Page 1

74-2958-1

yrig

Excel 10

g

g

(

g

g

y

g

y

y (

y

y

g

W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

SYSTEM ENGINEERING

Contents

Introduction.................................................................................................................................. 6

Description of Devices.......................................................................................... 6

Control Application........................ ...... ................................................................. 7

Control Provided................................................................................................... 7

Products Covered................................................................................................. 8

anization of Manual........................................................................................ 8

Or

Applicable Literature.................................. ..... ...... ................................................ 8

Product Names..................................................................................................... 9

ency Listings .................................................................................................... 9

A

Abbreviations and Definitions............................................................................... 10

Construction......................................................................................................... 11

Controllers ...................................................................................................... 11

PERFORMANCE SPECIFICATIONS......................................................... 13

ONMARK

L

Inputs/Outputs: ............................................................................................... 18

ANALOG INPUTS:...................................................................................... 18

DIGITAL INPUTS:....................................................................................... 19

TRIAC OUTPUTS ON THE

DIGITAL OUTPUTS:................................................................................... 19

Wall Modules .................................................................................................. 20

Duct Sensor .................................................................................................... 20

urations...................................................................................................... 22

Confi

General ........................................................................................................... 22

Allowable Heatin

STAGED HEATING/COOLING CONTROL................................................ 24

MODULATING HEATING/COOLING CONTROL....................................... 24

HEAT PUMP CONTROL............................................................................. 24

ECONOMIZER CONTROL......................................................................... 25

PNEUMATIC ACTUATOR CONTROL........................................................ 25

MIXED-OUTPUT-TYPE CONTROL........................................................... 26

Occupanc

Window Open/Closed Di

Wall Module Options ....................................................................................... 26

Filter Monitor .......................................................................................... 27

Dirt

Indoor Air Qualit

Smoke Control ................................................................................................ 27

Freeze Stat ..................................................................................................... 27

Modes of Operation.............................................................................................. 27

® Functional Profile..................................................................... 17

W7750B,C MODELS ONLY):........................ 19

and Cooling Equipment Configurations ............................ 24

Sensor ......................................................................................... 26

ital Input ................................................................. 26

IAQ) Override .. ...... ........................................................... 27

Application Steps.................................................................................................................................. 29

Overview .............................................................................................................. 29

Step 1. Plan the S

Step 2. Determine Other Bus Devices Required.................................................. 29

Step 3. La

L

Power Wiring .................................................................................................. 32

Step 4. Prepare Wirin

® U.S. Registered Trademark

ht © 2000 Honeywell Inc. • All Rights Reserved

Cop

Out Communications and Power Wiring........................................... 30

ONWORKS

POWER BUDGET CALCULATION EXAMPLE .......................................... 32

LINE LOSS...................................... ..... ...... ..... ...... ..................................... 33

stem....................................................................................... 29

® Bus Layout ................................................................................ 30

Diagrams......................................................................... 35

Page 2

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

q

g

g

g

y

g

g

g

q

(

(

y

y

y

y

y

y

(

(

y

(

(

g

g

g

g

g (

g

y (

g

(

g

y

g

General Considerations .................................................................................. 35

W7750 Controllers .......................................................................................... 36

FACTORY DEFAULT DIGITAL OUTPUTS:................................................ 37

ONWORKS

L

Step 5. Order E

® Bus Termination Module ........................................................... 43

uipment ..................................................................................... 45

Step 6. Configure Controllers............................................................................... 48

Step 7. Troubleshootin

Troubleshootin

Excel 10 Controllers and Wall Modules ............................... 48

Temperature Sensor and Setpoint Potentiometer Resistance Ranges .......... 49

Alarms ............................................................................................................ 49

Broadcastin

the Service Message ................................................................ 50

W7750 Controller Status LED ........................................................................ 50

T7770C,D Wall Module B

T7560A,B Di

ital Wall Module Bypass Pushbutton and LCD Display Occupancy

Symbols .......................................................................................................... 51

Appendices.................................................................................................................................. 51

Appendix A. Usin

E-Vision to Commission a W7750 Controller......................... 51

Sensor Calibration .......................................................................................... 51

the Pid Parameters ............................................................................ 51

Settin

Appendix B. Se

uences of Operation. ................................................................. 52

Common Operations ........................ ............................................................. . 53

Room Temperature Sensor

Remote Setpoint

Setpoint Limits (LoSetptLim and HiSetptLim)............................................. 55

pass Mode (StatusOvrd and StatusLed)................................................ 55

B

BYPASSTIME............................................................................................. 55

OverrideT

OverridePriorit

cles per Hour (ubHeatCph and ubCoolCph).......................................... 55

C

pe.............................................................................................. 55

........................................................................................... 55

T7770C,D or T7560A,B Wall Module Bypass Pushbutton Operation......... 55

Standb

Mode (StatusOcySen).................................................................. 56

Continuous Unoccupied Mode ................................................................... 56

Occupanc

Time Clock

Mode and Manual Override Arbitration.................................... 56

Occ_Time_Clock)................................................................... 57

Schedule Master

Setpoint Ramping....................................................................................... 57

Recover

Ramping for Heat Pump Systems.............................................. 57

Fan Operation............................................................................................. 58

Window Sensor

Smoke Control............................................................................................ 58

Demand Limit Control

Dirty Filter Monitor...................................................................................... 59

Start-Up...................................................................................................... 59

Temperature Control Operations .................................................................... 59

ed Cooling Control .............................................................................. 60

Sta

ed Heating Control.............................................................................. 60

Sta

Cascade Control of Modulatin

Series 60 Modulatin

Pulse Width Modulatin

Outdoor Air Lockout of Heatin

Economizer Damper Control ...................................................................... 61

Indoor Air Qualit

Freeze Stat................................................................................................. 62

Dischar

e Air Low Limit Control................................................................. 62

Economizer Enable/Disable Control........................................................... 62

Appendix C. Complete List of Excel 10 W7750 Controller User Addresses. ....... 62

User Address Indexes

Mappable User Addresses and Table Number ............................................... 64

Failure Detect User Addresses and Table Number ........................................ 65

Appendix D. Q7750A Excel 10 Zone Mana

Approximate Memor

Appendix E. Sensor Data for Calibration. ............................................................110

Resistance Sensors. ...................................................................................... 110

e/Current Sensors. ............................................................................... 112

Volta

....................................................................................... 48

pass Pushbutton and Override LED ..................... 51

RmTemp)....................................................... 54

RmtStptPot)................................................................... 55

Sched_Master).............................................................. 57

StatusWndw)................................................................... 58

DLC)...................................................................... 58

Cooling/Heating........................................ 61

Control..................................................................... 61

PWM) Control..................................................... 61

/Cooling..................................................... 61

IAQ) Override ............................................................... 62

all in alphabetical order) ............................................ 63

er Point Estimating Guide...............109

Size Estimating Procedure. .........................................1 09

72-2958—12

Page 3

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

g

g

g

g

g

g

g

greyed)

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

(

g

g

)

g

g

g

g

g

g

g

g

g

g

g

(

g

g

g

g

g

g

g

g

g

g

g

List of Figures

Fig. 1. Typical system overview. ................................................................................................................................................ 6

. 2. Typical W7750 control application. ................................................................................................................................. 7

Fi

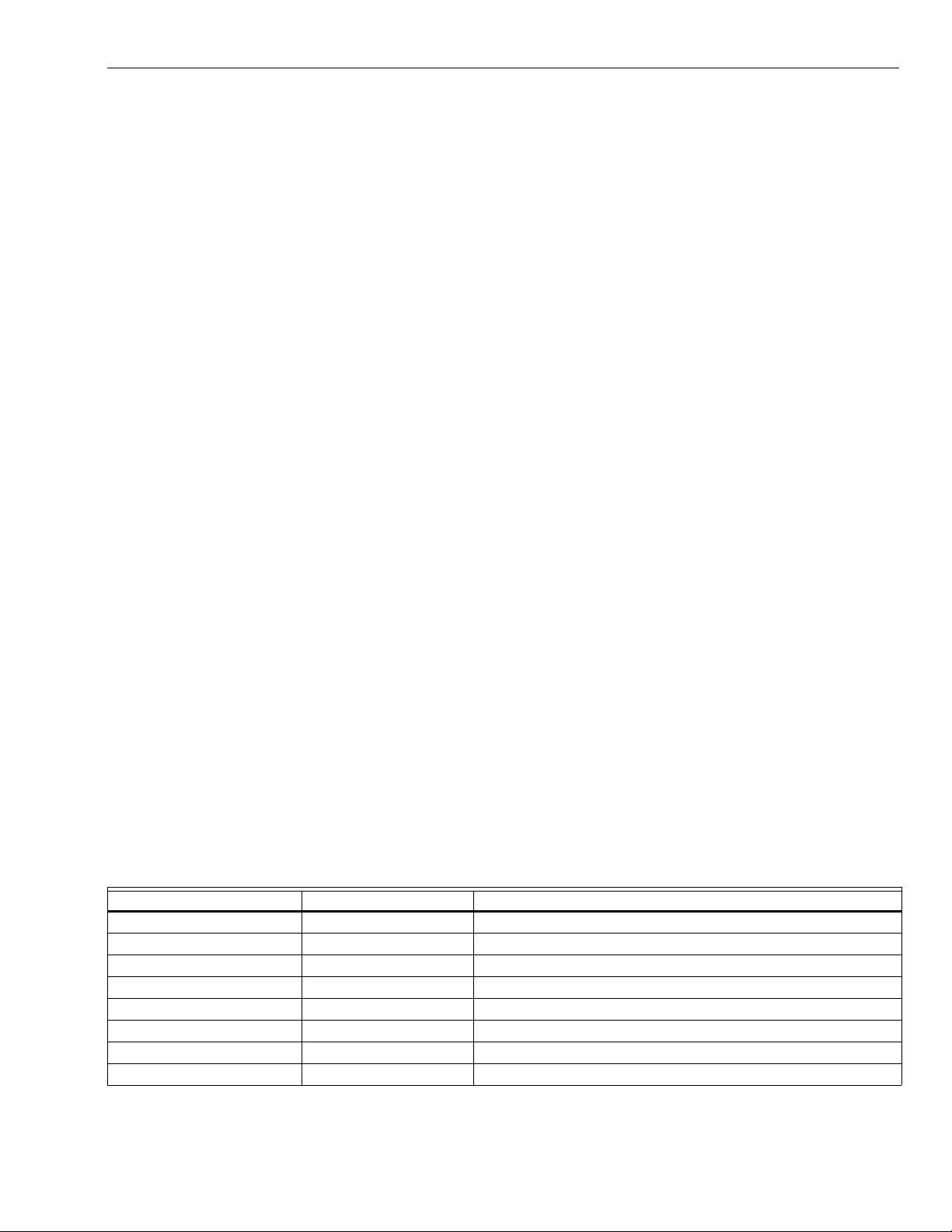

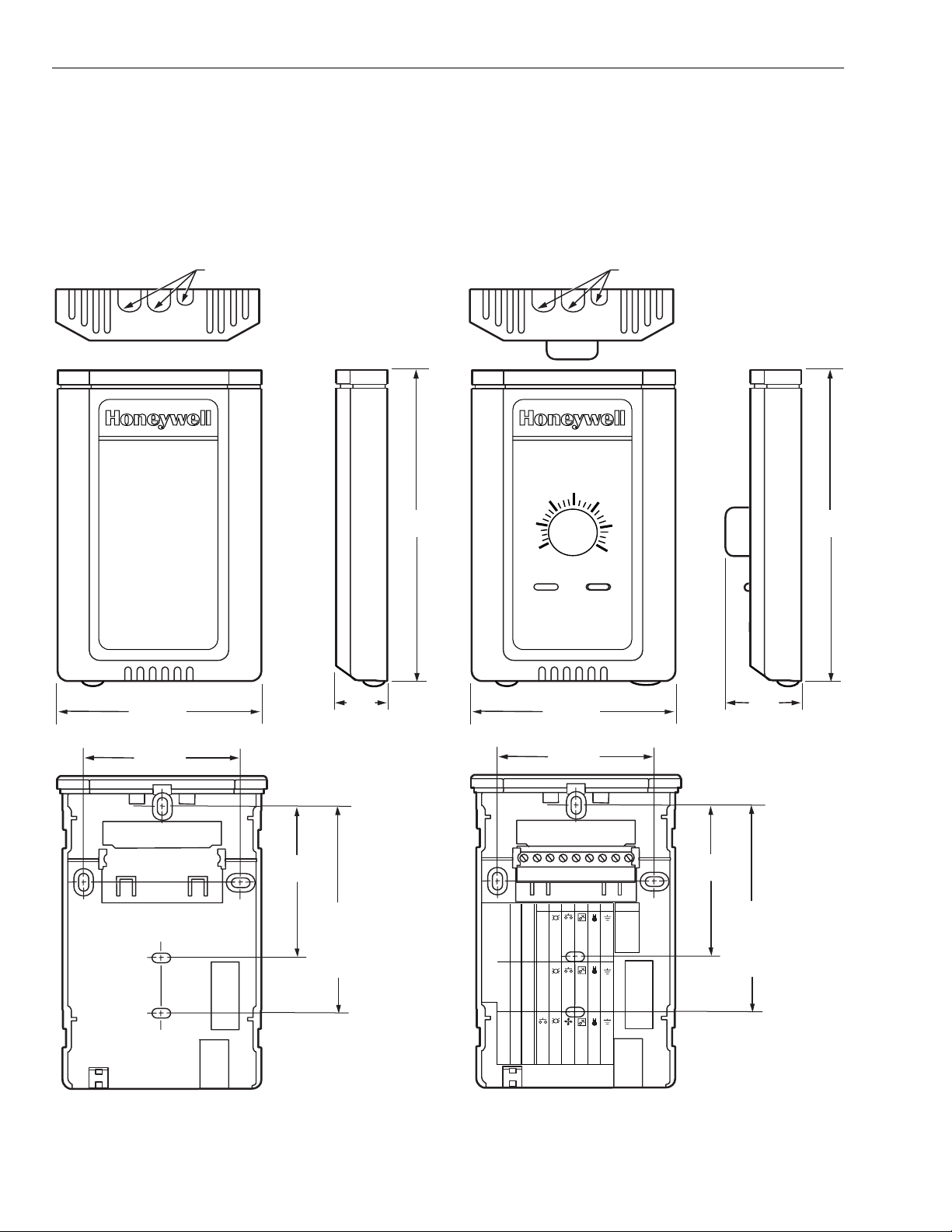

. 3. Excel 10 W7750A Constant Volume AHU Controller. ..................................................................................................... 12

