Page 1

W7340, W7345

W7340

W7345

Communicating Economizer Logic Modules

FOR VENTILATION CONTROL

PRODUCT DATA

FEATURES

• Solid state control package provides accuracy,

reliability and stability.

• Housed in high-impact, glass-fiber reinforced plastic

case.

• Terminals included for connecting optional S963B1136

Remote Potentiometer for remote minimum damper

position control.

• Communicates using a modified Modbus protocol.

• Case matches the lines of the M7215 Damper Motor.

• LED indicates the status of the device input.

W7340 Only

APPLICATION

The W7340 Communicating Economizer Logic Module is a full

featured economizer that incorporates Demand Control

Ventilation (DCV) to provide free cooling and ventilation for

occupants in a space while saving energy.

The W7345 Communicating Economizer Logic Module is a

dry bulb only economizer that does not incorporate Demand

Control Ventilation.

The W7340 is used with both solid state temperature and

humidity or enthalpy sensors. The W7345 is used with solid

state temperature sensors only.

• Operates from the Modbus input, environmental

sensors, and a DCV sensor to provide a totally

integrated control system.

• Combines minimum damper position potentiometer

with solid state temperature (10K NTC) and humidity or

enthalpy changeover control to provide economizer

free cooling function; this control can be overridden

by input via Modbus or DCV sensor.

W7345 Only

• Operates from the Modbus input and mixed/discharge

air sensor to provide a temperature control system.

• Combines the Modbus indoor and/or outdoor

temperature input with the mixed air input to provide

economizer dry bulb free cooling function.

Contents

Application.........................................................................1

Features ............................................................................1

Specifications ....................................................................2

Installation .........................................................................3

Wiring ................................................................................6

Operation...........................................................................7

Settings and Adjustment ...................................................7

Troubleshooting.................................................................11

63-2569—04

Page 2

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

SPECIFICATIONS

Models:

W7340: Communicating Economizer Logic Module with

minimum position potentiometer, setpoints for enthalpy or

dry-bulb, and DCV.

W7345: Communicating Economizer Logic Module with

minimum position potentiometer and setpoint for dry-bulb

temperature only.

IMPORTANT

W7340A, W7340B and W7345A:

1. Do not have the ability to set DCV minimum position

for damper position for demand control ventilation.

Damper may drive 100% open on call from CO

sensor.

2. Do not have the E (enthalpy or dry bulb) curve

setting.

3. W7340C has the ability to set DCV minimum position

and has the E curve setting.

