Page 1

VS8510,VS8520

OBSOLETE

Millivolt Gas Valve

INSTALLATION INSTRUCTIONS

APPLICATION

The VS8510, VS8520 Millivolt Gas Valve is compact and

has a 60,000 Btuh capacity (1 in. pressure drop for

straight through configuration). Its design makes it ideal

for fireplace and space heating applications.

SPECIFICATIONS

Main Gas Connection:

Pilot Gas Connection and Flow:

Connection Size: 7/16-24 UNS.

Flow: 1700 Btuh at 4.0 in. wc pressure drop.

Thermocouple and Pilot Threads:

Ambient Temperature Range:

0°F to 175°F (-18°C to 79°¡C).

Option for 225°F (107°C).

Pressure Regulation:

Servo regulator with adjustable outlet pressure.

Natural Gas: Typically 3.5 in. wc.

LP: Typically 11 in. wc.

Regulator Adjustments:

Natural Gas: 3 in. to 5 in. field adjustable.

LP: 8 in. to 12 in. field adjustable.

Vol ta ge:

VS8510: 750 mV operator.

VS8520: 750 mV operator, 30 mV thermocouple.

Approvals:

International Approval Services (IAS) Certificate:

C2030022.

European Community (CE) Certificate: Applied for.

Valve: 3/8 in. NPT thread.

Metric and UNS.

INSTALLATION

When Installing this Product...

Read these instructions carefully. Failure to follow

1.

them could damage the product or cause a

hazardous condition.

Check the ratings given in the instructions and on

2.

the product to make sure the product is suitable for

your application.

Installer must be a trained, experienced service

3.

technician.

After installation is complete, check out product

4.

operation as provided in these instructions.

WARNING

Oxygen depletion hazard.

Can cause injury or death due to

asphyxiation.

Use only vented gas valve models on vented

1.

appliances.

Use only unvented gas valve models on

2.

unvented appliances.

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

Follow these warnings exactly:

Disconnect power supply before wiring to

1.

prevent electrical shock or equipment damage.

To avoid dangerous accumulation of fuel gas,

2.

turn off gas supply at the appliance service

valve before starting installation, and perform a

Gas Leak Test after the installation is

complete.

Always install the sediment trap in the gas

3.

supply line to prevent contamination of the gas

control.

Do not force the gas control knob. Use only

4.

your hand to turn the gas control knob. Never

use any tools. If the gas control knob does not

operate by hand, the gas control should be

replaced by a qualified service technician.

Force or attempted repair can result in fire or

explosion.

® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. •All Rights Reserved

69- 1024- 5

Page 2

VS5810, VS5820 MILLIVOLT GAS VALVE

OBSOLETE

CAUTION

Equipment damage.

Can burn out heat anticipator in thermostat.

Never apply a jumper across or short the valve

coil terminals.

IMPORTANT

These gas controls are shipped with protective

seals over the inlet and outlet tappings. Do not

remove the seals until ready to connect the

piping.

Follow the appliance manufacturer instructions, if

available; otherwise, use these instructions.

Converting Between Natural and LP Gas

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

Do not use a gas control set for natural gas on

1.

an LP gas system or a gas control set for LP

gas on a natural gas system.

When making a conversion, the main pilot

2.

burner orifices must be changed to meet the

appliance manufacturer specifications.

When making a conversion, change main pilot burner

orifices to meet the appliance manufacturer

specifications. Refer to the appliance manufacturer

instructions for orifice specifications and changeover

procedure. Gas controls are factory-set for natural (and

manufactured) or LP gas. Do not attempt to use a control

set for natural (manufactured) gas on LP gas, or a control

set for LP on natural (manufactured) gas.

VS8510A and VS8520A gas controls with a standard

regulator can be converted from one gas to the other with

a conversion kit (ordered separately). Order part no.

395991 to convert from natural (manufactured) to LP

gas. Order part no. 395992 to convert from LP to natural

(manufactured) gas.