Fi

Fi

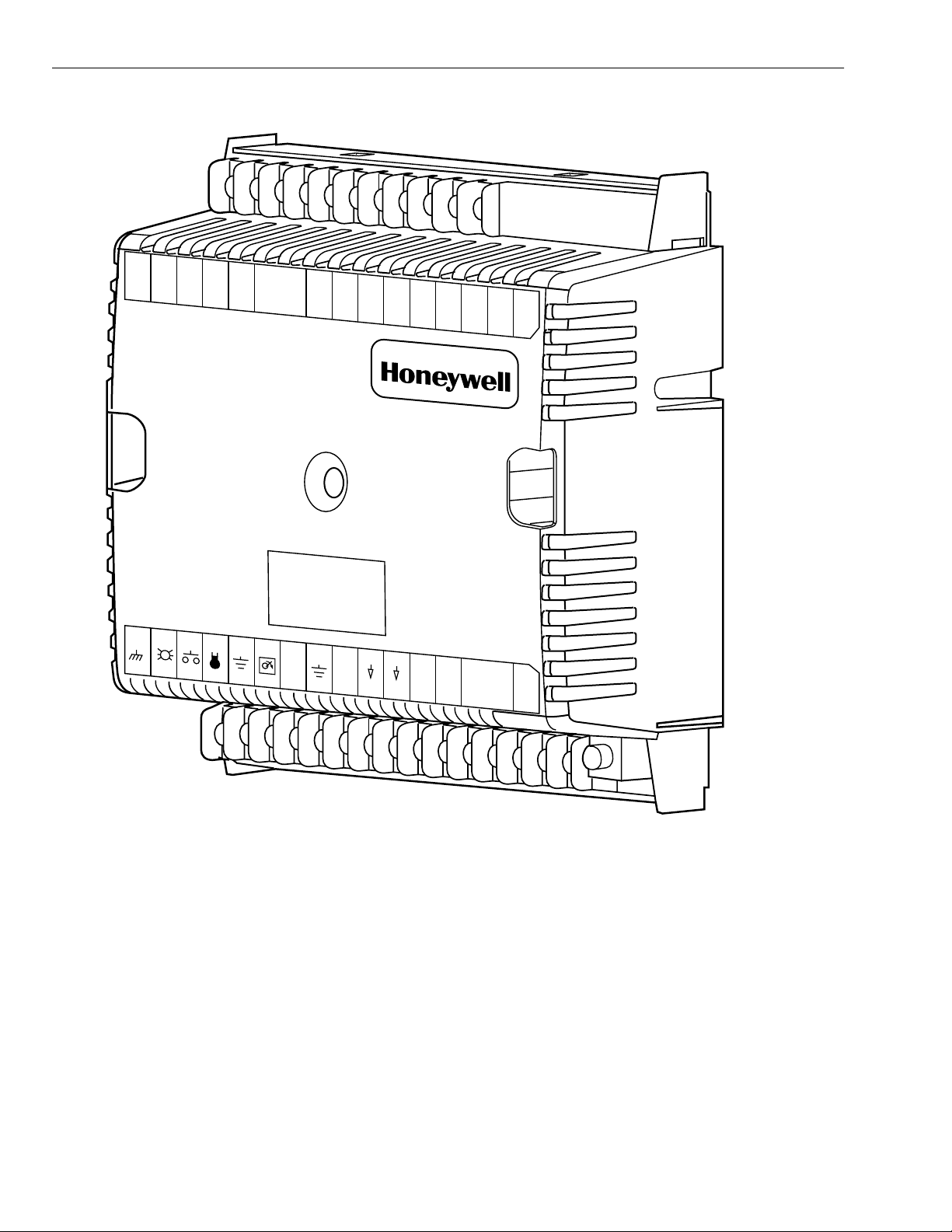

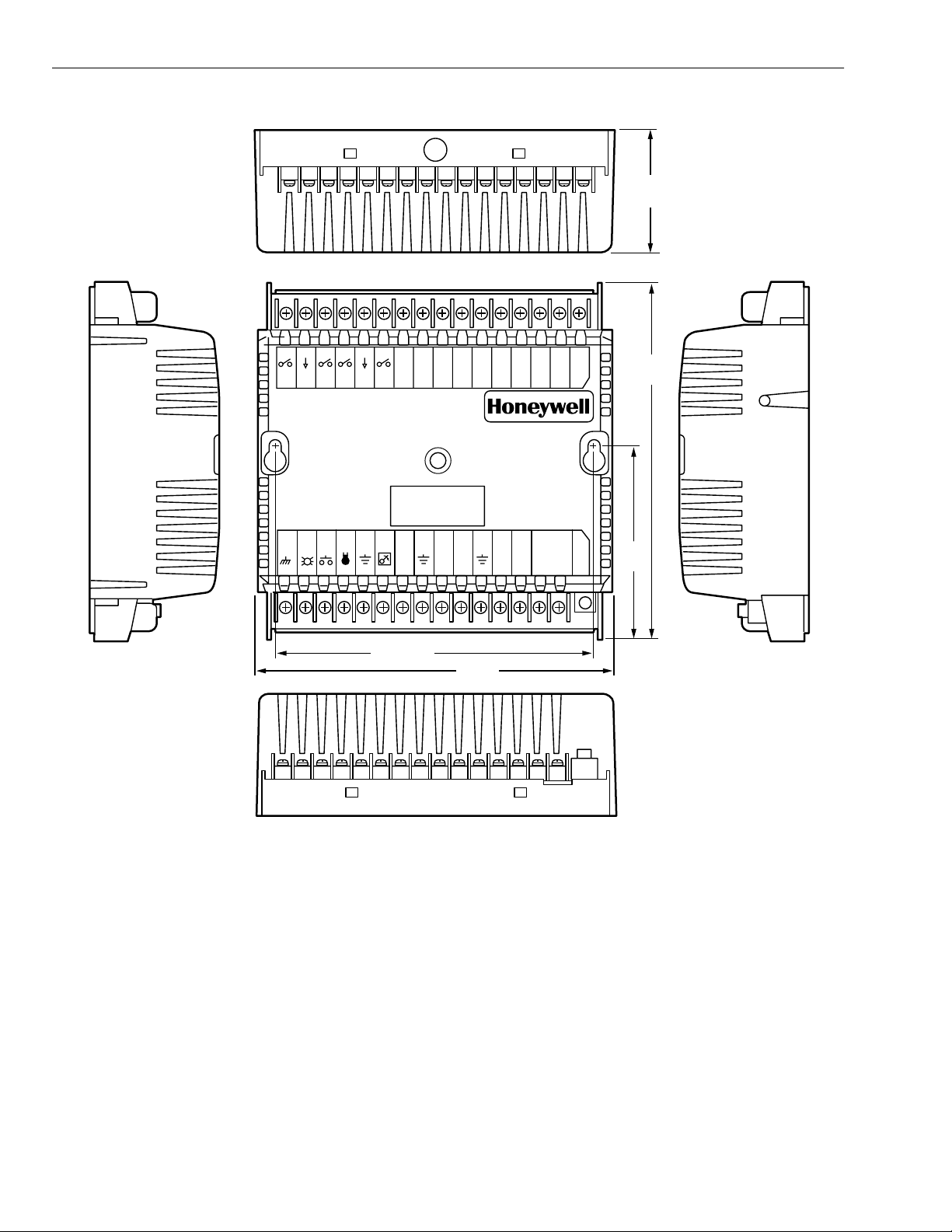

. 4. W7750A construction in in. (mm). ................................................................................................................................... 13

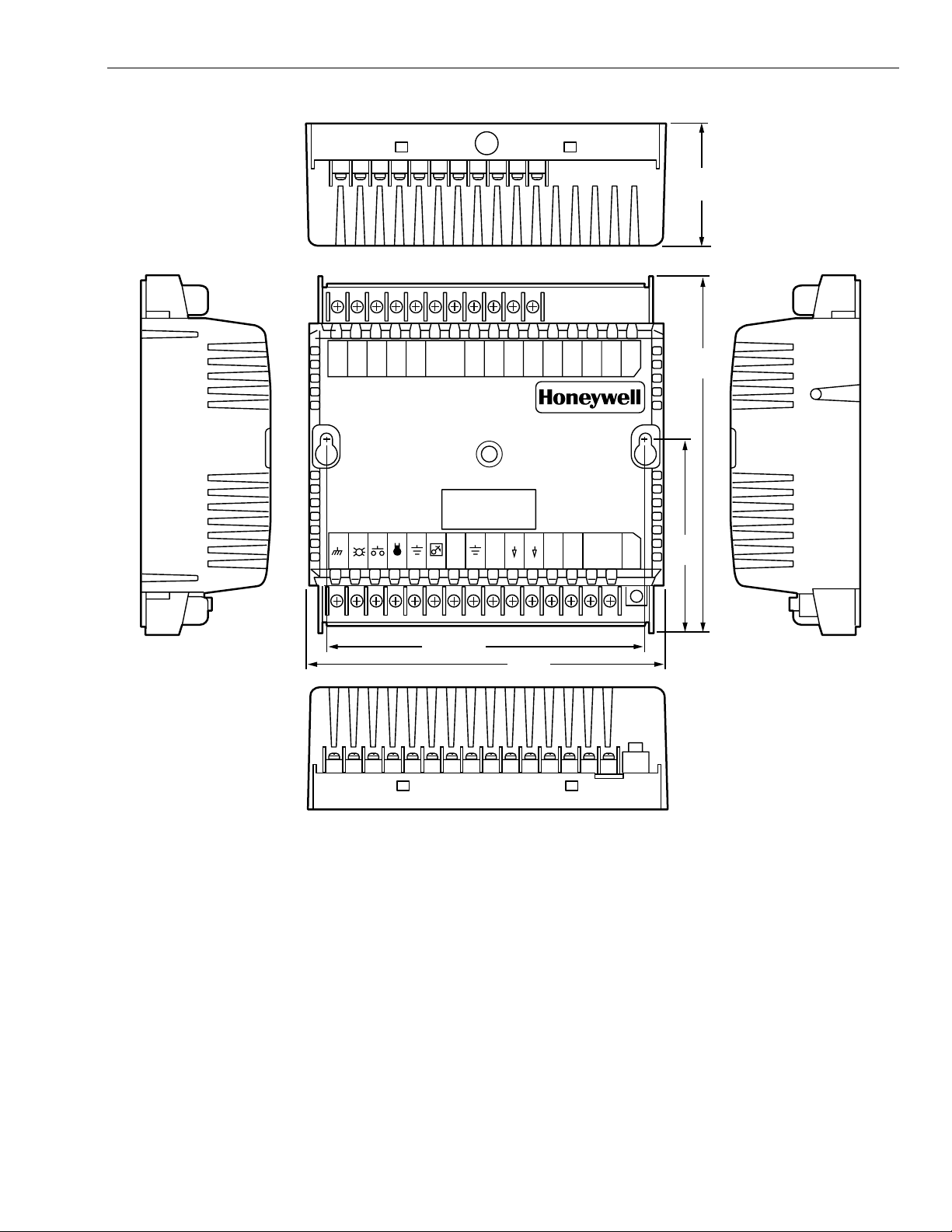

. 5. Excel 10 W7750B Constant Volume AHU Controller. ..................................................................................................... 14

Fi

. 6. Excel 10 W7750C Constant Volume AHU Controller. .................................................................................................... 15

Fi

Fi

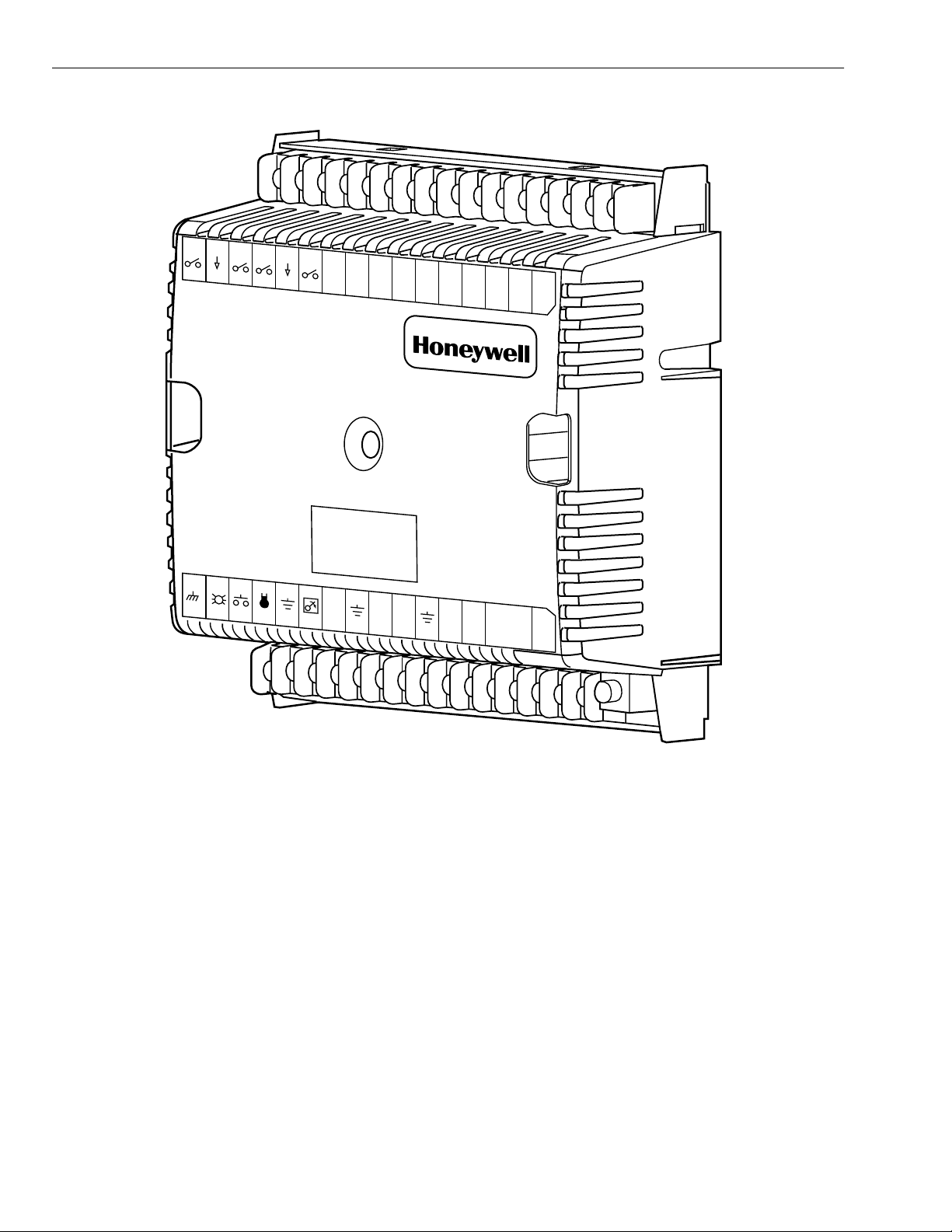

. 7. W7750B,C construction in in. (mm). W7750C (shown) has three 4 to 20 mA analog outputs.) ..................................... 16