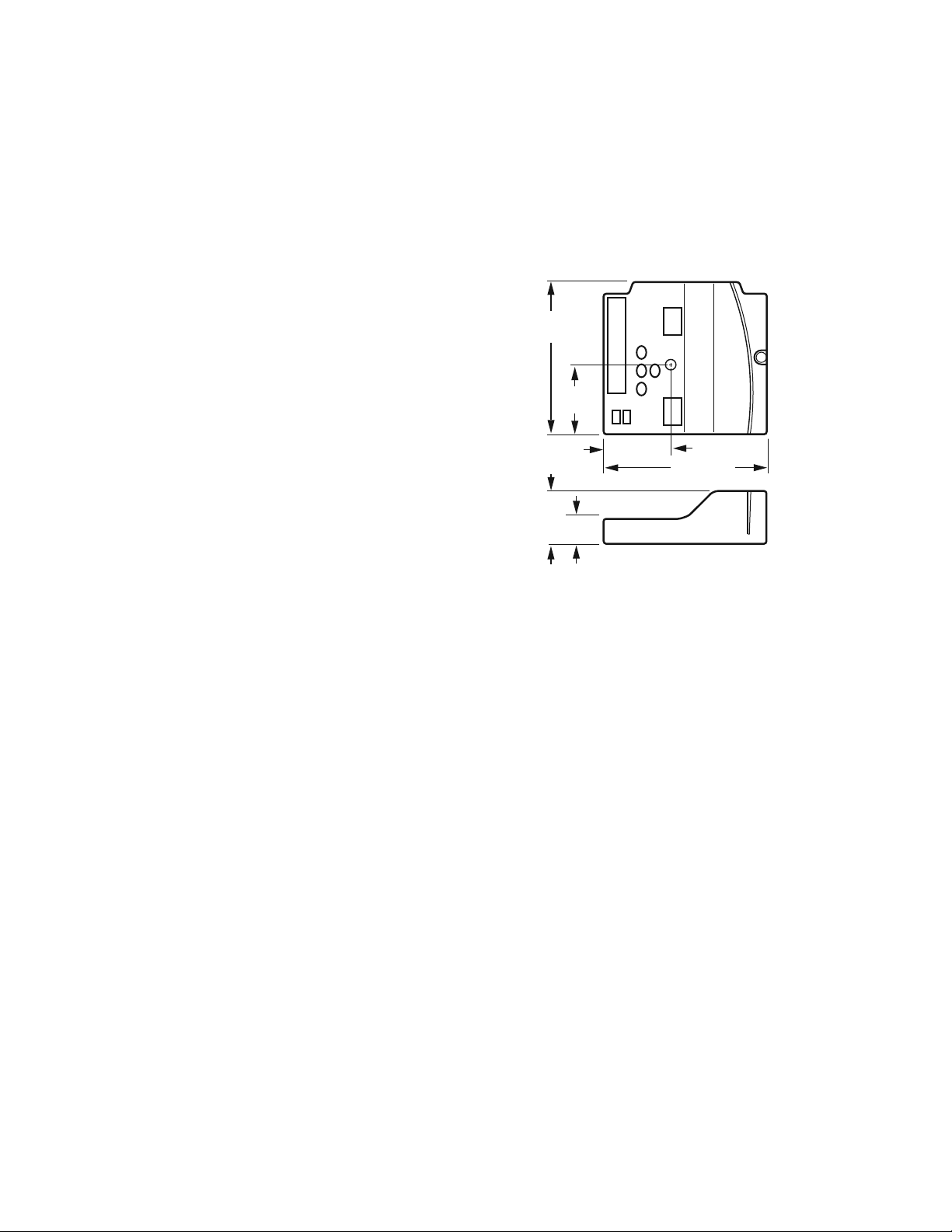

Dimensions: See Fig. 1.

Temperature Ratings:

Operating Ambient: -40 to +149 °F (-40 to +65 °C).

Shipping: -25 to +125 °F (-32 to +52 °C).

Humidity Ratings:

Noncondensing: 5 to 95% RH.

Condensing: 100% RH.

Inputs and Outputs: See Table 1.

Electrical Ratings:

Input Voltage: 24 Vac ±25%; 50/60 Hz (Class 2).

Nominal Power Consumption (at 24 Vac, 60 Hz): 5 VA.

Relay Contact Rating at 30 Vac (maximum power from class 2

input only): 1.5 A run, 7.5 A inrush.

Patents:

U.S. Patent 6,1,764.

Other Patents Pending.

2

Approvals:

cUL listed.

Underwriters Laboratories Inc. listed:

Meets UL873 plenum requirements.

Meets UL94-5VA plenum flammability requirements.

FCC Part 15 Class B.

CE.

This product complies with Title 24 Part 6 CEC standard for

Residential and Non-Residential Buildings - 2005, when

installed according to instructions.

4-1/16

(103)

1-15/16

(49)

1-3/4 (44)

4-7/16 (112)

1-3/8

(35)

5/8

(16)

M22813

Fig. 1. Dimensions of W7340 and W7345 in inches (mm).

Accessories:

32005191-001 Sensor, 10K ohm with 2-1/4 in. (57 mm) probe.

C7150B1046 Mixed Air Sensor, 10K ohm with mounting

bracket.

C7232 Carbon Dioxide Sensor for DCV.

C7632 Carbon Dioxide Sensor for DCV.

C7400A Solid State Enthalpy Sensor for use with W7340A

and W7340B.

C7400C Solid State Enthalpy Sensor for use with W7340C.

C7600C Relative Humidity Sensor.

S963B1136 Remote Potentiometer to provide remote control

of damper minimum position.

ST6008 Energy Management Timer for occupied/unoccupied

control.

ST7009 Electronic Programmable Timer for occupied/

unoccupied control.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2569—04 2

®

Catalog or price sheets for complete ordering number.

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

Page 3

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

CAUTION

CAUTION

Table 1. Logic Module Inputs and Outputs.

W7340 W7345

Inputs

Enthalpy

Modbus yes yes

Return Sensor optional —

Mixed/Discharge Air

Outdoor Sensor

Indoor DCV Sensor 0-10 Vdc control signal —

Remote Minimum

Position Potentiometer

Motor Feedback 2-10 Vdc —

Outputs

Modbus yes yes

Exhaust One set of 24 Vac

Motor Output Signal 2-10 Vdc —

a

2-wire (18, 20, 22 AWG) connection.

4-20 mA

10K ohm

10K ohm

optional optional

contacts (spst)

a

a

a

—

10K ohm

—

—

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Location and Mounting

Communicating Economizer Logic Modules

When planning the installation, allow enough clearance for

maintenance and service. Mount the device in a location

protected from rain, snow, and direct sunlight. The logic

module mounts on the side of an M7215 Damper Motor or

directly on a sheet metal duct or panel.

a

NOTE: Refer to Figures 4 and 5 for representative locations

of connected system devices.

