Page 1

Honeywell

W7620

PROVIDES CUSTOMIZED CONTROL OF HVAC

SINGLE ZONE EQUIPMENT. SPECIFIC

FEATURES THIS SYSTEM OFFERS INCLUDE:

COMMUNICATION, APPLICATION FLEXIBILITY,

DIRECT DIGITAL CONTROL, EASY

INSTALLATION AND PROGRAMMING, AND

INCREASED EQUIPMENT RELIABILITY.

0

0

q

SINGLE

W7620 Base Controller provides:

-

four relay outputs

-

network communication

-

T7660 Space Temperature Sensor inputs

W7621 Expansion Input

ditional input point expansion on one board of up

to:

-

two resistive inputs

-

two digital inputs

-

two voltage inputs (one dry contact, one

extended 24 Vac input)

W7622 Expansion Output Point

ditional output point expansion on one board of

up to:

-

three analog outputs

-

three digital outputs

ZONE CONTROL

Point

Boards provide ad-

Boards

SYSTEM

provide ad-

0

T7660 Space Temperature Sensor provides up to:

-

one space temperature input

-

one space temperature &point

-

one override push button/LED indication

Cl Up to four heat/four cool conventional or four-

compressor

heat pump

q Flexible control options:

-

analog/humidity switch

-

packaged or integrated economizer

-

indoor

air quality switches

HG/KH

8/91

Form Number 63-4224

©Honeywell 1991

Page 2

SYSTEM DESCRIPTION . . . ; . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INST~LATION........,..1..........................................

CHECKOUT

. . . . . . . . . . . . .

..1............~...........................11

SPECIFICATIONS. . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ACCESSORIES . . . . . . . . . . . .

..‘.......................................lS

7

WHEN PURCHASING REPLACEMENT AND

DISTRIBUTOR, REFER TO TRADELINE CATALOG OR PRICE SHEETS FOR COMPLETE ORDERING

IF YOU

PRODUCTS

1.YOUR LOCAL HONEYWELL

2. RESIDENTIAL AND BUILDING CONROLS

IN CANADA -

CANADA

HAVE ADDITIONAL QUESTIONS, NEED

OR

SERVICES;

RESIDENTIAL

MINNEAPOLIS, MINNESOTA 55422, (612)

AND BUILDING CONTROLS SALES

HONEYWELL LIMITED/HONEYWELL

M1P 2VP.

PLEASE WRITE OR

SALES OFFICE (CHECK WHITE PAGES OF YOUR PHONE DIRECTORY,. ASK FOR THE

INTERNATIONAL SALES AND SERVICE OFFICES IN ALL PRINCIPAL CITIES OF THE

MODERNIZATION

FURTHER INFORMATION

PHONE:

REPRESENTATIVE.

CUSTOMER

542-7500.

LIMITEE,

PRODUCTS FROM YOUR AUTHORIZED SYSTEMS

OR WOULD LIKE To COMMENT ON OUR

SERVICE HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH,

740 ELLESMERE ROAD, SCARBOROUGH ONTARIO

NUMBER.

WORLD.

Page 3

The W7620

new

can conveniently monitor and

zone equipment.

System features include CNAP (Control Network

Automation Protocol) communication, application

flexibility, DDC (Direct Digital Control), network

integration, easy installation and programming, and

increased

The basic

capability to process

programs, and communicate along with other devices on

the CNAP

The W7620

DDC has a control loop which periodically updates

outputs as a

given set of algorithms.

Single

Zone Control System is Honeywell’s

line

of single

equipment reliability.

W7620

network.

zone control

Single

I/O

(Input/Output) data,

See W7620 family photo.

Single Zone

function

of a set of measured inputs and

products. The W7620,

control

individual HVAC

Zone

Controller has built-in

run

DDC

Controller is a DDC device.

the

The

advantages of DDC

are:

Control

The W7620

control loops for accurate control of single zone equipment

that prevents

comfort in the

Single Zone

temperature

zone.