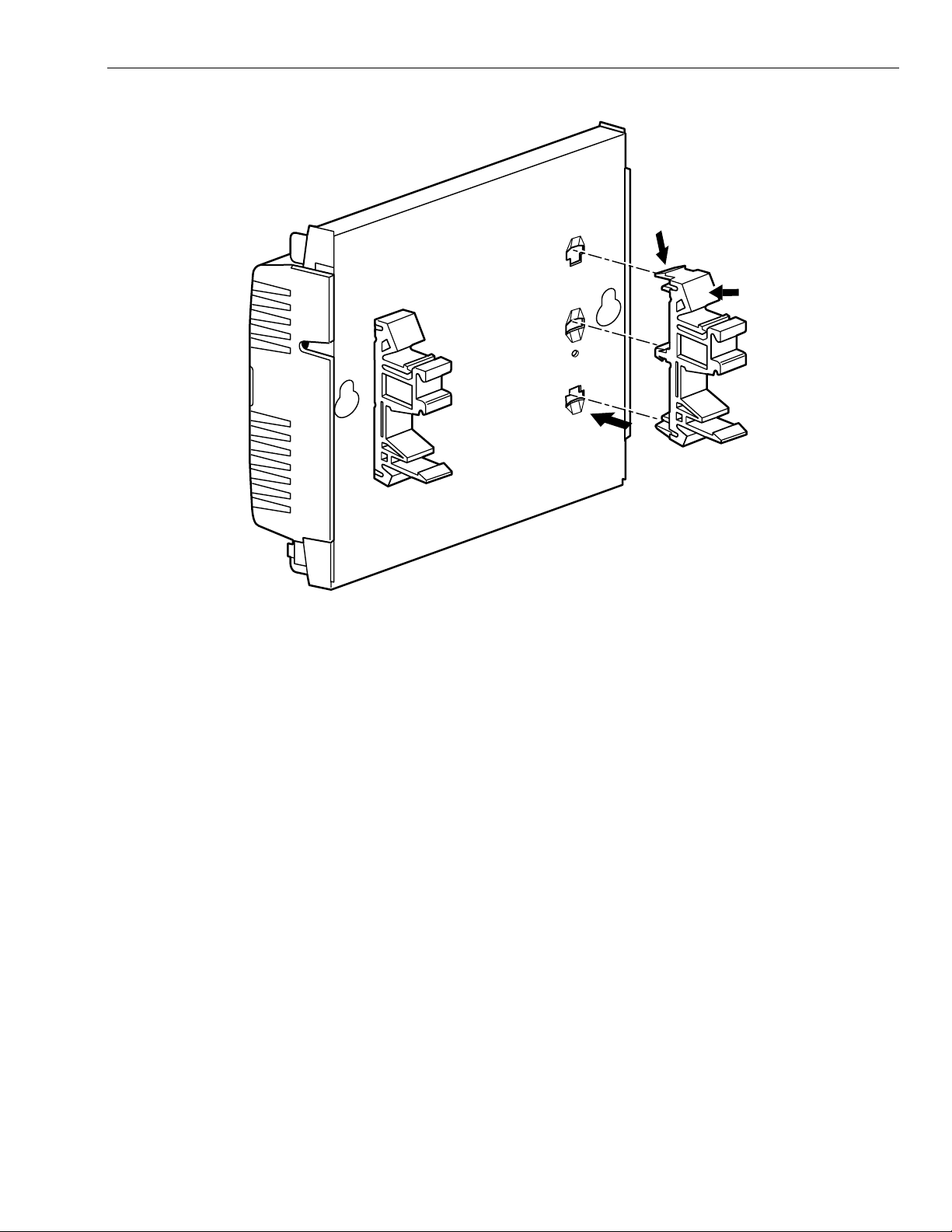

. 8. DIN rail adapters. ............................................................................................................................................................ 17

Fi

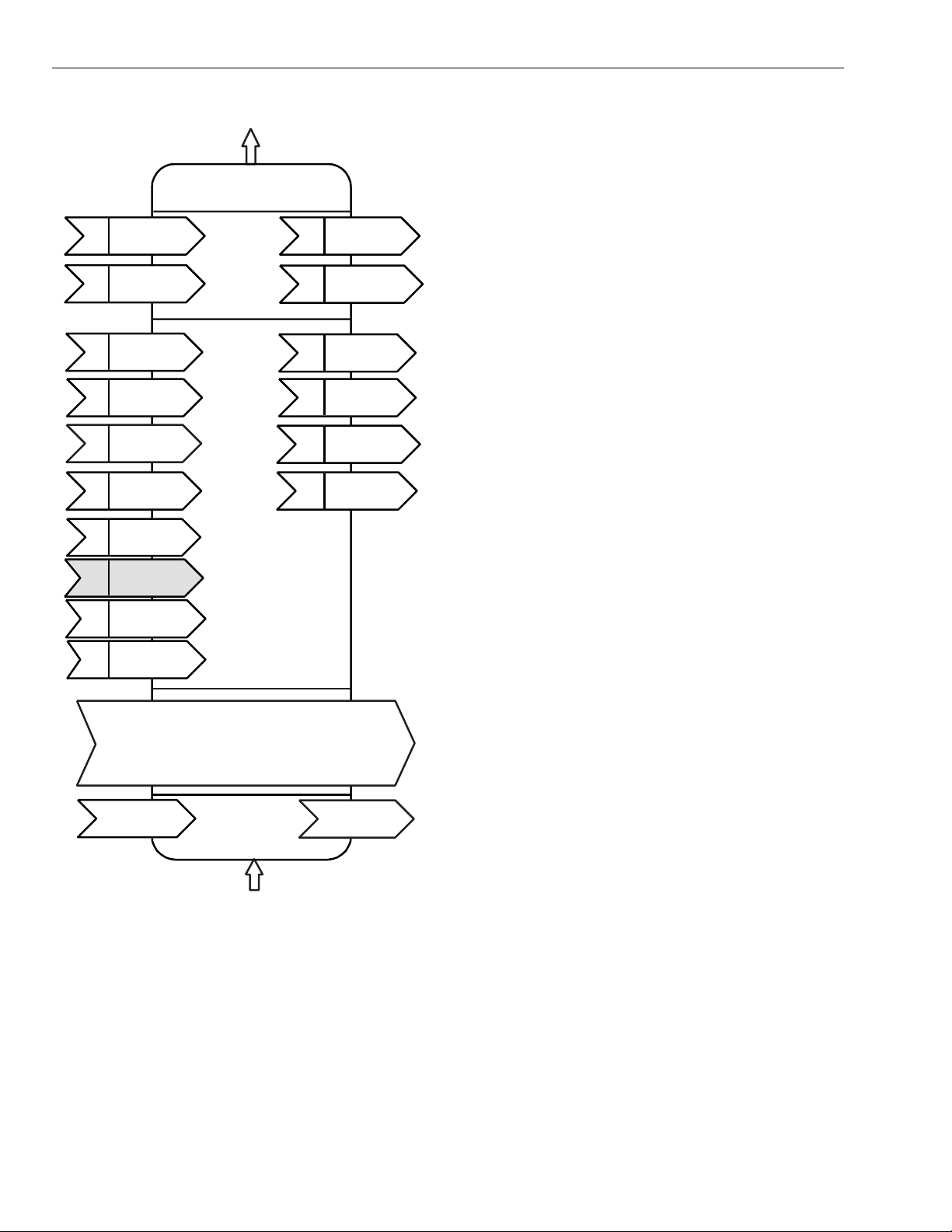

. 9. Functional profile of LONM

Fi

are

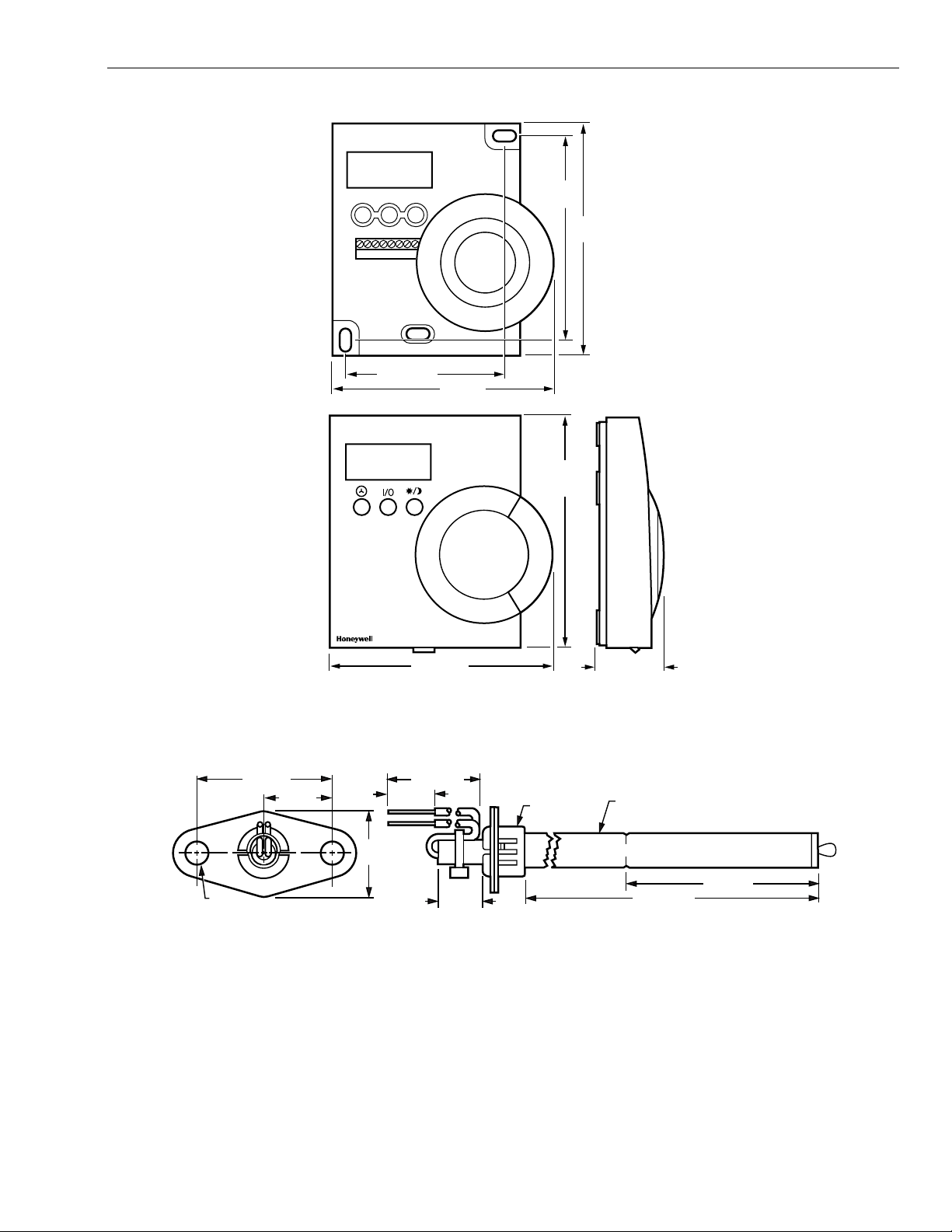

. 10. T7770A,B,C,D construction in in. (mm). ....................................................................................................................... 20

Fi

. 11. T7560A,B construction in in. (mm). ............................................................................................................................... 21

Fi

Fi

. 12. C7770A construction in in. (mm). ............................... ...... .............................................................. ............................... 21

. 13. Fan with two stages of heating and two stages

Fi

of coolin

Fi

. 14. Fan, modulating heating and modulating cooling. ......................................................................................................... 24

. 15. Heat pump with two compressors and auxiliary heat stage(s)....................................................................................... 25

Fi

. 16. Economizer control. ...................................................................................................................................................... 25

Fi

Fi

. 17. Modulating heat with pneumatic valve actuator............................................................................................................. 26

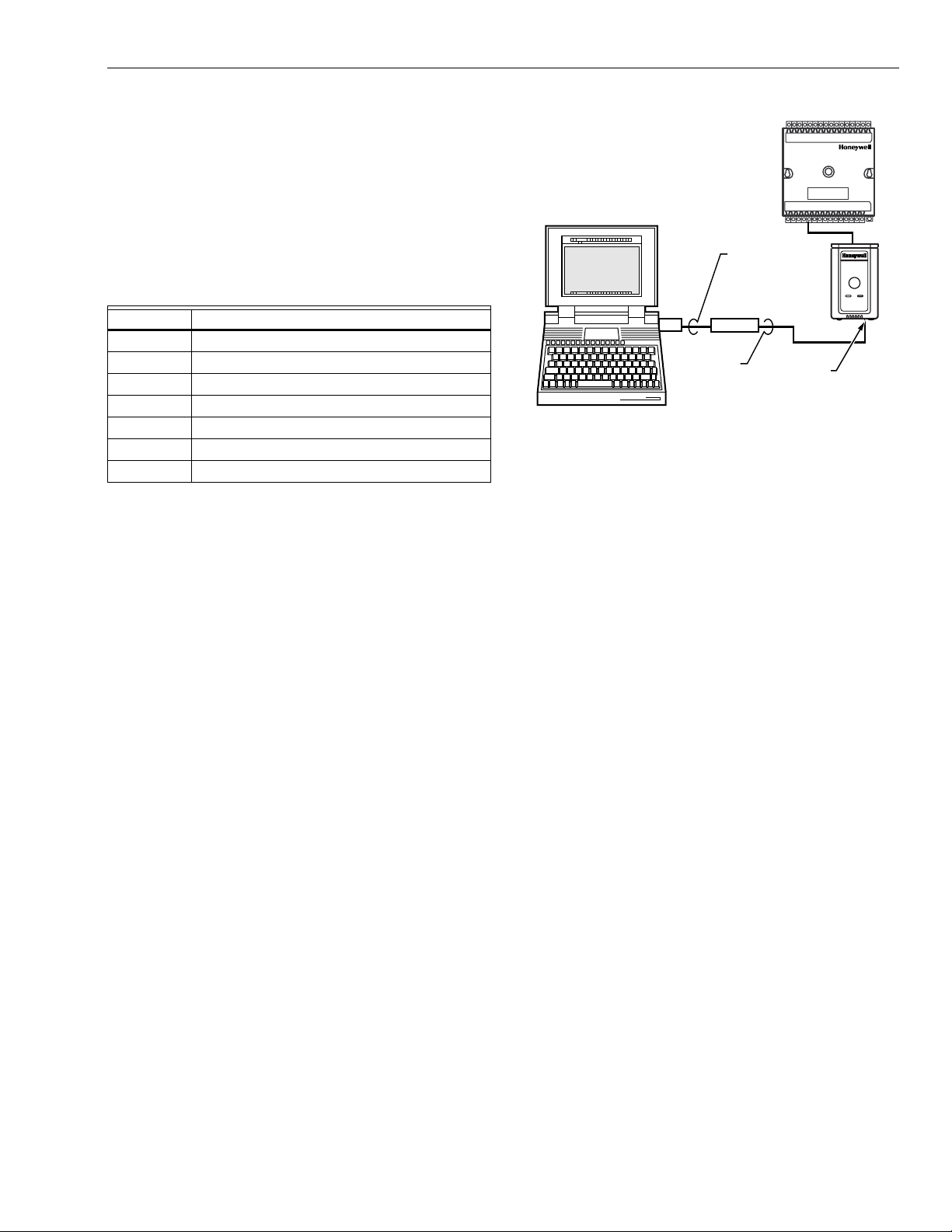

. 18. Connecting the portable operator terminal

Fi

to the L

Fi

. 19. Wiring layout for one doubly terminated daisy-chain LONW

. 20. Wiring layout for two singly terminated LONW

Fi

. 21. NEMA class 2 transformer voltage output limits............................................................................................................ 34

Fi

Fi

. 22. Power wiring details for one Excel 10 per transformer. ................................................................................................. 34

. 23. Power wiring details for two or more Excel 10s per transformer. .................................................................................. 34

Fi

. 24. Transformer power wiring details for one Excel 10 used in UL 1995 equipment (U.S. only)......................................... 35

Fi

Fi

. 25. Attaching two or more wires at terminal blocks.............................................................................................................. 36

. 26. W7750B High-Side/Low-Side selectable switching and jumper location.............................................................. ...... ... 36

Fi

. 27. Typical W7750A Controller AHU application wiring diagram. (For more information on note 2,

Fi

refer to Fi

. 28. Typical W7750A Controller with separate transformer application wiring diagram.