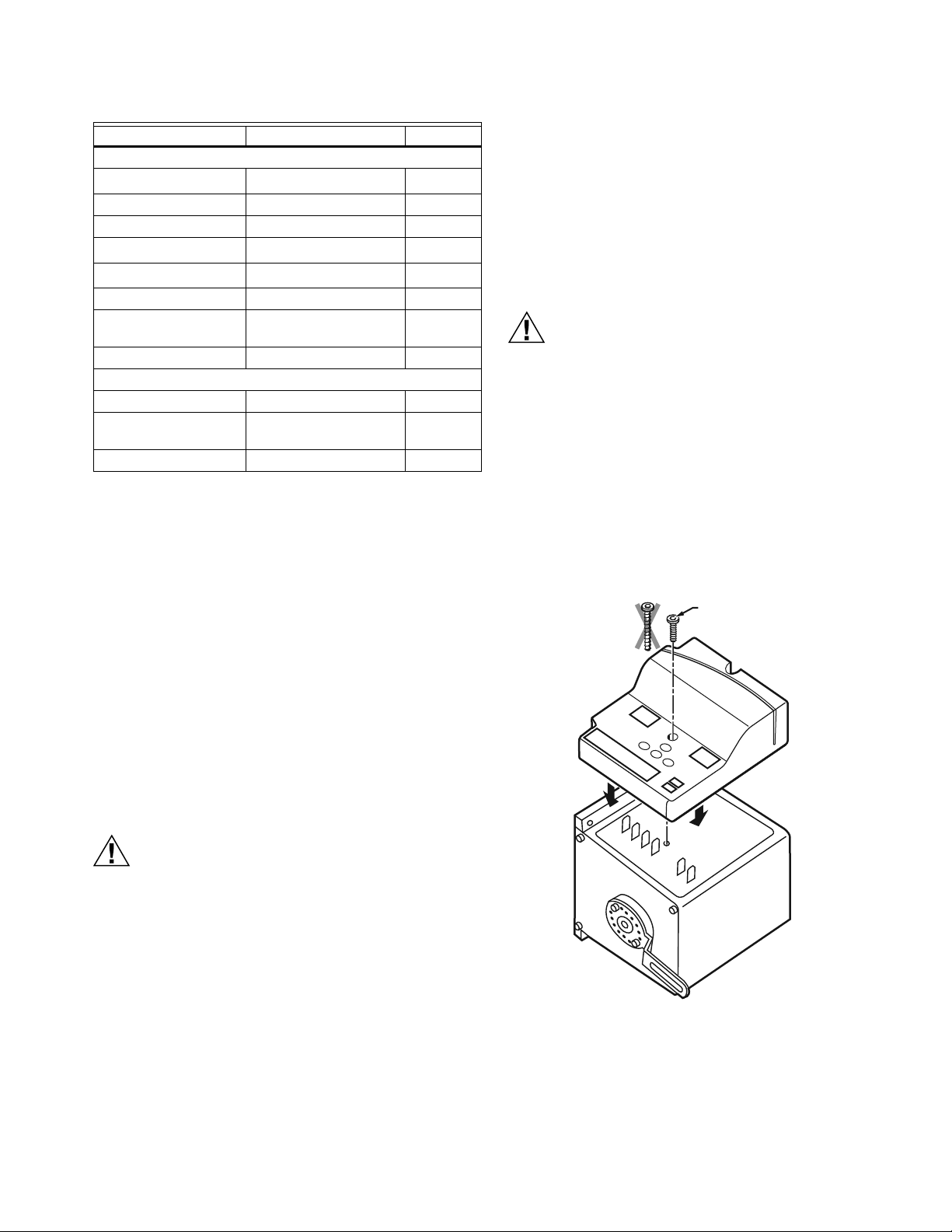

Equipment Damage Hazard.

Mounting screws longer than 5/8 in. can damage

internal motor components.

When mounting the module to an M7215 use only the

included #6 5/8 in. thread-forming screw.

MOUNTING DIRECTLY TO THE MOTOR

1. Mount the motor.

2. Secure the W7340 or W7345 to the motor using the

supplied mounting screw (See Fig. 2).

