Page 1

([FHO

:%')+

9$9,,&RQWUROOHUV

Introduction

............................................................................................................................... 4

Description of Devices........................................................................................... 4

Control Application................................................................................................. 4

Control Provided.................................................................................................... 7

Products Covered.................................................................................................. 9

Organization of Manual.......................................................................................... 9

Applicable Literature.............................................................................................. 10

Product Names...................................................................................................... 10

Agency Listings...................................................................................................... 11

Abbreviations and Definitions ................................................................................ 12

Zone Control Definitions ........................................................................................ 13

Variable Air Volume ATUs ................................................................................ 13

Air Terminal Unit Control................................................................................... 13

Pressure - Dependent And Pressure - Independent Control ............................ 13

Variable Air Volume ATUs (VAV)...................................................................... 13

Single Duct Variable Air Volume (VAV) Systems.............................................. 14

Pressure Dependent Throttling VAV Boxes...................................................... 14

Pressure Independent VAV Boxes.................................................................... 14

Series Fan Powered VAV Boxes....................................................................... 14

Parallel Fan Powered VAV boxes..................................................................... 14

Induction VAV Boxes ........................................................................................ 14

Single-Duct Constant Volume Zone Reheat Air Terminal Units........................ 15

Dual Duct Air Handling Systems....................................................................... 15

Variable Constant Volume (Zero Energy Band) Dual-Duct VAV Boxes............ 15

Dual Duct Constant Volume Systems............................................................... 15

Dual-duct mixing box terminal units.............................................................. 15

Dual-duct constant volume mixing box terminal units.................................. 15

Variable Volume/Variable Temperature (VVT).................................................. 15

Single Zone Rooftop Air Handling Unit Control (CVAHU)................................. 16

Temperature and Ventilation Control ........................................................... 16

Unitary Equipment Control................................................................................ 16

Construction........................................................................................................... 16

Controllers......................................................................................................... 16

Performance Specifications.......................................................................... 19

Communications:.......................................................................................... 19

Environmental .............................................................................................. 20

Inputs/Outputs.............................................................................................. 21

Digital Inputs................................................................................................. 21

Digital Outputs: ............................................................................................. 21

Wall Modules .................................................................................................... 21

Sensor (Duct Mount)......................................................................................... 21

Configurations........................................................................................................ 21

General ............................................................................................................. 21

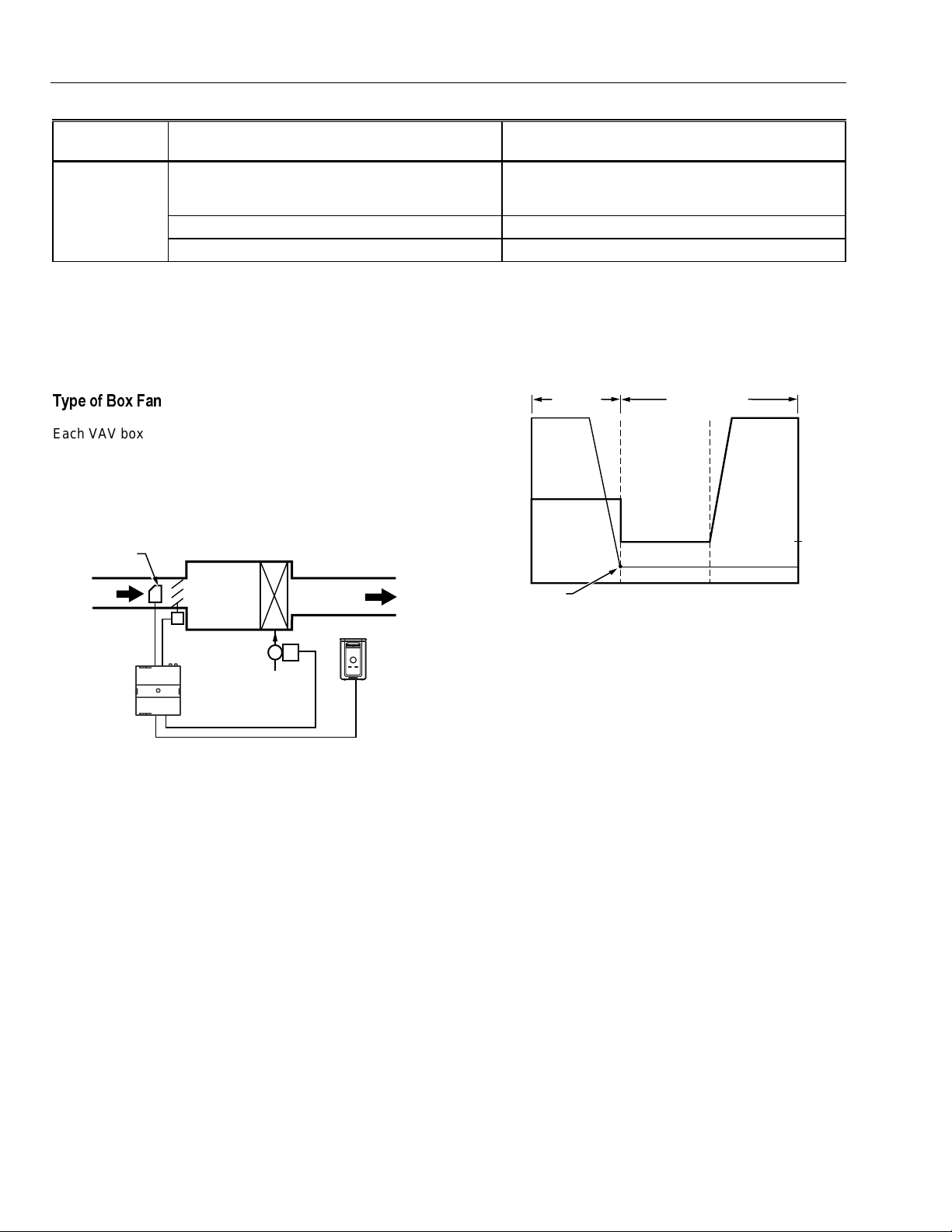

Type of Box Fan................................................................................................ 21

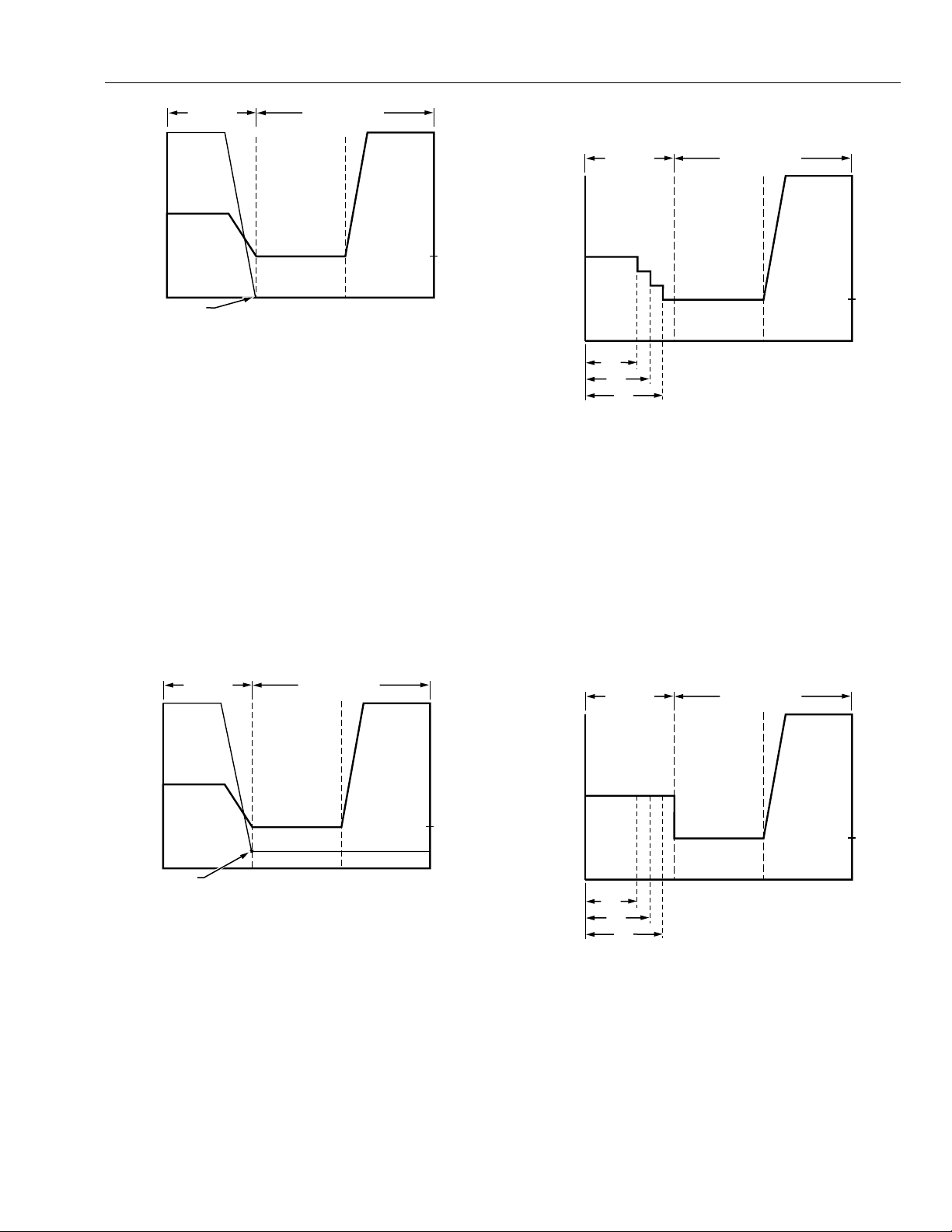

Dual Duct Flow Mixing: (For setup and Calibration refer to the

Dual Duct Calibration procedure in Appendix B.).................................... 21

Dual Duct No Flow Mixing: (For setup and Calibration refer to the

Dual Duct Calibration procedure in Appendix B.).................................... 21

Dual Duct Flow Mix: (Pressure independent cooling, pressure

dependent heating using one Excel 10.)................................................. 21

Dual Duct Flow Mix: (Alternate Configuration).............................................. 21

®U.S. Registered Trademark

Copyright © 1998 Honeywell Inc. • All ri ghts Reserved

74- 2949- 1

Page 2

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

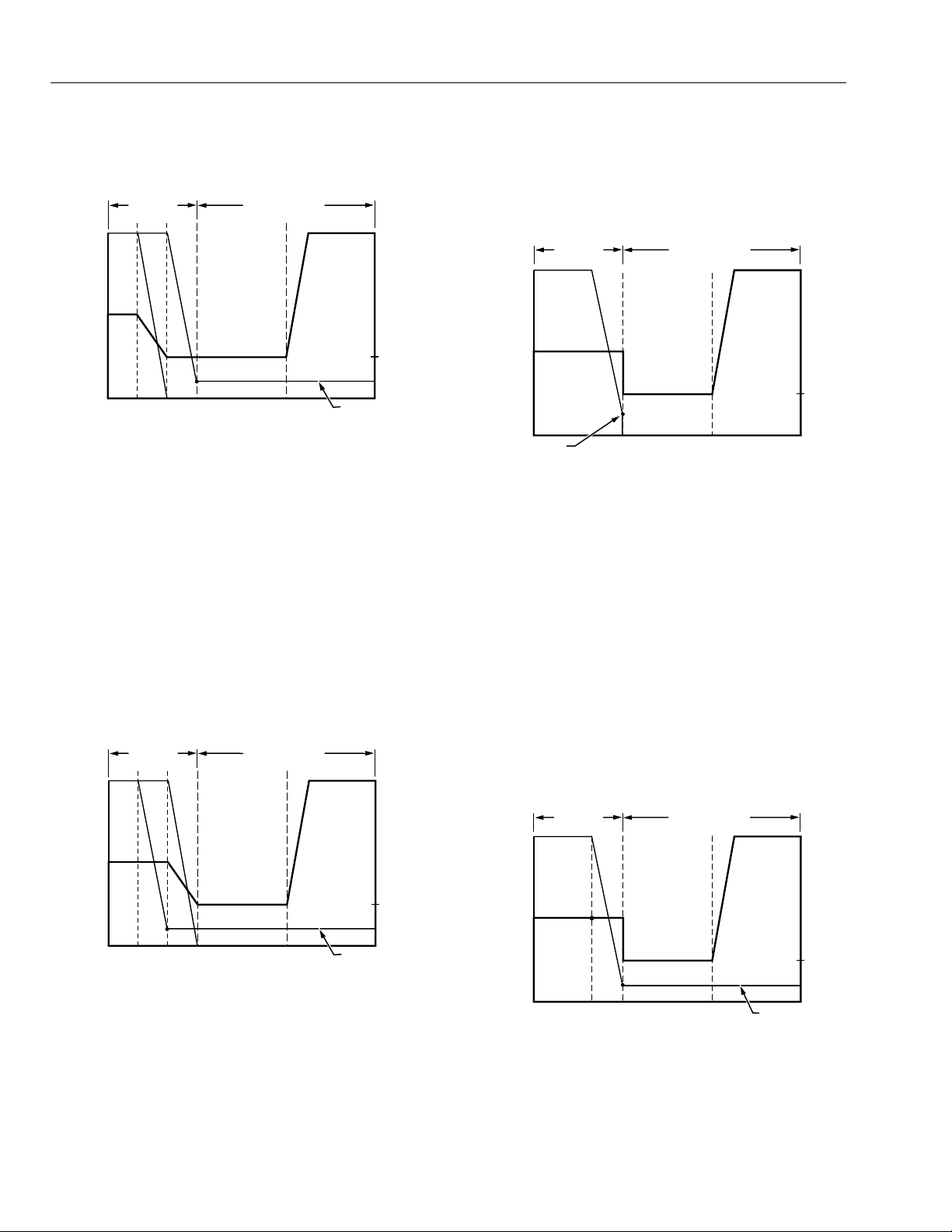

Dual Duct Constant Volume: (For setup and Calibration refer to the

Dual Duct Press Flow Mix: (Pressure dependent cooling and

Dual Duct Press Flow Mix: (Alternate Configuration).................................. 21

Dual Duct Discharge Sensor Constant Volume (pressure

Dual Duct Press Flow Mix (pressure dependent cooling and

Dual Duct Pressure Independent (pressure independent heating

PWM fan. ..................................................................................................... 21

T7780 DDWM Binding for VAVII Controllers................................................ 21

Type of Reheat Coil .......................................................................................... 21

Pneumatic Valve Actuator Control ............................................................... 21

Exhaust Tracking Option................................................................................... 21

Occupancy Sensor............................................................................................ 21

Window Open/Closed Digital Input ................................................................... 21

Heat/Cool change over ..................................................................................... 21

Wall Module Options......................................................................................... 21

Common Temperature Control (Share Wall Module)................................... 21

Sensor Options ................................................................................................. 21

Application Steps

Pneumatic Retrofit Applications........................................................................ 21

............................................................................................................................... 21

Overview................................................................................................................ 21

Step 1. Plan The System....................................................................................... 21

Step 2. Determine Other Bus Devices Required ................................................... 21

Step 3. Lay Out Communications and Power Wiring............................................. 21

E-Bus Layout..................................................................................................... 21

Power Wiring..................................................................................................... 21

Power Budget Calculation Example............................................................. 21

Line Loss...................................................................................................... 21

Step 4. Prepare Wiring Diagrams.......................................................................... 21

General Considerations.................................................................................... 21

W7751B OEM Version...................................................................................... 21

W7751D,F Field-Mount Versions...................................................................... 21

W7751H Version............................................................................................... 21

E-Bus Termination Module................................................................................ 21

Step 5. Order Equipment....................................................................................... 21

Step 6. Configure Controllers ................................................................................ 21

General............................................................................................................. 21

Hardware I/O Assignment................................................................................. 21

Fan Type...................................................................................................... 21

Reheat Definitions........................................................................................ 21

Reheat Type................................................................................................. 21

Flow Type..................................................................................................... 21

Miscellaneous............................................................................................... 21

Personality Information..................................................................................... 21

Commissioning ................................................................................................. 21

Job Commissioning...................................................................................... 21

ID Number......................................................................................................... 21

Bench Top Configuring................................................................................. 21

Configuring in the Field ................................................................................ 21

Configuring the Zone Manager..................................................................... 21

Excel 10 VAV Controller Point Mapping............................................................ 21

Step 7. Troubleshooting......................................................................................... 21

Troubleshooting Excel 10 Controllers and Wall Modules ................................. 21

Temperature Sensor and Setpoint Potentiometer Resistance Ranges ............ 21

Alarms............................................................................................................... 21

Broadcasting the Service Message................................................................... 21

W7751 Controller Status LEDs......................................................................... 21

T7770C or D Wall Module Override LED.......................................................... 21

T7770C,D or T7780 DDWM Bypass Pushbutton Operation............................. 21

T7780 DDWM Bypass Pushbutton ................................................................... 21

Dual Duct Calibration procedure in Appendix B.).................................... 21

heating using one Excel 10.)................................................................... 21

independent discharge using one Excel 10)........................................... 21

heating using one Excel 10).................................................................... 21

and cooling using one Excel 10)............................................................. 21

74-2949–1 2

Page 3

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

Appendices

...............................................................................................................................21

Appendix A. Creating a Work Bench for Configuring Excel 10 W7751D,F

VAV Controllers................................................................................................. 21

Appendix B. Using E-Vision to Commission a W7751 Controller.......................... 21

