Page 1

Economizer Logic Modules

APPLICATION

W6215, W7215, and W7460 Economizer Logic Modules are

used with an indoor sensor input (ISI), and solid state C7400

Enthalpy Sensors or C7650 Dry Bulb Temperature Sensors.

All models proportion outdoor and return air dampers for

control of free cooling in commercial HVAC equipment. The

W7215B and W7460B are used with an outdoor sensor input

(OSI) along with the ISI.

W6215, W7215, W7460

FOR VENTILATION CONTROL

PRODUCT DATA

FEATURES

• Operates from the space thermostat and an ISI to

provide a totally integrated control system.

• Solid state control package provides accuracy,

reliability and stability.

• Housed in high-impact, glass-fiber reinforced

plastic case.

• Mounts on sheet metal duct or remotely in a

mechanical room. Mounting screws included.

• The W6215 and W7215 are used with Honeywell

Series 62 and Series 72 actuators (respectively).

The W7460 is used with Honeywell M7415 Damper

Actuators.

• Combines minimum and maximum damper position

potentiometers and compressor staging relay

functions with solid state enthalpy or dry bulb

changeover control this control can be tempered

by ISI, and fan cycling.

• Outdoor Sensor input incorporated into logic of

W7215B and W7460B models.

• Shutdown and Air Change can be used with all

models.

• Purge cycling can be used with the W6215A, W7215A

and W7460A models.

• Terminals included for connecting optional S963B1128

Remote Potentiometers for remote minimum and

maximum damper position control.

• LED and relay terminals indicate when free cooling

is available.

• LED indicates when module is in ISI mode.

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Operation .......................................................................... 5

Settings and Adjustments ................................................. 6

Checkout and Troubleshooting ......................................... 26

63- 2544- 3

Page 2

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

SPECIFICATIONS

Models:

See Table 1.

Dimensions: See Fig. 1.

Electrical Ratings:

Input Voltage: 24 Vac +20%, -15%; 50/60 Hz (Class 2).

Nominal Power Consumption (at 24 Vac, 60 Hz):

W6215A: 12.5 VA.

W7215A, W7460A: 10 VA.

W7215B, W7460B: 10.5 VA.

Relay Contact Rating at 30 Vac (maximum power from class 2

input only): 1.5A run, 3.5A inrush.

Ambient Ratings:

Temperature:

Operating Ambient: -25°F to +125°F (-32°C to +52°C).

Shipping: -25°F to +125°F (-32°C to +52°C).

Humidity (Noncondensing): 5 to 95 percent rh.

Inputs:

Enthalpy (C7400): 2-wire (18,20,22 AWG) connection.

Dry Bulb Temperature (C7650): 2-wire (18,20,22 AWG)

connection.

Discharge Air (C7046): 2-wire (18,20,22 AWG) connection.

Mixed Air (C7150): 2-wire (18,20,22 AWG) connection.

Indoor Sensor: 2-10 Vdc control signal.

Outdoor Sensor (W7215B and W7460B only): 2-10 Vdc

control signal.

Outputs:

W7215: 2-10 Vdc.

W6215: Series 62 (Open/Close/Hold).

24 Vac out (W7215, W6215 only): 25 VA maximum.

Accessories:

32004783-001 Weather Shield Economizers.

4074EJM Bag Assembly. Consists of: Checkout jumper,

620 ohm, 1.2K ohm, 5.6K ohm, and 6.8K ohm checkout

resistors, and 536 ohm, 665 ohm, and 3480 ohm resistors

for use with Honeywell Series 90 Actuators.

C7046A Discharge Air Temperature Sensor.

C7150B Mixed Air Temperature Sensor.

C7400 Solid State Enthalpy Sensor.

C7650 Dry Bulb Temperature Sensor.

S963B1128 Remote Potentiometer to provide remote control

of damper minimum or maximum position.

ST6008 Energy Management Timer for occupied/unoccupied

control.

Approvals:

Underwriters Laboratories Inc. listed: Meets UL873

plenum requirements.

3/4 (19)

1

(25)

24VAC

TR Hot

BC

A

Maximum

Position

Open

Free Cool

Mininum

Position

Closed

6

2

ISI

Set Pt

ISI

50%

0%

Exhaust

Set Pt

Exhaust

100%

TR1

Com

+

D

So

+

Sr

5

1

2

3

4

T

T1

P

Q

AQ

+

AQ1

10

SD

SD1

AC

AC1

PC

PC1

8-5/8

P1

(219)

Q1

–

1

(25)

1-9/16

(40)

+

–

24VAC

Hot

24VAC

Com

2-10V

OUT

Free

Cool

Unit

Control

Exhaust

Fan

Indoor

Fan

W7215A

5-3/4 (146)

Fig. 1. W6215,W7215,W7460 dimensions

in in. (mm). [W7215A shown]

M11788A

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2544—3 2

Page 3

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

0

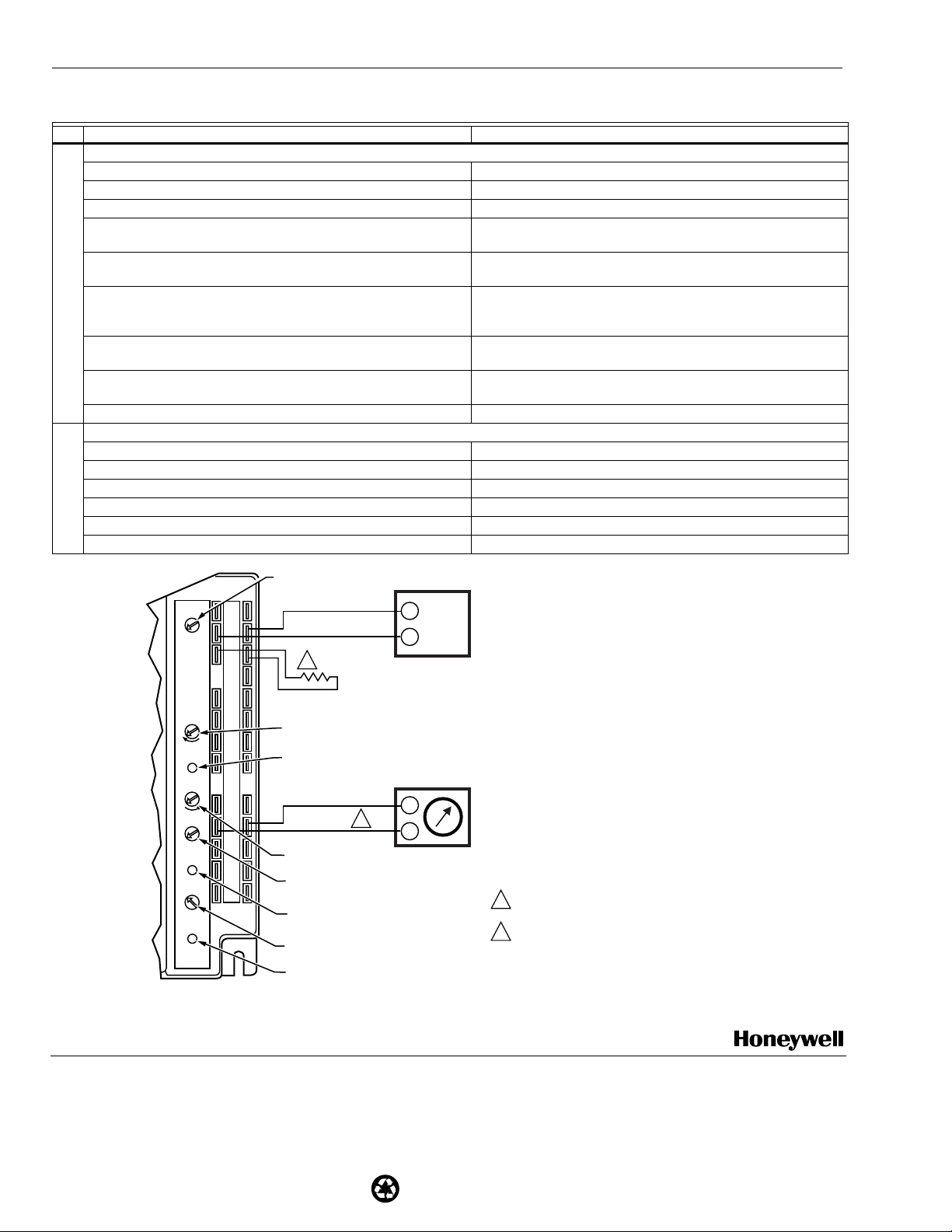

Table 1. W6215, W7215, and W7460 Economizer Models.

