Page 1

63-2700-10

JADE™ Economizer Module

(MODEL W7220)

System Components

The JADE™ Economizer System includes an Economizer

Module, 20k mixed air sensor, damper actuator, an optional

CO

sensor, and either a 20k outdoor air temperature sensor

2

or Sylk Bus sensors for measuring Outdoor Air and return air

enthalpy, temperature, and humidity.

Economizer Module

This is the core of the JADE™ Economizer System and

includes the user interface for the system. The W7220

Economizer Module provides the basic inputs and outputs to

provide simple economizer control. When used with the

optional Sylk Bus sensors, the Economizer Module provides

more advanced economizer functionality.

Sylk Bus Sensors (optional)

PRODUCT DESCRIPTION

The JADE™ Economizer System is an expandable

economizer control system, which includes a W7220

Economizer Module (controller) with an LCD and keypad. The

W7220 can be configured with optional sensors.

The W7220 Economizer Module can be used as a standalone economizer module wired directly to a commercial set

back space thermostat and sensors to provide Outdoor Air

dry-bulb economizer control.

The W7220 Economizer Module can be connected to optional

Sylk Bus sensors for single or differential enthalpy control. The

W7220 Economizer Module provides power and

communications on the Sylk Bus for the Sylk Bus sensors.

The W7220 Economizer Module automatically detects

sensors by polling to determine which sensors are present. If

a sensor loses communications after it has been detected, the

W7220 Economizer indicates a device fail error on its LCD.

The Sylk Bus Sensor is a combination temperature and

humidity sensor which is powered by and communicates on

the Sylk Bus. Up to three sensors may be configured with the

JADE™ Economizer Module. See page 2 for details.

CO2 Sensor (optional)

A CO2 sensor can be added for Demand Control Ventilation

(DCV). Either an analog (2-10 Vdc) or a wall-mount Sylk bus

TR40 CO2 sensor can be used with the Jade economizer.

PC MOD Tool (optional)

The PC MOD tool is connected to a personal computer and

communicates with the Jade economizer controller via the

Sylk bus. The W7220 PCMOD tool software is free and can be

downloaded from the url in the Accessories section.

Some features on the Jade controller can only be enabled or

disabled using the W7220 PC MOD tool. See the PC MOD

tool options section in Table 5.

Product Description .......................................................... 1

Specifications ................................................................... 2

Before Installation ............................................................ 3

Installation and Setup ...................................................... 3

Mounting .......................................................................... 3

Wiring ............................................................................... 4

Wiring Application Examples ........................................... 9

Interface Overview ........................................................... 18

Setup and Configuration .................................................. 18

Checkout .......................................................................... 30

Troubleshooting ................................................................ 31

PRODUCT DATA

Contents

E4436E4436

Page 2

JADE™ ECONOMIZER MODULE

SPECIFICATIONS

W7220A Economizer Module

The module is designed for use with any Honeywell 2 to 10

Vdc or Honeywell Sylkbus communicating actuator. The

module includes terminals for a CO

and an Outdoor Dry Bulb sensor. Enthalpy and other options

are available with Sylk Bus sensors.

User Interface: Provides status for normal operation, setup

parameters, checkout tests, and alarms and error

conditions with a 2-line 16 character LCD display and a

four button keypad.

Electrical

Rated Voltage: 20 to 30 Vac RMS; 50/60 Hz

Transformer: 100 VA maximum system input

Nominal Power Consumption (at 24 Vac, 60 Hz): 11.5 VA

without sensors or actuators

Relay Digital Output Rating at 30 Vac (maximum power

from Class 2 input only): 1.5A run;

3.5A inrush @ 0.45PF (200,000 cycles) or

7.5A inrush @ 0.45PF (100,000 cycles)

External Sensors Power Output: 21 Vdc +/- 5% @ 48mA

IMPORTANT

All inputs and outputs must be Class 2 wiring.

Inputs

sensor, Mixed Air sensor,

2

Dry Bulb Temperature (optional) and Mixed Air

(required), C7250A:

2-wire (18 to 22 AWG);

Temperature range -40 to 150 °F (-40 to 65 °C).

Temperature accuracy -0°F/+2°F

Temperature and Humidity, C7400S1000 (optional):

Sylk Bus; 2-wire (18 to 22 AWG)

Temperature: range -40 to 150 °F (-40 to 65 °C)

Temperature accuracy -0°F/+2°F

Humidity: range 0 to 100% RH with 5% accuracy.

NOTE: Up to three (3) SYLK Bus sensors may be

connected to the JADE™ Economizer module.

For outdoor air (OA), return air (RA) and

discharge (supply) air (DA).

DCV (CO

2-10 Vdc control signal; minimum impedance >50k ohm.

4 Binary inputs:

1-wire 24 Vac + common GND (see page 6 for wiring

details). 24 Vac power supply: 20 to 30 Vac 50/60Hz;

100 VA Class 2 transformer.

) Sensor (C7232 or C7632):

2

Outputs

Actuator signal: 2-10 Vdc; minimum actuator impedance is

2k ohm; Sylkbus two-wire output for Honeywell Sylkbus

communicating actuators.

Exhaust fan, Y1, Y2 and AUX1 O:

All Relay Outputs (at 30 Vac):

Running: 1.5A maximum

Inrush: 7.5A maximum

SENSORS:

NOTE: A Mixed Air (MA) analog sensor is required on all

W7220 units; either an Outdoor Air (OA) sensor

for dry bulb change over or an OA Sylkbus

sensor for outdoor enthalpy change over is

required in addition to the MA sensor. An

additional Return Air (RA) Sylkbus sensor can be

added to the system for differential enthalpy or

dry bulb changeover. For differential dry bulb

changeover a 20k ohm sensor is required in the

OA and a Sylkbus sensor in the RA. Dip switch

on RA Sylkbus sensor must be set in the RA

position.

Environmental

Operating Temperature: -40 to 150 °F (-40 to 65 °C).

Exception of display operation down to -4 °F with full

recovery at -4 °F from exposure to -40 °F

Storage Temperature: -40 to 150 °F (-40 to 65 °C)

Shipping Temperature: -40 to 150 °F (-40 to 65 °C)

Relative Humidity: 5% to 95% RH non-condensing

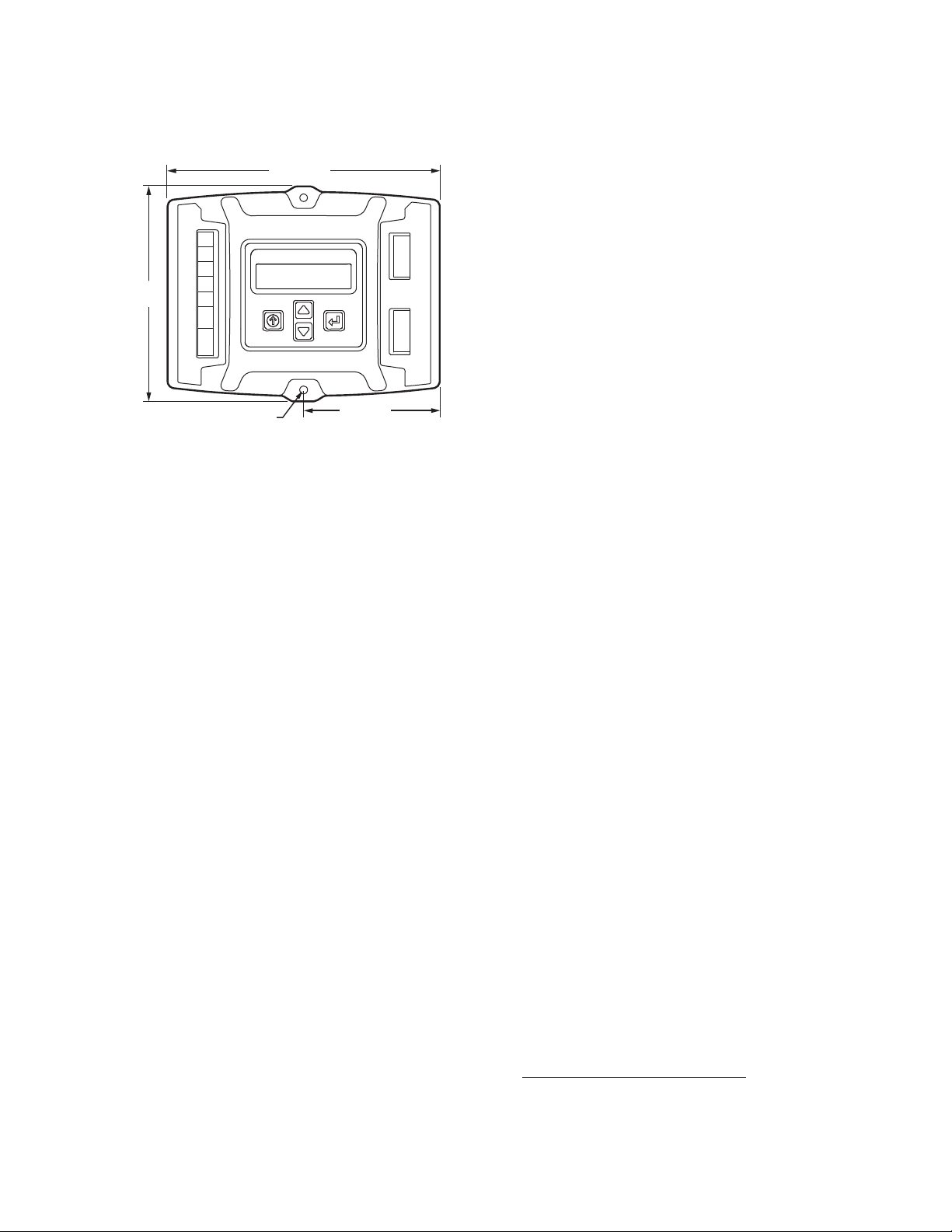

Dimensions (See Fig. 1 on page 3):

Height: 4.98 inches (126.4 mm)

Width: 6.3 inches (160 mm)

Depth: 1.34 inches (34 mm)

Weight: 0.58 lb. (0.265 kg)

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information,

or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1985 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

63-2700—10 2

Page 3

JADE™ ECONOMIZER MODULE

4-63/64

(126)

6-19/64 (160)

MOUNTING HOLE (X2)

M32273A

3-5/32 (80)

Approvals: UL listed (XAPX) for USA and Canada;

California Energy Commission (CEC) FDD ID number

HJW10.

Fig. 1. Dimensions in inches (mm) showing mounting

holes.

Accessories

— 50048926-001 2-pin edge connector for sensors (20

pieces per bag)

— 50048926-002 6-pin edge connector for field wiring (20

pieces per bag)

— C7250A 20k sensor for MA or OA (dry bulb changeover)

— C7400S Sylkbus sensor for enthalpy control in OA and/

or RA and RA for differential dry bulb changeover

— W7220 PCMOD interface tool for JADE controller and

Personal Computer. For the software, go to

www.customer.honeywell.com/economizertools

— 50053060-001 Duct mounting kit for sensors

— C7632 or C7232 CO

Sylk bus CO

sensor

2

analog sensors OR one TR40

2

INSTALLATION AND SETUP

The following installation procedures should be performed in

the order listed:

1. Mounting — see page 3.

2. Wiring — see page 4.

3. Interface and Programming overview – see page 18.

4. Setup and Configuration — see page 18

5. Checkout — see page 30.

Troubleshooting and Alarms—see page 31.

MOUNTING

This section describes the mounting procedures for the

JADE™ Economizer module and the sensors.

Economizer Module Location and Mounting

IMPORTANT

Avoid mounting in areas where acid fumes or other

deteriorating vapors can attack the metal parts of the

module’s circuit board, or in areas where escaping

gas or other explosive vapors are present.

IMPORTANT

The module must be mounted in a position that allows

clearance for wiring, servicing, and removal.

Mount the Economizer module on any convenient interior

location using the two mounting holes provided on the

enclosure using #6 or #8 screws (screws are not provided and

must be obtained separately). Use the dimensions in Fig. 1 on

page 3 as a guide.

BEFORE INSTALLATION

Review the “Specifications” on page 2 before installing the The

JADE™ Economizer System.

