT1

OUT2

765

9 10

8

1112

24VAC

COM

21

NOT EARTH

EARTH

3

4

GROUND

GND

SENSOR

SET PT

WALL

MODULE

24VAC COMM IN

PERIPHERAL HEAT

VALV E AC TUATOR

ML7984B

PWM VALVE ACTUATOR

COM

24 VAC

PWM 24VAC

FROM CNTRL

PWM OUTPUT

T6T5C B W R

TO ASSURE PROPER ELECTRICAL

CONTACT, WIRES MUST BE TWISTED

*

TOGETHER BEFORE INSERTION.

REHEAT

VALVE ACTUATOR

ML7984B

PWM VALVE ACTUATOR

COM

24 VAC

PWM 24VAC

FROM CNTRL

PWM OUTPUT

T6T5C B W R

****

CONFIGURATION DIP SWITCHES

LOCATED ADJACENT TO INPUT

TERMINAL BLOCK ON ML7948B

ON

OFF

Fig. 19. W7751H to PWM Valve Actuator

NOTE: Ensure that all transformer wiring is as shown.

Reversing terminations will result in equipment

malfunction.

W7751H

4321

7

EN1B-0279GE51 R0707B

Page 8

EXCEL 10 W7751H SMART VAV ACTUATOR

*

TRIAC

NOT EARTH

GROUND

EQUIVALENT

CIRCUIT

W7751H

LED

GND

BYPASS

SENSOR

SET PT

24VAC

COM

21

EARTH

MODULE

3

4

WALL

5

76

8

OUT1

9 10

OUT2

1112

LON

24VAC COMM IN

REHEAT

VALV E AC TUATO R

ML7984B

PWM VALVE ACTUATOR

COM

24 VAC

PWM 24VAC

FROM CNTRL

PWM OUTPUT

T6T5C B W R

CONTACTOR

(24 VAC)

SERIES OR

PAR ALLE L FAN

*

TO ASSURE PROPER ELECTRICAL

CONTACT, WIRES MUST BE TWISTED

TOGETHER BEFORE INSERTION.

Fig. 20. W7751H to PWM Valve Actuator and series or

parallel fan

Alarms

CARE is used to perform the ID Assignment task. Once ID

Assignment has been performed and commissioning has

been completed, check the L

determine if there are any alarms. Possible alarm causes can

be determined by viewing the nvoAlarm e.g. in CARE.

LONW

ORKS

Service LED

The LONW

ORKS

Service LED on the front of the W7751H (see

Fig. 2) provides a visual indication of the status of the device.

When the W7751H receives power, the LED appears in one

of the following allowable states:

1. OFF = no power to the processor.

2. Continuous ON = processor is in initialized state.

3. Slow blink = controlling, normal state.

4. Fast blink = the W7751H has an alarm condition.

When the W7751H has an alarm condition, it reports it to the

central node on the L

ONWORKS

10 Zone Manager). Also, the W7751H variables, AlarmLogX,

where X is 1 through 5, that store the last five alarms to occur

in the controller, are available. These points can be viewed

using XBS or the corresponding LNS plug-in. For a

description of Excel 10 Alarms, refer to Table 12 of Excel 10

W7751B,D,F,H,J Variable Air Volume Controller – Application

Guide (Product Literature No.: 74-2949)

NOTE: The node can be reset by switching the node to

MANUAL and then to the normal operating mode.

ONWORKS

service LED to

® network (typically, the Excel

TRIAC

NOT EARTH

GROUND

EQUIVALENT

CIRCUIT

W7751H

LED

GND

BYPASS

SENSOR

SET PT

24VAC

COM

21

EARTH

MODULE

3

4

WALL

765

8

OUT1

9 10

OUT2

1112

LON

24VAC COMM IN

OPTIONAL 24 VAC WIRING

TO NEXT CONTROLLER

*

MMC325 PNEUMATIC

TRANSDUCER

COM

COM

24 VAC

24 VAC

INCREASE

DECREASE

*

M

M

B

USE 1/4 IN. (6 MM)

MIN. TUBING.

BRANCH LINE MUST

BE 6 FT. (1.8 M)

OR LONGER.

PNEUMATIC

VALV E

Fig. 21. W7751H to pneumatic transducer

NOTE: Reverse wires (INCREASE/DECREASE) to reverse

action (DIRECT/REVERSE).

T7460 Wall Module Override LED

The remote override LED, located on either the T7460 Wall

Module, will display the "manual override" mode of the

W7751H. Possible modes are:

1. LED = OFF. No override active.

2. LED = Continuously ON. Bypass mode (timed occupied

override).

3. LED = One flash per second. Continuous unoccupied

override.

4. LED = Two flashes per second. Remote only, continuous

occupied override.

Step 3. I/O Tests

The W7751H controller must be configured using the LNS

plug-in. Once this is done, the W7751H can be commanded

to the "manual" mode, and each output and input can be

exercised/viewed to verify proper wiring connections and

equipment operation.

W7751H Actuator Checkout

To check out the W7751H actuator, determine the direction

the damper shaft moves to open the damper (CW or CCW).

See Fig. 7.

Connect the W7751H with the laptop PC. To do this, the

W7751H must be wired, powered, and connected to the

portable PC via the LonTalk adapter. The LonTalk® Adapter

connects to the W7751H either directly via the L

network or via the T7460-LONJACK (accessory available with

the T7460 and T7560 Wall Modules). Using the L

ONWORKS

ONWORKS

®

EN1B-0279GE51 R0707B

8

Page 9

EXCEL 10 W7751H SMART VAV ACTUATOR

tool, you should then drive the W7751H actuator fully open

and then closed. Observe the actuator's operation; if the

damper is closed, it should begin to open. If the damper is

open, it should begin to close.