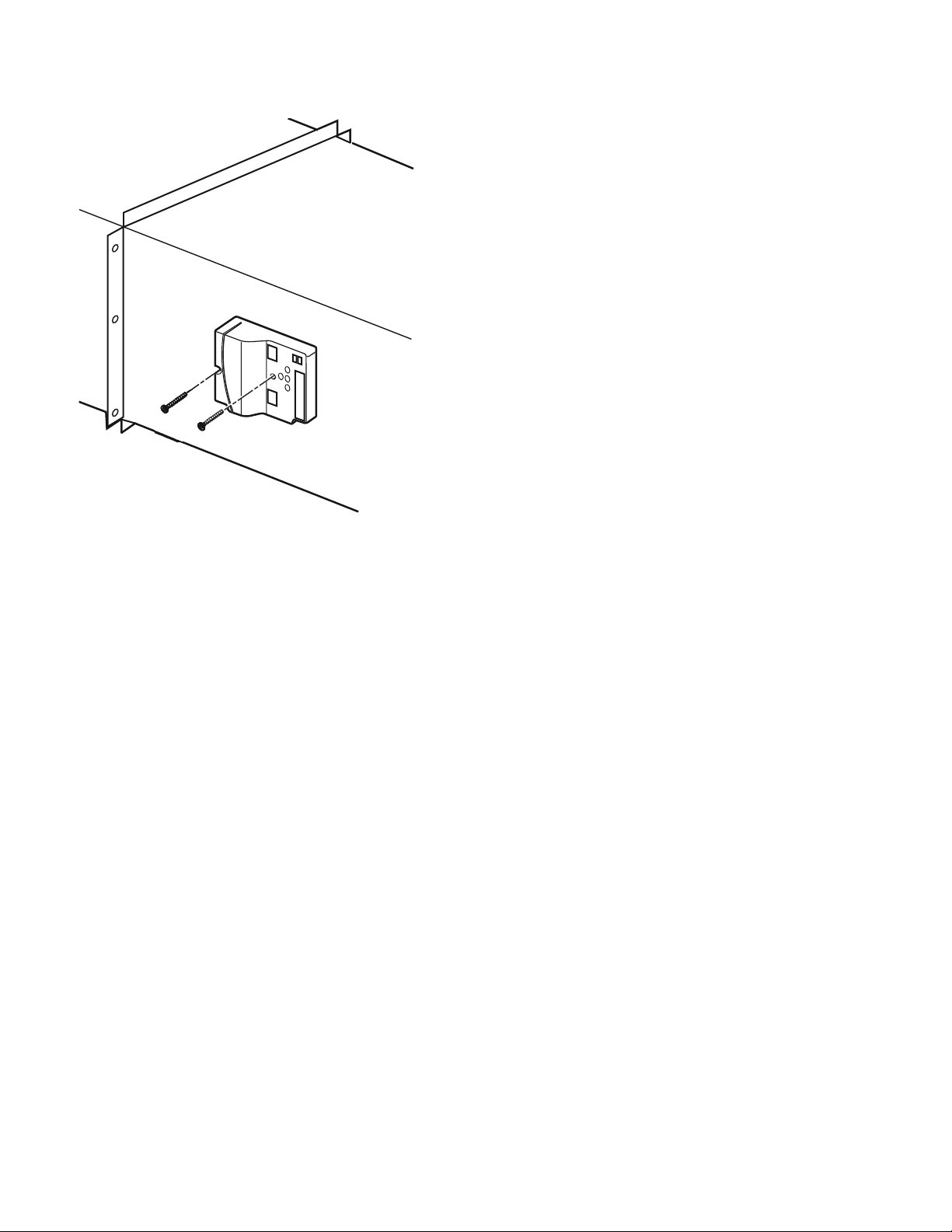

MOUNTING SEPARATE FROM THE MOTOR

Secure the device to the sheet metal using appropriate

fasteners (not supplied)(See Fig. 3).

5/8 INCH SCREW INCLUDED

WITH LOGIC MODULE.

ECONOMIZER

LOGIC MODULE

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

M7215

DAMPER

MOTOR

Fig. 2. Mounting Economizer Logic Module on Damper

Motor.

3 63-2569—04

M17550B

Page 4

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

M17638

IMPORTANT

W7340B: The W7340B DCV economizer logic modules

incorporate a minimum position setting that defaults to 20%,

but can be overridden using the Modbus communication link.

The W7340B DCV maximum position sets the damper position

to a position that the damper goes to if the CO

the minimum position set point is higher than the DCV

maximum position, on sensor failure, the damper goes to the

higher of the two DCV maximum and minimum position setting.

There is no limit on the damper position on a call from the CO

sensor (DCV); the damper can go 100% open.

W7340C: The W7340C DCV economizer logic module has the

ability to set DCV minimum damper position and minimum

position. The DCV minimum position is set to ventilate the

building contaminants and the minimum position is set to

ventilate for the building contaminants and the building

occupants. The installer sets the damper DCV minimum

position and the minimum position based on the design

occupancy and CFM of outdoor air requirements for the space.

The damper will modulate open between the DCV minimum

damper position and the minimum position based on input

from a CO2 sensor. The damper will not drive 100% open on a

Fig. 3. Mounting to a Duct or Panel.

call for ventilation, but can drive 100% open on a call for

cooling. If the CO

minimum position ventilating for building contaminants and

Enthalpy Sensor (W7340 only)

To measure enthalpy, the logic module accepts signals from

either:

the building occupants. If the DCV minimum position has not

been set using the following procedure, the default setting will

be 50% of the minimum position setting.

— C7600C Humidity and 10K NTC temperature sensors.

— or a C7400 Enthalpy Sensor.