When Installing This Product

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the product to

ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

NOTE: Jade will be in the "set up" mode for the first 60

minutes after powered. If a sensor for OA air or

Sylkbus device (sensor, actuator) is disconnected

during the set up mode, the Jade will not alarm

that failure. The MA sensor is a system "critical"

sensor, if the MA sensor is removed during the

set up mode, the Jade will alarm. After 60 minutes

the Jade controller will change to operation mode

and all components removed or failed will alarm

in the operation mode.

The Economizer module may be mounted in any orientation.

However, mounting in the orientation shown in Fig. 1 on page 3

permits proper viewing of the LCD display and use of the

keypad.

Sensor Location and Mounting

The JADE™ Economizer W7220 uses digital and

communicating sensors for control. The C7250 temperature

sensors (MA

for all applications and is mounted in the mixed air section of a

rooftop unit either directly to the sheet metal using self tapping

sheet metal screws or in the air stream using the duct

mounting kit. Duct mount kit is part number 50053060-001.

Optional OA, RA

the W7220 on the two-wire communication bus and can either

be wired using a two pin header or using a side connector.

Each Sylkbus sensor includes a two pin side connector with

the packaging. The SKU number of the Sylkbus sensor is

C7400S. All OA, RA and DA sensors are the same SKU

a

MA = Mixed Air

b

OA = Outdoor Air

c

RA = Return Air

d

DA = Discharge Air

3 63-2700—10

a

and OAb) are 20k NTC. A MA sensor is required

c

and DAd Sylkbus sensors communicate with

Page 4

JADE™ ECONOMIZER MODULE

WARNING

CAUTION

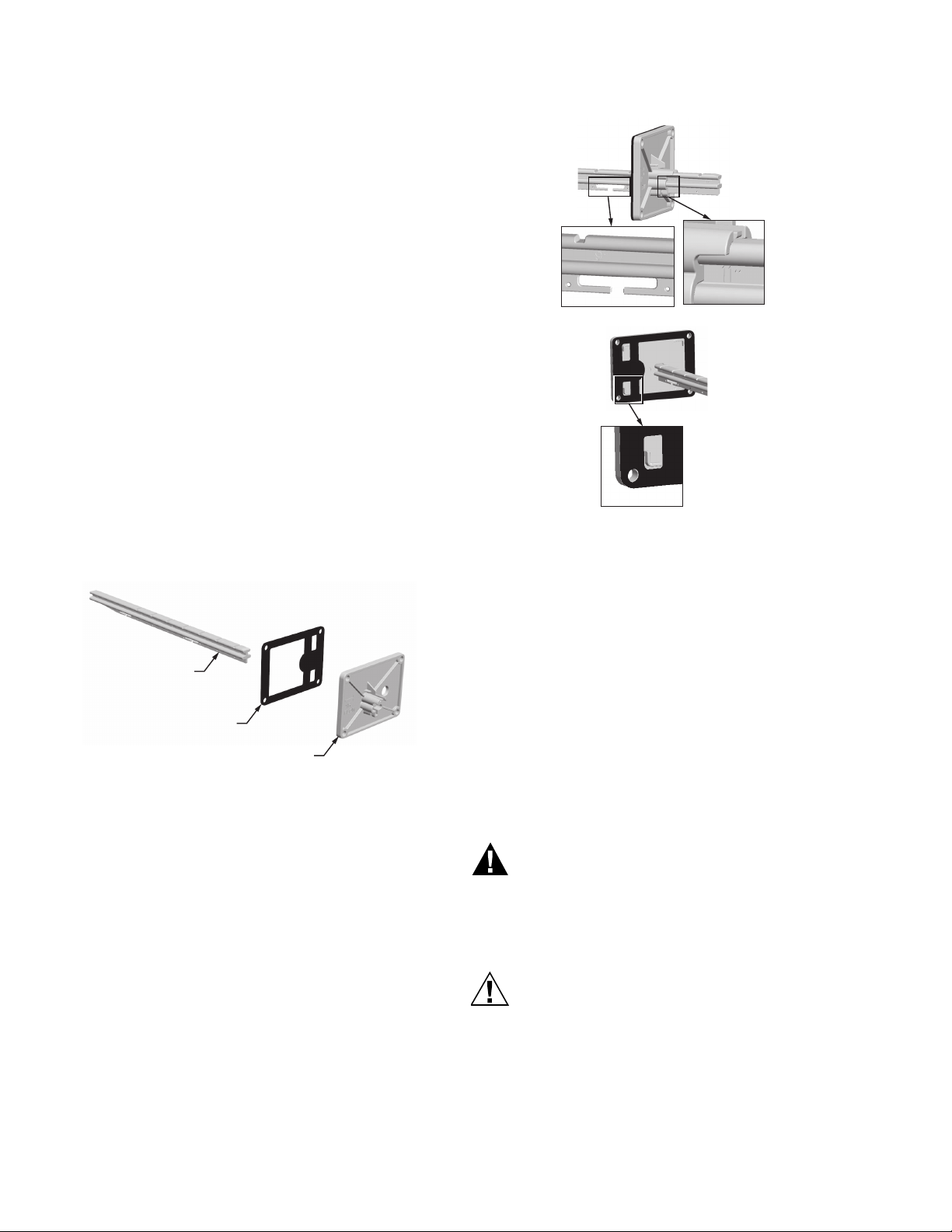

ROD - 1 PIECE

FLANGE - 1 PIECE

GASKET - 1 PIECE

M32281A

WIRE HO LDER

EXTENDED RELIEF

(FOR CORRECT MOUNTING)

M32282A

LENGTH ADJUSTS

6-12 INCHES

number. The sensor is set for the appropriate type of sensing

using the three position DIP switch located on the sensor. OA

position is OFF, OFF, OFF; RA is ON, OFF, OFF and DA is

OFF, ON, OFF. During installation the sensors are set for the

usage desired. See “Sylk Bus Sensor Wiring” on page 7 for

DIP switch details.

NOTE: The protective film on the dip switch is only nec-

essary during the factory assembly process. Simply push through the film to set the dip switches;

this will not harm the device.

Once installed, a sensor can be changed to a different

application by simply changing the DIP switch setting.

Sensor Mounting

The sensors can be mounted directly on to the sheet metal of

unit or can be mounted in the air stream using the duct

mounting kit (order separately).

The kit contains a rod to hold the sensor in the duct, a flange to

secure the sensor rod to the duct wall and fill the hole and a

gasket to prevent air from leaking through the duct wall. There

are five (5) kits in each bag assembly. See Fig. 2.

The rod has slots for threading the wire to prevent loose or

hanging wire in the duct and can be adjusted for 6 to 12 inch

length. The flange has extended relief for ease of mounting.

See Fig. 3.

Fig. 3. Duct Mounting Adjustments.

Fig. 2. Duct Mounting Kit (Part No. 50053060-001).

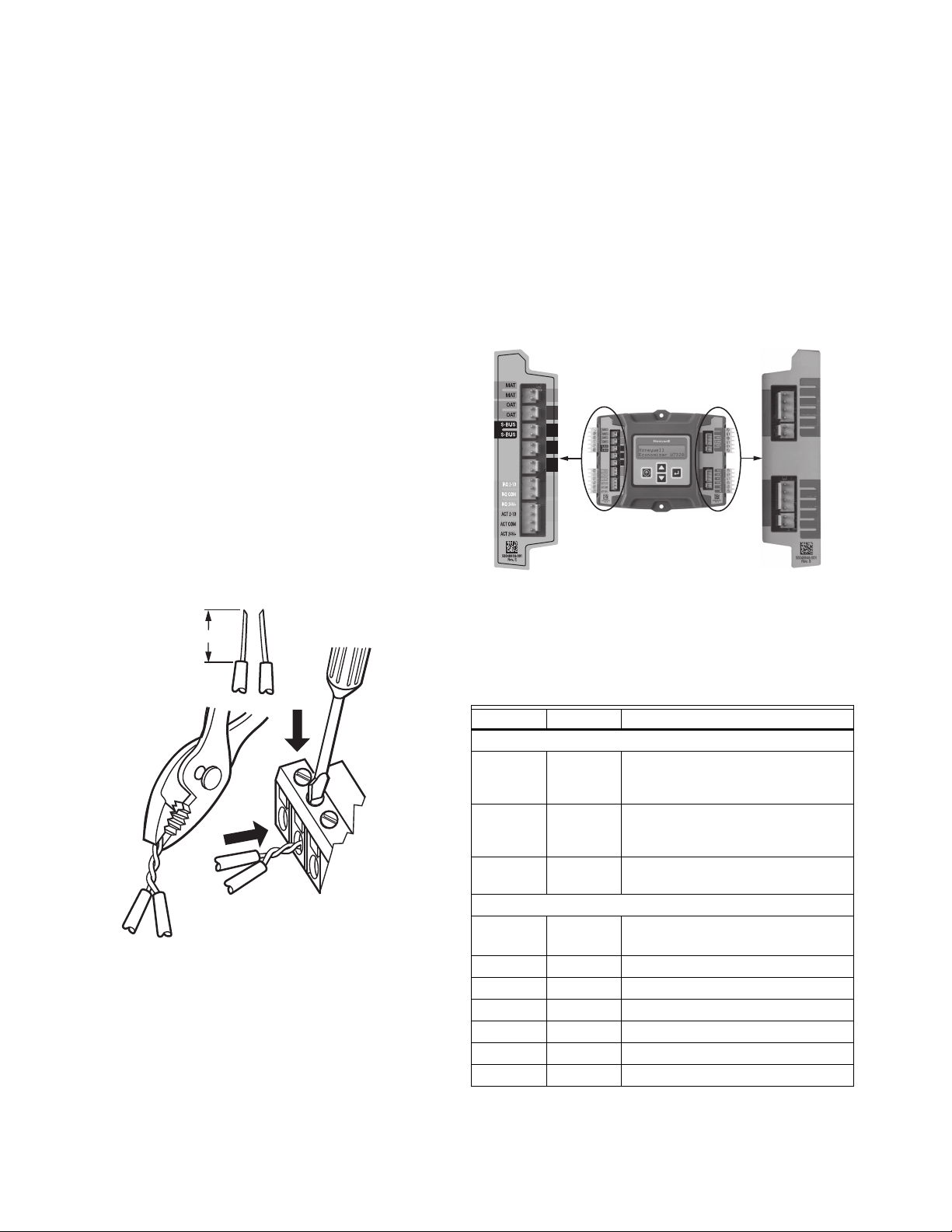

WIRING

All wiring must comply with applicable electrical codes and

ordinances, or as specified on installation wiring diagrams.

Module wiring in the field is terminated to the four screw

terminal blocks located on the left and right sides.

Module wiring at the OEM factory is terminated via the header

pin terminals located on the left and right sides. The header

terminal pins and the terminal blocks have common

terminations for the appropriate input or output. See OEM

wiring diagram in Fig. 20.

The remainder of this section describes the wiring for the

JADE™ Economizer module, W7220A.

Electrical Shock Hazard.

Can cause severe injury, death or property damage.

Disconnect power supply before beginning wiring, or

making wiring connections, to prevent electrical shock

or equipment damage.

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before handling

the unit.