Controller provides sophisticated

droop and provides greater

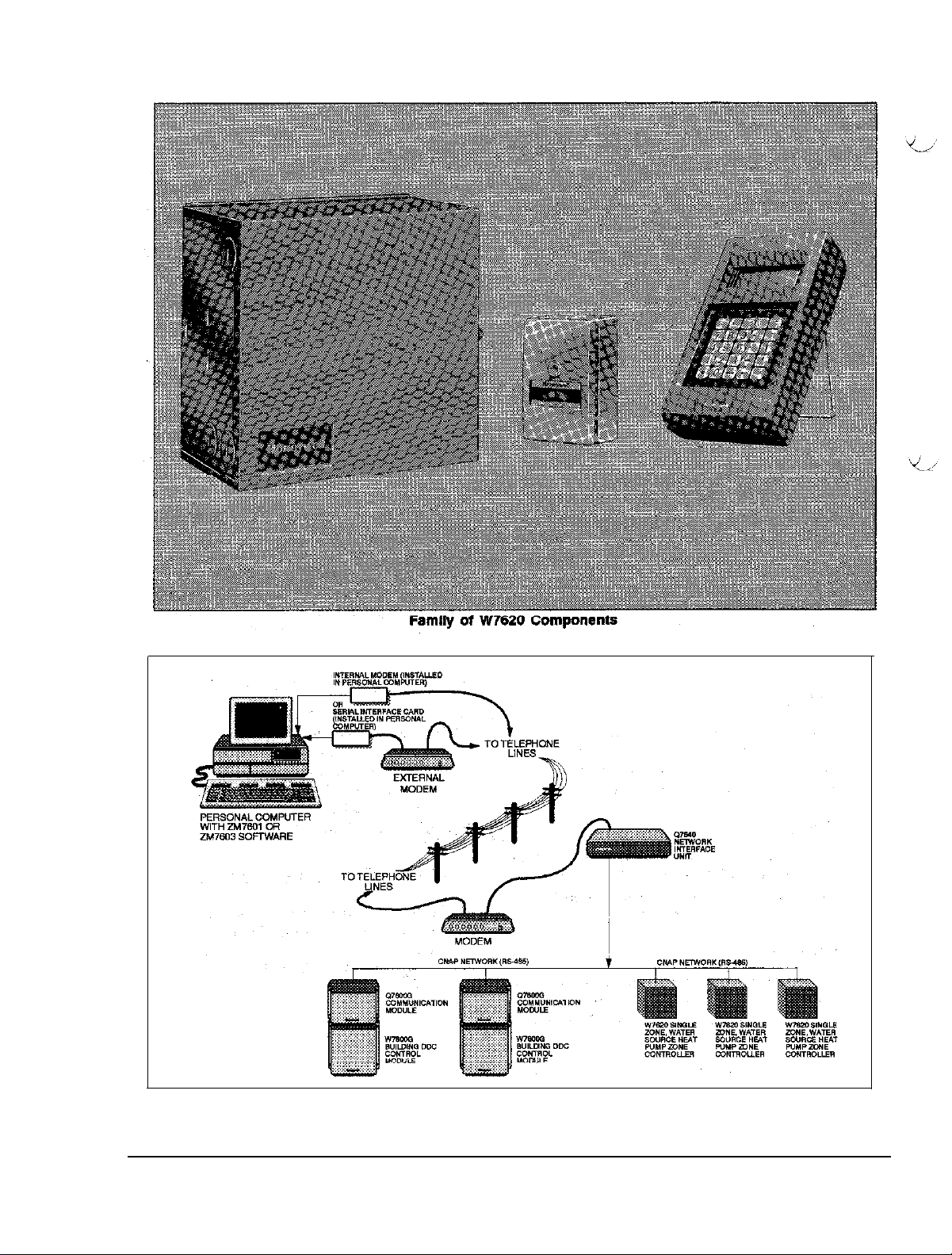

the RS-485 CNAP network. The CNAP

communication to multiple

well as to other

Module, 47640 NIU or a

a PC with ZM7603 Remote Monitoring

to the ZM7601 Configuration Tool/ZM7603 Remote

Monitoring

for a more detailed description.