Fi

........................................................................................................................................................................ 18

........................................................................................................................................................................... 24

ONWORKS

® Bus..................................................................................................................................................... 29

. 25.)................................................................................................................................................................ 38

For more information on note 2, refer to Fig. 25.)............................................................................................................ 38

Fi

. 29. W7750A Controller floating economizer damper wiring diagram. (For more information on note 2, refer to Fig. 25.)... 39

. 30. Typical W7750B Controller wi th staged heating and cooling wiring diagram. (For more information on note 2, ref er to Fig.

Fi

.................................................................................................................................................................................... 40

25.

Fi

. 31. W7750B Controller with floating heating, cooling and economizer wiring diagram. (For more information on note 2, refer

. 25.)......................................................................................................................................................................... 40

to Fi

. 32. W7750B,C Controller PWM damper actuator wiring diagram. (For more information on note 2, refer to

Fi

Fi

. 25.)............................................................................................................................................................................. 41

. 33. W7750B,C wiring diagram with 4 to 20 mA enthalpy sensors and digital inputs. (For more information on note 2, refer to

Fi

. 25.)............................................................................................................................................................................. 41

Fi

Fi

. 34. W7750B,C wiring diagram with C7600C 4 to 20 mA solid state humidity sensor. (For more information on note 2, refer to

. 25.)............................................................................................................................................................................. 42

Fi

. 35. W7750C Controller with 4-to-20 mA heating, cooling and economizer wiring diagram. AOs must use terminals 16, 17 or

Fi

18. The AOs can be set to be reverse actin

. 36. Pneumatic transducer to W7750B,C

Fi

B shown, see triangle note 4). ......................................................................................................................................... 43

Fi

. 37. RP7517,B pneumatic transducer to W7750C................................................................................................................ 43

. 38. Typical doubly terminated daisy-chain LONW

Fi

. 39. LONW

Fi

Fi

. 40. Temperature sensor resistance plots............................................................................................................................. 49

. 41. Location of the Service Pin Button................................................................................................................................. 50

Fi

. 42. LED location on W7750. ................................................................................................................................................ 51

Fi

Fi

. 43. The T7770C,D Wall Modules LED and Bypass pushbutton locations........................................................................... 51

. 44. The T7560A,B Digital Wall Module Bypass pushbutton location................................................................................... 51

Fi

. 45. LED and Bypass pushbutton operation. ....................................................................................................................... 56

Fi

Fi

. 46. Setpoint ramping parameters with ramp rate calculation............................................................................................... 57

. 47. Setpoint ramping parameters with setpoint calculation.................................................................................................. 58

Fi

ORKS

® Bus termination wiring options. ............................................................................................................... 45

ARK

® RTU object details (variables not implemented in Excel 10 CVAHU

ORKS

® Bus segment. ........................................................ 31

ORKS

® Bus segments............................................................................. 32

. (For more information on note 2, refer to Fig. 25.).................................... 42

ORKS

® Bus segment termination module wiring diagram. ..................... 44

3 74-2958—1

Page 4

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

Fig. 48. Setpoint ramping parameters with ramp rate calculation............................................................................................... 58

. 49. Schematic diagram for a typical W7750B Unit. .............................................................................................................59

Fi

Fi

. 50. Staged output control versus PID Error. ....................................................................................................................... 60

. 51. Point capacity estimate for Zone Manager. ..................................................................................................................109

Fi

. 52. Graph of Sensor Resistance versus Temperature............................................................................................. ........... . 110

Fi

Fi

. 53. Graph of Sensor Resistance versus Temperature............................................................................................. ........... . 110

. 54. Graph of Sensor Resistance versus Temperature............................................................................................. ........... . 111

Fi

. 55. Graph of Sensor Resistance versus Temperature............................................................................................. ........... . 111

Fi

Fi

. 56. Graph of Sensor Resistance versus Temperature............................................................................................. ........... . 112

. 57. Graph of Sensor Voltage versus Humidity...................................... ........... ........... ............ ........... ........... ...... ........... ...... 112

Fi

. 58. C7600C output current vs. humidity............................................................................................................................... 112

Fi

Fi

. 59. Graph of Sensor Current versus Enthalpy (volts)...................................... ........... ............ ........... ..... ............ ........... ...... 113

. 60. Partial psychometric chart for a C7400A Solid State Enthalpy Sensor. ........................................................................114

Fi

. 61. C7400A Solid State Enthalpy Sensor output current vs. relative humidity. ............................................................. ...... 114

Fi

Fi

. 62. Graph of Sensor Voltage versus CO2 concentration..................................................................................................... 115

. 63. Graph of Sensor Voltage versus input Voltage to A/D.................................................................................................. 115

Fi

. 64. Graph of Sensor Voltage (Vdc) versus Pressure (Inw).................................... ........... ........... ........... ............ ........... ..... . 116

Fi

74-2958—14

Page 5

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

g

g

g

g

g

g

y

g

y

gy

g

g

g

y (

g

g

ge (

List of Tables

Table 1. Agency Listing. ............................................................................................................................................................. 9

Table 2. List of Differences in W7750A and W7750B,C Controllers........................................................................................... 11

Table 3. Common Confi

Table 4. Confi

uration Options Summary For W7750A,B,C Controllers.................................................................................... 23

Table 5. Modes Of Operation For The Excel 10 W7750 Controller ........................................................................................... 27

Table 6. Application Steps.......................................................................................................................................................... 29

Table 7. L

ONWORKS

Table 8. VA Ratin

Table 9. Field Wirin

Table 10. W7750A Version I/O Description................................................................................................................................ 37

Table 11. Excel 10 W7750 Controller Orderin

Table 12. Excel 10 Alarms.......................................................................................................................................................... 49

Table 14. Common Confi

Table 15. Confi

Table 16. B

uration Options Summary For W7750A,B,C Controllers.................................................................................. 54

pass Pushbutton Operation.................................................................................................................................... 55

Table 17. Intersta

Table 18. Excel 10 W7750 Controller User

Address Point T

pes................................................................................................................................................................... 62

Table 20. Input/Output Points..................................................................................................................................................... 67

Table 21. Control Parameters..................................................................................................................................................... 73

Table 22. Ener

Management Points........................................................................................................................................ 78

Table 23. Status Points............................................................................................................................................................... 81

Table 24. Calibration Points........................................................................................................................................................ 93

Table 25. Confi

Table 26. L

uration Parameters........................................................................................................................................... 94

ONMARK

Table 27. Direct Access And Special Points..................................................................................................... ........... ............ ... 106

Table 28. Data Share Points.................................................................................................................................................... ... 108

Table 29. Sensor Resistance Versus Temperature.......................................................................................... ........... ............ ... 110

Table 30. Sensor Resistance Versus Temperature.......................................................................................... ........... ............ ... 110

Table 31. Sensor Resistance Versus Temperature.......................................................................................... ........... ............ ... 111

Table 32. Sensor Resistance Versus Temperature.......................................................................................... ........... ............ ... 111

Table 33. Sensor Resistance Versus Temperature.......................................................................................... ........... ............ ... 111

Table 34. Sensor Volta

Table 35. Sensor Volta

Table 36. Sensor Current Versus Enthalp

Table 37. Sensor Volta

Table 38. Sensor Volta

Table 39. Sensor Volta

uration Options Summary For W7750A,B,C Controllers..................................................................... 22

® Bus Configuration Rules And Device Node Numbers............................................................................. 30

s For Transformer Sizing.............................................................................................................................. 33

Reference Table (Honeywell listed as AK#### or equivalent).................................................................. 36

Information....................................................................................................... 46

uration Options Summary For W7750A,B,C Controllers................................................................... 53

e Minimum Times.......................................................................................................................................... 60

®/Open System Points................................................................................................................................ 97

e Versus Humidity................................................................................................................................ 112

e Versus Humidity................................................................................................................................ 112

volts)............................... ........... ........... ........... ...... ........... ........... ........... ............ ... 113

e Versus CO2 Concentration............................................................................................................... 115

e Versus Input Voltage To A/D............................................................................................................. 115

Vdc) Versus Pressure (Inw)........................... ........... ............ ........... ..... ............ ........... ........... ......... 116

5 74-2958—1

Page 6

(

g

g

y

g

g

y

j

y

g

g

g

(

g

y

y

Excel 10 W7750A,B,C Constant Volume AHU Controller

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

INTRODUCTION

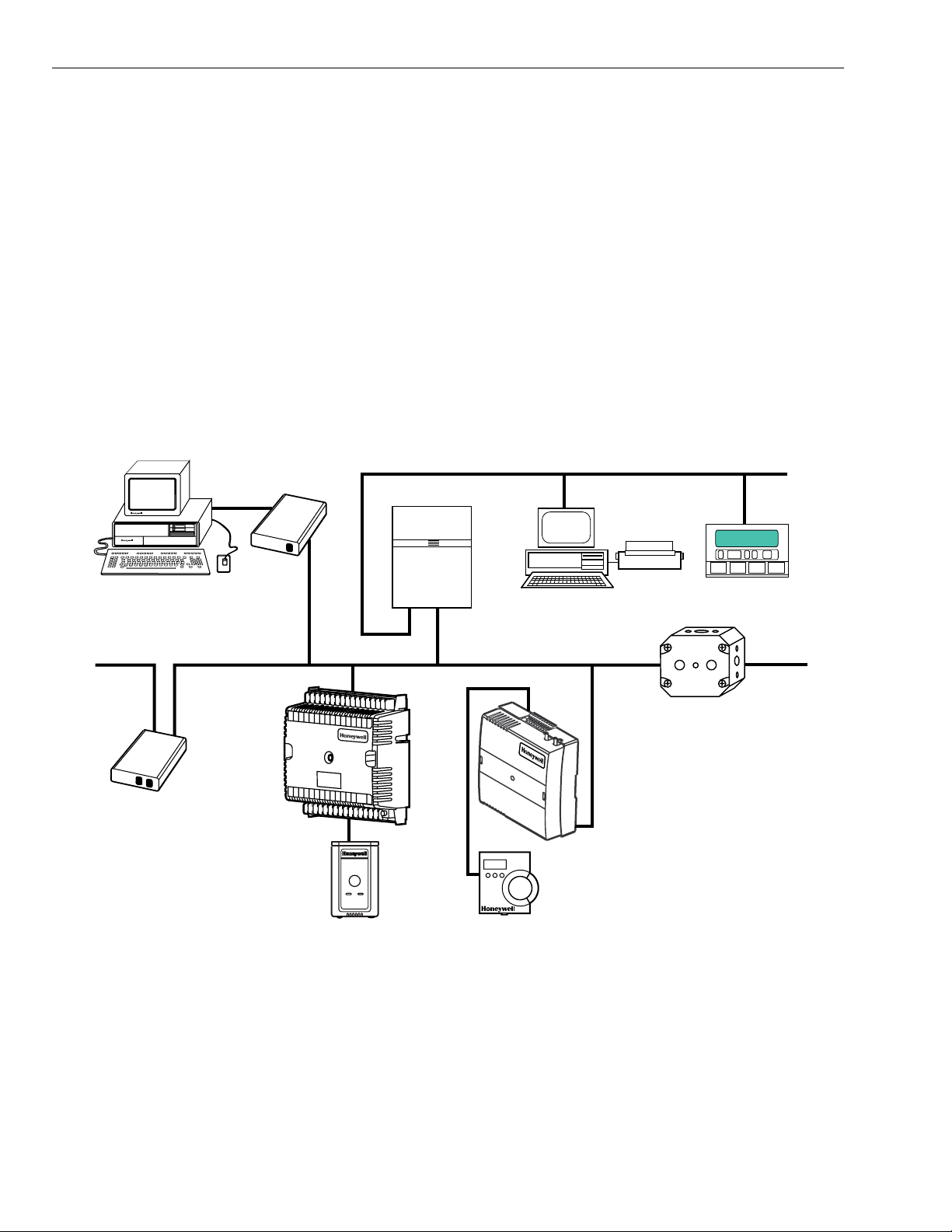

Description of Devices

The W7750 is the Constant Volume Air Handling Unit

CVAHU) Controller in the Excel 10 product line family. The

CVAHU is a LONM

le zone and heat pump air handlers. W7750 systems

sin

control the space temperature in a

the heating and cooling equipment in the air handler that

delivers air to that space. The W7750 air handler is t

an all-in-one constant air volume packa

the roof of the building. In addition to standard heating and

control, the W7750 provides many options and

coolin

advanced s

stem features that allow state-of-the-art

commercial building control. The W7750 Contro ller is capa ble

of stand-alone operation; however, optimum functional

benefits are achieved when the network communication

capabilities are used. The W7750 utilizes the Echelon

ARK

compliant device designed to control

iven zone by regulating

ed unit, located on

Q7752A

ONWORKS BUS

L

SERIAL

ADAPTER

pically

ONWORKS

L

and conforms with the L

network (LONW

ORKS

ONMARK

Bus) for communications,

HVAC Interoperability

standard for Roof Top Unit Controllers (see Fig. 9).

The T7770 or T7560 direct-wired Wall Modules are used in

con

unction with W7750 Controllers. The zone controlled by

the W7750 Controller t

pically can use a T7770A thr ough D or

a T7560A,B Wall Module. Additional features available in

T7770A throu

override di

ONWORKS

L

h D models include analog setpoint input knob,

ital input pushbutton, override status LED and

Bus network access jack. Additional features

available in T7560A,B models include analog setpoint input

knob, override di

ital input pushbutton, humidity sensor

T7650B model), override status LCD and digital displ ay.

The Q7750A Excel 10 Zone Mana

interface that allows devices on the L

er is a communications

ONWORKS

Bus network

to communicate with devices on the standard EXCEL 5000

stem C-Bus. Fig. 1 shows an overview of a typical system

S

out. The Q7750A also provides some control and

la

monitoring functions.

C-BUS COMMUNICATION NETWORK

PERSONAL COMPUTER TOOLS

E-VISION

CARE

ONWORKS-BUS COMMUNICATIONS NETWORK

L

EXCEL 10

W7750B

CVAHU

CONTROLLER

Q7751A

FTT

ONWORKS BUS

L

ROUTER

EXCEL 10 T7770

WALL MODULE

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

1

234

567

89

10 11 12 13 1

415J3

Fig. 1. Typical system overview.