63-2700—10 4

Page 5

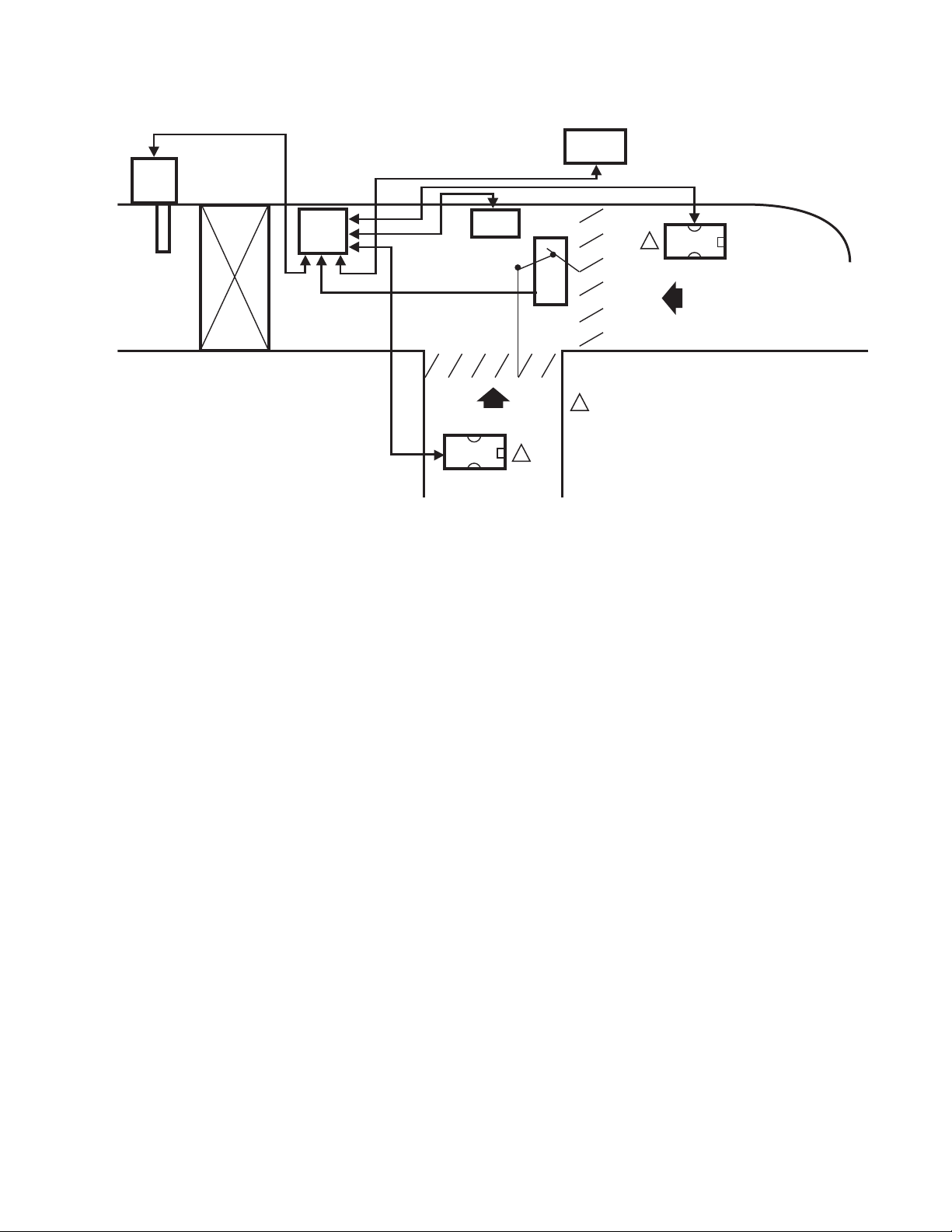

JADE™ ECONOMIZER MODULE

DISCHARGE

AIR SENSOR

C7400S

DIRECT

EXPANSION

COIL

C7400S

ENTHALPY

SENSOR

C7400S

ENTHALPY

SENSOR

RETURN AIR

OUTDOOR

AIR

C7250A

MIXED AIR

SENSOR

TWO STAGE COOL

PROGRAMMABLE

THERMOSTAT

FOR DIFFERENTIAL ENTHALPY, THE TWO C7400S ENTHALPY

SENSORS ARE CONNECTED TO THE W7720A ECONOMIZER

CONTROL ONE IS MOUNTED IN RETURN AIR, AND THE

OTHER IS MOUNTED IN OUTDOOR AIR. DIFFERENTIAL

ENTHALPY CONTROL PROVIDES GREATER ENERGY

SAVINGS THAN SINGLE ENTHALPY.

M35163

1

1

1

MS3103J

MS3105J

MS7505

ACTUATOR

W7720A

Fig. 4. Location of Outdoor Air, Return Air, Mixed Air, and Discharge Air Sensors in an economizer system.

5 63-2700—10

Page 6

JADE™ ECONOMIZER MODULE

1/2 (13)

1. STRIP 1/2 IN. (13 MM)

FROM WIRES TO

BE ATTACHED AT

ONE TERMINAL.

2. TWIST WIRES

TOGETHER WITH

PLIERS (A MINIMUM

OF THREE TURNS).

3. CUT TWISTED END OF WIRES

TO 3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING SCREW.

THEN PULL ON EACH WIRE IN ALL

TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M24382A

JADE CONTROLLER

LEFT TERMINAL

BLOCK LABEL

RIGHT TERMINAL

BLOCK LABEL

M32283C

AUX2-I

AUX1-O

AUX2-I

OCC

E-GND

EXH1

AUX1-O

Y2-I

Y2-O

Y1-I

Y1-O

C

R

Economizer Module Wiring Method

Wire the sensors and outputs, then wire the power connection.

Each terminal can accommodate the following gauges of wire:

• Single wire – from 18 AWG to 22 AWG solid or stranded

• Multiple wires – up to two 22 AWG stranded

• For the 24 Vac connections: single wire – from 14 to 18

AWG solid or stranded

• For S-BUS wiring, the sensors may be mounted up to 200

ft. (61 m) from the JADE controller. When the length of wire

is over 100 feet use twisted pair shielded wire.

• All sensor wiring to the Sylk bus and analog sensors is

polarity insensitive.

Prepare wiring for the terminal blocks, as follows:

1. Remove the plastic tabs from the side of the controller

where the connectors will slide onto the PWA.

2. Strip 1/2 in. (13 mm) insulation from the conductor.

3. Cut a single wire to 3/16 in. (5 mm). Insert the wire in the

required terminal location and tighten the screw.

4. If two or more wires are being inserted into one terminal

location, twist the wires together a minimum of three

turns before inserting them to ensure proper electrical

contact. See Fig. 5 on page 6.

5. Cut the twisted end of the wires to 3/16 in. (5 mm) before

inserting them into the terminal and tightening the screw.

6. Pull on each wire in all terminals to check for good

mechanical connection.

Economizer Module Wiring Details

The wiring connection terminals for each module/sensor are:

• “JADE™ Economizer Module Wiring” on this page.

• “Sylk Bus Sensor Wiring” on page 7.

JADE™ Economizer Module Wiring

Use Fig. 6 and Tables 1 and 2 to locate the wiring terminals for

the Economizer module.

NOTE: The four terminal blocks are removable. You can

slide out each terminal block, wire it, and then

slide it back into place.

Fig. 5. Attaching two or more wires at terminal blocks.

Fig. 6. W7220 Economizer module terminal connection

labels.

Table 1. Economizer Module - Left hand terminal blocks.

Label Type Description

Top Left Terminal Block

MAT

MAT

20k NTC

and

Mixed Air Temperature Sensor

(polarity insensitive connection)

COM

OAT

OAT

20k NTC

and

Outdoor Air Temperature Sensor

(polarity insensitive connection)

COM

S-BUS

S-BUS

SYLK Bus Sylk Bus sensor

(polarity insensitive connection)

Bottom Left Terminal Block

IAQ 2-10 2-10 Vdc Air Quality Sensor Input

(e.g. CO

sensor)

2

IAQ COM COM Air Quality Sensor Common

IAQ 24V 24 Vac Air Quality Sensor 24 Vac Source

ACT 2-10 2-10 Vdc Damper Actuator Output (2-10 Vdc)

ACT COM COM Damper Actuator Output Common

ACT 24V 24 Vac Damper Actuator 24 Vac Source

n/a The bottom pin is not used.

63-2700—10 6

Page 7

JADE™ ECONOMIZER MODULE

DIP

SWITCH

LABEL

M32271B

SYLK BUS

TERMINALS

(1 AND 2)

DIP

SWITCHES

(3)

SYLK BUS

2 PIN SIDE

CONNECTOR

Table 2. Economizer Module - Right hand terminal blocks.

Label Type Description

Top Right Terminal Block

n/a The first pin is not used

AUX2 I 24 Vac IN Shut Down (SD) or Heat (W)

Conventional only

or

Heat Pump Changeover (O/B) in

Heat Pump mode.

OCC 24 Vac IN Occupied / Unoccupied Input

E-GND EGND Earth Ground - System Required

EXH1 24 Vac OUT Exhaust Fan 1 Output

AUX1 O 24 Vac OUT Programmable:

Exhaust fan 2 output

or

ERV

or

System Alarm output.

Bottom Right Terminal Block

Y2-I 24 Vac IN Y2 in - Cooling Stage 2 Input from

space thermostat

Y2-O 24 Vac OUT Y2 out - Cooling Stage 2 Output to

stage 2 mechanical cooling

Y1-I 24 Vac IN Y1 in - Cooling Stage 1 Input from

space thermostat

Y1-O 24 Vac OUT Y1 out - Cooling Stage 1 Output to

stage 1 mechanical cooling

C COM 24 Vac Common

R 24 Vac 24 Vac Power (Hot)

Sylk Bus Sensor Wiring

The labels on the sensors and controller are color coded for

ease of installation. Orange labeled sensors can only be wired

to orange terminals on the controller. Brown labeled sensors

can only be wired to S-bus (brown) terminals. Use Fig. 7 and

Table 3 to locate the wiring terminals for each Sylk Bus sensor.

Use Fig. 7 and Table 4 to set the DIP switches for the desired

use of the sensor.

Table 3. SYLK Bus Sensor Wiring Terminations.

Terminal

Type DescriptionNbr Label

1 S-BUS SYLK

Bus

2 S-BUS SYLK

Bus

Sylk Bus Communications

(Sensor Bus) polarity insensitive

Sylk Bus Communications

(Sensor Bus) polarity insensitive

Table 4. SYLK Bus Sensor DIP Switch Settings.

DIP Switch Positions for Switches 1, 2, & 3

Use

a

DA

b

RA

c

OA

a

DA = Discharge Air

b

RA = Return Air

c

OA = Outdoor Air

123

OFF ON OFF

ON OFF OFF

OFF OFF OFF

NOTE: When using the Sylkbus sensors there will be a

slight delay while the Jade controller and the

sensor communicate. Analog sensors do not

communicate on the Sylkbus and output a 20k

ohm signal to the Jade controller so the response

time is instantaneous.

NOTE: When using the C7400S (Sylk bus enthalpy)

sensor there is an operation that will allow test of

the operation of the W7220 economizer when the

outdoor air conditions (temperature and humidity)

are too high for economizing.

1. Remove the C7250A dry bulb sensor from the OAT

terminals IF you are using temperature only economizing

change over.

2. If you are using enthalpy change over and have a

C7400S sensor with a date code prior to 1301, remove

the sensor and replace it with one with a date code after

1301.

3. Connect a C7400S Sylk bus sensor to the S-Bus

terminals (brown colored) on the W7220A Jade using

18 AWG to 22 AWG solid or stranded wires.

4. Check the STATUS screen for actual outdoor air (OA)

temperature and OA humidity readings.

5. Change the 3-position DIP switch on the C7400S sensor

from 1 OFF, 2 OFF, 3 OFF to 1 ON, 2 ON, 3 ON position

and immediately back to 1 OFF, 2 OFF 3 OFF position.

6. The output of the C7400S sensor to the W7220A will be

40 ºF and 40 %RH which will allow the economizer to go

into free cooling mode (economizing available).

7. Make sure you have 24 Vac on terminal Y1 In to simulate

a call for cooling.

8. After 15 minutes the C7400S sensor will change back to

the actual OA temperature and humidity.

NOTE: If you removed a dry bulb sensor, remove the

C7400S from the S-bus terminals and replace the

OAT sensor onto the OAT terminals.

Fig. 7. Sylk Bus sensor DIP switches.

7 63-2700—10

Page 8

JADE™ ECONOMIZER MODULE

Actuator Wiring Options:

1. The JADE economizer controller can only have one (1)

communicating actuator connected to it.

2. Up to four (4) non-communicating and two (2) 2-position

actuators (1 each on EXH1 and AUX1 O)

3. One (1) communicating and up to four (4) non-communicating and two (2) 2-position actuators (1 each on EXH1

and AUX1 O). When using a 2-position actuator on the

AUX1 O, the AUX1 O must be programmed for Exh2 and

the % open is the % open of the outdoor damper when

the 2-pos actuator opens. Connect 24 V to Exh1 and/or

AUX1 O and ground to the Jade "C" terminal.