IMPORTANT

• When using C7400 Enthalpy Sensors, connect the

enthalpy sensors to the humidity sensor terminals;

leave the temperature sensor terminals empty.

• Use C7400A sensor with W7340A or W7340B.

• Use C7400C sensor with W7340C.

OUTDOOR AIR SENSING

1. Mount each sensor in any orientation that exposes it to

freely circulating air and protects it from rain, snow, and

direct sunlight.

2. Connect it to the logic module.

DCV Min and Min Position Damper Set Up

Set up instructions for W7340C DCV damper positions:

1. Remove RAT sensor from RAT terminals.

2. Connect CO2 sensor to DCV terminals.

3. Apply power to economizer logic module.

4. Wait 10 to 15 seconds for the CO2 sensor to initialize.

5. Remove CO

6. DCV LED will blink 2 times. If LED does not blink, cut

7. Set DCV minimum position using MIN POS/DCV MIN

8. Remove RAT short.

9. DCV minimum position is saved to memory and DCV

RETURN AIR SENSING

1. For differential enthalpy or temperature control mount a

second sensor in the return air duct.

2. Connect it to the logic module.

10. Turn off power to economizer logic module.

11. Connect RAT sensor.

12. Turn power on to economizer logic module.

13. Set minimum position using MIN POS/DCV MIN

Demand Control Ventilation (DCV) Sensor Input (W7340 only)

The DCV sensor can be any sensor that provides a 0-10 Vdc

output over a range of 0 to 2000 ppm of CO

modulates the outdoor damper to provide ventilation based on

occupancy. Mount the sensor according to the manufacturer

specifications. If not available, mount the sensor in an area

with unobstructed air circulation.

. The DCV signal

2

IMPORTANT

• Ensure proper polarity of sensor connections.

Incorrect polarity negates the sensor signal.

sensor fails. If

2

sensor fails the damper will drive to the

2

Short RAT terminals.

sensor from DCV terminals.

2

power to economizer logic and repeat steps 1-5.

potentiometer.

LED blinks 5 times.

potentiometer.

Steps 3-8 must be completed within 3 minutes after

power up otherwise the configuration process will be

terminated, no changes will be saved and you will

need to repeat steps 1-13.

2

63-2569—04 4

Page 5

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

10K NTC

DISCHARGE

AIR SENSOR

DISCHARGE

AIR

1

FOR DIFFERENTIAL ENTHALPY, THE TWO C7400 ENTHALPY SENSORS

ARE CONNECTED TO THE ECONOMIZER MODULE—ONE IS MOUNTED

IN THE RETURN AIR DUCT, AND THE OTHER IS MOUNTED IN THE

OUTDOOR AIR DUCT. DIFFERENTIAL ENTHALPY CONTROL PROVIDES

GREATER ENERGY SAVINGS THAN SINGLE ENTHALPY CONTROL.

USE EITHER MIXED AIR SENSOR OR DISCHARGE AIR SENSOR, NOT BOTH.

2

3

A C7600 HUMIDITY SENSOR, USED IN CONJUNCTION WITH A 10K NTC

TEMPERATURE SENSOR CAN BE USED INSTEAD OF A C7400 ENTHALPY SENSOR.

FOR DRY BULB CONTROL, USE ONLY A 10K NTC TEMPERATURE SENSOR.

2

INDOOR

FAN

MODBUS

DIRECT

EXPANSION

COIL

M7215 MOTOR

WITH W7340

ECONOMIZER

LOGIC MODULE

Fig. 4. Representative Locations of Connected W7340 Economizer System Devices.

10K

NTC

C7400

ENTHALPY

SENSOR

RETURN AIR

MIXED AIR

SENSOR

2

1

3

C7232

C7400

ENTHALPY

SENSOR

EXHAUST

FAN

INDOOR

AIR CO2

SENSOR

1

3

EXHAUST AIR

OUTDOOR

AIR

M22814

10K NTC

DISCHARGE

AIR SENSOR

DISCHARGE

AIR

1

USE EITHER MIXED AIR SENSOR OR DISCHARGE AIR SENSOR, NOT BOTH.

1

INDOOR

FAN

MODBUS

DIRECT

EXPANSION

COIL

M7215 MOTOR

WITH W7345

ECONOMIZER

LOGIC MODULE

Fig. 5. Representative Locations of Connected W7345 Economizer System Devices.

MIXED AIR

10K

SENSOR

NTC

1

1

OUTDOOR

AIR

EXHAUST

FAN

EXHAUST AIR

RETURN AIR

M22822

5 63-2569—04

Page 6

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

CAUTION

P1

TR1

TR1

24 VAC

TR

TR

P

EXF

M23875

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

OPTIONAL REMOTE MINIMUM POSITION POTENTIOMETER.