Through the CNAP network, the controller can be

provided with information

only, or

controllers. ZM7601/ZM7603 software

provided

for

Figure 1.

a

The W7620 Zone Control System was designed for

application flexibility.

which is stored in EBPROM and by

and

be applied in a variety of applications.

network

W7620 Zone

controllers,

software

with information necessary for a group of

with periodic information on any controller data

monitoring, data gathering, or report generating. See

output requirements, the same

such as the

Q7650

PC Interface Card in

specification

specific

Simply

by changing

sheet,

Form 63-4272,

to its controlled

determining the input

W7620 controller can

enables

Controllers as

W7600

Control

software.

can, in turn,

Refer

the

algorithm

zone

zone

be

Maintainability

Use of a single programmed computer reduces

requirements for calibration checks because

fewer interconnected analog components. Periodic

recalibration is automatically

performed.

there

are

Reliability

EEPROM (Electrically Erasable Programma

Only Memory) and EPROM

Read Only Memory) hold the control program and

parameters

eliminating

the

(Erasable Programmable

need

for a

battery.

ble Read

Communlcatlon

Networking controllers together on a

using

CNAP software provides information for integration

of control functions, monitoring, trending, alarming, and

report

generation.

The W7620

stand-alone environment with distributed zone control

and

hard-wired time-of-day

applied as part of a

Single Zone

networked

Controller can be applied in a

functionality It can

system via connection

RS-485 network

also be

to

‘Ike W7620 Baseboard provides input dedicated to the

T7660 Space Temperature Sensor (space temperature,

remote

CNAP communication connections). The baseboard

provides four SPST

A variety of small point, single zone or heat pump

applications

The

one AC input, and two voltage

for a variety of inputs depending on application. One

W7621 input board

controller.

setpoint,

W7621

bypass switch with LED feedback, and

only

(Single

Pole, Single Throw) relays.

can

be met by using only the

Input Board

adds two resistive, one digital,

inputs that can

can

be

added

to the

W7620.