EXCEL 10

Q7750A

ZONE

MANAGER

C-BUS TO L

INTERFACE DEVICE

L

ONWORKS BUS COMMUNICATIONS NETWORK

ONWORKS BUS

EXCEL BUILDING SUPERVISOR

EXCEL 10 T7560A, B

WALL MODULE

EXCEL 10 W7751F

PANEL PLENUM

MOUNT VERSION

VARIABLE AIR VOLUME

CONTROLLER

EXCEL 500

Q7740A

2-WAY

REPEATER

M17487

74-2958—16

Page 7

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

g

(

y

g

g

g

g

g

g

g

g

(

y

g

g

g

q

g (

j

g

g

g

g

(

g

)

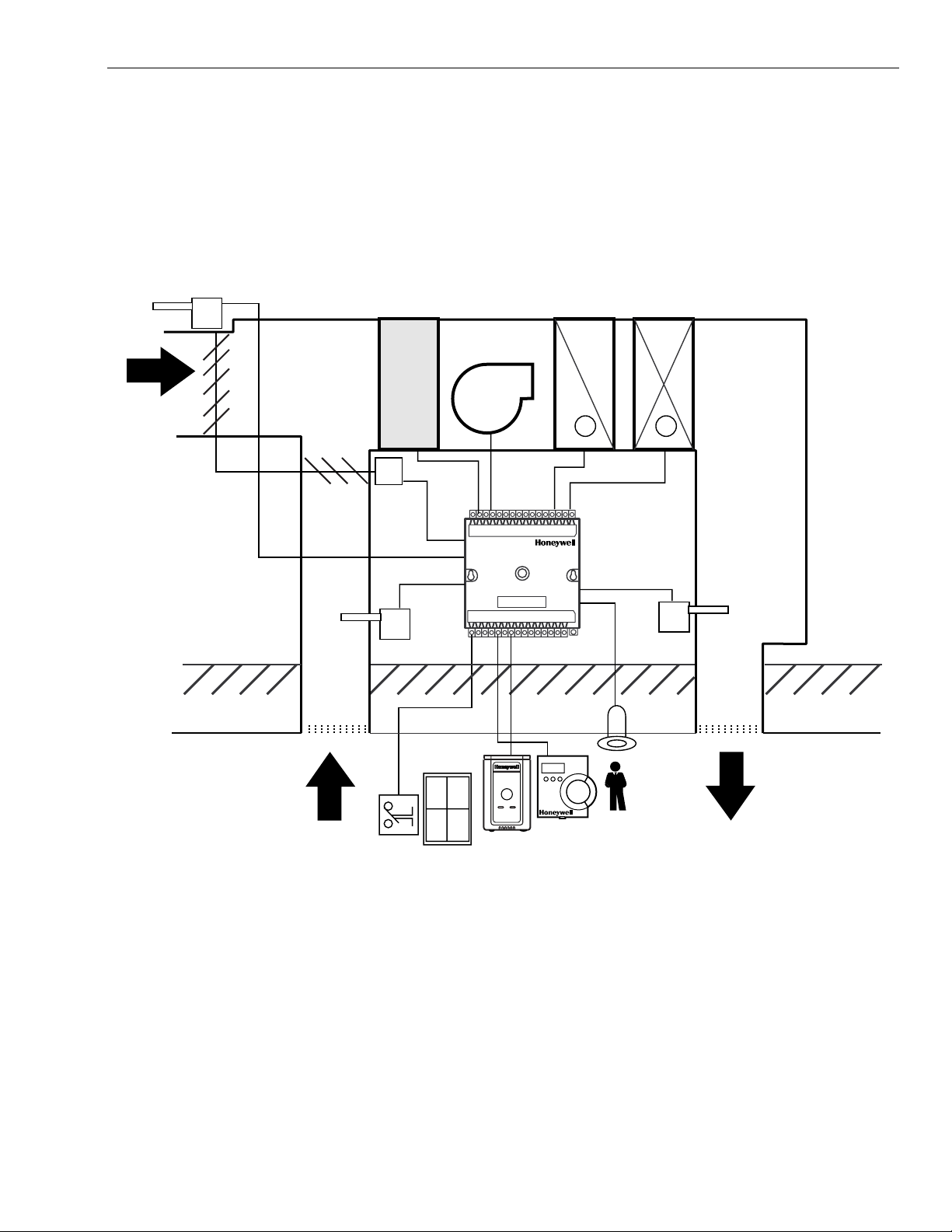

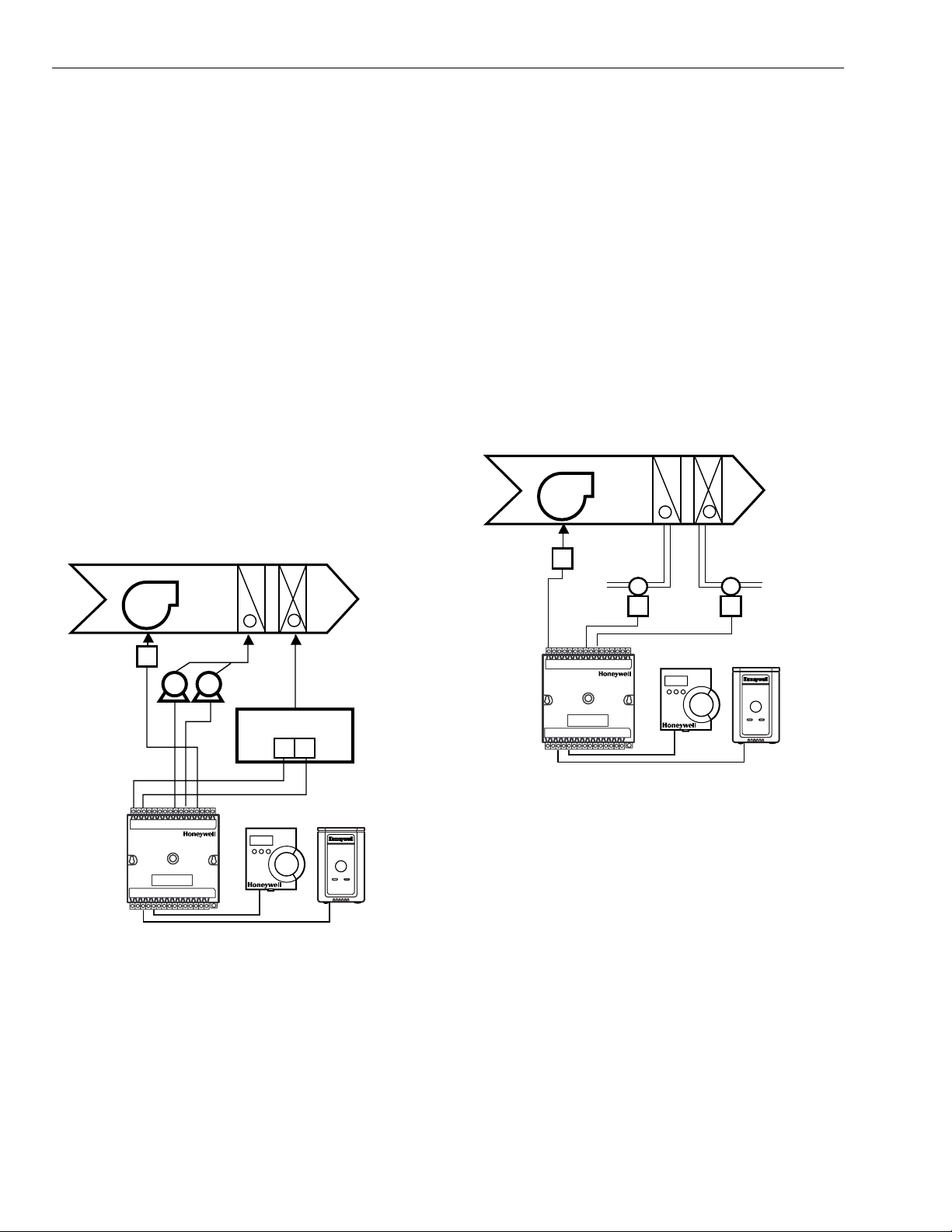

Control Application

W7750 systems in commercial build ings typically incorporate

a packaged air handler system that delivers a constant

volume of air at preconditioned temperatures to the zone

served. Each zone is usually serviced by a separate

bein

AHU; however, sometimes two or more AHUs service the

same zone. Note that the W7750 is not desi

Variable Air Volume

VAV) air handlers or Multi-Zone air

handlers, where one air handler simultaneously controls the

space temperature in man

OA TEMP

OUTDOOR

AIR

zones.

ned to control

FILTER

M

The W7750 can control sta

coils, mixed air economizer dampe rs, and the system

coolin

ed or modulating heating and

fan. Control of heat pump units, where the compressor(s) is

used for both coolin

and heating, is also provided. The zone

the W7750 services can use a T7770 or T7650 for space

temperature sensin

for users. Fi

FAN

and an LONW

. 2 shows a typical W7750 control application.

COOL

COIL

-

EXCEL 10

W7750

CVAHU

HEAT

COIL

+

ORKS

Bus network access

RA TEMP

RETURN

AIR

WINDOW CONTACT

Fig. 2. Typical W7750 control application.

Control Provide d

The W7750 Controller is designed to control a single air

handler to maint ain the units spa ce tempe ratur e at th e curre nt

setpoint. Heatin

ed or modulating equipment. Up to four stages of

sta

mechanical cooli ng and up to four stages of heating are

allowed. Modulatin

as a Series 6 0 control, or Pulse Width Modulated

W7750B,C only) control.

The economizer dampers can be controlled directl

floating or PWM outputs, or indirectly using a digital output as

an enable/disabl e si

The economizer enab le functio n, which dec ides when to allow

outdoor air to be used for free coolin

and cooling control is provided for either

outputs can be either

floating type

such

PWM

with

nal to a packaged economizer cont roller.

, can be configured to

T7770 OR T7560A,B

one of ten strate

see Appendix B—Se

DA TEMP

OCCUPANCY

SENSOR

DISCHARGE

AIR

ies based on the inputs. For more details,

uences of Operation. When the

ROOF

CEILING

M17488

economizer position is controlled from the W7750, the

minimum position settin

usted based on indoor air quality (IAQ) needs in the space.

ad

for ventilation requirements) can be

IAQ monitoring is provided through either a CO2 sensor or a

ital input from a space-mounted IAQ limit switch.

di

For heat pump confi

controlled, alon

heat/cool chan

urations, up to four compressors can be

with up to four stages of auxiliary heat, and a

e over valve. Including the supply fan, the

combination of these items may not exceed eight outputs if a

W7750B,C is used, or six outputs for a W7750A.

outputs on the W775 0C consi st of five di

ital and three analog

The eight

outputs.

7 74-2958—1

Page 8

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

y

(

)

y

y

g

y

g

g

y

g

g

(

(

g

g

g

g

g

g

g

g

g

g

g

g

g

Like the W7751 V AV Box Controller, the W7750 Contro ller can

monitor a space-mounted occupanc

window contact. These inputs affect the operational mode of

the controller

operation

The W7750 Controller a llows other con trollers in the s

use the W7750s ph

and an analog input can be configured to read switch states

and volta

over the L

Manager can use th ese values in custom control strategies.

Additionall

control pro

sent over the network, and are not controlled by the W7750

internal control al

see Table 5 for a list of all possible modes of

.

sical inputs and outputs. A digital input

e sensor values, respectively, and send them out

ONWORKS

, two of the W7750 digital outputs are av ai lab le for

ram use. These outputs only respond to signals

Bus network. The Q7750A Zone

orithms.

sensor, and a door/

stem to

Products Covered

This System Engineering Guide describes how to apply the

Excel 10 family of W7750 CVAHU Controllers and related

accessories to t

covered include:

• W7750A,B,C Controllers.

• T7770A throu

• T7560A,B Wall Modules.

• Q7750A Excel 10 Zone Mana

• Q7751A,B Router

• Q7752A Serial Interface.

• Q7740A,B Repeaters

• 209541B FTT Termination Module.

pical application s. The specific devices

h D Wall Modules.

er.

FTT to FTT and TPT to FTT).

2-way and 4-way).

Form No. Title

74-2956 Excel 10 W7750A,B,C Controll er Spe ci fic ati on

74-2697 Excel 10 T7770A,B,C,D,E,F,G Wall Module

74-3097 T7560A,B Di

74-2950 Excel 10 Q7750A, Zone Mana

74-2952 Excel 10 Q7751A,B Router Specification Data

74-2954 Excel 10 Q7752A Serial Interface Spec ification

74-3067 Q7752B PCMCIA LONW

74-2858 Excel 10 Q7740A,B FTT Repeaters

74-2951 Excel 10 Q7750A Zone Mana

95-7521 Excel 10 W7750A,B,C Controller Installation

95-7538 Excel 10 T7770A,B,C,D,E,F,G Wall Module

Data

Specification Data

ital Wall Module Specification

Data

Data

Data

Specification Data

Specification Data

and Test Manual

Instructions

Installation Instructions

er Specification

ORKS

PCC-10 Card

er Checkout

Organization of Manual

This manual is div ide d into three basic parts: the Introducti on,

the Application Steps, and the Appendices that provide

supportin

Steps 1 through 5 provide the information needed to make

accurate material orderin

the Appendices include confi

started using Excel E-Vision PC Software after the devic es

and accessories are ordered. Application Step 7 is

troubleshootin

The or

en

changing an existing system, the Table of Contents can

provide the relevant information.

information. The Introduction and Application

decisions. Application Step 6 and

uration engineering that can be

.

anization of the manual assumes a project is being

ineered from start t o finish. If an operato r is adding to, or is

Applicable Literature

The following list of documents contain s informati on related to

the Excel 10 W7750 CVAHU Controller and the EXCEL 5000

OPEN SYSTEM in

eneral.

95-7620 T7560A,B Di

Instructions

95-7509 Excel 10 Q7750A Zone Mana

Instructions

95-7510 Excel 10 Q7751A,B Router Installation

Instructions

95-7511 Excel 10 Q7752A Serial Interface Installation

Instructions

95-7613 Q7752B PCMCIA L

Installation Instructions

95-7555 Excel 10 Q7740A,B FTT Repeaters Installa tion

Instructions

95-7554 Excel 10 209541B Termination Module

74-2588 Excel E-Vision User’s Guide

74-5587 CARE User’s Manual

74-1392 CARE Excel 10 Zone Mana

74-5577 CARE Icon Guide

Installation Instructions

ital Wall Module Installation

er Installation

ONWORKS

PCC-10 Card

er User’s Guide

74-2039 XBS User’s Manual

74-5018 XBS Application Guide

74-2958—18

Page 9

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

(

y

y

y

j

(

g

y

y

g

q

g

(

(

(

(

(

)

q

y

)

)

)

(

g

q

q

Product Names

The W7750 Controller is available in three models:

W7750A

•

Version.

W7750B

•

Version.

W7750C

•

Version.

The T7770 Wall Module is available in four models. The

T7770 Wall Modules will work with all Excel 5000 and Excel

10 Controllers

T7770A1xxx

•

NTC sensor onl

T7770A2xxx

•

NTC sensor and L

T7770B1xxx

•

NTC sensor, 10 Kohm setpoint, a nd L

T7770C1xxx

•

NTC sensor, 10 Kohm setpoint, b

and L

T7770D1xxx

•

NTC sensor, b

ack.

Constant Volume AHU Controller - W7750A

Constant Volume AHU Controller - W7750B

Constant Volume AHU Controller - W7750C

except the W7751A,C,E,G):

Wall Module with nonlinearized 20 Kohm

.

Wall Module with nonlinearized 20 Kohm

ONWORKS

Wall Module with nonlinearized 20 Kohm

Wall Module with nonlinearized 20 Kohm

ONWORKS

Bus jack.