For Use

Model

W6215A Honeywell Series 62 C7150B or C7046A Sensor No Adjustable Yes

W7215A Honeywell Series 72 C7150B or C7046A Sensor No Adjustable Yes

W7215B Honeywell Series 72 C7150B or C7046A Sensor Yes Fixed No

W7460A Honeywell M7415 C7150B or C7046A Sensor No Adjustable Yes

W7460B Honeywell M7415 C7150B or C7046A Sensor Yes Fixed No

NOTE: All models include minimum and maximum position potentiometers, setpoint for enthalpy or dry-bulb, and ISI setpoint.

with Actuator

Discharge Air

Temperature Input

Outdoor Sensor

Input (OSI) Setpoint

Exhaust

Fan Setpoint Purge

INSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

Location and Mounting

All wiring must agree with applicable codes,

ordinances and regulations.

OUTDOOR AIR SENSING

1.

Mount sensor in any orientation that exposes it to freely

circulating air and protects it from rain, snow, and direct

sunlight.

2. Connect it to the S

RETURN AIR SENSING

1.

Ensure differential enthalpy control has a second

sensor in the return air duct.

2. Connect this sensor to the S

W6215, W7215, or W7460.

and + terminals of the device.

O

and + terminals of the

R

W6210 A 1003

W6215, W7215, W7460 Economizer Logic Module

W6215, W7215, and W7460 Logic Modules mount directly on

a sheet metal duct or panel. When planning the installation,

allow enough clearance for maintenance and service. Mount

device in a location protected from rain, snow, and direct

sunlight. Secure device to sheet metal using the three supplied

mounting screws, see Fig. 2.

NOTE: See Fig. 3 for representative locations of connected

system devices.

C7400 Enthalpy Sensor and

C7650 Dry Bulb Temperature Sensor

W6215,W7215,W7460 Logic Modules accept signals from

either the C7400 Enthalpy Sensor or the C7650 Dry Bulb

Temperature Sensor. The wiring is the same for either sensor.

IMPORTANT

When using differential sensing, both sensors must

be of the same type (enthalpy or dry bulb).

M1179

Fig. 2. Mounting W6215, W7215, W7460 on sheet metal.

Indoor Sensor Input

The ISI can be any sensor that provides a 2-10 Vdc output.

The ISI modulates the outdoor damper to provide ventilation

based on occupancy. The designer determines contaminants

to monitor, selects appropriate sensor, determines the sensor

threshold, and adjusts the ISI potentiometer accordingly. The

ISI LED lights when the ISI signal is above setpoint. Mount the

sensor according to the manufacturer specifications. If not

available, use the following guidelines:

1. Mount sensor in an area with unobstructed air circulation.

2. Connect it to the AQ

W7215, or W7460 (see Wiring section for details).

3. Adjust the ISI potentiometer setpoint to correspond to

ISI voltage output at the threshold.

IMPORTANT

Ensure proper polarity of sensor connections.

Incorrect polarity negates the sensor signal.

3 63-2544—3

and AQ1 terminals of the W6215,

Page 4

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

Outdoor Sensor Input (W7215B and W7460B only)

The OSI sensor can be any sensor that provides a 2-10 Vdc

output. Mount the sensor according to the manufacturer

specifications. If not available, use the following guidelines:

1. Mount sensor in an area with unobstructed air circulation

that is protected from rain, snow, and direct sunlight.

DISCHARGE

AIR SENSOR

INDOOR

FAN

DIRECT

EXPANSION

COIL

W6215,

W7215,

OR

W7460

C7046A

DISCHARGE

AIR

2

C7150B

MIXED AIR

SENSOR

C7400

ENTHALPY

SENSOR

IMPORTANT

Ensure proper polarity of sensor connections.

Incorrect polarity negates the sensor signal.

2. Connect it to the OA

or W7460B (see Wiring section for details).

and OA1 terminals of the W7215B,

3. Adjust the OSI potentiometer setpoint to correspond to

OSI sensor voltage output at the threshold.

SPACE

2

SERIES

62 OR 72

ACTUATOR

1

THERMOSTAT

1

C7400

OUTDOOR

AIR

SENSOR

INDOOR

AIR

SENSOR

ENTHALPY

SENSOR

OUTDOOR

AIR

FOR DIFFERENTIAL ENTHALPY, THE TWO C7400

1

ENTHALPY SENSORS ARE CONNECTED TO THE

W6215/W7215/W7460 ECONOMIZER CONTROL—ONE

IS MOUNTED IN RETURN AIR, AND THE OTHER IS

MOUNTED IN OUTDOOR AIR. DIFFERENTIAL

ENTHALPY CONTROL PROVIDES GREATER

ENERGY SAVINGS THAN SINGLE ENTHALPY.

2

USE EITHER MIXED AIR SENSOR OR DISCHARGE

AIR SENSOR, NOT BOTH.

Fig. 3. Representative locations of connected Economizer system devices.

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

1. All wiring must comply with applicable local codes,

ordinances and regulations.

2. Refer to Fig. 6 through 25 for typical wiring diagrams.

3. Refer to Table 2 for a list of the wiring diagrams and

corresponding Figure numbers in this document.

4. All device inputs and outputs must be 24 Vac Class 2.

NOTE: All connections with label designation ending in 1

(examples: TR1, T1, P1, Q1, AQ1) are ac/dc

common connections.

EXHAUST

FAN

RETURN AIR

EXHAUST AIR

M11816

Optional Applications

Remote Minimum Position Control

Remote control of outdoor air dampers is desirable when

requiring temporary additional ventilation. One potentiometer

controls the damper minimum position, another potentiometer

controls the damper maximum position. The addition of

S963B1128 Remote Potentiometers allows occupants to open

or close the dampers beyond minimum position for modified

ventilation. Connect the potentiometers as shown in Fig. 4.

IMPORTANT

Free Cool Timing

The Free Cool contacts close while the logic module operates

free cooling. Connecting a timer to these contacts allows

tracking of the free cooling usage time.

The minimum position signal takes priority to the

maximum position signal. With the maximum set

below the minimum, the logic module signals the

actuator to maintain the minimum position.

63-2544—3 4

Page 5

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

Table 2. Applicable Wiring Diagrams.

Logic Module Actuator Enthalpy Changeover Figure Comments

W6215A Honeywell Series 62 Single 8 Single-stage cooling system.

Single or Differential 9 Two-stage cooling system.

W7215A Honeywell Series 72 Single 10 Single-stage cooling system.

Single or Differential 11 Two-stage cooling system.

12 T775 controller.

Honeywell Series 90 n/a 6 Add Q7230 Interface Module.

W7215B Honeywell Series 72 Single 13 Single-stage cooling system.

Single or Differential 14 Two-stage cooling system.

15 T775 controller.

W7460A Honeywell M7415 Single 16 Single-stage cooling system.

Single or Differential 17 Two-stage cooling system.

W7460B Honeywell M7415 Single 18 Single-stage cooling system.

Single or Differential 19 Two-stage cooling system.

ALL n/a n/a 20 W7100 controller.

25 W973 Logic Panel.

4 S963 remote damper control.

Parallel Wiring

W6215 Honeywell Series 62 Single or Differential 21 Honeywell Series 62 Direct Coupled Actuators.

W7215A Honeywell Series 72 22 Honeywell Series 72 Direct Coupled Actuators.

23 Honeywell Series 72 Modutrol Motors.

Honeywell M7415 24 M7415 Motors.