CO2 Sensor Wiring

When using the C7232 Honeywell CO2 sensors the black and

brown common wires are internally connected and only one is

connected to "IAQ COM" on the Jade. Use the power from the

Jade to power the CO2 sensor OR make sure the ground for

the power supplies are common. See wiring diagram below for

the C7232 and C7632 wiring diagrams.

NOTE: When using the C7632 (or any 0-10 Vdc CO

sor) with the Jade you will need to set the

CO2ZERO to 400 ppm and the CO2SPAN to

1600 ppm in the ADVANCED SETUP menu.

NOTE: When using the TR40 CO

on the TR40-CO2 to 6. Only one TR40 CO

sensor set the address

2

can be used with the Jade economizer controller.

Address 6 is for a CO

communicating actuator.

sensor, address 11 is for a

2

sen-

2

sensor

2

C7232

ANALOG

24V

OUT

+

–

RED

BLACK

YELLOW

BROWN

ORANGE

GREEN

L1

(HOT)

L2

1

1 POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

Fig. 8. Wiring for C7232

C7632

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 9. Wiring for C7632

L1

(HOT)

L2

1

0-10 VDC

M34095

M17543B

63-2700—10 8

Page 9

JADE™ ECONOMIZER MODULE

ROOF TOP UNIT

Y1O

Y2O

Y1I

Y2I

OCC

24 VAC

1K1

1K1

E-GND

Y1

G

W2

W1

Y2

O/B

OCC

W7220 ECONOMIZER CONTROLLER MODULE

THERMOSTAT

CO2

SENSOR

2-10 VDC

(OPTIONAL)

MA

MA

OAT

OAT

C R

M28980D

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

AUX1-0

AUX2-I

OA TEMP

SENSOR

20K NTC

M7215

NOTE THAT THE C7250 20K NTC SENSOR CAN BE MOUNTED IN THE OAT ONLY IN THIS CONFIGURATION.

1

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS MAY DIFFER: W1 MAY BE LABELED O

OR B AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN ISOLATION RELAY BETWEEN O AND C.

2

3

3

1

MA TEMP

SENSOR

20K NTC

+

-

TR1

TR

IN

IN

2

R(+)

C(-)

1

2

ACTUATOR

EXH1 OR AUX1 O

NOTE: ON/OFF ACTUATORS CAN BE USED ON THE EXH1 OR AUX1

O TERMINAL WITH GROUND TO THE C TERMINAL. WHEN

PROGRAMMING THE EXH1 OR AUX1 O, THE % IS THE PERCENT

OPEN POSITION OF THE OUTDOOR AIR DAMPER WHEN THE

EXH1 OR AUX1 O TERMINAL IS ENERGIZED AND THE 2-POS

DAMPER GOES OPEN. IF USING THE AUX1 O TERMINAL

PROGRAM AUX1 O FOR EXH2.

C

M33409

V

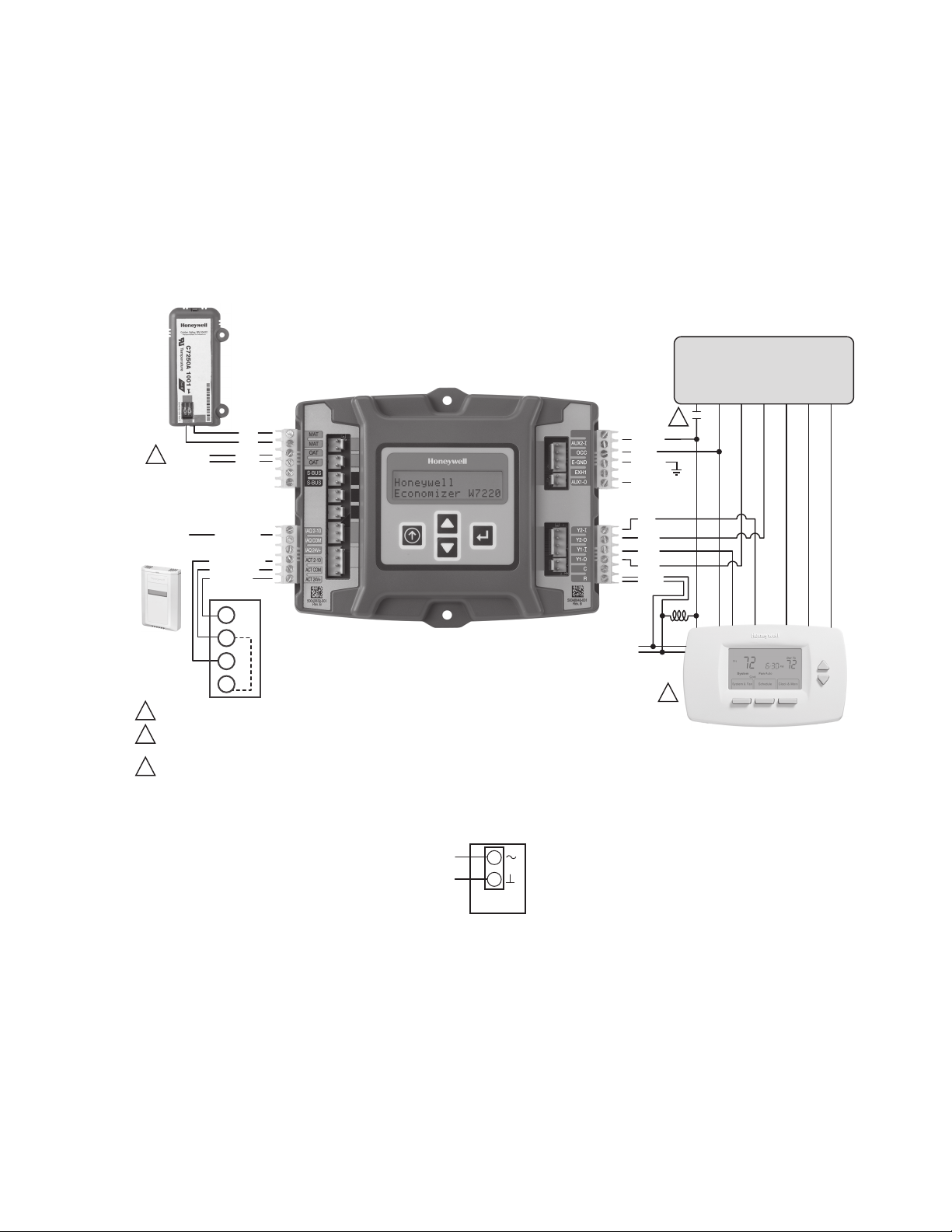

WIRING APPLICATION EXAMPLES

This section shows the wiring configurations for the JADE™ Economizer system.

Stand-alone Economizer

The most basic configuration is the stand-alone Economizer (see Fig. 10 and Fig. 15).

A stand-alone Economizer is directly wired to sensors, actuators, thermostat, and mechanical cooling controls in the roof top unit.

It does not require Sylk Bus communications.

Fig. 10. Stand-alone dry bulb Economizer configuration with black motor M7215.

Fig. 11. 2-position actuator.

9 63-2700—10

Page 10

JADE™ ECONOMIZER MODULE

M35158

TO THERMOSTAT

STATUS

LEDS

SENSORS

CONV

POWER

HEAT

COOL

FAN

U1

U2

U3

A

EIM

JADE W7220A1000

ON JADE CONTROLLER:

1. Y2-O CONNECT TO STAGE 2 MECHANICAL COOLING

2. Y1-O CONNECT TO STAGE 1 MECHANICAL COOLING

3. MAT IS MIXED AIR SENSOR C7250A1001

4. OAT IS TEMPERATURE CHAGEOVER C7250A1001

SENSOR OR S-BUS OA ENTHALPY SENSOR C7400S1000

5. AUX1 OUT PROGRAM TO SYS IN SYSTEM SETUP MENU

OCC

E-GND

AUX1 OUT

AUX2-I

Y1O

Y2O

Y1I

Y2I

C

TRANSFORMER

24

VAC

120

VAC

C

R

R

1

2

3

4

5

KIT WITH PRESTIGE AND EIM

YTHX9421R5051

EIM

THM5421R1013

RELAY

R822N1011

MS3103J1030

COMMUNICATING DCA

1

3

PRESTIGE

THX9421R5013

C

R

1

THE TRANSFORMER NEEDS

TO BE 100VA.

1

Fig. 12. Prestige and EIM with communicating actuator.

63-2700—10 10

Page 11

C7400S

OUTSIDE AIR

TEMP/HUMIDITY

(ENTHALPY)

SYLKBUS SENSOR

C7400S

RETURN AIR

TEMP/HUMIDITY

(ENTHALPY)

SYLKBUS SENSOR

ROOF TOP UNIT

Y1O

Y2O

Y1I

Y2I

OCC

E-GND

Y1

G

W2

W1

Y2

O/B

OCC

W7220 ECONOMIZER CONTROLLER MODULE

THERMOSTAT

C R

C(-)

M35159A

S-BUS

S-BUS

MAT

MAT

CO2

SENSOR

2-10 VDC

(OPTIONAL)

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

MA TEMP

SENSOR

20K NTC

AUX1-0

AUX2-I

3

1

2

MS3103J

OR MS3105J

S-BUS

4

5

S-BUS

R(+)

24 VAC

8

1K1

1K1

1

2

3

4

I/O BOARD ON SMARTVFD

HVAC DRIVE HVFDSD

G

C

Y2

Y1

W1

Y1

W1

Y2

G

Y2

W1

C

C

C

C

6

14

C

RELAY 1, DPDT RELAY, NO CONTACTS ENERGIZE DIGITAL INPUT 4 FOR HIGH SPEED FAN WITH W1 CALL.

RELAY 2, DPST RELAY, NO CONTACTS ENERGIZE DIGITAL INPUT 4 FOR HIGH SPEED FAN WITH Y2 CALL.

RELAY 3, SPST RELAY, NO CONTACTS ENERGIZE DIGITAL INPUT 1 FOR LOW SPEED FAN WITH Y1 CALL.

RELAY 4, SPST RELAY, NO CONTACTS ENERGIZE DIGITAL INPUT 1 FOR LOW SPEED FAN WITH G CALL.

LOW SPEED FAN IS CONFIGURED BY SETTING “MINIMUM FREQUENCY” WITH PARAMETER M1.8 OF THE STARTUP

WIZARD OF THE SMARTVFD HVAC.

HIGH SPEED FAN IS CONFIGURED BY SETTING “PRESET FREQUENCY 1” WITH PARAMETER M3.3.12 OF THE

SMARTVFD HVAC.

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS MAY DIFFER: W1 MAY BE LABELED O OR B

AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN ISOLATION RELAY BETWEEN O AND C.

NOTES: SEE INSTALLATION INSTRUCTIONS

62-0331 FOR SPECIFIC W7220 JADE

WIRING INFORMATION.