VS8510E and VS8520E gas controls with a Convertible

High/Low regulator can be converted from one gas to the

other with a conversion kit (ordered separately). Order

part no. 396087-1 to convert from LP to natural

(manufactured) gas. Order part no. 396087-2 to convert

from natural (manufactured) to LP gas.

High/Low regulator models VS8510D and VS8520D

cannot be converted.

VS8510R and VS8520R

Convertible Pressure Regulators

Gas valves with suffix letter R are convertible pressure

regulator models. They can be converted from natural

gas to LP or from LP to natural gas without a converter

kit.

Before converting the gas valve from one gas to another,

check the gas valve label and the appliance

manufacturer rating plate to make sure the pressure

regulator setting (factory set) meets the appliance

manifold requirements after conversion.

NOTE: Convertible pressure regulator models (suffix

R) do not have field-adjustable regulators. The

natural gas and LP settings are factory-manufactured.

IMPORTANT

Follow these instructions carefully.

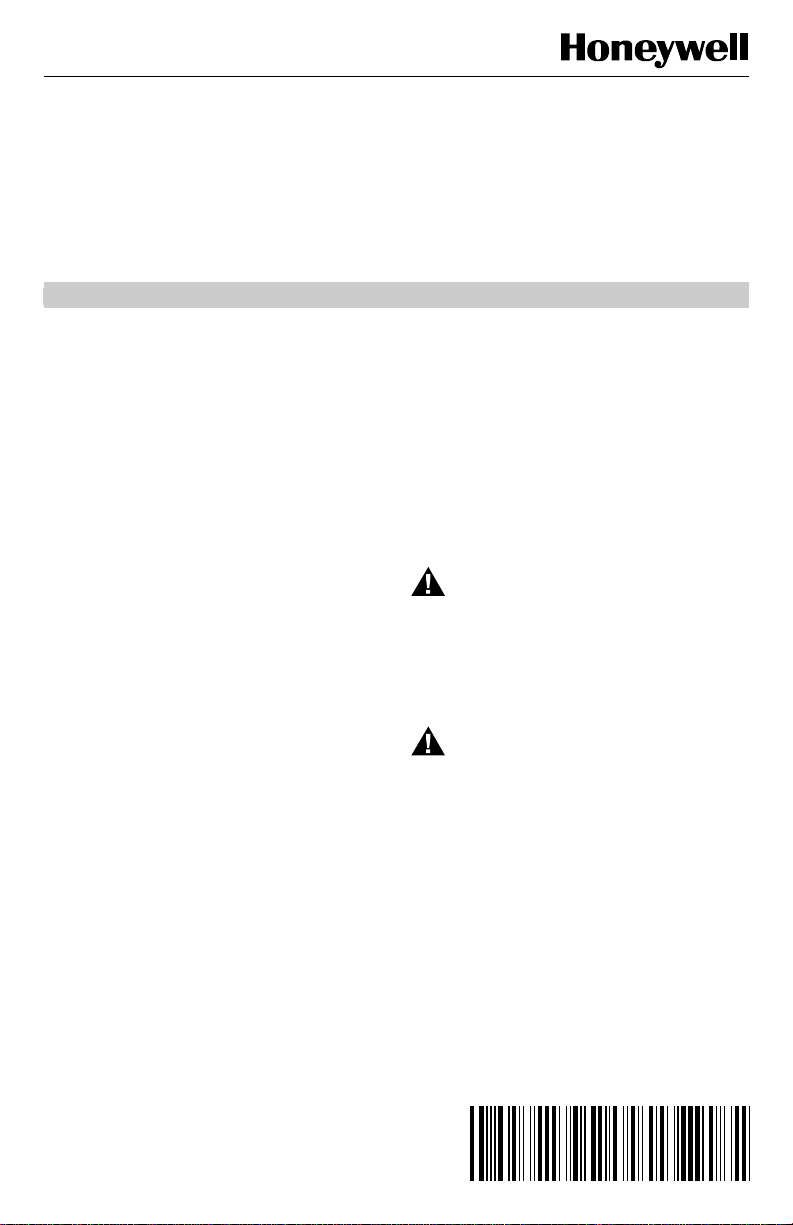

CONVERTING THE GAS VALVE

If the factory pressure regulator setting meets the

appliance manifold requirement, convert the gas valve as

follows (see Fig. 1):

Remove the black thread protective cap.