Wall Module with nonlinearized 20 Kohm

pass button and LED, and LONW

Bus jack.

ONWORKS

pass button and LED,

Bus jack.

ORKS

Bus

NOTE: The T7770B,C Models are available with a absolute

The T7560A,B Wall Module is available in two models:

•

•

Other products:

•

•

•

•

•

Refer to Table 11 in Appli cation Step 5. Order E

complete listing of all available part numbers.

NOTE: The Q7750A Zone Ma na

55 to 85°F

adjustable in E-Vision to ± 18°F (± 5°C).

T7560A

temperature, setpoint, Oc c/Unocc ov erride, overrid e status

LCD and di

T7560B

temperature, humidit

override, override status LCD and digital display.

Q7750A

Q7751A,B

Q7752A

Q7740A,B

209541B

Wall Module displays and provides space

Wall Module displa

Excel 10 Zone Mana

Serial Adapter.

FTT Termination Module.

in internal software and CARE.

10 to 85°C) or a relative scale plate

ital display.

s and provides space

sensor, setpoint, Occ/Unocc

er.

Bus Router.

FTT Repeaters.

uipment for a

er is referred to as (E-Link)

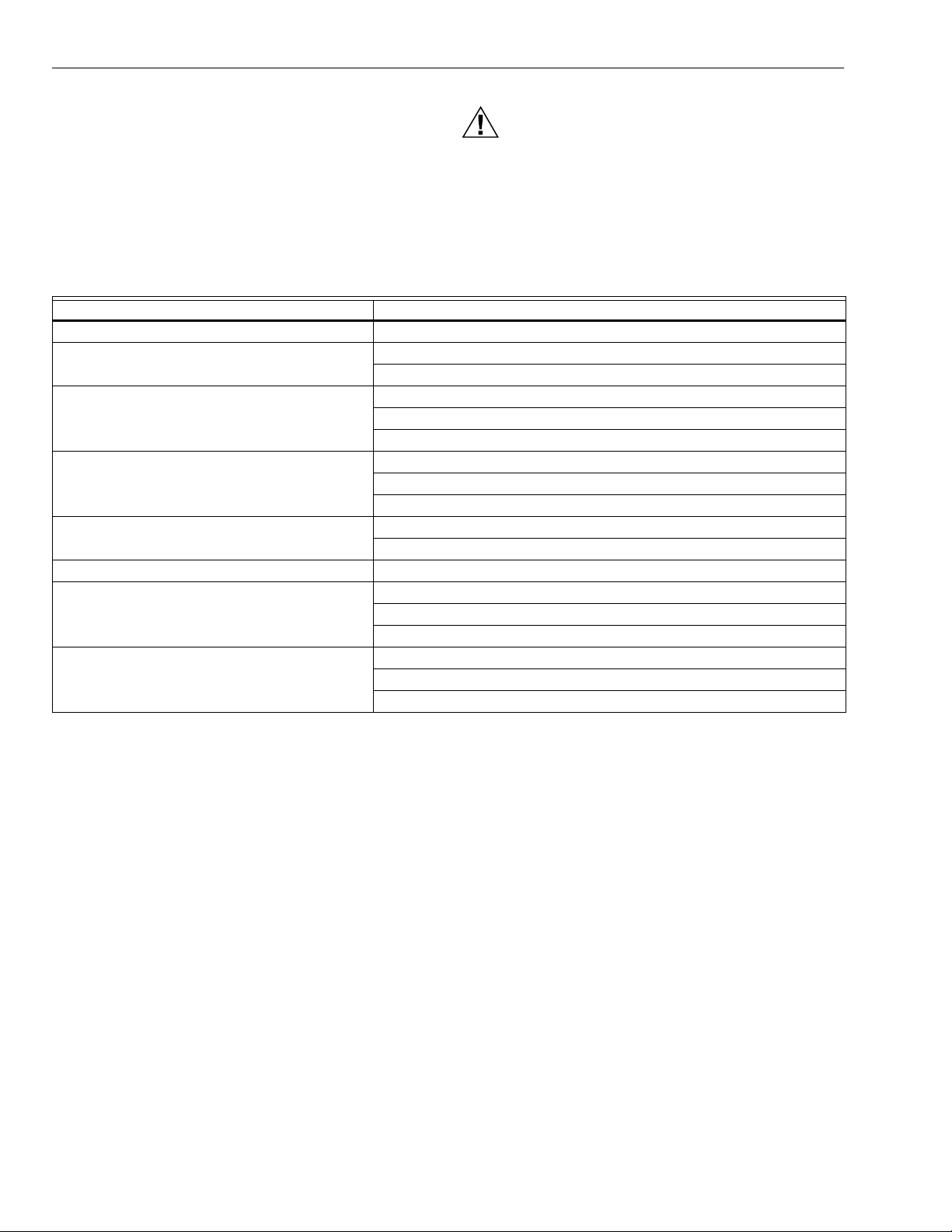

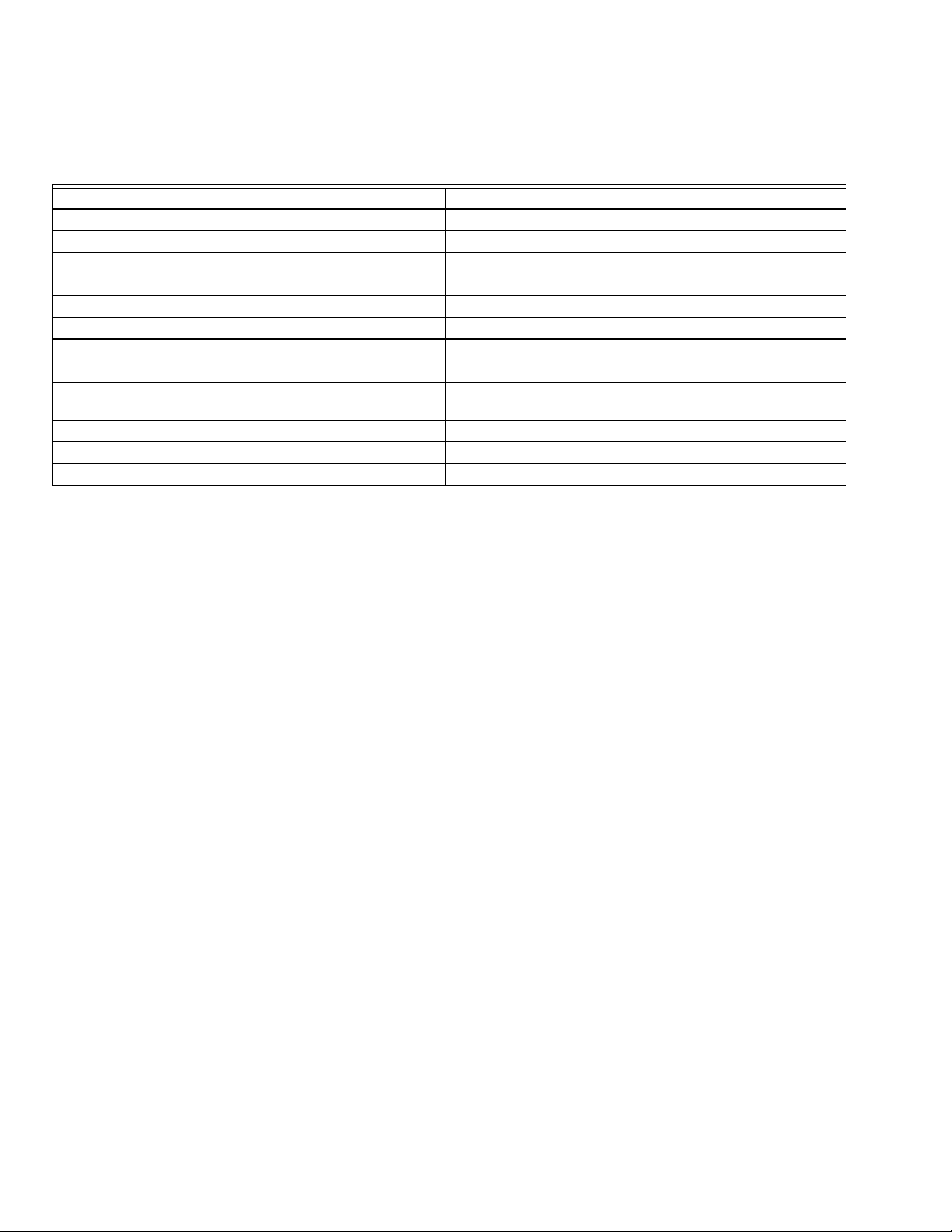

Agency Listings

Table 1 provides information on agency listings for Excel 10

products. Be sure to always follow Local Electrical Codes.

Device Agency Comments

W7750A,B,C Controllers

T7770A,B,C,D and

T7560A,B Wall Modules

Q7750A Ex cel 10

Zone Manager

Q7740A,B FTT

Repeaters, Q7751A,B

Routers and

Q7752A Serial Adapter

Table 1. Agency Listing.

UL Tested and listed under UL916

Controllers are UL94-5V listed and suitable for plenum mounting.

cUL Listed

CE Gene ral Imm un ity per European Consortium Standards EN50081-1 (CISPR 22, Class B)

FCC Complies with re

UL(Not applicable.

cUL(Not applicable.

FCC(Not applicable.

UL Tested and listed under UL916, file number S4804

CSA Listin

FCC Complies with requirements in FCC Part 15 rules for a Class A Computing Device.

UL UL1784.

CSA Listed.

FCC Complies with re

E87741).

and EN 50082-1:1992

EN 61000-4-2: IEC 1000-4-2 (IEC 801-2) Electromagnetic Discharge.

EN 50140, EN 50204: IEC 1000-4-3

EN 61000-4-4: IEC 1000-4-4

EN 55022: 1987 Class B.

CISPR-22: 1985.

Operation in a residentia l area can ca use interfe rence to radio or TV reception and require

the operator to take steps necessar

pending.

Operation in a residentia l area can ca use interfe rence to radio or TV reception and re

the operator to take steps necessary to correct the interference.

based on Residential, Commercial, and Light Industrial).

Electrical Fast Transient (Burst). Radiated Emissions and

Conducted Emissions:

uirements in FCC Part 15 rules for a Class B Computing Device.

uirements in FCC Part 15 rules for a Class B Computing Device.

file number E87741). The CVAHU W7750A,B,C

IEC 801-3) Radiated Electromagnetic Field.

IEC 801-4

to correct the interference.

QVAX, PAZY).

uire

9 74-2958—1

Page 10

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

q

y

q

g

y

g

y

g

y

y

g

y

g

g eq

g

g

gy

g

gy

y

y

gy

(

g

y

g

y

g

g

gy

y

g

g

gory

y

g

g

j

g

y

g

g

j

Abbreviations and Definitions

AHU

Air Handling Unit; the central fan system that includes

the blower, heating equipment, co oling equipment,

ventilati on air e

CO

Carbon Monoxide. Occasio nall

indoor air quality.

CO

Carbon Dioxide. Often used as a measu r e of indo or air

2

uality.

CARE

Computer Aided Regulation Engineering; the PC

based tool used to confi

devices.

C-Bus

Hone

communications between EXCEL 5000

controllers and components.

CPU

Central Processin

SYSTEM controller module.

cUL

Underwriters Laboratorie s Canad a

CVAHU

Constant Volume AHU; refers to a t

handler with a sin

amount of suppl

DDF

Delta Degrees Fahrenheit.

D/X

Direct Expansion; refers to a t

where refri

heat-exchanging coil that is mounted in the air stream

supplied to the conditioned space.

Echelon

The compan

and the Neuron chips used to communicate on the

ONWORKS

L

Economizer

the quantity of outdoor air that enters the building. In

cool outdoor conditions, fresh air can be used to

supplement the mechanical coolin

Because this action saves energy, the dampers are

often referred to as

EMI

Electroma

cause problems with communications signals.

E-Link

Refers to the Q7750A Zone Mana

used in internal software and in CARE software.

EMS

and al

Management System; refers to the controllers

Ener

orithms responsible for calculating optimum

operational parameters for maximum ener

the building.

EEPROM

Memor

Electricall

; the variable storage area for saving user

setpoint values and factory calibration information.

Enthalpy

EPROM

The ener

pound

KiloJoules per Kilogram).

Erasable Programmable Read Only Memory; the

firmware that contains the control al

Excel 10 Co ntroller.

uipment, and other related equipment.

used as a measure of

ure C-Bus and LONW

well proprietary Control Bus for

System

Unit; an EXCEL 5000 OPEN

pe of air

le-speed fan that provi des a cons tant

air to the space it serves.

pe of mechanical cooling

erant is (expanded) to its cold state, within a

that developed the LONW

Bus.

Refers to the mixed-air dampers that re

uipment.

economizer dampers

.

netic Interference; electrical noise that can

er. This name is

Erasable Programmable Read Only

content of air measured in BTUs per

orithms for the

ORKS

Bus

ORKS

Bus

ulate

savings in

Excel 10 Zone Manager

interface between the C-Bus and the L

A controller that is used to

ONWORKS

The Excel 10 Zone Manager also has the functionality

of an Excel 100 Controller, but has no ph

sical I/O

points.

NOTE: The Q7750A Zone Mana

er can be referred to as

E-Link in the internal software, CARE.

E-Vision

User interface software used with devices that

operate via the FTT L

ONWORKS

Bus communications

protocol.

Firmware

Software stored in a nonvol ati le mem or

such as an EPROM.

Floating Control

a valve or damper. Floatin

Refers to Series 60 Modulatin

Control utilizes one digital

output to pulse the actuator open, and another digital

output to pulse it closed.

FTT

Free Topolo

IAQ

Indoor Air Quality. Refers to the quality of the air in the

Transceiv er.

conditioned space, as it relates to occupant health and

comfort.

I/O

Input/Output; the ph

sical sensors and actua tors

connected to a controller.

I x R

I times R or current times resistance; refers to Ohms

Law: V = I x R.

K

Level IV

rees Kelvin.

De

Refers to a classification of di

wire. Formerly known as UL Level IV, but

to Cate

compatibilit

IV cable. If there is any question about wire

, use Honeywell-approved cables (see Step

ital communication

not

5 Order Equipment section).

L

ONWORKS

LONW

NEC

NEMA

Node

Bus

Echelons LONW

communication amon

Bus Segment

ORKS

containin

can be

no more than 60 Excel 10s. Two segments

oined together using a router.

ORKS

network for

Excel 10 Controllers.

An LONW

ORKS

Bus section

National Electrical Code; the body of standards for

safe field-wirin

practices.

National Electrical Manufacturers Association; the

standards developed b

for safe field wirin

an organization o f companies

practices.

A Communications Connection on a network; an

Excel 10 Controller is one node on the L

ONWORKS

network.

NV

Network Variable; an Excel 10 parameter that can be

viewed or modified over the L

PC

An Personal Computer with Pentium processor capable

of runnin

Pot

Potentiometer. A variable resistance electronic

Microsoft Windows 95.

ONWORKS

Bus network.

component located on the T7770B,C or T7560A,B Wall

Modules; used to allow user-ad

usted setpoints to be

input into the Excel 5000 or Excel 10 Controllers.

