Page 1

APPLICATION

These gas controls combine a Lite-Rite manual

gas cock, safety shutoff Pilotstat assembly,

millivoltage automatic valve operator, and optional

gas pressure regulator. They require the use of a

750 mv Powerpile generator (thermopile). The

generator, heated by the pilot burner flame, provides the electrical energy to operate the combination gas control.

A millivoltage thermostat with suitable accessory controls completes the automatic control

system for the heating appliance.

Models equipped with the standard pressure

regulator are identified by the suffix letter “A“

WS820A.j Models without pressure regulator

carry the suffix letter “6” (VS820B). Suffix letter

“C” (VS82OC) identifies models having step

opening type regulators.

Pressure regulators and operator are standardized and interchangeable on all models in the two

capacity ranges - 225 and 335 cubic feet per

hour.

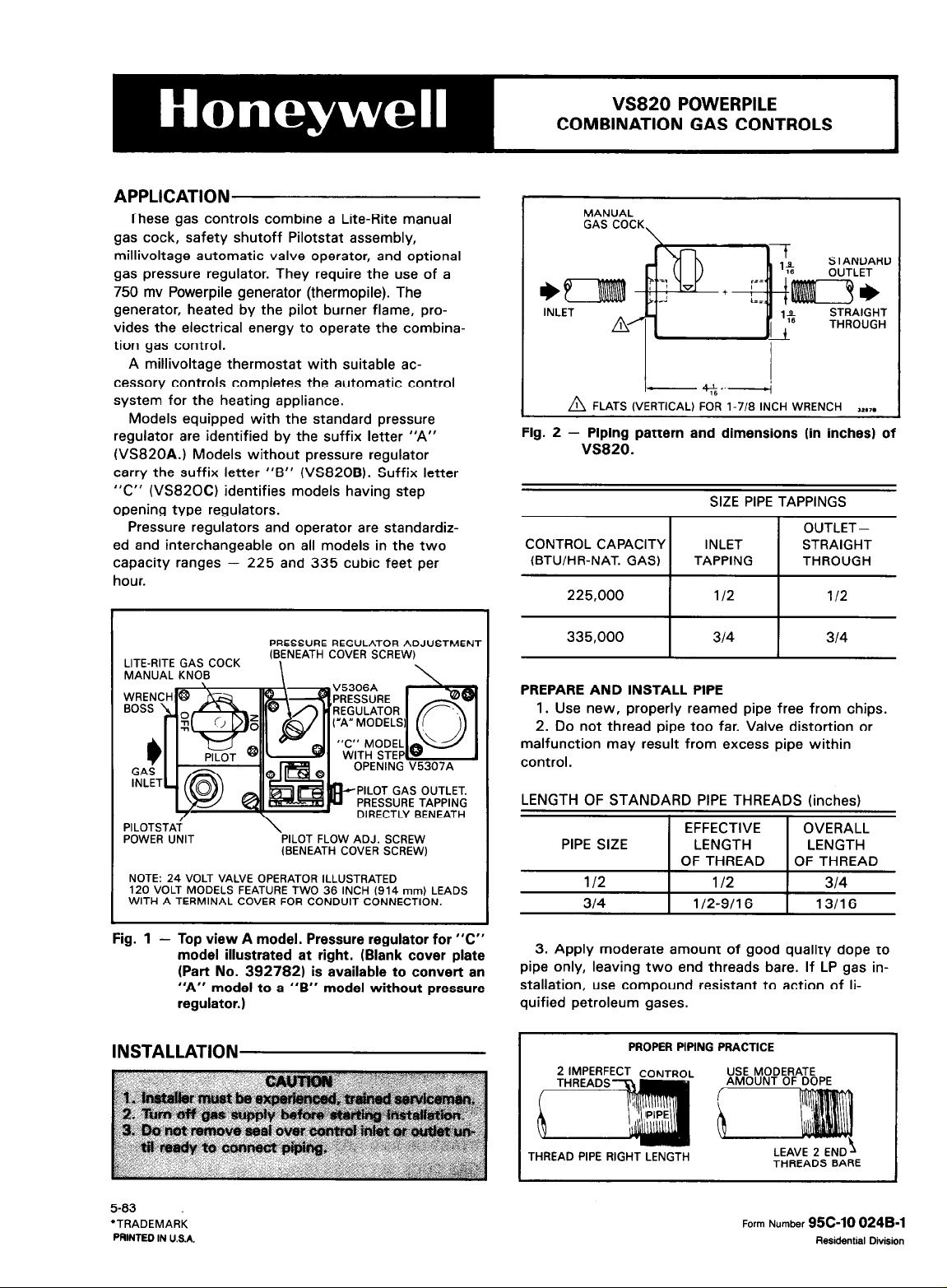

MANUAL

GAS COCK

INLET STRAIGHT

\

STANDARD

OUTLET

I,

THROUGH

-4&.-W

A FLATS (VERTICAL) FOR l-7/8 INCH WRENCH

,a,,.

Fig. 2 - Piping pattern and dimensions (in inches) of

VS820.