3

4

2

1

5

6

5

6

1 +10 Vref REFERENCE OUTPUT

2AI1+

ANALOG INPUT,

VOLTAGE OR CURRENT*

VOLTAGE

3

AI1- ANALOG INPUT COMMON

(CURRENT)

4AI2+

ANALOG INPUT,

VOLTAGE OR CURRENT

CURRENT

5

AI2 ANALOG INPUT COMMON

(CURRENT)

6 24Vout 24V AUX. VOLTAGE

7 GND I/O GROUND

8

DI1 DIGITAL INPUT 1

START FWD

9 DI2 DIGITAL INPUT 2

START REV

10

DI3

DIGITAL INPUT 3

FAULT

11 CM

COMMON A FOR DIN1-DIN6**

12 24Vout 24V AUX. VOLTAGE

13 GND I/O GROUND

14 DI4

DIGITAL INPUT 4 PRESET

FREQ

SELECT 1

15 DI5

DIGITAL INPUT 5 PRESET

FREQ

SELECT 2

16 DI6 DIGITAL INPUT 6

FAULT RESET

17

C

COMMON A FOR DIN1-DIN6**

18

AO1 ANALOG SIGNAL (+OUTPUT)

OP FREQ

19

AO-/GND ANALOG OUTPUT COMMON

30

+24 Vin

24V AUXILIARY INPUT VOLTAGE

A

RS485

DIFFERENTIAL RECEIVER/

TRANSMITTER

B

RS485

DIFFERENTIAL RECEIVER/

TRANSMITTER

BASIC I/O BOARD

TERMINAL SIGNAL DEFAULT

8

7

8

7

JADE™ ECONOMIZER MODULE

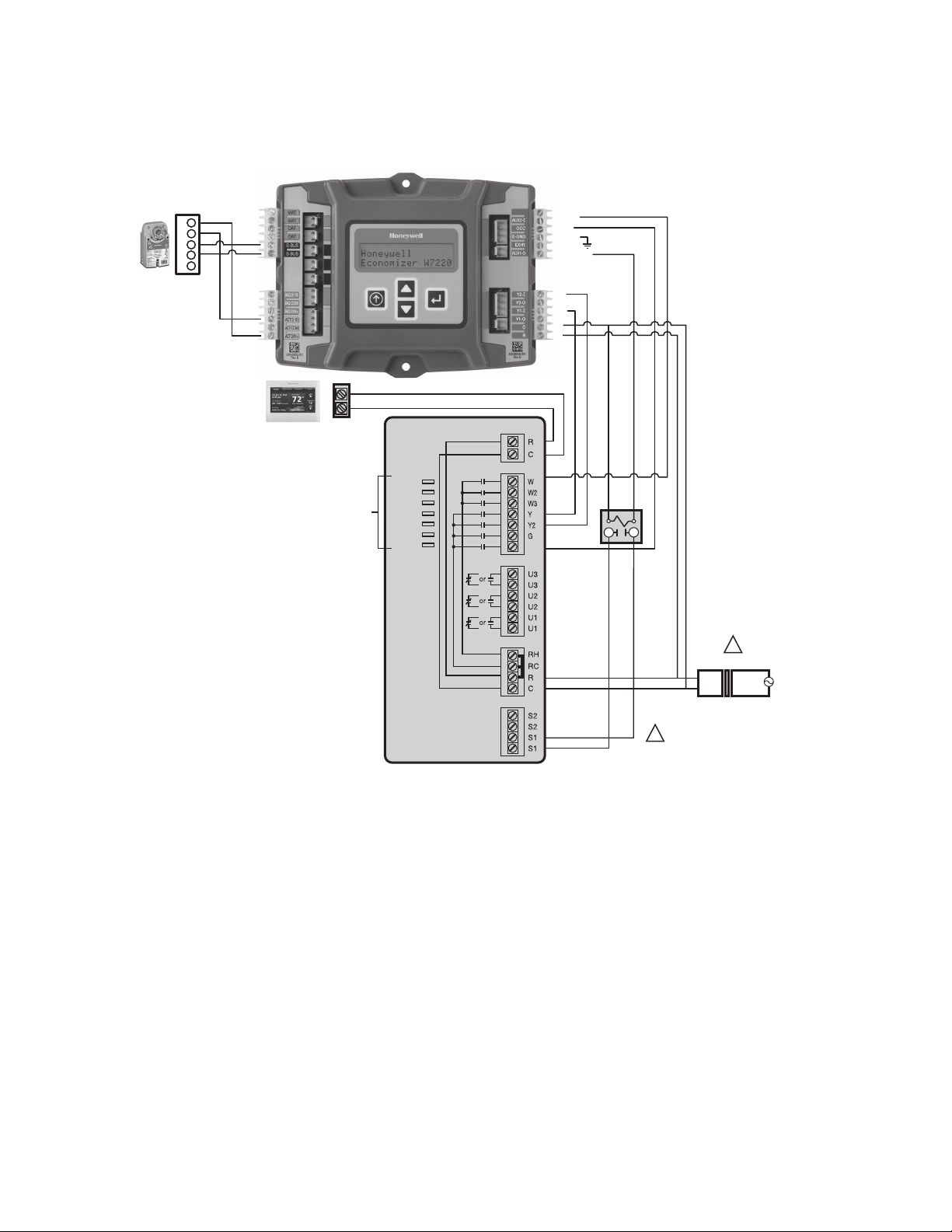

Fig. 13. Jade with Prestige IAQ thermostat, communicating actuator, CO2 and VFD.

11 63-2700—10

Page 12

JADE™ ECONOMIZER MODULE

M35157

TO THERMOSTAT

STATUS

LEDS

SENSORS

CONV

POWER

HEAT

COOL

FAN

U1

U2

U3

A

EIM

JADE W7220A1000

ON JADE CONTROLLER:

1. Y2-O CONNECT TO STAGE 2 MECHANICAL COOLING

2. Y1-O CONNECT TO STAGE 1 MECHANICAL COOLING

3. MAT IS MIXED AIR SENSOR C7250A1001

4. OAT IS TEMPERATURE CHAGEOVER C7250A1001

SENSOR OR S-BUS OA ENTHALPY SENSOR C7400S1000

5. AUX1 OUT PROGRAM TO SYS IN SYSTEM SETUP MENU

OCC

E-GND

AUX1 OUT

AUX2-I

Y1O

Y2O

Y1I

Y2I

C

TRANSFORMER

24

VAC

120

VAC

C

R

R

TR

IN

IN

PRESTIGE

THX9421R5013

KIT WITH PRESTIGE AND EIM

YTHX9421R5051

EIM

THM5421R1013

RELAY

R822N1011

1

3

TR1

+

–

M7215

ACT (2-10V)

ACT COM

ACT 24V

C

R

THE TRANSFORMER NEEDS

TO BE 100VA.

1

1

Fig. 14. Jade with Prestige IAQ thermostat and EIM, communicating actuator, CO2 and VFD.

63-2700—10 12

Page 13

JADE™ ECONOMIZER MODULE

ROOF TOP UNIT

Y1O

Y2O

Y1I

Y2I

OCC

24 VAC

E-GND

Y1

G

W2

W1

Y2

O/B

OCC

W7220 ECONOMIZER CONTROLLER MODULE

THERMOSTAT

CO2

SENSOR

2-10 VDC

(OPTIONAL)

MAT

MAT

OAT

OAT

C R

M32564D

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

3

OAT TEMP

SENSOR

20K NTC

MS7503 OR MS7505

NOTE THAT THE 20K NTC SENSOR CAN BE MOUNTED IN THE OAT TERMINALS ONLY IN THIS CONFIGURATION.

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS MAY DIFFER: W1 MAY BE LABELED O

OR B AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN ISOLATION RELAY BETWEEN O AND C.

1

1

MA TEMP

SENSOR

20K NTC

R(+)

C(-)

AUX1-0

AUX2-I

2

3

2

3

1K1

1K1

EXH1 and EXH2 wiring:

Relay Digital Output Rating at 30 Vac (maximum powerfrom Class 2 input only): 1.5A run;

3.5A inrush @ 0.45PF (200,000 cycles) or

7.5A inrush @ 0.45PF (100,000 cycles)

If the inrush or FLA amps is above listed limits OR if the fan is a line voltage fan, an external relay will be required.

If no relay is required, the EXH1 or AUX1 out is wired to one side of the fan and the other side is wired to system common "C" on

the W7220 or equipment terminal board. (W7220 powered off the system transformer).

If a relay is required, the coil of the relay would be wired between the EXH1 or AUX1 and the C terminal of the W7220.

Fig. 15. Stand-alone dry-bulb Economizer configuration with Honeywell MS7503 or MS7505 Direct Coupled Actuator.

13 63-2700—10

Page 14

JADE™ ECONOMIZER MODULE

ROOF TOP UNIT

Y1O

Y2O

Y1I

Y2I

OCC

24 VAC

E-GND

Y1

G

W2

W1

Y2

O/B

OCC

W7220 ECONOMIZER CONTROLLER MODULE

THERMOSTAT

CO2

SENSOR

2-10 VDC

(OPTIONAL)

MAT

MAT

OAT

OAT

C R

R(+)

C(-)

M32650D

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

3

1

2

OAT TEMP

SENSOR

20K NTC

MS3103J

OR MS3105J

1

1

MA TEMP

SENSOR

20K NTC

S-BUS

4

5

S-BUS

AUX1-0

AUX2-I

NOTE THAT THE 20K NTC SENSOR CAN BE MOUNTED IN THE OAT TERMINALS ONLY IN THIS CONFIGURATION.

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS MAY DIFFER: W1 MAY BE LABELED O

OR B AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN ISOLATION RELAY BETWEEN O AND C.

2

2

3

3

1K1

1K1

Fig. 16. Stand-alone dry-bulb Economizer configuration with Honeywell MS3103J or MS3105J communicating actuators.

63-2700—10 14

Page 15

JADE™ ECONOMIZER MODULE

Economizer with Sylk Bus Sensors

A standalone economizer with Sylk Bus sensors uses Sylk Bus communications (see Fig. 17, Fig. 18 and Fig. 19). The Sylk Bus

reduces wiring requirements while providing additional functionality.

CO2

SENSOR

2-10 VDC

(OPTIONAL)

1

MA TEMP

SENSOR

20K NTC

MAT

MAT

S-BUS

S-BUS

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

TR

TR1

IN

+

IN

-

2

W7220 ECONOMIZER CONTROLLER MODULE

M7215

OUTSIDE AIR

TEMP/HUMIDITY (ENTHALPY)

SYLKBUS SENSOR

RETURN AIR

TEMP/HUMIDITY (ENTHALPY)

SYLKBUS SENSOR

ROOF TOP UNIT

O/B

4

1K1

AUX2-I

OCC

E-GND

AUX1-0

Y2I

Y2O

Y1I

Y1O

1K1

C R

R(+)

24 VAC

IN THIS CONFIGURATION, AN OPTIONAL DISCHARGE AIR TEMP/HUMIDITY

1

(ENTHALPY) SYLKBUS SENSOR CAN BE ADDED FOR ADVANCED CONTROL

AS SHOWN IN THE LOWER LEFT OF THIS FIGURE.

DO NOT USE THE C7250 20K NTC SENSOR WITH THE OA TERMINAL IN THIS

2

CONFIGURATION.

3

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS

MAY DIFFER: W1 MAY BE LABELED O OR B AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN ISOLATION

4

RELAY BETWEEN O AND C.

C(-)

3

OCC

Y1

Y2

THERMOSTAT

W1

G

W2

M32565D

Fig. 17. Economizer with Sylk Bus sensors for enthalpy configuration with Honeywell M7215 black motor.

15 63-2700—10

Page 16

JADE™ ECONOMIZER MODULE

OUTSIDE AIR

TEMP/HUMIDITY (ENTHALPY)

SYLKBUS SENSOR

RETURN AIR

TEMP/HUMIDITY (ENTHALPY)

SYLKBUS SENSOR

ROOF TOP UNIT

Y1O

Y2O

Y1I

Y2I

OCC

E-GND

Y1

G

W2

W1

Y2

O/B

OCC

W7220 ECONOMIZER CONTROLLER MODULE

THERMOSTAT

C R

R(+)

C(-)

M32566D

IN THIS CONFIGURATION, AN OPTIONAL DISCHARGE AIR TEMP/HUMIDITY

(ENTHALPY) SYLKBUS SENSOR CAN BE ADDED FOR ADVANCED CONTROL AS

SHOWN IN THE LOWER LEFT OF THIS FIGURE.

DO NOT USE THE C7250 20K NTC SENSOR WITH THE OA TERMINAL IN THIS

CONFIGURATION.

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS MAY DIFFER:

W1 MAY BE LABELED O OR B AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN ISOLATION

RELAY BETWEEN O AND C.

1

1

2

MS7503 OR MS7505

3

S-BUS

S-BUS

MAT

MAT

CO2

SENSOR

2-10 VDC

(OPTIONAL)

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

MA TEMP

SENSOR

20K NTC

AUX1-0

AUX2-I

2

3

4

3

4

1K1

1K1

24 VAC

Fig. 18. Economizer with Sylk Bus sensors for enthalpy configuration with a Honeywell MS7503 or MS7505 Direct

63-2700—10 16

Coupled Actuator.

Page 17

JADE™ ECONOMIZER MODULE

C7400S

OUTSIDE AIR

TEMP/HUMIDITY (ENTHALPY)

SYLKBUS SENSOR

C7400S

RETURN AIR

TEMP/HUMIDITY (ENTHALPY)

SYLKBUS SENSOR

ROOF TOP UNIT

Y1O

Y2O

Y1I

Y2I

OCC

E-GND

Y1

G

W2

W1

Y2

O/B

OCC

W7220 ECONOMIZER CONTROLLER MODULE

THERMOSTAT

C R

C(-)

M32653D

IN THIS CONFIGURATION, AN OPTIONAL DISCHARGE AIR TEM/HUMIDITY

(ENTHALPY) SYLKBUS SENSOR CAN BE ADDED FOR ADVANCED

CONTROL AS SHOWN IN THE LOWER LEFT OF THIS FIGURE.