Bus.

medium

Control of

equivalent

Bus

74-2958—110

Page 11

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

y

g

y

g

g

y

g

y sy

g

g

y

q

(

(

q

g

g

g

g

y

g

g

y

y

(

(

(

g

(

y

g

y

g

g

g

g

y

(

y)

)

y

PWM

RTD

Subnet

TOD

TPT

VA

Vac

VAV

VOC

Pulse Width Modulated output; allows analog

modulatin

on the controller.

Resistance Temperature Detector; refers to a t

temperature sensor who se resis tan ce out put cha n

according to the temperature change of the sensing

element.

router from its Q7750A Zone Manager.

Time-Of-Da

Unoccupied times of operation.

Twisted Pair Transceiver.

Volt Amperes; a measure of electrical power output or

consumption as applies to an ac device.

Volta

volta

Variable Air Volume; refers to either a t

distribution system, or to the W7751 Excel 10 VAV Box

Controller that controls a sin

volume deliver

Volatile Organic Compound; refers to a class of

common pollutants sometimes found in buildin

Sources include outproduction-line by-products, and general cleaning

solvents. A VOC is occasionall

indoor air

control of equipment using a digital output

ONWORKS

A L

e alternating current; ac voltage rather than dc

e.

Bus segment that is separated by a

; the scheduling of Occupied and

pe of air

le zone in a variable air

stem.

assing of construction materials,

used as a measure of

uality.

pe of

s.

es

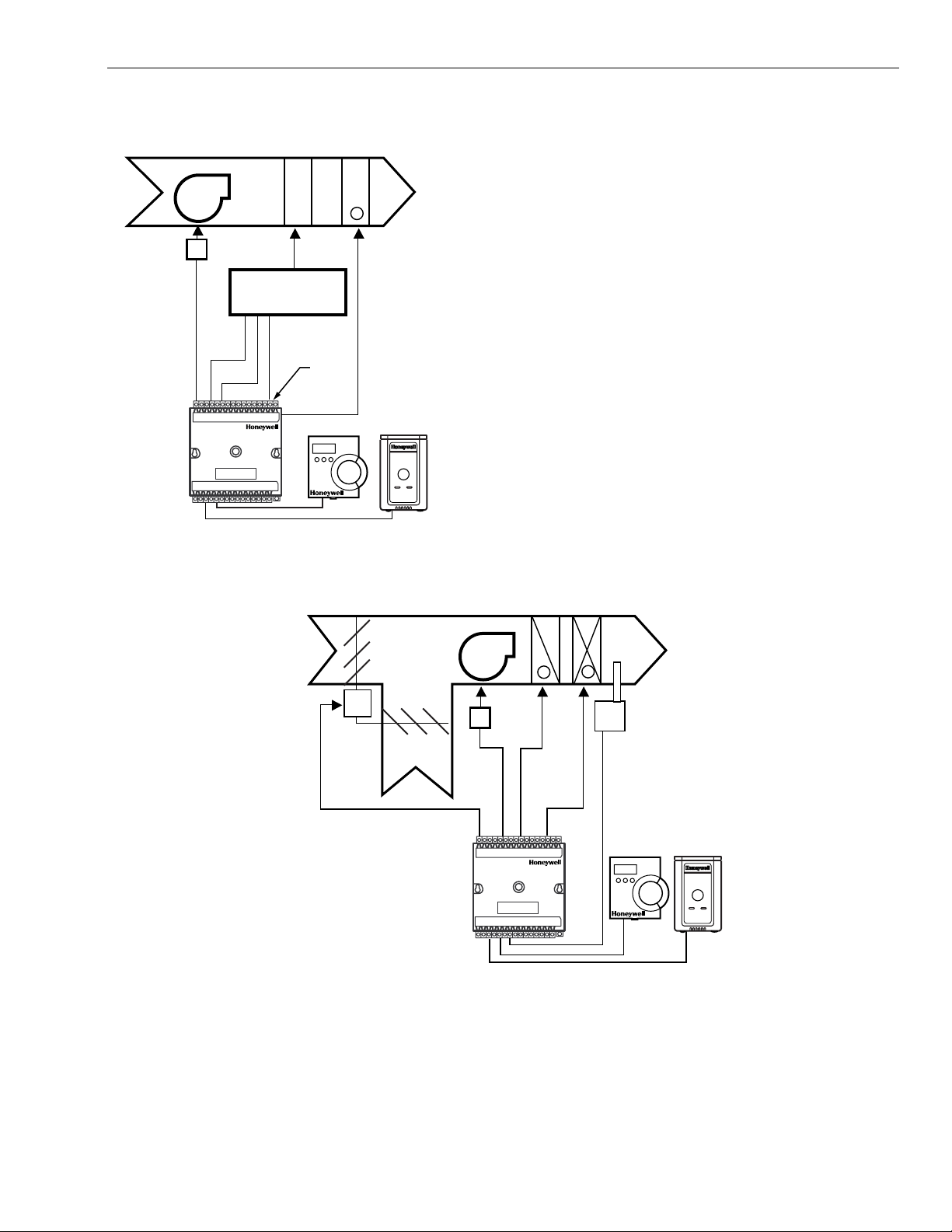

Construction

Controllers

The Excel 10 W7750 Controller is available in three different

models. The W7750A Model, which is a low cost controller

made for simple sin

controls. The W7750B,C Models are intended for more

complex applications.

The W7750B,C Models use Triacs for their di

where as the W7750A Model uses dr

W7750C Model also has three analog outputs available on

terminals 16, 17 and 18.

All wirin

terminal blocks. Connection for operator access to the

ONWORKS

L

cable into the LONW

The W7750A,B,C Model s c on si st o f a s in

is mounted in a sheet metal subbase and protected by a

factor

ph

W7750A) and different labels next to the wiring terminals

see Fig. 3, 5 or 6). Wires are attached to the screw terminal

blocks on both sides of the controller. The controllers mount

with two screws

mounted usin

purchase two DIN rail adapters

TKAD, from Thomas and Betts, see Fig. 8, then snap onto

standard EN 50 022 35 mm b

DIN rail. DIN rail is available throu

connections to the controller are made at screw

Bus is provided by plugging the SLTA connector

snap-on cover. The three controllers have the same

sical appearance except for terminals 16 through 20

le zone air handlers and heat pump

-contact relays. The

ORKS

Bus communications jack.

see Fig. 4 or 7). The W7750 can also be

DIN rail. To mount the W7750 on DIN rail,

obtain locally) part number

7.5 mm (1-3/8 in. by 5/16 in.)

h local suppliers.

ital outputs,

le circuit board tha t

W7750

W7751

Wall Module

XBS

Digital Outputs

Digital Inputs

Wall Module

Analog Outputs

Analog Inputs

DC Power

Floating (Series 60) Control

PWM Control

*The T7770 or the T7560 W al l Mod ules inclu des I/O p oints for

two analo

knob, a di

The model number of the Excel 10 CVAHU

Controllers

The model number of the Excel 10 VAV Box

Controllers

other optional controller inputs are contained in the

T7770 or the T7560A,B Wall Modules. See Application

Step 5. Order E

models of Wall Modules.

Excel Buildin

monitorin

also see CVAHU).

also see VAV).

The Excel 10 Space Temperature Sensor and

uipment for details on the various

Supervisor; a PC based tool for

and changing parameters in C-Bus devices.

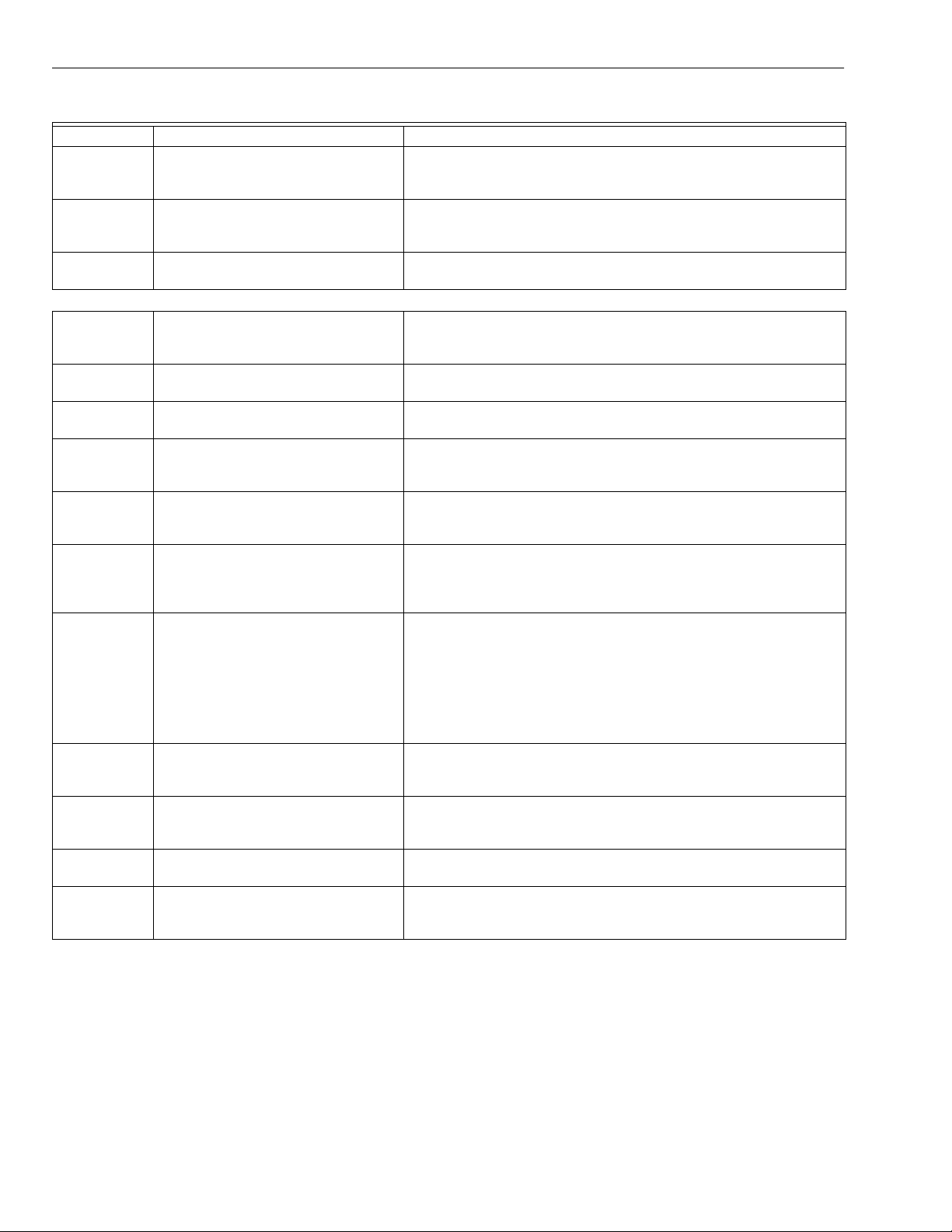

Table 2. List of Differences in W7750A and W7750B,C Controllers.

W7750A Model W7750B,C Models

Six Relay Outputs Eight Triac Outputs

Two Four

One* One*

None Three 4 to 20 mA Outputs

One (Resistive Input Only)Four (Two Resistive and two Voltage/Current Inputs

None 20 Vdc available to power optional sensors

Economizer Onl

None Heating, Cooling, and/or Economizer

inputs for the space temperature and the setpoint

ital input for the Bypass pushbutton, and a digital

A channel in the cover allows the controller status LED to be

visible when the cover is in place. There are no fieldserviceable parts on the circuit board and, therefore,

intended that the cover never be removed

The W7750A,B,C can be mounted in an

Ventilation ope nin

proper heat dissipation re

See Fig. 4 and 7.

The input/output and control differences between the two

models are summarized in Table 2. The I/O points in Table 2

are the free I/O points that are not reserved for Wa ll Mo dul e

use.

Heating, Cooling, and/or Economizer

output for the LED B

points are configurable, but are normally used for the Wall

Module.

s were designed into the cover to allow

ardless of the moun ting orientation.

W7750C onl

pass Indicator. These W7750 I/O

.

orientati on.

it is

11 74-2958—1

Page 12

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

W7750A

31 30 29 28 27 26 25

W1

W

2

Y1

Y2

G

NETWORK

DO

Rc

Rh

24 23 22

24

VAC

21

24

VAC

COM

20 19 18

NOT

NOT

USED

USED

USED

NOT

17 16

NOT

USED

USED

NOT

E

GND

1

LED

2

BYPASS

3

SNSR

GND

SET PT

AI-1

GND

DI-1

GND

GND

DI-2

10 11 12

NOT

L

ON

W

BUS

ORKS

USED

13 14 15 J3

JAC

L

ON

K

456

OHM

789

Fig. 3. Excel 10 W7750A Constant Volume AHU Controller.

74-2958—112

Page 13

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

y

(R)

g

y

g

g

2-1/8

(54)

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

WI W2 Y1 Y2 G

E

LED BYPASS SNSR GND SET PT AI-1

GND

123456789101112131415J3

NEYWORK

DO

Rc Rh

GND DI-1 GND GND DI-2 NOT

OHM

5-3/16 (132)

24

VAC

6 (152)

24

NOT

VAC

USED

COM

NOT

NOT

NOT

USED

USED

NOT

USED

USED

USED

LON

LONW

ORKS

JACK

BUS

3-1/16

(77)

5-5/8

(143)

Fig. 4. W7750A construction in in. (mm).