SIZE PIPE TAPPINGS

225,000

II2

I

I

II2

PRESSURE REGULATOR ADJUSTMENT

LITE-RITE GAS COCK

MANUAL KNOB \ \

PlLOTSTAi

POWER UNIT

NOTE: 24 VOLT VALVE OPERATOR ILLUSTRATED

120 VOLT MODELS FEATURE TWO 36 INCH (914 mm) LEADS

WITH A TERMINAL COVER FOR CONDUIT CONNECTION.

(BENEATH COVER SCREW)

*PILOT GAS OUTLET.

PRESSURE TAPPING

\

PILOT FLOW ADJ. SCREW

(BENEATH COVER SCREW)

DIRECTLY BENEATH

Fig. 1 - Top view A model. Pressure regulator for “C”

model illustrated at right. (Blank cover plate

(Part No. 392782) is available to convert an

“A” model to a “B” model without pressure

regulator.)

335,000

314

I

314

I

PREPARE AND INSTALL PIPE

1. Use new, properly reamed pipe free from chips.

2. Do not thread pipe too far. Valve distortion or

malfunction may result from excess pipe within

control.

LENGTH OF STANDARD PIPE THREADS (inches)

4

3. Apply moderate amount of good quality dope to

pipe only, leaving two end threads bare. If LP gas in-

stallation, use compound resistant to action of liquified petroleum gases.

PROPER PIPING PRACTICE

2 IMPERFECT CONTROL USE MODERATE

5-83

*TRADEMARK

PRINTED IN U.S.A.