Job Commissioning ............................................................................................... 21

ID Number.............................................................................................................. 21

Bench Top Configuring ..................................................................................... 21

Configuring in the Field..................................................................................... 21

Configuring the Zone Manager ......................................................................... 21

Sensor Calibration............................................................................................. 21

Air Flow Balancing (For Pressure Independent applications only)................... 21

Procedure.......................................................................................................... 21

Resetting Air Flow Calibration to Factory Defaults............................................ 21

VAVII Calibration Sequence.............................................................................. 21

Appendix C. Sequences of Operation................................................................... 21

Common Operations......................................................................................... 21

Room Temperature Sensor (RmTemp)........................................................ 21

Remote Setpoint (RmtStptPot or DischargeAir_Sensor).............................. 21

Setpoint Limits (StptLoLim and StptHiLim)................................................... 21

Bypass Mode (StatusOvrride and StatusLed).............................................. 21

BypassTime.................................................................................................. 21

OverrideType................................................................................................ 21

OverridePriority............................................................................................. 21

Standby Mode.............................................................................................. 21

Window Sensor............................................................................................ 21

CAV Control ................................................................................................. 21

Continuous Unoccupied Mode..................................................................... 21

Share Wall Module....................................................................................... 21

Night Purge .................................................................................................. 21

Morning Warm-Up........................................................................................ 21

Smoke Control.............................................................................................. 21

Demand Limit Control................................................................................... 21

Start-Up........................................................................................................ 21

Air Flow Control Sequences of Operation.................................................... 21

Dual Duct, Pressure Independent, with flow mixing, with cold and

hot duct flow pickups (uses a satellite Excel 10 for hot duct)........................ 21

Dual Duct Flow Mixing: (For setup and Calibration refer to the

Dual Duct Calibration procedure in Appendix B)..................................... 21

Dual Duct, Pressure Independent, without flow mixing, with cold and

hot duct flow pickups (uses a satellite Excel 10 for hot duct)........................ 21

Dual Duct No Flow Mixing: (For setup and Calibration refer to the

Dual Duct Calibration procedure in Appendix B)..................................... 21

Dual Duct, Pressure Independent cooling, Pressure Dependent heating

with flow mixing, with cold duct flow pickup................................................... 21

Dual Duct Press Flow Mix (pressure dependent cooling and heating

using one Excel 10)................................................................................. 21

Dual Duct, Pressure Independent cooling and heating, constant volume

with hot and cold duct flow pickups............................................................... 21

Dual Duct Constant Volume:........................................................................ 21

Dual Duct, Pressure Dependent cooling and heating, with Flow mixing

and no flow pickups....................................................................................... 21

Dual Duct Press Flow Mix (pressure dependent cooling and heating

using one Excel 10)................................................................................. 21

Dual Duct, Pressure Independent cooling and Pressure Dependent

heating, with Constant Volume and Discharge Air Flow pickup.................... 21

Dual Duct Discharge Sensor Constant Volume (pressure dependent

cooling and heating using one Excel 10). ............................................... 21

Appendix D. Complete List of Excel 10 VAVII Controller User Addresses............ 21

Appendix E. Q7750A Excel 10 Zone Manager Point Estimating Guide................. 21

Approximate Memory Size Estimating Procedure............................................. 21

Appendix F. Custom Flow Pickup Tables (not Applicable for

Pressure Dependent Applications).................................................................... 21

Method 1. Pressure Velocity Formula............................................................... 21

Method 2. Pressure Versus Flow Graph........................................................... 21

3 74-2949–1

Page 4

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

,1752'8&7,21

'HVFULSWLRQRI'HYLFHV

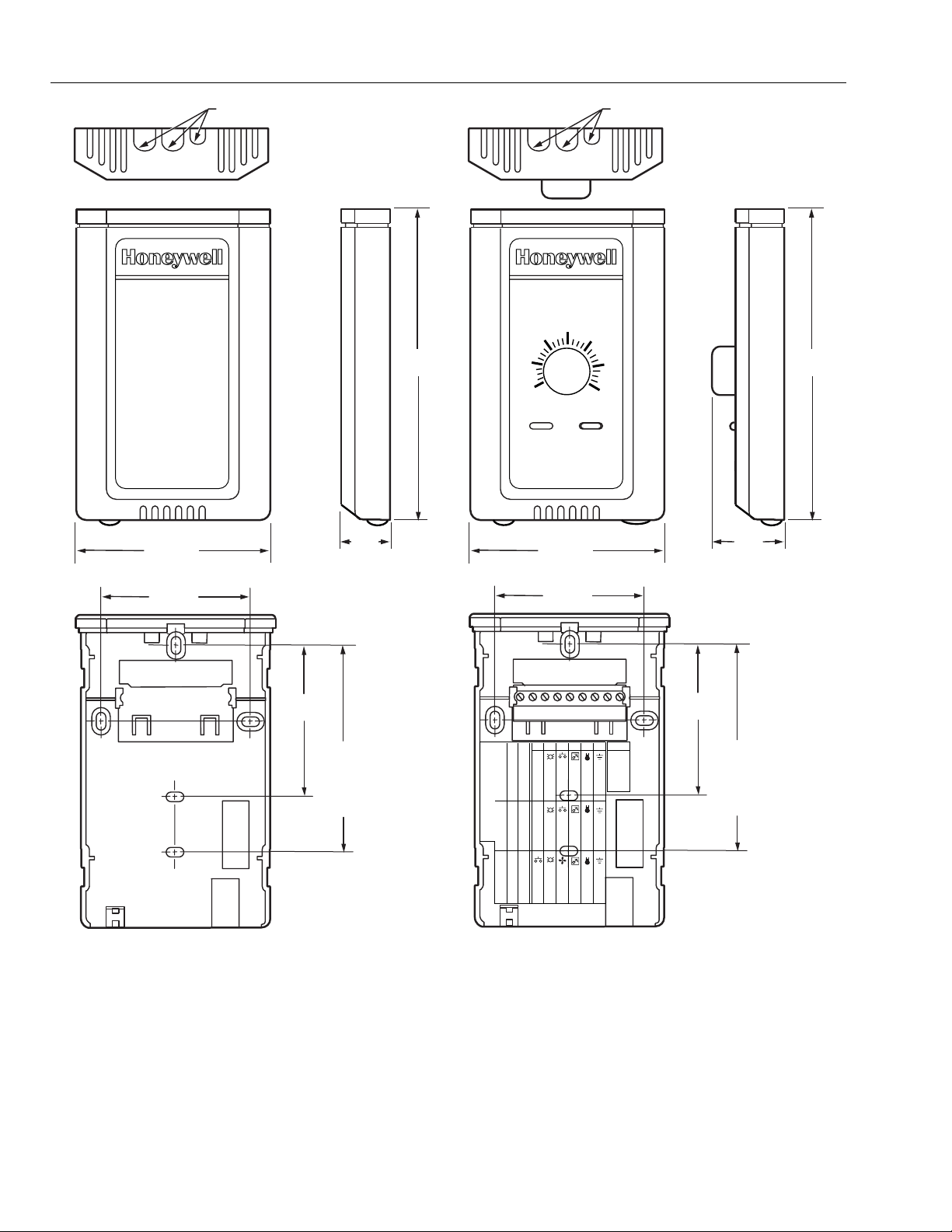

The W7751B,D,F,H Excel 10 VAV II Box Controllers

provide enhanced control solutions for single duct, dual

duct and constant volume air terminal units. They feature

preprogrammed heating/cooling or reheat control

algorithms for standard VAV Box control applications that

are selected through the E-Vision software configuration

tool. They use Echelon® LonWorks® communication

technology and the new Free Topology Transceiver (FTT)

for greater installation flexibility. In addition, they are the

first VAV Box Controllers in the marketplace from any

manufacturer that use the LonMark® VAV Controller

compliance profile for true openness and interoperability

with third party LonMark® devices. They can be used in

stand-alone applications or be used in combination with

Excel 10 Zone Manager (FTT), other Excel Controllers,

and the Excel Building Supervisor, to provided a complete

and low cost control solution for small to large commercial

buildings.

The W7751B,D,F,H Excel 10 VAV Box Controllers are

configurable direct digital controllers designed for pressure

independent or pressure dependent single duct VAV, dual

duct VAV and constant volume air terminal unit control

solutions. Four models are available including a low cost

circuit board version (W7751B) for internal panel

mounting, two plenum mounted controllers complete with a

wiring subbase for easy field installation (W7751D and F)

and the low cost W7751H Smart VAV Actuator consisting

of the Excel 10 Controller that is factory mounted and

wired to a 90 second ML6161B Actuator. All four of the

Excel 10 VAV Box Controllers contain an integral

microbridge air flow sensor that provides flow

measurement for pressure independent applications. The

controller configuration is selected using a personal

computer and the E-Vision and CARE software

configuration tools. The Excel 10 VAV Box Controllers

offer many features required in todays commercial

buildings including energy saving setpoint reset for

electrical demand limit control, standby setpoints for

setpoint reset in the occupied mode and unoccupied

setpoints for both heating and cooling. The control

solutions are scaleable from stand-alone installations, to a

networked system using a Zone Manager as the network

master or they can be fully integrated into the complete

Excel 5000 system with Excel 80, 100, 500 and 600

controllers and Excel Building Supervisor. In addition, they

provide true open communication with the use of the

LonMark® Controller compliance profile and the FTT for

greater flexibility in network wiring and integration with third

party LonMark® devices.

The T7770 are direct-wired wall modules used in

conjunction with W7751B,D,F,H Controllers. The zone

controlled by the W7751 Controllers will typically use a

T7770 Wall Module with a temperature sensor for space

temperature measurement in a minimum system

configuration. Additional features available in the T7770

model include analog setpoint input, override digital input

pushbutton, override status LED and E-Bus network

access jack.

The T7780 Digital Display Wall Module (DDWM) has all of

the features of the T7770 Wall Modules but communicates

via the E-Bus.

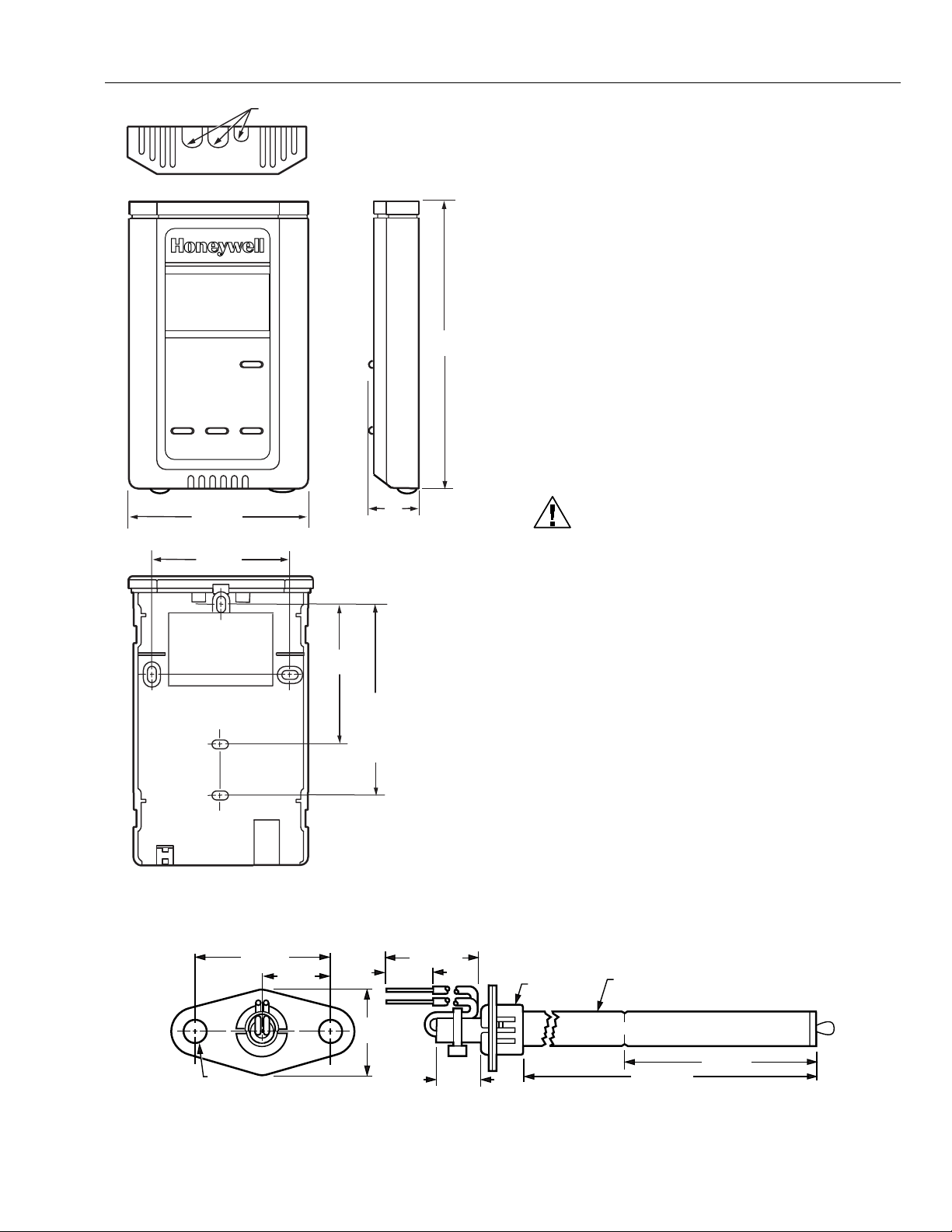

The C7770A Air Temperature Sensor is a direct wired

temperature sensor that is used to sense discharge or

return air in a duct controlled by a W7751 Controller.