OPERATION

The purpose of the economizer is to use outdoor air for

cooling, whenever possible, to reduce compressor operation.

When wired as shown in Fig. 6 through 25, the logic module

responds to the cooling thermostat signal. This system

uses C7400 Solid State Enthalpy Changeover Sensor(s) or

C7650 Dry Bulb Temperature Sensor(s). The C7400 responds

to both dry bulb temperature and humidity, allowing use of

outdoor air at higher temperatures for free cooling when

humidity is low. The C7650 responds only to dry bulb

temperature; use only in dry, arid climates.

The logic module functions as a true first stage of cooling

providing maximum fuel economy during the cooling cycle.

It automatically locks out free cooling during heating; holding

the outdoor air damper at the minimum position setting.

The logic module can operate as either a basic free cooling

controller, or it can incorporate additional functions. Tables 3

and 5 detail the input/output (I/O) logic of the module. Certain

functions—Purge, Shutdown, and Air Change—override

others, see Table 3. When these functions are all off, the logic

module energizes the Unit Control and Indoor Fan contacts,

operating according to Table 5.

Purge (W6215A, W7215A, and W7460A only)

When terminals PG and PG1 connect through relay contacts

or a jumper:

1. Outdoor damper drives fully closed.

2.

Exhaust fan turns on.

S963B1128 REMOTE

OPEN

MINIMUM

POSITION

ADJUSTMENT

CW

MAXIMUM

POSITION

ADJUSTMENT

CW

W6215/W7215/W7460 ECONOMIZER

P1

P

Q1

Q

Fig. 4. S963B1128 Remote Potentiometer used with

W6215, W7215, W7460 for remote damper control.

POTENTIOMETER

R

CCW

OPEN

135 OHM

S963B1128 REMOTE

POTENTIOMETER

CCW

OPEN

135 OHM

CW

CLOSE

R

CW

CLOSE

M11796A

WB

WB

5 63-2544—3

Page 6

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

Table 3. W6215, W7215, W7460 Economizer Purge,

Shutdown, and Air Change I/O Logic.

INPUTS OUTPUTS

Purge

Shut-

a

down

Air

Change Damper

Unit

Control

Indoor

Fan Exhaust

On - - Fully Closed Off Off On

Off On - Off

Off On Fully Open On On

a

Purge present only on W6215A, W7215A, and W7460A.

Shutdown

One contact closure shuts down all systems. When terminals

SD and SD1 connect through relay contacts or a jumper:

1.

Outdoor damper drives fully closed.

2.

Exhaust fan turns off.

3. Indoor fan turns off.

Air Change

When terminals AC and AC1 connect through relay contacts

or a jumper:

1. Outdoor damper drives fully open.

2. Exhaust fan turns on.

3. Indoor fan turns on.

NOTE: With Purge, Shutdown, and Air Change de-

energized, Exhaust will be de-energized unless the

signal exceeds the exhaust fan setpoint; other logic

module functions remain unaltered.

SETTINGS AND ADJUSTMENTS

Potentiometers with screwdriver adjustment slots, located on

the device face, provide adjustments for several parameters

(see Fig. 5 for locations on device):

— ISI setpoint.

— OSI setpoint (W7215B and W7460B only).

— Minimum damper position.

— Maximum damper position.

— Enthalpy changeover.

— Exhaust setpoint (W6215A, W7215A and W7460A only).

Indoor Sensor Input Setpoint

The logic module modulates the outdoor damper to provide

ventilation based on the 2-10 Vdc ISI. With no cooling signal,

the ISI overrides the outdoor air damper when ventilation

requires outdoor air.

Outdoor Sensor Input Setpoint (W7215B and W7460B only)

The OSI logic operates from a 2-10 Vdc sensor signal. The

operation of these logic modules is slightly different from the

other models, see Table 4.

Table 4. W7215B and W7460B OSI Operation.

OSI ISI Actuator OSI LED Alarm

Below set Below set

Above set

Modulates

Modulates

Modulates

Above set Below set Fully closed On Off

Above set

a

Modulation based on signal from mixed air sensor.

b

With ISI signal greater than mixed air sensor signal:

Modulates

Modulation, based on ISI signal, between minimum and

maximum positions.

c

With ISI signal less than mixed air sensor signal:

Modulation, based on mixed air sensor signal, between:

M7215B: Minimum and full open positions

M7460B: Minimum and maximum positions.

d

Modulation based on mixed air sensor signal;

connect to energize warning light, audio alarm, or air cleaner.

a

Off Off

b

c

d

On On

Alarm

terminals

Table 5. W6215, W7215, W7460 Economizer I/O Logic.

INPUTS OUTPUTS

a

Y1

b

Y2

b

Damper

Compressor

On Off On Off

Modulating

c

On Off

ISI

Below set

(ISI LED Off)

Enthalpy

Outdoor Return 1 2

High (Free Cooling LED Off) Low On On Minimum position On On

Low (Free Cooling LED On) High On On

On Off Off Off

Above set

(ISI LED On)

High (Free Cooling LED Off) Low On On

On Off On Off

Low (Free Cooling LED On) High On On

Modulating

Modulating

d

e

On On

On Off

On Off Off Off

a

For single enthalpy control, the module compares outdoor enthalpy to the ABCD setpoint.

b

If both stages of cooling are off, the system is off and the damper is at: • Minimum position if ISI is below setpoint.

c

W6215, W7460: Modulation, based on the mixed air sensor signal, between minimum and maximum positions.

W7215: Modulation, based on the mixed air sensor signal, between minimum and full-open positions.

d

Modulation, based on the ISI, between minimum and maximum positions.

e

Modulation, based on the greater of ISI and mixed air sensor signals, between minimum and either maximum position (ISI) or

• Modulating if ISI is above setpoint.

fully open (mixed air signal).

NOTE: Each sensor has it’s own setpoint for threshold and LED indication.

63-2544—3 6

Page 7

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

T

24VAC

24VAC

Hot

24VAC

Com

+

2-10V

OUT

–

Free

Cool

Unit

Control

Exhaust

Fan

Indoor

Fan

LED LIGHTS WHEN EXHAUST IS ON

W7215A

TR Hot

BC

A

Mininum

Position

Open

Free Cool

Maximum

Position

Closed

2

ISI

Set Pt

ISI

50%

0%

Exhaust

Set Pt

Exhaust

TR1

Com

+

D

So

+

Sr

5

1

2

3

4

T

T1

P

P1

Q

Q1

AQ

6

+

AQ1

–

Q

10

SD

SD1

AC

AC1

Q

PG

PG1

Q

100%

Fig. 5. Potentiometer and LED locations.

ENTHALPY

CHANGEOVER

SETPOINT

MINIMUM

DAMPER

POSITION

SETTING

LED LIGHTS

WHEN

OUTDOOR

AIR IS

SUITABLE

FOR FREE

COOLING

MAXIMUM

DAMPER

POSITION

SETTING

INDOOR AIR

SENSOR

SETPOINT

LED LIGHTS

WHEN INDOOR

SENSOR INPU

IS ABOVE

SETPOINT

EXHAUST

FAN

SETPOINT

M11787A

NOTE: Make minimum position adjustments with at least a

10°F [6°C] temperature difference between outdoor

and return air.

1. Calculate the appropriate mixed air temperature, see

Equation 1.

2. Disconnect mixed air sensor from terminals T and T1.

3. Ensure that either the factory-installed jumper is in

place across terminals P and P1 or, of remote damper

position is required, that it is wired according to Fig. 4

and turned fully clockwise.

4.

Connect 24 Vac across terminals TR and TR1.

5. Carefully adjust the potentiometer on the face of the

device with a small screwdriver until the mixed air

temperature reaches the calculated value.

NOTE: Ensure that the sensed air is well mixed.

Equation 1. Formula to aid in minimum position

adjustment.

TOOA×()TRRA×()+ TM=

Where:

TO = Outdoor air temperature

OA = Percent of outdoor air

= Return air temperature

T

R

RA = Percent of return air

= Resulting mixed air temperature

T

M

IMPORTANT

This procedure requires use of a quality thermometer

capable of reading to 0.5°F [0.25°C].