THREAD PIPE RIGHT LENGTH

LEAVE 2 END

THREADS BARE

Form Number 9!%10 0248-l

Residential Division

Page 2

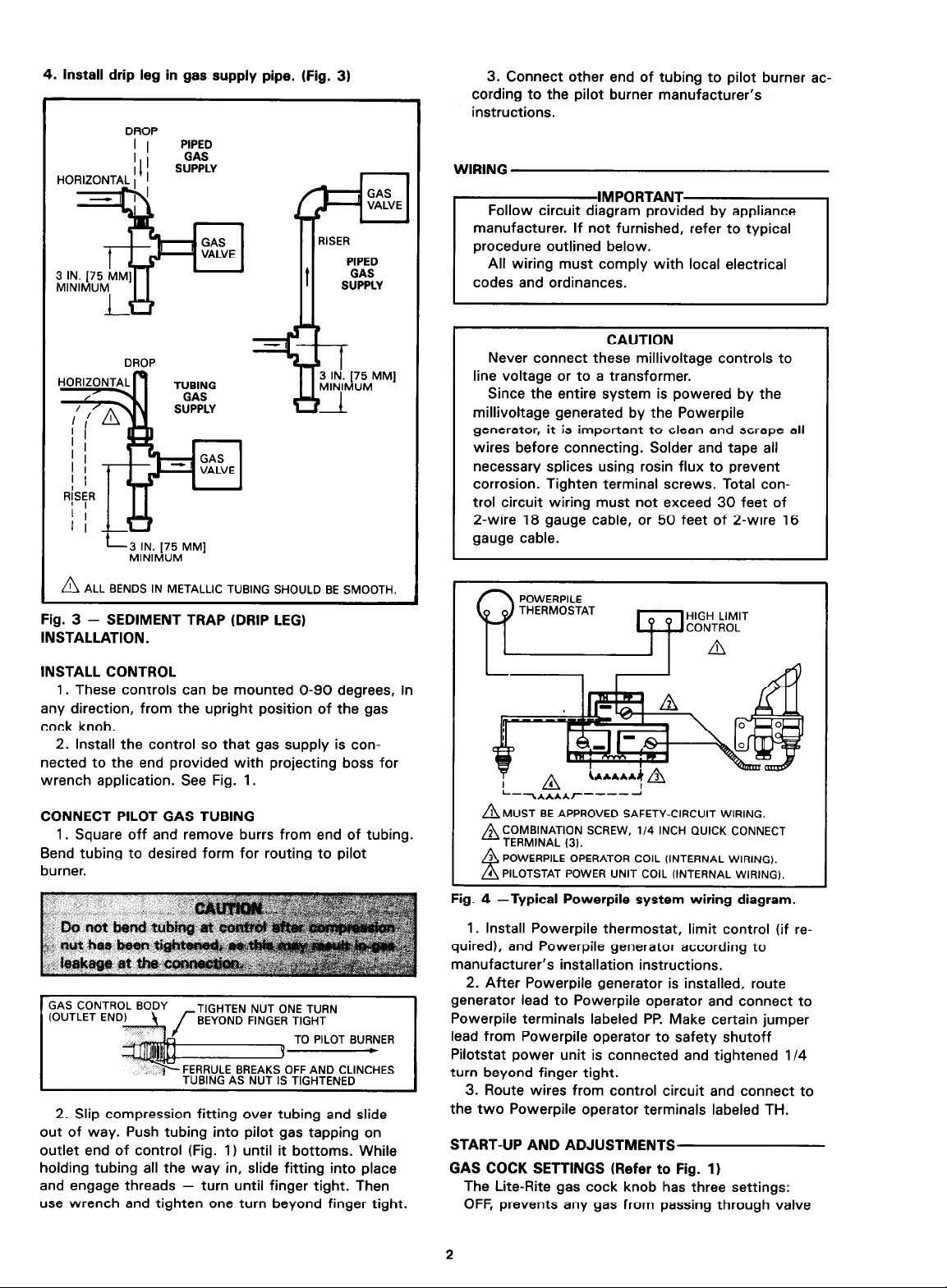

4. Install drip leg in gas supply pipe. (Fig. 31

DROP

DROP

I I

PIPED

t

PIPED

GAS

SUPPLY

3. Connect other end of tubing to pilot burner according to the pilot burner manufacturer’s

instructions.

WIRING

CAUTION

Never connect these millivoltage controls to

line voltage or to a transformer.

Since the entire system is powered by the

millivoltage generated by the Powerpile

generator, it is important to clean and scrape all

wires before connecting. Solder and tape all

necessary splices using rosin flux to prevent

corrosion. Tighten terminal screws. Total con-

trol circuit wiring must not exceed 30 feet of

2-wire 18 gauge cable, or 50 feet of 2-wire 16

gauge cable.

A ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.

Fig. 3 - SEDIMENT TRAP (DRIP LEG)

INSTALLATION.

INSTALL CONTROL

1. These controls can be mounted O-90 degrees, in

any direction, from the upright position of the gas

cock knob.

2. Install the control so that gas supply is connected to the end provided with projecting boss for

wrench application. See Fig. 1.

CONNECT PILOT GAS TUBING

1. Square off and remove burrs from end of tubing.

Bend tubing to desired form for routing to pilot

burner.

GAS CONTROL BODY

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

TO PILOT BURNER

FERRULE BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

t

2. Slip compression fitting over tubing and slide

out of way. Push tubing into pilot gas tapping on

outlet end of control (Fig. 1) until it bottoms. While

holding tubing all the way in, slide fitting into place

and engage threads - turn until finger tight. Then

use wrench and tighten one turn beyond finger tight.

In POWERPILE

-W

y A

L-

-k****r-----

A MUST BE APPROVED SAFETY-CIRCUIT WIRING.

A COMBINATION scREw, 114 INCH 0uicK CONNECT

TERMINAL (3).