be used

W7620

Zone

3

63-4224

Page 4

Figure

1 - CNAP Network Diagram

Page 5

The W7622 output board has a

on

depending

any type

The W7622 drives any output (for heat, cool, etc.), either

digital

relay outputs have both

closed contacts. The

The

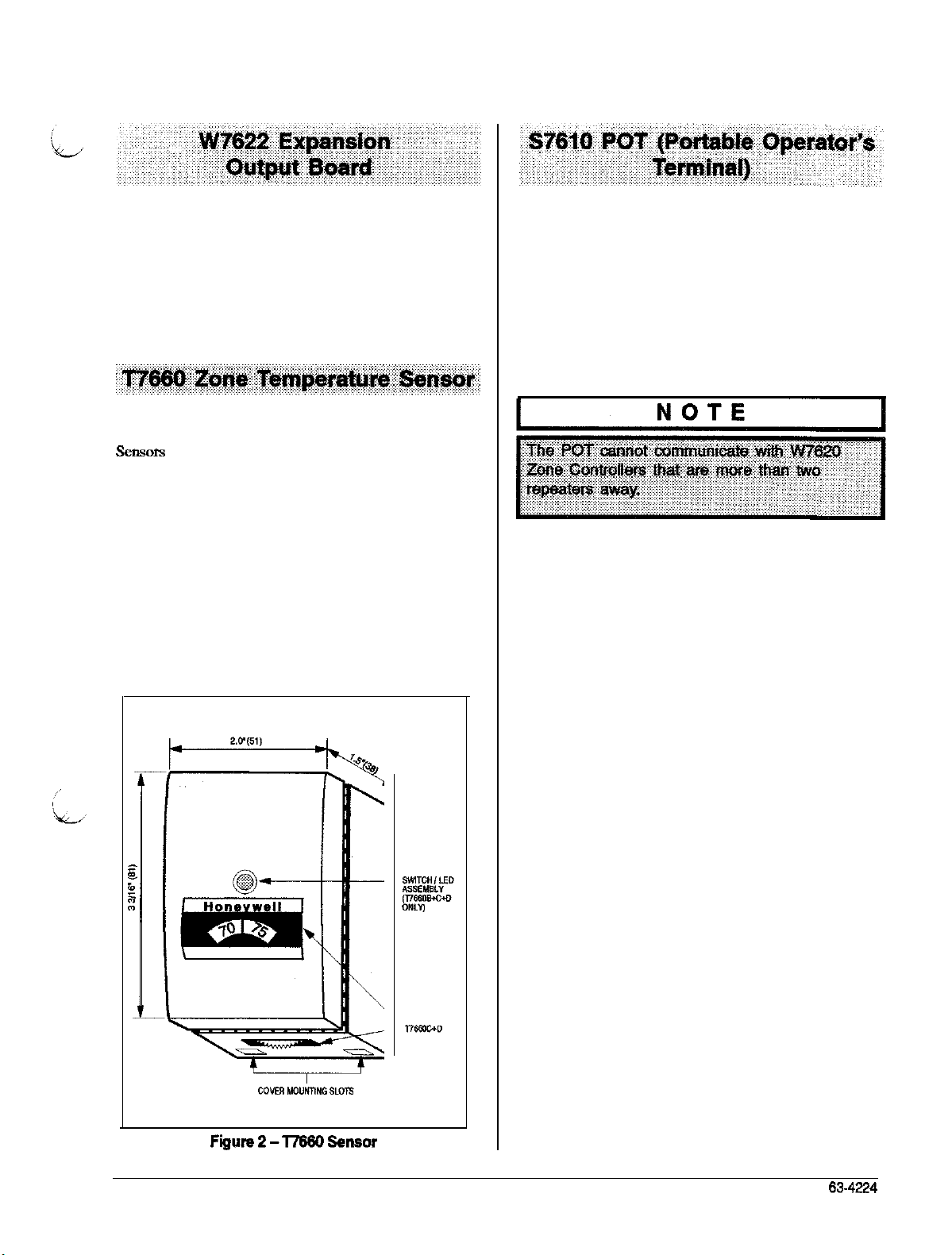

‘I7660

Device) that is placed in the

Sensors are

adjustment dial or an occupant override push button with

status

LED (Figure 2). The push button allows setting

the heating or

the control system is in an unoccupied

can be

The LED indicates

are furnished with an RJ11 connector for local operation

of an

S7610

the T7660A-D Space Temperature Sensors Information

and

Installation

the model

can

be added to the

or

analog. Function depends upon application. The

is a platinum RTD (Resistive Temperature

available with or without an

cooliig

used

to initiate a

the

POT (Portable Operator’s Terminal). (See

sheet,

number.

normally open

analog

outputs are 0-10

zone

system to an occupied mode when

continuous unoccupied period.

override

Form

selection

One output board of

W7620

for temperature readings.

status.

These zone sensors

63-4219, for

of outputs

Zone Controller.

and

normally

Vdc.

integral setpoint

mode.

Also, it

more

details.)

The S7610

means to set, test, and monitor point and parameter values.

The POT utilizes the RS-485 CNAP nehvork for

communication and connects to

cable to an RJ11 jack at

Sensor, or to an RJ11 jack inside

The POT

network.

63-4225, for information on operation. See Figure 3.

POT

is a hand-held &vice that provides a

the T7660

can

communicate to

See the S7610 Zone

the

controller through a

Zone

Temperature

the

controller

any controller on the

Control

POT Guide,

case.

Form

Page 6

Figure

3 -POT (Portable Operator’s Terminal)

Page 7

When

installing

1.

Read these

them could damage the product or cause

hazardous condition.

2.

Check the

section and on

product is suitable for the application.

3. The installer must be a

service or installation technician.

4.

After installation is complete, check system

operation as provided in

5.

Verify

with

procedures.

6.

Verify that the T7660

installed in

T7660

this product . . .

instructions

ratings

that the W7620s are

the

job

drawings

accordance

Specification Sheet (63-4219).

carefully. Failure to

given in

the

product to make

the

SPECIFICATION:

trained,

experienced

these instructions.

installed in

and

these installation

Space

Temperature Sensor

with job drawings and

sure that the

accordan

a

follo

the

surface-before removing the W7621 or W7622

expansion board from the antistatic bag.

Failure to do so might damage the board.