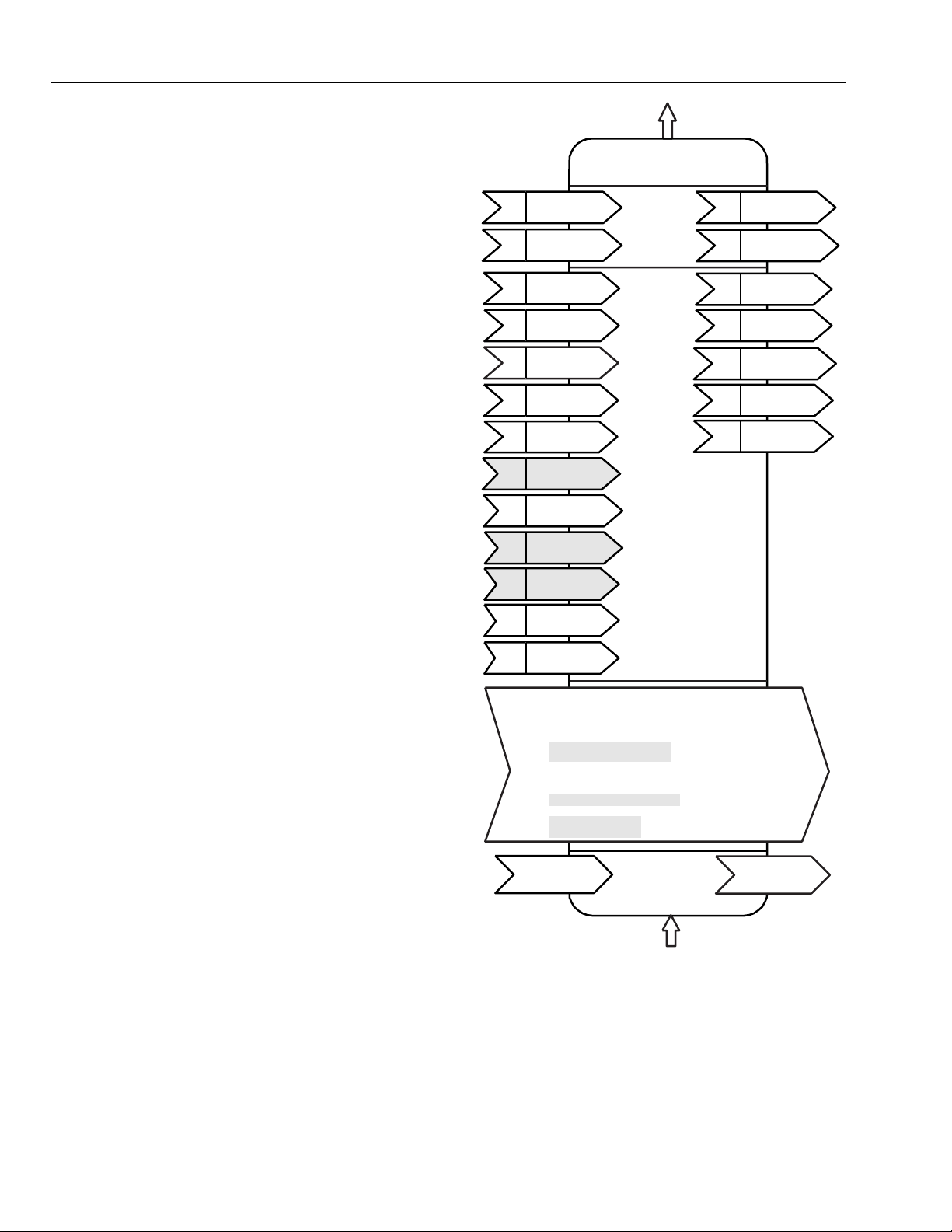

The Q7750A Excel 10 Zone Manager is a communications

interface that allows devices on the E-Bus network to

communicate with devices on the EXCEL 5000® System

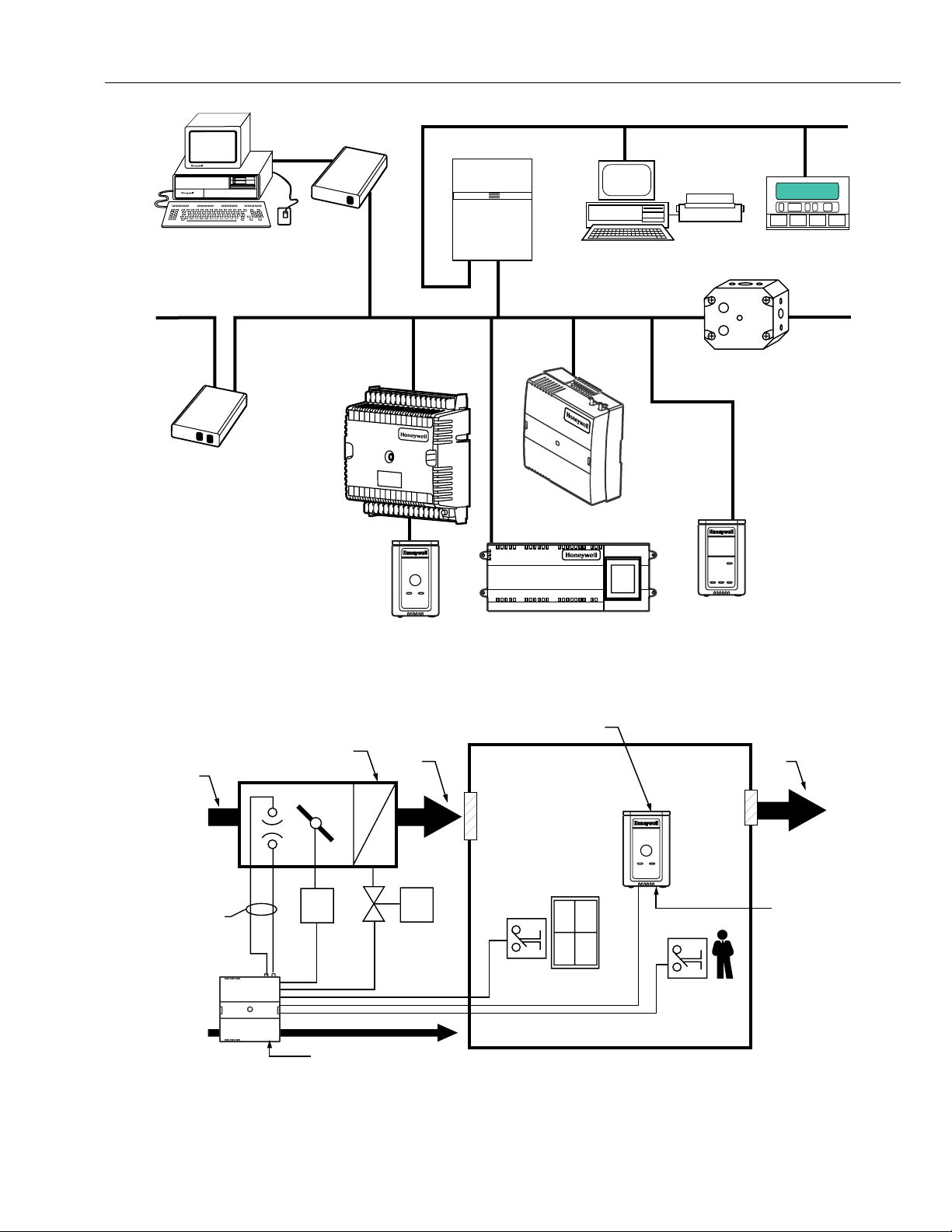

C-Bus. Fig. 1 shows an overview of a typical system

layout. The Q7750A also provides some control and

monitoring functions.

&RQWURO$SSOLFDWLRQ

VAV systems in commercial buildings typically incorporate

a central air handler that delivers a modulated volume of

air at a preconditioned temperature to multiple zones.

Each zone is serviced by a VAV terminal box unit. Each

box incorporates an air flow pickup assembly and

motorized damper with optional fan and/or reheat coil. The

controller determines and regulates the air flow of

conditioned air to the space. The zone being fed by the

terminal box will use a T7770 Wall Module or a T7780

DDWM for space temperature determination and access to

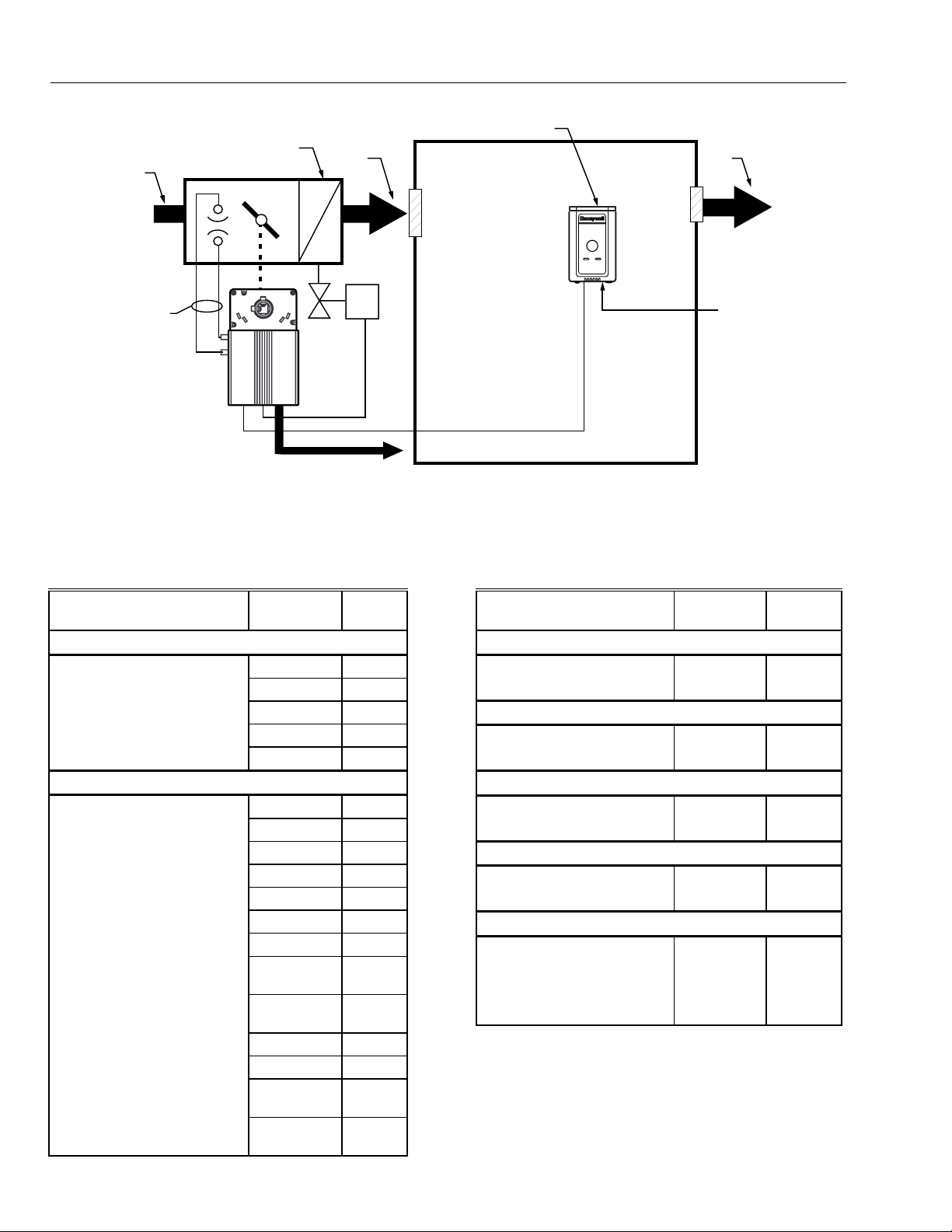

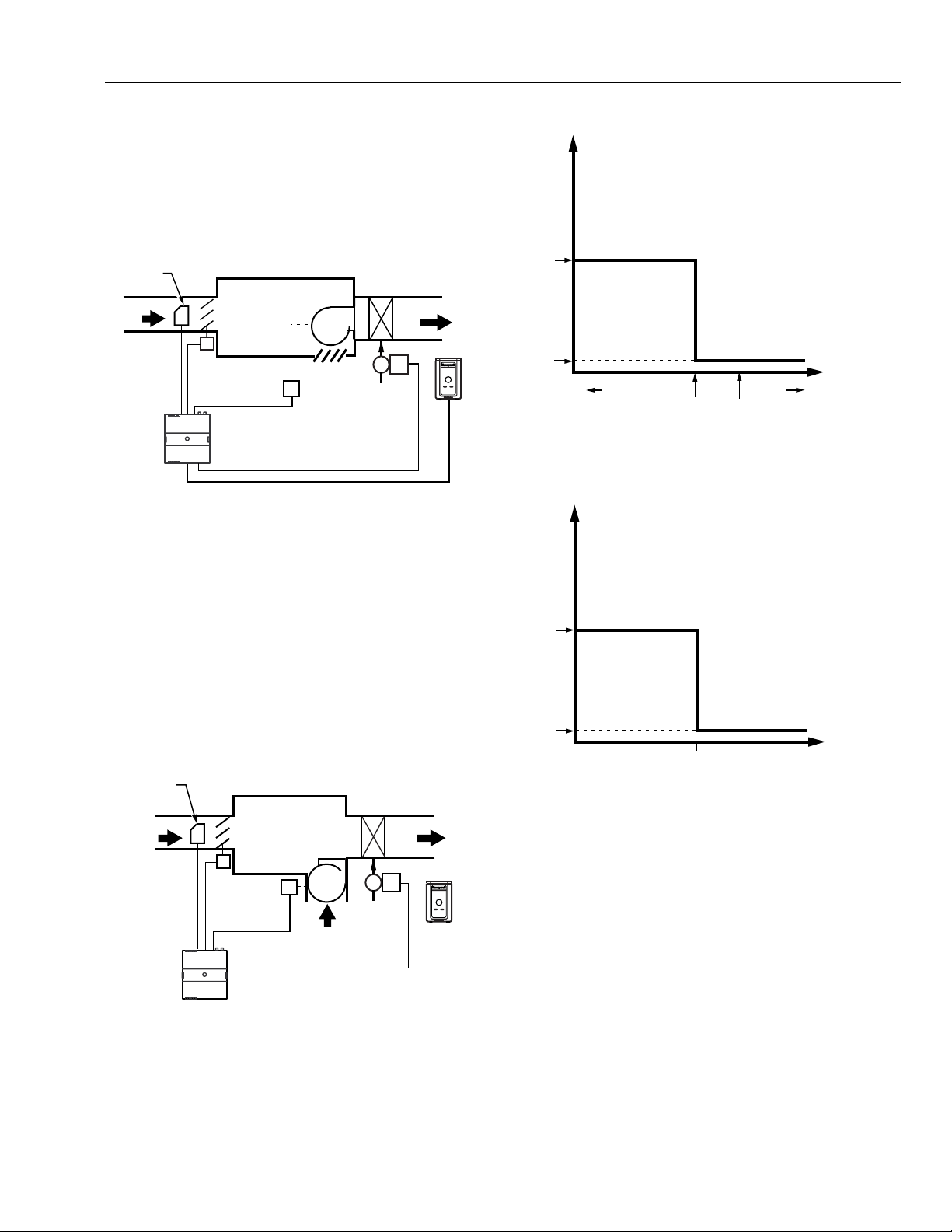

the E-Bus network for operators. Fig. 2 shows a typical

VAV box control application for the W7751B,D,F

Controllers. Fig. 3 shows a typical VAV box control

application for the W7751H Smart VAV Actuator. Table 1

shows the capabilities of the Excel 10 VAV Box

Controllers.

74-2949–1 4

Page 5

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

PERSONAL COMPUTER TOOLS

E-VISION

CARE

FTT E-BUS COMMUNICATIONS NETWORK

EXCEL 10

Q7751A

FTT

E-BUS

ROUTER

W7750B

CVAHU

CONTROLLER

EXCEL 10 T7770

WALL MODULE

Q7752A

FTT E-BUS

SERIAL

ADAPTER

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

1234567 89101112131415J3

C-BUS COMMUNICATION NETWORK

EXCEL 10

Q7750A

FTT ZONE

MANAGER

C-BUS TO E-BUS

INTERFACE DEVICE

FTT E-BUS COMMUNICATIONS NETWORK

EXCEL 10

W7752 FTT

FAN COIL UNIT CONTROLLER

EXCEL BUILDING SUPERVISOR

FTT E-BUS

COMMUNICATIONS

NETWORK

EXCEL 10 W7751F

PANEL PLENUM

MOUNT VERSION

VARIABLE AIR

VOLUME

CONTROLLER

EXCEL 500

Q7740A

2-WAY

REPEATER

EXCEL 10 T7780

DIGITAL DISPLAY

WALL MODULE

PRIMARY

AIR

∆P

PICKUP

TERMINAL HEAT

AIR TERMINAL UNIT

M1

Fig. 1. Typical system overview.

ECHELON BUS

DISCHARGE

AIR

M2

TEMPERATURE SENSOR WITH

REMOTE SETPOINT ADJUSTMENT

AND UNOCCUPIED BYPASS

OVERRIDE BUTTON

WINDOW CONTACT

OCCUPANCY

CONTACT

RETURN

AIR

E-BUS

NETWORK

ACCESS

M11817

EXCEL 10 VAV

CONTROL MODULE W7751

E-BUS NETWORK ACCESS

Fig. 2. Typical W7751B,D,F VAV box control application.

M1 = DAMPER ACTUATOR

M2 = VALVE ACTUATOR

M11818

5 74-2949–1

Page 6

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

PRIMARY

AIR

TERMINAL HEAT

AIR TERMINAL UNIT

DISCHARGE

AIR

TEMPERATURE SENSOR

WITH REMOTE SETPOINT

ADJUSTMENT

RETURN

AIR

∆P

PICKUP

EXCEL 10

W7751G

SMART VAV

ACTUATOR

M1-REHEAT

VALVE

ACTUATOR

E-BUS

M1

E-BUS

NETWORK

ACCESS

M11819

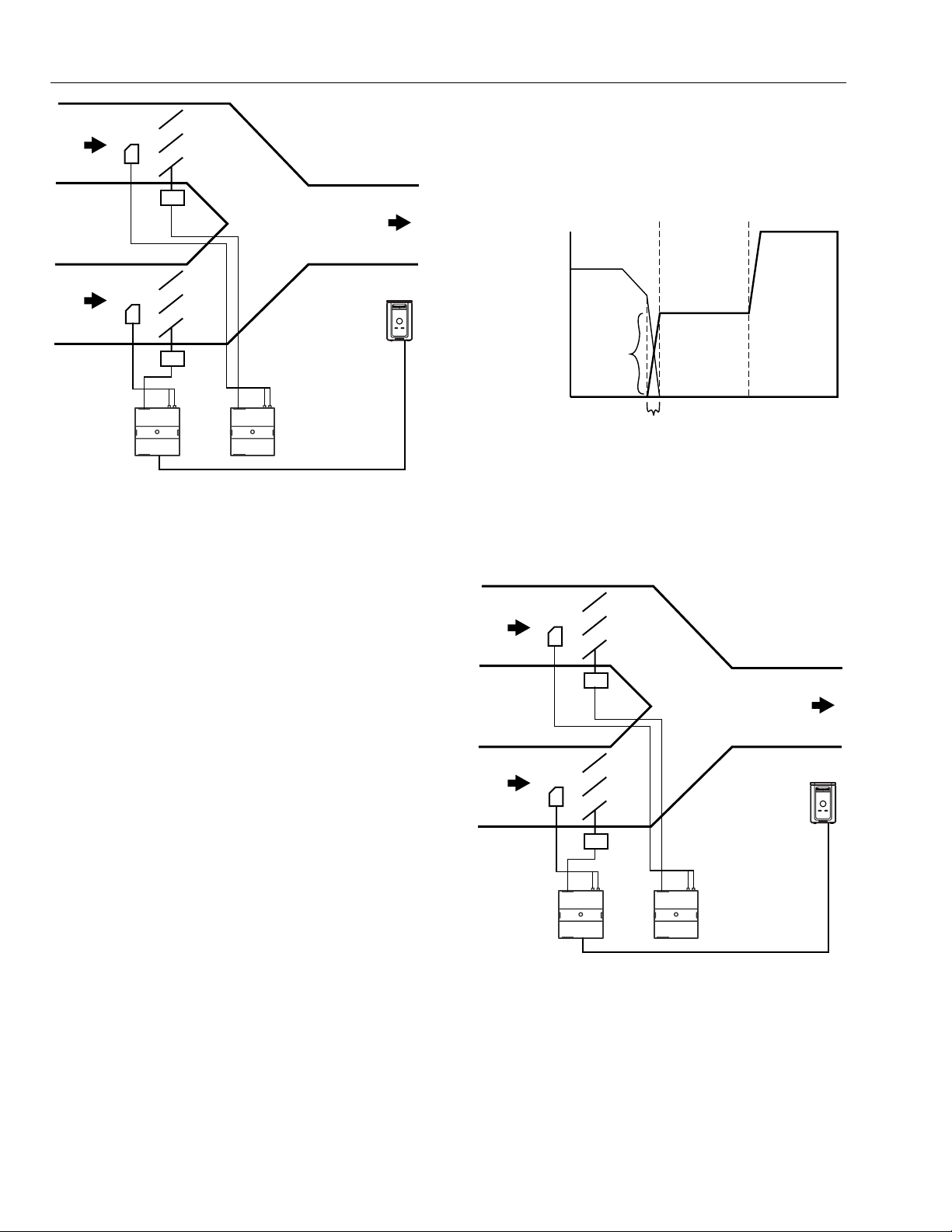

Fig. 3. Typical W7751H Smart VAV Actuator box control application (Smart VAV Actuator mounts directly on the

damper shaft as represented by the dotted line). (The W7751H does not include a window contact or occupancy

sensor contact terminals, which are available via the network only.)