1.

Remove the conversion flip cap by turning it

counterclockwise .

Invert the conversion flip cap so the bottom of the

2.

letters and associated arrow for the gas type

appropriate for the appliance application are face

down toward the valve. NAT is for natural gas and

LP is for liquid petroleum gas.

Tighten the conversion flip cap by turning it clockwise

, using 10 in. lbs of force.

Replace the black thread protective cap.

PROTECTIVE

LP

NAT

Fig. 1. Converting the gas valve (shown

assembled for natural gas).

LP

NAT

CAP

CONVERSION

FLIP CAP

PRESSURE

REGULATOR

HOUSING

M16521

Location

Locate the combination gas control where it cannot be

affected by steam cleaning, high humidity, dripping water,

corrosive chemicals, dust or grease accumulation or

excessive heat. To assure proper operation, follow these

guidelines:

• Locate gas control in a well-ventilated area.

• Mount gas control high enough to avoid exposure to

flooding or splashing water.

• Assure the ambient temperature does not exceed the

ambient temperature ratings for each component.

• Cover gas control if appliance is cleaned with water,

steam, or chemicals or to avoid dust and grease

accumulation.

• Avoid locating gas control where exposure to

corrosive chemical fumes or dripping water is likely.

69-1024—5 2

Page 3

VS5810, VS5820 MILLIVOLT GAS VALVE

OBSOLETE

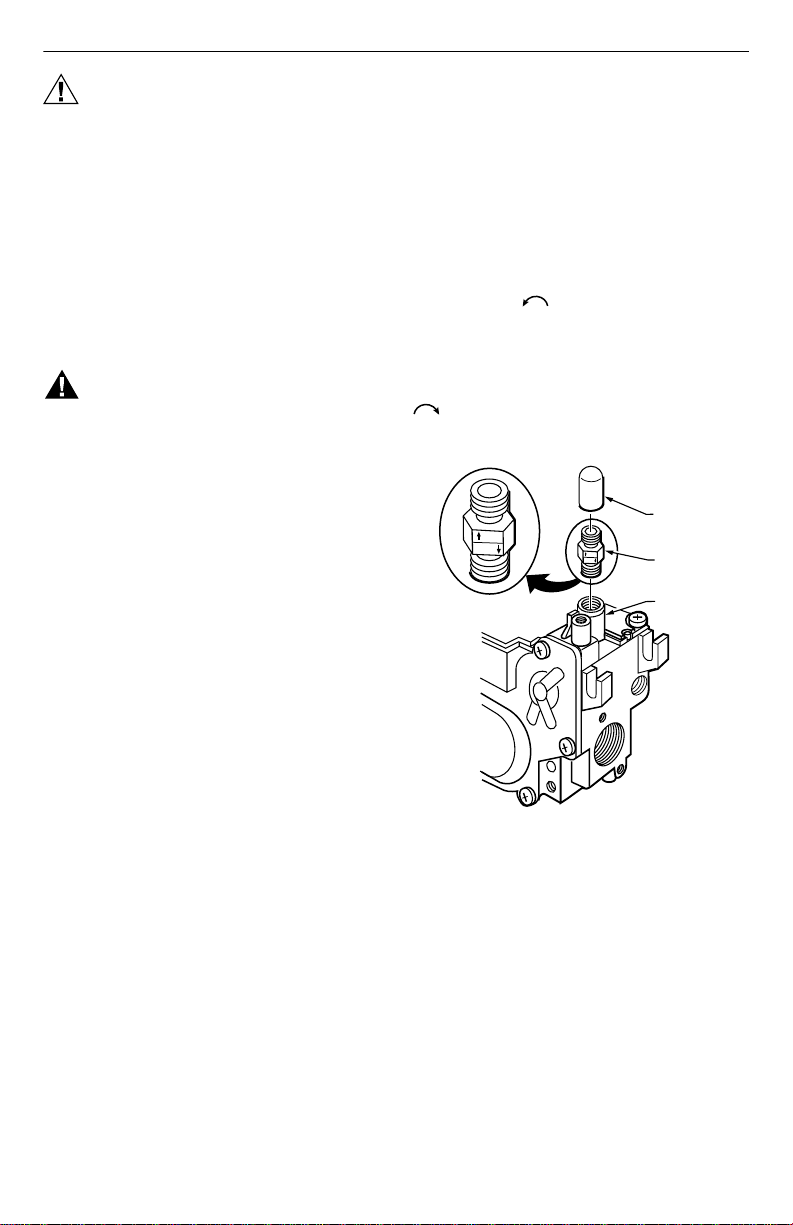

Install Piping to Gas Control

All piping must comply with local codes and ordinances

or with the National Fuel Gas code (ANSI Z223.1 NFPA

No. 54), whichever applies. Tubing installation must

comply with approved standards and practices.

Use new, properly reamed pipe free from chips.

1.

When tubing is used, assure the ends are square,

deburred and clean. All tubing bends must be

smooth and without deformation.

Run pipe or tubing to the control. If tubing is used,

2.

obtain a tube-to-pipe coupling to connect the

tubing to the control.

Install sediment trap in the supply line to the gas

3.

control. See Fig. 1.

Install Control

Mount control 0 to 90 degrees, in any direction,

1.

from the upright position of the gas control knob,

including vertically.