1

1

THE S-BUS COMPONENTS MAY BE DAISY CHAINED TO ANOTHER S-BUS

COMPONENT.

WHEN USING A HEAT PUMP THERMOSTAT, THERMOSTAT TERMINALS

MAY DIFFER: W1 MAY BE LABELED O OR B AND W2 MAY BE LABELED W.

WHEN USING A HEAT PUMP WITH DEFROST FEEDBACK, ADD AN

ISOLATION RELAY BETWEEN O AND C.

2

S-BUS

S-BUS

MAT

MAT

CO2

SENSOR

2-10 VDC

(OPTIONAL)

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

MA TEMP

SENSOR

20K NTC

AUX1-0

AUX2-I

3

1

2

MS3103J

OR MS3105J

S-BUS

4

5

S-BUS

2

R(+)

24 VAC

3

3

4

1K1

1K1

4

Fig. 19. Economizer with Sylk Bus sensors for enthalpy configuration with a Honeywell MS3103J or MS3105J

communicating actuators.

AUX2-1

E-GND

AUX1-O

EXH1

OCC

Y2-I

Y2-O

Y1-I

Y1-O

R

C

RIGHT TERMINAL

BLOCK LABEL

AUX2 IN

AUX2-I

OCC

E-GND

EXH1

AUX1 OUT

AUX1-O

Y2-I

Y2-O

Y1-I

Y1-O

C

R

6-PIN CONNECTOR

NEEDED (VHR-6N)

M31402E

PART NUMBER PIN COUNT MANUFACTURER

JST VH CONNECTOR PLASTIC HOUSING VHR-2N PLUS 2 PIECES SVH-21T-P1.1 METAL CONTACT 2 JST VH

JST VH CONNECTOR PLASTIC HOUSING VHR-3N PLUS 3 PIECES SVH-21T-P1.1 METAL CONTACT 3 JST VH

JST VH CONNECTOR PLASTIC HOUSING VHR-4N PLUS 4 PIECES SVH-21T-P1.1 METAL CONTACT 4 JST VH

JST VH CONNECTOR PLASTIC HOUSING VHR-6N PLUS 6 PIECES SVH-21T-P1.1 METAL CONTACT 6 JST VH

TYPE 42743-2 1 AMP 1/4 INCH QUICK CONNECT

FOR M7215 BLACK MOTOR

NOTE: THOSE ARE NOT HONEYWELL PART NUMBERS. TO PLACE AN ORDER - CONTACT YOUR SALES REPRESENTATIVE.

Fig. 20. OEM wiring harness information. Refer to previous wiring diagrams for detailed application wiring.

2-PIN CONNECTOR

NEEDED (VHR-2N)

3-PIN CONNECTOR

NEEDED (VHR-3N)

4-PIN CONNECTOR

NEEDED (VHR-4N)

LEFT TERMINAL

BLOCK LABEL

MAT

MAT

OAT

OAT

S-BUS

S-BUS

S-BUS

S-BUS

S-BUS

S-BUS

IAQ 2-10

IAQ COM

IAQ 24V+

ACT 2-10

ACT COM

ACT 24V+

NOT USED

JADE CONTROLLER

NOT USED

17 63-2700—10

Page 18

JADE™ ECONOMIZER MODULE

M32274A

2 LINE

LCD

SELECT (ENTER)

BUTTON

SCROLL

(UP/DOWN)

BUTTONS

MENU UP

(EXIT)

BUTTON

INTERFACE OVERVIEW

This section describes how to use the Economizer’s user

interface for:

• Keypad and menu navigation

• Settings and parameter changes

• Menu structure and selection

User Interface

The user interface consists of an LCD display and a 4-button

keypad on the front of the Economizer module. The LCD is a

16 character by 2 line dot matrix display.

Fig. 21. Economizer LCD and Keypad Layout.

• Press the

parameter value.

• Press the button to decrease (change) the displayed

parameter value.

• Press the button to accept the displayed value and store it

in non-volatile RAM.

• CHANGE STORED displays.

• Press the button (MenuUp/Exit) to return to the

previous menu.

a

When values are displayed, pressing and holding the or

button causes the display to automatically increment.

button to increase (change) the displayed

a

a

Menu Structure

Table 5 on page 19 illustrates the complete hierarchy of menus

and parameters for the JADE™ Economizer system.

The Menus in display order are:

•STATUS

• SETPOINTS

• SYSTEM SETUP

• ADVANCED SETUP

• CHECKOUT

•ALARMS

IMPORTANT

Table 5 on page 19 illustrates the complete hierarchy.

Your menu parameters will be different depending on

your configuration.

Keypad

The four navigation buttons illustrated in Fig. 21 are used to

scroll through the menus and menu items, select menu items,

and to change parameter and configuration settings.

Using the Keypad with Menus

To use the keypad when working with menus:

• Press the

• Press the button to move to the next menu.

• Press the button (Enter) to display the first item in the

currently displayed menu.

• Press the button (Menu up) to exit a menu’s item and

return to the list of menus.

button to move to the previous menu.

Using the Keypad with Settings and

Parameters

To use the keypad when working with Setpoints, System and

Advanced Settings, Checkout tests, and Alarms:

• Navigate to the desired menu.

• Press the button (Enter) to display the first item in the

currently displayed menu.

•Use the

parameter.

• Press the button (Enter) to display the value of the

currently displayed item.

and buttons to scroll to the desired

For example if you do not have a DCV (CO

then none of the DCV parameters appear and only

MIN POS will display. If you have a CO2 sensor, the

DCV MIN and DCV MAX will appear AND if you have

2 speed fan DCV MIN (high and low speed) and DCV

MAX (high and low speed will appear).

) sensor,

2

SETUP AND CONFIGURATION

Before being placed into service, the JADE™ Economizer

module must be setup and configured for the installed system.

IMPORTANT

During setup, the Economizer module is live at all

times.

The setup process uses a hierarchical menu structure that is

easy to use. You press the

forward and backward through the menus and press the

button to select and confirm setup item changes.

Time-out and Screensaver

When no buttons have been pressed for 10 minutes, the LCD

displays a screen saver, which cycles through the Status items.

Each Status items displays in turn and cycles to the next item

after 5 seconds.

and arrow buttons to move

63-2700—10 18

Page 19

JADE™ ECONOMIZER MODULE

Table 5. Menu Structurea.

Parameter

Range and

Increment

b

Notes

Menu Parameter

Parameter

Default

Val ue

STATUS ECON AVAIL NO YES/NO YES = economizing available; the system can use Outdoor Air for

free cooling when required.

ECONOMIZING NO YES/NO

YES = Outdoor Air being used for 1

st

stage cooling.

OCCUPIED NO YES/NO YES = OCC signal received from space thermostat or unitary

controller.

YES = 24 Vac on terminal OCC

No = 0 Vac on terminal OCC.

HEAT PUMP

n/a

c

COOL

HEAT

Displays COOL or HEAT when system is set to heat pump (nonconventional)

COOL Y1-IN OFF ON/OFF Y1-I signal from space thermostat or unitary controller for

cooling stage 1.

ON = 24 Vac on term Y1-I

OFF = 0 Vac on term Y1-I

COOL Y1-OUT OFF ON/OFF Cool Stage 1 Relay Output to mechanical cooling (Y1-OUT

terminal).

COOL Y2-IN OFF ON/OFF Y2-I signal from space thermostat or unitary controller for

second stage cooling.

ON = 24 Vac on term Y2-I

OFF = 0 Vac on term Y2-I

COOL Y2-OUT OFF ON/OFF Cool Stage 2 Relay Output to mechanical cooling (Y2-OUT

terminal).

MA TEMP _ _._ ºF -40 to 150 ºF Displays value of measured mixed air from MAT sensor.

Displays --.- if not connected, short, or out- of-range.

DA TEMP _ _._ ºF -40 to 150 ºF Displays when Discharge Air Sylk Bus sensor is connected and

displays measured discharge air temperature.

Displays --.-°F if sensor sends invalid value, if not connected,

short or out-of-range.

OA TEMP _ _._ ºF -40 to 140 ºF Displays measured value of outdoor air temperature.

Displays --°F if sensor sends invalid value, if not connected,

short or out-of-range.

OA HUM _ _ % 0 to 100% Displays measured value of outdoor humidity from OA Sylkbus

sensor. Displays --% if not connected, short, or out- of-range.

RA TEMP _ _._ ºF 0 to 140 ºF Displays measured value of return air temperature from RA

Sylkbus sensor. Displays --°F if sensor sends invalid value, if not

connected, short or out-of-range.

RA HUM _ _ % 0 to 100% Displays measured value of return air humidity from RA Sylkbus

sensor. Displays --% if sensor sends invalid value, if not

connected, short or out-of-range.

IN CO2 _ _ _ ppm 0 to 2000 ppm Displays value of measured CO2 from CO2 sensor. Invalid if not

connected, short or out-of-range. May be adjusted in Advanced

menu by Zero offset and Span. See note on page 6 concerning

C7632 sensor.

DCV STATUS n/a ON/OFF Displays ON if above setpoint and OFF if below setpoint, and

ONLY if a CO2 sensor is connected.

DAMPER OUT 2.0V 2.0 to 10.0 V

Displays output voltage or position to the damper actuator.

e

ACT POS n/a 0 to 100% Displays actual position of actuator.

ACT COUNT n/a 1 to 65,535 Displays number of times actuator has cycled. 1 Cycle equals

the sum of 180° of movement in any direction.

ACTUATOR n/a OK/Alarm (on

Displays Error if voltage or torque is below actuator range

Alarm menu)

EXH1 OUT OFF ON/OFF Output of EXH1 terminal. Displays ON when damper position

reaches programmed percentage setpoint.

ON = 24 Vac Output; OFF = No Output.

19 63-2700—10

Page 20

JADE™ ECONOMIZER MODULE

Table 5. Menu Structure

Parameter

Range and

Increment

Menu Parameter

STATUS

EXH2 OUT OFF ON/OFF Output of AUX1 O terminal Displays ON when damper position

Parameter

Default

Val ue

CONTINUED

ERV OFF ON/OFF Output of AUX1 O terminal, ON = 24 Vac Output, OFF = No

MECH COOL ON

0 0, 1, or 2 Displays number of mechanical cooling stages that are active.

or

HEAT STAGES ON

FAN SPEED n/a LOW or HIGH Displays speed of fan on a 2-speed fan unit

W (HEAT IN) n/a ON/OFF Displays status of heat on a 2-speed fan unit.

SETPOINTS MAT SET 53ºF 38 to 70 ºF;

increment by 1

LOW T LOCK 32ºF -45 to 80 ºF;

increment by 1

DRYBLB SET 63ºF 48 to 80 ºF;

increment by 1

ENTH CURVE ES3 ES1, ES2, ES3,

ES4, or ES5

DCV SET 1100ppm 500 to 2000

ppm

increment by

100

MIN POS 2.8 V 2 to 10 Vdc Displays ONLY if a CO2 sensor is NOT connected.

VENTMAX 2.8 V 2 to 10 Vdc Displays only if a CO2 sensor is connected.

100 to 9990 cfm

increment by 10

2 to 10 Vdc With 2-speed fan units VENTMAX L (low speed fan) and

VENTMIN 2.25 V 2 to 10 Vdc Displays only if CO2 sensor is connected.

100 to 9990 cfm

increment by 10

2 to 10 Vdc With 2-speed fan units VENTMIN L (low speed fan) and

ERV OAT SP

d

32ºF 0 to 50 ºF;

increment by 1

a

. (Continued)

b

Notes

reaches programmed percentage setpoint

ON = 24 Vac Output, OFF = No Output; displays only if AUX1 O =

EXH2

Output; displays only if AUX1 O = ERV

Displays the stage of heat pump heating that is active.

The economizer will modulate the OA damper to maintain the

mixed air temperature at the setpoint.