Adjusting Minimum and Maximum Positions

The minimum position potentiometer maintains the minimum

outdoor air flow into the building during occupied period. The

maximum position potentiometer allows the installer to limit

the amount of outdoor air flow into the building, when the ISI

overrides the mixed air sensor. Setting the maximum position

of the damper prevents the introduction of large amounts of

hot or cold air into the space.

IMPORTANT

NOTES:

Minimum Position Adjustment

For detailed assistance in minimum position selection

reference the Economizer Application Guide (form 63-8594)

Ventilation section. The following provides basic guidelines for

minimum position selection and adjustment:

IMPORTANT

With the maximum position set below the minimum

position, the minimum position overrides the

maximum position (negating most functions of the

logic module, as the damper cannot move).

— When the mixed air sensor takes control, it

overrides the maximum position potentiometer.

— If mixed air temperature drops to 40°F, the mixed

air sensor overrides the ISI and closes the damper

to minimum position to protect from freezing the

hot or chilled water coils. Control returns to normal

once the mixed air temperature rises to 43°F.

Adjust the minimum position potentiometer to allow

the minimum amount of outdoor air, as required by

local codes, to enter the building.

NOTE: The following sample calculation uses only

Fahrenheit temperature.

EXAMPLE: Assume local codes require 10% outdoor air

during occupied conditions, outdoor air is 60°F

and return air is 75°F. Under these conditions,

what is the temperature of the mixed air?

0.1 60°F×()0.9 75°F×()+ 6.0°F 67.5°F+ 73.5°F==

Mixed air will be 73.5°F when OA is 60°F and RA is 75°F with

10 percent outdoor air entering the building.

Maximum Position Adjustment

1. Disconnect mixed air sensor from terminals T and T1

and short terminals T and T1.

2. Make sure either the factory-installed jumper is in place

across terminals Q and Q1 or, if remote damper position

is required, that it is wired according to Fig. 4 and turned

fully clockwise.

3. Connect 24 Vac across terminals TR and TR1.

4. Adjust the potentiometer on the face of the device with a

screwdriver for desired maximum position.

Enthalpy Changeover

Outdoor Enthalpy Changeover Setpoint

The outdoor enthalpy changeover setpoint returns the outdoor

air damper to minimum position when enthalpy rises above its

setpoint. Enthalpy setpoint scale markings, located in the

device, are A, B, C, and D. See Fig. 7 for the corresponding

control point. The factory-installed 620-ohm jumper must be in

place across terminals S

and +.

R

7 63-2544—3

Page 8

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

85

100

105

110

)

0

)

Differential Enthalpy Changeover Setting

Differential enthalpy control uses two C7400 Enthalpy

Sensors connected to one logic module. The logic module

compares outdoor air to return air instead of to a setpoint as it

does for single enthalpy. Turn the setpoint potentiometer fully

clockwise to the D setting. The logic module selects the lower

enthalpy air (return or outdoor) for cooling; for example, when

outdoor air has lower enthalpy than return air, the outdoor air

damper opens to bring in outdoor air for free cooling.

Exhaust Setpoint

Except for Purge, Shutdown, and Air Change, the exhaust

setpoint determines when the exhaust fan runs based on the

damper position. When the ISI call for exhaust comes, the

module provides a 45 ±15 second delay before exhaust fan

activation. This delay allows the damper to reach the

appropriate position to avoid unnecessary fan overload.

Adjustable Exhaust Setpoint (W6215A, W7215A, and W7460A only)

The W6215A, W7215A, and W7460A Logic Modules have an

adjustable setpoint. This potentiometer allows the installer to

set the exhaust setpoint at an actual damper position

percentage open from fully closed.

Fixed Exhaust Setpoint (W7215B and W7460B)

The W7215B and W7460B Logic Modules have a fixed

exhaust setpoint. The logic module uses an exhaust setpoint

of 60 percent. When the damper reaches 60 percent open

(from fully closed), the logic module calls for exhaust.

W7215A

HONEYWELL

SERIES 90

ACTUATOR

(ML9175,

ML9185,

M9175,

M9185)

1

M11903A

W

R

1

B

USE 1/2 WATT, 1% RESISTORS OF

SPECIFIED OHM RATINGS (INCLUDED

IN 4074EJM RESISTOR KIT). FOR

MOD IV MOTORS, THE Q7230 MODULE

CAN REPLACE THE RESISTORS.

665

Ohms

3480

Ohms

536

Ohms

Fig. 6. W7215A used with Honeywell Series 90 Actuator.

24 VAC HOT

24 VAC COM

+

2-10V

OUT

–

TR

TR1

CONTROL

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46

CURVE

A

B

C

D

CONTROL POINT

APPROX. °F (°C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

ENTHALPY—BTU PER POUND DRY AIR

60

(16)

55

(13)

B

50

C

(10)

45

D

(7)

40

(4)

35

(2)

75

(24)

70

(21)

100

90

65

(18)

80

70

A

80

(27)

60

50

(29)90(32)95(35)

RELATIVE HUMIDITY (%)

40

30

(38)

20

(41)

(43

10

35

40

45

50

(2)

(4)

(7)

(10)

55

(13)

APPROXIMATE DRY BULB TEMPERATURE—°F (°C)

Fig. 7. W6215, W7210, and W7460/C7400 performance characteristics for enthalpy changeover settings.

63-2544—3 8

60

(16)

65

(18)

70

(21)

A

B

C

D

105

75

80

(24)

85

(27)

(29)90(32)95(35)

100

(38)

(41)

(43

M11806

11

Page 9

HONEYWELL

SERIES 62

ACTUATOR

(ML6275,

ML6285,

M6275,

M6285)

24 VAC HOT

24 VAC COM

CLOSE

OPEN

W6215A

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

TR1

TR

C7400

OUTDOOR

+

S

O

+

S

R

620 OHM

RESISTOR

5

6

9

+

AIR

ENTHALPY

S

SENSOR

500 OHM

W2

1S

OPEN

WIPER

CLOSED

5

Y1

Y2

4

1S1

MINIMUM POSITION

ADJUSTMENT

MAXIMUM

FREE

POSITION

COOL

ADJUSTMENT

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

T6031 AMBIENT

W

LOCKOUT

CONTROL

R

50 F SETPOINT

1K

2K

1

3

T

P

Q

AQ

SD

AC

PG

2

4

T1

P1

Q1

AQ1

SD1

AC1

PG1

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

2-10 VDC

INDOOR AIR

SENSOR

+

SHUT DOWN

AIR CHANGE

PURGE

Y1

W2

9

8

UNOCCUPIED

ST6008

TIMER

OCCUPIED

C

COOL 1

HEAT 2

2

HEAT 1

FAN

DELAY

RELAY

FAN

M11803A

3

L2

L1

(HOT)

1

W1

G

RH

RC

7

X

T7300 OR T874

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA

LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

4

BY A 24 VAC INPUT.

5

THE COMMON FOR THE W6215A IS DIFFERENT THAN THE

COMMON (WIPER) FOR THE SERIES 62 ACTUATORS. BE SURE

TO CONNECT EACH TO A DIFFERENT CIRCUIT.

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD NOT BE

REMOVED. DIFFERENTIAL ENTHALPY NOT RECOMMENDED FOR USE

WITH SINGLE-STAGE COOLING SYSTEMS OR SINGLE-STAGE COOLING

THERMOSTATS.

7

FOR T7300 ONLY.

8

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

9

FOR TWO-STAGE THERMOSTATS ONLY.

Fig. 8. W6215A used in single-stage cooling system with single enthalpy changeover and Honeywell Series 62 Actuator.