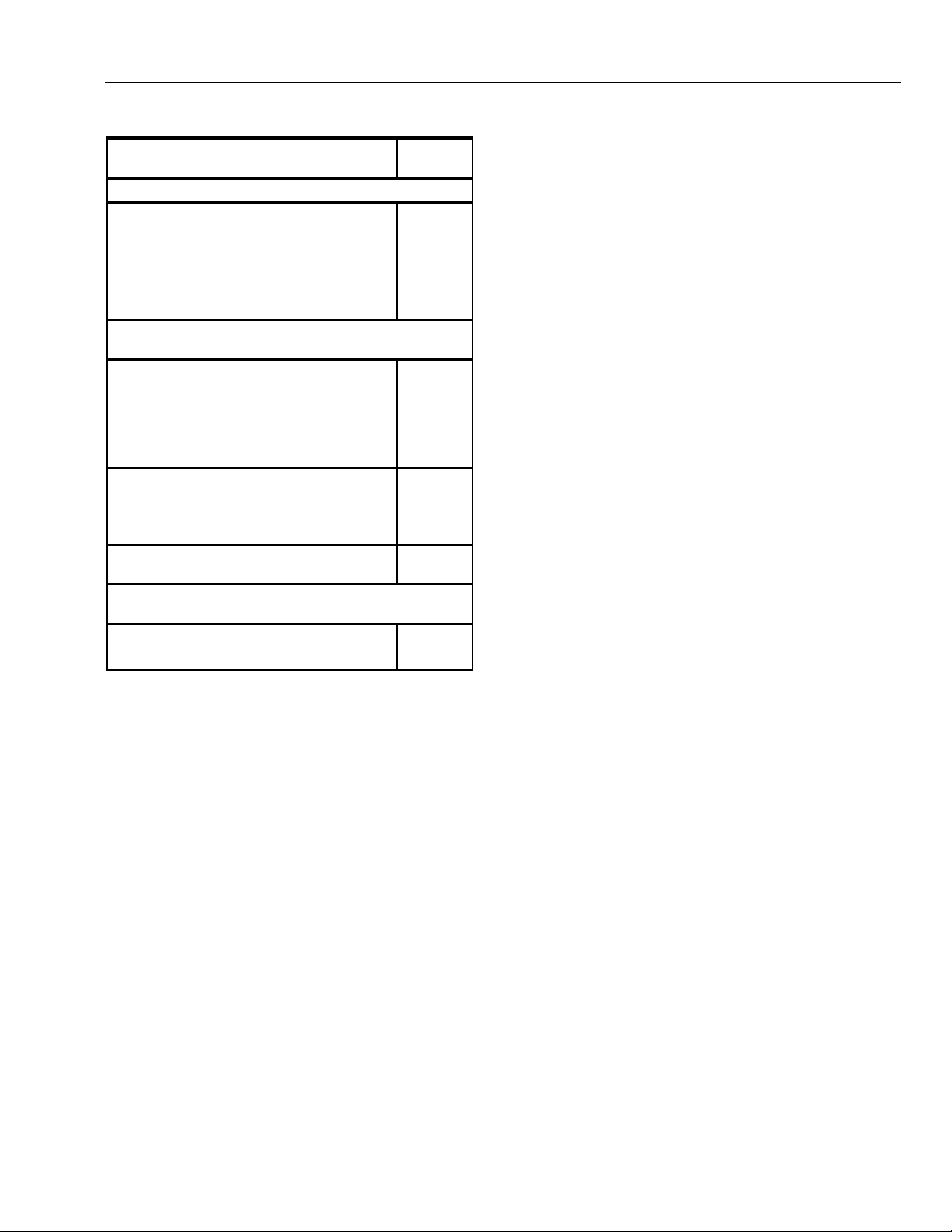

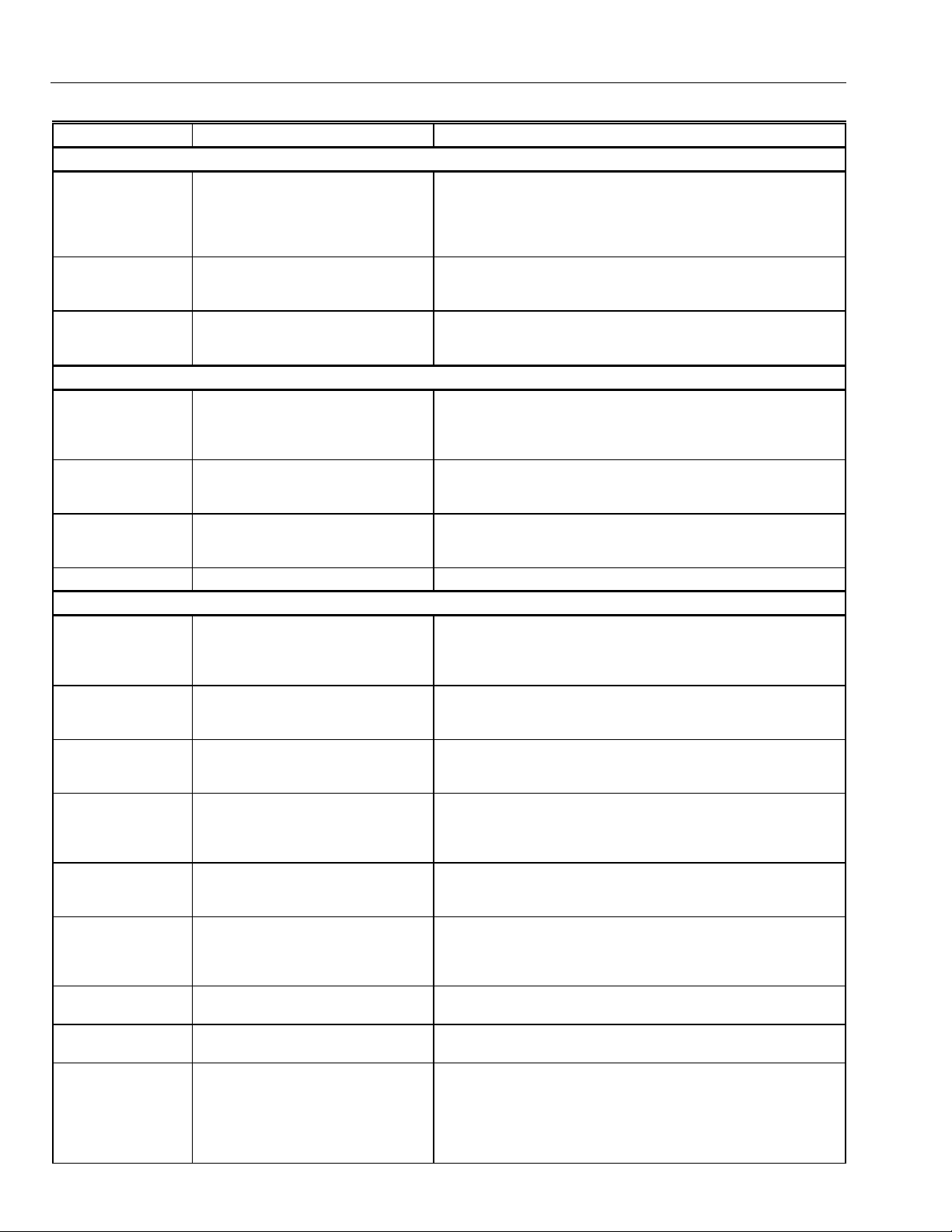

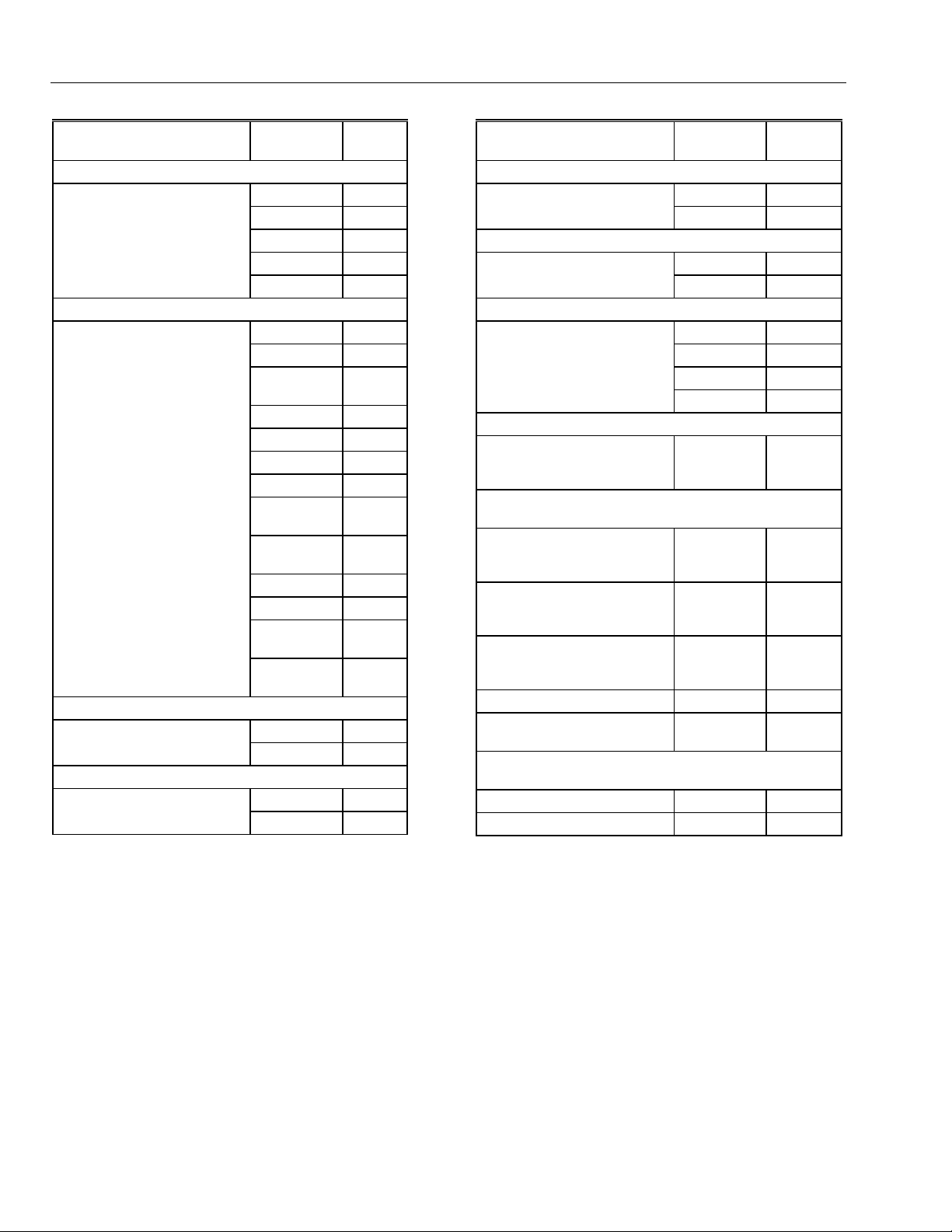

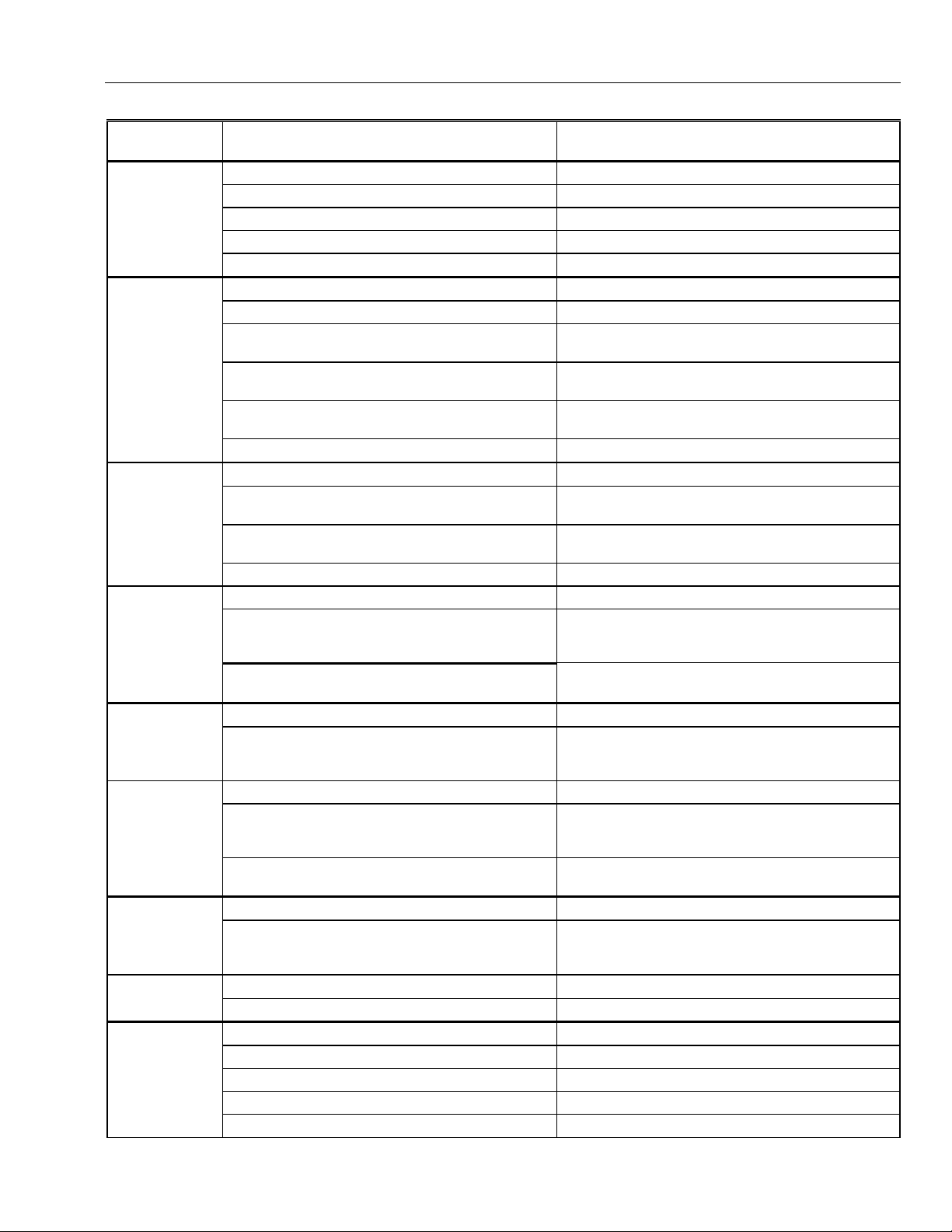

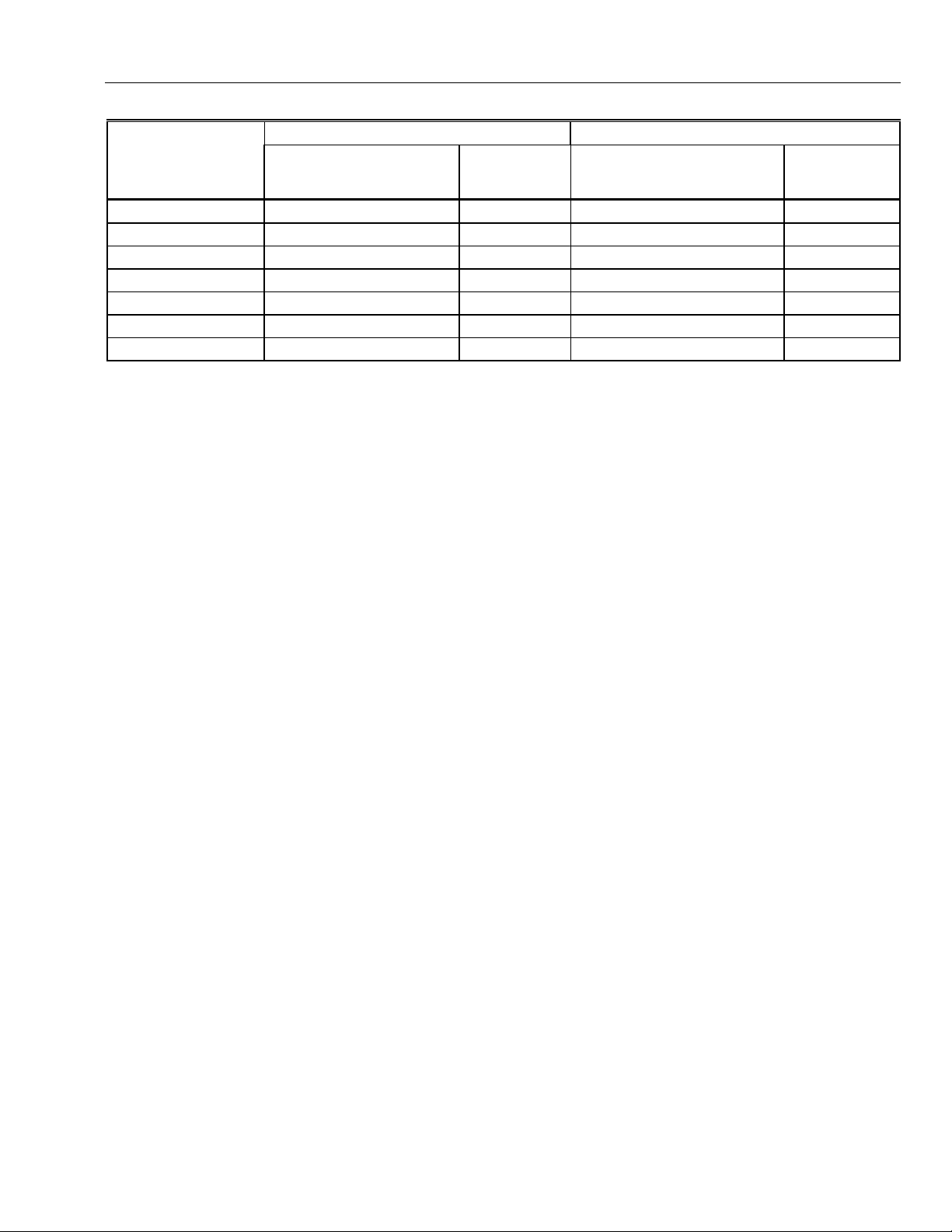

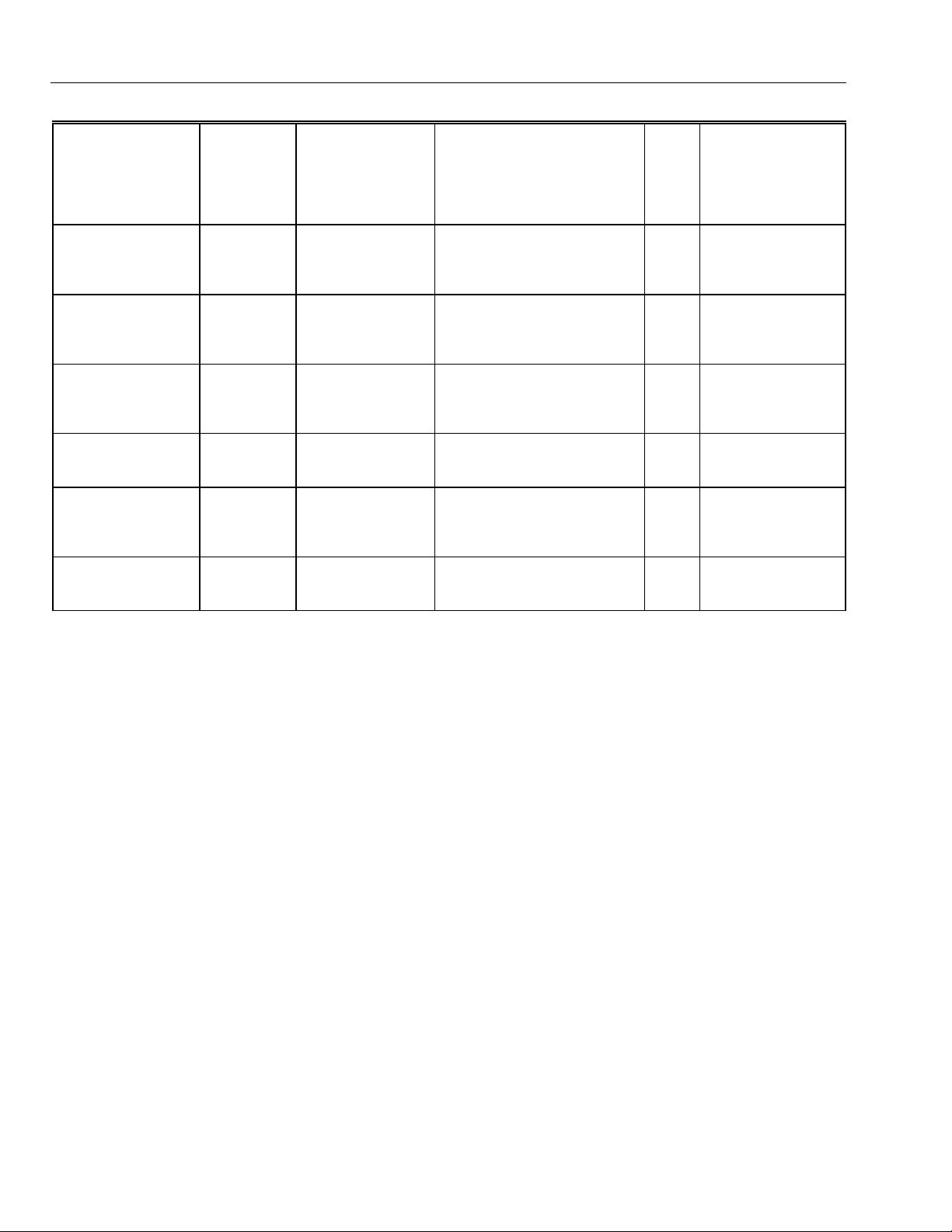

Table 1. Excel 10 VAV Box Controller Capability.

Excel 10 VAV Box Controller

Capability W7751B,D,F W7751H

Fan

None X X

Series X X

Parallel - Temp X X

Parallel - Flow X X

Parallel - PWM

XX

Reheat

None X X

One Stage Reheat X X**

Two Stages Reheat X X**

Three Stages Reheat X —

One Stage Periph X X**

Floating Reheat (Two outputs) X X**

Floating Periph (Two outputs) X X**

Floating Reheat then Periph

X—

(Four outputs)

Floating Periph then Reheat

X—

(Four outputs)

Excel 10 VAV Box

Controller Capability W7751B,D,F W7751H

Exhaust Tracking

Disabled X X

Enabled X X

Occupancy Sensor

None X X

Connected X —*

Window Contact

None X X

Connected X —*

Wall Module Configuration

Local X X

Shared X X

Wall Module Type

Sensor Only X X

Sensor and Setpoint X X

Sensor, Setpoint and Bypass X X

Sensor and Bypass X X

PWM Reheat (One output) X X**

PWM Periph (One output) X X**

PWM Reheat then Periph

XX**

(Two outputs)

PWM Periph then Reheat

XX**

(Two outputs)

(continued)

74-2949–1 6

Page 7

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

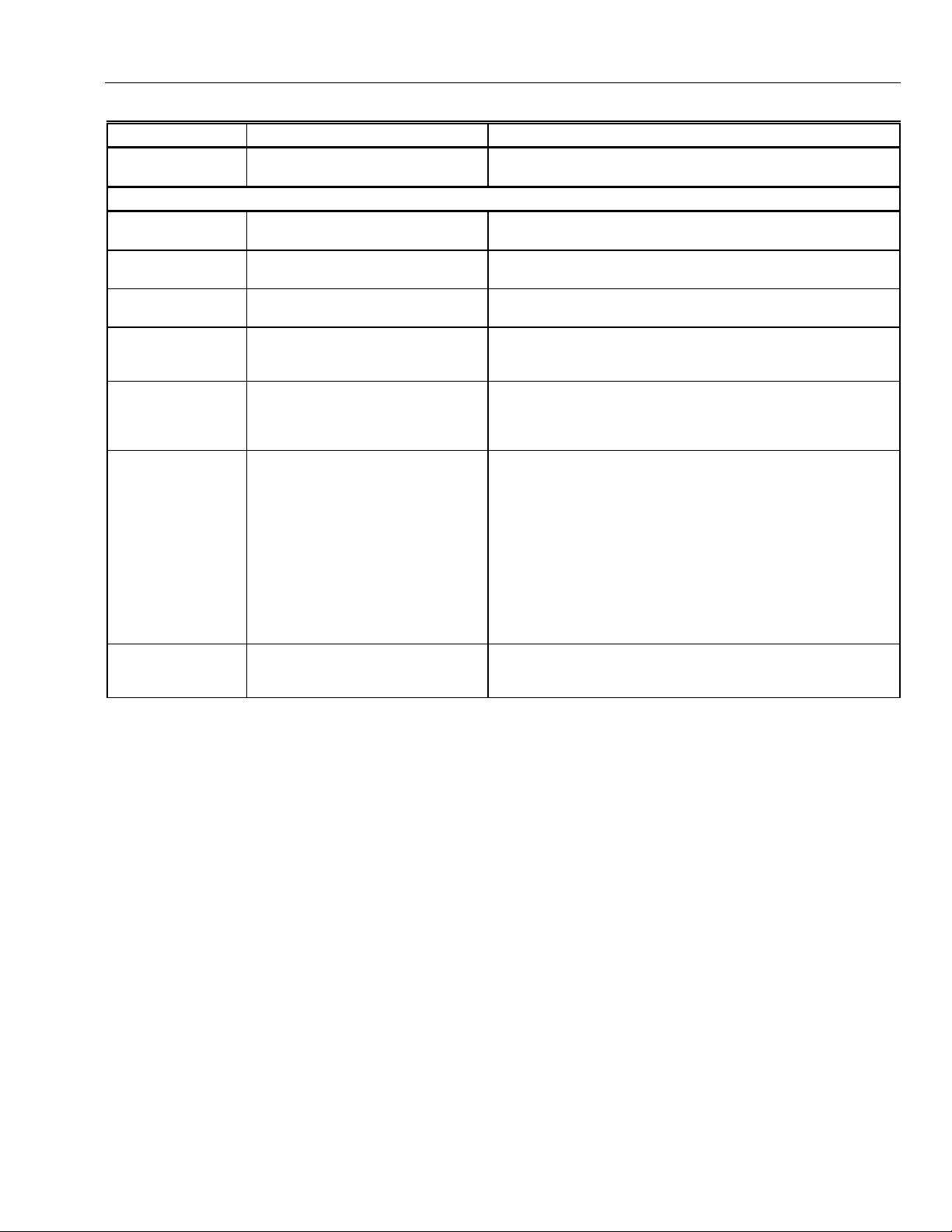

Table 1. Excel 10 VAV Box Controller Capability

Excel 10 VAV Box

Controller Capability W7751B,D,F W7751H

Air Temperature Sensor

20 K ohm air temperature

sensors can be used in

conjunction with wall modules

(Either a wall module or an air

temperature sensor can be

used with the W7751H, but

not both.)

Dual Duct Pressure

Independent

Flow mixing

Cold and hot duct flow

pickups

Without flow mixing

Cold and hot duct flow

pickups

Constant volume

Cold and hot duct flow

pickups

With cold duct pickup only X X

Constant volume with

discharge pickup only

Dual Duct Pressure

Dependent

With flow mixing X X

Without flow mixing X X

* Available only via the network for the W7751H.

** The W7751H Smart VAV Actuator provides damper

control and two configurable outputs available for

two stages of reheat, floating reheat (requires two

outputs), PWM Reheat or Periph (one output

required), PWM Reheat and Periph (two outputs

required) or one stage of reheat or Periph (can be

PWM also) and a serial or parallel fan.

*** These applications require two W7751 Excel 10

controllers per zone.

**** Flow sensor in discharge air. The temperature

control loop controls the cool damper position and

the flow controls adjust the heating damper position.

(Continued).

XX

X*** X***

X*** X***

X*** X***

X**** X****

&RQWURO3URYLGHG