If no movement is observed, check to see if 24 Vac is present

at the W7751H. With proper wiring, with 24 Vac present, and

with proper commands from the LNS plug-in, the actuator

should operate properly.

Step 4. Verify Sequences of Operation

For the detailed descriptions of the sequences of operation,

see Excel 10 W7751B,D,F,H,J Variable Air Volume Controller

– Application Guide (Product Literature No.: 74-2949).

Optional Accessories

Spare Parts Kit

Order no.: A7211.2071. Contains:

• 1 anti-rotation bracket + screws

• 2 universal terminal blocks

• 2 strain-relief clamps

• 2 grommets*

• 2 adjustable end stops

*In order to guarantee IP54, only original Honeywell

grommets may be used.

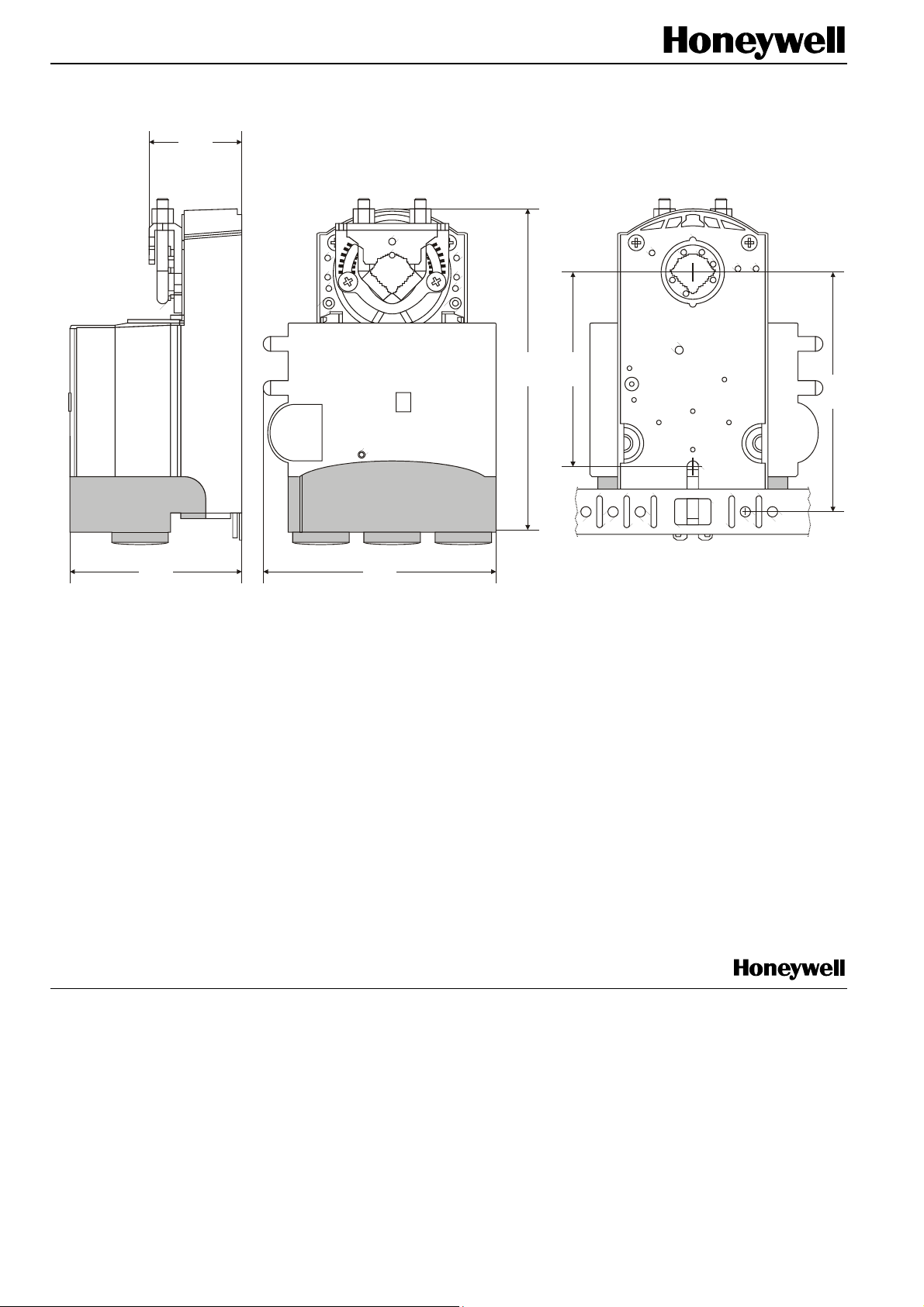

Table 1. Internal end switches of SSW2

terminal type of switch

S1

S2 / S3

S5 / S6

common lead for switches A and B

change-over switch A (S1/S2 opens and S1/S3

closes when shaft adapter moves CW past 5°;

reverts to original state when shaft adapter

moves CCW past 5°).

change-over switch B (S1/S5 opens and S1/S6

closes when shaft adapter moves CW past 85°;

reverts to original state when shaft adapter

moves CCW past 85°).

SSW2 Auxiliary Switch Kit

Fig. 22. Internal end switches of SSW2 (max. 230 V, 5 A)

NOTE: Both internal end switches must be connected to the

same power source.

9

EN1B-0279GE51 R0707B

Page 10

41

85

142

105

76

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Straße 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany

EN1B-0279GE51 R0707B

103

Fig. 23. Dimensions (in mm)

Loading...

Loading...