Mount the control so gas flow is in the direction of

2.

the arrow on the side of the control.

Thread pipe 9/16 in. into the control. Do not insert

3.

deeper than 3/8 in. Valve distortion or malfunction

can result if the pipe is inserted too deeply.

Apply a moderate amount of good quality pipe

4.

compound (do not use Teflon tape) to pipe only,

leaving two end threads bare. On LP installations,

use compound resistant to LP gas. See Fig. 2.

Remove seals over control inlet and outlet, if

5.

necessary.

Connect pipe to control inlet and outlet. Use

6.

wrench on either side of the pipe outlet. Refer to

Fig. 3 through 5.

Wiring

Follow the wiring instructions furnished by the appliance

manufacturer, if available, or use the general instructions

provided below. Where these instructions differ from the

appliance manufacturer, follow the appliance

manufacturer instructions. For typical wiring diagrams,

see Fig. 6 and 7.

All wiring must comply with applicable electrical codes

and ordinances.

Disconnect power supply before making wiring

connections to prevent electrical shock or equipment

damage.

Check the power supply rating on the gas control

1.

and make sure it matches the available supply.

Install the transformer, thermostat, and other

controls, as required.

This valve can only be used in a self-generating

2.

system.

Adjust the thermostat heat anticipator to the 0.1A

3.

at 750 mV rating stamped on the valve operator.

OPERATION

The Millivolt Gas Valve System has two different

configurations. The first configuration includes a gas

valve, quick drop-out thermocouple, thermopile, millivolt

thermostat and a pilot burner. In this configuration, the

thermopile drives the operator and the quick dropout

thermocouple operates the power unit. See Fig. 7. The

second configuration includes a gas valve, thermopile,

millivolt thermostat, and a pilot burner. The thermopile

drives the operator and the power unit. See Fig. 8.

DROP

HORIZONTAL

3 INCHES

(76 MM)

MINIMUM

HORIZONTAL

ISER

3 INCHES

(76 MM)

MINIMUM

CAUTION

GAS LEAKAGE HAZARD.

FAILURE TO FOLLOW PRECAUTIONS CAN

RESULT IN A GAS-FILLED WORK AREA.

SHUT OFF THE MAIN GAS SUPPLY BEFORE REMOVING END CAP.