9 63-2544—3

Page 10

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W6215A

HONEYWELL

SERIES 62

ACTUATOR

(ML6275,

ML6285,

M6275,

M6285)

24 VAC HOT

24 VAC COM

CLOSE

OPEN

TR1

TR

C7400

OUTDOOR

+

S

O

+

S

R

620 OHM

RESISTOR

5

6

+

AIR

ENTHALPY

S

SENSOR

500 OHM

Y1

Y2

1S

OPEN

WIPER

CLOSED

5

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

1K

2K

1

3

T

P

Q

AQ

SD

AC

PG

2

4

T1

P1

Q1

AQ1

SD1

AC1

PG1

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

T6031 AMBIENT

LOCKOUT

CONTROL

50 F SETPOINT

2-10 VDC

INDOOR AIR

+

SENSOR

SHUT DOWN

AIR CHANGE

PURGE

C

Y1

Y2

W

R

COOL 1

COOL 2

UNOCCUPIED

8

ST6008

TIMER

OCCUPIED

W2

W1

G

RH

RC

7

1

2

3

4

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA

LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Fig. 9. W6215A used in two-stage cooling system with a Honeywell Series 62 Actuator.

63-2544—3 10

2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

3

L2

L1

(HOT)

1

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

THE COMMON FOR THE W6215A IS DIFFERENT THAN THE COMMON

(WIPER) FOR THE SERIES 62 ACTUATORS. BE SURE TO CONNECT EACH

TO A DIFFERENT CIRCUIT.

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

6

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

7

FOR T7300 ONLY.

8

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

M11800A

Page 11

HONEYWELL

SERIES 72

ACTUATOR

(ML7275,

ML7285,

ML7295A,C

M7275,

M7285)

W7215A

24 VAC HOT

24 VAC COM

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

TR1

TR

C7400

OUTDOOR

+

S

O

+

S

R

620 OHM

RESISTOR

5

6

9

+

AIR

ENTHALPY

S

SENSOR

W2

1S

+

+

2-10 VDC

OUT

––

5

Y1

Y2

W

R

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

T6031 AMBIENT

LOCKOUT

CONTROL

50° F SETPOINT

1K

2K

1

Q

AQ

SD

AC

PG

2

4

3

C7150B MIXED

T1

T

P1

P

Q1

AQ1

SD1

AC1

PG1

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

+

AIR SENSOR

SHUT DOWN

AIR CHANGE

PURGE

C

Y1

W2

9

COOL 1

HEAT 2

8

ST6008

TIMER

UNOCCUPIED

OCCUPIED

2

HEAT 1

FAN

DELAY

RELAY

FAN

3

L2

L1

(HOT)

M11804A

1

W1

G

RH

RC

7

1

2

3

4

5

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA

LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

FOR THE ML7295A,C, USE THE 4-20mA MODEL ACTUATOR. THESE

MODELS HAVE 500 OHM INPUT IMPEDENCE THAT ALLOWS THE

ACTUATOR TO ACCEPT A 2-10 VDC SIGNAL.

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD NOT BE

REMOVED. DIFFERENTIAL ENTHALPY NOT RECOMMENDED FOR USE

WITH SINGLE-STAGE COOLING SYSTEMS OR SINGLE-STAGE COOLING

THERMOSTATS.

7

FOR T7300 ONLY.

8

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

9

FOR TWO-STAGE THERMOSTATS ONLY.

Fig. 10. W7215A used in single-stage cooling system with single enthalpy changeover and Honeywell Series 72 Actuator.

11 63-2544—3

Page 12

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W7215A

HONEYWELL

SERIES 72

ACTUATOR

(ML7275,

ML7285,

ML7295A,C

M7275,

M7285)

24 VAC HOT

24 VAC COM

TR1

TR

C7400

OUTDOOR

S

+

O

S

R

620 OHM

+

RESISTOR

5

6

+

AIR

ENTHALPY

S

SENSOR

1S

+

–

5

Y1

Y2

+

2-10V

OUT

–

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

1K

2K

1

T

Q

AQ

SD

AC

PG

2

4

3

T1

P1

P

Q1

AQ1

SD1

AC1

PG1

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

T6031 AMBIENT

LOCKOUT

CONTROL

50° F SETPOINT

2-10 VDC

–

INDOOR

+

AIR SENSOR

SHUT DOWN

AIR CHANGE

PURGE

C

Y1

Y2

W

R

UNOCCUPIED

ST6008

TIMER

COOL 1

COOL 2

OCCUPIED

8

W2

W1

G

RH

RC

7

1

2

3

4

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA

LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Fig. 11. W7215A used in two-stage cooling system with Honeywell Series 72 Actuator.

63-2544—3 12

2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

3

L2

L1

(HOT)

1

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

FOR THE ML7295A,C, USE THE 4-20 mA MODEL ACTUATOR. THESE

MODELS HAVE 500 OHM INPUT IMPEDENCE THAT ALLOWS THE

ACTUATOR TO ACCEPT A 2-10 VDC SIGNAL.

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

7

FOR T7300 ONLY.

8

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

M11801A

Page 13

HONEYWELL

SERIES 72

ACTUATOR

(ML7275,

ML7285,

ML7295A,C

M7275,

M7285)

24 VAC HOT

24 VAC COM

W7215A

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

TR1

TR

C7400

S

+

S

O

+

S

R

620 OHM

RESISTOR

5

6

OUTDOOR

AIR

ENTHALPY

+

SENSOR

1S

4

7

NC

COM

NO

+

2-10V

OUT

–

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

1S1

MAXIMUM

POSITION

ADJUSTMENT

+

–

5

T775 THERMOSTAT

NC

COM

NO

NO

COM

NC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

ENSURE THAT EQUIPMENT TRANSFORMER IS SIZED TO HANDLE

THE EXTRA LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

4

BY A 24 VAC INPUT.

1K

2K

W

T6031 AMBIENT

LOCKOUT

R

CONTROL

50° F SETPOINT

2

1

4

3

C7150B MIXED

T1

T

P1

P

Q1

Q

AQ

AQ1

SD

SD1

AC

AC1

PG

PG1

5

FOR THE ML7295A,C, USE THE 4-20 MA MODEL ACTUATOR. THESE MODELS

HAVE 500 OHM INPUT IMPEDENCE THAT ALLOWS THE ACTUATOR TO ACCEPT

A 2-10 VDC SIGNAL.

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

T775 REQUIRES A MINIMUM OF THREE RELAY OUTPUTS: TWO FOR COOLING

7

AND ONE FOR FAN CONTROL. A MAXIMUM ONE STAGE OF HEATING IS

POSSIBLE WHEN THE SYSTEM IS WIRED IN THIS FASHION.

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

PURGE

C

Y1

Y2

G

R

HVAC EQUIPMENT

TERMINAL STRIP

COOL 1

COOL 2

2

FAN

UNOCCUPIED

ST6008

TIMER

OCCUPIED

L2

L1

(HOT)

M11792A

3

1

Fig. 12. W7215A used with T775 Controller and Honeywell Series 72 Actuator.

13 63-2544—3

Page 14

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W7215B

HONEYWELL

SERIES 72

ACTUATOR

(ML7275,

ML7285,

ML7295A,C

M7275,

M7285)

+

5

24 VAC HOT

24 VAC COM

1S

4

+

2-10 VDC

OUT

––

FREE

COOL

ALARM

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

1S1

MINIMUM POSITION

ADJUSTMENT

MAXIMUM

POSITION

ADJUSTMENT

1K

2K

Q

AQ

SD

AC

OA

TR

S

O

S

R

1

3

T

P

Q1

AQ1

SD1

AC1

OA1

TR1

+

+

5

2

4

T1

P1

620 OHM

RESISTOR

6

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

–

2-10 VDC

OUTDOOR

AIR SENSOR

+

+

S

9

C7400

OUTDOOR

AIR

ENTHALPY

SENSOR

9

T6031 AMBIENT

Y1

Y2

W2

W1

G

RH

RC

7

1

2

3

4

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA

LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

W

LOCKOUT

CONTROL

50° F SETPOINT

R

C

ST6008

TIMER

UNOCCUPIED

OCCUPIED

M11812A

2

COOL 1

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

Y1

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

FOR THE ML7295A,C, USE THE 4-20 mA MODEL ACTUATOR. THESE MODELS

HAVE 500 OHM INPUT IMPEDENCE THAT ALLOWS THE ACTUATOR TO

ACCEPT A 2-10 VDC SIGNAL.