The W7751B,D,F,H Controllers are primarily intended for

pressure independent, single or dual-duct VAV box

control. Pressure independent control specifies that the

individual zone terminal unit has a means for maintaining a

consistent volume of air into the zone regardless of the

input static pressure. The controller modulates the air flow

into the zone to satisfy the Zone Temperature Setpoint.

Minimum Air Flows are maintained except during

emergency strategy periods or during building Unoccupied

periods if using physical position stops, a MIN/MAX air flow

is always maintained (see Table 2).

Pressure dependent control specifies that the damper

position is controlled by space temperature only and not by

a measurement of air flow volume. The amount of air

delivered to the zone at any given damper position is

dependent on the static pressure in the supply air duct

(physical position stops, range stop pins, are used to keep

the damper at a fixed position).

VAV systems generally only provide cool air to the zones;

therefore, the W7751 Controller provides additional

outputs for control of heating systems such as reheat coils

for Heat mode or Morning warm-up mode operation. The

heating equipment can be staged-resistive heating, staged

2-position (solenoid) valve, or modulated steam or hot

water valve.

The possible modes of operation are listed in Table 2.

7 74-2949–1

Page 8

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

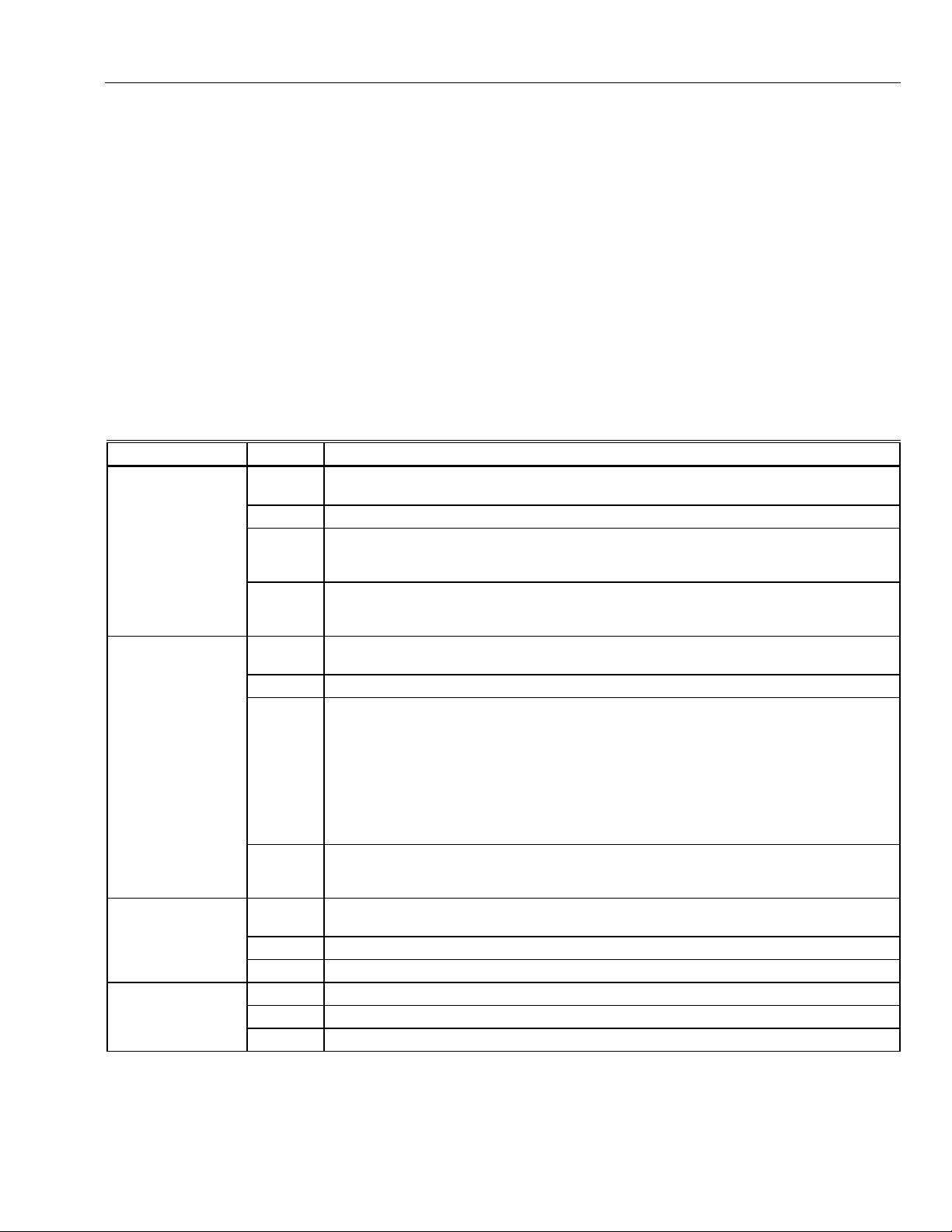

Table 2. Modes Of Operation For Excel 10 VAV Controller.

Mode Description Events Causing a Controller to Switch to This Mode

Effective Occupancy (User Address: StatusOcc)

OCCUPIED* Controller is in Occupied mode. Any of the following: Network input (DestSchedOcc) containing

STANDBY* Controller is in Standby mode. Network input (DestSchedOcc) containing time-of-day schedule

UNOCCUPIED Controller is in Unoccupied mode. Network input (DestSchedOcc) containing time-of-day schedule

Override Modes (User Address: StatusOvrride)

OCCUPIED* Controller is in Occupied mode. Network input (DestSchedOcc) containing time-of-day schedule

UNOCCUPIED Controller is in Unoccupied mode. Network input (DestSchedOcc) containing time-of-day schedule

BYPASS User-initiated Bypass of the

NOT ASSIGNED No Bypass action. No Override input received.

Operational Modes (User Address: StatusMode)

START-UP AND

WAIT (followed by)

FLOAT_OUT_SYNC

COOLING The Excel 10 VAV Controller is

HEATING The Excel 10 VAV Controller is

REHEAT The Excel 10 VAV Controller is

MORNING

WARM-UP

NIGHT PURGE The main AHU is supplying fresh

PRESSURIZE The box damper is set at

DEPRESSURIZE The box damper is set at

FLOW TRACKING Temperature control is turned off.