Setpoint determines outdoor temperature when the mechanical

cooling cannot be turned on. Commonly referred to as the

Compressor lockout. At or below the setpoint the Y1-O and

Y2-O will not be energized on the controller.

Dry bulb setpoint will only appear if using dry bulb change over.

Setpoint determines where the economizer will assume outdoor

air temperature is good for free cooling; e.g.; at 63 ºF setpoint

unit will economizer at 62 ºF and below and not economize at

64 ºF and above. There is a a 2 ºF deadband.

ES curve will only appear if using enthalpy changeover.

Enthalpy boundary “curves” for economizing using single

enthalpy.

See page 22 for description of enthalpy curves.

Displays ONLY if a CO2 sensor is connected.

Setpoint for Demand Control Ventilation of space. Above the

setpoint, the OA dampers will modulate open to bring in

additional OA to maintain a space ppm level below the setpoint.

With 2-speed fan units MIN POS L (low speed fan) and MIN POS

H (high speed fan) settings are required. Default for MIN POS L

is 3.2V and MIN POS H is 2.8V.

Used for Vbz (ventilation max cfm) setpoint. VENTMAX is the

same setting as MIN POS would be if you did not have the CO2

sensor.

If OA, MA RA and CO2 sensors are connected and DCV CAL

ENABLE is set to AUTO mode, the OA dampers are controlled by

CFM and displays from 100 to 9990 cfm.

VENTMAX H (high speed fan) settings are required. Default for

VENTMAX L is 3.2V and VENTMAX H is 2.8V.

Used for Va (ventilation min cfm) setpoint. This is the ventilation

requirement for less than maximum occupancy of the space.

If OA, MA RA and CO2 sensors are connected and DCV CAL

ENABLE is set to AUTO mode, the OA dampers are controlled by

CFM and displays from 100 to 9990 cfm.

VENTMIN H (high speed fan) settings are required. Default for

VENTMIN L is 2.5V and VENTMIN H is 2.25V.

Only when AUX1 O = ERV

63-2700—10 20

Page 21

JADE™ ECONOMIZER MODULE

Menu Parameter

SETPOINTS

EXH1 SET 50% 0 to 100%;

CONTINUED

EXH2 SET 75% 0 to 100%;

SYSTEM

INSTALL 01/01/11 Display order = MM/DD/YY

SETUP

UNITS DEG ºF ºF or ºC Sets economizer controller in degrees Fahrenheit or Celsius.

EQUIPMENT CONV CONV

AUX2 IN n/a Shutdown (SD)

Table 5. Menu Structure

Parameter

Default

Val ue

Parameter

Range and

Increment

increment by 1

increment by 1

HP

Heat (W1)

HP(O)

HP(B)

a

. (Continued)

b

Notes

Setpoint for OA damper position when exhaust fan 1 is powered

by the economizer.

With 2-speed fan units Exh1 L (low speed fan) and Exh1 H (high

speed fan) settings are required. Default for Exh1 L is 65% and

Exh1 H is 50%

Setpoint for OA damper position when exhaust fan 2 is powered

by the economizer. Only used when AUX1 O is set to EHX2.

With 2-speed fan units Exh2 L (low speed fan) and Exh2 H (high

speed fan) settings are required. Default for Exh2 L is 80% and

Exh2 H is 75%

Setting order = DD, MM, then YY.

CONV = conventional.

HP O/B = Enables Heat Pump mode. Use AUX2 I for Heat Pump

input from thermostat or controller.

In CONV mode:

SD = Enables configuration of shutdown (default);

W = Informs controller that system is in heating mode.

NOTE: If using 2-speed fan mode, you must pro-

gram CONV mode for W. Shutdown is not

available in the two-speed fan mode.

In HP O/B mode:

HP(O) = energize heat pump on Cool (default);

HP(B) = energize heat pump on Heat.

FAN SPEED 1 speed 1 speed/

2 speed

Sets economizer controller for operation of 1 speed or 2 speed

supply fan. The controller does not control the fan but positions

the OA and RA dampers to the heating or cooling mode. See

page 23 for modes and position.

NOTE: 2-speed fan option also needs Heat (W1) pro-

grammed in AUX 2 In.

FAN CFM 5000cfm 100 to 50000

cfm;

increment by

This is the capacity of the RTU. The value is found on the label

from the RTU manufacturer. The cfm of the fan is only used with

DCV CAL ENABLE AUO

100

AUX1 OUT NONE NONE

ERV

EXH2

SYS

• NONE = not configured (output is not used)

• ERV= Energy Recovery Ventilator

d

• EXH2 = second damper position 24 Vac out for second

exhaust fan.

• SYS = use output as an alarm signal

OCC INPUT INPUT or

ALWAYS

When using a setback thermostat with occupancy out (24 Vac),

the 24 Vac is input “INPUT” to the OCC terminal. If no

occupancy output from the thermostat then change program to

“ALWAYS” OR add a jumper from terminal R to OCC terminal.

FACTORY DEFAULT NO NO or YES Resets all set points to factory defaults when set to YES. LCD

will briefly flash YES and change to NO but all parameters will

change to factory default values.

21 63-2700—10

Page 22

JADE™ ECONOMIZER MODULE

Menu Parameter

ADVANCED

MA LO SET 45 ºF 35 to 65 ºF;

SETUP

FREEZE POS CLO CLO

CO2 ZERO 0ppm 0 to 500 ppm;

CO2 SPAN 2000ppm 1000 to 3000

STG3 DLY 2.0h 0 min, 5 min, 15

SD DMPR POS CLO CLO

DA LO ALM 45 ºF NONE

DA HI ALM 80 ºF NONE

DCVCAL ENA MAN MAN (manual)

MAT T CAL 0.0 F° +/-2.5F° Allows for the operator to adjust for an out of calibration

OAS T CAL 0.0F° +/-2.5F° Allows for the operator to adjust for an out of calibration

OAS H CAL 0% RH +/-10% RH Allows for the operator to adjust for an out of calibration

RA T CAL 0.0F° +/-2.5F° Allows for the operator to adjust for an out of calibration

RA H CAL 0% RH +/-10% RH Allows for the operator to adjust for an out of calibration

DA T CAL 0.0 F° +/-2.5F° Allows for the operator to adjust for an out of calibration

2SP FAN DELAY 5 Minutes 0 to 20 minutes

Table 5. Menu Structure

Parameter

Default

Val ue

Parameter

Range and

Increment

increment by 1º

MIN

increment by 10

ppm;

increment by 50

min, then 15

min intervals.

Up to 4h or OFF

OPN

35ºF to 65ºF in

5ºF increments

70 ºF to 180 ºF

in 5º F

increments

AUTO

in 1 minute

increments.

a

. (Continued)

b

Notes

Temp to activate Freeze Protection (close damper or modulate to

MIN POS if temp falls below set value)

Damper position when freeze protection is active (closed or MIN

POS).

CO2 ppm level to match CO2 sensor start level.

CO2 ppm span to match CO2 sensor; e.g.; 500-1500 sensor

output would be 500 CO2 zero and 1000 CO2 span. See note on

page 6 for C7632 CO2 sensor.

Delay after stage 2 for cool has been active. Turns on 2nd stage

of mechanical cooling when economizer is 1st stage call and

mechanical cooling is 2nd stage call. Allows three stages of

cooling, 1 economizer and 2 mechanical.

OFF = no Stage 3 cooling.

Indicates shutdown signal from space thermostat or unitary

controller. When controller receives 24 Vac input on the SD

terminal in conventional mode, the OA damper will open if

programmed for OPN and OA damper will close if programmed

for CLO. All other controls, e.g., Y1-O, Y2-O, EXH1, etc. will shut

off.

Used for alarm for when the DA air temperature is too low. Set

lower range of alarm, below this temperature the alarm will

show on the display.

Used for alarm for when the DA air temperature is too high. Set

high range of alarm, above this temperature the alarm will show

on the display

Turns on the DCV automatic control of the dampers. Resets

ventilation based on the RA, OA and MA sensor conditions.

Requires all sensors (RA, OA, MA and CO2).

This operation is not operable with a 2-speed fan unit.

temperature sensor

temperature sensor

humidity sensor

temperature sensor

humidity sensor

temperature sensor

When in economizing mode this is the delay for the high speed

fan to try to satisfy the call for second stage cooling before the

first stage mechanical cooling is enabled.

63-2700—10 22

Page 23

JADE™ ECONOMIZER MODULE

a

. (Continued)

b

system. See Table 6.

Notes

Menu Parameter

f

CHECKOUT

DAMPER MINIMUM

POSITION

Table 5. Menu Structure

Parameter

Default

Val ue

Parameter

Range and

Increment

n/a n/a The checkout for the damper minimum positions is based on the

DAMPER OPEN n/a n/a Positions damper to the full open position.

Exhaust fan contacts enable during the DAMPER OPEN test.

Make sure you pause in this mode to allow for exhaust contacts

to energize due to the delay in the system.

DAMPER CLOSE n/a n/a Positions damper to the fully closed position.

CONNECT Y1-O n/a n/a Closes the Y1-O relay (Y1-O).

See CAUTION on page 30

CONNECT Y2-O n/a n/a Closes the Y2-O relay (Y2-O).

See CAUTION on page 30

CONNECT AUX1-O n/a n/a Energizes the AUX1-O output. If AUX1-O setting is:

• NONE – no action taken

• ERV – 24 Vac out. Turns on or signals an ERV that the

conditions are not good for economizing but are good for

ERV operation.

d

• SYS – 24 Vac out. Issues a system alarm.

CONNECT EXH1 n/a n/a Closes the power exhaust fan 1 relay (EXH1)

ALARMS(#) Alarms display only when they are active. The menu title

“ALARMS (#)” includes the number of active alarms in

parenthesis (). When using SYLK bus sensors, "SYLK" will

appear on the screen, and when using 20k OA temperature

sensors, "SENS T" will appear on the screen.

MA T SENS ERR n/a n/a Mixed air sensor has failed or become disconnected - check

wiring then replace sensor if the alarm continues

CO2 SENS ERR n/a n/a CO2 sensor has failed, gone out of range or become

disconnected - check wiring then replace sensor if the alarm

continues

OA SYLK T ERR n/a n/a Outdoor air enthalpy sensor has failed or become disconnected -

OA SYLK H ERR n/a n/a

check wiring then replace sensor if the alarm continues

RA SYLK T ERR n/a n/a Return air enthalpy sensor has failed or become disconnected -

RA SYLK H ERR n/a n/a

check wiring then replace sensor if the alarm continues

DA SYLK T ERR n/a n/a Discharge air sensor has failed or become disconnected - check

wiring then replace sensor if the alarm continues

OA SENS T ERR n/a n/a Outdoor air temperature sensor has failed or become

disconnected - check wiring then replace sensor if the alarm

continues

ACT ERROR n/a n/a Actuator has failed or become disconnected - check for stall,

over voltage, under voltage and actuator count. Replace actuator

if damper is moveable and supply voltage is between 21.6 V and

26.4 V. Check actuator count on STATUS menu.

FREEZE ALARM n/a n/a Check if outdoor temperature is below the LOW Temp Lockout

on setpoint menu. Check if Mixed air temperature on STATUS

menu is below the Lo Setpoint on Advanced setup menu. When

conditions are back in normal range then the alarm will go away.

SHUTDOWN ACTIVE n/a n/a AUX2 IN is programmed for SHUTDOWN and 24 V has been

applied to AUX 2IN terminal

DMP CAL RUNNING n/a n/a If DCV Auto enable has been programmed, when the Jade is

completing a calibration on the dampers, this alarm will display.

Wait until the calibration is completed and the alarm will go

away. Must have OA, MA and RA sensors for DCV calibration;

set up is in the Advanced setup menu

DA SENS ALM n/a n/a Discharge air temperature is out of the range set in the

ADVANCED SETUP Menu. Check the temperature of the

discharge air.

23 63-2700—10

Page 24

JADE™ ECONOMIZER MODULE

a

. (Continued)

b

Notes

sensors, etc.), the AUX1-O terminal has 24 Vac out.