TEST FOR GAS LEAKAGE WHEN INSTALLATION IS COMPLETE.

1

ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.

TWO IMPERFECT

THREADS

THREAD PIPE ACCORDING TO

INSTALLATION PROCEDURE FOR

INSERTION INTO GAS CONTROL.

PIPED

GAS

SUPPLY

GAS

CONTROL

DROP

TUBING

1

GAS

SUPPLY

GAS

CONTROL

Fig. 2. Sediment trap installation.

GAS CONTROL

PIPE

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND TO PIPE ONLY

(LEAVE TWO END THREADS BARE).

RISER

PIPED

GAS

SUPPLY

3 INCHES

(76 MM)

MINIMUM

GAS

CONTROL

M4603A

M6913

Fig. 3. Use moderate amount of pipe compound.

3 69-1024—5

Page 4

VS5810, VS5820 MILLIVOLT GAS VALVE

OBSOLETE

WIRING

TERMINALS

HI

O

L

OUTLET

PRESSURE TAP

Fig. 4. Top view of gas control with HI/LO regulator.

INLET

PRESSURE TAP

HI/LO REGULATOR

PILOT

ADJUSTMENT SCREW

PILOT

ON

GAS

CONTROL KNOB

APPLY WRENCH

FROM BOTTOM OF

GAS CONTROL TO

SHADED AREA

OFF

M6914

WIRING

TERMINALS

OUTLET

PRESSURE

TAP

INLET

PRESSURE TAP

PRESSURE REGULATOR

ADJUSTMENT (UNDER

CAP SCREW)

Fig. 5. Top view of gas control with

standard regulator.

ON

PILOT

OFF

GAS

CONTROL

KNOB

PILOT

ADJUSTMENT

SCREW

M6915

M6916

Fig. 6. Proper use of wrench on gas control.

Pilot Gas and Lighting Procedure

Turn the knob counterclockwise to PILOT

1.

position, push the knob down, and hold in position.

The pilot valve opens and allows gas to flow to the

pilot burner.

Light the pilot burner while holding the knob down

2.

until a strong flame is present (approximately 60

seconds).

Release the knob. The shaft will move upward and

3.

engage the safety valve lever that opens the safety

valve.

Turn the knob counterclockwise to the ON

4.

position. On a call-for-heat, the main valve opens

and the main burner ignites.

Shut off Procedure

To shut off the system, turn the knob

1.

clockwise to the OFF position. This action

closes the main gas and safety valves. However,

69-1024—5 4

the power unit must drop out before the lighting

sequence can begin again. The VS8510 drops out

within three minutes. The VS8520 drops out within

30 seconds.

To relight the pilot light, follow the steps in the Pilot

2.

Gas and Lighting Procedure section.

HI/LO Regulator

As you turn the HI/LO knob, the gas pressure changes.

Turn the knob clockwise towards the HI set-

1.

ting to increase gas pressure.

Turn the knob counterclockwise towards the LO

setting to decrease gas pressure.

Minimum and maximum regulator settings vary for each

individual gas valve. See gas valve label for actual

minimum and maximum ranges. Table 1 lists possible

minimums and maximums for gas valves.

Page 5

VS5810, VS5820 MILLIVOLT GAS VALVE

OBSOLETE

MILLIVOLT

THERMOSTAT

HIGH LIMIT

CONTROL

HI

O

L

HI/LO

REGULATOR

Fig. 7. Millivolt system wiring diagram with

MILLIVOLT

THERMOSTAT

HIGH LIMIT

CONTROL

TARGET

PILOT

ON

GAS

CONTROL

KNOB

quick drop-out thermocouple.

Q313

THERMOPILE

QUICK DROP-OUT

THERMOCOUPLE

ELECTRODE

VS8520 HI/LO

MILLIVOLT

GAS VALVE

OFF

PILOT

ADJUSTMENT

SCREW

Q313

THERMOPILE

Table 1. HI/LO and Standard Regulator Specification

Type of

Gas

Natural 1.2 in. minimu m to

LP 3.7 in. minimum to

Pressures in in. wc (kPa).