WHEN USING C7400 ENTHALPY SENSORS, CONNECT THE ENTHALPY SENSOR TO THE

HUMIDITY SENSOR TERMINALS. LEAVE THE TEMPERATURE SENSOR TERMINALS EMPTY.

1

2

3

3

3

3 3

2

R

B W

CCW

OPEN

MOD

BUS

CW

CLOSE

S963B

M7215

W7340

2-10 Vdc

FEEDBACK

OUTPUT

2-10 Vdc

CONTROL

SIGNAL INPUT

2-10 Vdc

FEEDBACK

INPUT

MIN POS/

DCV MIN

DCV

SETPOINT

2-10 Vdc

CONTROL

SIGNAL

OUTPUT

POWER

EXHAUST

CONTACTOR

MIXED

AIR TEMP

SENSOR

10K NTC

OUTDOOR

AIR TEMP

SENSOR

10K NTC

RETURN

AIR TEMP

SENSOR

10K NTC

C7600C

OUTDOOR

AIR

HUMIDITY

C7600C

RETURN

AIR

HUMIDITY

DCV

SENSOR

(0-10 Vdc)

MAT

OAH

OAT

RAT

RAH

DCV

AE

B

C

+–+–

+– +– +–

+–

MOD BUS –

MOD BUS +

1

–

24 VAC

L1

L2

+

D

WIRING

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

1. All wiring must comply with applicable local codes,

ordinances and regulations.

2. Refer to Figures 6 and 7 for typical wiring diagrams.

3. All inputs and outputs to the device must be 24 Vac

Class 2.

4. Ensure proper polarity of sensor connections.

Incorrect polarity negates the sensor signal.

NOTE: All connections with label designation ending in 1

(examples: TR1, P1) are ac/dc common connections.

Fig. 6. W7340 Typical Wiring.

63-2569—04 6

Page 7

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

P1

TR1

TR1

24 VAC

TR

TR

P

MOD BUS –

MOD BUS +

M23876

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

OPTIONAL REMOTE MINIMUM POSITION POTENTIOMETER.

1

1

2

2

R

B W

–

24 VAC

L1

L2

+

CCW

OPEN

MOD

BUS

CW

CLOSE

S963B

M7215

W7345

MINIMUM

POSITION

MIXED

AIR TEMP

SENSOR

10K NTC

MAT

+–

AE

BCD

Fig. 7. W7345 Typical Wiring.

OPERATION

The purpose of the economizer logic modules are to use

outdoor air for cooling, whenever possible, to reduce

compressor operation.

IMPORTANT

• Use C7400A sensor with W7340A or W7340B.

• Use C7400C with W7340C.

The W7340, when wired as shown in Fig. 6, responds to a

signal from the Modbus. This system uses C7400 Solid State

Enthalpy Changeover Sensor(s). The C7400 Enthalpy Sensors

respond to both dry bulb temperature and humidity, allowing

use of outdoor air at higher temperatures for free cooling when

humidity is low.

The logic module functions as a first stage of cooling and

provides maximum fuel economy during the cooling cycle. The

logic module automatically locks out free cooling during

heating. It holds the outdoor air damper at the minimum

position setting.

The W7340 operates as a basic free cooling controller. Table 2

details the input/output (I/O) logic of the W7340. The logic

module energizes the Unit Control and Indoor Fan contacts,

and operates according to Table 2.

SETTINGS AND ADJUSTMENT

W7345

Potentiometers with screwdriver adjustment slots, located on

the face of the device, provide adjustments for Minimum

Damper Position parameters (See Fig. 8 for locations on

device).

MINIMUM

DAMPER

POSITION

MAT

OAT

RAT

P P1

OPEN

C

B

A

TR1 24V COM

MIN POS/

DVC MIN

D

E

MBUS-

MBUS+

TR 24V AC

-

Fig. 8. Location of W7345 Potentiometers and LED.

DRY BULB

CHANGEOVER

SETPOINT

STATUS LED

M23877

7 63-2569—04

Page 8

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

W7340

Potentiometers with screwdriver adjustment slots, located on

the face of the device, provide adjustments for several

parameters (See Fig. 9 for locations on device):

— DCV minimum and minimum damper position.

— Enthalpy changeover.

— DCV setpoint.

MIN POS/DCV

MIN DAMPER

ExF

MAT

+

OAH

_

OAT

RAT

+

RAH

_

DCV

PP1

OPEN

C

B

A

TR1 24V COM

2-10 VDC

DAMPER

POSITION

2-10 VDC

DAMPER

POSITION

OVERRIDE

MIN POS/

DCV MIN

D

E

DCV

SETPOINT

1500500

MBUS-

MBUS+

TR 24V AC

+

-

+

-

POSITION

ENTHALPY

CHANGEOVER

SETPOINT

STATUS LED

DEMAND

CONTROL

VENTILATION

SETPOINT

M23878

Fig. 9. Location of W7340 potentiometers and LED.