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD NOT BE

REMOVED. DIFFERENTIAL ENTHALPY NOT RECOMMENDED FOR USE

WITH SINGLE-STAGE COOLING SYSTEMS OR SINGLE-STAGE COOLING

THERMOSTATS.

7

FOR T7300 ONLY.

8

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

9

FOR TWO-STAGE THERMOSTATS ONLY.

3

L2

L1

(HOT)

8

1

Fig. 13. W7215B used in single-stage cooling system with single enthalpy changeover and Honeywell Series 72 Actuator.

63-2544—3 14

Page 15

HONEYWELL

SERIES 72

ACTUATOR

(ML7275,

ML7285,

ML7295A,C

M7275,

M7285)

W7215B

24 VAC HOT

24 VAC COM

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

TR1

TR

C7400

+

S

+

O

+

S

R

620 OHM

RESISTOR

5

6

OUTDOOR

AIR

ENTHALPY

S

SENSOR

1S

+

–

5

Y1

Y2

+

2-10V

OUT

–

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

ALARM

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

1K

2K

Q

AQ

SD

AC

OA

1

3

T

P

Q1

AQ1

SD1

AC1

OA1

2

4

T1

P1

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

T6031 AMBIENT

50° F SETPOINT

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

–

2-10 VDC

OUTDOOR

+

AIR SENSOR

C

Y1

Y2

LOCKOUT

CONTROL

W

R

COOL 1

COOL 2

ST6008

TIMER

8

UNOCCUPIED

OCCUPIED

W2

W1

G

RH

RC

7

X

T7300 OR T874

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA

LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

4

BY A 24 VAC INPUT.

Fig. 14. W7215B used in two-stage cooling system with Honeywell Series 72 Actuator.

2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

3

L2

1

L1

(HOT)

M11810A

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

FOR THE ML7295A,C, USE THE 4-20 mA MODEL ACTUATOR. THESE MODELS

HAVE 500 OHM INPUT IMPEDENCE THAT ALLOWS THE ACTUATOR TO

ACCEPT A 2-10 VDC SIGNAL.

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

7

FOR T7300 ONLY.

8

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

15 63-2544—3

Page 16

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W7215B

POSSIBLE WHEN THE SYSTEM IS WIRED IN THIS FASHION.

HONEYWELL

SERIES 72

ACTUATOR

(ML7275,

ML7285,

ML7295A,C

M7275,

M7285)

+

–

5

24 VAC HOT

24 VAC COM

+

2-10V

OUT

–

1S

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

ALARM

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

TR1

TR

C7400

OUTDOOR

+

S

O

+

S

R

1K

1

3

2K

T

P

Q

Q1

AQ1

AQ

SD

SD1

AC

AC1

OA

OA1

620 OHM

RESISTOR

5

2

4

T1

P1

6

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

–

2-10 VDC

OUTDOOR

AIR SENSOR

+

+

AIR

ENTHALPY

S

SENSOR

T775 THERMOSTAT

NC

COM

NO

NO

COM

NC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

ENSURE THAT EQUIPMENT TRANSFORMER IS SIZED TO HANDLE

THE EXTRA LOAD OF THE ECONOMIZER AND ACTUATOR.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

4

BY A 24 VAC INPUT.

7

NC

COM

NO

Fig. 15. W7215B used with T775 Controller and Honeywell Series 72 Actuator.

C

Y1

T6031 AMBIENT

W

LOCKOUT

CONTROL

50° F SETPOINT

R

5

FOR THE ML7295A,C, USE THE 4-20 mA MODEL ACTUATOR. THESE MODELS

HAVE 500 OHM INPUT IMPEDENCE THAT ALLOWS THE ACTUATOR TO ACCEPT

A 2-10 VDC SIGNAL.

6

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

7

T775 REQUIRES A MINIMUM OF THREE RELAY OUTPUTS: TWO FOR COOLING

AND ONE FOR FAN CONTROL. A MAXIMUM OF ONE STAGE HEATING IS

Y2

G

R

HVAC EQUIPMENT

TERMINAL STRIP

COOL 1

COOL 2

2

FAN

ST6008

TIMER

UNOCCUPIED

OCCUPIED

3

L2

1

L1

(HOT)

M11815A

63-2544—3 16

Page 17

W7460A

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

TR1

TR

C7400

+

S

+

O

+

S

R

620 OHM

RESISTOR

5

4

OUTDOOR

AIR

ENTHALPY

S

SENSOR

7

M7415

TR1

L2

P1

TR

L1

(HOT)

Y1

Y2

W2

1S

4

3

+

M7415

OUT

P

1

–

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

T6031 AMBIENT

W

LOCKOUT

CONTROL

50° F SETPOINT

R

1K

2K

PG

1

T

P

Q

AQ

SD

AC

2

4

3

T1

P1

Q1

AQ1

SD1

AC1

PG1

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

PURGE

Y1

W2

7

C

COOL 1

HEAT 2

ST6008

TIMER

6

UNOCCUPIED

OCCUPIED

2

HEAT 1

FAN

DELAY

RELAY

FAN

L2

L1

(HOT)

M11805A

W1

G

RH

RC

5

1

2

3

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. M7415 MOTOR MUST USE AN

INDEPENDENT TRANSFORMER.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

4

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD NOT BE

REMOVED. DIFFERENTIAL ENTHALPY NOT RECOMMENDED FOR USE

WITH SINGLE-STAGE COOLING SYSTEMS OR SINGLE-STAGE COOLING

THERMOSTATS.

5

FOR T7300 ONLY.

6

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

7

FOR TWO-STAGE THERMOSTATS ONLY.

Fig. 16. W7460A used in single-stage cooling system with single enthalpy changeover and M7415 Motors.

17 63-2544—3

1

Page 18

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W7460A

TR

S

O

S

R

TR1

+

+

5

620 OHM

RESISTOR

5

C7400

+

OUTDOOR

AIR

ENTHALPY

S

SENSOR

M7415

TR1

L2

P1

P

TR

L1

(HOT)

1S

3

+

M7415

OUT

–

1

Y1

Y2

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

1K

2K

1

3

P

Q

AQ

SD

AC

PG

2

4

T1

T

P1

Q1

AQ1

SD1

AC1

PG1

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

T6031 AMBIENT

LOCKOUT

CONTROL

50° F SETPOINT

–

2-10 VDC

INDOOR

+

AIR SENSOR

SHUT DOWN

AIR CHANGE

PURGE

C

Y1

Y2

W

R

UNOCCUPIED

COOL 1

COOL 2

ST6008

TIMER

OCCUPIED

4

W2

W1

G

RH

RC

6

X

T7300 OR T874

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. M7415 MOTOR MUST USE AN

INDEPENDENT TRANSFORMER.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Fig. 17. W7460A used in two-stage cooling system with M7415 Motors.

63-2544—3 18

2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

L2

L1

(HOT)

M11802A

1

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

4

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

5

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

6

FOR T7300 ONLY.

Page 19

W7460B

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

TR1

TR

C7400

+

S

+

O

+

S

R

620 OHM

RESISTOR

5

4

OUTDOOR

AIR

ENTHALPY

S

SENSOR

7

M7415

TR1

L2

1

P1

TR

L1

(HOT)

Y1

Y2

W2

1S

3

+

M7415

OUT

P

–

FREE

COOL

ALARM

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

7

W

R

1S1

MINIMUM POSITION

ADJUSTMENT

MAXIMUM

POSITION

ADJUSTMENT

T6031 AMBIENT

LOCKOUT

CONTROL

50° F SETPOINT

1K

2K

Q

AQ

SD

AC

OA

1

3

T

P

SD1

Q1

AQ1

AC1

OA1

2

4

C7150B MIXED

T1

P1

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

–

2-10 VDC

OUTDOOR

+

AIR SENSOR

Y1

W2

C

COOL 1

HEAT 2

ST6008

TIMER

6

UNOCCUPIED

OCCUPIED

2

HEAT 1

FAN

DELAY

RELAY

FAN

L2

L1

(HOT)

M11813A

W1

G

RH

RC

5

1

2

3

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. M7415 MOTOR MUST USE AN

INDEPENDENT TRANSFORMER.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

4

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD NOT BE

REMOVED. DIFFERENTIAL ENTHALPY NOT RECOMMENDED FOR USE

WITH SINGLE-STAGE COOLING SYSTEMS OR SINGLE-STAGE COOLING

THERMOSTATS.