I

Mount

the

wiring, servicing

controller in a location that allows clearance

Remove the cover by loosening the two side

screws

location appropriate to the equipment being

controlled.

secure the controller to the mounting surface

through the four

(Figure

and removal of

4) and mount

screws

key

holes

inside

the

cover.

the controller in a

(obtain locally) to

the case,

for

1.

2. Use No. 8 sheet metal

I

Disconnect power supply before beginning

installation

equipment damage.

radiate radio frequency energy. not installed

and used in accordance with the instruction

manual, it may cause interference to radio

communications. Pursuant to FCC Rules,

Subpart J of Part 15, this equipment has

been tested and found to comply with the

limits for a Class A computing device. These

limits are designed to provide reasonable

protection against interference when operating

in a commercial environment. Operating this

equipment in a residential environment is

likely to cause interference, in which case the

user at his own expense will be required to

take whatever measures necessary to correct

the interference.

to prevent electrical shock and

3. Test the

4. Replace and secure the controller cover after

wiring

controller

is

complete.

and equipment operation.

Mountlng Additional Boards

To install additional input or output expansion boards

(W7621 or

on

following:

1.

2.

3. Lean the input or output board in at the base to

4. Snap the board into place

5. Secure the board into place by applying and

W7622) which

the

base board assembly (Figure 5) complete

Align the

baseboard with

the input board

Align the white plastic standoff tab with the hole

located near the lo-pin connector.

catch the metal tab located on the bottom of the

controller.

tightening the two board screws provided with

each expansion

IO-pin

are

not

manufacturer installed

connector (J4) or

the

10-pin inverse

(J15)

or output board (13).

board.

the

(J5) on the

connector on

7

63-4224

Page 8

,&Knockout for

h

Double knockout for

l/2

in. conduit fittings.

l/2

or

3/4

in. conduit fittings.

Figure 4 - W7620 Mounting

STANDOFF HOLE

PLASTIC STANDOFF

Figure 5 -Mounting Additional Board

8

PIN CONNECTOR

10

Page 9

r

If securing screws are not used, the

expansion board will

will

result in improper operation or damage to

the

device.

I

not be

grounded. This

Pull the

controller

terminals marked CNAP +/- (Figure 6).

I

pair of CNAP communication cables to each

on

the network and connect to the screw

NOTE

I

NOTE

The

W7620

63-4220,

designations to function

wiring

and the J/O Control Function Cross-Reference provided

on

the

Wire as follows:

1.

strip % inch (5 mm)

conductor.

2. Insert the wire in the required terminal location

and tighten

Figure 6 illustrates the terminal arrangement in the

controller. All

terminal arrangement similar to

Single Zone Application Guide, Form

provides information on corresponding

was done according

inside cover of

screw terminal.

controller

the

connections.

to the wiring diagram provided

W7620.

insulation

models are

that

Verify that the

from the

furnished with

shown in

terminal

this

figure.

a

I

Power Wire Lengths

1. Power requircmcnts limit 24 Vac power

transmission distance. The following data can be

used in calculating load versus wire length:

Device

VA

W7620 3.9

output relay

Analog output 0.6

Power relay 4-10

2.

The power relay load rating depends on the relay

can

used. Power relays

current

from separate 24 Vac supply.

3.

The operating voltage range for

to 30 Vac.

Pull a pair of 24 Vac

or

shared transformer to each controller on

ml connect to Terminals TR

be wired to draw coil

power

cables from either an isolated

0.5

the

and

TR earth-ground.

W7620 is 20

the net

work

Figure 6 -Terminal Designation Label

Page 10

T and Al). See the T7660 Space

Sensor

correct temperature to

cross-reference.

specification

sheet, Form 63-4219,

measure resistance

Temperature

for the

value

3.

Observe the fan or measure

expected result is not achieved, measure the

resistance across the correct

OUT1 A and C). The resistance should hold at

approximately

1.0 when the output is ON.

the

output. If the

terminals

(e.g.,

4.If long sensor

supplied to the W7620 by both

sensor and the leadwire for greater accuracy.

wiring

is used,

m-

the

temperature

resistance

Output Point Test Procedures

Testing outputs consists of observing the analog or digital

output states of physical points to see that the value

state is comparable to the point value as displayed on

the S7610

devices can be used to

known state to facilitate checkout.

procedures:

1.