HI/LO Regulator

Setting Ranges

3.5 in. maximum.

11.0 in. maximum.

3.0 minimum to 5.0

maximum.

8.0 in. minimum to 12.0

in. maximum.

Standard Regulator

Standard Pressure Regulator

Check the manifold pressure listed on the appli-

1.

ance nameplate. Gas control outlet pressure

should match the nameplate.

With the main burner operating, check the gas

2.

control flow rate using the meter clocking method

or measure the pressure by attaching a plastic

tube with a 1/4 in. shell I.D. to the manometer and

connecting the manometer to the outlet pressure

tap on the gas control. See Fig. 5.

If necessary, adjust the pressure regulator to

3.

match the appliance rating. See Table 1 for

factory-set nominal outlet pressure and adjustment

range.

a. Remove pressure regulator adjustment cap

M6917A

screw.

b. Using a screwdriver, turn inner adjustment

screw clockwise to increase or

counterclockwise to decrease gas

pressure to burner.

c. Always replace cap screw and tighten firmly to

prevent gas leakage.

If desired outlet pressure or flow rate cannot be

4.

achieved by adjusting the gas control, check gas

control inlet pressure using a manometer at the

gas control inlet pressure tap. If inlet pressure is in

the normal range (see Table 1), replace gas

control. Otherwise, take the necessary steps to

provide proper gas pressure on the control.

CHECKOUT

Setting Ranges

VS8510 HI/LO

MILLIVOLT

GAS VALVE

HI

O

L

HI/LO

REGULATOR

Fig. 8. Millivolt system wiring diagram without

quick drop-out thermocouple.

PILOT

ON

GAS

CONTROL

KNOB

OFF

PILOT

ADJUSTMENT

SCREW

M6918

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

1. Do not force the gas control knob on the

appliance. Use only your hand to turn the gas

control knob. Never use any tools.

2. If the knob does not operate by hand, the

control should be replaced by a qualified

service technician.

Gas Control Knob Settings

Gas control knob settings are as follows:

• OFF: Prevents main gas flow through the control.

• ON: Permits main burner and pilot gas flow. Gas

control and thermostat control main burner gas flow.

• PILOT: Opens pilot valve and allows gas flow to pilot

burner.

• HI/LO: Manually adjusts outlet pressure.

NOTE: Controls are shipped with the gas control knob

in the ON position.

5 69-1024—5

Page 6

VS5810, VS5820 MILLIVOLT GAS VALVE

OBSOLETE

Perform Gas Leak Test

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

1. Stand away from the main burner while

lighting. Hidden gas leaks can cause

flashbacks in the appliance vestibule.

2. Check for gas leaks with rich soap and water

solution any time work is done on a gas

system.

Gas Leak Test

Paint the pipe connections upstream of the gas

1.

control with rich soap and water solution. Bubbles

indicate a gas leak.

If a leak is detected, tighten the pipe connections.

2.

Light the main burner.

3.

With the main burner in operation, paint the pipe

4.

joints (including adapters) and control inlet and

outlet with a rich soap and water solution.

If another leak is detected, tighten the adapter

5.

screws, joints, and pipe connections.

Replace part if leak cannot be stopped.

6.

Turn on System

Rotate the gas control knob counterclockwise to

ON.

Turn on Main Burner

Follow the instructions provided by the appliance

manufacturer or turn up the thermostat to call for heat.

Check and Adjust Gas Input and Burner Ignition

CAUTION

Equipment Damage Hazard.

Improper adjustment of gas input and burner

can cause carboning and/or unnecessary

shutdown of the system.

1. Do not exceed the input rating stamped on the

appliance nameplate, or manufacturer

recommended burner orifice pressure for size

orifice(s) used. Be sure primary air supply to

the main burner is properly adjusted for

complete combustion. Follow the instructions

of the appliance manufacturer.