Menu Parameter

ALARMS(#)

SYS ALARM n/a n/a When AUX1-O is set to SYS and there is any alarm (e.g., failed

CONTINUED

Table 5. Menu Structure

Parameter

Default

Val ue

Parameter

Range and

Increment

ACT UNDER V n/a n/a Voltage received by Actuator is above expected range

ACT OVER V n/a n/a Voltage received by Actuator is below expected range

ACT STALLED n/a n/a Actuator stopped before achieving commanded position

FEATURES ADJUSTABLE ONLY BY USE OF THE W7220 PC MOD TOOL

ACT STALL ALARM

SUPPRESSION

SELECT TYPE OF

CONTROLLER

Disabled Enabled or

Disabled

W7220 W7220, W7218

or Preprogrammed

If enabled this feature allows the operator to suppress the stall

alarm in a specific range of the actuator stroke.

The operator can configure a program for a customer or job and

save the program in the file. Found on the configuration page of

the Trade version

special

ACTUATOR SLIPPAGE

ALARM

Enabled Enabled or

Disabled

Alarms if the actuator becomes disconnected from the damper

or is slipping on the shaft.

If Enabled, the Jade system will complete a system air

temperature check.

If there is the expected change in system air temperature, then

Jade assumes the actuator is connected to the damper.

If the expected system air temperature changes do not occur,

then an actuator slippage alarm is displayed on the Jade LCD.

Found on the configuration page of the Trade version.

ACTUATOR SLIPPAGE

ALARM SENSITIVITY

Low Low, Standard

or High

Sensitivity can be set to HIGH, STANDARD or LOW. High means

the system will check 5 times for the damper to move before

displaying the alarm. Standard is 10 times before the alarm is

displayed. Low is 20 times before the alarm is displayed. Found

on the economizer page of the Trade version.

LOCATION OF

ECONOMIZER

CONTROL SENSOR

Before the

cooling

coil

Before coil or

AUTO

The operator can choose if the economizer control sensor

(normally referred to as the Mixed air sensor) is placed in the

mixed air (before the coil) or Auto in the case the sensor is

placed after the cooling coil. Found on the configuration page of

the Trade version.

DAMPER AIA

THRESHOLD

15

degrees

5 to 40 degrees Damper threshold feature (Adaptive Integral Action) is the

difference in the mixed air temperature reported by the MAT

sensor and the MAT setpoint. Lower (2 degrees) transfer rate

between the actual MAT sensor reading and the MAT setpoint

normally means the damper is closing and opening faster.

Larger transfer rate (up to 20 degrees) between the sensor

reading and the setpoint normally means the damper is opening

and closing slower. Used in applications where there is a large

MA space or there is a long duct between the OA and the MA

causing a delay. Found on the economizer page of the Trade

version.

a

Table 5 illustrates the complete hierarchy. Your menu parameters may be different depending on your configuration.

For example if you do not have a DCV (CO

b

When values are displayed, pressing and holding the or button causes the display to automatically increment.

c

n/a = not applicable

d

ERV Operation: When in Cooling mode AND the conditions are NOT OK for economizing - the ERV terminal will be energized. In

) sensor, then none of the DCV parameters appear.

2

the Heating mode the ERV terminal will be energized when the OA is below the ERV OAT setpoint in the setpoint menu.

e

When used with Honeywell communicating actuator the damper out is reported in XX.X% open versus XX.X Vdc.

f

After 10 minutes without a command or mode change, the controller will change to normal operation.

63-2700—10 24

Page 25

JADE™ ECONOMIZER MODULE

Table 6. Damper minimum position settings and readings on checkout menu.

Demand Control Ventilation

Fan Speed

(CO2 Sensor) Setpoints Checkout

1 NO MIN POS VMAX-HS

1NO N/A N/A

2 NO MIN POS H VMAX-HS

2 NO MIN POS L VMAX-LS

1 YES VENT MIN VMIN-HS

1 YES VENT MAX VMAX-HS

2 YES VENT MIN H VMIN-HS

2 YES VENT MAX H VMAX-LS

2 YES VENT MINL N/A

2 YES VENT MAX L N/A

SEQUENCE OF OPERATION

Table 7. Dry Bulb Operation No DCV (CO2 sensor) - 1 Speed Fan.

OA Good to

DCV

None No Off Off High 0-v/Off 0-v/Off MIN POS Closed

None Yes Off Off High 0-v/Off 0-v/Off MIN POS Closed

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

call for Y1-I and Y2-I have not been satisfied.

DCV

Below CO2

set

Above CO2

set

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

On Off High 24-v/On 0-v/Off MIN POS Closed

On On High 24-v/On 24-v/On MIN POS Closed

On Off High 0-v/Off 0-v/Off MIN POS to Full-

Closed to Full-Open

Open

On On High 24-v/On

0-v/Off

a

MIN POS to FullOpen

Closed to Full-Open

Table 8. Dry Bulb Operation With DCV (CO2 sensor) - 1 Speed Fan.

OA Good to

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

No Off Off High 0-v/Off 0-v/Off VENTMIN Closed

On Off High 24-v/On 0-v/Off VENTMIN Closed

On On High 24-v/On 24-v/On VENTMIN Closed

Yes Off Off High 0-v/Off 0-v/Off VENTMIN Closed

On Off High 0-v/Off 0-v/Off VENTMIN to Full-

Closed to Full-Open

Open

a

On On High 24-v/On

0-v/Off

VENTMIN to FullOpen

No Off Off High 0-v/Off 0-v/Off VENTMIN to

Closed to Full-Open

Closed

VENTMAX

On Off High 24-v/On 0-v/Off VENTMIN to

Closed

VENTMAX

25 63-2700—10

Page 26

JADE™ ECONOMIZER MODULE

DCV

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

On On High 24-v/On 24-v/On VENTMIN to

Closed

VENTMAX

OA Good to

Yes Off Off High 0-v/Off 0-v/Off VENTMIN to

Closed

VENTMAX

On Off High 0-v/Off 0-v/Off VENTMIN to Full-

Closed to Full-Open

Open

a

On On High 24-v/On

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

0-v/Off

VENTMIN to FullOpen

Closed to Full-Open

call for Y1-I and Y2-I have not been satisfied.

Table 9. Enthalpy Operation No DCV (CO2 sensor) - 1 Speed Fan.

OA Good to

DCV

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

None No Off Off High 0-v/Off 0-v/Off MIN POS Closed

On Off High 24-v/On 0-v/Off MIN POS Closed

On On High 24-v/On 24-v/On MIN POS Closed

None Yes Off Off High 0-v/Off 0-v/Off MIN POS Closed

On Off High 0-v/Off 0-v/Off MIN POS to Full-

Closed to Full-Open

Open

On On High 24-v/On

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

0-v/Off

a

MIN POS to FullOpen

Closed to Full-Open

call for Y1-I and Y2-I have not been satisfied.

Table 10. Enthalpy Operation With DCV (CO2 sensor) - 1 Speed Fan.

OA Good to

DCV

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

Below set No Off Off High 0-v/Off 0-v/Off VENTMIN Closed

On Off High 24-v/On 0-v/Off VENTMIN Closed

On On High 24-v/On 24-v/On VENTMIN Closed

Yes Off Off High 0-v/Off 0-v/Off VENTMIN Closed

On Off High 0-v/Off 0-v/Off VENTMIN to Full-

Closed to Full-Open

Open

On On High 24-v/On

Above set No Off Off High 0-v/Off 0-v/Off VENTMIN to

0-v/Off

a

VENTMIN to FullOpen

Closed to Full-Open

Closed

VENTMAX

On Off High 24-v/On 0-v/Off VENTMIN L to

Closed

VENTMAX

On On High 24-v/On 24-v/On VENTMIN H to

Closed

VENTMAX

Yes Off Off High 0-v/Off 0-v/Off VENTMIN L to

Closed

VENTMAX

On Off High 0-v/Off 0-v/Off VENTMIN to Full-

Closed to Full-Open

Open

On On High

DELAY

b

24-v/On

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

0-v/Off

a

VENTMIN to FullOpen

Closed to Full-Open

call for Y1-I and Y2-I have not been satisfied.

b

With 2SP FAN DELAY (Advanced Setup Menu) when in the economizing mode there is a delay for the high speed fan to try to

satisfy the call for second stage cooling by turning on the fan to high and opening the OA damper 100% before the first stage

mechanical cooling is enabled.

63-2700—10 26

Page 27

JADE™ ECONOMIZER MODULE

Table 11. Dry Bulb Operation No DCV (CO2 sensor) - 2 Speed Fan.

OA Good to

DCV

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

None No Off Off Low 0-v/Off 0-v/Off MIN POS L Closed

On Off Low 24-v/On 0-v/Off MIN POS L Closed

On On High 24-v/On 24-v/On MIN POS H Closed

None Yes Off Off Low 0-v/Off 0-v/Off MIN POS L Closed

On Off Low 0-v/Off 0-v/Off MIN POS L to Full-

Closed to Full-Open

Open

On On High

DELAY

b

24-v/On

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

0-v/Off

a

MIN POS H to FullOpen

Closed to Full-Open

call for Y1-I and Y2-I have not been satisfied.

b

With 2SP FAN DELAY (Advanced Setup Menu) when in the economizing mode there is a delay for the high speed fan to try to

satisfy the call for second stage cooling by turning on the fan to high and opening the OA damper 100% before the first stage

mechanical cooling is enabled.

Table 12. Dry Bulb Operation With DCV (CO2 sensor) - 2 Speed Fan.

OA Good to

DCV

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

Below set No Off Off Low 0-v/Off 0-v/Off VENTMIN L Closed

On Off Low 24-v/On 0-v/Off VENTMIN L Closed

On On High 24-v/On 24-v/On VENTMIN H Closed

Yes Off Off Low 0-v/Off 0-v/Off VENTMIN L Closed

On Off Low 0-v/Off 0-v/Off VENTMIN L to Full-

Closed to Full-Open

Open

On On High 24-v/On

Above set No Off Off Low 0-v/Off 0-v/Off VENTMIN L to

0-v/Off

a

VENTMIN H to FullOpen

Closed to Full-Open

Closed

VENTMAX

On Off Low 24-v/On 0-v/Off VENTMIN L to

Closed

VENTMAX

On On High 24-v/On 24-v/On VENTMIN H to

Closed

VENTMAX

Yes Off Off Low 0-v/Off 0-v/Off VENTMIN L to

Closed

VENTMAX

On Off Low 0-v/Off 0-v/Off VENTMIN L to Full-

Closed to Full-Open

Open

On On High

DELAY

b

24-v/On

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

0-v/Off

a

VENTMIN H to FullOpen

Closed to Full-Open

call for Y1-I and Y2-I have not been satisfied.

b

With 2SP FAN DELAY (Advanced Setup Menu) when in the economizing mode there is a delay for the high speed fan to try to

satisfy the call for second stage cooling by turning on the fan to high and opening the OA damper 100% before the first stage

mechanical cooling is enabled.

Table 13. Enthalpy Operation No DCV (CO2 sensor) - 2 Speed Fan.

OA Good to

DCV

NO CO2

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

No Off Off Low 0-v/Off 0-v/Off MIN POS L Closed

SENSOR

On Off Low 24-v/On 0-v/Off MIN POS L Closed

27 63-2700—10

Page 28

JADE™ ECONOMIZER MODULE

DCV

economize? Y1-I Y2-I FAN SPD Y1-O Y2-O Occupied Unoccupied

On On High 24-v/On 24-v/On MIN POS H Closed

Yes Off Off Low 0-v/Off 0-v/Off MIN POS L Closed

OA Good to

On Off Low 0-v/Off 0-v/Off MIN POS L to Full-

Closed to Full-Open

Open

On On High

DELAY

b

24-v/On

a

With stage 3 delay (STG3 DLY) in Advanced setup menu can turn on 2nd stage of mechanical cooling Y2 –O after the delay if the

0-v/Off

a

MIN POS H to FullOpen

Closed to Full-Open

call for Y1-I and Y2-I have not been satisfied.

b

With 2SP FAN DELAY (Advanced Setup Menu) when in the economizing mode there is a delay for the high speed fan to try to

satisfy the call for second stage cooling by turning on the fan to high and opening the OA damper 100% before the first stage

mechanical cooling is enabled.

Table 14. Enthalpy Operation With DCV (CO2 sensor) - 2 Speed Fan.

OA Good to

DCV