5

FOR T7300 ONLY.

6

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

7

FOR TWO-STAGE THERMOSTATS ONLY.

Fig. 18. W7460B used in single-stage cooling system with single enthalpy changeover and M7415 Motors.

19 63-2544—3

1

Page 20

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W7460B

TR

S

O

S

R

TR1

+

+

5

620 OHM

RESISTOR

5

C7400

OUTDOOR

+

AIR

ENTHALPY

S

SENSOR

M7415

TR1

L2

1

P1

P

TR

L1

(HOT)

Y1

Y2

+

M7415

OUT

–

FREE

COOL

ALARM

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

1S

1S1

MINIMUM POSITION

ADJUSTMENT

MAXIMUM

POSITION

ADJUSTMENT

1K

3

2K

AQ

OA

SD

AC

2

1

3

4

C7150B MIXED

T1

T

P1

P

Q

Q1

AQ1

SD1

AC1

OA1

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

–

2-10 VDC

OUTDOOR

+

AIR SENSOR

T6031 AMBIENT

LOCKOUT

CONTROL

50° F SETPOINT

W

R

4

UNOCCUPIED

C

Y1

Y2

COOL 1

COOL 2

ST6008

TIMER

OCCUPIED

W2

W1

G

RH

RC

6

1

2

3

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. M7415 MOTOR MUST USE AN

INDEPENDENT TRANSFORMER.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Fig. 19. W7460B used in two-stage cooling system with M7415 Motors.

63-2544—3 20

2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

L2

L1

(HOT)

1

M11811A

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

4

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

5

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED

ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO SR AND + FOR

DIFFERENTIAL ENTHALPY.

6

FOR T7300 ONLY.

Page 21

HONEYWELL

T

ACTUATOR

3

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W6215/W7215/W7460 ECONOMIZER

L2

L1

(HOT)

1

AT72A (40 VA)

TRANSFORMER

2

GND

TR

TR

W

R

B

Y

10

9

24 VAC

ECONO

CHANGE

OVER

1S

1S1

W7100

1K

2K

COOL

COOL

COOL

COOL

COOL

COOL

5

2

1

4

3

T6031 AMBIENT

LOCKOUT

W

CONTROL

R

50° F SETPOIN

POWER

SUPPLY

6

B

C

A

5

B

C

A

4

B

C

A

3

B

C

A

2

B

C

A

1

B

C

A

COOL 6

COOL 5

COOL 4

COOL 3

COOL 2

COOL 1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

510 OHM 1/4 WATT. 5 PERCENT RESISTOR (CONTAINED IN 4074EFV BAG ASSEMBLY) ELIMINATES ECONOMIZER DELAYS.

3

ACTUATOR MODEL DEPENDENT ON LOGIC MODULE MODEL.

Fig. 20. W6215, W7215, or W7460 used with W7100 Controller.

21 63-2544—3

M11897A

Page 22

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

MASTER

ML6275, ML6285

1

3

BLACK

RED

YELLOW

BLUE

8

500 OHM

SLAVE

ML6275, ML6285

BLACK

RED

YELLOW

BLUE

9

24 VAC HOT

24 VAC COM

CLOSE

OPEN

OPEN

WIPER

CLOSED

W6215A

1S

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

TR1

TR

C7400

S

+

S

O

+

S

R

1K

1

3

2K

T

P

Q

AQ

SD

AC

PG

5

2

4

T1

P1

Q1

AQ1

SD1

AC1

PG1

620 OHM

RESISTOR

6

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

PURGE

OUTDOOR

AIR

ENTHALPY

+

SENSOR

Y1

Y2

W2

W1

G

RH

RC

7

X

T7300 OR T874

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE LOAD

OF ALL ACTUATORS.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

4

BY A 24 VAC INPUT.

5

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

Fig. 21. W6215 controlling parallel-wired Honeywell Series 62 Direct Coupled Actuators.

C

2

COOL 1

COOL 2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

1

ST6008

TIMER

UNOCCUPIED

OCCUPIED

L2

L1

(HOT)

Y1

Y2

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD

6

BE REMOVED ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED

TO SR AND + FOR DIFFERENTIAL ENTHALPY.

7

FOR T7300 ONLY.

8

CONNECT ONLY THE MASTER ACTUATOR TO THE W6215

FEEDBACK OUTPUT.

9

THE COMMON FOR THE W6215A IS DIFFERENT THAN THE COMMON

(WIPER) FOR THE SERIES 62 ACTUATORS. BE SURE TO CONNECT

EACH TO A DIFFERENT CIRCUIT.

5

M16060A

63-2544—3 22

Page 23

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

ML7285

24 VAC HOT

1

3

RED

BLACK

WHITE

BROWN

ML7285

RED

BLACK

WHITE

BROWN

24 VAC COM

+

2-10V

OUT

–

W7215A

1S

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

TR1

TR

C7400

S

+

S

O

+

S

R

1K

1

3

2K

T

P

Q

AQ

SD

AC

PG

5

2

4

T1

P1

Q1

AQ1

SD1

AC1

PG1

620 OHM

RESISTOR

6

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

2-10 VDC

–

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

PURGE

OUTDOOR

AIR

ENTHALPY

+

SENSOR

C

2

COOL 1

COOL 2

HEAT 2

HEAT 1

FAN

DELAY

RELAY

FAN

Y1

Y2

W2

W1

G

RH

RC

7

1

2

3

4

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE LOAD

OF ALL ACTUATORS.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Y1

Y2

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD

6

BE REMOVED ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED

TO SR AND + FOR DIFFERENTIAL ENTHALPY.

7

FOR T7300 ONLY.

Fig. 22. W7215A controlling parallel-wired Honeywell Series 72 Direct Coupled Actuators.

ST6008

TIMER

5

UNOCCUPIED

OCCUPIED

L2

1

L1

(HOT)

M11793A

23 63-2544—3

Page 24

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

E

W7215A

24 VAC HOT

24 VAC COM

MOD MOTOR

SERIES 72

1

T1

T2

+

–

+

2-10V

OUT

–

MOD MOTOR

SERIES 72

T1

T2

+

–

1S

4

1S1

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

MAXIMUM

POSITION

ADJUSTMENT

TR1

TR

C7400

S

+

S

O

620 OHM

+

S

R

1K

1

3

2K

T

P

Q

AQ

SD

AC

PG

5

2

4

T1

P1

Q1

AQ1

SD1

AC1

PG1

RESISTOR

6

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

+

AIR SENSOR

SHUT DOWN

AIR CHANGE

PURGE

OUTDOOR

AIR

ENTHALPY

+

SENSOR

Y1

Y2

W2

W1

G

RH

RC

5

1

2

3

4

X

T7300 OR T874

THERMOSTAT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Fig. 23. W7215A controlling parallel-wired Honeywell Series 72 Modutrol Motors.

C

2

COOL 1

COOL 2

HEAT 2

HEAT 1

FAN

ST6008

TIMER

UNOCCUPIED

OCCUPIED

L2

L1

(HOT)

Y1

Y2

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

FOR T7300 ONLY.

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD B

6

REMOVED ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED TO

SR AND + FOR DIFFERENTIAL ENTHALPY.