POWERPILE OPERATOR COIL (INTERNAL WIRING).

PILOTSTAT POWER UNIT COIL (INTERNAL WIRING).

Fig. 4 -Typical Powerpile system wiring diagram.

1. Install Powerpile thermostat, limit control (if required), and Powerpile generator according to

manufacturer’s installation instructions.

2. After Powerpile generator is installed, route

generator lead to Powerpile operator and connect to

Powerpile terminals labeled PP. Make certain jumper

lead from Powerpile operator to safety shutoff

Pilotstat power unit is connected and tightened l/4

turn beyond finger tight.

3. Route wires from control circuit and connect to

the two Powerpile operator terminals labeled TH.

START-UP AND ADJUSTMENTS

GAS COCK SETTINGS (Refer to Fig. I)

The Lite-Rite gas cock knob has three settings:

OFF, prevents any gas from passing through valve

2

Page 3

to either main or pilot burner.

PILOT, which permits gas to flow to pilot burner

only (when gas cock knob is held depressed or when

generator is heated sufficiently to hold valve open).

ON, which permits gas to flow to both main and

pilot burners when the system is calling for heat.

PILOT LIGHTING PROCEDURE

1. Slightly depress Lite-Rite knob if at PILOT

position and turn clockwise m to OFF. Wait 5

minutes for all unburned gas to vent. REMEMBER

that LP gas does not vent upward naturally.

2. Turn the Lite-Rite knob to PILOT, depress it

completely, and light the pilot burner. The knob must

be held down about one minute before the pilot

burner will stay lit after releasing the knob.

3. Turn the knob to ON, and set the thermostat

above room temperature to turn on main burner.

TEST FOR GAS LEAKS

WARNING - DO NOT OMIT THIS TEST

With main burner in operation, paint pipe joints,

pilot gas tubing connections, and valve gasket lines

with rich soap and water solution. Bubbles indicate

gas leakage. To stop leak, tighten joints and screws

or replace the gasket.

ADJUST PILOT FLAME

The pilot flame should envelop 3/8 to l/2

inch of the tip of the thermocouple. Remove

pilot adjustment cover screw (refer to Fig. 1).

Turn inner adjustment screw clockwise mto

decrease or counterclockwise n to increase

pilot flame. Be sure to replace cover after

adjustment to prevent possible gas leakage.

PROPER

3/S TO 112 INCH

CHECK GAS INPUT TO APPLIANCE

IMPORTANT

Do not exceed input rating stamped on

nameplate of appliance, or manufacturer’s

recommended burner orifice pressure for size

orifice(s) used. Make certain primary air supply

to main burner is properly adjusted for complete

combustion. Follow instructions of appliance

manufacturer if provided.

‘A” MODEL PROCEDURE (with pressure regulator)

1. Check input to main burner by clocking gas

meter or by using a pressure gauge (manometer)

connected to downstream tapping (Fig. 1). The

standard natural gas model is factory set at 3.5

inches WC outlet pressure, and the standard LP gas

model is set at 11 inches. If adjustment is required,

proceed with step 2.

2. Remove cover screw (see Fig. 1). Using

screwdriver, turn adjusting screw clockwise m to

increase or counterclockwise n to decrease gas

pressure to burner. (Note: Adjustment fitting is

plastic and may require slightly greater turning force

than metal thread.) Replace cover screw.

“B” MODEL PROCEDURE (no pressure regulator)

1. With main burner off, connect pressure gauge

(manometer) to downstream pressure tapping (Fig. 1).

2. With main burner operating, check burner

manifold pressure.

3. If pressure is not as specified by the appliance

manufacturer, readjust regulator on LP gas storage

tank.

STEP-OPENING PRESSURE REGULATOR

1°C” MODELS)

1. With main burner operating, check input by

clocking gas meter, or check burner manifold

pressure using pressure gauge (manometer)

connected to downstream pressure tapping (Fig. 1).

2. If adjustment is required, remove cover screw.

Using a small screwdriver, turn adjusting screw

clockwise m to increase or counterclockwise

n to decrease gas pressure to burner. Replace

cover screw.

3. Check burner performance at step pressure,

observing burner ignition and flame characteristics.