2. Measure or observe the output

3.If the output does not follow the command

4. Clear the override condition.

POT

or ZM760l/ZM7603 software. These

override

Set the

value with the S7610 POT or ZM7601/ZM7603

software.

turns

override condition, isolate

checking connections and measurements at

output destination as

override

on).

on an output point to a desired

well as

the output point to a

Use

the following

condition

the

problem by

at the W7620.

(e.g., fan

or

the

Example:

The

following

any

one of the outputs, 1-7, depending on

output options

Zone/WSHP

63-4220.

1.

Display Fan (OUT.) on the S7610 POT or

ZM7601/03 software.

2. Set into override the point to the desired state, ON

or OFF.

procedure is for Fan (can be

selected,

Application

see W7620 Single

Guide, Form

Page 11

The following steps for complete checkout and testing

of a W7620 are described fully below. The procedures

are

as follows:

1.

Check W7620 installation and wiring, including

power to the W7620.

2.

Start-up W7620 (connect S7610 POT or

ZM7601/ZM7603 software) and assign a network

node address and application (even when using

device in a nonnetworked application). Refer to

W7620 Application Manual, Form 63-4220.

3. Test analog and digital input points

4. Test analog and digital output points.

5.

Verify

parameter point values.

1.

Verify that the connections between the W7620

and peripheral equipment are secure.

2.

Verify that

grounding

is correct in

accordance

with

GROUNDING in this guide as follows:

a.

Verify that each W7620 case is grounded

when the

individual

b. Verify that all W7620 cases are grounded

when the

c-on

c.

Verify that if

transformer

side is connected to earth-ground on the

W7620 (TR earth-ground).

d.

Verify that neither of the CNAP network wires

is grounded or

e.

Verify that the

network wires is correct, positive to positive

and negative to negative in alI cases.

3.

Verify the CNAP network termination and biasing

resistors

Network Interface Unit

(63-4290).

4.

Turn on power and

least 20 Vac at Terminals TR and TR

earth-ground.

W7620s are

transformers.

W7620s

transformer.

the

secondaries, that the grounded

are installed in accordance with 47640

powered from

are powered from a

application calls for grounded

connected

polarization

verify

to the 24 Vac wires.

of the CNAP

specification

that each W7620 has at

sheet

Testing physical points requires either the actual sensor

be at a known

known value or digital state be applied to the input point

terminals.

condition of the controlled equipment must be known,

or the output terminals of the W7620 can be measured

with an indicating device or meter. The Hardware

Configuration Data table shows all of the possible physical

points with terminal designation and use. The General

Guide for Input/Output Point Testing table can be used

to determine what can be used to provide inputs and

what to use to

value or

In the case of physical output points, the output

measure

digital state, or that a simulated

outputs.

Input Point lest Procedures

1.

Read point value through the S7610 POT or the

ZM7601/ZM7603 software to verify approximate

analog value or digital state. If the data is

acceptable, proceed to the next point.

2.

For analog points that display FA (sensor

next to the

a.

Provide a known measurable value to the input.

b. Compare the input point value displayed on

the POT or ZM7601/ZM7603 software with

the known value.

c.If the difference between the two values

exceeds the acceptable range, isolate the

problem by taking a measurement at the

input

wire), and the W7620.

Example:

The following is the procedure for input

Point 1 (SPACE TEMP).

1.

Measure the

Fahrenheit

thermometer, near the actual sensor.

2.

Verify

ZM76Ol/ZM7603 software

expected temperature.

3.

If the accuracy of the measurement is in question,

measure resistance supplied by the sensor at the

Space Sensor itself to fmd sensed value Terminal

engineering

source, the conductors (e.g., cable,

input

with another source, such as a

that the S7610 POT or the

unit:

space temperature in degrees

value

reads the

failure)

Page 12

or removing connections from Terminals TR

and TR earth-ground.

2. To disable a controller, remove both legs of

I

the AC power. Removing only one leg may

prevent other controllers on the same

transformer from communicating on the

CNAP network.