*Available only via the network for the W7751H.

Unoccupied mode.

Flow Diversity on power-up provides

a staggered start sequence to evenly

apply the load to the supply fan and

electrical system.

controlling the Cooling mode.

controlling the Heating mode.

controlling the Reheating mode.

The main AHU is supplying warm air,

and the box damper is set at

(WarmupDmprPos).

(100 percent outdoor) air, and the

box damper is set at

(PurgeDmprPos).

(PressDmprPos).

(DepressDmprPos).

The box maintains a Flow Setpoint

based on the sum of all of the

controllers supplying the zone (the

SrcBoxFlow controller provides other

controllers with DestFlowTrack input).

time-of-day schedule flag from either the Excel 10 Zone

Manager, a C-Bus controller, an Occupancy Sensor Digital Input,

or from Network input (DestManMode) for manual override to

OCCUPIED mode.

flag from the Excel 10 Zone Manager must be OCCUPIED and

the Occupancy Sensor Digital Input must be UNOCCUPIED.

flag from the Excel 10 Zone Manager, the C-Bus, or the network

input CmdManOcc has a value of UNOCCUPIED.

flag from the Excel 10 Zone Manager, the C-Bus, the Occupancy

Sensor Digital Input or from the Network input (DestManMode)

for manual override to OCCUPIED mode.

flag from the Excel 10 Zone Manager, the C-Bus, or the network

input DestManualOcc has a value of UNOCCUPIED.

Digital input (Bypass pushbutton) has been pressed, and the

Bypass duration timer has not yet expired, or the network input

DestManualOcc has a value of BypassTime.

These modes occur on controller power-up, and after

downloading to the controller from E-Vision or going to auto

mode to manual mode (DestManMode). Temperature and flow

control loops are disabled.

Network input (DestHvacMode) containing AHU operational

mode information from other E-Bus controllers that have the

value of COOL/AUTO.

Network input (DestHvacMode) containing AHU operational

mode information from other E-Bus controllers that have the

value of HEAT/AUTO.

Network input (DestHvacMode) has the value of AUTO, so that

when cool air is supplied to the box and the space temperature is

below the Heating Setpoint, causes the Excel 10 VAV Controller

control algorithm to energize the Reheat coil(s).

Network input (DestHvacMode) containing AHU operational

mode information from E-Bus controllers that have the value of

MORNING WARM-UP.

Network input (DestHvacMode) containing AHU operational

mode information from E-Bus controllers that have the value of

NIGHT PURGE.

Network input (DestHvacMode) containing smoke control signal

from E-Bus controllers that have the value of PRESSURIZE.

Network input (DestHvacMode) containing smoke control signal

from E-Bus controllers that have the value of DEPRESSURIZE.

Configuration parameter is box type (Flow_Tracking).

NOTE: See Fig. 45.

FlowTrackOfst (Flow Offset) determines the differential between

the boxes that are the supply air flow and the exhaust air flow.

(continued

)

74-2949–1 8

Page 9

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

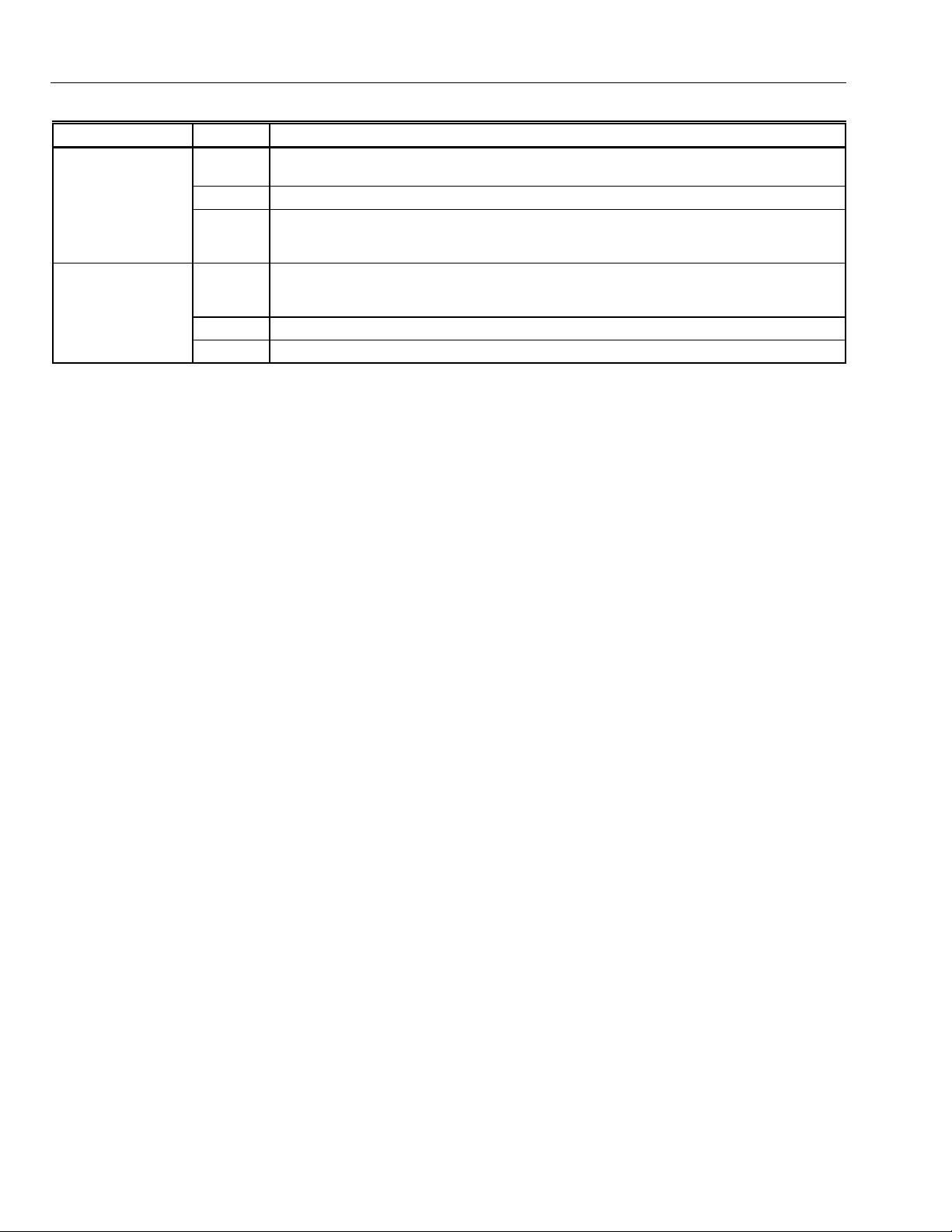

Table 2. Modes Of Operation For Excel 10 VAV Controller (Continued).

Mode Description Events Causing a Controller to Switch to This Mode

MANUAL POSITION Box damper is set to (ManDamp). Typically this is done through E-Vision or XBS by setting the

Operational Modes (User Address: StatusMode)

MANUAL FLOW Air Flow Setpoint is set to

MANUAL See comments for FlowManState in

CLOSED* Indicates a window is open; box

SELF TEST Control algorithm is disabled; various

I/O TEST Control algorithm is disabled, various

FLOAT_OUT_SYNC Controller is synchronizing actuators. Control loops are temporarily suspended. NOTE: For controllers

(DestManFlowSpt).

Appendix D,

damper is set to (WinOpnDmprPos).

hardware tests can be performed.

hardware tests can be performed

(see I/O Test Mode, Application Step

7. Troubleshooting).

Table D7. LonMark®.

point DamperPos to Manual mode.

Typically this is done through E-Vision or XBS by setting the

point SupplyFlow to Manual mode.

The (Window) Digital Input contacts are open and the controller

is configured for a window sensor.

The variable (TestMode) was set to TESTING. NOTE: This mode

is available in Excel 10 VAV Controller versions and also include

the W7751H Smart VAV Actuator.

The I/O test pin/pad is shorted (see the I/O Test Mode,

Application Step 7. Troubleshooting).

NOTE: The I/O Test Mode is not available on the W7751H

Smart VAV Actuator.

that enter the Unoccupied mode, its actuators are controlled and

resynchronize during a time frame of 125 percent of the

actuators motor speed; for example, if an actuators motor speed

is 90 seconds, the actuator would resynchronize after 112

seconds once its controller entered the Unoccupied mode.

If a controller remains in continuous Occupied mode, the

actuators that it controls resynchronize approximately once every

24 hours based on the CPU clock of the controller. If a controller

remains in continuous Occupied mode it resynchronizes

randomly during this time period of one hour.

DISABLED Shutoff control algorithm Network input (DestManMode) containing AHU operational mode

*Available only via the network for the W7751H.

3URGXFWV&RYHUHG

This System Engineering Guide describes how to apply

the Excel 10 family of W7751 VAV Controllers and related

accessories to typical applications. The specific devices

covered include:

W7751B,D,F,H Controllers.

•

T7770A through D Wall Modules.

•

T7780 Digital Display Wall Module.

•

Q7750A Excel 10 Zone Manager.

•

Q7751A,B Bus Router.

•

Q7752A Serial Adapter.

•

Q7740A,B FTT Repeaters.

•

209541B FTT Termination Module.

•

information from other E-Bus controllers that have the value of

DISABLED.

2UJDQL]DWLRQRI0DQXDO

This manual is divided into three basic parts: the

Introduction, the Application Steps, and the Appendices

that provide supporting information. The Introduction and

Application Steps 1 through 5 provide the information

needed to make accurate material ordering decisions.

Application Step 6 and the Appendices include

configuration engineering that can be started using Excel

E-Vision PC Software after the devices and accessories

are ordered. Application Step 7 is troubleshooting.

The organization of the manual assumes a project is being

engineered from start to finish. If an operator is adding to,

or is changing an existing system, the Table of Contents

can provide the relevant information.

9 74-2949–1

Page 10

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

$SSOLFDEOH/LWHUDWXUH

The following list of documents contains information

related to the Excel 10 family of VAV Box Controllers and

the EXCEL 5000® System in general.

Form No. Title

74-2076C Excel 10 Technical Literature Collation

74-2942 Excel 10 W7751B,D,F Controller

Specification Data

74-2953 Excel 10 W7751H Smart VAV Actuator

Specification Data

74-2697 T7770A through G Wall Module

Specification Data

74-2955 T7780 Digital Display Wall Module

Specification Data

74-2868 Excel 10 C7770A Air Temperature Sensor

Specification Data

74-2950 Excel 10 Q7750A, Zone Manager

Specification Data

74-2952-1 Excel 10 Q7751A,B Router Specification

Data

74-2954-1 Excel 10 Q7752A Serial Interface

Specification Data

74-2858 Excel 10 Q7740A,B FTT Repeaters

Specification Data

74-2951 Excel 10 Q7750A Zone Manager Checkout

and Test Manual

95-7504 Excel 10 W7751B,D,F Controller

Installation Instructions

95-7538 T7770A,B,C,D,E,F,G Wall Module

Installation Instructions

95-7558 T7780 Digital Display Wall Module

Installation Instructions

95-7509 Excel 10 Q7750A Zone Manager

Installation Instructions.

95-7510 Excel 10 Q7751A,B Router Installation

Instructions

95-7511 Excel 10 Q7752A Serial Interface

Installation Instructions

95-7516 Excel 10 SLTA Connector Cable Installation

Instructions

95-7555 Excel 10 Q7740A,B FTT Repeaters

Installation Instructions

95-7554 Excel 10 209541B Termination Module

Installation Instructions

74-2588 Excel E-Vision User’s Guide

74-5587 CARE User’s Manual

74-1392 CARE Excel 10 Zone Manager User’s

Guide

74-5577 CARE Icon Guide

74-2039 XBS User’s Manual

74-5018 XBS Application Guide

3URGXFW1DPHV

The W7751 Controller is available in four models:

W7751B VAV Box Controller for OEM mounting on a

•

VAV box.

W7751D VAV Box Controller mounts on either a

•

standard 4 in. by 4 in. electrical junction box or a

standard 5 in. by 5 in. electrical junction box (wire

passes through junction box to wiring subbase). It can

also be snapped onto standard EN 50 022 DIN rail 35

mm by 7.5 mm (1-3/8 in. by 5/16 in.).

W7751F VAV Box Controller mounts into either a panel

•

with screws or snaps onto standard EN 50 022 DIN rail

35 mm by 7.5 mm (1-3/8 in. by 5/16 in.). Wires are

terminated externally to wiring subbase.

W7751H Smart VAV Actuator is a VAV controller that is

•

factory mounted to an ML6161B1000 Actuator. The

actuator/controller assembly is field mounted to the

VAV box damper shaft similar to the mounting of a

standard actuator, and the controller wiring is

terminated to the screw terminals that are located under

a snap-on cover.

The T7770 Wall Module is available in five models:

T7770A1006 Wall Module with temperature sensor.

•

Use with Excel 5000 or Excel 10 Controllers.

T7770A2004 Wall Module with temperature sensor and

•

E-Bus network connection. Use with Excel 5000 or

Excel 10 Controllers.

T7770B Wall Module with temperature sensor, setpoint,

•

and E-Bus network connection. Use with Excel 5000 or

Excel 10 Controllers.

T7770C Wall Module with temperature sensor, setpoint,

•

Bypass button and LED, and E-Bus network

connection. Use with Excel 5000 or Excel 10

Controllers.

T7770D Wall Module with temperature sensor, Bypass

•

button and LED, and E-Bus network connection. Use

with Excel 5000 or Excel 10 Controllers.

NOTE: The T7770B,C Models are available with a

The T7780 DDWM is available in four models:

•

Other products:

• Q7750A Excel 10 Zone Manager.

• Q7751A,B Bus Router.

• Q7752A Serial Adapter.

• Q7740A,B FTT Repeaters

• 209541B FTT Termination Module

• ML6161 Series 60 Damper Actuator.

• M6410A Series 60 Valve Actuator (use with V5812 or

• ML684A Series 60 Versadrive Valve Actuator (use with

• MMC325-010 Transducer, Series 60 to pneumatic 0 to

• MMC325-020 Transducer, Series 60 to pneumatic 0 to

• ML6464A Direct Coupled Damper Actuator, 66 lb.-in.

• ML6474 Direct Coupled Damper Actuator, 132 lb.-in.

• ML6185A Direct Coupled Damper Actuator, Spring

relative scale plate adjustable in E-Vision °F

(± 5°C).

T7780 DDWM displays and provides space

temperature, setpoint, Occ/Unocc override, Application

Mode, and Fan mode/speed selection for all Excel 10

controllers (except W7751A,C,E,G).

V5813 Valves).

V5011 and V5013 Valves).

10 psi.

20 psi.

torque, Series 60.

torque, Series 60.

Return, Series 60.

74-2949–1 10

Page 11

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

• ML7984B Direct Coupled Valve Actuator, PWM (use

with V5011 or V5013F,G Valves).

•

EL7680A1008 Wall Module Infrared Occupancy

Sensor.

•

EL7628A1007 Ceiling Mounted Infrared Occupancy

Sensor.

•

EL7611A1003 Ultrasonic Occupancy Sensor.

•

EL7612A1001 Ultrasonic Occupancy Sensor.

•

AK3781 E-Bus (non-plenum): 22 AWG (0.325 mm

2

)

twisted pair solid conductor, non-shielded wire (one

twisted pair).

•

AK3782 E-Bus (non-plenum): 22 AWG (0.325 mm

2

)

twisted pair solid conductor, non-shielded wire (two

twisted pairs).

$JHQF\/LVWLQJV

Table 3 provides information on agency listings for Excel 10 products.

Table 3. Agency Listings.

Device Agency Comments

W7751B,D,F

Controllers

W7751H Smart VAV

Actuator

UL Tested and listed under UL916 (file number E87741).

CSA Listed (LR95329-3).

FCC Complies with requirements in FCC Part 15 rules for a Class A Computing Device.

Operation in a residential area may cause interference to radio or TV reception and require

the operator to take steps necessary to correct the interference.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing Device.

Operation in a residential area can cause interference to radio or TV reception and require

the operator to take steps necessary to correct the interference.

UL Tested and listed under UL916 (file number E87741).

cUL Tested and listed under UL916 (file number E87741).

CE General Immunity per European Consortium standards EN50081-1 (CISPR 22 Class B)

and EN 50082-1:1992 (based on Residential, Commercial, and Light Industrial).

EN 61000-4-2 IEC 1000-4-2 (IEC 801-2) Electromagnetic Discharge.

EN 50140, EN 50204 IEC 1000-4-3 (IEC 801-3) Radiated Electromagnetic Field.

EN 61000-4-4 IEC 1000-4-4 (IEC 801-4) Electrical Fast Transient (Burst).

•

AK3791 E-Bus (plenum): 22 AWG (0.325 mm

2

) twisted

pair solid conductor, non-shielded wire (one twisted

pair).

•

AK3792 E-Bus (plenum): 22 AWG (0.325 mm

2

) twisted

pair solid conductor, non-shielded wire (two twisted

pairs).

Refer to Table 10 in Application Step 5. Order Equipment

for a complete listing of all available part numbers.

NOTE: The Q7750A Zone Manager is referred to as

(E-Link) in internal software and CARE.

Radiated Emissions and Conducted Emissions.

EN 55022:1987 Class B.

CISPR-22: 1985.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing Device.

Operation in a residential area may cause interference to radio or TV reception and require

the operator to take steps necessary to correct the interference.

T7770A through D

UL (Not applicable.)