IMPORTANT

Before powering the device read the following Enthalpy

changeover setpoint guidelines:

1. Using the Enthalpy changeover setpoint, the setpoint

can be adjusted until three minutes after powering the

device. until three minutes after powering the device.

2. Through the Modbus, the Enthalpy changeover

setpoint can be modified at any time.

3. If the Enthalpy changeover potentiometer is changed

after the three minute power-up time, no change to

the Enthalpy changeover setpoint will occur unless

power is removed from the device then reapplied.

NOTES:

— The DCV setpoint can be changed at anytime by

adjusting the pot.

— For Enthalpy changeover setpoint see comments

above.

— MIN POS can be changed anytime by adjusting

the pot.

— DCV Min can be changed by procedure on page 4.

Demand Control Ventilation (DCV) Setpoint

The logic module modulates the outdoor damper to provide

ventilation based on the 2-10 Vdc DCV sensor. With no cooling

signal, DCV overrides the DCV minimum damper position

when ventilation requires outdoor air.

Table 2. W7340 Economizer I/O Logic.

INPUTS OUTPUTS

Enthalpy

DCV

Below

High Low On On On On Minimum

set

a

Y1bY2

On Off On Off

Low High On On On Off

Compressor

b

DamperOutdoor Return Stage 1 Stage 2

position

Modulating

On Off Off Off

Above

High Low On On On On

set

On Off On Off

Low High On On On Off

Modulating

Modulating

On Off Off Off

a

For single enthalpy control, the module compares outdoor

enthalpy to the ABCDE setpoint.

b

If both stages of cooling are off, the system is off and the

damper is:

• At DCV minimum position if DCV is below setpoint.

• Modulating if DCV is above setpoint.

c

Modulation based on mixed air sensor signal, modulating

between DCV minimum position and 100% open.

d

Modulation based on DCV signal, limited by minimum

position.

e

Modulation based on the greater of the DCV and mixed air

sensor signals.

Adjusting Minimum Damper Position

The minimum position potentiometer maintains the minimum

outdoor air flow into the building during occupied period.

NOTE: If the mixed air temperature drops to 45° F (7° C), the

mixed air sensor overrides the DCV sensor and

closes the damper to DCV minimum position to

protect the hot or chilled water coils from freezing.

When the mixed air temperature rises to 48° F (9° C),

control reverts to normal operation.

For detailed assistance in minimum position selection,

reference the Economizer Application Guide (form 63-8594)

Ventilation section. The following provides basic guidelines for

minimum position selection and adjustment:

IMPORTANT

1. Adjust the minimum position potentiometer to allow

the amount of outdoor air, as required by local codes,

to enter the building for building contaminants and the

maximum building occupants.

2. This procedure requires use of a quality thermometer

capable of reading to 0.5° F (0.-17.5° C).

c

d

e

63-2569—04 8

NOTE: Make minimum position adjustments with at least a

10° F (-12° C) temperature difference between

outdoor and return air.

See section on DCV setpoint set up on page 4.

Page 9

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

T

O

OA×()TRRA×()+ T

M

=

TOT

R

–()OA TR+× T

M

=

0.1x 6° F()0.9x 75° F()+ 6.0° F 67.5° F+ 73.5° F==

60° F 75° F–()0.1 75° F+× 1.5– 75° F+ 73.5° F==

Limit On Minimum Damper Position

On the W7340A and B models, the logic module as shipped

from the factory, limits the minimum position setpoint to 50%.

The logic module will not allow a minimum position greater

than 50% open (from fully closed).

NOTE: This setpoint limit can only be changed using a

Modbus command.

Equation 1. Formula to aid in minimum position adjustment.

or

Where:

T

= Outdoor air temperature

O

OA = Percent of outdoor air

= Return air temperature

T

R

RA = Percent of return air

T

= Resulting mixed air temperature

M

NOTE: The following sample calculation uses only

Fahrenheit temperature.

EXAMPLE: Assume local codes require 10% outdoor air

during occupied conditions, outdoor air is 60° F

and return air is 75° F. Under these conditions,

what is the temperature of the mixed air?

Differential Enthalpy Changeover Setting

Differential enthalpy control uses:

— W7340A and B use two C7400A Enthalpy Sensors

connected to one logic module, or

— Two 10K NTC temperature sensors and two C7600C

Humidity Sensors connected to one logic module.

— W7340C uses C7400C Enthalpy Sensor(s) or

— Two 10K NTC temperature sensors and two C7600C

Humidity Sensors connected to one logic module.

With outdoor and return air sensors, the logic module

compares outdoor air to return air instead of to a setpoint as it

does for single enthalpy. The logic module selects the lower

enthalpy air (return or outdoor) for cooling; for example, when

outdoor air has lower enthalpy than return air, the outdoor air

damper opens to bring in outdoor air for free cooling.