I

L

The

W7620

Zone Control System must be earth-grounded

W7620

at each cluster of

controllers powered by a single 24 Vac transformer). Use

No. 18 AWG or larger copper conductor

earth-ground, such as a water pipe driven into the earth

or the ground connection found within the power

distribution panel. The power distribution panel must be

earth-grounded per National Electric Codes. Do not “se

or

the ductwork

necessarily provide a good ground. The following

provides

1.

Earth-ground one

W7620s

the wiring conduit since these do not

grounding details:

connected to a given

controllers (one or mote

run

W7620

within a group of

transformer.

W7620

to a known

Connect the

screw on the

ground wire

W7620

chassis. See Figure 7.

to the

green ground

connect the same side of the

transformer secondary to the same terminal

number on each W7620.

2.

Grounded Transformer Secondaries: If the

has

Transformer

necessary

ohm meter to test for conductivity between one

side of the transformer and the suspected

grounding plane (usually the controller chassis).

If one side of the transformer is grounded,

connect

earth-ground

earth-ground).

a grounded

to identify the

the

grounded

connection on the

secondary,

grounded

secondary

it is

side. Use an

to the

W7620 (TR

to connect grounded secondary to

will cause damage to the

Tie each

W7620

(using ground

screw) together in the cluster.

Earth-ground each cluster at some

accessible point that is a good

distribution ground.

Page 13

Electrical Ratings

Supply

Voltage

Current

System

Inputs:

Outputs:

Relay (expansion)

Draw

Resistive

Voltage 0-10 Vdc with 2

Digital

AC

Analog O-IO

Relay (base)

Temperature Ratings

Ambient

20-30

Vac, 50 or 60 HZ

maximum at 30 Vac,

8.5 VA

29104370 ohm (-40 to 265°F temperature range with

platinum sensors)

Vdc

j External contact (switch,

Input

Up to three 24 Vac

from same

separately or together to determine the final state of input.

2.0 amp maximum running, 7.5

60 Hz

1.6 amp maximum

60

40 to 110°F [4 to 44°C]

transformer, All three Inputs

Vdc,

20 mA maximum

Hz

running,

50 or 60 HZ

overrange

relay or

source indicating digital

transistor) Into

can

amp

In-rush at 30 Vac, 50 or

7.5 amp In-rush at 30

15

Vdc,

response to

be used

Vac,

15

call

50 or

5-95%

RH,

noncondensing

any surface using

temperature, and

ctrical,

anchoring screws (not provided

humidity ratings

can

be

Page 14

bl

Knockout for

Q

Double knockout for 1 /2 or 3/4 in. conduit fittings.

l/2

in. conduit fittings.

Figure 8 - W7620 Dimensions

14

63-4224

Page 15

Base Unit

Input

Expansion

(with

cover)

Boards

Damper Actuator

Use with

W7459 Economizer Logic Module,

modulating spring

Page 16

This

digital apparatus

for radio noise

limits

set

out

I”

the Radio

Canadian Department of Communications.

Dear Customer,

welcome

We

this publication.

Your assistance

provide

HONEYWELL MINNEAPOLIS, MN

Australia, Canada, Finland, France, Germany,

your comments

is greatly appreciated and will enable us to

better technical information

does not exceed the

emission

I-

and suggestions

fmm

Regulations Of the apparelIs

for you.

55408

INTERNATIONAL Sales offices I” all

digital apparatus

Canadian EMI

Class A

for Improving

Japan,

Mexico,

Le prdsent apparelI “wn&-lque “&net pas

rad4c&ctiques

le R@lament SW le bmufllege

!aar 18 mlnlstBr@ des Communlcstions du

send your

Please

Honeywell Inc.

Bluewater

8500

Albuquerque. NM 87121-1958

Technical Editor

ATTN:

Netherlands, Spain,

depassant les llmltes appllcables BUX

nutirlques de la

comments

N.W.

principal cities

Taiwan, United Kingdom, U.S.A.

Classe

radl,Mktrlqua

and suggestions

of the

de

btults

A praadtes dens

Bdlctd

Canada.

to:

world. Manufacturing

PRINTED IN U.S.A.

In

Loading...

Loading...