Wall Modules

CSA (Not applicable.)

FCC (Not applicable.)

T7780 DDWM CE Emissions; EN50081-1, EN55022 (CISPR 22 Class B), Immunity 50082-1

UL &cUL Tested and listed under UL916, S8L9 Energy Management Equipment.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing Device.

11 74-2949–1

(contifnued)

Page 12

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

Table 3. Agency Listings (Continued).

Device Agency Comments

Q7750A Excel 10

Zone Manager

Q7751A,B Router,

Q7752A Serial

Adapter

UL Tested and listed under UL916, file number S4804 (QVAX, PAZY).

CSA Listing pending.

FCC Complies with requirements in FCC Part 15 rules for a Class A Computing Device.

Operation in a residential area can cause interference to radio or TV reception and require

the operator to take steps necessary to correct the interference.

UL UL1784.

CSA Listed.

FCC Complies with requirements in FCC Part 15 rules for a Class B Computing Device.

$EEUHYLDWLRQVDQG'HILQLWLRQV

AHU

- Air Handling Unit; the central fan system that

includes the blower, heating equipment, cooling

equipment, ventilation air equipment, and other

related equipment.

Box

- A VAV terminal unit box.

CAV

- Constant Air Volume; a TUC that maintains a

fixed air flow through the box.

CO

- Carbon Monoxide. Occasionally used as a

measure of indoor air quality.

CO

- Carbon Dioxide. Often used as a measure of

2

CARE

C-Bus

CVAHU

DDWM

E-Bus

E-Bus Segment

Echelon®

Economizer

indoor air quality.

- Computer Aided Regulation Engineering; the PC

based tool used to configure C-Bus and E-Bus

devices.

-Honeywell proprietary Control Bus for

communications between EXCEL 5000® System

controllers and components.

CPU

- Central Processing Unit; an EXCEL 5000®

System controller module.

cUL

- Underwriters Laboratories Canada.

-Constant Volume AHU; refers to a type of air

handler with a single-speed fan that provides a

constant amount of supply air to the space it

serves.

DDF

- Delta Degrees Fahrenheit.

-Digital Display Wall Module.

D/X

- Direct Expansion; refers to a type of mechanical

cooling where refrigerant is (expanded) to its cold

state, within a heat-exchanging coil that is

mounted in the air stream supplied to the

conditioned space.

- Honeywell implementation of Echelon®

LonWorks® network for communication among

Excel 10 Controllers.

than 60 Excel 10s. Two segments can be joined

together using a router.

and the Neuron® chips used to communicate on

the E-Bus.

regulate the quantity of outdoor air that enters the

building. In cool outdoor conditions, fresh air can

be used to supplement the mechanical cooling

equipment. Because this action saves energy, the

dampers are often referred to as

dampers

- An E-Bus section containing no more

- The company that developed the LON® bus

- Refers to the mixed-air dampers that

economizer

.

EMI

- Electromagnetic Interference; electrical noise that

can cause problems with communications

E-Link

EEPROM

EPROM

Excel 10 Zone Manager

NOTE: The Q7750A Zone Manager can be referred to as

Firmware

Floating Control

Level IV

OEM

signals.

- Refers to the Q7750A Zone Manager. This name

is used in internal software and in CARE

software.

EMS

- Energy Management System; refers to the

controllers and algorithms responsible for

calculating optimum operational parameters for

maximum energy savings in the building.

- Electrically Erasable Programmable Read Only

Memory; the variable storage area for saving user

setpoint values and factory calibration

information.

- Erasable Programmable Read Only Memory; the

firmware that contains the control algorithms for

the Excel 10 Controller.

interface between the C-Bus and the E-Bus. The

Excel 10 Zone Manager also has the functionality

of an Excel 100 Controller, but has no physical

I/O points.

E-Link in the internal software, CARE.

- Software stored in a nonvolatile memory

medium such as an EPROM.

of a valve or damper. Floating Control utilizes one

digital output to pulse the actuator open, and

another digital output to pulse it closed.

IAQ

- Indoor Air Quality. Refers to the quality of the air

in the conditioned space, as it relates to occupant

health and comfort.

I/O

- Input/Output; the physical sensors and actuators

connected to a controller.

I x R

- I times R or current times resistance; refers to

Ohm’s Law: V = I x R.

K

- Degrees Kelvin.

- Refers to a classification of digital

communication wire. Formerly known as UL Level

IV, but

there is any question about wire compatibility, use

Honeywell-approved cables (see Step 5 Order

Equipment section).

-Original Equipment Manufacturer; the company that

builds the VAV boxes.

- Refers to Series 60 Modulating Control

not

- A controller that is used to

equivalent to Category IV cable. If

74-2949–1 12

Page 13

NEC

- National Electrical Code; the body of standards

NEMA

Node

PWM

Subnet

W7751

Wall Module

for safe field-wiring practices.

- National Electrical Manufacturers Association; the

standards developed by an organization of

companies for safe field wiring practices.

- A Communications Connection on a network; an

Excel 10 Controller is one node on the E-Bus

network.

NV

- Network Variable; an Excel 10 parameter that can

be viewed or modified over the E-Bus network.

PC

- An IBM compatible Personal Computer with 386

or higher processor and capable of running

Microsoft® Windows™ Version 3.1.

Pot

- Potentiometer. A variable resistance electronic

component located on the T7770B,C Wall

Module; used to allow user-adjusted setpoints to

be input into the Excel 10 Controller.

- Pulse W i dth Modulated output; allows analog

modulating control of equipment using a digital

output on the controller.

RTD

- Resistance Temperature Detector; refers to a

type of temperature sensor whose resistance

output changes according to the temperature

change of the sensing element.

- An E-Bus segment that is separated by a router

from its Q7750A Zone Manager.

TOD

- Time-Of-Day; the scheduling of Occupied and

Unoccupied times of operation.

TCU

- Terminal Control Unit; industry can refer to VAV

box controllers such as the Excel 10 VAV

Controller as TCUs.

TUC

- Terminal Unit Controller; industry can refer to

VAV box controllers such as the Excel 10 VAV

Controller as TUCs.

VA

- Volt Amperes; a measure of electrical power

output or consumption as applies to an ac device.

Vac

- Voltage alternating current; ac voltage rather than

dc voltage.

VAV

- Variable Air Volume; refers to either a type of air

distribution system, or to the W7751 Excel 10

VAV Box Controller that controls a single zone in

a variable air volume delivery system.

VOC

- Volatile Organic Compound; refers to a class of

common pollutants sometimes found in buildings.

Sources include out-gassing of construction

materials, production-line by-products, and

general cleaning solvents. A VOC is occasionally

used as a measure of indoor air quality.

-The model number of the Excel 10 VAV Box

Controllers (also see VAV).

- The Space Temperature Sensor and other

optional controller inputs are contained in the

T7770 or T7780 Wall Modules. See Application

Step 5. Order Equipment for details on the

various models of Wall Modules.

XBS

- Excel Building Supervisor; a PC based tool for

monitoring and changing parameters in C-Bus

devices.

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

=RQH&RQWURO'HILQLWLRQV

9DULDEOH$LU9ROXPH$78V

Variable air volume (VAV) ATUs are commonly called VAV

boxes. Each VAV box has a controller that controls the

temperature of a room or zone by modulating a damper in

the VAV box to vary the amount of conditioned air supplied

to the zone rather than changing the temperature of the

conditioned air. They are used in larger buildings that have

many zones along with a central air handling fan that

supplies conditioned air via a pressurized main air duct

system. The central air handling fan has a separate

equipment controller that controls discharge air

temperature, humidity, and supply duct static pressure.

$LU7HUPLQDO8QLW&RQWURO

Air terminal units (ATUs) regulate the amount of

conditioned air delivered to satisfy the temperature

requirements of a room or space. ATUs are classified by

air handling system design and are available in several

configurations. ATUs may be of variable air volume or

constant volume design, and may be used in single-duct or

dual-duct air handling systems. ATU controls can be as

basic as a room thermostat controlling a damper or a more

complex direct digital controller operating a damper, a

terminal fan and enabling a reheat coil. In all cases, each

ATU has a controller that is used to control the

environment of the room or space.

3UHVVXUH'HSHQGHQW$QG3UHVVXUH,QGHSHQGHQW

&RQWURO

Static pressure variations in an air handling system can

affect terminal unit operation. Pressure-dependent terminal

units are affected by changing duct static pressures

because their damper position is determined by space

temperature only. They may have mechanical or electric

minimum and maximum air flow limits. Pressureindependent terminal units can automatically adjust to duct

pressure changes because they contain air flow sensors

and the controllers compensate for pressure changes in

the main air distribution system. The damper position in

pressure independent terminal units is determined by both

space temperature and air flow volume.

9DULDEOH$LU9ROXPH$78V9$9

Variable air volume (VAV) ATUs are commonly called VAV

boxes. Each VAV box has a controller that controls the

temperature of a room or zone by modulating a damper in

the VAV box to vary the amount of conditioned air supplied

to the zone rather than changing the temperature of the

conditioned air. They are used in larger buildings that have

many zones along with a central air handling Unit (AHU)

that supplies conditioned air via a pressurized main air

duct system.

13 74-2949–1

Page 14

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

6LQJOH'XFW9DULDEOH$LU9ROXPH9$96\VWHPV

Single duct VAV systems are used in over 80 percent of

the VAV applications and employ one main supply air duct

from the central air handling system. The air handling unit

supplies cool air virtually one hundred percent of the time,

with the only exception being a morning warm-up cycle

that is used in buildings that are not continuously

occupied, that temporarily raises the discharge air

temperature of the central air handling system to quickly

warm the building from its unoccupied zone temperatures

to the occupied zone temperatures. Since the central air

handling system is usually supplying cool air, single or

multiple electric reheat coils or a modulating hot water

(hydronic) reheat coil are often added in the VAV box

discharge air duct to reheat the cool air when the zone

becomes too cold. VAV boxes with reheat coils typically

have a series or parallel fan in the VAV box to ensure air

flow across the coil in the heating mode.

3UHVVXUH'HSHQGHQW7KURWWOLQJ9$9%R[HV

Pressure dependent throttling VAV boxes are the simplest

and least expensive ATU. A controller modulates a damper

actuator according to the temperature in the zone. The

pressure dependent VAV box usually has minimum and/or

maximum damper position setpoint stops in the controller

for limiting air volume. Because the unit is pressure

dependent, the volume of air distributed to the zone at any

given space temperature varies with the supply duct static

pressure at the inlet of the VAV box. Maintaining a stable

duct static pressure is important for proper operation and

proper setting of the minimum damper position setpoint

stop is essential for adequate circulation. When reheat

coils and/or finned tube radiation are used the controller

will set the damper position at a minimum position during

the heating mode to ensure some air flow into the space

and optimize heat transfer from the reheat coil. Pressure

dependent VAV boxes are used in smaller buildings or in

areas of larger buildings where the supply duct static

pressure is low and stable.

3UHVVXUH,QGHSHQGHQW9$9%R[HV

Pressure-independent or variable constant-volume VAV

boxes are essentially air flow control devices that deliver a

constant volume of air to a conditioned space at a given

temperature despite a varying supply duct static pressure.

An air flow sensor in the inlet of the VAV box is used to

measure the volume of air and the

resets the air flow volume setpoint as the thermal load

changes in the space

VAV box controller provides two control sequences; zone

temperature control and terminal unit air flow control. The

controller usually has a minimum air flow setpoint to

maintain air flow at light load conditions and a maximum

air flow setpoint to limit the air flow to meet the design

conditions for the zone. A single zone sensor can be used

to control multiple VAV boxes with differing volume ratings.

When reheat coils and/or finned tube radiation are used

with this unit the controller will lower the air flow setpoint

during the heating mode to ensure air flow into the room

and optimize heat transfer from the reheat coil. Pressure

independent VAV boxes are used in buildings with larger

air handling systems that have constant duct static

pressure fluctuations due to the large number of zones.

. Therefore, a pressure independent

VAV box controller

6HULHV)DQ3RZHUHG9$9%R[HV

Series Fan-powered VAV boxes are similar to pressure

dependent and/or pressure independent VAV boxes,

except they include an integral fan in series with the VAV

box discharge duct that recirculates space air at constant

volume and enhances the air distribution in the zone.

Primary air is modulated by the VAV box damper to meet

space demand for cooling and as primary air modulates

down, more plenum air is drawn in by the fan to maintain a

constant discharge volume to the zone. Typically the

series fan is on continuously during occupied hours, or it

can be programmed to be activated as primary air

decreases to ensure adequate air circulation. In addition to

enhancing air distribution, the units serving the perimeter

area of a building usually include a reheat coil that is

sequenced with the primary air damper to supply heat

when required. When the primary air system is not

operating (nighttime or unoccupied control mode), the

night operating mode of the controller enables the fan and

the reheat coil to maintain the lower unoccupied

temperature setpoint in the space. Series Fan Powered

VAV boxes can be pressure independent or pressure

dependent.

3DUDOOHO)DQ3RZHUHG9$9ER[HV

Parallel Fan Powered VAV boxes or Bypass Fan Induction

Terminal Units are similar to Series Fan-powered VAV

terminal units, except the fan is located in the return

plenum and does not run continuously during occupied

hours. When the zone temperature is low and the need for

primary air decreases, the controller modulates the

primary air damper to a minimum and enables the fan,

which recirculates warm air from the return plenum into the

zone acting as the first stage of reheat. If a reheat coil is

used the fan is cycled on when the reheat coil is enabled.

As the space warms, the reheat valve closes and the fan

cycles off as the primary air damper opens to allow

delivery of conditioned air from the air handling system.

When heating is required in the unoccupied mode, the fan

at the central air handling system remains off , the VAV

box fan and the reheat coil are enabled and the zone is

heated to a reduced night setback temperature using air

from the return air plenum. Parallel Fan Powered VAV

boxes can be pressure independent or pressure

dependent.

,QGXFWLRQ9$9%R[HV

Induction VAV boxes use induced return air as the reheat

medium which means no parallel fan is present in the VAV

box. Induction VAV boxes are usually installed above the

ceiling and draw return air from the plenum created by a

false ceiling. The VAV box controller uses an air flow

sensor for controlling air flow and a room sensor for

controlling room temperature similar to pressure

independent VAV boxes. The volume of air coming

through the primary damper is controlled by positioning

both dampers simultaneously so that as the primary air

damper closes, the return air damper opens. Return air is

thus drawn into the unit and recirculated into the space.

Like pressure independent VAV boxes the controller resets

the air flow setpoint of the controller as the thermal load

changes in the conditioned space. For extremely cold

design conditions, a reheat coil can be added.

74-2949–1 14

Page 15

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

The induction VAV ATU maintains satisfactory air motion

at lower loads than a throttling VAV box can, however, the

wide use of Parallel Fan Powered VAV boxes has now

limited the use of Induction VAV boxes.

6LQJOH'XFW&RQVWDQW9ROXPH=RQH5HKHDW$LU

7HUPLQDO8QLWV

Single-Duct Constant Volume Zone Reheat Systems are

used in low static pressure systems and have a heating

coil (hot water, steam, or electric) in the branch supply

duct to each zone. The central air-handling unit supplies

constant temperature air and a manual balancing damper

in each zone is set in a fixed position to determine the

amount of air delivered to that zone. The volume of air

delivered to each zone will change as the static pressure

of the supply duct changes, however, in low static pressure

systems the changes in the supply duct static pressure are

small and do not have a dramatic effect on the amount air

delivered to the zone. The control strategy used in single

zone reheat systems is simple and involves activating

electric heat or positioning a valve in conjunction to the

zone temperature. In most cases this is accomplished

using a simple space thermostat. However, direct digital

controllers can be used in these cases to control multiple

zone valve positions the reheat coil valve (or electric

heating elements) as required to maintain space condition.

'XDO'XFW$LU+DQGOLQJ6\VWHPV

In a dual-duct air handling system, supply air is divided at

the central fan and hot air and cold air flow through

separate ducts to the perimeter zones in the building.

Dual-duct terminal units are essentially mixing boxes with

two supply inlets and one discharge outlet. The air is

allowed to mix in the mixing box section and is discharged

out of a single duct into the zone. Since a source of

heating is available reheat coils are not used in the zone.

Basic dual-duct mixing systems were not economical

because supply air was cooled and heated year round and

modern energy codes prohibited their use in many cities in

the U.S. except in critical applications like hospitals,

nursing homes, etc. However, with direct digital controllers

and networked systems the individual zone data can be

used to reset hot and cold duct temperatures as needed,

allowing dual duct systems to be used more often in

todays applications. Dual duct systems are often used in

conjunction with single duct systems in the same building.

9DULDEOH&RQVWDQW9ROXPH=HUR(QHUJ\%DQG

'XDO'XFW9$9%R[HV

Variable Constant Volume (Zero Energy Band) Dual-Duct

VAV Boxes have inlet dampers (with individual damper

actuators and air flow sensors) on the cooling and heating

supply ducts. The air flow is pressure independent and the

Dual Duct VAV Box controller uses the zone temperature

to determine the required flow of hot and cold air from the

respective ducts into the mixing box and resets the hot

duct and cold duct air flow setpoints in sequence as space

load changes. The Zero Energy Band (ZEB) is an energy

conservation technique that allows temperatures to float

between programmable settings to prevent the

consumption of heating or cooling energy while the

temperature is in this range. As space temperature rises to

approach the controller setpoint, the hot air flow volume

drops to zero. If space temperature continues to rise

through the ZEB, the output signal from the controller

modulates the cold-air damper open. The controller

maintains adjustable minimum flows for ventilation, with no

overlap of damper operations, during the ZEB when

neither heating nor cooling is required. For example, if a

zone had a setpoint of 74 degrees and a zero energy band

of 2 degrees then the zone temperature would be allowed

to float between 73 degrees and 75 degrees before the

controller would use hot air to heat the zone or cool air to

cool the zone. When the ZEB technique is properly used

the comfort of the occupants is not sacrificed in the

process of saving energy.