NOTE: When using the W7340 for differential enthalpy, keep

the setpoint potentiometer set at D.

Exhaust Setpoint (W7340 only)

The exhaust setpoint determines when the exhaust fan will run

based on the damper position.

The logic module, as shipped from the factory, uses an

exhaust setpoint of 25%. When the damper position is greater

than 25% open (from fully closed), relay contact for the

exhaust fan is closed. When the damper position is below 22%

open, the relay is de-energized.

or

Mixed air will be 73.5° F when OA is 60° F and RA is 75° F with

10 percent outdoor air entering the building.

NOTE: The W7340C model min position and DCV min must

be set in the field by the installer. See Section DCV

Min and Min Position Damper Set up.

Enthalpy Changeover (W7340 only)

Outdoor Enthalpy Changeover Setpoint (Single Enthalpy Changeover)

The outdoor enthalpy changeover setpoint returns the outdoor

air damper to minimum position when enthalpy rises above its

setpoint. Enthalpy setpoint scale markings, located on the

device, are A, B, C, D and E. See Fig. 10 for the corresponding

control point.

Control Configuration (W7340 only)

The W7340 can be configured for humidity or enthalpy

sensors. Configuration can be performed manually or over the

Modbus.

IMPORTANT

If only a temperature sensor is connected to the

W7340, the device will operate using dry bulb

changeover control.

To configure the W7340 manually:

1. Within the first three minutes after powering the device,

short the external minimum damper position terminals

(P-P1).

NOTE: The LED will go solid within five seconds of

shorting these terminals.

2. Maintaining the short for another five seconds causes

the LED to flash quick pulses (between off periods)

indicating the sensor configuration type:

a. Two quick pulses: Humidity.

b. Three quick pulses: Enthalpy.

3. To toggle the sensor configuration type:

a. Remove the short until the LED goes solid again.

b. Reapply the short for another five seconds.

NOTE: Once the short is removed for over 10 seconds,

the device saves the most recent configuration.

9 63-2569—04

Page 10

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

CONTROL

CURVE

A

B

C

D

E

CONTROL POINT

APPROX. °F (°C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

55 (13)

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46

90

100

80

70

60

50

40

30

20

10

ENTHALPY—BTU PER POUND DRY AIR

85

(29)90(32)95(35)

100

(38)

105

(41)

110

(43)

35

(2)

35

(2)

40

(4)

40

(4)

105

(41)

110

(43)

45

(7)

45

(7)

50

(10)

50

(10)

55

(13)

55

(13)

60

(16)

60

(16)

65

(18)

65

(18)

70

(21)

70

(21)

75

(24)

75

(24)

80

(27)

80

(27)

85

(29)90(32)95(35)

100

(38)

APPROXIMATE DRY BULB TEMPERATURE— °F (°C)

A

A

B

B

C

C

D

D

M23879

RELATIVE HUMIDITY (%)

1

1

HIGH LIMIT CURVE FOR W7210D, W7212, W7213, W7214, W7340B.

E

E

Fig. 10. W7340 Performance Characteristics for Enthalpy Changeover Settings.

Table 3. W7345 Performance Characteristics

for Temperature Changeover Settings.

Temperature

Changeover Setting

A7323

Approximate Control Point

°F °C

B7021

C6719

D6317

E5513

63-2569—04 10

Page 11

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

TROUBLESHOOTING

The status LED is visible through a hole in the device cover. A

priority-based LED flash sequence indicates a detected fault.

0.25 seconds elapses between each pulse, a higher pulse

count indicates higher priority. A two-second on period

precedes each repeated sequence.

The diagnostic bit position corresponds to the Modbus

diagnostic register. The diagnostic bit resets when the

respective fault is present. To read all active faults, read the

diagnostic register via Modbus function code 8 (no flash

priority needed).

NOTES:

— All pulse counts (Table 4) are based on the

number of times the light pulses off.

— In the event of a Communications Failure, the LED

pulses on for 0.25 seconds every 2 seconds.

Table 4. W7340 Economizer Checkout.

Pulse

Description

Booting (0-3 min. after power-up) NA 12

Mixed air temperature sensor fault 87

Outdoor air temperature sensor fault 76

Outdoor air humidity sensor fault 65

Return air temperature sensor fault 43

Return air humidity sensor fault 32

Indoor air quality sensor fault 21

Actuator fault 10

Proper operation (outdoor air

appropriate for free cooling)

Proper operation (NO free cooling) 2 Hz flash NA

Communications failure 1 (pulses

count

Solid

ON NA

on) NA

Diagnostic

bit

11 63-2569—04

Page 12

W7340, W7345 COMMUNICATING ECONOMIZER LOGIC MODULES

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2007 Honeywell International Inc.

63-2569—04 J.I. Rev. 06-07

Loading...

Loading...