2. IF CHECKING GAS INPUT BY CLOCKING

GAS METER: Be sure there is no gas flow

through the meter other than to the appliance

being checked. Other appliances must remain

off with the pilots extinguished (or the

consumption must be deducted from the meter

reading). Convert the flow rate to Btuh as

described in the Gas Controls Handbook, form

70-2602, and compare to the Btuh input rating

on the appliance nameplate.

3. IF CHECKING GAS INPUT WITH MANOMETER: Both the inlet and outlet pressure

taps have a captive screw. To measure the

pressure of the tap, loosen, but do not remove

the captive screw, attach a plastic tube with a

1/4 in. shell I.D. and connect the manometer.

After checking the pressure, turn the gas

control knob to the OFF position. Before

opening the outlet press ure tap, be sure the

gas control is in the OFF position. Before

opening the inlet pressure tap, shut off the gas

supply at the manual valve in the gas piping to

the appliance or, for LP, at the tank. Repeat the

Gas Leak Test at the pressure tap with the

main burner operating.

Check Safety Shutdown Performance

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

Perform the safety shutdown test any time work

is done on a gas system.

Place gas control knob in PILOT position. Main

1.

burner should go off and pilot should remain lit.

Extinguish pilot flame. The VS8510 pilot gas flow

2.

should stop within three minutes; the VS8520 pilot

gas flow stops within thirty seconds. Safety shutoff

of pilot gas proves complete shutdown because

safety shutoff valve prohibits main burner and pilot

gas flow.

Relight pilot burner and operate the system

3.

through one complete cycle to ensure all controls

operate properly.

MAINTENANCE

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

Do not attempt to take apart the gas control or to

clean it. Improper assembly and cleaning can

cause unreliable operation.

Regular preventive maintenance is important in

applications that place a heavy load on system controls

such as those used in the commercial cooking and

agricultural and industrial industries because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000 to 200,000

cycles per year. Such heavy cycling can wear out the

gas control in one to two years.

• Exposure to water, dirt, chemicals and heat can

damage the gas control and shut down the control

system.

The maintenance program should include regular

checkout of the system as outlined in the Checkout

section, and checkout of the control system as described

in the appliance manufacturer literature.

69-1024—5 6

Page 7

Maintenance frequency must be determined individually

OBSOLETE

for each application. Some considerations are:

• Cycling frequency. Appliances that may cycle 20,000

times annually should be checked monthly.

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

• Consequence of unexpected shutdown. Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

• Dusty, wet, or corrosive environment. Because these

environments can cause the gas control to deteriorate

more rapidly, the system should be checked more

often.

Any control should be replaced if it does not perform

properly on checkout or service. In addition, replace any

module if it is wet or looks like it has ever been wet.

SERVICE

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

Do not disassemble the gas control; it contains

no replaceable components. Attempted

disassembly or repair can damage the control.

CAUTION

Equipment damage.

Can burn out heat anticipator in thermostat.

Do not apply a jumper across (or short) the valve

coil terminals even temporarily.

If Main Burner does not Come on with Call for Heat

Confirm that the gas control knob is in the ON posi-

1.

tion.

Adjust the thermostat several degrees above the

2.

room temperature.

Use a dc voltmeter to measure the voltage across

3.

the THTP and TP terminals.

If no voltage is present, check the control circuit for

4.

proper operation.

If proper control system voltage is present, replace

5.

the gas control.

VS5810, VS5820 MILLIVOLT GAS VALVE

WARNING

Fire or explosion hazard.

Can cause property damage, severe injury or

death.

Exactly follow the warnings and the lighting

instructions.

1. Before lighting, smell around the appliance

area for gas. If the appliance uses LP (bottled)

gas, be sure to smell next to the floor because

LP gas is heavier than air. If you smell gas,

immediately shut off the manual valve in the

gas piping to the appliance or, on LP, at the

tank. Do not try to light any appliance. Do not

touch any electrical switch or use the phone.

Leave the building and call your gas supplier. If

your gas supplier cannot be reached, call the

fire department.