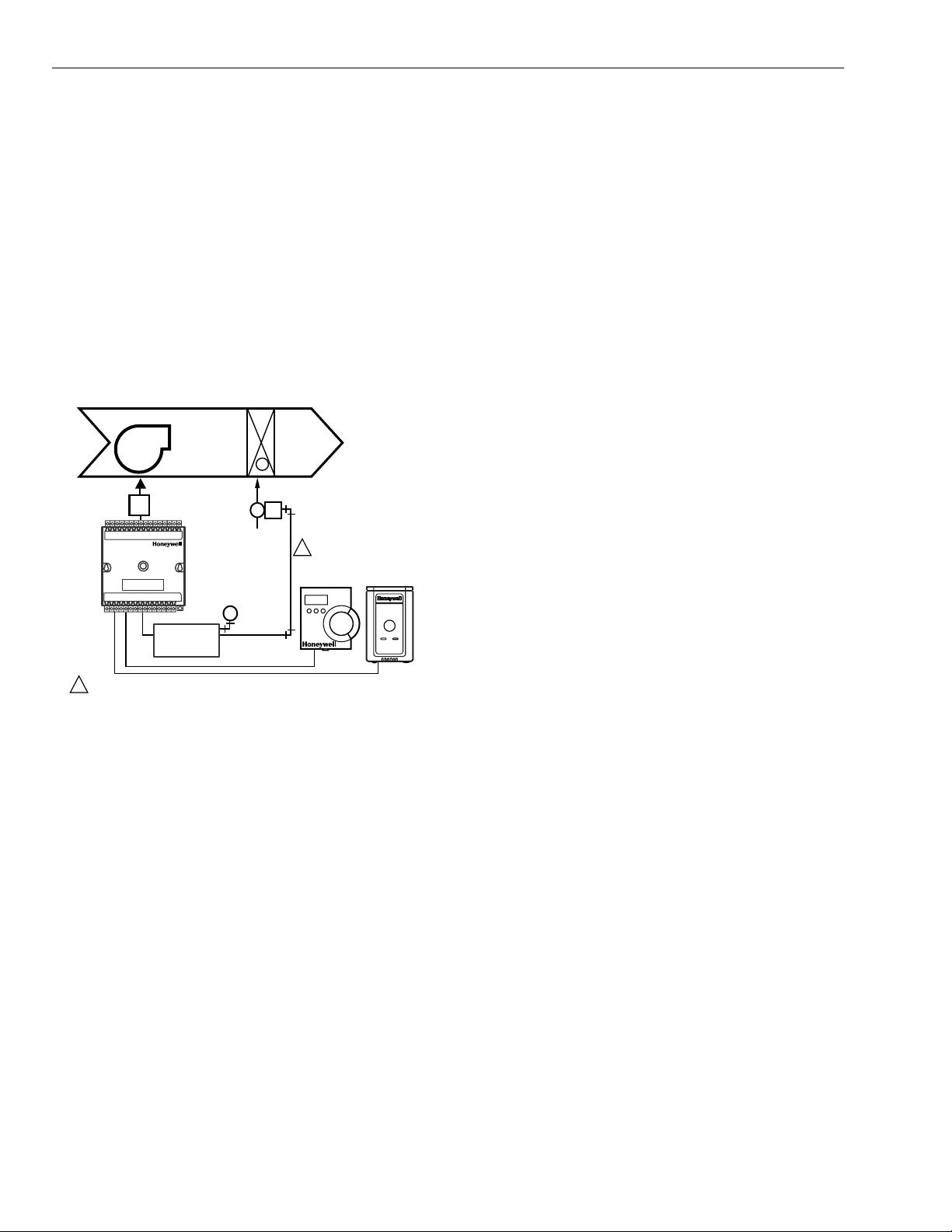

PERFORMANCE SPECIFICATIONS

Power:

24 V ac wi th a mi nimum of 2 0 Vac and a maximum of 30 Vac at

either 50 or 60 Hz. The W7750A power consumption is 6 VA

maximum at 50 o r 6 0 Hz . The W7750B,C power consumption

is 12 V A ma xi mu m at 50 or 60 H z.T he W77 50A, B ,C is a NEC

Class 2 rated device. This li stin

of power the product ca n cons ume or directl

imposes limits on the am ount

control to a total

of 100 VA.

M10098B

Special Note for the W7750B,C Unit:

The individual Triac outputs incorporate an internal common

connection with the input power transformer. The Triacs

provide a switched path from the hot side

transformer throu

h the load to the common of the

transformer. The W7750B,C Controller design

same power transformer for an

controller; see Fi

. 30.

loads connected to that

of the

must

use the

Each individual Triac is rated 1A at 30 Vac maximum. Under

all operatin

conditions, the maximum load/source power

budget for the W7750B,C Controller is 100 VA. Actual

allowable Triac current is 500 mA MAX.

13 74-2958—1

Page 14

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

g

(

y

(

(

(

31

30 29 28 27 26 25

DI-4

DI

DI-3

GND

DI-2

GND

DI

VAC

DI-1

24 23 22 21

VAC

24

COM

1

OUT

24

OUT

2

20 19 18

3

OUT

OUT

4

17 16

5

6

OUT

7

OUT

8

OUT

OUT

E

LED BYPASS

GND

1

23

SNSR

AI

SET PT AI-1

GND

456

OHM

7

AI

A1-2

GND

OHM

89

Fig. 5. Excel 10 W7750B Constant Volume AHU Controller.

CPU:

Motorola or Toshiba 3150 Neuron processor, containin

ht-bit CPUs. Each Neuron has a unique 48-bit network

ei

identification number.

Memory Capacity:

64K ROM/PROM

6K reserved for network operations, 58K

usable for control algorithm code).

tes EEPROM.

512 b

2K RAM.

AI-3

V/mA

GND

10

11 12

three

AI

AI-4

20VDC

V/mA

OUT

13 14

L

ON

W

ORKS

L

ON

BUS

JACK

15

J3

M6854B

Specified Space Temperature Sensing Range:

45 to 99°F

from 50 to 90°F

and 55 to 85°F

7 to 37°C) with an allowabl e control setpoint r ange

10 to 32°C) when initiated from the network

13 to 29°C) when configured and connected

to T7770 or T7560 Wall Modules.

74-2958—114

Page 15

31

30 29 28 27 26 25

DI-4

DI

DI-3

G

ND

DI-2

GND

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

24 23 22 21

DI

VAC

VAC

DI-1

24

COM

1

OUT

24

OUT

2

20 19 18

3

OUT

OUT

17

4

5

OUT

16

A0

A0

A0

1

2

3

E

GND

1

LED BYPASS

SNSR

AI

SET PT AI-1

23

GND

456

AI

A1-2

OHM

GND

OHM

789

V/mA

10

AI-3

AI

GND

11 12

V/mA

AI-4

20VDC

OUT

13 14

L

ON

W

ORKS

L

ON

BUS

JACK

15

J3

Fig. 6. Excel 10 W7750C Constant Volume AHU Controller.

M17489

15 74-2958—1

Page 16

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

gy

(

g

g

g

y

g

)

(

)

(

(

)

2-1/8

(54)

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

DI

DI-4

GND

E

LED

GND

123456789101112131415J3

DI-3 DI-2

BYPASS

SNSR

DI

GND

AI

GND

VAC

DI-1

24

SET PT

AI-1

OHM

5-3/16 (132)

VAC

24

COM

AI

GND

1

OUT

AI-2

OHM

2

OUT

AI-3

V/mA

6 (152)

3

OUT

AI

GND

4

OUT

AI-4

V/mA

5

OUT

20VDC

OUT

A0

1

LONW

BUS

A0

2

ORKS

A0

3

L

JACK

ON

3-1/16

(77)

5-5/8

(143)

Fig. 7. W7750B,C construction in in. (mm). W7750C (shown) has three 4 to 20 mA analog outputs.)

Communications:

The W7750A,B,C Controller uses a Free Topolo

Transceiver

runnin

FTT) transformer-coupled co mm uni ca tio ns port

at 78 kilobits per second (kbps). Using the

transformer-coupled communications interface offers a much

her degree of common-mode noise rejection while

hi

ensurin

dc isolation.

Approved cable t

wirin

is Level IV 22 AWG (0.34 mm

pes for LONW

rated unshielded, twisted pair, solid conductor wire. For

nonplenum areas, use Level IV 22 AWG

U.S. part AK3781

plenum areas, use plenum-rated Level IV, 22 AWG

2

such as U.S. part AK3791 (one pair) or U.S. part

mm

one pair) or U.S. part AK3782 (two pair). In

AK3792 (two pair). (See Tables 9 and 11 for part numbers.)

Contact Echelon Corp. Technical Support for the

recommended vendors of Echelon approved cables.

74-2958—116

ORKS

Bus communications

2

plenum or nonplenum

0.34 mm

M17490

2

such as

0.34

Page 17

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

y

gy

y

g (

g

y

g

g

g

)

g

g

g

y

y

y

g

g

g

(

2

3

1

Fig. 8. DIN rail adapters.

The FTT supports polarit

insensitive free topology wiring.

This frees the system installer from wiring using a specific bu s

topolo

supported b

. T-tap, star, loop, and mixed wiring topologies are all

this architecture. The maximum LONW

ORKS

Bus

length when using a combination of T-tap, star, loop, and bus

singly terminated) is 1640 ft. (500m) with the maximum

wirin

node-to-node len

th of 1312 ft. (400m). In the event that the

total wire length is exceeded, then a Q7 740A 2-W ay Repeater

or a Q7740B 4-Wa

number of devices to be spread out as well as increasin

th of wire over which they communicate. The maximum

len

number of repeaters p er se

. A Q7751A,B LONW

router

to effectively double the maximum LONW

The advanta

to a se

ment while when using the repeater, all traffic is

Repeater can be used to allow the

the

ment is one (on either side of the

ORKS

Bus Router can also be used

ORKS

Bus length.

e of using the router is that it segregates traffic

repeated on each segment. When utilizing a doubly

terminated L

ONWORKS

Bus structure, use a continuous daisy-

M6857

chain with no stubs or taps from the main backbone, The

maximum L

ONWORKS

maximum node-to-node len

FT T netw orks are ver

maintain, but it is imperative to carefull

out and create and maintain accurate documentation. This

la

Bus length is 4593 ft. (1400m) with the

th of 3773 ft. (1150m).

flexible and convenient to install and

plan the network

aids in compliance verification and future expansion of the

FTT network. This also keeps unknown or inaccurate wire run

ths, node-to-node (device-to-device) distances, node

len

counts, total wire len

and misplaced or missin

ONWORKS

L

Bus Wiring Guidelines form, 74-2 865 for comple te

th, inaccurate repeater/router locations,

terminations minimized. Refer to

description of network topology rules.

L

W7750 Controllers support the L

® FUNCTIONAL PR OFILE

ONMARK

ONMARK

Functional Profile

number 8030 Roof Top Unit Controller, version 1.0

see Fig. 9).

17 74-2958—1

Page 18

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

g

(

g

(

(

)

y

g

(

y

)

g

(

(

(

)

(

y

)

g

g

(

)

y

y

y

y

(

y

y

(

g

(

(

Inputs/Outputs:

The W7750A Unit supports the foll owing hardware features:

• Three 20 Kohm NTC

• Three dry contact digital inputs (one reserved for the

• LED di

• Six 24 Vac rela

nviSpaceTemp

nv1

SNVT_temp_p

nv2

nviSetPoint

SNVT_temp_p

Hardware

Output

Roof Top Unit

Controller number 8030

Mandatory

nv3

Network

Variables

nv4

nvoSpaceTemp

SNVT_ temp_p

nvoUnitStatus

SNVT_hvac_status

1000 through 150,000 ohm) or

PT3000 (250 through 12,000 ohm) resistive analog inputs

one reserved for space temperature and one reserved for

the setpoint knob

pass pushbutton).

B

ital output

.

only

for the wall module LED) 2.5V at 3

mA.

digital outputs (1.5A relays rated at 7.5A

inrush current

.

nviApplicMode

nv5

SNVT_hvac_mode

nviOccCmd

nv6

SNVT_occupancy

nviSetPtOffset

nv7

SNVT_ temp_p

nviOutsideTemp

nv8

SNVT_ temp_p

nviOutsideRH

nv9

SNVT_lev_percent

nviSpaceRH

nv13

SNVT_ lev_percent

nviCO

nv14

SNVT_ppm

nviEmergCmd

nv15

SNVT_hvac_emerg

nvoEffectSetPt

nv10

SNVT_ temp_p

nvoOutsideTemp

nv11

SNVT_ temp_p

Optional

Network

Variables

2

nvoOutsideRH

nv12

SNVT_ lev_percent

nvoCO

nv16

SNVT_ppm

Configuration Properties

nc49 - Send Heartbeat (mandatory)

nc60 - Occupancy Temperature Setpoints

nc17 - Location

nc42 - CO2Limit

(mandatory)

(optional)nc48 - Maximum Receive Time

(optional)

(mandatory)

The W7750B,C Units s upp ort the fo llowin

• Four 20 Kohm NTC

PT3000

250 through 12,000 ohm) resistive analog inputs

1000 through 150,000 ohm) or

hardware features:

one reserved for space temperature and one reserved for

the setpoint knob

• Two 0.2 to 10 VDC or 2 to 20 mA

.

user selectable) analog

inputs.

2

pushbutton

• Five dr

contact digital inputs (one reserved for the Bypass

.

• Eight on the W7750B (five on the W7750C) 24 Vac Triac

ital outputs (500 mA MAX). The W7750C Unit also

di

supports three 4 to 20 mA analo

• LED digital output

only

for the wall module LED, T7770

models or LCD, T7560A,B

• One 20 Vdc power su ppl

for auxiliary devices with a

outputs.

2.5V at 3 mA.

maximum current of 50 mA.

ANALOG INPUTS:

NOTE: Only one of each type of input is allowed. For

example, onl

one Outdoor Air Temperature sensor

is allowed. No duplicate Outdoor Air Temperature

sensors are usable on the same controller.

Space Temperature:

pe: RTD.

T

Supported Sensors: T7770A,B,C,D; T7560A,B.

Manufacturer

Defined

Section

Discharge Air Temperature:

pe: RTD.

T

Supported Sensors: C7100A1015*, C7770A1006,

C7031B1033, C7031C1031, C7031D1062, C7031F1018

Hardware

Input

M11580

W7750B,C only), C7031J1050, C7031K1017.

Outdoor Air Temperature:

pe: RTD.

Fig. 9. Functional profile of LONM

® RTU object details

ARK

(variables not implemented in Excel 10 CVAHU

T

Supported Sensors: C7170A1002.

are greyed).

Return Air Temperature:

pe: RTD.

Environmental:

Operatin

Temperature: -40 to 150°F (-40 to 65.5°C).

T

Supported Sensors: C7100A1015*, C7770A1006,

C7031B1033, C7031C1031, C7031D1062, C7031F1018

Shipping Temperature:

-40 to 150°F

-40 to 65.5°C).

Relative Humidity:

5% to 95% noncondensin

.

W7750B,C only), C7031J1050, C7031K1017.

*The PT3000 sensor is not recommended for floatin

real time - discharge or return configured as space sensor).

The PT3000 sensor is intended for monitoring or differential

staged) control

Vibration:

Rated V2 level compliant.

74-2958—118

control

Page 19

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

(

(

(

(

y

(

y

y

y

y

y

y

gh q

(

g

g

g

y

g

g

y

q

y

(

)

y

y

)

g

CAUTION

(

g

(

)

Outdoor Air Humidity (W7750B,C

Type: Voltage/Current.

Supported Sensors: C7600B1000 and C7600B1018

2 to 10V), C7600C1008 (4 to 20mA).

Return Air Humidity (W7750B,C

Type: Voltage/Current.

Supported Sensors: C7600B1000 and C7600B1018

2 to 10V), C7600C1008 (4 to 20mA).

Outdoor Air Enthalpy (W7750B,C

Type: Current.

Supported Sensors: C7400A1004

Return Air Enthalpy (W7750B,C

Type: Current.

Supported Sensors: C7400A1004

Air Filter Differential Pressure (W7750B,C

Type: Voltage.

Supported Sensors: Third part

1.25 kPa) differential pressure sensors.

CO

Sensor (W7750B,C

2

Type: Voltage.

Supported Sensors: Third part

sensors.

CO

2

only):

only):

only):

only):

4 to 20mA).

only):

4 to 20mA).

only):

2 to 10V, 0 to 5 inw

0 to 10V, 0 to 2000 ppm

— Dirty Filter:

Contact Closed = Dirt

— Shutdown Signal:

Contact Closed = Shut off all e

— Occupanc

Contact Closed = Room is Occupied; Contact Open =

Room is Unoccupied

— Window Monitor:

Contact Closed = Window is Closed

— Coil Freeze Stat:

Contact Closed = Coil Freeze condition sensed

— Wall Module Bypass Pushbutton:

Momentar

for b

TRIAC OUTPUTS ON THE (W7750B,C MODELS ONLY):

— Power ratin

MAX current for any voltage.