3

1

M11794A

63-2544—3 24

Page 25

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

W7215A

24 VAC HOT

TR1

24 VAC COM

1

5

M7415

TR

TR1

P1

P

M7415

TR

TR1

P1

P

Q769C

Q769C

1S

4

+

–

+

–

+

2-10V

OUT

–

MINIMUM POSITION

ADJUSTMENT

FREE

COOL

UNIT

CONTROL

EXHAUST

FAN

INDOOR

FAN

1S1

MAXIMUM

POSITION

ADJUSTMENT

2K

TR

C7400

S

+

S

O

+

S

R

1K

1

3

T

P

Q

AQ

SD

AC

PG

5

2

4

T1

P1

Q1

AQ1

SD1

AC1

PG1

620 OHM

RESISTOR

6

C7150B MIXED

AIR OR

C7046A

DISCHARGE

AIR SENSOR

–

2-10 VDC

INDOOR

AIR SENSOR

+

SHUT DOWN

AIR CHANGE

PURGE

OUTDOOR

AIR

ENTHALPY

+

SENSOR

Y1

Y2

W2

W1

G

RH

RC

7

X

T7300 OR T874

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. M7415 MOTOR MUST USE AN

INDEPENDENT TRANSFORMER.

2

ACTUATOR SPRING-RETURNS CLOSED WHEN FAN IS NOT RUNNING.

3

FOR T7300, USE CONTACTS A1 AND A2 INSTEAD OF THE TIMER.

4

1S IS AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED

BY A 24 VAC INPUT.

Fig. 24. W7215A controlling parallel-wired M7415 Motors.

C

2

COOL 1

COOL 2

HEAT 2

HEAT 1

FAN

ST6008

TIMER

3

UNOCCUPIED

OCCUPIED

L2

L1

(HOT)

Y1

Y2

W2

W1

FDR

G

FDR

R

HVAC EQUIPMENT

TERMINAL STRIP

5

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE LOAD

OF ALL ACTUATORS.

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD

6

BE REMOVED ONLY WHEN A C7400 ENTHALPY SENSOR IS ADDED

TO SR AND + FOR DIFFERENTIAL ENTHALPY.

7

FOR T7300 ONLY.

1

M11795A

25 63-2544—3

Page 26

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

T

T

W6215/W7215/W7460 LOGIC MODULE

HONEYWELL

ACTUATOR

2

5

W973B LOGIC PANEL

2 1

HEAT

3 HEAT

2 1

COOL

MOD-HEAT

WH BH RH

SENSOR STAT 24 VAC

T

C +20 H N

T134251TRTR

RC BC WC

3 COOL

MOD-COOL

1S

1S1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ACTUATOR MODEL DEPENDENT ON LOGIC MODULE MODEL.

2

1K

2K

2

1

4

3

W

R

COOL 1

COOL 2

COOL 3

M11991A

T6031 AMBIEN

LOCKOUT

CONTROL

50° F SETPOIN

1

L2L1

(HOT)

Fig. 25. W6215, W7215, or W7460 used with W973B Logic Panel.

CHECKOUT AND TROUBLESHOOTING

Checkout requires a 9V battery, 620 ohm, 1.2K ohm,

5.6K ohm, and 6.8K ohm resistors. Use Table 6 and Fig. 26

for checkout.

63-2544—3 26

CAUTION

Equipment Damage Hazard.

Excessive force can damage potentiometer

controls.

Use a small screwdriver when adjusting enthalpy

changeover and minimum damper position controls.

Page 27

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

Table 6. Checkout For W6215, W7215, W7460 Economizer Connected To Honeywell Actuator.

Step Checkout Procedure Proper Response

1. CHECKOUT PREPARATION

a. Disconnect power at TR and TR1. Free Cool, Unit Control, Indoor Fan, and Exhaust Fan contacts are open.

b. Disconnect devices at P and P1, and Q and Q1. c. Jumper P to P1, and Q to Q1.

d. Turn minimum position potentiometer fully CCW.

e. Turn maximum position potentiometer fully CW.

f. Place 6.8K ohm resistor across T and T1.

g. Jumper TR to 1.

h. If connected, remove C7400 Enthalpy Sensor from terminals S

Connect 1.2K ohm 4074EJM Checkout Resistor across terminals S

and +.

O

and +.

O

i. Set both ISI and Exhaust potentiometers fully CCW.

j. Put 620 ohm resistor across S

and +.

R

k. Set enthalpy potentiometer to D.

l. Apply power (24 Vac) to terminals TR and TR1.

2. DIFFERENTIAL ENTHALPY

a. Execute step one, Checkout Preparation. b. Place 620 ohm resistor across S

c. Place 1.2K ohm resistor across S

and +. -

O

and +. Free cool LED turns on.

R

d. Remove 620 ohm resistor from SO and +. Free cool LED turns off.

3. SINGLE ENTHALPY

a. Execute step one, Checkout Preparation. b. Set enthalpy potentiometer to A (fully CCW). Free cool LED turns on.

c. Set enthalpy potentiometer to D (fully CW). Free cool LED turns off.

4. ISI AND EXHAUST

a. Execute step one, Checkout Preparation. b. Ensure terminals AQ and AQ1 are open. LED for both ISI and Exhaust should be off.

Actuator drives fully closed.

c. Connect 9V battery positive to AQ and negative to AQ1. LED for both ISI and Exhaust turn on.

Actuator drives 90 to 95 percent open.

d. Turn Exhaust potentiometer CW until Exhaust LED turns off. Exhaust LED turns off with potentiometer at approximately 90 percent.

Actuator remains in position.

e. Turn ISI potentiometer CW. ISI LED turns off with potentiometer at approximately 9V.

Actuator drives fully closed.

f. Turn ISI and Exhaust potentiometers CW until Exhaust LED turns on. 45 seconds after Exhaust LED turns on, Exhaust contacts close.

5. FREEZE PROTECTION

a. Execute step one, Checkout Preparation. b. Connect 9V battery positive to AQ and negative to AQ1. LED for both ISI and Exhaust turn on.

Actuator drives 90 to 95 percent open.

c. Remove 6.8K ohm resistor from T and T1. Exhaust LED turns off. Actuator drives fully closed.

d. Replace 6.8K ohm resistor across T and T1. Exhaust LED turns on. Actuator drives 90 to 95 percent open.

6. MINIMUM AND MAXIMUM POSITION

a. Execute step one, Checkout Preparation. b. Connect 9V battery positive to AQ and negative to AQ1. ISI LED turns on. Actuator drives 90 to 95 percent open.

c. Turn maximum position potentiometer to midpoint. Actuator drives to between 20 and 80 percent open.

d. Turn maximum position potentiometer to fully CCW. Actuator drives fully closed.

e. Turn minimum position potentiometer to midpoint. Actuator drives to between 20 and 80 percent open.

f. Turn minimum position potentiometer fully CW. Actuator drives fully open.

27 63-2544—3

Page 28

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

W6215, W7215, W7460 ECONOMIZER LOGIC MODULES

R

Table 6. Checkout For W6215, W7215, W7460 Economizer Connected To Honeywell Actuator. (Continued)

Step Checkout Procedure Proper Response

7. AIR CHANGE, SHUTDOWN, AND PURGE

a. Execute step one, Checkout Preparation. b. Ensure terminals AQ and AQ1 are open. c. Turn minimum position potentiometer to midscale. Actuator drives to between 20 and 80 percent open.

d. Make sure Air Change, Purge, and Shutdown terminals are empty. Exhaust LED turns on.

Unit Control and Indoor Fan contacts close.

e. Jumper Air Change terminals. Exhaust LED turns on. Unit control contacts open.

Indoor Fan contacts close. Actuator drives fully open.

f. Jumper Shutdown terminals. Exhaust LED turns off.

Unit Control, Indoor Fan, and Exhaust Fan contacts open.

Actuator drives fully closed.

g. Remove Shutdown jumper. Exhaust LED turns on. Unit control contacts open.

Indoor Fan contacts close. Actuator drives fully open.

h. Jumper Purge terminals. Exhaust LED turns off. Unit Control, and Indoor Fan contacts open.

Exhaust Fan contacts close. Actuator drives fully closed.

i. Jumper Shutdown terminals. -

8. MIXED AIR INPUT

a. Execute step one, Checkout Preparation. b. Set enthalpy potentiometer to A. Free cool LED turns on.