2. Do not force the gas control knob on the

appliance. Use only your hand to turn the gas

control knob. Never use any tools. If the knob

does not operate by hand, have a qualified

service technician replace the control. Force or

attempted repair can result in fire or explosion.

3. The gas control must be replaced if it has been

flooded with water. Call a qualified service

technician.

4. The gas control is a safety device. It must be

replaced in case of any physical damage such

as bent terminals, missing or broken parts,

stripped threads, or evidence of exposure to

heat.

IMPORTANT

Follow the operating instructions provided by

the manufacturer of your heating appliance.

TROUBLESHOOTING

IMPORTANT

Troubleshooting procedures should only be performed by an experienced, qualified service

technician.

Use Fig. 9 and Table 2 or 3 to assist in troubleshooting

the VS8510 or VS8520.

TH

TH

TH

TP TPTH

M17511

Fig. 9. Test points for troubleshooting the

VS8510/VS8520 Millivolt Gas Valves.

7 69-1024—5

TP

TP

Page 8

VS5810, VS5820 MILLIVOLT GAS VALVE

OBSOLETE

Table 2. VS8510 Troubleshooting Tests.

Tes t

Letter Test Connect Meter to Set Thermostat to Meter Reading

A Coil Resistance TP and TH Open 3.6 ohms maximum.

B Thermopile TP and TPTH Open 460 mV minimum.

C Operator Pull-In TH and TP Open 155 mV minimum.

D Resistance System — Closed 1.7 ohms maximum.

A—Have thermostat contacts open and pilotstat knob turned to OFF. Coil resistance should be maximum of 3.6 ohms.

If not, replace the valve.

B—Have thermostat contacts open and pilot burning with pilotstat knob turned to PILOT. There should be a minimum of

460 mV. If not, replace thermopile.

C—Have thermostat contacts open and pilot burning with pilotstat knob in the PILOT position. Close

contacts. The thermopile should provide 155 mV. If not, replace the thermopile. If output is 155 mV or greater, the

valve operator will make an audible sound or click when it pulls in. If the valve does not make a sound, replace the

valve.

D—The system resistance from the remote switch or thermostat and leadwires should not exceed 1.7 ohms. If it does,

reduce the resistance.

Tes t

Letter Test Connect Meter to

A Coil Resistance TP and TH Open 3.6 ohms maximum.

B Thermopile TP and TPTH Open 460 mV minimum.

C Thermocouple Tip Open 18 mV minimum.

D Operator Pull-in TH and TP Open 155 mV minimum.

E Resistance system — Closed 1.7 ohms maximum.

A—Have thermostat contacts open and pilotstat knob turned to OFF. Coil resistance should be maximum of 3.6 ohms.

If not, replace the valve.

B—Have thermostat contacts open and pilot lit with pilotstat knob turned to PILOT. There should be a minimum of 460

mV. If not, replace thermopile.

C—Have thermostat contacts open and pilot burning with the pilotstat knob turned to PILOT. The voltage should be 18

mV for a new thermocouple. You must press pilotstat knob to maintain the gas flow. If the output does not meet the

minimum voltage, replace the thermocouple. The power unit will hold in down to 3 mV. If the output of the thermocouple is below 3 mV, replace the thermocouple.

D—Have thermostat contacts open and pilot burning with pilotstat knob in the PILOT position. Close

contacts. The thermopile should provide 155 mV. If not, replace the thermopile. If output is 155 mV or greater, the

valve operator will make an audible sound or click when it pulls in. If the valve does not make a sound, replace the

valve.

E—The system resistance from the remote switch or thermostat and leadwires should not exceed 1.7 ohms. If it does,

reduce the resistance.

Table 3. VS8520 Troubleshooting Tests.

Set Thermostat

to Meter should read

the thermostat

the thermostat

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limitée

Honeywell Plaza 155 Gordon Baker Road

P.O. Box 524 North York, Ontario

Minneapolis, MN 55408-0524 M2H 3N7

69-1024—5 G.R. Rev. 6-00 www.honeywell.com

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...