'XDO'XFW&RQVWDQW9ROXPH6\VWHPV

Dual-duct mixing box terminal units

Dual-duct mixing box terminal units generally apply to lowstatic pressure systems that require large amounts of

ventilation. The warm duct damper and the cool duct

damper are linked to operate in reverse of each other from

a single damper actuator. The controller positions the

mixing dampers through a damper actuator to mix warm

and cool supply air to maintain space condition. Discharge

air quantity depends on the static pressure in each supply

duct at that location.

Dual-duct constant volume mixing box terminal units

Dual-duct constant volume mixing box terminal units

typically used on high-static-pressure systems where the

air flow quantity to each space is critical. The units are the

same as those described in the previous paragraph,

except that they include either an integral mechanical

constant volume regulator or an air flow constant volume

control furnished by the unit manufacturer to change the

damper position to maintain a constant air flow volume

with changes in duct static pressure.

are

9DULDEOH9ROXPH9DULDEOH7HPSHUDWXUH997

VVT systems are also called commercial zoning systems

and use a constant volume air supply (roof top unit, heat

pump, small air handler) with heating, cooling and

economizer functions and vary the flow rates and supplyair temperature into smaller, damper-controlled zones

through a single duct distribution system. Each zone

damper is modulated based on space temperature.

However, damper control is based only on zone

temperature and there is no flow control at the zone level

as there is in a pressure independent variable air volume

(VAV) system. Typically, the zone damper is modulated

using an analog signal, providing excellent zone

temperature control. A method of providing feedback of

zone demand is provided which allows a controller at the

rooftop to provide the minimum required amounts of

heating and cooling (using economizer when acceptable)

based on zone demand.

Because a number of zone dampers can possibly be

closed, there needs to be a way to relieve pressure in the

supply duct. A bypass damper is normally added in a duct

between the supply and return ducts to relieve pressure.

The pressure relief damper is normally controlled by

sensing supply duct pressure and opening to vent supply

air directly to return. This is one difference between a

commercial zoning system and true VAV. A true VAV air

handler actually varies air volume through the blower.

15 74-2949–1

Page 16

EXCEL 10 W7751B,D,F,H VAVII CONTROLLERS

VVT makes it possible to operate a single-zone

heating/cooling unit with multiple-zones and is often used

in smaller buildings. Small buildings are not appropriate for

VAV systems because the heating and cooling loads are

not large enough for a VAV system to operate properly.

VVT systems also cost less than VAV systems due to the

use of constant volume packaged units, lower pressure

ductwork, and they often do not require expensive

perimeter heat. The main difference between VAV and

VVT is the fact that VAV systems vary the amount of air

entering a zone and not the temperature, where a VVT

system varies both the amount of air and the temperature

of the air entering the zone.

6LQJOH=RQH5RRIWRS$LU+DQGOLQJ8QLW&RQWURO

&9$+8

Single-zone systems use a Constant Volume Air-Handling

Unit (CVAHU) which are usually factory-packaged units

mounted on the rooftop of the building, however, single

zone air handling units can also be located in a

mechanical room of buildings. Single zone units are used

in smaller buildings, buildings that have a uniform

heating/cooling load in large open zones, or in zones that

have special comfort requirements that are different from

other areas of the building. The building must also have

the space available for the associated air handling

equipment. Typical installations include; office/warehouse

buildings, large open buildings such as supermarkets,

restaurants, and ballrooms and lobbies of large buildings

and hotels. Since single zone units are associated with

only one zone, many single zone air handling units can be

installed in a building. Fan volume control, as found in

Variable Air Volume systems is not required, because fan

volume and duct static pressure are set by the

manufacturer to meet the design needs of the zone.

Temperature and Ventilation Control

A single space controller or thermostat controls the heating

coil, ventilation dampers, and cooling coil in sequence as

thermal load varies in the conditioned space. On rooftop

mounted units the heating coils are typically electric and

the cooling is by a self contained air-conditioning system

using direct expansion cooling coils. However, single zone

air handling systems that are located in a mechanical room

of a building often employ hot water (hydronic) heating

coils and use chilled water coils for cooling. The ventilation

dampers (Outdoor air, Return air, and Exhaust air) are

controlled to use outdoor air for the first-stage cooling

when the conditions are appropriate. When outdoor air

temperature or heat content (enthalpy) rises to the point

that it can no longer be used for cooling, an outdoor air

limit control overrides the signal to the ventilation dampers

and moves them to the minimum ventilation position, as

determined by the minimum positioning switch or the

minimum position setpoint in the controller. Indoor air

quality control is also accomplished with the Single Zone

controller using sensors and control strategies that

increase the minimum position of the outdoor air damper

to allow more fresh air into the building when the indoor air

quality is poor. A zero energy band often separates the

heating and cooling control ranges, thus saving energy.

8QLWDU\(TXLSPHQW&RQWURO

Unitary equipment includes natural convection units,

radiant panels, unit heaters, unit ventilators, fan coil units,

and heat pumps. Unitary equipment does not require a

central fan. Depending on design, unitary equipment may

perform one or all of the functions of HVAC - ventilation,

filtration, heating, cooling, humidification and distribution.

Unitary equipment frequently requires a distribution system

for steam or hot and/or chilled water.

Control of unitary equipment varies with system design.

Typically, a room thermostat provides a signal to a

controlled device to regulate the unit. The unit may use a

day/night thermostat for operation at lower setpoints during

unoccupied hours. If the unit has a fan, a time clock may

be used to turn the fan off at night, and a night thermostat

may be used to control the temperature within night limits.

When DDC control is used all of the thermostat and time

clock functionality is contained in the controller.

&RQVWUXFWLRQ

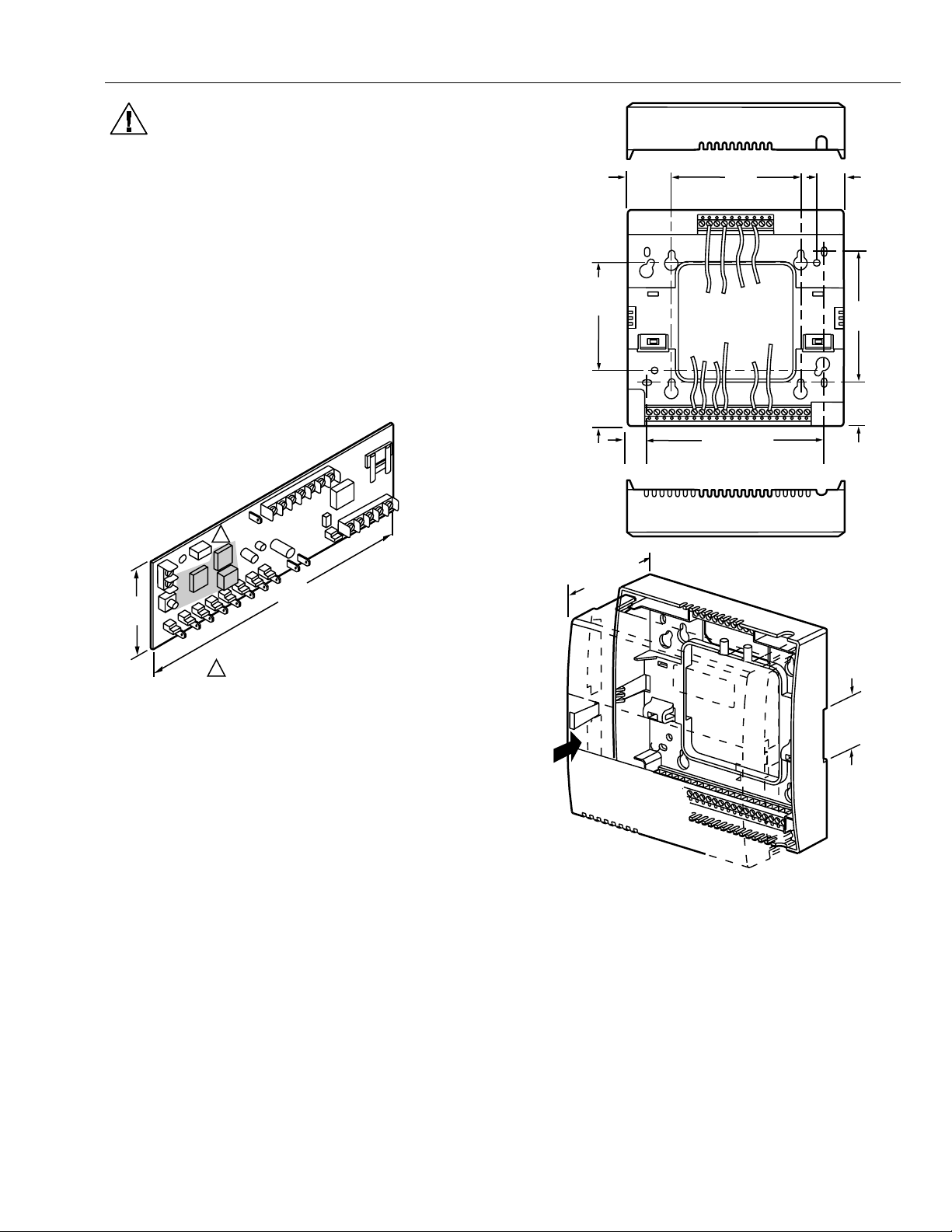

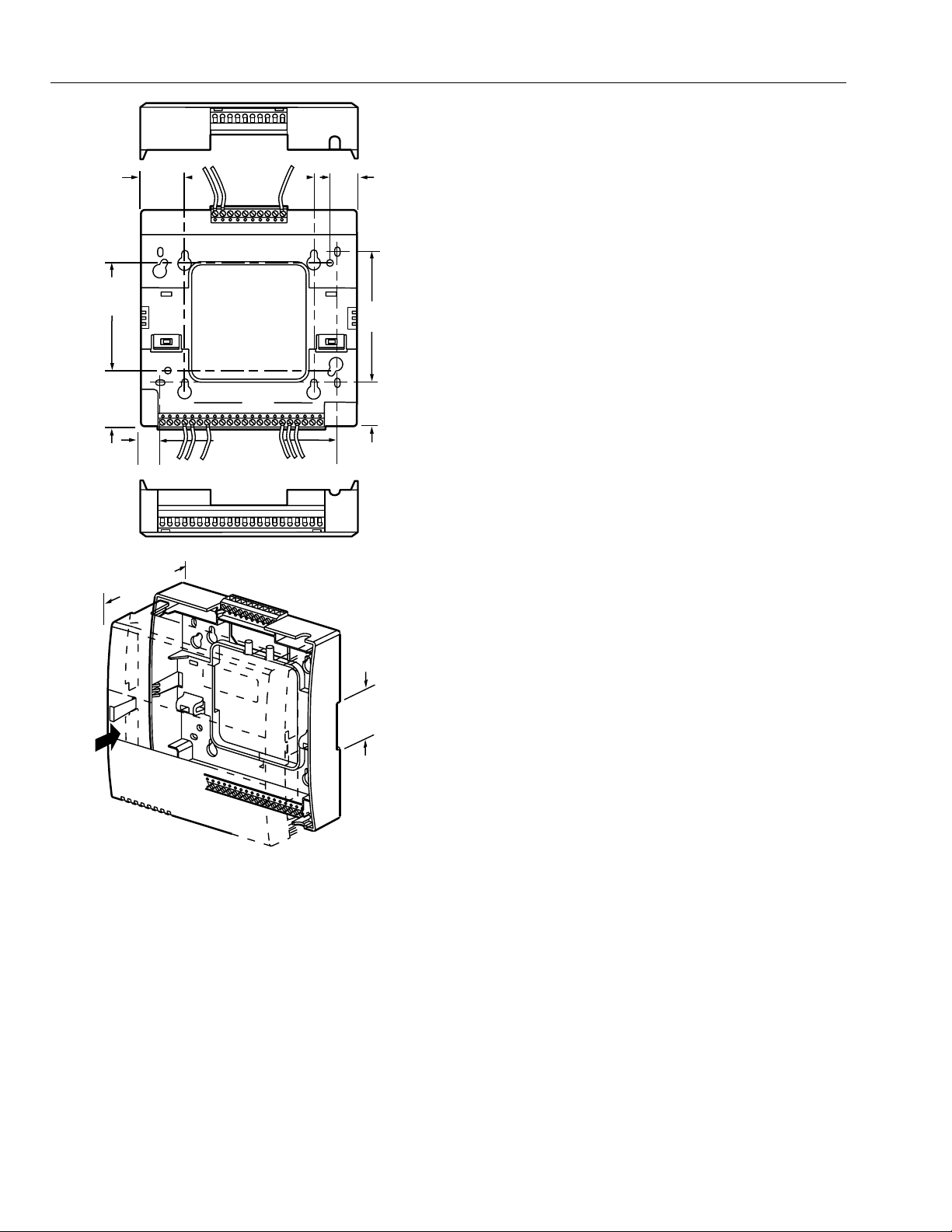

&RQWUROOHUV

The Excel 10 VAV Controller is available in four different

models. The W7751B circuit board is ready to be snapped

into a section of standard 3.25 in. (82 mm) by 9 in. (228

mm) snaptrack, part number 207912. The W7751B model

is intended for OEM installation on VAV boxes at the

factory. Connections to the wall module terminals

(19 through 23) and the E-Bus communications terminals

(29 and 30) are made at screw terminal blocks.

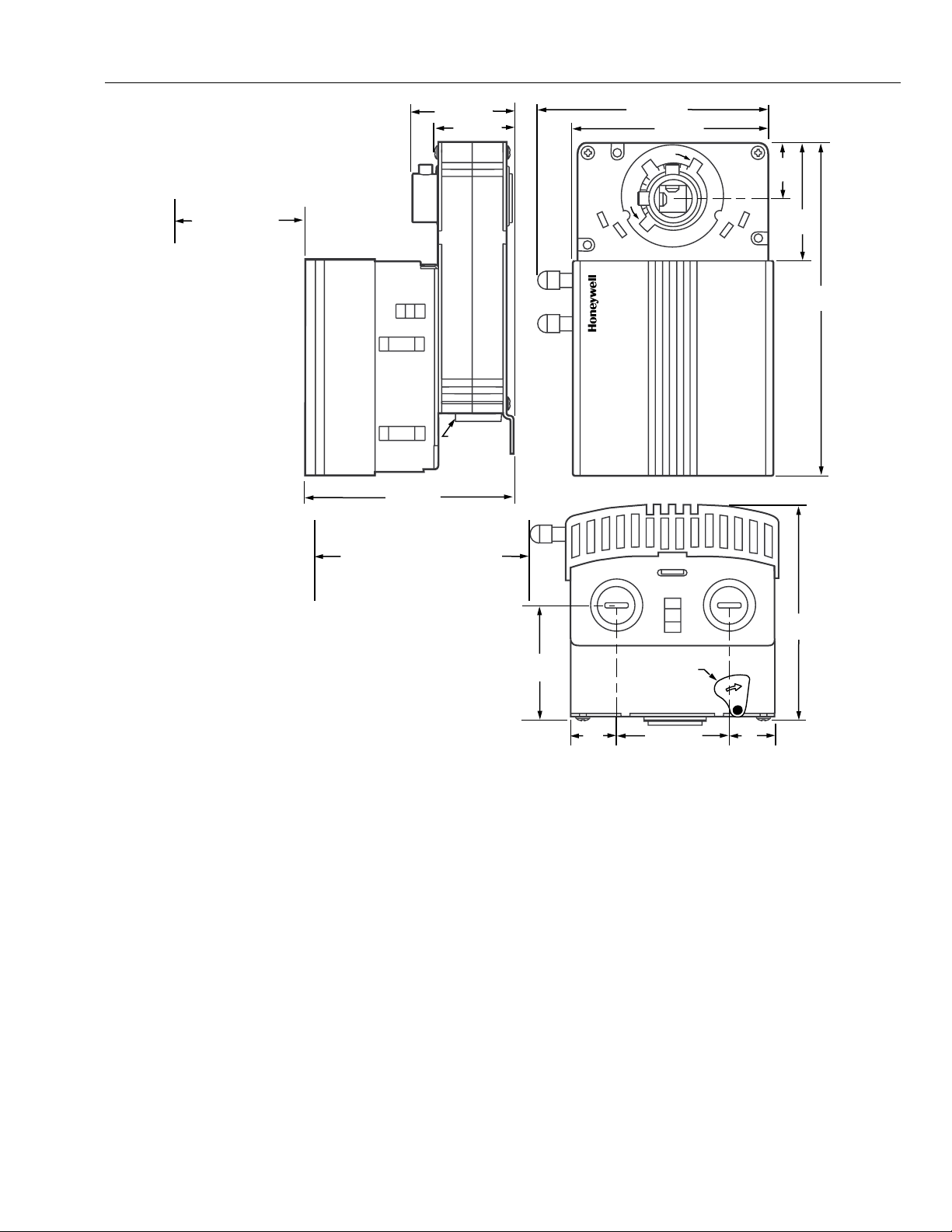

Connection for access to the E-Bus is provided by