Burner should ignite properly and without flashback

to orifice, and all ports should remain lit. Cycle

burner several times (wait 30 seconds between

cycles to allow servo regulator to resume step

action.) Repeat after allowing appliance to cool.

NOTE: IF METER CLOCKING METHOD IS USED

Make certain there is no gas flow through the

meter other than to the appliance being checked.

Other appliances must remain off, and the pilot

extinguished (or their consumption deducted from

the meter reading).

CHECKOUT

Put the system into operation and observe through

complete cycle to be sure all controls function

properly. Make certain the Pilotstat unit shuts off gas

flow to main burner within 2-l/2 minutes after pilot

flame is extinguished.

3

Page 4

PILOT GOES OUT WHEN LITE-RITE KNOB IS

RELEASED

1. Check pilot flame adjustment. See page 3.

2. Check the Powerpile generator connection to

Pilotstat power unit (Fig. 1). This is an electrical connection and must be clean and secure. Also check the

Powerpile generator connections to the valve operator.

3. If power unit still does not hold in, use the W720

Systems Tester to obtain the exact open and closed

circuit output voltages of the generator. Compare with

the Acceptable Range Charts in W720 manual or Gas

Controls Service Handbook. Next check resistance of

Pilotstat power unit.

OPERATING INSTRUCTIONS FOR THE

HOMEOWNER

‘MPORTANT

Follow the operating instructions provided by the

manufacturer of your heating appliance. The infor-

mation below will be of assistance in a typical control application, but the specific controls used and

the procedures outlined by the manufacturer of

your appliance may differ, requiring special

instructions.

LITE-RITE KNOB SETTINGS

Refer to GAS COCK SETTINGS, page 2.

If W720 or other meter is not available, first replace

generator. If this does not correct the condition

replace power unit (adjacent to gas cock knob - see

Fig. 1). Turn off gas supply to appliance (at service

cock or meter) and remove power unit with wrench.

Install and tighten new power unit. Turn on gas supply

and check for gas leakage.

COMPONENT AND PARTS REPLACEMENT

The automatic valve operators and servo regulators

may be added in the field, or replaced in service

maintenance. (Model number is stamped on side of

component.) Complete instructions are furnished with

the component.

REPLACEMENT VALVE OPERATOR: VS824A.

REPLACEMENT SERVO PRESSURE REGULATOR:

V5306 standard and V5307 step opening type.

Either models are field addable to “B” models.

VS820 “A” or “C” models can be converted to

“B” models by removing the pressure regulator and

applying a blank plate and gasket, Pt. No. 392782.

REPLACEMENT PARTS:

Pilotstat power unit (750 mv) - 392395.

Compression fitting for pilot tubing connection-

386449.

Pilot gas filter - 391158.

TO LIGHT PILOT AND TURN ON MAIN BURNER

Follow PILOT LIGHTING PROCEDURE, page 3.

TO SHUT OFF

1. For TEMPORARY situations: Main burner can be

shut off by turning clockwise m from ON to

PILOT. Pilot will remain lit - ready for return to normal service without relighting. (This is the recommended summer shutdown position.)

2. For COMPLETE SHUTDOWN: Slightly depress

Lite-Rite knob when at PILOT position and turn

clockwise m to OFF Both pilot and main burner

now are shut off.

AUTOMATIC SAFETY SHUTOFF

The automatic safety shutoff valve blocks gas flow

to the main burner and pilot burner if the pilot flame

goes out or becomes too small for adequate ignition.

If safety shutoff occurs, check pilot flame after

relighting and adjust if necessary. See ADJUST

PILOT FLAME, page 3. If shutoff reoccurs, contact

your local dealer or gas utility to correct condition

causing shutdown.

ELECTRICAL DATA:

Pilotstat Power Unit - Hold-in 15 ma maximum;

dropout 10.5 to 4.5 ma; resistance 11 ohms.

Valve Operator - Pull-in 65 ma maximum; coil

resistance 2 ohms.

This material is proprietary to Honeywell Limited and shall not be reproduced, copied or used in any manner without prior written consent of

Honeywell Limited.

HONEYWELL l 740 Ellesmere Road l Scarborough l Ontario MlP 2V9

Loading...

Loading...